Patents

Literature

123 results about "Copper naphthenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper naphthenate is the copper salt of naphthenic acid.Naphthenic acid is a term commonly used in the petroleum industry to collectively refer to all of the carboxylic acids naturally occurring in crude oil.

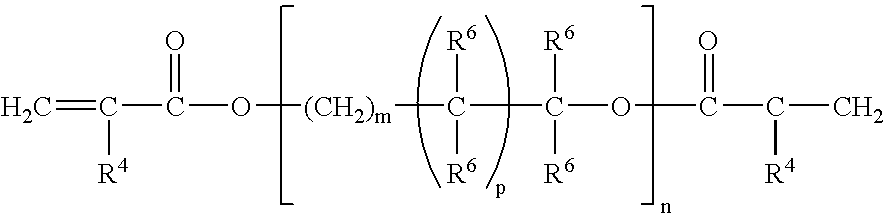

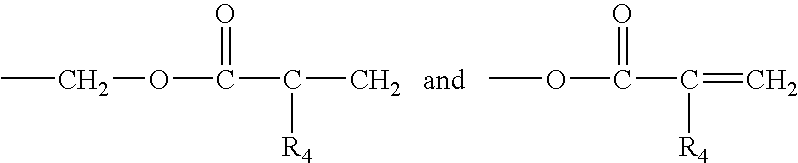

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS20080242764A1Improve adhesionImprove propertiesSynthetic resin layered productsOrganic non-macromolecular adhesiveCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerization in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

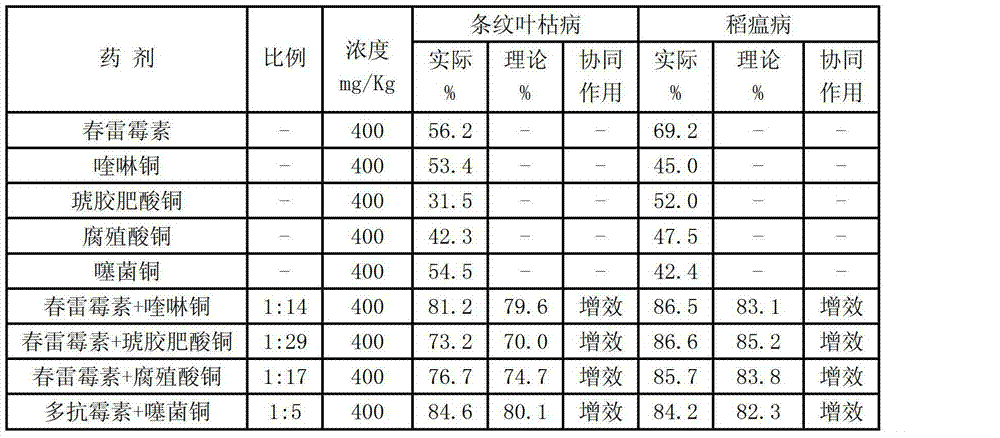

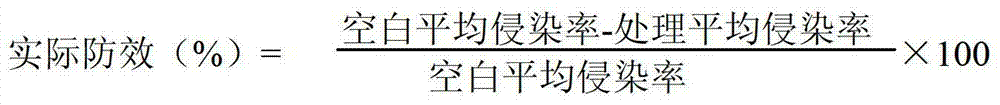

Kasugamycin-containing sterilization composition and application thereof

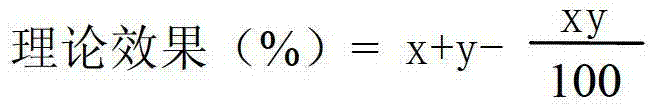

The invention belongs to the field of plant protection, and relates to a kasugamycin-containing sterilization composition and an application thereof. The kasugamycin-containing sterilization composition contains effective amounts of A and B, wherein A is kasugamycin, B is one of oxine-copper, copper(succinate+glutarate+adipate), thiediazole copper, humic acid copper, nitroacid copper, copper naphthenate, amino acid copper, copper acetate and sulfamic acid copper, and the mass fraction ratio of A to B is (10:1)-(1:100). The composition can be processed into wettable powder, water dispersible granules, an aqueous emulsion, a microemulsion and a suspending agent, and the mass sum of A and B accounts for 1-80% of the total mass of the preparation. The composition can be used for preventing and treating fungi and bacterial diseases of multiple plants such as rice, wheat, vegetables and fruit trees and has an excellent effect on late blight and gray mold of tomatoes, rice stripe diseases and rice blast, angular leaf spot of watermelons and citrus bacterial canker diseases.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Wood preservation method and preserved wood

InactiveCN101491910APrevent rotImprove organizational structureWood treatment detailsWood impregnation detailsCopper naphthenateSolvent

The invention provides a method for timber preservation and preserving timber. The method comprises the steps of: mixing copper naphthenate and solvent oil according to a ratio of 1:1.5-3.5 to prepare an antiseptic and insect-resisting agent; soaking timber dried at low temperature in the antiseptic and insect-resisting agent; pressurizing the timber under a pressure of 6 to 10kg / cm for 8 to 15 hours; and drying the timber to obtain the preserving timber. The radial thickness of the surface, impregnated with the copper naphthenate antiseptic and insect-resisting agent, of the preserving timber is 10 to 50 percent of the diameter of the timber, the inner layer of the timber is a brown copper naphthenate antiseptic and insect-resisting agent and oil solvent layer, the humidity of the timer is 12 to 17 percent, and the copper content of the timber is more than or equal to 0.04pcf.

