High abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying

An electrostatic spraying, high wear-resistant technology, applied in conductive coatings, coatings, fire-resistant coatings, etc., can solve the problems of unguaranteed wear resistance, high viscosity, and poor anti-sag performance of paint films, and achieve improved light curing Performance, improvement of overall performance, and effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

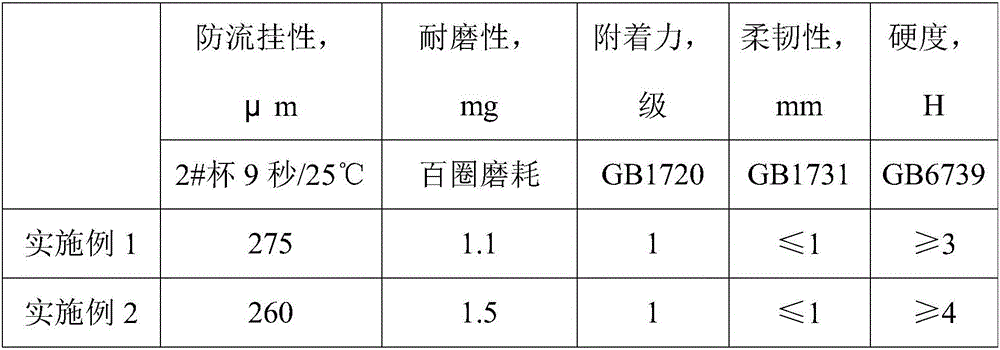

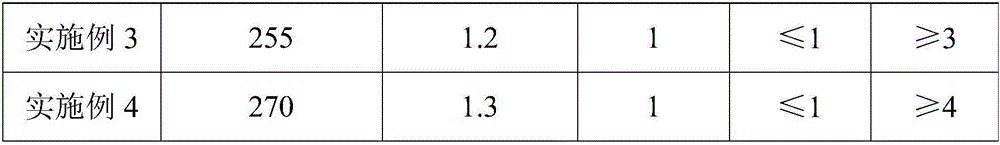

Examples

Embodiment 1

[0022] A high wear-resistant UV white primer for electrostatic spraying, comprising the following raw materials in parts by weight: 40 parts of epoxy acrylic resin, 35 parts of hydroxyl acrylic resin, 10 parts of thermoplastic acrylic resin, 30 parts of reactive diluent, modified graphite 5 parts of alkene, 6 parts of nano-silica, 1 part of nano-titanium dioxide, 5 parts of heavy calcium carbonate, 5 parts of montmorillonite, 20 parts of white pigment, 2 parts of zinc stearate, 6 parts of sodium hydroxymethyl cellulose, 1 part of polyamide wax, 2 parts of leveling agent, 0.1 part of defoamer, 6 parts of photoinitiator, 5 parts of organic solvent;

[0023] Wherein, the epoxy acrylic resin is a bisphenol A type epoxy acrylic resin, and the number average molecular weight is 500; Obtained by ester copolymerization, the number average molecular weight of the hydroxy acrylic resin is 10000, and the hydroxyl value is 80mgKOH / g; the glass transition temperature of the thermoplastic a...

Embodiment 2

[0027] A high wear-resistant UV white primer for electrostatic spraying, comprising the following raw materials in parts by weight: 70 parts of epoxy acrylic resin, 15 parts of hydroxyl acrylic resin, 20 parts of thermoplastic acrylic resin, 15 parts of reactive diluent, modified graphite 25 parts of alkenes, 2 parts of nano-silica, 5 parts of nano-titanium dioxide, 1 part of heavy calcium carbonate, 15 parts of montmorillonite, 10 parts of white pigment, 5 parts of zinc stearate, 2 parts of sodium hydroxymethyl cellulose, 5 parts of polyamide wax, 0.5 parts of leveling agent, 0.5 parts of defoamer, 2 parts of photoinitiator, 15 parts of organic solvent;

[0028]Wherein, the epoxy acrylic resin is a bisphenol A type epoxy acrylic resin, and the number average molecular weight is 1000; The number-average molecular weight of the hydroxyl acrylic resin is 5000, and the hydroxyl value is 130mgKOH / g; the glass transition temperature of the thermoplastic acrylic resin is above 80°C;...

Embodiment 3

[0032] A high wear-resistant UV white primer for electrostatic spraying, comprising the following raw materials in parts by weight: 50 parts of epoxy acrylic resin, 25 parts of hydroxyl acrylic resin, 15 parts of thermoplastic acrylic resin, 20 parts of reactive diluent, modified graphite 15 parts of alkenes, 4 parts of nano silicon dioxide, 3 parts of nano titanium dioxide, 3 parts of heavy calcium carbonate, 10 parts of montmorillonite, 15 parts of white pigment, 3 parts of zinc stearate, 4 parts of sodium hydroxymethyl cellulose, 3 parts of polyamide wax, 1 part of leveling agent, 0.3 parts of defoamer, 4 parts of photoinitiator, 10 parts of organic solvent;

[0033] Wherein, the epoxy acrylic resin is bisphenol A type epoxy acrylic resin, the number average molecular weight is 800; It is obtained by copolymerization of ethylene, acrylonitrile and hydroxypropyl acrylate, the number average molecular weight of the hydroxy acrylic resin is 7000, and the hydroxyl value is 100m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com