Patents

Literature

277results about How to "High intrinsic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified olefin (co)polymer composition, process for preparing the same, and modified olefin (co)polymer composition molding

InactiveUS6231804B1Specific limiting viscosityHigh intrinsic viscosityElectric/magnetic/electromagnetic heatingPolypropylenePolyolefin

A high molecular weight polyethylene prepared by preliminary polymerization is added at the time of main polymerization of an olefin, for example, propylene, to prepare an olefin (co)polymer composition comprising the above high molecular weight polyethylene finely dispersed as fine particles in the polyolefin, such as polypropylene, and a cross-linked structure is formed in the olefin (co)polymer composition. This process can provide a modified olefin (co)polymer composition improved in the strength in a molten state in terms of melt tension or the like and in crystallization temperature and excellent in moldability such as high-speed producibility, and a molded modified olefin (co)polymer composition excellent in properties such as heat resistance and rigidity.

Owner:JNC CORP

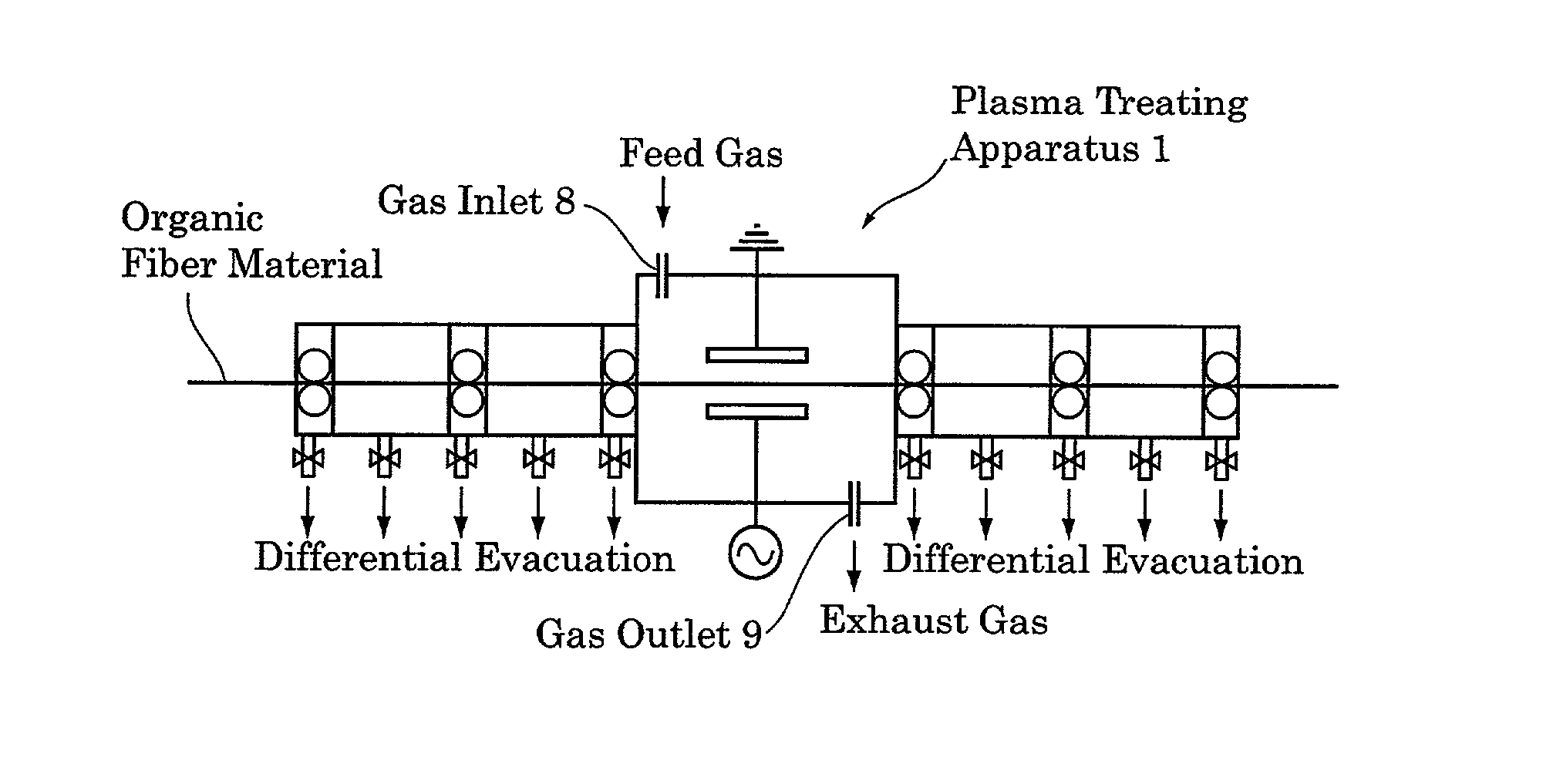

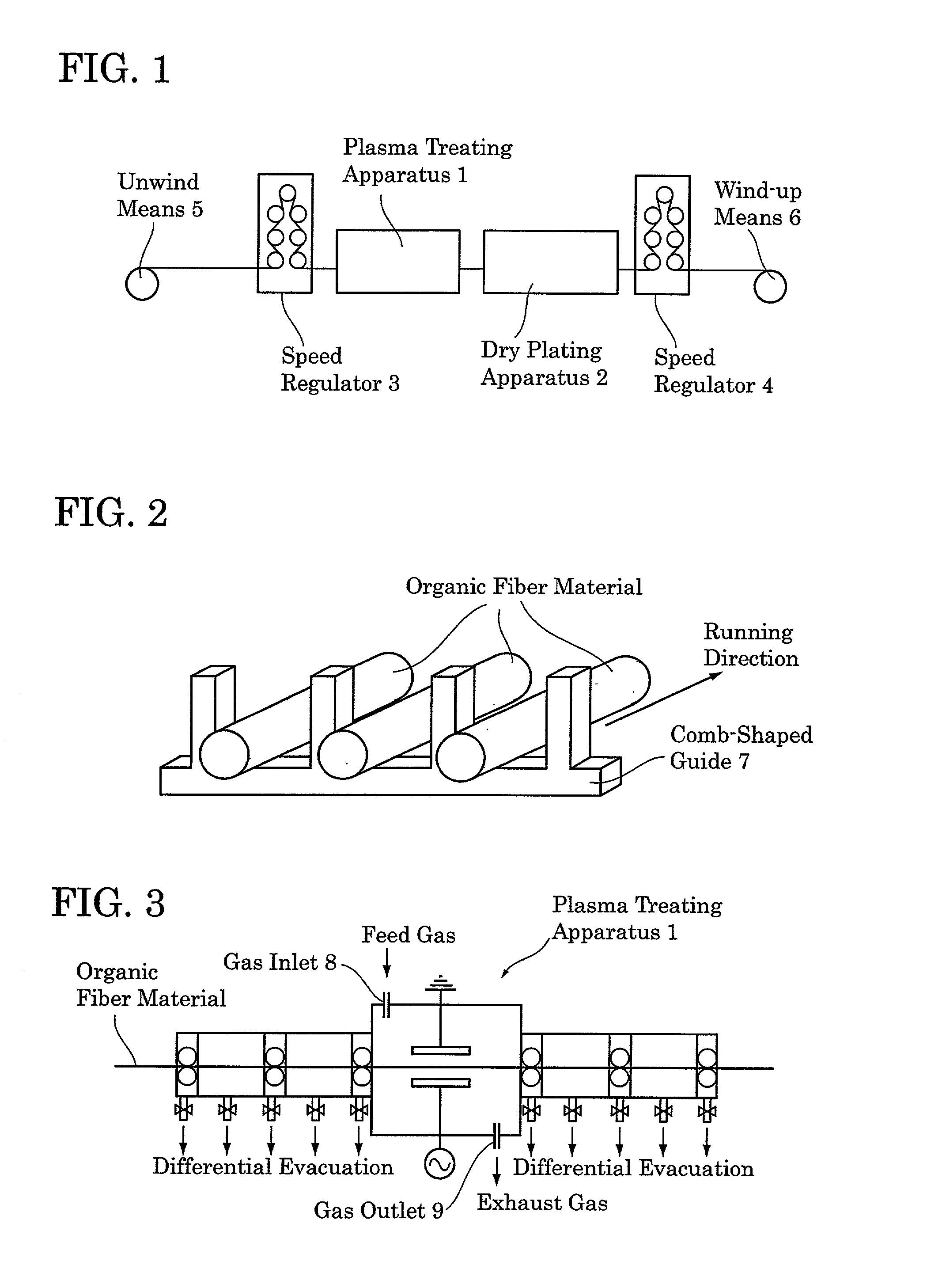

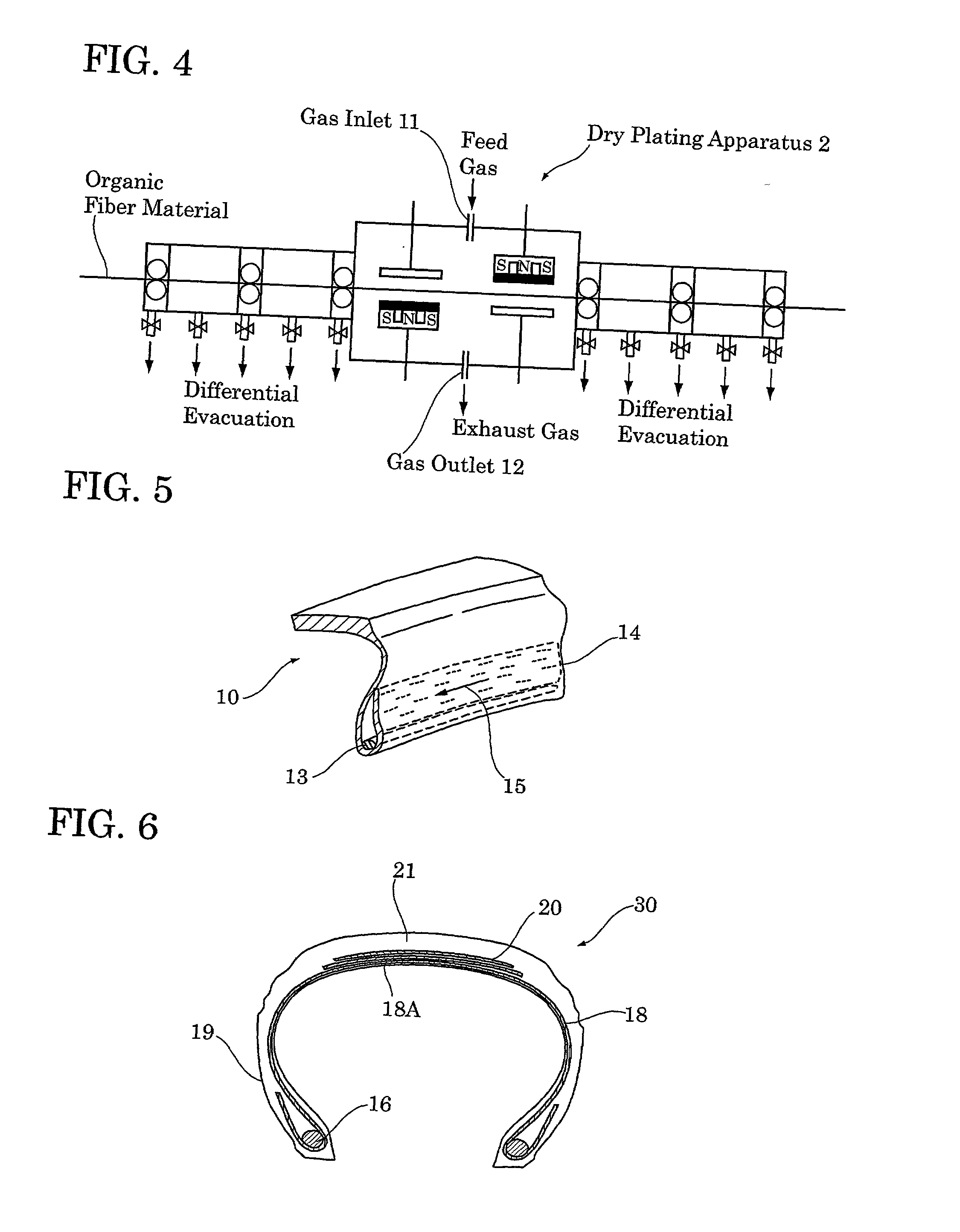

Rubber-reinforcing fiber, process for producing the same, and rubber product and pneumatic tire each made with the same

InactiveUS20030000619A1Sufficient fatigue resistanceSolve the lack of resistanceLiquid surface applicatorsTyresFiberTitanium

The rubber-reinforcing fiber of the present invention is provided with a coating layer of a thickness of 10 Å to 40 mum. The coating layer is formed by dry plating and contains at least one metal and / or metal compound selected from the group consisting of cobalt, zinc, copper, titanium, silver, nickel and compounds of the aforesaid metals. With such a coating layer, the rubber-reinforcing fiber of the present invention forms a firm adhesion to a rubber component and drastically improves the fatigue resistance and durability of a rubber article, particularly, a pneumatic tire.

