Patents

Literature

1331results about "Clay processing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

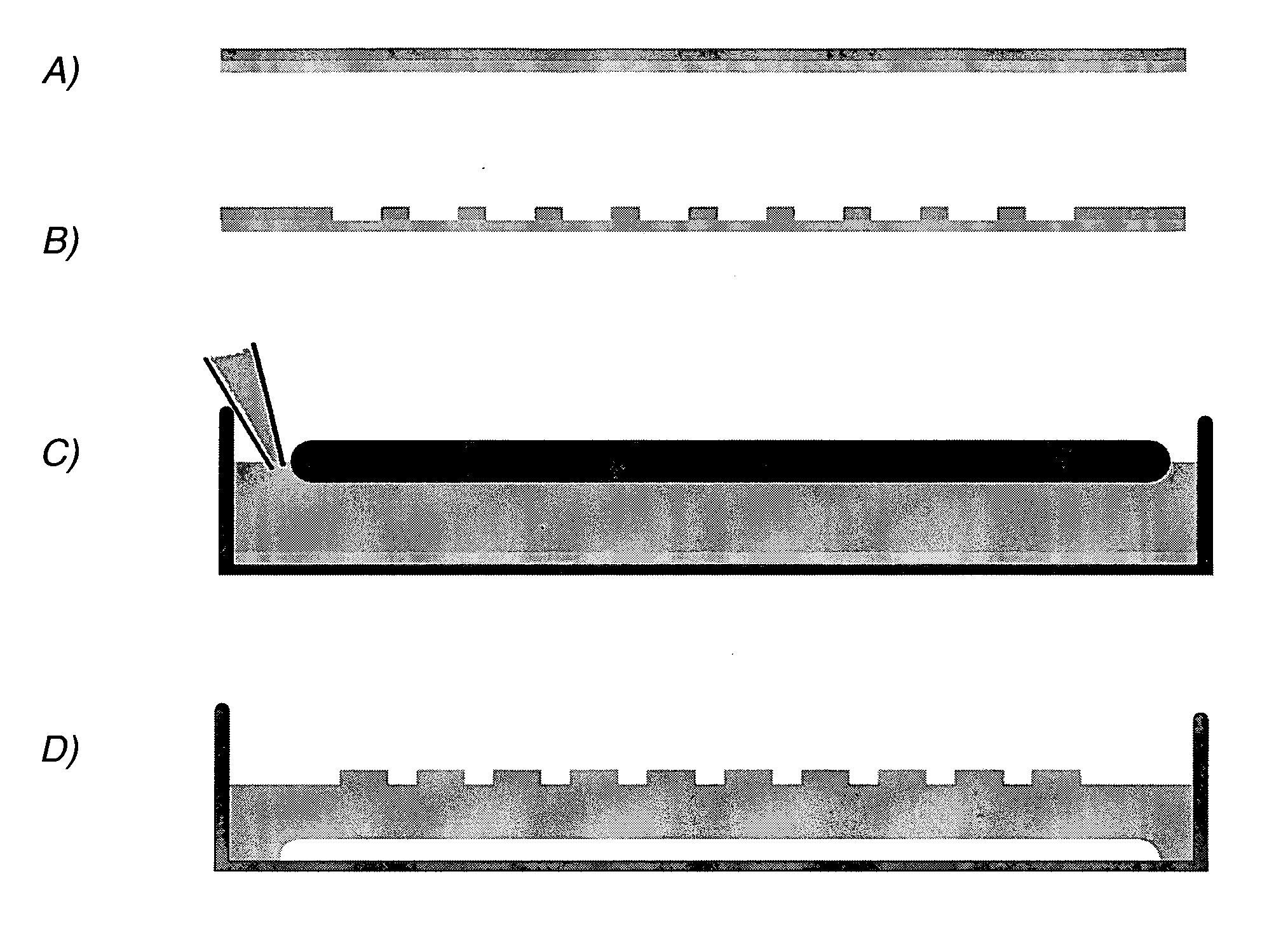

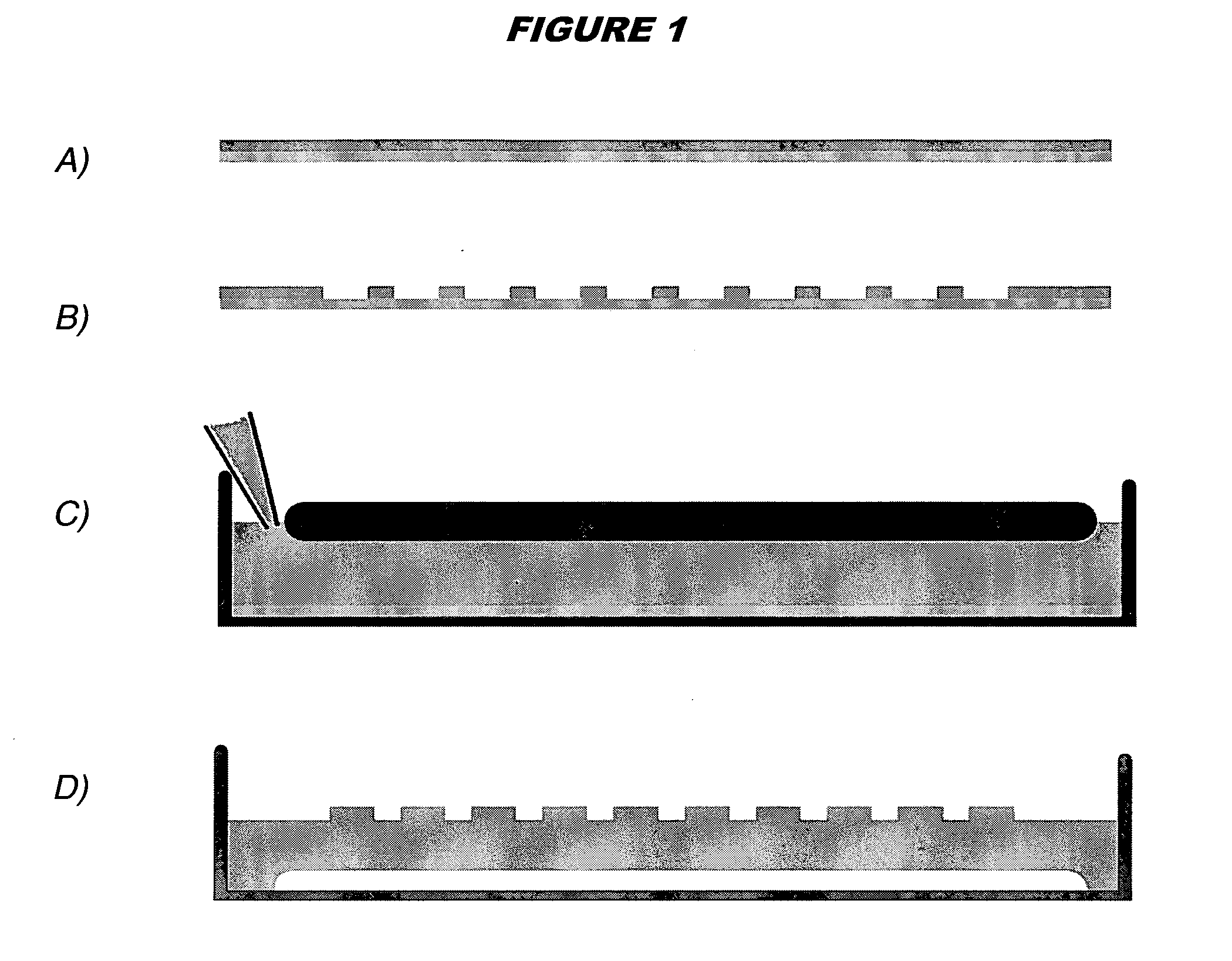

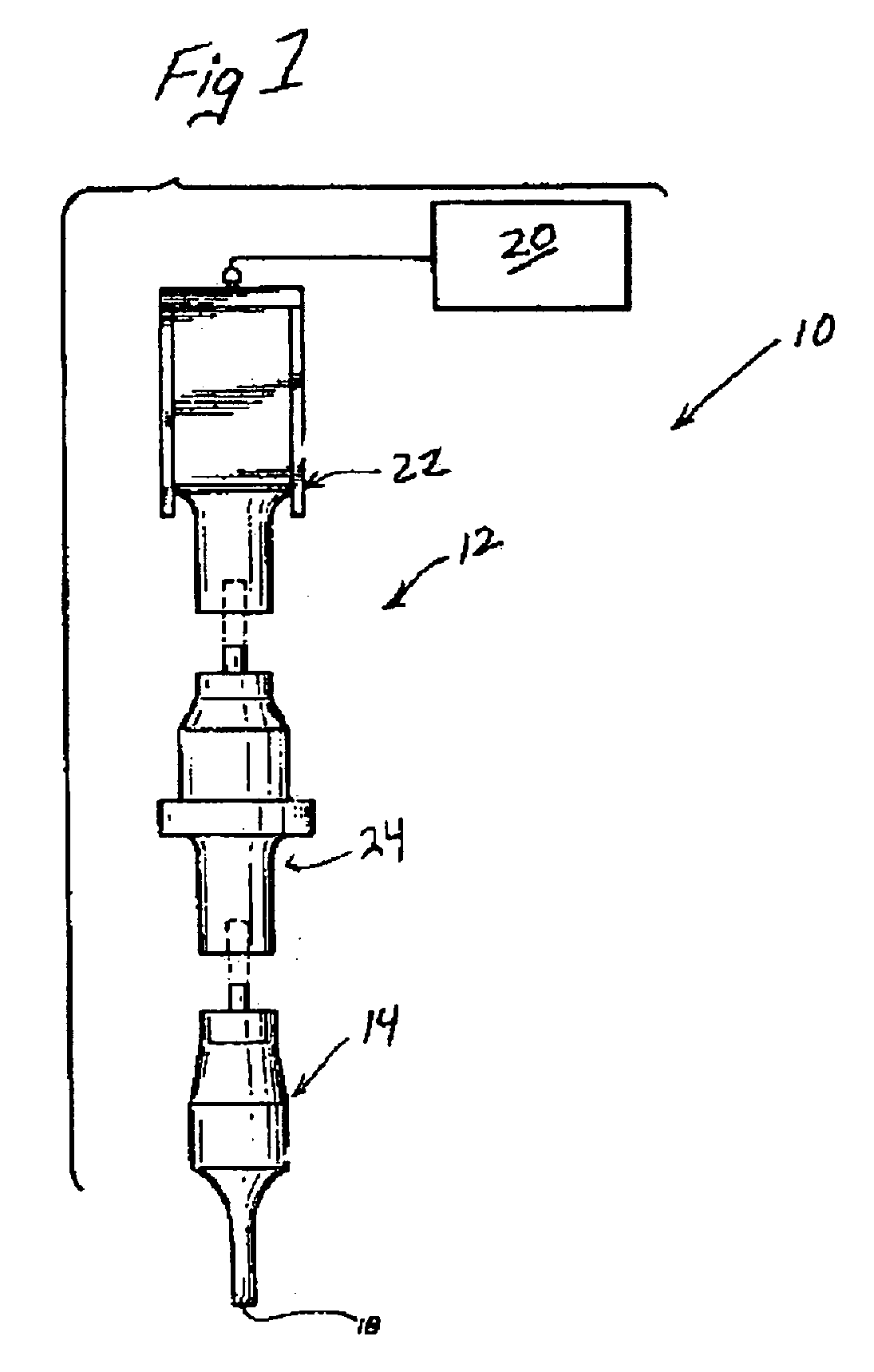

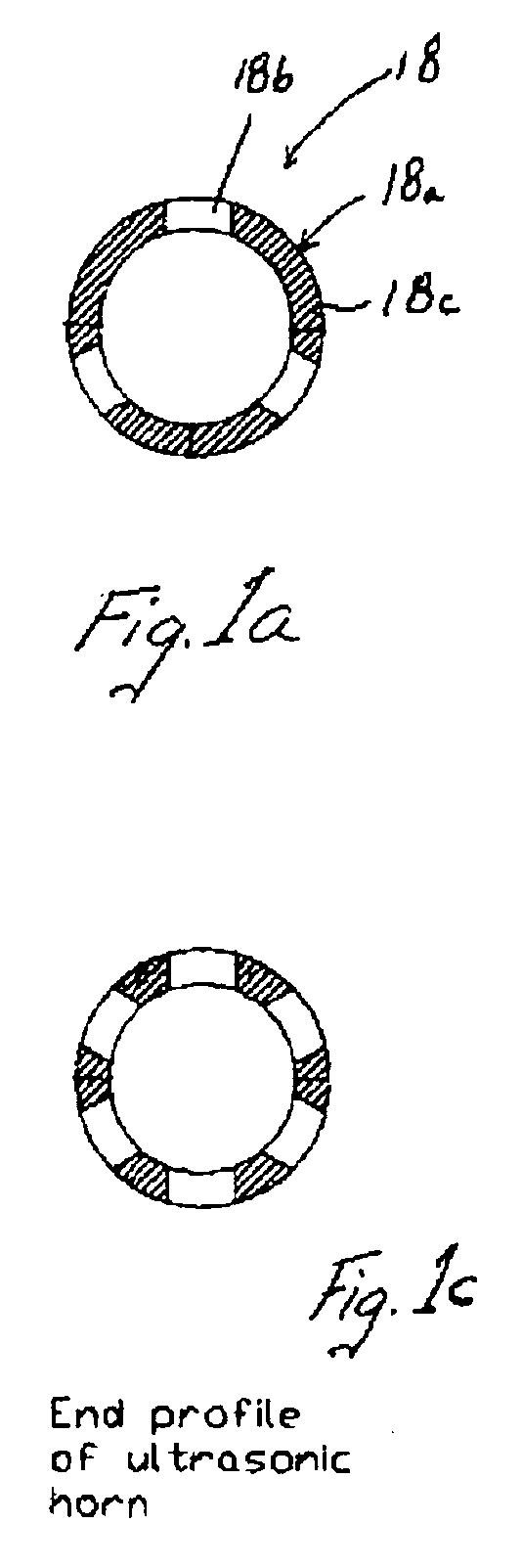

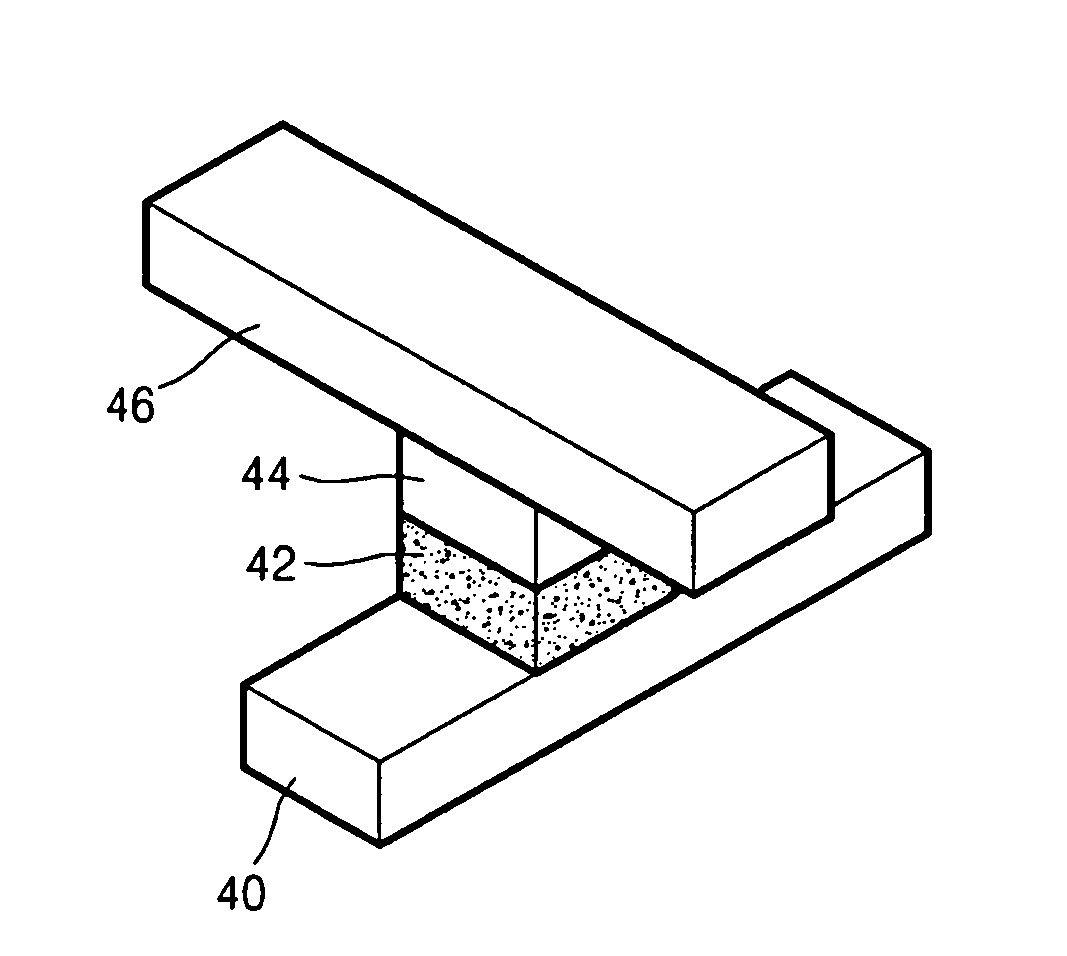

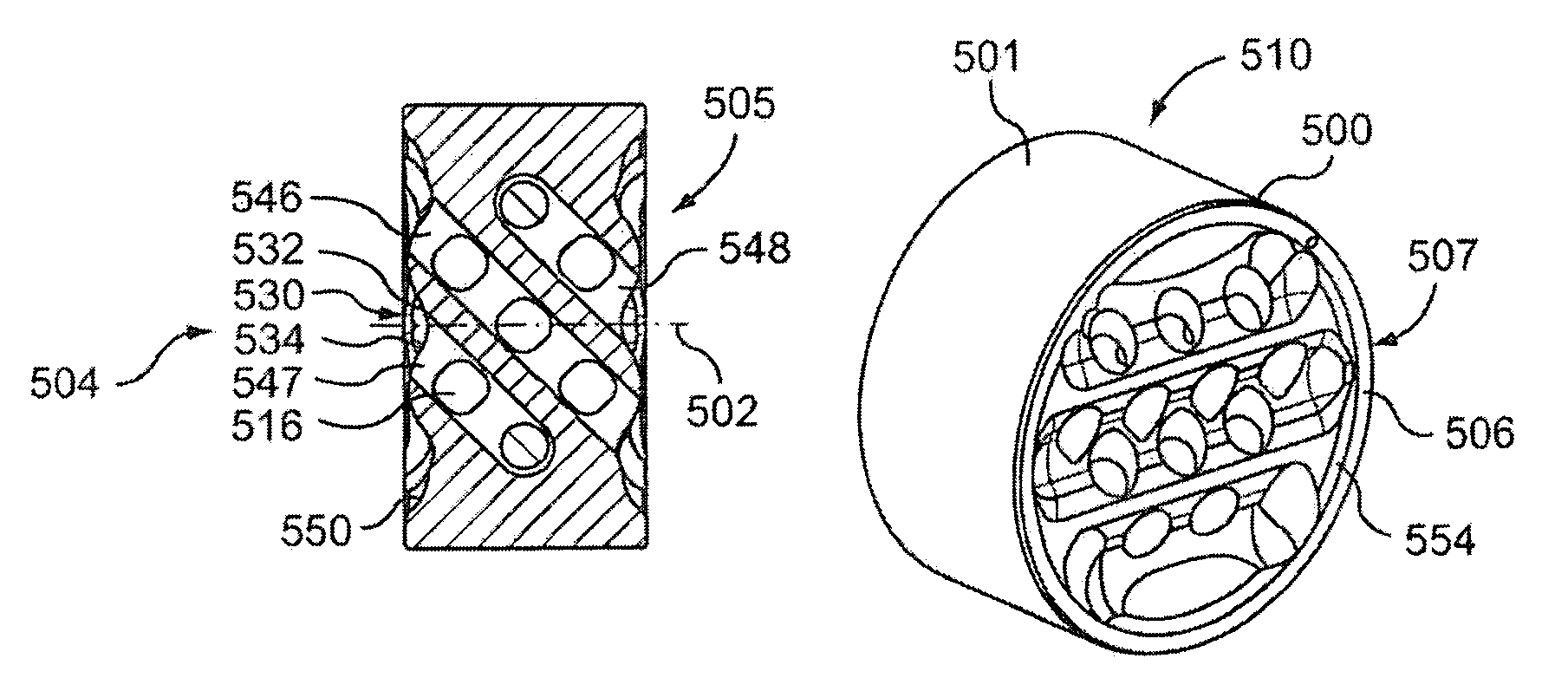

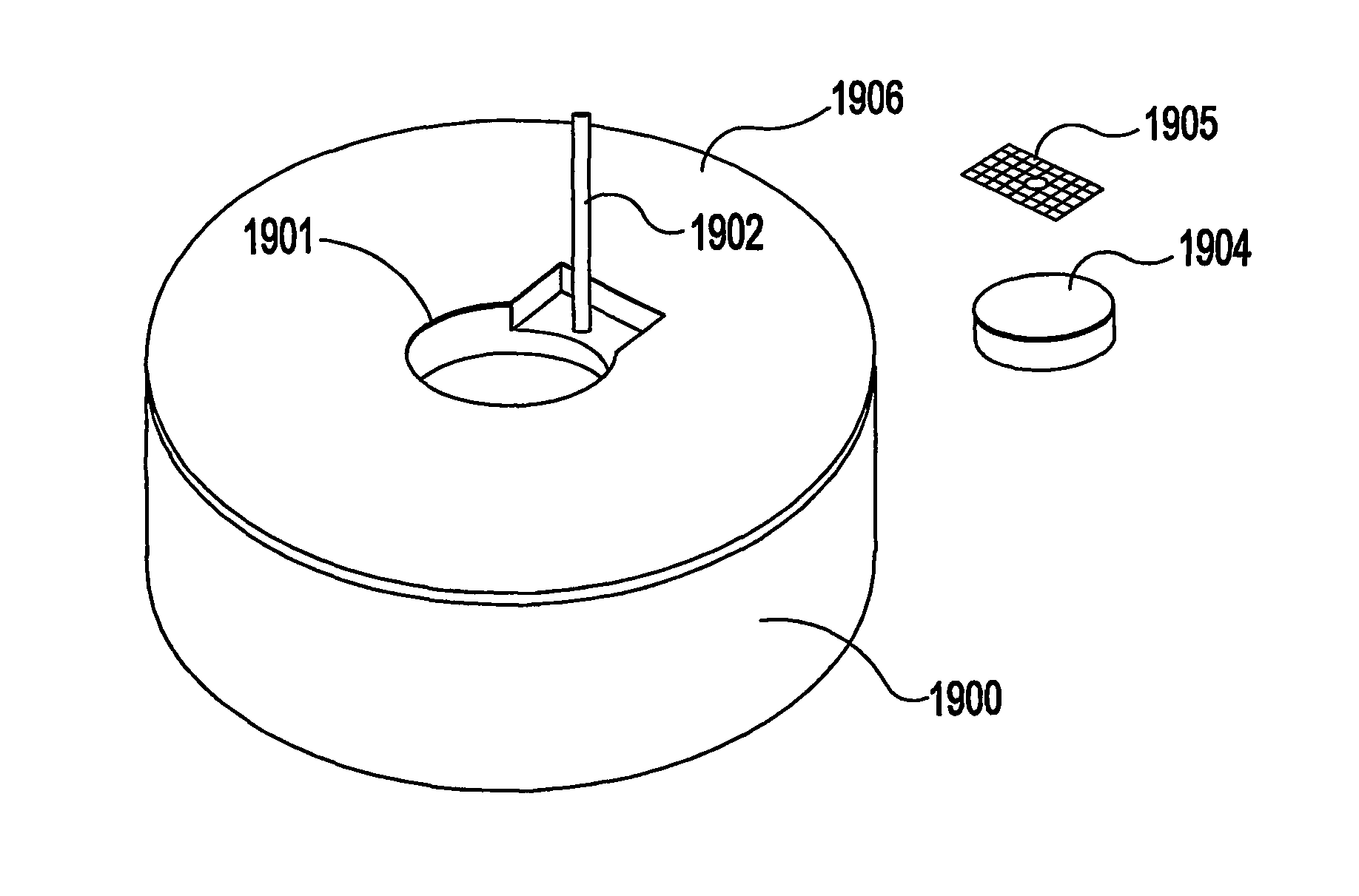

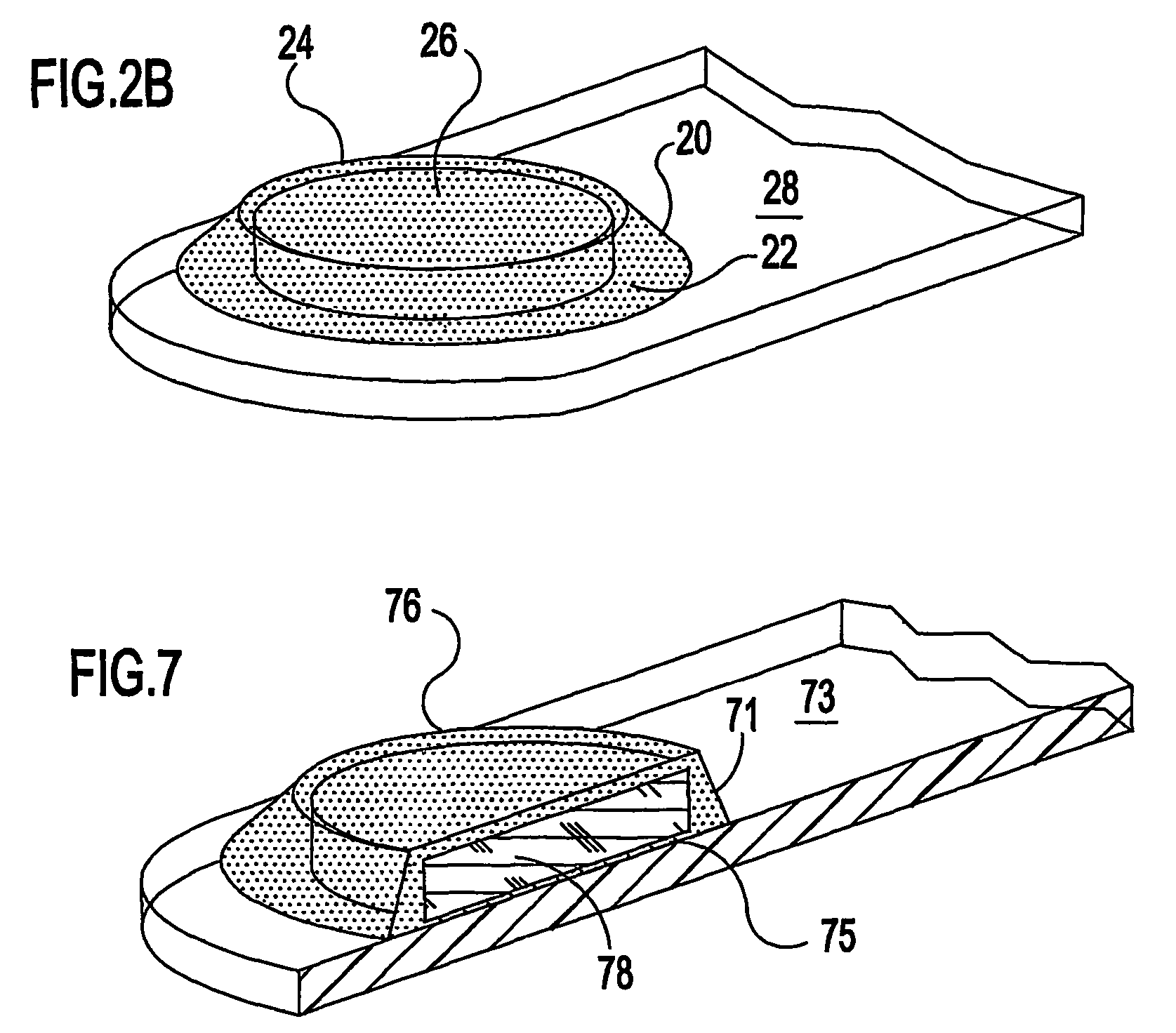

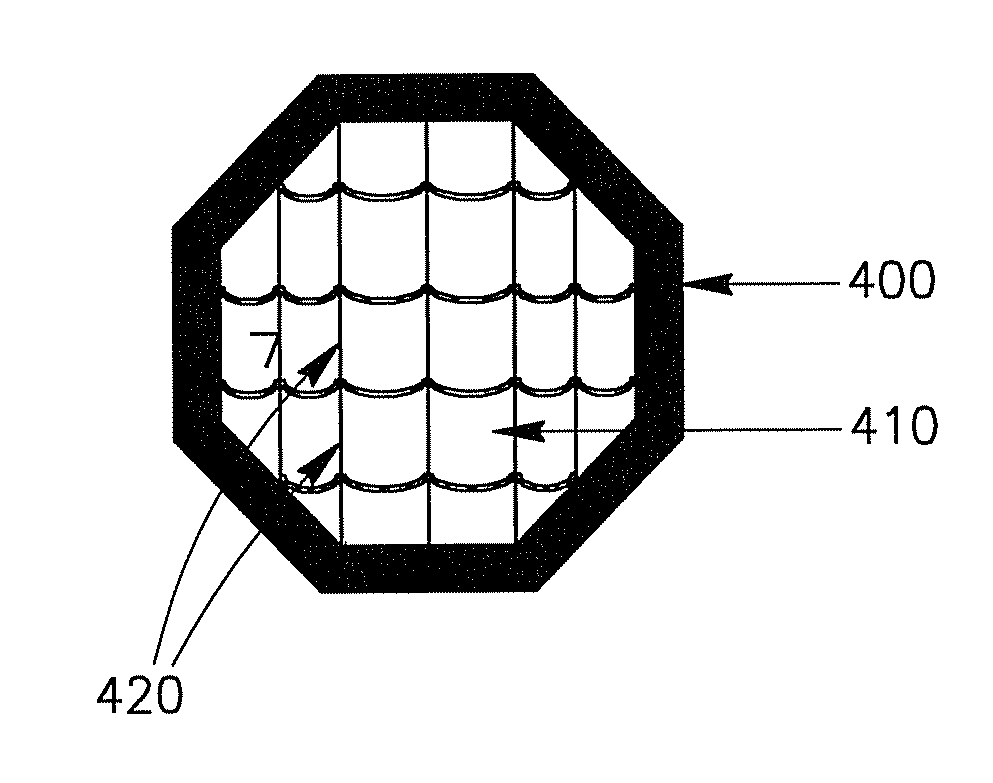

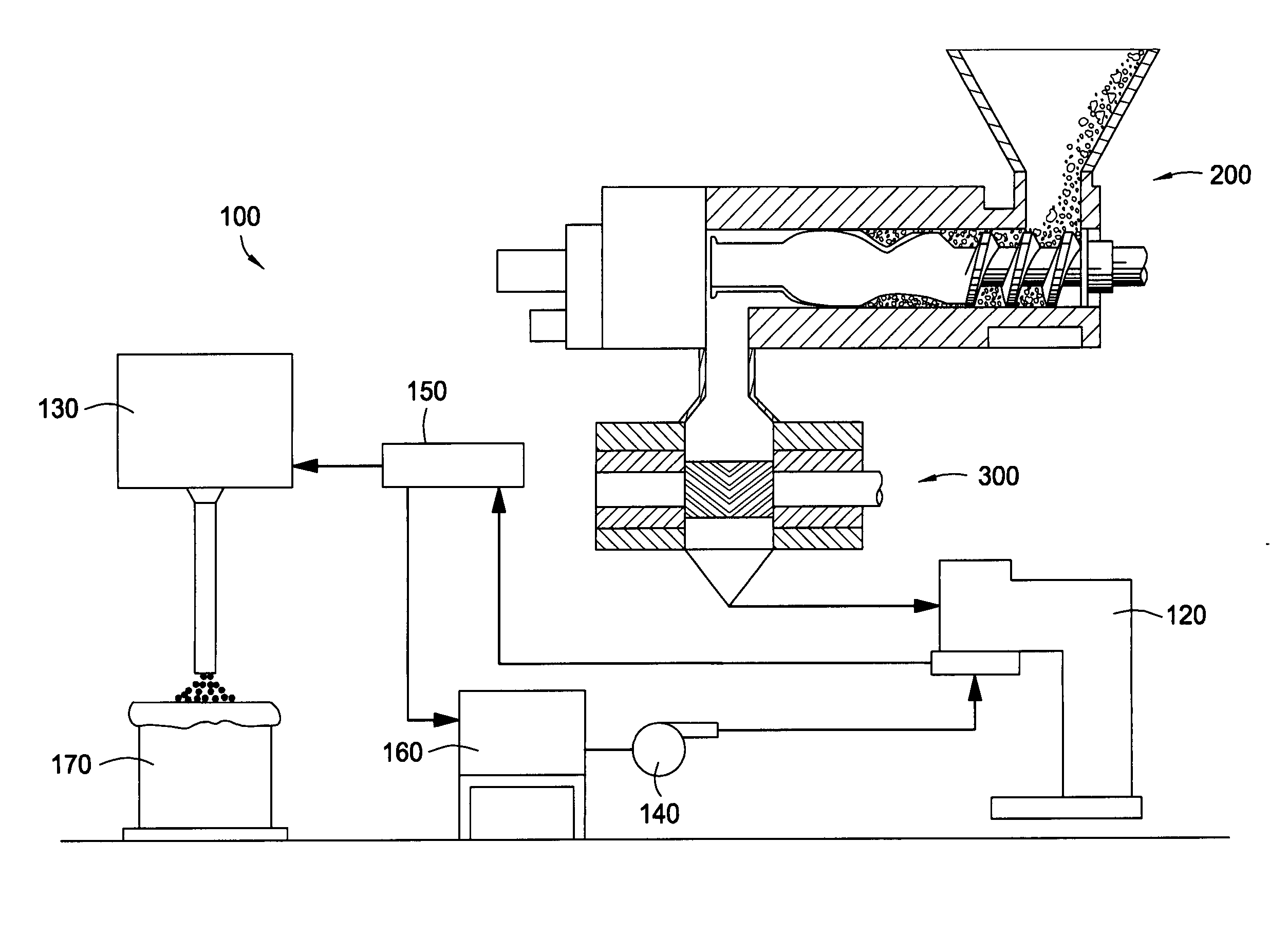

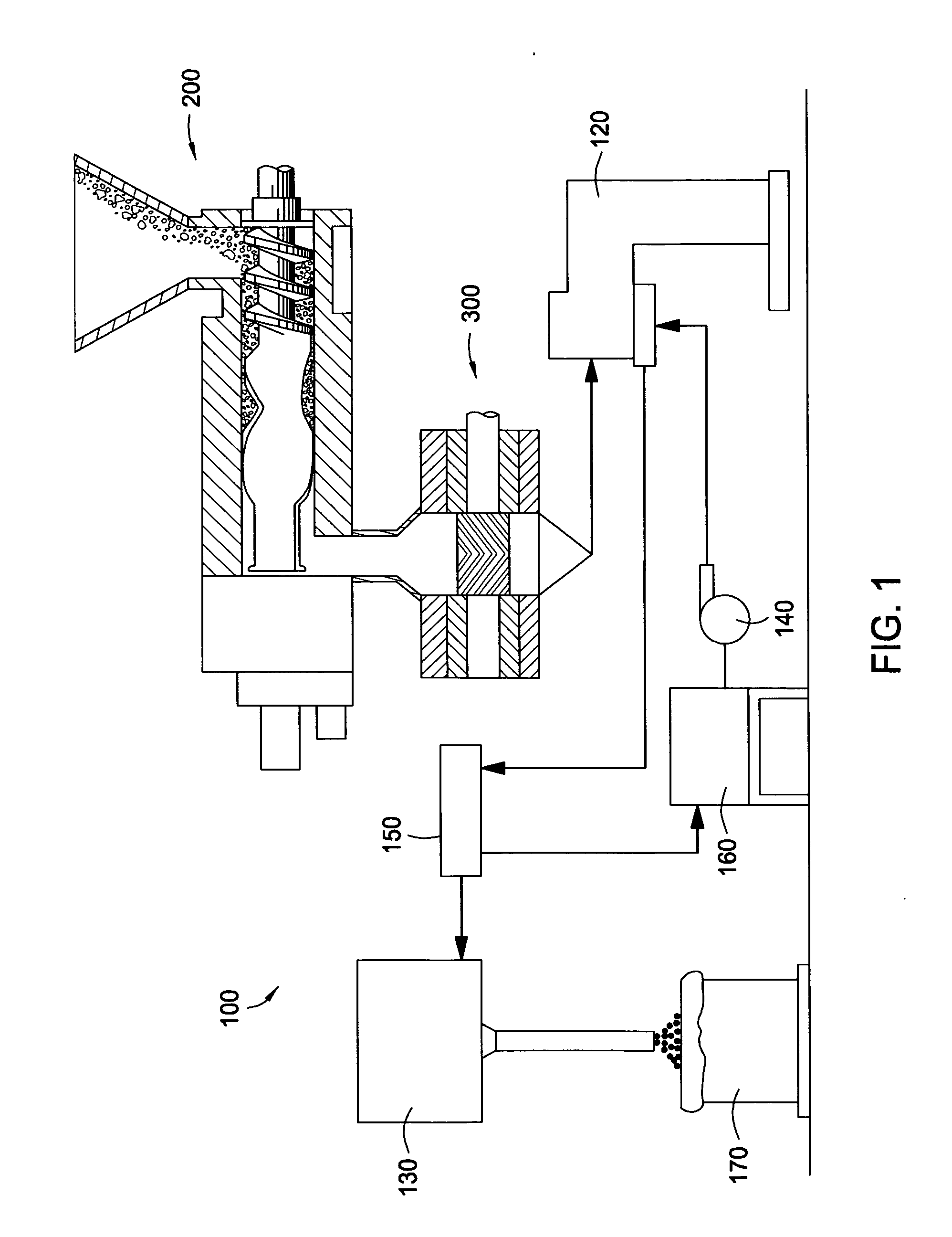

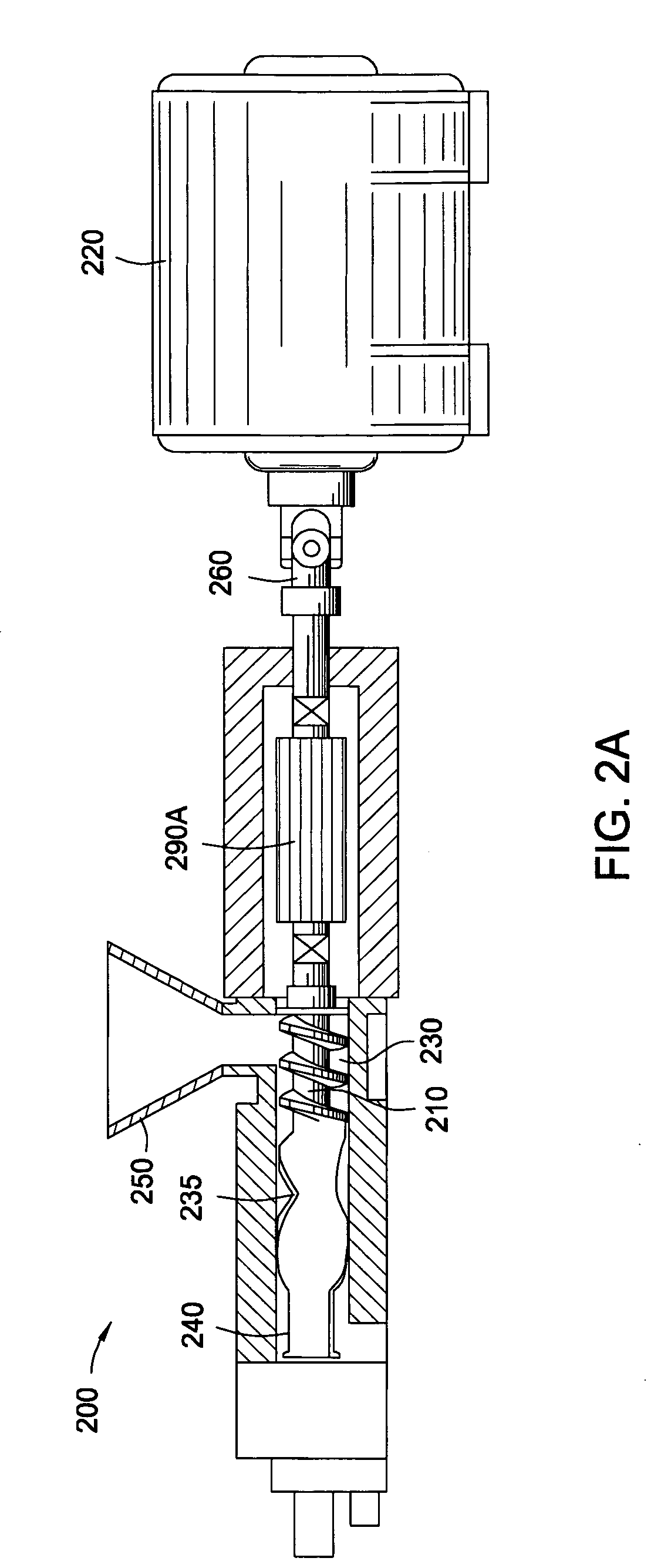

Contact lens mold assemblies and systems and methods of producing same

ActiveUS20070035051A1Prevent materialEnhanced cavitationOptical articlesStereotype platesEngineeringContact lens

Methods and apparatus are provided for making an ophthalmic lens. Apparatus are provided for filling contact lens shaped cavities of contact lens molding assemblies. Methods of coupling and fusing contact lens mold sections are also provided and generally include providing first and second mold sections which when coupled together are effective to form a lens-shaped cavity and contact regions between the mold sections. One or both of the mold sections may include one or more recessed regions or projections which provide areas of non-fusion and areas of fusion, respectively, when the mold sections have been filled with a contact lens precursor material and are fused together, for example, by means of focused ultrasound energy.

Owner:COOPERVISION INT LTD

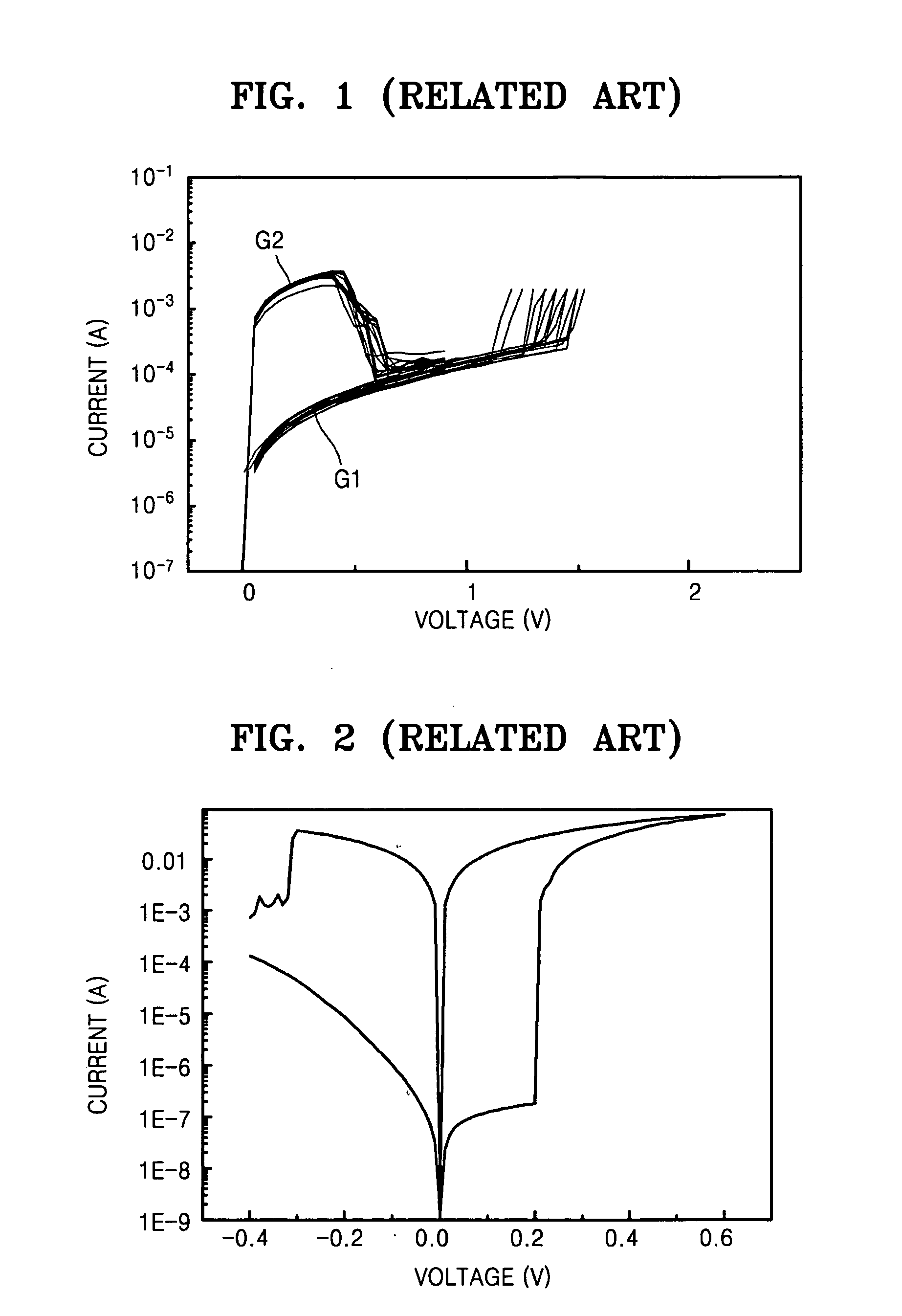

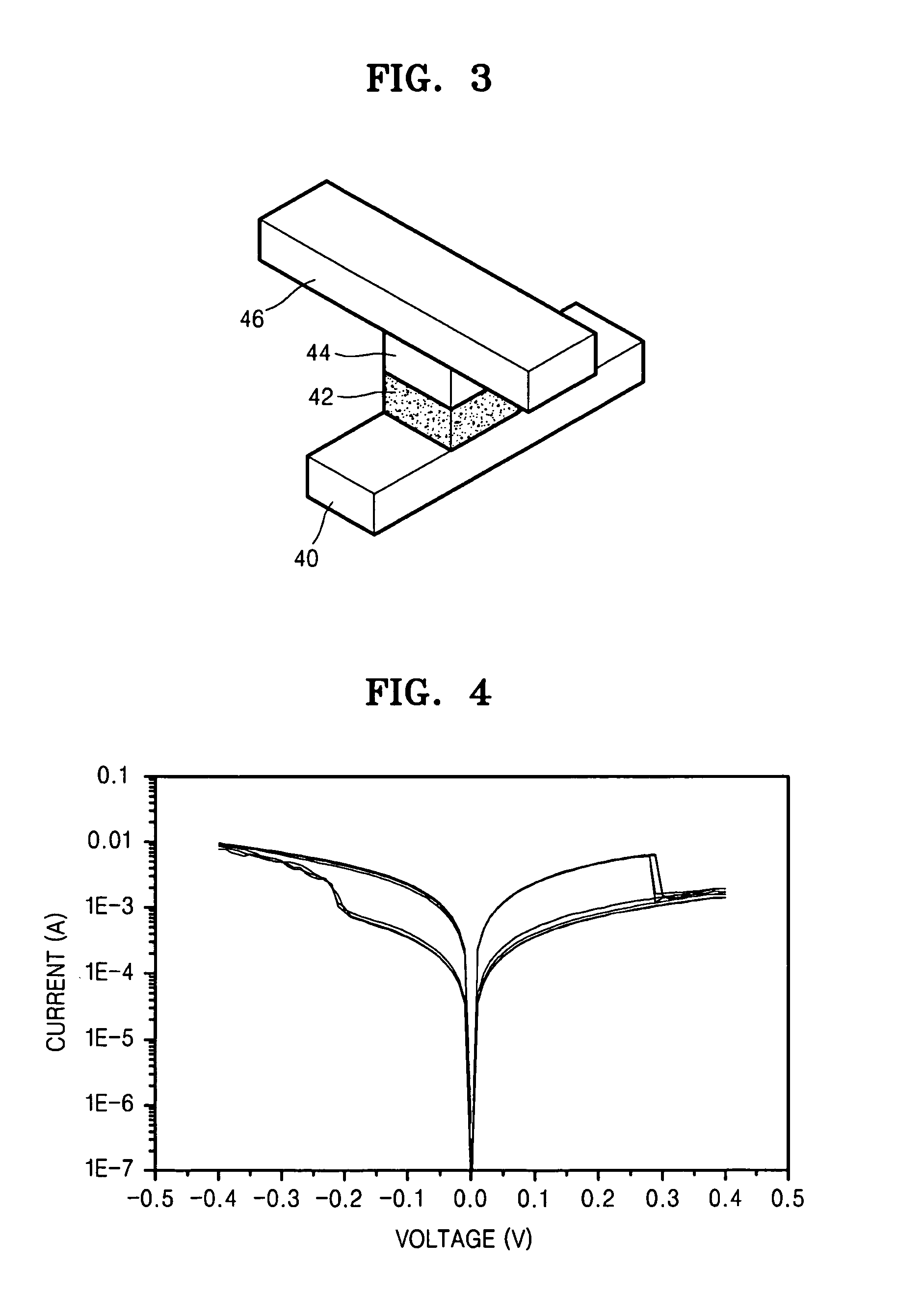

Resistive RAM having at least one varistor and methods of operating the same

Resistive memory devices having at least one varistor and methods of operating the same are disclosed. The resistive memory device may include at least one bottom electrode line, at least one top electrode line crossing the at least one bottom electrode line, and at least one stack structure disposed at an intersection of the at least one top electrode line and the at least one bottom electrode line including a varistor and a data storage layer.

