Patents

Literature

96results about How to "Efficient melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

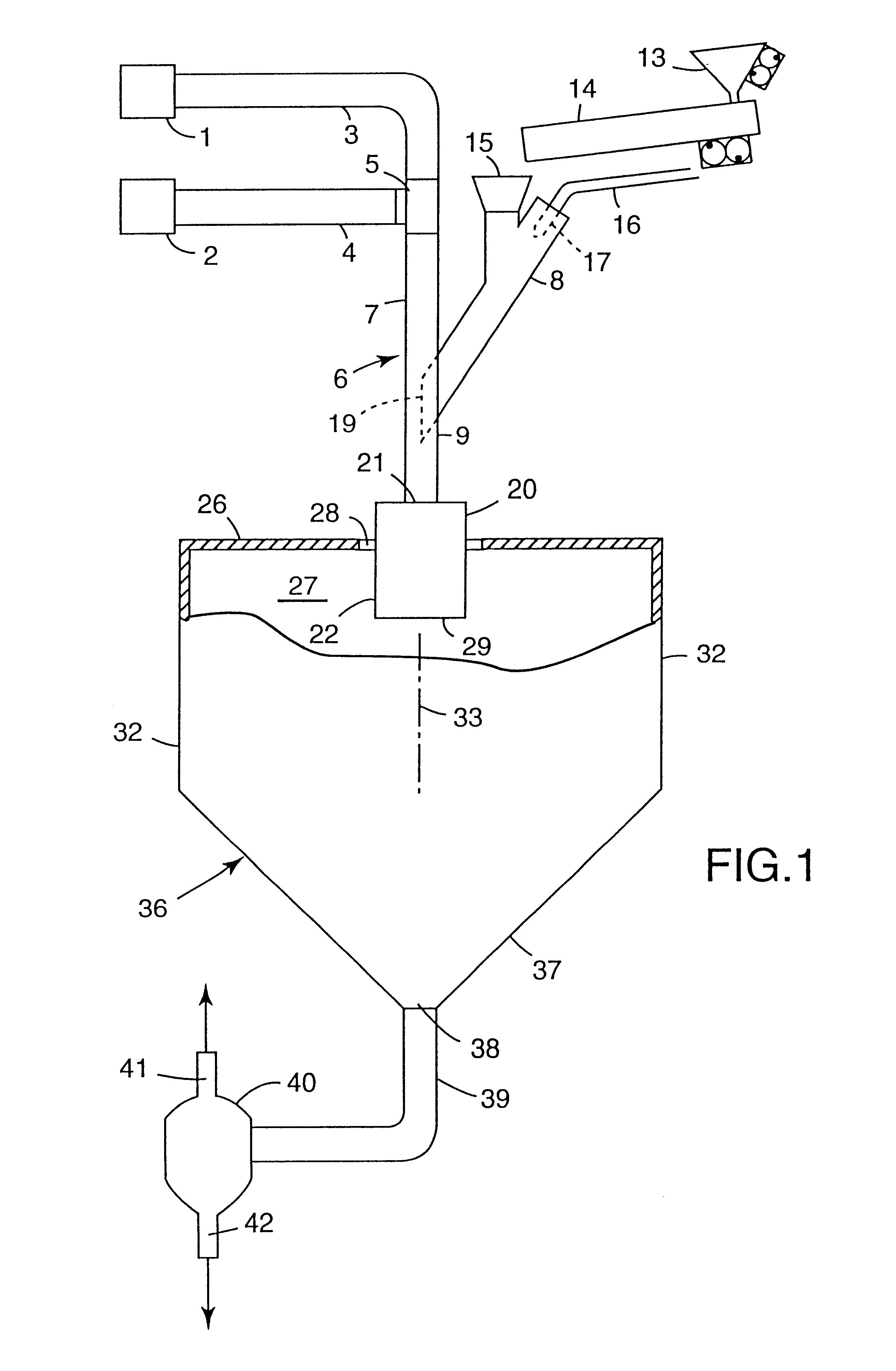

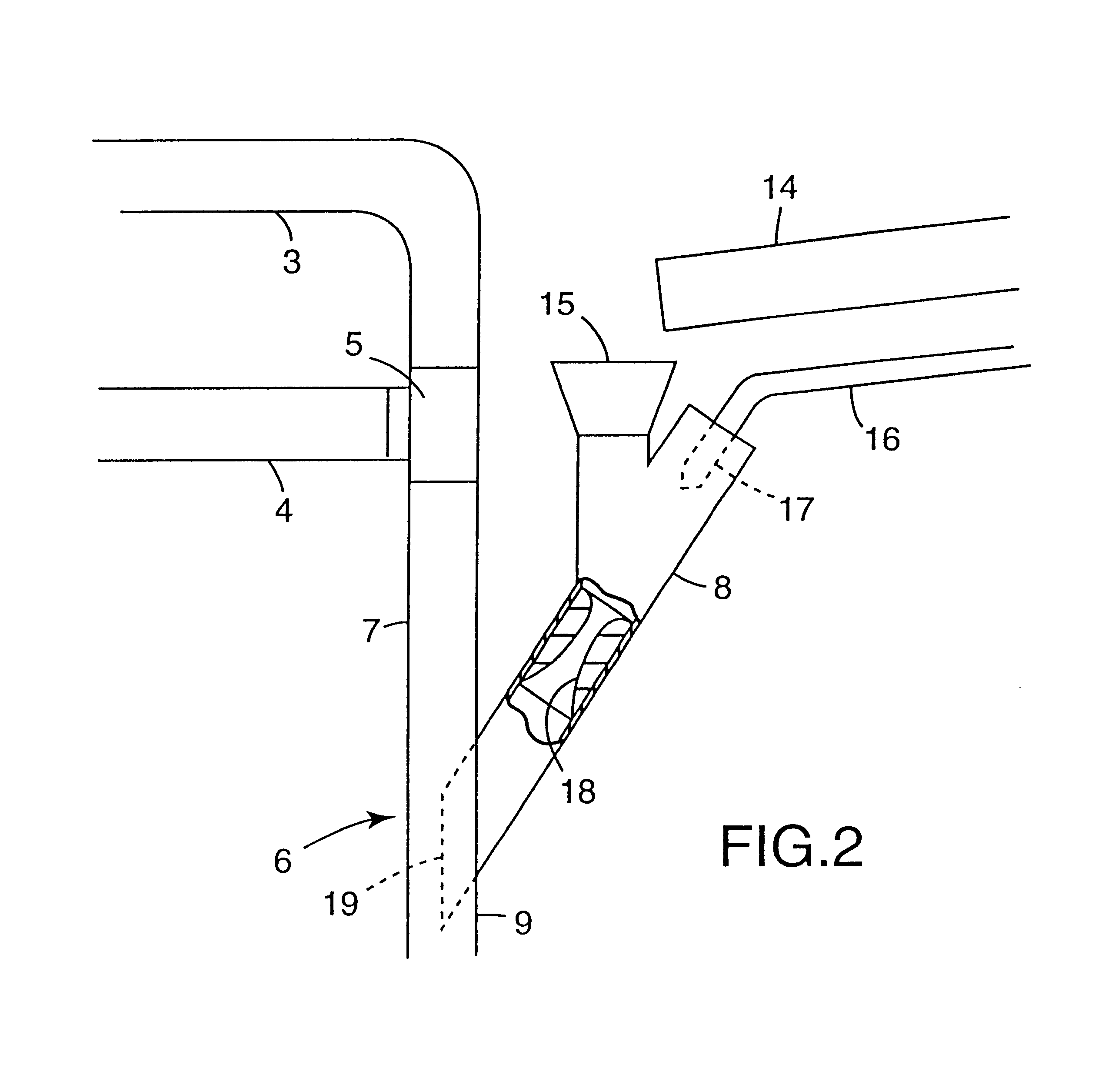

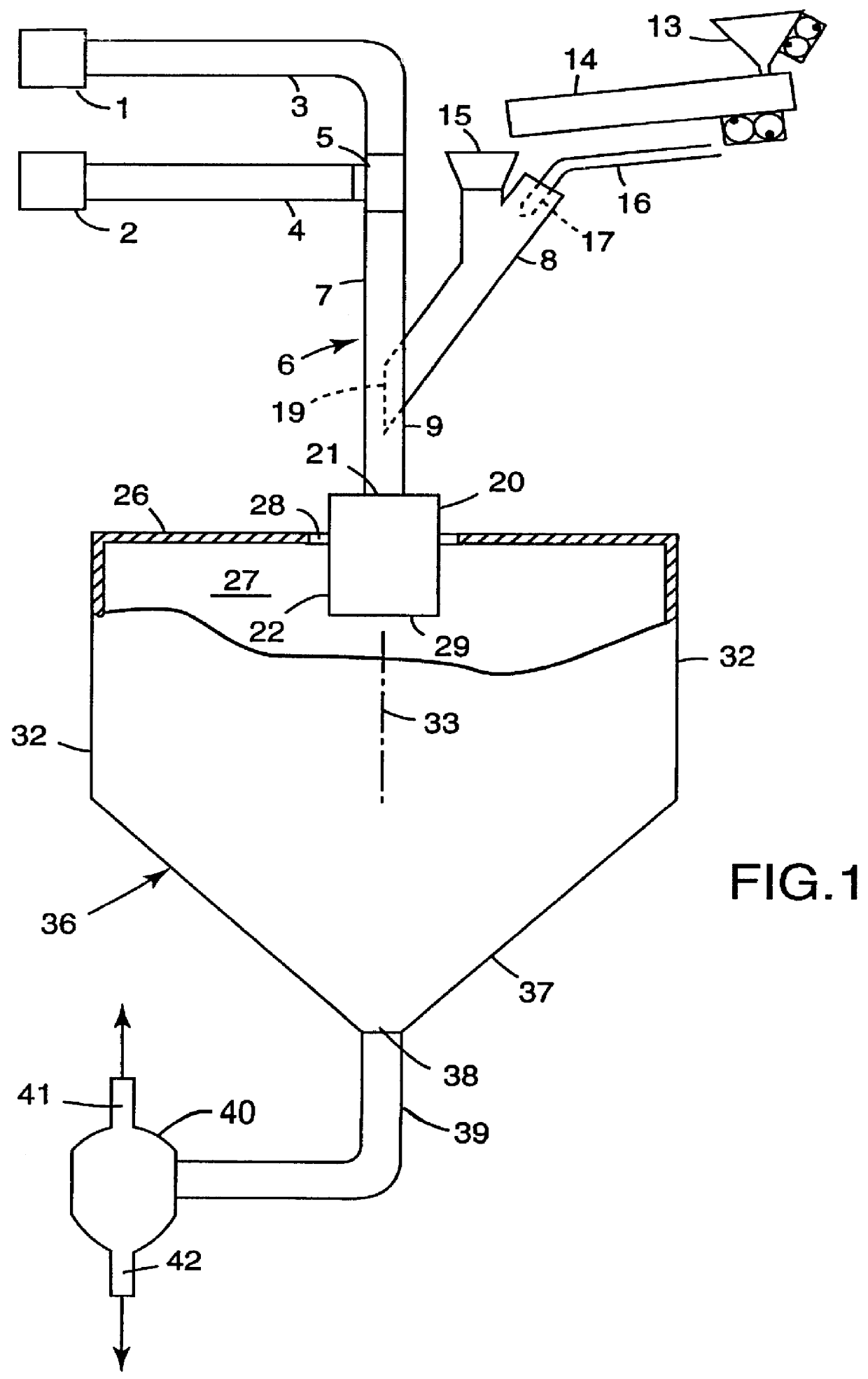

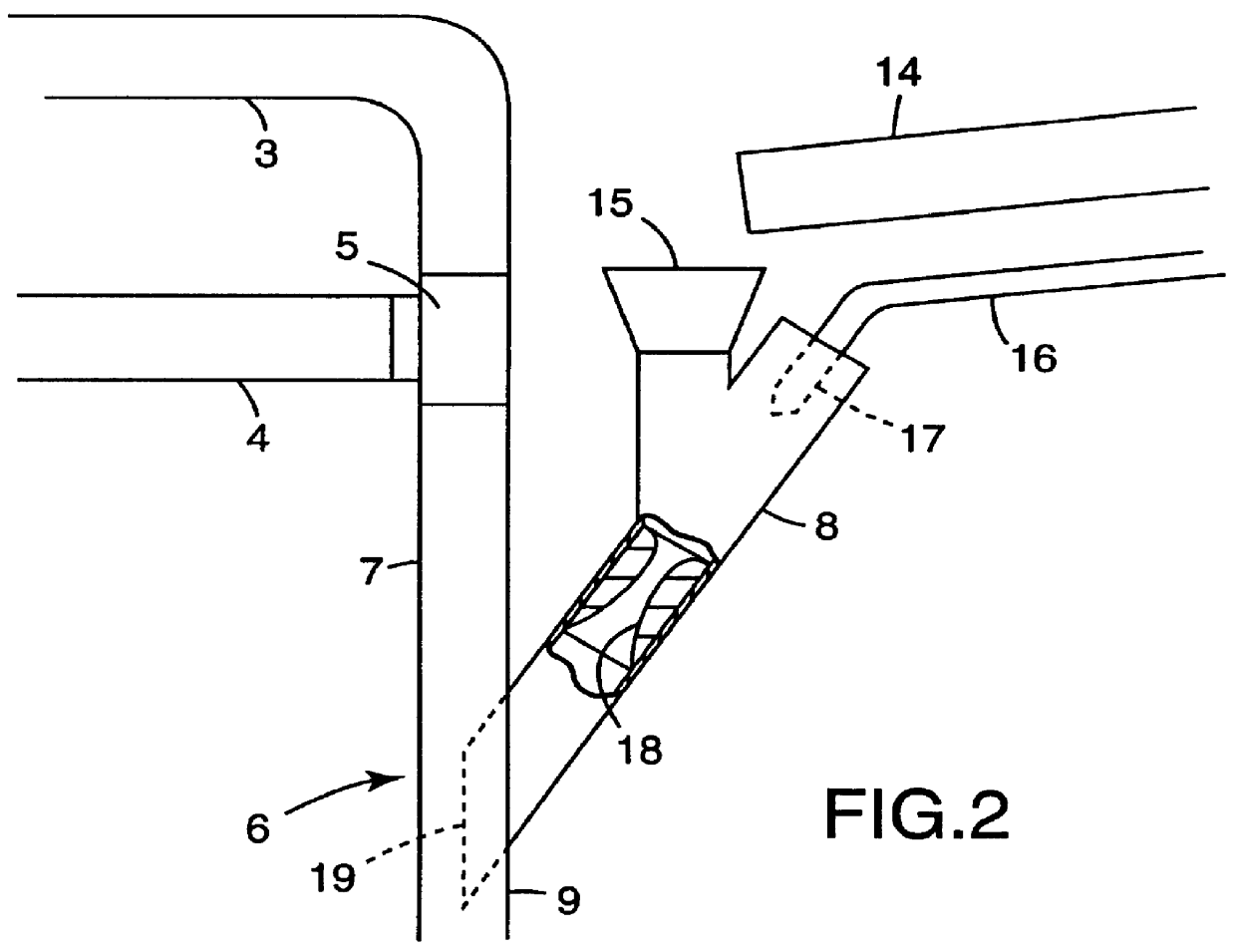

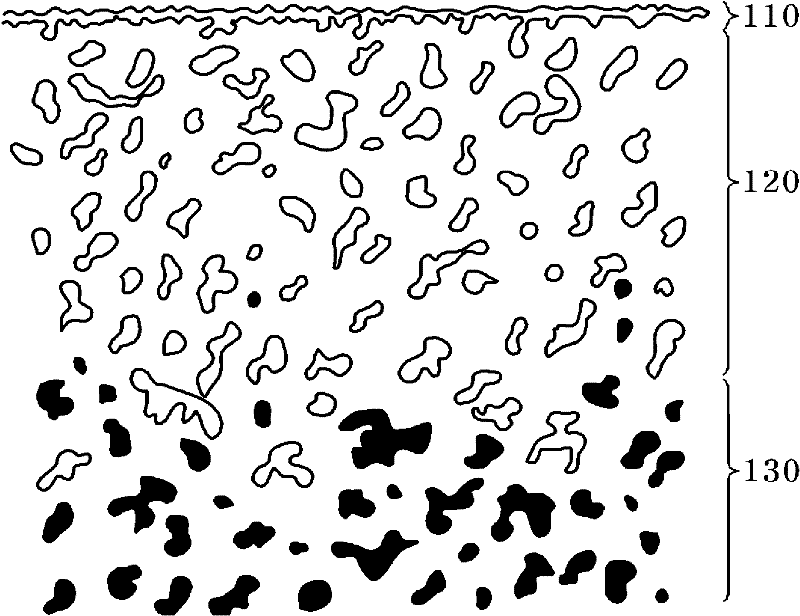

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

At least partly fused particulates and methods of making them by flame fusion

InactiveUS6045913AEfficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsEllipsoidal particleProduct gas

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

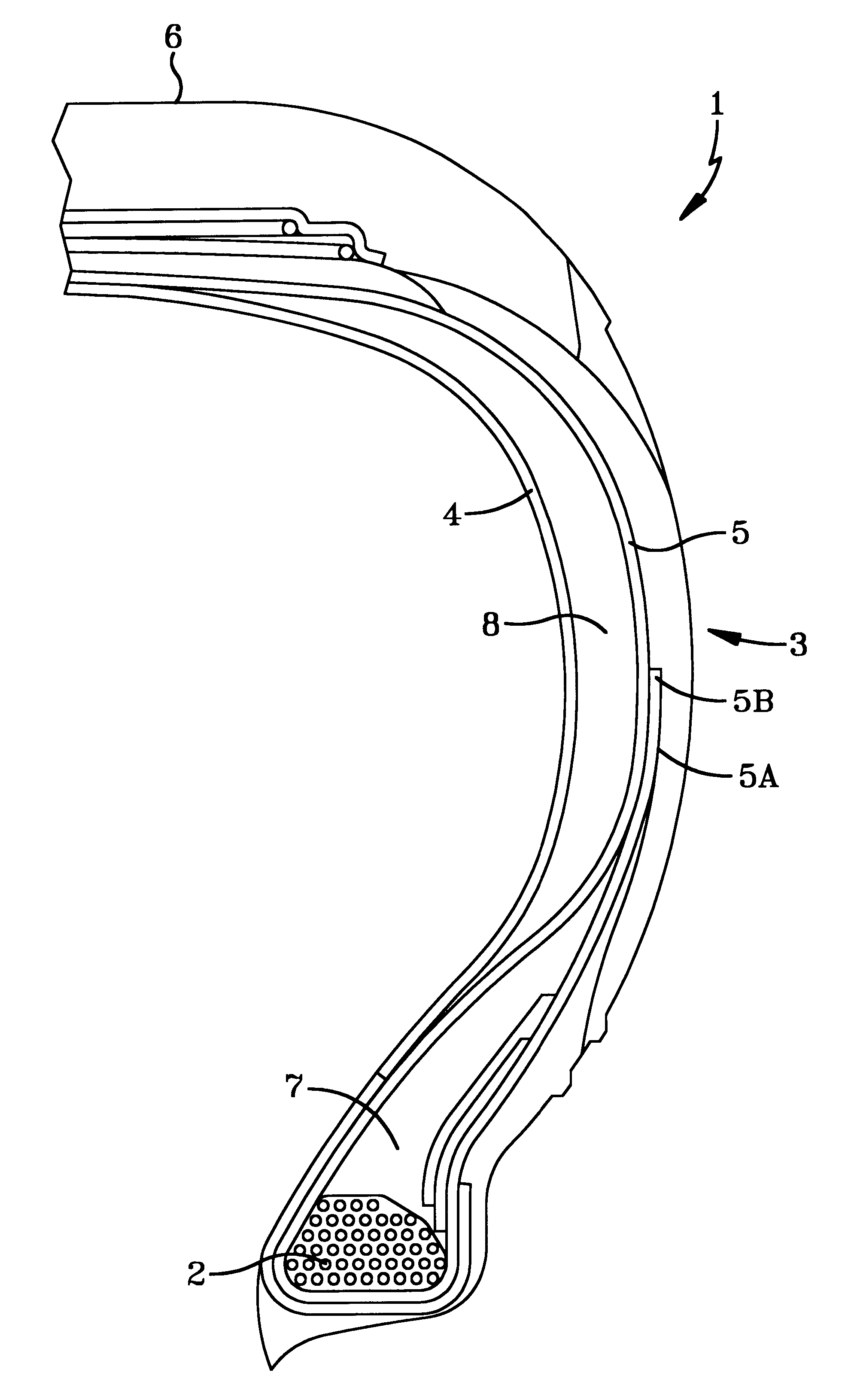

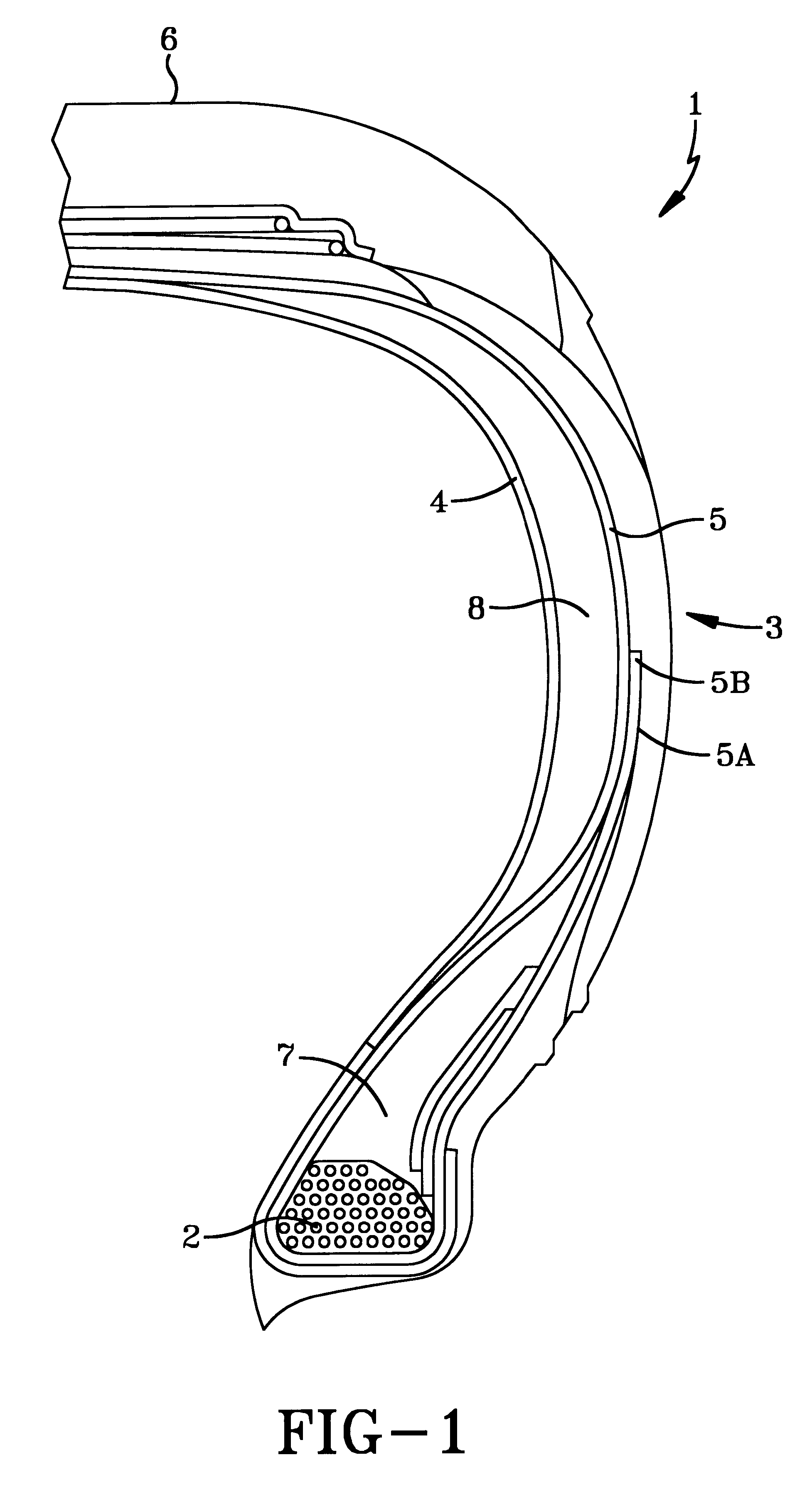

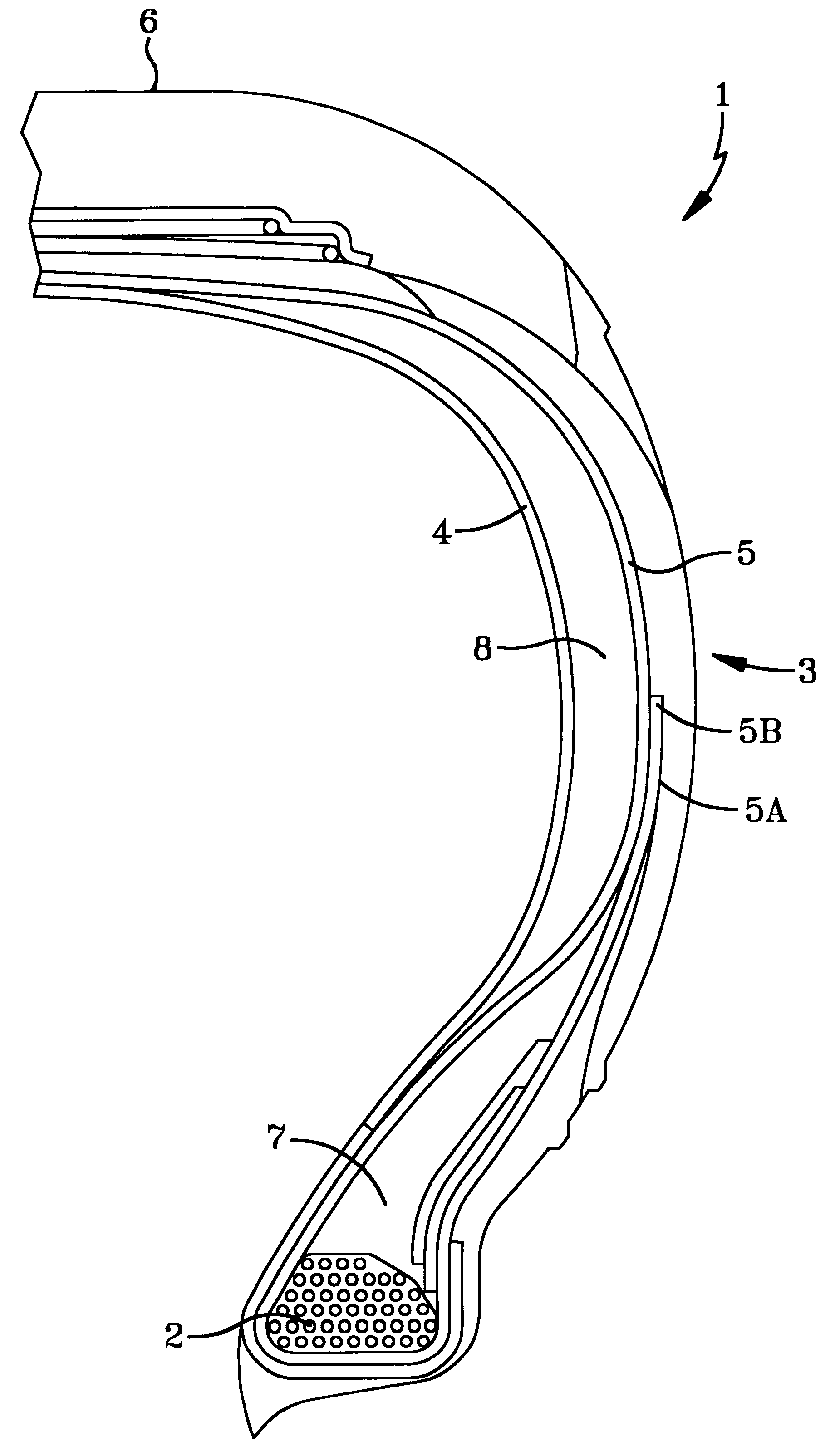

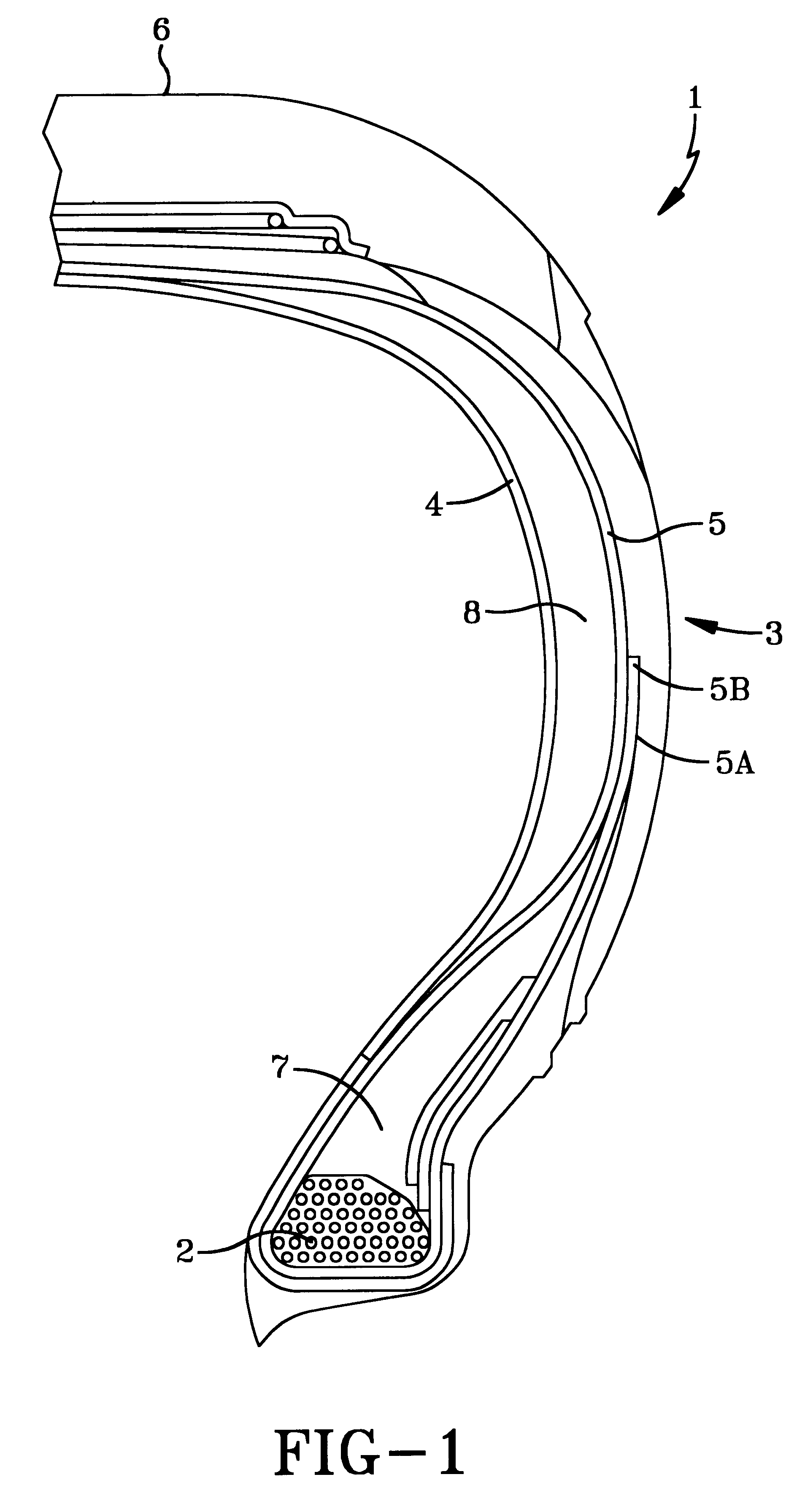

Tire with sidewall rubber insert

InactiveUS6202726B1Improve propertyHigh modulusPaper coatingSpecial tyresUltra-high-molecular-weight polyethyleneMechanical engineering

A pneumatic tire has a sidewall rubber insert axially inward of at least one carcass ply. Such insert may, for example, be an apex extending radially outward from the bead core region of the tire into the tire sidewall. Alternatively, it may be positioned higher in the sidewall portion of the tire and away from the bead core. Such insert is a rubber composition containing a dispersion of an ultra high molecular weight polyethylene and a dispersion of a starch composite.

