Preparation method of high-strength high-conductivity creep-resistant graphene enhanced aluminium alloy material

A technology of aluminum alloy materials and graphene, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of decreased dispersion effect and achieve the effects of improved tensile strength, adjustable process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

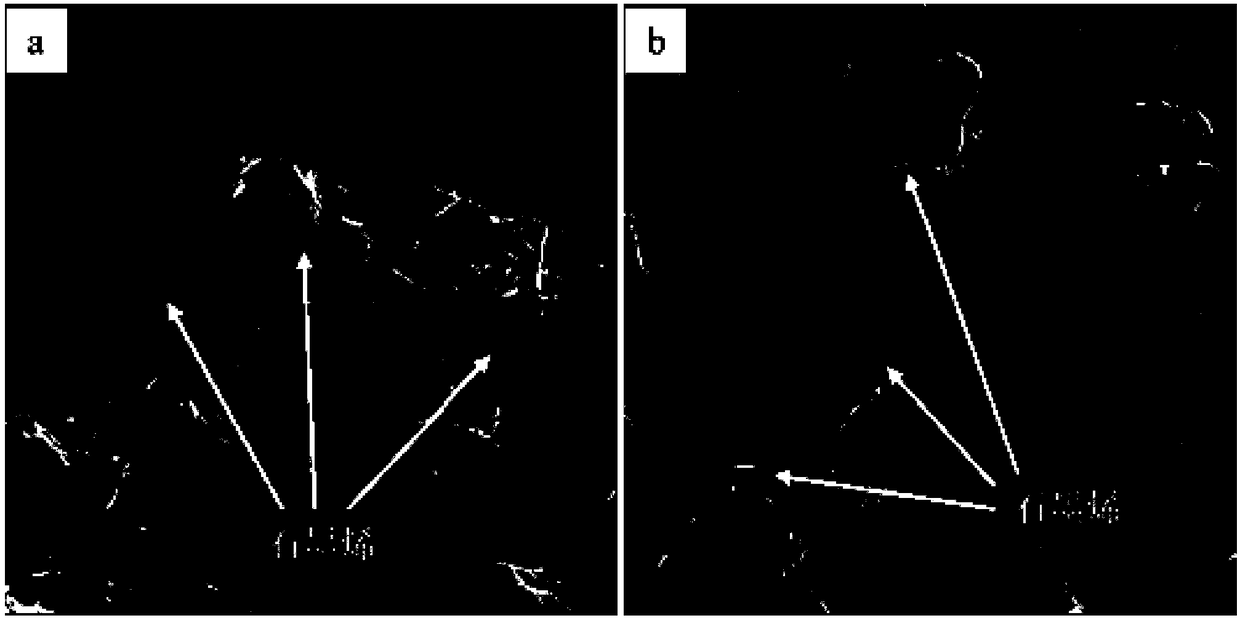

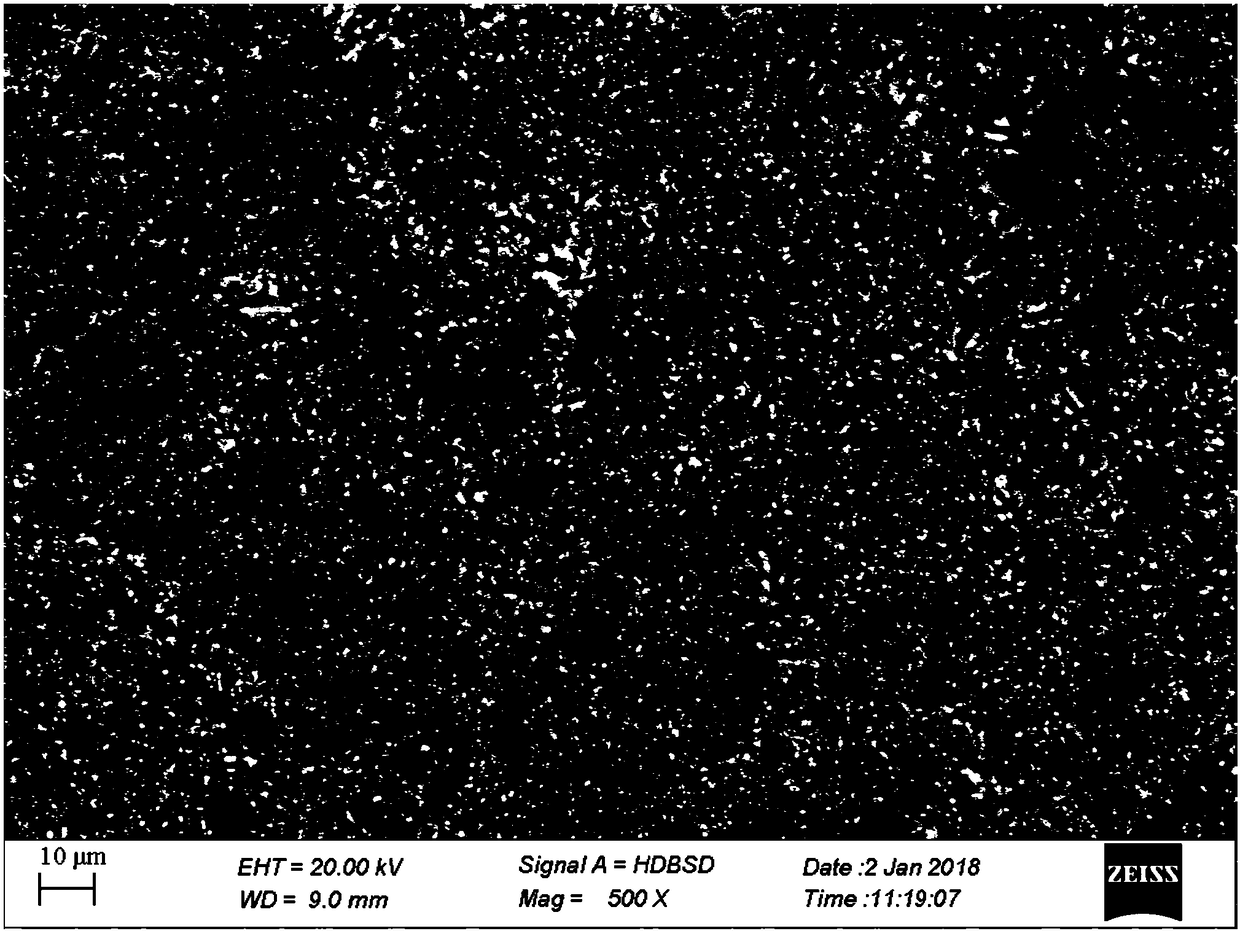

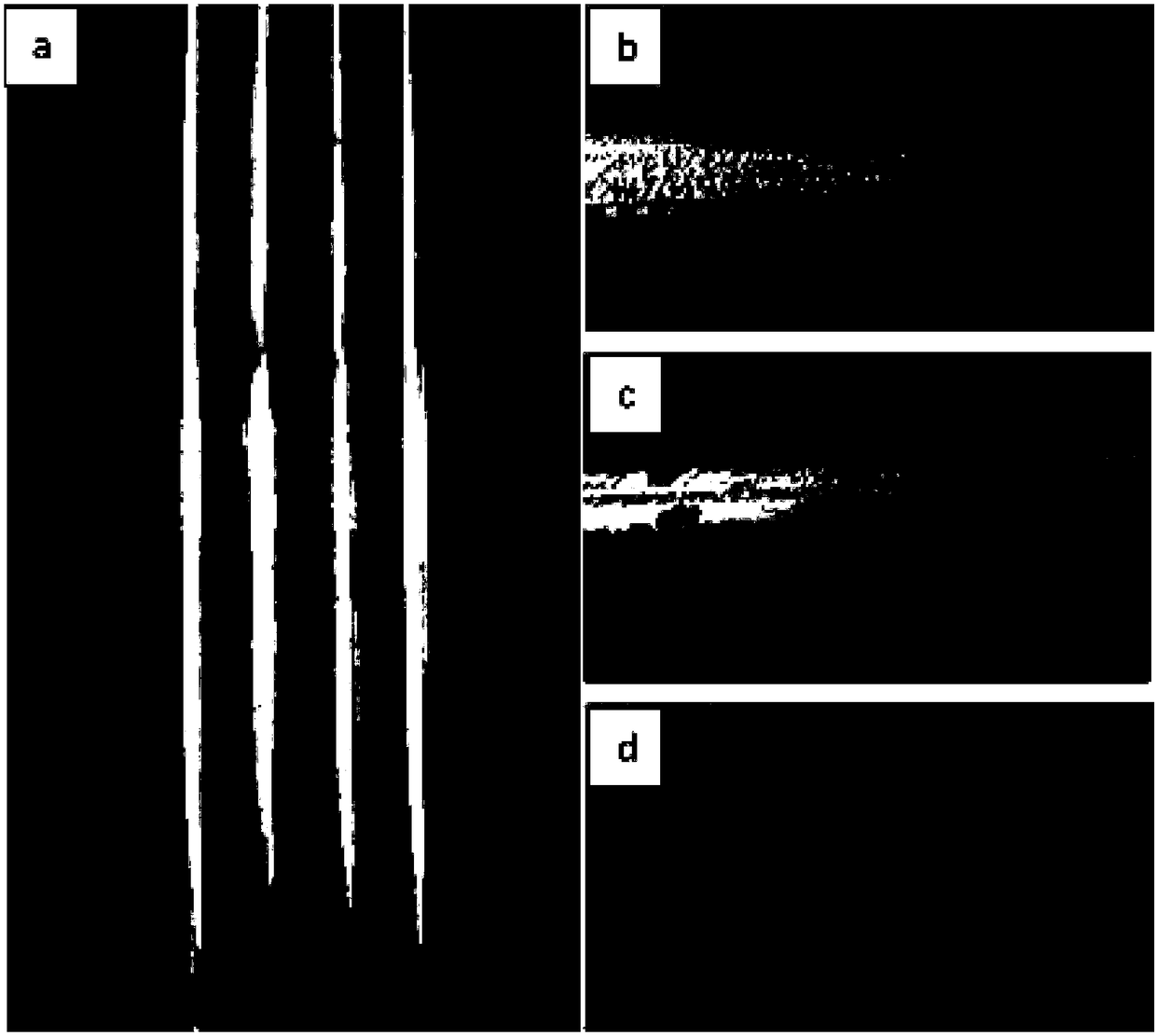

Image

Examples

preparation example Construction

[0041] A kind of preparation method of graphene reinforced aluminum alloy material, comprises the steps:

[0042] 1) graphene is physically dispersed in an organic solvent to obtain a graphene dispersion;

[0043] 2) modifying the aluminum alloy powder with an organic hydrophilic modifier, and then removing the free organic hydrophilic modifier to obtain a surface-modified aluminum alloy powder;

[0044] 3) adding an appropriate amount of organic solvent to the surface-modified aluminum alloy powder and then slowly adding the graphene dispersion, wet mixing evenly, and drying to obtain graphene-coated aluminum alloy powder;

