Patents

Literature

991results about How to "Short process route" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

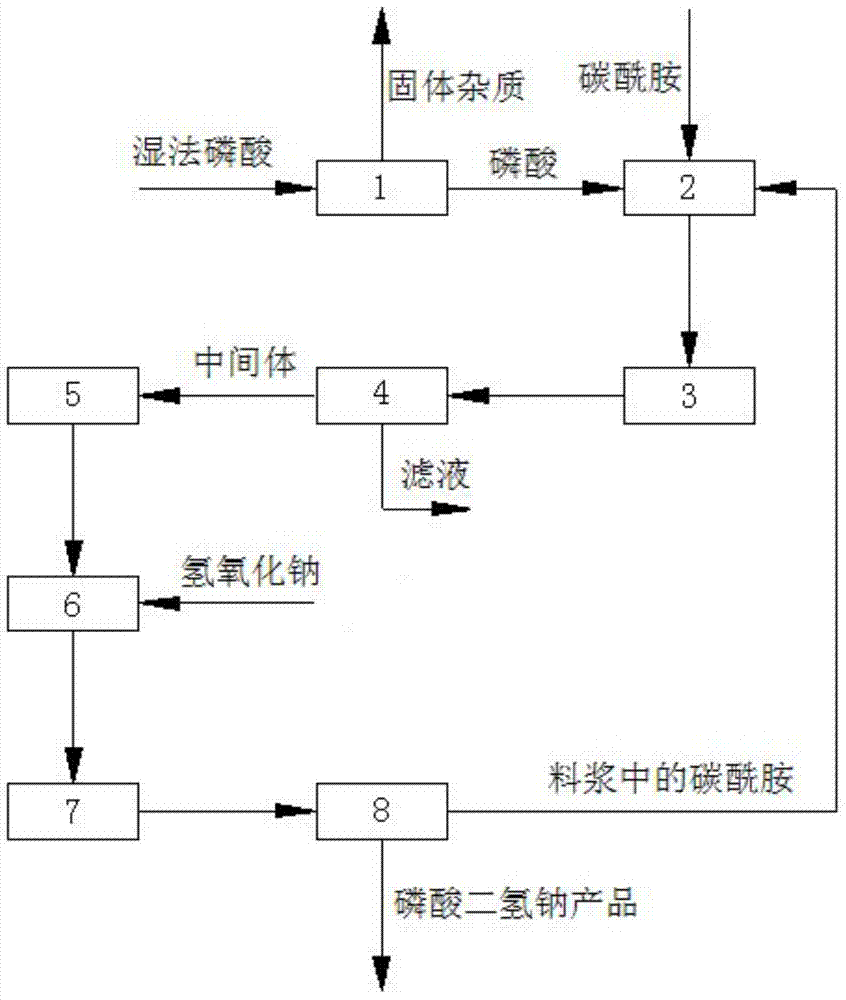

Method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process

InactiveCN103787293AReduce manufacturing costShort process routePhosphorus compoundsHigh energyPhosphoric acid

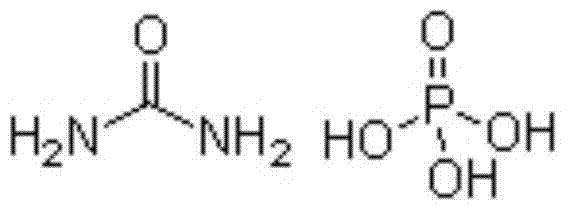

The invention discloses a method for preparing sodium dihydrogen phosphate by utilizing phosphoric acid by wet process. The method comprises the steps of carrying out reaction on carbamide and the phosphoric acid by the wet process to obtain intermediate, and then carrying out a reaction on the intermediate and sodium hydroxide to obtain the sodium dihydrogen phosphate product. The method is short in process route, low in energy consumption, stable in product quality, low in production cost, convenient to operate and safe in production; the by-product slurry can be completely recycled; the whole production process is environment-friendly, clean and free from pollution as well as emission of waste gas, waste water and waste residue; therefore, the method responses to the policy of energy conservation and emission reduction as well as clean production, and solves the problems of complicated technology, unstable product quality, high energy consumption, environmental pollution and the like in the prior art; the obtained sodium dihydrogen phosphate product has the purity of more than or equal to 98%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

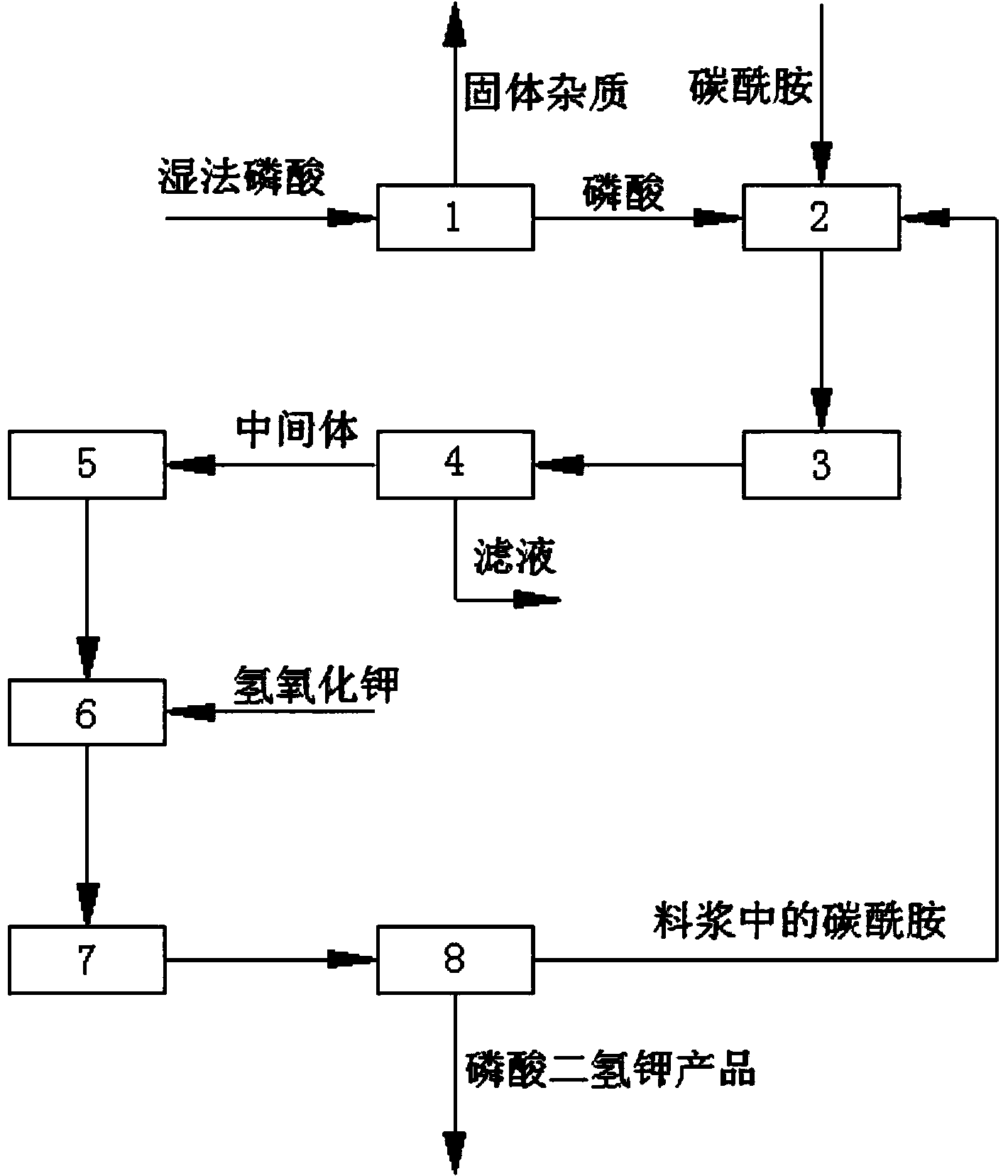

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

Metallic nanowire-graphene bridge structural composite material and preparation method thereof

InactiveCN104934108AImprove technical performance indicatorsMeet industrial application requirementsMaterial nanotechnologyConductive layers on insulating-supportsElectronMultiple layer

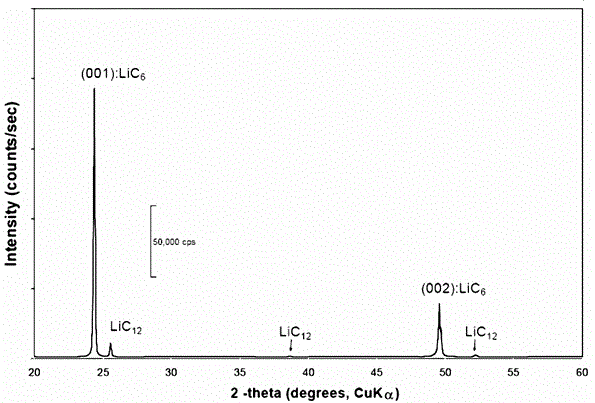

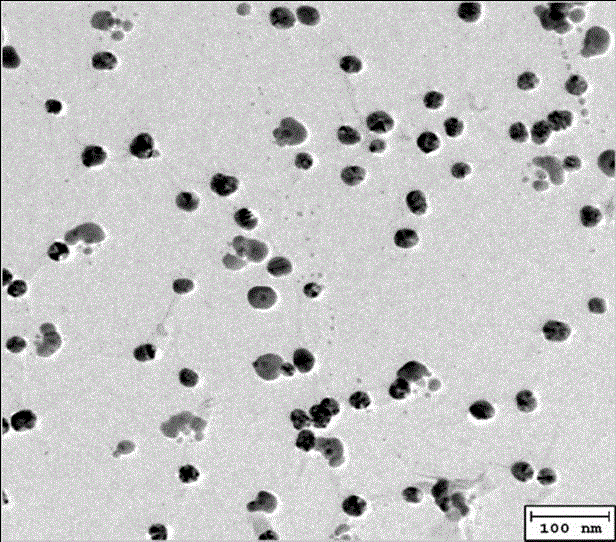

The present invention discloses a metallic nanowire-graphene bridge structural composite material which comprises multiple layers of grapheme and metallic nanowires and is characterized in that the metallic nanowires are arranged at one side or two sides of the surface of a grapheme sheet layer, the metallic nanowires are welded to the metallic nanoparticles at the surface of the grapheme, and a metallic nanowire-graphene bridge structural composite material is formed. According to the composite material, the transmittance is larger than 85% to 92%, the surface resistance is smaller than 1 Omega at the same time, in an optimal embodiment, a transparent conductive film with the transmittance larger than 90% and the surface resistance smaller than 1 Omega is realized, and the current and future industrial application requirements are fully satisfied. Through growing the metallic nanoparticles with proper density at the surface of the single-layer or few-layer grapheme and assembling and welding the metallic nanowires (such as silver nanowires and copper nanowires) on the metallic nanoparticles, grapheme-metallic nanowires are formed and are assembled and processed to form a grapheme-metallic nanowires bridge structure, a transport path is provided for electrons, and thus the surface resistance of a grapheme assembly film is greatly reduced.

Owner:CHONGQING YUANSHI GRAPHENE TECH DEVCO LTD

Refining method of carbon 11-18 long chain diacid

InactiveCN1410408AShort process routeLow costCarboxylic compound separation/purificationOrganic solventPetroleum

A process for refining (or purifying) C11-18 long-chain dibasic acid includes such steps as dissolving the said long-chain dibasic acid prepared by fermenting petroleum in organic solvent, filtering,cooling the filtrate, crystallizing and drying. Its advantages are high purity and output rate, and low cost.

Owner:ZIBO GUANGTONG CHEM

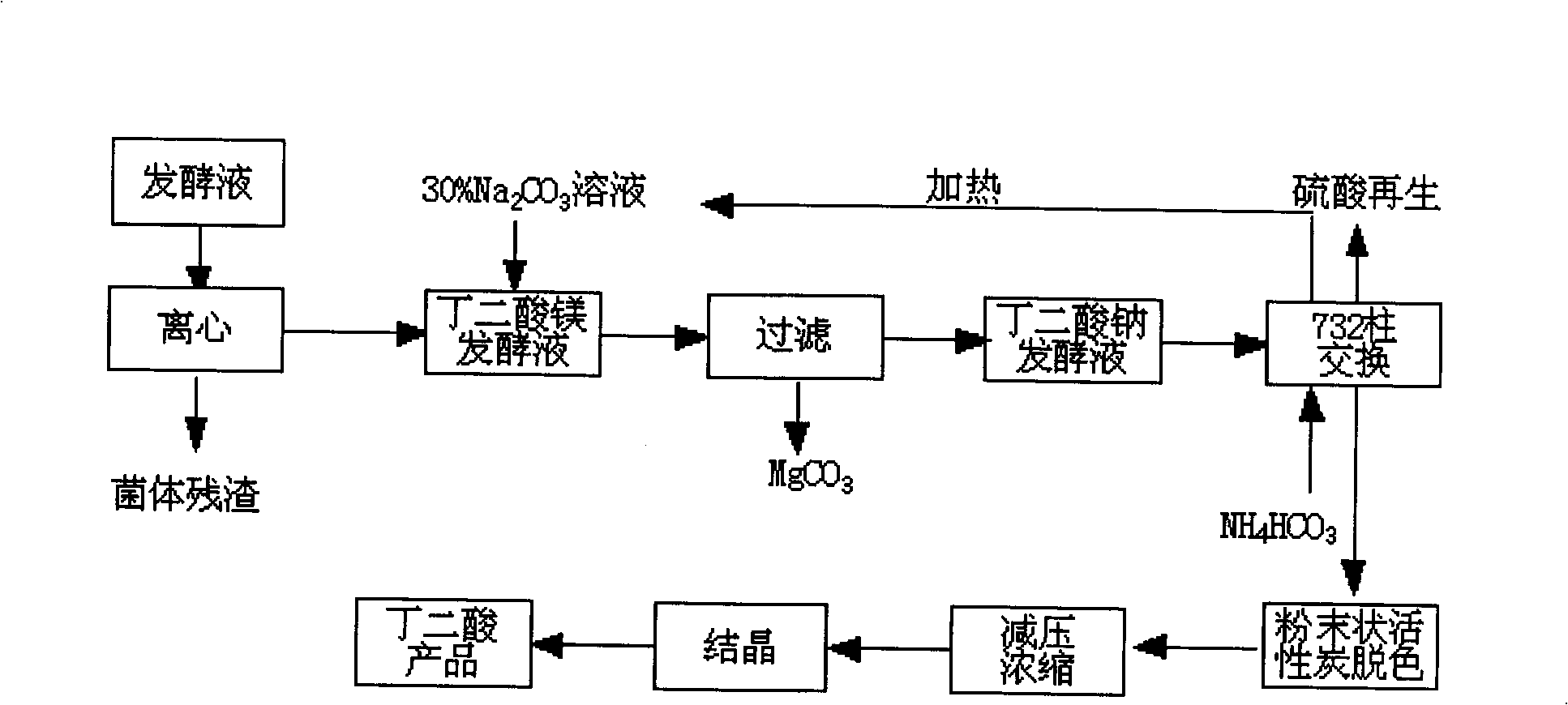

Method for extracting amber acid in fermentation liquor by cationic resin exchange

InactiveCN101348429AAchieving a circular economyShort process routeAmmonium sulfatesFermentationSodium bicarbonateSuccinic acid

A method for extracting succinic acid from fermentation broth through cation resin exchange belongs to the biochemical technical field. The method comprises the following steps that fermentation broth undergoes heated centrifugal filtration or membrane filtration so as to eliminate thalli; sodium carbonate is added in the clear solution to generate magnesium carbonate precipitation; a filter cake is reclaimed after filtration; then, the filtrate flows through a cation resin column, and the effluent is succinic acid solution; a succinic acid product is obtained after decoloring, concentration and crystallization; the cation resin column is eluted by ammonium carbonate after exchange so as to obtain sodium bicarbonate effluent; sodium salt is reclaimed and reused in fermentation broth treatment after ammonia is eliminated by heating; furthermore, resin regeneration can be realized by sulphuric acid through a conventional method, and the generated (NH4)2 SO4 can be used as a fertilizer. The method does not need to carry out acidification for the filtrate, and has the advantages of short technological line and high yield, thereby realizing element cycle economy. The invention provides a method for extracting succinic acid from microorganism fermentation broth with simple operation and economical efficiency.

