Patents

Literature

180results about How to "Reduce construction area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

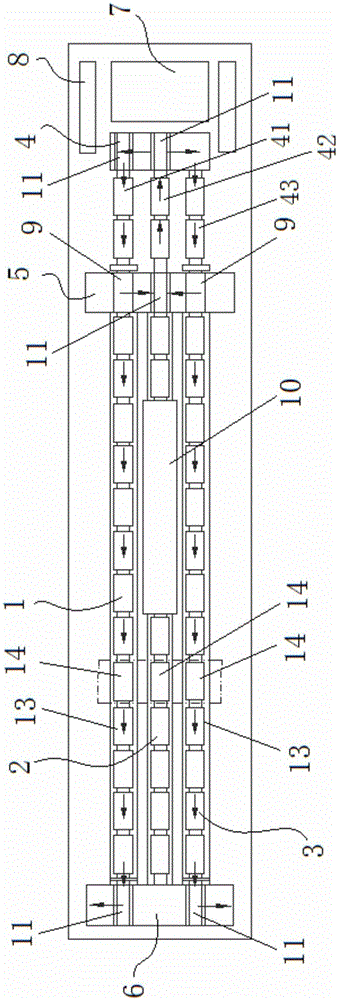

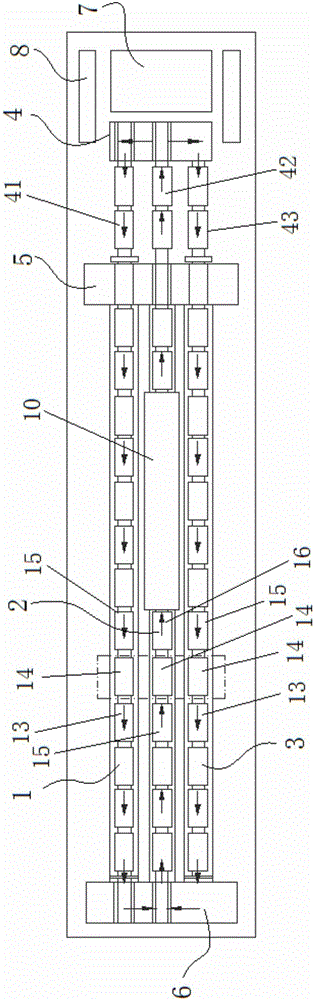

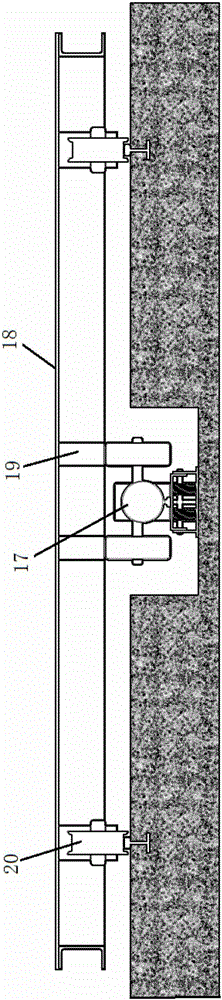

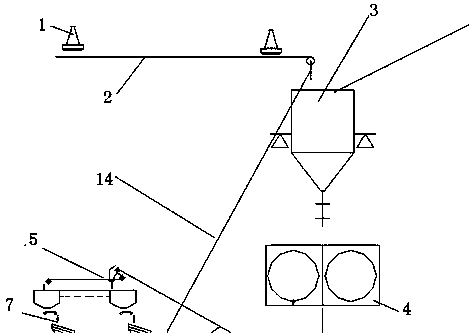

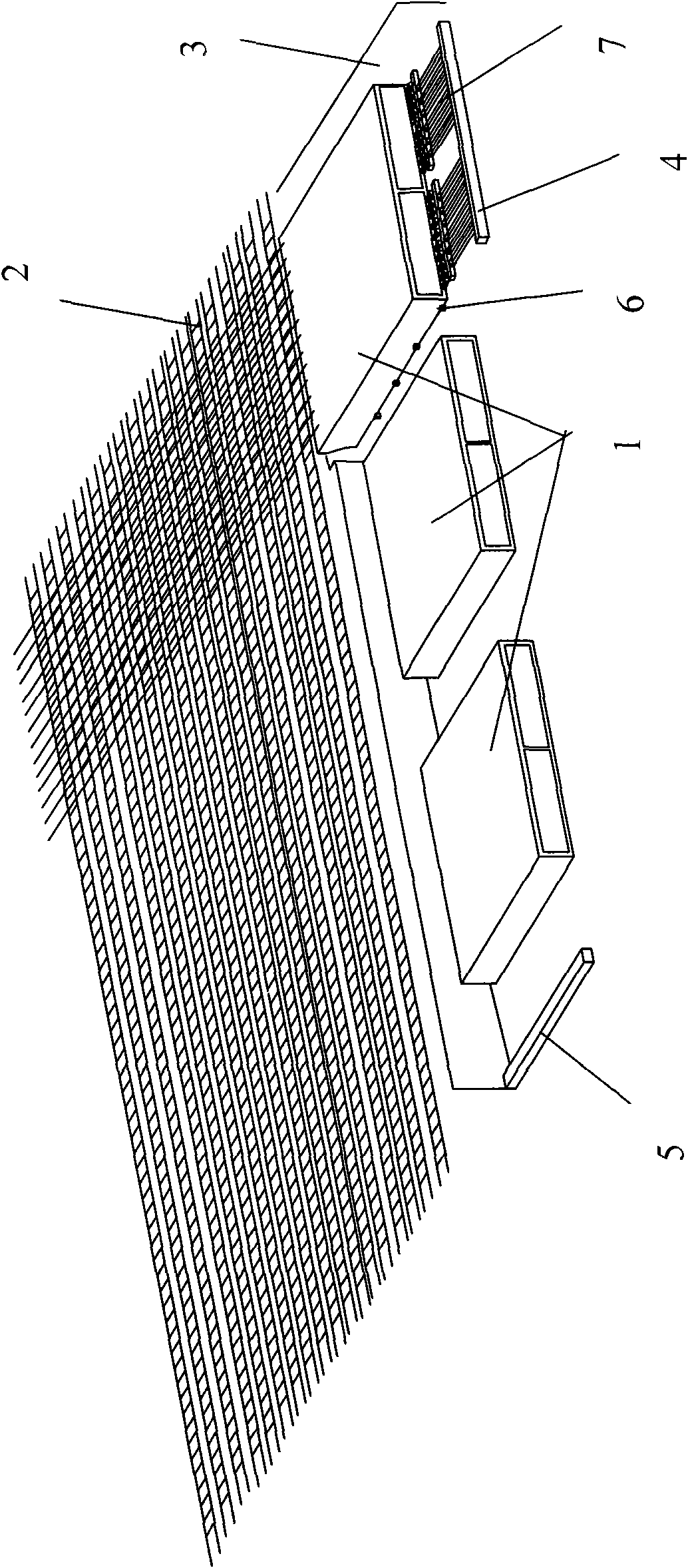

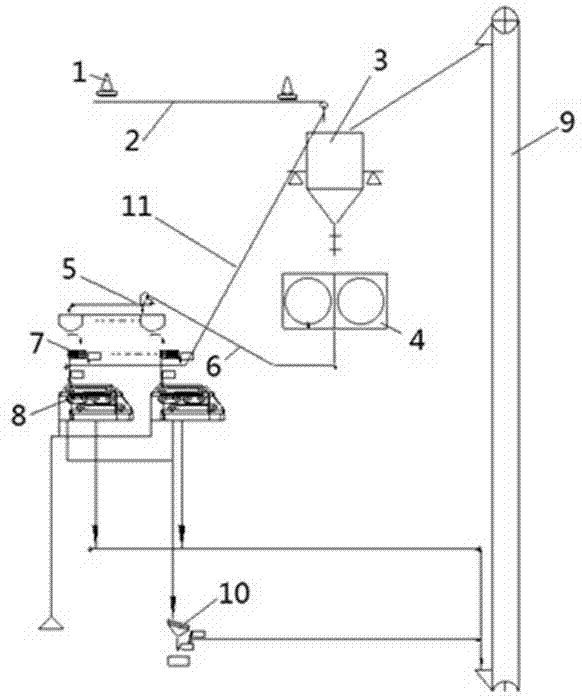

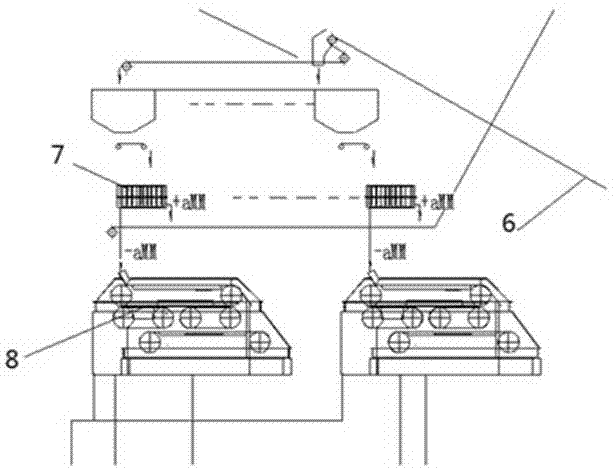

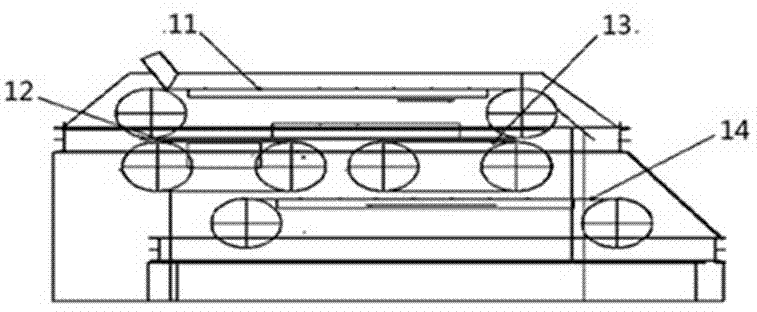

Three-dimensional production system of prefabricated components

ActiveCN105773827AIncreased production flexibilityIncrease productivityCeramic shaping plantsManufacturing engineeringKiln

The invention relates to the field of production of prefabricated components, in particular to a three-dimensional production system of the prefabricated components. The system comprises a prefabricated component production area on the upper layer, a maintenance area on the lower layer and a wheel type mold table; the prefabricated component production area includes a component prefabrication operation area, a component demolding operation area and an edge mold cleaning operation area; the maintenance area is provided with a linear maintenance kiln; the components are borne on a production line in the prefabricated component production area through the wheel type mold table, and move in the linear maintenance kiln in the maintenance area; a mold table ferry transverse moving station is arranged in the prefabricated component production area; a mold table lifting transverse moving device is arranged on the mold table ferry transverse moving station; a special production line and a production secondary line are arranged in the component prefabrication operation area; and the special production line drives the wheel type mold table to transversely move through the mold table lifting transverse moving device so as to connect with the production secondary line in parallel. The system comprehensively improves a prefabricated component production system, can realize multiple production modes, is more flexible in production, and greatly improves the production efficiency.

Owner:国新德

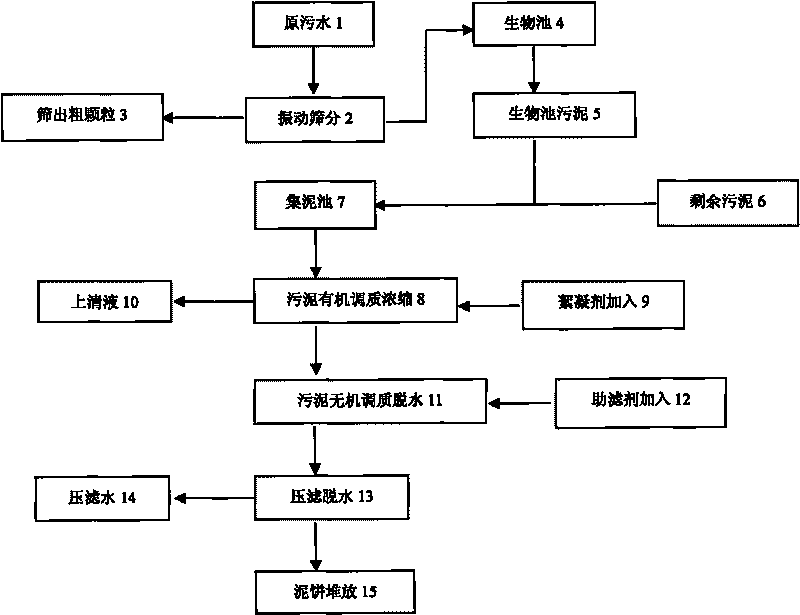

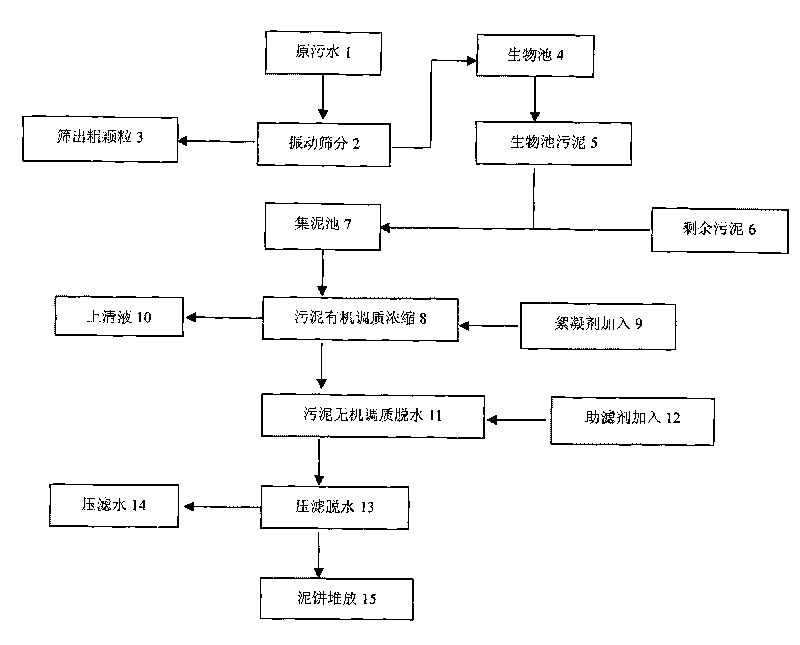

Method for screening and dewatering urban sludge efficiently

ActiveCN101696077ARealize automatic controlRealize managementSludge treatment by de-watering/drying/thickeningRemote controlWastewater

Owner:SAFECLEEN TECH

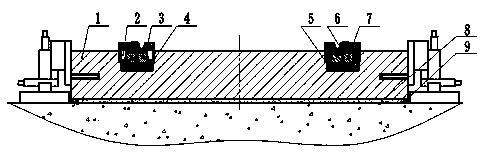

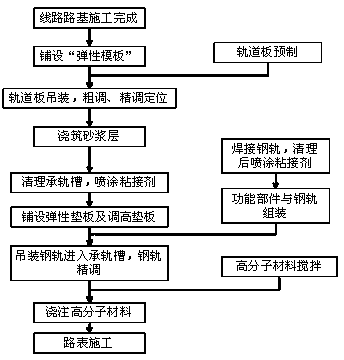

Quick construction method of embedded rail system

ActiveCN103362036ANovel construction methodReasonable construction methodRailway tracksHardnessPlastic film

The invention discloses a quick construction method of an embedded rail system. The quick construction method comprises the following construction steps: performing construction preparation; paving a template; paving rail plates; casting a mortar layer; performing rail bearing groove pretreatment; welding a steel rail; adjusting the steel rail finely; performing antipollution protection and partitioning the rail bearing groove; casting the rail bearing groove; uniformly stirring high polymer material; casting material to the partitioned rail bearing groove with special equipment; clearing plastic films or adhesive tapes after the high polymer material achieves required hardness; and paving on the surfaces of the top surfaces of the rail plates according to construction requirements. Through being combined with prefabricated rail plates, the quick construction method has the characteristics of being quick in construction, high in efficiency and little in influence on surrounding environment, and is a green and environment-friendly construction method.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

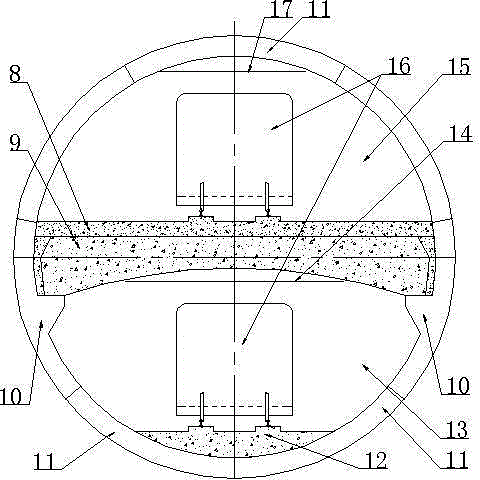

Rapid shuttle single-tunnel double-decker track subway

ActiveCN104816732AImprove effective time utilizationAvoid the restriction of short station distanceRailway tunnelsDouble deckerVehicle frame

The invention discloses a rapid shuttle single-tunnel double-decker subway, a train running space configured by shuttle tunnels with a upper and a lower track and double stereo train stations, the subway herein requiring less land occupation and digging work load. According to the subway herein, lines are composed of express lines, train stations, and launching lines, allowing separation of trains which are running from trains which stop for allowing passengers to get on and get off. The subway herein allows changes to train tracking operation, launches of express shuttles as needed, reduction of stops, and increasing of train operating density and running velocity. The subway herein also allows using train hooks to conduct rapid train re-arrangements, increasing train re-arrangements in peak time, operating non-stop trains or limited-stops trains so as to increase passenger capacity. The subway herein further allows decreasing of train re-arrangements in normal time or low peak time in a manner whereby trains stop at each and every train station so as to reduce operation cost. According to the subway herein, a recessed bottom train frame structure is adopted in the train for reducing train height and center of gravity, and tunnel diameter is decreased. By planning of different passenger capacities, selecting different train re-arrangements, and adopting various running patterns based on passenger flow time frames, the subway herein obtains an improved cascade-type passenger capacity ranging from 10,000 to more than 90,000 per hour for a single direction. The rapid shuttle single-tunnel double-decker subway of the invention adjusts to capacity demands in megacities, and can reduce starting-point requirements for building subways, like size of city passenger flow and population.

Owner:谭培炎

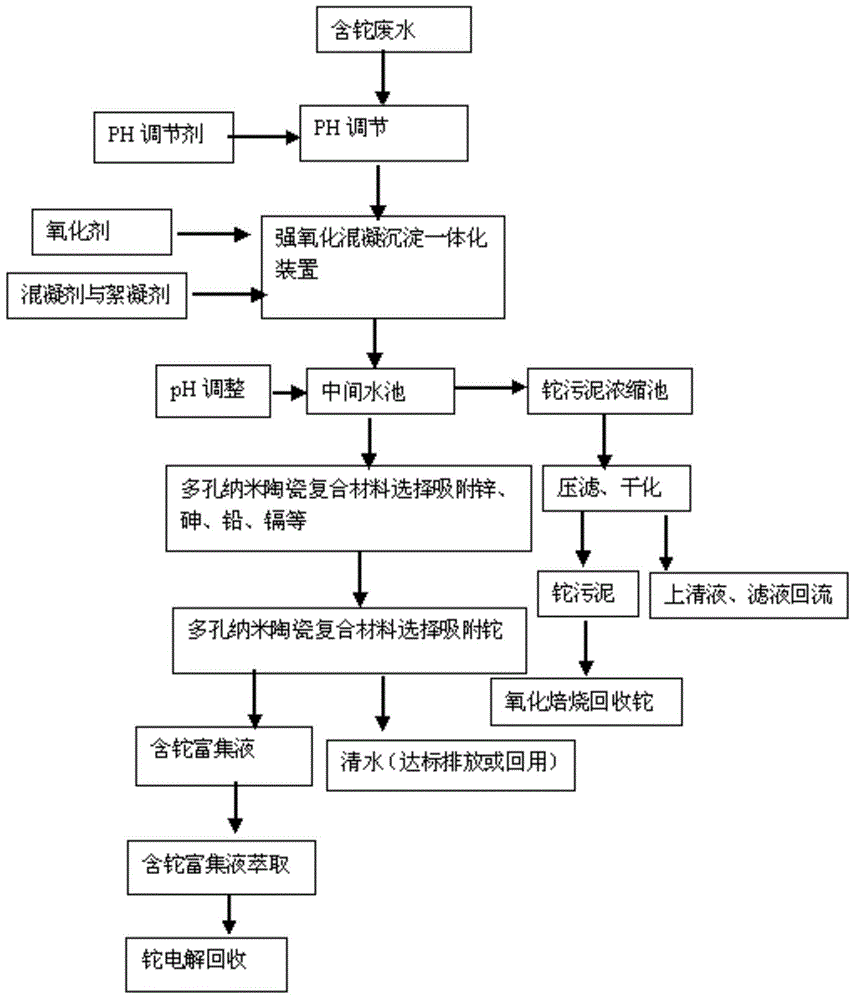

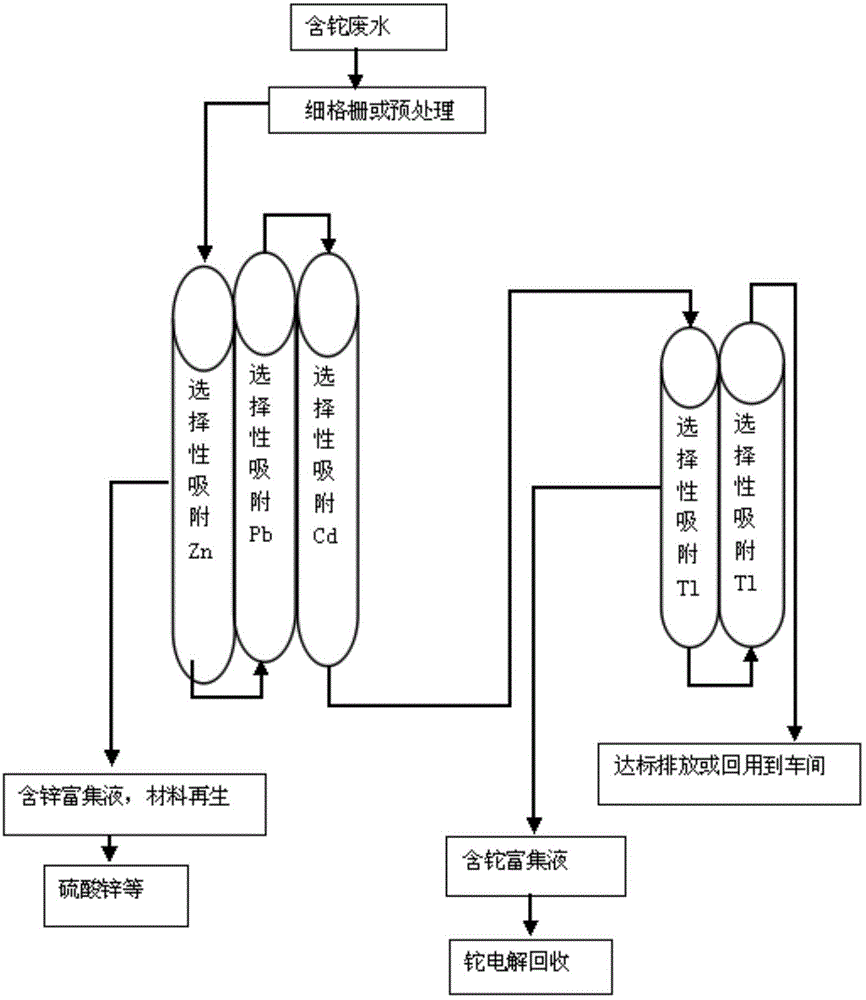

Thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process

ActiveCN104310672AHighly selective adsorptionLarge specific surface areaWater treatment parameter controlSludge treatmentFiltrationSludge

The invention provides a thallium-containing wastewater strongly oxidizing, coagulating, adsorbing and recovering process. The process includes the following procedures: thallium-containing wastewater concentration, pH regulation, strong oxidization, coagulation, flocculation, precipitated sludge treatment, pH regulation, solid impurity filtration, removal of Zn, Pb, Cd and Tl, and the like. The process has the beneficial effects that the process has the advantages of advanced technology, maturity, good effluent quality, stability in operation, conciseness in process, strong practicability, easiness in start and stop, convenience in maintenance and management, small investment, low operating cost, small floor area for construction, short construction period and large application ranges of projects; treatment of heavy metal ion polluted sewage is not limited by temperatures; the limitation that a biological method can not be used in cold regions in the north can be overcome.

Owner:HUNAN JINGYUAN ENVIRONMENTAL ENG

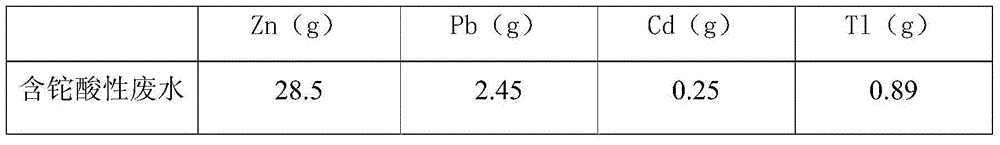

Method of repairing local damaged coating on metal surface

ActiveCN1608744AWide range of applicationsPrevents peeling and peeling of edgesPretreated surfacesCoatingsLacquerVarnish

The method of repairing local damaged coating on metal surface includes cleaning and polishing damaged part; spraying primer and polishing the area of 4-5 times of the primer area; spraying color lacquer to the area of 2-3 times of the primer area; painting varnish in the area of 1-1.2 times the color lacquer area; spraying the edge of varnish area with interface solution; and final polishing. The said technological process is suitable for repairing all painted metal surface, such as automatic, motorcycle, ship, etc. and can reach natural fusion with original coating.

