Patents

Literature

101results about How to "Solve easy loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active carbon immobilized imidazole ionic liquid, preparation method thereof and application thereof

InactiveCN102513063ASolve easy lossImprove bindingOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonChemical reaction

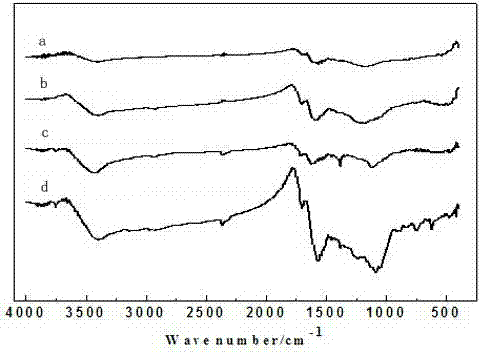

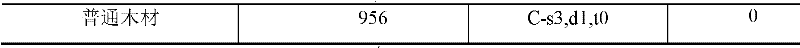

The invention discloses an active carbon immobilized imidazole ionic liquid, a preparation method thereof and an application thereof. The active carbon immobilized imidazole ionic liquid is obtained through immobilizing an imidazole ionic liquid on the surface of active carbon by a silane coupling agent. The preparation method comprises the following steps: preparing the active carbon, modifying the active carbon, silanizing the modified active carbon, and immobilizing the imidazole ionic liquid. According to the invention, the imidazole ionic liquid is firmly and chemically bonded on the active carbon, so the binding force between the ionic liquid and the active carbon is enhanced, thereby a problem of easy loss of the ionic liquid of traditional physical dipping load methods is solved. The prepared active carbon immobilized imidazole ionic liquid which can be applied to the adsorbing separation of a carbon dioxide, hydrogen sulfide, benzene and formaldehyde gas can also be used as acatalyst for a liquid phase chemical reaction, and has the advantages of adjustable adsorption performance and catalytic performance, easy recycle, environmental protection and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

Catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride and its preparation method and application

ActiveCN103769117AHigh activityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActivated carbonActive component

The invention discloses a catalyst for hydrogenating cis-butenedioic anhydride to prepare butanedioic anhydride, the catalyst uses activated carbon as a carrier, at least one of cobalt and nickel as an active component, at least one of molybdenum and tungsten as a first aid, at least one of iron, copper and zinc as a second aid, and comprises, by the final catalyst weight, 1%-10% of the active component, 3%-15% of the first aid and 5%-20% of the second aid. A preparation method of the catalyst for hydrogenating the cis-butenedioic anhydride to prepare the butanedioic anhydride is as follows: using the activated carbon as the carrier, and using an impregnation method for successive loading of the active component, the first aid and the second aid. The catalyst has the advantages of simple preparation process, and the prepared catalyst for hydrogenating the cis-butenedioic anhydride to prepare the butanedioic anhydride solves the problems that when a non-noble metal is used as the active component, the catalyst activity and the butanedioic anhydride selectivity are low.

Owner:CHINA PETROLEUM & CHEM CORP +1

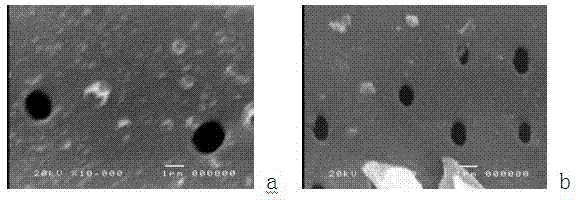

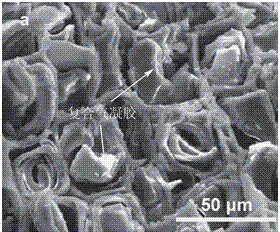

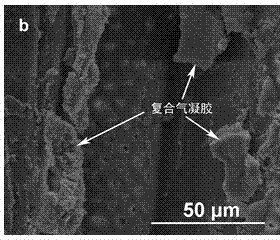

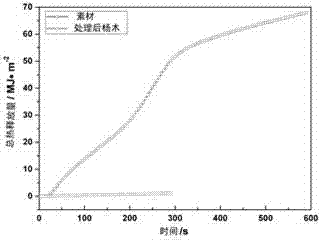

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

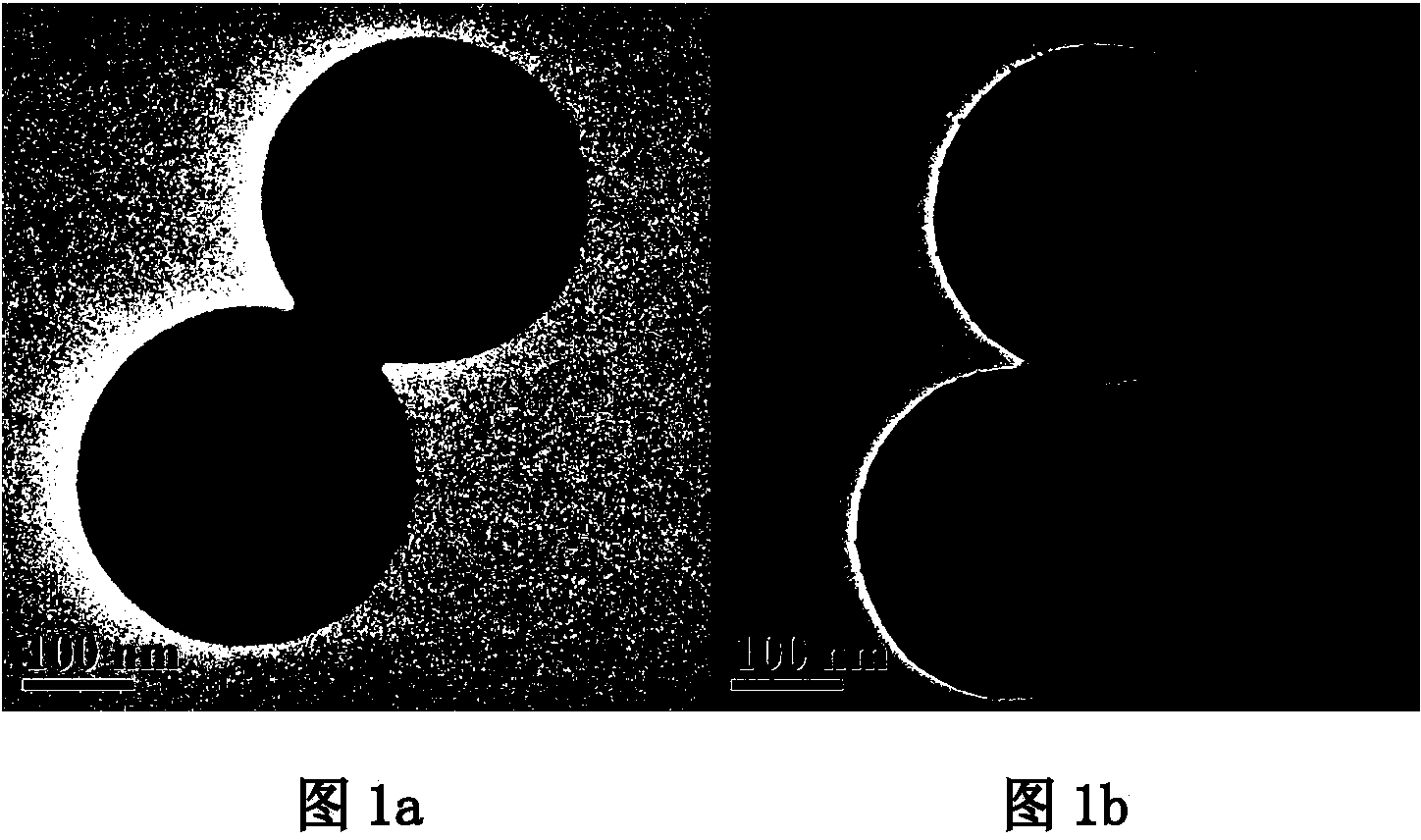

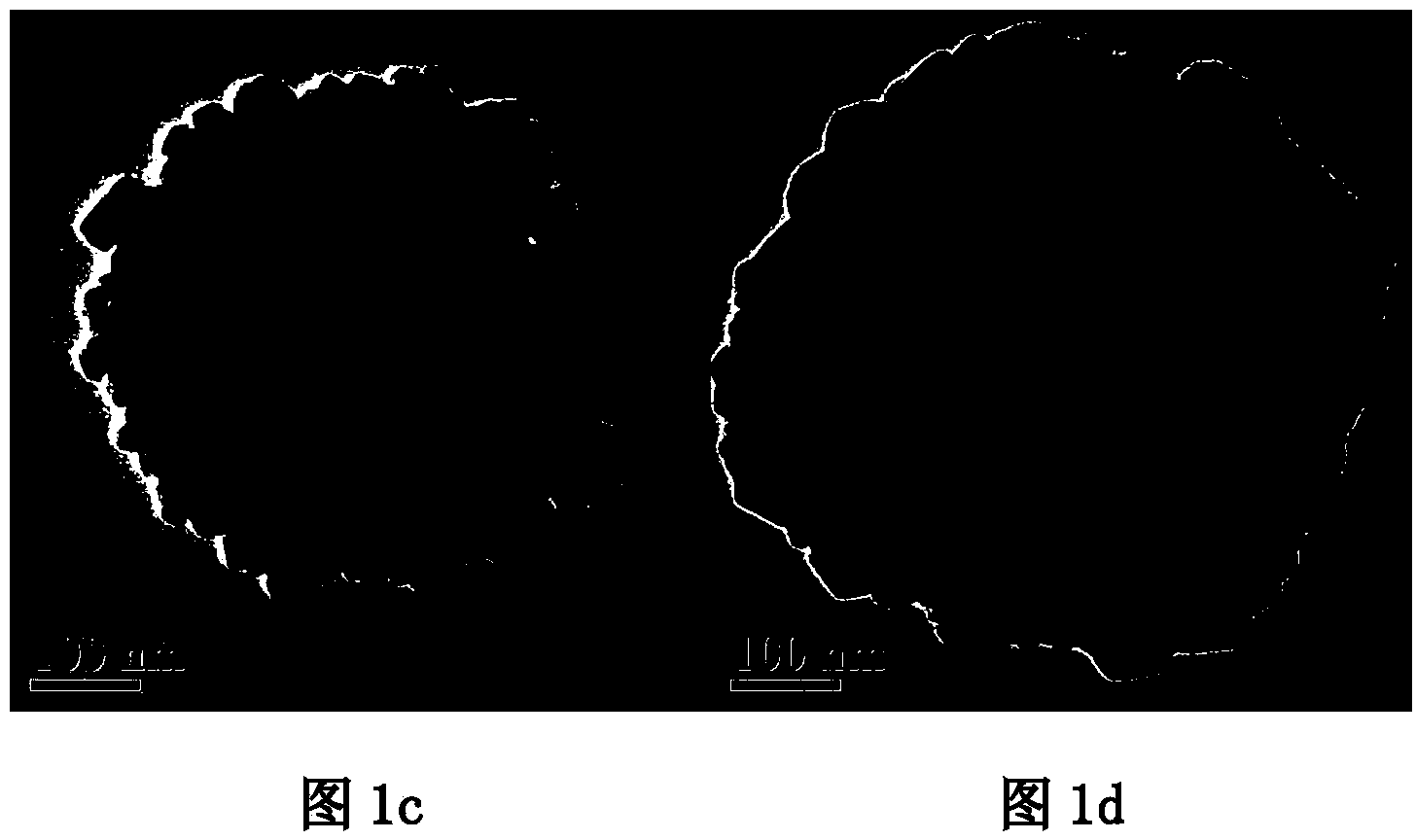

Method for preparing selectivity-adjustable efficient supported precious-metal core-shell catalyst coated with metal-organic framework ZIF-8 membrane

InactiveCN103908976AHigh selectivityReduced activityOrganic-compounds/hydrides/coordination-complexes catalystsPolyelectrolyteActive component

The invention relates to a method for preparing a selectivity-adjustable efficient supported precious-metal core-shell catalyst coated with a metal-organic framework ZIF-8 membrane, and belongs to the technical field of new materials. The method comprises the following steps: coating a pre-prepared supported precious-metal catalyst with a ZIF-8 membrane selective-separation layer, repairing the defect of the membrane layer through polyelectrolyte, adjusting and controlling the membrane forming times to obtain continuous ZIF-8 membranes with different compactnesses, and thereby the catalyst has the adjustable high selectivity. Compared with the same kind of catalyst, the selectivity-adjustable efficient supported precious-metal core-shell catalyst has the advantages of simple preparation process, mild conditions and easiness in large-scale amplification. The selectivity-adjustable efficient supported precious-metal core-shell catalyst solves the problem that a multiphase supported precious-metal catalyst has the low selectivity to reactants and products, and simultaneously is beneficial to relieve the fact that active components of the multiphase supported precious-metal catalyst are easily lost and poisoned.

Owner:DALIAN UNIV OF TECH

Lubricating grease for wire rope and its production

A kind of grease lubricant used to protect tightwire, the weight content basing on the whole weight of the compound of each component is as following: (1) the proportion of the animal fat is 10-50%. (2) The proportion of hydrogenated oil is 1-10%. (3) The proportion of the wool grease rust-preventing agent is 0.5-8%. (4) Vgetable oil remainder. The hydrogenated oil of above is produced by hydrotreating of the animal oil, and the molecular weight of it is 850-890.The melting point of the wool oil is 38-42DEG C, and the iodine value of it is 18-36. The fat in this invention is kind of grease lubricant used to protect the tightwire which is friendly to the environment, and independent to petroleum raw material, and the biological degradation property of it is very good. It can be smeared on the surface of the tightwire during the process of it, or the hemp center can be dipped in it, it can prevent the rust-eaten of the tightwire, and also can act as a lubricant. The dropping point of the grease lubricant is more than 65DEG C, and it can resolve the problem that the dropping point of the hydrocarbon-based grease lubricant is too low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant solid wood composite section and manufacturing method thereof

InactiveCN102248559AOvercoming the problem of not being flame retardantGood dimensional stabilityVeneer manufactureWood veneer joiningSolid woodWeather resistance

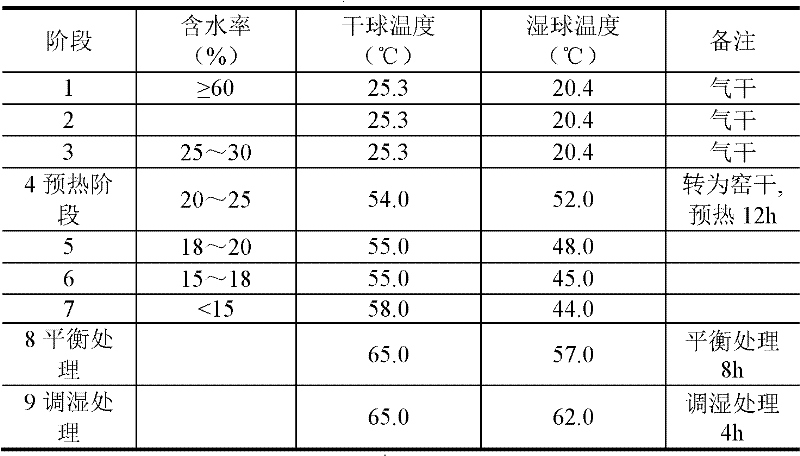

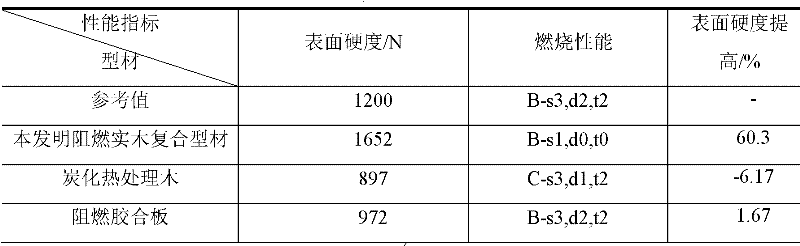

The invention relates to a method for improving functionality of wood, in particular to a flame-retardant solid wood composite section improved through processes of wood heat treatment and flame retardant treatment and a manufacturing method thereof, belonging to the technical fields of wood functionality improvement and wood processing. The manufacturing method of the flame-retardant solid wood composite section comprises the steps of: (1) wood chip manufacturing; (2) first stacking and drying; (3) heat treatment improvement; (4) normal-pressure impregnation flame retardant treatment on wood chips; (5) second stacking and drying; and (6) gluing and fixing. By means of the method, the advantages of the wood subjected to the carbonization heat treatment and the flame retardant treatment are combined together and the respective disadvantages are overcome to ensure that the obtained solid wood composite section has the advantages of high dimensional stability, strong decay and weather resistance, good flame retardant effect because of a uniformly permeated flame retardant, simple production facility, low production cost and high wood outturn percentage. The obtained solid wood composite section is a good material applied to indoor structure beams, furniture and flame retardant wood doors.

