Anti-yellowing unsaturated polyester resin and synthetic method thereof

A polyester resin, unsaturated technology, applied in the field of polymer chemistry, can solve the problems of loss of use function, product surface pulverization, structural damage, etc., to expand the scope of use, good yellowing resistance and weather resistance, and improve yellowing resistance The effect of changing abilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

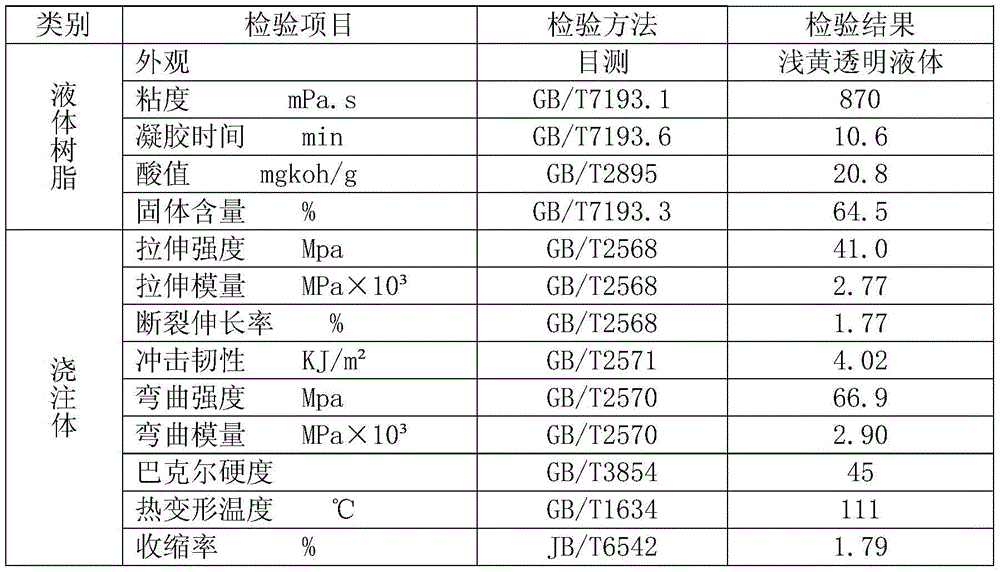

Examples

Embodiment 1

[0012] formula:

[0013] Reaction kettle formula: antioxidant 1g, adipic acid 290g, maleic anhydride 590g, neopentyl glycol 150g, ethylene glycol 190g, propylene glycol 300g, polymerization inhibitor methyl hydroquinone 0.2g;

[0014] Dilution kettle recipe: 500g styrene, 80g methyl methacrylate, 0.8g paraffin, 0.3g copper naphthenate, 2g light stabilizer.

[0015] making process:

[0016] Check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal, and put other reaction kettle formula raw materials into the reaction pot according to the recipe, except for the polymerization inhibitor methyl hydroquinone, and raise the temperature after feeding the materials, and the temperature of the raw materials will rise Supply nitrogen to 145°C (speed 0.5m 3 / h), horizontal condenser water supply, when the material temperature rises to 150°C, start stirring, when the distillation temperature rises to 98°C vertical condenser water su...

Embodiment 2

[0018] formula:

[0019] Reaction kettle formula: antioxidant 0.8g, adipic acid 438g, maleic anhydride 490g, neopentyl glycol 150g, ethylene glycol 190g, propylene glycol 300g, polymerization inhibitor methyl hydroquinone 0.2g;

[0020] Dilution kettle recipe: 500g styrene, 0.3g copper naphthenate, 0.8g paraffin, 80g methyl methacrylate, 2g light stabilizer.

[0021] making process:

[0022] Check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal, and put other reaction kettle formula raw materials into the reaction pot according to the recipe, except for the polymerization inhibitor methyl hydroquinone, and raise the temperature after feeding the materials, and the temperature of the raw materials will rise Supply nitrogen to 148°C (speed 0.5m 3 / h), horizontal condenser water supply, when the material temperature rises to 155 ° C, start stirring, when the distillation temperature rises to 100 ° C vertical condenser w...

Embodiment 3

[0024] formula:

[0025] Reaction kettle formula: antioxidant 0.8g, adipic acid 290g, maleic anhydride 590g, neopentyl glycol 150g, methyl propylene glycol 270g, propylene glycol 300g, polymerization inhibitor methyl hydroquinone 0.2g;

[0026] Dilution kettle recipe: 500g styrene, 80g methyl methacrylate, 0.2g copper naphthenate, 0.8g paraffin, 2g light stabilizer.

[0027] making process:

[0028] Check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal, and put other reaction kettle formula raw materials into the reaction pot according to the recipe, except for the polymerization inhibitor methyl hydroquinone, and raise the temperature after feeding the materials, and the temperature of the raw materials will rise Supply nitrogen to 146°C (speed 0.5m 3 / h), horizontal condenser water supply, when the material temperature rises to 153 ° C, start stirring, when the distillation temperature rises to 99 ° C vertical cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com