Owner:北京冠都永顺汽车技术服务有限公司

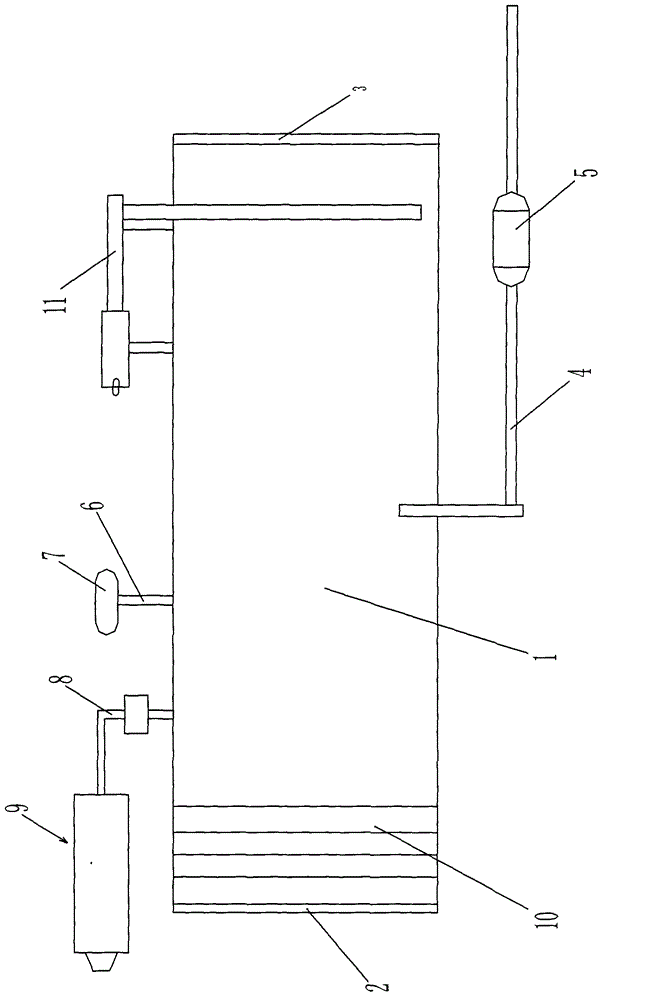

Ethylene oxide preheating, sterilization and resolution integrated cabinet and sterilizing method

ActiveCN102743773AReduce construction areaAvoid lossLavatory sanitoryChemicalsEthylene oxideWater jacket

The invention relates to an ethylene oxide preheating, sterilization and resolution integrated cabinet and a sterilizing method. The integrated cabinet comprises a cabinet body, wherein a sealing door is arranged on the front part of the cabinet body; a cavity in the cabinet body is connected with a vacuum pump through a vacuumizing pipeline; the cavity in the cabinet body is connected with a humidifying device through a humidifying pipeline; the cavity in the cabinet body is connected with wet and hot air making devices through wet and hot air delivery pipelines; a heating water jacket is arranged outside the cabinet body; a circulating air pipeline is arranged on the outer side of the cabinet body; a fan is connected in series to the circulating air pipeline; an air inlet of the circulating air pipeline is arranged on one side in the cabinet body; an air outlet of the circulating air pipeline is arranged on the other side in the cabinet body; and the cabinet body is connected with an ethylene oxide container through a pipeline provided with a valve. The ethylene oxide preheating, sterilization and resolution integrated cabinet has the advantages of high operating efficiency, few matched facilities, low fault rate, short construction period, low daily using cost and low energy loss, and can reduce pollution to human body and environment and improve the comprehensive benefit by over 40 percent.

Owner:北京长丰诚耀技术服务中心

Magnetite beneficiation method

InactiveCN103736663APerfect development conditionsReduce constructionSolid separationTailings damMining engineering

The invention relates to the field of beneficiation, in particular to a magnetite beneficiation method. Through technological closed cycle production, technological path is shortened, and production and transport costs are remarkably saved; energy is saved by 0.5-1 degree / ton; plant construction area is reduced; building of tailings ponds is reduced due to dry discarding. By the beneficiation method, large-scale tailings discarding before milling is realized, milling grade is remarkably improved, and technical parameters of ball-milling magnetic separation sections are changed thoroughly. The magnetic-gravitational beneficiation process can be applied to preconcentration of low-grade ore, ore resources are pre-concentrated, the milling grade is improved, and beneficiation cost is reduced; the magnetic-gravitational beneficiation process can also be applied to recleaning of tailings to recover the tailings relatively concentrated on dry slope sections of tailings dams; the magnetic-gravitational beneficiation process can be further applied to powdered iron purification of dressing plants to discard lean intergrowth and gangue in powdered iron, product grade is improved, and technical additional value of products of the dressing plants is increased. The magnetic-gravitational beneficiation process substitutes for the wet-type magnetic separation process and is a qualitative leap for dry-type preconcentration and tailings discarding of beneficiation of mines.

Owner:陕西三沅重工发展股份有限公司

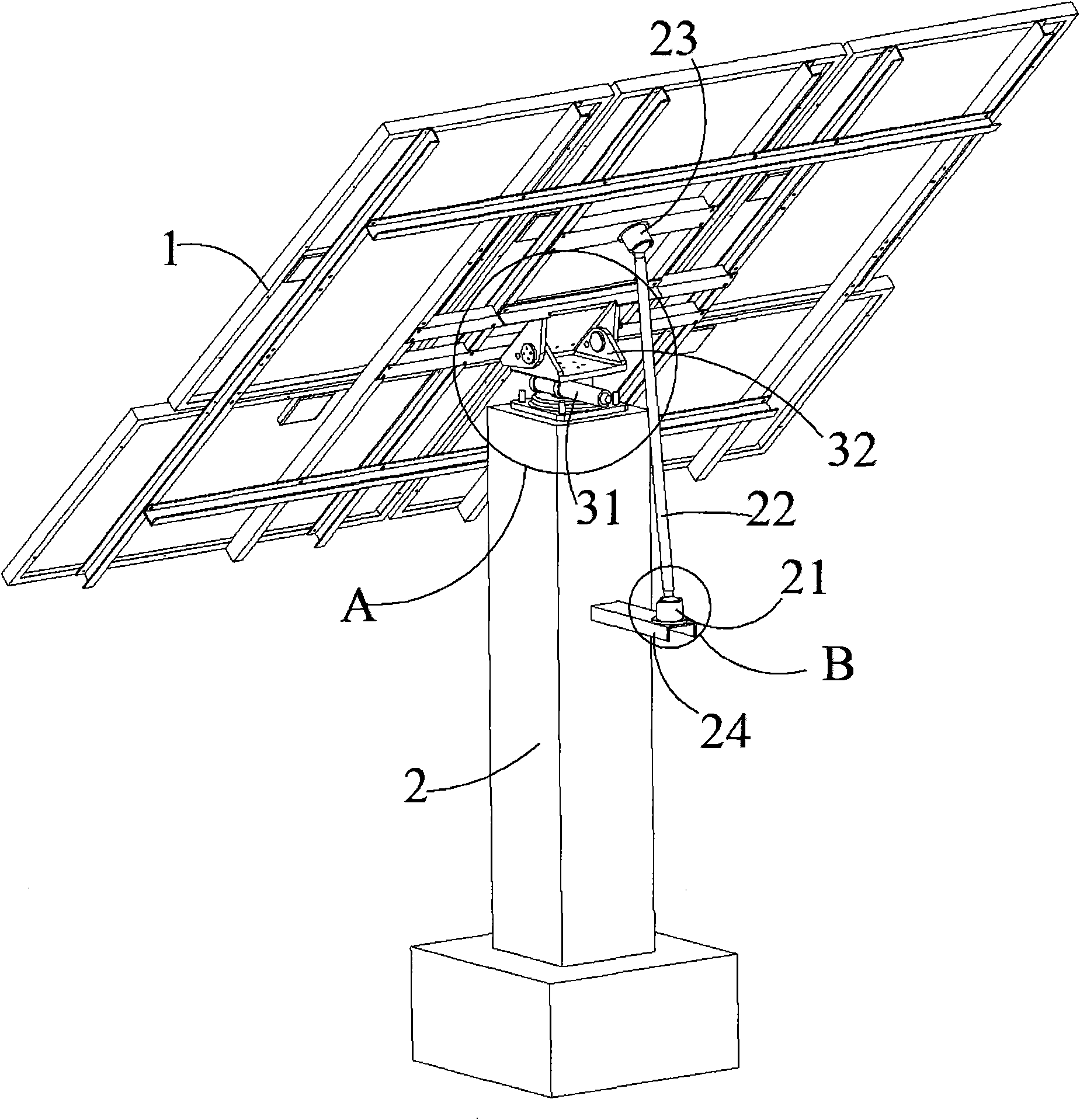

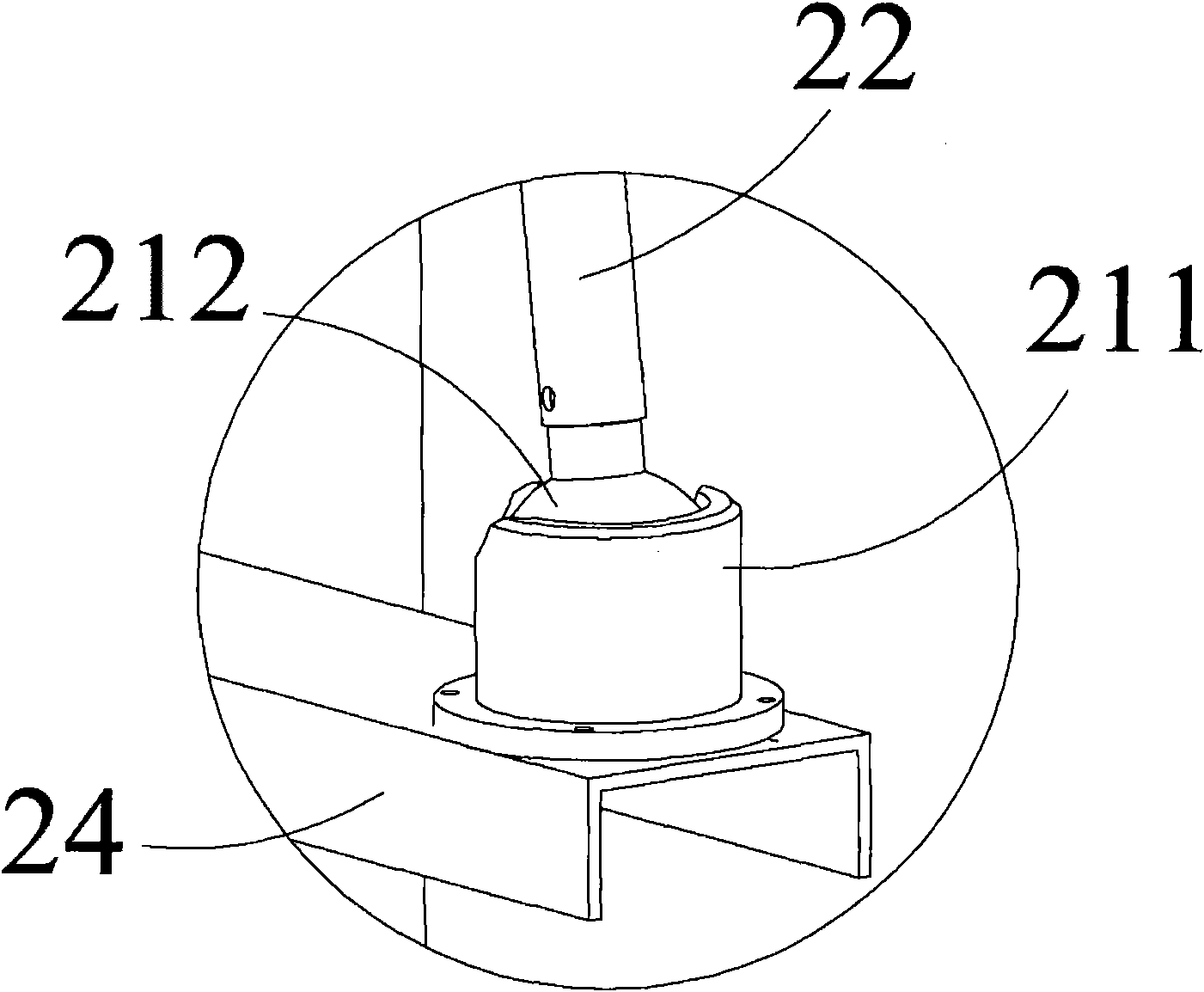

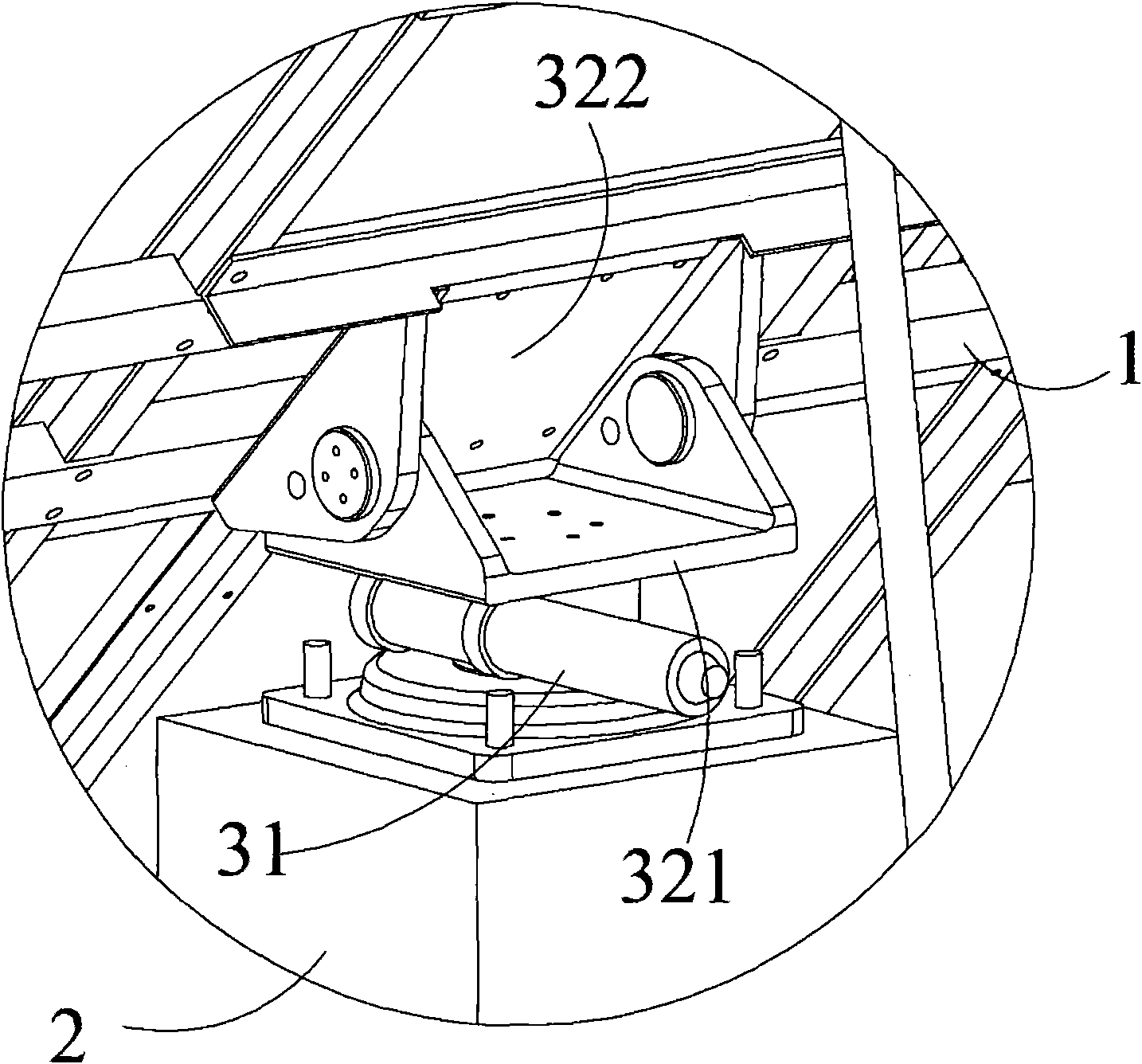

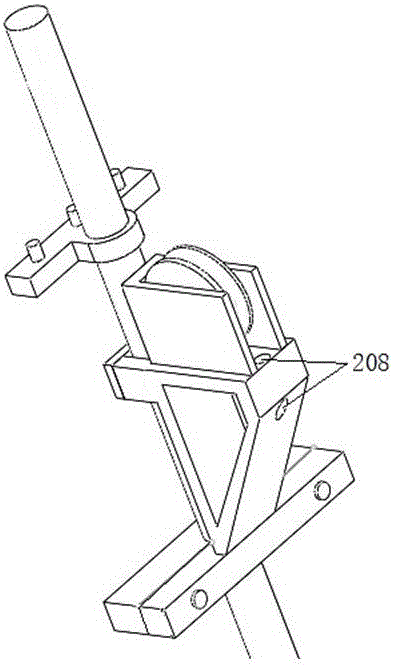

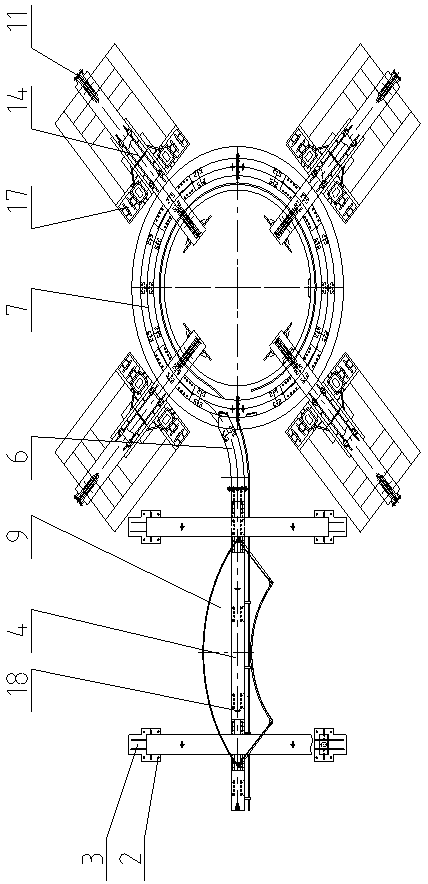

Photovoltaic power generation device with two-dimensional photovoltaic sun-positioning mechanism

InactiveCN102035435AImprove power generation efficiencySimple mechanical structurePhotovoltaic supportsControl using feedbackPhotovoltaic power generationElectric motor

The invention relates to a photovoltaic power generation device with a two-dimensional photovoltaic sun-positioning function. The photovoltaic power generation device comprises a photovoltaic battery plate and a support pillar and also comprises a two-dimensional photovoltaic sun-positioning mechanism, wherein the two-dimensional photovoltaic sun-positioning mechanism contains a first multi-turn element, a second multi-turn element, a connecting piece and a one-dimensional steering unit; the first multi-turn element is arranged on the side edge of the support pillar; the second multi-turn element is arranged on the back of the photovoltaic battery plate; the connecting piece is connected with the steering output ends of the first multi-turn element and the second multi-turn element; the one-dimensional steering unit contains an electric motor and a transmission device; and the electric motor is controlled by a drive unit to realize that the photovoltaic battery plate rotates along with the axial direction of the support pillar.

Owner:北京意科能源技术有限公司

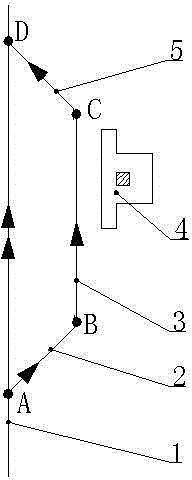

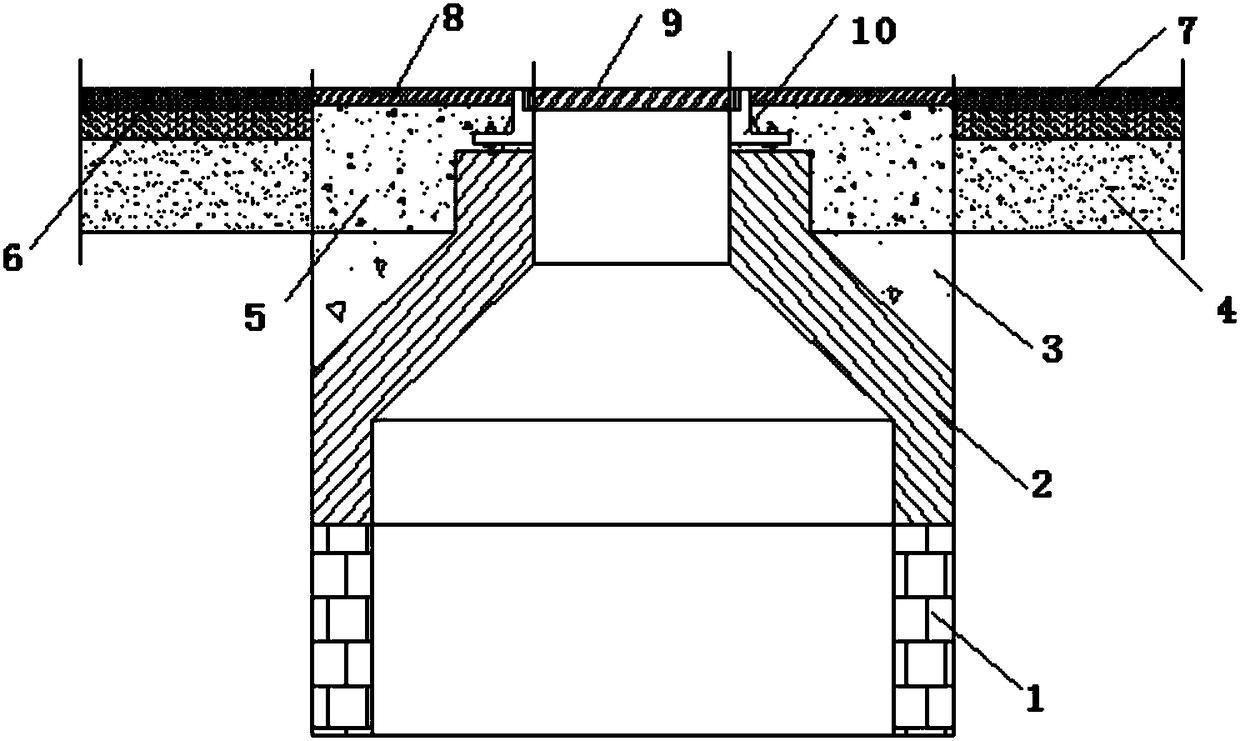

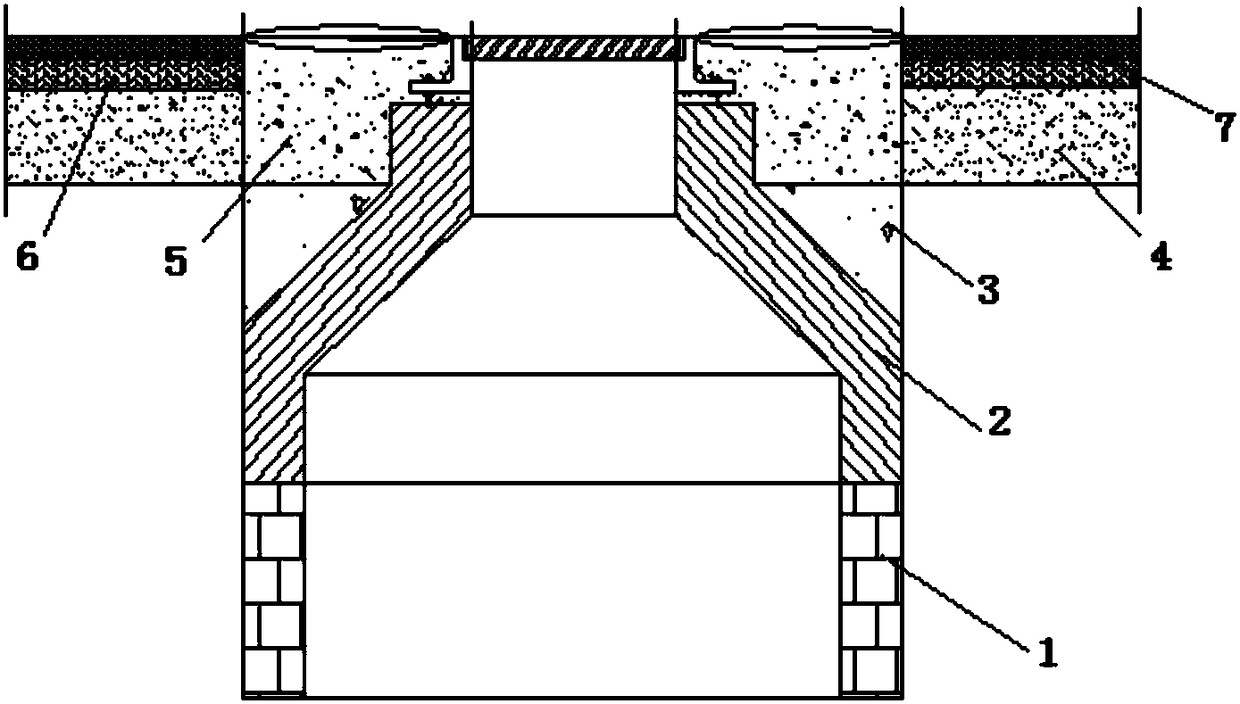

Subway station body structure and four-joint-arch PBA underground excavation construction method thereof

