Patents

Literature

4611results about How to "Quick measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

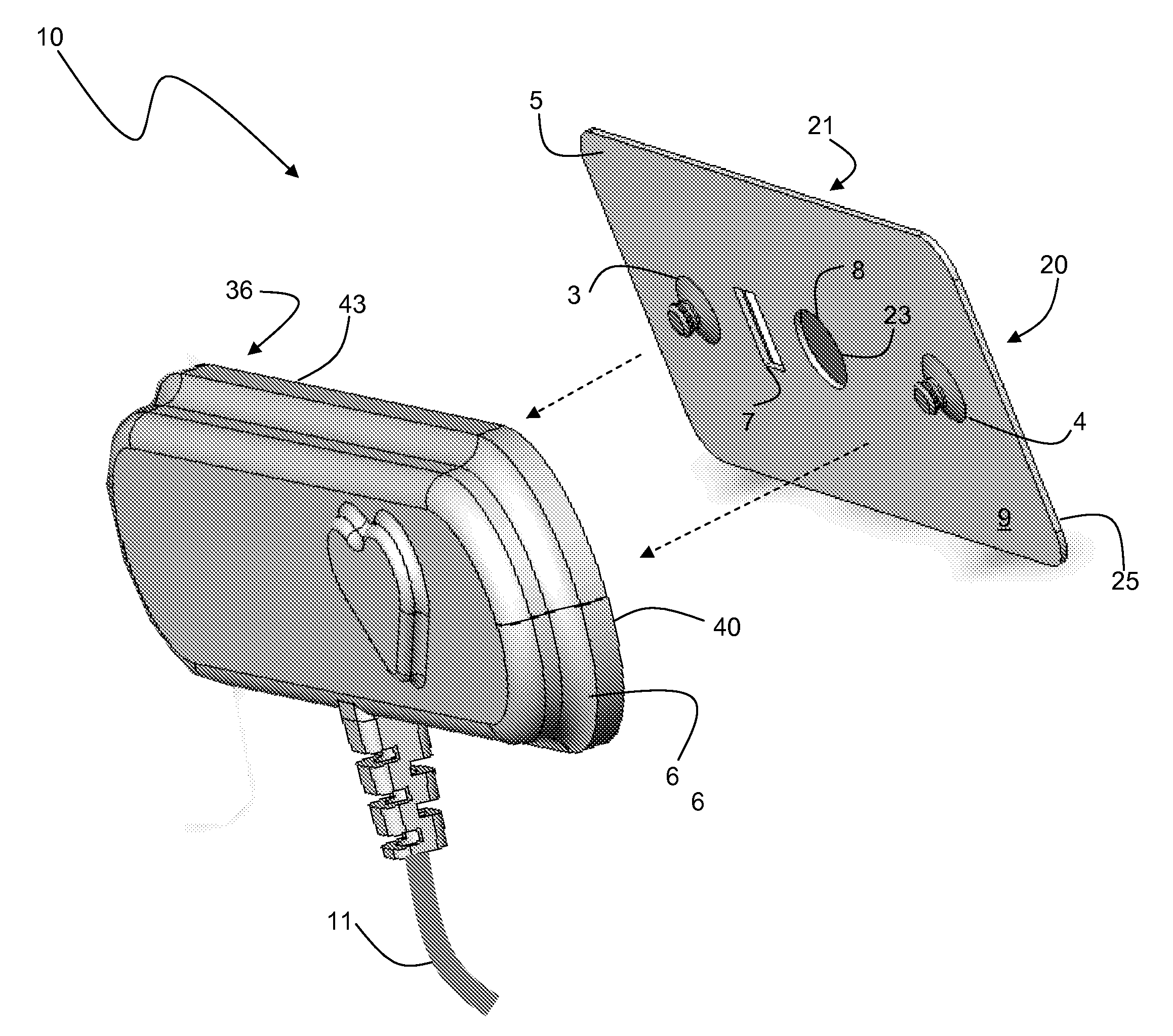

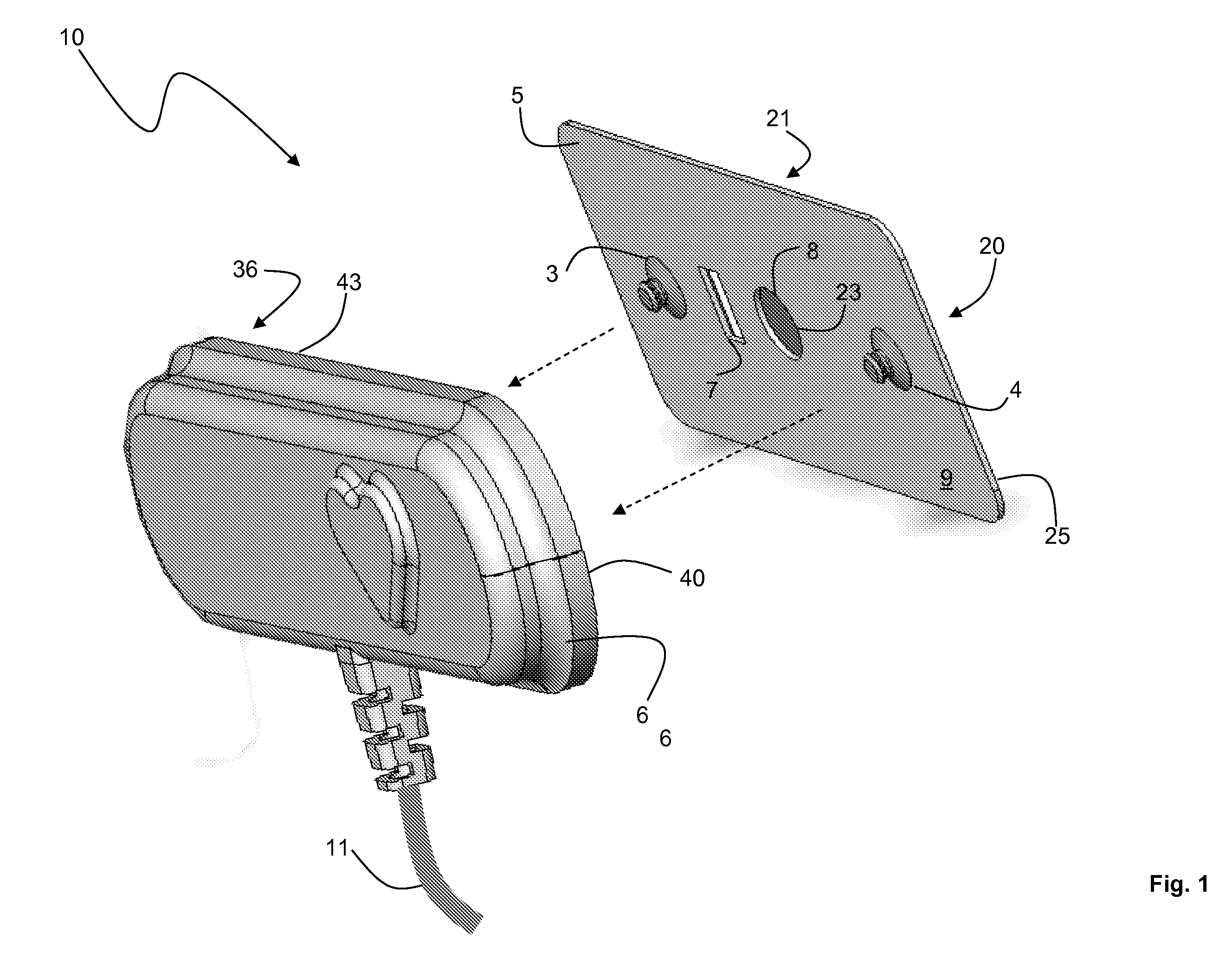

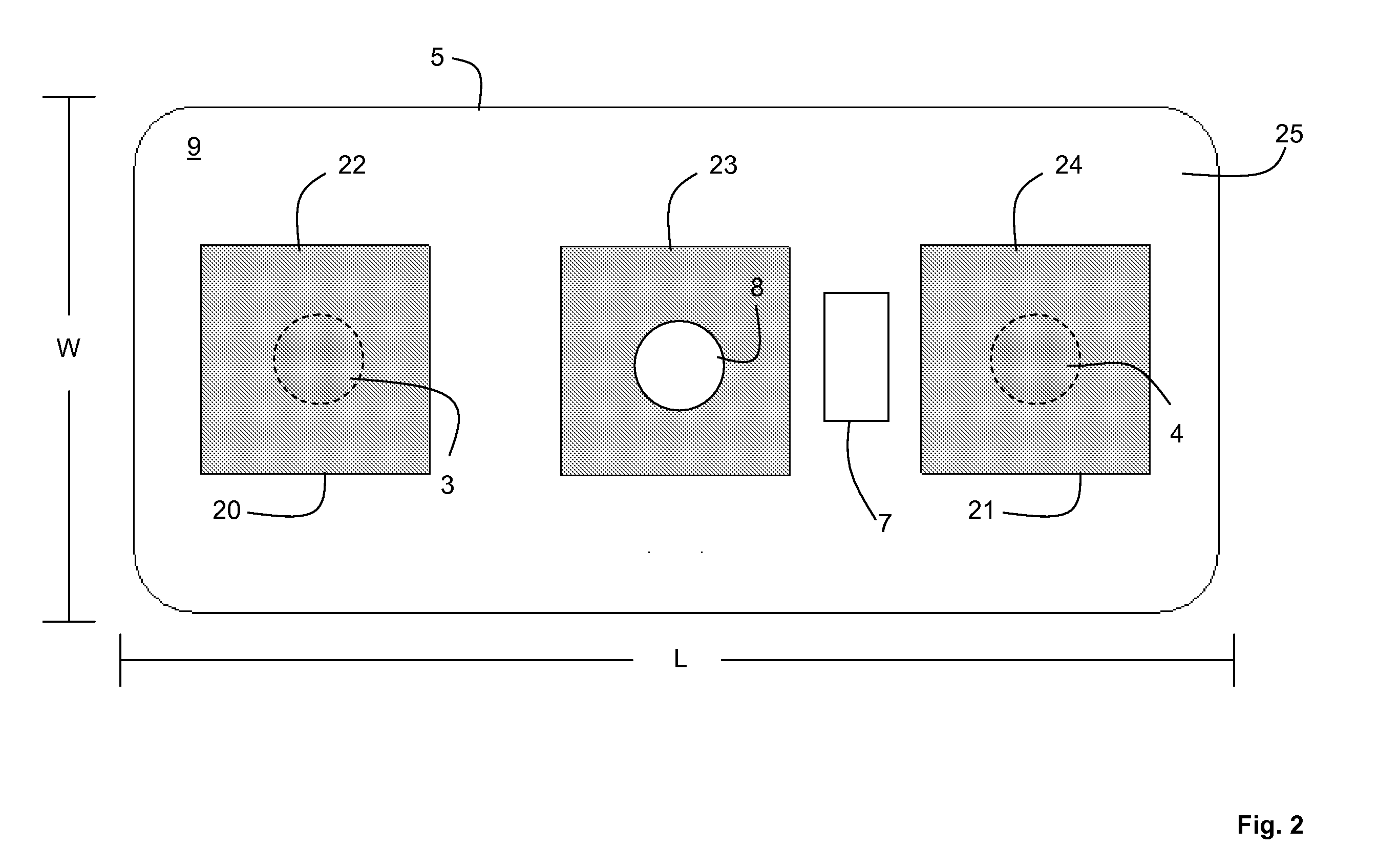

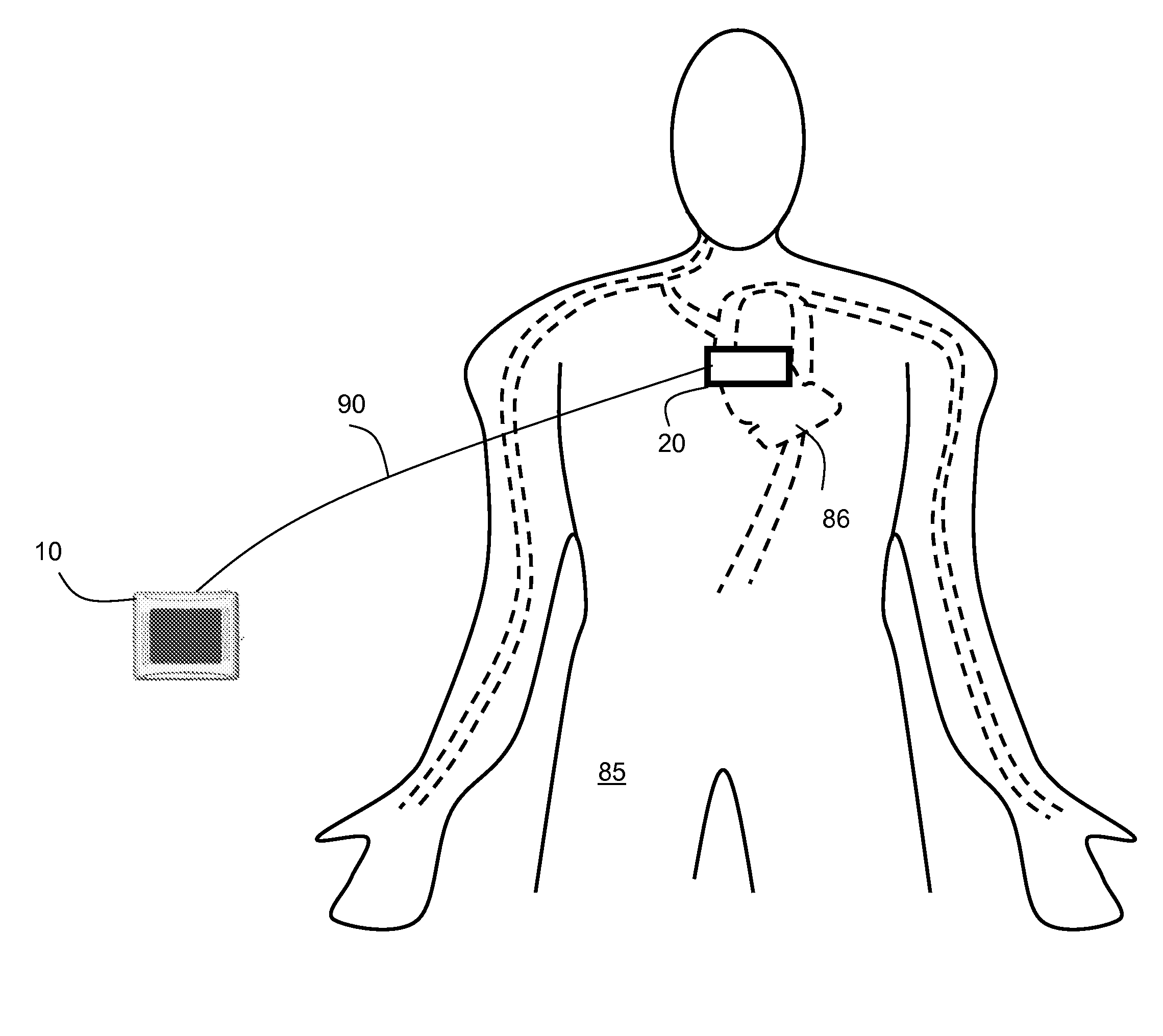

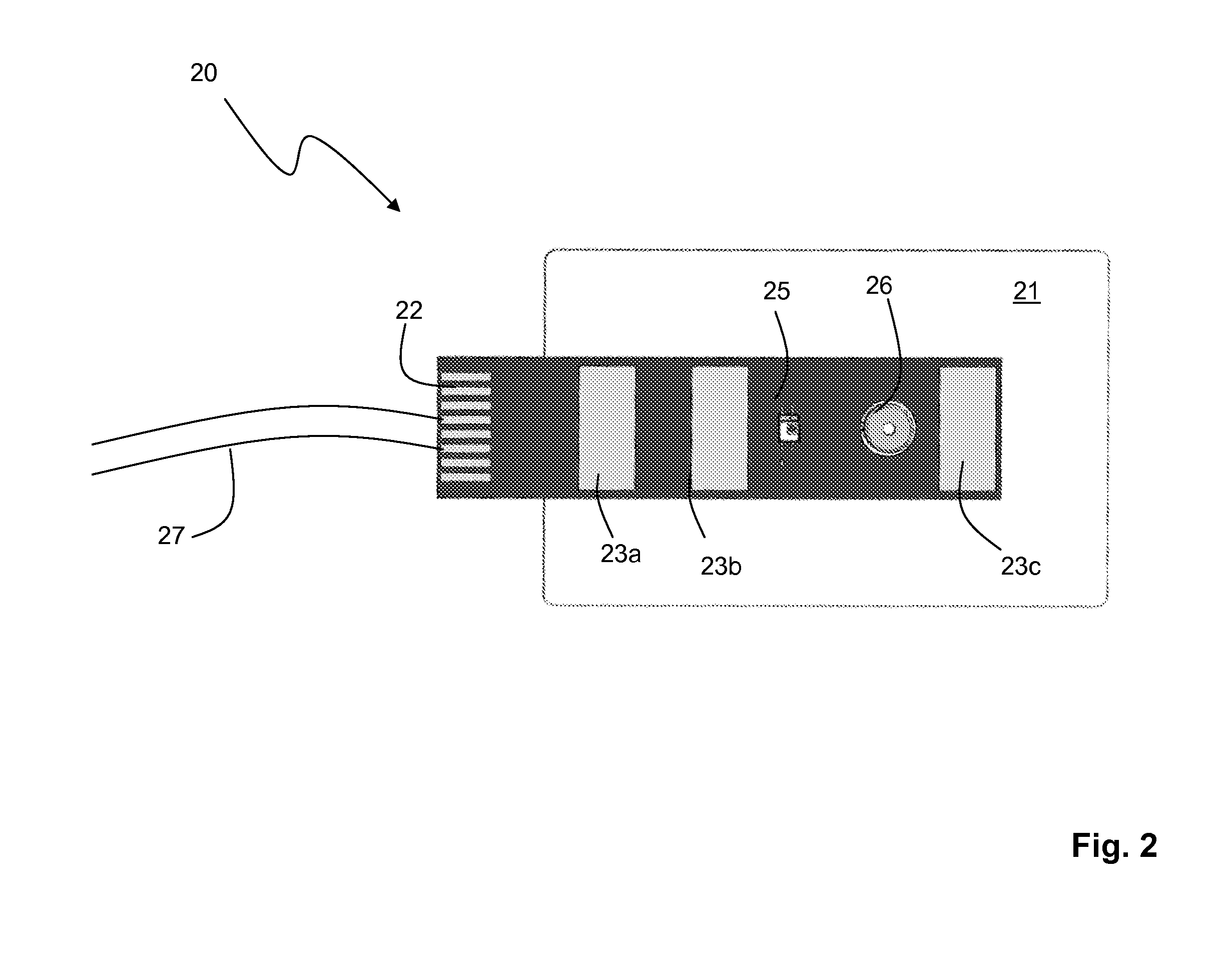

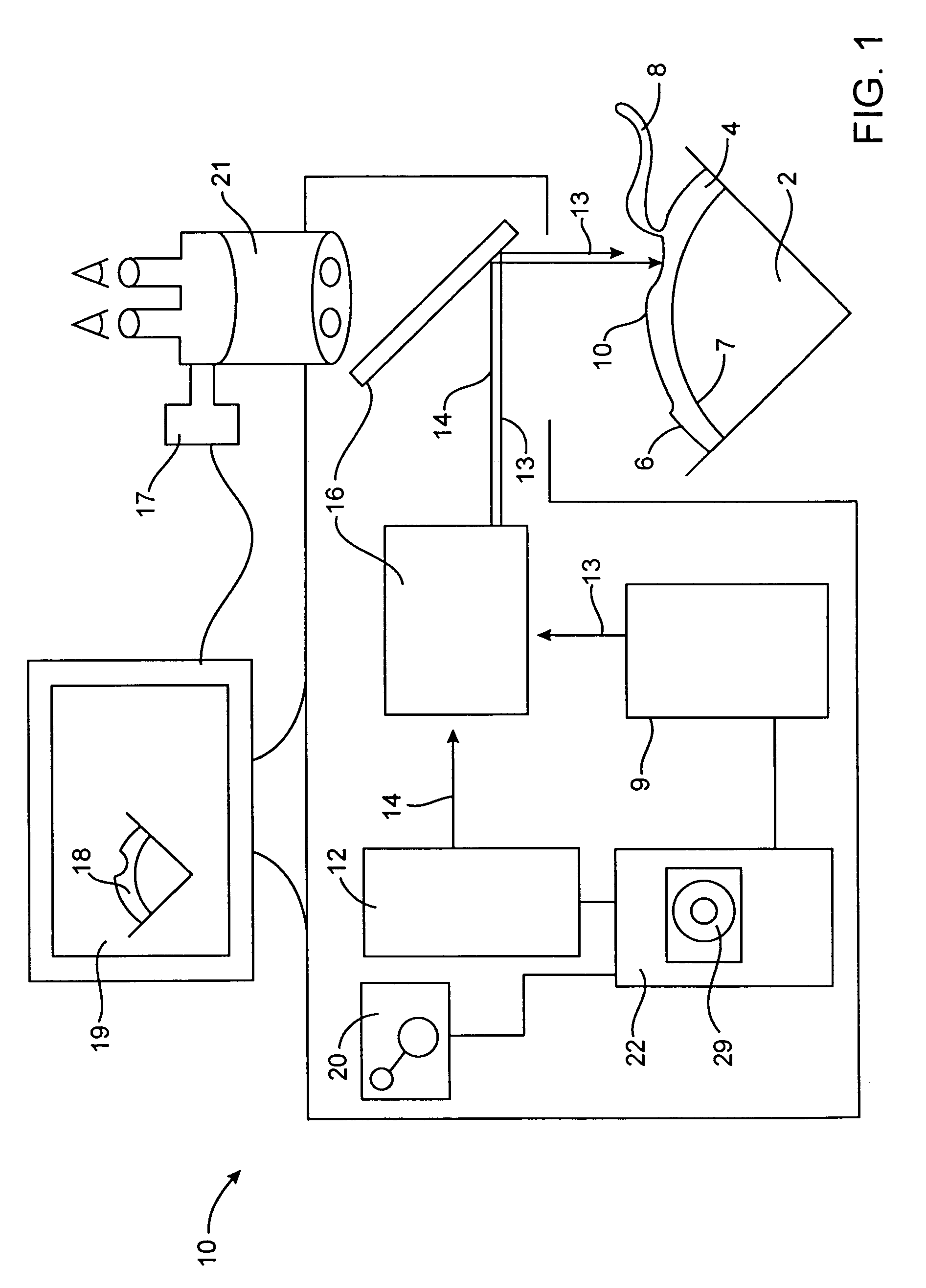

Two-part patch sensor for monitoring vital signs

ActiveUS20080114220A1Quick measurementLittle and no discomfortUltrasonic/sonic/infrasonic diagnosticsElectrocardiographyOptical radiationPhotodetector

A two-component monitoring device and system for monitoring blood pressure from a patient is disclosed herein. The two-component monitoring device includes a disposable component and a main component. The disposable component features: i) a backing structure having a first aperture; and ii) first and second electrodes, each electrode connected to the backing structure and including an electrical lead and a conductive electrode material, and configured to generate an electrical signal that passes through the electrical lead when the conductive electrode material contacts the patient. The main component includes: i) first and second connectors configured to connect to the first and second electrical leads to receive the first and second electrical signals; and ii) an optical component comprising a light source that generates optical radiation and a photodetector that detects the optical radiation. The optical component inserts into the first aperture of the disposable component. The main component optionally includes an acoustic sensor. The system utilizes a processing device, connected to the monitoring device by a cable which receives and processes a plurality of signals to determine real-time blood-pressure values for the patient.

Owner:SOTERA WIRELESS

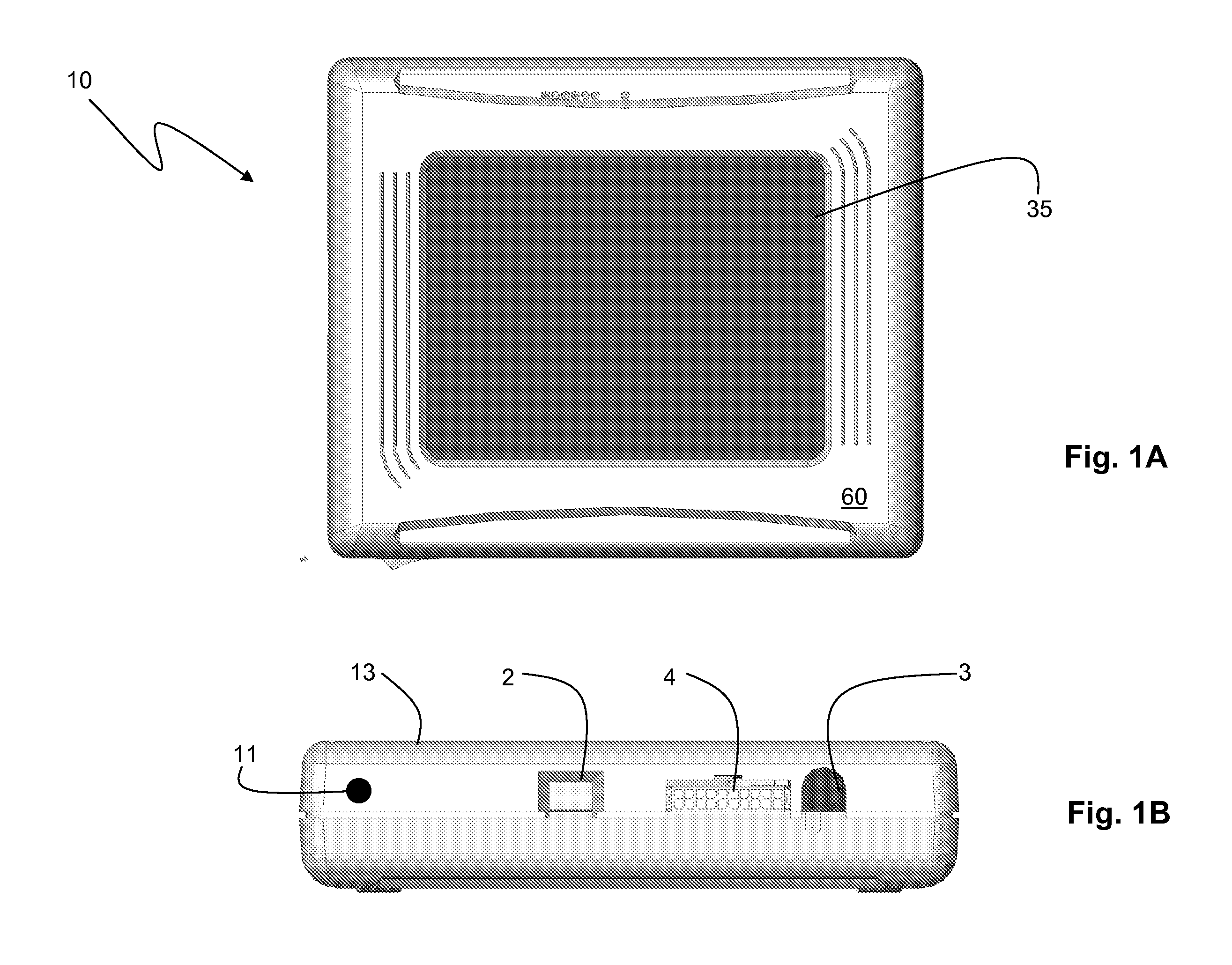

Hand-held vital signs monitor

ActiveUS20080077026A1Improve accuracyThe way is simple and fastElectrocardiographyStethoscopeGraphical user interfaceCoaxial cable

The invention features a vital sign monitor that includes: 1) a hardware control component featuring a microprocessor that operates an interactive, icon-driven GUI on an LCD; and, 2) a sensor component that connects to the control component through a shielded coaxial cable. The sensor features: 1) an optical component that generates a first signal; 2) a plurality electrical components (e.g. electrodes) that generate a second signal; and, 3) an acoustic component that generates a third signal. The microprocessor runs compiled computer code that operates: 1) the touch panel LCD; 2) a graphical user interface that includes multiple icons corresponding to different software operations; 3) a file-management system for storing and retrieving vital sign information; and 4) USB and short-range wireless systems for transferring data to and from the device to a PC.

Owner:SOTERA WIRELESS

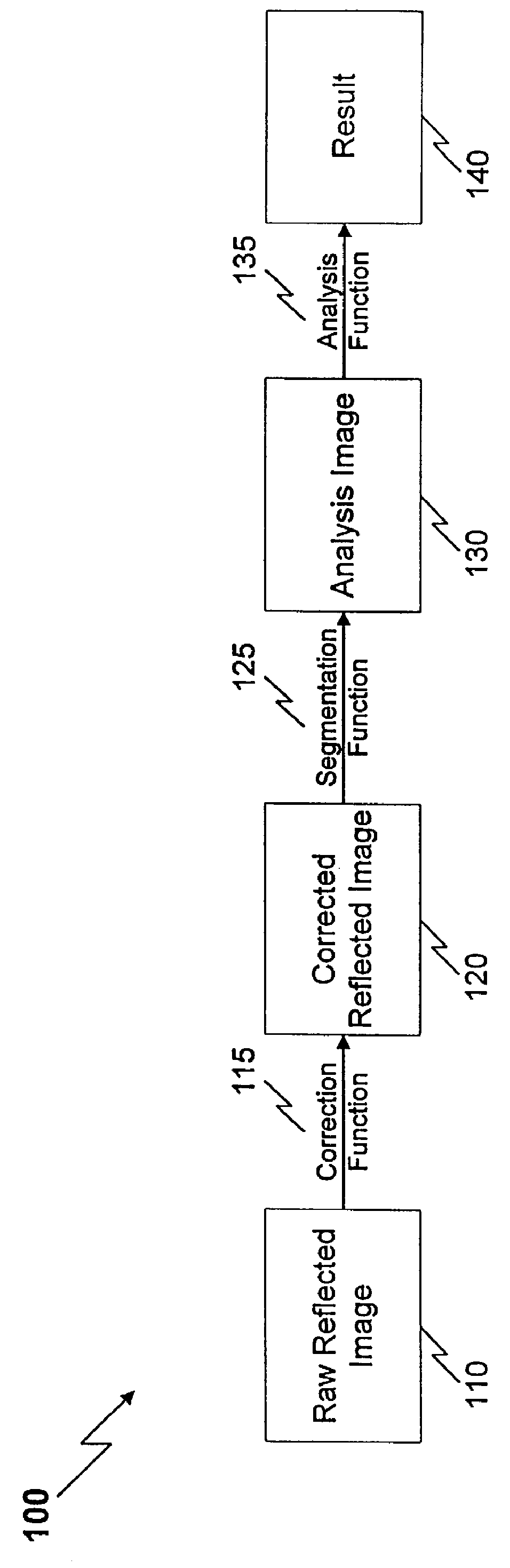

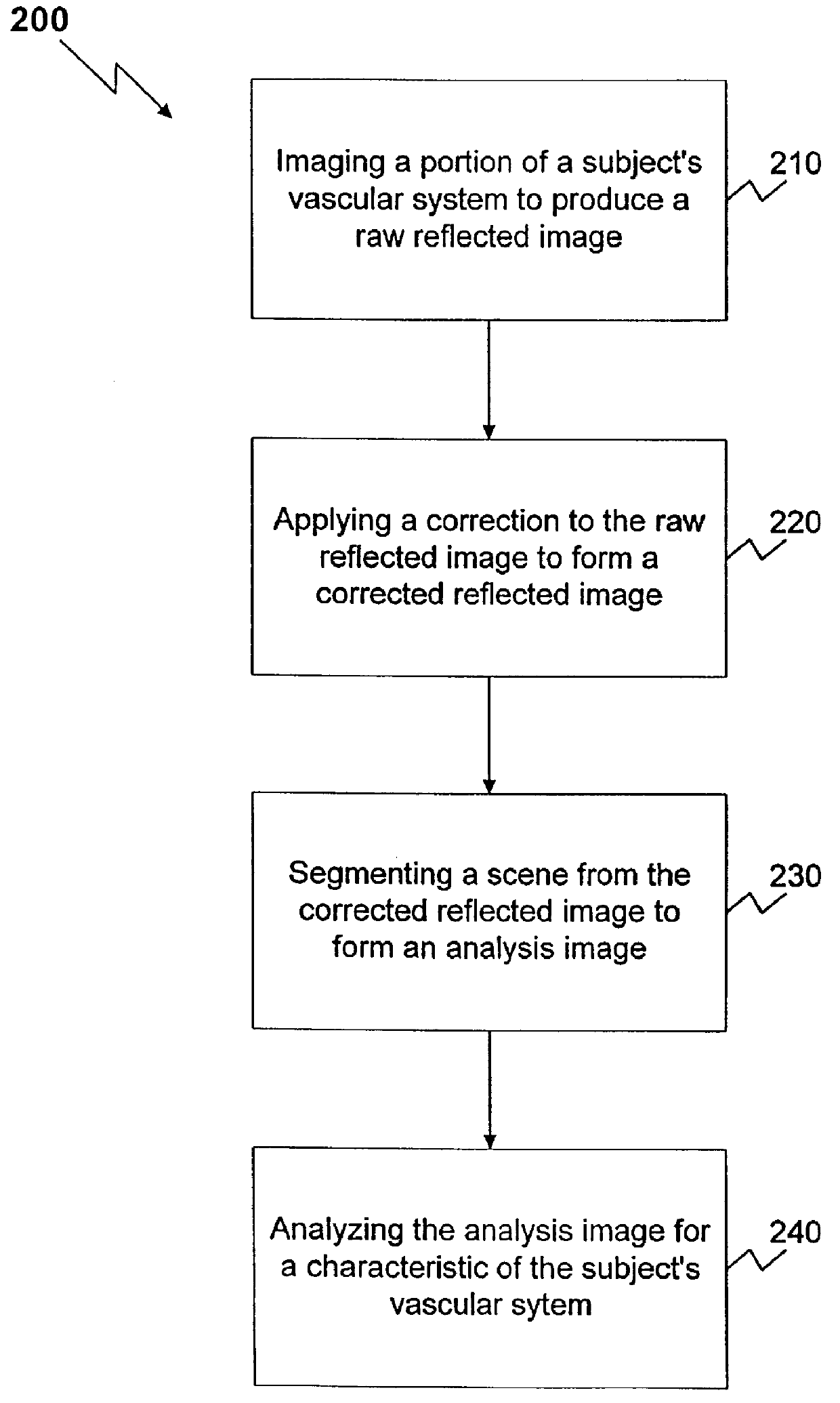

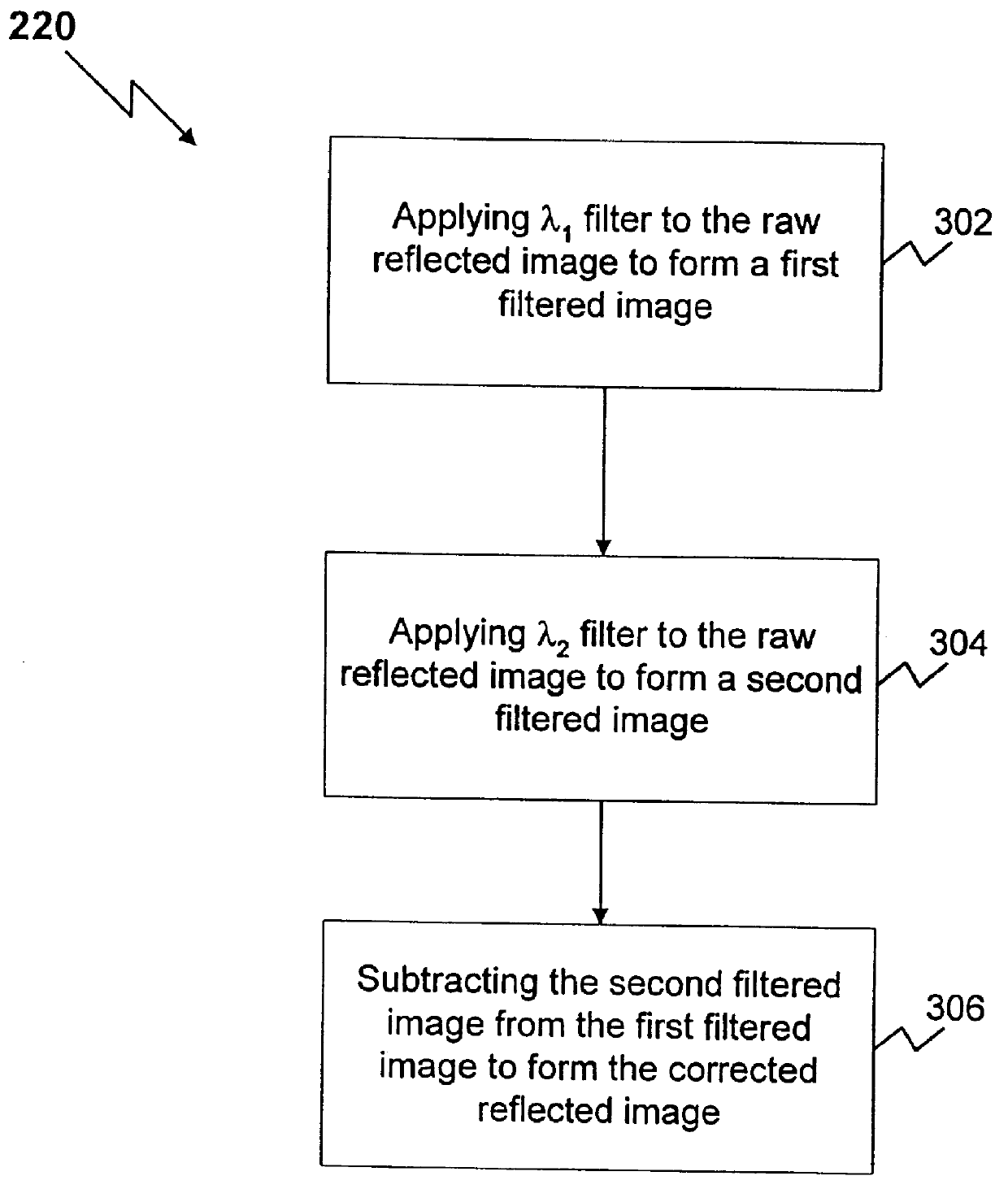

Method and apparatus for reflected imaging analysis

InactiveUS6104939AQuick measurementPolarisation-affecting propertiesScattering properties measurementsWhite blood cellPolarizer

Method and apparatus for reflected imaging analysis. Reflected imaging is used to perform non-invasive, in vivo analysis of a subject's vascular system. A raw reflected image (110) is normalized with respect to the background to form a corrected reflected image (120). An analysis image (130) is segmented from the corrected reflected image to include a scene of interest for analysis. The method and apparatus can be used to determine such characteristics as the hemoglobin concentration per unit volume of blood, the number of white blood cells per unit volume of blood, a mean cell volume, the number of platelets per unit volume of blood, and the hematocrit. Cross-polarizers can be used to improve visualization of the reflected image.

