Electromagnetic contactor, electromagnetic contactor gas encapsulating method, and electromagnetic contactor manufacturing method

a technology of electromagnetic contactor and gas encapsulation chamber, which is applied in the direction of electromagnetic relay details, air-break switches, relays, etc., can solve the problems of increasing the amount of encapsulated gas consumed, the size of the gas encapsulation chamber b>14/b> is also unavoidably large, and the time for evacuating and charging the gas encapsulation chamber is considerable, so as to reduce the time for encapsulation and reduce equipment cost a gas encapsulation of electromagnetic contactor gas encapsulation of electromagnetic contactor gas encapsulation of electromagnetic contactor gas encapsulation of electromagnetic contactor, electromagnetic contactor, electromagnetic contactor, electromagnetic contactors, electromagnetic contactors, etc., reduce the effect of encapsulation time reduces the effect of encapsulation tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

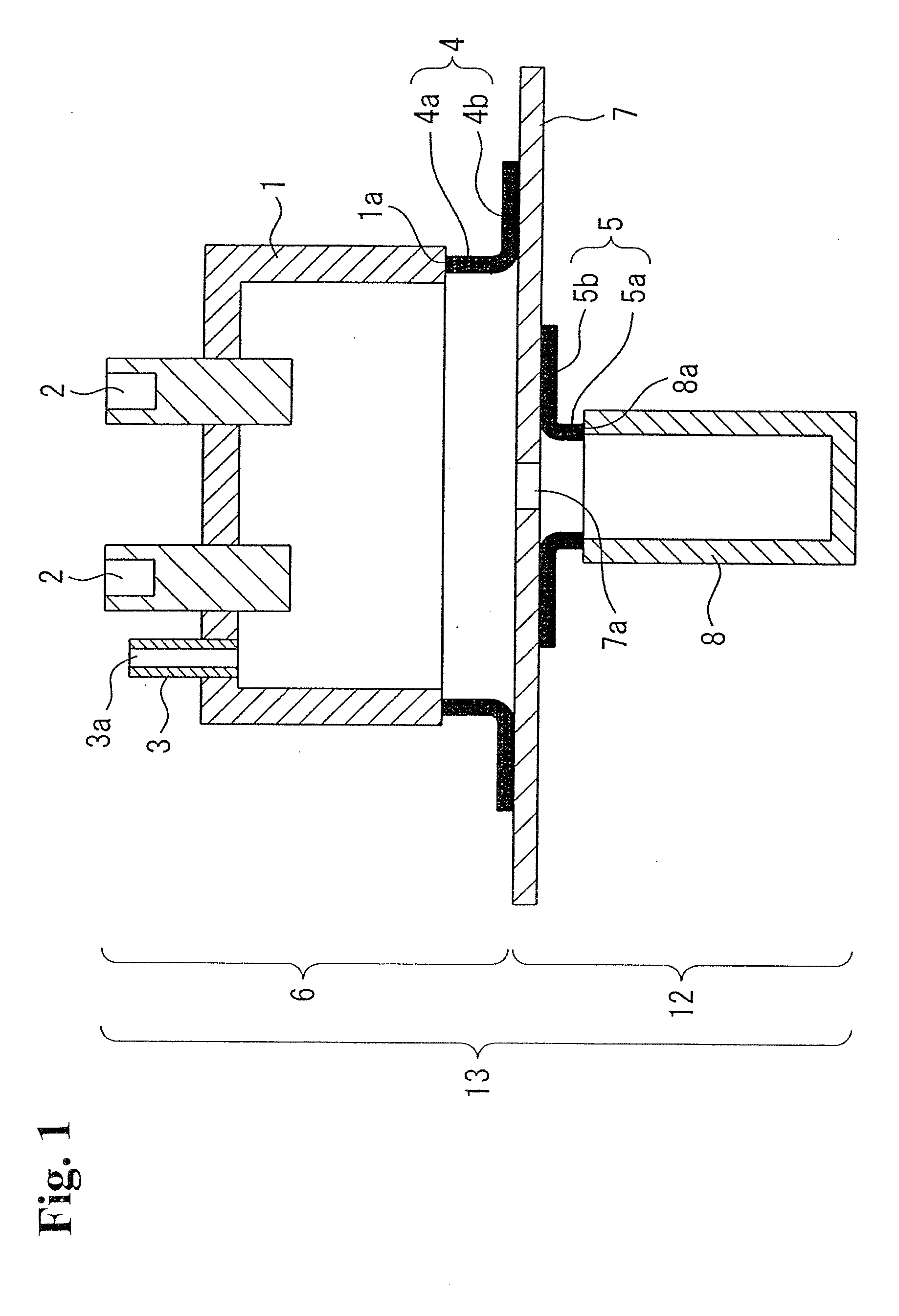

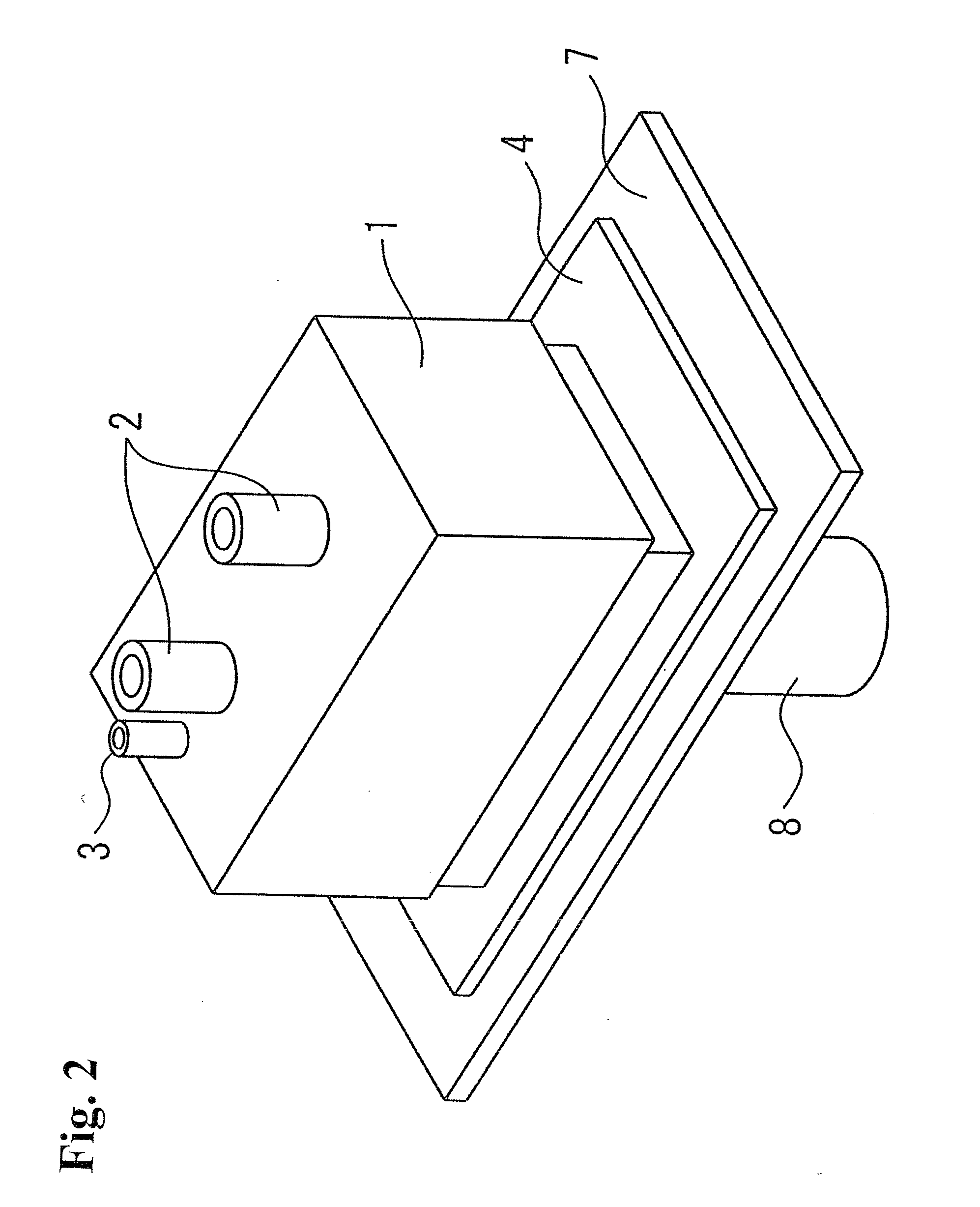

[0048]In this way, it is possible to simultaneously braze the fixed terminals 2, pipe 3, and first connection member 4 to the arc extinguishing chamber 1. Because of this, it is possible for the connection of the fixed terminals 2 and pipe to the arc extinguishing chamber 1 and the formation of the arc extinguishing chamber connection portion 6 to be carried out simultaneously, and thus possible to simplify the step of forming the arc extinguishing chamber 1 and arc extinguishing chamber connection portion 6. Also, the encapsulating of gas in the arc extinguishing chamber 1 and cap 8 can also be carried out easily.

