Patents

Literature

226results about How to "Shorten milling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing flake silver powder with low bulk density

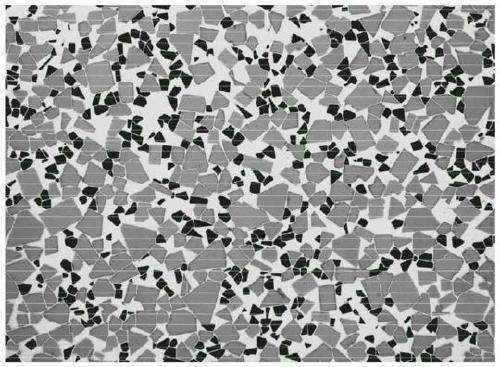

The invention provides a method for preparing flake silver powder with low bulk density. The method comprises the following steps of reducing silver powder, i.e. adding pure water into a reaction container, and adding silver nitrate under a stirring condition to make the silver nitrate completely dissolved; adding a PH(Potential Of Hydrogen) value regulator, stirring, adding formaldehyde serving as a reducer to perform chemical reaction, washing the silver powder and drying; and ball-milling, i.e. weighing the silver powder, adding zirconia, filling in a ball-milling pot, adding a ball-milling solvent, a ball-milling aid and an emulsifier, ball-milling, sieving, washing by using a cleaning solvent, and drying to obtain the flake silver powder. The silver powder prepared in the reducing process by the method is not added with any dispersing agent, has low impurity content and high purity; and moreover, the technical process is simple, the ball-milling time is short, and the method is easily industrialized.

Owner:湘潭市泽宇新材料科技有限公司

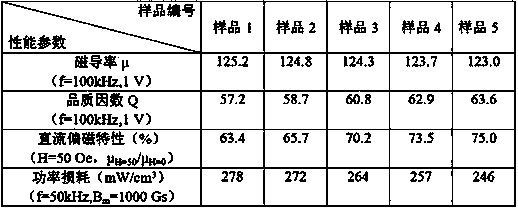

Preparing method of metal magnetic powder core

InactiveCN104036902AImprove processing performanceShorten milling timeInorganic material magnetismAlloy elementQuenching

The invention discloses a preparing method of a metal magnetic powder core. The preparing method includes the following steps that (1) master alloy is melt through a vacuum induction furnace, and an alloy thin belt is obtained through a quick quenching device; (2) ball milling is conducted on the thin belt; (3) annealing is conducted on powder; (4) particle size distribution is conducted on the annealed powder; (5) passivant is added into the distributed powder to conduct passivating on the powder, and then a binding agent and an insulating agent are added into the powder to conduct insulating bonding and wrapping on the powder; (6) a lubricating release agent is then added, the mixture is mixed, and compression moulding is conducted; (7) annealing is conducted on a sample obtained through compression moulding, and the sample is cooled along with the furnace, and spraying and coating are conducted to obtain the target product. According to the preparing method, the master alloy contains an appropriate number of alloy elements, so that the alloy processing performance is improved; the alloy powder and an insulating medium are mixed and pressed to be the magnetic powder core, so that eddy-current loss under a high frequency can be greatly reduced; meanwhile, the problem that alloy materials are limited in use due to single shapes is solved through shape diversity of the magnetic powder core.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD +1

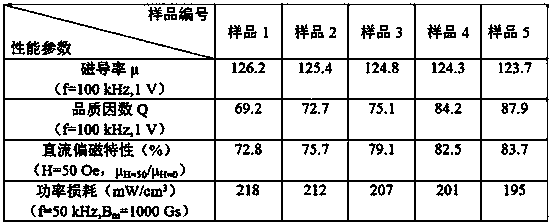

Making method for electromagnetic wave interference resisting iron ,silicon, aluminum and nickel alloy

The invention discloses a preparation method for electromagnetic wave interference resistant iron silicon aluminum nickel alloys. The invention comprises the following steps: firstly, ferrum, aluminum, silicon and nickel with a purity more than 99.9 weight percent are taken as raw materials and laid into a medium frequency vacuum induction furnace for smelting, and a master alloy is obtained; secondly, the master alloy after smelting is laid into a quick quenching device; an alloy ingot casting is quickly poured on a water-cooling roll wheel which rotates at high speed after arc remelting under the protection of high purity inert gases, and a quickly condensed sheet band or a quickly condensed sheet is obtained; thirdly, the sheet band or the sheet is laid into a ball mill for ball milling flat processing, and flat powder is obtained; fourthly, the flat powder is laid into a stainless steel tube which is then vacuumized and filled with high purity inert gases for protection, and then the stainless steel tube is laid into a tube furnace for heating, heat preservation and cooling along with the furnace; fifthly, the flat powder and binding agents are mixed and milled for processing the sheet. The preparation method for the electromagnetic wave interference resistant iron silicon aluminum nickel alloys adds adequate nickel into Sendust alloys, thereby the processability of the alloys is improved; the ball milling time is reduced; the cost of industrial production is saved; simultaneously the magnetic conductivity can be improved and the magnetic shielding effect can be improved.

Owner:ZHEJIANG UNIV +1

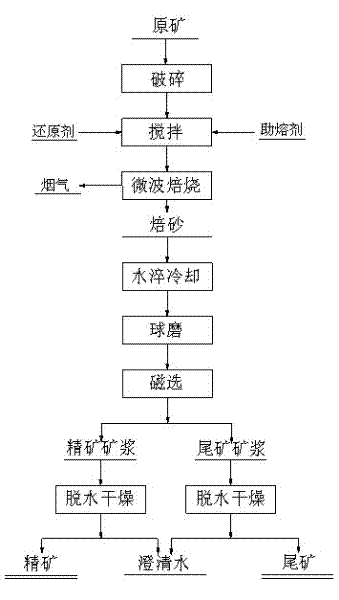

Method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation

InactiveCN102212677AReduce grinding energy consumptionShorten milling timeMagnetic separationMixed materialsQuenching

The invention relates to a method for refining iron and removing phosphorus from complex refractory high-phosphorus iron ore, in particular to a method for sorting high-phosphorus iron ore by combining microwave reduction roasting and low intensity magnetic separation, and belongs to the technical field of mineral processing, particularly iron ore beneficiation. The method comprises the following steps: crushing refractory high-phosphorus iron ore used as raw material into granules with granularity of less than 2mm; mixing the crushed raw ore with a fluxing agent and a reducing agent in a certain proportion; transferring the obtained mixed material into a microwave reaction furnace for reduction roasting; and carrying out water-quenching, cooling, ball-milling and wet-magnetic-separating on the obtained roasted ore to finally obtain iron ore concentrate. In the method, the ore is reduced by utilizing a microwave roasting technology, wherein microwave reduction roasting time is short, and the temperature of the ore is raised quickly; and meanwhile the fluxing agent is added so as to promote gangue softening and improve refractory ore structure together with microwave roasting reaction. By utilizing the method for sorting the high-phosphorus iron ore, the iron ore concentrate with grade of more than 58.39% can be obtained, and phosphorus removal rate reaches over 70.44%, thus a new technique is provided for sorting the high-phosphorus iron ore.

Owner:KUNMING UNIV OF SCI & TECH

Nano hard alloy material containing spherical face-centered cubic structure cobalt powder and preparation process thereof

The invention provides a nano hard alloy material containing spherical face-centered cubic structure cobalt powder and a preparation process thereof and belongs to the technical field of hard alloy preparation. The method comprises the steps of using 12-14 wt.% of the spherical face-centered cubic structure cobalt powder with the average grain diameter in a range of 200-300nm, 65-70 wt.% of tungsten carbide with the average grain diameter in a range of 200-300nm, 16-23 wt.% of tungsten carbide-titanium carbide-vanadium carbide-tantalum carbide-chromium carbide solid solution powder with the average grain diameter in a range of 300-400nm and a proper amount of an active and surface dispersing agent, and combining with airtight inert gases to protect high-speed ball milling, spray drying and overpressure sintering, so that sintering bodies are compact to the maximum extent, grain growth is restrained, the high-temperature performance of an alloy is optimized, and finally the high-hardness high-strength hard alloy material is obtained. The process is optimal in technology, easy to operate and applicable to industrial production.

Owner:重庆金锐新材料技术研究院有限公司

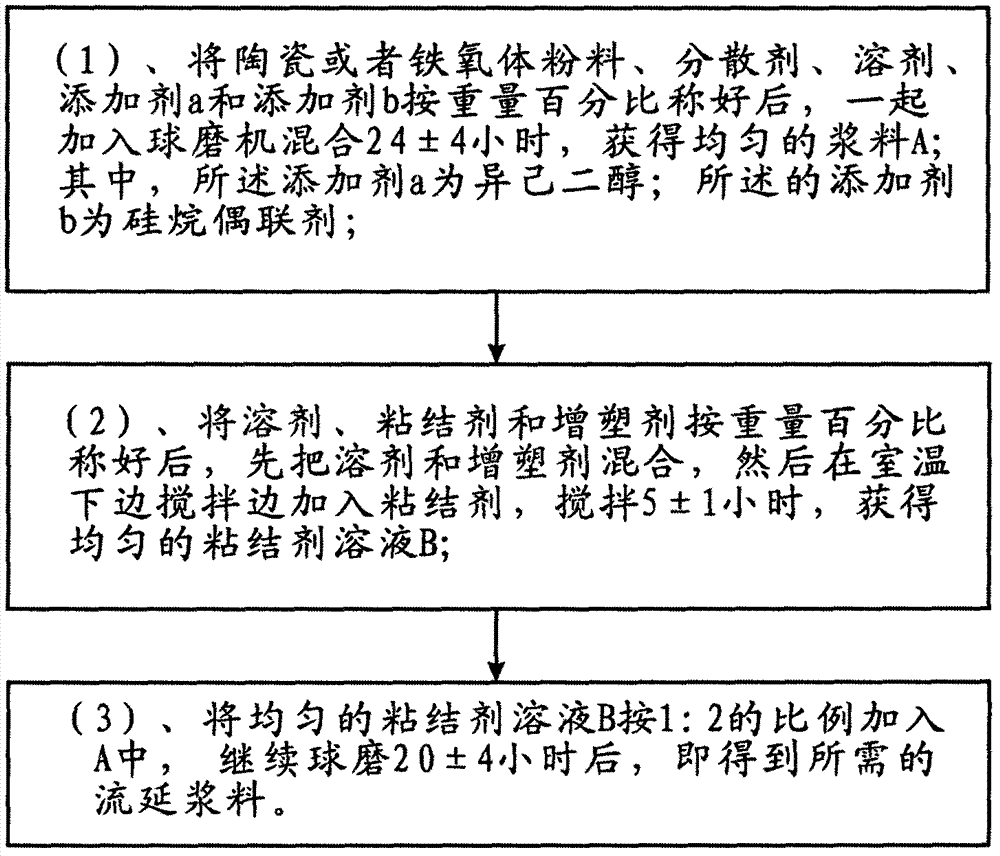

Tape casting slurry for laminated sheet type electronic component and preparation method for tape casting slurry

The invention discloses tape casting slurry for a laminated sheet type electronic component and a preparation method for the tape casting slurry. The tape casting slurry comprises 45 to 55 weight percent of ceramic or ferrite powder, 0.1 to 1.0 weight percent of dispersing agent, 30 to 48 weight percent of solvent, 3 to 8 weight percent of adhesive, 3 to 5 weight percent of plasticizer, 0.1 to 0.5 weight percent of 2-methyl-2,4-pentendiol serving as an addition agent a and 0.1 to 0.5 weight percent of silane coupling agent serving as an addition agent b. The 2-methyl-2,4-pentendiol is added, so that the problems that the viscosity of the slurry is rapidly increased, and the performance of a membrane is rapidly deteriorated because boric is added are solved; the silane coupling agent is added, so that the slurry is low in viscosity and high in dispersing performance, the green density of the membrane is increased, and the ductility is enhanced; and the finally prepared slurry is uniform, stable and suitable for large-scale production.

Owner:SHENZHEN GUDIAN ELECTRONICS

Method for preparing superfine AgSnO2 doped electrical contact material by high energy ball milling method

The invention discloses a method for preparing a superfine AgSnO2 doped electrical contact material by a high energy ball milling method. The method comprises the following specific steps: (1), a superfine SnO2, La2O3, CuO and CdO mixed oxide suspension is prepared with a high energy ball milling wet mixing method; (2), two types of silver powder with different particle sizes are mixed, and added to the superfine SnO2, La2O3, CuO and CdO mixed oxide suspension; (3), the mixed silver power and superfine mixed oxide power are subjected to ball milling treatment to form AgSnO2 composite powder; (4), the AgSnO2 composite powder is subjected to annealing treatment; (5), the annealed AgSnO2 composite is moulded and sintered; and (6), the superfine AgSnO2 doped electrical contact material is obtained. According to the method, oxide and the silver powder are mixed uniformly before high energy ball milling, and subjected to the high energy ball milling and subsequent processing, and then the contact material with superfine oxide dispersedly distributed in a silver substrate can be prepared.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Nano microstructure silicon negative electrode material preparation method

ActiveCN108336345AInhibition of volume expansionEnsure structural stabilityMaterial nanotechnologyElectrode manufacturing processesLithiumNano silicon

The invention discloses a nano microstructure silicon negative electrode material preparation method. The preparation method comprises the following steps: 1) metallurgy nano silicon is dispersed in organic dispersion liquid; 2) HF-metal salting liquid is prepared as an etching agent, the etching agent is slowly added in silicon pre-dispersion liquid, and the nano silicon with the surface deposited with the metal particles can be obtained; 3) the nano silicon with the surface deposited with the metal particles is re-dispersed in the organic dispersion liquid; 4) a HF-H2O2 solution is added inthe silicon dispersion liquid, and the organic dispersion liquid is intermittently added; 5) porous silicon is immersed in a HNO3 solution to obtain the high-purity porous silicon; and 6) the high-purity porous silicon is subjected to ball milling processing with a controllable oxidation degree. The method employs combination of metal auxiliary chemical etching and ball milling with the controllable oxidation degree, and the nano microstructure silicon negative electrode material with the surface coated with a layer of compact oxide SiOx and having micropores inside can be prepared, a lithium ion transmission path is shortened, silicon volume expansion can be accommodated, and the method has excellent cycle stability.