Owner:INTPROP MVM

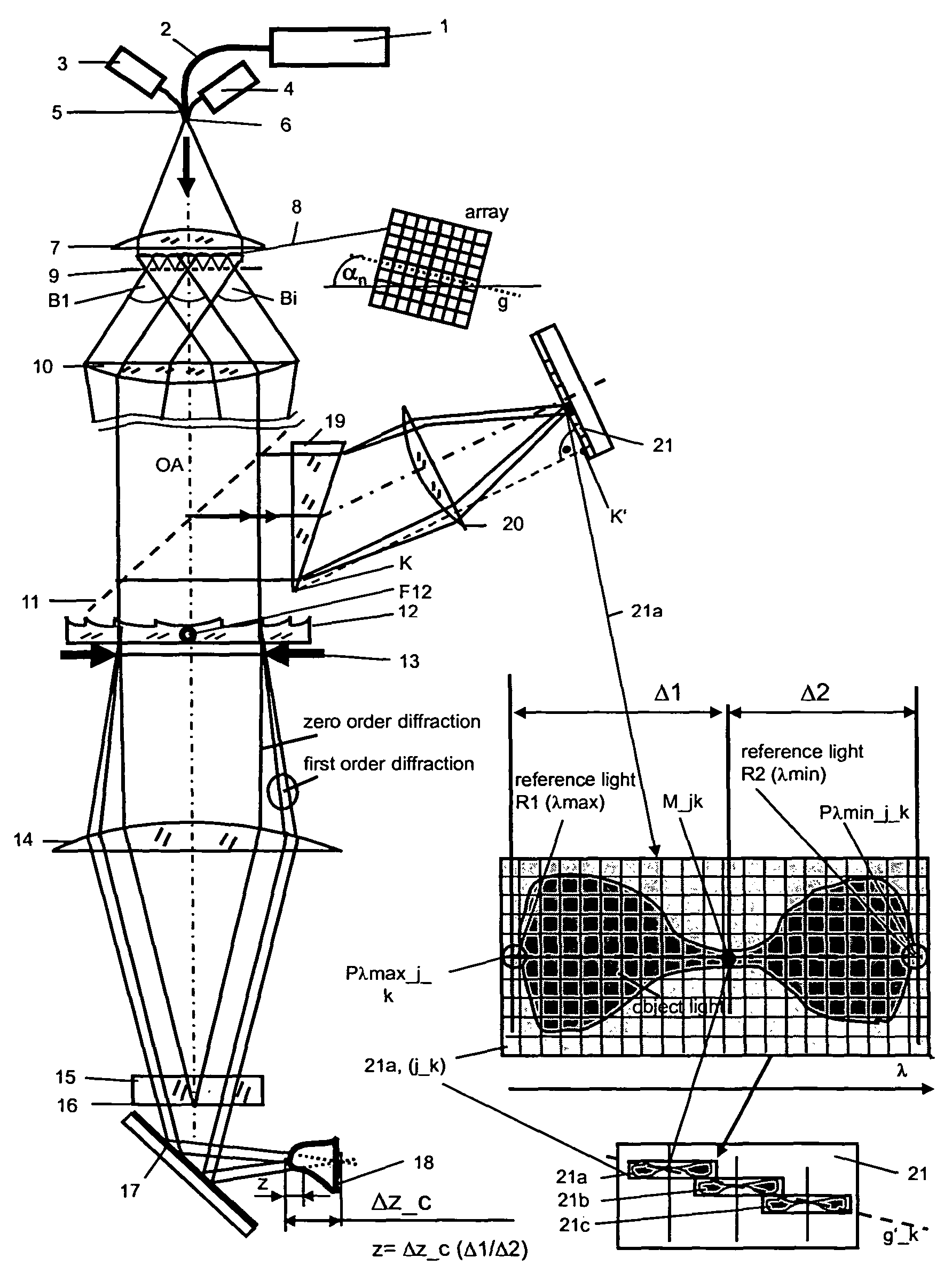

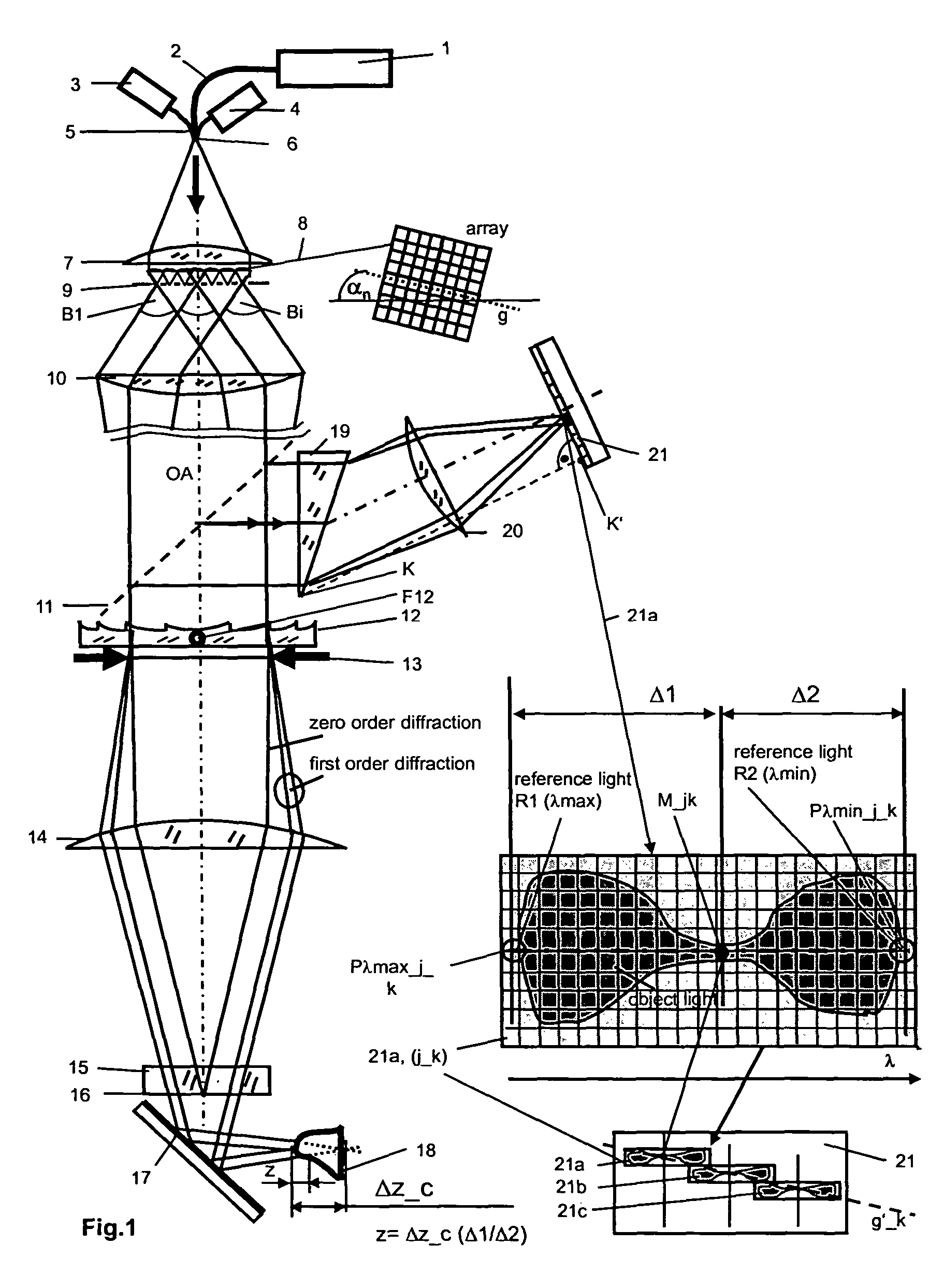

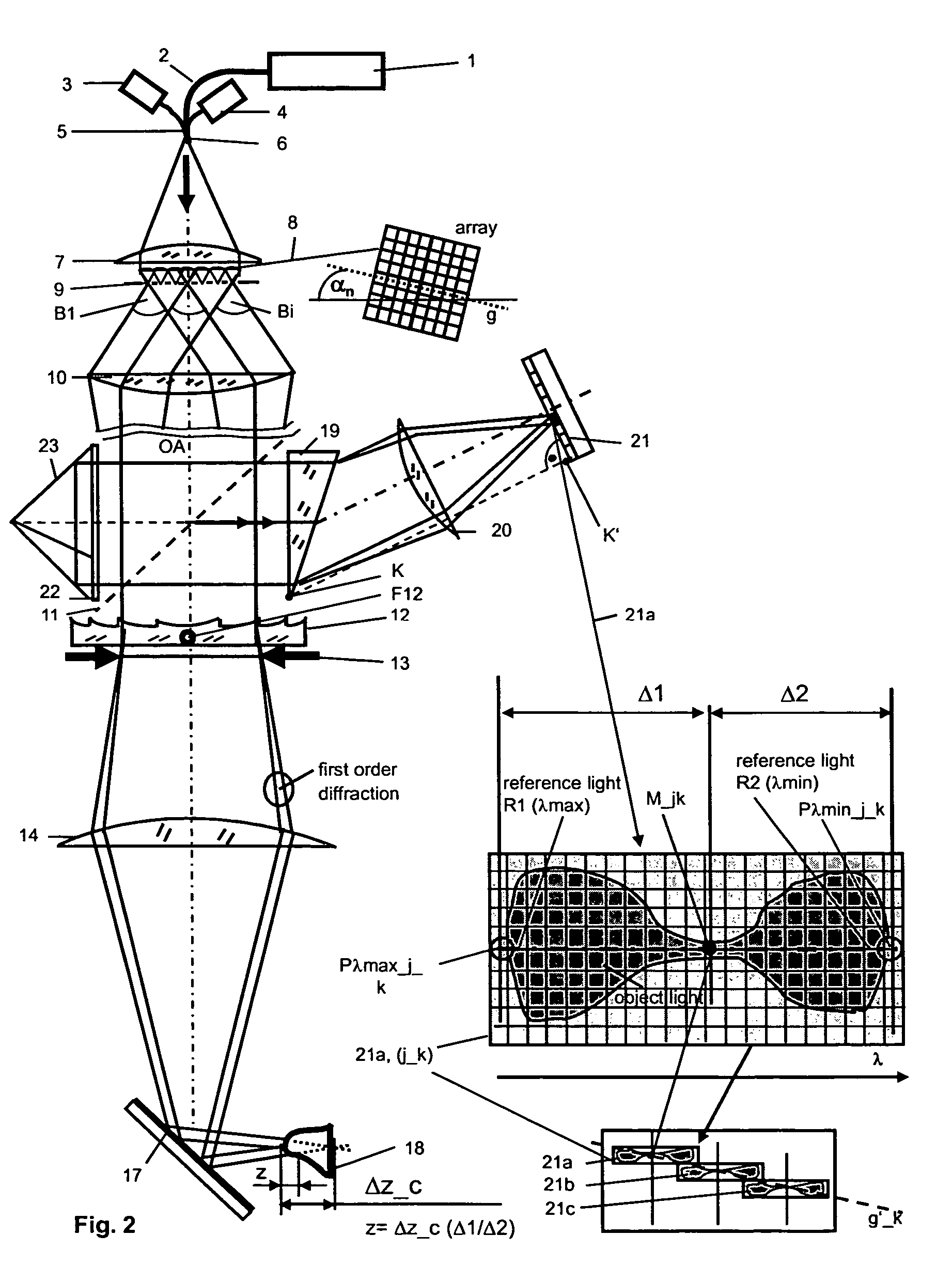

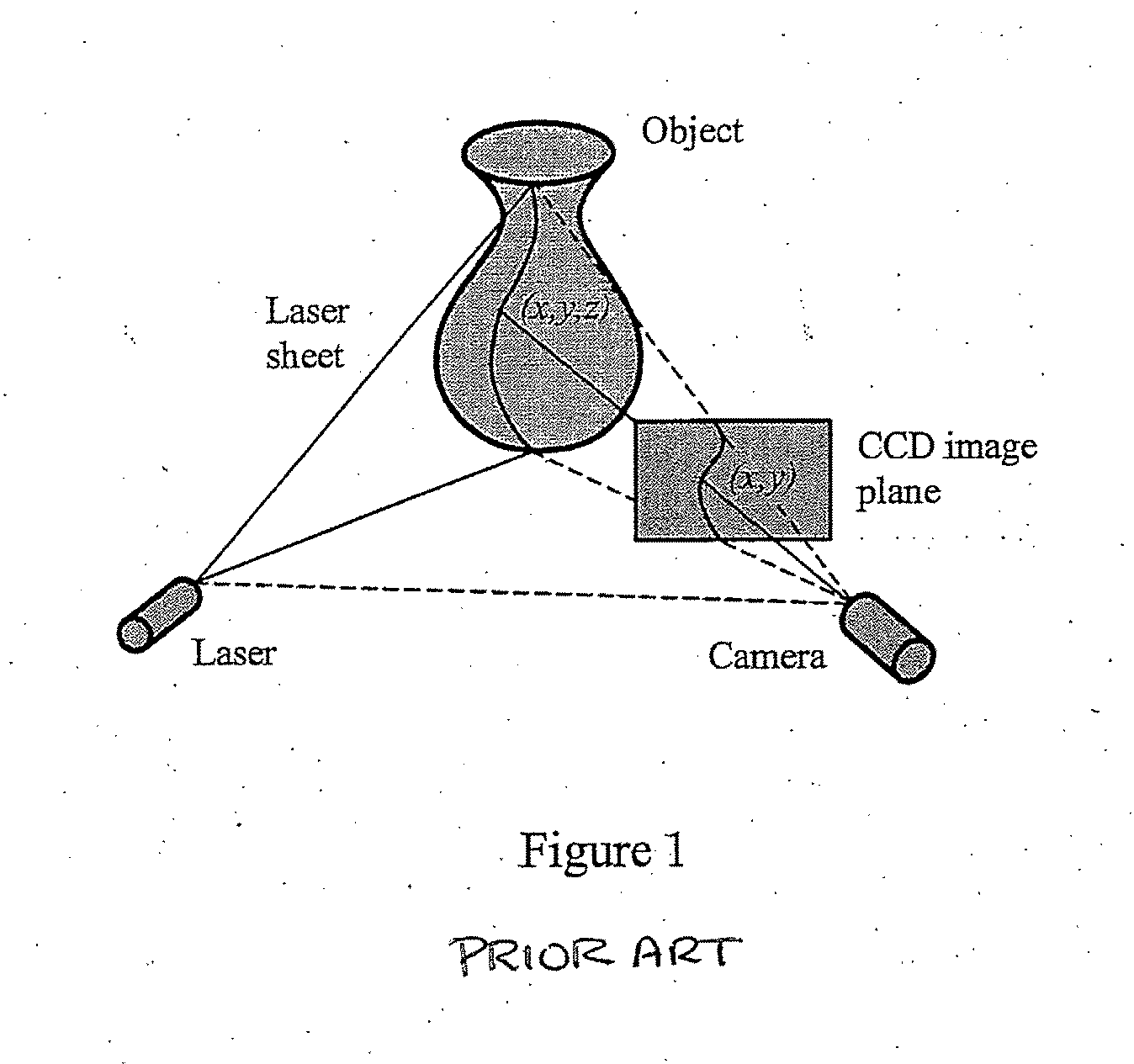

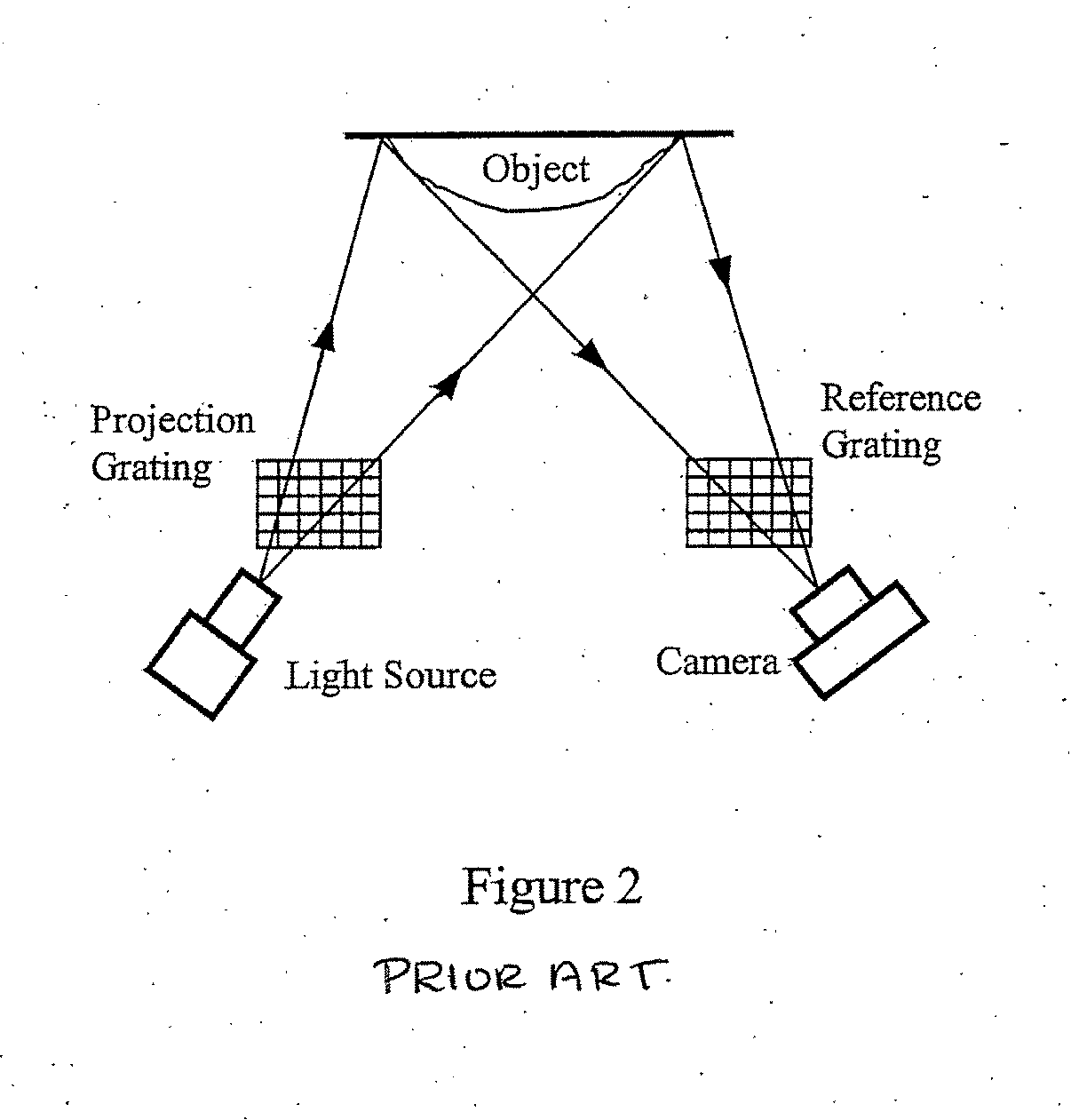

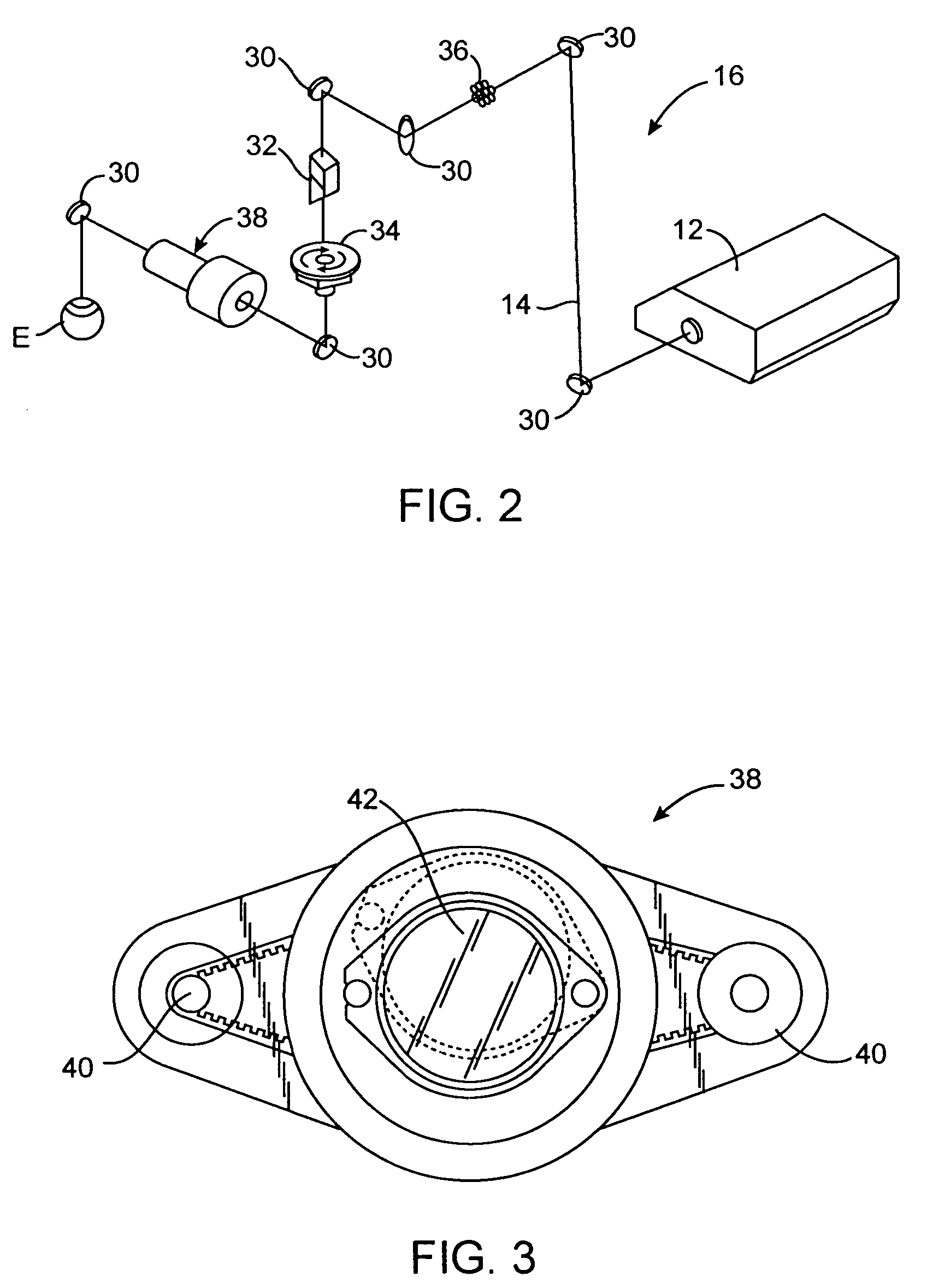

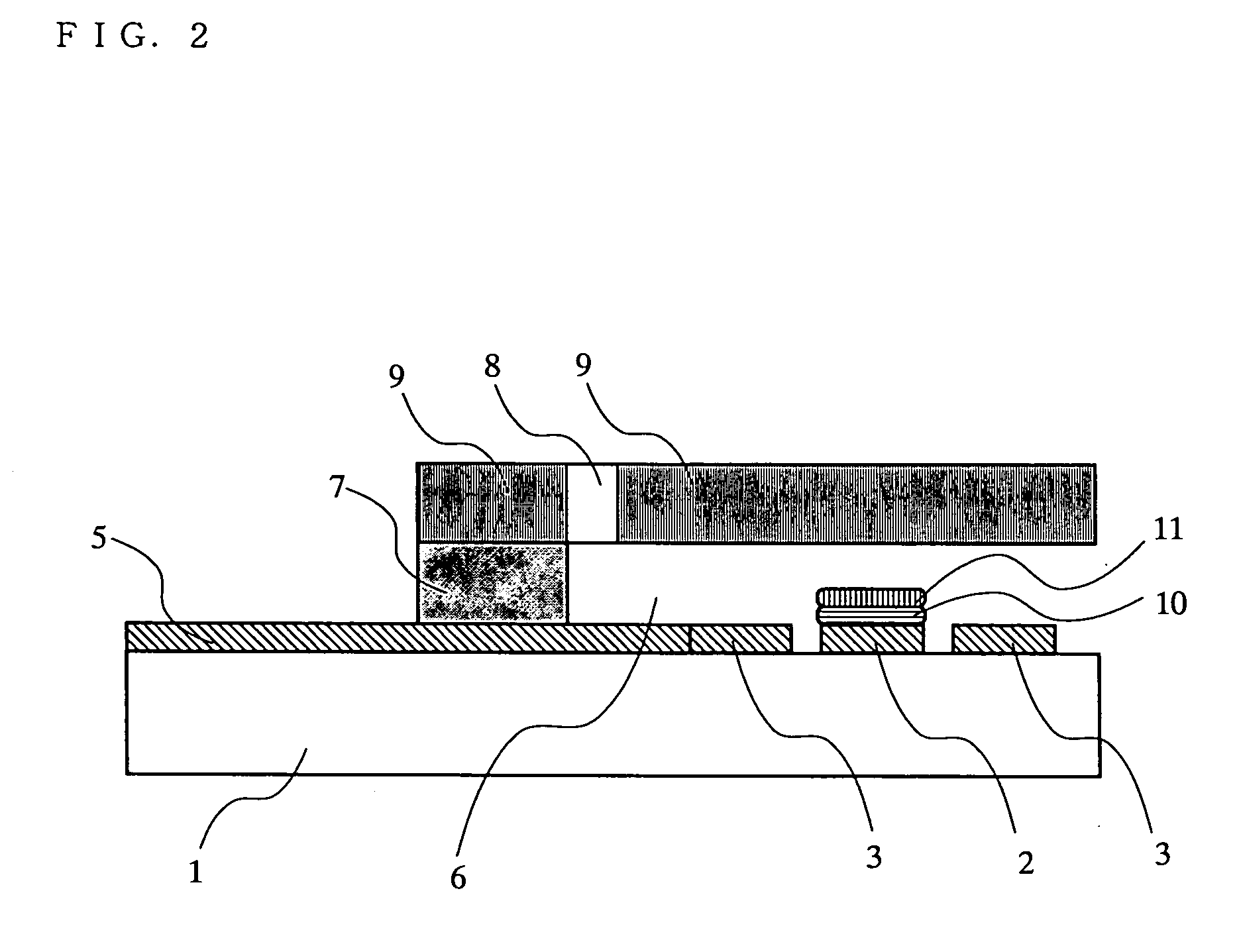

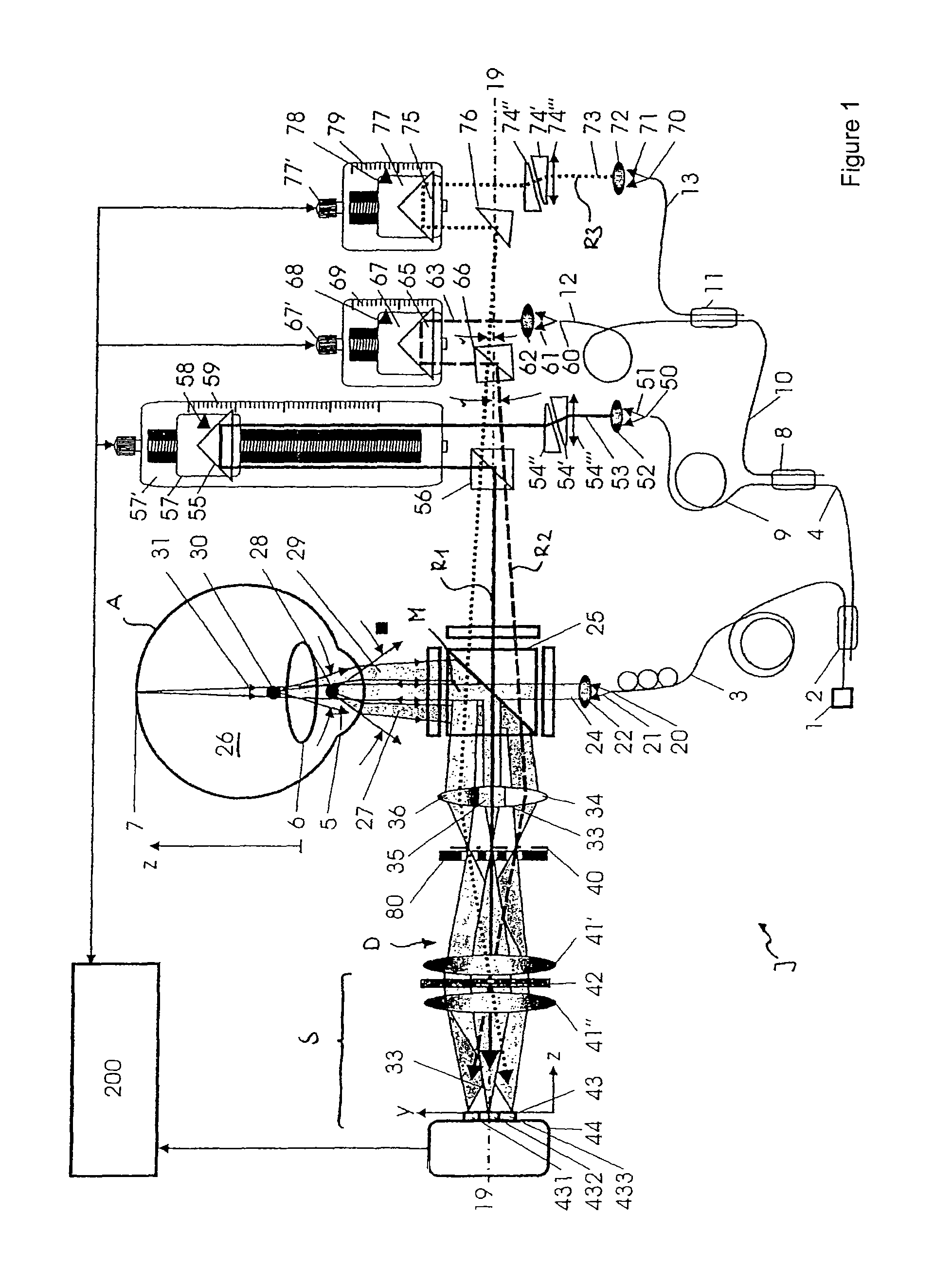

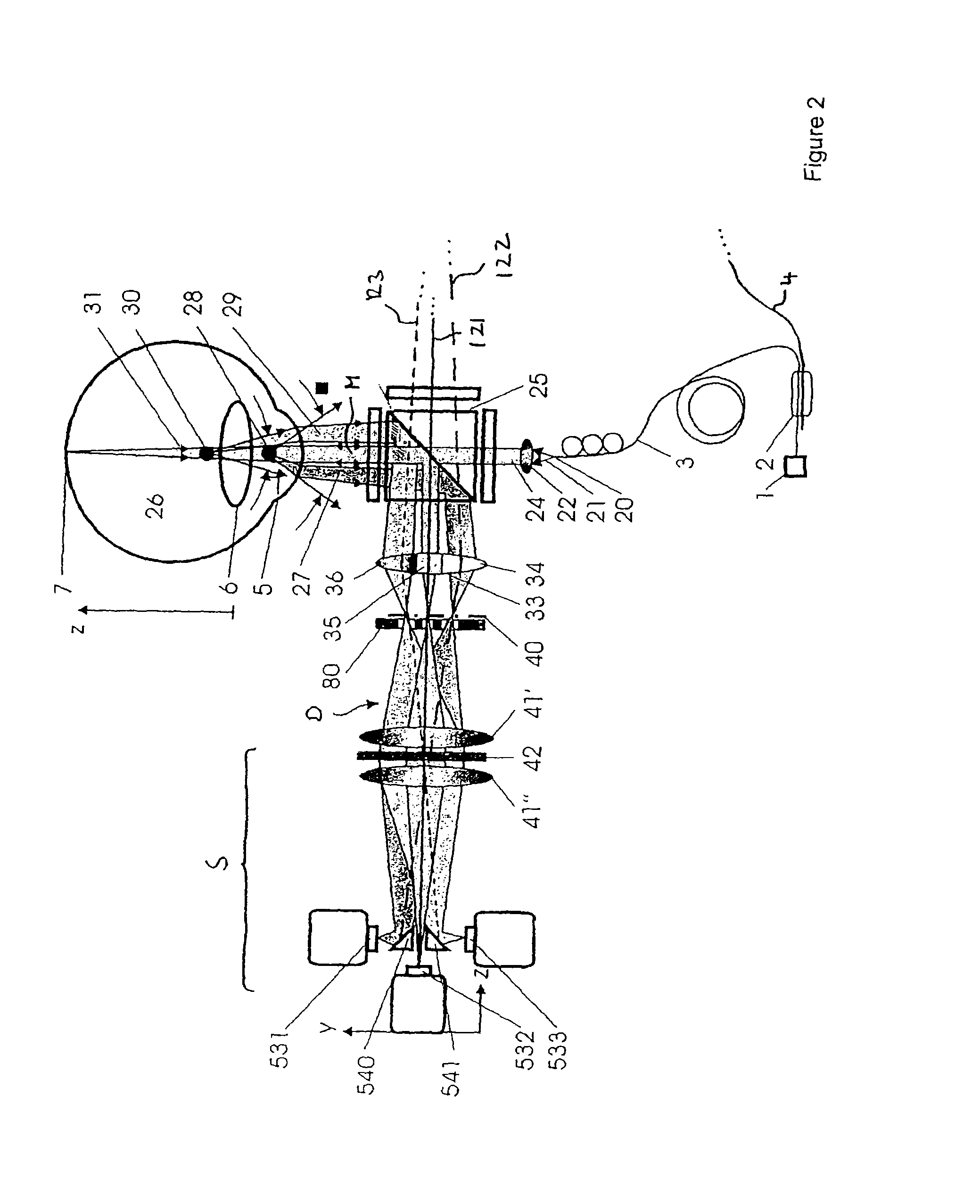

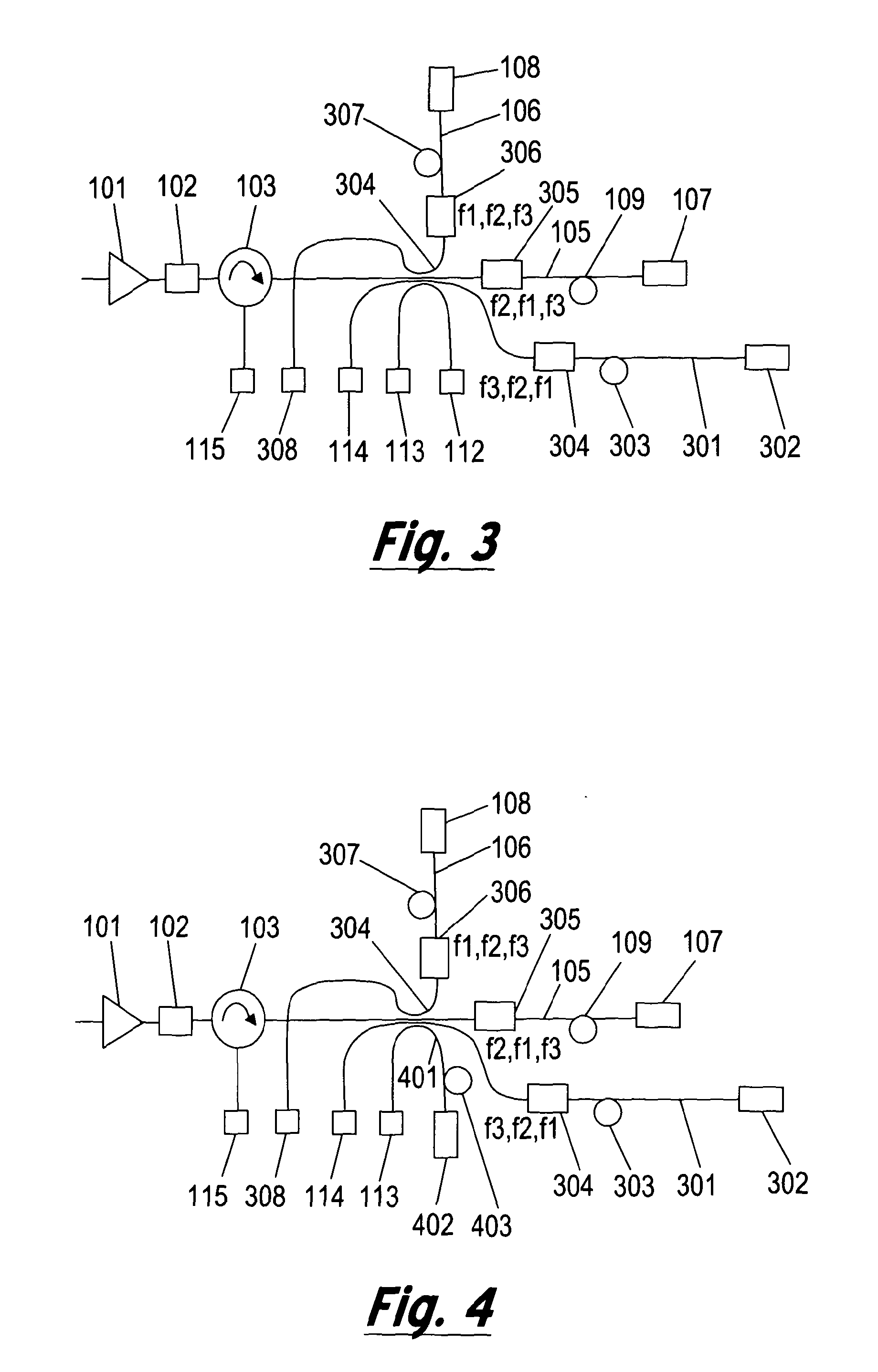

Method and arrangement for a rapid and robust chromatic confocal 3D measurement technique

ActiveUS7787132B2Quick measurementImprove robustnessImage analysisUsing optical meansPoint lightBeam splitter

A chromatic confocal technique and apparatus for the rapid three-dimensional measurement of an object shape, particularly of a tooth in a patient's jaw, using an array of polychromatic point light sources, a planar detector matrix, a beam splitter for lateral spectral separation, and an objective for illuminating and recording the object. Spectral defined reference light bundles are generated, injected into the detection beam path via a reference beam path and, following spectral splitting, are focused on the detector matrix as reference image points, wherein laterally shifted sub-matrices are numerically defined on the detector matrix for spectral analysis of the object light, which sub-matrices are implemented as spectral cells for three-dimensional measurement of the shape of the object.