Owner:上海勤功线路器材有限公司

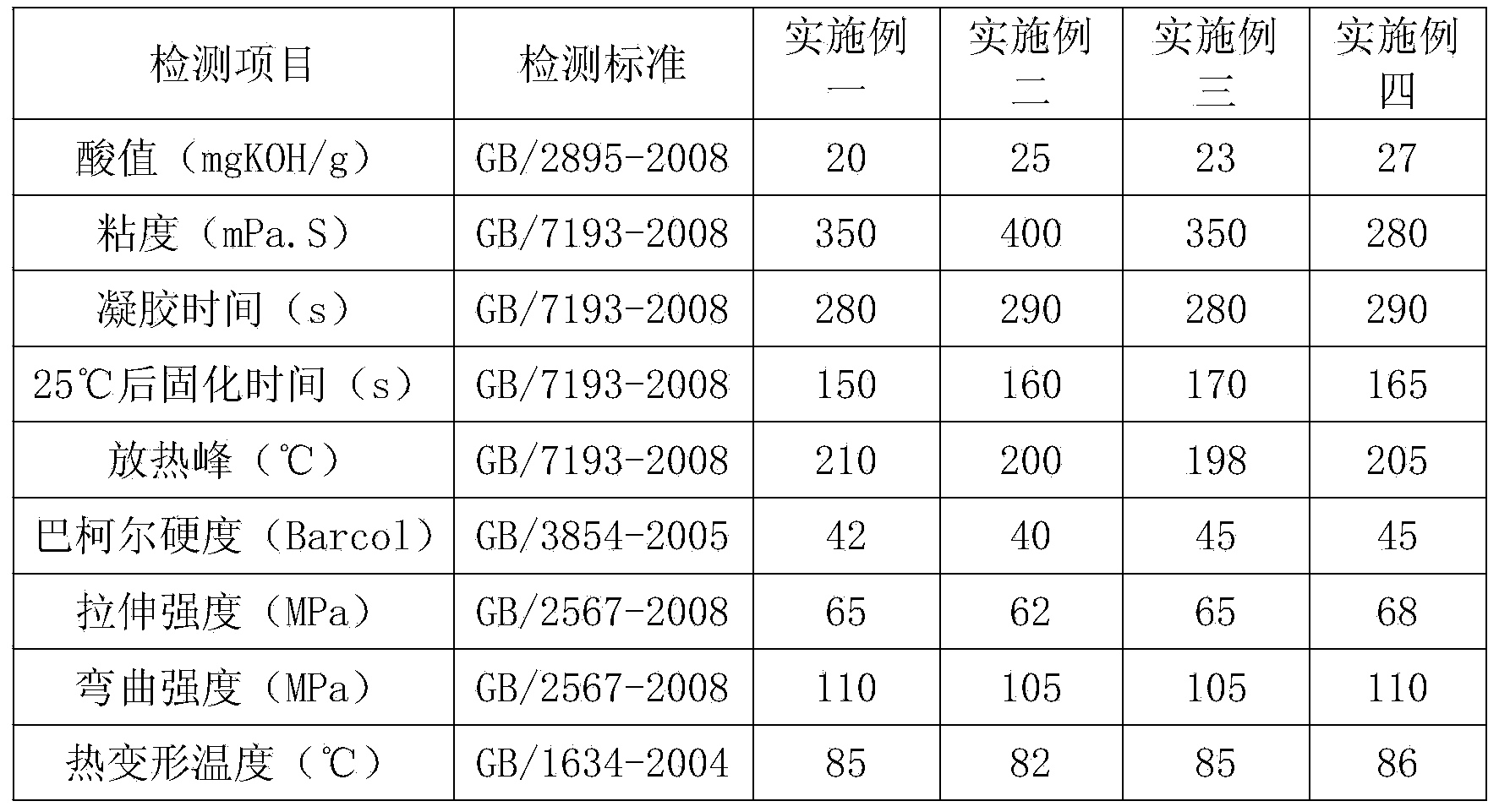

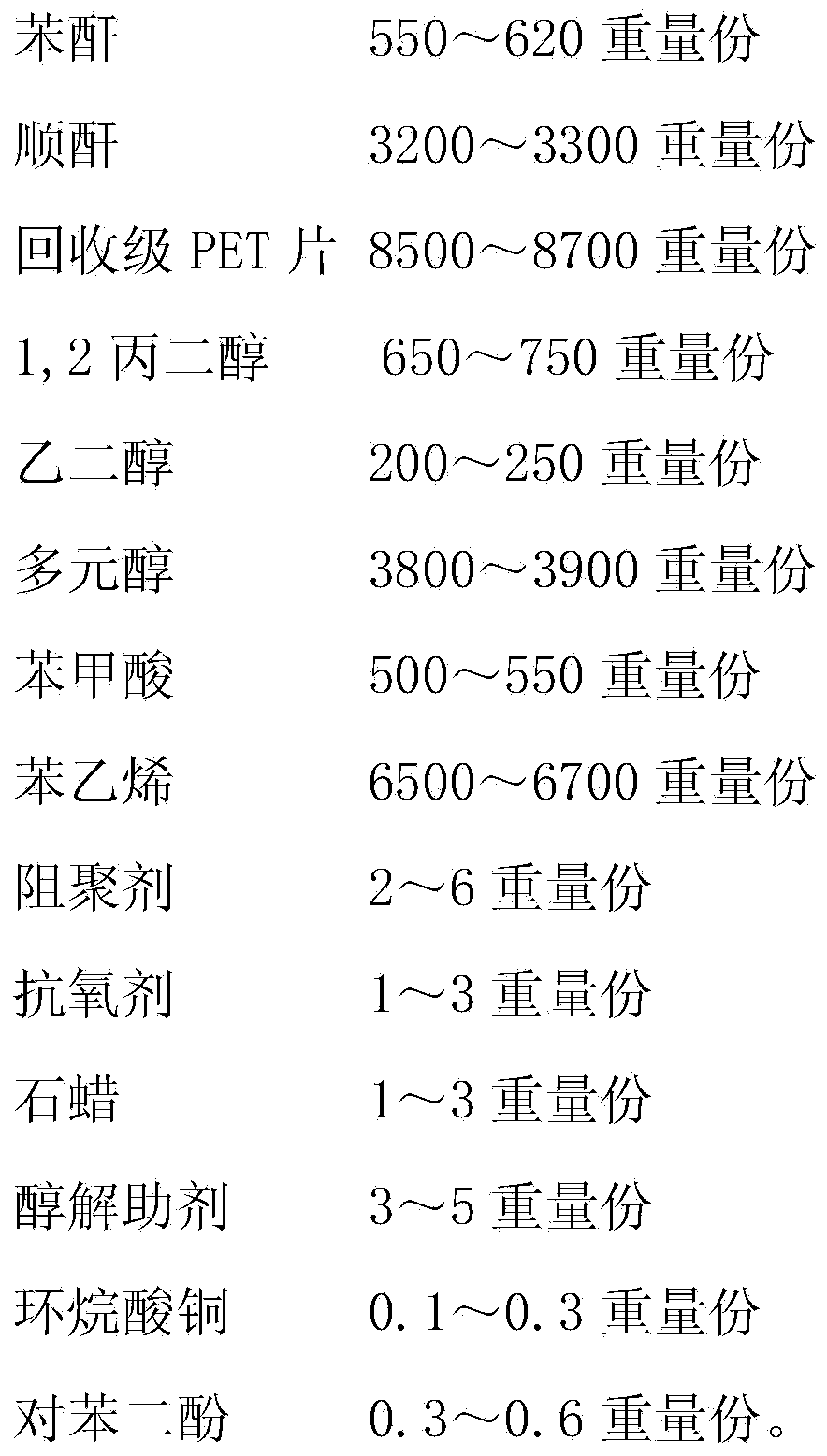

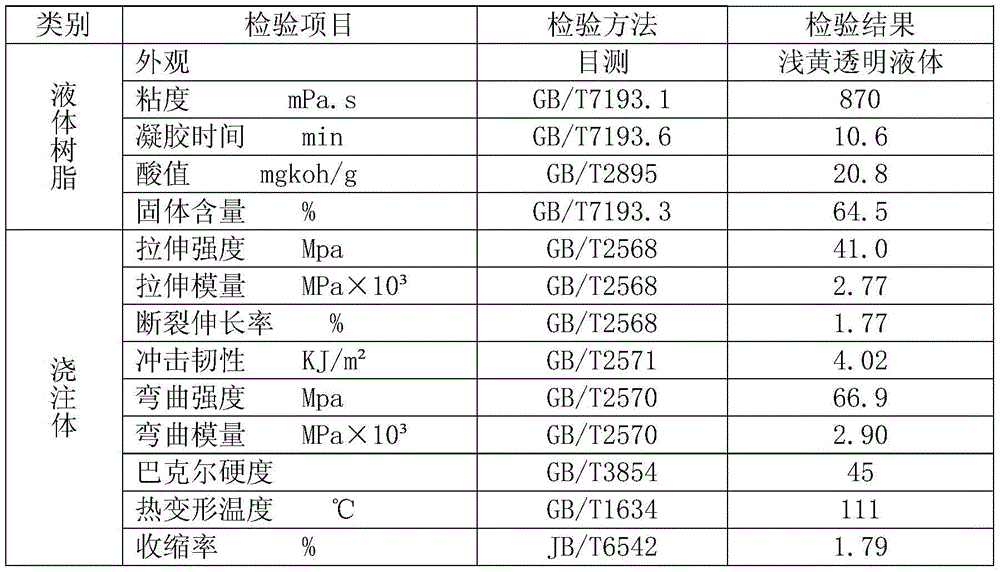

Unsaturated polyester resin for polyester concrete and preparation method of unsaturated polyester resin

InactiveCN104311749AHigh tensile strengthHigh heat distortion temperaturePlastic recyclingPolyesterBenzoic acid

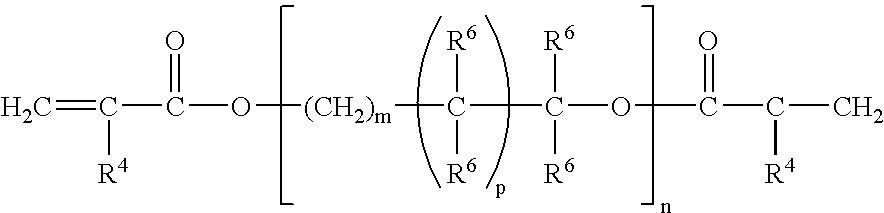

The invention particularly discloses unsaturated polyester resin for polyester concrete. The unsaturated polyester resin has a formula comprising the following components: phthalic anhydride, maleic anhydride, recoverable-grade PET flakes, 1,2 propanediol, ethylene glycol, polyhydric alcohol, benzoic acid, styrene, a polymerization inhibitor, an antioxidant, paraffin, an alcoholysis aid, copper naphthenate and p-benzenediol. The invention further discloses a preparation method of the unsaturated polyester resin which is prepared through an alcoholysis reaction, a condensation reaction and a dilution process. Compared with the prior art, the unsaturated polyester resin disclosed by the invention is low in viscosity, high in reaction activity, short in post-curing time, resistant to acid, alkali and water, and excellent in mechanical property, further, the recoverable-grade PET flakes are adopted, therefore, the cost is greatly reduced, and the production period is shortened.