Owner:SAMSUNG ELECTRONICS CO LTD

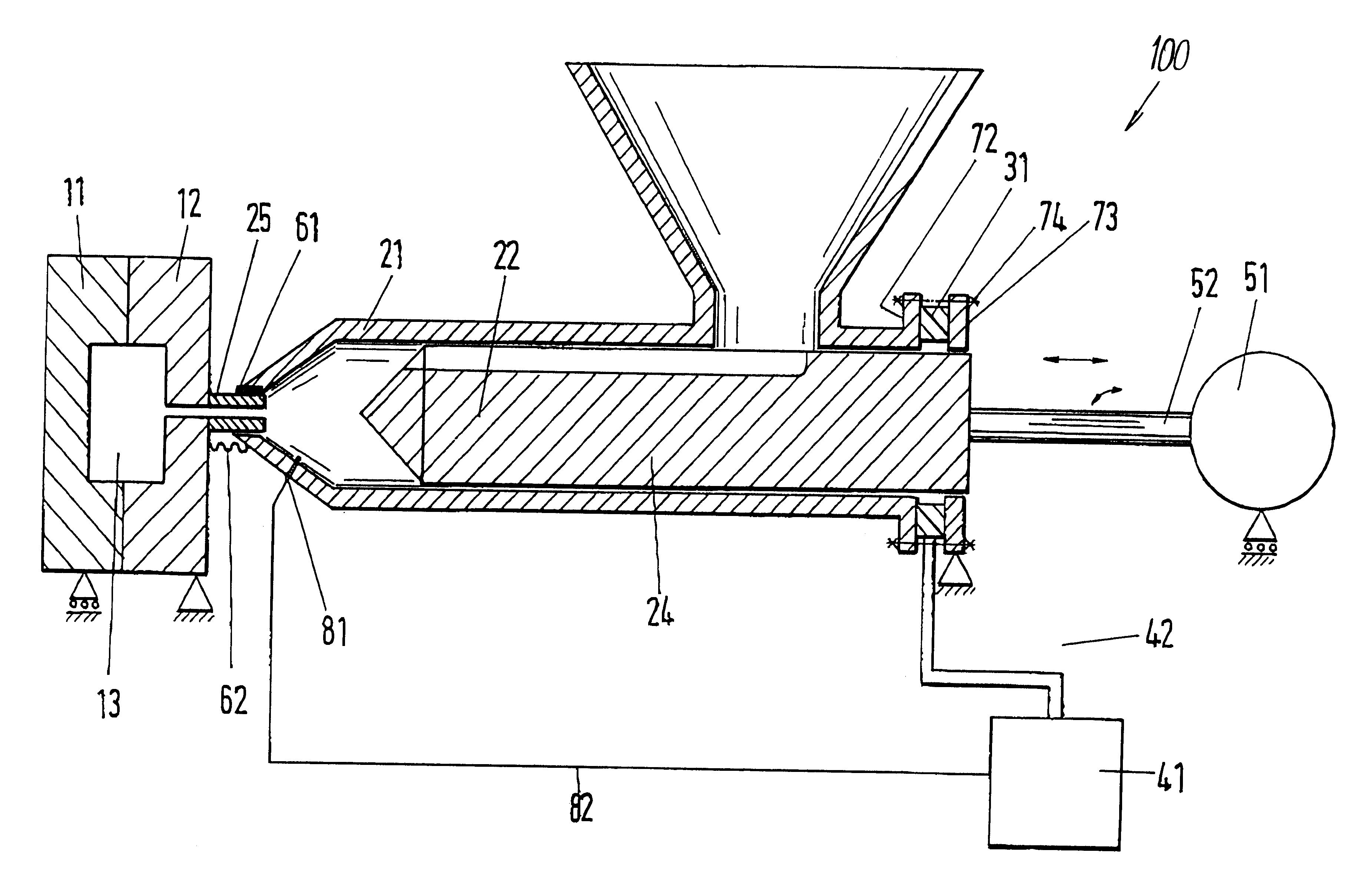

Two-step method for dehydrating plastic dispersions

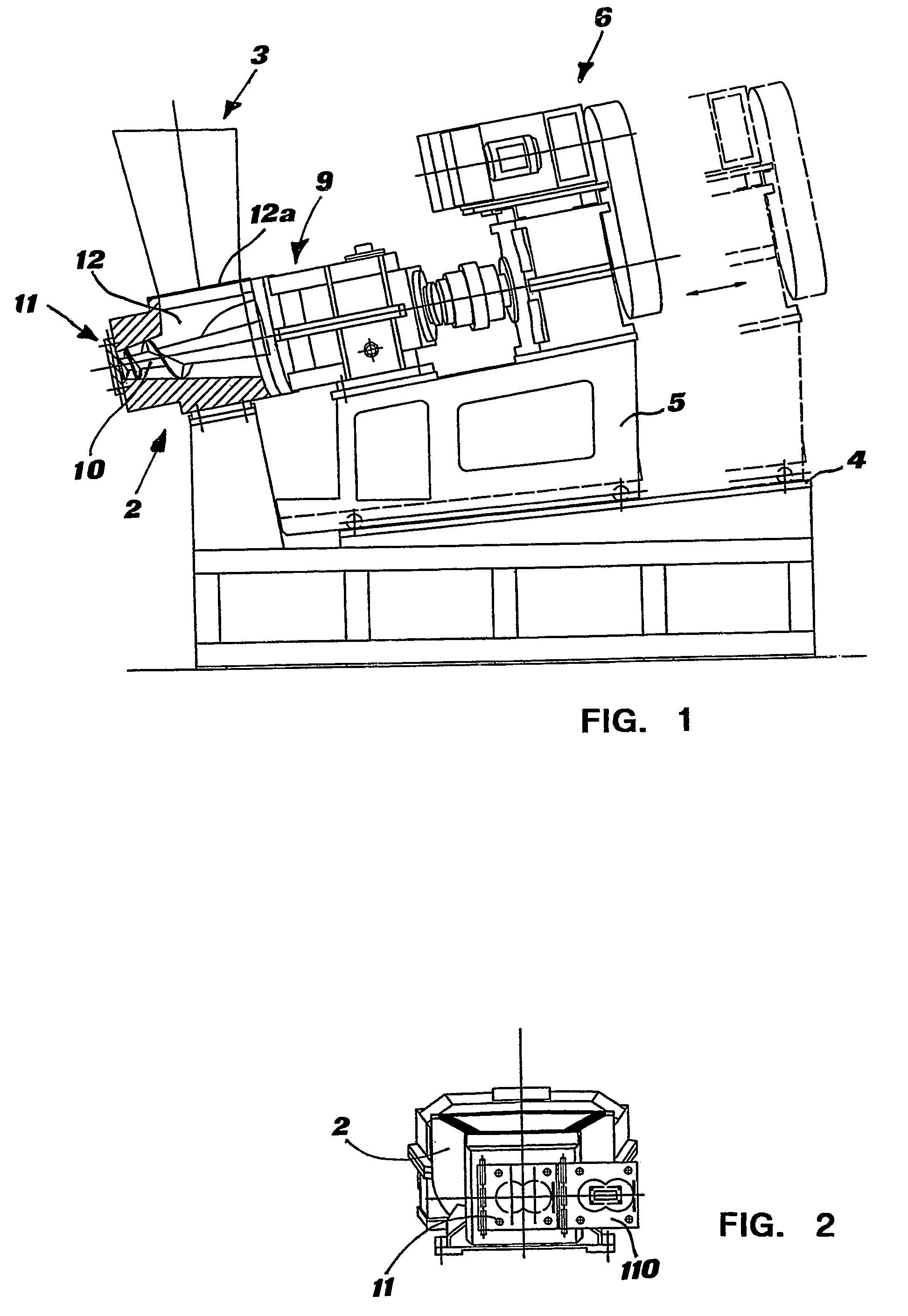

InactiveUS6287470B1Avoid excessive wearQuality improvementLiquid degasificationRotary stirring mixersPolymer scienceOrganic chemistry

The invention relates to a method for dehydrating a two-phase liquid mixture consisting of a thermoplastic synthetic melt phase and an aqueous phase, comprising the following steps: a) coagulation of the two-phase liquid mixture in a first extruder; b) dehydration of the coagulate in a twin screw extruder with a de-watering zone and screws working in an opposite direction; c) separation of constituents by degasifying. The inventive method is characterized in that a single screw extruder or a twin screw extruder with screws working in the same direction is used as a first extruder in step a).

Owner:EVONIK ROEHM GMBH

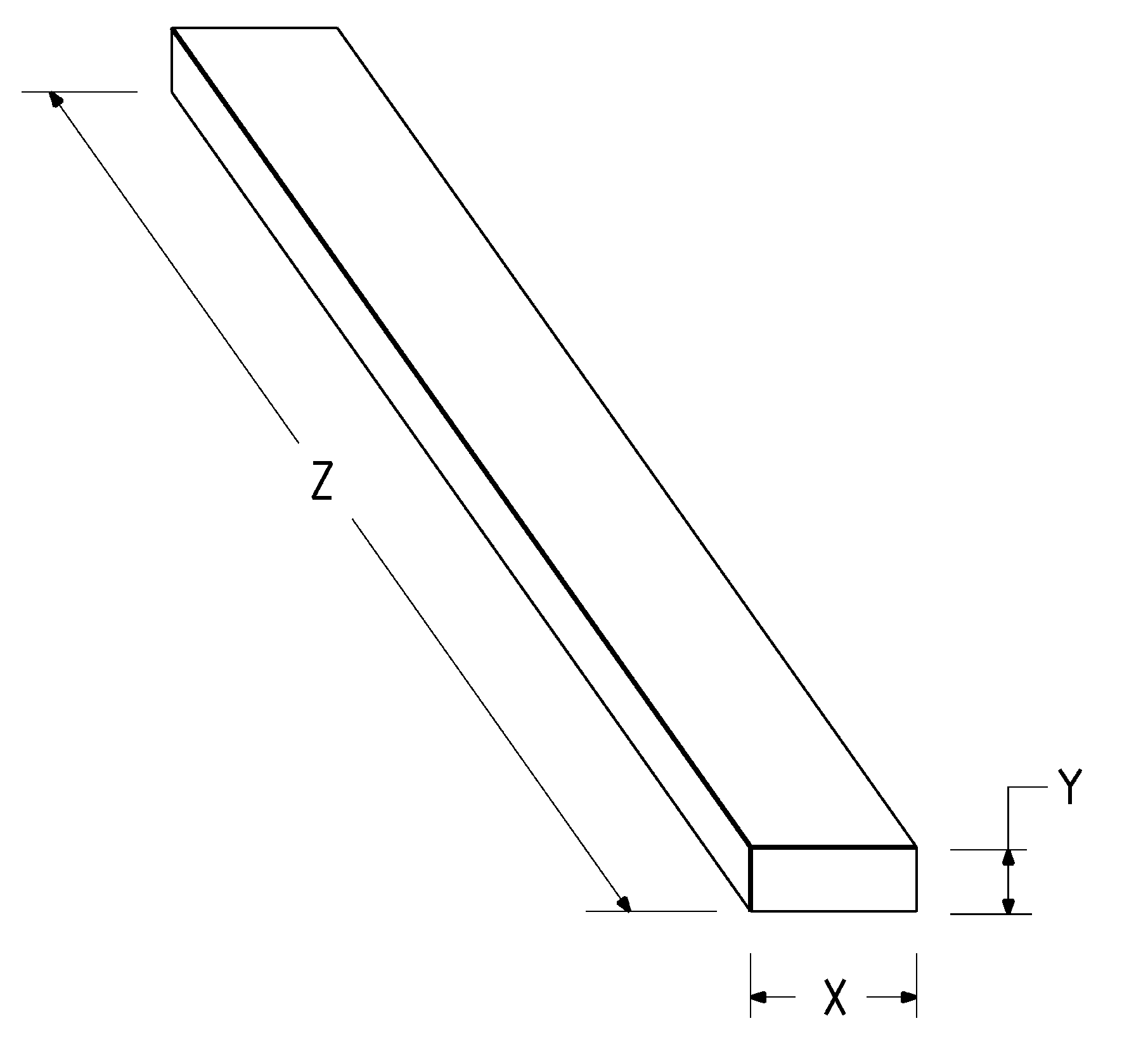

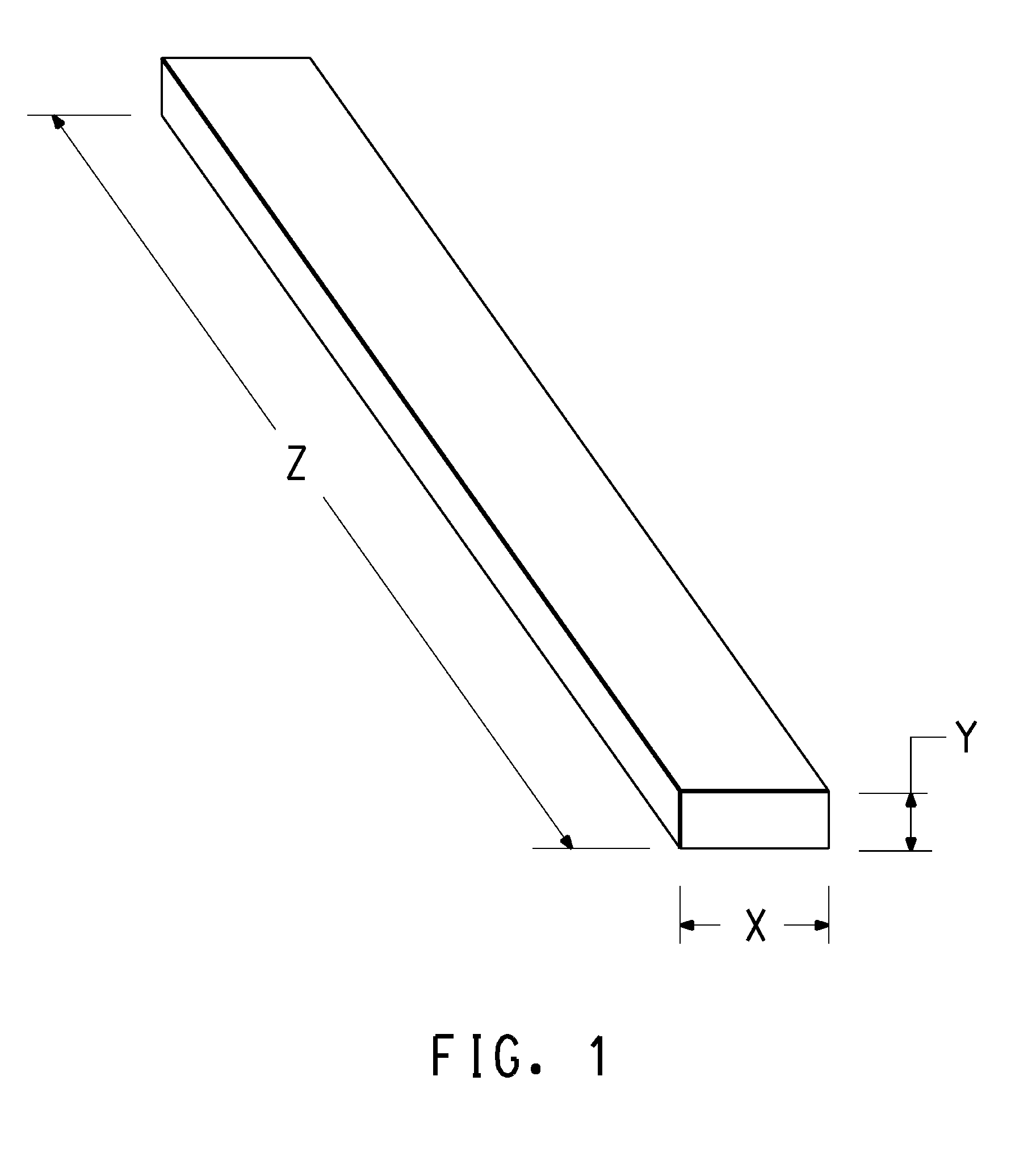

High-temperature polyamide molding compounds reinforced with flat glass fibers

ActiveUS20090062452A1Advantage in mechanical propertyAdvantage in in processingRotary stirring mixersSpecial tyresFlat glassGlass fiber

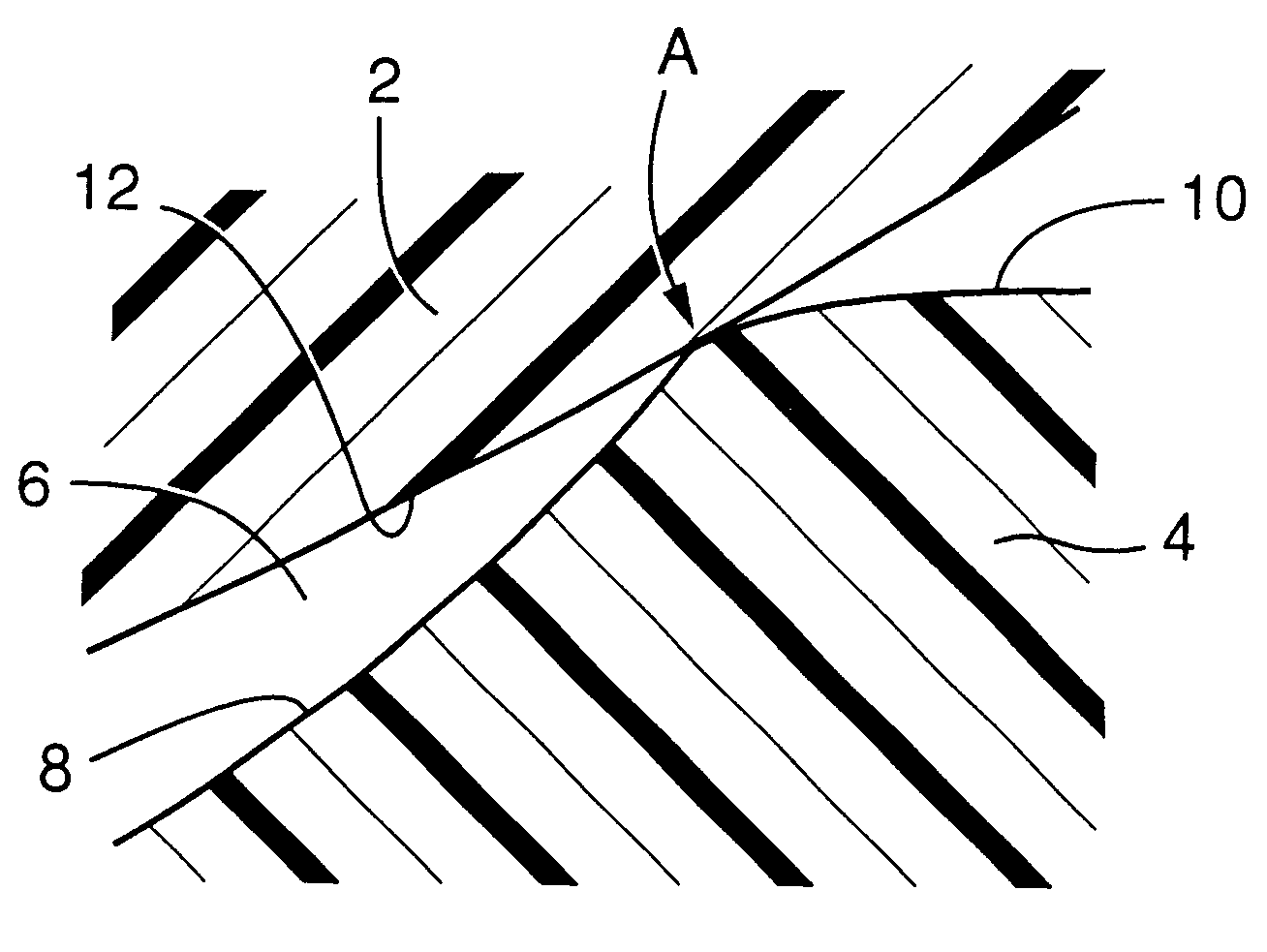

The present invention relates to reinforced polyamide molding compounds containing high-melting partially aromatic polyamides and flat glass fibers, in particular with a rectangular cross section, i.e., glass fibers with a noncircular cross-sectional area and a dimension ratio of the main cross-sectional axis to the secondary cross-sectional axis of 2 to 6, in particular 3 to 6, most especially preferably from 3.5 to 5.0. The present invention also relates to a method for manufacturing polyamide molding compounds and molded articles manufactured therefrom, i.e., in particular injection-molded parts. The inventive molded parts have a high transverse stiffness and transverse strength.