Owner:东莞市华富立装饰建材有限公司

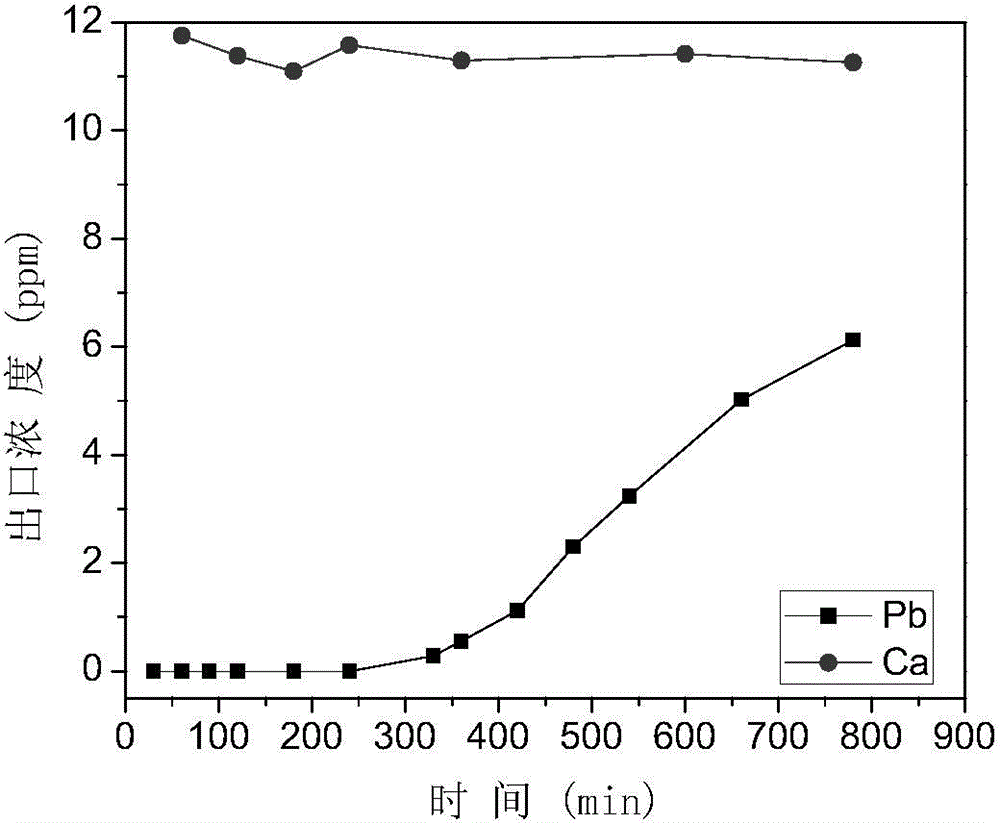

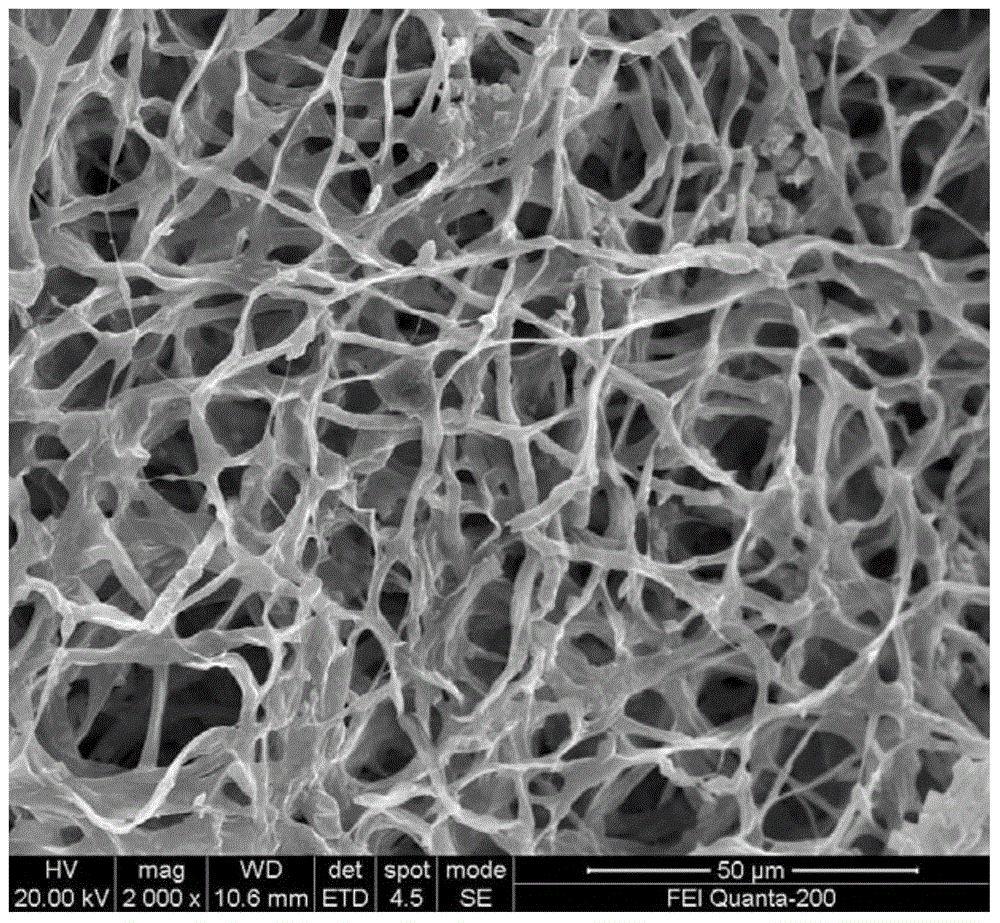

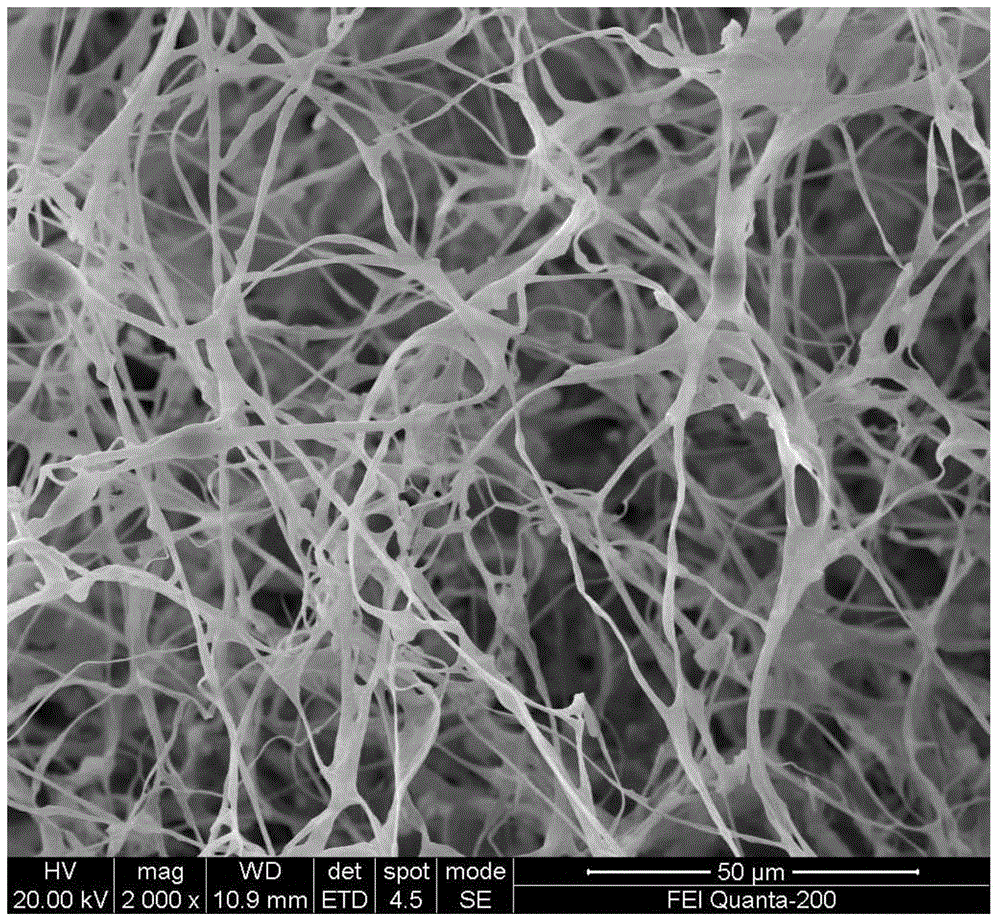

Adsorptive separation composite fiber film, preparation method and uses thereof

ActiveCN106031863ASolve reunionSolve churnOther chemical processesAlkali metal oxides/hydroxidesFiberComposite film

The present invention relates to an adsorptive separation composite fiber film, a preparation method and uses thereof, wherein the composite fiber film is a nanometer particle / polymer fiber composite film. The concrete method comprises: firstly synthesizing nanometer particle / polymer fiber composite fibers, preparing into a composite fiber film, loading the film into a filter, and carrying out dynamical adsorbing and filtering to remove heavy metal ions in the water. According to the present invention, the preparation method has characteristics of simpleness, green concrete, low cost, high heavy metal waste water treatment efficiency, good selectivity and recycling, and the adsorptive separation composite fiber film can be used for purification and treatment of heavy metals in industrial and domestic wastewater.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

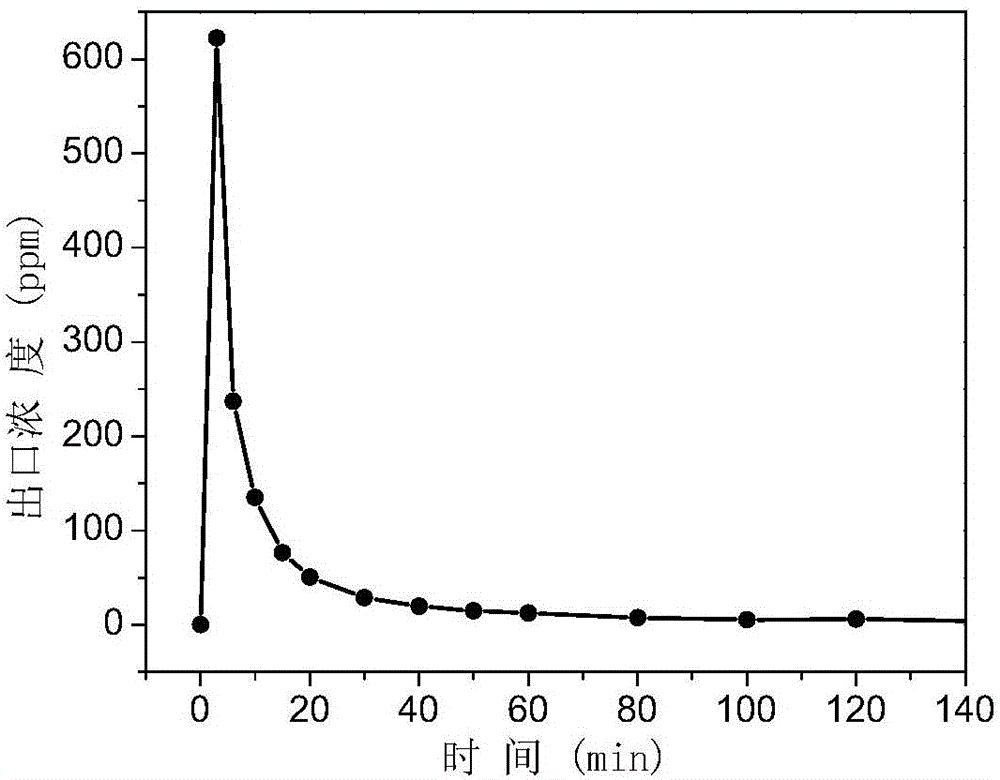

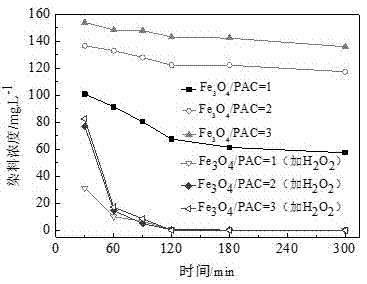

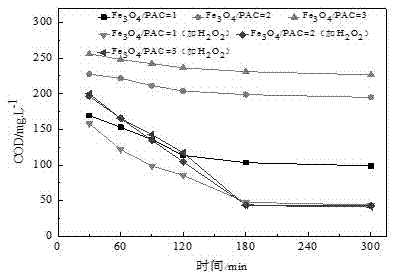

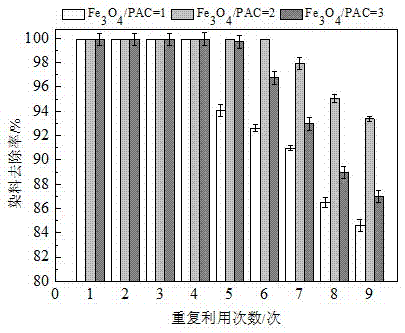

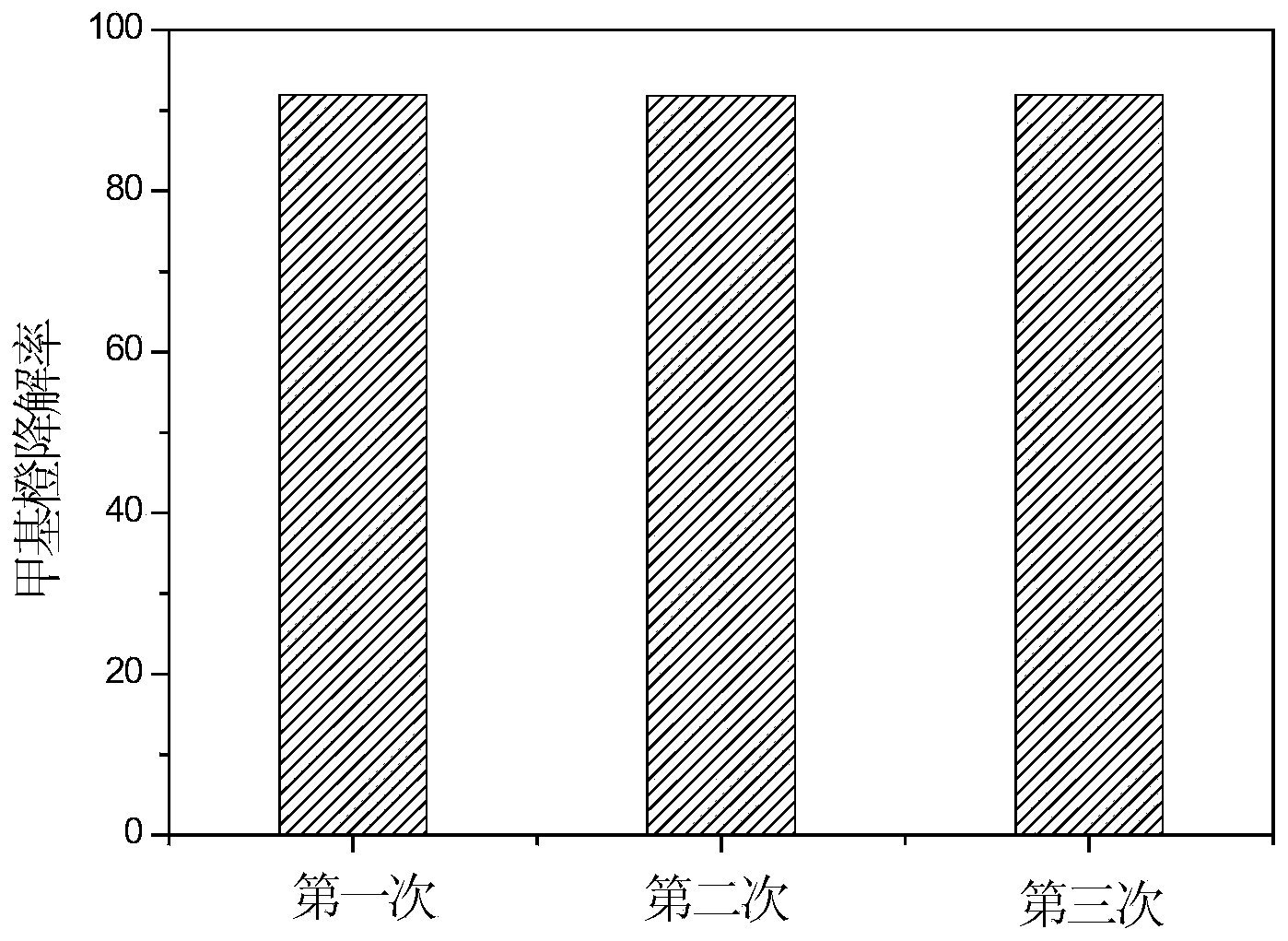

Method for integrated treatment of dyeing wastewater by using magnetic activated carbon

InactiveCN105439238AAchieve regenerationEasy to handleOther chemical processesWater contaminantsActivated carbonSludge

The present invention relates to a method for integrated treatment of dyeing wastewater by using magnetic activated carbon. According to the method, an improved magnetic activated carbon adsorption process and an Fe3O4-H2O2 based Fenton-like technology are organically combined based on the preparation of a PAC-Fe3O4 composite material, and a dyeing wastewater treatment technology integrated with adsorption and regeneration is proposed, and the materials after adsorption can be synchronously regenerated by using the Fenton-like technology in the processing system. According to the method, the adsorption property of the PAC-Fe3O4 composite material and the Fe3O4 Fenton-like catalyst characteristic are fully used. At the time that the material performs adsorption effect on the dye pollutants, H2O2 is synchronously added to form a Fe3O4-H2O2 Fenton-like system to perform regeneration, so that the processing ability of the system is effectively improved, and the processing cost is lowered. The advantages of a pure PAC process and a conventional Fenton process are organically combined, so that the shortages that the conventional PAC and the treated wastewater are difficult to separate are easily to be lost, and cannot be regenerated are solved, and the problems that ferric salt needs to be continuously added in the conventional Fenton process, and the sludge output amount is large are improved. The method has the advantages of being simple, efficient, economical and the like, thereby having a large potential market in dyeing wastewater treatment applications.

