Patents

Literature

595results about "Emergency protective device manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

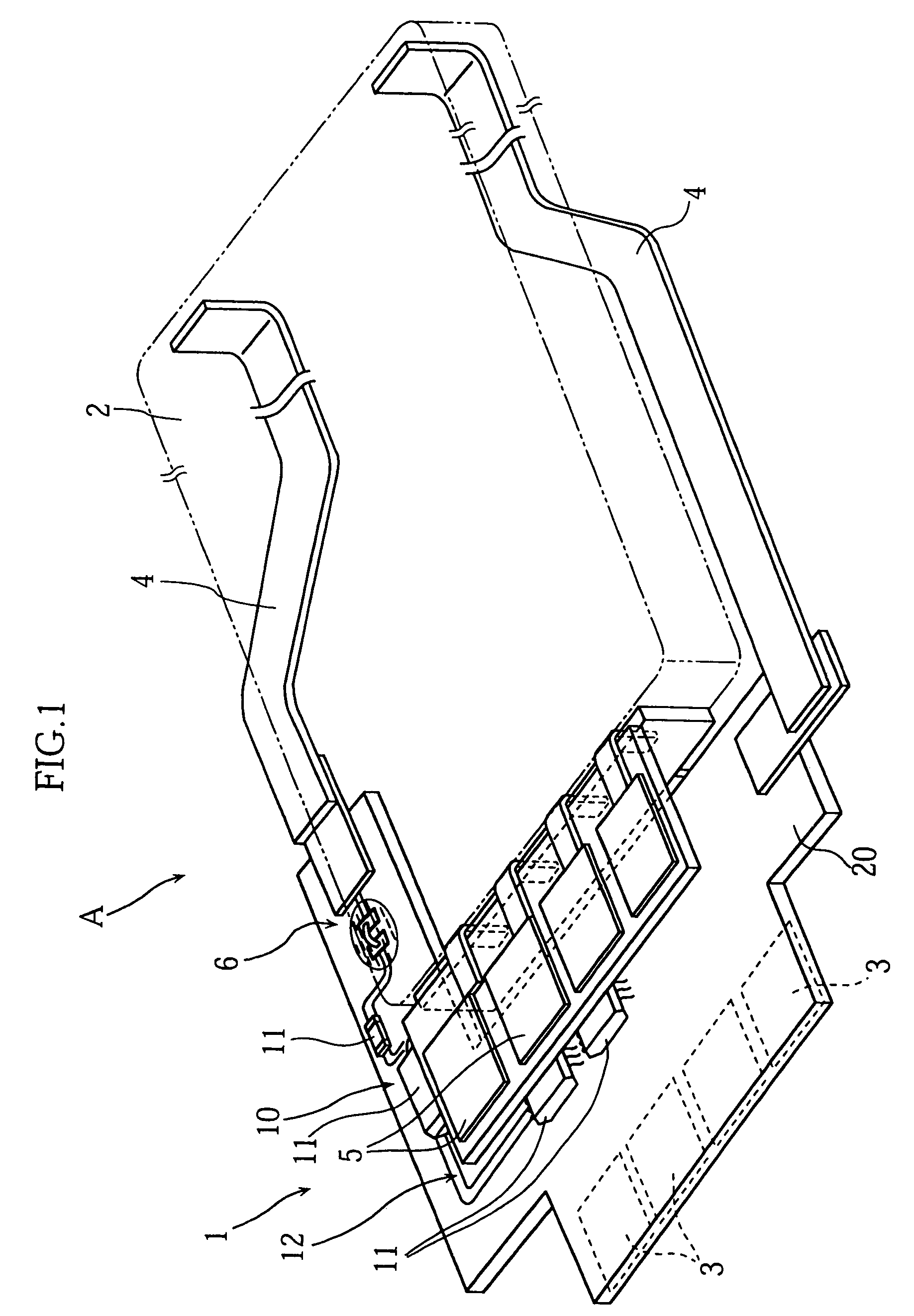

Printed-circuit board with fuse

InactiveUS7116208B2Simple and inexpensive meanPrinted circuit aspectsCircuit fluid transportPrinted circuit board

Owner:ROHM CO LTD

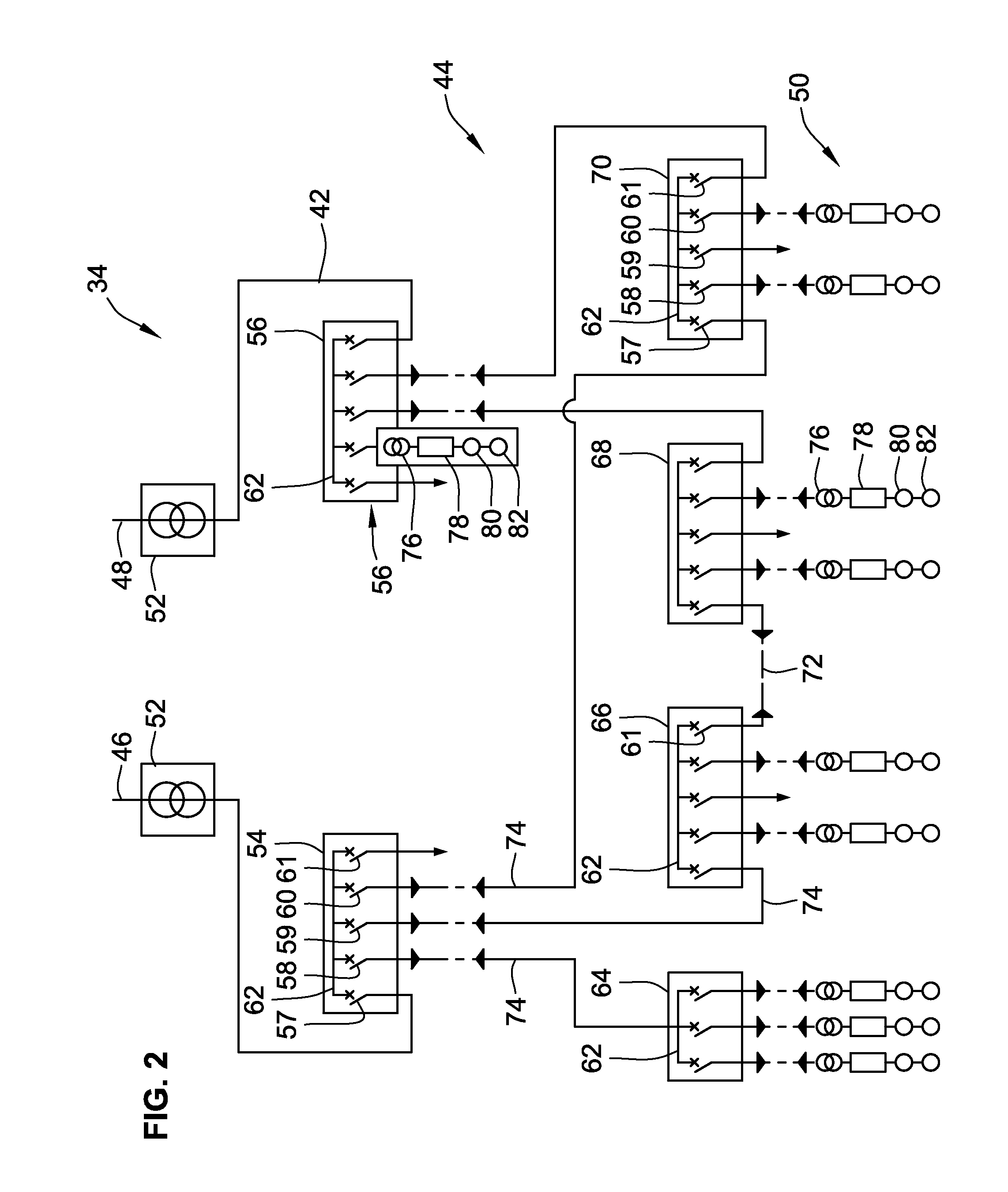

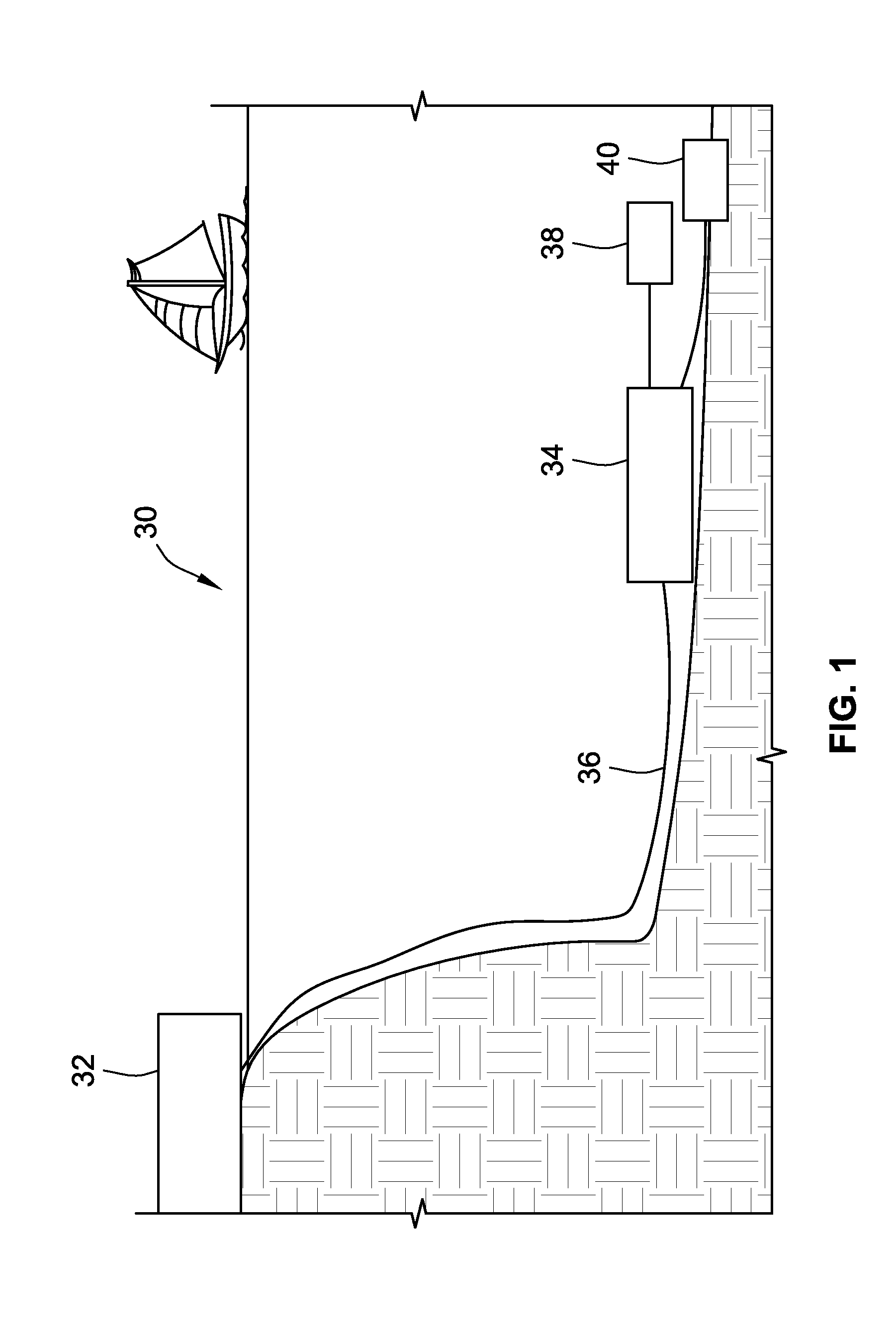

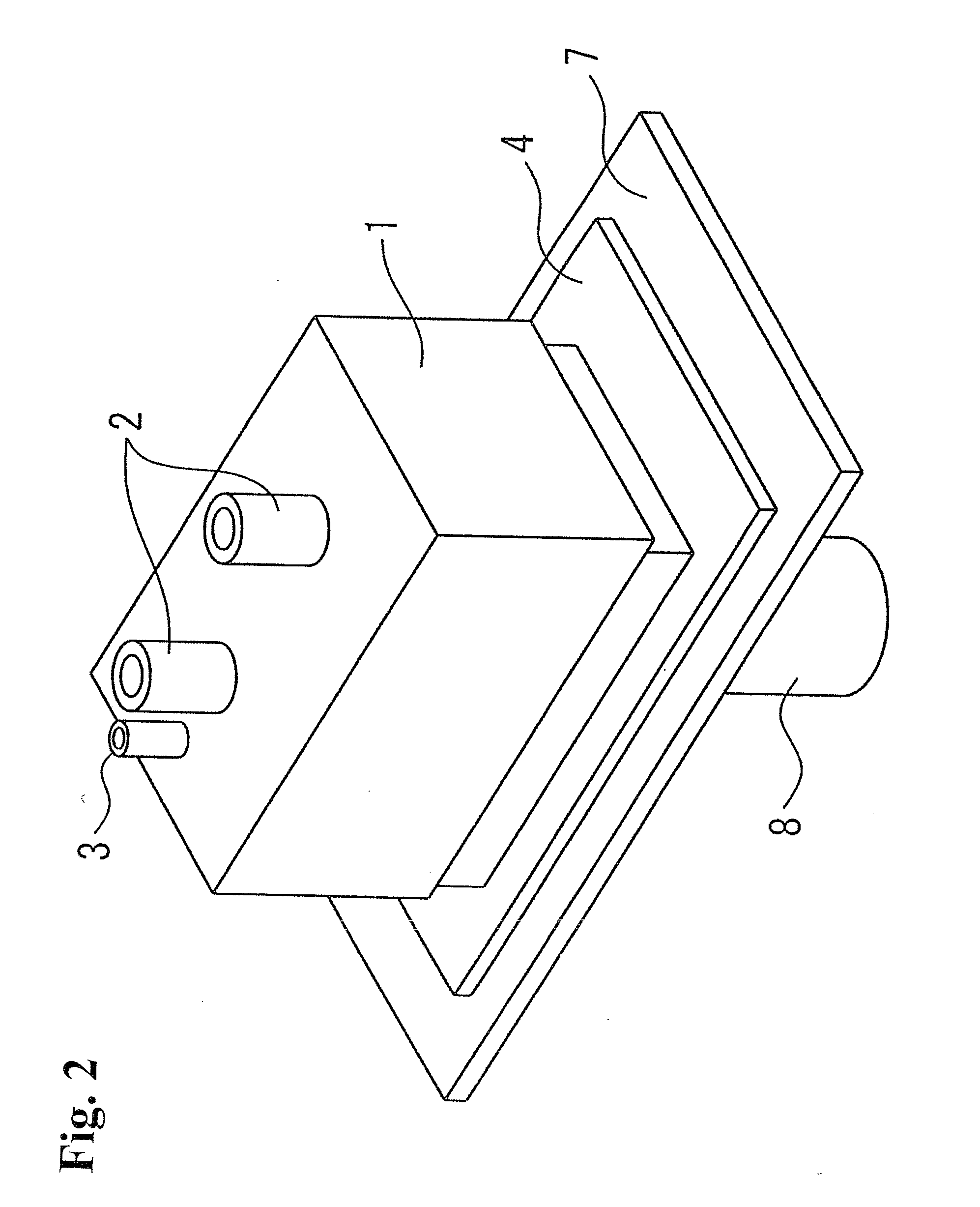

Subsea Electrical Distribution System Having a Modular Subsea Circuit Breaker and Method for Assembling Same

InactiveUS20130286546A1Increase contactKeep full controlBus-bar/wiring layoutsLine/current collector detailsElectricityBusbar

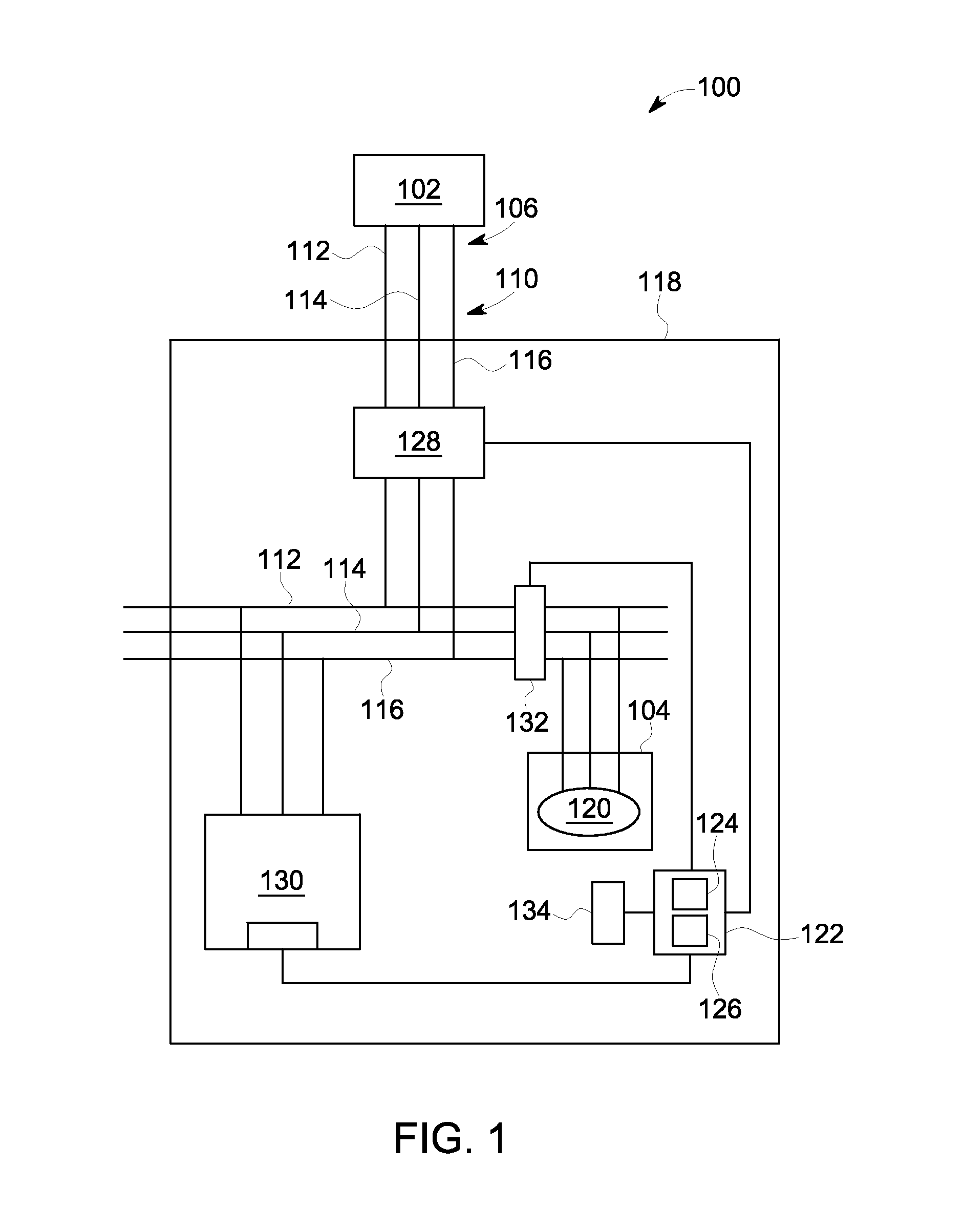

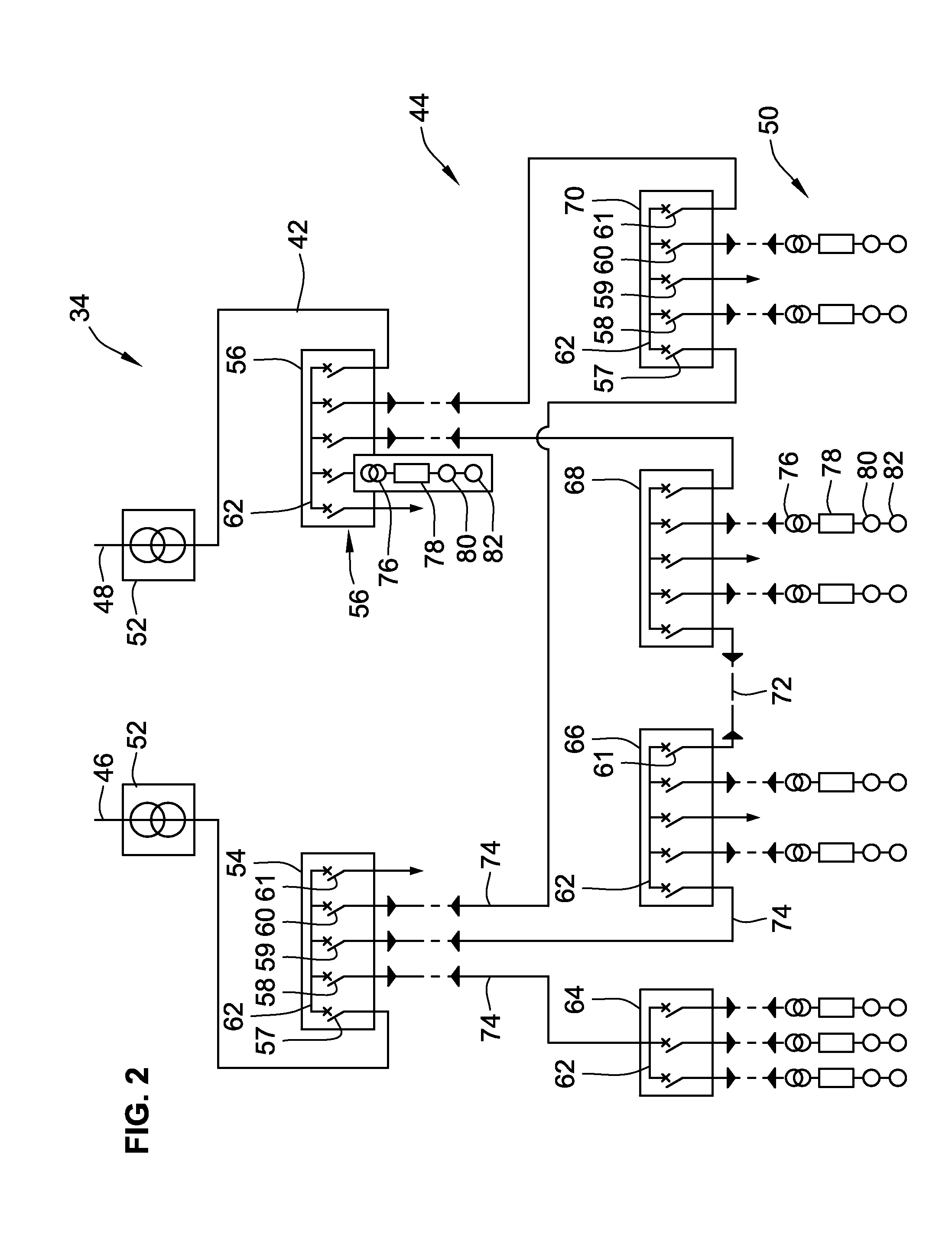

A system and method for coupling electrical power subsea. The system comprises a subsea electrical distribution system having at least one subsea circuit breaker assembly. The subsea circuit breaker assembly comprises a modular subsea busbar assembly configured to receive a plurality of modular cubsea circuit breaker assemblies and at least one modular subsea circuit breaker assembly secured to the modular subsea busbar assembly. The modular subsea circuit breaker assemblies may be coupled by subsea power cables to a source or power, an electrical load, or other subsea circuit breaker assemblies.

Owner:SCHNEIDER ELECTRIC IND SAS

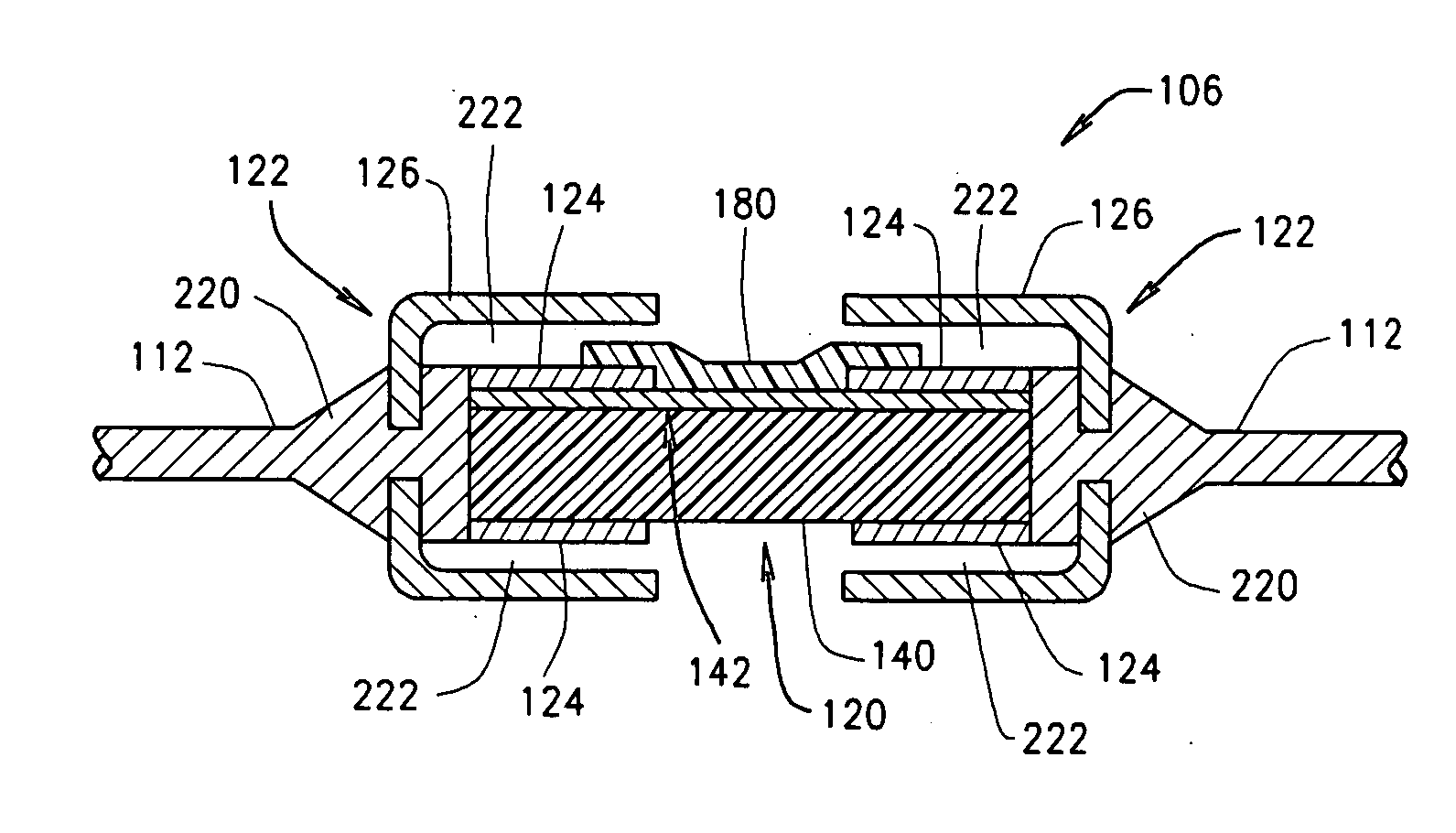

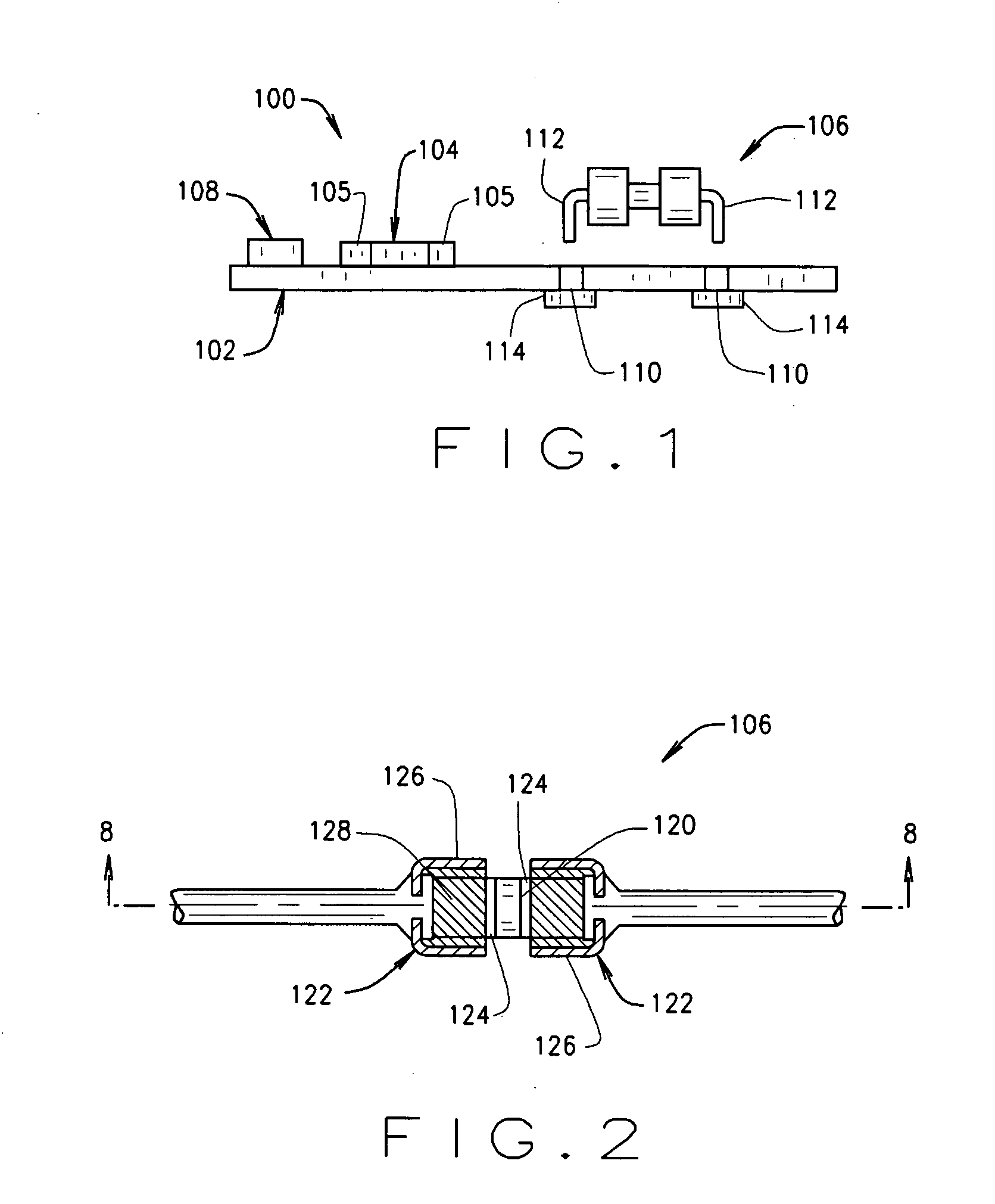

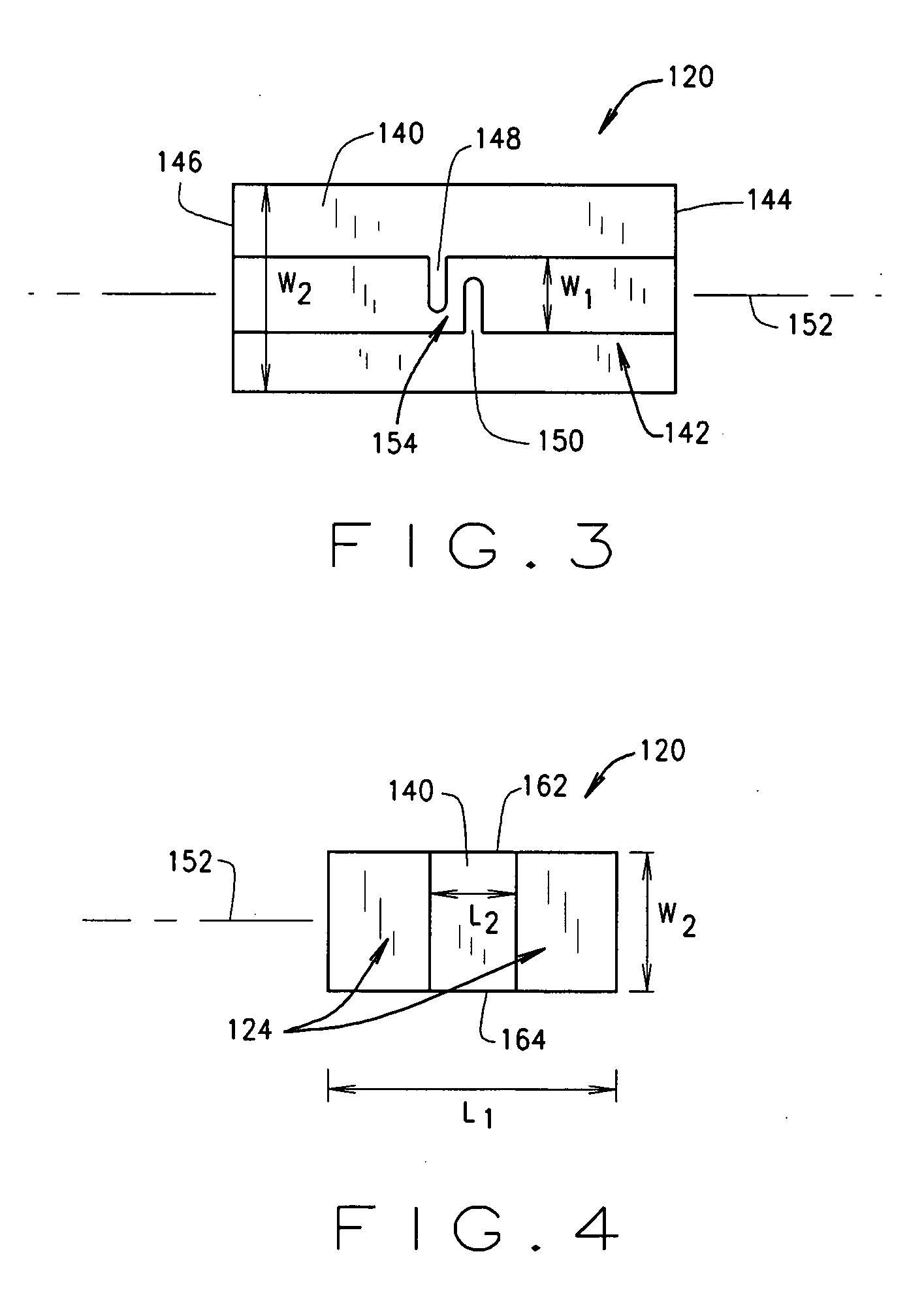

Hybrid chip fuse assembly having wire leads and fabrication method therefor

InactiveUS20060214259A1Final product manufactureSemiconductor/solid-state device detailsContact padElectrical connection

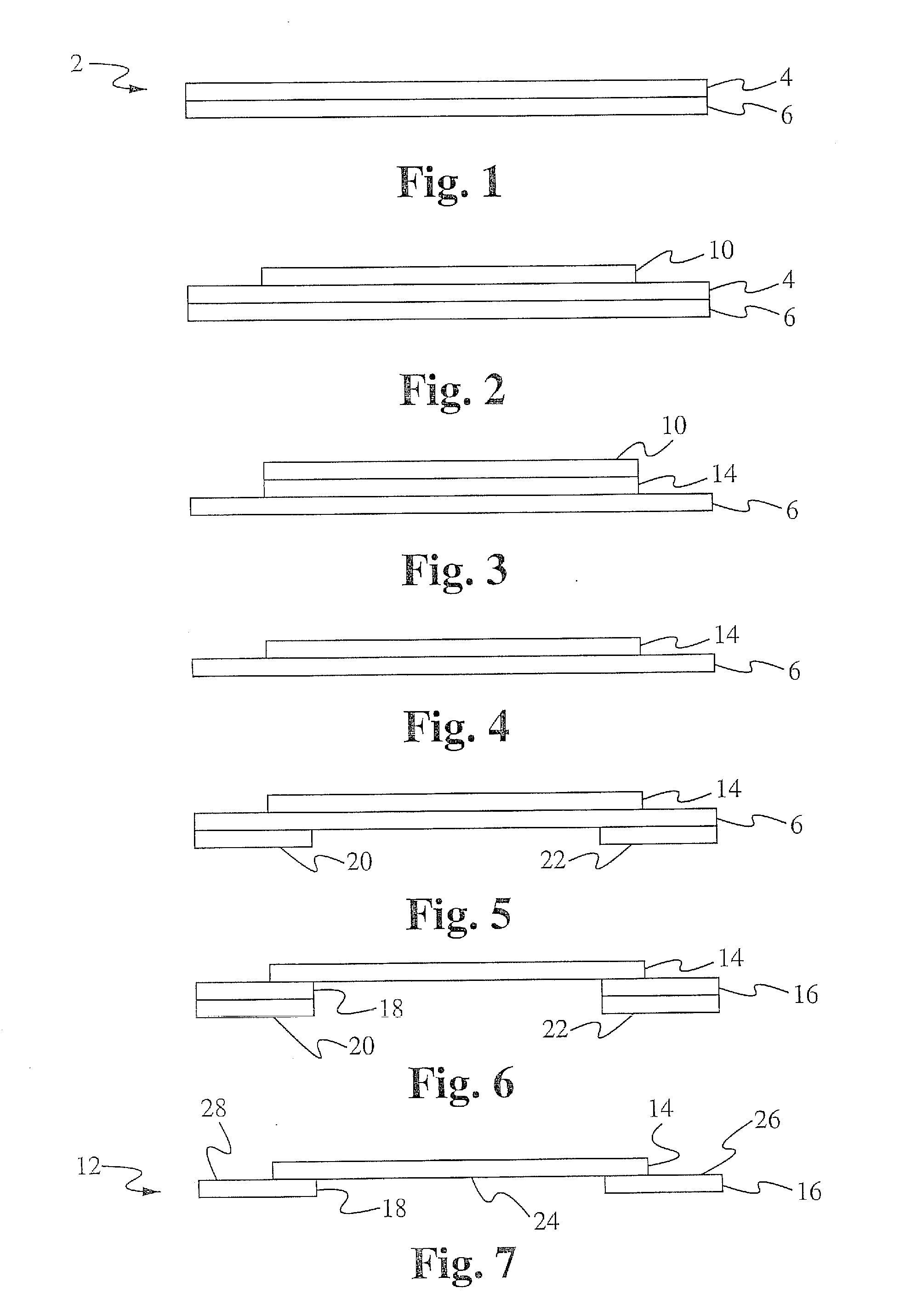

A chip fuse includes a substrate, a fuse element extending on the substrate, and first and second wire leads coupled to the fuse element. Contact pads may extend over portions of the fuse element and establish electrical connection to the first and second leads. A conductive medium such as solder encircles the substrate to securely form a mechanical and electrical connection to the leads.

