Patents

Literature

79 results about "Pvc matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer and preparation method thereof

InactiveCN101735532AImprove hydrophobicityGood miscibilityOxygen/ozone/oxide/hydroxidePolymer sciencePolyethylene glycol

The invention discloses a high weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer which is composed of the following raw materials in percentage by weight: 20-40% of calcium stearate, 15-25% of zinc stearate, 10-30% of hydrophobicity nano-hydrotalcite, 1-1.5% of hyperdispersant, 5-15% of lubricating agent, 4-7% of surface modifier and 5-15% of assistant heat stabilizer, wherein, hydrophobicity nano-hydrotalcite is prepared with a coprecipitation method by adding sodium oleate, and the molar ratio of Mg to AL in hydrophobicity nano-hydrotalcite is 2-3:1; the hyperdispersant is copolymer of maleic anhydride-sodium allyl sulfonate-crylic acid polyethylene glycol monoester. The nano-hydrotalcite prepared by the invention has better hydrophobic property and favorable compatibility with PVC matrix. Hydrophobicity nano-hydrotalcite and hyperdispersant are added to lower balancing torque, improve handling characteristics and weather resistance and lower cost. The preparation method of the invention has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

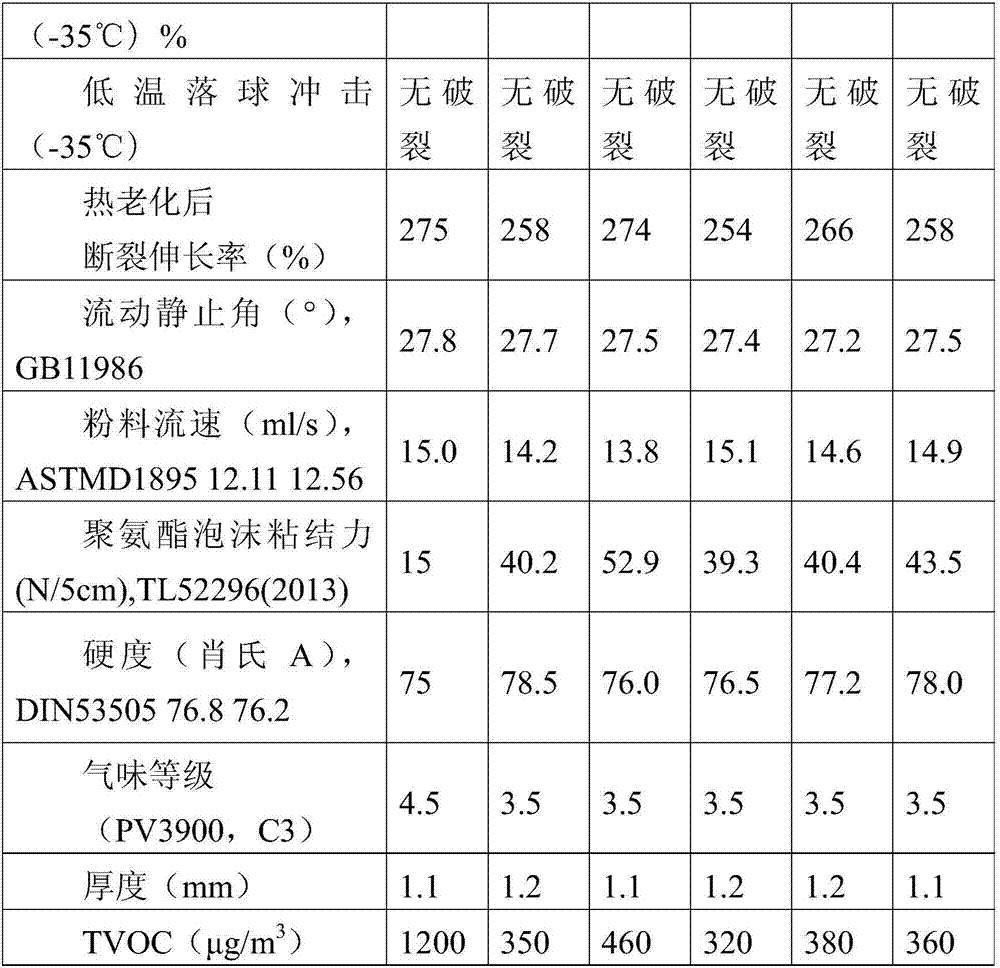

Low-odor PVC powder for automotive upholstery and preparing method thereof

The invention relates to low-odor PVC powder. The low-odor PVC powder comprises 100 parts of PVC resin, 35-50 parts of plasticizer, 5-10 parts of heat stabilizer, 0.2-1.0 part of light stabilizer, 0.3-1.0 part of antioxidant, 3-5 parts of dispersant and 1-5 parts of deodorant. The deodorant is formed by at least one of nano calcium carbonate, nano zinc oxide, fumed silica, precipitated silica and hot-melt rubber powder. The low-odor PVC powder further comprises a coupling agent formed by at least one of an aluminate coupling agent, a borate coupling agent, an aluminum-titanium coupling, a titanate coupling and dispersible rubber powder, and the mass ratio of the coupling agent to the deodorant is (1-5):100. The invention further provides a preparing method of the low-odor PVC powder. The surface of the deodorant is modified by the coupling agent, and the compatibility between the deodorant and the PVC matrix is improved.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

Method for preparing hydrophobic nanometer hydrotalcite

InactiveCN101538019AUniform particle size distributionImprove hydrophobicityNanostructure manufactureOxide/hydroxide preparationPolymer scienceHydrotalcite

The invention relates to a method for preparing hydrophobic nanometer hydrotalcite. The hydrophobic nanometer hydrotalcite with Mg<2+> / Al<3+> of which the molar ratio is 2-3:1 is prepared by adopting a coprecipitation method by adding eunatrol, and leached by using methylbenzene under the action of a phase transfer agent. The hydrophobic nanometer hydrotalcite can be mixed with calcium stearate and zinc stearate and then is added with a lubricating agent, a surfaction agent and an auxiliary stabilizing agent to prepare a composite heat stabilizing agent for hydrophobic nanometer hydrotalcite base PVC. The hydrophobic nanometer hydrotalcite prepared by the method has better hydrophobicity and good compatibility with PVC matrixes, can be used as a stabilizing agent for processing plastics such as PVC, and the like and has the characteristics of no easy separation and good stabilizing effect. The addition of the hydrophobic nanometer hydrotalcite can reduce the balancing torque, improve the processing performance and reduce the cost.

Owner:慧科高新科技股份有限公司

Preparation method and application of compound PVC (polyvinyl chloride) antistatic agent

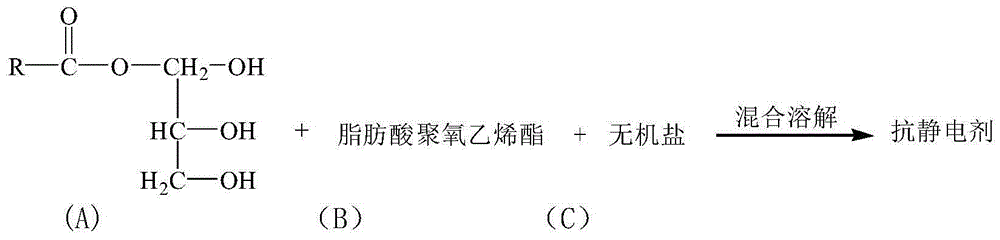

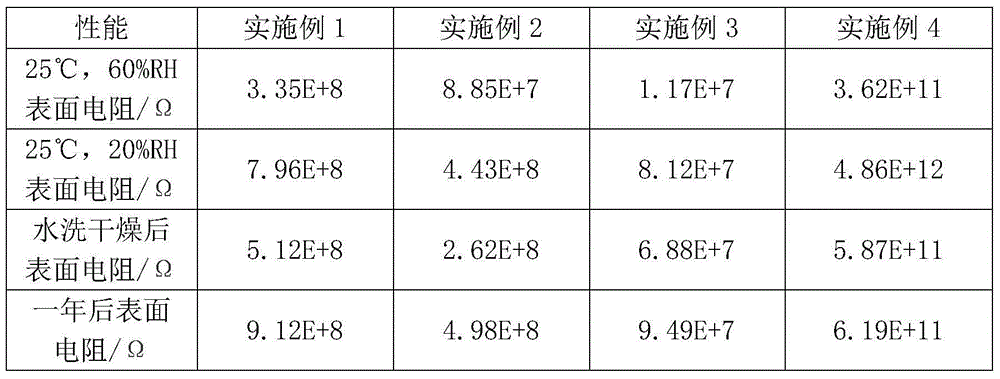

InactiveCN104962011AImprove antistatic performanceImprove heat resistanceMonoglycerideHeat resistance