Owner:THE GOODYEAR TIRE & RUBBER CO

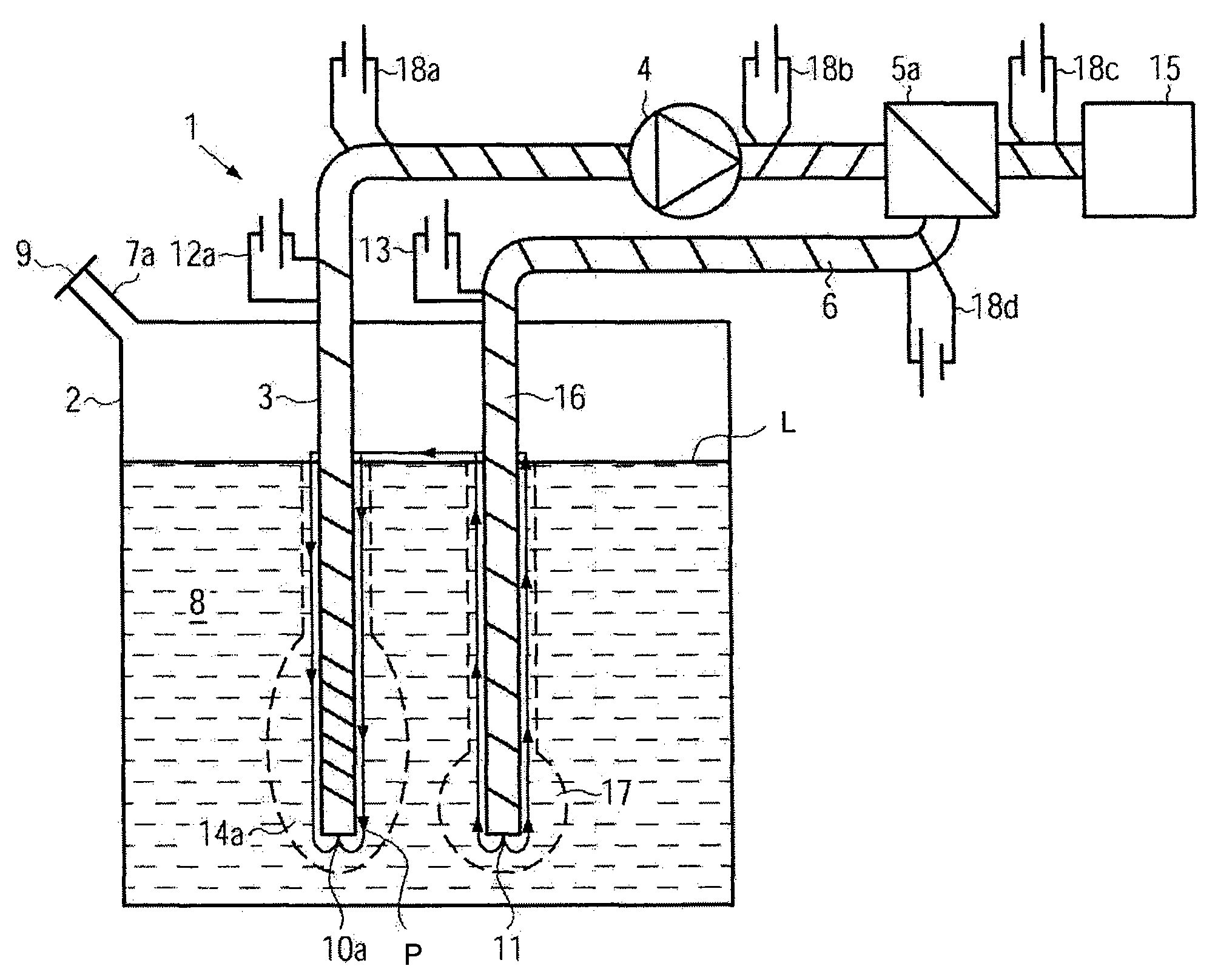

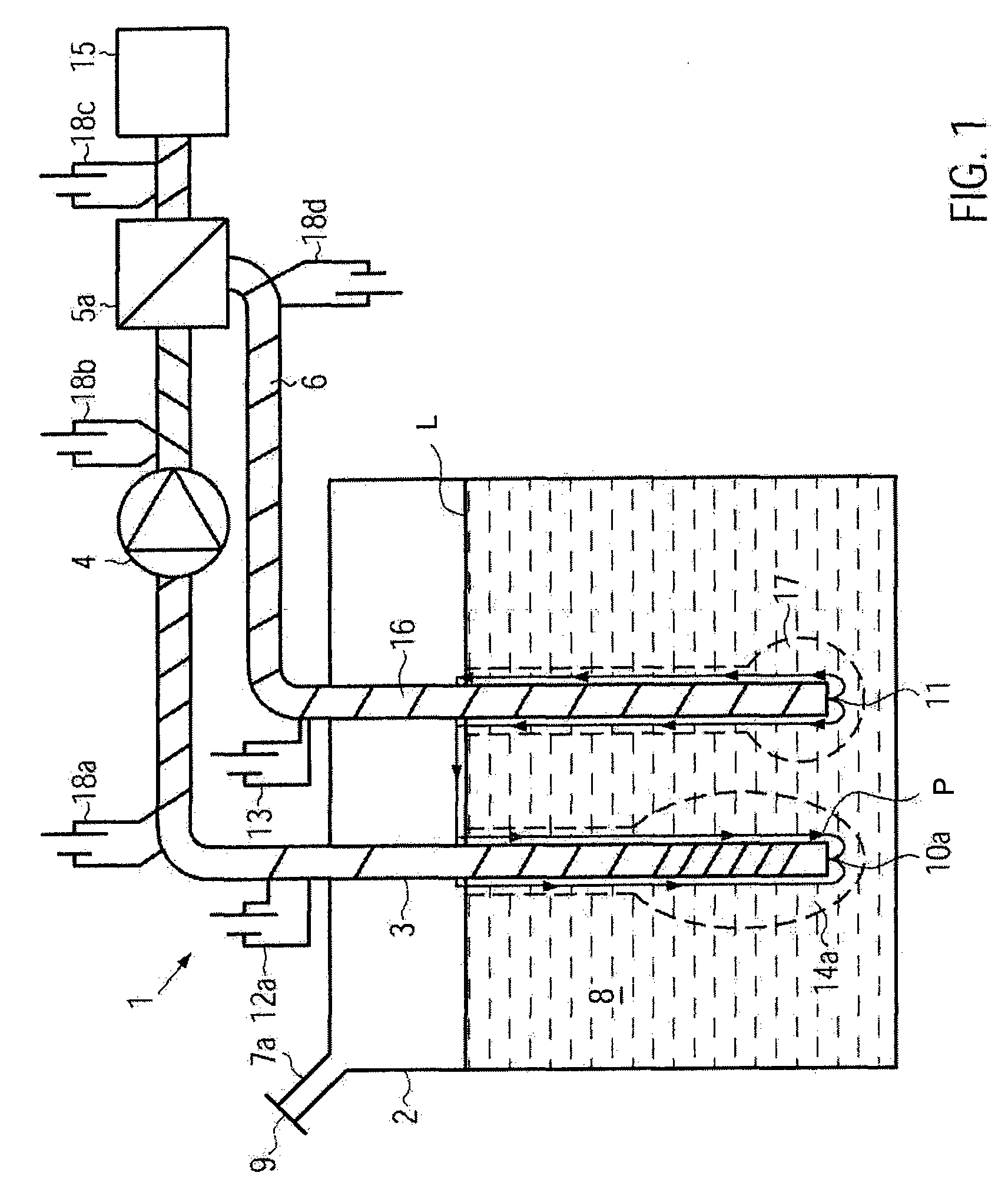

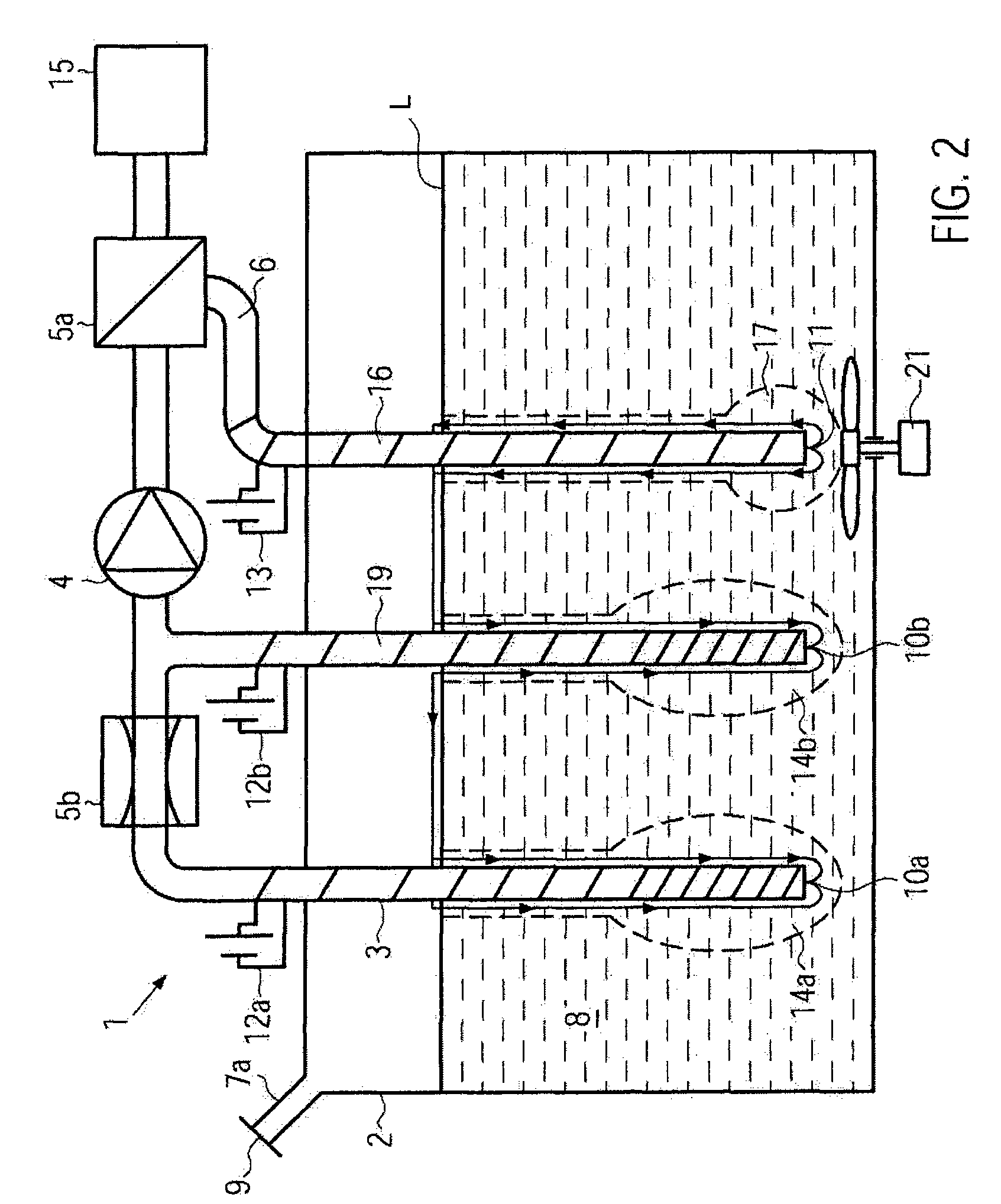

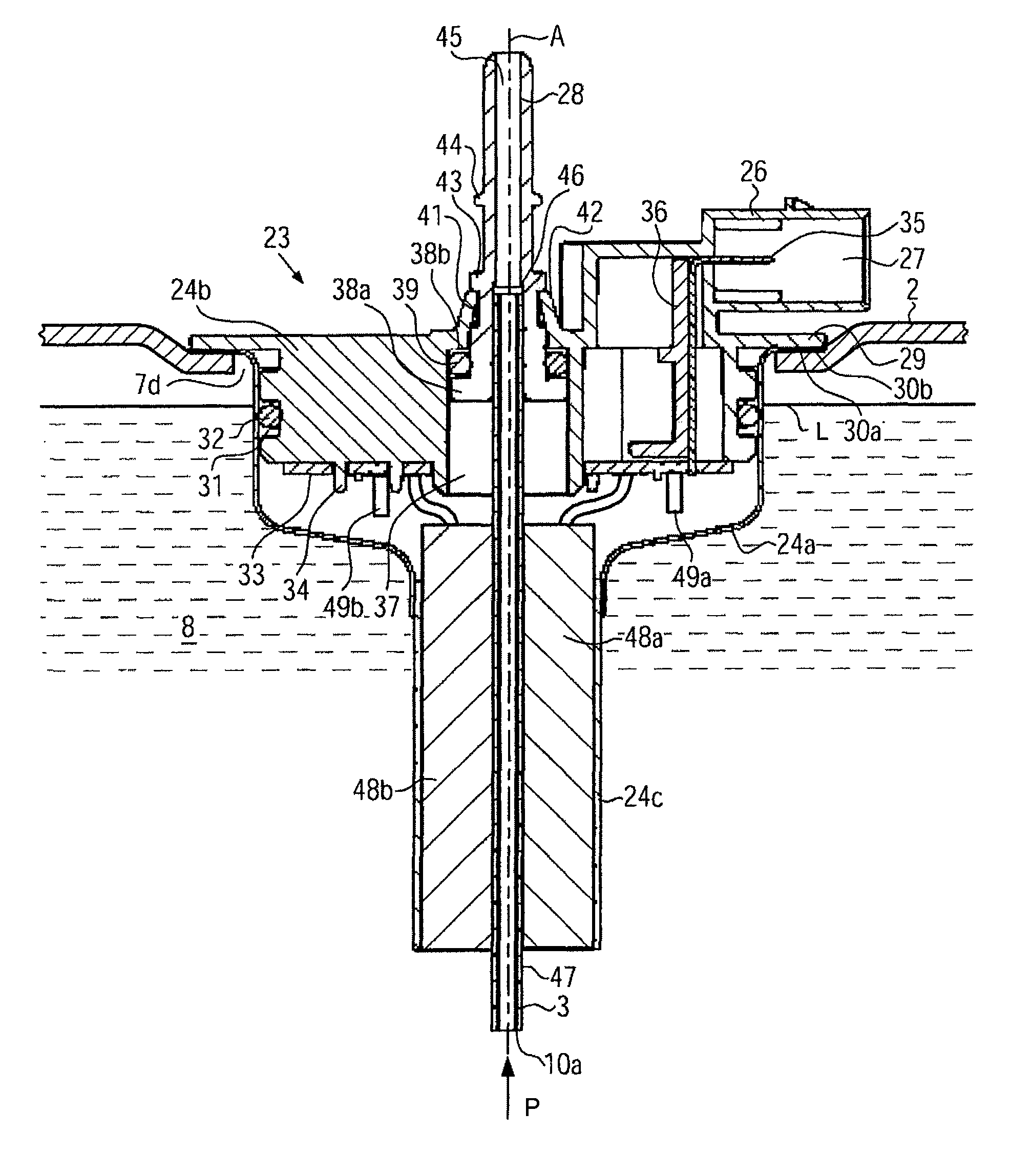

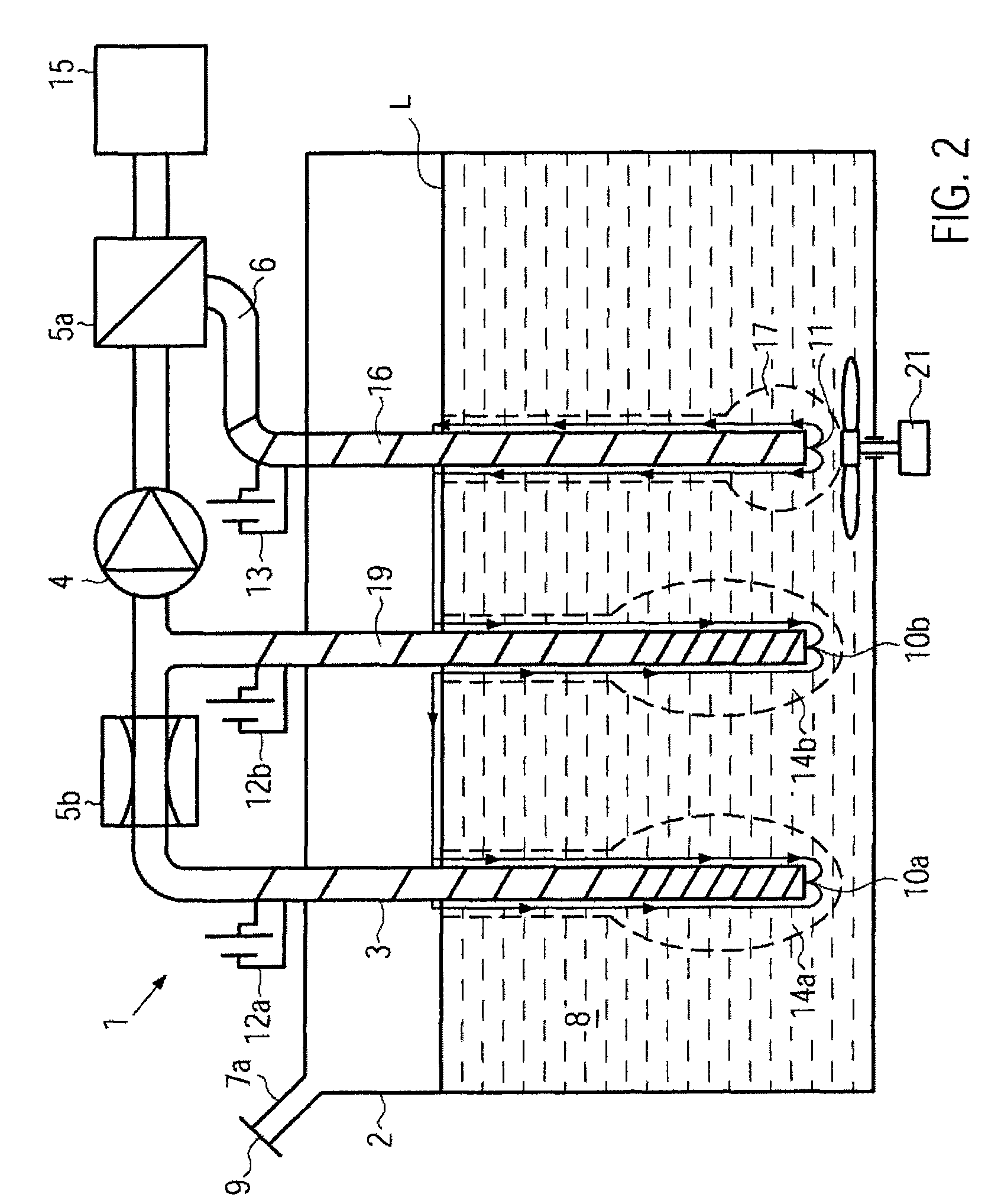

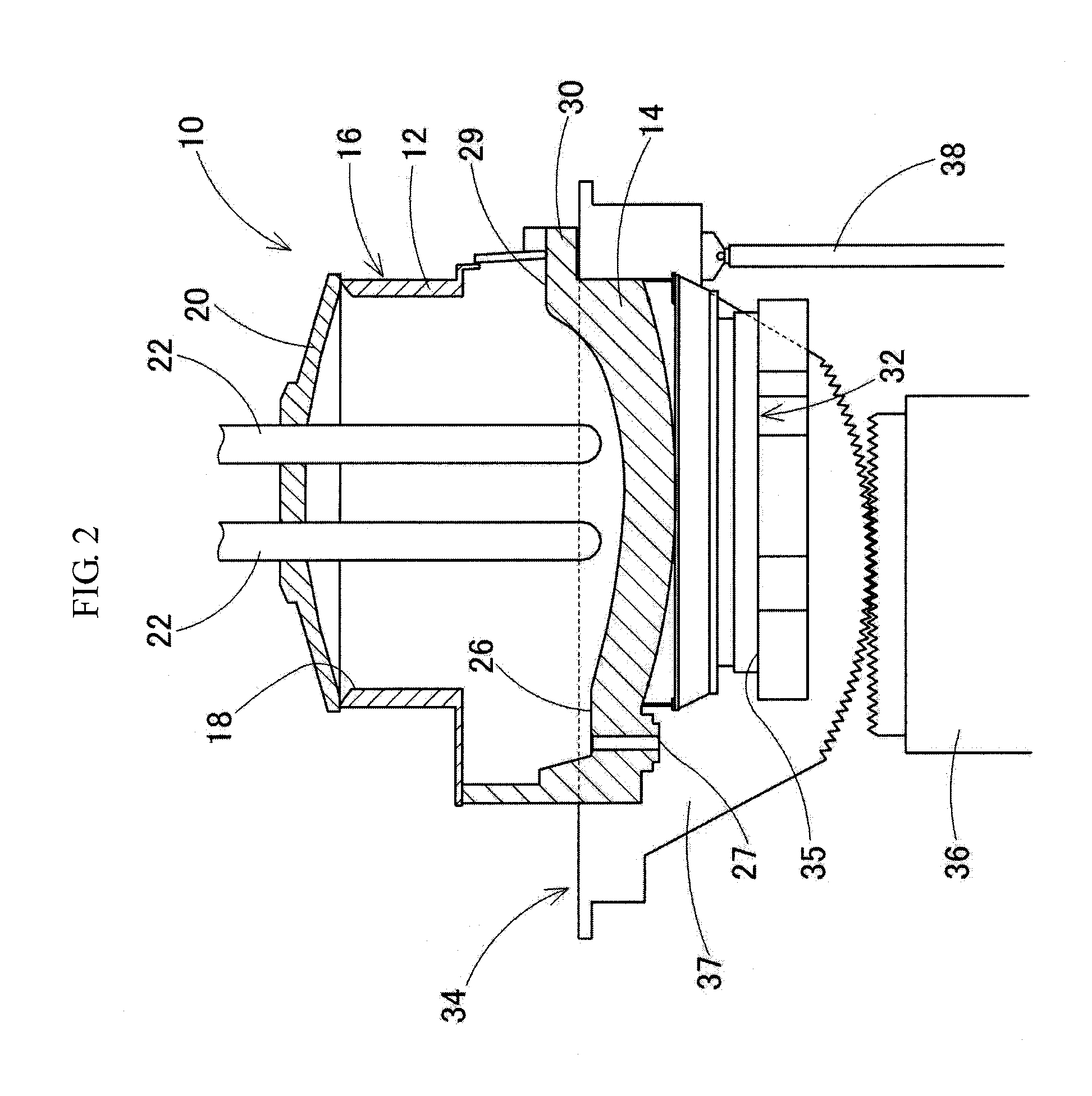

Tank withdrawal system with electric and fluidic heating device

InactiveUS20090183778A1Increase heating powerFast heat conductionInternal combustion piston enginesExhaust apparatusFuel tankEngineering

The invention relates to a tank withdrawal system for a vehicle tank filled with a frozen liquid. The tank withdrawal system comprises a heating system comprising at least one electric heating element as primary heating device and a conduit system provided with at least one withdrawal conduit with a withdrawal opening arranged in the vehicle tank. The cold start volume of the frozen liquid extending around the withdrawal opening can be melted by the primary heating device. To quickly melt a cold start volume while melting off the remaining frozen liquid consuming as minimal amount of energy, the heating system comprises a secondary heating device supplied with a heating fluid and the conduit system comprises at least one heating conduit through which the heating fluid can flow and which is arranged in the liquid in the vehicle tank.