Owner:SIRONA DENTAL SYSTEMS

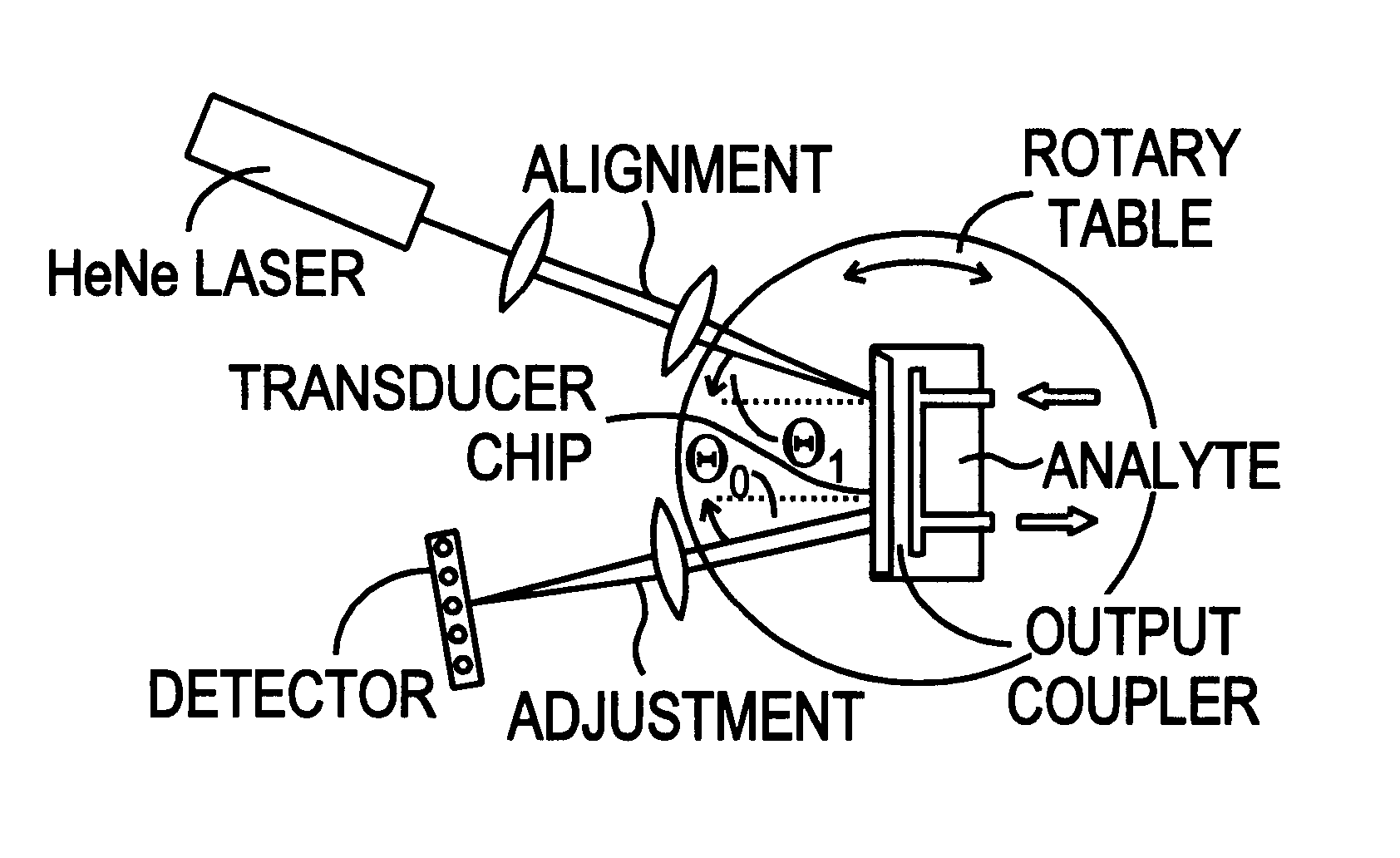

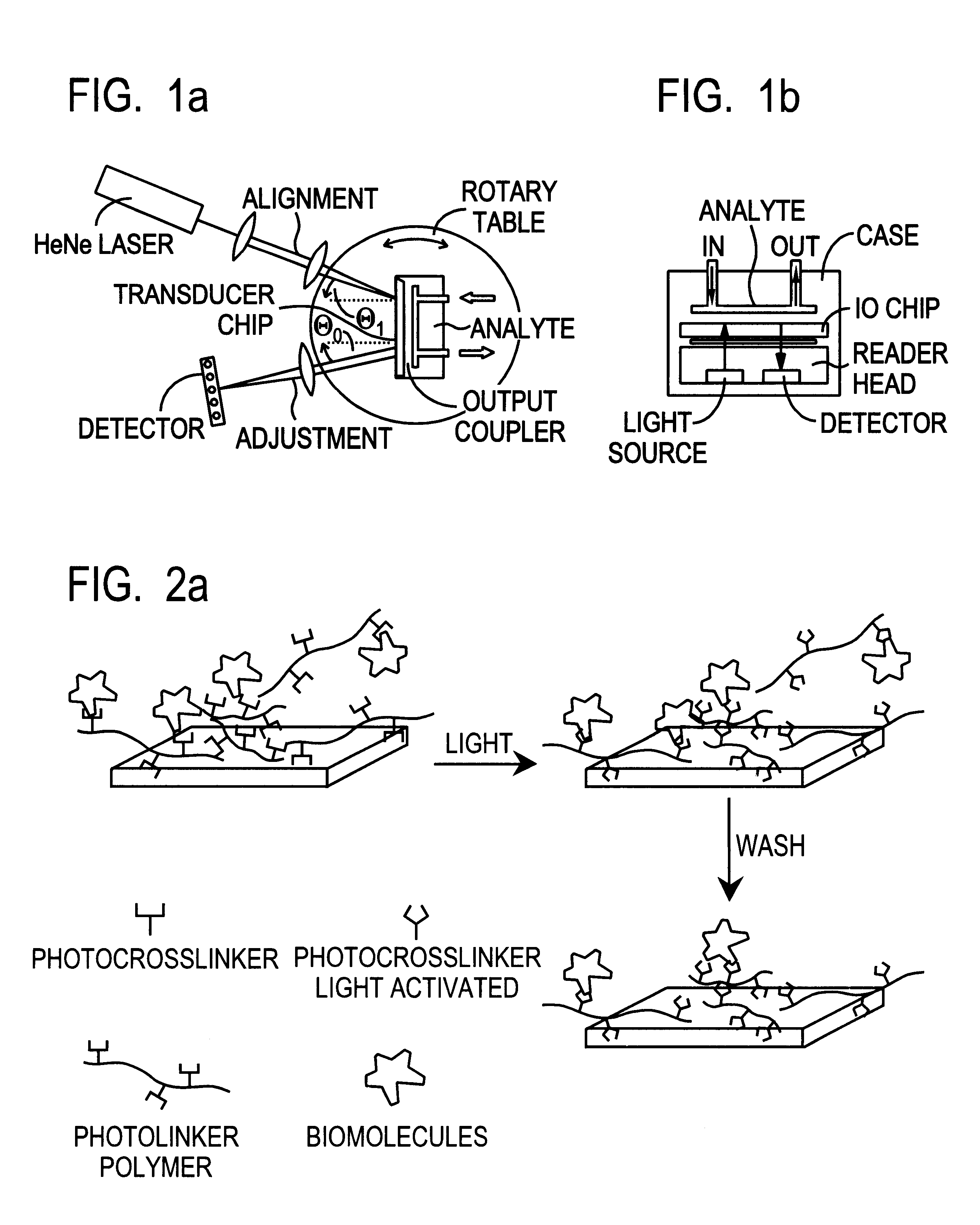

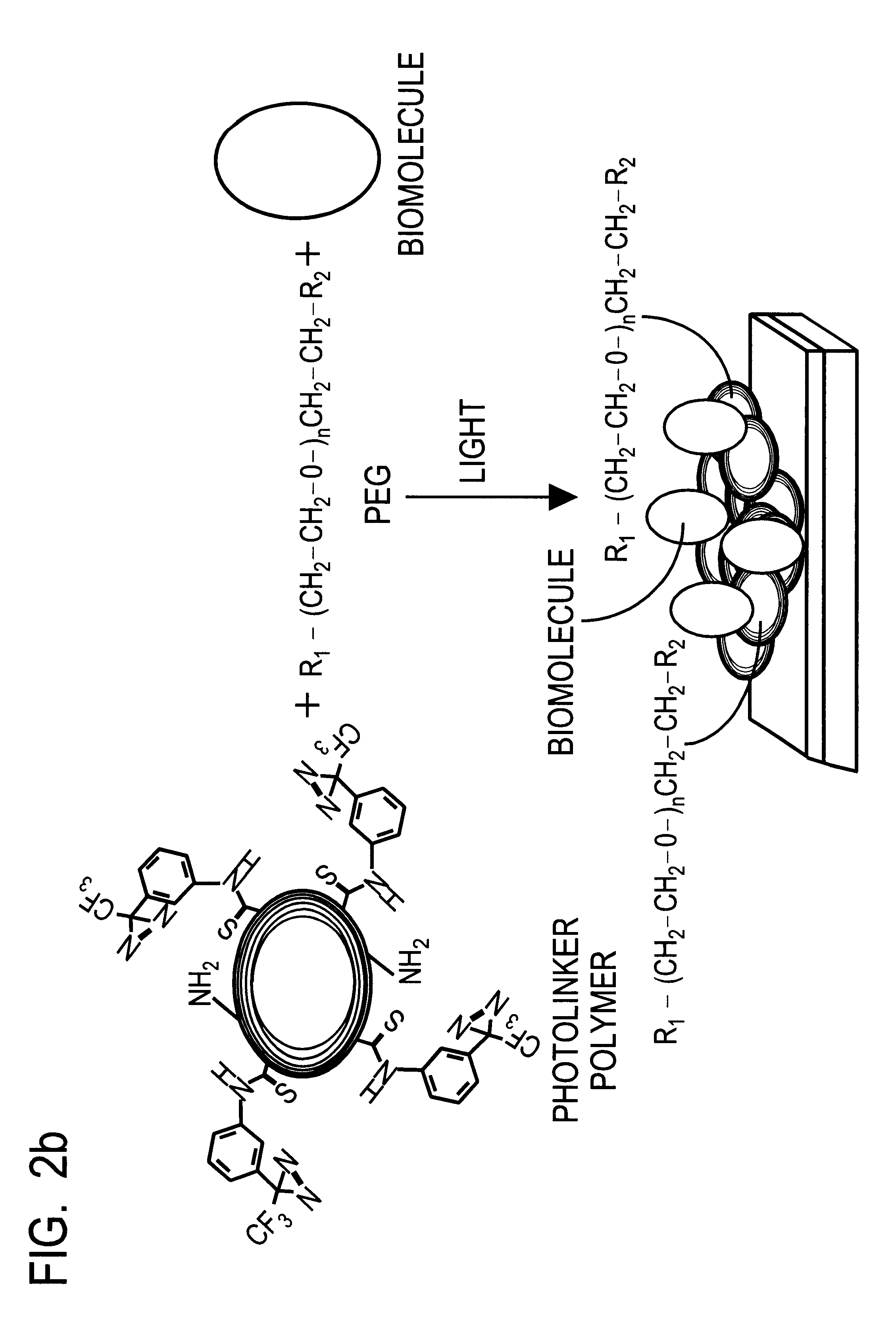

Optical sensor unit and procedure for the ultrasensitive detection of chemical or biochemical analytes

InactiveUS6346376B1High sensitivitySelective retentionBioreactor/fermenter combinationsBiological substance pretreatmentsSpecific detectionNon-covalent interactions

This document describes an optical sensor unit and a procedure for the specific detection and identification of biomolecules at high sensitivity in real fluids and tissue homogenates. High detection limits are reached by the combination of i) label-free integrated optical detection of molecular interactions, ii) the use of specific bioconstituents for sensitive detection and iii) planar optical transducer surfaces appropriately engineered for suppression of non-specific binding, internal referencing and calibration. Applications include the detection of prion proteins and identification of those biomolecules which non-covalently interact with surface immobilized prion proteins and are intrinsically involved in the cause of prion related disease.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

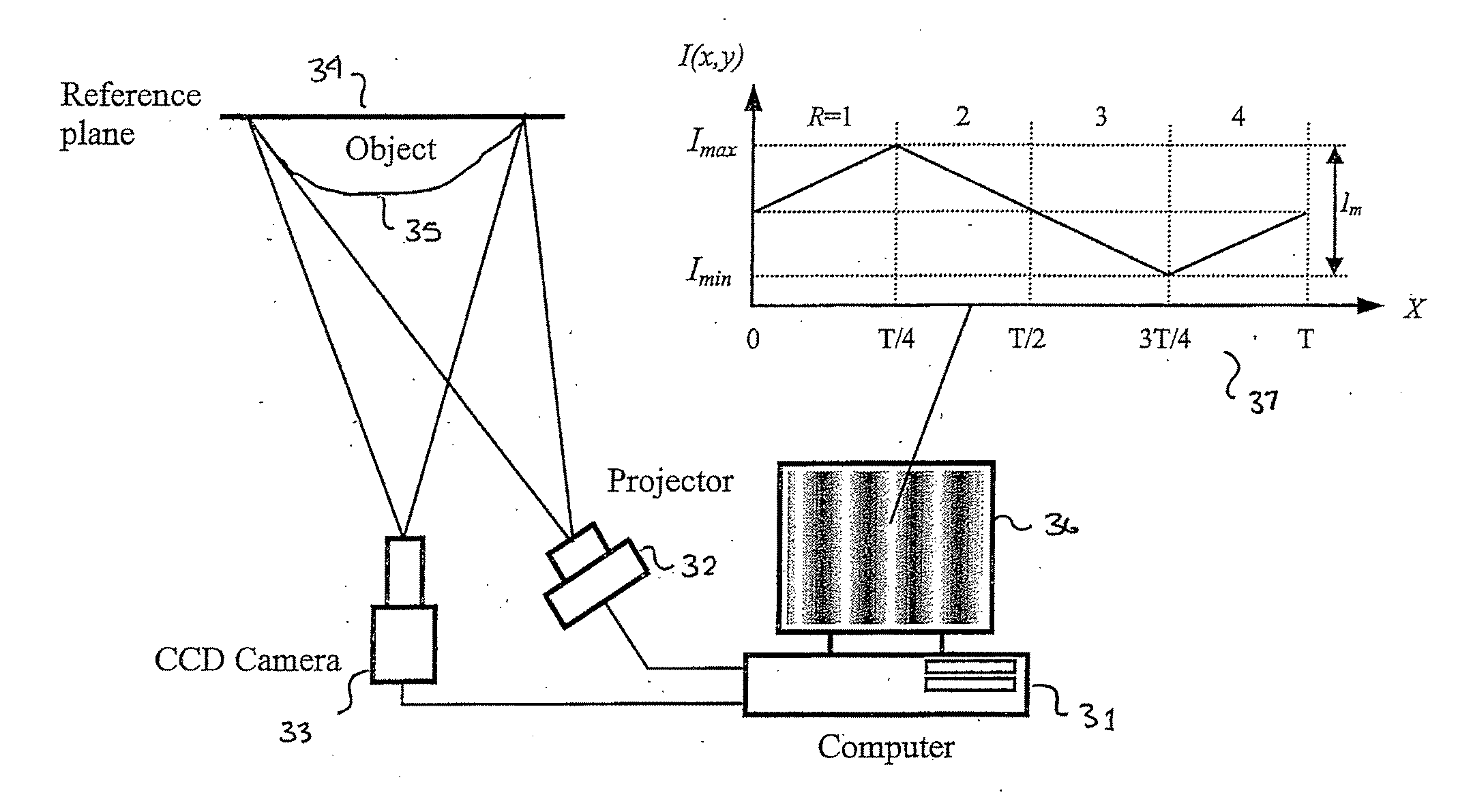

Full-field three-dimensional measurement method

InactiveUS20070206204A1Improve processing speedSimple calculationUsing optical meansTriangulationFull field

A method and system for full-field fringe-projection for 3-D surface-geometry measurement, referred to as “triangular-pattern phase-shifting” is disclosed. A triangular grey-scale-level-coded fringe pattern is computer generated, projected along a first direction onto an object or scene surface and distorted according to the surface geometry. The 3-D coordinates of points on the surface are calculated by triangulation from distorted triangular fringe-pattern images acquired by a CCD camera along a second direction and a triangular-shape intensity-ratio distribution is obtained from calculation of the captured distorted triangular fringe-pattern images. Removal of the triangular shape of the intensity ratio over each pattern pitch generates a wrapped intensity-ratio distribution obtained by removing the discontinuity of the wrapped image with a modified unwrapping method. Intensity ratio-to-height conversion is used to reconstruct the 3-D surface coordinates of the object. Intensity-ratio error compensation involves estimating intensity-ratio error in a simulation of the measurement process with both real and ideal captured triangular-pattern images obtained from real and ideal gamma non-linearity functions. A look-up table relating the measure intensity-ratio to the corresponding intensity-ratio error is constructed and used for intensity-ratio error compensation. The inventive system is based on two-step phase-shifting but can be extended for multiple-step phase-shifting.

Owner:UNIVERSITY OF WATERLOO

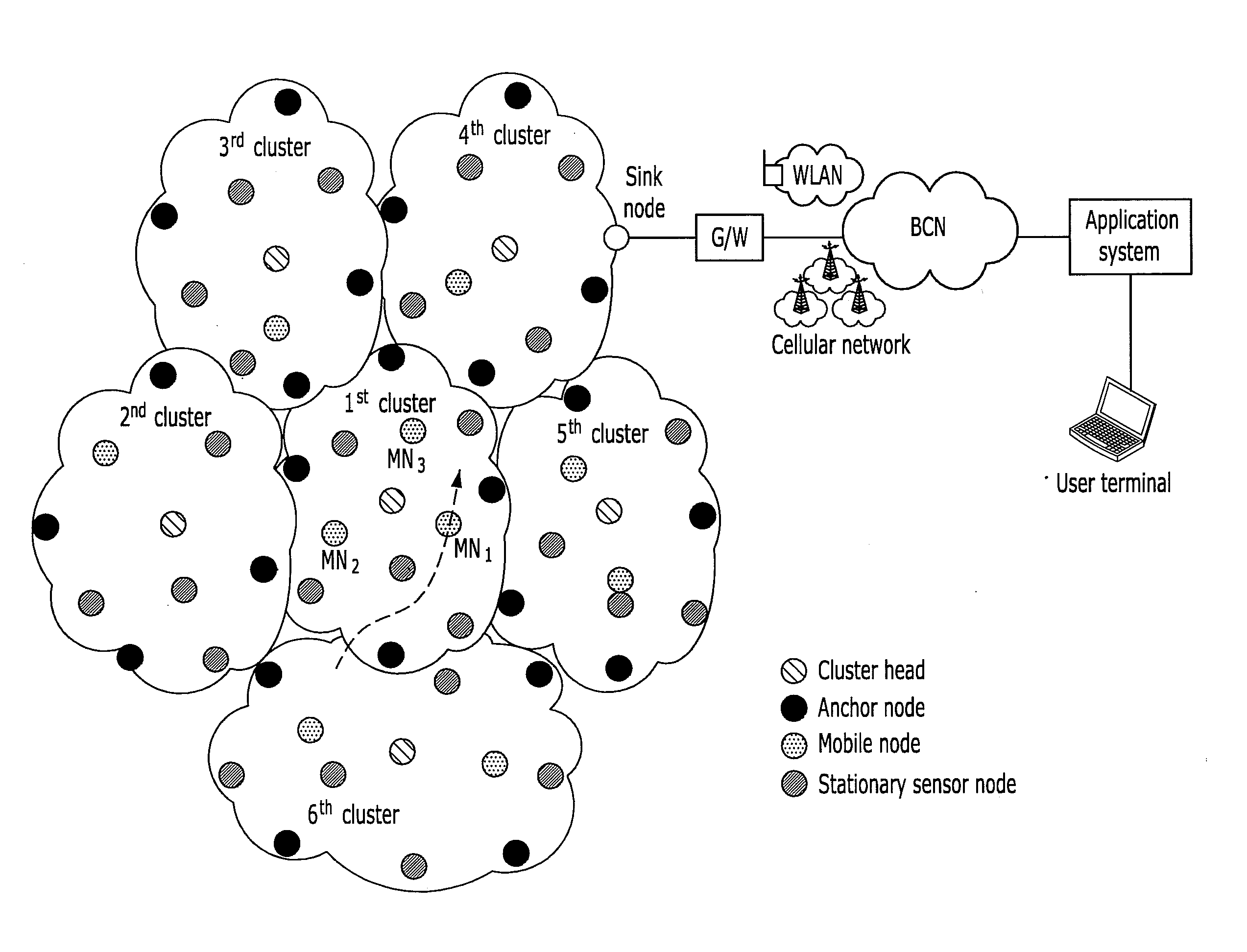

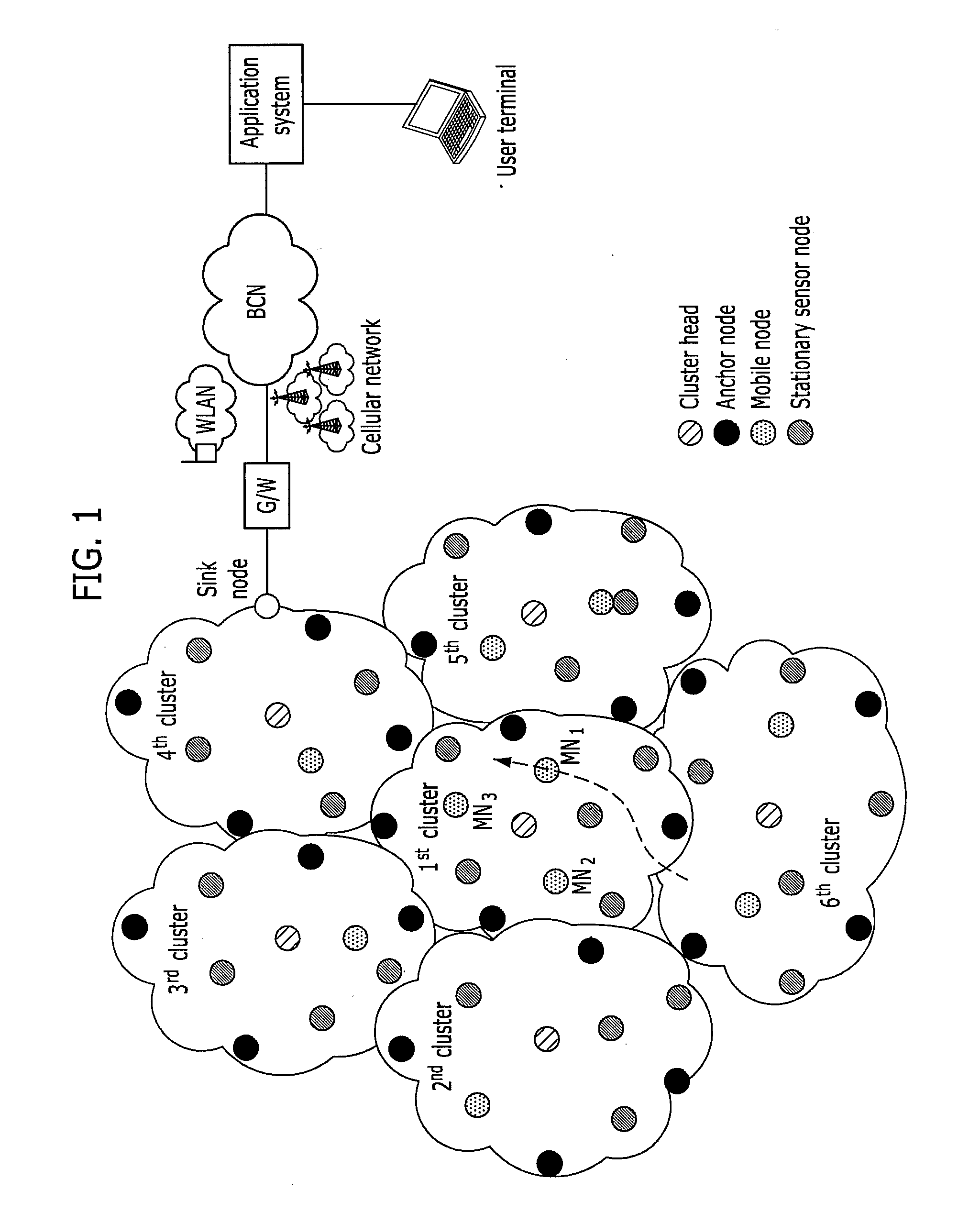

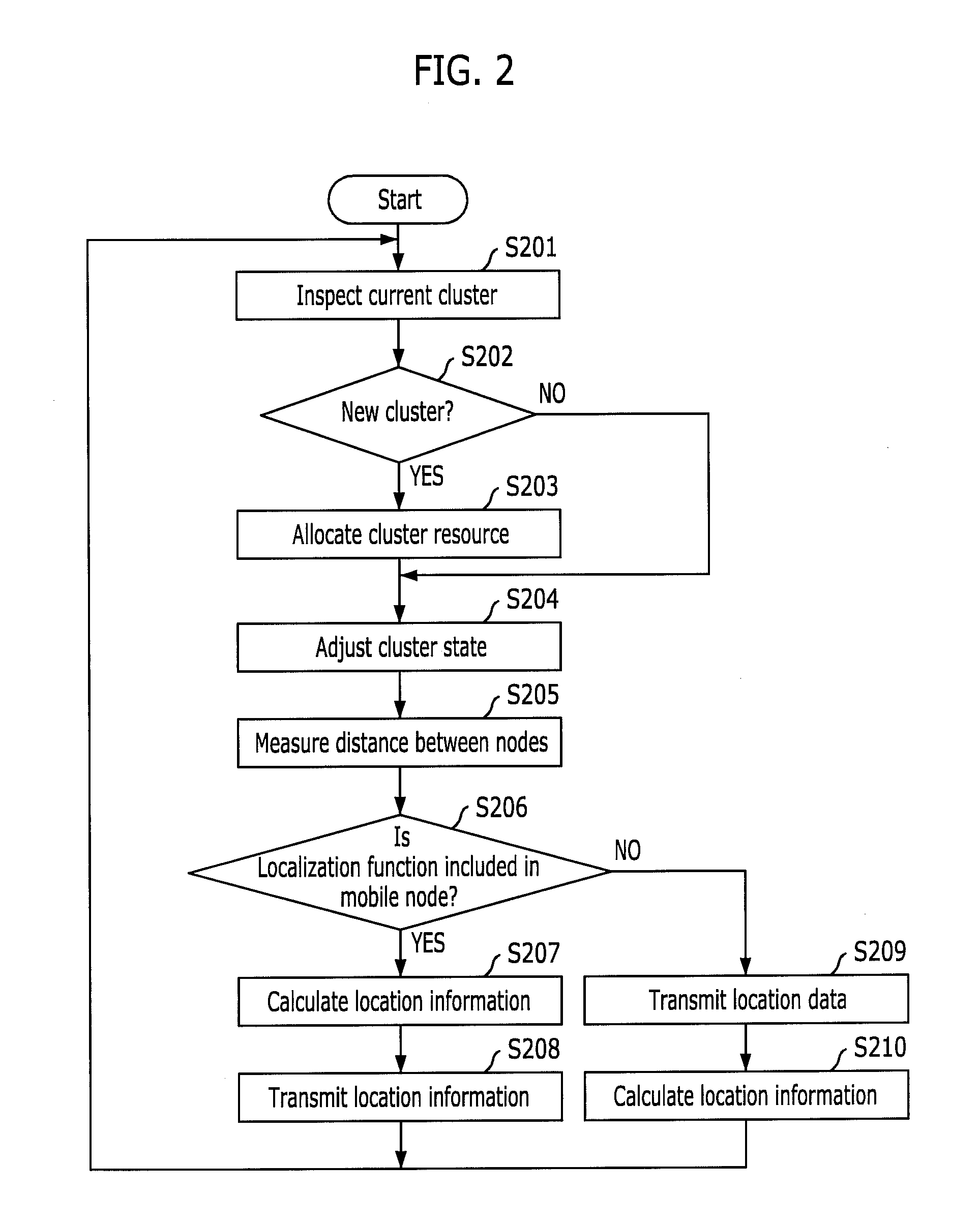

Method on localization message process for supporting mobility of wireless nodes

ActiveUS20100074133A1Quick measurementSupport mobilityError preventionFrequency-division multiplex detailsComputer networkComputer science

Owner:KT CORP

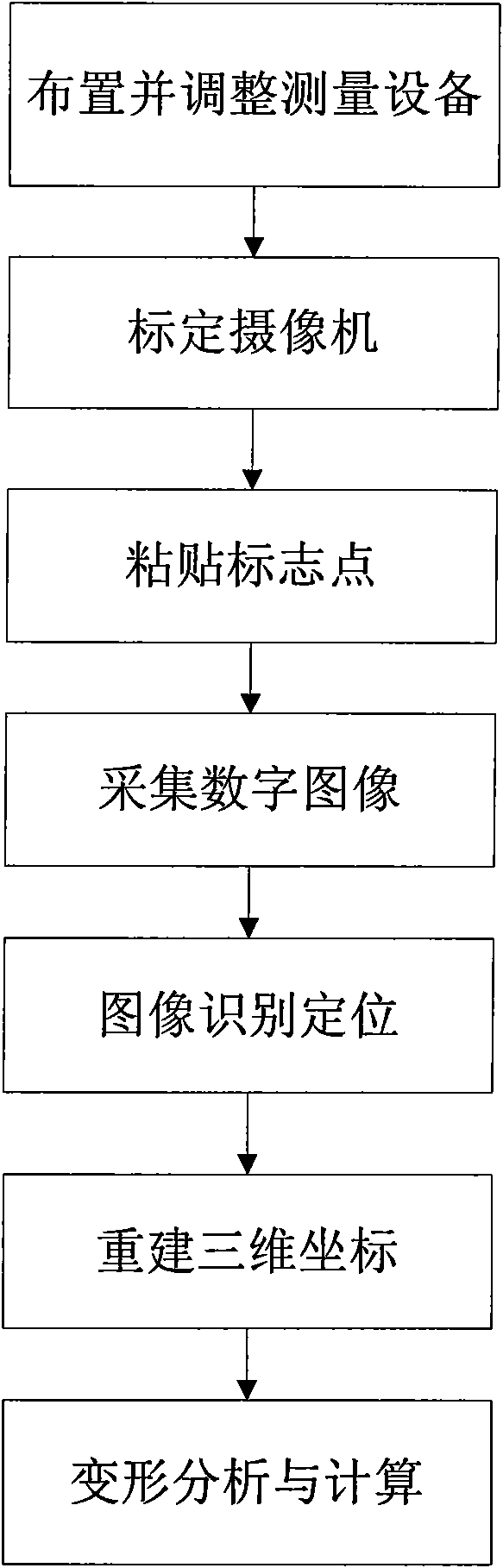

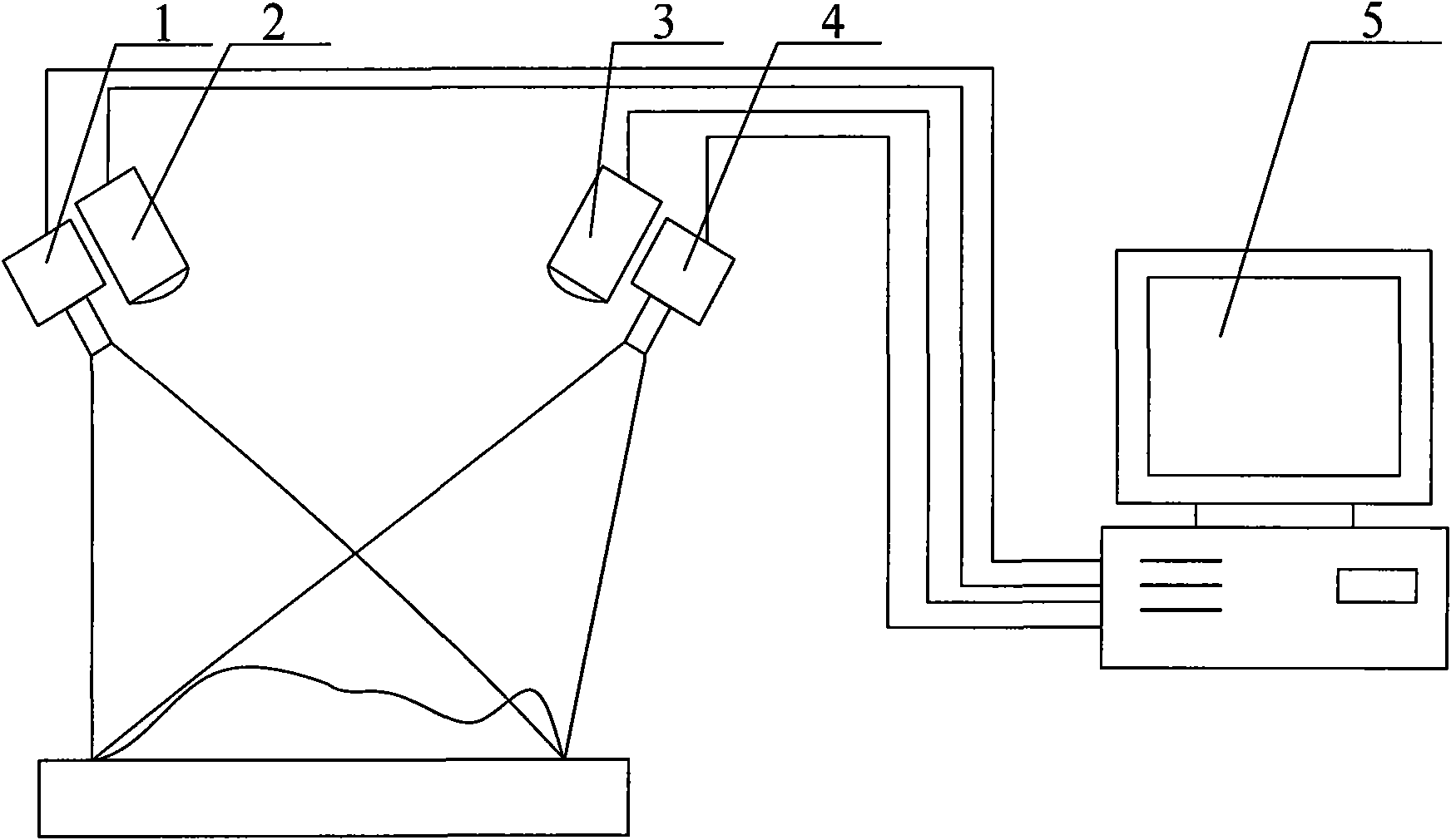

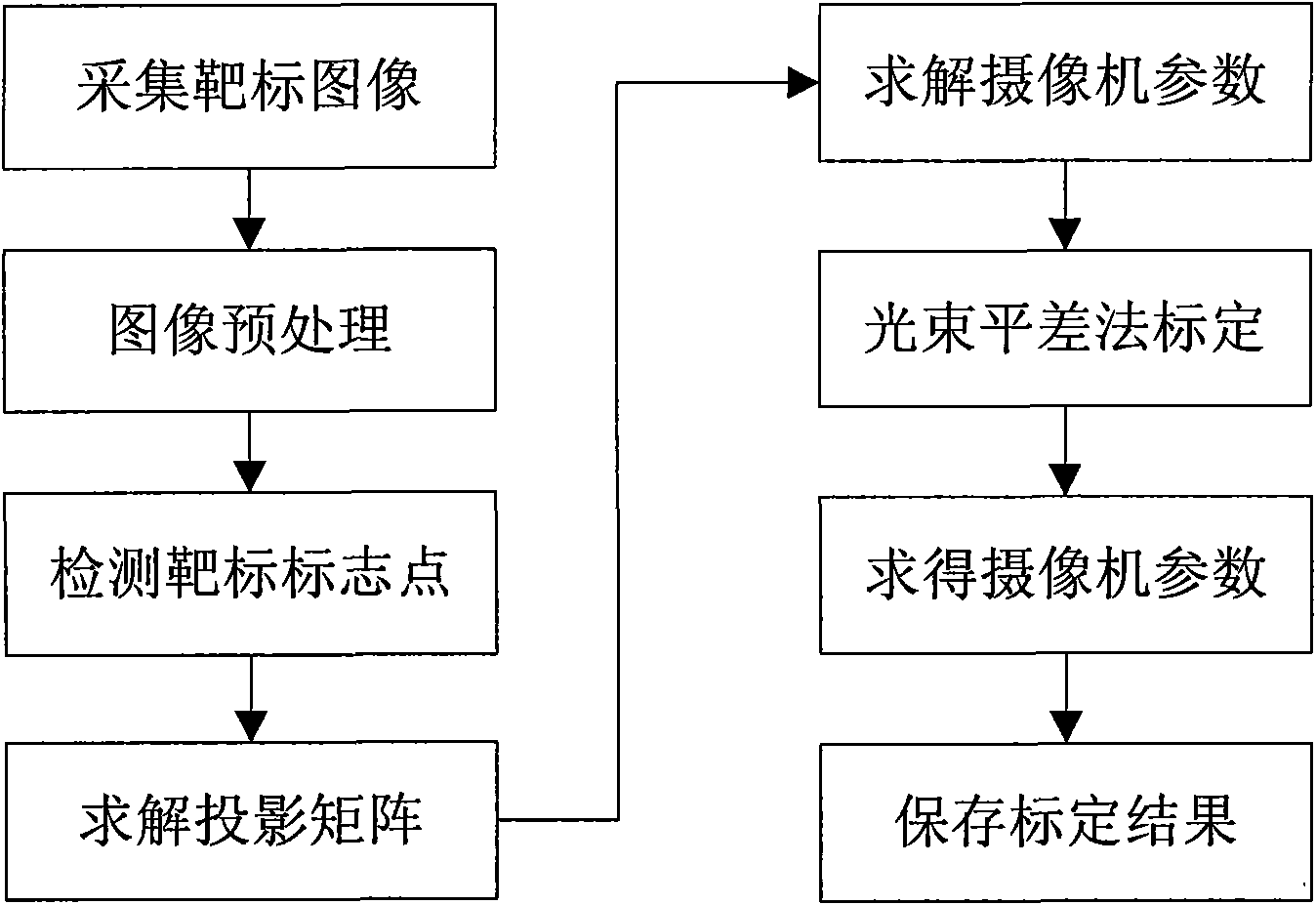

Method for measuring object deformation in real time

The invention discloses a method for measuring object deformation in real time, which comprises the following steps: arranging and adjusting measuring equipment, namely symmetrically arranging two cameras and corresponding LED illumination lamps above a measured object, and making optical axes of the two cameras intersected in a distance of 1 meter in front of the cameras; then calibrating the cameras, namely tightly sticking mark points to the surface of an object to be measured according to the size and shape of the measured object and the measurement requirement; next, placing the measured object stuck with the mark points under the two cameras in about 1 meter or moving the whole measuring equipment to make the measured object enter a measurement range and enable each camera to acquire the mark points on the surface of the measured object, starting the two cameras to shoot sequence images, and acquiring digital images; then identifying and positioning the images; reversely solving a projection matrix according to the calibration result of the cameras, and combining image coordinates of the solved mark points on the surface of the measured object on the images of the two cameras to reconstruct a three-dimensional coordinate of the mark points; and finally, carrying out deformation analysis and calculation for the mark points on the surface of the measured object.

