Patents

Literature

441results about How to "The content is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

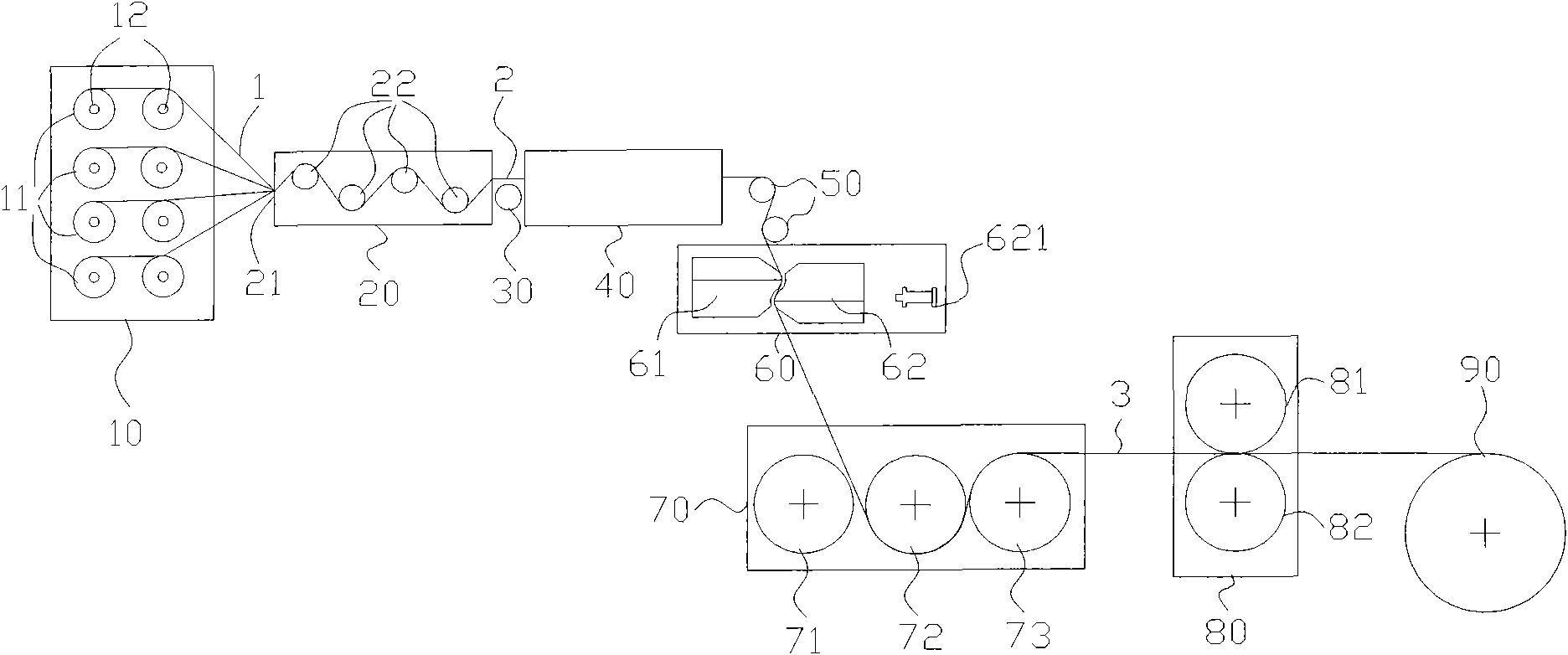

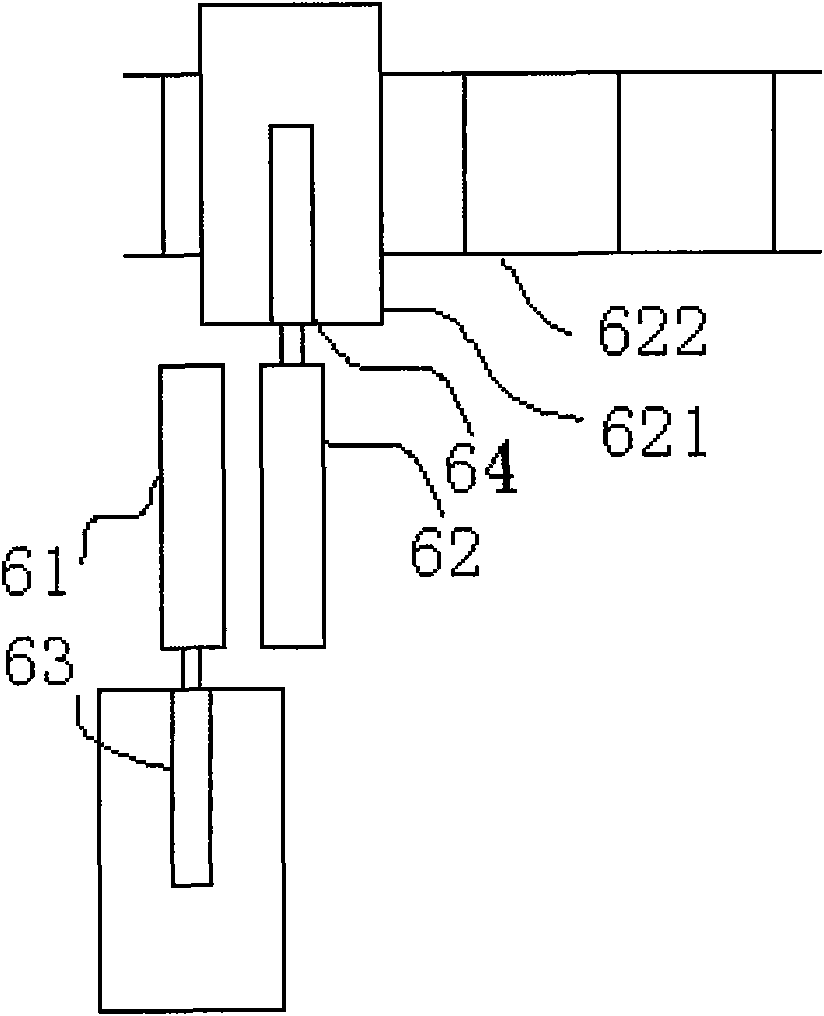

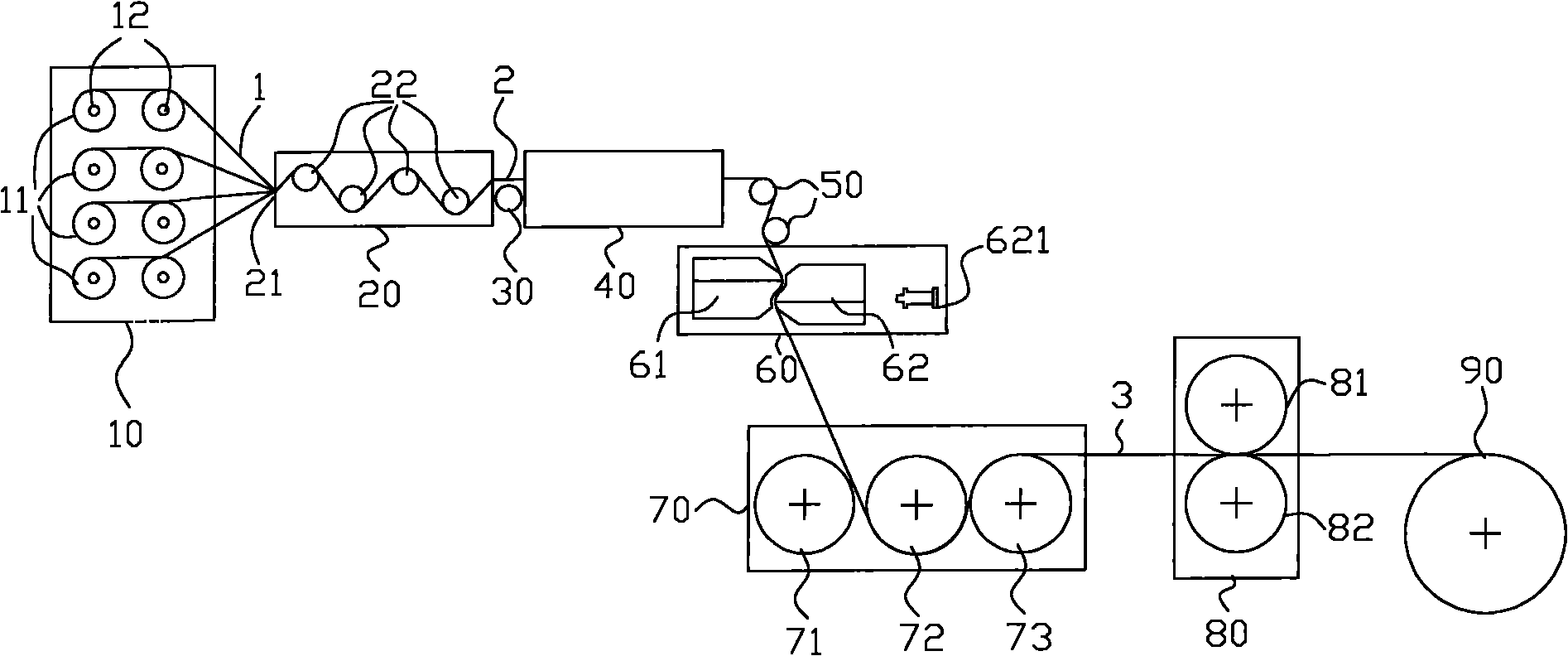

Preparation method of continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof

The invention relates to a preparation method of a continuous fiber reinforced thermoplastic composite material prepreg and equipment thereof. The method comprises the following steps: (a) leading out and unfolding continuous fiber from a creel (10) to pass a tension adjusting device (20) and a static elimination device (30) in sequence, sending the fiber to a preheating oven (40) to preheat, and then passing a tension adjusting device (50); (b) leading a preheated continuous fiber band into a dual-extrusion die head set which can be opened and closed in a staggered manner to presoak; and (c) leading the presoaked continuous fiber band into a soaked rolling roll set (70) to soak, then cooling by a cooling roll-in device (80), and finally leading into a traction rolling device (90) for shaping by winding to obtain the product. Compared with the prior art, the invention significantly improve the dispersion, infiltrating property and operability of the fiber, and obtains the continuous fiber reinforced thermoplastic composite material prepreg which has uniformly dispersed and completely soaked fiber.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