Owner:EMS PATENT AG

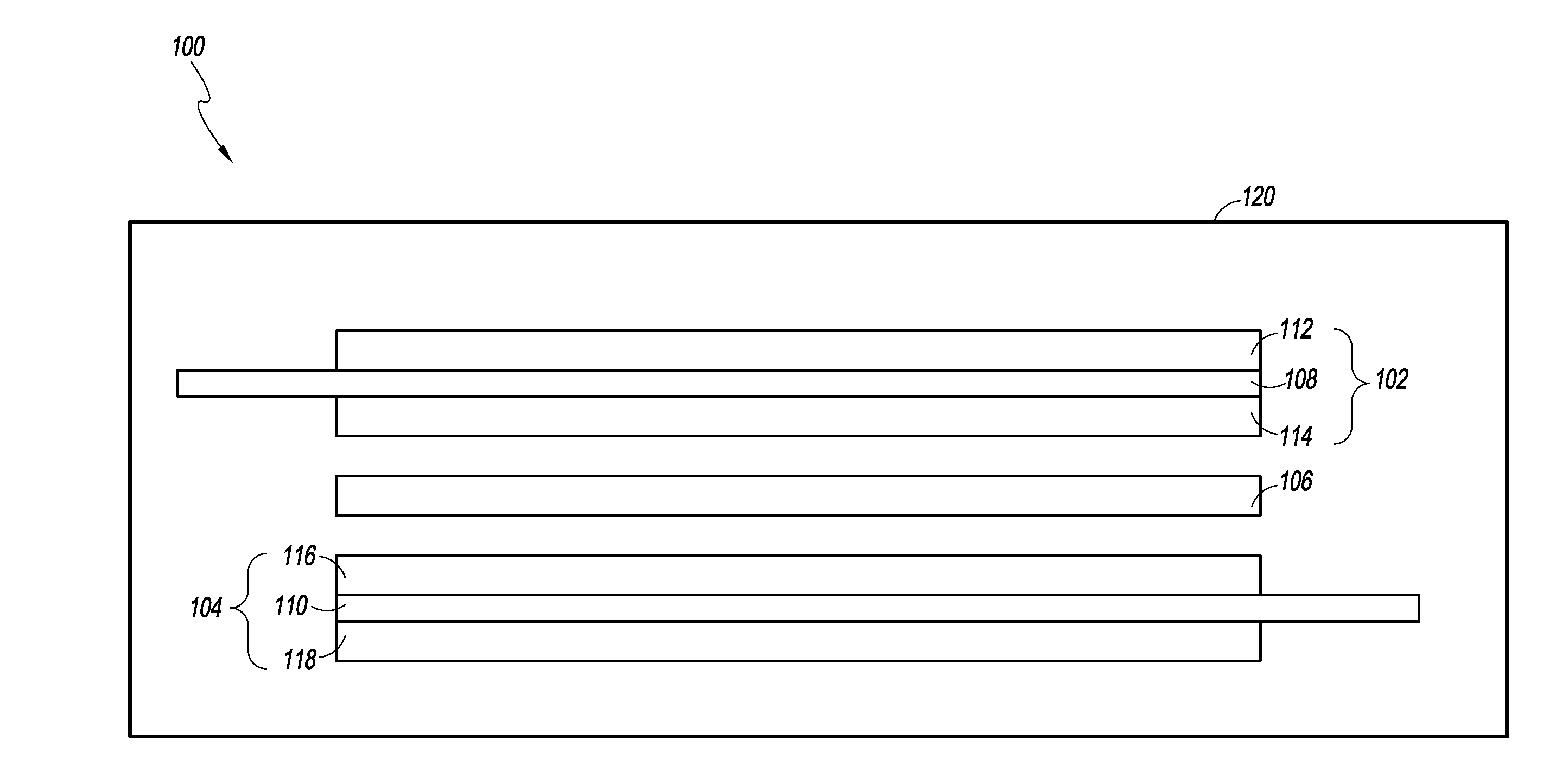

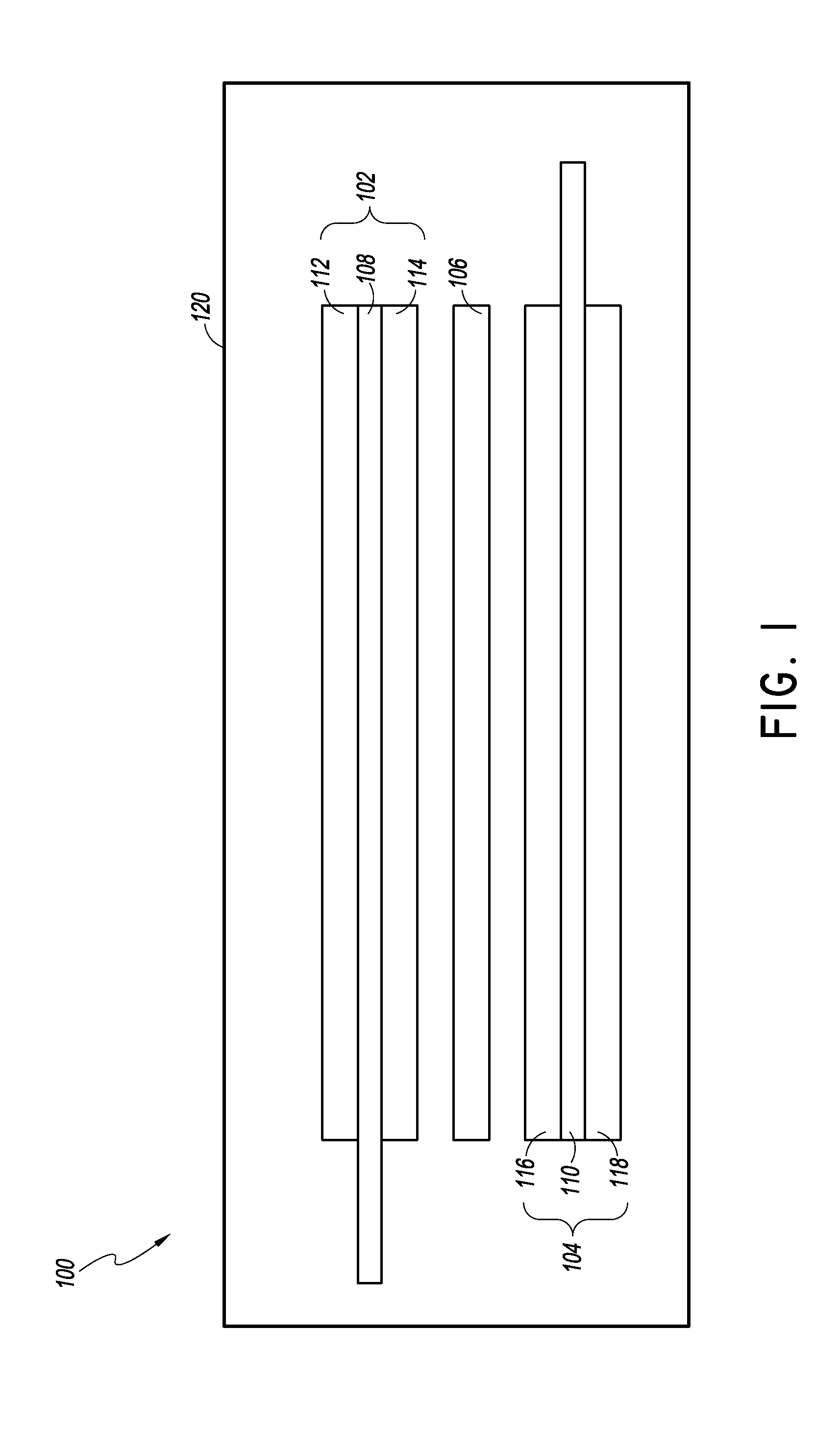

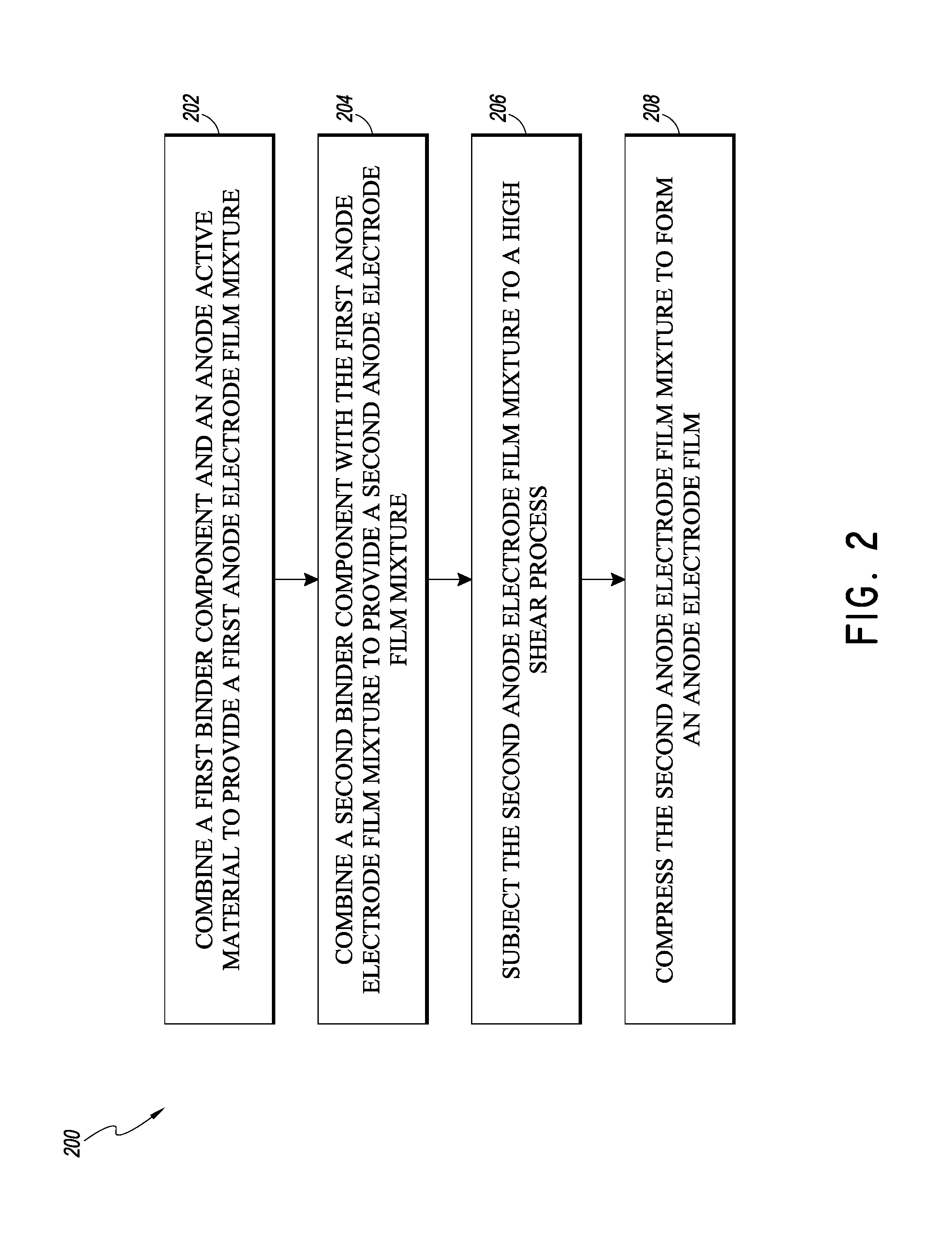

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

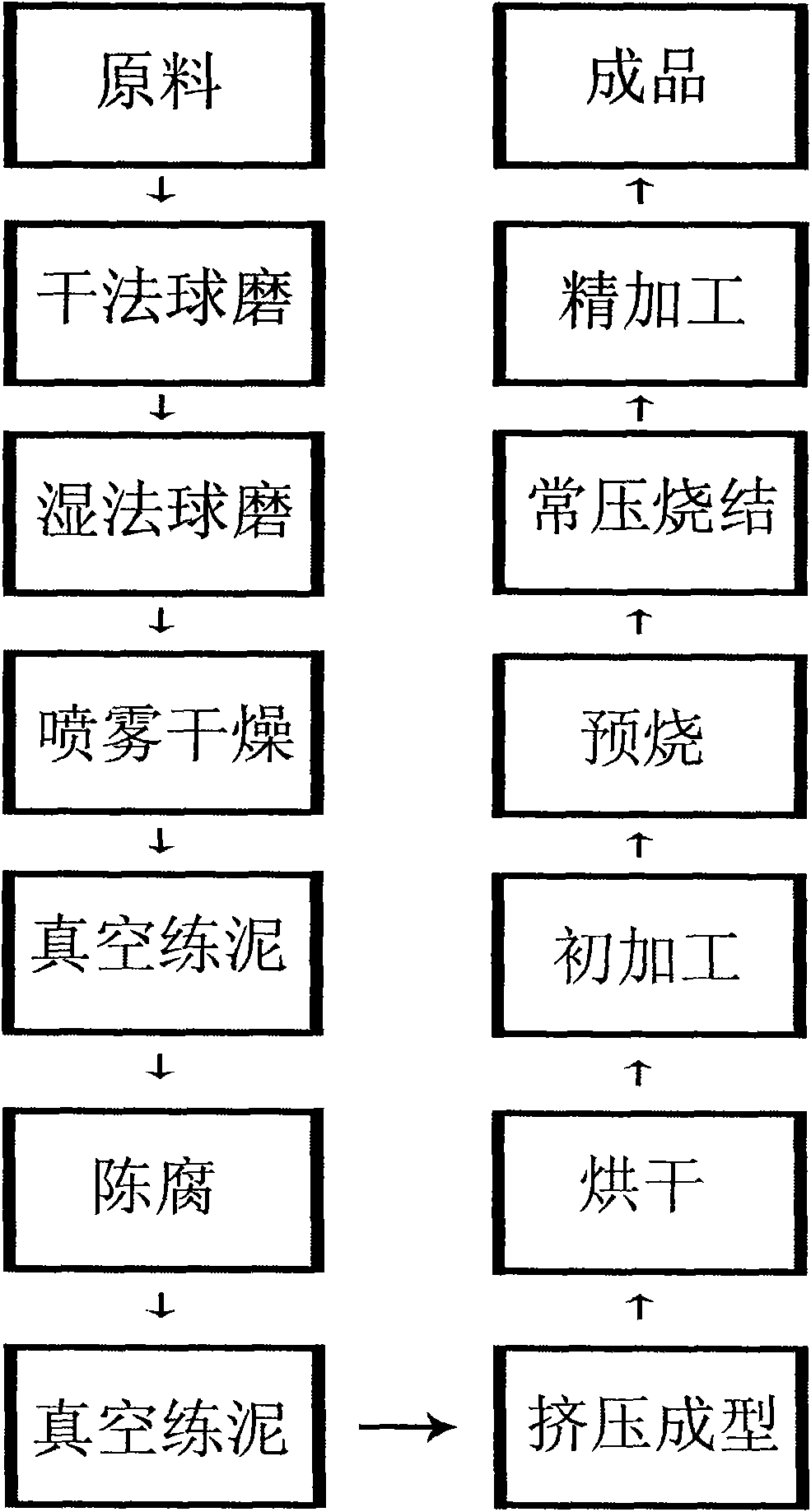

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

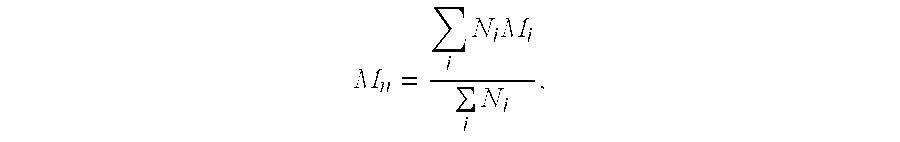

Process for the production of polyester nanocomposites

InactiveUS20080315453A1Increase polyester molecular weightHigh molecular weightMaterial nanotechnologyRotary stirring mixersCompound aMasterbatch

A method for dispersing sepiolite-type clay particles in a polyester matrix by melt-compounding a mixture of: sepiolite-type clay, at least one linear polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition; and, optionally, subjecting said nanocomposite composition to solid state polymerization to increase polyester molecular weight. Further described is a method for preparing a polyester nanocomposite composition from a masterbatch, comprising melt-compounding a mixture of: sepiolite-type clay, at least one polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition containing a greater concentration of sepiolite-type clay than is desired in the final resin composition; optionally, subjecting said nanocomposite composition to solid state polymerization to increase the polyester molecular weight; and further melt compounding said nanocomposite composition with polyester polymer and, optionally, additional ingredients.

Owner:EI DU PONT DE NEMOURS & CO

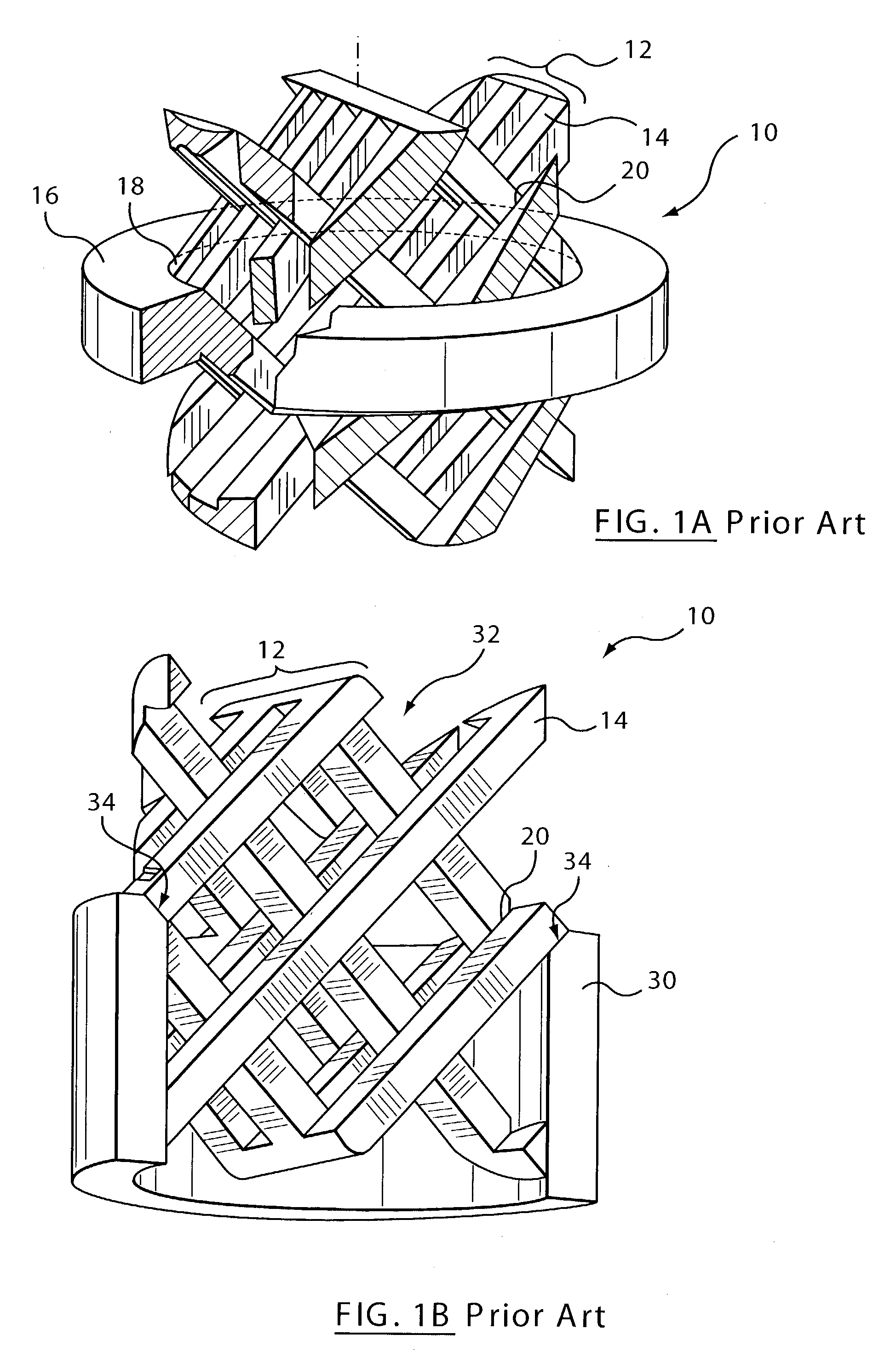

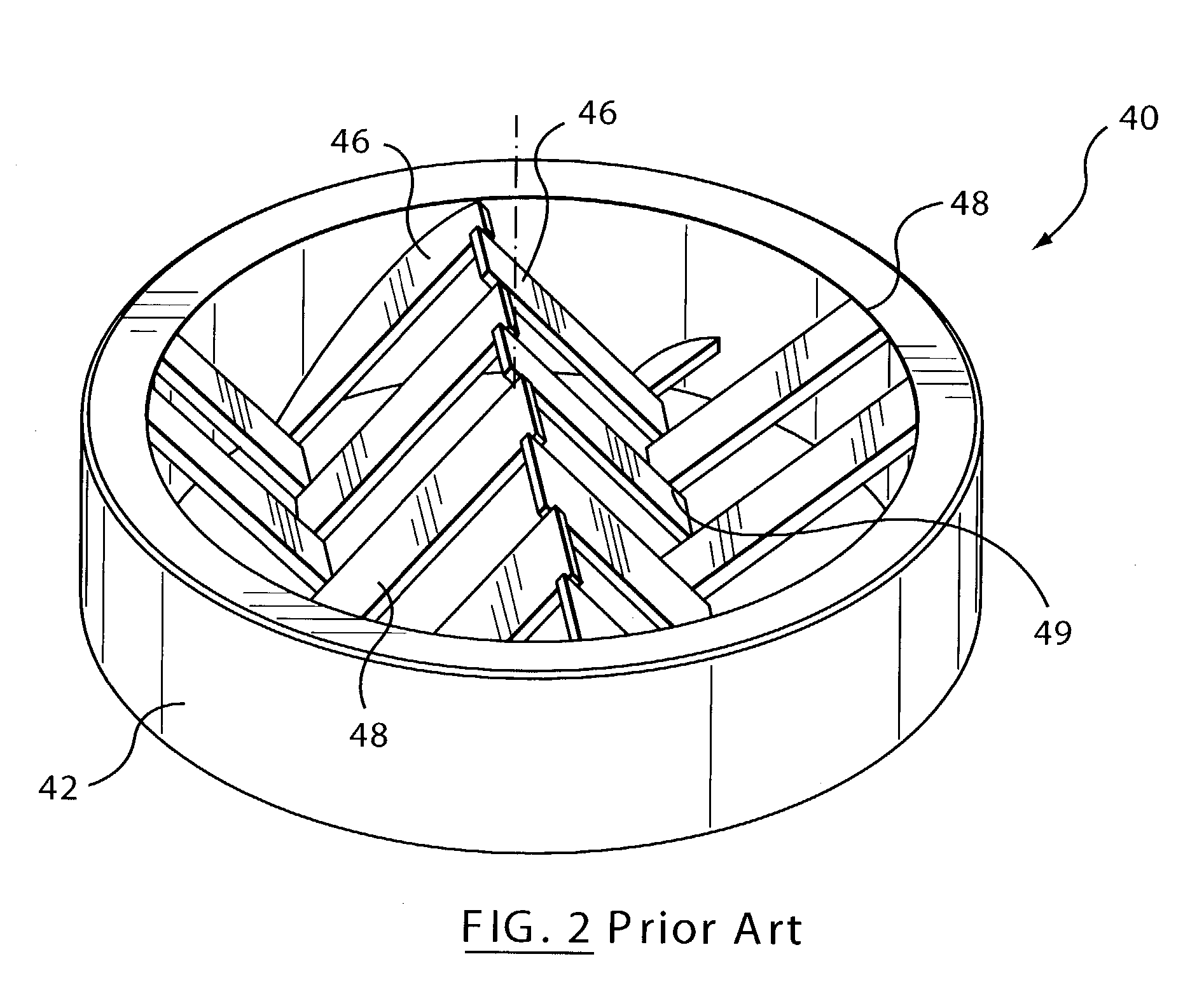

Static mixer and a method of manufacture thereof

ActiveUS7198400B2Evenly distributedConsistent levelFlow mixersTransportation and packagingEngineeringStatic mixer

Owner:HUSKY INJECTION MOLDING SYST LTD

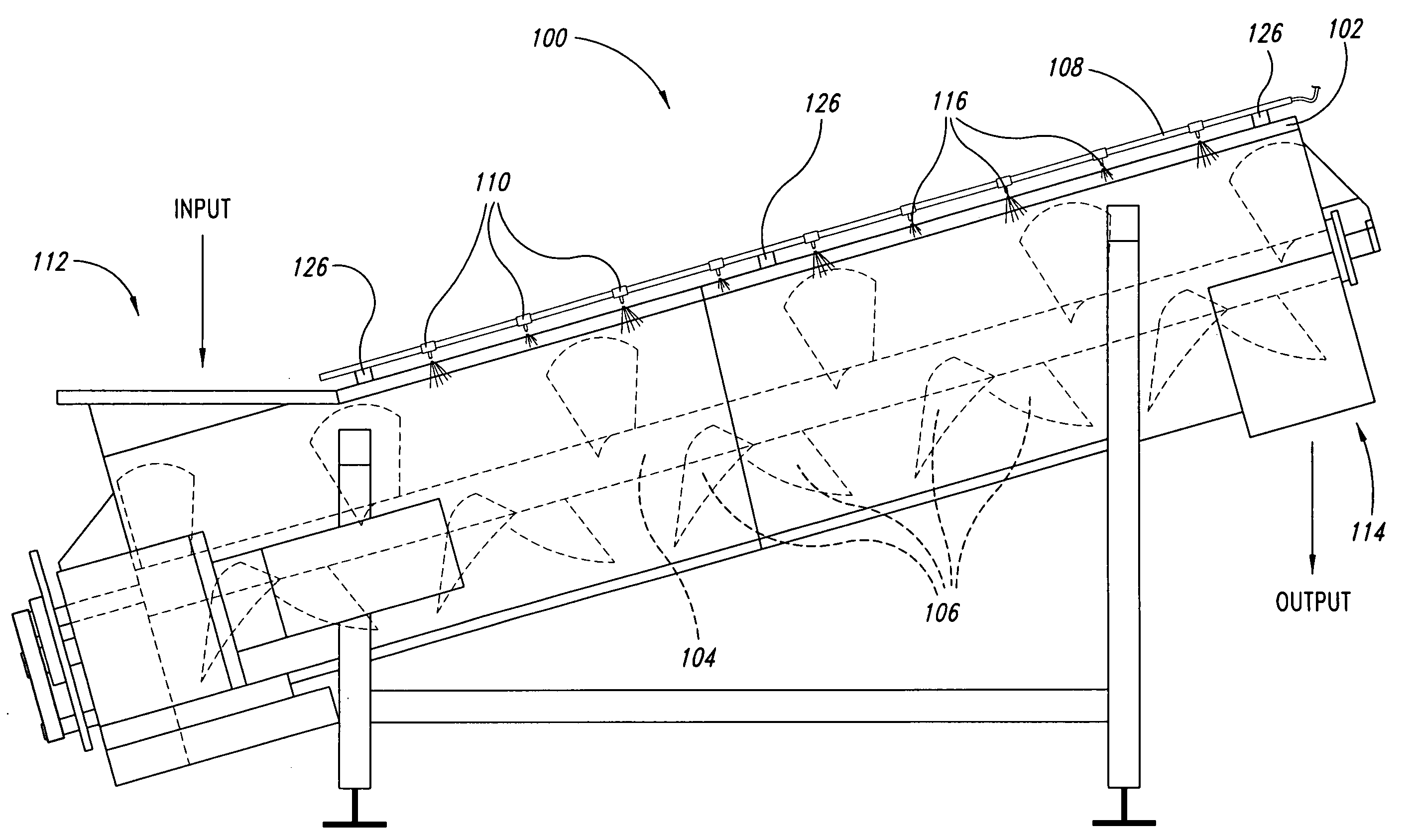

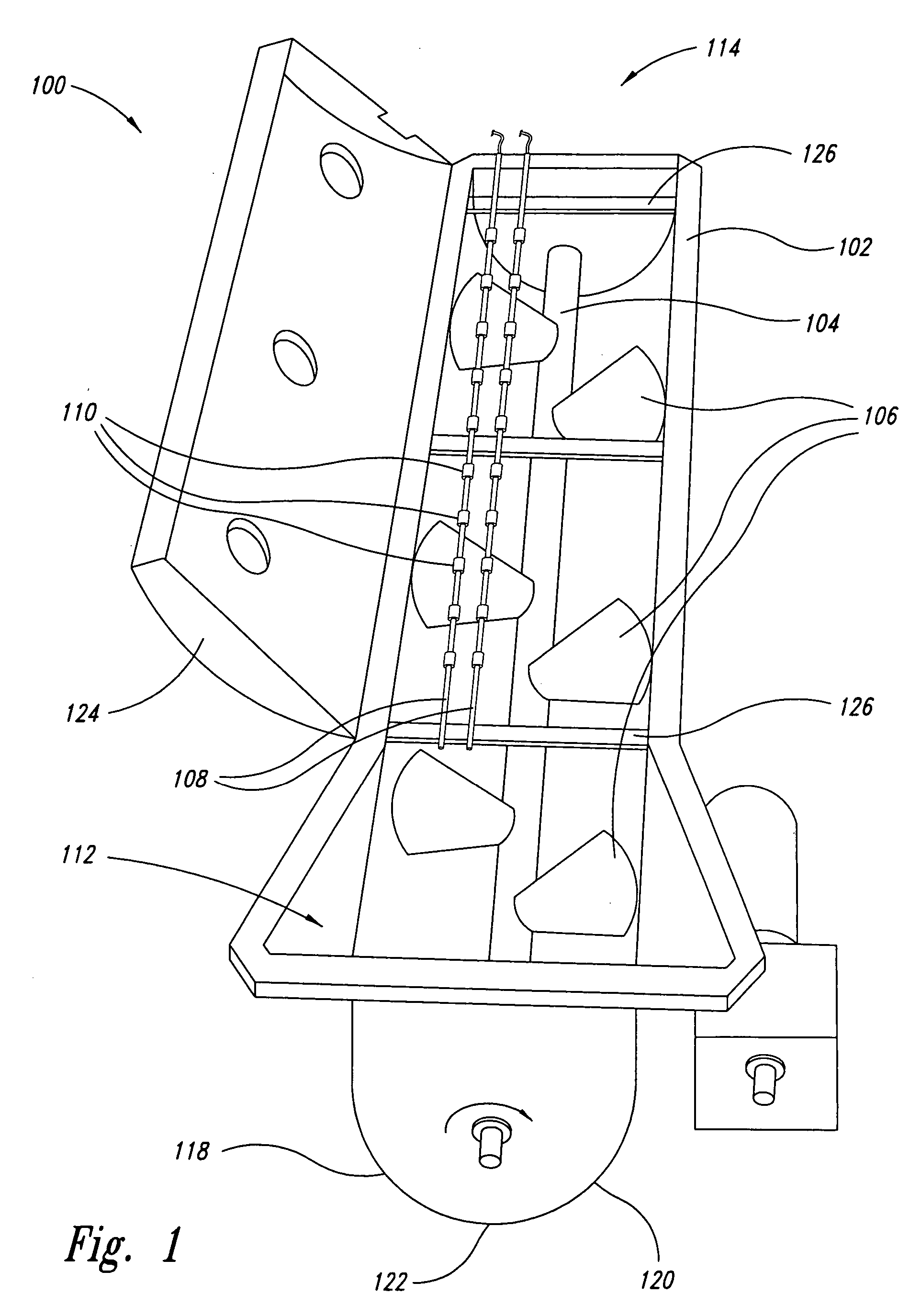

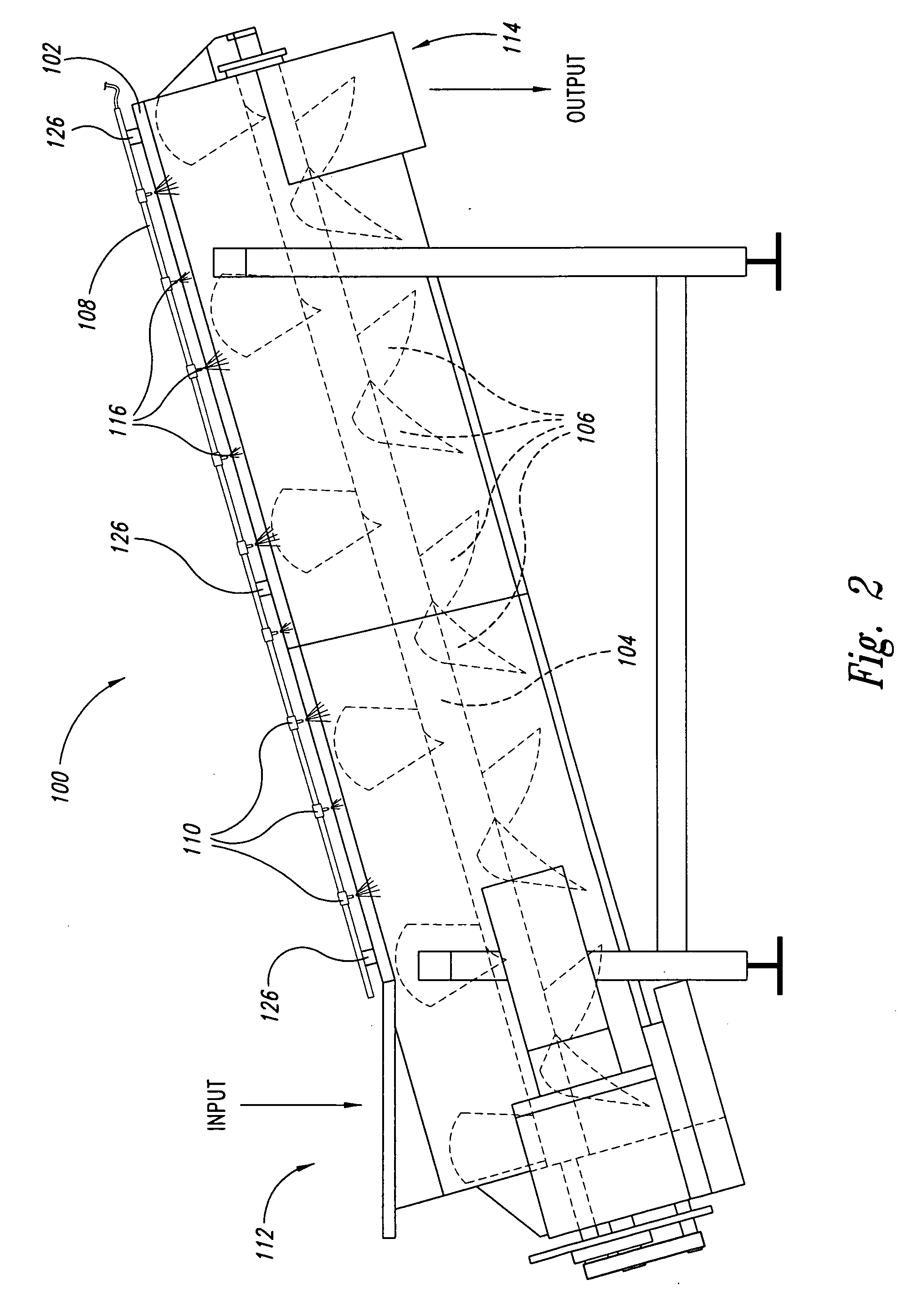

Treatment fluid application apparatus for foodstuffs and methods related thereto

InactiveUS20050058013A1Good lookingImprove EdibilityRotary stirring mixersMeat/fish preservation using liquidsSpiral bladeDisinfectant

Apparatus and methods for applying treatment fluids, such as disinfectants, flavoring agents, and tenderizing agents, to foodstuff surfaces to, for example, reduce populations of microorganisms or fungi, alter taste, or alter texture. In representative embodiments, the apparatus includes a housing, a fluid delivery system, and a shaft with a protruding surface, the latter adapted to rotatably convey, while agitating and tumbling, the foodstuffs from an inlet to an outlet of the housing, as the fluid delivery system applies a treatment fluid to the foodstuffs. In more specific embodiments, the protruding surface may be paddles, or paddles interconnected by a solid web and having angled distal surfaces, or a spiral blade with radial protrusions, or such a spiral blade along a first longitudinal portion of the shaft and paddles along a second longitudinal portion of the shaft.

