Patents

Literature

36results about How to "Improved flowability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct compression metformin hydrochloride tablets

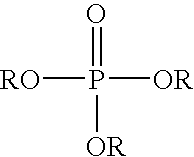

InactiveUS6117451AGood compressibilityImproved flowabilityPowder deliveryBiocideMetformin HydrochlorideHigh doses

Metformin Hydrochloride (herein referred to as metformin HCl) that may be 98.5%-100% pure is a high dose drug capable of being directly compressed with specific excipients into tablets having desired, hardness, disintegrating ability, and acceptable dissolution characteristics. Metformin HCl is not inherently compressible and thus presents formulation problems. Excipients used in the formulation enhance the flow and compaction properties of the drug and tableting mix. Optimal flow contributes to uniform die fill and weight control. The binder used ensures sufficient cohesive properties that allow metformin HCl to be compressed using the direct compression method. The tablets produced provide an acceptable in-vitro dissolution profile.

Owner:PHARMALOGIX

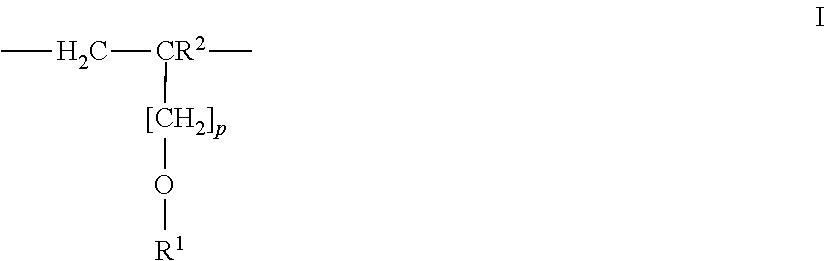

Resin dispersions having uniform particle diameters, resin particles and processes for producing both

The present invention provides a method of producing an aqueous dispersion. A resin (b) or a solvent solution thereof, or a precursor (b0) of the resin (b) or a solvent solution thereof is dispersed in an aqueous dispersion of resin particles (A) composed of resin (a), and is caused the precursor (b0) to react where the precursor (b0) or a solvent solution thereof is used, to prepare resin particles (B) composed of said resin (b). Thereby, an aqueous dispersion (X1) of resin particles (C) having a structure such that the resin particle (A) adheres to the surface of the resin particle (B) is obtained.

Owner:SANYO CHEM IND LTD

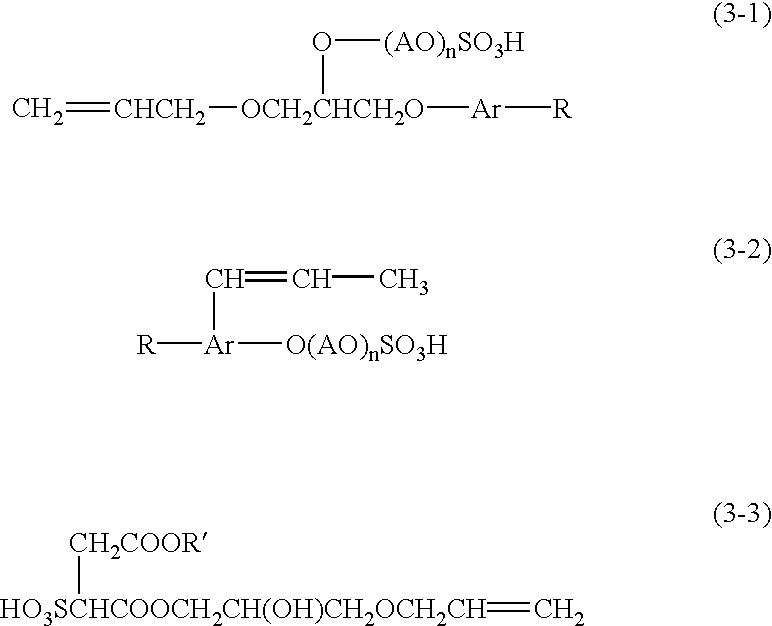

Foamed slurry and building panel made therefrom

A gypsum slurry is described that includes water, a hydraulic component comprising at least 50% calcined gypsum by weight based on the dry weight of the hydraulic component, foam, a defoamer, a polycarboxylate dispersant having olefinic unsaturated mono-carboxylic acid moieties and (poly)oxyalkylene moieties, a first portion of a retarder and a second portion of a retarder. In some embodiments of the invention, the defoamer is combined with the dispersant prior to being added to the gypsum slurry. The defoamer and dispersant can be added as a physical mixture, wherein the defoamer is attached onto the dispersant polymer, or a combination thereof. In some embodiments, a gypsum building panel is made from the gypsum slurry.

Owner:UNITED STATES GYPSUM CO

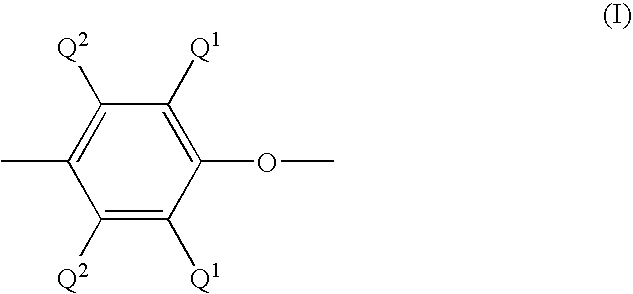

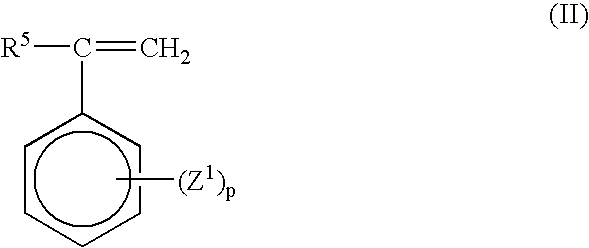

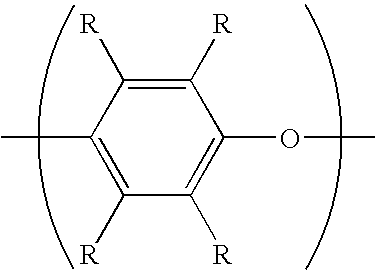

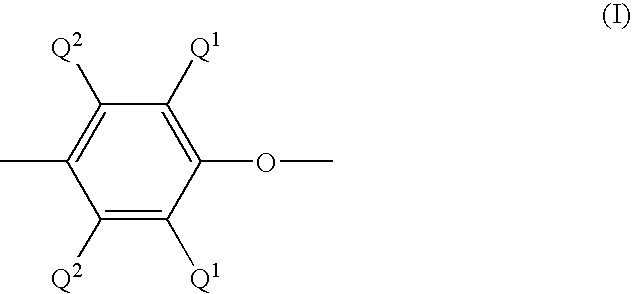

Flame retardant resin compositions

InactiveUS6822025B2Improved flowabilityHigh strengthFireproof paintsPlastic/resin/waxes insulatorsAlcoholPhosphate

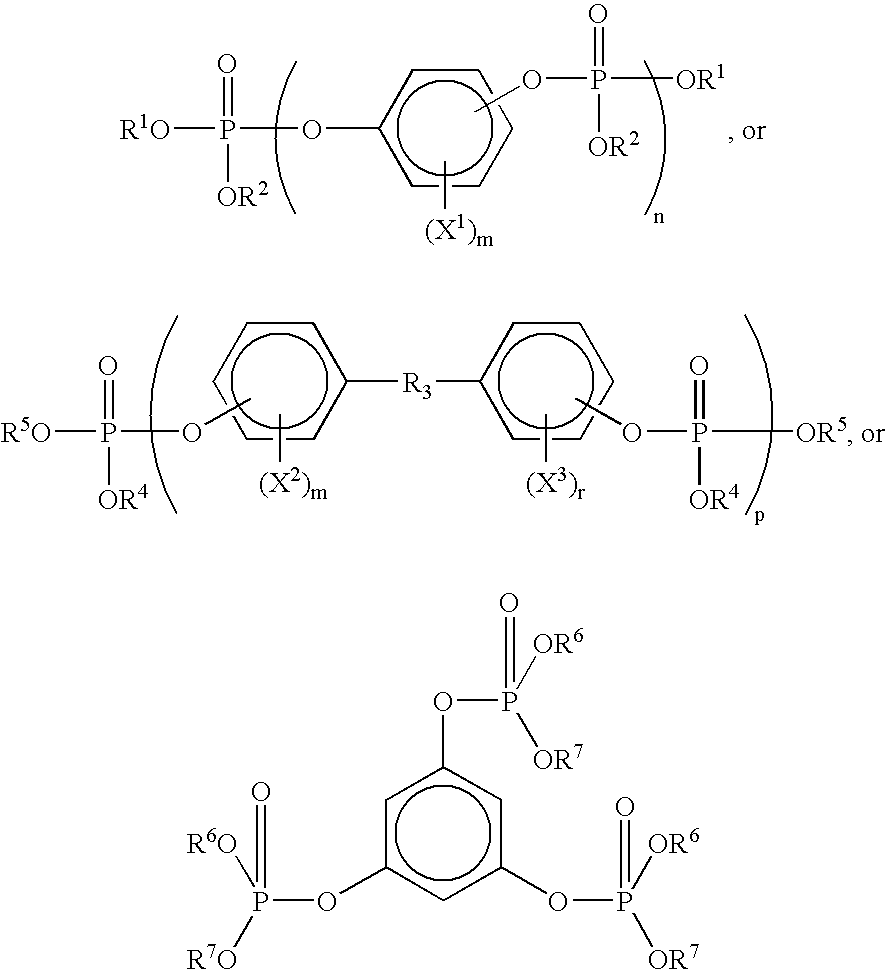

A flame retardant thermoplastic resin composition comprises a thermoplastic resin comprising a polyphenylene ether resin, a high impact polystyrene resin or an acrylontrile-butadiene-styrene resin; an organo phosphate compound in an amount less than or equal to about 20 parts by weight for every 100 parts by weight of the thermoplastic resin; and a polyhydric alcohol compound in an amount of about 0.5 to about 5.0 parts for every 100 parts by weight of the thermoplastic resin. A method for the manufacture of the thermoplastic resin composition is also disclosed. The thermoplastic resin composition exhibits high flow characteristics and improved impact strength while providing effective flame retardance.

Owner:SABIC INNOVATIVE PLASTICS IP BV

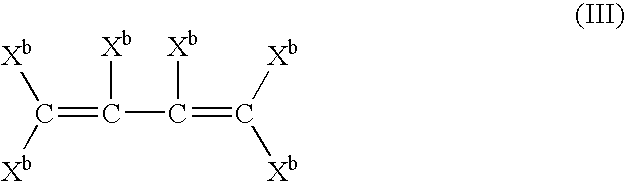

Additive for thermoplastic resins and flame retardant resin compositions

InactiveUS6689825B1High intrinsic viscosityIncrease tensile elongationAntifouling/underwater paintsPlastic/resin/waxes insulatorsHeat deflection temperatureChemistry

A thermoplastic resin composition with improved flame retardance, flow and heat deflection temperature includes a thermoplastic resin; resorcinol diphenyl phosphate; and an additive blend. The additive blend includes a combination of melamine polyphosphate and ferrocene. The thermoplastic composition reduces the amounts of resorcinol diphenyl phosphate required for effective flame retardancy. Moreover, the effective amounts of melamine polyphosphate and ferrocene do not deleteriously affect other properties of the thermoplastic composition such as Izod strength, flow properties, and heat deflection temperatures. A process for manufacturing a thermoplastic composition is also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

