Boron carbide-silicon carbide complex ceramic and preparation method thereof

A technology of boron carbide, silicon carbide, and multiphase ceramics, which is applied in the field of ceramic materials, can solve problems such as difficulty in solving, hindered development, poor wettability of aluminum melt, etc., and achieves excellent mechanical properties and avoids the effect of aluminum carbide formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

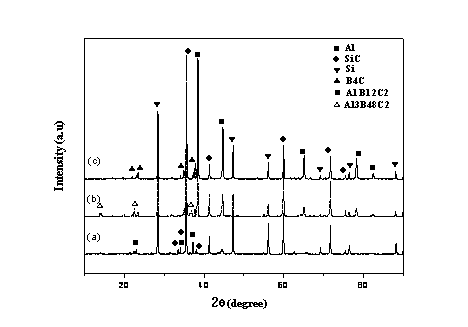

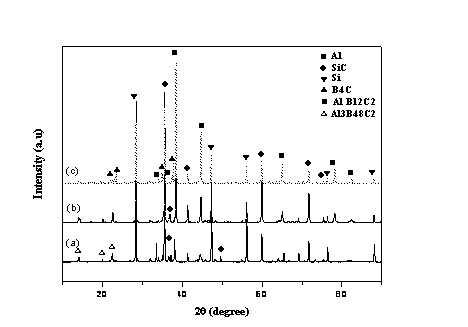

Embodiment 1

[0052] The raw materials of the prefabricated body are as follows (by weight percentage):

[0053] Boron carbide powder with a particle size of 50-100 microns 75% Boron carbide powder with a particle size of 2-10 microns 15%

[0054] Graphite powder 3.0% Activated carbon powder 4.0%

[0055] Phenolic resin 1.5% Tetramethylammonium hydroxide 0.5%

[0056] Motor oil 0.3% glycerin 0.7%;

[0057] The weight percent of the above-mentioned boron carbide powder is based on pure boron carbide.

[0058] Alloy composition: 80% silicon, 20% aluminum.

Embodiment 2

[0060] The raw materials of the prefabricated body are as follows (by weight percentage):

[0061] Boron carbide powder with a particle size of 50-100 microns 75% Boron carbide powder with a particle size of 2-10 microns 15%

[0062] Graphite powder 3.0% Activated carbon powder 4.0%

[0063] Phenolic resin 1.5% Tetramethylammonium hydroxide 0.5%

[0064] Motor oil 0.3% glycerin 0.7%;

[0065] The weight percent of the above-mentioned boron carbide powder is based on pure boron carbide.

[0066] Alloy composition: 55% silicon, 45% aluminum.

Embodiment 3

[0068] The raw materials of the prefabricated body are as follows (by weight percentage):

[0069] Boron carbide powder with a particle size of 50-100 microns 75% Boron carbide powder with a particle size of 2-10 microns 15%

[0070] Graphite powder 3.0% Activated carbon powder 4.0%

[0071] Phenolic resin 1.5% Tetramethylammonium hydroxide 0.5%

[0072] Motor oil 0.3% glycerin 0.7%;

[0073] The weight percent of the above-mentioned boron carbide powder is based on pure boron carbide.

[0074] Alloy composition: 36% silicon, 64% aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com