Owner:ALCIDE CORP

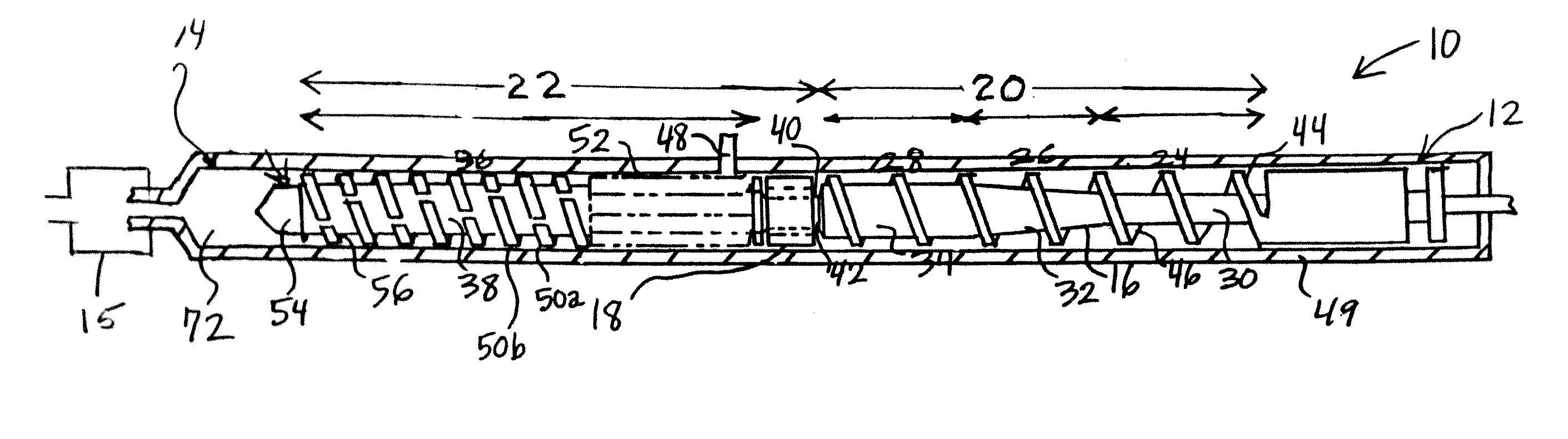

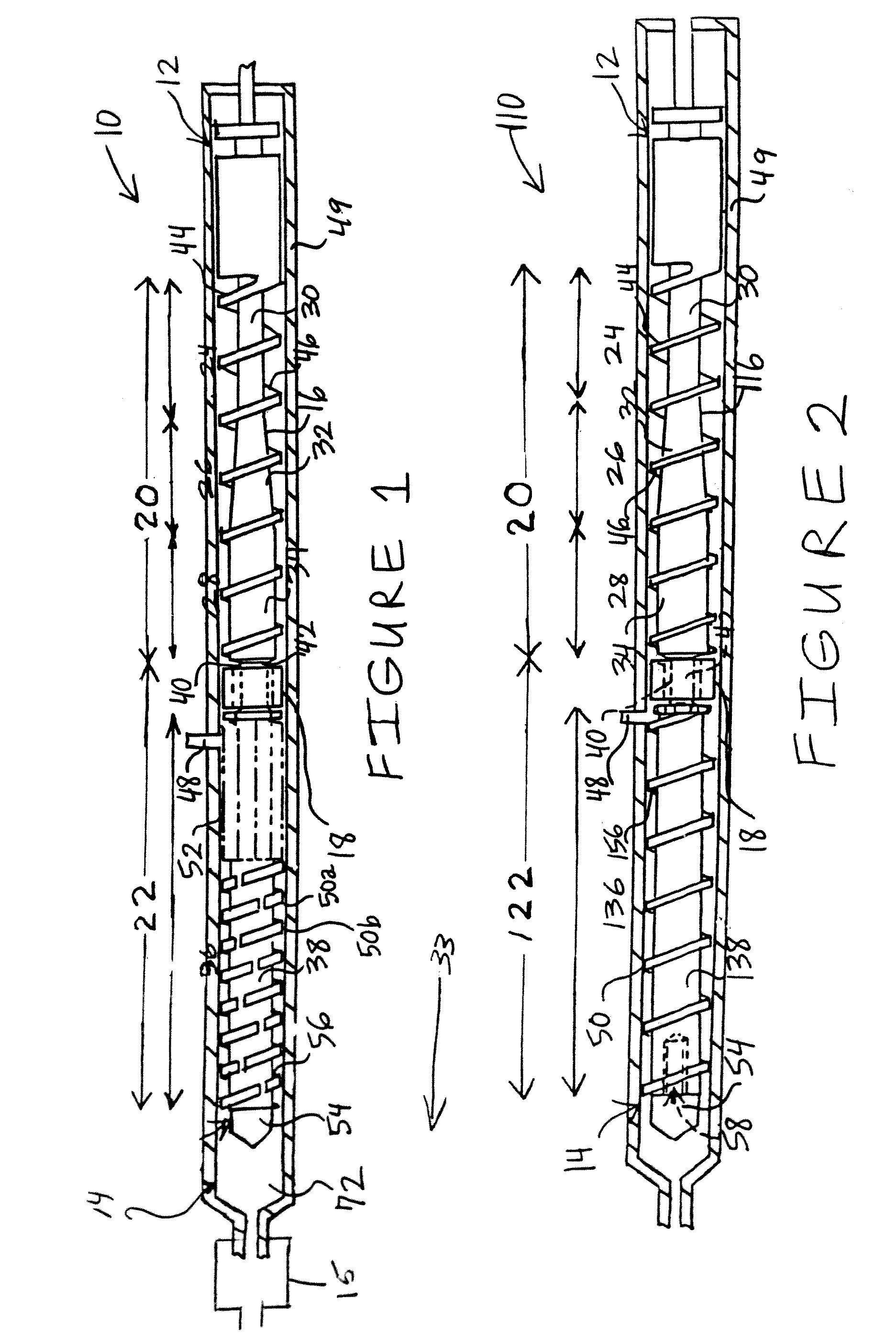

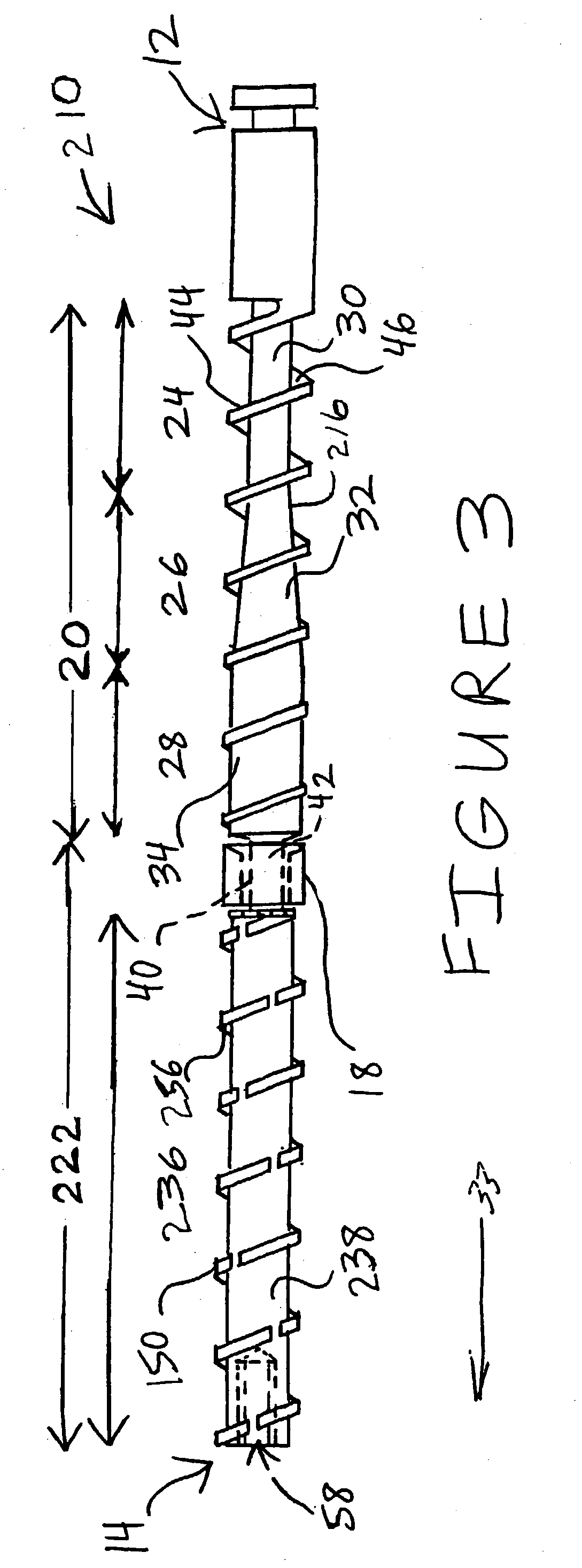

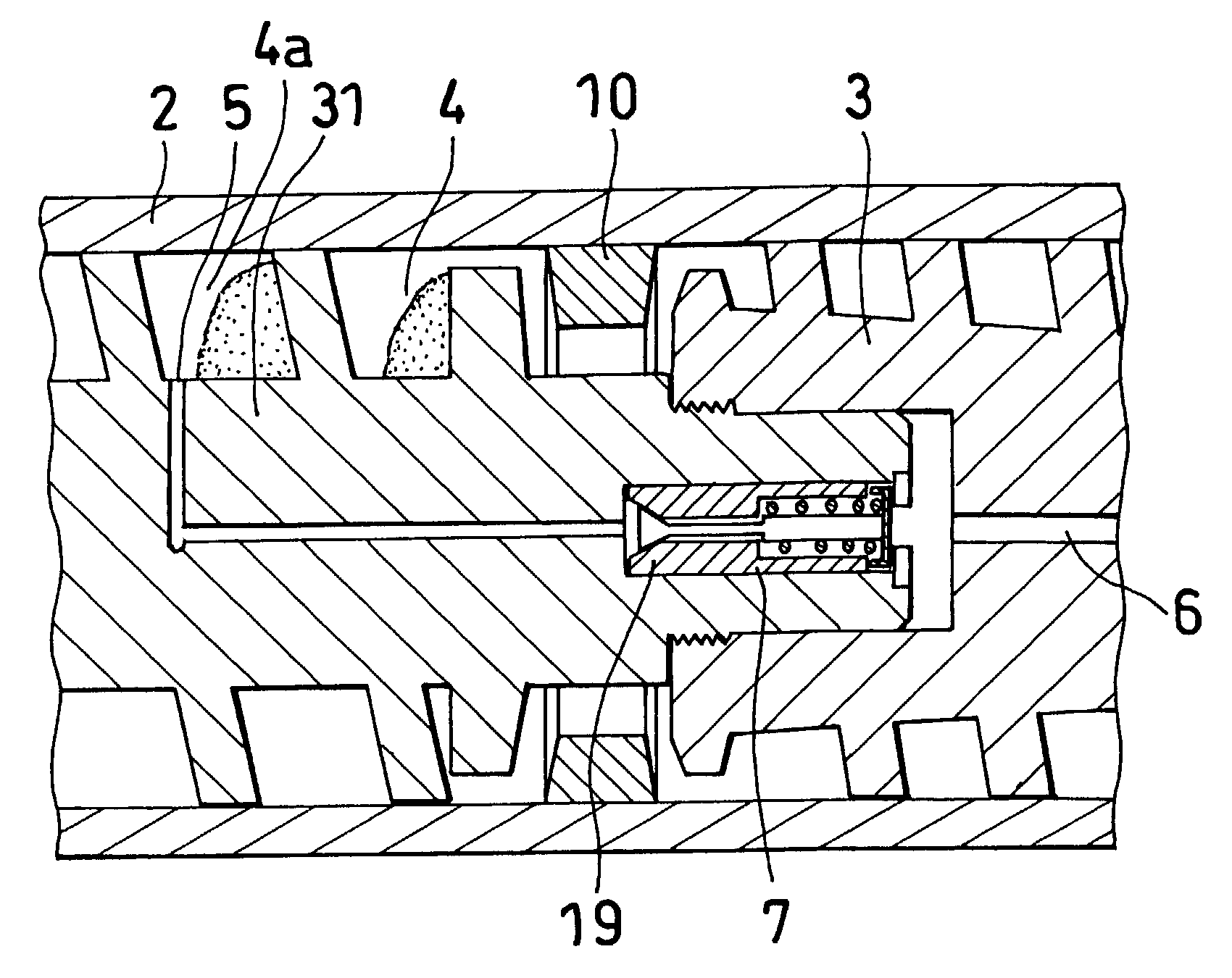

Injection molding screw

InactiveUS7172333B2Minimized pressure lossRotary stirring mixersFrozen sweetsEngineeringInjection molding machine

An injection molding screw for metal injection molding includes a first end, a second end, a longitudinal body with a first stage and a second stage extending axially along a length of the screw between the ends, a pressure retention device, and optionally, a screw tip. The pressure retention element minimizes loss of pressure in the second stage portion.

Owner:SOUTHCO +1

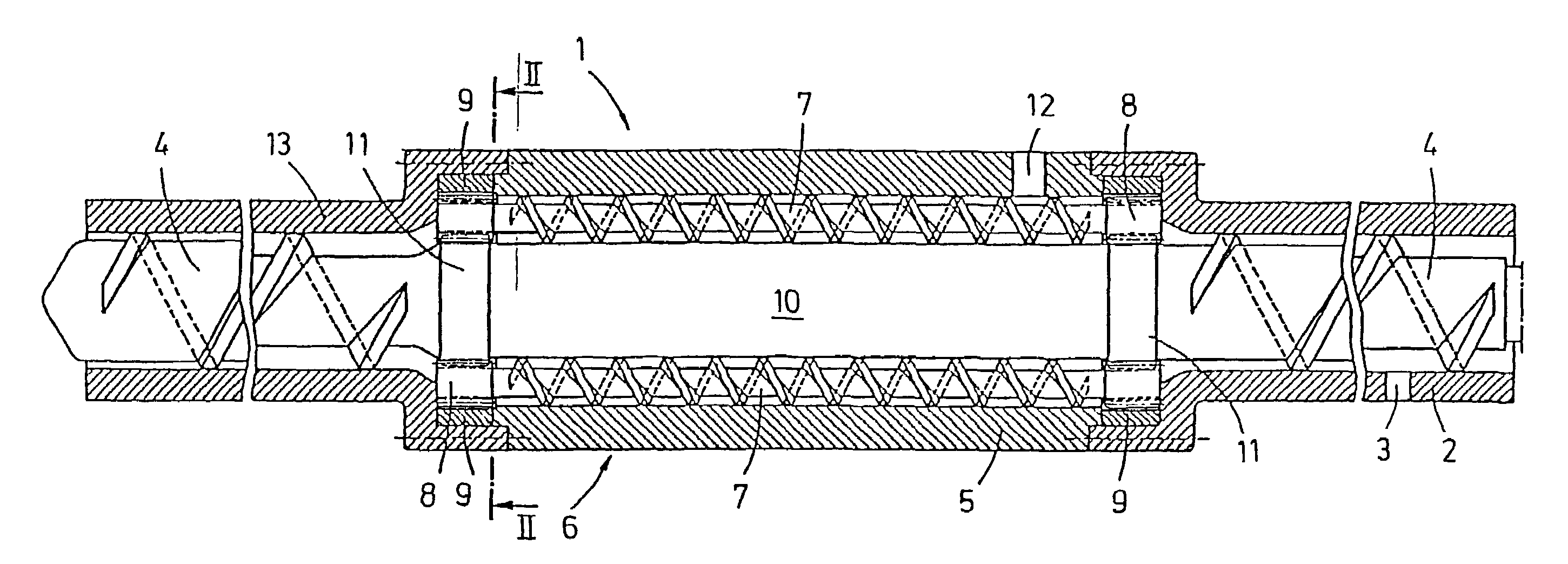

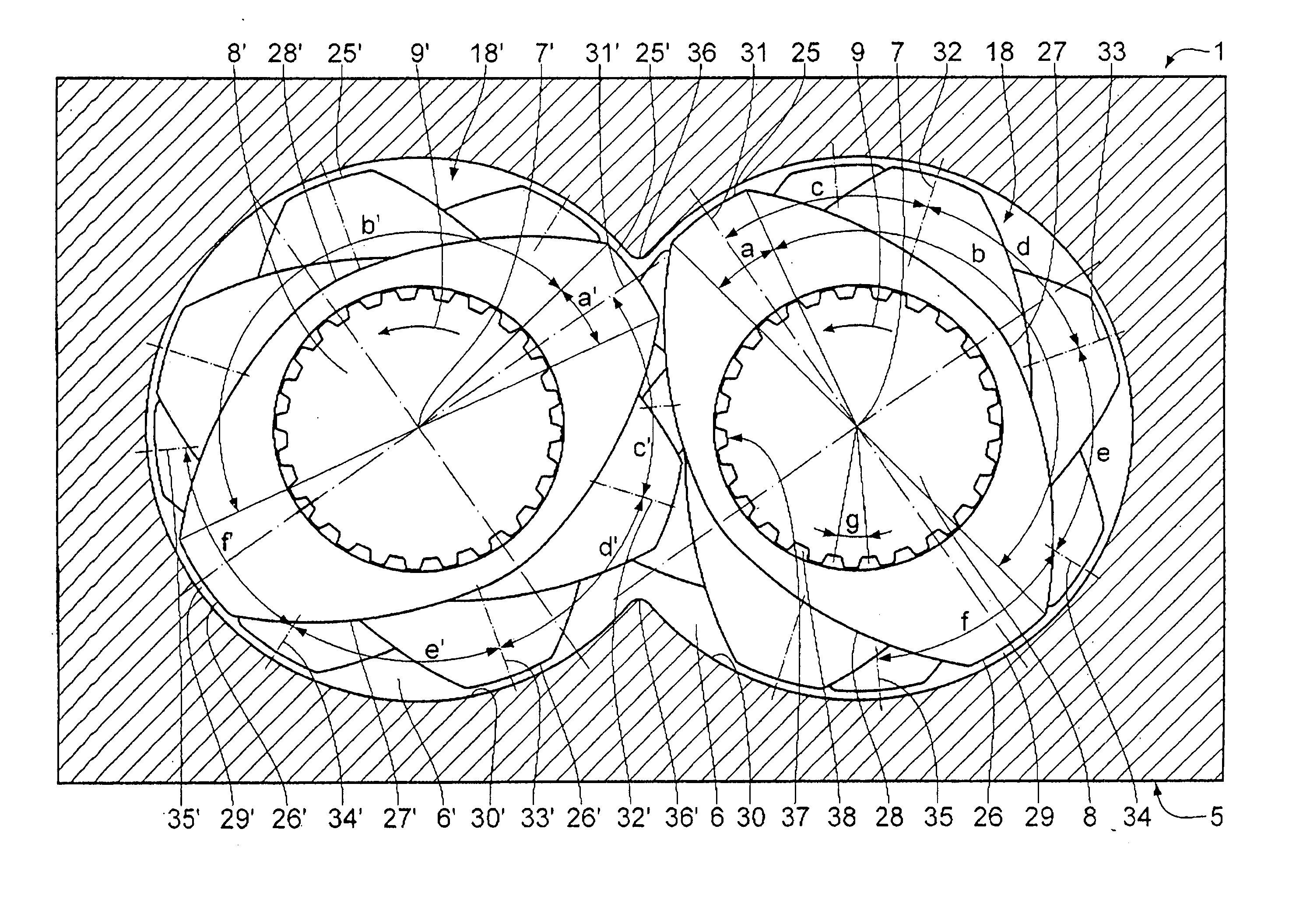

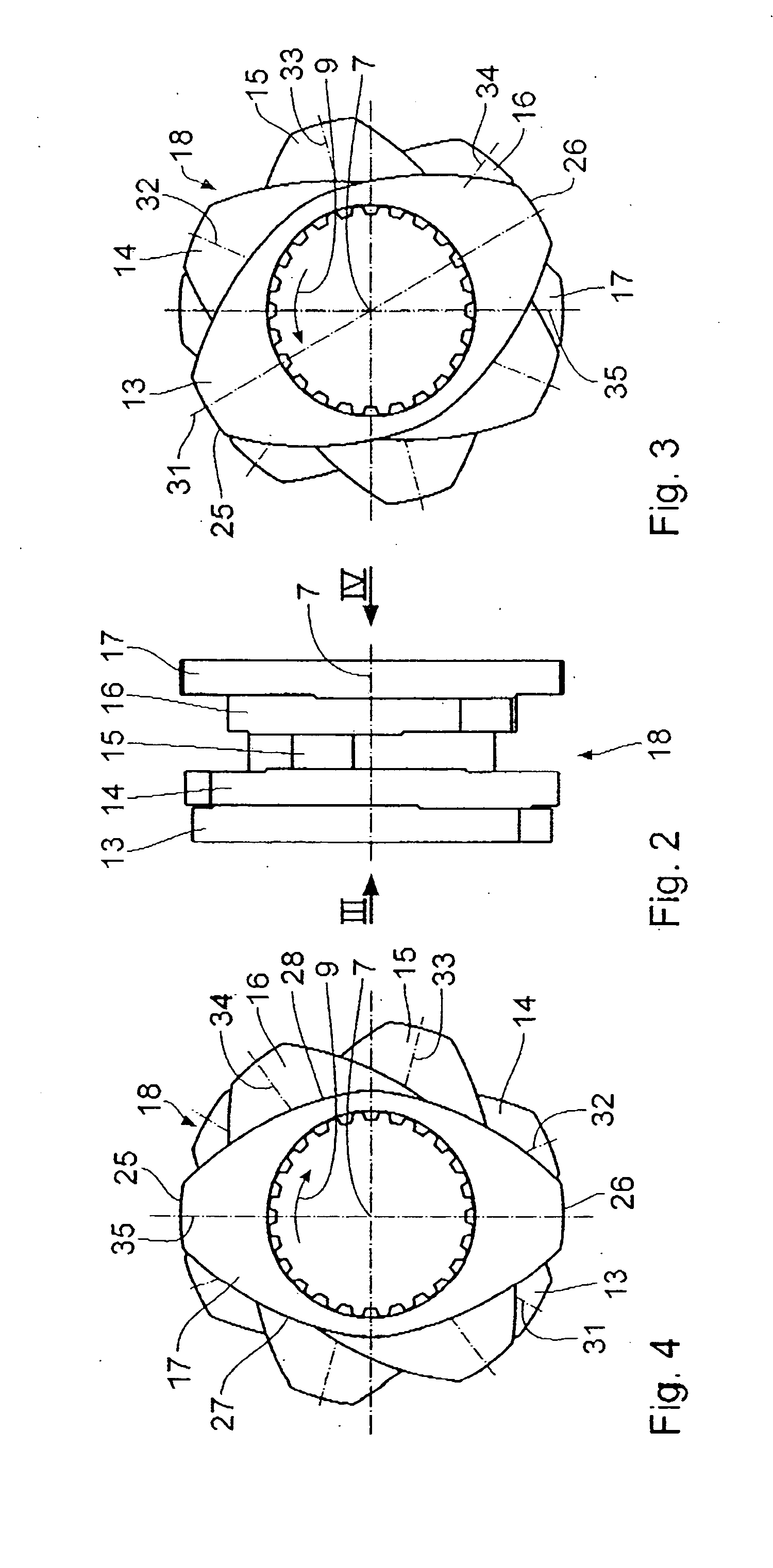

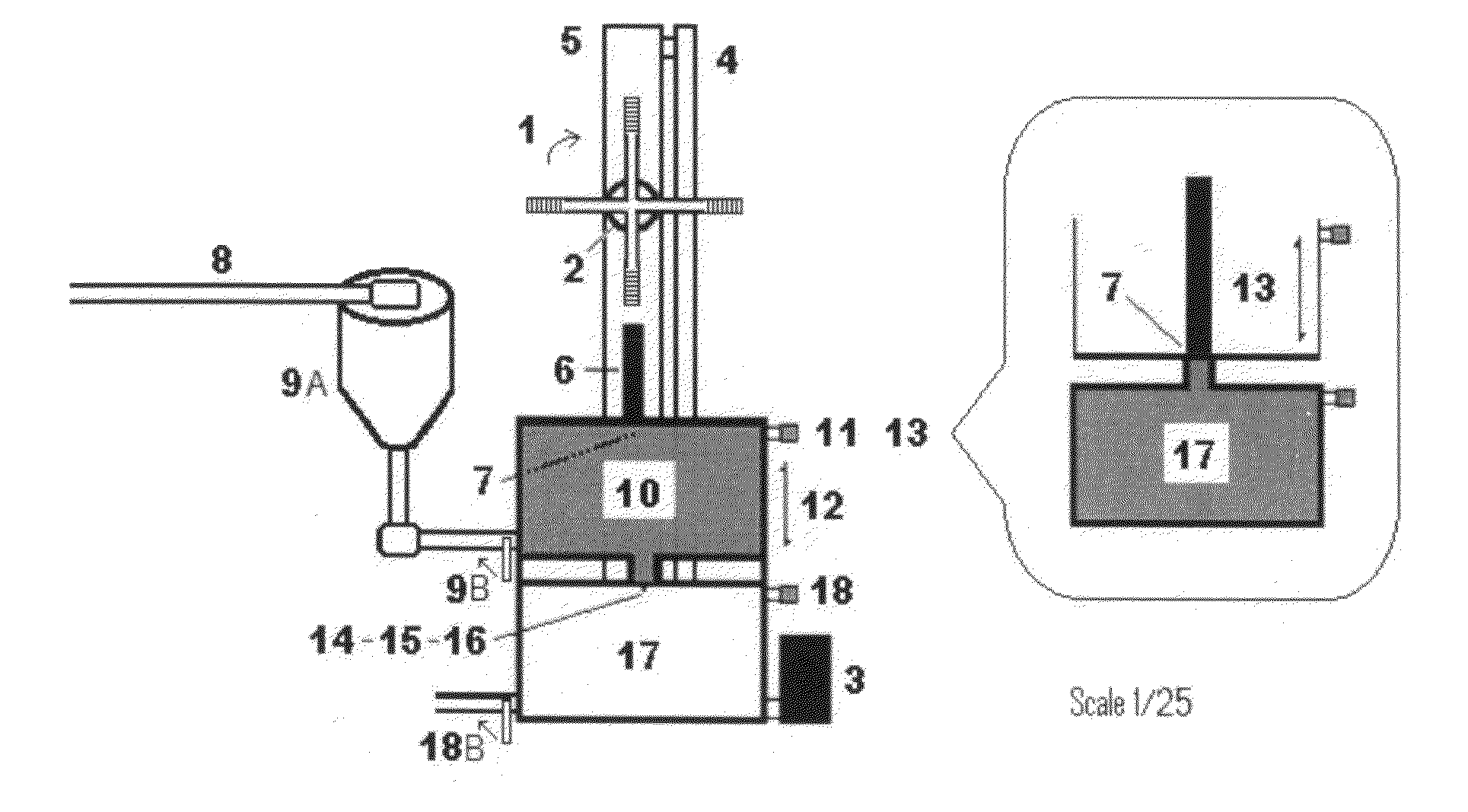

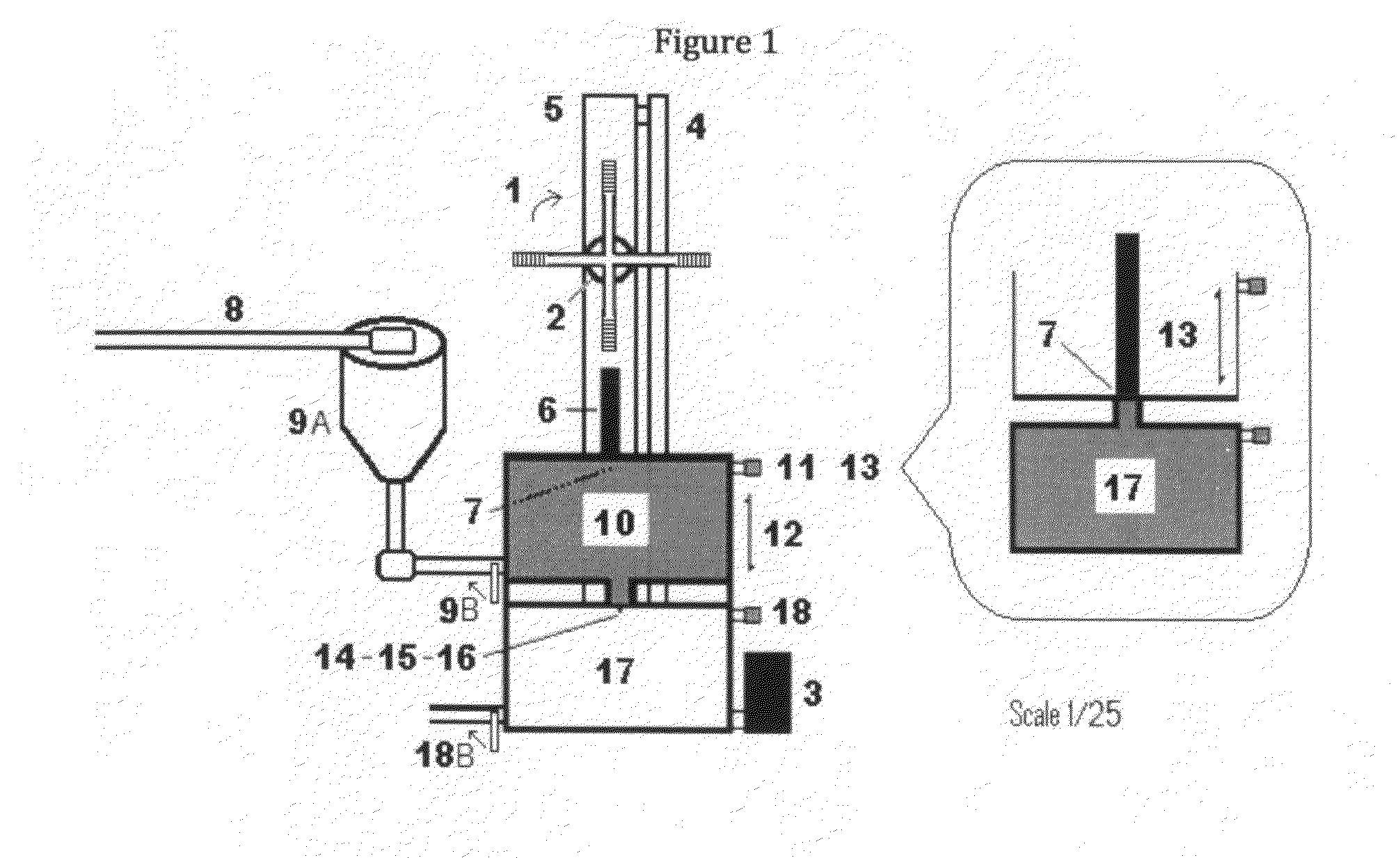

Extruder for producing molten plastic materials

InactiveUS7513677B2Simple designAvoid damageRotary stirring mixersMixing/kneading with horizontally-mounted toolsFoaming agentThin layer

The invention concerns an extruder for producing molted plastic materials from plastic granules available on the market, by heating and mixing granules, with heated single- or double-screw extruders, and for carrying out polycondensation or polymerization using part of a multiple-screw extruder and by means of vacuum chambers for removing the constituents of low molecular weight and / or foaming agents or the like, for obtaining larger molecules and hence a higher viscosity, and for increasing the mechanical strength of plastic materials produced from said molten material. The invention aims at designing said extruder such that the molten material can be processed in thin layers enabling exposure of large surfaces in contact with the vacuum, and hence a molten plastic material ensuring desired levels of degassing and polymerization using simple means. Therefor, the envelopes of the stems of the screws (7) are mutually spaced apart at least in the polycondensation zone of said extruder part with multiple screws (6), relative to the extruder screw (4) or its shaft section (10) and relative to cylindrical zones enclosing them, by a distance not less than zero (≧0).