Owner:BRIDGESTONE CORP

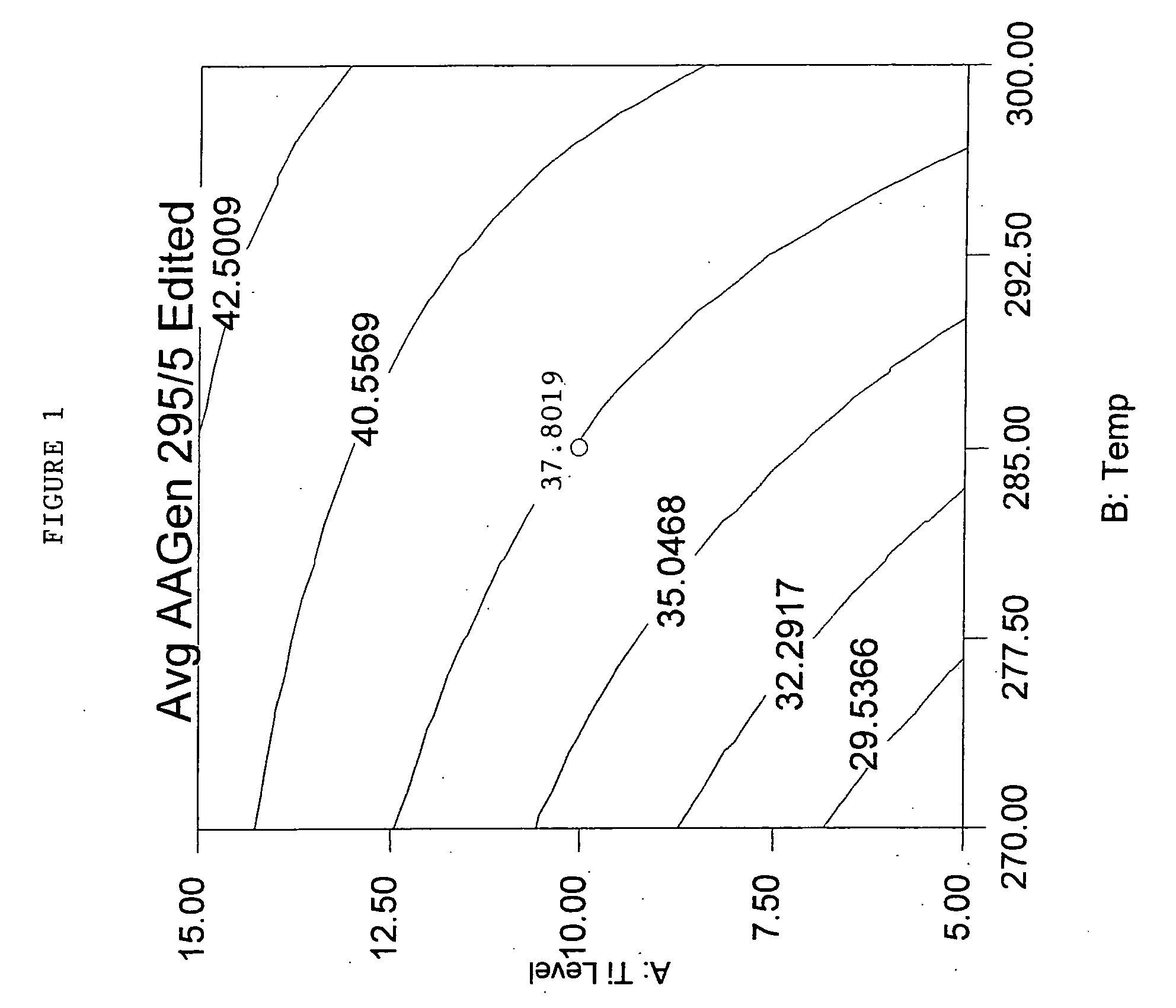

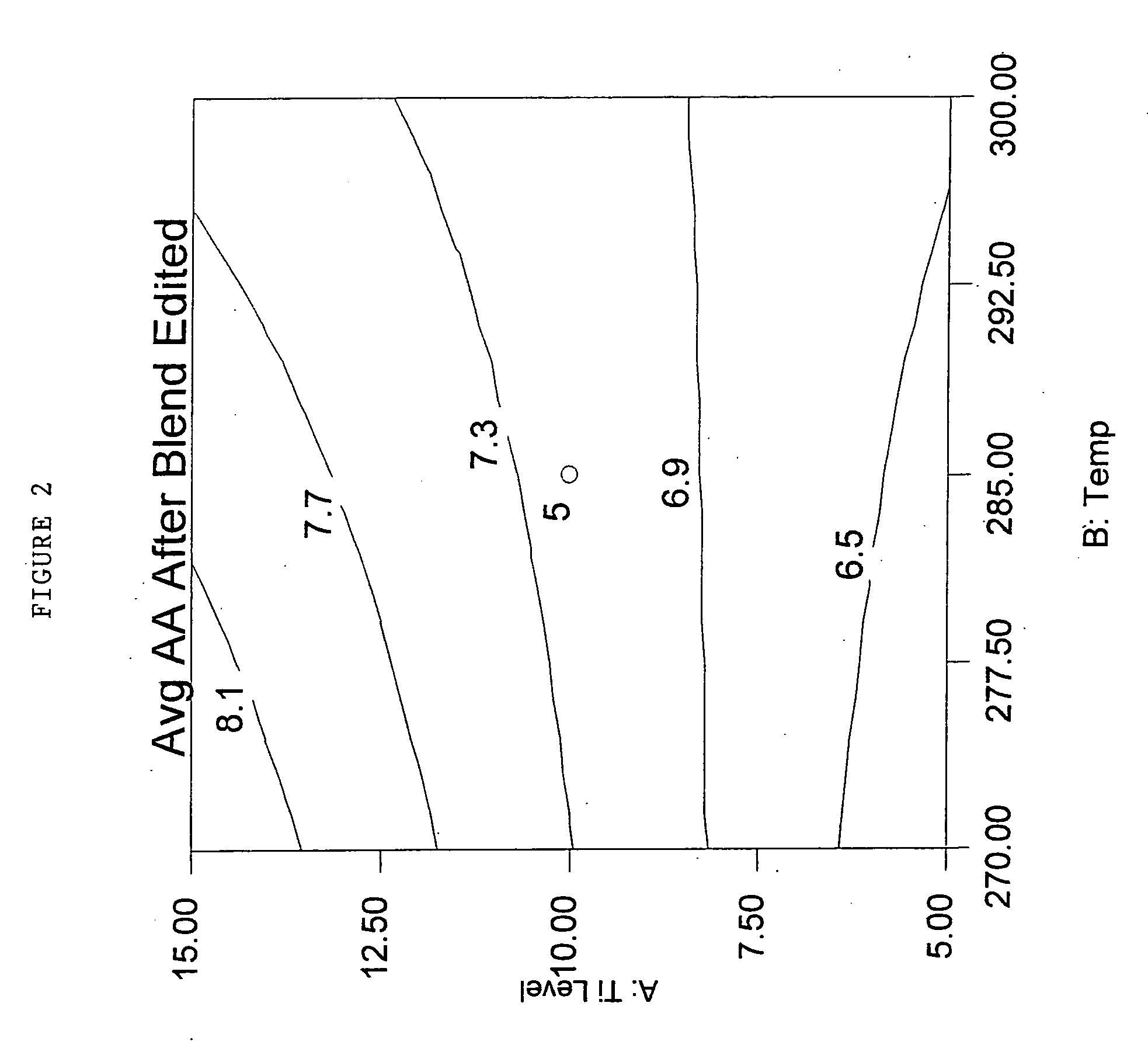

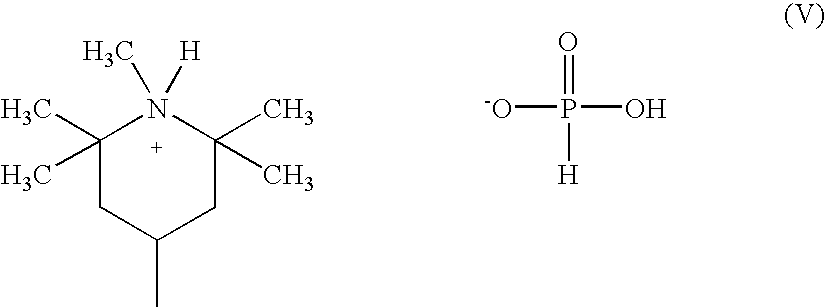

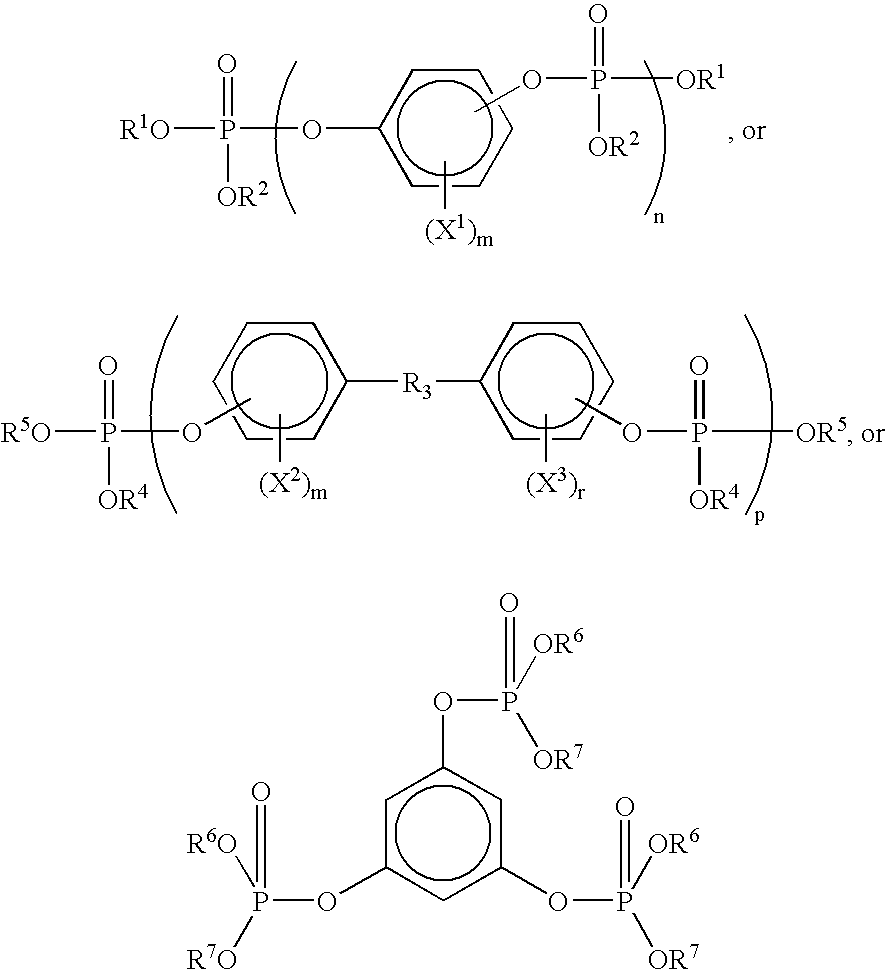

Phosphorus containing compounds for reducing acetaldehyde in polyesters polymers

InactiveUS20070066794A1High intrinsic viscosityLow in acetaldehydeOrganic-compounds/hydrides/coordination-complexes catalystsTobacco devicesPolyesterPolyethylene terephthalate glycol

Polyesters whose polycondensation is catalyzed by titanium-containing catalysts and which are susceptible to acetaldehyde formation during polycondensation or subsequent molding operations are prepared with low finished acetaldehyde content and reduced acetaldehyde generation by adding an ammonium or amine salt of an oxyphosphorus-acid. Polyesters, especially polyethylene terephthalate, may be produced with high inherent viscosity in reduced processing time, without the necessity of further polymerization in the solid state.