Owner:湖南宸星新材料研究院有限公司

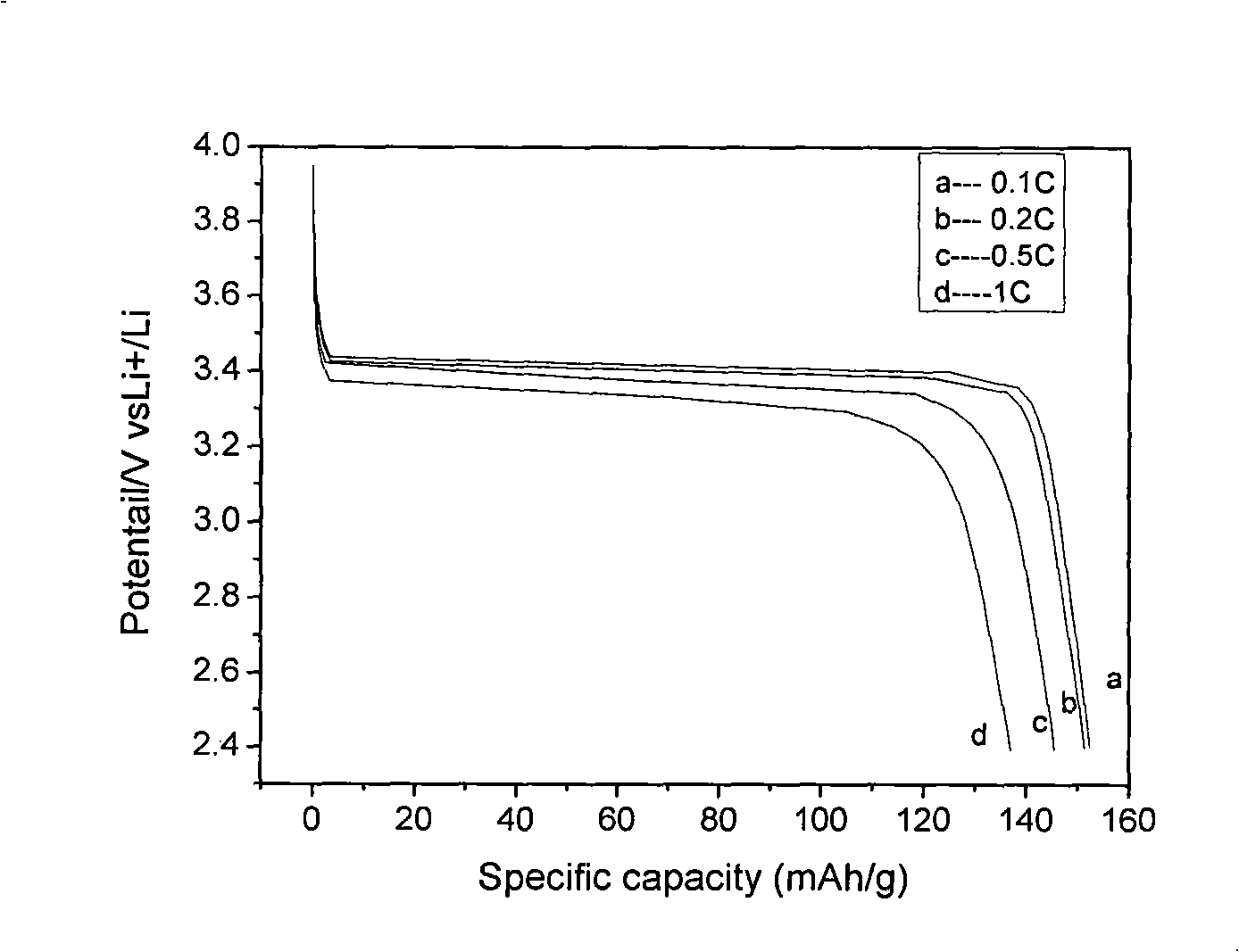

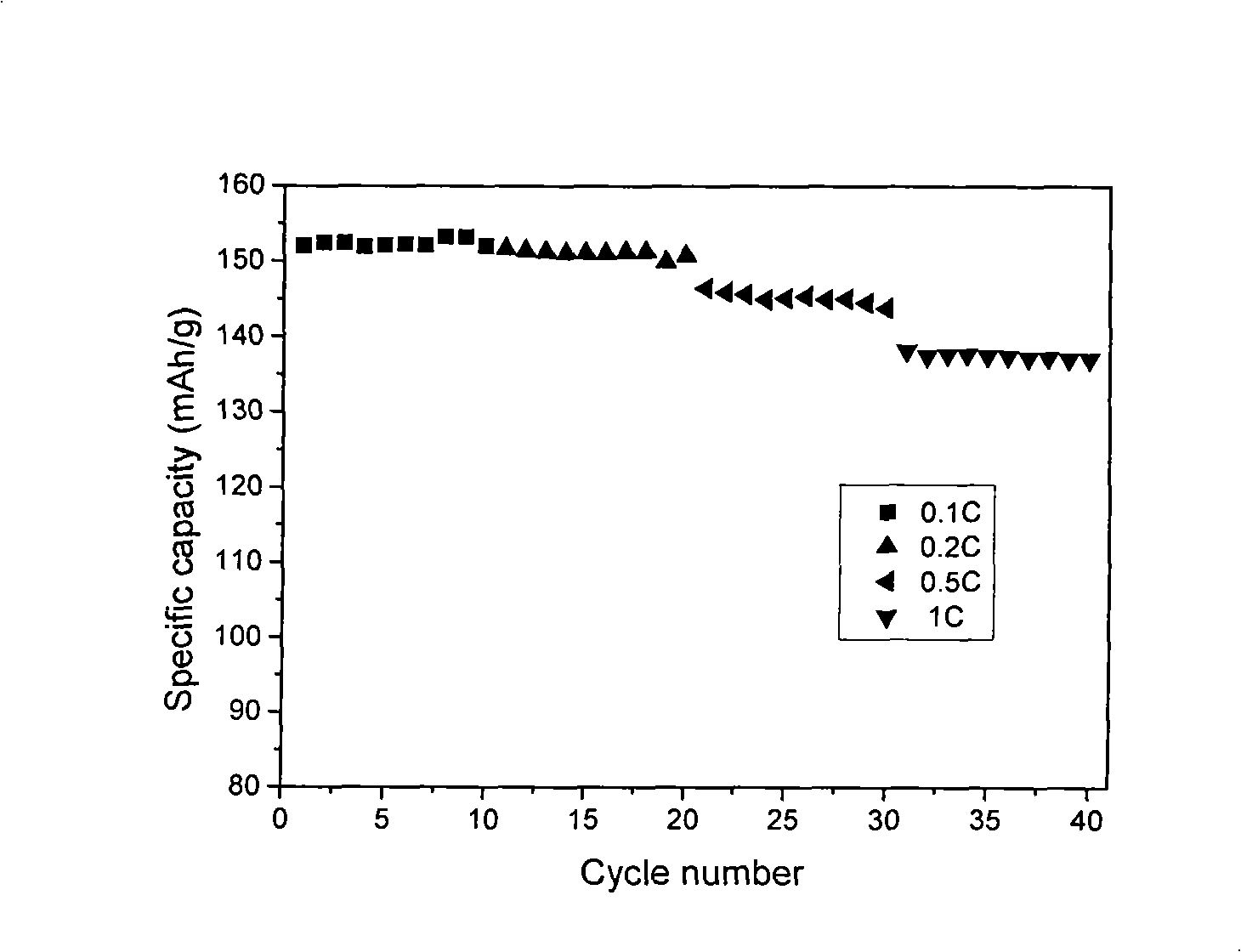

Method for preparing ferric phosphate lithium anode material combining solid and liquid

A method for preparing a lithium iron phosphate anode material through solid-liquid combination comprises the following steps that a lithium source compound, an iron source compound, a phosphoric acid and phosphorus source compound and a small amount of carbonic organic precursor are weighed in proportion and mixed evenly, and then dried at a temperature of between 80 and 120 DEG C; the dried mixture undergoes ball milling inside a star-type ball-milling tank for 10 to 60 minutes so as to obtain a precursor powder material; the precursor powder material undergoes sweeping in the inert atmosphere or the reducing atmosphere for 3 to 5 minutes and then is sealed; the precursor powder material is heated to 400 to 800 DEG C at a heating rate of between 1 and 30 DEG C / min, and the temperature is maintained for 3 to 8 hours; and finally, the material is cooled down to room temperature, and is crushed to prepare lithium iron phosphate powder. Due to adopting solid-liquid combined raw materials, the method not only ensures that the raw materials are mixed more evenly, but also provides effective reducing atmosphere to synthesize the anode material with excellent electrochemical property during later sintering; moreover, a high-temperature solid-liquid combination method is adopted to reduce reaction temperature, reaction time and production cost.

Owner:CHONGQING TERUI BATTERY MATERIAL

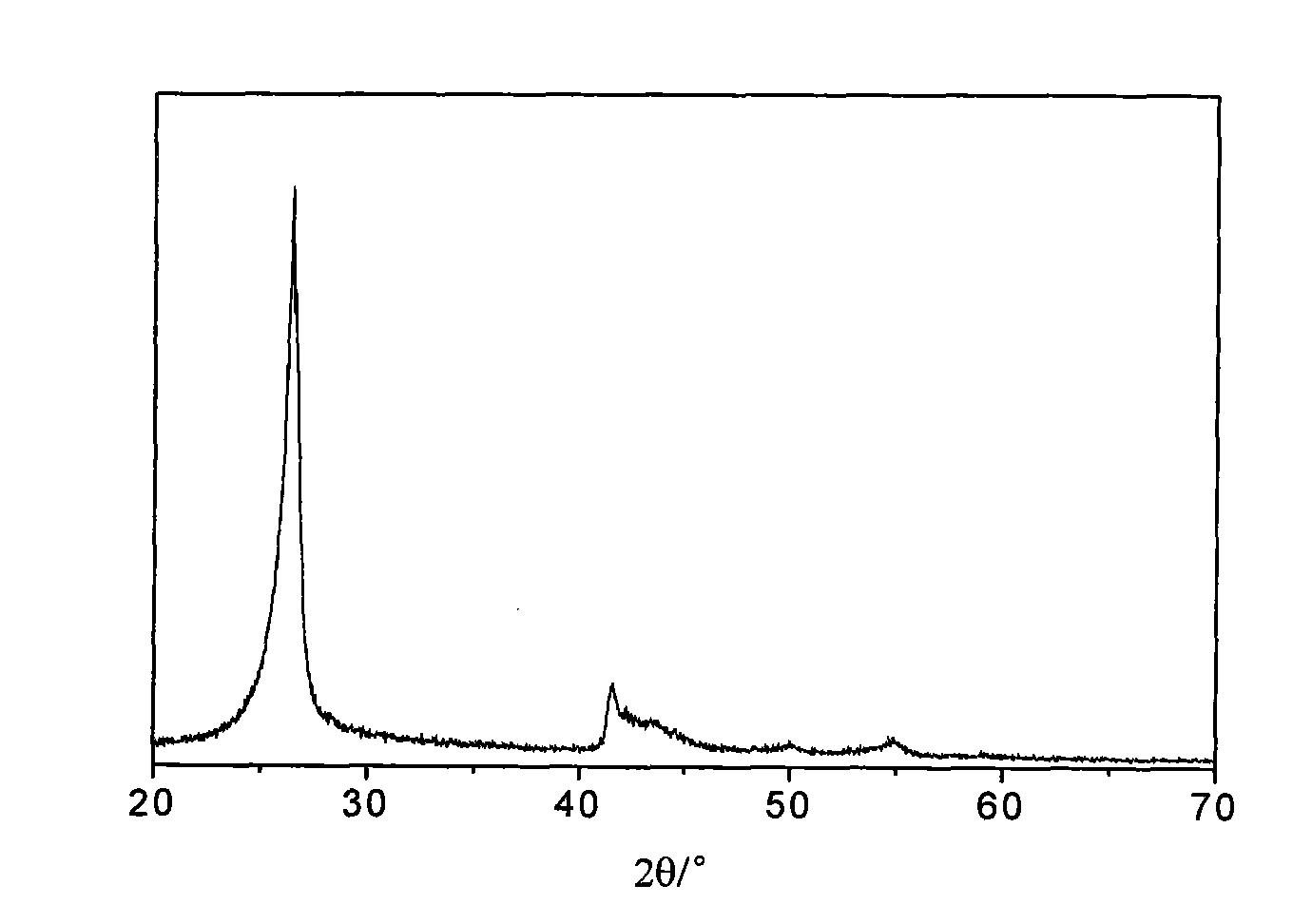

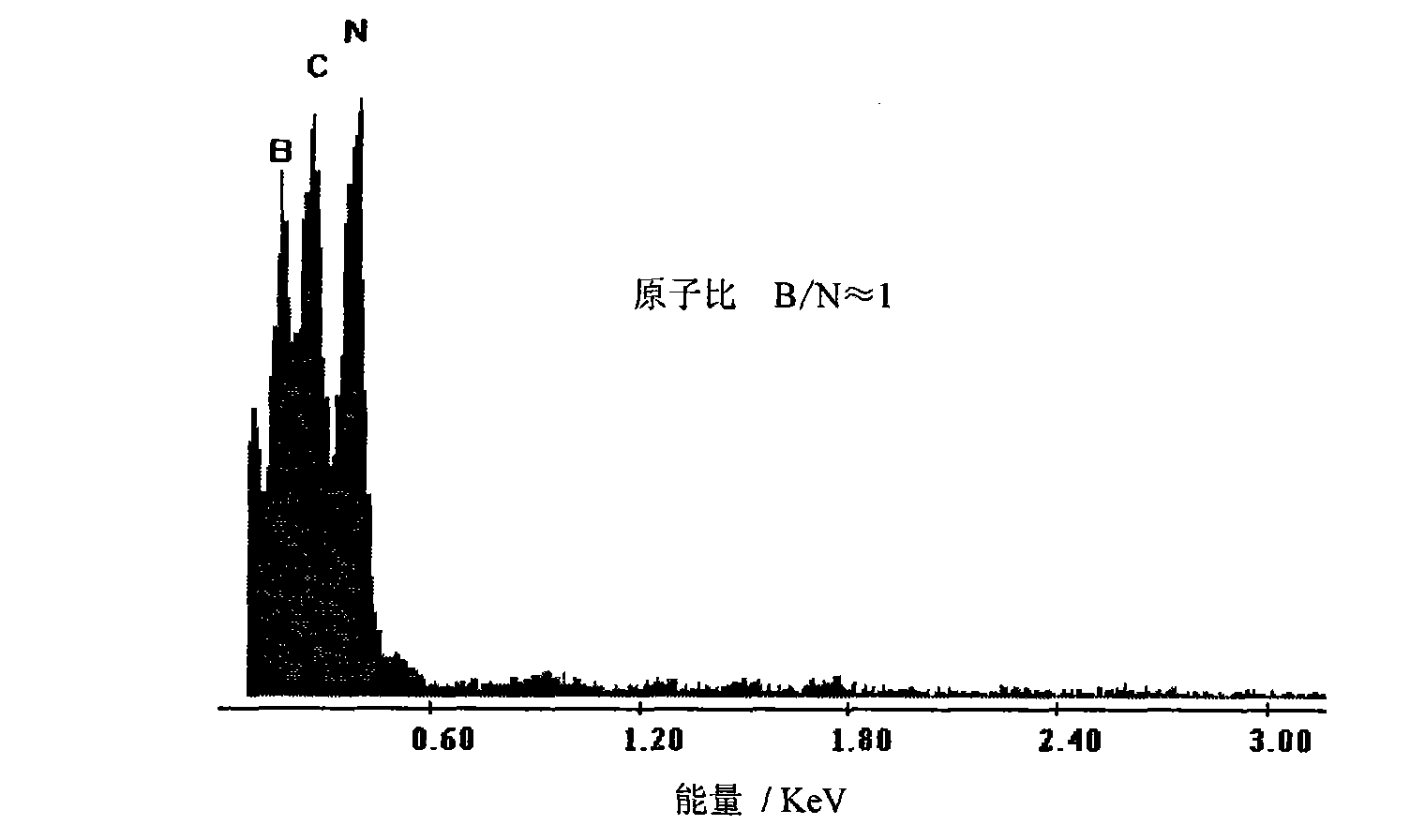

Preparation method of boron nitride nano tube with controllable dimension

InactiveCN101633498AHigh yieldEasy to purifyNanostructure manufactureNitrogen compoundsBoron nitrideNitrogen gas

The invention belongs to the field of inorganic nano material. The prior preparation method of a boron nitride nano tube has the problems of low production rate, high cost, complicated technology, difficult dimension control and the like. The preparation method comprises the steps: putting boron and a catalyst on the basis of weight ratio of 1 to (0.01 to 0.05) into a plastic bottle; using a nonaqueous solvent as a medium; ball-milling the boron and the catalyst for 8 to 24 hours; sieving the boron and the catalyst in a screen of 100 meshes after drying; heating a sieved mixture under the protection of argon gas; stopping leading the argon gas and leading nitrogen gas or the mixed gas of ammonia gas and the nitrogen gas when the temperature reaches 1000 DEG C to 1300 DEG C; keeping the temperature for 0.5 to 5 hours; reducing the temperature to room temperature after the constant temperature is finished; adding an obtained product to nitric acid for ultrasonic processing; removing the remained catalyst; and obtaining the boron nitride nano tube. The preparation method has the advantages of low cost, simple preparation technology, good repeatability and easy control and amplification of reaction; and the obtained boron nitride nano tube has the advantages of high production efficiency, easy purification, controllable tube diameter, controllable length and the like.

