Antibacterial microporous color master batch

A color masterbatch and microporous technology, which is applied in the field of plastics, can solve the problem of single function of color masterbatch and achieve the effect of improving the enhancement effect, ensuring the enhancement effect, and exposing and stabilizing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

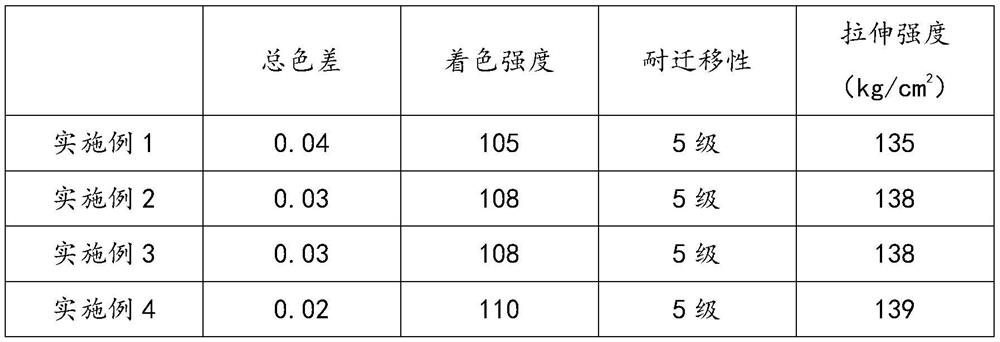

Examples

Embodiment 1

[0029] An antibacterial microporous masterbatch

[0030] The mass ratio is as follows: 40 parts of polypropylene, 20 parts of expanded polytetrafluoroethylene, 20 parts of colorant, 10 parts of filler, 2 parts of heat stabilizer, 5 parts of dispersant, and 1 part of antioxidant.

[0031] The modified porous light calcium carbonate of the bamboo charcoal fiber takes porous calcium carbonate as the epidermis, takes the modified bamboo charcoal fiber as the core, and the modified bamboo charcoal fiber is nano-zinc oxide-nanometer titanium dioxide modified bamboo charcoal fiber; the modified bamboo charcoal fiber The preparation method of permanent light calcium carbonate comprises the steps of: a1, adding bamboo charcoal fiber to ethanol for ultrasonic dispersion for 20min, filtering to obtain clean bamboo charcoal fiber, the mass ratio of said bamboo charcoal fiber to ethanol is 2:5, ultrasonically dispersed The temperature is 20°C, and the ultrasonic frequency is 50kHz; a2, add...

Embodiment 2

[0043] An antibacterial microporous masterbatch

[0044] The mass ratio is as follows: 50 parts of polypropylene, 30 parts of expanded polytetrafluoroethylene, 30 parts of colorant, 20 parts of filler, 5 parts of heat stabilizer, 9 parts of dispersant, and 3 parts of antioxidant.

[0045] The modified porous light calcium carbonate of the bamboo charcoal fiber takes porous calcium carbonate as the epidermis, takes the modified bamboo charcoal fiber as the core, and the modified bamboo charcoal fiber is nano-zinc oxide-nanometer titanium dioxide modified bamboo charcoal fiber; the modified bamboo charcoal fiber The preparation method of permanent light calcium carbonate comprises the steps of: a1, adding bamboo charcoal fibers to ethanol for ultrasonic dispersion for 30min, filtering to obtain clean bamboo charcoal fibers, the mass ratio of the bamboo charcoal fibers to ethanol is 2:9, ultrasonically dispersed The temperature is 50°C, and the ultrasonic frequency is 80kHz; a2, ...

Embodiment 3

[0057] An antibacterial microporous masterbatch

[0058] The mass ratio is as follows: 45 parts of polypropylene, 25 parts of expanded polytetrafluoroethylene, 25 parts of colorant, 15 parts of filler, 4 parts of heat stabilizer, 8 parts of dispersant, and 2 parts of antioxidant.

[0059] The modified porous light calcium carbonate of the bamboo charcoal fiber takes porous calcium carbonate as the epidermis, takes the modified bamboo charcoal fiber as the core, and the modified bamboo charcoal fiber is nano-zinc oxide-nanometer titanium dioxide modified bamboo charcoal fiber; the modified bamboo charcoal fiber The preparation method of permanent light calcium carbonate comprises the following steps: a1, adding bamboo charcoal fibers to ethanol for ultrasonic dispersion for 25min, filtering to obtain clean bamboo charcoal fibers, the mass ratio of the bamboo charcoal fibers to ethanol is 2:7, ultrasonically dispersed The temperature is 40°C, and the ultrasonic frequency is 70kH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com