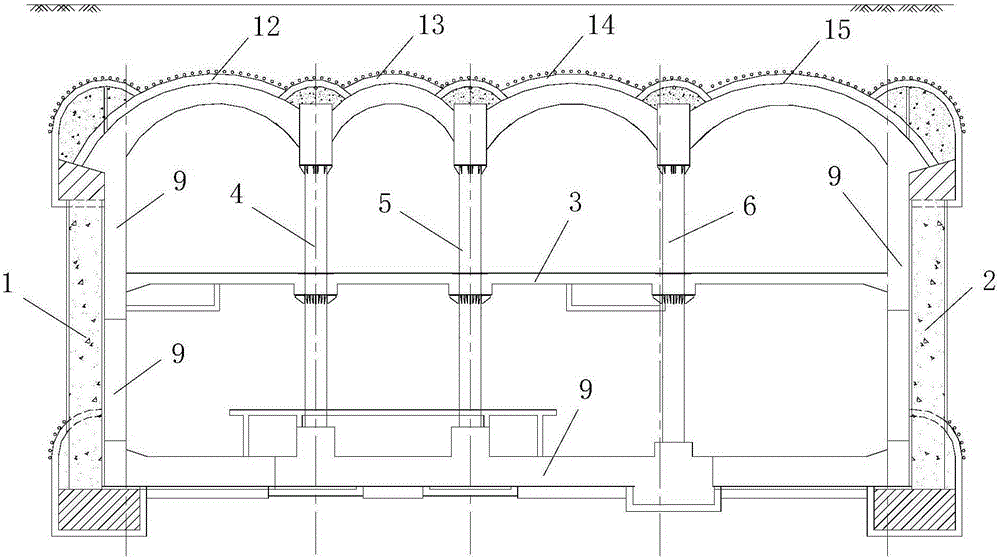

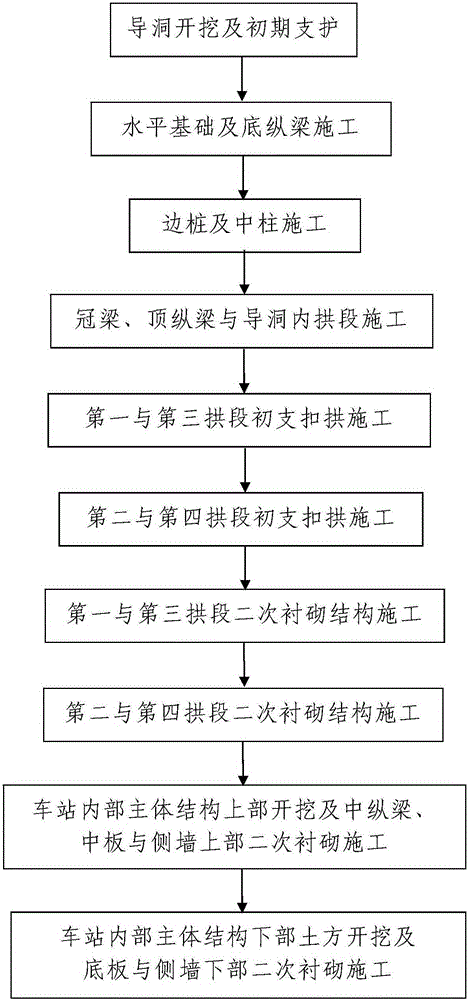

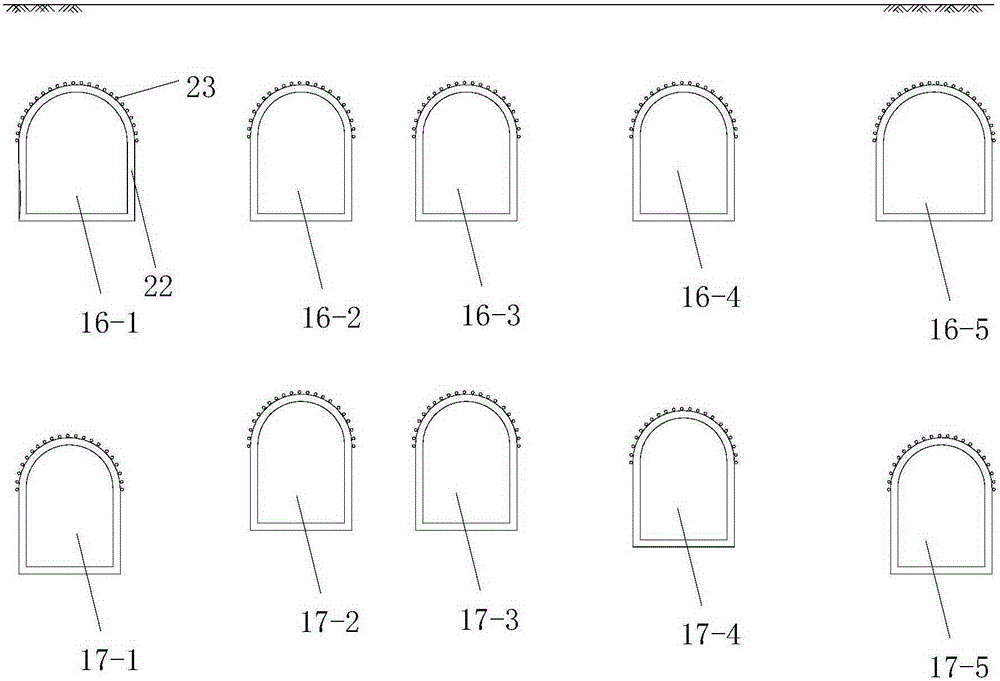

ActiveCN105201516AReasonable structural designStable structureUnderground chambersTunnel liningStructure of the EarthSubway station

The invention discloses a subway station body structure and a four-joint-arch PBA underground excavation construction method thereof. The subway station body structure comprises a station inner body structure, multiple left piles, multiple right piles, three sets of middle columns, middle plates and body arches. The body arches are four-joint arches. The construction method comprises the steps of pilot tunnel excavation and primary support; horizontal base and bottom longitudinal beam construction; side pile and middle column construction; crown beam, top longitudinal beam and pilot tunnel inner arch section construction; first and third arch section primary support buckle arch construction; second and fourth arch section primary support buckle arch construction; secondary lining structure construction of first and third arch sections; secondary lining structure construction of second and fourth arch sections; excavation of the upper portion of the station inner body structure, and secondary lining construction of the middle longitudinal beams, the middle plates and the upper portion of the side wall; earth excavation of the lower portion of the station inner body structure and secondary lining construction of bottom plates and the lower portion of the side wall. The construction is easy, the construction progress is fast, the subway station body structure constructed and formed is firm, and the using effect is good.

Owner:NO 1 ENG LIMITED OF CR20G

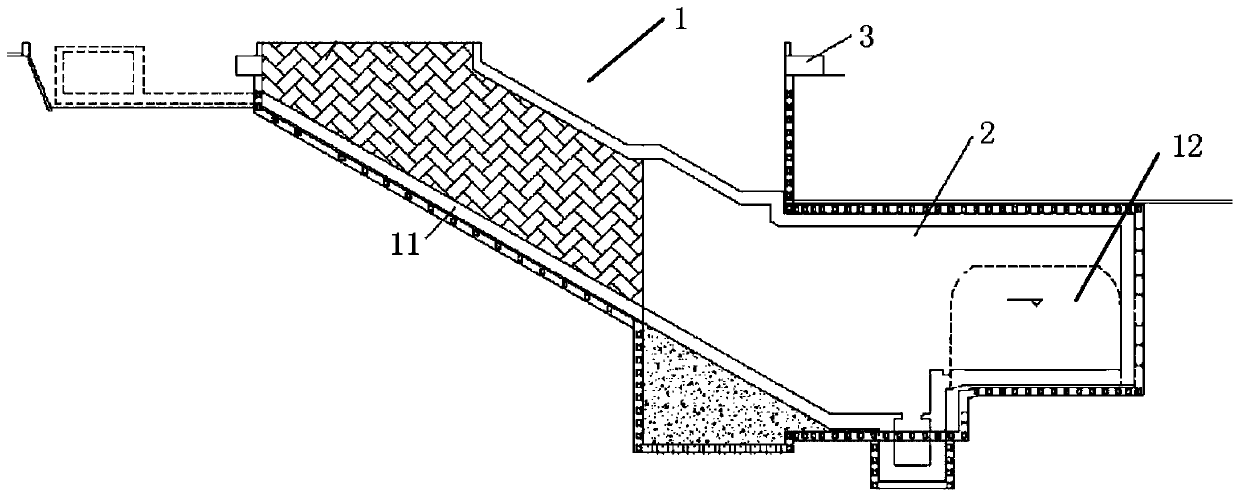

Construction method of station entrance-exit main body structure close to urban buildings and roads

ActiveCN110067563AReduce disturbanceEnsure safetyUnderground chambersShaft sinkingDeep holeUrban building

The invention provides a construction method of a station entrance-exit main body structure close to urban buildings and roads. The construction method specifically includes the steps that a first open-excavated vertical shaft is constructed, an underground-excavated channel is constructed and a second open-excavated vertical shaft is constructed, wherein the first open-excavated vertical shaft and the second open-excavated vertical shaft both are excavated through an upside-down well wall method and the first open-excavated vertical shaft is excavated to the location of the underground-excavated channel, the excavated area of the underground-excavated channel is subjected to deep hole strengthening grouting and is strengthened by erecting a pipe roof bracket, then a CRD construction method is adopted to construct the underground-excavated channel, after the first open-excavated vertical shaft and the underground-excavated channel are constructed, the other open-excavated areas are excavated while the second open-excavated vertical shaft is adopted, and the construction process of the station entrance-exit main body structure is completed.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

Construction method for controlling two-dimension jacking of large-scale case

ActiveCN101538832ASmall construction areaLow costBridge erection/assemblySystem constructionRailway line

The invention discloses a construction method for controlling the two-dimension jacking of a large-scale case. The method comprises the following steps: all the large-scale cases are previously arranged in a foundation pit at one side of a railway which needs to be paved with a frame bridge under a condition that the underway existing railway normally runs; after a first section of the large-scale case is jacked, all the remaining large-scale cases are transversely moved behind the first section of the large-scale case on by one; and then all the large-scale cases are jacked with the previously jacked large-scale case. In such a way, original buildings near a railway line do not need to be demolished, therefore, the invention not only has small construction occupied area and low cost but also greatly reduces interference to the surrounding environment and the existing railway cause by construction operation, reduces the demolishing quantities of the adjacent buildings caused by the construction, and effectively guarantees the normal running of the existing railway.

Owner:CHINA RAILWAY SIXTH GROUP +1

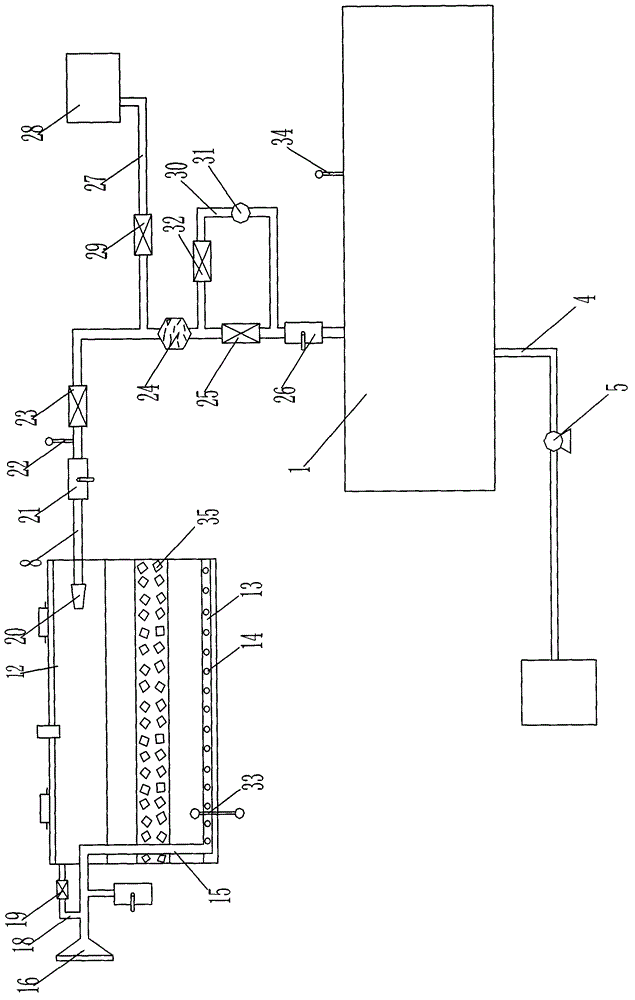

Closed dry separation equipment for low-grade magnetite

InactiveCN103878060AReduce constructionReduce construction areaMagnetic separationMagnetic separatorMagnetite

The invention relates to the field of machinery and in particular relates to closed dry separation equipment for low-grade magnetite. The equipment comprises a raw ore conveying belt, wherein a high-pressure roller mill is arranged below a discharging part of the raw ore conveying belt; a belt is arranged below a discharging hole below the high-pressure roller mill; a combined dry magnetic separator is arranged below the belt conveying end; ores separated by the combined dry magnetic separator are connected to vertical middling conveying equipment; an outlet above the middling conveying equipment is communicated to a feeding hole of the high-pressure roller mill through the belt. The equipment has the beneficial effects that through a closed cycle production process, the process route is shortened and the production and transportation costs are greatly saved; the energy is saved by 0.5-1 kilowatt hour / ton; the construction area of factory buildings is reduced; the construction of tailings ponds is reduced through a dry throwing process; large-scale tailing throwing before milling is realized, the milling grade is greatly increased, and the technical parameters of the magnetic separation section during ball-milling are radically changed; the adaptive range of a dry separation station process of the low-grade magnetite is wide.

Owner:陕西三沅重工发展股份有限公司

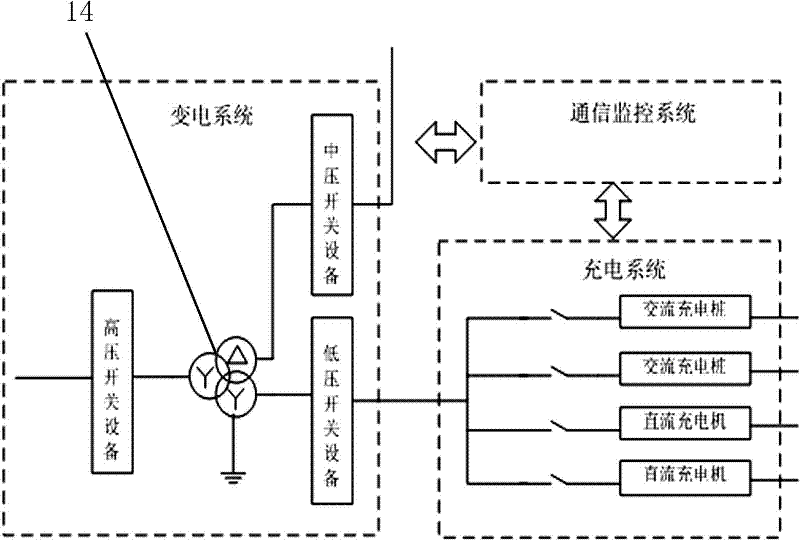

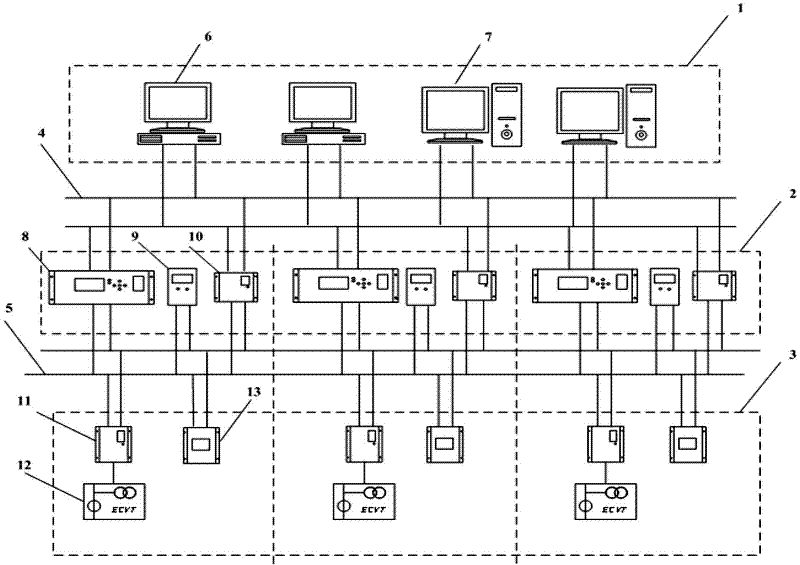

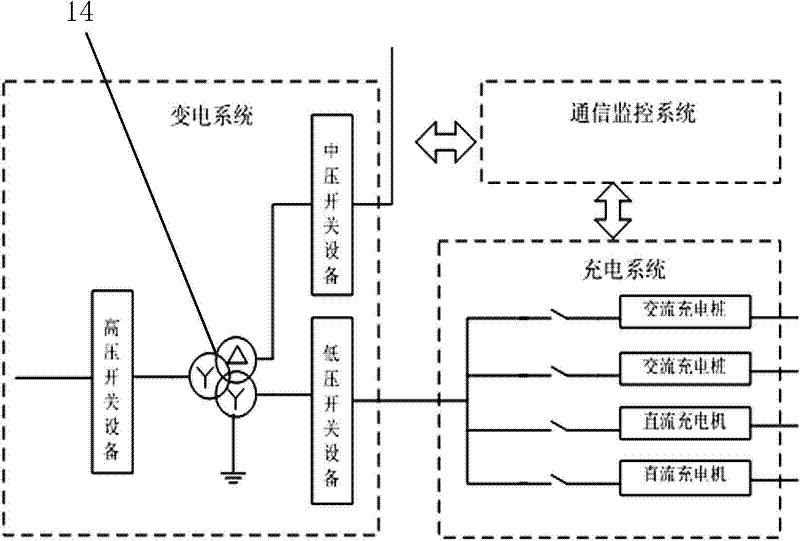

Multifunctional intelligent station integrating transformation, charging and conversion

InactiveCN102394506AReduce construction investment costsSave construction investmentBatteries circuit arrangementsStar/tree networksLand acquisitionInformatization

The invention belongs to the electric power equipment technology field and especially relates to a multifunctional intelligent station integrating transformation, charging and conversion. And specifically, the invention relates to an intelligent transformer station and an electric automobile charging station, and the integrated multifunctional intelligent station possessing transformation, charging and conversion functions. The multifunctional intelligent station of the invention mainly comprises: a transformer substation system, a charging system and a communication monitoring system. The transformer substation system is connected with the charging system. The communication monitoring system constructs Ethernet through a fiber to realize communication with the transformer substation system and the charging system and monitoring the transformer substation system and the charging system. By using the multifunctional intelligent station of the invention, construction and investment costs of an electric automobile charging station distribution transformer can be directly saved. The construction and investment costs are small. A whole construction area of the transformer station and the electric automobile charging station can be directly reduced. Building land acquisition demands can be directly reduced. Information sharing in the intelligent station can be realized. Levels of automation, informatization and intellectualization of the intelligent station are high. The multifunctional intelligent station is suitable for dense population areas in cities and the areas where land expropriation is difficult, and has a good application prospect.

Owner:NORTHEAST POWER SCI RES INSTITUTION +3

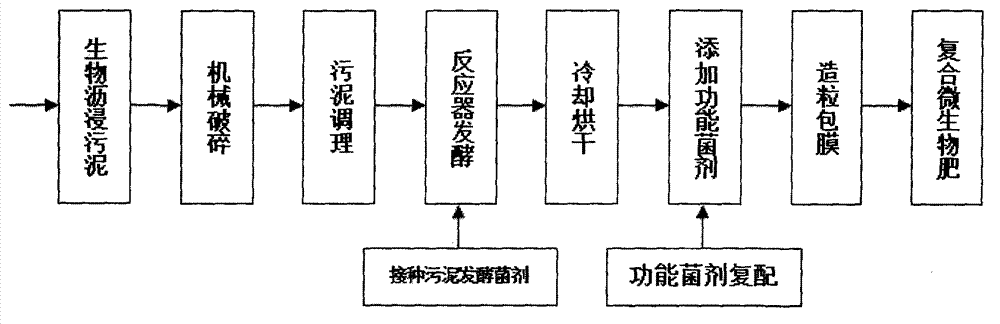

Preparation method for composite microbial fertilizer with bioleached sludge and composite microbial fertilizer

ActiveCN103319218AAdjust moisture contentLow costBio-organic fraction processingClimate change adaptationSludgePotassium

The invention discloses a preparation method for a composite microbial fertilizer with bioleached sludge. The method comprises following steps: taking half-dried bioleached sludge, mechanically grinding, sludge conditioning, fermenting in a reactor, drying, adding functional bacteria, and pelletizing and coating. The invention also discloses the composite microbial fertilizer which is prepared by the method discussed above with bioleached sludge. The composite microbial fertilizer contains organic matter, and nutrient elements which are essential for plant growth, such as nitrogen, phosphor and potassium. Because of the nutrient substances which are added in bioleaching processes and contain iron and sulfur, the composite microbial fertilizer also contains relatively abundant iron and sulfur, and can be used to provide nutrition for photosynthesis, and protein and nucleic acid synthesis of plant. The functional bacteria added into the composite microbial fertilizer possesses high stability and safety, and excellent ability for dissolving K and P. Compatibility of the functional bacteria is reasonable, and effective viable bacteria number is 0.025 billion per gram.

Owner:天津市环投绿化工程有限公司

Pretreatment method for anchor cable group penetrating through shield driving fracture surface

ActiveCN106437798AMake sure to removeFlexible holesAnchoring boltsPretreatment methodBuilding construction

The invention discloses a pretreatment method for an anchor cable group penetrating through a shield driving fracture surface. The pretreatment method comprises the steps of adopting a warehouse-jumping method to construct an artificial wellhole of a preorder; arranging a working platform at a position where the anchor cable can be found, cutting off the anchor cable, and arranging a removing tool on the working platform; adopting the removing tool to loosen and drag out the anchor cable; backfilling the artificial wellhole and recovering the ground; adjusting the orientation and the diameter of the artificial wellhole of a postorder according to the residual anchor cable condition of the artificial wellhole of the preorder, but guaranteeing that a plum blossom connection is formed between the artificial wellhole of the preorder and the artificial wellhole of the postorder; repeating the steps above until all the anchor cables are removed. The pretreatment method adopts the warehouse-jumping method to dig the artificial wellhole and has a flexible hole arrangement, therefore, not only is construction area reduced, but also construction speed is improved; plum blossom connections are adopted between a number of artificial wellholes, continuous construction regions are formed on a shield path so as to ensure that all the anchor cables can be removed. The pretreatment method for the anchor cable group which passes through the shield driving fracture surface belongs to the field of anchor cable removing.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Construction process for manhole cover device on road

ActiveCN108487323ARelieve pressureSolve the subsidence problemArtificial islandsUnderwater structuresInstabilityHigh pressure

The invention discloses a construction process for a manhole cover device on a road. The construction process for the manhole cover device on the road comprises the steps of breaking an asphalt concrete and a part of base layer, blowing off scums on the periphery through high pressure air, spraying water for wetting, leveling for stabilizing a well curb, erecting a form on the inner side of the well curb, mixing a super-early strength black C30 concrete, and pouring the concrete. According to a process technology for solving the problems of sinking and instability of a manhole cover, the sinking problem of the manhole cover is solved by using a technological achievement of rising a manhole through the super-early strength black concrete, a manhole cover installing or a sunken manhole covermaintaining process, and a combined application technology of the technological achievement of rising the manhole through the super-early strength black concrete and a novel composite manhole cover;a back circle problem of the 'technological achievement of rising the manhole through the super-early strength black concrete' is solved; the instability problem of the manhole cover is solved; an anti-falling problem is further solved according to the needs; and through the two process technologies, the aims of small construction surface, timeliness and quickness can be achieved.

