Method for treating landfill leachate with composite photocatalysis bio-adsorbent

A biosorbent and landfill leachate technology, applied in biological water/sewage treatment, chemical instruments and methods, energy wastewater treatment, etc., can solve problems such as high content of refractory biodegradable substances, large changes in water quality and quantity, and high ammonia nitrogen concentration , to achieve the effects of improving processing efficiency, improving mechanical properties, and improving photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

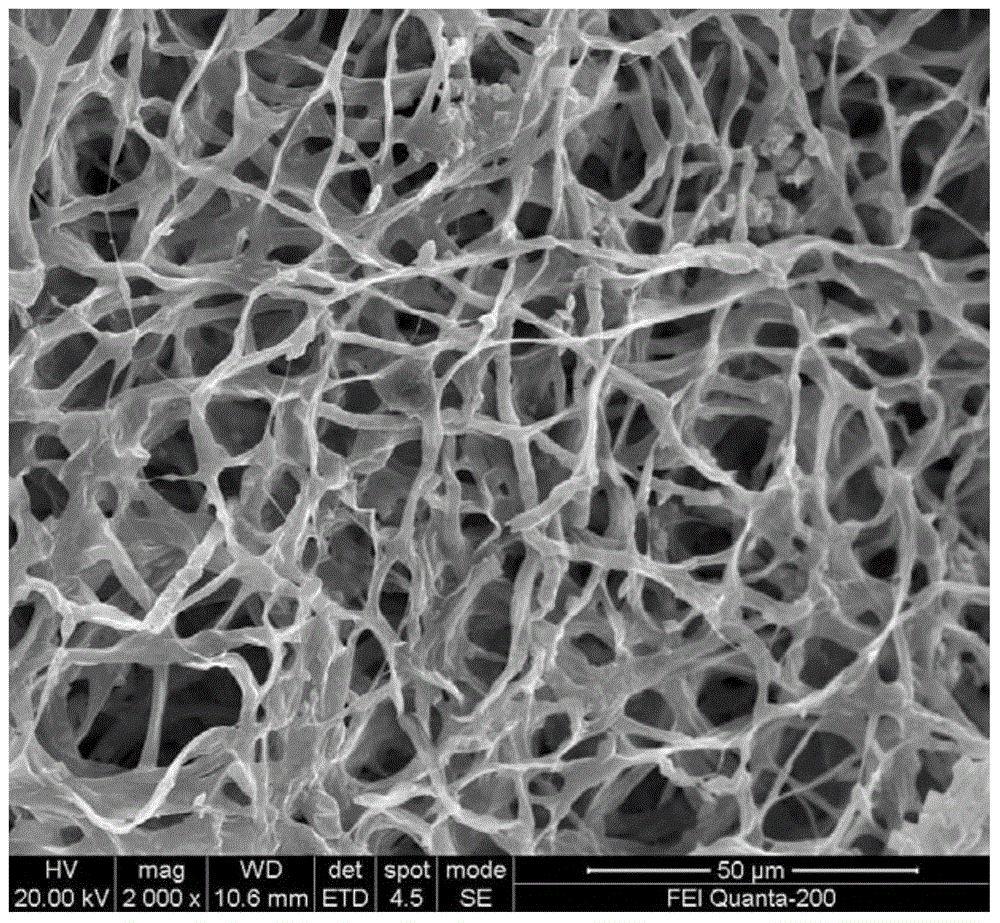

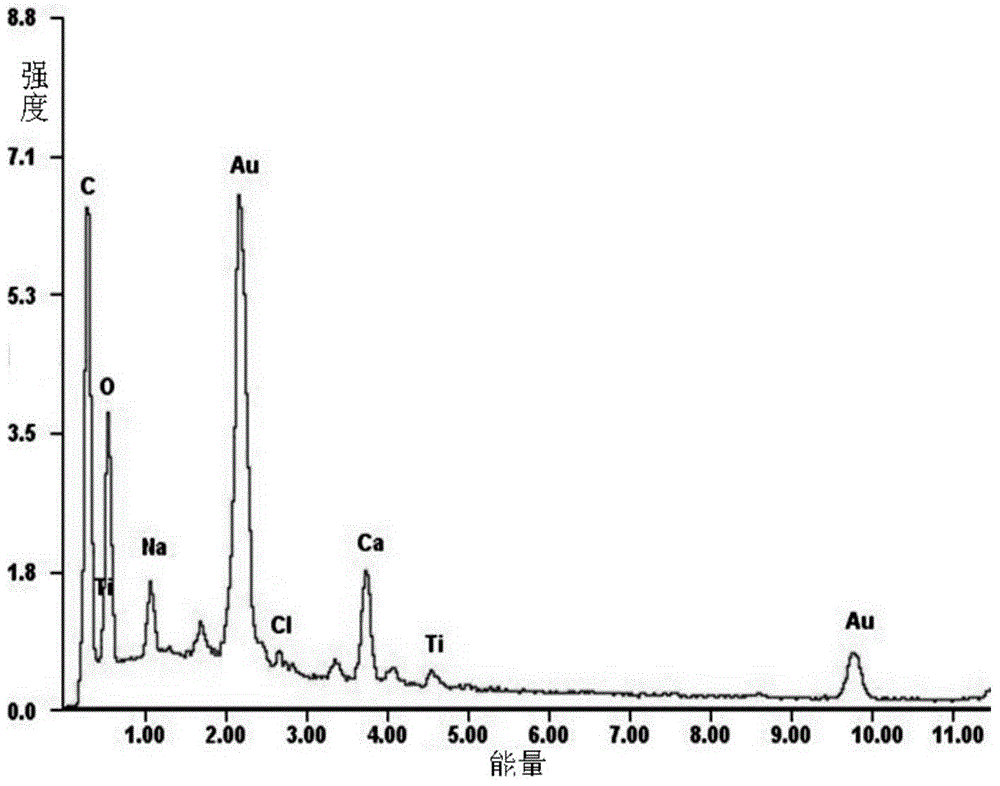

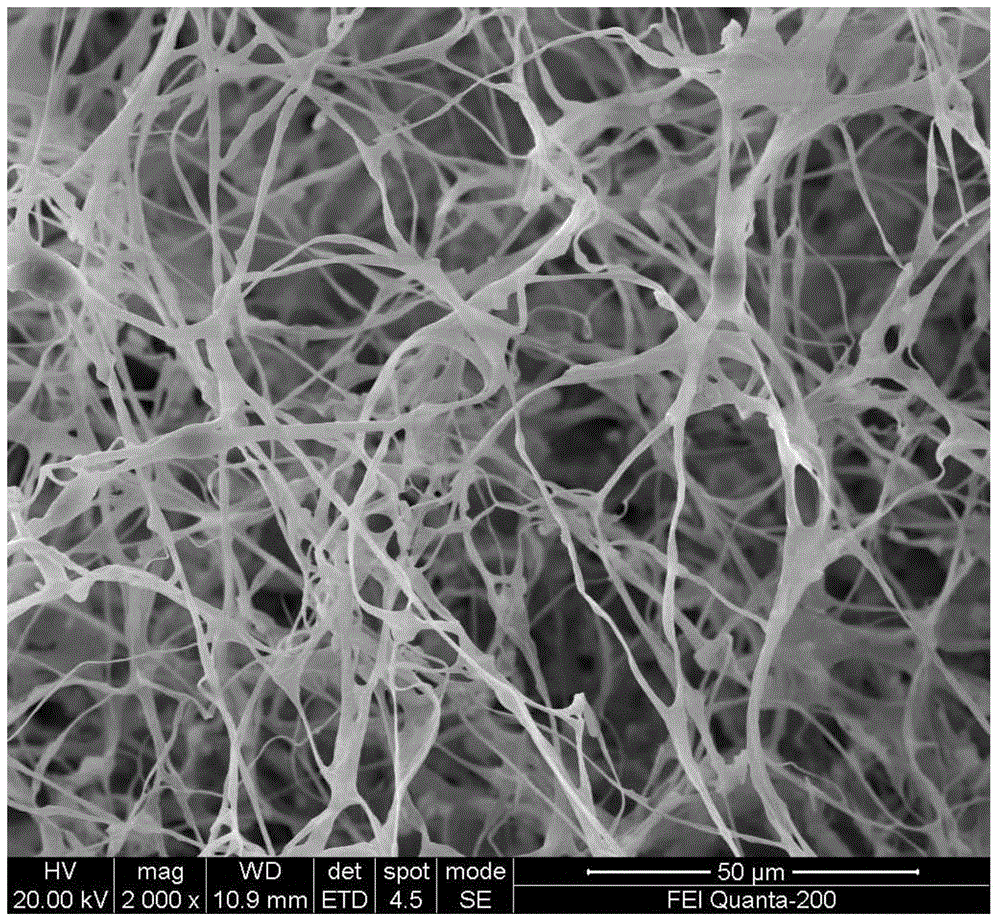

[0038] A composite photocatalytic biosorbent of the present invention, the composite photocatalytic biosorbent is based on white rot fungus living mycelia as a carrier, the mycelium is wound into a ball, and the inside of the ball is embedded with nitrogen-modified TiO 2 Nanoparticles and calcium alginate, calcium alginate as the immobilization medium to mycelium and nitrogen modified TiO 2 The nanoparticles are tightly connected together, and the nitrogen-modified TiO embedded in the bacteria ball 2 The mass ratio of nanoparticles to calcium alginate was 1:4 (nitrogen-modified TiO 2 It can be implemented when the mass ratio of nanoparticles and calcium alginate is 1:3-5).

