Calibration technology for multiple structured light projected three-dimensional profile measuring heads

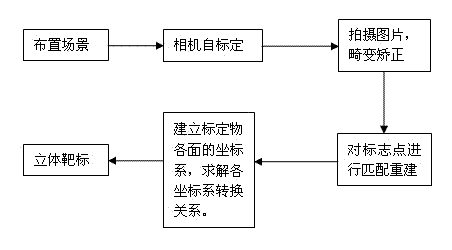

A technology of structured light projection and surface measurement, applied in the field of optical measurement, can solve the problem of inability to meet the calibration requirements of multiple structured light projection three-dimensional profile measurement heads, and achieve the effects of reducing measurement time, improving measurement accuracy, and avoiding error accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Calibrator and scene design

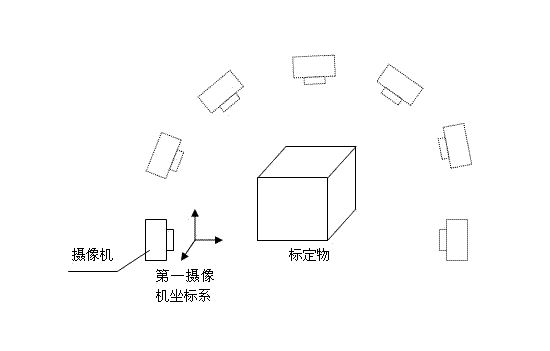

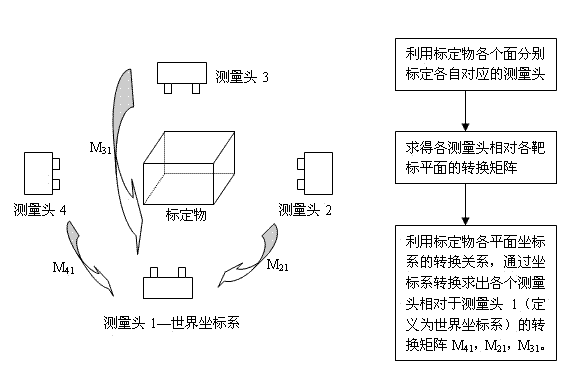

[0017] Aiming at the calibration of different numbers of optical measuring heads, the present invention respectively designs a plurality of polyhedrons with different numbers of calibration planes. For example, the calibration of two measuring heads, three measuring heads and four measuring heads can be designed to have at least two flat plate calibration objects, three plane triangular cylinder calibration objects and four plane cuboid calibration objects, such as figure 1 shown. The size of the calibration object depends on the size of the measurement field of view.

[0018] like figure 1 In the measurement scenes shown, the measuring heads are evenly distributed around the three-dimensional calibration object, and the orientation of each optical measuring head must be directly opposite to each calibration plane of the calibration object. Each calibration plane can also be designed as a calibration object at a certain angle to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com