Owner:COOPER TECH CO

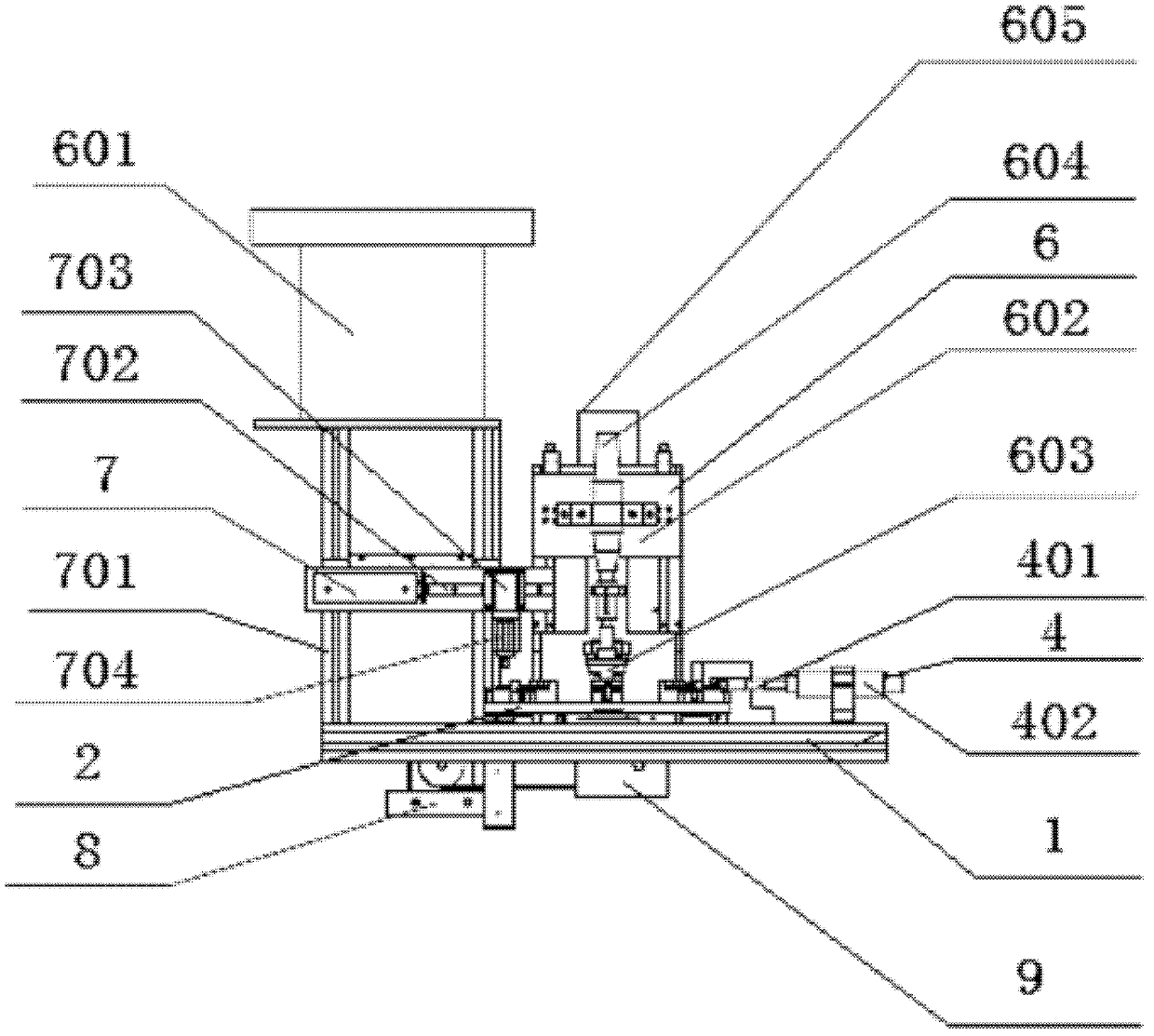

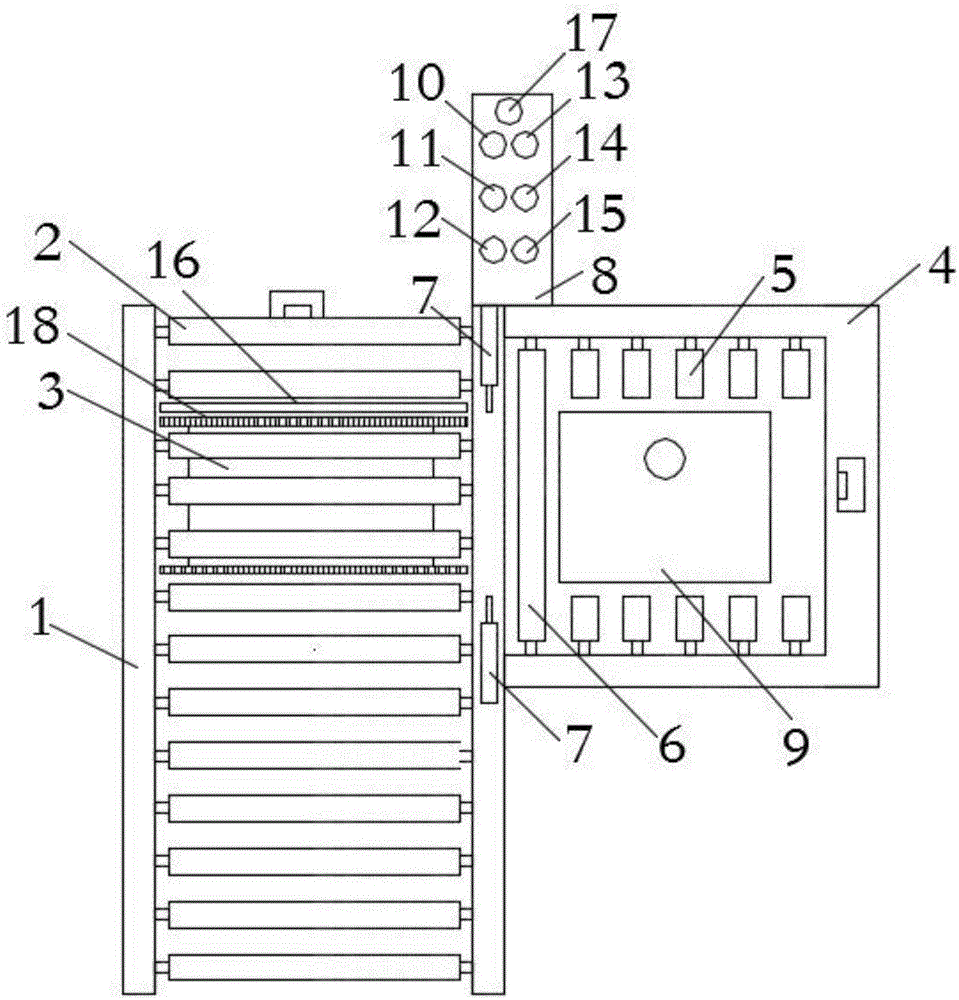

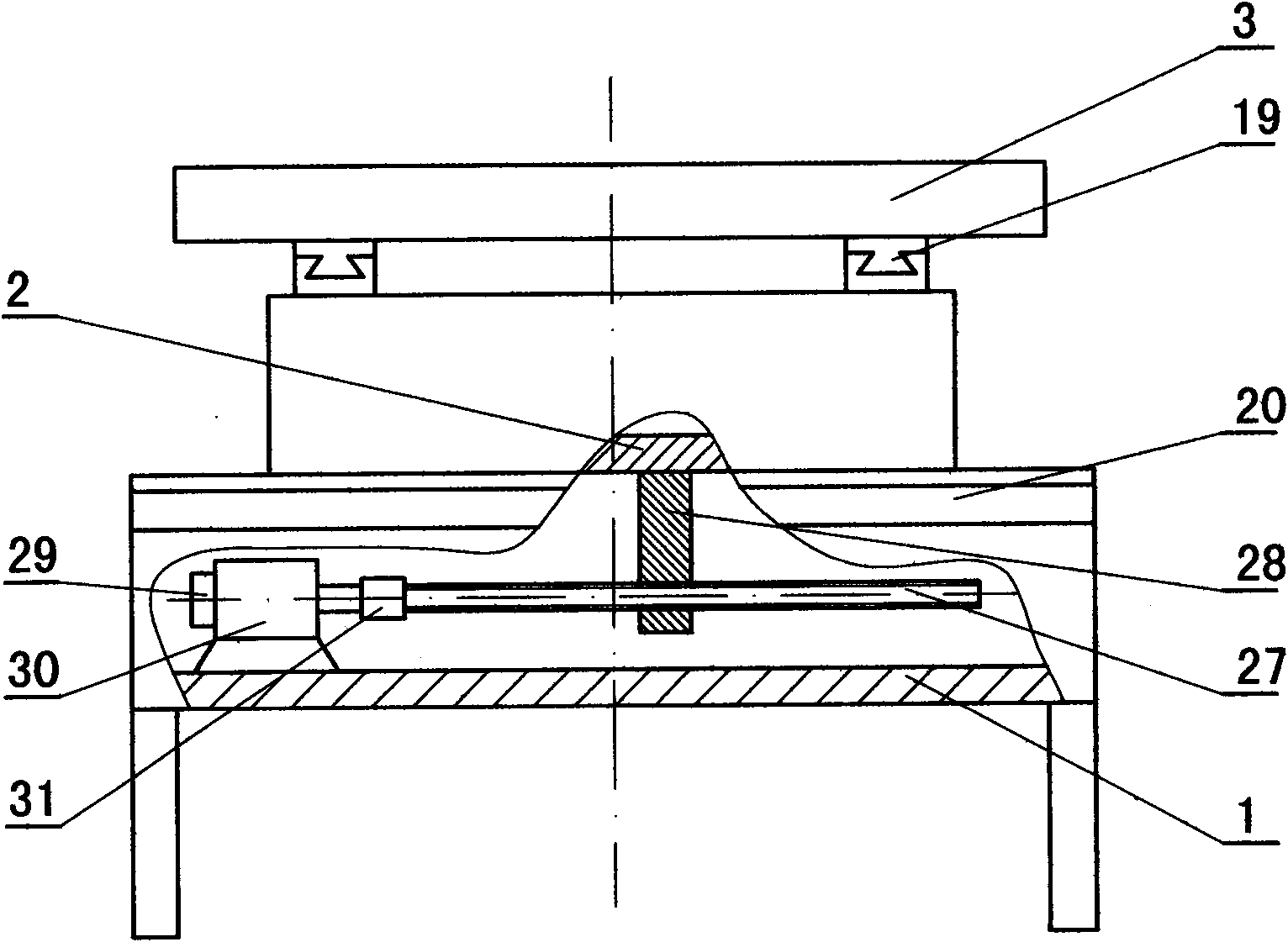

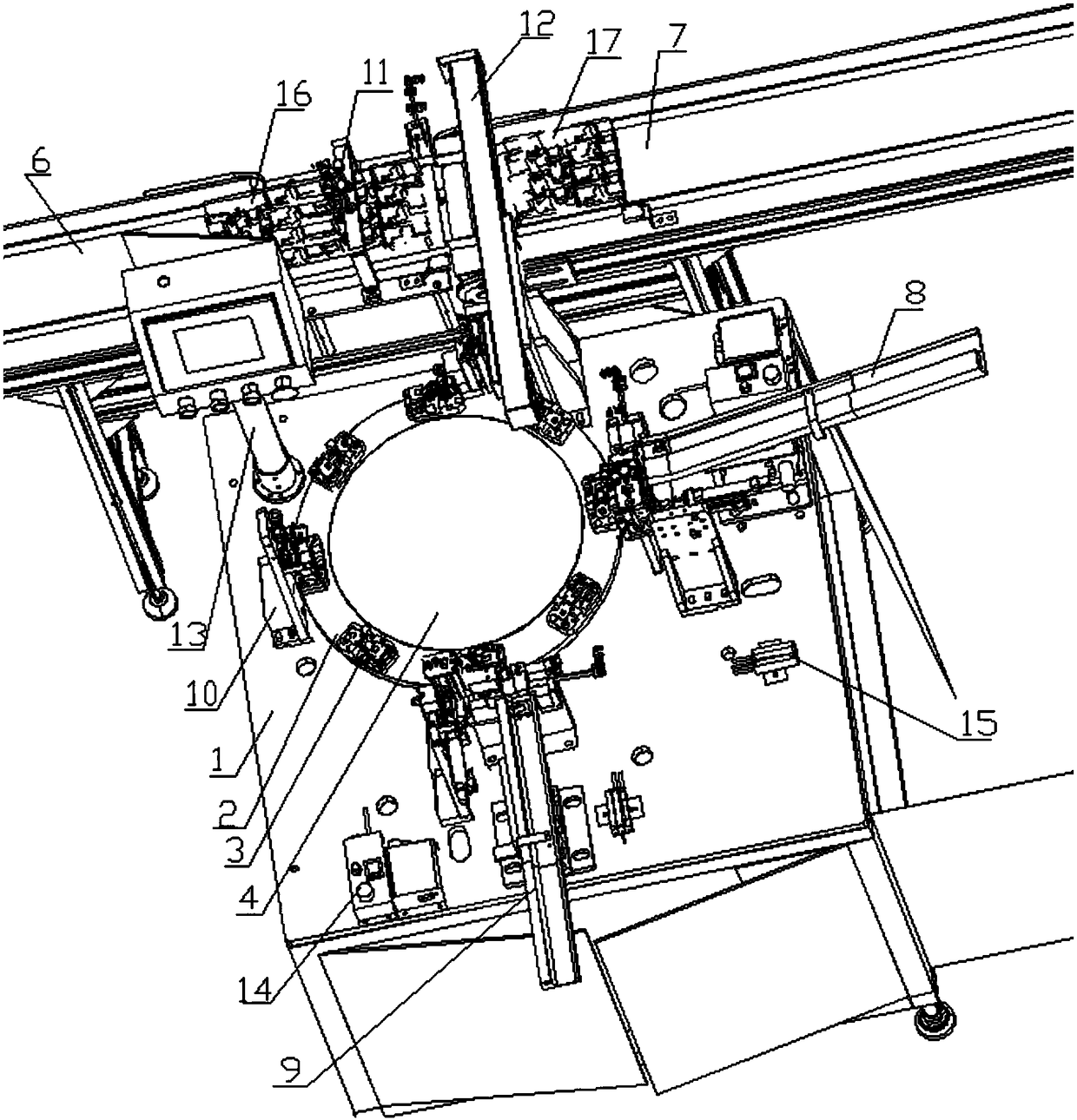

Breaker semi-automatic auxiliary assembling device

InactiveCN102386022AWaste less timeIncrease productivityEmergency protective device manufactureRobot handElectrical connection

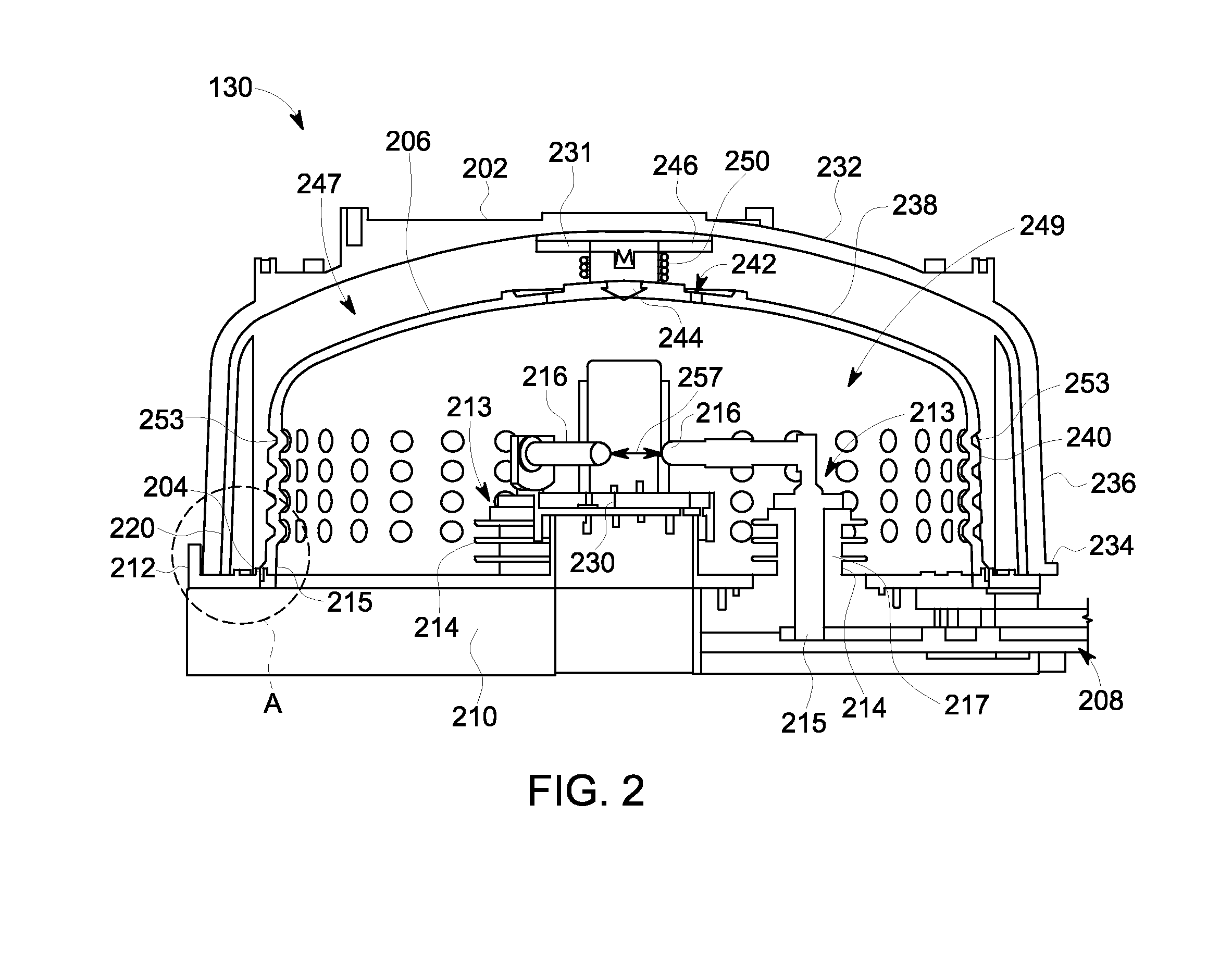

The invention discloses a breaker semi-automatic auxiliary assembling device, comprising a working platform. The breaker semi-automatic auxiliary assembly device is characterized in that the working platform is provided with a rotary table which is driven to rotate by a driving device, the rotary table is provided with a plurality of breaker assembly preassembling fixtures on the circumference at intervals; and the working platform is sequentially provided with a sleeve riveting device, a product automatic detecting device, a screw automatic assembling device and a manipulator material fetching device along the rotating direction of the rotary table, wherein the product automatic detecting device is electrically connected with the screw automatic assembling device. By applying the breaker semi-automatic auxiliary assembling device provided by the invention, production efficiency can be improved, and product assembling consistency and continuity can be greatly improved, thus industrial semi-automatic production of breakers is realized.

Owner:FORETECH ELEC APP JIANGSU CORP

Circuit breaker assembling device

InactiveCN105059905AImprove assembly efficiencyImplement follow-up operationsMetal working apparatusEmergency protective device manufactureEngineeringAssembly line

The invention discloses a circuit breaker assembling device. The circuit breaker assembling device comprises a conveying mechanism and an assembling mechanism. The conveying mechanism comprises a rack, conveying rollers, a jacking translation device and a plurality of baffles, wherein the conveying rollers are arranged between the two parts of the rack; the jacking translation device is disposed under the conveying rollers; the multiple baffles are mounted among the conveying rollers; the jacking translation device comprises a plurality of chains which are disposed among the conveying rollers; the chains are perpendicular to the rolling direction of the conveying rollers; the baffles are parallel to the chains, arranged on one sides of the chains and used for stopping conveying of a circuit breaker. The assembling mechanism is fixedly arranged on one side of the conveying mechanism and comprises an assembling framework, a driving device, a control console and an assembling table, wherein the driving device is disposed on the inner side of the assembling framework. The circuit breaker assembling device has the beneficial effects that the flow line production and the assembling mechanism are combined so as to perform circuit breaker mechanism assembly and production; therefore, the assembling efficiency is increased; the labor intensity of workers is relieved; off-line repair or detection is achieved without limit of an existing assembling mechanism provided with only one assembly line which only conveys similar products.

Owner:YIHE ELECTRIC GRP

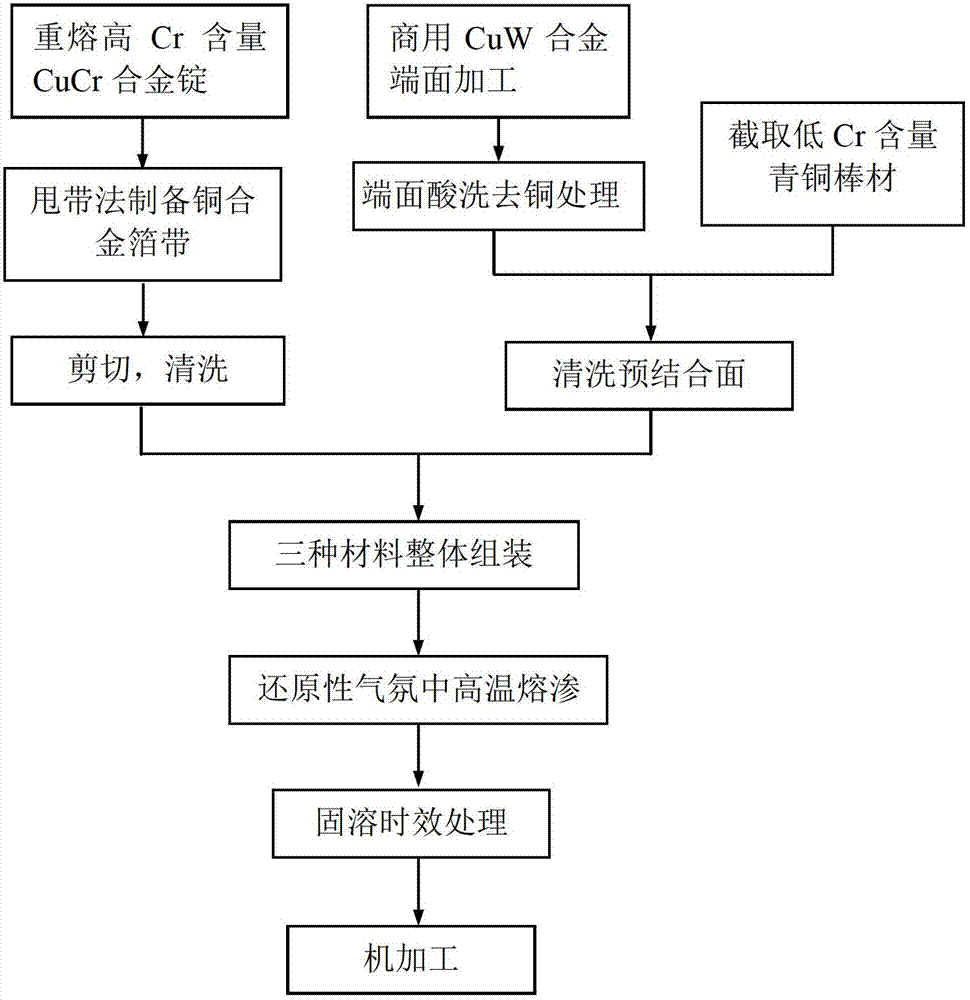

Preparation method of CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact

ActiveCN102760597AImprove the bonding strength of the interfaceReduce manufacturing costElectric switchesEmergency protective device manufactureReducing atmosphereSolid solution

The invention discloses a preparation method of a CuW (Copper Tungsten) and CuCr (Copper Chromium) integrated material used for high voltage electric contact. The method comprises the following steps: firstly, a high copper alloy foil strip is prepared by using a rapid solidification melt-spinning method; subsequently the de-coppering treatment is carried out on a CuW pre-combining plane by using an acid dissolving method; a porous W-framework is obtained on the combining plane; the overall sintering infiltration is carried out on the CuW, the alloy foil stripe and the CuCr alloy inside a reducing atmosphere furnace so as to obtain the CuW and CuCr integrated material; and subsequently the solid solution aging treatment is carried out on the material. As the Cr element inside the alloy foil stripe is filled and infiltrated into the porous framework during the infiltration process and is formed into W-Cr solid solution with the W, the metallurgical bonding is realized between the framework and a substrate copper phase; and the boundary bonding strength of the integrated material is improved.

Owner:XIAN UNIV OF TECH

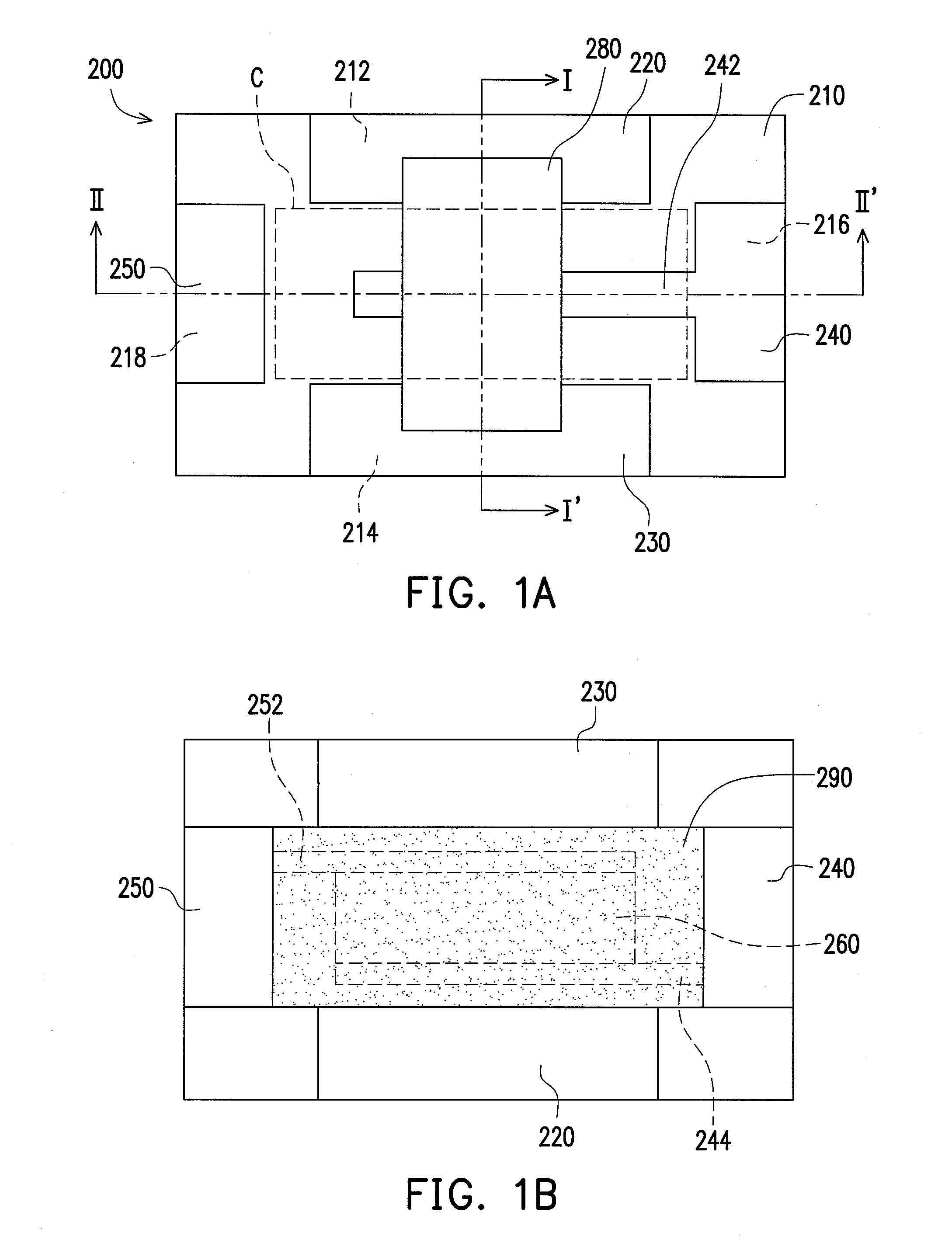

Fuse element and manufacturing method thereof

InactiveUS20090009281A1High currentHigh operating requirementsSemiconductor/solid-state device manufacturingEmergency protective device manufactureInsulation layerSurface roughness

A fuse element comprises a substrate having a top surface, a bottom surface opposite to said top surface, and side surfaces, a heat insulation layer including a first surface and a second surface opposite to said first surface, said first surface of said heat insulation layer disposed on said top surface of said substrate, and said second surface having a surface roughness, a protective layer disposed above said heat insulation layer, and a fuse layer disposed between said heat insulation layer and said protective layer.