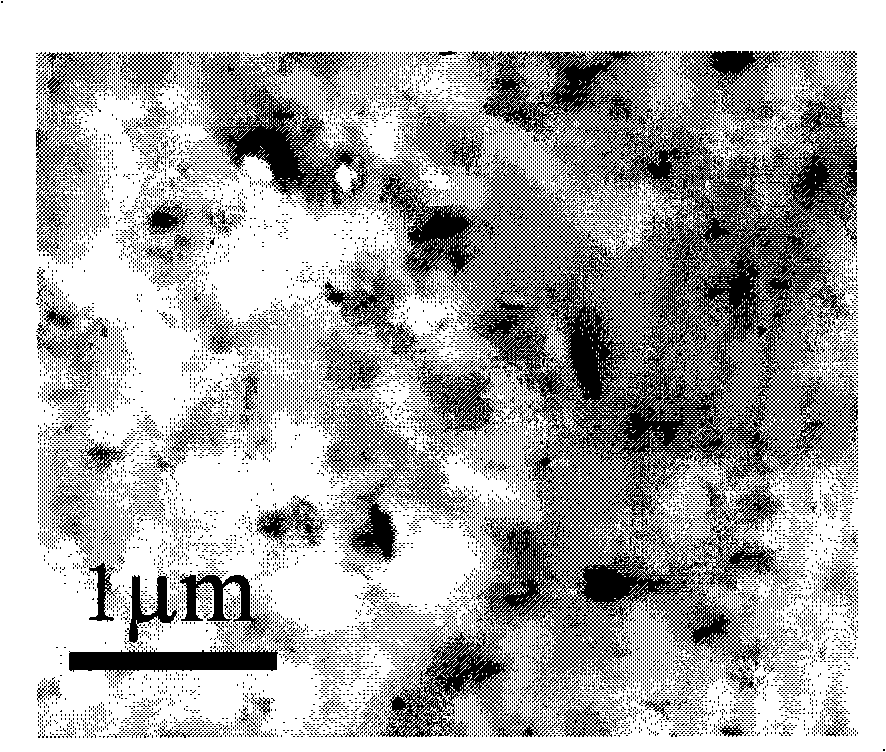

The invention discloses a preparation method and application of a compound PVC (polyvinyl chloride) antistatic agent. The preparation method of the antistatic agent comprises the following two key steps: 1. preparation of fatty acid monoglyceride: reacting esterification raw materials glycerol and fatty acid at 110-160 DEG C under the action of a catalyst for 1-6 hours; and 2. mixing and compounding the fatty acid monoglyceride and other materials to obtain the finished antistatic agent product. The antistatic agent is compounded from the following materials in percentage by weight: 50-80% of fatty acid monoglyceride, 10-30% of polyoxyethylene fatty acid ester and 10-30% of inorganic metal salt. The PVC antistatic agent is compounded from the two nonionic surfactants and inorganic metal salt. Under the synergic antistatic actions of the three components, the PVC antistatic agent has the characteristics of favorable heat resistance, favorable compatibility with the PVC matrix, lower cost, favorable antistatic property and the like, and has significant application value in PVC antistatic materials.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Polychloroethylene / layered double hydroxide nano composite material and preparation thereof

InactiveCN101353466AImprove thermal stabilityImprove hydrophobicityThermal stabilityNanoscopic scale

The invention provides a polyvinyl chloride / layered double hydroxide nano-composite material and a preparation method thereof. The composite material is compounded by polyvinyl chloride and layered hydroxide with the molecular formula of [Mg1-xAlx (OH) 2] question mark R. The preparation method of the material comprises the following steps: 1) the water solution of magnesium nitrate and aluminum nitrate is reacted with the water solution of organic salt and strong base; the temperature is then raised to 70 to 80 DEG C for constant temperature reaction, and layered double hydroxide with modified surface is obtained; and 2) the layered double hydroxide with modified surface reacts with polyvinyl chloride and the product is obtained. The preparation method of the invention has simple process and obvious modification effect; the polyvinyl chloride / layered double hydroxide nano-composite material LDHs obtained by using the method can scatter in a PVC matrix by nanometer scale with obviously improved thermal stability without poison and heavy metals such as lead, etc., environment-friendly, can be directly used for producing various PVC products without adding heat stabilizer and has high application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

PVC alloy for use in air bag doors

A thermoplastic alloy of a melt processible crosslinked olefin thermoplastic elastomer dispersed in a PVC matrix. Improved compatibility of the alloyed components may be achieved through the use of a chlorinated olefin thermoplastic elastomer. The thermoplastic alloy is characterized by lessened mechanical deterioration from heat aging, and improved performance under low temperature conditions.

Owner:COVESTRO LLC

Environment-friendly wallpaper polystyrene foam and preparation method thereof as well as wallpaper

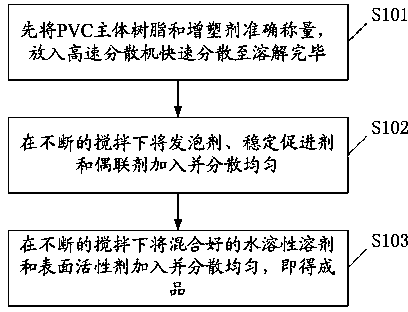

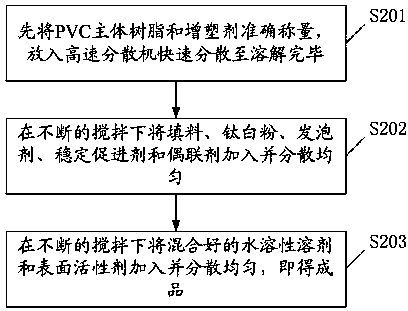

InactiveCN104179068AReduce concentrationReduce or eliminate discomfortCoatings with pigmentsSpecial paperFoaming agentPlasticizer

The invention discloses environment-friendly wallpaper polystyrene foam. The environment-friendly wallpaper polystyrene foam comprises the following main raw materials in percentage: 32-60% of PVC matrix resin, 15-30% of a plasticizer, 1-10% of a foaming agent, 2-10% of a water-soluble solvent, 2-10% of a stable accelerant, 2-10% of a surfactant and 0.2-1% of a coupling agent. Correspondingly, the invention also discloses a method for preparing the environment-friendly wallpaper polystyrene foam and wallpaper produced by using the environment-friendly wallpaper polystyrene foam. According to the environment-friendly wallpaper polystyrene foam, the water-soluble wallpaper polystyrene foam has the characteristics of high foaming height, excellent adhesive force and elasticity, environmental friendliness, energy conservation, high production efficiency and the like and is easy to wash.

Owner:佛山市三水灏诚合成树脂有限公司

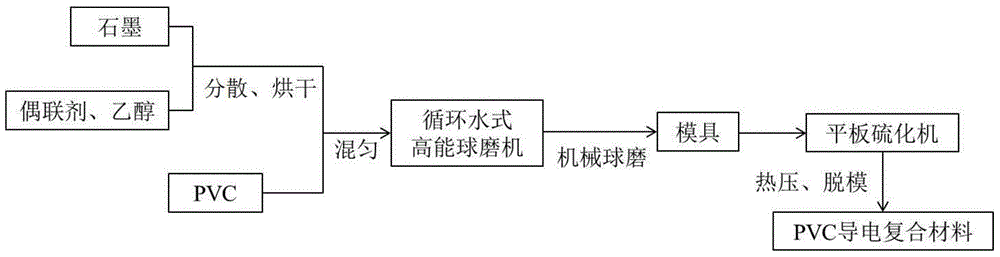

Method for preparing PVC conductive composite material through mechanical milling method

InactiveCN104672704AChange surface propertiesImprove conductivityGrain treatmentsMixed materialsBall mill

The invention relates to the field of conductive composite material processes and particularly discloses a method for preparing a PVC conductive composite material through a mechanical milling method. The method comprises the following steps: putting the graphite in the absolute ethyl alcohol containing a coupling agent, stirring under a constant temperature till the graphite is dispersed in the ethyl alcohol, performing extraction filtration, baking the graphite to obtain the modified graphite, putting the modified graphite and the PVC at a ratio of (15-20%): (80-85%) into a circulating water type high-energy ball mill, performing mechanical milling for 0.5-2.5 hours to obtain the mixed materials, filling the mixed materials in a mould of a press vulcanizer, performing high temperature heat pressing and demoulding to obtain the PVC conductive composite material. By adopting the preparation method, the interface difference between the graphite and the PVC is eliminated so that the graphite is uniformly dispersed in the PVC matrix; a dense conductive network is formed inside the composite material so that the conductive performance of the composite material is obviously reinforced; and besides the method is high in reaction efficiency, energy-saving, free of industrial waste and low in production cost.

