Patents

Literature

451results about How to "Reduced assembly steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

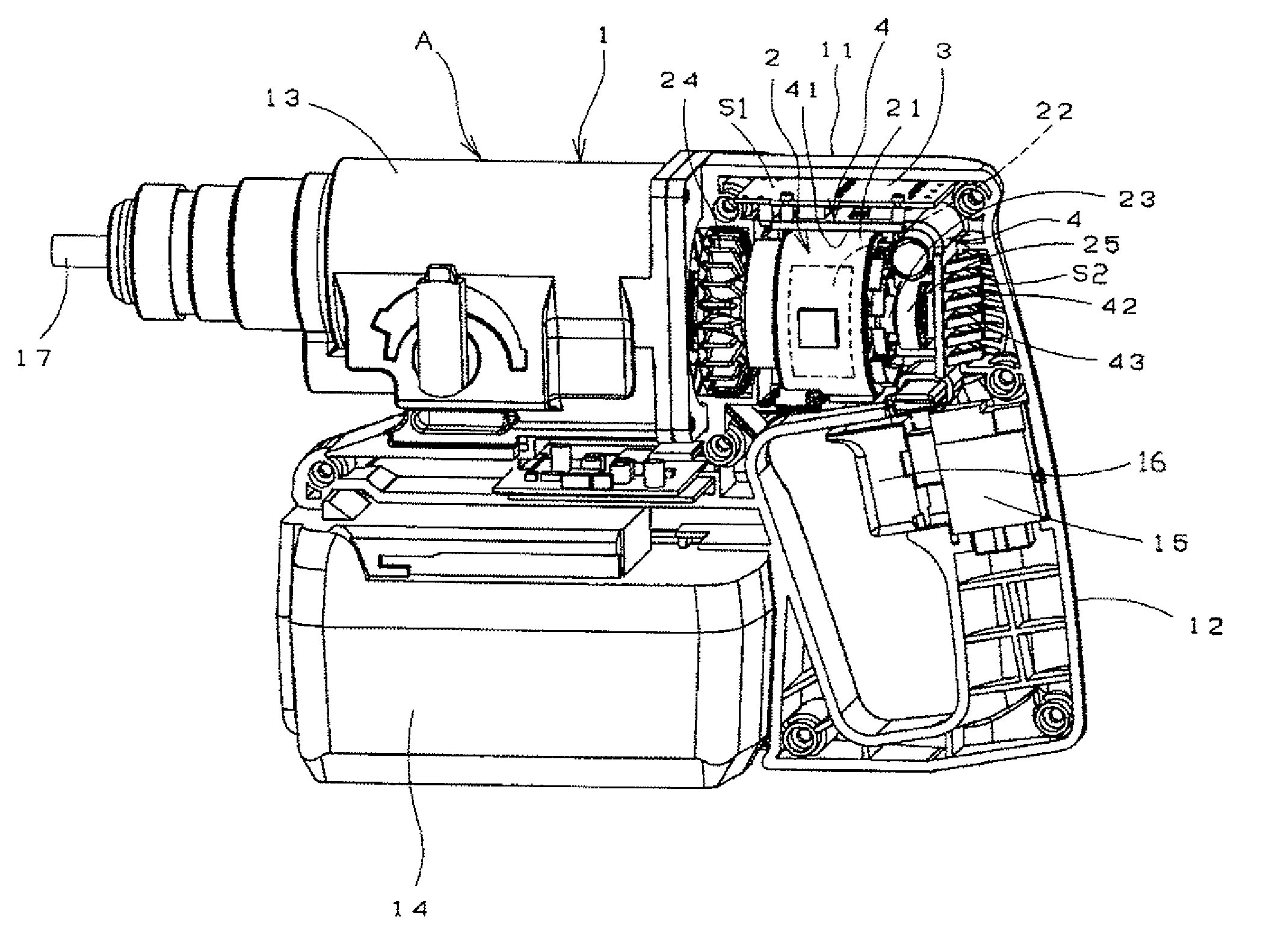

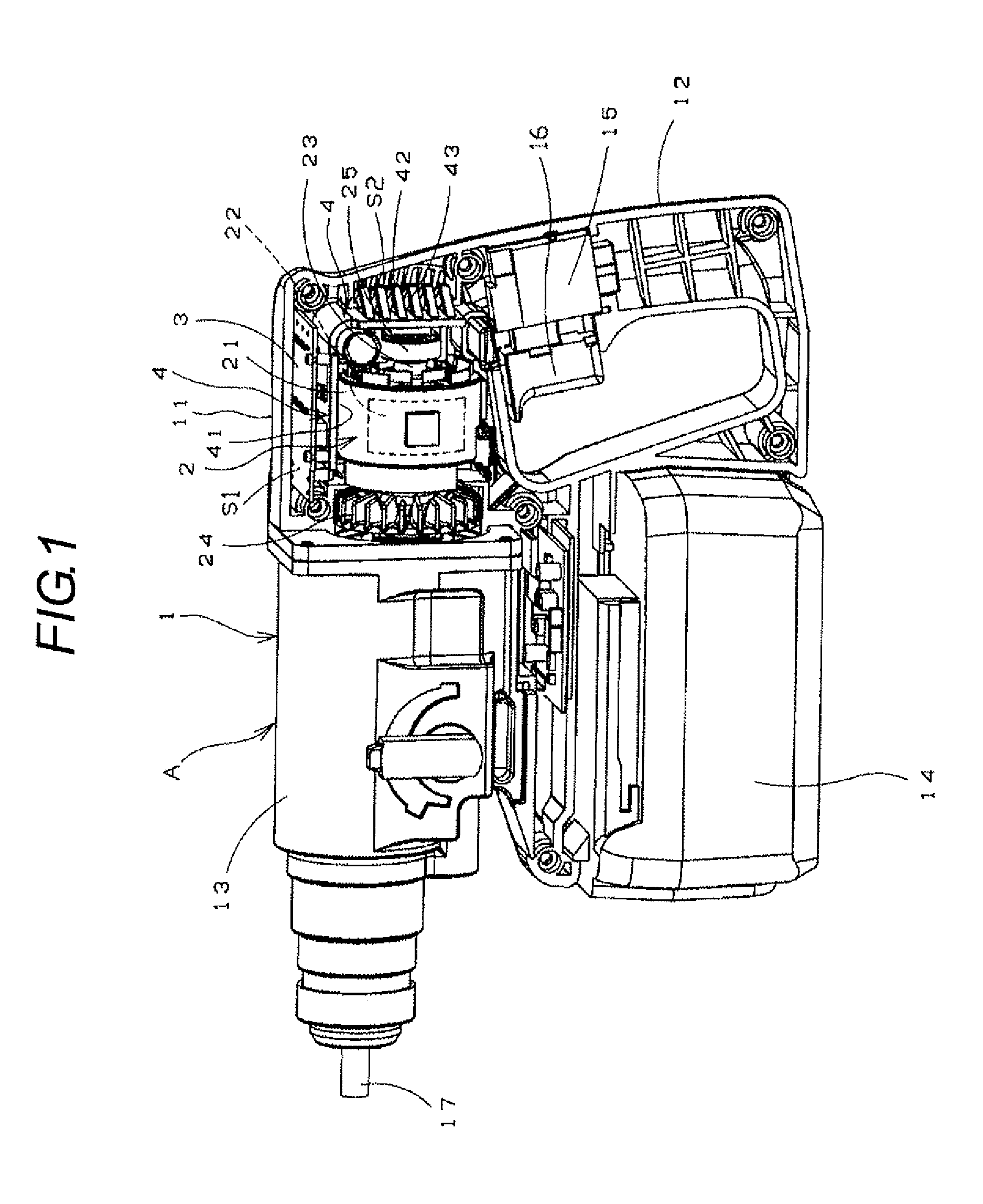

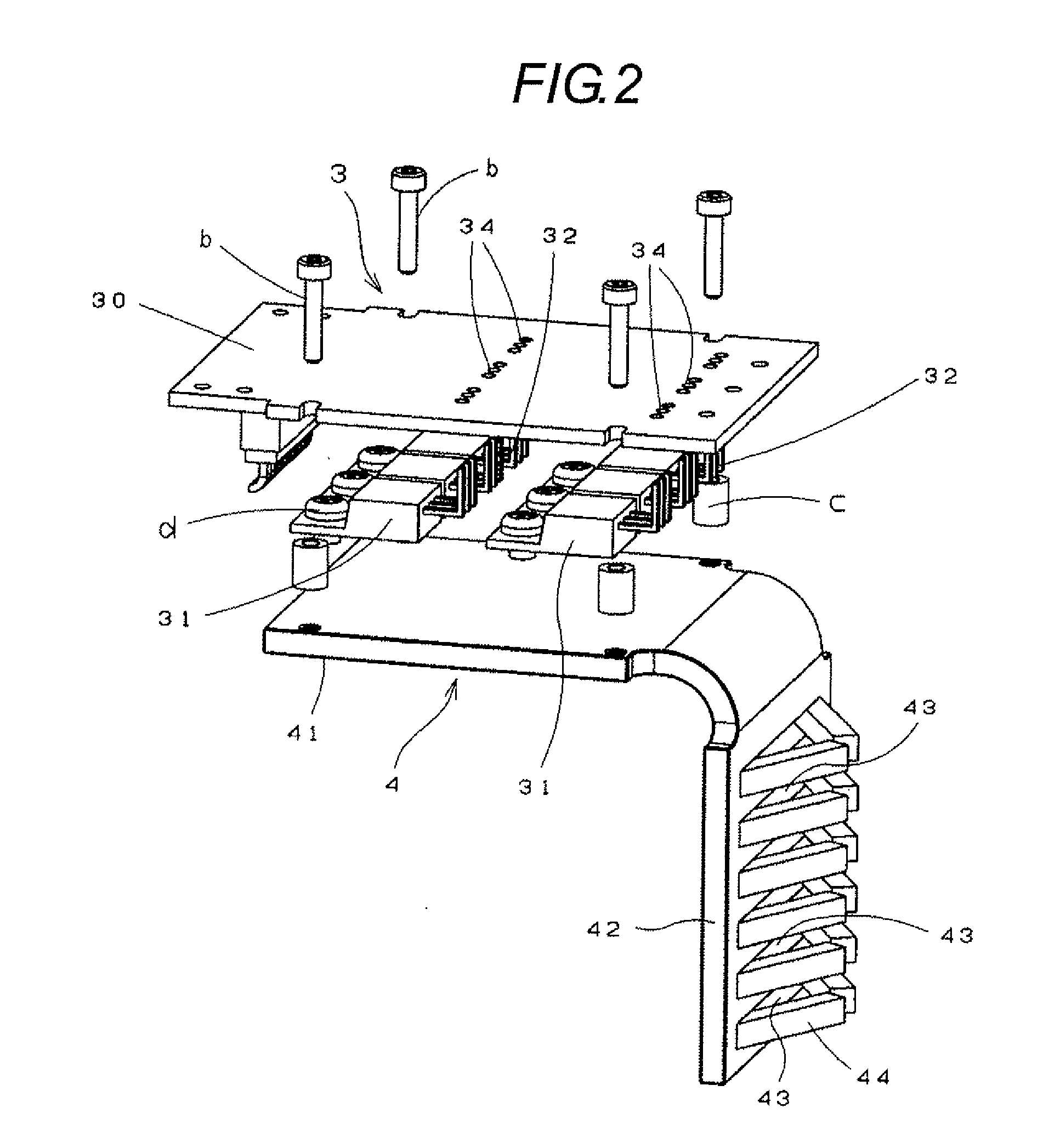

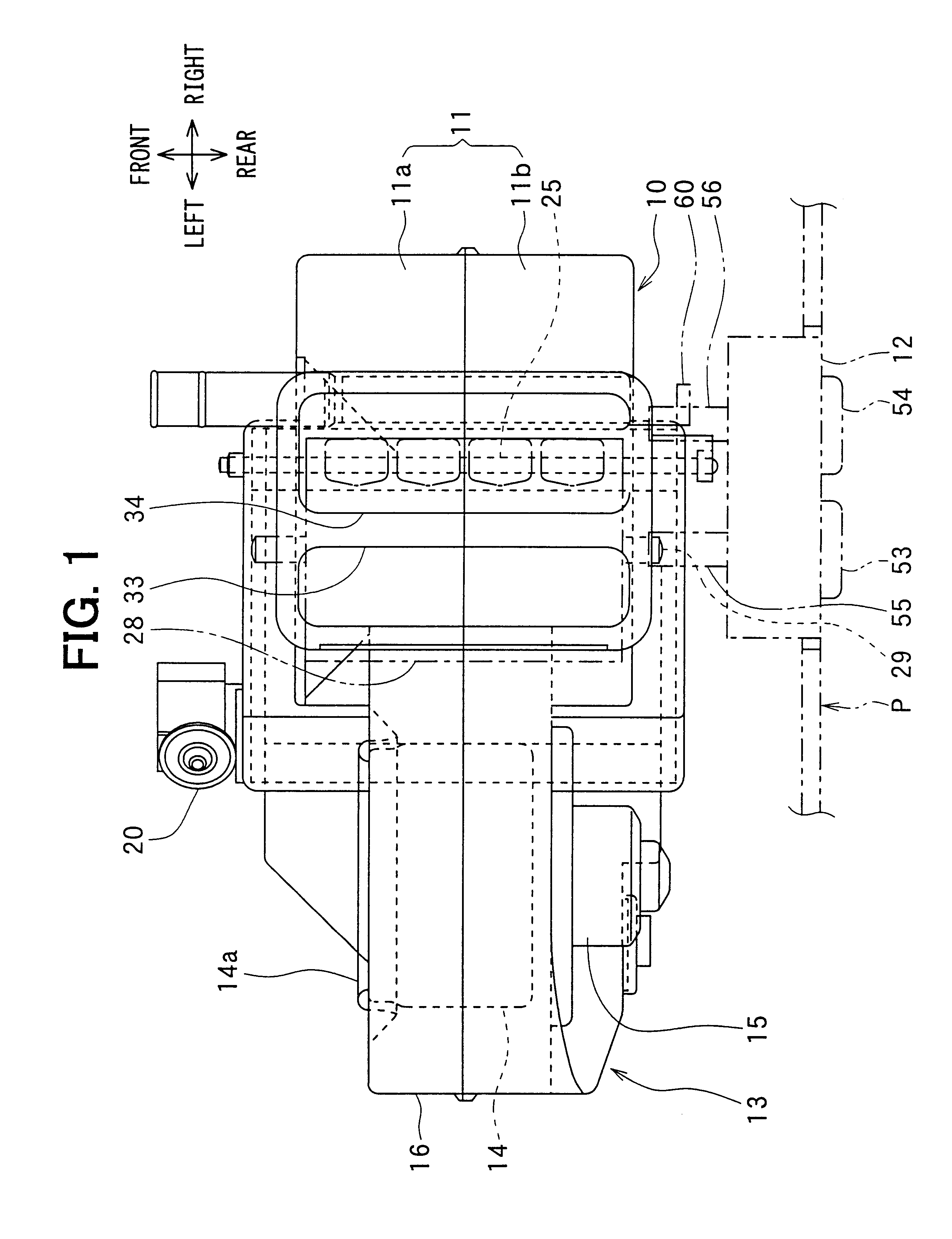

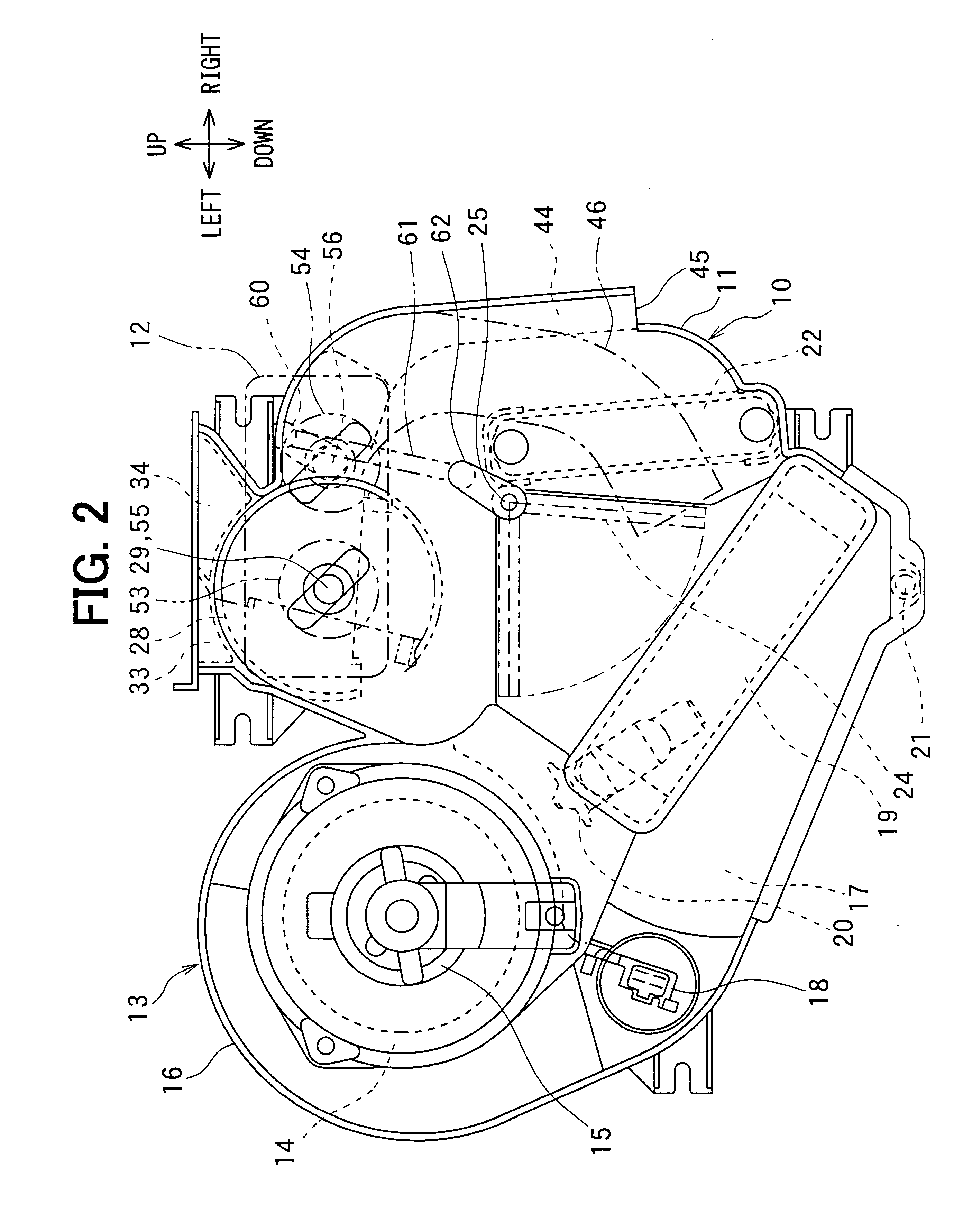

Power tool with brushless motor

InactiveUS20100253162A1Improve assembly efficiencyAvoid voltage dropAssociation with control/drive circuitsPortable percussive toolsBrushless motorsPower tool

In a first space S1 formed upwardly of a brushless motor, there is arranged a power substrate 3 including an electronic part for controlling a rotation of the brushless motor, and, in a second space S2 formed backwardly of the brushless motor, there is arranged a heat sink for cooling the power substrate 3.

Owner:MAX CO LTD

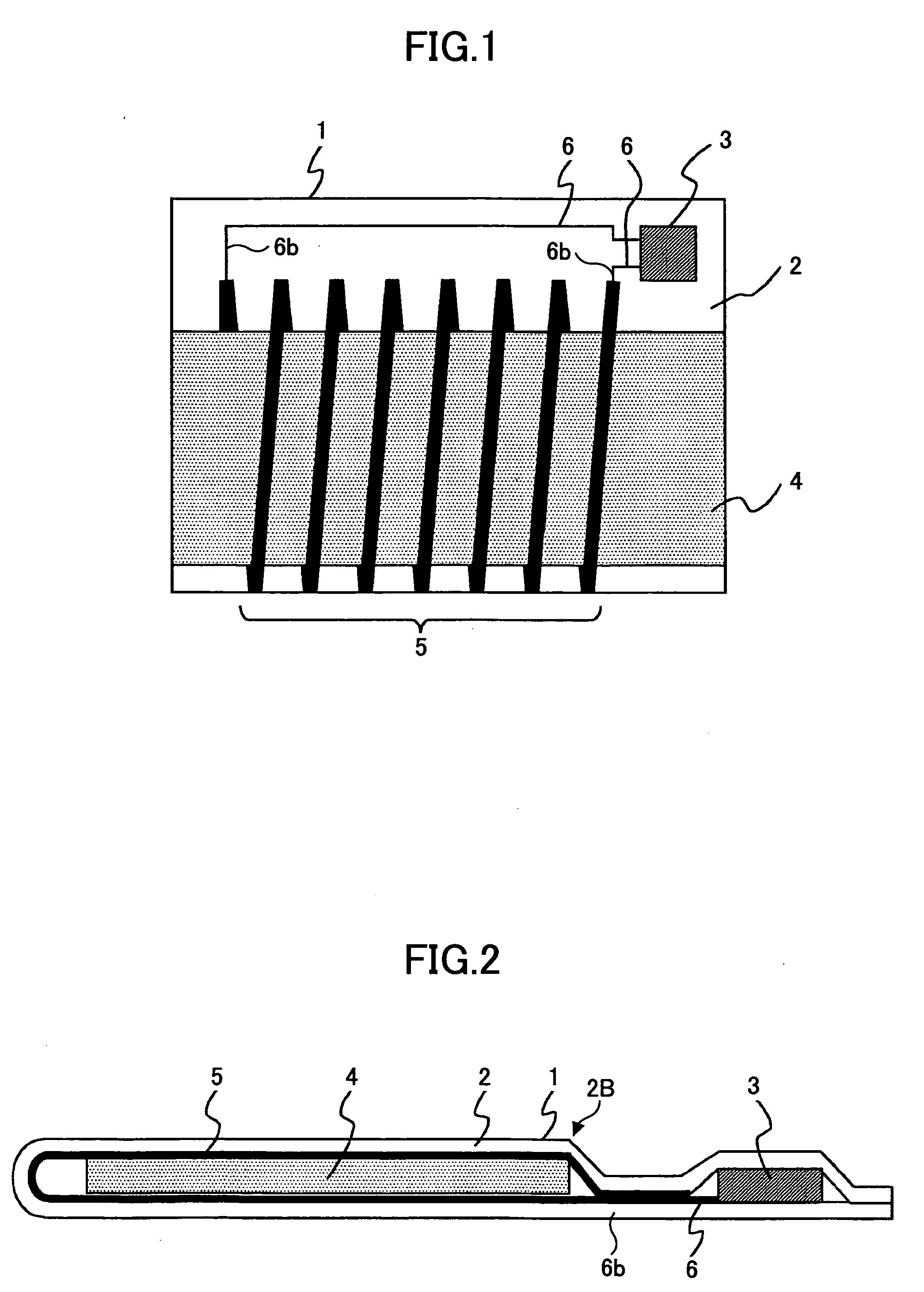

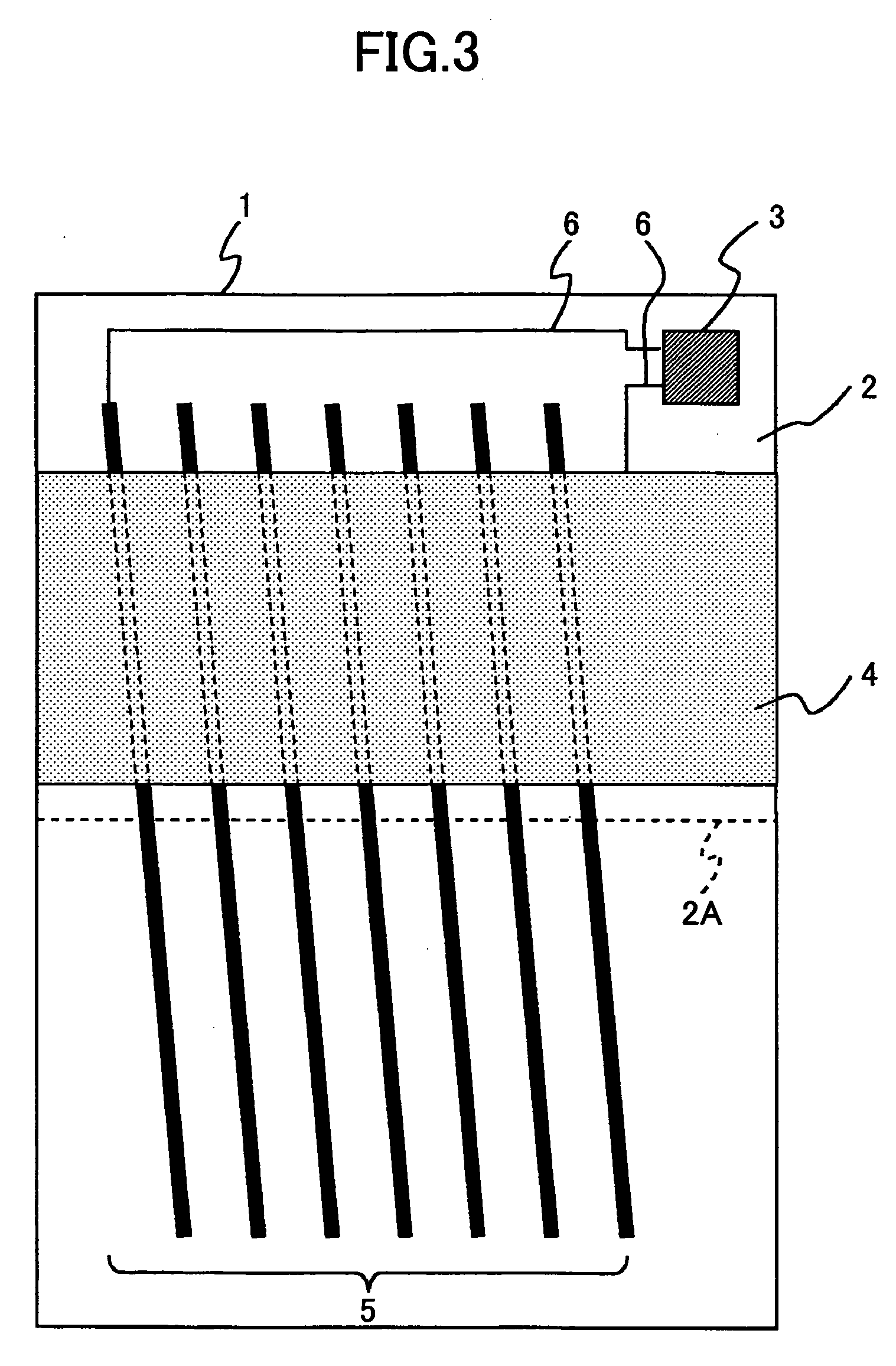

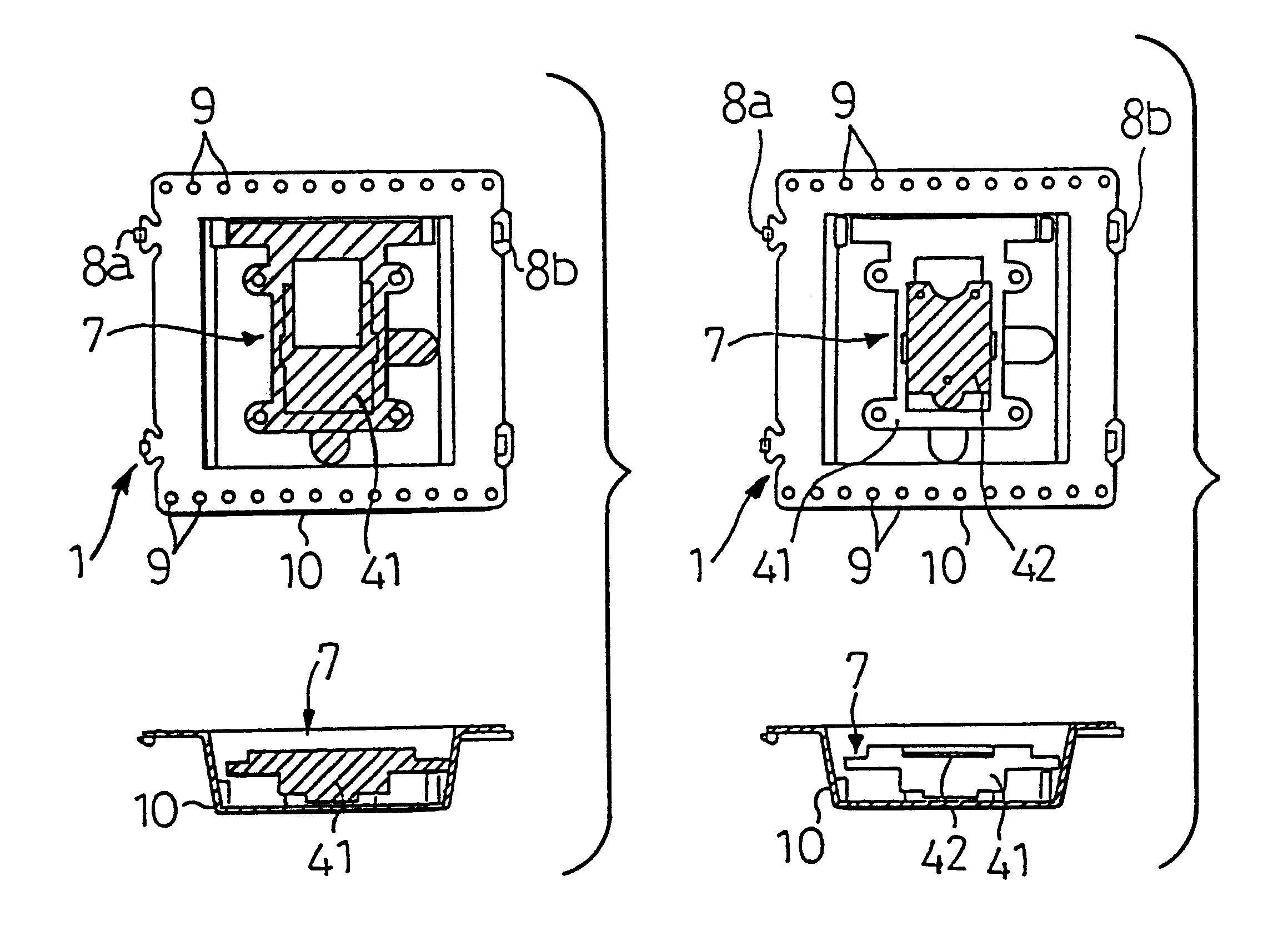

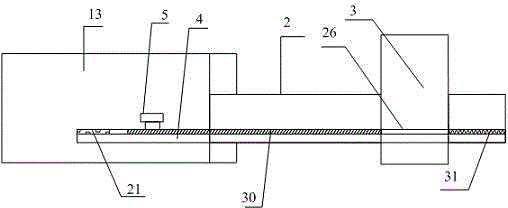

RFID tag and manufacturing process thereof

InactiveUS20070023517A1Reduce thicknessImprove reliabilitySolid-state devicesSensing record carriersElectrical conductorManufacturing technology

An RFID tag comprises a semiconductor chip storing therein information of an object to be discriminated and carrying out radio communication with a reader / writer device; and an antenna coil provided with a magnetic core member and connected electrically to the semiconductor chip. The semiconductor chip and the magnetic core member are wrapped by an insulation sheet carrying an interconnection pattern connecting a pad of the semiconductor chip and the antenna coil electrically and plural coil patterns on one side thereof. The plural coil patterns includes bar-shaped conductor patterns formed obliquely to the magnetic core member, each of the bar-shaped conductor patterns having an end connected to an end of an adjacent coil pattern, the bar-shaped conductor patterns thereby forming together a spiral coil around the magnetic core member. The coil patterns being connected with each other at a part where the coil patterns overlap with each other.