[0039] A preparation method of the above-mentioned composite photocatalytic biosorbent of the present embodiment, comprising the following steps:

[0040] (1) Preparation of nitrogen-modified TiO by sol-gel method 2 Nanoparticles: First weigh 0.282g of urea into a 250mL Erlenmeyer flask, add 40mL of abs...

Embodiment 2

[0050] A method for treating landfill leachate by a composite photocatalytic biosorbent, the composite photocatalytic biosorbent is derived from Example 1, comprising the following steps:

[0051] (1) Prepare landfill leachate with COD concentrations of 100mg / L, 200mg / L, 400mg / L, and 600mg / L, adjust the pH value to 6.0, and fill the landfill leachate with the above concentrations in 250mL conical flasks 100mL, sterilized at 105°C for 30min.

[0052] (2) In the sterile landfill leachate, add the composite photocatalytic biosorbent after immobilized culture in Example 1, and the addition amount is to add the composite photocatalytic biosorbent with wet weight in every 100mL sterile landfill leachate. Biosorbent 4.0g (the addition amount of composite photocatalytic biosorbent is 20g / L~80g / L, can be implemented), at 37°C, rotation speed 150rpm, 20W incandescent lighting conditions, vibration adsorption and degradation for 96h (oscillation adsorption The rotation speed is 150rpm-1...

Embodiment 3

[0063] In this embodiment, the composite photocatalytic biosorbent is used for treating landfill leachate with different initial pH values. The composite photocatalytic biosorbent is derived from Example 1 and includes the following steps:

[0064] (1) Prepare landfill leachate with a COD concentration of 200mg / L, adjust the pH values to 3.0, 3.5, 4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5, 8.0, 8.5 in a 250mL Erlenmeyer flask Fill them with 100mL of landfill leachate with the above pH values, and sterilize at 105°C for 30min.

[0065] (2) In the above-mentioned sterilized landfill leachate, add the composite photocatalytic biosorbent after immobilized culture in Example 1, and the addition amount is to add the compound type of wet weight in every 100mL sterile landfill leachate Photocatalytic biosorbent 4.0g, oscillating adsorption and degradation at 37°C, 150rpm, 20W incandescent light for 96 hours, separated the liquid phase and solid phase after standing, adjusted the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com