Owner:JIANGNAN UNIV

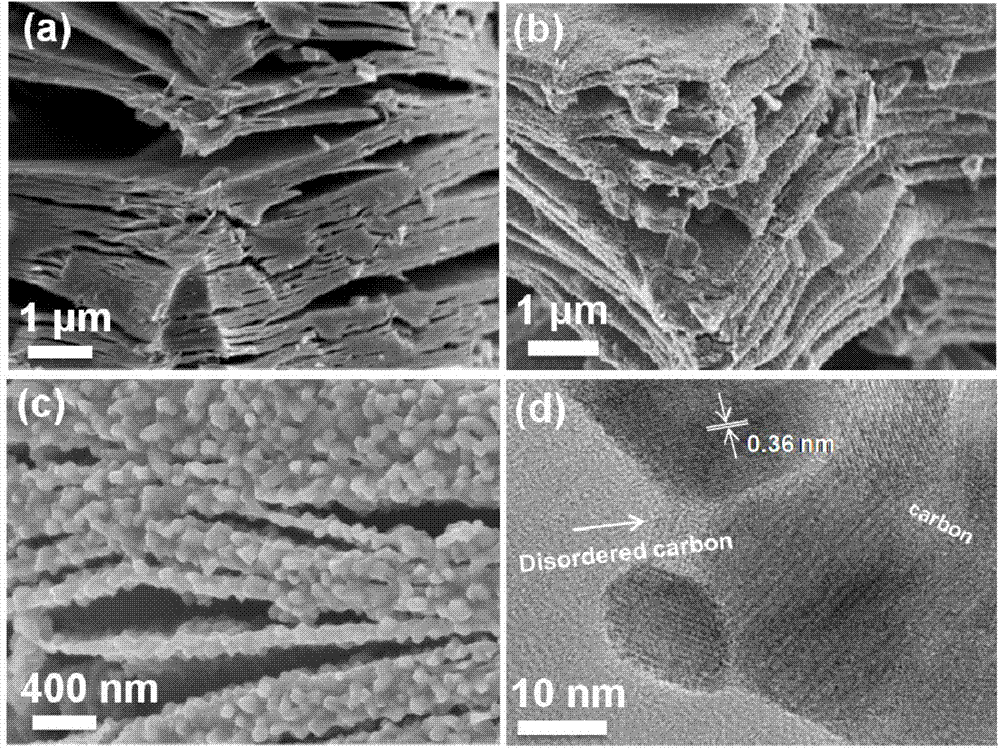

Preparation method of transition metal oxide/carbon-based laminated composite material

InactiveCN104733712ALengthy process routeLong process routeHybrid capacitor electrodesCell electrodesNew energyConductive materials

The invention relates to a preparation method of a transition metal oxide / carbon-based laminated composite material. According to the preparation method, a conducting material such as metal carbide, metal nitride or metal carbonitride with a two-dimensional laminated structure is taken as a precursor, a gas containing oxygen elements is taken as an oxidant, and the two-dimensional conducting material is converted into the transition metal oxide / carbon-based laminated composite material by in-situ oxidation under the condition of controlling the oxidation temperature at 300-1000 DEG C and controlling the oxidation time at 1-300 min. The method disclosed by the invention has the advantages of simplicity and easiness in operation, controllable structure and morphology, controllable crystal form and electrochemical properties of metal oxides, and the like; the preparation method is environment-friendly, and nuisanceless, has no by-product, can be used for reducing the economic costs of traditional preparation methods, and can be popularized; and the transition metal oxide / carbon-based laminated composite material not only can be used as a key electrode material of a new energy storage device, but also can be used as a denitration catalyst, so that the material can be applied to the fields of environmental remediation, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur

ActiveCN104208992AHigh activityReduce energy consumptionDispersed particle separationSulfur preparation/purificationCombustionLiquid state

The invention discloses a method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur sequentially comprises the following steps: introducing the acid gas into a combustion furnace to be mixed with air introduced by the other pipeline so as to carry out a combustion reaction; introducing the gas reacted in the combustion furnace into a cooler to be cooled to 230-250 DEG C, after cooling, separating the cooled liquid sulfur at a liquid outlet, introducing mixed gas in the combustion furnace into a catalyst reactor, enabling hydrogen sulfide to react with sulfur dioxide in the catalyst reactor so as to generate sulfur and water, and separating the generated liquid sulfur at the liquid outlet of the catalyst reactor; introducing the mixed gas in the catalyst reactor into a hydrogenation reactor and enabling the sulfur dioxide to react with hydrogen in the hydrogenation reactor; introducing the gas in the hydrogenation reactor into a hydrogen sulfide absorption device and preparing the hydrogen sulfide into elemental sulfur under the action of an alkaline solution, a complex catalyst and the introduced air. The method for desulfurizing acid gas containing hydrogen sulfide and recycling sulfur has the advantages of short process route, high quality of produced sulfur and low energy consumption, is capable of fully removing SO2 gas and is green and environmentally friendly.

Owner:NINGBO RES & DESIGN INST OF CHEM IND

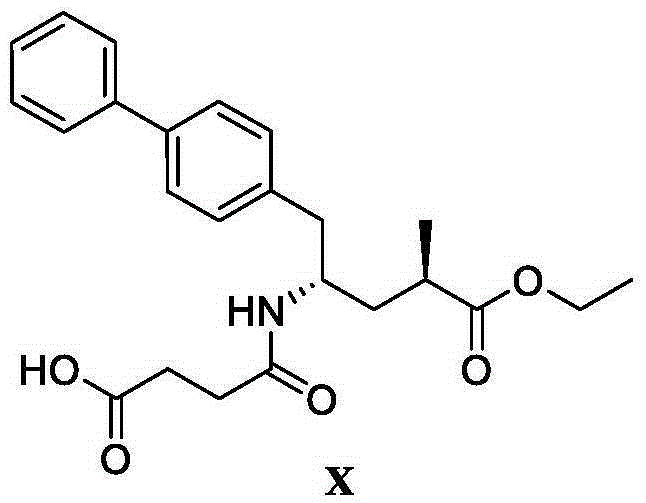

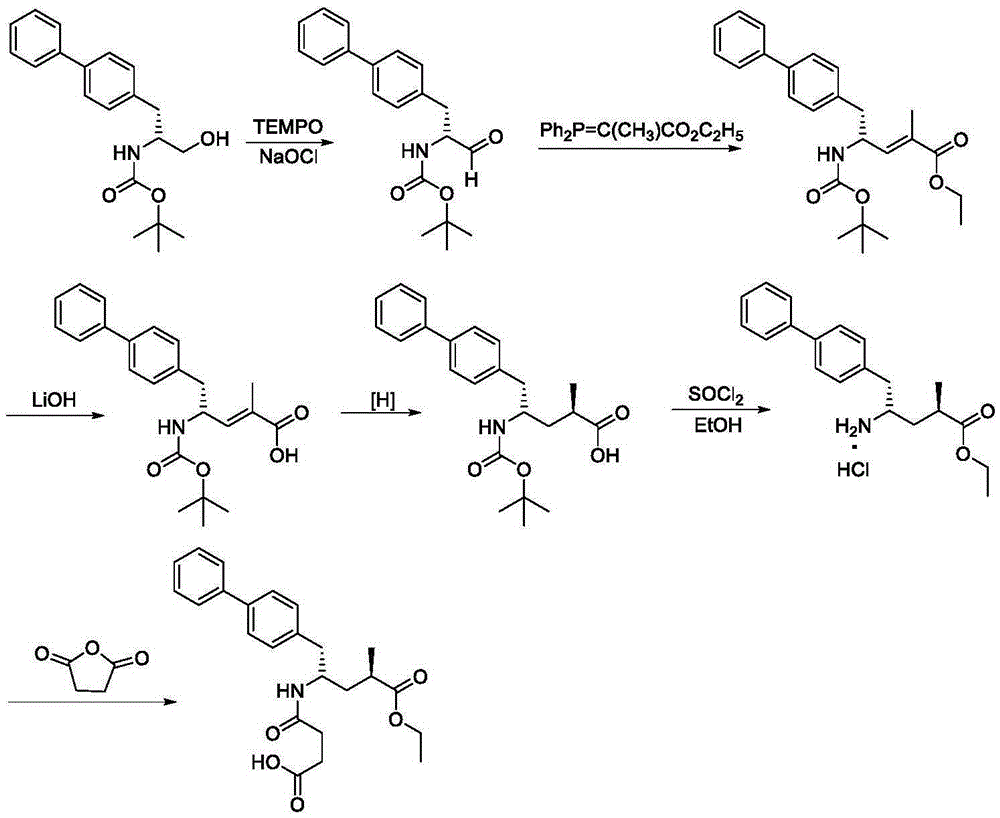

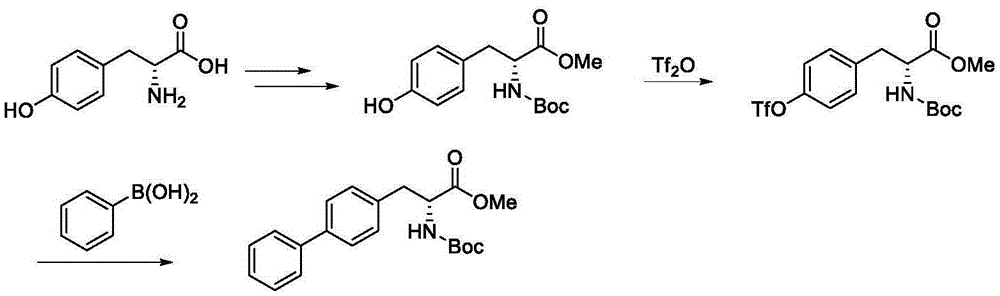

Preparation method of (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol

InactiveCN105330569AMild reaction conditionsImprove conversion rateCarbamic acid derivatives preparationOrganic compound preparationAlcoholTert-Butyloxycarbonyl protecting group

The invention discloses a preparation method of (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol represented by formula (I). The method comprises the following steps: carrying out an Erlenmeyer-Plochl cyclization reaction on biphenylcarboxaldehyde and N-acylglycine, hydrolyzing or alcoholyzing, and carrying out asymmetric hydrogenation to obtain (R)-N-acylbiphenylalanine or an ester thereof; and carrying out acid hydrolysis, reduction and amino protection on the (R)-N-acylbiphenylalanine or the ester thereof, or carrying out reduction, acid hydrolysis and amino protection on the (R)-N-acylbiphenylalanine or the ester thereof, or directly reducing the (R)-N-acylbiphenylalanine or the ester thereof in order to obtain the product (R)-2-(N-tertbutyloxycarbonylamino)biphenylpropanol. The product is a key intermediate of Sacubitril (AHU-377) which is one of a novel blood pressure reducing medicine LCZ696. The method has the advantages of easily available raw materials, and suitableness for industrial production.