Owner:RICOH KK

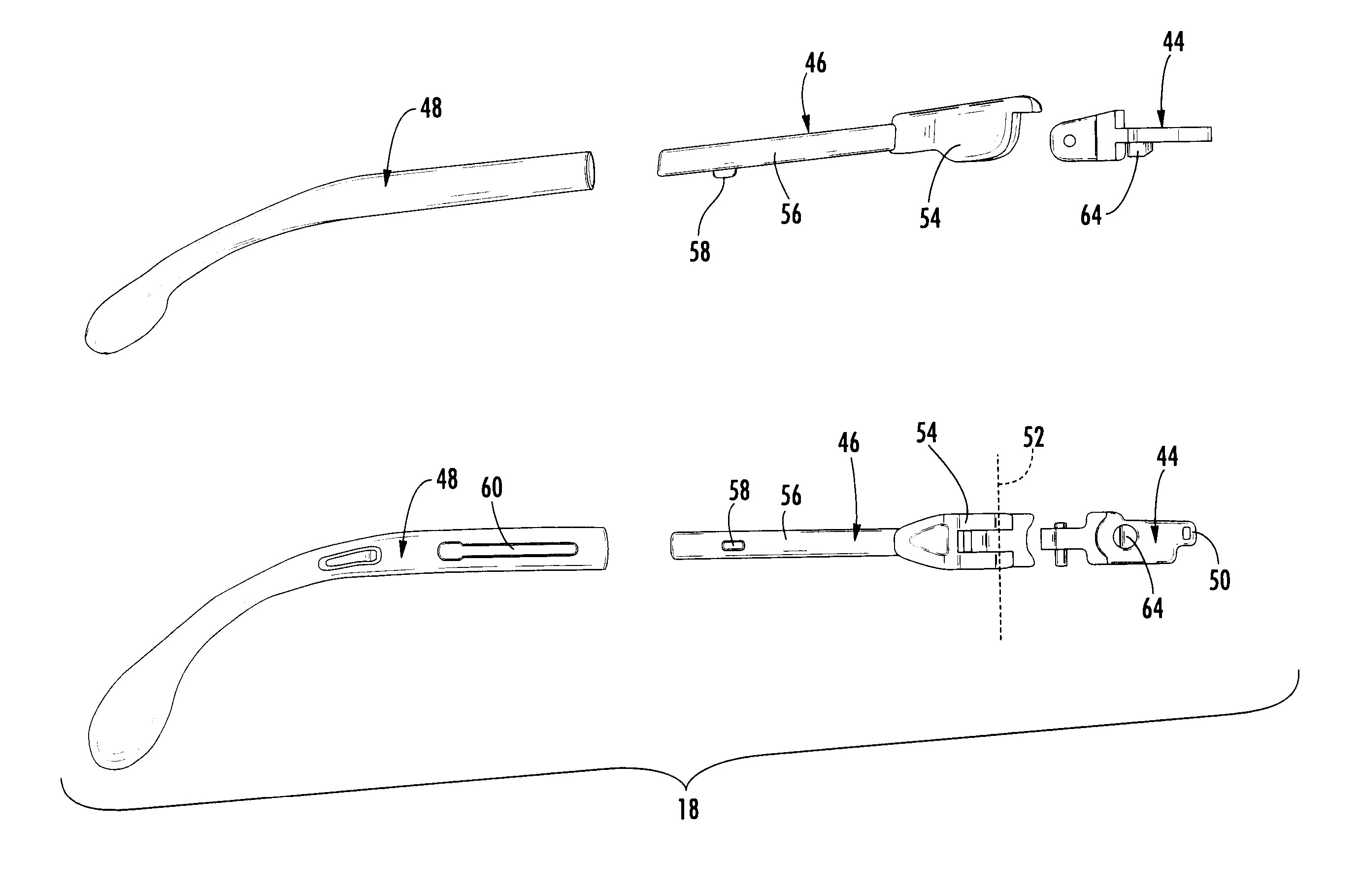

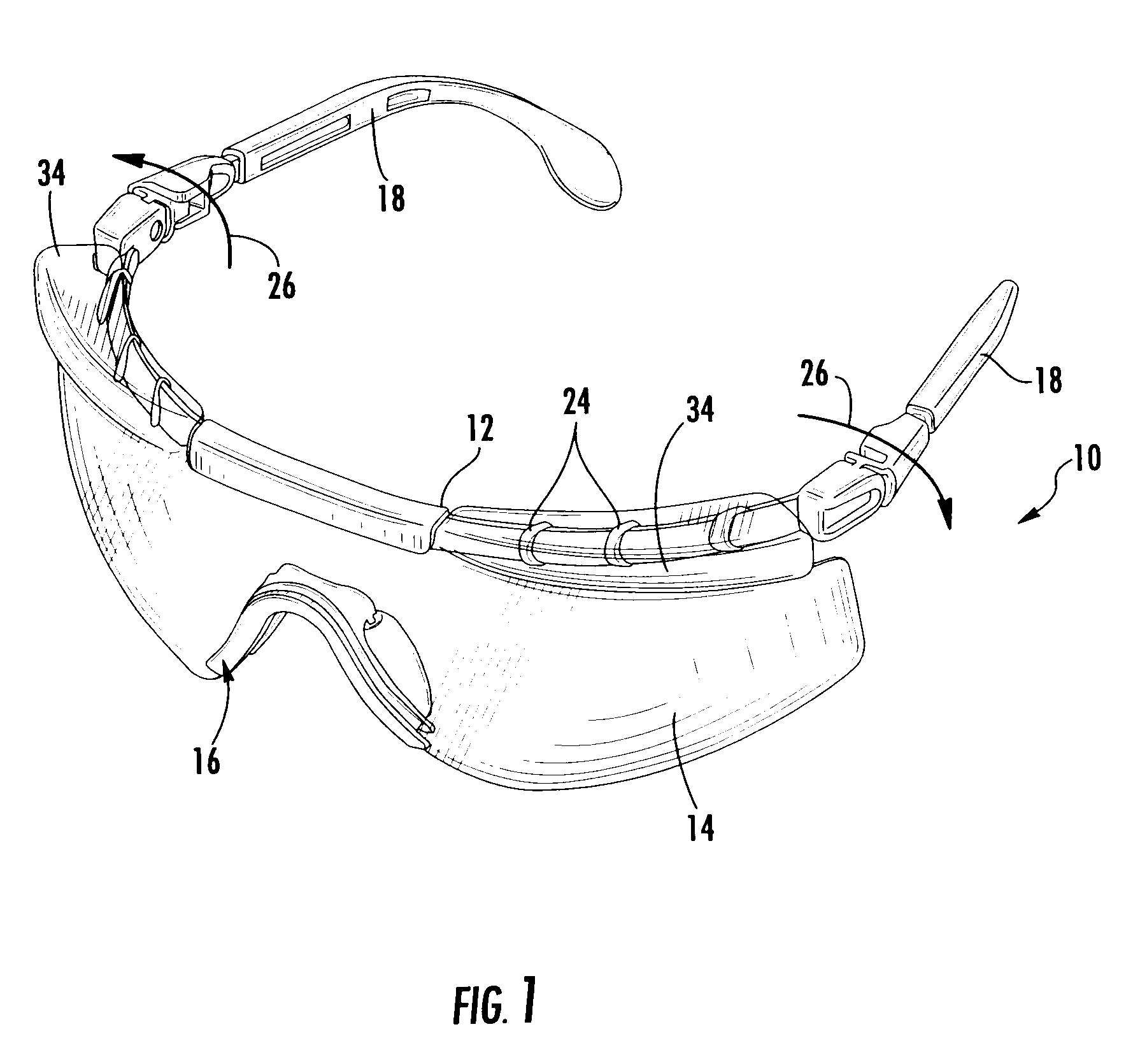

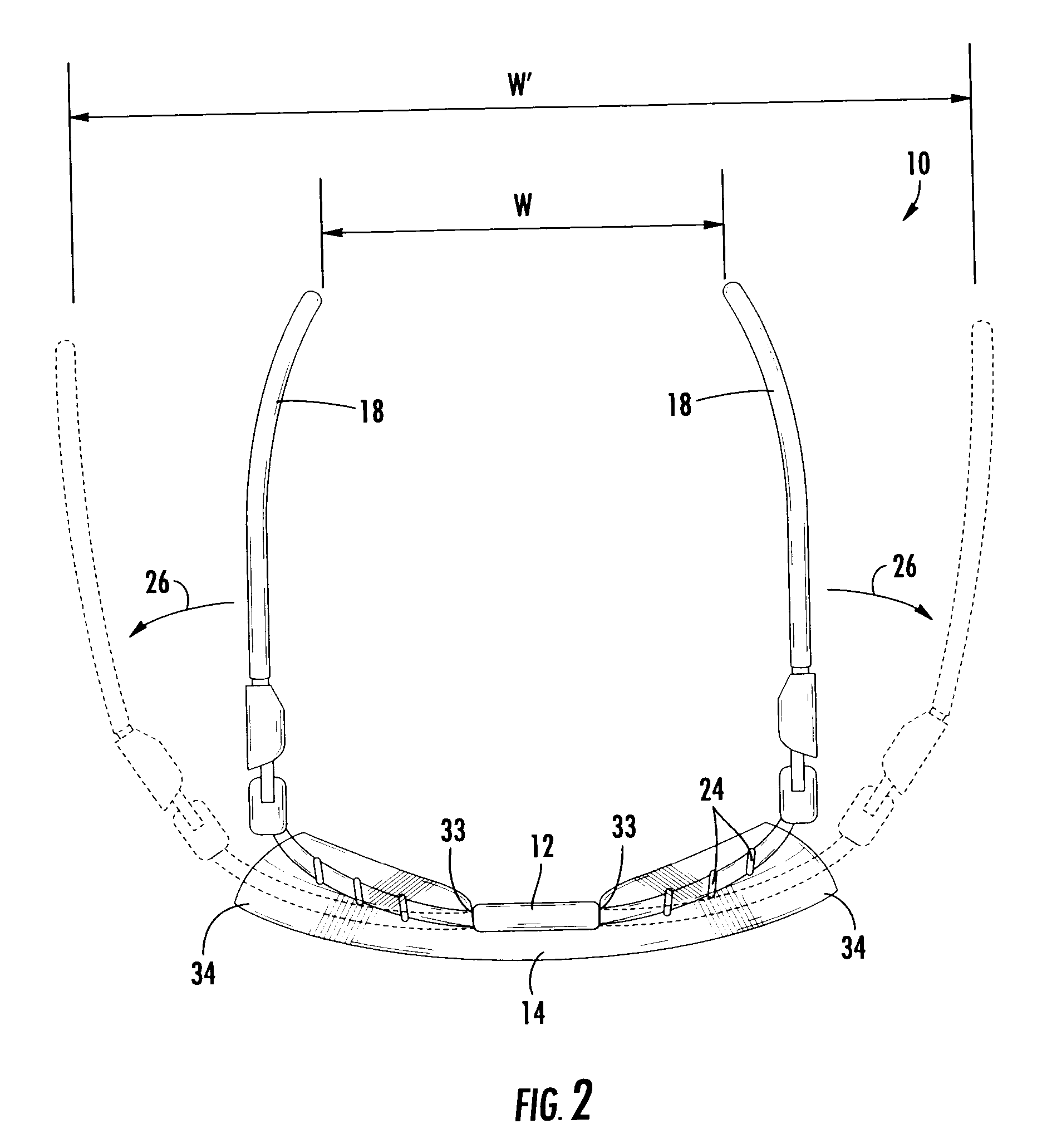

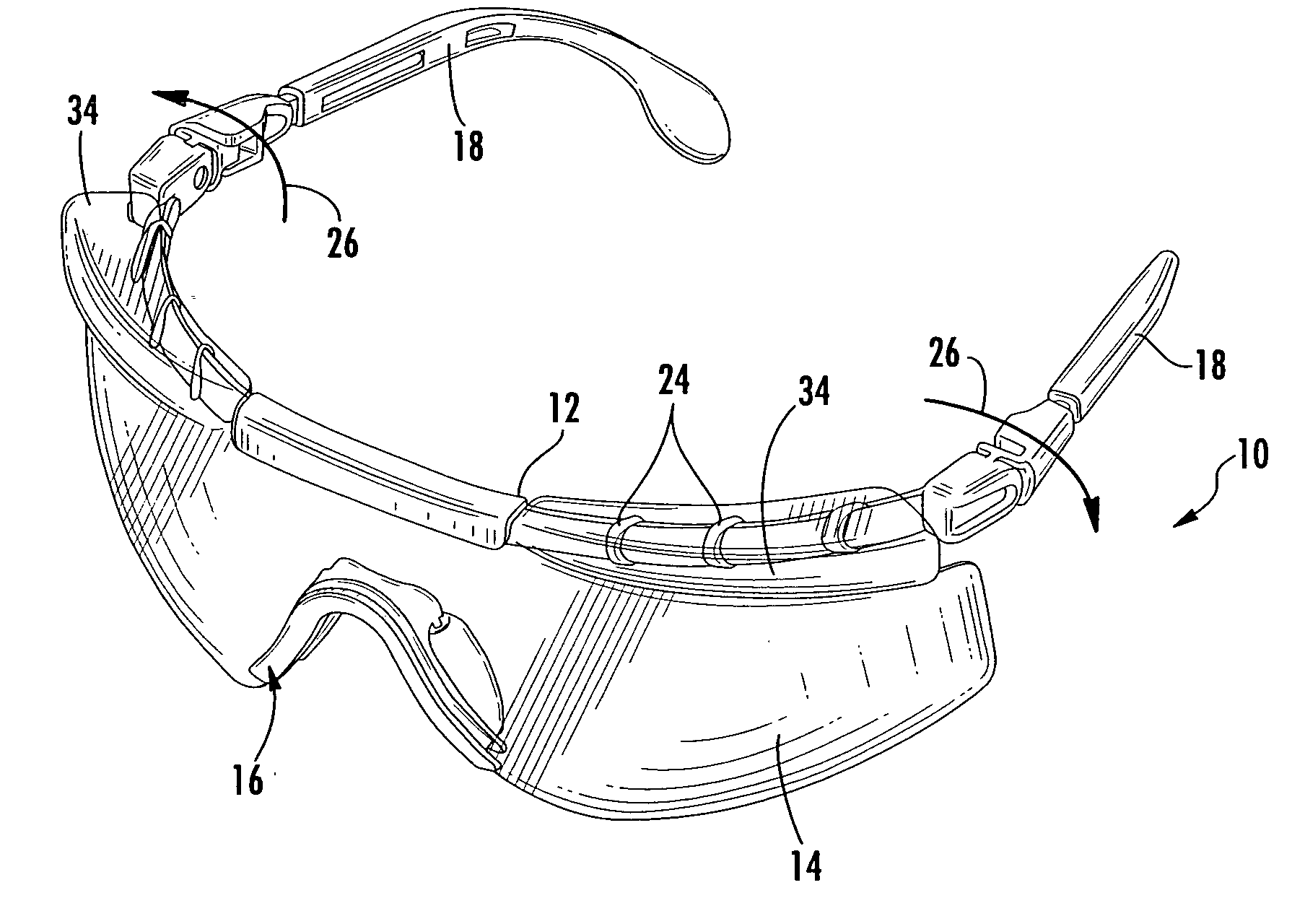

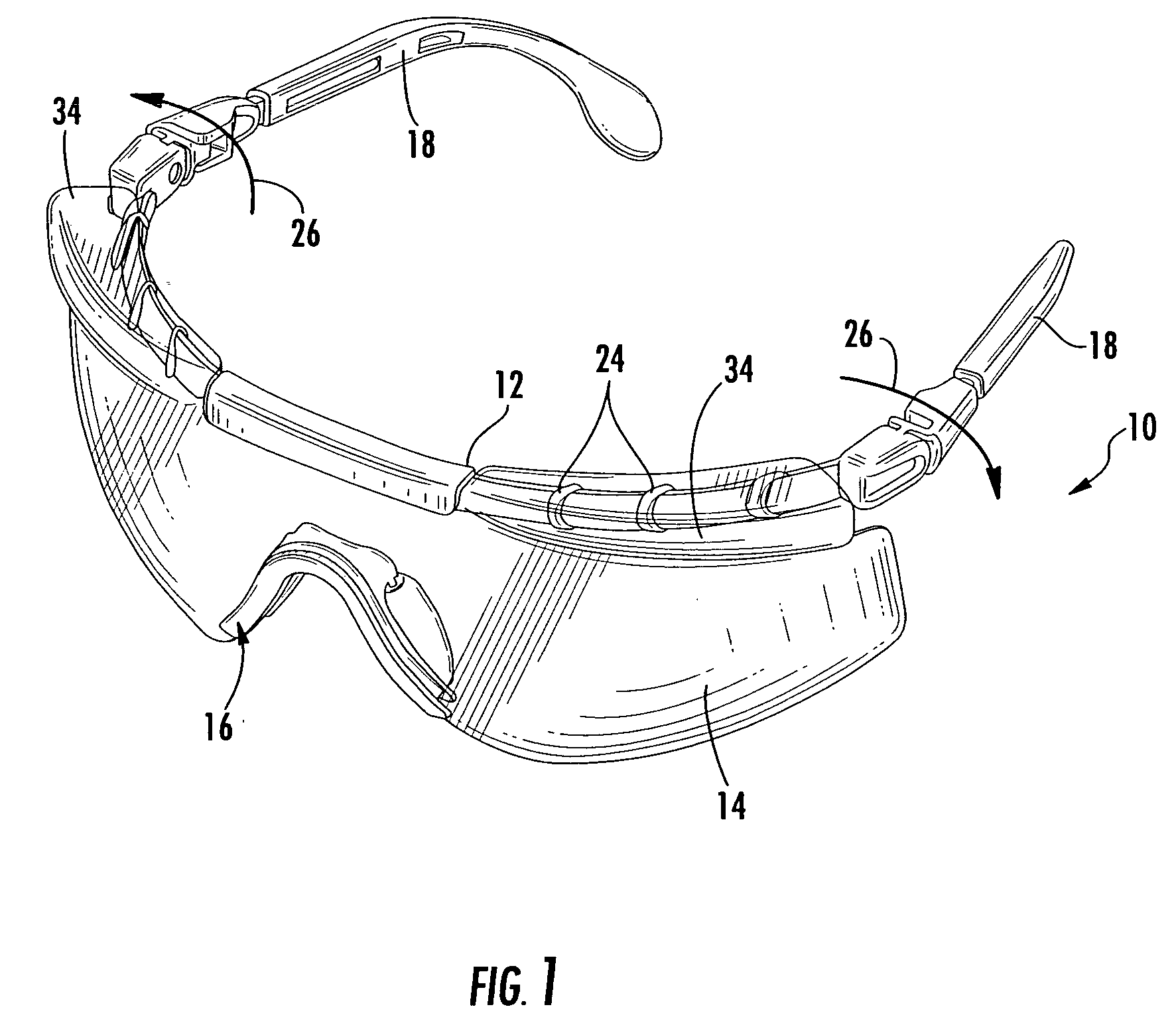

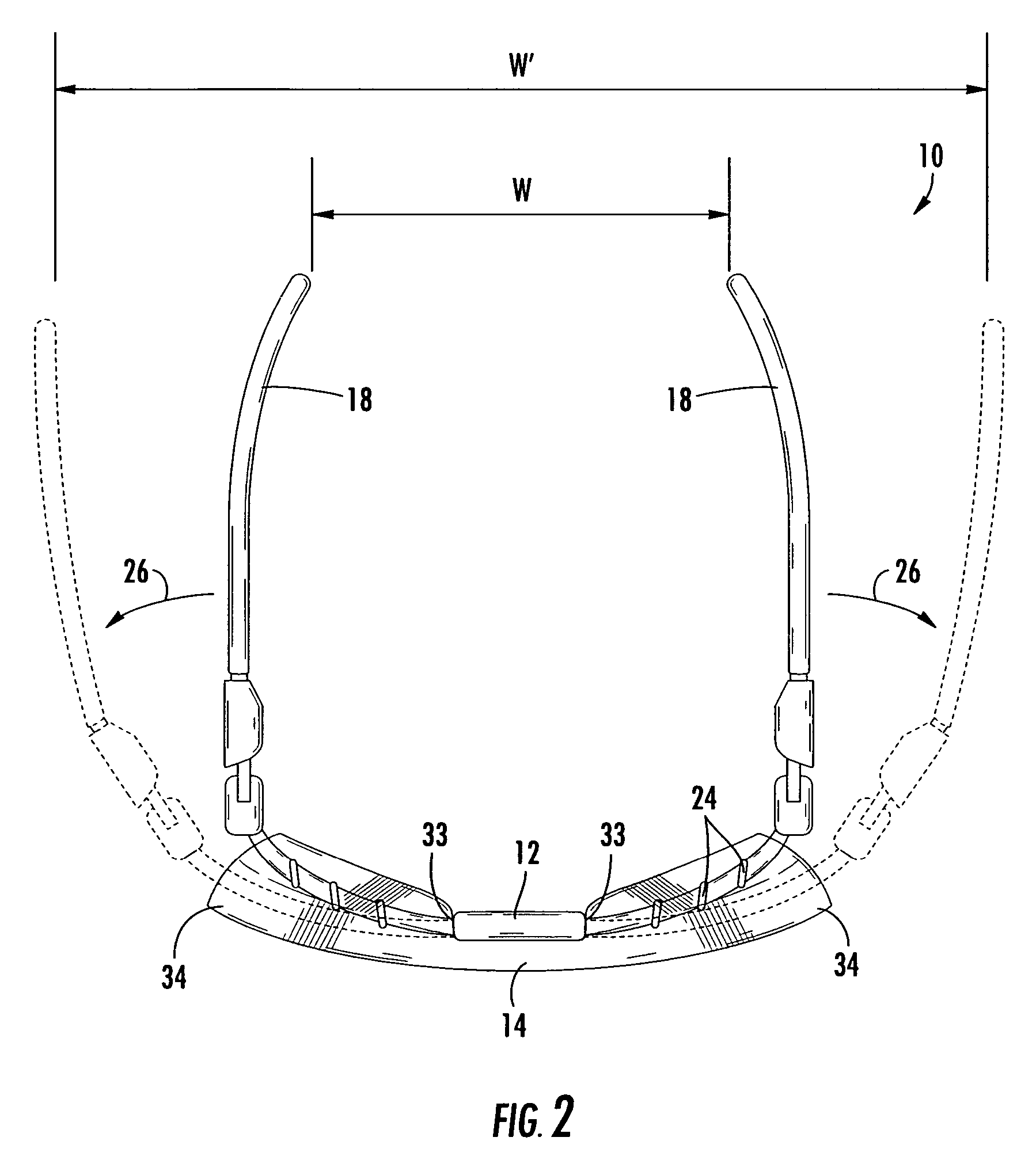

Adjustable length upper frame member for eyeglasses

InactiveUS20050270477A1Easy to adjustReduce complexitySpectales/gogglesNon-optical adjunctsEngineeringMechanical engineering

A frame assembly for eyeglasses is provided wherein the overall width of the eyeglass frame is adjustable by utilizing a telescoping brow bar. The upper frame member or brow bar is formed to include either a pair of telescoping or indexed joints allowing the length of the brow bar to be adjusted thereby placing the hinge points and temple bars further apart from one another. The adjustable length of the brow bar provides excellent adjustability of the overall width of the eyeglass frame in simple mechanical construction. Further, in a unique method of forming the adjustable brow bar assembly a central portion may be formed in a first molding step and an adjustable hinge section is then molded directly over the central portion in a second molding step. The present invention utilizes in-mold-assembly techniques to reduce the assembly steps required to form such an adjustable brow bar assembly while further resulting in an eyeglass frame that has increased adjustability and utility.

Owner:SPERIAN EYE & FACE PROTECTION

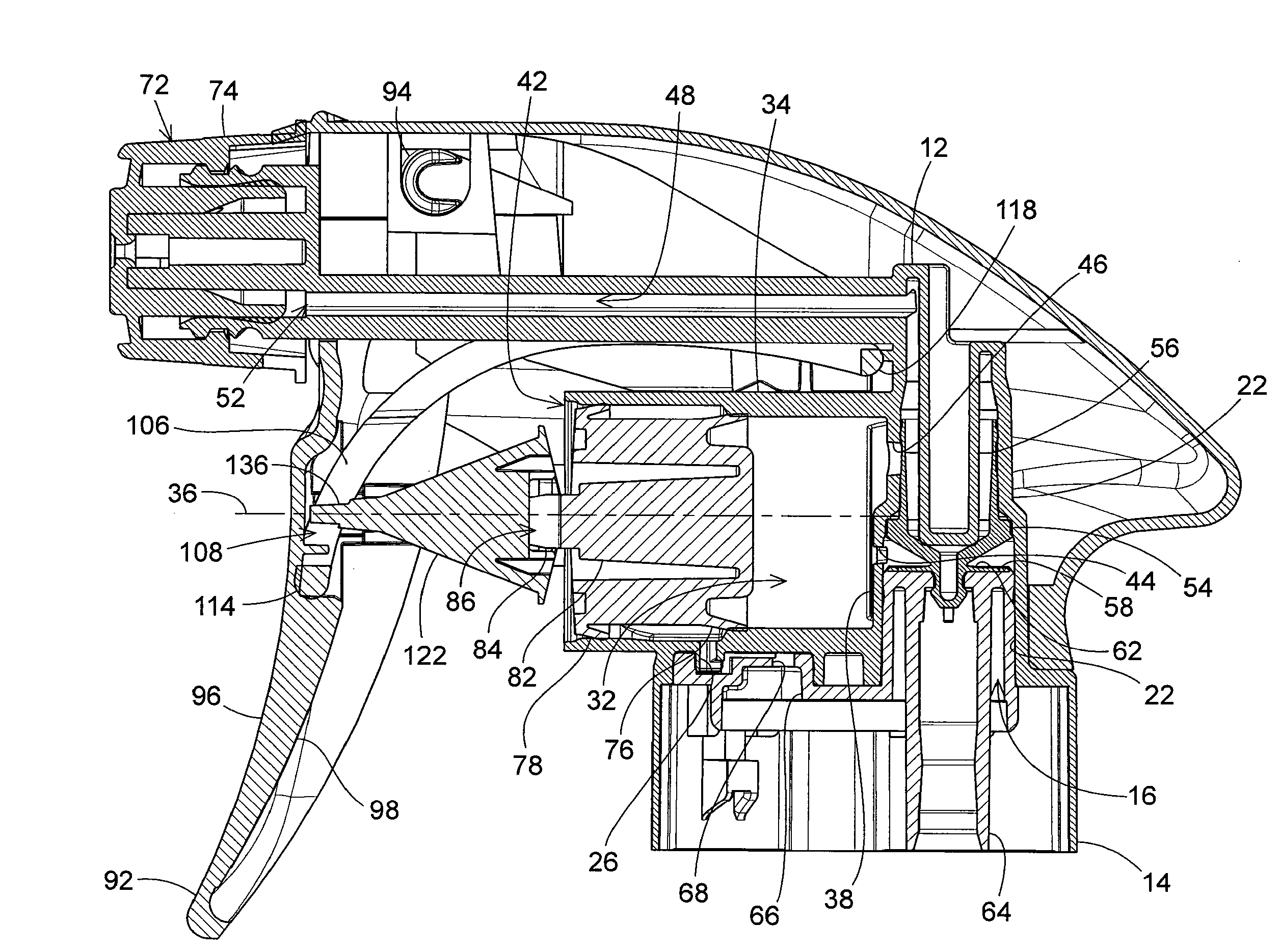

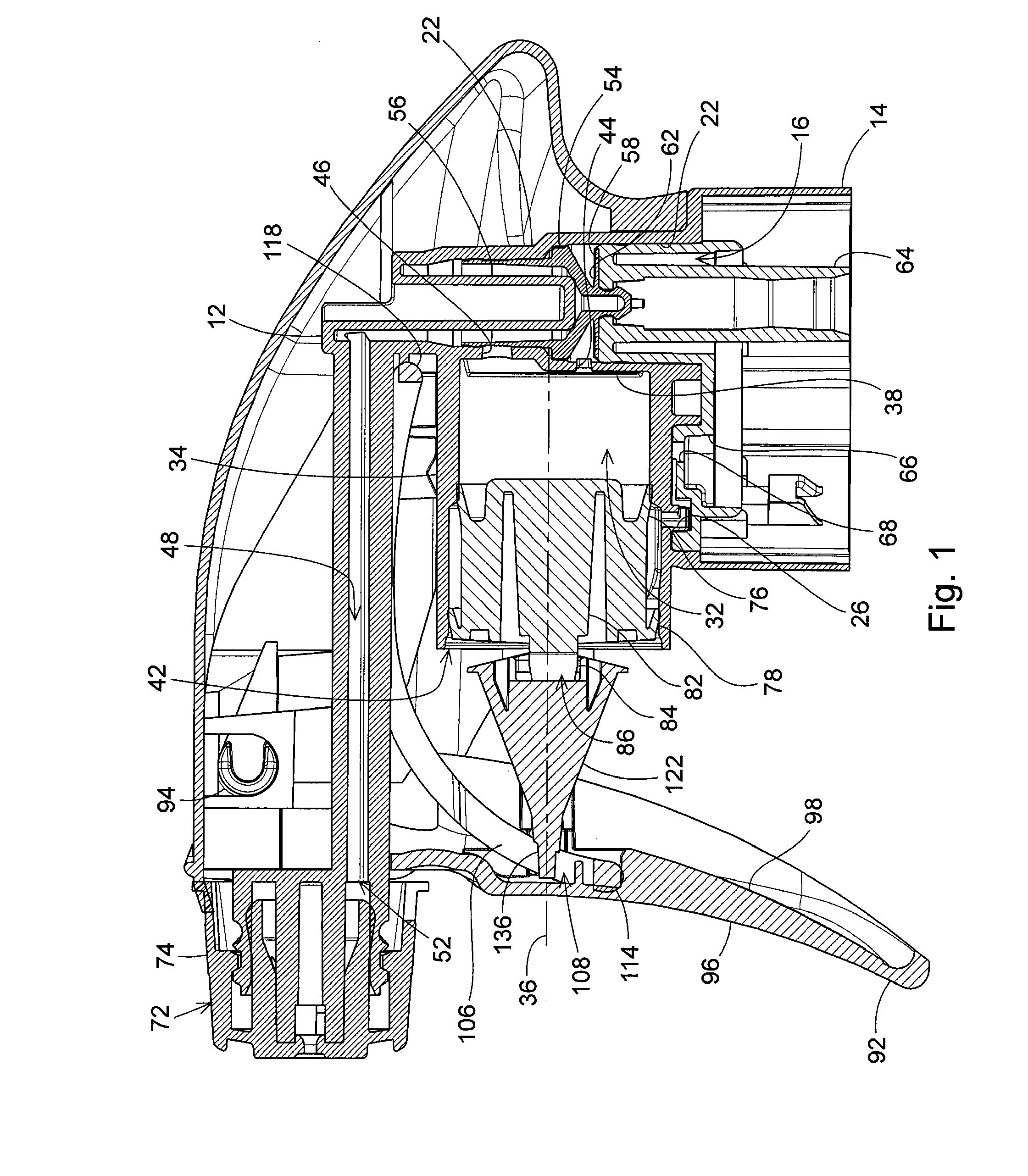

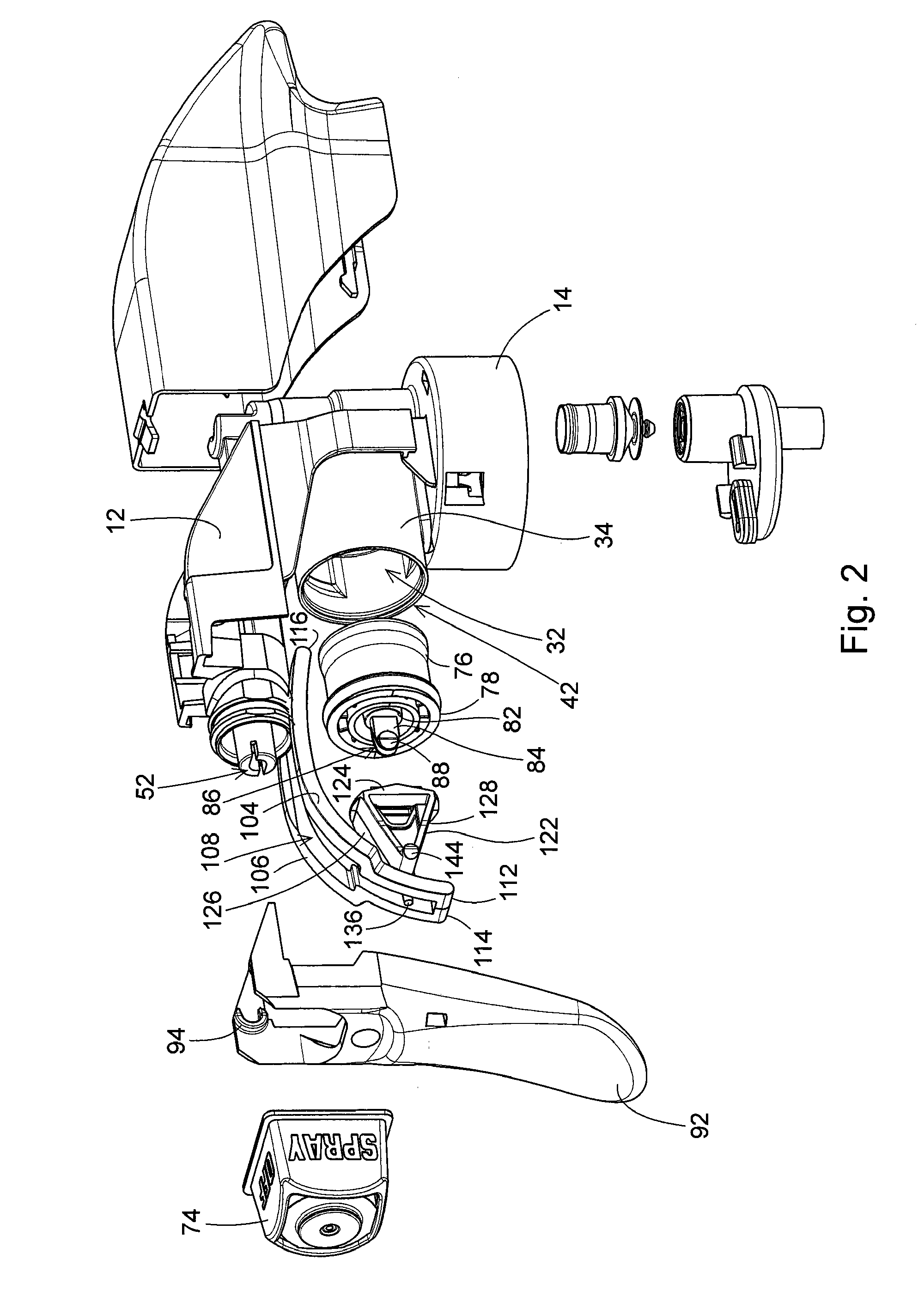

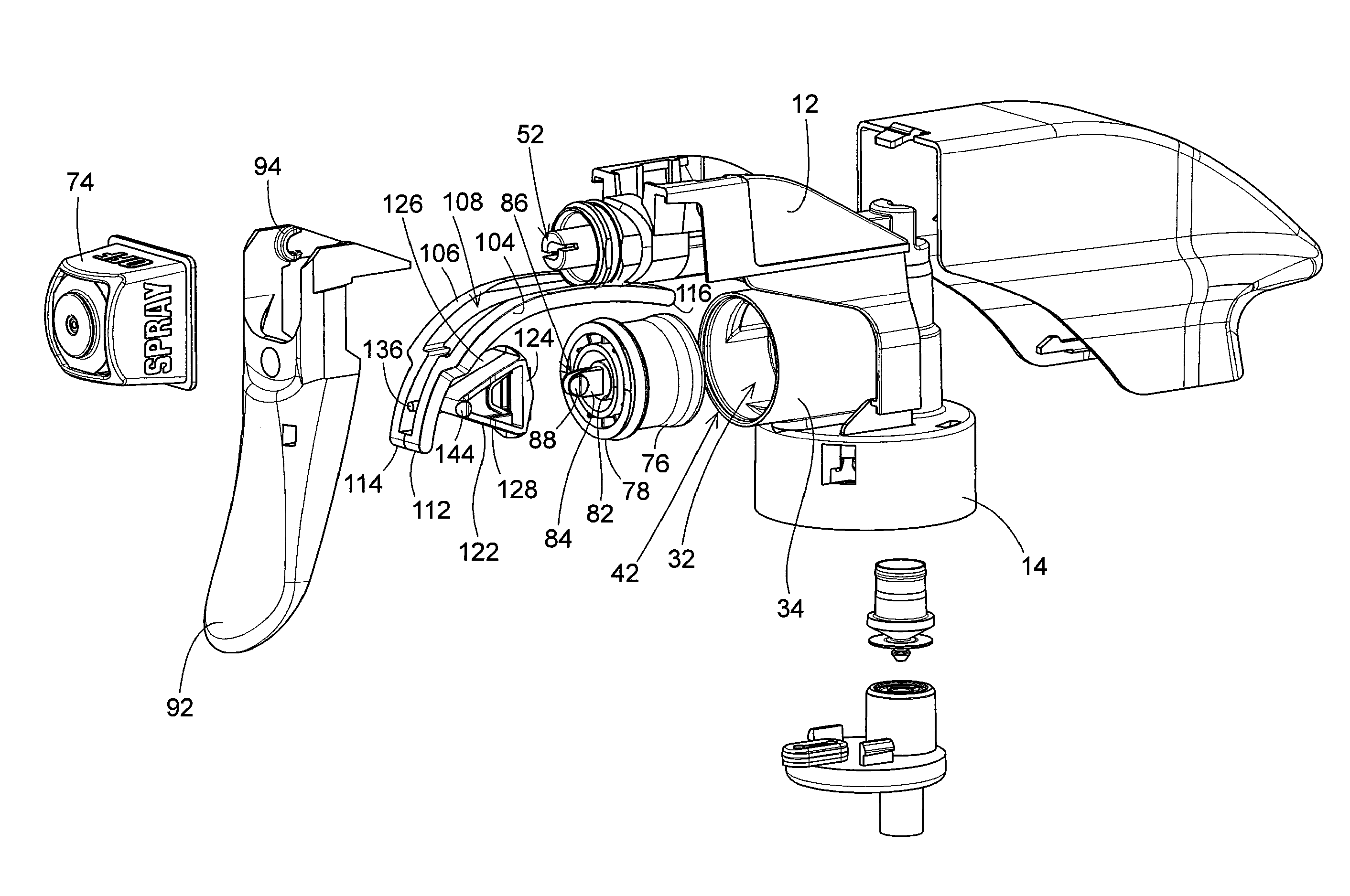

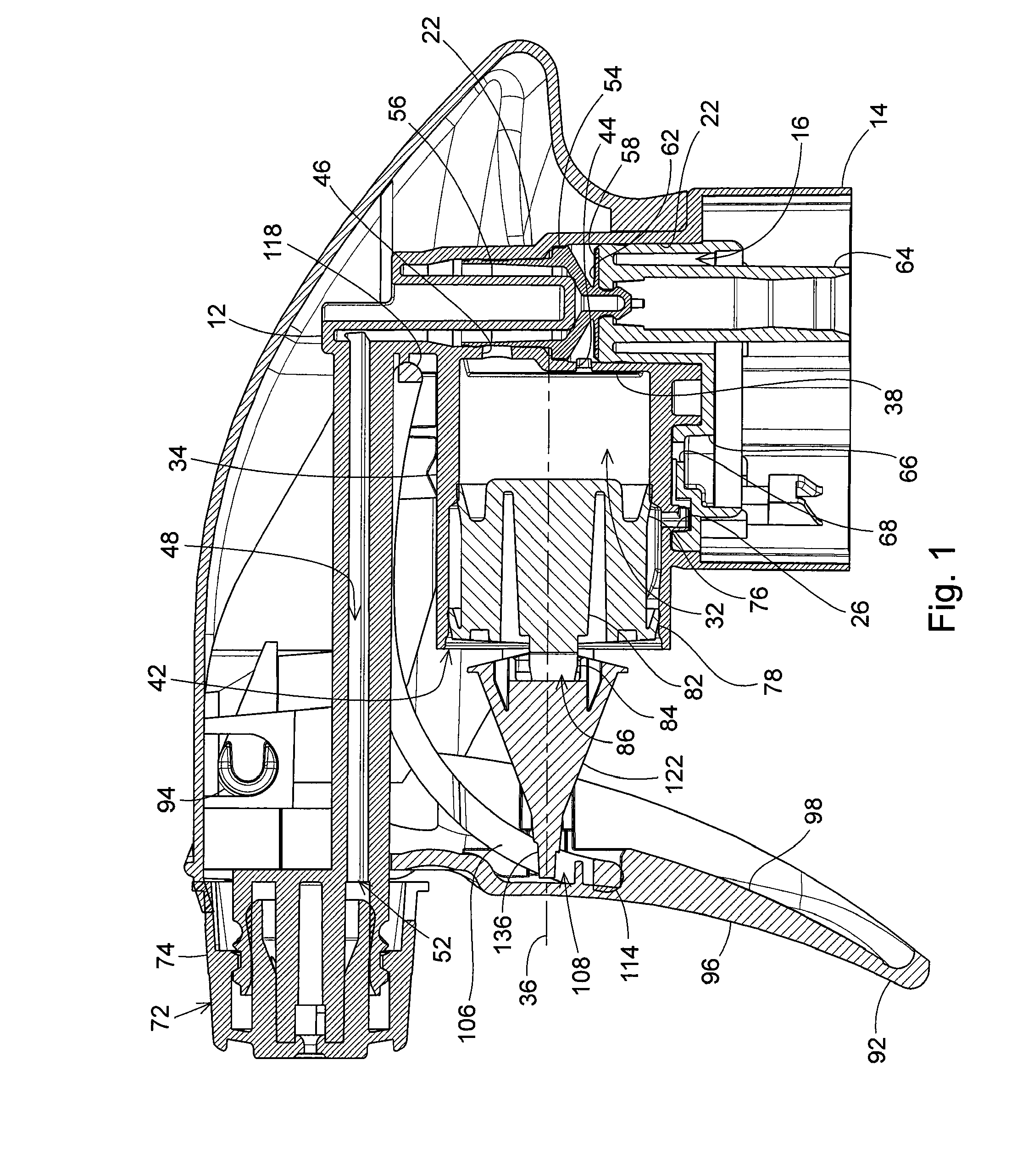

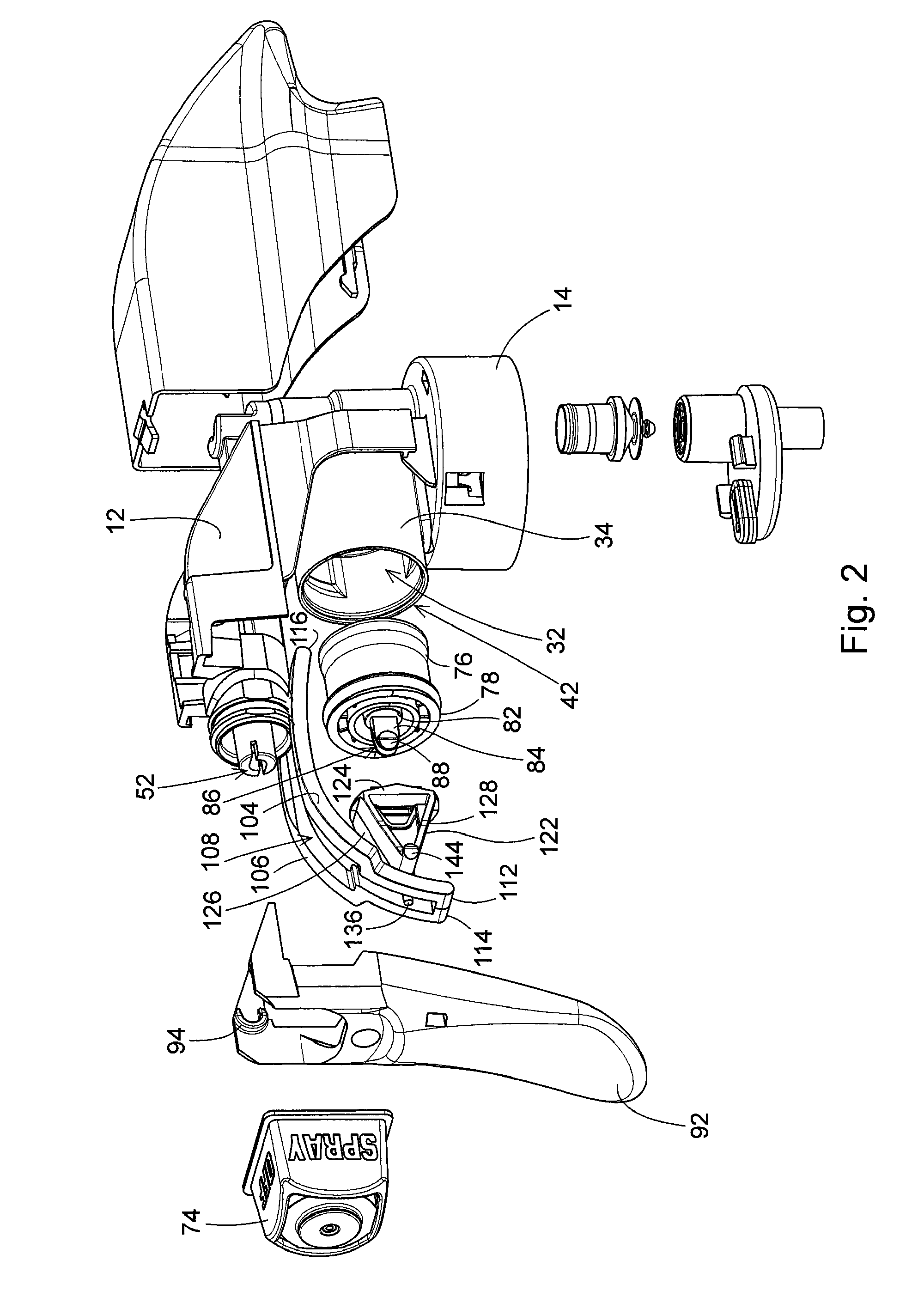

Break-Away Spring and Piston Rod for a Trigger Sprayer

ActiveUS20090152304A1Reduce manufacturing costReduce in quantityClosure using stoppersLarge containersSprayerHand manoeuvre

A manually operated trigger sprayer has an integral plastic spring and pump piston rod that are connected by a breakable connection, whereby the spring and piston rod can be assembled to the trigger sprayer as one piece and are subsequently broken into two separate pieces in response to their assembly to the trigger sprayer, or subsequent manual operation of the trigger sprayer.

