Patents

Literature

72results about How to "Increase the amount of smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

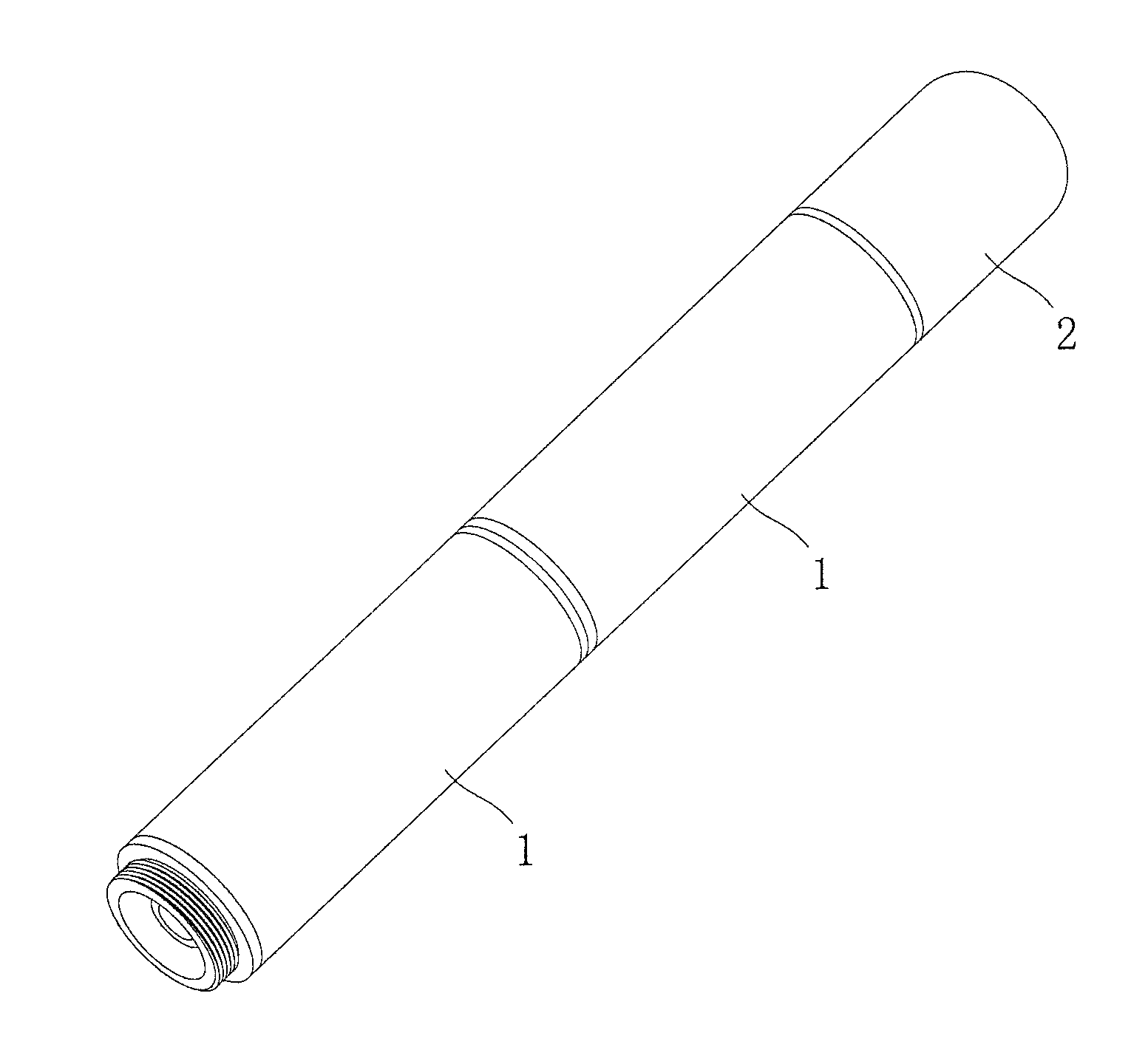

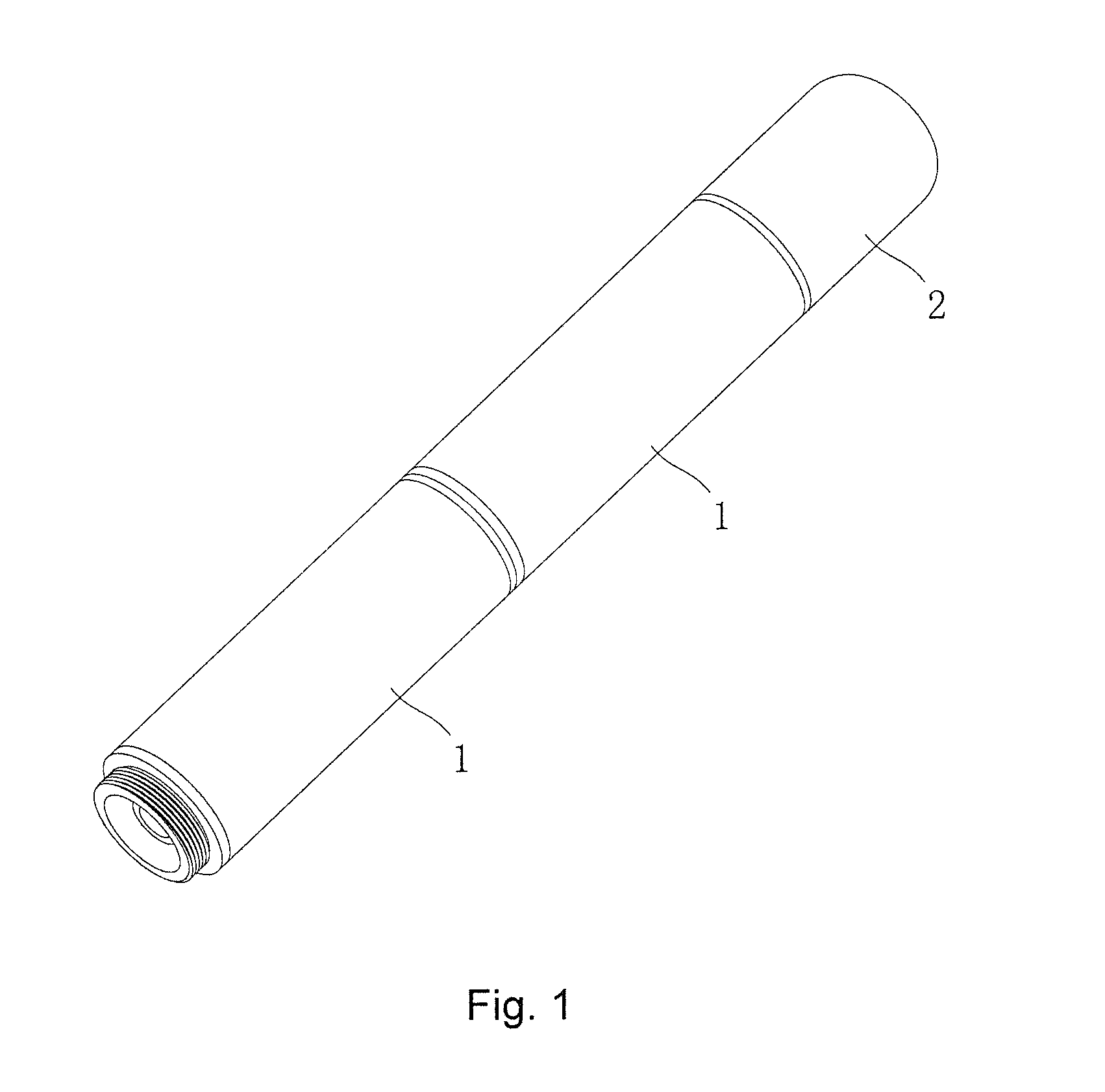

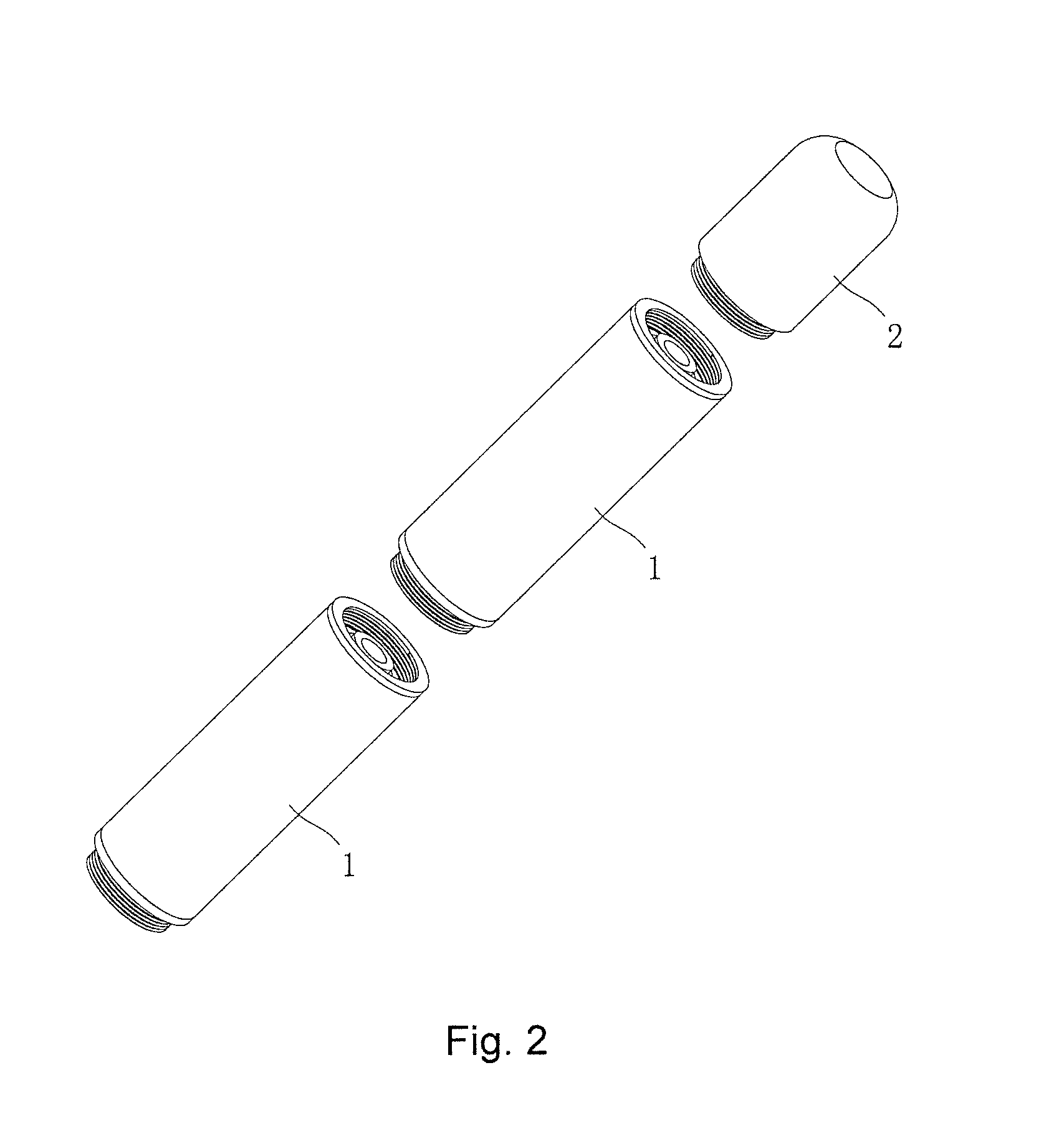

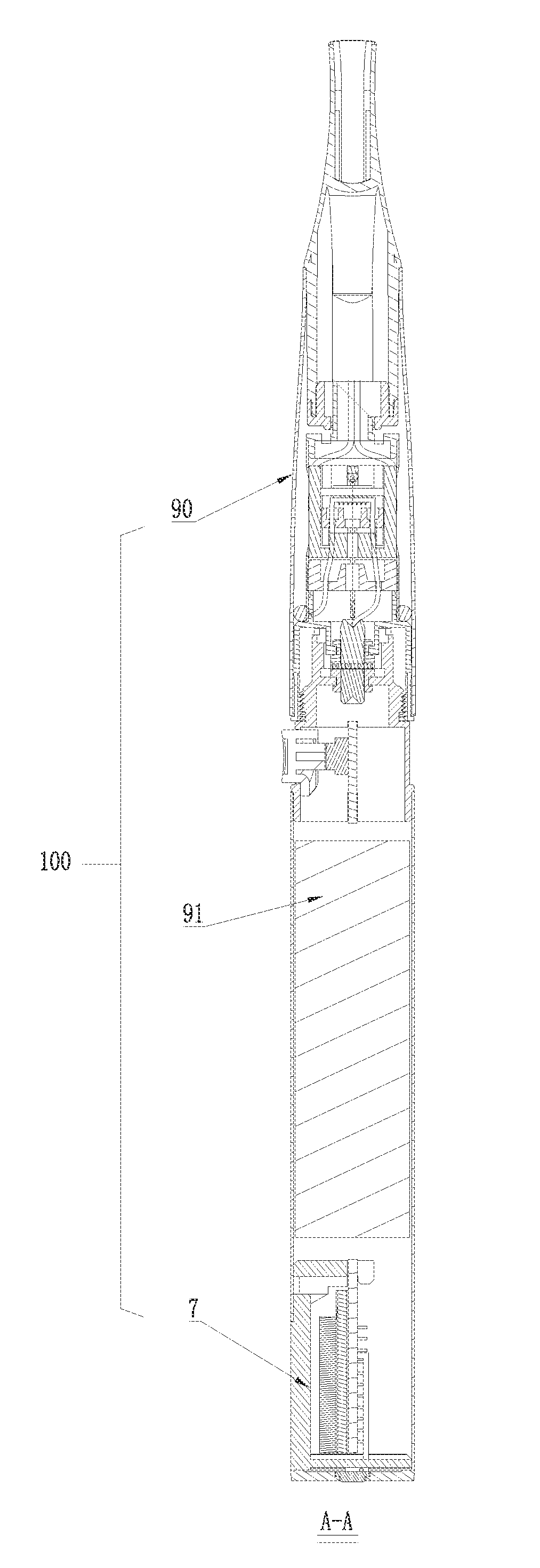

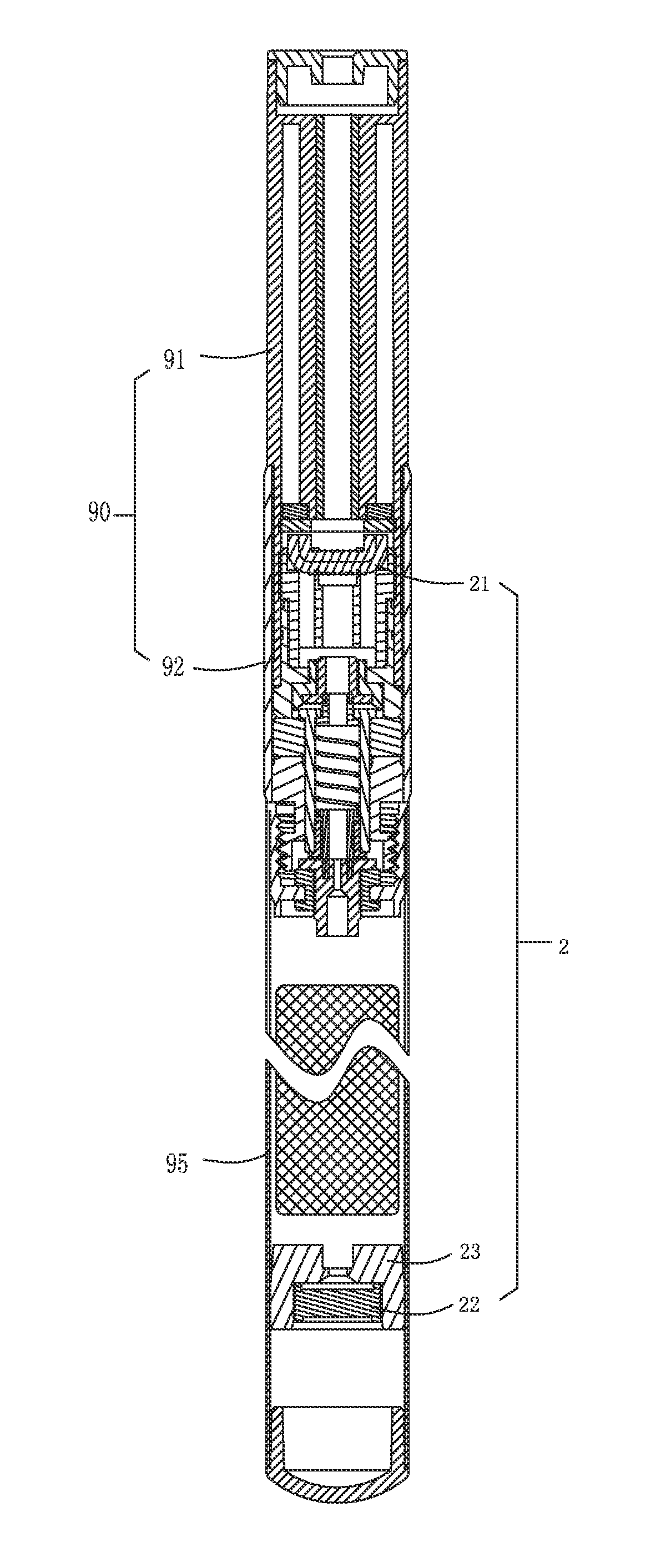

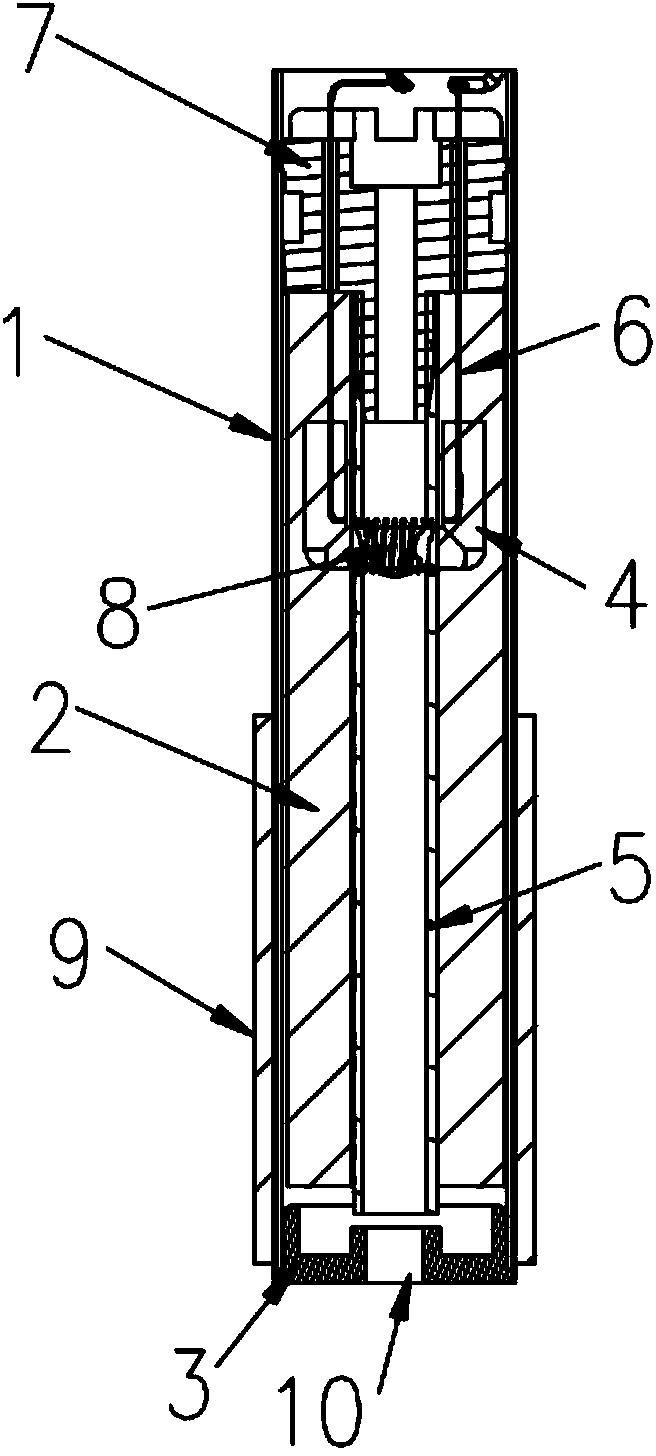

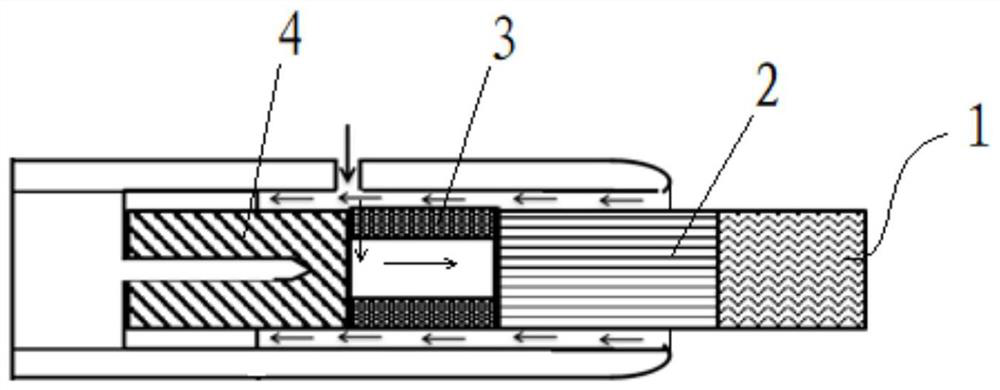

Electronic cigarette atomizer and electronic cigarette using the same

InactiveUS20150196059A1Generate large amount of smokeIncrease the amount of smokeTobacco pipesTobacco devicesElectricityEngineering