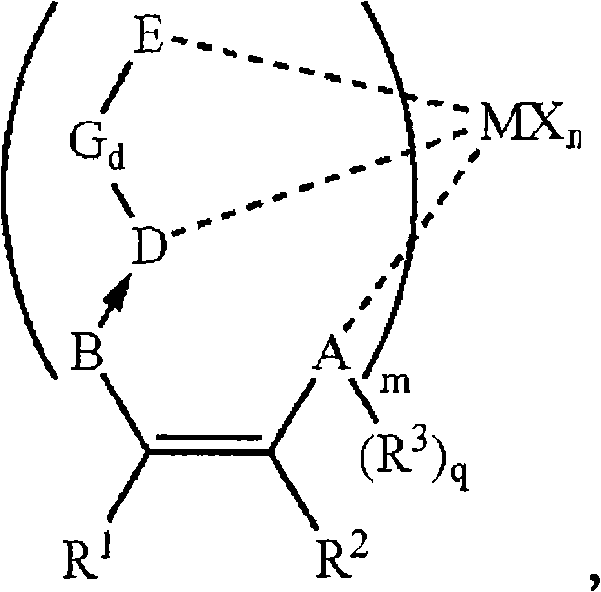

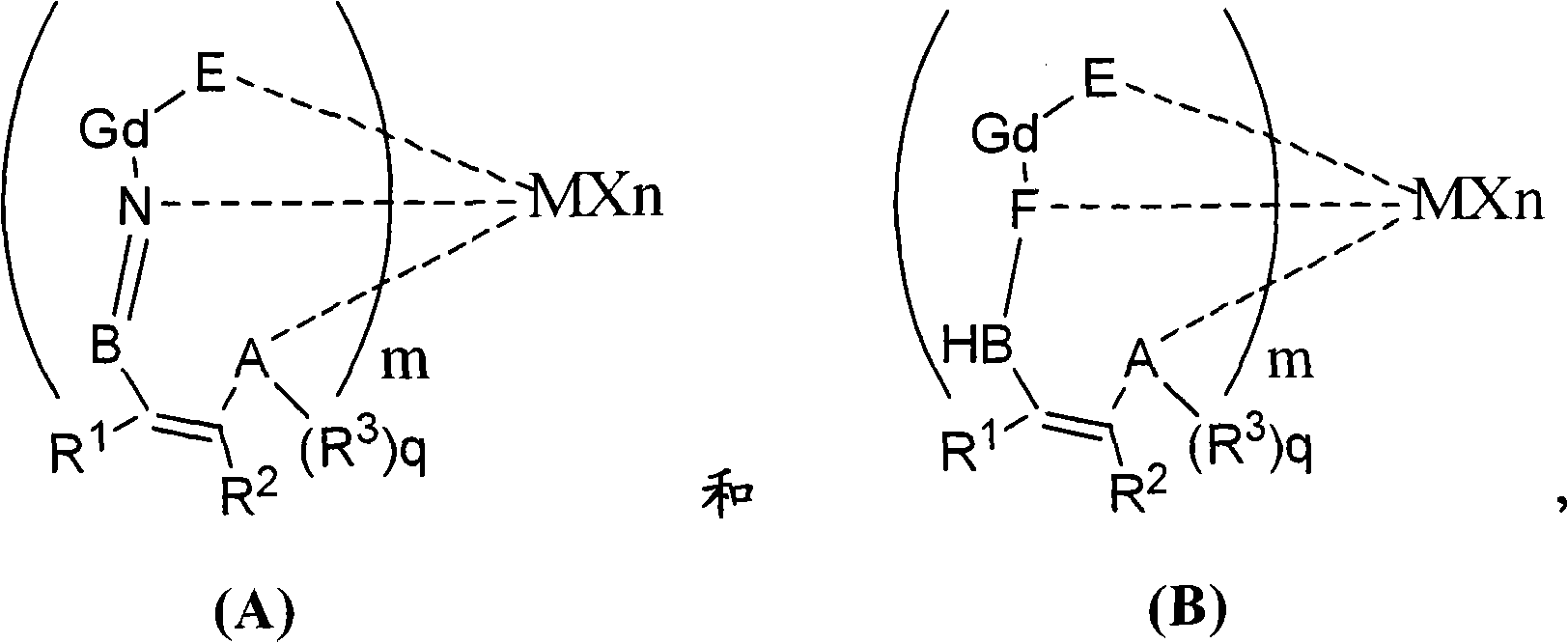

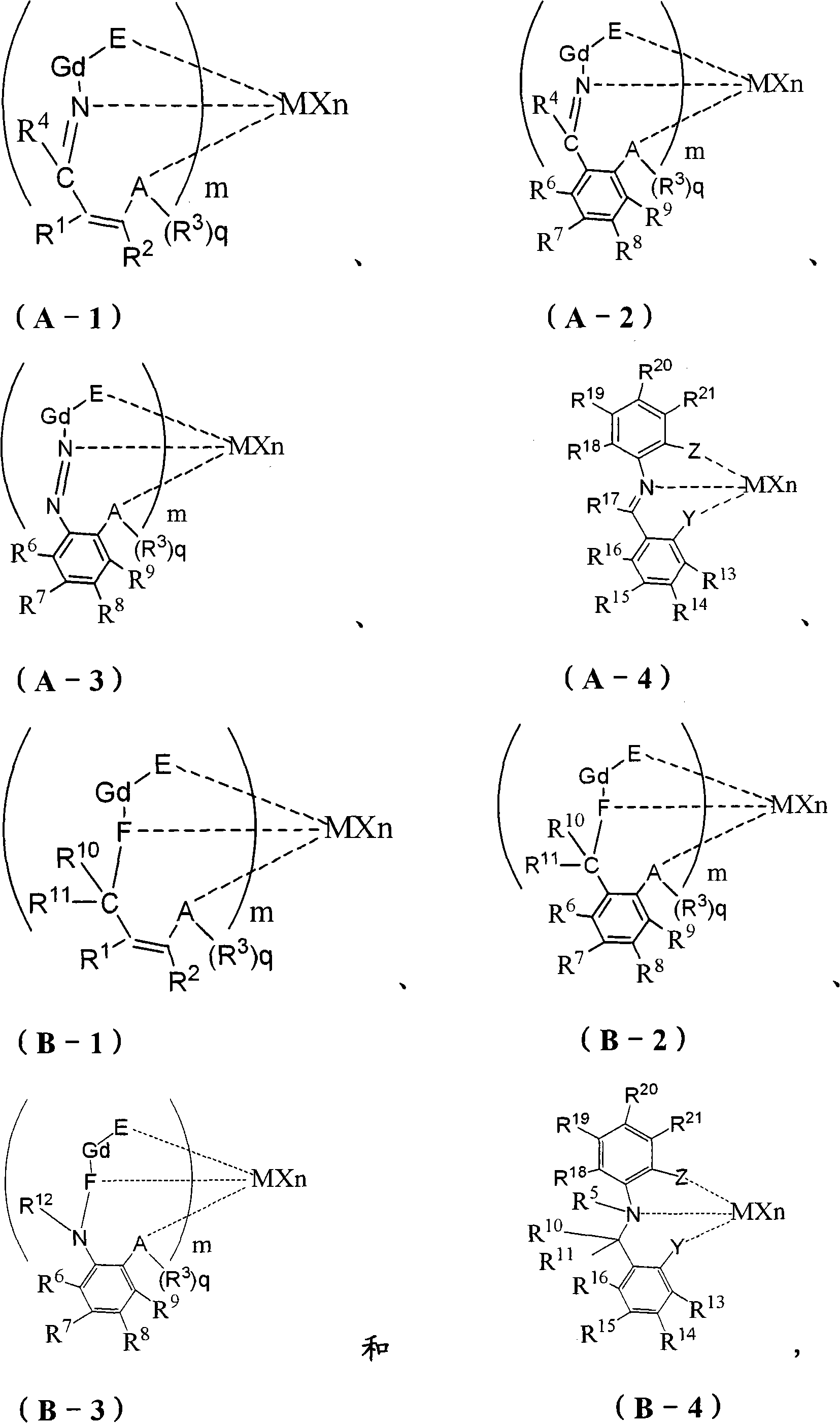

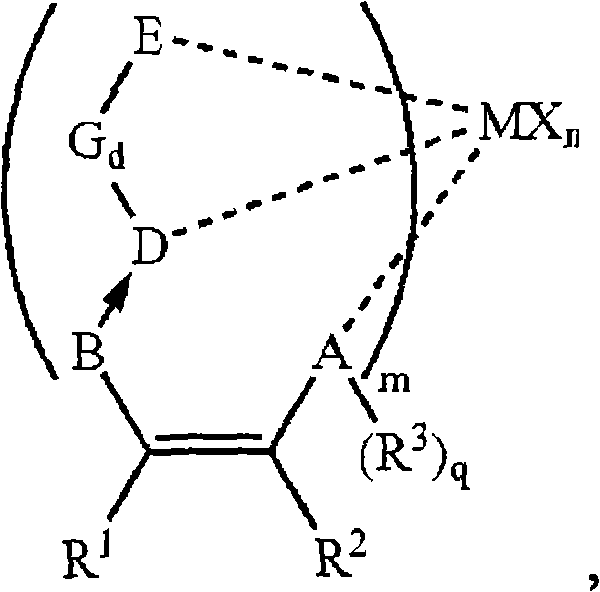

Load type non-metallocene catalyst, preparation method and application thereof

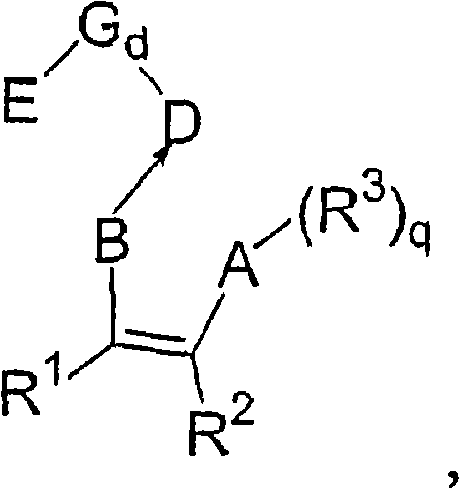

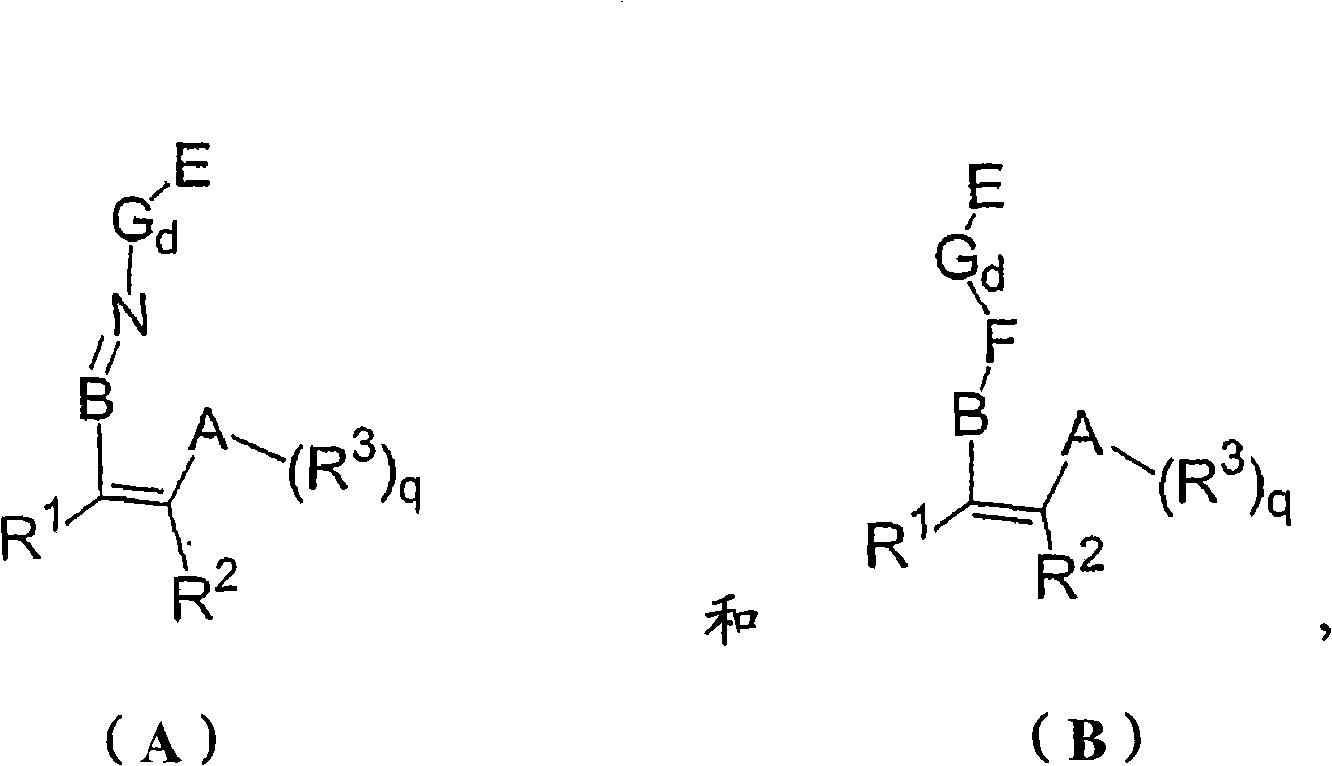

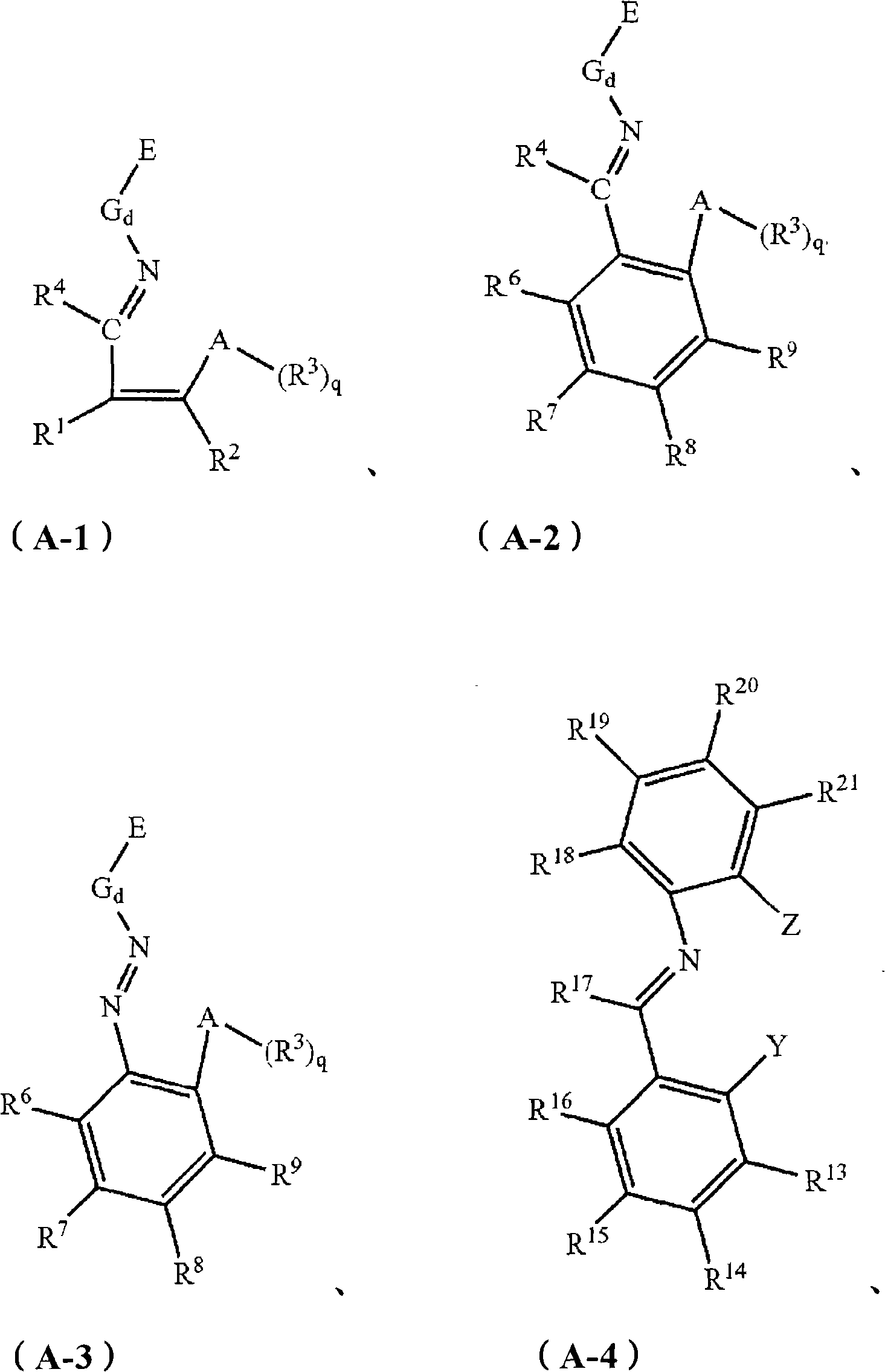

ActiveCN102039186AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryAlkene

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared withthe prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