Owner:YONGYUE SCI & TECH

Light-power high-light-stability cable material and preparation method thereof

InactiveCN104559036ASimple recipeEasy to preparePlastic/resin/waxes insulatorsPolyvinyl chlorideStearic acid

The invention discloses a high-power high-light-stability cable material which is prepared from the following raw materials in parts by weight: 3-5 parts of bisphenol A, 2-3 parts of stearic acid, 30-40 parts of ABS (acrylonitrile-butadiene-styrene) resin, 12-16 parts of polyvinyl chloride resin, 6-8 parts of ABS high rubber powder, 1-2 parts of antioxidant 1035, 2-4 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 5-6 parts of melamine borate, 5-7 parts of polyethylene wax, 3-4 parts of copper naphthenate, 3-5 parts of diphenylmethane diisocyanate, 2-4 parts of isophorone diisocyanate, 2-3 parts of magnesium oxide, 4-6 parts of butyl phenolformaldehyde resin and 8-12 parts of filler. The formula and preparation method of the cable material are simple; the multiple fillers are added to enhance the light stability and chemical resistance of the cable material; and the cable material has favorable mechanical properties and wide economic prospects.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

Flame-retarded resin

InactiveCN102558800AHigh temperature resistant and flame retardantFlame retardantFiberCopper naphthenate

The invention discloses a flame-retarded resin. The flame-retarded resin comprises the following components in percentage by weight: 45-60% of unsaturated polyester resin, 10-20% of clay fiber, 5-8% of copper naphthenate, 2-5% of cobalt iso-octoate, 20-30% of calcium carbonate, 1-5% of polyvinyl fluoride and 8-12% of silicon dioxide. The flame-retarded resin has good permeability on a variety of fiber products due to small viscosity and good wetting property, is adjustable in viscosity and long in service cycle, can be widely applied to processes of mechanical winding, casting, manual pasting, die pressing and the like, and has a wide market value and a huge market potential.

Owner:李霞

Antifouling paint and preparation method thereof

InactiveCN103436171AControlled release rateEfficient killingAntifouling/underwater paintsRosin coatingsMethyl carbamateChlorinated paraffins

The invention discloses an antifouling paint and a preparation method thereof and relates to the technical field of chemical engineering. The antifouling paint comprises the following components by weight percent: 8-12% of 40% vinyl chloride-vinyl isobutyl ether copolymer liquor, 17-23% of 60% rosin resin liquor, 18-25% of cuprous oxide, 2-4% of chlorinated paraffin, 2-5% of tetrachloroisophthalonitrile, 4-6% of 5-isopropyl-m-toluene methyl carbamate, 2-4% of anhydrous cupric sulfate, 8-12% of 95% zinc oxide, 4-6% of 4% copper naphthenate, 11-14% of iron oxide red powder, 1-3% of talcum powder, 0.2-0.8% of bentonite and the balance of xylene. The antifouling paint can be used for solving the problem that an object on the bottom of a ship or soaked in seawater can be easily stained by animals and plants in the seawater.

Owner:DRAGON FISH PAINT

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS8865794B2Enhanced anaerobicImprove curing effectSynthetic resin layered productsOrganic dyesCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerizations in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

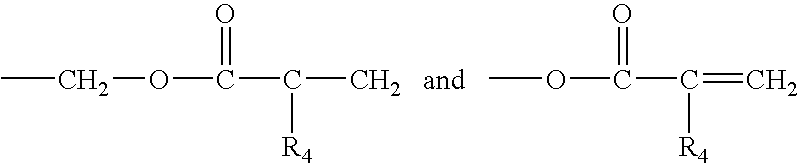

Synthetic method of unsaturated polyester resin for producing agglomerated stones

The invention discloses a synthetic method of unsaturated polyester resin for producing agglomerated stones. The synthetic method comprises the following steps: (1) putting PET (polyethylene terephthalate) flakes, dihydric alcohol and binary acid or polybasic acid in a reaction kettle, adding a reaction accelerating agent to the reaction kettle, slowly heating, and when the acid value is in the range from 4 to 6, cooling; (2) cooling, adding the dihydric alcohol and unsaturated binary acid to the reaction kettle, and slowly heating till the acid value reaches below 30mgKOH / g; (3) vacuumizing till the acid value is reduced to 20-22mgKOH / g, cooling to 170 DEG C and adding a polymerization inhibitor; (4) cooling, and adding styrene; and (5) cooling, adding an additive, pumping the styrene into a dilution kettle, adding a proper amount of copper naphthenate, pressing polyester into the dilution kettle, ending material pressing, cooling, filtering and packaging. According to the synthetic method, the PET flakes are used for synthesizing the unsaturated polyester resin for producing the agglomerated stones; the cost can be saved; the quality is improved; the utilization rate of resources is increased; and environments are improved.

Owner:WUQIAO HAOTONG RESIN

Wood preservative

InactiveCN105437339AReasonable compositionSimple preparation processWood impregnation detailsMachine partsAdditive ingredient

The invention provides a wood preservative. The wood preservative comprises the following main ingredients in percentage by weight: 8-12% of nanometre copper oxide particles, 4-6% of sodium metabisulfite, 2-4% of tebuconazole, 5-8% of polyethylene glycol, 1-3% of copper naphthenate, 2-5% of acetic acid, and the balance deionized water. The invention discloses a wood preservative. The wood preservative is reasonable in ingredient configuration, simple and convenient in preparation process, and moderate in cost; the prepared preservative has good use performance, has no toxic by-products generated during preparation and use processes, meets the environmental protection concept, and can be widely applied to various natural wood, fibre board and shaving board products, and machined parts.

Owner:常熟市石林木材有限责任公司

Anti-yellowing unsaturated polyester resin and synthetic method thereof

ActiveCN105482087AImprove anti-yellowing effectHigh heat distortion temperatureAntioxidantCis-Butenedioic Acid

The invention provides anti-yellowing unsaturated polyester resin, comprising the following components in percentage by weight: 13-20% of adipic acid, 23-28% of maleic anhydride, 30-33% of dihydric alcohol, 0.04-0.05% of an antioxidant, 0.01% of an inhibitor, 23-24% of styrene, 4% of metacrylic acid methyl ester, 0.04% of paraffin, 0.01% of copper naphthenate and 0.1% of a light stabilizer, wherein the dihydric alcohol is a mixture of neopentyl glycol, glycol and propylene glycol, or a mixture of neopentyl glycol, methyl propylene glycol and propylene glycol. The unsaturated polyester resin provided by the invention has very good yellowing resistance and weather resistance.

Owner:广东百汇达新材料有限公司

Method for producing unsaturated polyester resin by using glycerinum

The invention discloses a method for producing unsaturated polyester resin by using glycerinum. The method adopts the following concrete steps: (1) feeding glycerinum, a monobasic acid and an organic tin catalyst to a reaction kettle according to the proportion, and slowly heating up; (2) cooling, feeding other dihydric alcohols and unsaturated dicarboxylic acid to the reaction kettle, and slowly heating up; (3) vacuumizing until the acid value is reduced to below 35mgKOH / g, cooling and adding a polymerization inhibitor; (4) adding styrene, controlling at 70-90 DEG to agitate, cooling, filtering and discharging; and (5) cooling after reaction is ended, and infiltrating formula weight of styrene to a dilute kettle and adding assistants such as copper naphthenate and the like, pressing polyester into the dilute kettle, continuing to agitate after swaging is finished, and packaging if being qualified. The method has the advantages that the cost is saved, and the quality is improved by adopting glycerinum, the method is low in glycerinum price and wide in source, not only is dependence of unsaturated resin industry on petroleum industry reduced, but also pollution to the environment is reduced.