Owner:GUANGXI UNIV

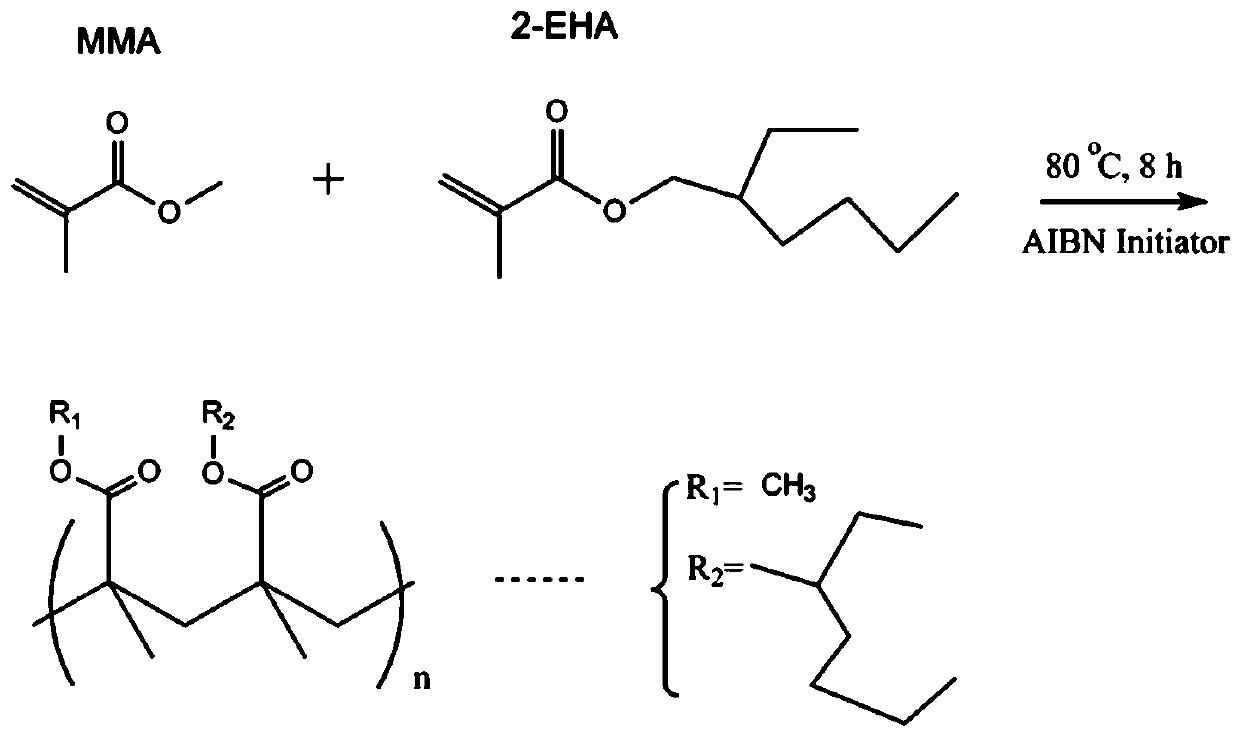

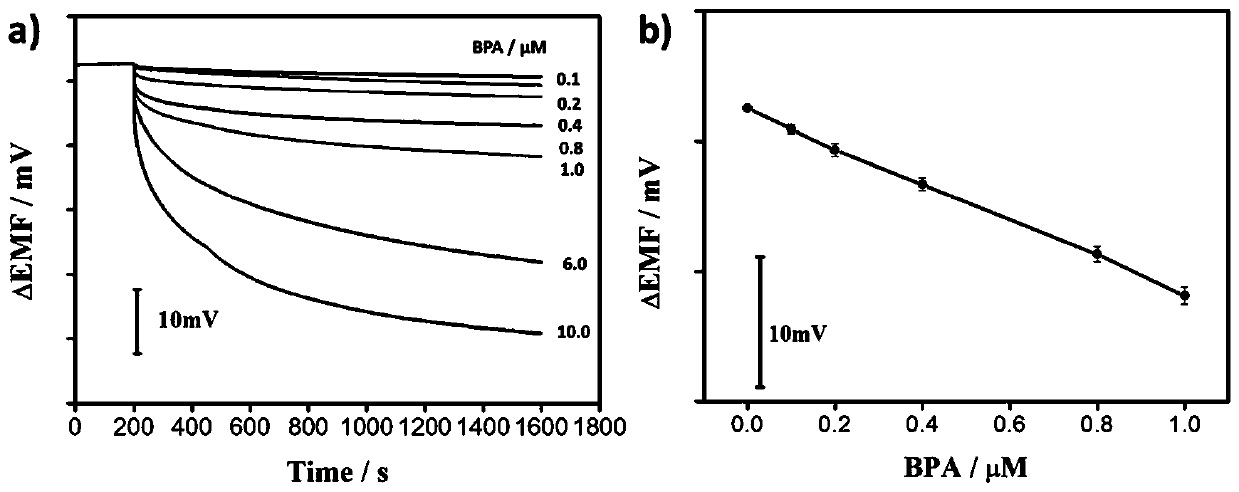

Plasticizer-free molecularly imprinted polymer membrane ion-selective electrode sensitive membrane

ActiveCN111551612ASolve the leakReduce usageOther chemical processesMaterial analysis by electric/magnetic meansPlasticizerMolecularly imprinted polymer

The invention relates to a polymer membrane ion-selective electrode sensitive membrane and particularly relates to a plasticizer-free molecularly imprinted polymer membrane ion-selective electrode sensitive membrane. The sensitive film contains a molecularly imprinted polymer serving as a recognition carrier and an electrode sensitive film matrix; wherein the electrode sensitive film matrix is a methyl methacrylate copolymer. According to the method disclosed by the invention, the use of a plasticizer-containing polyvinyl chloride (PVC) matrix in the preparation of a traditional molecularly imprinted polymer membrane ion selective electrode sensitive membrane is avoided, so that the problem of plasticizer leakage always existing in the PVC matrix is eliminated, the stability of the electrode is effectively improved, the service life of the electrode is effectively prolonged, and the biocompatibility of the electrode is effectively improved.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Low-temperature toughened PVC drainage pipe material, preparation method and application thereof

The invention relates to a low-temperature toughened PVC drainage pipe material, a preparation method and application thereof. The PVC drainage pipe material is prepared according to the following preparation method: taking nanometer silicon dioxide and acrylonitrile-butadiene-styrene copolymer as raw materials to prepare a compound modified particle with a core-shell structure through an emulsion polymerization method; and then blending the compound modified particle with PVC through melt, so as to prepare a ternary nanometer compound material. By selecting a specific nanometer particle to organically combine with an elastomer, the core-shell structural compound modified particle taking nanometer silicon dioxide as a core and ABS as a shell is formed, and then the compound modified particle and PVC resin are subjected to melt blending, so that the compound modified particles are well dispersed in PVC matrix and give play to toughening reinforcing modification effect on PVC.