Owner:GRUPO PETROTEMEX DE C V

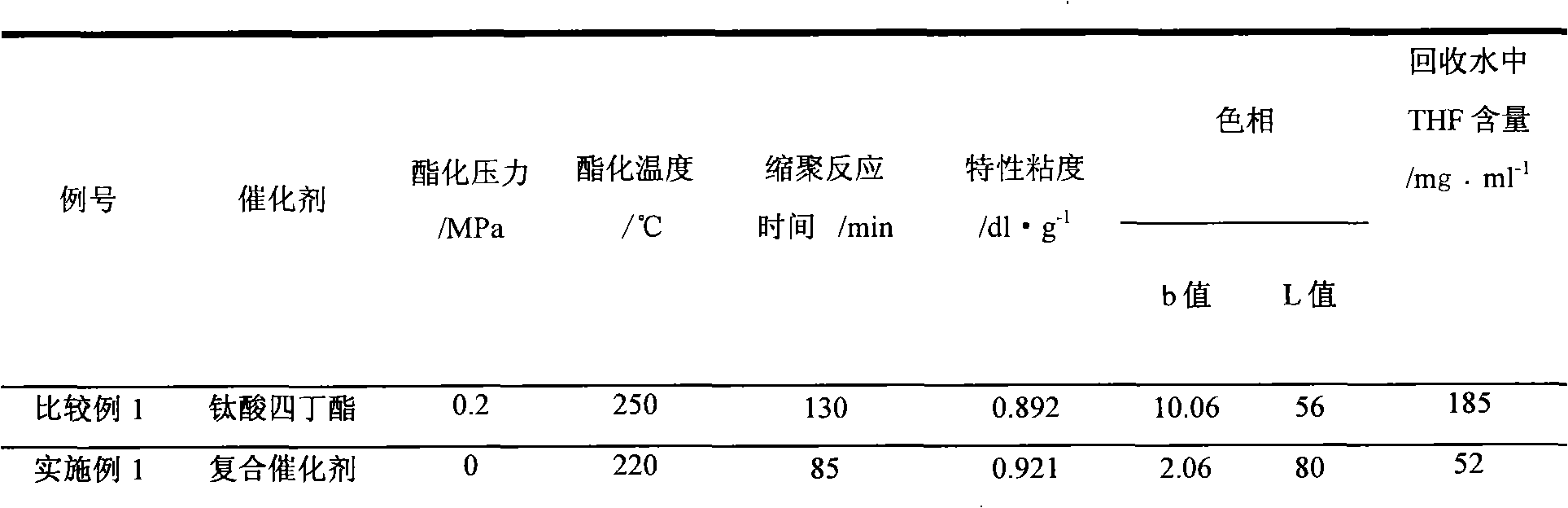

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

Optically clear UV and hydrolysis resistant polyester film

ActiveUS20110305913A1High intrinsic viscosityReduce smogSynthetic resin layered productsElectrical equipmentPolyesterEnd-group

Biaxially oriented polyester films including polyester polymer, a carbodiimide hydrolysis stabilizer, and a UV absorber are described. The polyester films have a carboxyl end group concentration of 5-20 equivalents per ton, and a haze value of 2% or less. The films exhibit superior transparency and possess stable light transmission characteristics. Methods of making the films and articles produced from the films are also described.

Owner:TORAY PLASTICS AMERICA

Direct fusion method for preparing poly lactic acid in high molecular weight

In the method, prepolymer of polylactic is obtained by direct melt polycondensation, then chain extender containing two active functional groups in which one is easy to react with hydroxyl and another is easy to react with carboxy is added. The viscosity of polylactic prepared by the chain extendor can be increased up to 1.0-1.5 dl / g.

Owner:马鞍山同杰良生物材料有限公司

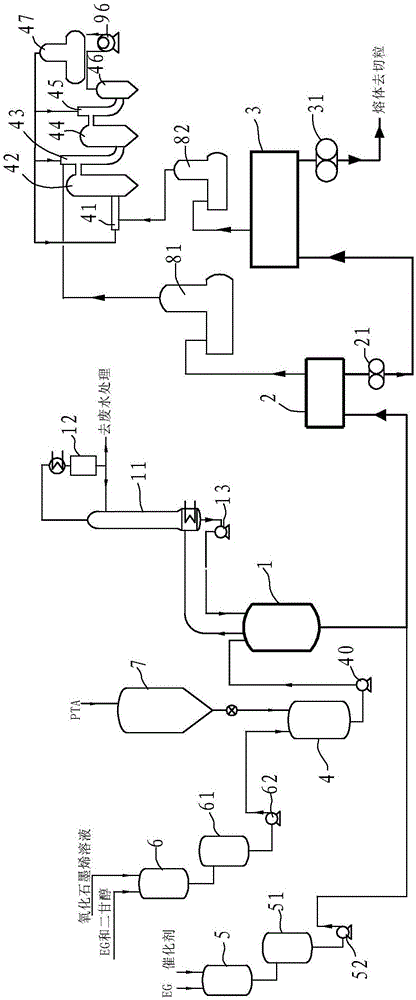

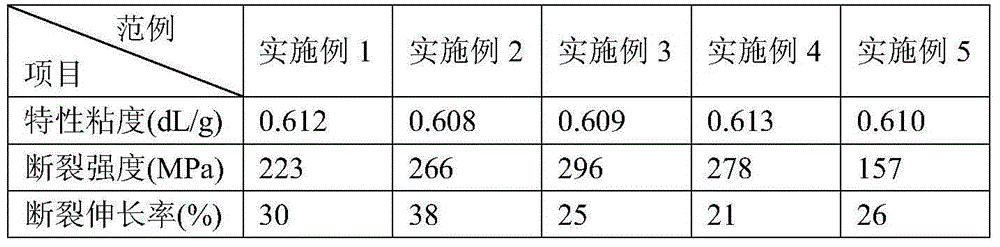

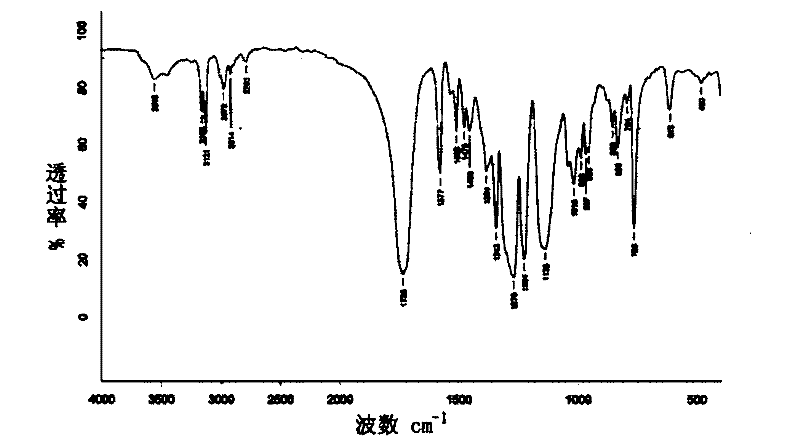

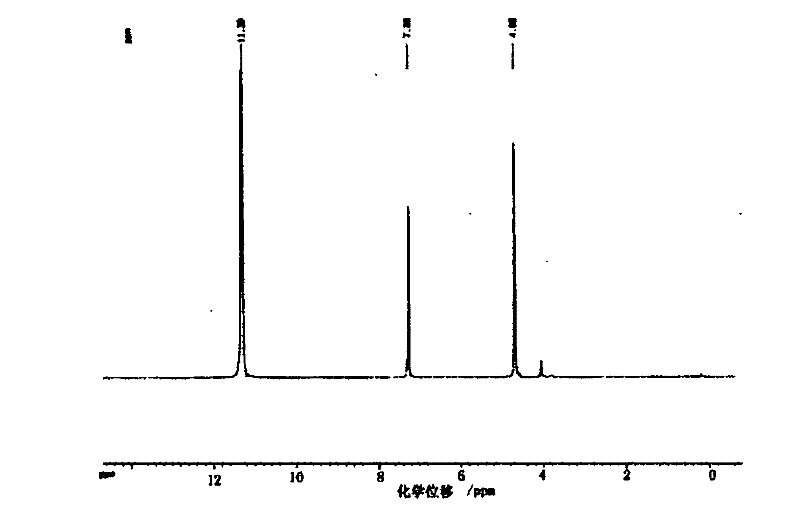

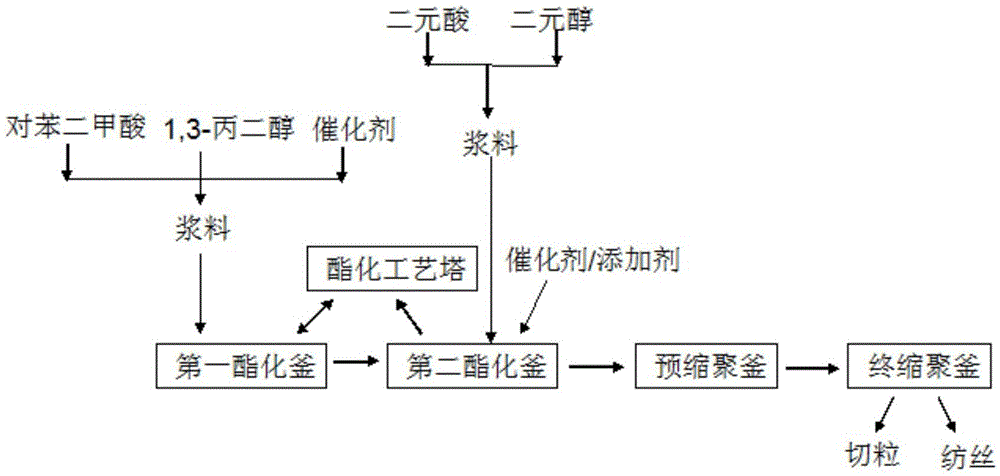

Preparation method of oxidized graphene modified PET (polyethylene terephthalate) material

InactiveCN105017511AHigh intrinsic viscosityHigh breaking strengthPolyethylene terephthalate glycolSlurry

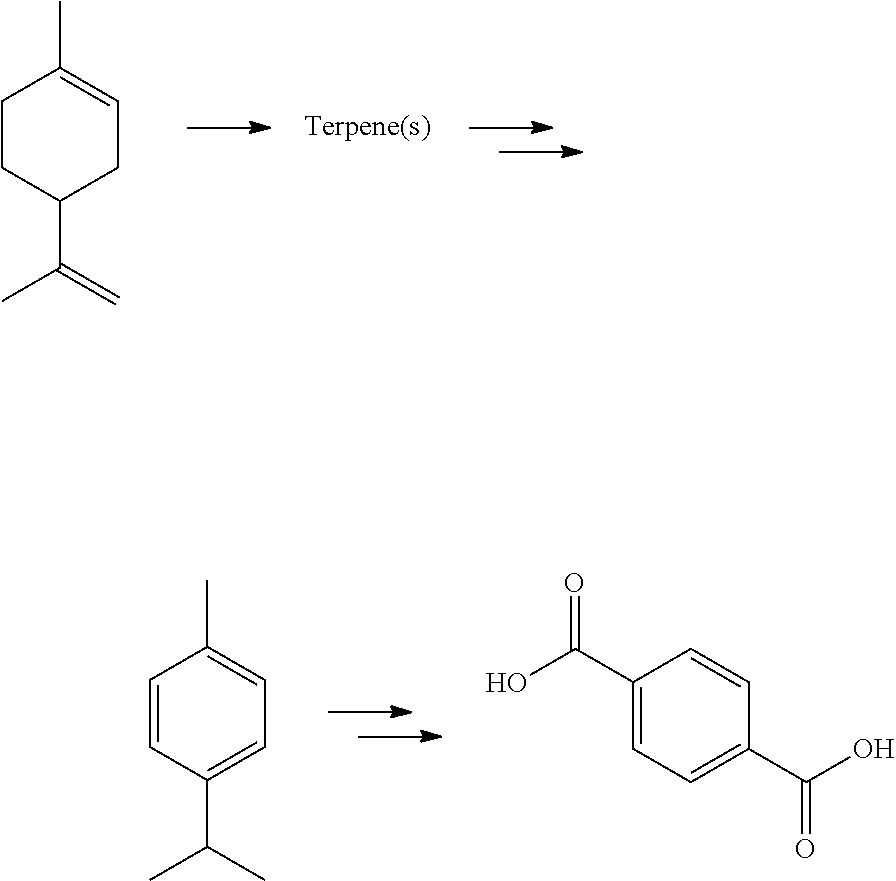

A preparation method of an oxidized graphene modified PET (polyethylene terephthalate) material is characterized by comprising steps as follows: purified terephthalic acid, binary acid, ethylene glycol, dihydric alcohol and a solution of an oxidized graphene liquid and ethylene glycol are firstly mixed to form slurry, and the esterification rate of an esterification reaction kettle outlet is larger than or equal to 92%; a catalyst is added after an esterification reaction ends; a monomer prepared through the esterification reaction is subjected to a second-stage condensation polymerization reaction in a pre-condensation kettle; the temperature of the material subjected to pre-condensation ranges from 265 DEG C to 275 DEG C; the absolute pressure ranges from 1 KPa to 30 KPa, and the time ranges from 1 hour to 1.5 hours; low-grade polymer obtained after the pre-condensation reaction is conveyed to a final condensation polymerization tank for a further condensation polymerization reaction, and the intrinsic viscosity is increased to be at least 0.60 dl / g. Compared with the prior art, the preparation method has the advantages as follows: the oxidized graphene in an appropriate proportion is added to the material, the intrinsic viscosity, the breaking strength and the elongation at break are remarkably improved, and the application range of PET is greatly widened.