Owner:DAVID & BAADER DBK

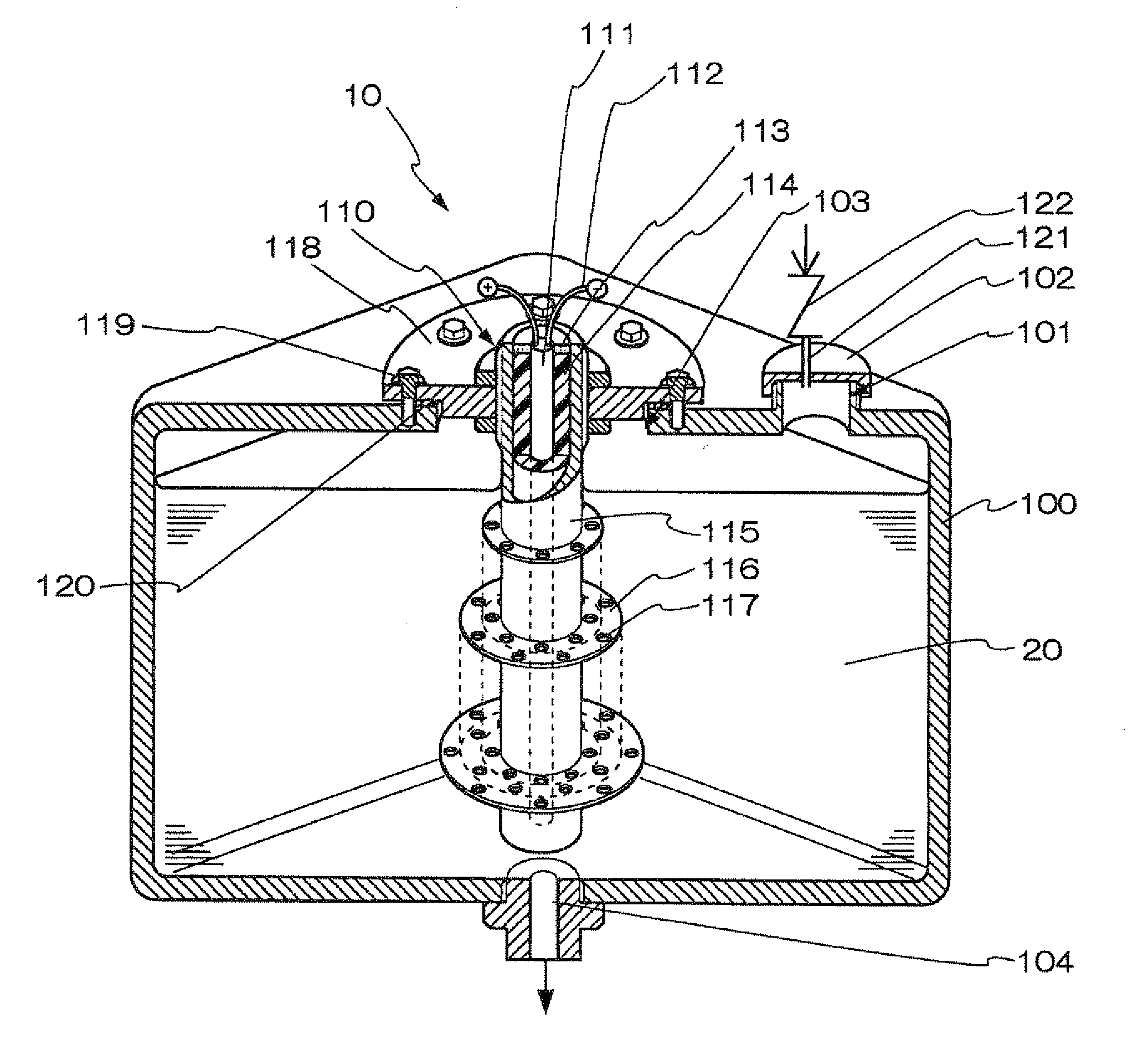

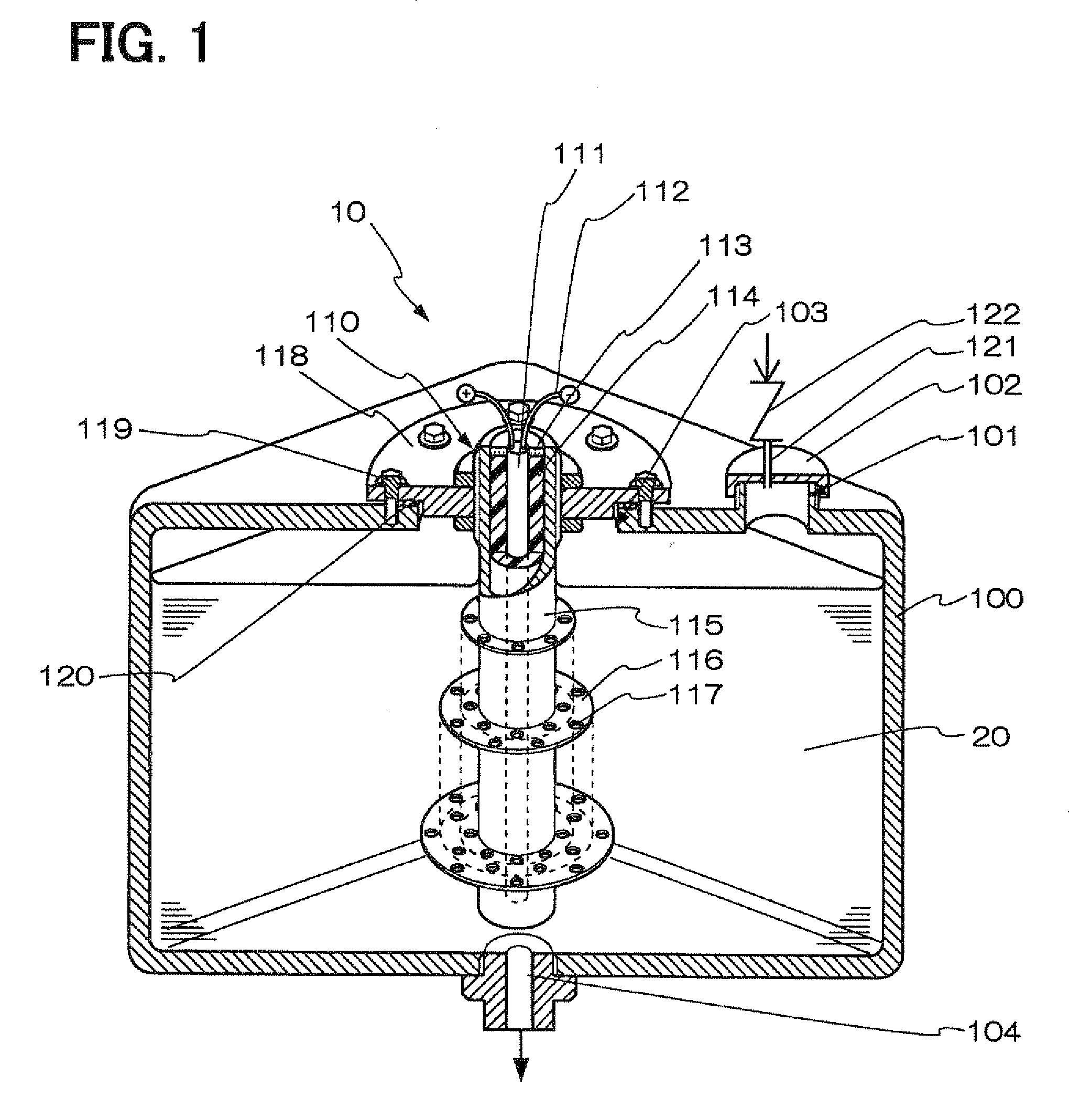

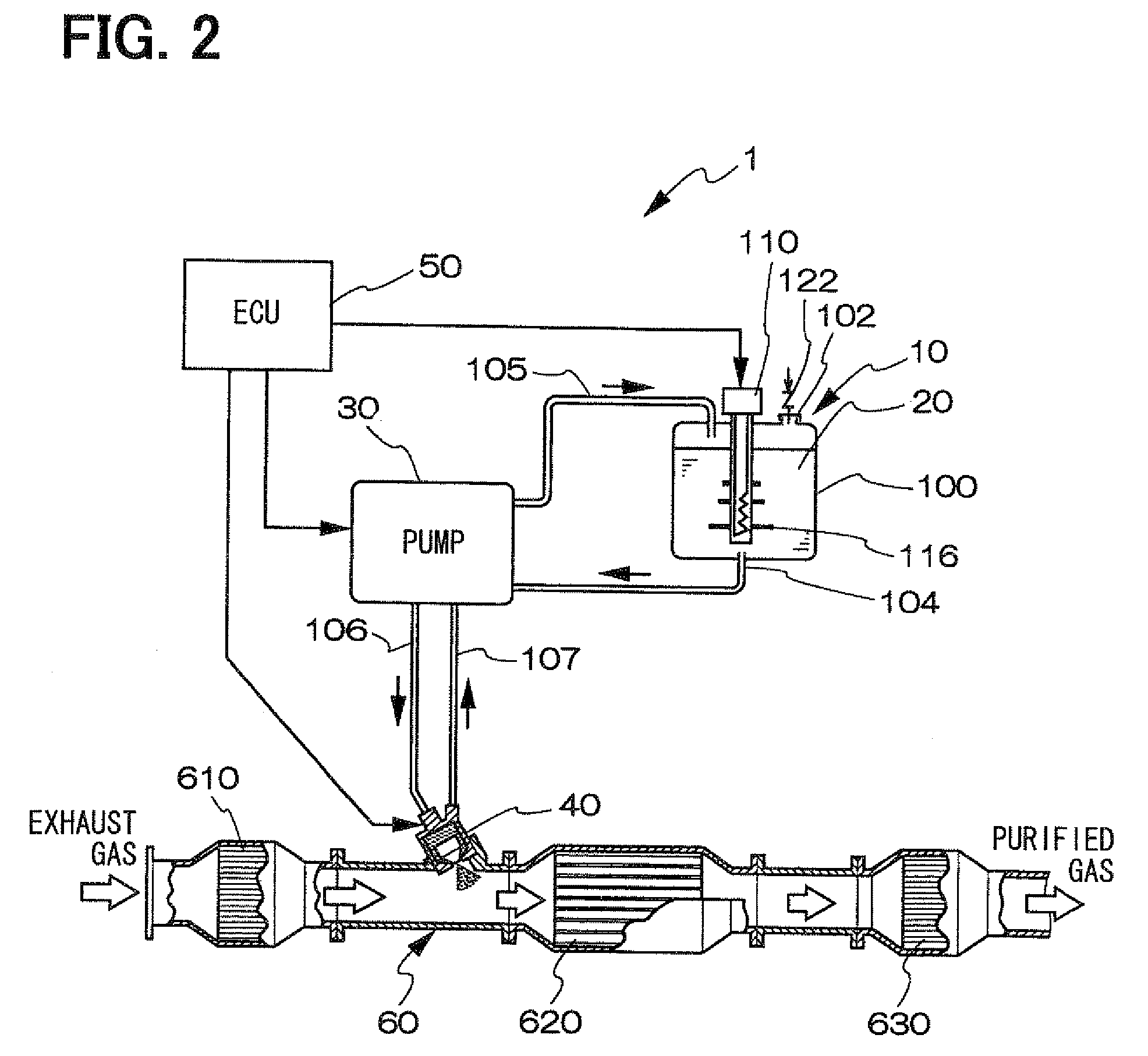

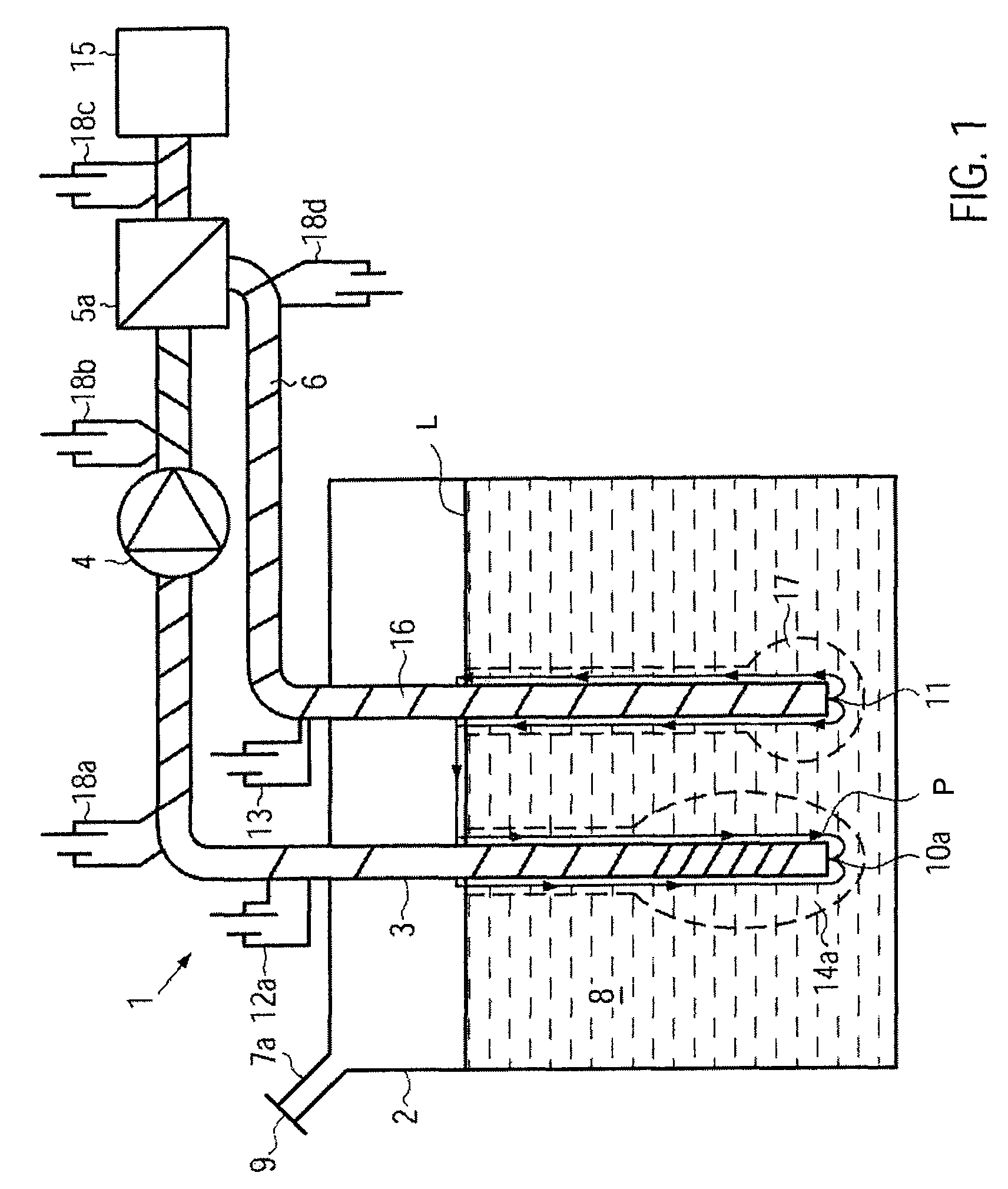

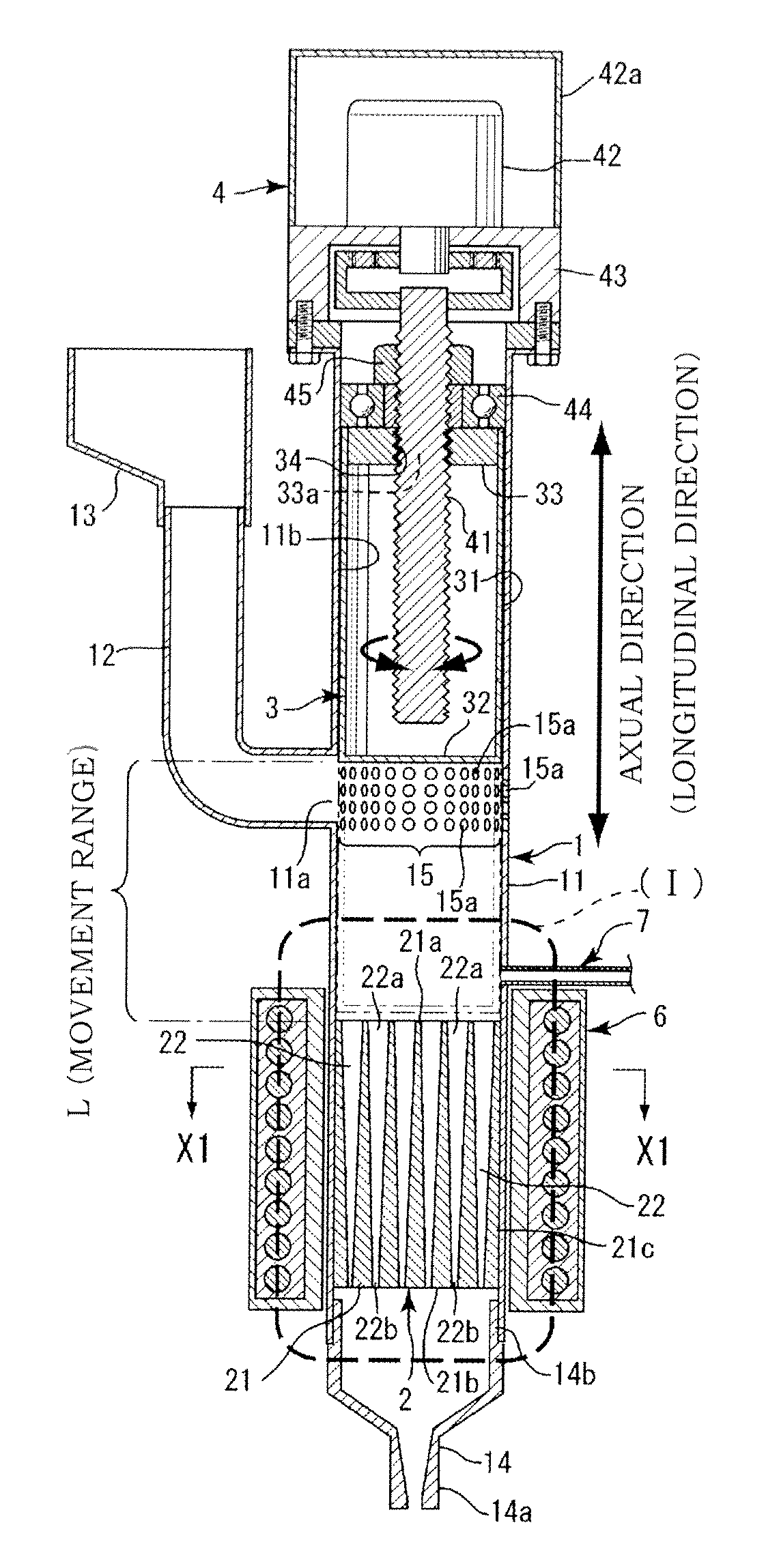

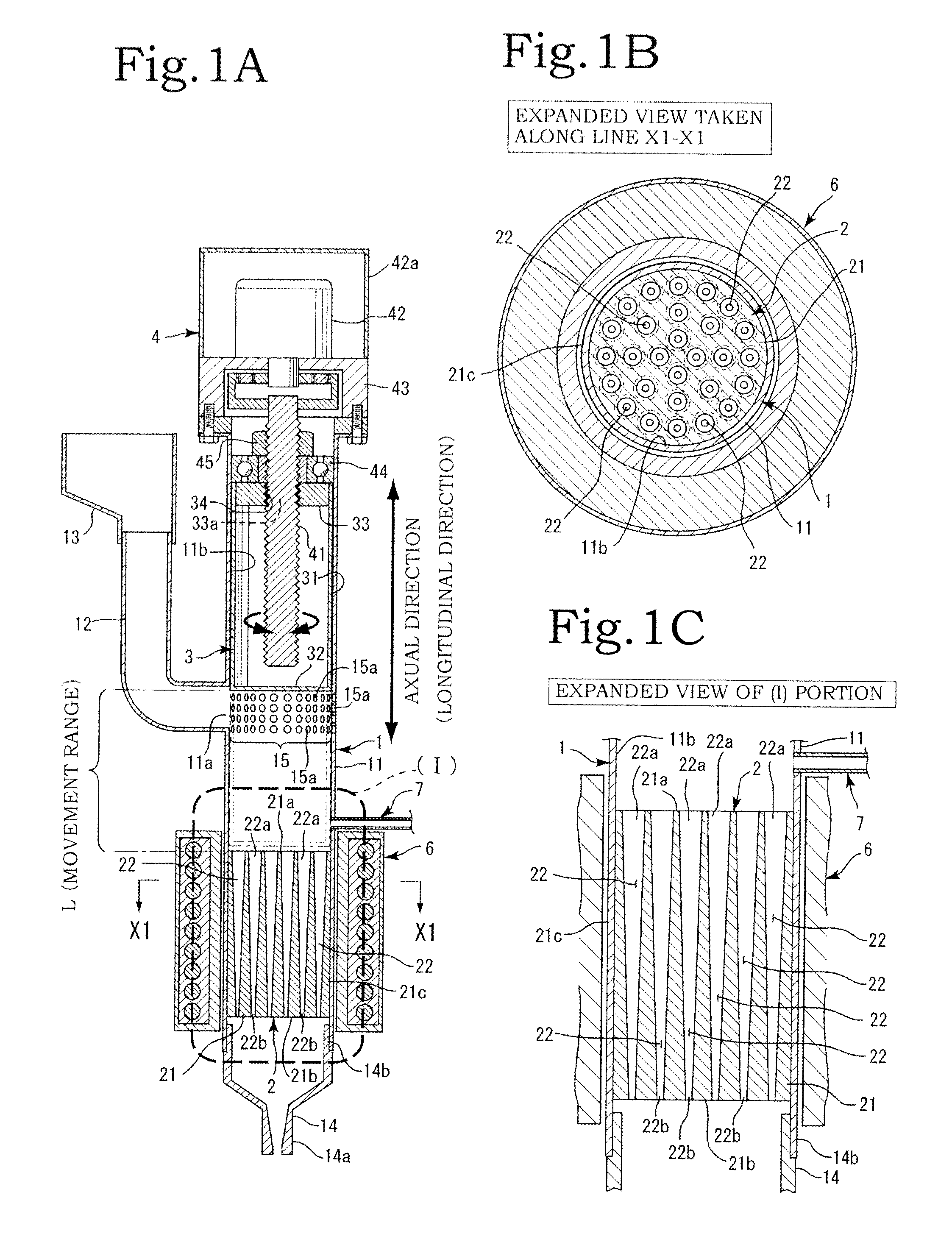

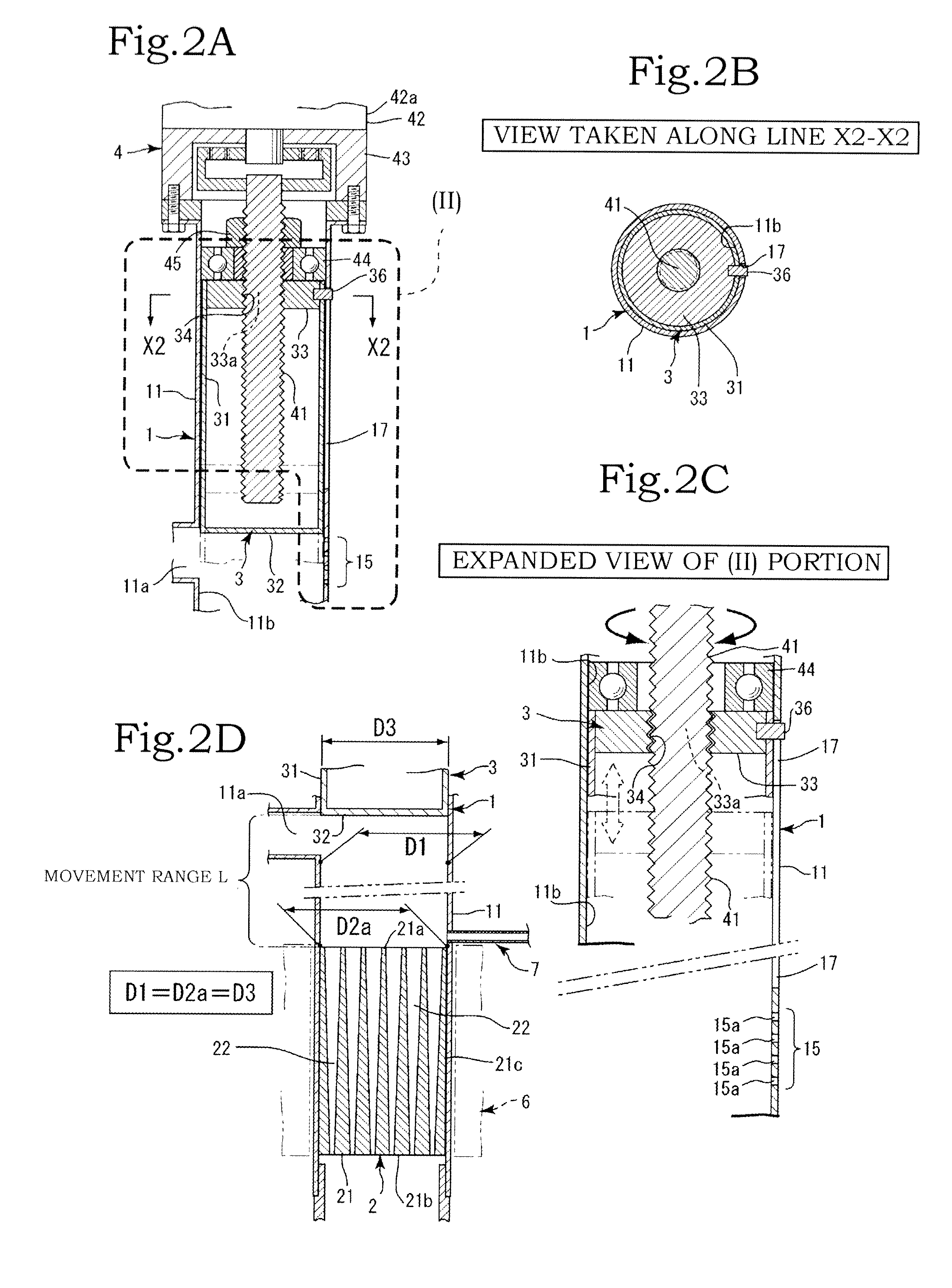

Fluid heating device and exhaust gas purifying apparatus

InactiveUS20080256937A1High thermal efficiencySimple structureInternal combustion piston enginesExhaust apparatusElectricityExhaust fumes

A fluid heating device includes a heating part and a plurality of heat transfer sections. The heating part is disposed in a fluid stored in a container and is elongated in an axial direction for heating the fluid between a lower portion and an upper portion of the container by being supplied with electricity. The heat transfer sections arranged along the axial direction of the heating part. Each of the heat transfer sections has a plate shape extending from the heating part to a radial outside of the heating part approximately perpendicularly to the axial direction of the heating part.

Owner:DENSO CORP

Apparatus integrated with ceramic bushing for manufacturing mineral/basalt fibers

ActiveUS20060218972A1Low costImprove stabilityGlass furnace apparatusRotary drum furnacesComposite applicationMicrometer

The apparatus integrated with ceramic bushing / s for manufacturing mineral / basalt fibers from natural basalt rocks is disclosed. The apparatus and the ceramic bushing / s are integrated into one unit capable provide all operations which are needed: melt basalt rock materials, homogenize basalt glass body suitable for forming fibers to be drawn / attenuated into continuous fibers and gathered into a strand of elemental fibers from 7 to 20 micrometers (μm) in diameter. Also the coarse fibers at the diameters from 20 μm to 100 micrometers (μm) having amorphous structural state which exhibit ductile / flexible properties. The ceramic bushing / s are designed to eliminate precious Pt, Rd metals using instead corrosion resistant ceramic materials to reduce basalt fiber products cost and to increase its commercial compatibility when compared to the other fibers currently been on the market in reinforced concrete / composite applications, including Three Dimension Fiber Reinforced Concrete-3D FRC.

Owner:BLACKBULL IND INC +1

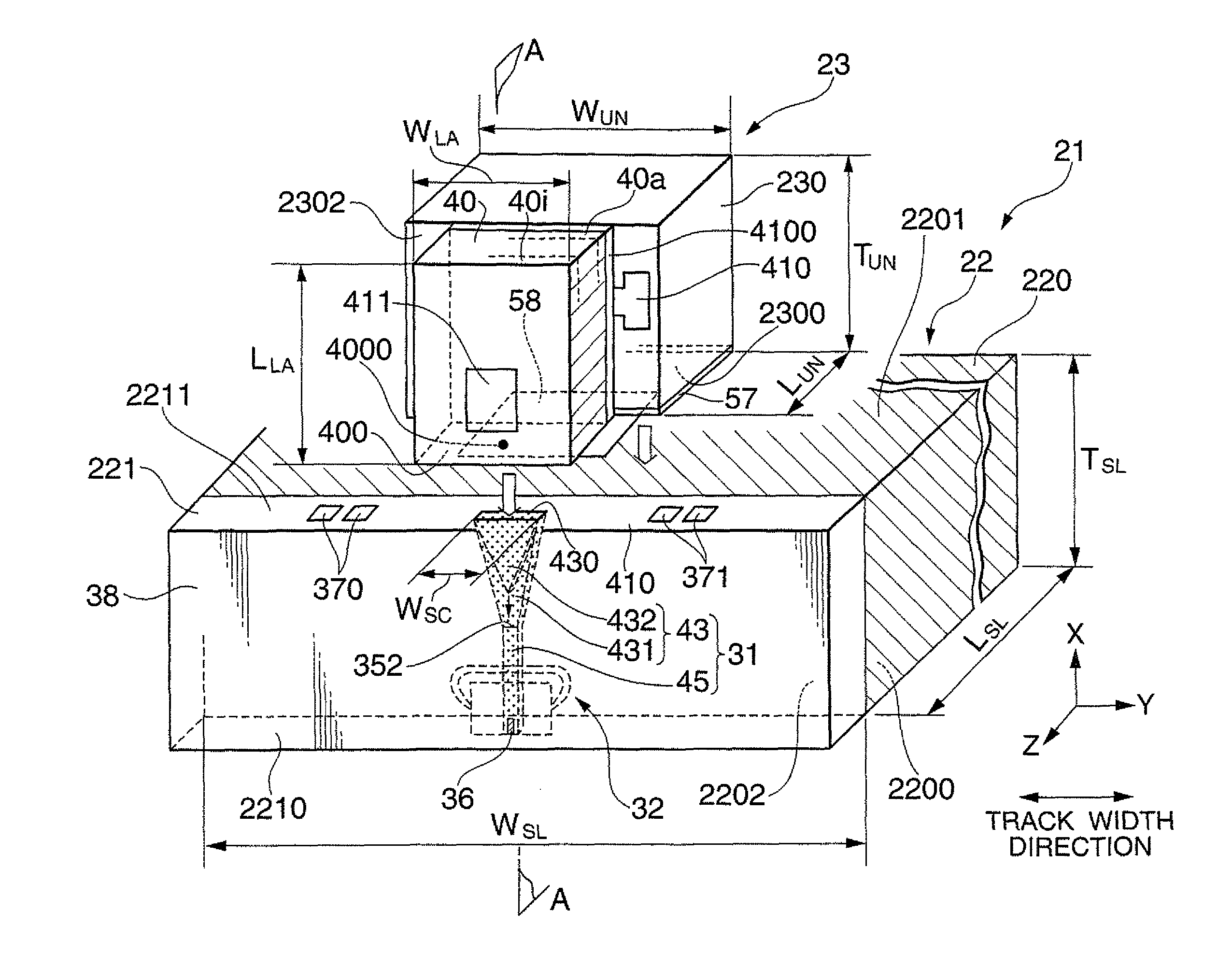

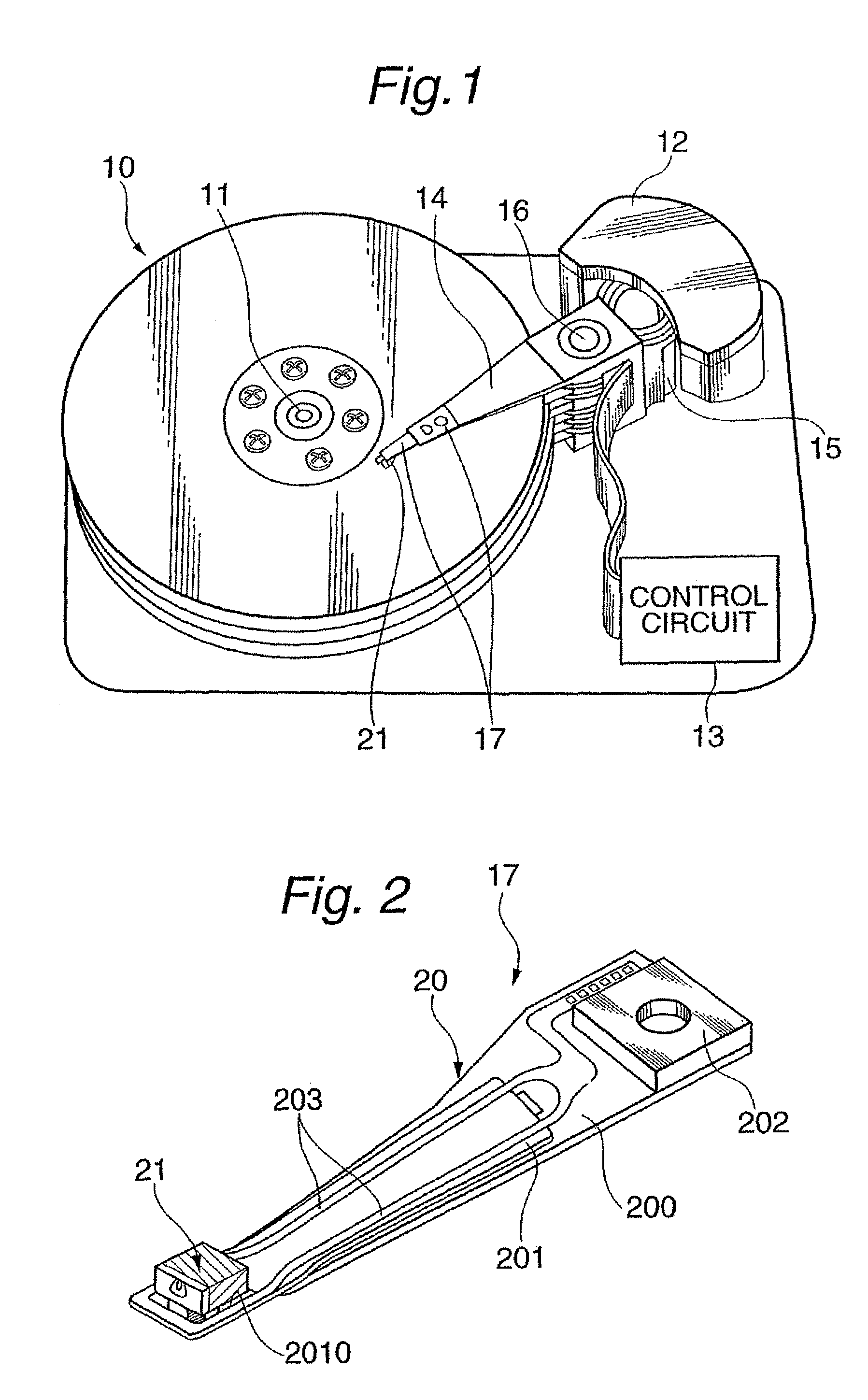

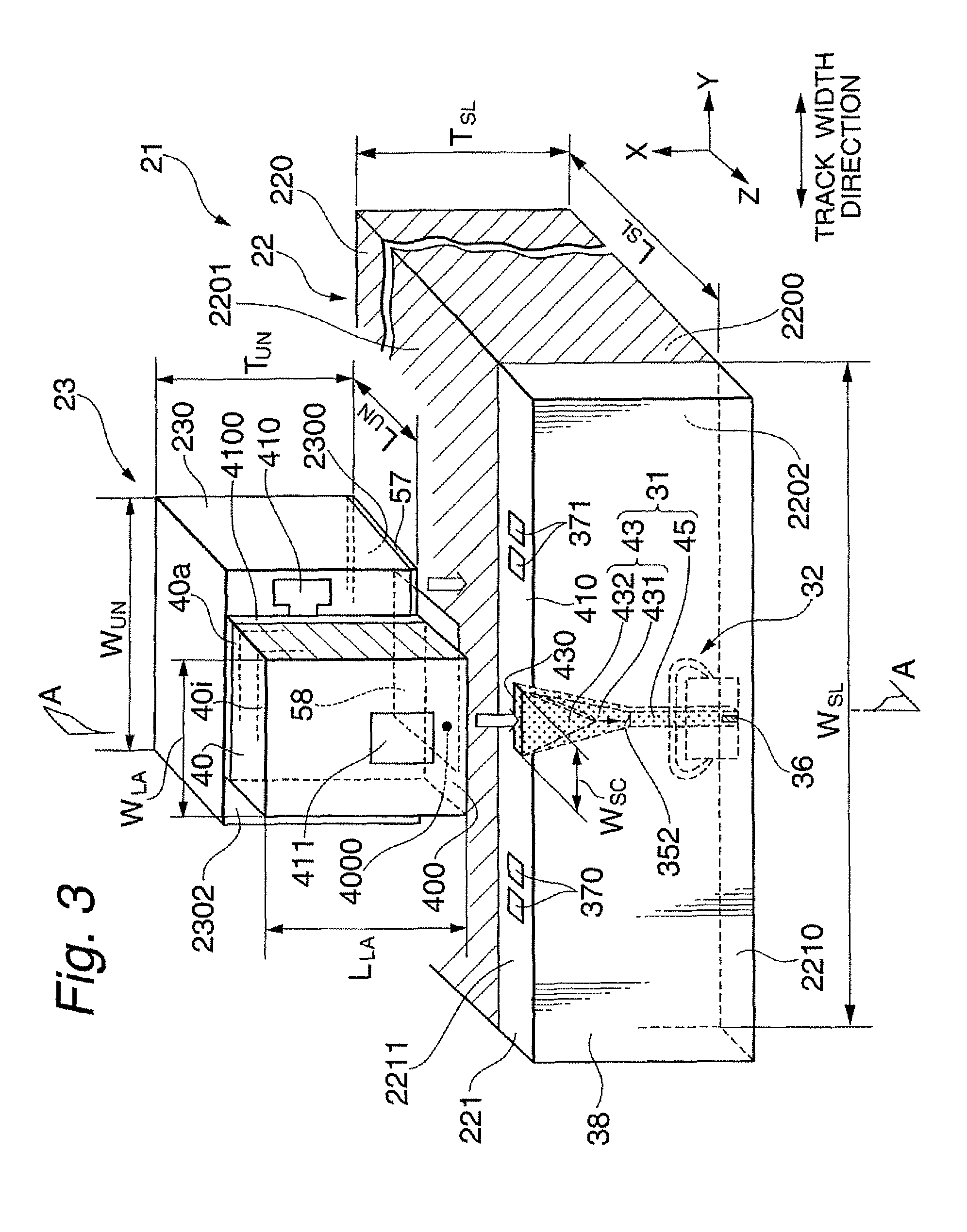

Method for manufacturing thermally-assisted magnetic recording head comprising light source unit and slider

ActiveUS8248897B2Improve alignment accuracyHigh bonding strengthCombination recordingPrinted circuit assemblingHeat-assisted magnetic recordingAlloy

A method for manufacturing a thermally-assisted magnetic recording head is provided, in which a light source unit including a light source and a slider including an optical system are bonded. A unit substrate is made of a material transmitting light having a predetermined wavelength, and a unit adhesion material layer that contains Sn, Sn alloy, Pb alloy or Bi alloy is formed on the light source unit and / or the slider. The manufacturing method includes: aligning the light source unit and the slider in such a way that a light from the light source can enter the optical system and the unit adhesion material layer is sandwiched therebetween; and causing a light including the predetermined wavelength to enter the unit substrate to melt the unit adhesion material layer. The unit adhesion material layer melted by the light including the predetermined wavelength can ensure high alignment accuracy as well as higher bonding strength and less change with time.

Owner:TDK CORPARATION +1

Tank withdrawal system with electric and fluidic heating device

InactiveUS8301020B2Prevent freezingEfficient meltingInternal combustion piston enginesExhaust apparatusFuel tankEngineering

Owner:DAVID & BAADER DBK

Tire with sidewall rubber insert

InactiveUS6539996B1High modulusEnhanced interactionPaper coatingSpecial tyresTire beadPolymer science

A pneumatic tire has a sidewall rubber insert axially inward of at least one carcass ply. Such insert may, for example, be an apex extending radially outward from the bead core region of the tire into the sidewall. Alternatively, it may be positioned higher in the sidewall portion of the tire and away from the bead core. Such insert is a rubber composition containg a dispersion of an ultra high molecular weight polyethylene and a dispersion of a starch composite.

