Method for preparing super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation

A technology for preparing supercapacitors and activated carbon, applied in the field of electrochemistry, can solve the problems of accumulation of heavy metal antibiotics in biogas residues, limited utilization of biogas residue aquaculture, low product yield, etc., and achieves simple and feasible operation methods, high repeatability, and developed pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

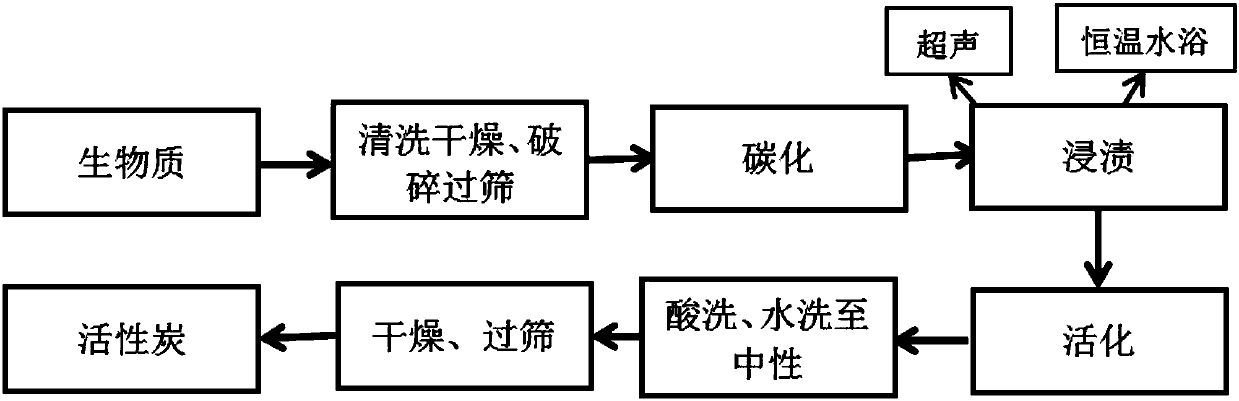

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the supercapacitor was prepared as follows:

[0030] (1) Wash the collected biomass after anaerobic dry fermentation with deionized water, then dry it at 105° C. for 10 hours, crush it through a 40-mesh sieve, and obtain spare biogas residue particles.

[0031] (2) Take 10g of the spare biogas residue obtained in step (1) and place it in a quartz boat and put it in a high-temperature tube furnace. Under the protection of inert gas nitrogen, the temperature is raised to 400°C at a heating rate of 10°C / min, and carbonized at a constant temperature 0.5h, then stop heating, continue to cool to room temperature under the protection of inert gas, take it out and grind into powder to obtain carbonized material powder;

[0032] (3) Take 3g of the carbonized material powder obtained in step (2) and 12g of solid powder KOH and dissolve it in 100mL of deionized water, then disperse uniformly by ultrasonic, then heat it in a water bath at 80℃ for 10h, and finally put i...

Embodiment 2

[0039] In this embodiment, the supercapacitor was prepared as follows:

[0040] (1) The collected biomass after anaerobic dry fermentation is soaked in dilute sulfuric acid with a mass concentration of 0.75% and stirred for 3 hours, then washed with deionized water until it is neutral, and then dried at 105°C 10h, crush through a 40-mesh sieve to obtain spare biogas residue particles;

[0041] (2) Take 10g of the spare biogas residue obtained in step (1) and place it in a quartz boat and put it in a high-temperature tube furnace. Under the protection of inert gas nitrogen, the temperature is raised to 400°C at a heating rate of 10°C / min, and carbonized at a constant temperature 0.5h, then stop heating, continue to cool to room temperature under the protection of inert gas, take it out and grind into powder to obtain carbonized material powder;

[0042] (3) Take 3g of the carbonized material powder obtained in step (2) and 12g of the activator KOH and dissolve it in 100mL of deionize...

Embodiment 3

[0049] In this embodiment, the supercapacitor was prepared as follows:

[0050] (1) After anaerobic dry fermentation of the collected biomass, the biogas residue is soaked in a sodium hydroxide solution with a mass concentration of 20% and stirred for 3 hours, then washed with deionized water until it is neutral, and then at 105°C Dry for 10 hours and smash through a 40-mesh sieve to obtain spare biogas residue particles.

[0051] (2) Take 10g of the spare biogas residue obtained in step (1) and place it in a quartz boat and put it in a high-temperature tube furnace. Under the protection of inert gas nitrogen, the temperature is raised to 400°C at a heating rate of 10°C / min, and carbonized at a constant temperature 0.5h, then stop heating, continue to cool to room temperature under the protection of inert gas, take it out and grind into powder to obtain carbonized material powder;

[0052] (3) Take 3g of the carbonized material powder obtained in step (2) and 12g of KOH solid powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com