Owner:天台宜生生化科技有限公司

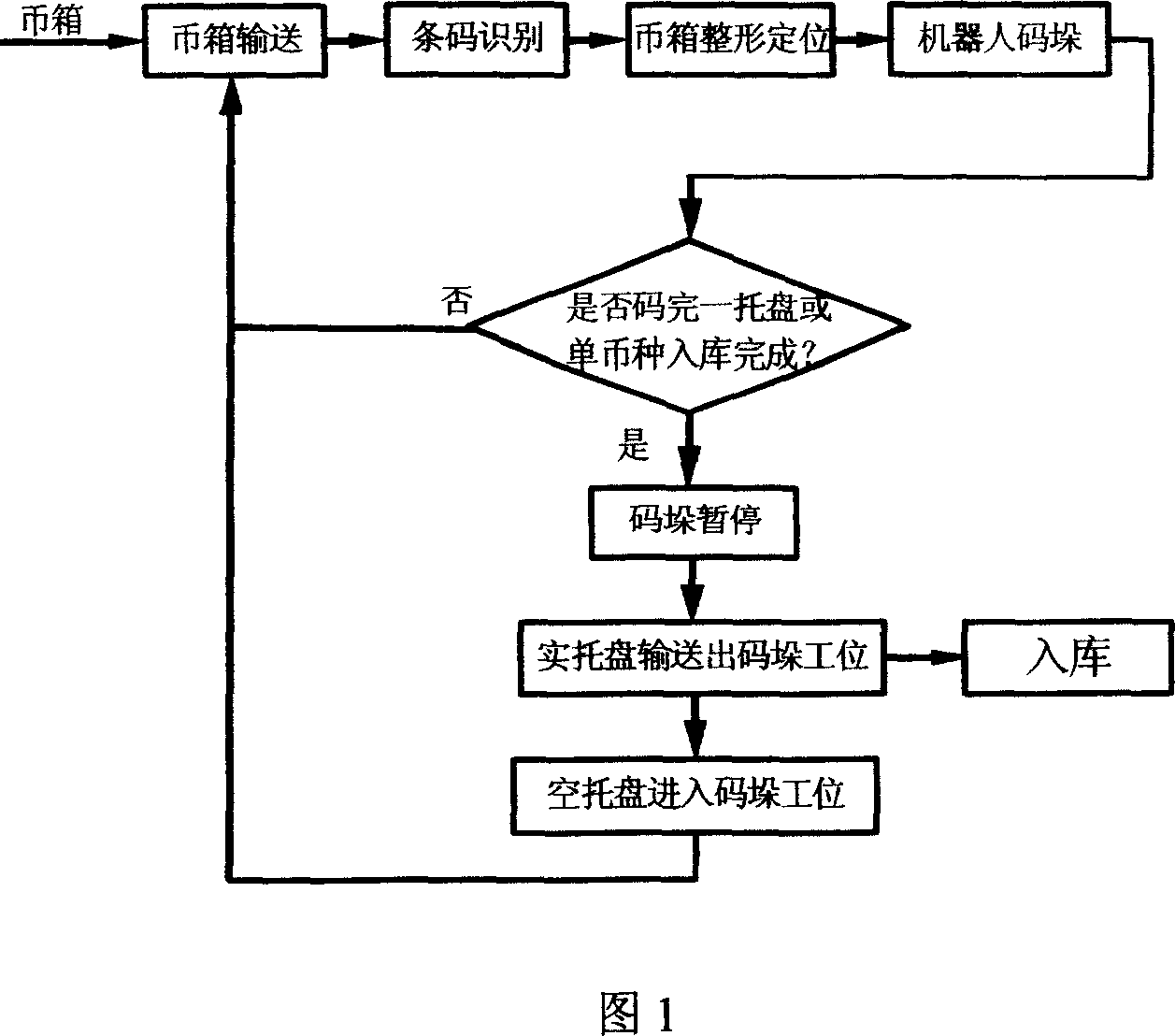

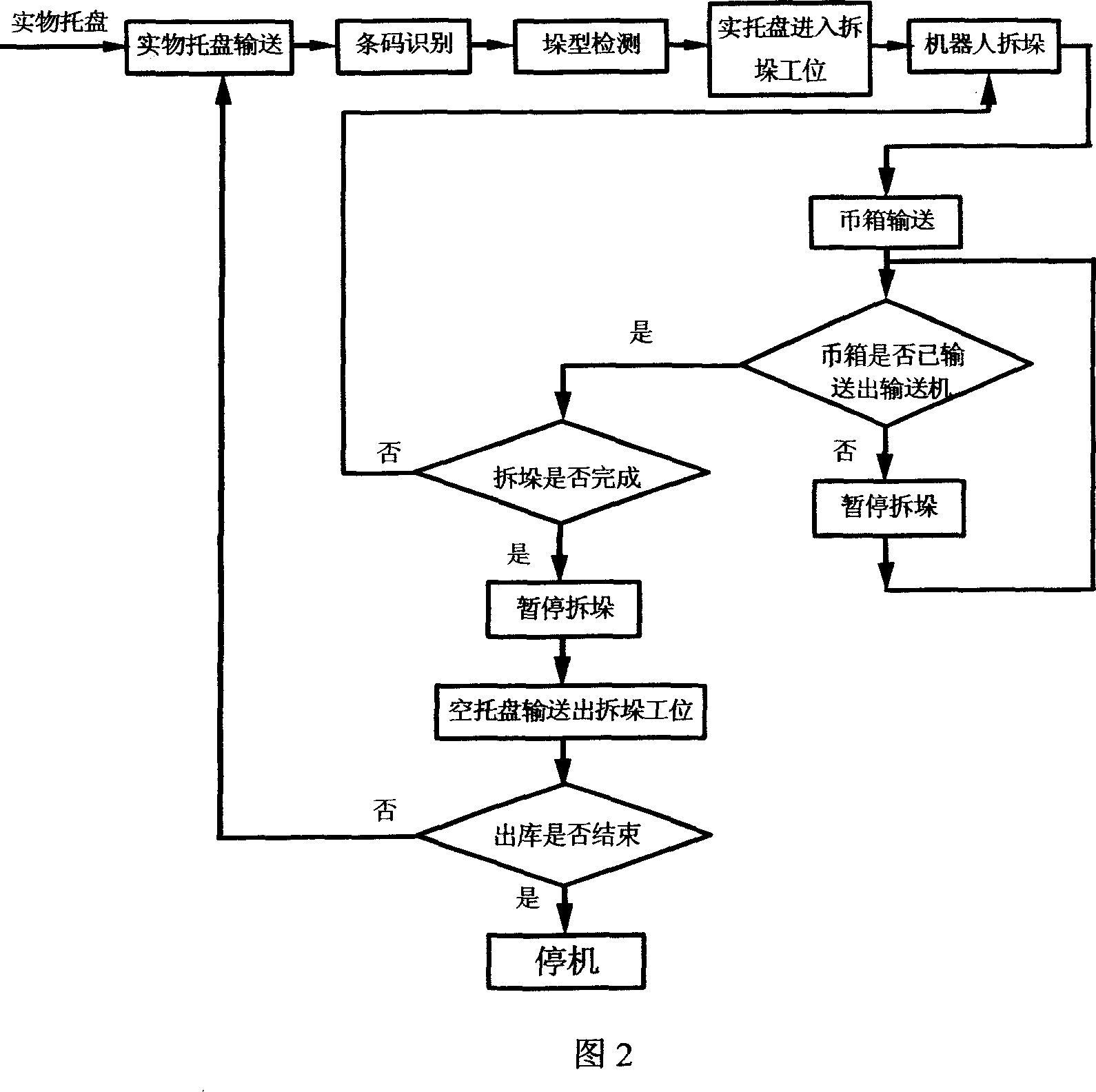

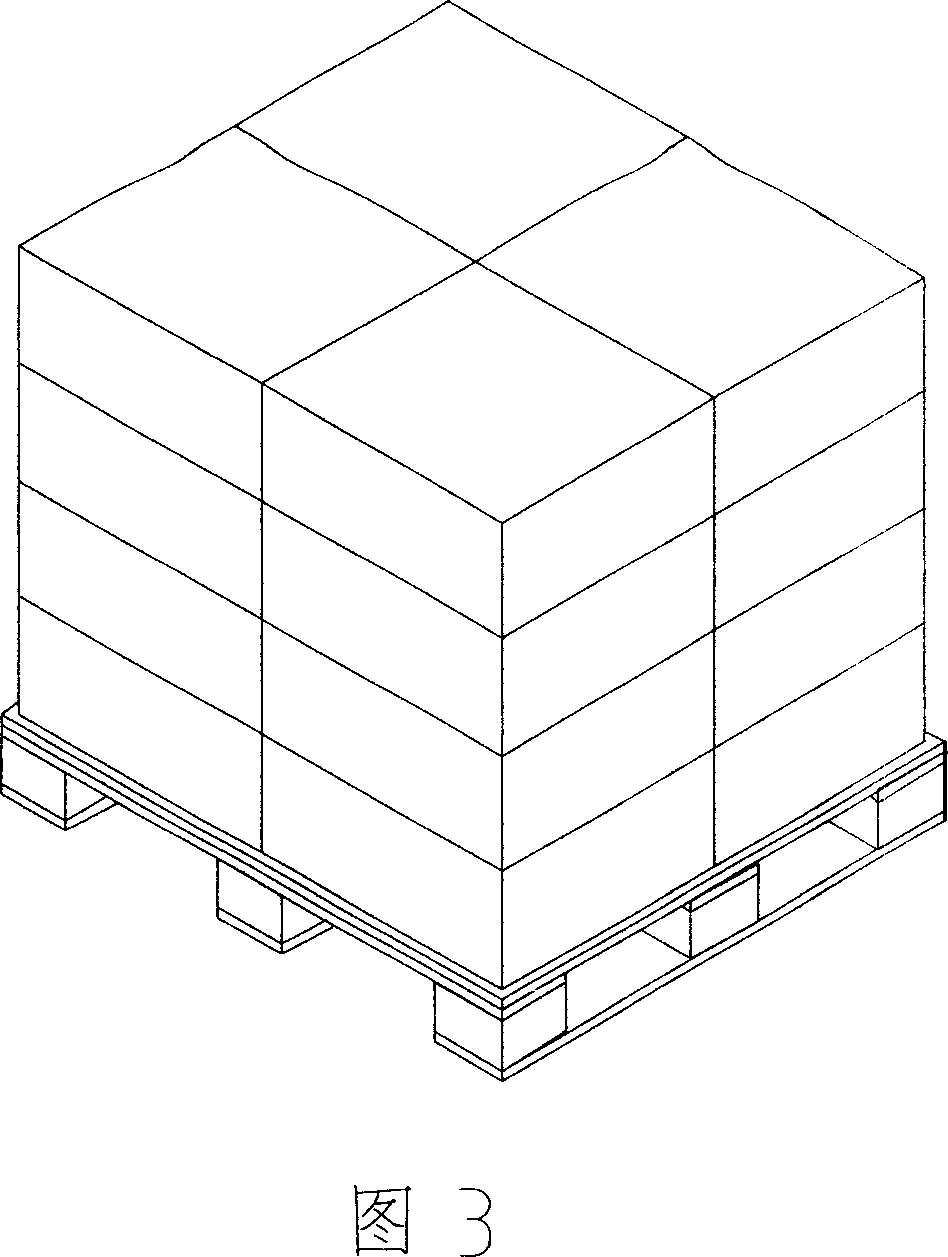

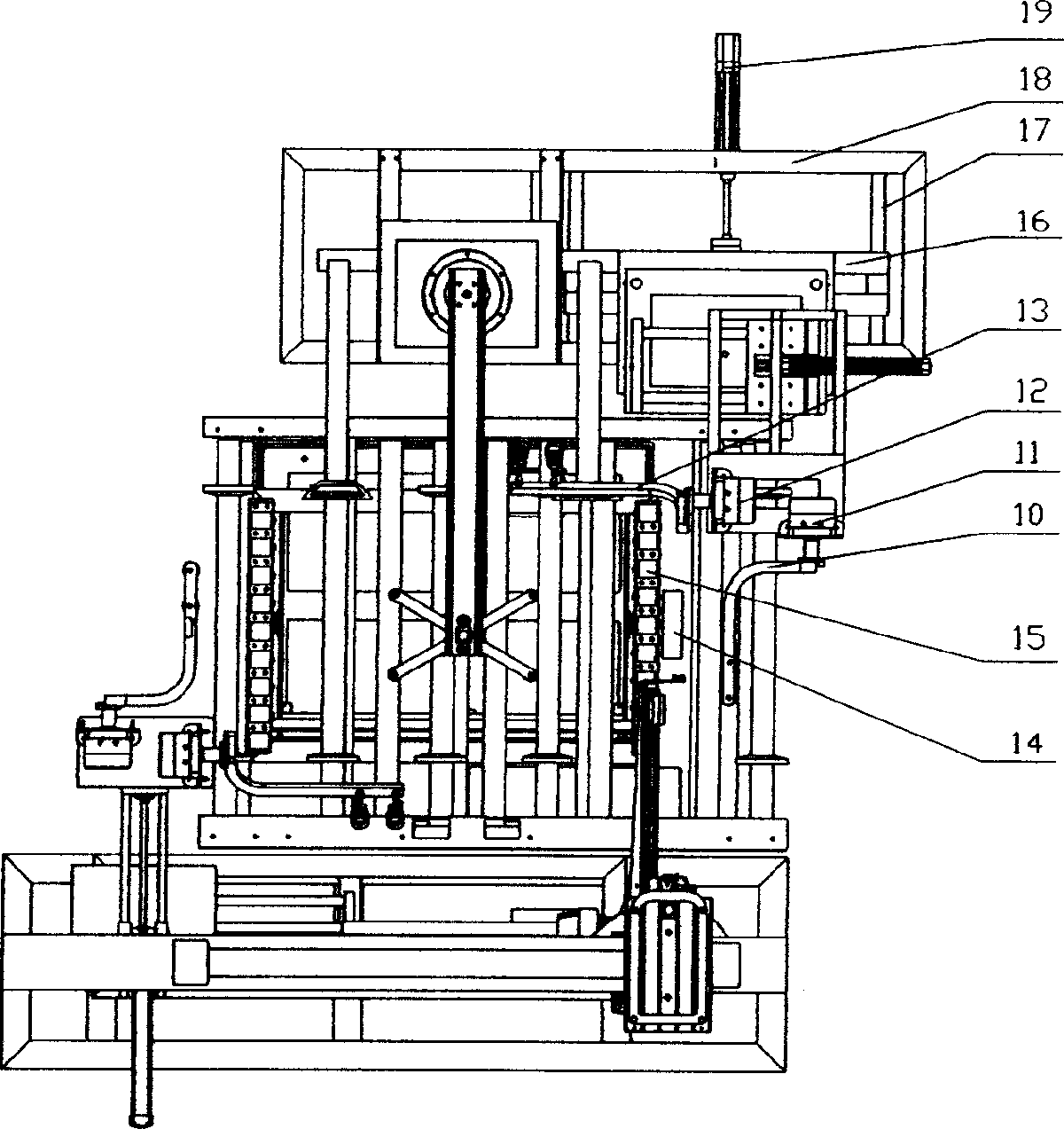

Automatic de-stacking and stacking technology and system for putting currency-box into and out of bank exchequer

ActiveCN1923644AQuick and easy palletizingPalletizing works accuratelyProgramme-controlled manipulatorControl devices for conveyorsStructural engineeringCartesian coordinate robot

The automatic de-stacking and piling process and system for entry and exit of money case in the bank exchequer comprises of the entry piling and exit de-stacking; the system comprises of a Cartesian coordinate robot (5) and the fixture (6) at the bottom, with the transverse conveyer (1) and money box conveyer (10) equipped at the lower part of the robot sequentially. Inside the transverse conveyer and under the robot's piling and de-stacking position, there locates an alighting conveyer (12), whose outlet has an vertical conveyer (14) perpendicular to the transverse conveyer that has an check sensor (29) (19) on it. Above or the side of the transverse conveyer and the money box conveyer, separately locate the bar code scanner (13) (9) and the side of money box conveyer close to the robot has a money box regularizing and positioning device and a check sensor (15), (17). It can use the same system to realize the automatic de-stacking and piling operation of money boxes, automatic hand over of money box's entry and exit of the exchequer with high automation level, small occupant area, and quick and accurate de-stacking and piling.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

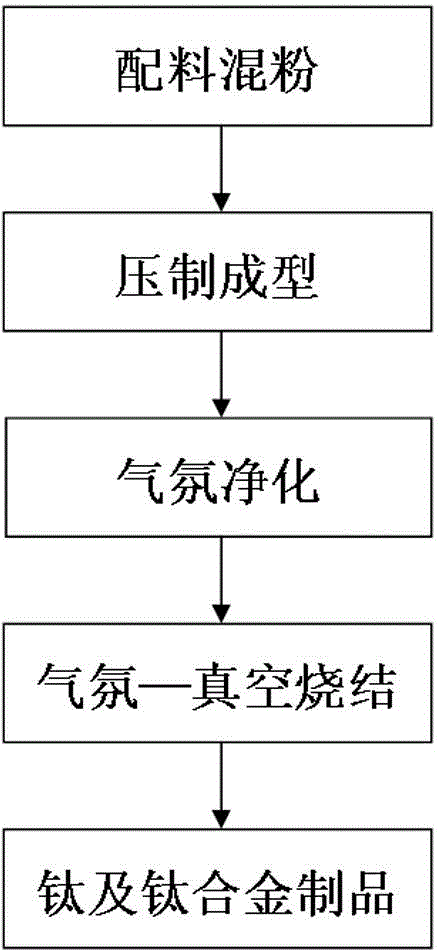

Powder metallurgy method for preparing high-density titanium and titanium alloy

The invention discloses a powder metallurgy method for preparing high-density titanium and titanium alloy products. The method comprises the following steps: preparing raw materials and mixing; performing pressure forming; performing atmosphere purifying; performing atmosphere-vacuum sintering. According to the method, titanium powder or titanium alloy mixed powder is adopted as the raw material and is subjected to pressure forming and atmosphere-vacuum sintering in sequence; the atmosphere sintering is adopted at the temperature of 400-600 DEG C, mixed gas of hydrogen and argon is introduced, and heat is preserved for 2-3 hours, thus generating TiHx (x is more than 0 and not more than 2); the vacuum sintering is adopted at the temperature of 600-1350 DEG C, and heat is preserved at 1200-1350 DEG C for 4-6 hours; by virtue of the diffusion analysis effect and the interstitial solid solution of hydrogen, the vacancy concentration and dislocation in titanium are increased, the surface activity of titanium is improved, and the sintering free energy effect is reduced, thus obtaining dense titanium and titanium alloy. The titanium / titanium alloy products prepared by adopting the method are high in density, the process route is short, a subsequent pressure processing process can be reduced or shortened, and the processing cost is lowered. The problems of high cost and low density of a conventional powder metallurgy method for preparing titanium and titanium alloy are solved.

Owner:KUNMING METALLURGY INST

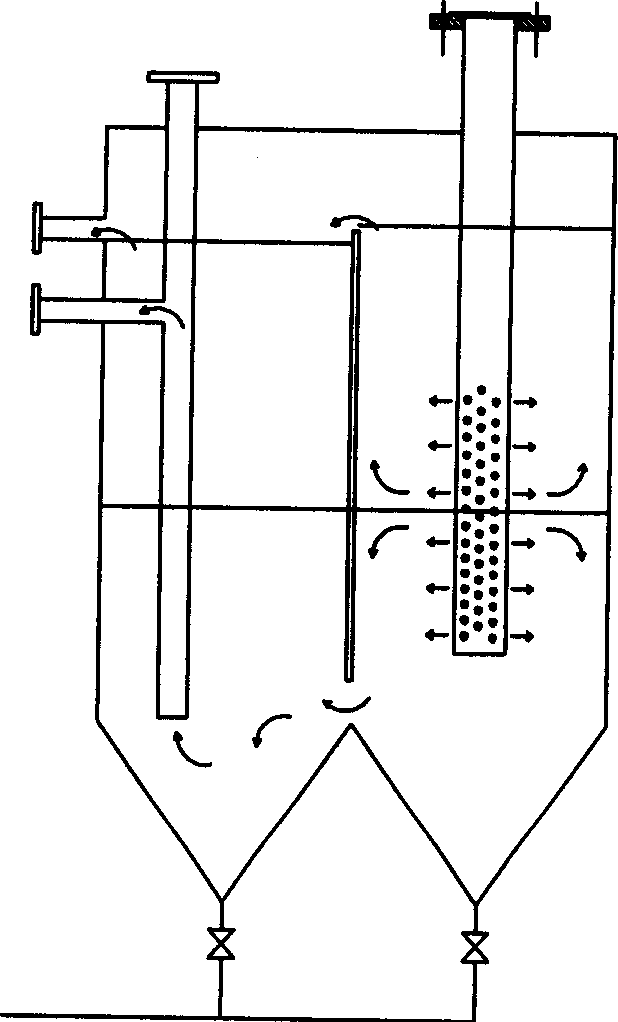

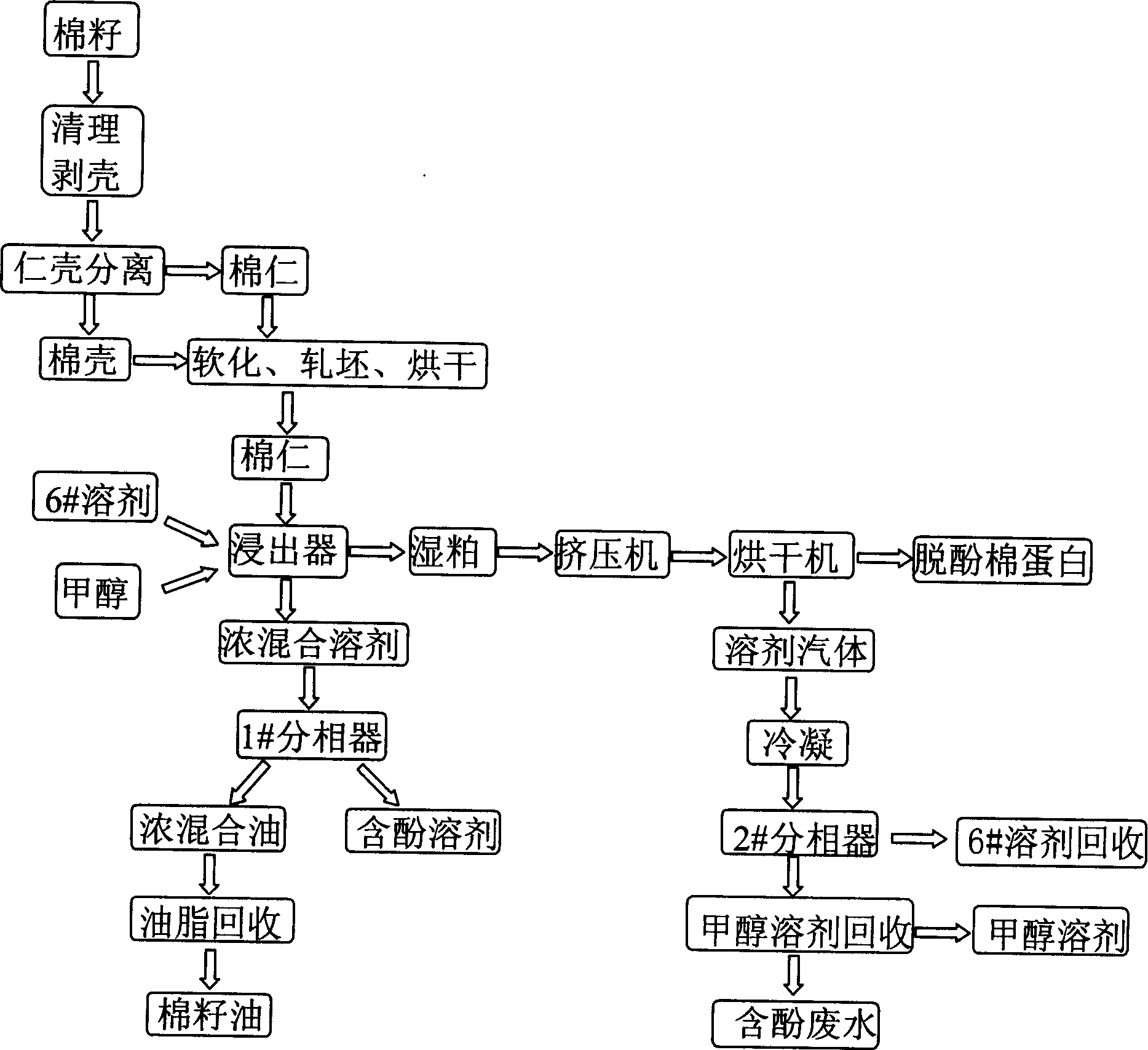

One-step method for producing dephenolized cotton protein

InactiveCN1775061AShort process routeUse less equipmentFatty-oils/fats refiningVegetable proteins working-upOil processingAlcohol

The present invention relates to the field of feed and oil processing technology, in particular, it relates to an one-step method for producing dephenolized cotton protein. It is characterized by that said invention fully utilizes the characteristics of 6# solvent and methyl alcohol mixed solvent, and utilizes the mutual incompatibility of polar solvent and non-polar solvent and simultaneously uses two solvents in one equipment so as to attain the goal of simultaneously extracting gossypol and oil, and can recover 6# solvent, methyl alcohol and oil.