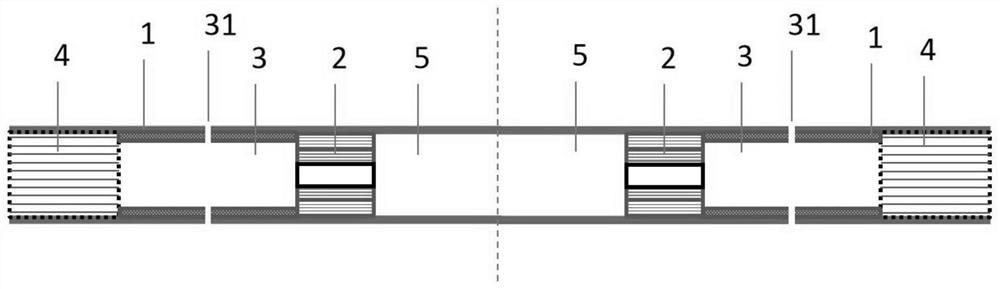

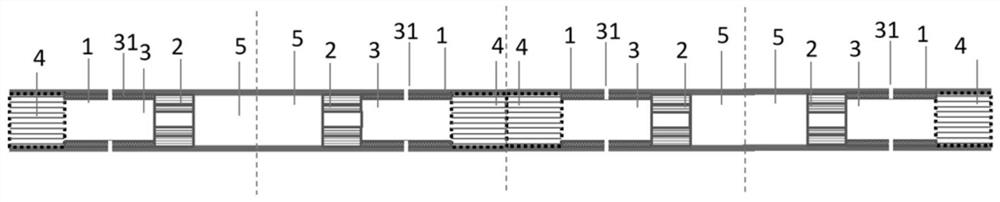

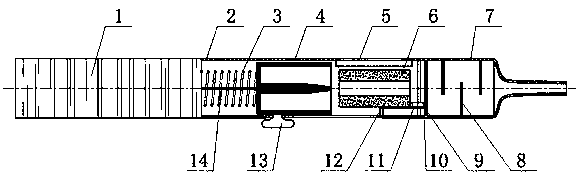

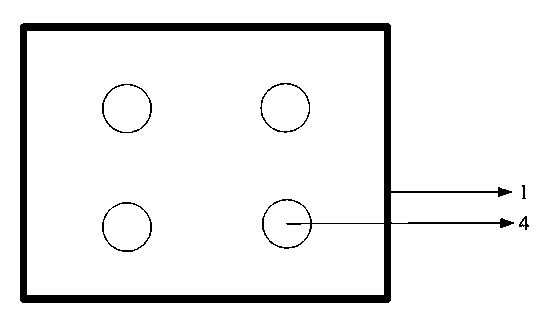

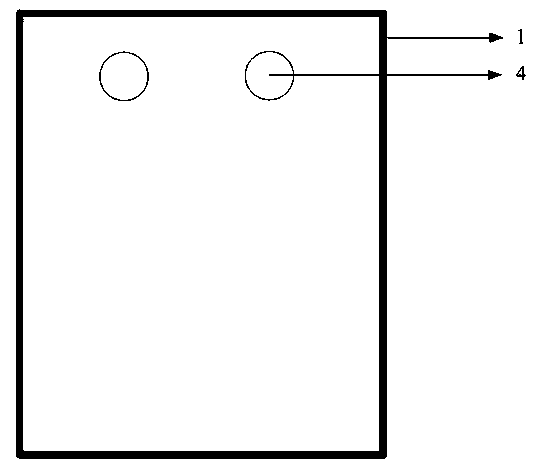

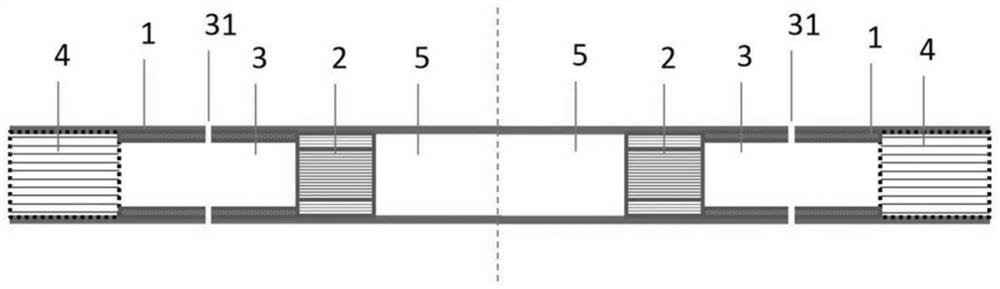

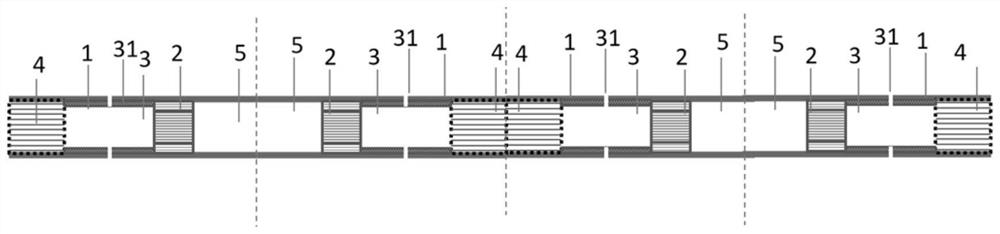

The present application discloses an electronic cigarette atomizer and an electronic cigarette using the electronic cigarette atomizer. The electronic cigarette atomizer comprises a plurality of atomizing assemblies, and each atomizing assembly includes at least one heating wire and defines a smoke channel configured to discharge smoke. The atomizing assemblies are all coaxial and thereby form a string, and the smoke channels of every two adjacent atomizing assemblies communicate with each other. The heating wires of all the atomizing assemblies are electrically connected successively, and the heating wire of each atomizing assembly is entirely or partially received in the smoke channel of the atomizing assembly. Pluralities of detachable connecting structure are mounted between every two adjacent atomizing assemblies to detachably connect every two adjacent atomizing assemblies with each other.

Owner:HUIZHOU KIMREE TECH

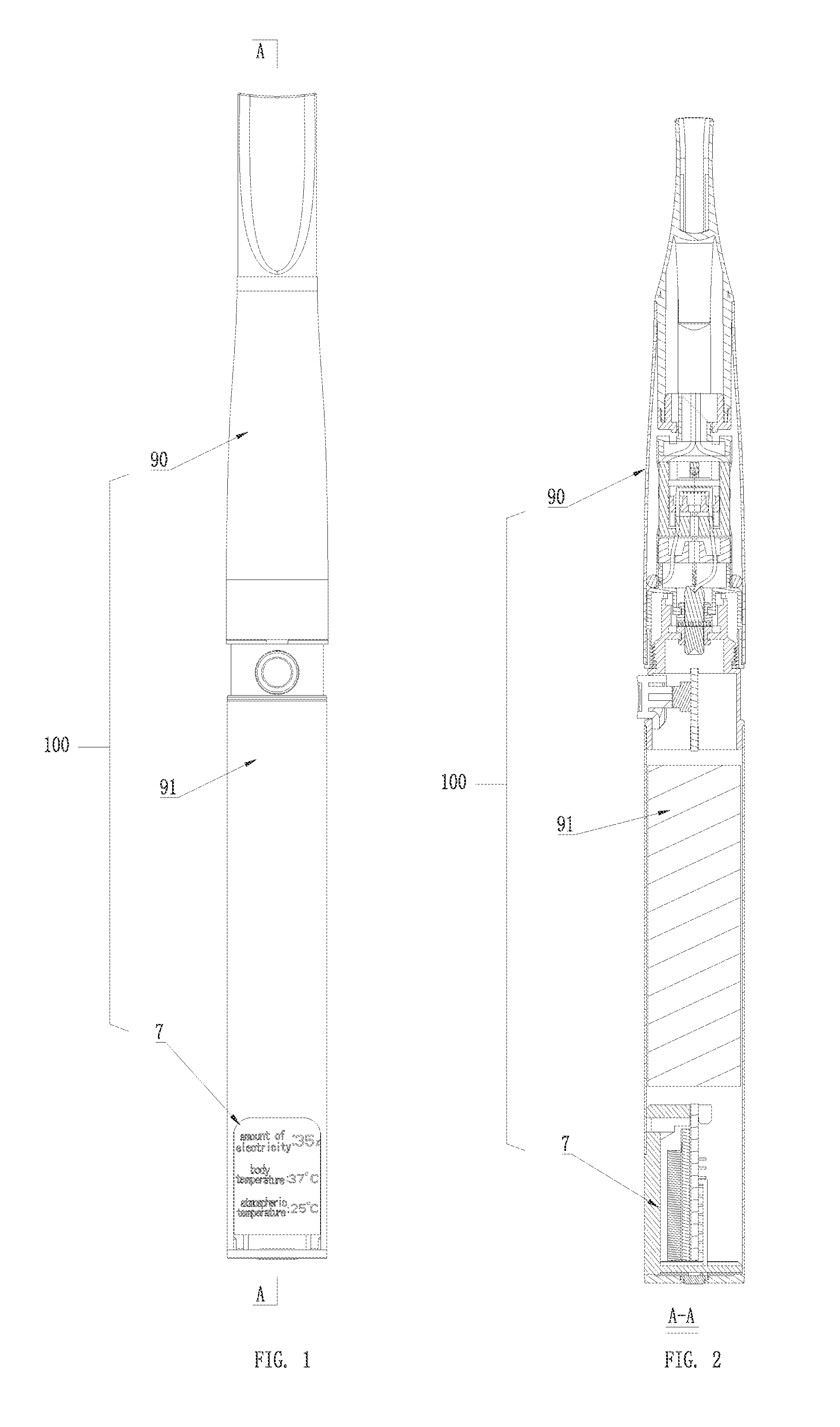

Electronic Cigarette and Electronic Cigarette Device

InactiveUS20130333711A1Easy to disassemblePromote repairTobacco pipesTobacco devicesElectricityComputer module

This invention refers to an electronic cigarette and an electronic cigarette device. The electronic cigarette includes an outer shell defining a display window, and a thermometer module disposed on the outer shell; the thermometer module comprises a measuring unit, a display unit located within the outer shell and a circuit processing unit; the measuring unit gets a temperature data of an object to be measured or medium and transmits the temperature data to the circuit processing unit, and finally the circuit processing unit controls the display unit to display the temperature data. The measuring unit comprises a temperature sensing component located at an outer wall of the outer shell of the electronic cigarette and pins electrically connected the temperature sensing component to the circuit processing unit. The electronic cigarette has a function of sensing and measuring body temperature, or temperature of other objects or medium, such as the ambient temperature.