Owner:XI AN JIAOTONG UNIV

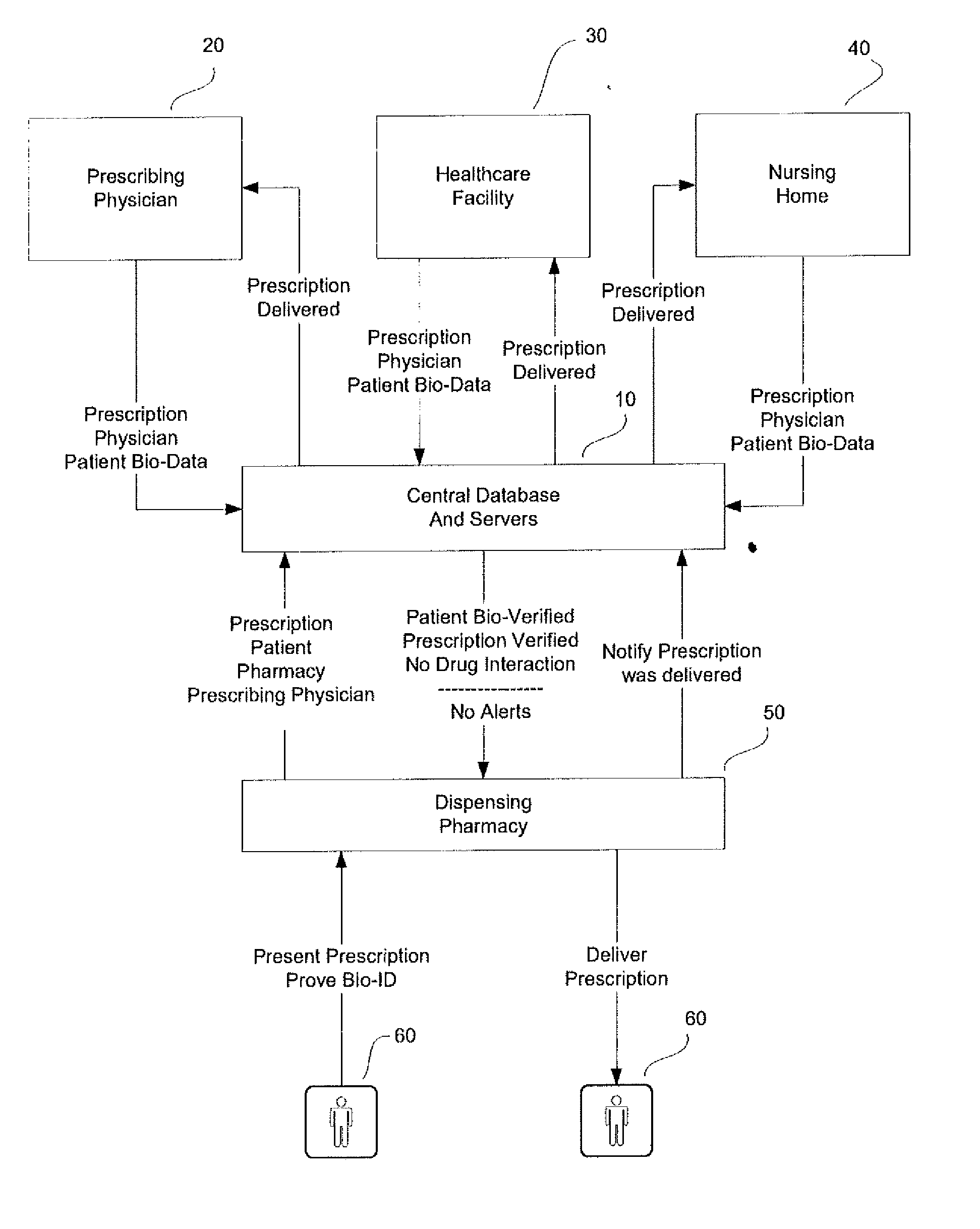

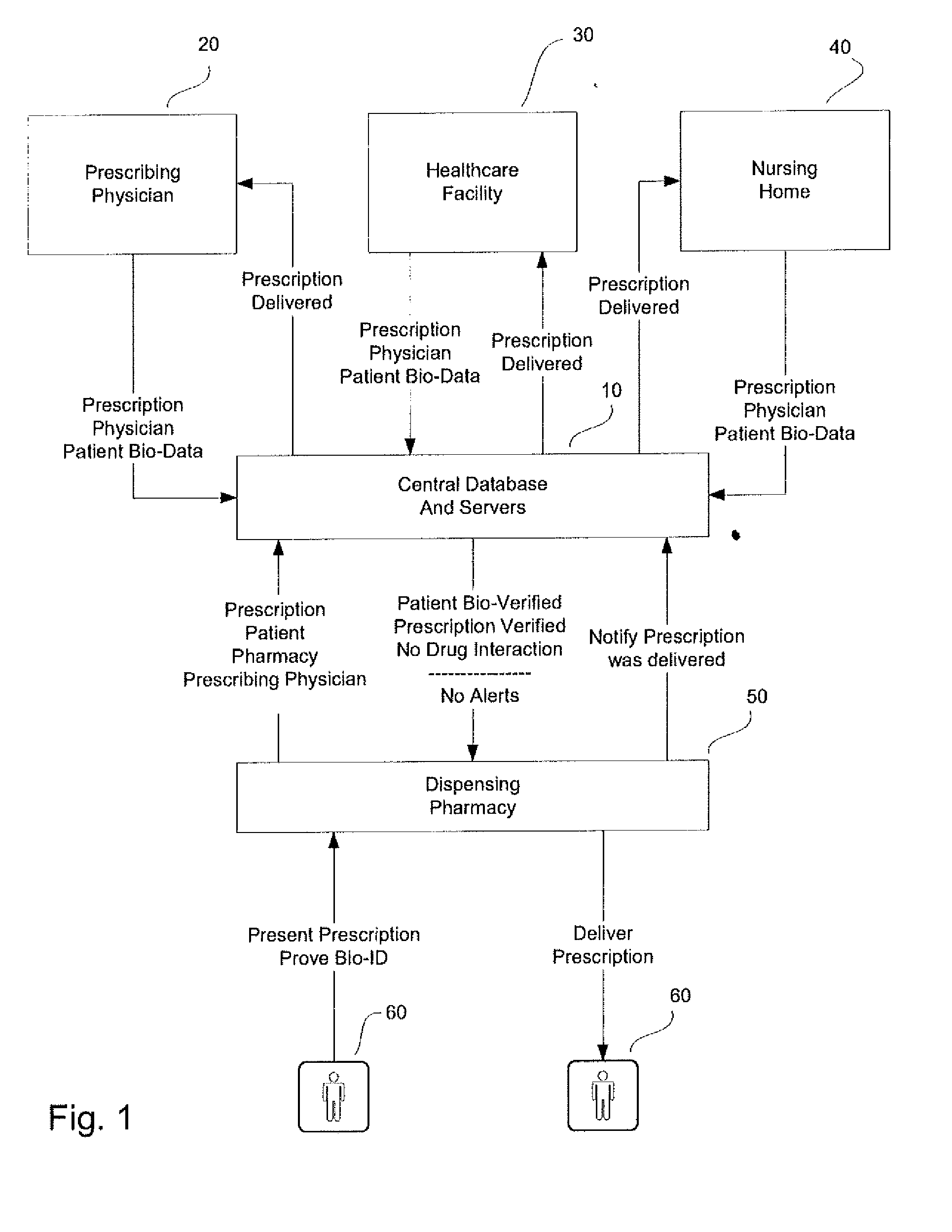

System and method for monitoring medication prescriptions using biometric identification and verification

InactiveUS20100299158A1Quick measurementEasily verifiable biometricDrug and medicationsResourcesBiometric dataDrug interaction

This invention is a system and method for a matching system that cross-references patients anonymously with doctors and pharmacies. The invention uses patient-unique biometrics, such as fingerprinting, retinal scanning, or another such unique identifier, for patient identification and verification without revealing a patient's name or other personal information. The system tracks patient prescriptions and produces alerts to indicate potential problems, such as drug interactions or possible fraudulent behavior. The system utilizes the biometric data of the prescribing physician as authorization of the prescription. The system can produce a traceable paper trail, for investigation or prosecution, and protects the medical industry, patients, and the public from the consequences of doctor shopping.

Owner:BIO TECH MEDICAL SOFTWARE

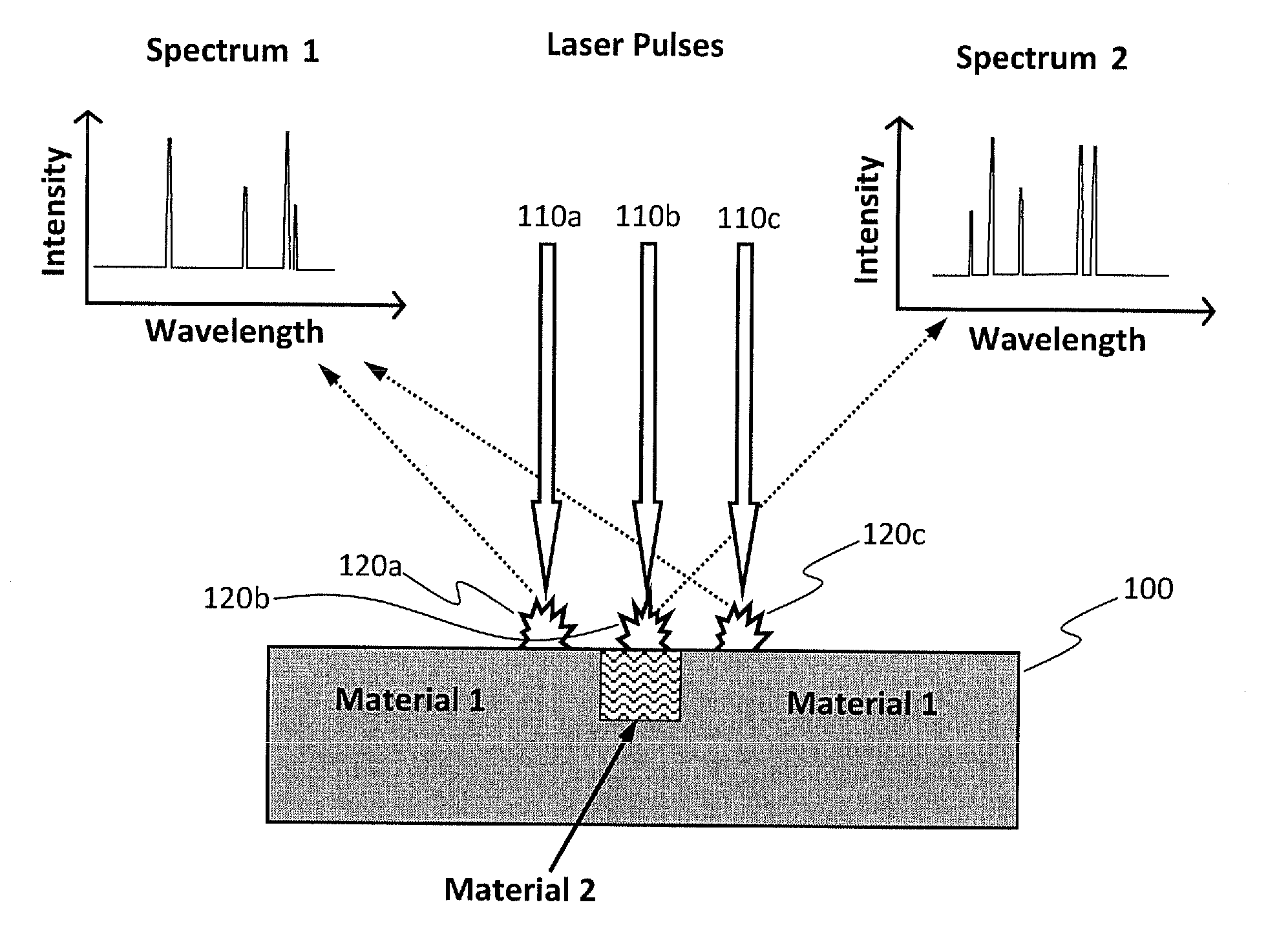

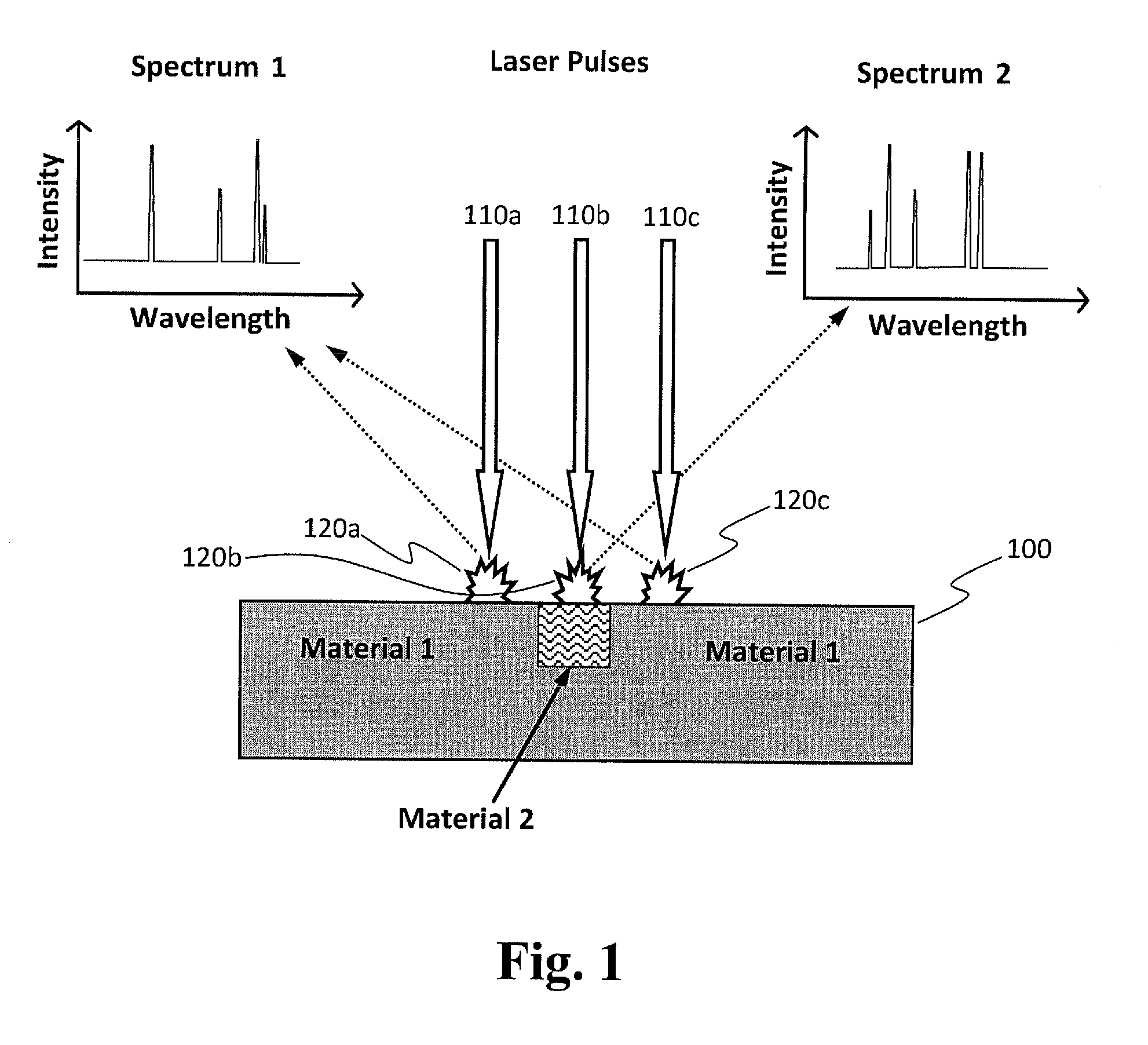

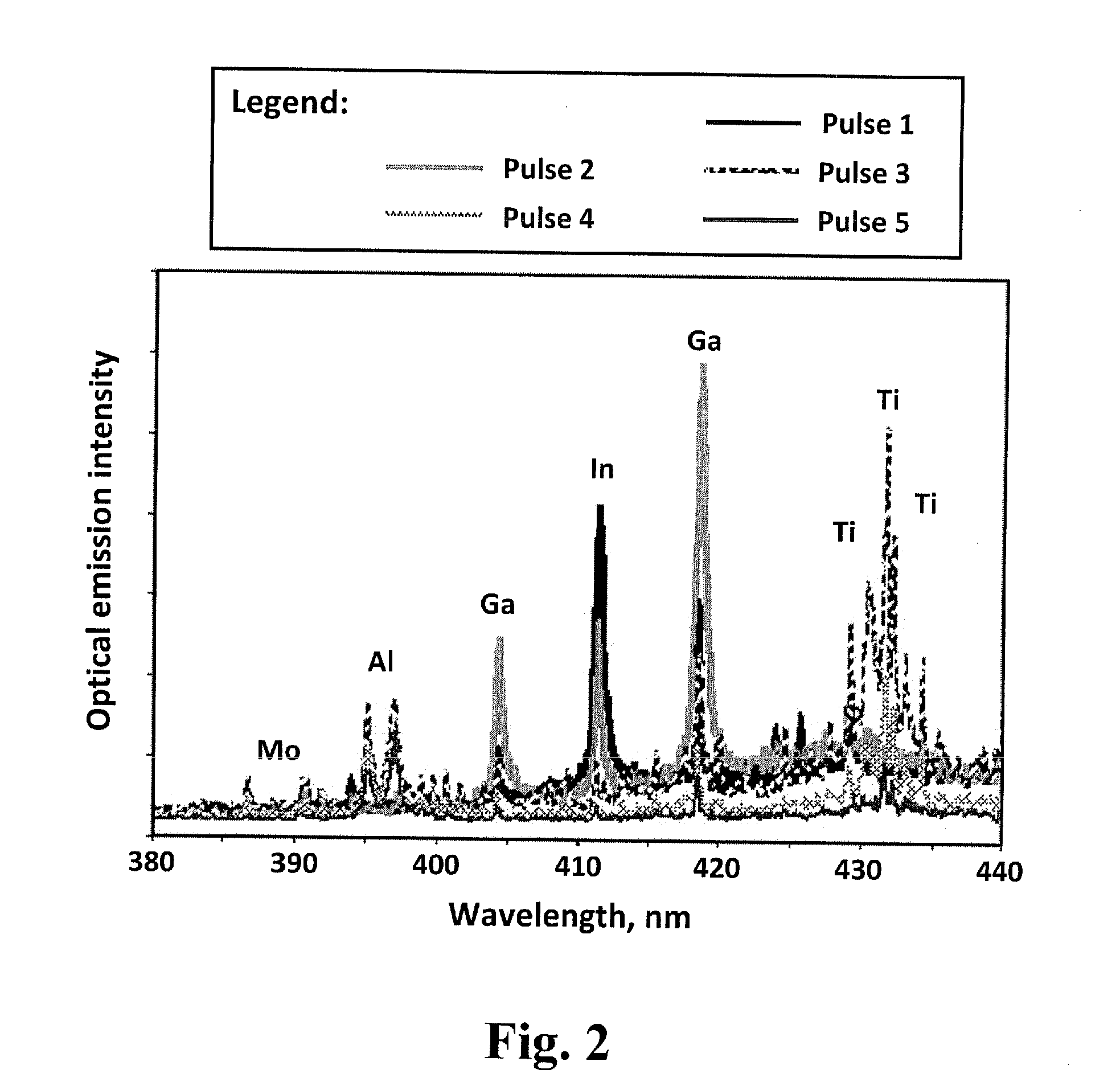

Method for real-time optical diagnostics in laser ablation and laser processing of layered and structured materials

ActiveUS20110100967A1Strong specificityImprove efficiencyMaterial analysis by electric/magnetic meansLaser beam welding apparatusLaser processingOptical diagnostics

A method for real-time optical diagnostics in laser ablation and laser processing of layered or structured materials or material structures. Diagnostics is provided during laser ablation that is utilized regularly in laser processing and / or chemical analysis of structured materials, by means of measuring optical emission generated as a result of the pulsed laser-material interaction in real time. The method can involve a single-layer-film or a stack of multiple layers or a structure of different domains. The method is particularly beneficial in fabrication of thin-film structures, such as photovoltaic and electronic devices or circuits of devices.

Owner:APPLIED SPECTRA

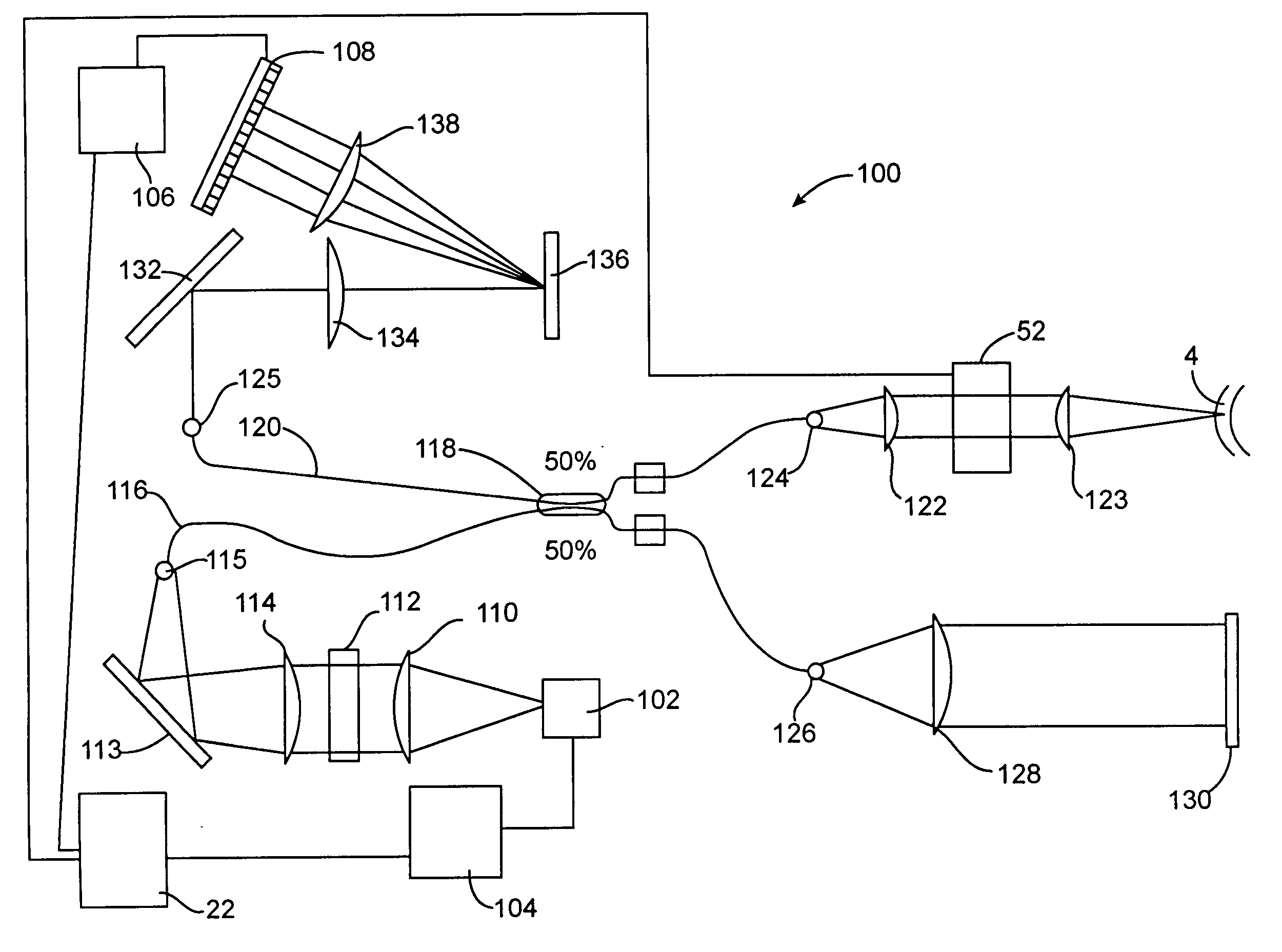

Integrated scanning and ocular tomography system and method

InactiveUS20040021874A1Quick measurementQuick monitoringLaser surgerySurgeryMeasurement deviceFast measurement

Systems and methods of the present invention measure at least one reflecting surface of an object disposed along an optical path. In some embodiments a measured optical interference signal for each of at least three wavelengths of reflected light may be used to determine a modulation of frequency components of a Fourier series. Frequency components of a Fourier series may be transformed to spatial components that describe intensities and positions of light reflected along an optical path. Systems and methods of the present invention permit rapid measuring and may monitor corneal thickness during surgery. The invention may do so by integrating an ablation device and a measurement apparatus into a single system. An integrated scanning and monitoring system may include an ablative light source producing an ablative beam and a measurement light source producing a measurement beam.

Owner:AMO MFG USA INC

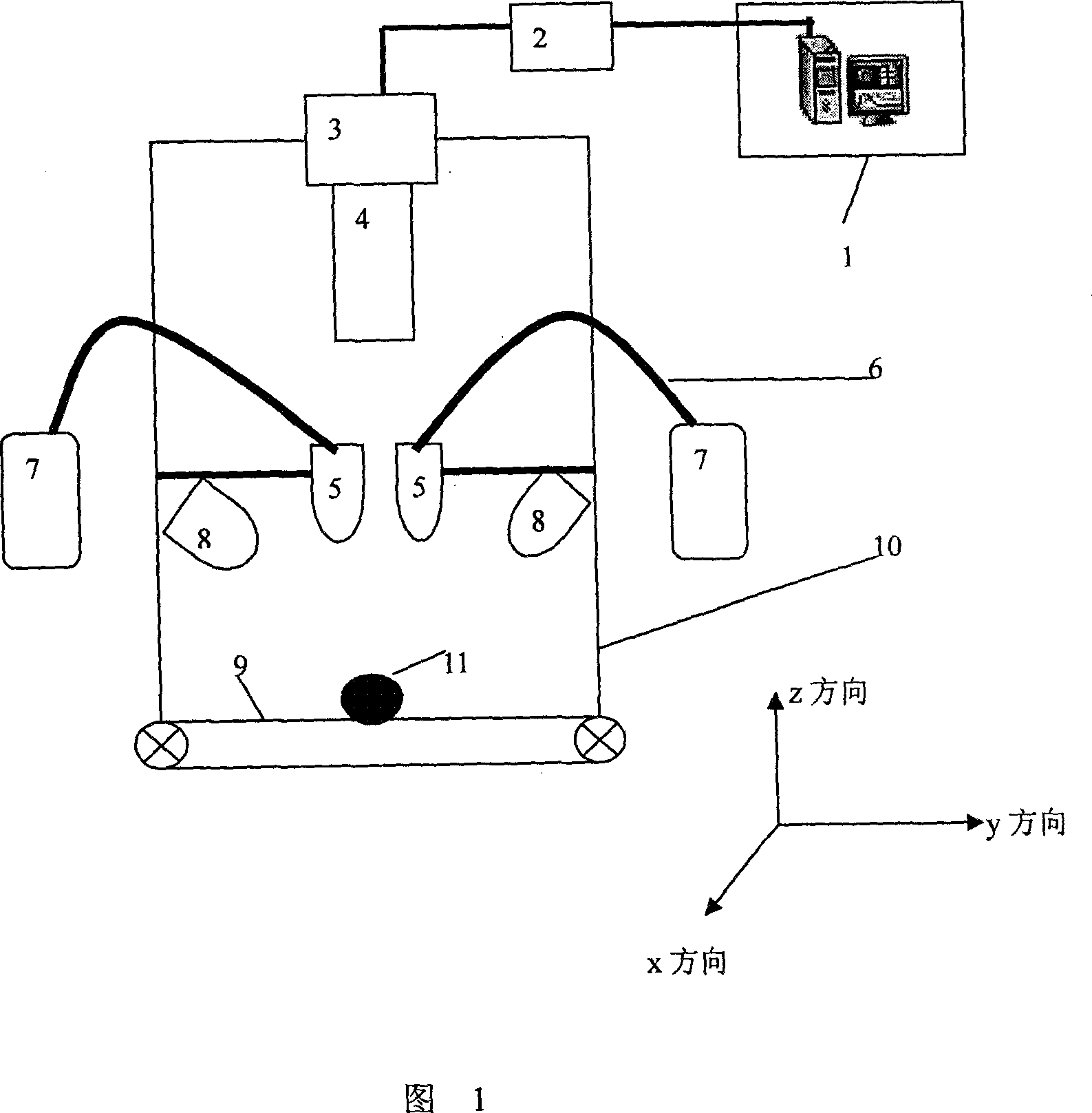

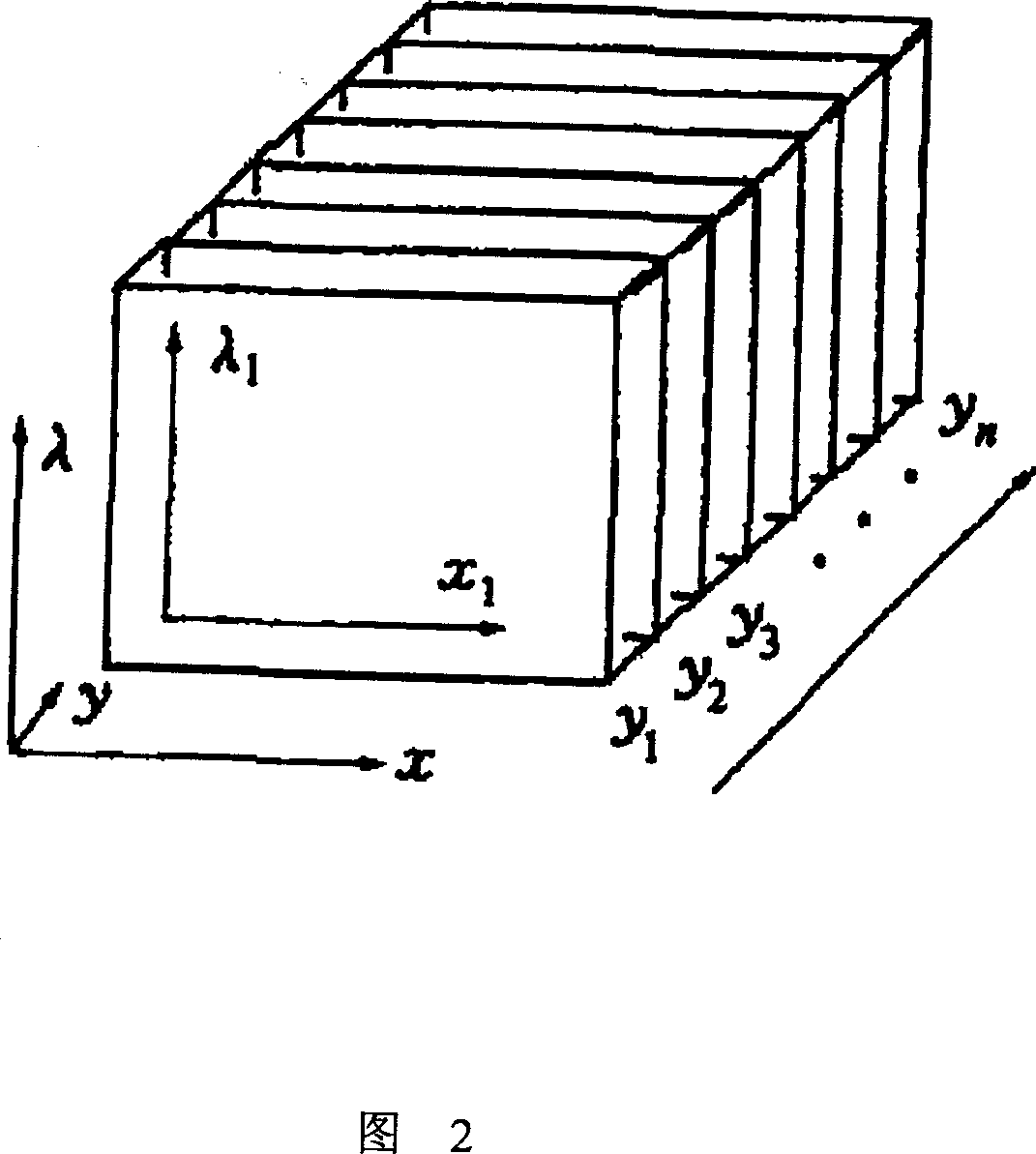

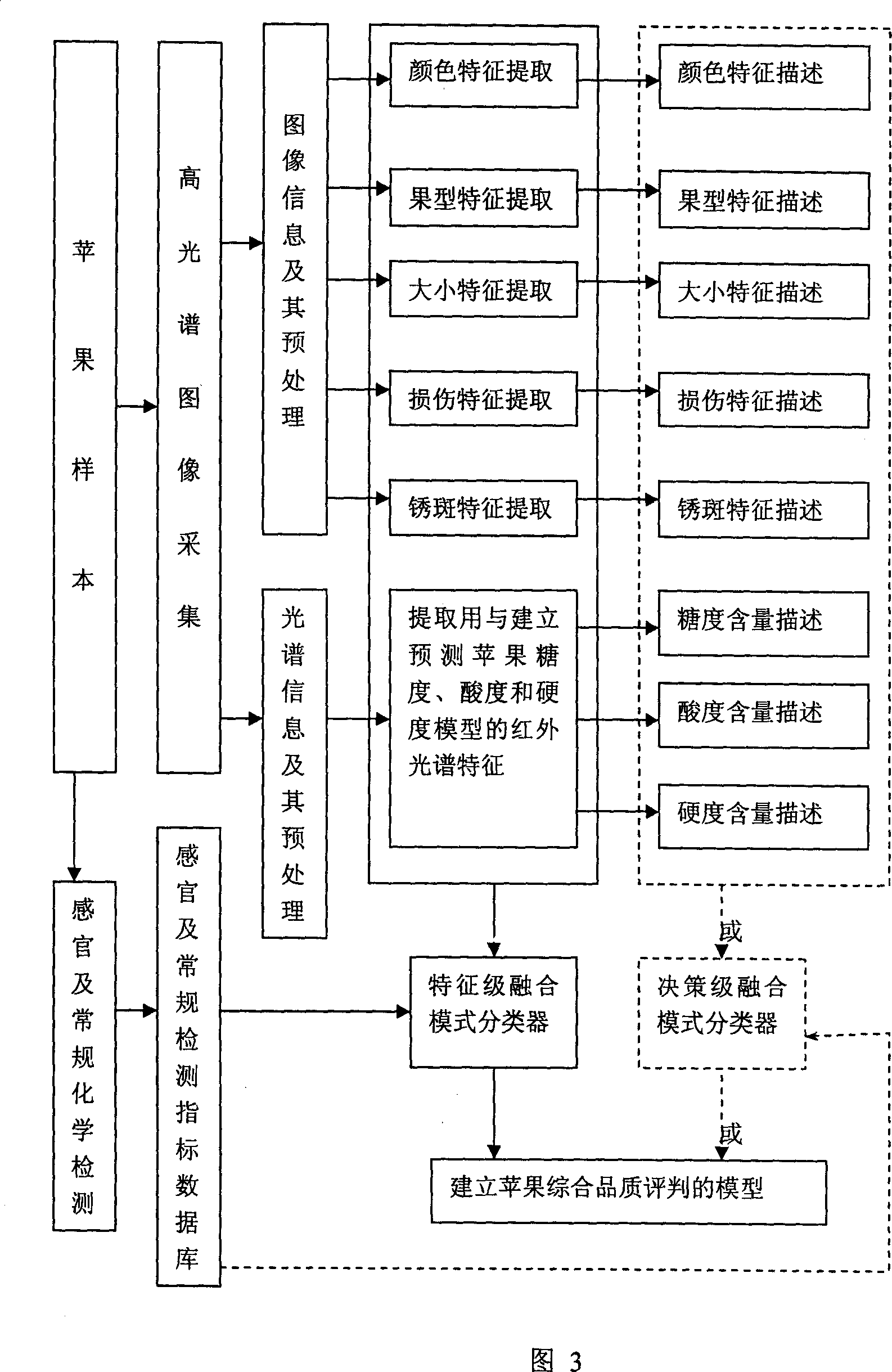

Non-destructive detection method and device for agricultural and animal products based on hyperspectral image technology

InactiveCN1995987AWith artificial intelligenceGuaranteed sampling qualityImage analysisMaterial analysis by optical meansNon destructiveAnimal product

The invention relates to high optical spectral image technique without harm to agricultural products. It can reflect the appearance of the agriculture products like color, shape, texture, dimension, scar and son on, and internal features like hardness, protein content and connected with knowledge base and experience of experts to make judgment. It can make quick, accurate, timely judgment of products, controlling the overall production with guarantee of the agriculture quality.