Owner:GNEUSS KUNST

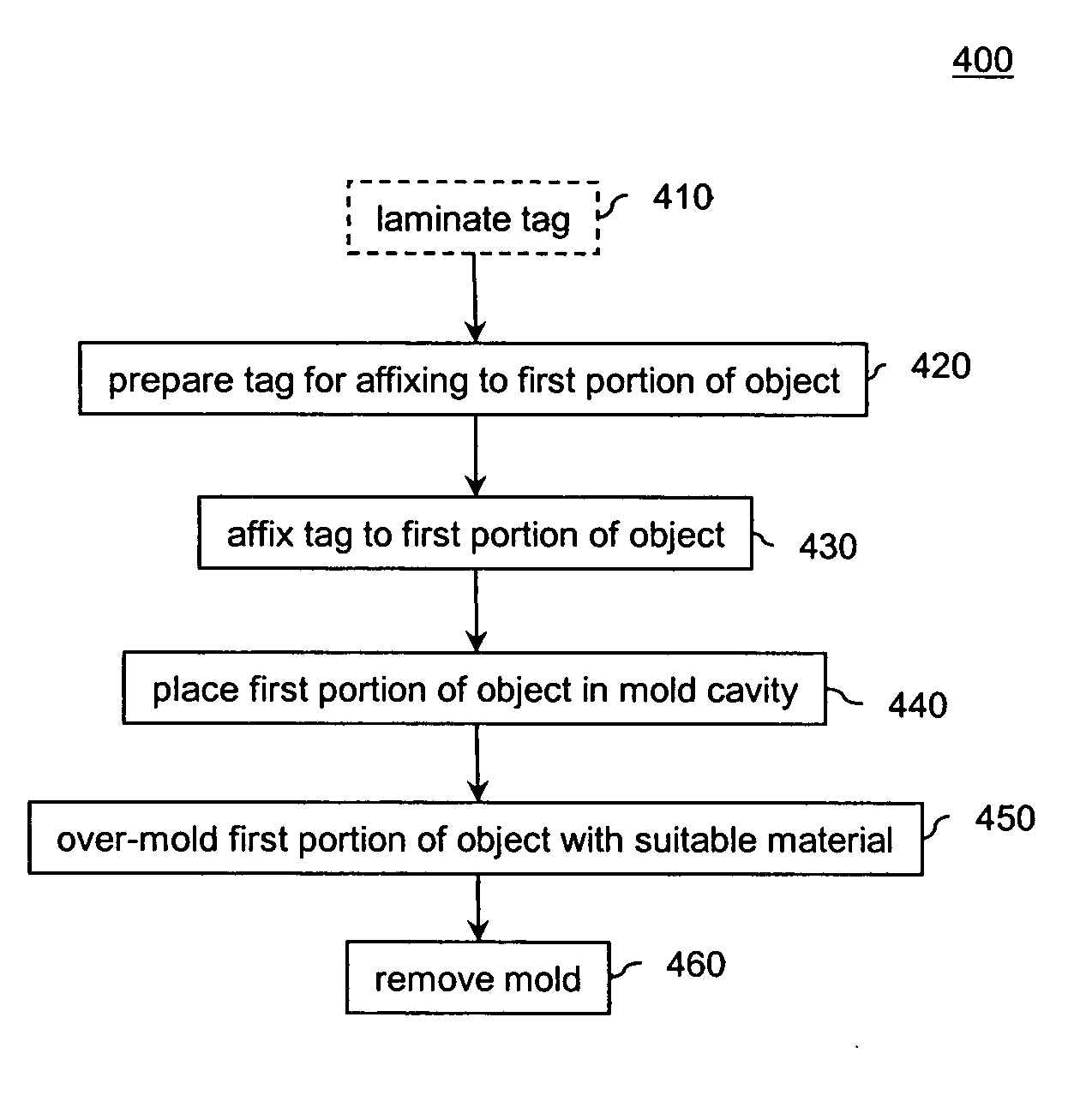

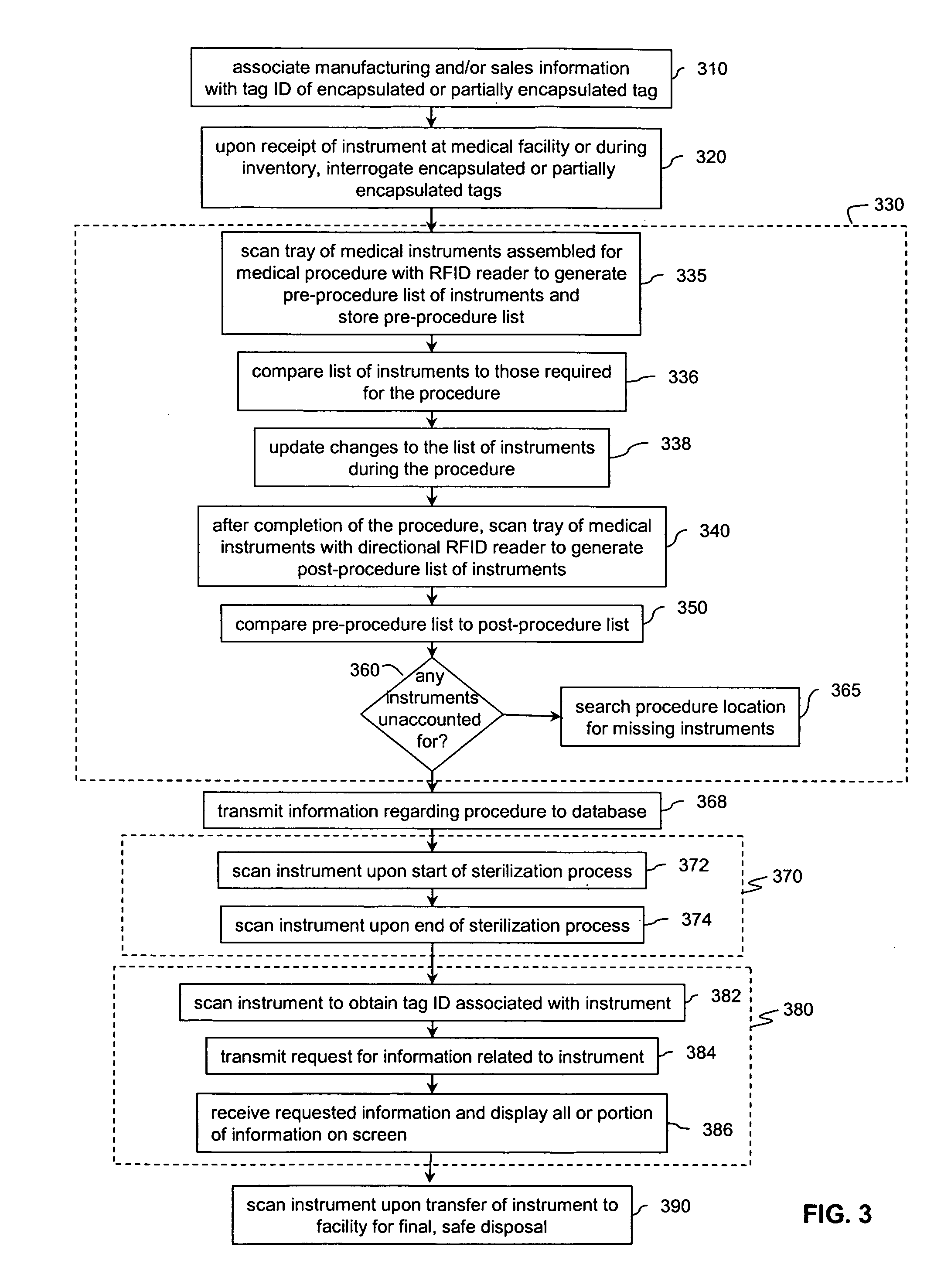

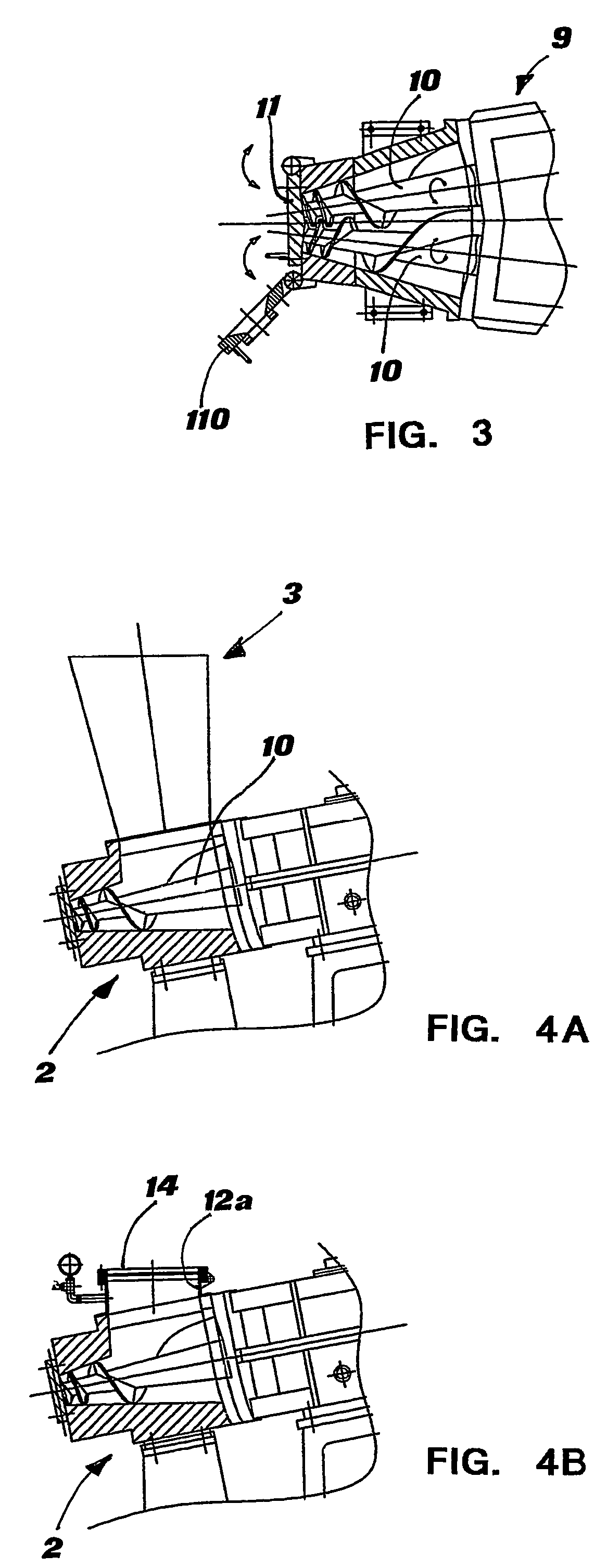

Radio frequency identification (RFID) solution to lost time spent on instrument inventory

A method for manufacturing an object having an encapsulated radio frequency identification (RFID) tag is provided. An RFID tag is mechanically or chemically affixed to a first portion of the object being manufactured. The first portion of the object, with the RFID tag affixed is placed in a cavity of a mold. The first portion is then over-molded with a first material such as high temperature thermoplastic or low temperature thermoset to generate a seamless object. A method for manufacturing an object having a partially encapsulated RFID tag is also provided. An RFID tag is laminated with a lamination material, such as high temperature thermoplastic. The laminated RFID tag is affixed to a mold. The laminated RFID tag is then over-molded with a first material to generate a seamless object. Methods for tracking medical instruments having encapsulated or partially encapsulated RFID tags are also provided.

Owner:SYMBOL TECH INC

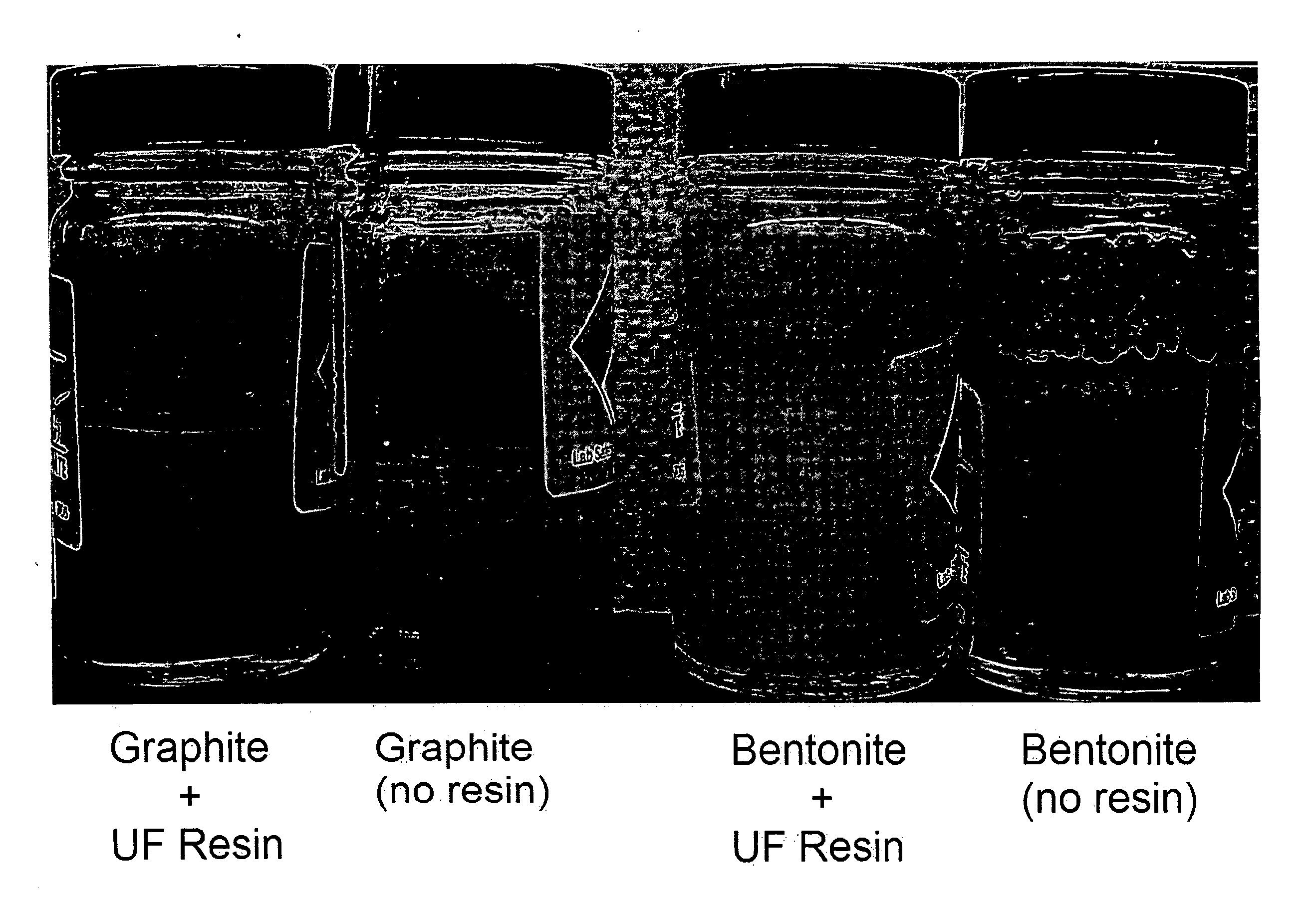

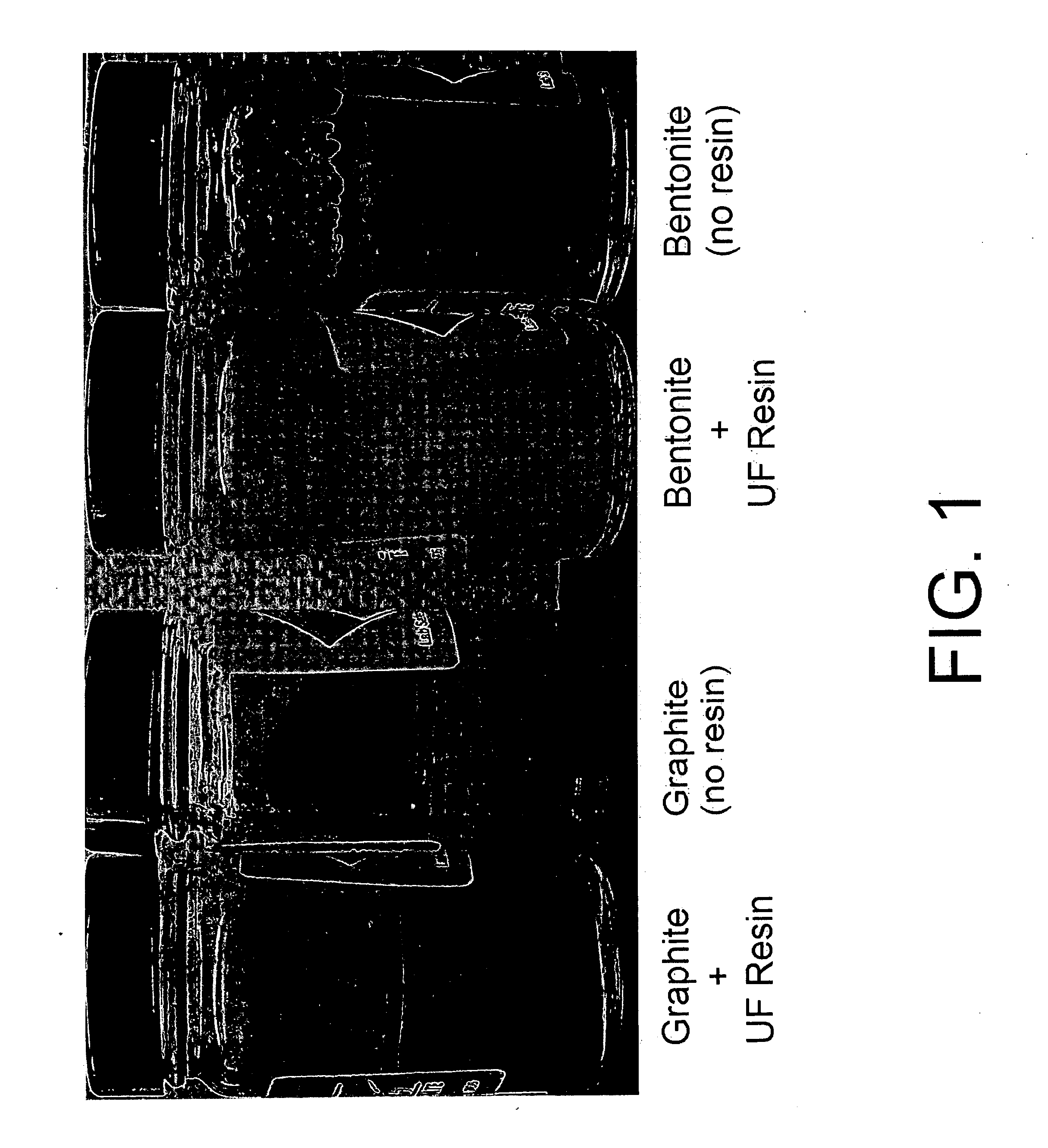

Amine-aldehyde resins and uses thereof in separation processes

InactiveUS20060151397A1Highly versatileEffective isolationWaste water treatment from quariesWaste water treatment from ceramic industriesParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants in the separation of bitumen from sand and / or clay or in the beneficiation of clay (e.g., kaolin clay) from an impure clay-containing ore. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

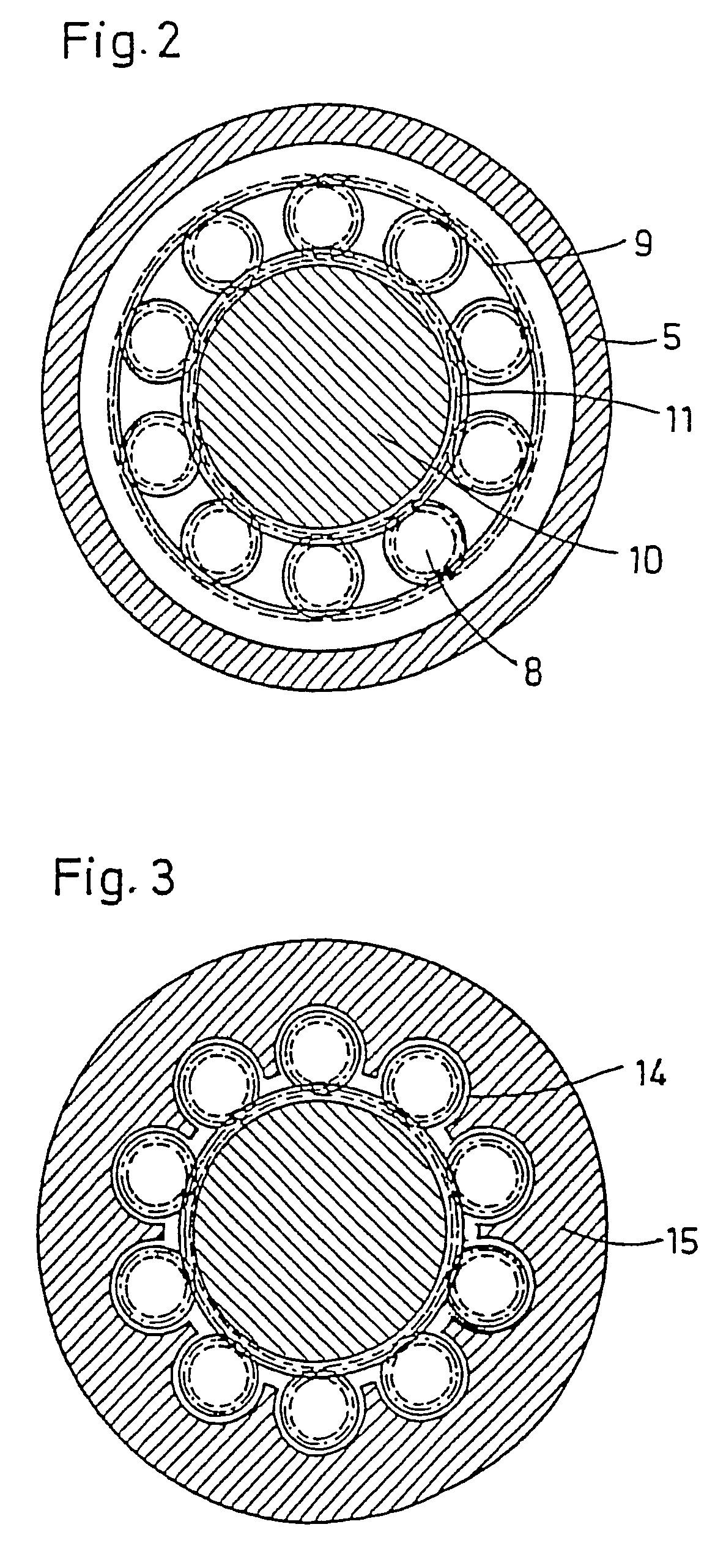

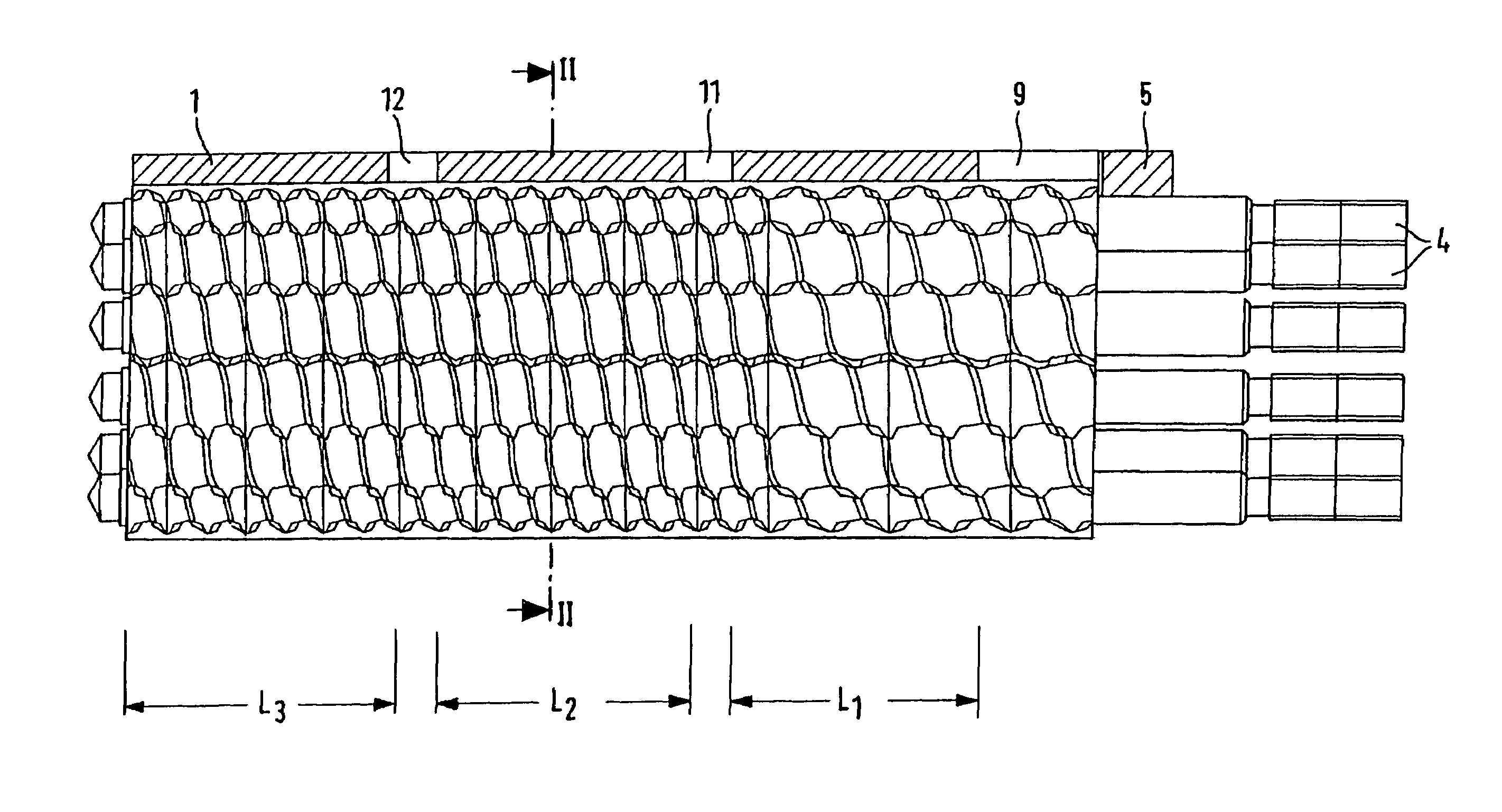

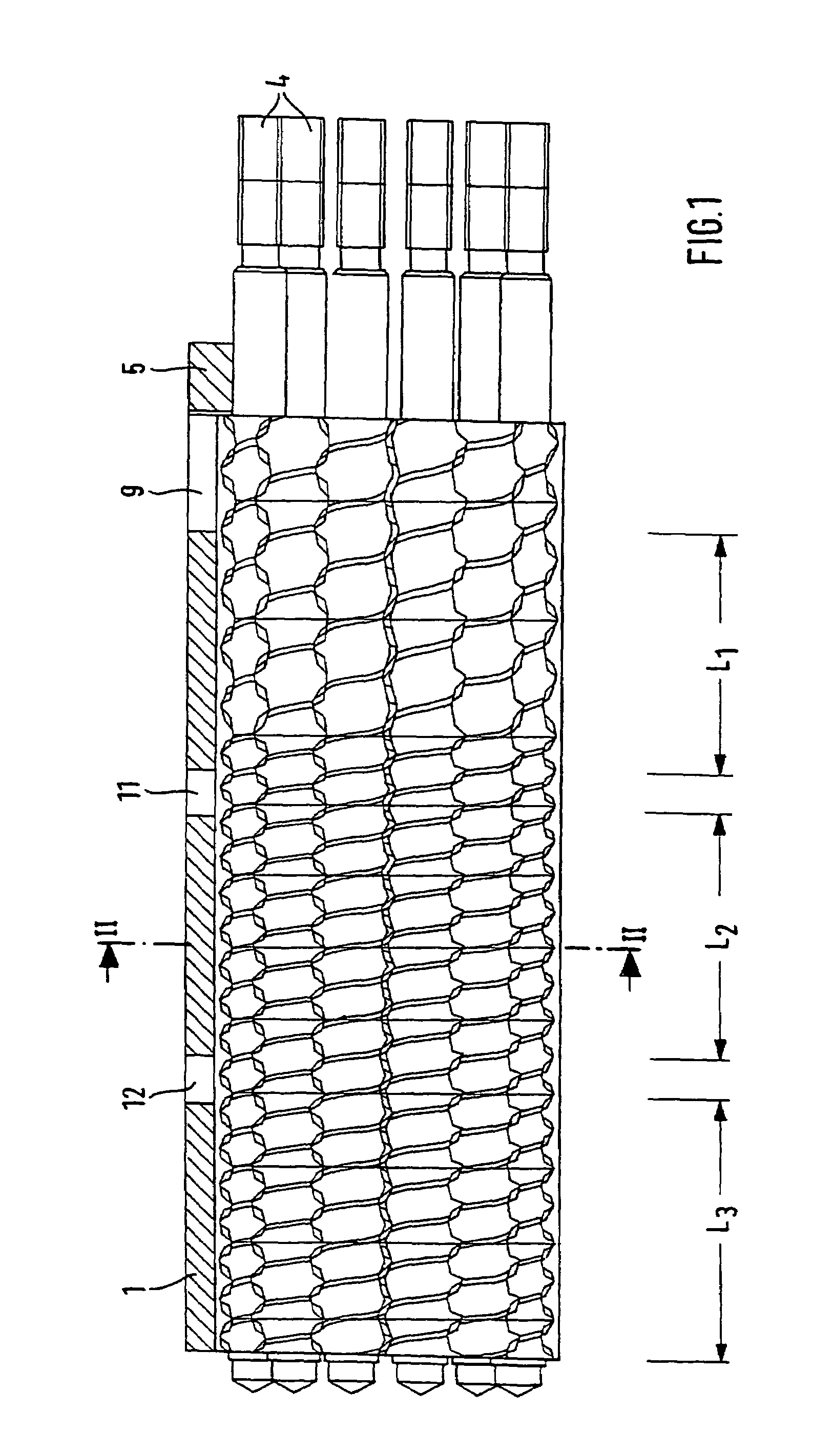

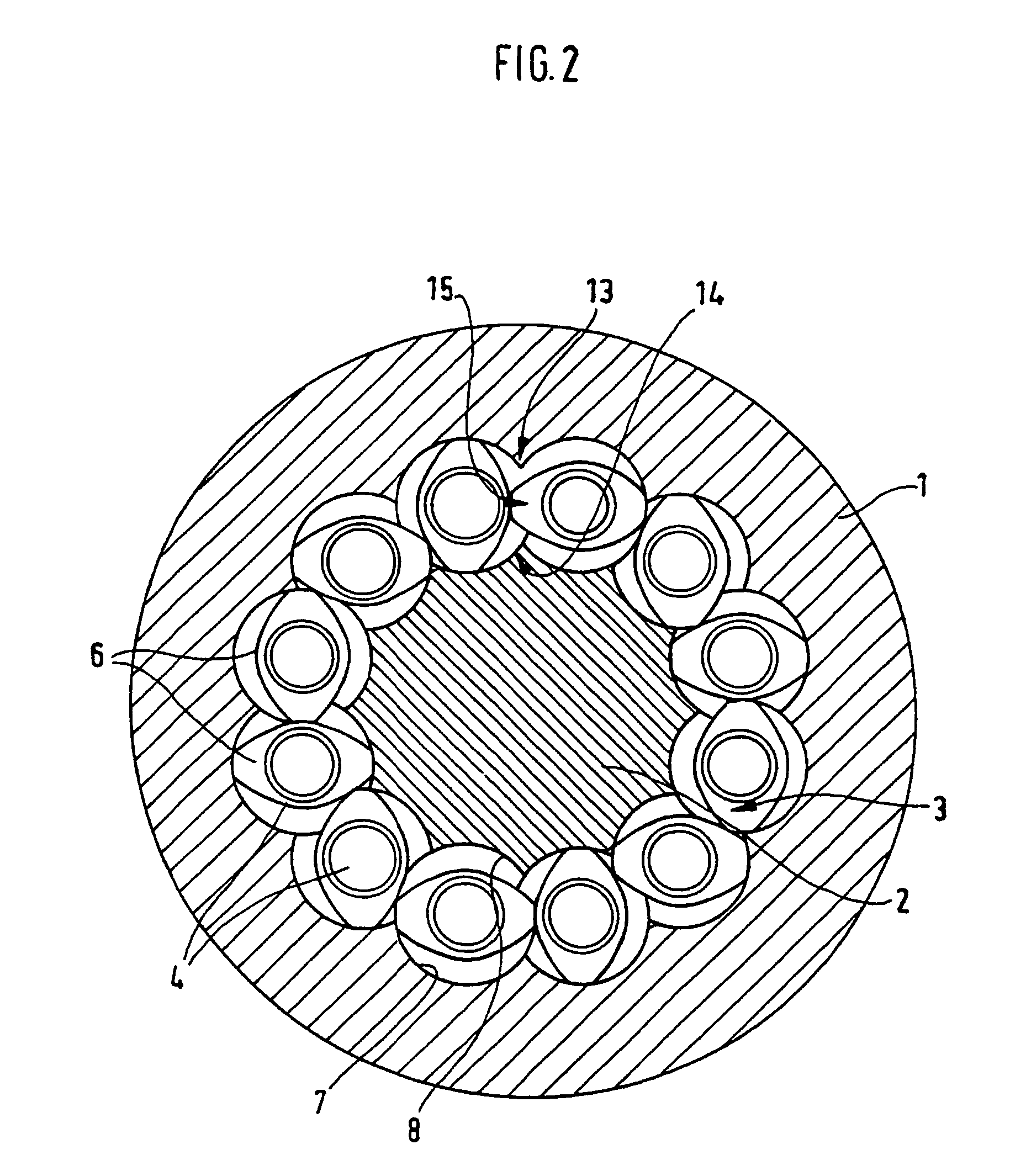

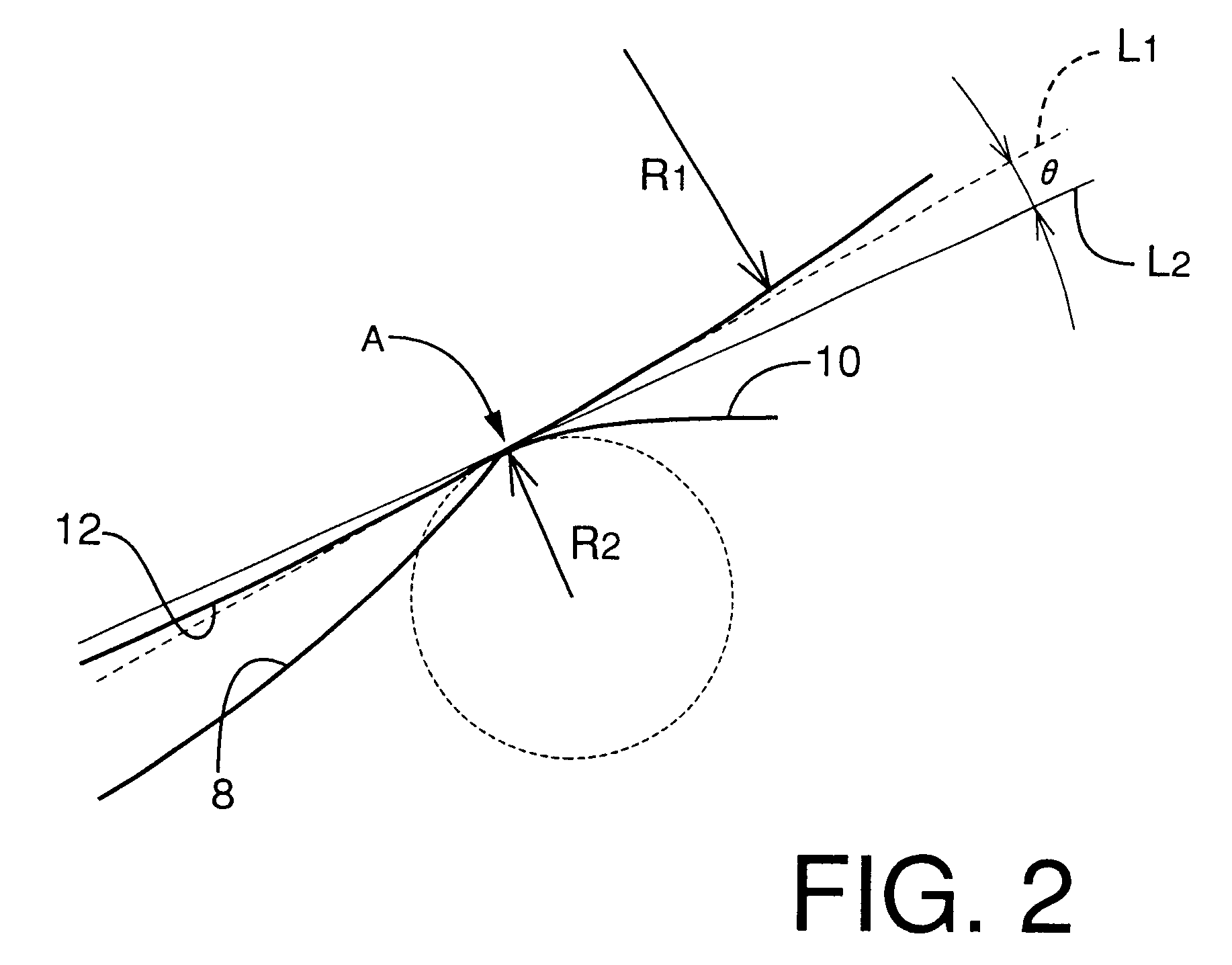

Homogenizing and/or dispersing device comprising endless screws

An apparatus for homogenizing and / or dispersing at least one viscous substance and at least one solid and / or at least one other substance of different viscosity includes in a space in a housing axis-parallel rotatable shafts disposed along a circle with equal central-angle distance and provided with tightly intermeshing screw elements. The shafts in the area outside the openings in the housing are provided with screw elements having a pitch (S) of at most three quarters of the outside screw diameter (D) over a length (L=L1+L2+L3) corresponding to at least ten times the outside diameter (D) of the screw elements.