Owner:HIT YIXING ACAD OF ENVIRONMENTAL PROTECTION +1

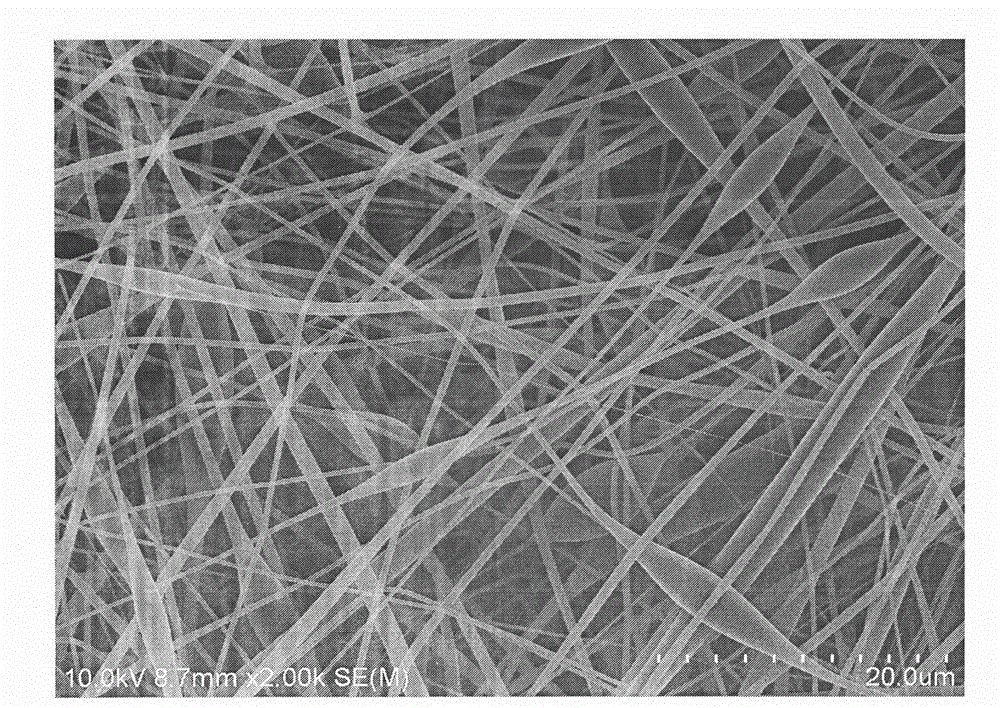

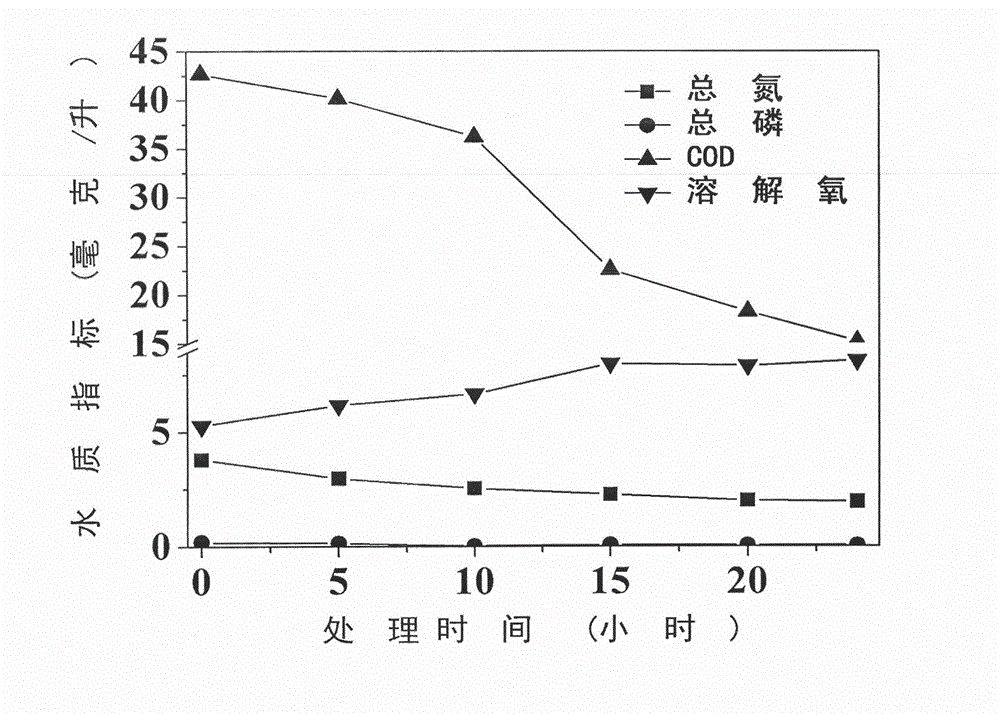

Method for eutrophic water pollution treatment through polylactic acid fiber membrane immobilized compound enzyme technology

ActiveCN102716684ASolve easy lossNo secondary pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisEutrophic waterAlpha-amylase

The invention relates to a multi-enzyme immobilized electrospun fiber membrane used for treating a eutrophic polluted water body. By using an electrospinning technology, a multi-enzyme system which comprises alpha-amylase, hormone sensitive lipase, papain, fungal cellulose, fungal laccase, soybean urease and the like and can decompose various organic matters causing eutrophic water body pollution is immobilized in a polylactic acid electrospun fiber membrane and directly covers the surface of the eutrophic polluted water body to catalytically degrade various nitrogen-containing organic matters, so as to achieve the goal of reducing the eutrophic pollution in the water body. The polylactic acid electrospun fiber membrane which carries the multi-enzyme system can rapidly and conveniently remove typical eutrophic pollutants in the water body in time to rapidly recover water quality. Compared with other eutrophic pollution treatment techniques, the multi-enzyme immobilized electrospun fiber membrane has the advantages of high efficiency and good performance, can be expected to be used for remediation of urban moderate or severe eutrophic polluted water bodies or in the aquiculture field.

Owner:BEIJING NORMAL UNIVERSITY

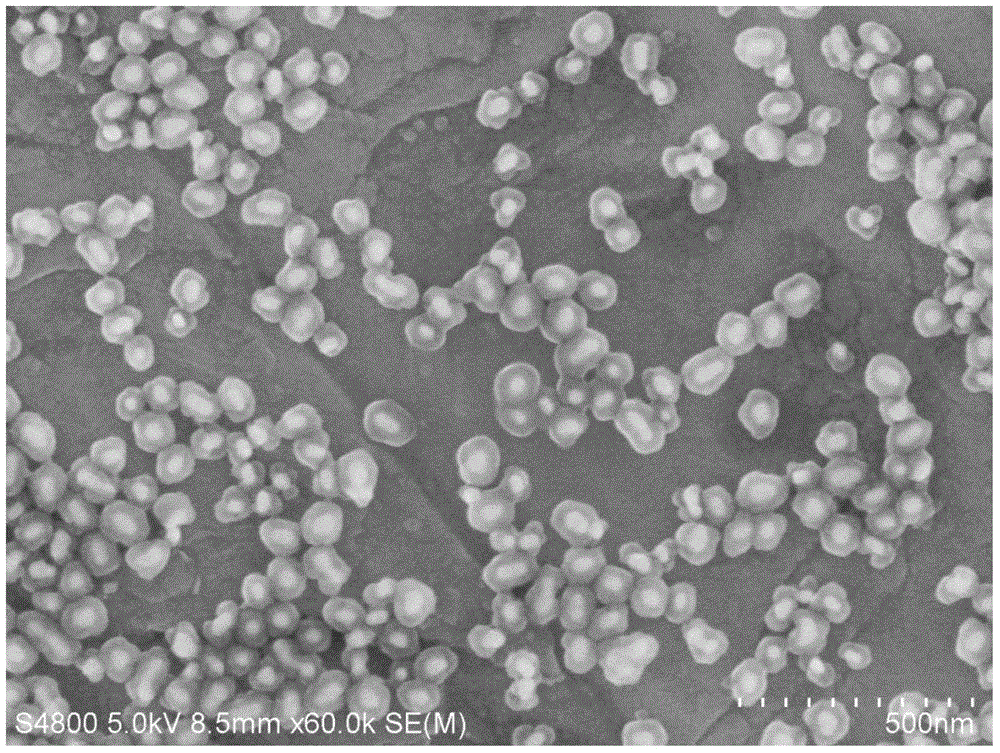

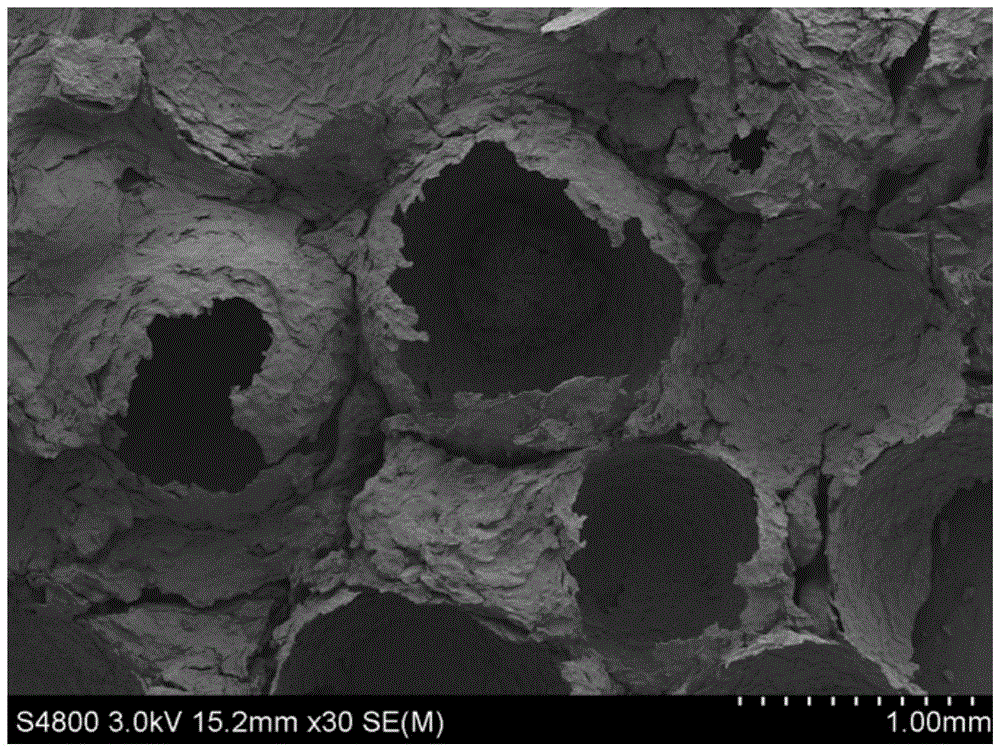

Porous carbon load noble metal catalyst and preparation method thereof

ActiveCN105126828AShape stableImprove performanceMetal/metal-oxides/metal-hydroxide catalystsPorous carbonCarbonization

The invention relates to a porous carbon load noble metal catalyst and a preparation method thereof. The catalyst is prepared from porous cage-shaped carbon materials and noble metal nanometer particles distributed in the porous cage-shaped carbon materials. The preparation method of the catalyst includes the steps of firstly, adding a dispersing agent solution to noble metal nanometer dispersion liquid, removing supernate through centrifugal separation, and obtaining surface-decorated noble metal nanometer particles; secondly, mixing the surface-decorated noble metal nanometer particles with absolute ethyl alcohol and deionized water, dispersing the mixture evenly through ultrasonic waves, adding ammonia water and tetraethyl orthosilicate, and obtaining noble metal @SiO2 core-shell particles; thirdly, mixing the noble metal @SiO2 core-shell particles with PS micro-balloons, a carbon substrate material and a dilute sulphuric acid solution, dispersing the mixture evenly through ultrasonic waves to have a reaction at a temperature of 120 DEG C to 200 DEG C, conducting full carbonization and thermal treatment, putting the mixture into an HF solution to be treated for 10 h to 15 h after naturally cooling the mixture so that silicon dioxide can be removed, and finally conducting washing and drying to obtain the porous carbon load noble metal catalyst.

Owner:WUHAN UNIV OF TECH

Catalyst for producing ethyl orthosilicate by silicon powder method and preparation method thereof

InactiveCN102489299AHigh activitySolve easy lossSilicon organic compoundsCatalyst activation/preparationAlcoholActive component

The invention relates to a catalyst for producing ethyl orthosilicate by a silicon powder method and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 20%-50% of cuprous oxide, 10%-40% of copper oxide, 10%-40% of copper powder and 10%-30% of catalyst carrier. The preparation method comprises the following steps of: uniformly mixing the active components such as cuprous oxide, copper oxide and copper powder according to the composition of the catalyst; preparing a 30-40% alcohol or aqueous solution of the catalyst carrier; and adding the mixed active components in the alcohol solution of the catalyst carrier, stirring for 1-2 hours, then dripping a small amount of distilled water, continuously stirring for 1-24 hours, and then filtering,thus obtaining filter residue; and drying the filter residue at the temperature of 70-120 DEG C, and roasting for 8-24 hours with air isolation at the temperature of 400-700 DEG C, thus obtaining thecatalyst. The catalyst has the characteristics of high activity and stability, long service life and capability of being utilized repeatedly for multiple times.