Owner:BEIJING UNIV OF TECH

Double-component conductive ink and preparing method thereof

The invention discloses a double-component conductive ink and a preparing method thereof. The double-component conductive ink is prepared from, by mass, 6-30 parts of conductive filler, 6-15 parts of resin, 0.5-1.5 parts of a dispersing agent, 1-5 parts of an auxiliary and 48.5-85 parts of a solvent. The preparing method of the double-component conductive ink comprises the following steps that firstly, a part of the solvent is taken and mixed with the resin through stirring until a transparent bonding material is obtained; secondly, the bonding material, the conductive filler, the auxiliary, the dispersing agent and the rest of the solvent are added into a ball grinder, and ball milling beads are added for grinding for 3-10 h after the conductive filler is wetted; thirdly, the ground material is filtered, and the finished product conductive ink is obtained. By means of the double-component conductive ink and the preparing method thereof, the problem that the preparing process and the preparing period of conductive ink are long in the prior art is solved, and the conductive ink has better conductivity and higher dispersibility.

Owner:DEYANG CARBONENE TECH

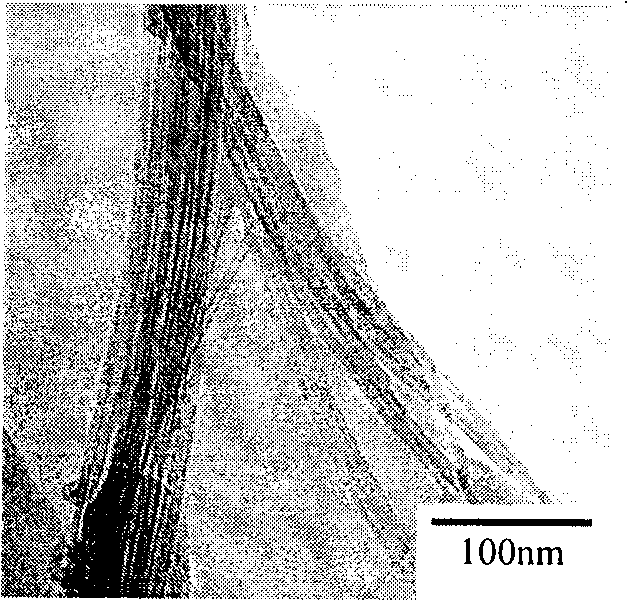

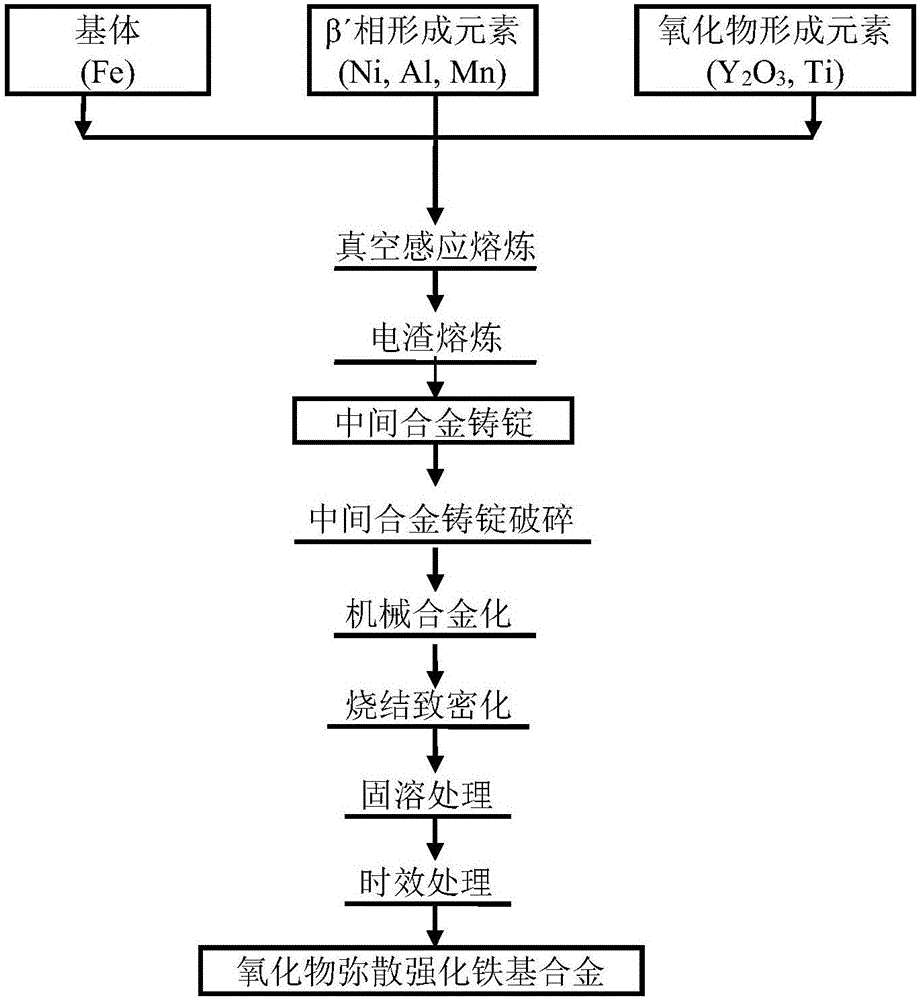

Method for preparing oxide dispersion strengthened iron-base alloy

The invention discloses a method for preparing an oxide dispersion strengthened iron-base alloy, and belongs to the technical field of metal dispersion strengthening. The method comprises the following steps of: taking iron blocks, a Fe-Mn alloy and an Ni-Al alloy as raw materials, performing a vacuum smelting and electroslag smelting duplex process to obtain a pure intermediate alloy cast ingot; crushing the intermediate alloy cast ingot in a crusher with protective atmosphere to obtain intermediate alloy powder; and performing high-energy ball-milling on intermediate alloy powder, matrix powder and oxide powder to obtain the oxide dispersion strengthened iron-base alloy. Oxide dispersion strengthened iron-base alloy powder is subjected to hot isostatic pressing treatment and thermal treatment to obtain the final oxide dispersion strengthened iron-base alloy. The method adopts the duplex smelting process, so that content of oxygen and nonmetal impurities in cast ingot is effectively reduced; the alloyed intermediate alloy prevents oxidization of an element Mn, ball-milling time can be shortened and energy consumption is reduced. The prepared oxide dispersion strengthened iron-base alloy is co-strengthened by a L21 type Ni2AlMn intermetallic compound and an oxide dispersed phase, so that the strengthening effect is remarkable.

Owner:UNIV OF SCI & TECH BEIJING

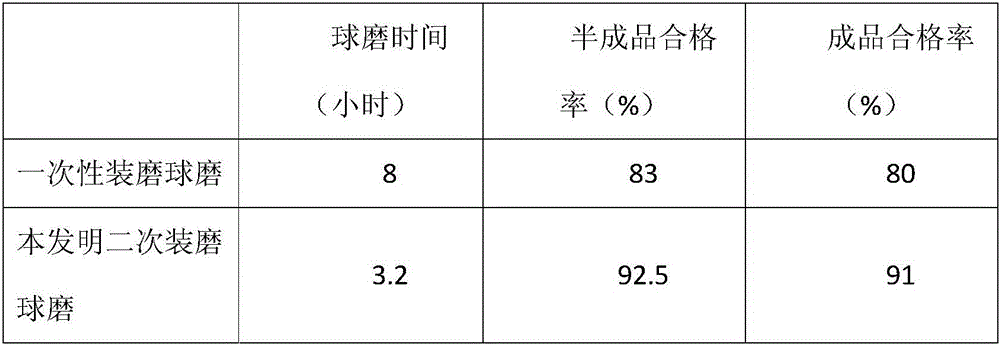

Process method for producing high-quality medium-alumina ceramic ball by inferior raw material

The invention discloses a process method for producing high-quality medium-alumina ceramic balls by inferior raw materials, which comprises the following steps: firstly washing a main raw material - inferior bauxite clinker with water, picking out to remove impurities, adding the inferior bauxite clinker with removed impurities, diaspore, clay, an efficient flux component and a diluent into a ball mill on a weight basis, performing ball milling twice with a proper amount of water, performing primary coarse milling and sieving by a 400-mesh sieve, performing secondary fine milling and sieving by a 600-mesh sieve, performing wet washing of the prepared slurry to remove iron, performing spray granulation and homogenization to prepare a mud blank, then performing dry-pressing, classification and molding with a mould, drying to prepare a semi-finished ceramic ball, charging the semi-finished ceramic ball into a kiln, sintering the ceramic ball at a preserved temperature of 1340 DEG C. The invention shortens the ball milling time, saves energy, reduces cost, uses a large amount of inferior raw materials, widens the range for material selection, produces high-quality medium-alumina ceramic balls with high strength, good wear resistance, and comparable application effect to existing medium-alumina ceramic balls, reduces production cost by 10-15%, is energy-saving and high-efficient, and facilitates healthy economic development.