Owner:陕西中恒粮油工程技术有限公司

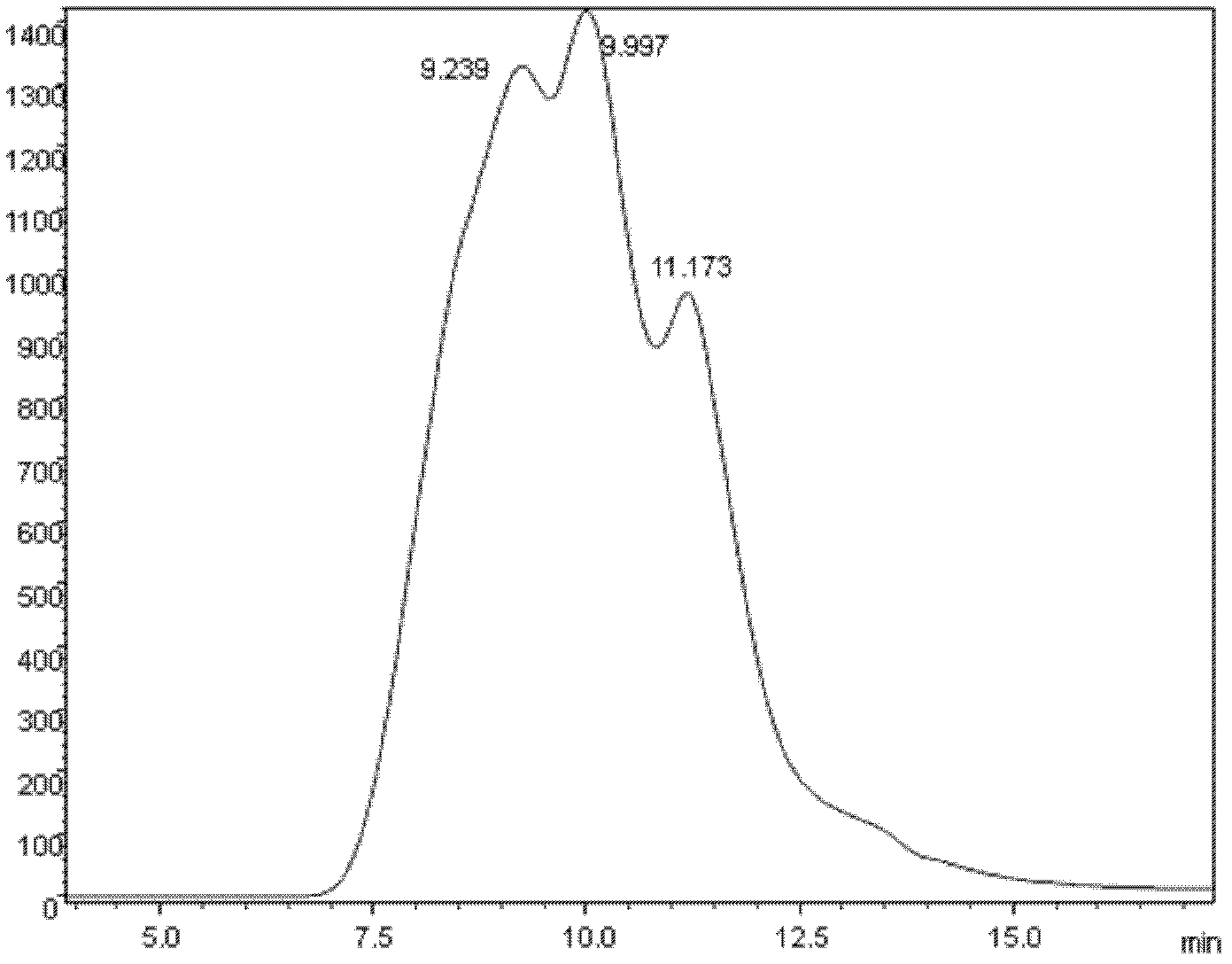

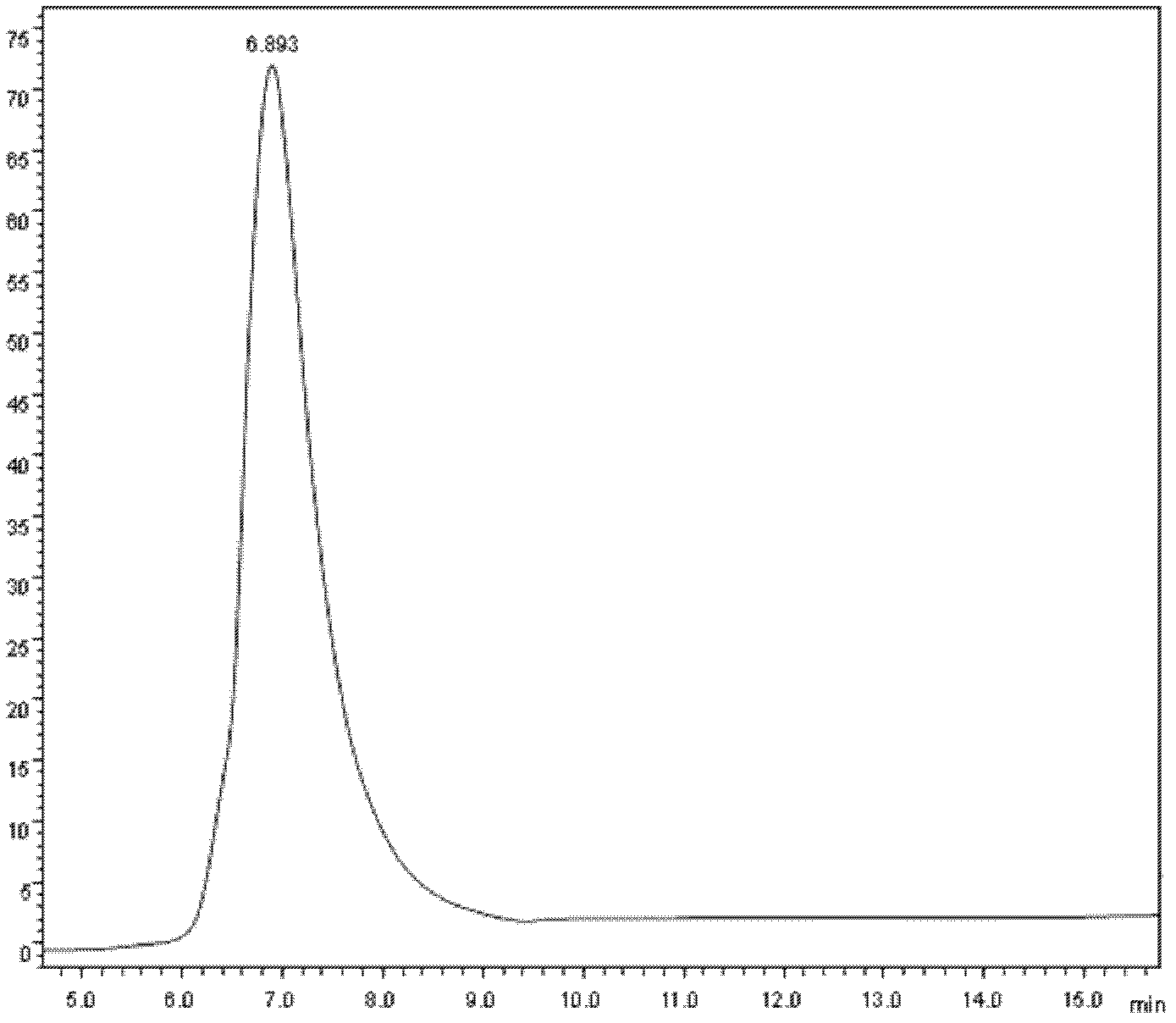

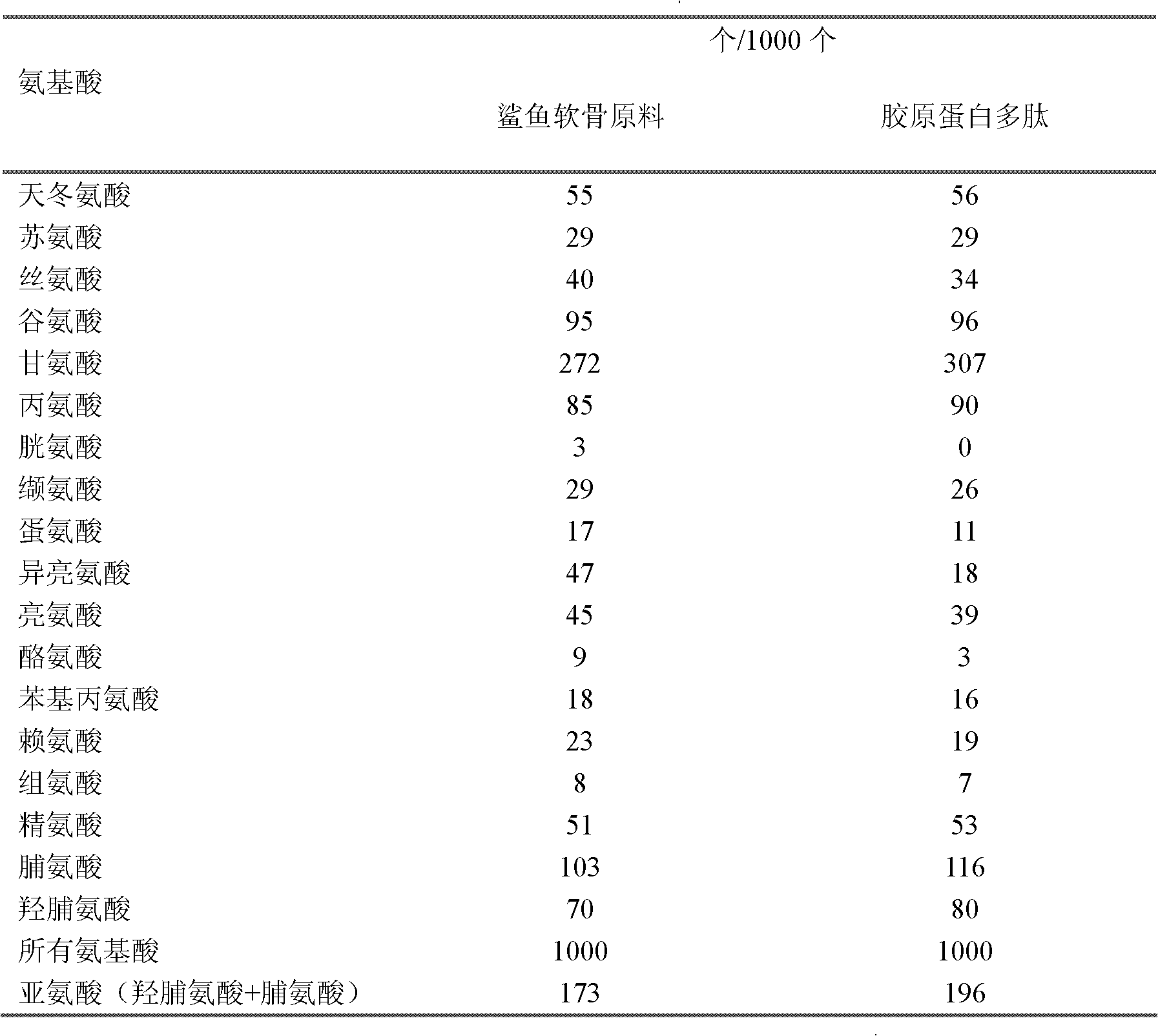

Method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages

ActiveCN102533915ARealize high-value utilizationEfficient separation and extractionPeptide preparation methodsFermentationAlcoholUltrafiltration

The invention discloses a method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages, which comprises the following steps: crushing animal cartilage materials to obtain cartilage powder; hydrolyzing the cartilage powder with protease, and then carrying out ultrafiltration and concentration to obtain a concentrated solution; passing the concentrated solution through an anion exchange resin column, and collecting an effluent solution A; eluting with pure water, and collecting a water washing solution B; merging the effluent solution A and the water washing solution B, carrying out ultrafiltration and concentration, and carrying out spray drying to obtain the collagen polypeptide; and eluting the anion exchange resin column with an NaCl solution, carrying out ultrafiltration and concentration on the eluent solution, carrying out alcohol precipitation, dehydrolyzing, and drying to obtain the chondroitin sulfate. The invention realizes the high-valued utilization of cartilage resources, can simultaneously and efficiently extract and separate the chondroitin sulfate and the collagen polypeptide, increases the added values of the products and reduces the environment pollution.

Owner:ZHEJIANG UNIV OF TECH

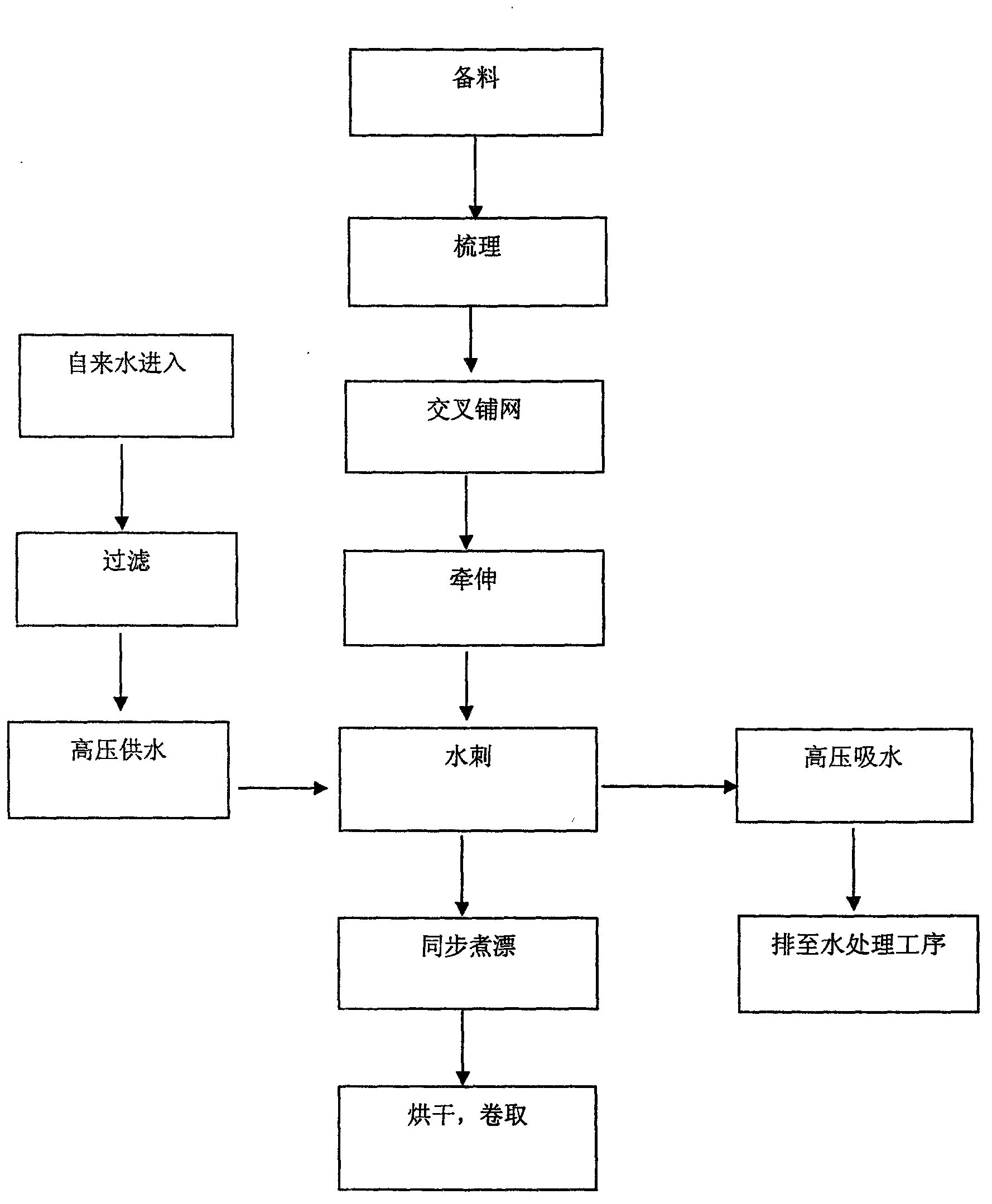

Method for producing pure cotton non-woven fabrics for life and hygiene

ActiveCN103290617AOvercoming the disadvantages of anti-stickingAdapt to diversityBleaching apparatusNon-woven fabricsThree levelWater flow

The invention discloses a method for producing pure cotton non-woven fabrics for life and hygiene. The method is mainly characterized by comprising the steps of carding cotton, enabling cotton fiber to conduct single fibrillating to the greatest extent, cleaning up dust and cotton flocks in the cotton, and carding the cotton to form a fiber web; conducting reciprocating cross laying on the fiber web to form a thick fiber web in the 45-degree direction, again conducing traction, after conducting stretching, evenness and orderliness on the thick fiber web, utilizing high-pressure water flow to conduct three-level spunlace on the thick fiber web so as to enable the thick fiber web to be wound, then again utilizing a synchronous scouring and bleaching method, conducting single function producing, such as synchronously conducting bleaching, degreasing and dyeing, also just conducting bleaching without degreasing or just conducting degreasing without bleaching, completing the production procedure of the pure cotton non-woven fabrics, finally enabling the pure cotton non-woven fabrics to be dried, and conducting curling. The method not only saves time, labor, manpower and cost, but also effectively ensures production quality, shortens the process route, improves process efficiency and reduces production cost. The method is an ideal and stable pure cotton non-woven fabric production technology.