Owner:KUNMING METALLURGY INST

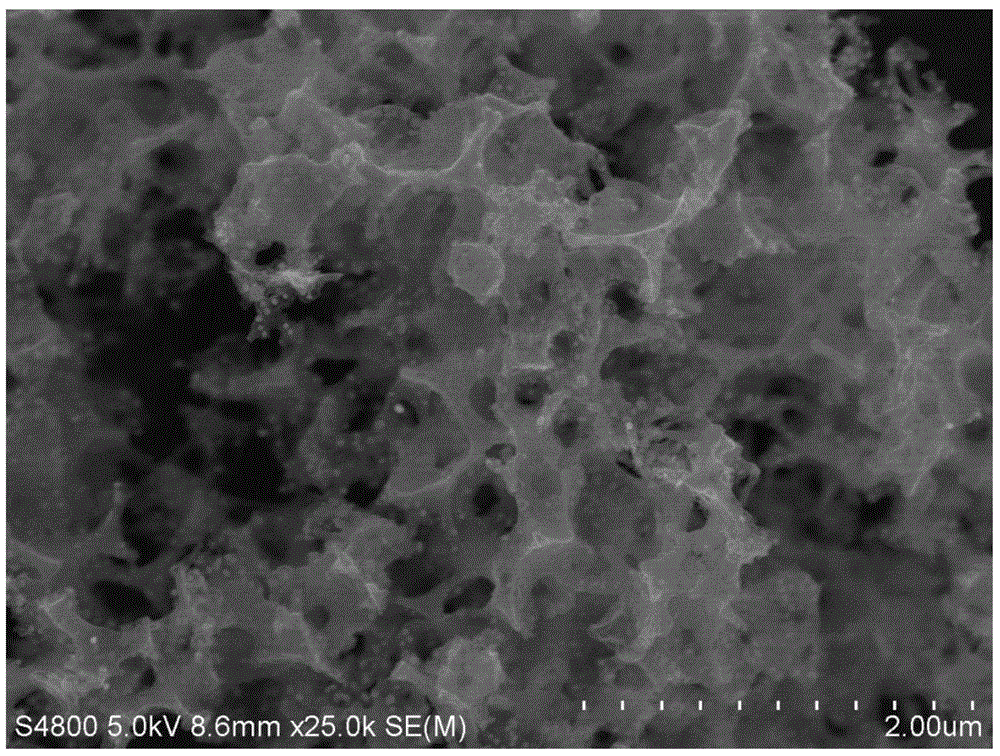

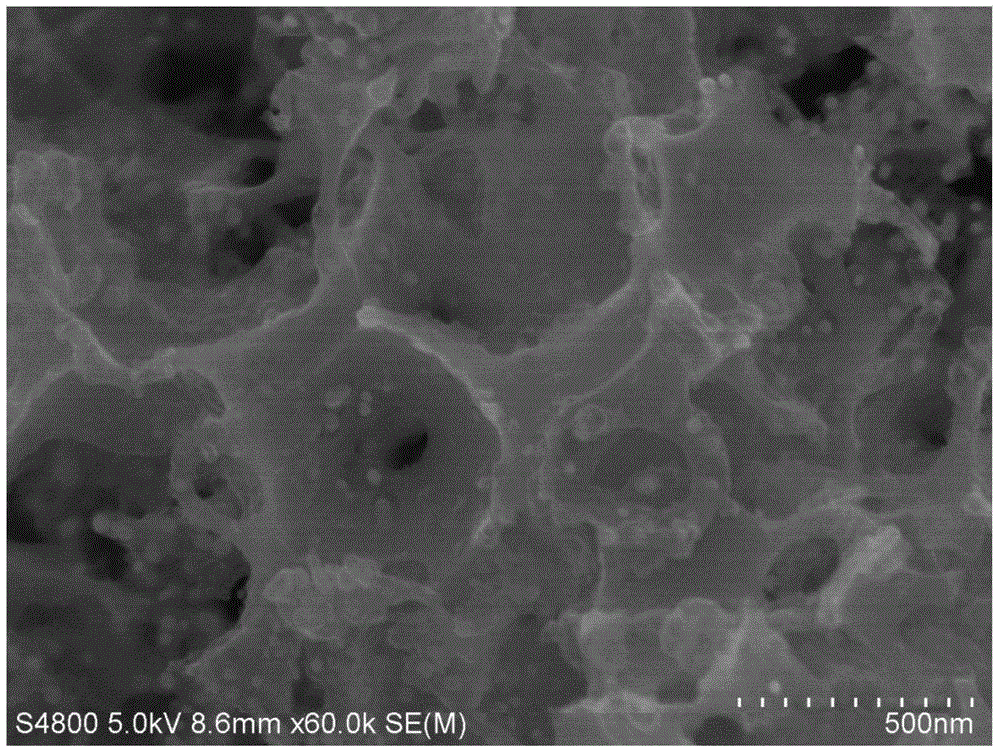

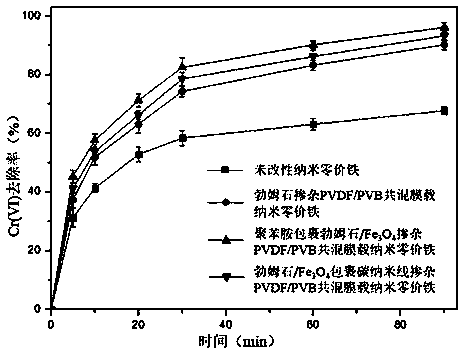

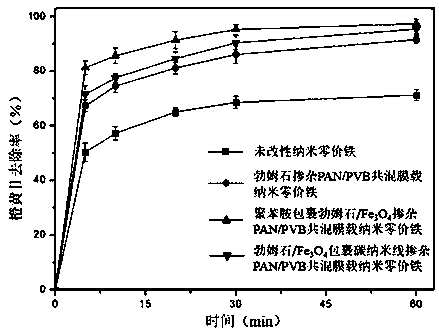

Hydrophilic material-doped blended membrane nanoscale zero-valent iron-loading composite material as well as preparation method and application thereof

ActiveCN108483613AEasy reunionSolve pollutionWater contaminantsWater/sewage treatment by sorptionWastewaterPolymer solution

The invention discloses a hydrophilic material-doped blended membrane nanoscale zero-valent iron-loading composite material as well as a preparation method and application thereof. The method comprises the steps of (1) synthesizing a hydrophilic material; (2) doping the hydrophilic material during a blended membrane synthesis process; (3) soaking the hydrophilic material-doped blended membrane into a bioinspired polymer solution, and functionalizing; (4) soaking the functionalized hydrophilic material-doped blended membrane into a soluble ferric salt solution, and loading an iron ion onto a boehmite-doped blended membrane; (5) soaking the iron-loading blended membrane into a borohydride solution, thus forming the hydrophilic material-doped blended membrane nanoscale zero-valent iron-loadedcomposite material through a high reduction function. The method is low in cost, and the operation process is simple and convenient; and the prepared nanoscale zero-valent iron particles are good indispersing performance, high in reaction activity and easy to recycle, has a good removal capability on heavy metals, organic dyestuffs and antibiotic wastewater, cannot cause secondary pollution, andhas a wide application prospect in the field of environment pollution remediation.

Owner:KUNMING UNIV OF SCI & TECH

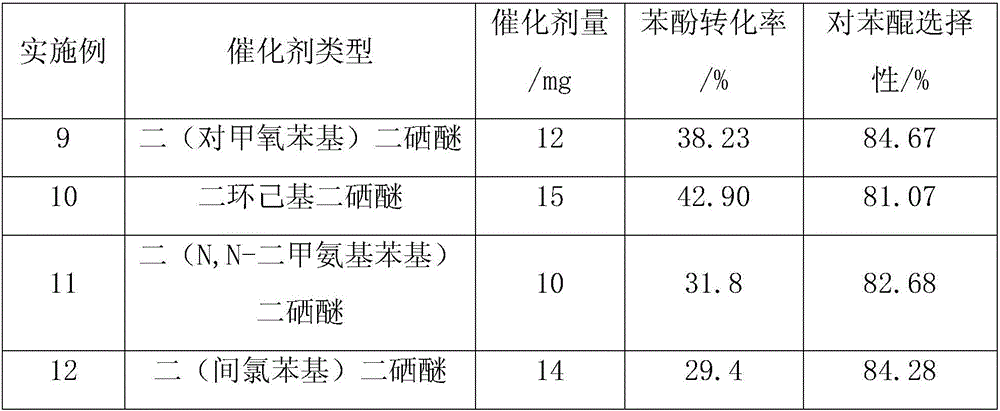

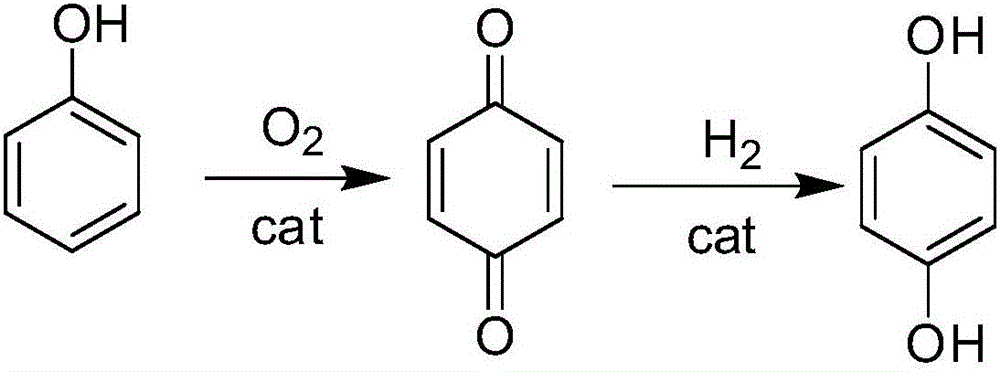

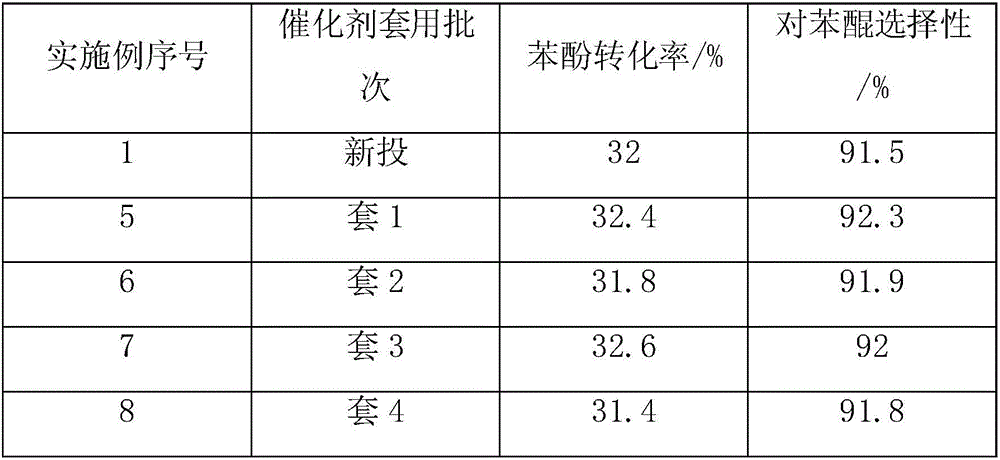

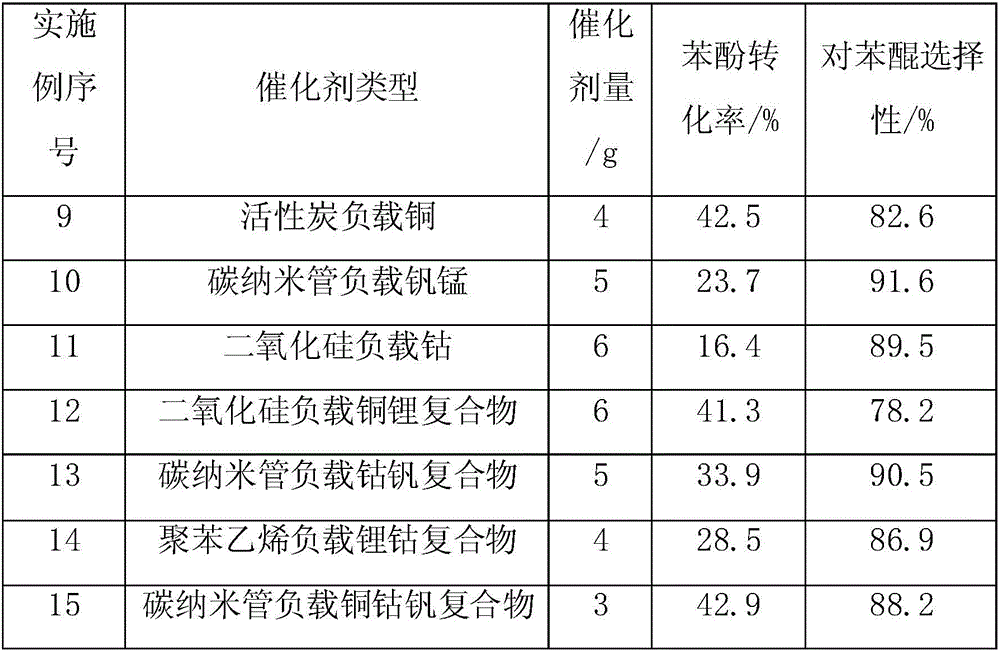

Method for catalyzing oxidation of phenol and hydrogen peroxide with selenium-containing catalyst for synthesis of p-benzoquinone

ActiveCN106588618AMild process conditionsImprove securityQuinone preparation by oxidationOrganic-compounds/hydrides/coordination-complexes catalystsSolventBottle

The invention relates to a method for catalyzing oxidation of phenol and hydrogen peroxide with a selenium-containing catalyst for synthesis of p-benzoquinone. The method is mild in reaction conditions and can be implemented at normal pressure. According to a technical scheme in the invention, the method comprises the following steps: adding phenol, a solvent, the selenium-containing catalyst and hydrogen peroxide into a glass reaction bottle and carrying out a reaction at a certain temperature, wherein analysis results of oxidized liquid show that the conversion rate of phenol is about 30 to 50%, the selectivity of p-benzoquinone is 80 to 90% and resorcinol and ortho-isomers are not produced. High-selectivity preparation of hydroquinone can be realized through hydrogenation reduction of p-benzoquinone.

Owner:JIANGSU YANGNONG CHEM GROUP +2

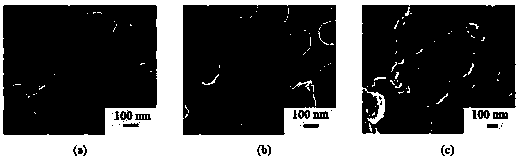

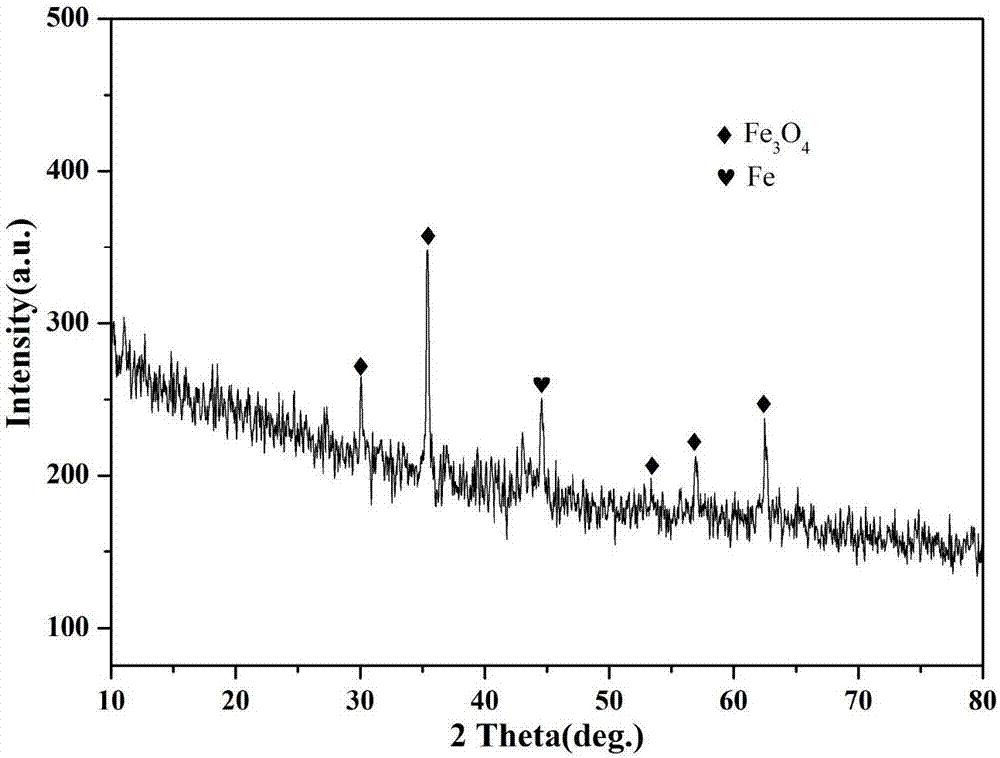

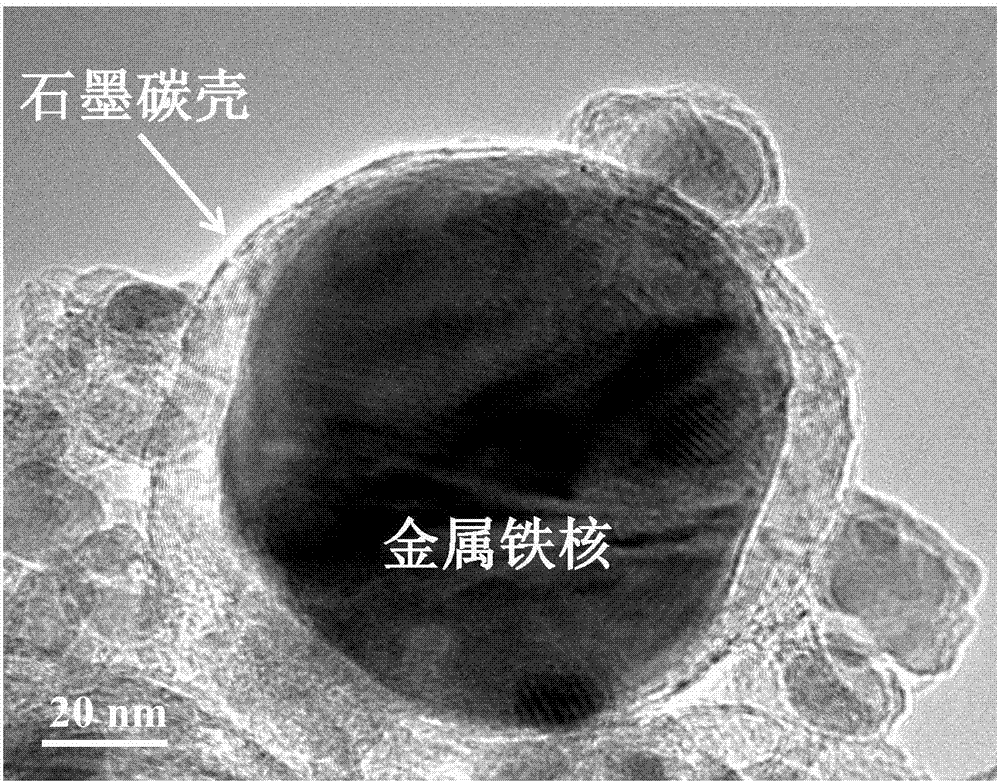

Carbon-coated metal nanoparticle-loaded PVDF (Polyvinylidene Fluoride) membrane as well as preparation method and application thereof

ActiveCN107118477AEasy reunionAvoid secondary pollutionWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a carbon-coated and metal nanoparticle-loaded PVDF (Polyvinylidene Fluoride) membrane as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, synthesizing carbon-coated metal nanoparticles; secondly, mixing the carbon-coated metal nanoparticles with polyvinylidene fluoride powder, an organic additive and a dispersion medium and stirring to obtain a casting membrane solution; thirdly, obtaining a target product by a solution phase conversion method. The carbon-coated and metal nanoparticle-loaded PVDF membrane disclosed by the invention disclosed by the invention can efficiently mineralize toxic organic pollutants in a water body and is high in degradation rate; a catalytic membrane reactor is constructed to carry out a catalytic degradation reaction of the organic pollutants; macromolecular organic pollutants are prevented from passing through on the basis of a micronano separation effect of a membrane pore structure, so an interception effect is realized, conversion rate and selectivity of degradation are improved, the technical problems that metal nanoparticles are easy to agglomerate and lose are solved, and potential secondary pollution to the water body is avoided; in addition, the preparation method has the advantages of lower cost, simple process, controllable structure, high maneuverability, easiness for industrial application and the like.