Owner:ZHEJIANG WANKAI NEW MATERIAL

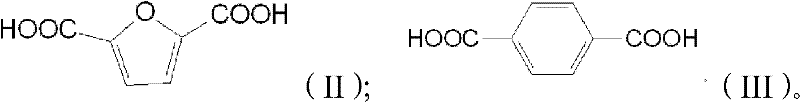

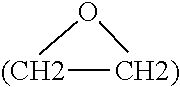

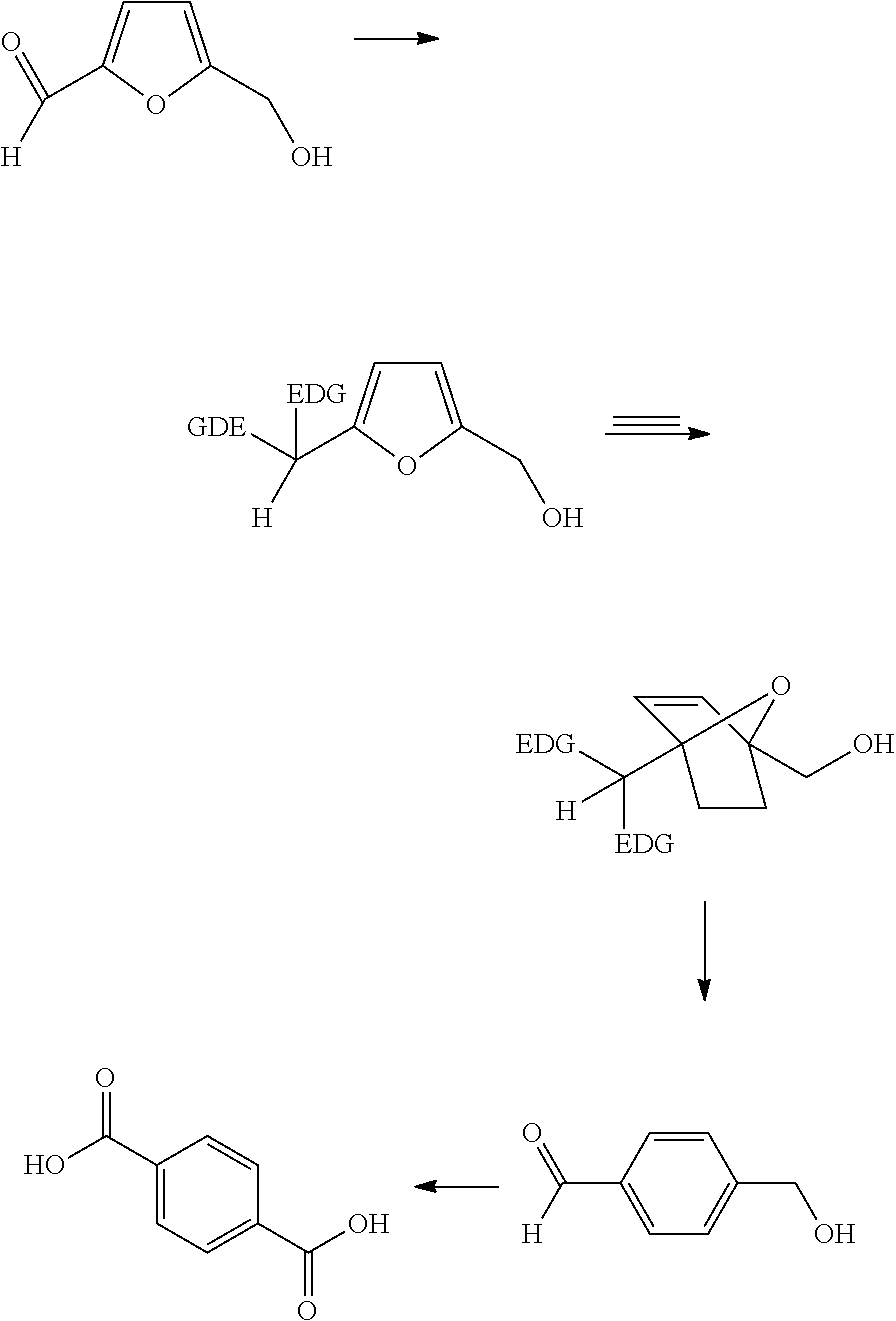

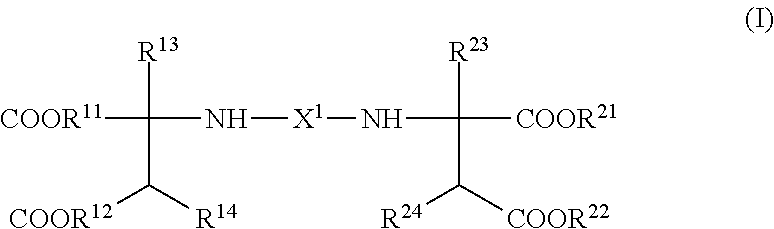

Poly(ethylene 2,5-furandicarboxylate), and preparation method thereof

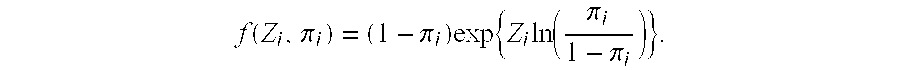

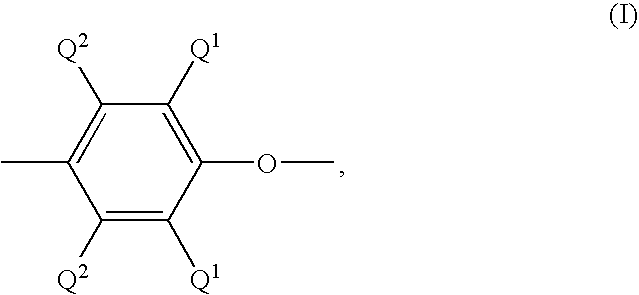

InactiveCN102190785AImprove performanceWide variety of sourcesEsterification reactionGlass transition

The invention provides poly(ethylene 2,5-furandicarboxylate), which contains the repeating units shown in formula (I) and has a characteristic viscosity not smaller than 0.2 dL / g. The invention also provides a preparation method for poly(ethylene 2,5-furandicarboxylate) provided by the technical scheme, which comprises the following steps of: carrying out esterification reaction on 2,5-furandicarboxylic acid and ethylene glycol under the action of a tin catalyst to obtain a first intermediate product, wherein the esterification reaction pressure is 0.1-0.4 MPa; and carrying out condensation polymerization reaction on the first intermediate product under the pressure of 10-70 Pa to obtain poly(ethylene 2,5-furandicarboxylate). Experiments show that poly(ethylene 2,5-furandicarboxylate) provided by the invention is dark brown, and has a characteristic viscosity of not smaller than 0.2 dL / g, a glass transition temperature of 60-63 DEG C and a melting point of 210-215 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

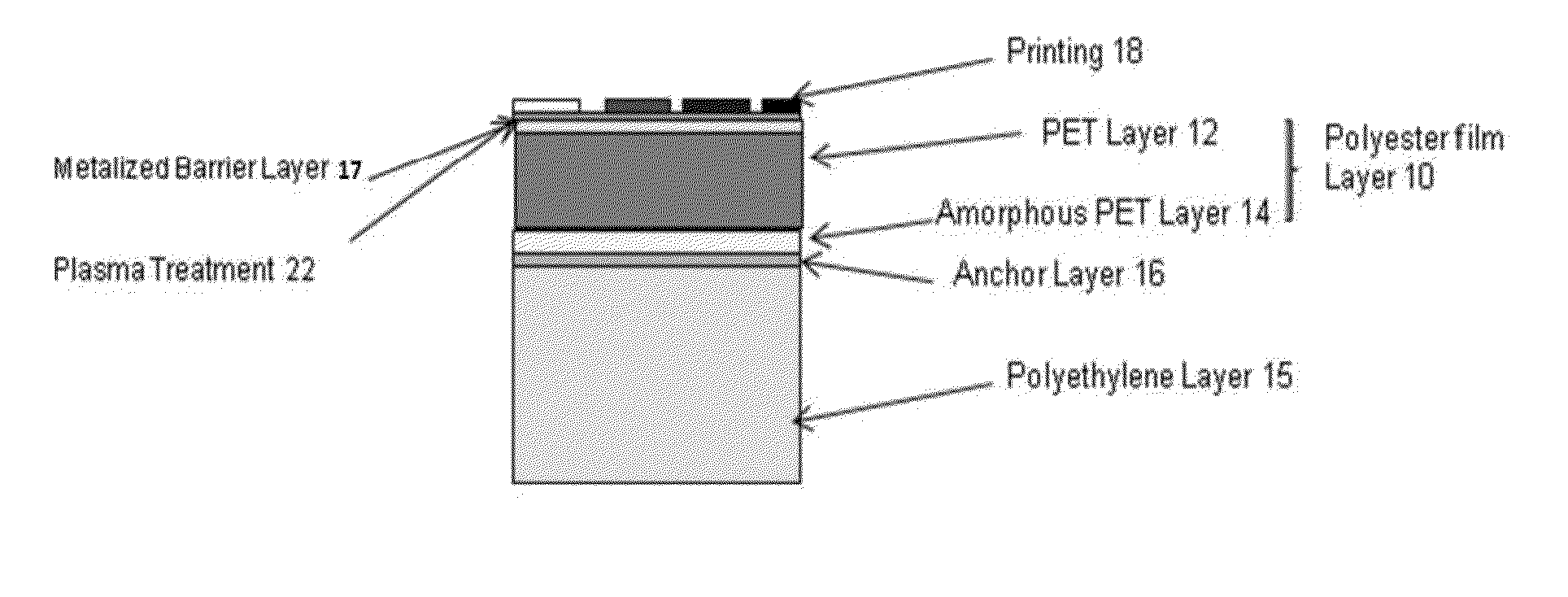

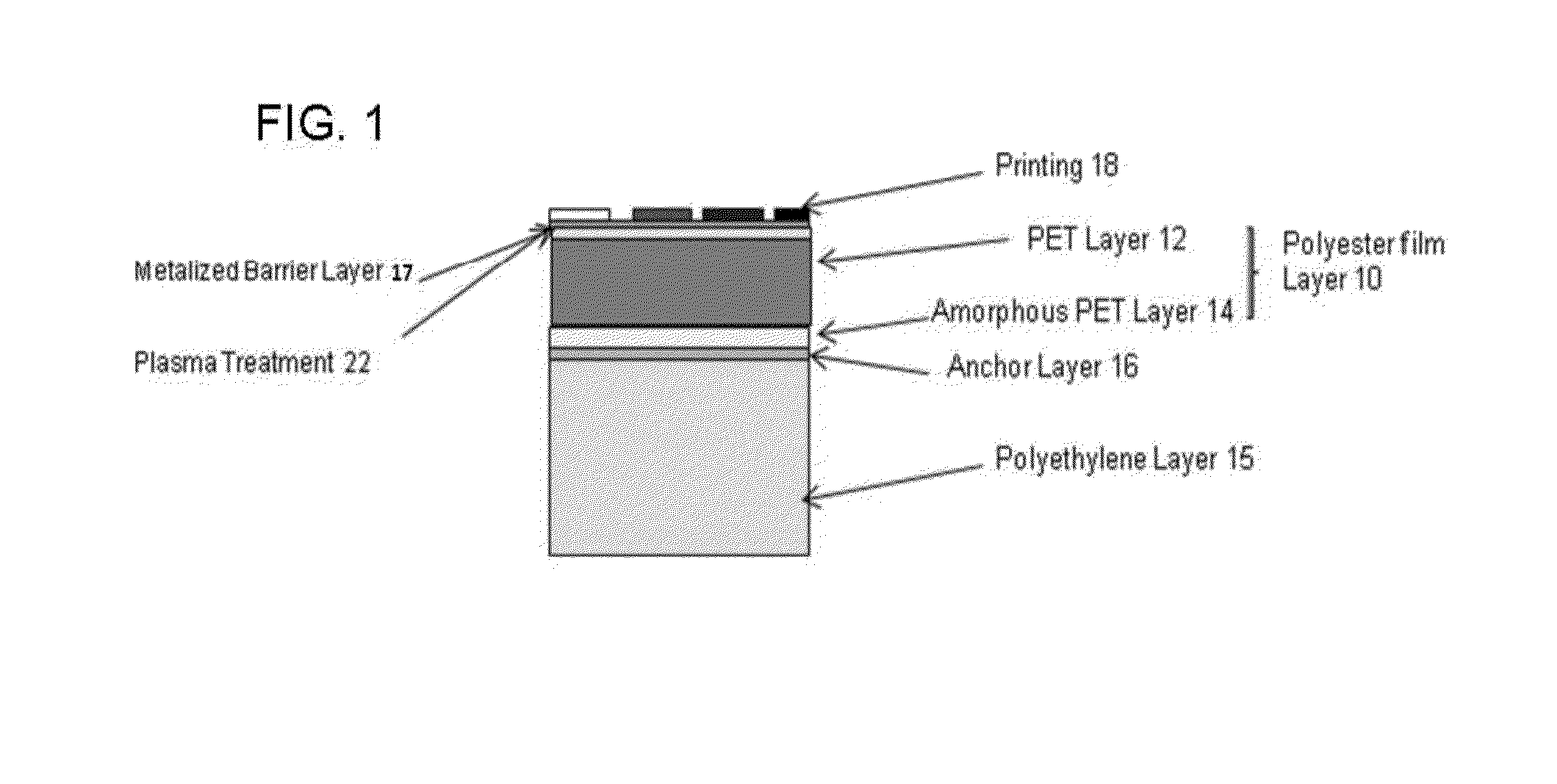

Lighter than air balloons from laminates comprising bio-based polyester films and bio-based polyethylene films