Owner:PINGXIANG WUXING CERAMIC

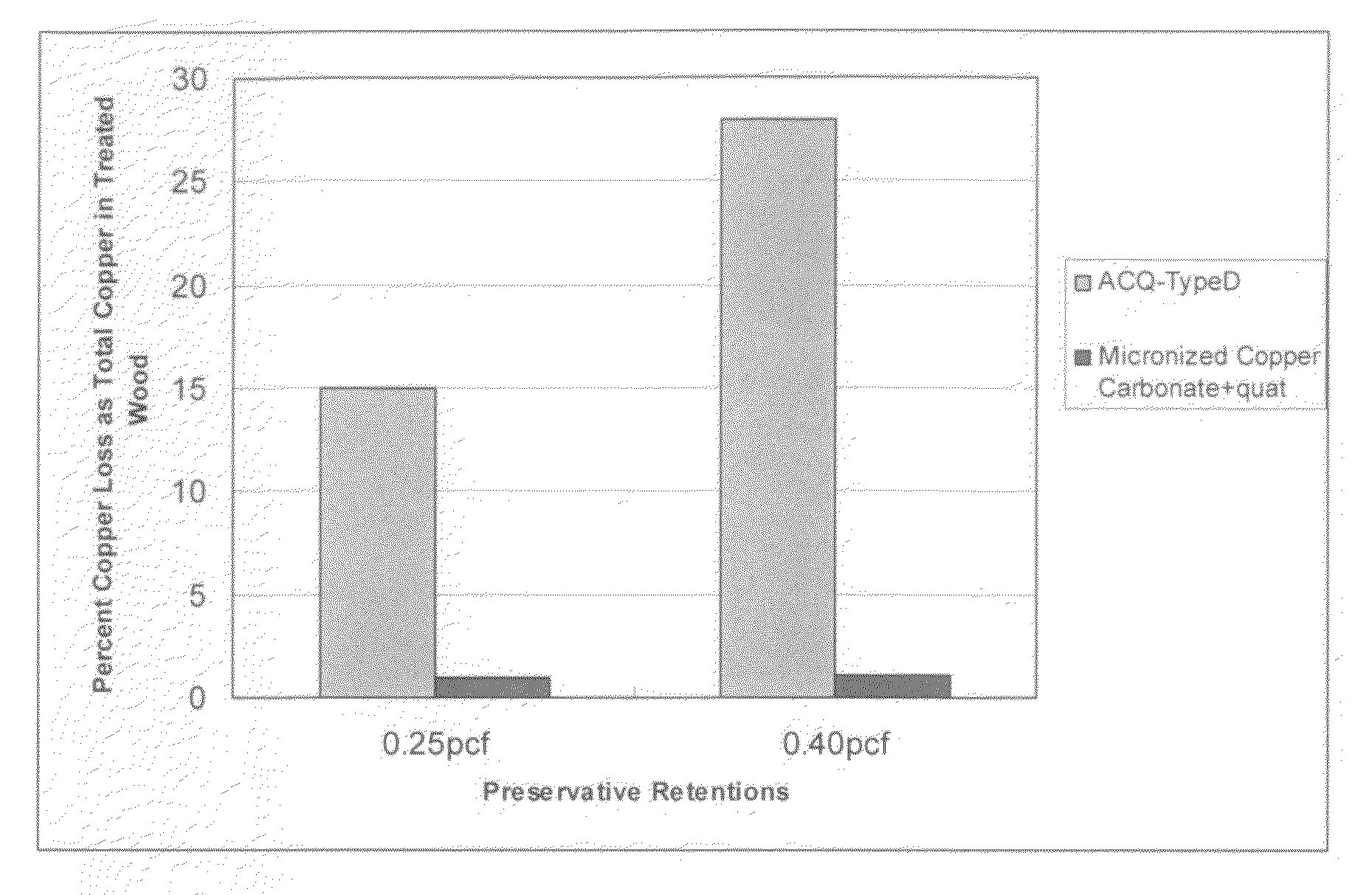

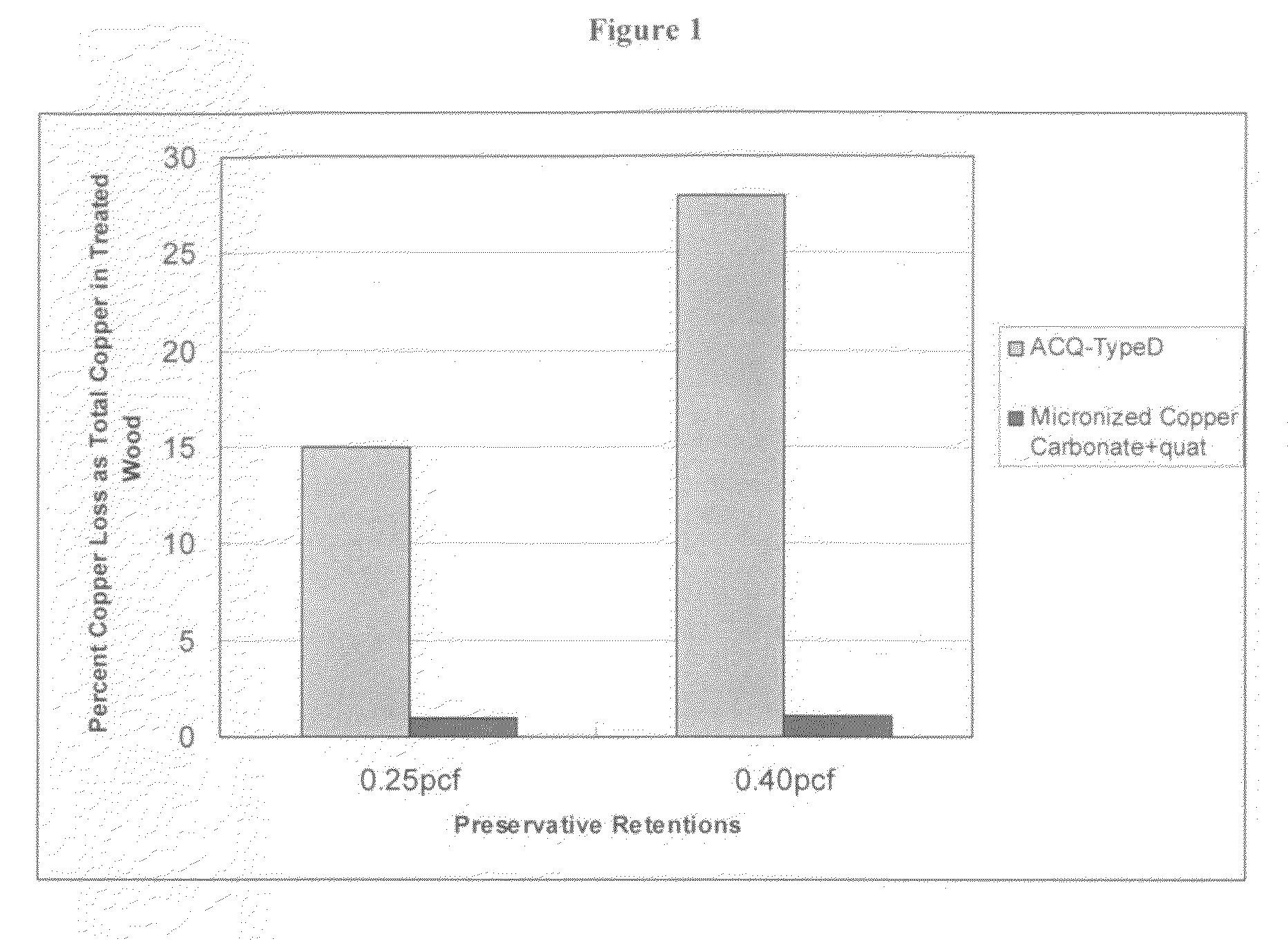

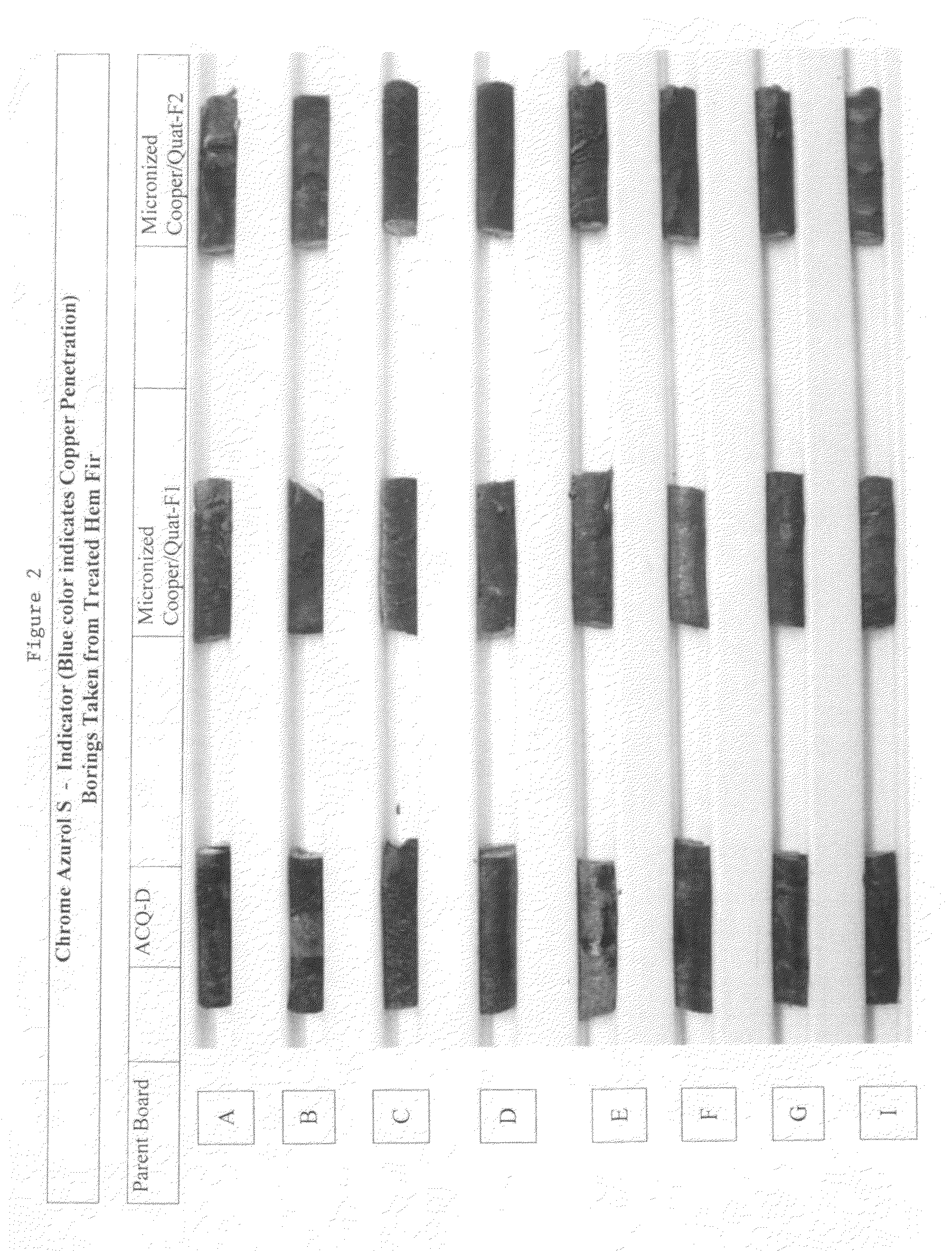

Process for preparing fine particle dispersion for wood preservation

The present invention provide a method for producing micronized solid particles through a two-step process. The solid particles of the invention comprise metals or metal compounds, especially copper and copper compounds. The solid particle of the invention further comprise organic biocides. The invention further provides a wood preservative composition and wood comprising the solid particles of the invention, which may be diluted to the target concentration with or without addition of a co-biocide and vacuum / pressure impregnated into a variety wood species including refractory wood species to effectively preserve the material from fungal and insect attack.

Owner:KOPPERS PERFORMANCE CHEM

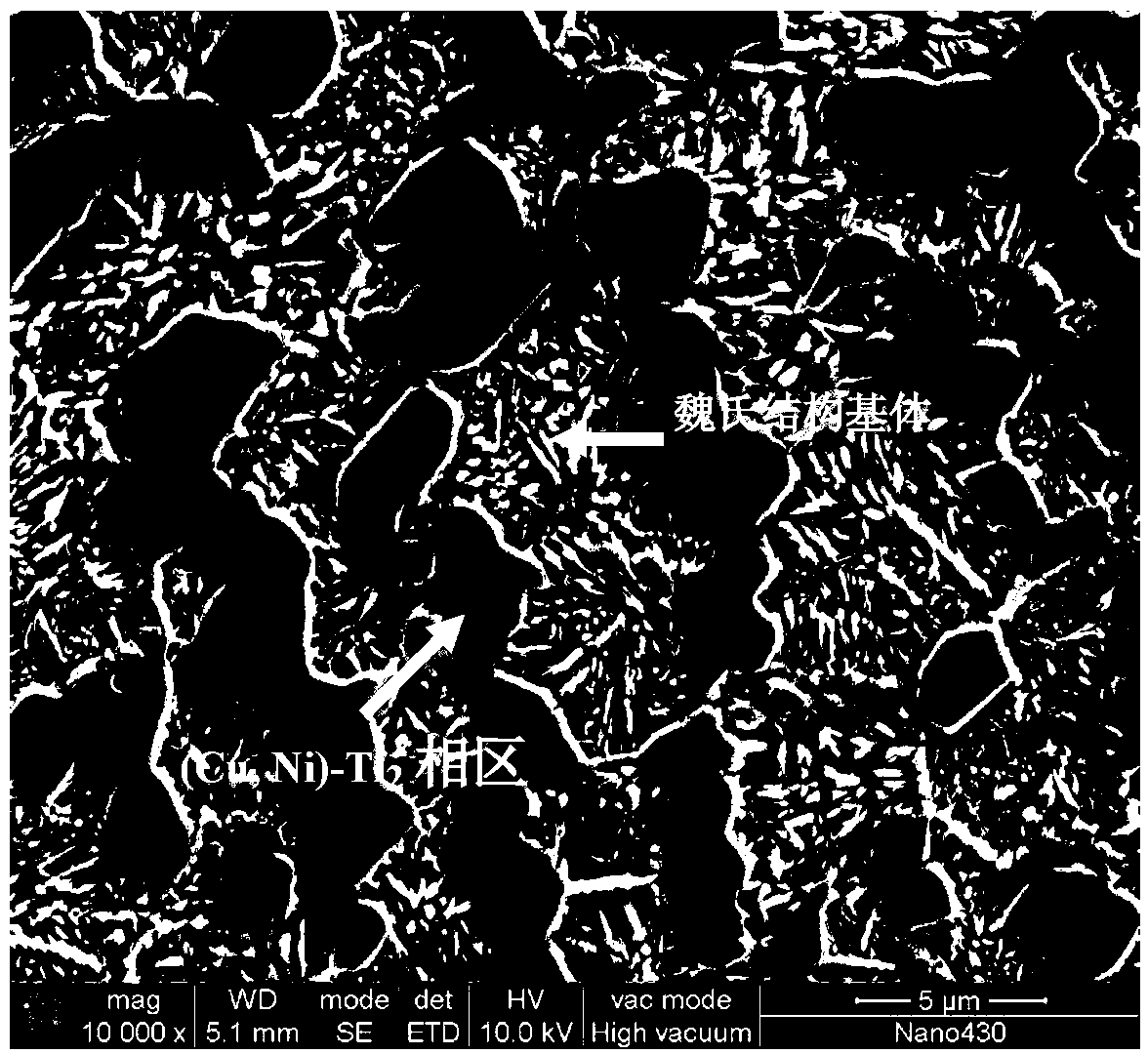

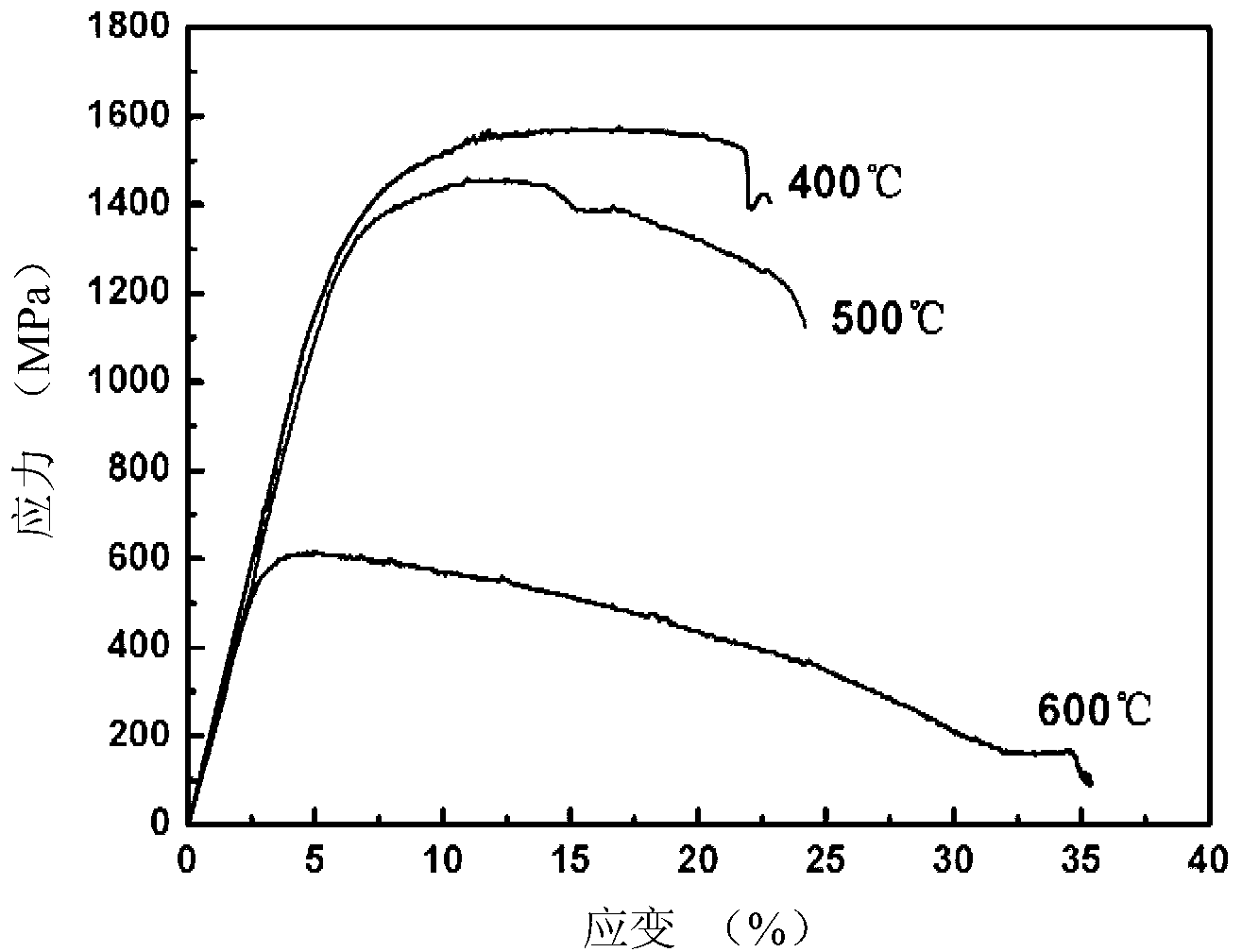

Ti-based high temperature alloy with high toughness in bi-state structure and preparation method and application thereof