Owner:福建省健为医疗用品有限公司

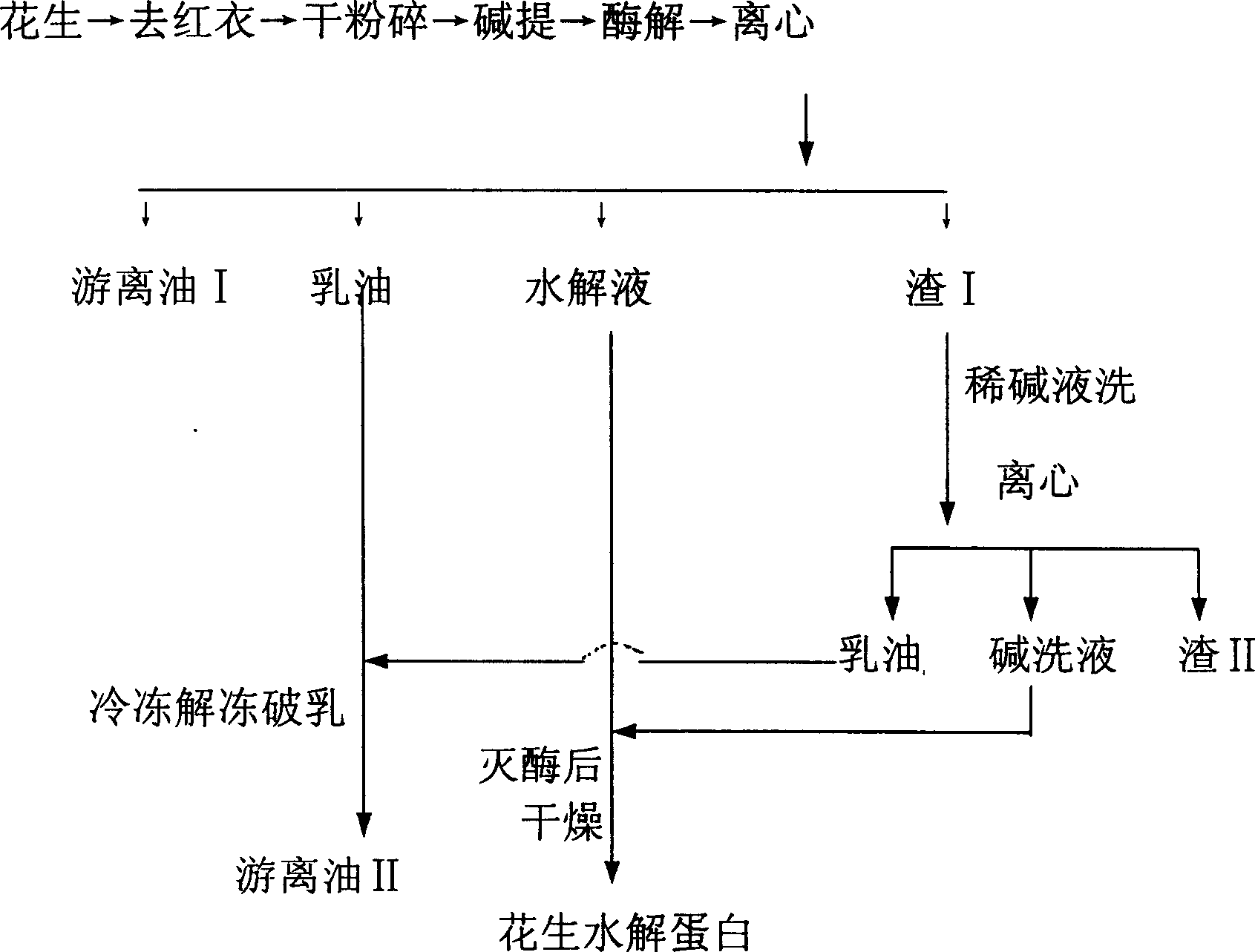

Technology of extracting oil and hydrolyzed protein from peanut using hydroenzyme method

InactiveCN1555714AQuality improvementOperational securityProtein composition from vegetable seedsEdible oils/fatsNutritive valuesAlkaline proteinase

A process for extracting oil and hydrolytic protein from peanut by water-enzyme method includes such steps as extracting emulsified oil by use of alkaline proteinase, and demulsifying it by freezing and thawing to obtain free oil while recovering hydrolytic protein powder in the form of micropeptide. Its advantages are high oil output and high nutritive value.

Owner:JIANGNAN UNIV

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

Preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid

ActiveCN104370755ANon-hazardousImprove conversion rateOrganic compound preparationAmino-carboxyl compound preparationSolventHydrolysis

The present invention discloses a preparation method for optical activity active 3-amino butanol and optical activity 3-amino butyric acid. The optical activity active 3-amino butanol preparation method comprises: in a solvent, under effects of a hydroboration reduction agent and a Lewis acid, carrying out a reduction reaction on a compound represented by a formlu 65 to produce a compound represented by a formlu 14. The optical activity active 3-amino butyric acid preparation method comprises: carrying out a hydrolysis reaction on a compound represented by a formlu 64 to produce a compound represented by a formlu 65. According to the present invention, the preparation method has characteristics of cheap and easily-available raw materials, simple operation, short process route, no hazard of raw materials, high yield, little waste production, environment protection, high raw material conversion rate, high product chemical purity and high product optical purity, and the industrialization is easily achieved. The formulas 64, 65 and 14 are defined in the instruction.