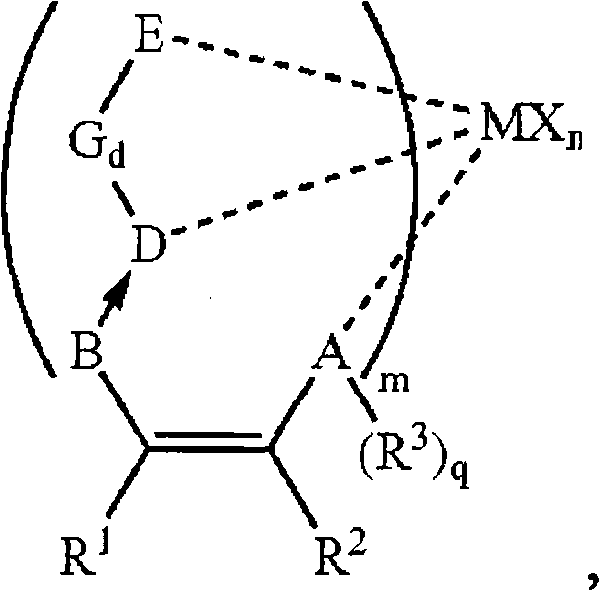

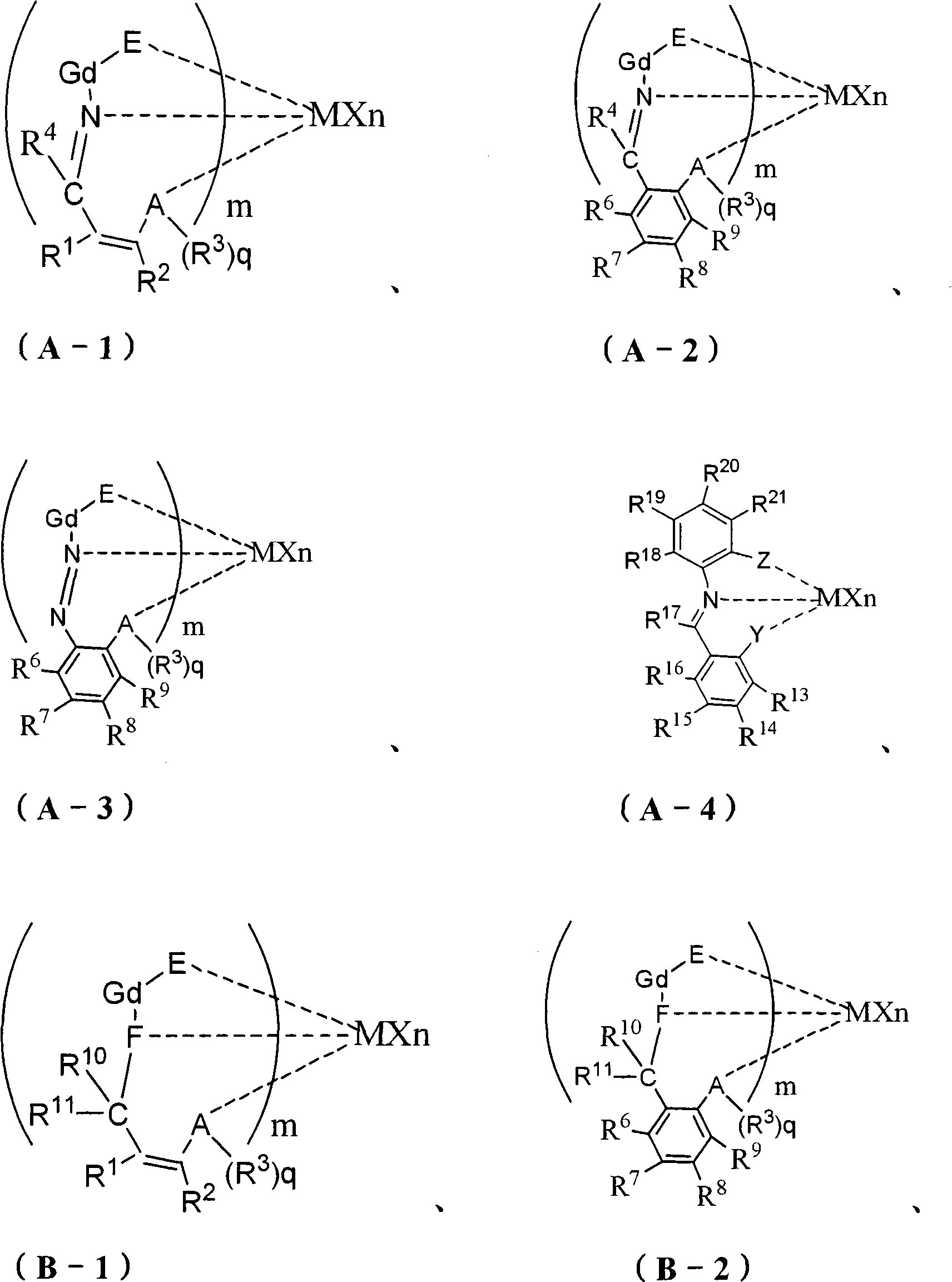

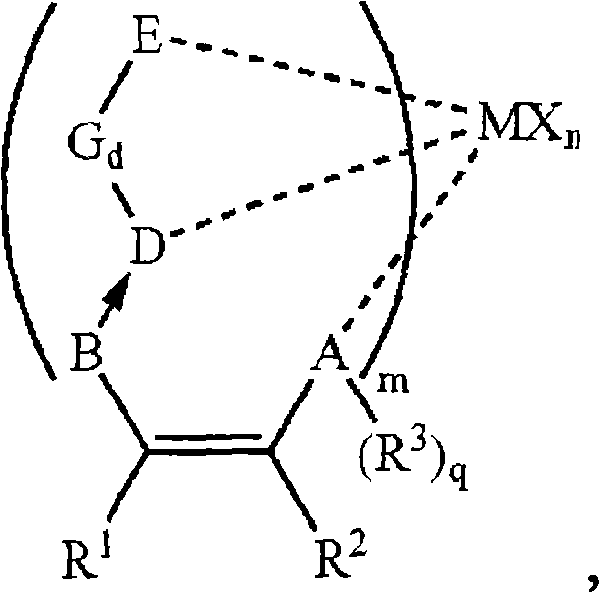

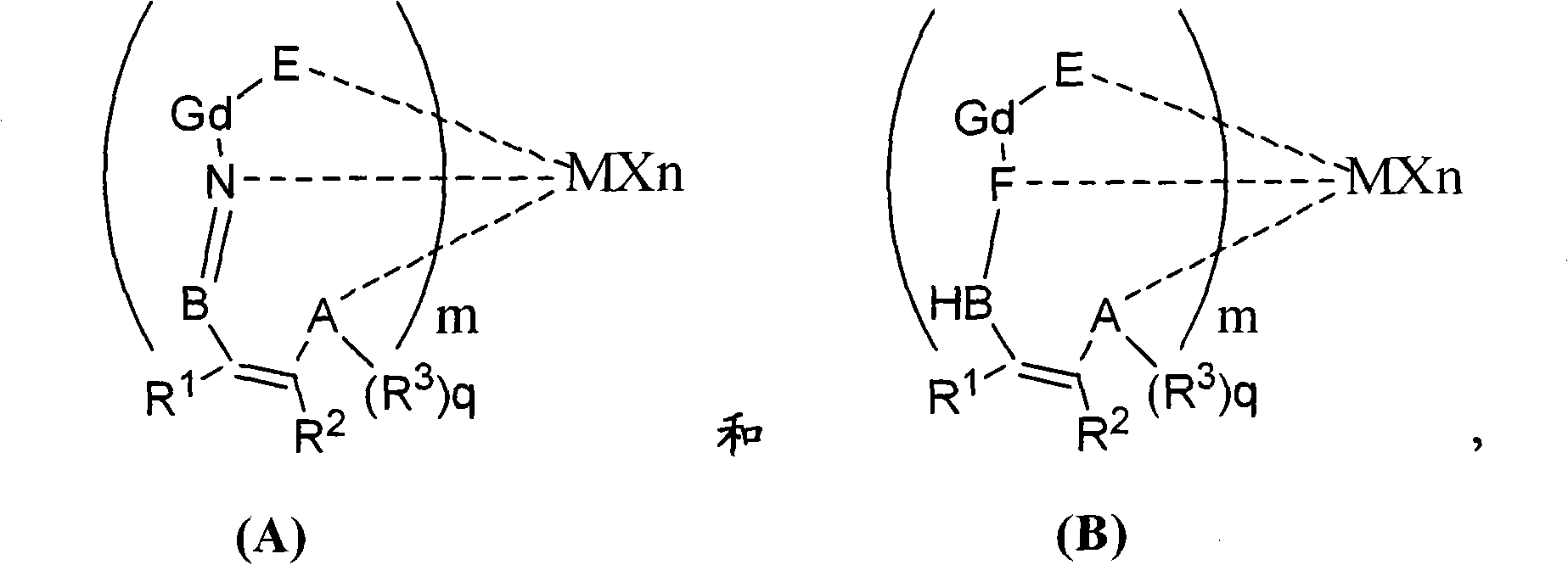

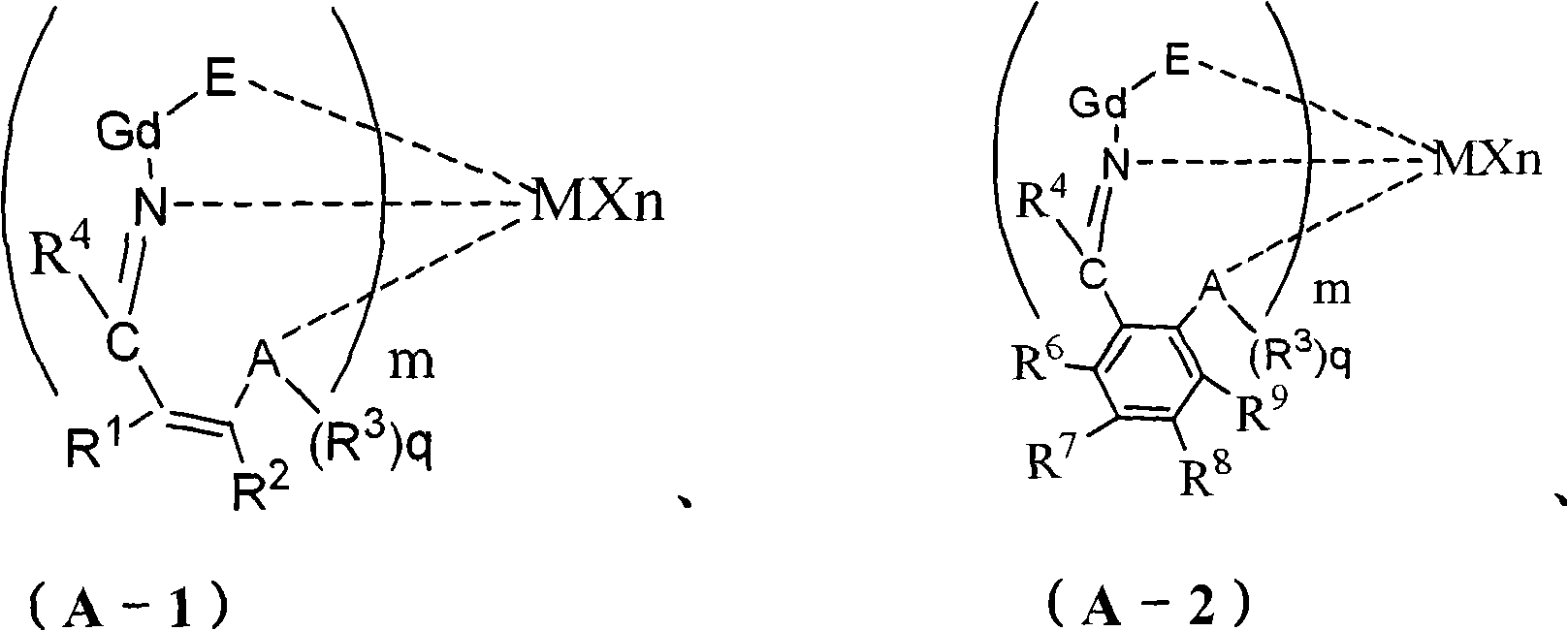

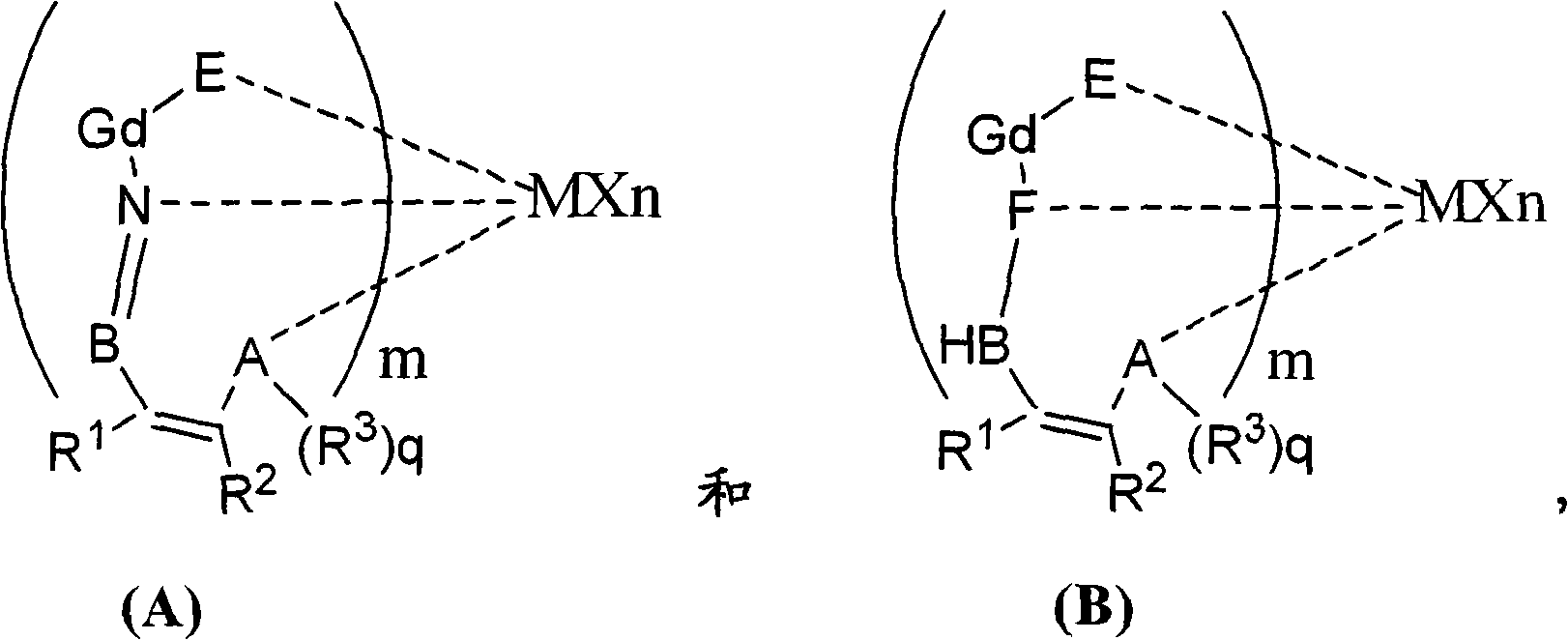

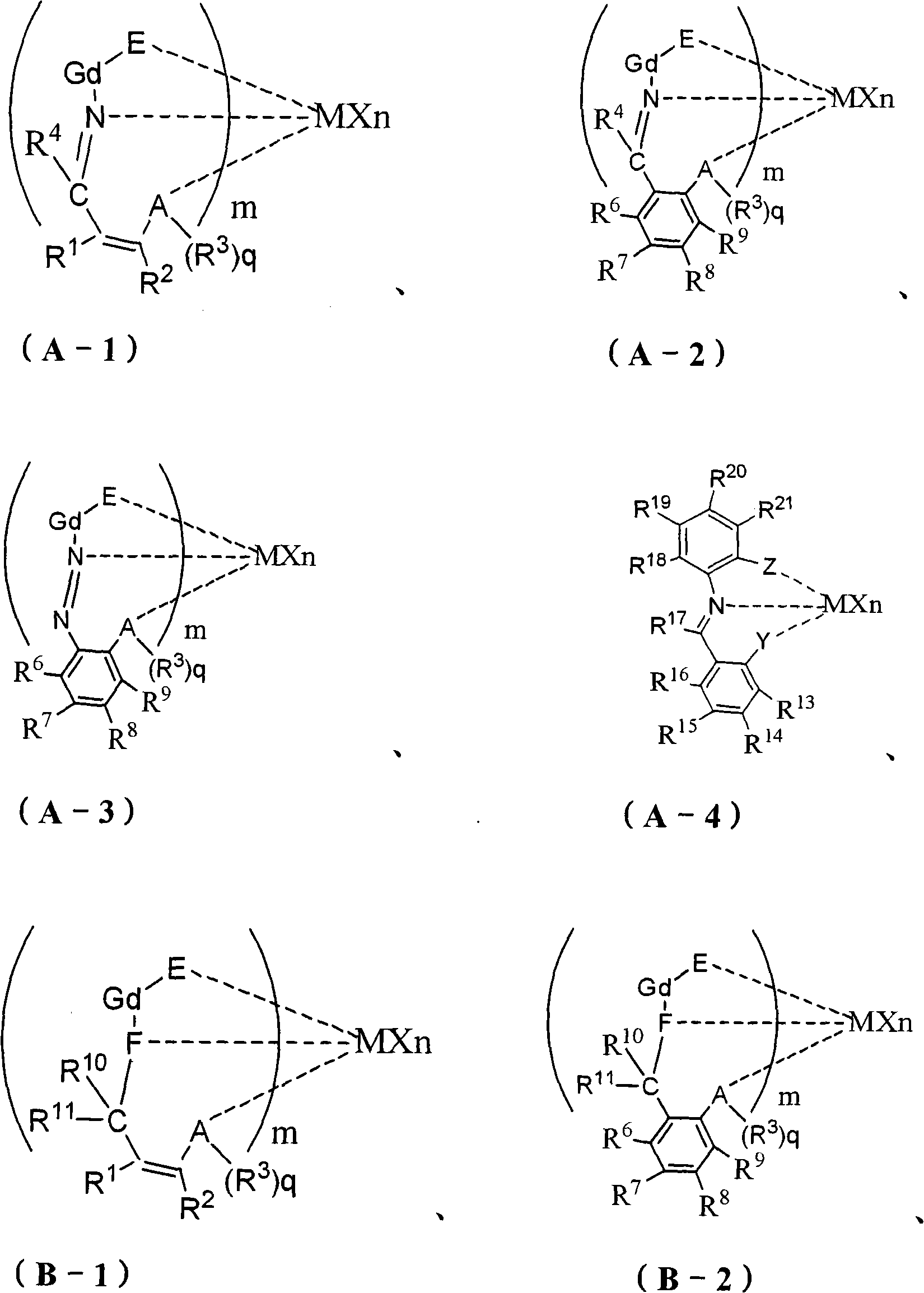

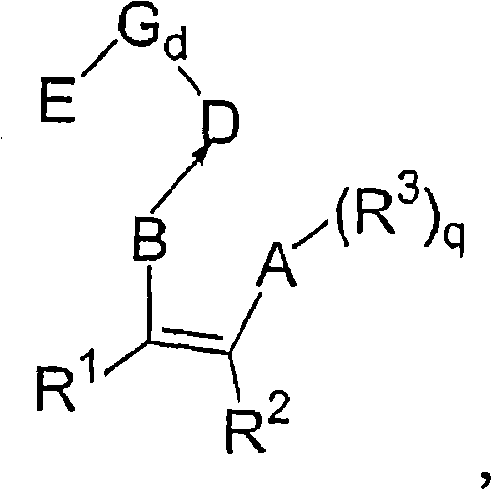

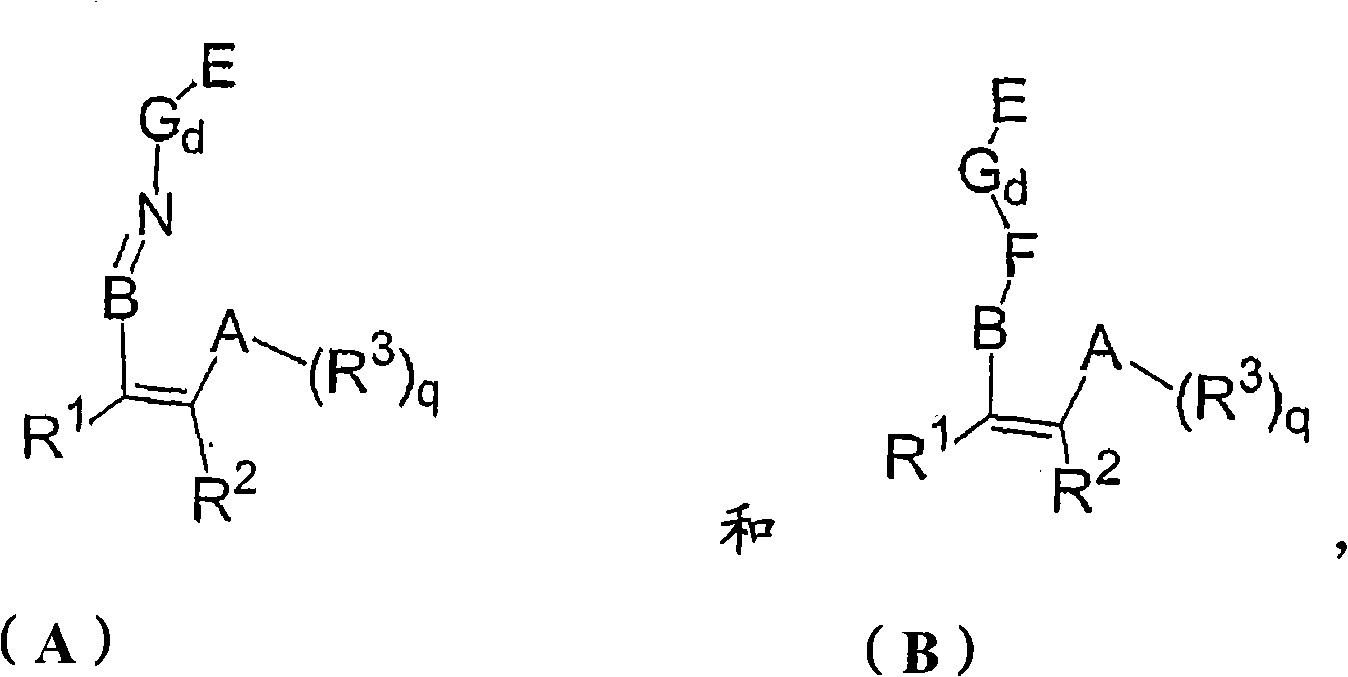

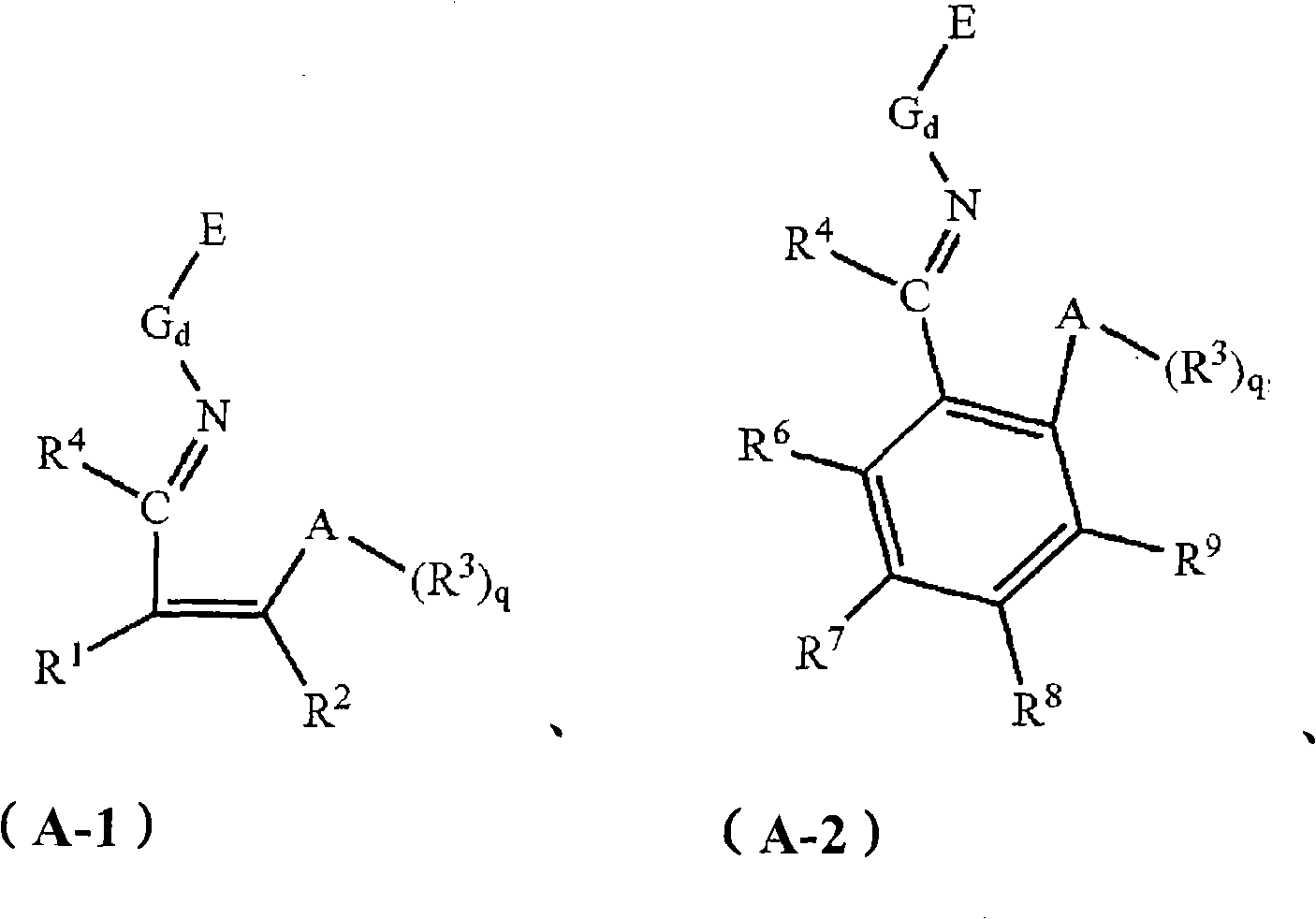

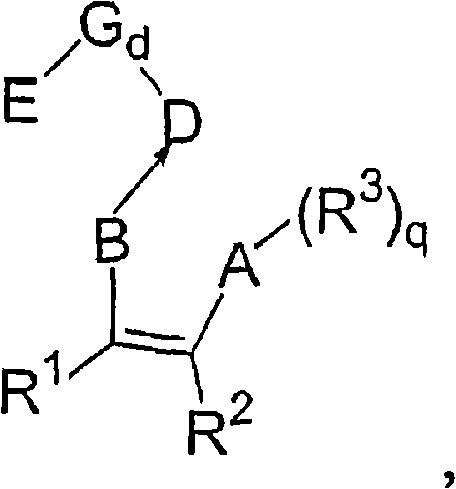

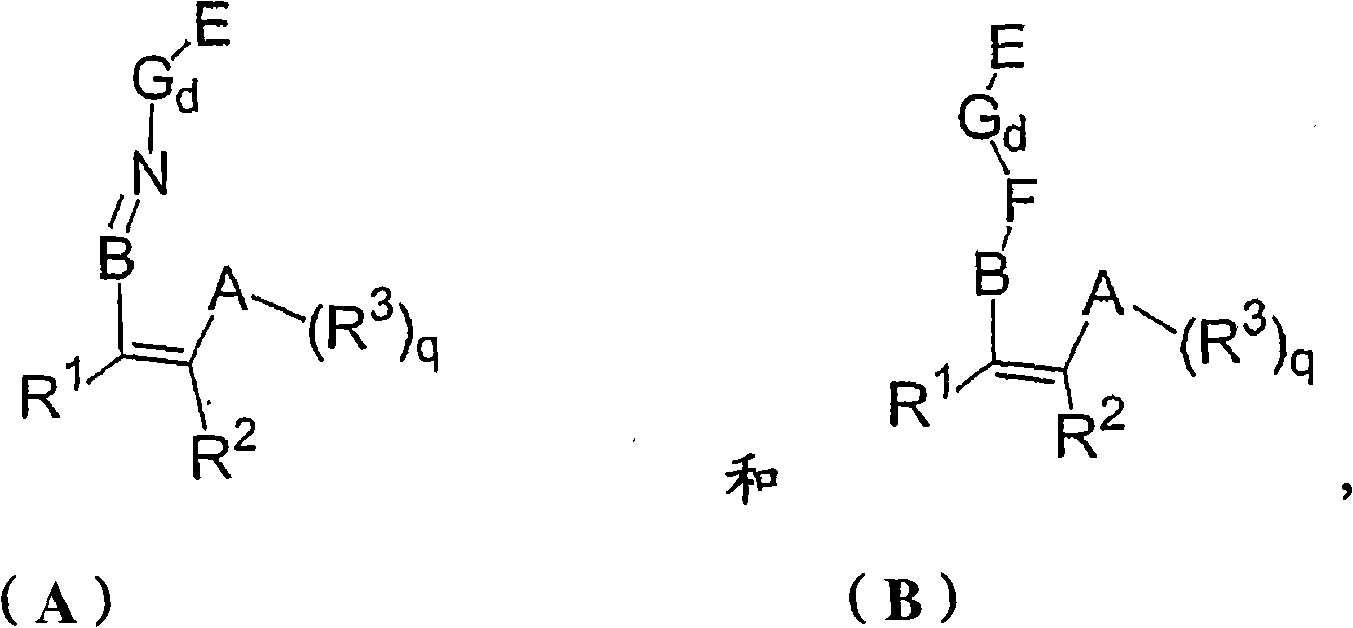

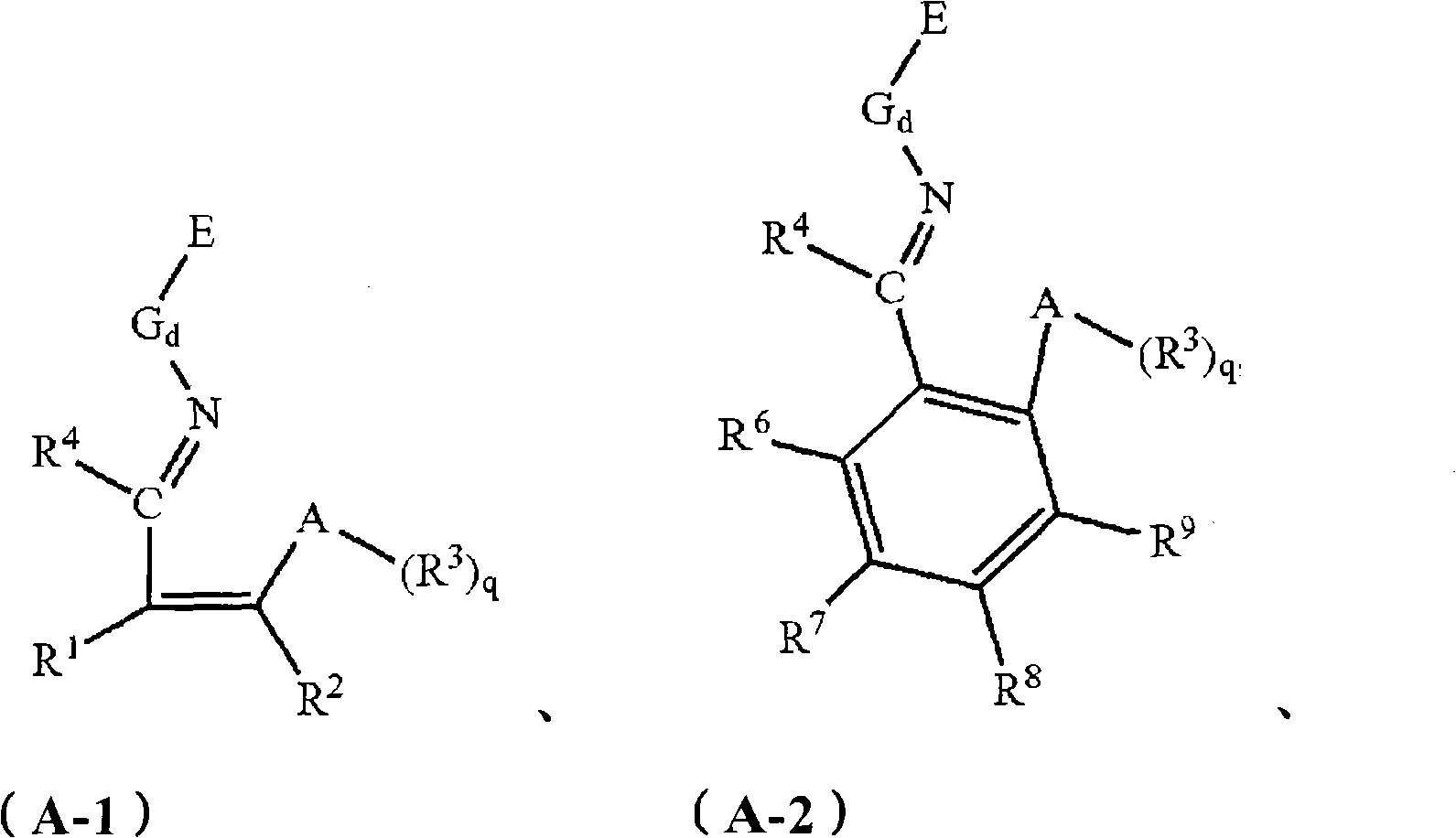

Supported non-metallocene catalyst as well as preparation method and application thereof