Owner:CYNTEC

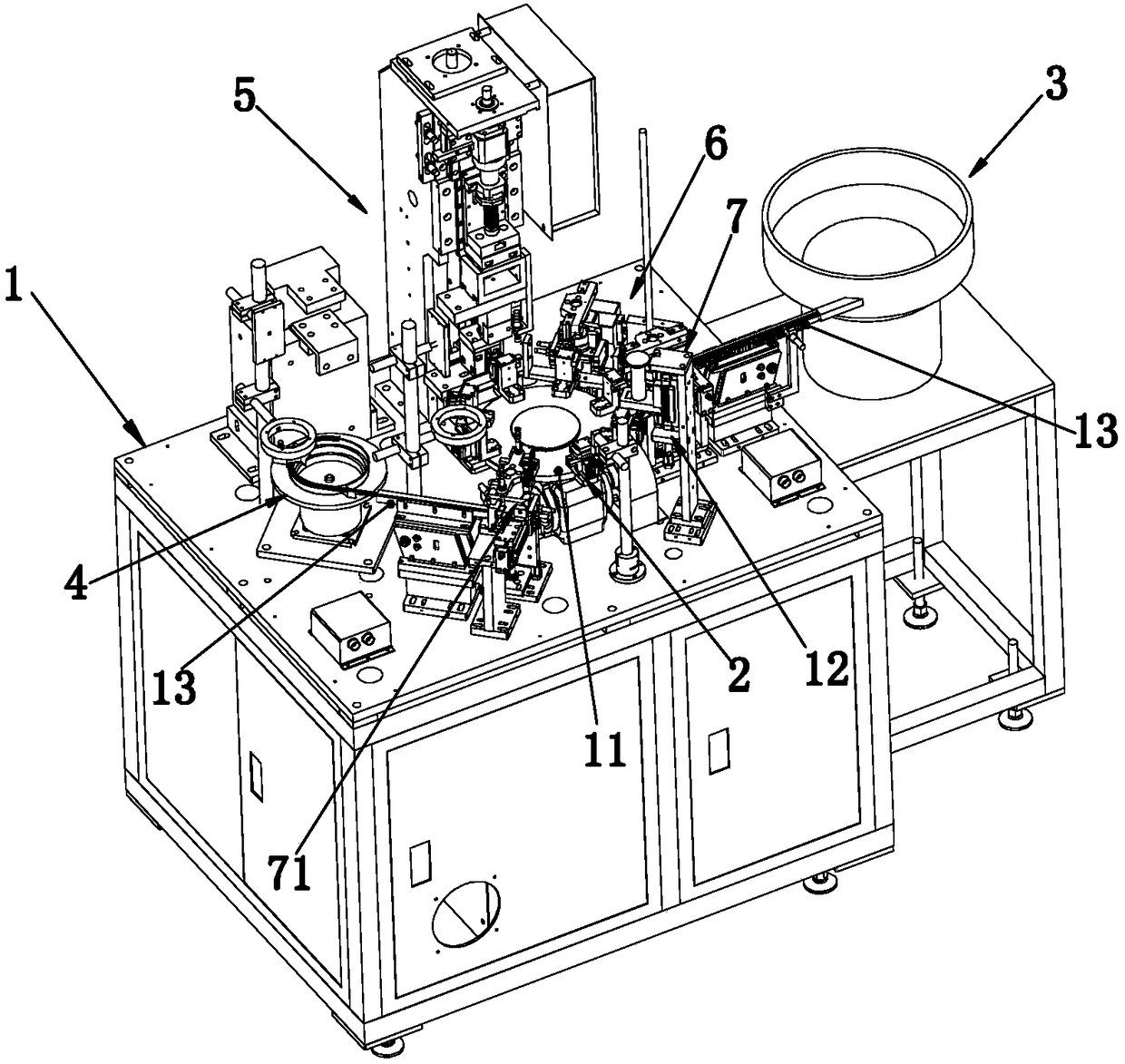

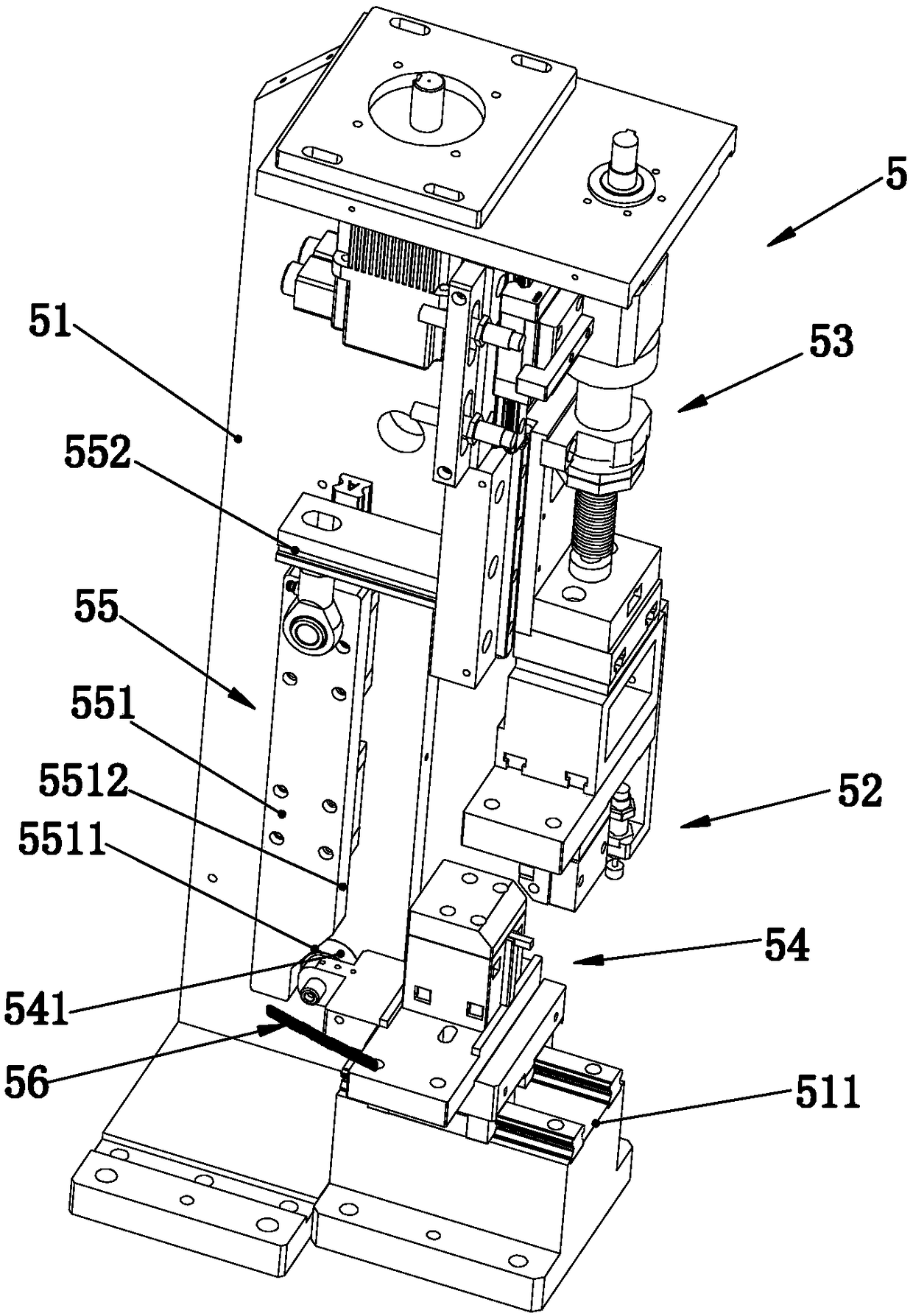

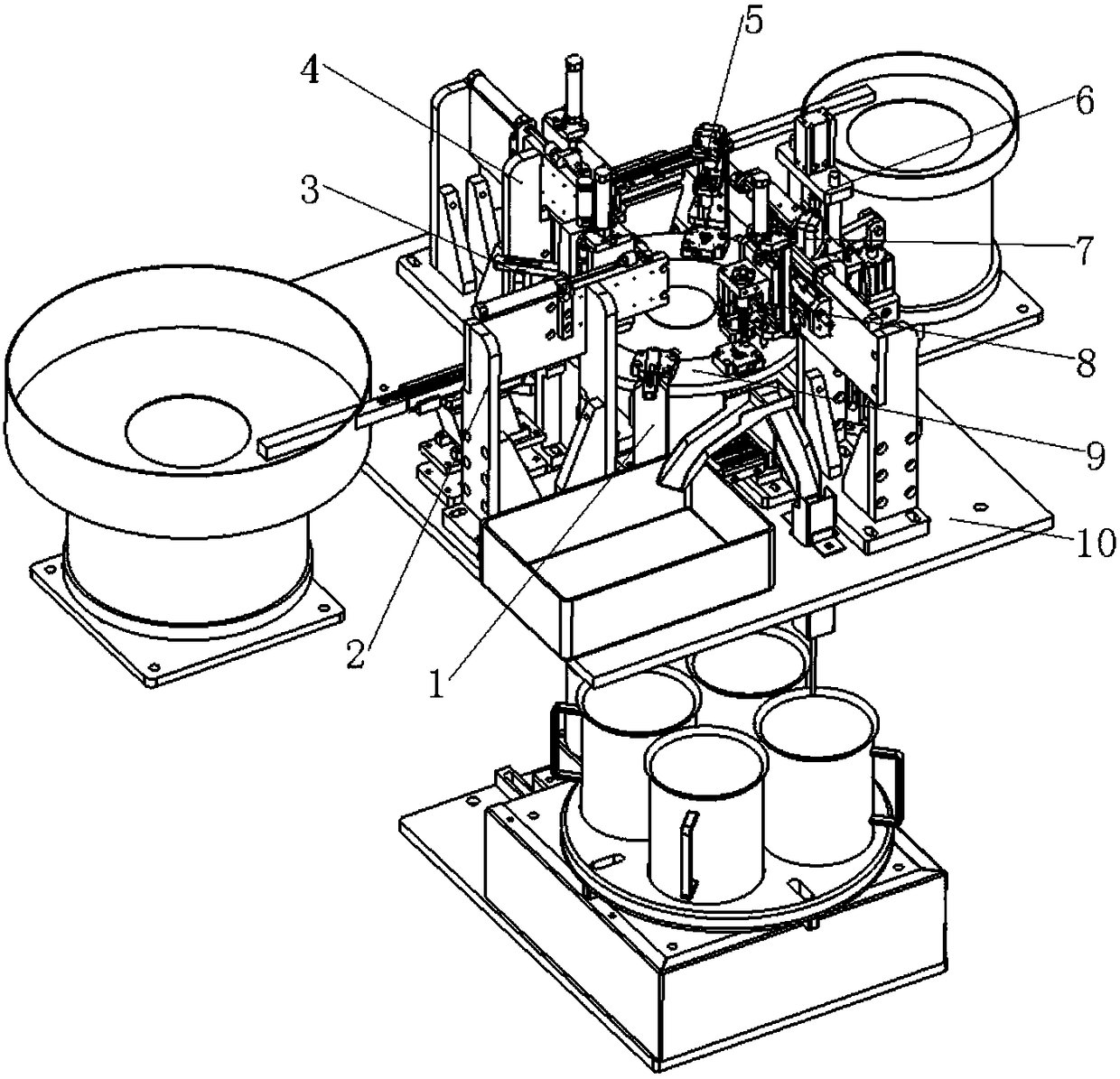

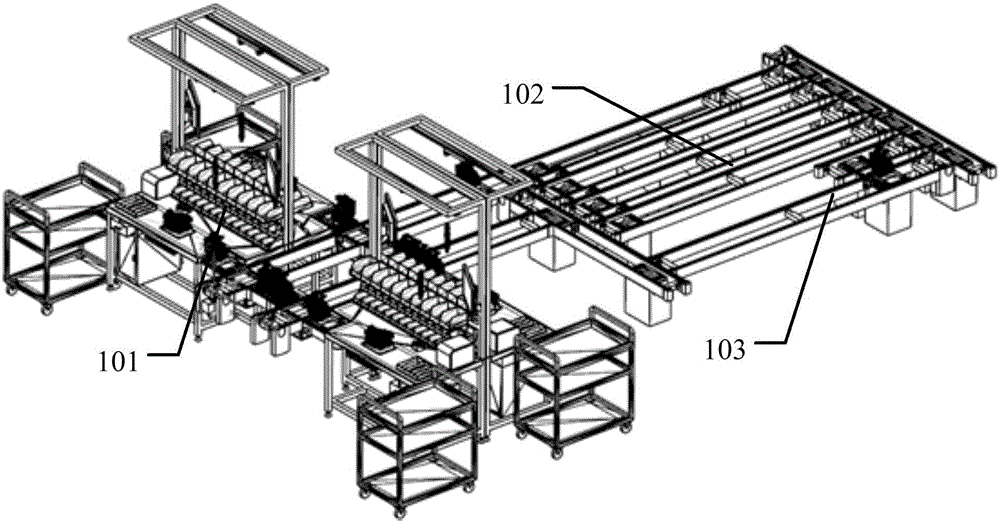

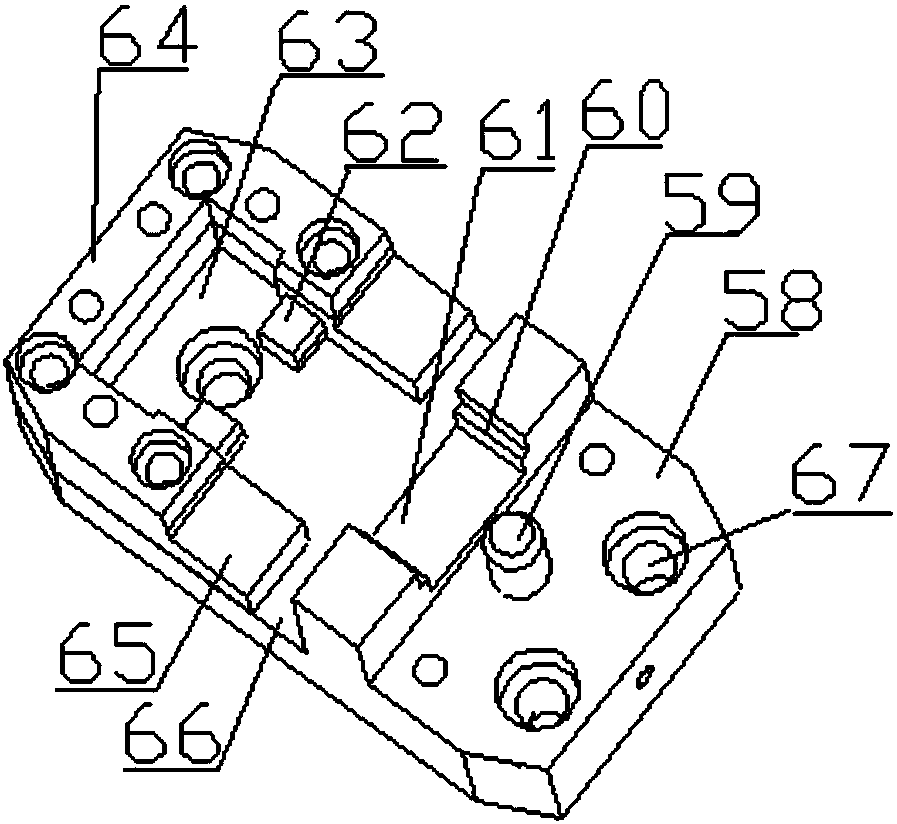

Full-automatic circuit breaker contact and silver point welding equipment

PendingCN108321037AFast transit deliveryShort transfer distanceEmergency protective device manufactureSolder feeding devicesEngineeringOutput device

The invention relates to full-automatic circuit breaker contact and silver point welding equipment. The full-automatic circuit breaker contact and silver point welding equipment comprises a machine body a rotation disc, a clamping device arranged along the edge of the rotation disc, a contact vibration charging tray, a contact drop soldering paste device, a silver point vibration charging tray, acontact and silver point welding device and a product output device. The contact vibration charging tray and the silver point vibration charging tray are connected to the clamping device through a transport channel. Conveying devices are arranged between the contact vibration charging tray and the contact drop soldering paste device and between the silver point vibration charging tray and the welding device. The welding device comprises a support seat erected on the machine body, a welding mechanism, a lifting component and a welding seat. The support seat is provided with a slide rail, wherein the welding seat carries out reciprocation slip on the slide rail. And the support seat is provided with a linkage component. In the technical scheme, the full-automatic circuit breaker contact andsilver point welding equipment is provided; and through using the equipment, welding efficiency is increased, a welding point is accurate, linkage performance is good, clamping is stable and the structure is simple.

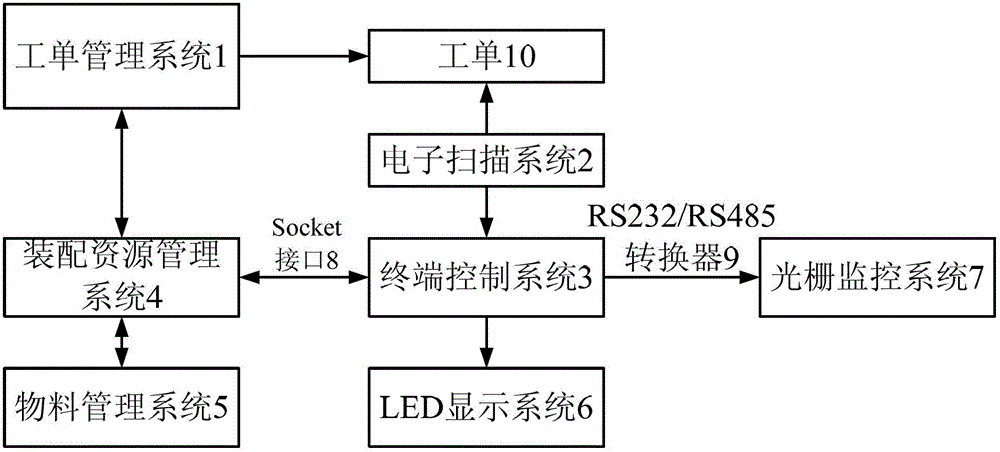

Misassembly preventive system for electrical product assembly

ActiveCN102723243AReduce the possibility of errorConvey accuratelyEmergency protective device manufactureGratingLED display

The invention discloses a misassembly preventive system for electrical product assembly. A work order management system generates and prints a work order according to an assembly plan, an electronic scanning system scans bar code information on the work order and transmits the bar code information to a terminal control system, the terminal control system transmits the bar code information to a material management system through an assembly resource management system, the material management system inquires all material information related to the work order and transmits the material information to the terminal control system through the assembly resource management system, the terminal control system enables material list information to be displayed on an LED display system and synchronously transmits the material list information to a grating monitoring system, and the grating monitoring system detects whether workers take materials from correct material cabinets or not, and if not, alarms and displays. Relationships between materials and assembly products are established by the work order management system, assembly workers learn materials needed for assembly by scanning the work order and monitor by utilizing gratings on material shelves, and accordingly problems of neglected assembly, misassembly of electrical products and the like are effectively solved.

Owner:SHANGHAI JIAO TONG UNIV

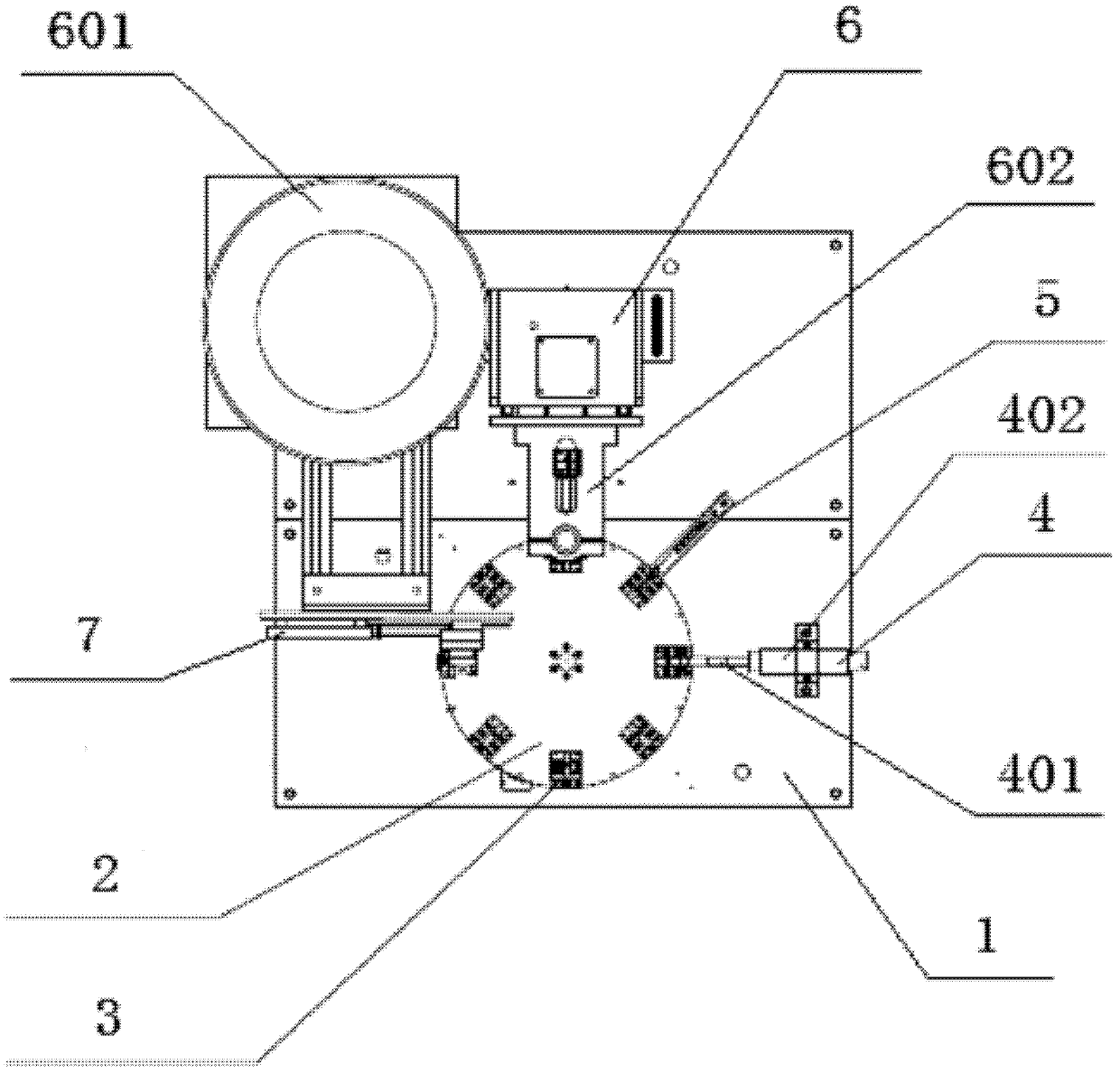

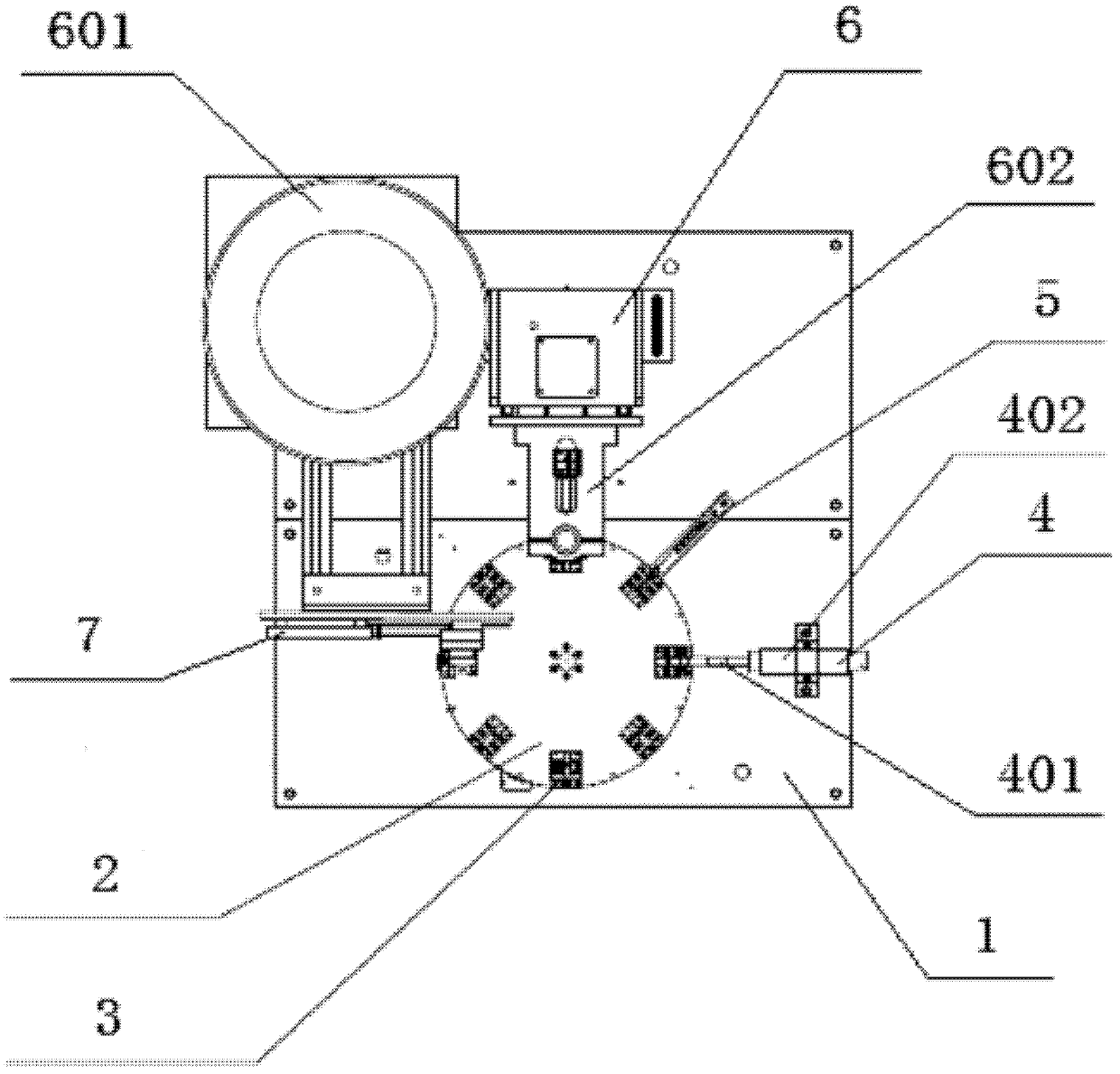

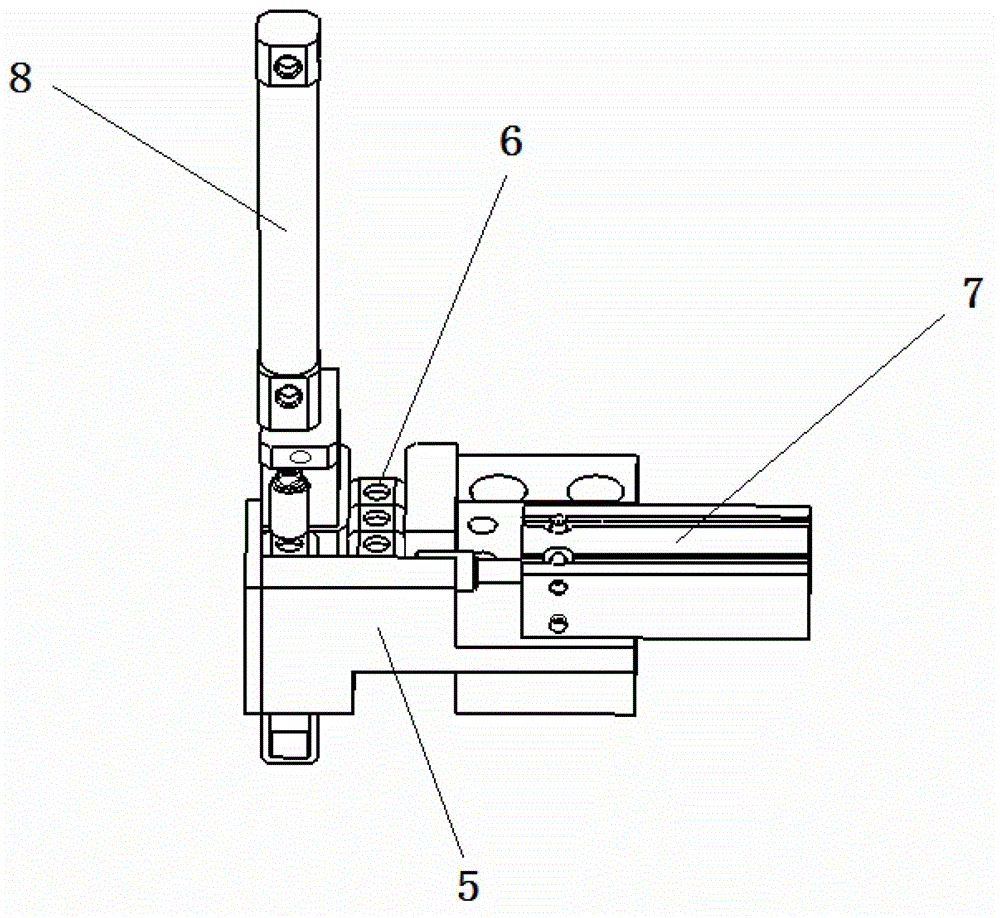

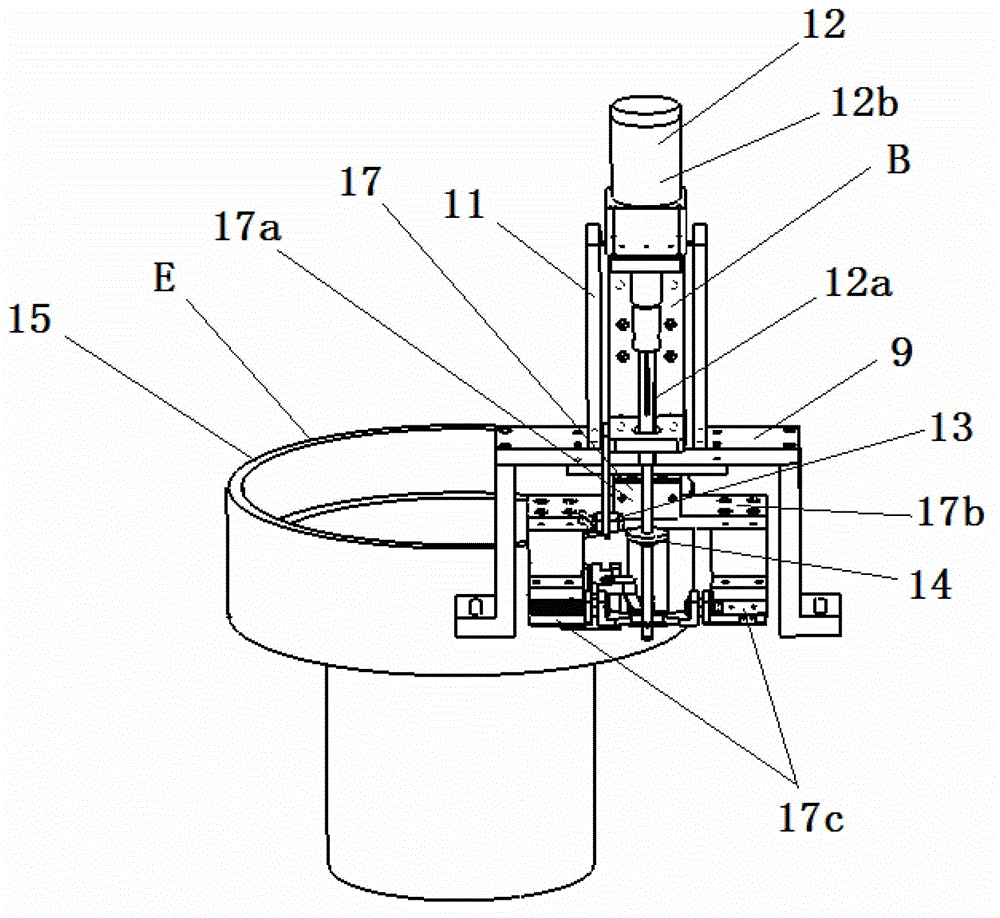

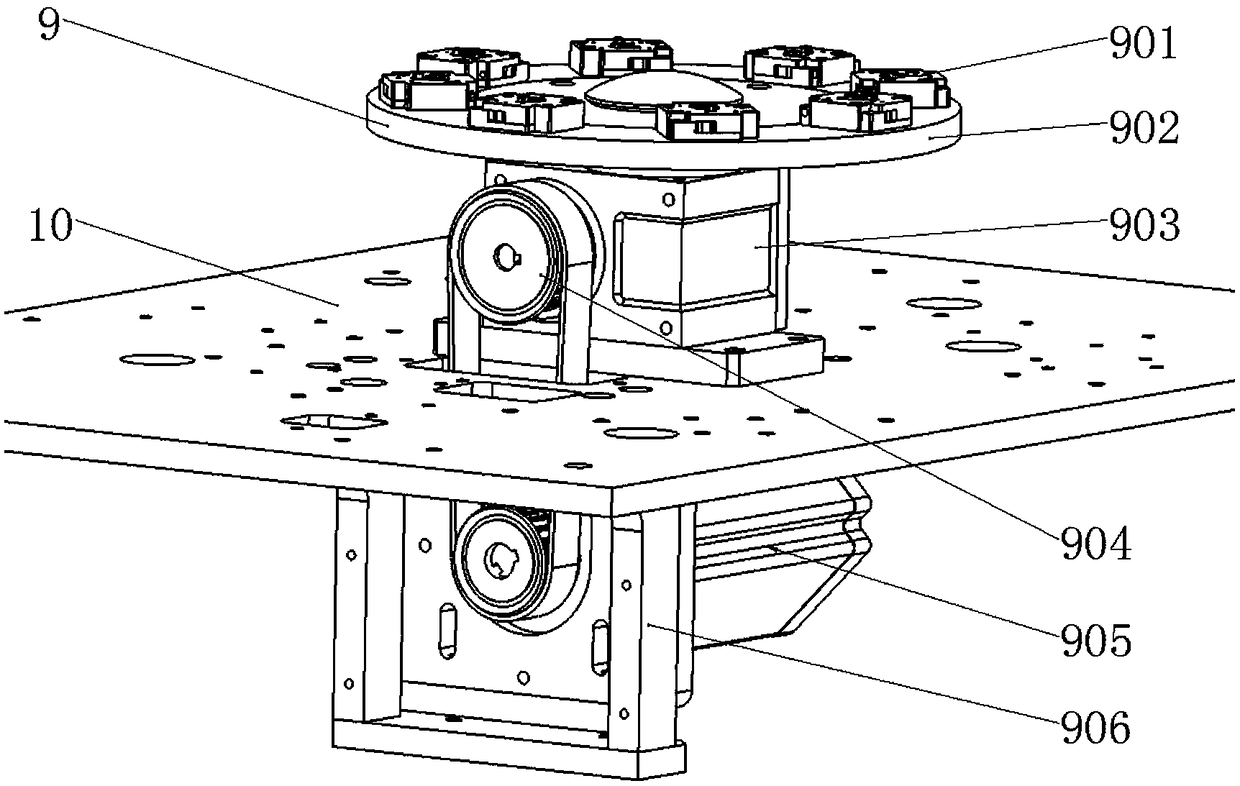

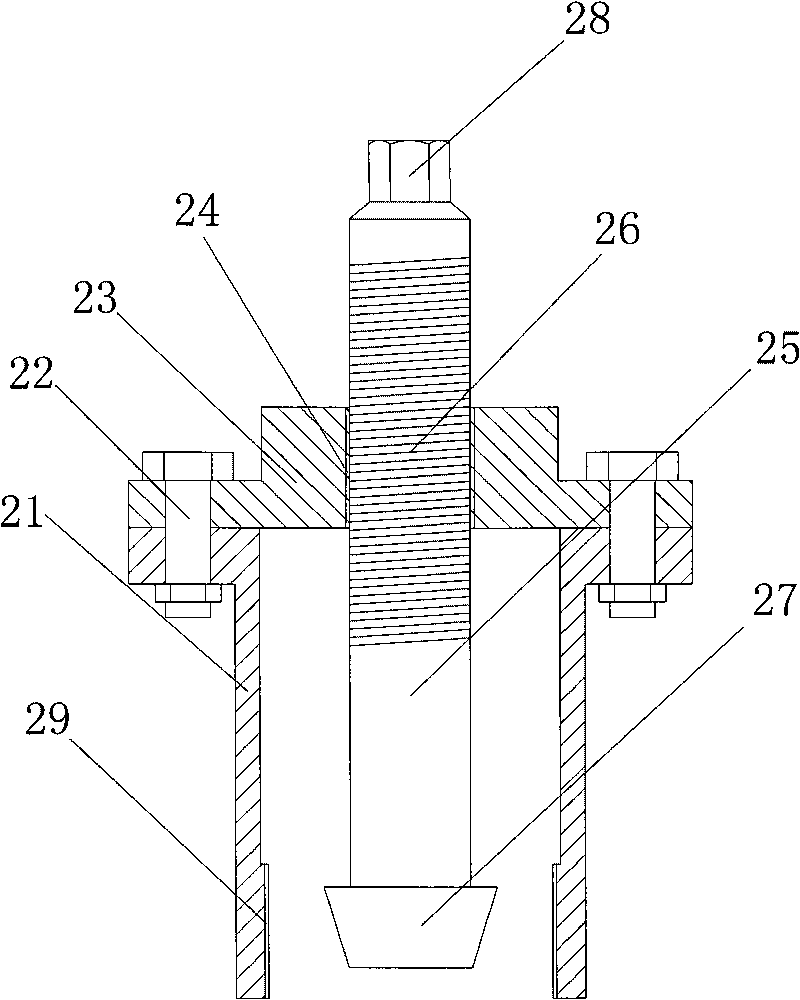

Automatic assembly device of breaker terminal screw

ActiveCN102945773AImprove assembly qualityIncrease productivityEmergency protective device manufactureProgrammable logic controllerControl engineering

The invention discloses an automatic assembly device of a breaker terminal screw. The device comprises a bench. The device is characterized in that a rotary disk which is driven by a rotary disk drive device to rotate, a terminal feeding device, a screw matching detection device, a screwing back device and a qualified product unloading device are installed on the bench, the terminal feeding device, the screw matching detection device, the screwing back device and the qualified product unloading device are arranged on four stations on the periphery of the rotary disk along the rotary direction of the rotary disk sequentially, at least one terminal positioning hole which rotates through the rotary disk and corresponds to the devices on the stations is arranged on the rotary disk, a screw feeding device and a defective product unloading device which correspond to the screw matching detection device are arranged on the bench, and all devices are connected to a Programmable Logic Controller (PLC). By the aid of the device, the assembly of the breaker terminal screw can be completed automatically, defective products can be removed, the production efficiency is improved effectively, the labor cost is reduced and the assembly quality of the breaker terminal screw is stable and reliable.

Owner:FORETECH ELEC APP JIANGSU CORP

Automatic assembly device for handle and torsion spring of circuit breaker

PendingCN108321038AHigh precisionImprove consistencyEmergency protective device manufactureEngineeringTorsion spring

The invention provides an automatic assembly device for a handle and a torsion spring of a circuit breaker, which is reasonable in structural design, safe, reliable, high in work efficiency and good in finished product quality and used for automatically assembling the handle and the torsion spring into a workpiece according to special unit and assembly accuracy requirements of the handle and torsion spring of the circuit breaker. The automatic assembly device comprises a vacancy detection assembly, a handle feeding assembly, a handle detection assembly, a torsion spring feeding assembly, a torsion spring detection assembly, a torsion spring steering assembly, a torsion spring steering detection assembly, a workpiece blanking assembly, a workbench assembly and a base plate, wherein the vacancy detection assembly, the handle feeding assembly, the handle detection assembly, the torsion spring feeding assembly, the torsion spring detection assembly, the torsion spring steering assembly, the torsion spring steering detection assembly and the workpiece blanking assembly are sequentially arranged at the periphery of the workbench assembly. The automatic assembly device provided by the invention for the handle and the torsion spring of the circuit breaker can effectively improve the assembly accuracy, consistency and efficiency of products and reduce the rejection rate through settingfour detection stations.