InactiveUS20140004286A1Improve bindingImprove raw materialsSynthetic resin layered productsToy aircraftsLinear low-density polyethylenePolyester resin

A balloon made from a laminate film including at least one bio-based polyester layer of at least about 19.0 pMC of radiocarbon (14C) content is disclosed. The laminate film could further have additional layers such as a second bio-based polyester resin-containing layer of at least about 21.5 pMC of radiocarbon (14C) content, a linear low density polyethylene bio-based resin-containing layer of at least about 94 pMC of radiocarbon (14C) content, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol

The invention discloses a method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol, comprising the following steps: heating starch milk of which the weight concentration is 10-45% and the pH value is 3.5-6.5 to 40-70 DEG C, adding Pullulanase of which the dosage is 1-40ASPU per gram of starch, and keeping for 8-48hrs; inactivating enzymes, assisting by acid alcohol processing, cooling, filtering, drying, crushing and sieving to obtain the product. The invention takes starch as a raw material, adopts the biological technology and acid alcohol processing means, thus greatly improving the content of the resistant starch, simplifying the process for preparing the resistant starch, effectively enhancing the yield, and lowering energy consumption. The obtained product not only has the function of dietary fiber, but also has the characteristics of fat substitute, and can be widely used as functional food materials and biochemical drug carriers.

Owner:SOUTH CHINA UNIV OF TECH

Propylene polymer compositions

The invention relates to propylene polymer compositions comprising 45-79 parts per weight of a propylene homo- or copolymer, 10-27 parts per weight of a first elastomeric ethylenepropylene copolymer, 5-22 parts per weight of a second elastomeric ethylene-propylene copolymer, 1-15 parts per weight of an elastomeric ethylene-1-octene copolymer and 5-15 parts per weight of inorganic filler. The propylene polymer compositions are suitable for injection molding of large articles, which do not show flow marks and which have a good impact strength / stiffness ratio.

Owner:BOREALIS TECH OY

Method for preparing butadiene/isoprene copolymers and resulting copolymers

The present invention relates to a process for the preparation random copolymers of butadiene and isoprene, essentially consisting of reacting a catalytic system in the presence of butadiene and isoprene and using, as catalytic system, a system based on at least:—a conjugated diene monomer,—an organic phosphoric acid salt of one or more rare earth metals,—an alkylating agent consisting of an alkylaluminium of the formula AlR3 or HAlR2, and—a halogen donor consisting of an alkylaluminium halide, said salt being in suspension in at least one inert, saturated and aliphatic or alicyclic hydrocarbon solvent, which is included in said catalytic system, and the “alkylating agent:rare earth salt” molar ratio falls within a range of from 1 to 8, and performing the copolymerisation reaction in an inert hydrocarbon polymerisation solvent or without solvent. These copolymers are in particular such that the butadiene and isoprene units which they comprise each have an elevated content of cis-1,4 linkages.

Owner:MICHELIN RECH & TECH SA

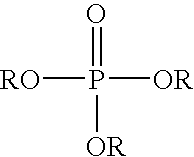

Additive for thermoplastic resins and flame retardant resin compositions

InactiveUS6689825B1High intrinsic viscosityIncrease tensile elongationAntifouling/underwater paintsPlastic/resin/waxes insulatorsHeat deflection temperatureChemistry

A thermoplastic resin composition with improved flame retardance, flow and heat deflection temperature includes a thermoplastic resin; resorcinol diphenyl phosphate; and an additive blend. The additive blend includes a combination of melamine polyphosphate and ferrocene. The thermoplastic composition reduces the amounts of resorcinol diphenyl phosphate required for effective flame retardancy. Moreover, the effective amounts of melamine polyphosphate and ferrocene do not deleteriously affect other properties of the thermoplastic composition such as Izod strength, flow properties, and heat deflection temperatures. A process for manufacturing a thermoplastic composition is also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

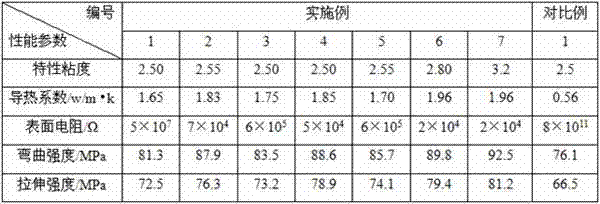

High-content graphene modified nylon 6 master batch as well as preparation method and application thereof

ActiveCN107459642AControl dispersion speedDispersion speed can be controlledElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiberFlexural strength

The invention provides a high-content graphene modified nylon 6 master batch as well as a preparation method and application thereof. The master batch is prepared from caprolactam, graphene oxide, coupling agents, dispersing agents, catalysts and molecular weight modifiers. The method comprises the following steps of (1) mixing the graphene oxide and the coupling agents; performing heating and ultrasonic agitation; then, adding dispersing agents; performing heat stirring; then, adding catalysts; performing heating stirring to obtain graphene slurry; (2) heating and stirring the caprolactam and the molecular weight modifiers; adding the graphene slurry; performing ring-opening reaction; performing vacuum pumping, polymerization, still standing, temperature reduction nitrogen filling, discharging, cooling pelletizing to obtain a semi-finished product; (3) performing hot water extraction and drying to obtain a finished product. The master batch has the advantages of high intrinsic viscosity and high graphene content; the prepared composite material has high heat conduction coefficient, low surface resistance, high bending intensity and high stretch intensity. The method provided by the invention has the advantages that the process is simple; the cost is low; the mass production can be realized.