Owner:HUIZHOU KIMREE TECH

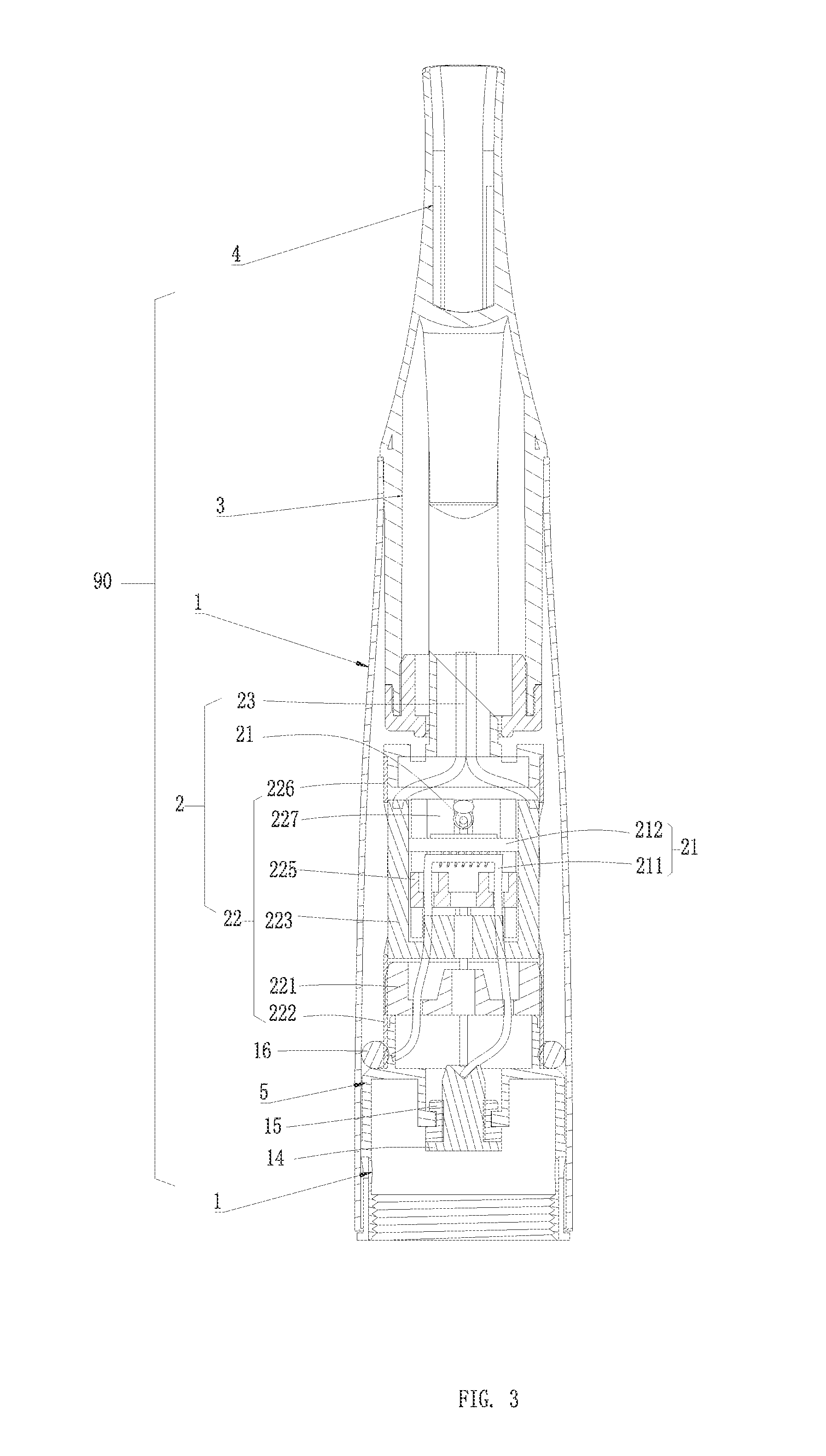

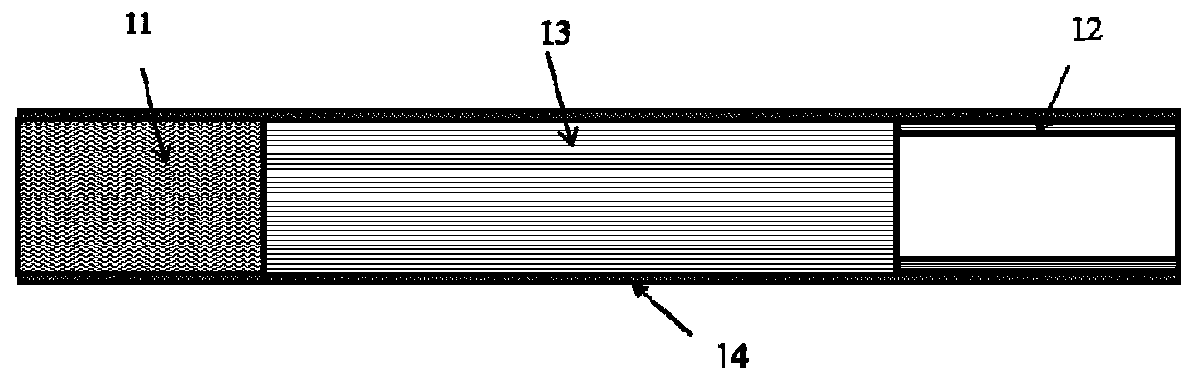

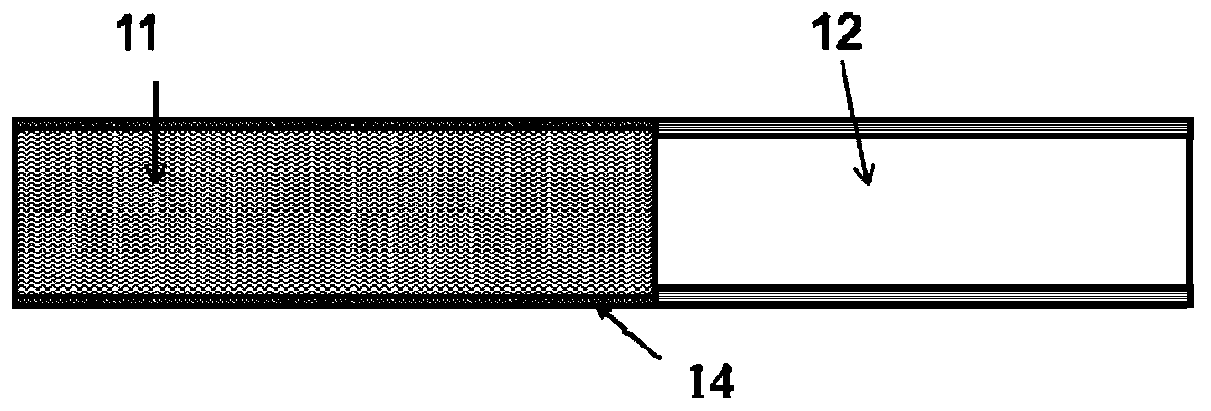

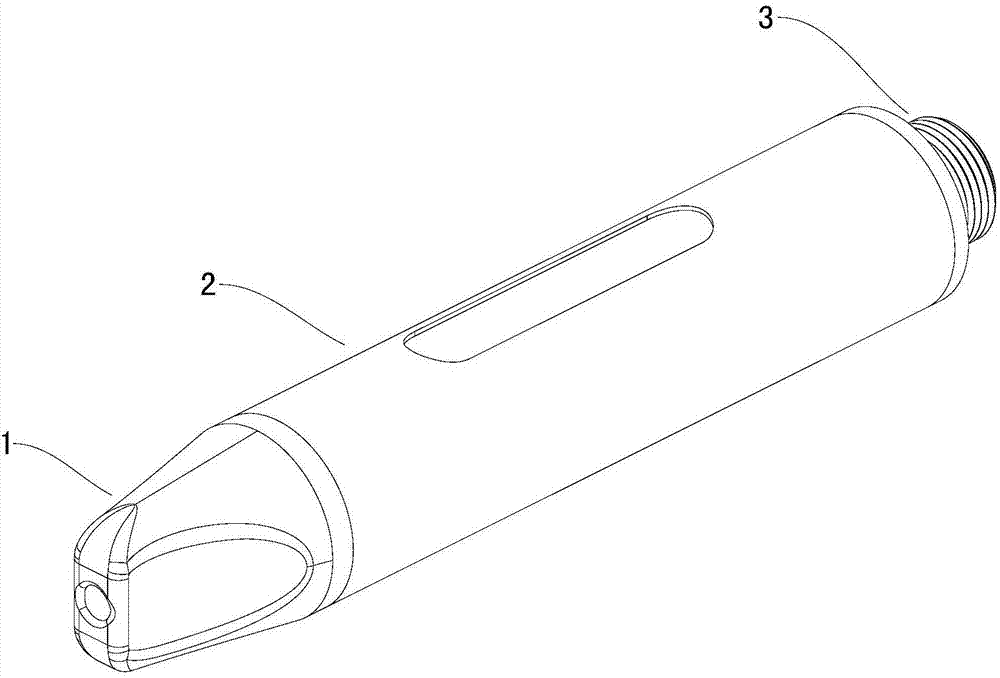

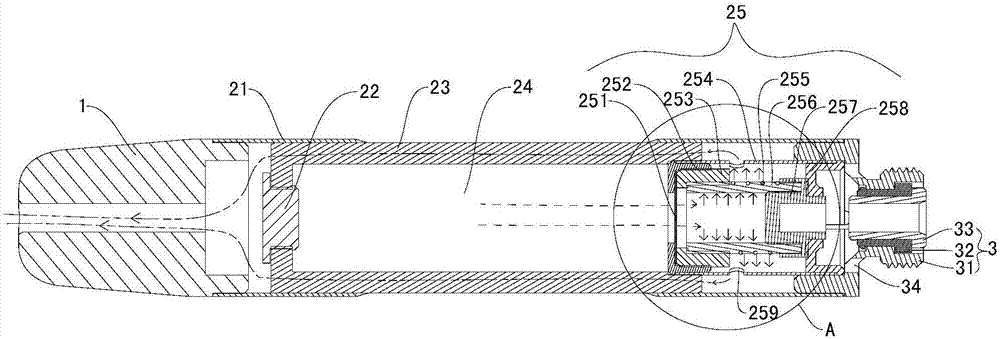

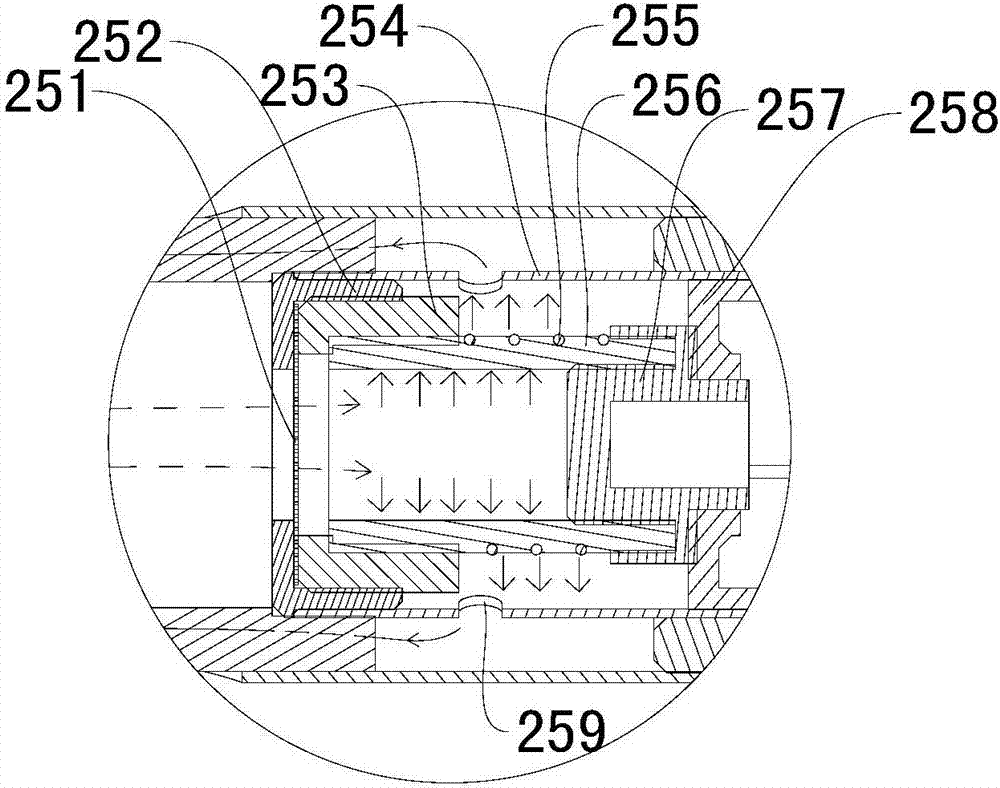

Smoke Condensation Resistant Electronic Cigarette

InactiveUS20140150784A1Increase the amount of smokeReduce smokeTobacco devicesInhalatorsEngineeringElectronic cigarette

A smoke condensation resistant electronic cigarette includes absorption stem and a power source stem which are connected with each other detachably; an atomizer for transforming cigar liquid stored in the absorption stem into smoke and a smoke path for conducting the smoke out of the absorption stem are provided in the absorption stem. Here a smoke condensation resisting mechanism for preventing cooling and condensing of the smoke on an inner wall of the smoke path during flowing process is disposed in the absorption stem. The electronic cigarette of the present invention increases amount of smoke taken in by a smoker and prevents cigar liquid drips being inhaled by the smoker or greatly reducing amount of smoke taken in by the smoker. In addition, it facilitates reduction of manufacture and using cost, and also facilitates assembly, disassemble and replacement of the electronic cigarette.

Owner:HUIZHOU KIMREE TECH

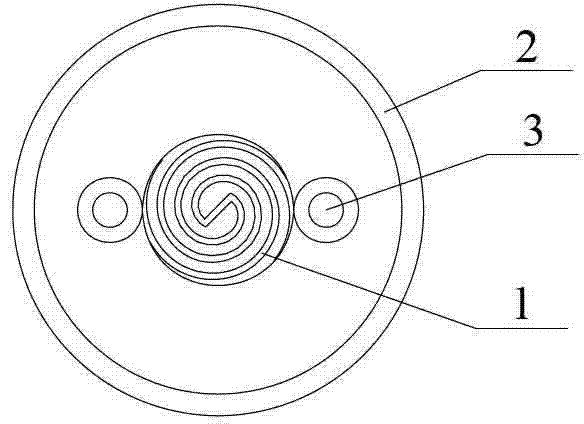

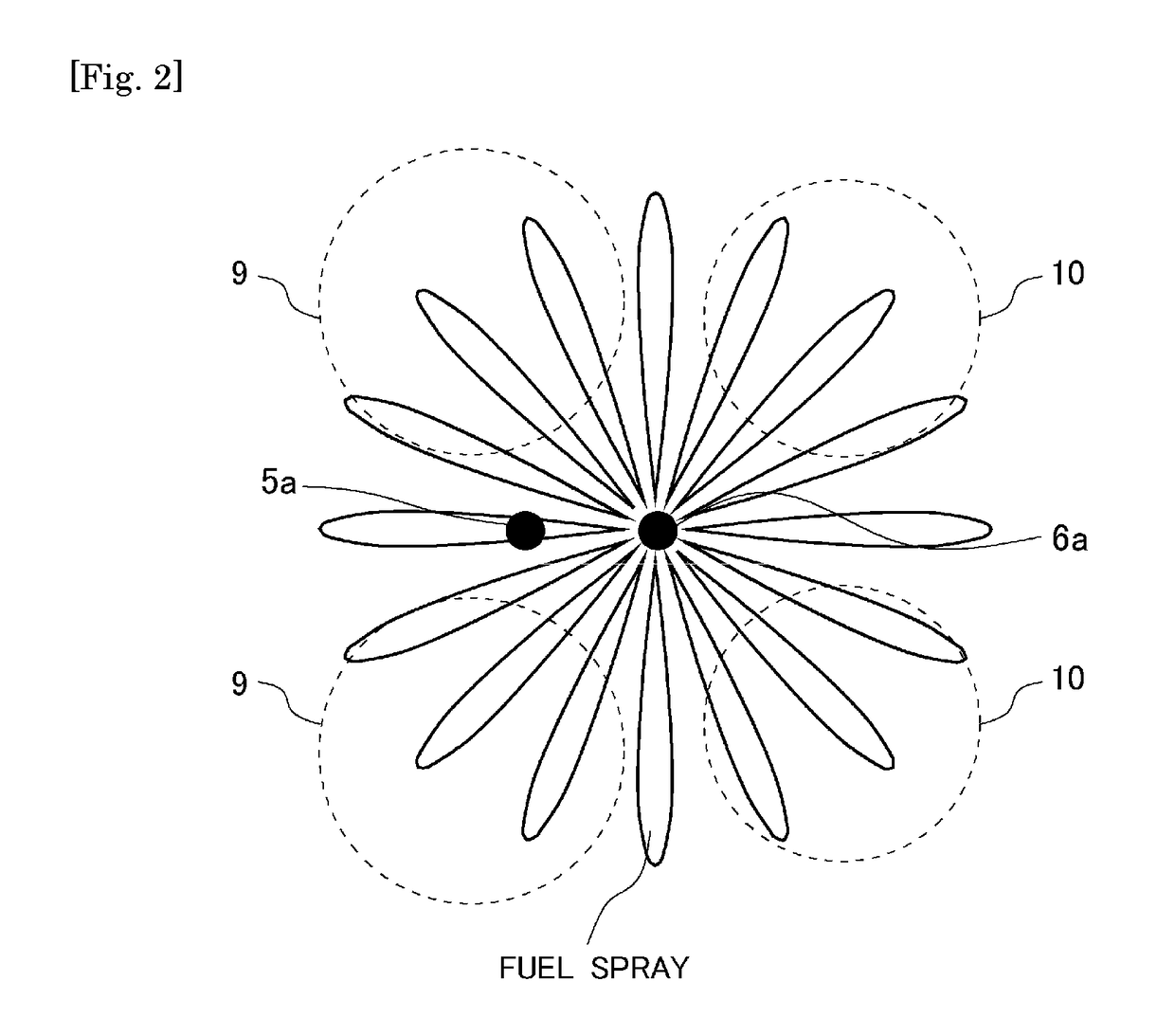

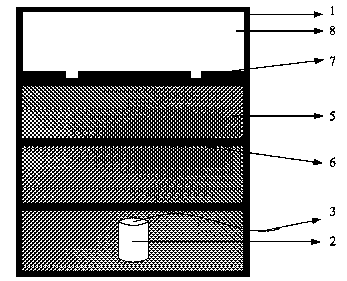

Plant essential oil mist atomizer and production method thereof

InactiveCN102861694AIncrease the amount of smokeExtended service lifeTobacco devicesLiquid spraying apparatusHigh resistanceGlass fiber

The invention discloses a plant essential oil mist atomizer and a production method thereof. The plant essential oil mist atomizer comprises a heating wire and an oil storing pipe, two ends of the heating wire are fixedly connected with power supply wires respectively, a heat insulation glass fiber plate is covered on an opening of the oil storing pipe, the heating wire is in a plane curve shape and is fixed on the bottom surface of the glass fiber plate, high temperature resistant cotton is arranged below the heating wire, and oil storing cotton is filled below the high temperature resistant cotton. According to the plant essential oil mist atomizer, the heating wire is bent into the plane curve shape, so that areas of atomization and evaporation are increased, atomization effects are good, mist amount of plant essential oil mists is substantially increased, and by means of the high-resistance heating wire, service life of a battery is prolonged.

Owner:SHENZHEN BOGE TECH

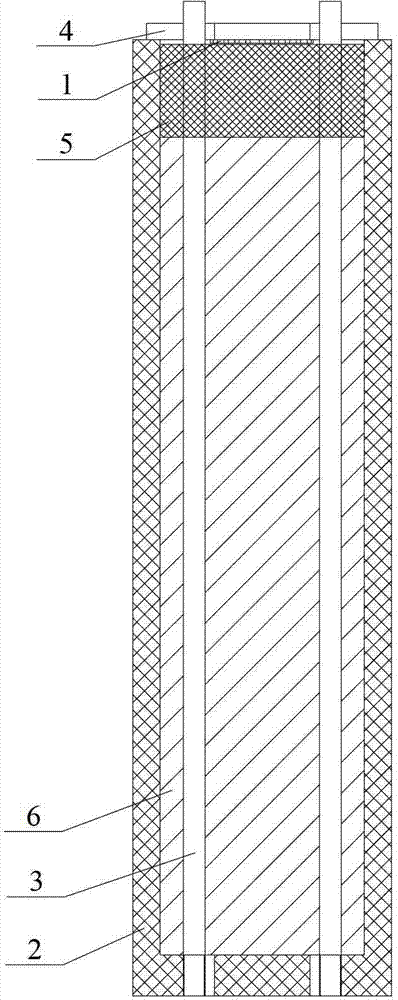

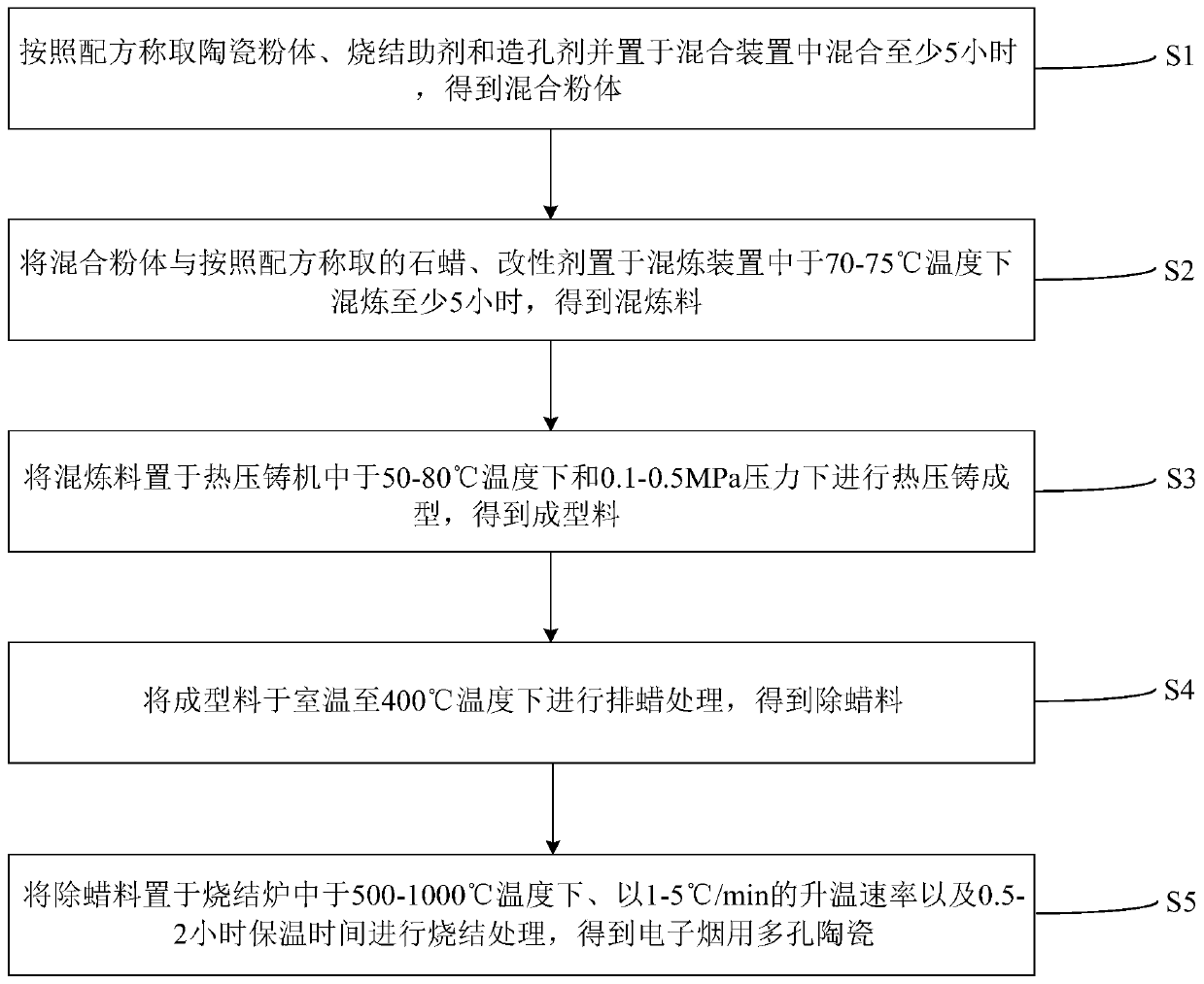

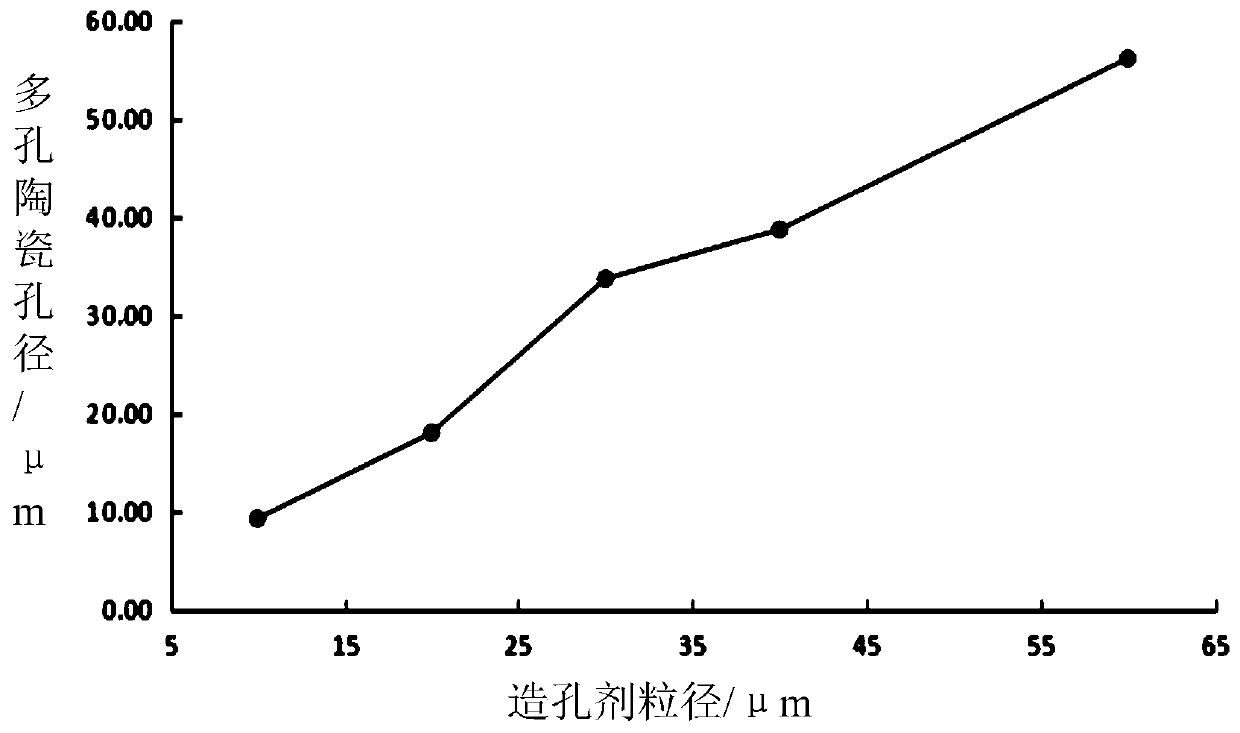

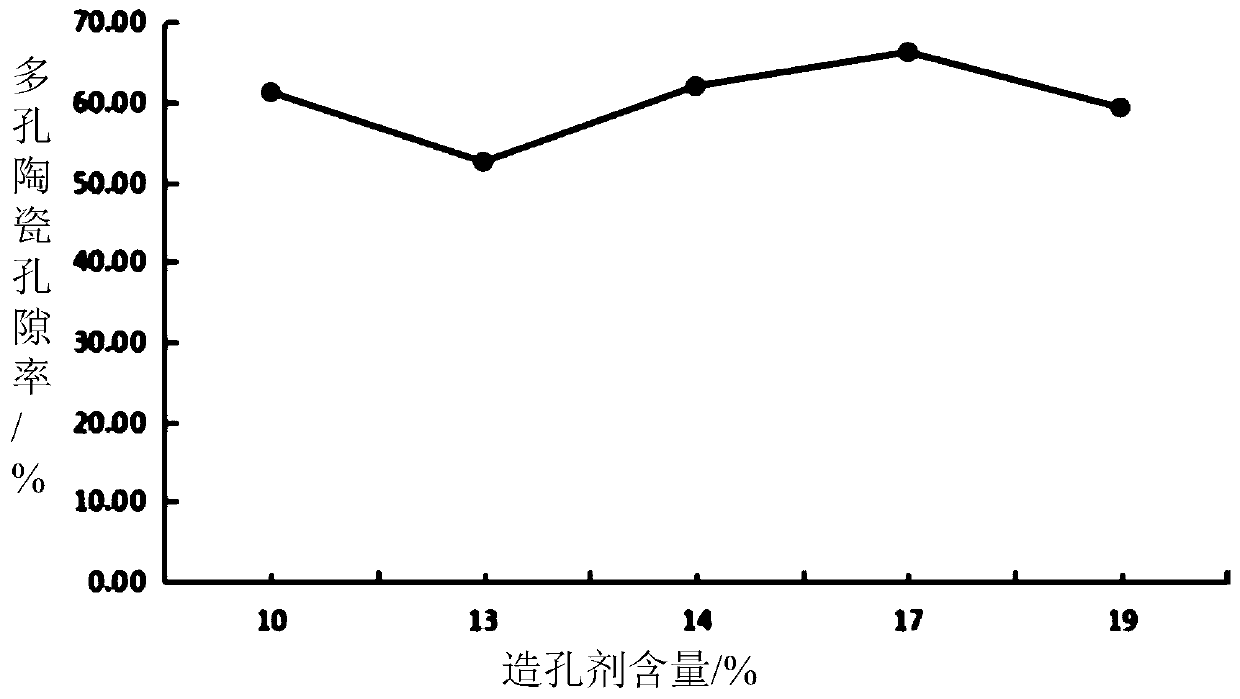

Porous ceramic for electronic cigarette and preparation method thereof

InactiveCN111205104AStable pore size distributionIncrease atomization rateTobacco devicesCeramicwareParaffin waxCarbide silicon

The invention relates to the technical field of electronic cigarettes. The invention particularly relates to porous ceramic for an electronic cigarette and a preparation method thereof. The porous ceramic for the electronic cigarette is composed of the following components in percentage by mass: 30-60% of ceramic powder, 1-30% of a pore forming agent, 5-40% of a sintering aid, 10-40% of paraffin and 1-10% of a modifier. The ceramic powder comprises at least two of diatomite, cordierite, fly ash, aluminum oxide, zirconium oxide, silicon carbide, silicon nitride, quartz sand, zircon sand, glasssand, kaolin and clay. The porous ceramic prepared by the method is uniform and stable in pore size distribution; the aperture and porosity of the porous ceramic can be adjusted according to the tasteof a user and the characteristics of tobacco tar, so that the tobacco tar can be fully adsorbed and atomized, the tobacco tar atomization rate is greatly increased, the smoke amount is increased, andthe problems of poor tobacco tar atomization effect and poor taste in the current market are solved.