Owner:浙江汇聚自动化设备有限公司

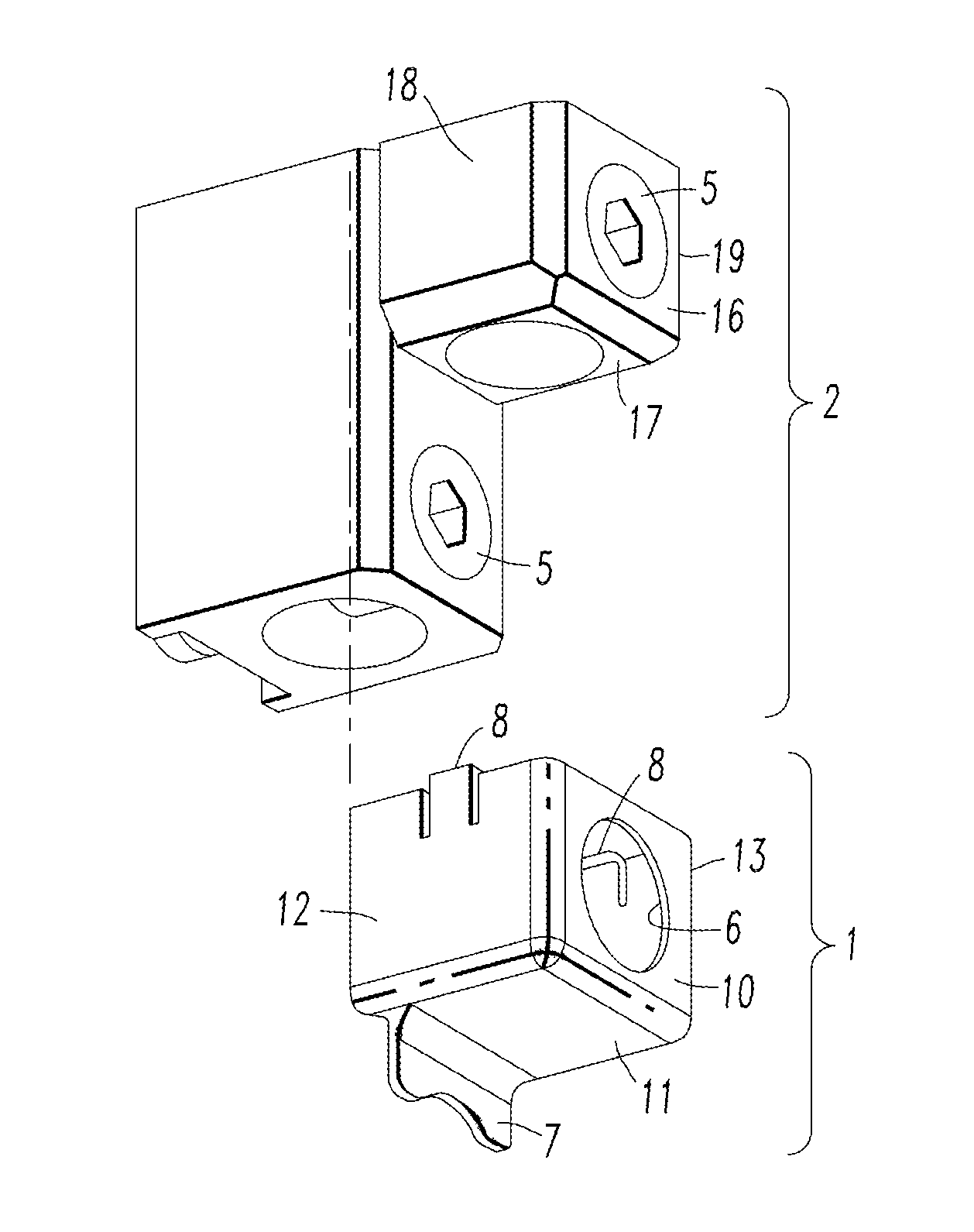

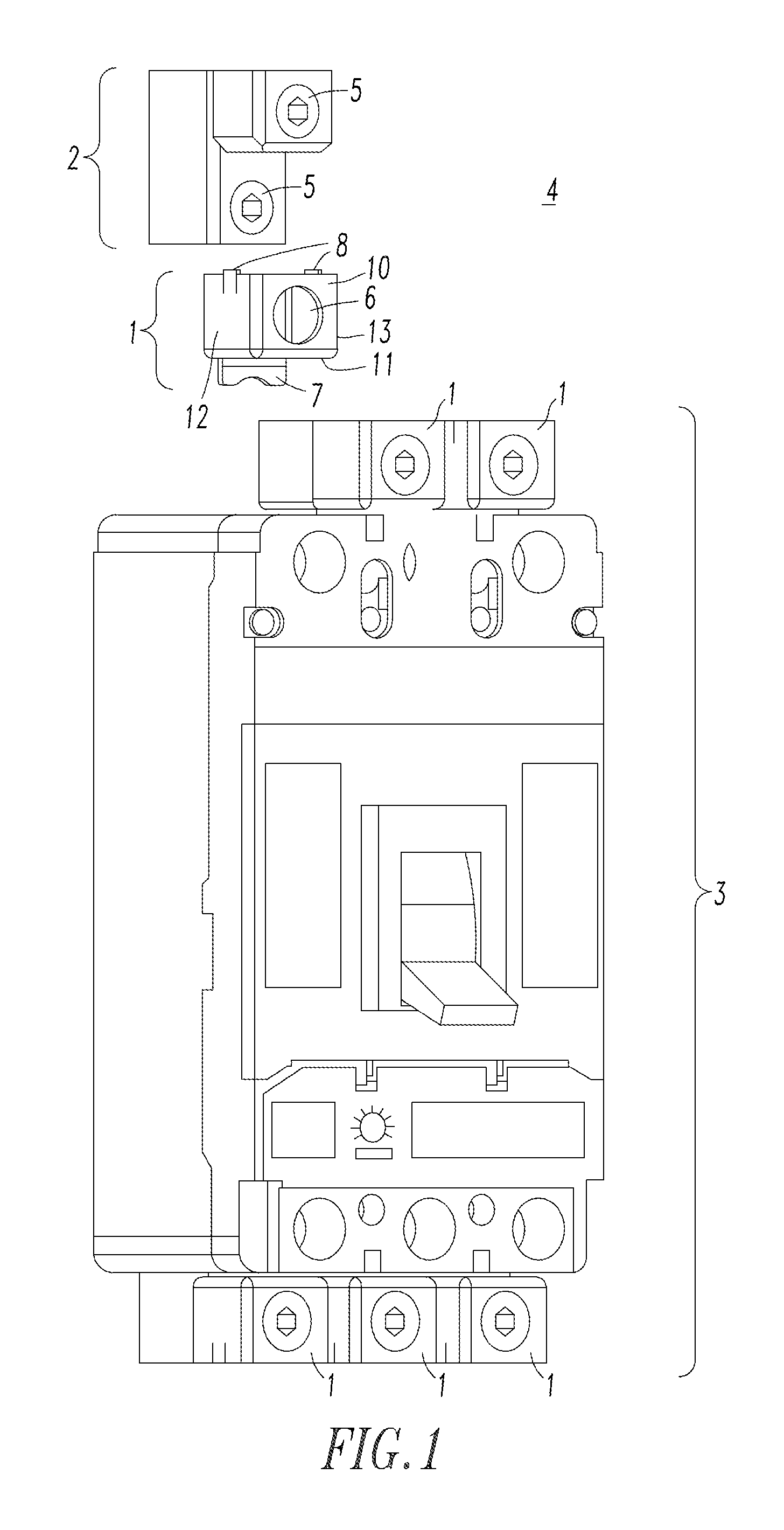

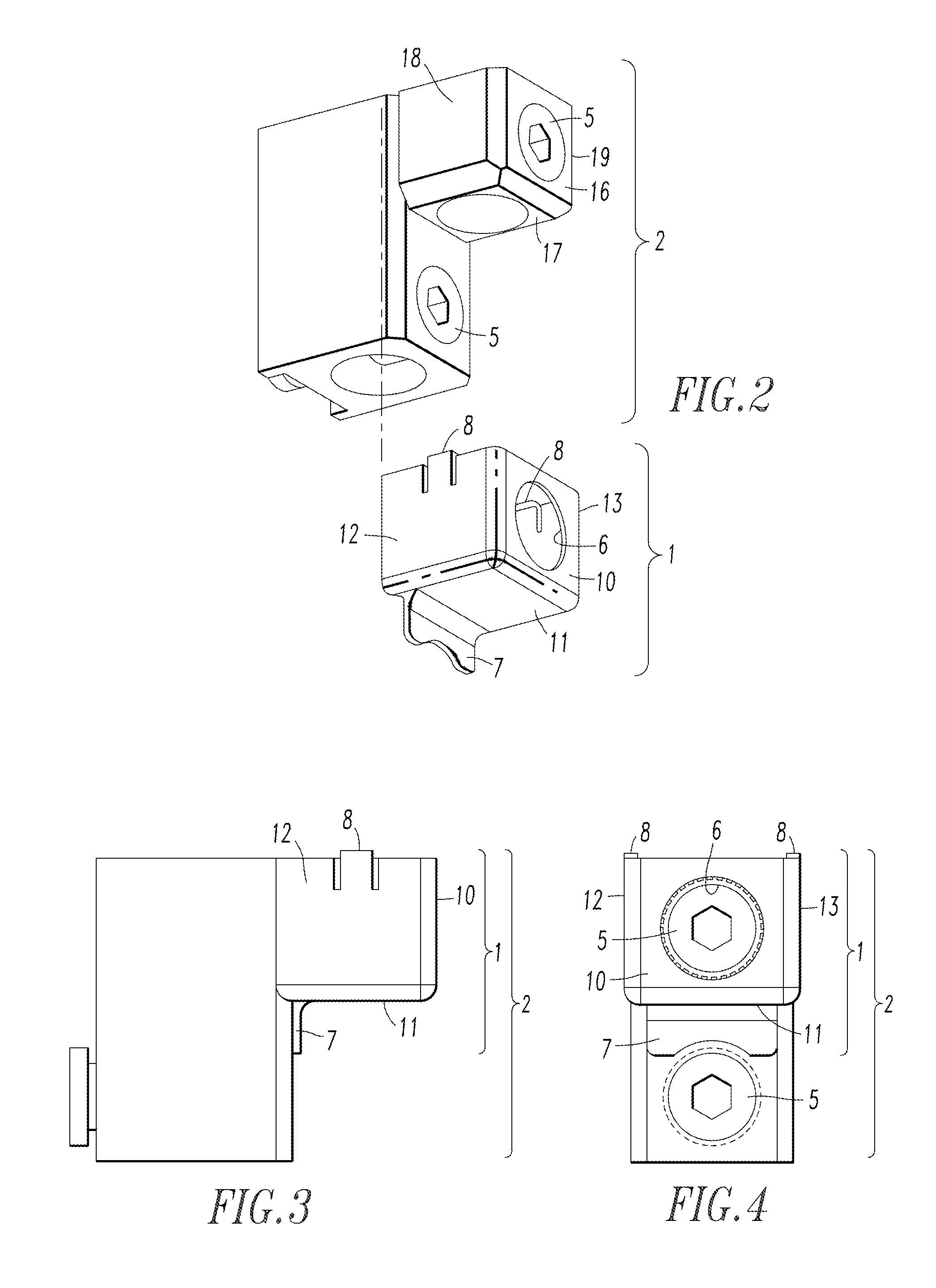

Circuit breaker, circuit breaker terminal lug cover, and method of protecting a terminal lug

ActiveUS8853576B2Circuit-breaking switches for excess currentsCoupling device detailsEngineeringCircuit breaker

Owner:EATON INTELLIGENT POWER LTD

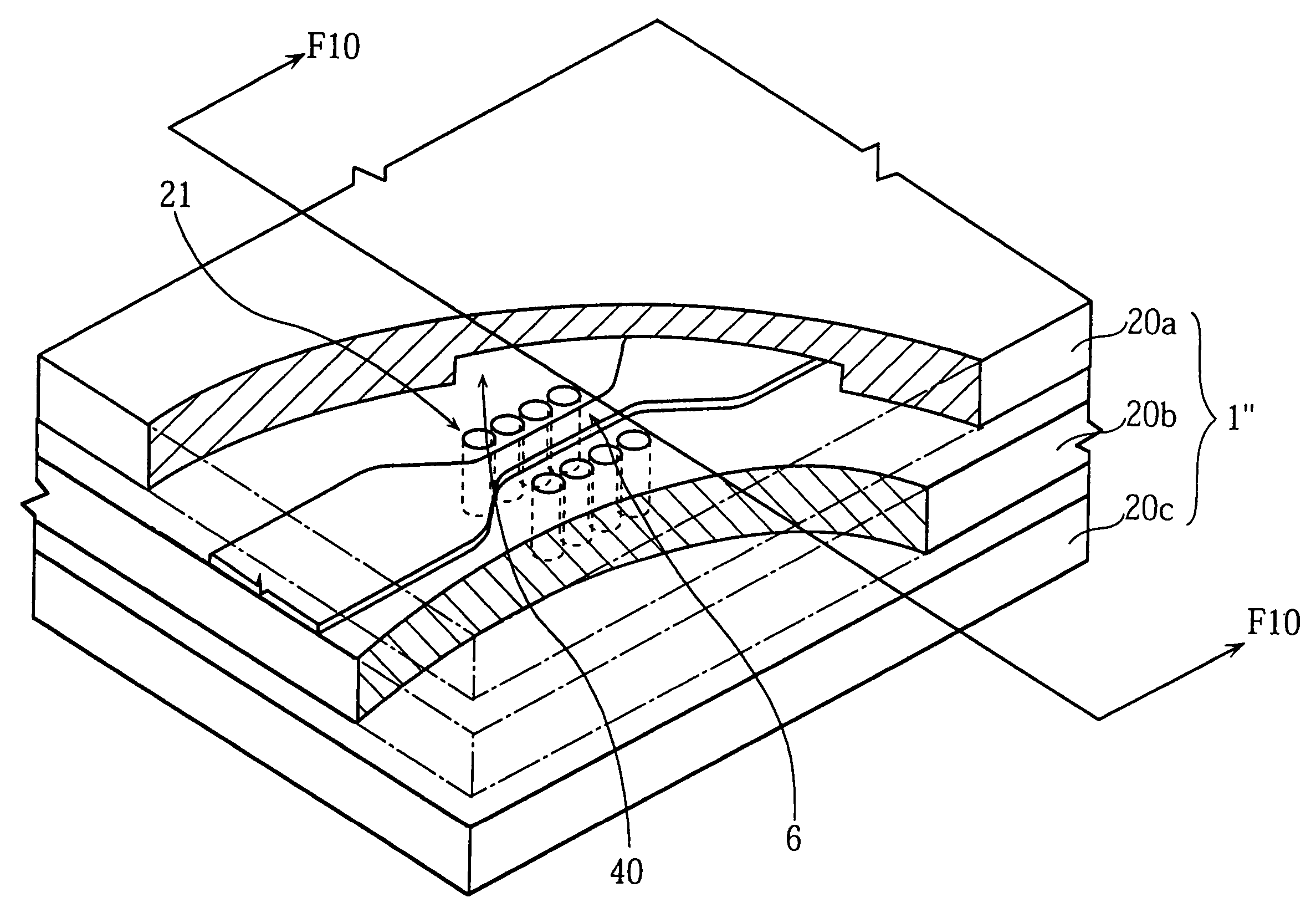

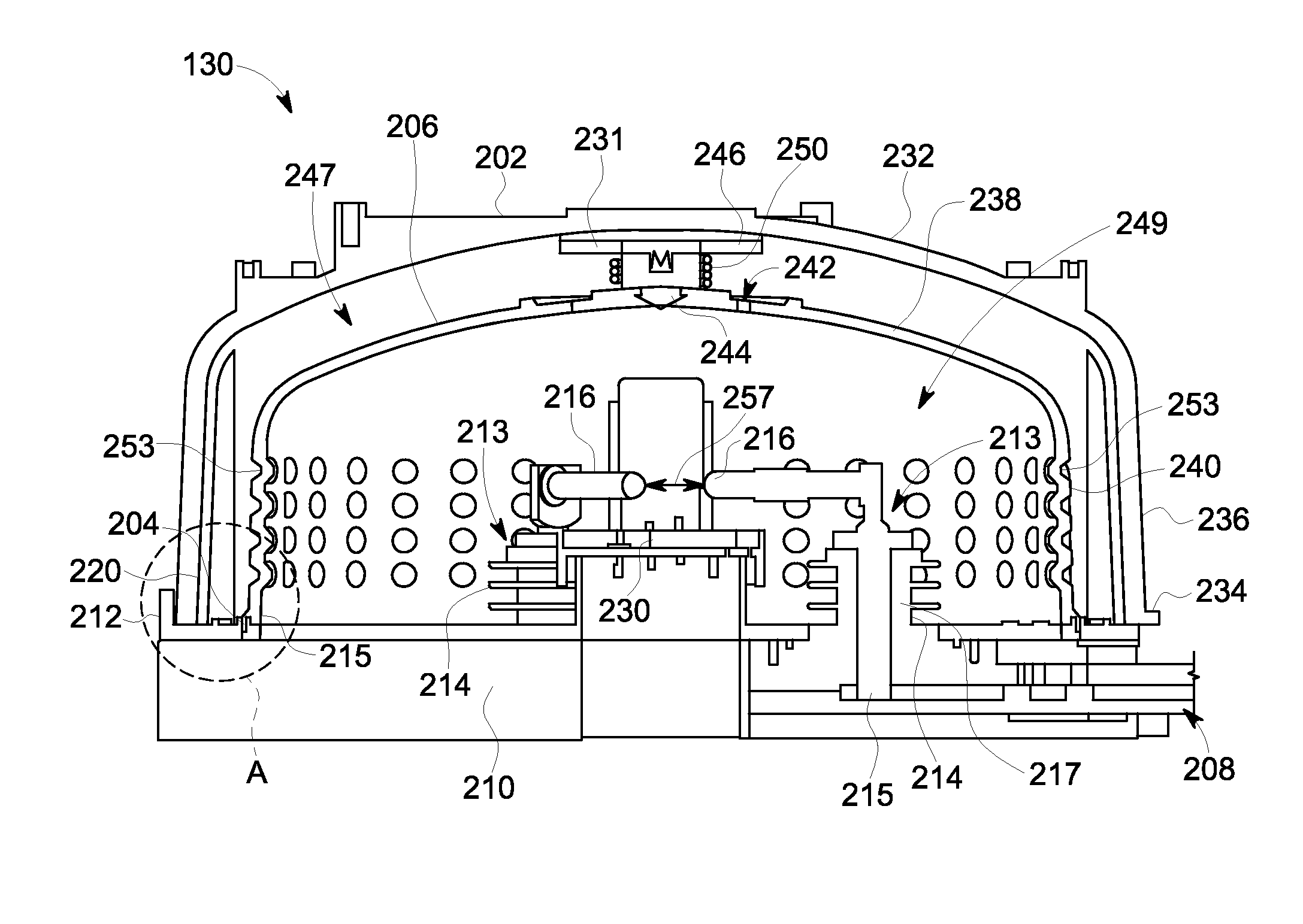

Variable venting and damping arc mitigation assemblies and methods of assembly

ActiveUS20140160634A1Line/current collector detailsSpark gap detailsElectrical conductorClassical mechanics

Equipment protection systems, arc containment devices, and methods of assembling arc containment devices are disclosed. In one example, an electrical isolation structure includes a conductor base, a cover coupled to the conductor base and defining an isolation chamber, a containment shield disposed on the conductor base within the isolation chamber, and a biasing assembly positioned between the cover and the containment shield. The containment shield defines a containment chamber configured to enclose the plurality of electrode assemblies. The containment shield is configured to at least partially contain the arc products within the containment chamber. The biasing assembly is configured to permit the containment shield to move away from the conductor base to thereby define a gap between the conductor base and the containment shield to enable at least some of the arc gases to vent from the containment chamber.

Owner:ABB (SCHWEIZ) AG

Method of making fusible links

ActiveUS20120103930A1High melting temperatureHigh resistivityElectric switchesCell component detailsElectrical conductorStamping process

Methods of fabricating the fusible link are directed to processing a multi-layer clad foil having a first layer suitable for forming a fusible link and a second layer suitable for forming one or more welding pads. In some embodiments, the first layer is an aluminum layer and the second layer is a nickel layer. A two-step etching process or a single step etching process is performed on the clad foil to form an etched clad foil having multiple tabs made of the second layer used as current collector conductor pads and battery cell conductor pads, and one or more tabs made of the first layer that form aluminum conductors. The aluminum conductors are shaped and sized to form aluminum fusible conductors during either the etching process or a subsequent stamping process. A single fusible link or an array of fusible links can be formed.

Owner:SINOELECTRIC POWERTRAIN

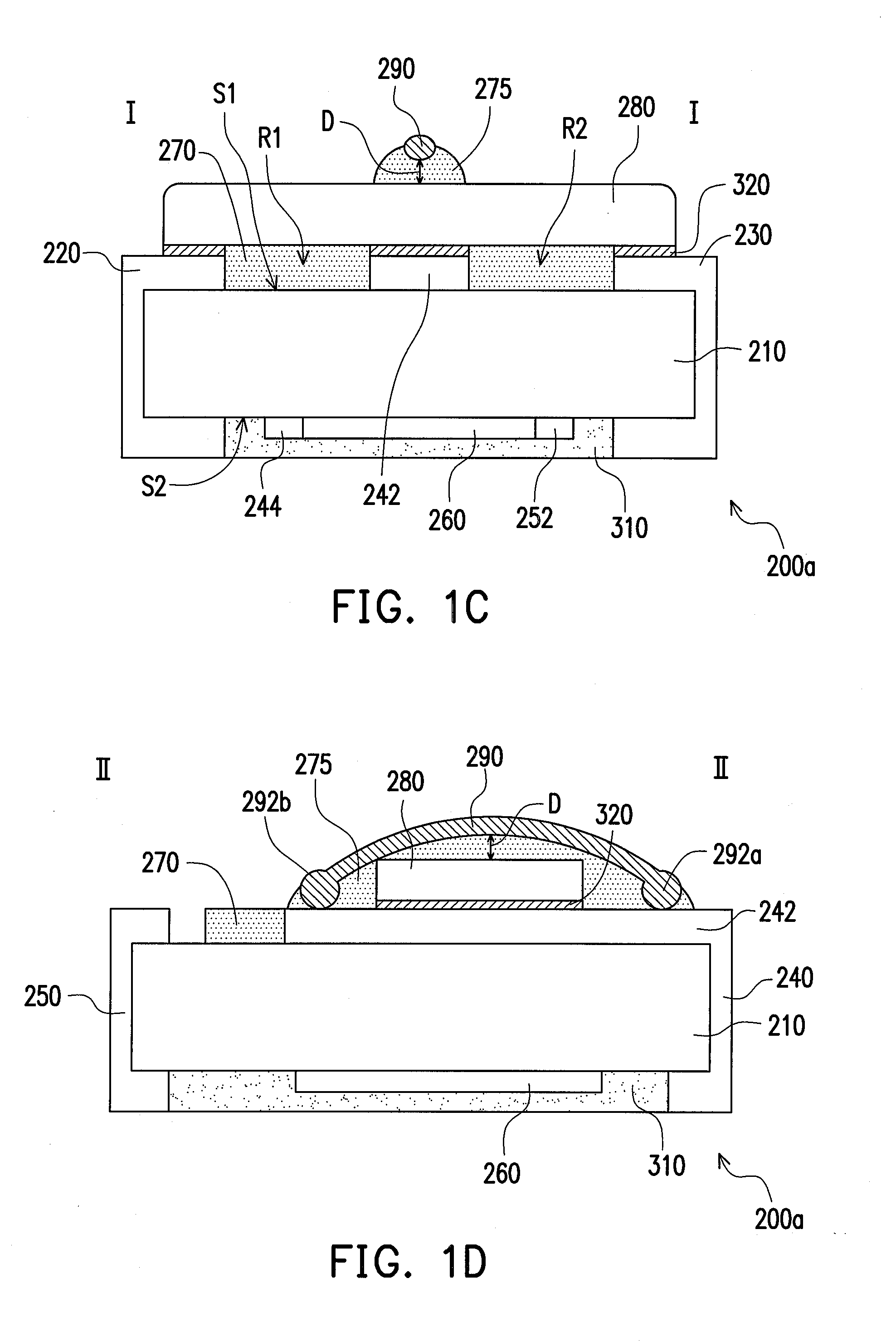

Protective device

ActiveUS20110057761A1Inhibit currentPrevents voltageEmergency protective device manufacturePower flowOptoelectronics

A protective device including a substrate, a conductive section and a bridge element is provided. The conductive section is supported by the substrate, wherein the conductive section comprises a metal element electrically connected between first and second electrodes. The metal element serves as a sacrificial structure having a melting point lower than that of the first and second electrodes. The bridge element spans across the metal element in a direction across direction of current flow in the metal element, wherein the bridge element facilitates breaking of the metal element upon melting.