Owner:HEFEI UNIV OF TECH

MOF supported metal peroxide catalyst

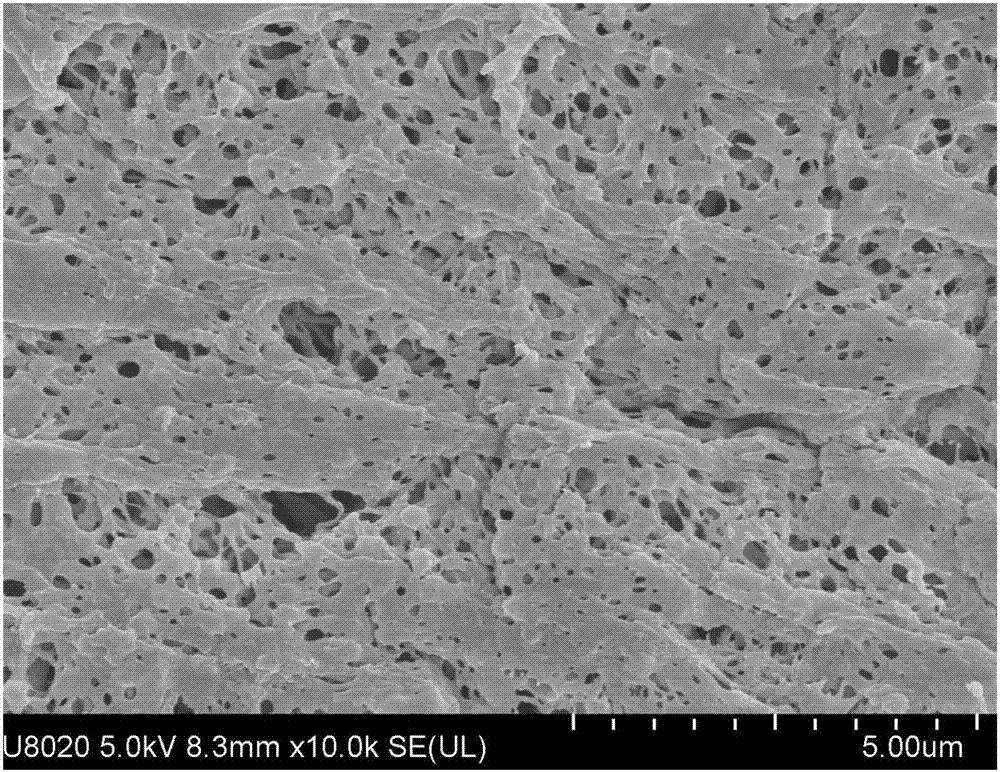

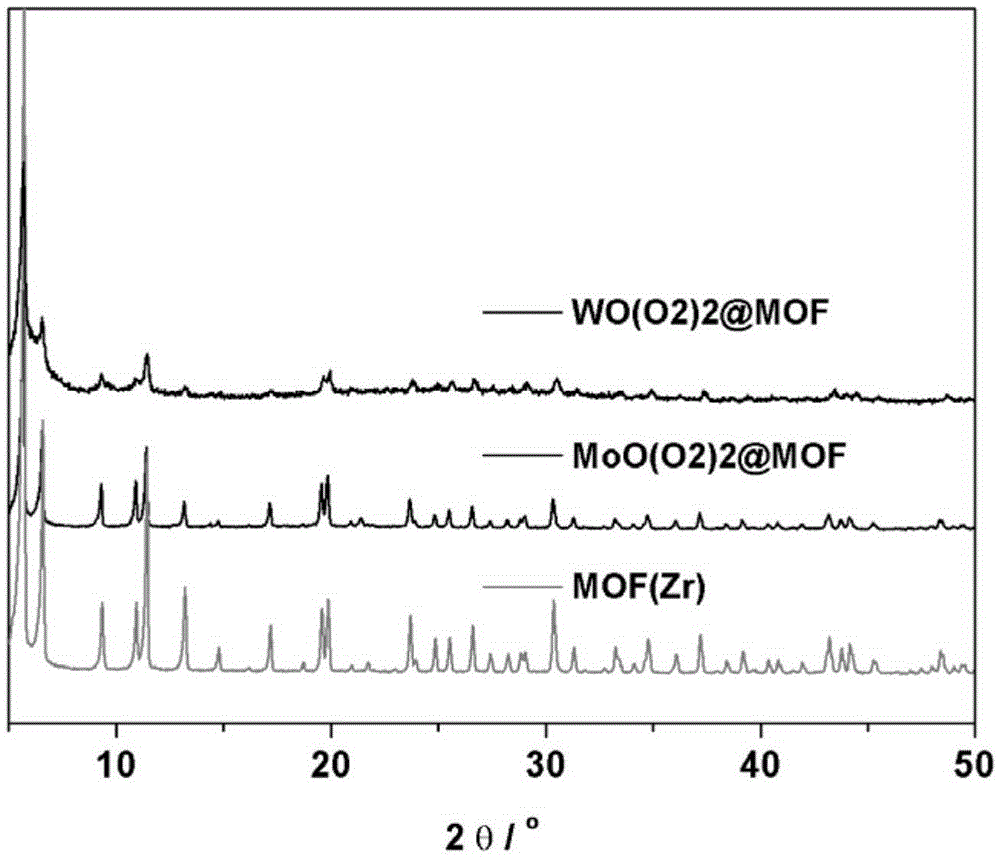

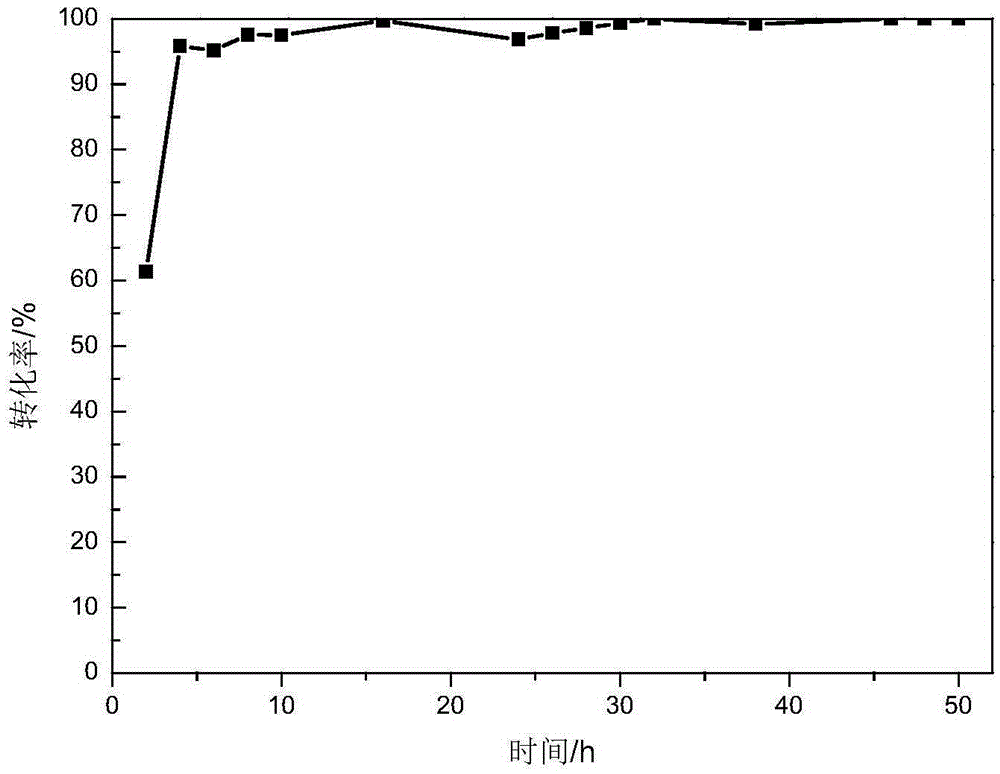

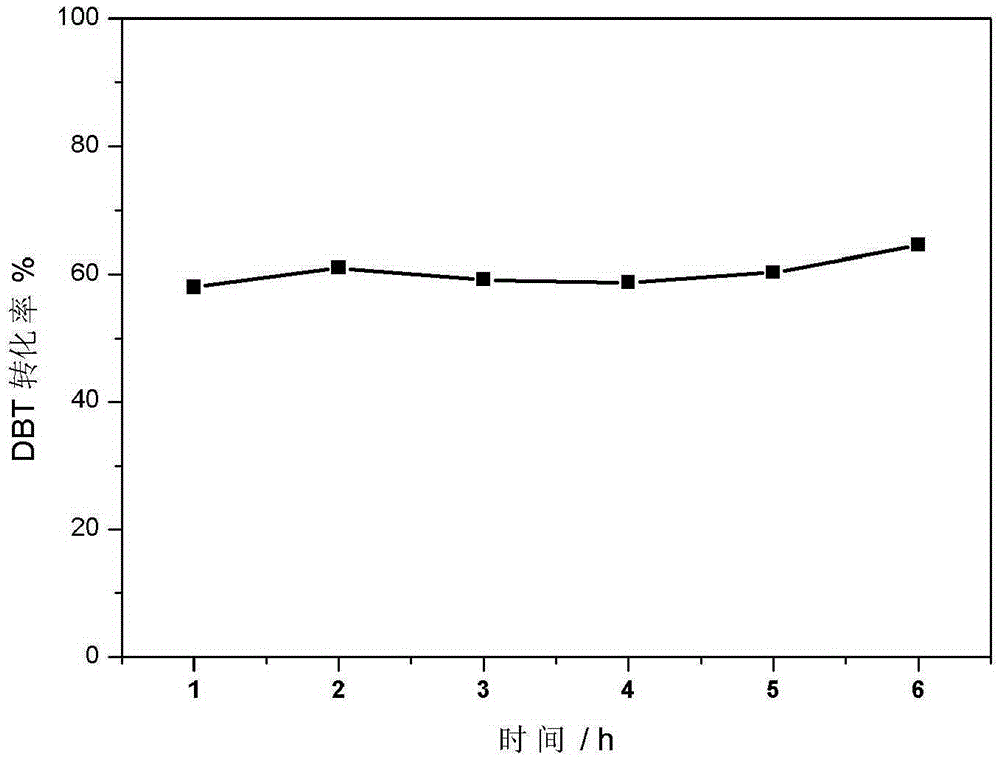

InactiveCN105289732AHigh activityAvoid churnOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsCatalytic oxidationMetal-organic framework

The invention provides an MOF supported metal peroxide catalyst. The catalyst comprises a metal organic skeleton carrier and a metal peroxide species MO(O2)2, wherein M represents Mo6 or W6+. The catalyst is prepared in the mode that in the metal organic skeleton material synthesizing process, MO(O2)2 with catalytic oxidation activity is anchored to a metal organic skeleton material through a pre-modification or post-modification method. According to the catalyst, metal peroxide is highly dispersed on a crystal skeleton, and the metal peroxide species is coordinated with organic ligand based on dipyridyl chelation locus, so that high stability is kept; when applied to an oxidation sweetening reaction, high activity and stability are kept, and the catalyst has important industrial application value.

