Carbon fiber reinforced resin film and preparation method thereof

A technology of resin film and carbon fiber, which is applied in the field of carbon fiber reinforced resin film and its preparation, can solve the problems of easy sliding of carbon fiber, unsatisfactory effect of enhancing the mechanical strength of polymer film, and inability to fix, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 The preparation method of a kind of carbon fiber reinforced resin film that this embodiment involves comprises the following steps:

[0029] Step 1. Add 1 g of multi-walled carbon nanotubes into a mixed solution of 100 mL of concentrated sulfuric acid and concentrated nitric acid (3:1), stir at room temperature for 24 hours, dilute with a large amount of water, filter with suction, wash with water, and dry at room temperature;

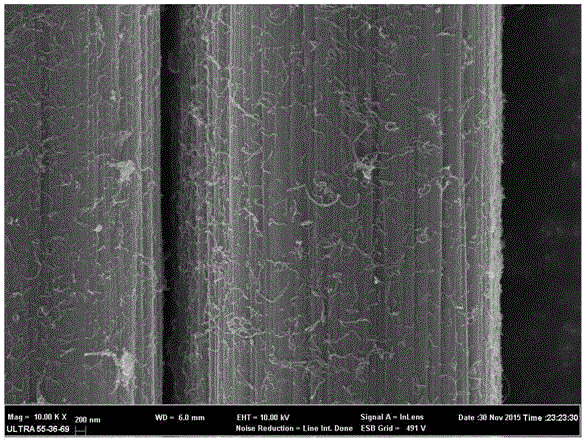

[0030] Step 2: Heat the carbon fiber at 350°C for 6 hours to remove the organic matter on the surface of the carbon fiber so that the surface can have hydroxyl groups, then add 0.7g of the above-mentioned treated carbon fiber to a mixed solution of 100mL ethanol and water (1:1), add Add 1gKH-550, stand at room temperature for 24h, wash with water, and dry;

[0031] Step 3: Add 0.5 mg / mL carboxy-modified multi-walled carbon nanotube dispersion into the electrolytic cell, connect the carbon fiber to the positive pole of the power suppl...

Embodiment 2

[0033] Example 2 The preparation method of a kind of carbon fiber reinforced resin film that this embodiment involves comprises the following steps:

[0034] Step 1. Add 1 g of multi-walled carbon nanotubes into a mixed solution of 100 mL of concentrated sulfuric acid and concentrated nitric acid (3:1), stir at room temperature for 24 hours, dilute with a large amount of water, filter with suction, wash with water, and dry at room temperature;

[0035] Step 2: Heat the carbon fiber at 350°C for 6 hours to remove the organic matter on the surface of the carbon fiber so that the surface can have hydroxyl groups, then add 0.7g of the above-mentioned treated carbon fiber to a mixed solution of 100mL ethanol and water (1:1), add Add 1gKH-550, stand at room temperature for 24h, wash with water, and dry;

[0036] Step 3: Add 0.5 mg / mL carboxy-modified multi-walled carbon nanotube dispersion into the electrolytic cell, connect the carbon fiber to the positive pole of the power suppl...

Embodiment 3

[0038] Example 3 The preparation method of a kind of carbon fiber reinforced resin film that this embodiment involves comprises the following steps:

[0039] Step 1. Add 1 g of multi-walled carbon nanotubes into a mixed solution of 100 mL of concentrated sulfuric acid and concentrated nitric acid (3:1), stir at room temperature for 24 hours, dilute with a large amount of water, filter with suction, wash with water, and dry at room temperature;

[0040] Step 2: Heat the carbon fiber at 350°C for 6 hours to remove the organic matter on the surface of the carbon fiber so that the surface can have hydroxyl groups, then add 0.7g of the above-mentioned treated carbon fiber to a mixed solution of 100mL ethanol and water (1:1), add Add 1gKH-550, stand at room temperature for 24h, wash with water, and dry;

[0041] Step 3: Add 0.5 mg / mL carboxy-modified multi-walled carbon nanotube dispersion into the electrolytic cell, connect the carbon fiber to the positive pole of the power supply,...

PUM

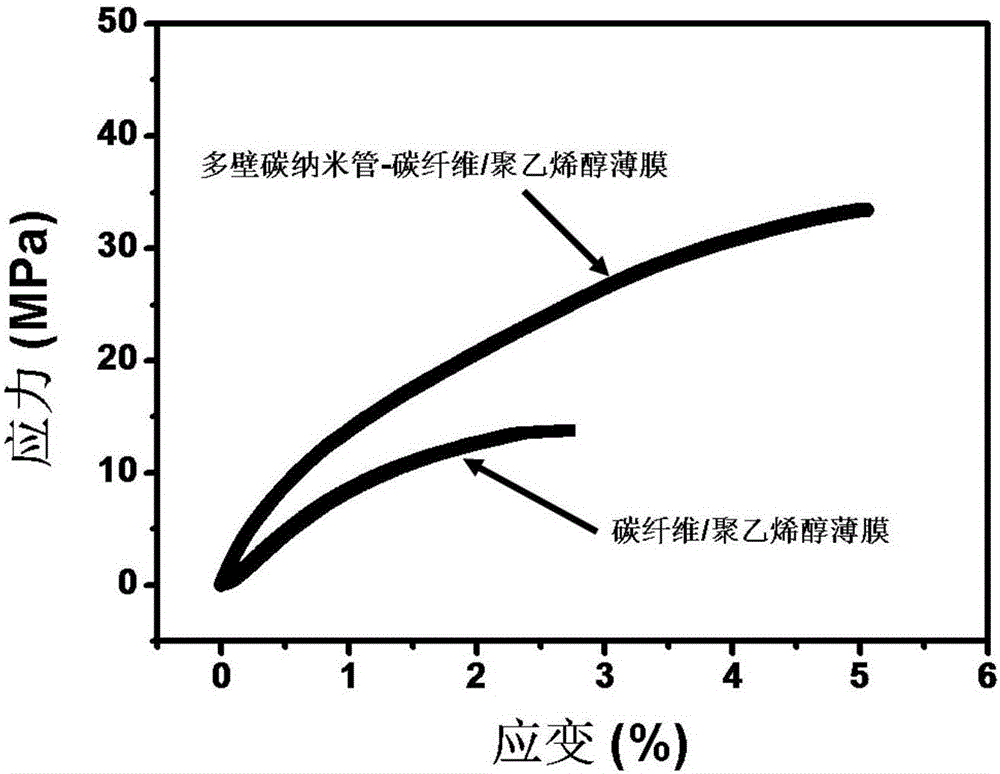

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com