Method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages

A technology of collagen polypeptide and chondroitin sulfate, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of low content of collagen polypeptides, limited product application fields, and complex components of complexes, etc., and achieve reduction The content of miscellaneous protein, increase the added value of the product, the obvious effect of economic benefit and environmental benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

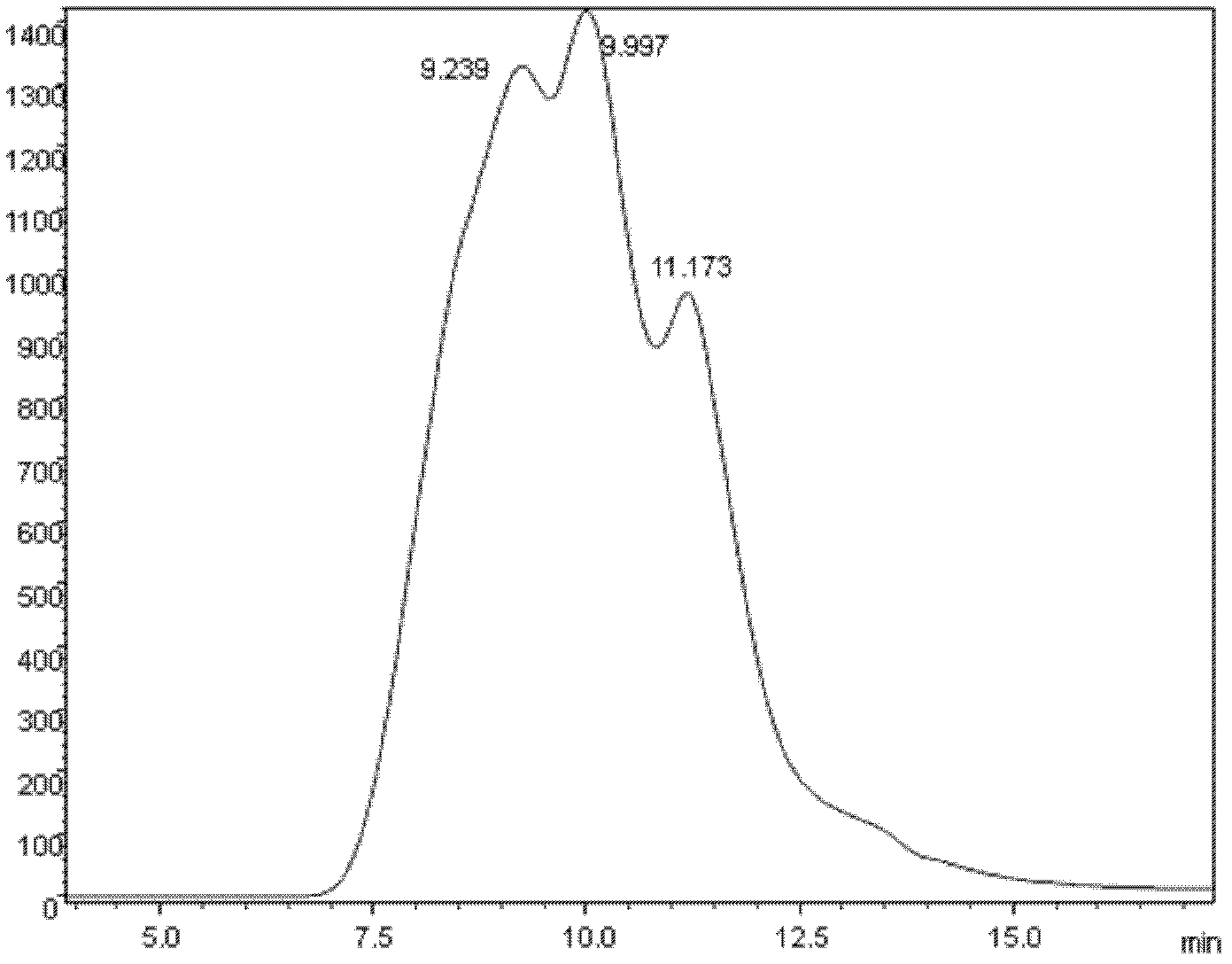

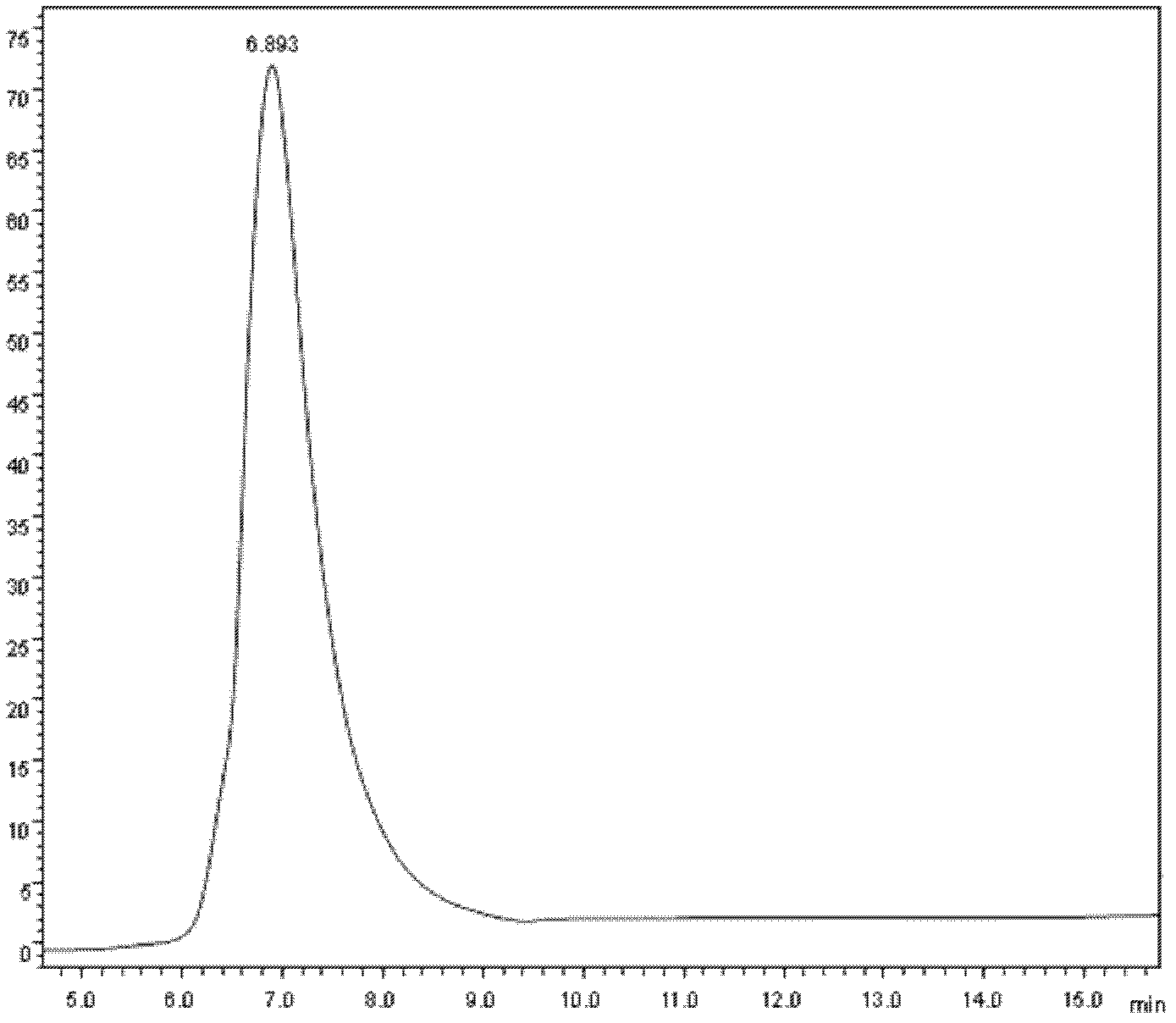

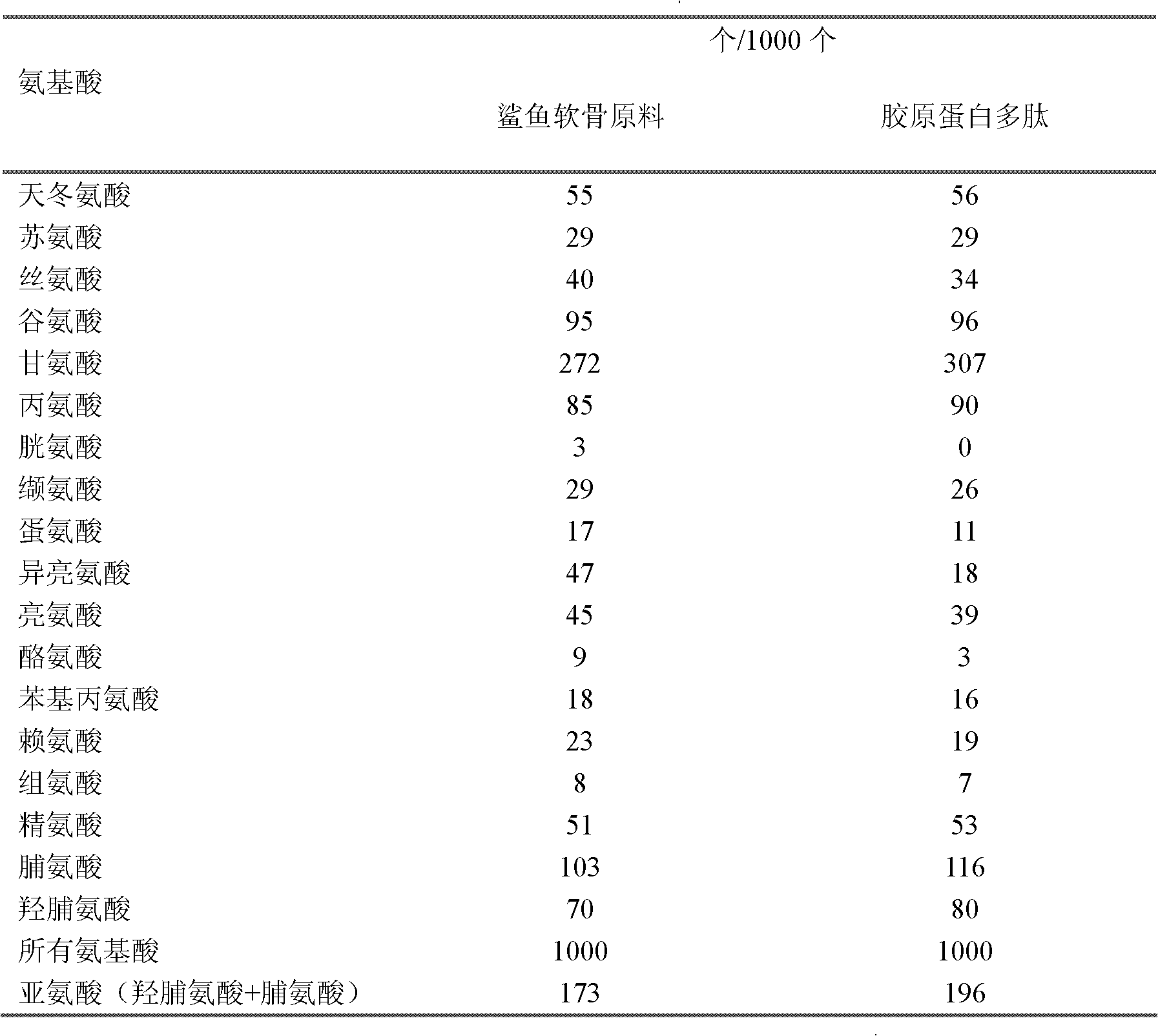

[0046] The dried shark cartilage (water content 8%) is crushed to an average particle diameter of about 0.1-1mm, and 10kg is accurately weighed, and 0.1kg alkaline protease (200,000 U / g) and 100L water are added respectively, and the mass concentration is Adjust the pH to 9.0 with 40% NaOH solution, and stir at 55°C for 12h. After the enzymatic hydrolysis, the temperature was raised to 70°C and kept for 30 minutes to inactivate the enzyme. After the enzymolysis solution is cooled, filter, get the filtrate, adjust the pH value to 7 with 6mol / L HCl solution, and concentrate by ultrafiltration (the molecular weight cut-off of the ultrafiltration membrane is 3000), to obtain 9.8L of concentrated solution of 20% chondroitin sulfate concentration (potential Titration method to detect the content of chondroitin sulfate in the concentrate). Use 6mol / L HCl solution to adjust the pH of the concentrated solution to 2.0, wet the D202 type anion exchange resin column with a resin volume o...

Embodiment 2

[0052] Grind the dried shark cartilage (water content 8%) to an average particle size of about 0.1-1mm, accurately weigh 10kg, add 0.15kg bromelain (2400GDU / g) and 150L water respectively, adjust with 6mol / L HCl solution pH to 6.0, stirred at 30°C for 4h. After the enzymatic hydrolysis, the temperature was raised to 70°C and kept for 60 minutes to inactivate the enzyme. After the enzymolysis solution is cooled, filter, take the filtrate, adjust the pH value to 7 with a mass concentration of 40% NaOH solution, and concentrate by ultrafiltration (the molecular weight cut-off of the ultrafiltration membrane is 3000), to obtain 95 L of concentrated solution with a concentration of chondroitin sulfate of 2%. Use 6mol / L HCl solution to adjust the pH of the concentrated solution to 3.0, wet the D315 type anion exchange resin column with a resin volume of 57L at a flow rate of 0.5VB / h, and collect the effluent A; then, use 114L pure water at 0.5VB / h The flow rate of h is eluted, the ...

Embodiment 3

[0055] Grind the dried shark cartilage (water content 8%) to an average particle size of about 1-5mm, accurately weigh 10kg, add 0.05kg acid protease (50,000 U / g) and 100L water respectively, and use 6mol / L HCl The pH of the solution was adjusted to 2.0, and stirred at 55 °C for 5 h. After the enzymatic hydrolysis, the temperature was raised to 80°C and kept for 10 minutes to inactivate the enzyme. After cooling the enzymolysis solution, filter it, take the filtrate, adjust the pH value to 7 with a mass concentration of 40% NaOH solution, and concentrate by ultrafiltration (the molecular weight cut-off of the ultrafiltration membrane is 3000), to obtain 38L of a concentrated solution with a concentration of 5% chondroitin sulfate. Use 6mol / L HCl solution to adjust the pH of the concentrated solution to 4.0, wet the D307 type anion exchange resin column with a resin volume of 23L at a flow rate of 1VB / h, and collect the effluent A; then, use 230L pure water at 0.1VB / h The flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com