Owner:CYNTEC

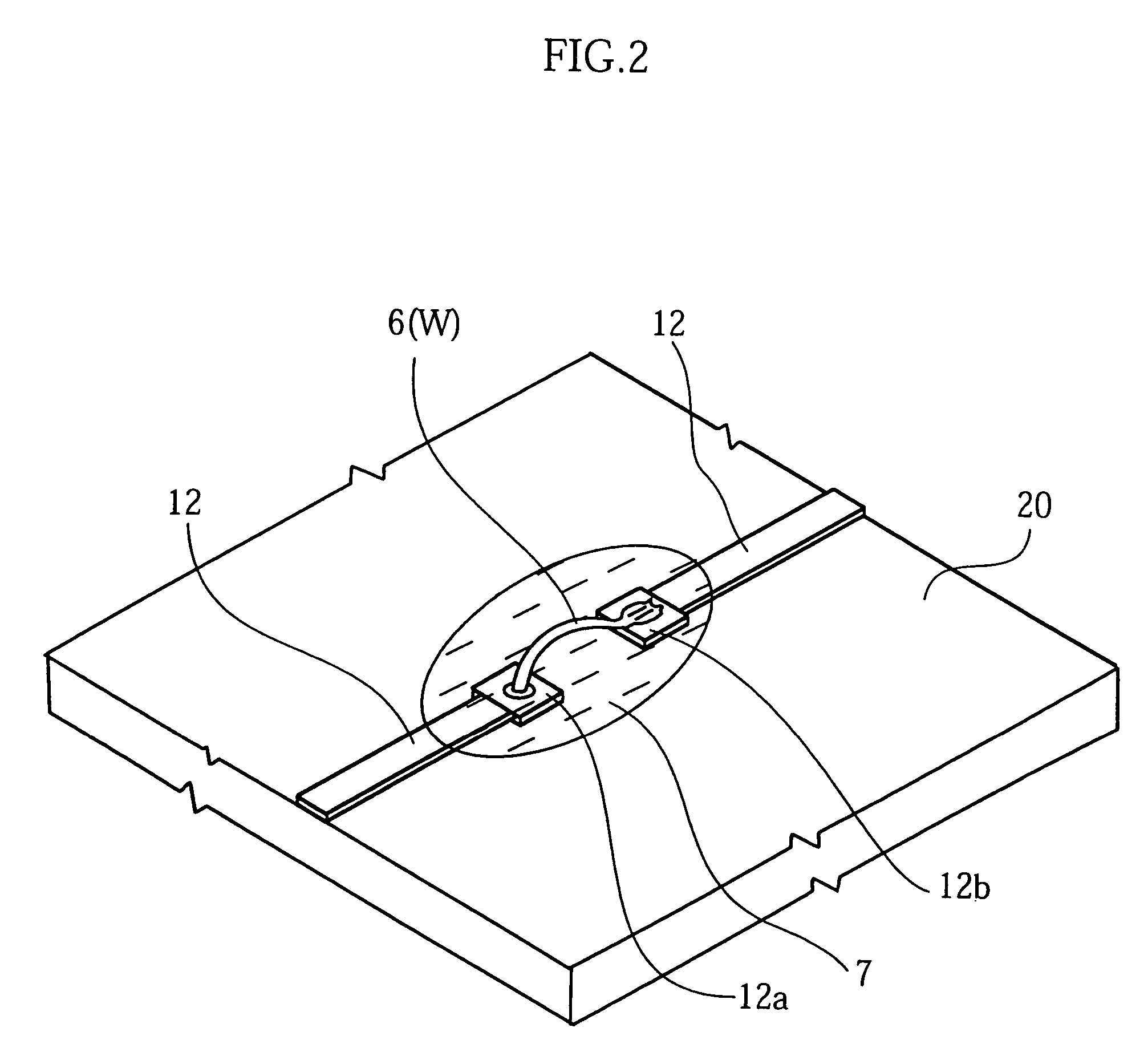

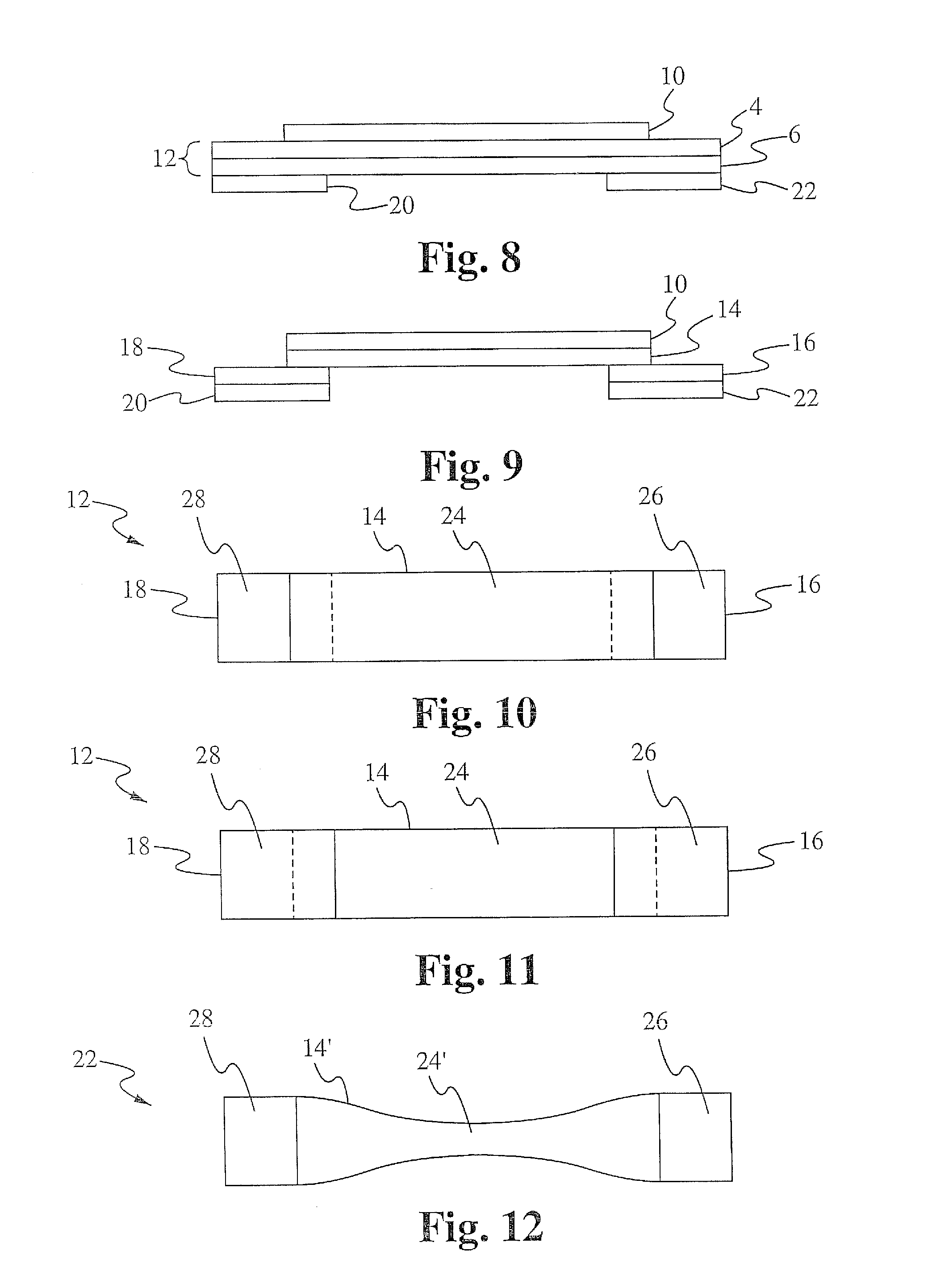

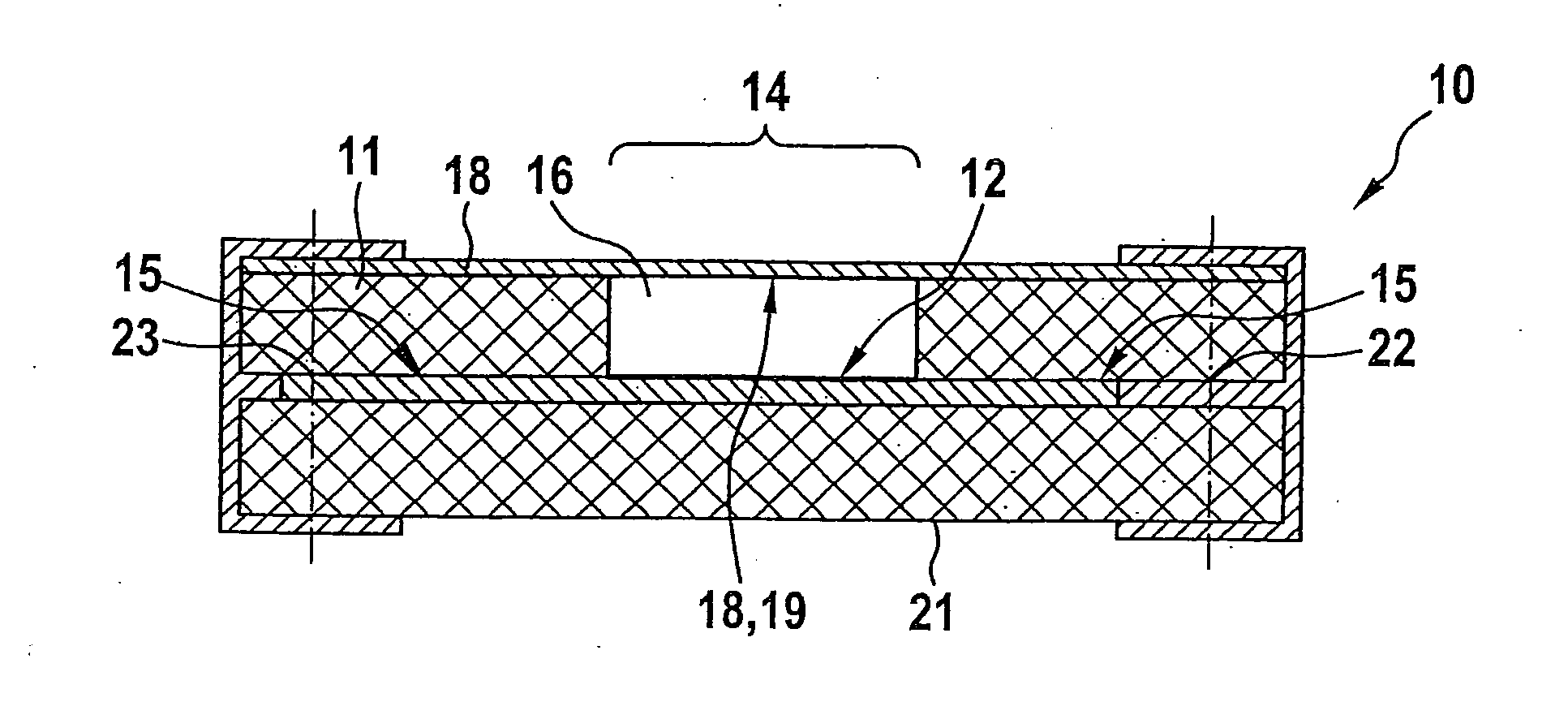

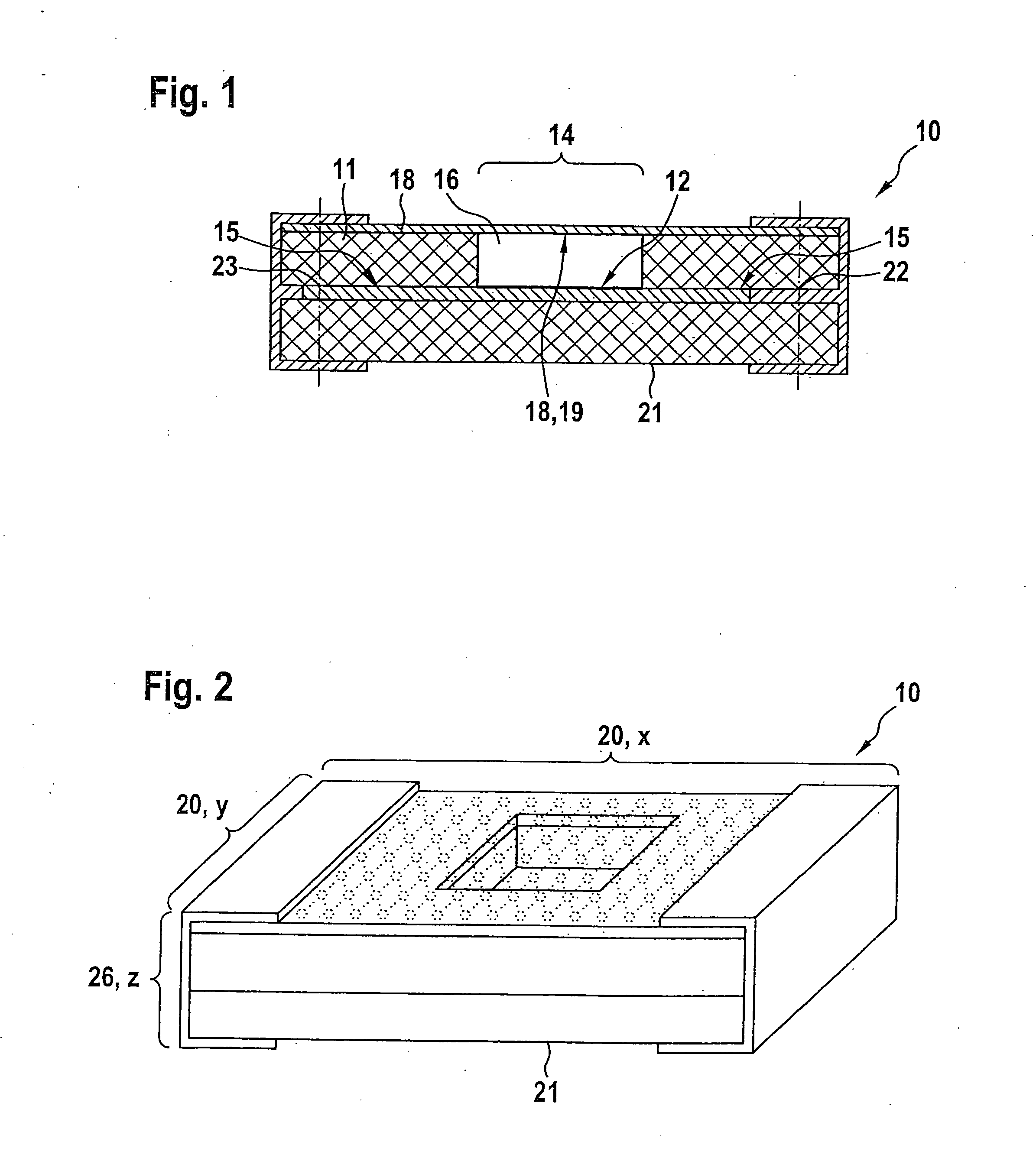

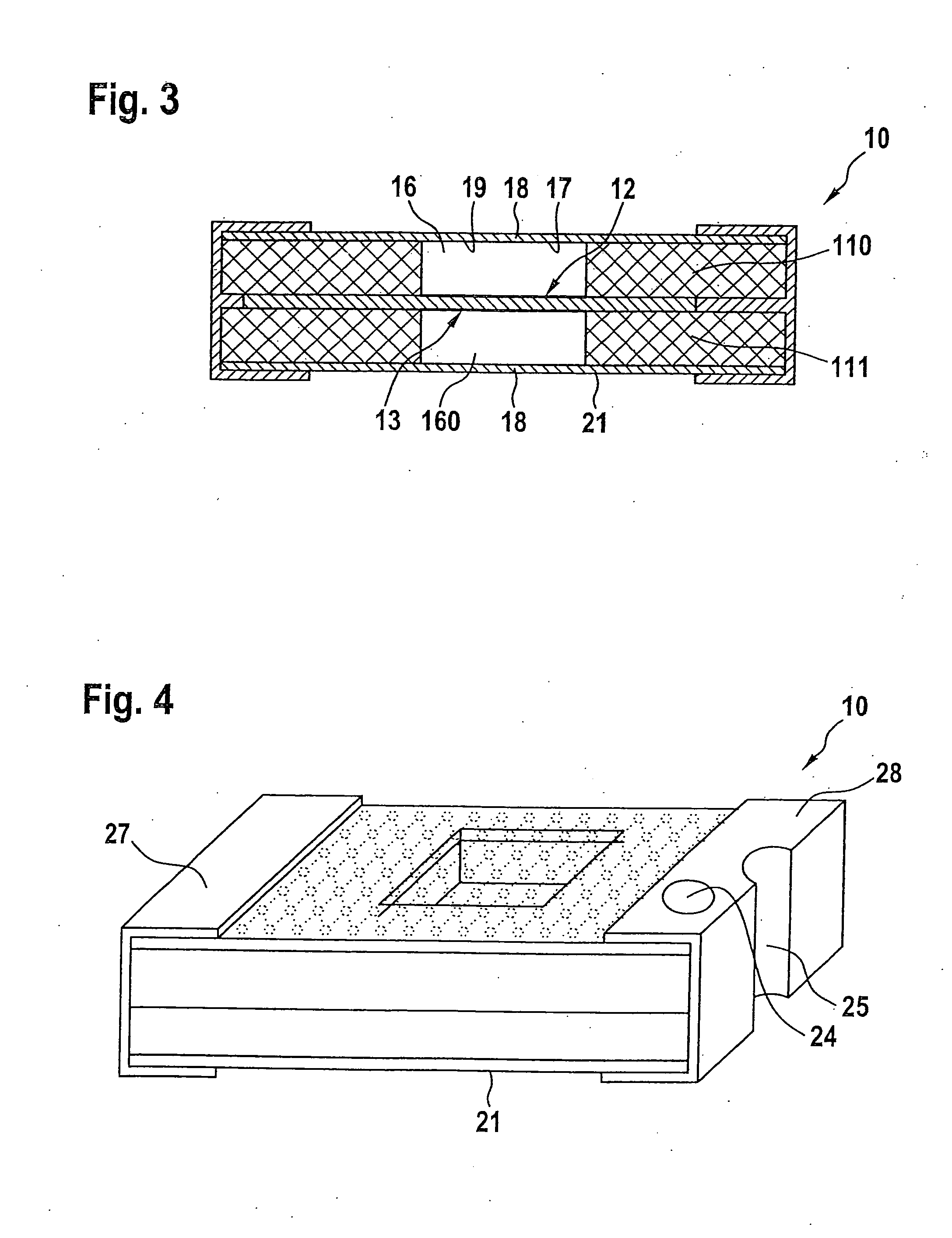

Fuse element

ActiveUS20120013431A1Stable Dielectric StrengthReduce materialPrinted circuit aspectsEmergency protective device manufactureMetal alloyThermal expansion

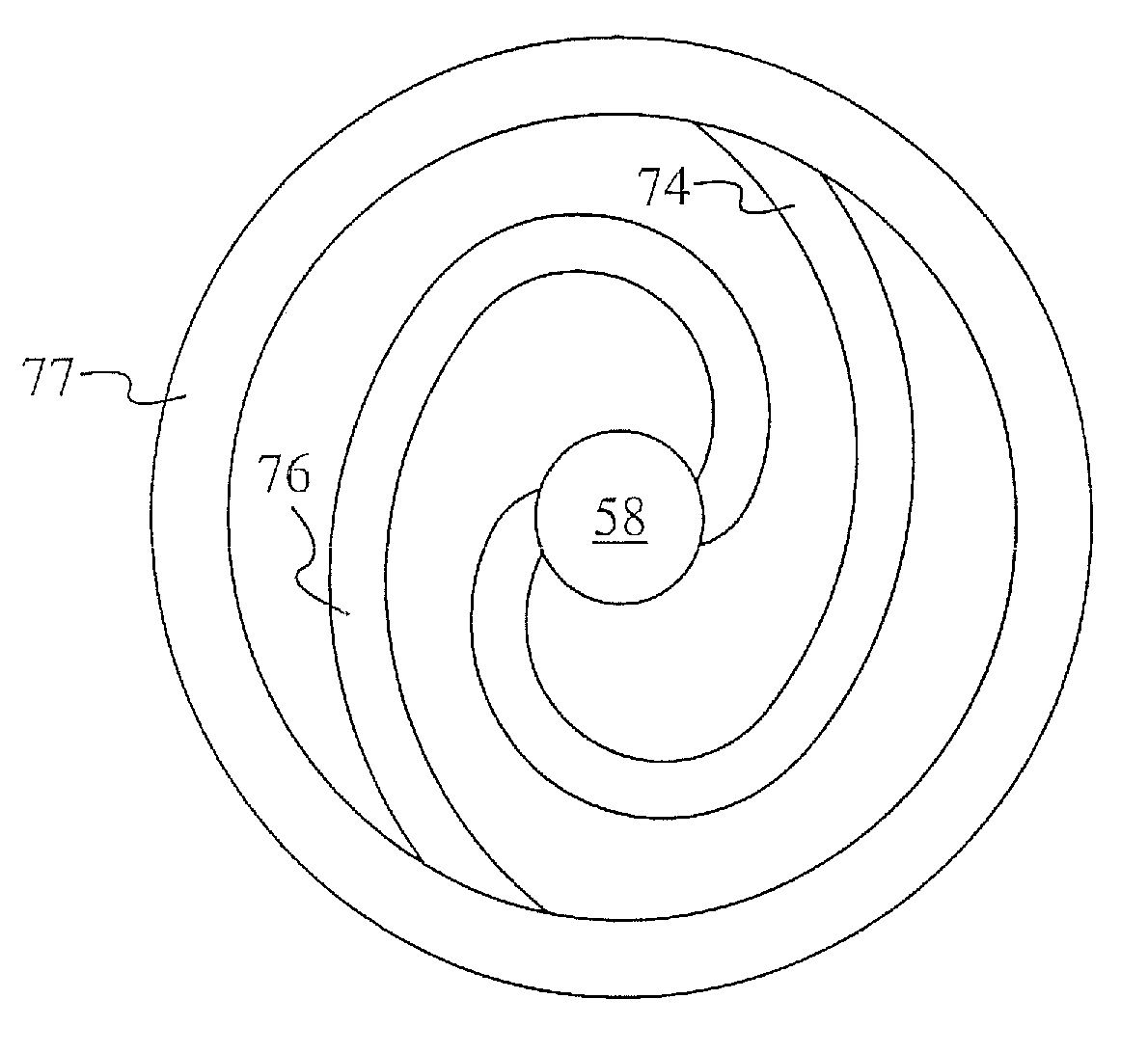

A fuse element (10), in particular suited for use in electric and / or electronic circuits constructed by multilayer technology, including a printed circuit board substrate material (11), which is usable particularly in the multilayer technology and is coated with a metal or metal alloy (15), from which metal or metal alloy the fuse (12) is generated by means of photolithographic and / or printing image-producing techniques and ensuing etching or engraving processes, is proposed. The fuse (10) is distinguished in that the printed circuit board substrate material (11), on which the fuse (12) can be provided, includes at least a high-temperature-stable, electrically insulating material, with a coefficient of thermal expansion that varies essentially analogously to the coefficient of thermal expansion of the metal or metal alloy (15) from which the fuse (12) is made.

Owner:SCHURTER

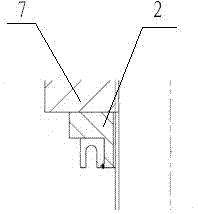

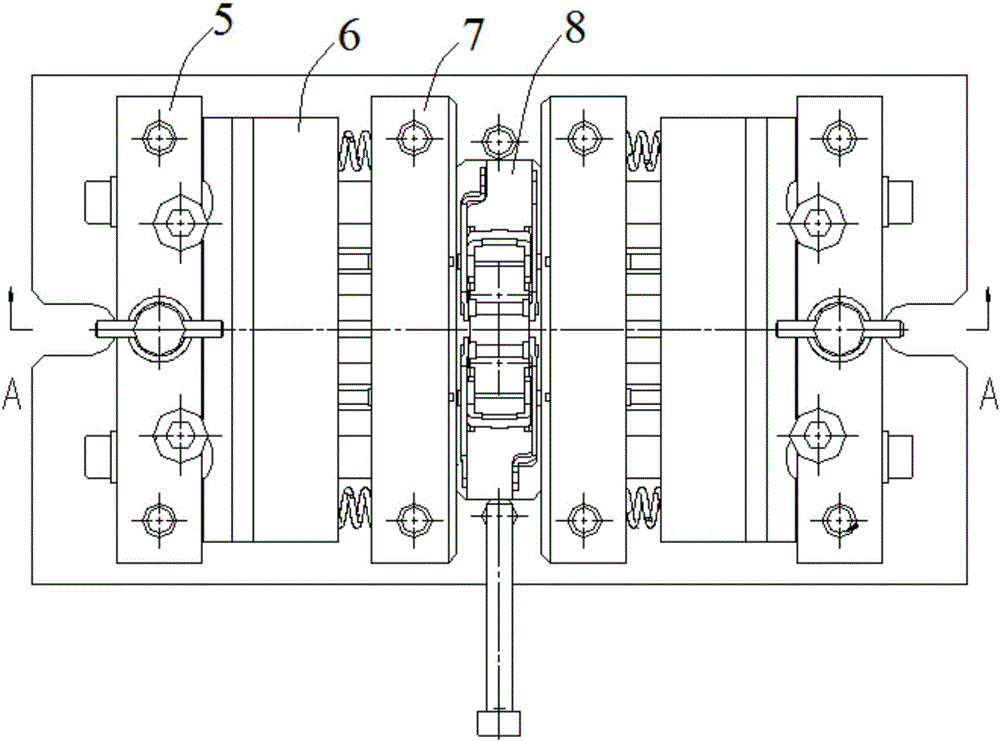

Contact finger spring assembly tooling

ActiveCN102779691AEasy to installEasy to operateEmergency protective device manufactureUltimate tensile strengthHinge joint

The invention discloses a contact finger spring assembly tooling. The contact finger spring assembly tooling comprises a guide rod, the guide rod is matched with a central hole in a contact base in a positioning mode, the guide rod is vertically provided with a guide sleeve and a positioning sleeve, the guide sleeve is sleeved on the guide rod in a sliding mode, the positioning sleeve is fixedly sleeved on the guide rod, pressure rods which are distributed along the circumferential direction of the guide sleeve at intervals are assembled on the guide sleeve in a rotating mode, draw rods are assembled on the positioning sleeve in a rotating mode, support rods are connected between corresponding pressure rods and draw rods, all support rods are matched with each other to form a conical framework used for supporting contact finger springs, corresponding pressure rods, draw rods and support rods are matched with the guide rod to form a four-rod linkage mechanism, the support rods are provided with guiding sections, and each of the guiding sections extends from corresponding draw rod hinge joint position and guides the contact finger springs to the installation position of a petal-shaped contact finger. The contact finger spring assembly tooling has the advantages that the whole tooling is convenient to operate, the installation of the contact finger springs of the petal-shaped contact fingers with different installation diameters is achieved, the contact finger springs are freely slipped to the installation position depending on changes of inclined angle of the support rods, manual shifting is not required, the labor intensity is reduced, and the installation is rapid and accurate.

Owner:HENAN PINGGAO ELECTRIC +1

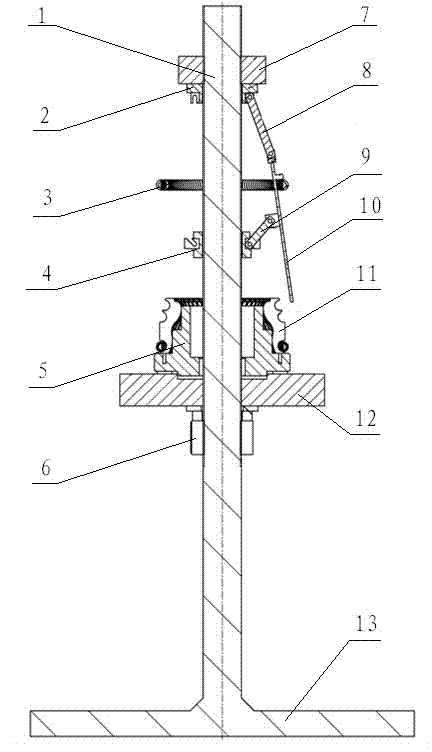

Laser scanning location device

InactiveCN101677045ASolve stereotaxic problemsReduce front and rear processesElectric switchesEmergency protective device manufactureLaser scanningEngineering

The present invention provides a laser scanning location device. To solve problem of stereotactic location, the present invention provides a technical scheme that the laser scanning location device comprises a X-Y double-shaft workbench, etc., the down part of a guide pillar fixedly connects with an installing plate, the guide pillar locates in a guide sleeve, both sides slidably connect each other; the guide sleeve fixedly connects with a top plate; a Z-directional motor fixedly connects with the installing plate through a connection rack; an output shaft of the Z-directional motor connects with the down part of a screw through a connecting piece, the upper part of the screw locates in a nut; the nut and a laser sensor also fixedly connect with the top plate, an output control terminal ofan automation circuit connects with a terminal of the laser sensor and a terminal of the Z-directional motor respectively. The invention has beneficial effects in that: the laser scanning location device solves problem of stereotactic location, has high location precision, rapid motion and little electro-optical, etc.