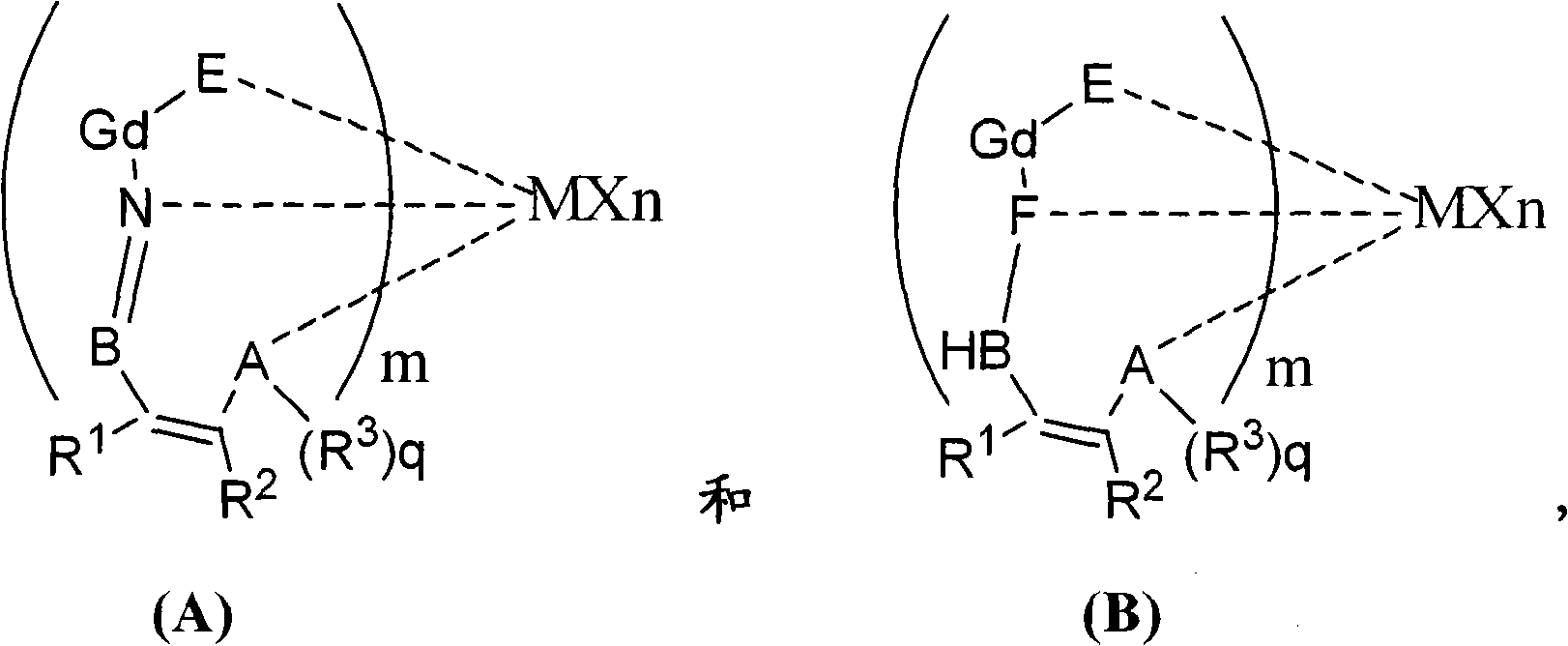

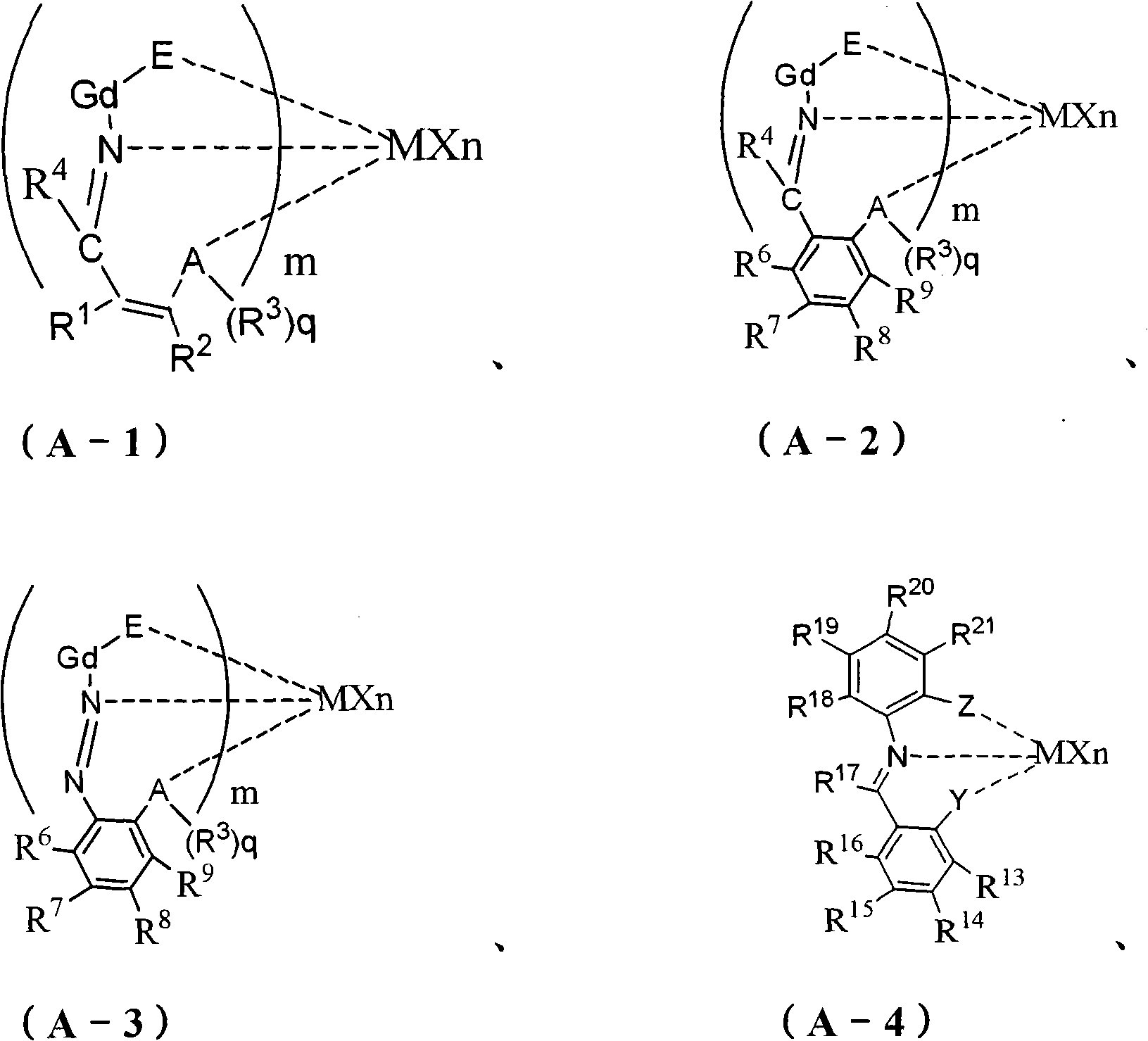

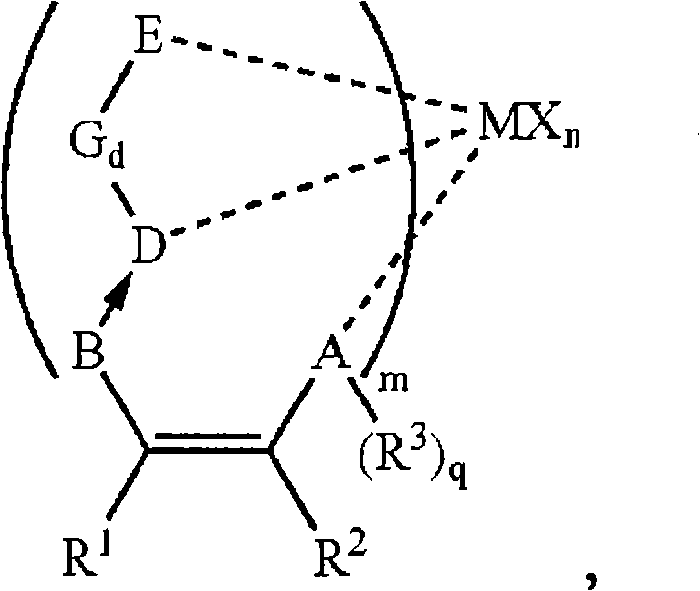

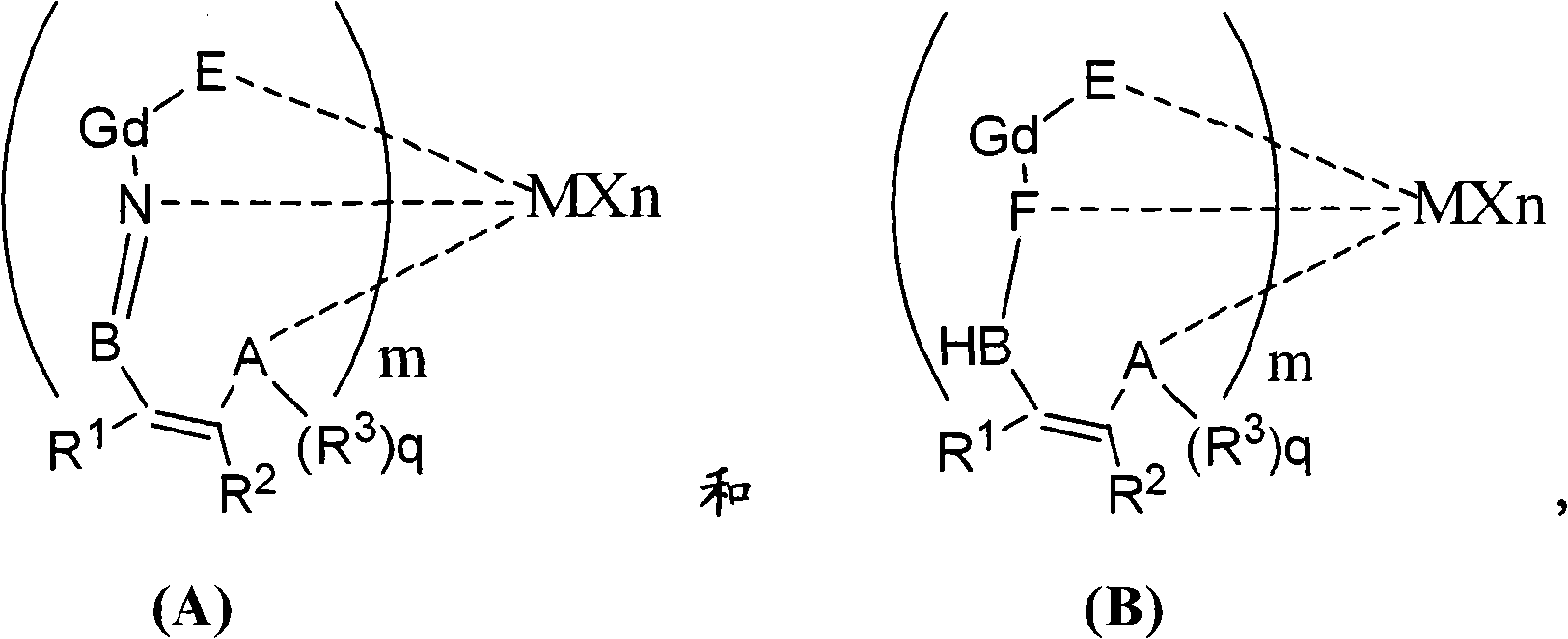

ActiveCN102039184AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentAlkene

The invention relates to a supported non-metallocene catalyst and a preparation method thereof. The catalyst has the characteristics of simple and practical preparation method, flexible and adjustable polymerization activity and the like, and the non-metallocene compound in the catalyst and the chemical treatment agent have synergy beneficial to giving play to activity. The invention also relatesto an application of the supported non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the catalyst is characterized in that the dosage of the promoter is less in the application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst, its preparation method and uses

ActiveCN102039185AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryAlkene

The invention relates to a supported non-metallocene catalyst and its preparation method. The preparation method of the supported non-metallocene catalyst is characterized by simple and convenient preparation method, flexible and adjustable polymerization activity etc. The invention also relates to use of the supported non-metallocene catalyst in homopolymerization / copolymerization of alkenes, and less co-catalysts are required compared with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst, its preparation method and uses

ActiveCN102039188AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentCompound (substance)

The invention relates to a supported non-metallocene catalyst and its preparation method. The supported non-metallocene catalyst is characterized by simple preparation method, flexible polymerization activity etc. In addition, non-metallocene complexes in the catalyst cooperate with the chemical disposal agent to enhance the activity. The invention also relates to the application of the supportednon-metallocene catalyst in alkene homopolymerization / copolymerization. Less amount of co-catalyst is required in use compared with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Load type non-metallocene catalyst, preparation method and application thereof

ActiveCN102039191AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOrganic chemistry

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like, and synergistic reaction which is beneficial to activity development is formed between non-metallocene complexes and chemical conditioning agents inthe catalyst. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059153AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059151AThe load is easy to controlEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

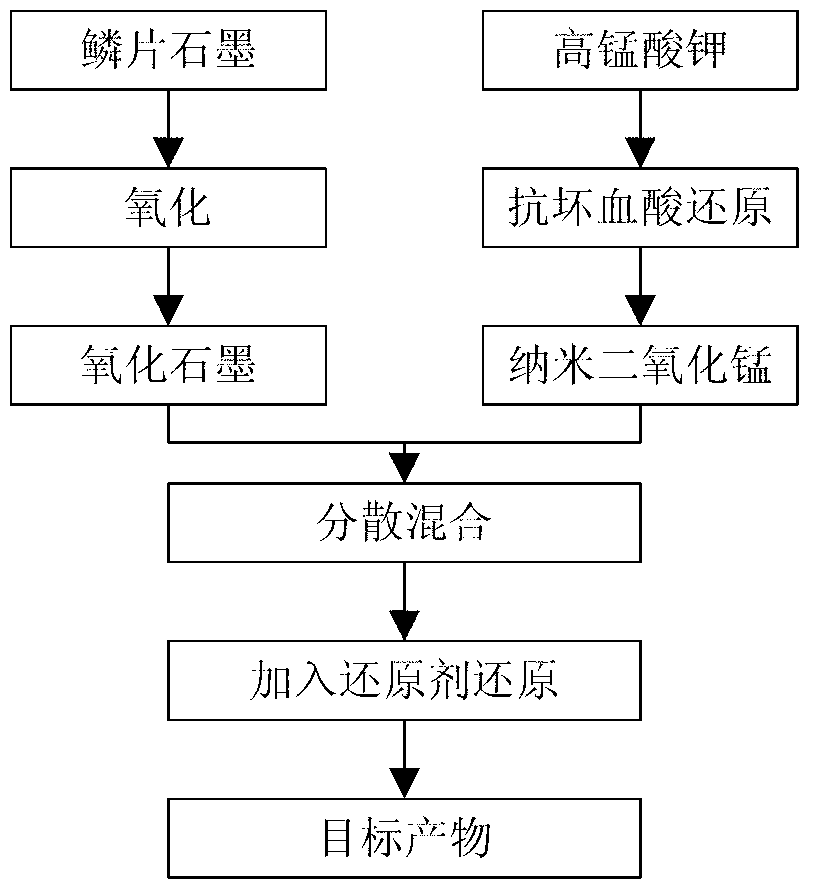

Graphene-cladding manganese dioxide combination electrode material and method for producing same

InactiveCN102709061AImprove conductivityImprove cycle stabilityElectrolytic capacitorsHybrid capacitor electrodesCvd grapheneNanometre

A graphene-cladding manganese dioxide combination electrode material and a method for producing the same, belonging to the technical field of electronic functional materials, the graphene-cladding manganese dioxide combination electrode material comprises nano manganese dioxide particles and graphene cladded with manganese dioxide particles, wherein the mass ratio of graphene and the nano manganese dioxide particles is 1:(1.25-10). The method comprises the following steps: preparing the nano manganese dioxide particles and graphite oxide respectively, and mixing and ultrasonically dispersing to obtain the graphene-cladding manganese dioxide dispersing agent, finally, reducing the graphite oxide to obtain the graphene-cladding manganese dioxide combination electrode material. The graphene is used to clad the manganese dioxide, so the electrical conductivity and cycling stability of the electrode material parts can be improved; and meanwhile, the existence of the manganese dioxide particles also effectively prevents the graphene from reunion, so the specific capacity of the electrode material of a supercapacitor is obviously increased. The method has a simple technology, reaction products are easy to control, the purity is high, and the produced combination electrode material is suitable for producing an electrode plate of the supercapacitor.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for preparing collagen-modified bacteria cellulose compound film

ActiveCN102352051APromote recoveryExcellent biocompatibility and wound repair abilityCosmetic preparationsToilet preparationsChemistryBacterial cellulose

The invention provides a method for preparing a collagen-modified bacteria cellulose compound film, which relates to relevant fields of biomedical medical materials, medical appliances and cosmetics. The preparation method comprises the following steps of: pretreating and purifying a bacteria cellulose film to obtain purified bacteria cellulose, and functionalizing the hydroxyl of the purified bacteria cellulose; and physically compounding or chemically combining the bacteria cellulose film and a collagen suspension to obtain a collagen-modified bacteria cellulose compound film. Due to the adoption of the collagen-modified bacteria cellulose compound film obtained with the method, the recovery of collagen content in defect tissues can be promoted, the problems of poor water permeability, poor air permeability, poor drainage and poor absorbing effect existing in the conventional collagen medicament are solved simultaneously; a novel method for collagen application is provided, high cell affinity is achieved, and the tissue growth is facilitated. The method has a simple preparation process and a mature process, and is suitable for industrial production of collagen-modified bacteria cellulose compound films with different requirements.