Owner:长沙五犇新材料科技有限公司

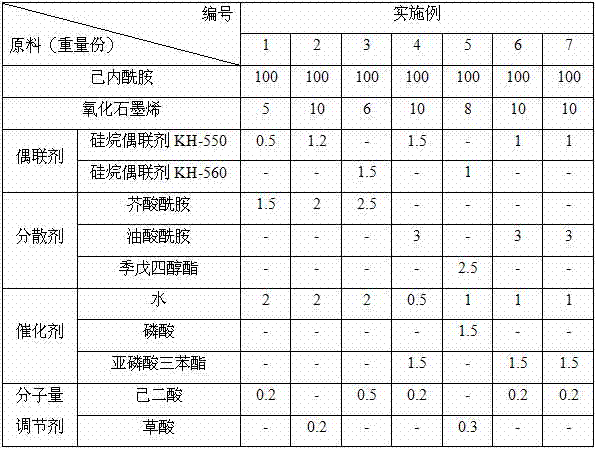

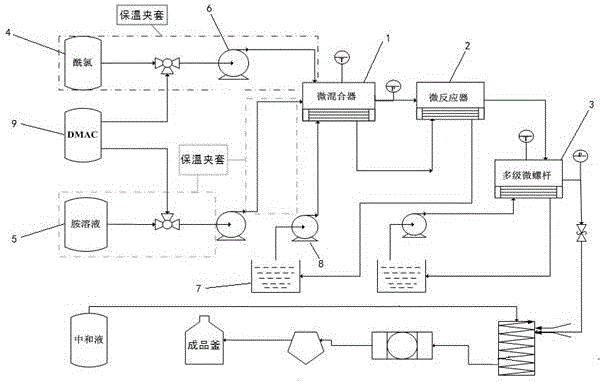

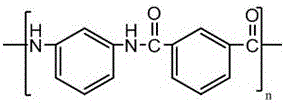

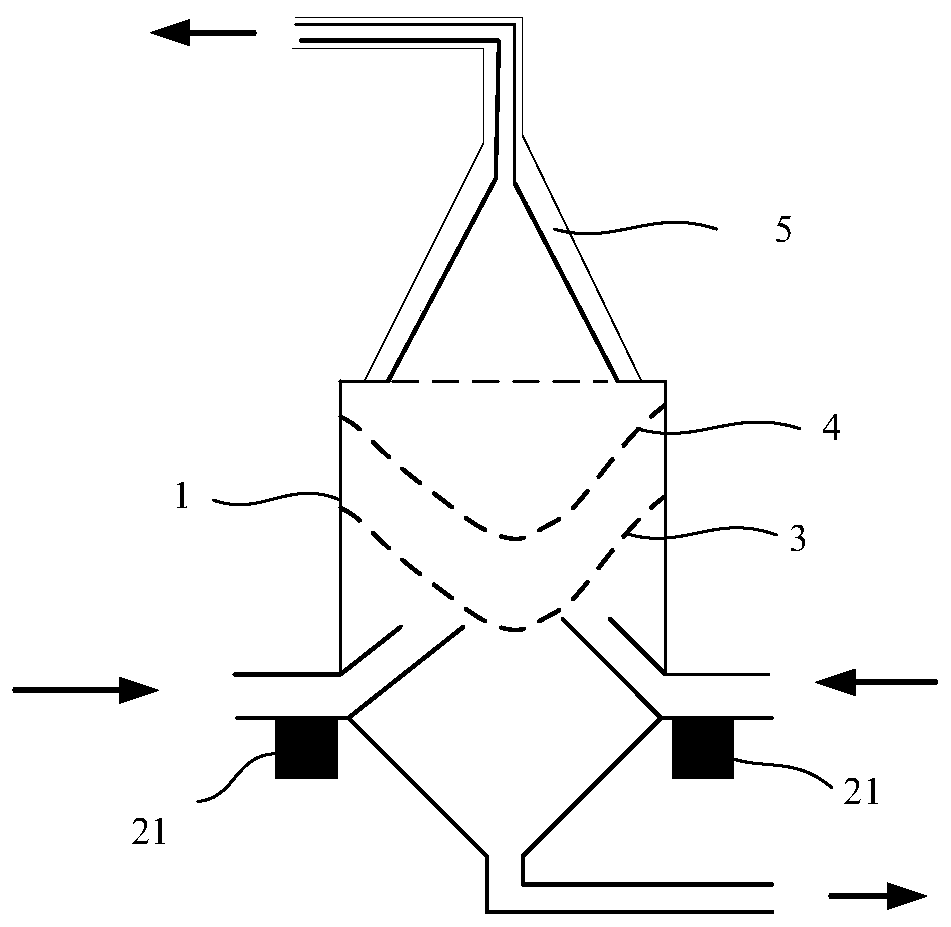

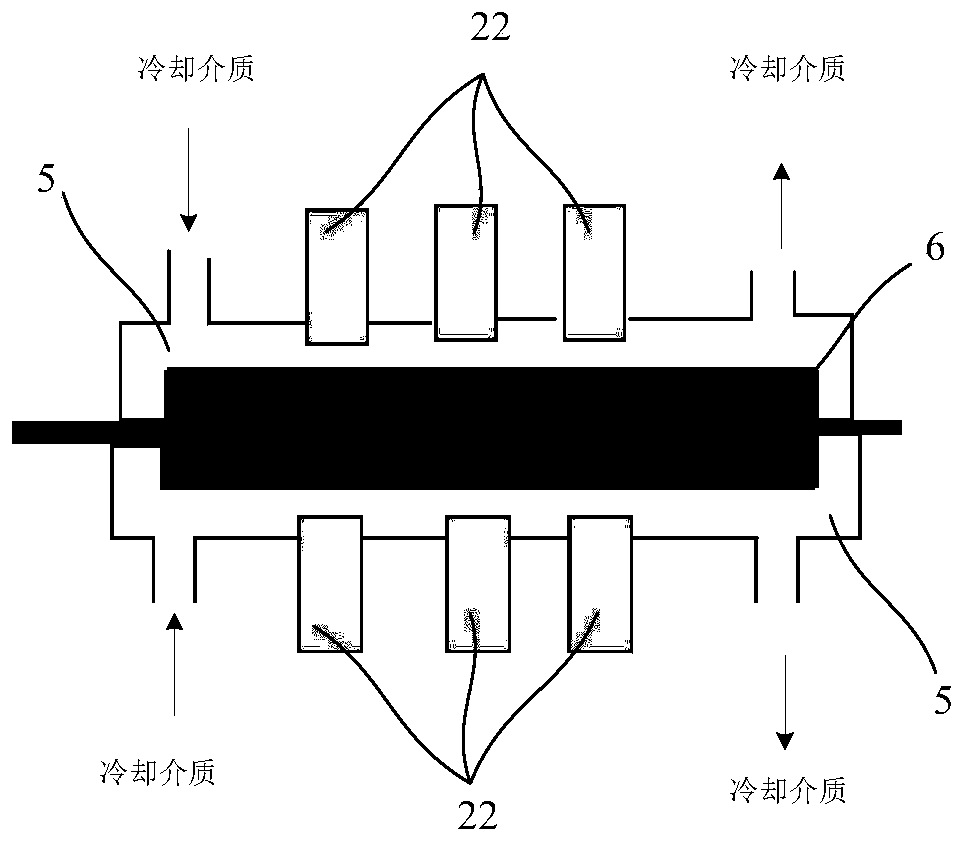

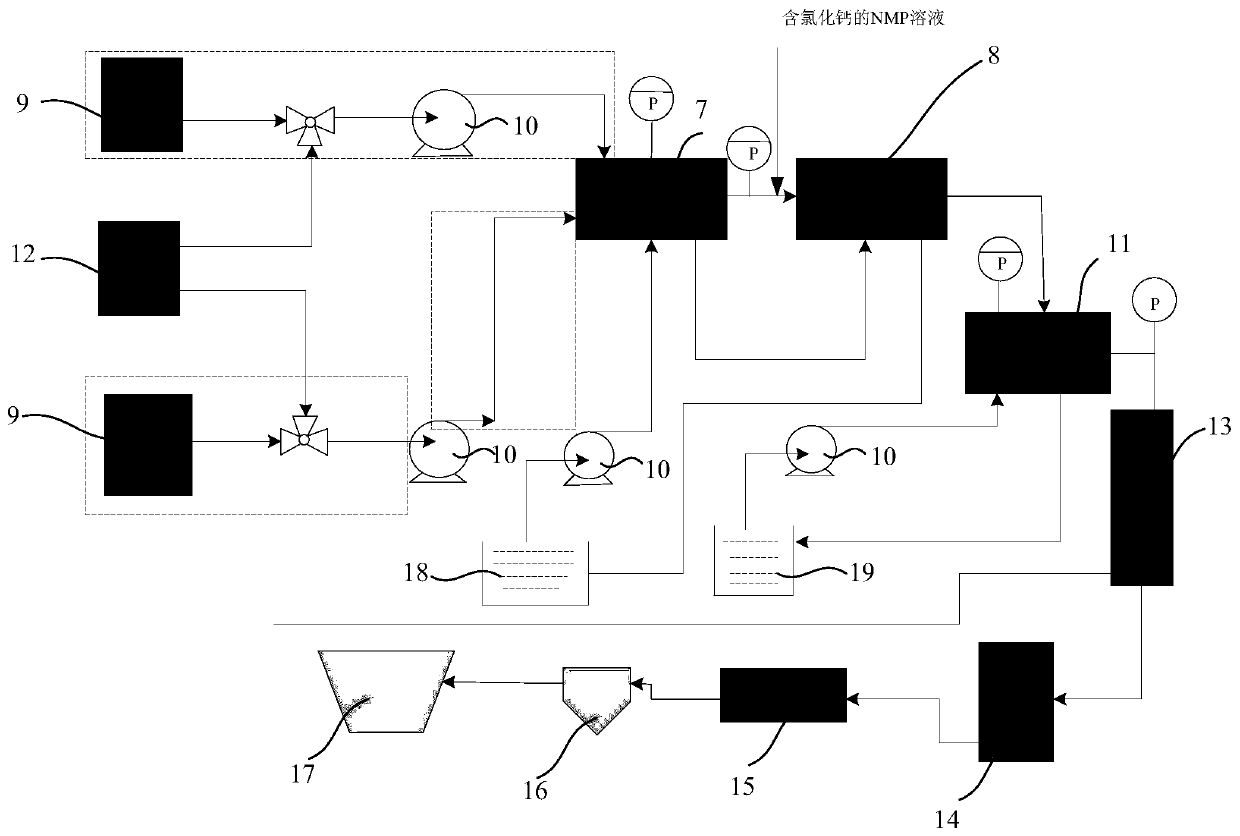

Continuous micro-reaction device and method for preparing meta-aramid resin and product

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

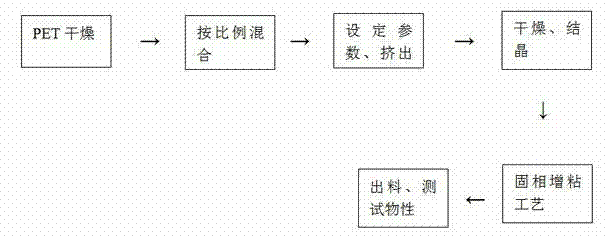

Foamed PET (polyethylene glycol terephthalate) plate slice, and preparation method thereof

The invention belongs to the field of high polymer material and particularly relates to a foamed PET (polyethylene glycol terephthalate) plate slice and a preparation method of the plate slice. The PET (polyethylene glycol terephthalate) plate slice is prepared by adding 0.1 to 5 parts of chain extender, 0.1 to 10 parts of flow promoter and 0.1 to 5 parts of antioxidant into 100 parts of bottle-level PET, mixing uniformly, extruding, cutting into particles, and then conducting solid-phase polymerization and adhesion-promotion. According to the PET plate slice and the preparation method, the chain extender is in moderate crosslinking with the PET to form the mesh branched structure and then the length of the molecular chain is enhanced by solid-phase adhesion-promotion so as to enhance the melt strength of the bottle-level PET, so that the intrinsic viscosity of the foamed PET (polyethylene glycol terephthalate) plate slice reaches to be 0.8-1.2dl / g and the melt index MFI is equal to 5-30g / 10min.

Owner:GUANGDONG LIANSU TECH INDAL

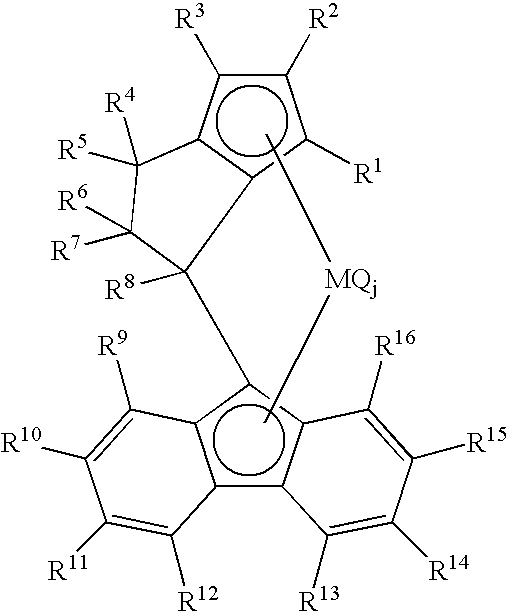

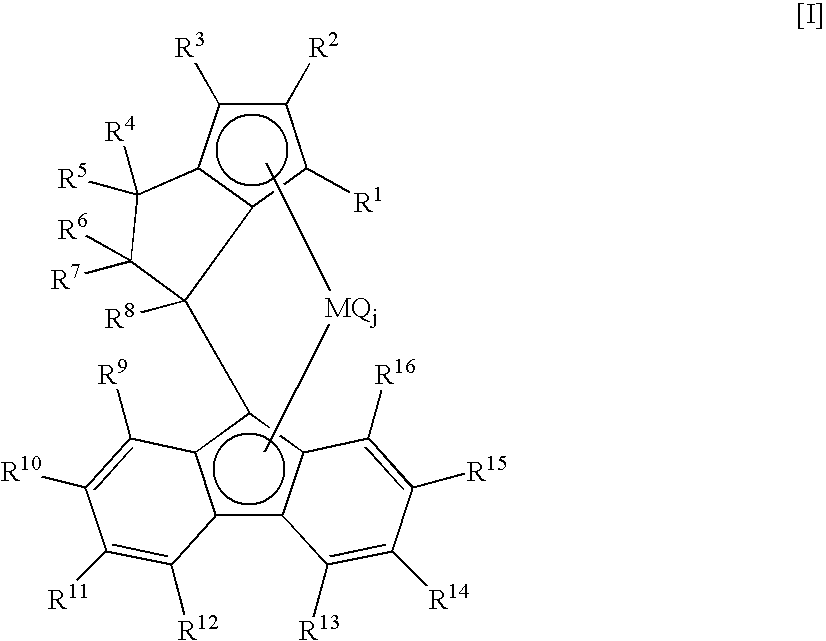

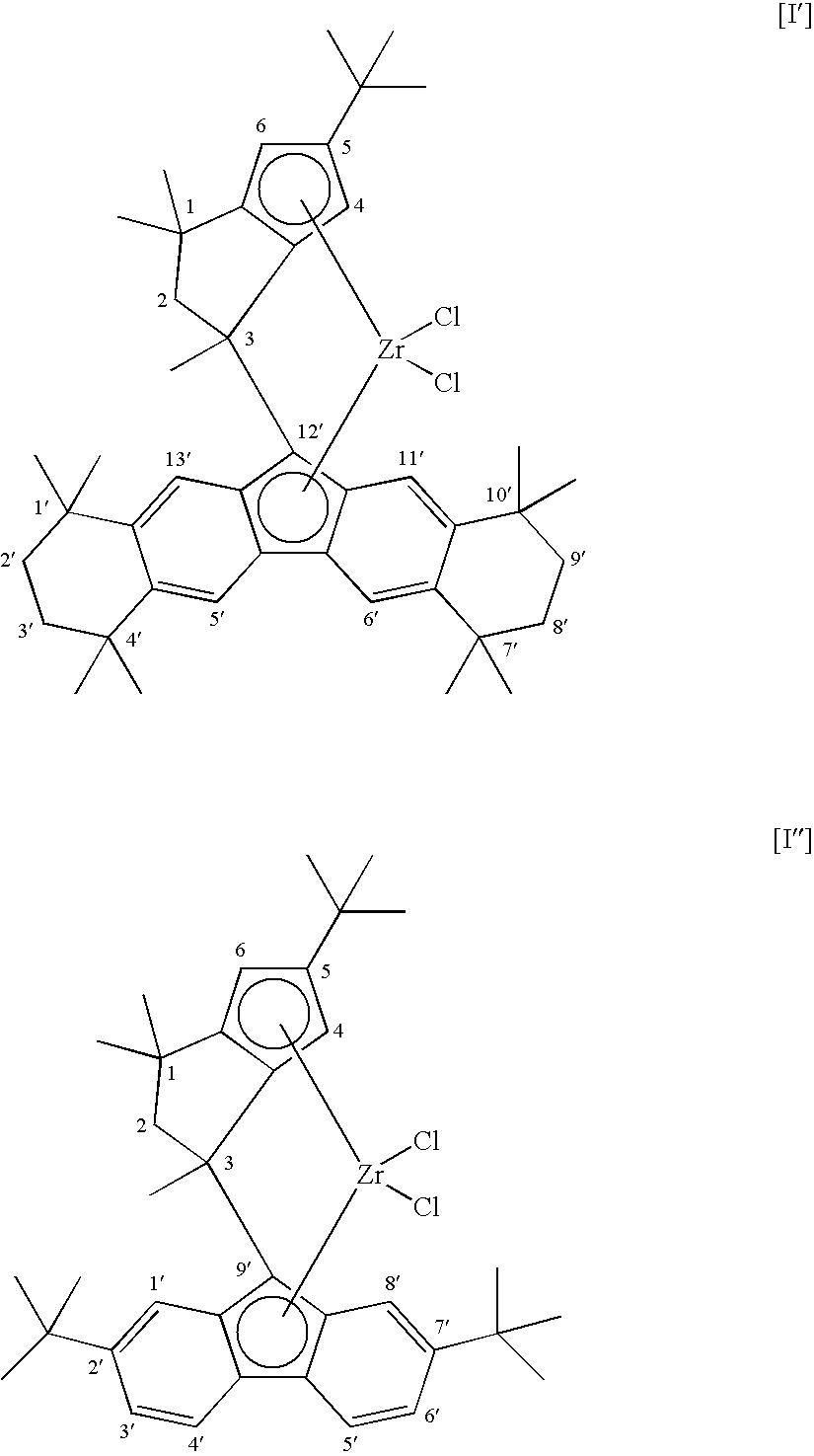

Propylene Polymer, Composition Comprising the Polymer, and Molded Product Obtained Therefrom

InactiveUS20080038498A1High intrinsic viscosityImprovements in other specific itemsSynthetic resin layered productsThin material handlingIntrinsic viscosityMelting point

A propylene polymer which is constituted of 10 to 40 wt % room-temperature n-decane soluble part (Dsol) and 60 to 90 wt % room-temperature n-decane insoluble part (Dinsol), comprises skeletons derived from propylene (MP) and at least one kind of olefin (MX) selected from ethylene and C4 or more α-olefins, and satisfies all of the following requirements [1] to [5]. The polymer is characterized by having a high melting point and a high molecular weight and is suitable for use in producing various moldings therefrom. [1] the molecular weight distribution (Mw / Mn) of both Dsol and Dinsol as determined by GPC is 4.0 or less; [2] the melting point (Tm) of Dinsol is 156° C. or more; [3] the sum of the 2,1-bond content and the 1,3-bond content in Dinsol is 0.05 mol % or less; [4] the intrinsic viscosity [η] (dl / g) of Dsol satisfies the relationship 2.2<[η]≦6.0; and [5] the concentration of skeletons derived from the olefin (MX) in Dinsol is 3.0 wt % or less.