Owner:DALIAN UNIV OF TECH

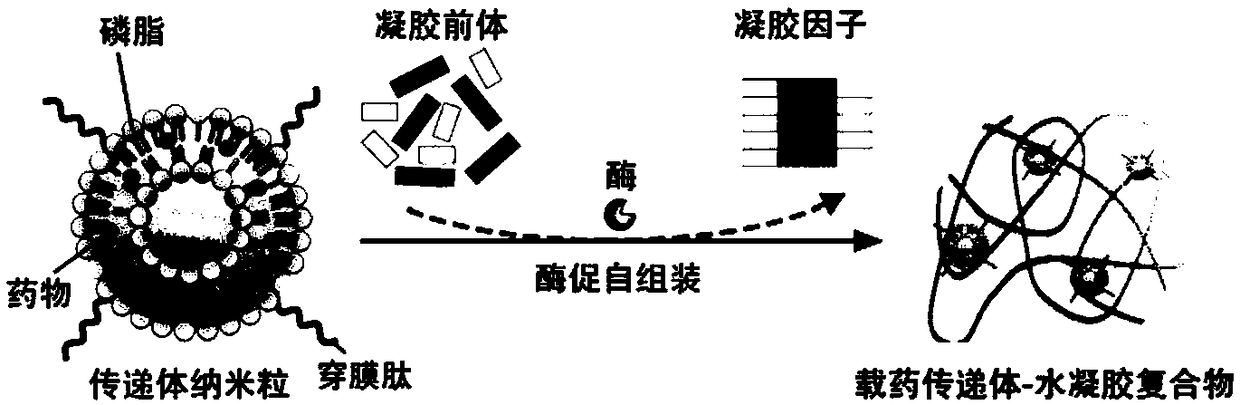

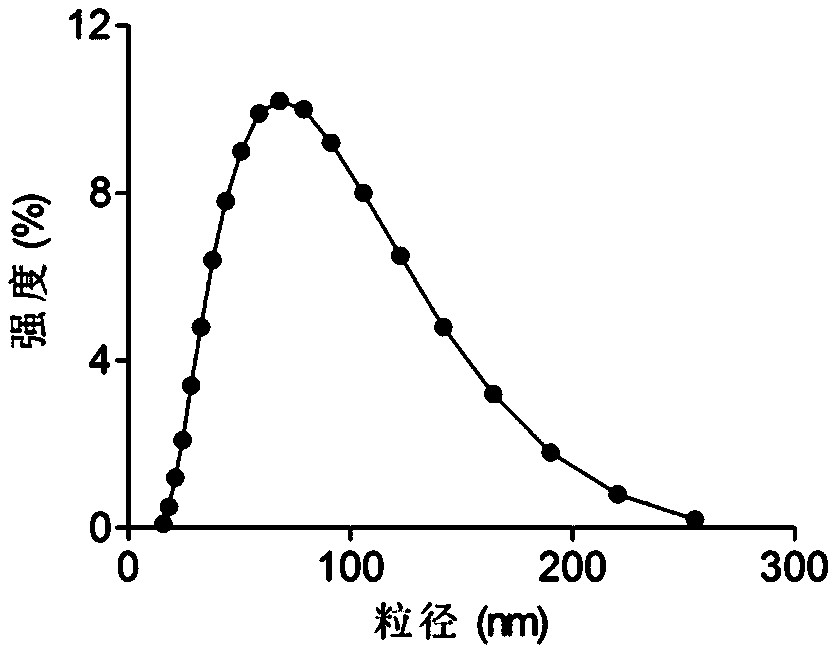

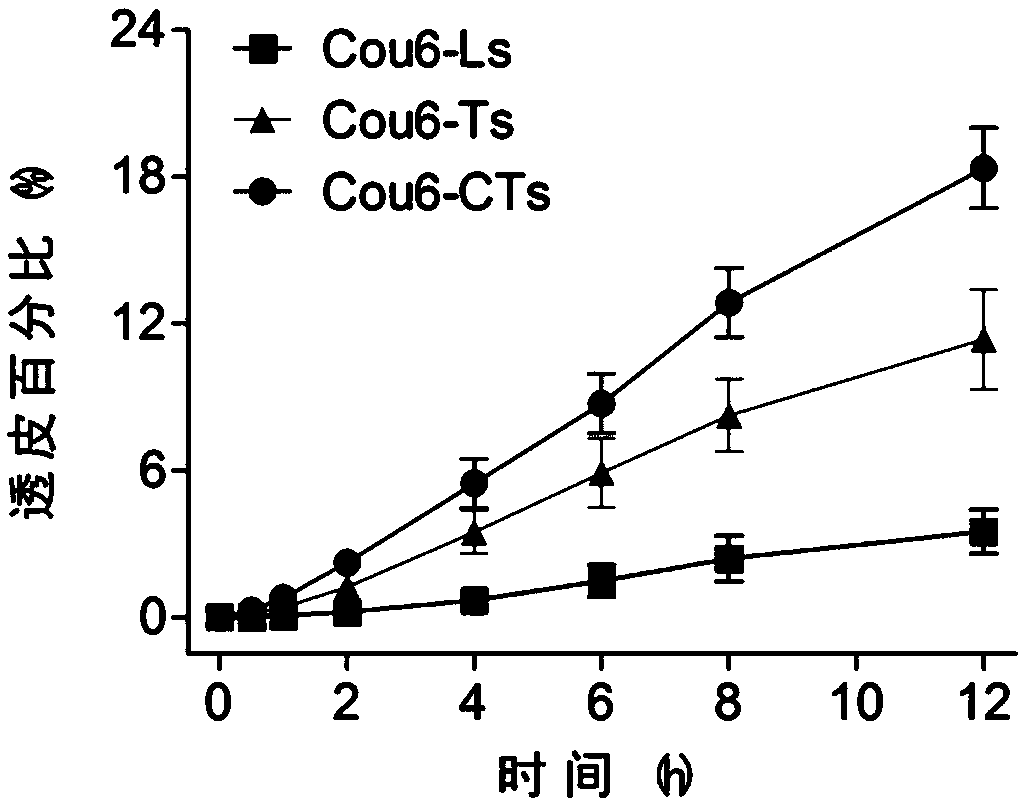

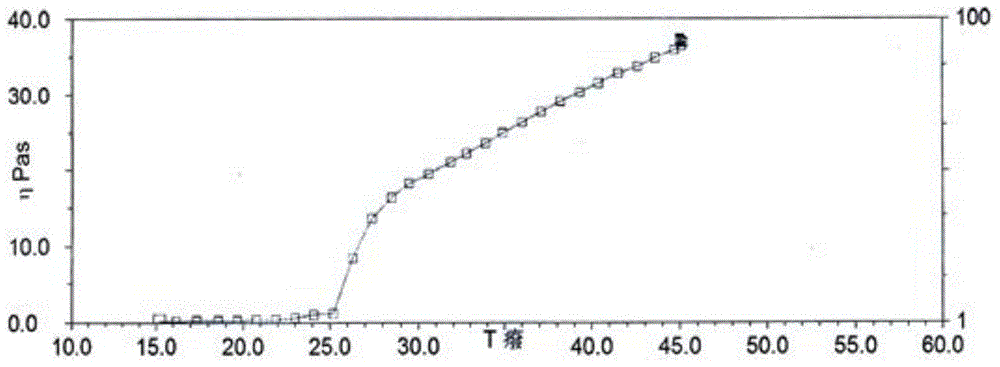

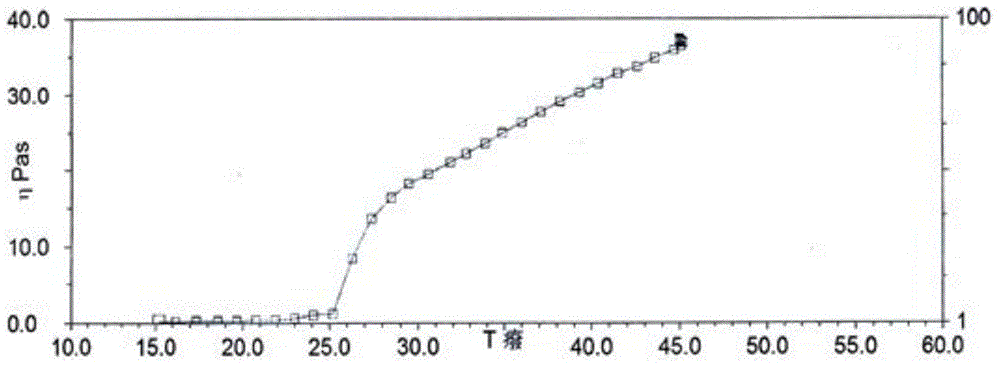

Small molecule hydrogel-nanoparticle compound drug carrier and application thereof in skin/mucosa drug delivery system

ActiveCN109077994AImprove permeabilitySolve easy lossOrganic active ingredientsAerosol deliverySolution Dosage FormCompounding drugs

The invention discloses a small molecule hydrogel-nanoparticle compound drug carrier and application thereof in skin / mucosa drug delivery system. The small molecule hydrogel-nanoparticle compound drugcarrier comprises drug-carrying nanoparticles and small molecule hydrogel, wherein the drug-carrying nanoparticles are dispersed in the small molecule hydrogel, and the surfaces of the nanoparticlesare modified with cell penetrating peptides. The small molecule hydrogel-nanoparticle compound drug carrier is used for skin / mucosa drug delivery, the skin / mucosa and lesion part penetrating performance of drugs can be evidently increased by modifying the surfaces of the nanoparticles with the cell penetrating peptides, and the problem that solution-dosage-form drug delivery is prone to drug lossis solved by the small molecule hydrogel.

Owner:NANJING UNIV OF TECH

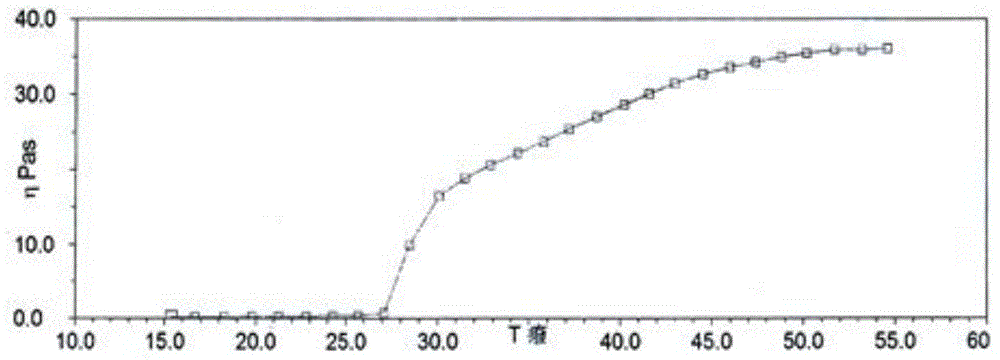

Compound amur cork-tree temperature-sensitive gel for treating sore and ulcer and traumatic infection and preparing method thereof

InactiveCN106031756AEasy to useHeat-clearing and detoxifyingAerosol deliveryAntisepticsSubstrate networkGlycerol

Compound amur cork-tree temperature-sensitive gel for treating sore and ulcer and traumatic infection and a preparing method thereof are provided. The temperature-sensitive gel comprises 5-15% by weight of a compound amur cork-tree extract liquid, 18-20% by weight of poloxamer 407, 1.5-2.5% by weight of poloxamer 188, 5-10% by weight of propylene glycol, 5-10% by weight of glycerol, 0.5-1% by weight of ethyl p-hydroxybenzoate and 41.5-65% by weight of distilled water. A problem that gel structures are irreversibly destroyed because traditional Chinese medicine extracts at present are complex in components and react with base auxiliary materials, or because traditional Chinese medicine extract liquids are hypertonic systems and cause exosmosis of water in gel substrate network structures is overcome. A gel substrate adopted can be primarily determined according to physical and chemical properties and dosage forms of effective components.

Owner:SHANDONG HANFANG PHARMA

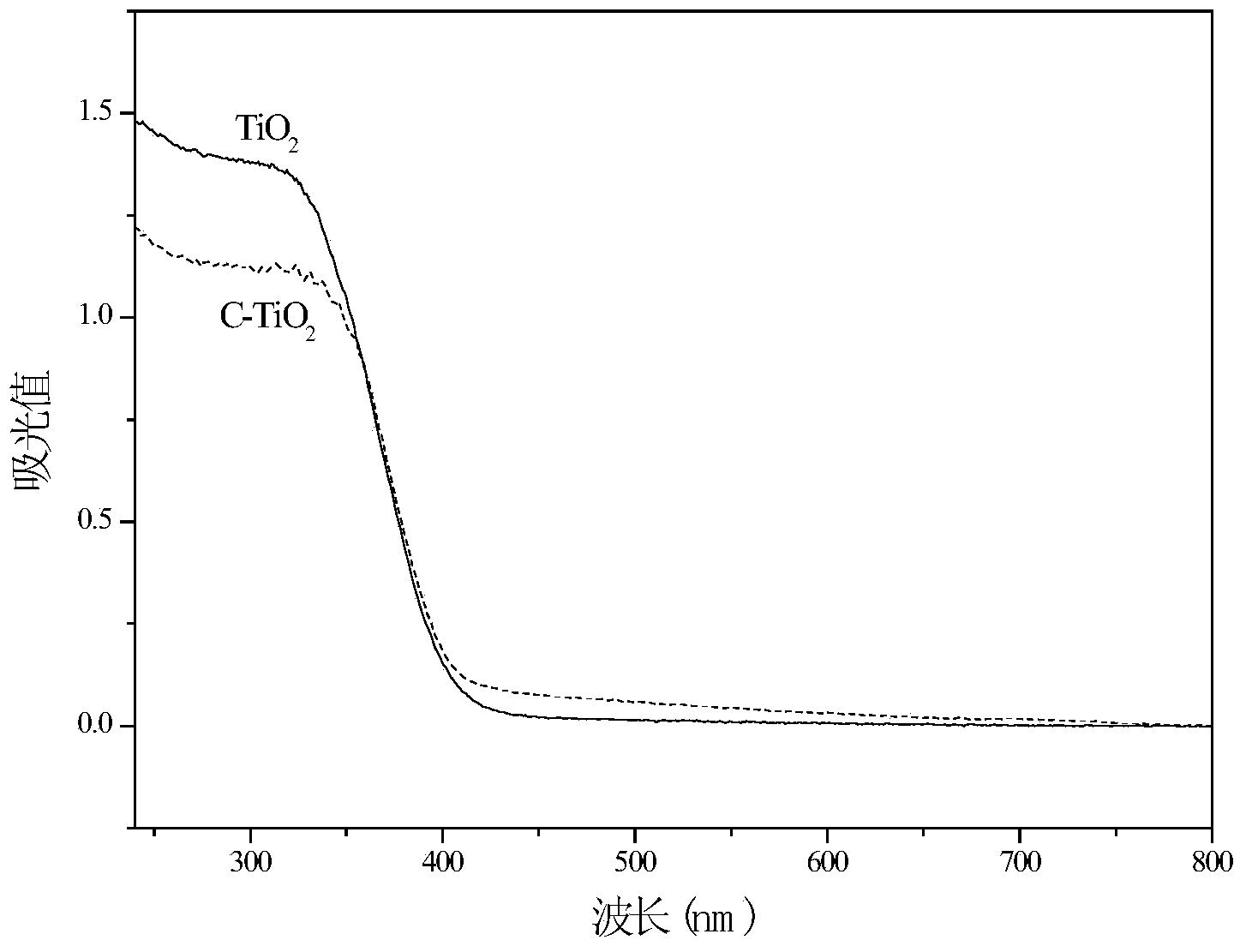

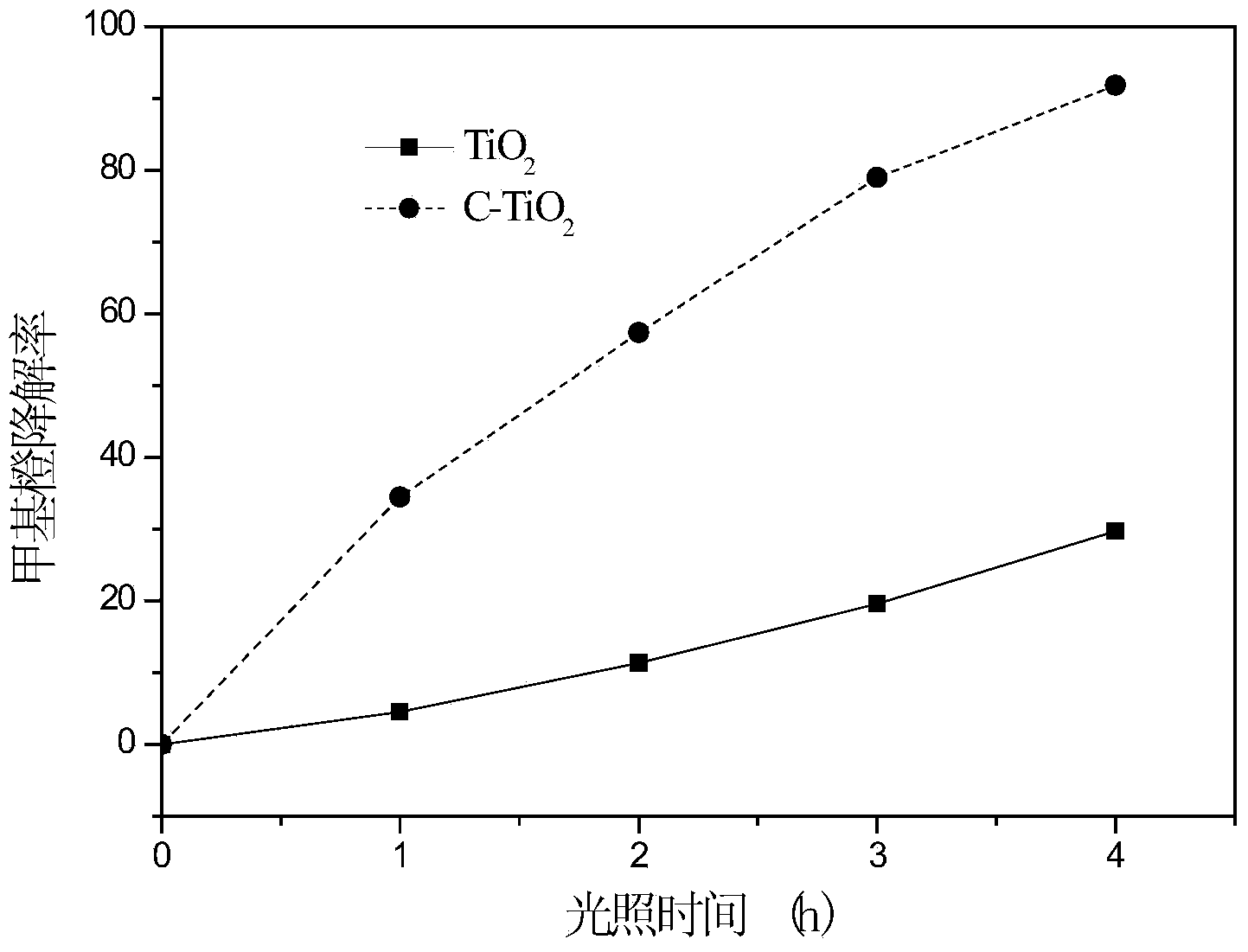

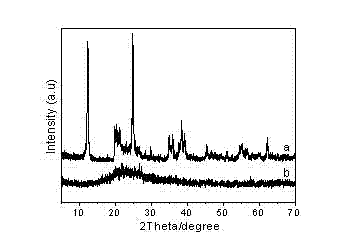

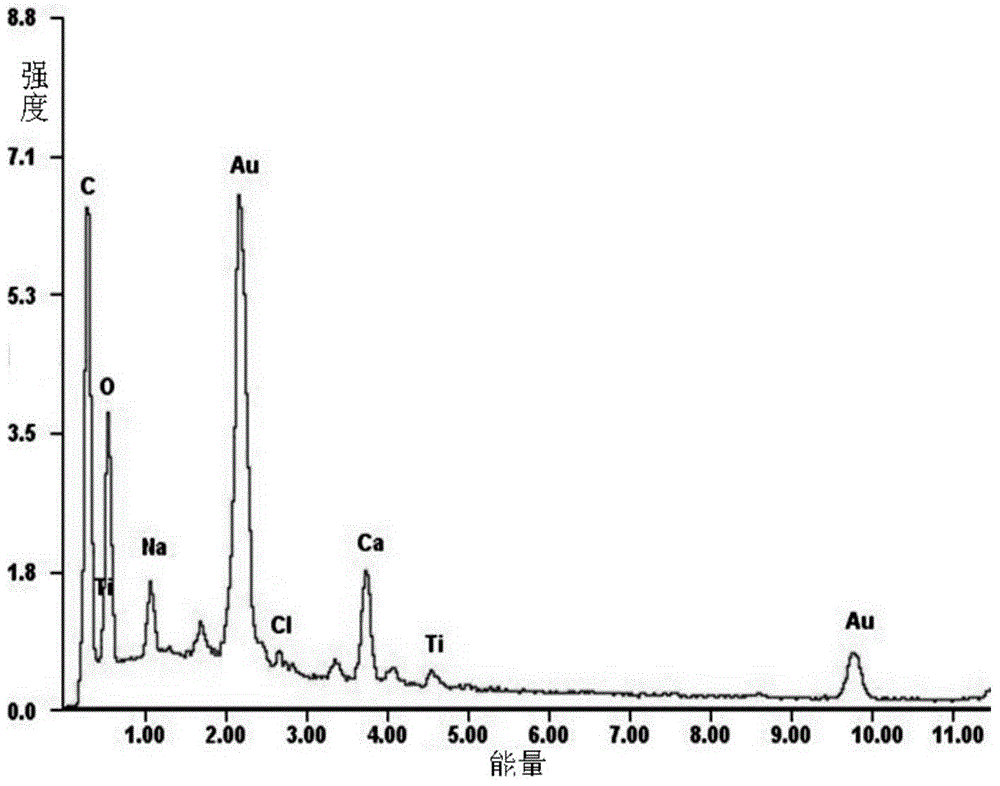

Carbon-doped TiO2 visible light-responding catalytic film on glass carrier and preparation method thereof

InactiveCN103506104AEasy to separateSolve easy lossPhysical/chemical process catalystsPhotocatalytic reactionElectron

The invention discloses a carbon-doped TiO2 visible light-responding catalytic film on a glass carrier. The carbon-doped TiO2 visible light-responding catalytic film on the glass carrier is prepared by taking tween 80 as template ions and a carbon source to prepare a non-metallic carbon-doped nano TiO2 photocatalytic film, and loading the non-metallic carbon-doped nano TiO2 photocatalytic film on the glass carrier. The invention further discloses a preparation method of the catalytic film. The TiO2 catalyst film can utilize 400-700nm visible light for photocatalytic reaction and can directly utilize inexhaustible sunlight as a light source; by doping a non-metallic element carbon, separation of TiO2 photo-generated electrons and a hole can be facilitated, so that the catalytic film can fully play an oxidizing and reducing role and the photocatalytic activity can be improved; and the catalytic film is loaded on the glass carrier with stable physical and chemical properties, thereby overcoming the defects of easy loss and difficult recycle of a powdery catalyst in the using process and the like.