Owner:JIANGXI LONGLIFE BIO PHARM CO LTD +1

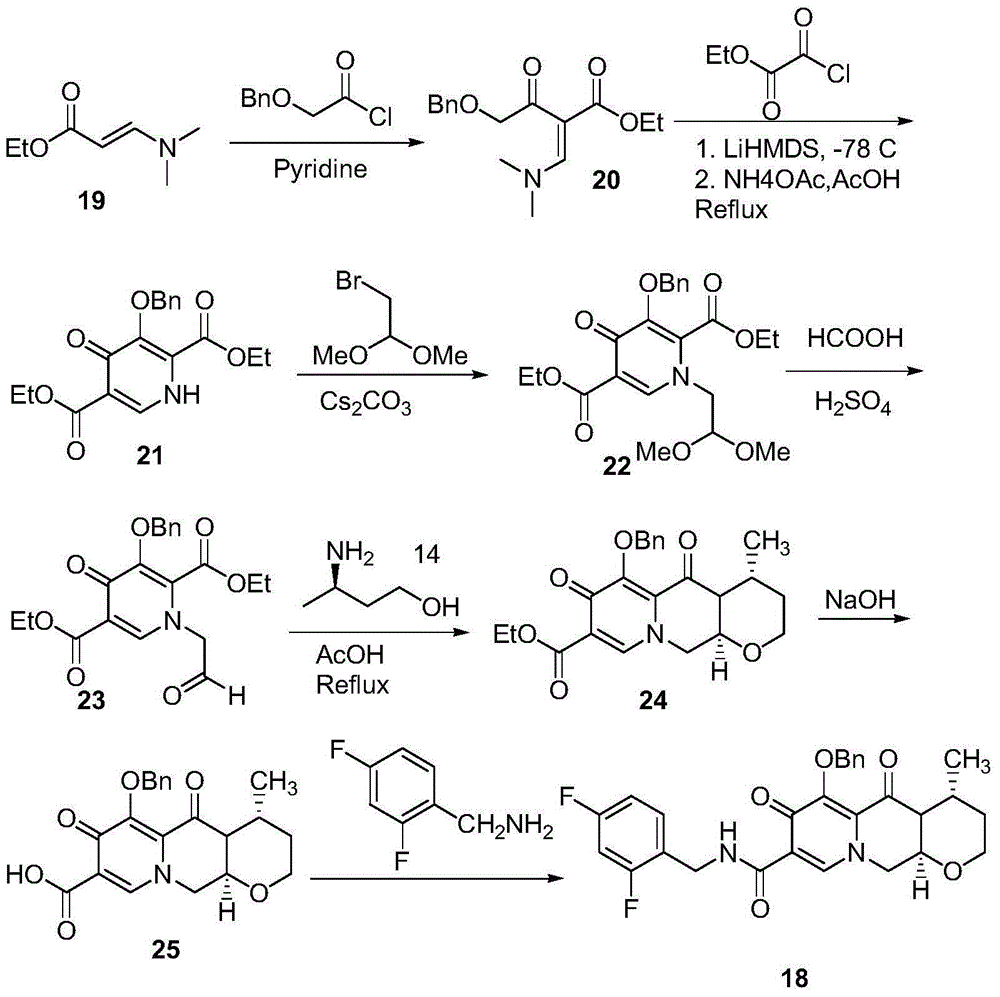

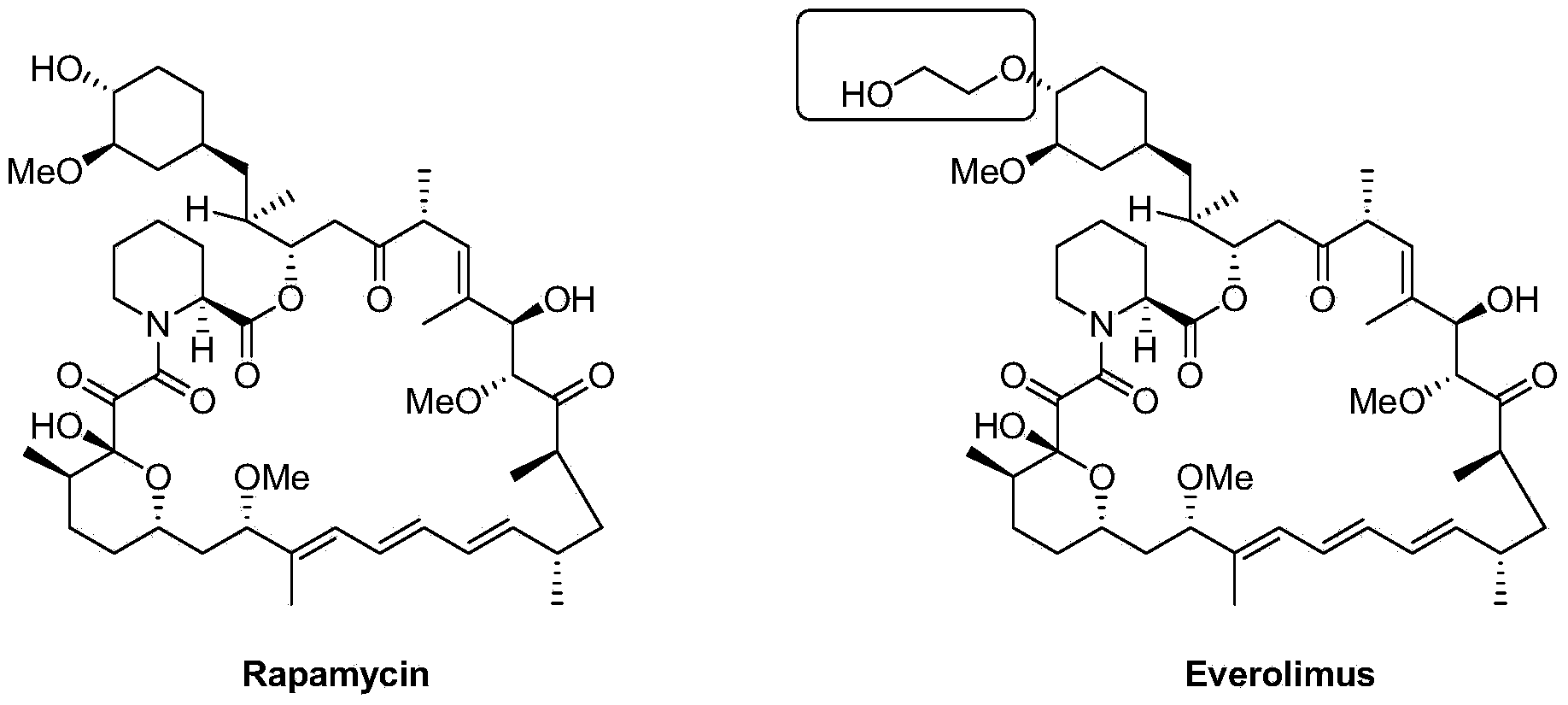

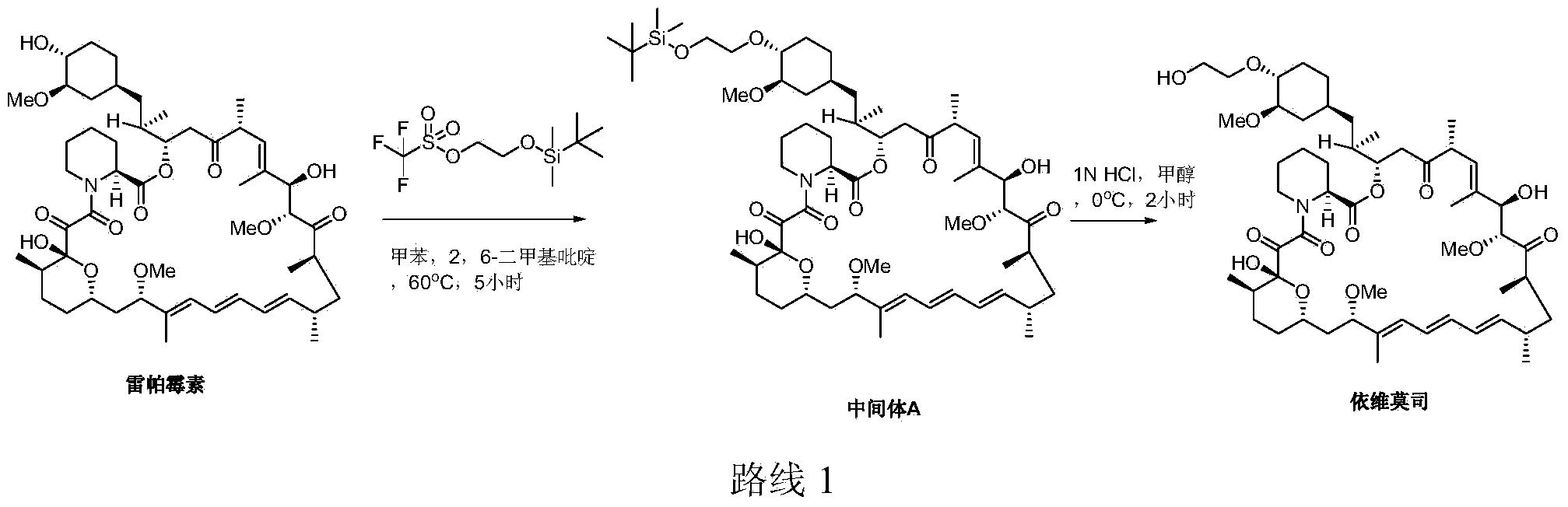

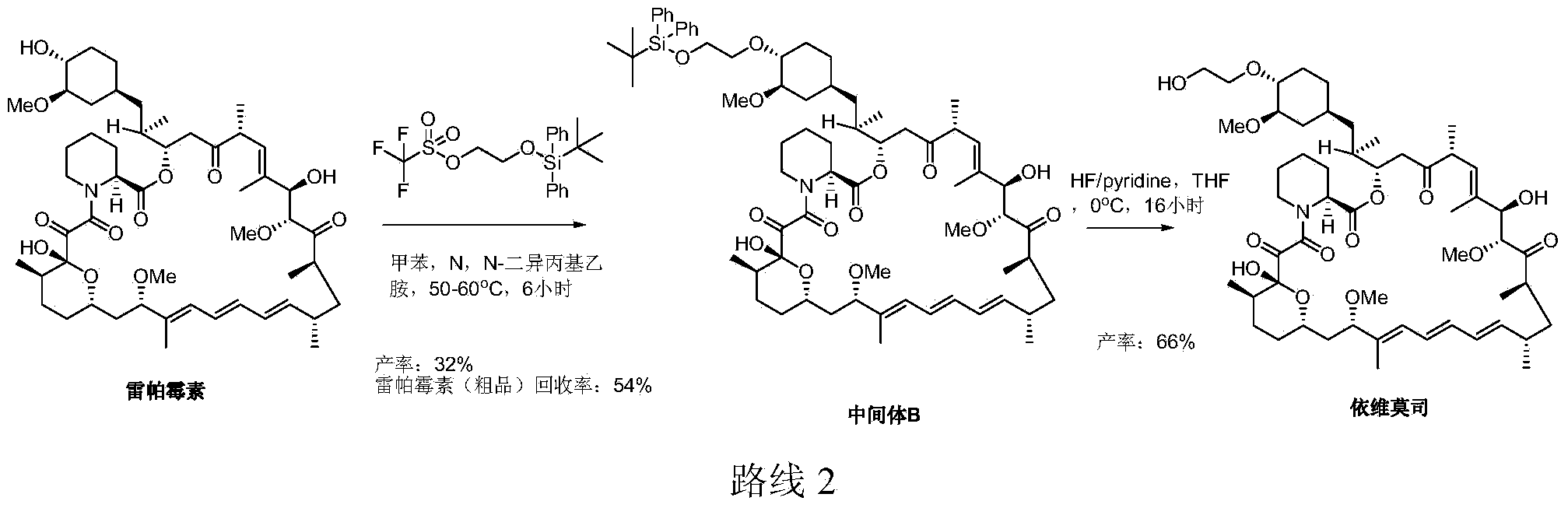

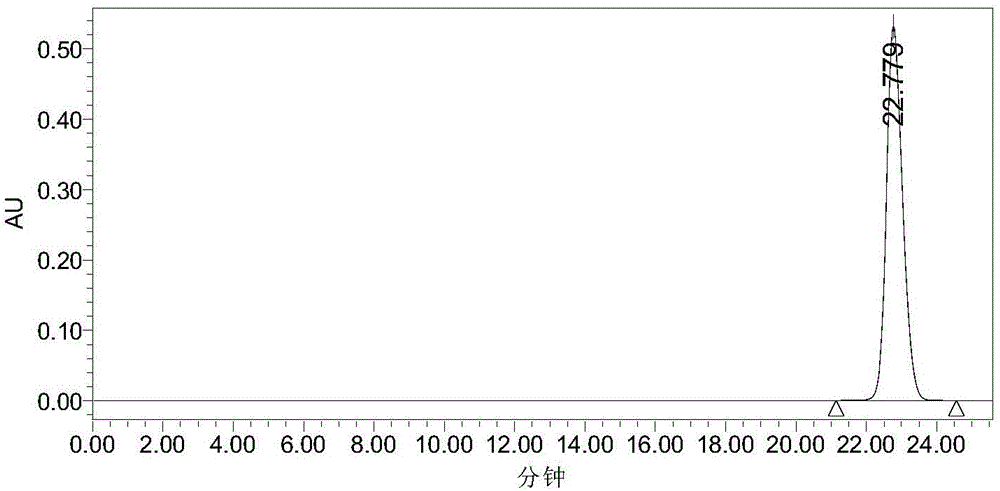

Preparation technology for everolimus

The invention provides a preparation technology for everolimus. The preparation method comprises the two steps of: 1) reacting sirolimus with 2-(tert-butyldiMethylsilyloxy) ethyl trifluoromethane sulfonate in the presence of proper solvent and organic base, to obtain an intermediate A; 2) reacting the intermediate A with inorganic acid in an organic solvent to obtain everolimus, wherein the organic base used in the step 1) is selected from large-steric hindrance or non-nucleophilic bases such as triethylamine, N,N-diisopropylethylamine, 1,8-diazabicycloundec-7-ene or N-methylmorpholine, acid used in the step 2) is hydrochloric acid, sulfuric acid or phosphoric acid. According to the technology, the total yield in the two steps and the purity of a final product are greatly improved as compared with those reported by the existing literature, the process route is short, the reaction conditions are mild, and the reaction result is also stable and reliable.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

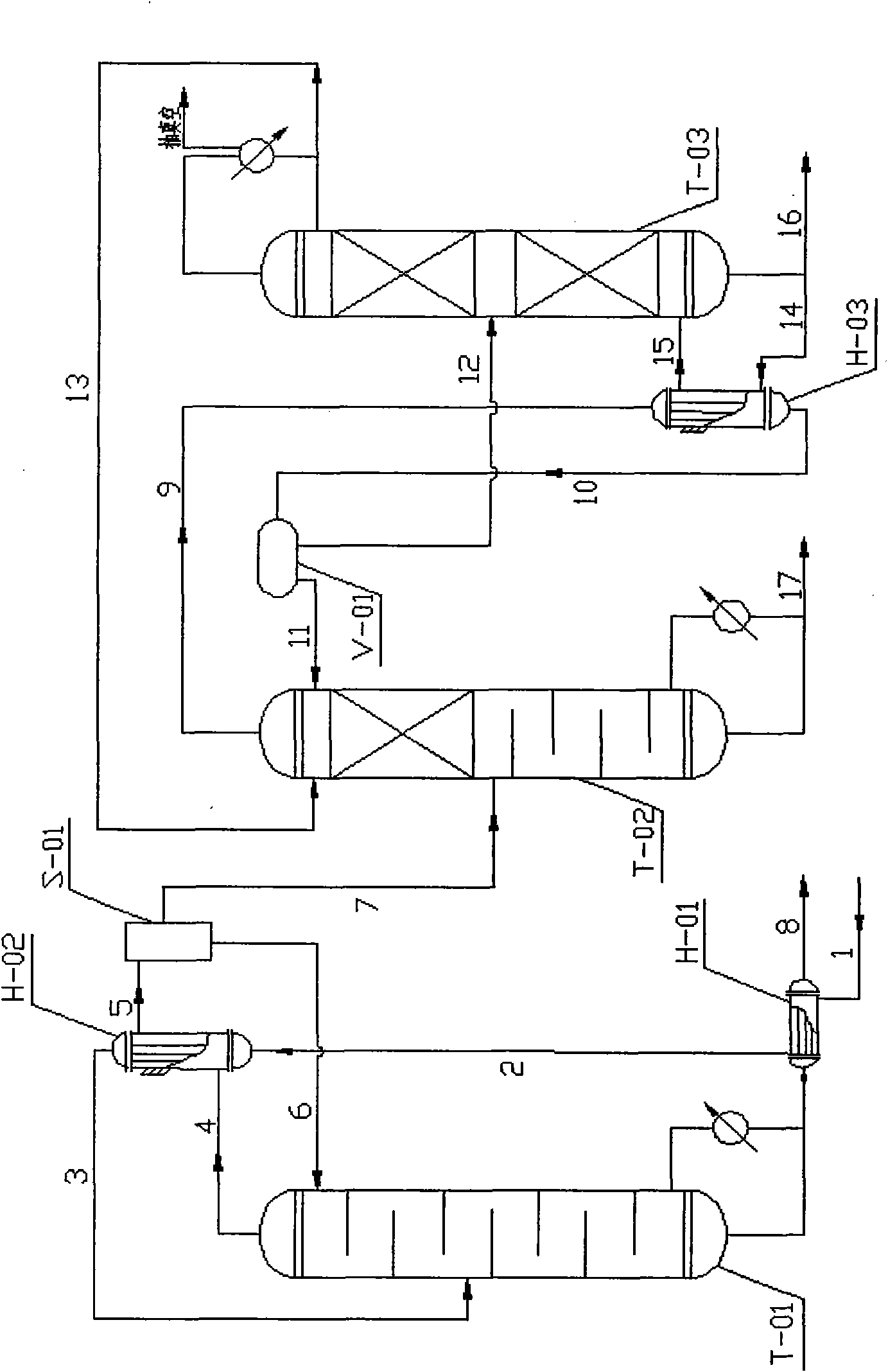

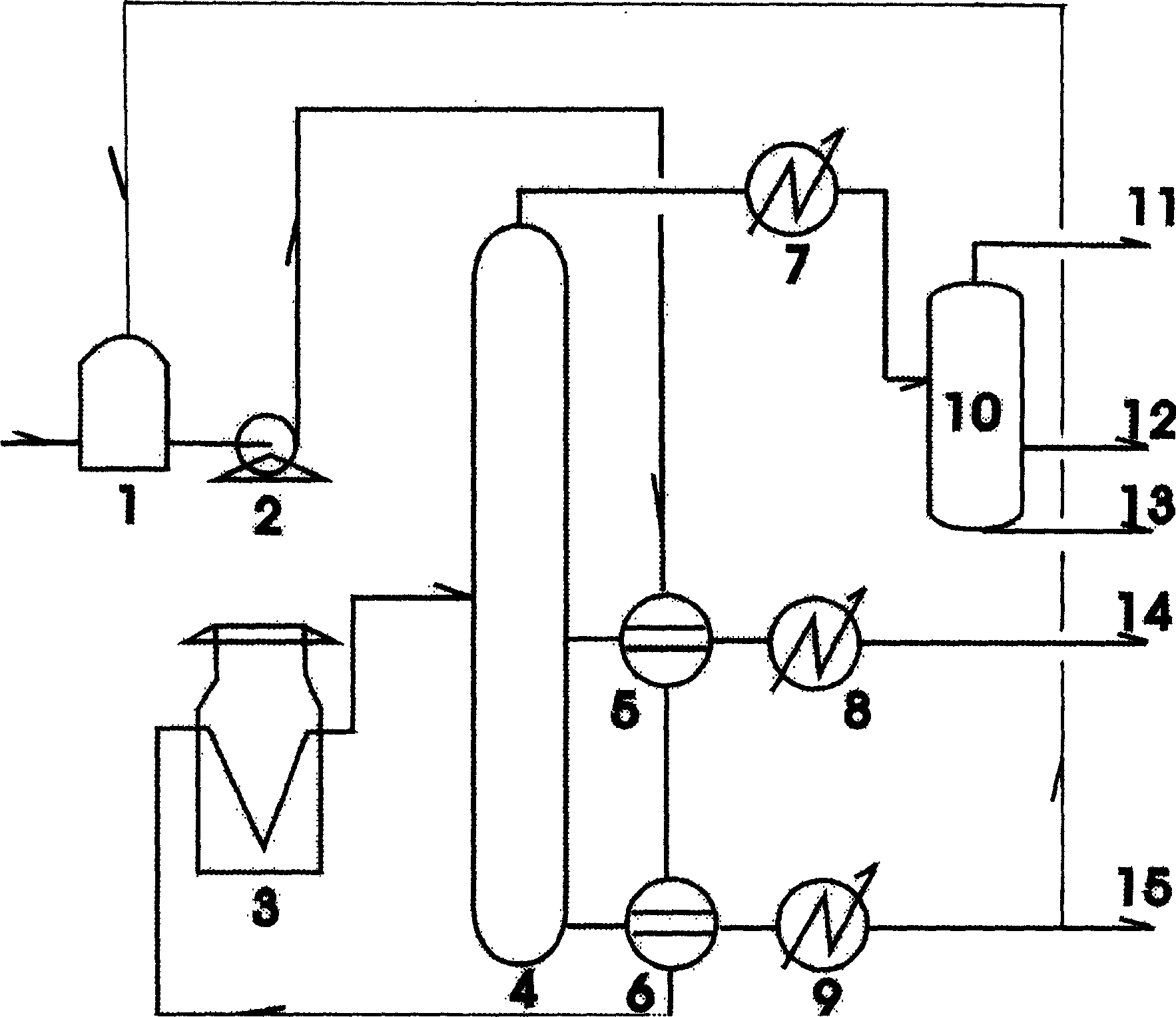

Process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification

ActiveCN101811965AHigh purityEasy to recycleOrganic compound preparationCarboxylic acid esters preparationAlcoholButyl acetate

The invention relates to a process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification, comprising the following steps of: carrying out normal-pressure distillation and thickening on the wastewater containing the butyl alcohol, the butyl acetate, water and organic residues in a first rectifying tower T-01 to obtain pure water and the organic residues through a tower kettle; delaminating condensed steam at a tower top, flowing a water layer back, and causing an organic layer to enter a second rectifying tower T-02 for pressurization and rectification under 120-200 Kpa so that the high-purity butyl acetate is extracted by the tower kettle and the steam with the alcohol ester ratio of 3 / 1-9 / 1 is obtained at the tower top; condensing to cause one part of a condensate to back flow and one part of the condensate to enter a third rectifying tower T-03 for pressure reduction and rectification under 3-15 KPa so that the high-purity butyl alcohol is extracted by the tower kettle and the steam with the alcohol ester ratio of 1 / 3-1 / 2 is obtained at the tower top; and after condensing and cooling, causing the steam with the alcohol ester ratio of 1 / 3-1 / 2 to enter the tower from a feed inlet of the second rectifying tower T-02 for continuous thickening and purification. The process has the advantages of environmental protection, low energy consumption, investment saving, no entrainer addition, high recovery rate (above 99%) of solvents and the like.

Owner:NANJING UNIV

Process for extracting lithium salt from spodumene by adopting sulfuric acid pressure boiling method

ActiveCN104071811AFully recycleShort process routeLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention discloses a process for extracting lithium salt from spodumene by adopting a sulfuric acid pressure boiling method. The process comprises the following steps: transforming the spodumene at high temperature, and adding sulfuric acid for pressure boiling to obtain soluble lithium sulfate and insoluble high-silicon residues, and separating lithium from lithium concentrate to further prepare lithium carbonate and obtain a byproduct-high-silicon soil; adding lime for purifying leachate liquid containing a small quantity of aluminum, iron and other alkali metal sulfate, removing impurities in a multi-step way to obtain a high-purity lithium sulfate solution, and carbonizing to generate a lithium carbonate product and a sodium sulfate byproduct. According to the process, the yield is high, the wastewater discharge quantity is low, mother liquor can be recycled, and the cost is low.