Owner:SILGAN DISPENSING SYST CORP

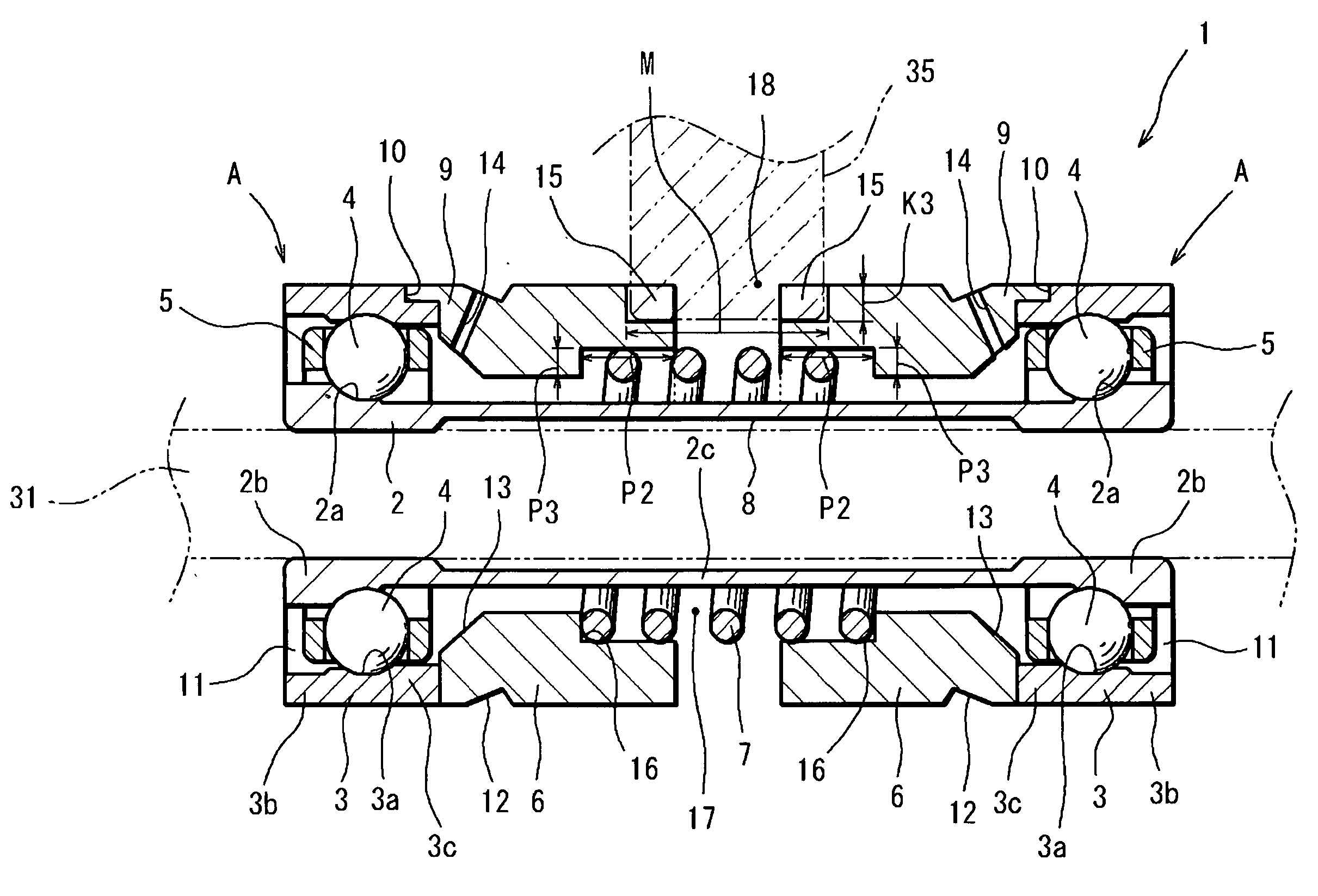

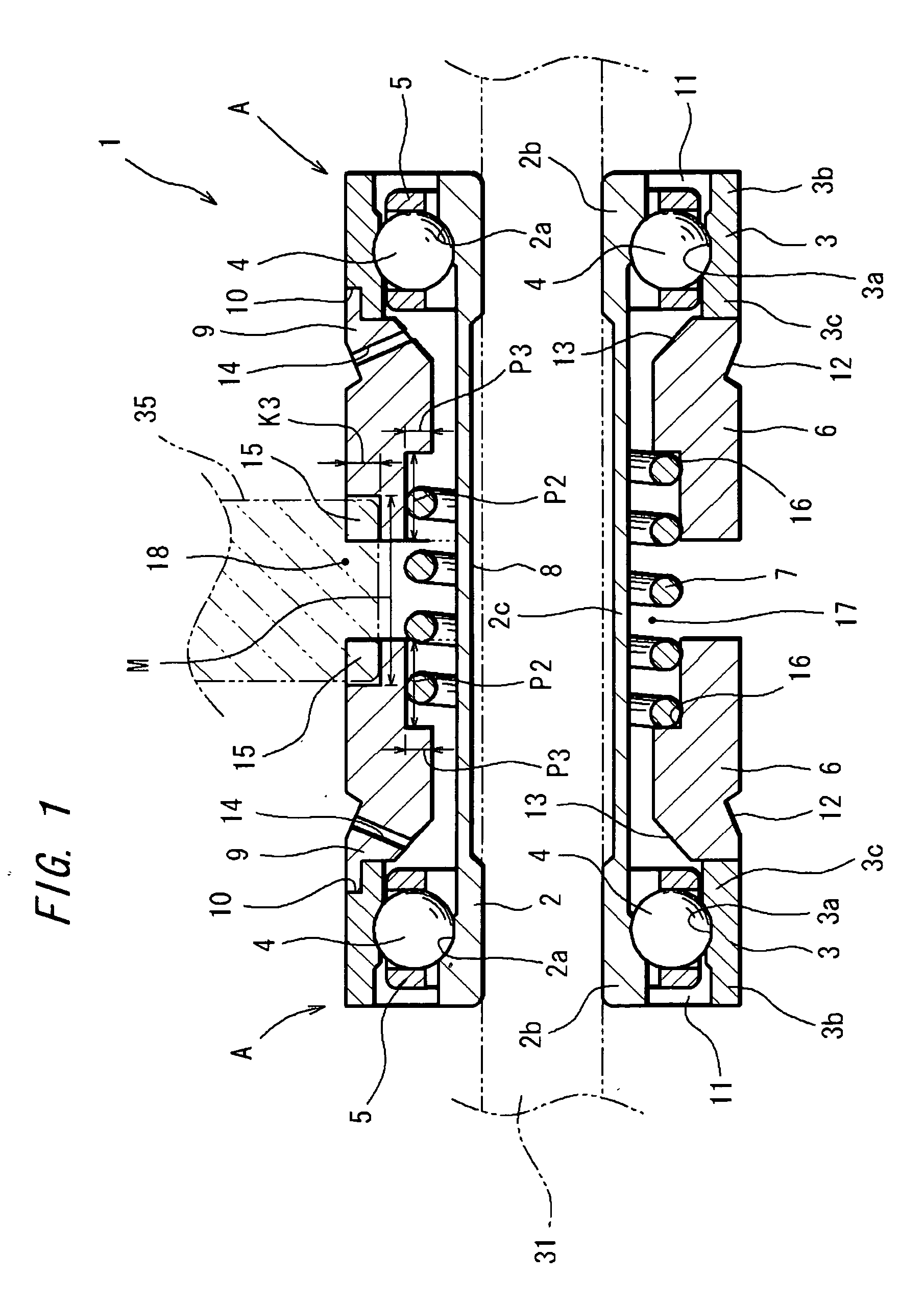

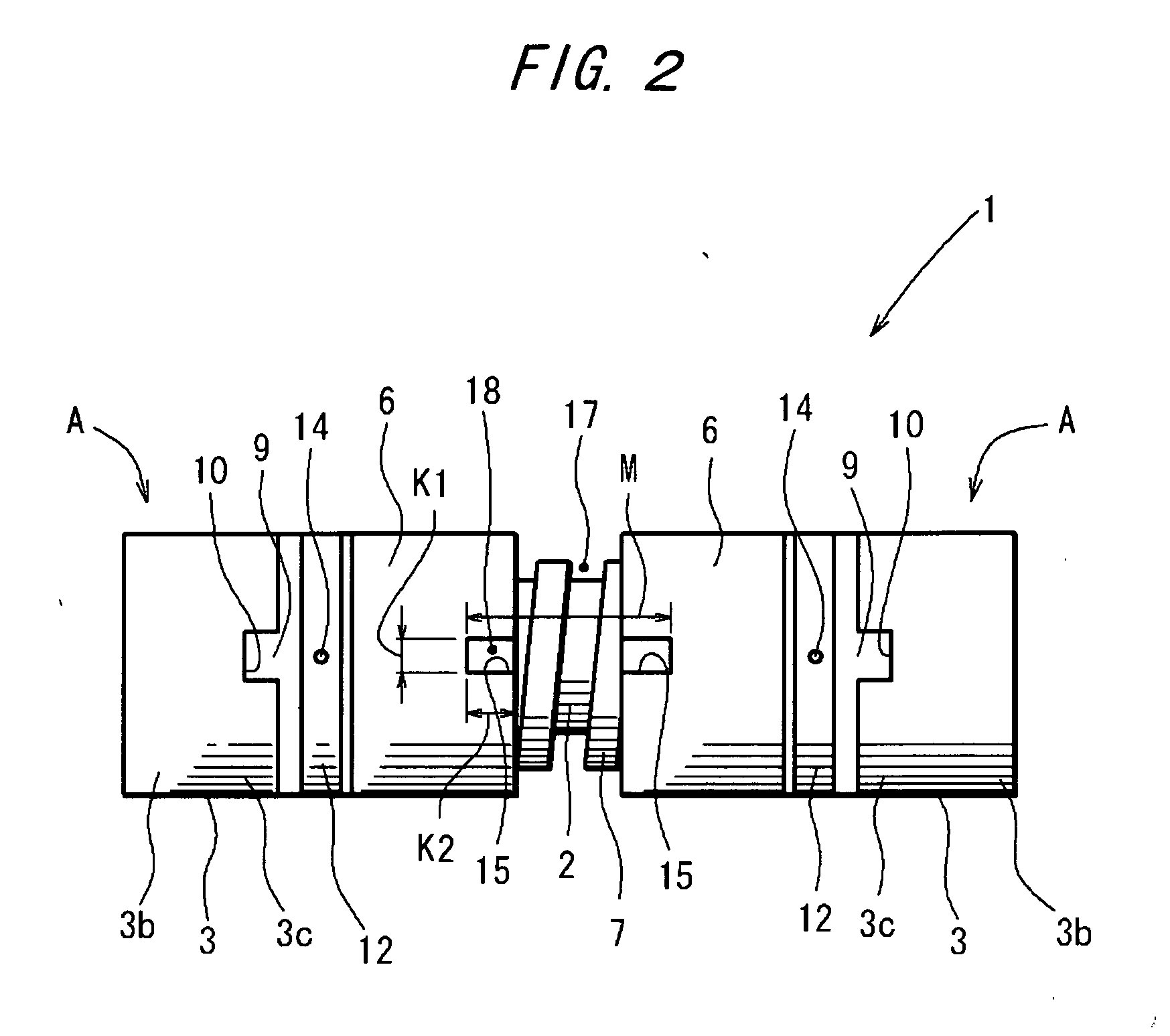

Turbocharger bearing assembly

InactiveUS20070183704A1Simple configurationReduce component countRolling contact bearingsBearing assemblyTurbochargerEngineering

A turbocharger bearing assembly is disposed in a housing for rotatably supporting an intermediate portion of a rotary shaft of a turbocharger. A pair of outer rings formed with outer raceways are mounted to opposite ends of a substantially cylindrical inner ring formed with inner raceways, thereby constituting a bearing unit including two angular bearings. Thus, the number of assembly steps is reduced to facilitate an assembly work. A pair of sleeves are inserted in a gap defined between the outer rings. The sleeve is formed with an engaging portion on an outer periphery thereof for restricting its rotation relative to the housing and the outer ring. This makes it easy to position the bearing in the housing.

Owner:JTEKT CORP

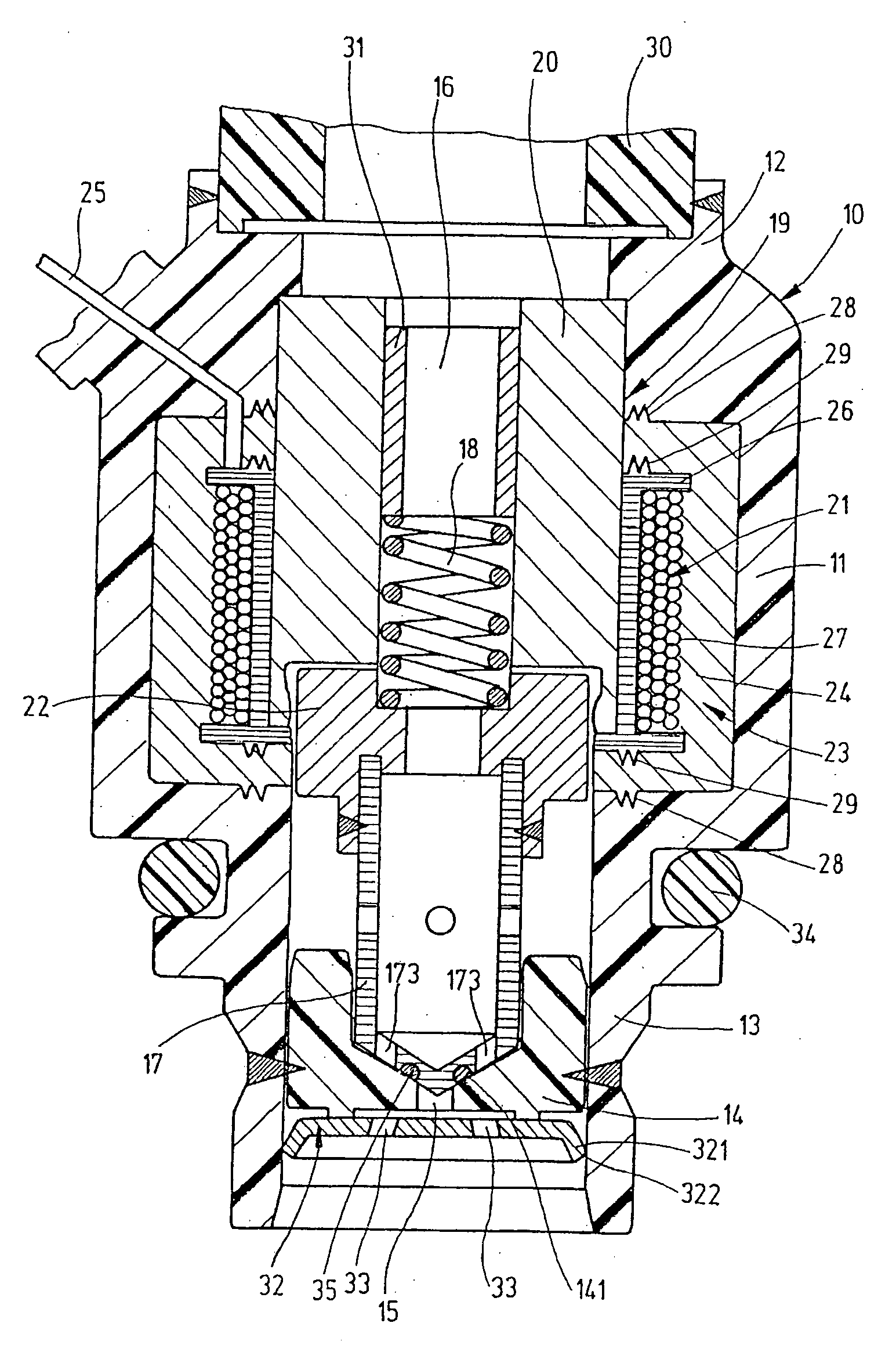

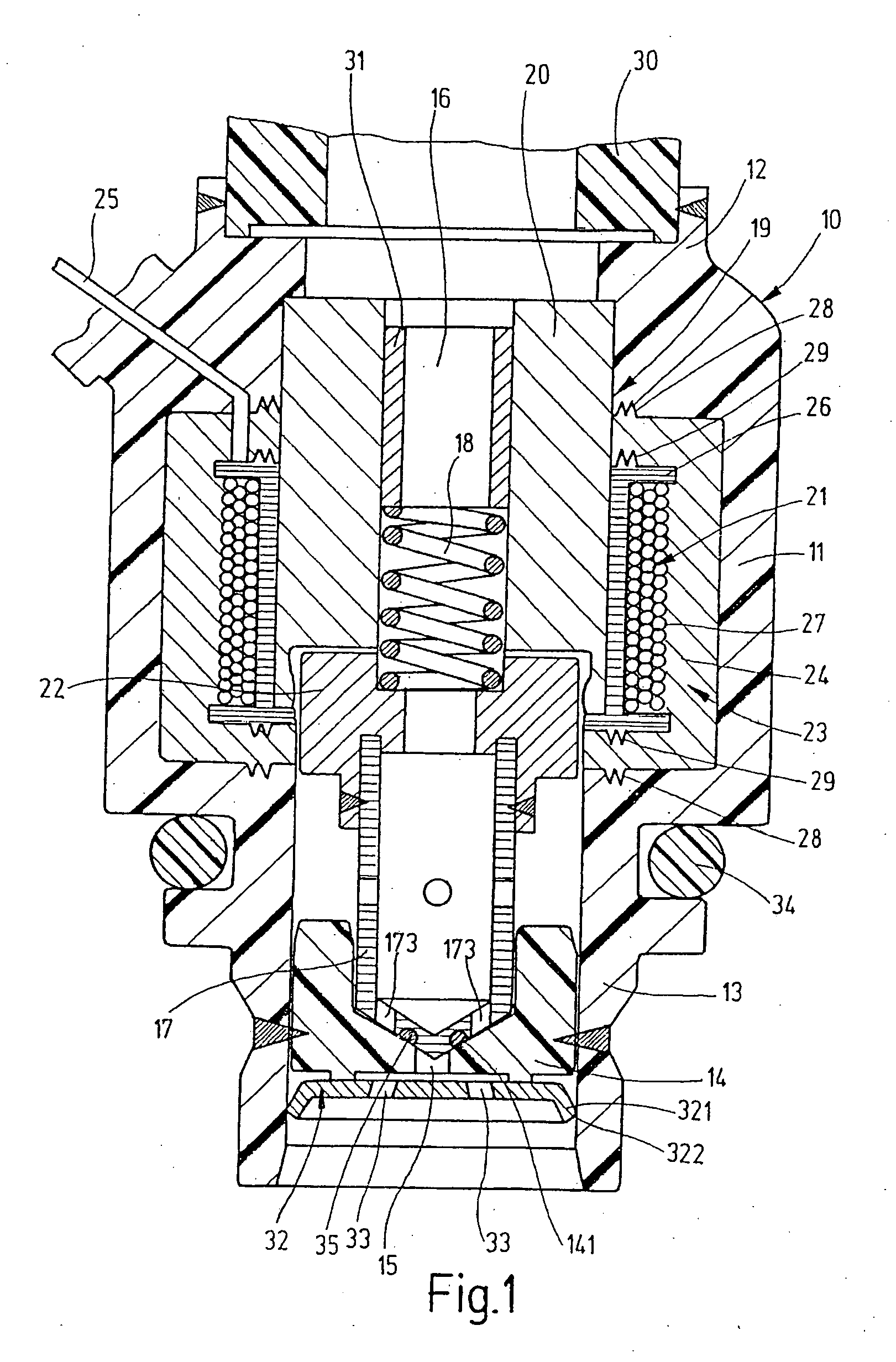

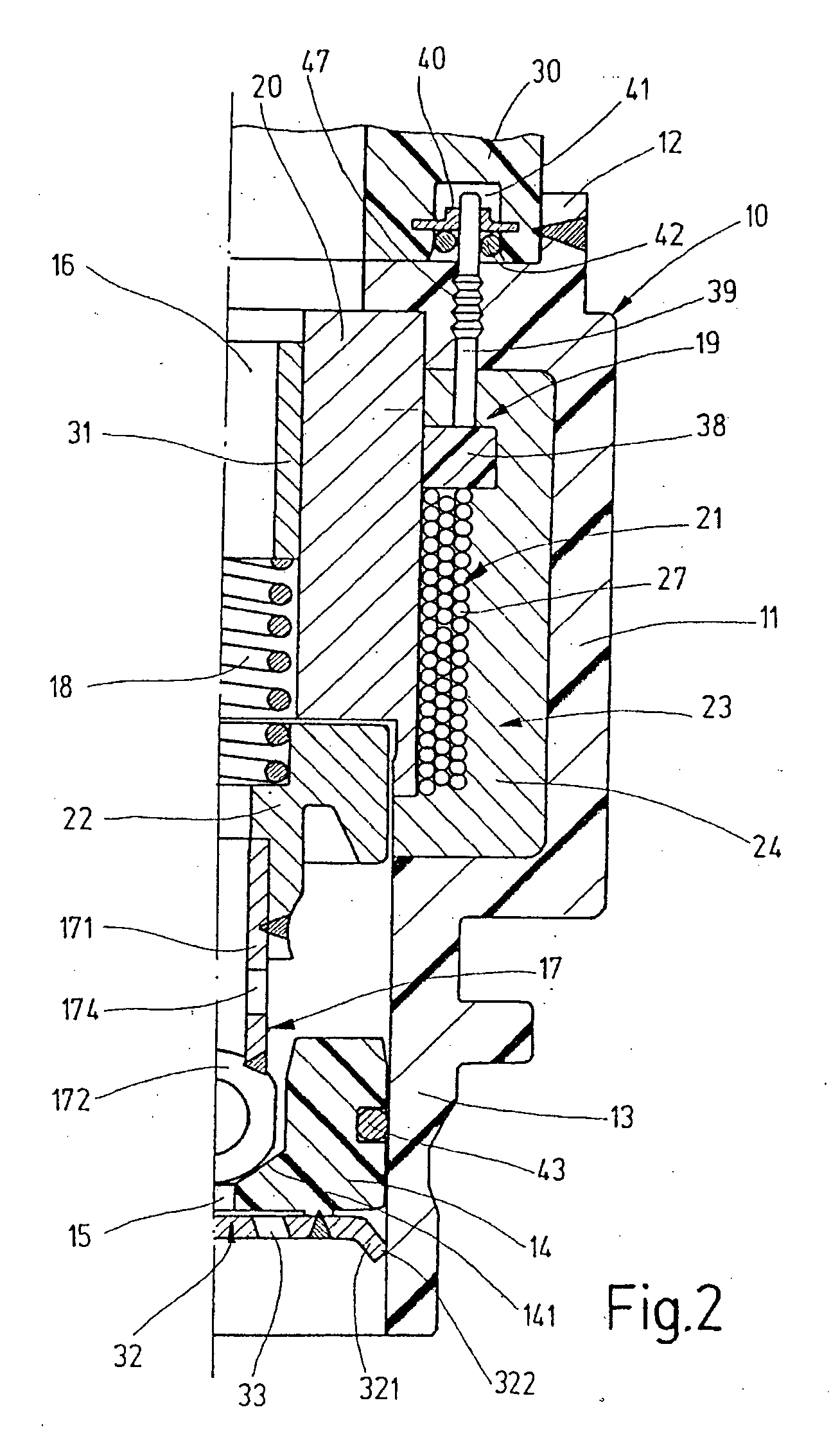

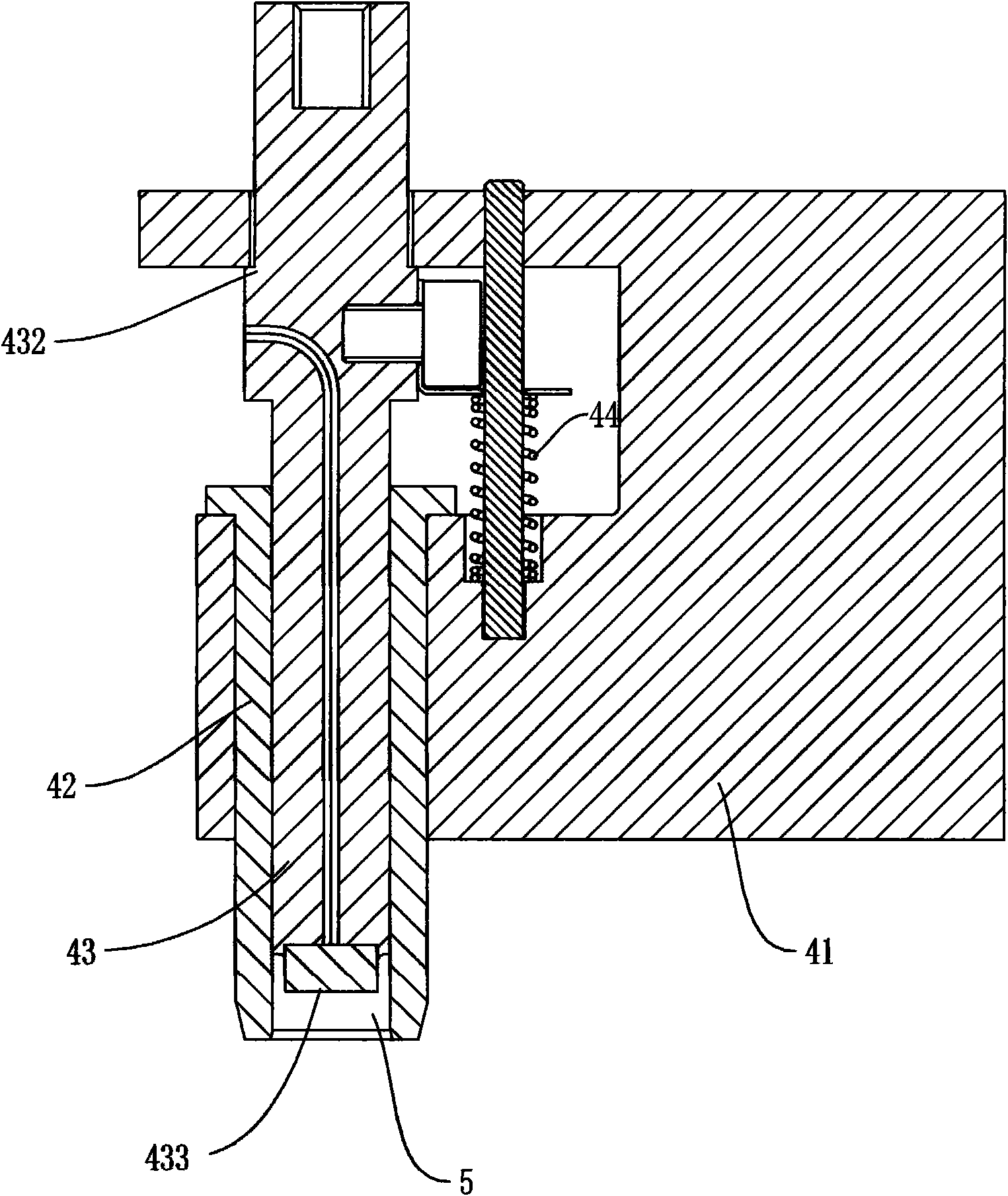

Injection Valve for Fuel Injection

InactiveUS20080061171A1Less complicated and cost-effective manufactureSimple methodOperating means/releasing devices for valvesSealing arrangements for enginesEngineeringFuel supply

A fuel injection valve has a connection piece for a fuel-supply line, a valve-seat support having a valve-seat body provided with a valve opening, a solenoid for activating a valve member, which controls the valve opening, and a plastic extrusion coat enclosing the connection piece, the solenoid and the valve-seat support. To achieve a cost-effective manufacture by requiring fewer components for the injection valve and providing a reduction in the assembly costs, the connection piece and the valve-seat support are made of plastic and designed as one-piece plastic housing together with the plastic extrusion coat. The yoke element for closing the magnetic circuit of the solenoid, which extends across the magnetic core and magnetic armature, is a magnetic material extrusion coat, which encloses the solenoid coil and adjoins the magnetic core in a gapless manner and ends in front of the magnetic armature with a gap clearance.

