Aircraft component digitized flexible assembling measuring method based on laser tracking measuring technique

A technology of laser tracking measurement and assembly measurement, applied in aircraft assembly, aircraft parts, ground installations, etc. Effects of accessory models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

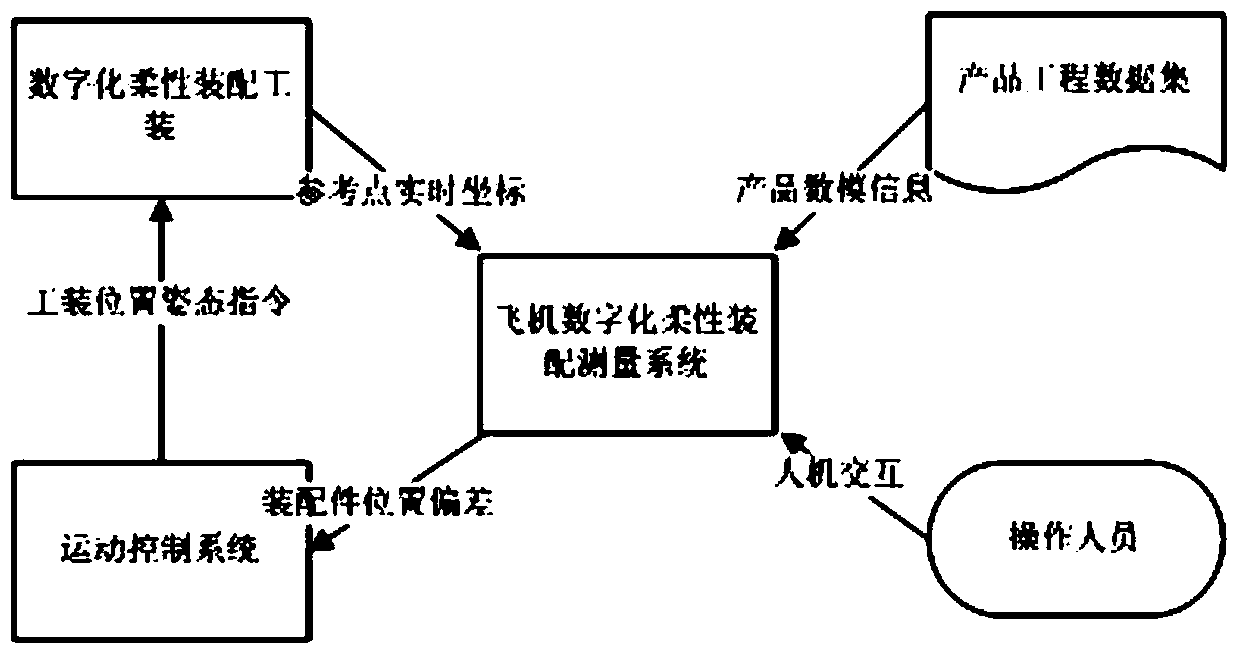

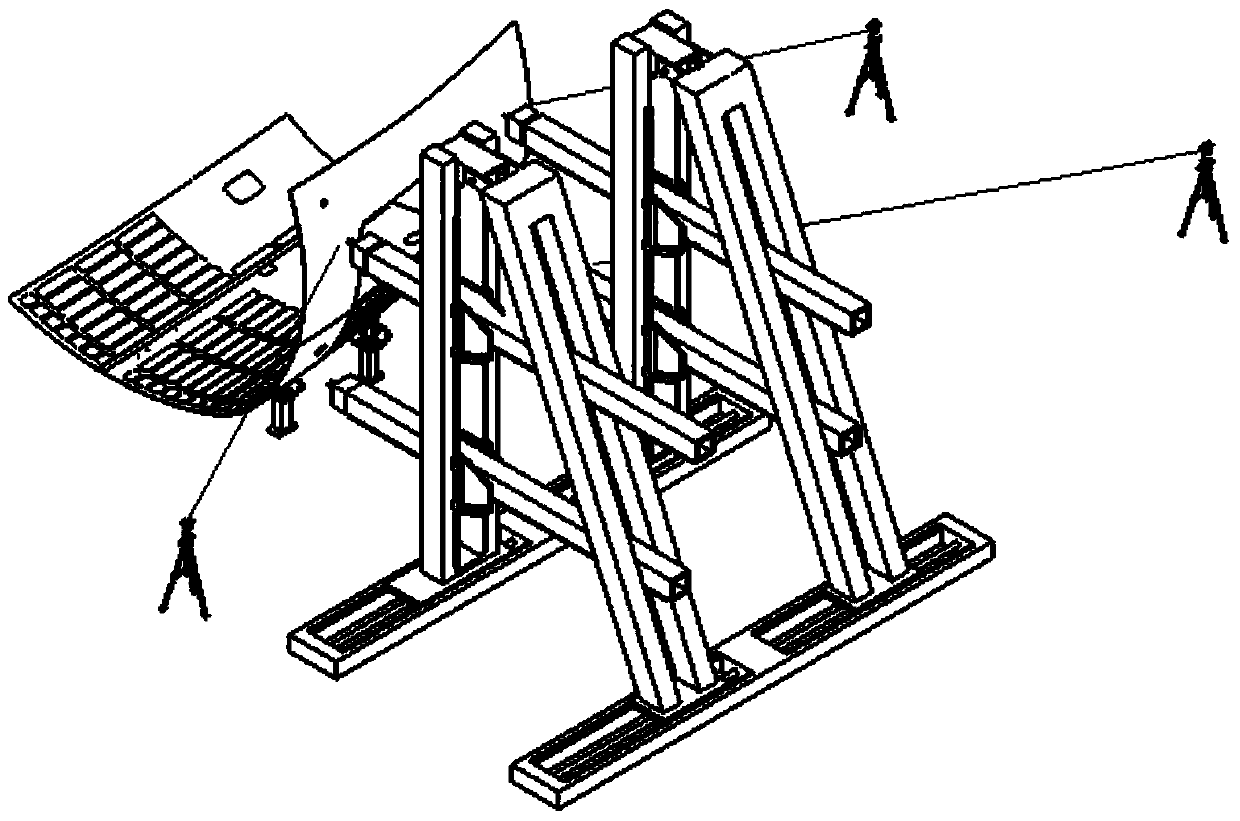

[0069] The specific implementation of the assembly measurement method will be introduced in detail below in conjunction with the digital flexible assembly of aircraft components. In the digital flexible assembly system, the software platform of the entire assembly measurement system is a software system with Opencascade as the