Owner:JIANGSU UNIV

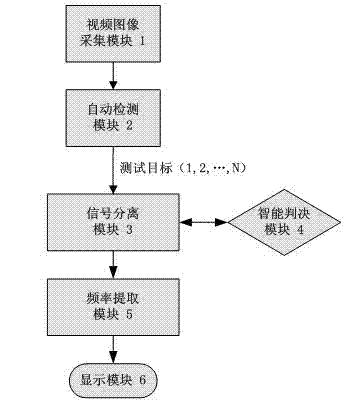

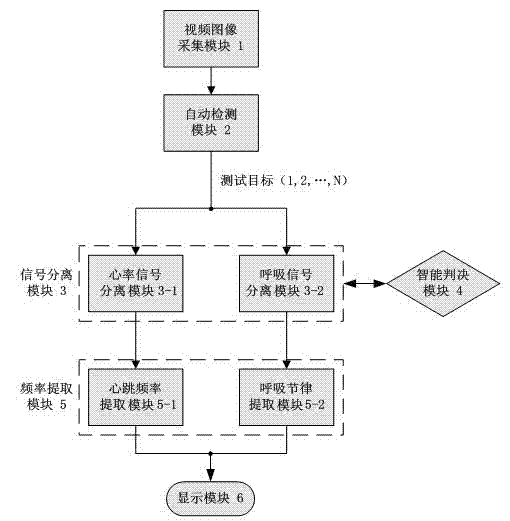

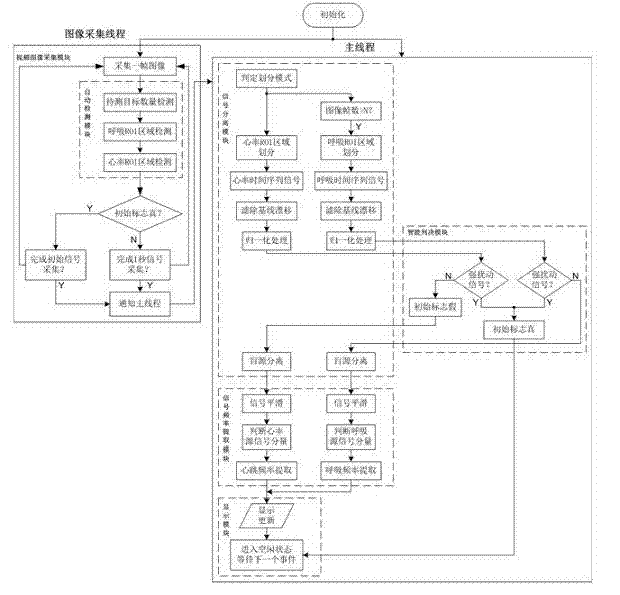

Video-image-based method and system for detecting non-contact vital sign

ActiveCN102499664AImprove the immunityRealize simultaneous measurementMedical imagingRespiratory organ evaluationVital sign detectionVideo image

The invention discloses a video-image-based method for detecting a non-contact vital sign. The method comprises the following steps of: acquiring video images continuously according to a fixed frame frequency, detecting a region of interest (ROI) region automatically, separating a vital sign signal from a multichannel signal separated from the ROI region, extracting the frequency of the vital sign signal and converting the frequency into the vital sign to acquire a detection result. The invention also discloses a video-image-based system for detecting the non-contact vital sign. The method and the system have the advantages of quickness, real time, capacity of realizing continuous monitoring, high robustness, low cost, wide application range and the like.

Owner:XISHUANGBANNA DADU YUNHAI BIOLOGICAL TECH DEV

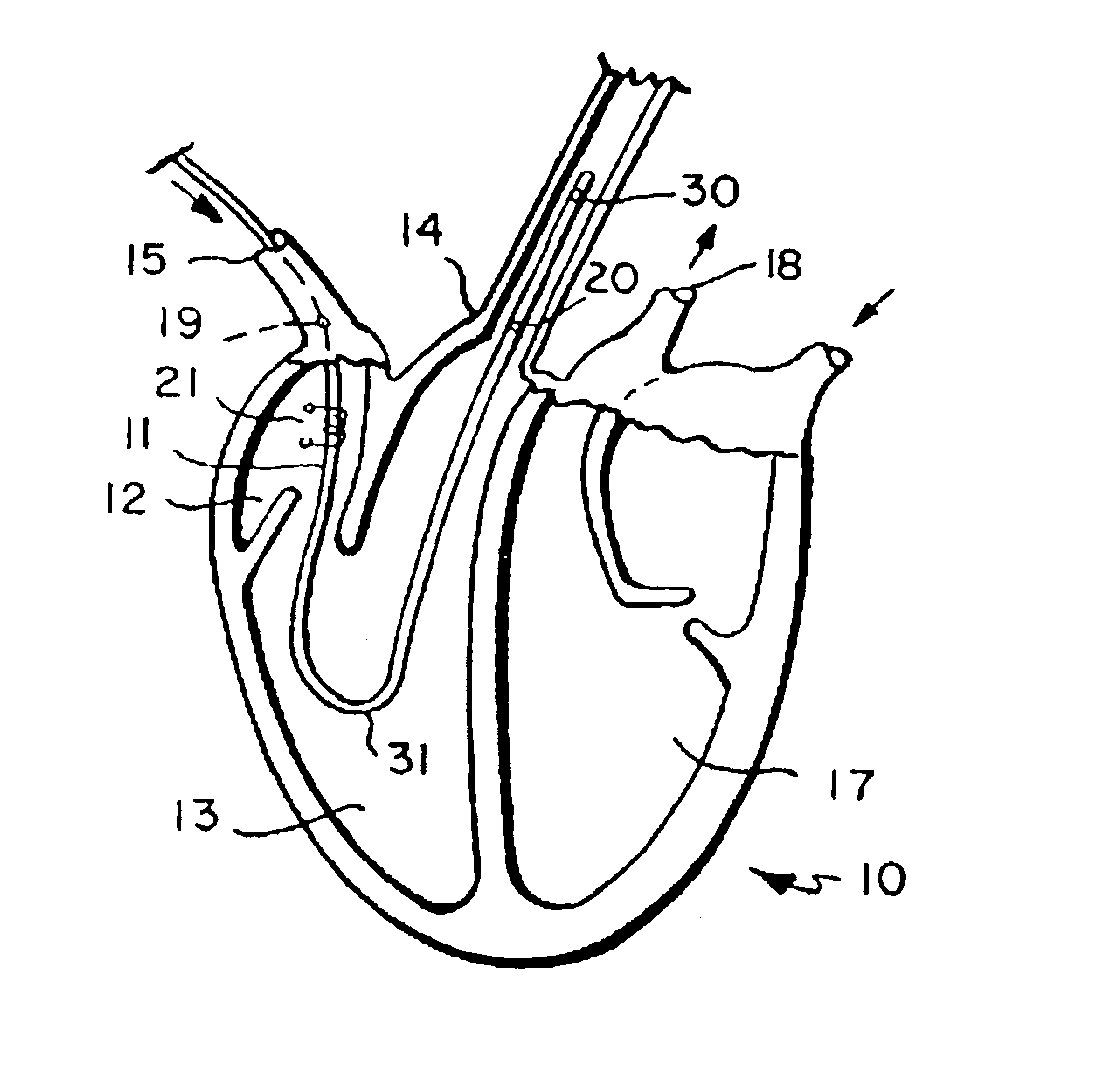

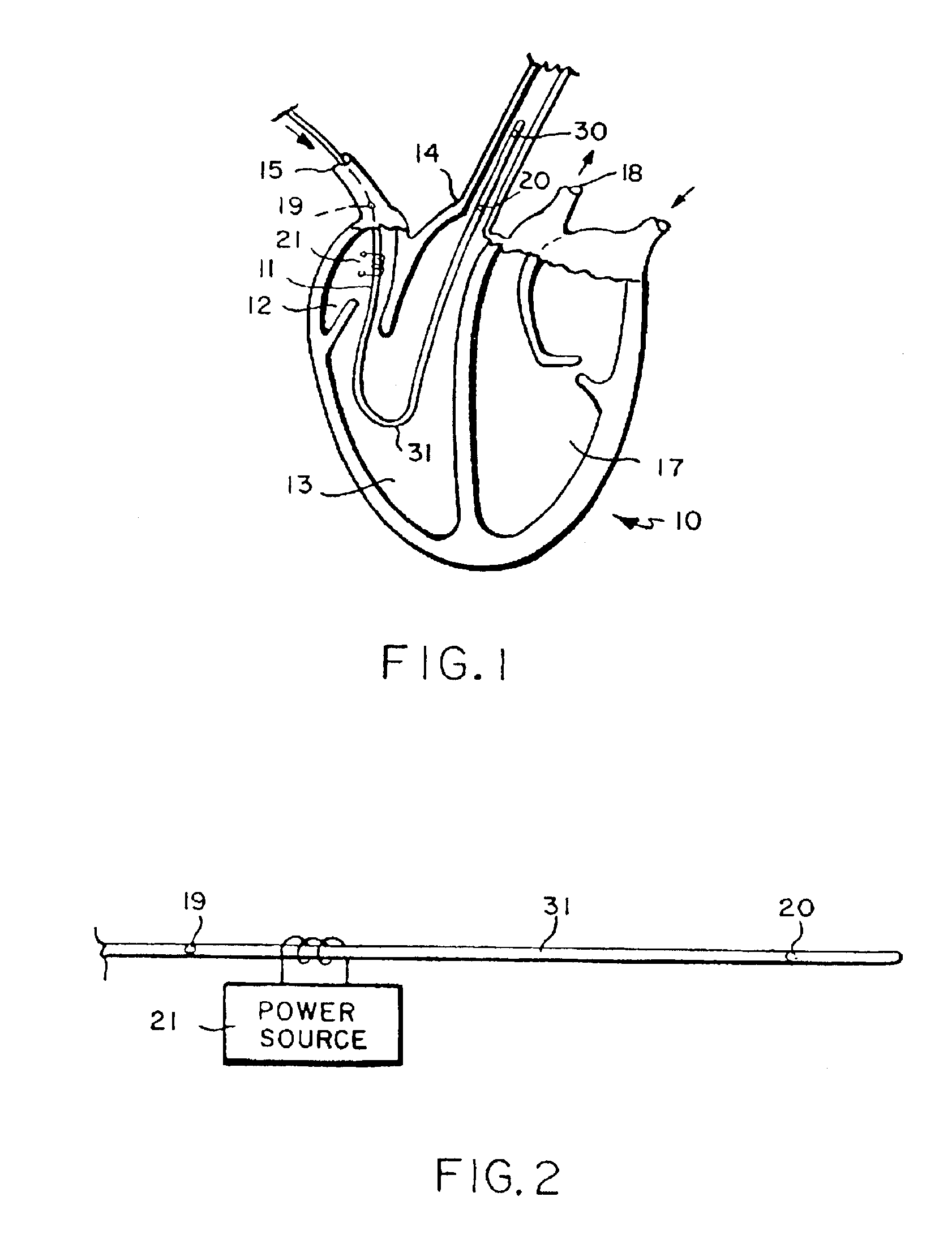

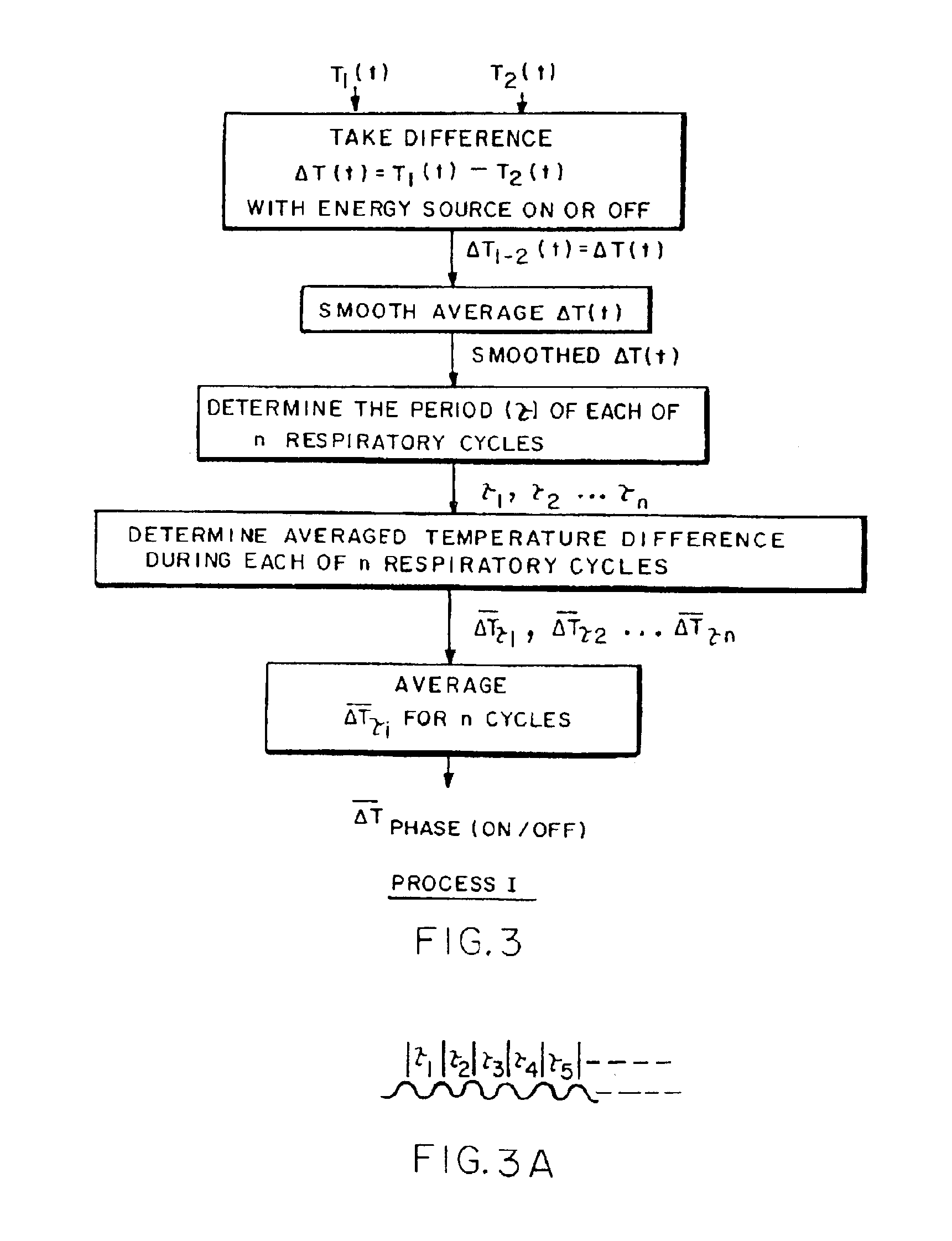

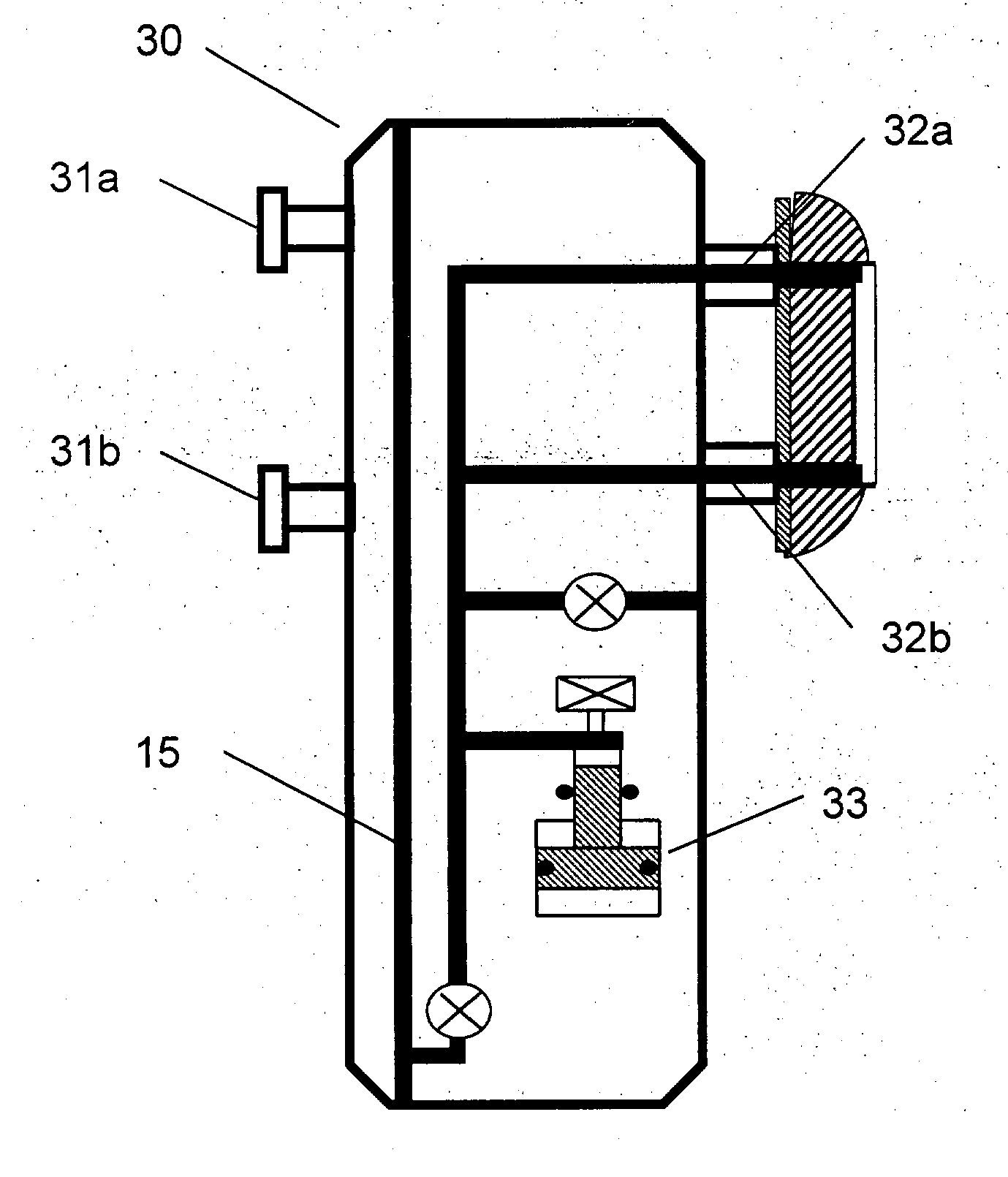

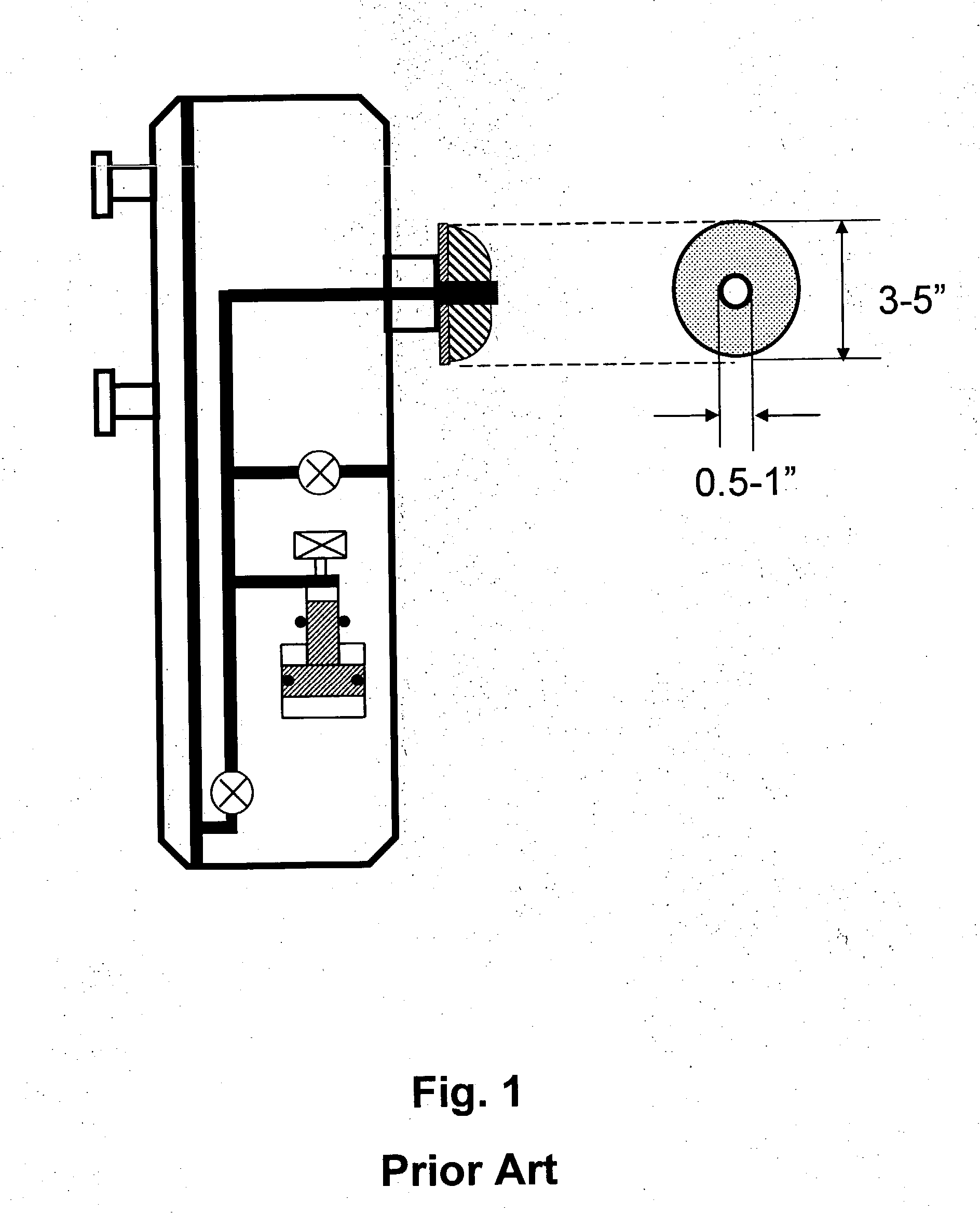

Method for measuring blood flow

InactiveUS6913576B2Efficiently obtainedQuick measurementCatheterSensorsThermal energyTemperature difference

A technique for determining blood flow in a living body by changing the thermal energy level by a predetermined amount at a site in a blood flow path and detecting temperatures at locations upstream and downstream of the site. The temperature difference at such locations is determined and the blood flow is calculated as a function of the change in energy level and of the temperature differences measured prior to and following the change in energy level.

Owner:THERMAL TECH

Formation testing and sampling apparatus and methods

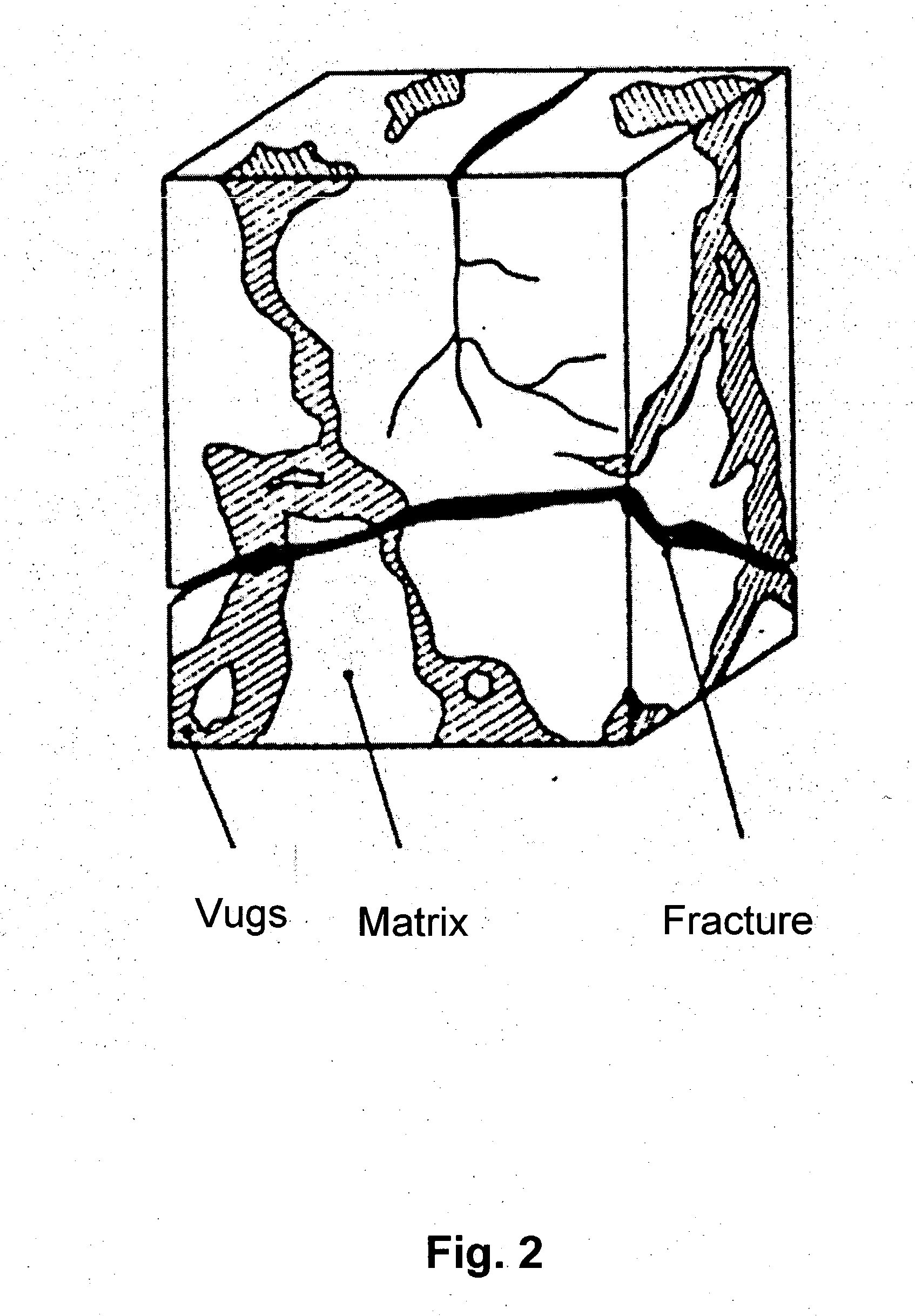

InactiveUS20040173351A1Increase the circulation areaAccurate test measurement resultSurveyFluid removalTester deviceEngineering

Systems and methods for downhole formation testing. The invention is based on the use of one or more elongated sealing pads capable of sealing off and collecting or injecting fluids from elongated portions along the surface of a borehole. The, modified probe pads of a device-made in accordance with the invention increase the flow area by collecting fluids from an extended portion along the surface of a borehole, which is likely to straddle one or more layers in laminated or fractured formations. A tester device using the elongated sealing pads is capable of fast deployment and withdrawal to speed up the measurement cycles. Various designs and arrangements for use with a fluid tester, which may be part of a modular fluid tool, are disclosed in accordance with different embodiments.

Owner:HALLIBURTON ENERGY SERVICES INC

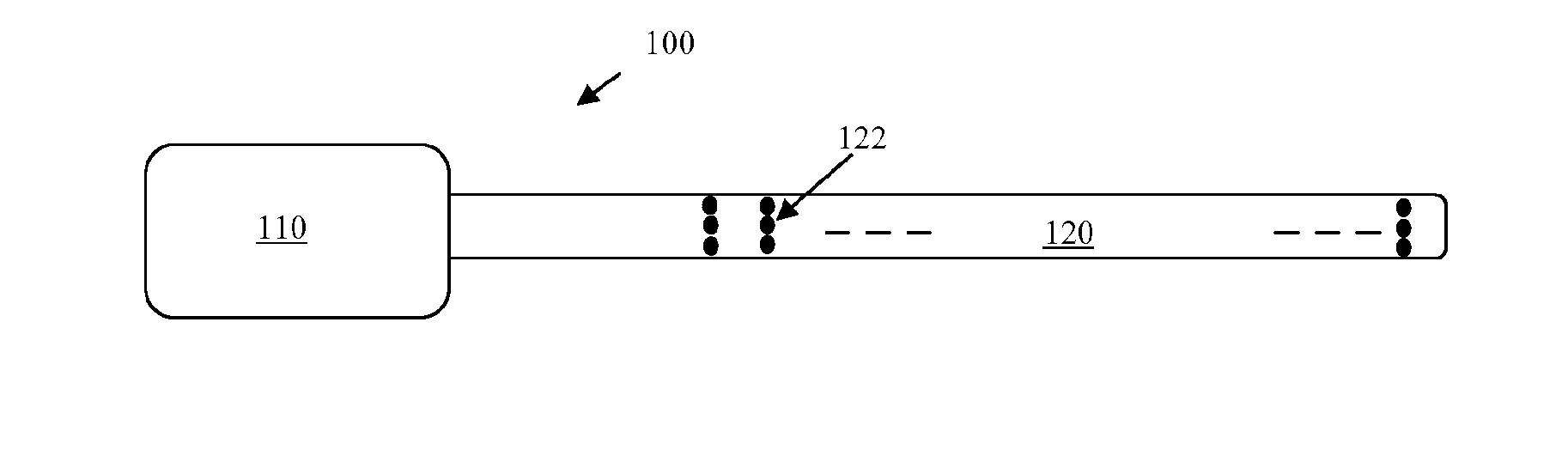

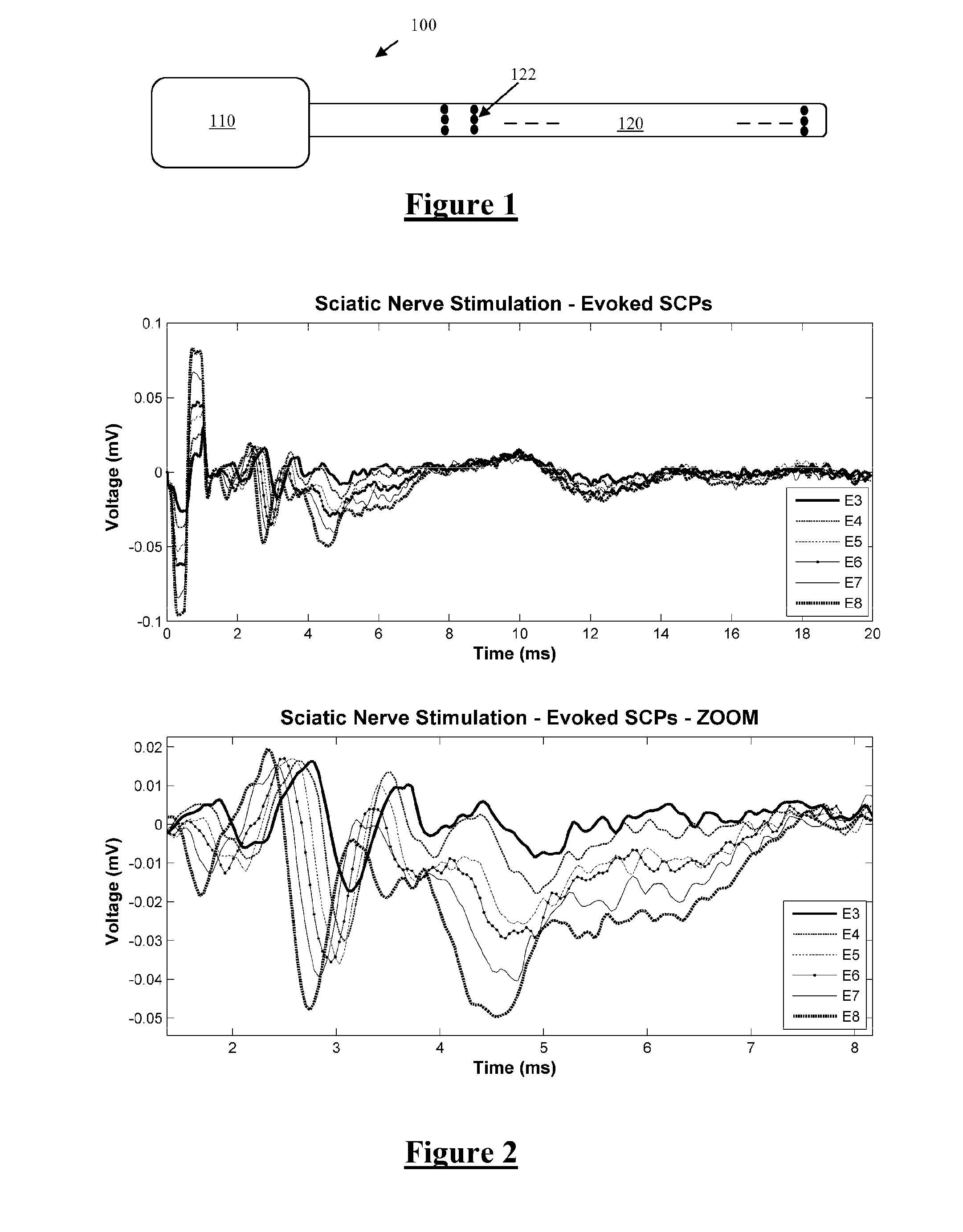

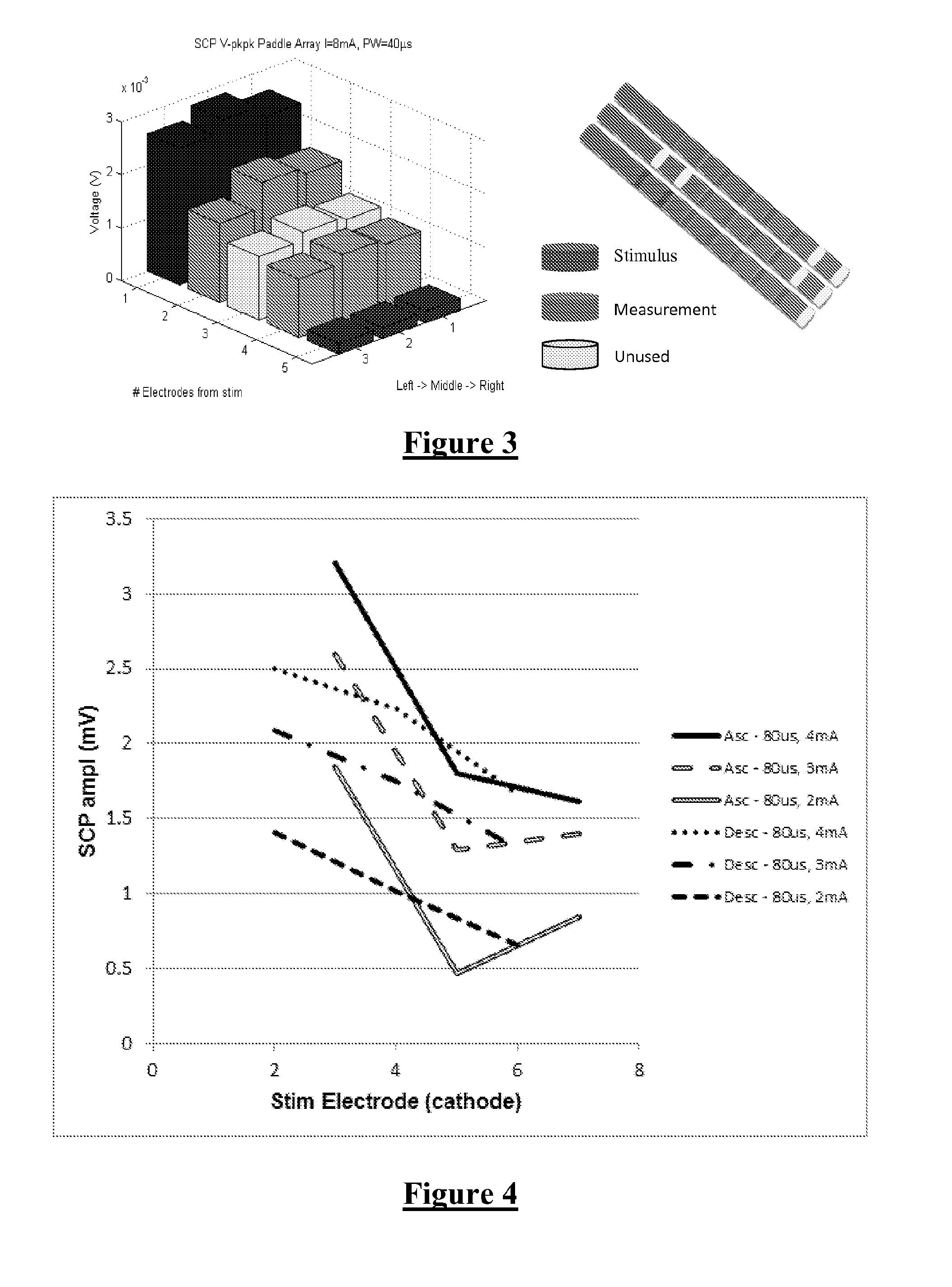

Method and apparatus for measurement of neural response

ActiveUS20140296737A1Improve signal-to-noise ratioHigh sensitivitySpinal electrodesImplantable neurostimulatorsMedicineAxonal action potential

A method for determining a desired location at which to apply a neural therapy. An array of electrodes is positioned proximal to neural tissue. A stimulus is applied from the array which evokes a neural compound action potential response in the neural tissue proximal to the array. A plurality of electrodes of the array simultaneously obtain respective measurements of the neural compound action potential response. From the measurements of the neural compound action potential response a desired location for a neural therapy is determined.