Owner:MITSUI CHEM INC

Continuous preparation method of polyhydroxy acid with high molecular weight

The invention relates to a continuous preparation method of polyhydroxy acid with high molecular weight and belongs to the technical field of environmentally-friendly high molecular materials. A one-segment / multi-segment temperature controllable screw reactor is used, organic / inorganic lewis acid is used as a catalyst, certain temperature, catalyst dose and screw rotation speed are controlled, a cyclic ester monomer and the catalyst are continuously subjected to polymerization, and a product is fast obtained by means of continuous discharge. The chromaticity of the polyhydroxy acid is regulated and the stability of the polyhydroxy acid is improved by directly adding an antioxidant and a blocking agent at the middle-rear segment of the reactor. The prepared polyhydroxy acid has the advantages of high molecular weight and low chromatic value.

Owner:CHANGZHOU UNIV

Biodegradable poly(butylene succinate-co-butylene fumarate) and preparation method thereof

The invention discloses biodegradable poly(butylene succinate-co-butylene fumarate) and a preparation method thereof. Maleic anhydride and 1,4-butanediol are taken as monomers, and esterification, hydrogenation, isomerization and melt phase polycondensation are carried out to obtain the poly(butylene succinate-co-butylene fumarate), wherein intrinsic viscosity of the poly(butylene succinate-co-butylene fumarate) product is 0.8dL / g, and the poly(butylene succinate-co-butylene fumarate) has good biodegradability, a higher melting temperature and lower crystallinity and can serve as general-purpose plastics and replace the traditional non-biodegradable plastics. The preparation method and aftertreatment of the biodegradable poly(butylene succinate-co-butylene fumarate) disclosed by the invention are simple, raw materials are available, operation is easy, and industrialized production can be realized.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

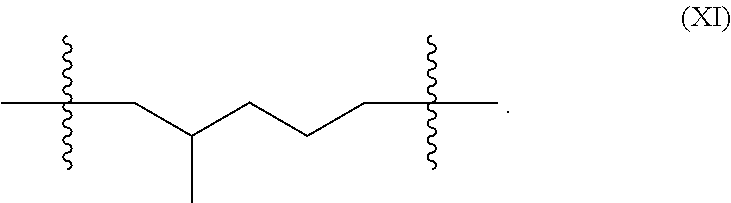

Long-carbon-chain semi-aromatic nylon PA14T and preparation method thereof

ActiveCN104327265AImprove toughnessEasy to processOrganic compound preparationAmino compound preparationPolymer scienceAutomotive industry

The invention relates to a long-carbon-chain semi-aromatic nylon PA14T and a preparation method thereof, belonging to the field of high polymer material synthetic technologies. The repeat unit is shown in the specification, and the degree of polymerization of the long-carbon-chain semi-aromatic nylon PA14T is n which is equal to 2 to 200. The preparation method comprises the following steps: (1) preparing nylon PA14T salt: adding 1,4-terephthalic acid and 1,14-tetradecanedioic diamine into water to perform salt forming reaction; (2) preparing semi-aromatic nylon PA14T: adding the nylon PA14T salt obtained in step (1) and a solvent into a polymerizer, heating up a reaction still to be at 200-240 DEG C under a condition of shielding gas, reacting for 1-4 hours under the pressure of 1.2 to 3 MPa, deflating until normal pressure is achieved and vacuumizing, and then carrying out polymerization reaction to obtain the semi-aromatic nylon PA14T. The PA14T is excellent in performance and is easy to process and form, and has the good market prospect, especially in electronic and electrical, automotive industries and the like; and besides, the long-carbon-chain semi-aromatic nylon PA14T is simple in technology, moderate in reaction condition, short in reaction time and low in energy consumption.

Owner:HENAN JUNHENG IND GRP BIOTECH CO LTD

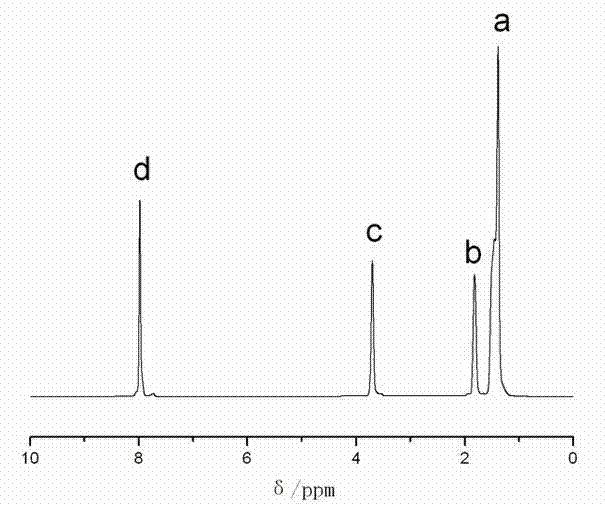

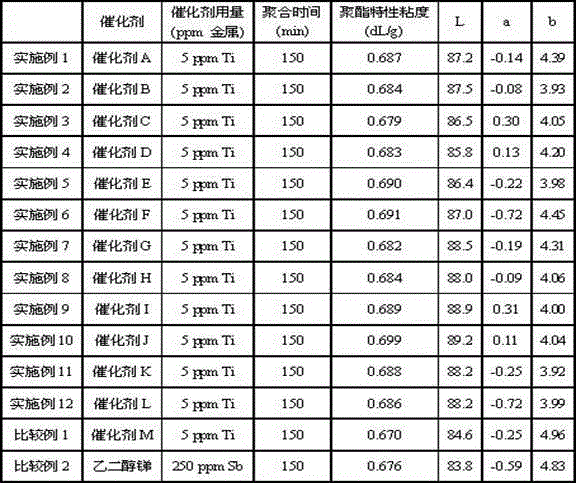

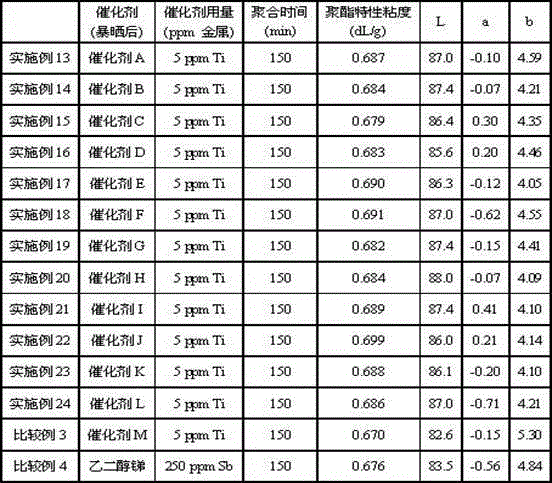

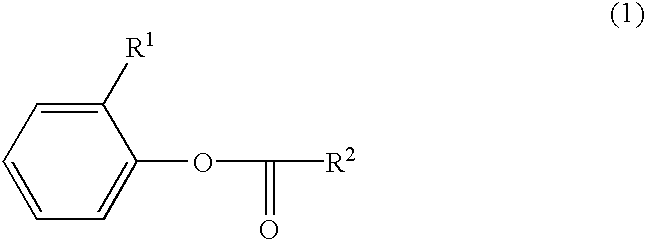

Titanium polyester catalyst

The invention relates to a titanium polyester catalyst. The titanium polyester catalyst is mainly used for solving the problems of secondary reactions such as thermal degradation due to too high activity of the prepared titanium dihydric alcohol compound catalyst and relatively low viscosity of prepared polyester chips in the prior art. The problems are well solved by adopting the technical scheme that a reaction product of a titanium compound, a salt compound of at least one metal selected from Group IIA, VIIB and IIB in a periodic table of elements and at least one phosphate compound is used as a catalyst. The catalyst can be applied in the industrial production of the polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing polycarbonate and apparatus for preparing polycarbonate

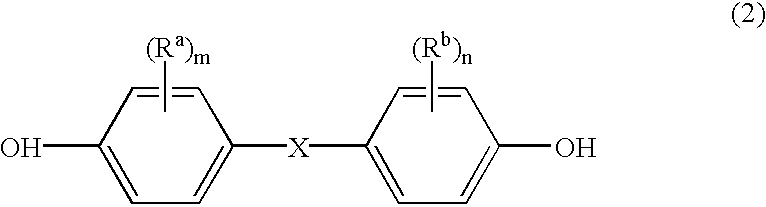

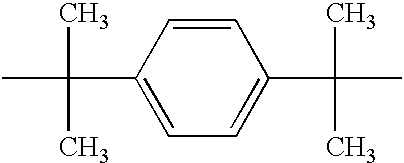

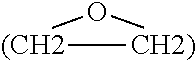

InactiveUS6620902B2Low viscosityHigh intrinsic viscosityChemical vapor deposition coatingHermetic sealPolycarbonate

A process for preparing an end-capped polycarbonate comprises melt reacting an aromatic dihydroxy compound, a carbonic acid diester, and optionally a catalyst in a prepolymerization vessel to form a polycarbonate product; transferring the polycarbonate product from the prepolymerization vessel; mixing the polycarbonate product with an end-capping agent under hermetic seal at a pressure of at least about 760 mm Hg; and transferring the polycarbonate product and end-capping agent mixture to a postpolymerization vessel to endcap the polycarbonate product. An apparatus for preparing an end-capped polycarbonate comprises a prepolymerization vessel having and inlet and an outlet; a postpolymerization vessel having an inlet and an outlet; a mixer in fluid communication with the outlet of the prepolymerization vessel and the inlet of the postpolymerization vessel; and a charging port through which an end-capping agent is charged to the mixer, wherein the mixer is hermetically sealed at greater than or equal to 760 mm Hg.

Owner:SABIC GLOBAL TECH BV

Biaxially oriented bio-based polyolefin film that has been extrusion coated with bio-based sealant for lidding applications

InactiveUS20140065315A1High intrinsic viscosityPretreated surfacesCoatingsLow-density polyethylenePolyolefin

A lidding film including a polyester film including a bio-based polyester, and an extrusion coated heat seal layer including a bio-based polymer. The polyester film may include a biaxially oriented core layer including bio-based polyester and an amorphous copolyester skin layer. The heat seal layer may include a low density polyethylene.