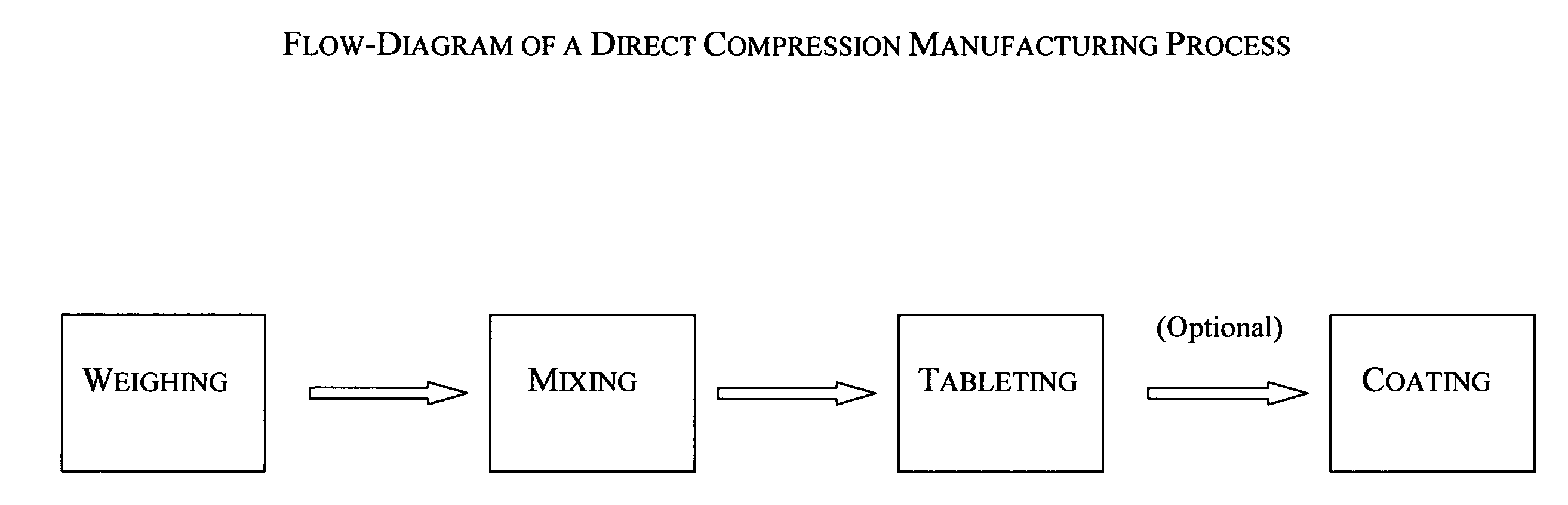

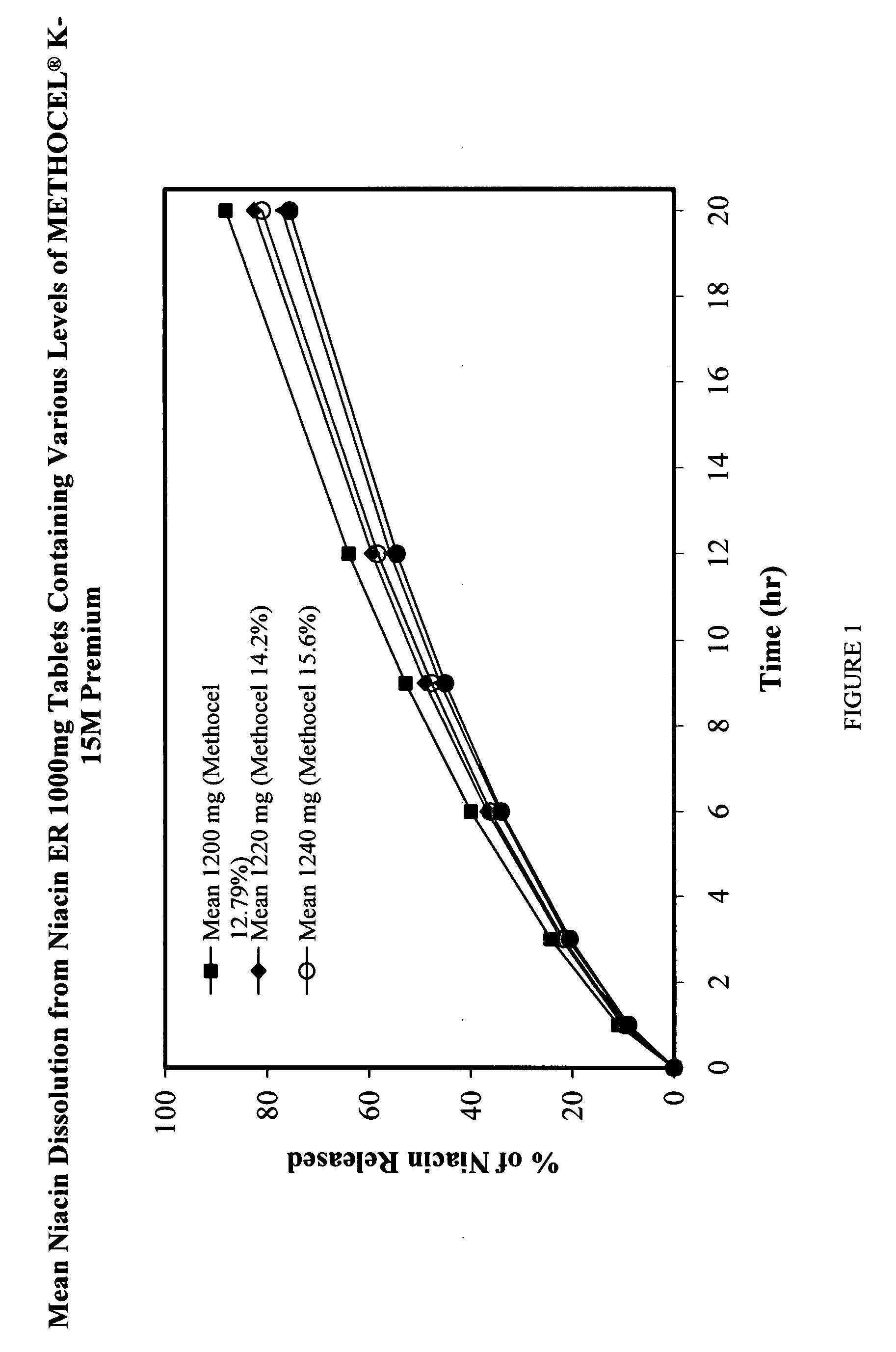

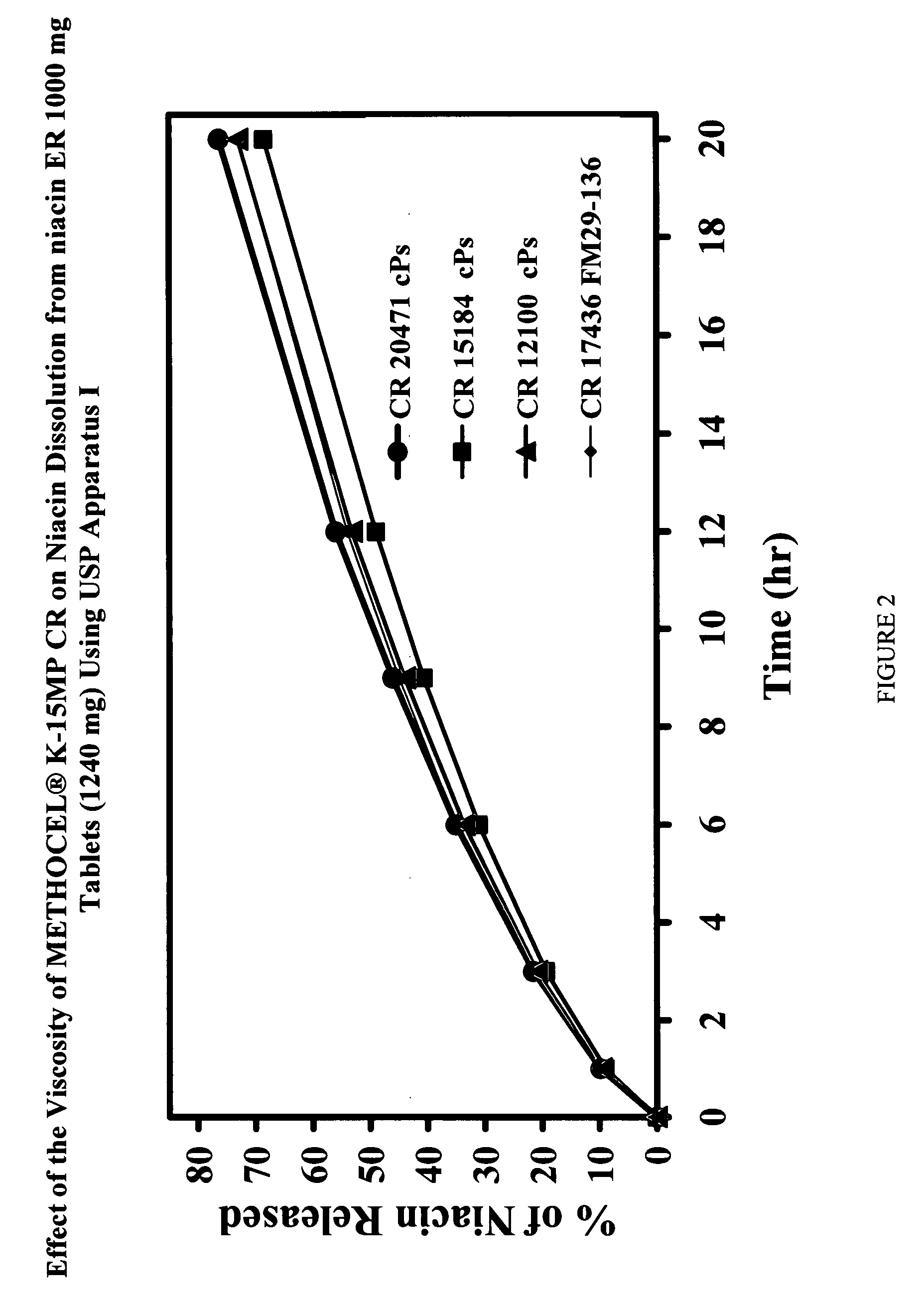

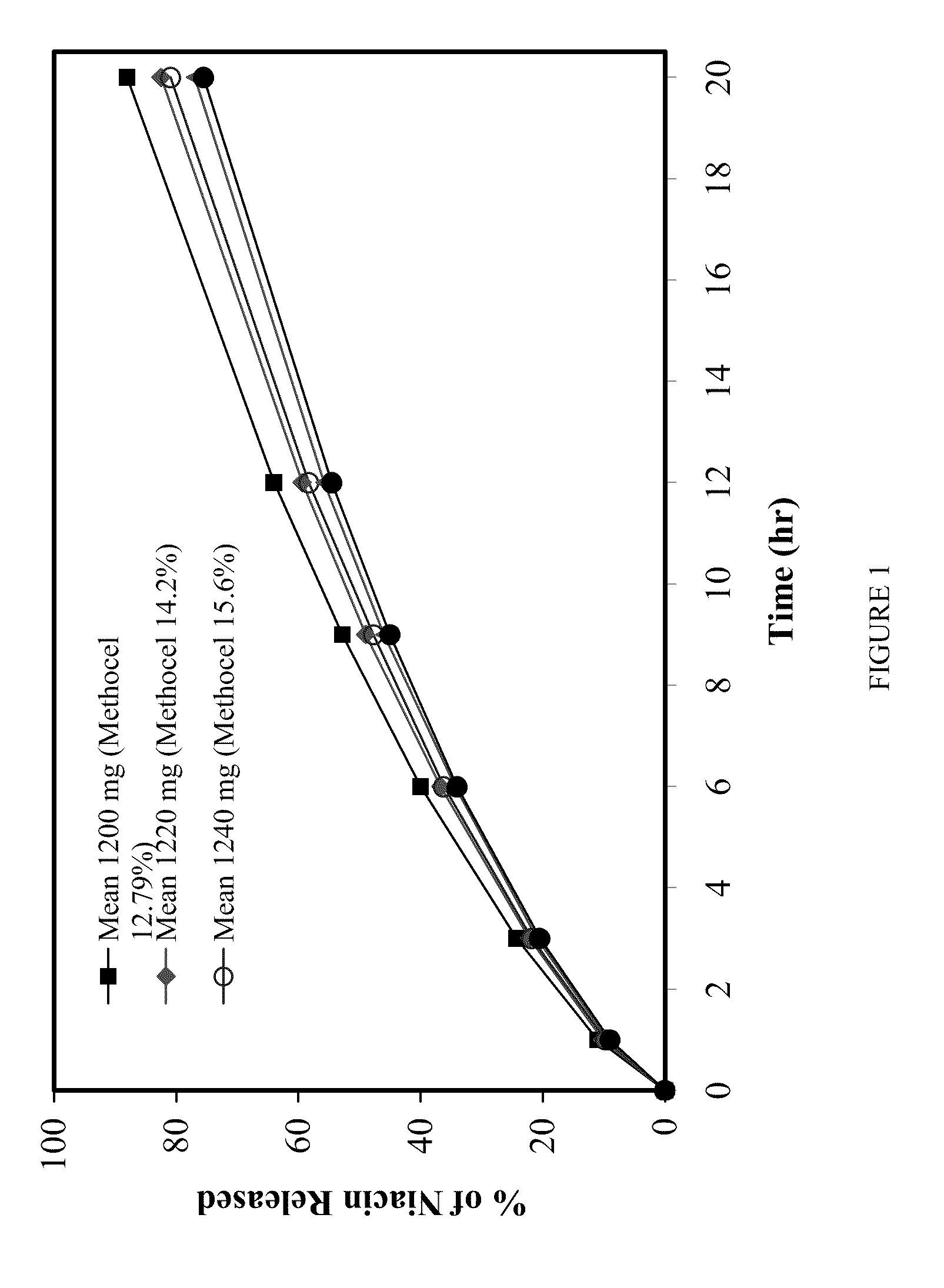

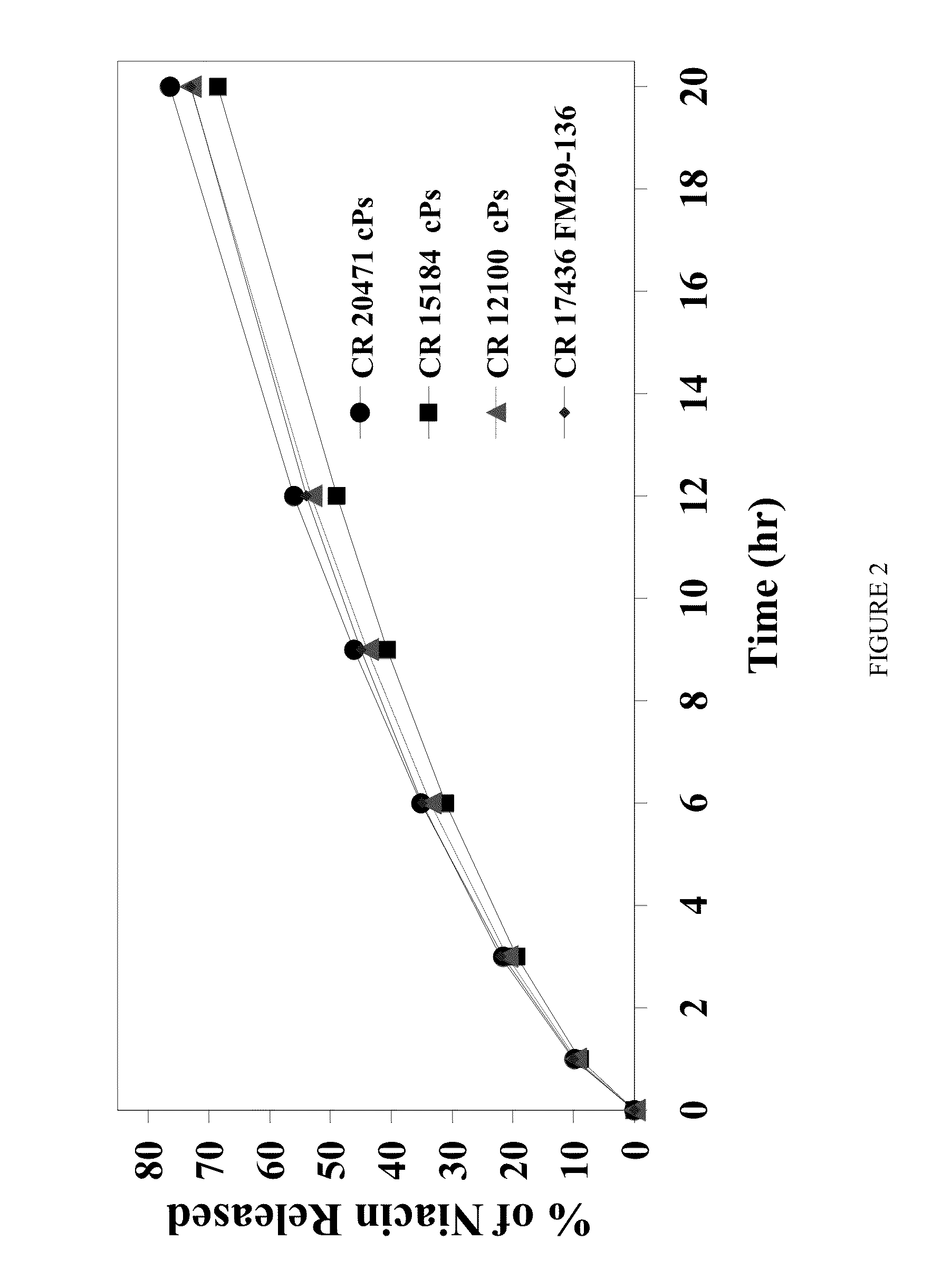

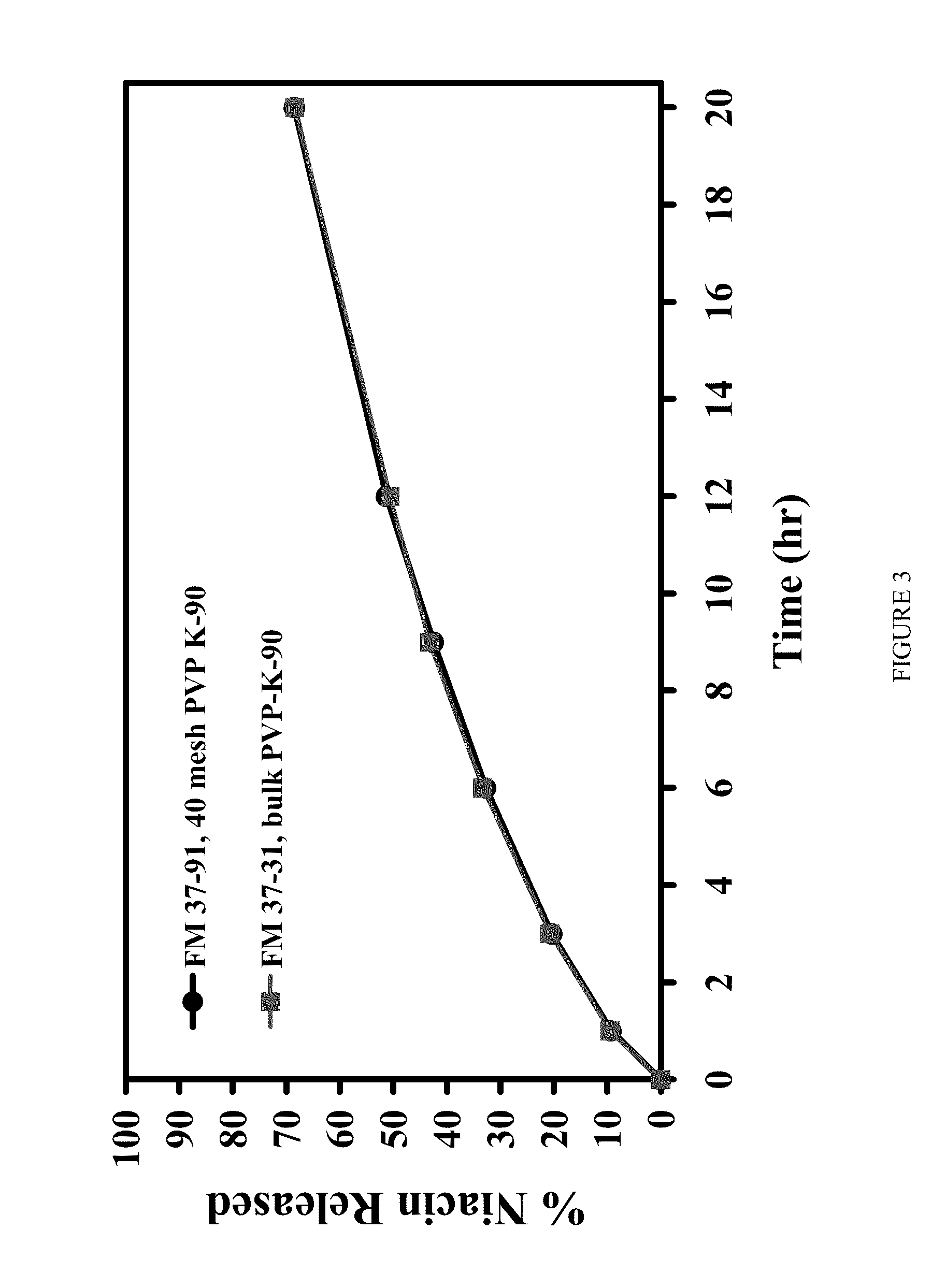

Low flush niacin formulation

The invention relates to an extended-release matrix formulation capable of being directly compressed into tablets comprising niacin, a release-retarding agent, and other excipients. The resulting tablets of the invention demonstrate favorable release characteristics and a reduction in the severity, duration and incidences of cutaneous flushing commonly associated with niacin treatment.

Owner:ABBOTT LAB INC

Low flush niacin formulation

InactiveUS20090069275A1Improved compactabilityGood compressibilityBiocideSalicyclic acid active ingredientsNiacinExcipient

The invention relates to an extended-release matrix formulation capable of being directly compressed into tablets comprising niacin, a release-retarding agent, and other excipients. The resulting tablets of the invention demonstrate favorable release characteristics and a reduction in the severity, duration and incidences of cutaneous flushing commonly associated with niacin treatment.

Owner:ABBOTT LAB INC

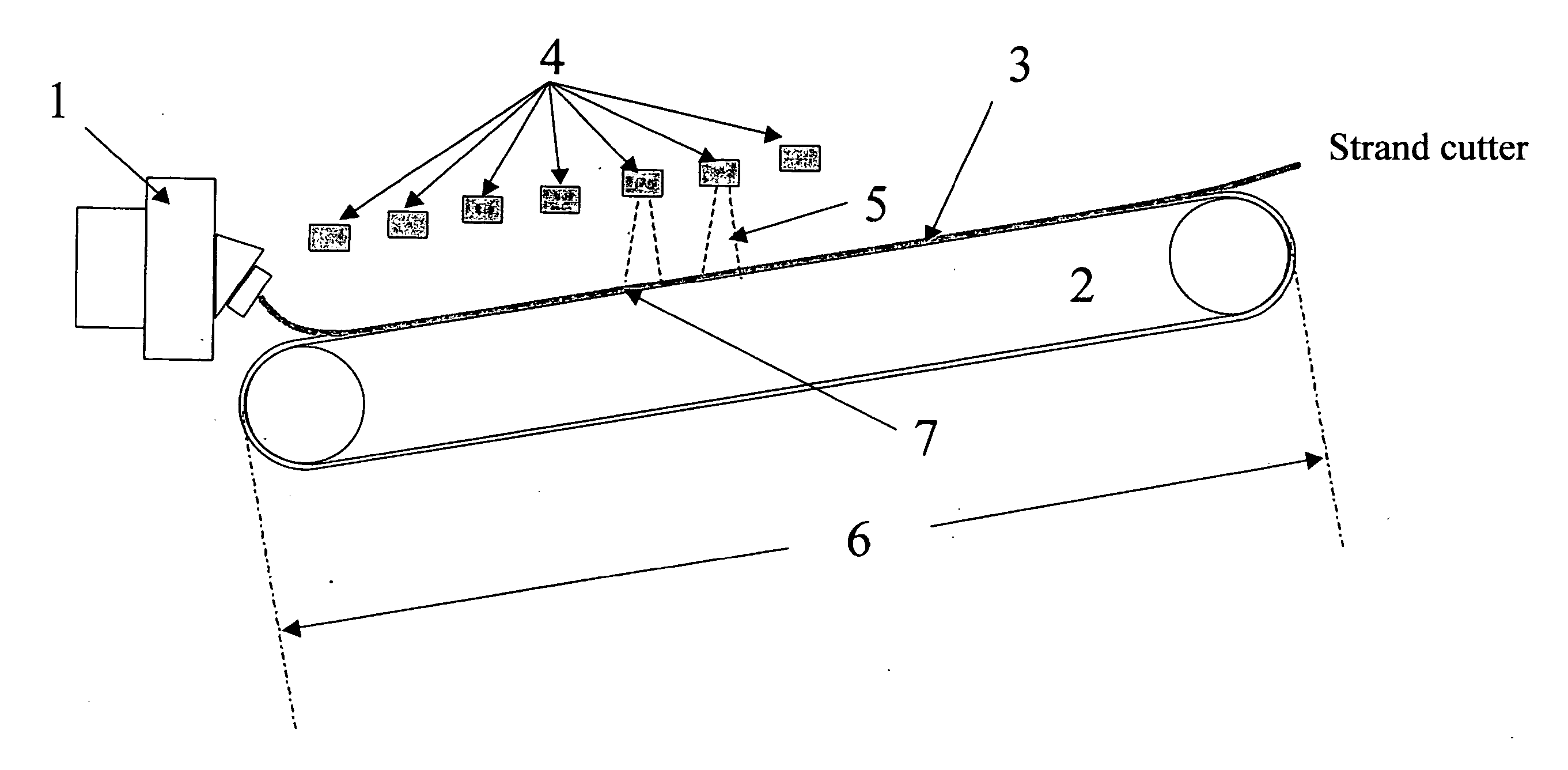

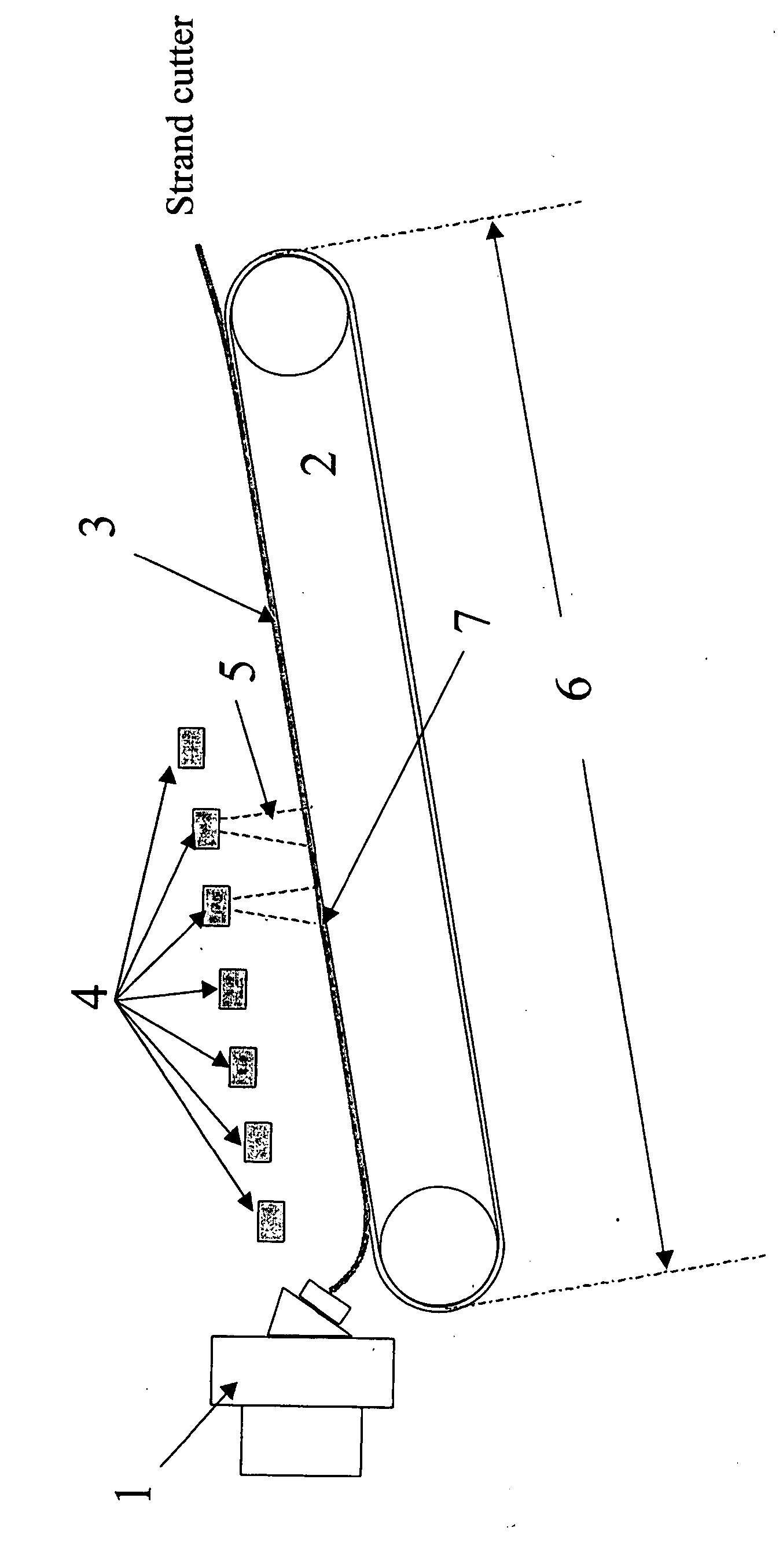

Method for producing resin strand

InactiveUS20070235893A1Increase productionInhibition formationElectroconductive/antistatic filament manufactureFilament/thread formingWire rodMoisture

The present invention can eliminate a breakage of strands on the way to increase yield, significantly suppress formation of adhered consecutive pellets, and obtain pellets having a low moisture content by a method for producing a resin strand comprising melt-kneading a resin composition in an extruder, extruding a strand-shaped molten resin onto a conveyor, and cooling the resin strand with cooling water, wherein the conveyed strand-shaped molten resin is brought into initial contact with the cooling water at a position downstream ranging from 20% to 70% of the total length of the conveying part of the conveyor.

Owner:ASAHI KASEI CHEM CORP

Flame retardant resin compositions

InactiveUS20040102549A1Improved flowabilityHigh strengthFireproof paintsPlastic/resin/waxes insulatorsAlcoholPhosphate

A flame retardant thermoplastic resin composition comprises a thermoplastic resin comprising a polyphenylene ether resin, a high impact polstyrene resin or an acrylonitrile-butadiene-styrene resin; an organo phosphate compound in an amount less than or equal to about 20 parts by weight for every 100 parts by weight of the thermoplastic resin; and a polyhydric alcohol compound in an amount of about 0.5 to about 5.0 parts for every 100 parts by weight of the thermoplastic resin. A method for the manufacture of the thermoplastic resin composition is also disclosed. The thermoplastic resin composition exhibits high flow characteristics and improved impact strength while providing effective flame retardance.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Thickened bleach compositions

InactiveUS20060199755A1Provide stabilitySufficient amountInorganic/elemental detergent compounding agentsCosmetic preparationsBleachRheology

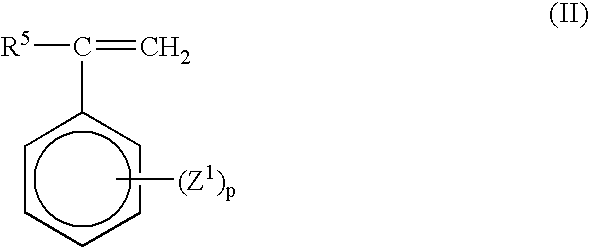

Surfactant-thickened active chlorine-containing bleach compositions including at least one water soluble anionic styrenic polymer are described. The styrenic polymer serves to improve the rheology properties of the thickened bleach composition. The thickened bleach composition additionally includes a surfactant-based thickening system including an amine oxide, and an alkaline agent to maintain the pH of the composition at about 10 or greater. The amine oxide includes at least 75% of one or more C14-C18 alkyl dimethyl amine oxides. The thickened bleach compositions have reduced viscosity, decreased elastic properties, with improved flow and pour properties resulting from the inclusion of the styrenic polymer.

