Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

A technology for reinforcing thermoplastic and continuous fibers, used in belts, other household appliances, coatings, etc., can solve the difficulty of fiber arrangement and yarn threading in the impregnation die, the easily oxidized resin content in the molten resin pool, and the difficulty in controlling fiber impregnation, etc. problem, to achieve the effect of realizing cost and continuous production, easier control of resin content, low cost and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

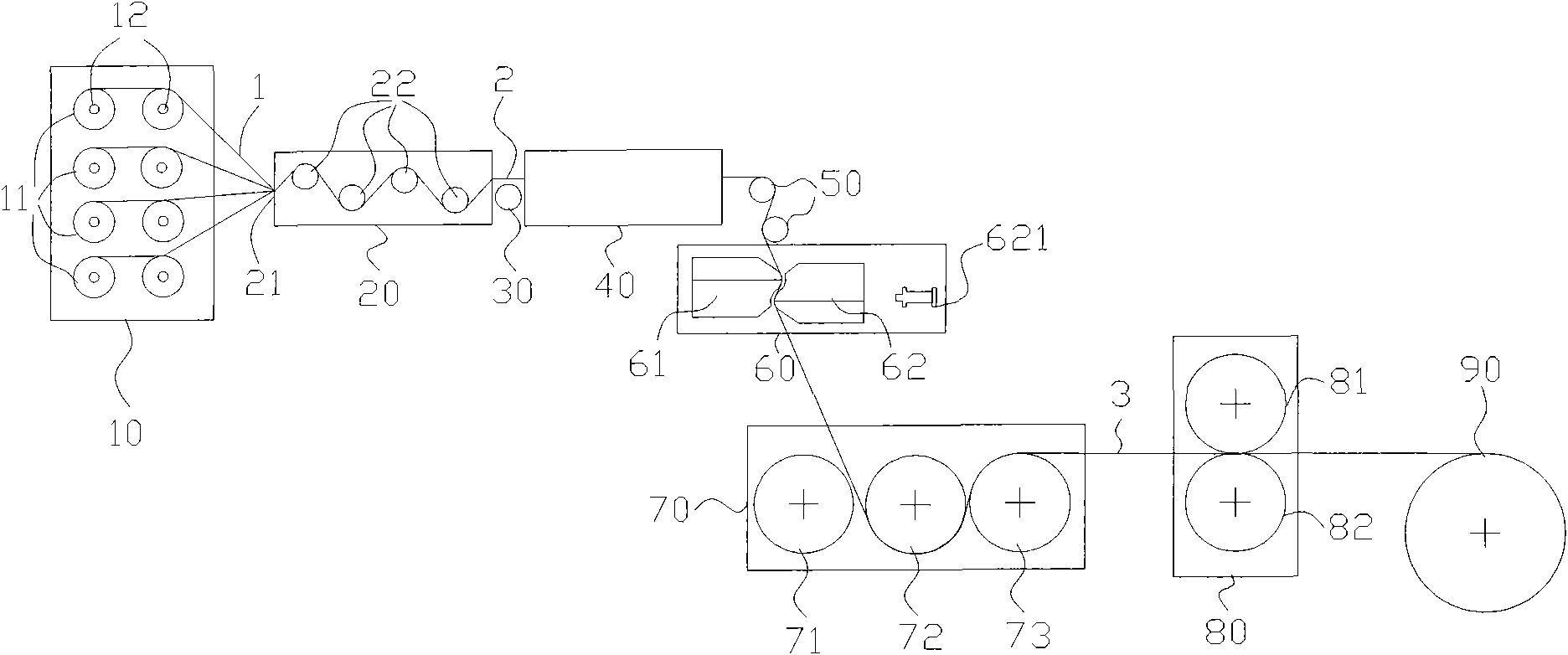

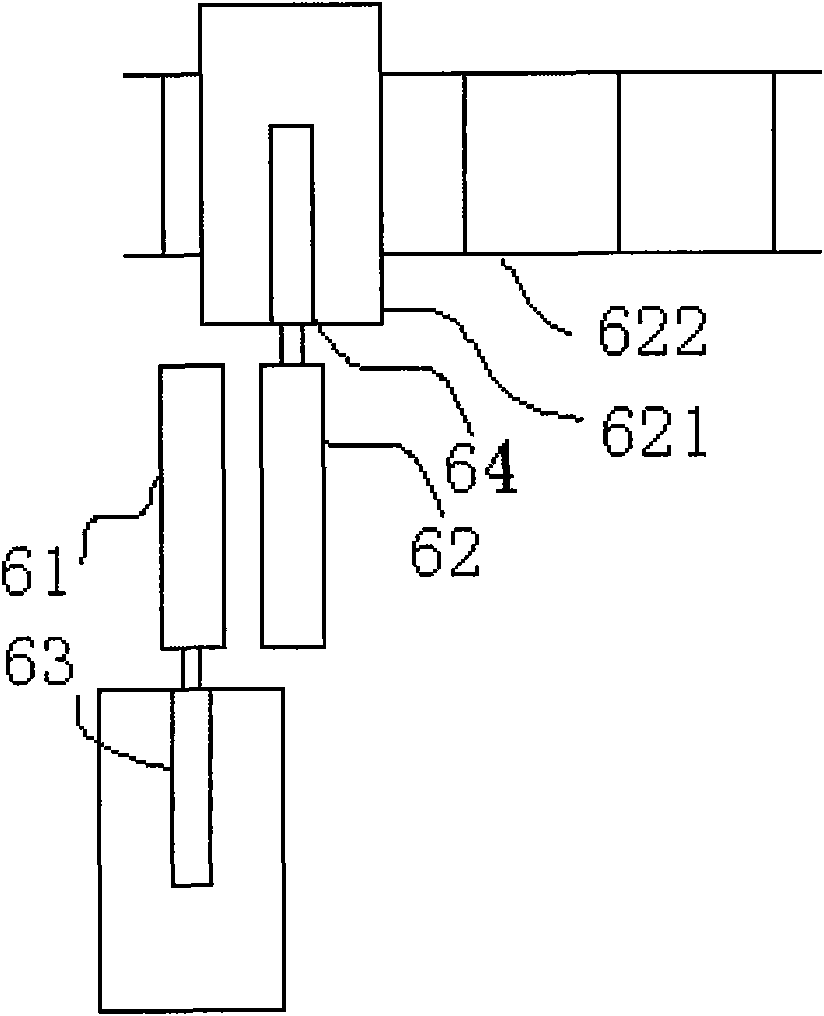

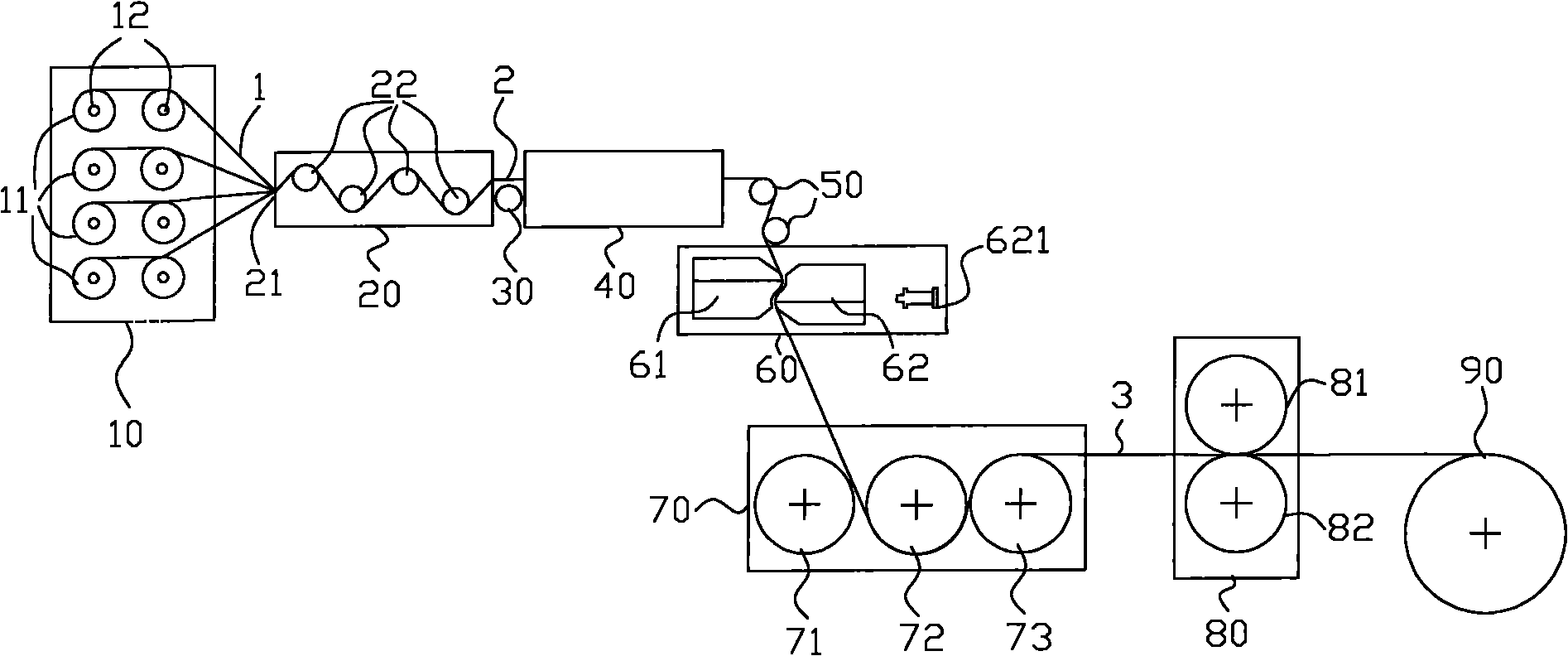

[0025] Such as Figure 1~2 Shown, a kind of equipment that implements the preparation method of continuous fiber reinforced thermoplastic composite material prepreg tape, this equipment comprises creel 10, tension adjustment device 20, static elimination device 30, preheating device 40, tension adjustment device 50, impregnation calendar The roller set 70, the cooling rolling device 80 and the winding device 90 also include a staggered openable and closable double extrusion die set 60, which is composed of an extrusion die 61, an extruded The die head 62 and the rail moving device 621 are composed, and the extrusion die head 61 and the extrusion die head 62 are parallel and form an S-shaped slit with the fiber strip.

[0026] The creel 10 is mainly used to place the continuous fiber roll 11 . Its main purpose is to unwind the continuous fiber bundle 1 from the fiber roll 11 in parallel. The creel 10 is provided with a horizontally rotating spindle support 12 for placing cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com