Closed dry separation equipment for low-grade magnetite

A magnetite, low-grade technology, applied in the field of machinery, can solve the problems of not being able to meet the requirements of the mineral processing process, and achieve the effects of saving production costs and transportation costs, reducing construction, and changing technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

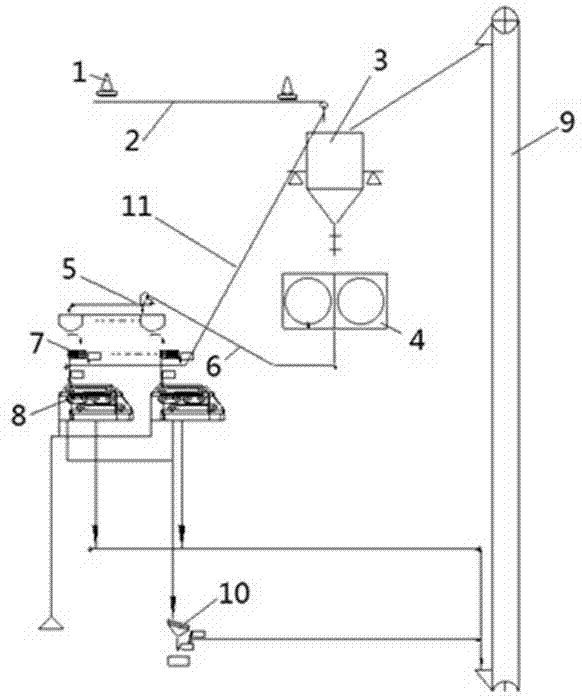

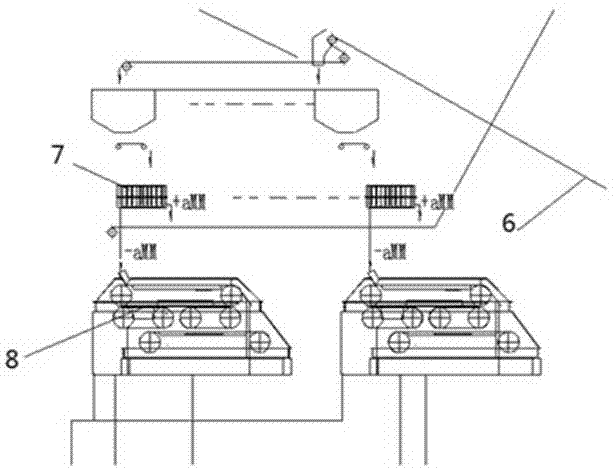

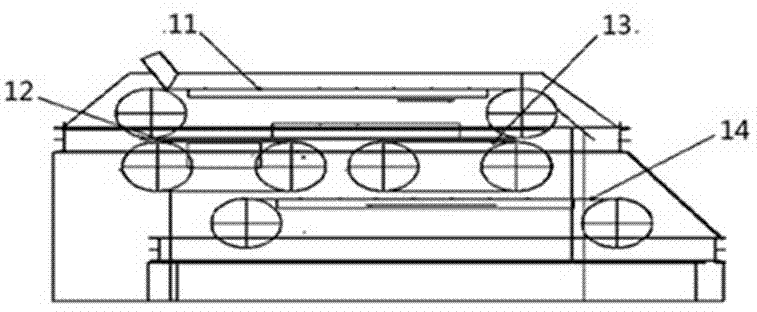

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0018] The low-grade magnetite closed-circuit dry separation equipment is characterized in that it includes a raw ore conveyor belt 2, a high-pressure roller mill 4 is located below the discharge part of the raw ore conveyor belt 2, and a discharge port below the high-pressure roller mill 4 Below is the belt, and below the conveyor end of the belt is the combined dry-type magnetic separator. The combined dry-type magnetic separator includes a frame, and the belts on the frame are installed by rollers. Both ends of the rollers can be rotatably installed on the frame, including the main belt. , there is a magnet between the upper and lower belt surfaces of the main belt, and the magnet is fixed by a plate on the frame. There are two rollers at both ends of the main belt, one of which is a magnetic roller, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com