Owner:SC JOHNSON & SON INC

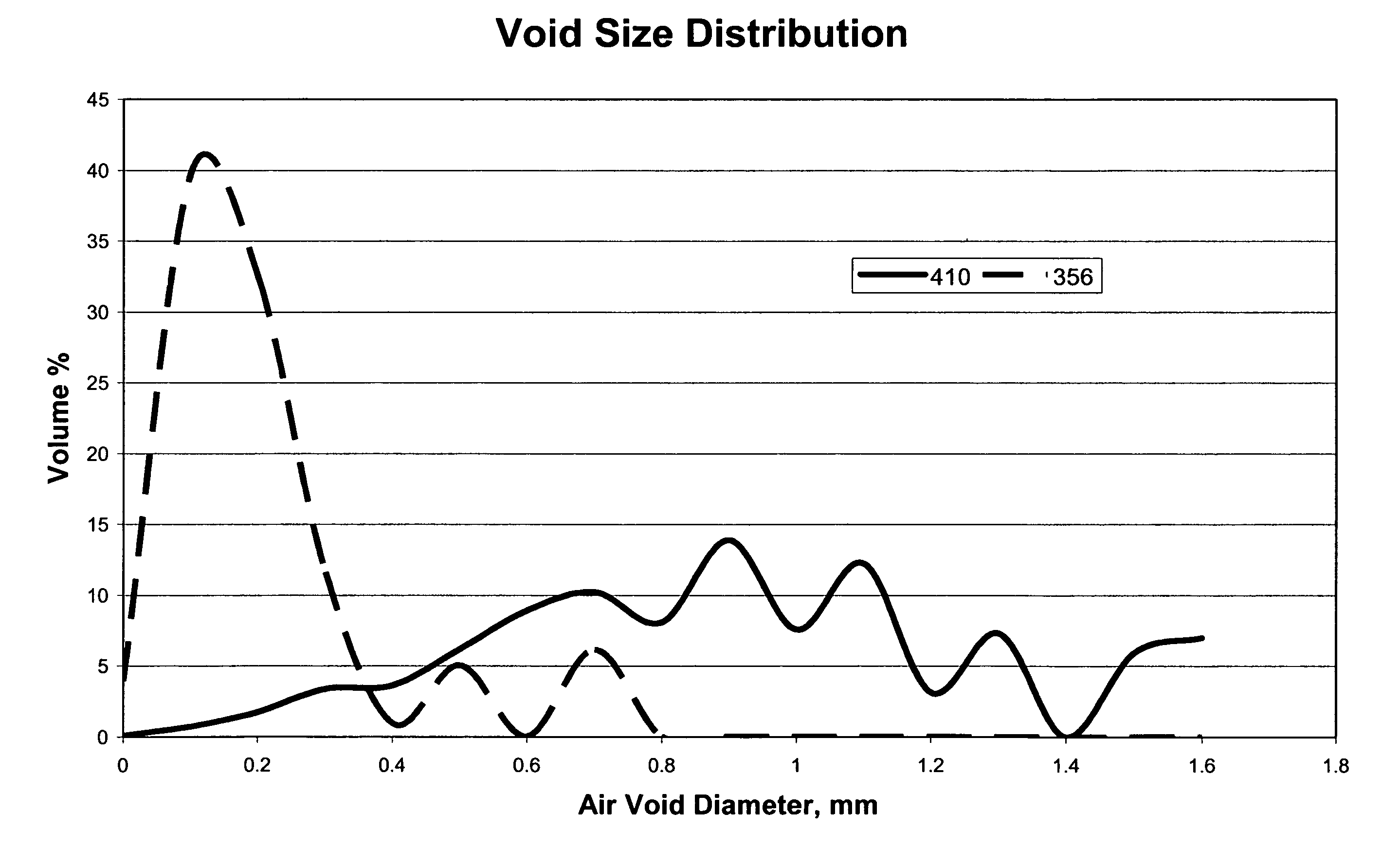

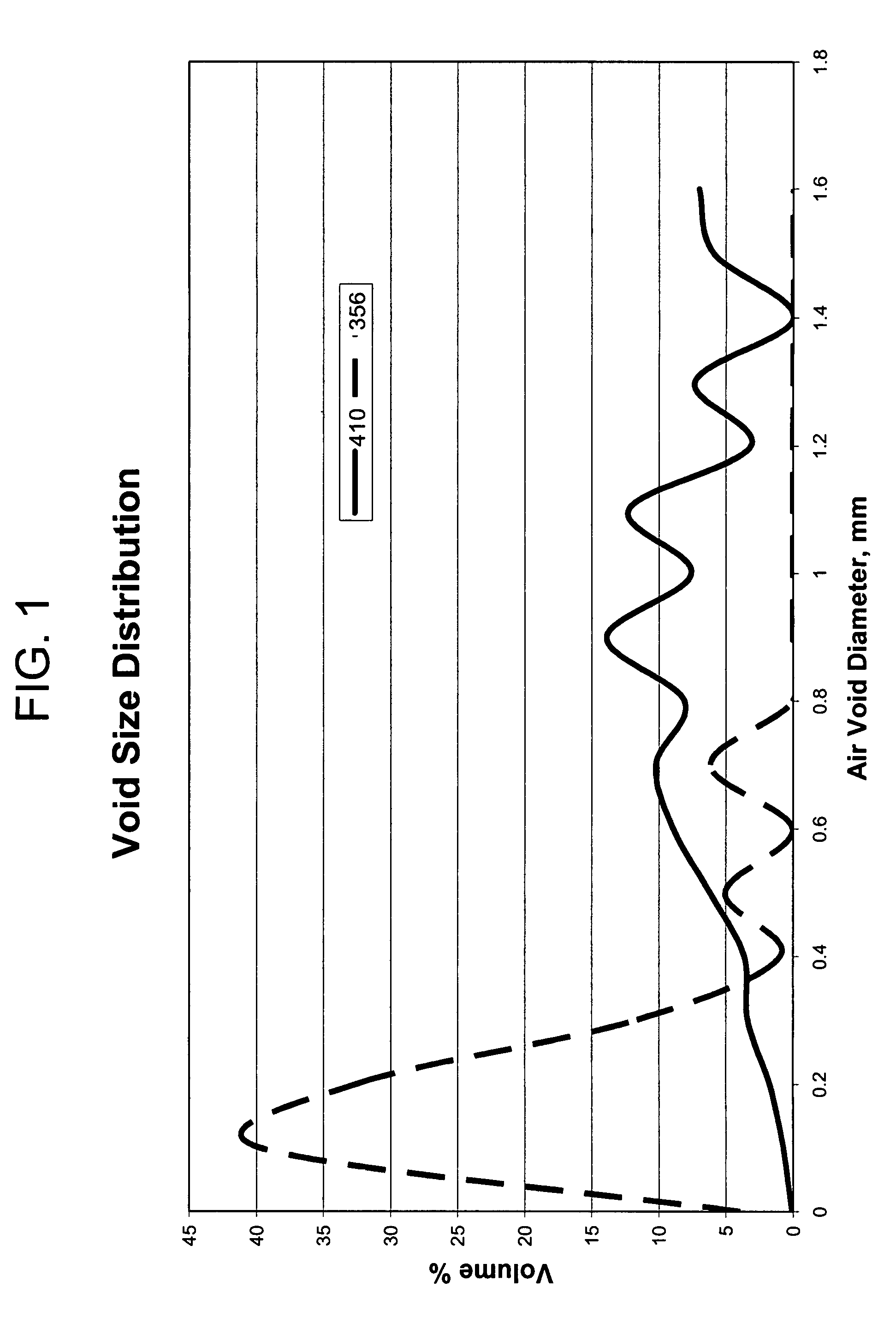

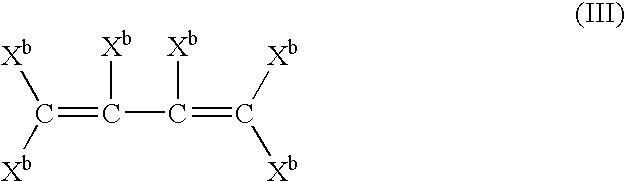

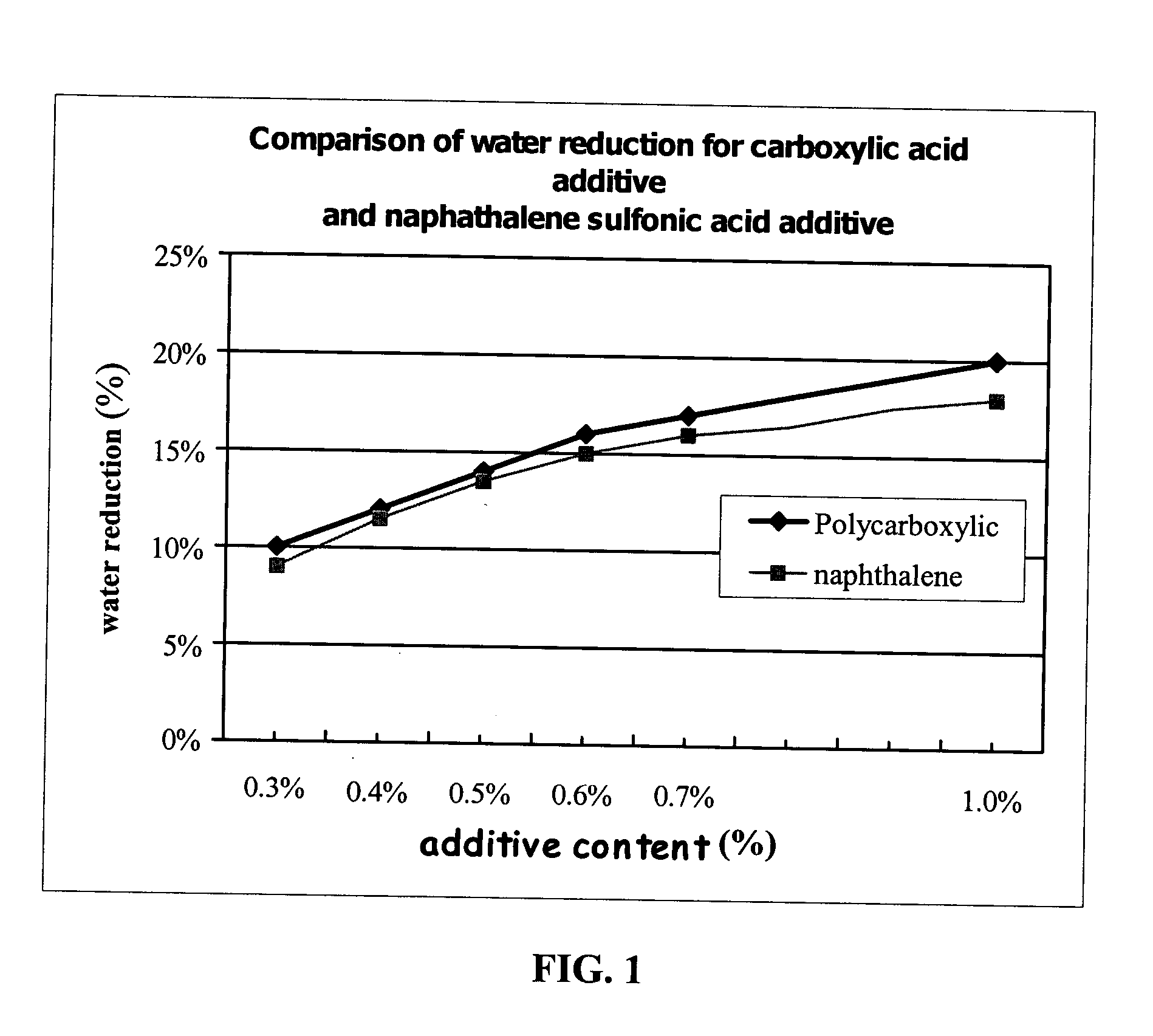

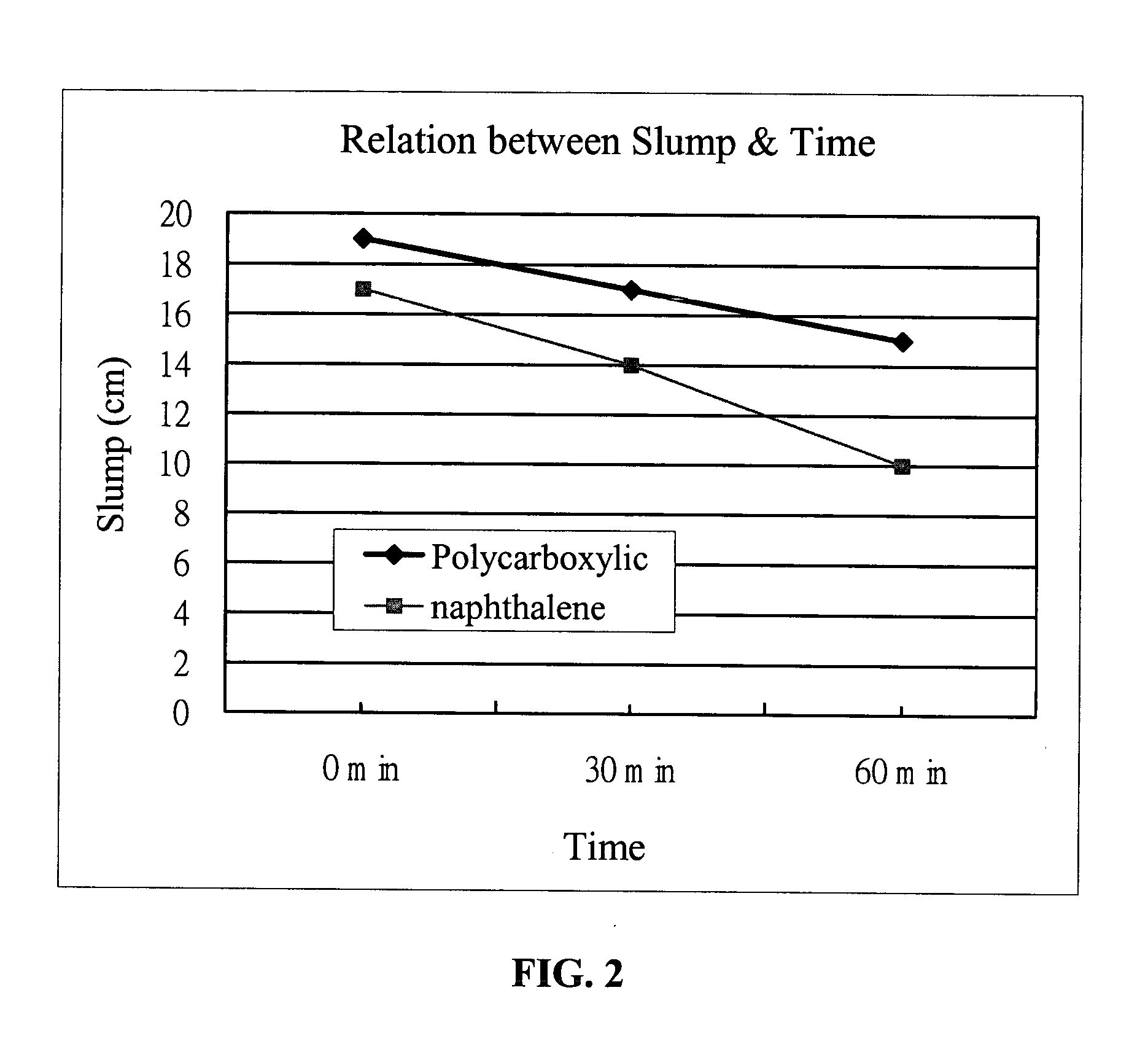

Concrete admixture additive

A new family of concrete admixture additives can be derived from reacting a mixture of olefins / cyclic olefins-maleic anhydride copolymers and methoxy polyethylene glycol amines and / or polyethylene glycol monoalkyl ethers, or a mixture of styrene-maleic anhydride copolymers and methoxy polyethylene glycol amines and / or polyethylene glycol monoalkyl ethers, or a mixture of styrene-olefins / cyclic olefins-maleic anhydride terpolymers and methoxy polyethylene glycol amines and / or polyethylene glycol monoalkyl ethers. These reactions lead to formation of a kind of carboxylic salt containing polymer, which can be used alone in concrete. Only a small amount of this substance is needed to provide excellent water reduction, high concrete flowability and high early strength.

Owner:TAIWAN GWAN CHIAN IND

Thickened bleach compositions comprising an amine oxide and anionic polymer

InactiveUS7390775B2Improve rheologyReduced elastic natureInorganic/elemental detergent compounding agentsCosmetic preparationsBleachAnionic polymers

Surfactant-thickened active chlorine-containing bleach compositions including at least one water soluble anionic styrenic polymer are described. The styrenic polymer serves to improve the rheology properties of the thickened bleach composition. The thickened bleach composition additionally includes a surfactant-based thickening system including an amine oxide, and an alkaline agent to maintain the pH of the composition at about 10 or greater. The amine oxide includes at least 75% of one or more C14-C18 alkyl dimethyl amine oxides. The thickened bleach compositions have reduced viscosity, decreased elastic properties, with improved flow and pour properties resulting from the inclusion of the styrenic polymer.