Owner:BLACH VERWALTUNGS GMBH

Preparation method of superfine ceramic powder injection molding mixture

The invention discloses a preparation method of a superfine ceramic powder injection molding mixture, which belongs to the technical field of ceramic injection molding. The preparation method of the superfine ceramic powder injection molding mixture comprises the steps: carrying out ultrasonic dispersion or high-speed ball grinding dispersion and surface modification of submicron or nanometer level ceramic powder in surface active agent solution; evenly mixing the surface modified powder with a non water-solubility organic binding agent, a water-solubility organic binding agent and other additives in a mixer according to a specific order; injecting and molding obtained injecting and mixing material on an injection molding machine to obtain a blank body; and quickly degreasing the blank body by water in water and ethanol mixing solution with a certain proportion under a certain degreasing temperature system. The obtained water-degreased injection material has even mixture, high strength of a green blank and good fluidity. The degreasing method has high degreasing speed and good blank shape maintaining performance and avoids the defects of cracking, bubbling, and the like.

Owner:TSINGHUA UNIV

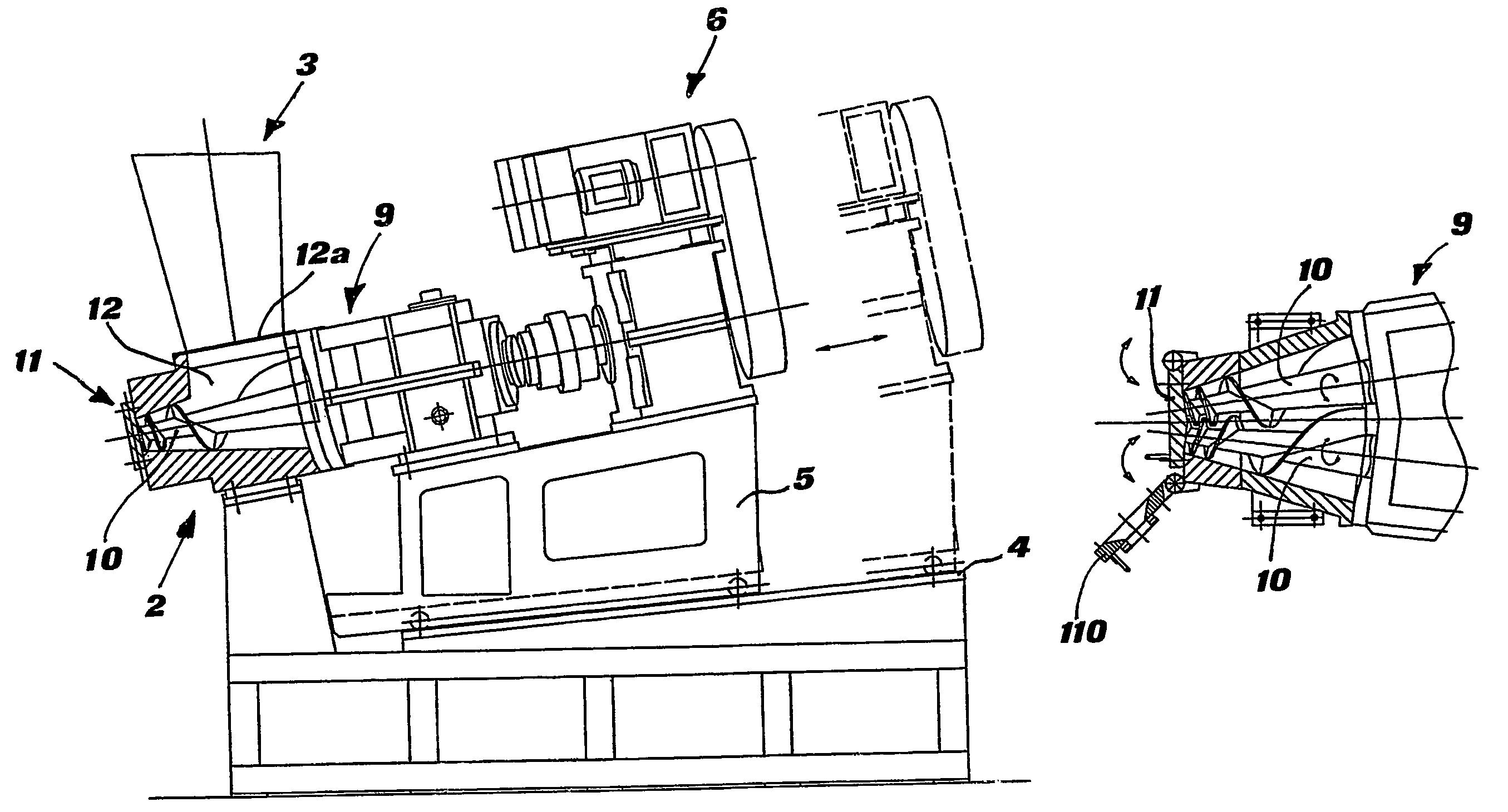

Machine for mixing and extruding rubber-based and silicone-based plastic materials and method therefor

A machine for the mixing and extrusion of rubber-based and silicone-based plastic materials and method thereof is disclosed, comprising a dump extruder with conical converging twin screws (10) arranged in a batching chamber (12) in which the outlet of the dump extruder is temporarily closed by a removable blind flange (11), the batching chamber also acting as a compounding chamber.

Owner:COLMEC

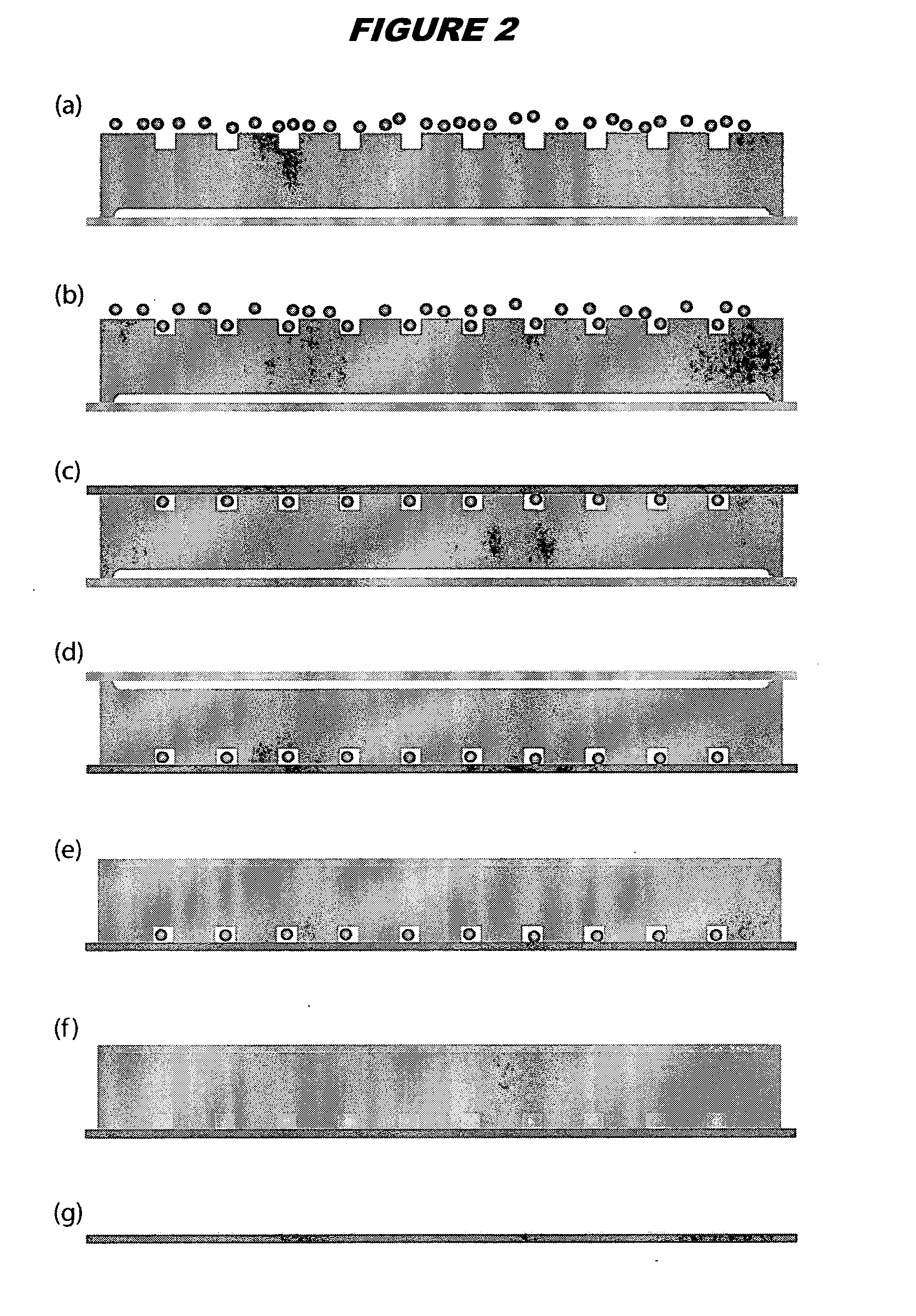

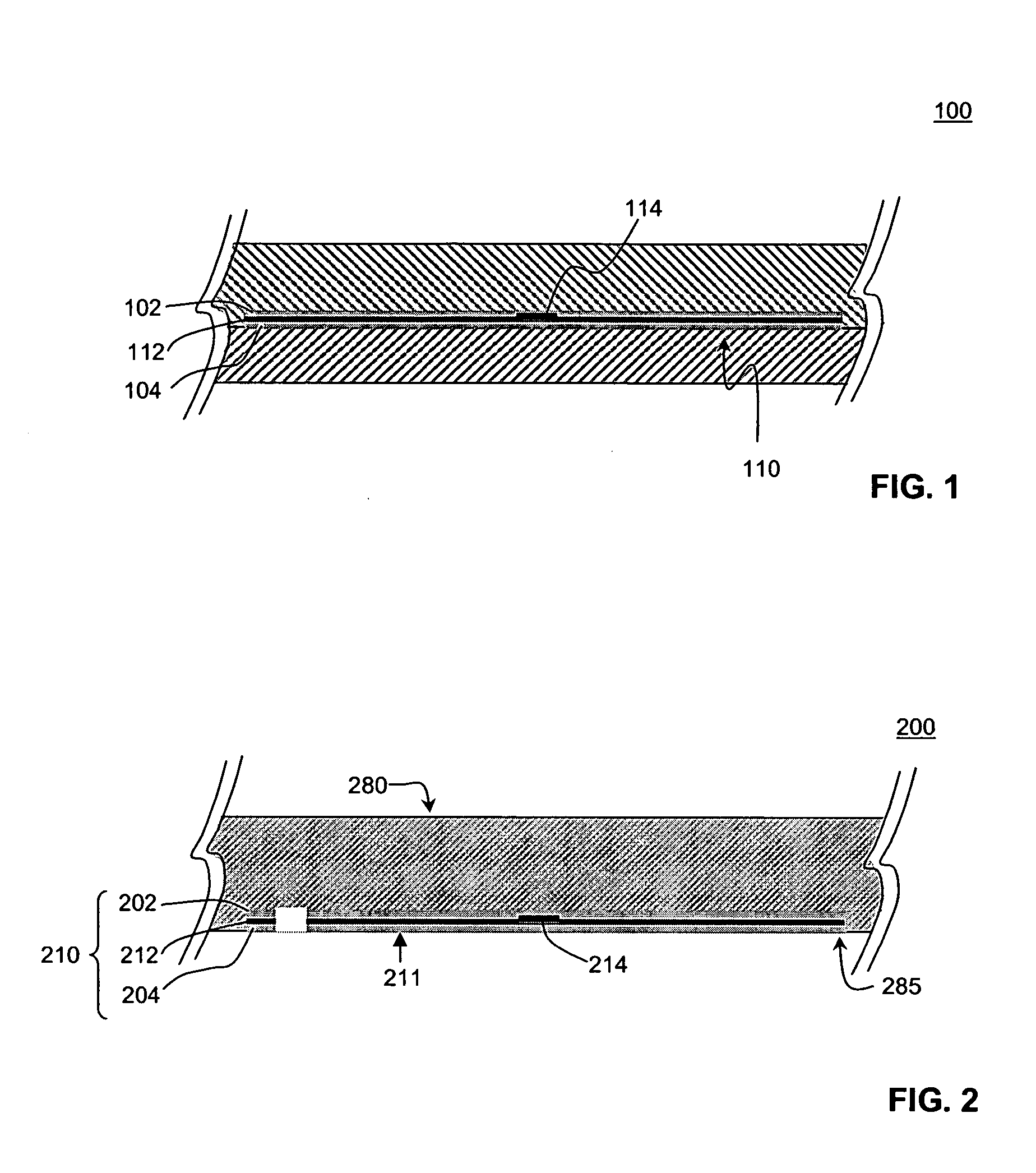

Ocular therapeutic agent delivery devices and methods for making and using such devices

ActiveUS7658364B2Increase release rateReached efficientlyOrganic active ingredientsSenses disorderDual modeOcular implant

Owner:UNITED STATES OF AMERICA

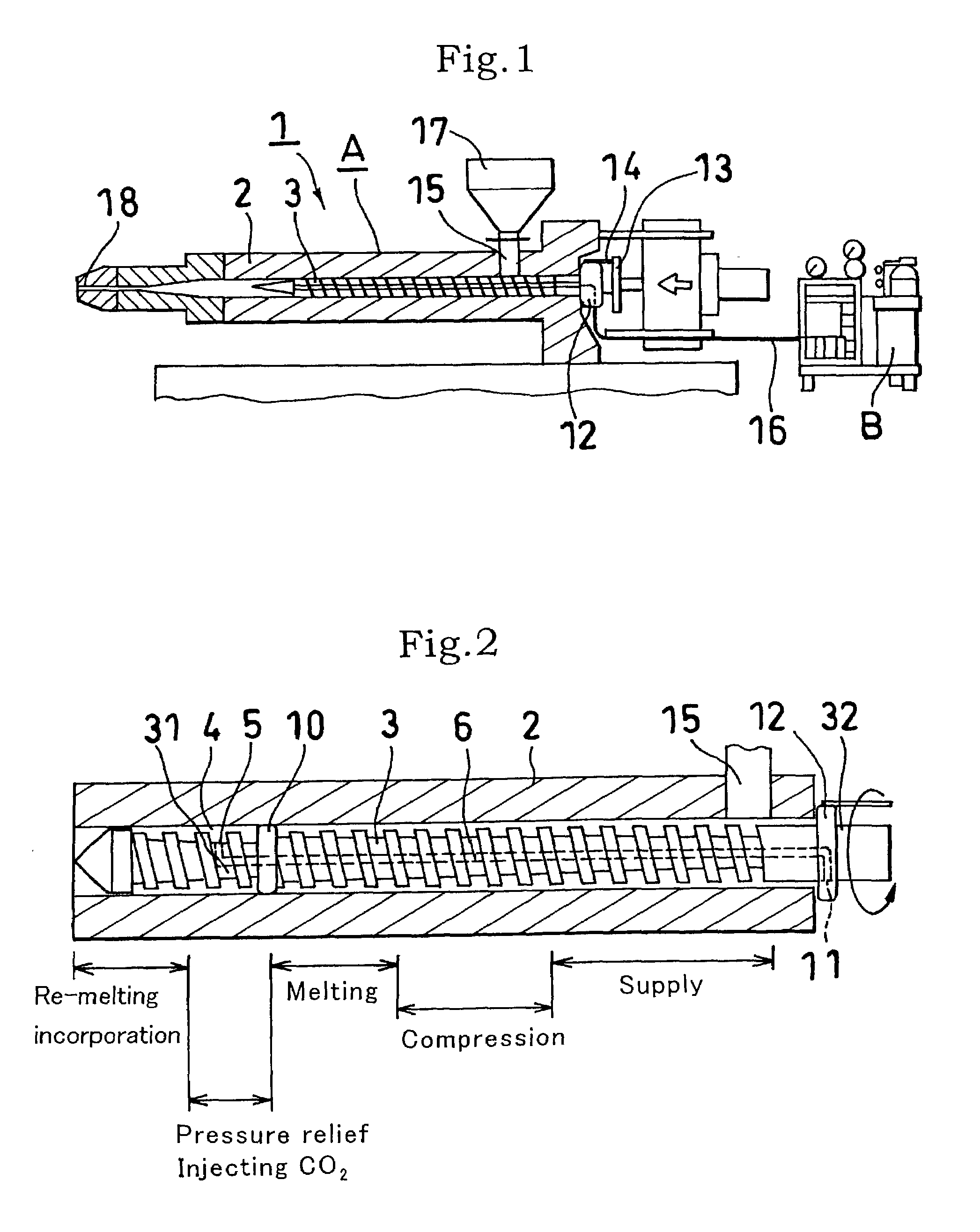

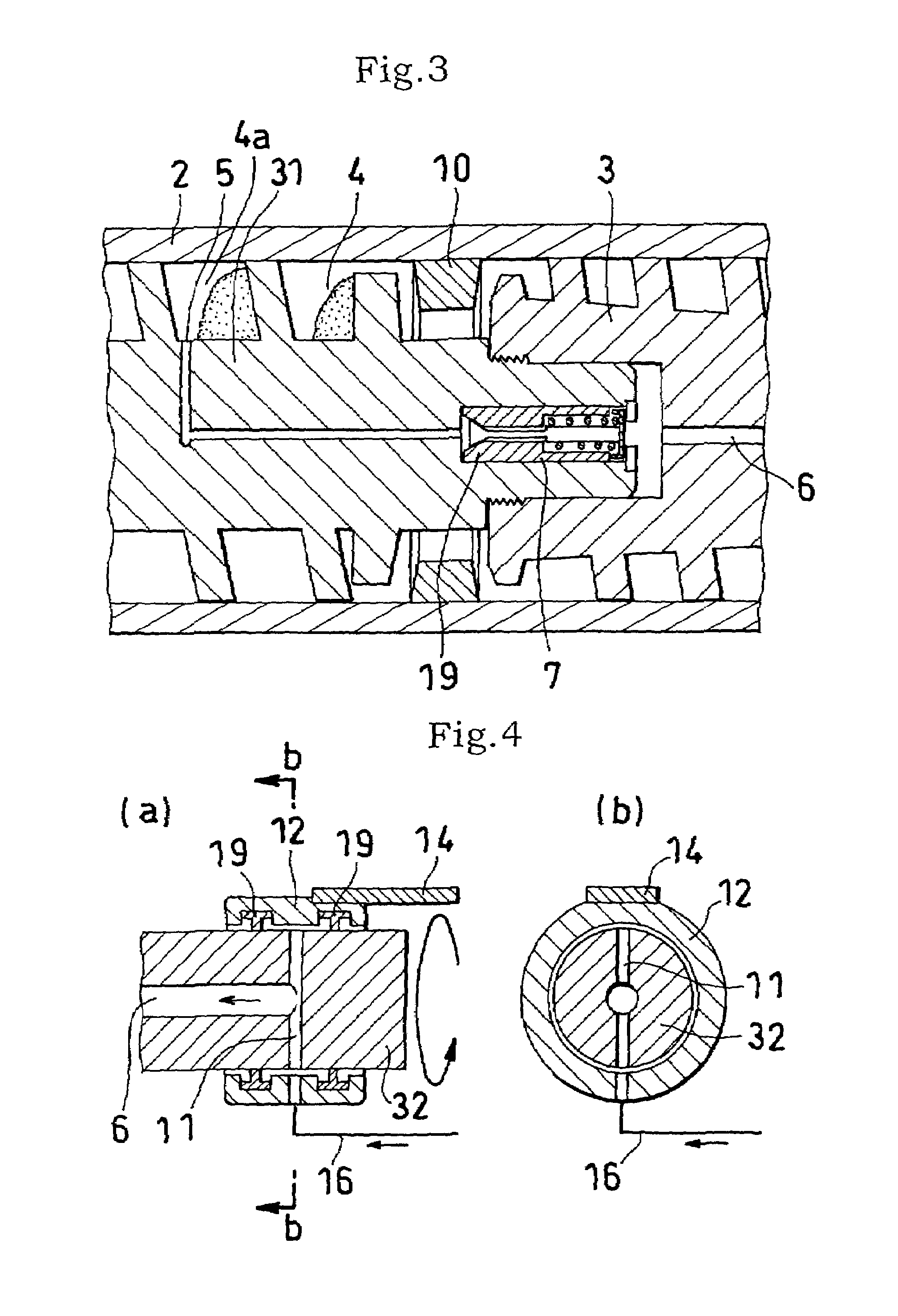

Injection molding process and injection molding apparatus for thermoplastic resin molded articles

InactiveUS6949208B1Efficient meltingIncrease pitchRotary stirring mixersFrozen sweetsFoaming agentReactive gas

Owner:SEKISUI CHEM CO LTD

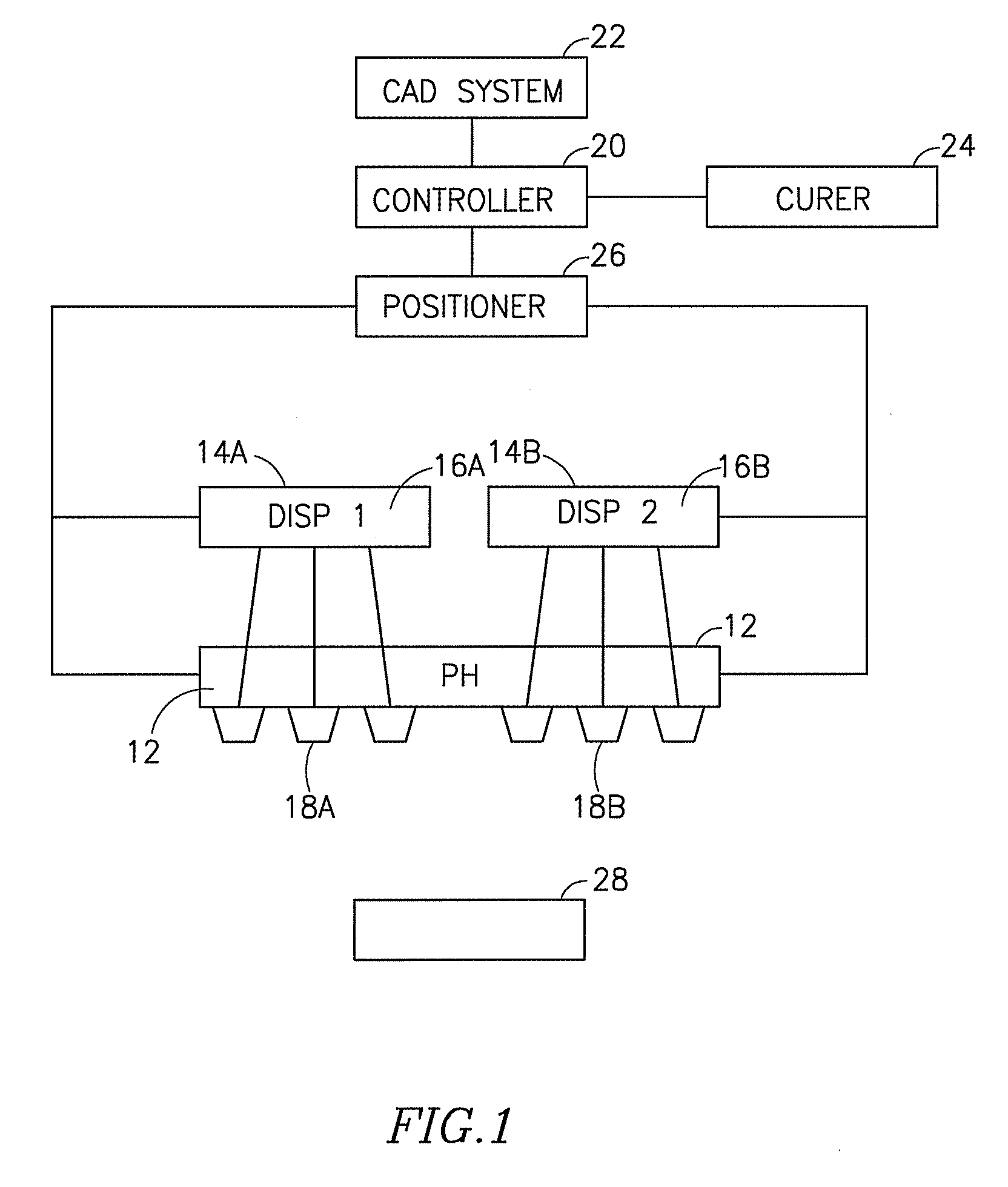

Compositions and methods for use in three dimensional model printing

InactiveUS20080105818A1Similar elasticitySimilar strengthButtonsRecord carriersInvestment castingMaterials science

Embodiments of the invention are directed to a method of producing three-dimensional prototype molds for use in investment casting. The method includes dispensing modeling material and support material in a predetermined arrangement, in layers, to produce a three-dimensional mold having an outer shell. Generally, the out shell includes modeling material and the interior of the mold includes support material. Then the mold is cured.