Owner:东莞市陶陶新材料科技有限公司

Method for preparing heat-not-burn tobacco bases containing active carbon

ActiveCN105747264AReduce the impactIncrease loadTobacco preparationTobacco treatmentActivated carbonFlavor

The invention discloses a method for preparing heat-not-burn tobacco bases containing active carbon.The method comprises the following steps that active carbon is weighed and mixed with water, defibering and pulping are conducted, and active carbon pulp is obtained; tobacco raw materials are weighed, soaked, filtered and pulped so that tobacco pulp can be obtained; by weight, 50-80 parts of tobacco pulp, 8-25 parts of wood pulp, 10-30 parts of active carbon pulp and 4-8 parts of adhesive are weighed and evenly mixed; the mixture is formed and dried so that the tobacco bases are obtained; by weight, 1-40 parts of tobacco essential oil, 2-20 parts of tobacco flavor material and 40-80 parts of atomization agent are weighed and evenly mixed so that coating liquid can be obtained; the coating liquid is sprayed to the tobacco bases, standing is conducted for 40-48 h under the constant-temperature and constant-humidity conditions, and finally the heat-not-burn tobacco bases containing active carbon are obtained.Cigarettes prepared from the tobacco bases are put in a smoking set to be used, good satisfaction can be brought to consumers, the amount of smoke is large, the fragrance concentration is high, and the quality of heat-not-burn cigarettes is improved better.

Owner:CHINA TOBACCO GUIZHOU IND

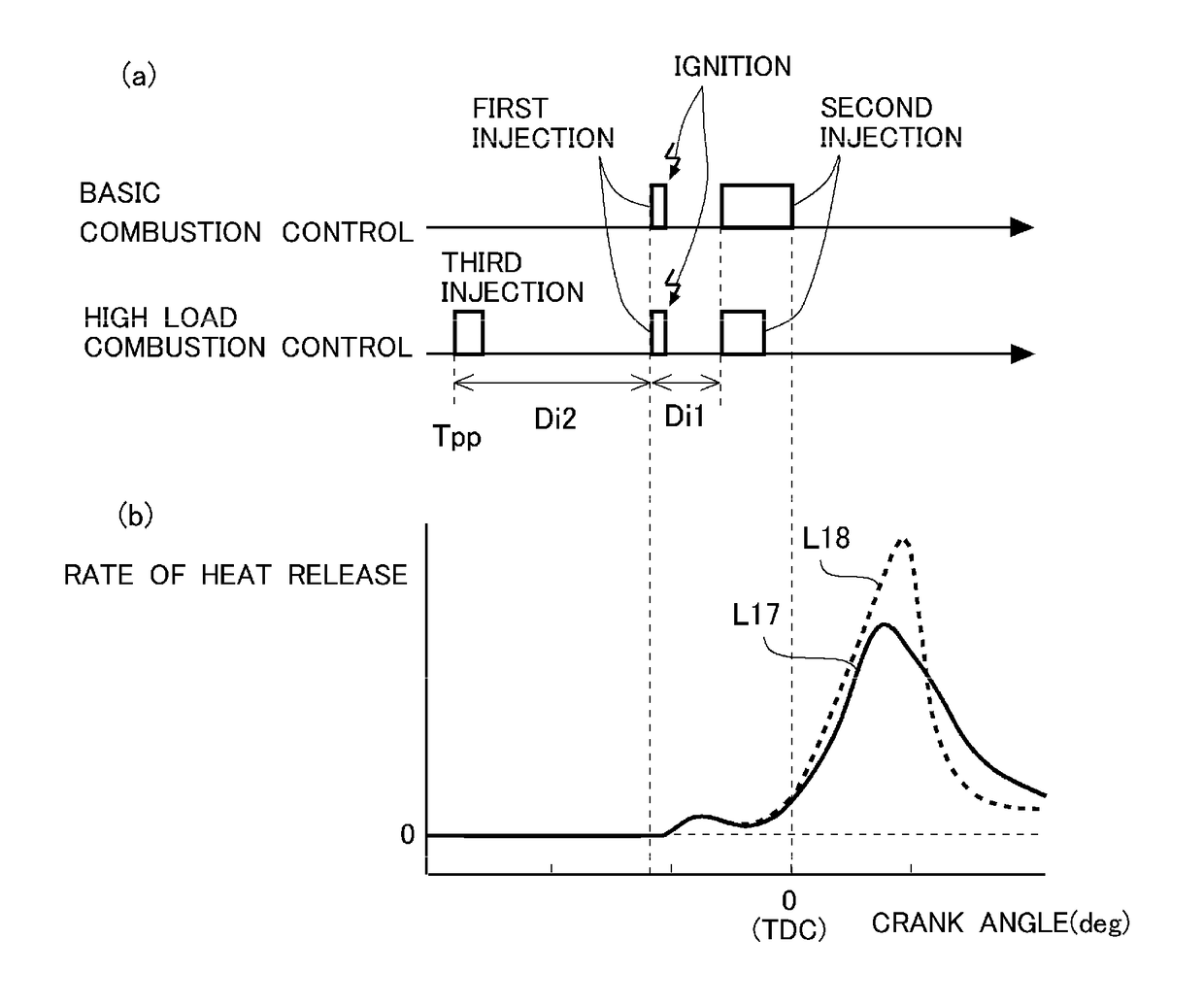

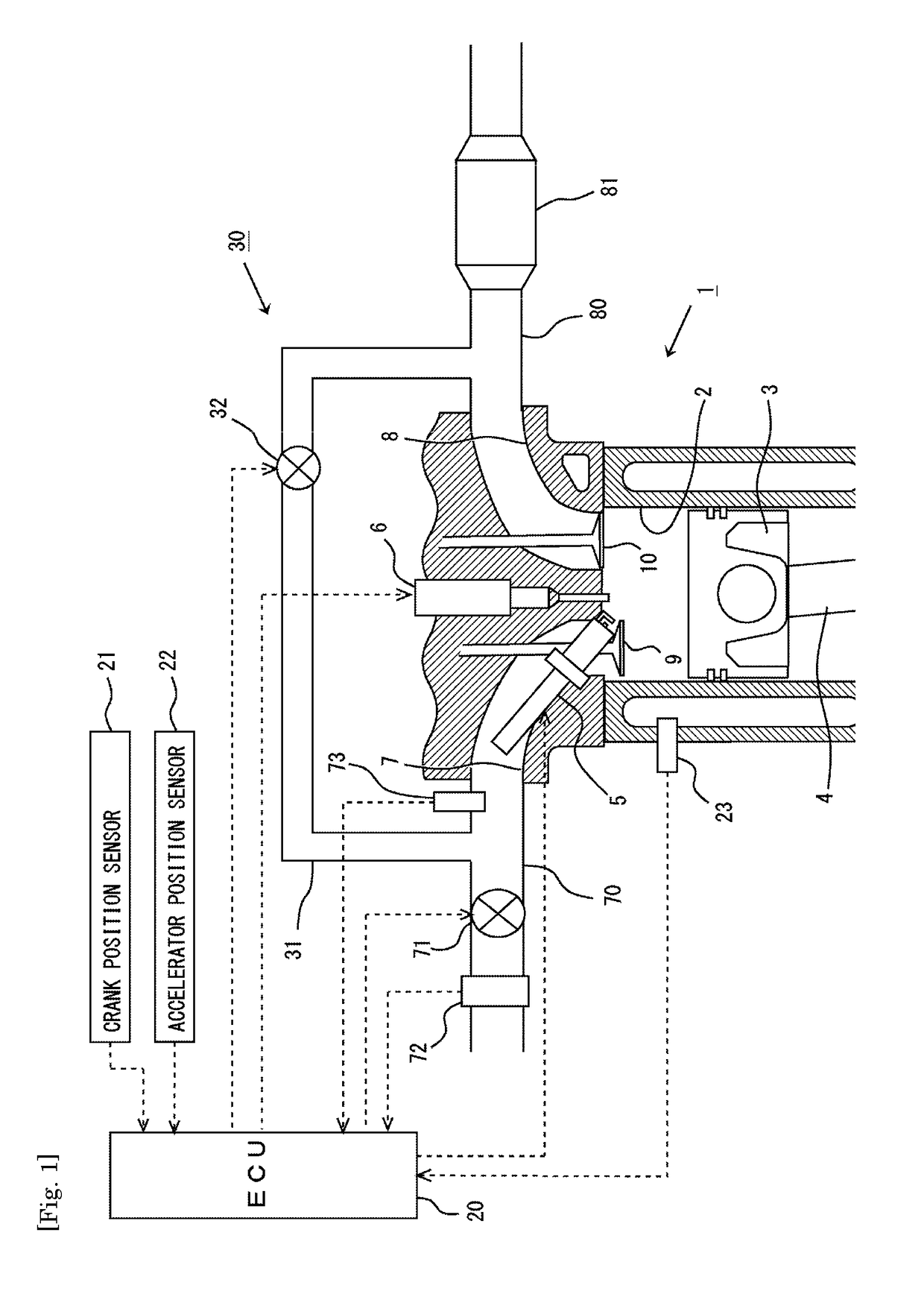

Control apparatus for internal combustion engine

InactiveUS20170284282A1Reduce smokeImprove stabilityElectrical controlInternal combustion piston enginesExternal combustion engineDiesel combustion

An object of the invention is to reduce the amount of smoke generated and to improve the stability of diesel combustion in cases where an EGR apparatus is used in an internal combustion engine that performs diesel combustion using fuel having a relatively high self-ignition temperature. A control apparatus performs first injection at a first injection time during the compression stroke, causes spray guide combustion to occur, and starts to perform second injection at such a second injection time that causes combustion of injected fuel to be started by flame generated by the spray guide combustion, thereby causing self-ignition and diffusion combustion of fuel to occur. The apparatus changes the ratio of the first injected fuel quantity to the total fuel injection quantity and the ratio of the second injected fuel quantity to the total fuel injection quantity for the same total fuel injection quantity in one combustion cycle, based on the EGR rate in the intake air.

Owner:TOYOTA JIDOSHA KK

Low-temperature cigarette containing metal wires and preparation method thereof

InactiveCN108669647AEnhance physical satisfactionIncrease the amount of smokeTobacco treatmentCigar manufactureAdditive ingredientEngineering

The invention provides a low-temperature cigarette containing metal wires and a preparation method thereof. The low-temperature cigarette comprises, by mass, 60-95% of tobacco sheets, tobacco shreds or other tobacco material, and 5-40% of metal wires; after the tobacco material and the metal wires are mixed well, tipping is performed to obtain the low-temperature cigarette. The production technique for cigarette tipping is unchanged; the metal wires are added only to the shredded tobacco, so that heat conductivity of the tobacco material is effectively improved. When a user smokes the low-temperature cigarette, a mist medium, an aromatic ingredient and an added fragrance included in both the tobacco material close to a heat source and the tobacco material far away from the heat source canbe effectively atomized and volatilized, physiological satisfaction brought by the low-temperature cigarette can be well improved, and smoke production is increased. In addition, the production technique for tipping of low-temperature cigarettes is mature and simple, is highly controllable and has stable quality.

Owner:HUBEI CHINA TOBACCO IND

Preparation method for preparing wrap paper of mixed type cigarette cores which do not combust when being heated and cigarette cores

ActiveCN107212471AImprove suction qualitySufficient amount of flue gasTobacco devicesNasal cavityEngineering

The invention relates to a preparation method for preparing wrap paper of mixed type cigarette cores which do not combust when being heated and the cigarette cores and belongs to the technical field of cigarettes. The preparation method comprises the steps of preprocessing, preparing first mixtures, preparing mixed slurry, preparing spicing liquid, preparing coating and preparing the cigarette cores. The prepared wrap paper products are used for preparing the cigarette cores which do not combust when being heated, due to the fact that a large amount of burley tobacco particle materials are attached to the wrap paper, the smoke amount is adequate, the puff number can reach 20, and the smoke strength can be remarkably improved; the spicing materials can make the aroma and taste full and harmonious, no obvious stimulus exists in a nasal cavity, accordingly the suction quality of the cigarettes which do not combust when being heated is remarkably improved, and the prepared wrap paper products have good application prospects.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

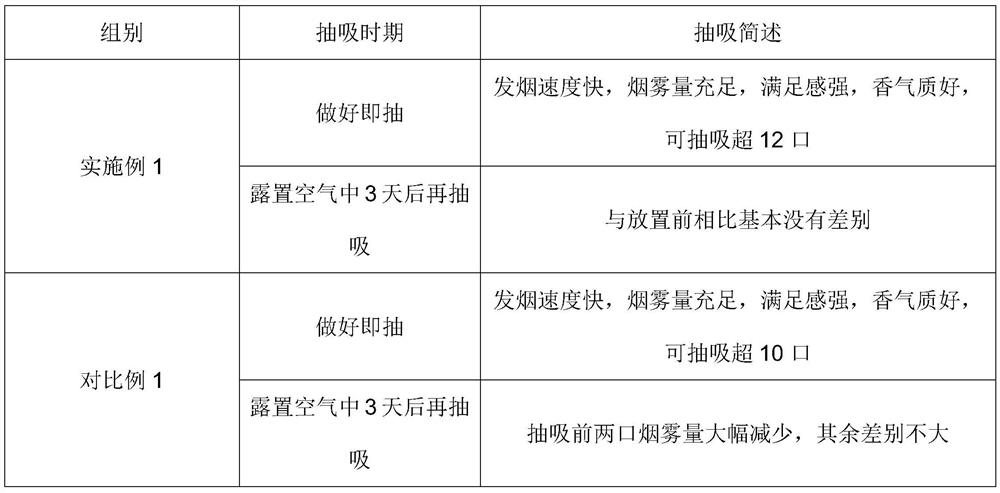

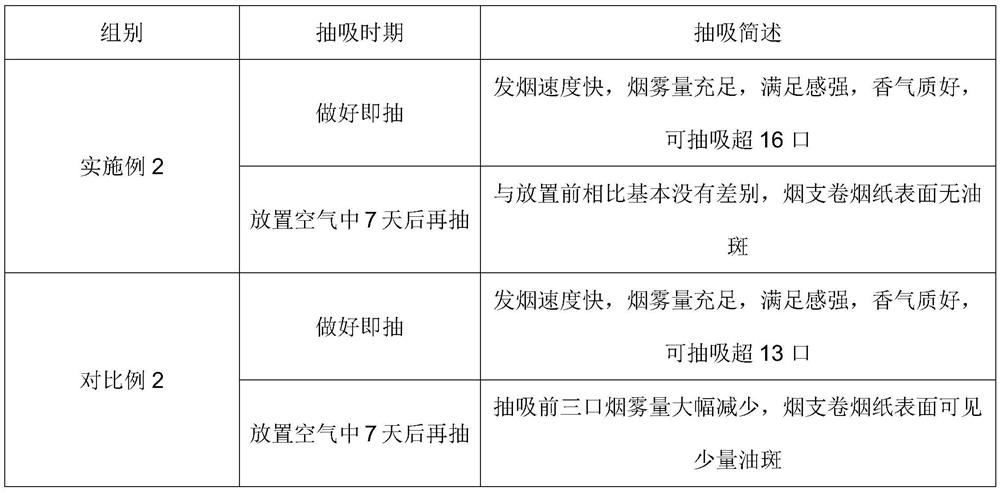

Cigarette sets applied to heat-not-burn cigarettes

PendingCN109349682AReduce adsorptionIncrease the amount of smokeTobacco devicesMechanical equipmentEngineering

The invention disclose cigarette sets applied to heat-not-burn cigarettes. The cigarette sets comprise smoke formation sections, hollowing sections, cooling sections and junction sections; the right ends of the smoke formation sections are connected with the hollowing sections, and the right ends of the hollowing sections are connected with the cooling sections; the hollowing sections are arrangedbetween the smoke formation sections and the cooling sections, and the right ends of the cooling sections are connected with the junction sections. By means of the hollowing sections of the cigarettesets, adsorption of smoke can be effectively reduced, the smoke amount is increased, and the sensory quality is obviously improved; the cooling process after a supplied material is burst belongs to physical cooling, the use of cooling materials can be reduced, and thus the cost of the materials is reduced; the supplied material can provide a smoke formation agent and part of flavor components which cannot be directly added to a smoke core material, the production technology can be simplified, the problem that currently, it is difficult to add the high-proportion smoke formation agent is solved, and meanwhile the richness of cigarette flavor can be improved; the cigarette sets can be achieved through existing equipment, mechanical equipment does not need to be developed independently, thecost of production equipment is reduced, and the production steps are reduced.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method for peripherally heated non-burning cigarette shreds

ActiveCN109820233AEasy to integrateFully absorbedTobacco preparationTobacco treatmentFlavorRoom temperature

The invention discloses a preparation method for peripherally heated non-burning cigarette shreds. The method comprises the following steps that 1, the moisture content of reconstituted tobacco is increased; 2, spices and a smoke generating agent are added into the reconstituted tobacco, and the moisture content of the reconstituted tobacco is increased, wherein the spices and the smoke generatingagent account for 5-30% of the weight of the tobacco; 3, the reconstituted tobacco in step 2 is cut into tobacco shreds; 4, the moisture content of the tobacco shreds is decreased at the low temperature; 5, the temperature of the tobacco shreds is lowered to the room temperature with low-humidity and dried air, and the moisture content is decreased to 9-14 wt%; 6, the spices and the smoke generating agent are added into the tobacco shreds for uniform mixing to obtain the heated non-burning cigarette shreds, wherein the addition quantity of the spices and smoke generating agent accounts for 0.5-7% of the weight of the tobacco shreds, and step 4 can be omitted. According to the method, the original flavor in the tobacco is not destroyed, the spices and the smoke generating agent which are added into the tobacco shreds are maintained to the maximum limit, the taste of smoke is improved, and the smoke amount is increased.