Owner:TORAY PLASTICS AMERICA

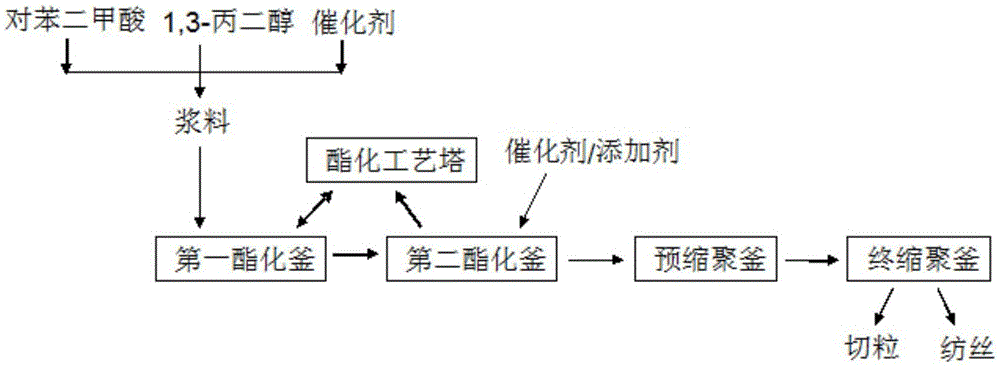

Preparation methods of high-viscosity polytrimethylene terephthalate and copolyester thereof

The invention discloses a preparation method of high-viscosity polytrimethylene terephthalate. The preparation method of high-viscosity polytrimethylene terephthalate comprises the following steps: mixing: preparing polyterephthalic acid and 1,3-propanediol into a slurry under atmospheric pressure; primary esterification: continuously delivering the slurry into a first esterification kettle, and carrying out primary esterification reaction to obtain a first esterification product; secondary esterification: delivering the first esterification product into a second esterification kettle, and carrying out secondary esterification reaction to obtain a second esterification product; pre-polycondensation: continuously delivering the second esterification product into a pre-polycondensation kettle, and carrying out polycondensation to remove small molecules, thereby obtaining a polytrimethylene terephthalate prepolymer; and final polycondensation: continuously delivering the polytrimethylene terephthalate prepolymer into a final polycondensation kettle, and carrying out condensation polymerization to remove small molecules, thereby obtaining the polytrimethylene terephthalate high polymer. The invention also discloses a preparation method of the high-viscosity polytrimethylene terephthalate copolyester. The products have the advantages of high inherent viscosity and high quality.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD

Liquid titanium-series catalyst used for poly(butylene succinate-co-butylene adipate)

The invention relates to a liquid titanium-series catalyst used for production of poly(butylene succinate-co-butylene adipate). The liquid titanium-series catalyst mainly overcomes the problem that conventional titanate catalysts have attenuated activity due to susceptibility to hydrolysis and inactivation under the influence of a reaction by-product, i.e., water, and the problems that conventional catalysts are intermiscible with intermiscible and have poor light stability. The liquid-state titanium-series catalyst in the invention comprises a reaction product of the following raw materials: (A) a titanium compound with a general formula of Ti(OR)4, wherein R is an alkyl group with 1 to 10 carbon atoms; (B) dihydric alcohol with 2 to 10 carbon atoms; (C) at least one aliphatic organic acid selected from organic acids; (D) a compound of at least one metal selected from the group IA in the periodic table of elements; and (E) at least one phosphate compound selected from phosphorus compounds. With such a technical scheme, the liquid-state titanium-series catalyst provided by the invention is applicable to industrial production of poly(butylene succinate-co-butylene adipate).

Owner:CHINA PETROLEUM & CHEM CORP +1

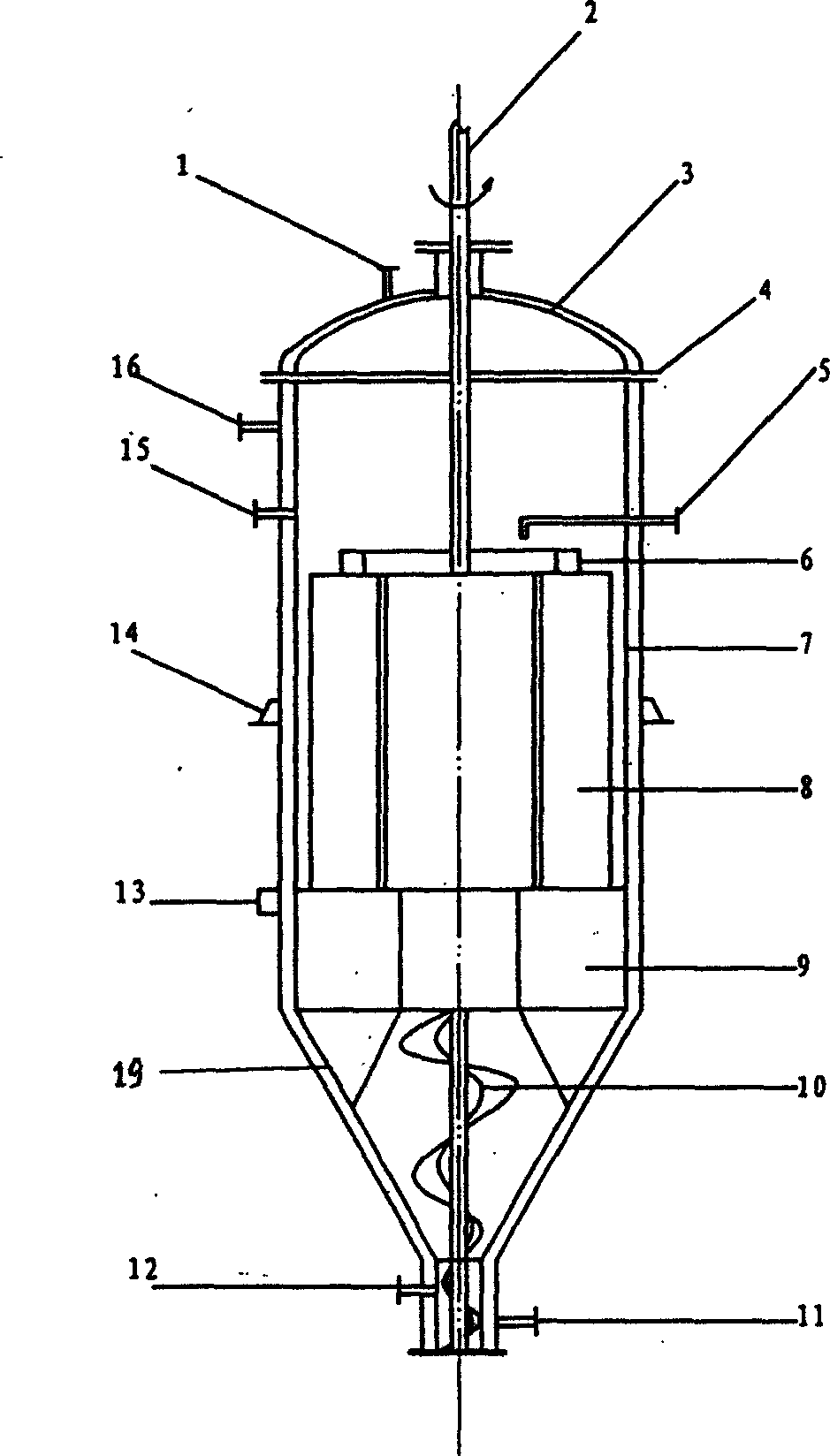

Liquid-phase continuous condensation polymerization apparatus of high-viscosity polyester (PET)

InactiveCN1470546AMeet the special requirements of mixing systemsReduce manufacturing costChemical/physical/physico-chemical stationary reactorsPolyesterVacuum pumping

The present invention discloses a high-viscosity polyester (PET) liquid phase continuous polycondensation production equipment, which utilizes the motor mounted in the top of reactor to drive the rotating shaft fixed in bottom of reactor and top of reactor by bearings, and in the reactor a self-cleaning stirring system formed from planetary gear and helicoid, a devolatilization system and vacuum-pumping pipeline are mounted, and the exterior of the reactor is closed to a homogenization viscosity-increasing reactor which is heated by biphenyl steam. Said reactors can be individually operated, also can be series-connected or parallelly-connected together for operation, and the material can be fed into and discharged out between all the reactors by means of metering pump.

Owner:王泽新

Beaded sodium polyacrylate and preparation method thereof

The invention provides beaded sodium polyacrylate (PAANa) and a preparation method thereof. The preparation method is characterized in that an efficient stable system is adopted and an inverse suspension polymerization process is adopted, so that a quick-dissolving PAANa product with high intrinsic viscosity (not less than 10dL / g) and excellent dissolubility (not more than 0.5h) can be prepared. Meanwhile, by adjusting the process, beaded superhigh molecular weight quick-dissolving PAANa products with different intrinsic viscosities can be prepared. The obtained PAANa product can replace aqueous solution type and powdery PAANa products with low intrinsic viscosity, and is expected to be widely applied to water treatment, papermaking, oil exploration, textile printing and dyeing, daily chemical industry and other aspects.

Owner:BEIJING HENGJU CHEM GRP +1

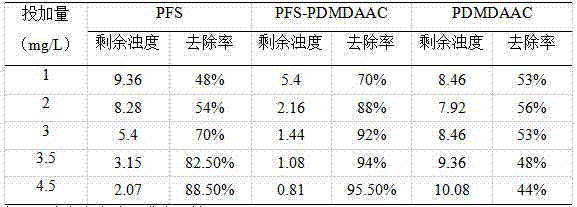

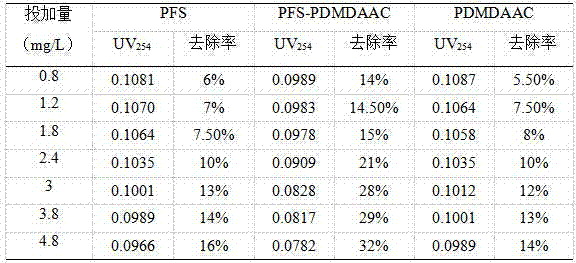

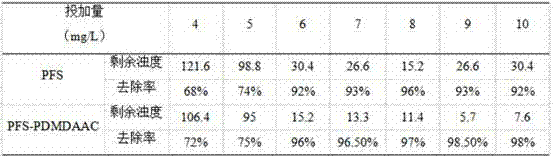

Preparation method of organic high-polymer flocculant, and preparation method and application of inorganic-organic high-polymer composite coagulant

InactiveCN104761038AGood effectSimple processWater/sewage treatment by flocculation/precipitationEngineeringPolymer composites

The invention discloses a preparation method of an organic high-polymer flocculant, and a preparation method and application of an inorganic-organic high-polymer composite coagulant. The preparation method of the organic high-polymer flocculant comprises the following step: in the presence of an initiator and a chelator, carrying out solution polymerization on dimethyl diallyl ammonium chloride monomer to obtain a polydimethyl diallyl ammonium chloride colloidal solution which is the organic high-polymer flocculant. The preparation method of the composite coagulant comprises the following steps: 1) heating and mixing a polyferric sulfate solution with the colloidal solution to obtain a colloid mixed solution; and 2) keeping the temperature, and dispersing until the mixed solution forms a homogeneous system. The invention also discloses application of at least one of the prepared flocculant and inorganic-organic high-polymer composite coagulant in coagulative purification or sludge dewatering treatment of polluted water bodies. The technique is simple, and the prepared composite flocculant has favorable effect. The flocculant and coagulant can be used for micropolluted water source-water coagulative purification, special wastewater treatment, sludge dewatering and the like, and are simple and quick to operate.

Owner:DONGGUAN UNIV OF TECH +1

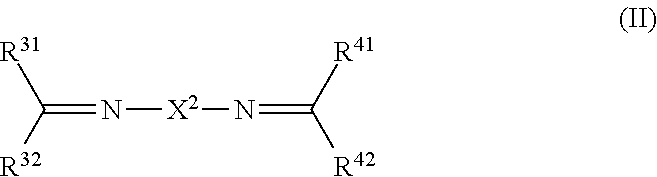

Coating composition and use thereof

InactiveUS20140194571A1Increase flexibilityExtended validity periodPolyurea/polyurethane coatingsPolyester coatingsMethacrylatePolymer science

The invention relates to a coating composition comprising: a) at least one alkyd binder with an oil content of at least 45 wt % and at most 85 wt %, a modified alkyd binder, or a combination thereof; b) at least one amine or imine component selected from the group comprising: polyaspartic acids and esters thereof, (meth)acrylate / aspartate amines, aldimines, ketimines, and combinations thereof; and c) at least one isocyanate compound.

Owner:PPG EURO BV

Ultrasonic atomization micro-mixer, micro-channel reactor, prepolymerization system and para-aramid resin continuous polymerization reaction system and method

PendingCN110605079ASolve removeEasy to removeProcess control/regulationSequential/parallel process reactionsInlet channelUltrasonic atomization

The invention provides an ultrasonic atomization micro-mixer, an ultrasonic oscillation micro-channel reactor, a prepolymerization system and a para-aramid resin continuous polymerization reaction system and method. The ultrasonic atomization micro-mixer comprises a mixing reactor body and an ultrasonic atomizer. The side lower part of the mixing reactor body is connected with a first raw materialinlet channel and a second raw material inlet channel in a penetrating manner, The ultrasonic atomizer acts in the first raw material inlet channel and the second raw material inlet channel and is used for atomizing a first raw material and a second raw material. A first outlet is formed in the upper end of the mixing reactor body, and a second outlet is formed in the lower end of the mixing reactor body. According to the technical scheme, the problem that in the para-aramid resin preparation process, reaction heat in the pre-polymerization stage is difficult to remove, and consequently temperature rise is large is solved, implosion and generation of low-molecular-weight byproducts caused by local overheating of a reaction system are prevented, and it is guaranteed that the intrinsic viscosity of product resin is stable and controllable.

Owner:惠生(中国)投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com