Four-layer tobacco loading bulk curing barn

A technology of intensive curing and cigarette loading, which is applied in the directions of tobacco, tobacco preparation, and application to achieve the effects of avoiding excessive wind speed, increasing the curing capacity, and increasing the curing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

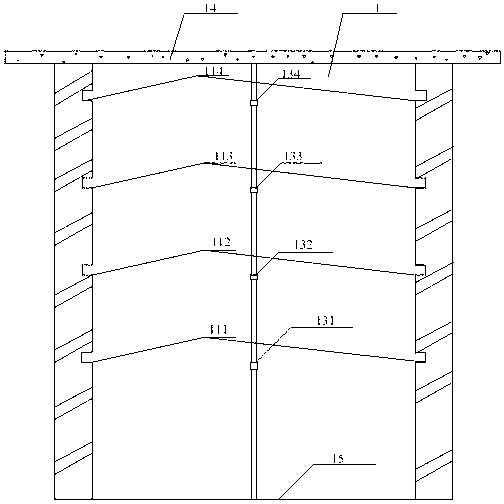

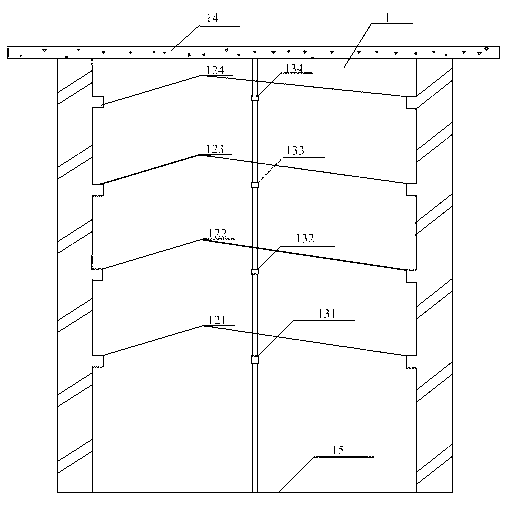

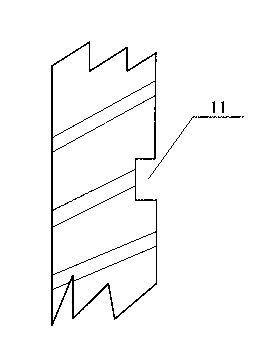

[0028] As shown in Figure 1-5. The four-layer smoke-packed intensive curing room of the present invention includes a tobacco-loading room 1, a hot air room 2, etc., wherein the hot air room 2, the air duct 21, the circulating fan 22, and the heating equipment 23 implement the current tobacco industry "Technical Specifications for Intensive Barns (Trial Implementation") ) Revised Edition" (National Tobacco Ban Zong [2009] No. 418) technical standards. The size of the smoke chamber 1 is the same as the current one, except that four grooves 11 are built on the walls on both sides, including the bottom groove 111, the second groove 112, the third groove 113 and the top groove 114. The openings of the grooves on the two walls are opposite and flush. The smoke rack 13 in the middle is consistent with the above-mentioned standards. It is connected by straight wood, or welded with angle iron or rectangular pipe. It is a single-sided frame structure. Four layers of longitudinal beams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com