Owner:TIANJIN JUSHI TECH DEV

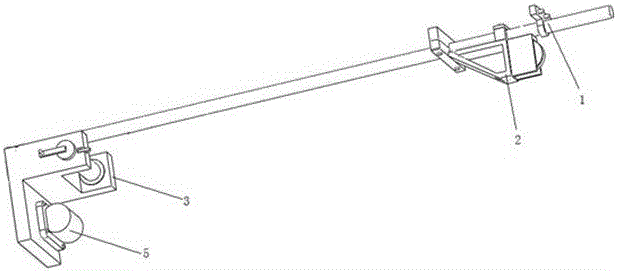

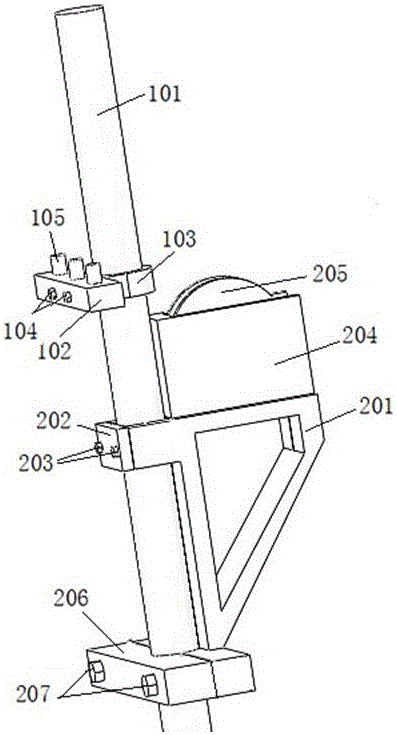

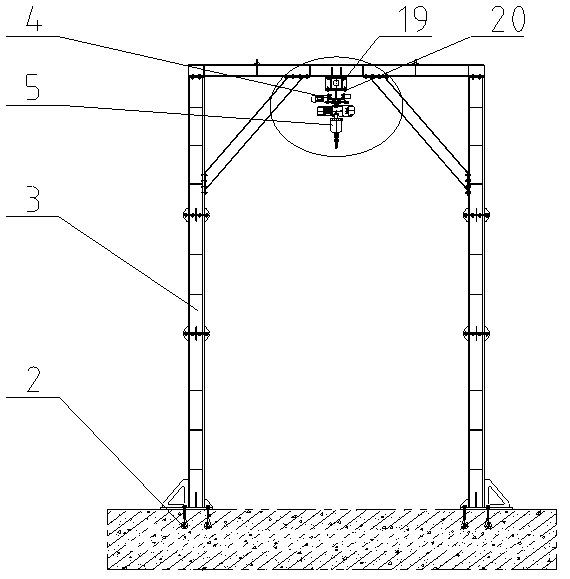

Wire tightening device for low-voltage stringing and stringing method

InactiveCN105762712AReduce volumeSmall footprintApparatus for overhead lines/cablesLow voltageEngineering

The invention discloses a wire tightening device for low-voltage stringing and a stringing method, which relate to the technical field of stringing in a power system. The device comprises a wire pole part, a pole-mounting device part, a ground device part, a steel wire guiding rope and a power part. The wire tightening device is small in size, small in occupied space, easy to transport, and suitable for being used in harsh environment areas and plain areas. The device is simple to manufacture, and compared with a stringing vehicle and an unmanned stringing machine, the device is low in needed cost and little in maintenance cost. A drum is used for tightening the wire, the occupied area is narrowed in the case of construction, and the device is suitable for being used in a mountain area with a harsh environment. When the wire is light, the wire tightening device can tighten the wire via a crank; when the wire is long and heavy, a motor generates power for stretching the wire; and thus, manpower can be greatly reduced and the operation is more convenient and quicker. The DC motor is adopted as the power part, and the motor is quick to start, good in speed regulation performance and easy to control.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Composite anti-explosion post of reinforced concrete with encased steel plate and construction method thereof

InactiveCN101899887AEnhance resilience against disruptionSmall sectionStrutsBuilding material handlingReinforced concrete columnSheet steel

The invention provides a composite anti-explosion post of a reinforced concrete with encased steel plate and a construction method thereof. The outer surface of the anti-explosion post is successively welded and coated with a long steel sleeve, an additional steel plate and a protective steel plate from inside to outside, wherein the periphery of the bottom end of the additional steel plate is welded with an annular steel plate and a junction plate with a radiation anchor plate, and the outer surface of the top end of the long steel sleeve is successively welded with the annular junction plate and the annular steel plate from top to bottom. The invention utilizes the steel plate to protect the outer surface of the reinforced concrete post and improves impact load resistance ability. The joint of the post and the reinforced concrete beam plate is connected by a metal junction plate to reduce the possibility of breaking a node when receiving impact load; and the metal junction plate with a radiation anchor plate on the bottom of the post is welded with the upper layer of reinforcing steel bar of a raft foundation, thus further improving the impact resistance of the reinforced concrete post.

Owner:SHENZHEN YJY BUILDING TECH +1

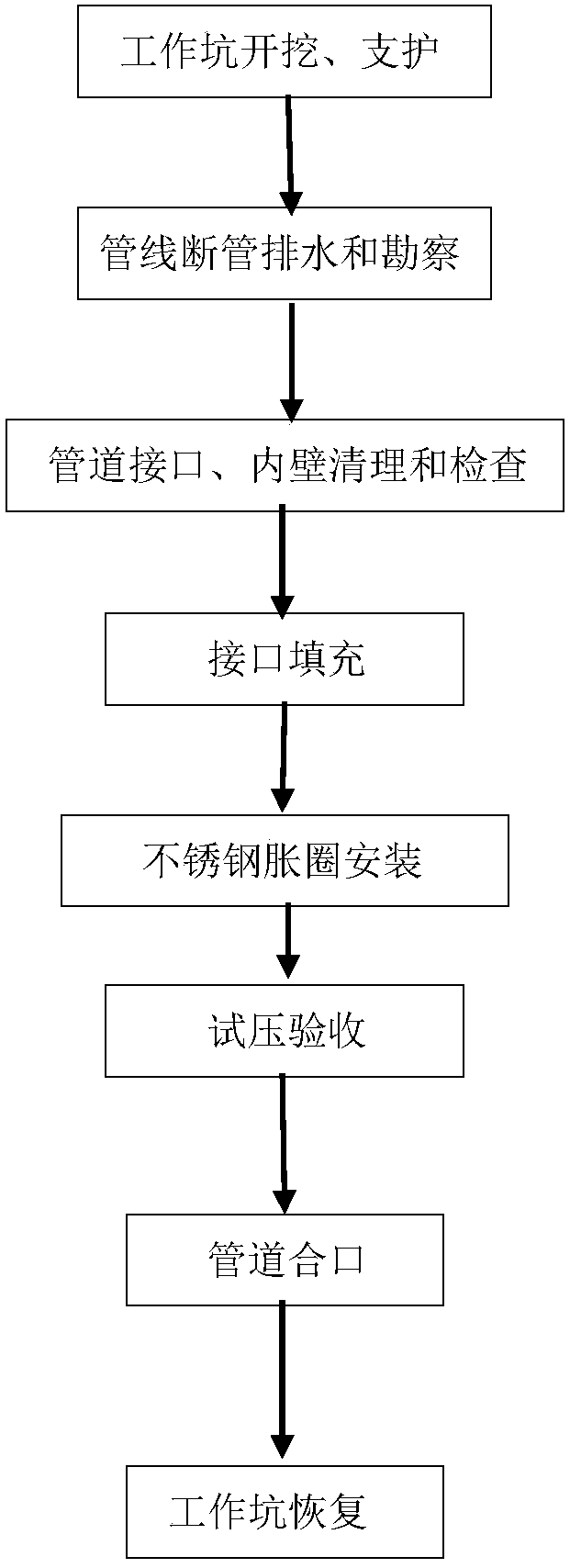

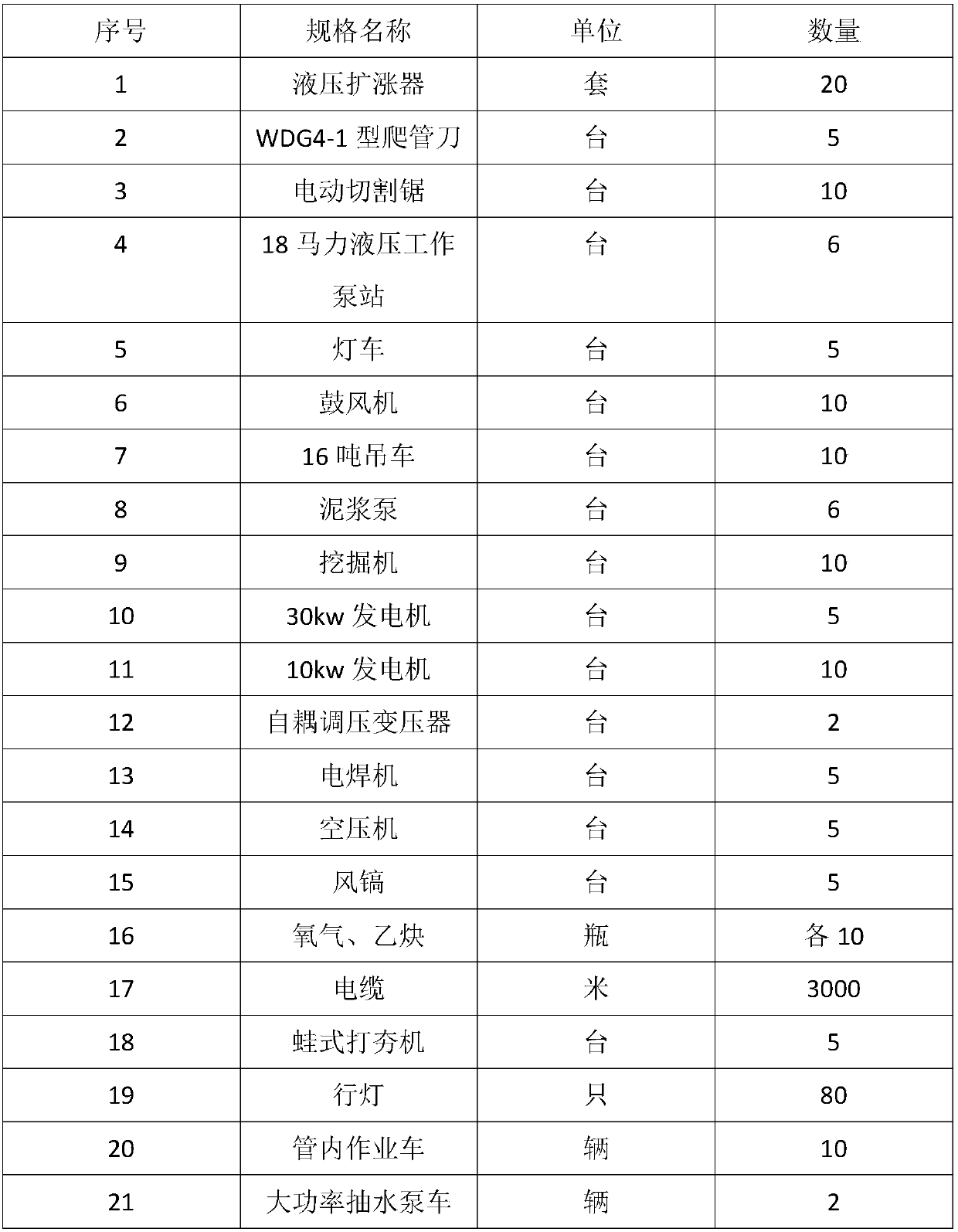

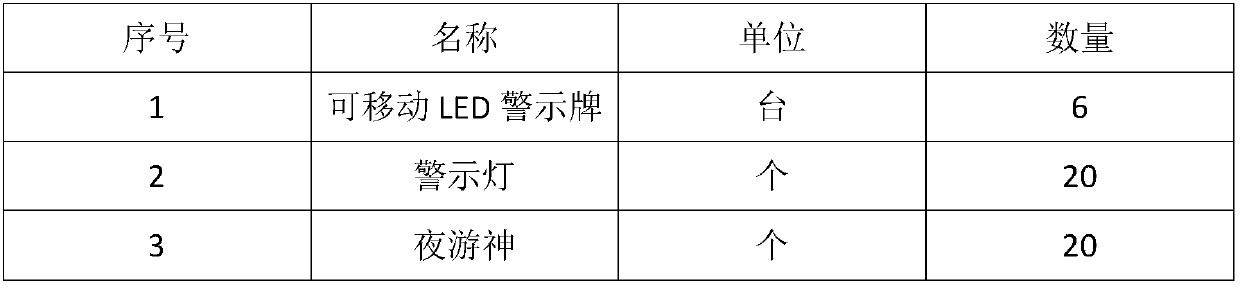

Internal expansion ring method pipe joint repair construction method

InactiveCN107763362AReduce construction intensityReduce construction areaPipe laying and repairPipe elementsState of artFlushing time

The invention discloses an internal expansion ring method pipe joint repair construction method, solves the problem of incapability of quickly and effectively repairing pipes in the prior art, and achieves such effects as high construction speed, no construction limitation from the ground and the environment, low cost and no limitation to the joint repair from the pipes. The internal expansion ring method pipe joint repair construction method comprises the following steps: working pits are excavated along pipelines in a construction site by every other set distance; the pipes are cut for breakage in the working pits to drain water remained in the pipes; pipe joints are cleaned and filled; sealing strips are bonded on the inner walls of the pipes in the pipe joints; internal expansion ringsare clamped in annular grooves of the sealing strips, and set pressure is applied to the internal expansion rings; two ends of the pipelines are blocked, and the pipe flushing time is set; steel pipes are arranged in the breakage places of the pipes to join the broken pipes; and the working pits are backfilled to recover pavements.