Owner:UNIV OF SCI & TECH BEIJING +1

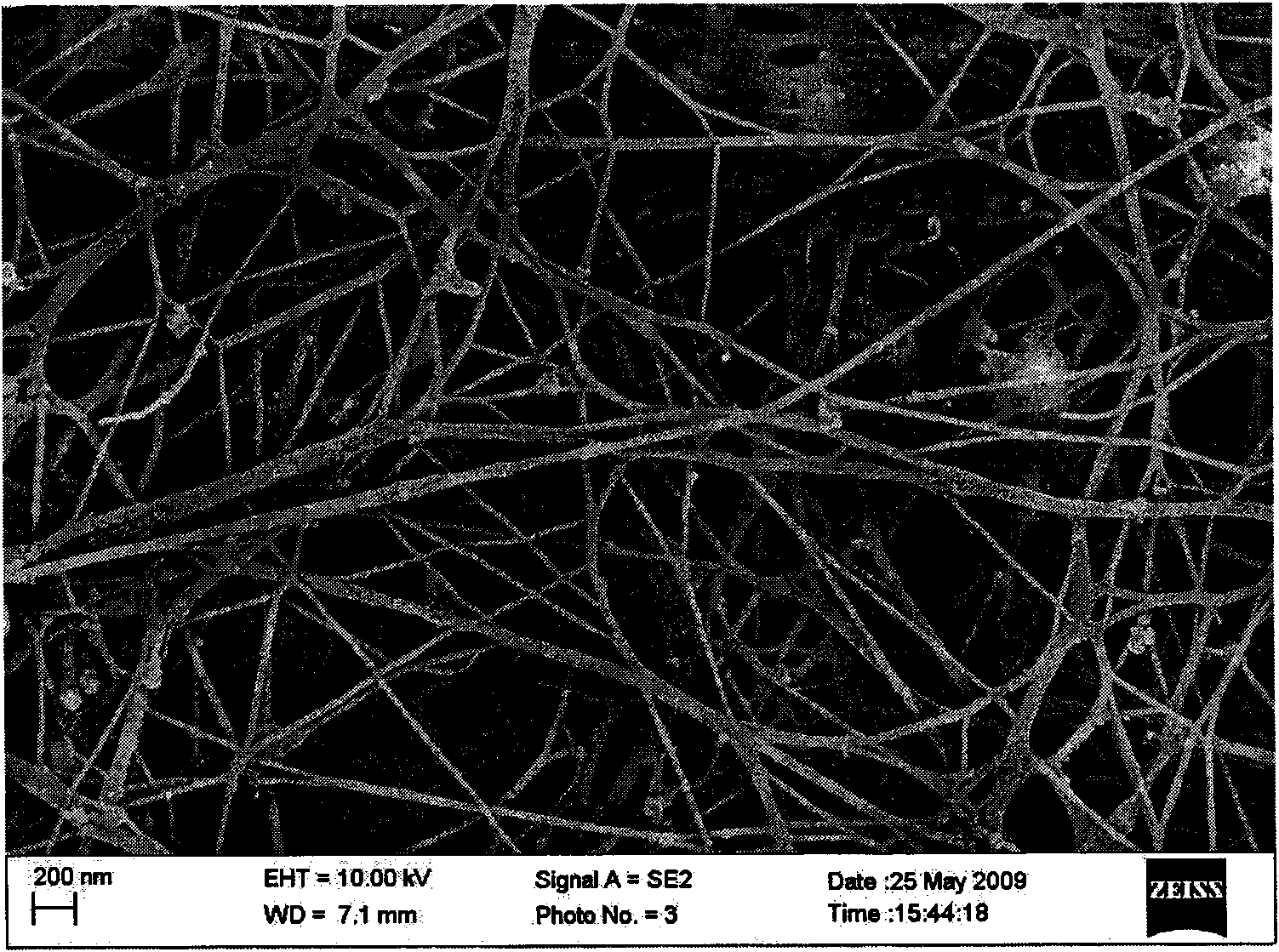

Preparation for in-situ compounding simple-substance nano silvery bacteria cellulose membrane

ActiveCN101586309AHigh antibacterial activityImprove antibacterial propertiesFibre treatmentMicroorganism based processesWound dressingFragility

The invention provides a preparation for the in-situ compounding simple-substance nano silvery bacteria cellulose membrane, and relates to the biological medical material field, characterized in that the bacteria cellulose membrane has special three-dimensional nano network structure, the silver-ammonia solution reacts with the chemical agent containing aldehyde group to generate silver simple-substance nano particle in situ in the network structure. In addition, in the invention, the special drying method is adopted to improve the defect of big fragility of the prepared silver-contained nano bacteria cellulose dry membrane. The bacteria cellulose membrane containing simple-substance nano silver particle provided by the invention has excellent antibacterial performance and simple preparation technique, and can be widely used in the biological medical field such as large-area wound dressing, bundling belt and the like, also can be used in the industry field such as the preparation of nano silver particle and silver catalyst, and the like.

Owner:UNIV OF SCI & TECH BEIJING +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059152AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

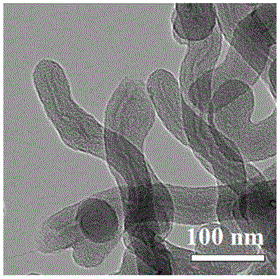

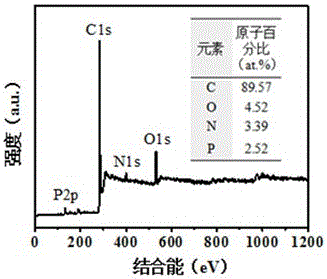

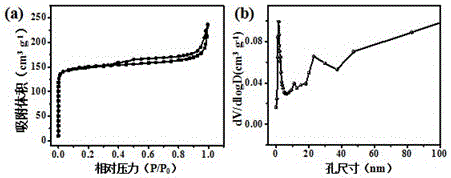

Nitrogen and phosphor co-doped porous carbon nanotube, and preparation method and application thereof

InactiveCN105006375AThe content is easy to controlQuantity is easy to controlMaterial nanotechnologyHybrid capacitor electrodesPorous carbonHigh capacitance

The invention relates to a preparation method of a nitrogen and phosphor co-doped porous carbon nanotube. The method includes the following steps: 1) preparing a carboxylation carbon nanotube; 2) preparing a melamine-phenolic resin wrapped carbon nanotube by taking melamine-resorcinol-presence of formaldehyde resin as a precursor; and 3) conducting phosphatization: mixing the melamine-phenolic resin wrapped carbon nanotube obtained from the step 2) with a phosphatization agent, dispersing the mixture in deionized water in an ultrasonic manner, drying the mixture, enabling a dried product to rise to 600-900 DEG C in an inert atmosphere and to be phosphatized for 120-180min, naturally cooling the product to a room temperature, washing obtained black powder with water, performing pumping filtration until the powder is neutral, drying and finally obtaining the nanotube. The prepared nitrogen and phosphor co-doped porous carbon nanotube enables the specific capacitance of a capacitor to be substantially increased.

Owner:ZHENGZHOU UNIV

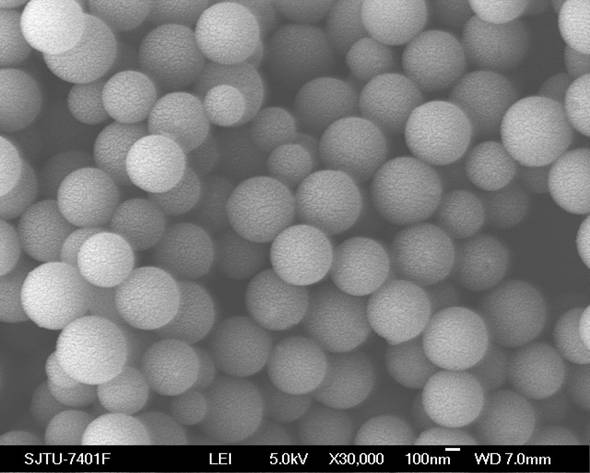

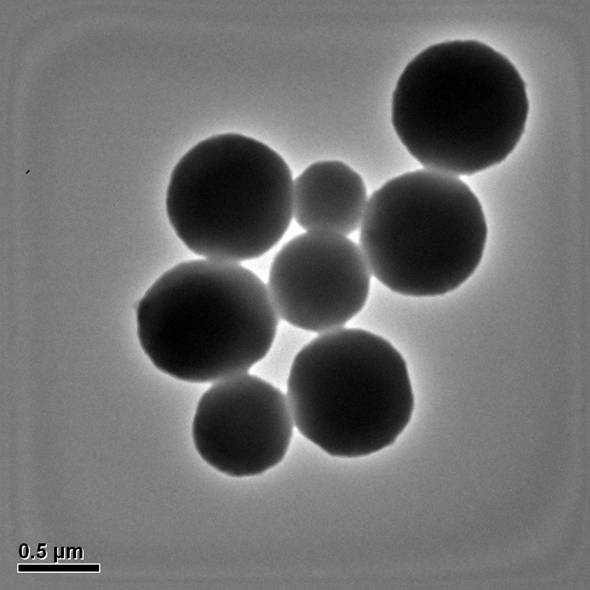

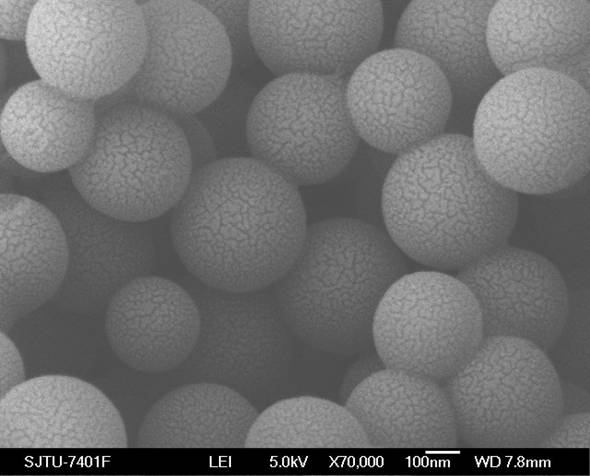

Method for preparing porous carbon spheres doped with nitrogen and phosphorus and application

The invention belongs to the technical fields of inorganic material chemistry and new energy, and discloses a method for preparing porous carbon spheres doped with nitrogen and phosphorus and an application. Water serves as a solvent, polyphosphazenes microspheres and activating agents are mixed in a mass ratio of (0.2-2):1, concentration of the polyphosphazenes microspheres is maintained at a level of 10-30wt%, stirring is performed completely, the mixture of the polyphosphazenes microspheres and the activating agents is obtained through centrifugal separation, the mixture of the polyphosphazenes microspheres and the activating agents is subjected to carbonization, and finally the porous carbon spheres doped with the nitrogen and the phosphorus are obtained. The activating agents are potassium hydroxide, sodium hydroxide, calcium chloride or zinc chloride. The polyphosphazenes microspheres serve as a carbon precursor in the method, are synthesized directly under the room temperature condition, and has a simple art process and high productivity. Simultaneously, the activating agents are used for processing polyphosphazenes so as to improve specific surface areas and pore structures of the porous carbon spheres greatly and be beneficial to improve hydrogen storage capacity.

Owner:ZHENGZHOU UNIV

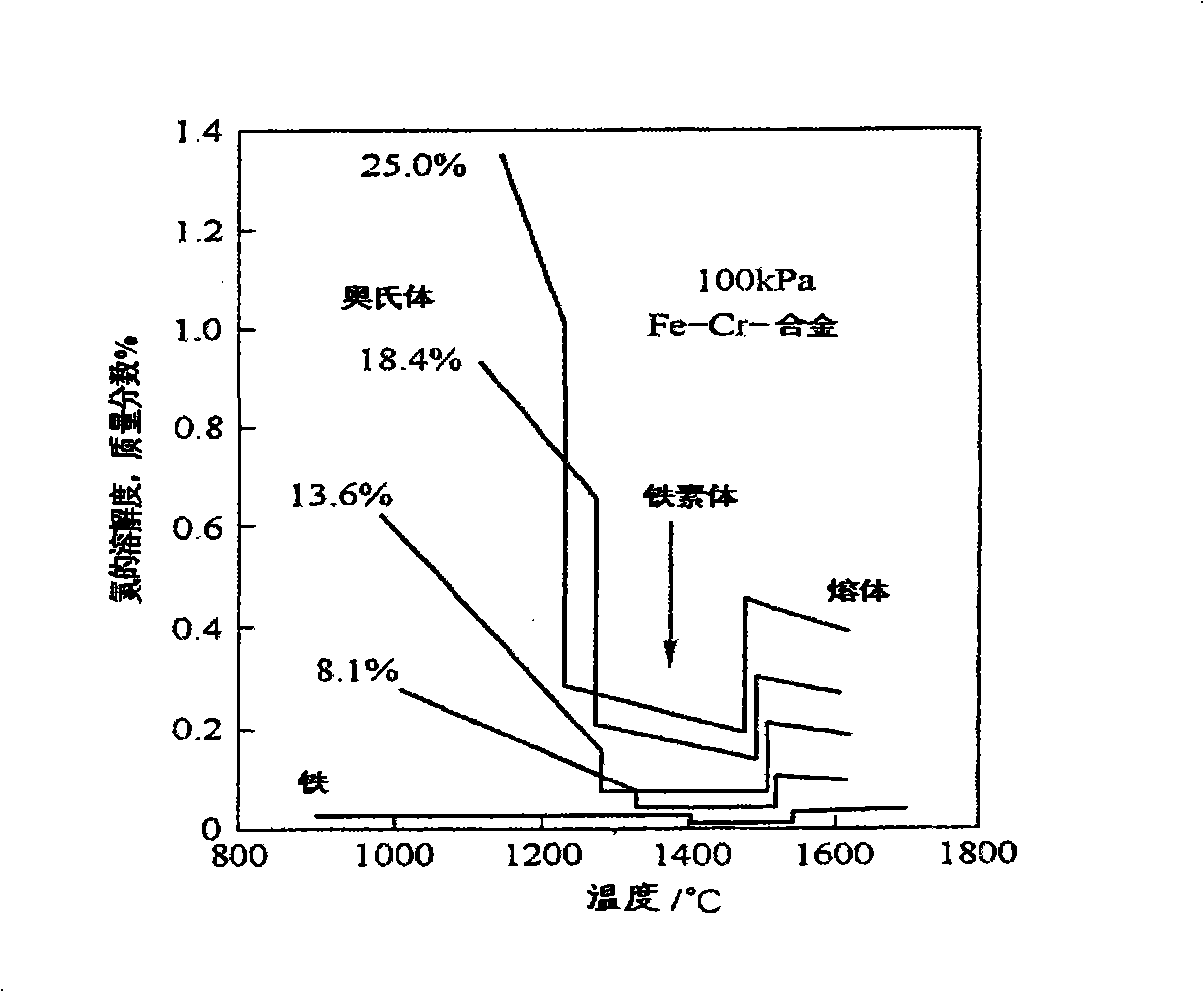

Method of manufacturing powder metallurgy nitrogen/high nitrogen containing stainless steel parts

The present invention relates to a method for preparing powder metallurgic nitrogen-contained / high-nitrogen stainless steel components, and comprises the following steps: raw materials preparation, forming, degreasing treatment, sintering and other static press, wherein, during the static press such as the sintering, the temperature increasing speed is 3 to 10 DEG C per minute; the sintering gas is the pure nitrogen or the mixed gas of the nitrogen, hydrogen and the argon; the pressure / partial pressure of the nitrogen is consistent with the solubility of the nitrogen in the alloy system; the sintering temperature is 1200 to 1450 DEG C, and the heat preservation period is 10 to 20 minutes; after the density is more than 90 to 95 percent, the pressure is increased to 3 to 10 MPa; the partial pressure is maintained the same during the pressure increasing process, and the pressure is distributed on the argon and the hydrogen, and the heat preservation period is 60 to 240 minutes; after the density is more than 99 percent, the pressure is decreased and rapid cooling is performed. The content of the nitrogen of the component that is made with the method hereinabove can be controlled to the highest level; the composition constitution is uniform, the density is high, the flexibility is good, the deformation is less, the precision is high and the corrosion-resistance is good.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

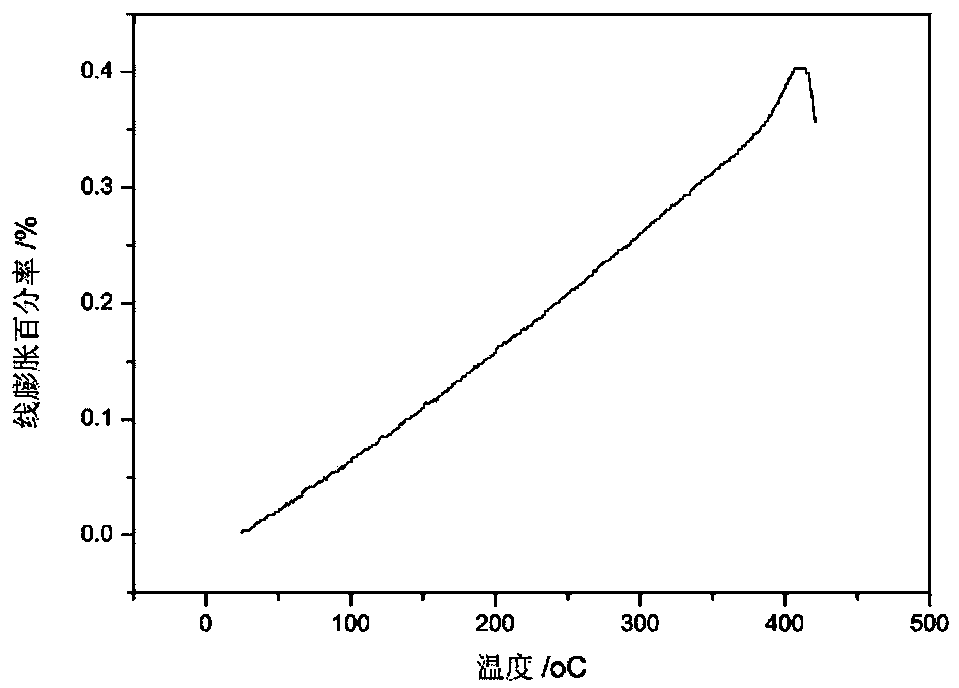

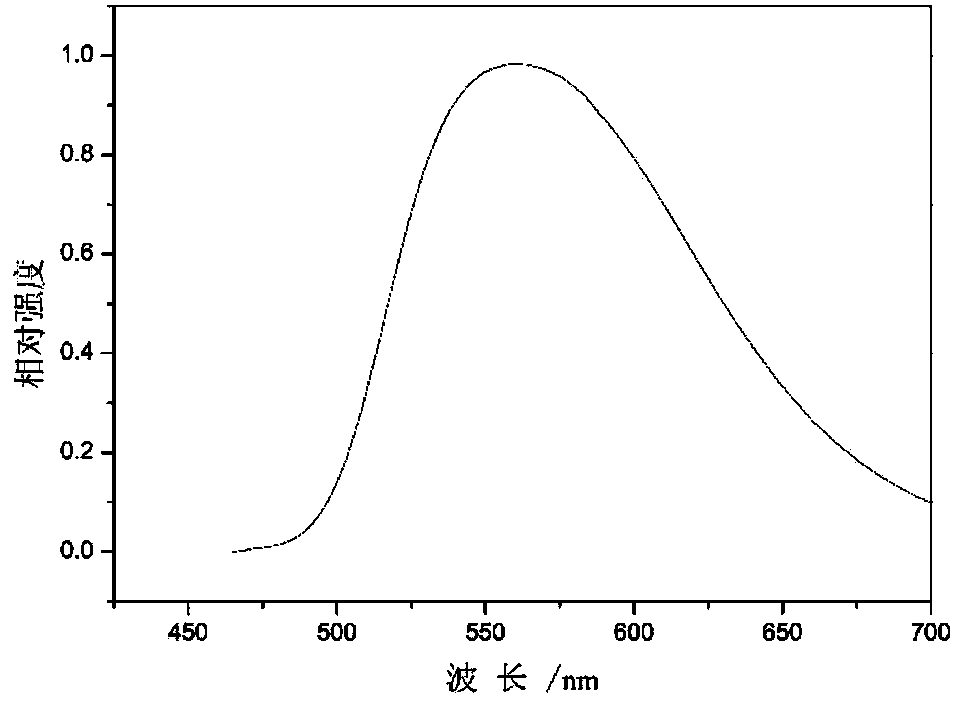

Semitransparent fluorescent powder/glass composite luminescent ceramic wafer and preparation method thereof

The invention relates to a semitransparent fluorescent powder / glass composite luminescent ceramic wafer and a preparation method thereof. The semitransparent fluorescent powder / glass composite luminescent ceramic wafer is obtained by carrying out 'pelletizing, compression moulding and sintering' on fluorescent powder and low-melting-point glass powder, wherein content of the fluorescent powder is 30-85wt%, and the content of the low-melting-point glass powder is 70-15wt%. The preparation method of the semitransparent fluorescent powder / glass composite luminescent ceramic wafer comprises the following steps: firstly, uniformly mixing fluorescent powder with glass powder in certain proportion, and adding a binding agent required by pelletizing and demoulding, so that pelletized powder of 60-100 meshes is obtained; secondly, carrying out compression moulding on the obtained pelletized powder by virtue of a mould, so that a green body of a certain shape is obtained; thirdly, carrying out heat treatment, namely carrying out glue drainage on the green body for 2-4 hours at the temperature of 300-395 DEG C, and sintering for 1-2 hours at the temperature of 395-410 DEG C, wherein the whole heat treatment process is carried out in the air atmosphere; and finally the fluorescent powder / glass composite luminescent ceramic wafer is obtained.