Owner:THE GOODYEAR TIRE & RUBBER CO

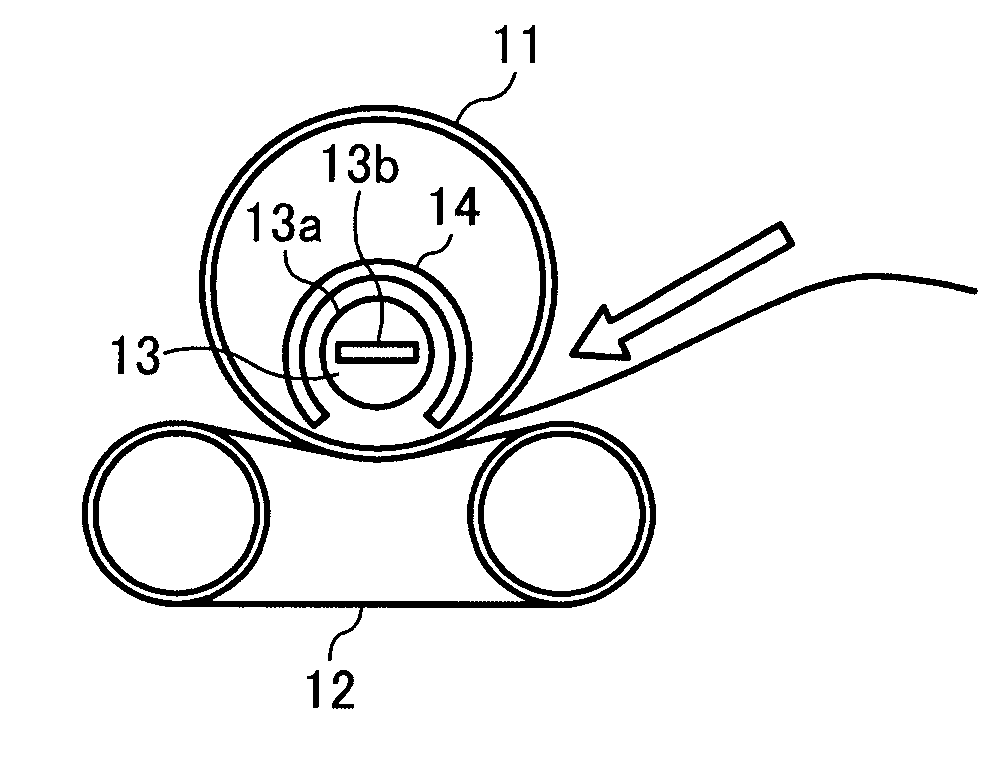

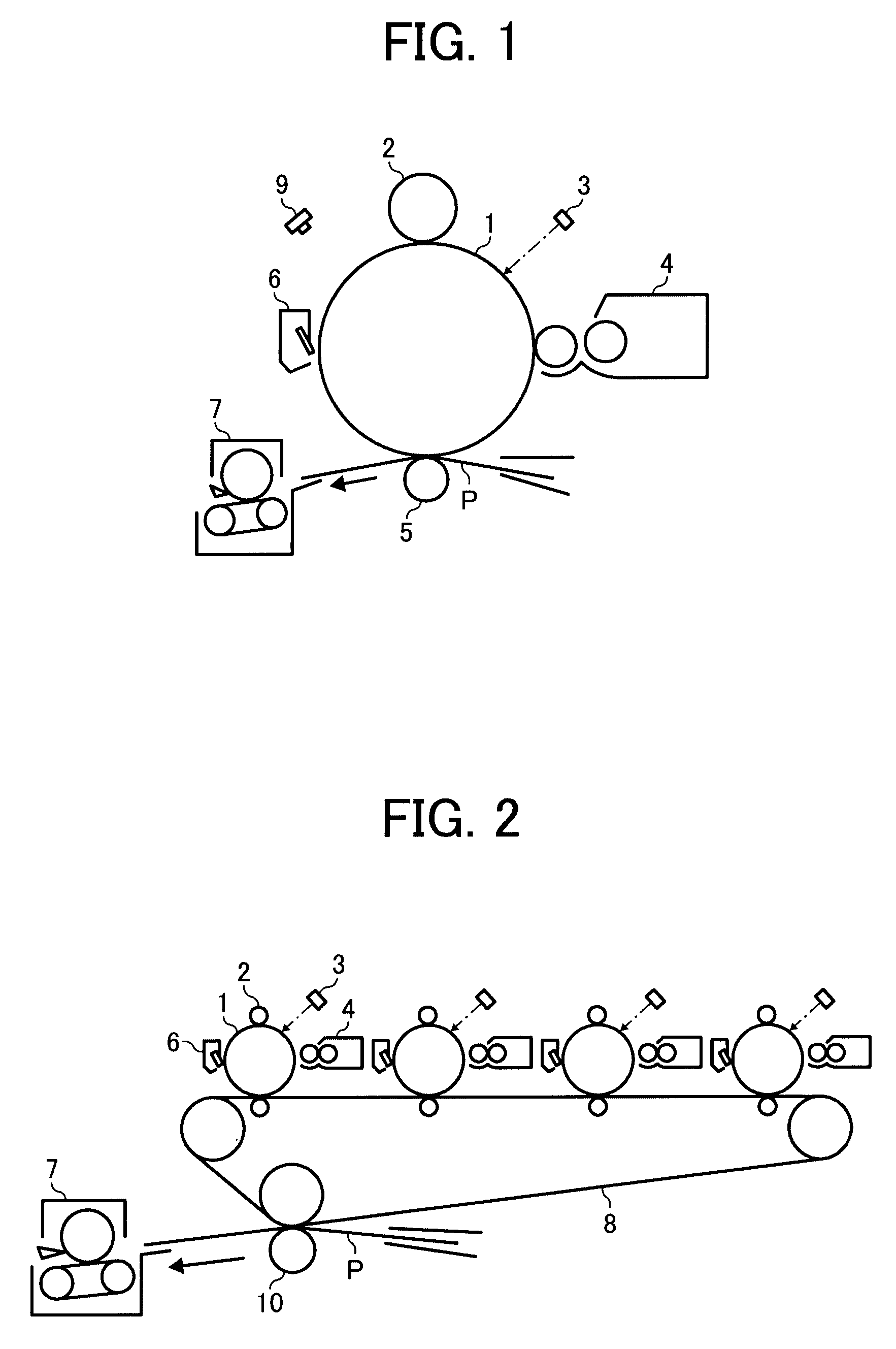

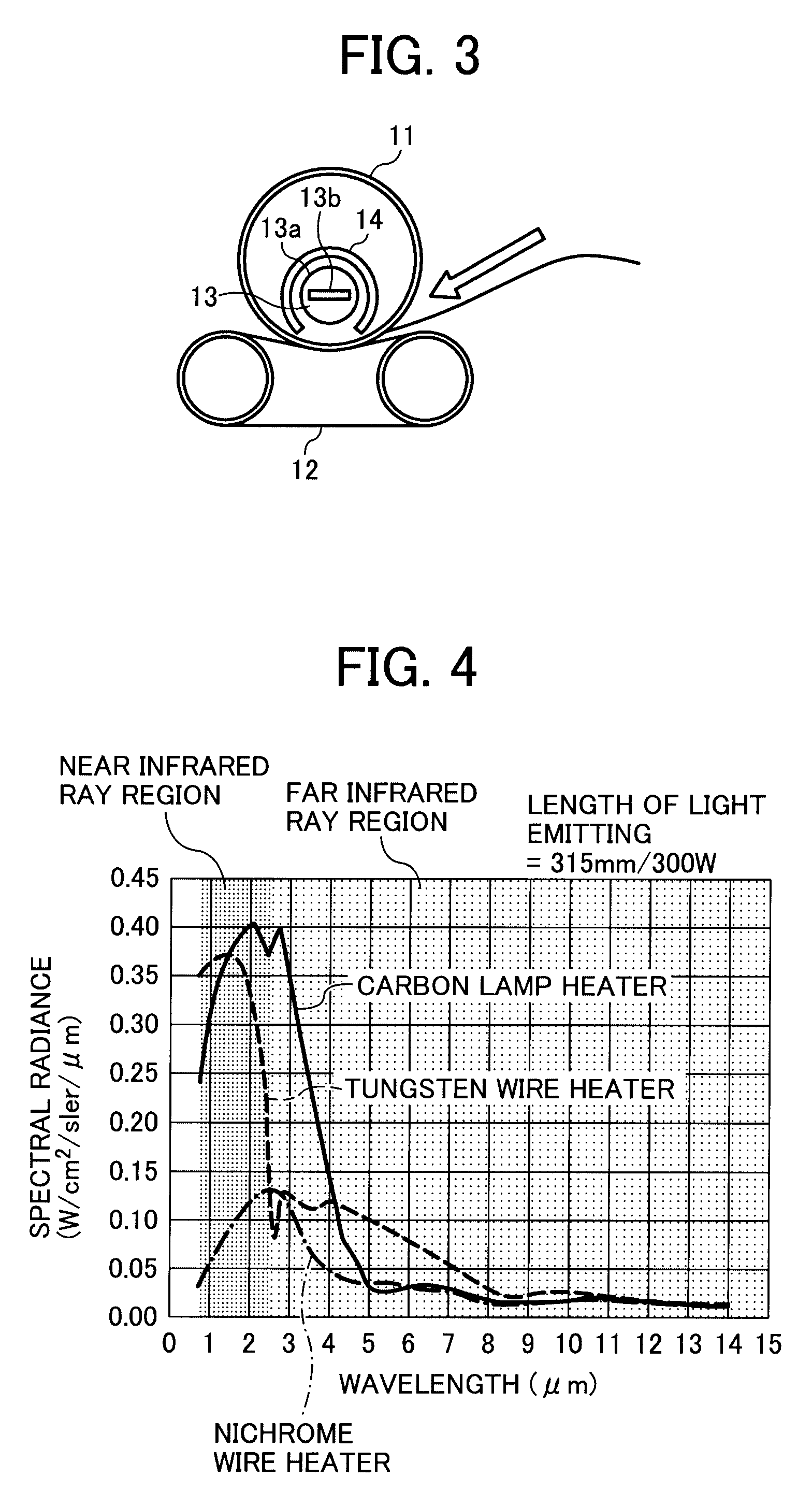

Image fixing device and image formation apparatus using the same

InactiveUS20080124152A1Avoid Inrush CurrentSimple structureElectrographic process apparatusInfraredImage formation

An image fixing device for use in an image forming apparatus. The fixing device includes a fixing member which fixes a toner image on a recording medium at a nip area, a pressurizing member which pressures the recording medium toward the fixing member at the nip area, a carbon lamp which emits infrared rays, and a reflecting member which reflects the infrared rays to the nip area.

Owner:RICOH KK

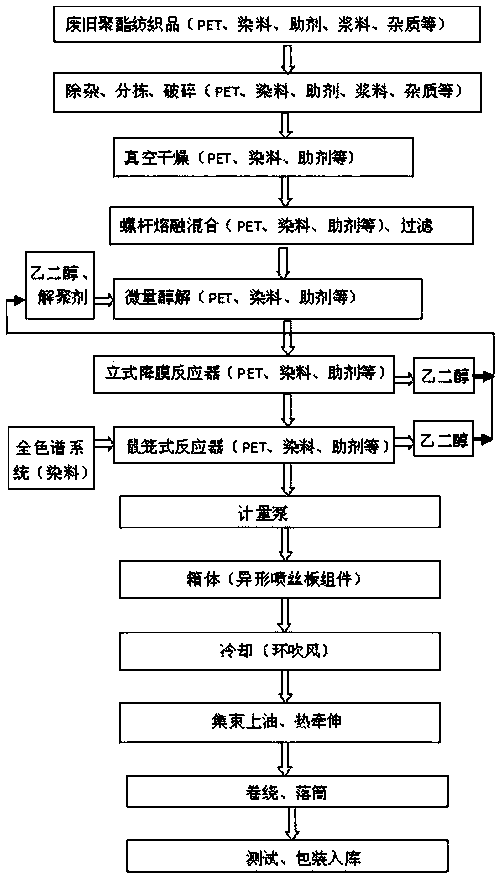

Method for producing high-performance regenerated polyester colored special-shaped filaments on basis of waste polyester textile products

InactiveCN108396392AEfficient removal of impuritiesSimple processDrying solid materials without heatMelt spinning methodsDepolymerizationHigh energy

The invention relates to a method for producing high-performance regenerated polyester colored special-shaped filaments on the basis of waste polyester textile products. By the aid of the method, theproblems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in existing waste textile product recycling procedures can be solved. The method includes steps of 1), pretreating the waste regenerated polyester textile products; 2), carrying out vacuum drying; 3), carrying out screw melting extrusion, micro-depolymerization, conditioning viscosity increasing, full-color-spectrum color matching and toning, spinning manifold treatment, circular air blowing cooling, bundling oiling and winding doffing on dried polyester textile products to obtain the high-performance regenerated polyester colored special-shaped filaments. The method has the advantages that the problems of high energy consumption and secondary pollution due to impurity removing, cleaning, drying and the like in the waste textile product recycling procedures can be solved by the aid of the method; the monofilament denier of fibers obtained by the aid of the method ranges from 1.0 dtex to 3.0 dtex; the yarn evenness of the fibers is lower than or equal to 2.2%; the breaking strength of the fibers is higher than or equal to 4.0 cN / dtex; the elongation at break ranges from 15% to 25%.

Owner:ZHEJIANG HAILI ENVIRONMENTAL TECH CO LTD

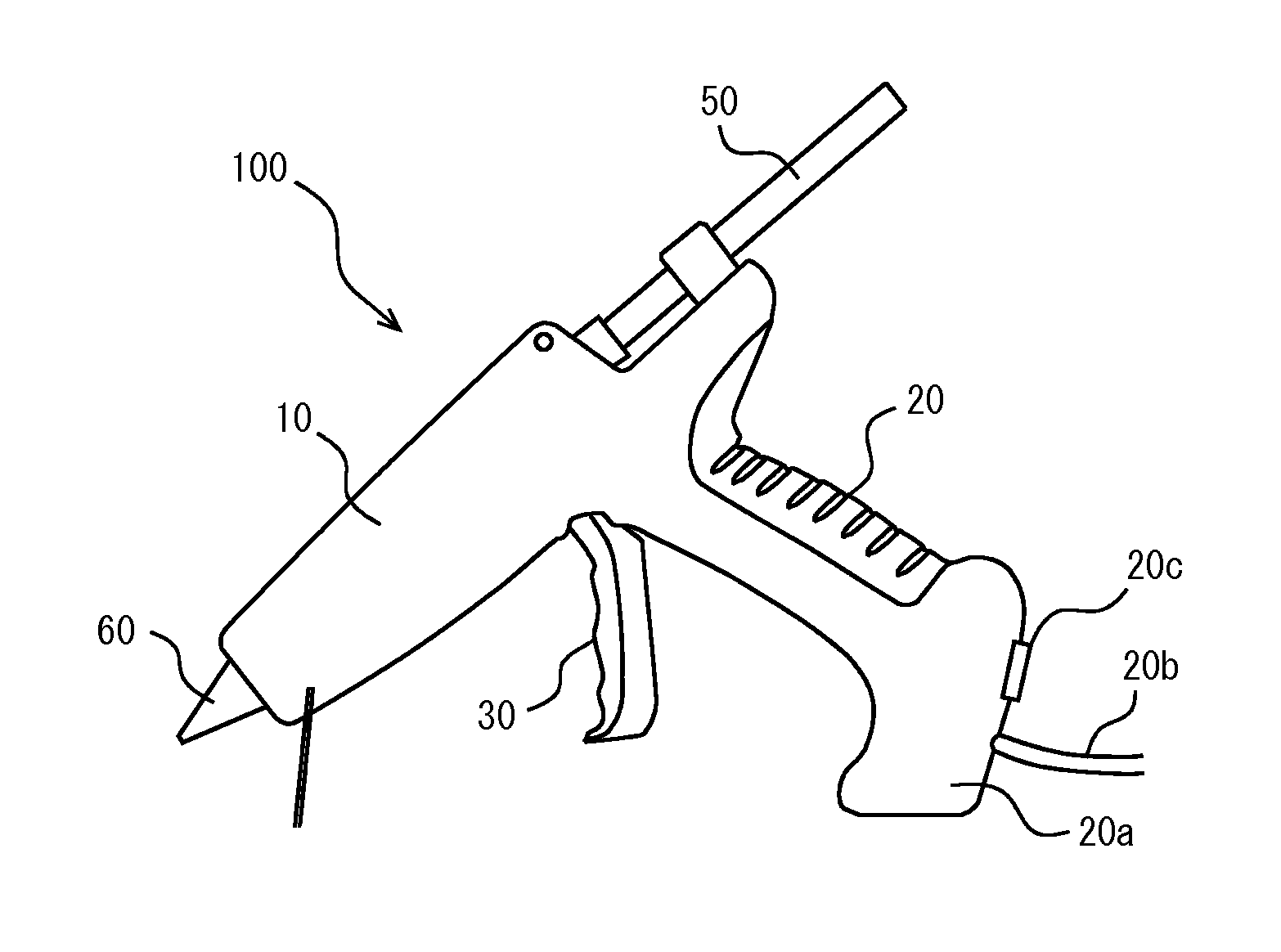

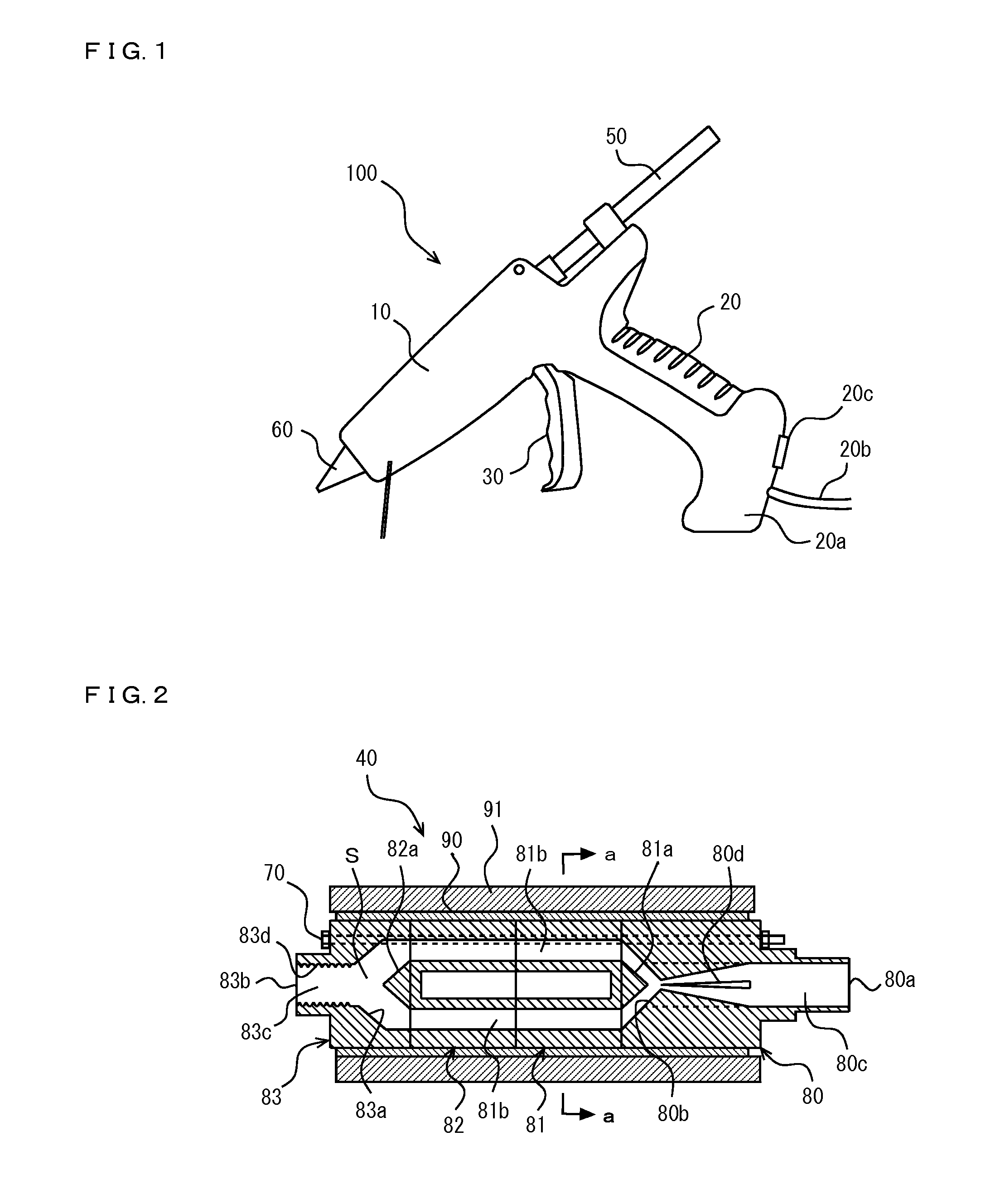

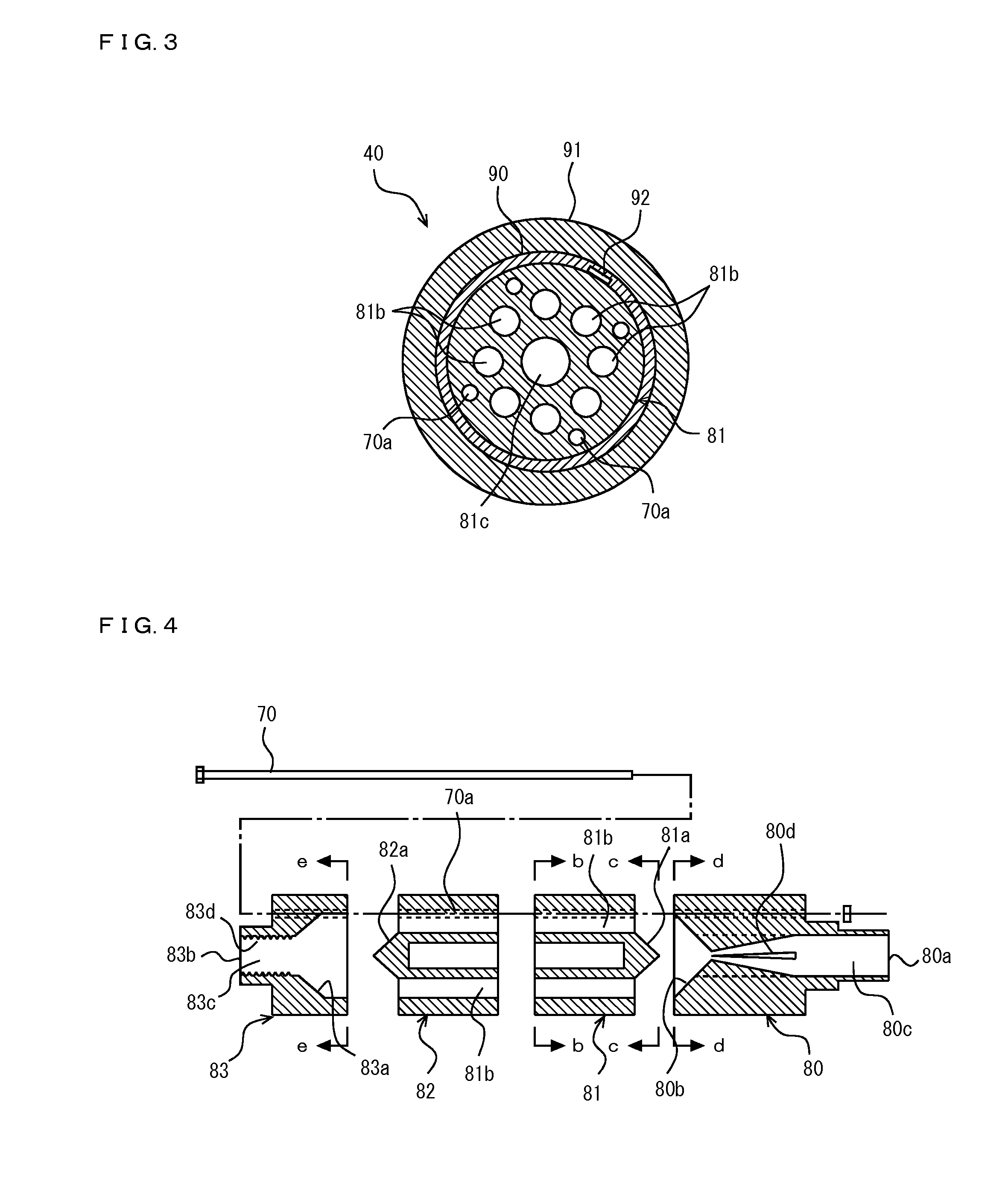

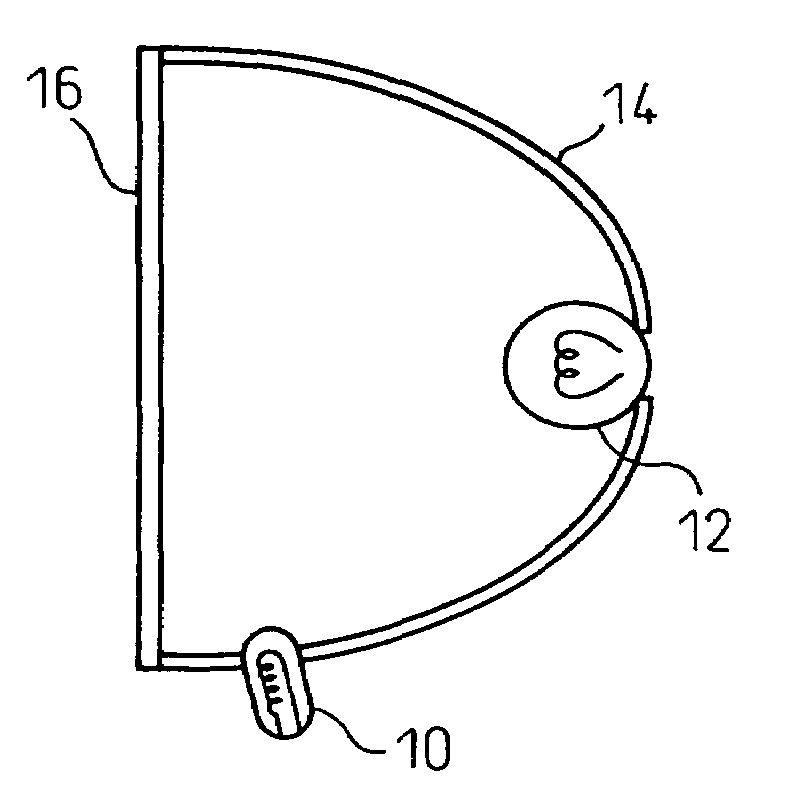

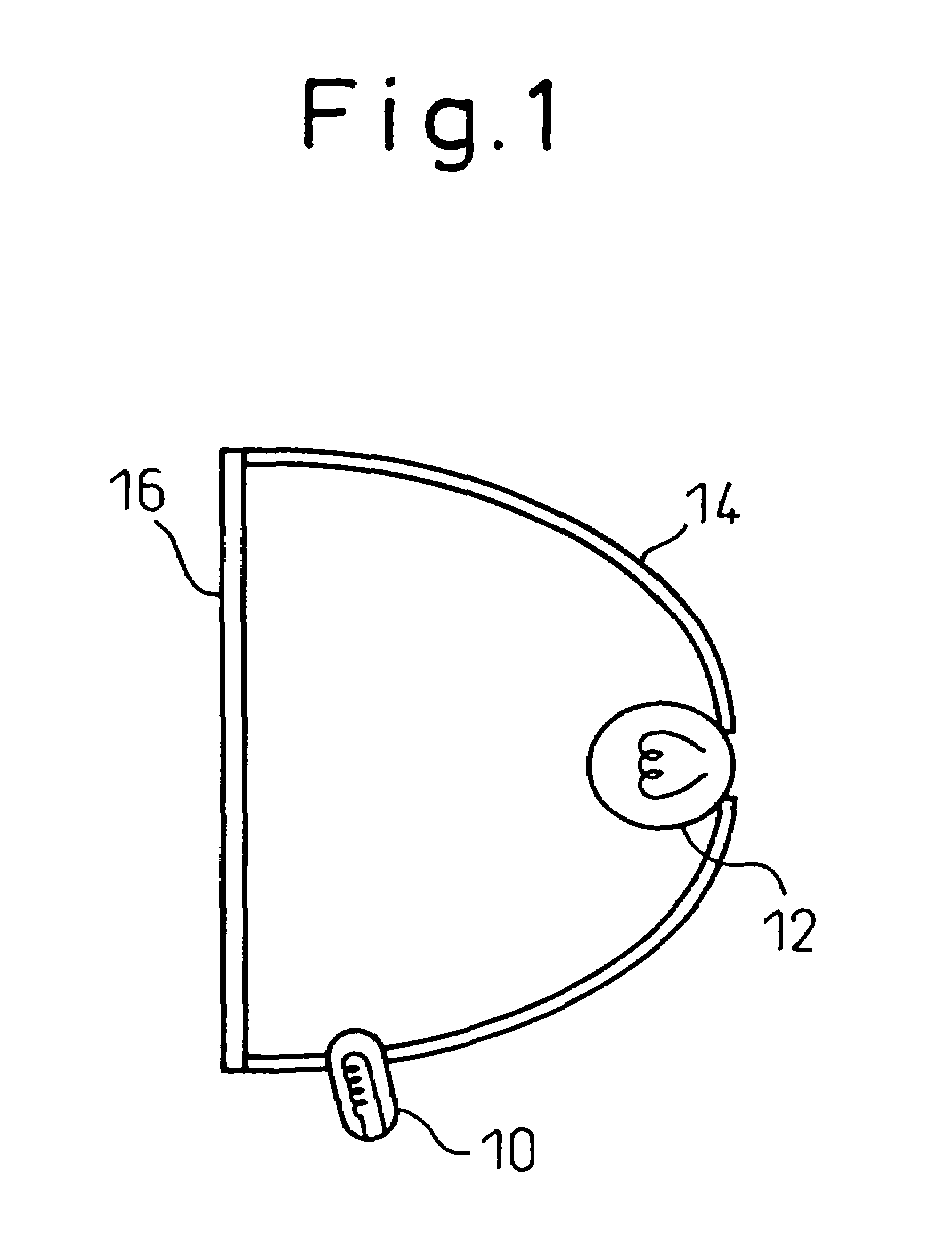

Glue gun

InactiveUS20150209820A1Efficient heatingEfficient meltingLiquid surface applicatorsLiquid transferring devicesPolymer scienceHot melt

A glue gun includes a melt portion configured to receive a stick-shaped hot melt adhesive, and then heat, melt, and inject the hot melt adhesive. The melt portion has an inlet opening to receive the stick-shaped hot melt adhesive, and an outlet opening to inject liquid hot melt adhesive. The liquid hot melt adhesive is prepared by heating and melting the stick-shaped hot melt adhesive. The inlet opening communicates with the outlet opening via a plurality of passages.