Owner:HUAZHONG AGRI UNIV

Drinking water arsenic-removal filter core and production method thereof

InactiveCN106914212AHigh strengthFully contactedOther chemical processesAluminium silicatesWater flowUltimate tensile strength

The invention belongs to the technical fields of a novel material and a water purifier, and relates to a drinking water arsenic-removal filter core and a production method thereof. The arsenic-removal filter core is obtained by uniformly mixing arsenic adsorption powder, a porous particle arsenic adsorbent, an additive and a binder in proportion, and the materials are molded at proper temperature. A material formula design and a molding technology are used for preparing the arsenic-removal filter core, a nano arsenic-removal active substance is used for being fixed in the filter core, water permeability and current uniformity of the filter core are kept, so that the problems of inconvenient usage, increased cost due to easy loss of the nano arsenic-removal particle and secondary pollution can be solved. The arsenic-removal filter core has the advantages of loose and porous performance, good water permeability, and excellent intensity, the material and water are fully contacted, so that the product has excellent arsenic removal performance.

Owner:苏州格绿新材料科技有限公司

Process for extracting total saponin from papermulberry fruit

The invention discloses a method which extracts total soap glucoside from papermulberry fruit. It follows below steps to preparing: drying and disintegrating the papermulberry fruit and getting the papermulberry fruit powder as A material; extracting A material through mechanical squeeze or carbon dioxide supercritical extraction device, separating the papermulberry fruit peach oil and the resulting mixture is B material; extracting and refinishing B material with organic solvent and getting papermulberry fruit total soap glucoside. The invention uses mechanical squeeze or carbon dioxide supercritical extraction device to removing papermulberry fruit peach oil, then refines and extracts the material using flavouring alcohol, the got total soap glucoside extraction rate >=1.84% which is higher then other methods extraction rate(0.51%) in prior technology 3.5 times. At the same time it solves the question of effective ingredients easily lost better, raises the rate of extraction but also solves the problems of removing impurities, improving purity and decreasing cost while increasing the rate of extraction, so achieves the purpose of the invention. The extracted papermulberry fruit total soap glucoside has many effects and can be used as processing raw materials of medicines and health products.

Owner:贵州三农楮桃产业开发有限公司

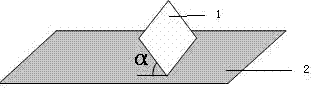

Hydrotalcite like compound-kaolin composite material and preparation method thereof

InactiveCN102674384AImprove bindingNot easy to fall offSilicon compoundsAluminium oxides/hydroxidesInorganic saltsMicrosphere

The invention discloses a hydrotalcite like compound-kaolin composite material which comprises a hydrotalcite like compound sheet and a kaolin substrate. The hydrotalcite like compound sheet grows on the kaolin substrate, an angle between the hydrotalcite like compound sheet and the the kaolin substrate is larger than 0 and smaller than 180 degrees. The invention further discloses a preparation method of the hydrotalcite like compound-kaolin composite material. The preparation method comprises the following steps of (1) conducting pretreatment on the kaolin substrate, and enabling kaolin raw materials or microballoons molded by atomizing to rise at temperature until a high temperature condition to roast; (2) enabling urea and soluble bivalence inorganic salt to be soluble in deionized water, adding the kaolin obtained in the step (1), stirring for warming crystallization at room temperature, using the deionized water to wash, then filtering, and drying to obtain the hydrotalcite like compound-kaolin composite material. The preparation method of the hydrotalcite like compound-kaolin composite material is simple in operation and soft in condition and has wide application prospect. The hydrotalcite like compound sheet in the hydrotalcite like compound-kaolin composite material prepared by using the preparation method has the advantages of being good in orientation, not easy to drop and the like.

Owner:EAST CHINA NORMAL UNIV

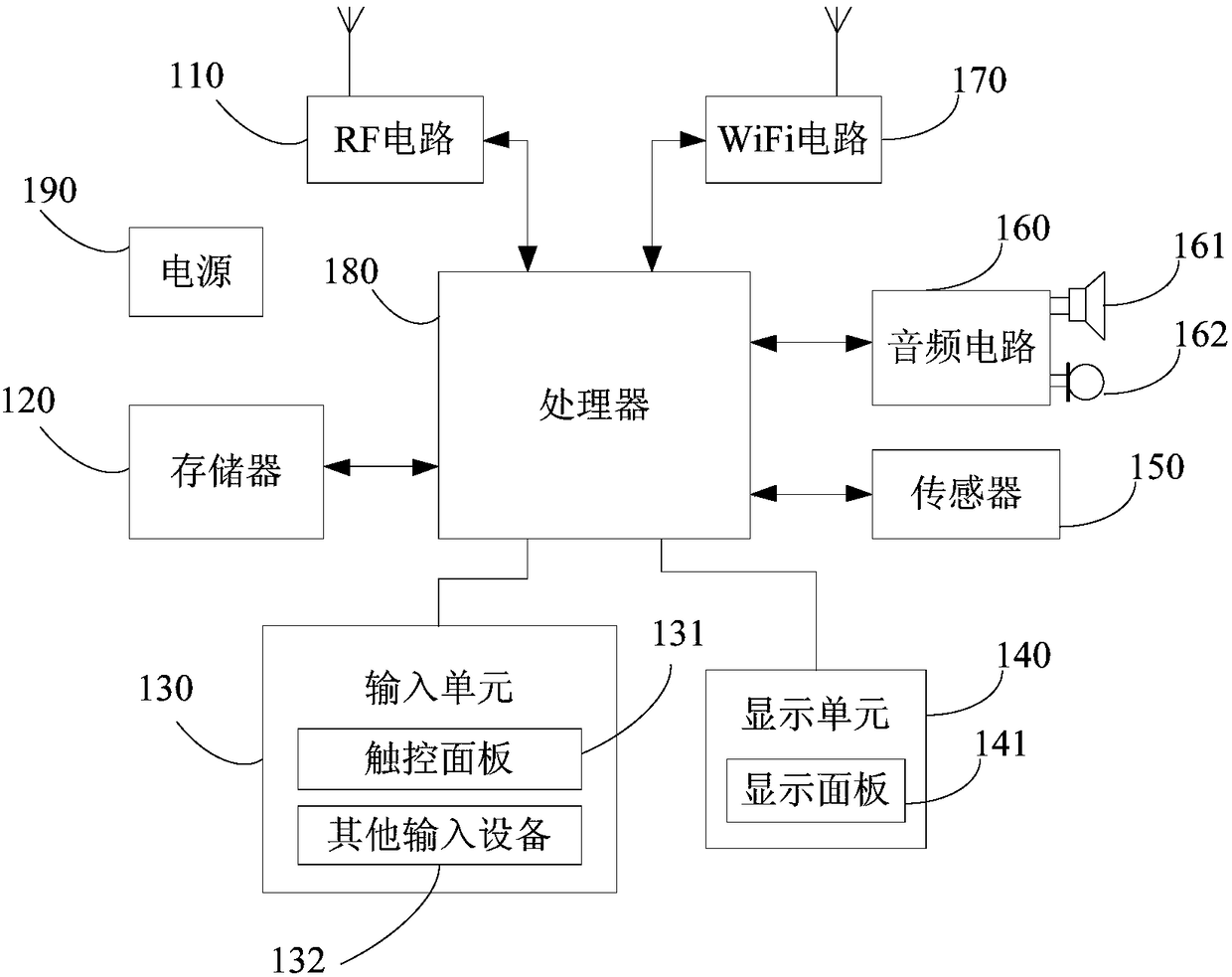

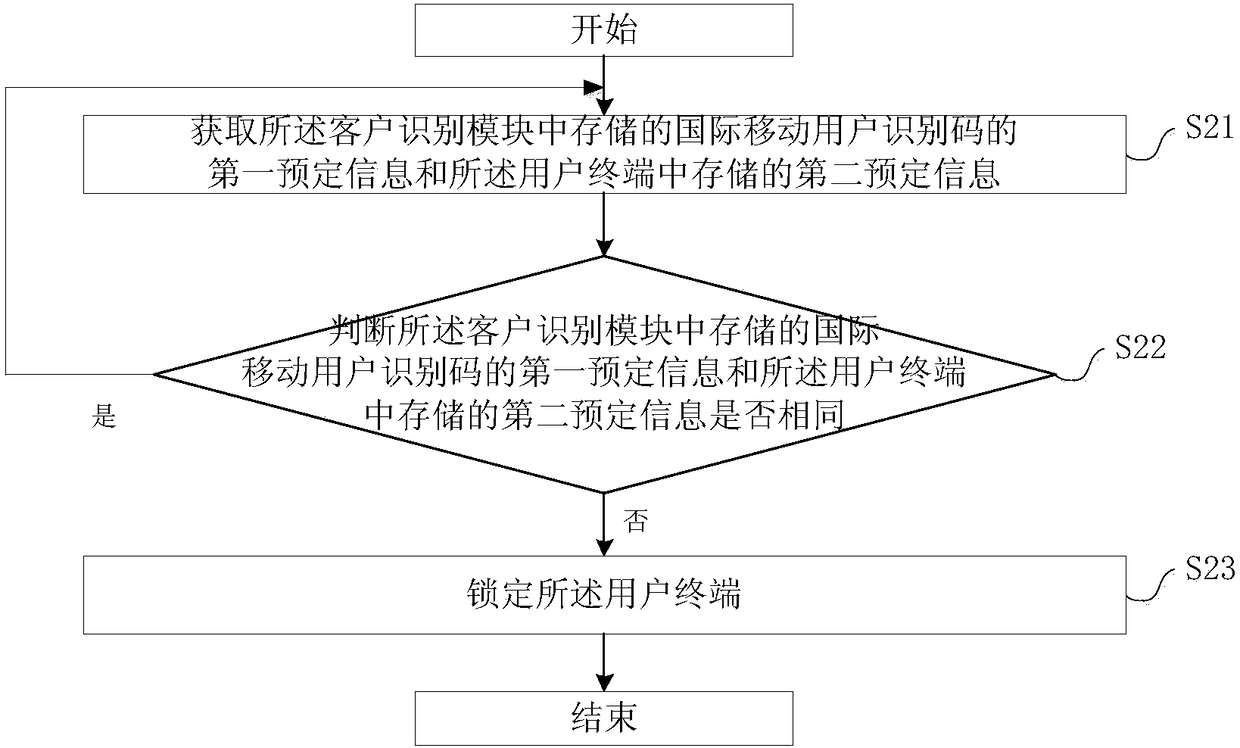

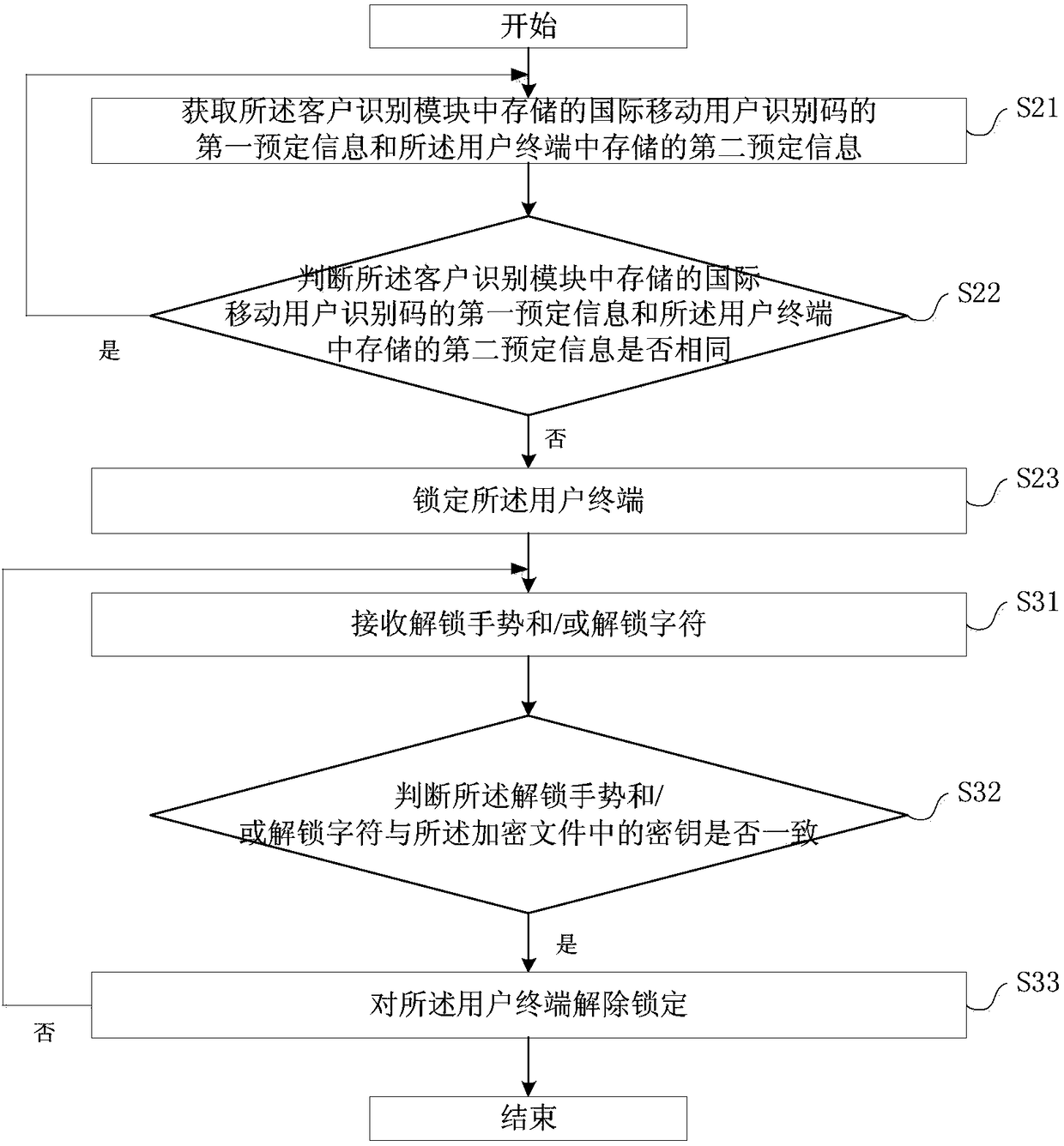

User terminal locking method and device and user terminal

The invention discloses a user terminal locking method and device and a user terminal. The user terminal is internally provided with a subscriber identification model. The user terminal locking methodcomprises the following steps: obtaining first predetermined information of international mobile subscriber identification number stored in the subscriber identification module and second predetermined information stored in the user terminal; judging whether the first predetermined information of the international mobile subscriber identification number stored in the subscriber identification module and the second predetermined information stored in the user terminal are same; and when the first predetermined information of international mobile subscriber identification number stored in the subscriber identification module is different from the second predetermined information stored in the user terminal, locking the user terminal. The method solves the problem that the user group of an existing customized user terminal is easy to lose.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Method and application of preparing high-level oxidation catalyst through cobalt ore smelting slag

ActiveCN102755892ALow costThe process is simple and controllableWaste water treatment from quariesMetal/metal-oxides/metal-hydroxide catalystsIonSewage treatment

The invention discloses a method of preparing a high-level oxidation catalyst based on sulfate radial by utilizing solid waste cobalt ore smelting slag as a raw material, and pickling, modifying and activating the raw material. In the catalysts, the silicon dioxide skeleton in the slag is used as a carrier, and such ions or compounds as cobalt and ferrum are fixedly carried on the granule surfaces through pickling and coprecipitation methods, so that the smelting slag has such characteristics as high-level oxidation, multi-metal concerted catalysis and heterogeneous catalysis, and the like, and a non-homogeneous phase catalyst system formed by the smelting slag enables the smelting slag to be easily separated from a water body. When being applied on industrial sewage treatment, the catalytic oxidation system not only has high catalytic oxidation efficiency, wide pH adaptation range, low metal ion loss quantity and easy separation with water body, but also recycles the cobalt ore slag solid waste to change the waste into valuable, thereby both meeting the sustainable development and the nation call of the energy conservation and emission reduction, and having low cost and is easy to generalize, so that the method in the invention has brilliant application prospect.

