Preparation method for flexible self-supporting porous carbon nanofiber electrode and application thereof

A nanofiber, self-supporting technology, applied in nanotechnology, battery electrodes, nanotechnology, etc., can solve the problems of high production cost and complex production process, and achieve the effect of improving electrical conductivity, good mechanical properties, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

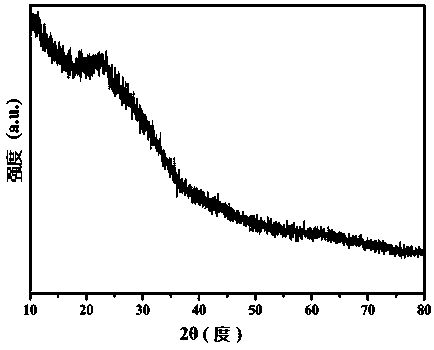

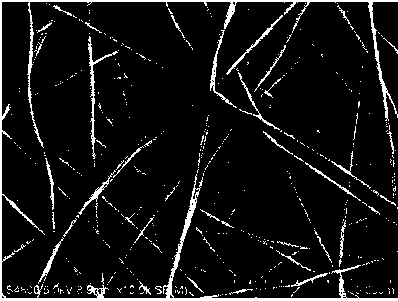

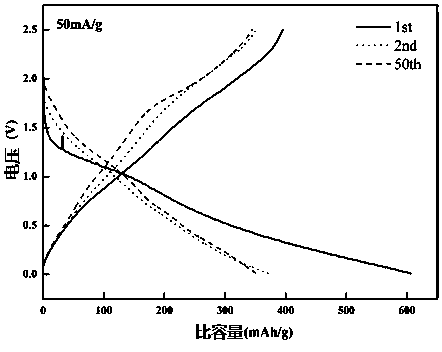

[0022] In this example, coaxial electrospinning is used to prepare nitrogen-doped flexible self-supporting porous carbon nanofiber electrode material, and it is used as a negative electrode material for sodium-ion batteries. The specific steps are:

[0023] Dissolve 1g of polyacrylonitrile and 1g of polyvinylpyrrolidone in 10 ml of organic solvent 1,2-dimethylformamide, respectively, and magnetically stir at 30 °C for 12 h to obtain an electrospinning precursor; A special coaxial needle, with polyvinylpyrrolidone solution as the core and polyacrylonitrile solution as the shell, at a temperature of 50 °C and a humidity of 10%, the two precursors flowed to the spinning needle at a constant speed of 10 μl / min. Adjust the distance from the needle to the receiver to 20 cm, form nanofibers under the action of an electrostatic field of 15kV, and use the receiver to receive the fibers to form spun fiber cloth; arrange the spun fibers in a muffle furnace for pre-oxidation, and the heati...

Embodiment 2

[0027] The process and method of this embodiment are the same as those in Embodiment 1. The difference is that the added polymer containing doping elements is changed from polyacrylonitrile to polythiophene.

Embodiment 3

[0029] The process and method of this embodiment are the same as those in Embodiment 1. The difference is that the added decomposing pore-forming polymer is changed from polyvinylpyrrolidone to polymethylmethacrylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com