Owner:济南普利市政管网工程有限责任公司

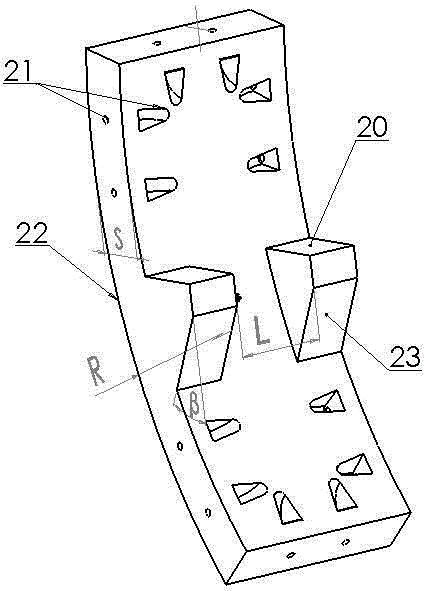

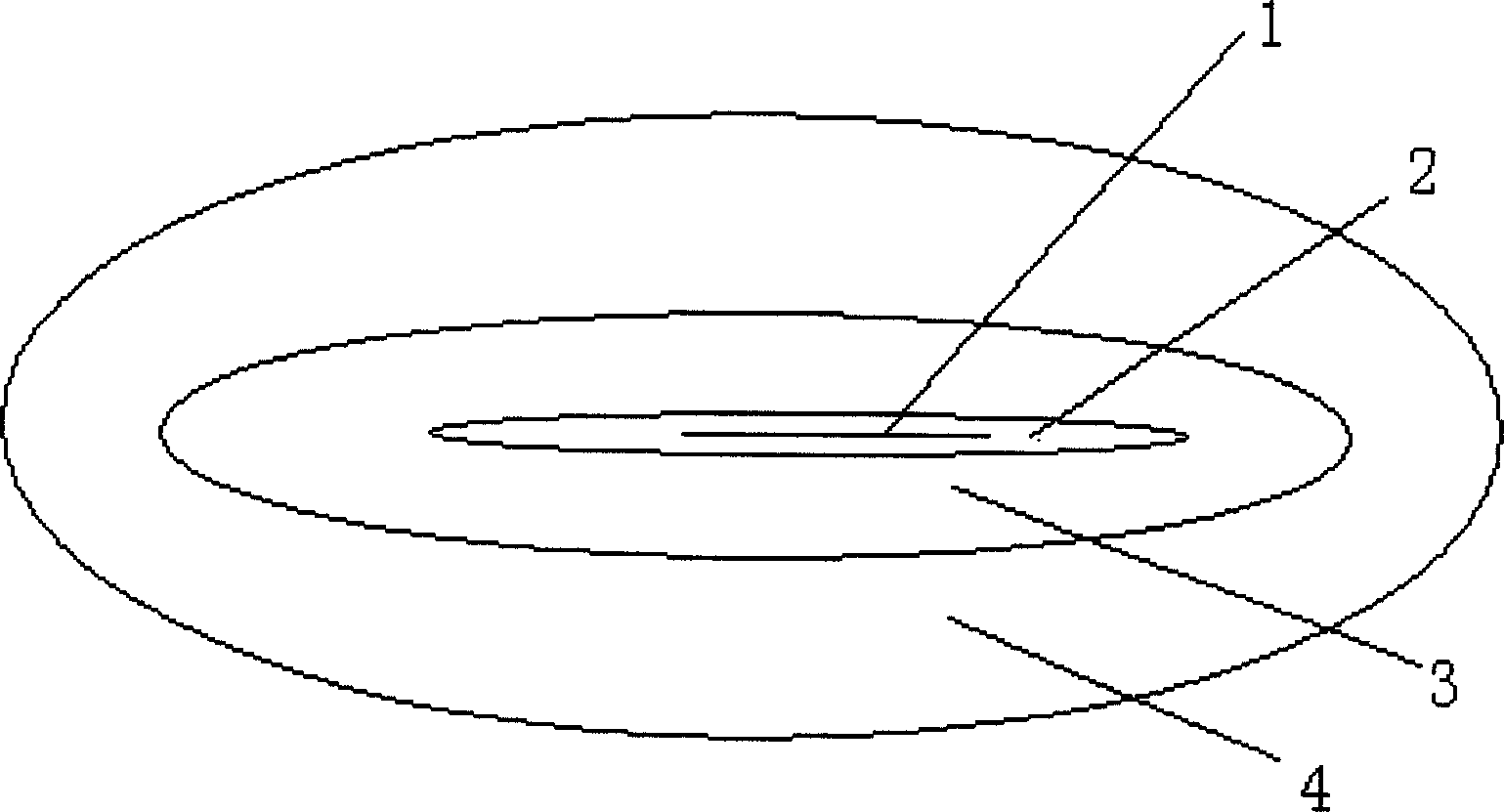

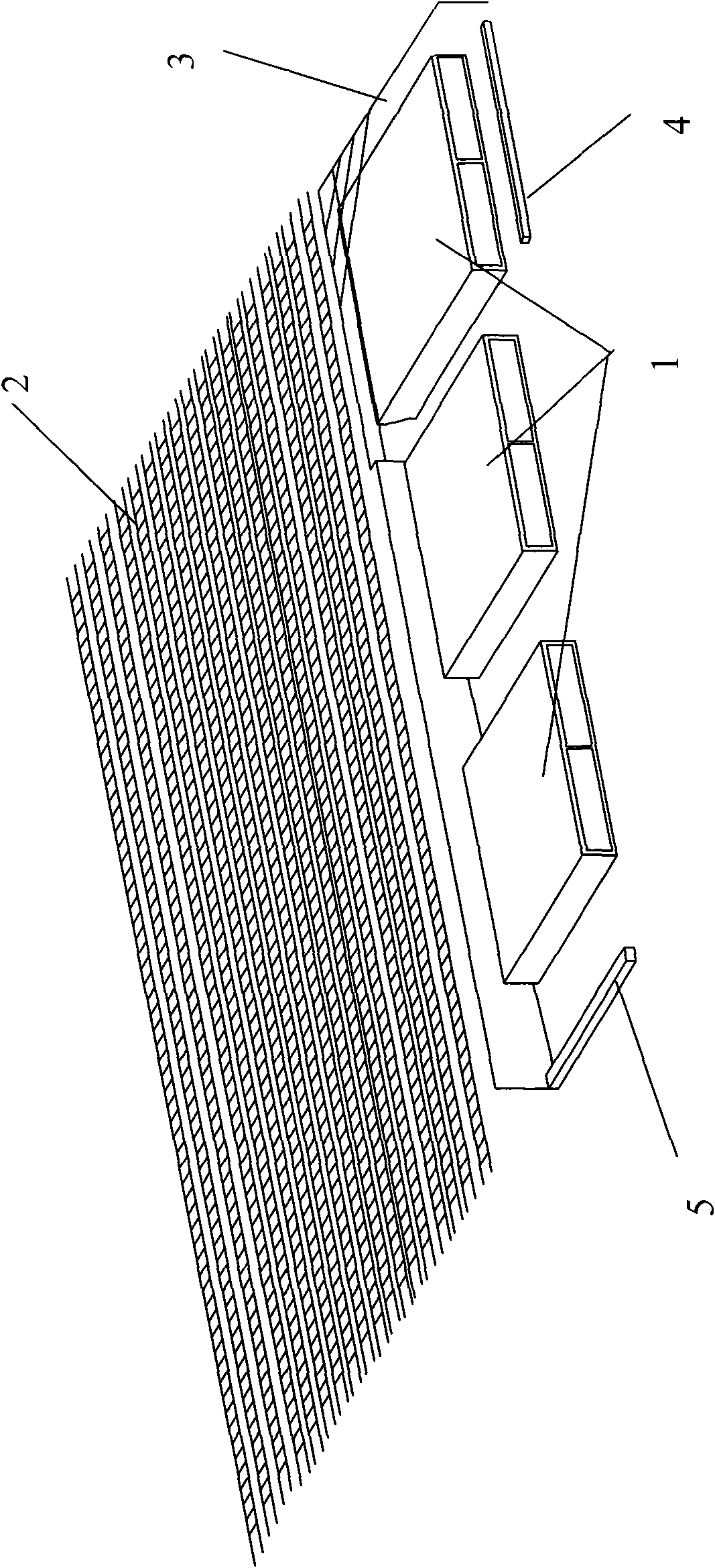

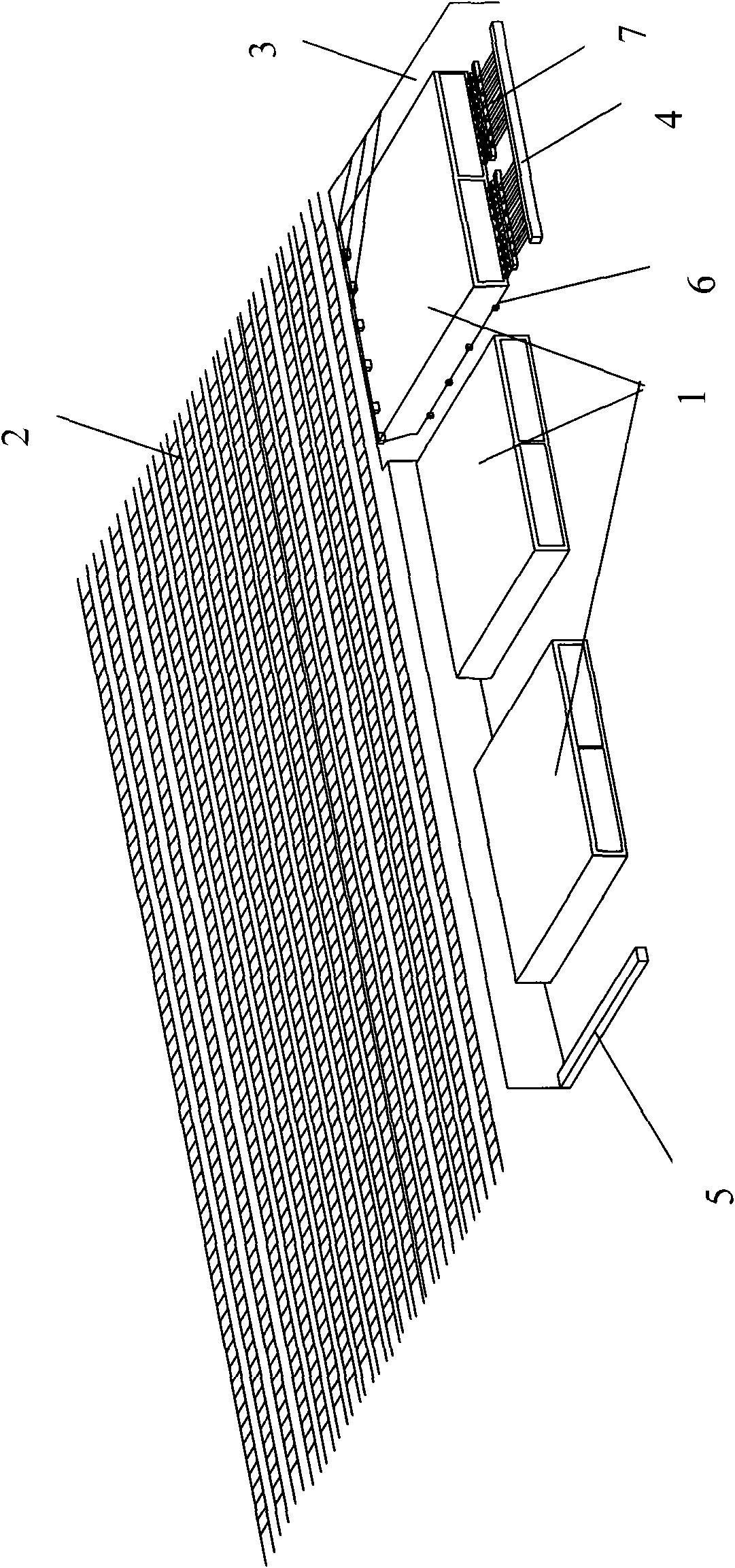

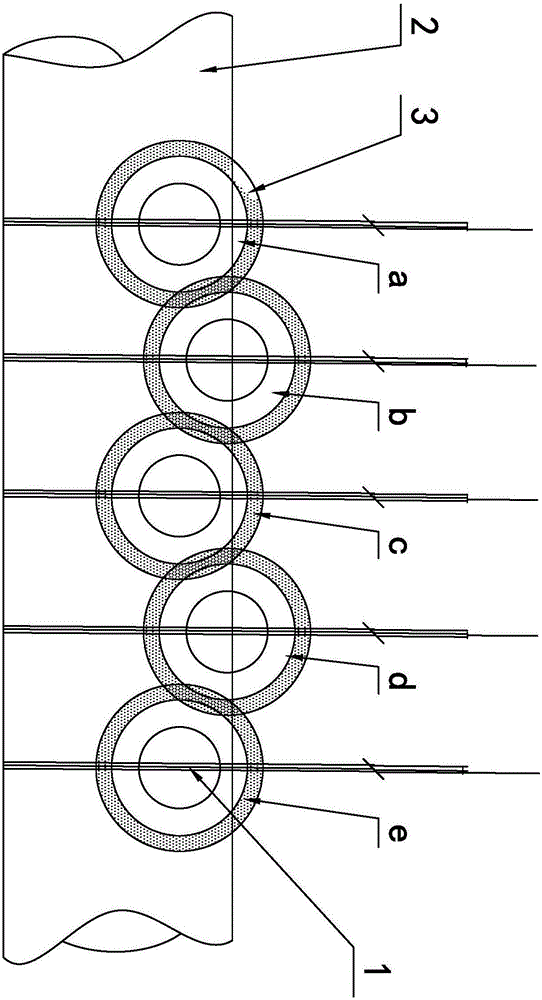

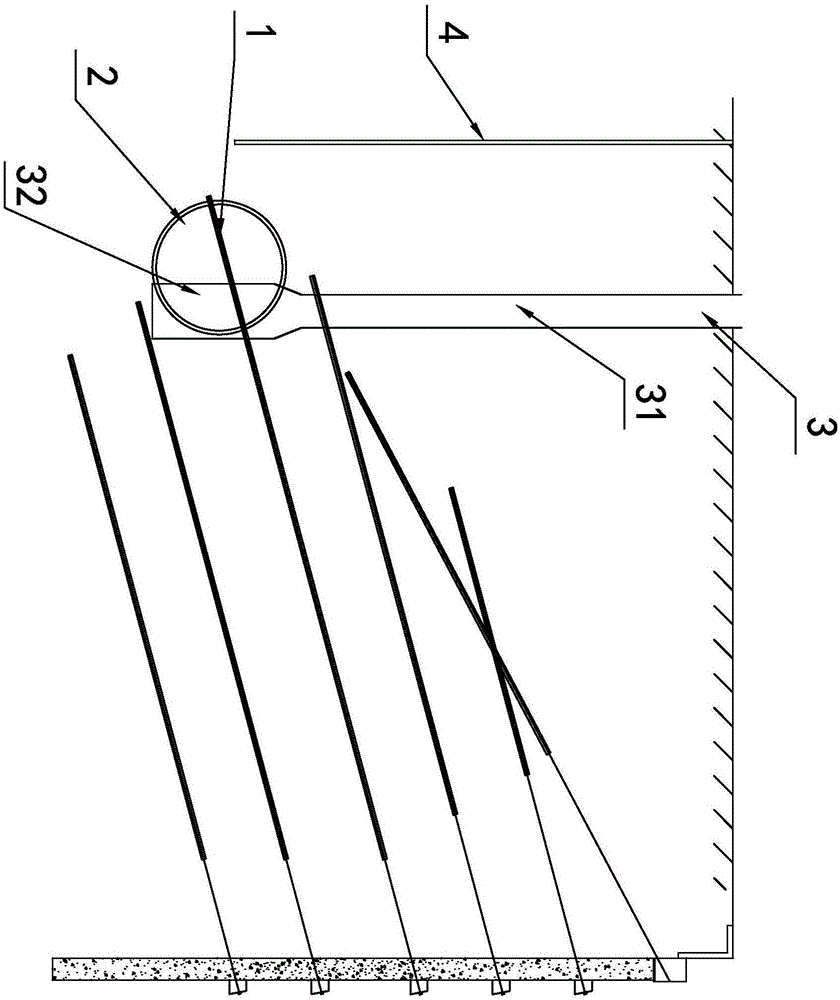

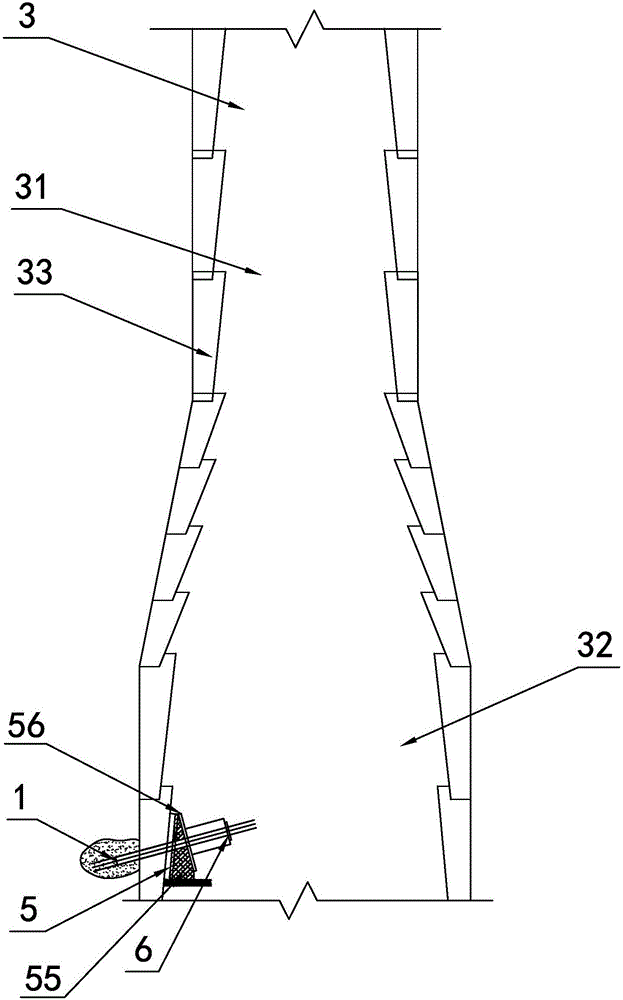

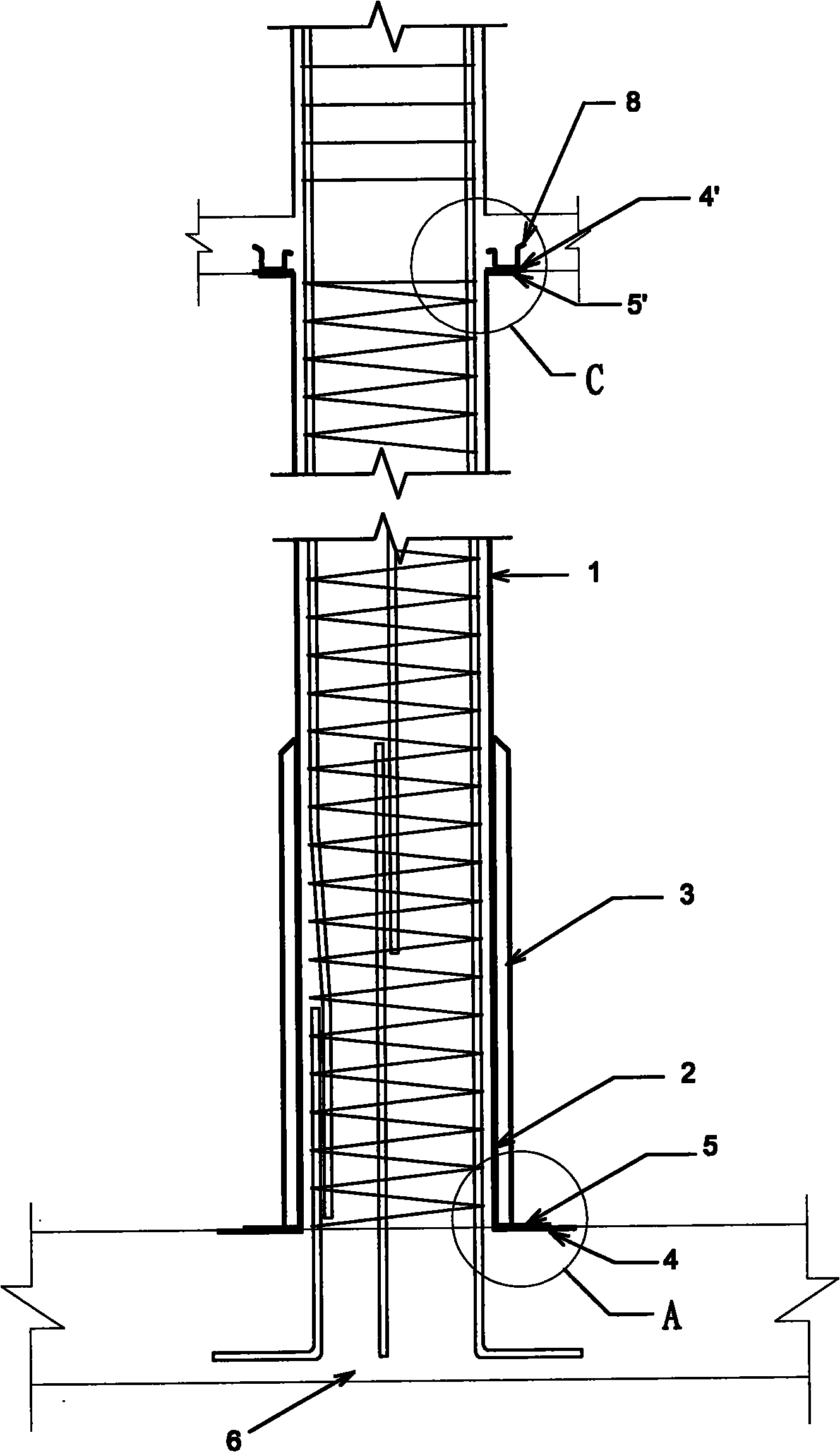

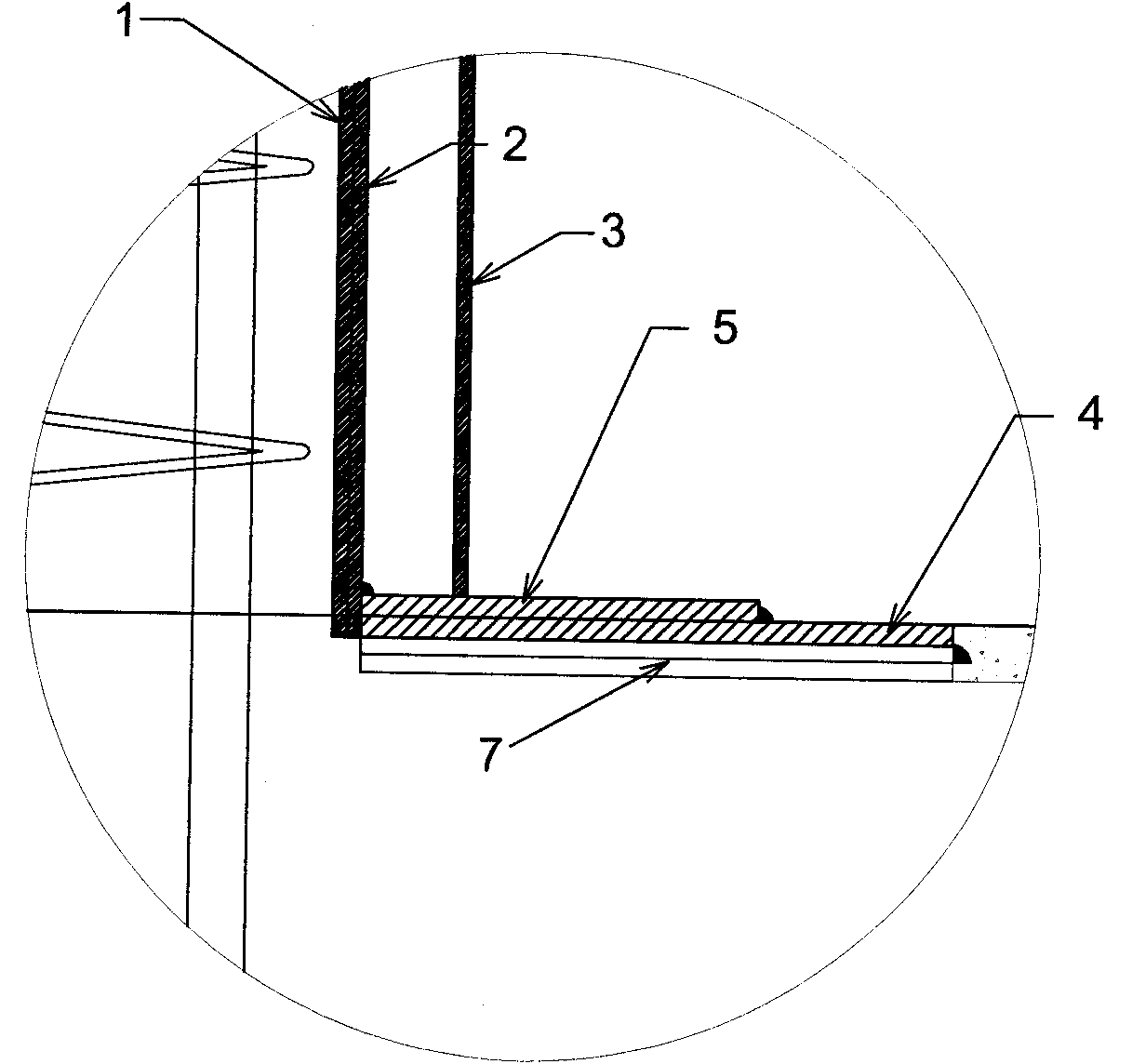

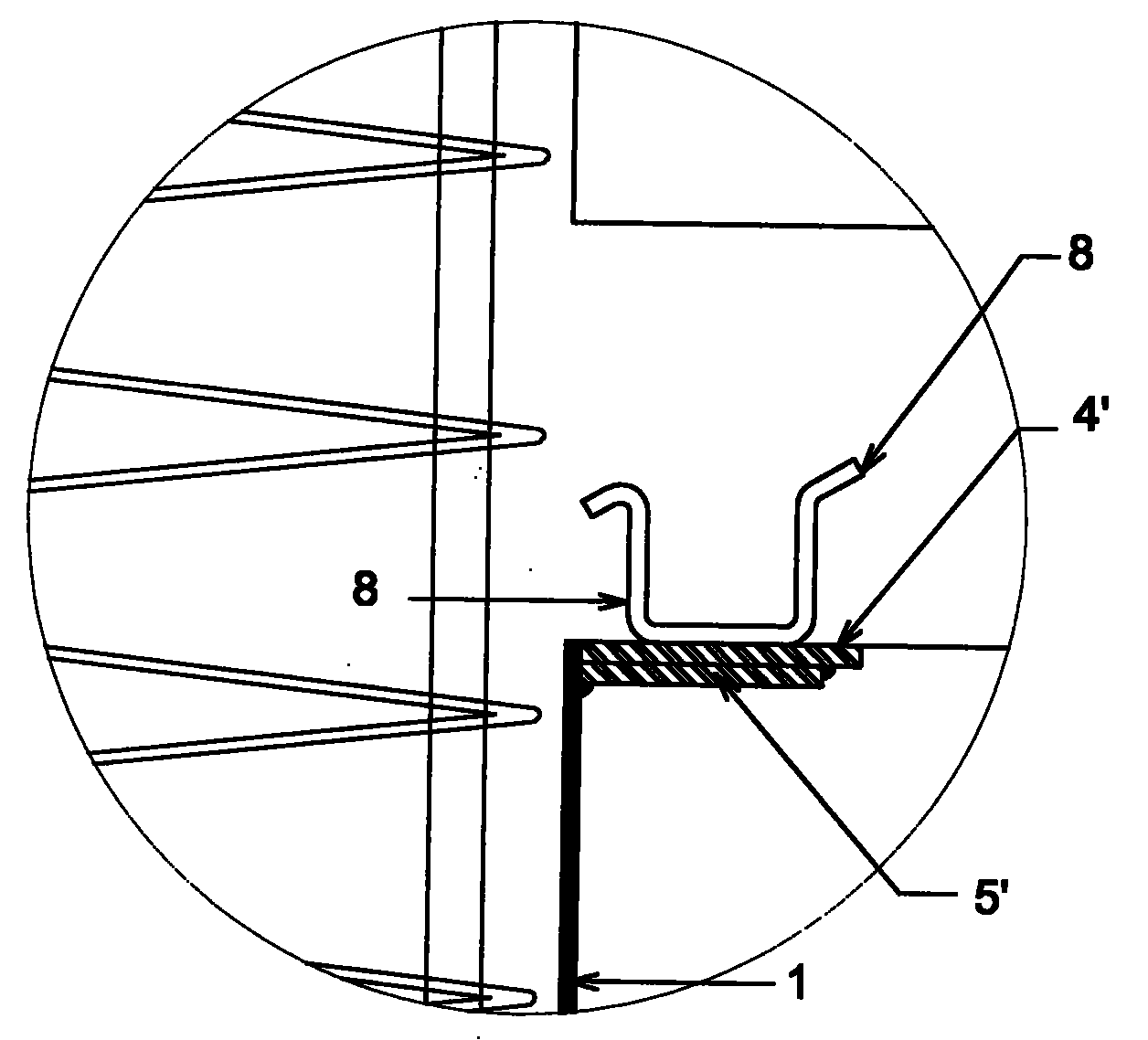

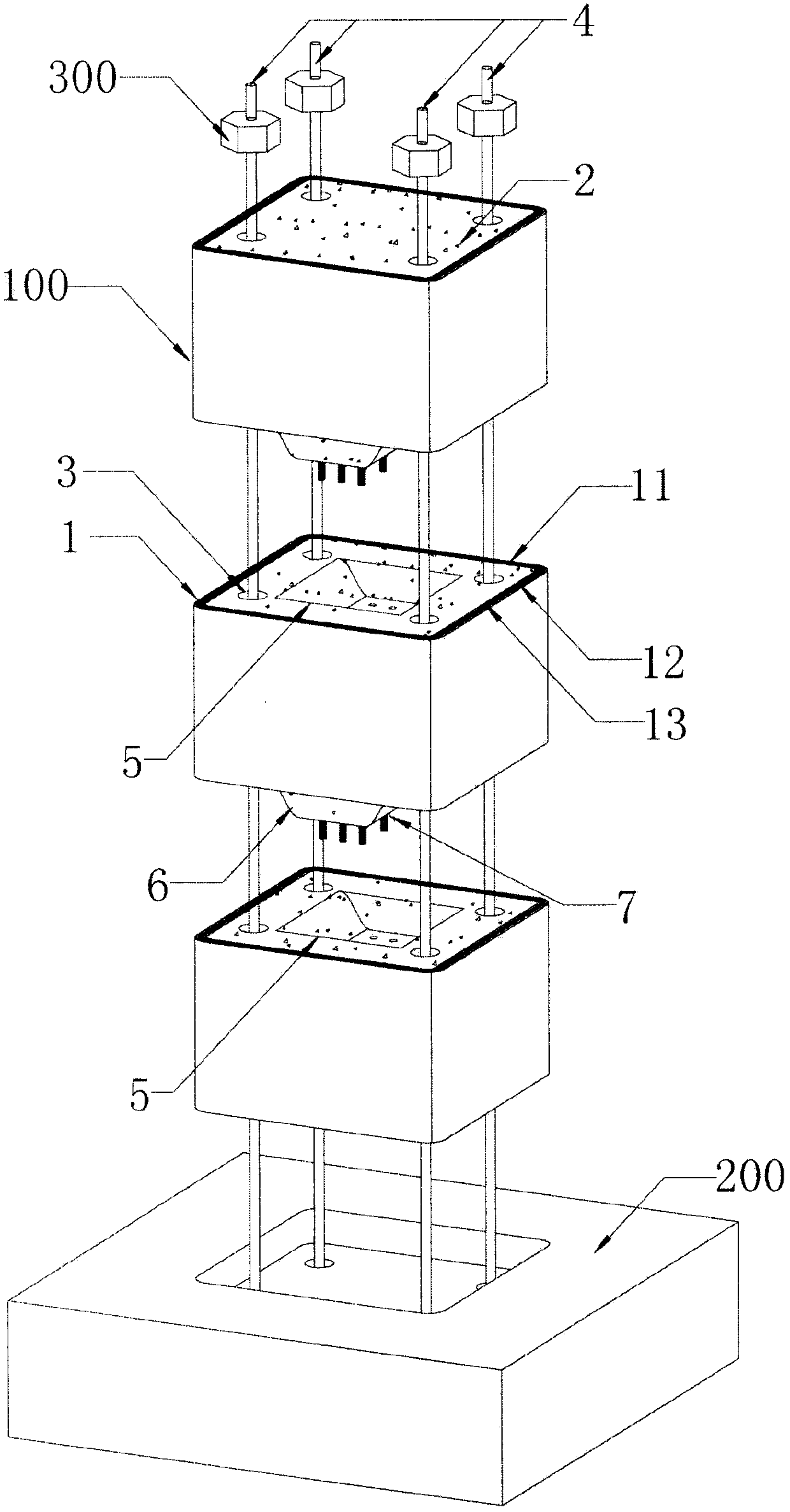

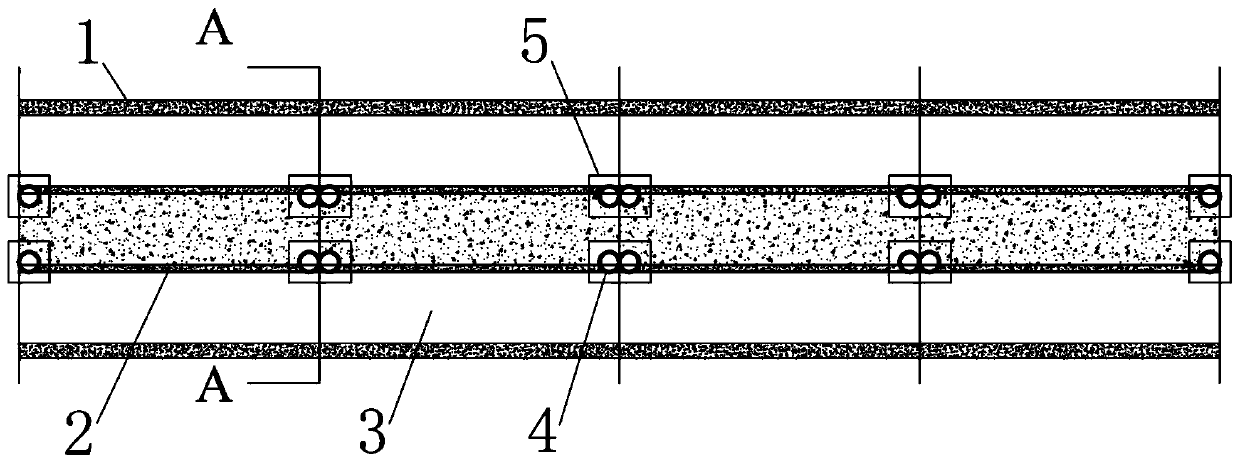

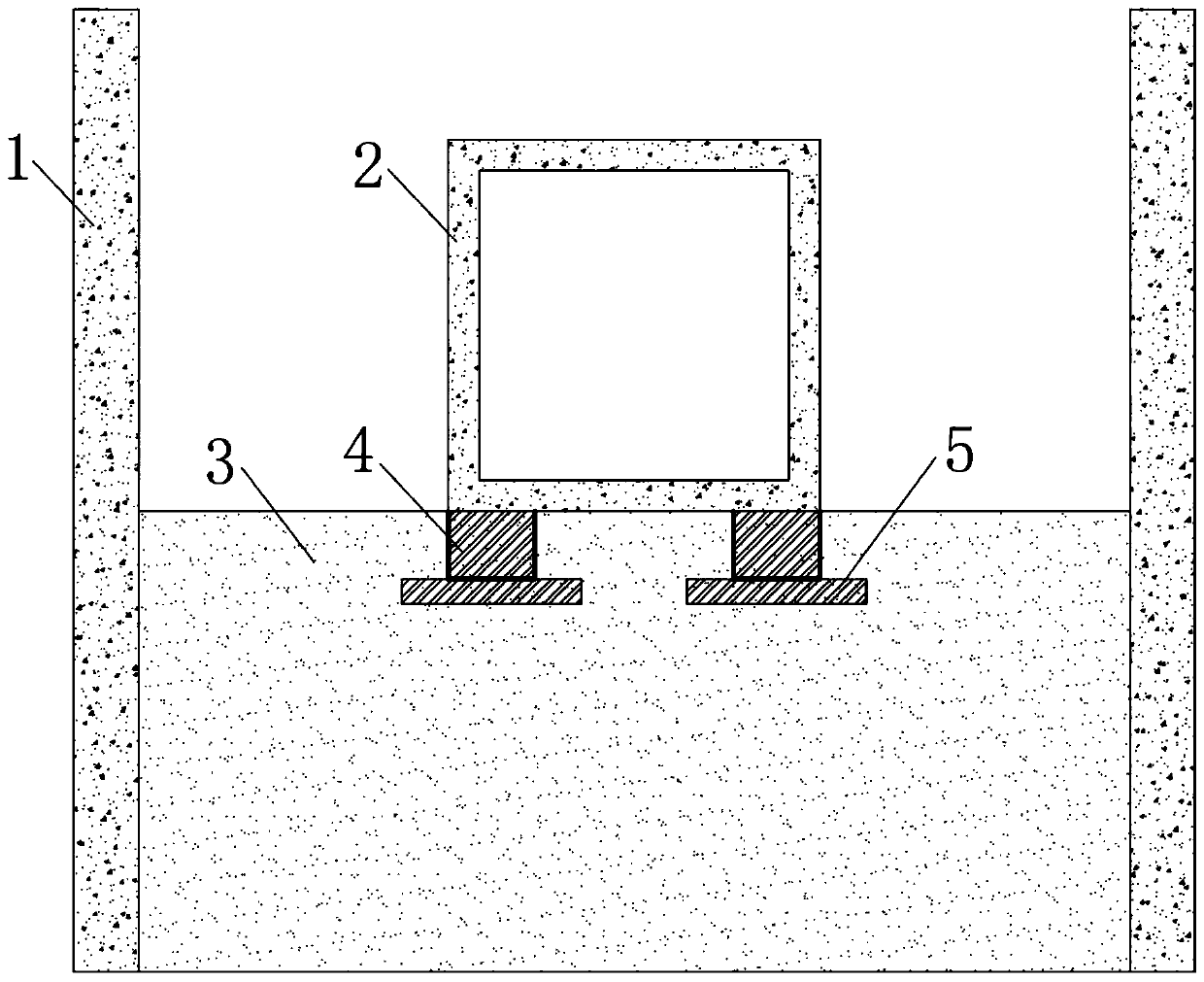

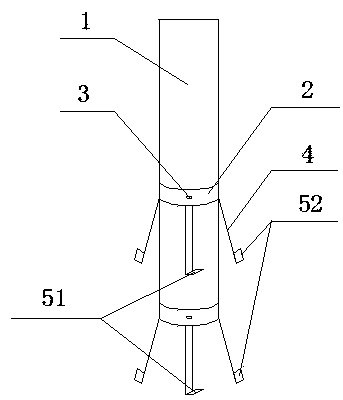

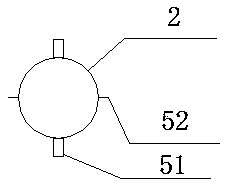

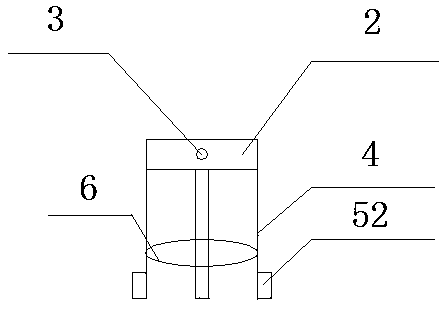

Assembly-type composite tube sea-water sea-sand concrete bridge pier and manufacturing method