Owner:SC JOHNSON & SON INC

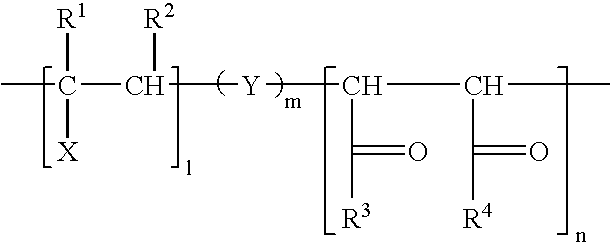

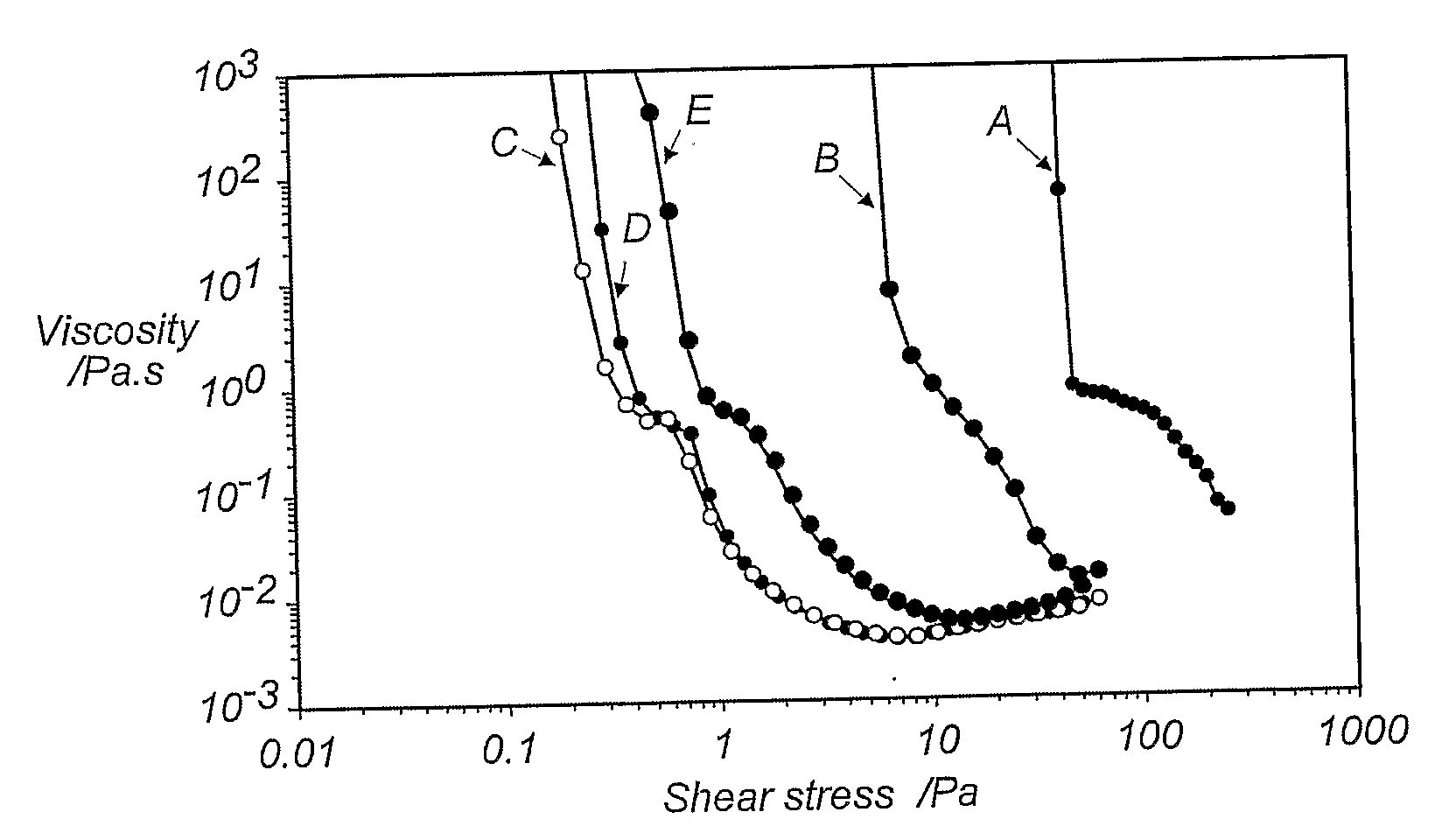

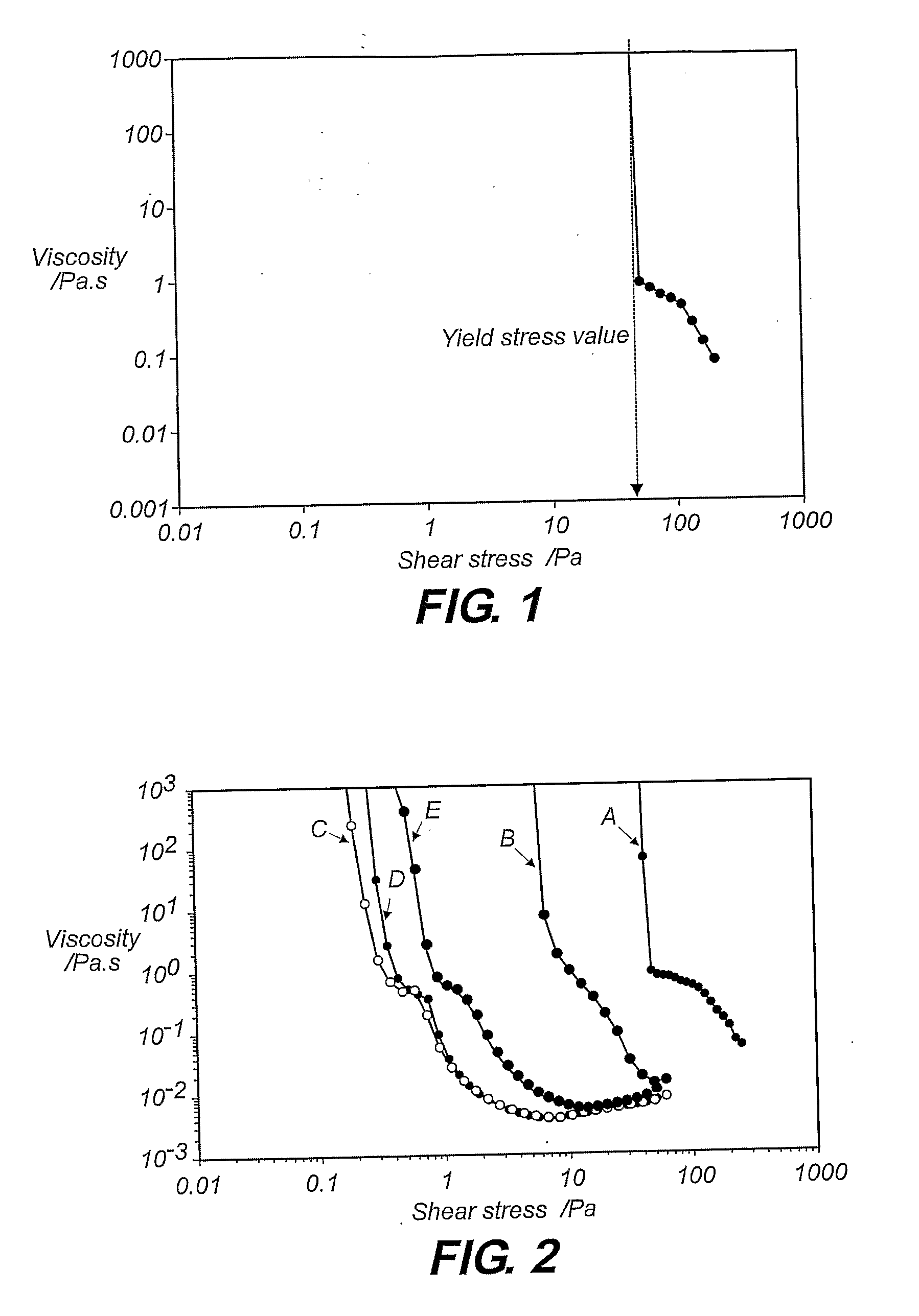

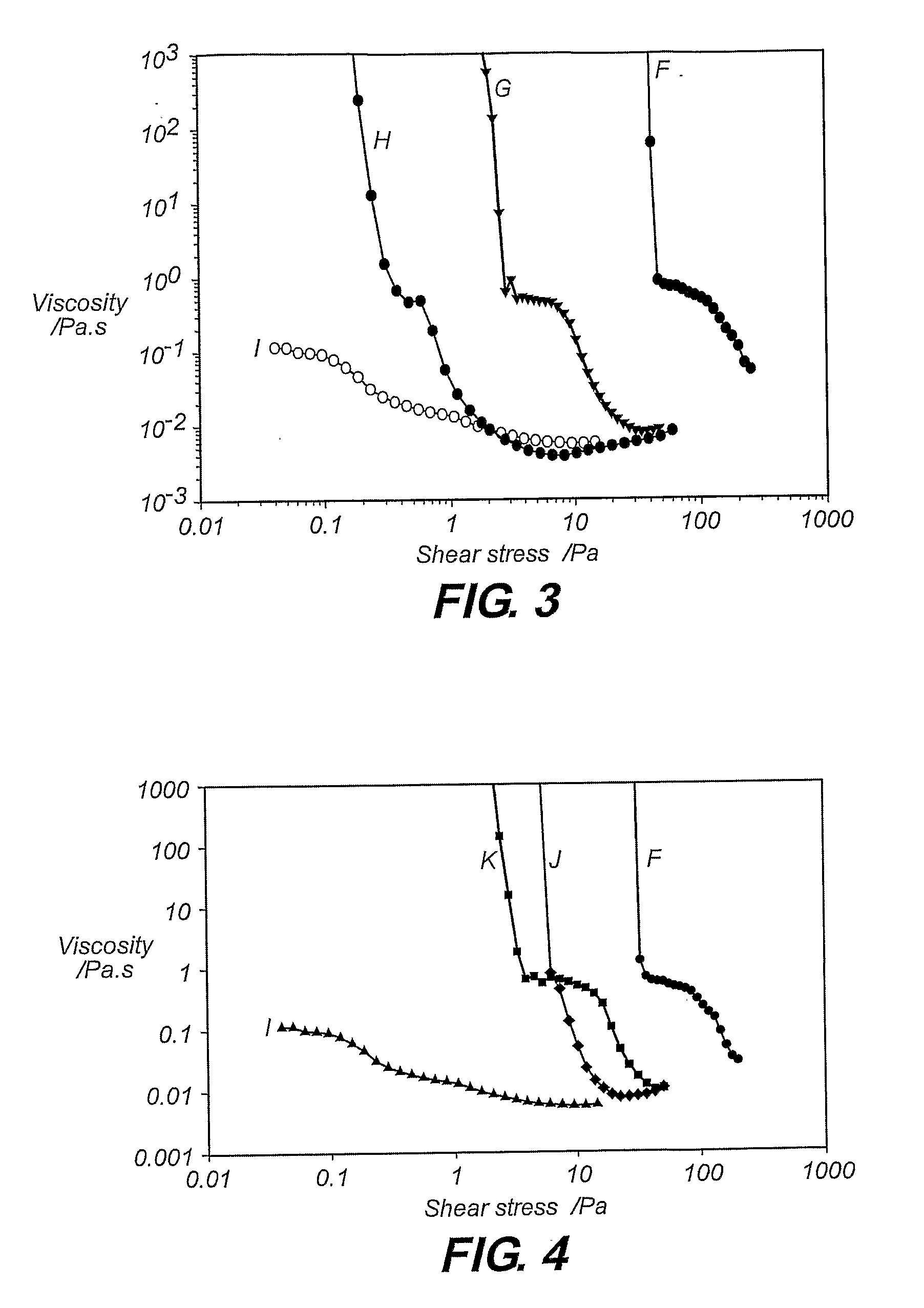

Dispersant For Reducing Viscosity Of Particulate Solids

InactiveUS20080145546A1Low viscosityReduces yield stress problemTransportation and packagingConductive materialHigh concentrationLow affinity

The invention provides a dispersant for an aqueous dispersion of positively charged or chargeable solid particulates which comprises a compound having an anchoring moiety linked to a polymeric hydrophilic moiety, the anchoring moiety containing at least one acid and / or hydroxy group and having an overall acidity or neutrality and the polymeric moiety having a lower affinity for the particulate surface than the anchoring moiety. The anchoring moiety preferably contains at least two acid groups, preferably carboxylic acid groups, attached either in a [1,1], [1,2] or [1,3] relationship and is linked to the polymeric moiety, which is preferably derived from acrylamide or methacrylamide monomer units, preferably by a sulfur atom. The dispersant can reduce the viscosity of an aqueous dispersion of positively charged or chargeable solid particulates and can reduce the tendency of the resulting dispersion to form a gel or a yield stress material. The dispersant facilitates the processing of the resulting compositions in manufacturing operations and it may be used, for example, as a component of a coating material, a ceramic, paint, refractory material, filler or in an inkjet recording paper or film. Additionally, the dispersant can allow the use of higher concentrations of solid particulates and enable control of the yield stress, as some yield is often beneficial in helping prevent or reduce sedimentation.

Owner:EASTMAN KODAK CO

Cement products and methods of making and using the same

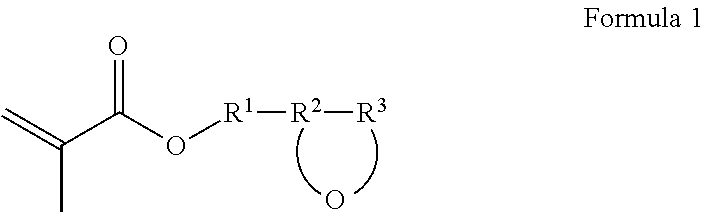

ActiveUS20110097420A1Appropriate flowabilityAppropriate propertyPowder deliveryImpression capsBone formationDouble bond

Owner:XTANT MEDICAL HLDG INC

Process for treating a gas contaminated by metals or organics compounds using a calcium-phosphate reactant comprising apatite

InactiveUS20180169573A1Reduce riskSolution value is not highGas treatmentOther chemical processesFuranPhosphate

Process for treating a gas contaminated by at least one element selected from the group consisting of heavy metals, organic compounds, and combinations thereof, wherein a calcium-phosphate reactant (reagent) particle comprising apatite is brought into contact with the contaminated gas at a temperature of at least 30° C. and preferably at most 1100° C. The metal(s) and / or organic compound(s) to be removed from the contaminated gas may be selected among the list of: Al, Ag, As, Ba, Be, Bi, Ce, Co, Cd, Cu, Cr, Fe, Hf, Hg, La, Li, Mg, Mn, Mo, Ni, Pb, Pd, Rb, Sb, Se, Sn, Sr, Th, Ti, U, V, Y, Zn, Zr, VOC, aromatic compounds, PAHs, dioxins, furans, or any mixture thereof. In such process, an alkaline compound particle comprising sodium bicarbonate, sodium carbonate, sodium sesquicarbonate (trona), quick lime, hydrated lime, lime stone or combinations thereof, may be further brought into contact with the contaminated gas.

Owner:SOLVAY SA

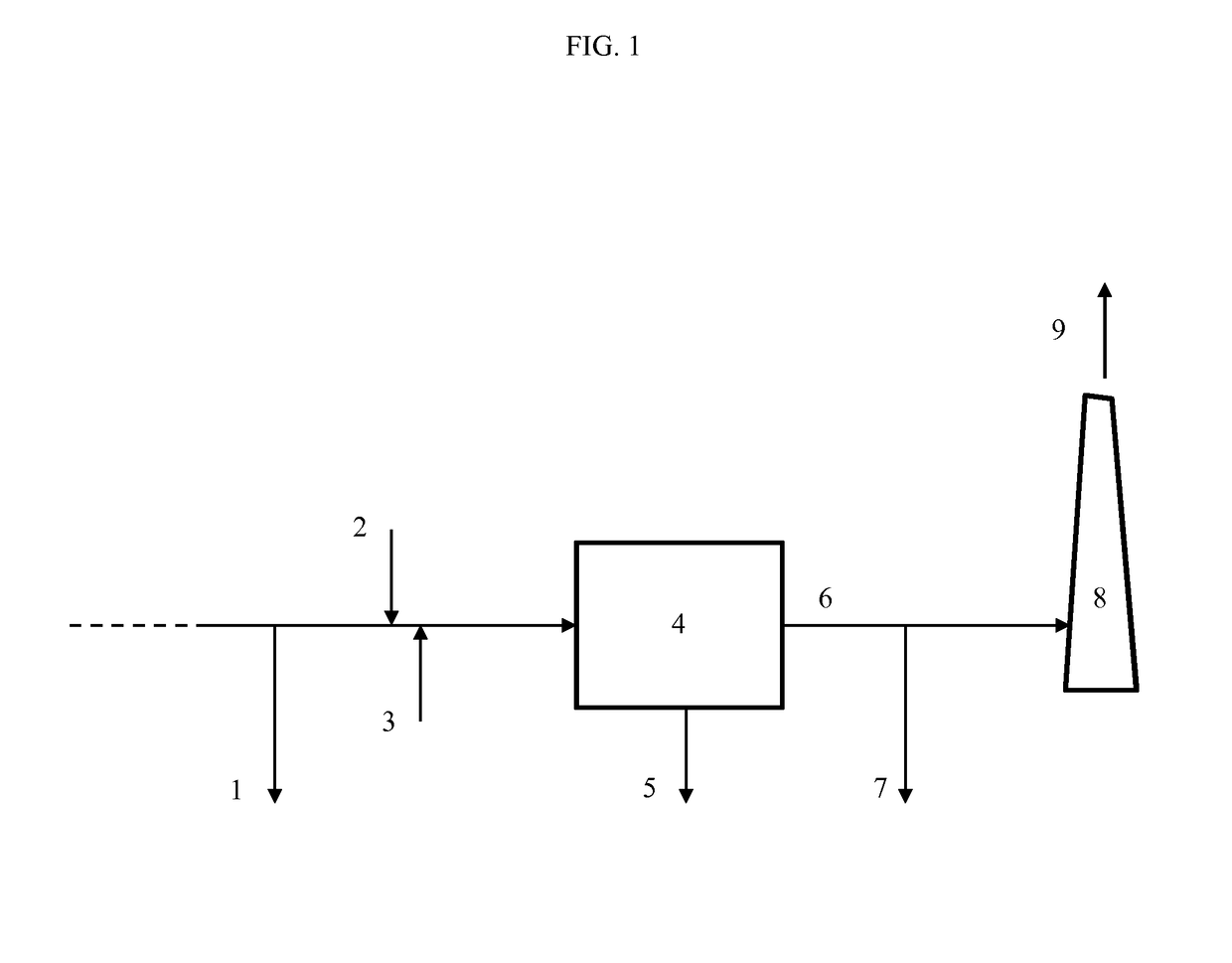

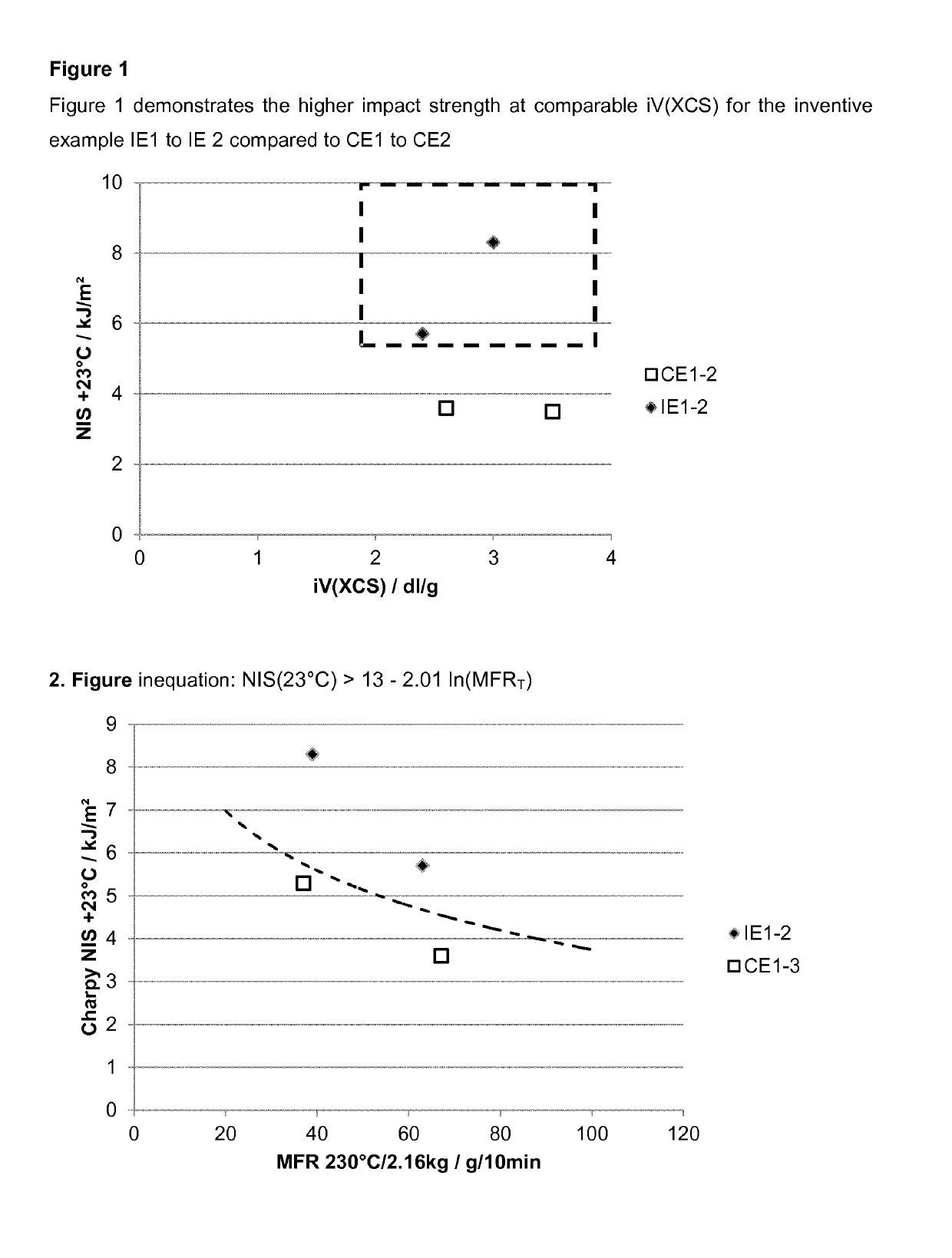

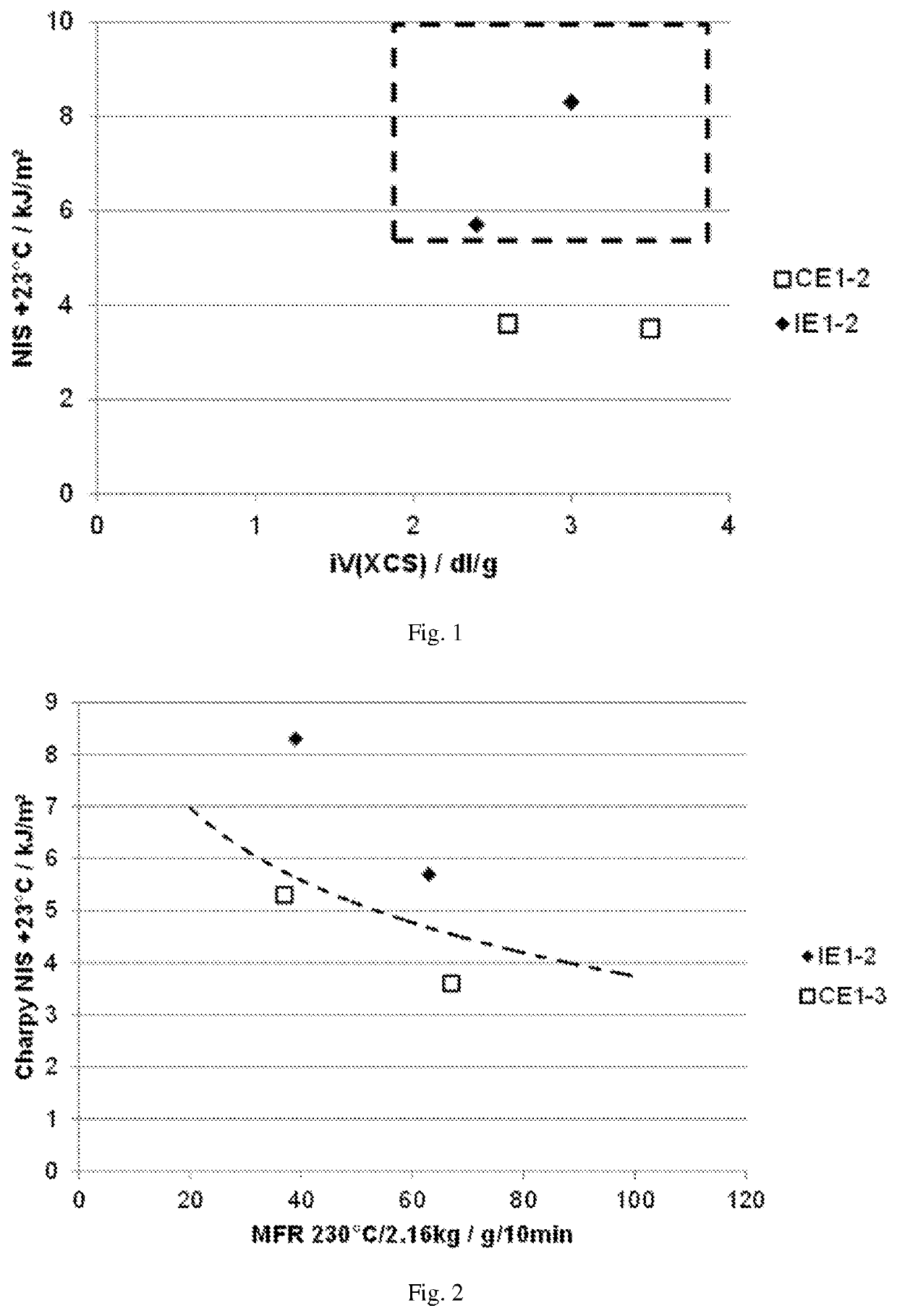

High flow heterophasic polyolefin composition having improved stiffness/impact balance

High flow nucleated heterophasic polyolefin compositions comprising a matrix comprising a propylene homo- and / or copolymer and an elastomeric alpha-olefin copolymer phase dispersed in the matrix, which have rather high melt flow rate, improved impact strength but also an excellent impact / stiffness balance and a process for the preparation of such a heterophasic polyolefin composition, articles made therefrom and uses of the heterophasic polyolefin composition.