Owner:WUQIAO HAOTONG RESIN

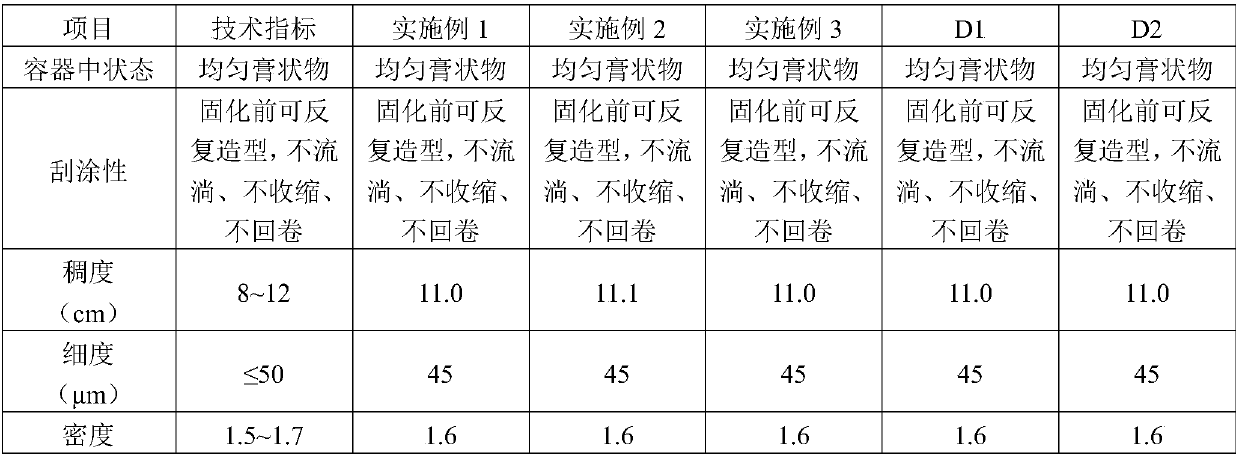

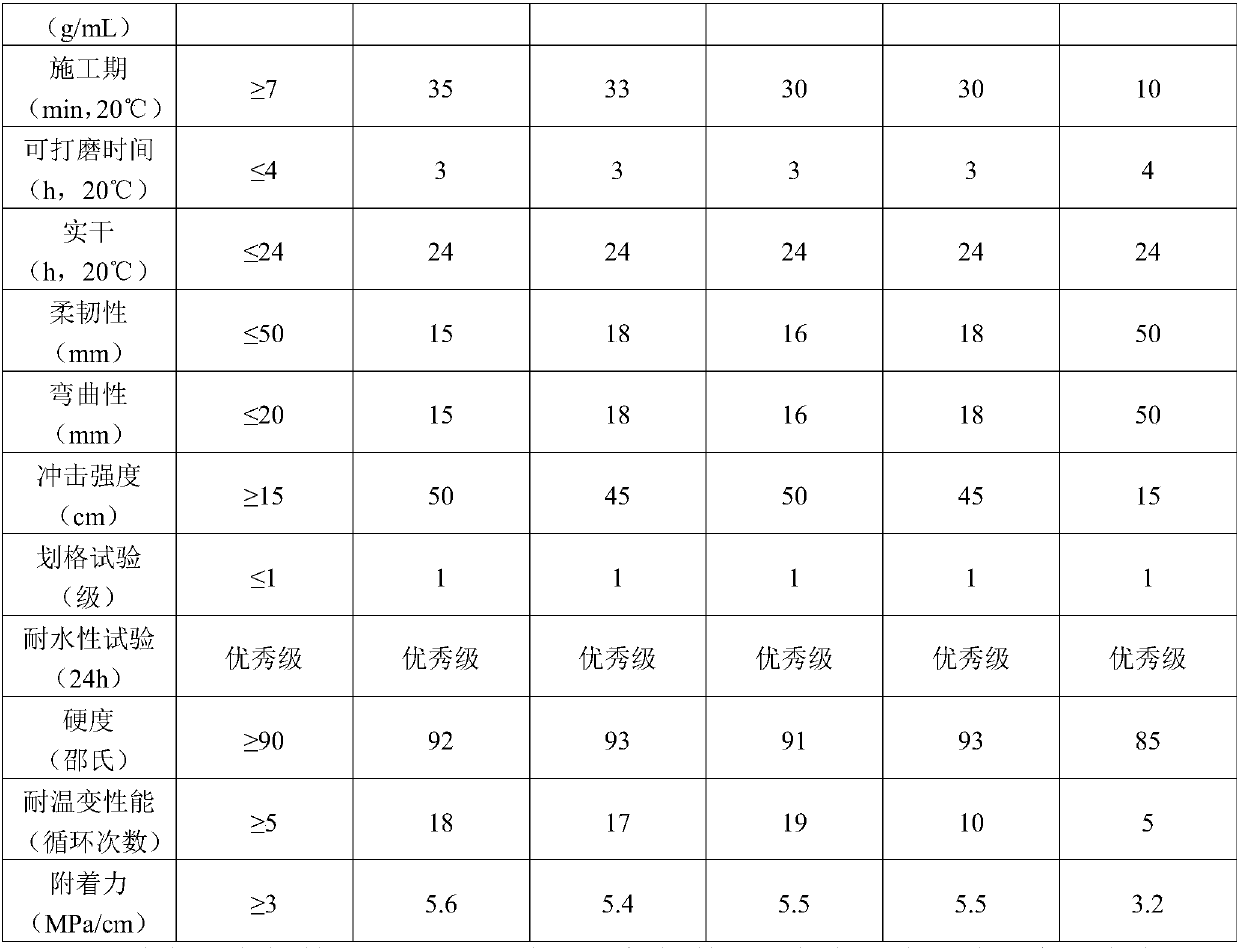

Poly putty specially used for multiple unit train as well as preparation method and application thereof

ActiveCN107641365AGood flexibilityImprove bending performanceFilling pastesCopper naphthenatePliability

The invention discloses poly putty specially used for a multiple unit train. The poly putty comprises main putty and a curing agent, wherein the main putty comprises the following components in partsby weight: 38-42 parts of unsaturated polyester resin, 0.7-0.8 part of cobalt isooctanoate with a weight fraction of 8%, 2-5 parts of styrene, 0.2-0.5 part of a composite auxiliary agent, 5-8 parts offumed silica, 5-10 parts of titanium dioxide, 25-30 parts of talcum powder with 325 meshes, and 8-15 parts of talcum powder with 600 meshes; and the composite auxiliary agent is composed of TBC, 1,4-naphthoquinone, antioxidant 264, copper naphthenate, and methyl ethyl ketoxime. The poly putty provided by the invention has the characteristics of high flexibility, high bendability, high impact resistance and very good temperature variation resistance, and the poly putty can withstand long-term high-low temperature change, is not easy to crack or fall, and fully meets the long-term operating requirements of the multiple unit train in areas with a high temperature difference.

Owner:河北新盾合成材料有限公司

Method for producing p-benzenoid unsaturated polyester resin

InactiveCN103951792AImprove utilization efficiencyImprove mechanical propertiesSolventTerephthalic acid

The invention discloses a method for producing p-benzenoid unsaturated polyester resin. The method for producing the p-benzenoid unsaturated polyester resin comprises the following steps: (1) adding terephthalic acid pool material, dihydric alcohol or polyhydric alcohol and an organic tin or organic zinc catalyst into a reaction kettle in proportion, and carrying out reaction at the temperature of 190-210 DEG C; (2) cooling until temperature is lower than 160 DEG C, adding unsaturated binary acid and / or binary alcohol into the system in another matching ratio, heating up to 200-205 DEG C, and carrying out reaction; (3) vacuumizing until acid value is reduced to be less than 30mgKOH / g, gradually cooling to 180-190 DEG C, and adding a polymerization inhibitor; (4) cooling until the temperature is lower than 130 DEG C, adding phenylethylene, controlling the temperature to be 70-90 DEG C, and stirring for 1 hour; (5) after reaction is finished, pumping phenylehtylene into a dilution kettle and adding auxiliaries like copper naphthenate, pressing polyester into the dilution kettle, and stirring after material settling is finished. The method for producing the p-benzenoid unsaturated polyester resin has the advantages that utilization efficiency of raw materials is improved, production cost of unsaturated polyester resin is reduced, environmental pollution is reduced, reaction speed is increased, and colour of the p-benzenoid unsaturated polyester resin product is improved; the unsaturated polyester resin obtained through reaction has good heat resistance, corrosion resistance and solvent resistance.