Owner:HENAN LIANSU IND

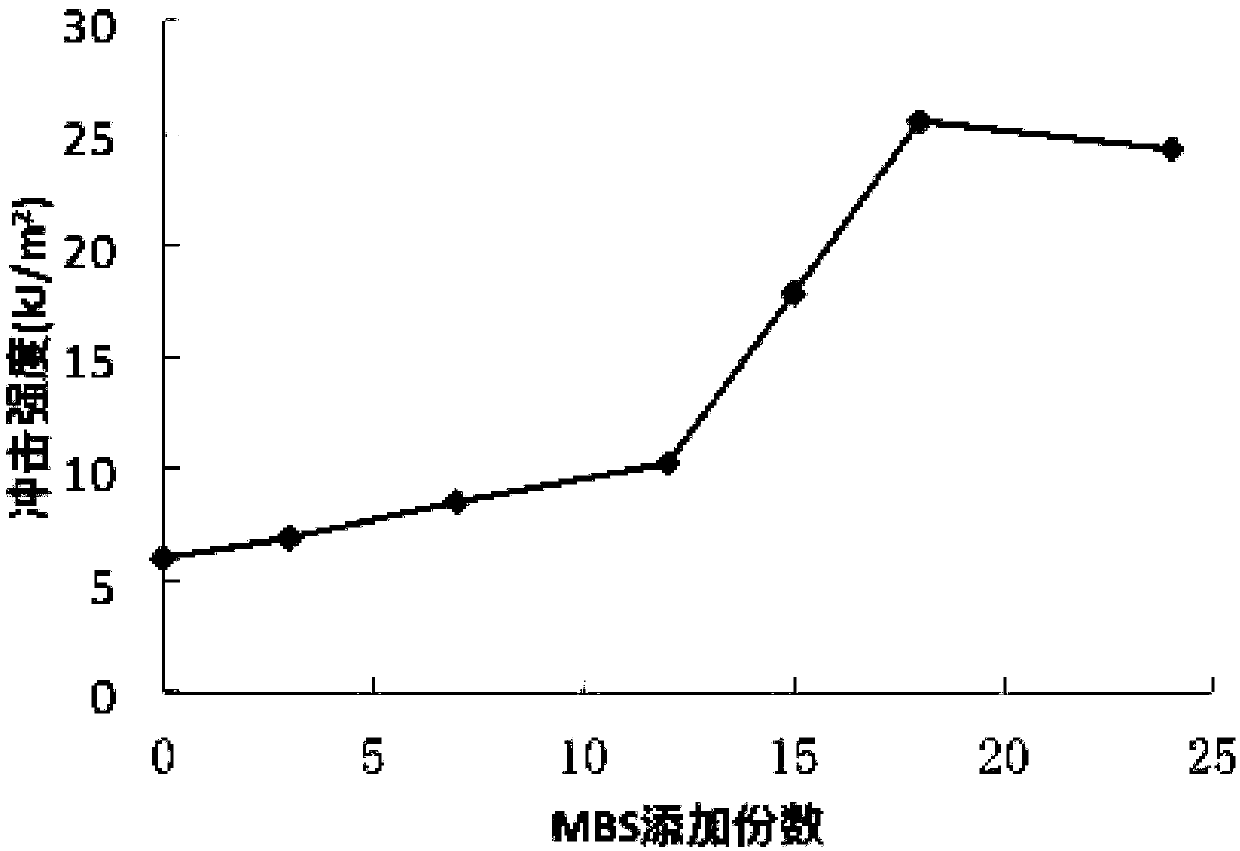

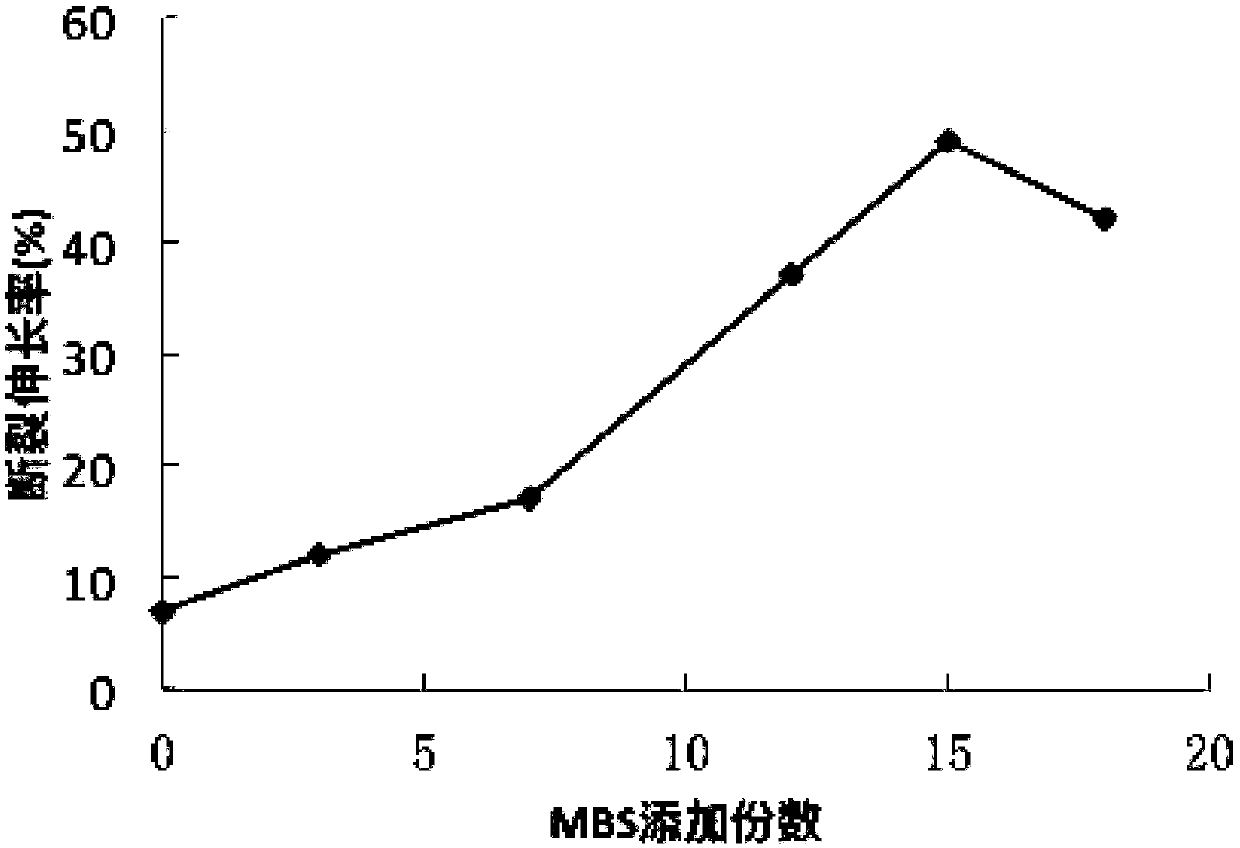

High-strength environment-friendly PVC shrink film and preparation process thereof

The invention discloses a high-strength environment-friendly PVC shrink film and a preparation process thereof. The PVC shrink film is prepared from the following raw materials in parts by weight: 88-100 parts of polyvinyl chloride, 6-10 parts of ethylaniline, 10-15 parts of dioctyl phthalate, 5-10 parts of MBS resin, 1-3 parts of a plasticizer, 2-4 parts of a heat stabilizer, 1-3 parts of an internal lubricant, 1-2 parts of an external lubricant and 3-5 parts of a processing aid. The PVC raw material is modified by virtue of an anti-impact enhancer, the plasticizer, the heat stabilizer, the internal lubricant, the external lubricant and the like through a polymer blending modification technique, and after being mechanically mixed with PVC, a modifier is well dispersed in a PVC matrix, sothat the heat stability of PVC is improved, the processing performance is improved, and meanwhile, the tenacity and impact resistance of PVC can be substantially improved.

Owner:厦门市瀚邦包装制品有限公司

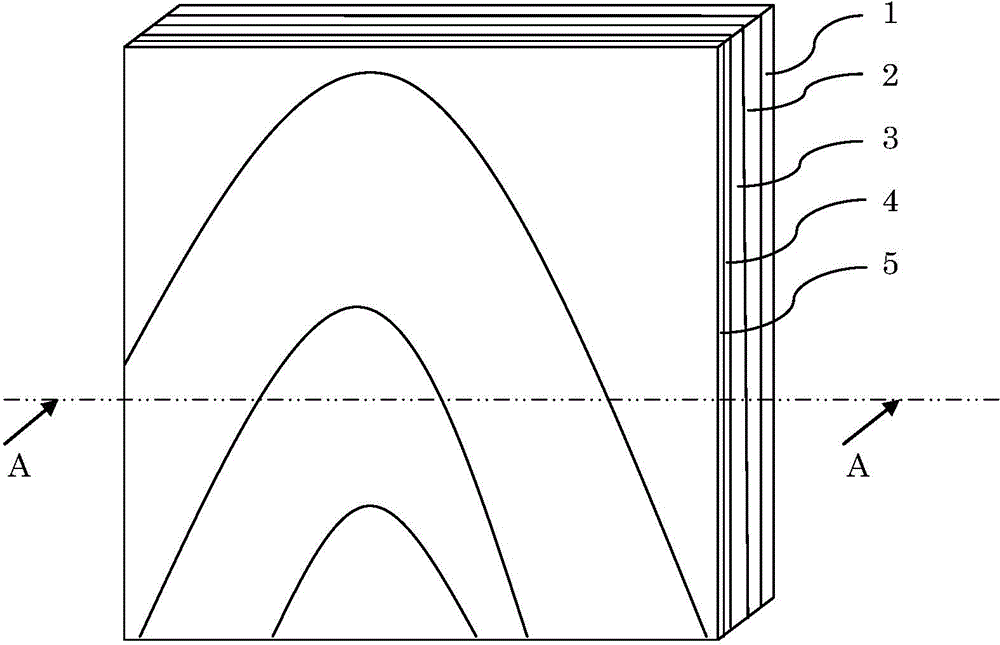

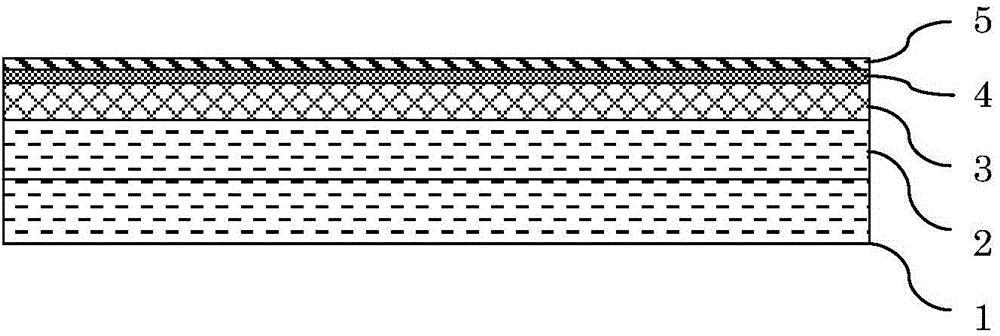

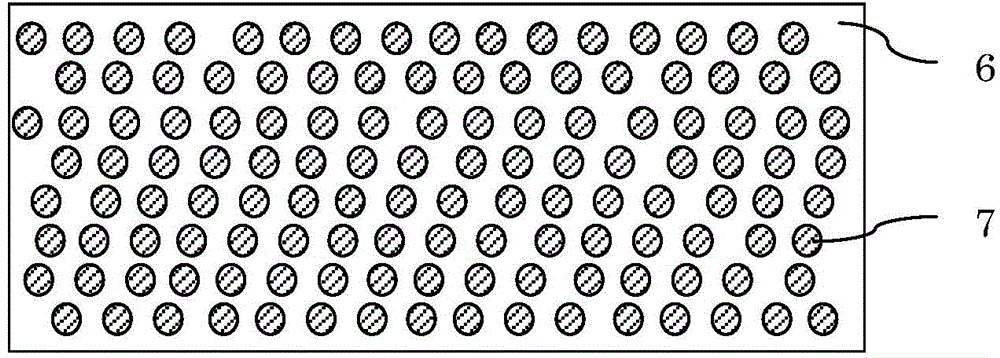

PVC plastic floor and preparation method thereof

ActiveCN105275180AReduce voidsReduce formationSynthetic resin layered productsFlooringEngineeringPvc matrix

The invention provides a PVC plastic floor comprising a substrate layer, a middle layer, a decoration layer, a wearing layer and a paint layer jointed in sequence; either one or both of the substrate layer and the middle layer comprise one layer of PVC matrix and filling particles scattering in the PVC matrix; the filling particles comprise SiO2, Al2O3, CaCO3, and NaC1; the invention also comprises a PVC plastic floor preparation method; the PVC plastic floor is more stable than a conventional normal PVC plastic floor.

Owner:大自然家居(中国)有限公司 +1

High-toughness PVC drainage-pipe material, and preparation method and application thereof

The invention relates to a high-toughness PVC drainage-pipe material, and a preparation method and application thereof. The PVC drainage-pipe material is prepared according to the following preparation method: taking nanometer calcium carbonate and chlorinated polyethylene as raw materials to prepare a compound modified particle with a core-shell structure through an emulsion polymerization method; and blending the compound modified particle with PVC through melting, so as to prepare a ternary nanometer compound material. By selecting a specific nanometer particle to organically combine with an elastomer, the core-shell structural compound modified particle taking nanometer calcium carbonate as a core and CPE as a shell, then the compound modified particle and PVC resin are subjected to melt blending, so that the compound modified particles are well dispersed in PVC matrix, and give play to toughening reinforcing modification effect on PVC.