Owner:SHANGHAI UNIV OF ENG SCI

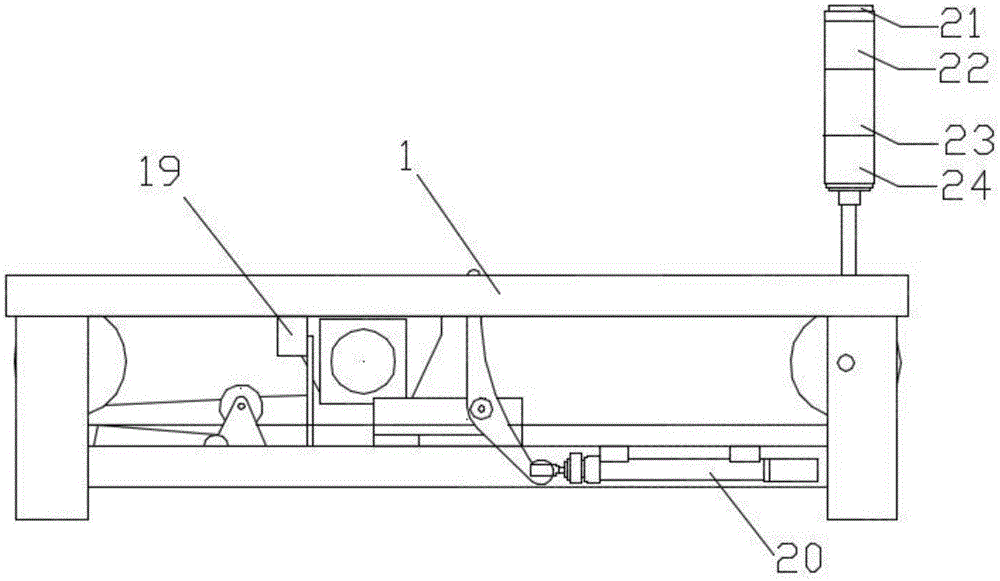

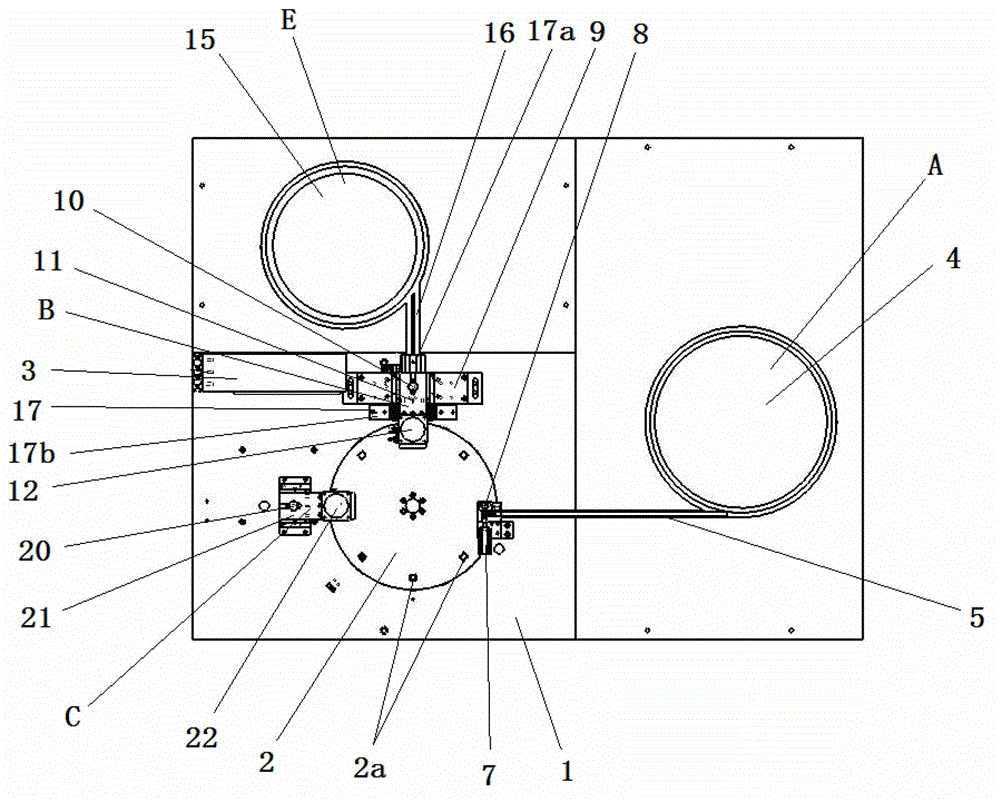

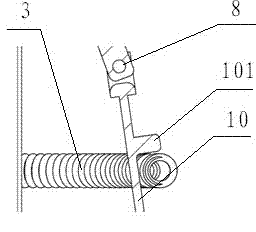

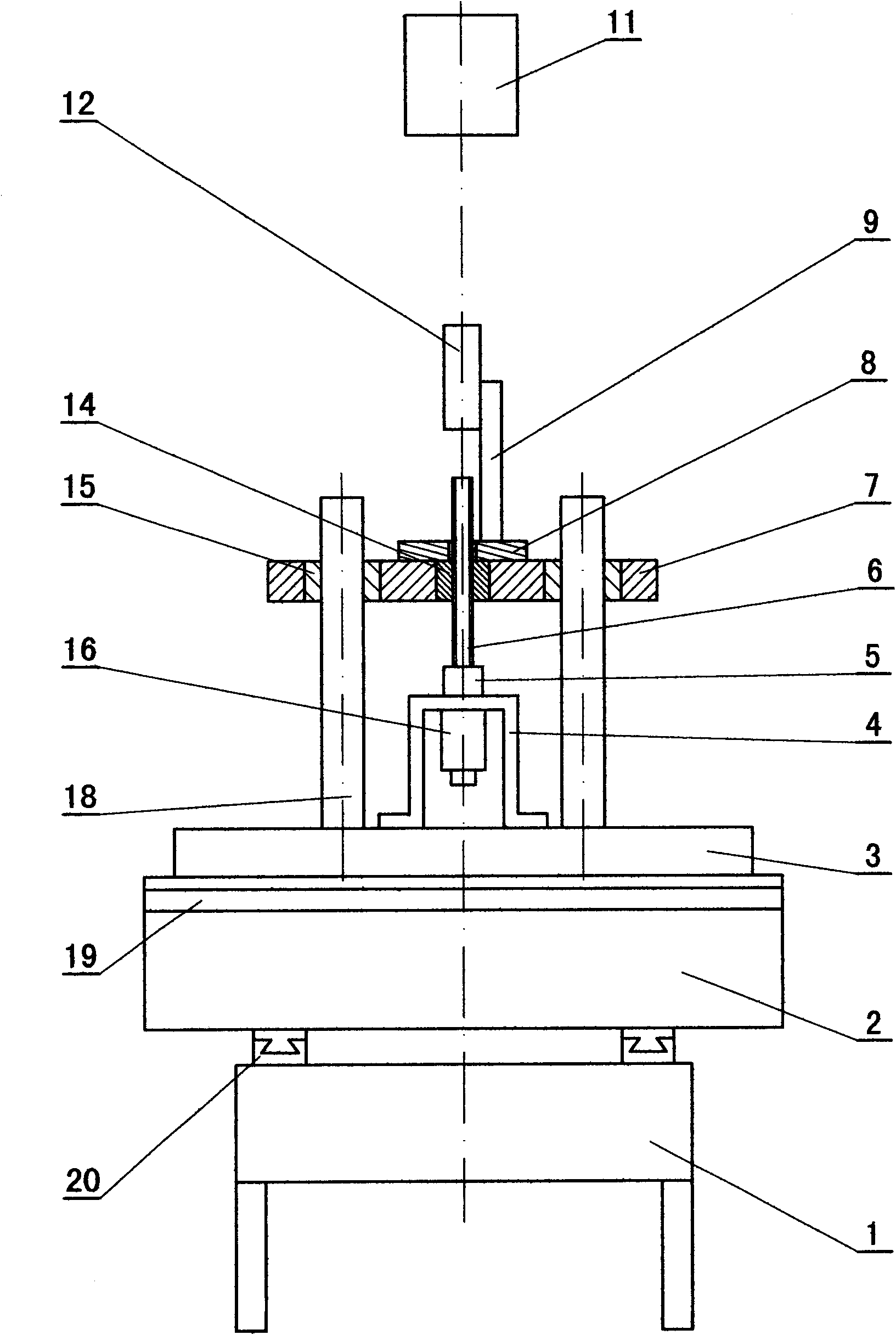

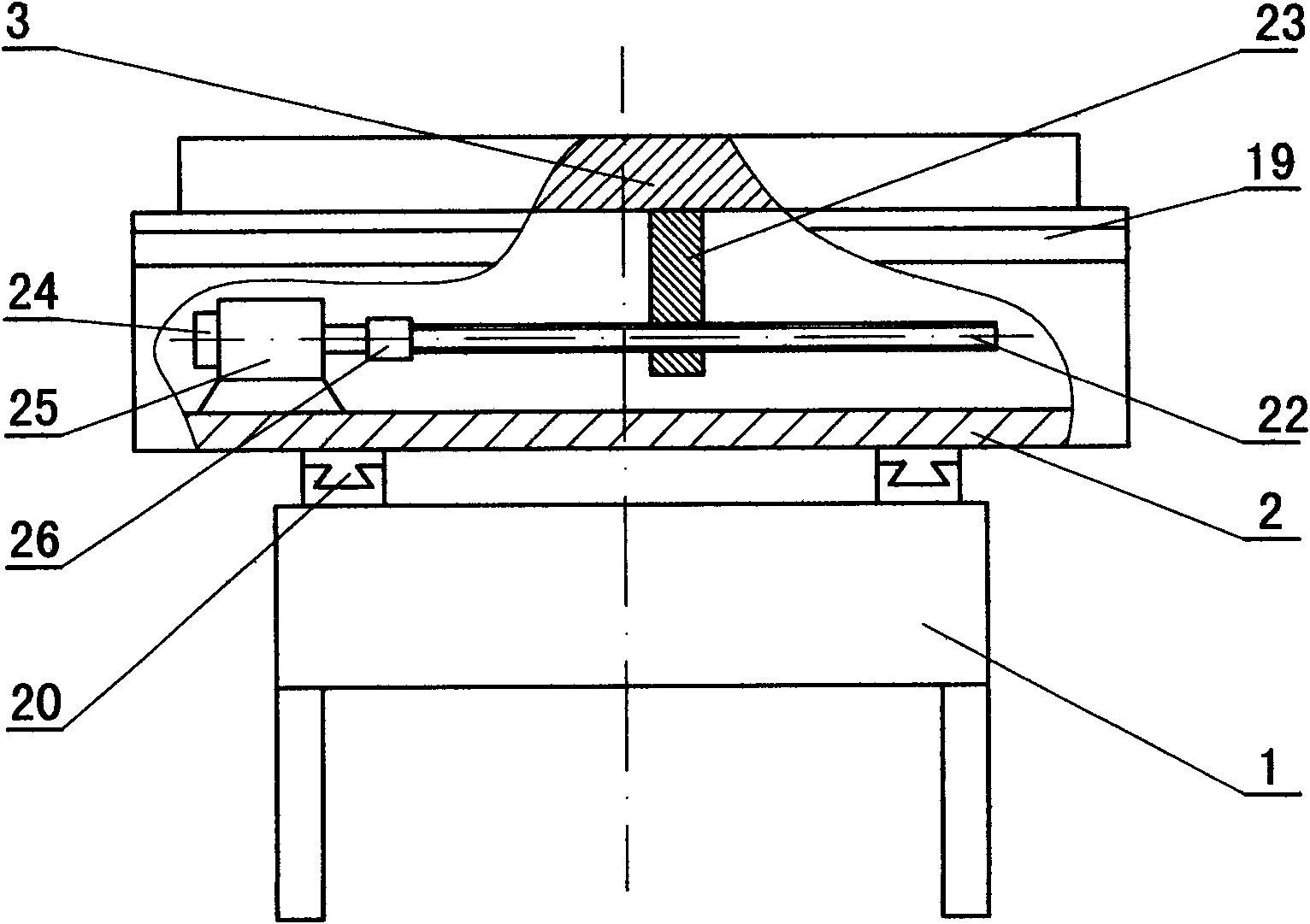

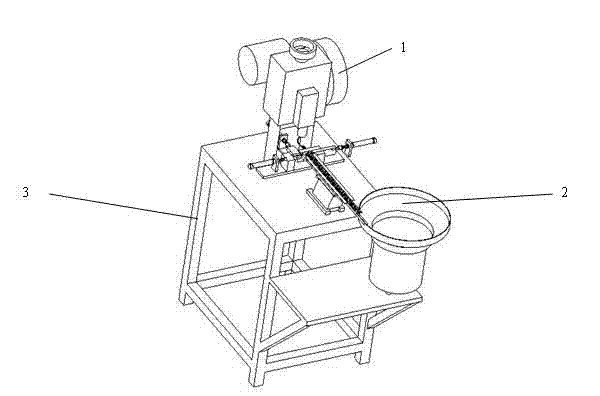

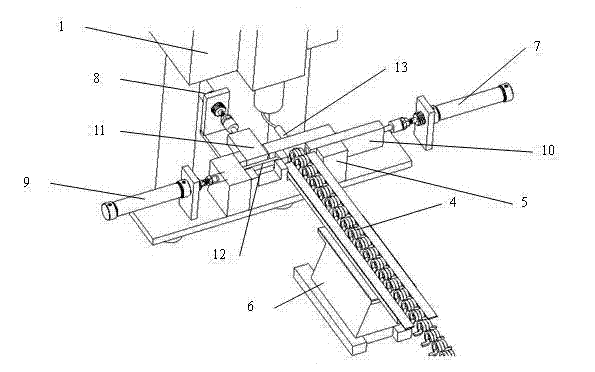

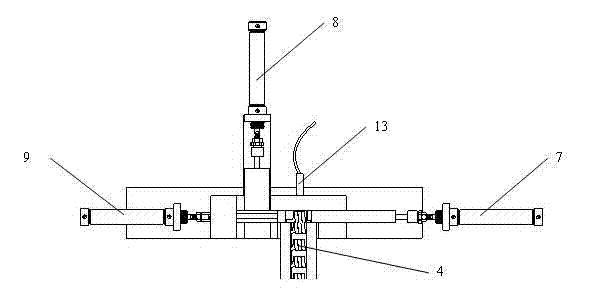

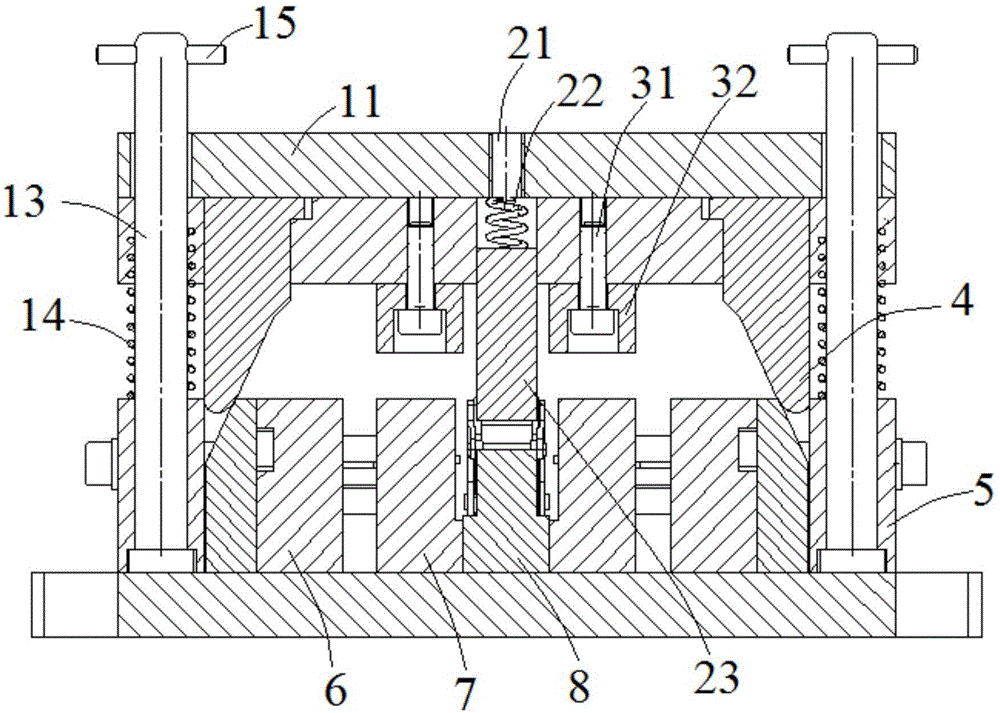

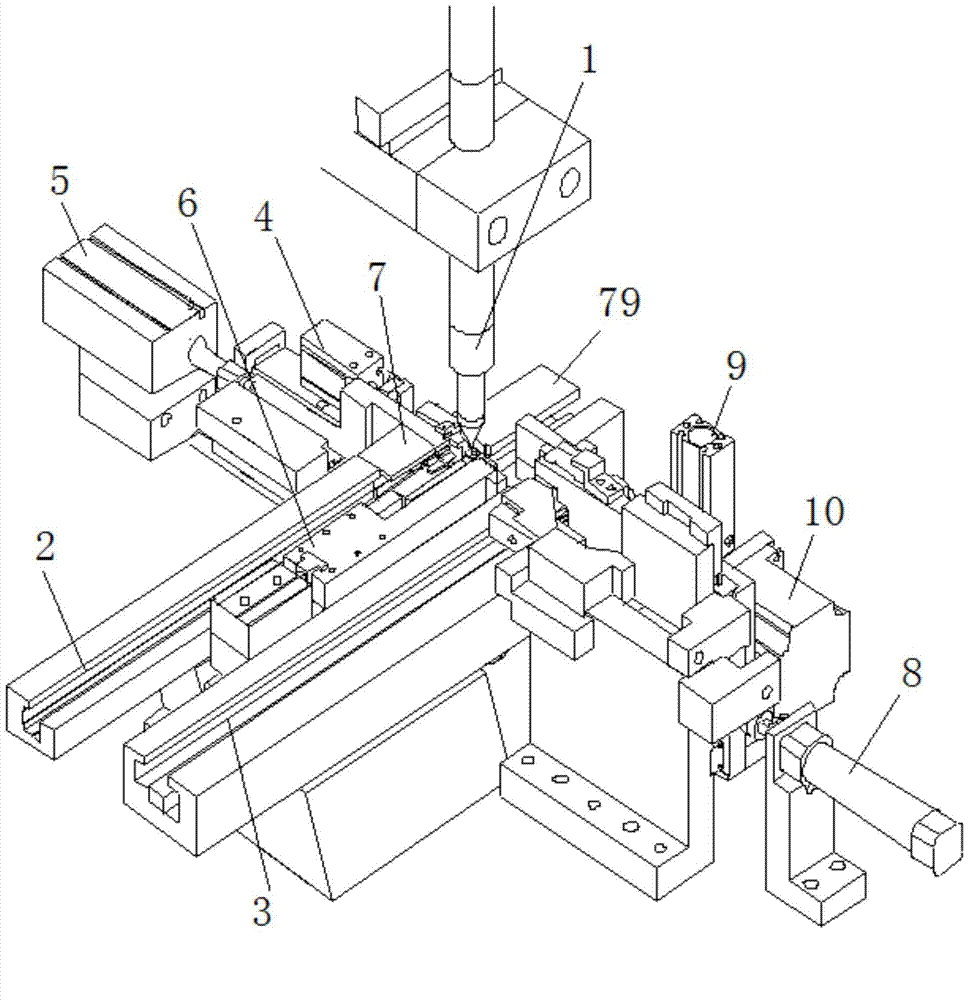

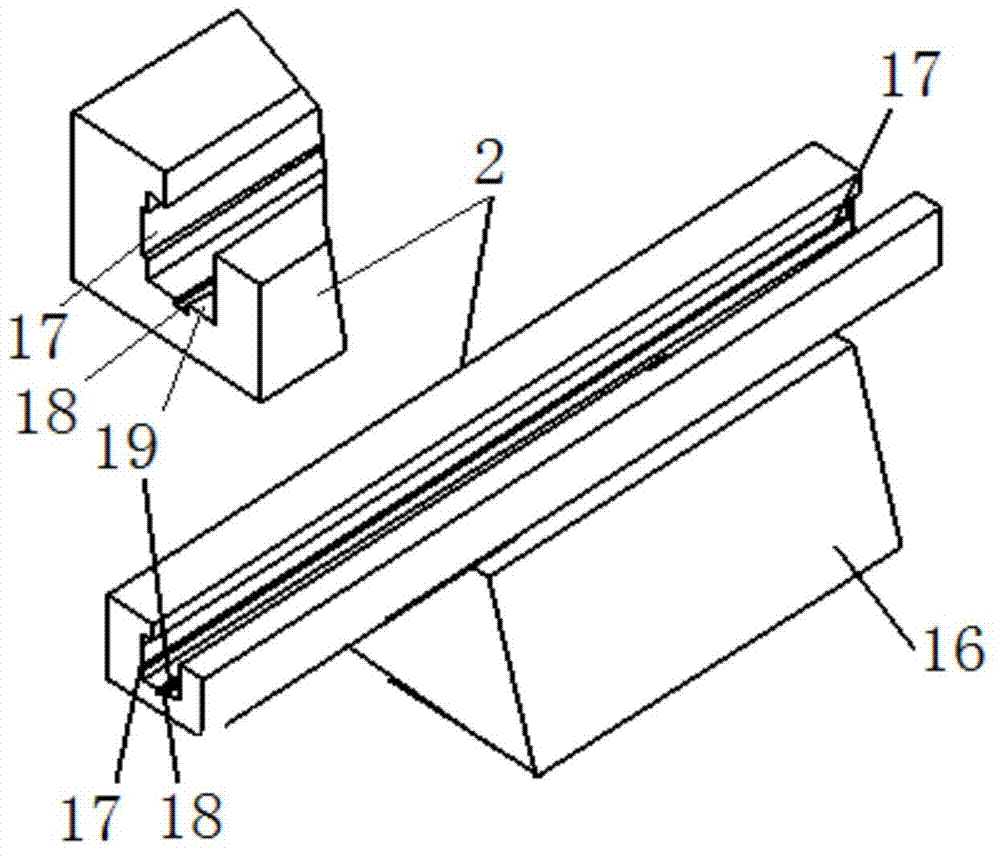

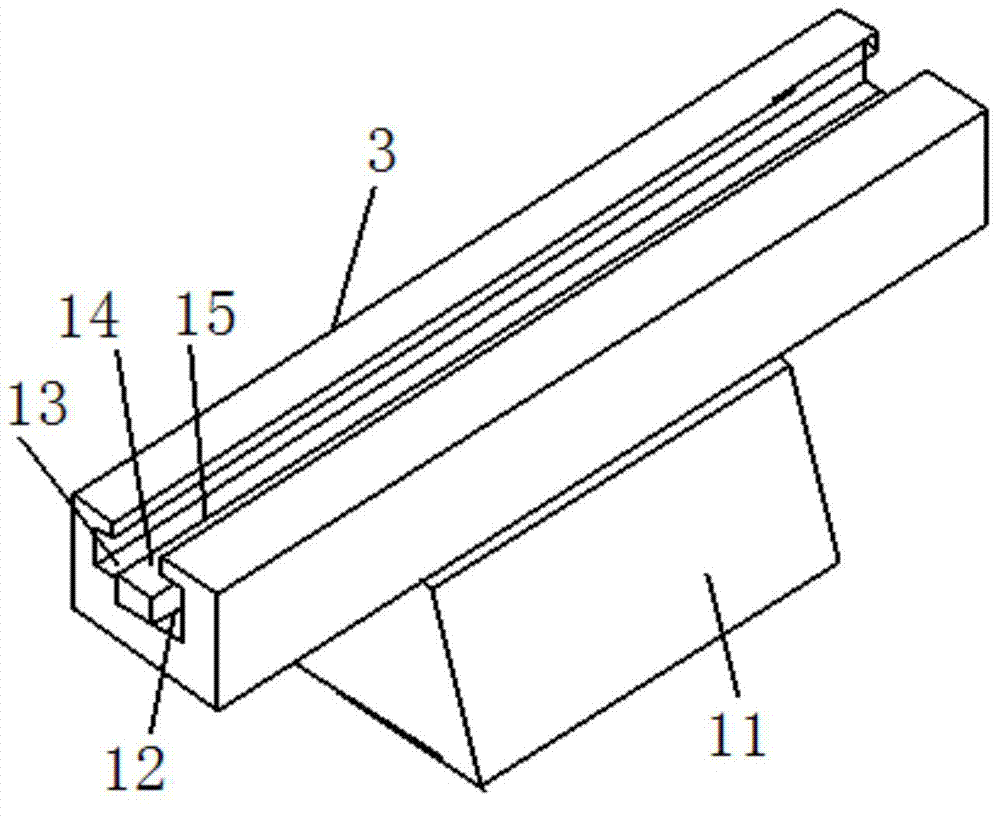

Circuit breaker coil automatic shaping equipment

ActiveCN102290291AReasonable structureSolve the disadvantages of low efficiency and poor consistencyEmergency protective device manufacturePunch pressEngineering

The invention discloses automatic reshaping equipment for a circuit breaker coil, which is characterized in that a workbench (3) of the automatic reshaping equipment is provided with an automatic punch (1), a fixture mainboard (5) and a flat vibration feeder (6), wherein the fixture mainboard (5) is positioned below the automatic punch (1) and is provided with a feeding sliding block (10), a discharging sliding block (11) and a locating rod (12); the feeding sliding block (10) is driven by a feeding cylinder (7); the discharging sliding block (11) is driven by a discharging cylinder (8); the locating rod (12) is driven by a locating cylinder (9); a feeding hole of the flat vibration feeder (6) is connected with a coil vibration disk (2); and the discharging hole of the flat vibration feeder (6) is connected with a corresponding notch on the fixture mainboard (5). According to the automatic reshaping equipment for the circuit breaker coil, the defects of low efficiency and poor consistency in the traditional manual production mode can be eliminated, the operations of supplying materials for workpieces, feeding, positioning, reshaping and discharging can be automatically finished, manual intervention is almost omitted, so that the production efficiency is improved, and the labor intensity is lowered.

Owner:JIANGSU SUZHONG CONSTR GROUP +1

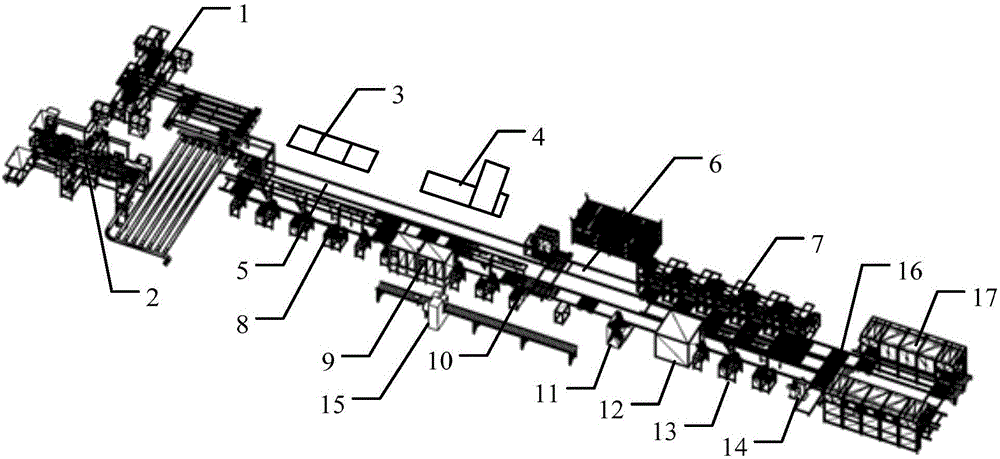

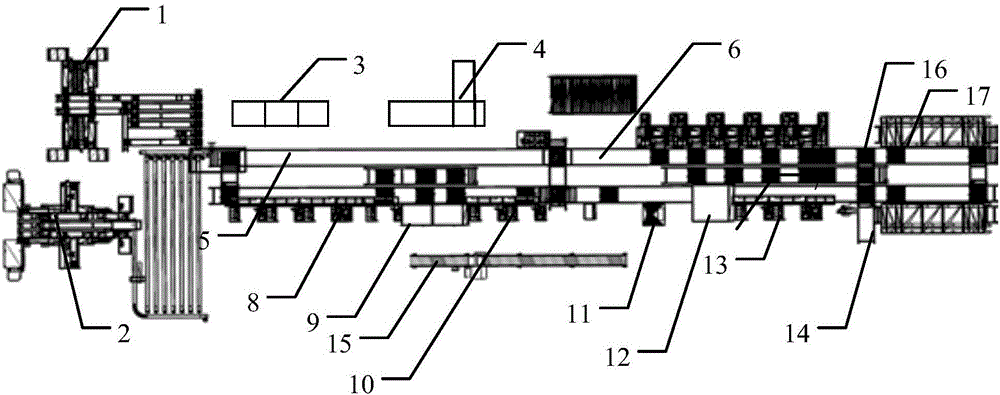

Automatic breaker production line and work method thereof

InactiveCN106252165ARealize automatic productionRealize resource coordinationEmergency protective device manufactureCombined testAgricultural engineering

The invention discloses an automatic breaker production line and a work method thereof. According to the method, an operation mechanism, a terminal box assembling mechanism, a BCB stock mechanism, an energy storage spring assembling mechanism, a BCB burdening mechanism, an accessory burdening mechanism, an accessory assembling mechanism, a BCB assembling mechanism, a running-in mechanism, an arc extinguishing cover mounting mechanism, a full-detection mechanism, a visual detection mechanism, a panel assembling mechanism, a laser marking machine, a package line, a visual inspection station mechanism and an integrated test stand are integrated and are controlled in a same mode, and automatic production of breakers can be realized. The automatic breaker production line comprises the operation mechanism, the terminal box assembling mechanism, the BCB stock mechanism, the energy storage spring assembling mechanism, the BCB burdening mechanism, the accessory burdening mechanism, the accessory assembling mechanism, the BCB assembling mechanism, the running-in mechanism, the arc extinguishing cover mounting mechanism, the full-detection mechanism, the visual detection mechanism, the panel assembling mechanism, the laser marking machine, the package line, the visual inspection station mechanism and the integrated test stand.

Owner:江门市博道工业自动化设备有限公司 +1

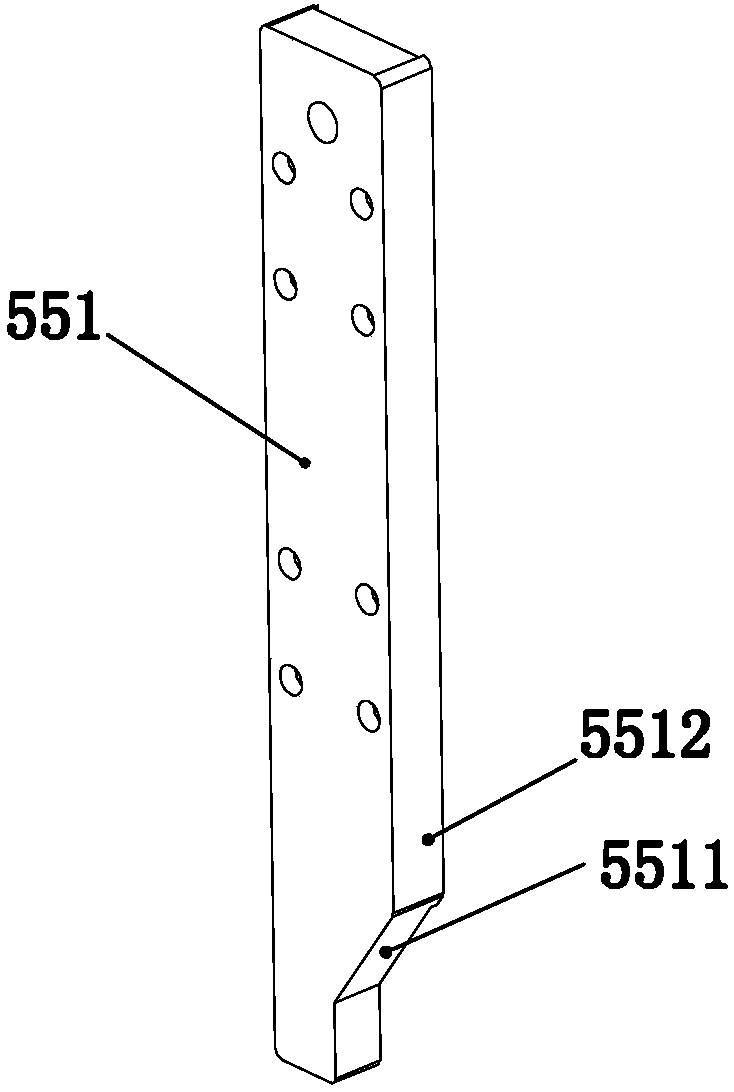

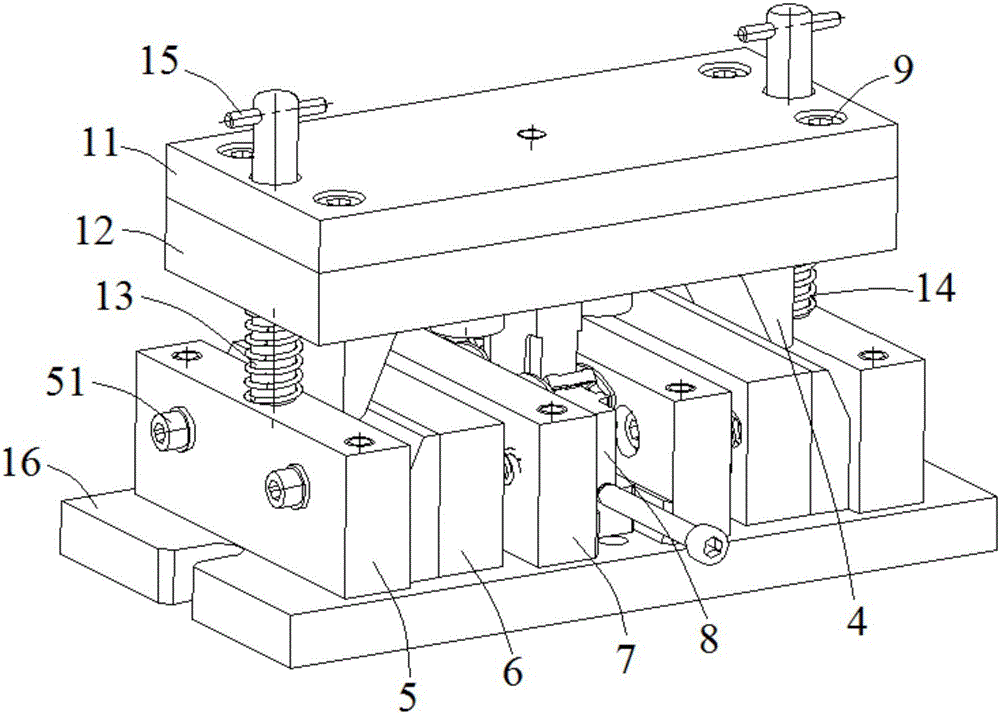

Jump catch clamp, integrated tool for jump catch riveting and flanging and machining method thereof

ActiveCN106653495AEasy to placeNot easy to scatterEmergency protective device manufactureEngineeringMechanical engineering

The invention discloses a jump catch clamp, an integrated tool for jump catch riveting and flanging and a machining method thereof, and the jump catch clamp is a special clamp. The tool disclosed by the invention comprises an upper die, a guide post, a guide post spring, a base plate, sliding block assemblies, a first lower die upright post plate and the jump catch clamp, wherein the guide post is serially connected to the upper die, the first lower die upright post plate and the base plate; the guide post spring is arranged on the guide post in a penetrating manner; the jump catch clamp can be inserted in a drawer groove in the middle part of the base plate; the sliding block assemblies capable of moving horizontally are arranged on the left side and the right side of the jump catch clamp; a riveting punch is arranged on the side, close to the jump catch clamp, of each sliding clock assembly, and an inclined wedge surface is arranged on the other side of each sliding block assembly; an inclined pressing block is arranged above each inclined wedge surface; the inclined pressing blocks are connected with the upper die; and the inclined pressing blocks are provided with inclined wedge surfaces matched with the inclined wedge surfaces of the sliding block assemblies. The jump catch can be assembled at a time, the riveting and flanging quality is reliable, and the production efficiency is improved.

Owner:JIANGSU DAQO KFINE ELECTRIC

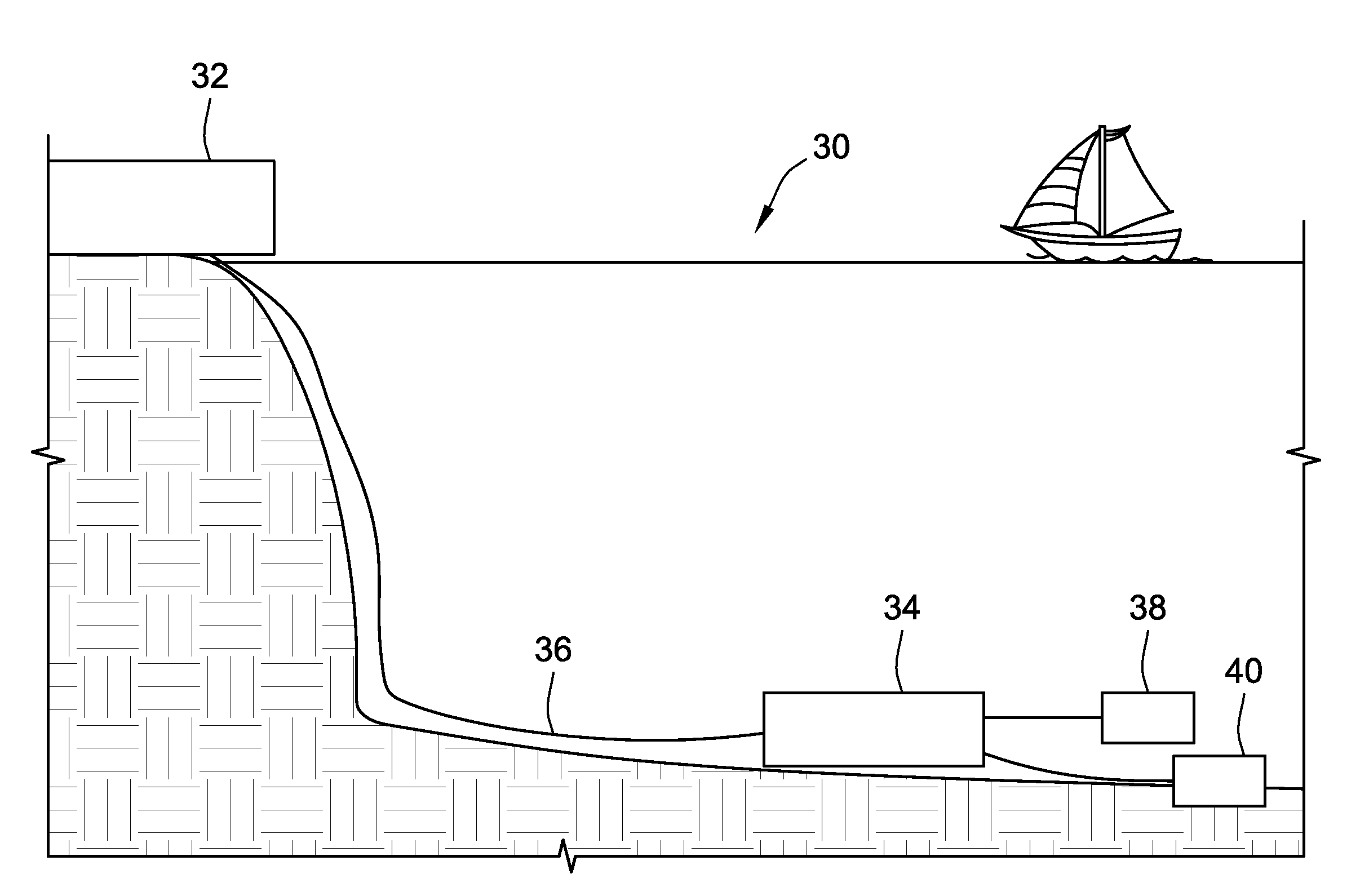

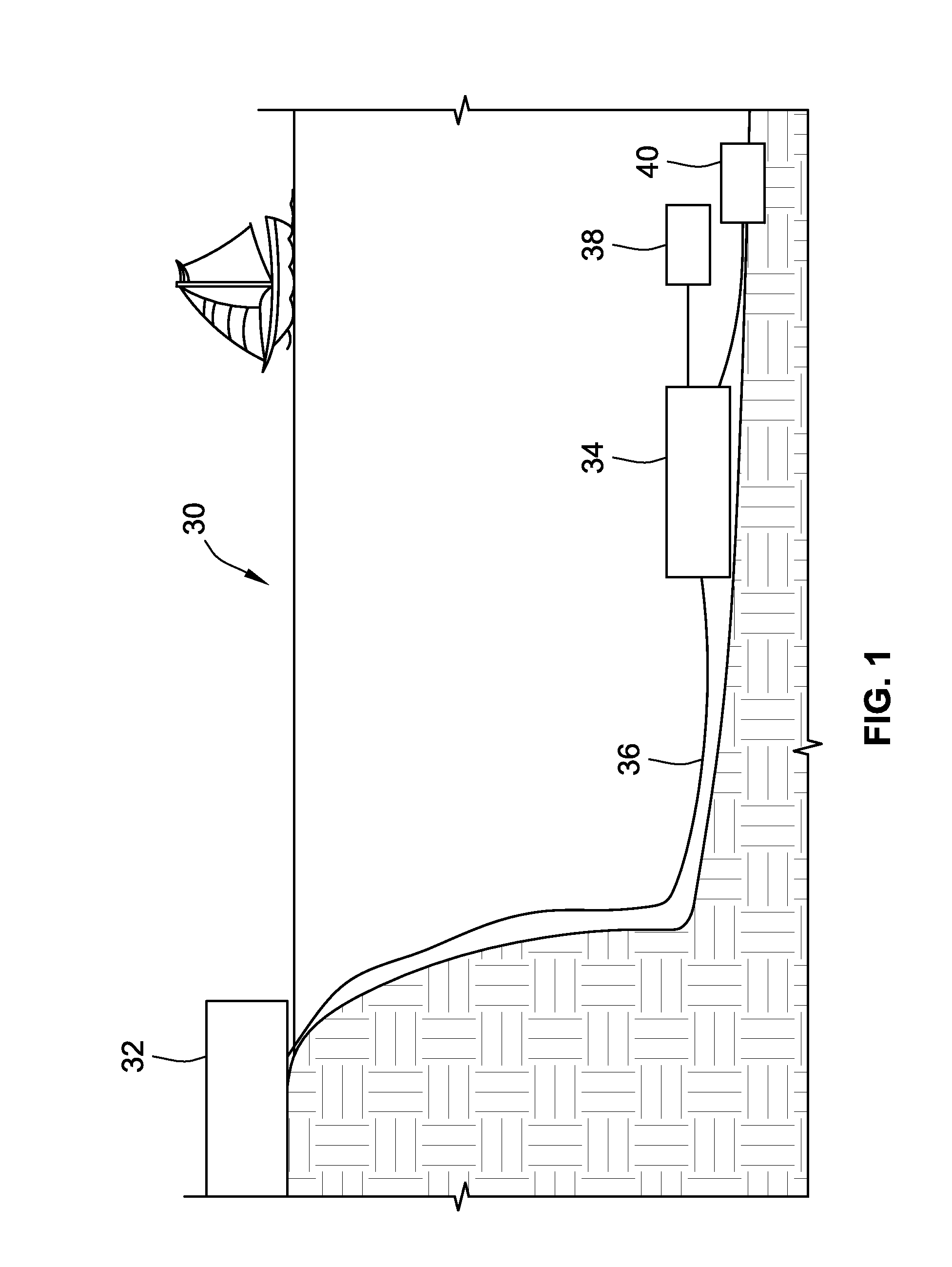

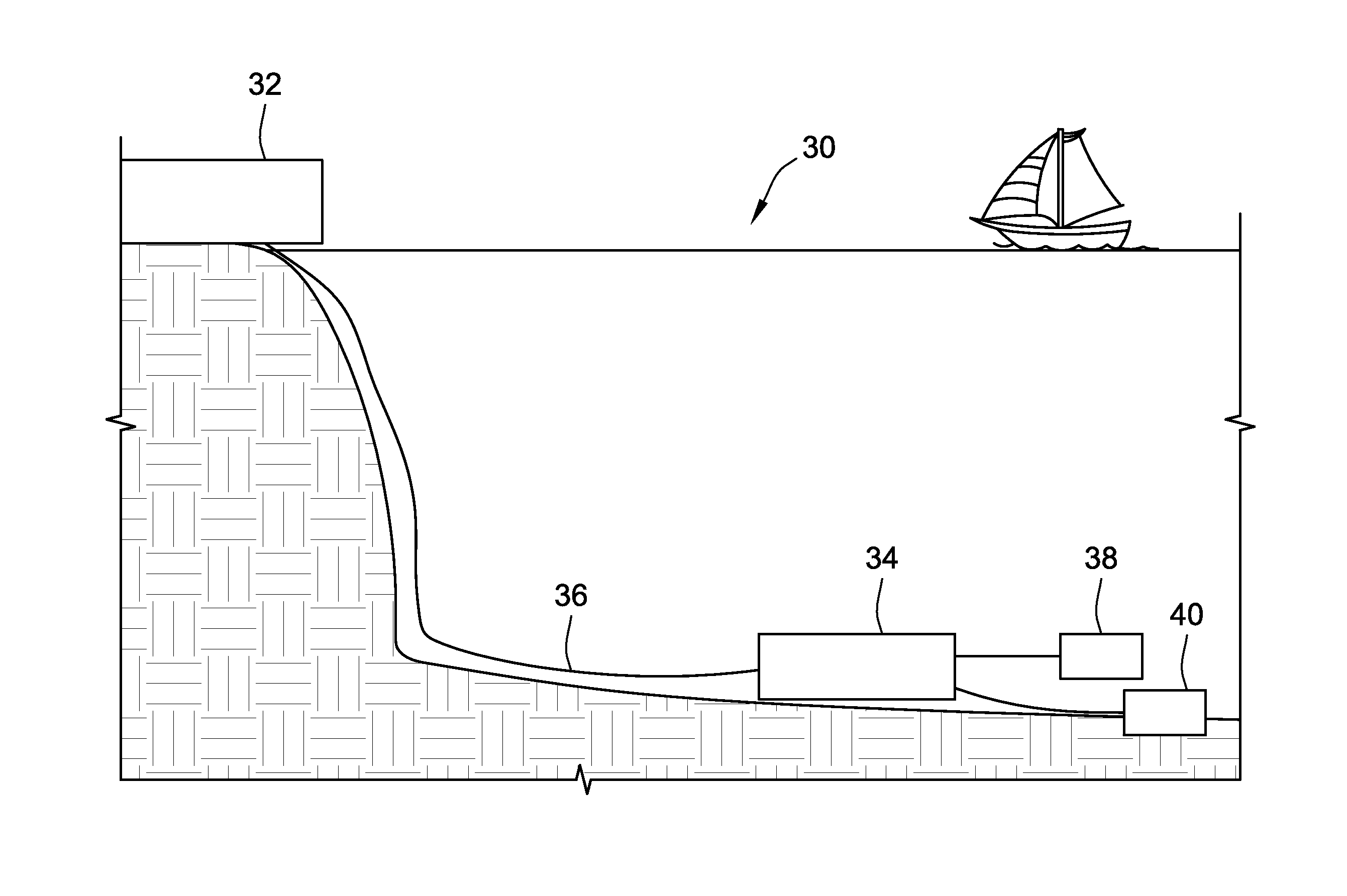

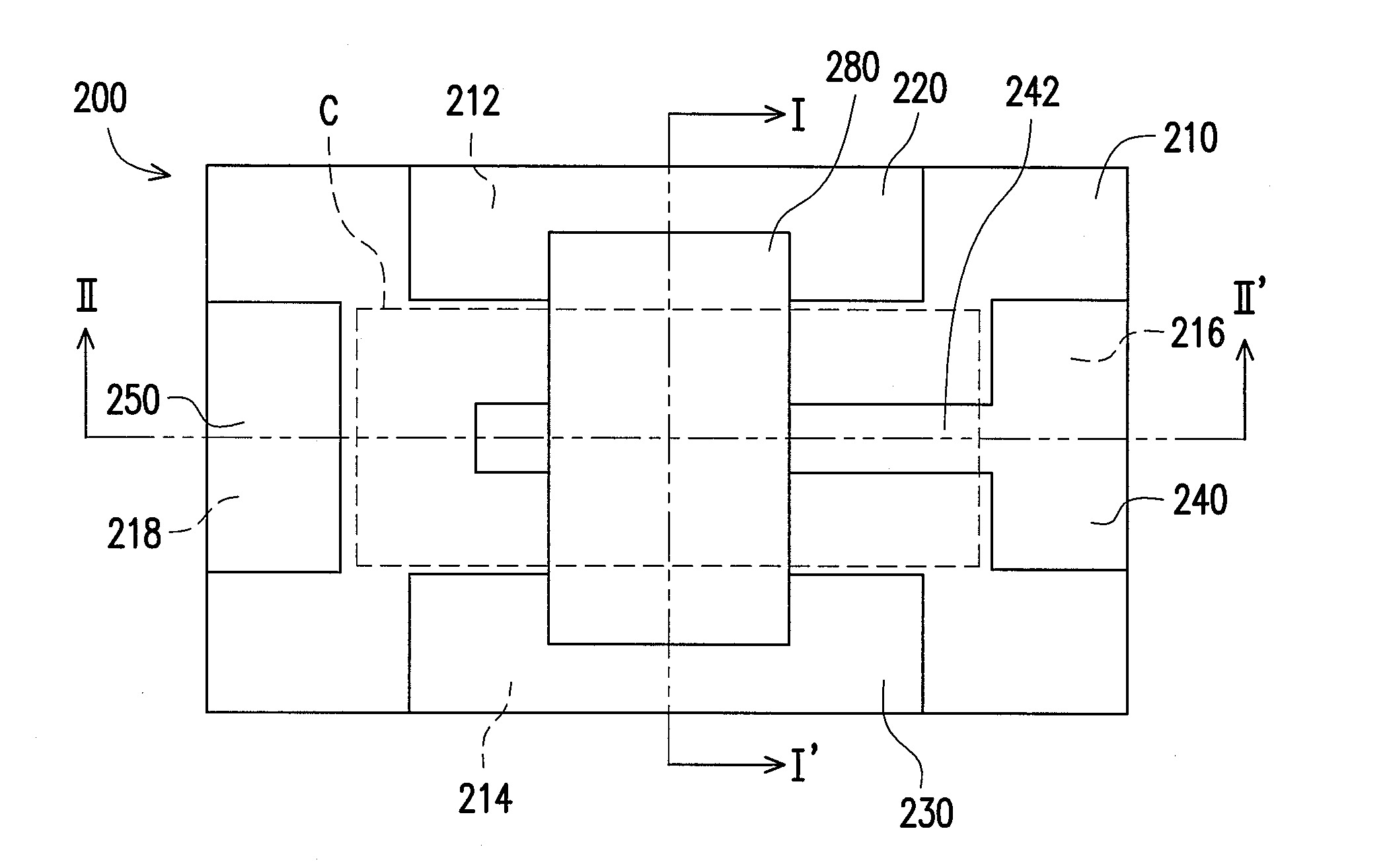

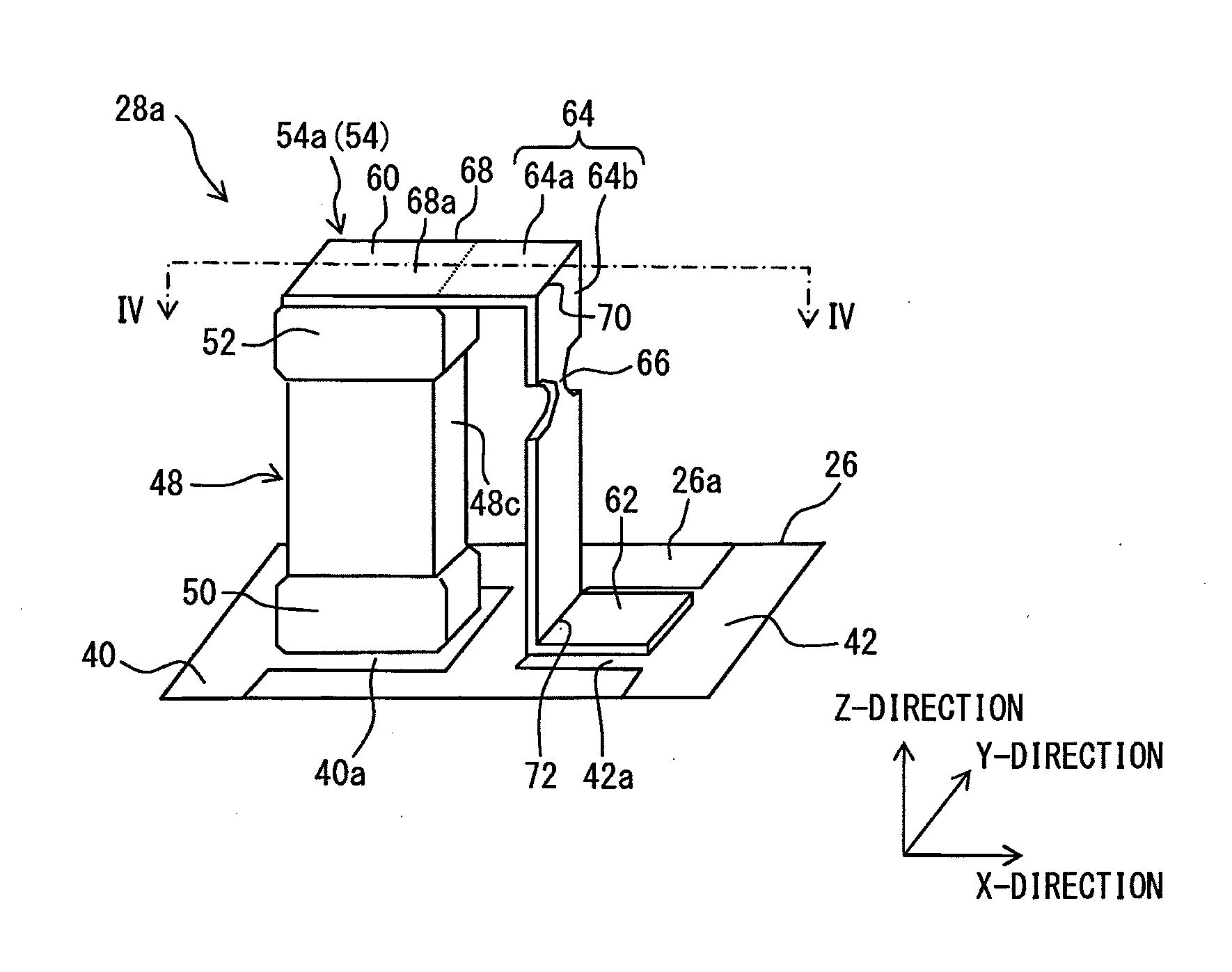

Modular Subsea Electrical Distribution System Having Subsea Cable Harness Assembly and Method for Assembling Same

ActiveUS20130286550A1Increase contactKeep full controlBus-bar/wiring layoutsGas-insulated substationsElectricityDistribution power system

A system and method for coupling electrical power subsea. The system comprises a subsea electrical distribution system having at least one modular subsea circuit breaker assembly. The modular subsea circuit breaker assembly may be coupled to sources of power and / or subsea loads via one or more subsea power cable harness assemblies. The modular subsea circuit breaker assembly has at least electrical connector. Each subsea power cable harness assembly has a corresponding electrical connector. At least one of these electrical connectors is extendable to engage an electrical connector opposite it.