Owner:厦门百嘉祥微晶材料科技股份有限公司

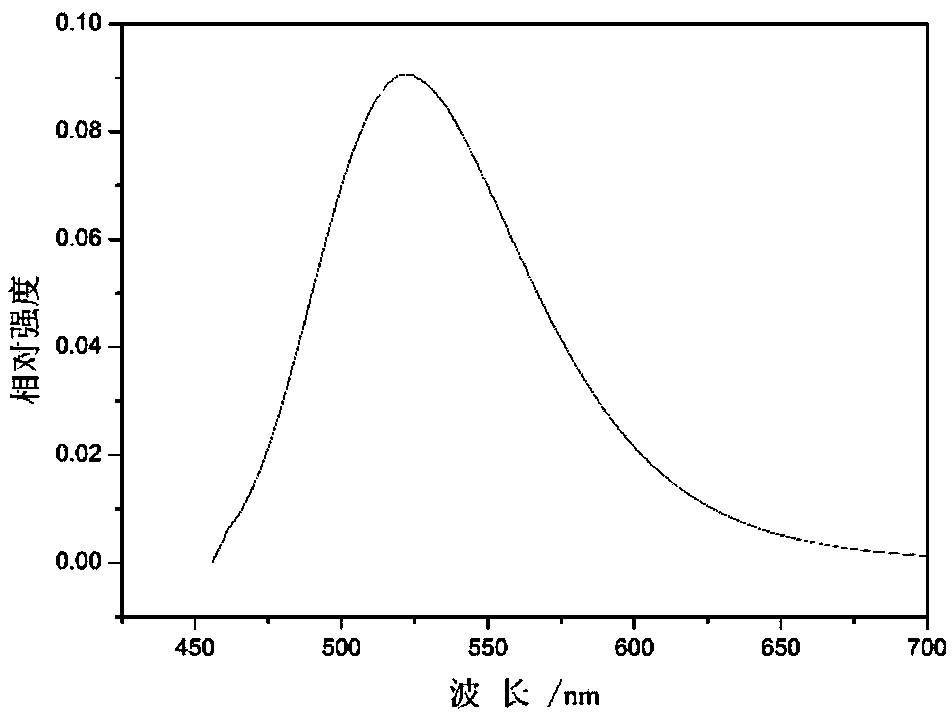

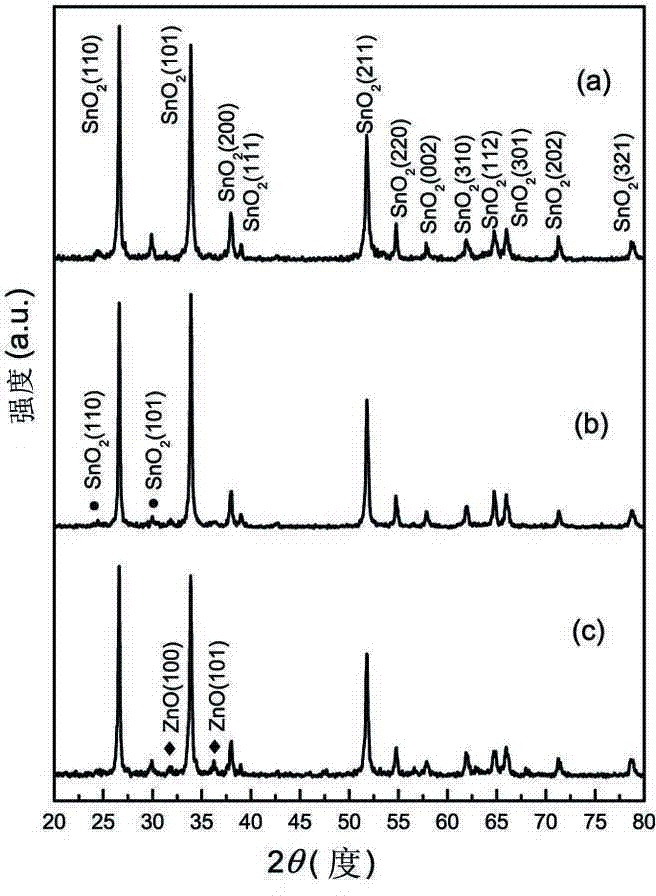

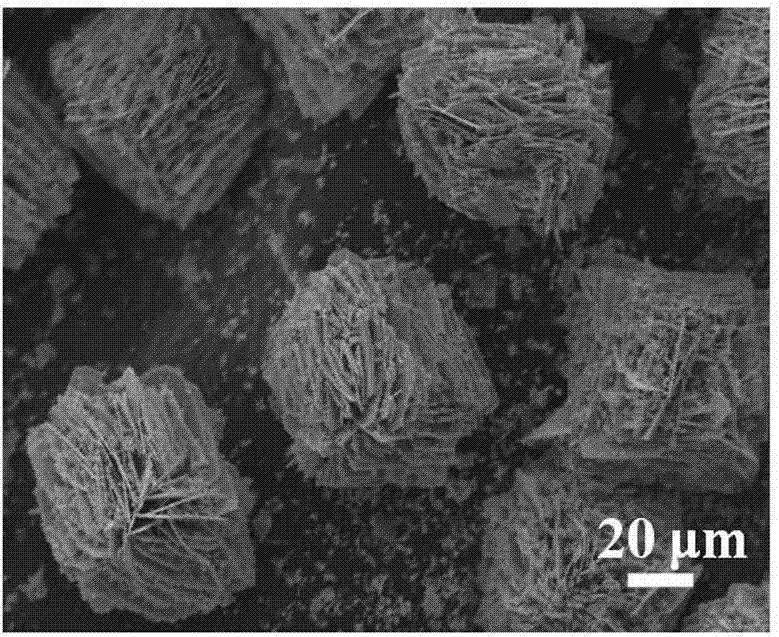

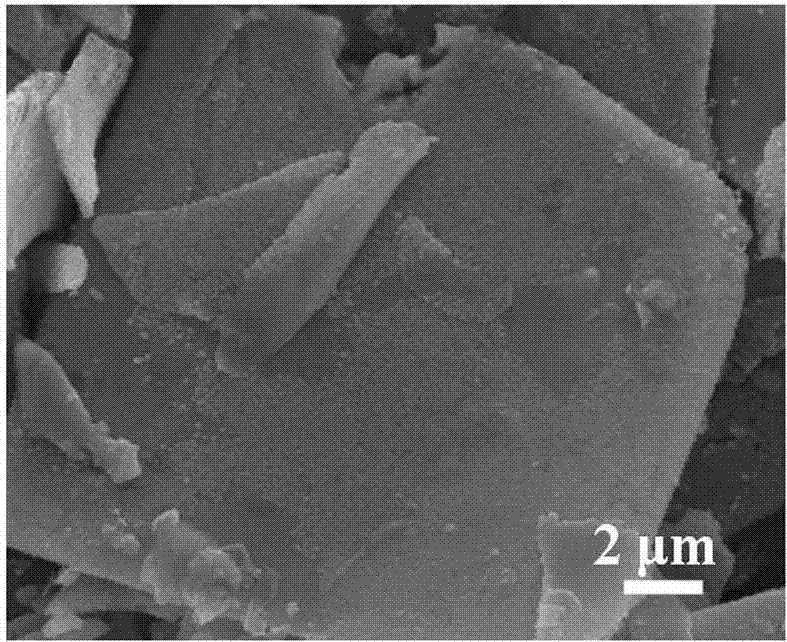

ZnO/SnO2 nano composite gas-sensitive material with flower-shaped grading structure and preparation method of material

InactiveCN103776870AReduced ethanol gas sensitivity performanceGood dispersionMaterial nanotechnologyMaterial analysis by electric/magnetic meansAir atmosphereSTANNOUS OXIDE

The invention provides a ZnO / SnO2 nano composite gas-sensitive material with a flower-shaped grading structure. The ZnO / SnO2 nano composite gas-sensitive material is prepared by the following steps: dripping a sodium hydroxide water solution into an ethanol solution of cetyl trimethyl ammonium bromide and stannous chloride dihydrate under electromagnetic stirring; after dripping, preparing a precursor solution by the continuous electromagnetic stirring; adding the precursor solution into a reaction kettle, reacting at 130 DEG C; carrying out centrifuging on a reactant, washing and drying to obtain a flower-shaped stannous oxide sacrifice template; adding the flower-shaped stannous oxide sacrifice template into a zinc acetate solution; agitating and carrying out ultrasonic treatment; removing a solvent to obtain a ZnO / SnO2 precursor; and carrying out heat preservation on the ZnO / SnO2 precursor for 2-4 hours in an air atmosphere of 700 DEG to obtain the composite gas-sensitive material. According to the ZnO / SnO2 nano composite gas-sensitive material with the flower-shaped grading structure, the controllable preparation of the composite gas-sensitive material on the appearance and components can be realized; the mass percent content of zinc oxide in the composite gas-sensitive material is 5%-15%; a flower shape is assembled by sheet-shaped tin dioxide and zinc oxide nano particles; the ZnO / SnO2 nano composite gas-sensitive material has a good gas sensitive performance and has a wide application prospect in the aspect of manufacturing a novel high-efficient gas sensor.

Owner:HENAN POLYTECHNIC UNIV

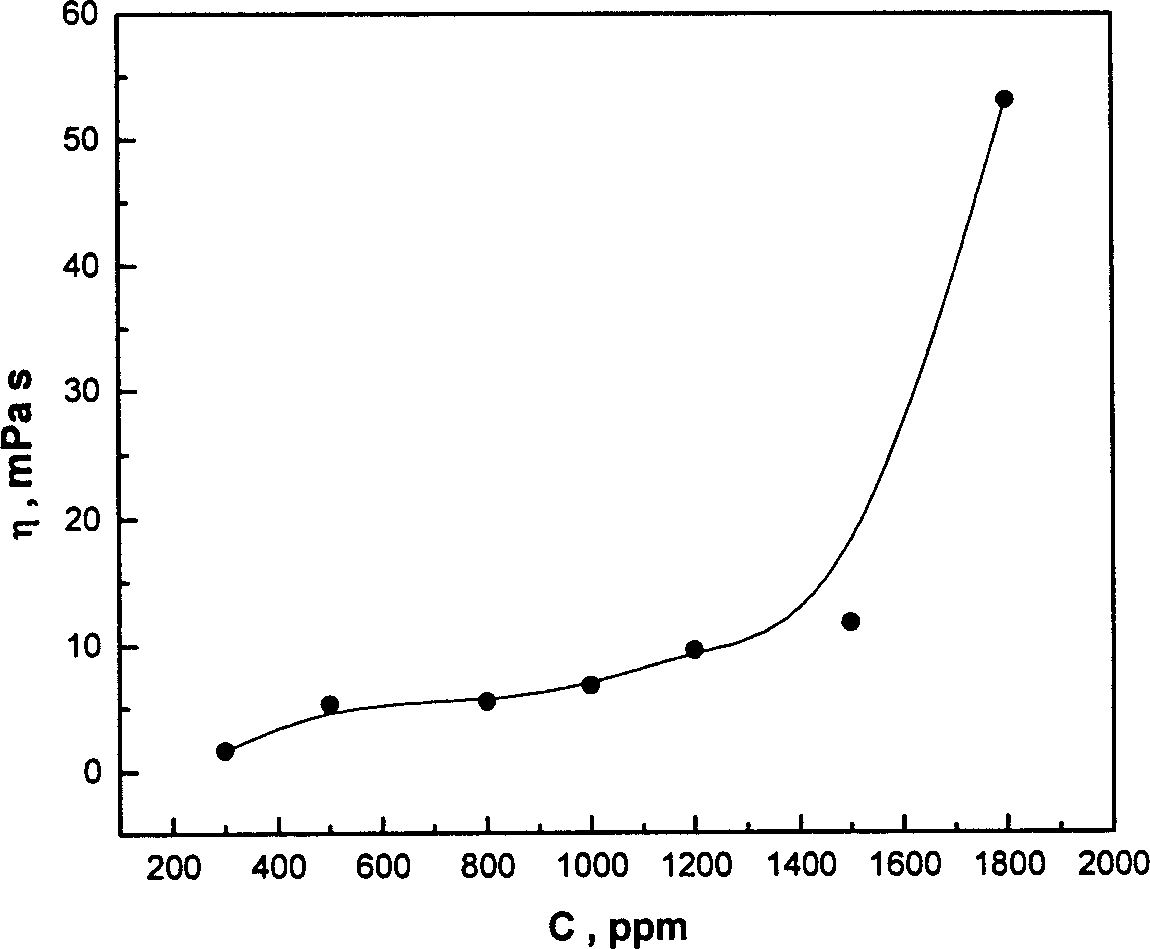

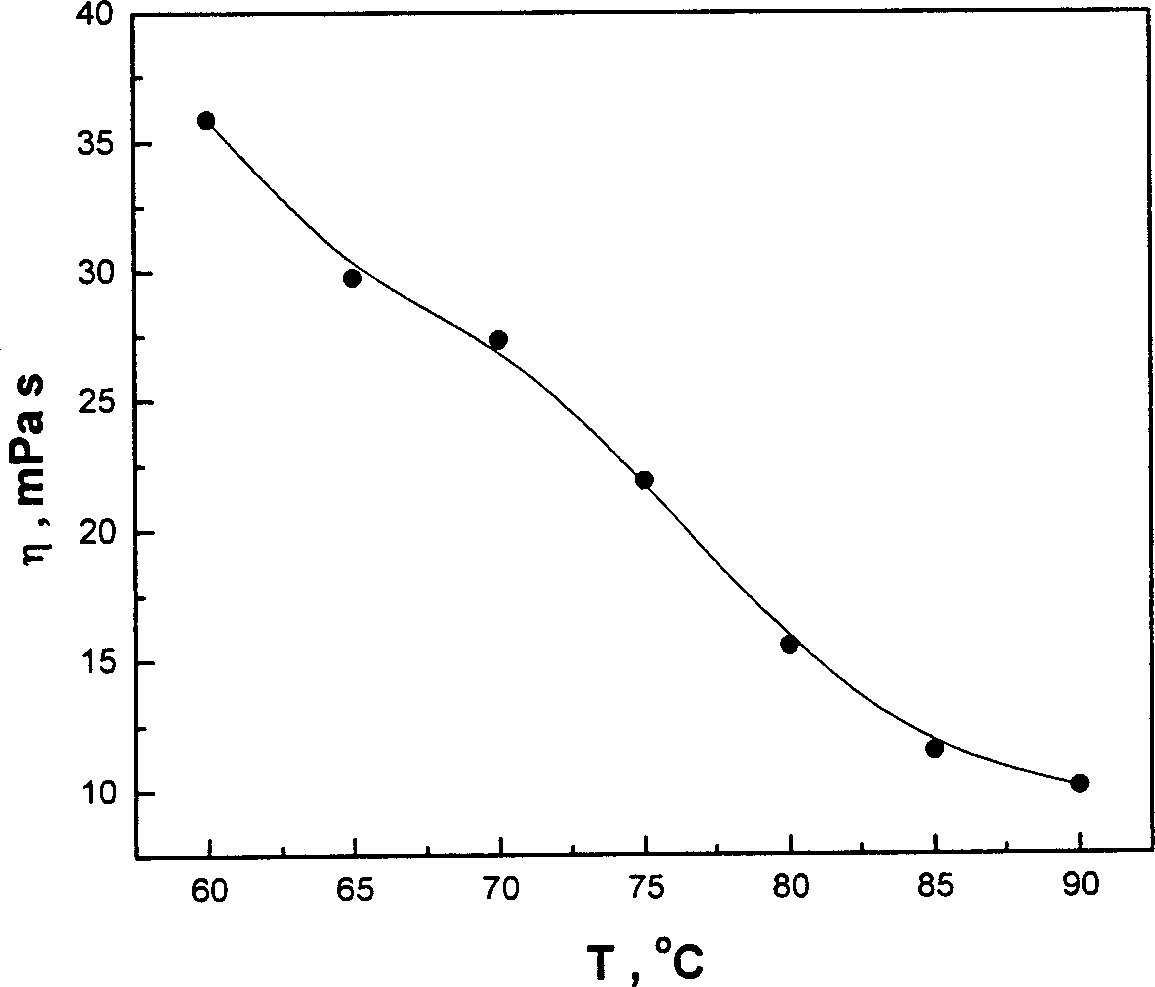

Hydrophobically associating polyacrylamide and its preparing method

The invention discloses a kind of hydrophobic association polyacrylamide and its preparative method. The product is the copolymer of acrylamide and dendritic I branch-like hydrophobic monomers, in which, the amount of monomeric unit of acrylamide is integer of 124013~139860, the amount of monomeric units of dendritic hydrophobic monomers is integer of 140~6527. In the invention, high degreed branching hydrophobic monomers are inlet on a chain of macromolecules by the way of micelles' copolymerization, the monomers can promote the capability of hydrophobic interaction of polymers' chain without any curling for its greater hydrophobic volume, so a better viscosity can be achieved. The content of the hydrophobic chain can be controlled by the way of controlling the amount of hydrophobic monomers to improve the solubility of copolymer