Owner:BOREALIS AG

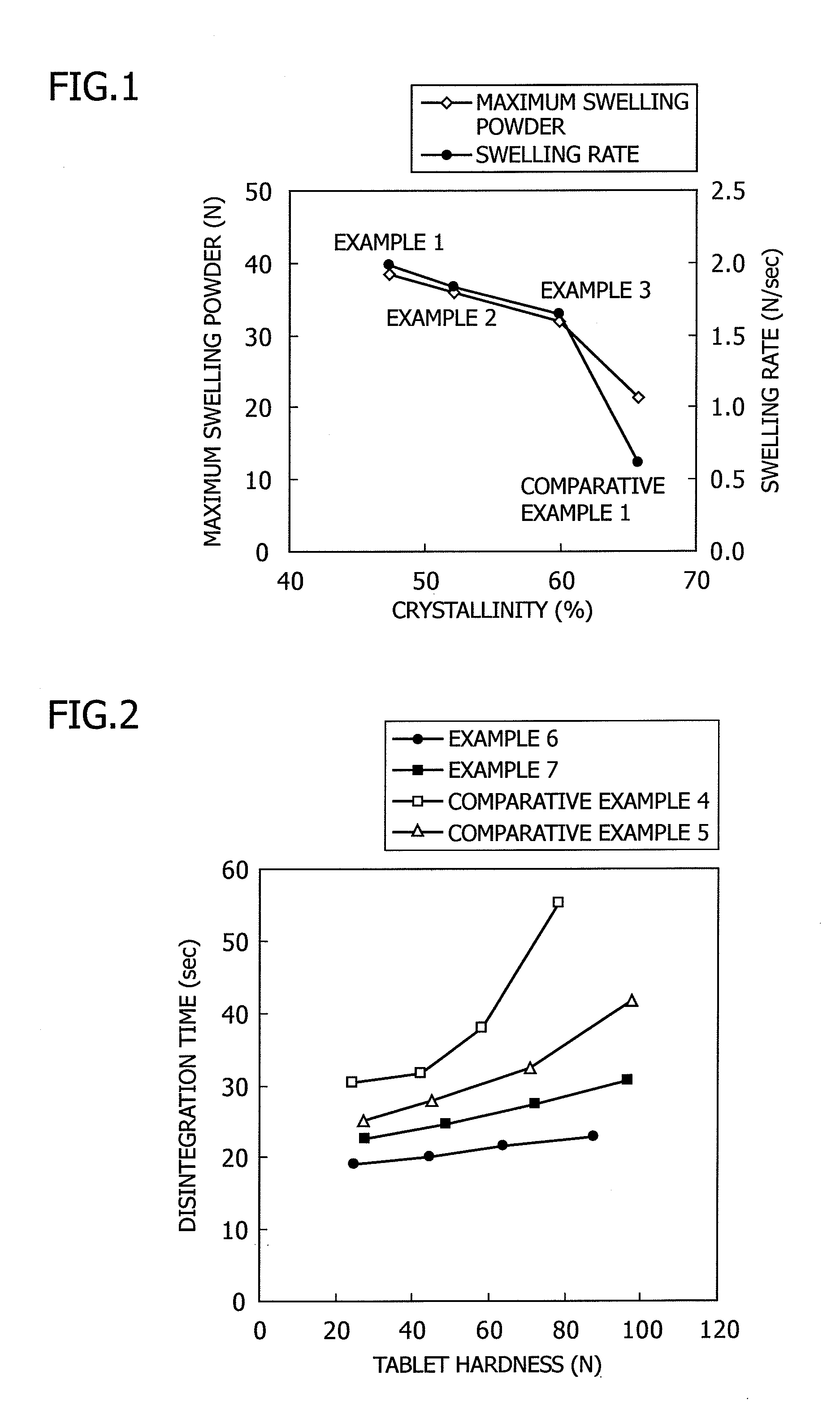

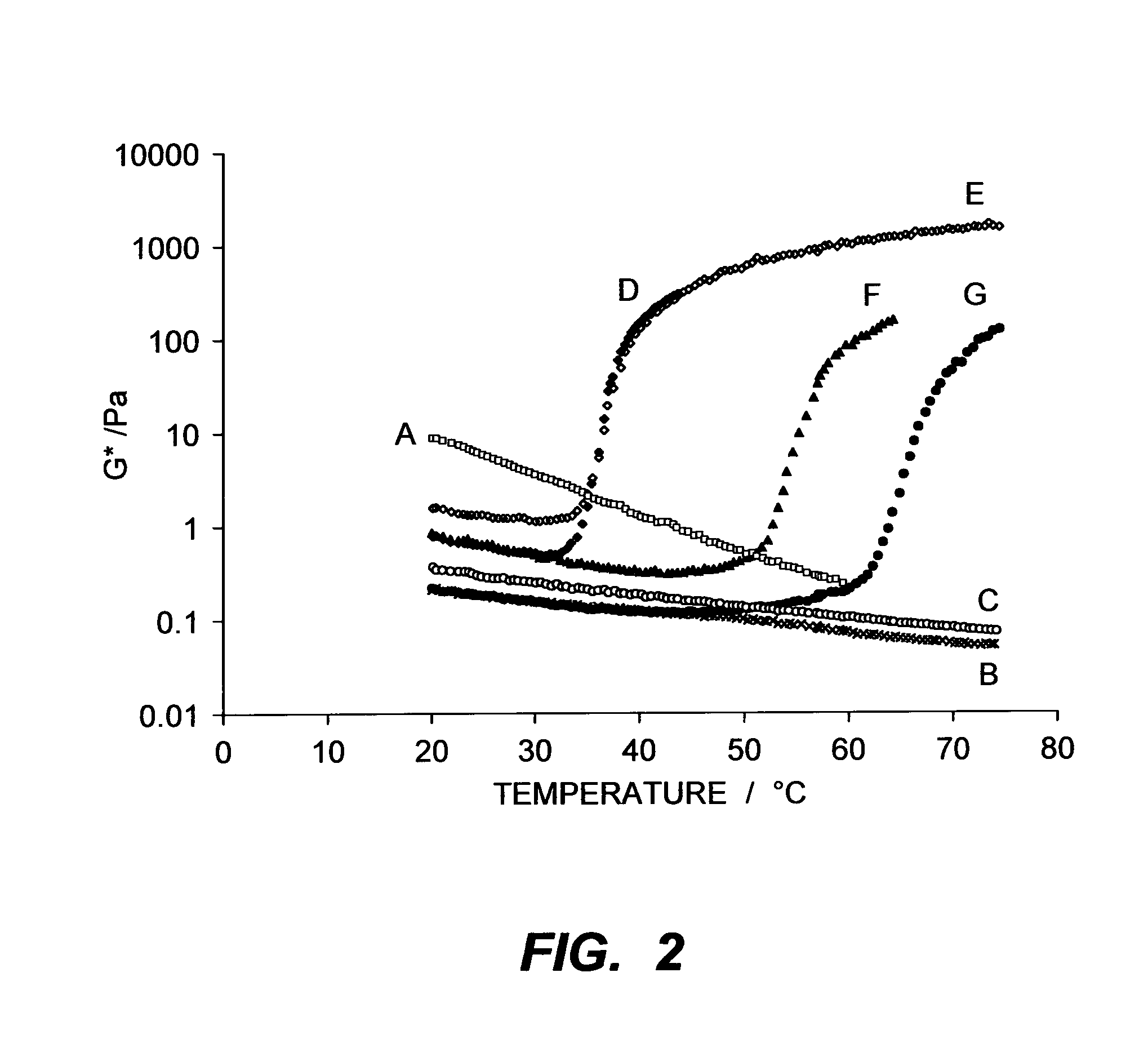

Low-Substituted Hydroxypropylcellulose and Solid Preparation Comprising the Same

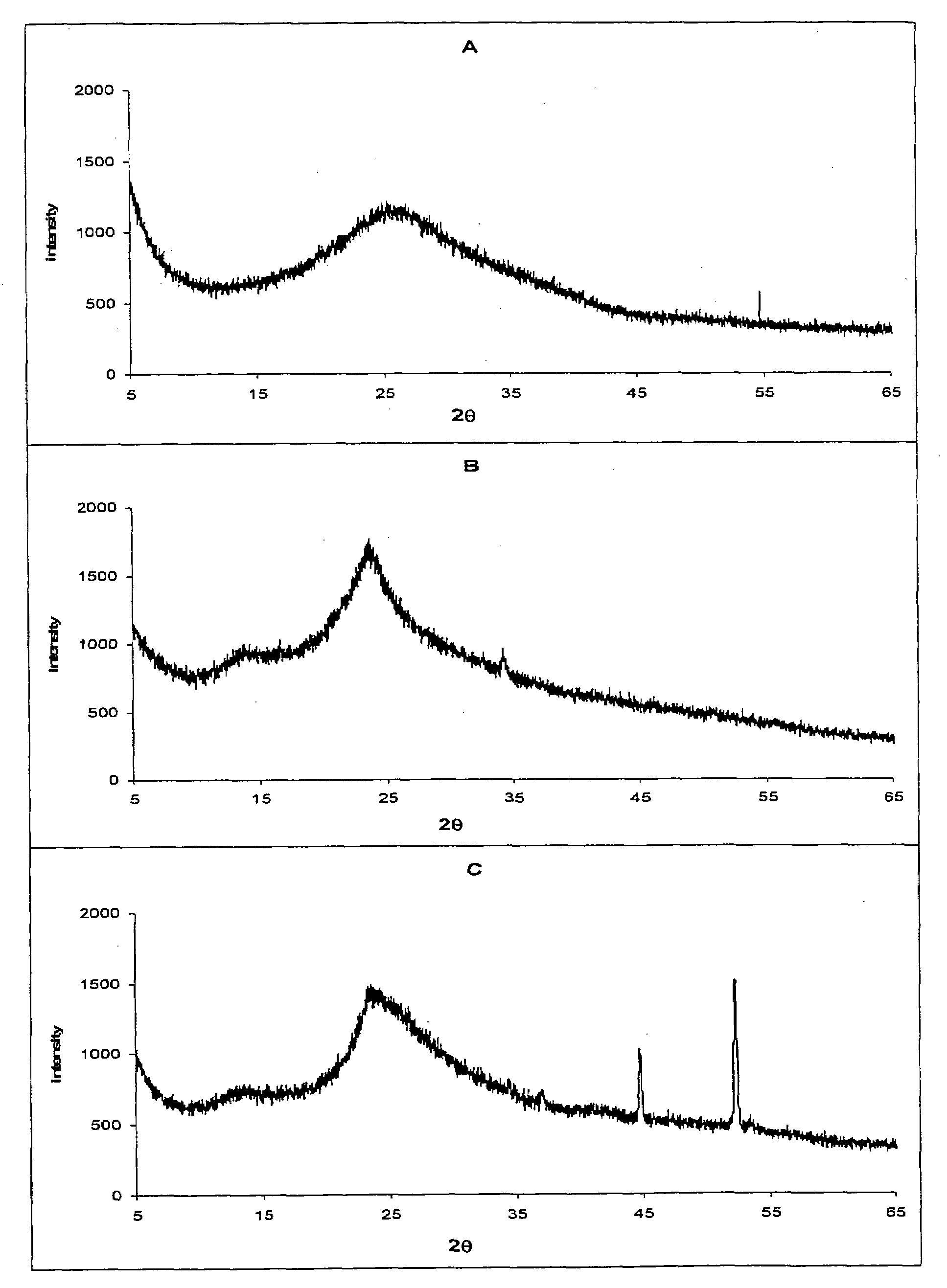

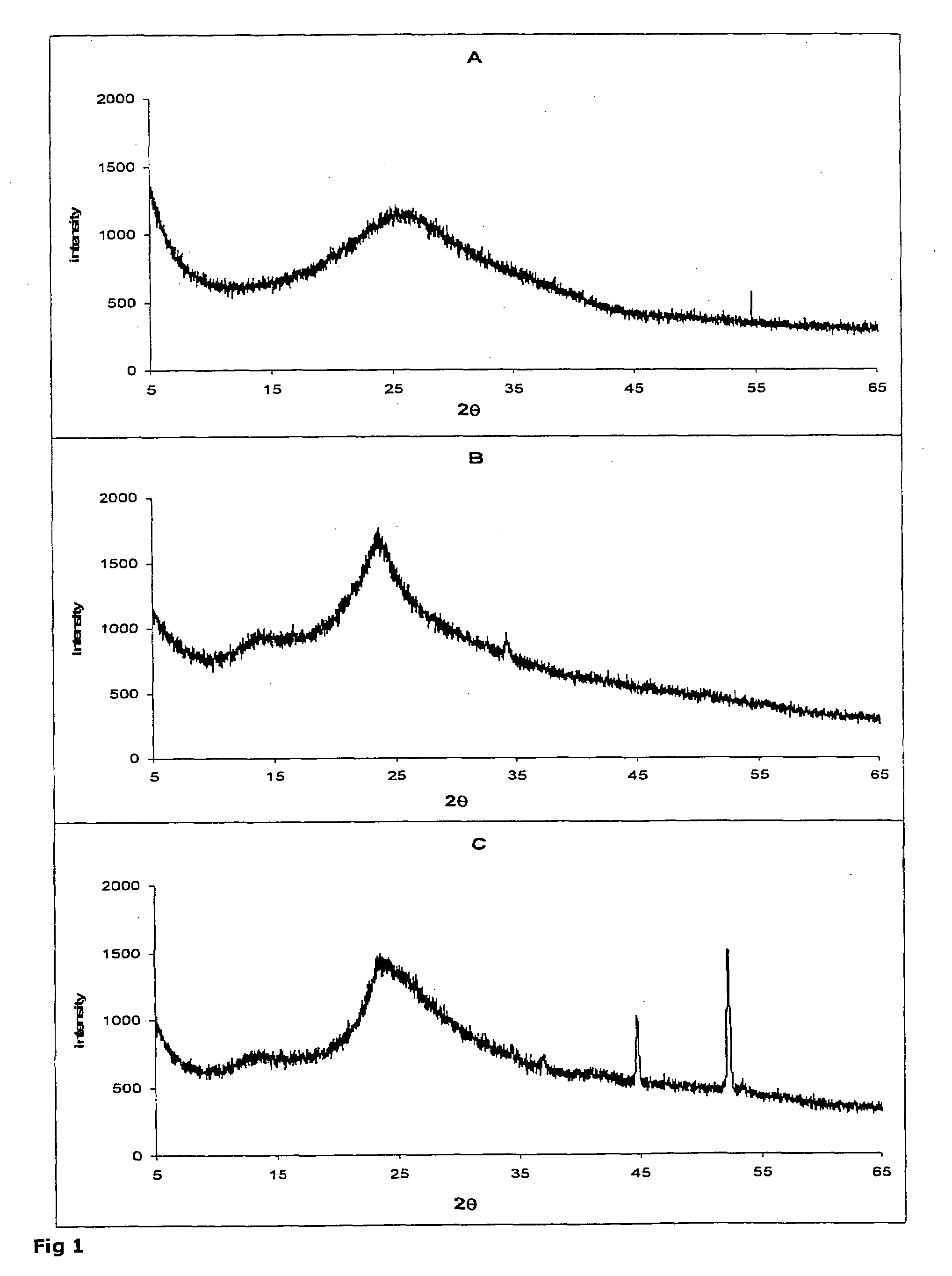

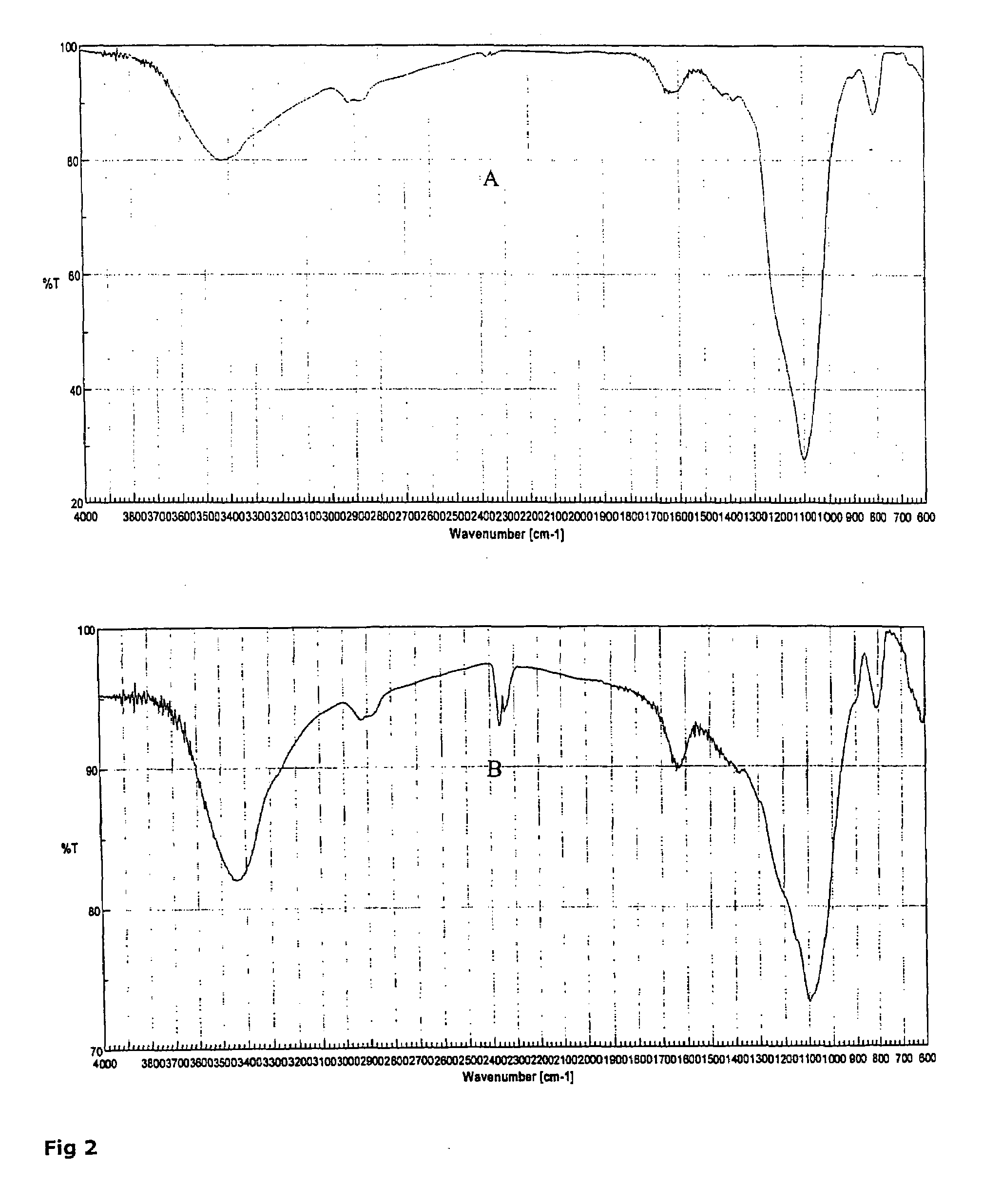

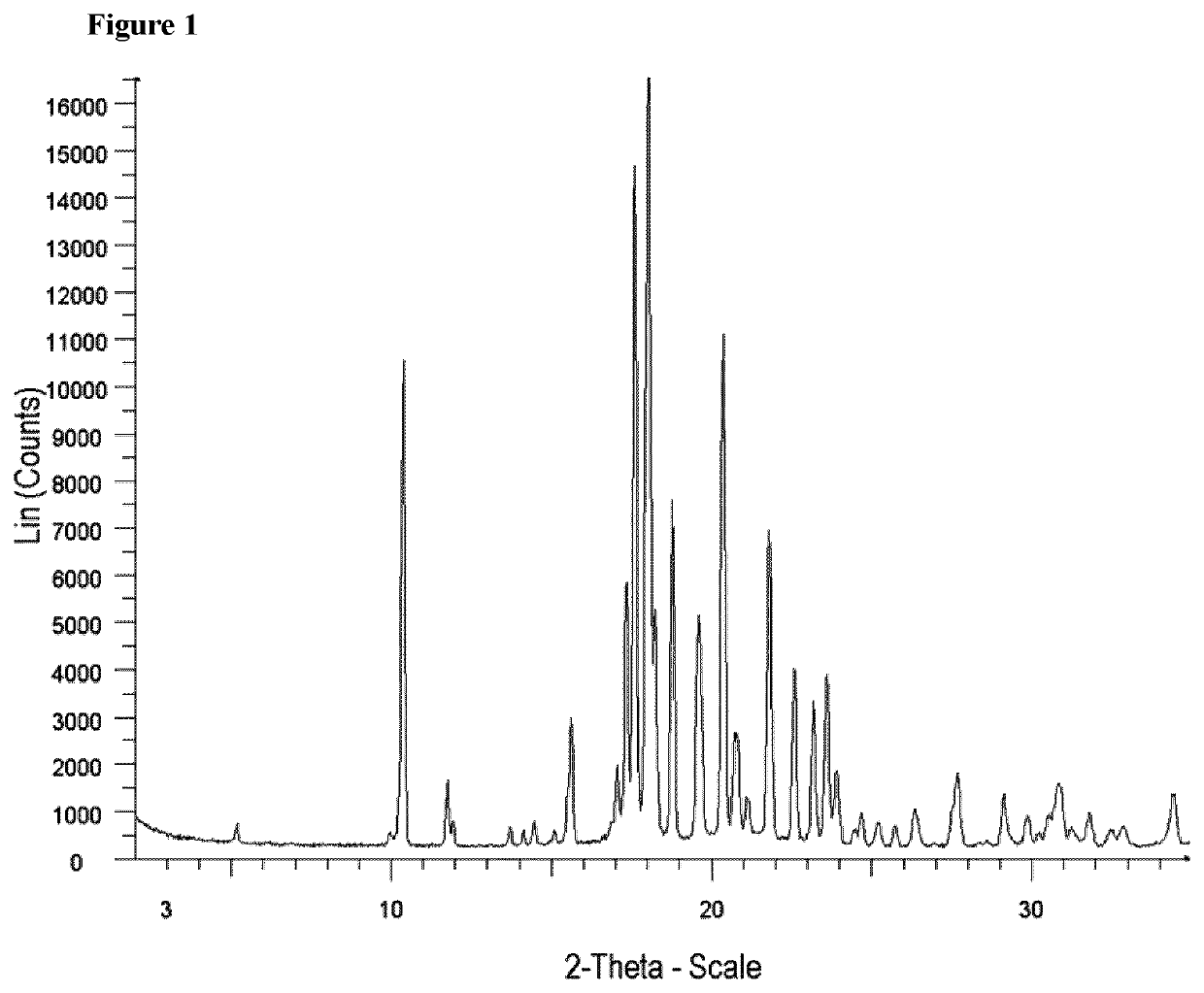

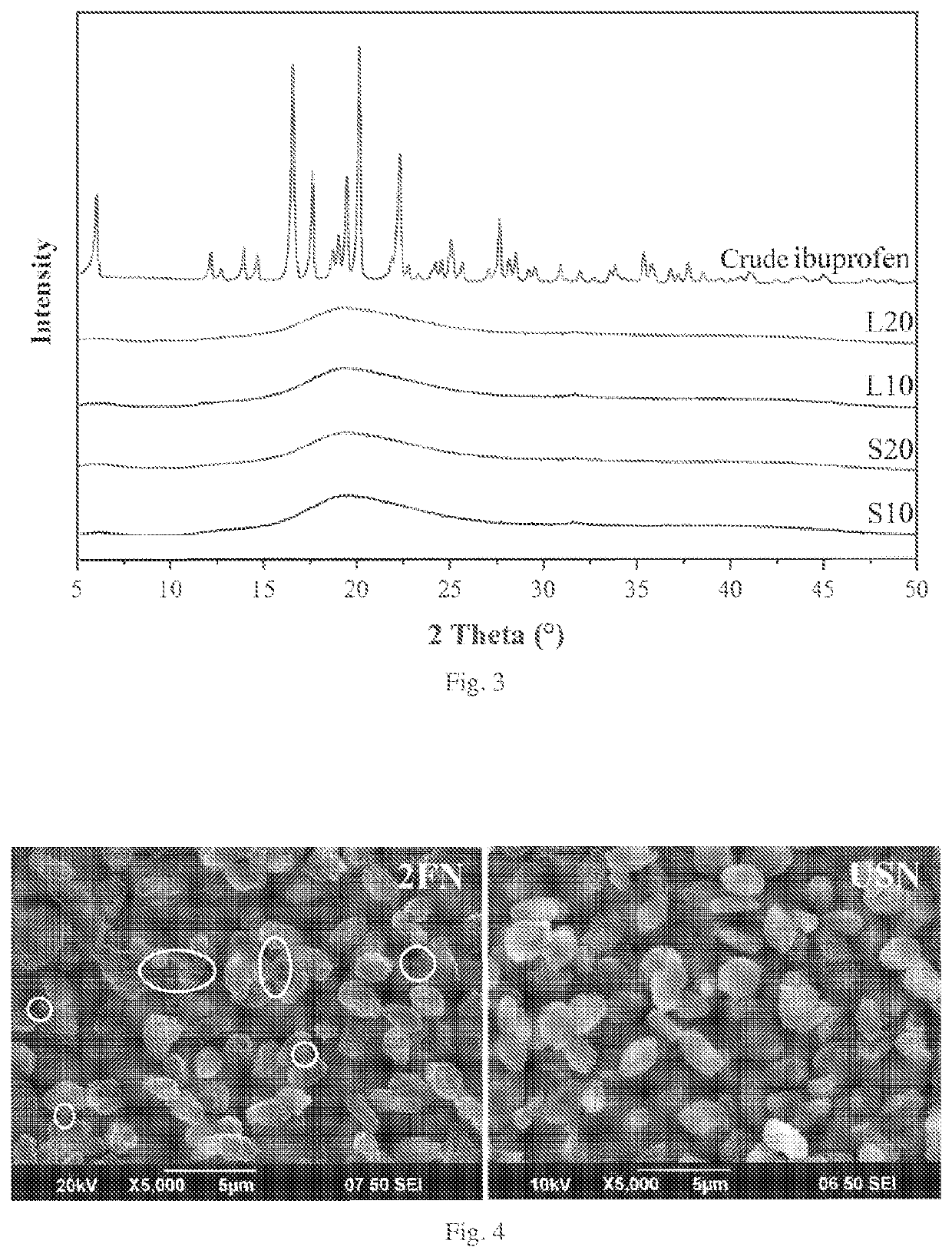

ActiveUS20110230656A1Improve compression performanceGood disintegrationOrganic active ingredientsPill deliveryLow-substituted hydroxypropylcelluloseX-ray

Provided is nonionic and excellently stable low-substituted hydroxypropylcellulose having improved compressibility and flowability, and further having improved disintegration and texture in oral cavity. More specifically provided is low-substituted hydroxypropylcellulose having a crystallinity of 60% or less, a degree of hydroxypropoxyl substitution of 5 to 9% by weight, and an aspect ratio of less than 2.5, wherein the crystallinity is calculated based on a diffraction intensity by wide-angle X-ray diffraction measurement according to the following formula (1):Crystallinity(%)={(Ic−Ia) / Ic}×100 (1)wherein Ic means a diffraction intensity at a diffraction angle 2θ of 22.5° and Ia means a diffraction intensity at a diffraction angle 2θ of 18.5°.

