Ultrasonic atomization micro-mixer, micro-channel reactor, prepolymerization system and para-aramid resin continuous polymerization reaction system and method

A technology of microchannel reactor and mixed reactor, which is applied in the field of chemical reaction system, can solve the problems of wide molecular weight distribution coefficient of para-aramid resin, poor uniformity of polymer molecular weight distribution, and inability to quickly and effectively transfer heat of reaction, so as to prevent Effects of implosion polymerization and low molecular weight by-products, enhanced stirring and mixing efficiency, and stable and controllable intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

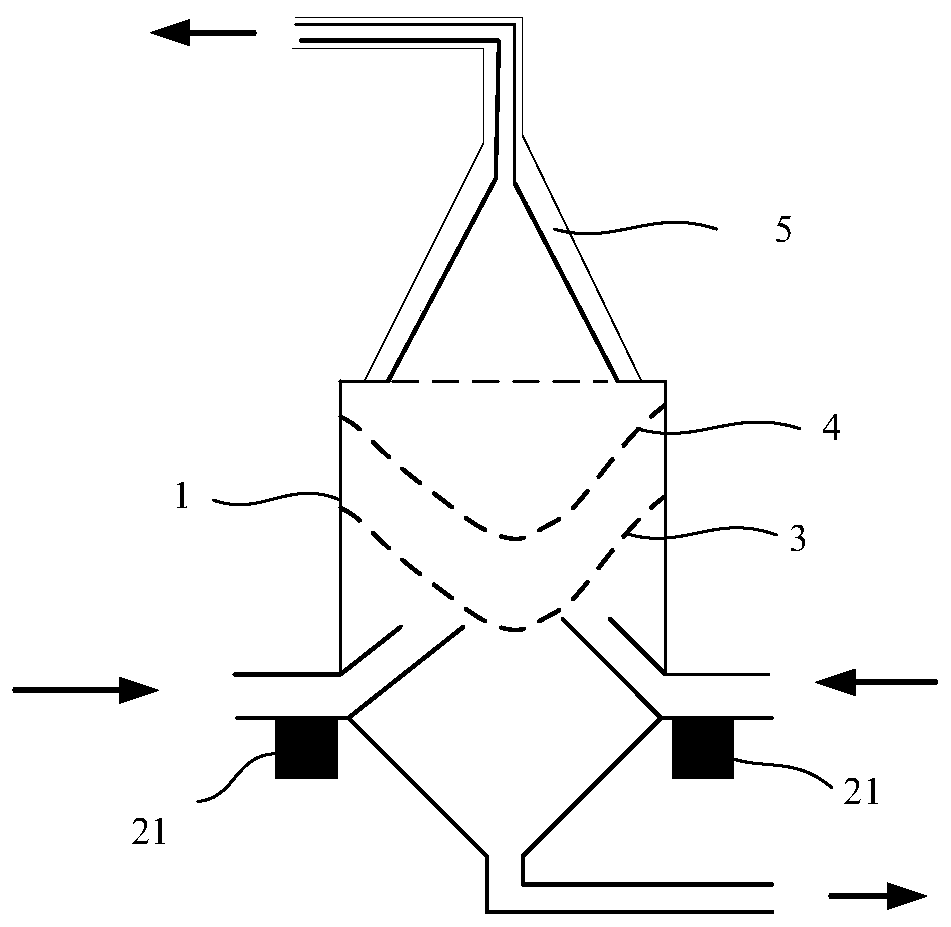

[0066] This embodiment is an embodiment of an ultrasonic atomizing micro-mixer, see for details figure 1 and image 3 .

[0067] Ultrasonic atomization micro-mixer, including a mixing reactor body 1 and an ultrasonic atomizer 21, the side lower part of the mixing reactor body 1 is connected with a first raw material inlet channel and a second raw material inlet channel; the ultrasonic atomization The device 21 acts in the first raw material inlet passage and the second raw material inlet passage for atomizing the first raw material and the second raw material; the upper end of the mixing reactor body 1 is provided with a first outlet; the The lower end of the mixing reactor body is provided with a second outlet.