Owner:CHINA TOBACCO YUNNAN IND

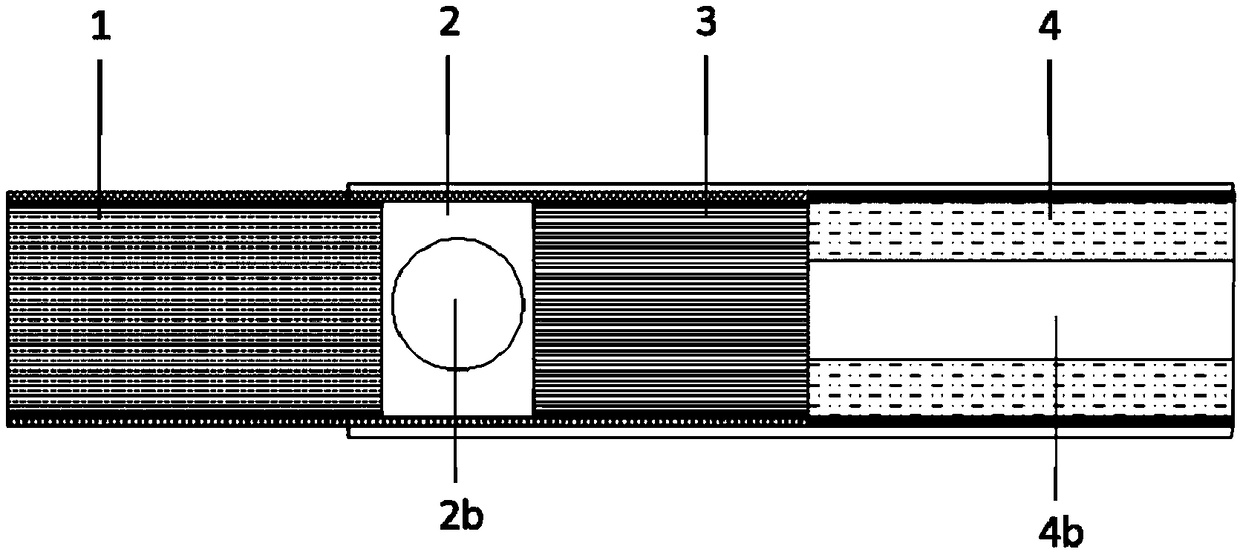

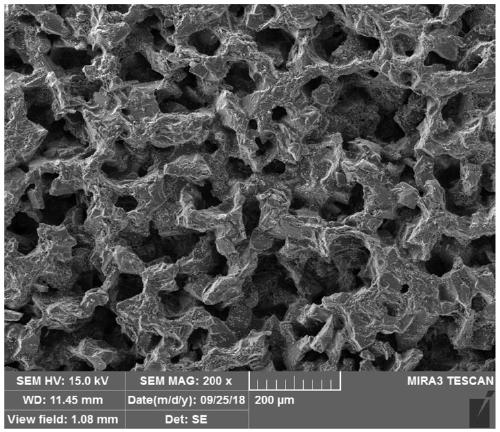

Porous ceramic raw material, porous ceramic as well as preparation method and application thereof

ActiveCN109721343ASmooth oil conductionIncrease the amount of smokeTobacco devicesCeramicwareSilicon dioxidePorous ceramics

The invention relates to a porous ceramic raw material, porous ceramic as well as a preparation method and application thereof, wherein the porous ceramic raw material comprises the following components in percentage by mass: 40%-80% of aluminum oxide, 1%-20% of silicon dioxide, 1%-20% of titanium dioxide and 1%-20% of a burning promoting agent. The 40%-80% Of aluminum oxide, the 1%-20% of silicondioxide, the 1%-20% of titanium dioxide and the 1%-22% of the burning promoting agent are used as the raw materials to prepare the porous ceramic with the pore size of 10 microns to 50 microns and porosity reaching 30%-70% without addition of a pore forming agent, the porous ceramic is smooth in oil guide, a heating circuit is plated on the surface of the porous ceramic, the heating circuit cannot permeate into pores to cause the situation that the heating circuit is burnt due to short circuit or uneven heating, the porous ceramic can replace oil guide cotton as an oil storage and oil guide function part of an atomizing core, the smoke volume and the taste can be greatly improved, and the service life is prolonged.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

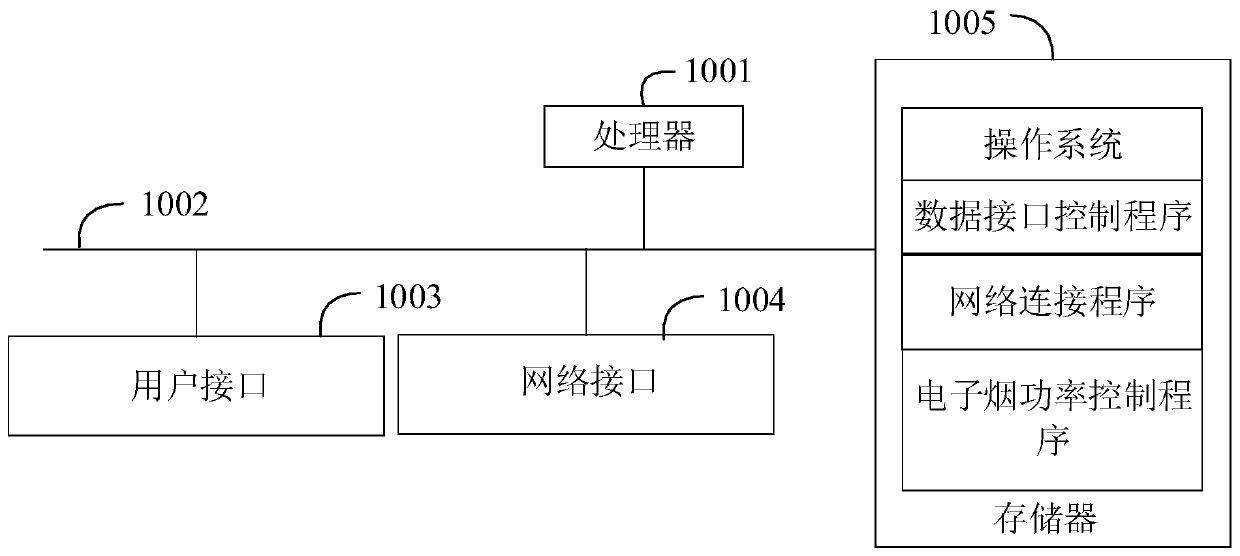

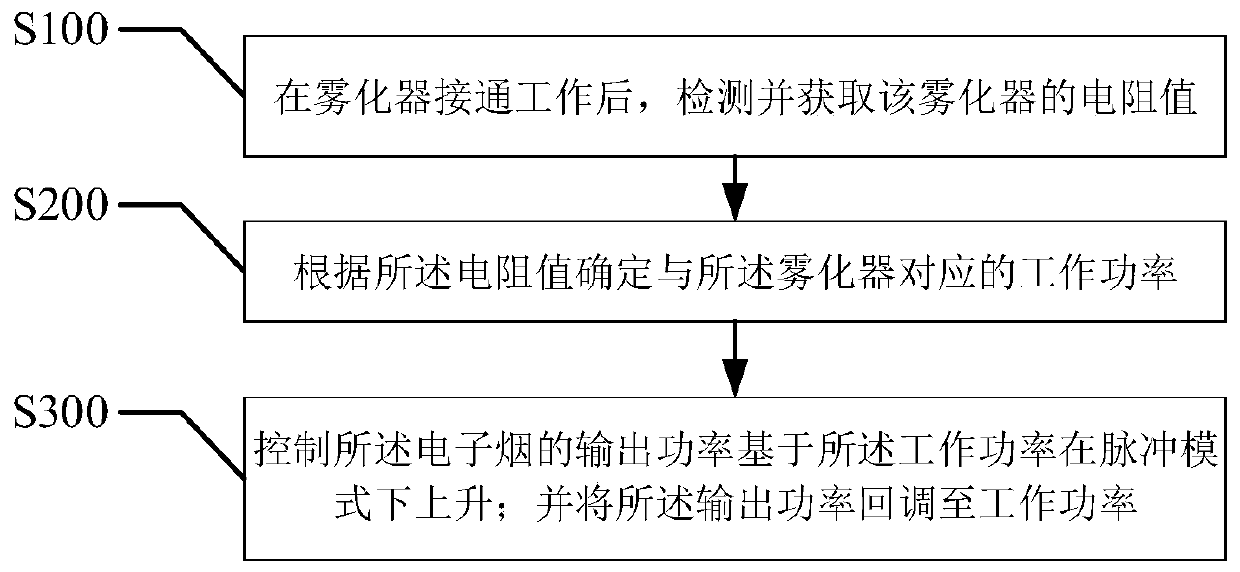

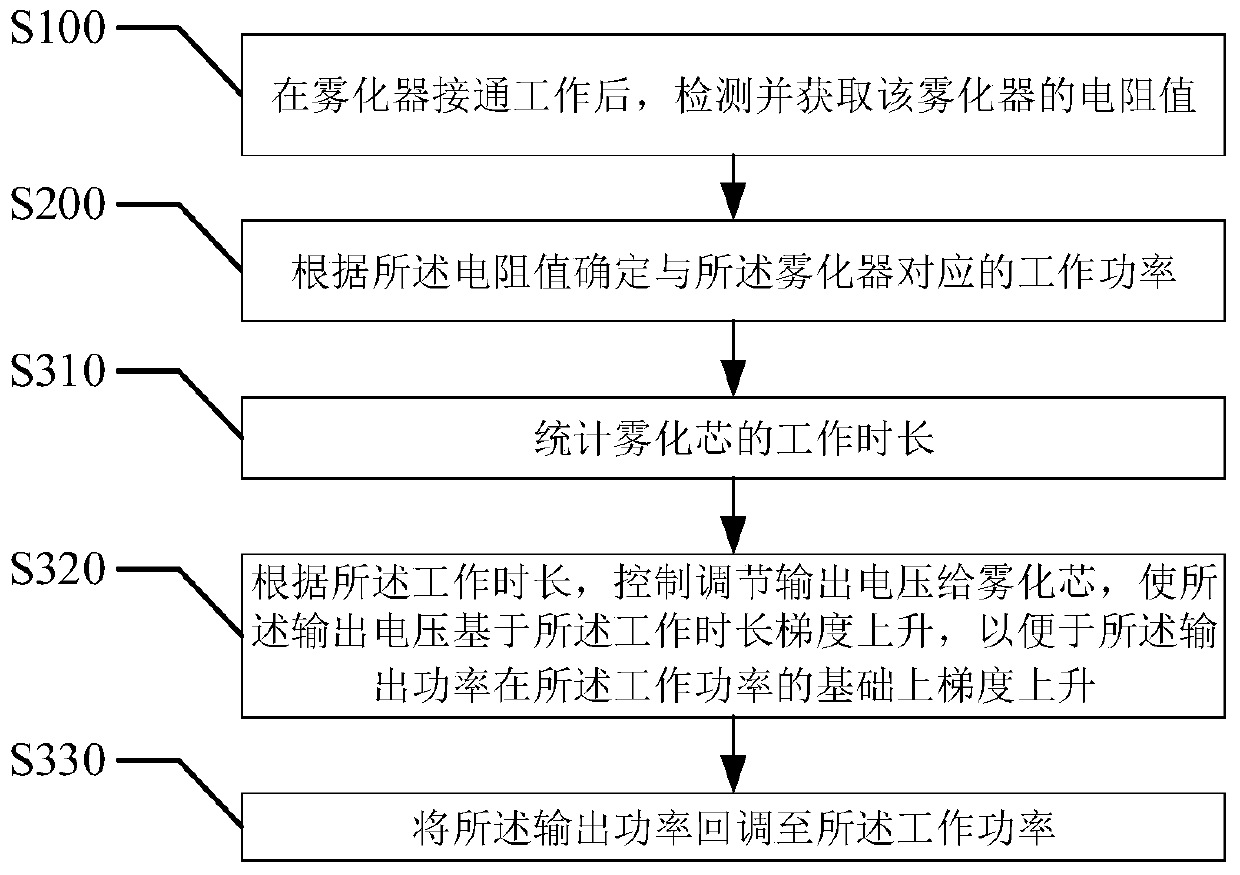

Electronic cigarette power control method, device and system

ActiveCN110326820AImprove experienceImprove atomization effectTobacco devicesElectric variable regulationPower controlEngineering

The invention provides an electronic cigarette power control method, device and system. The electronic cigarette power control method comprises the steps that a resistance value of an atomizer after the atomizer is turned on for work is detected and acquired; the working power corresponding to the atomizer is determined according to the resistance value; the output power of an electronic cigaretteis controlled to rise in the pulse mode; and the output power is called back to the operating power. According to the electronic cigarette power control method, device and system, the corresponding optimal working power is determined according to the resistance value of the atomizer, based on the optimal working power, the output power is controlled to perform pulse gradient rising and calling back, so that the pulse of the instantaneous output power is risen according to the actual resistance value of the atomizer when a person smokes with the electronic cigarette, the atomization effect isincreased, the amount of smoke is increased, so that a user can experience the taste of the large amount of smoke similar to tobacco cigarette smoking without using a large smoking strength when smoking, and the experience feeling of the user is improved.

Owner:SHENZHEN JIYOU TECH CO LTD

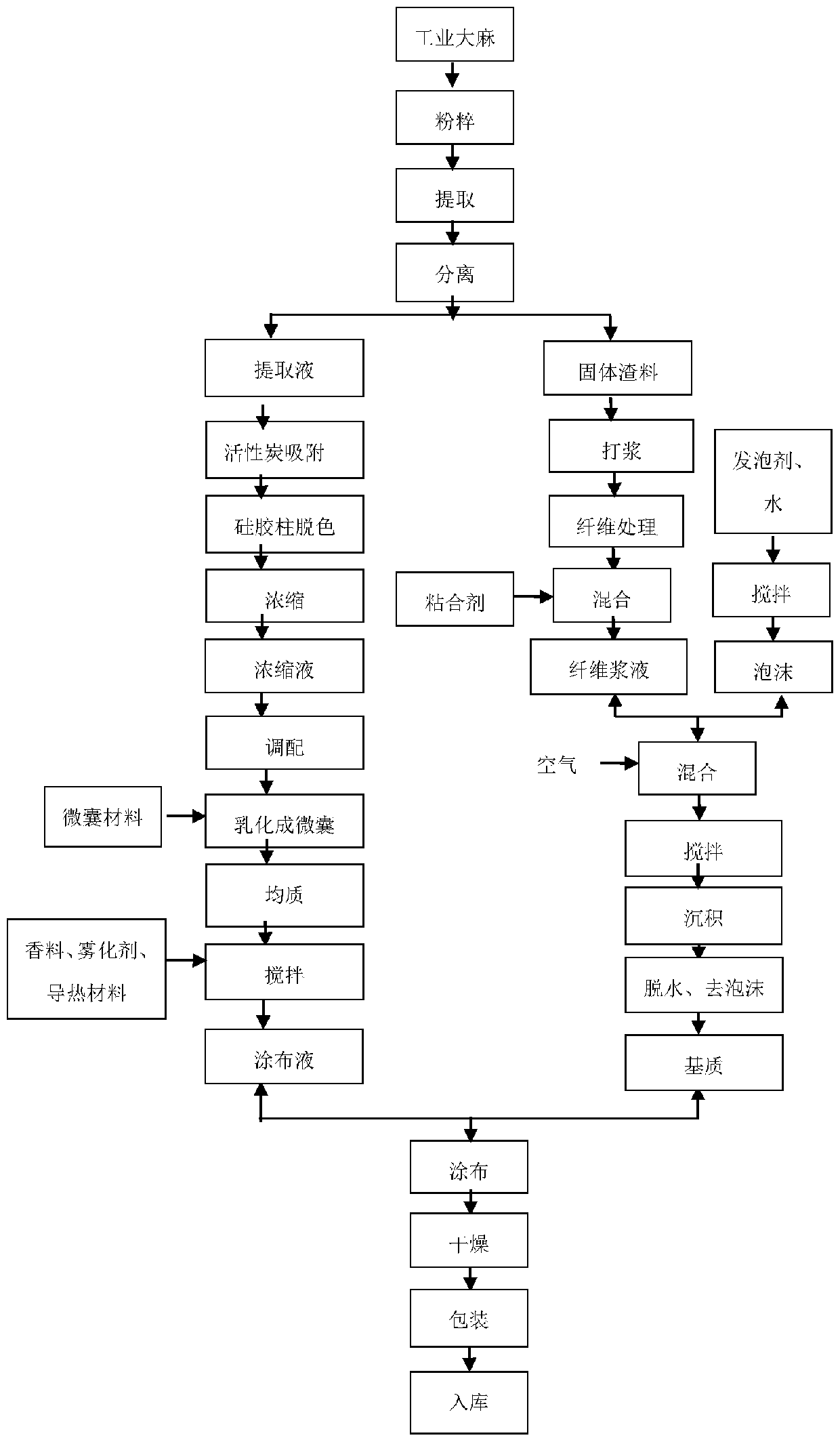

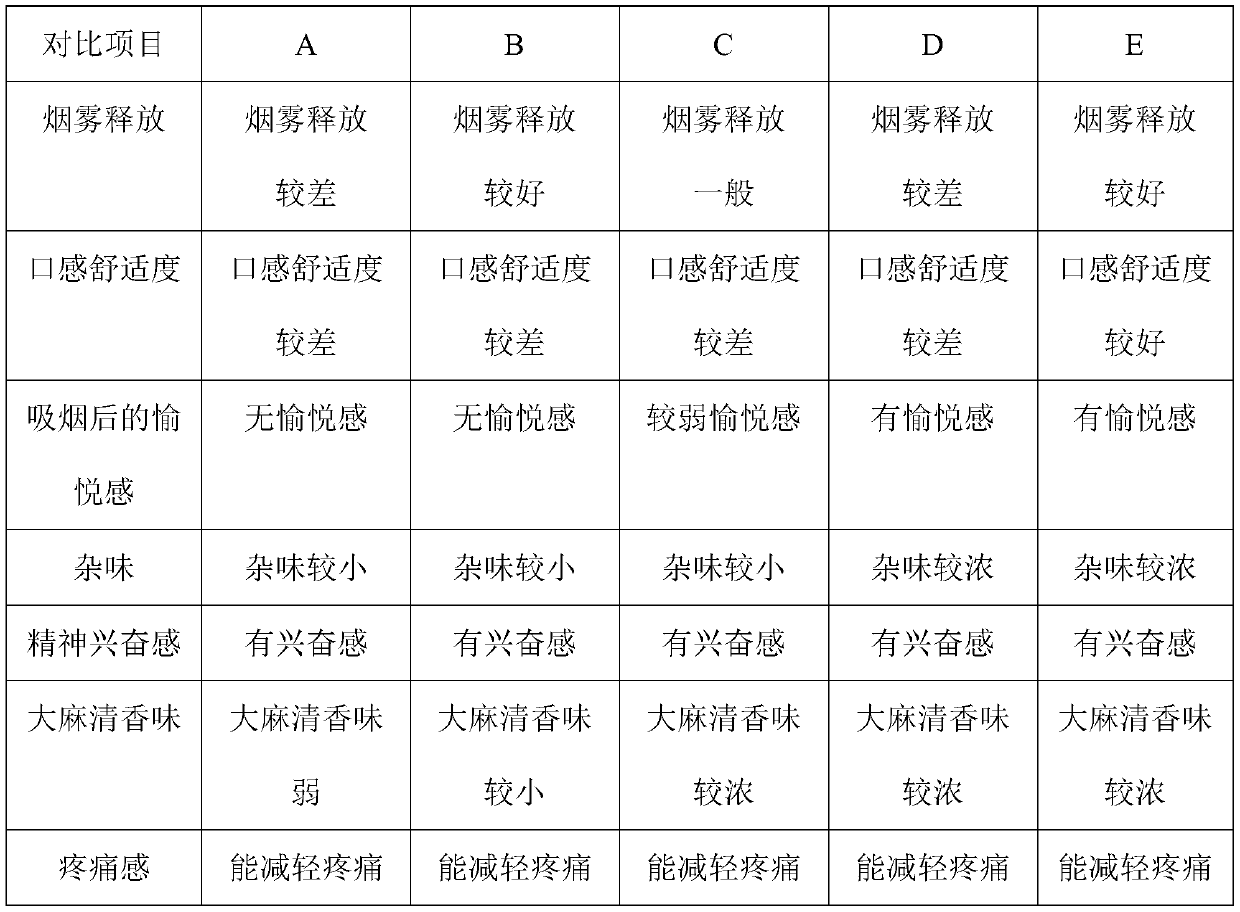

Tobacco product and preparation method thereof

InactiveCN109770411AImprove breathabilityHigh bulkTobacco preparationTobacco treatmentHeat conductingHeat not burn

The invention provides a tobacco product and a preparation method thereof. The preparation method comprises the specific steps that industrial hemp is taken as a raw material, a solid-phase substrateused for the tobacco product is prepared by adopting a foam forming method, a coating liquid containing cannabinoid is sprayed on the solid-phase substrate, and the tobacco product is obtained. The tobacco product has the advantages that the tobacco product replaces a traditional heat-not-burn tobacco product of a cigarette, the volatilization of effective components is fully achieved, the heat-conducting property is good, the smoke amount is large, and the taste is good.