Owner:WUQIAO HAOTONG RESIN

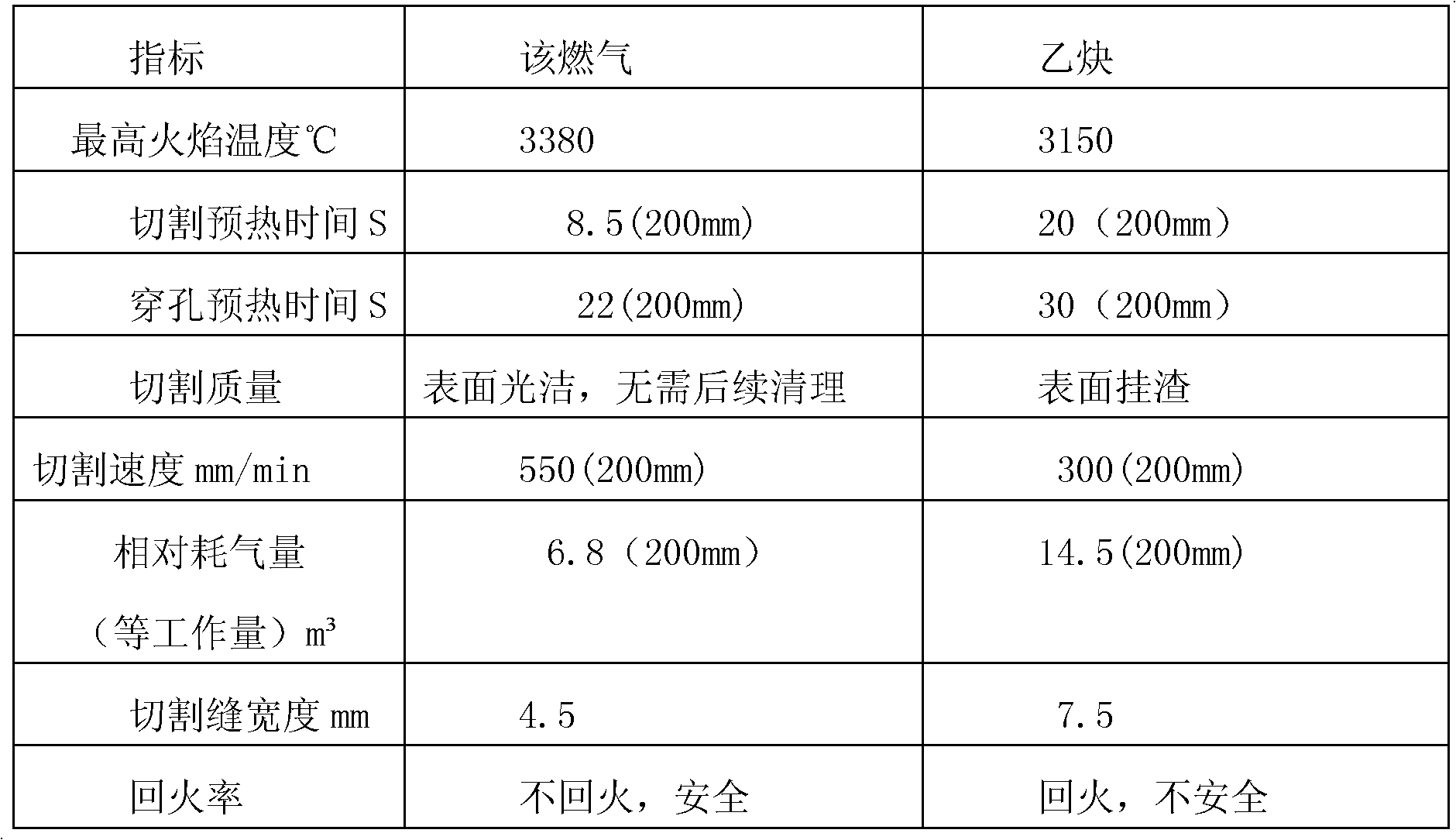

Synergistic mixed light hydrocarbon industry gas

InactiveCN1597879AMeet the use requirementsImprove evaporation effectGaseous fuelsPotassium hydroxideSolvent

The invention is a synergistic mixed light hydrocarbon industrial fuel gas, mixed of multifunctional synergistic agent and paraffin and olefin hydrocarbons in weight ratio of 1-3 %0, where the paraffin and olefin hydrocarbons are mixed of light and heavy hydrocarbon gases in the ratio of 1 to (0-0.2) and the multifunctional synergistic agent is prepared of 120# solvent oil, alcohol, methyl-tert-butyl ether, tung oil, tert-butyl ferrocene, sodium naphthenate, copper naphthenate, and potassium hydroxide in a certain proportion. It has low energy consumption, low pollution, low cost, safety, and flame temperature higher than that of acetylene flame, and is suitable to operate in the highly cold regions and ships, saving the fuel gas by above 30%.

Owner:北京划时代超能科技有限责任公司

Flame-retardant resin

The invention relates to a flame-retardant resin which comprises the following components in parts by mass: 10-20 parts of chlorinated styrene, 10-15 parts of maleic anhydride, 20-30 parts of tetrachloro phthalic anhydride, 40-55 parts of neopentyl glycol, 2-7 parts of methyl methacrylate, 8-15 parts of fiber, 6-10 parts of copper naphthenate, 1-3 parts of cobalt isooctoate, 20-30 parts of calcium carbonate and 8-12 parts of silicon dioxide. The tetrachloro phthalic anhydride used as the raw material can enhance the flame retardancy of the resin, and the chlorinated styrene used as the curing agent further enhances the flame retardancy of the resin. The flame-retardant resin has the characteristics of high temperature resistance, corrosion resistance, high strength, long service life of the prepared part, simple processing technique, no toxicity after curing, high bonding strength, simple and controllable technical process, short production cycle and the like, and can be cured at normal temperature. In the resin synthesis process, the heat generated by chemical reaction is fully utilized, thereby saving the energy and avoiding generating three wastes.

Owner:WUXI NANLIGONG TECH DEV

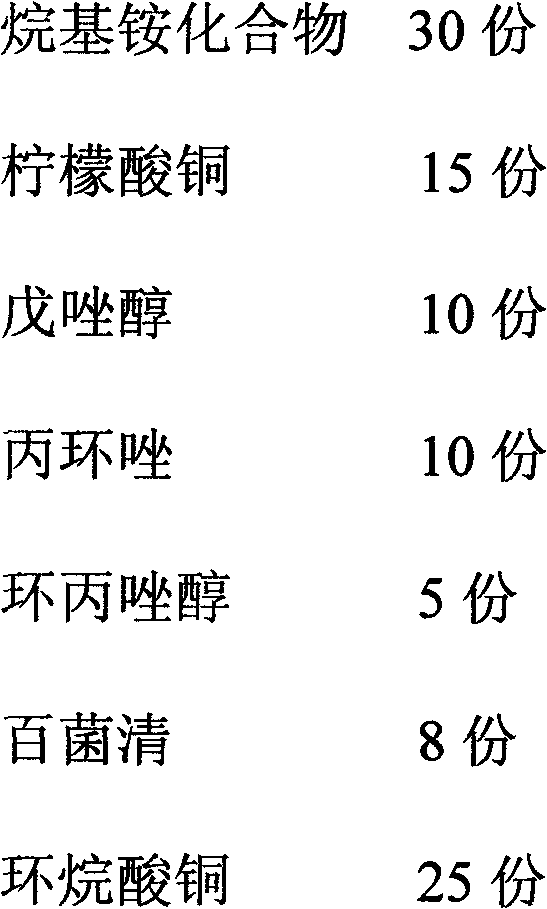

Wood preservative

InactiveCN102990741AMinor hazard damageTexture highlightsWood impregnation detailsAmmonium compoundsChlorothalonil

The invention relates to a wood preservative composed of an alkyl ammonium compound, copper citrate, tebuconazole, propiconazole, cyproconazole, chlorothalonil, and copper naphthenate. The preservative is an organic-solvent-type preservative. The wood preservative has the advantages of good durability, good stability, good penetration capacity, high safety, low corrosion, and small harmful damage to wood materials. When the preservative is injected into wood, volatilization and loss are prevented, and proper toxicity is maintained for a long time. The wood preservative has a certain dosage depth. The wood preservative has relatively high toxicity upon various bacteria and worms harming the wood, but low toxicity or no toxicity upon human and animals; and the wood preservative does not cause pollution or damage to the environment. The wood preservative causes low corrosion to various metals, and is relatively neutral. When a wood material is treated by the wood preservative, mechanical strength, good texture, and pleasant color of the wood material are not influenced.

Owner:赵强

Flame-retardant resin

The invention discloses flame-retardant resin, belonging to the technical field of high polymer materials. The technical scheme of the invention is as follows: the flame-retardant resin is composed of the following components in parts by weight: 25-60 parts of unsaturated polyester resin, 5-25 parts of glass wool, 2-10 parts of copper naphthenate, 1-5 parts of cobalt iso-octoate, 15-35 parts of calcium carbonate, 1-5 parts of talcum powder, 1-5 parts of polyvinyl fluoride, 6-14 parts of silicon dioxide, 2-12 parts of clay fiber, 2-12 parts of asbestos fiber, 2-10 parts of alumina cellucotton, and 2-6 parts of accelerant. Compared with the prior art, because the flame-retardant resin provided by the invention is low in viscosity and good in infiltrating property, the flame-retardant resin has a good penetration property to various fiber products; moreover, the flame-retardant resin is adjustable in viscosity and long in service life, therefore, the flame-retardant resin can be widely applied to processes of mechanical warping, casting, manual lay-up, mould pressing and the like, and has broad market values and huge market potential.

