Method for integrally forming connector, and connector

一种成型方法、连接器的技术,应用在连接装置的零部件、连接、接触件的组装/拆卸等方向,能够解决油扩散等问题,达到维持强度、提高自由度、实现批量生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

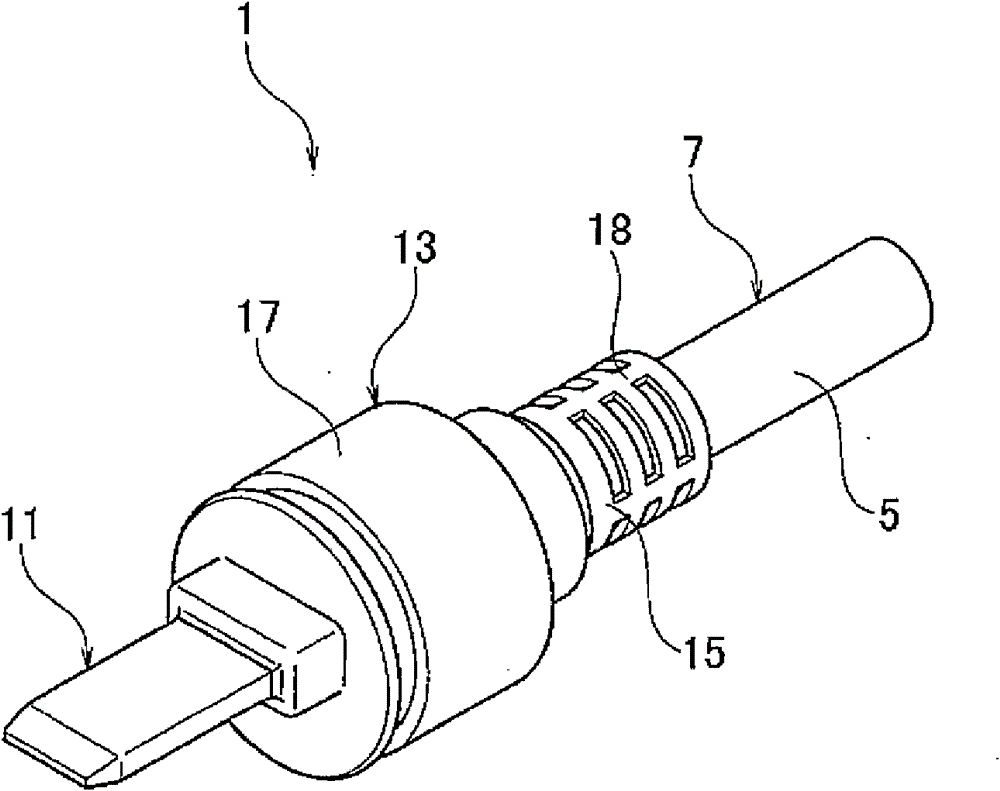

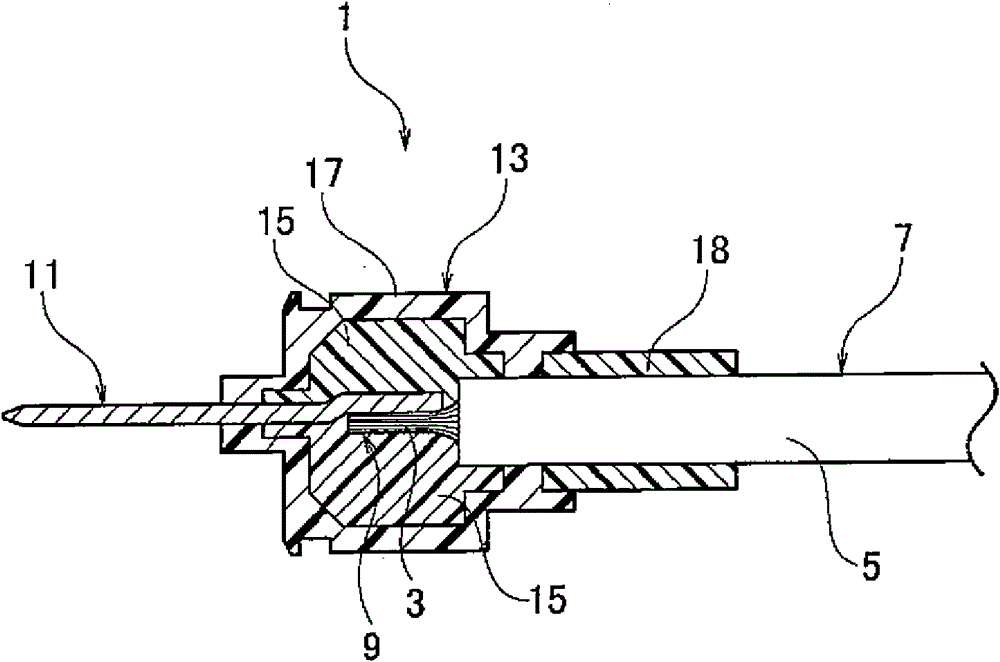

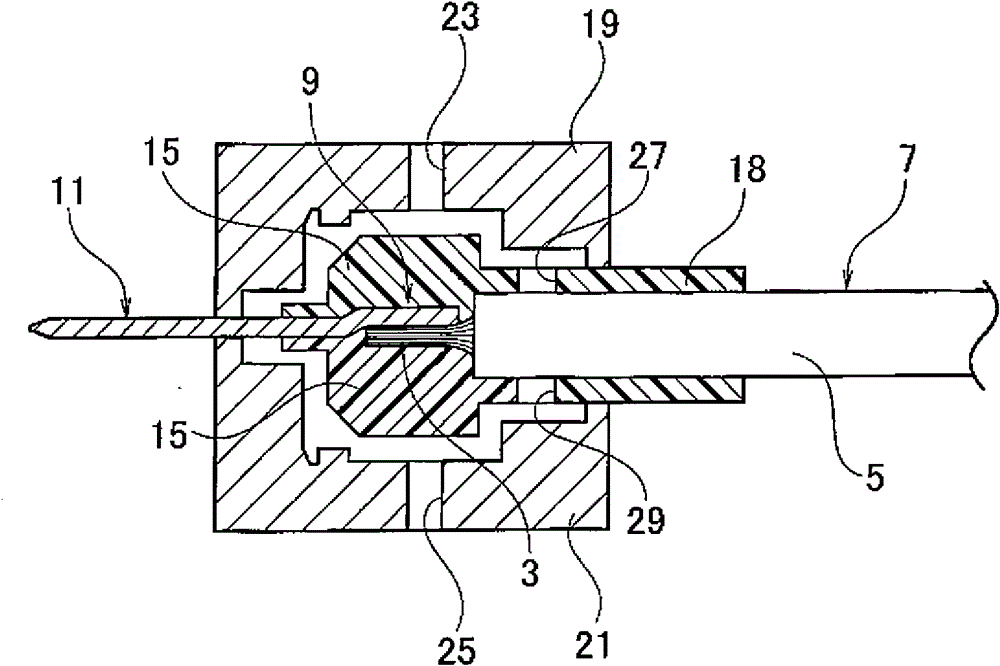

[0038] refer to Figure 1 to Figure 4 , a connector according to an embodiment of the present invention and a method of integrally molding the same will be described.

[0039] The connector 1 in this embodiment includes: an electric wire 7 whose core 3 is covered with a sheath 5; a terminal 11 having a connecting portion 9 connected to the core 3 of the electric wire 7; surrounding cover 13 . In addition, the cover member 13 includes an elastic resin 15 and a resin 17, the elastic resin 15 being provided around the connecting portion 9 and the end portion of the outer skin portion 5 near the connecting portion 9, joined to the outer skin part 5 and is crimped to the terminal 11 at the same time, the resin 17 is provided around the elastic resin 15 so as to compress the elastic resin 15 and bond to the elastic resin 15 .

[0040] This method of integrally molding the connector 1 includes: a first step: injecting the elastic resin 15 around the connecting portion 9 and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com