Owner:ROBERT BOSCH GMBH

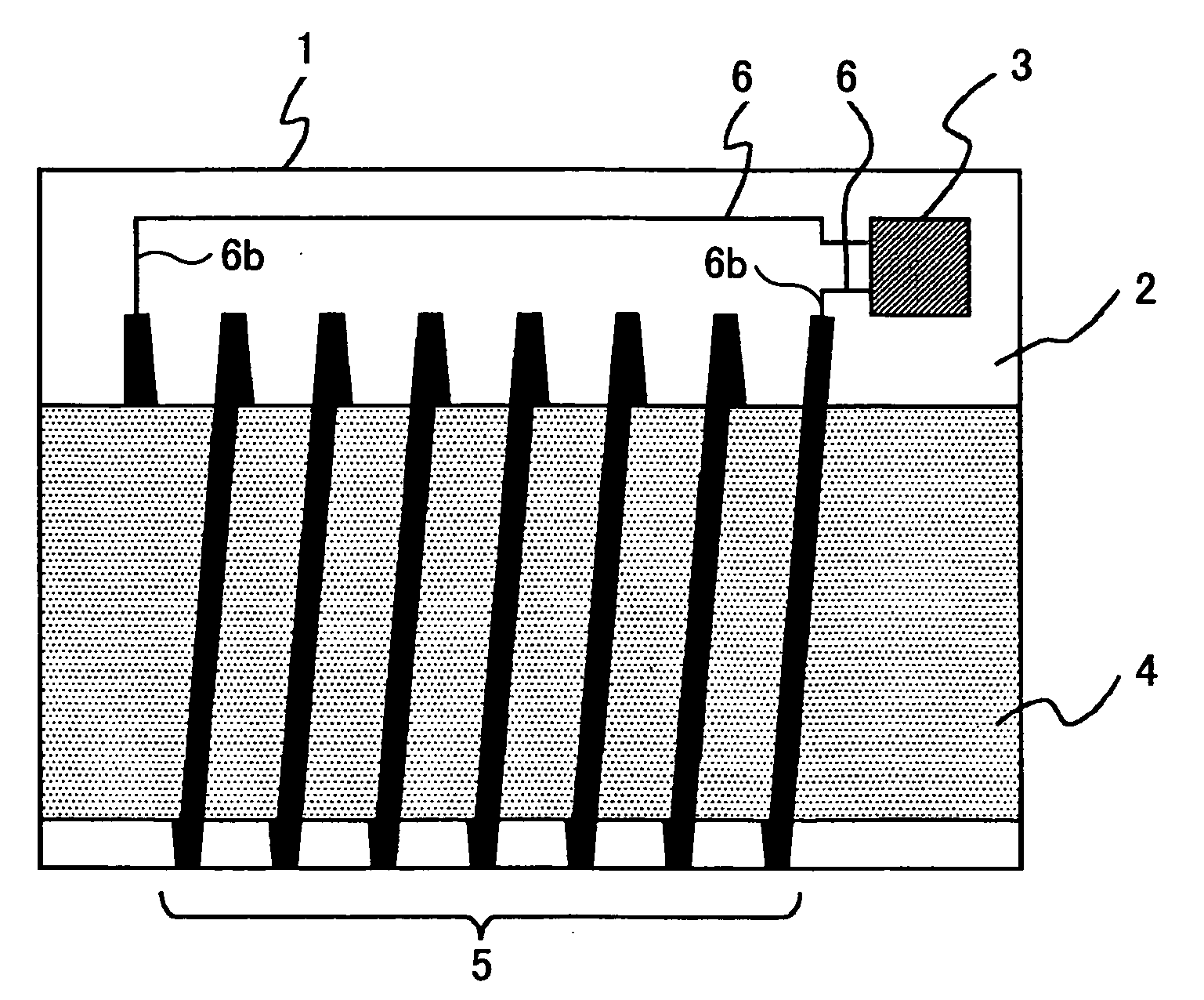

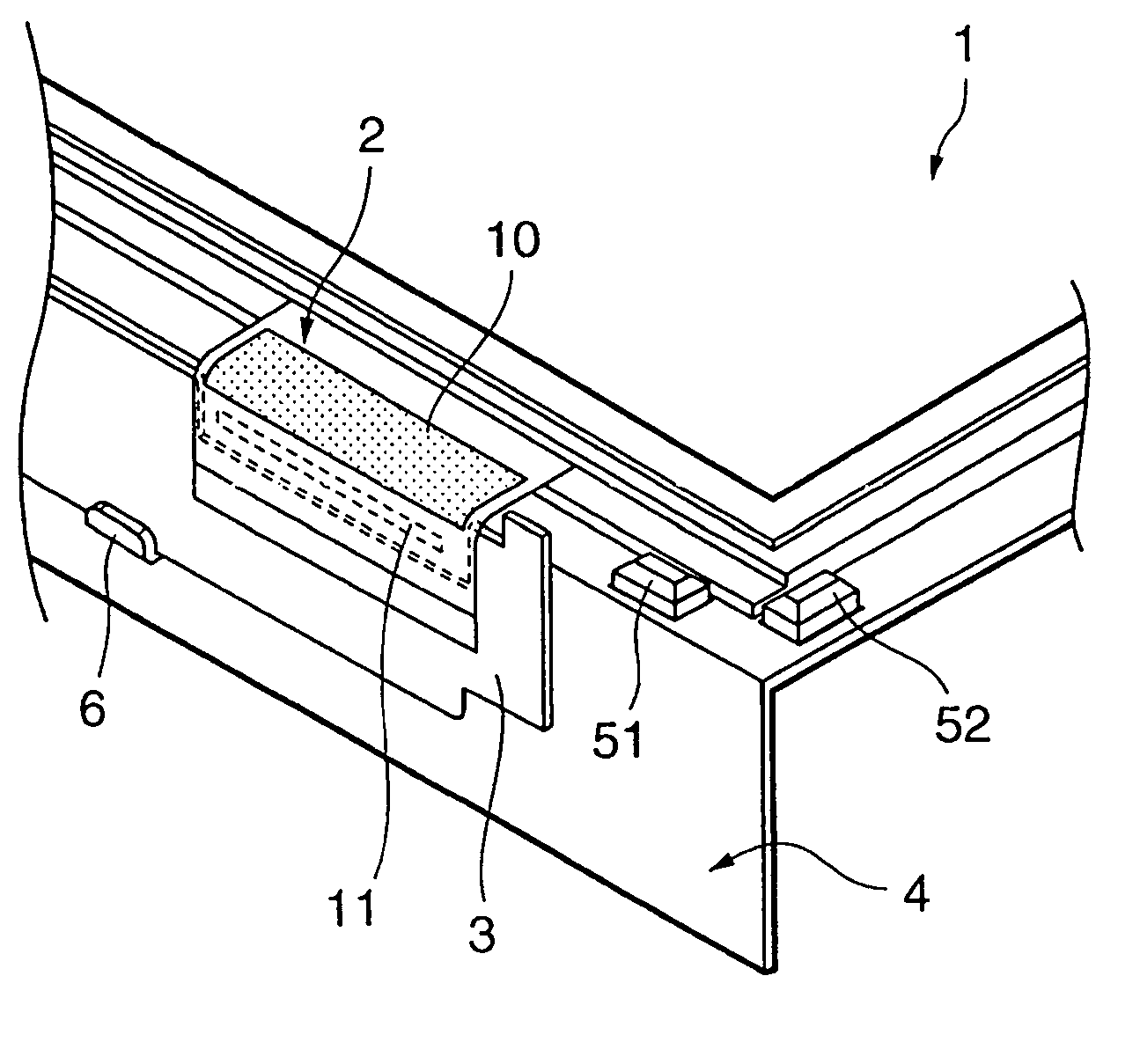

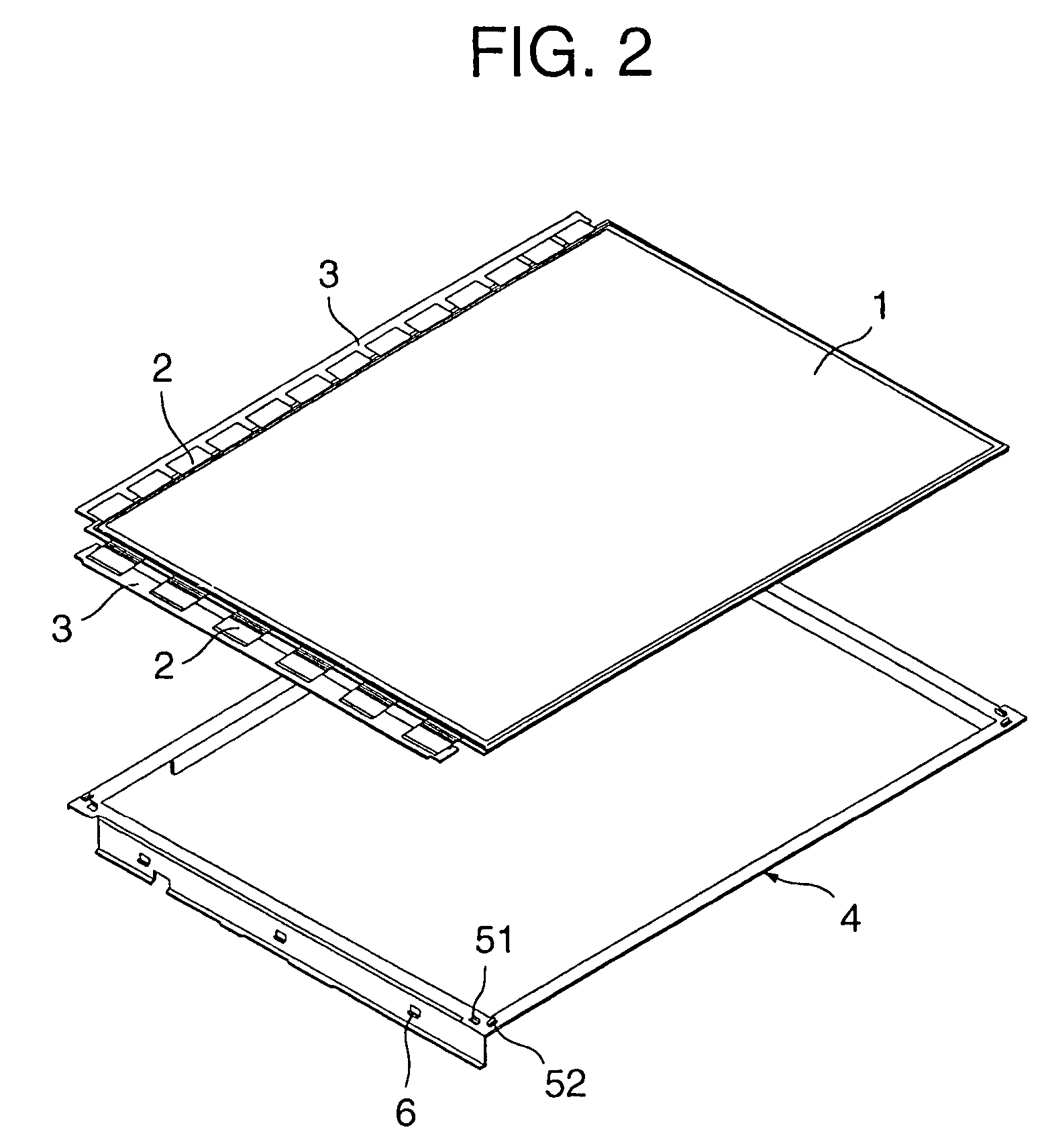

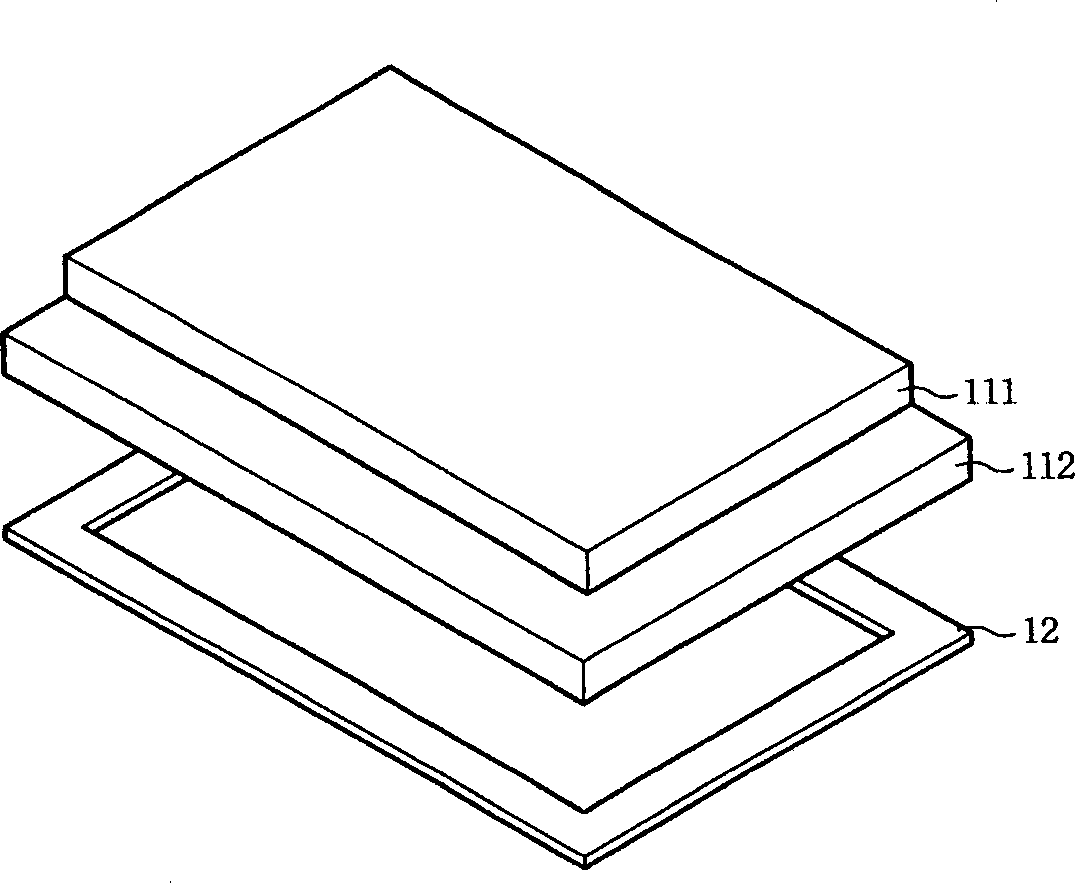

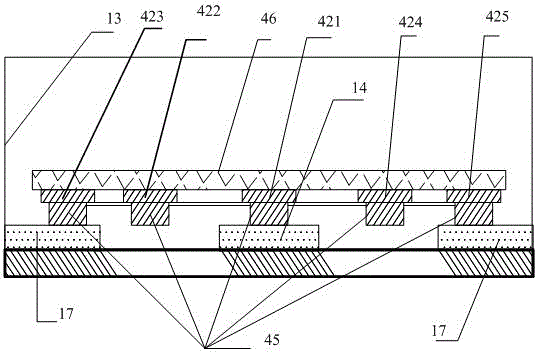

Flat panel display device and manufacturing method thereof

InactiveUS6995814B2Small sizeRelaxation stressStatic indicating devicesPrinted circuits structural associationsPeel forceElectrical and Electronics engineering

In a flat panel display device, in which a display panel 1 loosely fitted on a main surface of a chassis 4 and circuit substrates held in hook portions provided on side surfaces of the chassis are connected each other through TCP's by bending the latter TCP's, and a method for manufacturing the same device, a main slit for a rounded portion of each TCP is formed in a rounded portion of the TCP and an auxiliary sub slit is also formed adjacent to the main slit. In order to reduce the peeling force exerted on connecting / fixing portions between the TCP's and the display panel, the circuit substrate is pulled up by bending the main and sub slits and then returning the sub slit to a flat state to insert the circuit substrate into the hook portions.

Owner:GOLD CHARM LTD

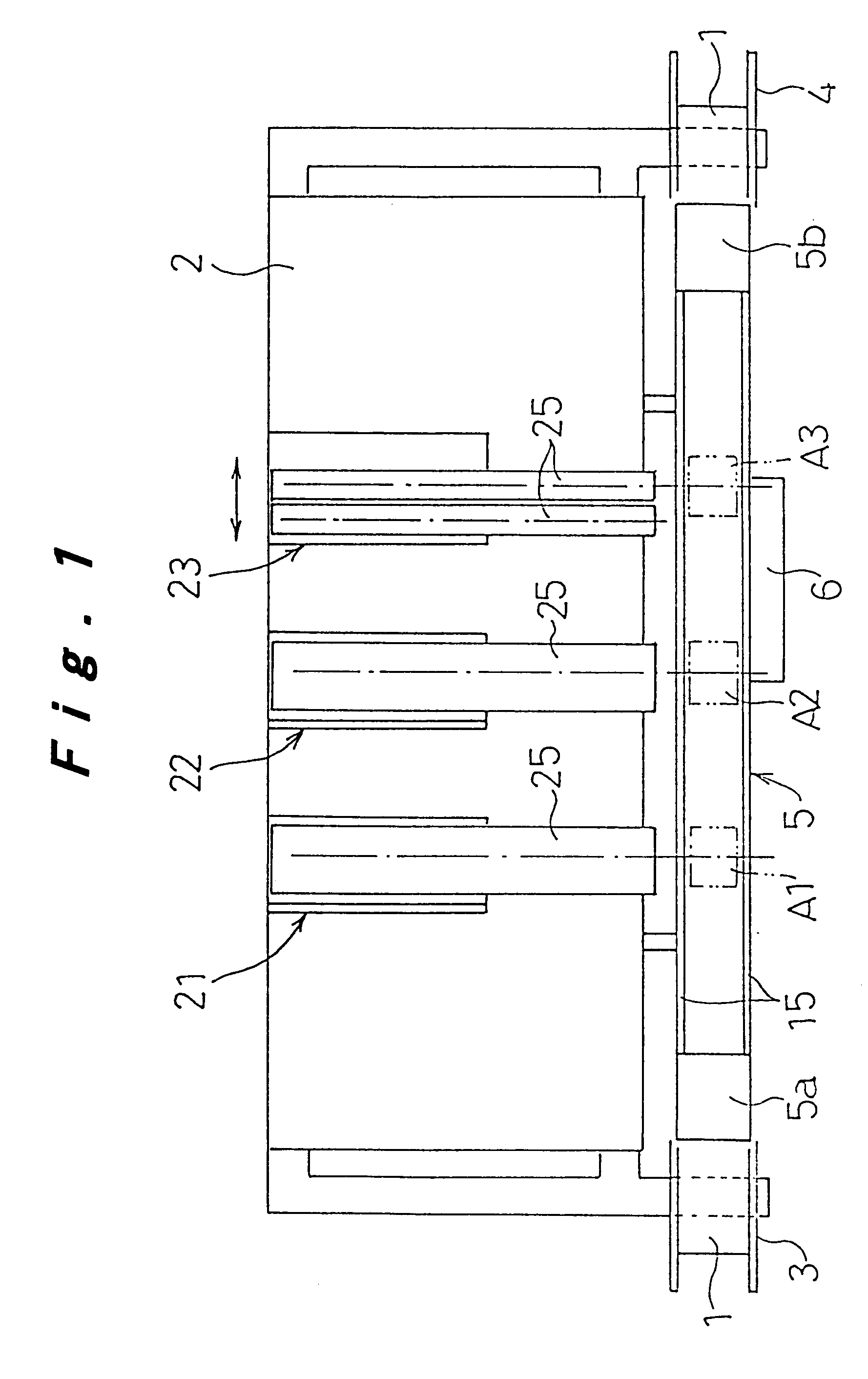

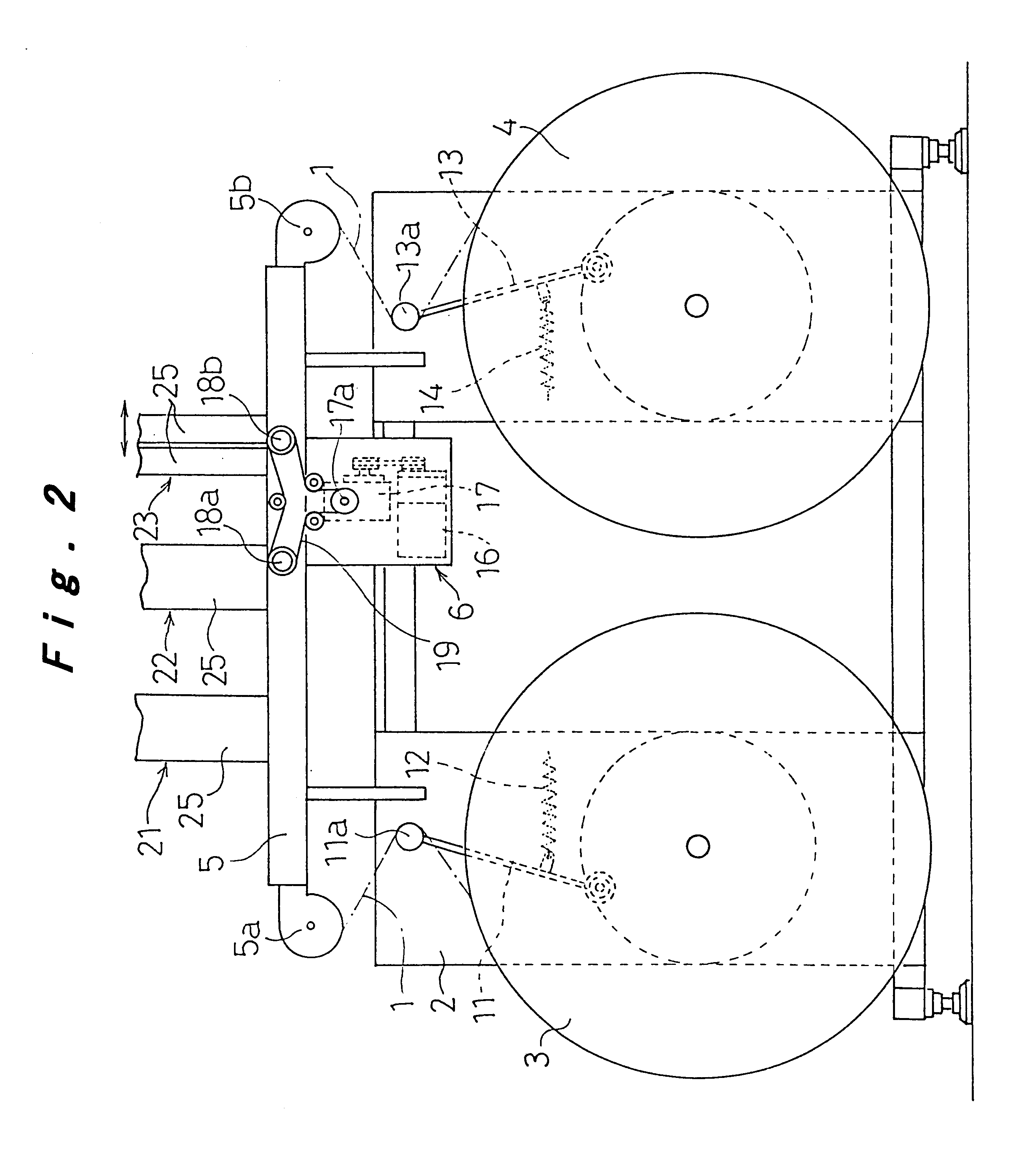

Component assembling method and component assembling apparatus

InactiveUS6389672B1Lower assembly costsSimple assembly structureOther accessoriesContainer/bottle contructionEngineeringMechanical engineering

Owner:PANASONIC CORP

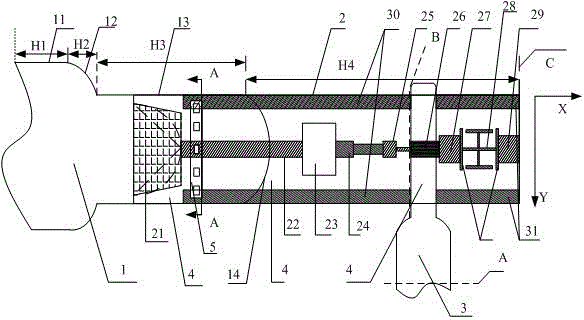

Terahertz frequency tripler based on coplanar waveguide transmission wires

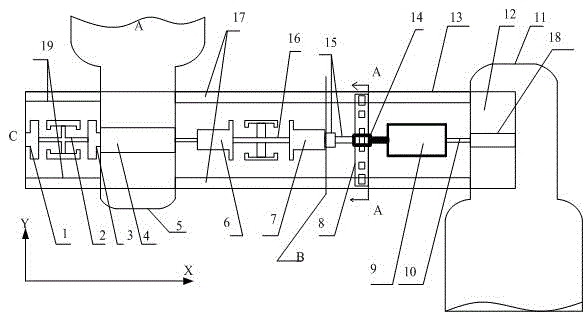

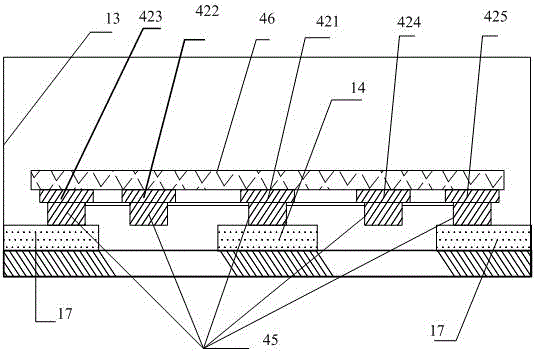

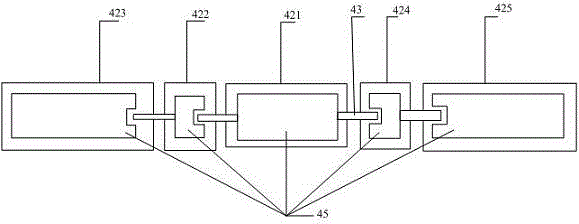

ActiveCN104600403AReduced assembly stepsReduced processing performanceWaveguide type devicesLow-pass filterCoplanar waveguide

The invention discloses a terahertz frequency tripler based on coplanar waveguide transmission wires. The terahertz frequency tripler based on the coplanar waveguide transmission wires comprises three waveguides, including a fundamental wave input wave guide, an output waveguide and a main body waveguide, a dielectric substrate inside the main body waveguide, and electrical structures arranged on the dielectric substrate through the coplanar waveguide transmission wires in an integrated mode, wherein the electrical structures are composed of a DC (direct current) bias low-pass filter, an input matching transmission wire, a fundamental wave low-pass filter, a fundamental wave matching transmission wire, a triple-harmonic matching transmission wire, a three-stage matching transmission wire, a four-stage matching transmission wire and an output matching transmission wire from left to right and takes the coplanar waveguide transmission wires as a ground wire. The coplanar waveguide transmission wires substitute traditional microstrip wires and traditional suspended microstrip wires for designing the peripheral passive circuit of the frequency tripler; the inside of the circuit is directly connected with a cavity wall to achieve a radio frequency grounding and DC circuit; by means of a fundamental wave input duplexer, DC bias and other circuits can be designed simultaneously, subsequent assembling steps can be reduced, and the circuit structure is easy to process and assemble.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

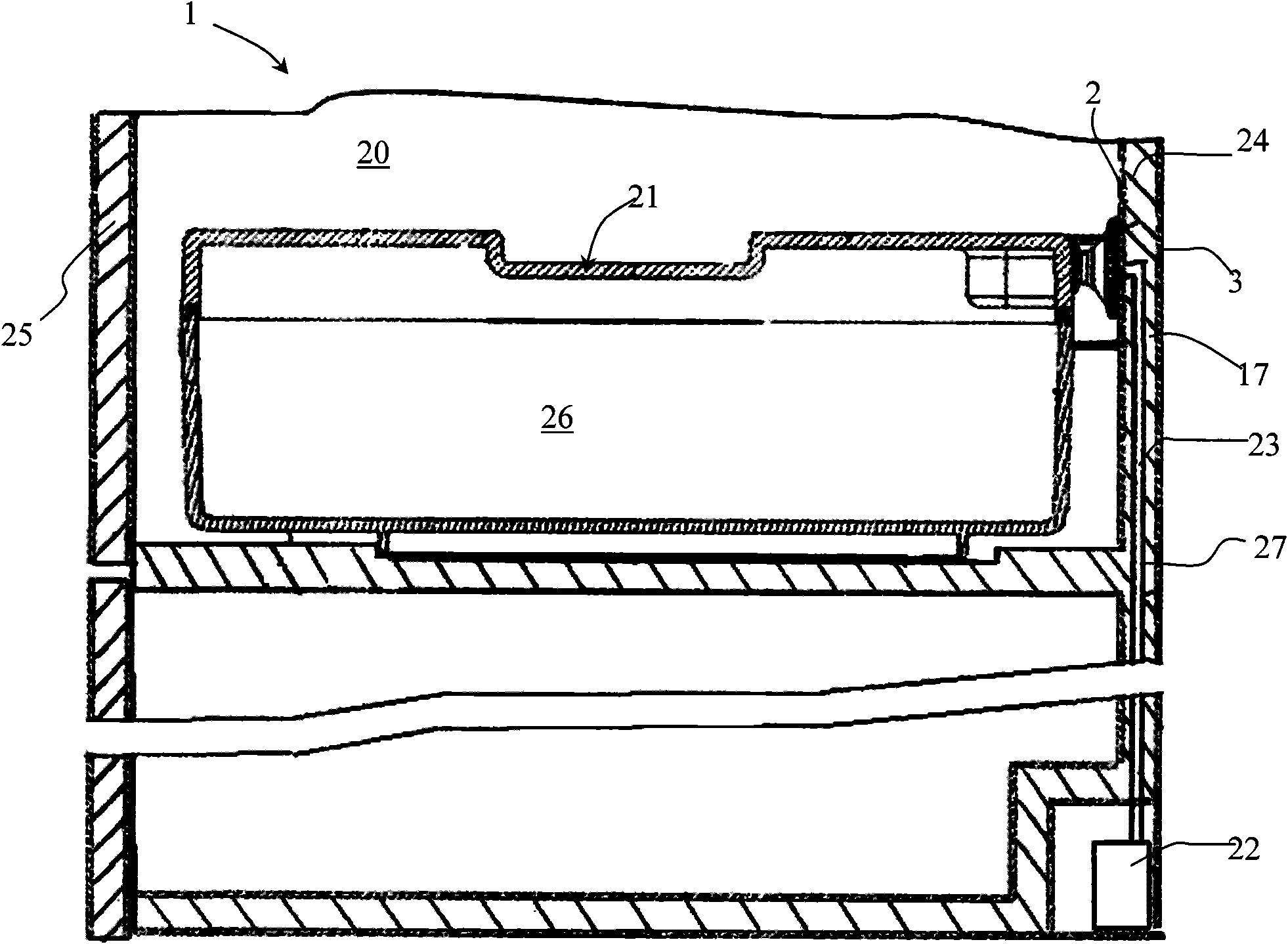

Refrigerator

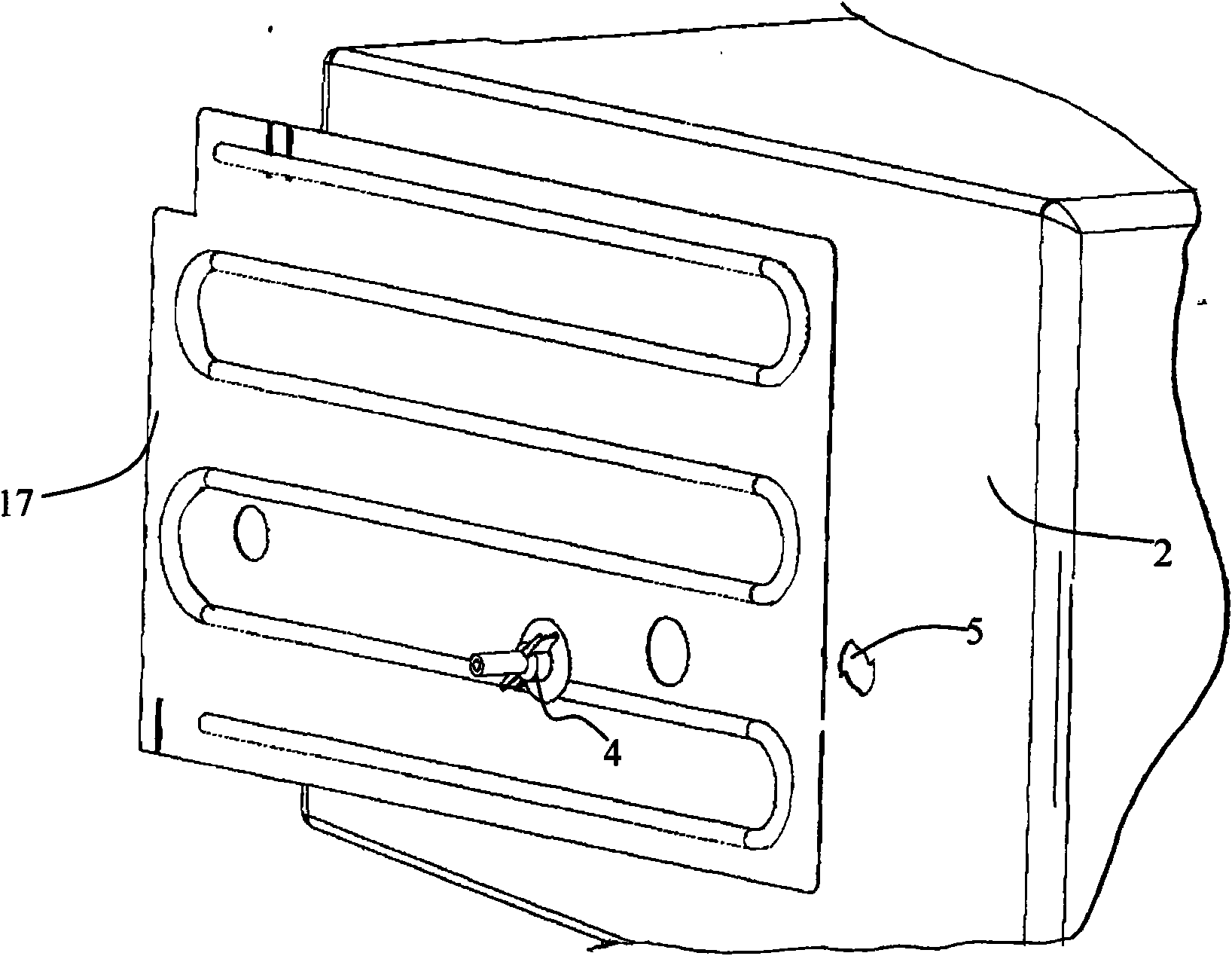

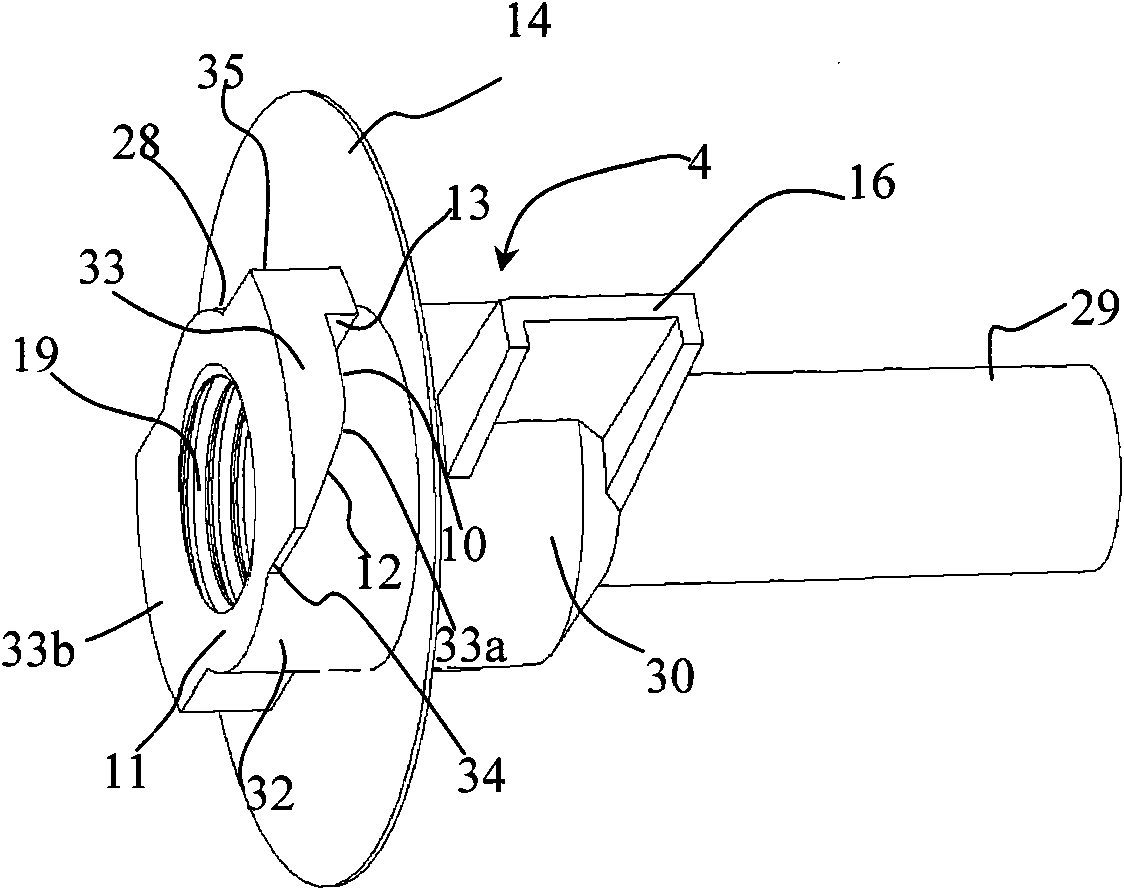

InactiveCN101865584AReduced assembly stepsLighting and heating apparatusDomestic refrigeratorsThermal insulationEngineering

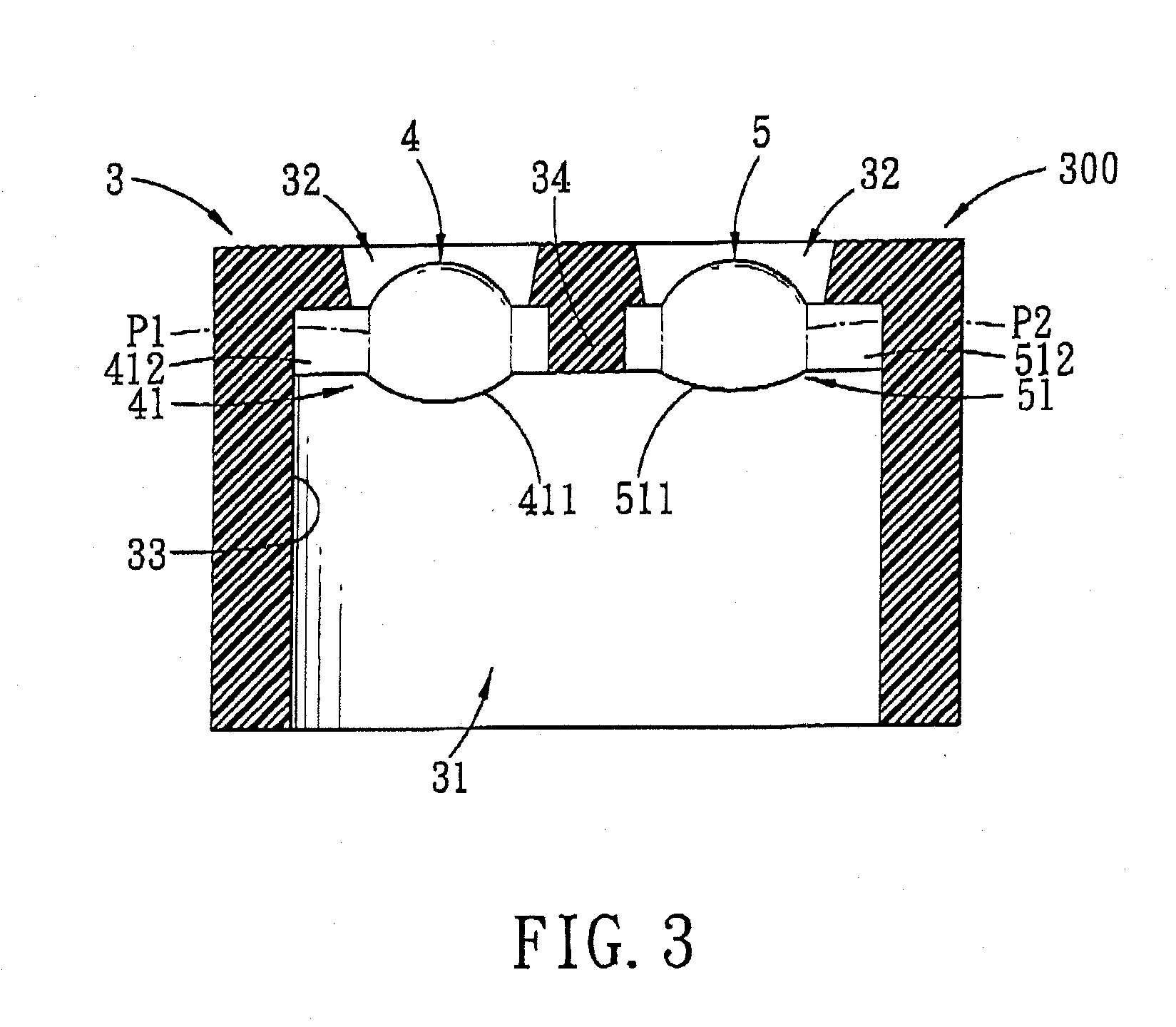

The invention discloses a refrigerator (1). The refrigerator (1) comprises a lining (2) defining at least one compartment (20), a shell (3), an insulation space (17), and at least one connector (4) connected to the lining (2), wherein the insulation space (17) is positioned between the lining (2) and the shell (3) and used for accommodating a thermal insulation material, and the lining (2) is provided with at least one connecting hole (5) used for connecting with the connector (4) and penetrating through the lining (2). According to the suggestion of the invention, the connector (4) comprises an isolating element (14) used for isolating the connecting hole (5) and the thermal insulation material.