Owner:HENAN LIANSU IND

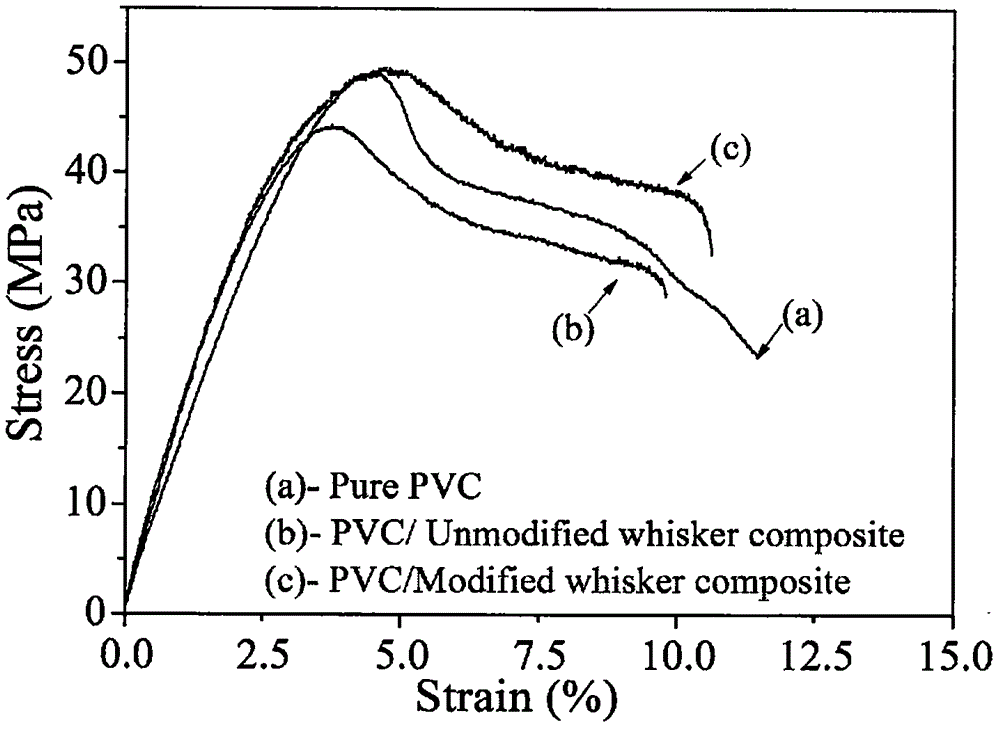

Surface treatment method for novel crystal whiskers applied to PVC

InactiveCN105860364AImprove mechanical propertiesImprove thermal stabilityEmulsion polymerizationWhiskers

The invention provides a surface treatment method for novel crystal whiskers applied to PVC. The calcium carbonate crystal whiskers and a coupling agent with a double bond react to obtain modified crystal whiskers with the double bond on the surface, organic monomers are grafted on the surface through in-situ emulsion polymerization, and therefore compatibility between the whiskers and a PVC matrix is improved. The compatibility between the calcium carbonate whiskers and PVC is improved, and after PVC is filled with the modified crystal whiskers, mechanical property and thermal stability of the matrix can be improved.

Owner:QINGHAI UNIVERSITY

Low-temperature toughened PVC drainage pipe material, preparation method and application thereof

The invention relates to a low-temperature toughened PVC drainage pipe material, a preparation method and application thereof. The PVC drainage pipe material is prepared according to the following preparation method: taking montmorillonite and methyl methacrylate-butadiene-styrene copolymer as raw materials to prepare a compound modified particle with a core-shell structure through an emulsion polymerization method; and then blending the compound modified particle with PVC through melt, so as to prepare a ternary nanometer compound material. By selecting a specific nanometer particle to organically combine with an elastomer, the core-shell structural compound modified particle taking montmorillonite as a core and MBS as a shell is formed, and then the compound modified particle and PVC resin are subjected to melt blending, so that the compound modified particles are well dispersed in PVC matrix and give play to toughening reinforcing modification effect on PVC.

Owner:HENAN LIANSU IND

Novel heat-resistant PVC plastic

InactiveCN108329624AImprove heat resistanceImprove flame retardant performanceHeat resistancePolyresin

The invention discloses a novel heat-resistant PVC plastic. The novel heat-resistant PVC plastic comprises the following components in parts by weight: 50-60 parts of a PVC matrix, 40-45 parts of ternary polymerized resin, 15-20 parts of MMA modified ABS resin, 5-10 parts of EnBACO grafted maleic anhydride, 1-5 parts of 9nm calcium carbonate, 5 parts of styrene and 10 parts of acrylate. The ternary polymerized resin is MMA-St-ChMI, and the ratio of the MMA-St-ChMI is 25: 35: 40. After being treated via a titanate coupling agent, nano calcium carbonate is added in the PVC matrix for blending and filling. The EnBACO grafted maleic anhydride is a compatibilizer. The novel heat-resistant PVC plastic has the advantages of good heat resistance and long service life.

Owner:JIANGSU FENGTENG PLASTIC CO LTD

PVC Alloy For Use In Air Bag Doors

InactiveUS20060252885A1Improve abilitiesDomestic articlesCoatingsThermoplasticThermoplastic elastomer

A thermoplastic alloy of a melt processible crosslinked olefin thermoplastic elastomer dispersed in a PVC matrix. Improved compatibility of the alloyed components may be achieved through the use of a chlorinated olefin thermoplastic elastomer. The thermoplastic alloy is characterized by lessened mechanical deterioration from heat aging, and improved performance under low temperature conditions.

Owner:COVESTRO LLC

High-color-stability PVC (polyvinyl chloride) resin

The invention relates to high-color-stability PVC (polyvinyl chloride) resin. A color master batch which is 2-5% of a matrix resin weight is added to PVC matrix resin. According to the resin providedby the invention, through adding the specially prepared color master batch, a color of the resin added with the color master batch has good temperature resistance.

Owner:蚌埠创特新材料科技有限公司

High-impact-resistance PVC tube

InactiveCN105968657AHigh tensile strengthGreat impact strengthShock resistanceUltimate tensile strength

The invention discloses a high-impact-resistance PVC tube. The high-impact-resistance PVC tube is prepared from, by weight, 100 parts of PVC resin, 5-10 parts of titanium dioxide, 0.1-0.3 part of CPE and 0.1-0.3 part of ACM. Compared with the prior art, according to the high-impact-resistance PVC tube, titanium dioxide and ACM are added in a PVC matrix, the tensile strength and impact-resistance strength can be improved, and the high-temperature stability is improved.

Owner:GUANGXI JINSHENG TECH DEV

High-strength PVC (polyvinyl chloride) conducting composite material and preparation method thereof

InactiveCN104530595AImprove conductivityHigh mechanical strengthNon-conductive material with dispersed conductive materialToxic industrial wasteWaste material

The invention relates to the field of conducting composite materials, particularly a high-strength PVC (polyvinyl chloride) conducting composite material and a preparation method thereof. The high-strength PVC conducting composite material is prepared from the following raw materials in percentage by weight: 15-18% of carbon black, 0.2-0.5% of manganese powder, 0.5-0.8% of iron powder, 2.0-3.0% of copper powder, 0.1-0.2% of zirconium powder, 1.6-1.8% of nickel powder, 0.05-0.2% of titanium white, 0.5-1.0% of dispersing agent and the balance of PVC powder. The preparation method comprises the following steps: proportionally and evenly mixing the raw materials, oscillating in an oscillation tank for 100-120 minutes until the components are uniformly dispersed into the PVC matrix, taking out the oscillated reaction product, filling into a mold of a flat vulcanizing machine, carrying out high-temperature hot pressing, and demolding to obtain the high-strength PVC conducting composite material. The high-strength PVC conducting composite material has the advantages of favorable conductivity and favorable tensile strength. The preparation method has the advantages of high reaction efficiency, energy saving, no industrial waste, low production cost and favorable market prospects.