Owner:SCHNEIDER ELECTRIC IND SAS

Welding device for small circuit breaker contact plate and coil

ActiveCN104752105AHigh control precisionOperational Hazard EliminationEmergency protective device manufactureCarrying capacityPower flow

The invention discloses a welding device for a small circuit breaker contact plate and a coil. According to feeding and processing routes of the contact plate and the coil, a feeding passage, a pushing mechanism, a contact plate retaining mechanism, a contact plate feeding mechanism, a coil feeding mechanism, a coil lifting mechanism and an electrode component are arranged respectively. A one-time processing and forming mode is adopted to complete automatic feeding, distributing, positioning, clamping, automatic welding, automatic detecting of welding and forming size and automatic sorting of the qualified and the unqualified, size control accuracy of an operating clamp is improved, qualification rate is increased, operating errors are reduced, operating dangerousness of personnel is eliminated, welding condition difference is small, welding quality is stable, and assemblability, current carrying capacity, synchronicity of contact engaging and disengaging, ultimate breaking capacity and service life of a welding finished product, current and stroke excess, temperature rise, influencing dynamothermal stability and using safety and performance are improved remarkably.

Owner:CHONGQING KUNLING ELECTRONICS TECH

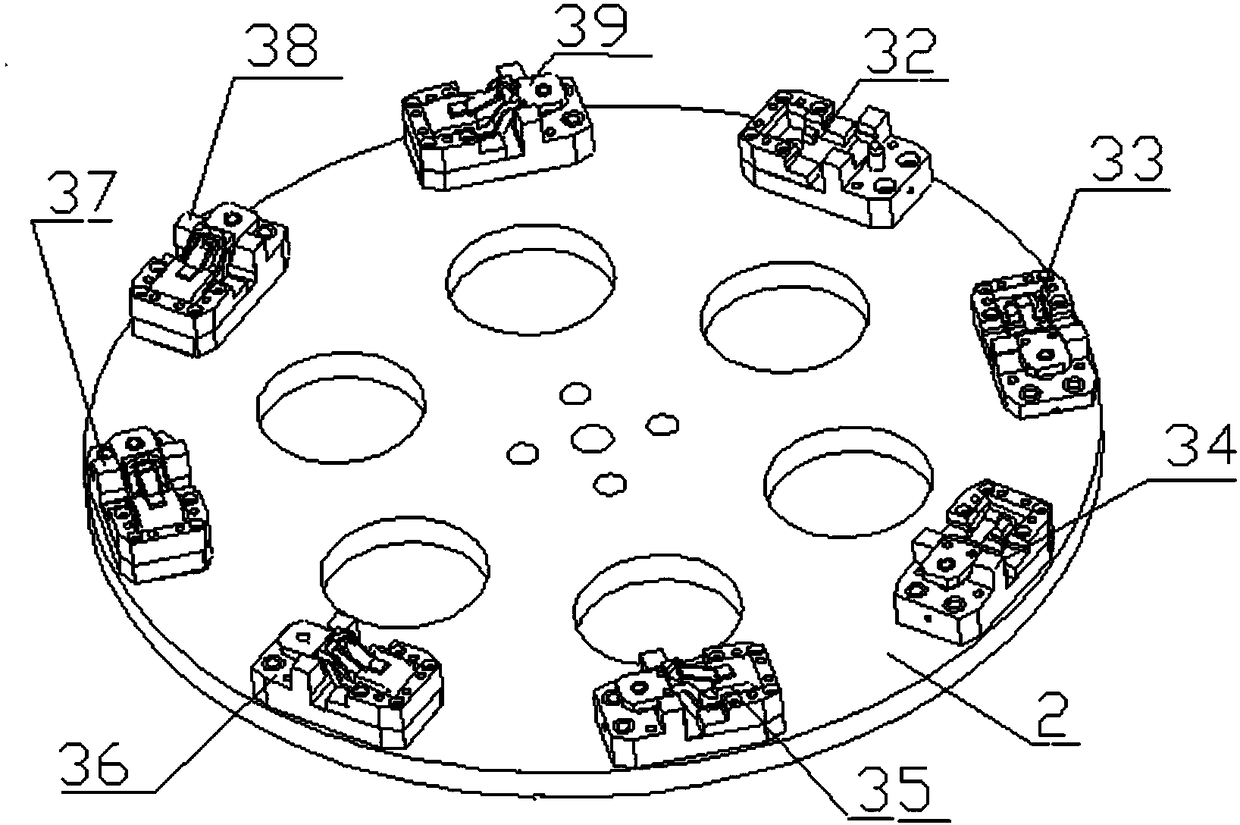

Device for automatically assembling reflecting plates and conductive plate of molded case circuit breaker

ActiveCN108198734AEasy to operateIncrease productivityMetal working apparatusEmergency protective device manufactureProduction lineEngineering

The invention discloses a device for automatically assembling reflecting plates and a conductive plate of a molded case circuit breaker. The device comprises a turntable arranged on a table, wherein eight assembly clamps are uniformly arranged along the peripheral direction of the turntable; a conductive plate feed mechanism, a reflector feed mechanism, a pressing mechanism, an isolation componentand a mobile assembly mechanism are arranged along the outer side of the turntable separately; an electric operation cabinet, a vibration disk regulator and a feed detection component are additionally arranged on the table; a base input line is arranged at the lower part of the isolation component; and the mobile assembly mechanism is arranged at the upper part of an initiating terminal of a baseoutput line. The device disclosed by the invention is capable of replacing a hand to assemble the reflecting plates and the conductive plate into a base, so that 3-4 persons can be reduced on each production line, the device is simple in operation and high in production efficiency, the assembly quality is improved and poor assembly is removed.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

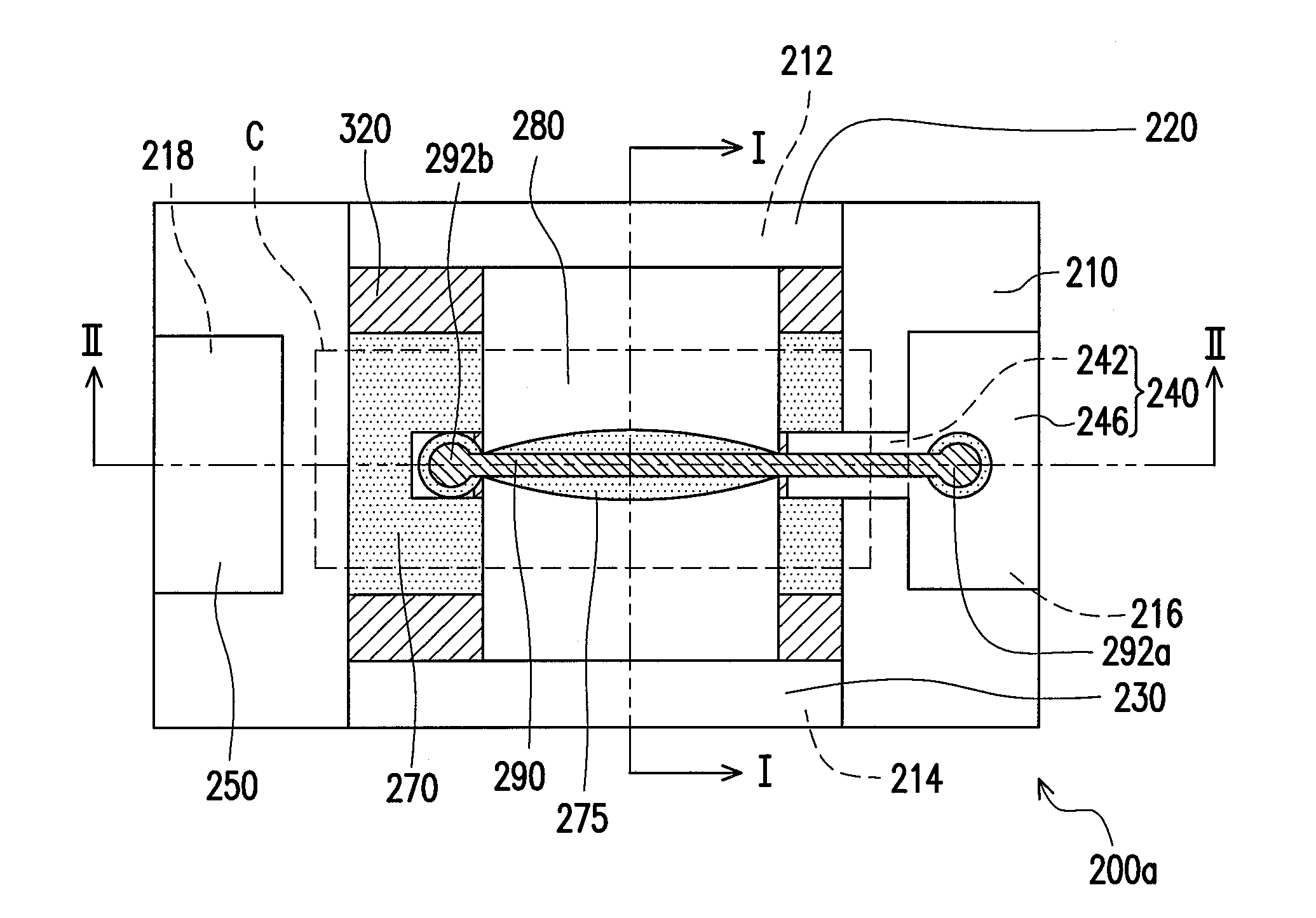

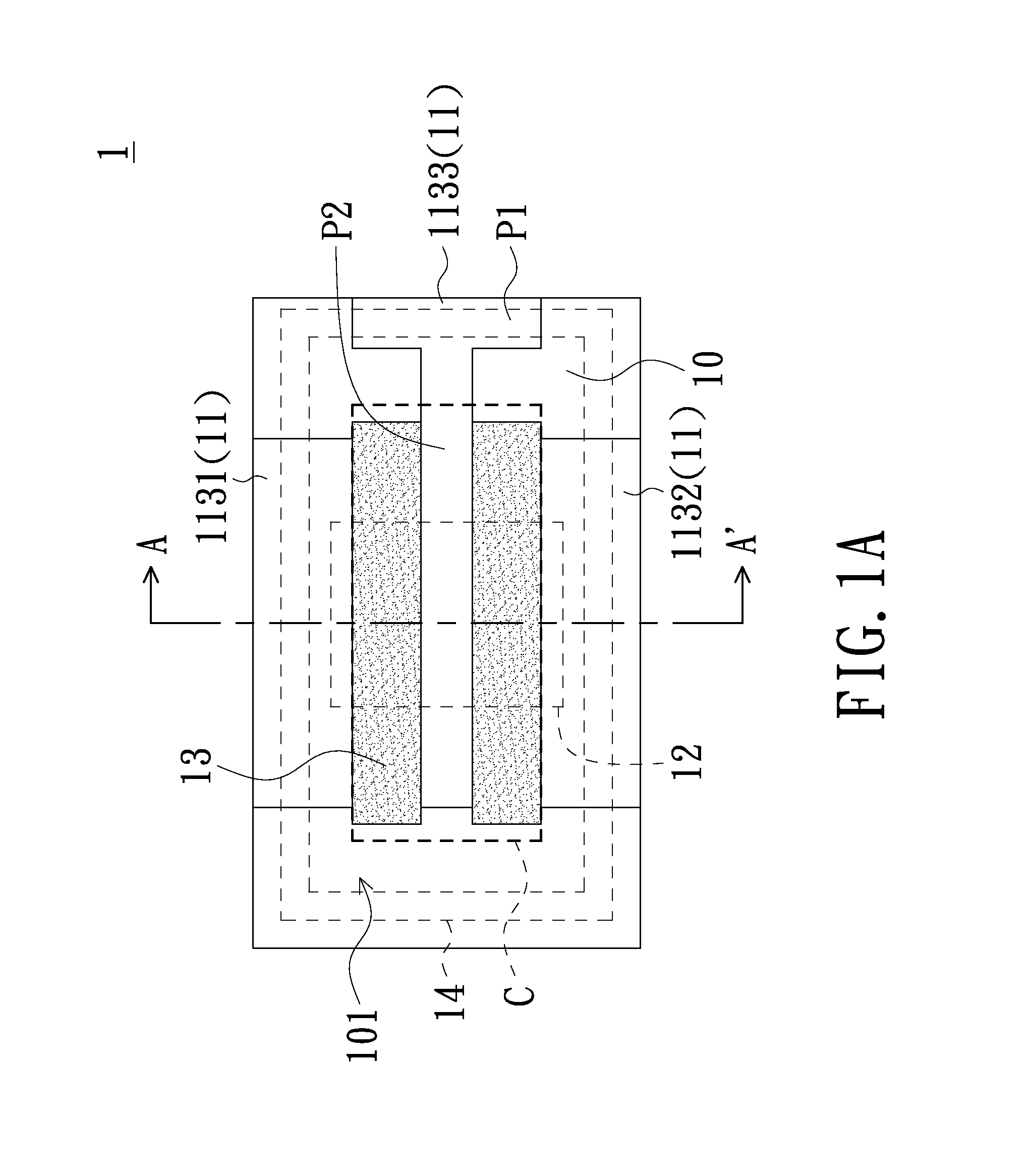

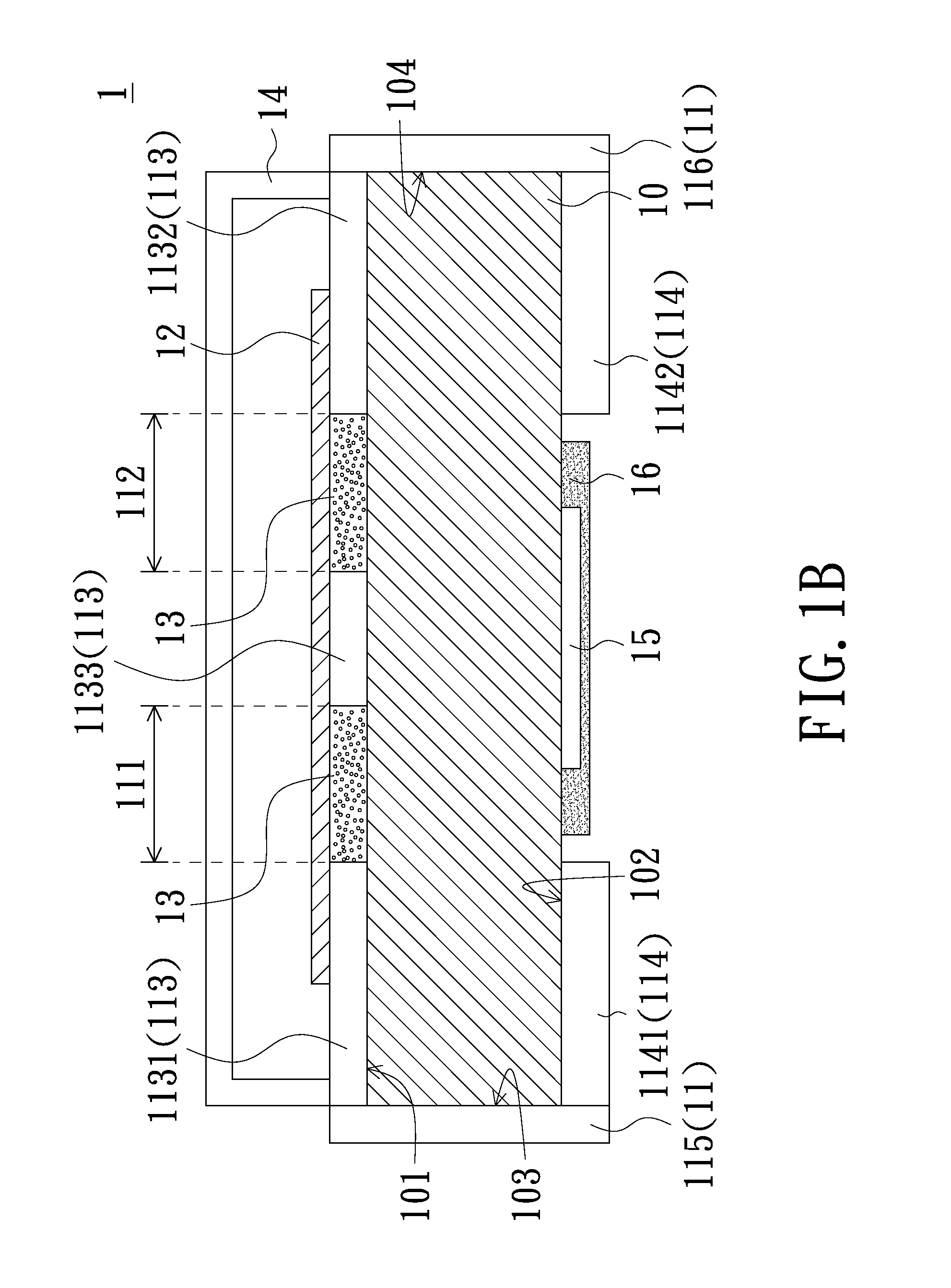

Protective device

ActiveUS20110058295A1Effective preventionEffectively preventArrangements responsive to excess currentEmergency protective device manufactureAuxiliary memoryMetal

A protective device including a substrate, a conductive section and a first auxiliary medium is provided. The conductive section is supported by the substrate, wherein the conductive section comprises a metal element electrically connected between first and second electrodes. The metal element serves as a sacrificial structure having a melting point lower than that of the first and second electrodes. The first auxiliary medium is disposed between the metal element and the substrate, wherein the first auxiliary medium has a melting point lower than that of the metal element. The first auxiliary medium facilitates breaking of the metal element upon melting.

Owner:CYNTEC

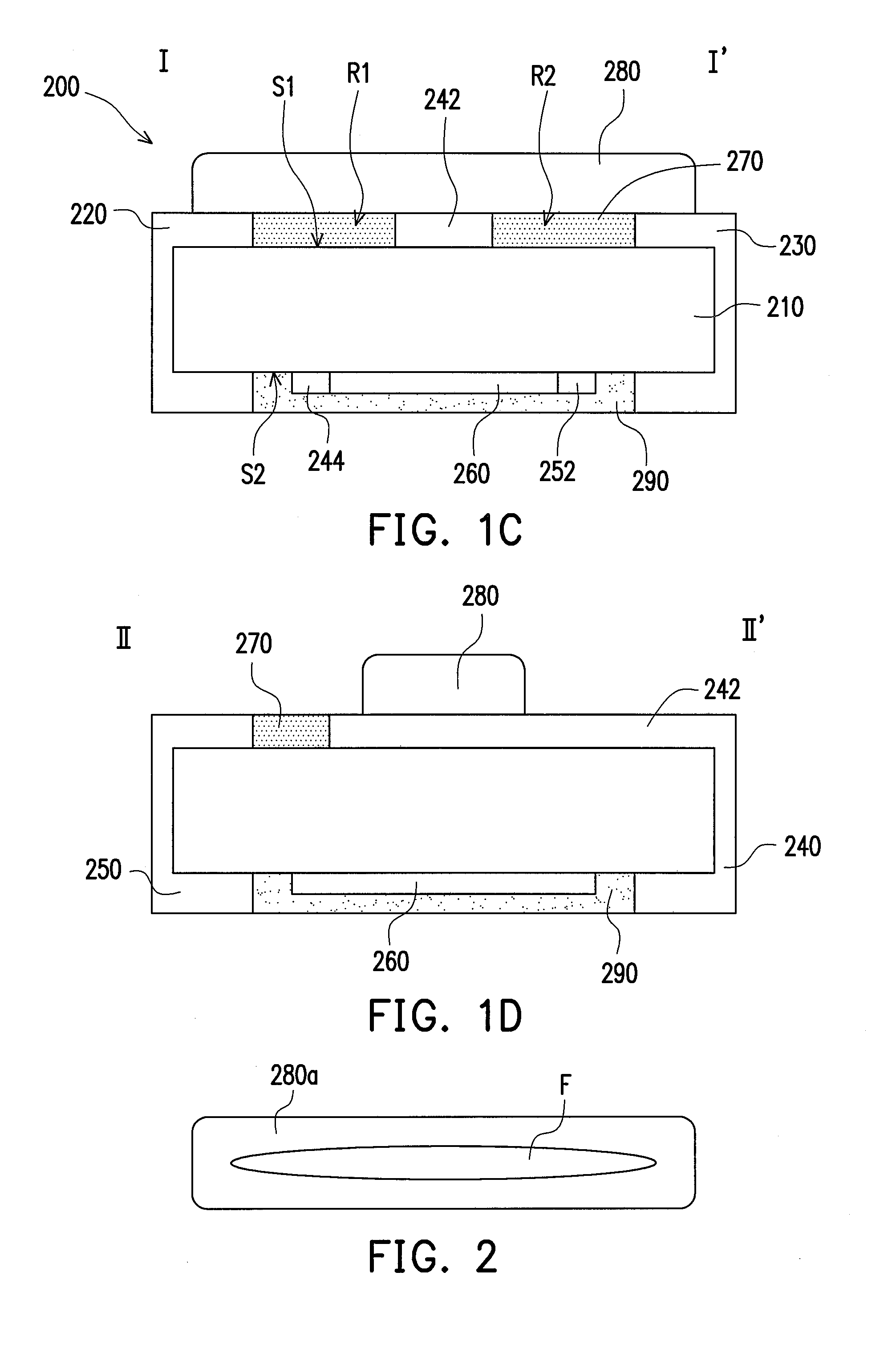

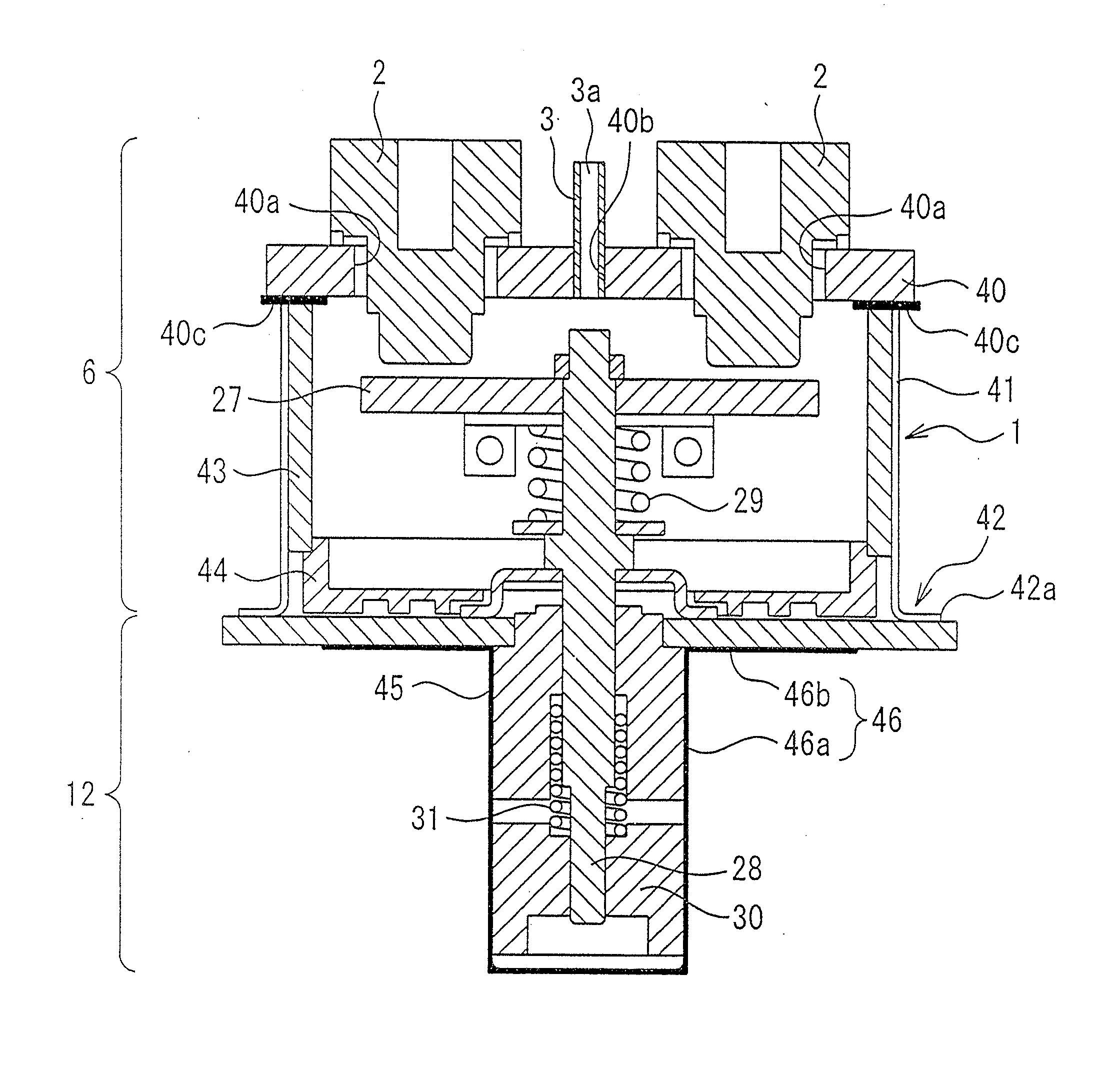

Electromagnetic contactor, electromagnetic contactor gas encapsulating method, and electromagnetic contactor manufacturing method

InactiveUS20130234813A1Reduce equipment costsShorten the timeHigh-tension/heavy-dress switchesContacts enclosures/screensFlangeContactor

An electromagnetic contactor has a base plate having an aperture hole; an arc extinguishing chamber having a fixed terminal and a pipe; and a bottomed tubular cap in which one end thereof is open. An arc extinguishing chamber connection portion is formed by the arc extinguishing chamber and a first connection member having a tube portion connected to the arc extinguishing chamber and a flange portion contacting with the base plate. A cap connection portion is formed by the cap and a second connection member having a tube portion connected to the cap and a flange portion connected to the base plate. The flange portions of the first and second connection members are attached to one surface and the other surface of the base plate accordingly. The arc extinguishing chamber connection portion and the cap connection portion are in communication through the aperture hole of the base plate.