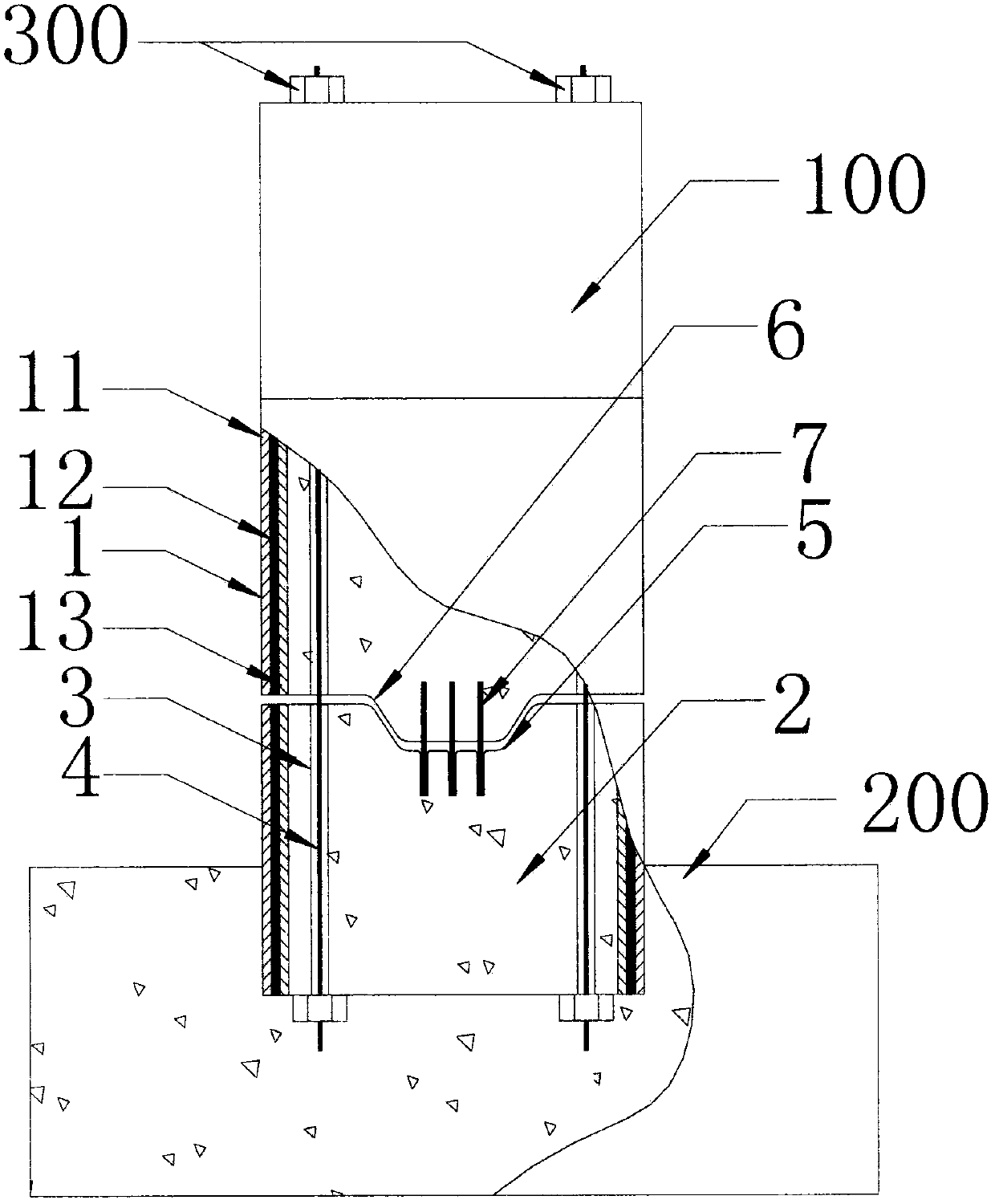

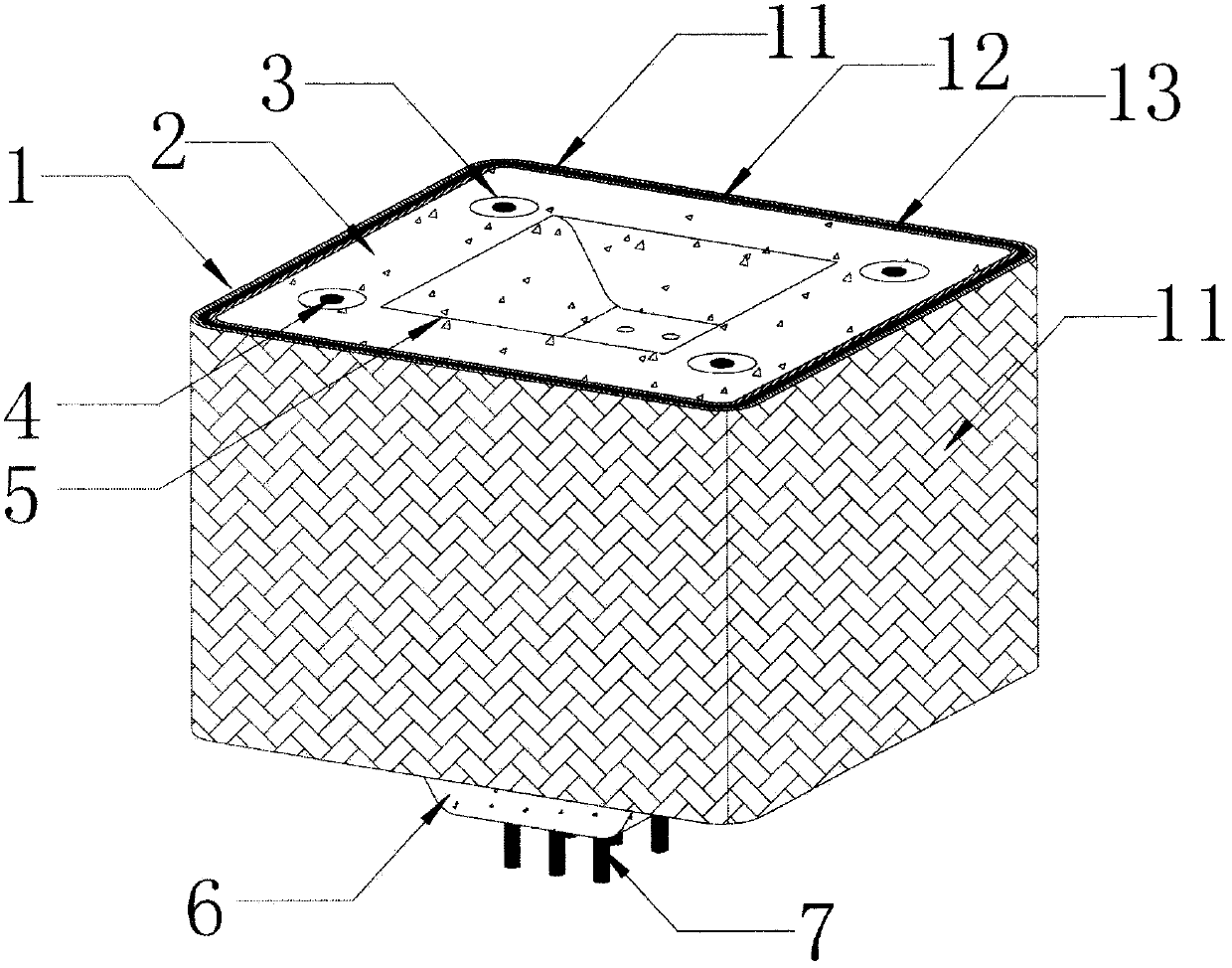

PendingCN107806010AImprove restraintGuaranteed shear capacityBridge structural detailsBridge erection/assemblyPre stressSeawater

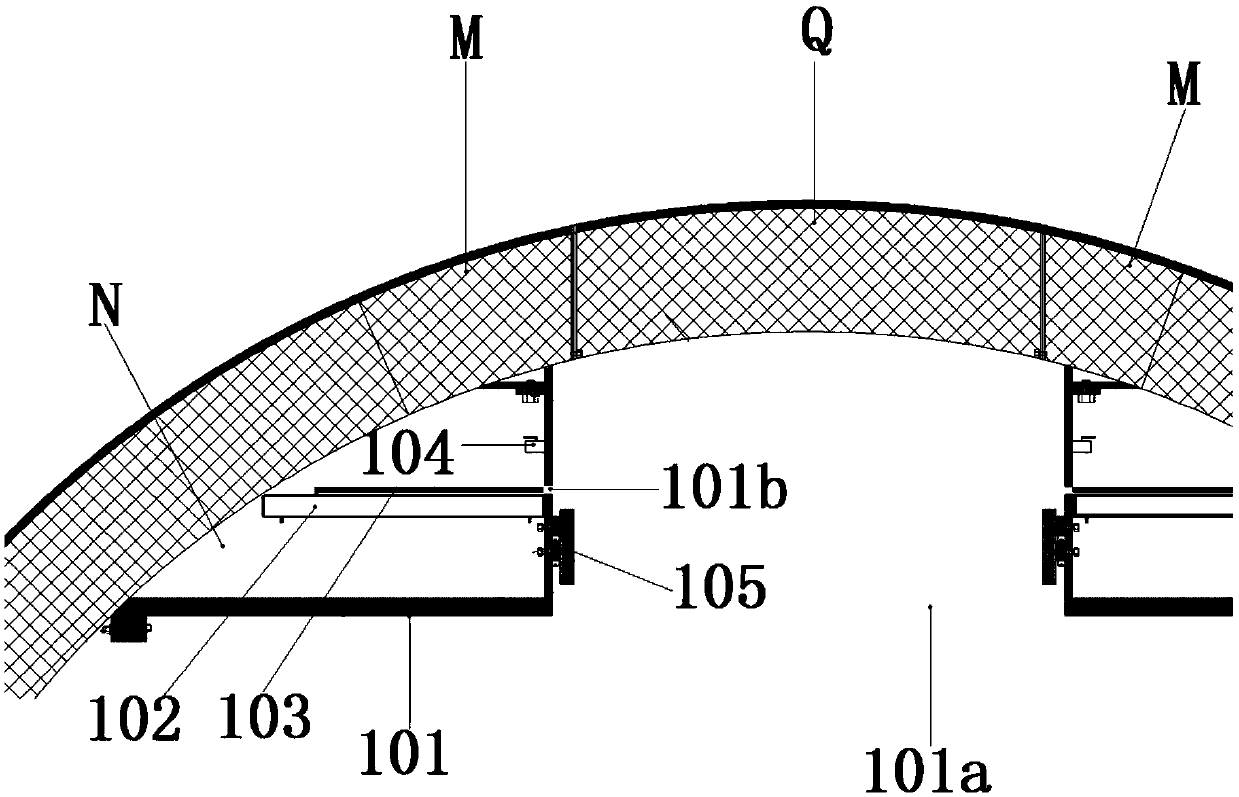

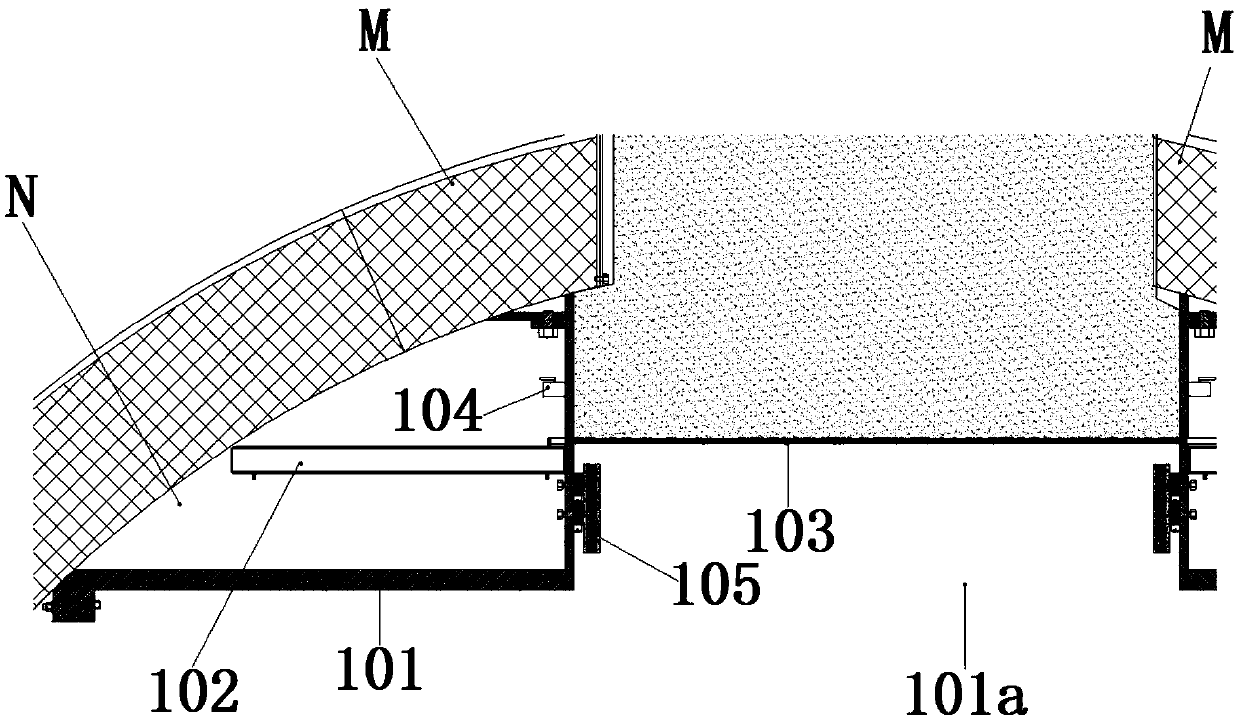

The invention discloses an assembly-type composite tube sea-water sea-sand concrete bridge pier. The structure of the bridge pier is composed of multiple composite tube sea-water sea-sand concrete column segments (100) which can be stacked, and the composite tube sea-water sea-sand concrete column segments (100) are connected into an entirety through back-tension prestressing force. The assembly-type composite tube sea-water sea-sand concrete bridge pier is characterized in that the composite tube sea-water sea-sand concrete bridge pier column segments are formed by composite tubes (1), sea-water sea-sand concrete (2), corrugated pipes (3), prestressing ribs (4) and anti-shear ribs (7), one or more pairs of protruding ribs (6) and grooves (5) are arranged between seams of every two composite tube sea-water sea-sand concrete bridge pier column segments, and the protruding ribs (6) and the grooves (5) are glued through a cementing material; each composite tube sea-water sea-sand concretebridge pier column segment (100) is provided with the corresponding corrugated pipe (3) in the height direction, and one or more prestressing ribs (4) penetrate through the corrugated pipes (3) of each column segment. The assembly-type composite tube sea-water sea-sand concrete bridge pier has the advantages that the bridge pier is good in durability, high in bearing capacity and good in corrosion resistance, the materials are easy to take, and the bridge pier is beneficial to sustainable development; meanwhile, the structure of the assembly-type composite tube sea-water sea-sand concrete bridge pier has the advantages that the structure can be prefabricated and transported in a large scale, is convenient to mount, short in construction period, low in energy consumption and little in environmental pollution, and can be suitable for marine engineering structural construction.

Owner:NANJING FORESTRY UNIV

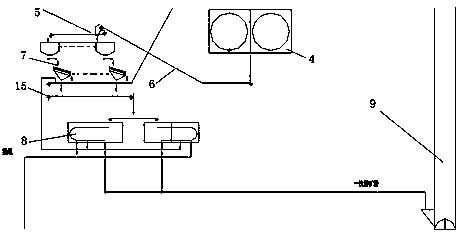

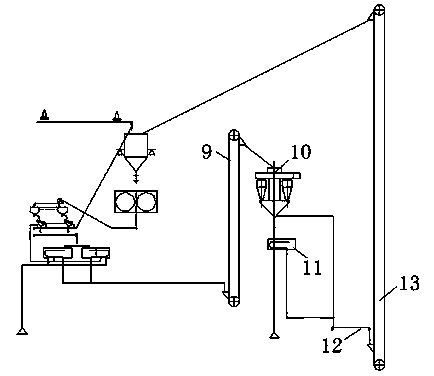

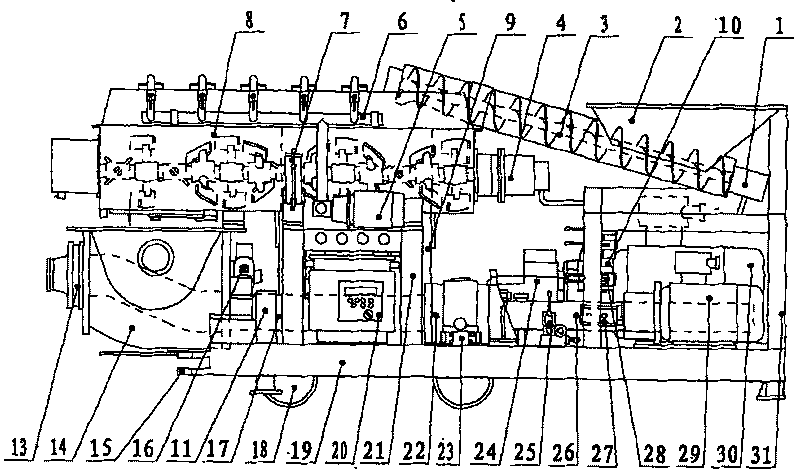

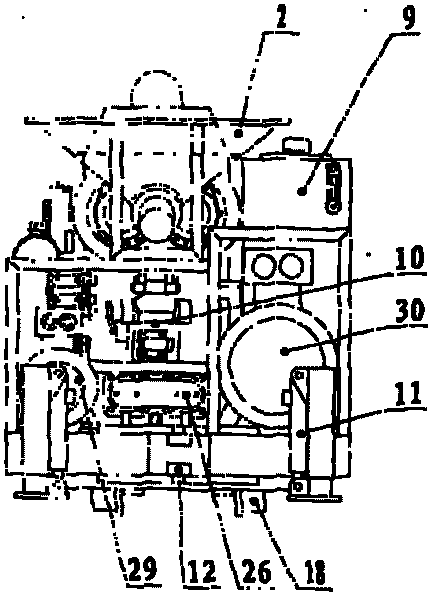

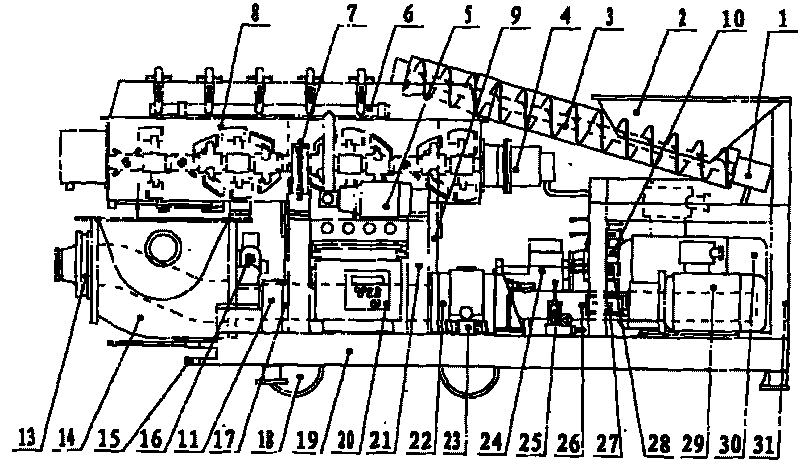

Concrete mixing and filling pump truck for mines

The invention discloses a concrete mixing and filling pump truck for mines. In the invention, a dry concrete mixed material feeder, a concrete mixer, a water supply system, a finished concrete conveying system, a hydraulic power system, a control system are all installed on a frame; rail wheels matched with rails are arranged at the lower end of the frame, and four support oil cylinders are arranged at the four corners of the frame. The mixer is a continuous double horizontal spindle concrete mixer used for realizing the continuous operation of concrete from dry material conveying to water supplying, mixing and conveying. The concrete mixing and filling pump truck for mines is small and flexible, does not need to be dissembled or assembled when moved in surface and underground operation, can work and be moved at anytime during working on the rails, and occupies small area in construction.

Owner:邵克文

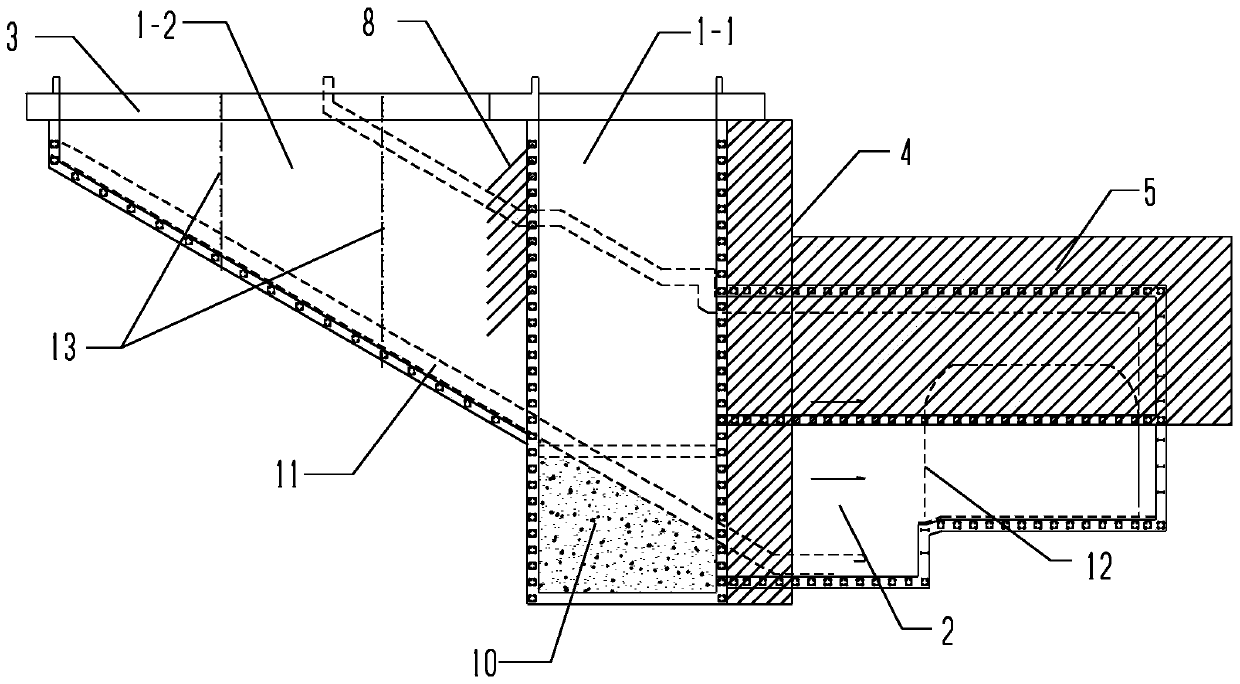

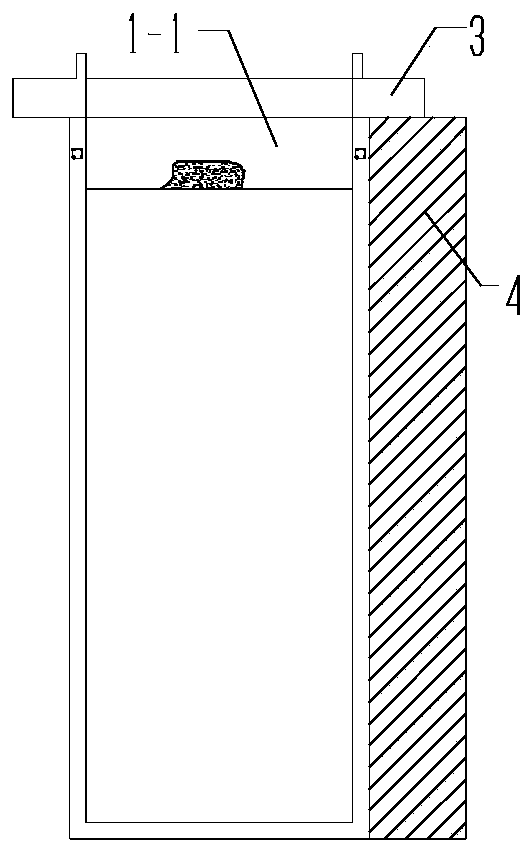

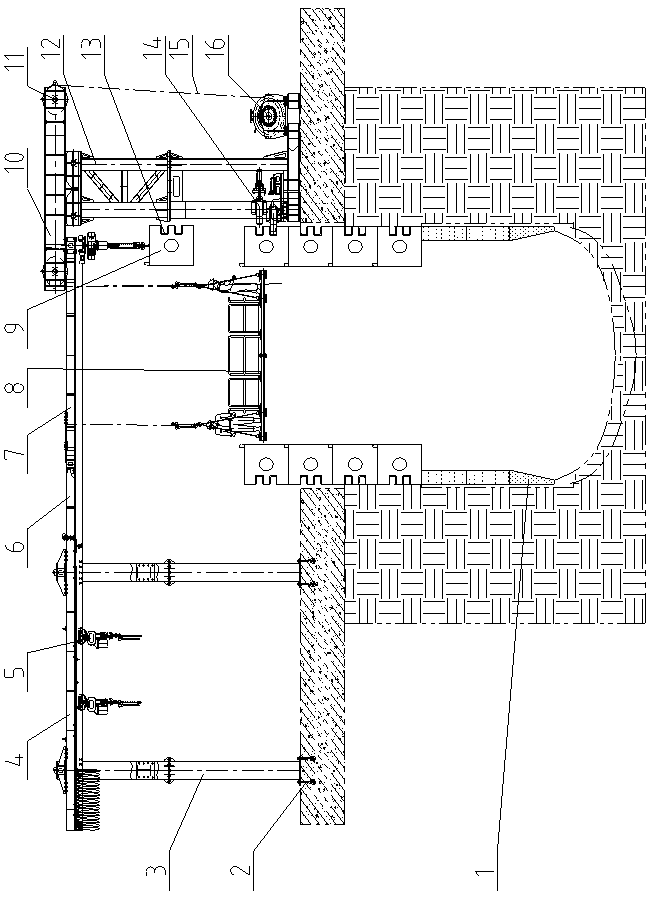

Segment mounting system applied to vertical shaft construction

The invention discloses a segment mounting system applied to vertical shaft construction. The system comprises a segment lifting device, wherein the segment lifting device comprises a segment crane and a crane rail, the crane rail comprises a horizontal rail, a connecting rail and an annular rail, the horizontal rail is fixed on a supporting frame I, and is connected with the annular rail throughthe connecting rail, and the annular rail is fixed on a supporting frame II, and is located above a vertical shaft opening. The system has the beneficial effects that the segments are prefabricated inadvance in a factory, are transported to a construction site in a blocking mode, and are small in occupied area; and the segment lifting device is controlled to travel along a specific track, and thesegments are lifted to a preset position, splicing, connecting and fixing of the segments are carried out on an operation platform, the segments are laid down through a segment lowering device, a segment splicing machine with a complicated freedom degree is not needed in the segment mounting process, and the mechanical equipment is simple in structure.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