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

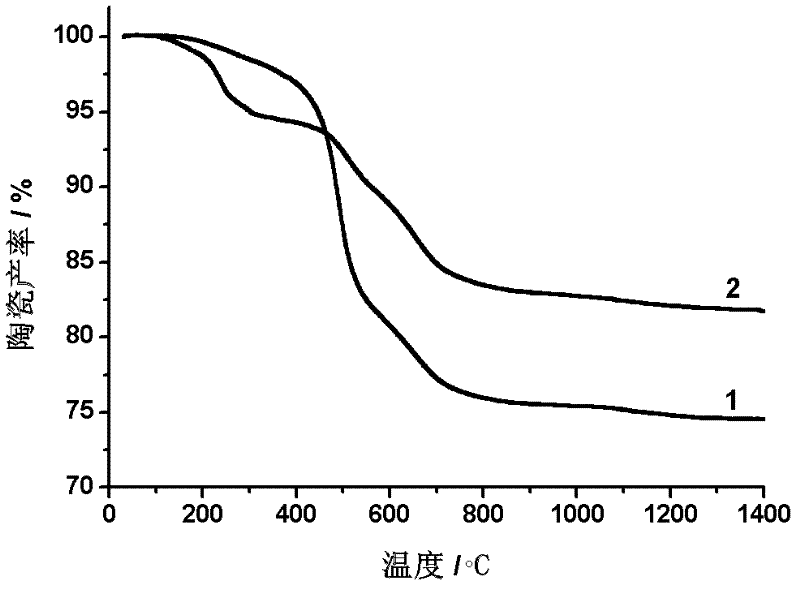

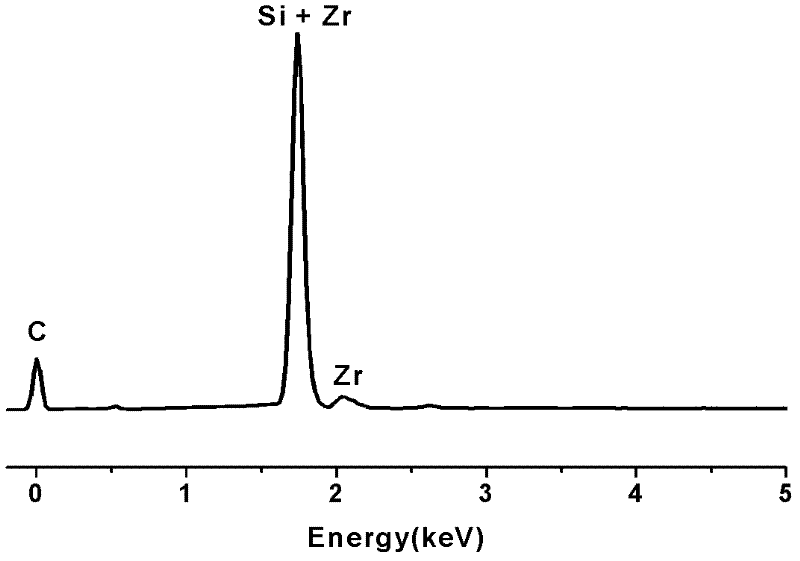

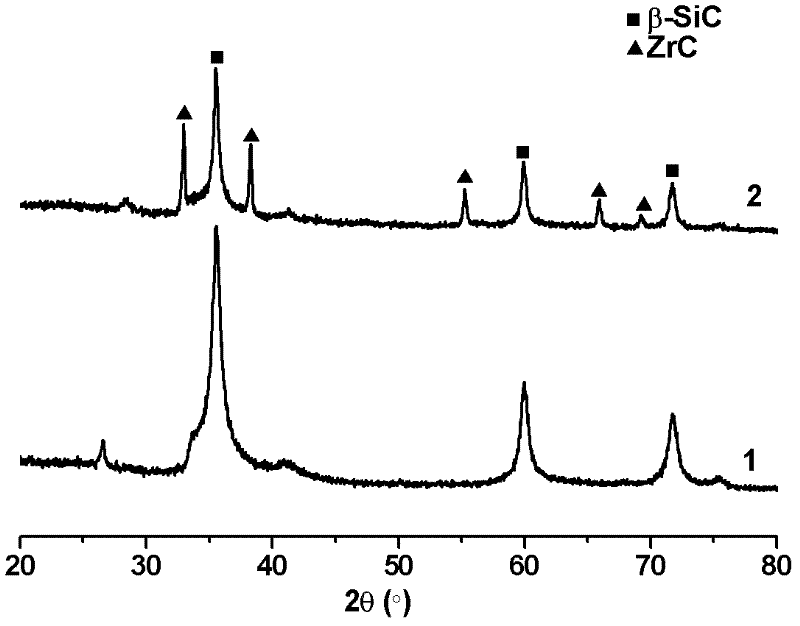

Preparation method of silicon carbide/zirconium carbide composite ceramic

The invention relates to a preparation method of silicon carbide / zirconium carbide composite ceramic, and relates to inorganic nonmetal material composite ceramic. The preparation method comprises the steps of: dissolving bis(cyclopentadienyl) zirconium dichloride with a solvent under the protection of inert atmosphere, and adding liquid hyperbranched polycarbosilane to obtain a mixture A; and distilling the mixture A under reduced pressure under the protection of inert atmosphere to remove the solvent, and carrying out cracking reaction in inert atmosphere to obtain the silicon carbide / zirconium carbide composite ceramic. According to the invention, bis(cyclopentadienyl) zirconium dichloride is used as a zirconium source, and is used for catalyzing the crosslinking reaction of liquid hyperbranched polycarbosilane, so as to increase ceramic yield; zirconium carbide can inhibit the growth of silicon carbide microcrystal grains, and improve high-temperature resistance and oxidation resistance of the composite material; the zirconium content in the composite ceramic can be controlled by controlling the content of bis(cyclopentadienyl) zirconium dichloride in a hybrid precursor; the liquid hyperbranched polycarbosilane / bis(cyclopentadienyl) zirconium dichloride hybrid precursor is free of oxygen, thus the gas escaped in the high-temperature cracking process is reduced; the ceramic has high compactness; and the preparation method is simple to operate, and is easy for engineering.

Owner:XIAMEN UNIV

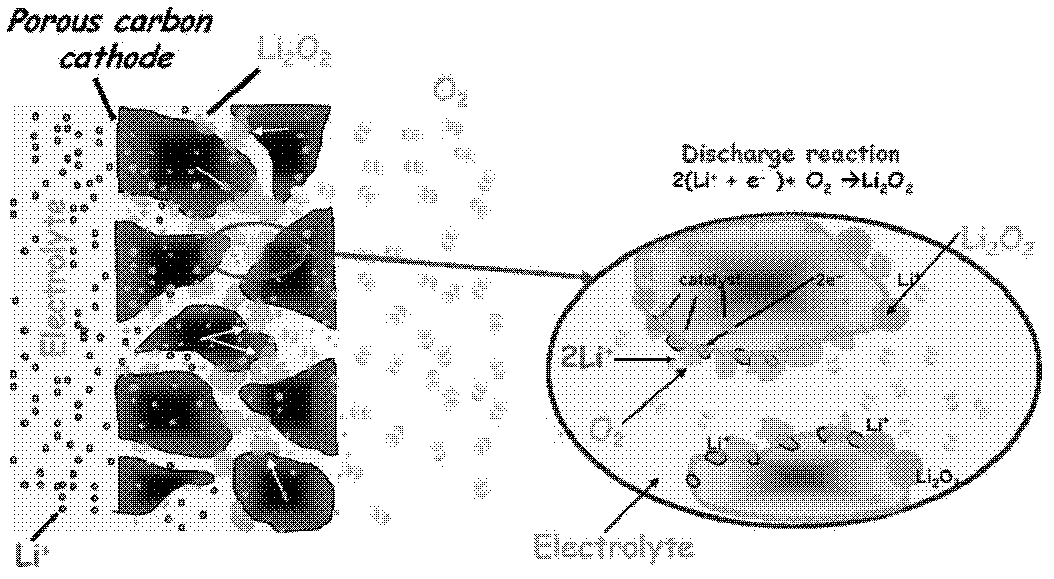

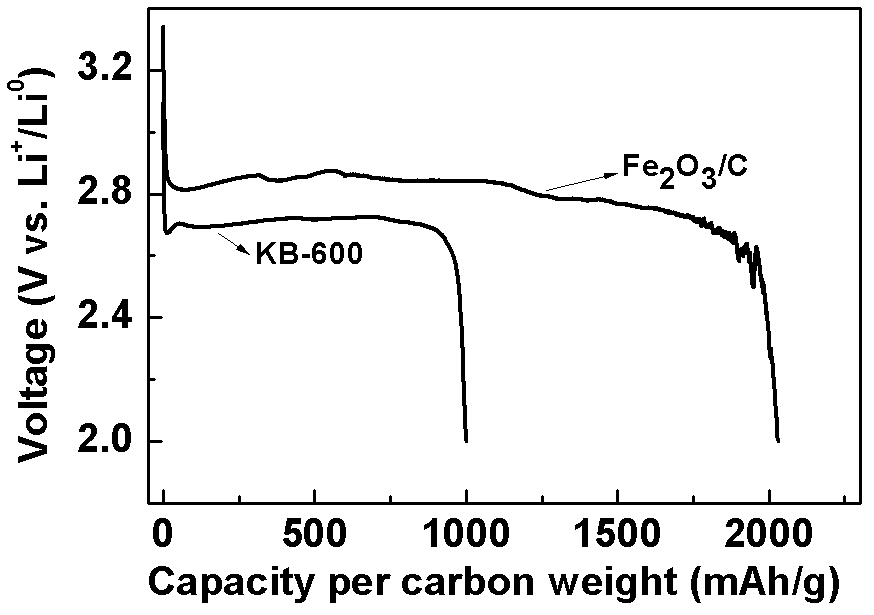

Application of carbon material containing in-situ doped component with catalytic activity to lithium-air battery

InactiveCN103050702AEvenly dispersedGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsIn situ dopingLithium–air battery

The invention relates to an application of a carbon material containing an in-situ doped component with catalytic activity to a lithium-air battery. The carbon material containing the in-situ doped component with catalytic activity is used as an electrode material in the lithium-air battery, the component with catalytic activity is doped in the carbon material in situ, and the component with catalytic activity is 1-80wt% of the carbon material. The component with catalytic activity is doped in situ in the preparation process of the carbon material and controllable in content, and the component with the catalytic activity is uniformly dispersed in the prepared carbon material, so that the dispersibility and coverage degree of the component with catalytic activity on the surface of the carbon material are greatly improved, the utilization ratio of the component with catalytic activity is increased in the charging and discharging processes, the discharging and discharging polarization potentials are reduced, and the energy efficiency of the lithium-air battery is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

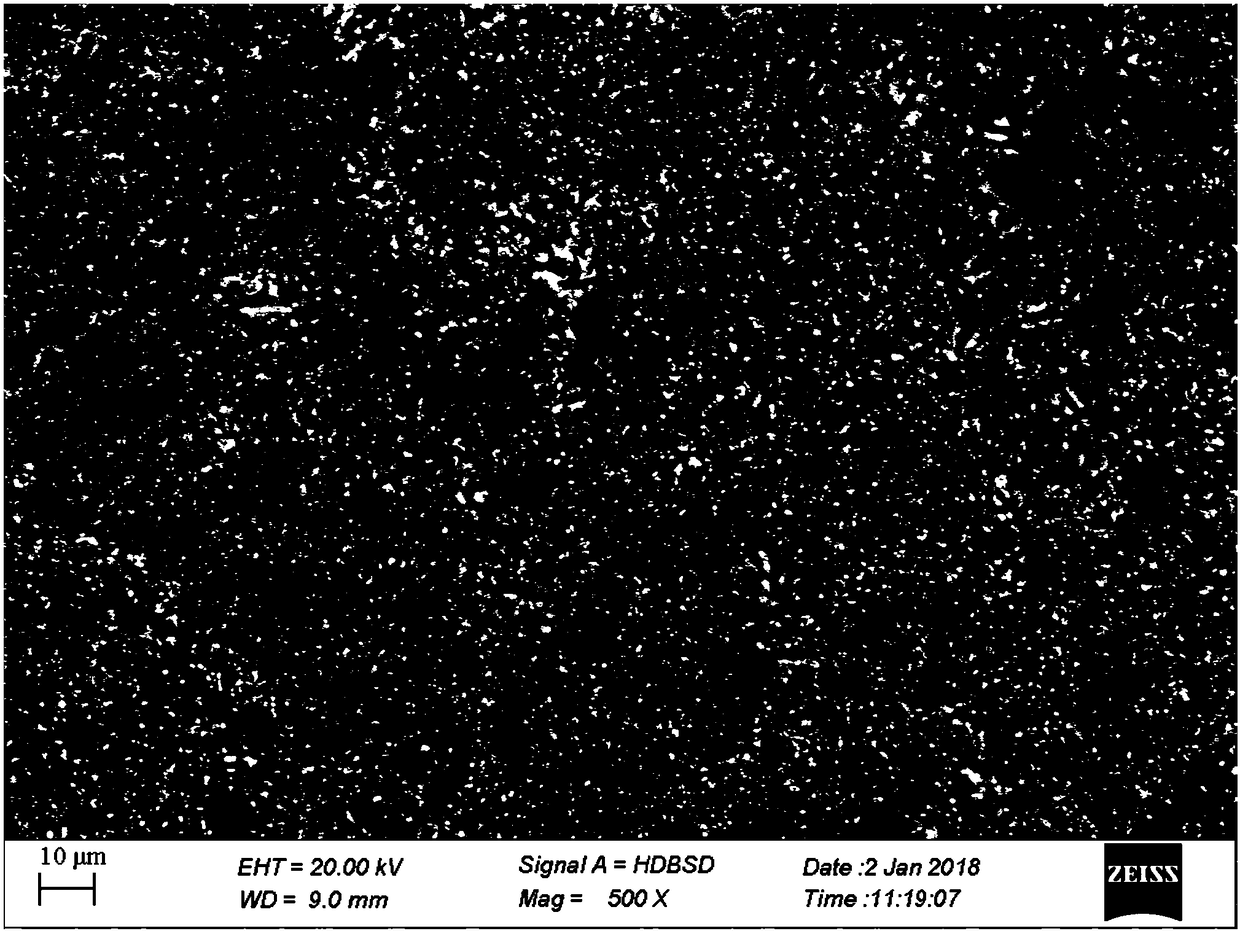

Preparation method of in-situ grown graphene reinforced metal-based composite material

The invention relates to a preparation method of an in-situ grown graphene reinforced metal-based composite material. Carbon-containing organic matter and metal or metal alloy powder are dissolved and mixed in a solvent, mechanically stirred, heated at the temperature of 50-150 DEG C and mixed, the solvent is evaporated, and prefabricated powder is obtained through vacuum drying at the temperature of 50-100 DEG C and grinding; and through the powder metallurgy technique of a hot-press forming method or a cold-press-sintering method or an SPS sintering method, the prefabricated powder is pressed and formed, the carbon-containing organic matter is transformed into graphene, and the three-dimensional graphene / metal-based composite material is obtained. The preparation method is simple, easy to implement and short in preparation cycle, and industrialized batch production is easy; and in addition, the graphene directly grows on a metal matrix in the preparation process, the crystallisation degree of the graphene in the obtained graphene reinforced metal-based composite material is high, the number of defects is small, and the dispersity is good. The preparation method has potential application prospects in the composite material field, the functional material field and the like.

Owner:TIANJIN UNIV

Silver nanoparticle-containing bacterial cellulose membrane and preparation method thereof

The invention relates to a silver nanoparticle-containing bacterial cellulose membrane and a preparation method thereof. Silver nanoparticles in the bacterial cellulose membrane are attached to the microfiber surface of a three-dimensional network structure of the bacterial cellulose membrane, and the silver nanoparticles are in an amount which is 0.1 to 15 percent of the total weight of the cellulose membrane and have the particle size of between 8 and 50nm. The preparation method comprises the following steps of: soaking the bacterial cellulose membrane in silver salt solution at room temperature for 10 minutes to 5 hours and taking the soaked membrane out; cleaning the surface of the bacterial cellulose membrane by using distilled water; irradiating by an ultraviolet radiation method for 0.5 to 6 hours to obtain a silver nanoparticle-containing bacterial cellulose wet membrane; and performing dehydration treatment to obtain the silver nanoparticle-containing bacterial cellulose membrane. The bacterial cellulose membrane has high bacteria resistance, high air permeability, high water-holding capacity and controllable moisture content and is suitable to be used as a trauma medical dressing; and in the invention, a chemical reduction reagent is not required to be added, an environment-friendly and safe process condition is realized, and equipment is simple and pollution-free.