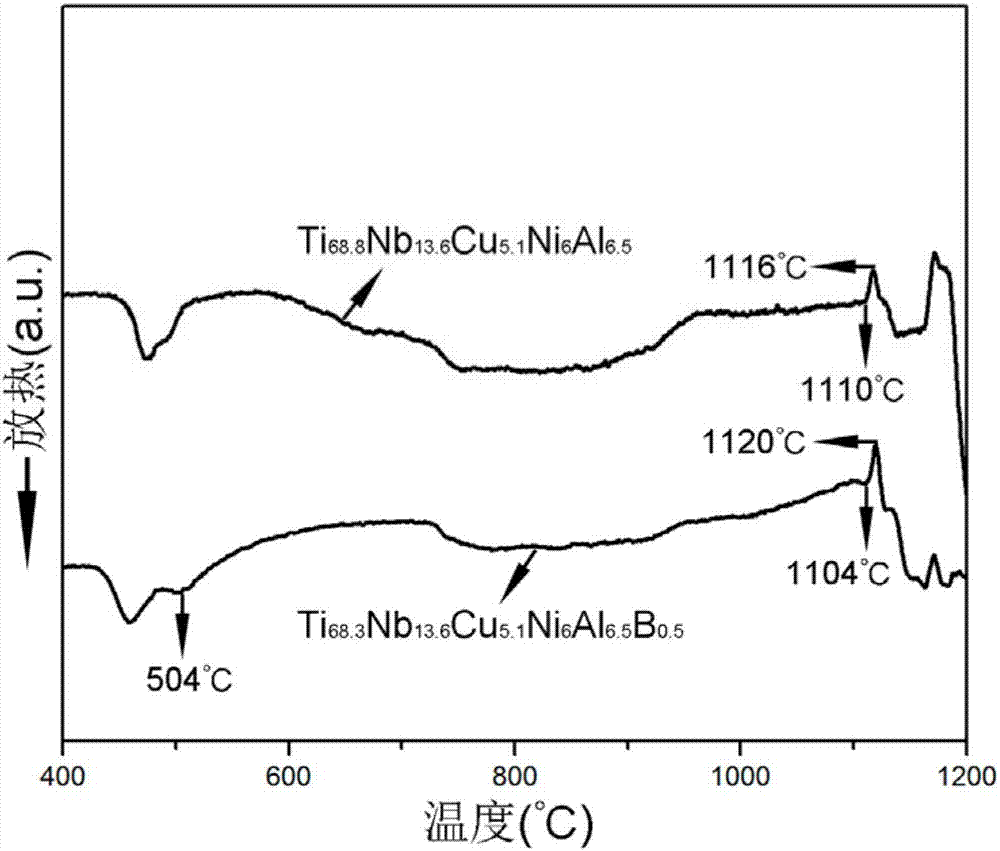

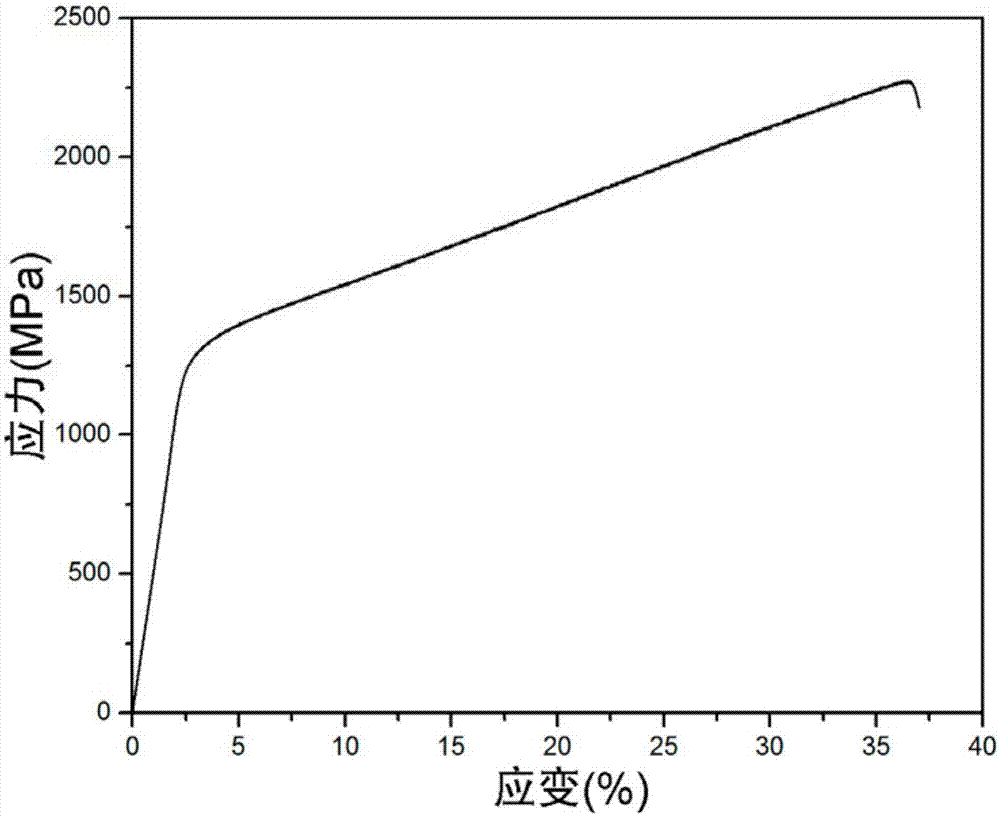

The invention belongs to the technical field of metal high temperature alloys, and discloses a ti-based high temperature alloy with high toughness in a bi-state structure and a preparation method and an application thereof. The high temperature alloy comprises the following components in atomic percent: 64-68at.% of Ti, 8-18at.% of Nb, 6-10at.% of Cu, 5-8at.% of Ni, 3-8at.% of Al and inevitable trace impurities. The structure of the ti-based high temperature alloy consists of a widmanstatten structural base body and an equiaxial (Cu, Ni)-Ti2 phase. The invention further discloses the preparation method of the ti-based high temperature alloy. The method comprises the following steps: first, preparing alloy powder by high energy milling; and then, quickly sintering alloy powder by pulse current, wherein the process condition is as follows: in a spark plasma sintering system of pulse current, sintering is carried out for 5-25 minutes at the sintering temperature of 800-1000 DEG C and the sintering pressure of 30-400MPa, and therefor the ti-based high temperature alloy with high toughness in the bi-state structure is obtained.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing ultra-coarse grain cemented carbide through utilizing high energy stirring and ball-milling technology

The invention relates to a method for producing ultra-coarse grain cemented carbide through utilizing a high energy stirring and ball-milling technology. Preparation raw materials comprise WC, Co and a small amount of NbC or / and TaC which is served as an additive, wherein the particle granularity of the WC is not less than 15 micrometers, and the WC accounts for 82.0-95.5wt%, the Co accounts for 4.5-18wt%, and the additive accounts for 0.0-0.5wt%. The preparation method comprises the following steps: (1) a high energy stirring and ball milling process, namely, filling all the preparation raw materials, i.e. the WC, cobalt powder and the additive into a high energy stirring ball mill, and adding a plasticizer and a ball-milling addition agent for ball milling; (2) a vacuum drying and granulating process; and (3) conventionally pressing a mixture for forming, and carrying out vacuum sintering or pressure sintering within a scope of 1400 DEG C-1480 DEG C. By utilizing the technology, the milling effect of the powder can be greatly improved, the ball milling time is obviously shortened, the production efficiency is improved, the energy consumption is reduced, and alloy crystal grains are uniformly distributed.

Owner:ZIGONG JINDUN CEMENTED CARBIDE

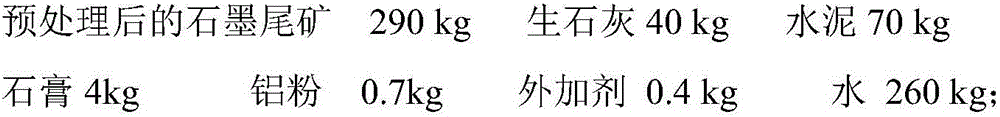

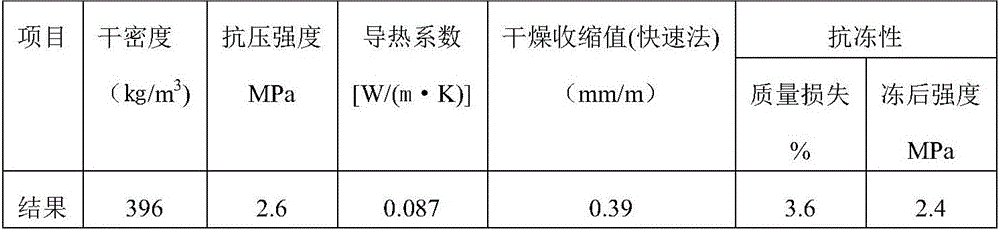

Method for preparing high-performance autoclaved aerated concrete blocks through graphite tailings

InactiveCN106365672ASmall sizeReduce ball mill energy consumptionSolid waste managementCeramicwareBuilding energyGraphite

The invention discloses a method for preparing high-performance autoclaved aerated concrete blocks through graphite tailings. The method includes the following steps of 1, graphite tailing pretreating; 2, mixing and stirring; 3, pouring, aerating, delaying curing and procuring blank preparing; 4, cutting, wherein procuring blanks prepared in the step 3 are cut and subjected to form removing; 5, autoclaved curing, wherein the cut blanks are subjected to autoclaved curing, and then the high-performance autoclaved aerated concrete blocks are obtained. According to the method for preparing the high-performance autoclaved aerated concrete blocks through the graphite tailings, a novel energy-saving wall material is prepared from the graphite tailings, the problem that the graphite tailings serve as solid waste and are stacked can be solved, the successfully-prepared high-performance autoclaved aerated concrete blocks can be used for a wall self-insulation system, the heat preservation and insulation performance of a building envelope structure is improved, and therefore building energy consumption is reduced.

Owner:湖北远固新型建材科技股份有限公司

Method for preparing ceramic tiles from calcium silicate slag

InactiveCN103641446ARealize mass utilizationReduce consumptionCeramic materials productionClaywaresCalcium silicatePyrophyllite

The invention relates to a method for preparing ceramic tiles from calcium silicate slag, belonging to the field of comprehensive utilization of resources and novel technologies for ceramic preparation. The ceramic tiles contain the following raw materials in percentage by weight: 30-60% of calcium silicate slag, 10-30% of clay, 2-25% of quartz, 0-20% of feldspar, 0-10% of pyrophyllite, 0-10% of green coke and 0-10% of talc. According to the method, ceramics are produced from calcium silicate slag, so that the stacked discharge of calcium silicate slag is reduced, the aim of resource recycling is achieved, and a new way for the high-added-value utilization of calcium silicate slag is added; the utilization ratio of calcium silicate slag in calcium silicate slag ceramics can reach 60%; by using the characteristic that a great deal of alkali metal ions are contained, a feldspar raw material can be replaced partially or totally, and the ceramic tiles are produced under the low-temperature condition of 1,130-1,180 DEG C; all properties of the ceramic tiles prepared by the method disclosed by the invention are better than the national ceramic standards.