Owner:OBJET GEOMETRIES

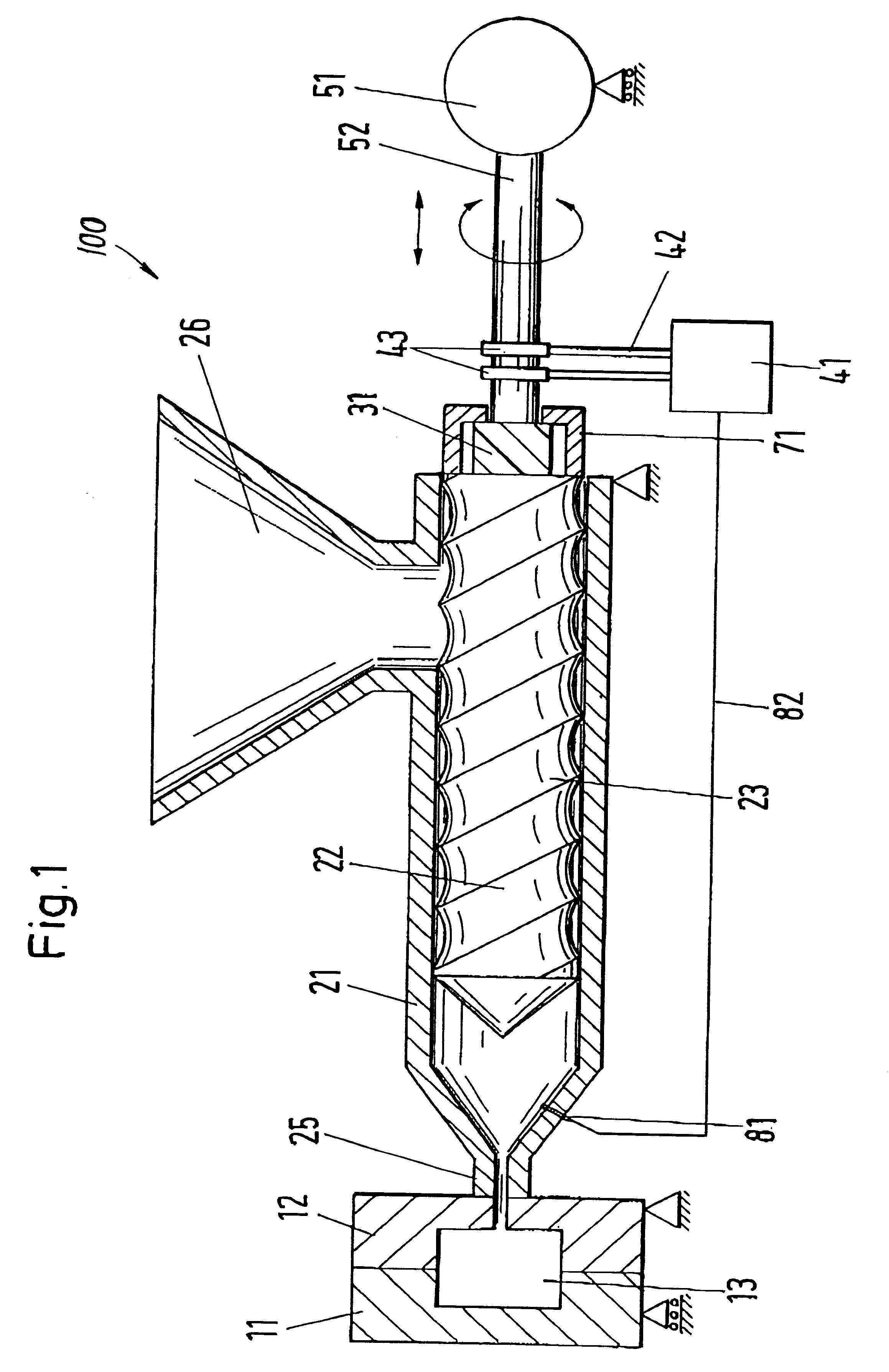

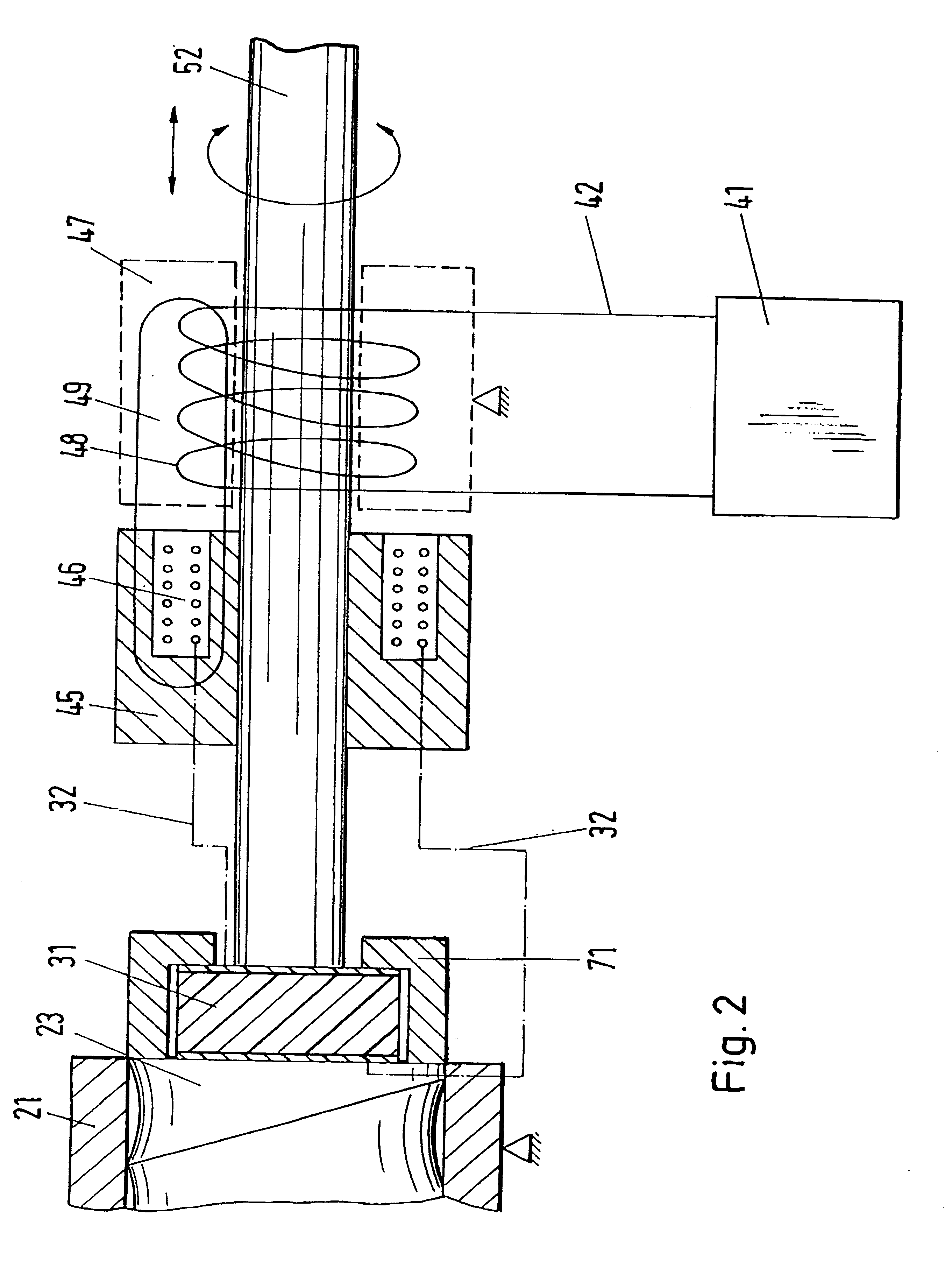

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

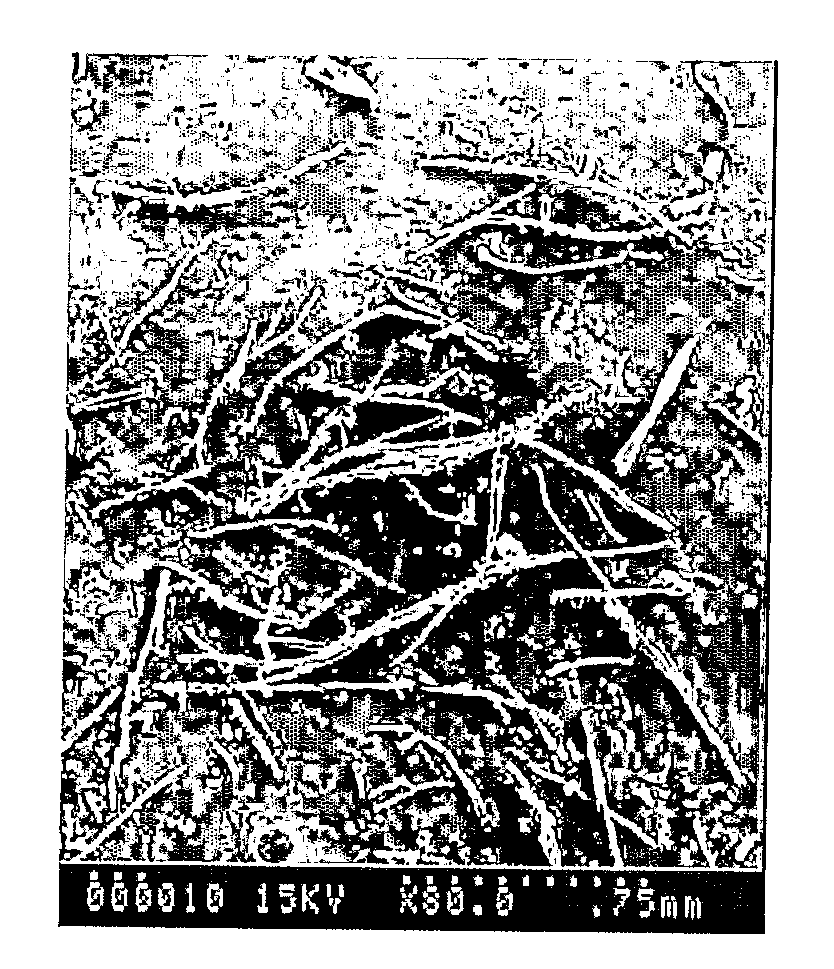

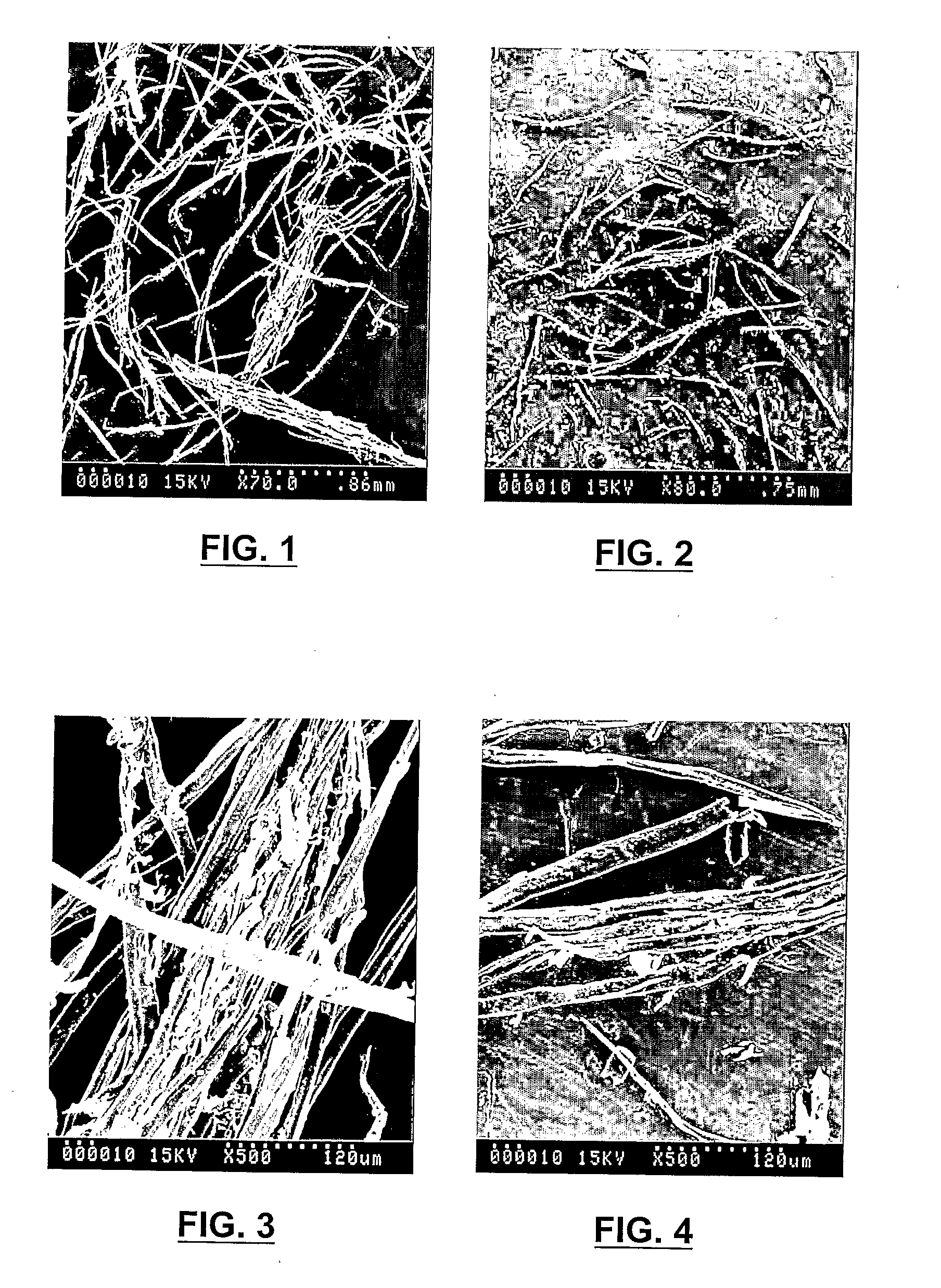

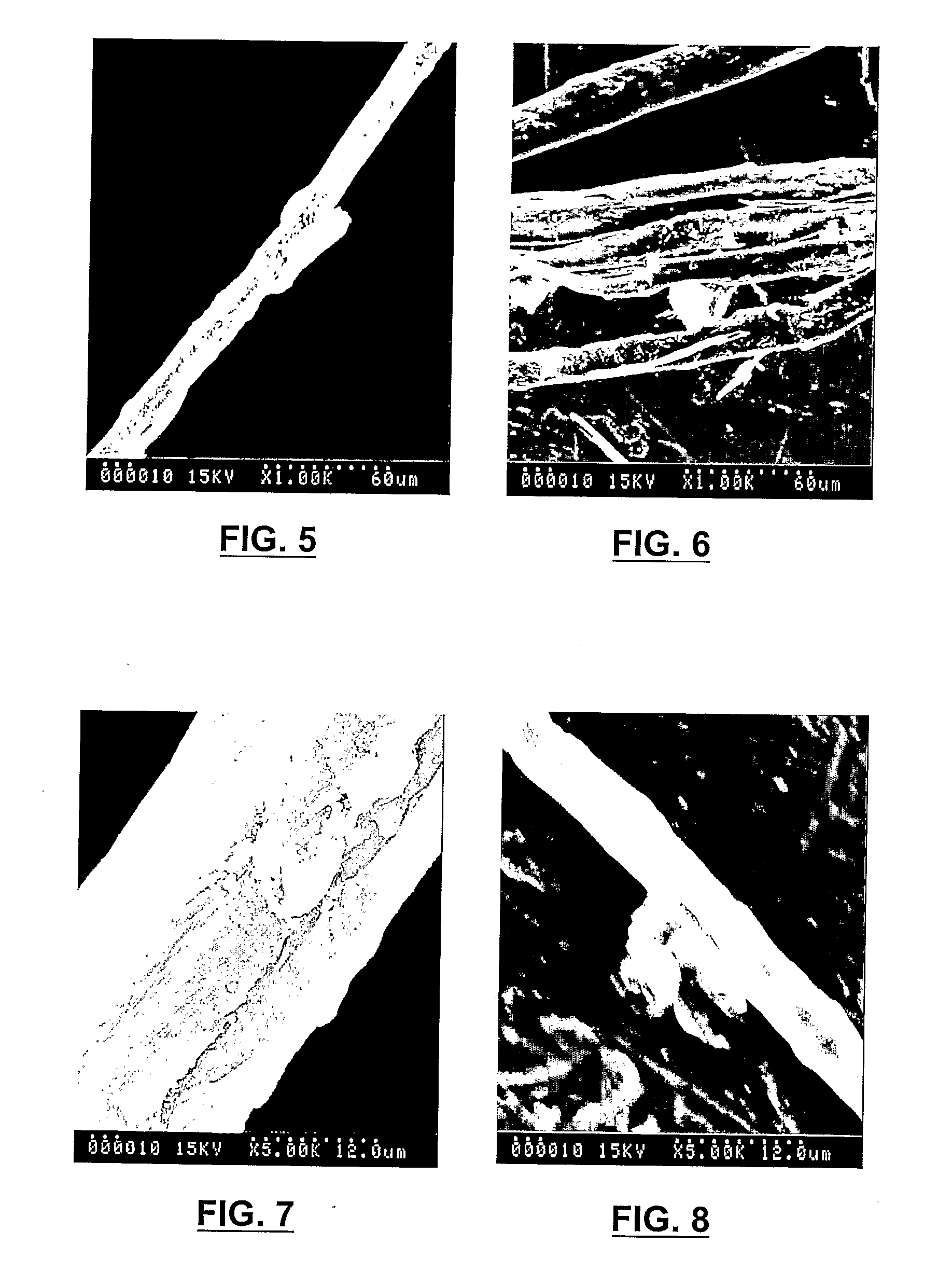

Manufacturing process for high performance lignocellulosic fibre composite materials

InactiveUS20090065975A1Structure moreStrict requirementsRotary stirring mixersLaminationDecompositionFlexural strength

The present invention relates to a process for the manufacture of composite materials having lignocellulosic fibres dispersed in a thermoplastic matrix, while generally maintaining an average fibre length not below 0.2 mm. The process comprises defibrillation of the lignocellulosic fibres using a mixer and at a temperature less than the decomposition temperature of the fibres in order to separate the fibres and generate microfibres, crofÊbres, followed by dispersion of the fibres in the thermoplastic matrix by mechanical mixing to get the moldable thermoplastic composition, followed by injection, compression, extrusion or compression injection molding of said composition. The process produces high performance composite materials having a tensile strength not less than about 55 MPa, a flexural strength not less than about 80 MPa, a stiffness not less than about 2 GPa, notched impact strength not less than about 20 J / m, and un-notched impact strength not less than about 100 J / m. The composite materials of the present invention are well-suited for use in automotive, aerospace, electronic, furniture, sports articles, upholstery and other structural applications.

Owner:SAIN MOHINI M +2

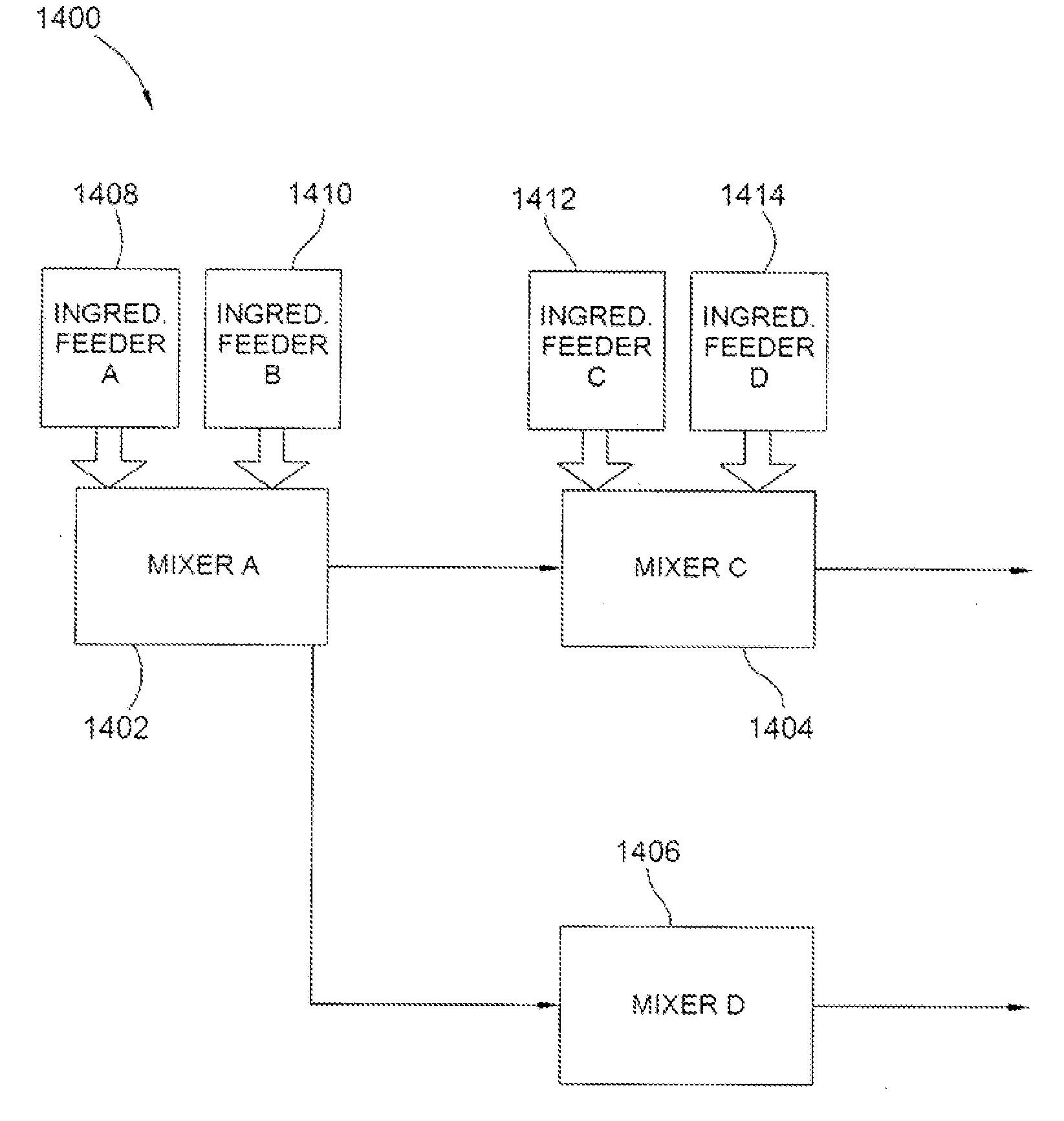

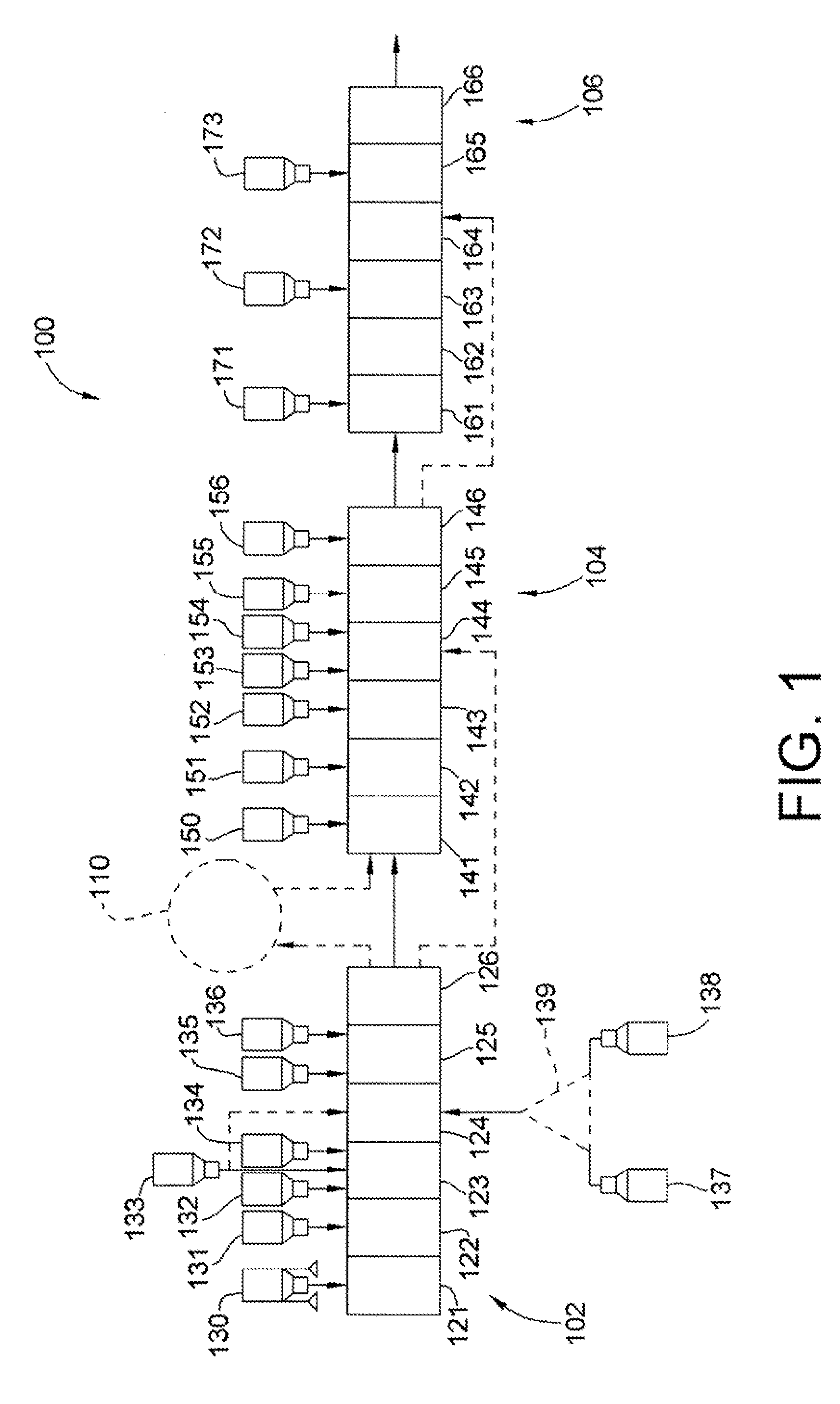

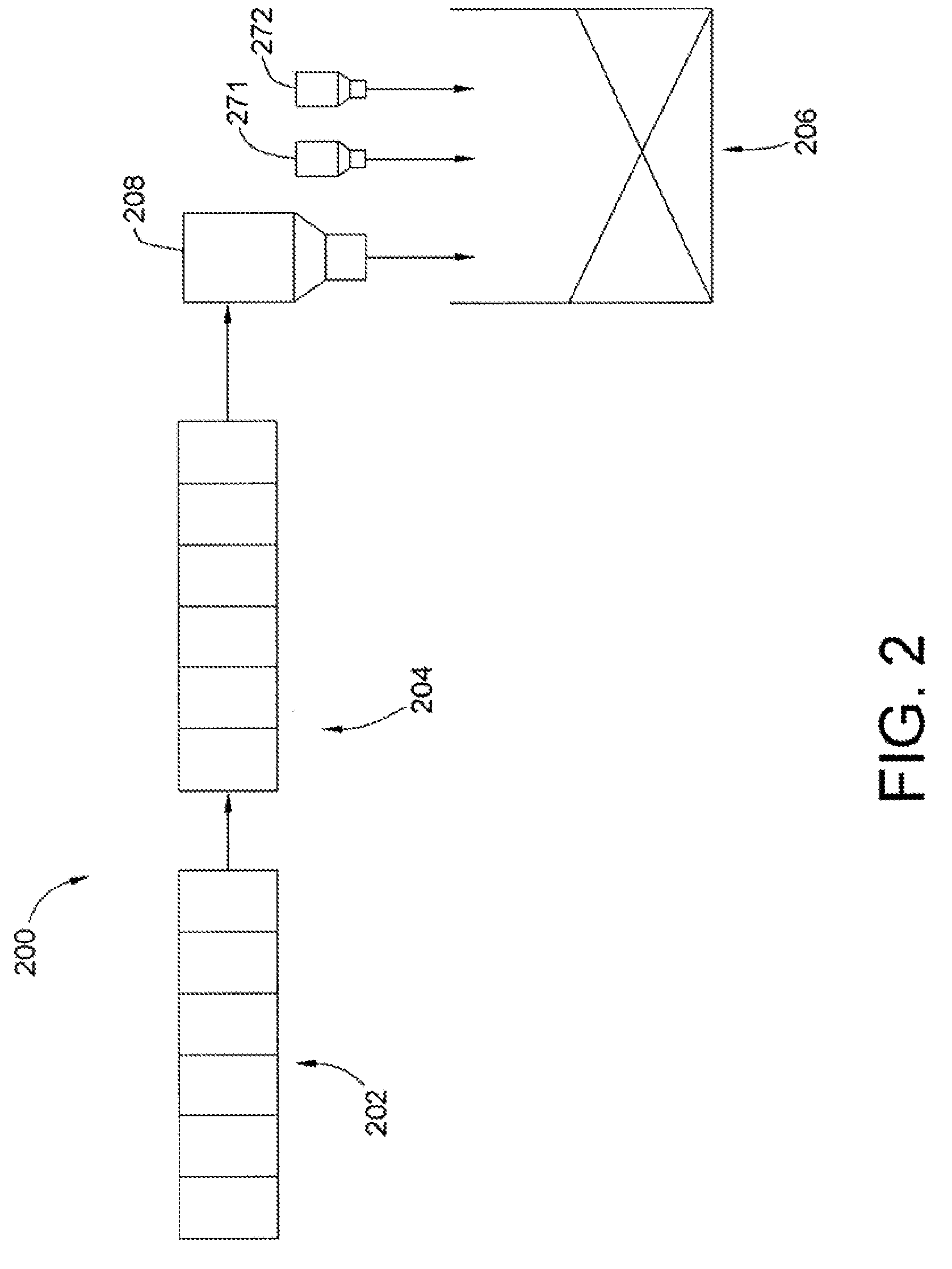

Parallel Gum Component Mixing Systems And Methods

InactiveUS20090162476A1Rotary stirring mixersMixing/kneading with horizontally-mounted toolsHybrid systemAdditive ingredient

A system and method for mixing and forming gum structures is provided. The system may include combinations of continuous and batch mixers arranged generally in parallel and / or series for mixing gum base ingredients with subsequent gum ingredients. In one embodiment, the system and method first forms a gum structure that is not a gum base and then adds a subsequent gum ingredient such that the gum structure is less than a gum base in combination with a subsequent gum ingredient. In other embodiments, the system and method includes forming a gum base in addition to some subsequent gum ingredients that are not quite finished gum. Further, in other embodiments, the system and method may perform some of the mixing of the ingredients at a first location while mixing of further ingredients is performed at a remote location.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Production technology of high

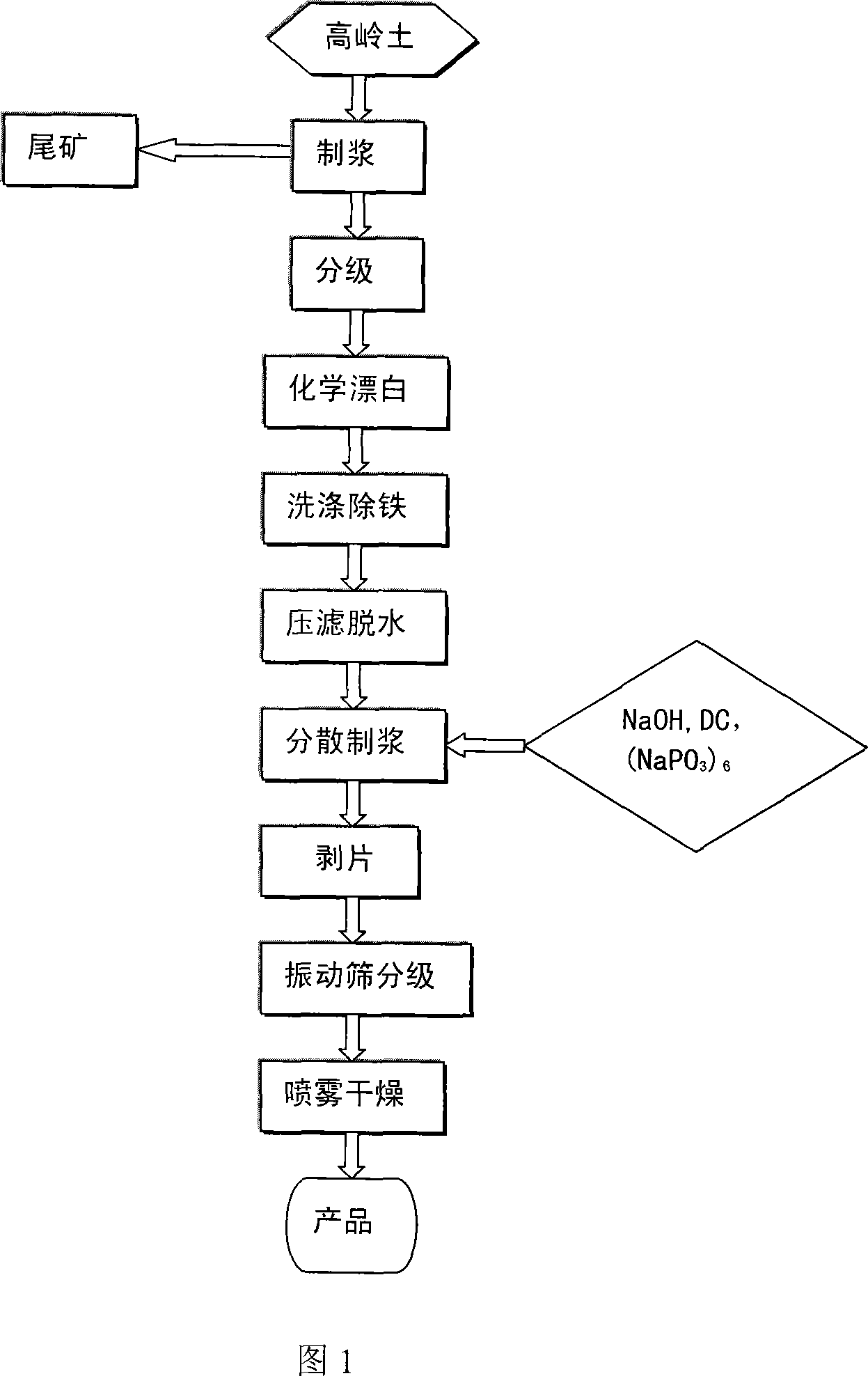

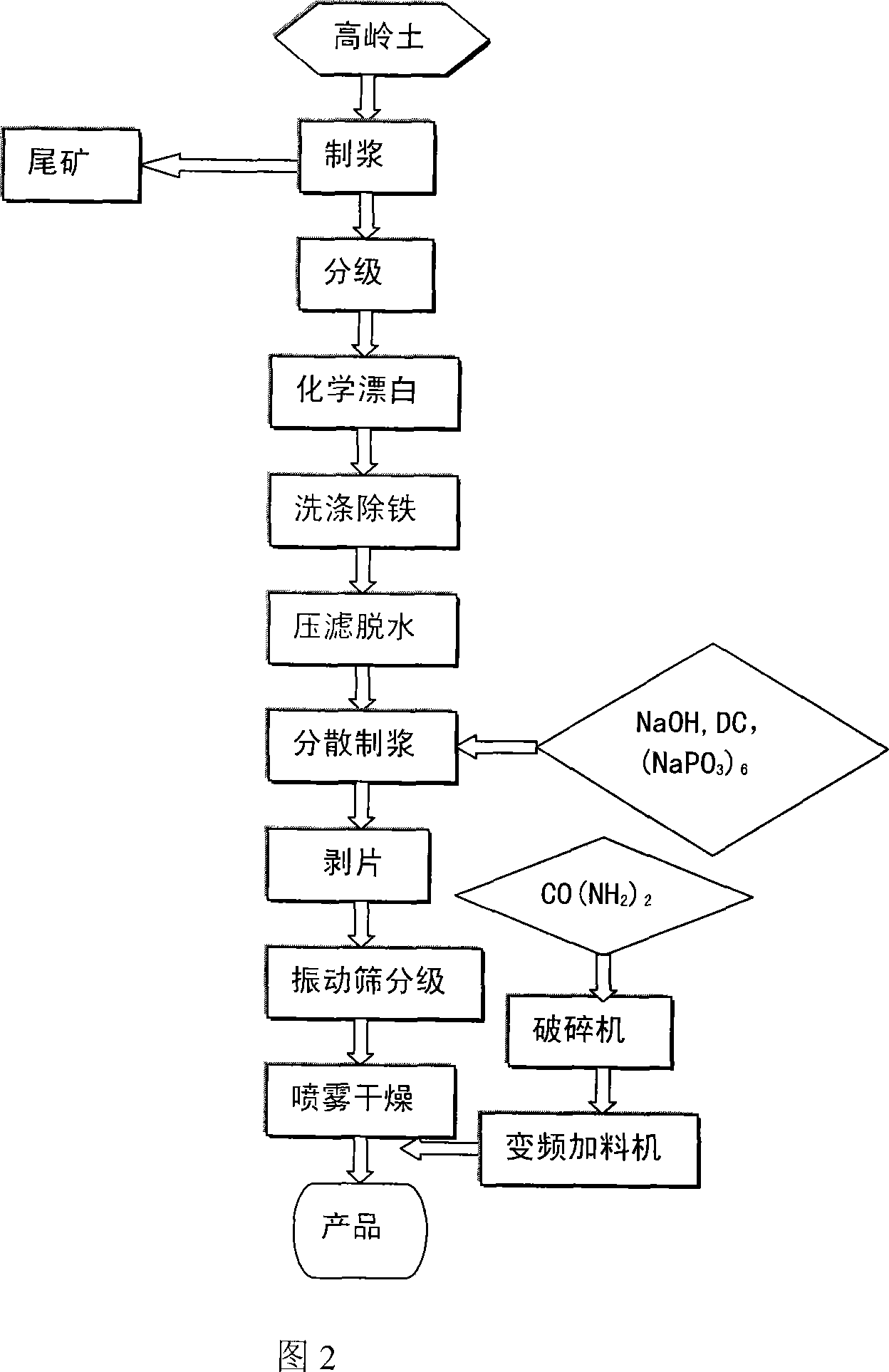

InactiveCN101117004AImprove performancePerformance impactClay processing apparatusThermal insulationKaolin clay

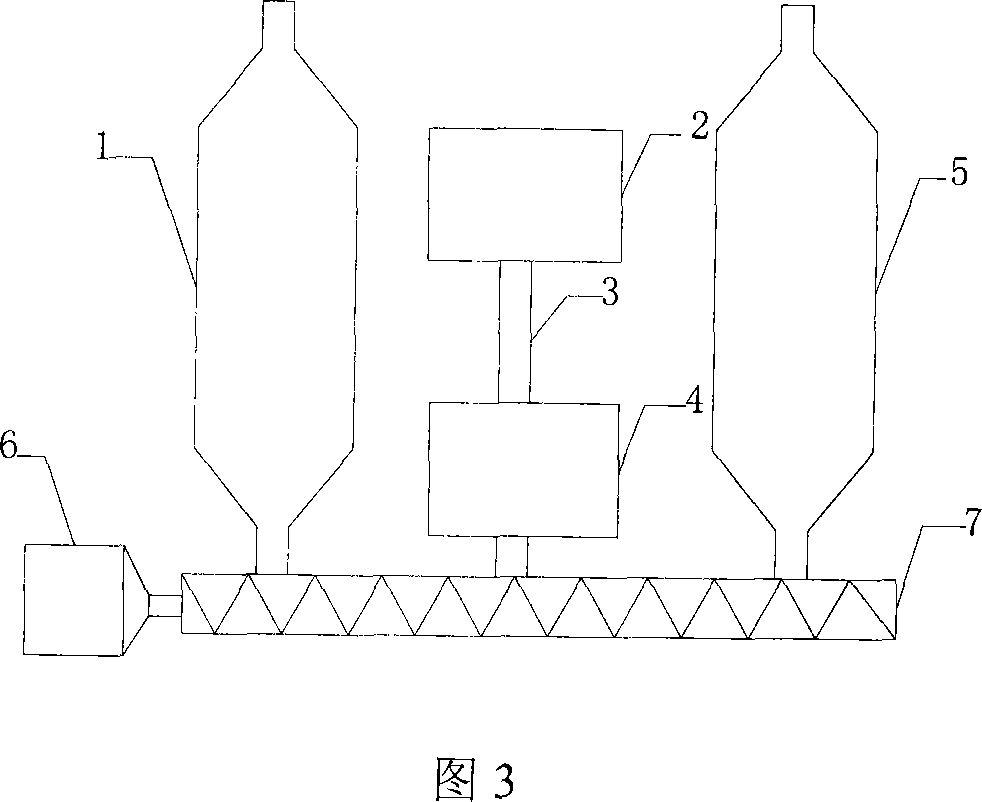

The present invention relates to a manufacturing technique of kaolin with high viscosity and concentration. A manufacturing technique of kaolin with high viscosity and concentration is characterized by comprising following procedures: 1) manufacturing kaolin slurry J with kaolin extracted by hydraulic machinery method undergoing pulping, classification, chemical bleaching, iron removal by washing, dehydrating through pressure filters, dispersed pulping, exfoliation, vibration screen classification ; 2) spray drying and intercalation which is accomplished by a) firstly, improving product lines of a spray drying equipment, that is, adding a thermal insulation layer to a packing auger, a lift pot and a storage hopper of the spray drying equipment, and then arranging a variable frequency feeding machine communicated with a urea crusher through pipelines on the packing auger of the bottom of a spray drying mouth of the spray drying equipment; b) spray drying to achieve kaolin powder; c) intercalating intercalation agent urea with the kaolin powder through the variable frequency feeding machine with parameter of a fresh feed pump between 2 HZ and 8 HZ and with additional of mass of the intercalation agent urea between 2 percent and 10 percent of the mass of the kaolin powder; thereby getting final kaolin products with viscosity and concentration between 72 percent and 73.7 percent. The manufacturing technique can produce kaolin with high viscosity and concentration.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