Owner:陈程 +2

PVC plastic with self-antibacterial property and preparation method thereof

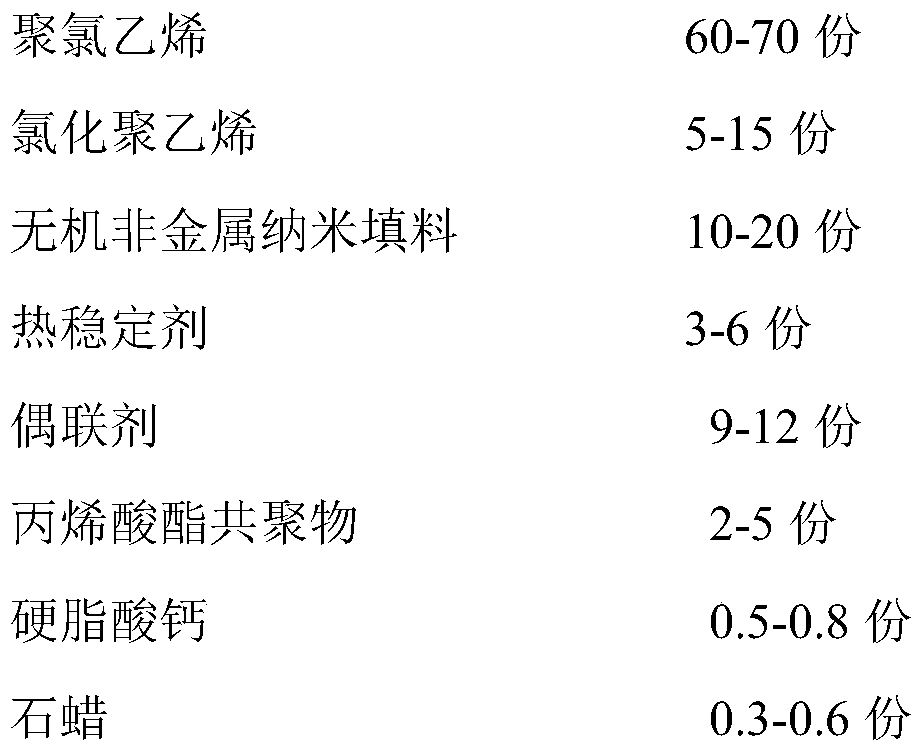

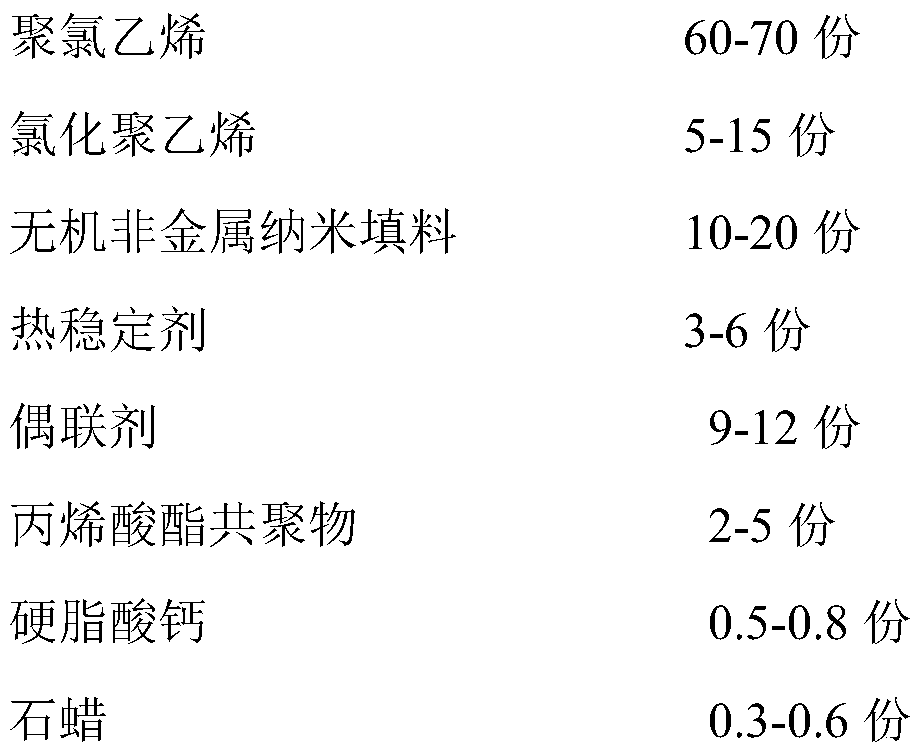

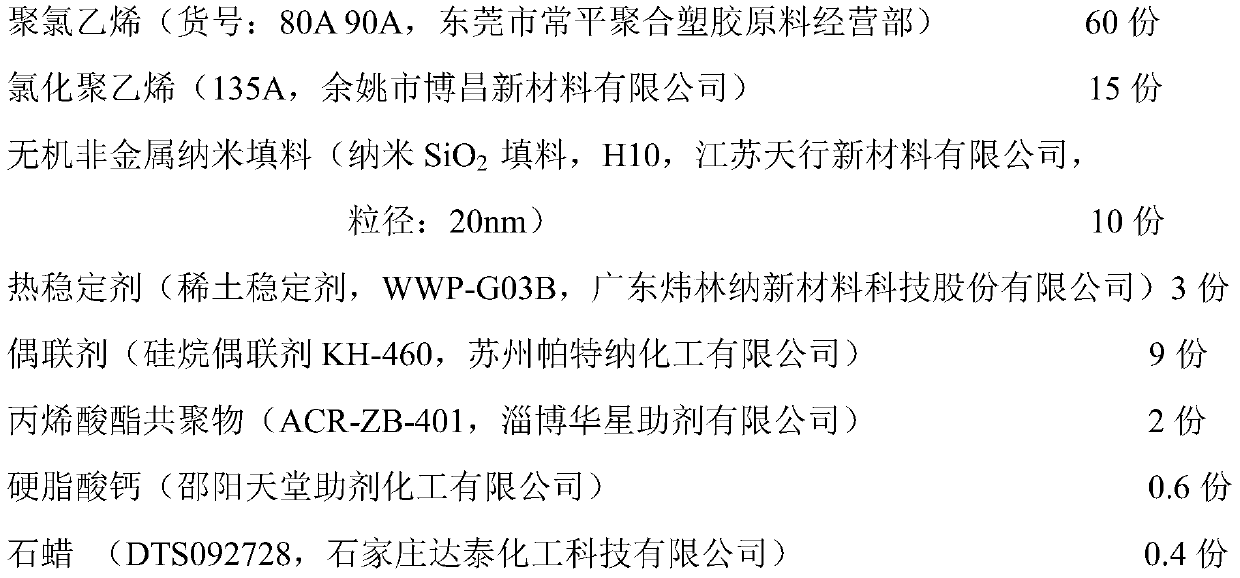

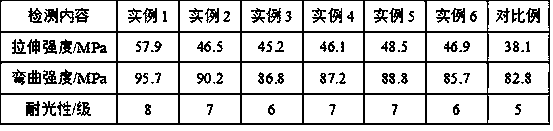

The invention discloses PVC plastic with a self-antibacterial property and a preparation method thereof. According to the raw material formula, the PVC plastic is prepared from the components in partsby mass: 60-70 parts of polyvinyl chloride, 5-15 parts of chlorinated polyethylene, 10-20 parts of inorganic nonmetallic nanometer filler, 3-6 parts of a heat stabilizer, 9-12 parts of a coupling agent, 2-5 parts of acrylate copolymer, 0.5-0.8 part of calcium stearate, and 0.3-0.6 part of paraffin. A bactericidal substance of the PVC plastic is an inorganic nonmetallic nanomaterial with high safety, the bactericidal substance uniformly disperses in a PVC matrix material without adding additional bactericidal substances, use of the bactericidal substance is more convenient, long-term effectiveness is achieved, the bactericidal substance of the PVC plastic has no selectivity to bacterial species, and has a wide antibacterial spectrum; and a PVC plastic sheet has the advantages of being non-toxic, being non-irritating, being non-corrosive, long acting time, repeated use and being environmental-friendly, the preparation process is simple, and operation is easy.

Owner:SOUTH CHINA UNIV OF TECH

Special high-glossiness modified master batch for transparent PVC (Polyvinyl Chloride) hard product

The invention discloses a special high-glossiness modified master batch for a transparent PVC (Polyvinyl Chloride) hard product and belongs to the technical field of high molecular materials. The special high-glossiness modified master batch for the transparent PVC hard product, provided by the invention, is prepared from pre-treated PVC matrix resin, a stabilizing agent, a plasticizer, a lubricant, a de-foaming agent, a filler and modified graphene oxide, wherein the pre-treated PVC matrix resin is obtained by mixing and swelling PVC resin and a solvent, carrying out heat treatment and ageingand then freezing and crushing; the modified graphene oxide is prepared by heating graphene oxide, octadecylamine and trichloromethane and stirring and reacting; in a preparation process, the pre-treated PVC matrix resin, the stabilizing agent, the plasticizer, the lubricant, the de-foaming agent and the filler are mixed and then the modified graphene oxide is added; after the components are continually and uniformly mixed, extrusion and granulation, cooling and packaging are carried out to obtain the special high-glossiness modified master batch for the transparent PVC hard product. The special high-glossiness modified master batch for the transparent PVC hard product, disclosed by the invention, has excellent transparency, mechanical properties and light stability.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

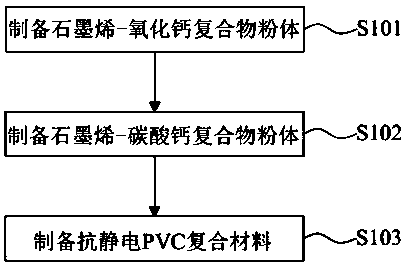

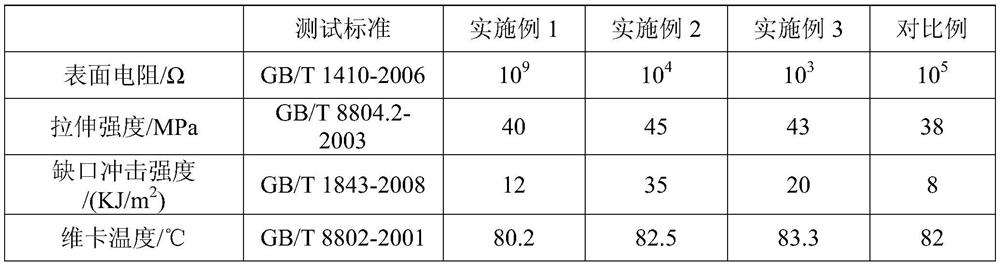

Preparation method of antistatic PVC composite material

PendingCN111138780AOvercome reunionAvoid flyingCalcium/strontium/barium carbonatesGraphenePtru catalystCarbonization

The invention relates to a preparation method of an antistatic PVC composite material. The method comprises the following steps: conveying a precursor into a tubular resistance furnace for high-temperature activation to obtain a catalyst, pulverizing and modifying the catalyst, conveying the catalyst into the tubular resistance furnace, and introducing a carbon source under a hydrogen-nitrogen atmosphere condition to grow graphene to obtain graphene-calcium oxide composite powder; digesting and aging the graphene-calcium oxide compound powder and water in a digestion kettle according to a preset mass ratio, conveying the graphene-calcium hydroxide compound powder into a carbonization kettle, introducing lime kiln gas for carbonization to obtain graphene-calcium carbonate compound powder; and mixing the graphene-calcium carbonate compound powder with PVC, and carrying out melt blending through a twin-screw extruder to obtain the antistatic PVC composite material. According to the preparation method provided by the invention, the problems of agglomeration of graphene and interfacial compatibility and interaction between graphene and a PVC matrix are effectively solved, and the resistivity of the PVC composite material can be regulated and controlled.