Owner:SHANDONG JIQING CHEM

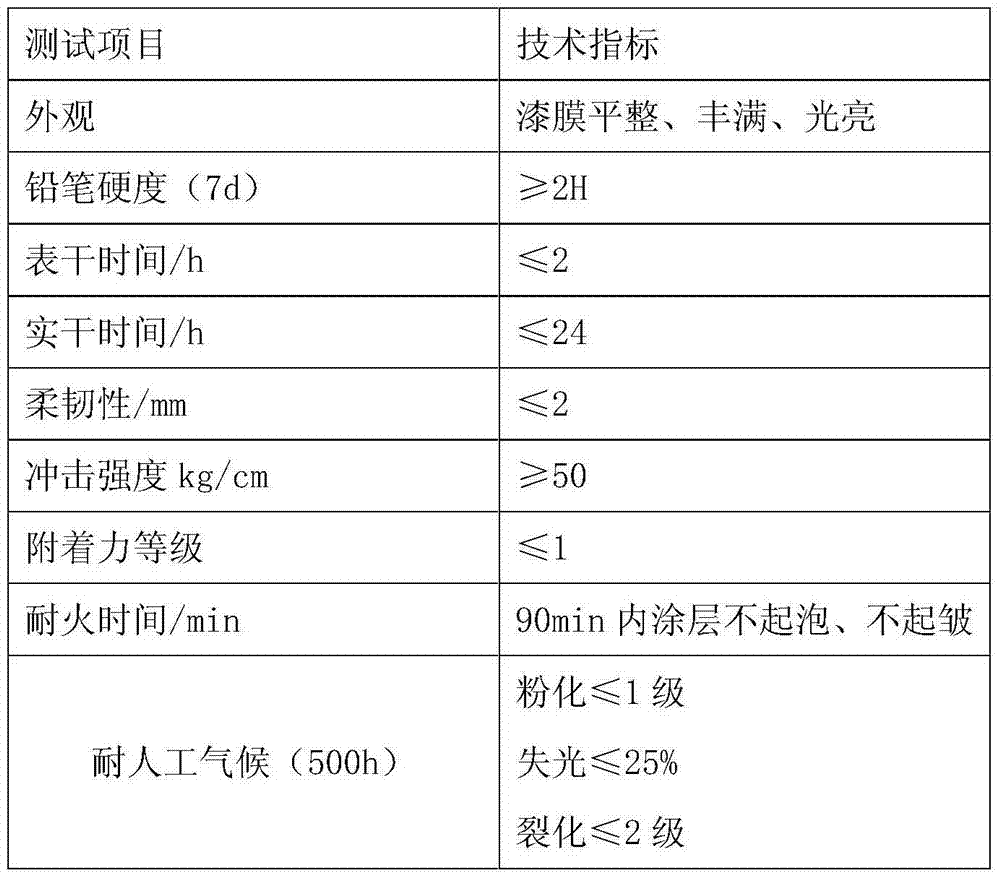

Wooden furniture surface coating material

The invention relates to the technical field of furniture surface treatment, in particular to a wooden furniture surface coating material. The wooden furniture surface coating material is prepared from a main agent and a curing agent, wherein the main agent is prepared from, by weight, 50-60 parts of saturated polyester resin, 5-10 parts of dimethylglyoxime, 3-5 parts of phosphoric acid triallyl ester, 2-4 parts of white corundum, 1-6 parts of attapulgite, 0.5-1.0 part of copper naphthenate, 0.2-0.4 part of cobalt iso-octoate and 2-6 parts of titanium dioxide, the curing agent is prepared from, by weight, 10-20 parts of methyl ethyl ketone peroxide, 5-8 parts of gas phase SiO2, 15-25 parts of dibutyl terephthalate and 0.1-0.3 part of polyvinylpyrrolidone. According to the wooden furniture surface coating material, no deformation or contraction of a base material will be caused in the base material treatment process, and therefore the decorative coating is not broken.

Owner:桐乡市美意家具有限公司

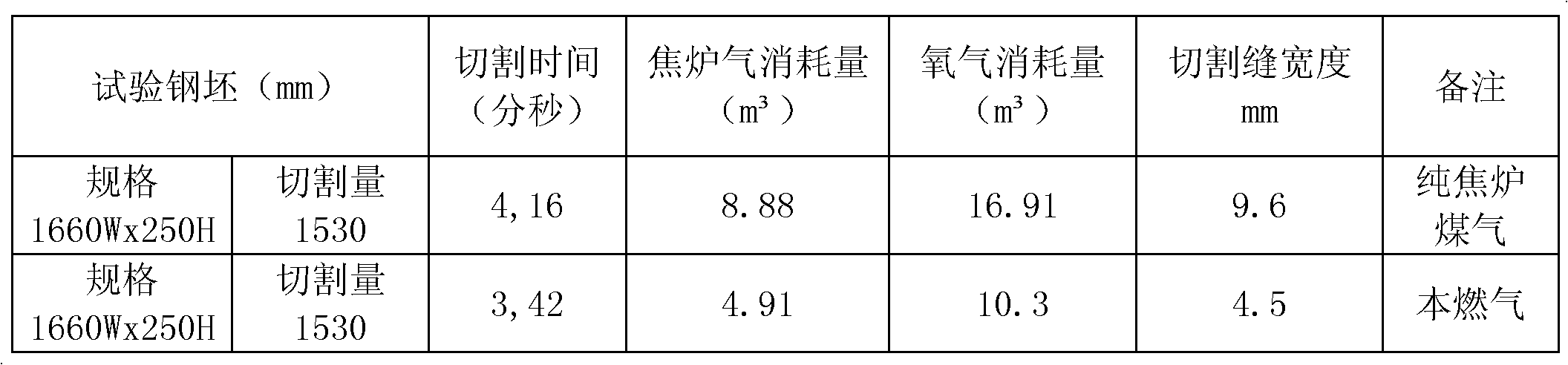

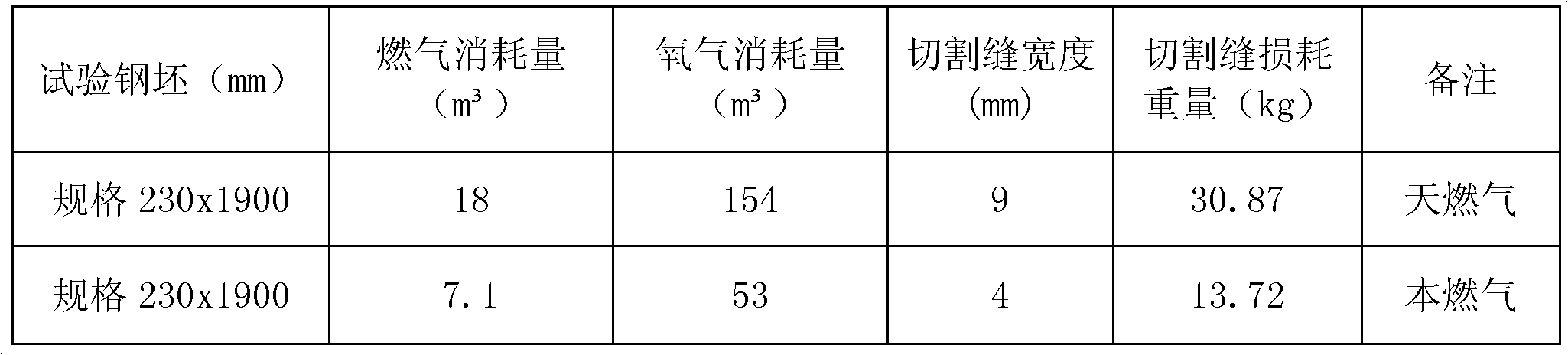

Efficient cutting gas used for continuous casting and based on coke oven gas

The invention discloses efficient cutting gas used for continuous casting and based on coke oven gas. The cutting gas comprises the coke oven gas and additive solution, wherein the additive solution is a mixture of copper naphthenate, methyl butyl ether, normal hexane, methanol, isooctyl glycollate and miscella No.200. The cutting gas can enable a gas appliance to have very good combustibility, safety and environmental friendliness, and has the characteristics of high combustion temperature, trim and smooth cutting face, small cutting slots and high cutting speed; meanwhile, no harmful gas exists when the cutting gas is used, so that human health is not harmed; and the metal yield is high.