Owner:YUNNAN HANSU BIO TECH CO LTD

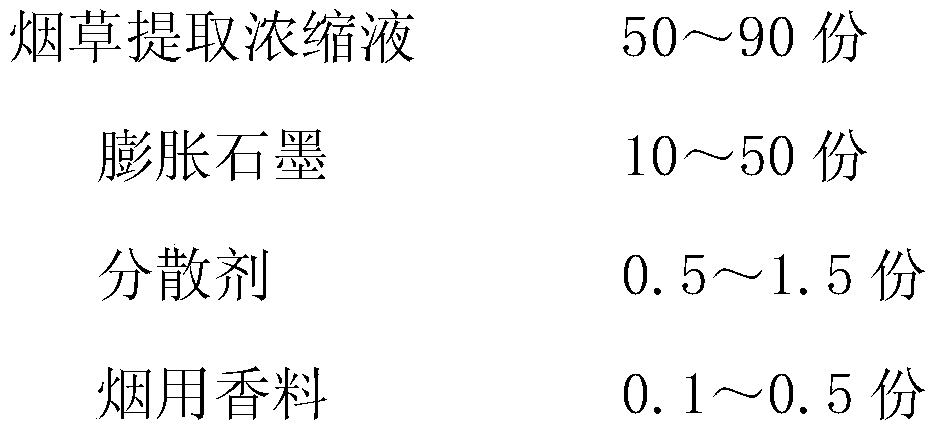

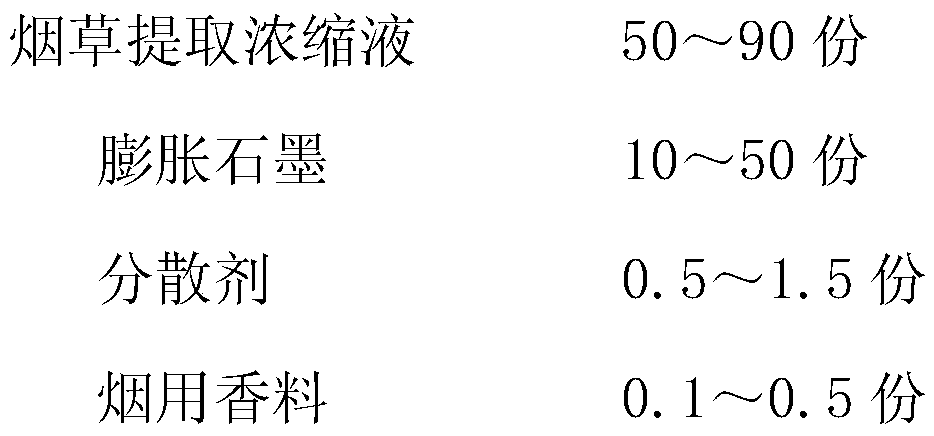

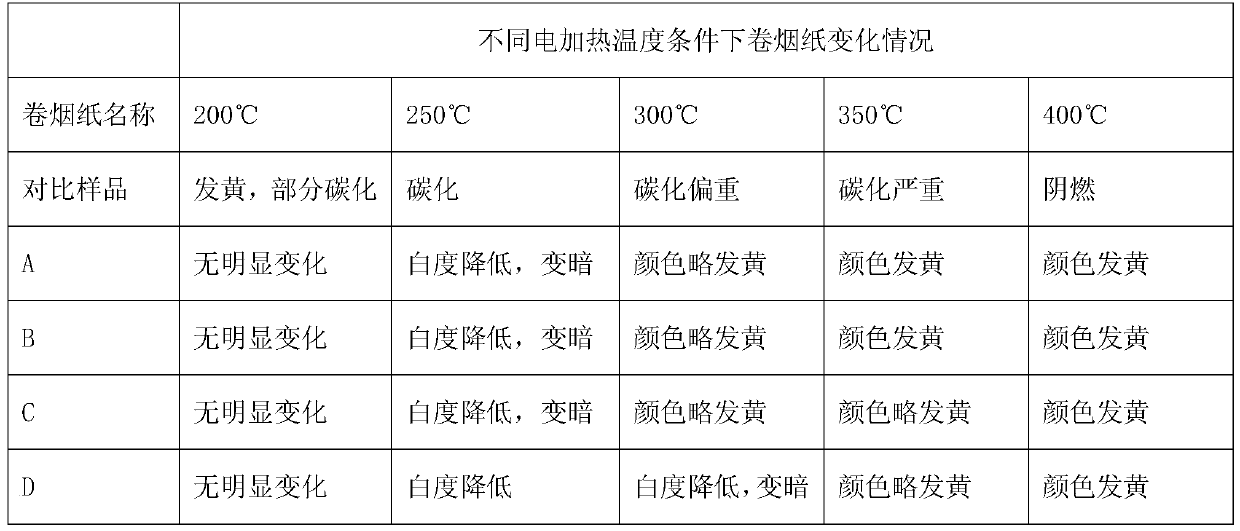

Coating liquid for heating incombustible tobacco product cigarette paper and preparation method and application of coating liquid

ActiveCN109763378APrevent high temperature heat deformationIncrease surface areaNon-fibrous pulp additionCoatings with pigmentsFlavorTobacco product

The invention provides coating liquid for heating incombustible tobacco product cigarette paper and a preparation method and application of the coating liquid. The coating liquid is prepared from thestep that tobacco extracting concentrated solution, expanded graphite particles, a dispersing agent and tobacco flavor are evenly mixed and subjected to ultrasonic dispersion for 7-15 minutes. The expanded graphite particles are prepared from the steps that expanded graphite particles with the particle diameters of 5-15[mu]m are placed in an atomizing agent solution, fully stirred under a negativepressure condition and absorb the atomizing agent solution, and drying at a low temperature of 70-100 DEG C is carried out. The tobacco extracting concentrated solution is prepared from the step thata tobacco extracting concentrated solution is subjected to vacuum concentration to the relative concentration of 1.21-1.28g / cm<3>. One surface of cigarette paper substrate paper is coated with the coating liquid evenly and subjected to drying slicing under the condition of 50-65 DEG C to obtain the cigarette paper, the cigarette paper can resist high temperature (about 300 DEG C), and the smoke releasing quantity during smoking can be improved.

Owner:HUBEI CHINA TOBACCO IND

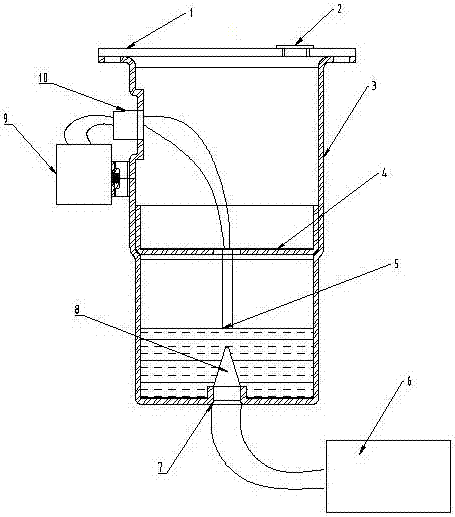

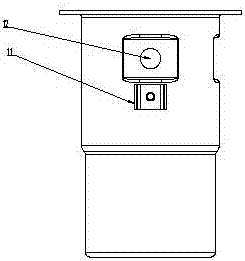

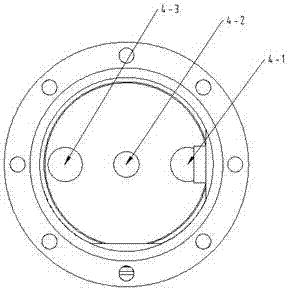

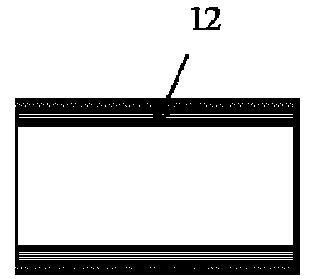

Automobile fuel oil steam emission system leakage detection device and manufacturing method thereof

ActiveCN107143439AIncrease the amount of smokeIncrease productivityNon-fuel substance addition to fuelMachines/enginesAir compressionSpray nozzle

The invention discloses an automobile fuel oil steam emission system leakage detection device and a manufacturing method thereof and belongs to the technical field of detection. The detection device comprises a barrel body, a barrel cover, an inner container, an air compression generation device, an air feeding pipe, a spray nozzle, a power source and a heating device. The barrel body is provided with an air outlet. Oil liquid in a heating barrel or liquid with fluorescent substances generates harmless smoke, the harmless smoke is led into an automobile fuel oil steam emission system through an exhaust hole, and leakage points of the automobile fuel oil steam emission system can be found out rapidly and accurately through the smoke or the fluorescent substances.

Owner:江苏创斯达科技有限公司

High-density hollow filter tip and composite filter tip thereof

PendingCN111134357AReduce suction resistanceLarge mixing cavityTobacco smoke filtersPolymer scienceCellulose diacetate

The invention discloses a high-density hollow filter tip which is of a hollow revolving body structure formed by rolling a high-density material; wherein the density range is 0.9 g / cm < 3 > to 1.6 g / cm < 3 >, the wall thickness is 0.05-0.7 mm, and the outer diameter is 5.0-8.0 mm. Materials for preparing the high-density hollow filter tip comprise cellulose acetate and derivatives thereof, polyhydroxyalkanoate and polyolefin organic high-molecular polymers; cellulose acetate and the derivatives thereof comprise cellulose diacetate, cellulose acetate propionate, cellulose acetate butyrate, methyl cellulose, ethyl cellulose and hydroxypropyl cellulose; the hydroxyl substitution degree of cellulose acetate and the derivative thereof is 1.5-2.8. The invention further discloses a composite filter tip comprising the high-density hollow filter tip and application of the composite filter tip in cigarette heating. When the composite filter tip is applied to heating cigarettes, the cigarette pressure drop can be reduced, a smoke mixing space can be increased, smoke adsorption can be reduced, the smoke temperature can be reduced, the smoke amount can be increased, and the cigarette smoking comfort can be kept.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

Electronic cigarette

The invention discloses an electronic cigarette. The electronic cigarette comprises an atomization module, wherein the atomization module comprises an atomization rod and tar storage cotton, suction nozzle, tar guide cotton, a suction tube, an atomization wire and an atomization seat arranged inside the atomization rod; the suction nozzle and the atomization seat are arranged at two axial ends of the atomization rod to be connected with the atomization rod in a sealing mode, the suction tube and the atomization rod form an inner cavity for storing the tar storage cotton, the tar guide cotton is transversely arranged inside the suction tube, the two ends of the tar guide cotton penetrate the suction tube to be in contact with the tar storage cotton, the atomization wire is in contact with the tar guide cotton and the atomization rod respectively, and the atomization wire comprises a winding end winding the tar guide cotton inside the suction tube. The electronic cigarette can generates large amount of smoke to meet needs of a user.