Owner:TECHNOS CO LTD

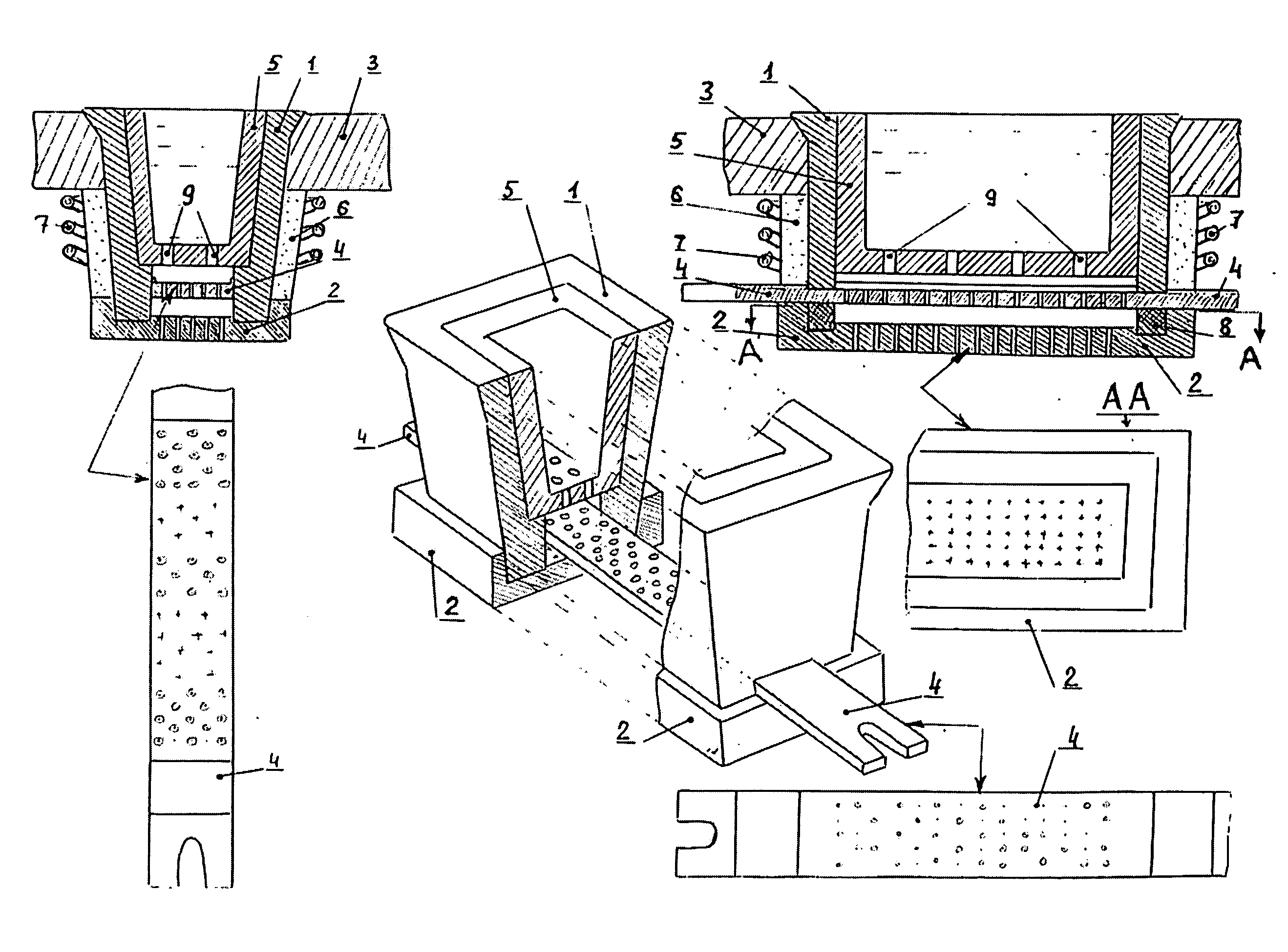

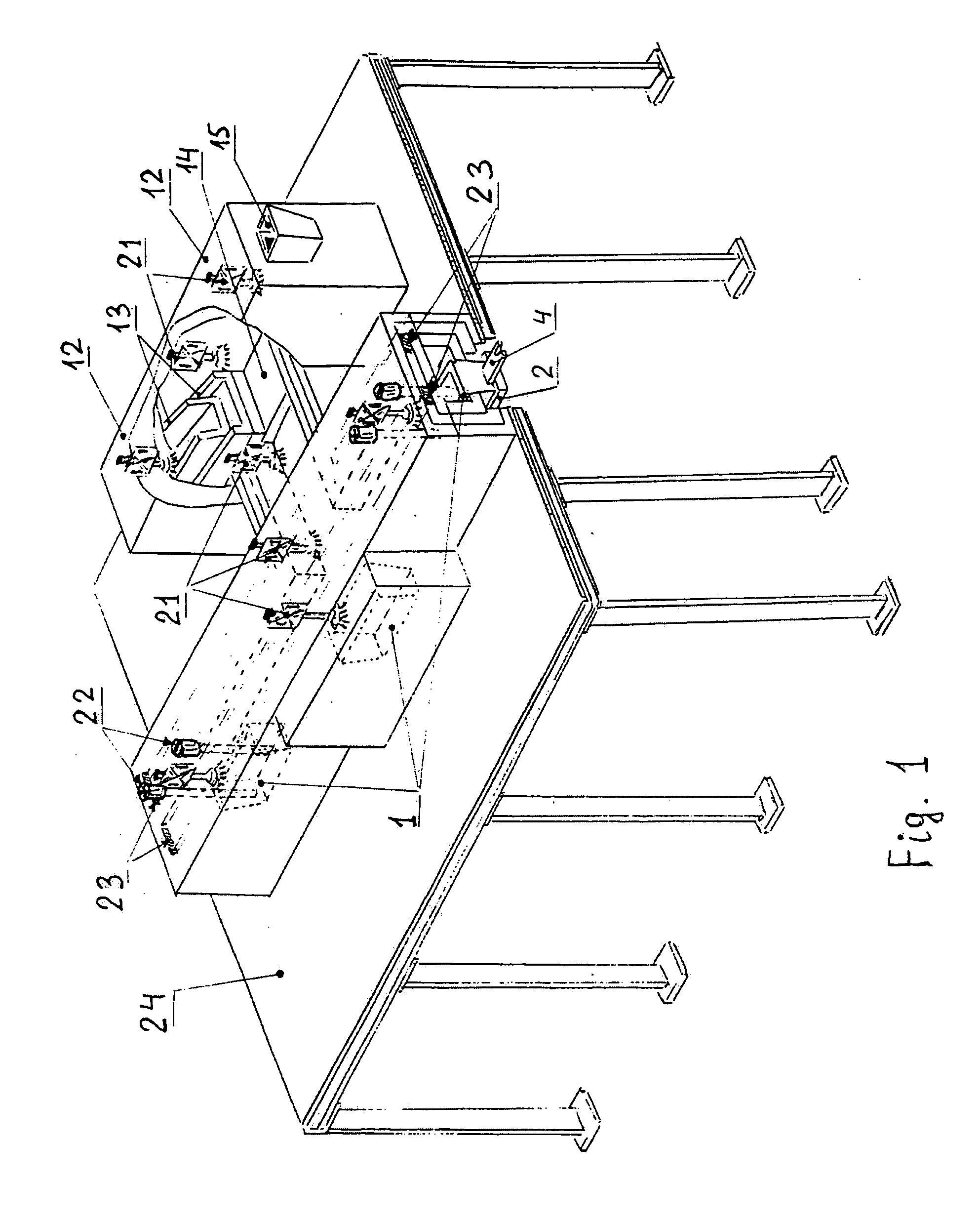

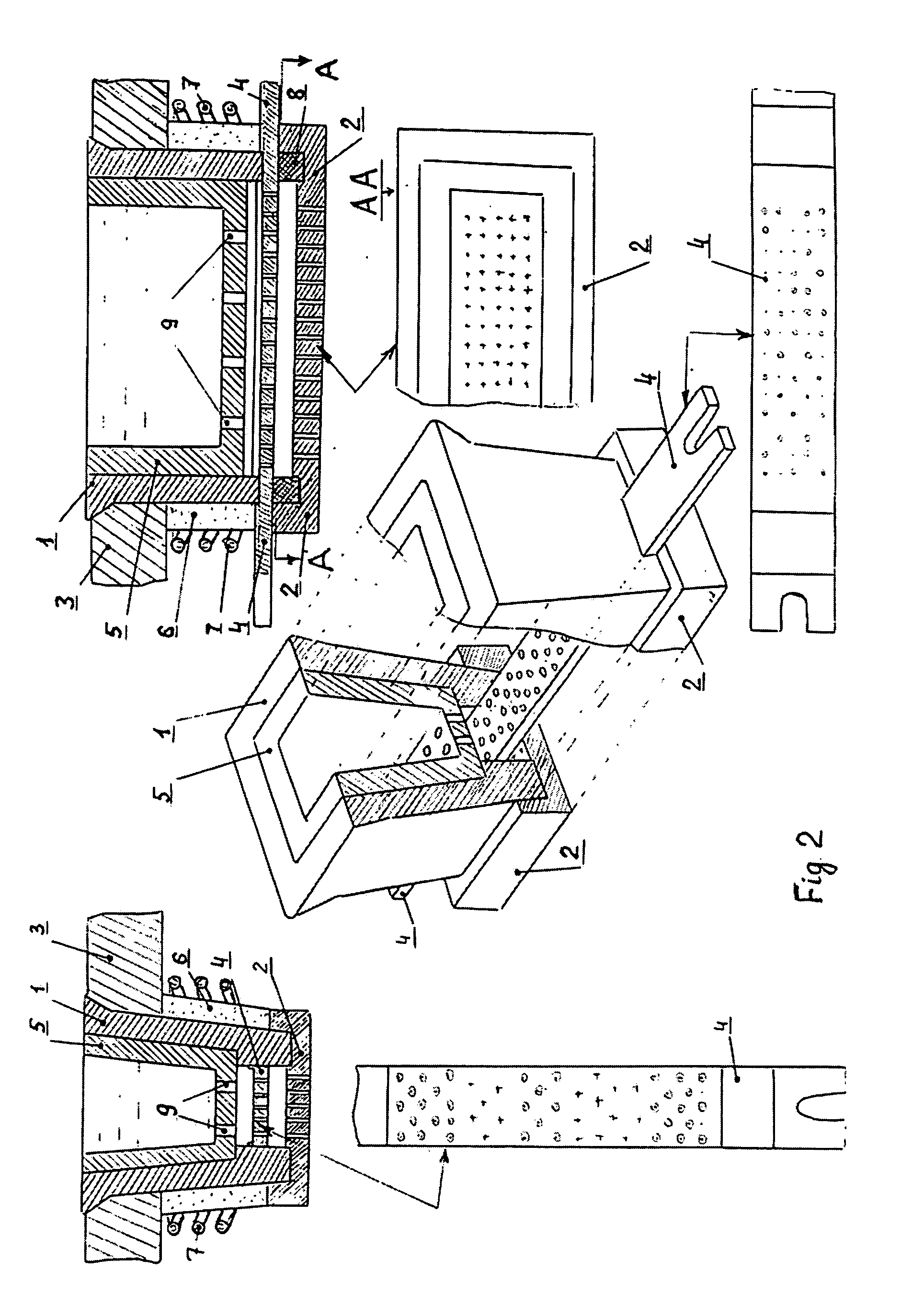

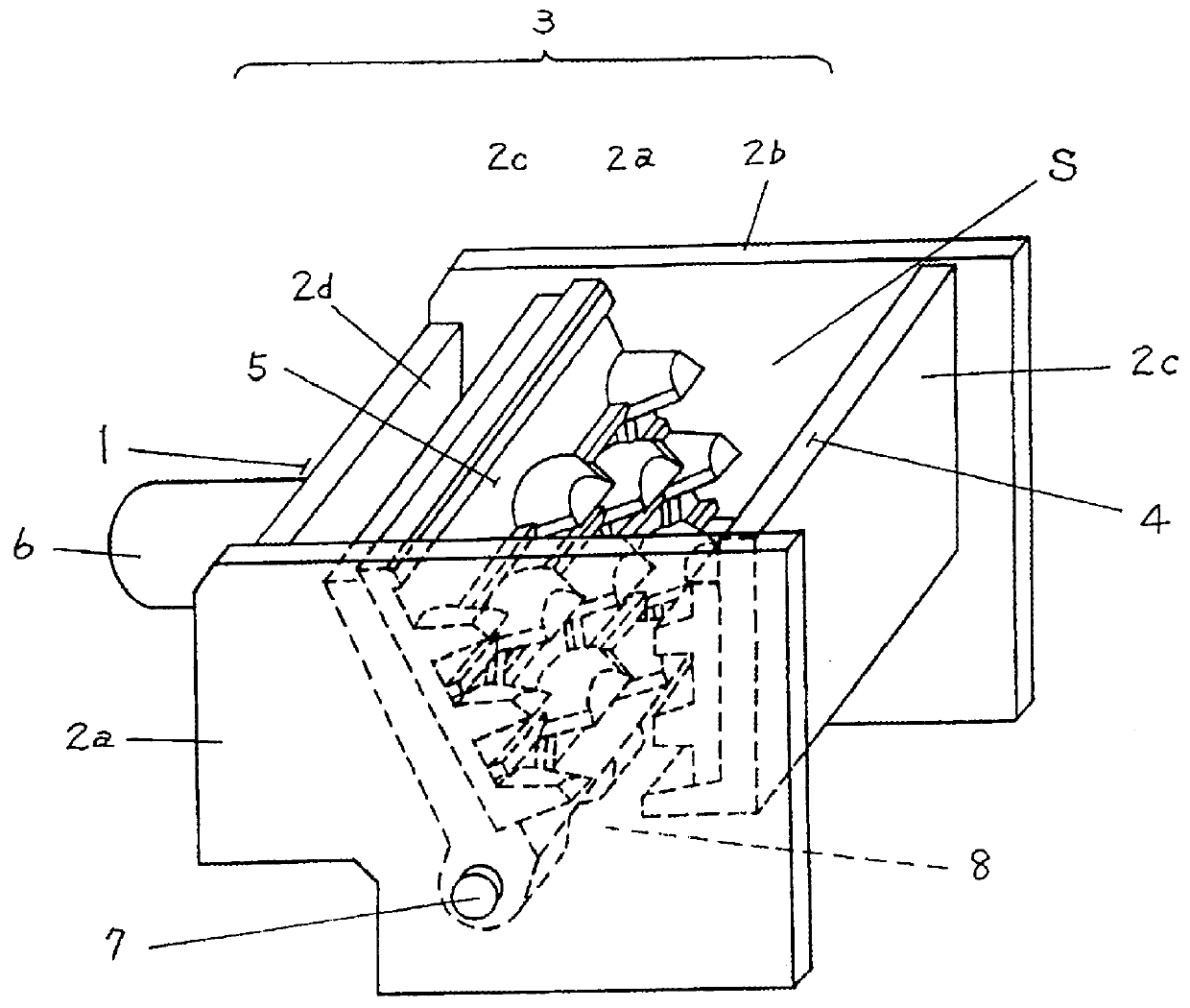

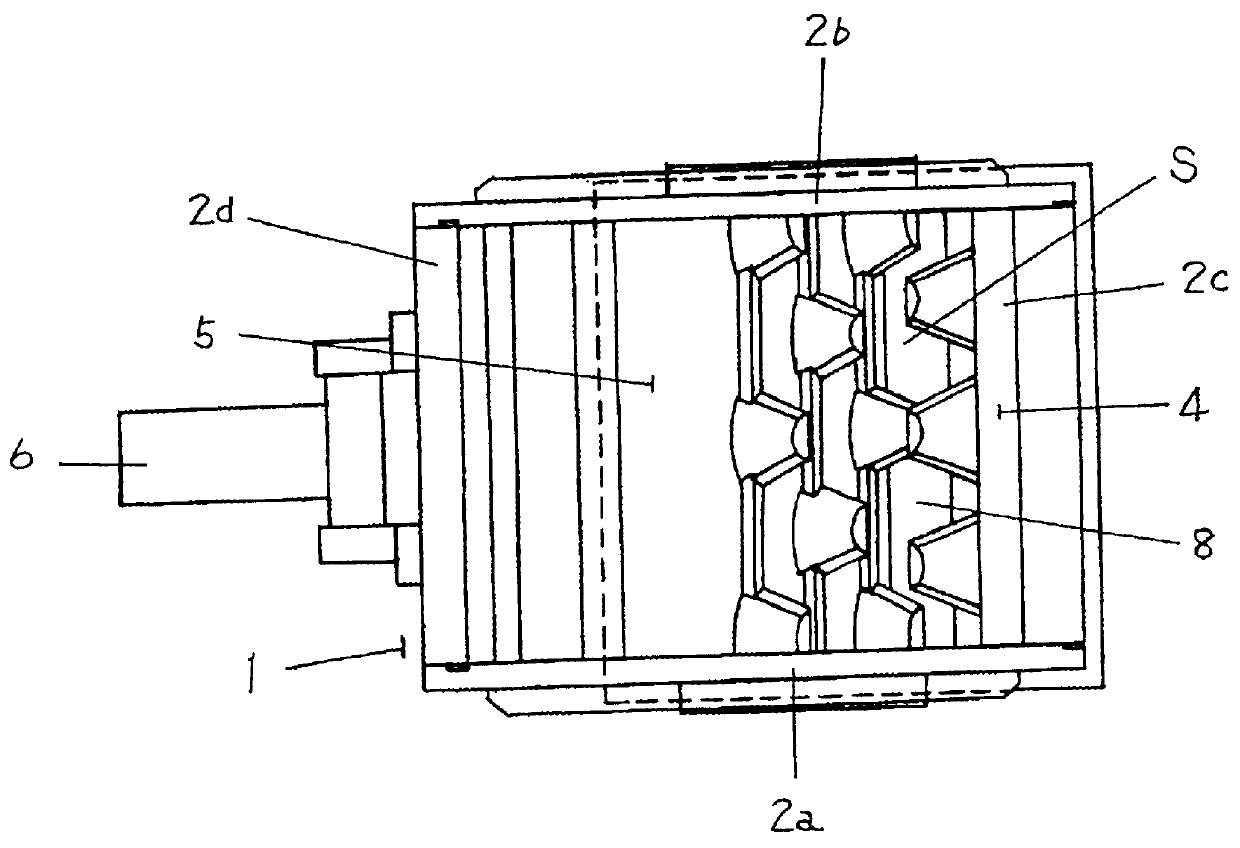

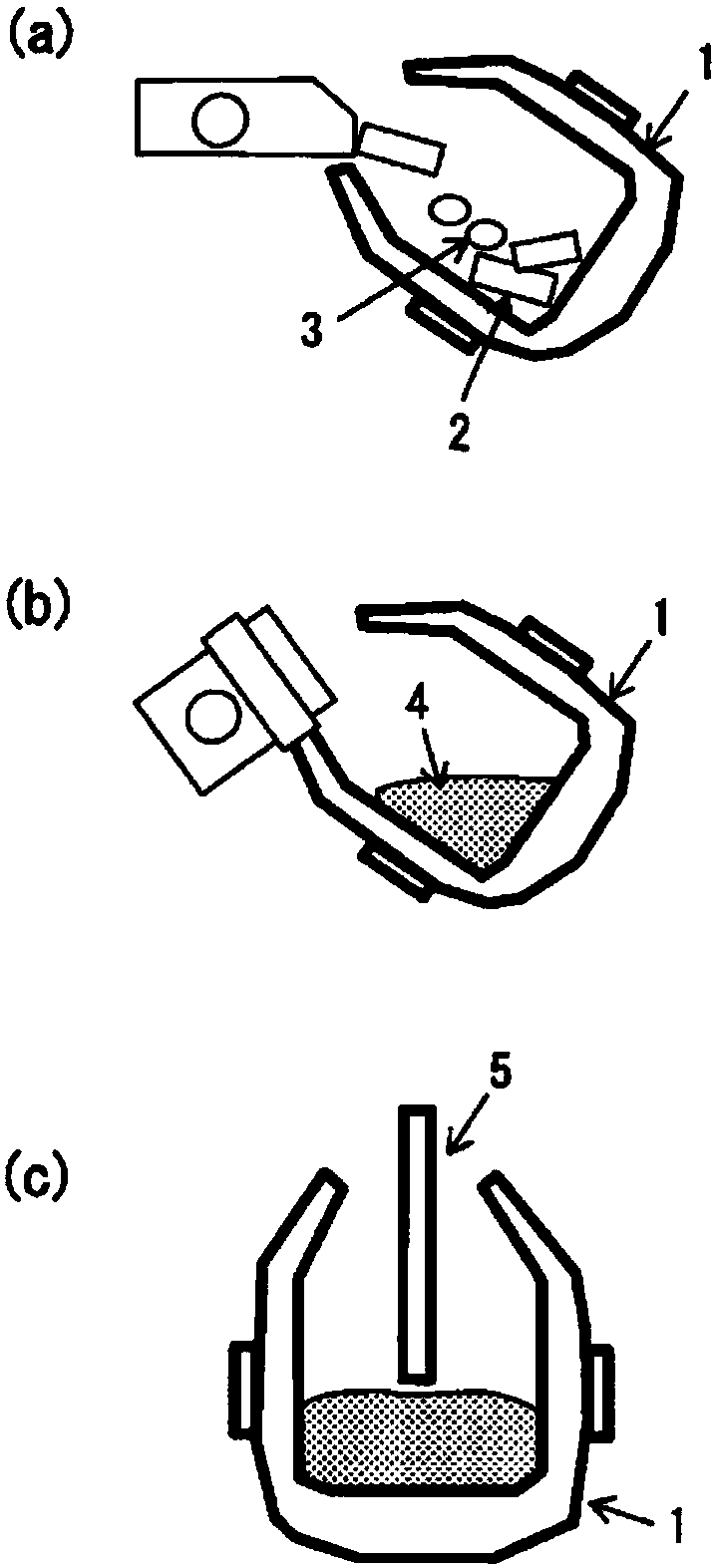

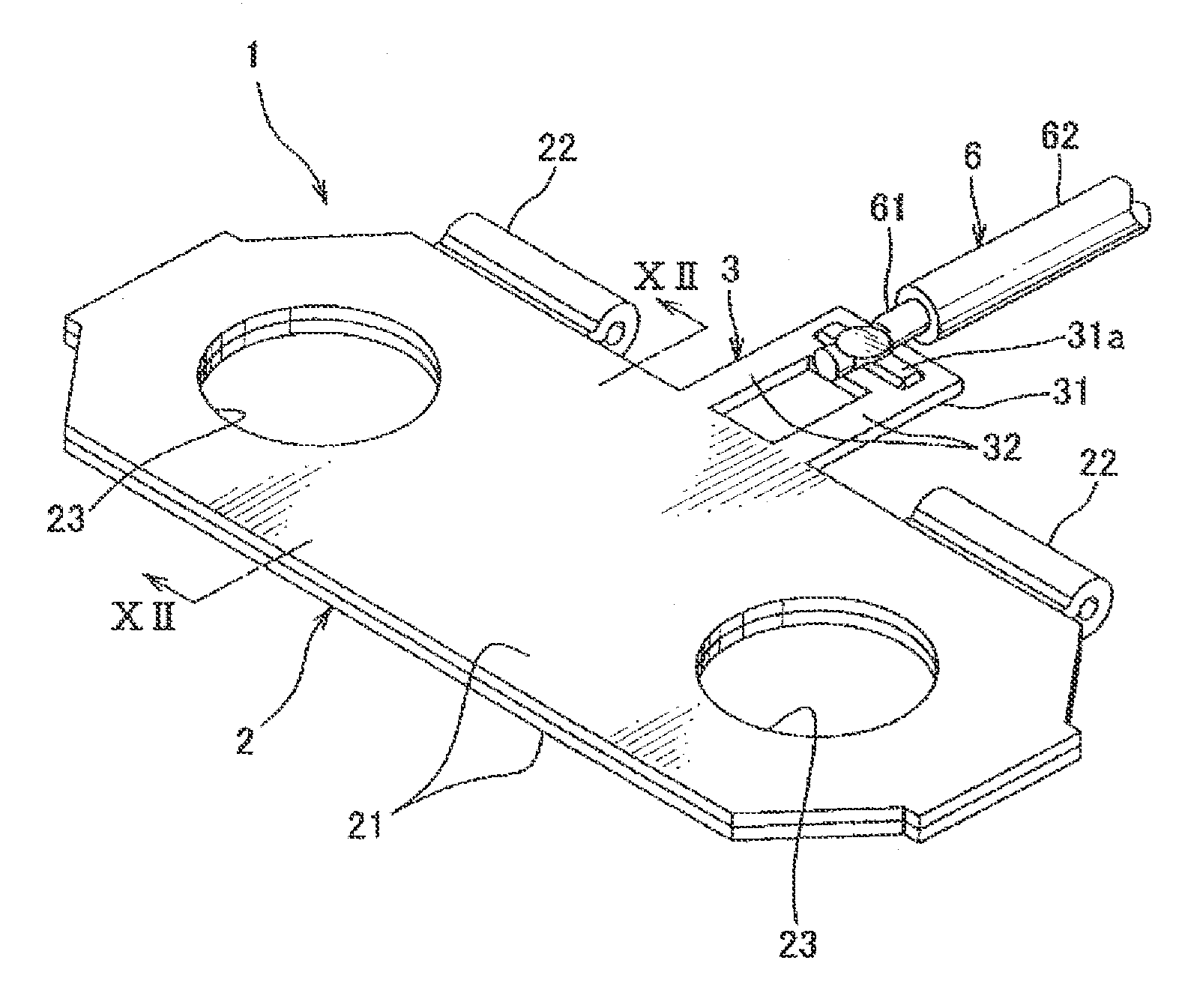

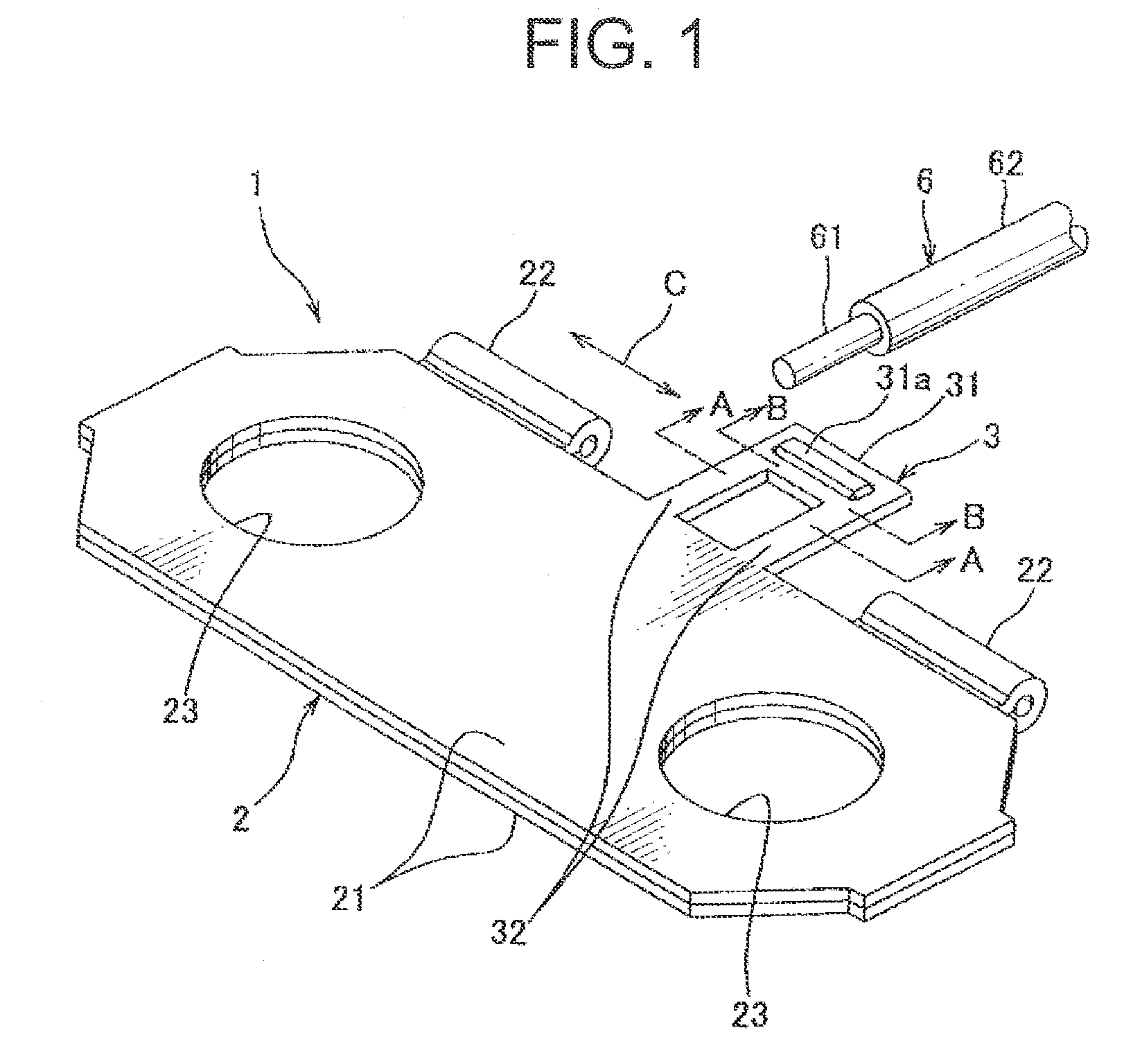

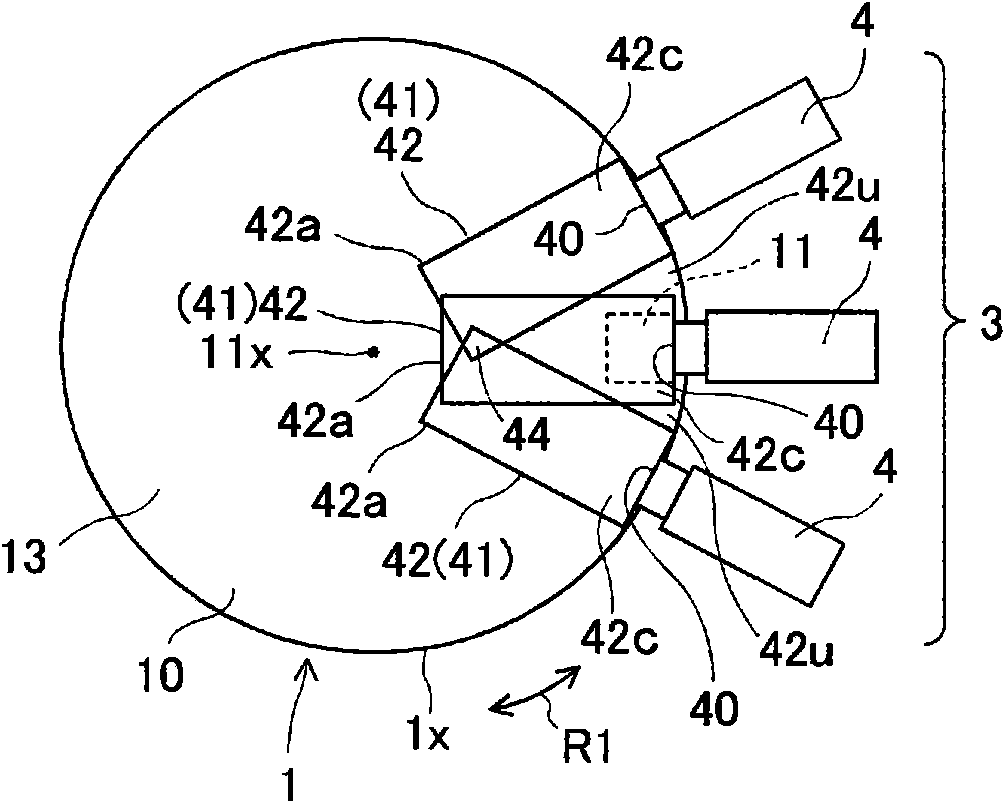

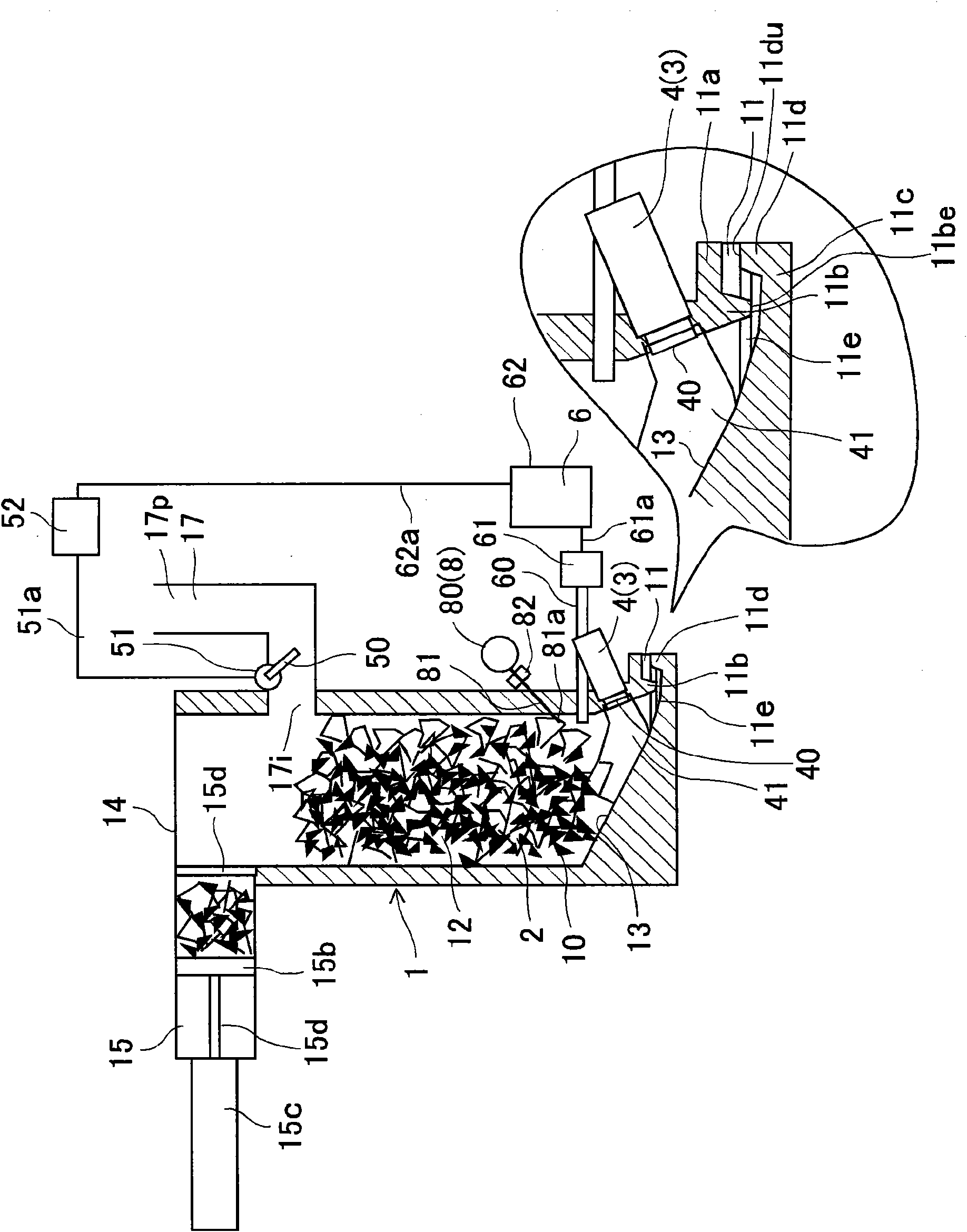

Layout of an apparatus for crushing-breaking useless casting products, a fixed cutter device and a rocking cutter device used for the apparatus, and a method for coating the fixed cutter device and the rocking cutter device

InactiveUS6145768AEasy to operateEfficient meltingCocoaGrain treatmentsEngineeringMechanical engineering

It is an object of the present invention to provide a layout of a crushing-breaking apparatus capable of achieving a full-automated factory, improving the efficiency in operation and ensuring the safety. The layer comprises a crushing-breaking apparatus for crushing and breaking sprues, weirs, runners of casting products and useless casting products, the apparatus being arranged at a predetermined position in the factory, a feeding device sequentially supplying the sprues, weirs, runners of casting products and the useless casting products to the apparatus, and a discharging device sequentially conveying recyclable casting products crushed and broken by the apparatus. The layout is characterized in that the feeding device, the apparatus, and the discharging device are arranged adjacent to one another so as to carry out a series of procedures.

Owner:OKUYA YASUAKI

Deicing and snow-removing composition, method for producing the same, and use thereof

InactiveUS6183664B1Efficient meltingEfficient removalOther chemical processesAdditive ingredientRoom temperature

A deicing and snow-removing composition, comprising 30 to 100 parts by weight of calcium oxide (CaO), 5 to 30 parts by weight of magnesium chloride (MgCl2), 3 to 10 parts by weight of calcium chloride (CaCl2), and 0.2 to 2 parts by weight of sodium alginate. A method for preparing such a composition in which the above-mentioned ingredients are combined, gradually heated to 100° C. or higher, and then rapidly heated up to 200° C., and cooled at room temperature.