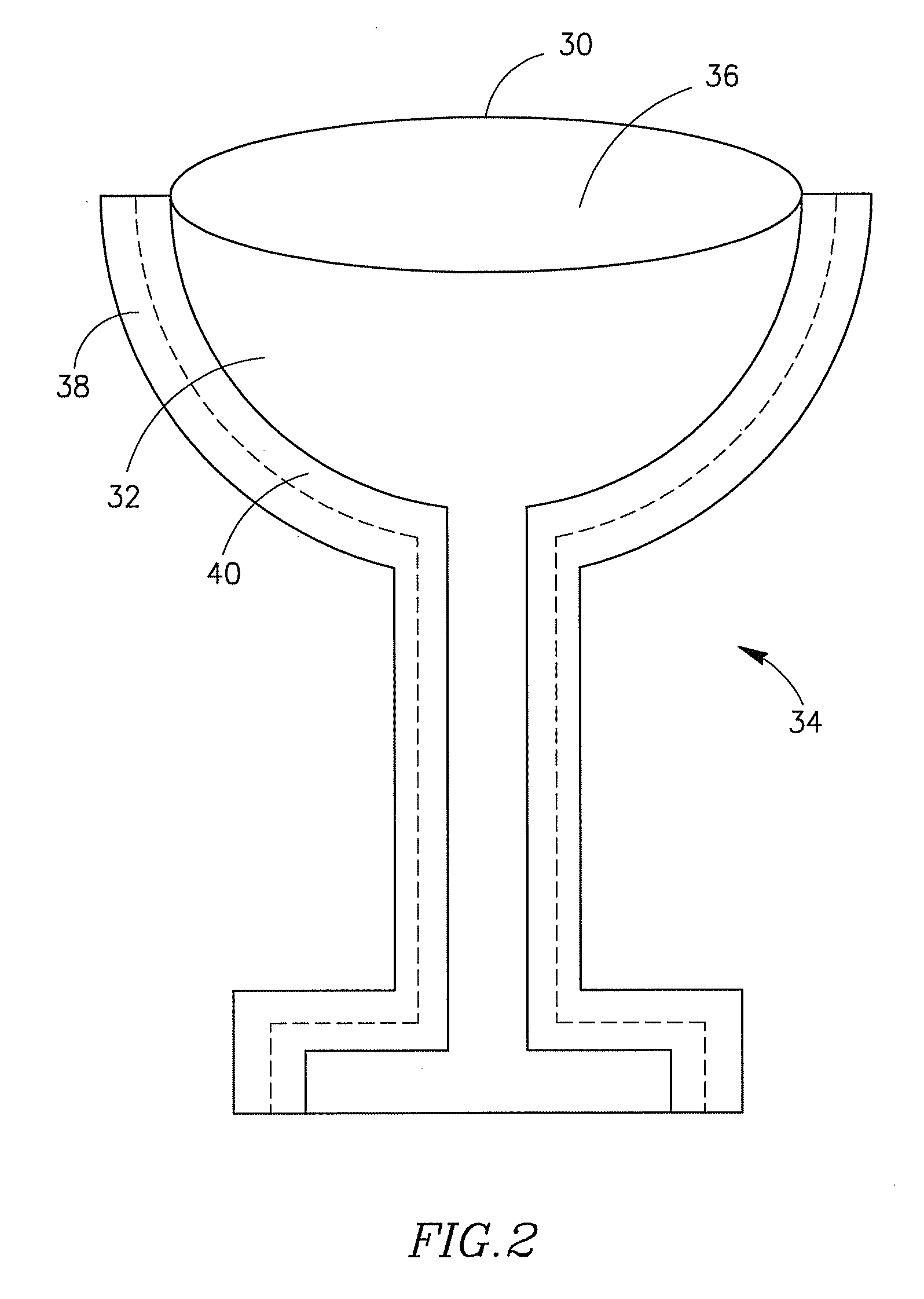

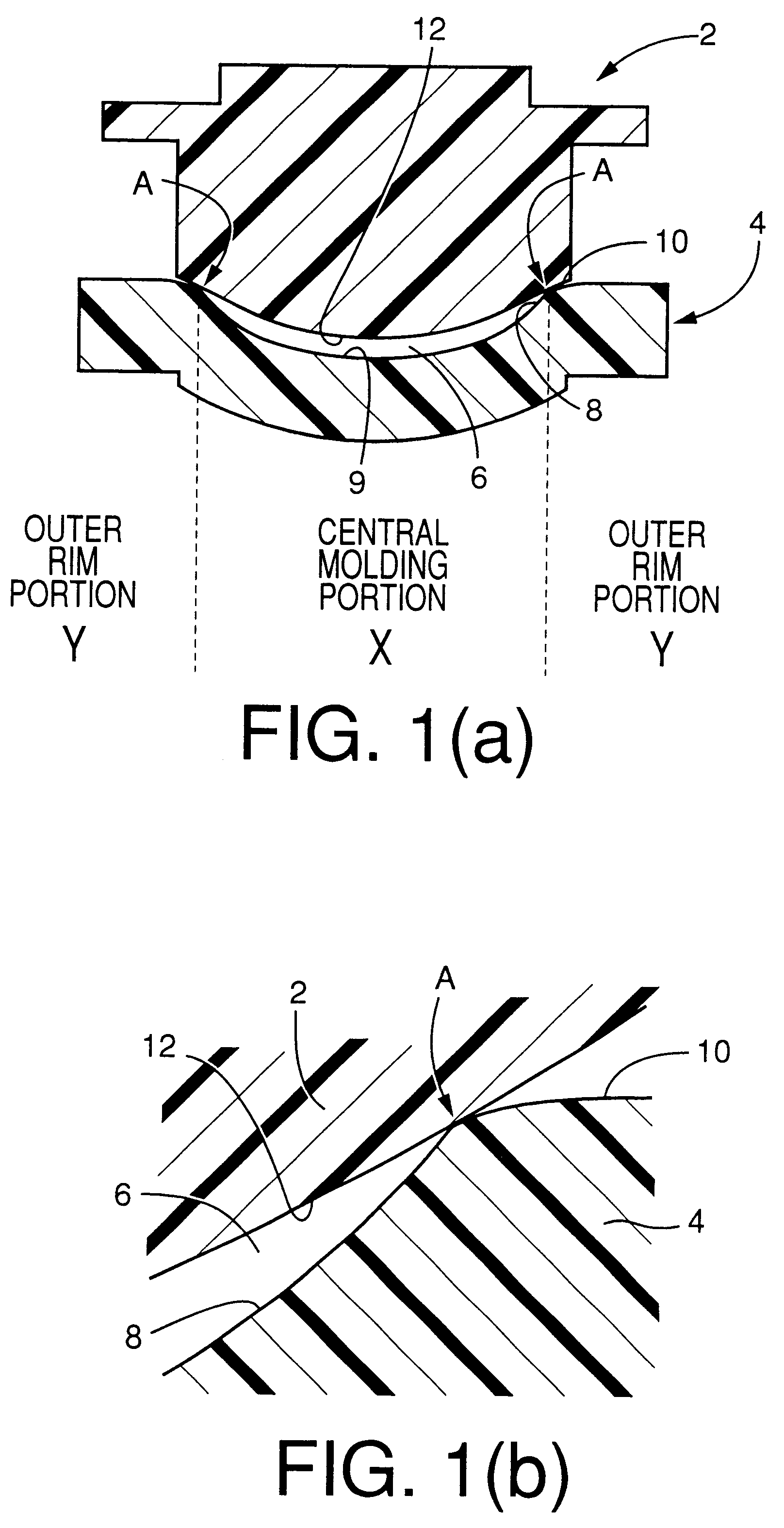

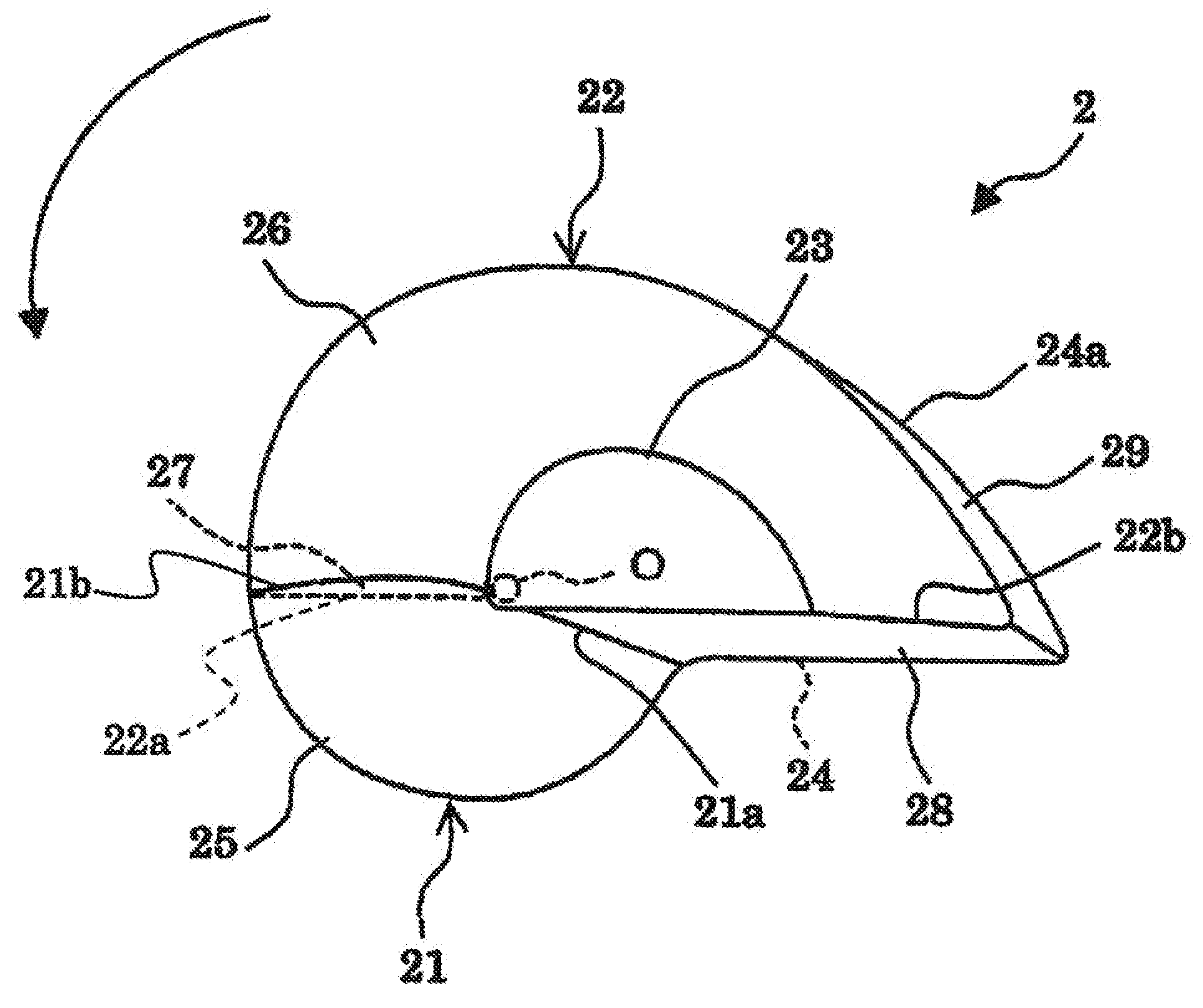

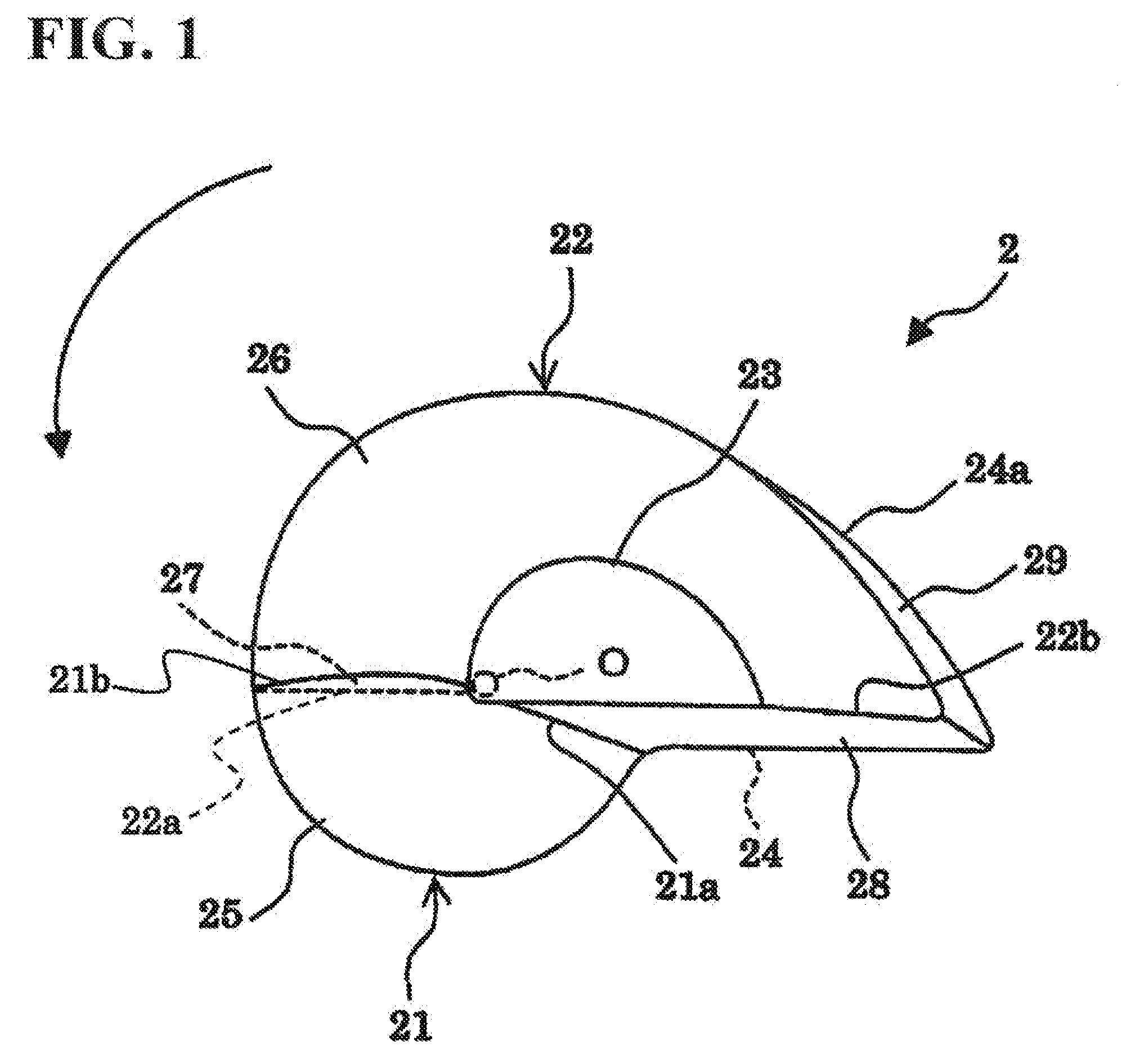

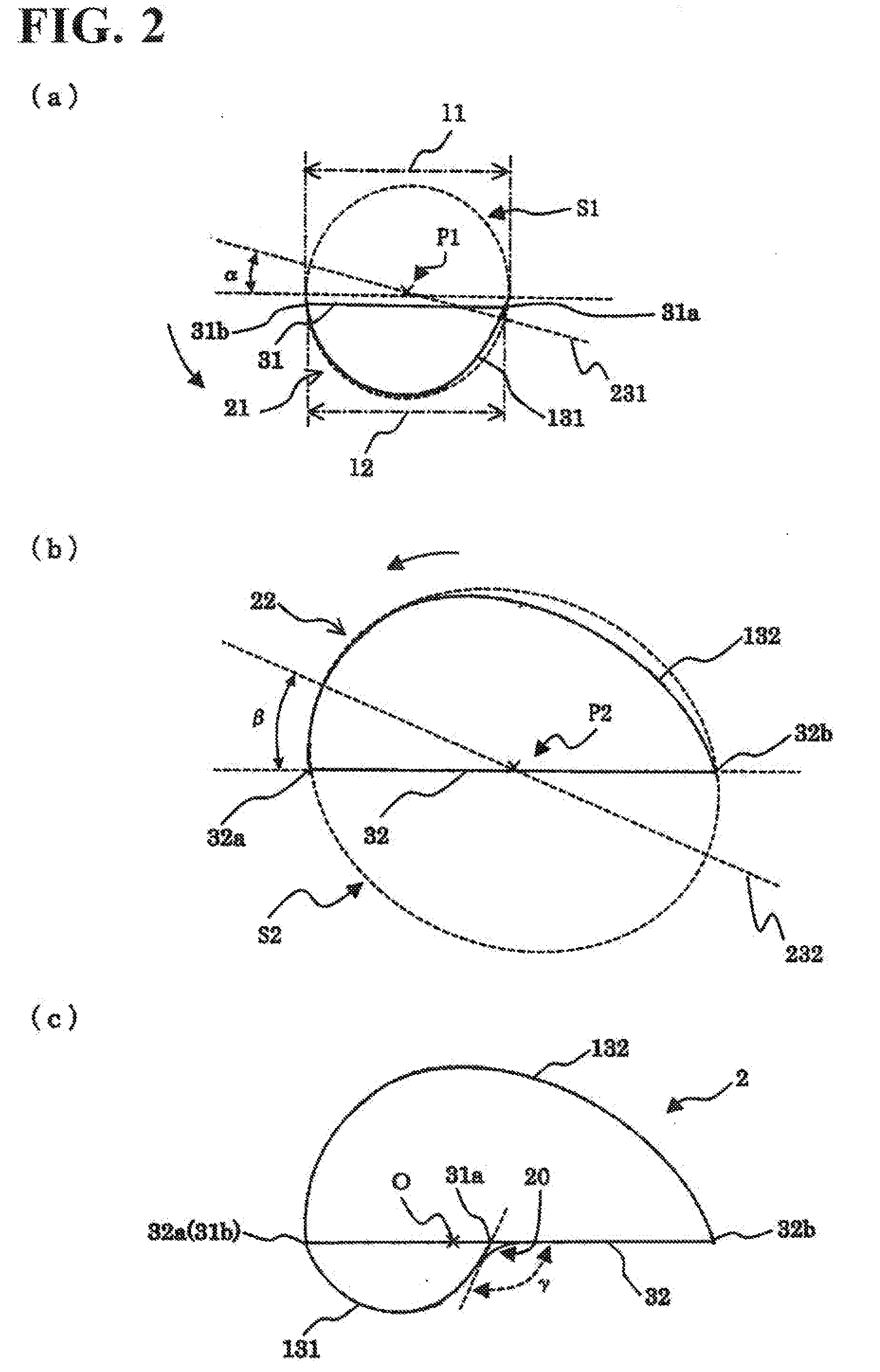

Mold assembly for forming ophthalmic lens

InactiveUS6257547B1Avoid Insufficient SealingImprove stabilityFoundry mouldsOptical articlesEntocentric lensRadial position

Lens mold assembly including a first and a second mold cooperating with each other to define a mold cavity for molding an ophthalmic lens with the first and second molds being held in line contact with each other at a radial position, wherein at least one of the two molds consists of a central molding portion located radially inwardly of the radial position, and an outer rim portion located radially outwardly of the radial position, the central molding portion cooperating with the other mold to define the mold cavity, the above-indicated at least one mold having a mold surface which is opposed to a mold surface of the other mold when the two molds are assembled together, the mold surface of the at least one mold consisting of a central lens-forming region in the central molding portion, and an outer peripheral non lens-forming region in the outer rim portion, at least a part of the lens-forming region adjacent to the radial position providing a concave portion, while at least a part of the outer peripheral non lens-forming region adjacent to the radial position providing a convex portion.

Owner:MENICON CO LTD

Screw-type extruding machine comprising mixing and kneading disks

InactiveUS20050041521A1Reduce decreaseRotary stirring mixersMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

A screw-type extruding machine comprises at least two casing bores with screw shafts disposed therein, on which several successive mixing and kneading disks are mounted, interengaging in pairs. Successive mixing and kneading disks make an angle of crest misalignment which is not integrally contained in 360°.

Owner:COPERION

Kneading Element of Kneader, Kneader, and Bread Machine

InactiveUS20100147160A1Efficient kneadingReduce adhesionMixing/kneading structural elementsRotary stirring mixersMechanical engineeringEngineering

Owner:JAPAN KNEADER

High speed and direct driven rotating equipment for polyolefin manufacturing

An apparatus and method for melting polymer is provided. In at least one embodiment, the apparatus includes a housing, two or more rotatable members at least partially contained within the housing, where each rotatable member having a shaft coupled thereto. The apparatus also includes a motor having a drive shaft directly coupled to the shaft of the rotatable members such that the rotatable members rotate at a speed of the motor drive shaft. The rotatable members are preferably non-intermeshing and counter-rotating.

Owner:UNIVATION TECH LLC

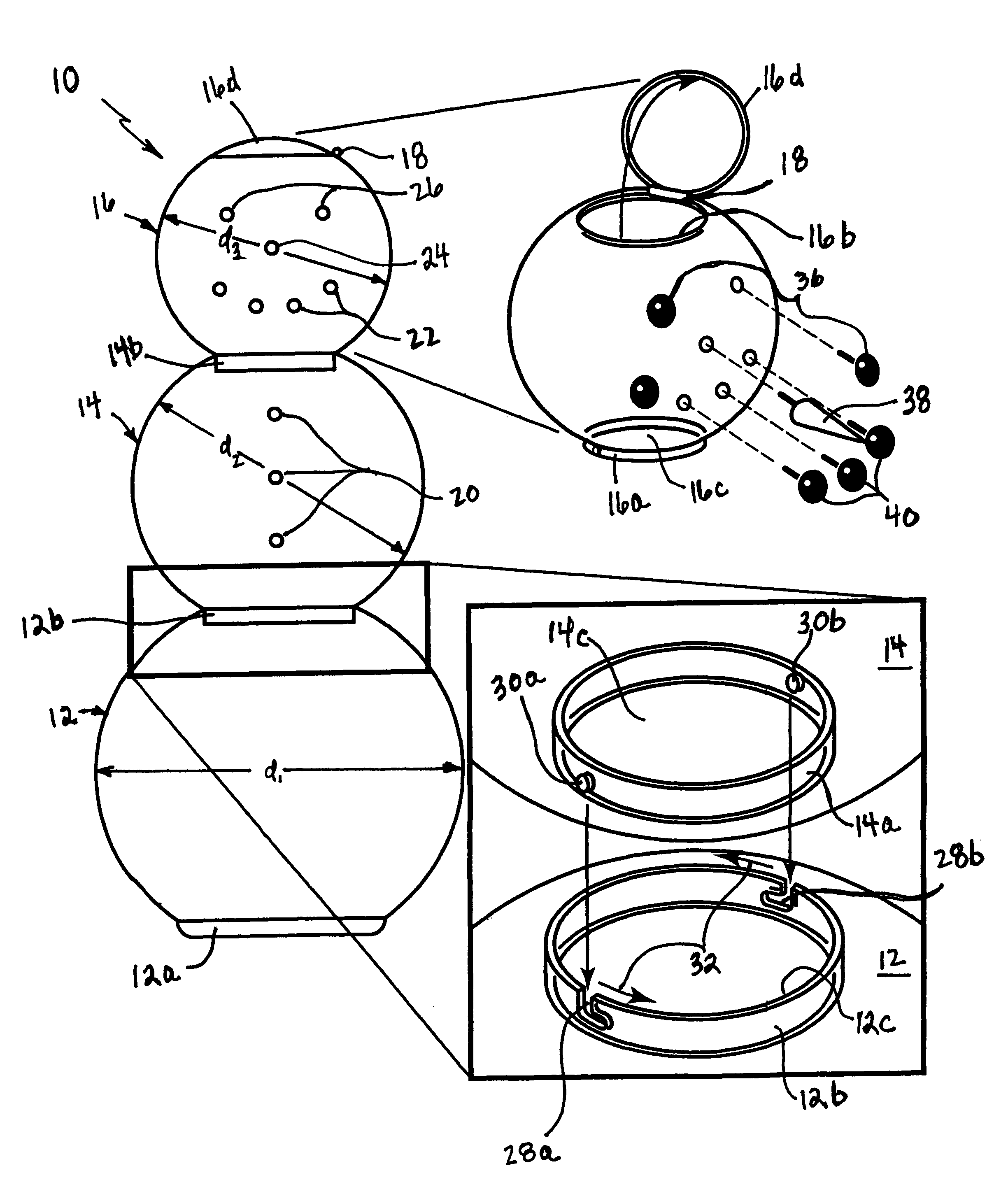

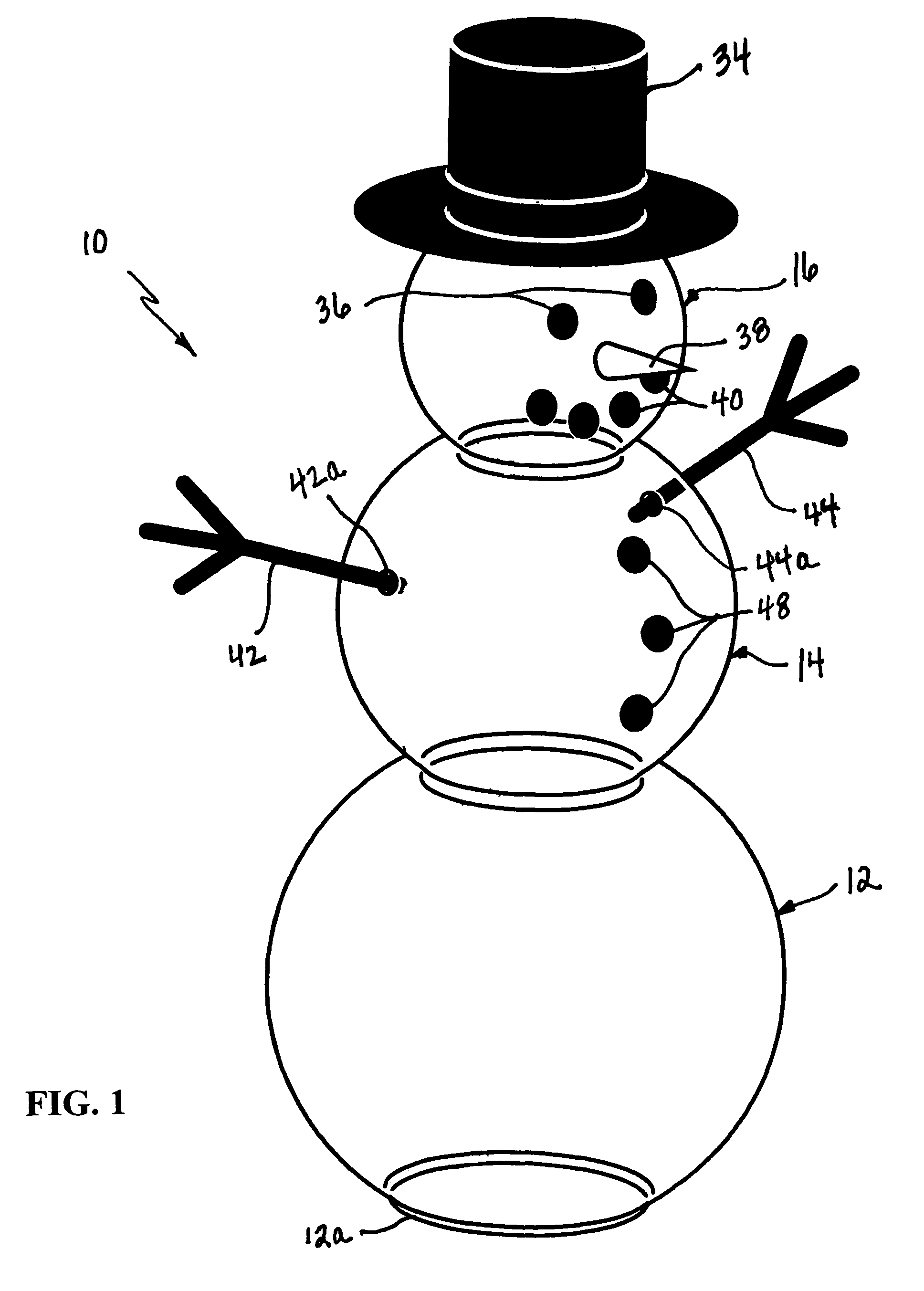

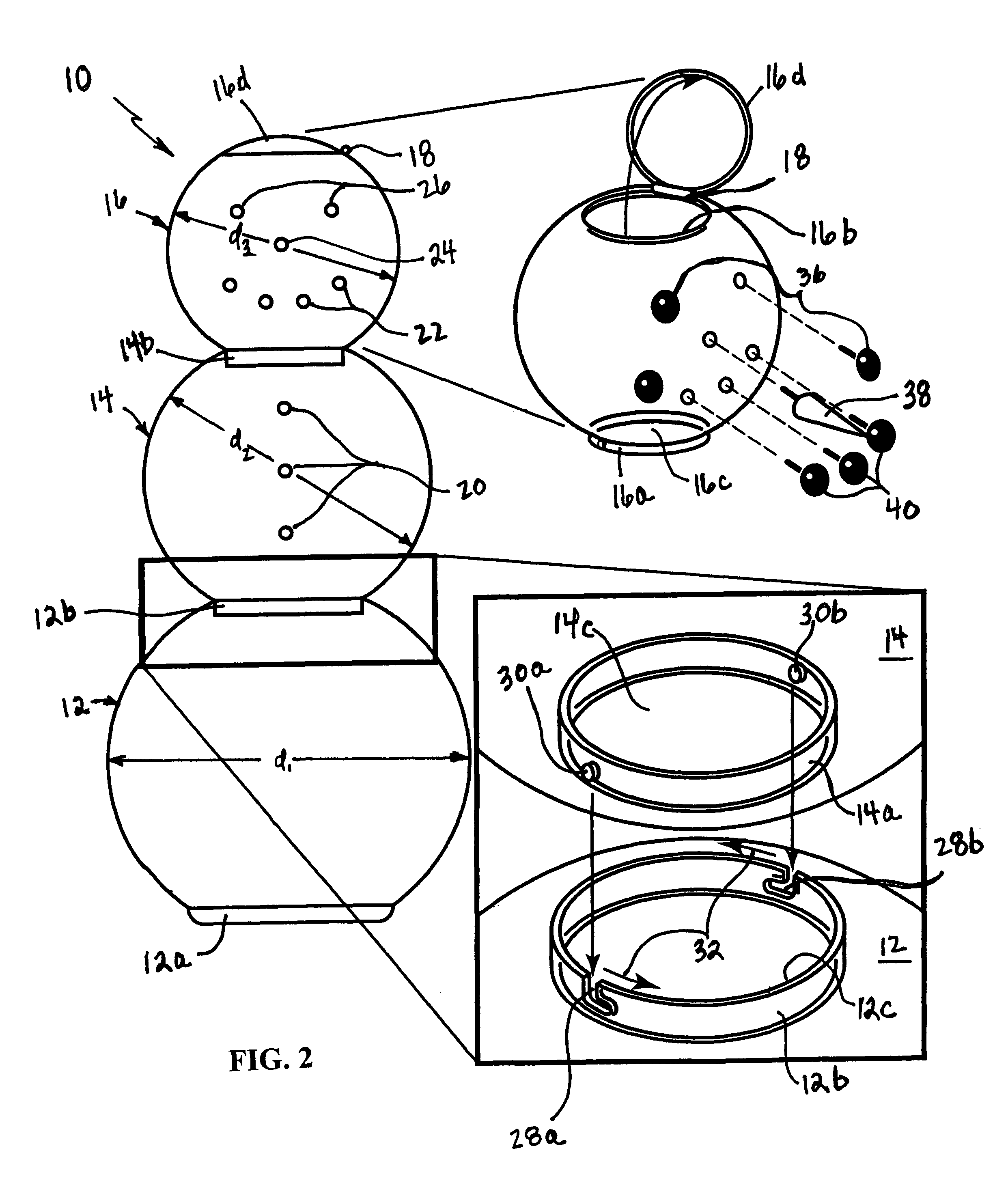

Snowman mold

ActiveUS7963500B1Easy to shapeReliable wayMould separation apparatusLighting and heating apparatusCouplingEngineering

A mold for forming a snowman includes lower, intermediate and upper generally spherical, hollow members comprised of clear plastic. Each plastic member includes an upper aperture for filling the member with snow. The lower member includes a generally flat base portion for positioning stability and an upper connection ring adapted for secure coupling to a lower connection ring on the intermediate member. The intermediate member also includes an upper connection ring adapted for secure coupling to a lower connection ring on the upper member. The three connected members form a hollow, vertical structure which when filled with snow provides a snowman of classic shape, symmetry and proportions. The individual spherical hollow members are easily connected and disconnected, with the intermediate and upper members having apertures for receiving eye, nose, mouth and arm indicia, with the upper member further including a hat mounting arrangement in one embodiment.

Owner:HOLIDAY ANGELA C

Non ionic groups of amphoteric polysaccharide linear or branched alkyl or acid and base distillation reservoir liquid or gas mechanically refined and Nano particle dispersion and recovery basin in vacuum processing for Building Materials and High Wear-Heat Resistant Parts Brushes; Windings; Coils; Battery Cells; Brake Pads; Bushings; 2.5 Phase Extrusions Die Cast Molding; Refrigeration; Polarized Glass; and Central Processing Unit Processors.

Manufacture process scientific formula mechanically refined and nanoparticle dispersion preform slurry non ionic or electrolyte carbon nanofoam CNFs with or without ionic suspension elements manufactured, Preform slurry high wear-heat resistant parts electronic component composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension element enhanced composite coils, composite windings, drawn, annealing, spun, coils, windings, wire, woven textile mesh, shielding, brushes, capacitors, battery cells, rheostats, electronic resistors, transformers, transducers, rectifiers, power supplies, or heat sinks, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, washers, spacers, and bushings, Preform slurry carbon nanofoam CNFs extrusion high wear-heat resistant parts precision casting molds manufacturing highly pure metal, Super Alloy, acid-solid, alkaline, glass, acrylic, halide, alkalide, or ceramics specializing in 2.5 phase die cast molding.

Owner:MATTHEWS ROBERT RICHARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com