[0045] 4) keeping the graphene-coated aluminum alloy powder in a solid state, isolating oxygen, removing the organic hydrophilic modifier by pyrolysis, and obtaining the graphene / aluminum alloy mixed powder;

[0046] 5) packing the graphene / aluminum alloy mixed powder into a can and compacting it;

[0047] 6) The powder is mixed in the heating tank unti...

Embodiment 1

[0076] 1) Take 299.1 g of 8030 brand aluminum alloy atomized powder (nitrogen atomized, purity ≥ 99.5%, particle size 20-50 μm) for commercial low-voltage construction; scientific research grade graphene (Simen Kaina Graphene Technology Co., Ltd. ~3 layers, sheet diameter 5~20μm, diameter-thickness ratio﹥1000)0.9g;

[0077] 2) Aluminum alloy powder pretreatment: Add 8030 aluminum alloy atomized powder to 3wt% polyvinyl alcohol (PVA) aqueous solution, ultrasonically + mechanically stir for 30 minutes, filter, and wash with deionized water to obtain PVA-modified 8030 aluminum alloy powder;

[0078] 3) Graphene pretreatment: Graphene is placed in 300ml of absolute ethanol and dispersed by ultrasonic+mechanical stirring for 2h, and the amount of graphene added is 0.3wt% of the prepared graphene / 8030 aluminum alloy composite material;

[0079] 4) No-sphere wet mixing of graphene and PVA-modified aluminum alloy powder: Add appropriate amount of anhydrous alcohol to the PVA-modified ...

Embodiment 2

[0088] Same as Example 1, the difference is that the addition of graphene is adjusted to 0.5wt%, and the semi-solid extrusion temperature is adjusted to 650°C (calculated by the phase diagram, the liquid phase ratio is 18.5wt%).

[0089] The room temperature tensile strength of the prepared 0.5wt% graphene / 8030 aluminum alloy composite rod is 216.5MPa, the elongation is 17.9%, and the steady-state creep rate is 3.1×10 -8 mm·s -1 , and the conductivity (IACS) was 61.9%. 8030 aluminum alloy matrix bar without adding graphene prepared by the same process (tensile strength 175.4MPa, elongation 18.2%, steady-state creep rate 7.8×10 -8 mm·s -1 , IACS 62.5%), elongation and electrical conductivity are also equivalent, tensile strength increased by 23.4%, steady-state creep rate decreased by 60.3%, strength and creep resistance are improved.

[0090] Yu Guoliang, Wu Zhenjiang and others from Shanghai Xinyi Power Line Equipment Co., Ltd. published the mechanical properties of indust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com