Owner:KIM KI BUM

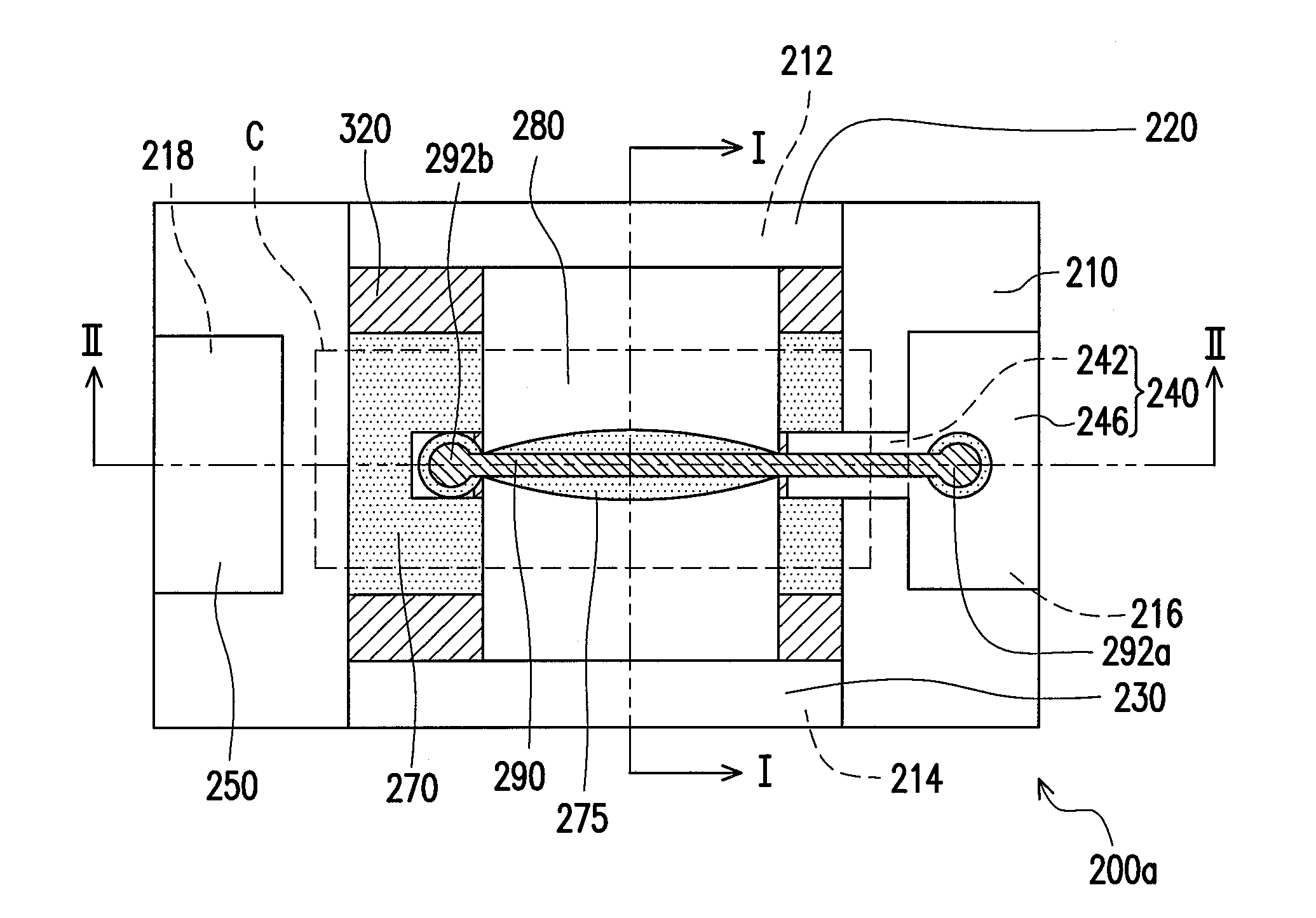

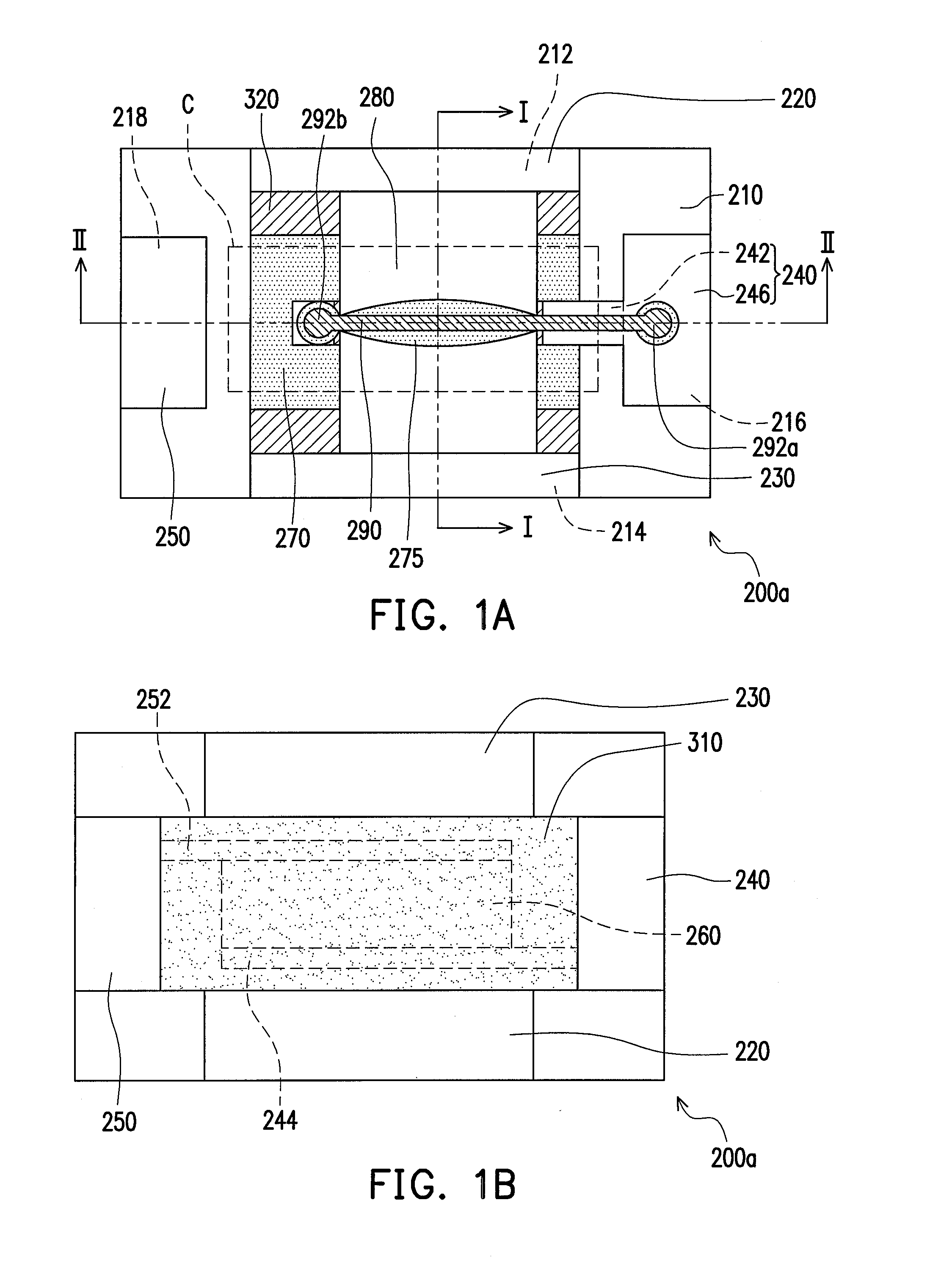

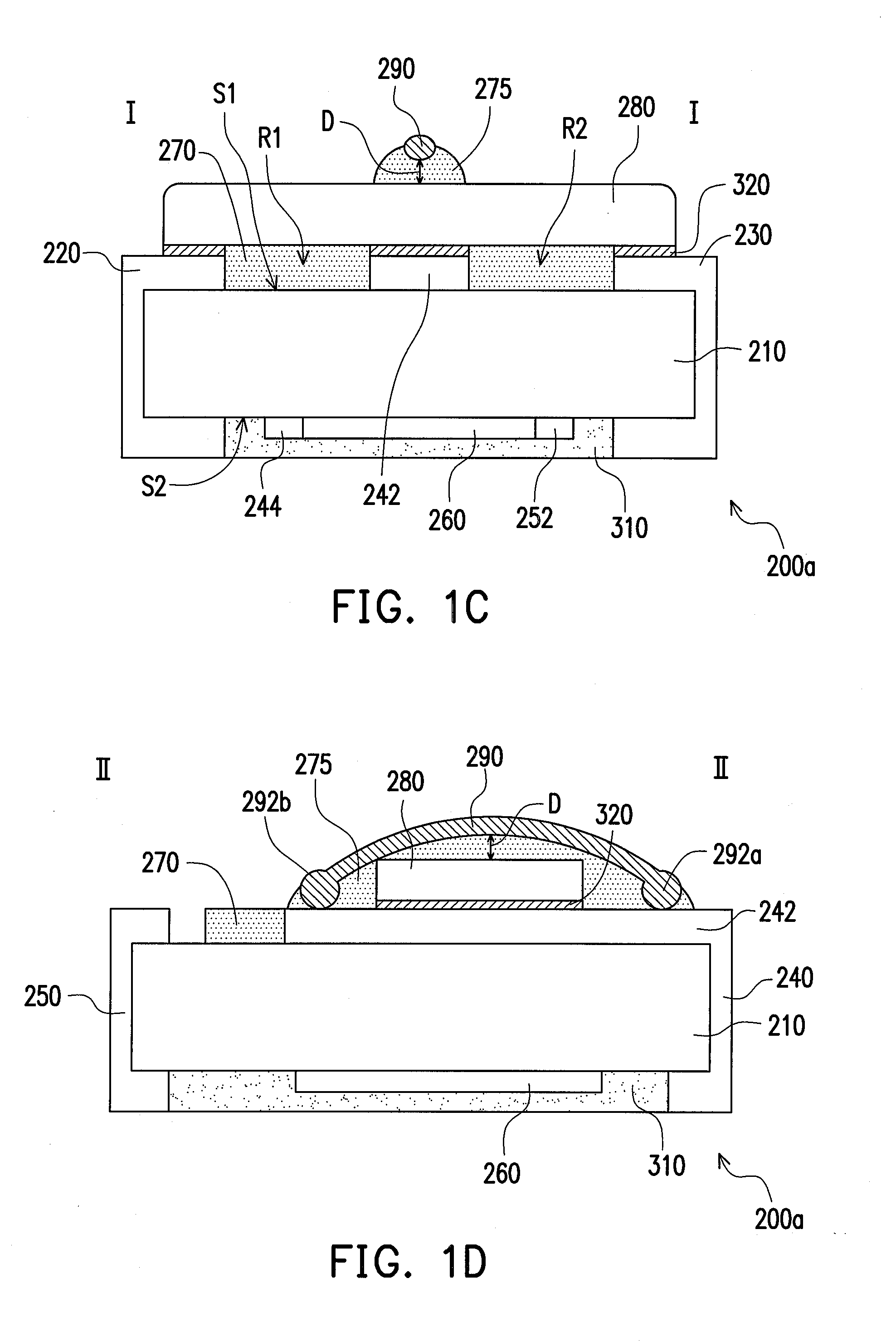

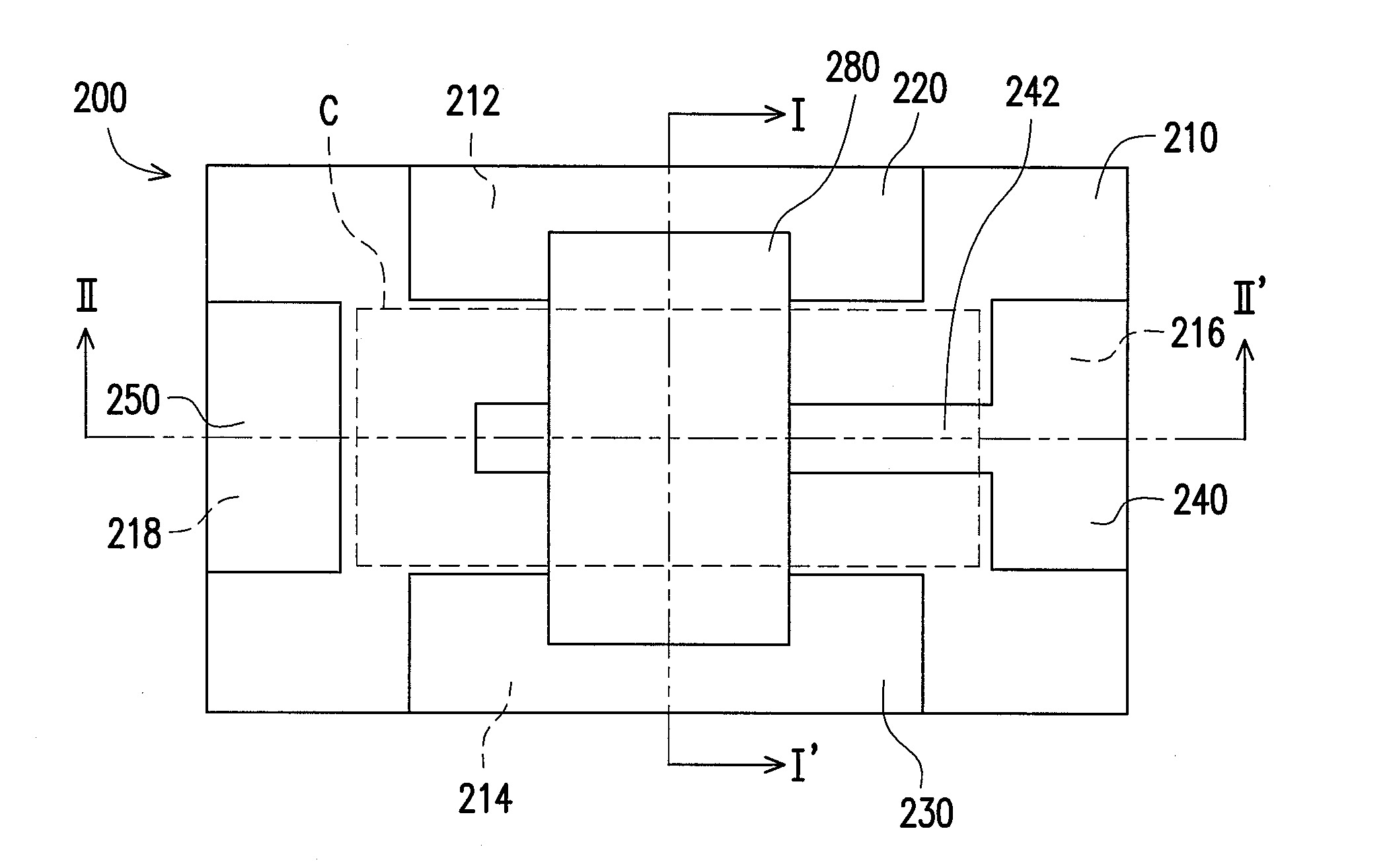

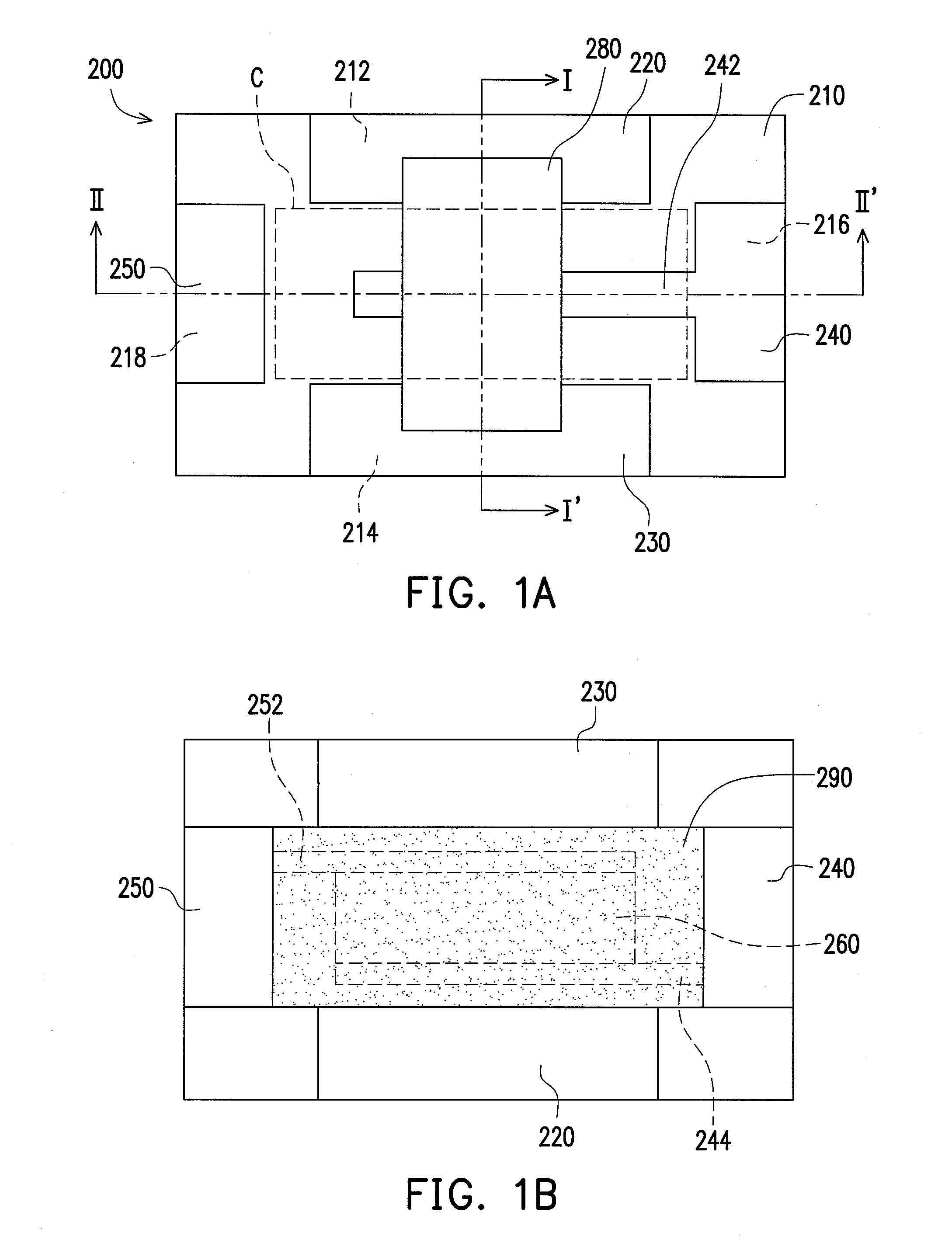

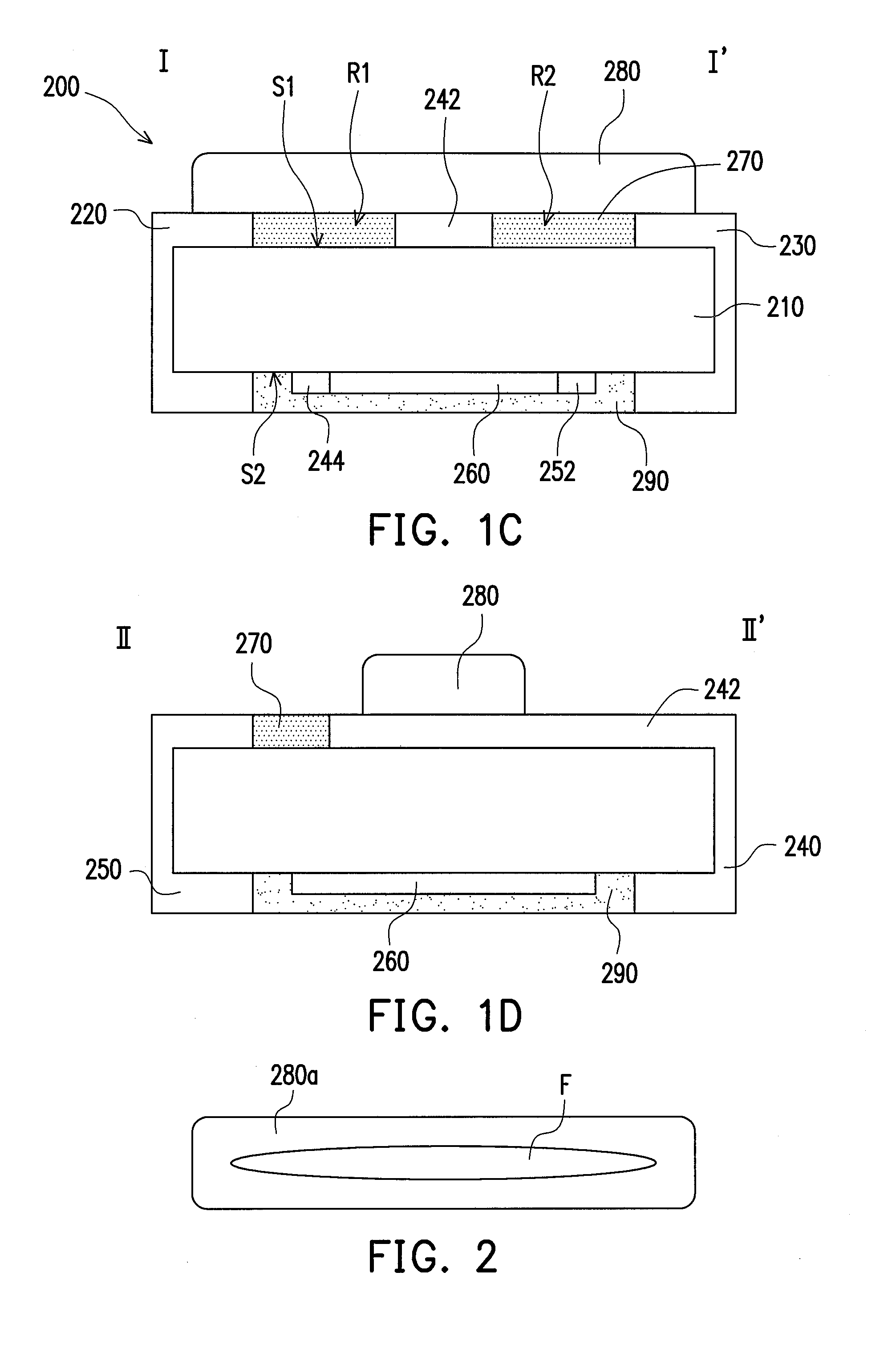

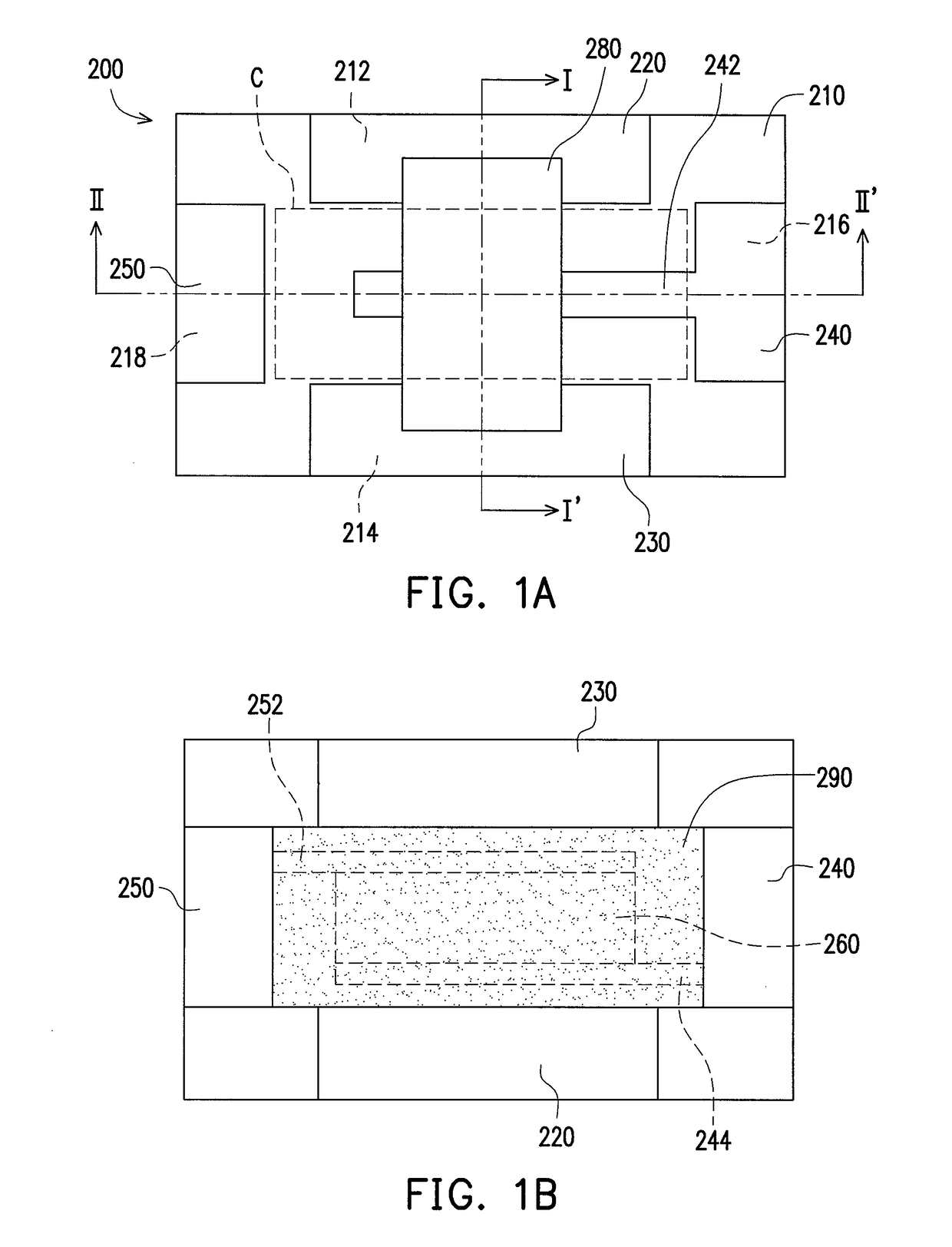

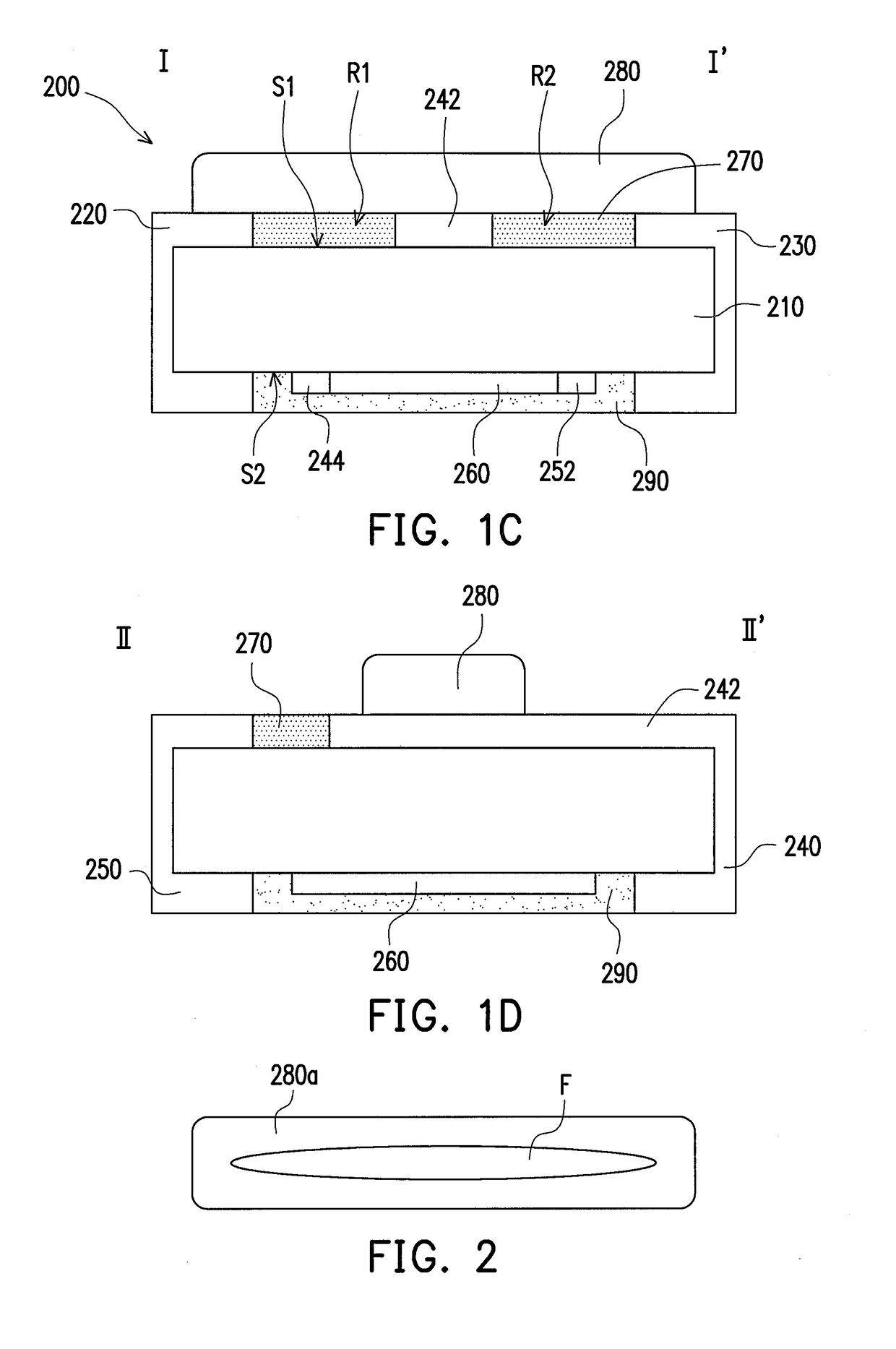

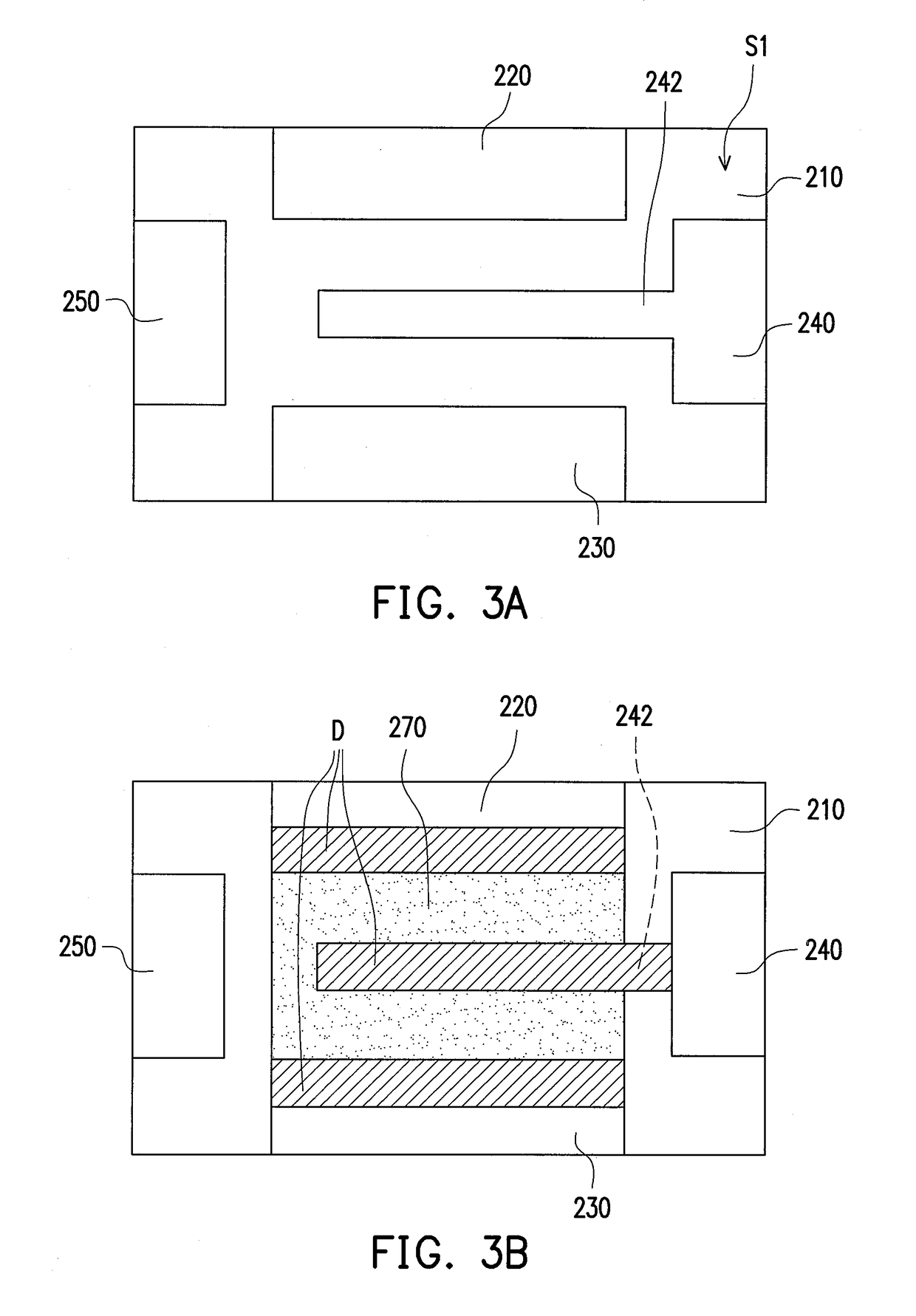

Protective device

ActiveUS20110057761A1Inhibit currentPrevents voltageEmergency protective device manufacturePower flowOptoelectronics

A protective device including a substrate, a conductive section and a bridge element is provided. The conductive section is supported by the substrate, wherein the conductive section comprises a metal element electrically connected between first and second electrodes. The metal element serves as a sacrificial structure having a melting point lower than that of the first and second electrodes. The bridge element spans across the metal element in a direction across direction of current flow in the metal element, wherein the bridge element facilitates breaking of the metal element upon melting.

Owner:CYNTEC

Protective device

ActiveUS20110058295A1Effective preventionEffectively preventArrangements responsive to excess currentEmergency protective device manufactureAuxiliary memoryMetal

A protective device including a substrate, a conductive section and a first auxiliary medium is provided. The conductive section is supported by the substrate, wherein the conductive section comprises a metal element electrically connected between first and second electrodes. The metal element serves as a sacrificial structure having a melting point lower than that of the first and second electrodes. The first auxiliary medium is disposed between the metal element and the substrate, wherein the first auxiliary medium has a melting point lower than that of the metal element. The first auxiliary medium facilitates breaking of the metal element upon melting.