Owner:博西华家用电器有限公司

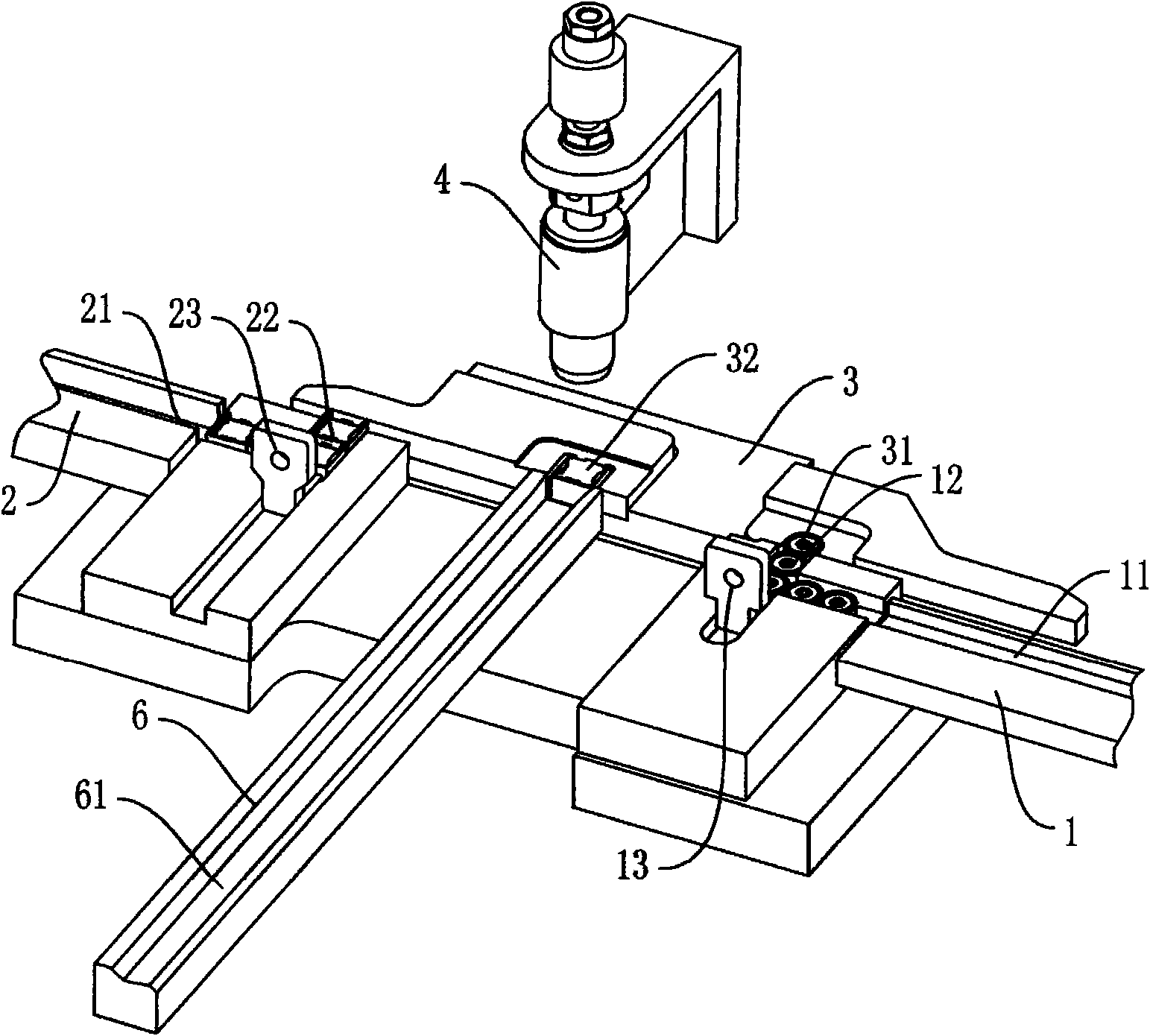

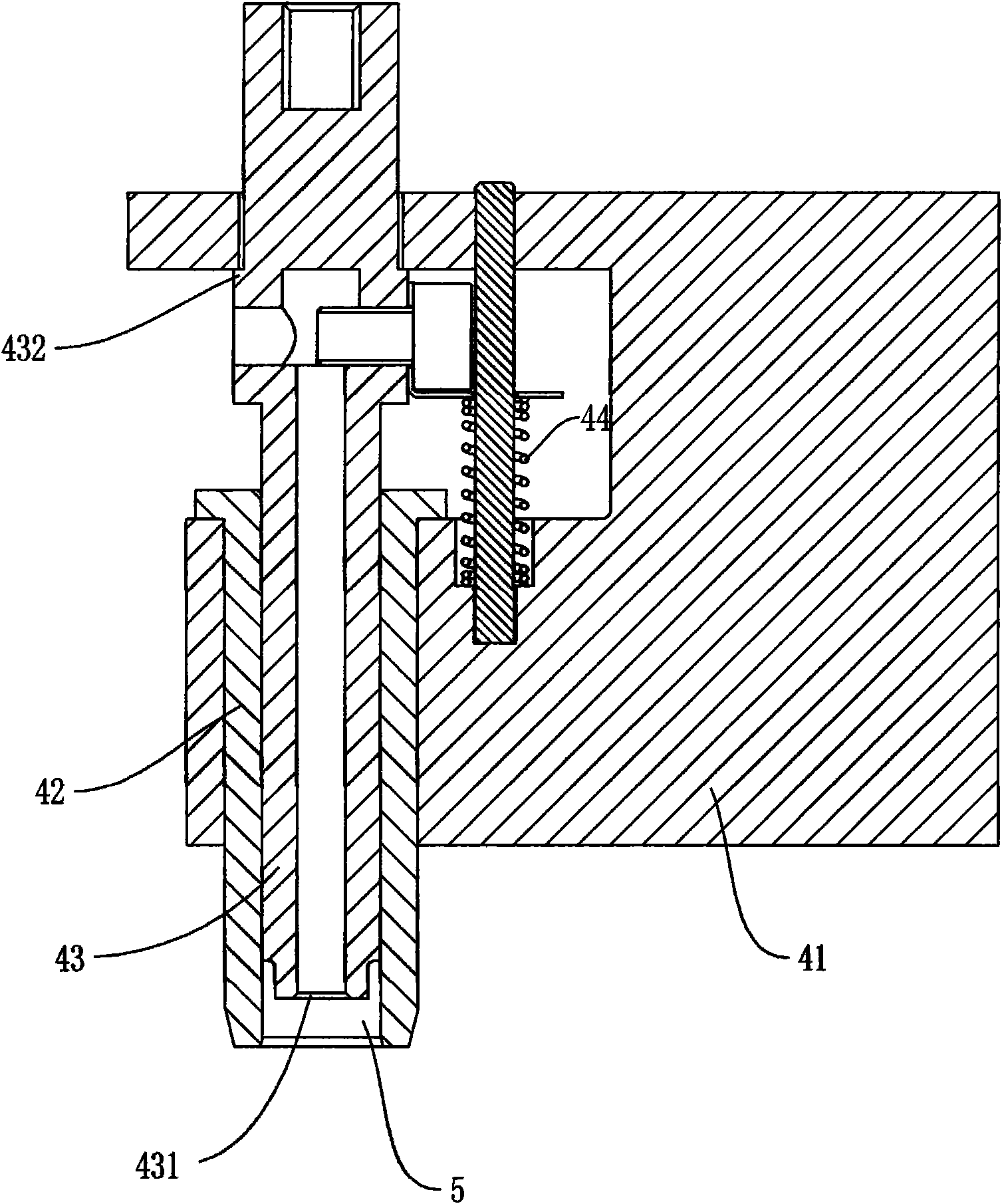

Automatic assembling device for elements and assembling method thereof

The invention discloses an automatic assembling device for elements and an assembling method thereof. The automatic assembling device comprises a reciprocating motion working platform, a first element feeding device and a second element feeding device which are both fixedly arranged at one side of the reciprocating motion working platform, an element lifting device and an unloading device for conveying the assembled element group, wherein the reciprocating motion working platform reciprocates between the first element feeding device and the second element feeding device, captures two elements and automatically assembles the two elements, enables the elements to position independently and transfers the elements. The invention has simple structure, short stroke of mechanisms and high production efficiency, reduces the assembling steps, improves the production efficiency; besides, the element lifting device does not need to be positioned twice, thereby the assembling precision and the product quality are improved.

Owner:GOERTEK INC

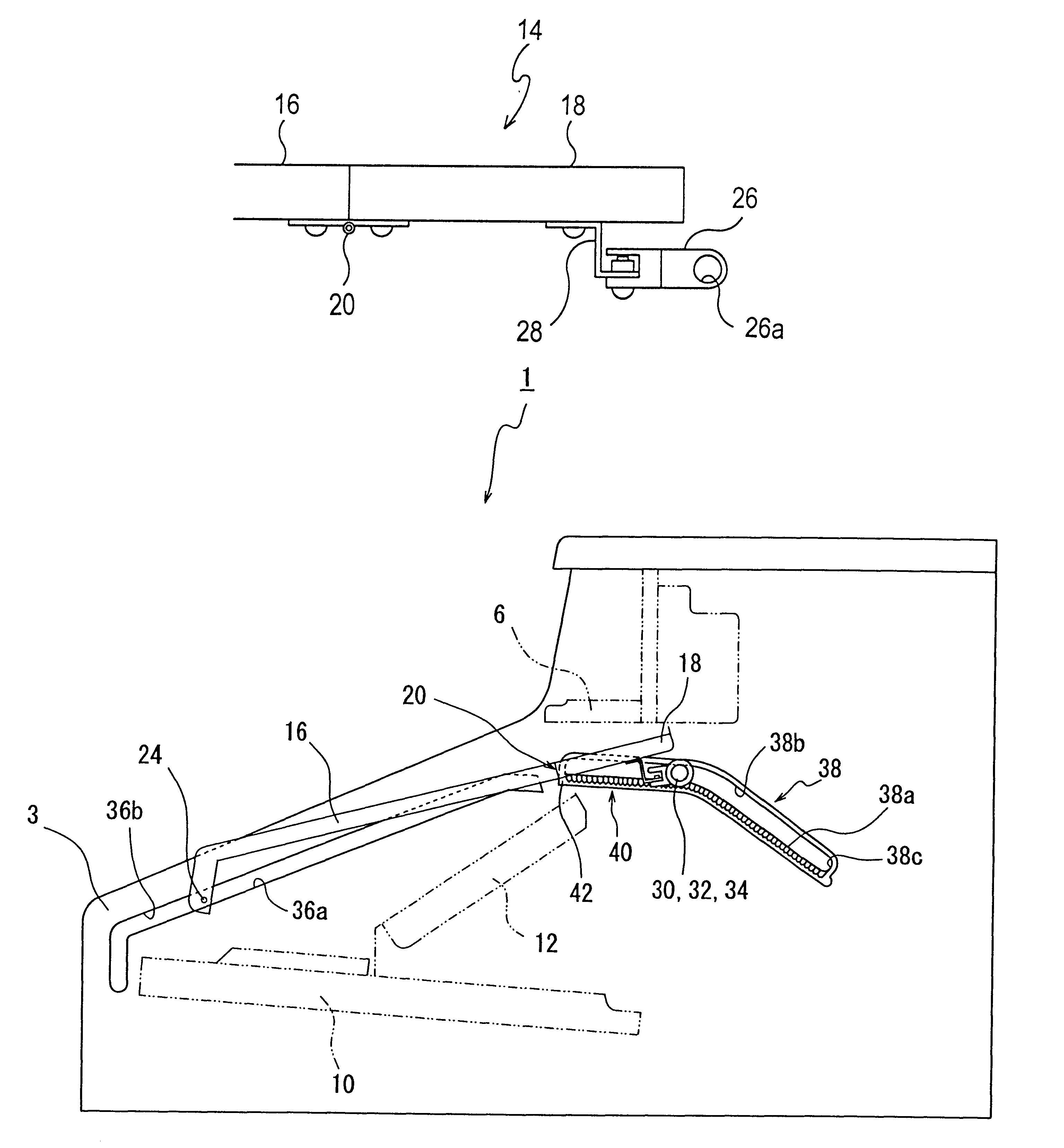

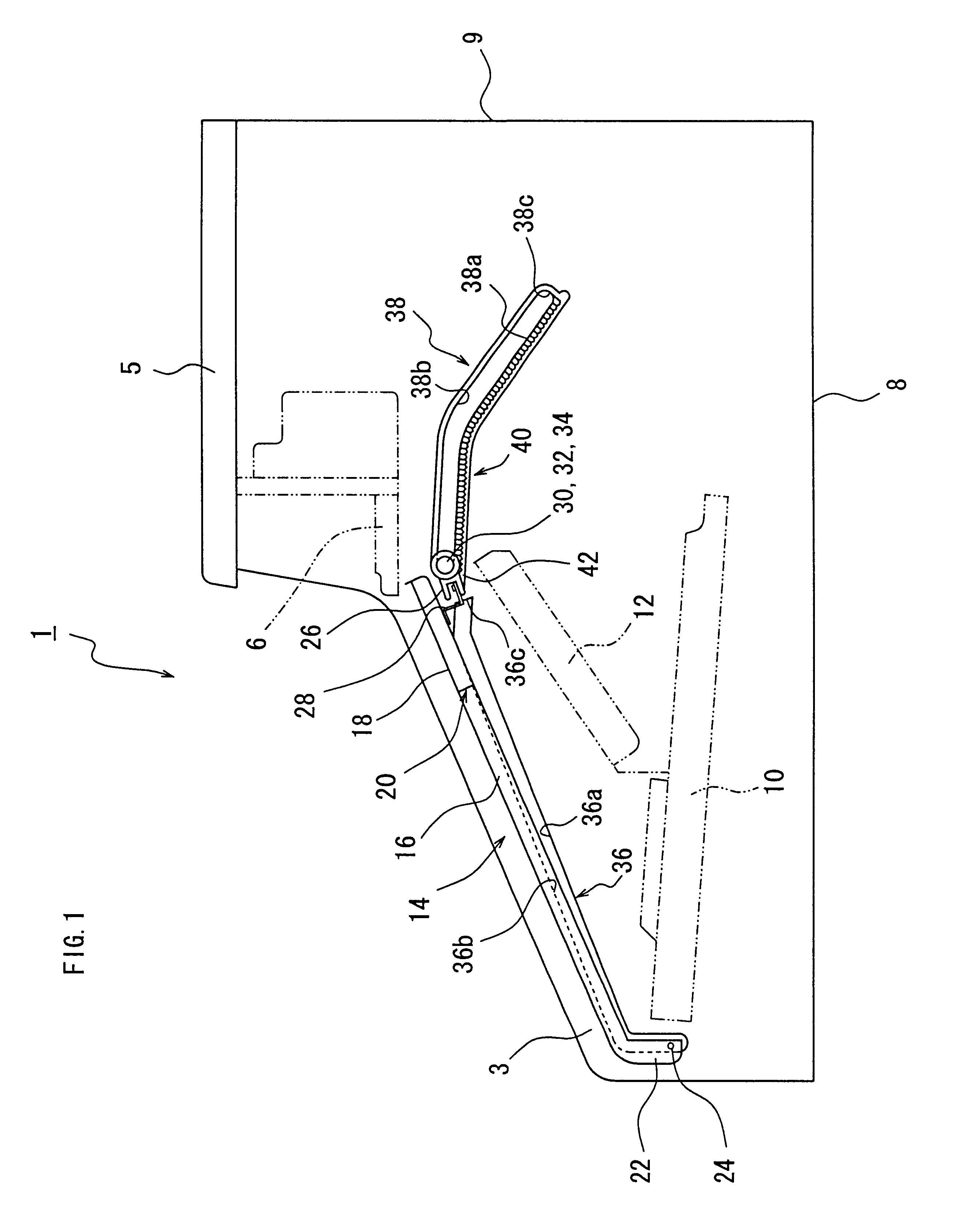

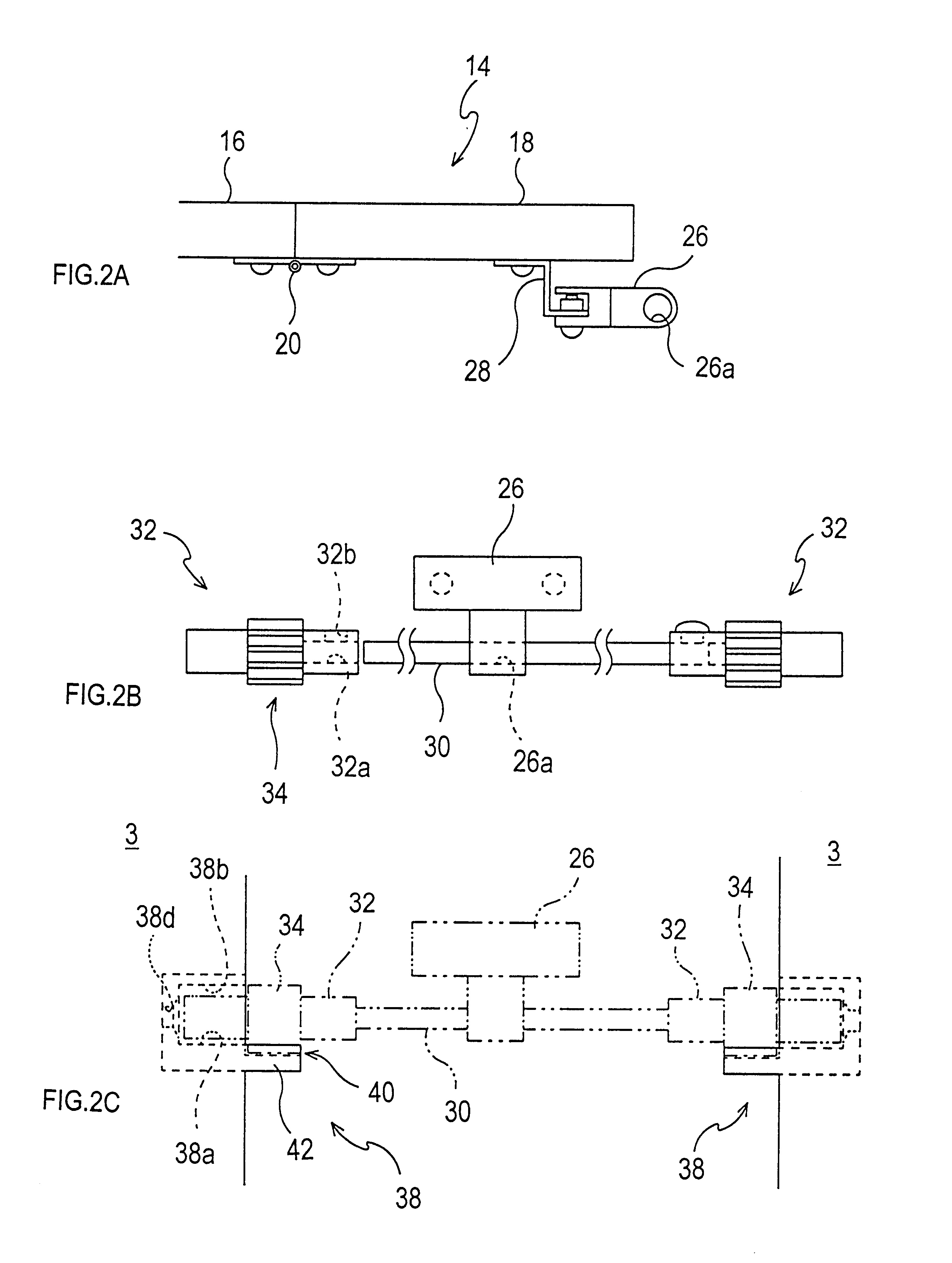

Keyboard lid opening and closing mechanism for keyboard musical instrument and keyboard musical instrument

InactiveUS6673991B2Large installation spaceSimple structureElectrophonic musical instrumentsStringed musical instrumentsEngineeringMoving parts

A keyboard lid opening and closing mechanism for a keyboard musical instrument having a simple structure and not requiring a large space for installation thereof. To house a keyboard lid in the folded state inside the keyboard musical instrument, the mechanism is provided with a reverse V-shape forming portion disposed at the place where the undersurface of the keyboard lid passes while moving, a rotation support portion including first connecting groove walls, and a keyboard lid stop portion including second connecting groove walls. Therefore, the structure of the mechanism for opening and closing the keyboard lid is simplified, and a large space for installation of the mechanism is not necessary since these portions include no movable parts.

Owner:KAWAI MUSICAL INSTR MFG CO

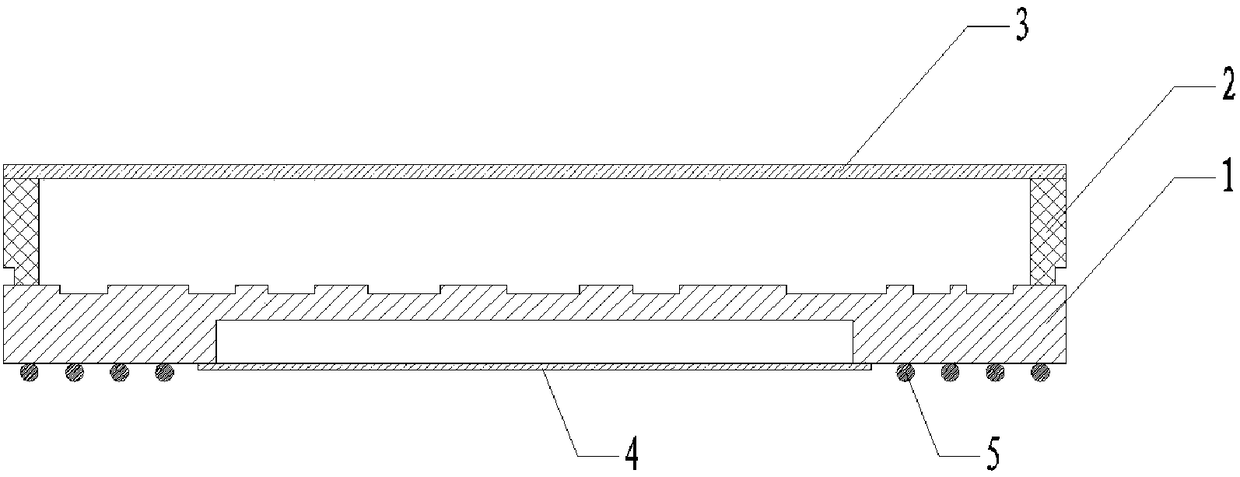

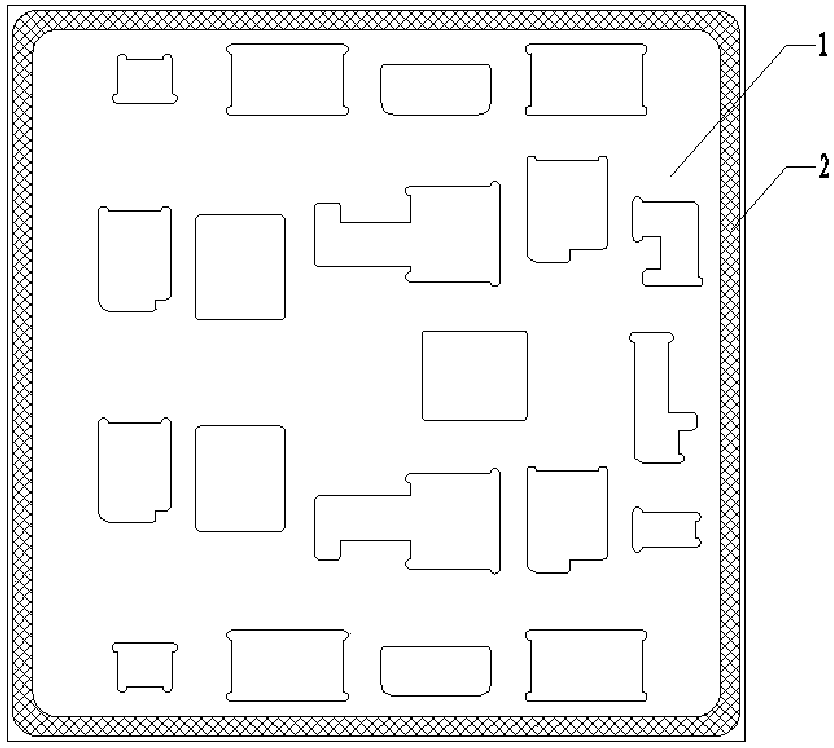

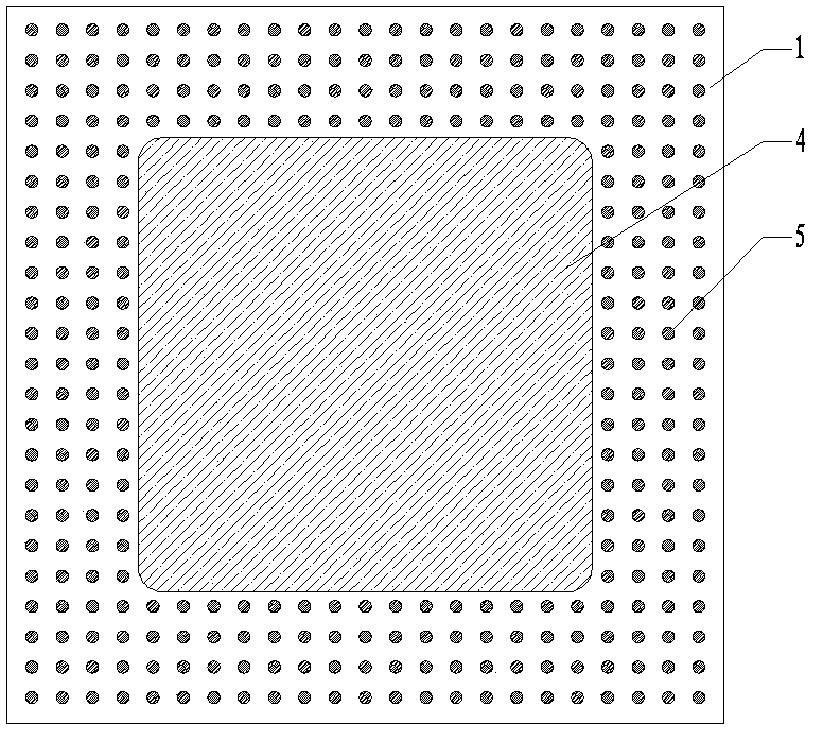

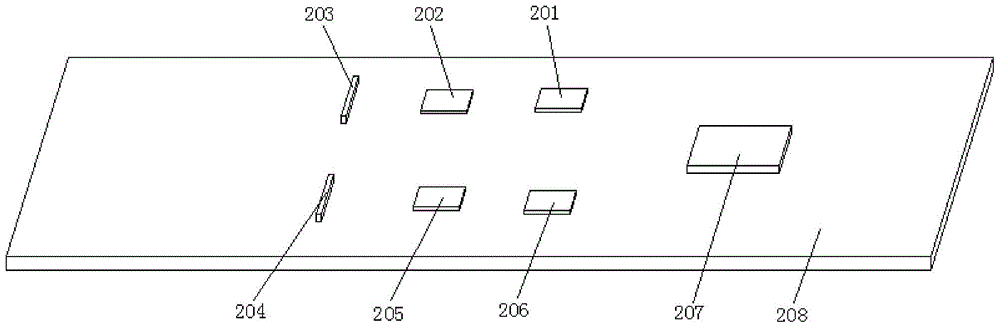

Ceramic double-side three-dimensional integrated structure and packaging method of ultra-wideband radio frequency micro-system

ActiveCN108428672ARealize ceramic double-sided three-dimensional integrated packagingReduce volume occupancySemiconductor/solid-state device detailsSolid-state devicesUltra-widebandOccupancy rate

The invention provides a ceramic double-sided three-dimensional integrated structure of an ultra-wideband radio frequency micro-system and belongs to the technical field of ultra-wideband radio frequency packaging. The structure comprises a ceramic substrate, a metal micro frame, a front cover plate, a back cover plate and a BGA solder ball. Both sides of the ceramic substrate are provided with cavity grooves for mounting chips. The metal micro frame is welded on the front surface of the ceramic substrate. The front cover plate is welded on the metal micro frame. The back cover plate is weldedon the back cavity groove of the ceramic substrate. The back surface of the ceramic substrate except the back cover plate is provided with a BGA solder pad. The BGA solder ball is welded on the backsurface of the ceramic substrate through the BGA solder pad. The invention also provides a packaging method of the integrated structure. According to the invention, the internal integration density nearly is doubled. The volume occupancy rate of external interconnection interface and airtight package is greatly reduced. The structure has the advantages of simple structure and less procedure and isan effective method for realizing the three-dimensional stacking of the ultra-wideband radio frequency micro-system.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

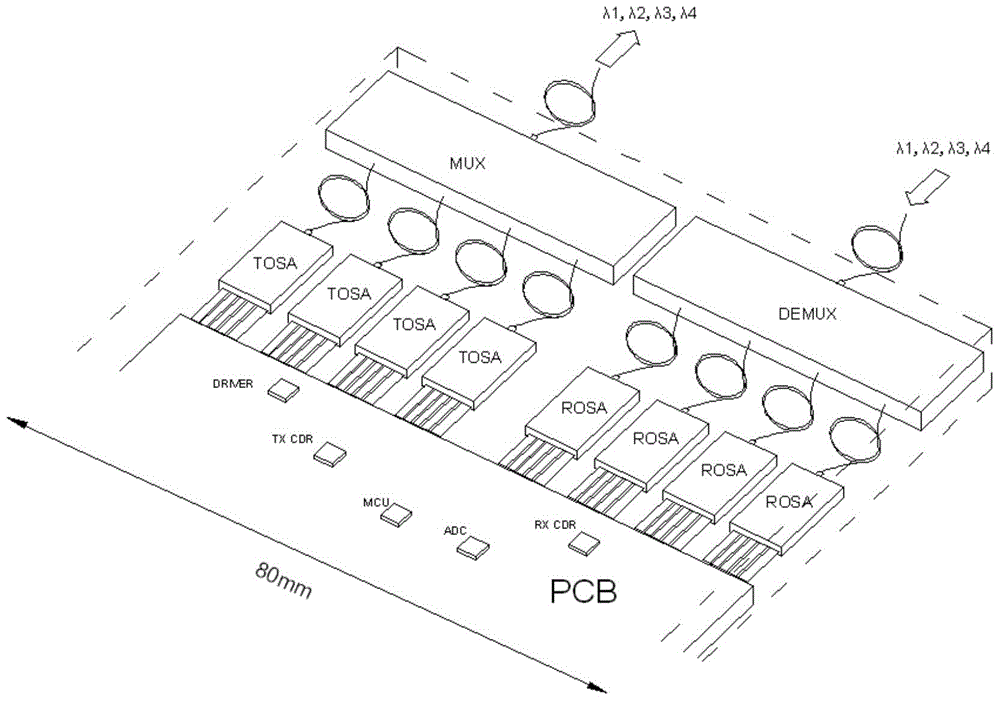

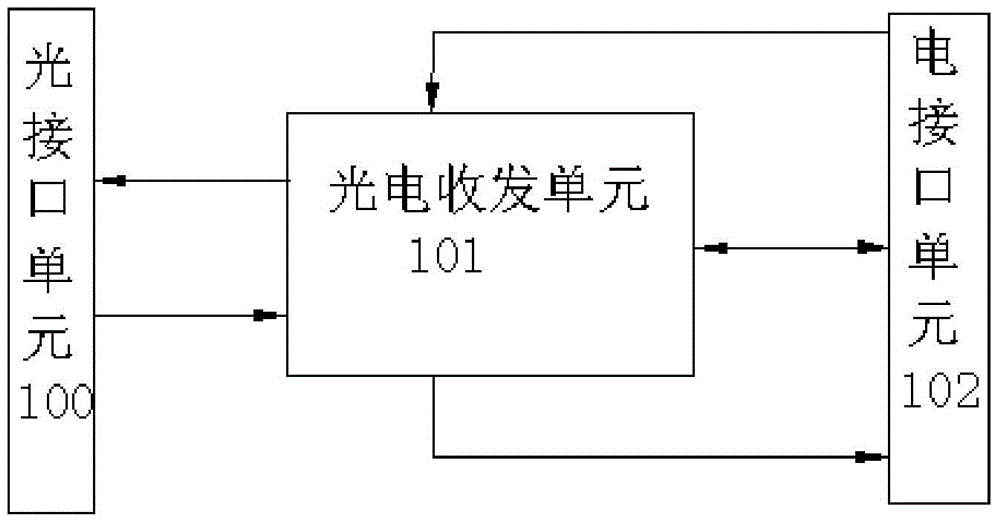

400 Gbps hot-plug high-speed optical transceiver module

ActiveCN104601244ARealize transmissionReduced assembly stepsElectromagnetic transceiversShortest distanceEngineering

The invention provides a 400 Gbps hot-plug high-speed optical transceiver module which is suitable for the optical communication technical field. The 400 Gbps hot-plug high-speed optical transceiver module comprises an optical interface unit, a photoelectric transceiver unit and an electrical interface unit; the photoelectric transceiver unit is used for achieving the functions of photoelectric conversion and high-speed electrical signal processing through a photoelectric transceiver chip; the internal working process of the photoelectric transceiver chip comprises receiving an electrical signal input through the electrical interface unit by a transmitting terminal data clock recovery circuit, loading the electrical signal to a laser after the pretreatment through a driving circuit, converting the high-speed electrical signal into a high-speed optical signal through the laser, reusing the high-speed optical signal through a wavelength division multiplexer to be output, reusing the received optical signal into a 16-channel optical signal through a wavelength division demultiplexer to be transmitted to an optical detector and transmitting the 16-channel optical signal to a trans-impedance amplifier and a receiving terminal data clock recovery circuit after photoelectric conversion to be processed. According to the 400 Gbps hot-plug high-speed optical transceiver module, the factors such as the cost, the transmission loss, the chromatic dispersion and the size are considered to select different optical transceiver modules and accordingly the long-distance single-mode optical fiber transmission or the short-distance multimode transmission is implemented.