Owner:UNIV OF SCI & TECH BEIJING

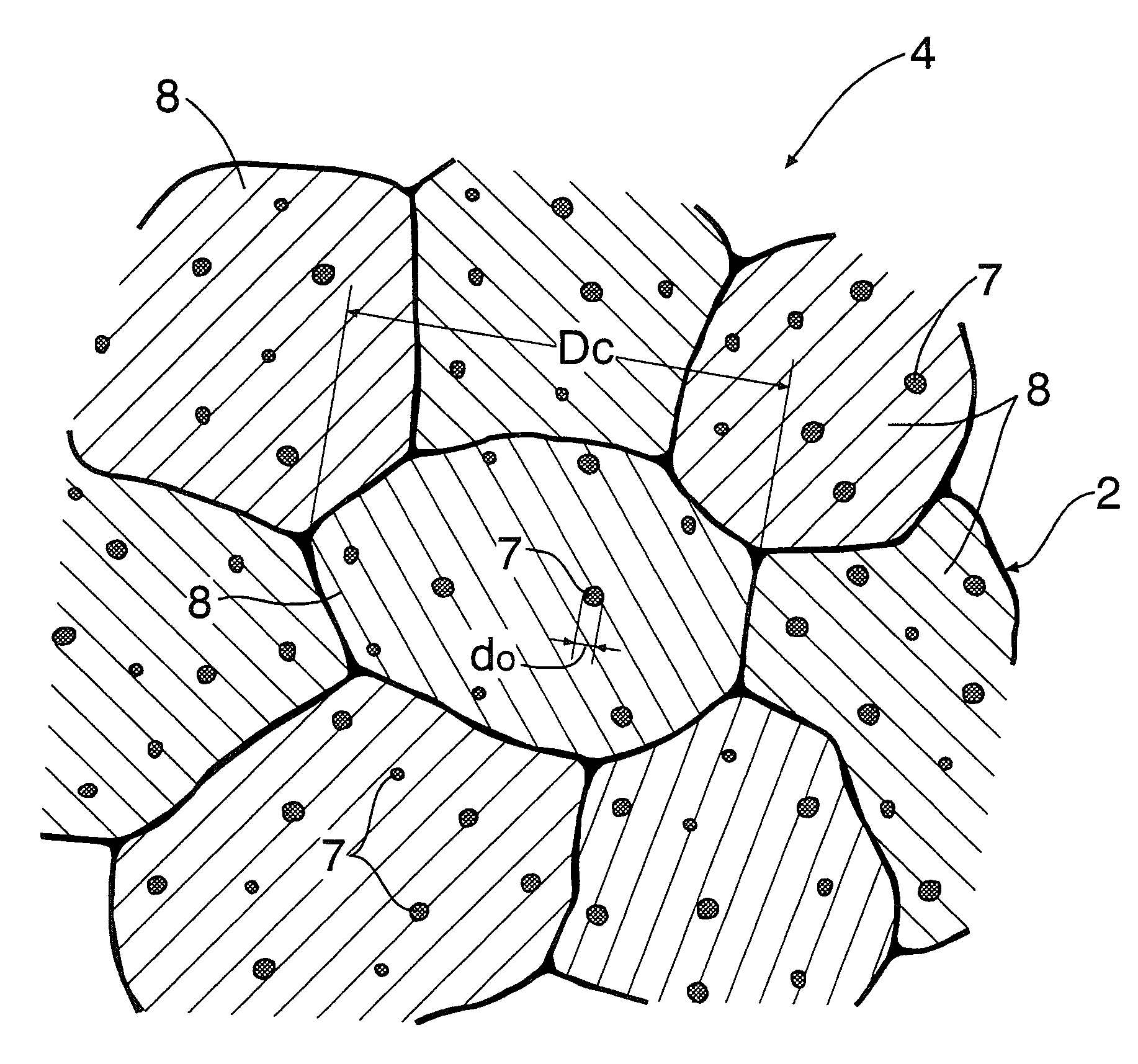

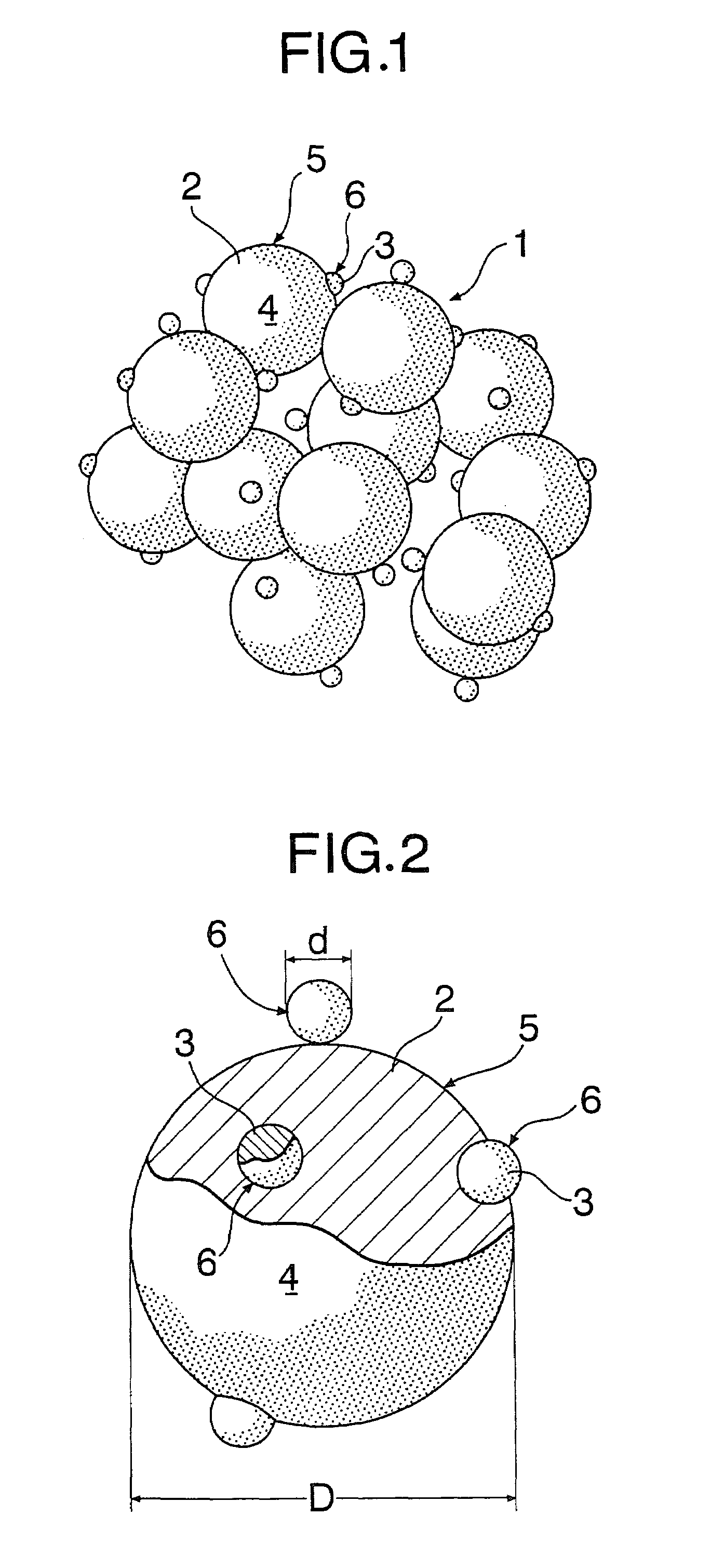

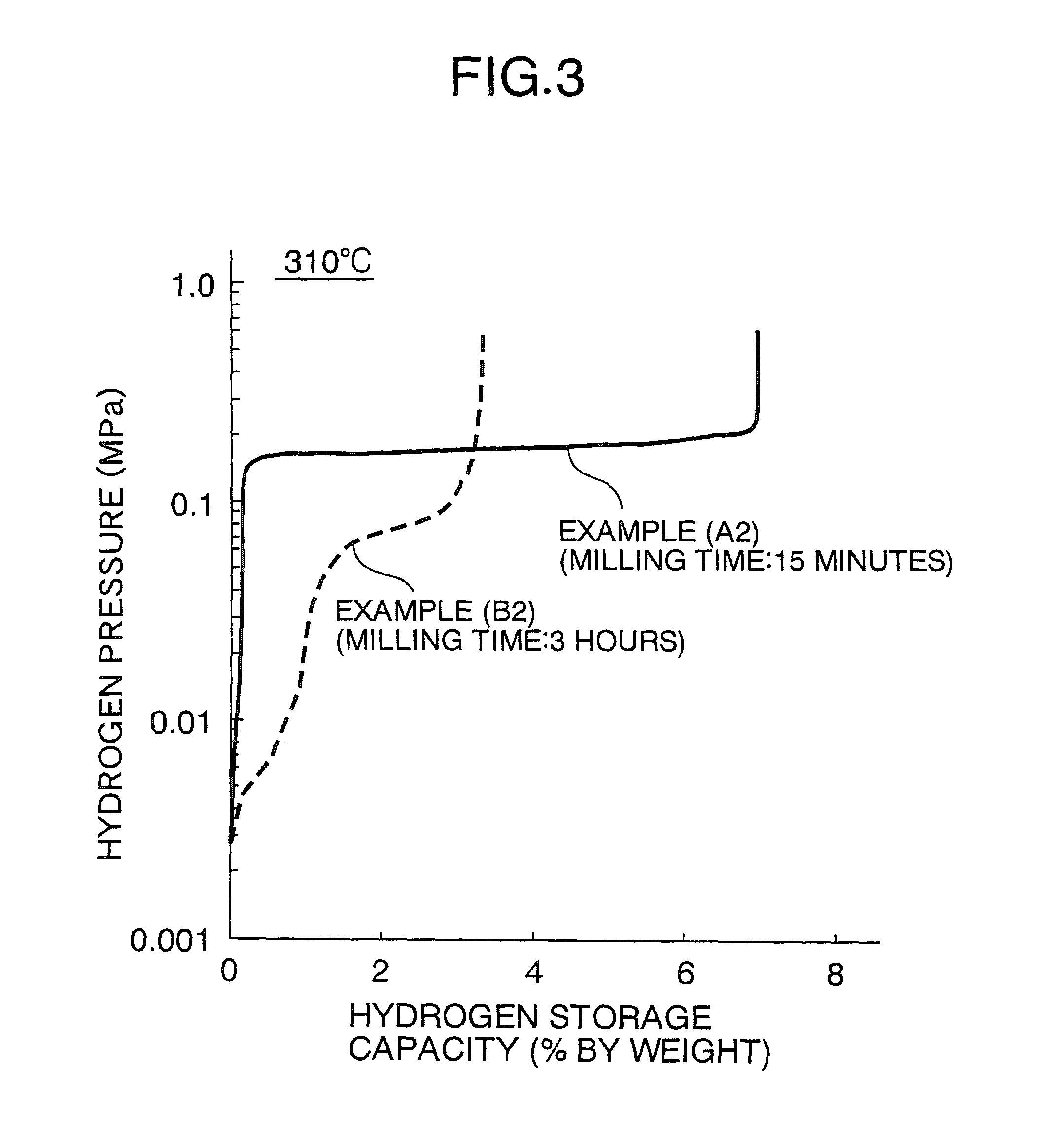

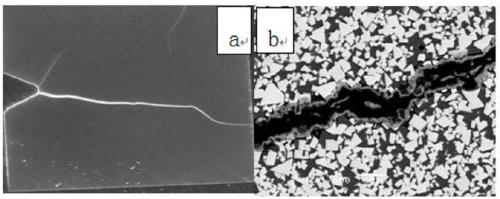

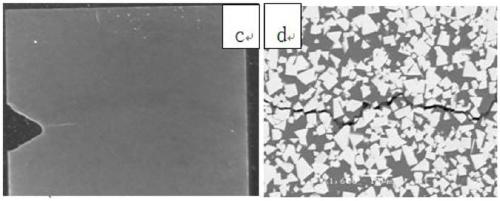

Hydrogen absorbing alloy powder and hydrogen storing tank for mounting in a vehicle

InactiveUS7060120B1Shorten milling timeLong milling timeHydrogenTransportation and packagingMetalHydrogen absorbing alloy

To produce a hydrogen absorbing alloy powder which is an aggregate of alloy particles each including a metal matrix and added-components, an aggregate of metal matrix particles and an aggregate of added-component particles are used, and mechanical alloying is carried out. In this case, the relationship between the particle size D of the metal matrix particles and the particle size d of the added-component particles is set at d≦D / 6. Thus, the milling time can be shortened remarkably.

Owner:HONDA MOTOR CO LTD

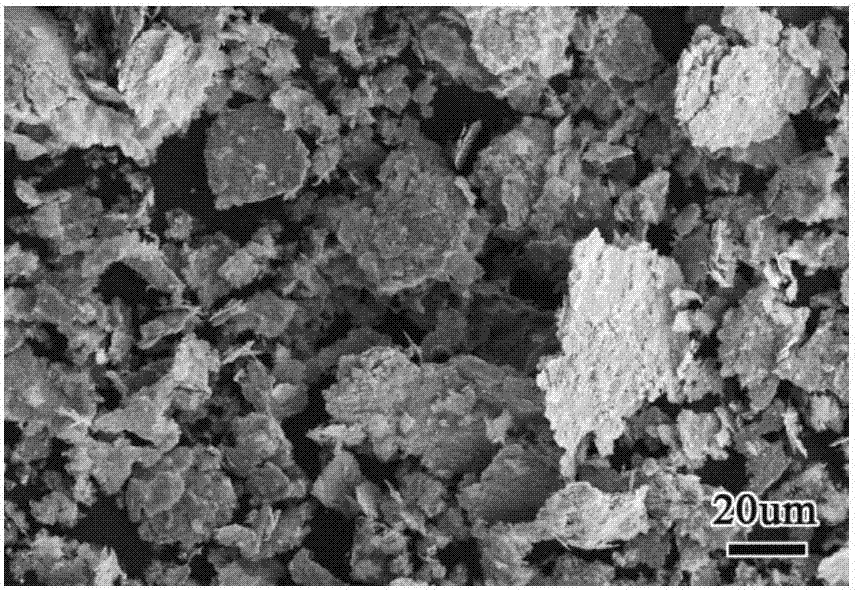

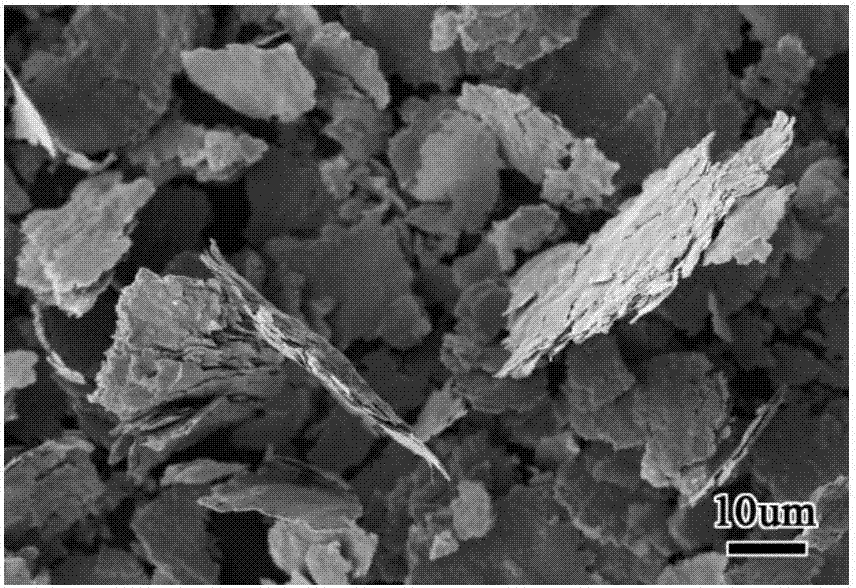

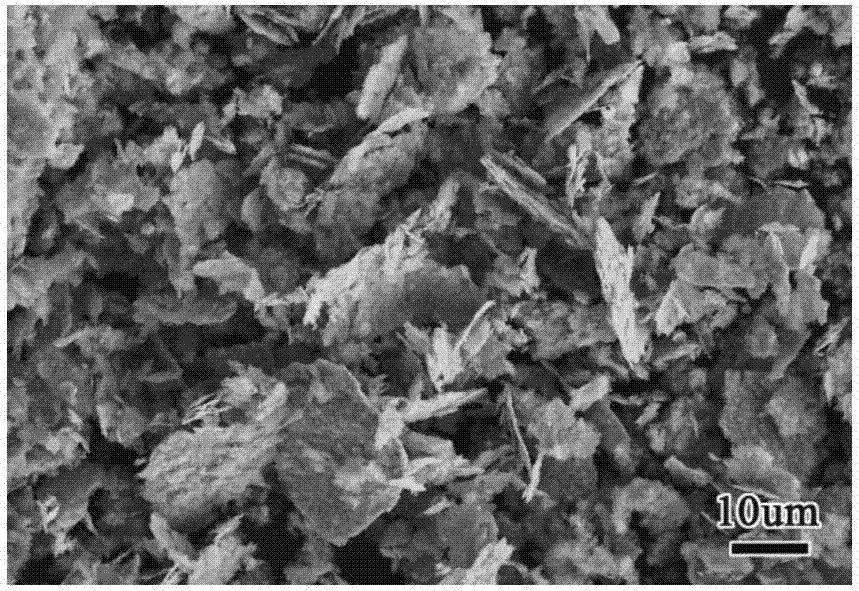

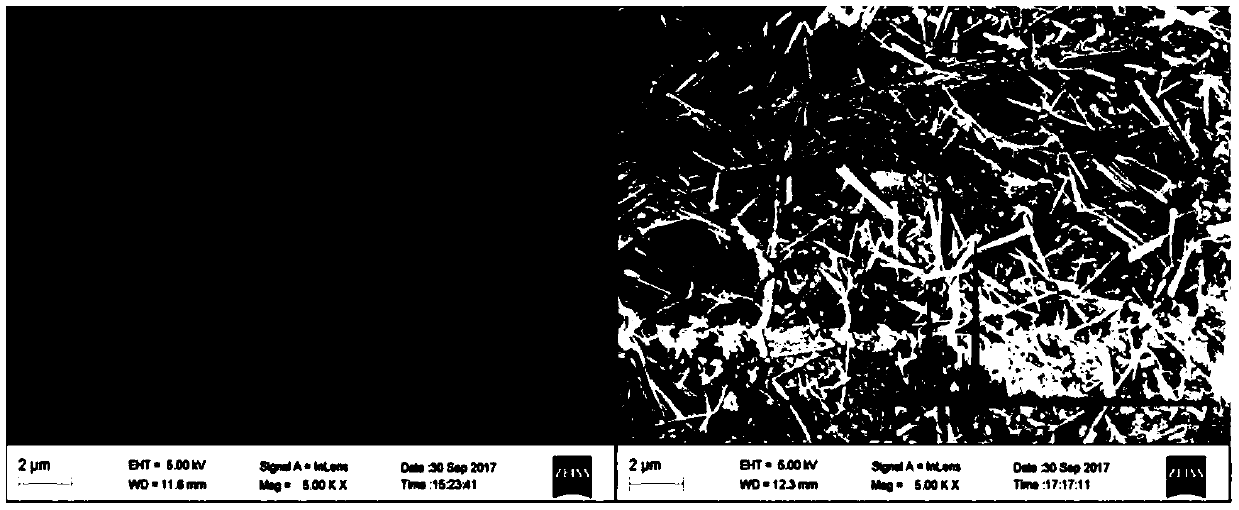

Method of preparing sheet-like carbonyl iron powder with plasma assisted ball milling

ActiveCN106946295AEasy to operateEase of industrial productionIron carbonylsIron powderControllability

The invention discloses a method of preparing sheet-like carbonyl iron powder with plasma assisted ball milling. The method includes the steps of: (1) under protection with inert gas, dry-milling carbonyl iron powder with average particle size being 5-200 [mu]m by a plasma assisted ball milling machine to produce multilayer sheet-like carbonyl iron powder being less than 100 [mu]m in particle size; and 2) dry-milling the multilayer sheet-like carbonyl iron powder through planetary ball milling to obtain secondary sheet-like carbonyl iron powder with average particle size being 2-50 [mu]m. The method is high in purity and activity of the product, has advantages in industrial promotion, achieves effective controllability of sheet size and has important significance in preparation of high-performance magnetic wave-absorbing materials.