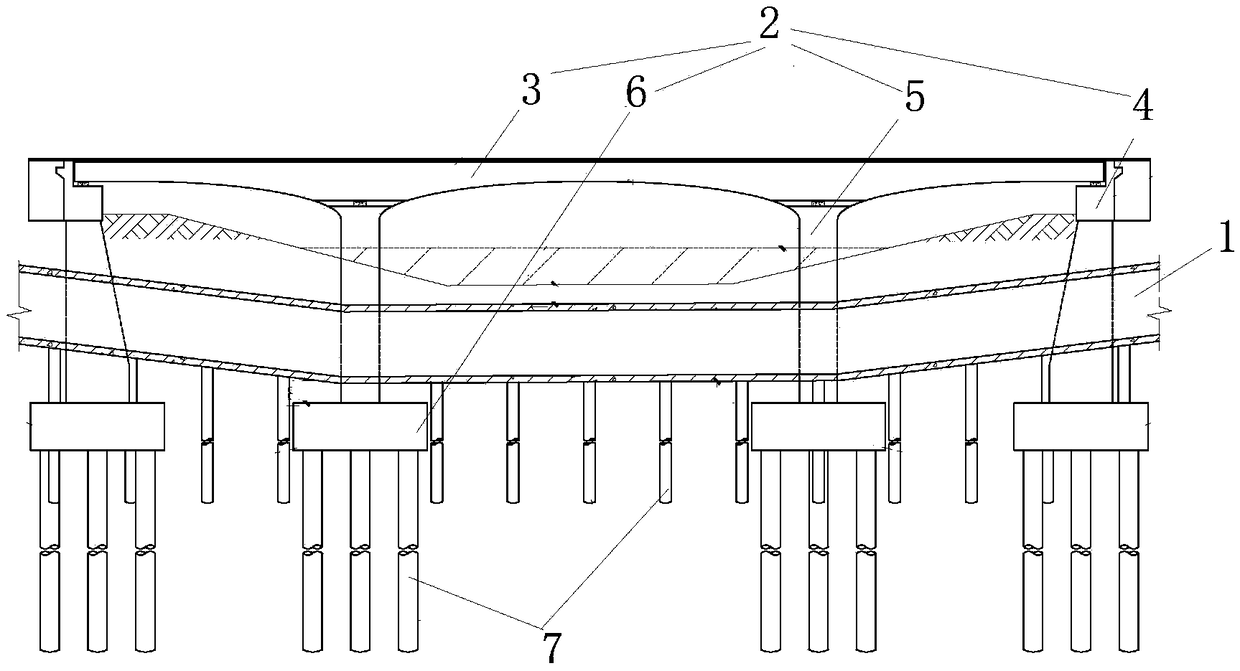

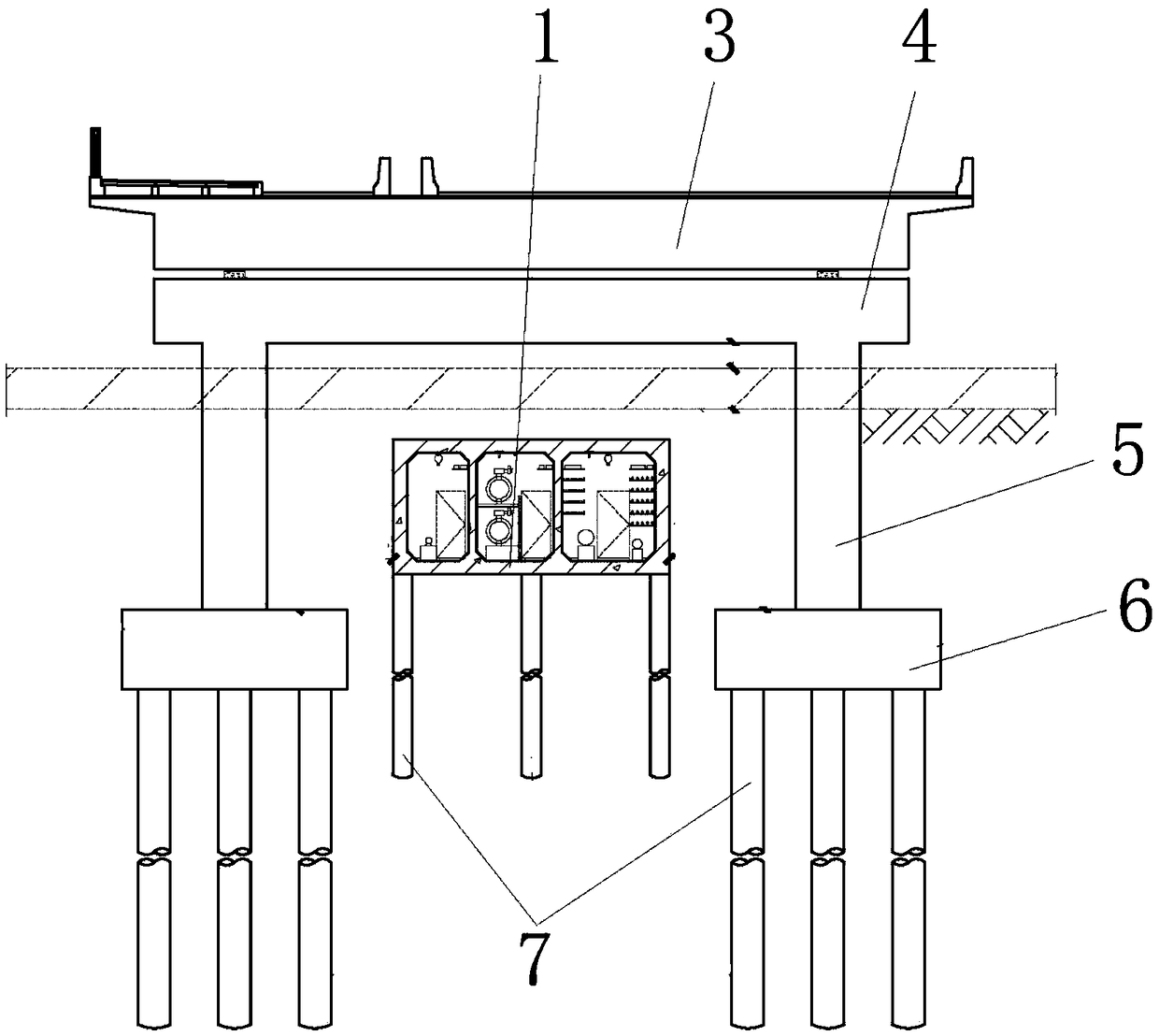

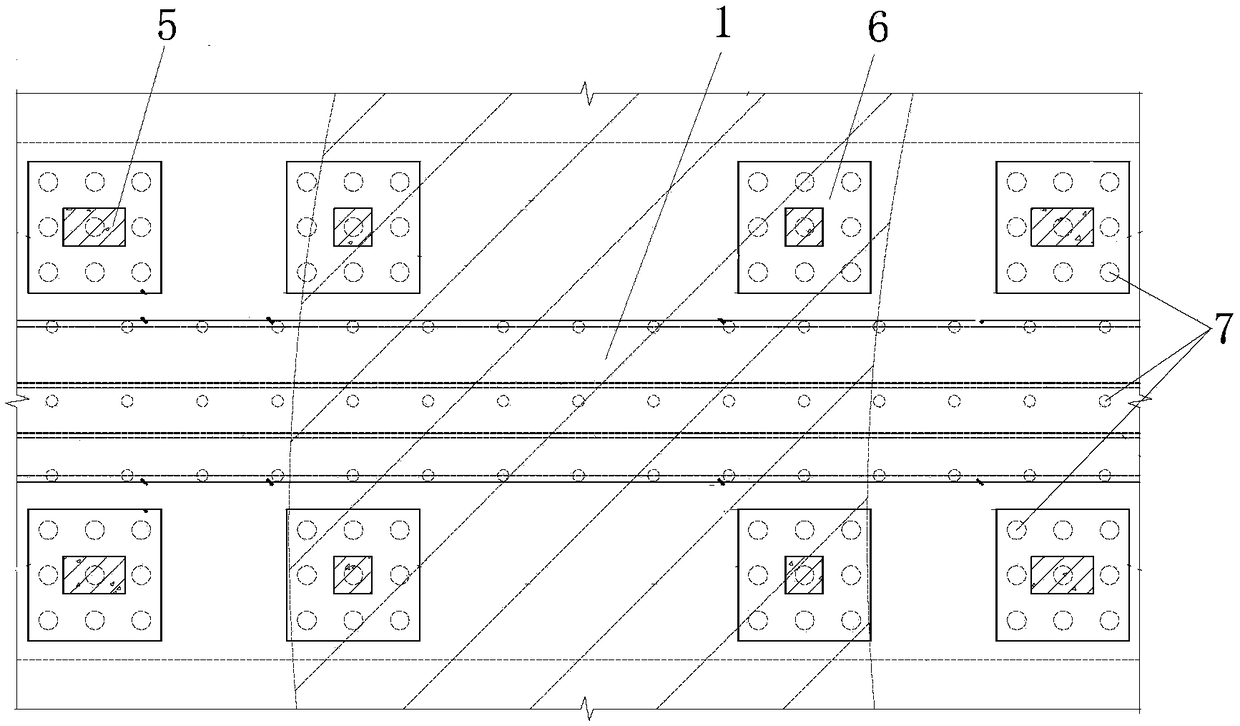

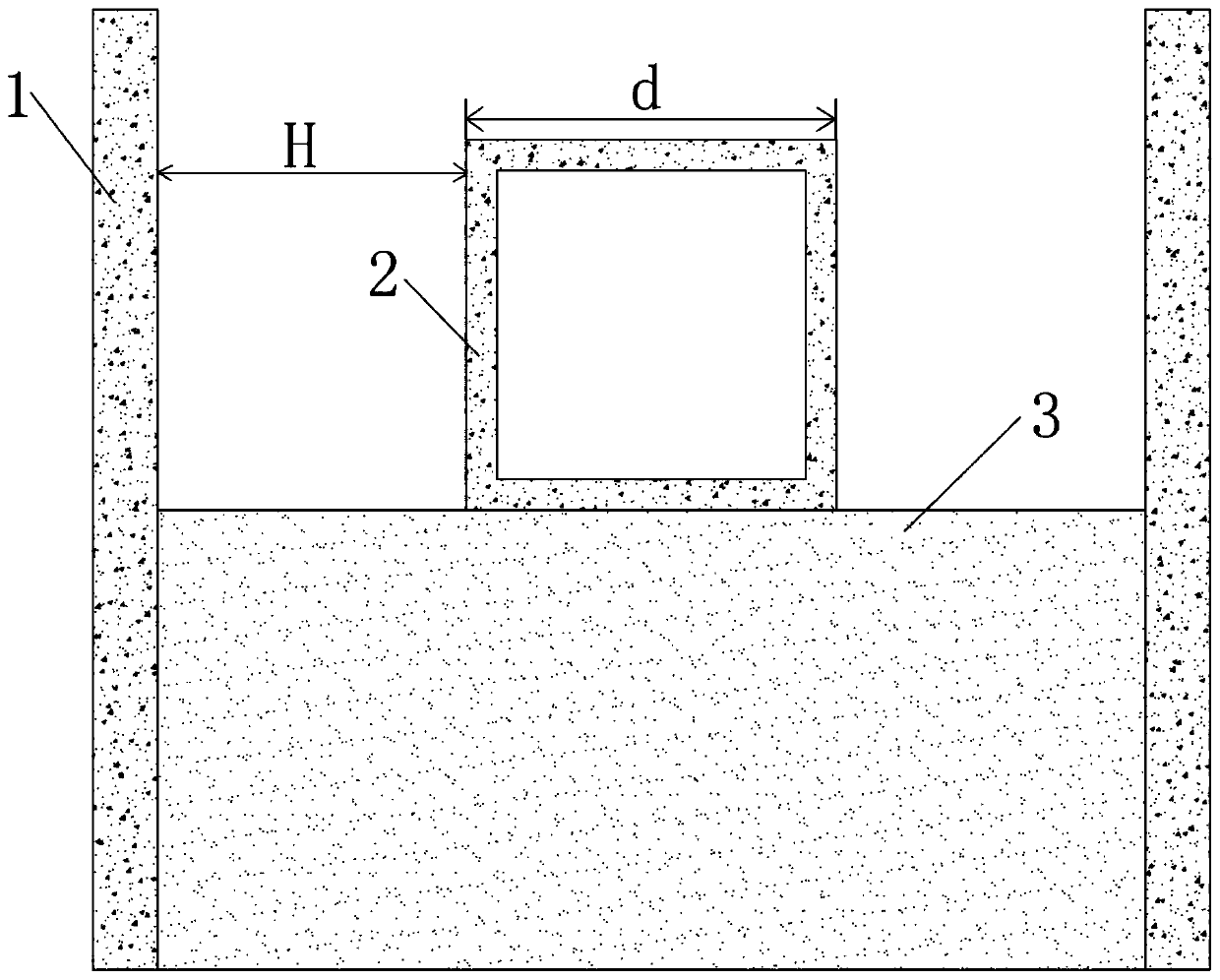

Underground tunnel pass-through bridge structure

PendingCN109235221AReduce space consumptionRealize the purpose of intensive land useArtificial islandsBridgesUnderground tunnelBridge deck

The invention discloses an underground tunnel pass-through bridge structure, which comprises an underground tunnel and a bridge, wherein the bridge comprises a bridge span, a bearing cap, a bridge pier and a pier abutment; the underground tunnel is arranged directly below the bridge span; the underground tunnel is consistent with the extension direction of the bridge span; and foundation piles arearranged at the bottom of the underground tunnel and the pier abutment. In the invention, the technical scheme avoids the underground tunnel from bypassing the bridge and crossing the river, reducesthe space occupation, thereby realizing the purpose of intensive land use, meanwhile, reduces the envelope construction area, reduces the earth excavation cost, and thus reduces the engineering cost.By setting up underground tunnels, including pedestrian tunnels, vehicle tunnels and pipe corridors, the traffic pressure on the bridge deck can be effectively alleviated, and the traffic efficiency and safety can be improved.

Owner:SHANGHAI UNDERGROUND ARCHITECTURAL DESIGN & RESEARCH INSTITUTE

Existing pipe gallery underground space and supporting structure thereof and construction method of supporting structure

PendingCN110777850ASmall construction areaReduce construction areaArtificial islandsProtective foundationArchitectural engineeringPipe

The invention provides an existing pipe gallery underground space and a supporting structure thereof and a construction method of the supporting structure. The method comprises the steps that soil around a pipe gallery is pre-reinforced, and supporting walls are arranged along the two sides of the pipe gallery; soil is excavated to the bottom level position of the pipe gallery, soil is drawn out below the pipe gallery in the length direction of the pipe gallery, so that multiple dispersed containing spaces are formed below the pipe gallery, and first support structures are arranged in the containing spaces; soil is excavated to the position below the pipe gallery, the first support structures are dismounted in sequence, meanwhile, plate-shaped second support structures are paved below thepipe gallery to replace the first support structures, and the second support structures are jointed to form a support plate to abut against the position below the pipe gallery; the underground space is excavated, and support piles are arranged according to the positions of structure piles in the design drawing of the newly-added underground space; and a bottom plate is poured at the bottom of theunderground space, and the bottom plate, the support piles and the supporting walls are connected into a whole. A construction foundation of a reverse building method is provided for excavation of theunderground space, and on the premise of guaranteeing that the existing pipe gallery is not influenced, the underground space is built.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

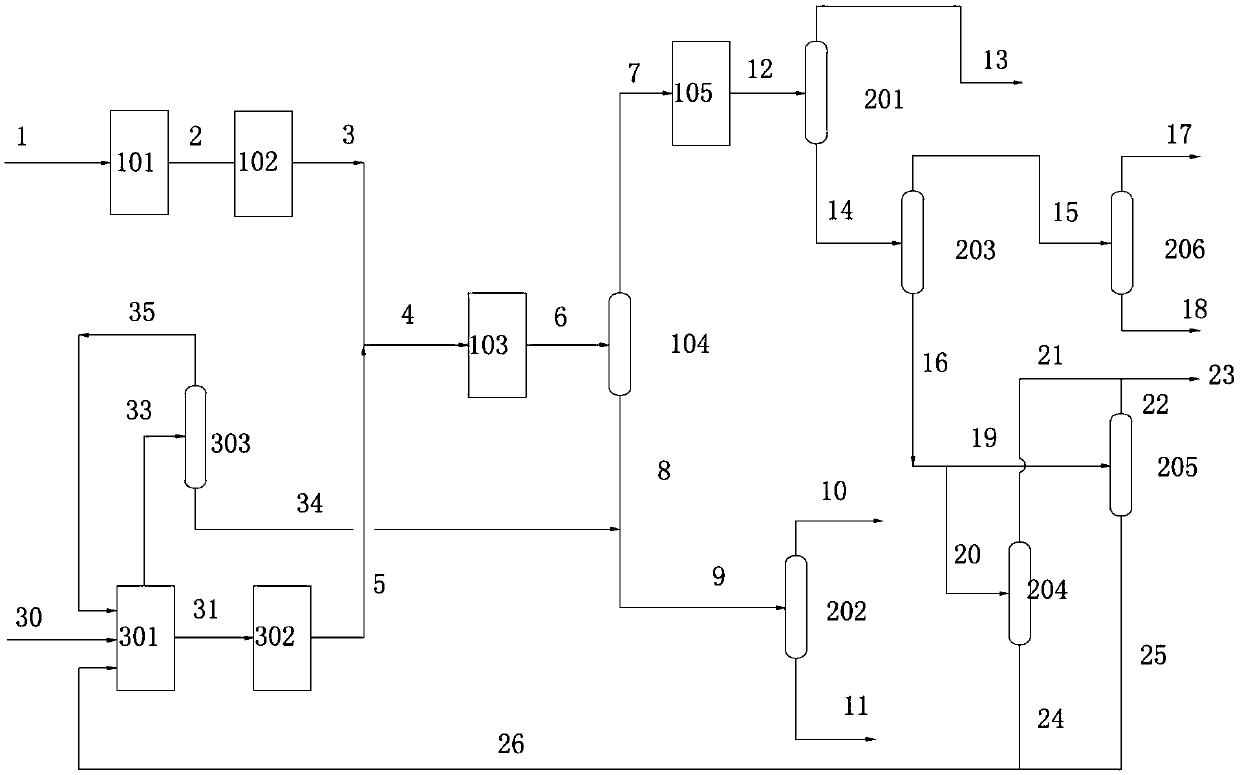

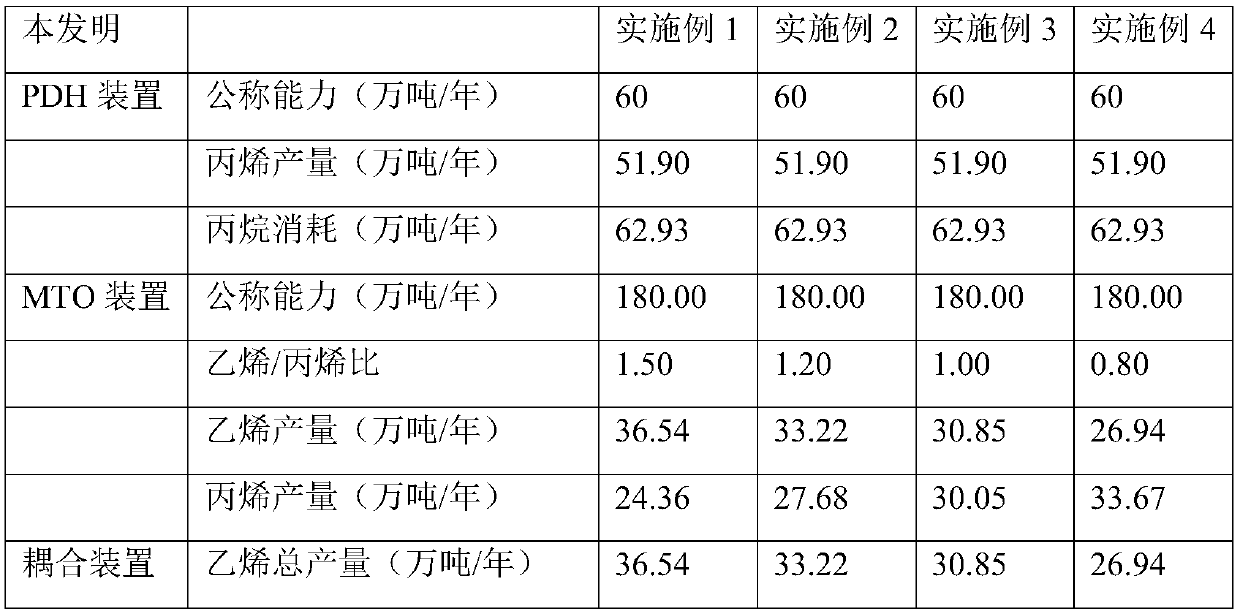

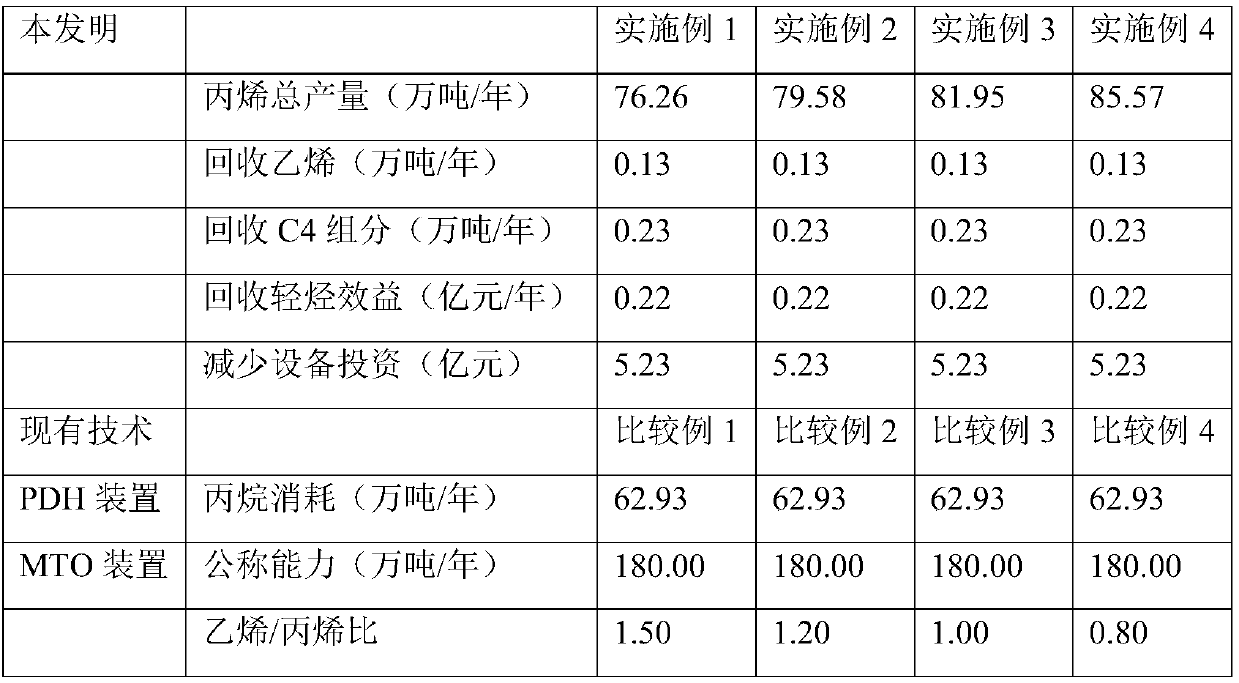

Coupling method of MTO process and propane dehydrogenation process

InactiveCN109651038AHigh recovery rateLow investment costHydrocarbon from oxygen organic compoundsHydrocarbonsHectareCoupling

The invention relates to a coupling method of MTO process and propane dehydrogenation process, and mainly solves the problems of low recovery rate of low carbon olefin, high equipment investment and large floor space in the prior art. The invention utilizes the method of coupling MTO process with propane dehydrogenation process, for a 1.8 million ton / year MTO device and 600,000 ton / year PDH device, the method utilizes the price advantage of methanol and propane, and depends on the existing equipment of MTO device to reduce the adding of new equipment, realizes the coupling of MTO and PDH, therefore, the light hydrocarbon recovery benefit is 22 million yuan / year, the equipment investment can be reduced by 523 million yuan, and the land occupation can be used by 1.8 hectares. The technical scheme well solves the problems, and can be applied to the coupling of MTO process and propane dehydrogenation process.