Owner:SHIN ETSU CHEM IND CO LTD

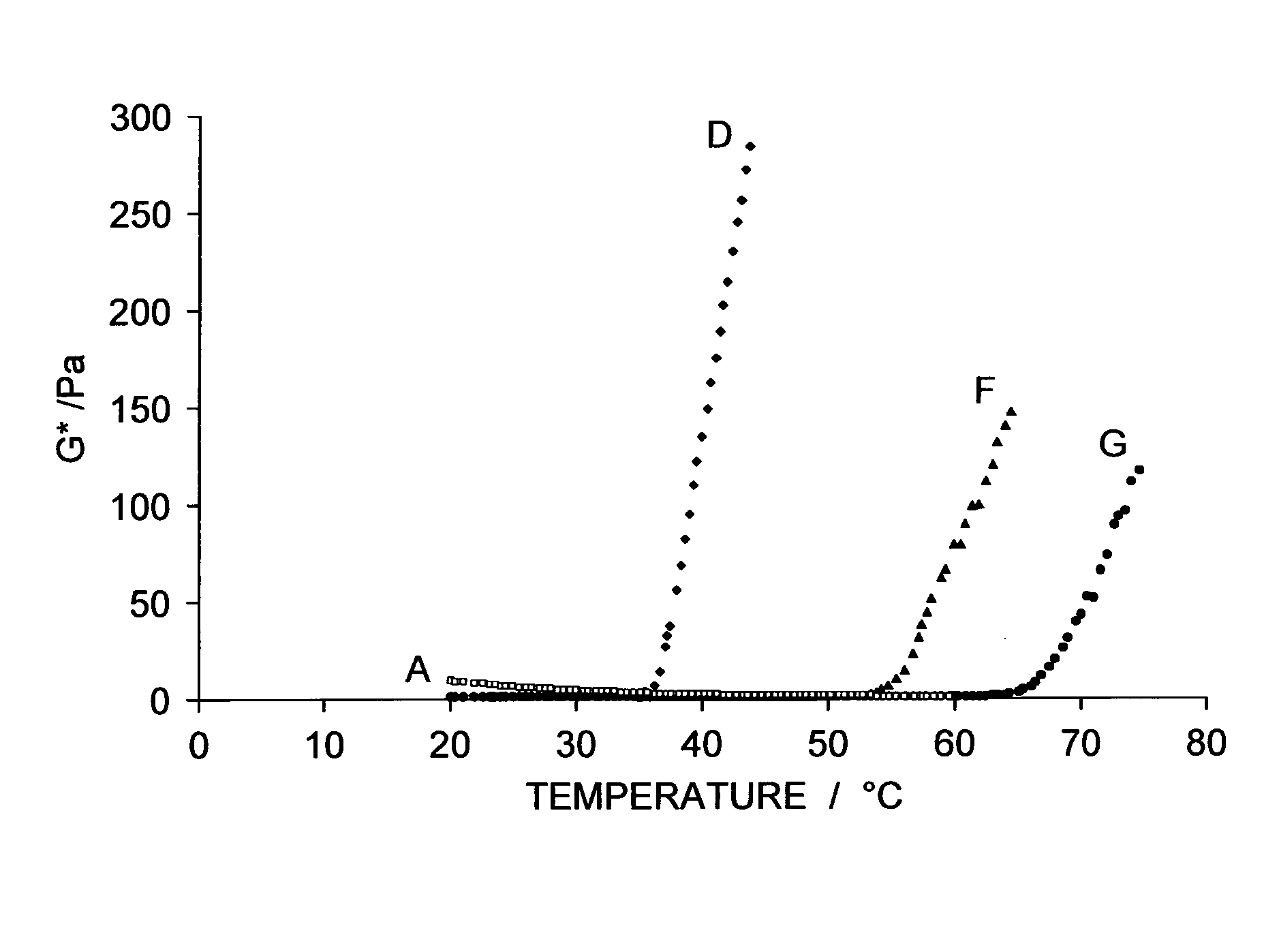

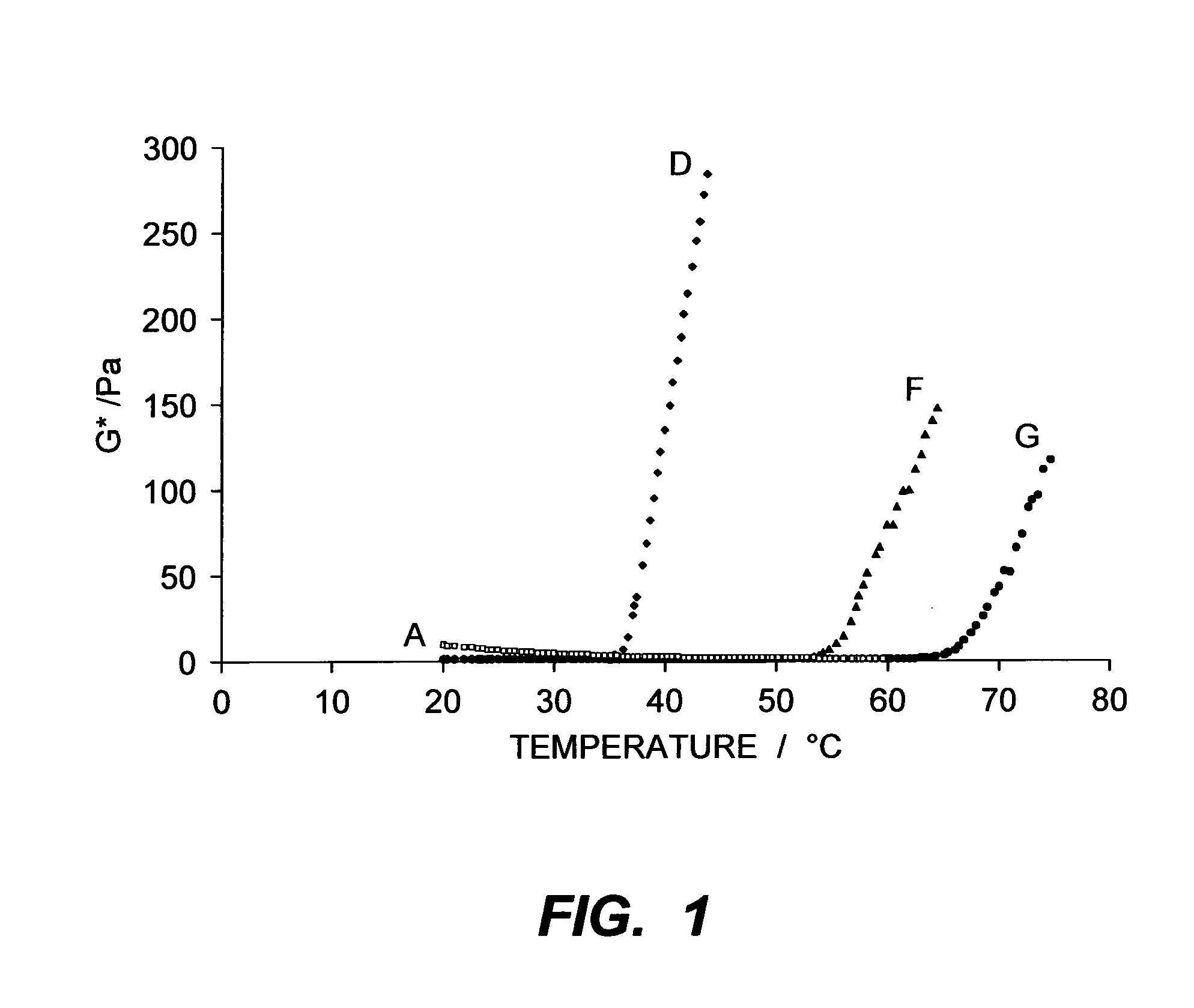

Thermally-responsive dispersants for media formulations

ActiveUS8318853B2Low viscosityEasy to operateTransportation and packagingDuplicating/marking methodsLow affinityParticulates

A thermally-responsive dispersant for an aqueous dispersion of positively- or negatively-charged or chargeable solid or liquid particulates, comprises a compound having an anchoring moiety linked to a thermally-responsive polymeric stabilizing moiety, other than a polyalkylene oxide, the polymeric moiety having a lower affinity for the surface than the anchoring group below the thermal transition temperature, the particulates being positively-charged or chargeable when the anchoring moiety contains an acid and / or hydroxy group and has a net acidity or neutrality and the particulates being negatively-charged or chargeable when the anchoring moiety has a basic group and has a net basicity, wherein the dispersion exhibits a change in sign from negative to positive and an increase in magnitude of a rheological property (viscosity at low shear and / or complex modulus at low amplitude oscillatory shear), on increasing the temperature from below to above the thermal transition temperature.

Owner:EASTMAN KODAK CO

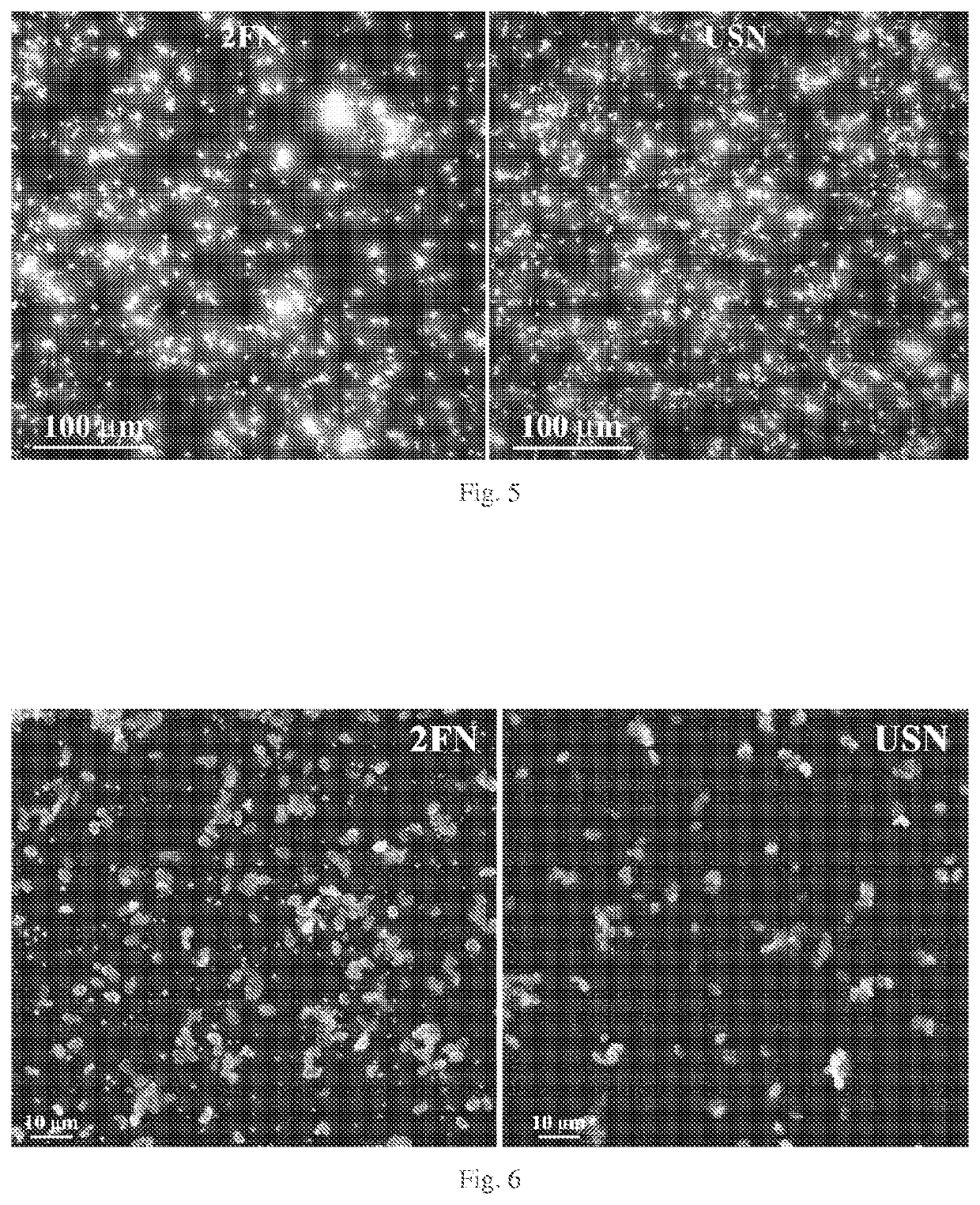

Novel process for preparing dexibuprofen ready to compress granules

InactiveUS20130217774A1Improved compressibility and flowabilityGood compressibilityBiocidePharmaceutical product form changeDexibuprofenPharmaceutical formulation

Preparing a dexibuprofen pharmaceutical formulation in the form of granules that can be directly compressed into tablets. The process consists of two steps: (i) preparation of base granules, and (ii) blending base granules with a compression aid. The process of preparing base granules involves use of liquid bed granulator with top spray method, or slugging by roll compaction. The granules prepared by using both the methods showed improved compressibility and flowability compared to granules prepared by conventional granulation process using rapid mixer granulator. The ready-to-compress granules prepared by the process show no signs of sticking when compressed on a high-speed commercial scale tablet compression machine.

Owner:SUNDARAMOORTHY VIVEKANANDAN +3

Low-substituted hydroxypropylcellulose and solid preparation comprising the same

ActiveUS8822675B2Good compressibilityImproved flowabilityOrganic active ingredientsSugar derivativesLow-substituted hydroxypropylcelluloseX-ray

Provided is nonionic and excellently stable low-substituted hydroxypropylcellulose having improved compressibility and flowability, and further having improved disintegration and texture in oral cavity. More specifically provided is low-substituted hydroxypropylcellulose having a crystallinity of 60% or less, a degree of hydroxypropoxyl substitution of 5 to 9% by weight, and an aspect ratio of less than 2.5, wherein the crystallinity is calculated based on a diffraction intensity by wide-angle X-ray diffraction measurement according to the following formula (1):Crystallinity(%)={(Ic−Ia) / Ic}×100 (1)wherein Ic means a diffraction intensity at a diffraction angle 2θ of 22.5° and Ia means a diffraction intensity at a diffraction angle 2θ of 18.5°.

Owner:SHIN ETSU CHEM IND CO LTD

Method for Manufacturing Composite Structure

InactiveUS20180272630A1Improved flowabilityEasily flowLaminationLamination apparatusComposite structureAdhesive

A metal plate, a fabric formed of reinforcing fibers, and thermosetting adhesives are layered on each other in a die in a die clamping direction. The thermosetting adhesives are forced to enter the fabric by clamping the die to produce a fiber reinforced plastic material with the thermosetting adhesives therein being in an uncured state. At the same time, the fiber reinforced plastic material is molded into a shape specified by the die. The thermosetting adhesives are allowed to cure in the die to cure the molded fiber reinforced plastic material, and the fiber reinforced plastic material and the metal plate are bonded each other.

Owner:AISIN TAKAOKA CO LTD

Chitosan-Silicon Dioxide Coprecipitate and Use as Excipient in Solid Dosage Forms

InactiveUS20080214677A1Improved flowabilityEasy to compressBiocideOrganic active ingredientsImmediate releaseSilicon dioxide

Chitosan silicon dioxide coprecipitate composition, method of production thereof, pharmaceutical composition comprising the chitosan silicon dioxide coprecipitate composition and use of the chitosan silicon dioxide coprecipitate composition for manufacturing a sustained or immediate release formulation.