Owner:NANJING ULTRAPURE WATER UPW TECH

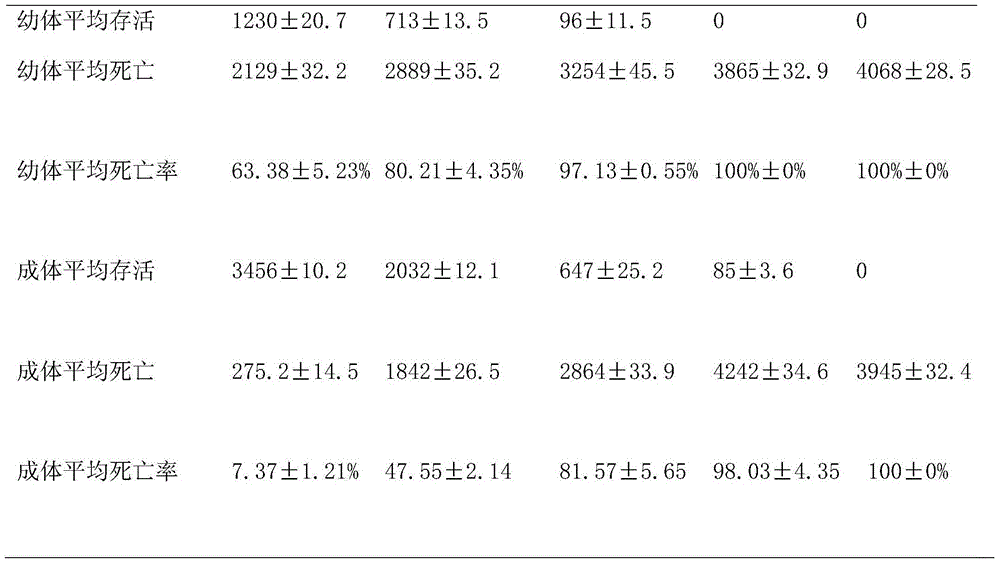

Amino resin paint for flexible and weather-resistant copper sculpture

The invention relates to paint, and particularly relates to an amino resin paint for a flexible and weather-resistant copper sculpture. The paint disclosed by the invention is prepared from the following raw materials in parts by weight: 34-36 parts of amino resin, 2-3 parts of copper naphthenate, 1-2 parts of tetra-ammonium acetate, 5-10 parts of propylene glycol methyl ether acetate, 2-5 parts of polydimethylsiloxane, 14-18 parts of polyether acrylate, 20-24 parts of trimethylolpropane triacrylate, 6-8 parts of dibutyl phthalate, 0.5-1.5 parts of accelerants DTDM, 1.5-3.0 parts of silane coupling agent KH-560, 10-15 parts of semi-reinforcing carbon black, 5-9 parts of diamino diphenyl sulfone, 1-2 parts of dicumyl peroxide, 5-6 parts of assistants, 10-12 parts of xylene and 10-12 parts of butyl acetate. The paint disclosed by the invention is gloss in paint film in glossiness and fullness, good in adhesive force, flexible and hard, durable and flame-retardant, weather-resistant and anti-ageing, safe to use, and relatively simple in production technology, and can be widely applied to various bronze crafts.

Owner:TONGLING XINJIUDING COPPER CULTURE IND

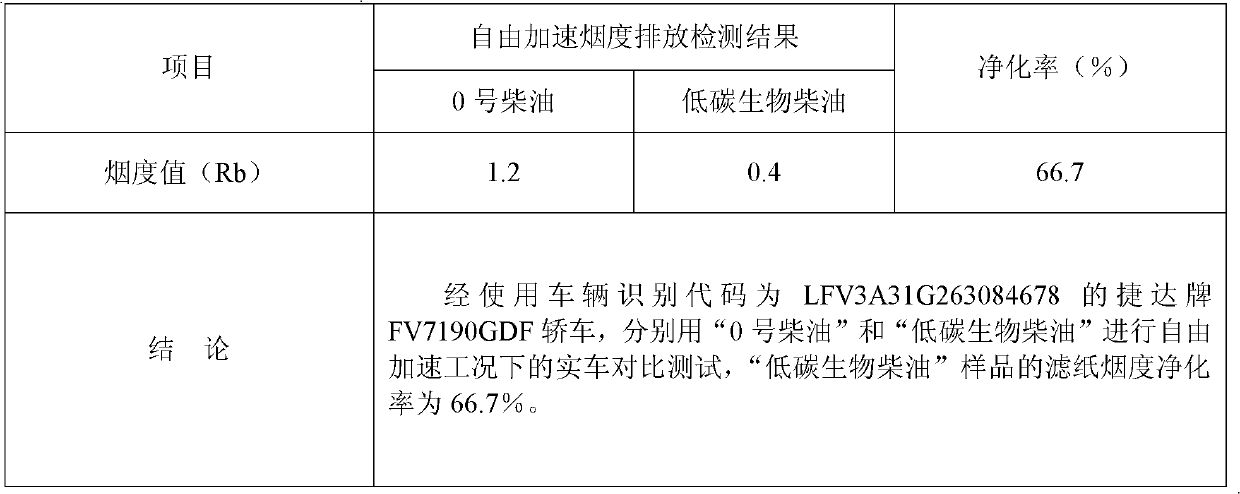

Vehicle low-carbon biodiesel

ActiveCN101768478ANo power dropNo corrosionLiquid carbonaceous fuelsPolyethylene vinyl acetateOctanol

The invention relates to a vehicle low-carbon biodiesel which uses coal methanol, butanol, octanol, oleic acid, 0# diesel and 200# solvent oil as raw materials. The preparation method comprises the following steps: firstly mixing methanol and oleic acid with octanol and butanol at room temperature under normal pressure, adding N,N'-phenylenediamine, sodium alkylsulfonate and copper naphthenate tostir evenly to inject into a preparation tank, secondly blending 200# solvent oil with 0# diesel, adding alkyl acid amide, ethylene glycol methyl ether, a mixture of chromium salt and calcium salt offatty acid, polyethylene vinyl acetate (T1804) and N,N'-bis(salicylidene)-1,2-propylene diamine, heating the obtained mixture to 55 DEG C with a fuel oil heat exchanger, injecting the mixture to the preparation tank, and using a stirred tank to stir for 1 hour to obtain the uniform low-carbon biodiesel. The vehicle biodiesel is convenient to use, the vehicle engine is not needed to modify, and the vehicle biodiesel can be used alone or mixed with vehicle diesel and biodiesel freely. The low-temperature start of fuel is good, the stability is high, the CO, HC and NOX contents of the emitted exhaust can be effectively reduced and the biodiesel of the invention is the preferred biomass vehicle fuel for energy conservation and carbon reduction now.

Owner:北京雄韬伟业能源科技发展有限公司

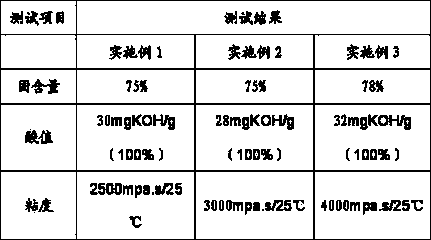

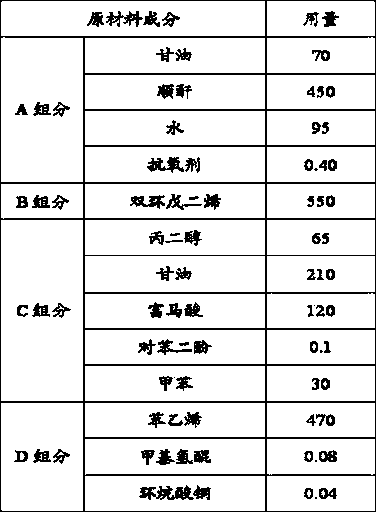

Cheap dicyclopentadiene modified unsaturated polyester resin and preparation method thereof

The invention discloses a cheap dicyclopentadiene modified unsaturated polyester resin and a preparation method thereof. The preparation method comprises the following steps: adding a component A (comprising 70-80 pars of glycerin, 400-450 parts of maleic anhydride, 95-100 parts of water and 0.40-0.60 parts of an antioxidant) into a reaction kettle, heating to 80DEG C, stopping heating, naturally heating to 105-110DEG C, and keeping the temperature constant; adding a component B (550-560 parts of dicyclopentadiene) to an elevated tank in a dropwise manner within 2h, heating to 120DEG C, and carrying out heat insulation for 2.5h; adding a component C to the reaction kettle, heating to a refluxing temperature of 130DEG C, and carrying out heat insulation for 0.5h; slowly heating to 190DEG C within 2h, maintaining the temperature constant, and cooling to 120DEG C when the acid value is not more than 35mgKOH / g (100%) and the viscosity is 12-14s; and adding a component D (comprising 470-480 parts of styrene, 0.08 parts of methylhydroquinone and 0.04 parts of copper naphthenate), and diluting to complete the production. The resin prepared in the invention has the characteristics of low price, high gloss, good levelability, good fullness and good greening effect.

Owner:YINGDE YAJIA PAINT

Antibacterial decorative board and preparation method thereof

InactiveCN106010151AImprove tensile resistanceEasy to cleanFireproof paintsCovering/liningsFiberCarbon fibers

The invention relates to an antibacterial environment-friendly board, particularly an antibacterial decorative board and a preparation method thereof. The antibacterial decorative board comprises, from top to bottom in order, an antibacterial surface layer, a decorative paper line layer, a balance enhancement layer, a substrate layer and a balance layer that are bonded to each other. The preparation method consists of: firstly making a stearic acid salt, calcium carbonate, carbon fiber and glass fiber, phenolic resin, unsaturated polyester resin, polyvinyl fluoride, copper naphthenate, cobalt iso-octoate, a coupling agent, and an acrylonitrile-butadiene-styrene copolymer into the substrate layer, pasting the balance enhancement layer and the balance layer respectively, performing pressing, then sticking the decorative paper line layer and conducting pressing, applying an antibacterial paint, and performing drying to form the antibacterial surface layer. The invention adopts a multilayer structure to ensure the board strength, the coating also can effectively prevent scratching, the balance enhancement layer and the balance layer improve the tensile properties of the board, and the substrate layer is made of a resin material, is elastic and can absorb the impact of external force, and the construction is convenient and fast.