Owner:WUHAN TELECOMM DEVICES

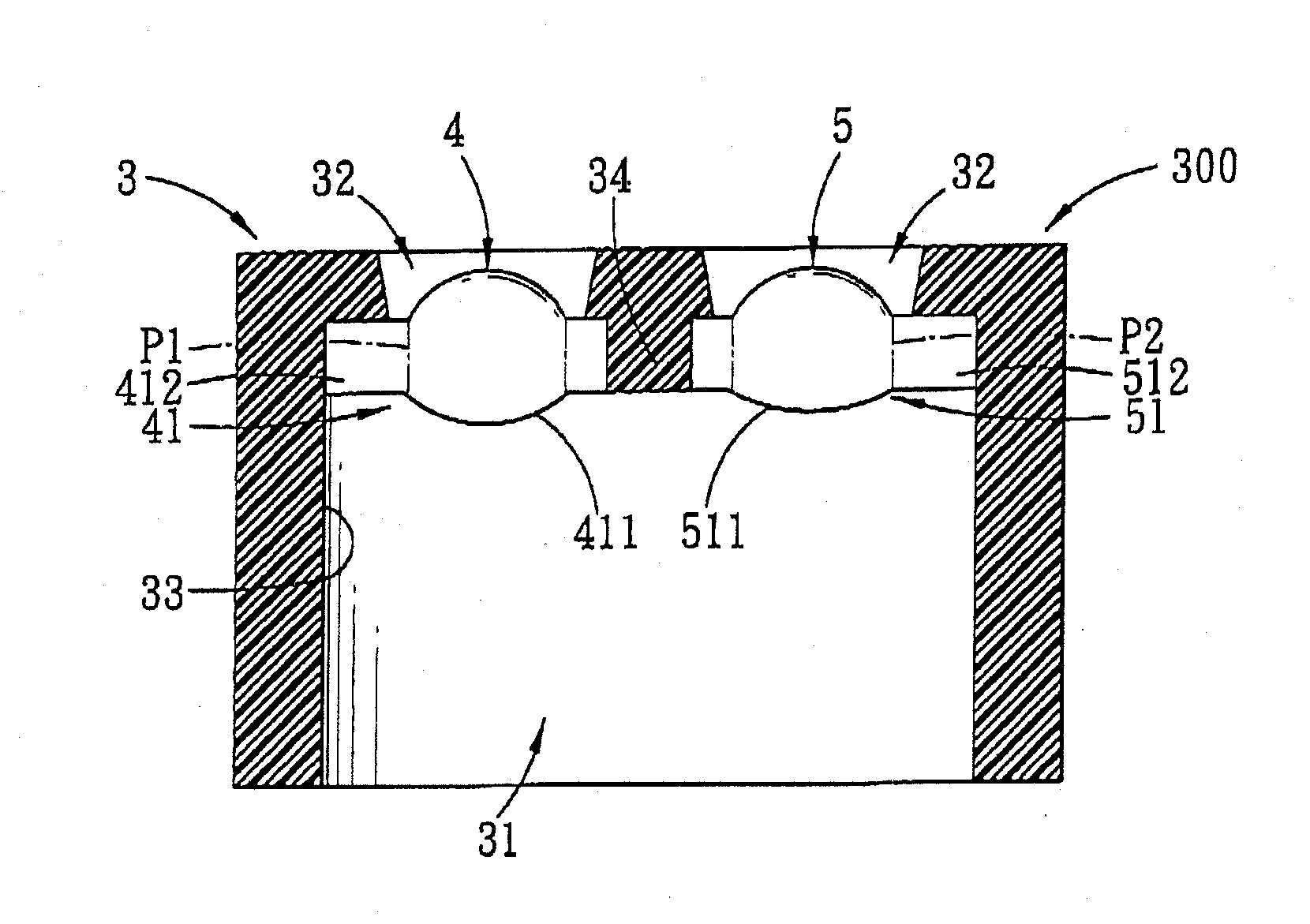

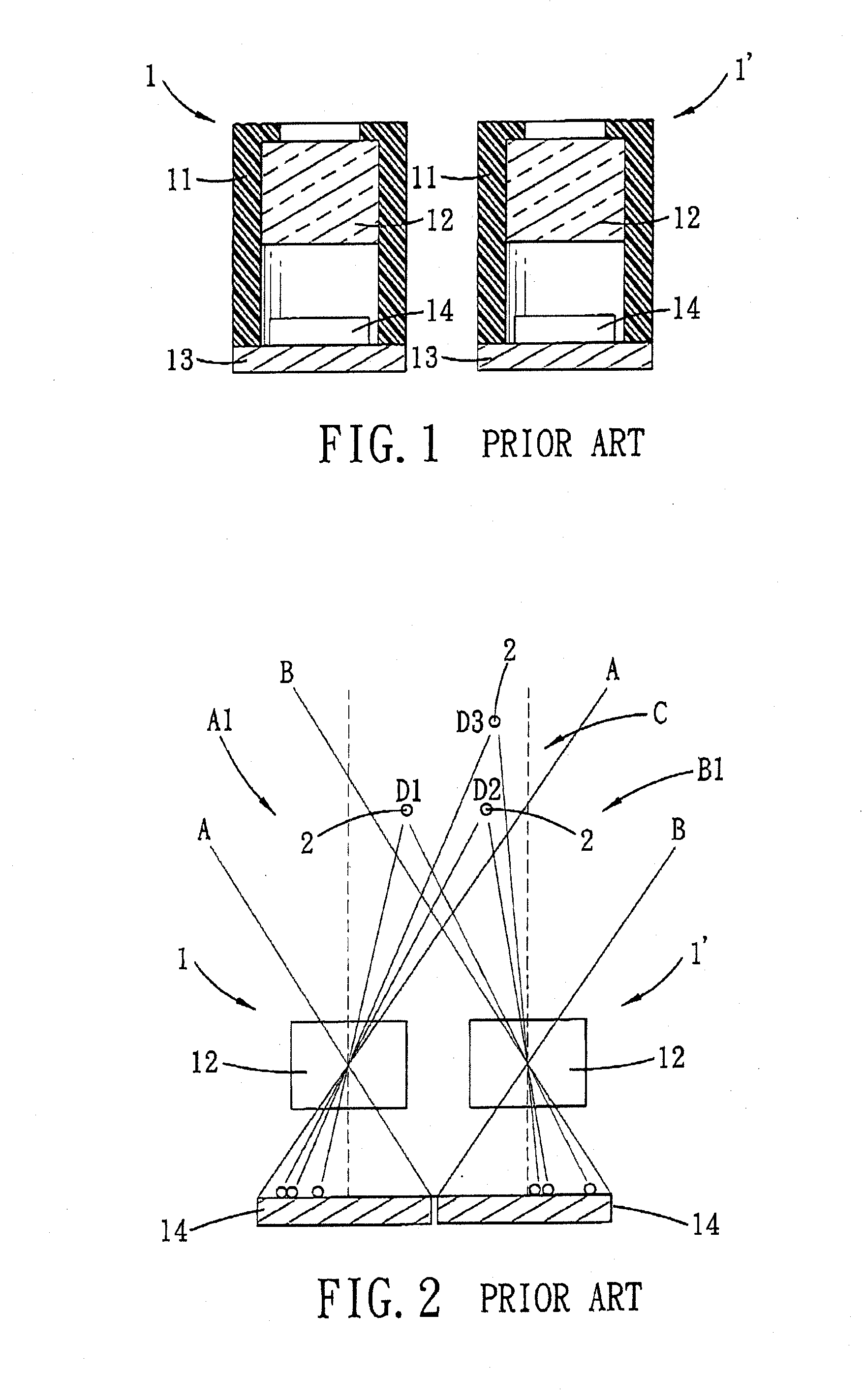

Lens module

InactiveUS20110141585A1Shorten the timeReduce manufacturing costPosition fixationMountingsCamera lensEngineering

A lens module includes a base, and first and second lens units. The base defines a receiving space, and has two spaced-apart through holes for fluid communication of the receiving space with an area external to the base. The first lens unit is disposed within the receiving space, and defines a first light communicating path that corresponds in position to one of the through holes. The second lens unit is disposed within the receiving space in a side-by-side manner with the first lens unit, and defines a second light communicating path that corresponds in position to the other one of the through holes.

Owner:LUXVISIONS INNOVATION LTD

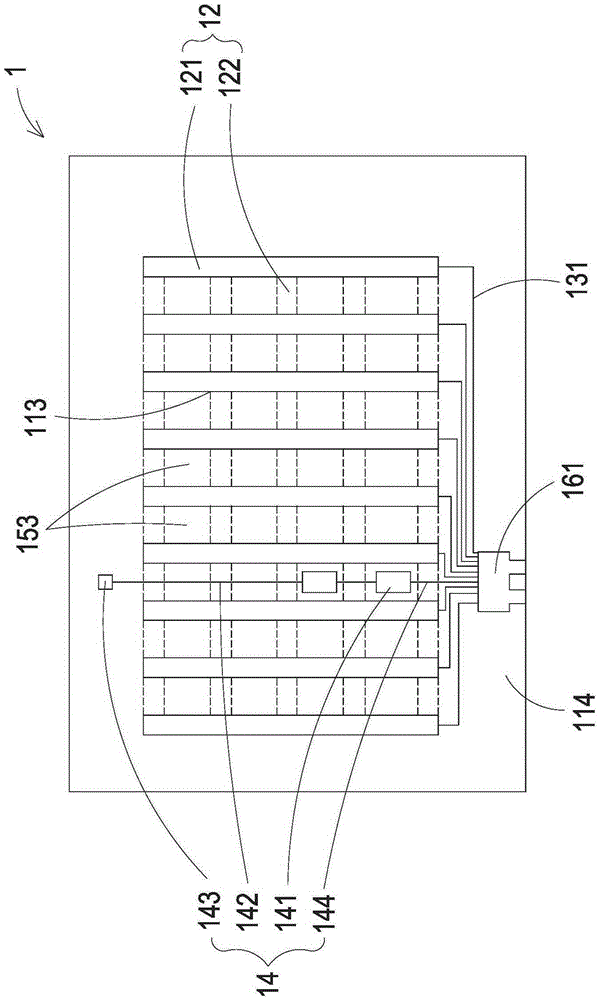

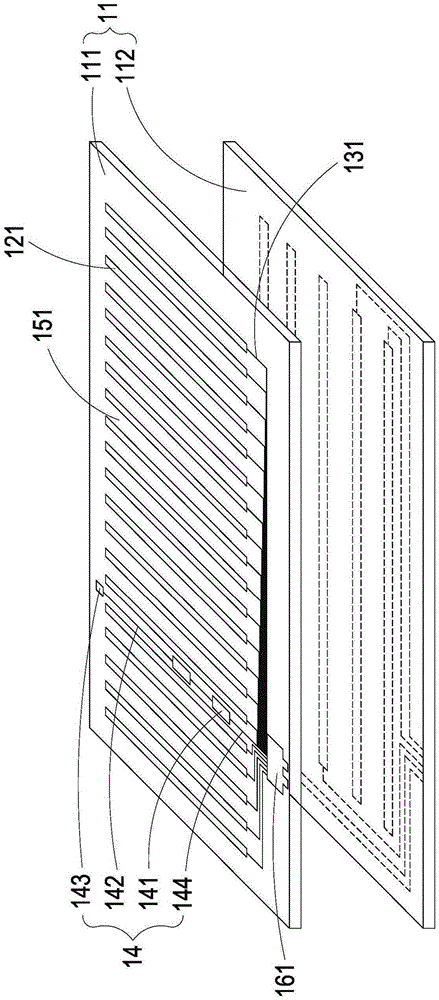

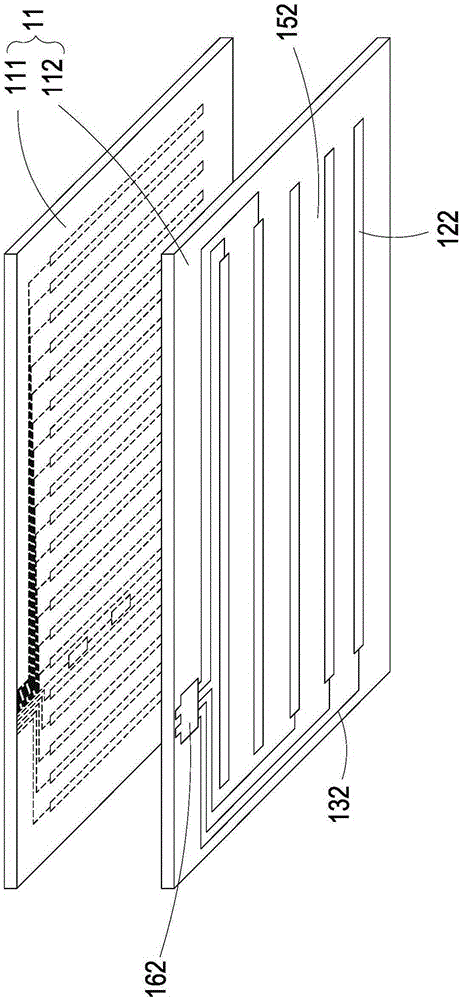

Touch module with transparent antenna and touch display apparatus using same

PendingCN106708309AHigh sensitivityDoes not affect build sizeElongated active element feedAntenna detailsVertical projectionCover glass

A touch display apparatus with a transparent antenna and a touch display apparatus using same are disclosed. The touch display apparatus including a cover glass, a display module, and a touch module. The touch module is disposed between the cover glass and the display module. The touch module includes a transparent substrate, a metal mesh touch sensor, and an antenna. The metal mesh touch sensor is disposed on at least one surface of the transparent substrate and configured to form a viewable area, wherein the viewable area comprises at least an overlapping dummy area free of a vertical projection of the metal mesh touch sensor. The antenna is disposed on the at least one surface of the transparent substrate, and at least portion of the antenna being located in the overlapping dummy area, wherein the antenna and the metal mesh touch sensor are insulated from each other.

Owner:J TOUCH CORPORATION

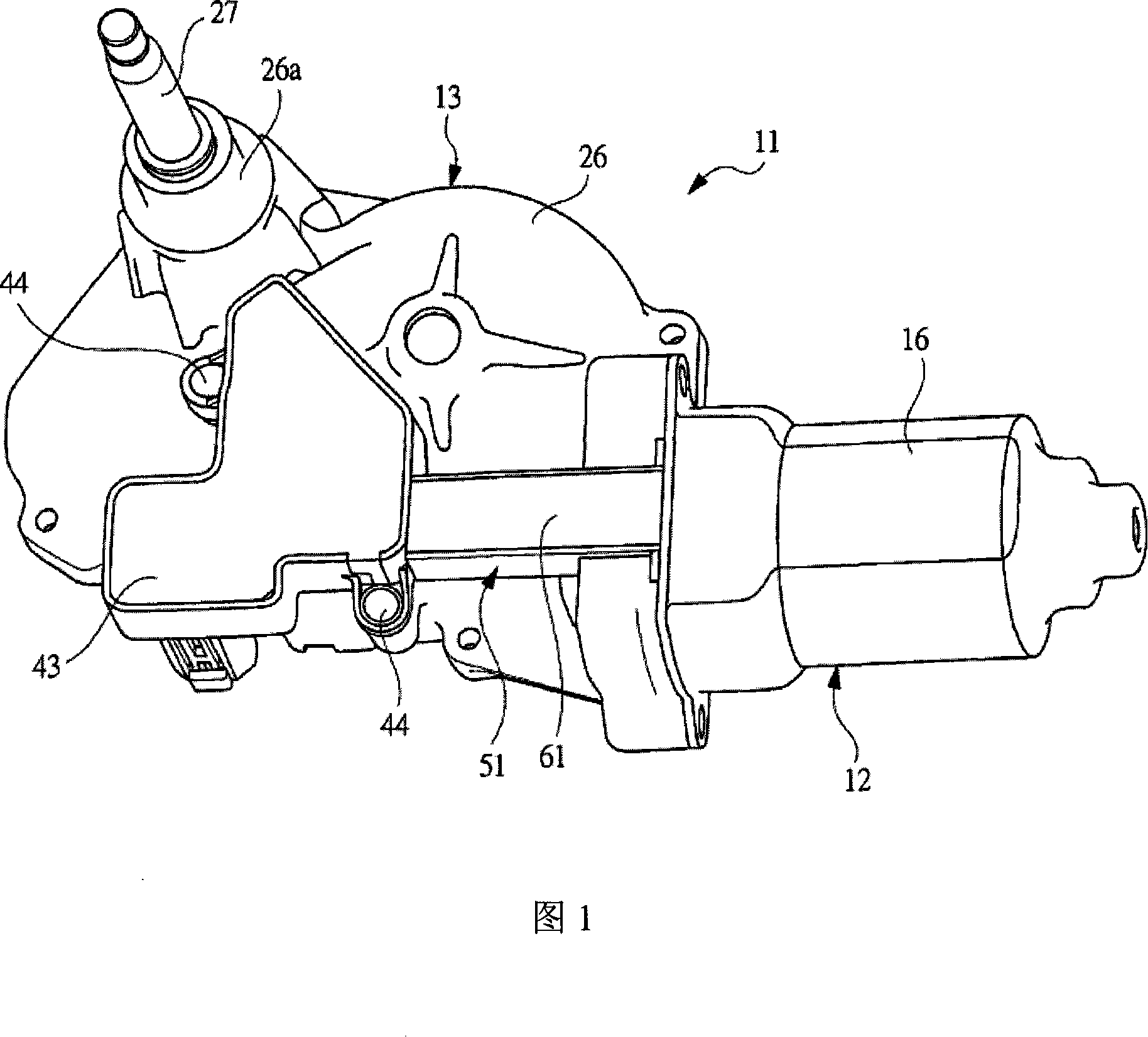

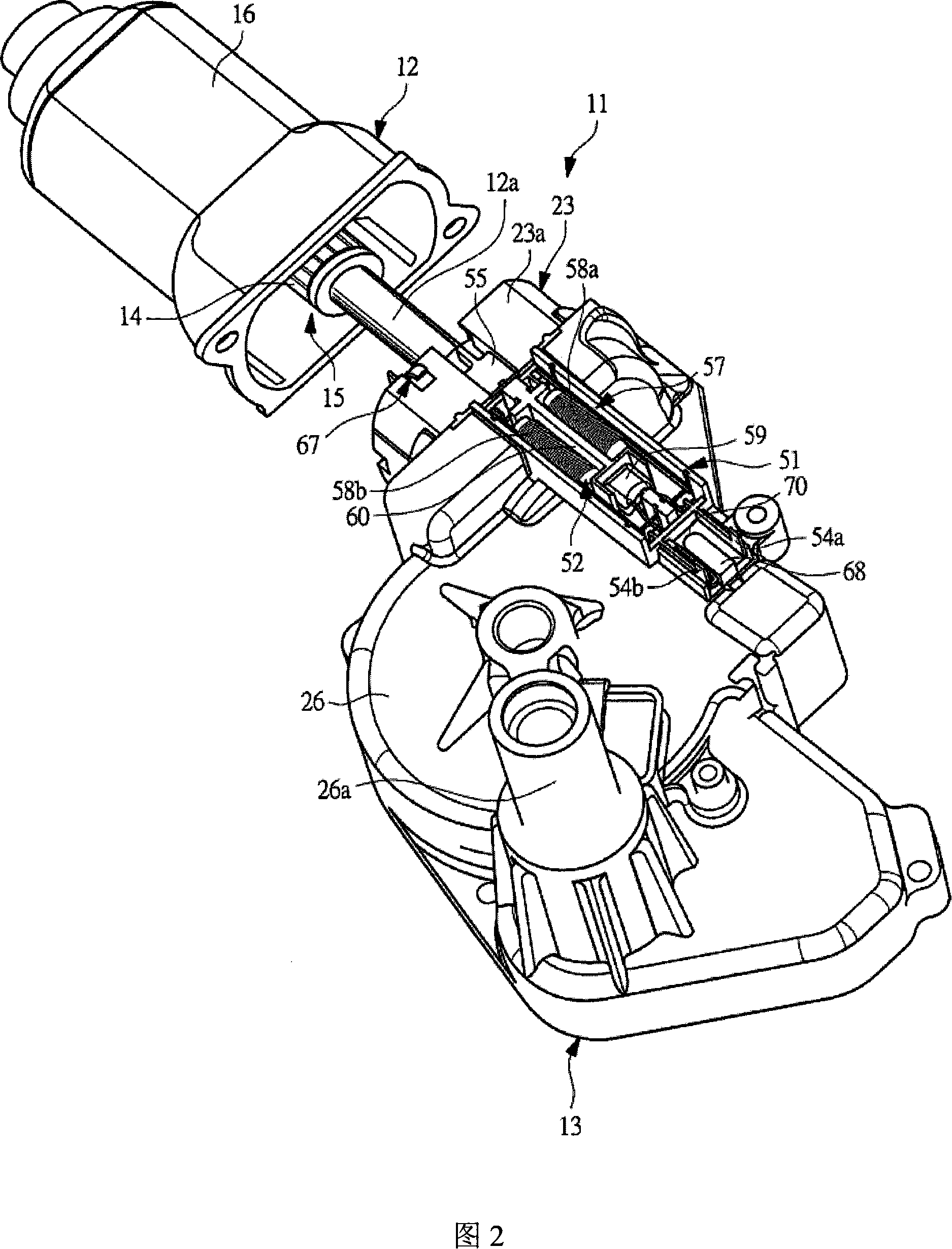

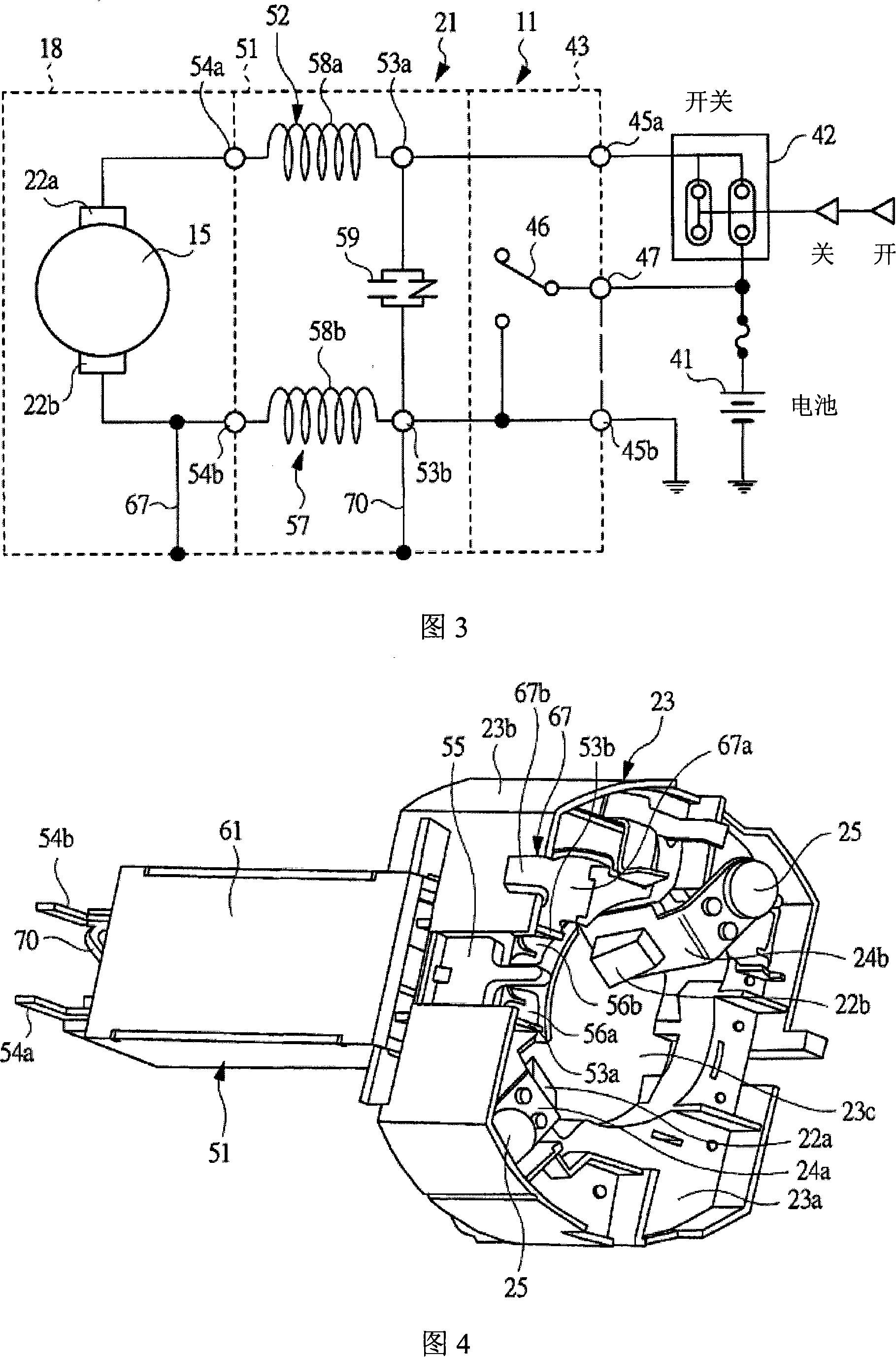

Electric motor with reduction gear mechanism

ActiveCN101114781AReduce noiseSufficient deflection lengthDC commutatorSupports/enclosures/casingsGear wheelEngineering

In an electric wiper motor with a motor body and a deceleration mechanism. A holding case is arranged on a brush holder, and the brush holder is on the motor body and the holding case is on the outer surface of a gear case, therefore a motor yoke is stuck out. A noise prevention means with a pair of chokes and a bi-directional rheostat held in the holding case and connected between a power supply terminal of a connector and brush, wherein the connector is arranged on said gear case. The noise generated by the supply circuit is absorbed by the noise prevention means and the noise leaking outside via an opening of said motor yoke is also absorbed by the noise prevention means.

Owner:MITSUBA CORP

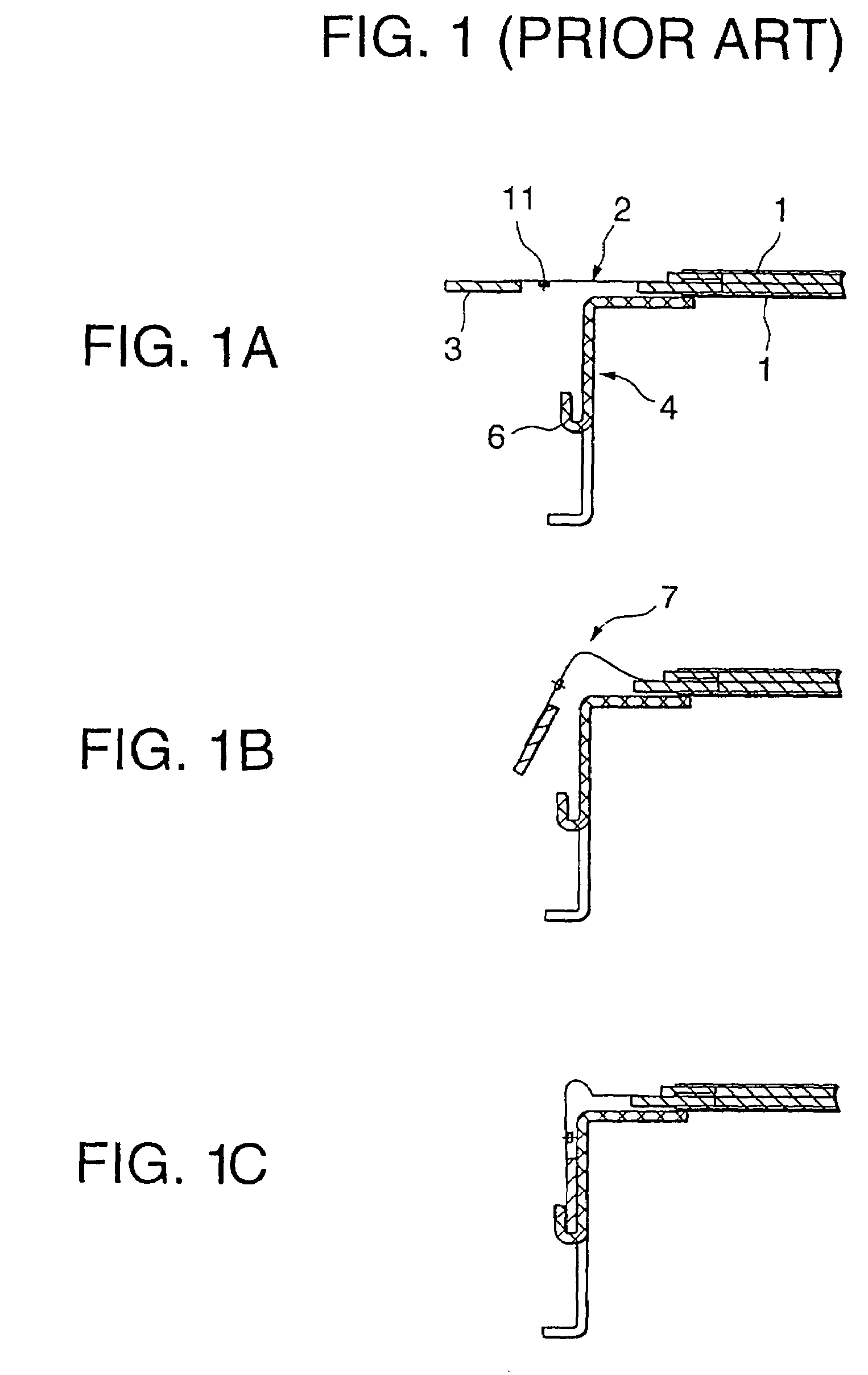

Nose pad assembly for eyeglasses

InactiveUS20050270475A1Easy to adjustReduce complexitySpectales/gogglesNon-optical adjunctsNoseBall and socket joint

A novel nose pad assembly for eyeglasses is provided wherein the support and nose pad are formed as a fully articulating ball and socket joint. The ball and socket joint provides excellent adjustability of the nose pads in a simple mechanical construction. In a unique method of forming the nose pad assembly the support structure (ball) is formed in a first molding step and an adjustable pad member is molded directly over the ball of the support structure in a second molding step. The present invention utilized in-mold-assembly techniques to reduce the assembly steps required to form such a nose pad assembly while further resulting in a nose pad that has increased adjustability and utility. Alternately, the pad portion may be formed first and the support structure formed second. Also, the materials selected may include either hard or soft plastics to form either component.

Owner:SPERIAN EYE & FACE PROTECTION

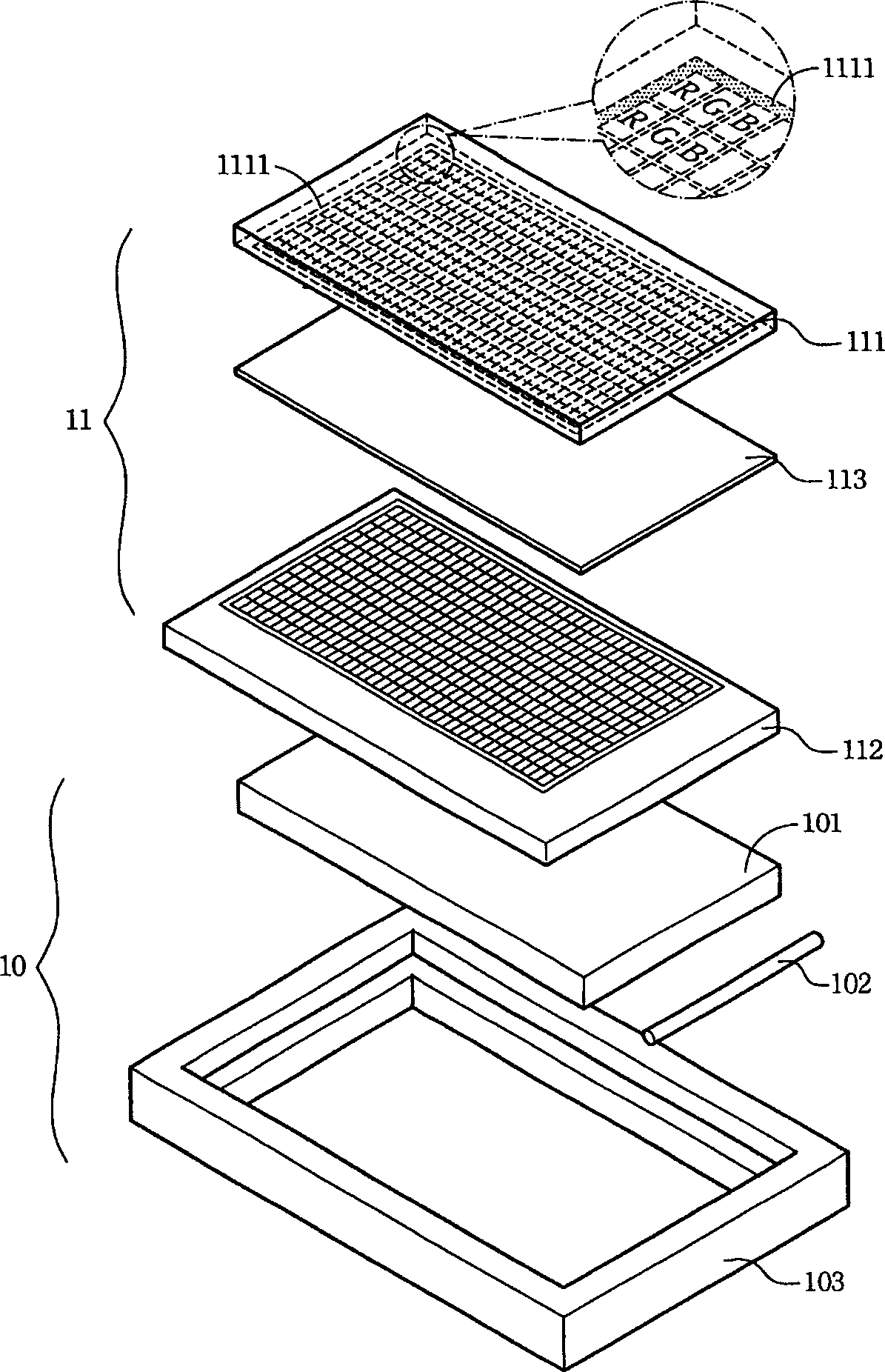

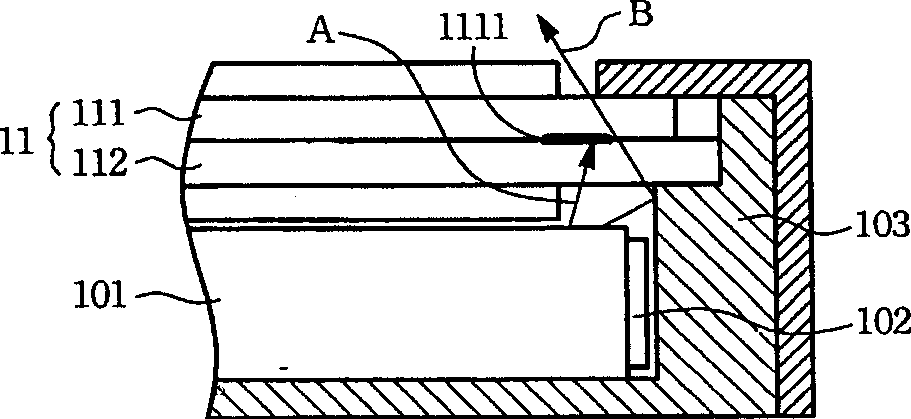

LCD with function of preventing light leak, and backlight module

ActiveCN1873495APrevent light from escapingReduce labor costsStatic indicating devicesNon-linear opticsLiquid-crystal displayLight guide

The invention relates to a liquid crystal display with light leak proof function and the backlight module. The display includes a light guiding board, a light resource and a frame. The light resource is set at the side of the light guiding board, and the frame is set outside the light guiding board. The inner margin of the frame is set to avoid light leak that could avoid light leaking to outside from the brim of the display.