Owner:SOUTH CHINA UNIV OF TECH

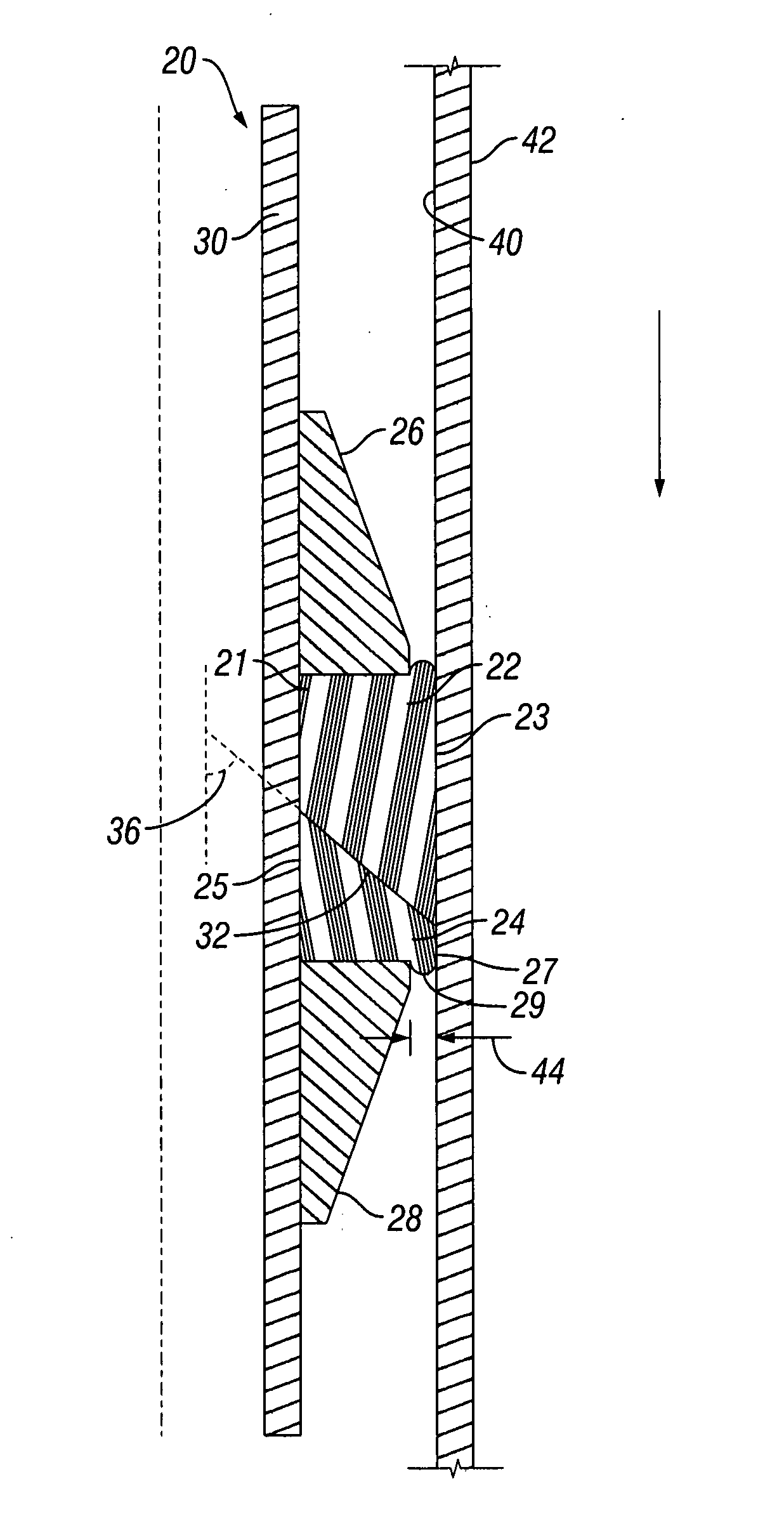

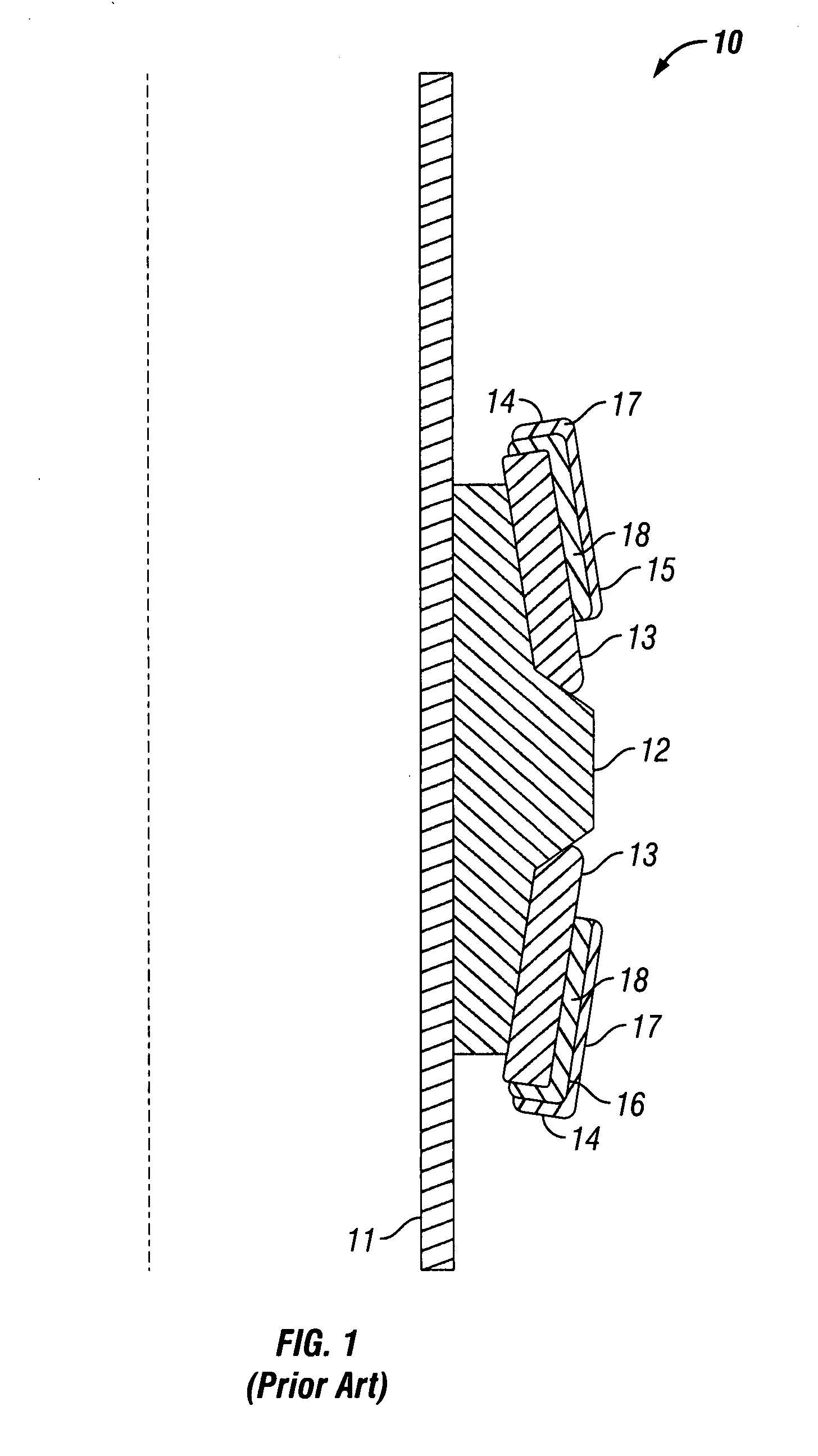

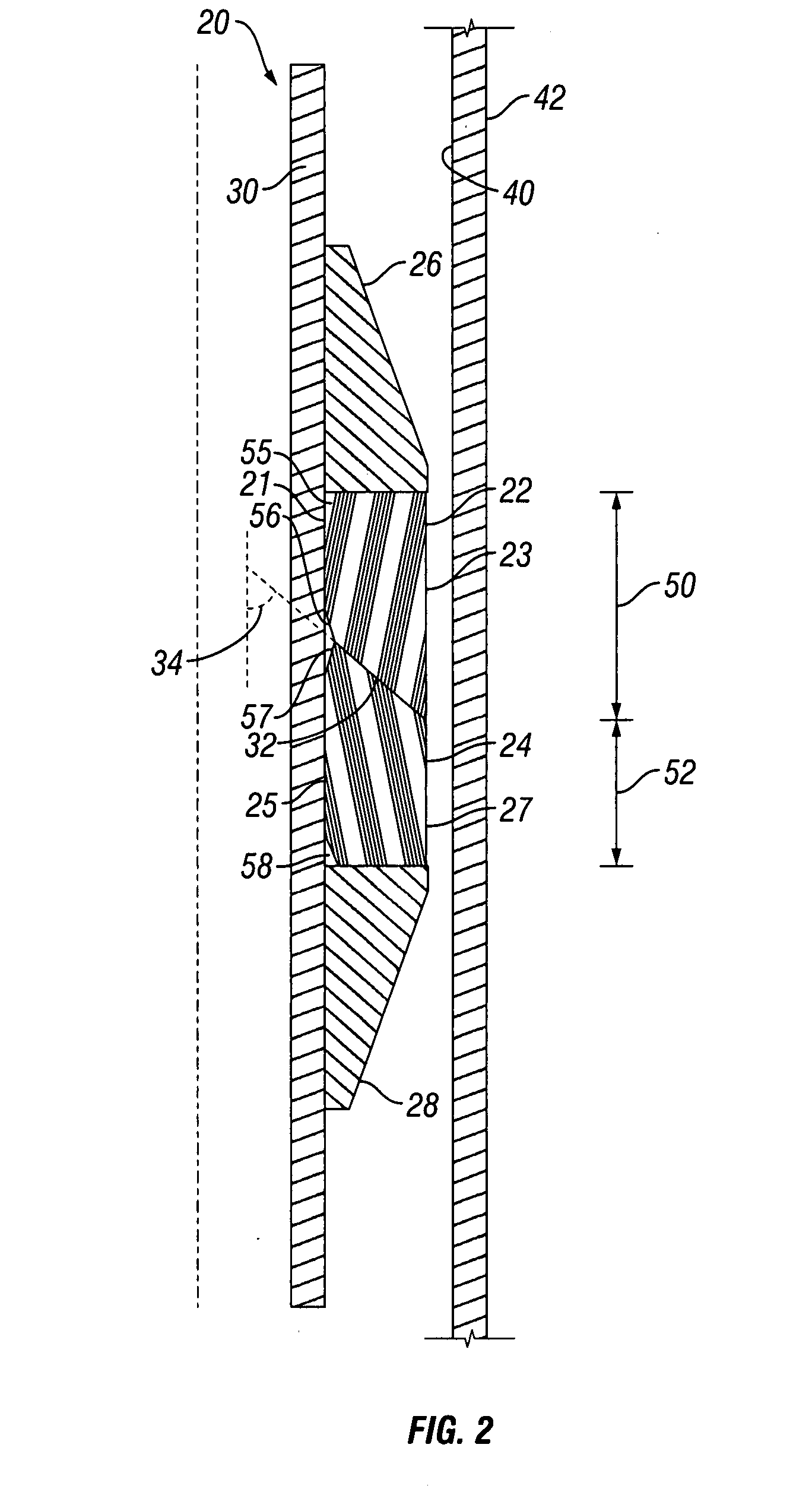

Non-backed-up packing element system

InactiveUS20080156501A1Improve sealingLess axial loadingFluid removalSealing/packingEngineeringCantilever

Well tool packing element systems that do not require a back-up element or component include a mandrel, an upper supporting member, a lower supporting member, a cantilever element, and a ramp element disposed on the mandrel. The cantilever element and ramp element are disposed on the mandrel with an interface angle between the cantilever element and the ramp element, the interface angle being less than 90 degrees, preferably in a range from 40 degrees to 60 degrees, and more preferably at an angle greater than 45 degrees. When an axial load is applied to upper and lower supporting members, cantilever element and ramp element are forced outward and into an inner wall surface of a casing to seal off the casing bore.

Owner:BAKER HUGHES INC

Novel high-strength ceramic insulator and preparation method thereof

InactiveCN102795836AImprove mechanical propertiesReduce manufacturing costClaywaresMechanical propertyMaterials science

The invention discloses a novel high-strength ceramic insulator which is prepared from the following raw materials in parts by weight: 2-5 parts of smolmitza, 35-45 parts of alumina, 5-10 parts of Zhangcun soil, 8-20 parts of Jingyang soil, 6-15 parts of Zuoyun soil, 7-15 parts of Qingcaoling, 11-20 parts of white glue slime, 5-15 parts of feldspar, 1-5 parts of Ninghai soil and 1-5 parts of Xinhui soil. The ceramic insulator disclosed by the invention has the advantages of favorable mechanical properties and low production cost, and can easily implement technical control. All the raw materials are common ceramic mineral raw materials; and the adoption of the Jingyang soil shortens the ball milling time, lowers the cost and improves the technical properties. Different mineral types of clay are reasonably matched, so that the material has favorable technical properties, especially firing property, can easily implement technical control, and enhances the qualification rate of the ceramics.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Hot cracking resistant mixed-crystal hard alloy and preparation method thereof

PendingCN109487142AThe average crystal diameter ratio is accurately controlledHigh strengthGranularityDiameter ratio

The invention discloses a hot cracking resistant mixed-crystal hard alloy and a preparation method thereof. The hot cracking resistant mixed-crystal hard alloy comprises a hard phase, a bonding phraseand optional temperature resistant components. The hard phase comprises coarse tungsten carbide (WC) and fine WC. The ratio of the average crystal diameter of the coarse WC to the average crystal diameter of the fine WC is (1.7: 2.1). The average grain size of the hard alloy is between 2.4 Mu m and 3.4 Mu m. According to the hot cracking resistant mixed-crystal hard alloy provided, control over the average crystal diameter ratio of of the coarse WC to the fine WC is accurate; intensity is high; rigidity is high; and the hot cracking resistant property is good. When the hard alloy is used in an environment of thermal mechanical corrosion fatigue, crack initiation is late; hot crack growth is slow; the hard alloy is especially suitable for rolling of threaded steel on a small profile rolling mill; blocks are not easy to drop; rolled steel is good in quality; and the service life is improved by more than 20%.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

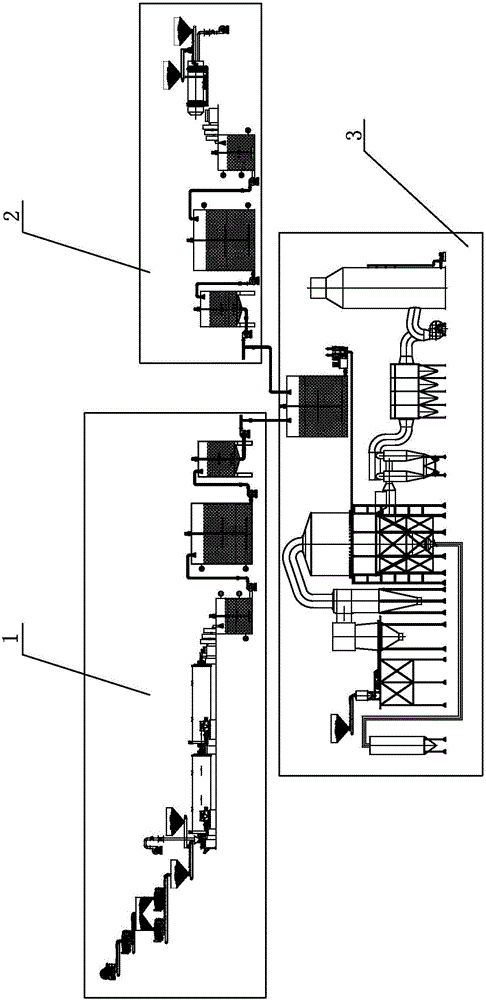

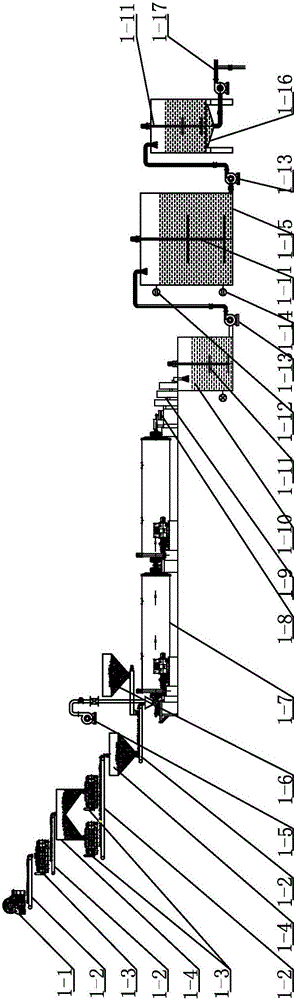

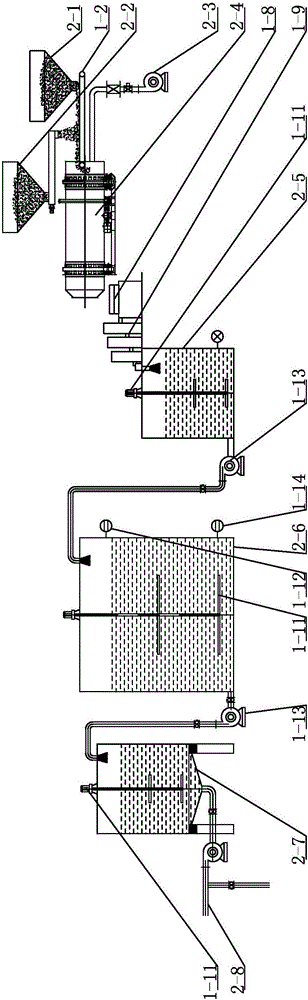

Ceramic raw material independent-grinding centralized preparation technique and device

ActiveCN105773834AReduce energy consumptionAvoid energy consumptionClay processing apparatusGrain treatmentsEconomic benefitsSlurry

The invention relates to a ceramic raw material independent-grinding centralized preparation technique and device and belongs to the technical field of ceramic raw material preparation. The ceramic raw material independent-grinding centralized preparation technique comprises the steps that firstly, various single kind of raw materials are crushed independently through a crusher; secondly, the crushed single kind of raw materials are conveyed to a ball mill for continuous ball milling; thirdly, the raw materials subjected to ball milling and mud are conveyed into a slurry mixing and storing tank according to a formula to be evenly mixed; and finally, evenly-mixed finished slurry is conveyed to a drying tower to be dried. The ceramic raw material independent-grinding centralized preparation device comprises a hard material treatment device, a mud treatment device and a slurry drying device. By the adoption of the technique and device, the existing disorder situation of raw materials for processing ceramic can be avoided, and the technique and device have remarkable economic benefits.