Owner:江西雅保锂业有限公司

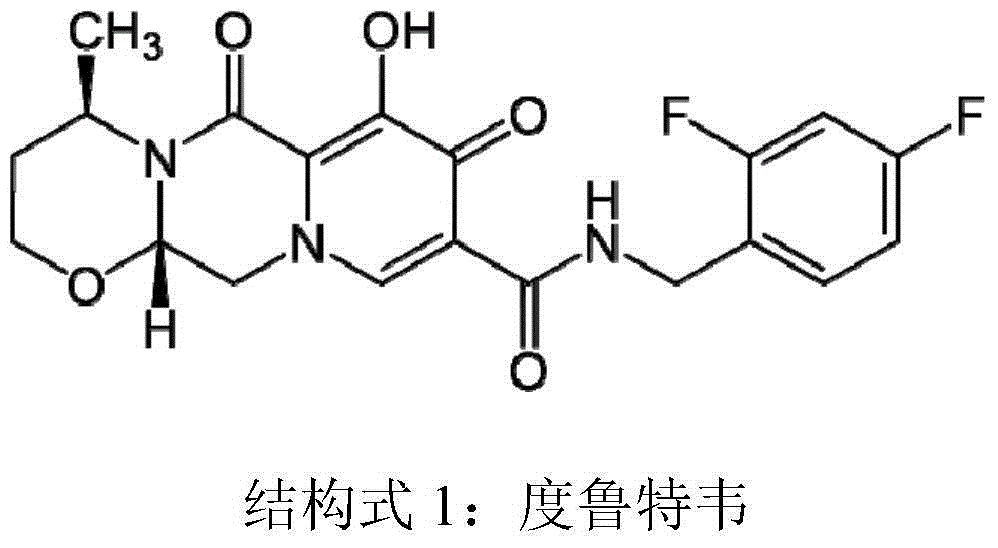

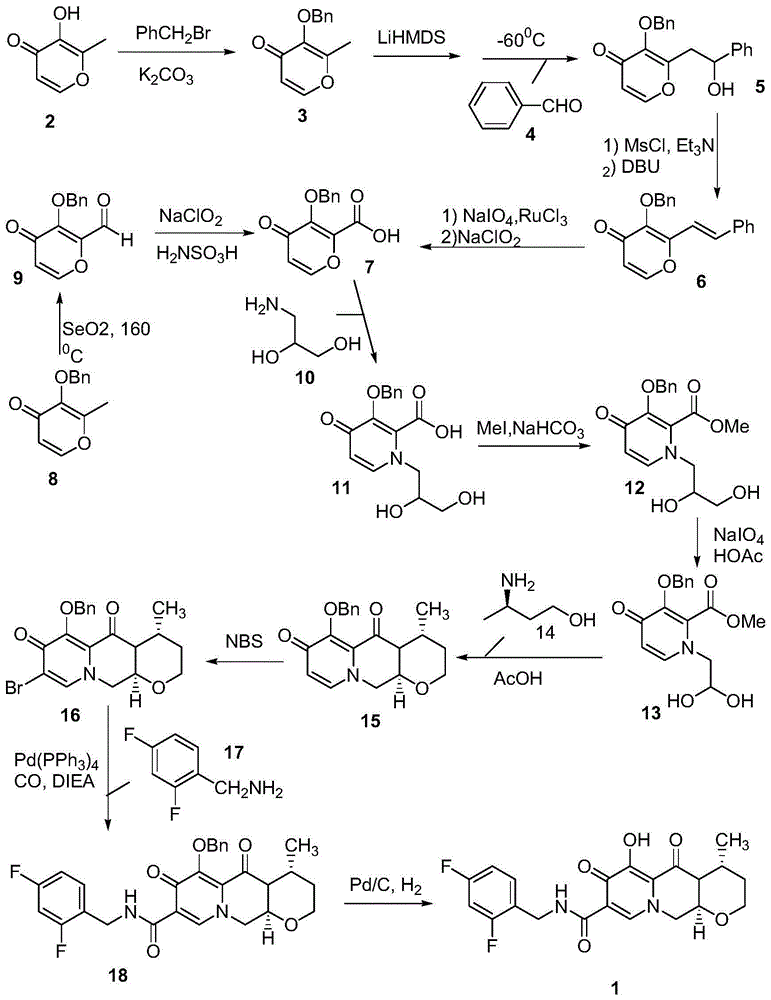

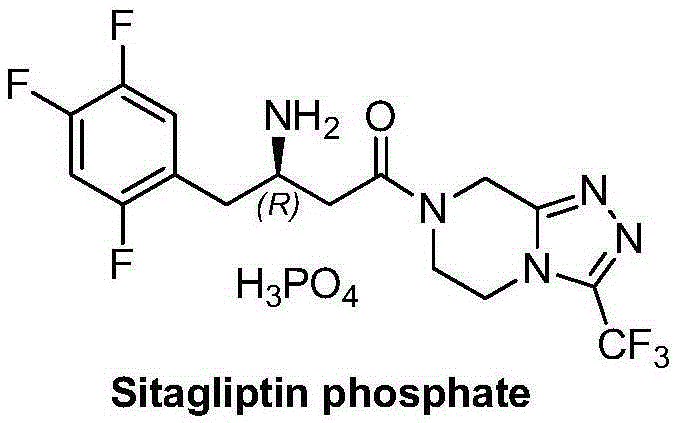

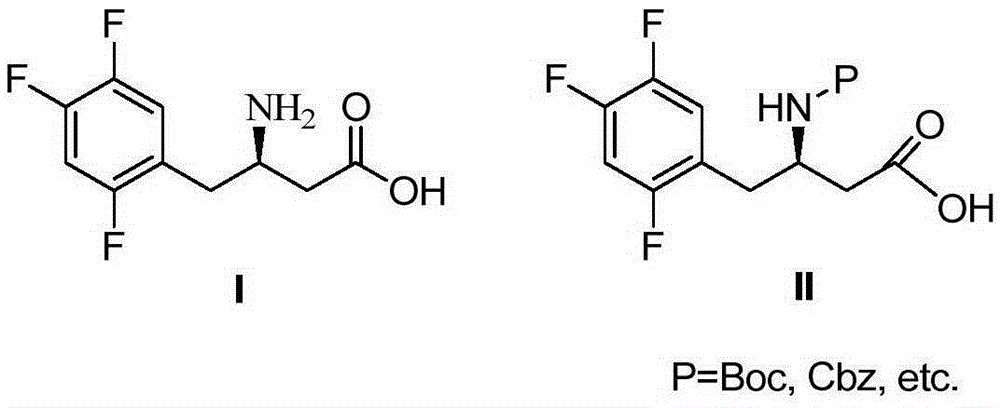

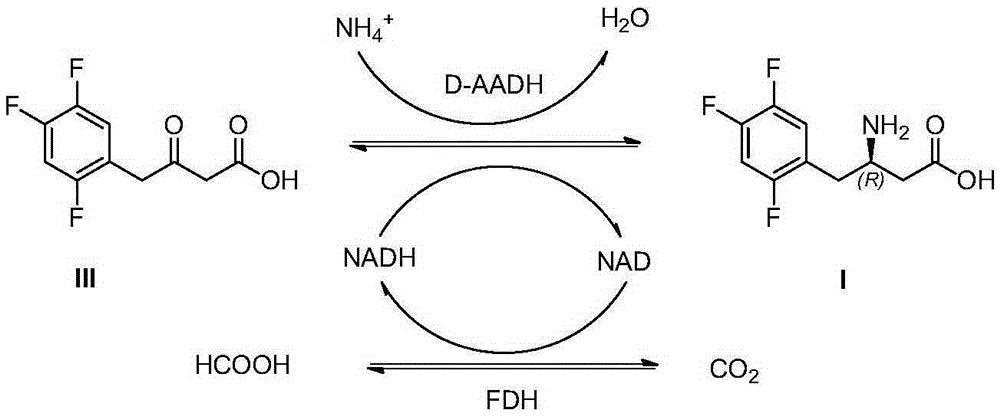

Sitagliptin and enzyme-chemical preparation method of intermediate of sitagliptin

The invention discloses sitagliptin and an enzyme-chemical preparation method of an intermediate of the sitagliptin. The method comprises the steps of mixing 3-carbonyl-4-(2, 4, 5-trifluoro-phenyl)butyrate, D-amino acid dehydrogenase, a cofactor, cofactor-catalyzing cyclophorase, an amino doner, a cosolvent and a buffer solution according to a certain ratio to obtain a product (R)-3-amino-4-(2, 4, 5 trifluoro-phenyl)butyrate; enabling the (R)-3-amino-4-(2, 4, 5 trifluoro-phenyl)butyrate to be subjected to the steps of amino protection, condensation and deprotection to obtain sitagliptin free alkali. Compared with the prior art, the method adopted by the invention is less in process route, shorter in reaction time, improved in product purity and yield and lower in production cost, and is suitable for industrial production.

Owner:ZHEJIANG SUPOR PHARM CO LTD

Treatment method of arsenic wastewater

ActiveCN103112974AShort process routeShort construction periodMultistage water/sewage treatmentFlocculationResource recovery

The invention discloses a treatment method of arsenic wastewater. The treatment method comprises the following steps: optionally adding acid liquor into the arsenic wastewater to adjust the pH value to 0-5; introducing the arsenic wastewater into a reaction unit, continuously removing arsenic by adding sulfide in multistage manner; carrying out solid-liquid separation on the effluent after reaction, recycling the separated arsenic slag; adding alkali into the separated effluent to perform electrochemical advanced treatment, wherein the electrochemical advanced treatment includes an electrolytic coagulation step, an electrolytic flotation step and an electrolytic oxidation reduction step, in the electrolytic coagulation, cations are generated by the electrolyzation of a soluble anodic iron plate for flocculation; carrying out aerated oxidation on the effluent after flocculation to generate floc and micelle sediment including ferric ions, and then carrying out solid-liquid separation, wherein the liquid supernatant after separation can be recycled or reach the standard and drain outwards. The treatment method of arsenic wastewater has the advantages of simple technology, low investment, low cost and high resource recovery and recycling rate, and being green and environment-friendly, and being capable of treating continuously and the like.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Process for directly producing natural benzaldehyde using cassia twig leaf and cassia bark as raw material

InactiveCN1749231AReduce investmentShort process routeCarbonyl compound preparation by hydrolysisBenzaldehydeGas phase

The process of producing natural benzaldehyde directly with cassia twig, leaf and bark as raw material includes the steps of: crushing cassia twig, leaf and bark, and distilling in distiller; hydrolysis of the mixed gas of steam and cassia oil from the distiller, inside hydrolysis reactor with inlet connected to the outlet of the distiller and through contact with alkaline catalyst to produce benzaldehyde in the steam mixture; and condensing the mixture to obtain coarse benzaldehyde product. The present invention can produce natural benzaldehyde by increasing one hydrolysis reactor to available cassia oil producing apparatus, and has short technological path, low power consumption, low cost and coarse benzaldehyde yield of 0.5 %.

Owner:GUANGXI UNIV

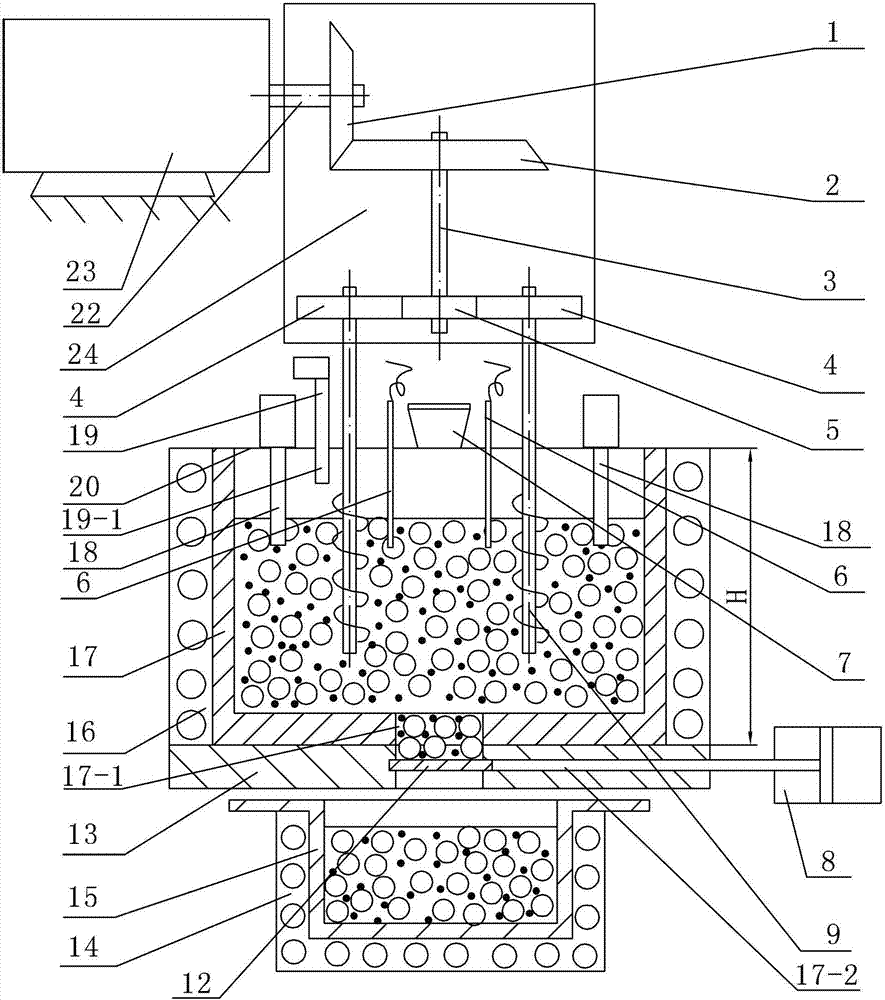

Device and method for preparing nanometer ceramic particle-reinforced aluminum-based composite

A device and a method for preparing a nanometer ceramic particle-reinforced aluminum-based composite relate to a device and a method for preparing a metal matrix composite and aim at solving the problems of long preparing technical path, excessive required equipment and high cost in the existing powder metallurgic method for preparing the nanometer ceramic particle-reinforced aluminum-based composite, as well as the problems of non-uniform distribution, layering and conglobation of nanometer ceramic particles in the existing stirring method. The device comprises a motor, a gearbox, a first gear shaft, a feeding hopper, a baffle, a heating base plate, a first heating device, a slurry collecting groove, a second heating device, a crucible, a cover plate, a hydraulic driving device, an argon protection device, two temperature measuring elements, two screw type stirring impellers and two ultrasonic devices, wherein stirring ends of the screw type stirring impellers extend into the crucible arranged below the gearbox, and probes of the ultrasonic devices penetrate through the cover plate and extend into the crucible. The device and the method, provided by the invention, are used for preparing the nanometer ceramic particle-reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

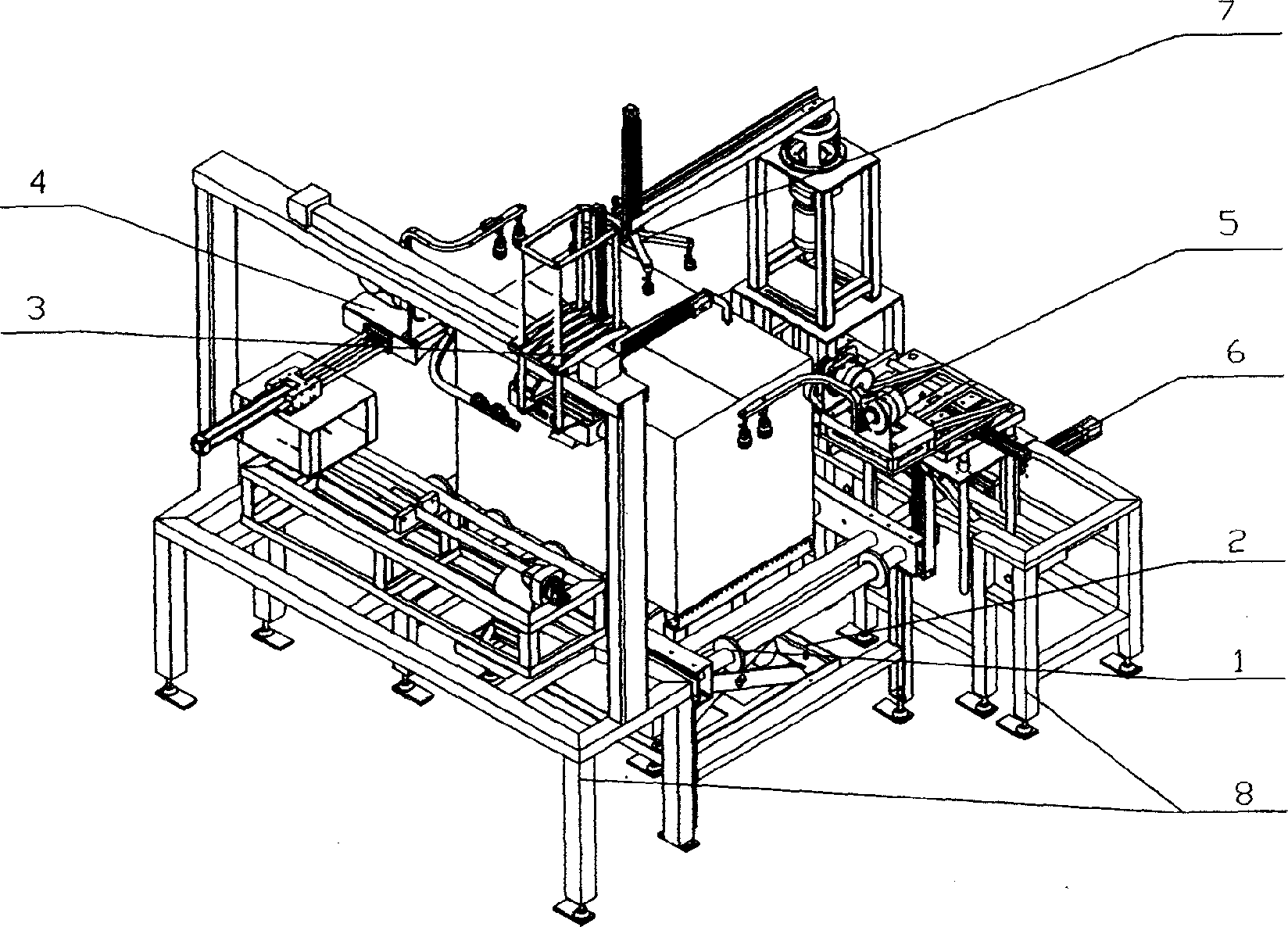

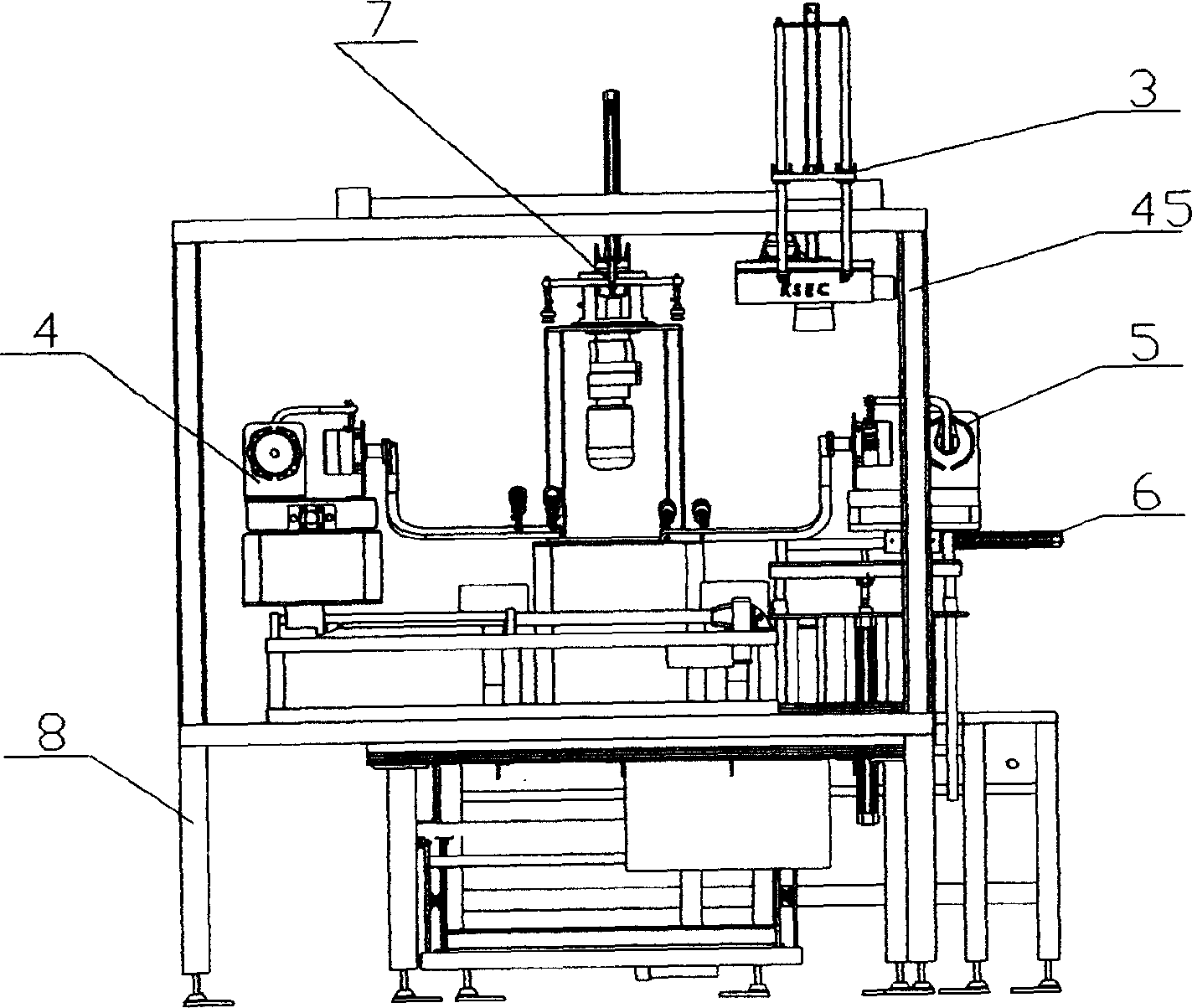

Full automatic opening method and device for paper box

ActiveCN1616305AProcess arrangement is reasonableImprove work efficiencyArticle unpackingCartonPulp and paper industry