Owner:AU OPTRONICS CORP

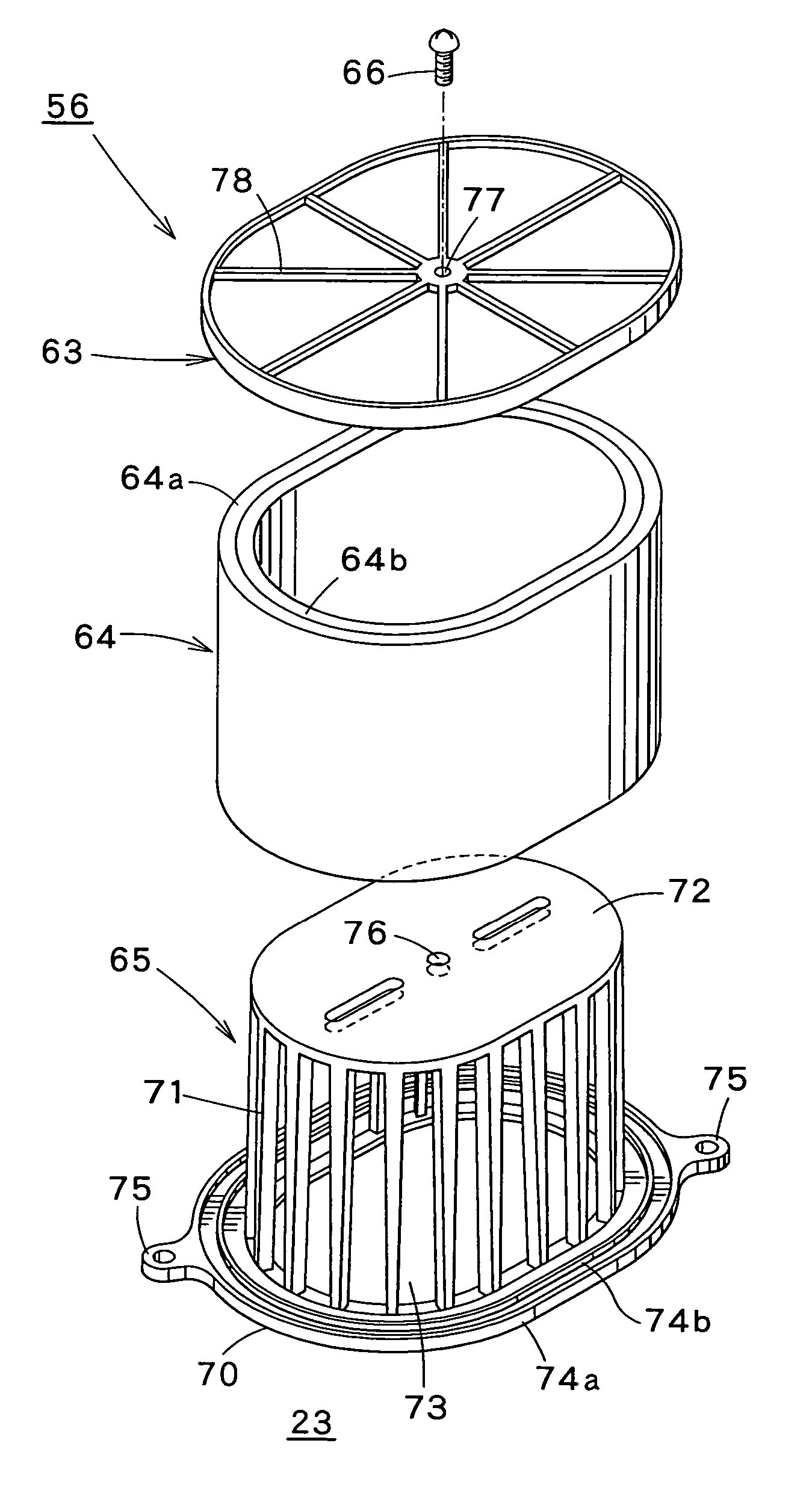

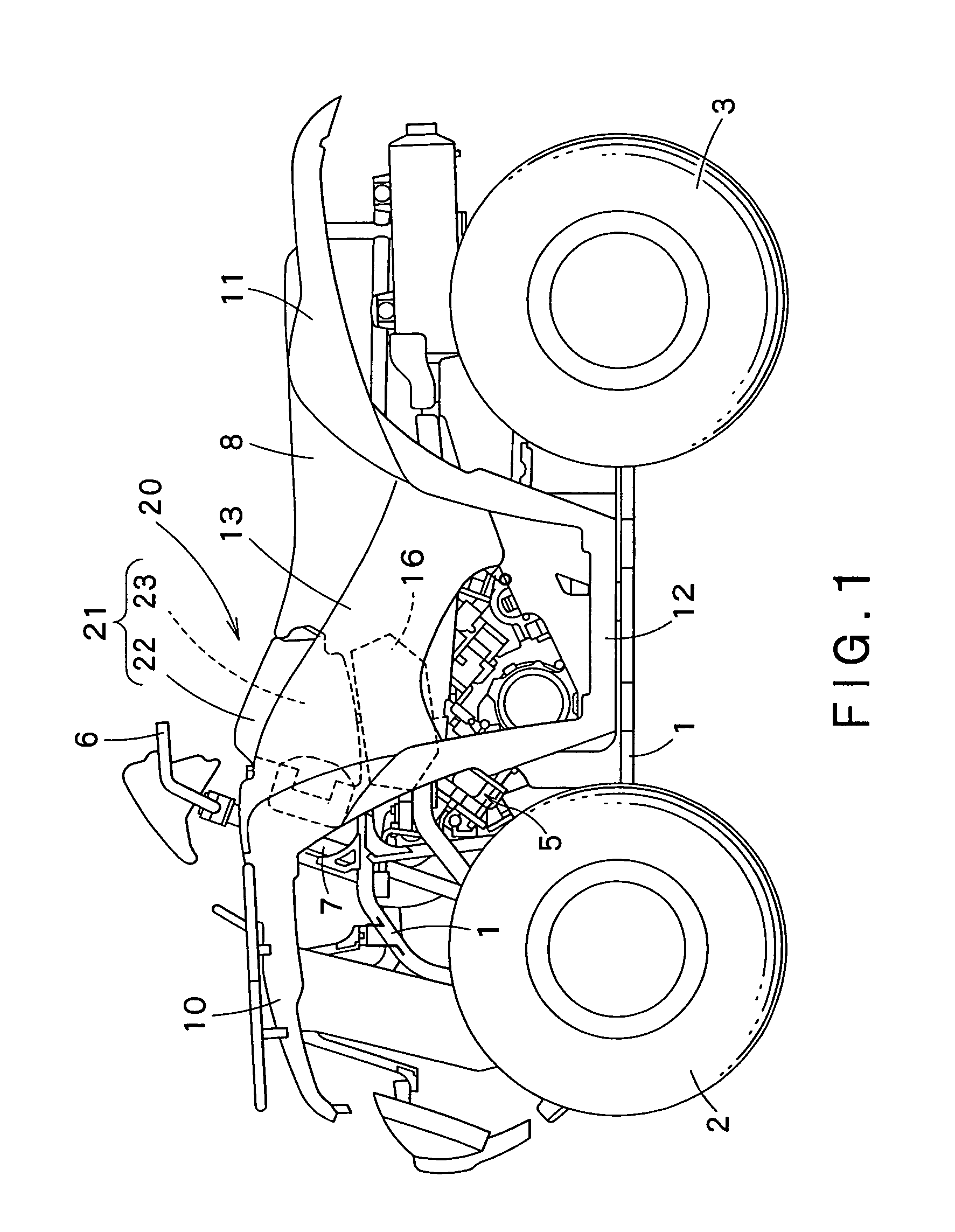

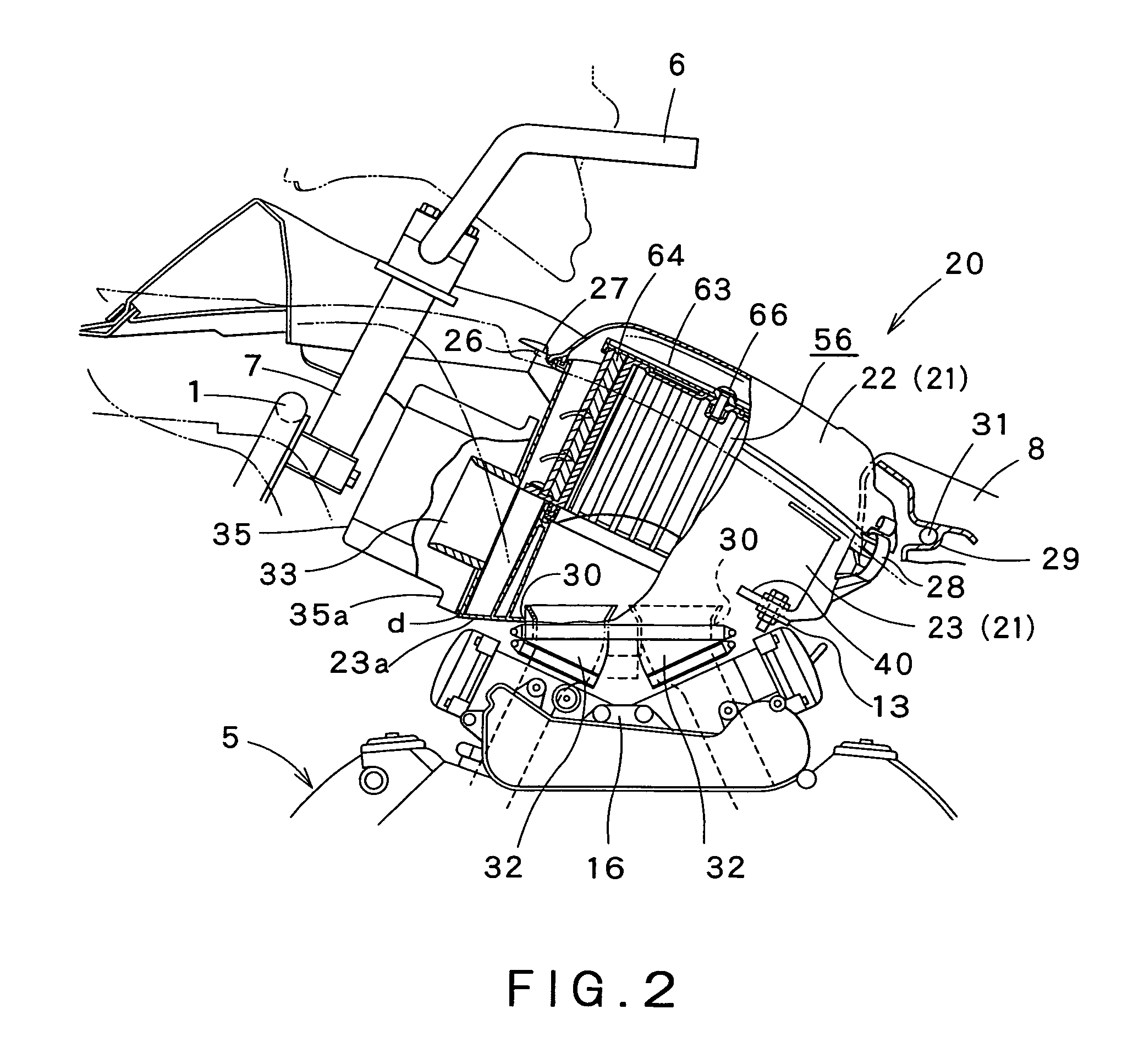

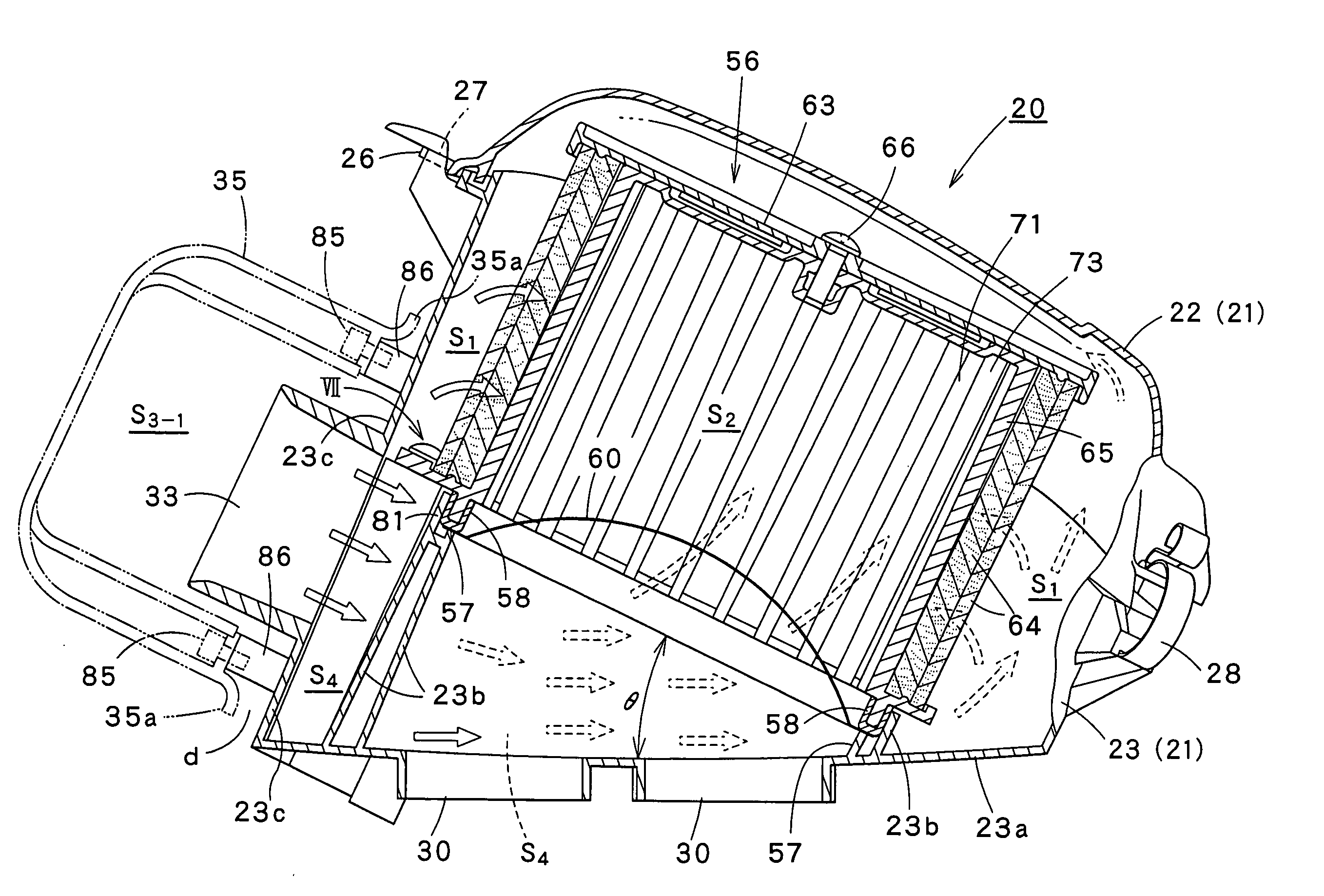

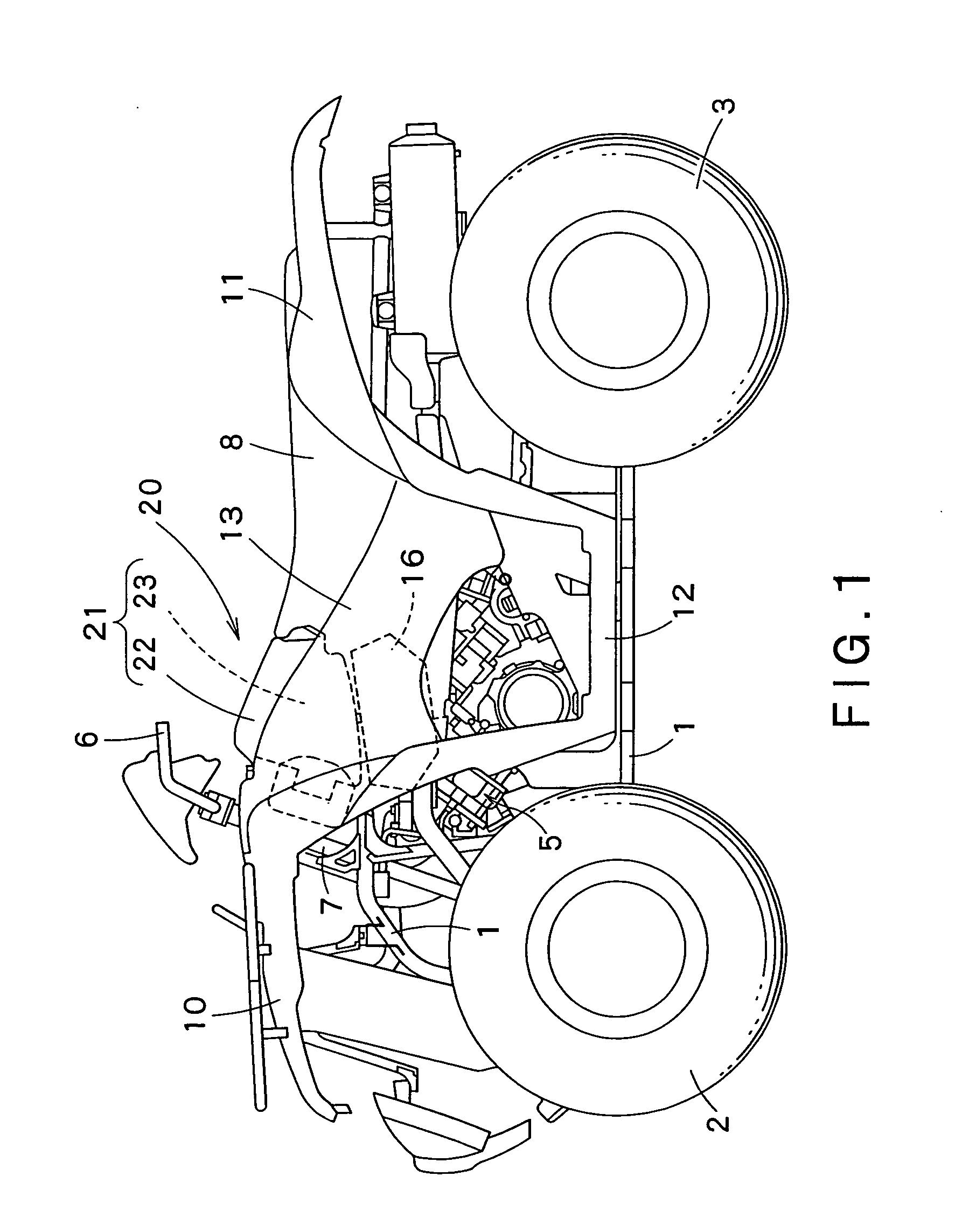

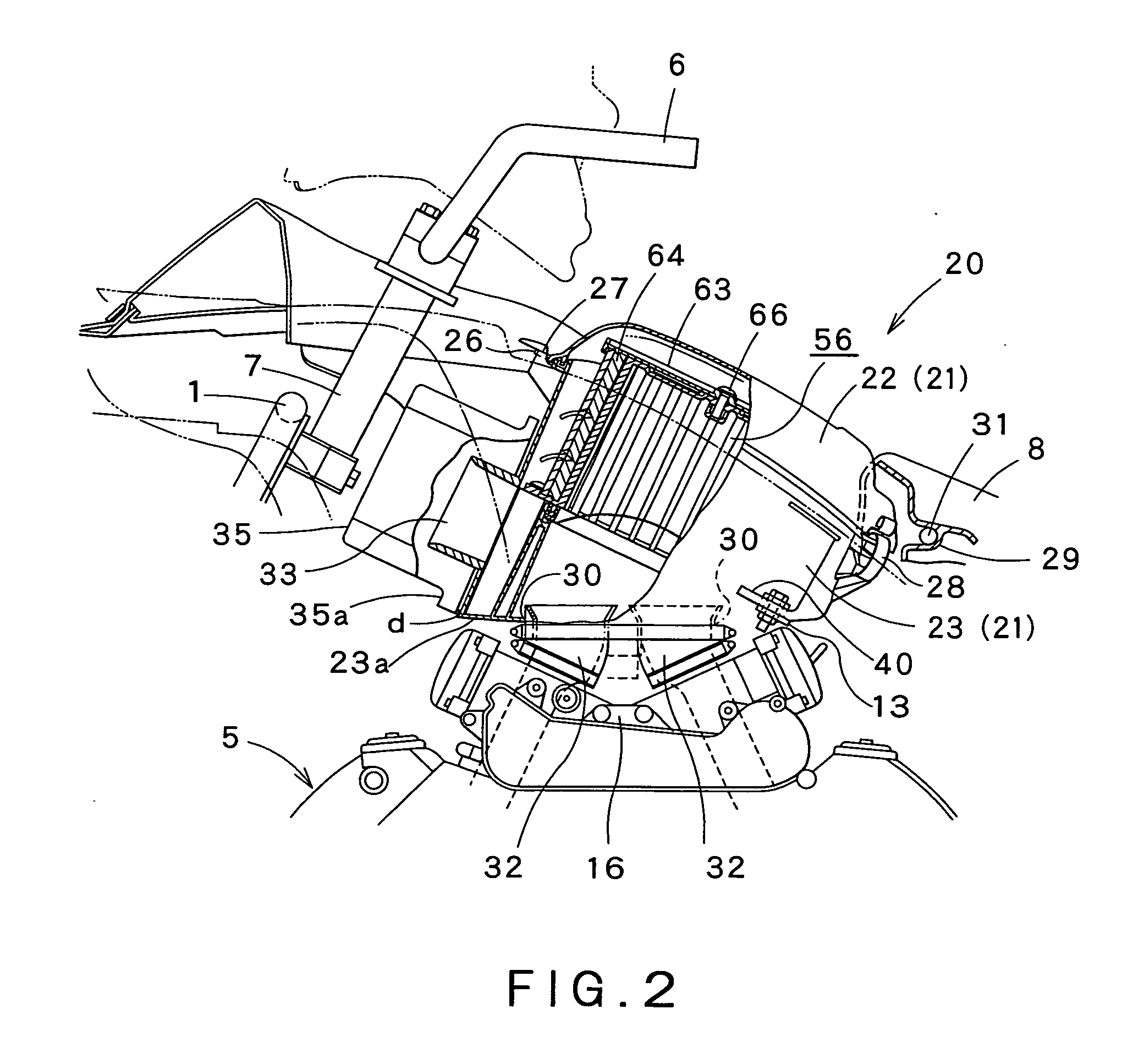

Air cleaner for engine of vehicle

ActiveUS7384440B2Simple structureSimplified weightCombination devicesNon-fuel substance addition to fuelEngineeringTop cap

The present air cleaner for an engine of a vehicle, includes: a cleaner case; and a filter assembly disposed in the cleaner case. The filter assembly includes a cylindrical cleaner element, an element supporting member supporting a lower end of the cleaner element and an inner circumferential surface of the cleaner element so that the cleaner element is kept in a predetermined cylindrical shape, and a plate-shaped top cover detachably fastened on an upper surface of the element supporting member so as to press an upper end of the cleaner element downward.

Owner:KAWASAKI MOTORS LTD

Air cleaner for engine of vehicle

ActiveUS20050241610A1Easy to manufactureReduce weightCombination devicesNon-fuel substance addition to fuelEngineeringTop cap

The present air cleaner for an engine of a vehicle, includes: a cleaner case; and a filter assembly disposed in the cleaner case. The filter assembly includes a cylindrical cleaner element, an element supporting member supporting a lower end of the cleaner element and an inner circumferential surface of the cleaner element so that the cleaner element is kept in a predetermined cylindrical shape, and a plate-shaped top cover detachably fastened on an upper surface of the element supporting member so as to press an upper end of the cleaner element downward.

Owner:KAWASAKI MOTORS LTD

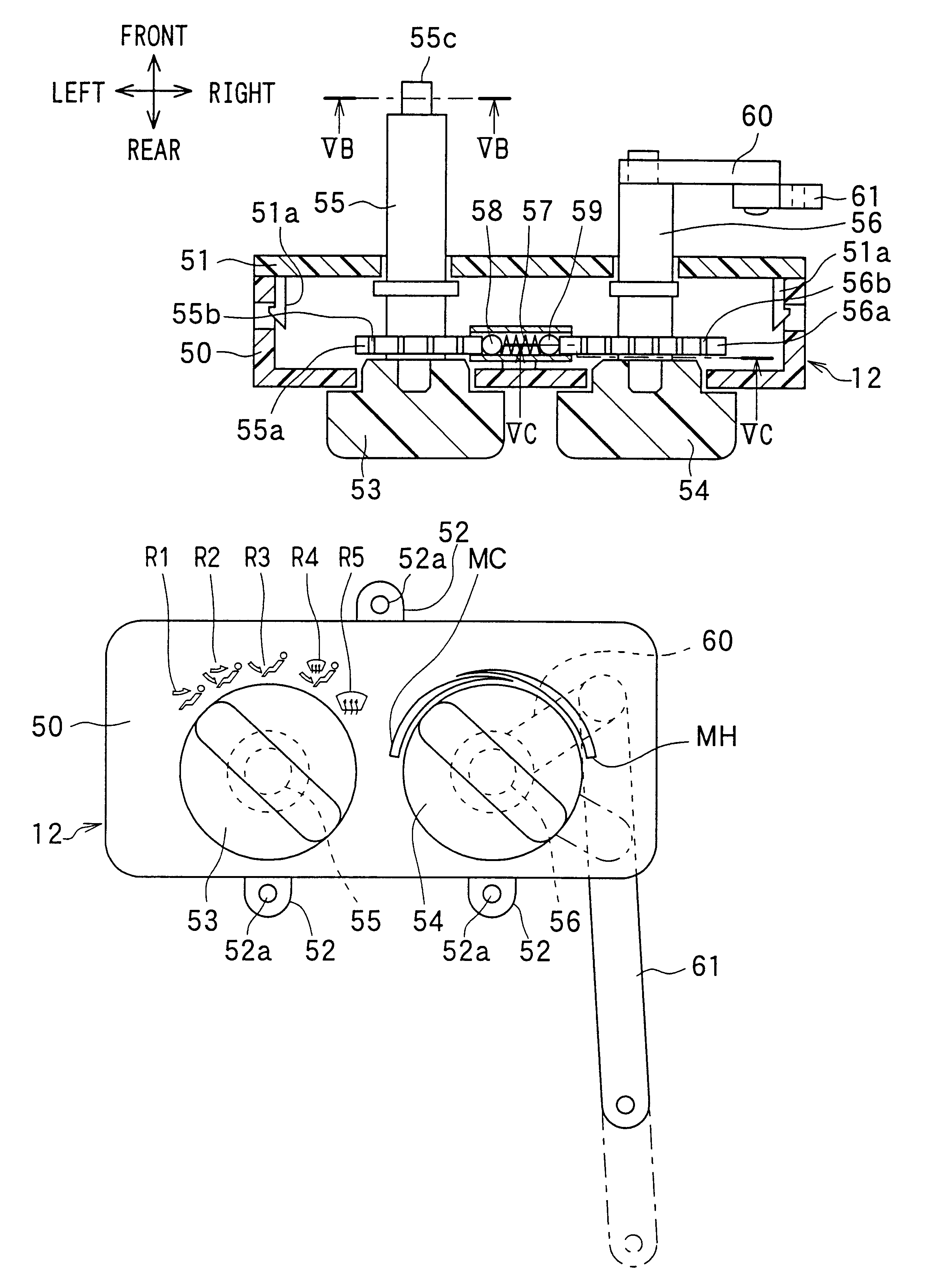

Vehicle air conditioner with manually operated operation member

InactiveUS6398638B1Low production costAvoid misuseAir-treating devicesHot-air central heatingRotational axisAir conditioning

In a vehicle air conditioner having manually operated operation members of an air-conditioning operation panel, rotation shafts of an air mixing door and a mode switching rotary door are disposed in a vehicle front-rear direction, so that an axial direction of the rotation shafts of the doors is made the same as that of rotation shafts of the operation members of the air-conditioning operation panel. Accordingly, operation force of the operation members can be directly transmitted to the rotation shafts of the doors by a simple structure.

Owner:DENSO CORP

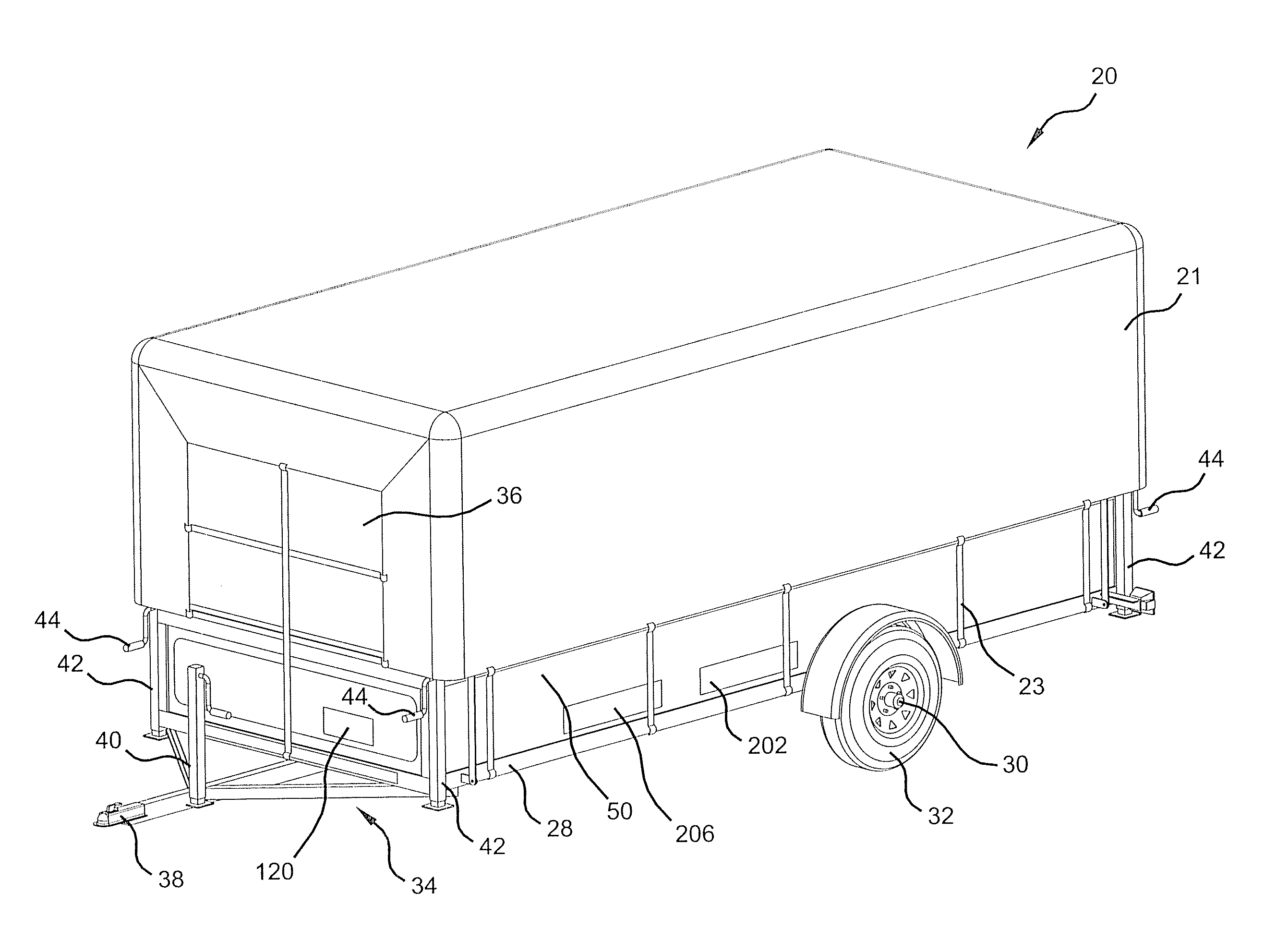

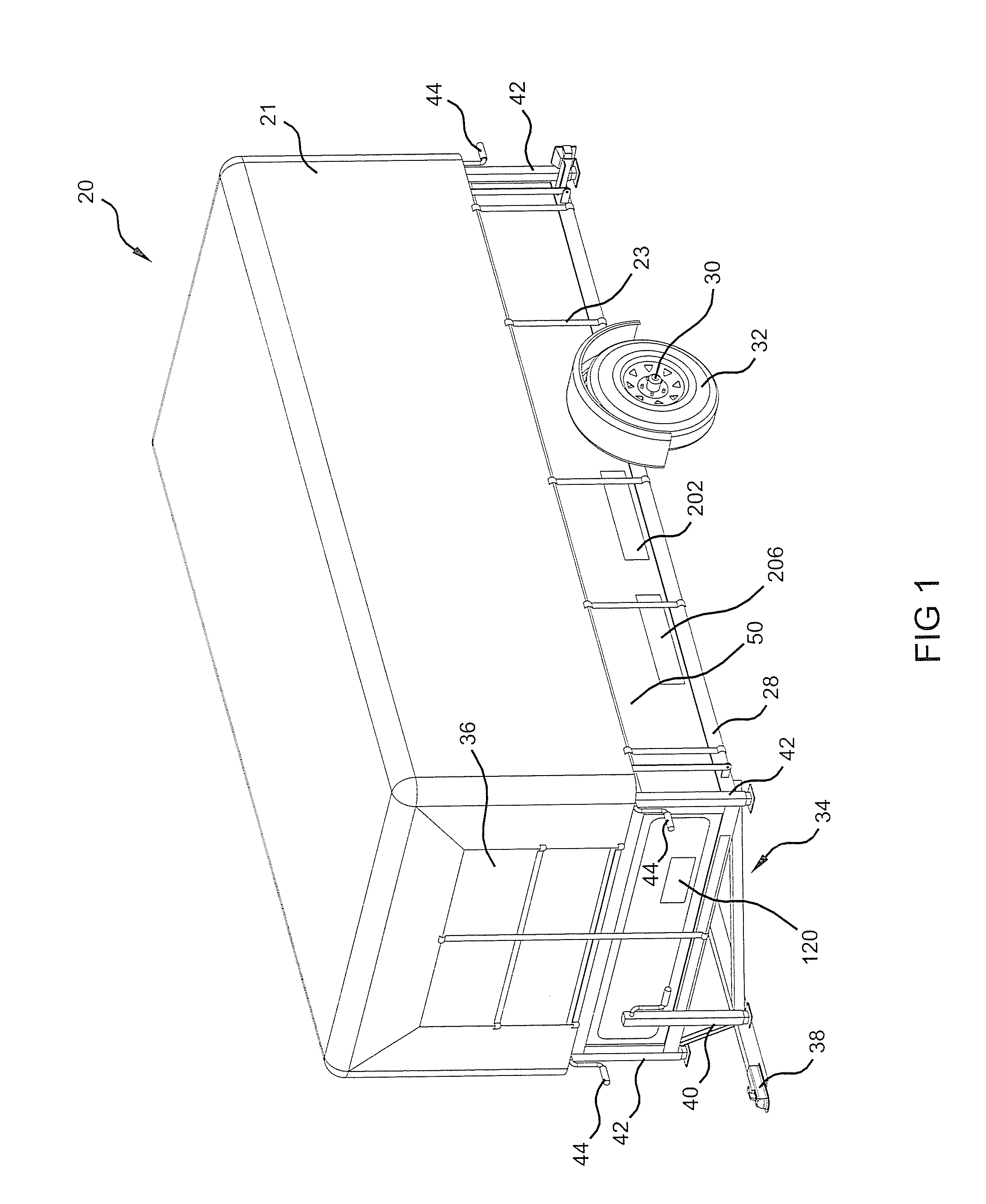

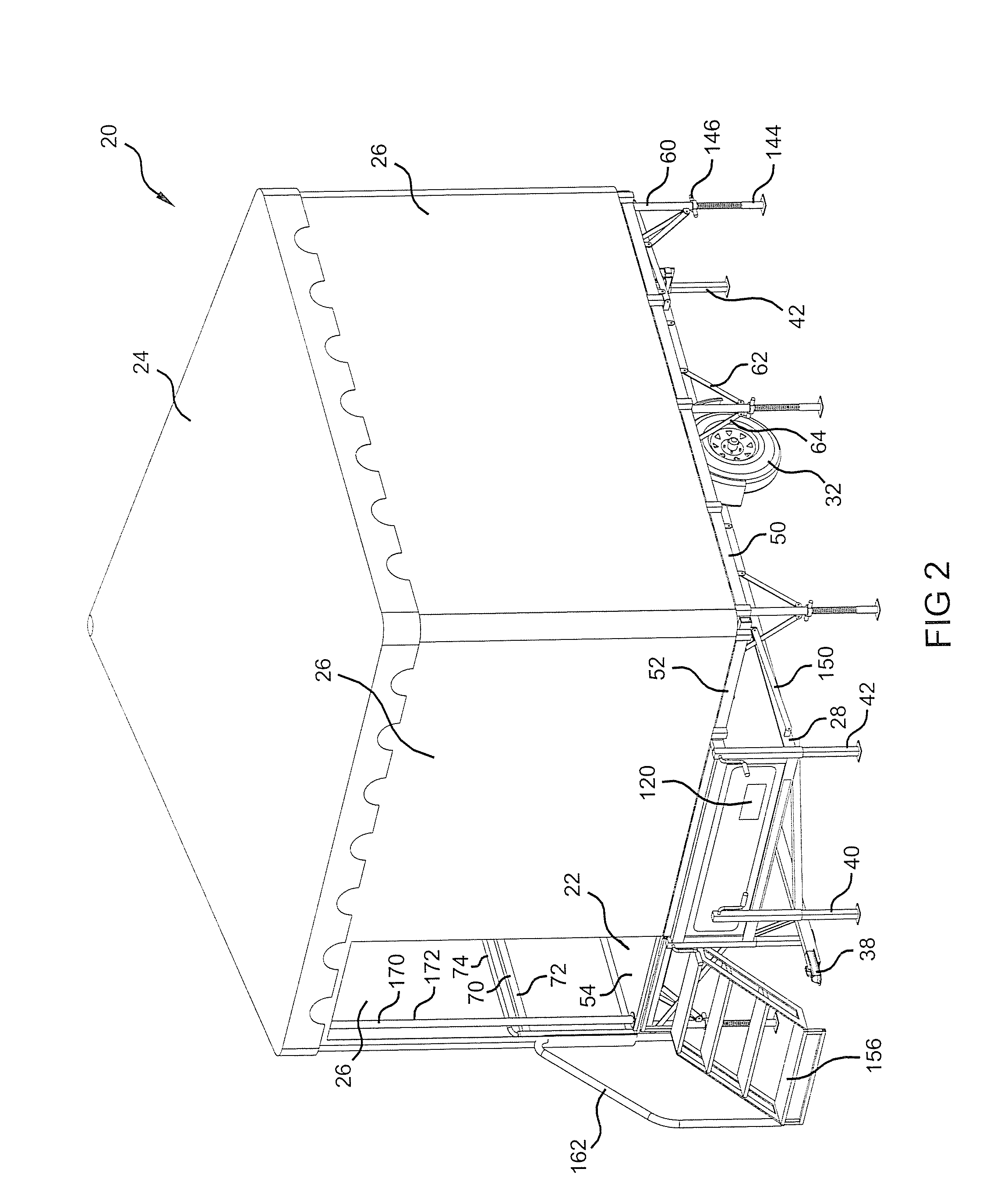

Mobile tent trailer

InactiveUS20080088146A1Easy accessReduce in quantityVehicle with living accommodationItem transportation vehiclesRoad surfaceEngineering

A mobile tent trailer includes a frame and wheels to allow the trailer to be pulled along a road surface. The frame can have a first floor surface. Side walls can be coupled to the frame and can be moved between a stored position facilitating movement of the trailer along the roadway and an open position wherein the side walls form a second floor surface. A handrail can be secured to the side walls and can move with the side walls between the stored and open positions. The first floor surface can align with the second floor surface to form an elevated platform upon which people may engage in activities when the side walls are in the open position.

