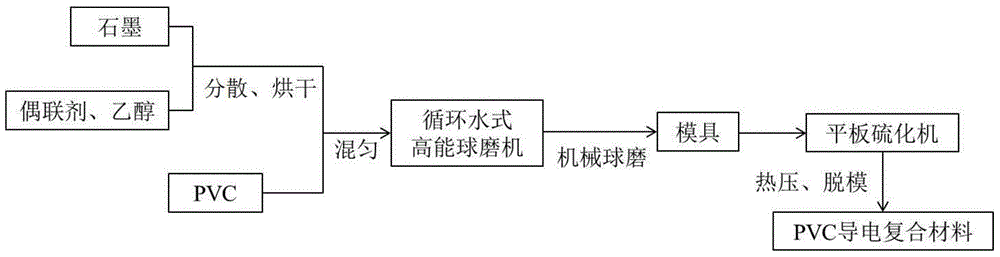

Method for preparing PVC conductive composite material through mechanical milling method

A conductive composite material, mechanical ball milling technology, applied in the direction of grain processing, etc., can solve the problems of uneven dispersion of fillers, uneven material composition, unstable performance, etc., to shorten the ball milling time, easy to adjust the resistivity, and electrical conductivity. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the PVC conductive composite material in this embodiment is firstly to place the graphite in absolute ethanol with the addition of coupling agent silane KH570, the amount of silane KH570 is 2% of the graphite weight, and stir at a constant temperature until the graphite is dispersed in ethanol , suction filtration, dry the graphite to obtain modified graphite, put the modified graphite and PVC in the ratio of 20%:80% into a circulating water type high-energy ball mill, and mechanically ball mill at a speed of 150 rpm and a temperature of 50°C for 1 h , disperse the graphite evenly into the PVC matrix to obtain a mixture, fill the mixture into the mold of a flat vulcanizer, heat press at a pressure of 5 MPa and a temperature of 165°C for 15 minutes, and demould to obtain a PVC conductive composite material.

[0036] The product prepared in this example has a conductive permeation threshold lower than 6%, a resistivity of 0.169 Ω·cm, a tensile str...

Embodiment 2

[0038] The preparation method of this PVC conductive composite material in the present embodiment, at first is that graphite is placed in the dehydrated alcohol that adds coupling agent aluminate, and the consumption of aluminate is 2.5% of graphite weight, is stirred at constant temperature until graphite is dispersed in In ethanol, filter with suction, dry the graphite to obtain modified graphite, put the modified graphite and PVC in the ratio of 15%:85% into a circulating water-type high-energy ball mill, and mechanically ball mill at a speed of 100 rpm and a temperature of 45°C 2.0 h, disperse the graphite evenly into the PVC matrix to obtain a mixture, fill the mixture into the mold of a flat vulcanizer, heat press at a pressure of 6 MPa and a temperature of 160°C for 20 minutes, and demould to obtain a PVC conductive composite material.

[0039] The product prepared in this example has a conductive percolation threshold lower than 6%, a resistivity of 0.499 Ω·cm, a tensil...

Embodiment 3

[0041] The preparation method of the PVC conductive composite material in this embodiment is firstly to place the graphite in absolute ethanol with the addition of coupling agent titanate, the amount of titanate is 1% of the weight of the graphite, and stir at a constant temperature until the graphite is dispersed in In ethanol, filter with suction, dry the graphite to obtain modified graphite, put the modified graphite and PVC in the ratio of 18%:82% into a circulating water-type high-energy ball mill, and mechanically ball mill at a speed of 300 rpm and a temperature of 48°C After 0.5 h, the graphite was evenly dispersed into the PVC matrix to obtain a mixture, which was filled into the mold of a flat vulcanizer, and hot-pressed at a pressure of 7 MPa and a temperature of 180°C for 10 minutes, and demolded to obtain a PVC conductive composite material.

[0042] The product prepared in this example has a conductive permeation threshold lower than 6%, a resistivity of 0.252 Ω·c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com