Owner:NINGBO JINGHUI OPTO ELECTRONICS CO LTD

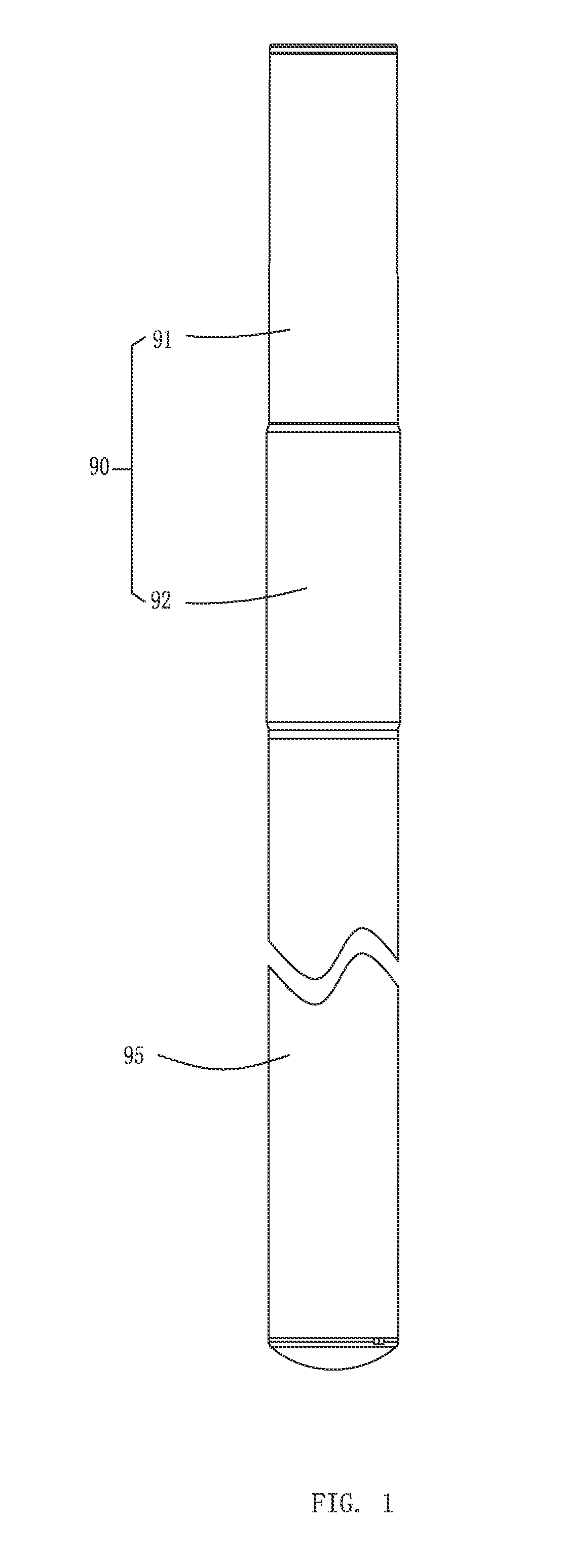

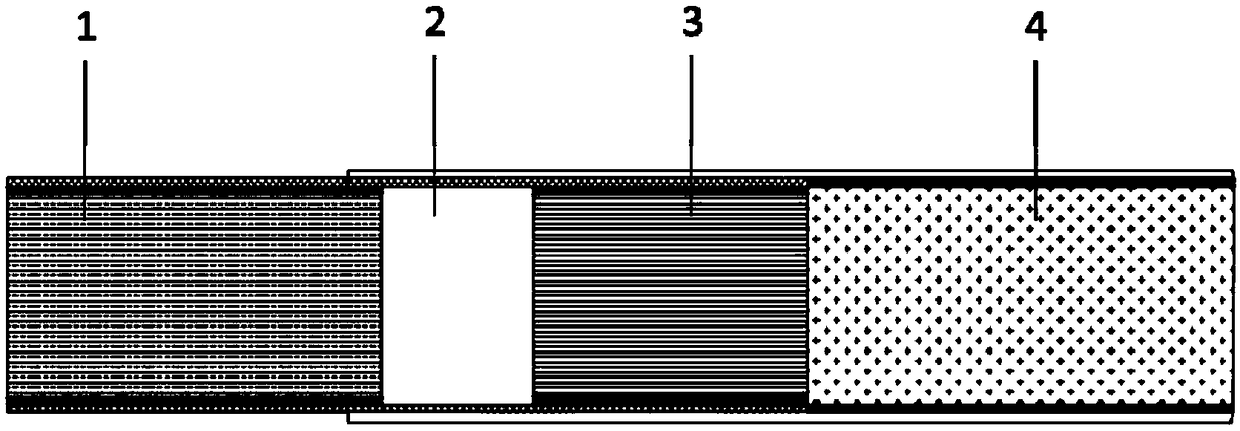

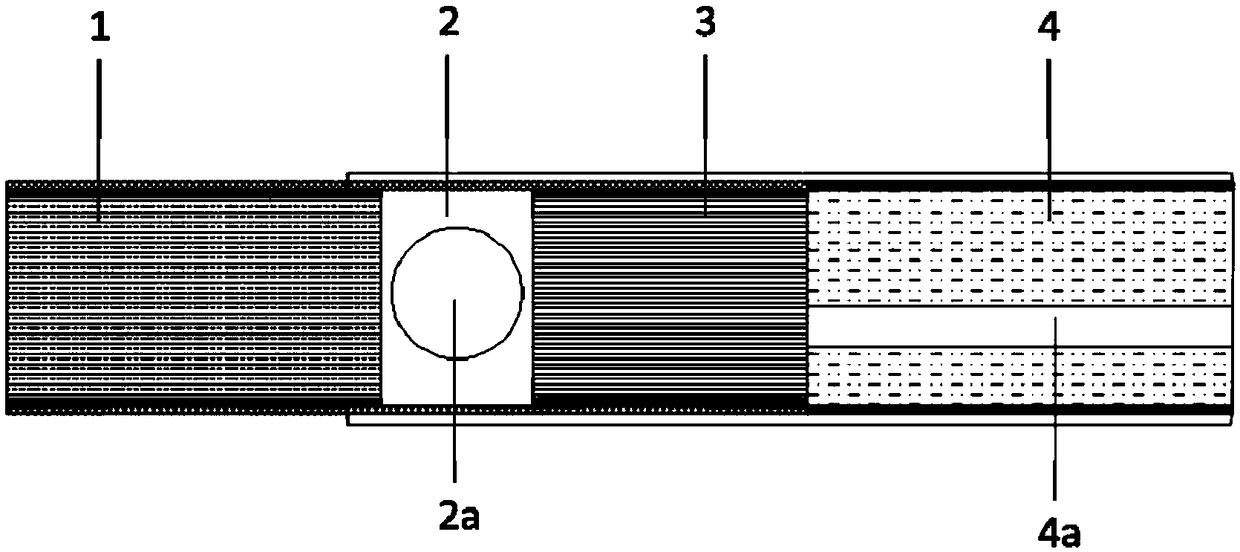

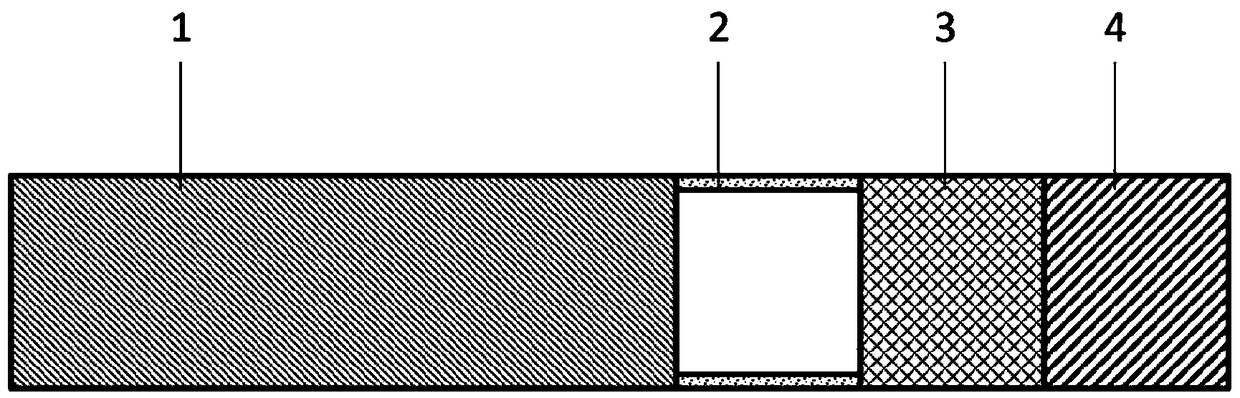

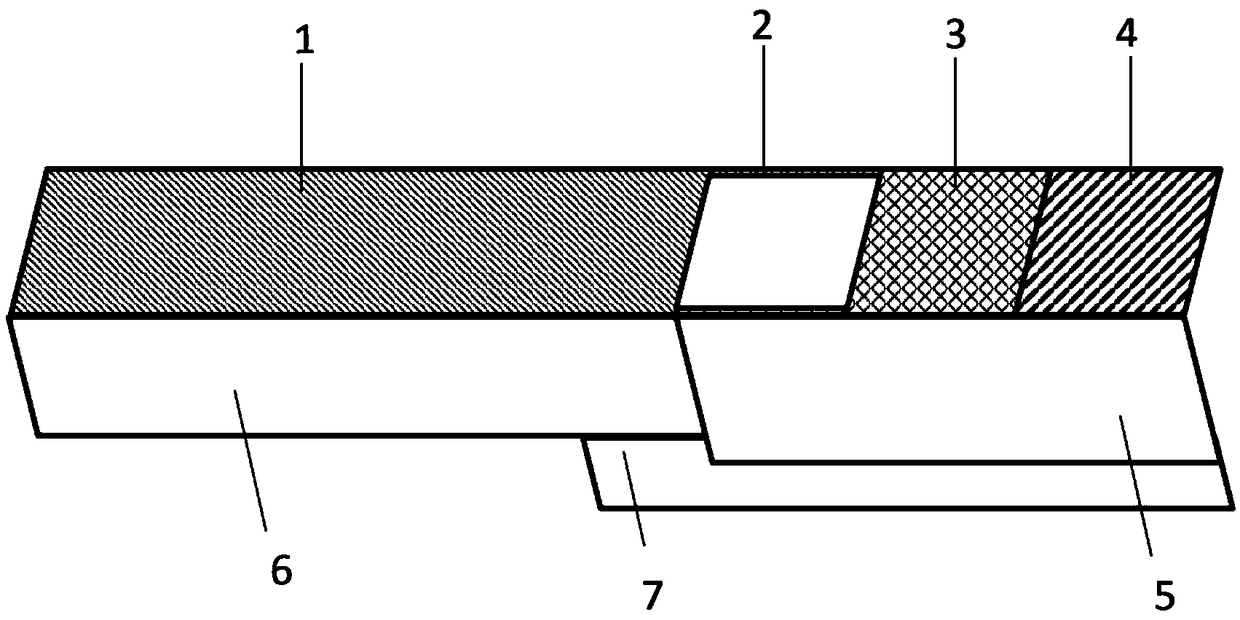

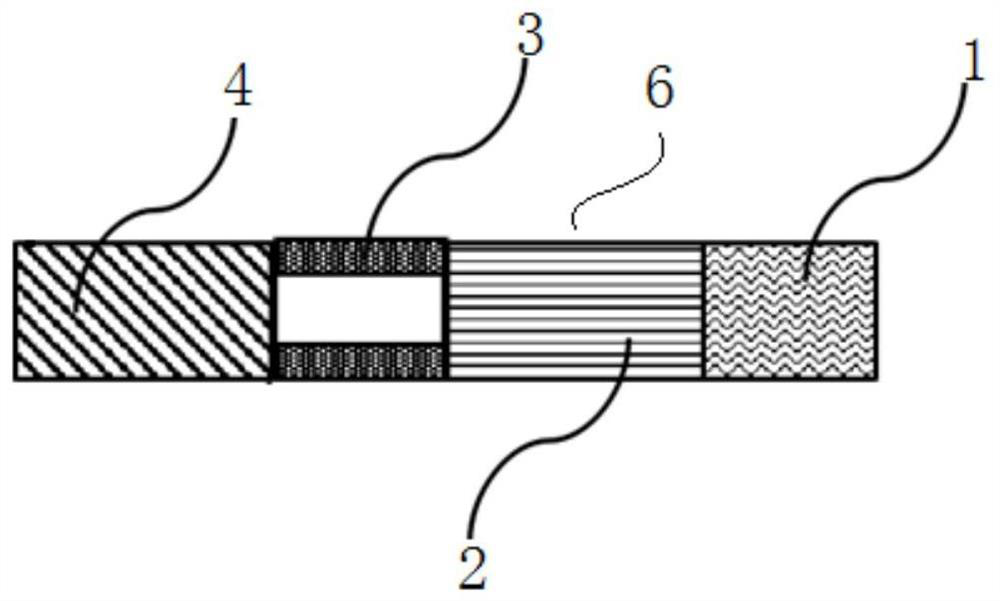

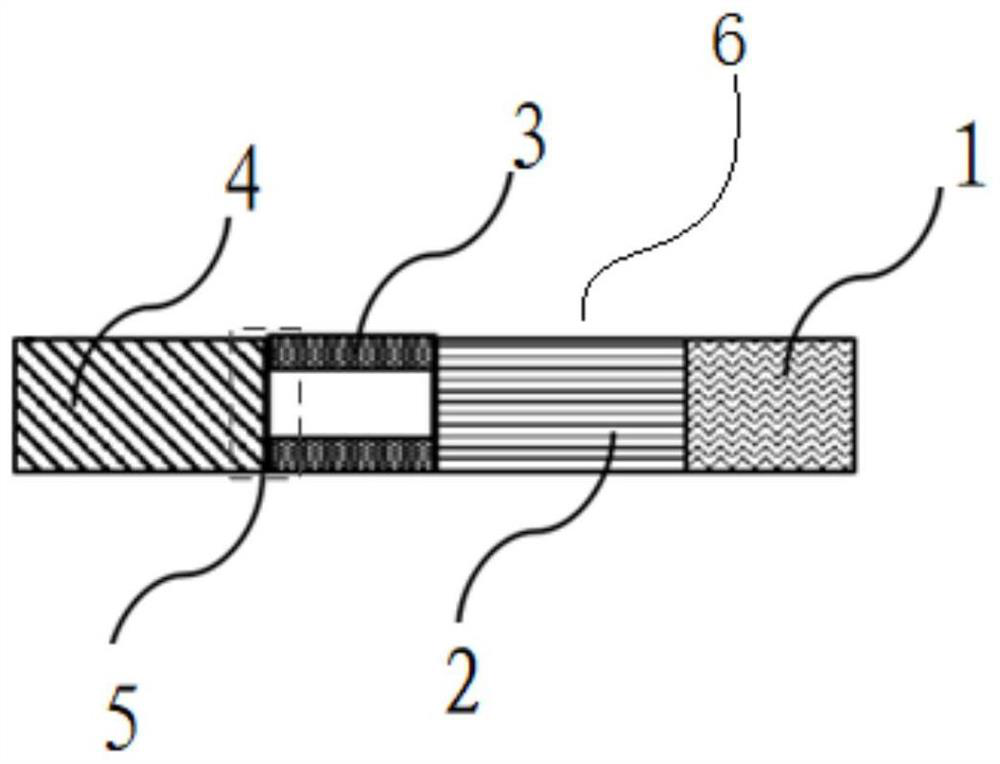

Cigarette body for circumferential heating non-burning cigarette

PendingCN109497618AAvoid problems that affect the tasteMeet design requirementsTobacco devicesFiberCooking & baking

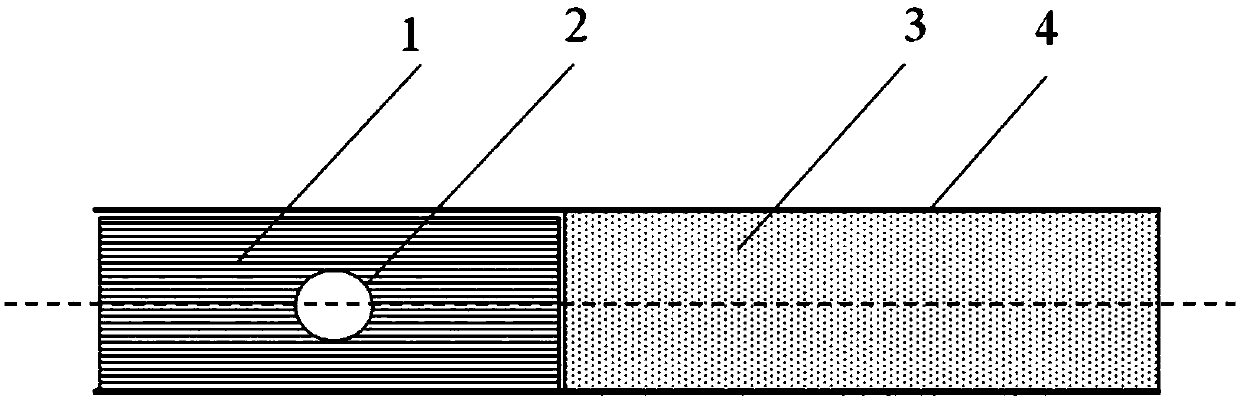

The invention discloses a cigarette body for a circumferential heating non-burning cigarette. The cigarette body is formed by successively connecting a cigarette core substrate (1), a paper tube unit(2), a filter rod unit (3) and a condensing unit (4). The paper tube unit (2), the filter rod unit (3) and the condensing unit (4) are wrapped by composite molding paper (5). The cigarette core substrate (1) is wrapped by cigarette paper (6). The composite molding paper (5) and the cigarette paper (6) are wrapped by tipping paper (7). The condensation unit (4) is processed by a high-molecular polymer material or a high-molecular polymer silk and diacetate fiber silk blend material. The paper tube unit is added between the cigarette core substrate and the filter rod unit to avoid the fact thata high-molecular polymer material of the filter rod unit collapses under direct or indirect baking of circumferential heating and generates plastic smell. The cigarette body structure is more in linewith the design requirements of the circumferential heating non-burning cigarette.

Owner:CHINA TOBACCO YUNNAN IND

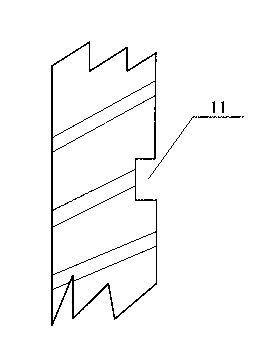

Aerosol generating product with multilayer groove corrugated structure

PendingCN114868960AIncrease the amount of smokeGuaranteed to blockTobacco treatmentCigar manufactureEngineeringMechanical engineering

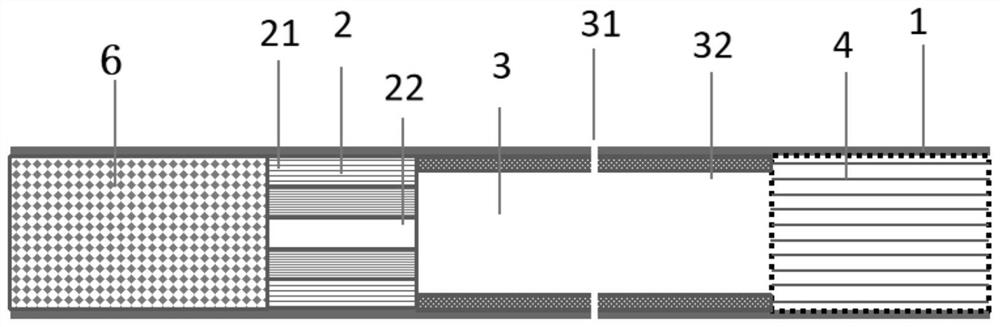

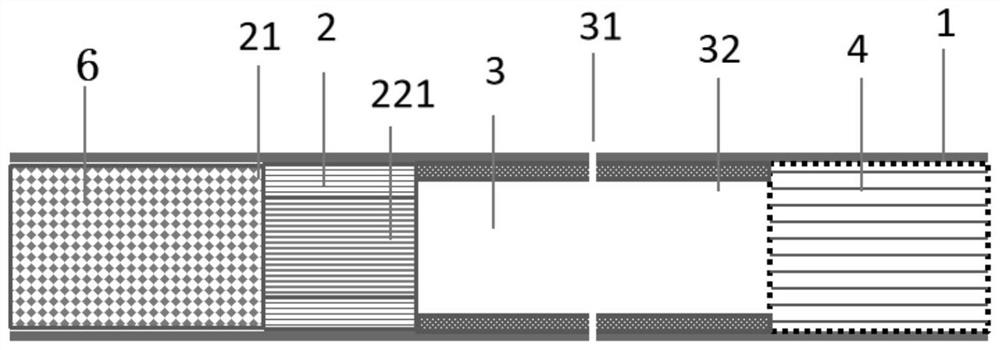

The invention discloses an aerosol generating product with a multilayer groove corrugated structure. The aerosol generating product comprises an integrated outer tube (1), and an aerosol generating substrate (6), a plugging piece (2), a cavity structure (3) and a filtering piece (4) which are positioned in the outer tube (1), the plugging piece (2) comprises a pipe wall (21) and a pipe cavity (22), the pipe wall (21) is of a groove corrugated structure and comprises an outer layer (211), an inner layer (212) and a groove corrugated layer (213) located between the outer layer (211) and the inner layer (212), the outer surface of the plugging piece (2) is limited by the outer layer (211), and the pipe cavity (22) is limited by the inner layer (212); a plurality of groove corrugated layers (213) are arranged in the pipe cavity (22), and a spacing layer (221) is arranged between every two adjacent groove corrugated layers (213). The plugging piece comprises the multiple groove corrugated layers, the multiple groove corrugated layers support one another, and more airflow channels can be reserved as much as possible on the premise that it is guaranteed that the aerosol generating material is plugged.

Owner:CHINA TOBACCO YUNNAN IND

Heat-not-burn aerosol generation product

PendingCN111053277AIncrease the content of atomizing agentIncrease the amount of smokeTobacco preparationTobacco treatmentChemistryAerosolize

The invention provides a heat-not-burn aerosol generation product, which comprises an aerosol forming matrix and a filter capsule. Specifically, the filter capsule contains an atomizing agent and is fixed in the aerosol forming matrix. According to the heat-not-burn aerosol generation product, the content of the atomizing agent in the aerosol generation product is effectively increased under the condition that the structure of the aerosol generation product is kept, so that the fuming amount of the aerosol generation product is obviously increased when the aerosol generation product is used, and the smoke effect is improved.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD +1

Heating incombustible solid cigarette core suction device

PendingCN108433195ASolve the condensation problemIncrease the amount of smokeTobacco devicesEngineeringInternal heating

The invention relates to a heating incombustible solid cigarette core suction device. The suction device comprises a shell body, wherein a power supply part, a heating cavity and a suction cavity aresequentially arranged in the shell body, the heating cavity and the suction cavity are separated by a partition plate, a plurality of venting holes are arranged on the partition plate, a plurality ofstopping plates are arranged in the suction cavity, and the stopping plates are arranged at intervals to form bent channels. The device disclosed by the invention has simpleness in use; by means of the movable ceramic heating cavity, the solid cigarette core can be taken and placed conveniently; internal heating and peripheral heating of the cigarette core are combined, so that the cigarette corecan be heated more completely, and a product utilization rate is improved; meanwhile, a gas-water separated type suction cigarette holder is utilized, so that the problem of condensate water at a smoke inlet is solved, and brand-new experience is brought to a customer; when the device is used to heat the solid cigarette core, released smoke is mellower and fuller, a smoke amount is high, harmony is better, and aftertaste and taste are both improved more greatly.

Owner:CHINA TOBACCO YUNAN NEW MATERIAL

Orchard frost-prevention smoke bomb and manufacture

The invention relates to an orchard frost-prevention smoke bomb and manufacture. The burning material filling layers of the orchard frost-prevention smoke bomb are designed in a multiple layered manner, each layer is sequentially composed of a mixture layer of saw dust and potassium nitrate and a coal powder layer, a layer of porous partition is covered on the top, and manufacturing procedures of the orchard frost-prevention smoke bomb are standardized. The orchard frost-prevention smoke bomb has the advantages of low cost as a traditional smoke method, environment-friendly materials are selected, smoke generating material ratio and smoke bomb processing and manufacturing are optimized, energy produced by burning is increased, released heat and smoke are increased, smoke is almost professional smoke agent, burning time is long, and toxic gas emission of sulfur dioxide and the like is reduced. By inventor implementing, operation is convenient and practical, the temperature of an orchard can be increased to 0.5 to 1.5 DEG C, and loss due to mild to moderate frost disasters of the orchard can be prevented and reduced effectively.

Owner:NINGXIA HUI AUTONOMOUS REGION METEOROLOGICAL SCI INST

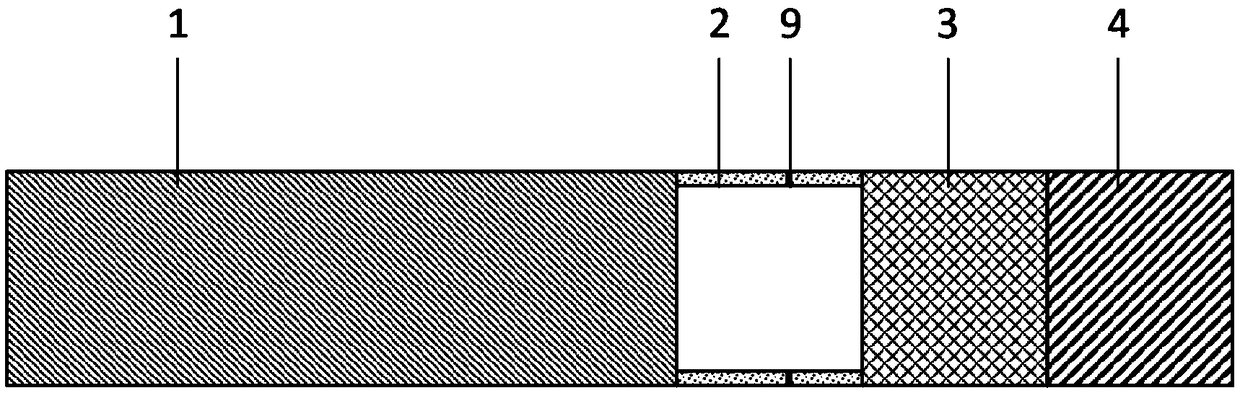

Aerosol generating product with composite form plugging piece

PendingCN114847543AImprove efficiencyIncrease the amount of smokeTobaccoCigar manufactureChemistryComposite material

The aerosol generating product comprises an integrated outer tube (1), and an aerosol generating substrate (6), a plugging piece (2), a cavity structure (3) and a filtering piece (4) which are positioned in the outer tube (1), the plugging piece (2) comprises a pipe wall (21) and a pipe cavity (22), the pipe wall (21) is of a groove corrugated structure and comprises an outer layer (211), an inner layer (212) and a groove corrugated layer (213) located between the outer layer (211) and the inner layer (212), the outer surface of the plugging piece (2) is limited by the outer layer (211), and the pipe cavity (22) is limited by the inner layer (212); a gathering sheet bar (221) is arranged in the pipe cavity (22). In the smoking process, the gathering sheet bar shrinks after being heated to block part of the middle airflow, so that more aerosol is in contact with aroma enhancing substances and / or fuming substances on the groove corrugated layer (213), and the effects of aerosol aroma supplementing and smoke amount increasing are further improved.