[0049]In the first embodiment, a description has been given of a case wherein the pipe 3 is fixed penetrating the upper side wall of the arc extinguishing chamber 1 but, not being limited to this, the pipe 3 may be joined penetrating a wall surface in a direction perpendicular to the fixed terminals 2 fixed to the arc extinguishing chamber 1, as shown in FIG. 3(a). When j...

second embodiment

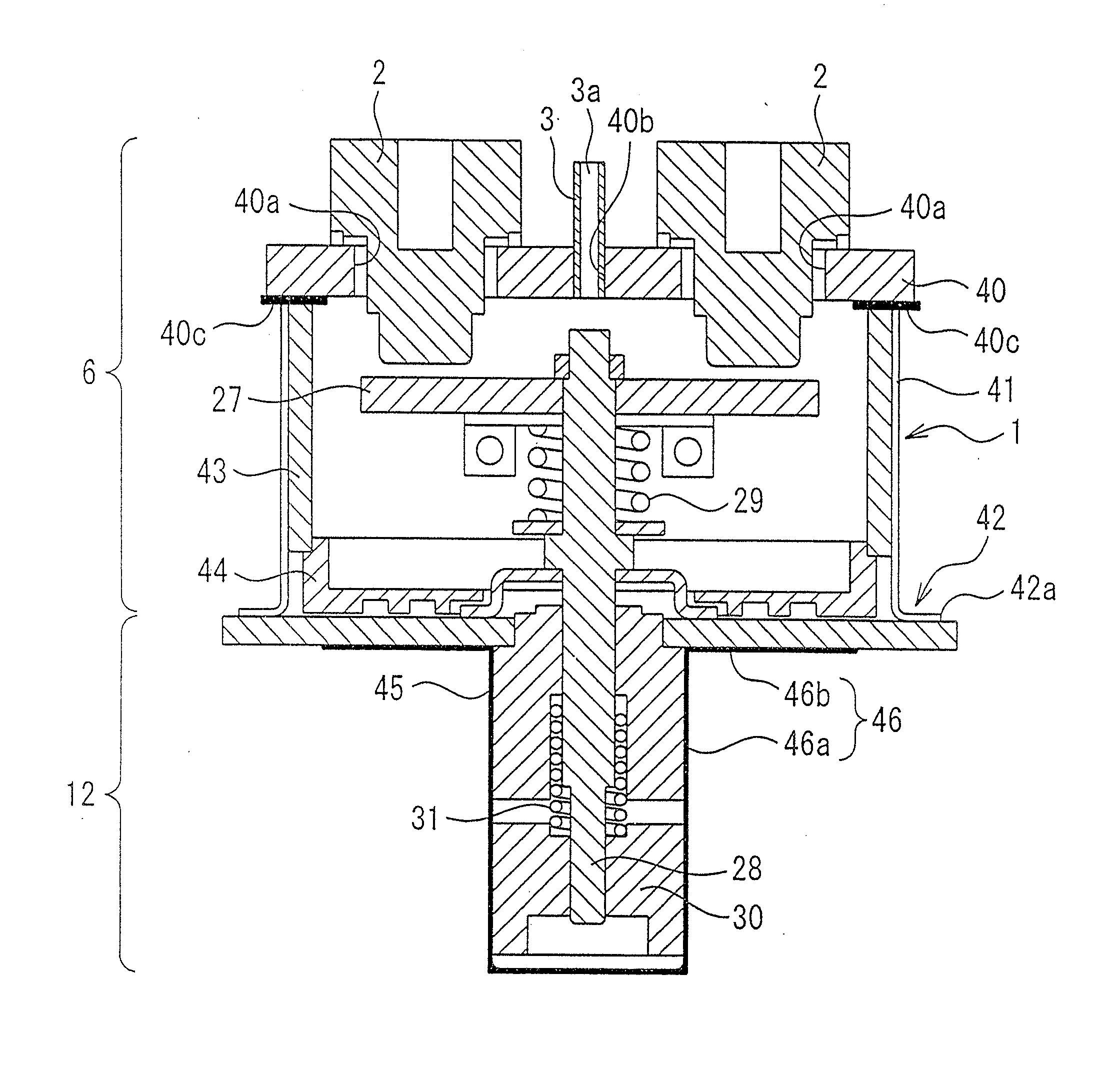

[0053]Next, a description will be given of the invention, based on FIG. 4.

[0054]The second embodiment is such that, instead of the case wherein the tub-like arc extinguishing chamber is formed integrally, the arc extinguishing chamber is formed of a terminal support insulating substrate and a third connection member.

[0055]That is, in the second embodiment, a fixed terminal support insulating substrate 40 is included. Through holes 40a that fix the pair of fixed terminals 2 and a through hole 40b that fixes the pipe 3 are formed in the fixed terminal support insulating substrate 40. Also, the fixed terminal support insulating substrate 40 is configured as a ceramic insulating substrate by a metalizing process being carried out with a metal such as copper foil on a plate-like ceramic base in which the through holes 40a and 40b are formed, around the through holes 40a and 40b and on an outer peripheral edge portion 40c of one surface.

[0056]Further, the fixed terminals 2 are inserted in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com