Owner:THE JORDANIAN PHARMA MFG

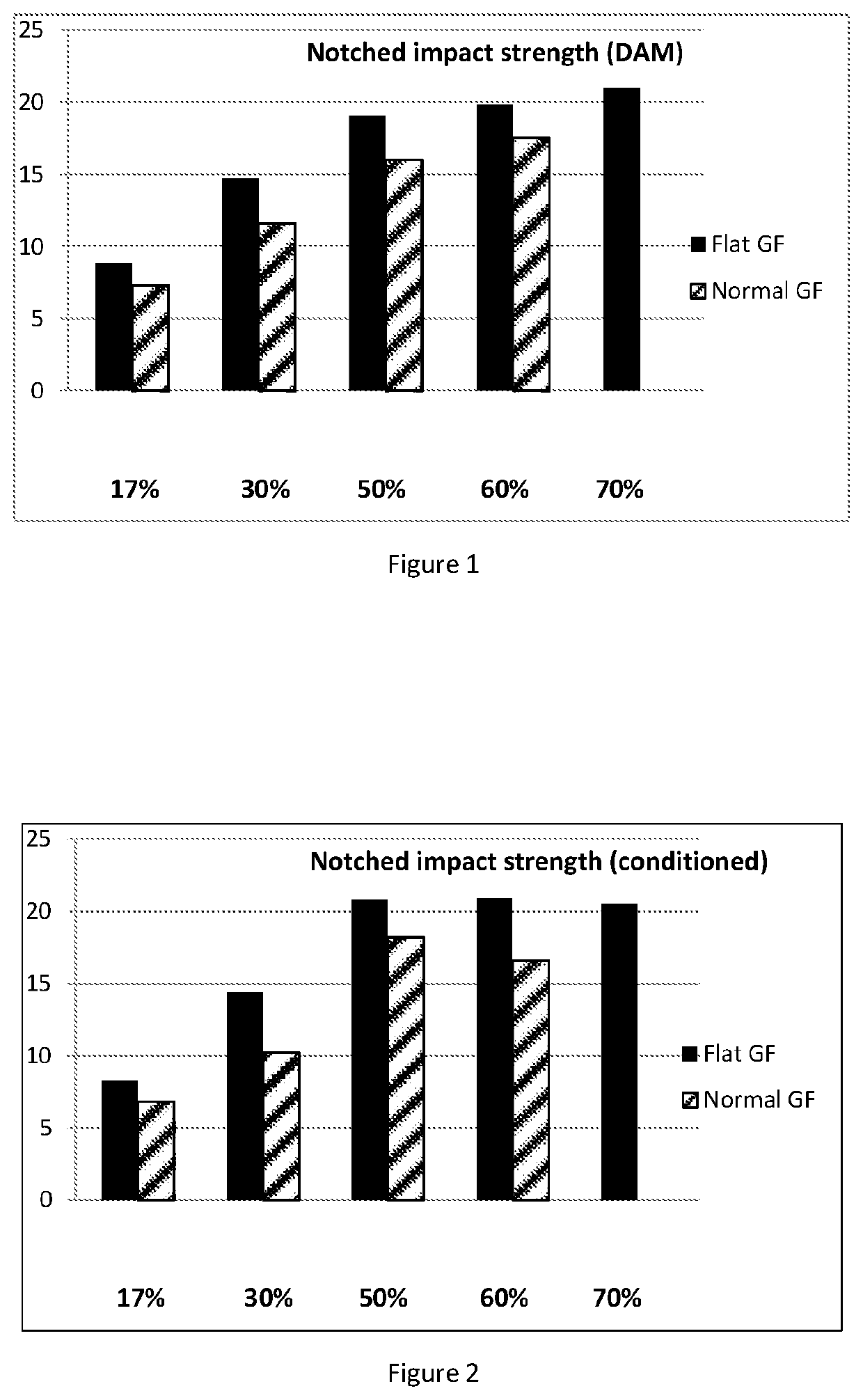

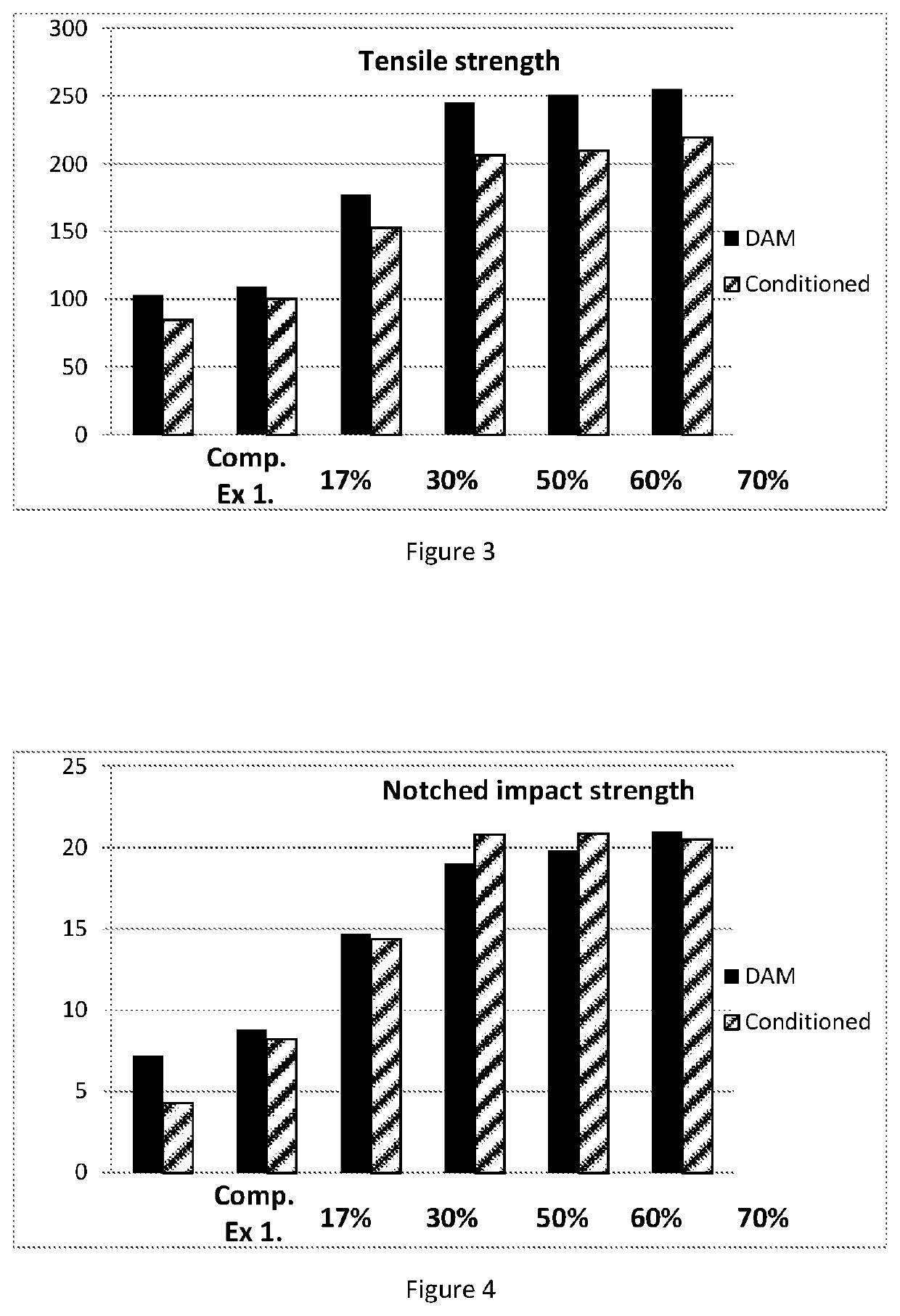

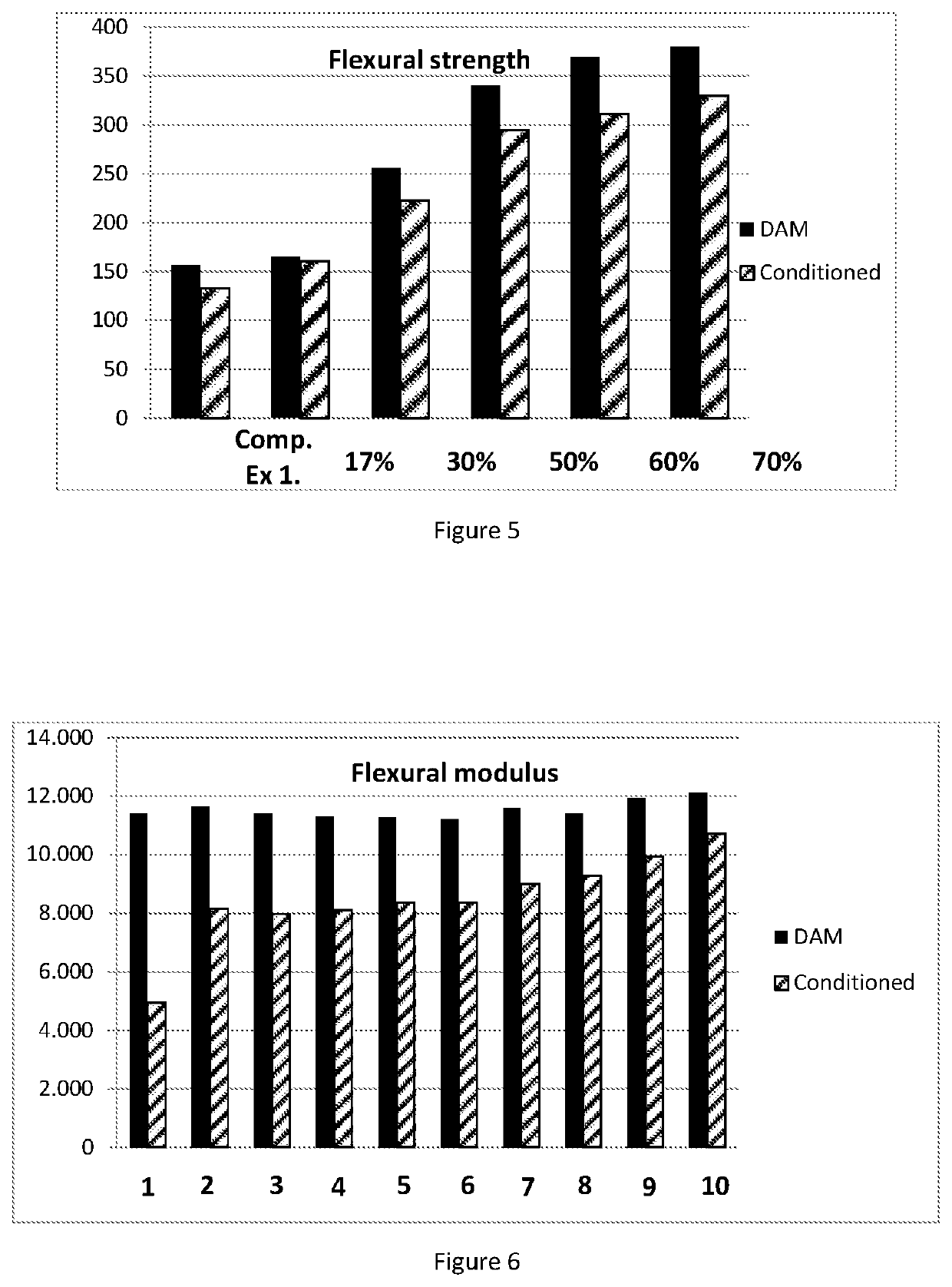

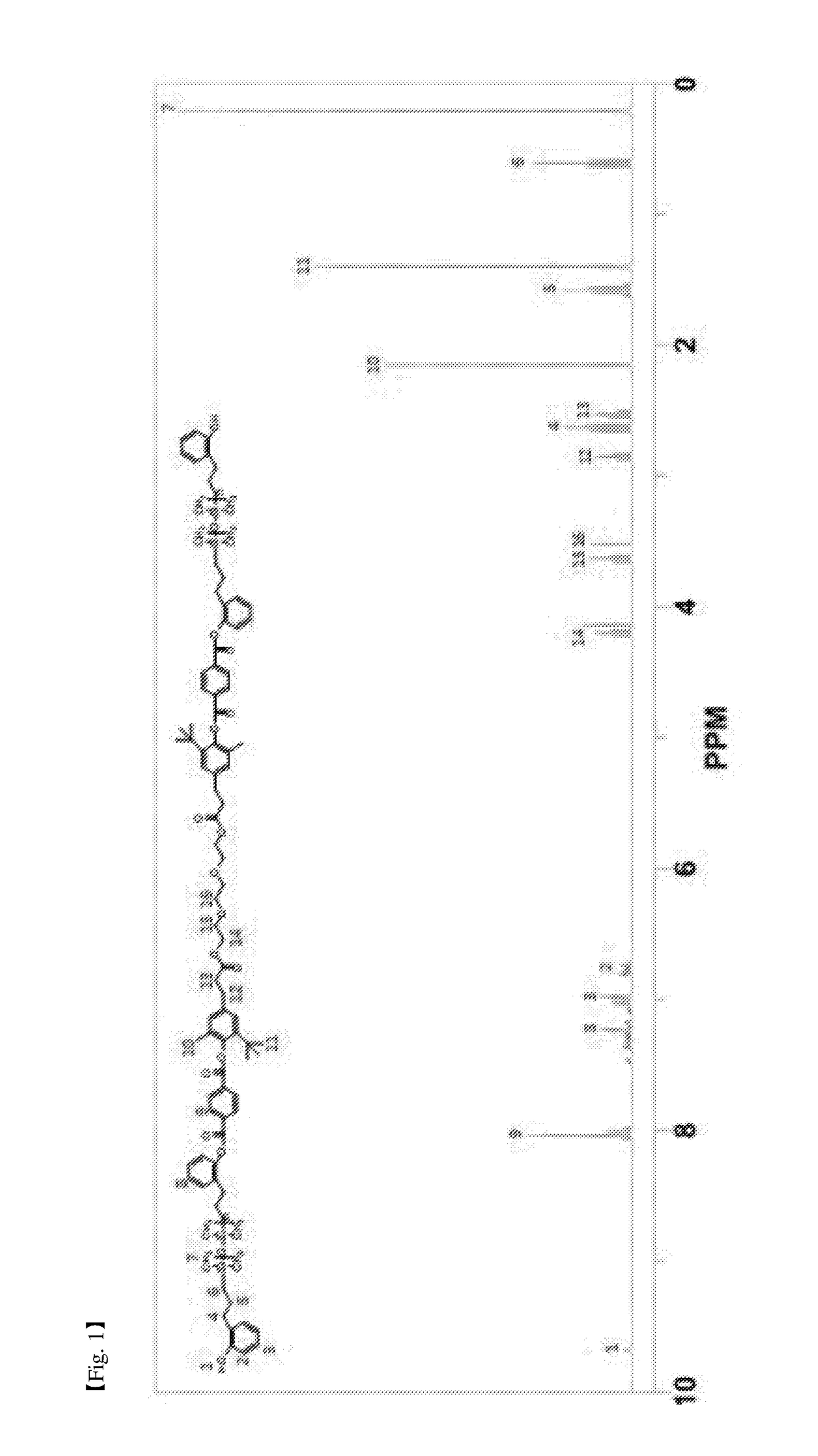

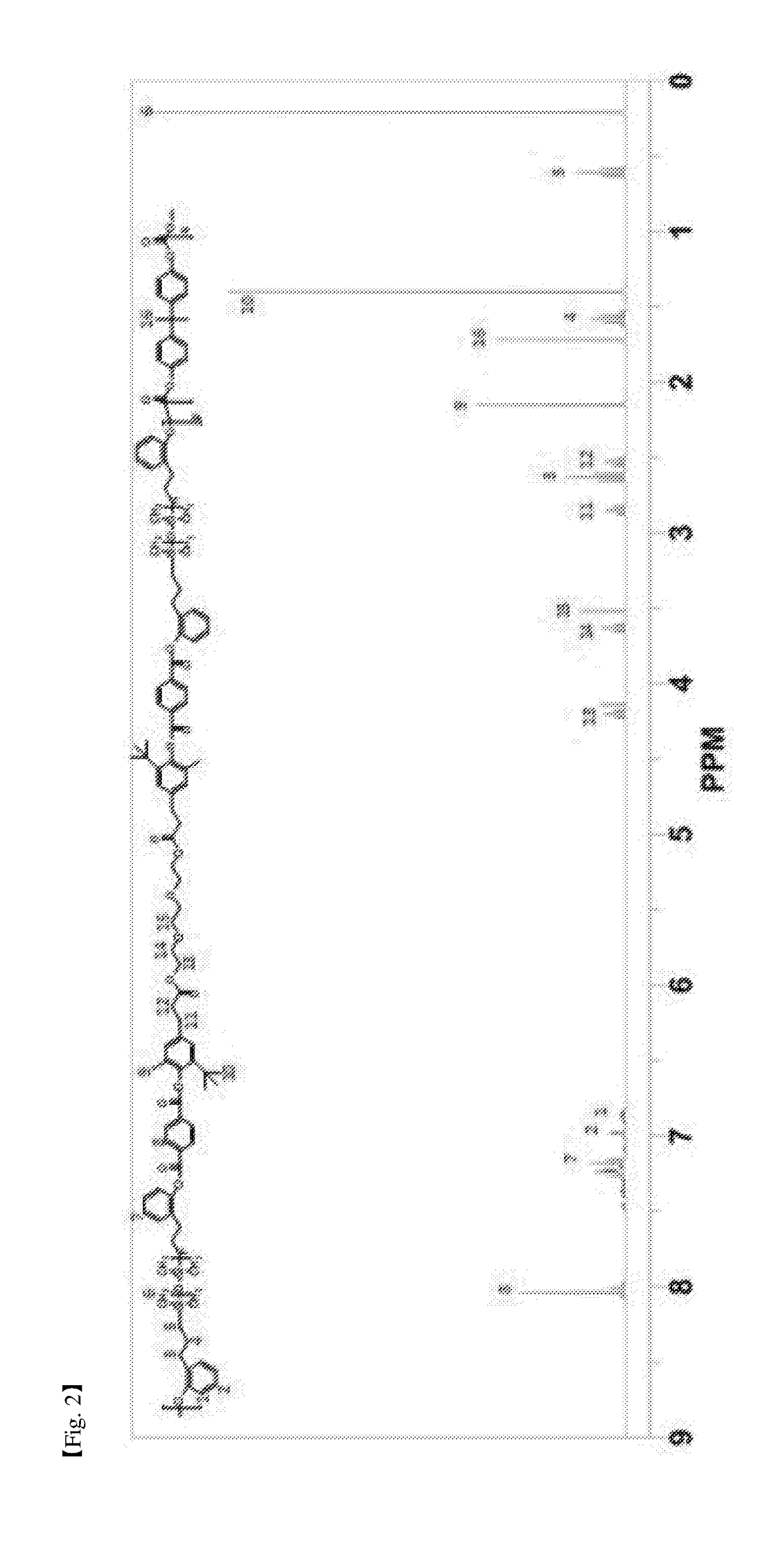

Polyamide formulations comprising semi-crystalline copolyamide and flat glass fibers

The present disclosure relates to a polyamide molding composition including a semi-aromatic, semi-crystalline copolyamide and flat glass fibers that shows a low tendency to absorb moisture and thus maintains its excellent mechanical and optical properties also during storage and / or use.

Owner:BASF SE

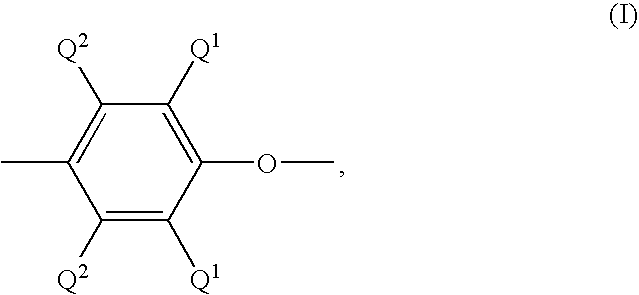

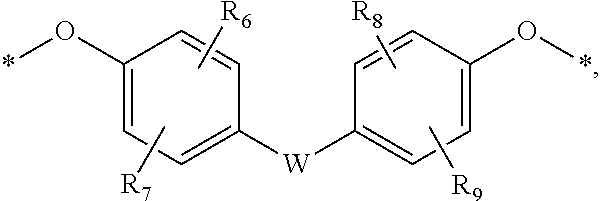

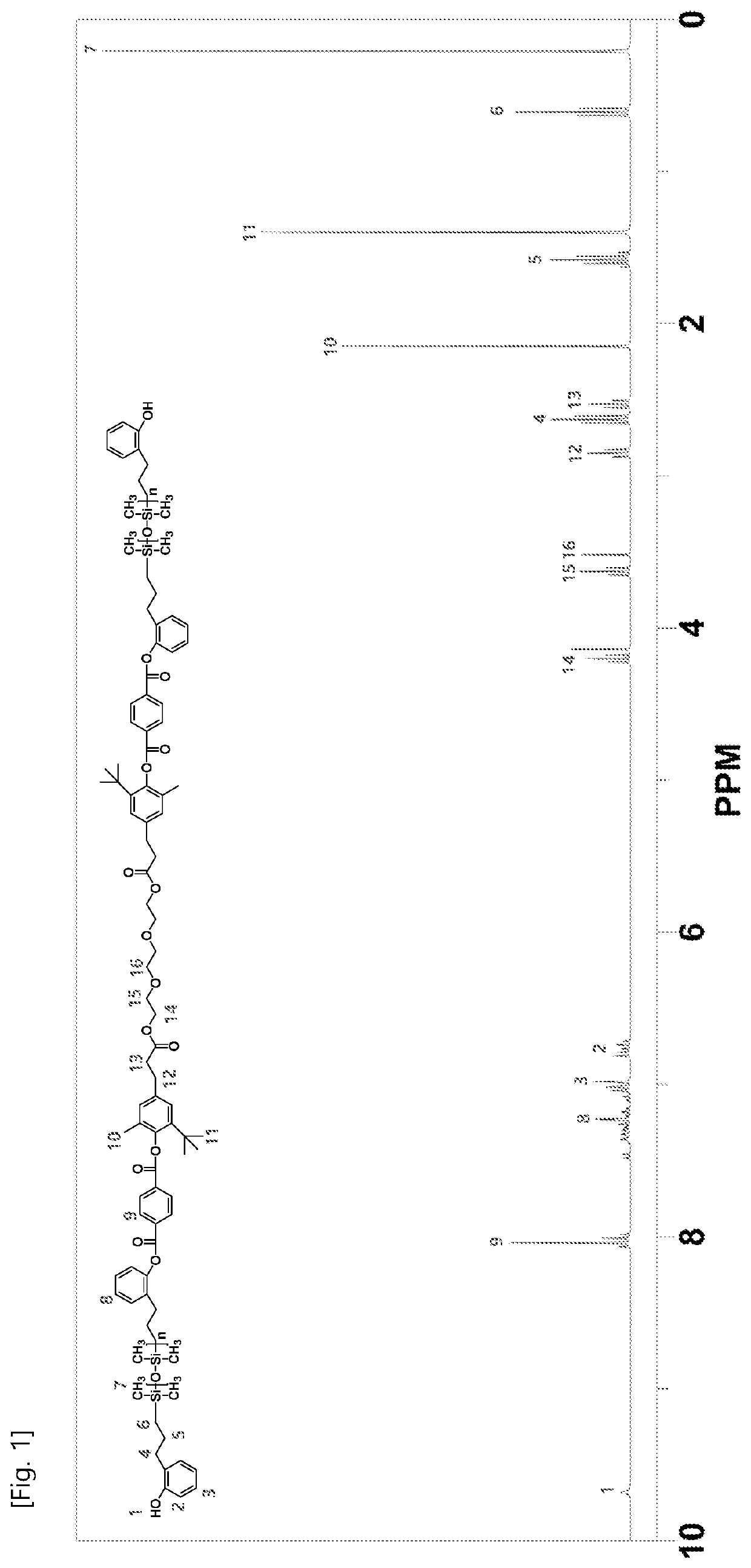

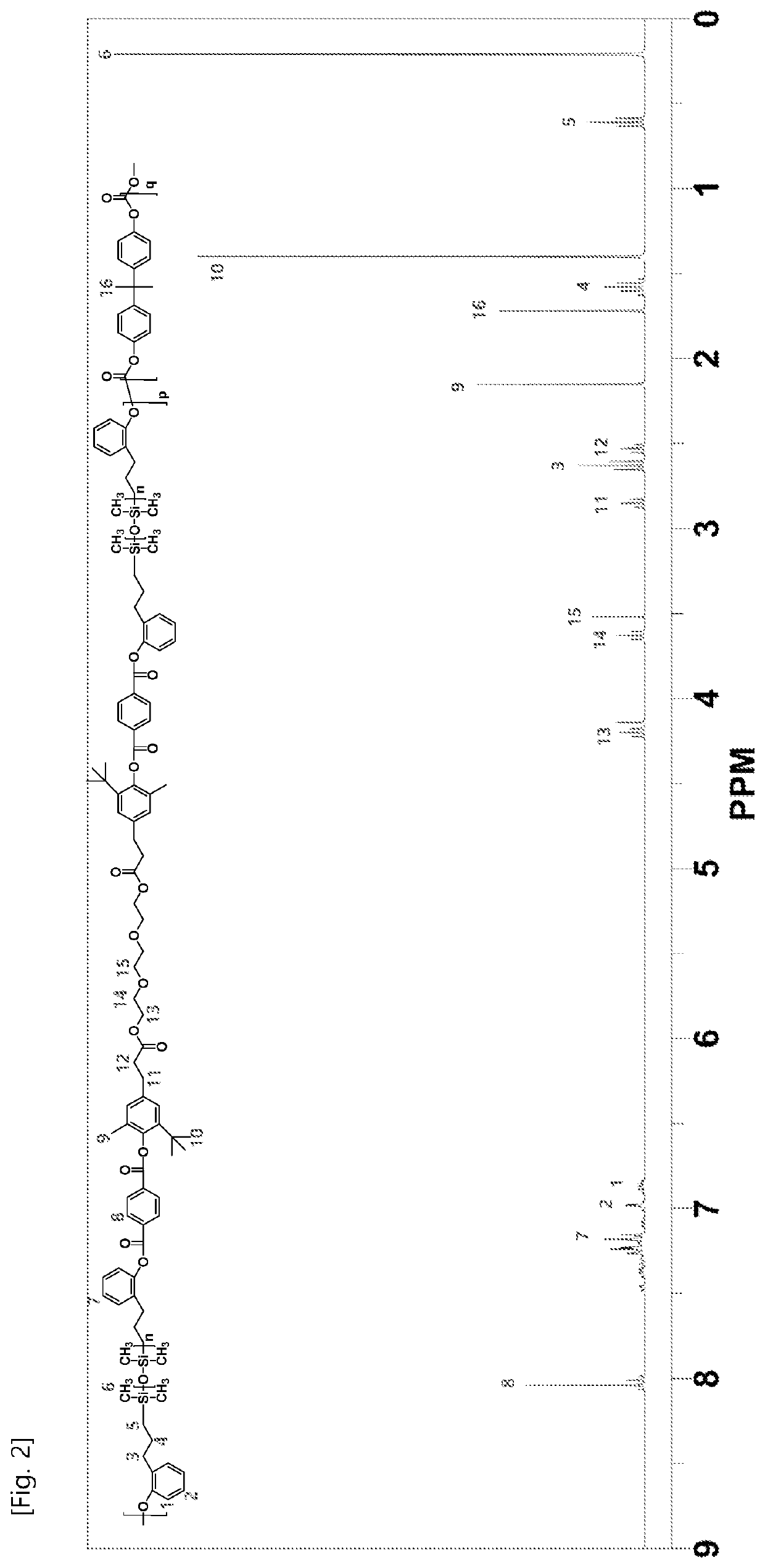

Novel polyorganosiloxane, and copolycarbonate prepared by using the same (amended)

ActiveUS20180194894A1Improved flowabilityGood weather resistanceSilicon organic compoundsPolymer sciencePolycarbonate

Provided are a novel polyorganosiloxane capable of preparing copolycarbonate with improved weather resistance and flowability while maintaining the intrinsic physical properties of polycarbonate resin, and a copolycarbonate prepared by using the same.