Owner:DONGHUA UNIV

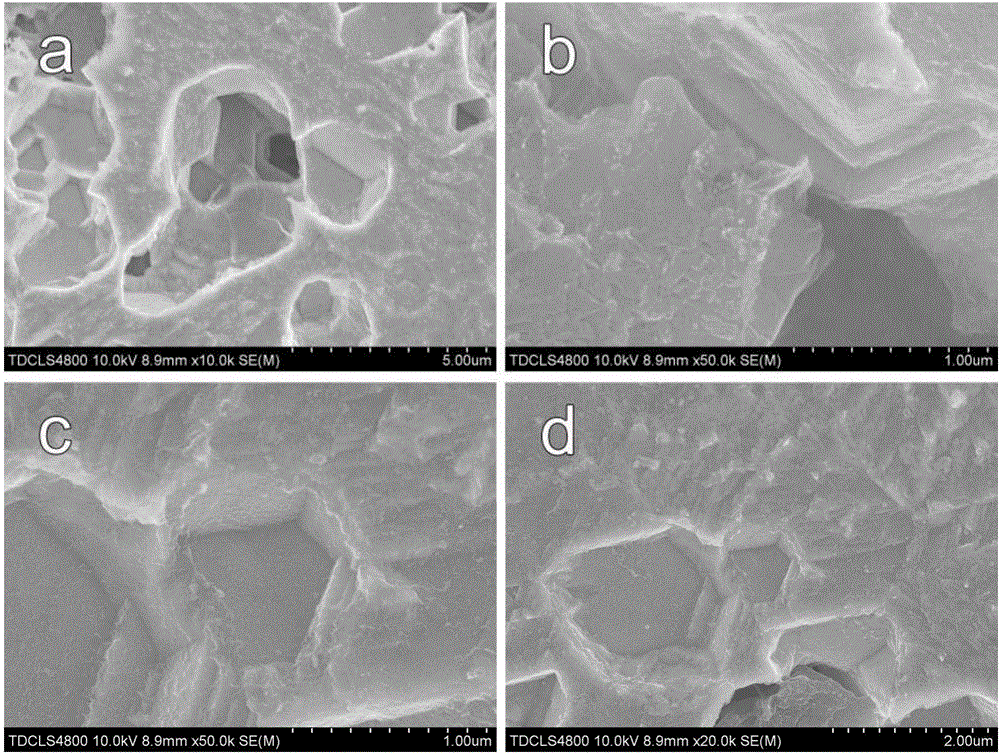

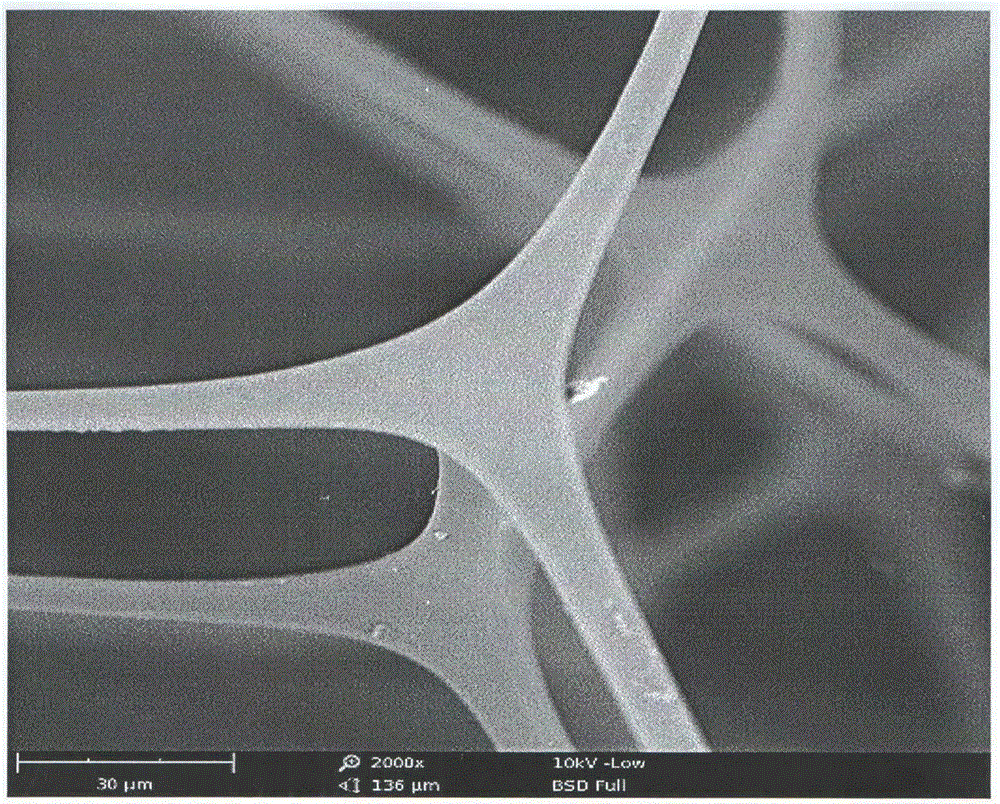

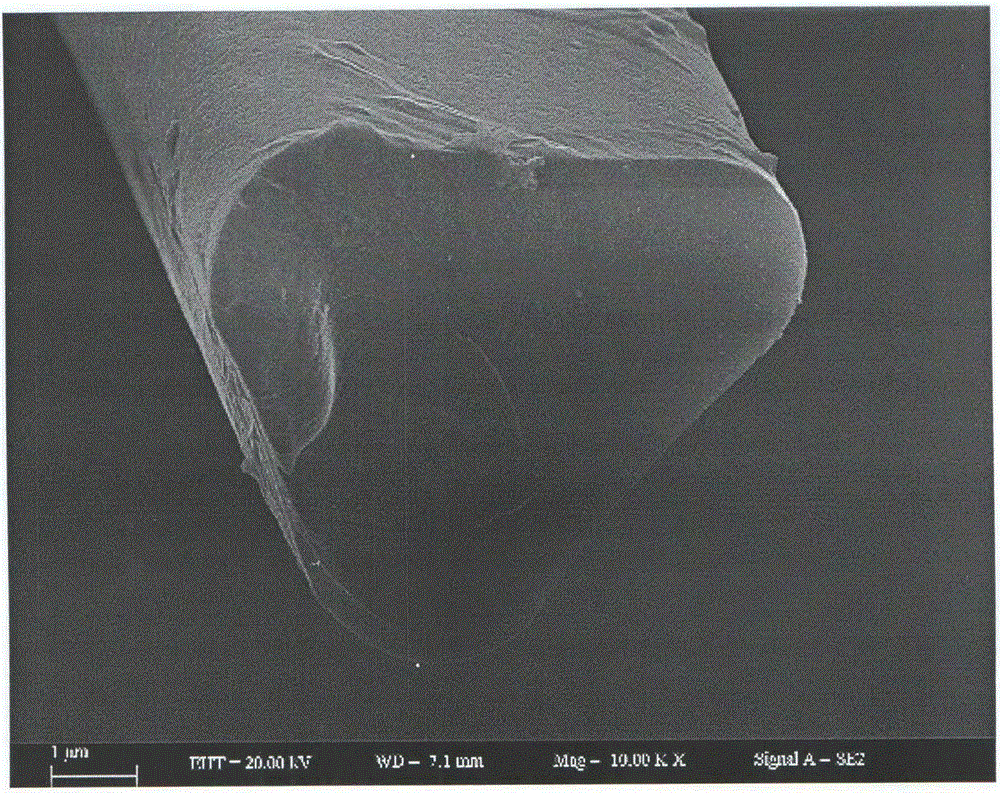

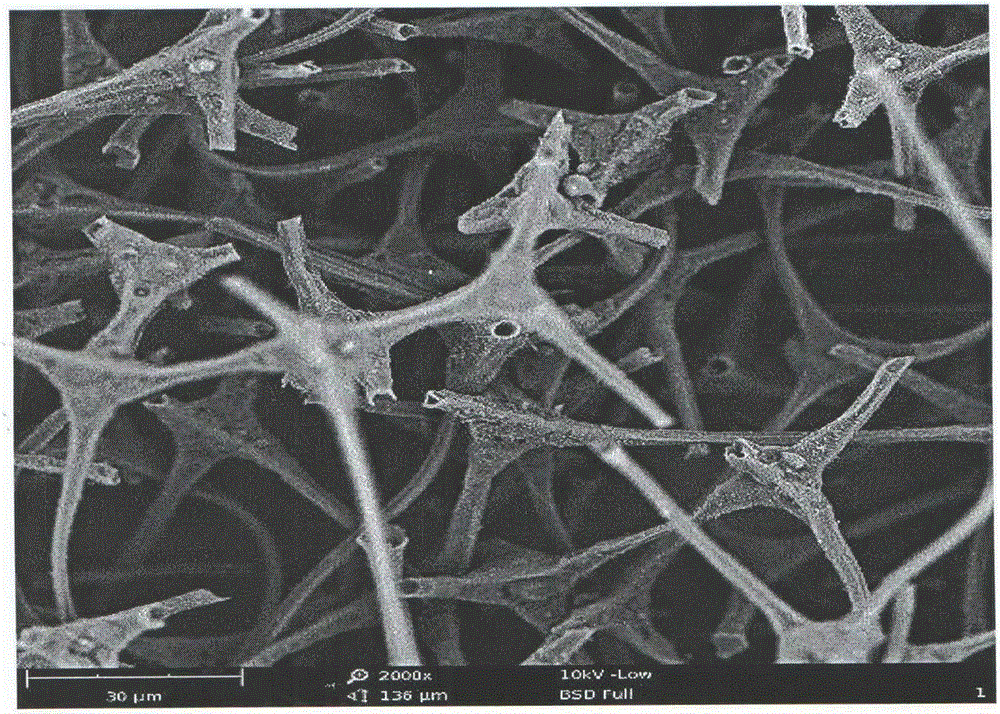

Preparing method for carbon nano tube foam material

ActiveCN105217603AExtensive sources of materialsLow costMaterial nanotechnologyMultiple dimensionControlled experiment

The invention provides a preparing method for a carbon nano tube foam material. The method comprises the steps that cheap polymer foam serves as a template, the processes of in-situ formation of a catalyst, partial thermal cracking removing of the polymer template, growth of carbon nanomaterials and the like are synchronously carried out by controlling experiment conditions, and the carbon nano tube foam material efficiently grows, wherein the carbon nano tubes are wound and woven into a mesh structure in the three-dimensional directions of a carbon framework and have distributed pore diameters of multiple dimensions, and the obtained material has the large specific surface area, the controllable porosity, good hydrophobicity, excellent electrical conductivity, a unique hollow frame structure, and application value in the fields of composite materials, sensing, oil and water separation and the like. According to the method, reaction conditions such as gas flow, gas introducing time, the reaction temperature and the catalyst are optimized, and thus the carbon nano tube foam material of a foam structure is obtained and has excellent adsorption performance on various kinds of oil and organic solvent. The defect of an existing carbon nano tube foam material preparing method is overcome.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +2

Preparation method for zeolite-immobilized photocatalyst

ActiveCN106362787ALow priceEasy to makeWater/sewage treatment by irradiationMolecular sieve catalystsNatural substanceSingle crystal

The invention relates to preparation technology of a photocatalyst and aims to provide a preparation method for a zeolite-immobilized photocatalyst. The preparation method comprises the following steps: dispersing a photocatalyst in deionized water, then adding a silicon source and carrying out a reaction under stirring; taking a reaction product out for washing and drying, subjecting the dried reaction product to mixing with a template and an aluminum source and then carrying out grinding; filling a reaction vessel with a mixture obtained in the previous step and carrying out solid-phase crystallization so as to produce a carrier with a zeolite structure; and washing and drying the carrier and then carrying out sintering in a muffle furnace to remove the template so as to obtain the zeolite-immobilized photocatalyst. According to the method, the usage amount of the template is low; due to improvement of the preparation method, the photocatalyst can be perfectly enveloped in a zeolite monocrystal, and the content of the photocatalyst is controllable; raw materials used in the method is low, and preparation process is simple; and in subsequent application, the utilization rate of the photocatalyst is high, the yield of the zeolite-immobilized photocatalyst is high, and the zeolite-immobilized photocatalyst has high organic pollutant degradation rate and exerts good protection effect on natural substances.

Owner:ZHEJIANG UNIV

Neodymium iron boron permanent magnet material and preparation method thereof

ActiveCN102237166AThe content is easy to controlImprove microstructureInductances/transformers/magnets manufactureMagnetic materialsCompression moldingAlloy

The invention relates to a neodymium iron boron permanent magnet material and a preparation method thereof. The neodymium iron boron permanent magnet material provided by the invention consists of a neodymium iron boron alloy and an additive, wherein the additive is nanometer silicon carbide; and the content of the nanometer silicon carbide is 0.02 to 3 weight percent of the content of the neodymium iron boron alloy. The invention also provides a preparation method of the neodymium iron boron permanent magnet material. The method comprises the following steps of: crushing the neodymium iron boron alloy into powder; adding the additive; carrying out magnetic-field orientation compression molding; and sintering and tempering under the protection of vacuum or inert gas. By the preparation method of the neodymium iron boron permanent magnet material, the operating temperature and the coercive force of the neodymium iron boron permanent magnet material can be improved at the same time.

Owner:BYD CO LTD

Eucalyptus seedling culture substrate and production process thereof

The invention discloses a eucalyptus seedling culture substrate. The eucalyptus seedling culture substrate comprises the following components in part by weight: 35 to 40 parts of coconut shell powder, 25 to 30 parts of peat, 15 to 20 parts of bentonite, 20 to 25 parts of attapulgite, 0.5 to 0.8 part of soil water-retaining agent, 15 to 20 parts of nutrient substance and 0.2 to 0.3 part of composite strain. A production process of the eucalyptus seedling culture substrate comprises the following steps of: drawing silk from a coconut shell to generate fragments; crushing the fragments; sieving until the granular size is 10 to 20 meshes; performing salt exclusion; mixing 35 to 40 weight parts of the coconut shell powder subjected to the salt exclusion, 15 to 20 weight parts of the nutrient substance and 0.2 to 0.3 weight part of high-temperature-resistant fermenting strain; adding clean water to stir and wet; stacking into a circular truncated cone shape; covering a membrane on the circular truncated cone so as to ferment; and after fermenting completely, adding the peat, the composite strain, the bentonite, the attapulgite and the soil water-retaining agent according to the weight ratio to mix and stir uniformly to prepare into block shapes. The coconut shell powder serves as a main raw material, so the materials are obtained singly and easily, the nutrient ingredients and the content are easy to control, and large-scale standard production can be performed easily.

Owner:XIAMEN JIANGPING BIOLOGICAL MATRIX TECHNOLGOY LTD BY SHARE LTD

Preparation method of high-temperature-resistant high-salt polymer oil-replacement agent

ActiveCN102181010AGood water solubilityImprove hydrophobicityDrilling compositionPolymer scienceCarbon chain

The invention relates to a preparation method of a high-temperature-resistant high-salt polymer oil-replacement agent, which comprises the following steps: dissolving 10-20 parts by weight of anionic monomer, 50-65 parts by weight of sodium allylsulfonate, 11-22 parts by weight of cationic monomer, 2-4 parts by weight of acrylate, 0-3.5 parts by weight of alpha-alkene and 50-60 parts by weight ofacrylamide in deionized water, wherein the total mass concentration of the monomers is 15-23%; adding a surfactant which accounts for 1-5% of the total weight of the monomers, regulating the pH valueof the solution to 9-10, introducing ammonia gas at 30-60 DEG C for 30 minutes, and adding a persulfate initiator which accounts for 0.05-0.1% of the total weight of the monomers; and reacting at 30-60 DEG C for 12 hours, precipitating with acetone, washing, and carrying out vacuum drying to obtain the white powdery polymer. The invention is characterized in that long-carbon-chain alkyl group, anionic and cationic unit structures are introduced into the water-soluble polymer macromolecules to obtain the high-temperature-resistant high-salt water-soluble polymer oil-replacement agent.

Owner:黑龙江吉地油田服务股份有限公司

Method for preparing flamazine/bacterial cellulose composite wound dressing

ActiveCN101905031ABroad spectrum antibacterialStrong antibacterial activityAbsorbent padsBandagesWound dressingMoisture absorption

The invention provides a method for preparing flamazine / bacterial cellulose composite wound dressing, which comprises the following steps of: performing pretreatment and purification treatment on a bacterial cellulose membrane to obtain purified bacterial cellulose; preparing flamazine suspension with the granularity of 50 to 5,000 nm under dark condition; reacting the bacterial cellulose membrane with the flamazine suspension to form a flamazine / bacterial cellulose composite membrane; and performing drying treatment to obtain a dry flamazine / bacterial cellulose composite membrane, or performing extruding dehydration to obtain a wet flamazine / bacterial cellulose composite membrane with different water content values to prepare the flamazine / bacterial cellulose composite wound dressing. The prepared flamazine / bacterial cellulose composite wound dressing has high mechanical performance, high antibacterial property, and high water and air permeability or good drainage and moisture absorption effects, can promote the drying, scabbing and healing of wound, and is used for preventing and treating the secondary wound infection of second-degree and third-degree burn or scald.

Owner:UNIV OF SCI & TECH BEIJING +1

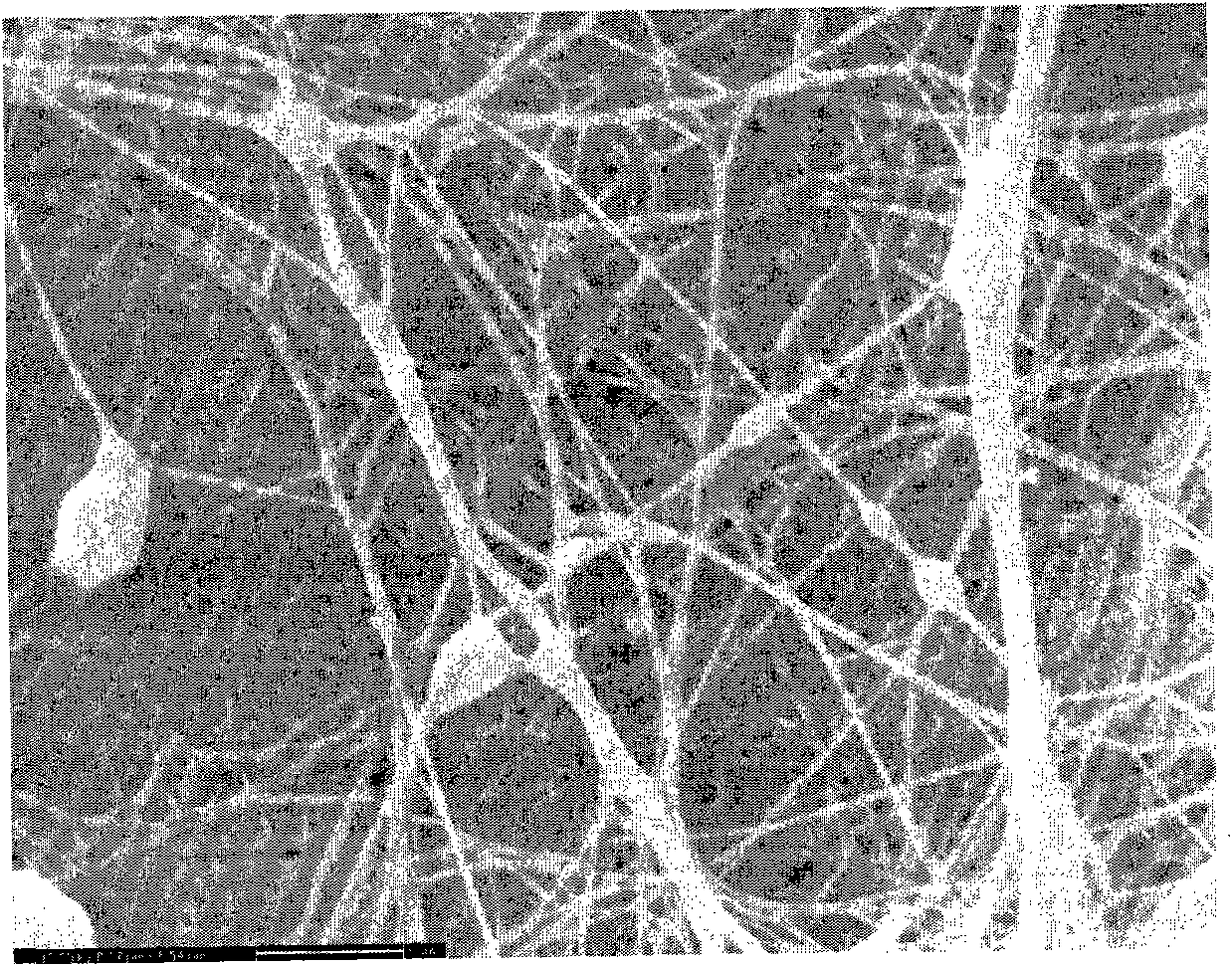

Preparation method of ribofuranose phosphate derivative

ActiveCN104610404APurity is easy to controlHigh yield of docking reactionSugar derivativesSugar derivatives preparationPhosphateGrignard reagent

The invention discloses a preparation method of a ribofuranose phosphate derivative. The preparation method comprises preparation steps as follows: L-alanine isopropyl ester hydrochloride, phenol dichlorophosphate and substituted phenol are taken as starting materials and have a docking reaction under the action of alkali; (2R)-2-deoxy-2-difluoro-2-methyl-D-erythropentonic acid GAMMA-lactone and 3,5-dibenzoate reduce carbonyl in a dichloromethane or ether solvent into an alcoholic hydroxyl group under the action of a strong reducing agent; an intermediate with a formula 2-1 has a reaction with paratoluensulfonyl chloride under the action of alkali to obtain p-toluenesulfonates; an intermediate with a formula 2-2 and a benzoyl cytosine derivative have a docking reaction under the action of a condensing agent; an intermediate with a formula 2-3 converts cytosine into uracil under the action of organic acid; benzoyl protection for an intermediate with a formula 2-4 is released under the action of an alkaline agent; an intermediate with a formula 2-5 and an intermediate with a formula 1 are docked under the action of a Grignard reagent to obtain Sofosbuvir.

Owner:NANTONG CHANGYOO PHARMATECH CO LTD

Preparation method of high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material

InactiveCN108396168AThe content is easy to controlIntegrity guaranteedTransportation and packagingMetal-working apparatusSemi solidAluminium powder

The invention discloses a preparation method of a high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material. Aluminium powder is modified to improve the affinity of the aluminium powder to graphene, and after that, semi-solid extrusion is performed to obtain the graphene enhanced aluminium alloy material. The preparation method is simple to operate, adjustable in process and controllable in graphene content; graphene is uniformly dispersed in the aluminium alloy material; the demand on an aluminium matrix is less; the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material can be compounded with various aluminium alloys to obtain corresponding graphene enhanced aluminium alloy materials; meanwhile, the integrity of graphene can be maintained to the utmost extent, and the binding force between the high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material and the matrix is improved. A prepared graphene / aluminium alloy-based composite has the compactness of 98.5% or above, has the conductivity equivalent to that of a matrix aluminium alloy rod piece (more than 61% IACS), and is improved by more than 20% in tensile strength and more than 50% in creep resistance. The preparation method is suitable for preparing the long graphene enhanced aluminium alloy material, and is low in production cost, suitable for industrial production and favorable in market prospect.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com