[0068] The ultrasonic atomizer 21 in this application atomizes the raw material components, and the atomized raw materials enter the mixing reactor body 1, which increases the contact area between the two. In a specific embodiment, the ultrasonic atomizer 21 inclu...

Embodiment 2

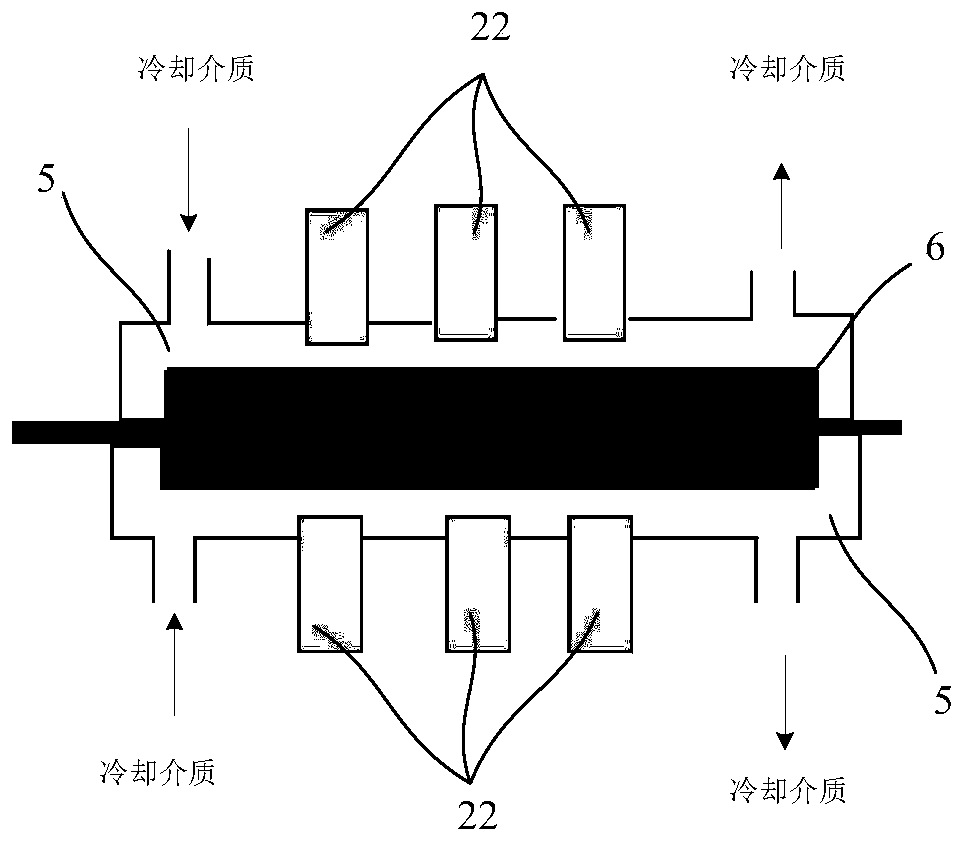

[0084] Provided in this embodiment is an ultrasonic oscillation microchannel reactor, comprising a microchannel reactor body 6, an ultrasonic generator 22 and a cooling assembly 5;

[0085] Both ends of the microchannel reactor body 6 are respectively provided with an inlet and an outlet;

[0086] The cooling assembly 5 surrounds the periphery of the microchannel reactor body 6;

[0087] The ultrasonic generator 22 is wound around the cooling assembly 5 .

[0088] According to the ultrasonic oscillating microchannel reactor described above in the present invention, the cooling assembly 5 in this application is a cooling channel through which a cooling medium such as circulating water passes.

[0089] In a specific embodiment of the present application, the microchannel reactor body is a microchannel reactor core plate.

[0090] According to the specific solution above in this embodiment, there are multiple ultrasonic generators. The ultrasonic generator transmits the ultras...