Owner:ZHEJIANG UNIV

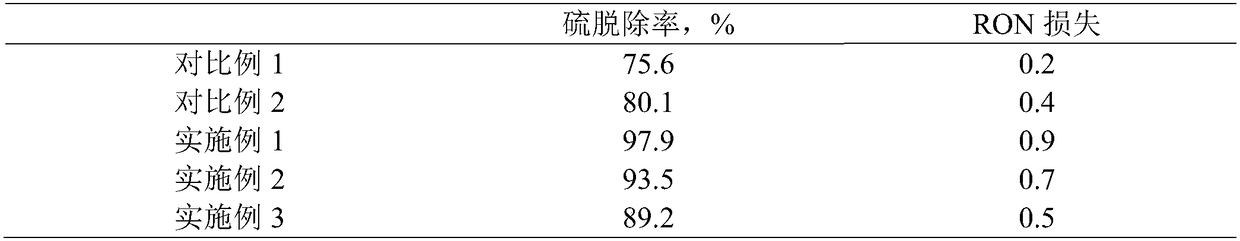

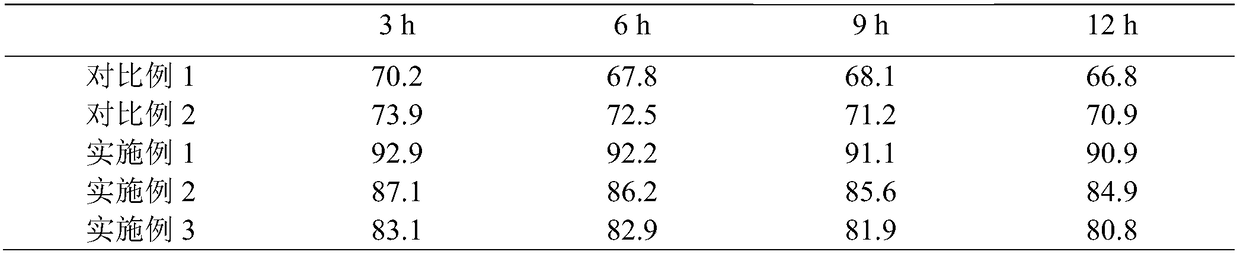

Multistage pore molecular sieve-supported heteropolyacid alkylation desulfurization catalyst and preparation method thereof

ActiveCN108126751ASolve the channel limitation problemHigh acid strengthMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferMolecular sieve

The invention discloses a multistage pore molecular sieve-supported heteropolyacid alkylation desulfurization catalyst and a preparation method thereof. A multistage pore molecular sieve prepared by acid-base compound treatment is taken as a carrier, and with the aid of microwaves, a supported heteropolyacid catalyst is subjected to in-situ synthesis through a hydrothermal dispersion method. A specific synthesis method of the catalyst comprises the following steps: firstly preparing the molecular sieve carrier with multistage pore channels by adopting acid-base hydro-thermal treatment and thenperforming in-situ synthesis on the supported heteropolyacid catalyst by adopting a hydrothermal dispersion method with the aid of the microwaves. Measured by 100 percent by weight of multistage poremolecular sieve, the catalyst comprises 5-40 percent by weight of heteropolyacid; in the multistage pore molecular sieve, the molar ratio of SiO2 to Al2O3 is 10:60; the specific surface area is 200-700 m<2> / g; the pore volume is 0.3-0.8 m<3> / g. The multistage pore molecular sieve-supported heteropolyacid catalyst disclosed by the invention has the characteristics of firm active component supporting and good reusability and has the advantages of high thiophene sulfide conversion rate, good stability and high selectivity and the like when being used in the gasoline sulfide alkylation conversionprocess especially.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

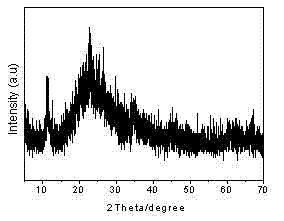

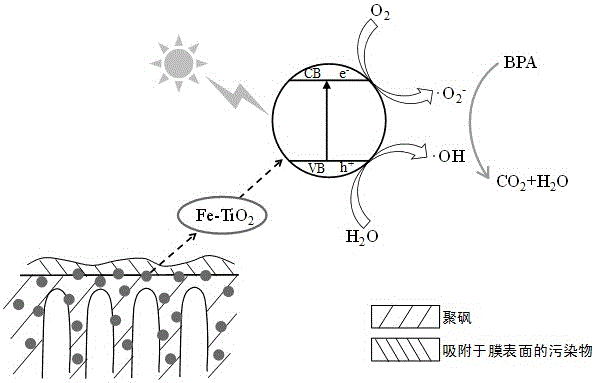

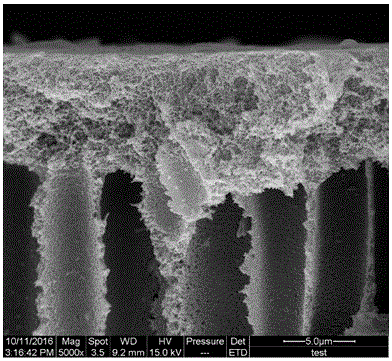

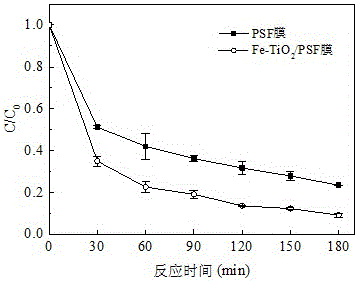

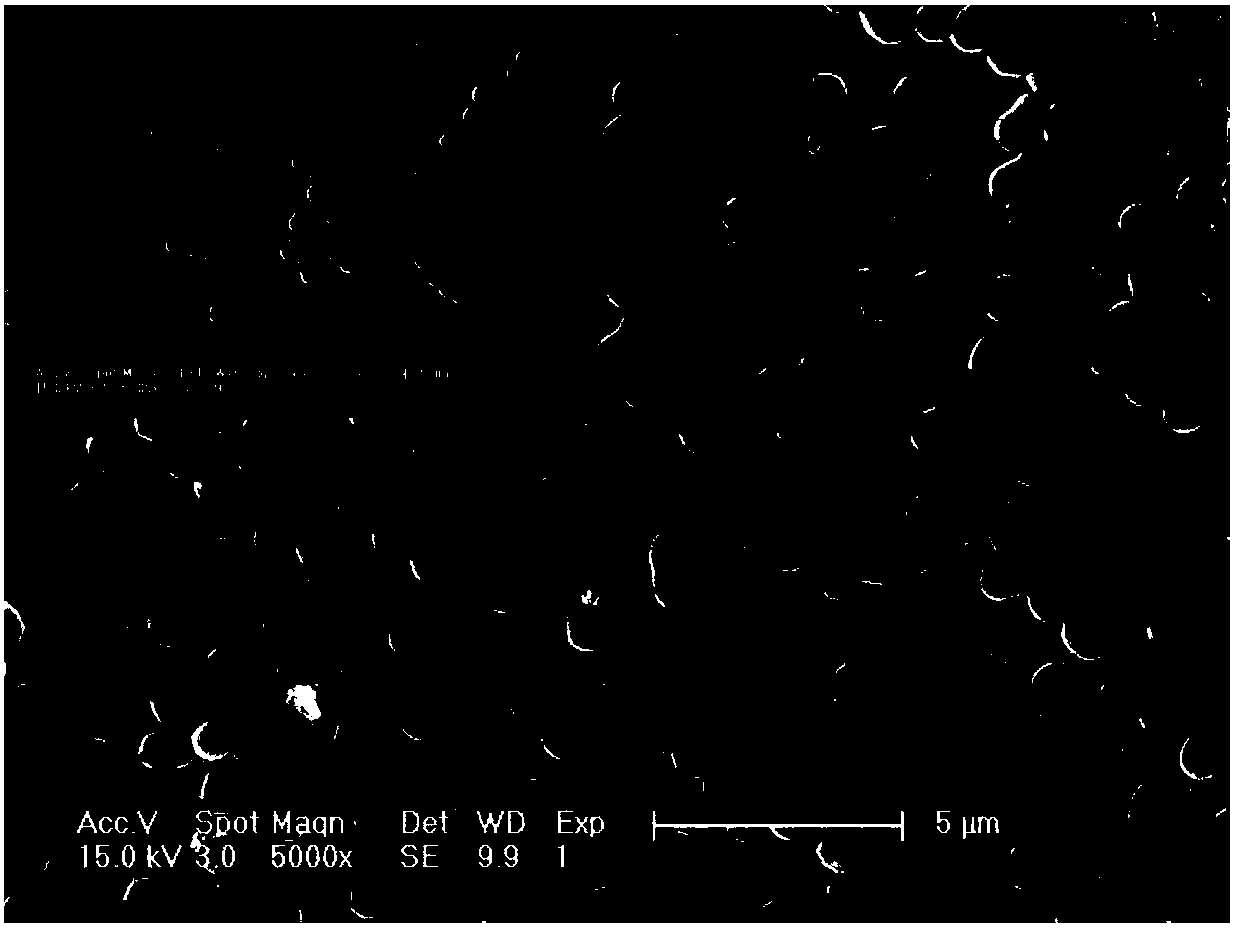

Preparation method of visible light catalytic composite ultrafiltration membrane

InactiveCN106731902ASimple and efficient operationImprove catalytic performanceMembranesWater/sewage treatment by irradiationIonUltrafiltration

The invention discloses a preparation method of a visible light catalytic composite ultrafiltration membrane. The method comprises the following steps: 1, weighing transition metal nitrate and titanium dioxide powder, adding the transition metal nitrate and the titanium dioxide powder into deionized water, mixing uniformly, pouring a polytetrafluoroethylene reaction kettle to perform reaction, cooling to room temperature, centrifugally washing for many times, performing vacuum drying, grinding and sieving to obtain a metal doped titanium dioxide visible light catalyst; 2, blending the light catalyst and a polysulfone membrane material, intensely and mechanically stirring under the water bath condition, and defoaming under the ultrasonic condition to obtain a uniform and bubble-free casting membrane solution; 3, pouring the casting membrane solution at one end of a glass plate, scraping the membrane by a glass stick with two ends tied with copper wires, performing standing, putting into coagulation bath to form a membrane, taking out and soaking into deionized water to obtain the visible light catalytic composite ultrafiltration membrane. By the method, the problem that the powdered catalyst in the current suspension system is liable to lose and difficult to recycle, and the problem of concentrated liquid generated by pure physical interception in the membrane separation technology are solved.

Owner:HARBIN INST OF TECH

Preparation method of immobilized microorganisms embedded with aerogel

PendingCN108251410AQuality improvementChemically stableOn/in organic carrier(Hydroxyethyl)methacrylatePolyacrylamide

The invention discloses a preparation method of immobilized microorganisms embedded with aerogel, and belongs to the fields of immobilized microorganism technology and environmental functional composite material preparation. The preparation method comprises the following steps: proportionally mixing monomer hydroxyethyl methacrylate, N-methylol acrylamide, polyacrylamide and diisodecyl adipate, and performing a series of treatment to prepare aerogel; and performing mixed culture on the prepared aerogel and bacterial liquid proportionally, uniformly mixing the bacterium-loaded aerogel with themixed liquid, then transferring the aerogel to a saturated calcium chloride solution to be crosslinked and hardened, and then cleaning the surfaces of immobilized spheres with sterile water to prepareimmobilized spheres embedded with the aerogel. The prepared immobilized microorganism spheres embedded with the aerogel have the advantages of large specific surface area, good mass transfer performance, good stability, high mechanical strength, low cost and the like and have wide application prospects in the aspect of environmental pollution remediation.

Owner:NANJING UNIV

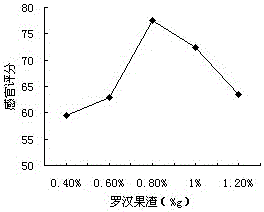

Rhizoma gastrodiae, Flos chrysanthemi and Momordica grosvenori tea and making method thereof

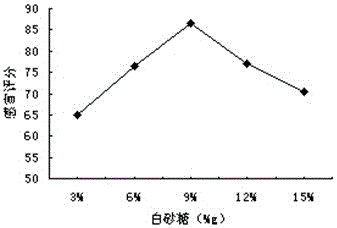

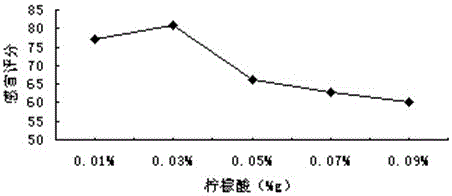

The invention discloses Rhizoma gastrodiae, Flos chrysanthemi and Momordica grosvenori tea and a making method thereof. The tea of 100 ml is prepared from 0.1 g of Rhizoma gastrodiae powder, 4 pieces of Flos chrysanthemi, 0.8 g of Momordica grosvenori residue, 9 g of white granulated sugar, 0.03 g of citric acid, 0.25 g of honey and 0.01 g of vitamin Vc. Sensory score of the tea can reach 86.6. Therefore, the tea has good flavor and taste; unpleasant flavor and stink odor of Rhizoma gastrodiae can be covered through Flos chrysanthemi, Momordica grosvenori residue, citric acid, honey and white granulated sugar; the tea contains Momordica grosvenori, vitamin Vc and honey, thereby having remarkable medicinal value, and body condition can be improved greatly after people drink the tea.

Owner:TONGREN UNIV

Method for preparing hydroquinone by oxidizing phenol

ActiveCN106146260AResolve separabilitySolve easy lossOrganic chemistryOrganic compound preparationHydroquinone CompoundSolvent

The invention relates to a method for preparing hydroquinone by oxidizing phenol. The method comprises the following steps: adding the phenol, a solvent and a supported catalyst into an oxidization high-pressure kettle; introducing oxygen with certain pressure and reacting at a specific temperature for certain time; after the materials are cooled, filtering out an oxidization catalyst to obtain an oxidized solution; adding the oxidized solution and a hydrogenation catalyst into a hydrogenation high-pressure kettle; introducing hydrogen and carrying out a catalytic hydrogenation reaction at a certain temperature; after the materials are cooled, filtering out the hydrogenation catalyst to obtain a hydrogenated solution; desolventizing the hydrogenated solution to obtain a mixture of the phenol and the hydroquinone; rectifying the mixture by negative pressure and separating the phenol and the hydroquinone; returning the phenol back to an oxidization procedure to be used as the raw material. The method is simple to operate and the phenol and benzoquinone do not need to be separated, so that the industrial implementation is easy to realize.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Method for treating landfill leachate with composite photocatalysis bio-adsorbent

InactiveCN104628150AIncrease concentrationImprove mechanical propertiesEnergy based wastewater treatmentBiological water/sewage treatmentTherapeutic effectPollution

The invention discloses a method for treating landfill leachate with a composite photocatalysis bio-adsorbent. The method comprises the following steps: adding the omposite photocatalysis bio-adsorbent into the landfill leachate at a dosage of 20g / L-80g / L by wet weight, performing light vibration and adsorption degradation, separating solid and liquid after reaction is completed, and adjusting pH of the filtrate to neutral to accomplish the treatment of the landfill leachate. The method for treating the landfill leachate with the composite photocatalysis bio-adsorbent has the advantages of simple treatment process and adsorption equipment, convenient operation, very low cost, high adsorption volume, high adsorption efficiency, no pollution, very good treatment effect of the landfill leachate. By virtue of the method, the operation cost of the treatment of the landfill leachate can be effectively reduced, and the landfill leachate can be effectively treated. The method can be widely adopted.

Owner:HUNAN UNIV

Glass powder enhanced Zr modification montmorillonite honeycomb block chromium sorbent and preparation method thereof

ActiveCN104785226AIncrease layer spacingIncrease the areaOther chemical processesWater/sewage treatment by sorptionCross-linkPolymer science

The invention relates to a glass powder enhanced Zr modification montmorillonite honeycomb block chromium sorbent and a preparation method thereof. The preparation method comprises the following steps: dissolving a monomer, a cross-linking agent and a dispersant, which are used for gel polymerization, in water to form a mixed solution; adding Zr modification montmorillonite powder, polystyrene spheres with particle diameters of 1-1.5 mm and glass powder into the mixed solution, and carrying out uniform mixing to obtain a slurry; adding a foaming agent, an initiating agent and a catalyst which are used for gel polymerization, carrying out uniform mixing for a polymerization reaction, and obtain a dry blank after the polymerization reaction is completed; conducting heat preservation on the dry blank at 330-440 DEG C and 550-700 DEG C respectively, and then obtain the glass powder enhanced Zr modification montmorillonite honeycomb block chromium sorbent. Through the polymerization reaction, the Zr modification montmorillonite powder, the polystyrene spheres and the glass powder are uniformly embedded in a polymer chain to form a regular block porous material which is high in water permeability; when being utilized for treating low-concentration chromium-containing wastewater, the formed regular block porous material has the advantages that the adsorption effect is good, and the Zr modification montmorillonite powder is effectively prevented from being lost along with wastewater discharge.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com