Owner:SALUDA MEDICAL PTY LTD

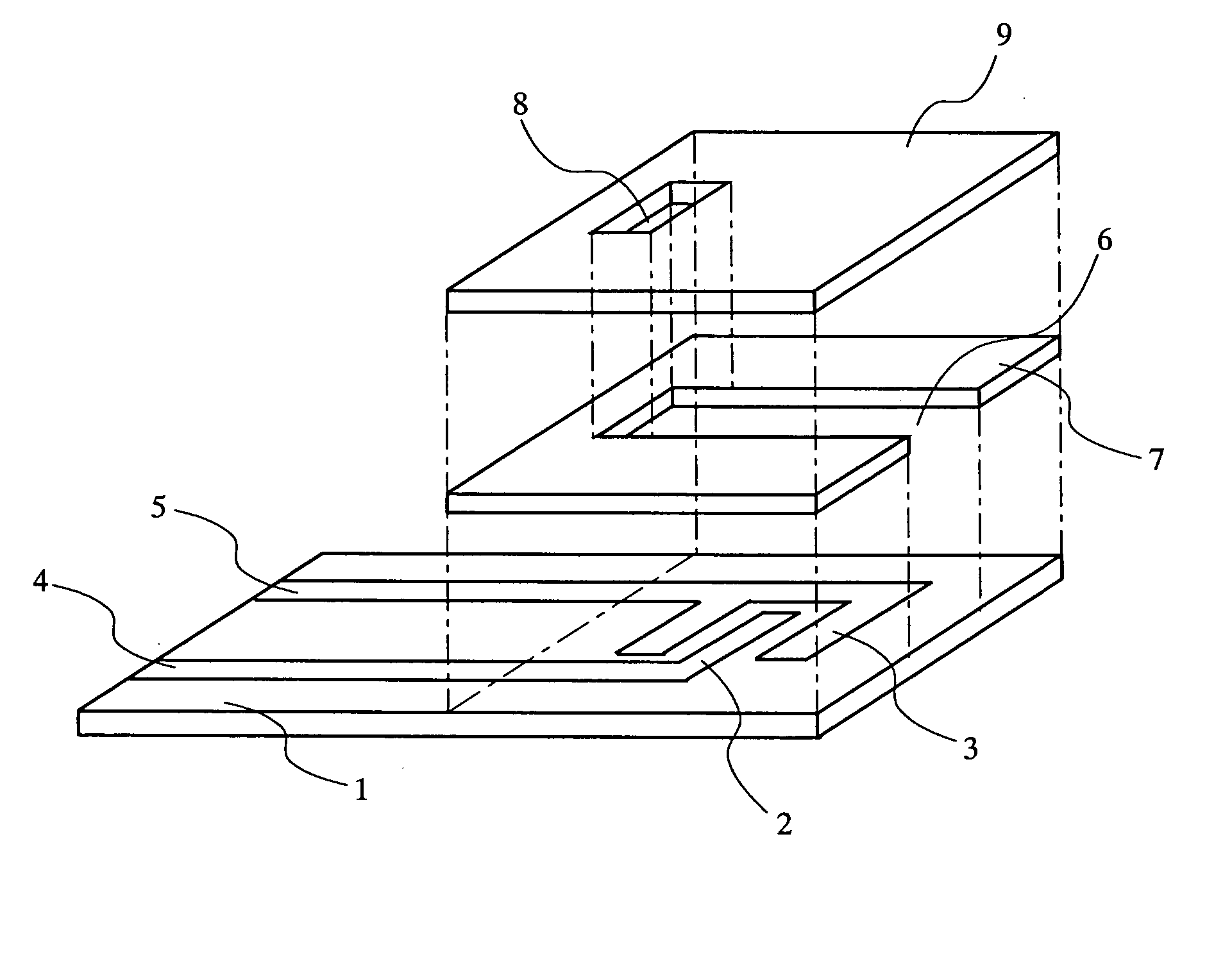

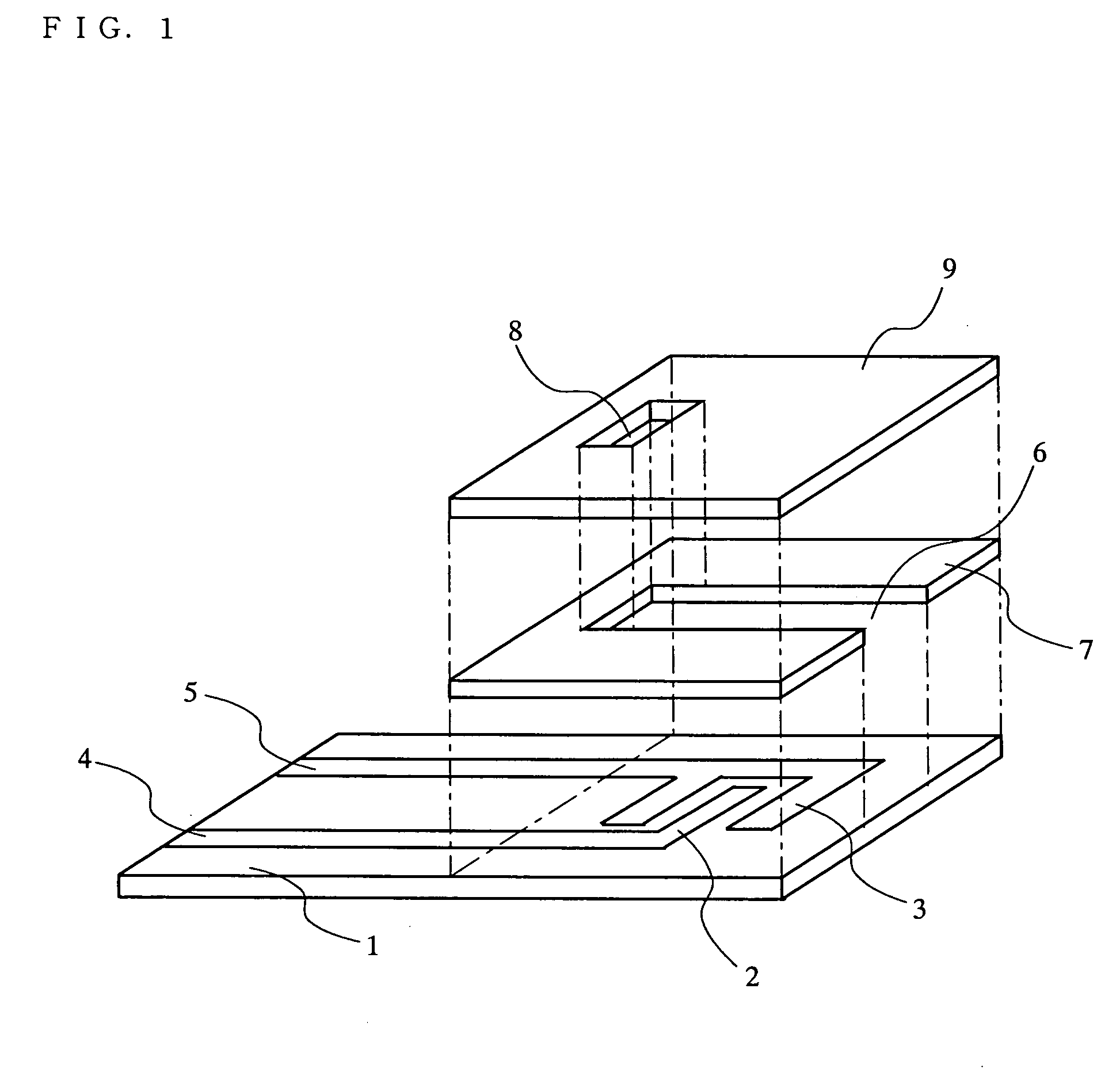

Biosensor

InactiveUS20050175509A1Eliminate measurement errorsHigh precisionMicrobiological testing/measurementBiological material analysisCompound (substance)Organic compound

The present invention relates to a biosensor which comprises an electrode system including at least one pair of electrodes, at least one insulating base plate for supporting the electrode system, a first reaction layer provided at least on a working electrode of the electrode system, including an organic compound having a functional group capable of bonding or being adsorbed to an electrode and a hydrophobic hydrocarbon group, a second reaction layer provided on the first reaction layer, including an amphiphilic lipid capable of bonding or being adsorbed to a hydrophobic portion of the first reaction layer, and a reagent system carried in a two-component membrane composed of the first and second reaction layers, including at least membrane-binding type pyrroquinoline quinone-dependent glucose dehydrogenase and an electron mediator.

Owner:PANASONIC CORP

Apparatus and method for interferometric measurement of a sample

ActiveUS7982881B2Quick measurementRadiation pyrometryInterferometric spectrometryLight beamWavelength

A device for the interferometric measurement of a sample, in particular the eye, including an interferometer arrangement with a first measurement beam path, through which a measurement beam falls onto the sample, and a first reference beam path, through which a reference beam runs, which is applied to the measuring beam for interference. The interferometer arrangement includes a second measuring beam path and / or second reference beam path. The optical path lengths of the second measuring beam path and / or second reference beam path are different from one of the first beam paths. The wave length difference is selected according to a distance of two measuring areas which are arranged at a distance in the depth direction of the sample.

Owner:CARL ZEISS MEDITEC AG

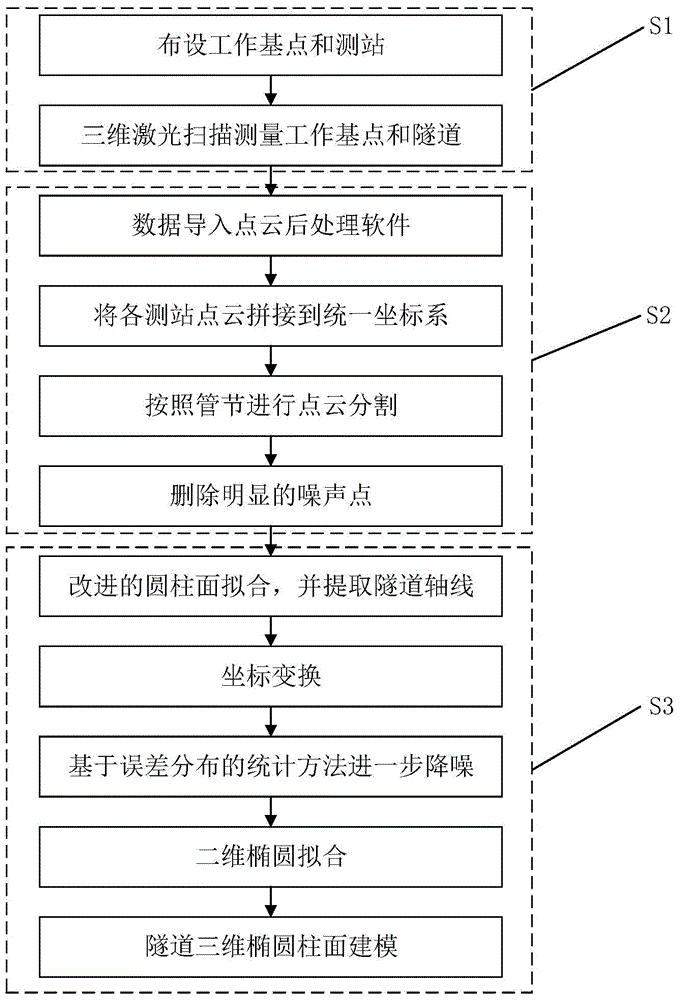

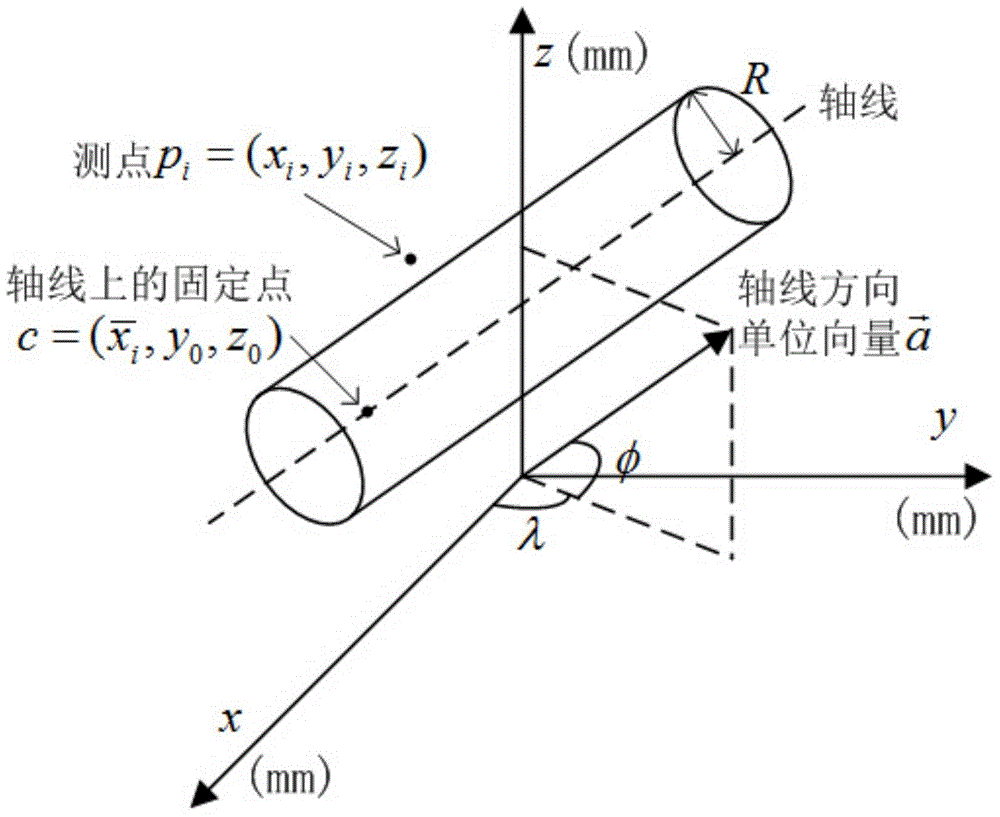

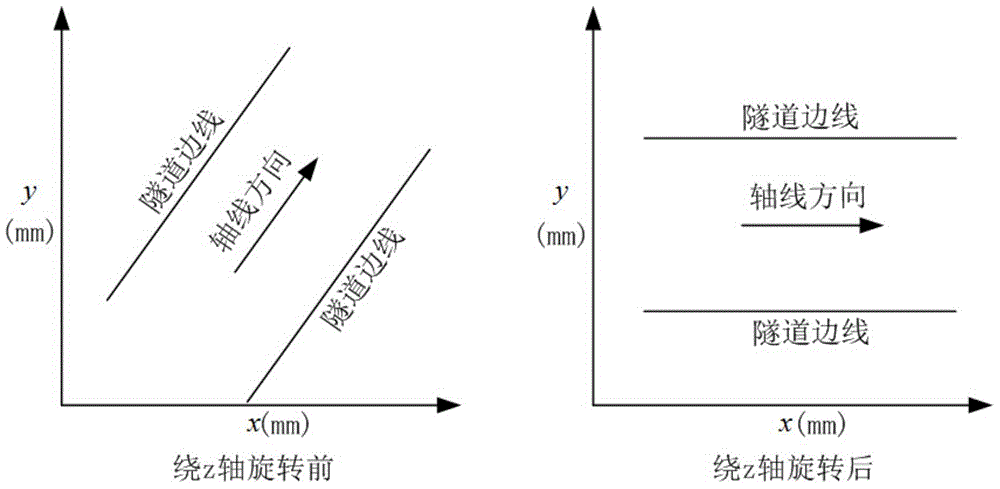

Method for measuring circular tunnel convergence deformation

ActiveCN104792274AReduce distractionsImprove measurement efficiencyUsing optical meansEllipseData point

The invention relates to a method for measuring circular tunnel convergence deformation. The method includes the steps of S1, by a three-dimensional laser scanner, acquiring the working base point coordinates and tunnel point cloud of each observation station; S2, using working base points as splicing datum points to merge the tunnel point cloud into a unified reference coordinate system, and segmenting into point cloud of a multi-ring pipe joint according to the pipe joint; S3, fitting the point cloud of a single-ring pipe joint into a cylindrical face according to an improved cylindrical face fitting algorithm, extracting pipe joint axis point coordinates, projecting the cylindrical face to a plane along the axis direction of the pipe joint to obtain a two-dimensional tunnel point cloud contour line, and fitting into an ellipse according to an ellipse fitting algorithm; S4, expanding the ellipse into a three-dimensional elliptic cylindrical surface along the axis so as to obtain the three-dimensional convergence deformation of a whole tunnel. Compared with the prior art, the method has the advantages that the longitudinal axis and convergence deformation of the tunnel under construction and the tunnel under operation can be acquired, monitoring point laying is not needed, high measuring efficiency is achieved, and comprehensive monitoring data is provided to tunnel construction and operation.

Owner:TONGJI UNIV

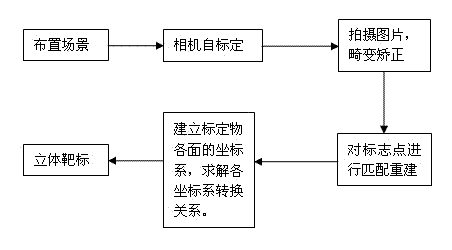

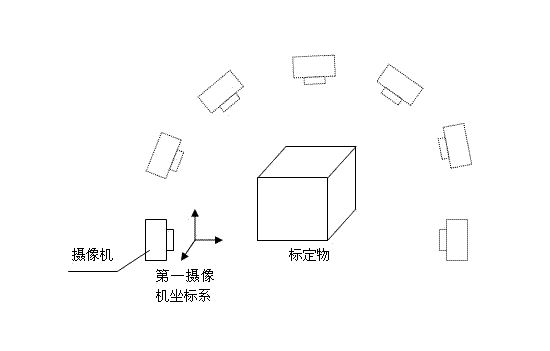

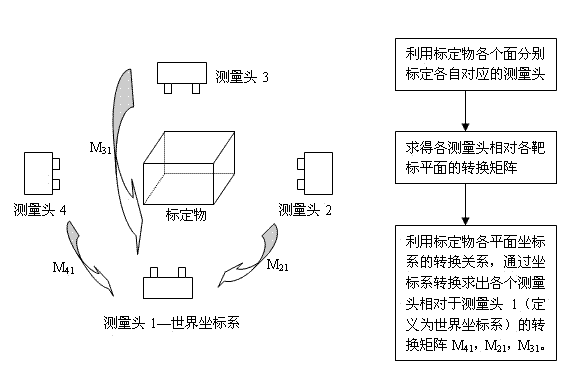

Calibration technology for multiple structured light projected three-dimensional profile measuring heads

InactiveCN102364299AAvoid stickingAvoid error accumulationUsing optical meansPoint cloudComputer graphics (images)

The invention relates to a calibration technology for multiple structured light projected three-dimensional profile measuring heads, discloses a technology for calibrating multiple structured light projected three-dimensional profile measuring heads in different directions, which can be used for the quick label-free measurement of an object profile projected by structured light, and belongs to the technical field of optical measurement. In the calibration technology, only a calibration object of a plane with a plurality of calibration patterns is required to be designed and is not required to be manufactured into a high-precision three-dimensional target with known geometrical relationships on all surfaces; and geometrical parameters among all planes of the calibration object can be obtained by a close-range photogrammetry technology to upgrade the calibration object into the three-dimensional target, so the difficulty of machining and maintaining the high-precision three-dimensional target directly is reduced. By utilizing the technology, multiple structured light projected three-dimensional profile measuring heads can be measured from different visual angles in a label-free mode, and point clouds scanned in different directions are unified to one coordinate system automatically, so error accumulation caused by splicing is avoided effectively, and the time of the three-dimensional appearance reconstruction of the object can be shortened.

Owner:SOUTHWEAT UNIV OF SCI & TECH

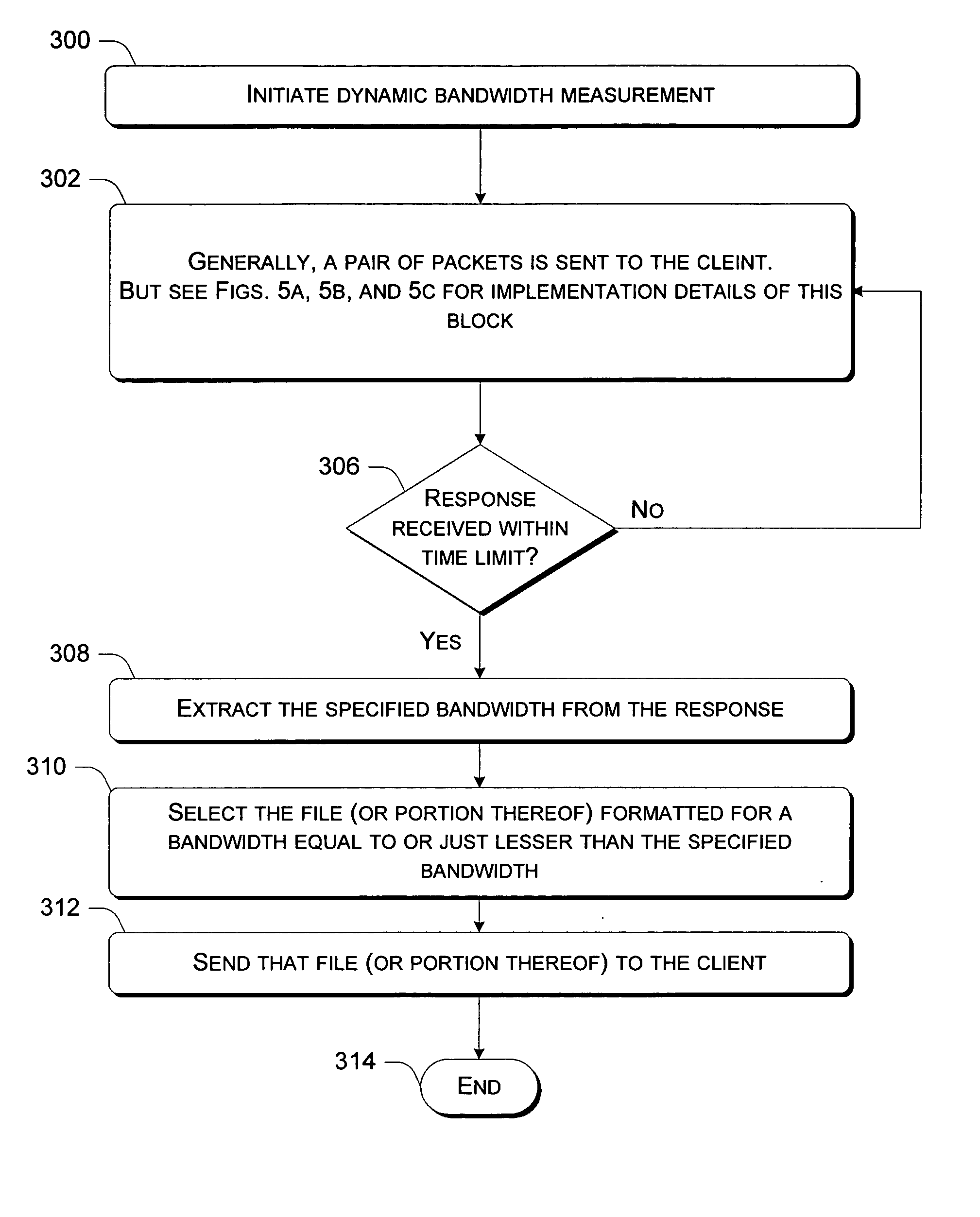

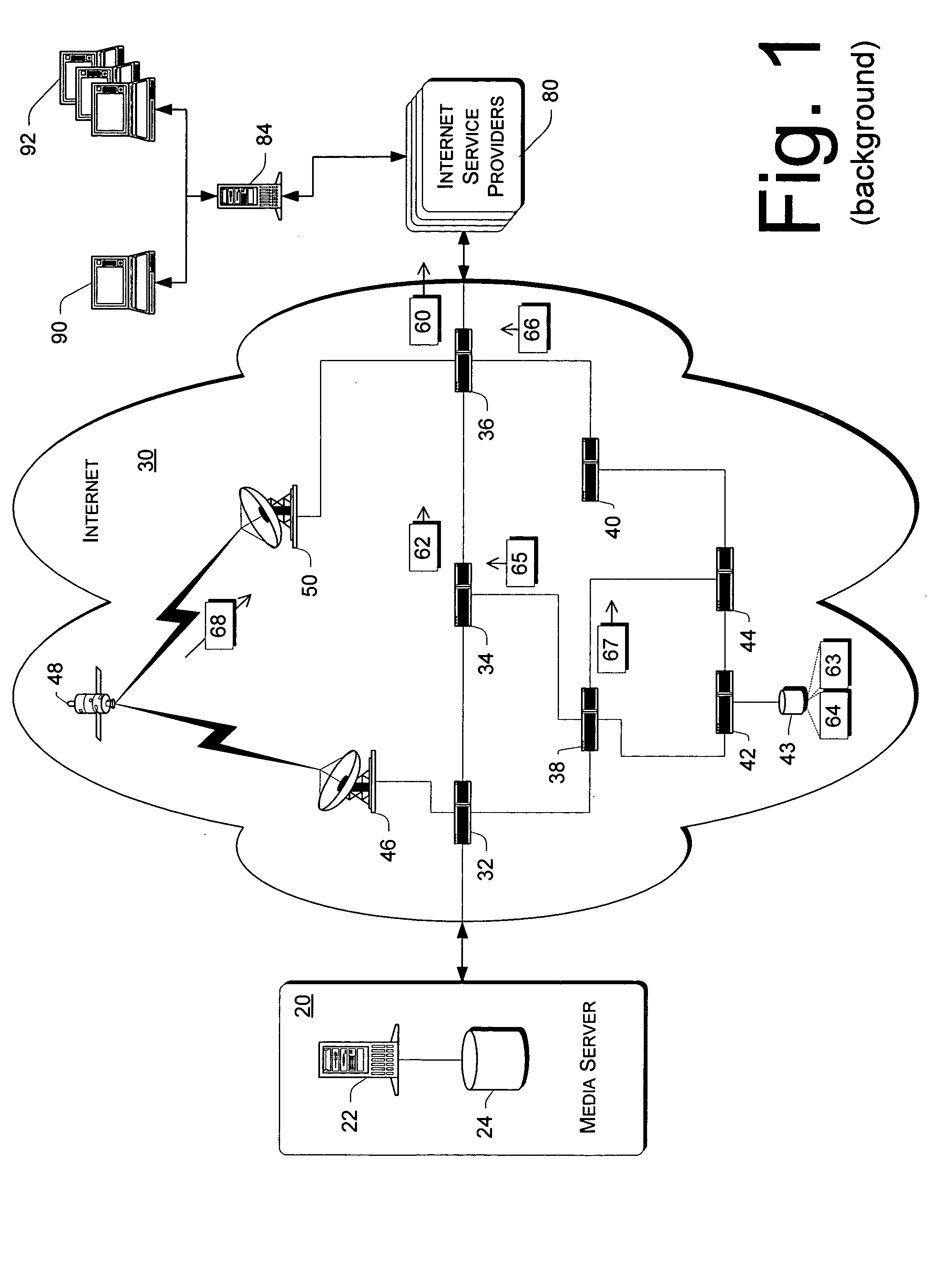

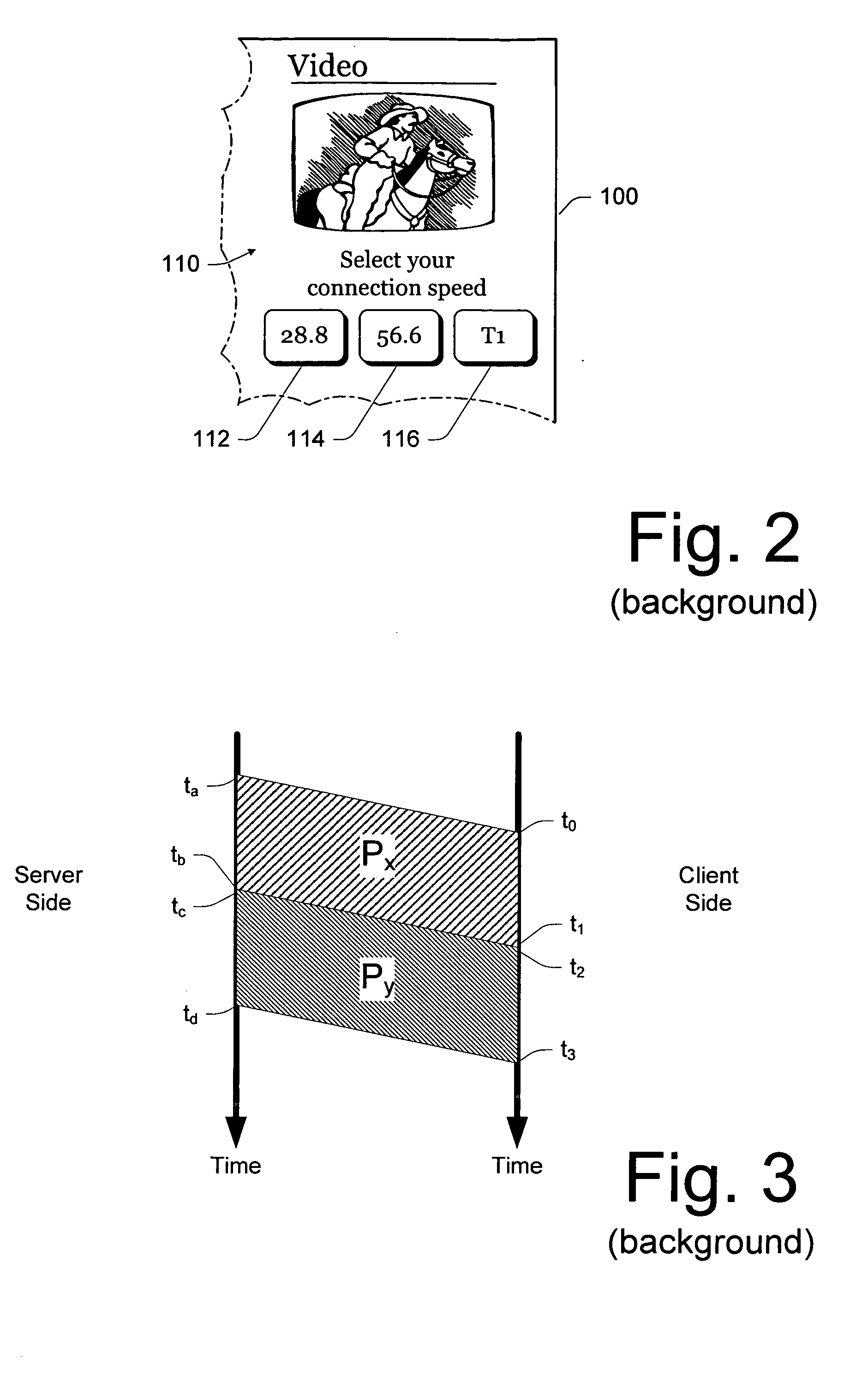

Fast dynamic measurement of bandwidth in a TCP network environment

InactiveUS20050108420A1Quick measurementDisabling applicationMultiple digital computer combinationsData switching networksCountermeasureSlow-start

The fast dynamic measurement of bandwidth in a TCP network environment utilizes a single pair of packets to calculate bandwidth between two entities on a network (such as the Internet). This calculation is based upon the packet-pair technique. This bandwidth measurement is extremely quick. On its journey across a network, communication devices may delay the packet pairs. In particular, TCP networks have two algorithms designed to delay some packets with the goal of increasing the overall throughput of the network. However, these algorithms effectively delay a packet pair designed to measure bandwidth. Therefore, they distort the measurement. These algorithms are Nagle and Slow Start. The fast dynamic measurement of bandwidth implements countermeasures to overcome the delays imposed by these algorithms. Such countermeasures include disabling the application of the Nagle Algorithm; minimizing the buffering of packets by sending a “push” packet right after the packet pair; and avoiding the Slow Start Algorithm by priming it with a dummy packet.

