Heat-not-burn aerosol generation product

An aerosol generation, heat-not-burn technology, applied in the field of tobacco, can solve problems such as the difference in the amount of smoke and affect the suction effect, and achieve the effects of increasing the amount of smoke, increasing the content of atomizers, and improving the visual and taste effects of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

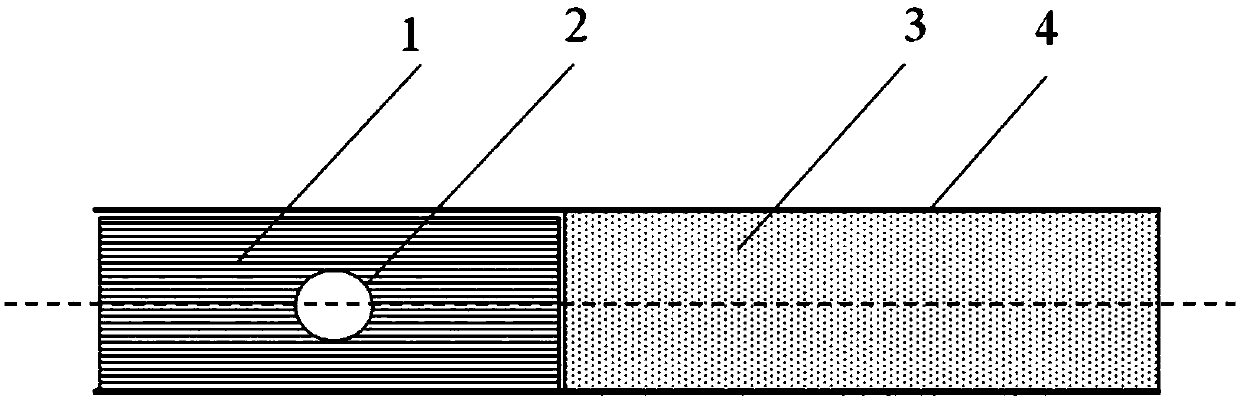

[0034] The heat-not-burn aerosol-generating product consists of an aerosol-forming substrate, a pop-up bead, a mouthpiece end, and cigarette paper;

[0035] Wherein, the aerosol-forming substrate is a strip-shaped tobacco sheet containing 18% (mass ratio) glycerol, and the aerosol-forming substrate weighs 0.3g;

[0036] The nozzle end consists of a solid filter rod and a cavity;

[0037] The atomizer blasting beads are wrapped by wall materials, which are made of sodium alginate and gelatin materials, and have certain rigidity;

[0038] The blasting beads of the atomizer are spherical, and the volume of the blasting beads is 0.01cm 3 ;

[0039] The atomizer in the pop-up beads is glycerin, and the weight of glycerin is 0.009g;

[0040] In the process of producing heat-not-burn aerosol-forming products, when the aerosol-forming matrix is formed, the cigarette machine belt, cigarette paper, suction ribbon, and tobacco strips move synchronously, before the cigarette paper se...

Embodiment 2

[0043] The heat-not-burn aerosol-generating product consists of an aerosol-forming substrate, two pop-up beads, a nozzle end, and cigarette paper;

[0044] Wherein, the aerosol-forming substrate is shredded tobacco containing 12% (mass ratio) of an atomizing agent, the atomizing agent is a mixture of glycerin and propylene glycol in a ratio of 1:1 (mass ratio), and the weight of the aerosol-forming substrate is 0.24 g;

[0045] The suction nozzle end is composed of a solid filter rod, a cavity and a hollow filter rod;

[0046] The popping beads are wrapped by wall materials, which are made of agar and polylactic acid materials, which have certain rigidity;

[0047] One of the two popping beads is an ellipsoid and the other is a sphere, and the internal volume is 0.02cm respectively 3 ;

[0048] The ellipsoid popping beads contain atomizing agent and tobacco flavor, the spherical popping beads contain atomizing agent and nicotine, the atomizing agent is composed of glycerin a...

Embodiment 3

[0053] The heat-not-burn aerosol-generating product is composed of an aerosol-forming substrate, three pop-up beads, a nozzle end, and paper-aluminum composite paper;

[0054] Wherein, the aerosol-forming substrate is a strip-shaped tobacco sheet containing 15% (mass ratio) glycerol, and the aerosol-forming substrate weighs 0.3g;

[0055] The nozzle end is composed of solid filter rod and cooling material;

[0056] The three popping beads are spindle, ellipsoid and sphere respectively;

[0057] Spindle blasting beads without wall material package, the volume is 0.01cm 3 , the inside of which is an atomizing agent, the atomizing agent is composed of butanediol and butanetriol, agar is added to the atomizing agent in the spindle body as a coagulant to solidify the atomizing agent, this curing effect is at 95 ℃ Ineffective, the aerosol becomes liquid and disperses into the aerosol-forming matrix;

[0058] Ellipsoid popping beads are composed of atomizer and tobacco flavor, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com