Owner:LG CHEM LTD

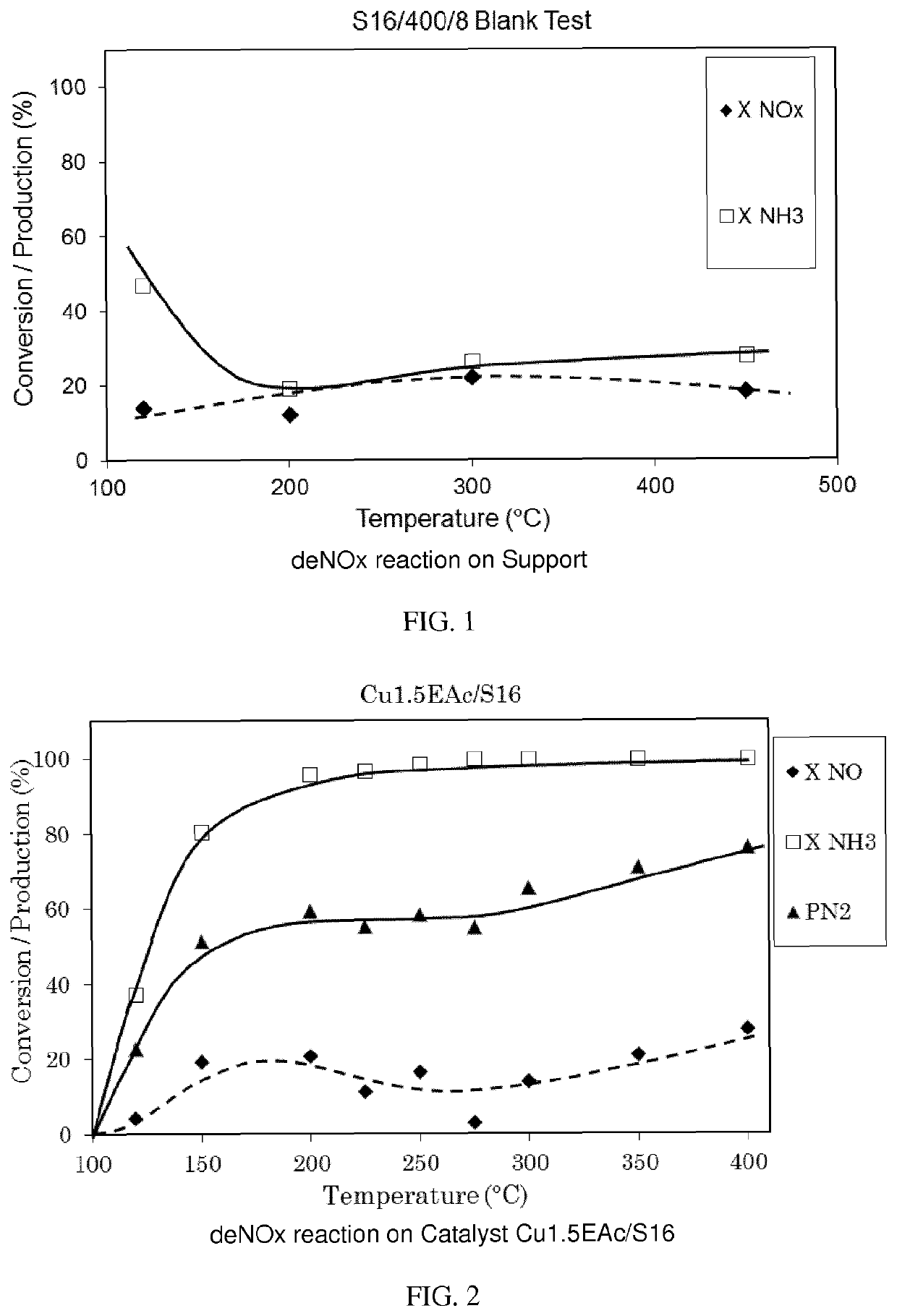

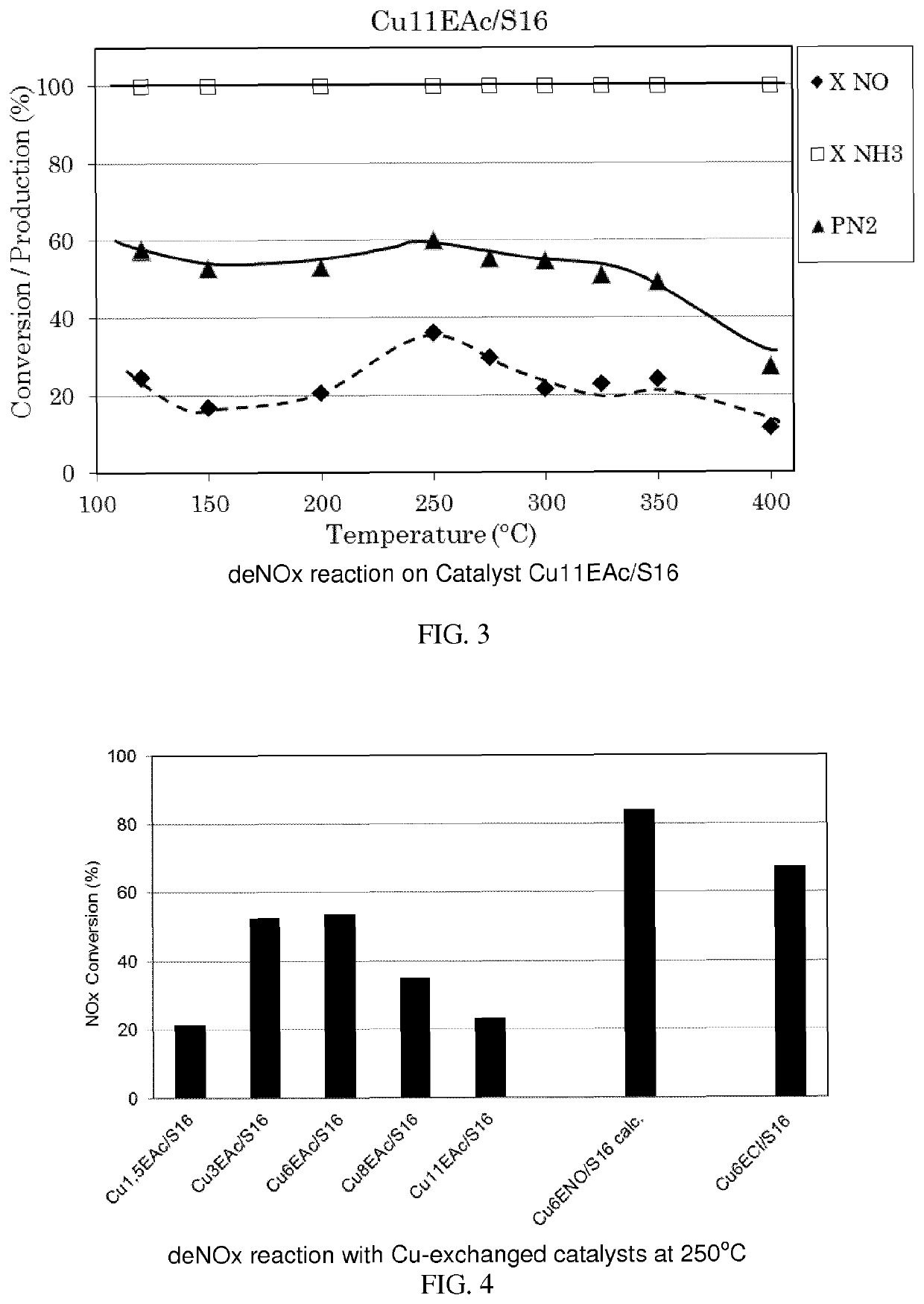

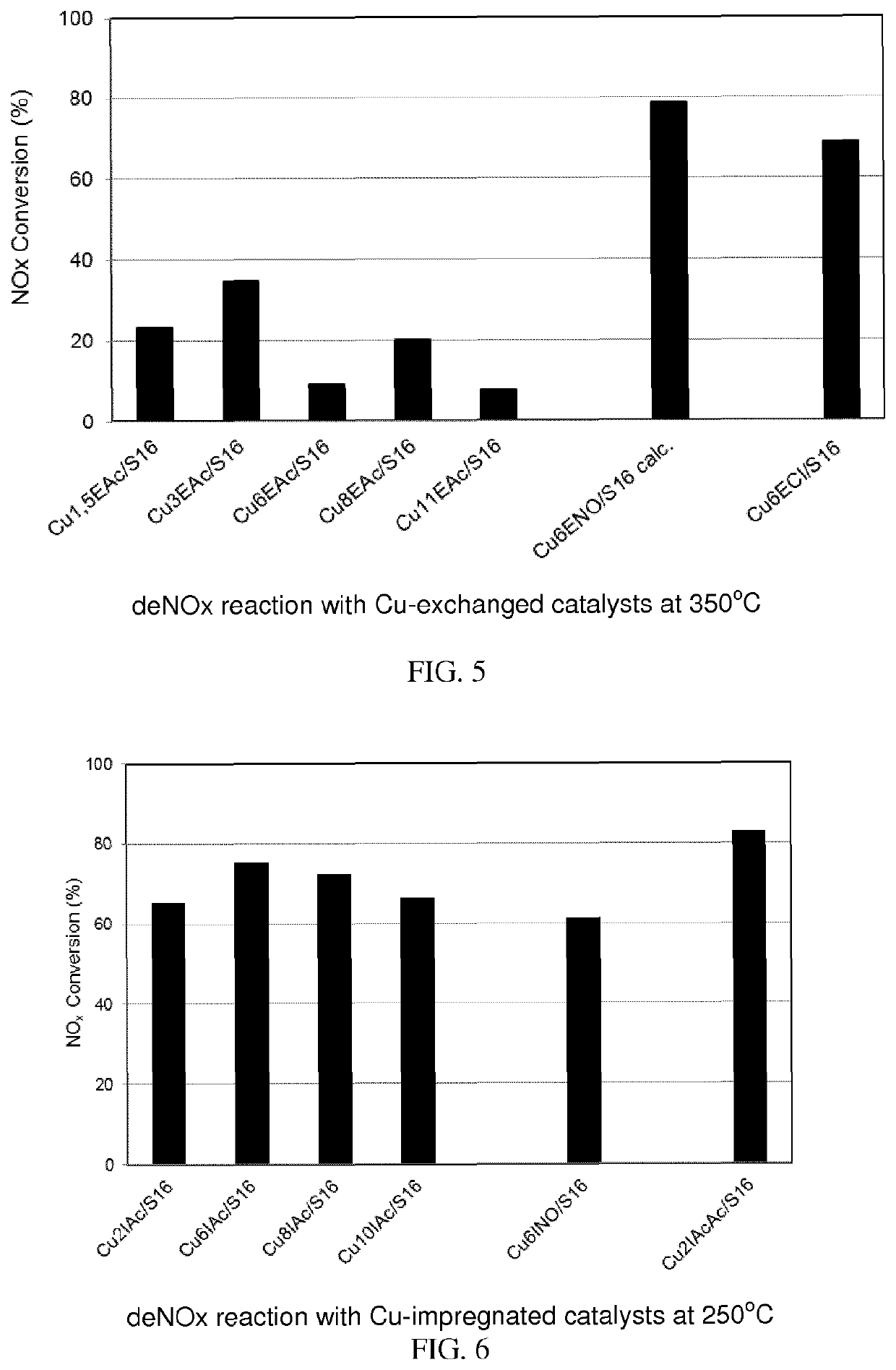

Copper supported catalyst comprising a ca-deficient hydroxyapatite for waste gas NOX removal

ActiveUS20190381452A1Good dispersionImproved flowabilityDispersed particle separationCatalyst activation/preparationApatiteNitrogen oxide

A porous material comprises at least 60 wt % of a calcium-deficient hydroxyapatite having a Ca / P molar ratio of less than 1.67, having a specific BET surface area of at least 110 m2 / g and a pore volume of at least 0.41 cm3 / g, both measured after heat treatment at 120° C. A catalyst composition for catalytic reduction of NOx compounds, comprising an active catalyst component: Cu and / or CuO deposited on the porous material as support. A deNOx process according to which an ammonia source is injected into a combustion waste gas stream containing NOx; and to which the catalyst composition is brought into contact with the waste gas stream at a temperature of at least 100° C. and preferably at most 600° C. to carry out, in the presence of O2, a reduction by NH3 of at least a portion of the NOx.

Owner:SOLVAY SA

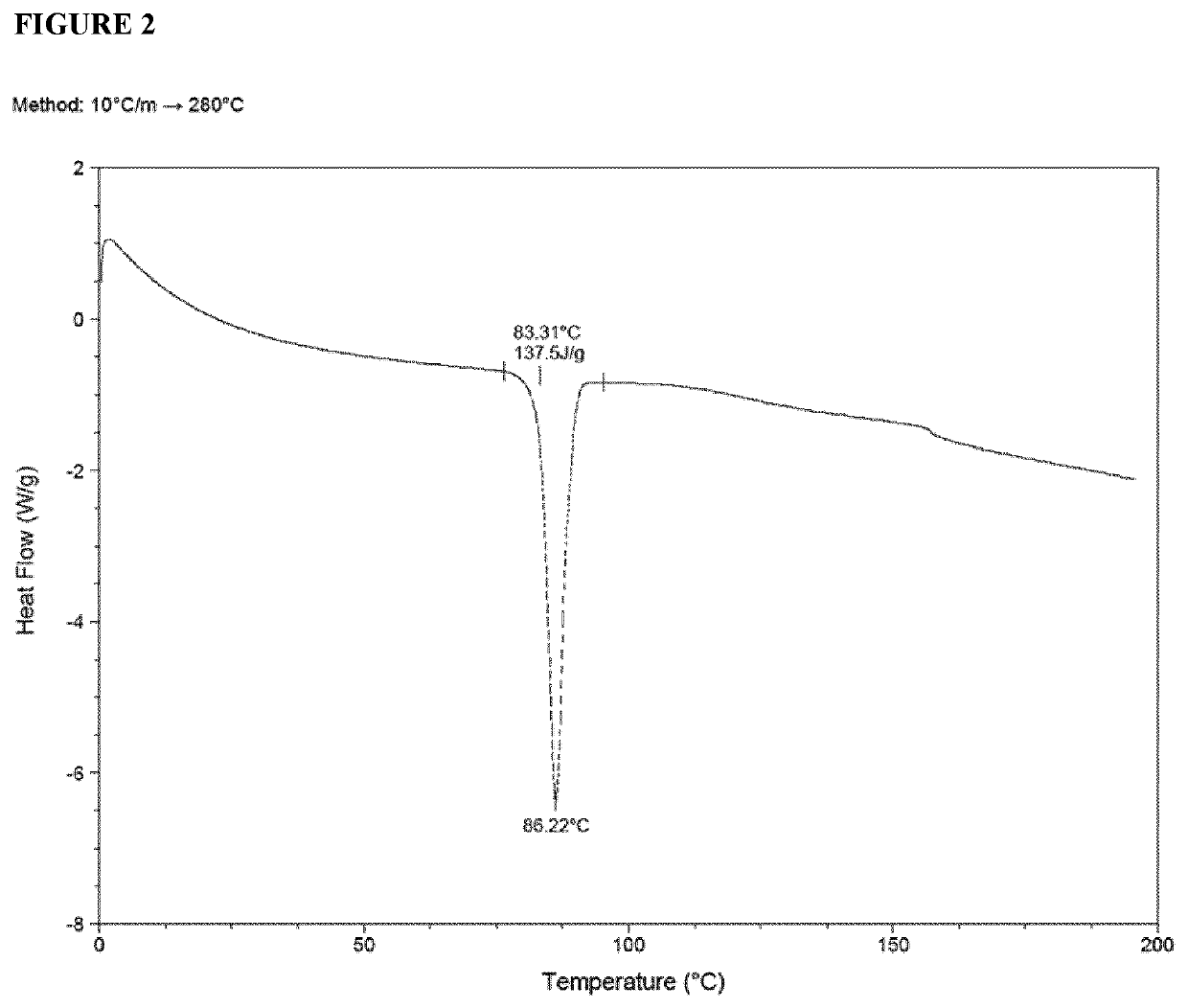

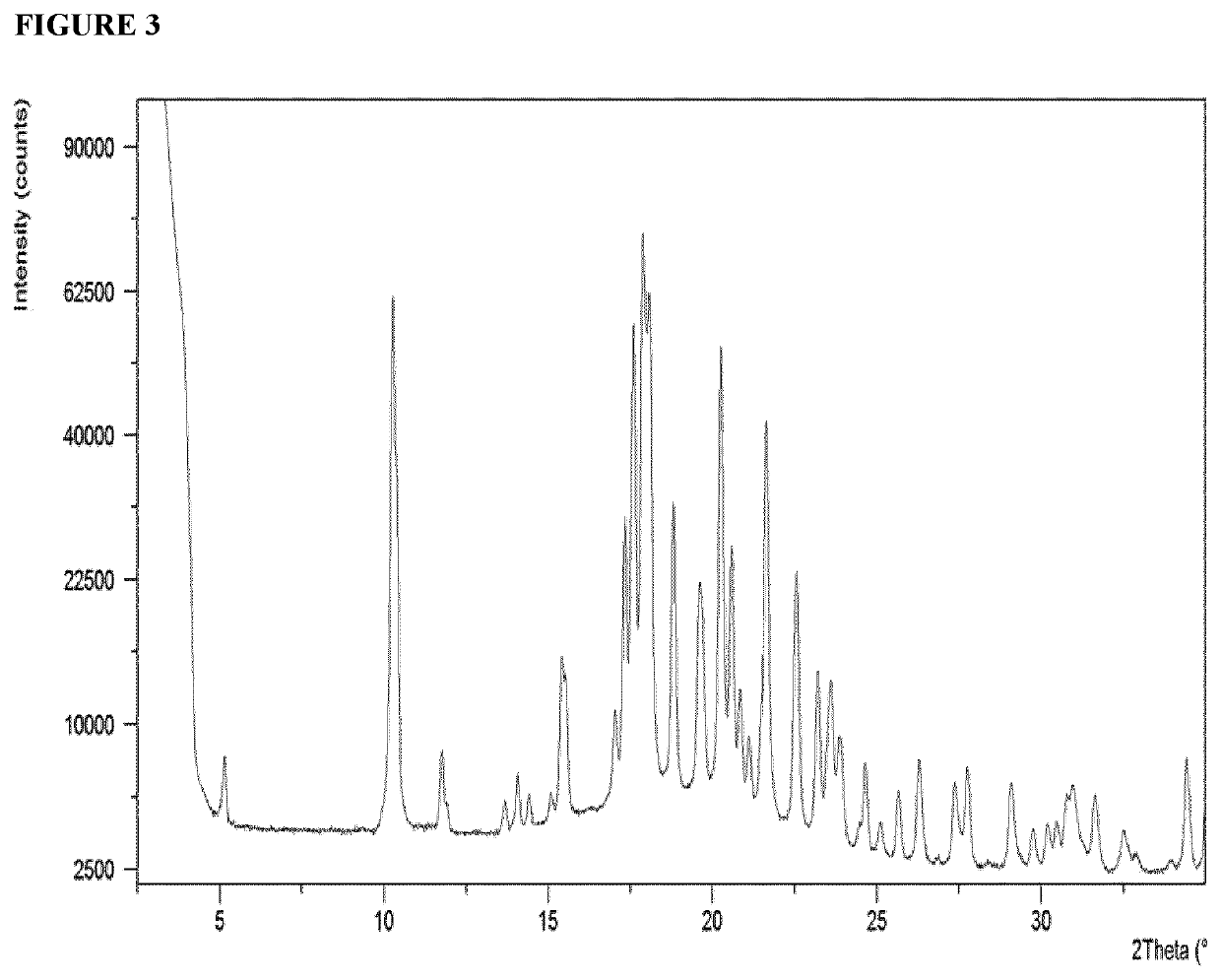

Crystalline forms of bempedoic acid

PendingUS20220348531A1High crystallinityImproved flowabilityOrganic chemistry methodsCarboxylic compound separation/purificationCrystallographyBempedoic acid

Owner:SYNTHON BV

Polyorganosiloxane, and copolycarbonate prepared by using the same

ActiveUS10577461B2Improved flowabilityIncrease resistanceSilicon organic compoundsPolymer sciencePolycarbonate

Provided are a novel polyorganosiloxane capable of preparing copolycarbonate with improved weather resistance and flowability while maintaining the intrinsic physical properties of polycarbonate resin, and a copolycarbonate prepared by using the same.

Owner:LG CHEM LTD

High flow heterophasic polyolefin composition having improved stiffness/impact balance

High flow nucleated heterophasic polyolefin compositions comprising a matrix comprising a propylene homo- and / or copolymer and an elastomeric alpha-olefin copolymer phase dispersed in the matrix, which have rather high melt flow rate, improved impact strength but also an excellent impact / stiffness balance and a process for the preparation of such a heterophasic polyolefin composition, articles made therefrom and uses of the heterophasic polyolefin composition.

Owner:BOREALIS AG

Method for Preparing Superabsorbent Polymer

PendingUS20220315715A1Promote absorptionAvoid stickinessPlastic recyclingPolymer scienceSuperabsorbent polymer

Owner:LG CHEM LTD

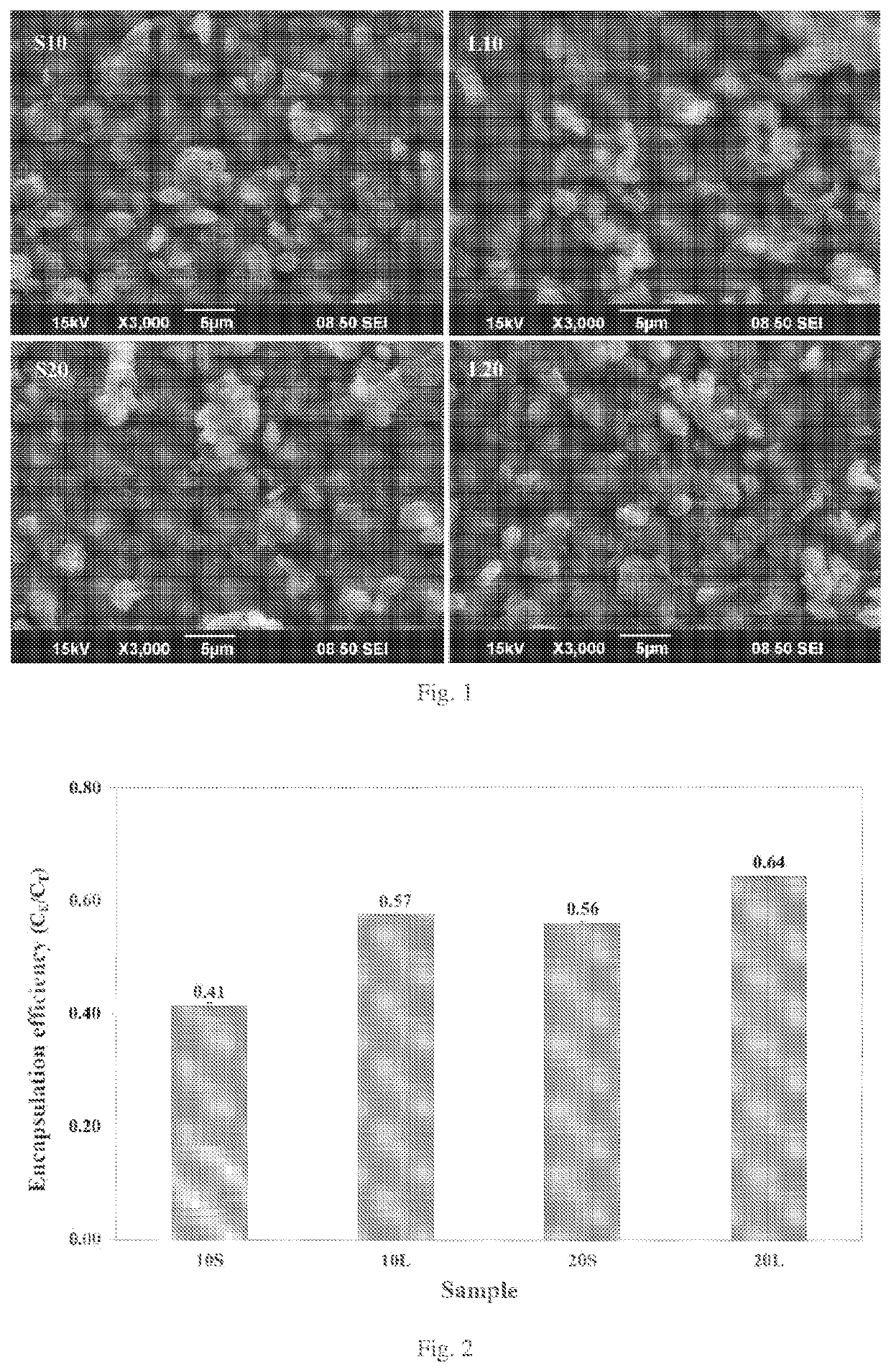

Method of production of a composite of yeast-derived beta glucan particle with incorporated poorly-water-soluble low-molecular-weight compound, pharmaceutical preparation and use thereof

PendingUS20220192985A1Fast dissolutionGood dispersibilityFungiHydroxy compound active ingredientsFood supplementBeta-glucan

A formulation of composites having yeast-derived beta glucan particles (GPs) and water-insoluble or poorly-water-soluble low-molecular-weight compounds, such as medicaments or food supplements is disclosed. The composites can exhibit different crystallinity degrees depending on the formulation and, consequently, dissolution kinetics can be controlled. Yeast-derived beta glucan particles are used as carriers for the encapsulation and amorphization of insoluble or poorly water-soluble low-molecular-weight compounds; amorphous formulations exhibiting faster dissolution rates, and consequently, enhanced oral bioavailability. A method of preparation of the composites by spray drying is also disclosed.

Owner:VYSOKA SKOLA CHEMICKO TECHCKA V PRAZE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com