Embodiment 3

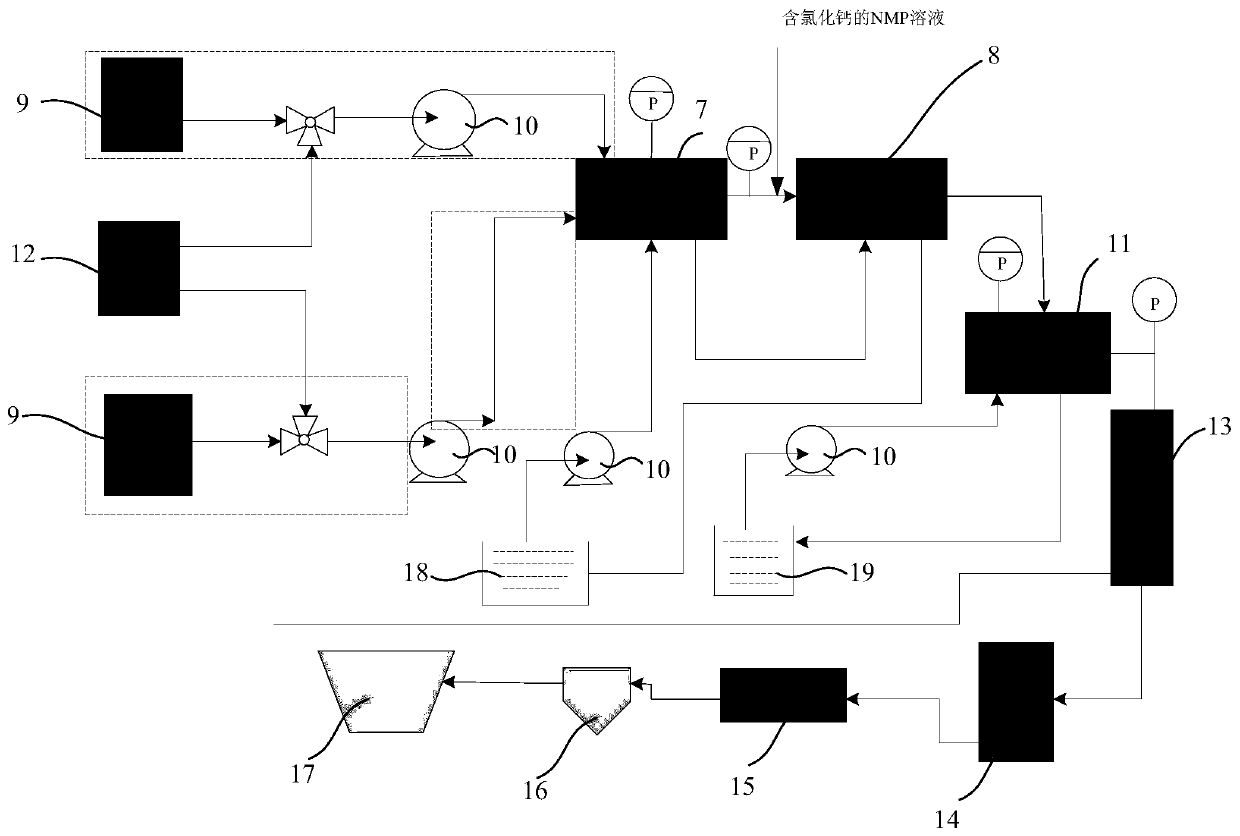

[0092] This embodiment also discloses a pre-polymerization system, which includes an ultrasonic atomizing micro-mixer 7 and an ultrasonic oscillating micro-channel reactor 8 connected in sequence.

[0093] According to the pre-aggregation system described in this embodiment, the pre-aggregation system further includes several raw material storage devices respectively connected to the first raw material inlet channel and the second raw material inlet channel of the ultrasonic atomizing micro-mixer.

[0094] According to the prepolymerization system described in this embodiment, booster pumps are further provided on the first raw material inlet passage and the second raw material inlet passage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com