Owner:陕西兴汉澜墨科技有限公司

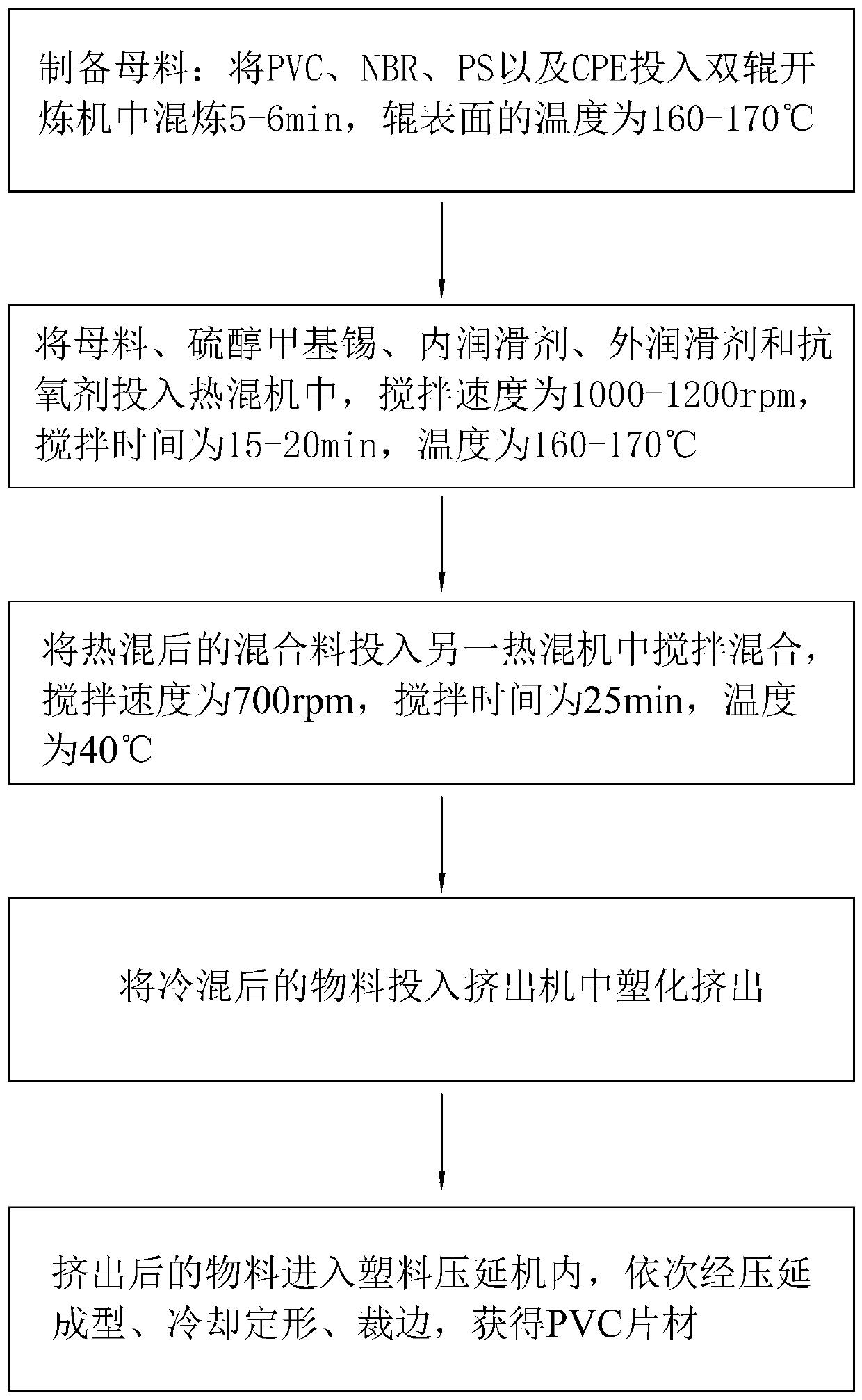

PVC sheet and preparation method thereof

The invention discloses a PVC sheet and a preparation method thereof, and relates to the technical field of macromolecule materials, wherein the PVC sheet comprises the following raw materials by weight: 80-90 parts of PVC, 5-6 parts of NBR, 1-3 parts of PS, 2-3 parts of methyl tin mercaptide, 1.5-3 parts of an internal lubricant, 0.5-1 part of an external lubricant, and 0.4-0.5 part of an antioxidant. According to the invention, NBR can endow the PVC board with good impact strength and good toughness, and can toughen the system, effectively improve the thermo-oxidative aging performance of the system and prolong the service life of the PVC sheet; and based on poor compatibility of PS and PVC, PS particles and a PVC matrix have an obvious interface, tiny holes exist around the PS particlesand are generated due to different shrinkage rates of two phases after melting mixing and cooling, the tiny holes deform to absorb energy when the material is impacted, and when the rigid particles are stressed and need to be separated from the matrix, the energy can be absorbed, so that the impact strength of the system is improved.

Owner:温州市隆昌塑料有限公司

MXene-graphene-PVC composite material and preparation method thereof

ActiveCN114031867AIncrease electrostatic repulsionReduce aggregationGraphene flakeChlorinated polyethylene

The invention belongs to the technical field of high polymer materials, and particularly relates to an MXene-graphene-PVC composite material and a preparation method thereof. The MXene-graphene-PVC composite material is prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 1 to 5 parts of a heat stabilizer, 3 to 15 parts of chlorinated polyethylene, 1 to 4 parts of an ACR processing aid, 1 to 20 parts of nano calcium carbonate, 0.3 to 2 parts of a lubricant, 1 to 5 parts of MXene-graphene and 0.1 to 0.5 part of an antioxidant. The MXene-graphene is prepared by the following steps: firstly, modifying graphene oxide by using amino molecules, then intercalating MXene into the graphene oxide, and finally reducing to obtain MXene-graphene. According to the invention, electrostatic repulsion among graphene sheet layers is increased, and aggregation of graphene in a PVC matrix is effectively reduced. Meanwhile, the dispersity, the conductivity and the toughness of the PVC composite material are greatly improved.

Owner:山东鲁泰控股集团有限公司石墨烯高分子复合材料研发中心 +1

Nitrogen-doped graphene/PVC composite waterproof coiled material and preparation method thereof

InactiveCN109294115AImprove waterproof performanceImprove mechanical propertiesNitrogenNitrogen doped graphene

The present invention provides a nitrogen-doped graphene / PVC composite material and a preparation method thereof. By improving the preparation method of graphene, the graphene is subjected to multi-component doping to introduce functional group-modified graphene, van der Waals force between the graphene sheets is weakened, graphene agglomeration is reduced or eliminated, the dispersion degree of graphene in a PVC matrix is increased, and the interface property of the graphene / PVC composite material is improved. At the same time, the graphene / PVC composite material is prepared by improving a solid-phase shearing and milling method, and the secondary compositing of graphene and PVC is combined to improve the comprehensive performance of the composite material.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