Owner:SINOPEC SHANGHAI ENG +1

Simple buried installation fixed bracket and installation method thereof

The invention discloses a simple buried installation fixed bracket and an installation method thereof. The simple buried installation fixed bracket comprises a column body, an installation ring which sleeves the column body, an installation hole which is formed in a middle position of the side surface of the installation ring, support rods which are arranged on the lower end edge of the installation ring, and upper and lower fixing legs or rotating fixing legs which are arranged on the tail ends of the support rods. By adopting the simple buried installation fixed bracket and the installation method thereof, simplicity in installation is realized, the manpower and material resources can be saved, the installation procedures can be simplified, the installation time can be saved, the installation efficiency can be improved, and the installation cost can be reduced; the support rod is recyclable, so that the recycling of the resources is realized, the construction area is reduced, energy conservation and environmental protection can be realized, flexibility in installation can be realized, upward unplugging, sinking and rotation can be prevented, the firmness degree is high, safety is high, and simplicity in maintenance can be realized.

Owner:袁见见

Lifting communication base station iron tower

The invention discloses a lifting communication base station iron tower which comprises a communication base station iron tower, an electromotor, a winch, a steel wire rope, pulleys and communication base station iron tower sections made from connected communication base station iron tower parts and components; the electromotor and the winch are arranged on the sections of a communication base station iron tower base; the pulleys are fixedly arranged on the upper ends of all sections of the communication base station iron tower; one end of the steel wire rope is fixed on the winch and the other end thereof sequentially passes through the pulleys and finally is fixed on the pulley arranged on the section of the iron tower of the communication base station iron tower to be locked, thus forming a full set of pulley system; all the sections of the communication base station iron tower can be foldable and sleeved together; when the communication base station iron tower is arranged, the electric machine drives the winch to rotate, the steel wire rope winds around the winch, and the steel wire rope is combined with the pulley group and drives the sections of the communication base station iron towers to lift section by section. The lifting communication base station iron tower has the advantages that the assembly of the sections of the communication base station iron tower can be finished before all the sections are transported into the construction site, the communication base station iron tower can be conveniently and rapidly arranged, has few upper air quantity of work, good safety and very small construction floor space, is easily coordinated and can be arranged and constructed at any time.

Owner:JILIN HONGBANG STEEL STRUCTURE MFG

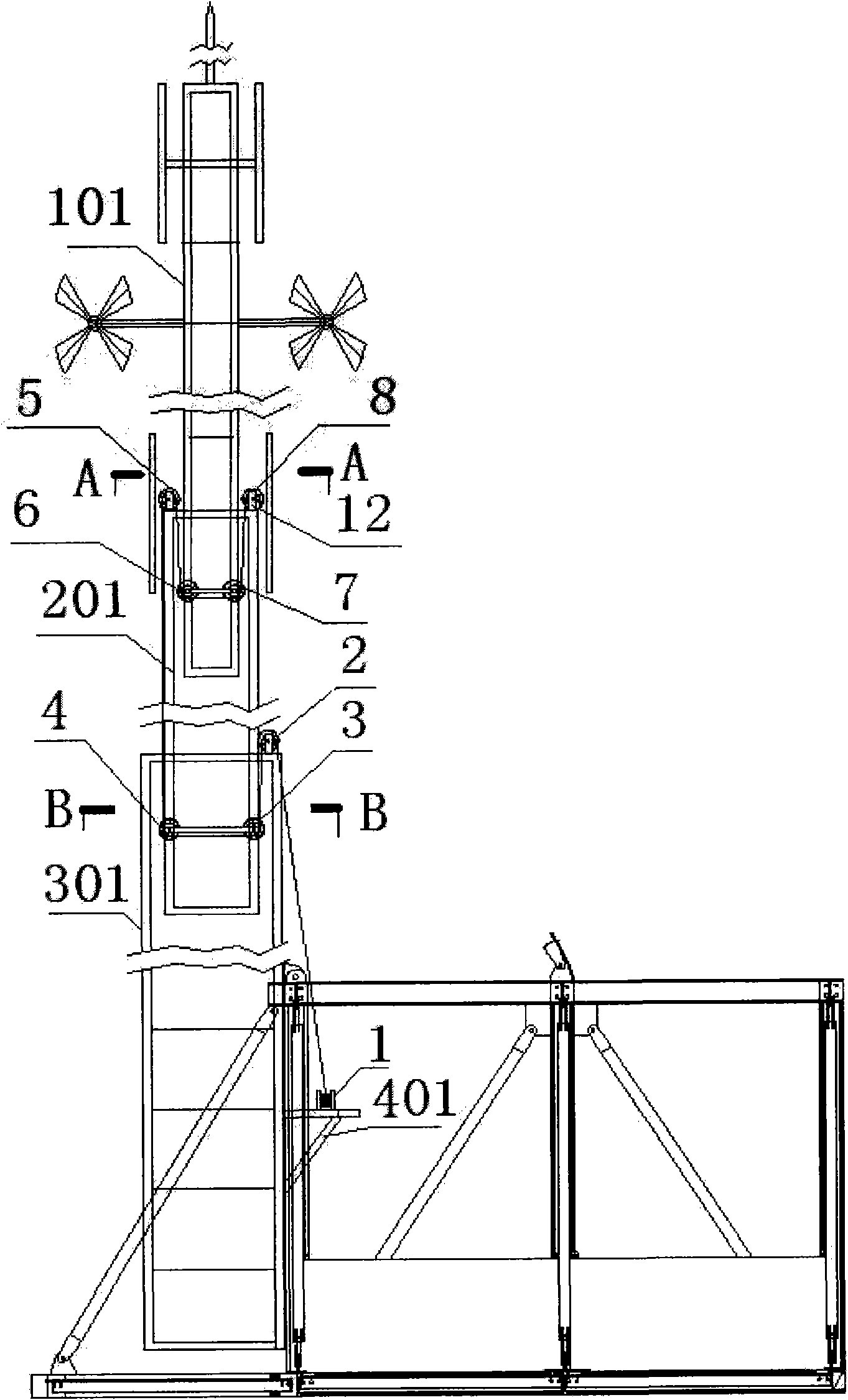

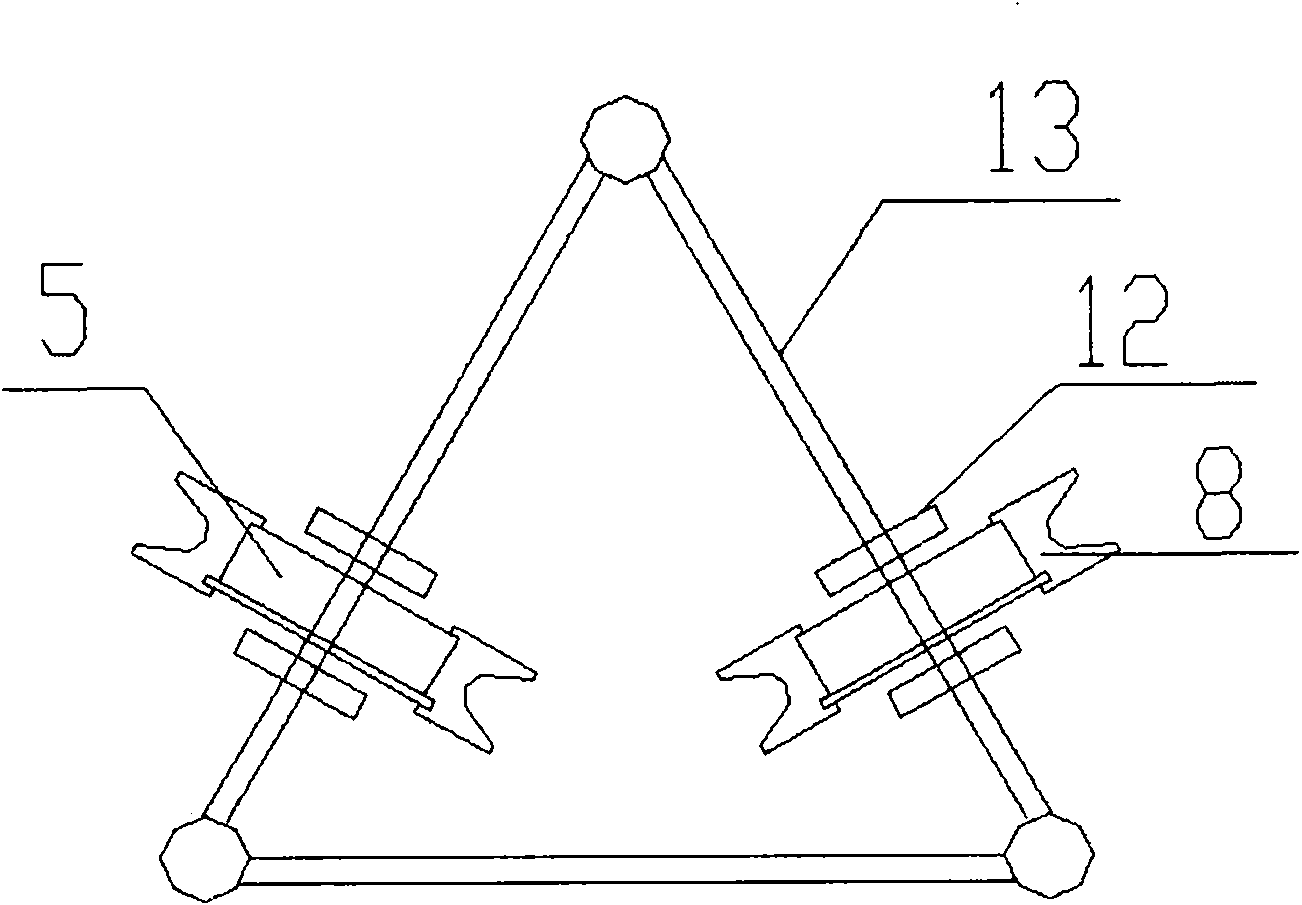

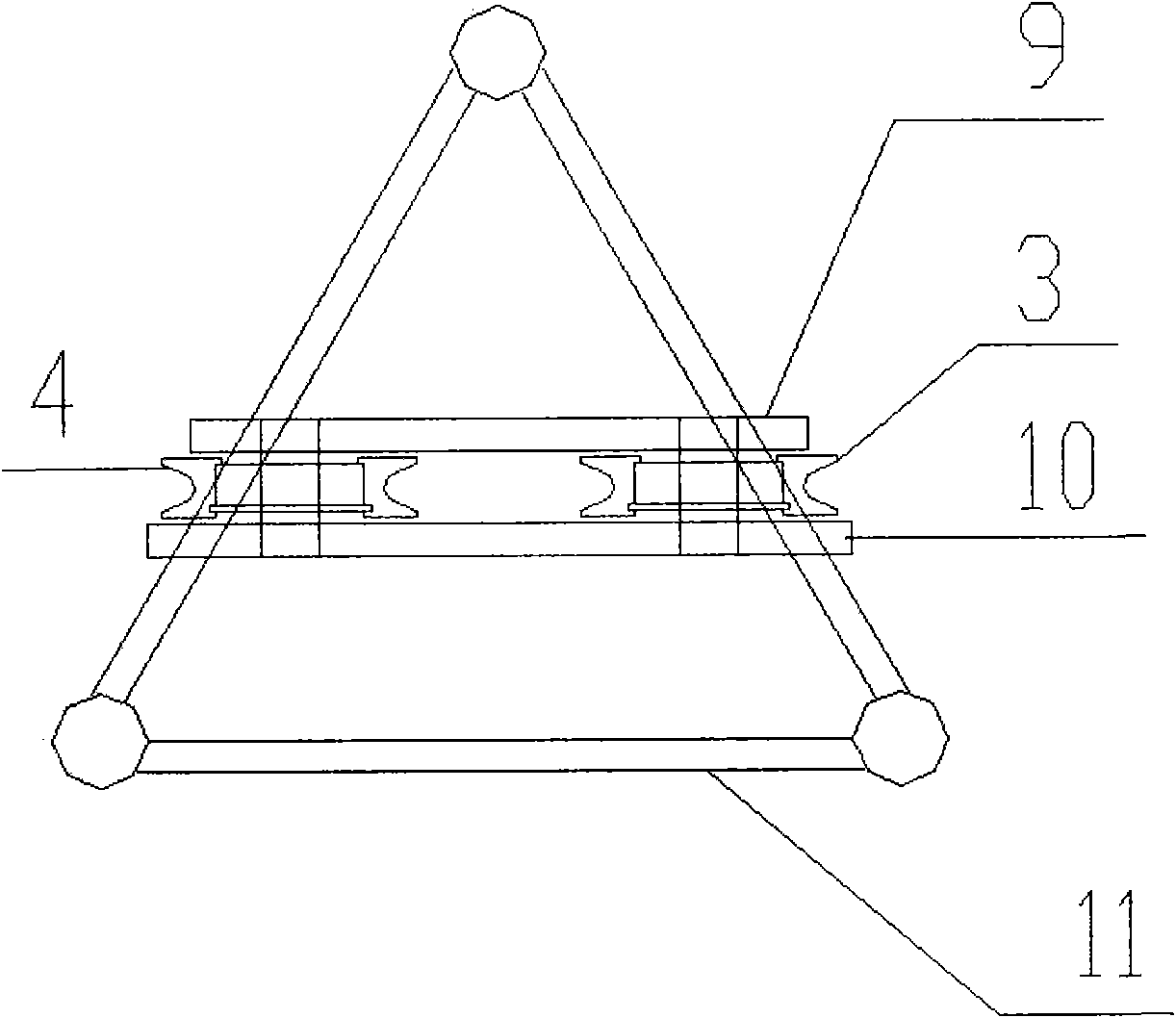

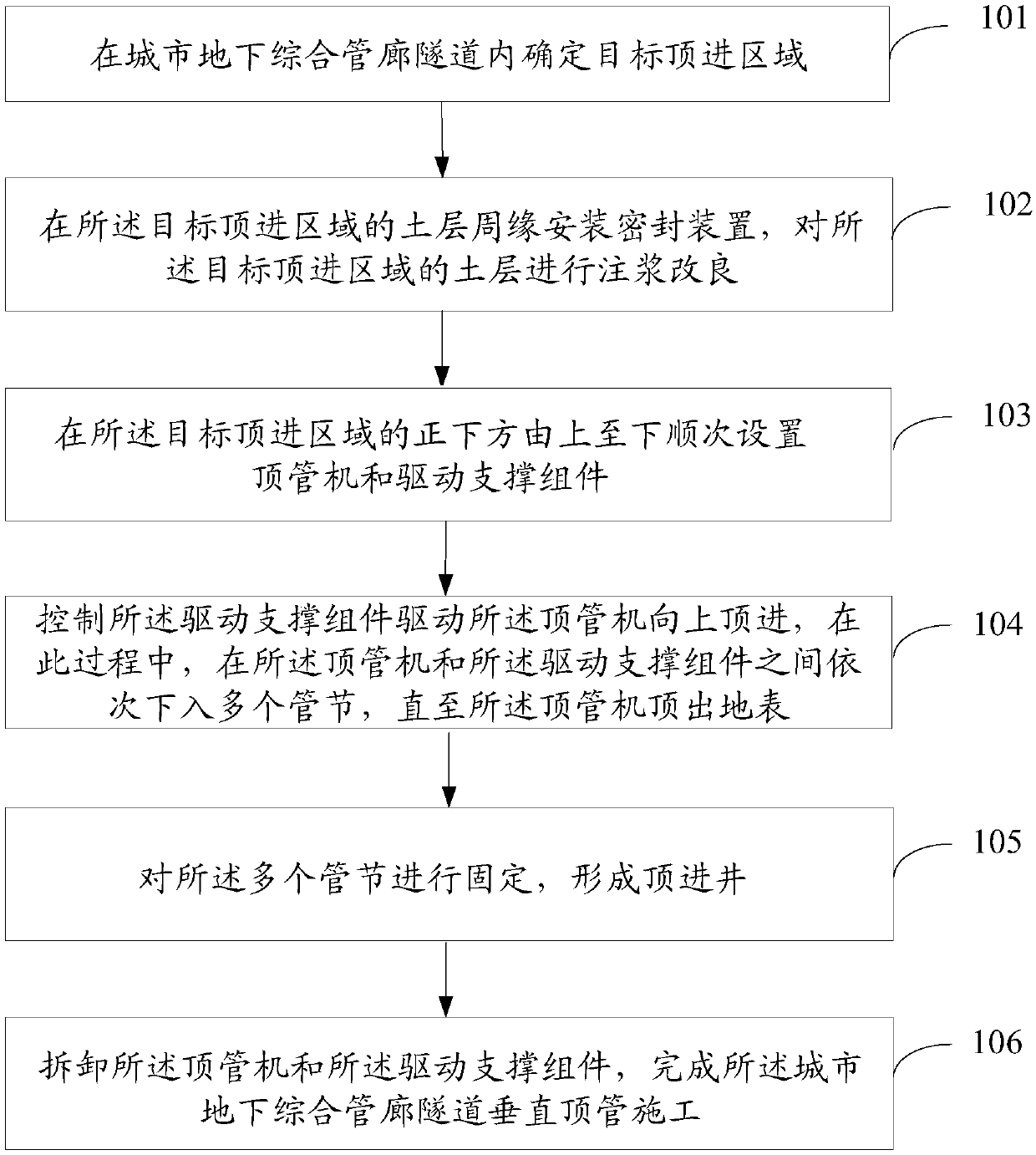

Construction method of vertical pipe jacking of urban underground comprehensive pipe gallery tunnel

ActiveCN110388215AImprove construction efficiencySmall construction areaTunnelsTunnel constructionSoil horizon

The invention discloses a construction method of the vertical pipe jacking of an urban underground comprehensive pipe gallery tunnel, and belongs to the technical field of pipe gallery tunnel construction. The method comprises the steps of determining a target jacking area in the urban underground comprehensive pipe gallery tunnel; installing a sealing device around a soil layer of the target jacking area, and improving the grouting of the soil layer of the target jacking area; arranging a pipe jacking machine and a driving support assembly in sequence from top to bottom just below the targetjacking area; controlling the driving support assembly to drive the pipe jacking machine to jack upwards, and arranging a plurality of pipe joints in sequence between the pipe jacking machine and thedriving support assembly in the process until the pipe jacking machine is ejected out of the ground; fixing the plurality of pipe joints so as to form a jacking well; and removing the pipe jacking machine and the driving support assembly so as to complete the construction of the vertical pipe jacking of the urban underground comprehensive pipe gallery tunnel. According to the method, by constructing the underground vertical pipe jacking, the construction efficiency is improved, the construction area is reduced, and potential safety hazards of collapse and the like are avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

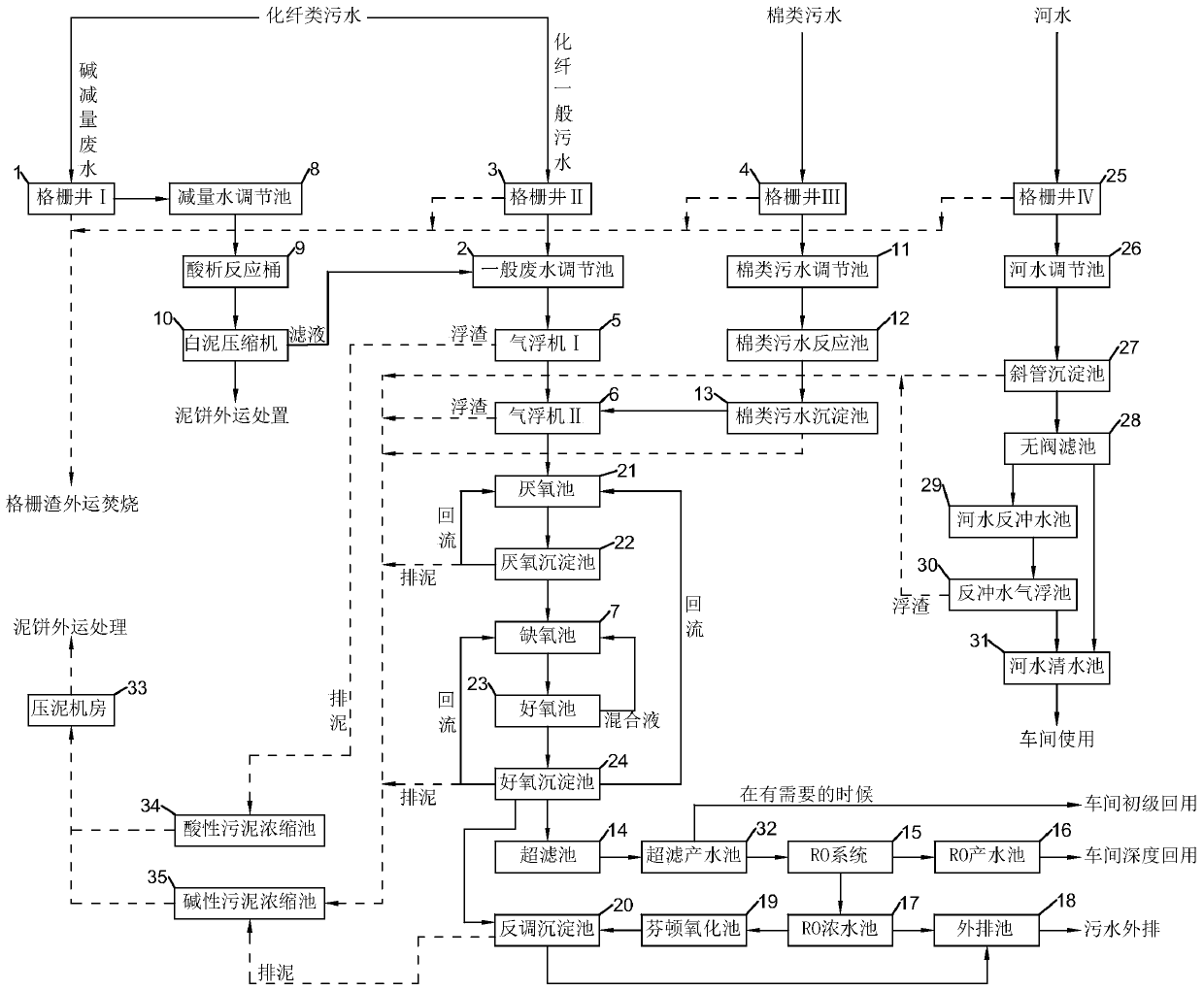

Printing and dyeing sewage classification treatment process

PendingCN110217947AGood technical effectLow running costWater treatment compoundsTreatment involving filtrationFiberSewage

The invention discloses a printing and dyeing sewage classification treatment process. Printing and dyeing sewage is divided into two broad categories of chemical fiber sewage and cotton comprehensivesewage, the chemical fiber sewage is divided into two sub-categories of alkali-reduced sewage and chemical fiber general sewage, and then treatment is carried out; an alkali-reduced filtrate is incorporated into a chemical fiber general filtrate, subsequent physicochemical process is carried out after adjustment, a medicament can be effectively saved, and thus the operation cost is reduced; the cotton comprehensive sewage is subjected to alkaline process treatment, and is use as an alkali source for reversed adjustment of a mixed sewage III, and thus an alkali use amount of chemical fiber sewage can be saved; cotton desizing sewage, cotton printing sewage and cotton dyeing sewage are combined into one category of sewage, namely the cotton comprehensive sewage, the concentration of pollutants can be averaged each other through mixing of three kinds of sewage, and treatment difficulty is reduced; at the same time, a construction area is reduced; and a pH value of the cotton comprehensive sewage can be controlled centrally to create prerequisites for the next step of mixing with the mixed sewage III.

Owner:浙江迈图环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com