Owner:MICROSOFT TECH LICENSING LLC

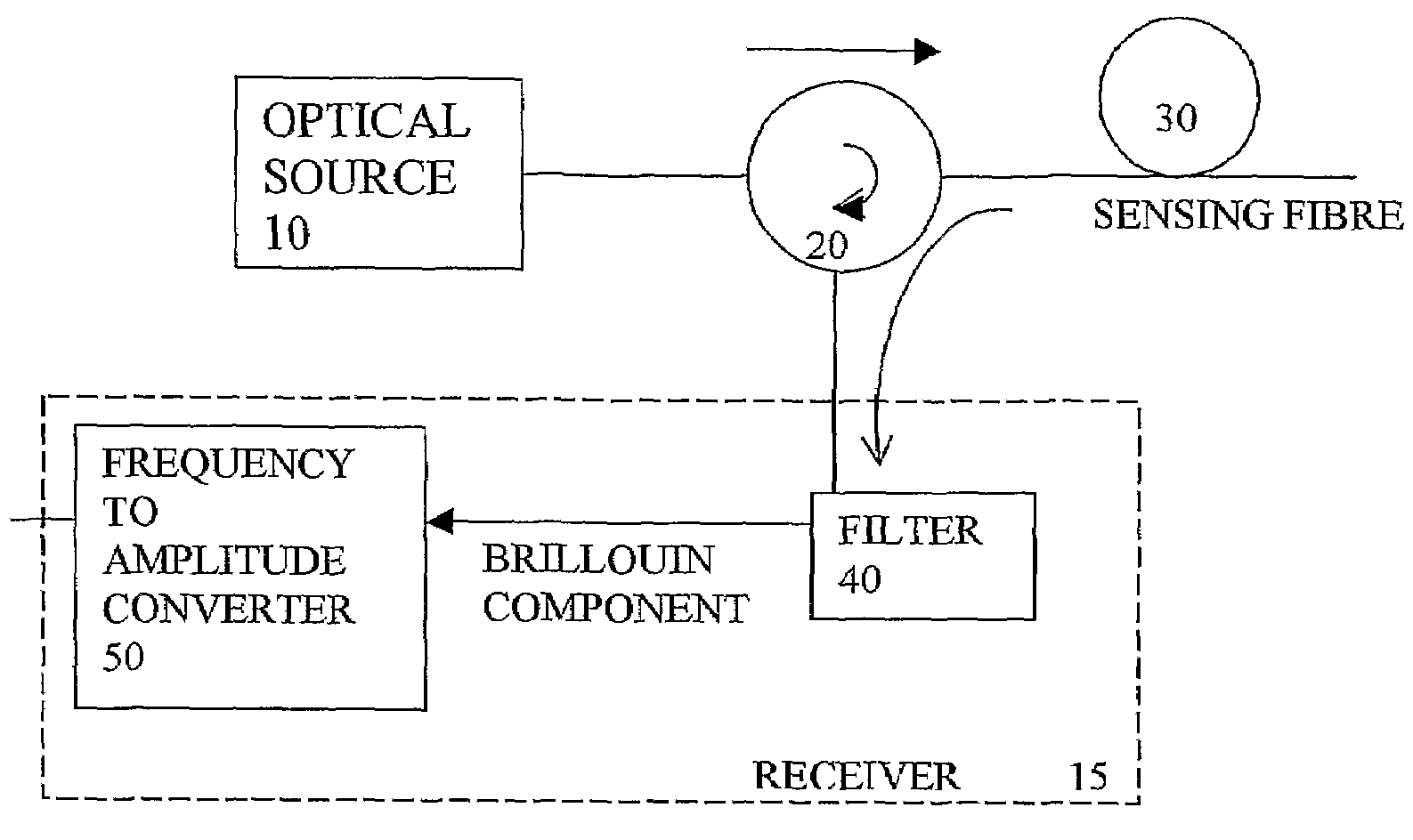

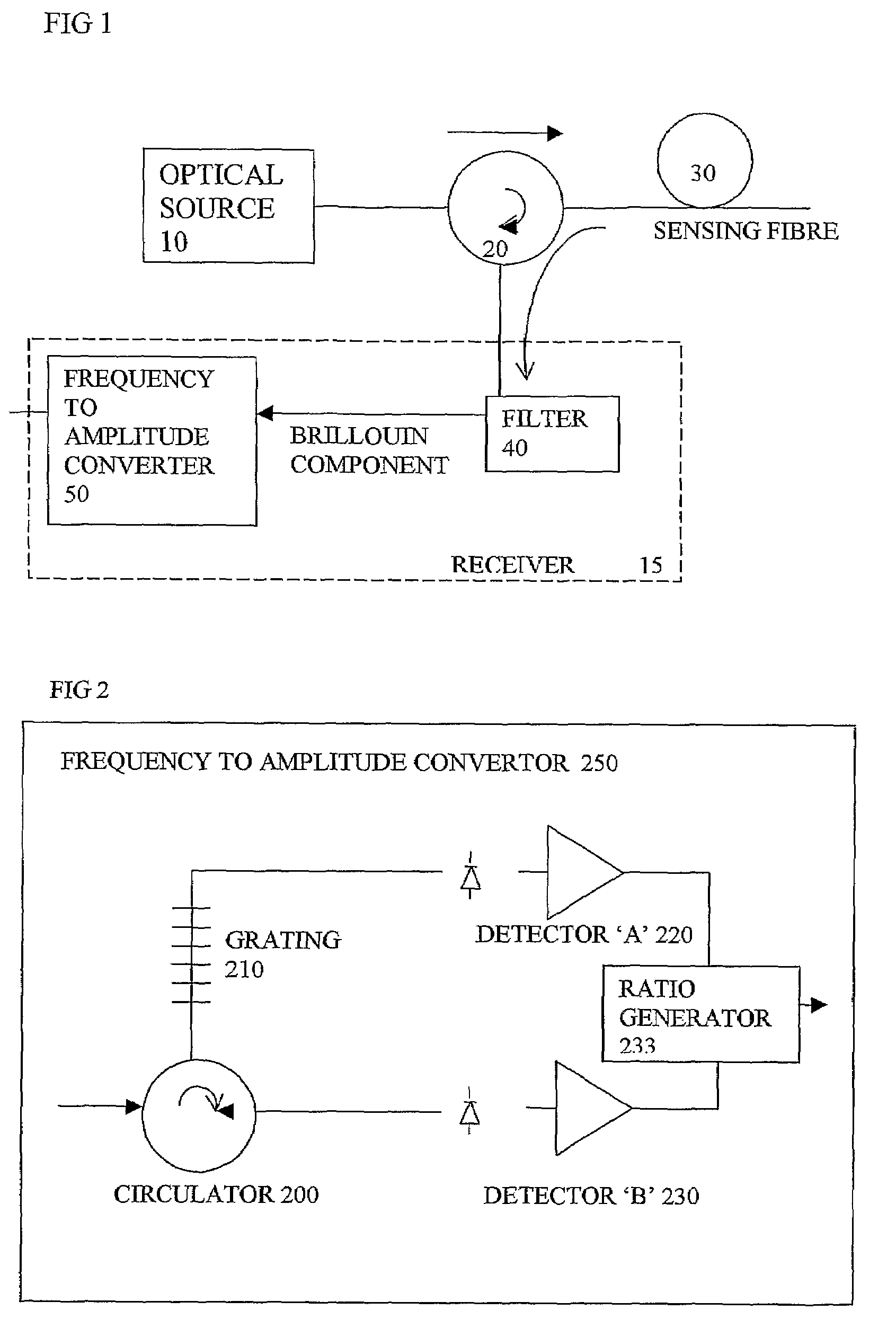

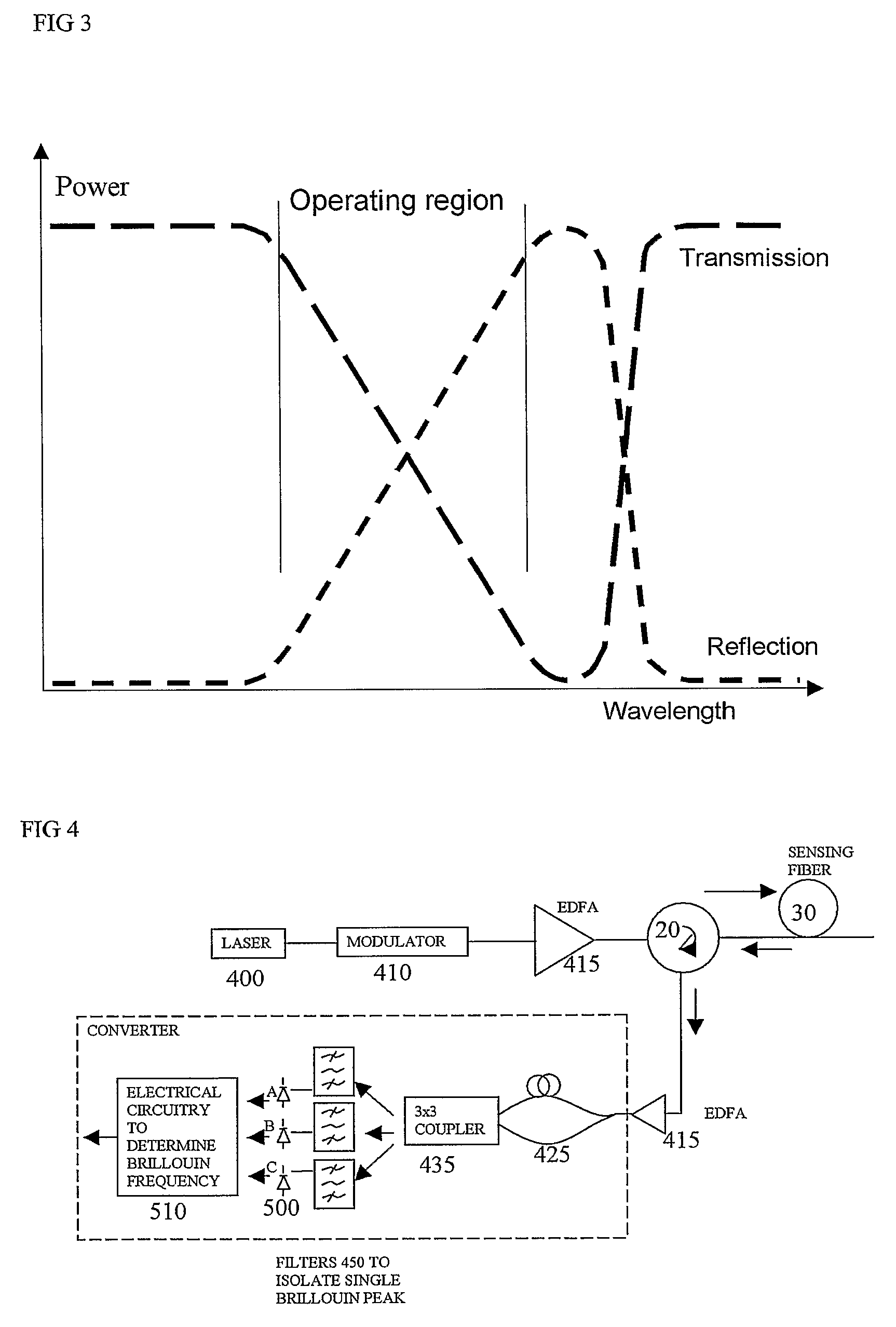

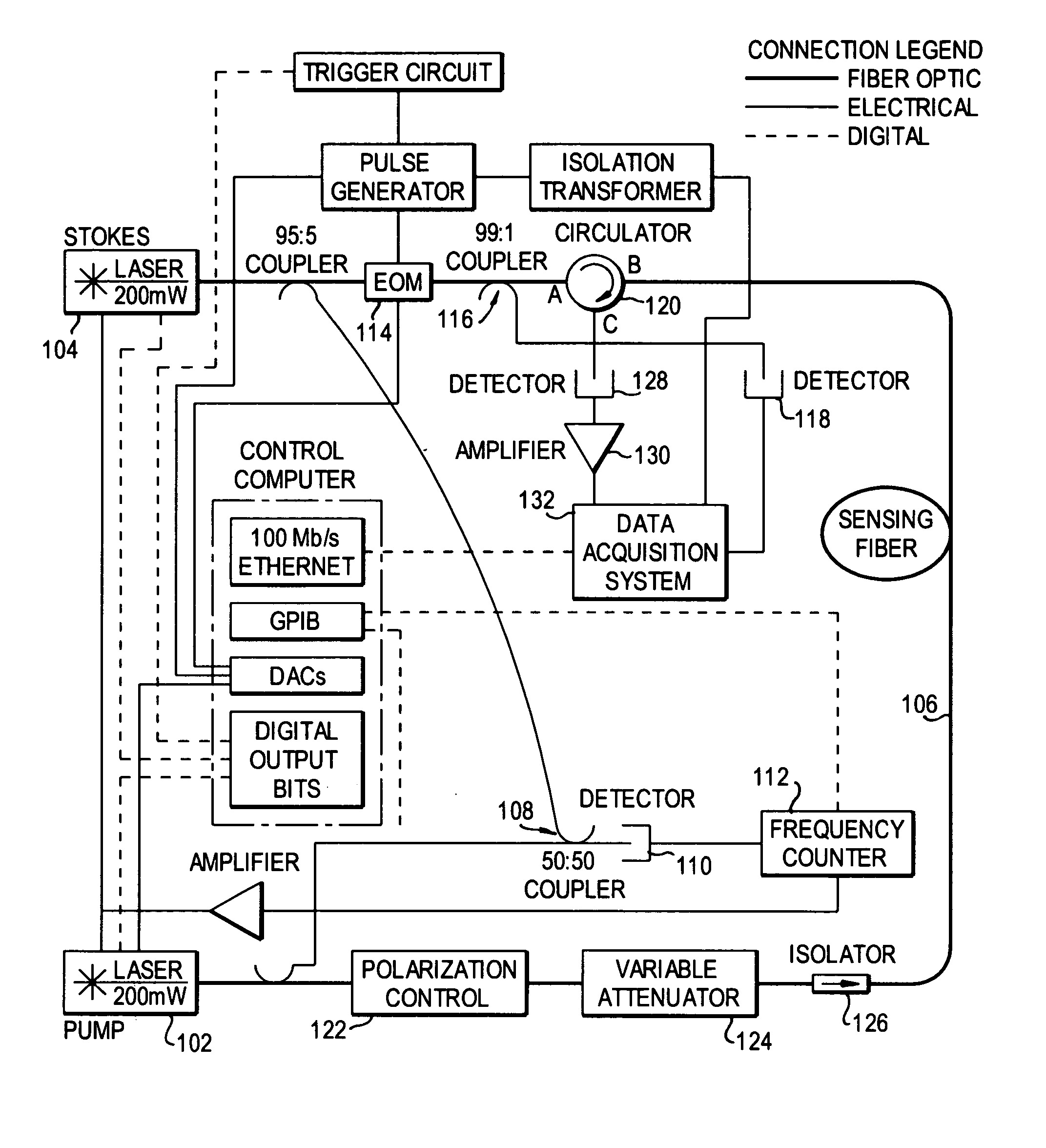

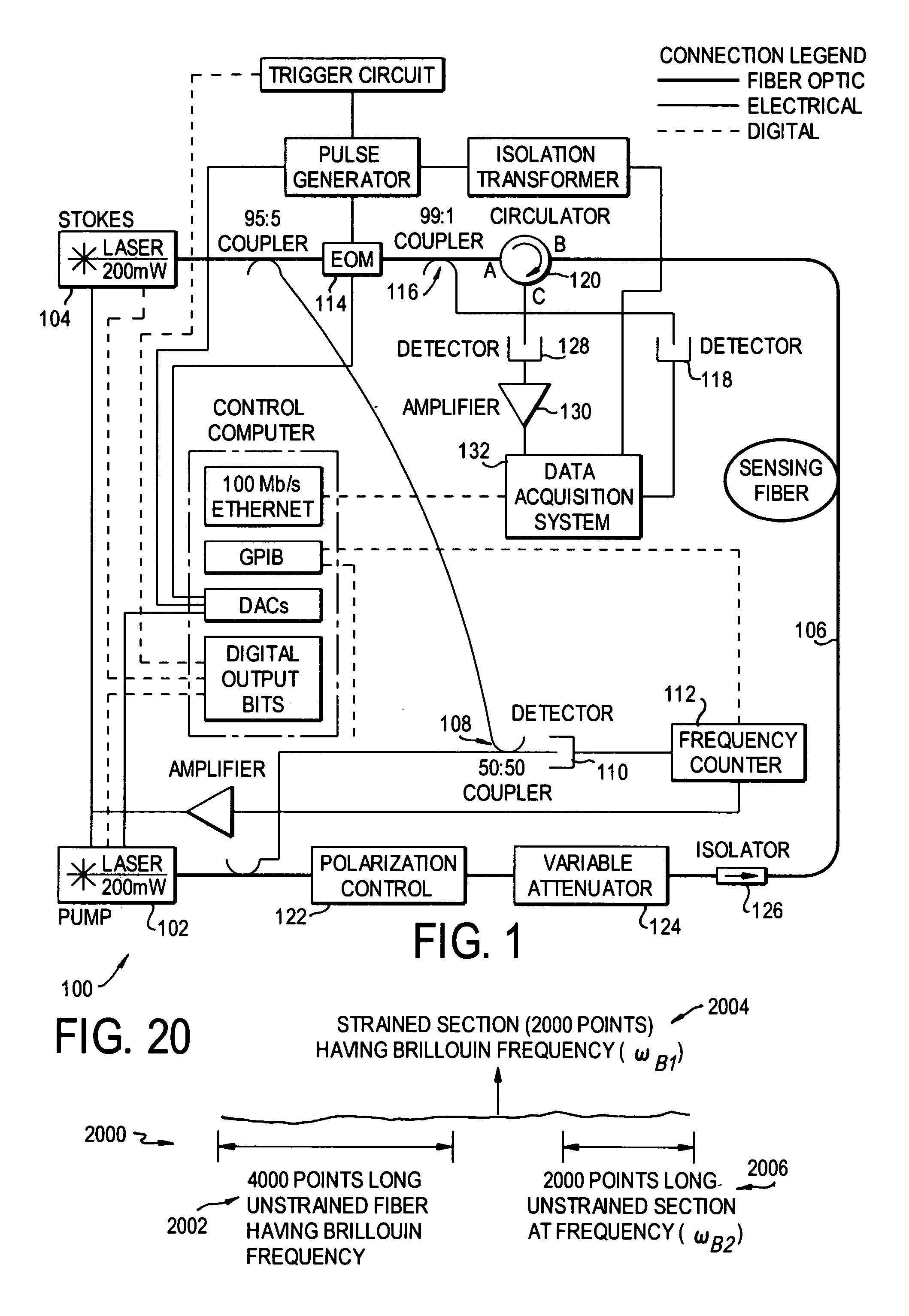

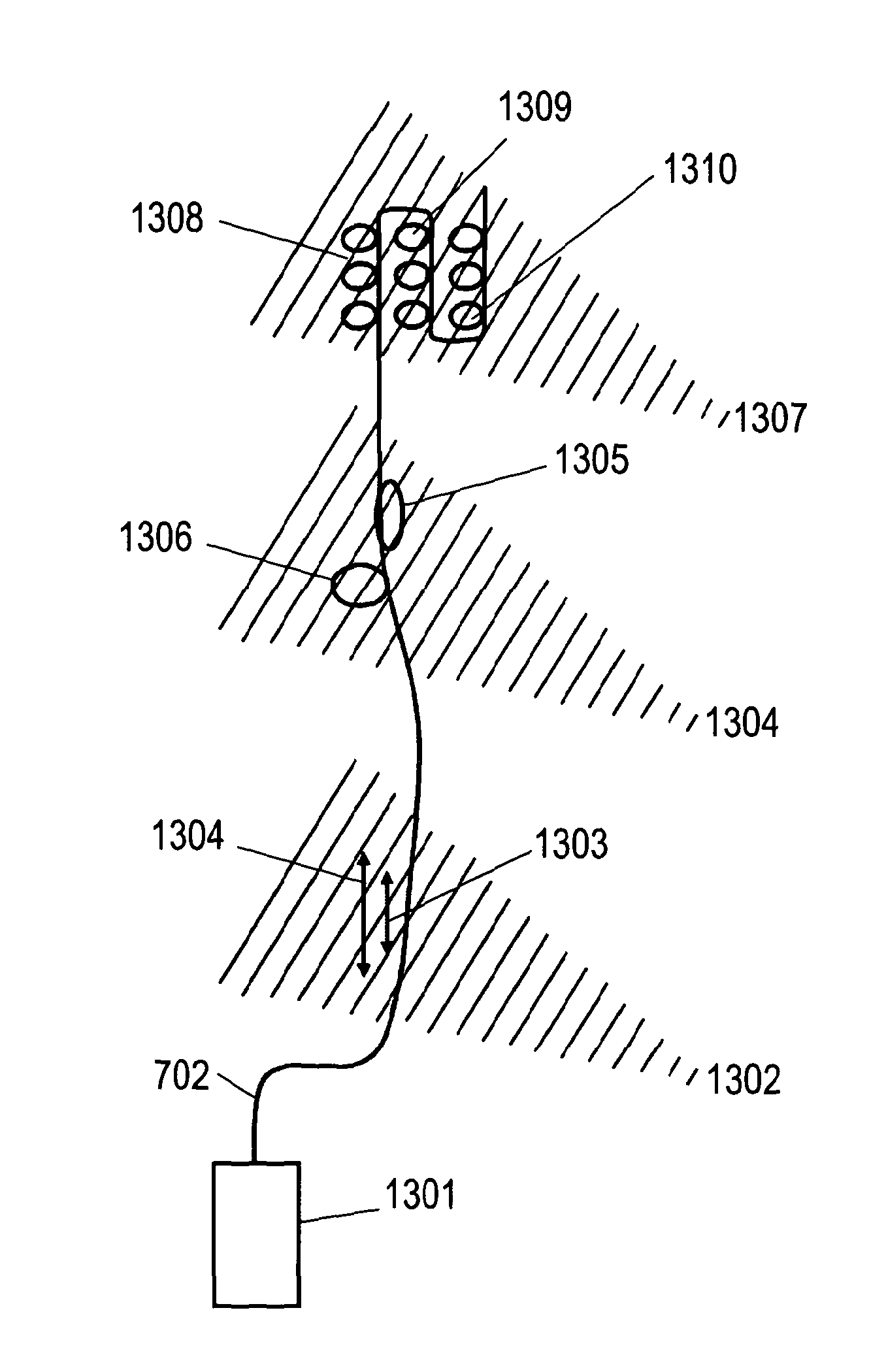

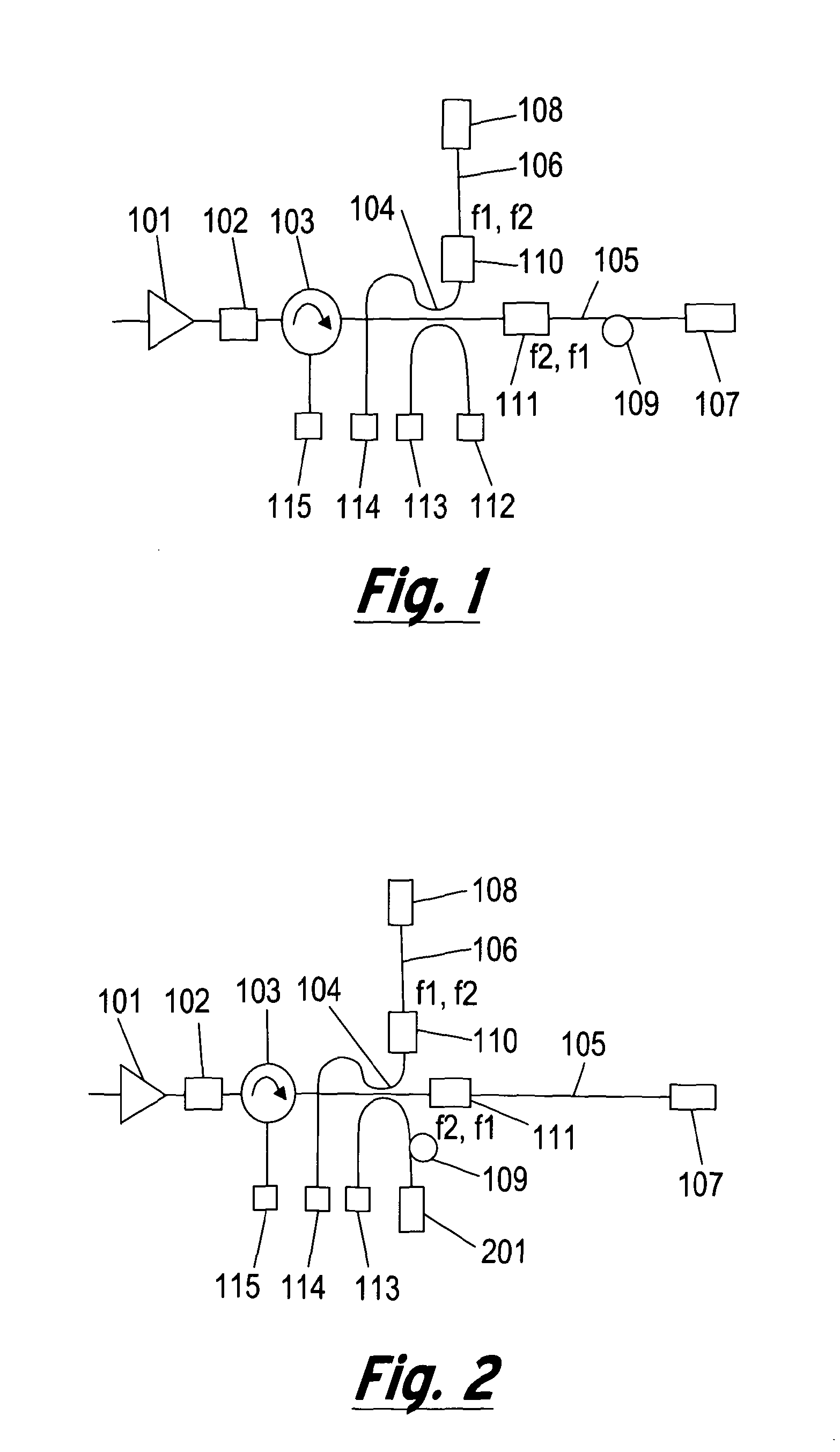

Direct measurement of Brillouin frequency in distributed optical sensing systems

InactiveUS7355163B2Avoid frequencyIncrease flexibilitySurveyRadiation pyrometryElectron interferometerGrating

An optical sensing system uses light scattered from a sensing fibre to sense conditions along the fibre, and has a receiver with a frequency to amplitude converter to obtain a frequency of a Brillouin component of the received scattered light, to deduce the conditions. This converter can avoid time consuming scanning of frequencies to obtain the Brillouin frequency spectrum, and avoids the heavy processing load of deducing a peak or average frequency from the spectrum. The converter can be implemented in the optical domain using a grating or interferometer, or in the electrical domain using a diplexer or electrical interferometer. It can generate complementary signals, having opposite signs, a ratio of these signals representing the frequency. This can avoid sensitivity to amplitude changes in the received scattered signals and provide common mode rejection of noise.

Owner:SENSORNET

Method for quickly measuring blade of large-sized water turbine

The invention discloses a method for quickly measuring a blade of a large-sized water turbine, which is characterized by comprising the following steps: firstly, sticking a mark point to the surface of the blade, then shooting a group of photos from different angles as measured primary data, and inputting the data to a computer to carry out analytic processing; by carrying out image detection for the group of photos in a measurement software, identifying the mark point in each photo and positioning the center of the mark point, and matching the mark points with the same name; finally, reconstructing a three-dimensional coordinate of corresponding object points according to a plurality of two-dimensional coordinates of the mark points, fitting a sparse framework model of a target by the reconstructed three-dimensional mark points, then scanning the surface of the blade block by block by using a binocular grating scanning method to acquire a local dense point cloud, and aligning the dense point cloud to an overall coordinate system according to the local mark points to acquire a dense point model of the blade; and by comparing the dense point model with a CAD designed model after aligning, calculating a three-dimensional processing error of the surface of a workpiece.

Owner:XI AN JIAOTONG UNIV

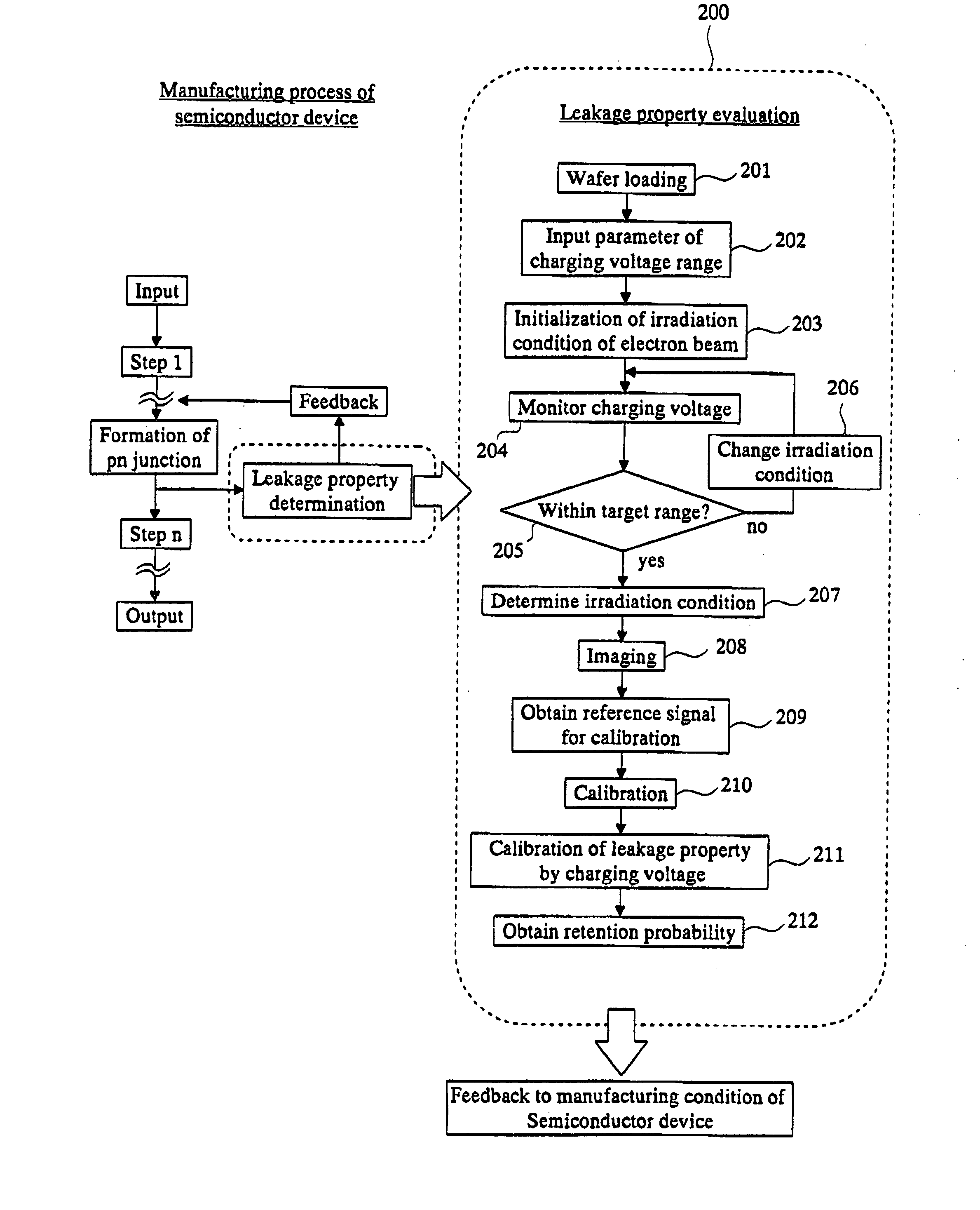

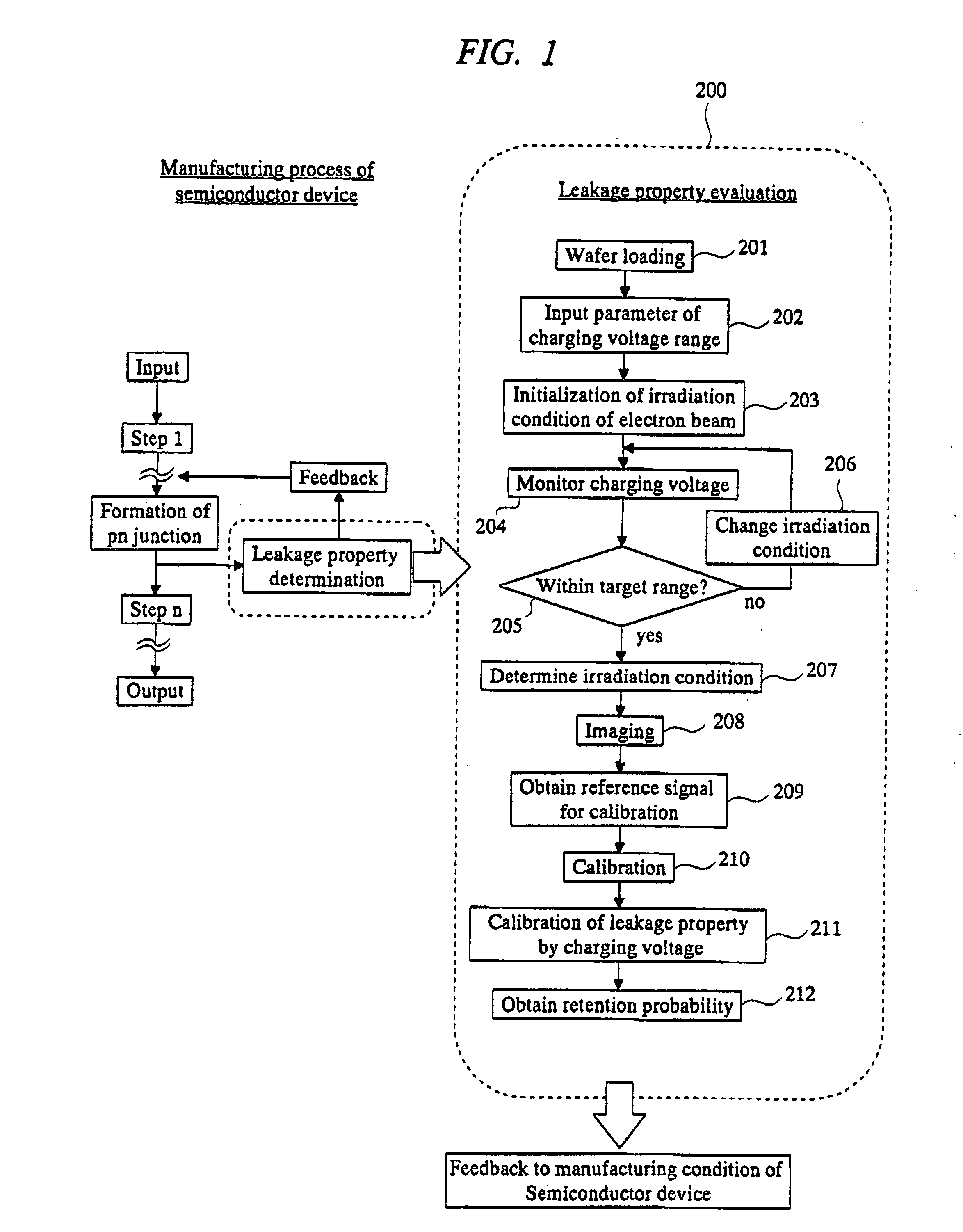

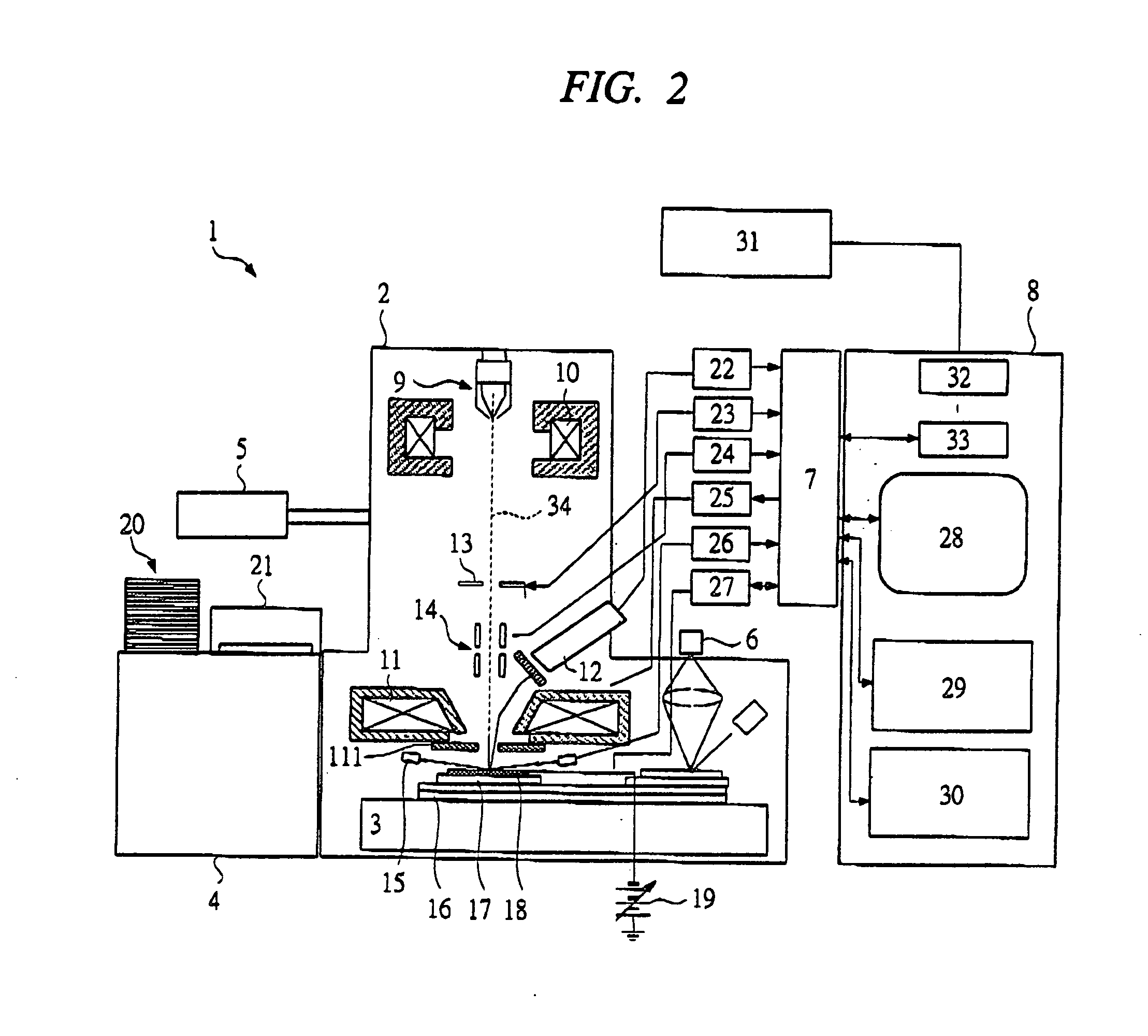

Evaluation method and manufacturing method of semiconductor device

InactiveUS20060022295A1Accurate measurementQuick measurementSemiconductor/solid-state device testing/measurementElectric discharge tubesDevice materialSecondary electrons

The electron beam is irradiated several times at predetermined intervals to the wafer surface on which the plugs are exposed in the course of the manufacturing process so that the pn junction is in the reverse bias state. Then, the irradiation conditions of the electron beam are changed while monitoring the charging voltage on the plug surface, and the secondary electron signals of the circuit pattern are obtained under the irradiation conditions that the charging is within a desired range, thereby evaluating the leakage property. Since the charging voltage of the pn junction is relaxed depending on the magnitude of the leakage current during the interval, the leakage property is evaluated based on the luminance signals of the voltage contrast image. By measuring the charging voltage and setting it within a desired range, the evaluation result reflects the state in the actual operation. Therefore, the accuracy is enhanced.

