Preparation method and application of antibacterial glass coating of antibacterial bone fracture plate

A technology of antibacterial glass and bone plate, applied in the field of bioengineering, can solve the problems of poor effect and non-antibacterial properties, and achieve the effects of easy operation, high antibacterial efficiency, and promotion of bone cell growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

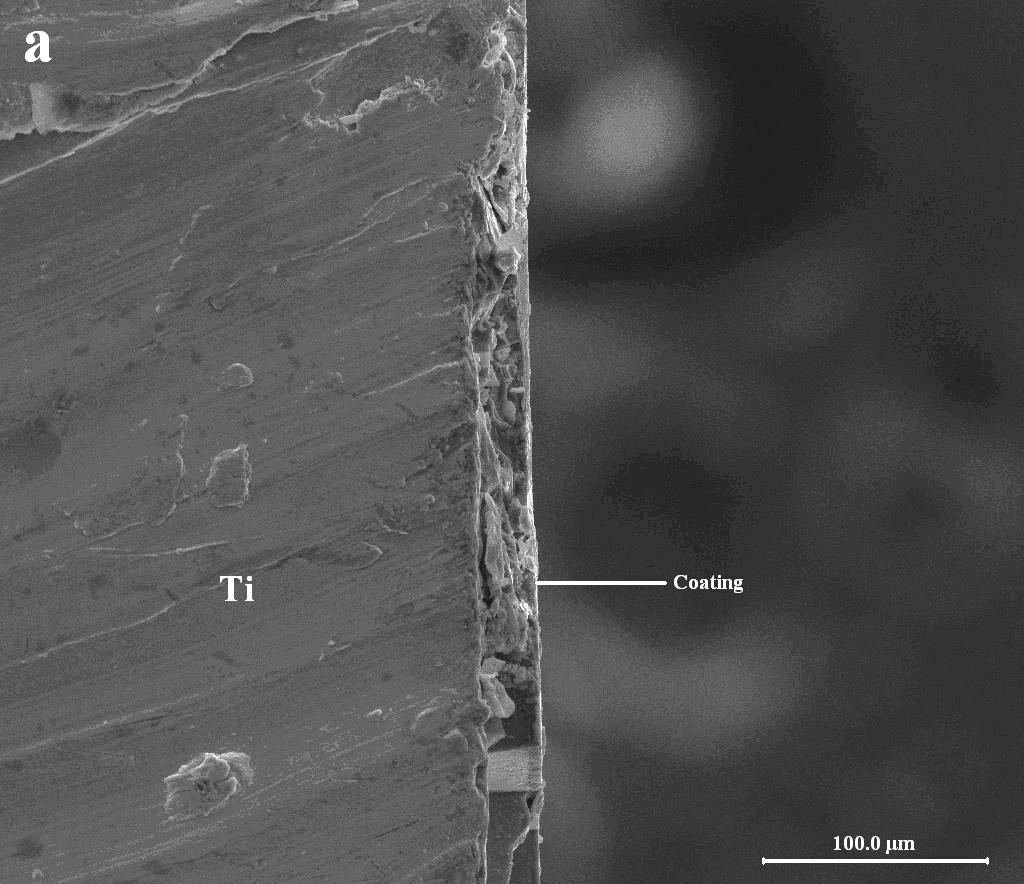

[0033] Example 1 : Preparation and in vitro characterization of copper-containing borate glass antibacterial bone plate coating

