Method for preparing flamazine/bacterial cellulose composite wound dressing

A technology of silver sulfadiazine and bacterial cellulose, which is applied in the field of biomedical materials and medical devices, can solve the problems of lack of competitiveness of high-end products, no series of products, poor water permeability and moisture absorption, etc., and achieves controllable particle size distribution, good Good antibacterial activity, antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Cut the commercially available bacterial cellulose film produced by Acetobacter xylinum into a bacterial cellulose sample of 10 × 10 cm, the steps are as follows:

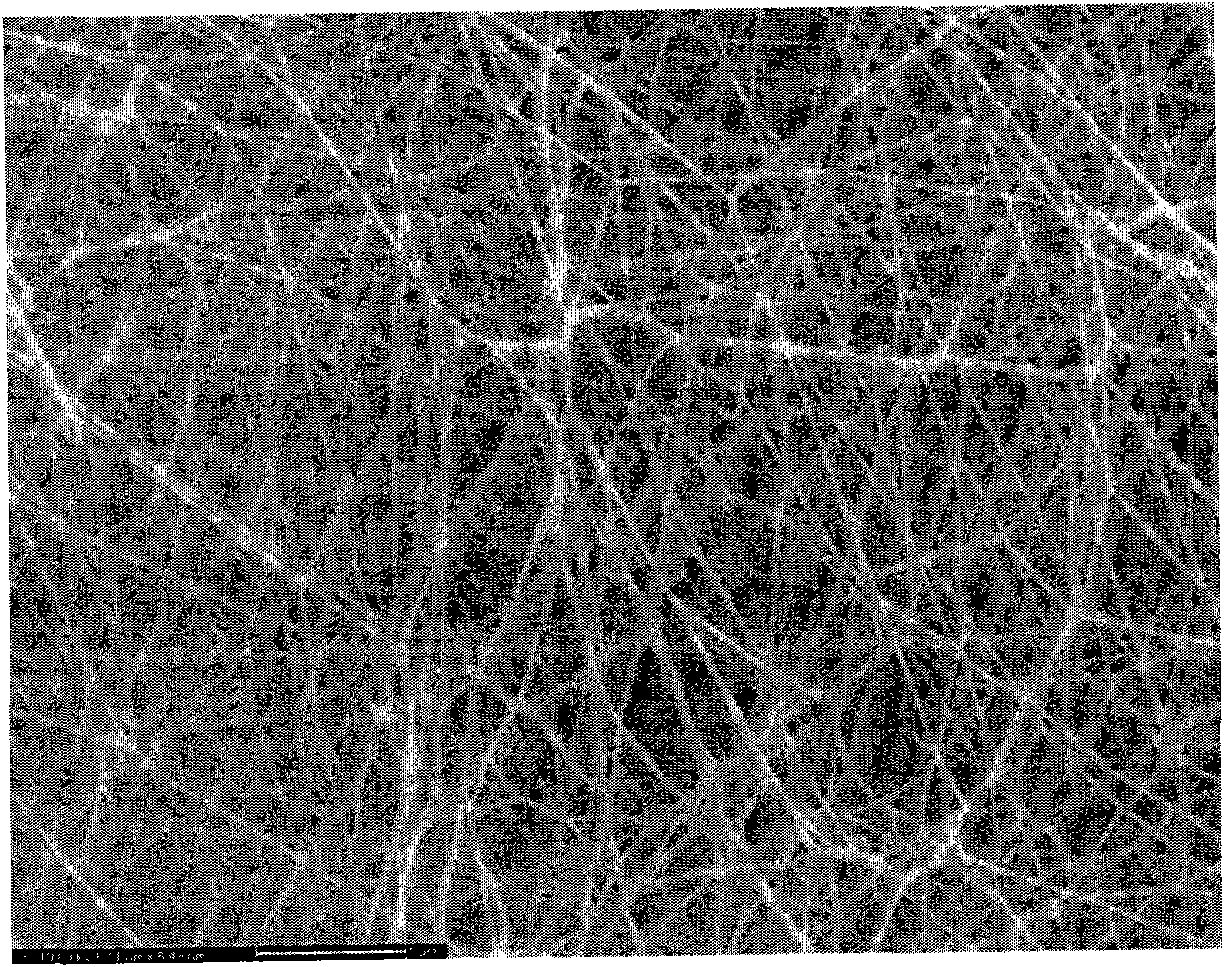

[0039] Step 1. Pretreatment of the bacterial cellulose membrane: washing the bacterial cellulose membrane prepared by the above-mentioned Acetobacter xylinum with clear water for several times to remove the culture medium and impurities on the surface of the membrane. Then soak the membrane in 0.1mol / L NaOH solution, boil at 80°C for 60min, and wash out the bacteria and residual culture medium in the bacterial cellulose membrane. Then soak the bacterial cellulose membrane in 0.05mol / L NaOH solution, boil at 80°C for 30min, and then rinse with distilled water several times; figure 1 It is the microstructure diagram of bacterial cellulose, showing the unique nano-network structure of bacterial cellulose.

[0040] Step 2. Purification of the bacterial cellulose membrane: the bacterial cellulose membrane after ...

Embodiment 2

[0046] The commercially available bacterial cellulose film produced by Acetobacter xylinum was cut into 10×10 cm bacterial cellulose samples.

[0047] Step 1. Pretreatment of the bacterial cellulose membrane: washing the bacterial cellulose membrane prepared by Acetobacter xylinum with clear water several times to remove the culture medium and impurities on the surface of the membrane. Then soak the membrane in 0.1mol / L NaOH solution, boil at 90°C for 60min, and wash out the bacteria and residual culture medium in the bacterial cellulose membrane. Then soak the bacterial cellulose membrane in 0.05mol / L NaOH solution, boil at 90°C for 30min, and then rinse with distilled water several times;

[0048] Step 2. Purification of the bacterial cellulose membrane: the bacterial cellulose membrane after the above pretreatment is sterilized by ultraviolet rays to meet the sterilization requirements of the process. The bacterial cellulose membrane after the above disinfection is soaked ...

Embodiment 3

[0054] The commercially available bacterial cellulose film produced by Acetobacter xylinum was cut into 10×10 cm bacterial cellulose samples.

[0055] Step 1. Pretreatment of the bacterial cellulose membrane: washing the bacterial cellulose membrane prepared by Acetobacter xylinum with clear water several times to remove the culture medium and impurities on the surface of the membrane. Then soak the membrane in 0.1mol / L NaOH solution, boil at 95°C for 60min, and wash out the bacteria and residual culture medium in the bacterial cellulose membrane. Then soak the bacterial cellulose membrane in 0.05mol / L NaOH solution, boil at 95°C for 30min, and then rinse with distilled water several times;

[0056] Step 2. Purification of the bacterial cellulose membrane: the bacterial cellulose membrane after the above pretreatment is sterilized by ultraviolet rays to meet the sterilization requirements of the process. The bacterial cellulose membrane after the above disinfection is soaked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com