Owner:HITACHI LTD +1

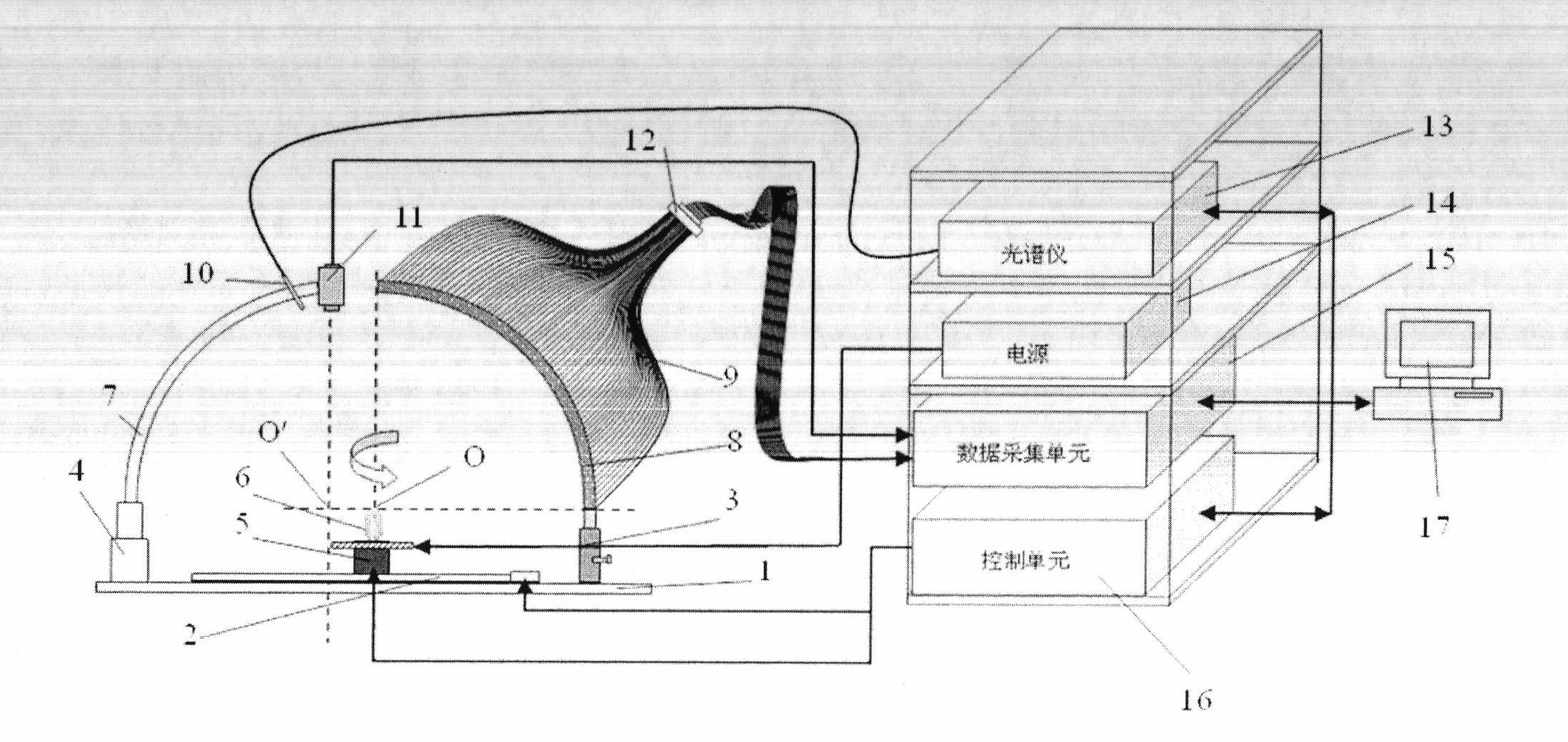

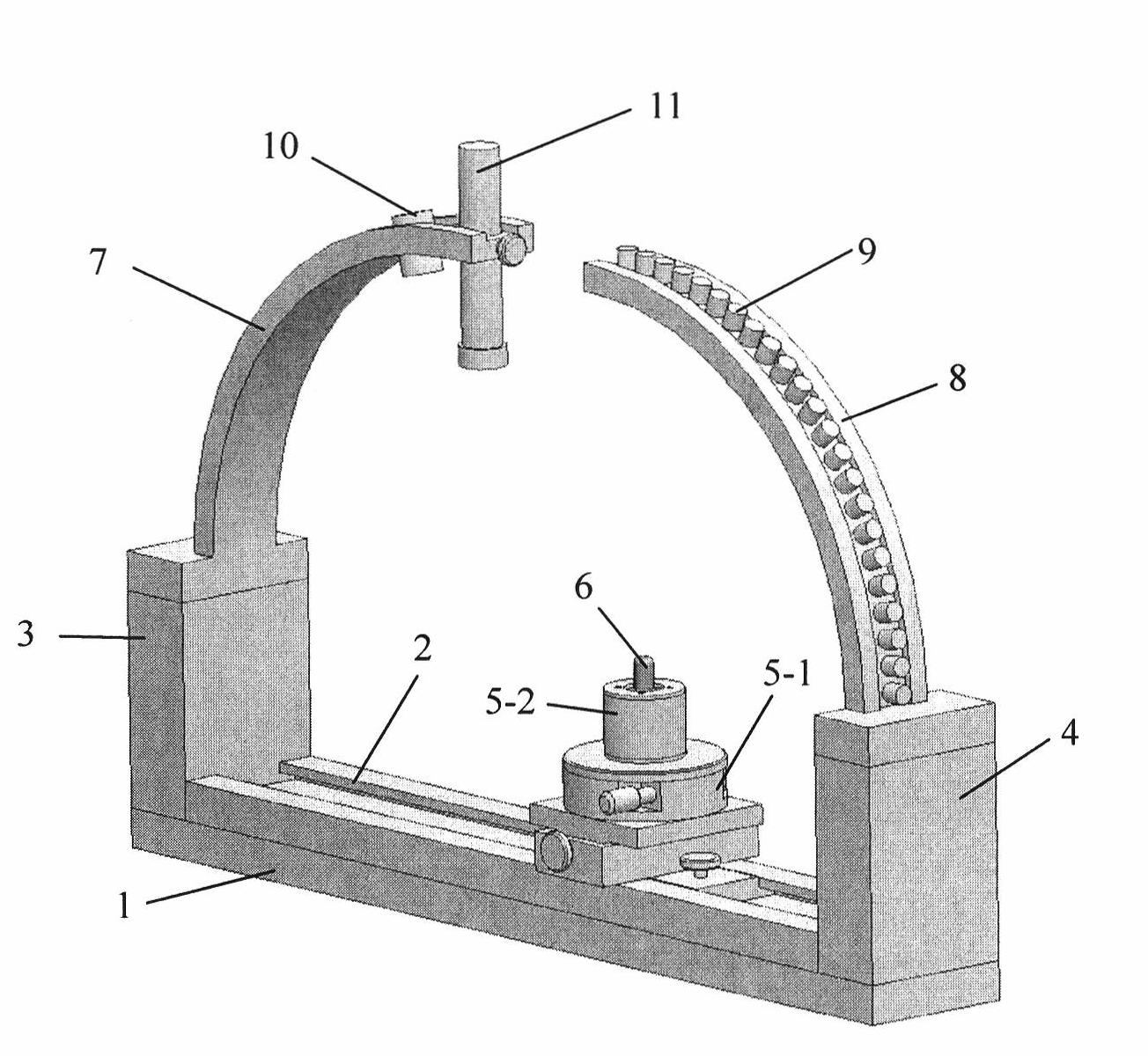

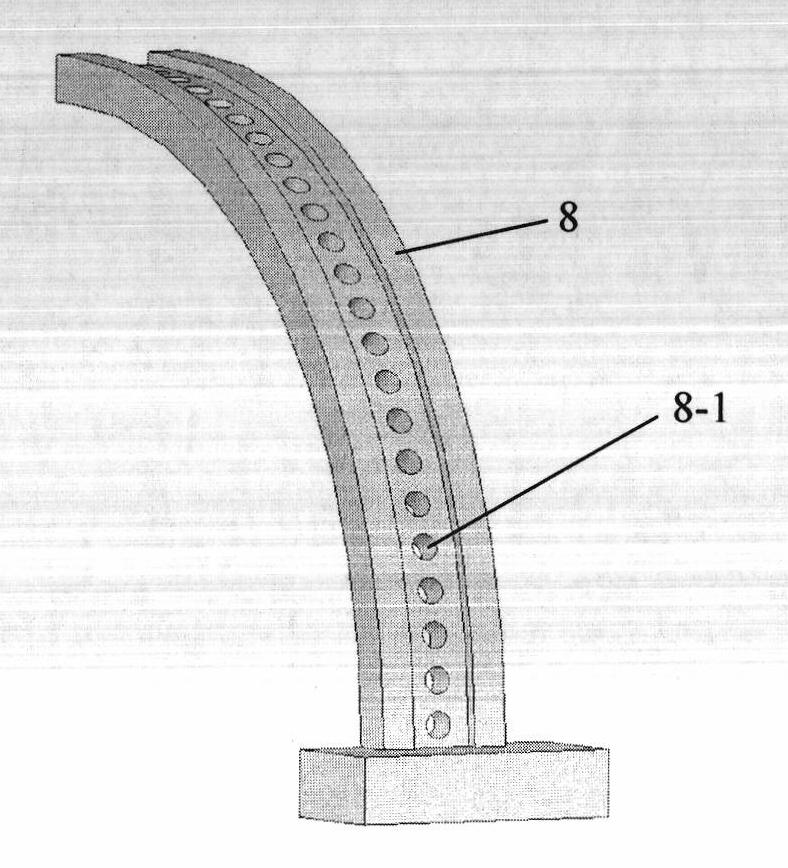

LED optical parameter comprehensive testing device

ActiveCN102213615AEfficient use ofAccurate measurementSpectrum investigationColor measuring devicesFiberMeasuring instrument

The invention discloses an LED optical parameter comprehensive testing device, belonging to the technical field of optical parameter measurement. The LED optical parameter comprehensive testing device is technically characterized in that one end of a horizontal base provided with a one-dimensional mobile platform is fixedly provided with an arc-shaped clamp provided with a fiber-optic probe and astandard luminosity probe, the other end of the horizontal base is fixedly provided with an arc-shaped light collector consisting of an arc fiber-optic array and a linear array CCD (Charge Coupled Device), and a rotary clamping table for holding an LED to be tested is arranged on the one-dimensional mobile platform; light information acquired by the fiber-optic probe is converted into a spectrum band by a spectrograph and then is sent into a computer, outputs of the standard luminosity probe and the linear array CCD are sent to the computer through the data acquisition unit, the computer performs corresponding processing and operation on measurement data through measurement software to finally obtain the luminescence characteristics of the LED to be tested. According to the invention, theproblem on comprehensively measuring the LED on a single measurement instrument is solved; and the LED optical parameter comprehensive testing device has the characteristics of simplicity for operation, compact structure, fastness for measurement, easiness for realization and the like.

Owner:CHINA NORTH IND NO 205 RES INST

Dynamic strain distributed fiber optic sensor

InactiveUS20060285850A1Short measurement timeQuick measurementRadiation pyrometryMaterial analysis by optical meansConstant frequencySpectral width

A distributed fiber optic sensor simultaneously interrogates the sensing fiber with two counter propagating light beams. One beam is set to a constant frequency. The second beam is modified to contain a “comb” of frequencies, with each frequency component in the comb offset by a predetermined amount. Each of the frequency components in the comb, herein referred to as teeth, is able to interact with the counter-propagating beam through the Brillouin scattering process. With proper selection of the comb characteristics such as the number of teeth, the frequency spacing of teeth, the spectral width of teeth, and the relative amplitude of the teeth, a representation of the Brillouin spectrum at each point in the fiber can be obtained simultaneously with a single pass through the fiber.

Owner:UNIVERSITY OF NEW BRUNSWICK

Method and apparatus for optical sensing

ActiveUS20120060615A1Fast quantitative measurementQuick measurementVibration measurement in solidsDetection of fluid at leakage pointImage resolutionEngineering

The present invention provides novel apparatus and methods for fast quantitative measurement of perturbation of optical fields transmitted, reflected and / or scattered along a length of an optical fibre. The present invention can be used for point sensors as well as distributed sensors or the combination of both. In particular this technique can be applied to distributed sensors while extending dramatically the speed and sensitivity to allow the detection of acoustic perturbations anywhere along a length of an optical fibre while achieving fine spatial resolution. The present invention offers unique advantages in a broad range of acoustic sensing and imaging applications. Typical uses are for monitoring oil and gas wells such as for distributed flow metering and / or imaging, seismic imaging, monitoring long cables and pipelines, imaging within large vessel as well as for security applications.

Owner:SILIXA

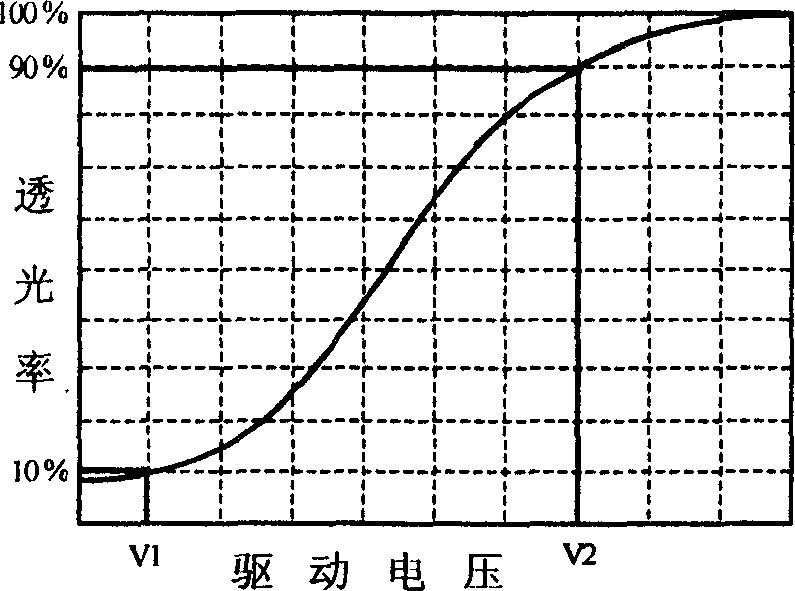

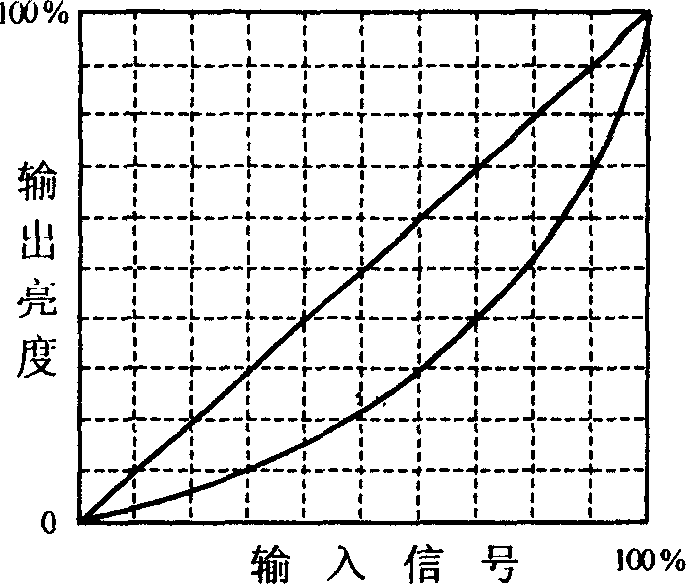

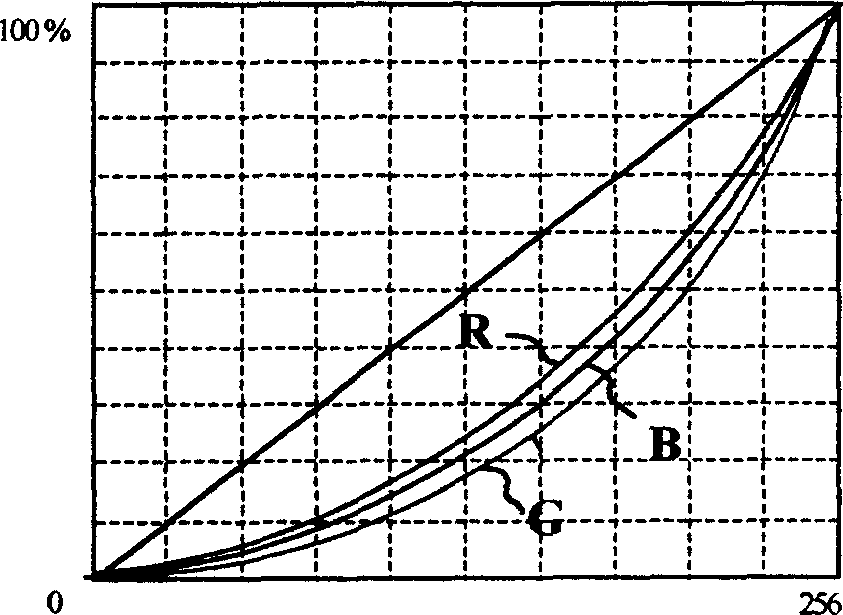

Automatic measurement and correction method and system for LCD GAMMA curve and color temperature

InactiveCN1845232AEasy CalibrationMiniaturizationStatic indicating devicesElectrical testingSystem configurationVideo image

The invention provides a GAMMA curvature correction and color-temperature automatic regulating method for liquid crystal display and the system. The said system consists of a system host-machine, a detector, a color analyzer, a video standard signal source, a data interface,and a system measure and correction software, which can perform GAMMA curvature correction and white balance adjustment for multi-purpose TV and computer display including LCD and high-resolution back projection and multi-structure liquid crystal display including TN, STN, DSTN and TFT to improve the videograph display quality of the liquid crystal display. The system host-machine connects multiple video signal sources, automatic measurement and correction software for GAMMA curvature and color-temperature and data interface together, the system parameter can be set manually or automatically, the system configuration is simple, GAMMA curvature correction and white balance adjustment software can be conveniently transferred, and can rapidly finish automatic measurement and correction for GAMMA curvature and color-temperature and can visually inspect the effect. The invention can be used in departments including scientific research, production, quality inspection and maintenance and can visually finish the GAMMA curvature correction and white balance adjustment for the LCD products with high accuracy and quick-speed.

Owner:ZHEJIANG UNIV

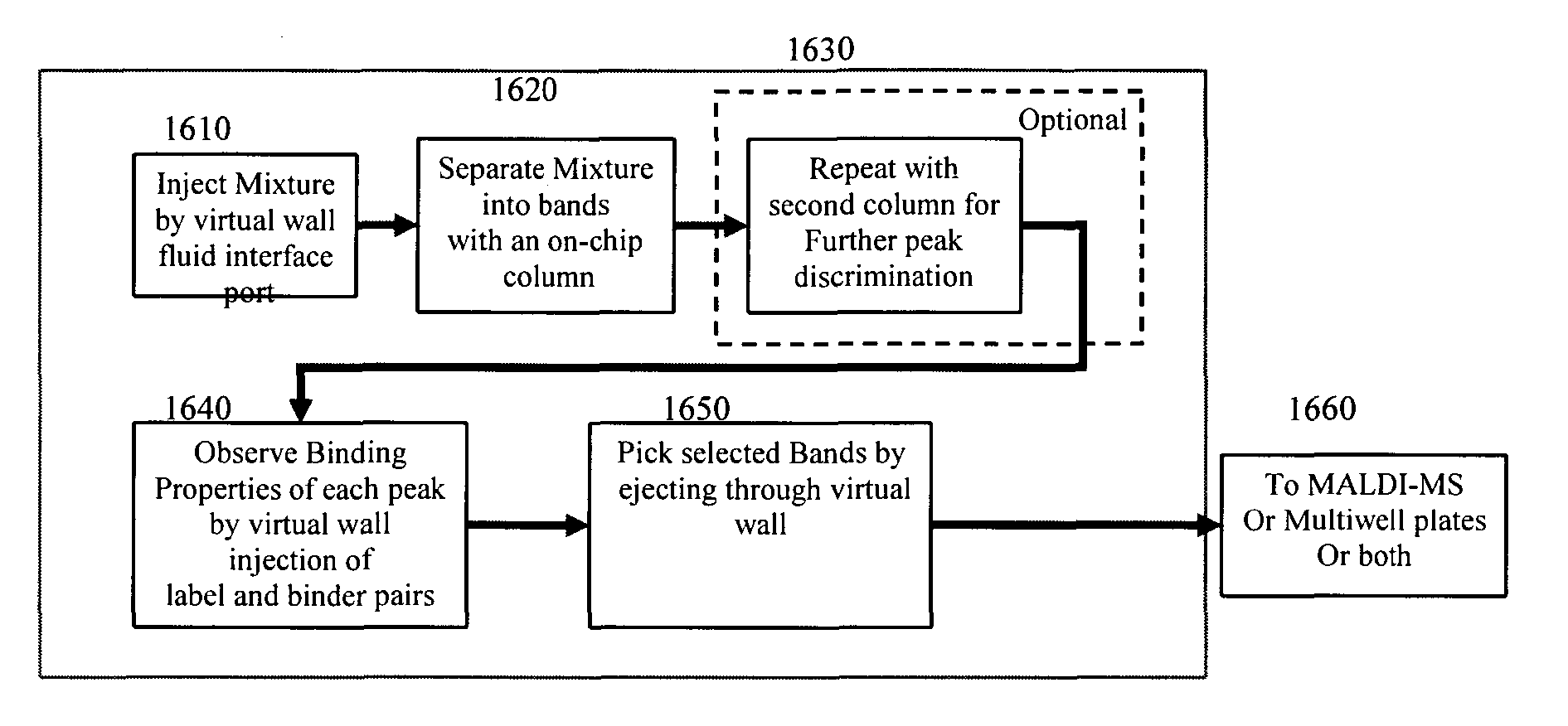

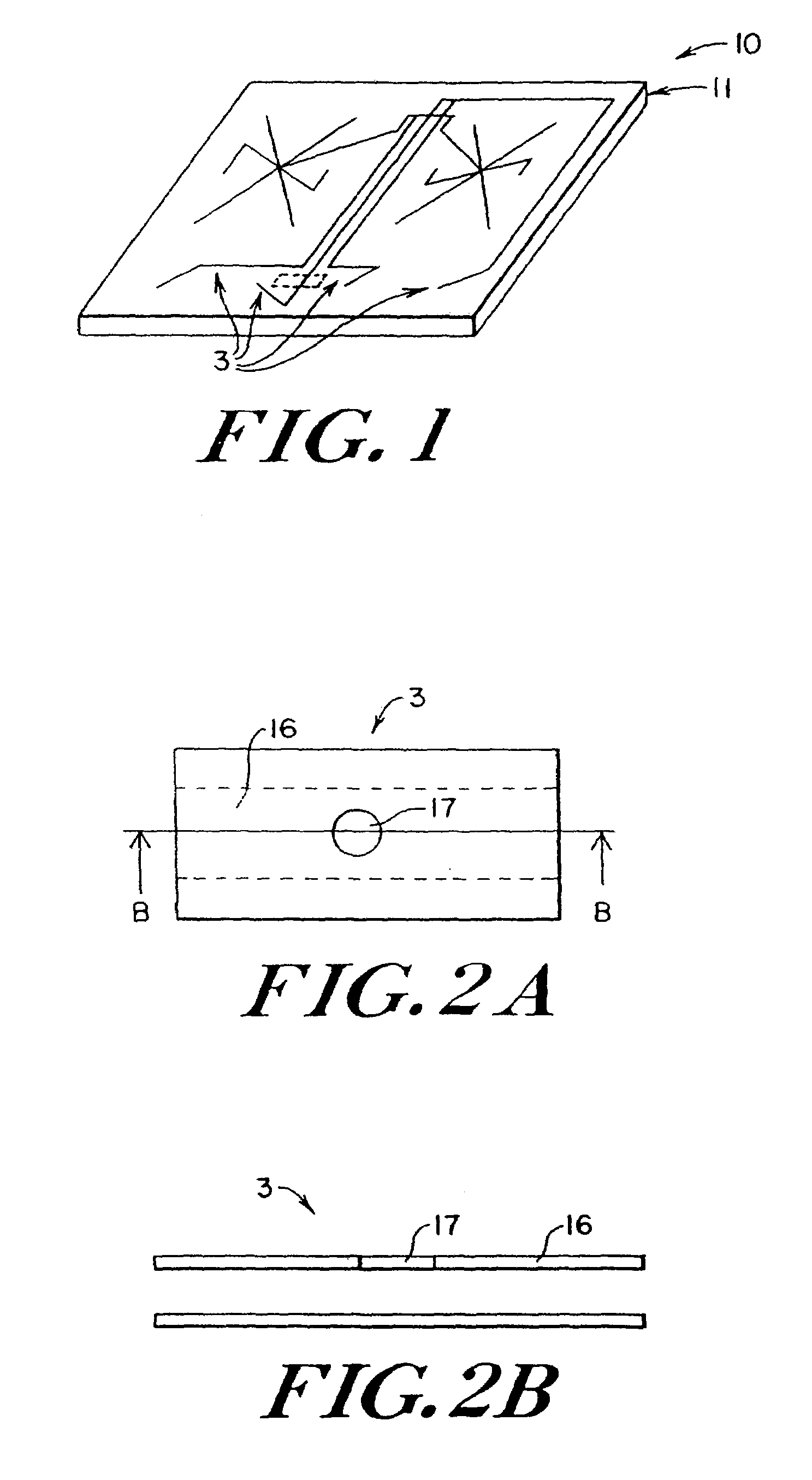

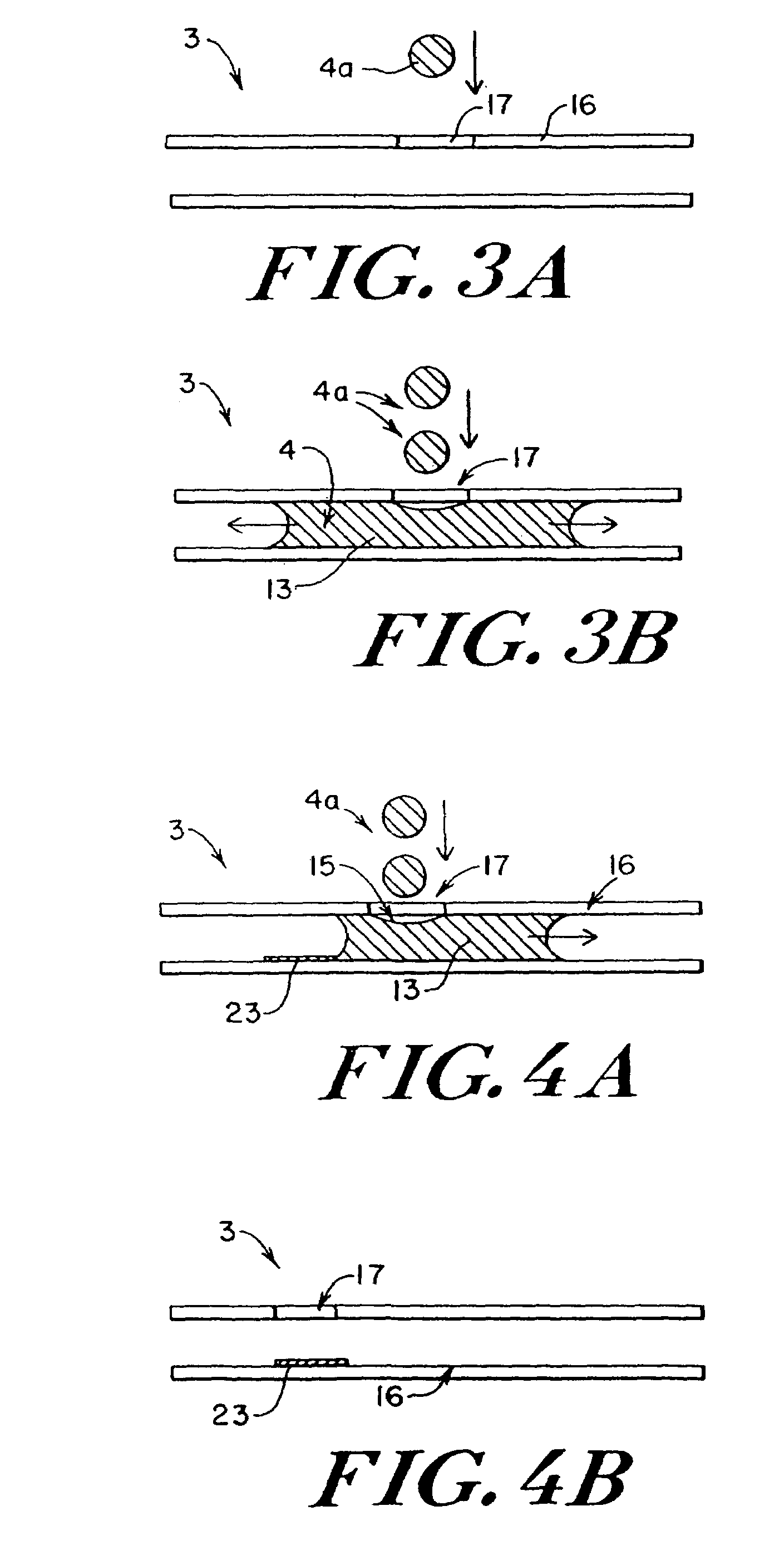

Microfluidic system including a virtual wall fluid interface port for interfacing fluids with the microfluidic system

InactiveUS7211442B2Quick measurementTransportation and packagingChemical/physical/physico-chemical microreactorsFluid interfaceBiomedical engineering

A fluid interface port in a microfluidic system and a method of forming the fluid interface port is provided. The fluid interface port comprises an opening formed in the side wall of a microchannel sized and dimensioned to form a virtual wall when the microchannel is filled with a first liquid. The fluid interface port is utilized to perform a labeling operation on a sample.

Owner:CYTONOMEST

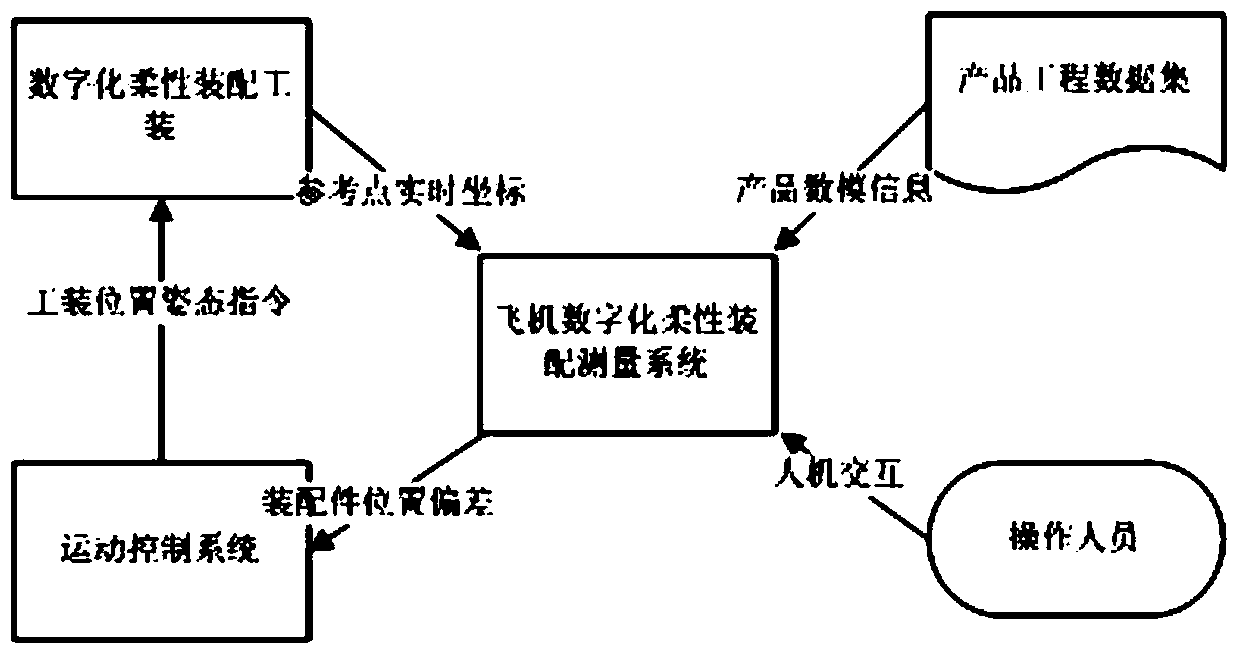

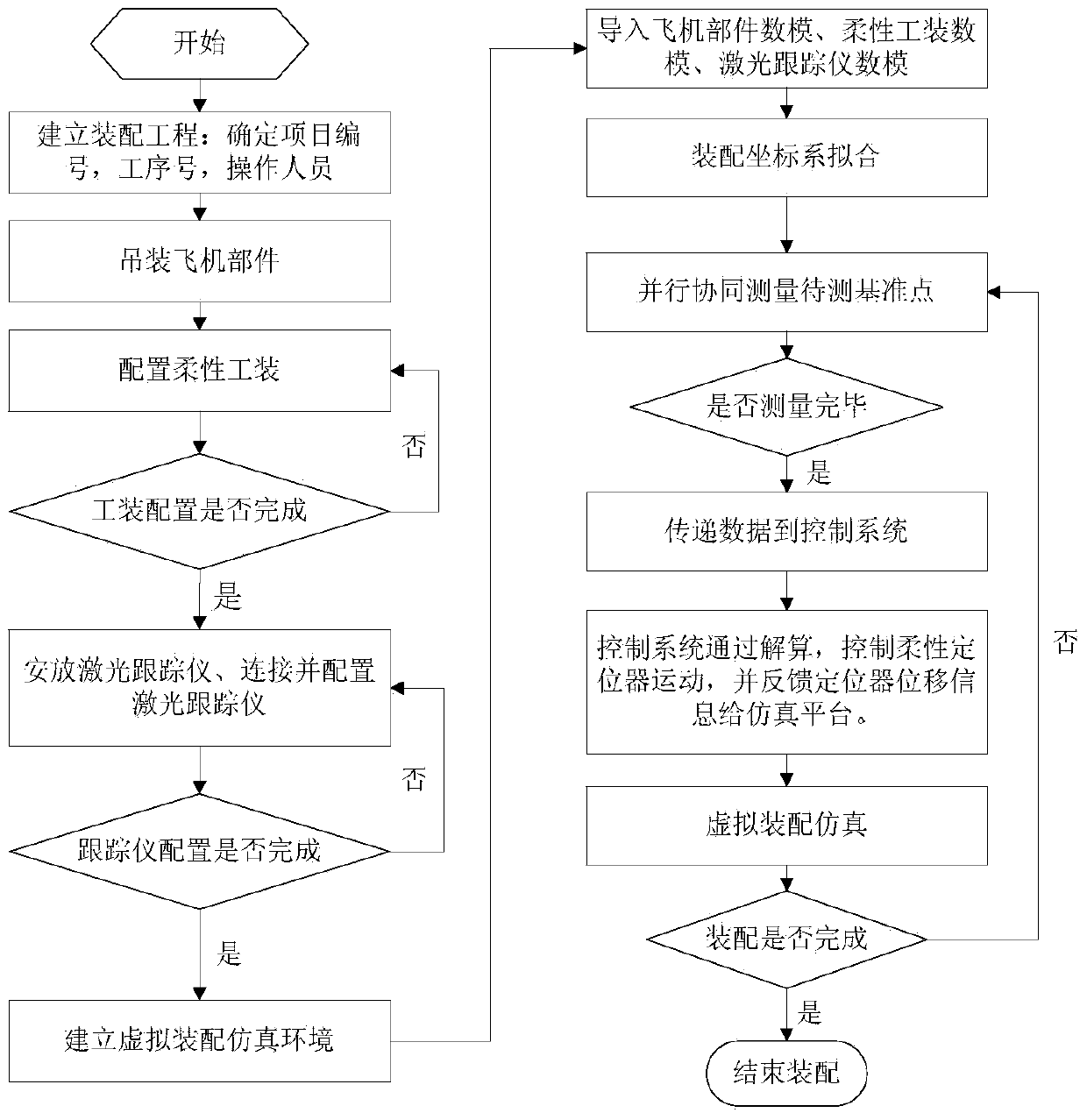

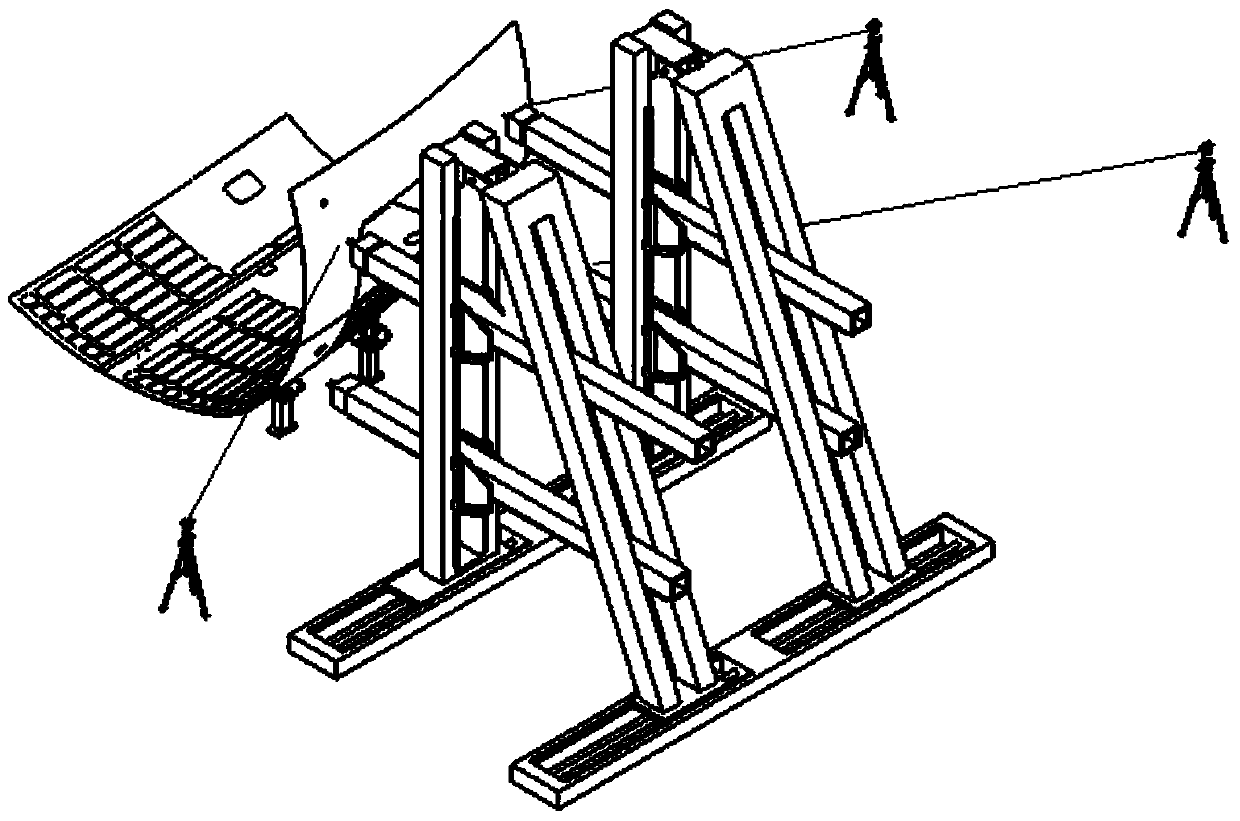

Aircraft component digitized flexible assembling measuring method based on laser tracking measuring technique

InactiveCN103434653AFacilitate assembly measurement simulationQuick measurementAircraft assemblyControl systemSimulation

Provided is an aircraft component digitized flexible assembling measuring method based on a laser tracking measuring technique. The assembling measuring method comprises the following steps of (1) carrying out preparation work of assembling measurement, (2) carrying out work of the assembling measurement, and (3) carrying out parallel collaborative measurement in real time. The aircraft component digitized flexible assembling measuring method based on the laser tracking measuring technique relates to the combination of an assembling technique and the measuring technique, the theoretical position information of engineering data concentrated product digital analogy is compared with the coordinates, obtained by a laser tracking instrument in real time, of reference points of assembly parts to form positional deviation, the positional deviation is transmitted to a movement control system, the movement control system generates tool pose control instructions by analyzing the positional deviation and transmits the tool pose control instructions to a flexible tool, the flexible tool drives a workpiece to adjust poses together, and through the coordinated operation of the movement control system, the flexible tool and the workpiece, a closed loop control system is formed to complete the assembling work. The aircraft component digitized flexible assembling measuring method based on the laser tracking measuring technique has good practical value and wide application prospect in the laser tracking measuring technique and the aircraft digitalized assembling field.

Owner:BEIHANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com