Owner:NEWMAN DAVID RUBEN

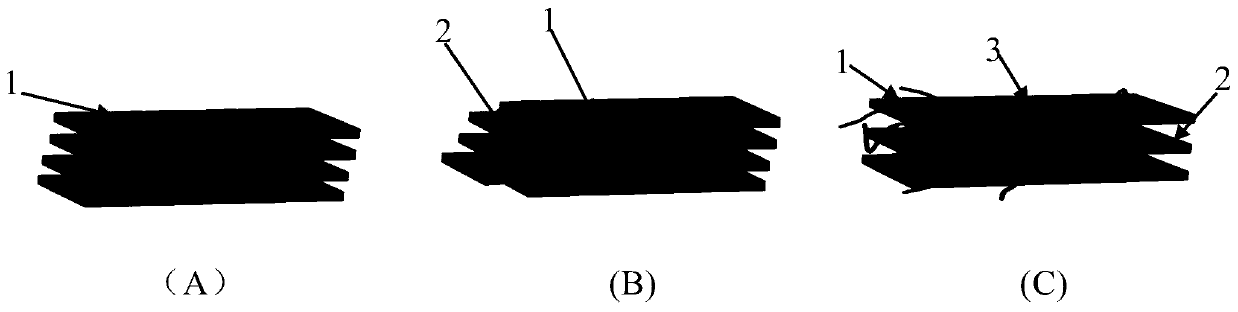

Negative material, negative plate, battery assembly and preparation methods

InactiveCN110299529AHigh mechanical strengthPrevent collapseCell electrodesFiltration membraneEngineering

The invention relates to a negative material, a negative plate, a battery assembly and preparation methods. The negative material of the invention includes layered MXene serving as the body of the negative material, and graphene inserted between the MXene layers in the form of intercalation. The negative plate disclosed by the invention includes the negative material. The battery assembly disclosed by the invention includes a diaphragm and the negative plate attached to the diaphragm. The preparation method of the negative material disclosed by the invention includes the steps as follows: S1,at 0-30 DEG C, adding graphene dispersion to MXene dispersion and carrying out ultrasonic treatment to obtain suspension; and S2, removing the solvent in the suspension to obtain a negative material.In step S2 of the preparation method of the negative plate disclosed by the invention, a negative plate is obtained by removing a membrane after suction filtration and drying. In step S2 of the preparation method of the battery assembly disclosed by the invention, the suction filtration membrane is a battery diaphragm, and the battery assembly is obtained after suction filtration and drying.

Owner:桑德新能源技术开发有限公司

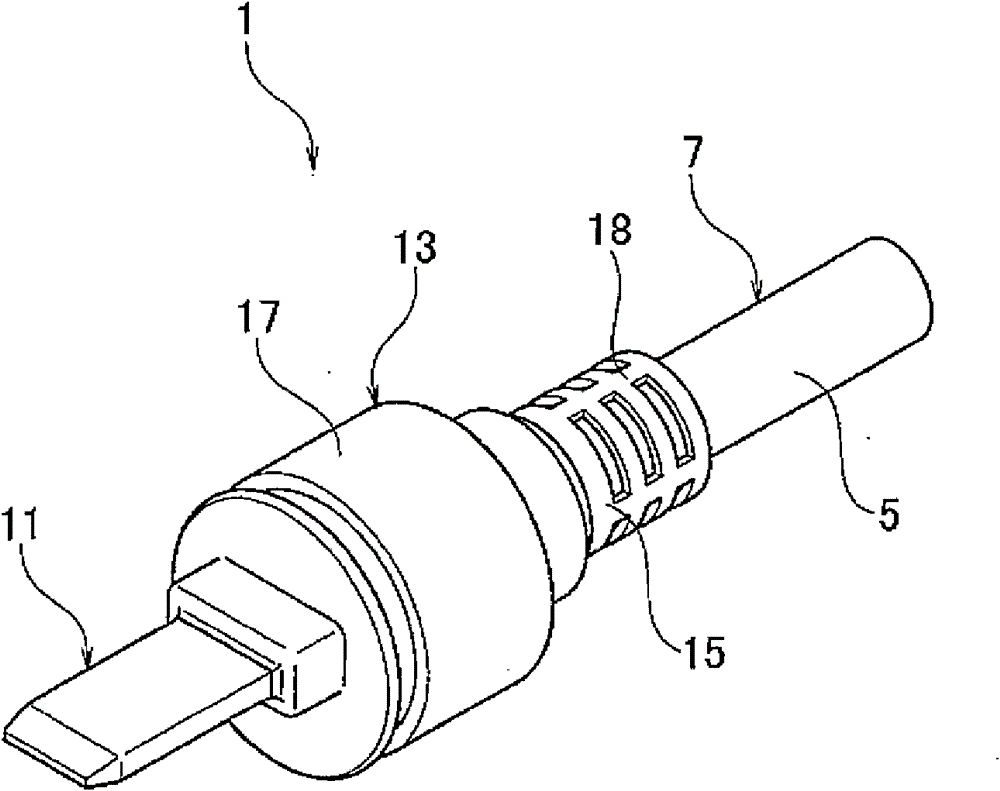

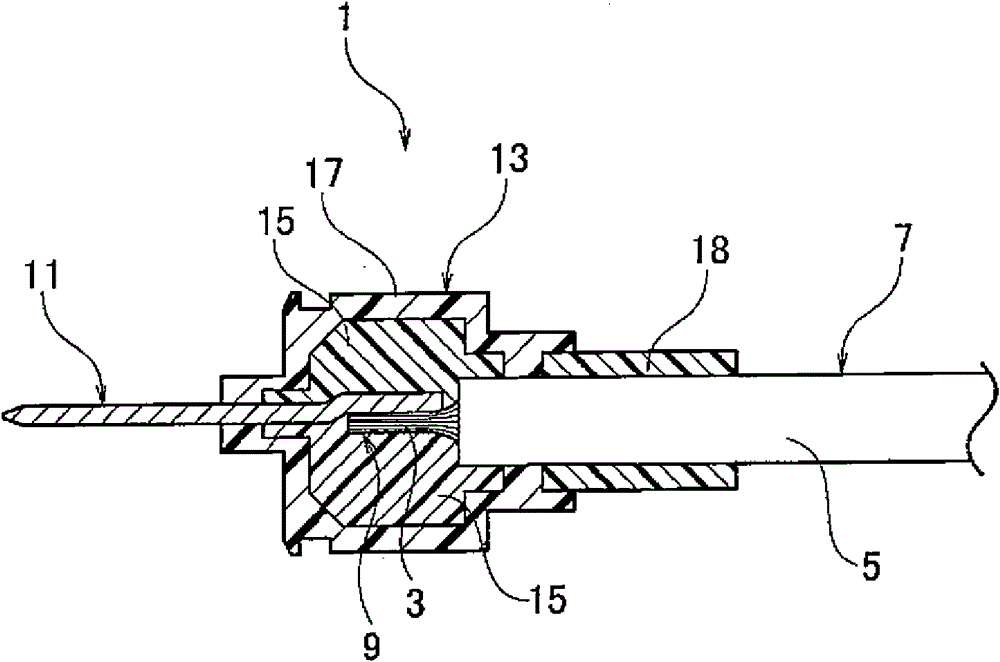

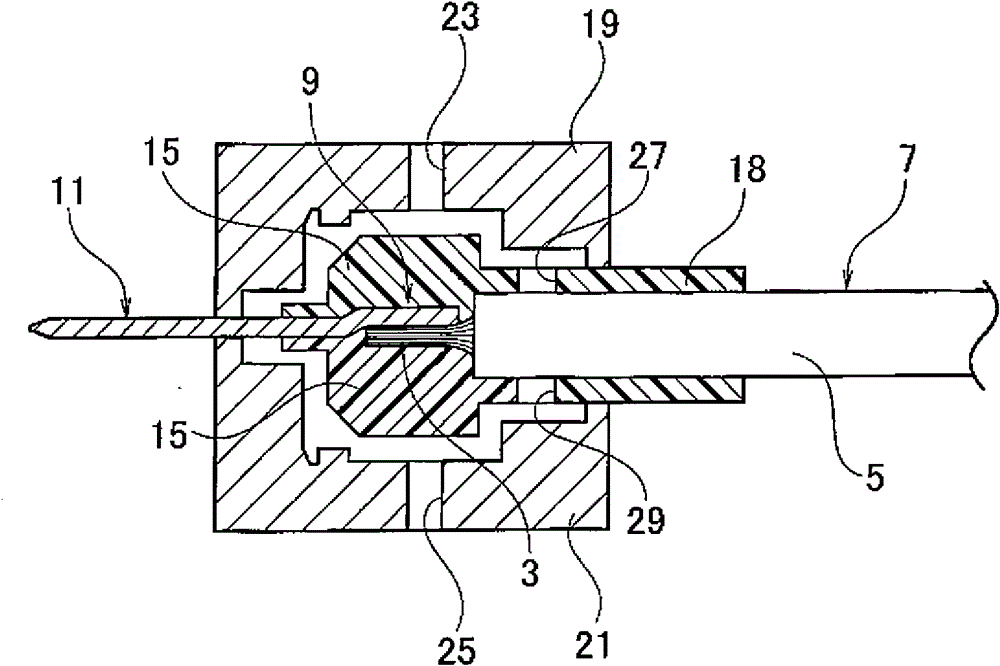

Method for integrally forming connector, and connector

ActiveCN102804513AImprove release characteristicsAchieve mass productionContact member assembly/disassemblyCouplings bases/casesProduction rateEngineering

Provided is a method for integrally forming a connector, by which the number of parts can be reduced and productivity can be improved. The method has: a first step wherein an elastic resin (15) is injection-molded around a connecting section (9) and a coating section (5) end portion positioned on the connecting section (9) side, and the coating section (5) and the elastic resin (15) are bonded to each other; and a second step wherein a resin (17) is injection-molded around the elastic resin (15) such that the elastic resin (15) shrinks, the elastic resin (15) and a terminal (11) are pressure-welded, and the elastic resin (15) and the resin (17) are bonded to each other.

Owner:YAZAKI CORP

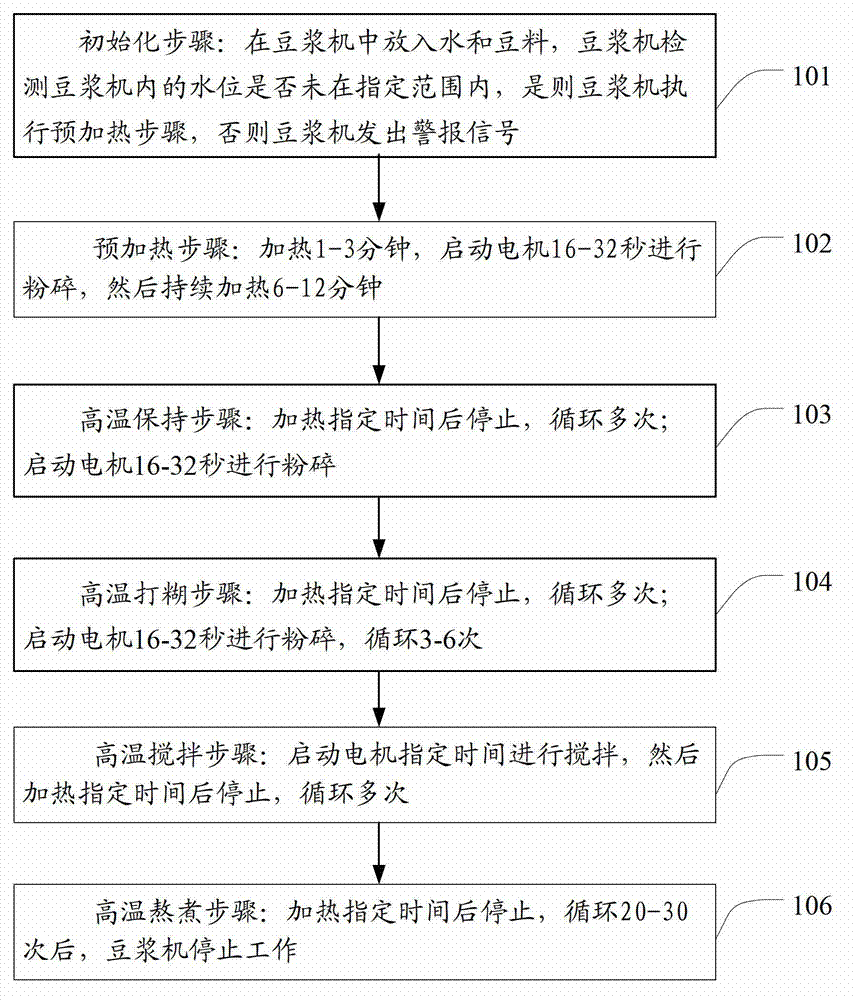

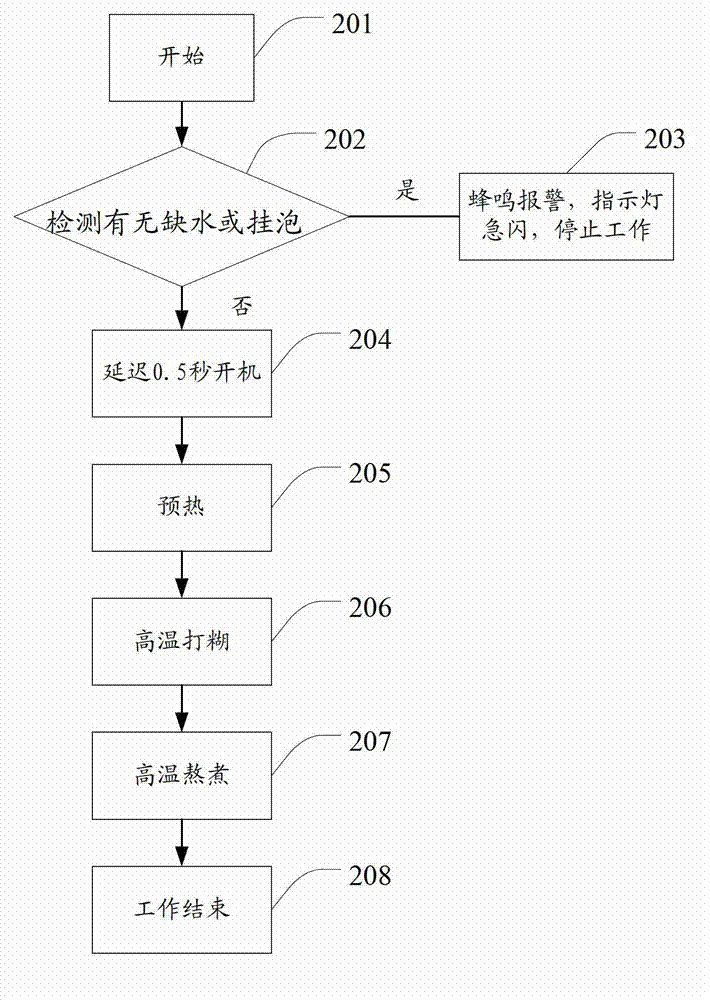

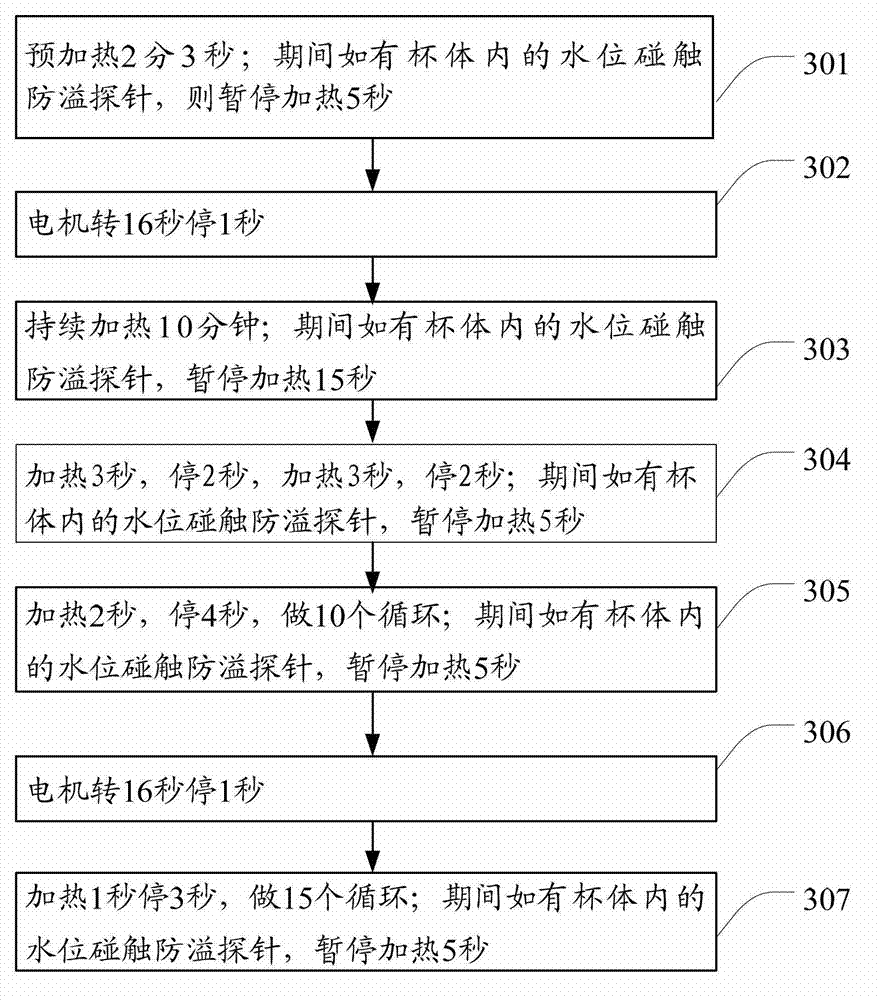

Paste preparing method of soybean milk machine

ActiveCN102948487AReduced costs and assembly stepsImprove reliabilityBeverage vesselsMilk substitutesHeating timeProcess engineering

The present invention discloses a paste preparing method of a soybean milk machine. The method comprises: 1, an initialization step: adding water and a soybean material in a soybean milk machine, and detecting whether a water level inside the soybean milk machine is within a specified range, wherein the soybean milk machine performs a preheating step if the water level is within the specified range, and the soybean milk machine sends an alarm signal if the water level is not within the specified range; 2, a preheating step: heating for 1-3 minutes, starting a motor for 16 seconds to carry out crushing, and then continuously heating for 10 minutes; 3, a high temperature holding step: stopping heating after a specified heating time is achieved, cycling a plurality of times, and starting the motor for 25 seconds to carry out crushing; 4, a high temperature paste beating step: stopping heating after a specified heating time is achieved, cycling a plurality of times, starting the motor for 25 seconds to carry out crushing, and cycling 2 times; 5, a high temperature stirring step: starting the motor for a specified time to carry out stirring, stopping heating after a specified heating time is achieved, and cycling a plurality of times; and 6, a high temperature boiling steps: stopping heating after a specified heating time is achieved, cycling 24 times, and stopping working. With the method, problems of overflow, charring, insufficient cooking and the like during the paste preparing process can be solved.

Owner:GREE ELECTRIC APPLIANCES ZHONGSHAN SMALL HOUSEHOLD APPLIANCES MFG +1

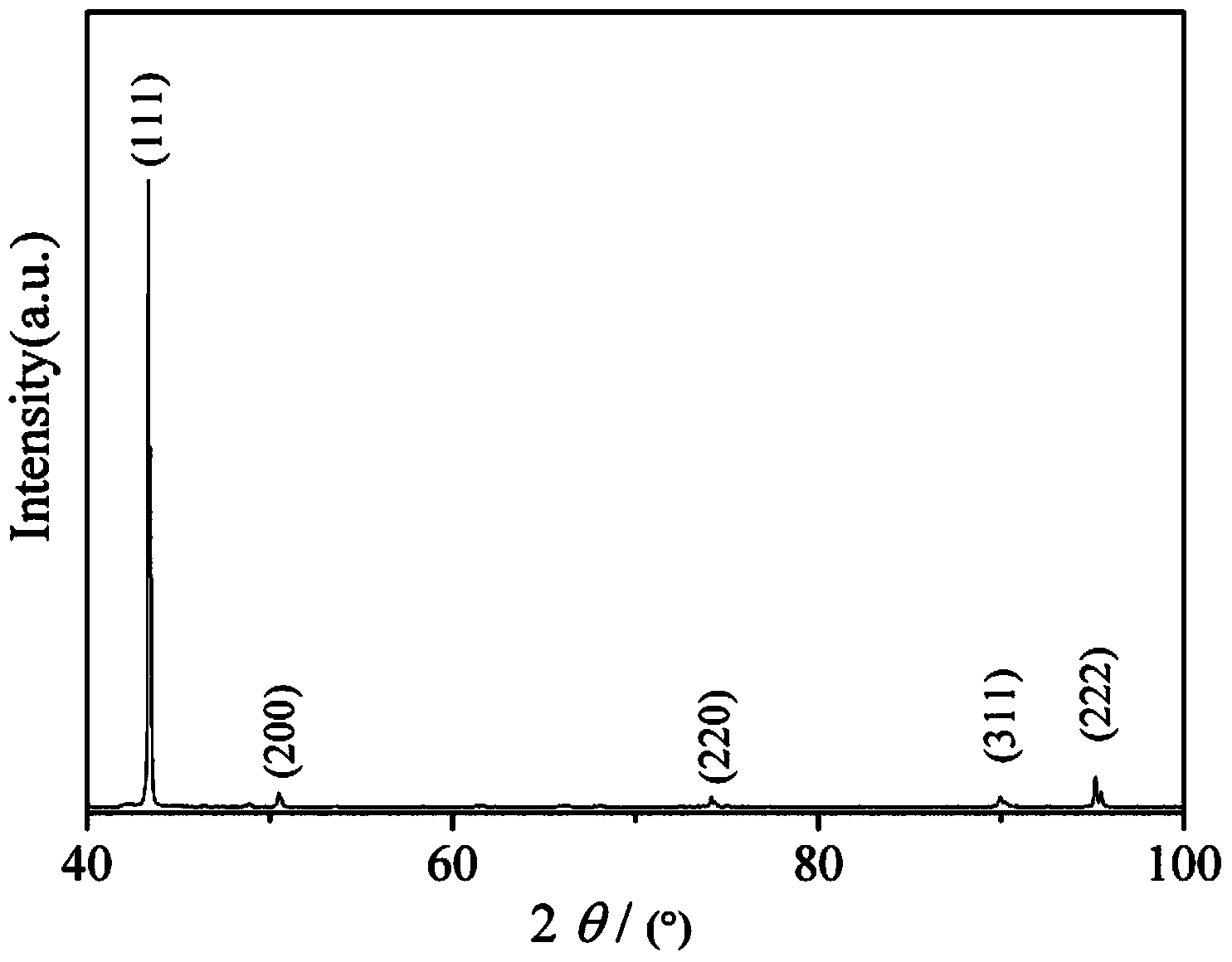

Glucose detection Cu-based CuO membrane electrode and reparation method thereof

ActiveCN103454328AReduced assembly stepsSolve sheddingMaterial analysis by electric/magnetic meansFlower likeSelf assemble

The invention discloses a glucose detection Cu-based CuO membrane electrode which comprises a Cu substrate and a CuO membrane attached on the surface of the Cu substrate, wherein the CuO membrane comprises a plurality of flower-like structure units, each flower-like structure unit is formed by self-assembling a CuO nano sheet vertical to the Cu substrate. In addition, the invention also discloses a preparation method of the Cu-based CuO membrane electrode. According to the Cu-based CuO membrane electrode, the preparation of a CuO active material and the combination with a conductive base body are synchronously completed, and assembling steps of a glucose non-enzyme biosensor are reduced. The CuO membrane of the glucose detection Cu-based CuO membrane electrode grows in situ on the surface of a metal Cu base body, the combining property of the CuO membrane and a base body material is good, and the stability is enhanced; the CuO membrane shows a well-aligned micro / nano hierarchical structure, and the problem of active center reduction caused by agglomeration when a powder body material is coated on the base body is not caused, therefore the electrocatalytic activity is high.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

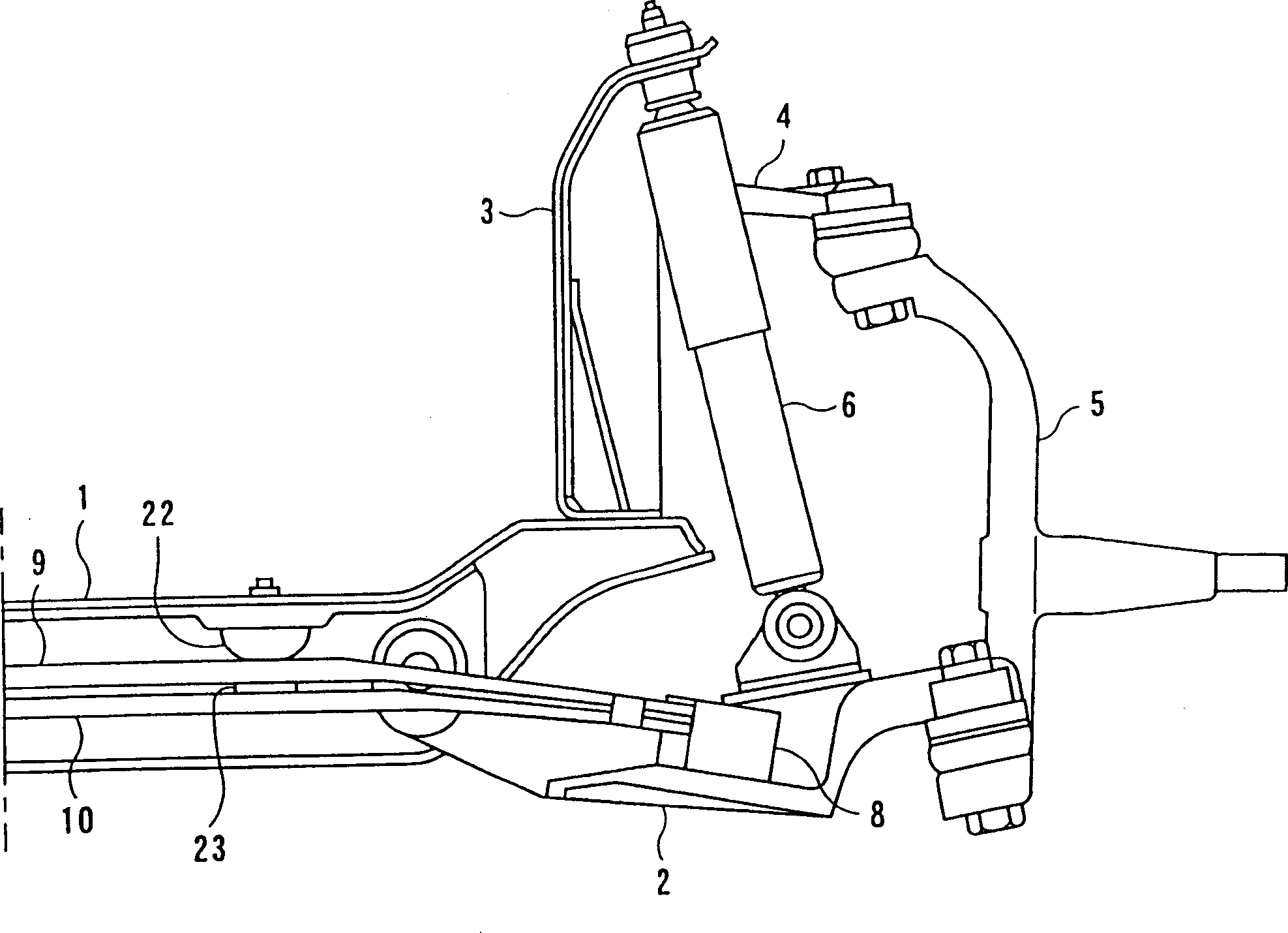

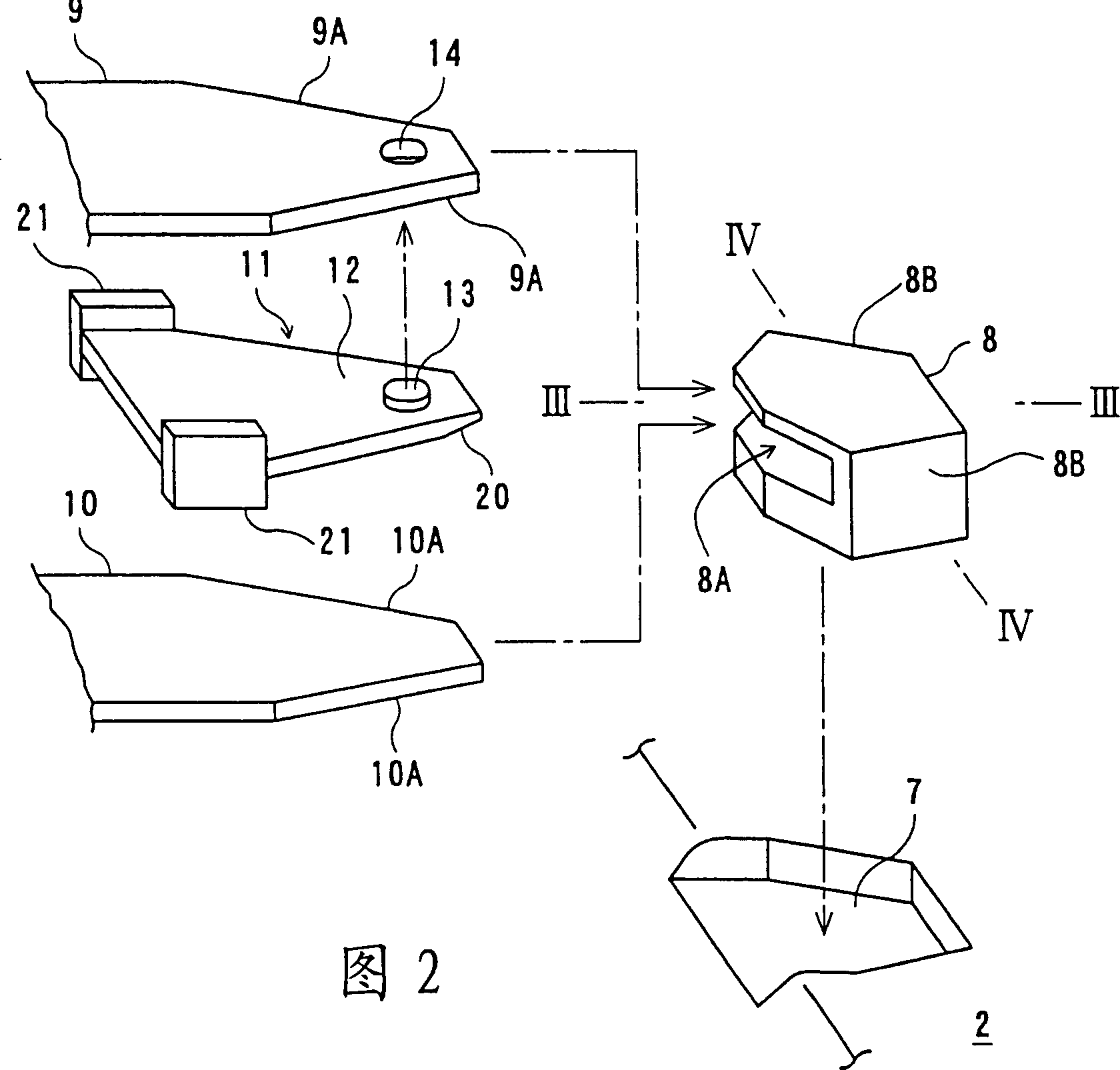

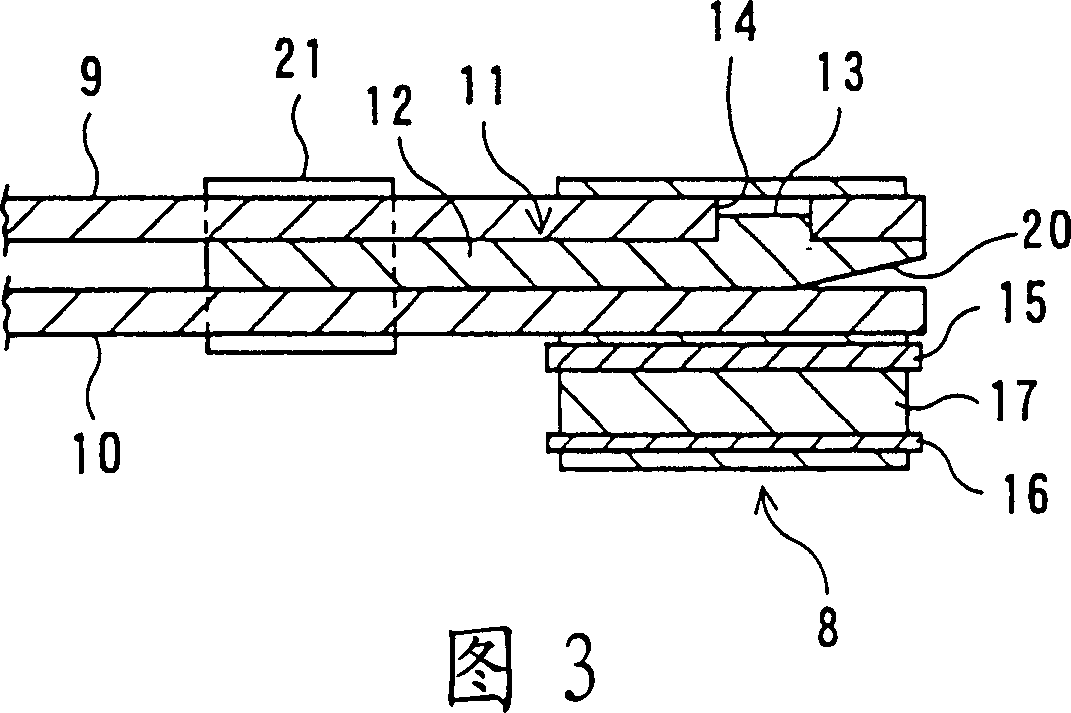

Suspension

InactiveCN1468743APrevent separationReduced assembly stepsLeaf springsResilient suspensionsEngineeringLeaf spring

A suspension includes: wheel supporting members for supporting wheels, a leaf spring having both end portions each arranged on an upper side of the respective wheel supporting member; a pivot supporting the leaf spring, and receiving pieces interposed between the wheel supporting members and the both end portions of the leaf spring respectively. Each of the wheel supporting members includes a recess portion on which one of the receiving pieces is mounted. Each of the receiving pieces includes an engaging portion for engaging with one of the both end portions of the leaf spring. Each of the receiving pieces includes an elastic member and a first metal plate joined on the elastic member. The elastic member can deform to follow a displacement of a relative position between the leaf spring and one of the wheel supporting members.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Terahertz frequency doubler using coplanar transmission line

ActiveCN104617880AReduced assembly stepsMinimize the impact of machining and assembly on resultsOscillations generatorsCross connectionPhysics

The invention discloses a terahertz frequency doubler using coplanar transmission line; the terahertz frequency doubler comprises a fundamental wave input waveguide and a main waveguide; the fundamental wave input waveguide is communicated with the main waveguide; a medium substrate is arranged on the bottom surface of an internal chamber of the main waveguide; the left end of the medium substrate stretches out from the main waveguide and then stretches into the fundamental wave input waveguide; the coplanar transmission lines, the lower surfaces of which are flush with the upper surface of the medium substrate, are arranged on the medium substrate; the coplanar transmission line comprises a short-circuit transmission line, a primary connection transmission line, a matching transmission line, an output waveguide matching transmission line and a DC bias low-pass filter connected to one another from left to right and further comprises an output waveguide; the output waveguide is in crossed connection with the main waveguide; the overlapped area of the output waveguide and the main waveguide is an area M; the output waveguide matching transmission line is arranged in the area M; two grounded transmission lines of the coplanar transmission line are arranged at the left side of the output waveguide; and the coplanar transmission line further comprises an upside-down four-core frequency-doubling diode.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Break-away spring and piston rod for a trigger sprayer

ActiveUS7942291B2Reduce manufacturing costReduce in quantityClosure using stoppersLarge containersEngineeringMechanical engineering

Owner:SILGAN DISPENSING SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com