Owner:CYNTEC

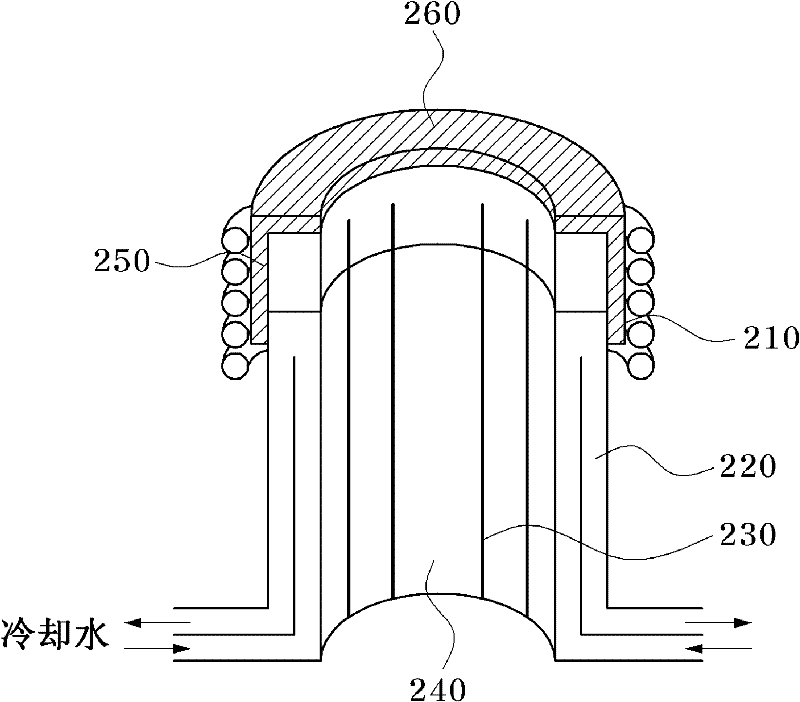

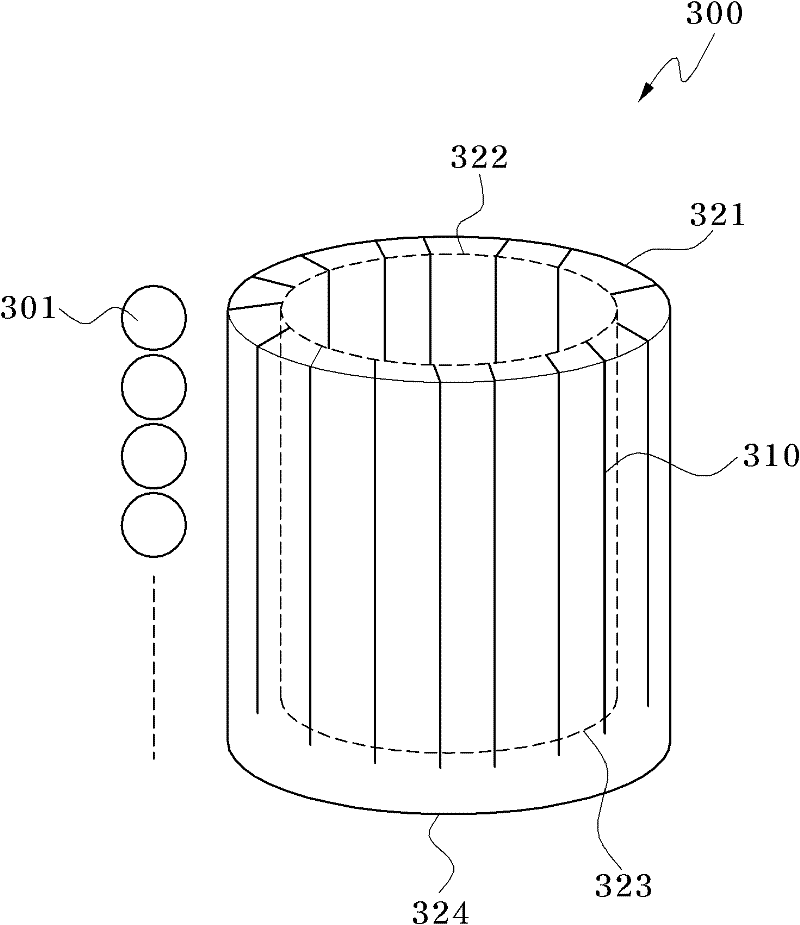

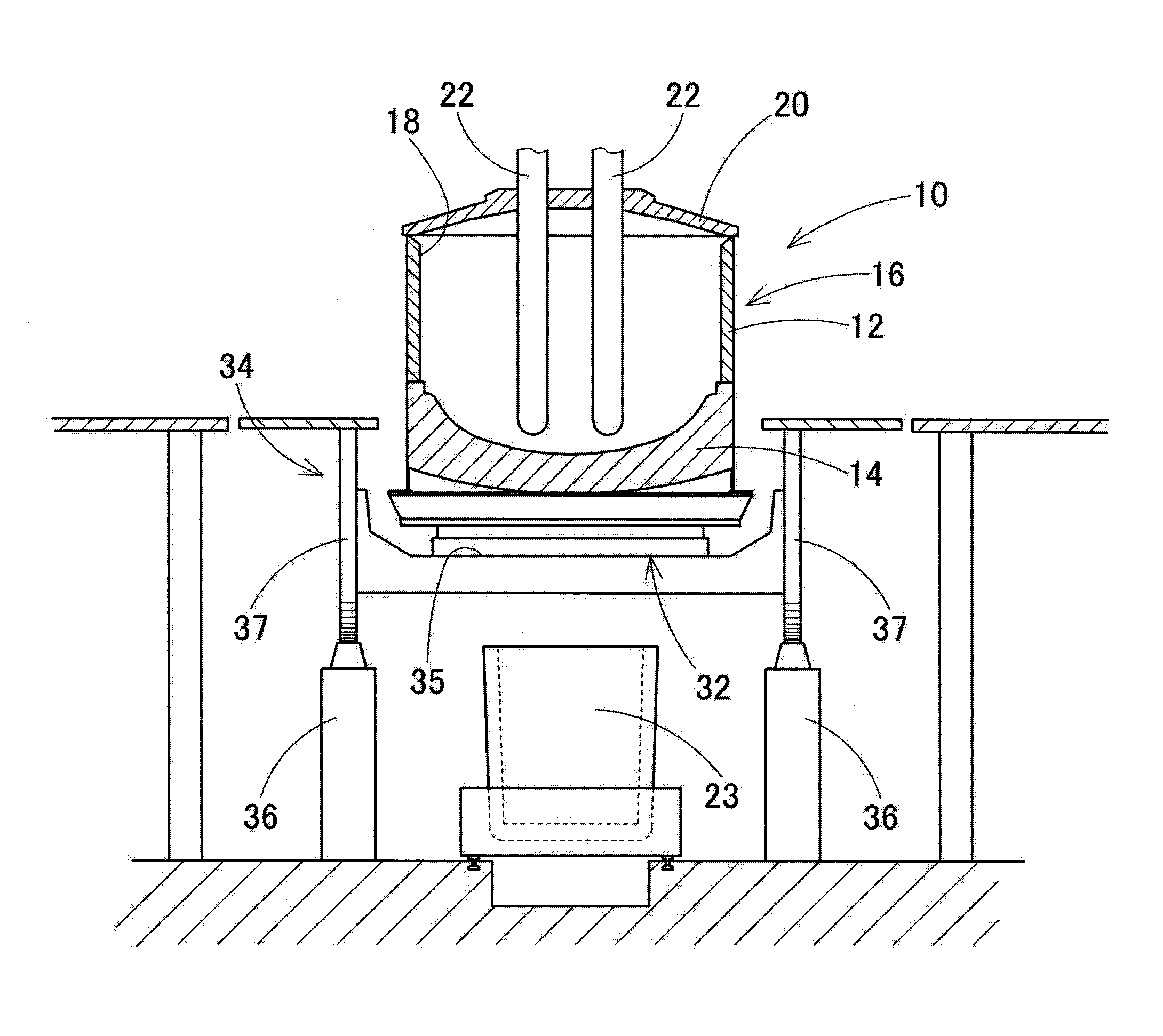

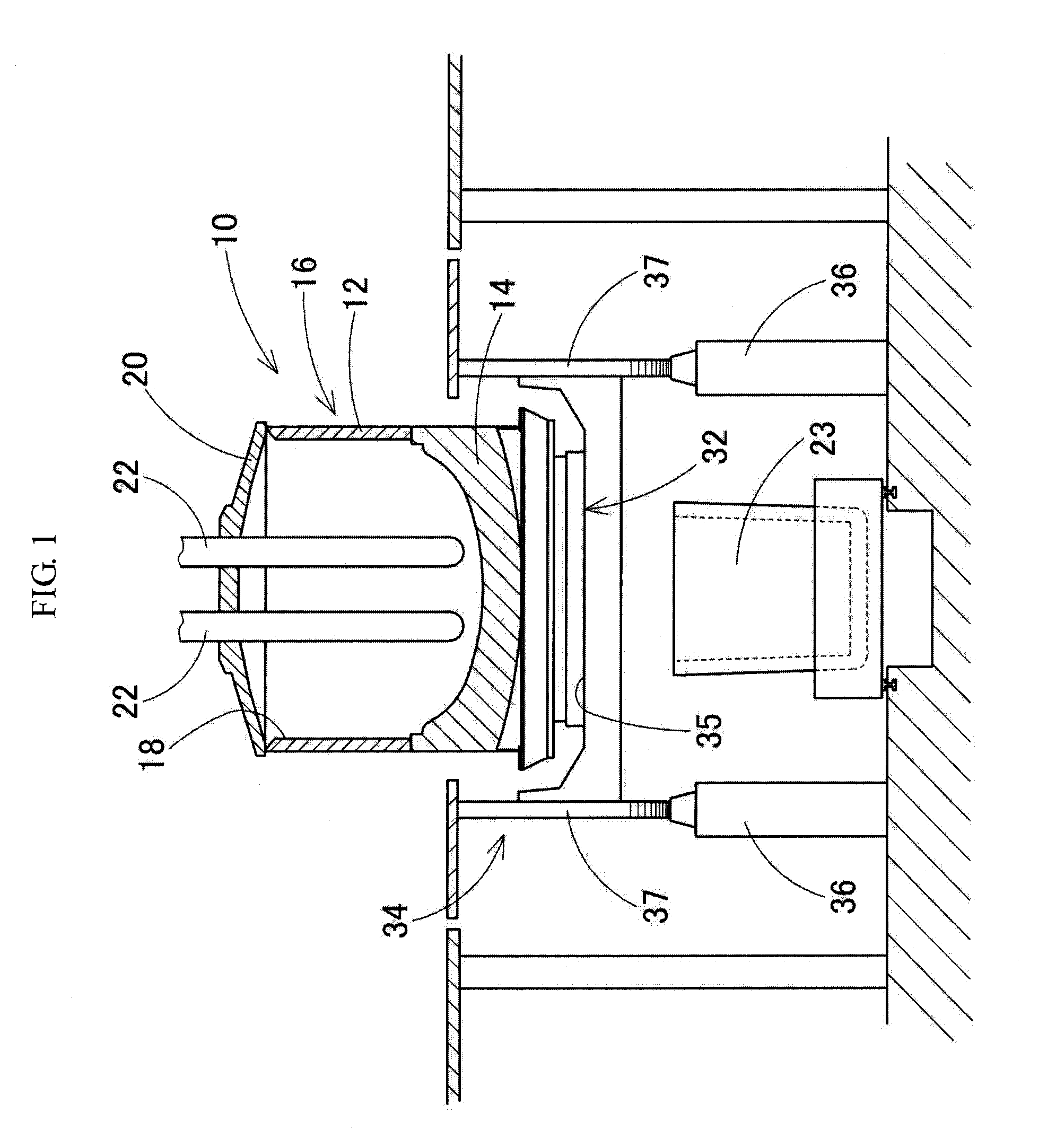

A graphite crucible for silicon electromagnetic induction heating and apparatus for silicon melting and refining using the graphite crucible

InactiveCN102177283AEliminate contactEliminate heat lossBy zone-melting liquidsBy pulling from meltSiliconElectromagnetic induction

Disclosed herein are a graphite crucible for electromagnetic induction- based silicon melting and an apparatus for silicon melting / refining using the same, which performs a melting operation by a combination of indirect melting and direct melting. The crucible is formed of a graphite material and includes a cylindrical body having an open upper part through which a silicon raw material is charged into the crucible, and an outer wall surrounded by an induction coil, wherein a plurality of slits are vertically formed through the outer wall and an inner wall of the crucible such that an electromagnetic force created by an electric current flowing in the induction coil acts toward an inner center of the crucible to prevent a silicon melt from contacting the inner wall of the crucible.

Owner:KOREA INST OF ENERGY RES

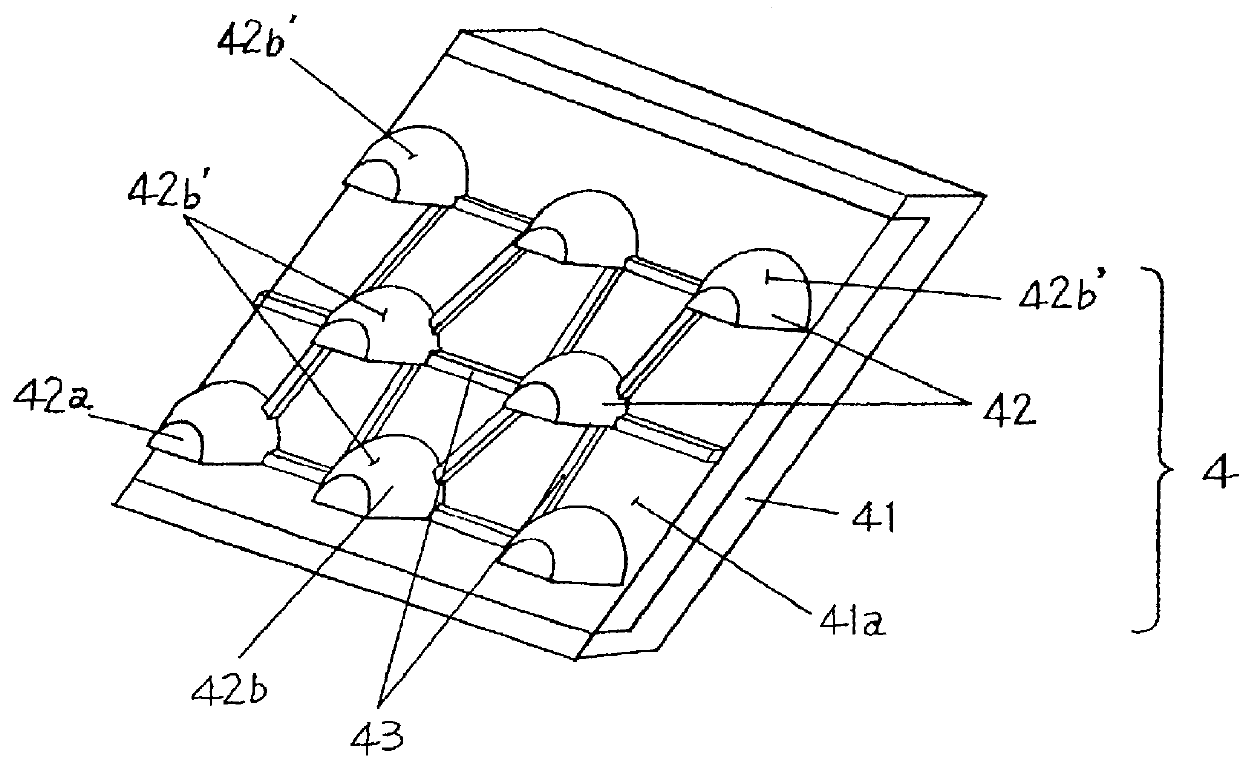

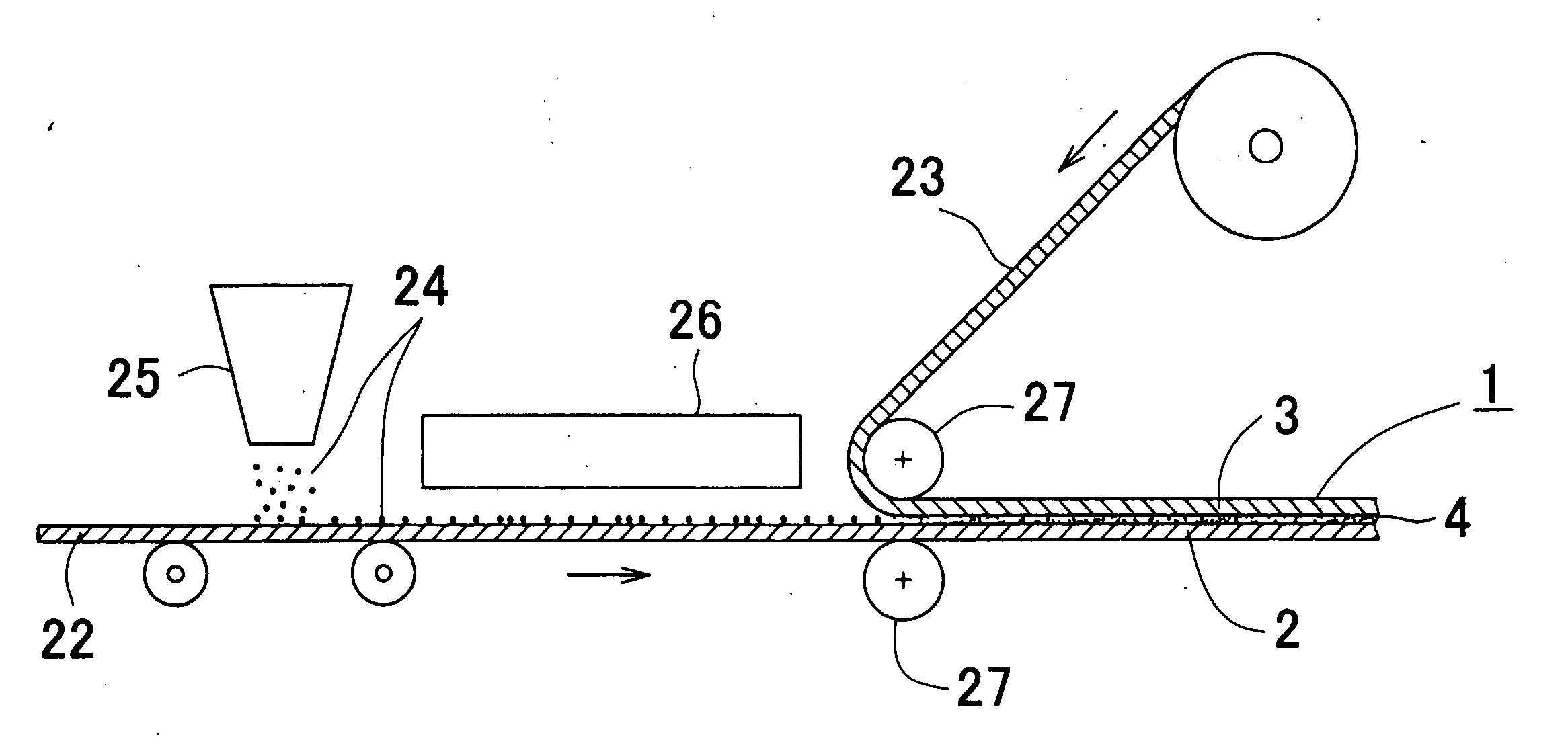

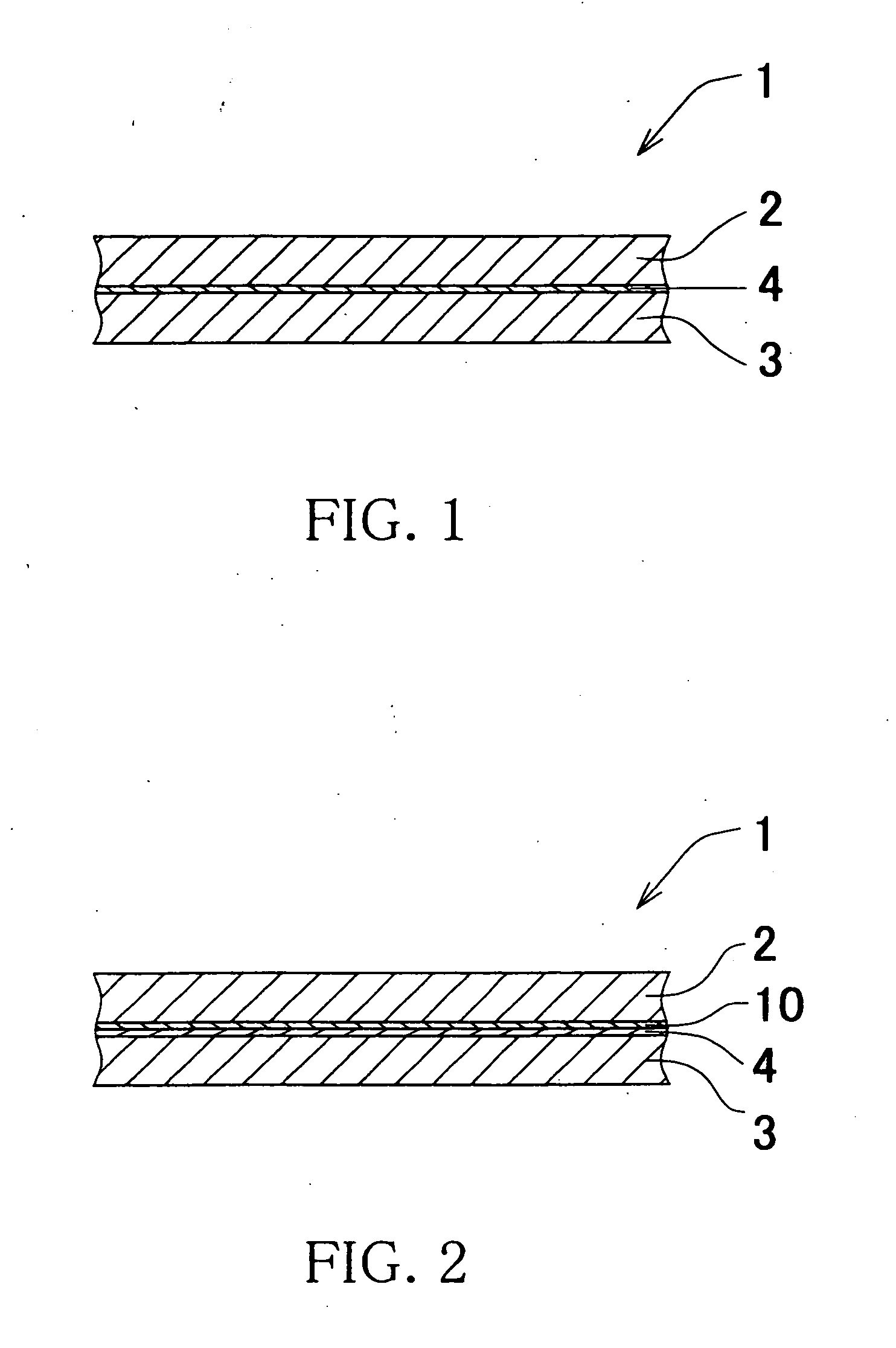

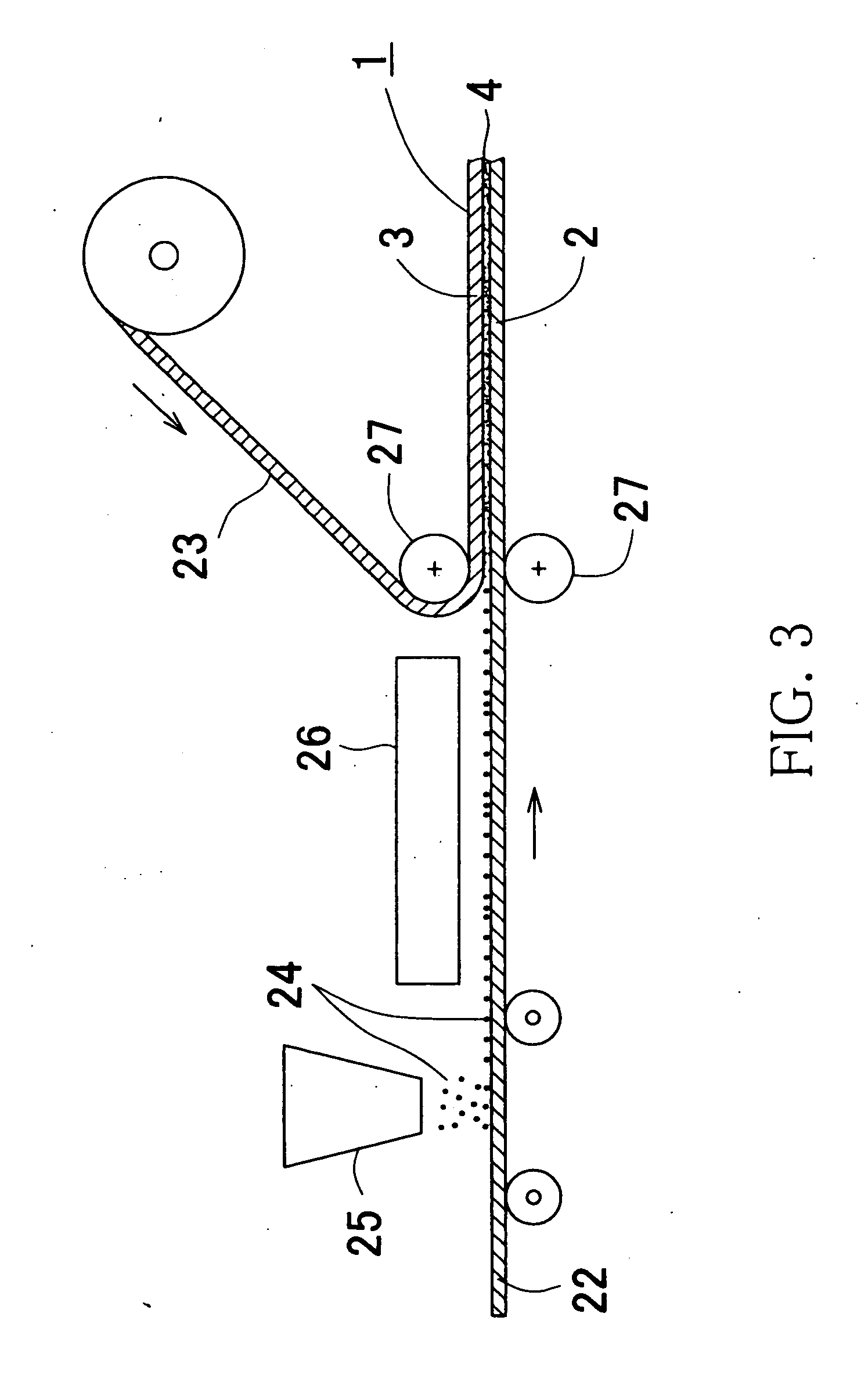

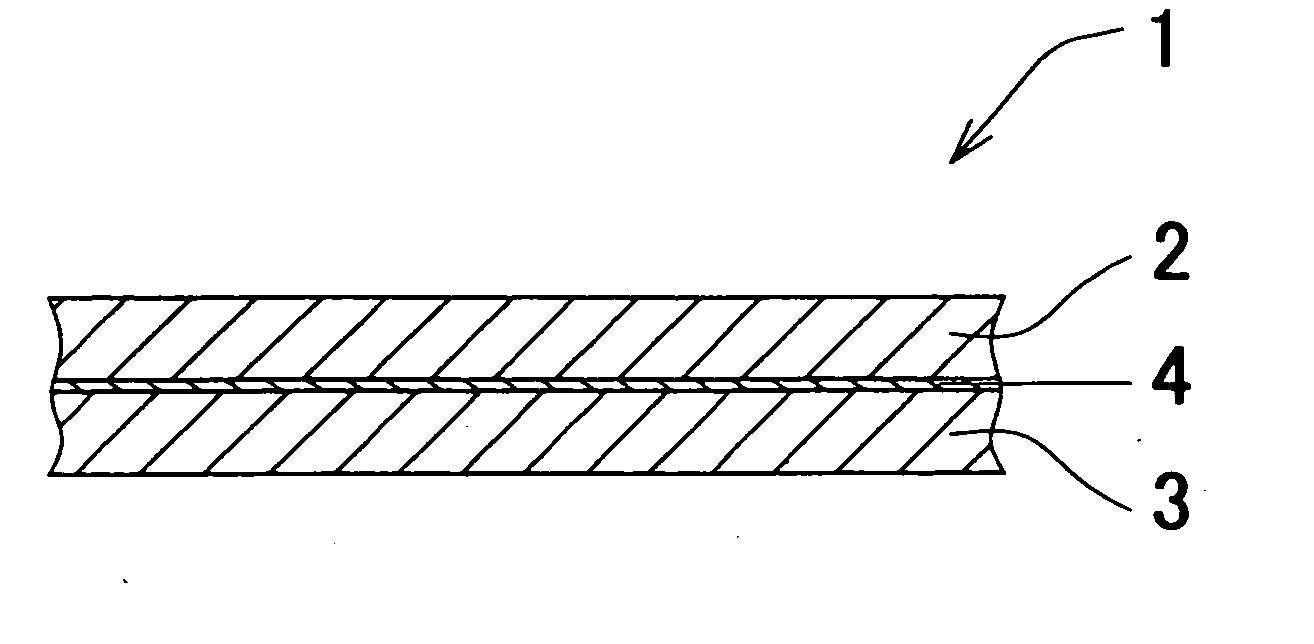

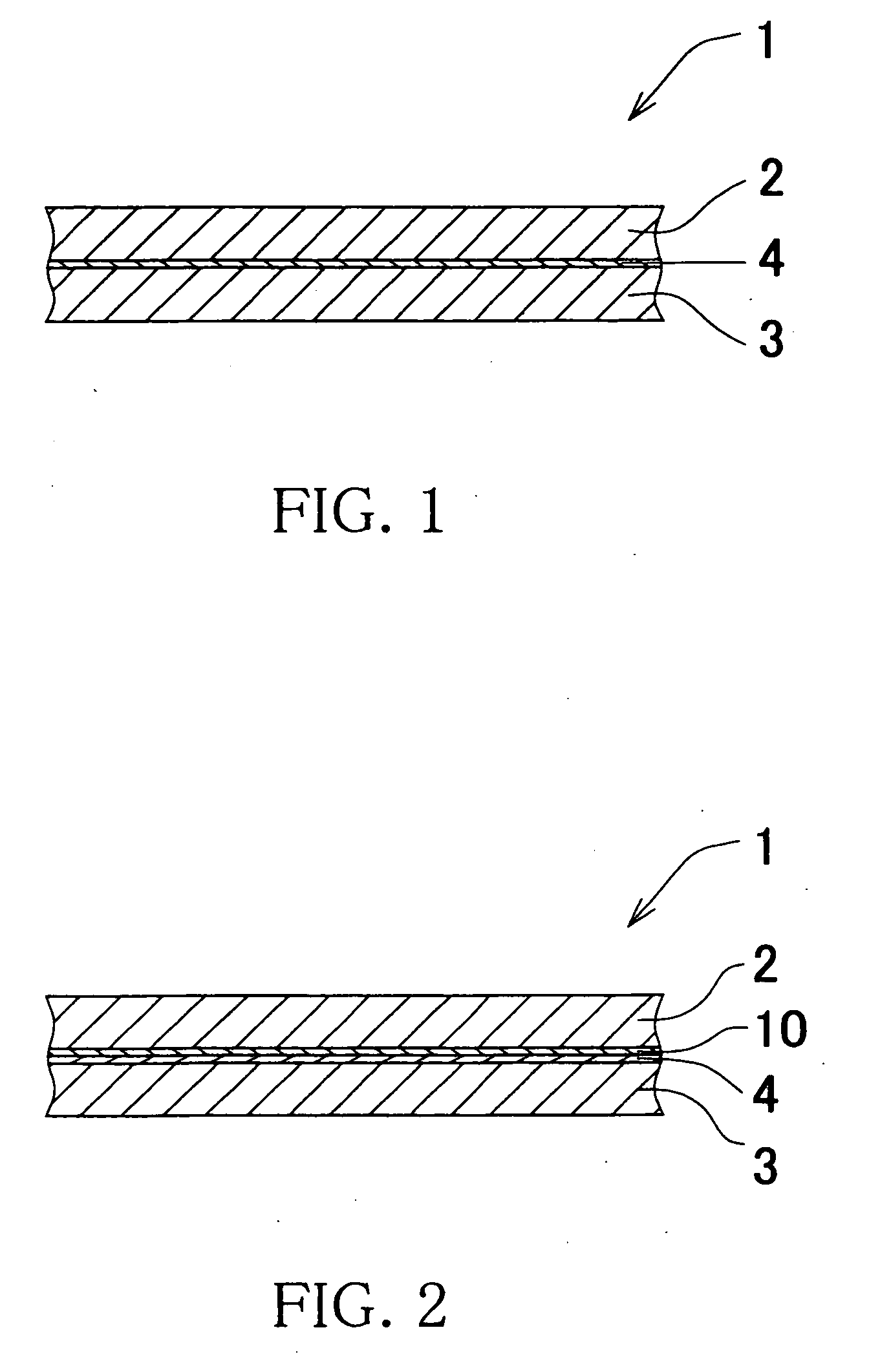

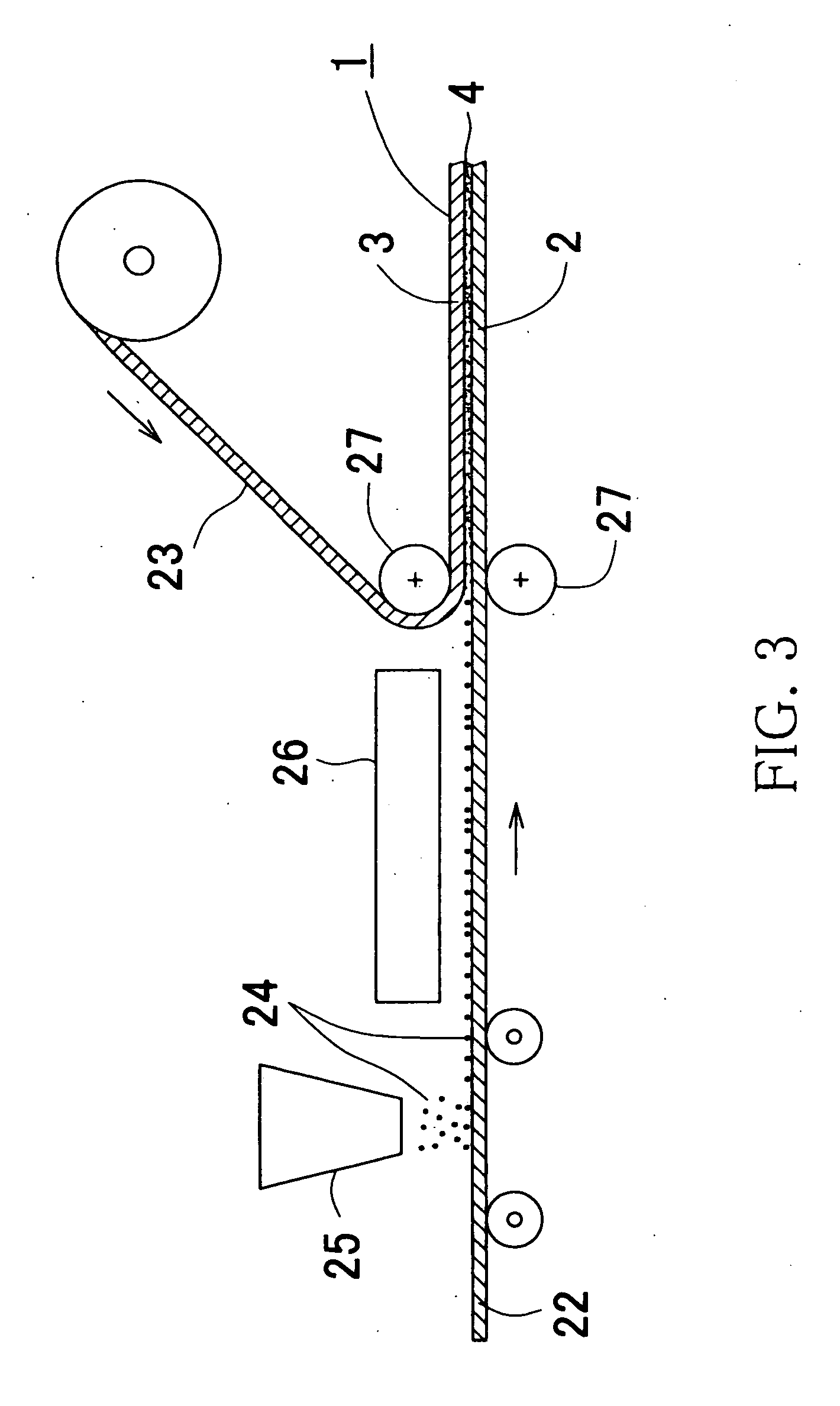

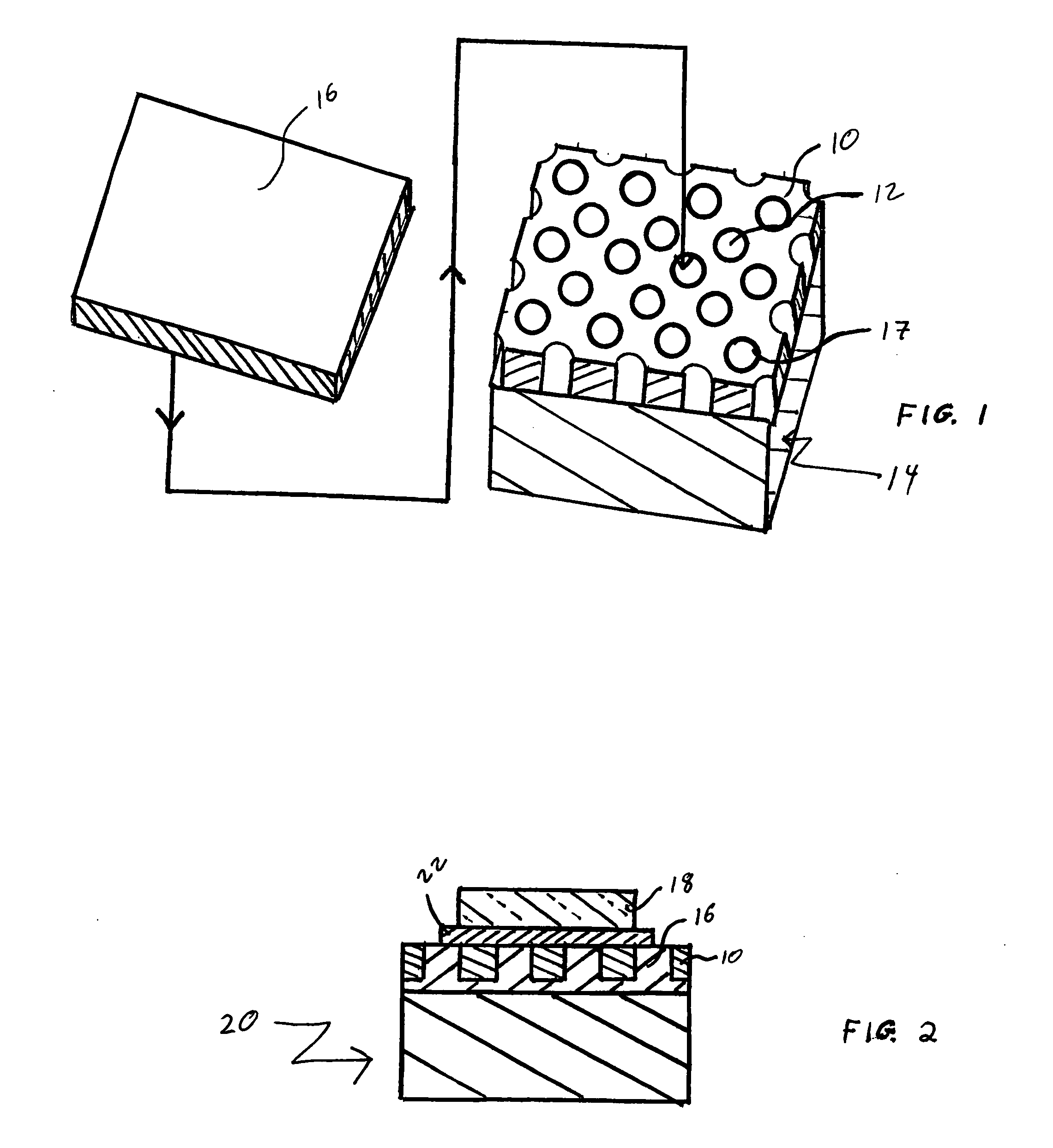

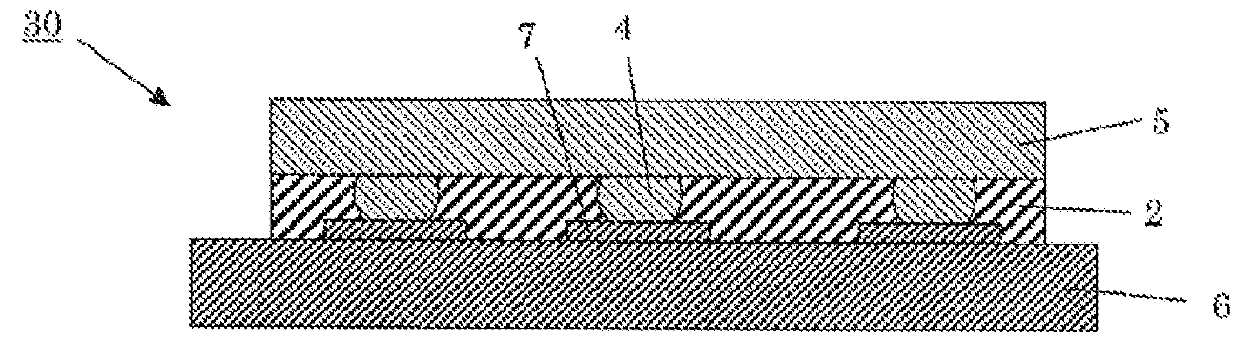

Carpet for vehicles and method for manufacturing the same

InactiveUS20050208261A1Effective noisePrevent noise leakageVehicle arrangementsGlass/slag layered productsSurface layerEngineering