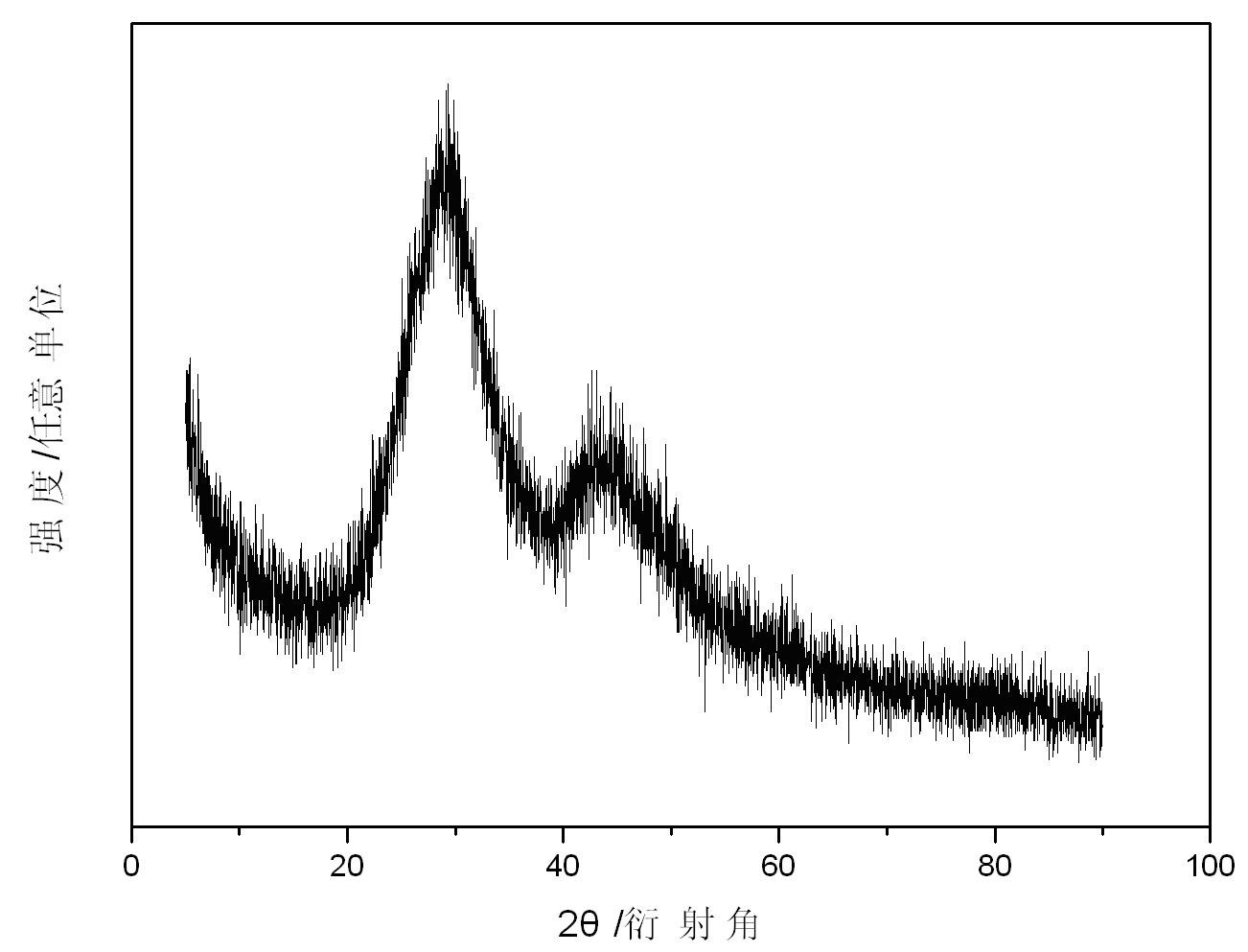

[0034] (1) Preparation of borate glass with 0.25% copper content

[0035] Weigh 1.888g anhydrous sodium carbonate, 12.311g anhydrous potassium carbonate, 6.921g basic magnesium carbonate, 10.698g calcium carbonate, 13.149g strontium carbonate, 9.632g silicon dioxide, 39.652g boric acid, 5.558g sodium dihydrogen phosphate, 0.192 g copper sulfate. After grinding, mix well to get the raw ingredients. The original ingredients were placed in a platinum crucible and kept at 1150°C for 120 min, and after taking it out, the resulting clear glass liquid was poured on a preheated steel plate to obtain a glass block. The obtained glass blocks are coarsely crushed by a horizontal ball mill, finely crushed by a ball mill, crushed by a jet mill, vibrating and sieved to obtain a glass powder with a particle size of 0.05-20 microns.

[0036] (2) Preparation of...

Embodiment 2

[0045] Example 2 : Release of antibacterial ions and antibacterial performance of zinc-containing borate glass antibacterial coating

[0046] According to the method described in Example 1, in the glass formula, copper sulfate is replaced by zinc sulfate, and 0.472g, 0.944g, 1.416g, and 1.888g of zinc sulfate are added respectively to prepare three kinds of borates with different zinc contents Glass, and further prepared zinc-containing borate glass antibacterial coating bone plates with zinc ion mass percentages of 0.5%, 1.0%, 1.5%, and 2.0%.

[0047] The prepared coating block was divided into every 1cm 2 The ratio of the surface area to 100 ml solution was soaked in SBF solution (Kokubo method, pH=7.25), placed in a 37°C incubator, and samples were taken out after 1d, 2d, 4d, and 7d. The concentration of zinc ions in the soaking solution was detected by inductively coupled plasma optical emission spectroscopy (ICP-OES, Optima 2100DV; PerkinElmer, Shelton, CT). Draw a gr...

Embodiment 3

[0054] Example 3 : Antimicrobial and bone growth-stimulating properties of silver-containing borate glass antimicrobial coatings in animals

[0055] According to the method described in Example 1, in the glass formula, copper sulfate is replaced by silver sulfate, and 0g, 0.269g, and 0.595g silver sulfate are added respectively to prepare three kinds of borate glasses with different silver contents, and then Bone plates with silver-containing borate glass antibacterial coating were prepared with silver ion mass percentages of 0.0%, 0.5%, and 1.0%.

[0056] Use pure titanium bone plate (no glass), no silver (BG coated titanium plate) and 0.5% silver (BG-0.5Ag coated titanium plate), 1.0% (BG-1Ag coated titanium plate) antibacterial Antimicrobial Coated Bone Plates of Borate Glass for In Vivo Animal Experiments. The experimental animals are New Zealand white rabbits with a body weight of 2-3 kg, and the number of experimental animals used in each group is 10. Animals were we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com