Owner:广东鼎汇能科技股份有限公司

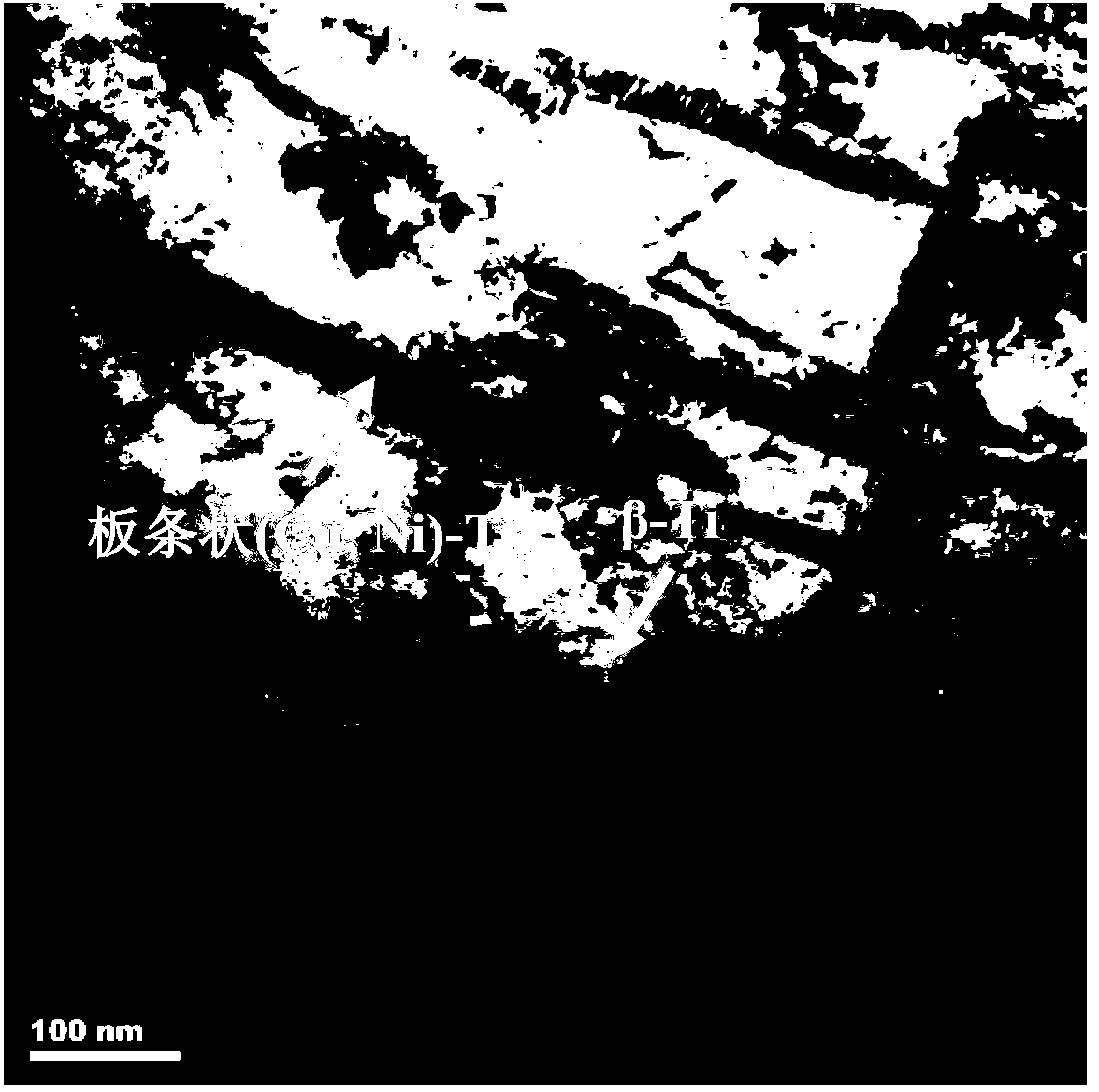

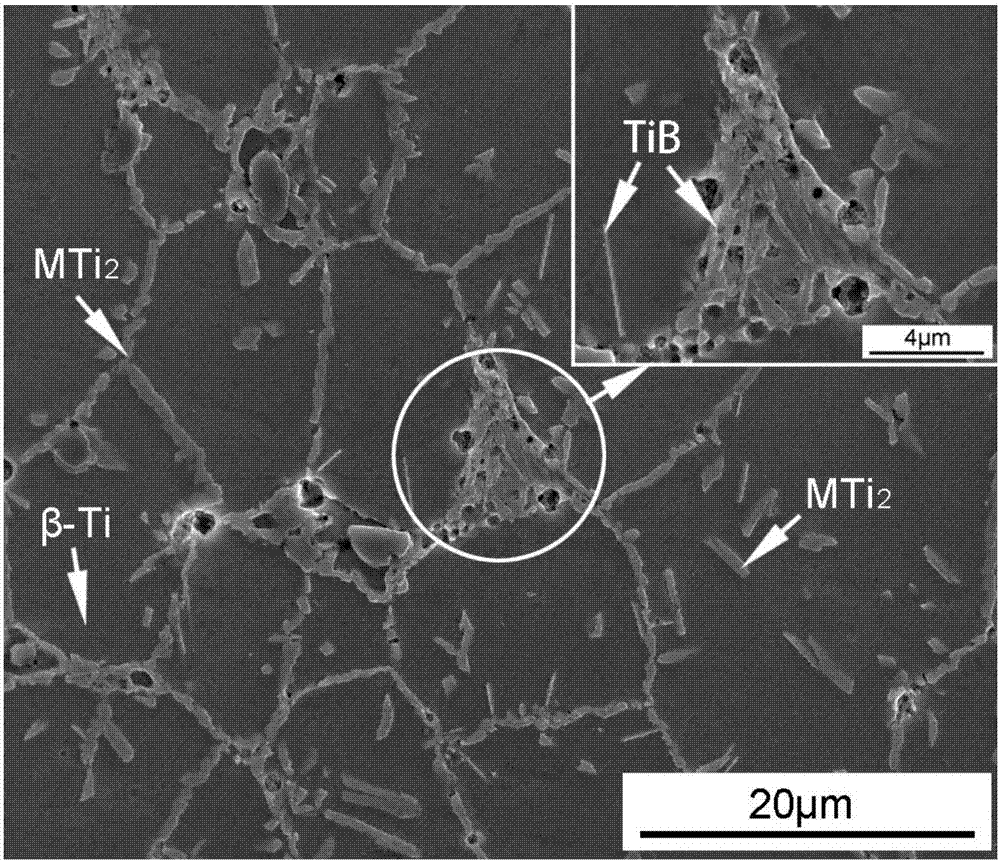

Double-scale structure titanium alloy based on in-situ whisker strengthening and toughening, preparation and application

The invention belongs to the field of titanium alloy materials, and discloses a double-scale structure titanium alloy based on in-situ whisker strengthening and toughening and a preparation method and application of the double-scale structure titanium alloy. The titanium alloy comprises elements including, by atomic percent, 58%-70% of Ti, 9%-16% of Nb, 4%-9% of Cu, 4%-9% of Ni, 2%-8% of Al and 0.5%-3% of B. According to a microstructure of the titanium alloy, part of ultra-fine grain fcc MTi2 is distributed along a micron grain bcc beta-Ti base body grain boundary in a long-strip-shaped manner, part of ultra-fine grain fcc MTi2 is distributed in the micron grain bcc beta-Ti in a long-strip-shaped manner, ultra-fine grain in-situ TiB whiskers are distributed in the ultra-fine grain fcc MTi2 and a micron grain bcc beta-Ti of the grain boundary, and M is equal to Cu and Ni. The fine-needle-shaped in-situ TiB whiskers are introduced in a double-scale structure of an ultra-fine grain second phase and a micron equiaxed grain base body, and further strengthening and toughening of the material are achieved.

Owner:SOUTH CHINA UNIV OF TECH

Multifunctional ceramic composite additive

The invention discloses a multifunctional ceramic composite additive, which is prepared by mixing layered crystalline sodium disilicate, modified 4A zeolite, sodium metasilicate, sodiumtripolyphosphate, sodium hexametaphosphate, polycarboxylate, sodium lignin sulfonate and sodium humate, has various functions of assisted grinding, slushing, plastifying and the like, and is suitable for preparation of ceramic mud added in various forming methods. The additive can lower the moisture content of the mud to 28-32%, improves the ball milling efficiency to a large extend, shortens the ball milling time by 20-30%, reduces the power consumption for raw material grinding by more than 40%, obviously enhances batch plasticity, increases the dried green strength of the product by 10-15%, and has the obvious functions of increasing production, saving energy and reducing consumption.

Owner:HUNAN HANLIN NEW MATERIALS

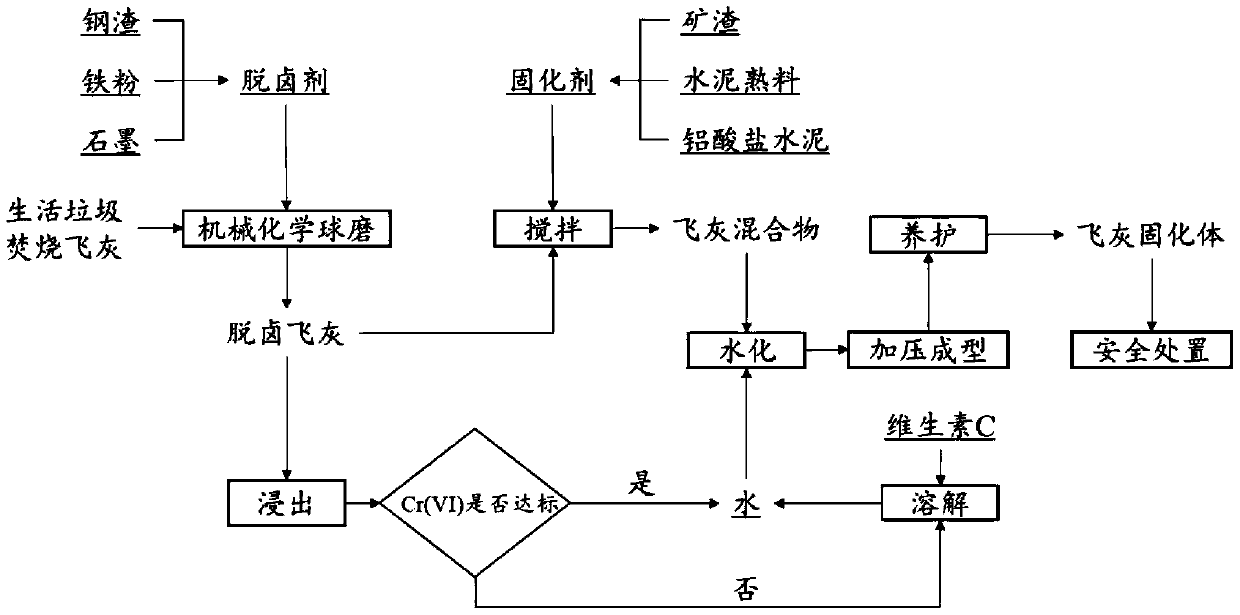

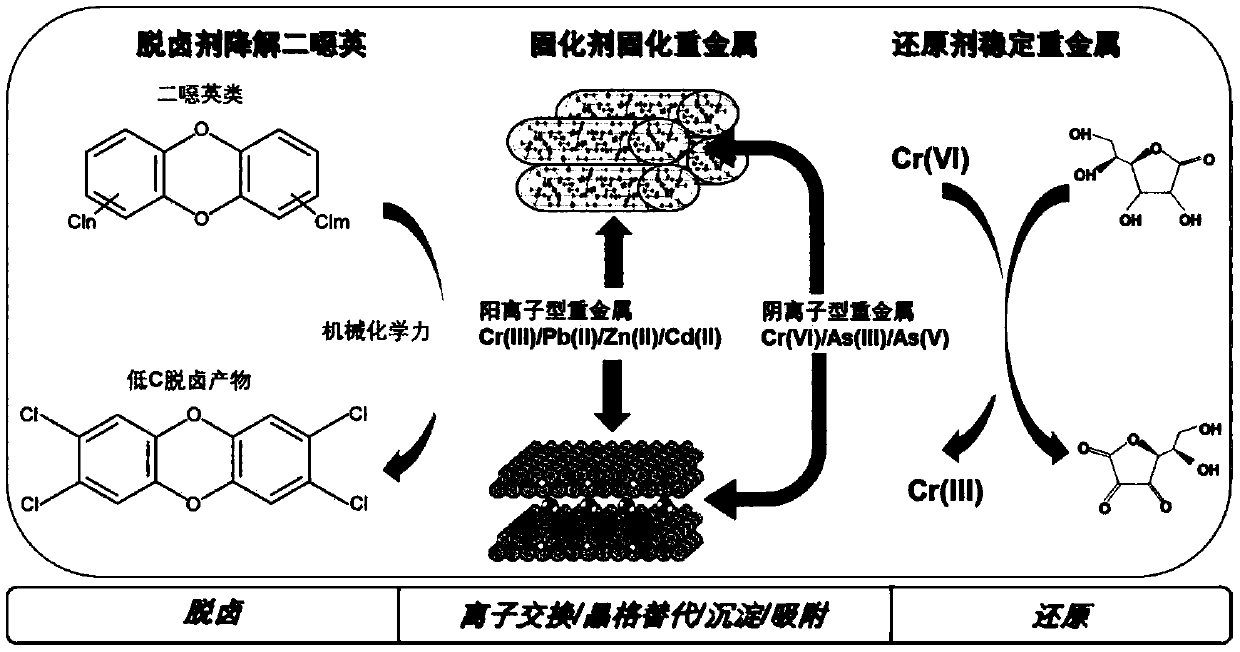

Cooperative treatment method for dioxin and heavy metal in flying ash on basis of steel slag and mineral slag

A cooperative treatment method for dioxin and heavy metal in flying ash on the basis of steel slag and mineral slag is characterized by comprising the following steps that (1) to-be-treated flying ashand a dehalogenation agent are mixed according to a mass ratio of 4:1-9:1, mixed milling is conducted by a planetary mill or a ball mill, and after 2-10 h of continuous ball milling, organochlorine degradation flying ash is obtained; (2) the organochlorine degradation flying ash and a curing agent are mixed according to the mass ratio of 4:1-9:1 and are stirred evenly, and a flying ash mixture isobtained; and (3) water or a reducing agent of the mass ratio of 15% is added into the flying ash mixture, the obtained mixture is put into a compaction die for compaction forming, pressure is 20-50kN, pressing time is 15-30 s, maintenance is conducted for 3-7 days, and a flying ash solidified body is obtained. Through the cooperative treatment method, dioxins and heavy metal pollutants can be treated simultaneously, steel slag serves as a main material of the dehalogenation agent and can be utilized efficiently, and the problem of a low comprehensive utilization rate of the steel slag is solved while the flying ash is treated.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Milling process of cashmere sweater product

The invention discloses a milling process of a cashmere sweater product. The milling process comprises the following steps: preparing, immersing, milling, immersing, rinsing, dehydrating, drying over a fire, shaping by steam pressing and packaging. By simplifying the processing step, the milling time of the cashmere sweater is shortened, and the production efficiency is improved; meanwhile, the cashmere sweater product processed by the milling process disclosed by the invention is soft in hand feeling and attractive in appearance, so that the milling process is beneficial to improvement of the economic benefit; due to the adoption of an added quality inspecting step, a production process of the cashmere sweater product can be controlled effectively and the yield of the product is effectively improved.

Owner:TAICANG SHARTEX SHENTAI SWEATER

Method for processing electronic ceramic casting slurry

The invention discloses a method for processing electronic ceramic casting slurry. The method comprises the following steps of: (1) sequentially adding a main solvent, a plasticizer, a surface lubricant and an adhesive into a ball-milling tank according to scheduled proportions, and performing ball milling for 2-4 hours; and (2) adding electronic ceramic powder in a scheduled proportion into the ball-milling tank, and continuously performing ball milling for 26-32 hours to obtain the electronic ceramic casting slurry, wherein the electronic ceramic powder is Al2O3 powder and accounts for 65-75% of the weight of the electronic ceramic casting slurry. According to the method, the main solvent, the plasticizer, the surface lubricant and the adhesive are added into the ball-milling tank once at first and are subjected to ball milling for 2-4 hours, then the electronic ceramic powder is added, and ball milling is continuously carried out for 26-32 hours, so that on the one hand, the ball milling time is greatly saved, and the preparation efficiency of the electronic ceramic casting slurry is improved.

Owner:湖南省新化县鑫星电子陶瓷有限责任公司

Sanitary ceramic slip ball-milling process

The invention discloses a sanitary ceramic slip ball-milling process. The sanitary ceramic slip ball-milling process comprises the steps that raw materials including, by weight, 900-1350 parts of a hard material, 600-950 parts of a soft material, 540-860 parts of water, 25-45 parts of water glass and 3-12 parts of sodium carbonate are weighed, and the materials are divided into primary entry milling materials and secondary entry milling materials, wherein 900-1350 parts of the hard material, 360-600 parts of the water, 150-300 parts of clay, 15-30 parts of the water glass and 3-12 parts of the sodium carbonate compose the primary entry milling materials, and the remaining parts, other than the primary entry milling materials, in the weighed raw materials compose the secondary entry milling materials; ball milling of the first time is conducted, wherein ball-milling elements and the primary entry milling materials are put into a ball mill, and ball milling is conducted for 6-9 hours, so that primary slip is obtained; and ball milling of the second time is conducted, wherein one third of the primary slip and the secondary entry milling materials are subjected to ball milling together for 30-50 minutes, so that secondary slip is obtained. By means of the process, energy consumption can be remarkably lowered, production efficiency can be improved, and the qualification rate of finished products can be increased.

Owner:福建科福材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com