An upper surface layer 2 and a nonwoven fabric sound absorption layer 3 are integrally secured via an air permeable adhesive resin layer 4 formed by melting thermoplastic resin powder, and the air permeability of the thickness direction of the entire carpet 1 falls within the range of 1 to 50 cm3 / cm2·second. This effectively absorbs noise from the upper side entering via a roof, doors and windows as well as noise from the lower side. The carpet can be manufactured by scattering thermoplastic resin powder on an upper surface member, heating the thermoplastic resin powder into melted thermoplastic resin, placing a nonwoven fabric on the upper surface member via the melted thermoplastic resin, and pressing the nonwoven fabric and the upper surface member in a laminated state. It is preferable that powder of particle size of 90 to 10,000 μm is scattered in the amount of 5 to 500 g / m2.

Owner:SUMINOE TEXTILE CO LTD

Injection device in molding machine

ActiveUS20130071510A1Uniform and well-balanced meltingSpeed up meltingFood shapingSpray nozzleMaterials science

A injection device in molding machine is capable of efficiently heating and melting a plurality of charged pellets in a short period of time, and injecting a melting resin with superior quality.The injection device has a cylinder including a pellet supply port, a plunger, a driving unit, a melting instrument with a plurality of melting holes, which are cone-shaped passages, formed in a cylinder-shaped instrument body to communicate from inflow-side large openings to outflow-side small openings, a nozzle provided on an injection side of the cylinder and a heating unit heating the melting instrument. A diameter of the tip-end of the plunger is set to be the same as a diameter of the outflow side face of the melting machine.

Owner:CENTURY INNOVATION CORP

Carpet for vehicles and method for manufacturing the same

InactiveUS20050287335A1Effective absorptionPrevent noise leakageVehicle arrangementsLaminationSurface layerEngineering

An upper surface layer 2 and a nonwoven fabric sound absorption layer 3 are integrally secured via an air permeable adhesive resin layer 4 formed by melting thermoplastic resin powder, and the air permeability of the thickness direction of the entire carpet 1 falls within the range of 1 to 50 cm3 / cm2·second. This effectively absorbs noise from the upper side entering via a roof, doors and windows as well as noise from the lower side. The carpet can be manufactured by scattering thermoplastic resin powder on an upper surface member, heating the thermoplastic resin powder into melted thermoplastic resin, placing a nonwoven fabric on the upper surface member via the melted thermoplastic resin, and pressing the nonwoven fabric and the upper surface member in a laminated state. It is preferable that powder of particle size of 90 to 10,000 μm is scattered in the amount of 5 to 500 g / m2.

Owner:SUMINOE TEXTILE CO LTD

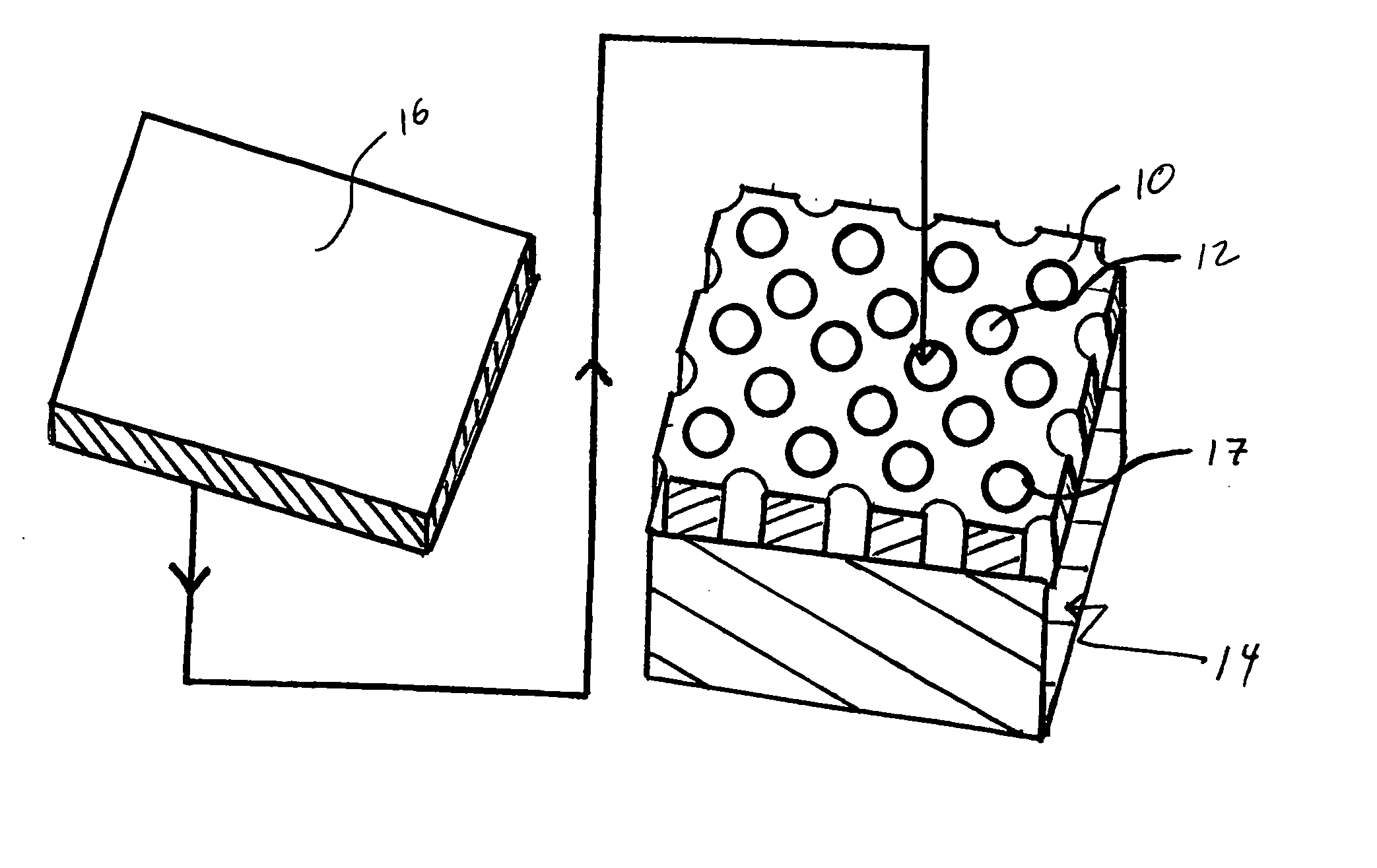

Heat spreader for use with light emitting diode

InactiveUS20060286358A1Improve thermal conductivityHigh tensile strengthPrinted circuit aspectsPrinted circuit manufactureThermal expansionLight-emitting diode

A substrate for an integrated circuit device includes a low coefficient of thermal expansion material having opposing first and second surfaces with an array of through holes extending from the first surface to the second surface. A high thermal conductivity substrate is adjacent to the second surface of the low coefficient of thermal expansion material and a wettable material bonds the low coefficient of thermal expansion material to the high thermal conductivity substrate while also substantially filling said array of through holes. An integrated circuit device, such as a light emitting diode, may be bonded to the first surface of the low coefficient of thermal expansion material by a compliant die attach material.

Owner:HCC AEGIS

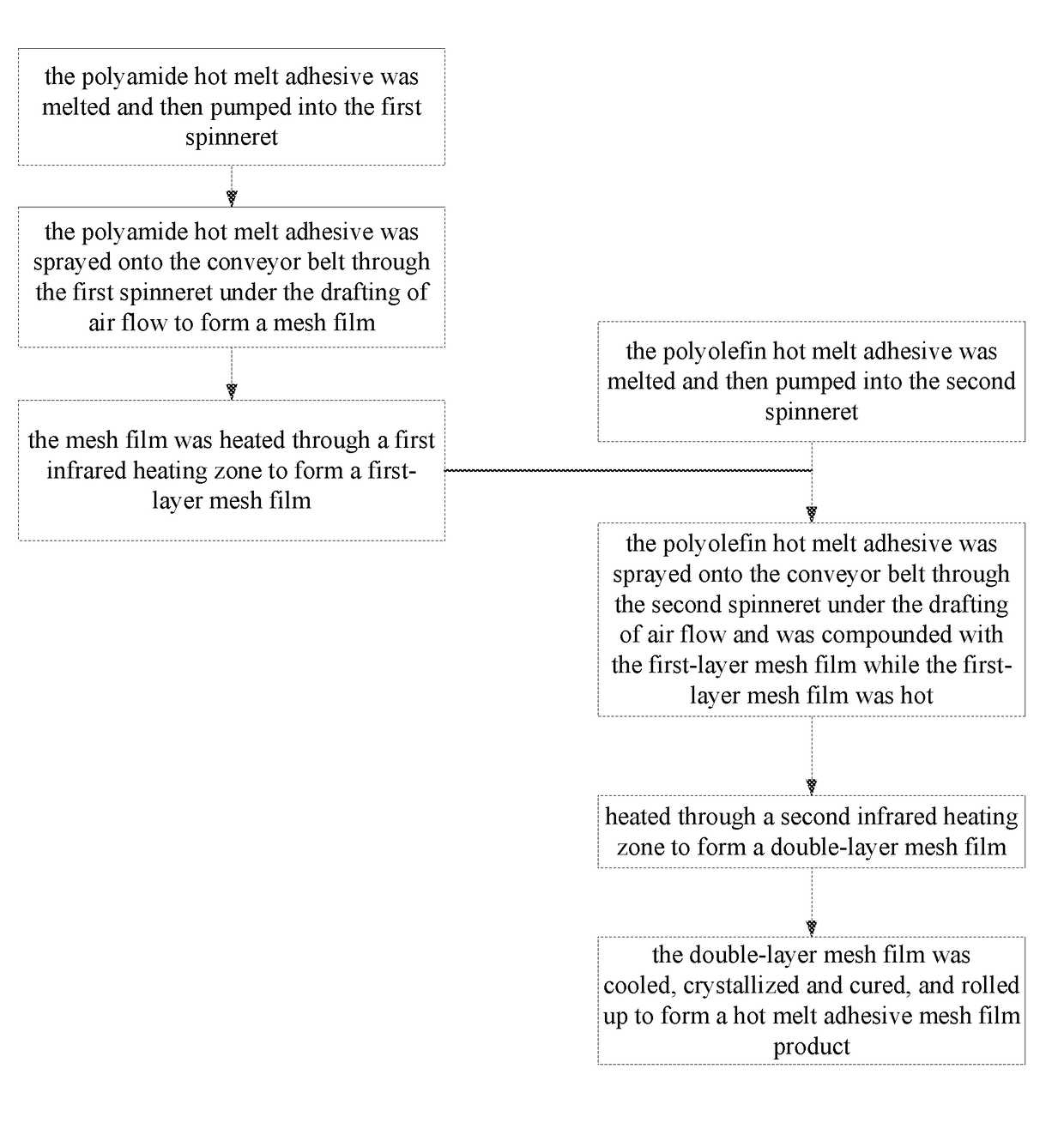

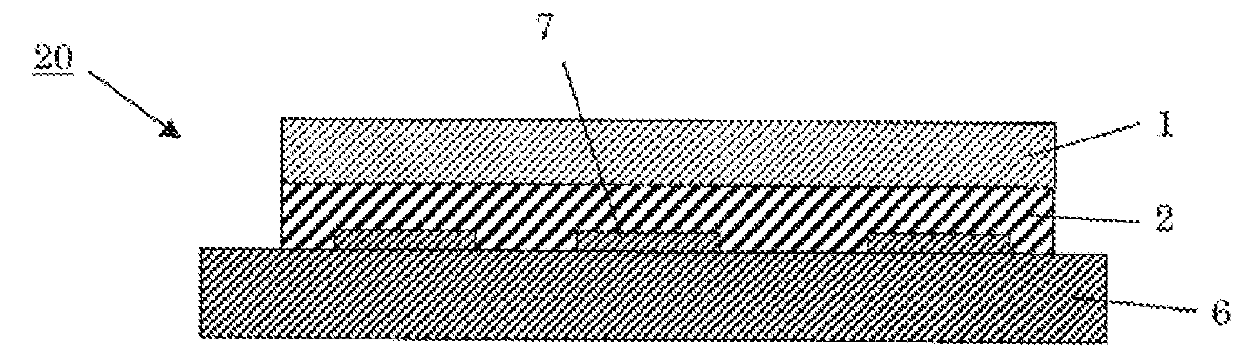

Composite hot-melt adhesive net film and manufacturing process thereof

ActiveUS20170349792A1High bonding strengthLasting and stable bondingNon-macromolecular adhesive additivesSpinnerette packsPolymer sciencePolyolefin

A composite hot-melt adhesive mesh film and preparation process thereof, in particular, a composite hot-melt adhesive mesh film and preparation process thereof for bonding metal and non-polar material are disclosed. The mesh film is compounded of a polar polyamide hot-melt adhesive and a non-polar polyolefin hot-melt adhesive mesh film containing a compatibilizer. The mesh film has a high adhesive strength and a durable and stable adhesion, and is especially suitable for bonding stainless steel, aluminum, copper or other metal materials and polyethylene, polypropylene or other non-polar polymers. Additionally, the preparation process is completed in one set of production process from raw material pretreatment to the final preparation of the hot melt adhesive mesh film product, thereby greatly reducing production failures, and providing high production efficiency and low costs.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Method of operating electric arc furnace

ActiveUS20160123664A1Speed up meltingReduce stepsCharge manipulationElectric furnaceElectric arc furnaceSlag

The present invention relates to a method of operating an electric arc furnace containing (a) a furnace shell having a tapping hole and / or a slag door, (b) a furnace roof having a plurality of electrodes provided so as to face downwards, and (c) a rotating apparatus that rotates the furnace shell around a vertical axis relative to the electrodes, the method contains a rotating step of rotating the furnace shell relative to the electrodes during melting of a metal material, and a holding step of stopping the rotation when any one of the plurality of electrodes reaches a holding position that is previously set close to the tapping hole or the slag door, and holding the furnace shell at the holding position.

Owner:DAIDO STEEL CO LTD

Vehicle lamp

InactiveUS7195365B2Reduce intensityImprove heating efficiencyFurnace componentsPoint-like light sourceEngineeringHeating element

Disclosed is a vehicle lamp that is designed to reliably remove snow, etc. adhering to a lens. A carbon-based heating element is mounted within a lamp body so that the heat rays radiated from the heating element irradiate a rear surface of the lens.

Owner:MITSUBISHI PENCIL CO LTD

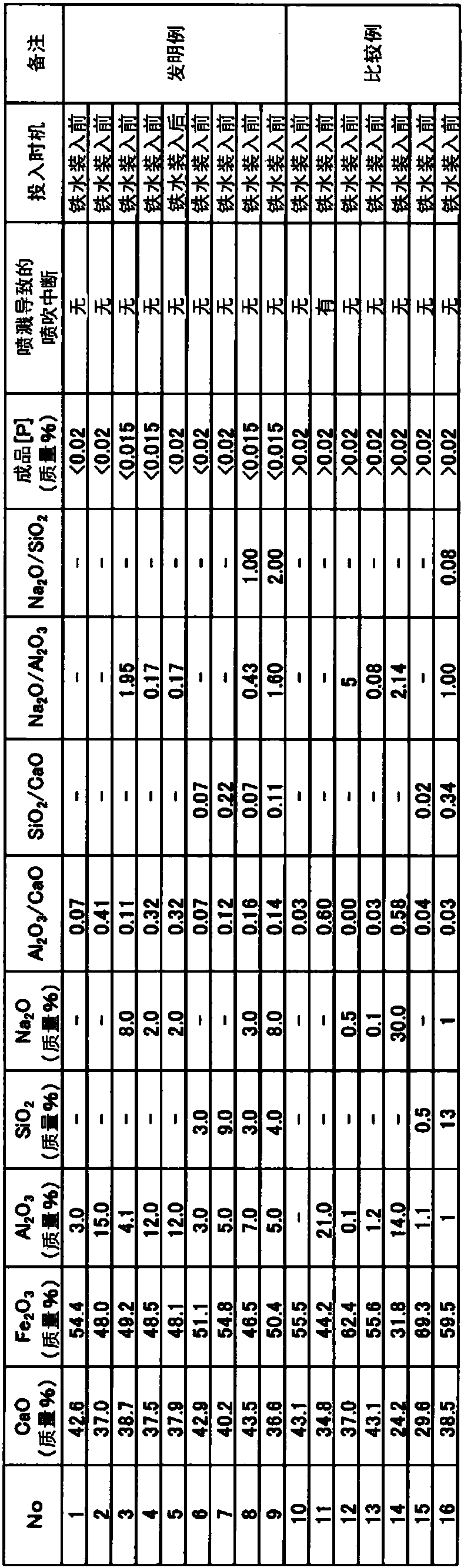

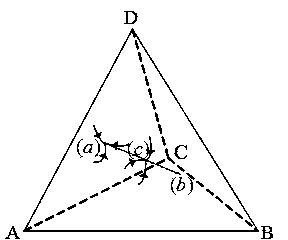

Molten iron dephosphorizing agent, refining agent, and dephosphorization method

InactiveCN107849625AFully meltedEfficient meltingManufacturing convertersProcess efficiency improvementImpurityCalcium ferrite

A molten iron dephosphorizing agent containing 2-20 mass% Al2O3, the balance being calcium ferrite and impurities and the (Al2O3 mass%) / (CaO mass%) ratio being 0.04-0.5. Dephosphorization of molten iron is performed by adding a refining agent comprising said dephosphorizing agent into a converter furnace.

Owner:NIPPON STEEL CORP

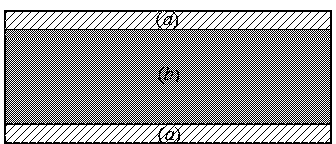

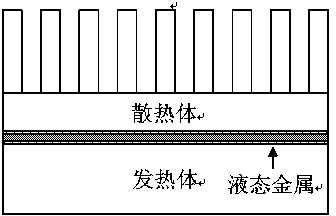

Quaternary liquid metal heat interface material with dual melting points

ActiveCN103722804AOvercome the problem of excessive liquidityEfficient meltingMetal layered productsIndiumLiquid metal

The invention discloses a quaternary liquid metal heat interface material with dual melting points. The liquid metal heat interface materials adopt a three-layered foil-shaped structure, wherein the upper layer and the lower layer are made of 50% of indium, 18% of bismuth, 24% of tin and 8% of zinc by mole; the middle layer is made of 33% of indium, 26% of bismuth, 29% of tin and 12% of zinc by mole. A hole between a heating element and a radiator can be completely filled with the quaternary liquid metal heat interface material at a relatively low temperature after initial mounting, and then the quaternary liquid metal heat interface material is solidified due to diffusion. The quaternary liquid metal heat interface material is solid at normal working temperatures. When the temperature of an electronic device is raised to a design value, the quaternary liquid metal heat interface material can be melted twice to cool the electronic device sharply. Therefore, the quaternary liquid metal heat interface material has a wide application prospect.

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

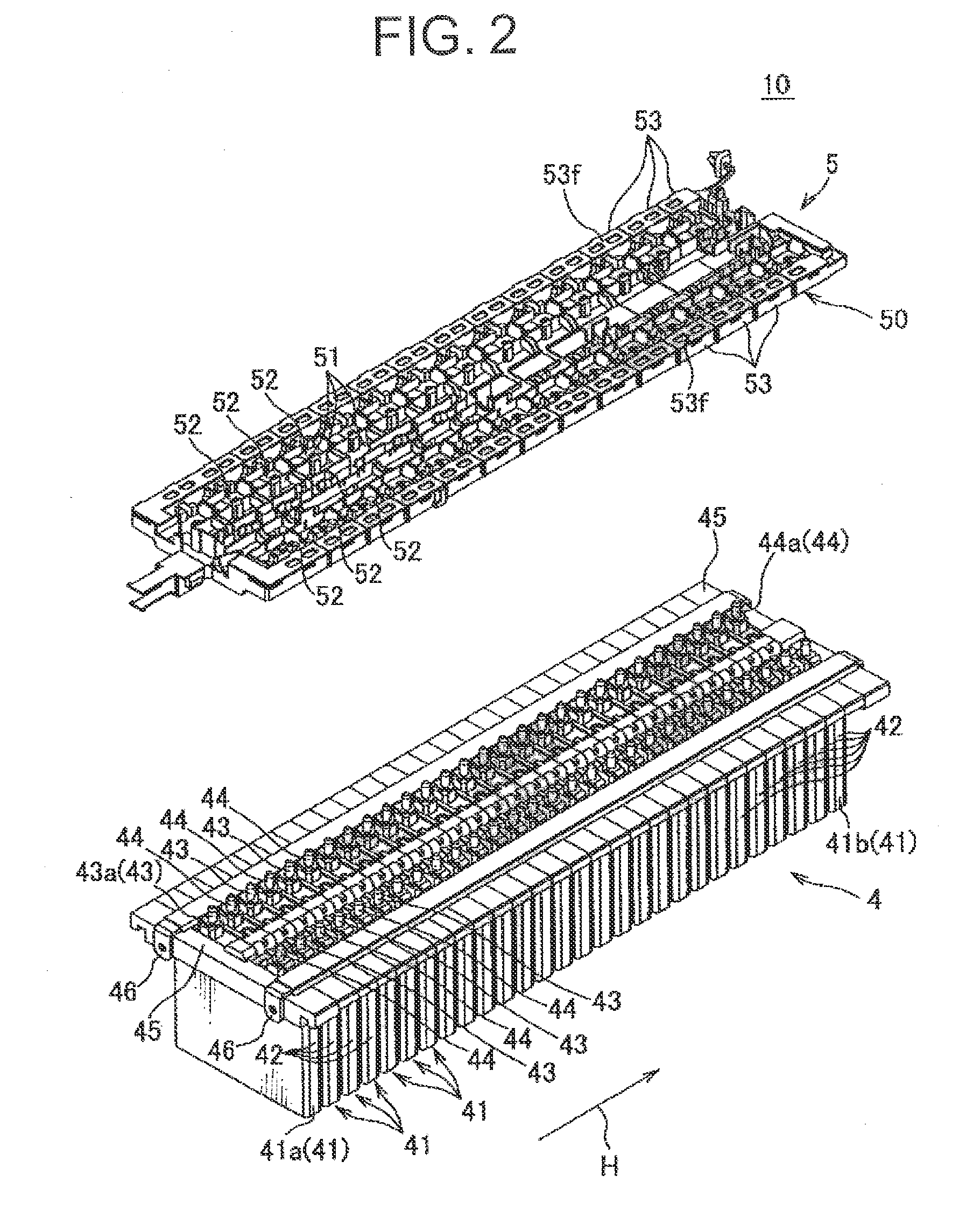

Busbar

ActiveUS8574003B2Reduce component countShorten assembly timeElectric discharge tubesCells structural combinationBusbarElectric wire

A busbar includes a battery connecting portion and a wire connecting portion as a circuit body connecting portion. The battery connecting portion connects electrodes of two batteries to each other. The wire connecting portion is continued to the battery connecting portion, and connected directly with an electric wire so as to overlap a core wire of an electric wire thereon. The wire connecting portion includes a welding portion which the core wire of the electric wire is welded to, and a bridge portion connecting the welding portion and the battery connecting portion. A cross-sectional area of the bridge portion along an intersecting direction intersecting a direction of connecting the welding portion and the battery connecting portion is formed to be smaller than a cross-sectional area of the welding portion along the intersecting direction.

Owner:YAZAKI CORP

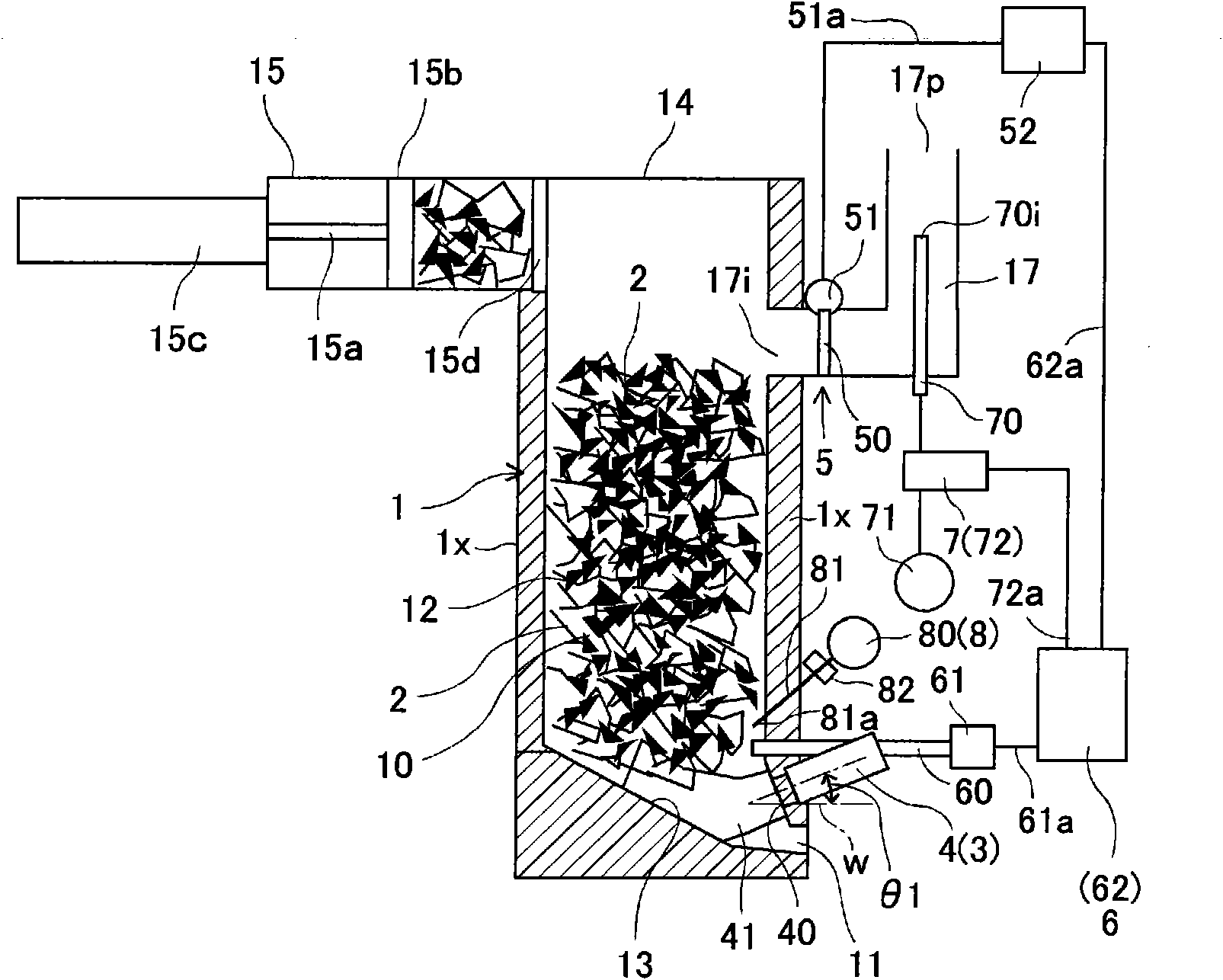

Gas cupola for melting metal

InactiveCN102047059AInhibition retentionReduce usageCharge manipulationShaft furnaceCombustorCupola furnace

The invention provides a gas cupola for melting metal. The gas cupola is capable of melting a charge efficiently with the burning flames of combustion burners. The gas cupola comprises a furnace casing (1) having a melting chamber (10) and a molten metal discharge port (11) for discharging molten metal, and a plurality of combustion burners (4) for forming burning flames (41). The combustion burners (4) jet the burning flames (41) into a charge (2) in the melting chamber (10) to thereby melt the charge (2) in the melting chamber (10). Each of the combustion burners (4) creates a hollow moltenportion (42) having a hollow shape in the charge (2) in the melting chamber (10) with the burning flame (41) jetted out from each combustion burner (4). In a sectional view of the furnace casing (1) taken in a horizontal direction, the combustion burners (4) are arranged such that adjacent hollow molten portions (42) overlap each other. At the melting time of the charge (2), each hollow molten portion (42) and the molten metal discharge port (11) communicate with each other.

Owner:AISIN TAKAOKA CO LTD

Protective device

ActiveUS8472158B2Effectively preventConvenient restEmergency protective arrangements for automatic disconnectionEmergency protective device manufactureAuxiliary memoryMaterials science

Owner:CYNTEC

Sealing sheet, method for producing semiconductor device, and substrate with sealing sheet

InactiveUS20160056123A1Easy to adjustImprove balanceAdhesive articlesSemiconductor/solid-state device detailsFilling materialsUltimate tensile strength

Provided are a sealing sheet capable of suppressing generation of voids due to satisfactory embeddability in irregularities of a semiconductor element or an adherend and with satisfactory workability before and after the sealing sheet is bonded to the adherend; a method for producing a semiconductor device using the sealing sheet; and a substrate with the sealing sheet bonded thereto. The sealing sheet includes a base material, and an under-fill material provided thereon having the following characteristics: a 90° peel strength from the base material of 1 mN / 20 mm or more and 50 mN / 20 mm or less; a rupture elongation of 10% or more at 25° C.; a minimum viscosity of 20,000 Pa·s or less at a temperature of 40° C. or more and 100° C. or less; and a minimum viscosity of 100 Pa·s or more at a temperature of 100° C. or more and 200° C. or less.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com