The automatic paper box opening process includes the following steps: detecting, dismantling and recovering packing belt on the paper box; and turning the cover. The device used in the said process includes paper box package dismantling and recovering unit, front cover turning unit and back cover turning unit set along the paper box conveying line. The present invention can complete the number detection, locating, shearing and fast recovering of packing belt on the surface of paper box, the turning of paper box cover and removing the upper lining inside the paper box automatically and successively, is suitable for paper boxes of different sizes and has high work efficiency.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

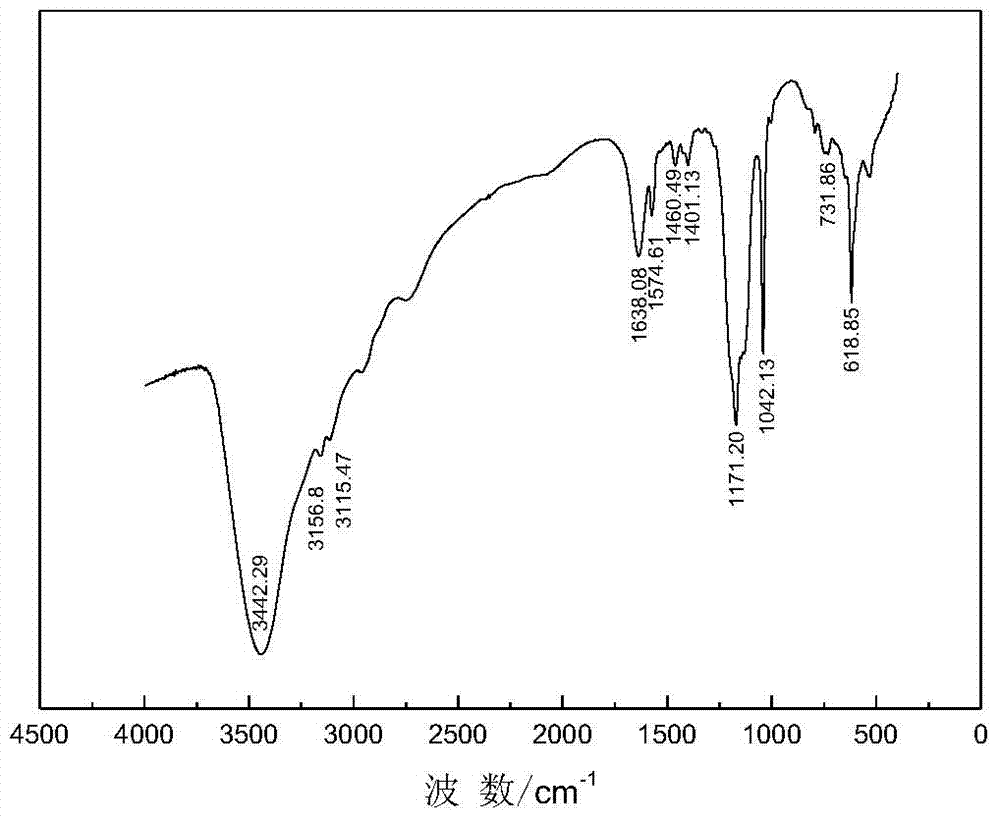

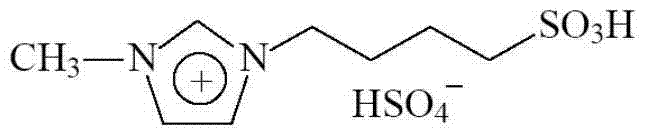

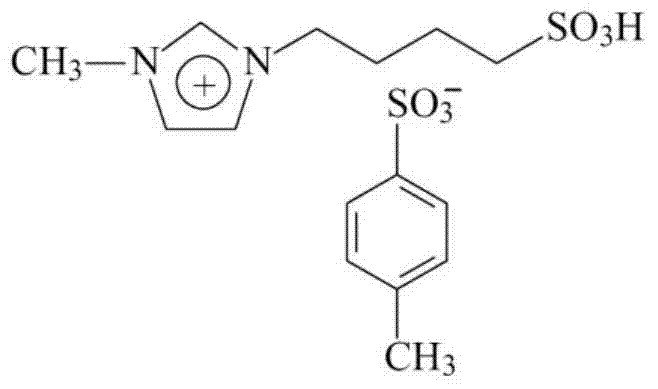

Preparation method of ionic liquid type hydroxylamine salt

ActiveCN103539742ARich varietyShort process routeSulfonic acids salts preparationHydroxylamineFiltration

The invention discloses a preparation method of an ionic liquid type hydroxylamine salt. The preparation method comprises following steps: (1) preparation of a free hydroxylamine salt aqueous solution, wherein the hydroxylamine salt is delivered into a reactor, deionized water is added for dissolving, alkali lye is added dropwise with stirring, and the solution is subjected to neutralization for 0.05 to 1h; after that the reacted solution is subjected to vacuum filtration so as to obtain a filtrate, a stabilizing agent is added into the filtrate, and the mixture is subjected to reduced pressure distillation so as to obtain a cut fraction which is the free hydroxylamine salt aqueous solution; and (2) preparation of the ionic liquid type hydroxylamine salt, wherein an acid ionic liquid is delivered into a reactor, the free hydroxylamine salt aqueous solution obtained in step (1) is added into the ionic liquid, and the mixed solution is stirred for 0.25 to 4h, and then is subjected to rotary evaporation so as to obtain the white solid ionic liquid type hydroxylamine salt. Process cycle is short, post treatment is simple, clean production can be realized, product yield is high, and quality is stable.

Owner:HEBEI UNIV OF TECH

Method for preparing titanium diboride dispersion-strengthened Cu-base composites by using mechanical alloying method

The invention discloses a method for preparing titanium diboride dispersion-strengthened Cu-base composites by using a mechanical alloying method, taking Cu powder, TiO2 powder, B2O3 powder and Mg powder with the granularity less than 100 meshes and purity more than 99 percent as raw materials. The method comprises the following steps of: thoroughly mixing the Cu powder, the TiO2 powder, the B2O3 powder and the Mg powder; carrying out high-energy ball-grinding on the mixed powder for 3 to 15 hours at the revolution speed of 1000 to 2000 rpm at room temperature; acid pickling the powder for 2 to 15 hours at the temperature of 20 to 80 DEG C with 1 to 3 mol / L hydrochloric acid to get mixed powder of Cu and TiB2; drying the mixed powder of Cu and TiB2, and carrying out high-energy ball-grinding on mixed powder of Cu and TiB2 for 1 to 3 hours ; cold pressing the mixed powder of Cu and TiB2 for forming; and at last sintering the mixture of Cu and TiB2 for 1 to 3 hours in a resistance furnace with argon protection gas at the temperature of 800 to 1000 DEG C to get the TiB2 dispersion-strengthened Cu-base composites with granularity of 5 to 10 microns. The method for preparing the TiB2 dispersion-strengthened Cu-base composites by using the simple high-energy ball-milling mechanical alloying method has the advantages of simple technology, low production cost, high product yield and high product quality.

Owner:KUNMING UNIV OF SCI & TECH

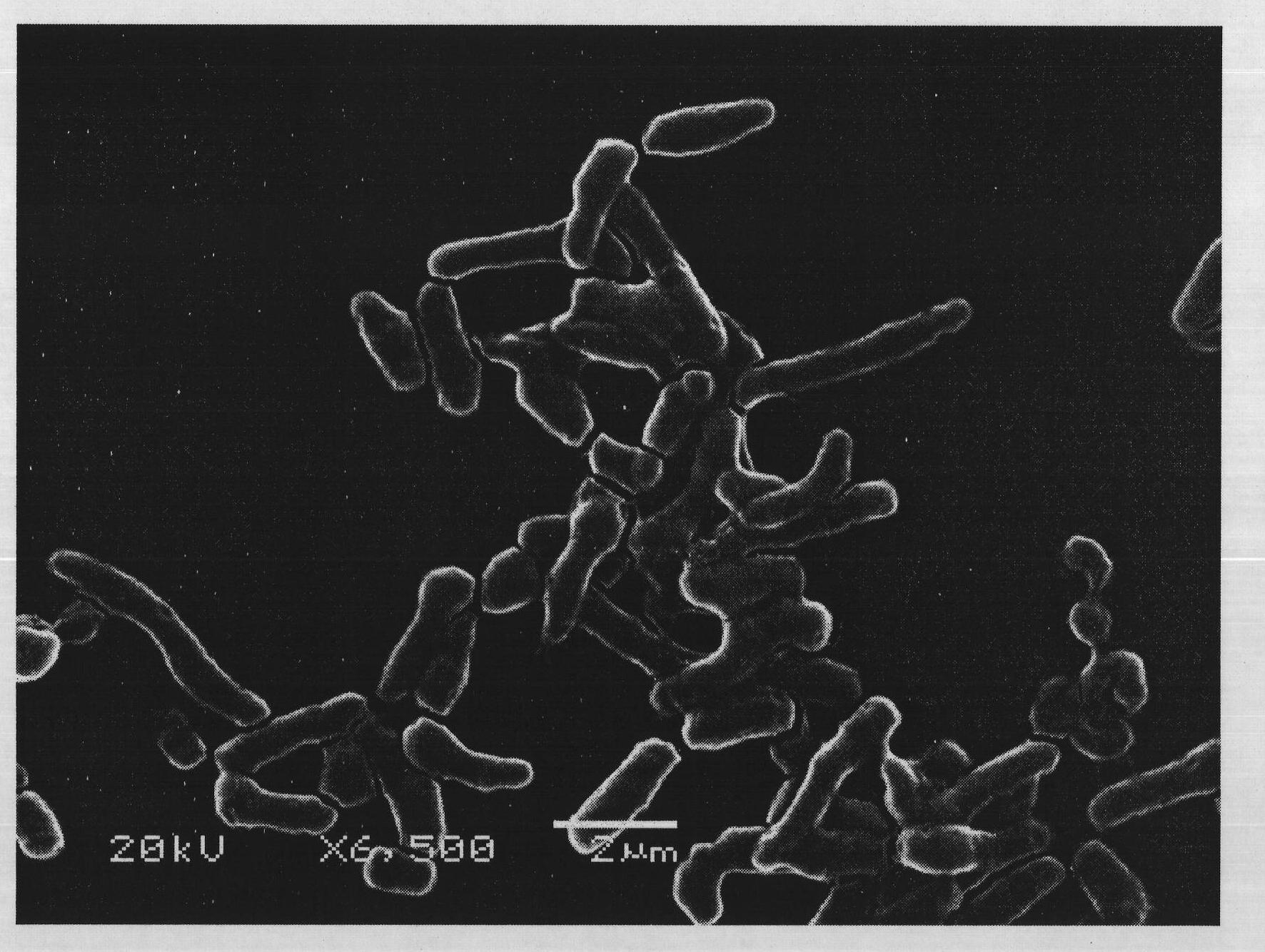

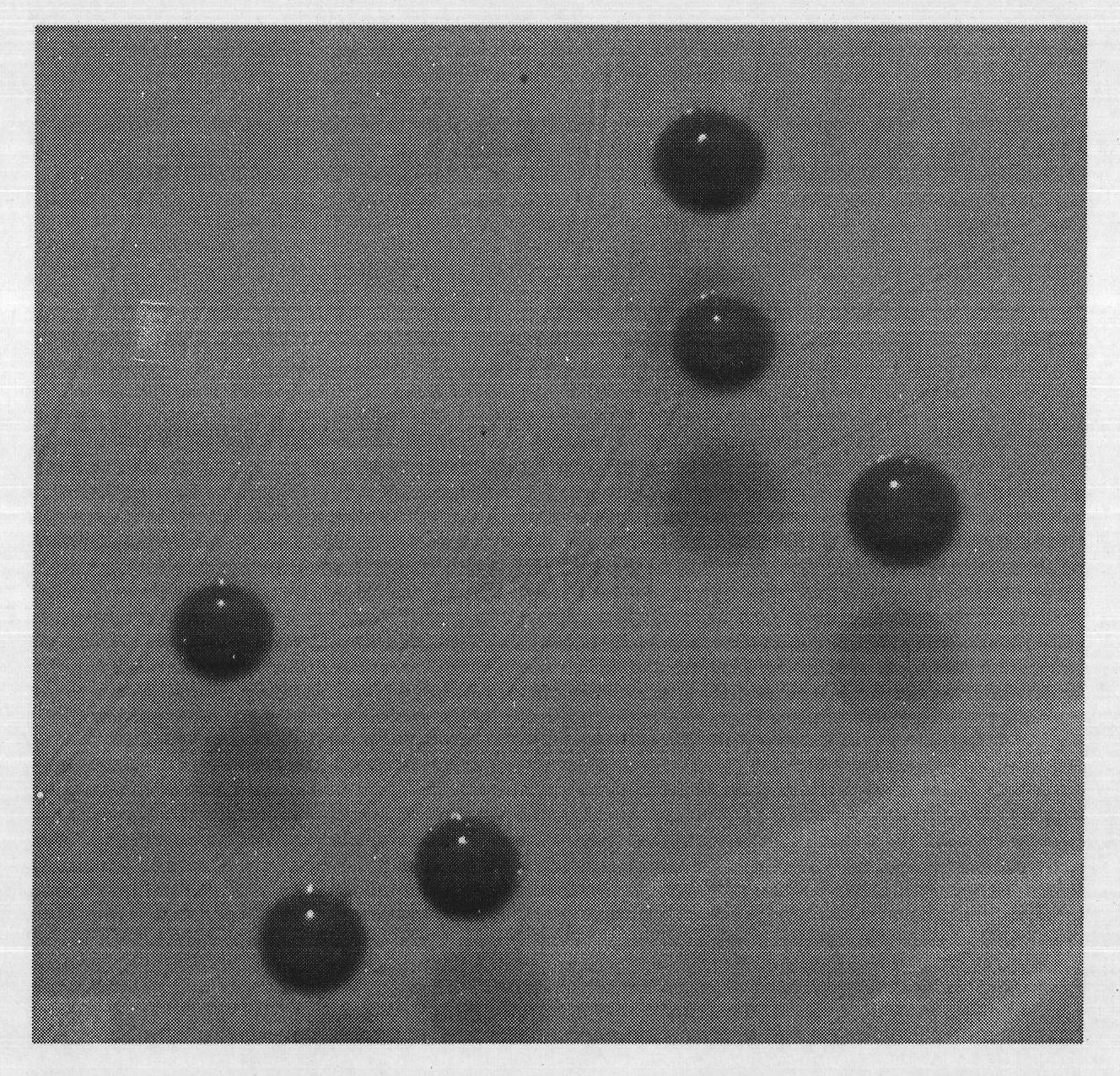

Heterotrophic nitrification aerobic denitrifying bacteria and culture method and application thereof

ActiveCN101875909AEfficient removalWide range of substratesTreatment using aerobic processesBacteriaHigh concentrationBacteroides

The invention belongs to the technical field of environmental microbiology, and relates to high-efficiency heterotrophic nitrification aerobic denitrifying bacteria and a culture method and application thereof. The bacteria are Rhodococcus sp. DN2.3 with the preservation registration number of CCTCC M209300, can effectively remove ammonia nitrogen, nitrite nitrogen, nitric nitrogen and the mixture thereof from a water body, also can remove CODCr from organic wastewater, are suitable for treating high-concentration organic nitrogen-containing wastewater; the accumulation of nitrite and nitrate is avoided in the denitrifying process; and the process for treating wastewater by using the strain is simple and the denitrifying effect is stable.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Process for preparing high molecular weight poly lactic acid by fusion polycondensation-solid phase polymerization

The fusion polycondensation and solid phase polymerization process for preparing high molecular weight polylactic acid includes: the fusion polycondensation step of decompression dewatering material L-lactic acid gradually and adding catalyst for polycondensation; and the solid phase polymerization step of constant temperature crystallizing the pre-polymer, crushing and adding molecular sieve for solid phase polymerization. The process of the present invention has short technological path, simple operation, low cost and high molecular weight of polylactic acid product.

Owner:SHANGHAI CHLOR ALKALI CHEM

Method for continuous producing fuel oil from deposed lubricant

InactiveCN1563305AExpand sourceChange stringent requirementsCatalytic crackingLubricant compositionFractionating columnWaste oil

A method for continuously producing fuel oil from waste lubricating oil is featured as carrying out treatment of stewing, setting, dewatering and impurity removing for raw material oil to separate out water and mechanical impurities, adding absorbent, catalytic cracking catalyst, molecular weight regulator, sending raw material oil with overheated steam into tube heater after heat exchanging and separating oil gas from heater outlet with fractionating column for obtaining different fue oil.

Owner:陈天晓

Process for extracting and separating coenzyme Q10 from mushroom dregs

The invention discloses a process for extracting and preparing high-purity coenzyme Q10 from mushroom dregs. The mushroom dregs serve as raw materials to be subjected to percolation extraction, and a coenzyme Q10 percolation extracting solution is obtained; the coenzyme Q10 percolation extracting solution is subjected to multilevel extraction for purification, and raffinate is obtained; the raffinate is subjected to crystallization treatment, finally, the high-purity coenzyme Q10 with the purity reaching 98% or above is obtained, and the yield is 95% or above. The whole process is simple, reliable and easy to operate and achieve, and parameters are convenient to control.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com