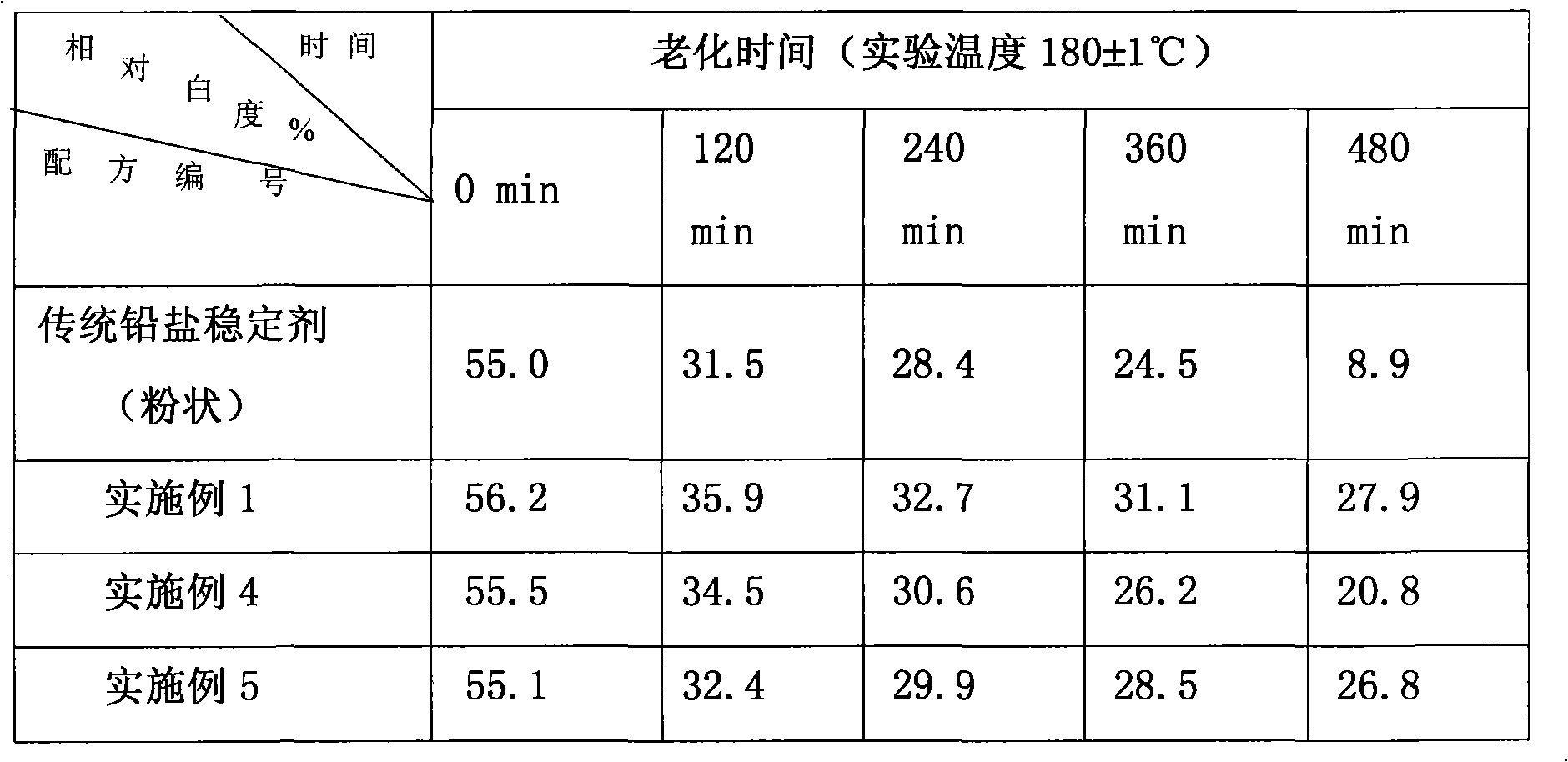

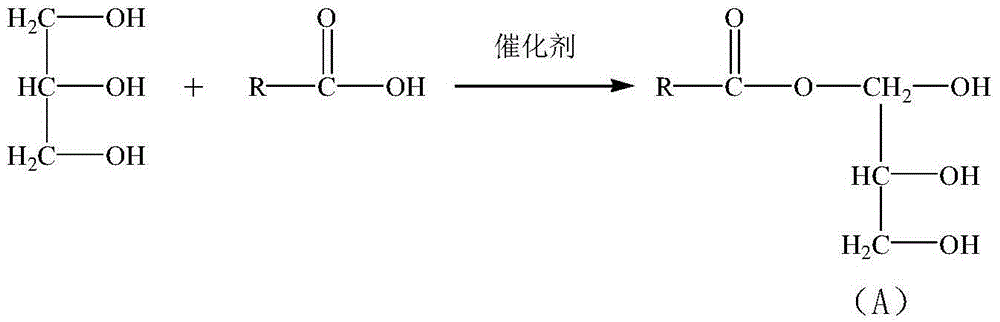

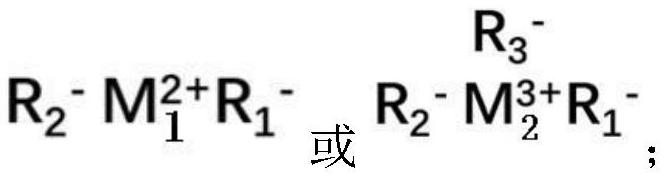

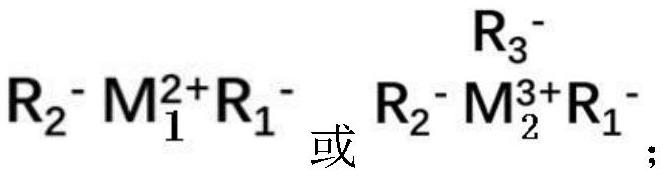

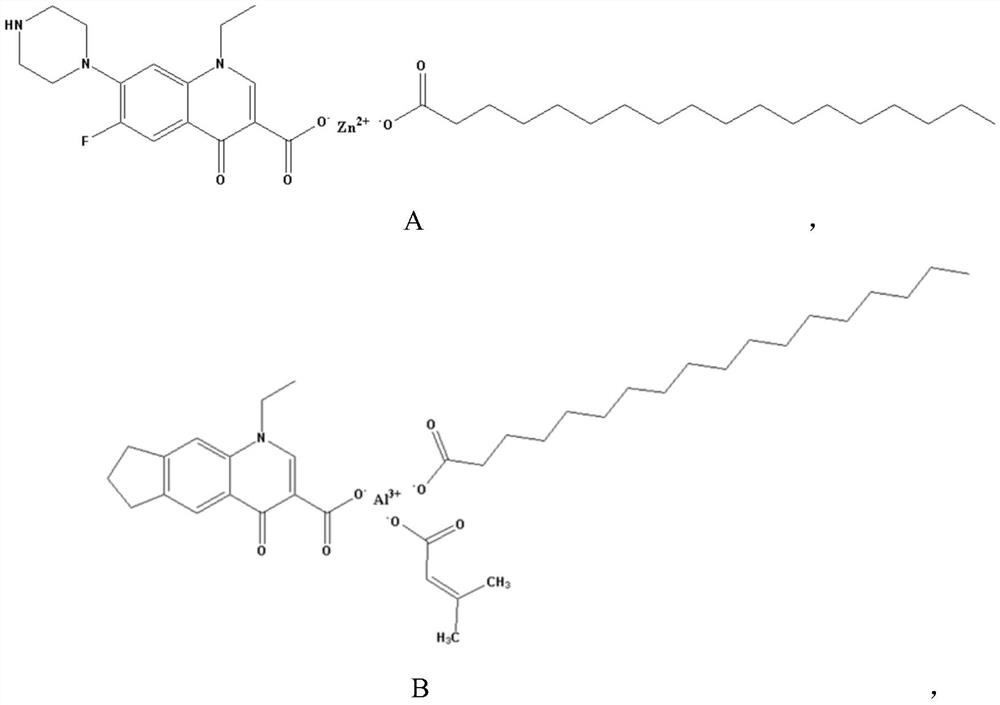

Polyanionic metal salt, preparation method thereof and heat stabilizer

The invention relates to the technical field of polyvinyl chloride heat stabilizers, solves the problem that a main stabilizer and an auxiliary heat stabilizer of a traditional PVC heat stabilizer are difficult to disperse in the same microscopic area in a PVC matrix, and provides a polyanion metal salt, a heat stabilizer and application thereof. The polyanionic metal salt has the following structural formula in the specification , wherein M1<2 +> is a divalent metal ion, M2<3 +> is a trivalent metal ion, and R1, R2 and R3 are organic anions. The polyanion metal salt has function adjustability, and PVC heat stabilizers with different functions and containing the polyanion metal salt can be customized by adjusting the anion structure; and the heat stabilizer has the advantages that the compatibility of anions and cations is high, the same cation is combined with two or more anions, so that the heat stabilizer has enough anion groups to make up the defects generated in the PVC stabilizing process of the cation, and the heat stabilizer can achieve a good heat stabilizing effect on the premise of a small dosage.

Owner:ZHEJIANG UNIV OF TECH

Inorganic nanoparticle modified PVC composite material craft shoe sole and preparation method thereof

The invention relates to the field of composite plastic materials, in particular to an inorganic nanoparticle modified PVC composite material craft shoe sole and a preparation method thereof. The inorganic nanoparticle modified PVC composite material craft shoe sole comprises the following raw materials in parts by weight: 120-150 parts of PVC resin, 10-15 parts of composite modified nanoparticles, 8-12 parts of chlorinated polyethylene, 1-3 parts of calcium stearate, 4-8 parts of a plasticizer and 2-5 parts of a stabilizer. According to the inorganic nanoparticle modified PVC composite material process shoe sole disclosed by the invention, nano TiO2, nano ZnO and nano SiO2 are coated with a polymer to form composite modified nanoparticles taking nano TiO2, nano ZnO and nano SiO2 as an inner core, polybutyl acrylate as an outer core and polymethyl methacrylate as a shell, and the composite modified nanoparticles are then blended with a PVC matrix, such that the impact resistance and the tensile resistance of the PVC material are effectively improved, the softening temperature of the PVC material is increased, and the application range of the PVC material is expanded.

Owner:JIEYANG SHENGLUBAO FOOTWARE LTD

Sunshine fabric fiber with high flame resistance and high mechanical strength and preparation method thereof

ActiveCN108486682AImprove flame retardant performanceTo satisfy the market's needsFlame-proof filament manufactureFilament/thread formingPolyesterHigh resistance

The invention discloses a method for preparing sunshine fabric fiber with high flame resistance and high mechanical strength. The sunshine fabric fiber comprises a core layer and a skin layer, whereinthe core layer is prepared from polyester fiber; the skin layer is prepared from a PVC (Polyvinyl Chloride) composite material; a weight ratio of the PVC composite material to the polyester fiber is(60 to 80):(40 to 20). The method comprises two steps of PVC composite material pelleting and polyester fiber coating, wherein the step of the PVC composite material pelleting comprises the steps: stirring PVC matrix resin, a phosphorus-nitrogen flame retardant, an ethylene-vinyl acetate copolymer and an optional additive according to a certain proportion, thus obtaining a PVC composite material mixture in uniform dispersion; extruding the PVC composite material mixture by using a double-screw extruder, and pelleting after cooling by a water tank, thus obtaining master batches of the PVC composite material. According to the preparation method disclosed by the invention, a synergistic interaction principle of the phosphorus-nitrogen flame retardant and the ethylene-vinyl acetate copolymer is utilized, and the obtained sunshine fabric fiber not only has good flame resistance, but also has better mechanical performance; in addition, the antibacterial performance, the anti-UV (Ultraviolet)performance and the color fastness performance can also meet demands of a market, sunshine fabric can be prepared and is suitable for building shading, and an application prospect is wide.

Owner:SHAOXING HONGPUTAO TEXTILE DECORATION CO LTD

PVC antistatic adhesive tape and preparation method thereof

InactiveCN108342169AImprove antistatic performanceGood compatibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEmulsionChlorinated paraffins

The invention discloses a PVC antistatic adhesive tape and a preparation method thereof, and the PVC antistatic adhesive tape comprises the following raw materials by weight: 110-130 parts of PVC, 2-3parts of sucrose acetate isobutyrate, 20-30 parts of antistatic emulsion, 0.1-0.2 part of lead sulfate tribasic, 1-2 parts of calcium stearate, 4-5 parts of chlorinated paraffin, 2-3 parts of divinylbenzene and 10-12 parts of calcium carbonate. The PVC antistatic adhesive tape adopts the divinylbenzene and the calcium carbonate as a filler, the compatibility of the filler in a PVC matrix can be improved by crosslinking modification, the toughness and mechanical strength of the PVC can be improved, and the PVC antistatic adhesive tape has strong electrostatic properties, high safety and comprehensive performance.

Owner:江苏亚龙新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com