geometric core, and C++ as the development language. The entire assembly measurement method is realized in this software environment, and the working object is the side of a certain type of aircraft. Wall board and bottom board, the size of the wall board (height x length x thickness) is about 4m x 4m x 2mm, the size is large and the thickness is small, the rigidity is poor, the assembly tolerance requirement is 0.5mm, and the bottom plate is a fixed part. The relationship between the assembly measurement system and the surrounding boundary system is as follows: figure 1 shown.

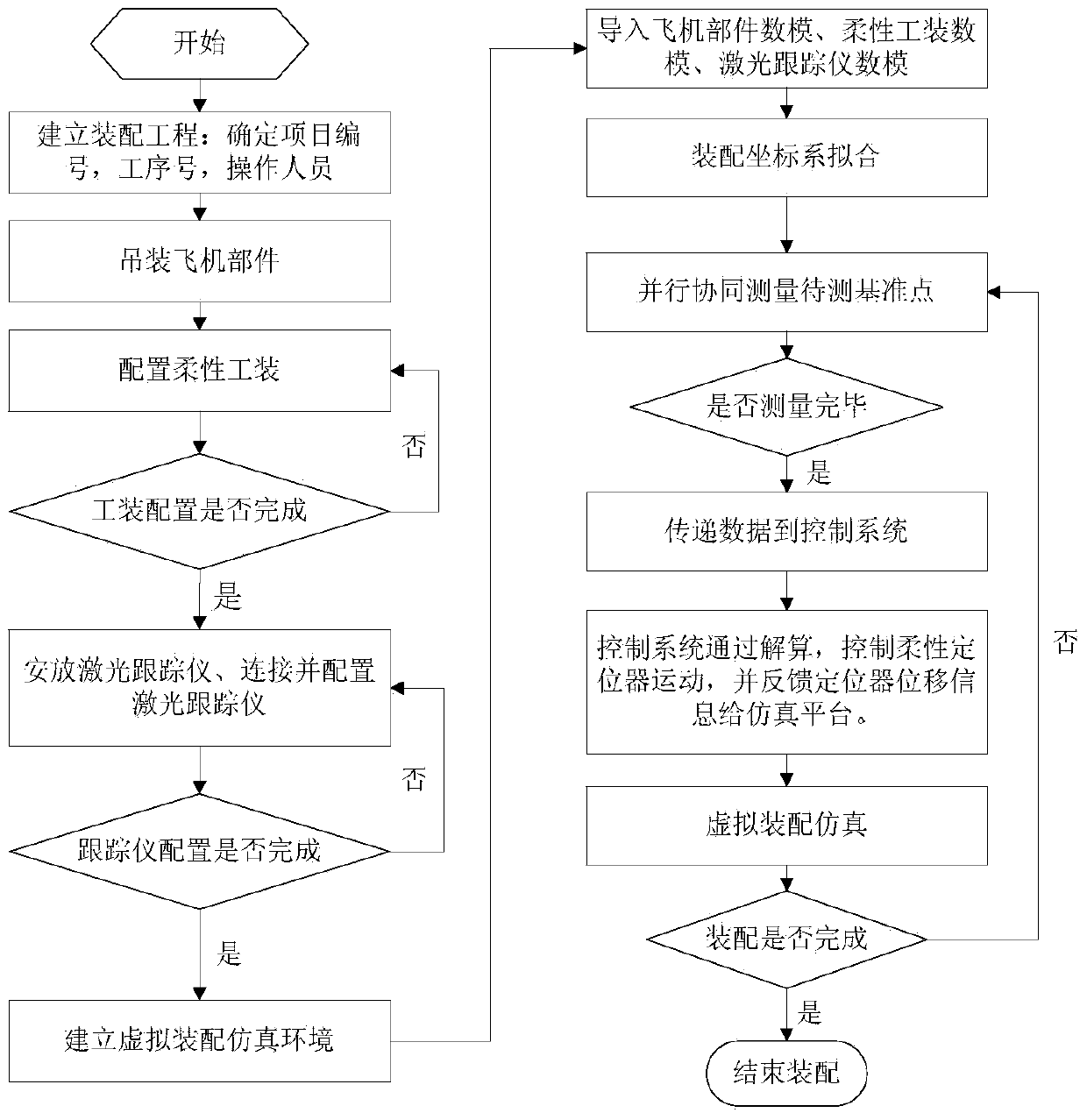

[0070] See figure 2 , the present invention is a digital flexible assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com