Owner:陈何怀

Putty for wooden furniture

InactiveCN102424733AGood construction performanceEasy to useFilling pastesCyclohexanoneSodium Bentonite

The invention discloses a putty for wooden furniture. The putty mainly comprises a main agent and a curing agent, wherein the main agent consists of the following components in part by weight: 64 to 66 parts of unsaturated polyester resin, 8 t o12 parts of styrene, 2 to 4 parts of phosphoric acid triallyl ester, 3 to 5 parts of bentonite, 3 to 5 parts of white corundum, 2 to 3 parts of gas-phase SiO2, 3 to 5 parts of attapulgite, 0.1 to 0.3 part of hydroquinone, 0.2 to 0.4 part of copper naphthenate, 0.2 to 0.4 part of dimethylaniline, 3 to 8 parts of titanium white and 1 to 2 parts of cobalt naphthenate; and the curing agent consists of the following components in part by weight: 10 to 14 parts of cyclohexanone peroxide, 2 to 3 parts of gas-phase SiO2, 3 to 5 parts of titanium white and 0.2 to 0.5 part of polyvinylpyrrolidone.

Owner:杨双明

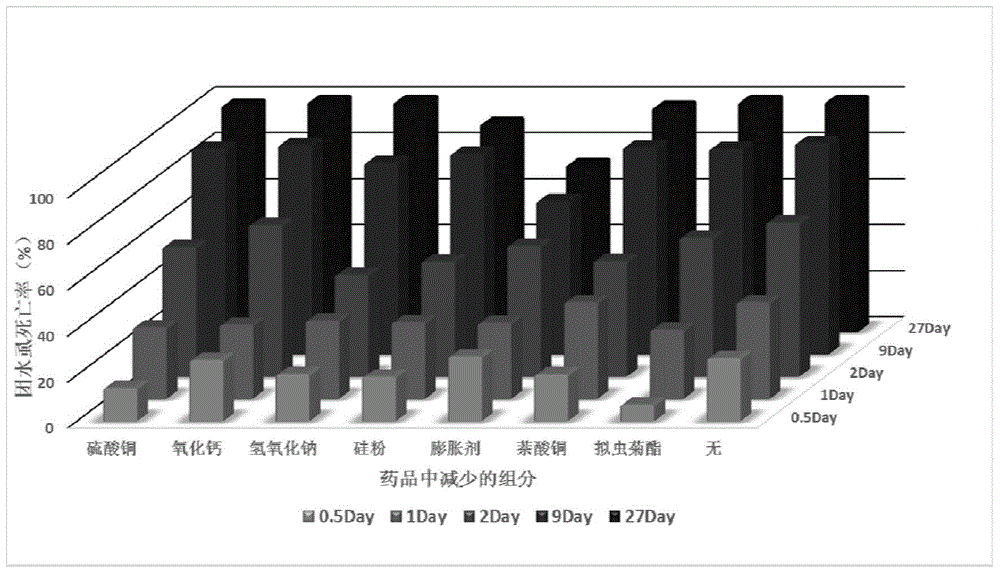

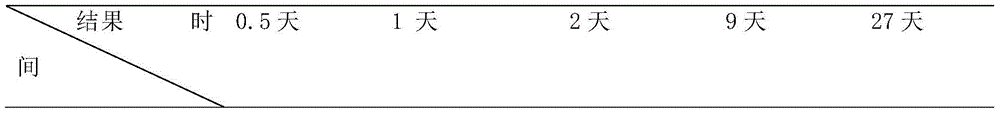

Drug for controlling sphaeromas, shipworms and other boring marine organisms and using method of drug

The invention discloses a drug for controlling sphaeromas, shipworms and other boring marine organisms and a using method of the drug. The drug comprises the following components: 30-50 parts of copper sulfate, 20-30 parts of calcium oxide, 20-30 parts of sodium hydroxide, 10-25 parts of silicon powder, 5-15 parts of an expanding agent, 30-35 parts of copper naphthenate, 20-30 parts of water and 0.001-0.01 part of pyrethroid. The using method comprises the following steps: sufficiently and uniformly stirring the components to prepare the drug for controlling the sphaeromas, the shipworms and other boring marine organisms; during a low tide, smearing the drug at positions, suffering from the sphaeromas and the shipworms, of a mangrove and a pier; after the drug is completely immersed, smearing tung oil to form a tung oil protection layer with the thickness of 0.2-0.3 cm. The drug is simple in formula and safe and effective to use, and can control the sphaeromas, the shipworms and other boring marine organisms.

Owner:HAINAN UNIVERSITY

Organic-silicon heat-resistant paint

The invention relates to oil paint and particularly relates to organic-silicon heat-resistant paint. The oil paint comprises the following materials in parts by weight: 30-34 parts of organic silicon resin, 5-8 parts of mica powder, 2-3 parts of kaolin, 2-3 parts of sodium fluosilicate, 2-3 parts of copper naphthenate, 1-2 parts of zinc phosphate, 2-3 parts of methyl hydrogen dichlorosilane, 1-2 parts of polytetrahydrofuran ether glycol, 12-14 parts of epoxypropyl methacrylate, 1-2 parts of dimethyl aminopropyl methacrylamide, 18-20 parts of methyl methacrylate, 5-6 parts of acrylic acid, 2-3 parts of titanate coupling agent TMC-TTS, 2-4 parts of stearic acid, 2-3 parts of crosslinking agent TAC, 1-2 parts of isocyanate, 5-6 parts of additive, 10-12 parts of dimethylbenzene and 10-12 parts of butyl acetate. The organic-silicon heat-resistant paint has the advantages that the adhesion is easy, the drying of a paint film is fast, weather resistance and ageing resistance are good, the insulating performance is good, the fire resistance and the heat resistance are good, and the safe and reliable effects are achieved, so that the organic-silicon heat-resistant paint is especially suitable for being used in the high-temperature environment.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Method for producing building material board

InactiveCN101164960AReduce contentLow in monochlorineSolid waste managementAdhesiveCopper naphthenate

This invention relates to a method for producing novel building material. It is characterized by; the raw materials magnesium oxide, anhydrous sulfuric acid, straw, inorganic adhesives, pearlite, silica flour, asbestos fiber, copper naphthenate, silica white and glass cloth are proportioned and then are proceeded steps: mixing, agitating, moulding, demoulding, drying to obtain the inventive product. This invention has advantages of: low cost, simple process, water-proof, sound-insulation.

Owner:荆德祥

High-temperature-resistant resin

The invention discloses high-temperature-resistant resin, comprising the following components in percent by weight: 45-60 percent of unsaturated polyester, 10-20 percent of rock wool, 5-8 percent of copper naphthenate, 2-5 percent of cobalt isooctanoate, 20-30 percent of calcium carbonate, 1-5 percent of talc powder and 8-12 percent of silicon dioxide. Due to low viscosity and good wetting property, the high-temperature-resistant resin provided by the invention has good penetration property, adjustable viscosity and long life cycle, can be widely used for processes such as mechanical winding, casting, hand lay-up and die pressing and has a wide market value and large market potential.

Owner:李霞

Processing technology for antiseptic and antibacterial furniture board

InactiveCN108274566AGood anti-corrosion and anti-bacterial functionEasy to operateImpregnation spraying apparatusWood treatment detailsEngineeringMoisture

The invention provides a processing technology for an antiseptic and antibacterial furniture board. The processing technology solves the technical problems that no corresponding processing process exists for an existing furniture board, the existing furniture board is processed only by the experience of operators, and processing is complicated. The processing technology for the antiseptic and antibacterial furniture board comprises the following steps that a, the board is dried till the moisture content ranges from 12% to 16%; b, the board is put into a closed pressure injection tank, and a preservative injected into the tank comprises, by weight, 8-12 parts of an emulsifier, 4-10 parts of copper naphthenate, 1-3 parts of diatomite, 2-5 parts of lignin, 4-8 parts of calcium propionate, 1-3parts of titanium diboride, 1-4 parts of sodium benzoate, 4-8 parts of acetic acid, 1-3 parts of tributyl phosphate, 2-3 parts of pyrithione and 20-30 parts of ethanol; c, high temperature qualitative treatment is carried out on the board material obtained in the step b; d, air drying treatment is carried out on the board after high-temperature qualitative treatment; and f, the surface of the board is coated with an antibacterial coating through a spraying system, and the antiseptic and antibacterial furniture board is obtained. The processing technology has the beneficial effect of being easy to implement.

Owner:海宁永欣科技咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com