Owner:FUJI ELECTRIC CO LTD +1

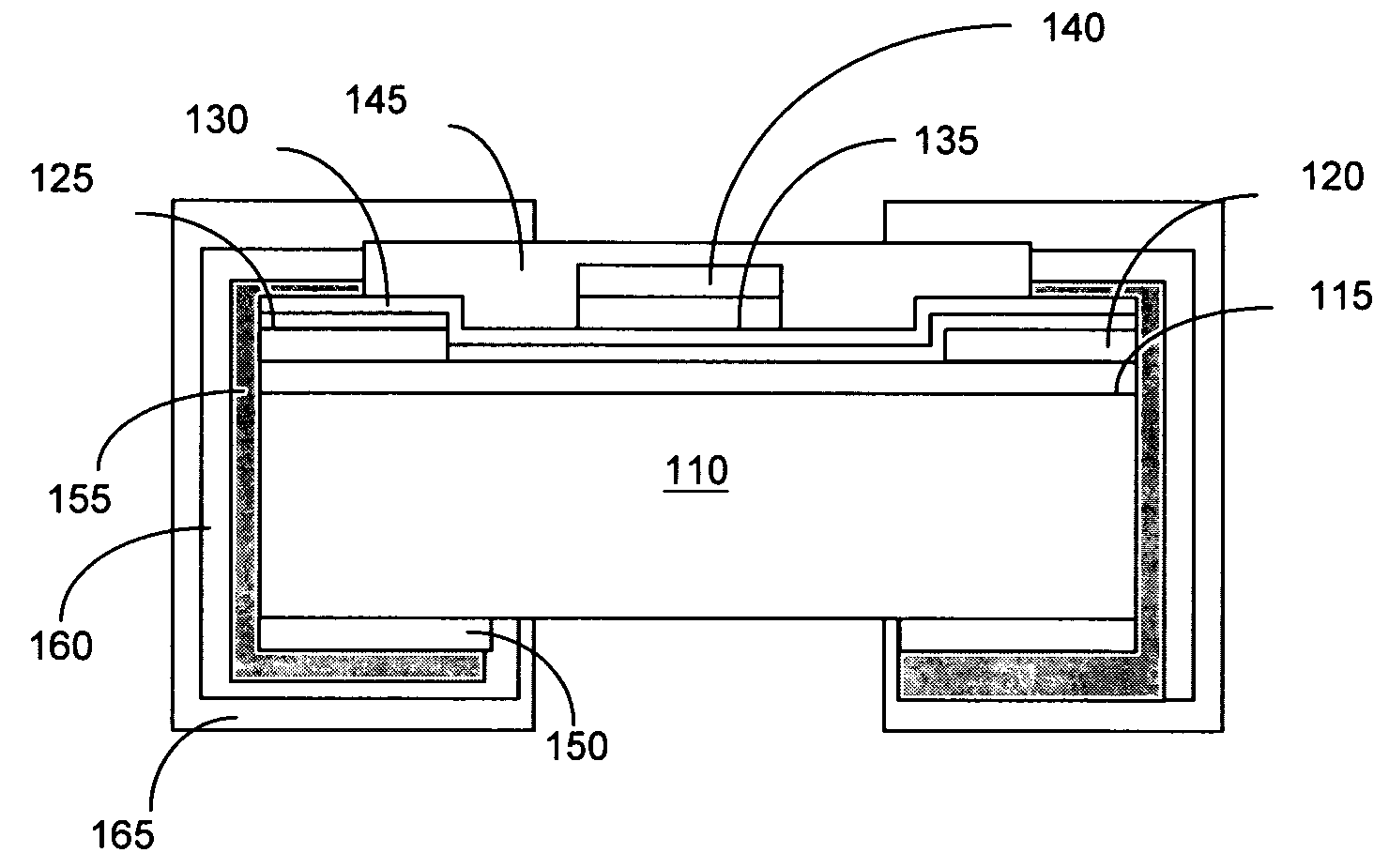

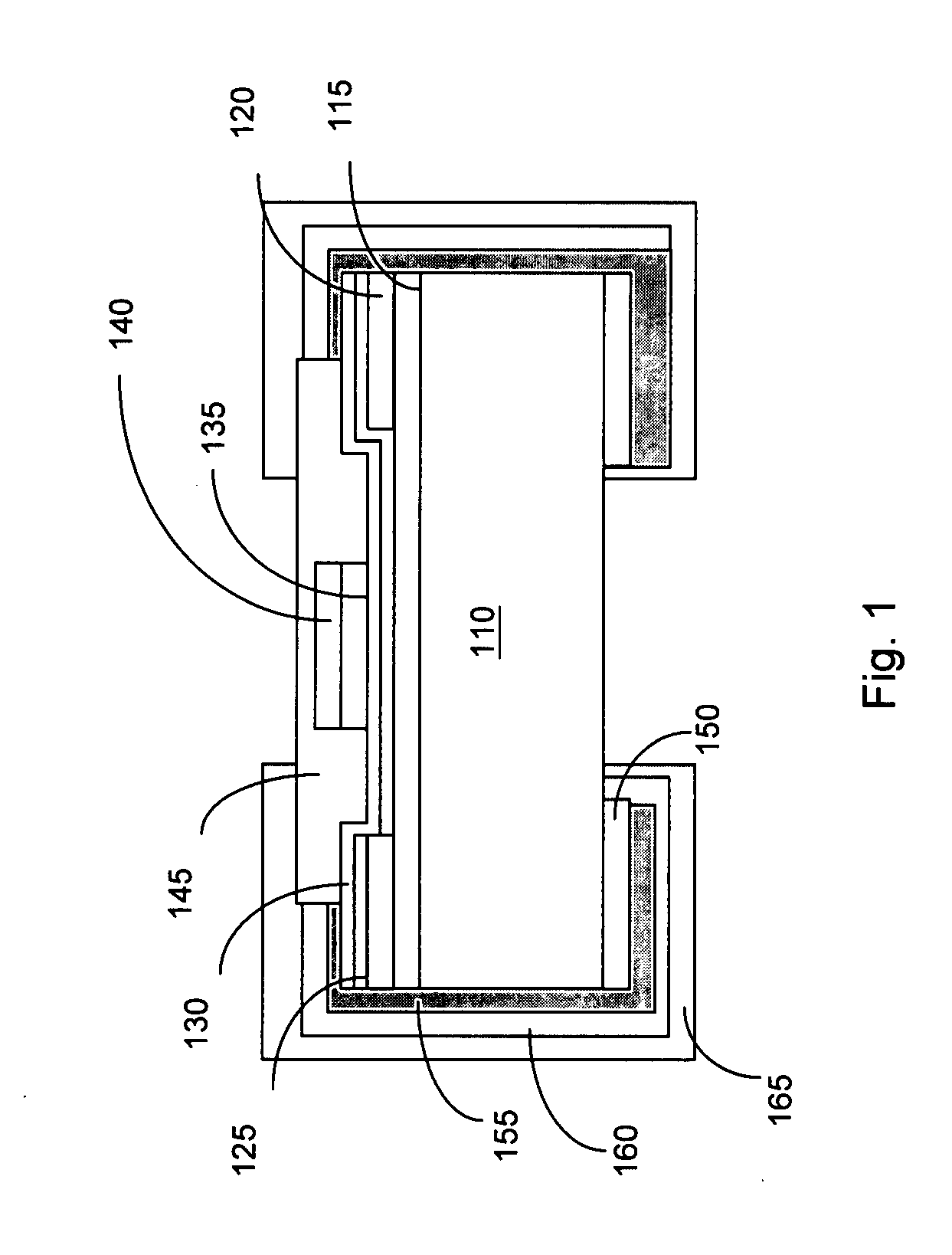

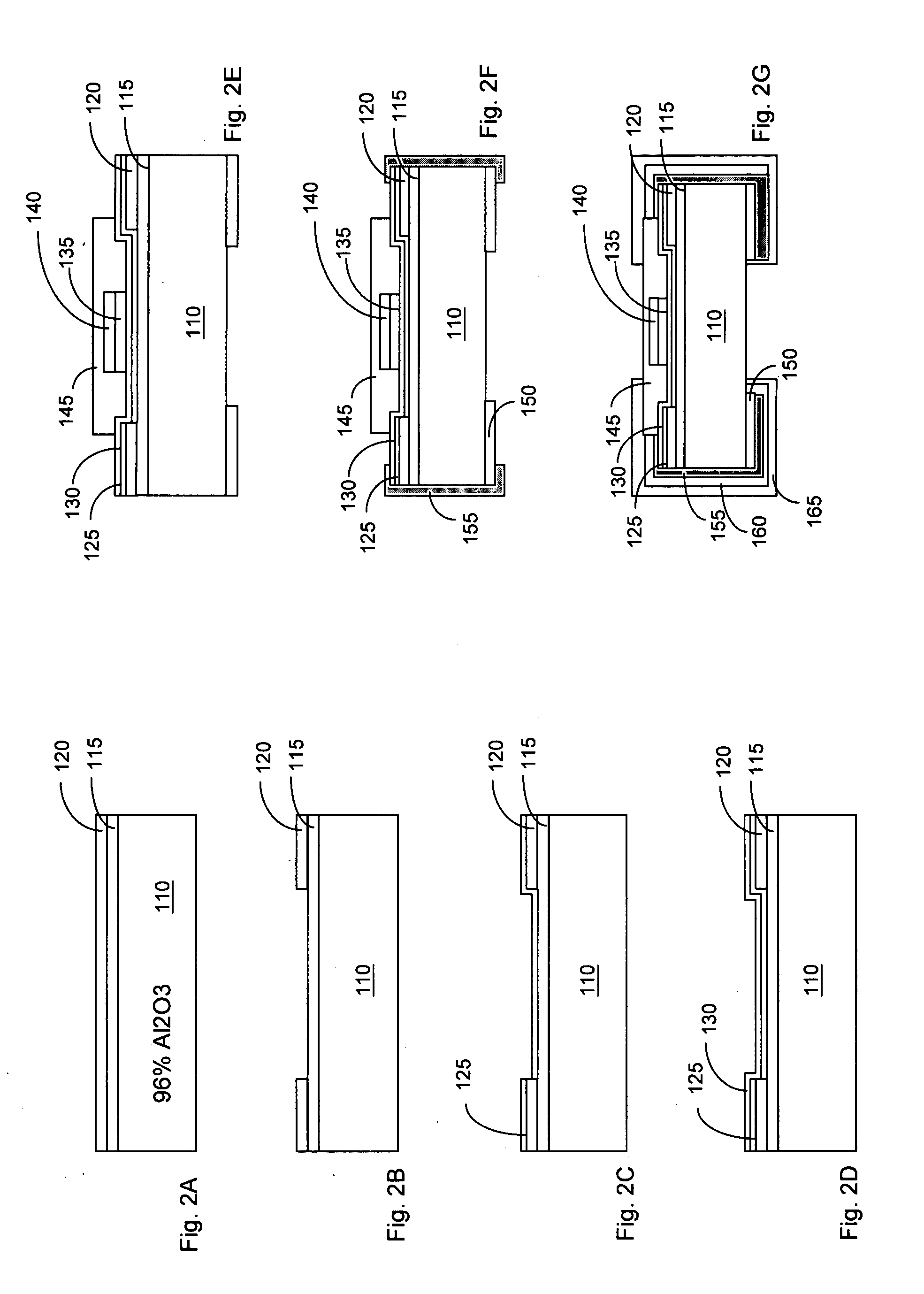

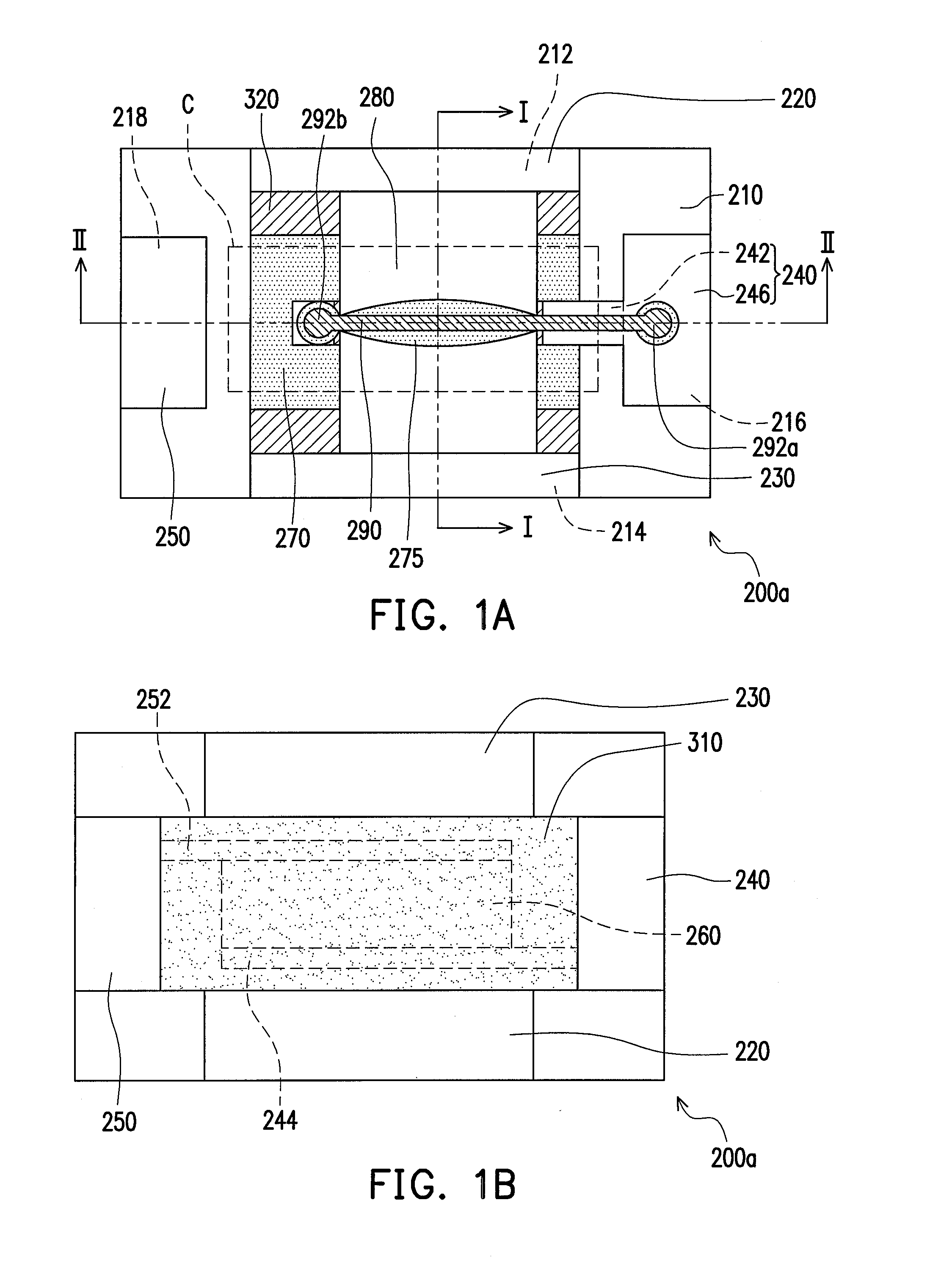

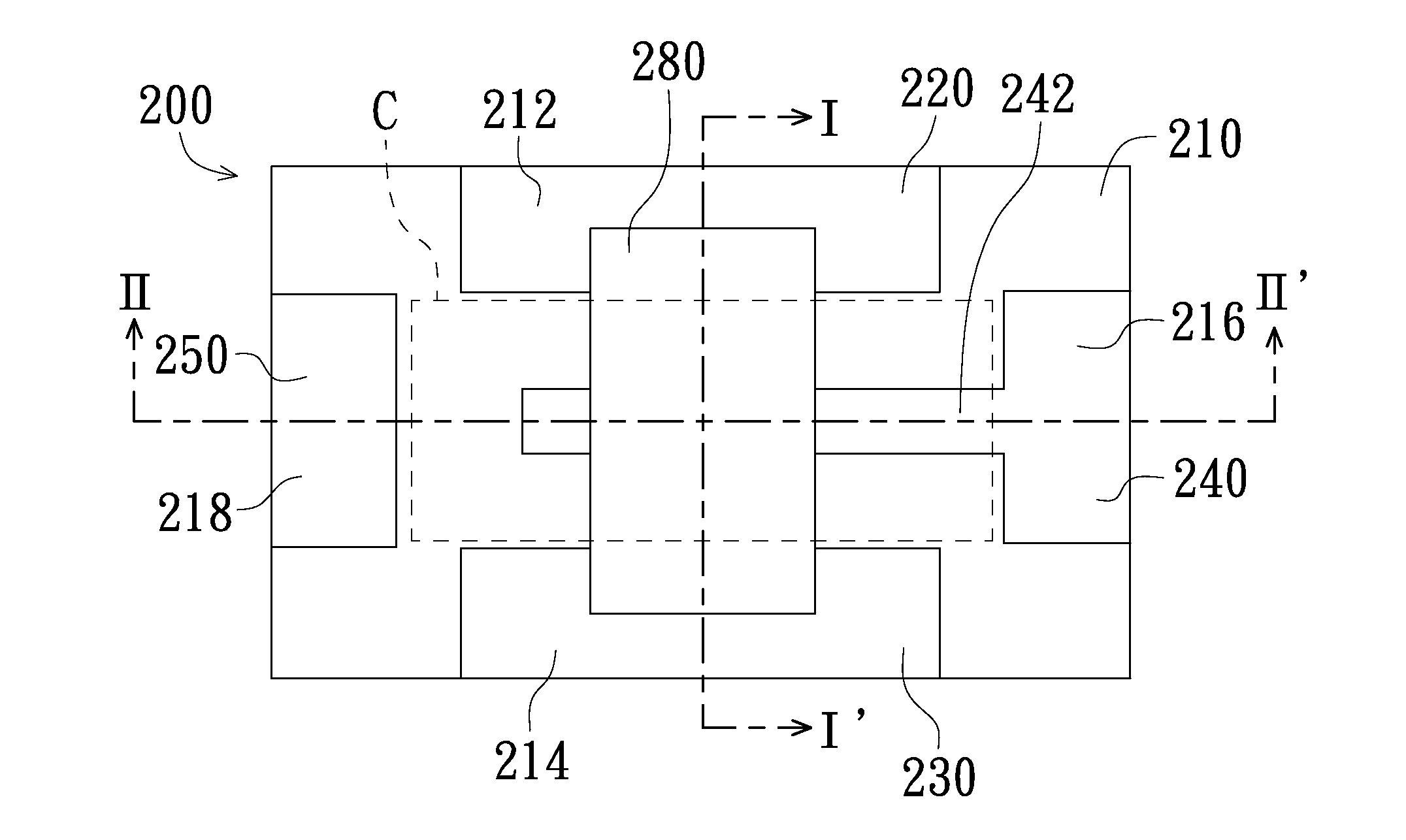

Protective device and protective module

ActiveUS20140133059A1Less numberAvoid problemsEmergency protective arrangements for automatic disconnectionEmergency protective device manufactureOptoelectronicsMelt temperature

A protective device includes a substrate, an electrode layer, a metal structure, an outer cover and an arc extinguishing structure. The electrode layer is disposed on the substrate. The electrode layer includes at least one gap. The metal structure is disposed on the electrode layer and located above the gap, and the metal structure has a melting temperature lower than a melting temperature of the electrode layer. The outer cover is disposed on the substrate and covers the metal structure and a portion of the electrode layer. The arc extinguishing structure is disposed between the outer cover and the substrate. A protective module is further provided.

Owner:CYNTEC

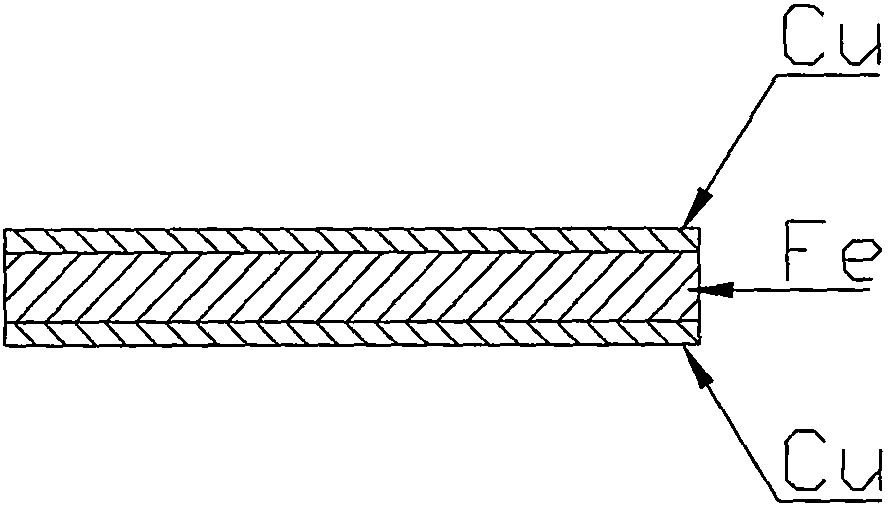

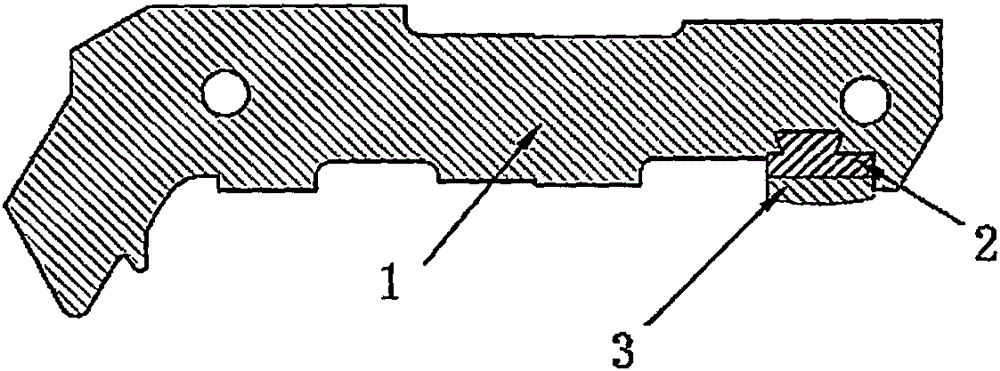

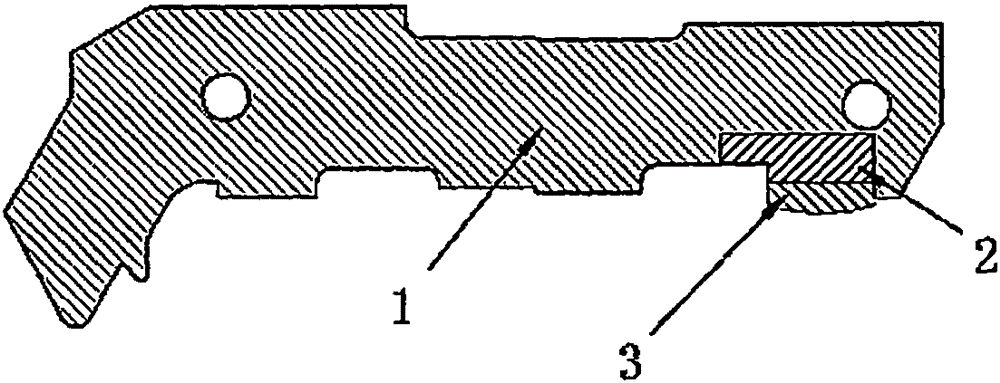

Circuit breaker electrical contact support member and preparation method thereof

InactiveCN105161380AReduce usageAvoid unstable contactEmergency protective device manufactureCircuit-breaking switch contactsPunchingMaterial consumption

The invention discloses a circuit breaker electrical contact support member and a preparation method thereof. The support member comprises a support member body made of a Cu / Fe / Cu material strip. One side of the support member body is provided with a built-in groove; the groove is embedded by a conductive insert block; and the insert block is provided with a contact point. The method is characterized by, carrying out thermal treatment on the Cu / Fe / Cu material strip, and rolling the Cu / Fe / Cu material strip obtained after thermal treatment; carrying out punching on the Cu / Fe / Cu material strip obtained after rolling to prepare the support member body; preparing the insert block, and inserting and welding the insert block to one side of the obtained support member body; and welding the contact point to the other side of the insert block. The support member is prepared by inserting the Cu block or other conductive metal blocks into the Cu / Fe / Cu composite strip, thereby improving the strength of the contact support member, ensuring stability of the current conduction when an electrical contact is contacted, and meanwhile, reducing copper material consumption and saving cost.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

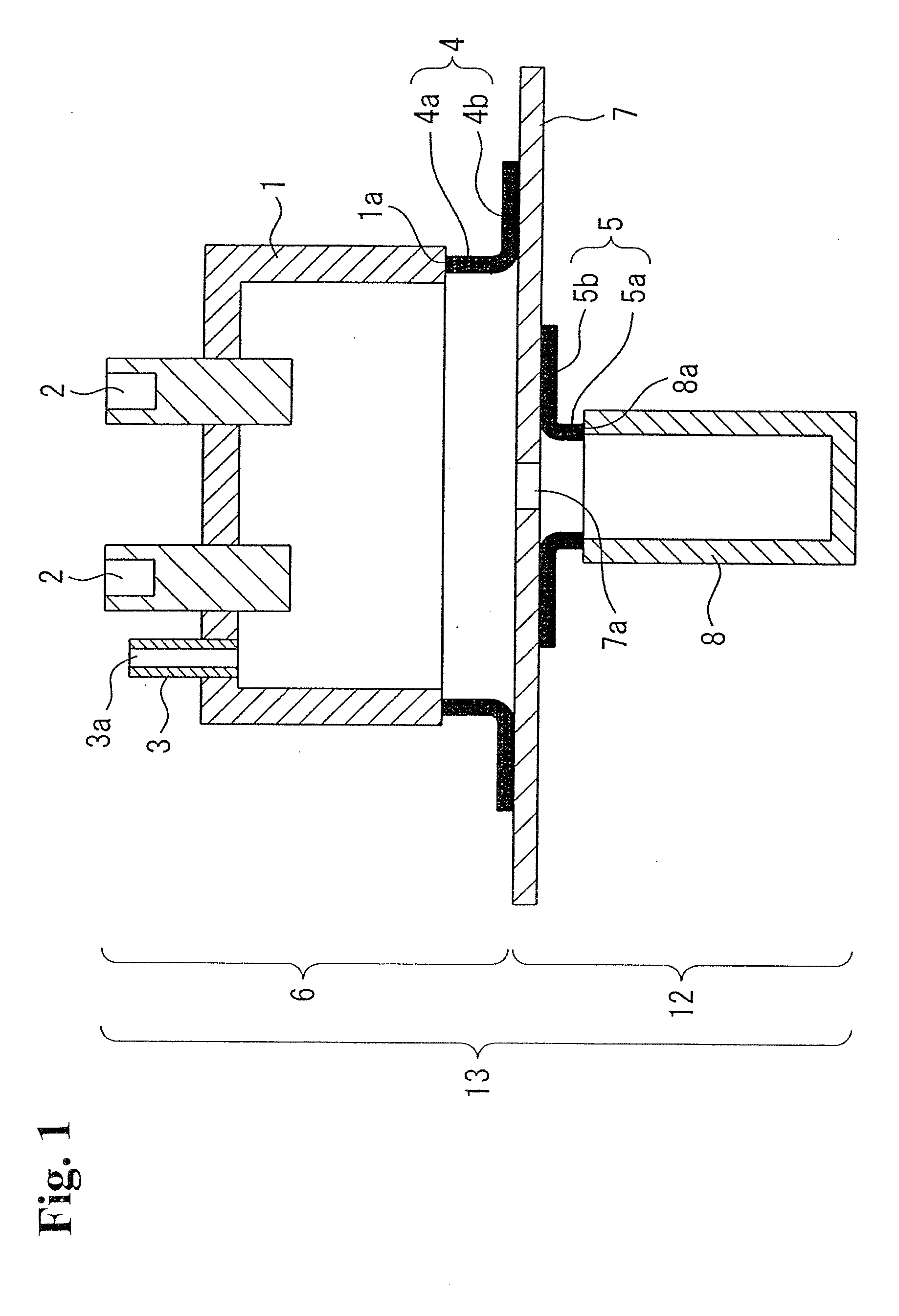

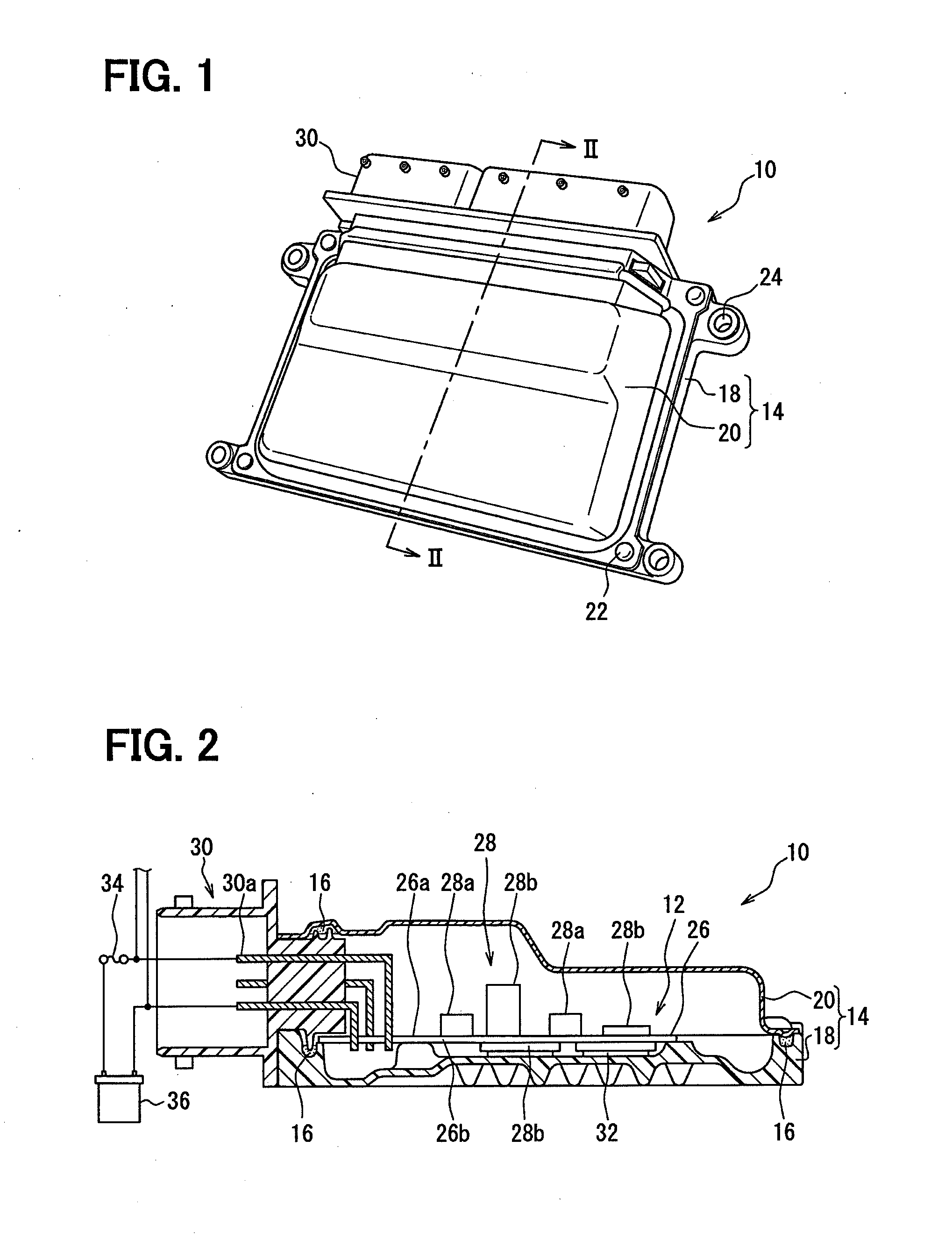

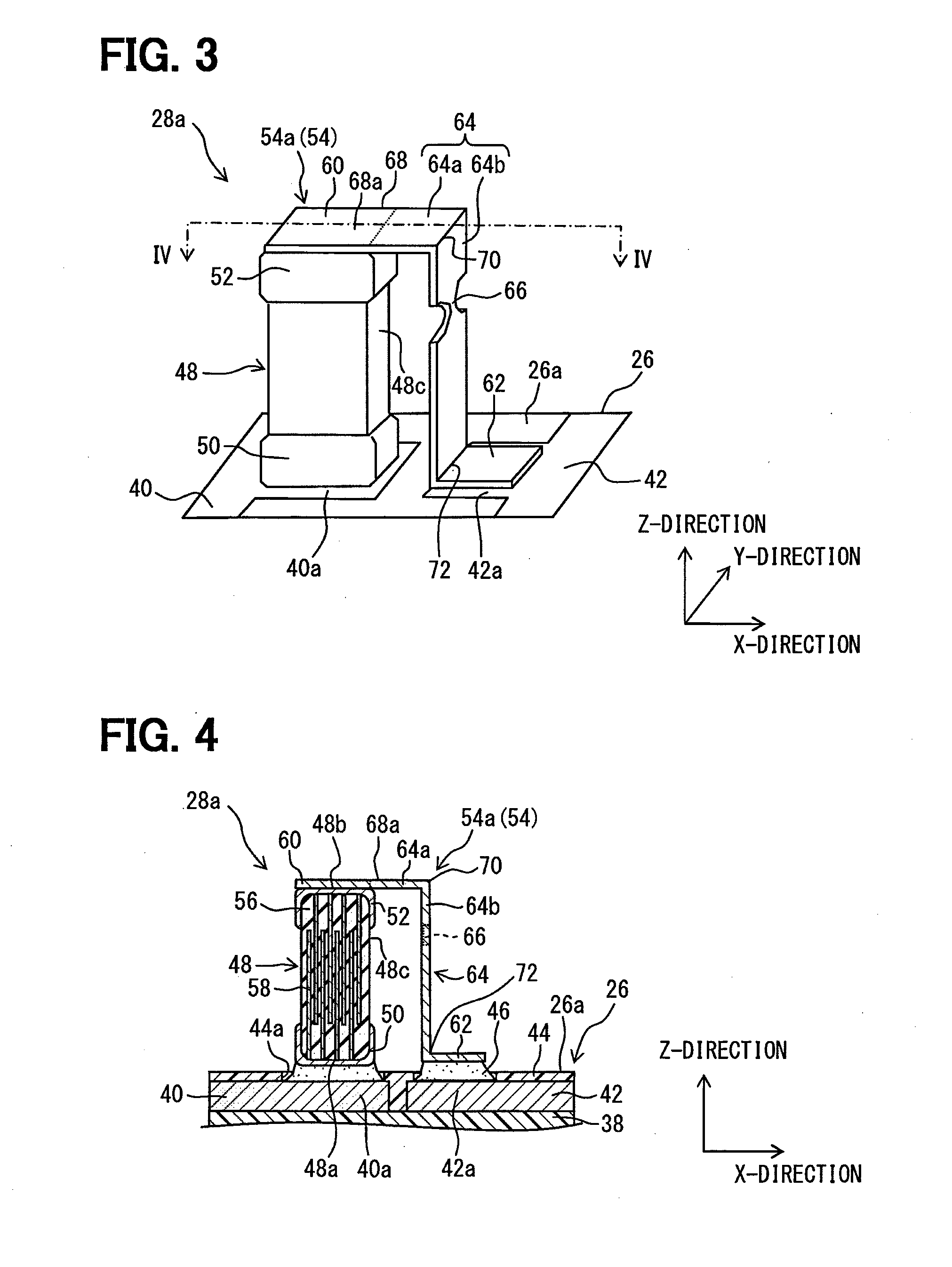

Electronic part and electronic control unit

ActiveUS20140240942A1Improve responseMade smallElectrically conductive connectionsPrinted circuit aspectsEngineeringElectrical and Electronics engineering

A main body of an electronic part is formed in a rectangular pillared shape having a first and a second axial end surface. A first electrode is formed on the first axial end surface electrically and mechanically connected to a first wiring pattern formed on a board surface of a printed board. A second electrode is formed on the second axial end surface, to which one end of a fuse terminal is electrically connected. The other end of the fuse terminal is connected to a second wiring pattern of the printed board or a wiring member which is formed as an independent member from the printed board. A cut-off portion is formed in a connecting portion of the fuse terminal.

Owner:DENSO CORP +1

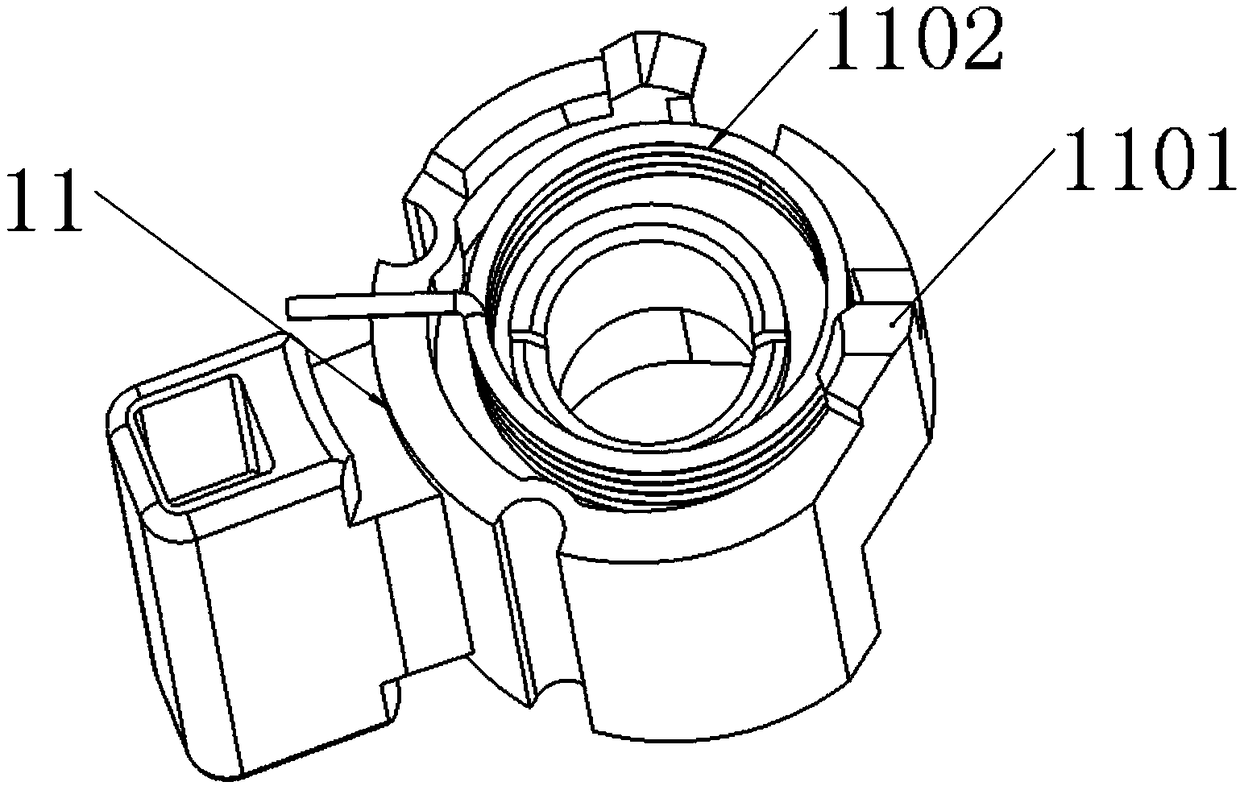

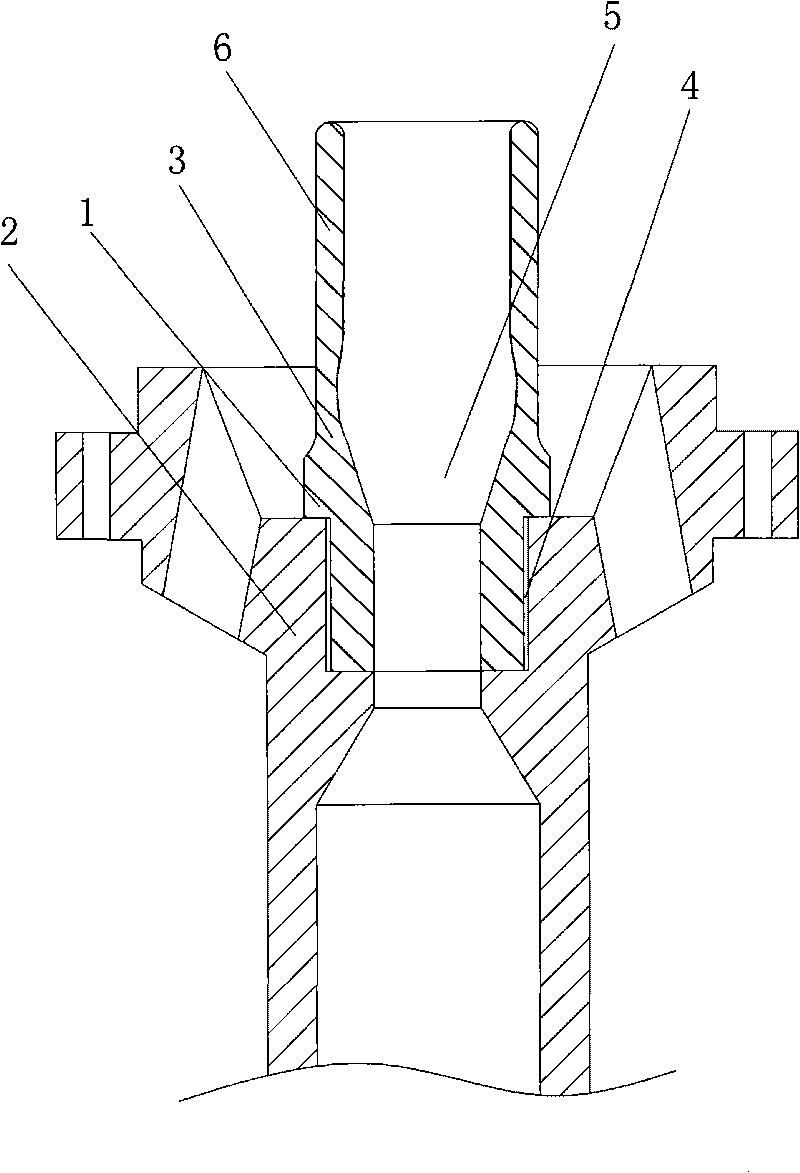

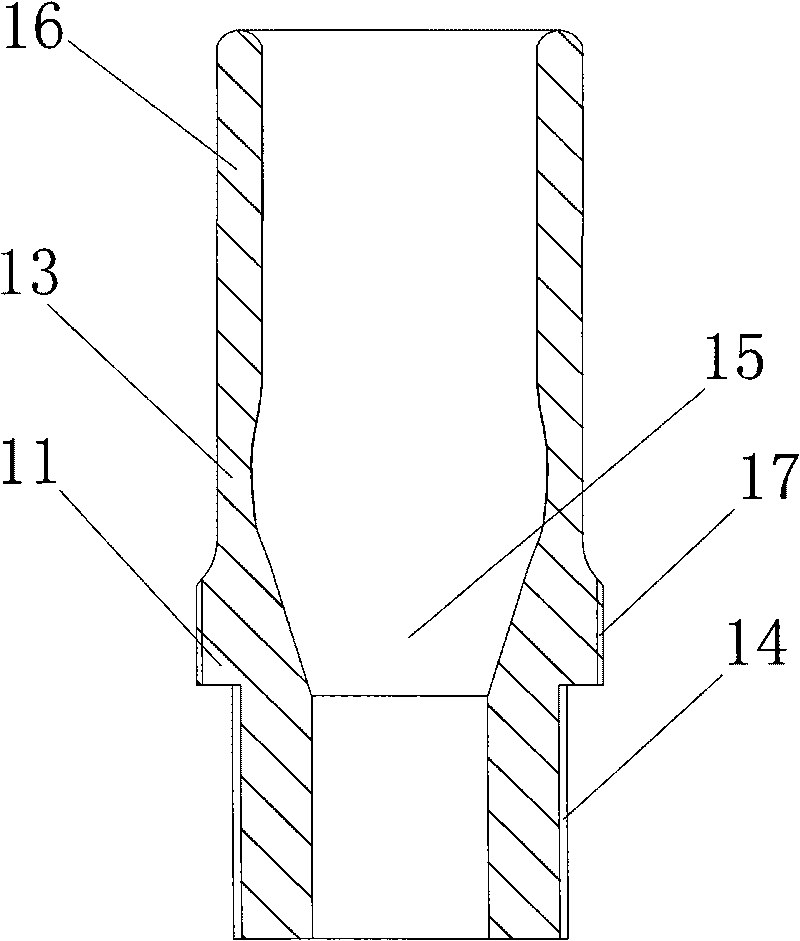

Dynamic arc contact, and installing method and special tool thereof

ActiveCN101752153AImprove installation qualityGuaranteed not to deformEmergency protective device manufactureCircuit-breaking switch contactsScrew threadFriction force

The invention discloses a dynamic arc contact. The dynamic arc contact comprises a tubular contact main body, wherein an outer peripheral face at one end of the contact main body is provided with a contact screw thread used for fixedly connecting a moving contact; the contact main body on the root part of the contact screw thread is provided with a baffle block projecting outwards; the inner hole wall of the contact main body is provided with a conical necked section; a small port end of the necked section faces towards the contact screw thread; and the radial outer surface of the baffle block is provided with a retaining screw thread having the same rotational direction as the contact screw thread. Simultaneously, the invention also discloses an installing method and a special tool for the dynamic arc contact. In the invention, the dynamic arc contact provided with the retaining screw thread is arranged in cooperation with the special tool and the dynamic arc contact is screwed on the moving contact through a friction force between a pressing head at the end of a compression carrier rod and the conical necked section in the dynamic arc contact, so a contact finger of the dynamic arc contact is prevented from being deformed, and the installing quality of the dynamic arc contact is improved. Therefore, the making and breaking performance of a circuit breaker is improved.

Owner:HENAN PINGGAO ELECTRIC +1

Popular searches

Multilayer circuit manufacture Non-metallic protective coating application Programmable/customizable/modifiable circuits Enclosed substations Electric power transfer ac network Ac-dc network circuit arrangements Substation/switching arrangement casings Electrical apparatus contructional details Information technology support system Solid-state devices

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com