Owner:CHINA TOBACCO YUNNAN IND

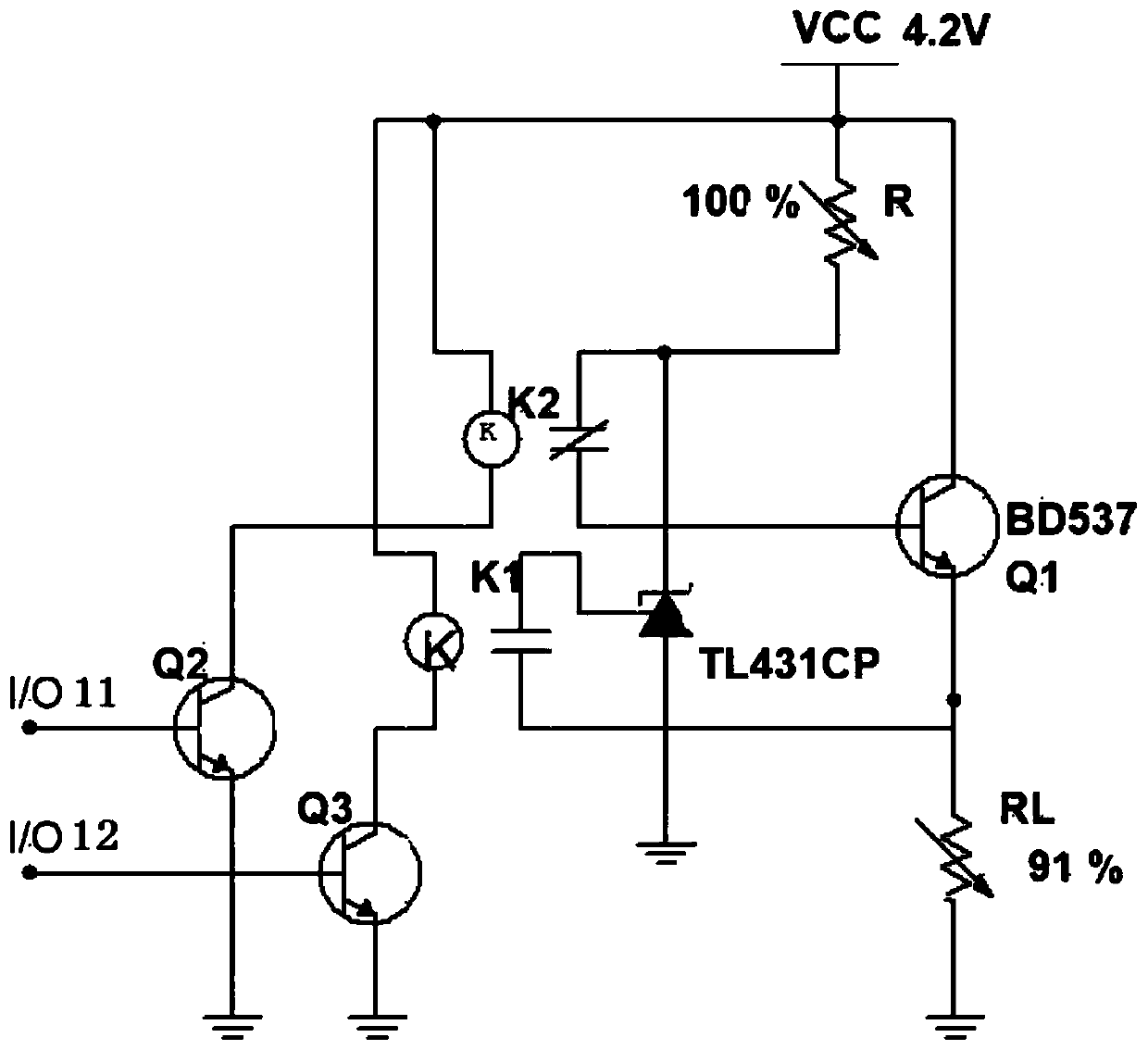

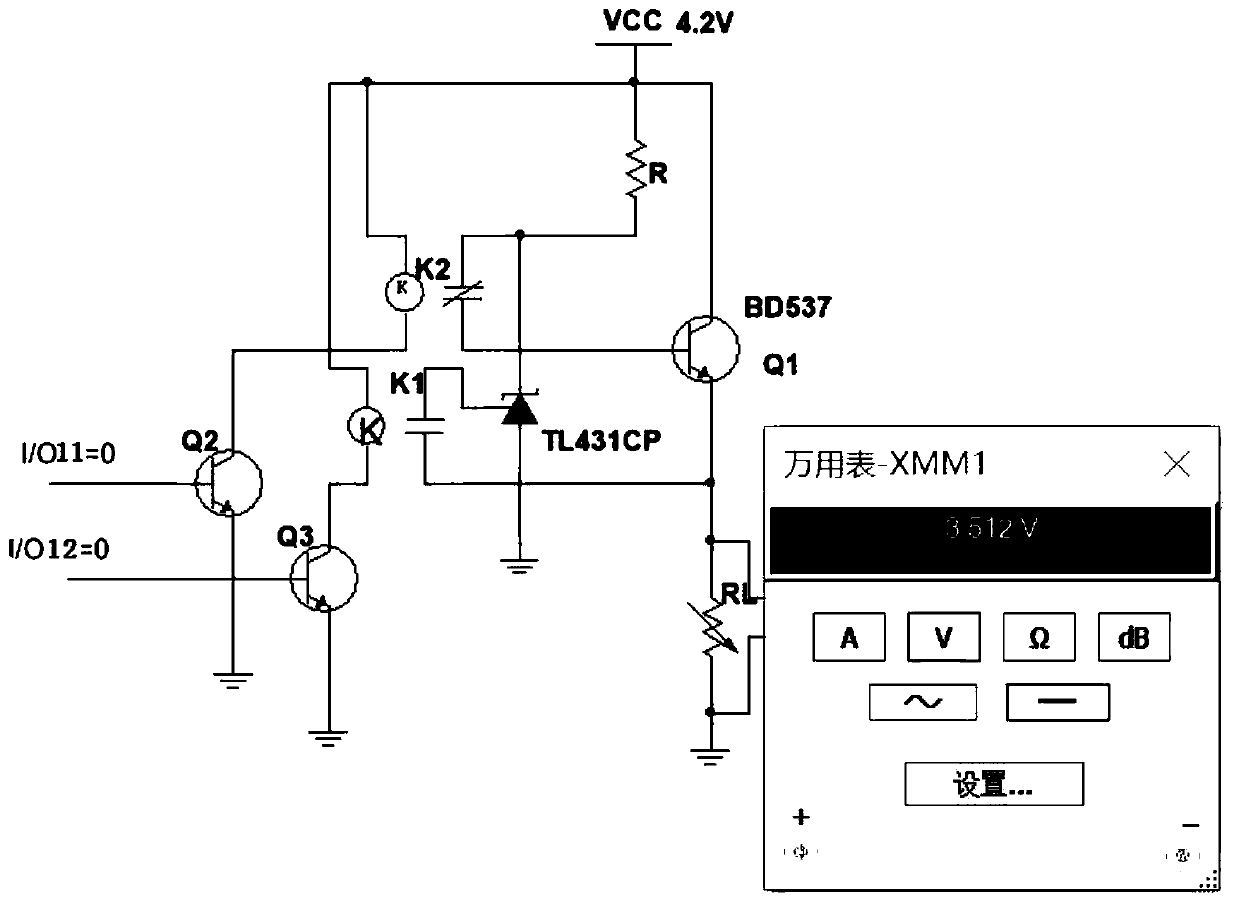

Constant temperature control circuit and method for heat-not-burn cigarettes

InactiveCN109793286AShorten warm-up timeEnsure consistencyAuxillary controllers with auxillary heating devicesTobacco devicesTemperature controlLow voltage

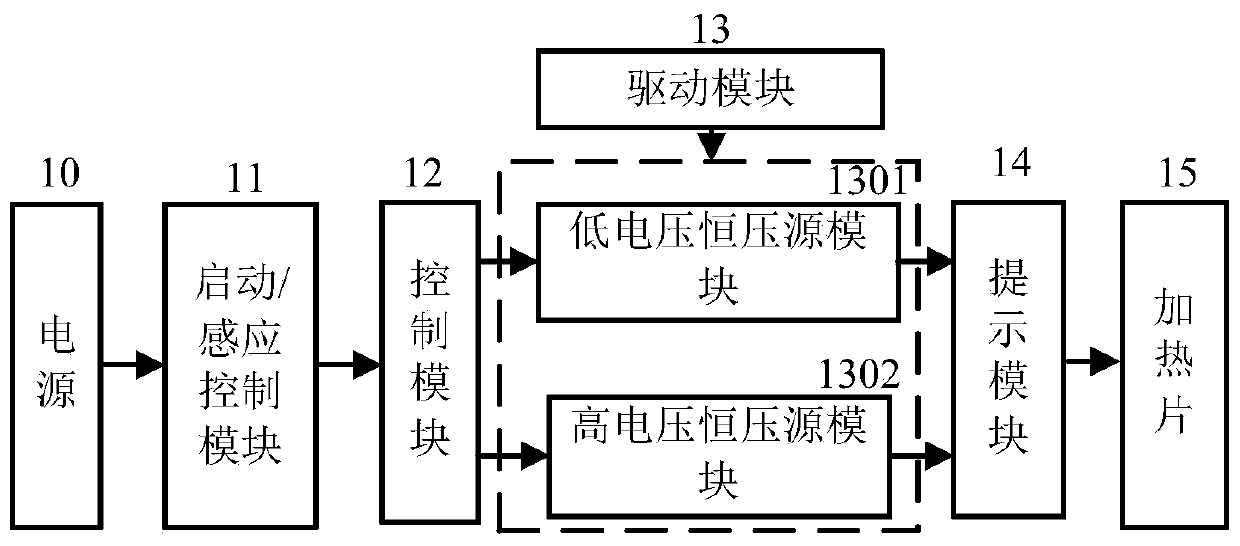

The invention relates to a constant temperature control circuit and method for heat-not-burn cigarettes and belongs to the technical field of e-cigarettes. The constant temperature control circuit comprises a power source, a startup / sensing control module, a control module, a driving module, a reminding module, and a heater. The startup / sensing control module is used for controlling the power source to power the whole control circuit or not; the control module is used for controlling the selection for a high-voltage constant voltage source module and a low-voltage constant voltage source module in the driving module, and reminding the selection for the modules above through the reminding module; the driving module is used for supplying constant high voltage or low voltage to the heater fordriving and heating the same so that the temperature of the heater rises; the reminding module is used for reminding of the control module's selection for the high-voltage constant voltage source module and the low-voltage constant voltage source module in the driving module. The constant temperature control circuit and method herein have the advantages that temperature control precision and accuracy are improved and temperature uniformity is ensured for smoking.

Owner:KUNMING UNIV OF SCI & TECH

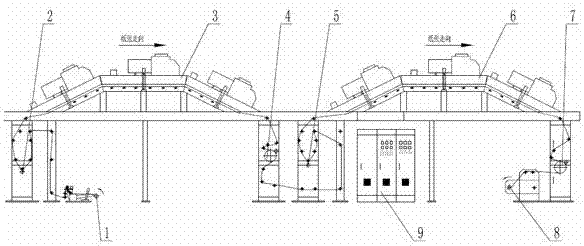

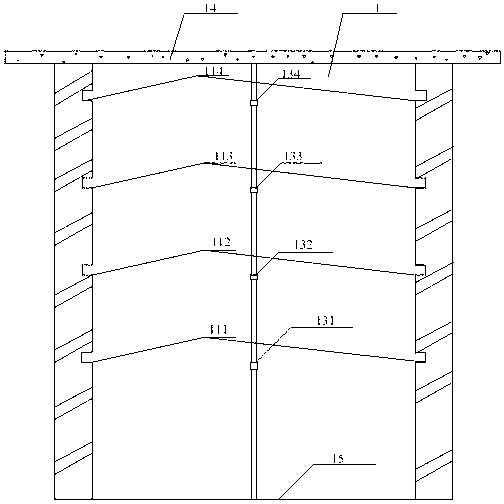

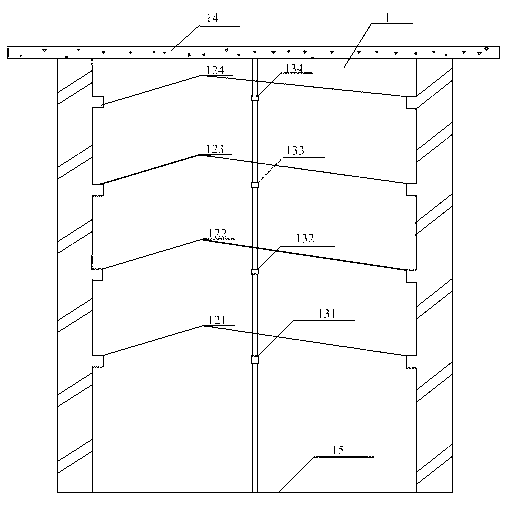

Four-layer tobacco loading bulk curing barn

InactiveCN103263070AIncreased baking capacityConducive to energy savingTobacco preparationMoistureSmoke

The invention discloses a four-layer tobacco loading bulk curing barn which comprises a hot air chamber and a tobacco loading chamber. Heat-partition walls are arranged between the hot air chamber and the tobacco loading chamber, the hot air chamber and the tobacco loading chamber are communicated with each other via hot air inlets and hot air return openings so that hot air flow circulation can be carried out, the four-layer tobacco loading bulk curing barn is provided with moisture removal openings connected with the external, a tobacco loading frame is arranged in the middle of the tobacco loading chamber and is provided with four layers of longitudinal beams and three upright columns, four grooves or bosses which are flush with the corresponding longitudinal beams of the tobacco loading frame are arranged on two opposite side walls of the tobacco loading chamber, one of the three upright columns is positioned at an end of one side of a curing barn door, the other two upright columns are positioned at trisection positions of the middle of the curing barn, and the other ends of the longitudinal beams are inserted into the heat-insulation walls. The four-layer tobacco loading bulk curing barn has the advantages that the tobacco loading frame is arranged by the aid of the grooves on the walls instead of being arranged on side walls of the tobacco loading chamber, the construction cost of the curing barn is greatly reduced, space occupied by existing wall leaning tobacco loading frames is vacated, tobacco hanging quantities of tobacco rods of various layers are increased, the quantity of tobacco which is loaded and cured at one step is increased by 30% at least, and the construction occupied area of the curing barn is reduced under the condition of identical tobacco loading capacity.

Owner:HONGHEZHOU BRANCH OF YUNNAN TOBACCO

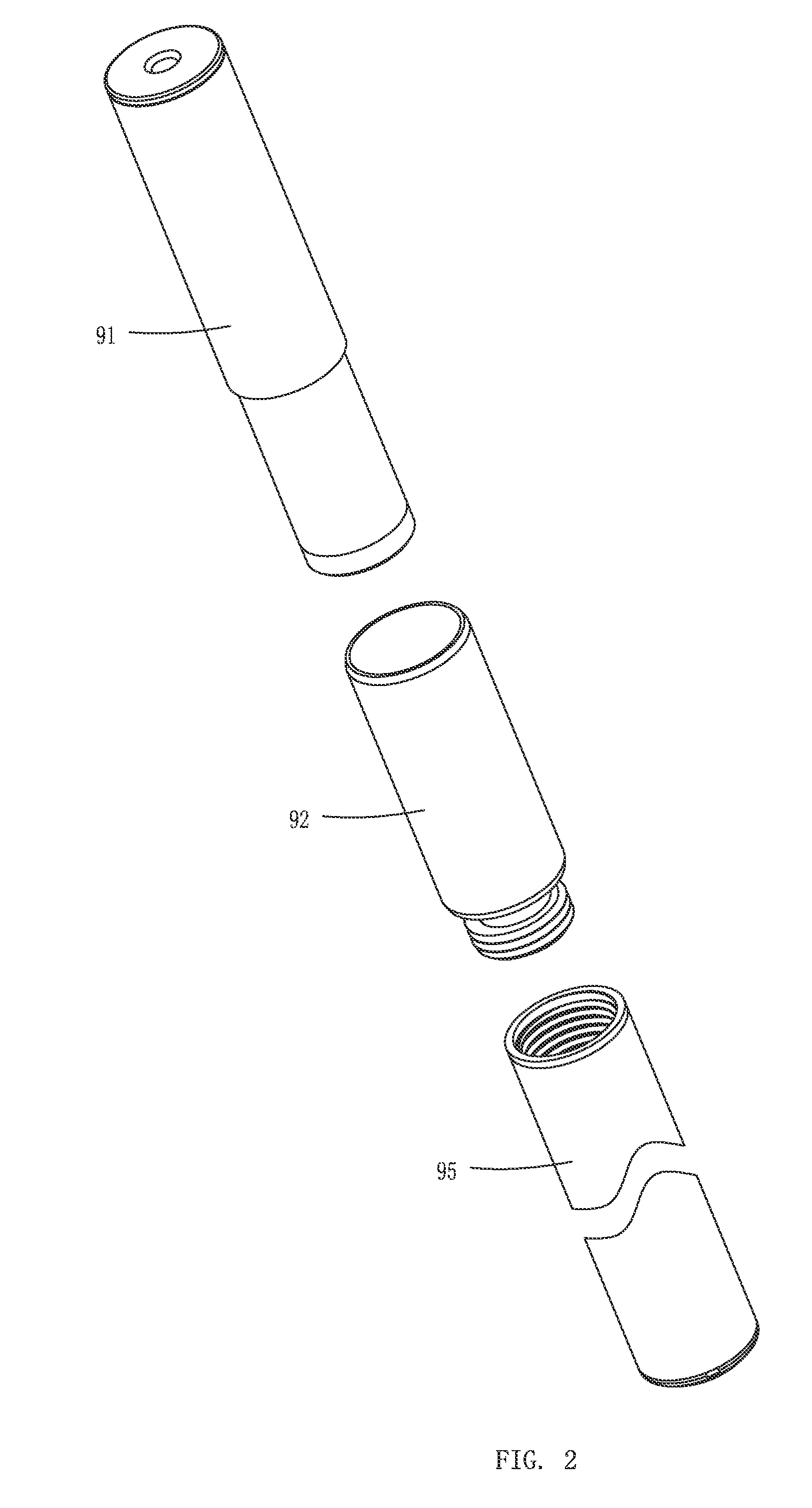

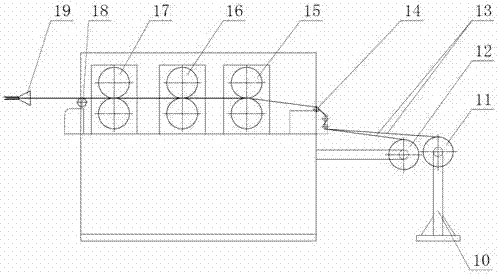

Novel electric cigarette atomizer and tobacco tar atomizing method thereof

PendingCN107960682AIncrease the heating surface areaIncrease the amount of smokeTobacco devicesPhysicsEngineering

Disclosed are a novel electric cigarette atomizer and a tobacco tar atomizing method thereof. The novel electric cigarette atomizer comprises a stick-like main body, a nozzle and a power connecting base, wherein the stick-like main body is composed of a first pipe, a tar storage device and an atomizing element module, the tar storage device and the atomizing element module are arranged inside thefirst pipe, the atomizing element module is composed of an external heating type atomizing element and a second pipe, the external heating type atomizing element is composed of a capillary tar guide unit and a heater wrapping the outer surface of the capillary tar guide unit and is arranged inside the second pipe, the wall of the second pipe is provided with an air hole, one end of the second pipeis communicated with the tar storage device, and a smoke channel is formed between the tar storage device and the first pipe. The tobacco tar atomizing method of the novel electric cigarette atomizercomprises inputting tobacco tar into the atomizing element from one end of the atomizing element; heating the atomizing element through an external wall heating manner to enable the tobacco tar to penetrate through and diffuse from inside to outside of the atomizing element in a capillary mode and then to be atomized into smoke on the outer surface of the atomizing element. The novel electric cigarette atomizer is large in amount of produced smoke and capable of avoiding tar leakage and tar bursting in an air channel.

Owner:MAINSTAY (GUANG DONG) BIOTECHNOLOGY CO LTD

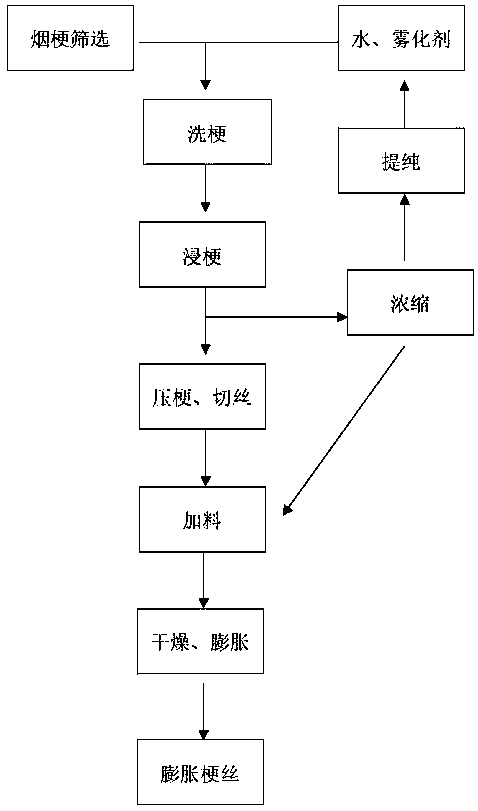

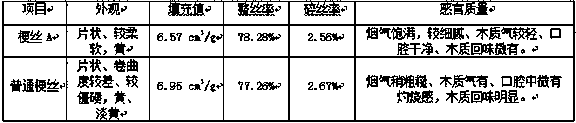

Preparation method and application of cut stems with relatively high concentration

InactiveCN110720652AIncrease concentrationEnhanced interactionTobacco treatmentBiotechnologyHorticulture

The invention provides a preparation method of cut stems with relatively high concentration. The preparation method comprises the following steps of: feeding and screening raw material tobacco stems;carrying out stem cleaning and stem dipping processing with mixed aqueous solution containing a nebulizer, and carrying out concentration processing on the mixed aqueous solution subjected to stem cleaning and stem dipping processing; carrying out stem pressing and shredding processing; carrying out charging processing; and carrying out drying expansion processing. The invention further provides application of the cut stems with the relatively high concentration. The prepared cut stems are used for conventional cigarettes; or the prepared cut stems and common tobacco shreds or a tobacco raw material added with the nebulizer are prepared into formula tobacco shreds which are used in heating noncombustible cigarettes. The preparation method is depended on conventional cigarette cut stem process equipment and utilizes an immersion wetting effect of the tobacco stems and water to promote interaction of the tobacco stems and the nebulizer so as to obtain the cut stems with 5 to 10% of nebulizer content; and the cut stems have the characteristic of relatively high smoke concentration, and not only can be used for the conventional cigarettes, but also can be used for the tobacco shreds ofthe heating noncombustible cigarettes.

Owner:HUBEI CHINA TOBACCO IND

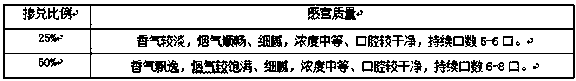

Tobacco particles, low-temperature smoke generating body, preparation method and heat-not-burn appliance

The invention relates to tobacco particles, a low-temperature smoke generating body, a preparation method and a heat-not-burn appliance. The tobacco particles comprise an inner core, a first coating layer wrapping the inner core and a second coating layer wrapping the first coating layer, the inner core comprises a fuming material, the first coating layer is mainly made of a waterproof material, and the second coating layer is mainly made of a viscous material. The atomizing agent and the tobacco extract in the tobacco particles are uniformly distributed, and the smoking stability and uniformity are better; on one hand, the first coating layer can prevent volatile components in the inner core from being lost, on the other hand, external moisture can be prevented from entering the inner core, it is guaranteed that the moisture content is stable, the storage period is prolonged, and the smoking taste consistency is guaranteed, the second coating layer made of a material with the bondingcapacity is used for treatment, and the bonding capacity and partial isolation capacity of the second coating layer are ingeniously utilized; glue is not required to be applied again in subsequent treatment, and industrial batch production is facilitated.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Heating cigarette with lateral air inlet function

PendingCN112754067AStable mass and heat transferReduce oxidation reactionCigar manufactureThermodynamicsEngineering

The invention discloses a heating cigarette with a lateral air inlet function. The heating cigarette is composed of a tobacco material section and a filter stick functional section, wherein tobacco shreds or sheets made of tobacco or containing tobacco materials are arranged in the tobacco material section, and the filter stick function section has the functions of smoke confluence, cooling, filtering and the like. A vent hole is formed in the connecting position of the tobacco material section and the filter stick functional section, and most air enters from the vent hole in the heating cigarette smoking process. The heating cigarette is advantaged in that the heating process of tobacco substances can be more stable, loss of flavor components is reduced, and the amount of smoke is increased.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com