Patents

Literature

266results about How to "Well-developed pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing activated carbon powder with lignin from alkaline papermaking black liquor

The invention provides a method for preparing activated carbon powder with lignin from an alkaline papermaking black liquor. The method comprises the steps as follows: the lignin is extracted from the alkaline papermaking black liquor through acidification and is prepared after being purified; KOH (potassium hydroxide) is added after the lignin is carbonized; the mixture is placed in an ultrasonic water bath to be subjected to ultrasonic treatment for 30 to 35 min; and after being dried, the mixture of the lignin and the potassium hydroxide is heated and activated for 0.5 to 2.0 hours at 650 to 850 DEG C, so as to prepare the activated carbon powder. The method has the advantages that the process is simple; waste utilization is realized; and the prepared activated carbon powder has the effects of large specific surface area, high porosity, strong adsorption effect and excellent properties and can effectively remove heavy metals and organic pollutants.

Owner:SHANDONG UNIV

Method for producing active carbon by using traditional Chinese medicine dregs

The invention discloses a method for producing active carbon by using traditional Chinese medicine dregs as raw materials and zinc chloride as an activator. The method comprises the following steps: firstly, drying the raw materials of the traditional Chinese medicine dregs until the moisture content is less than 15 percent, performing mechanical pulverization and sieving the materials through a 40-mesh sieve; secondly, soaking the dregs after pretreatment in 3-7 mol / l zinc chloride solution for 24 hours, wherein the soaking ratio, namely the ratio of the mass of the dregs to the mass of the zinc chloride solution is 1:1-1:2; thirdly, putting the traditional Chinese medicine dregs soaked by the zinc chloride solution into a pipe furnace, introducing an inert gas (such as nitrogen or carbon dioxide), raising the temperature to between 400 and 600 DEG C, and performing one-step carbonization (carbonization and activation simultaneously) for 0.5 to 1.5 hours; fourthly, cooling the activated carbides to room temperature, washing the carbides with 3 mol per liter hydrochloric acid solution, and rinsing the carbides with 60 DEG C water until the carbides are neutral; and finally, drying the products after the rinsing, and grinding the products to obtain the active carbon finished products.

Owner:CHENGDU UNIV OF INFORMATION TECH

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

Method for preparing porous carbon through co-pyrolysis of petroleum coke and oily sludge

ActiveCN103553040AImprove adsorption capacityThe effect of the pore-forming mechanism is significantCarbon compoundsOther chemical processesPorous carbonSludge

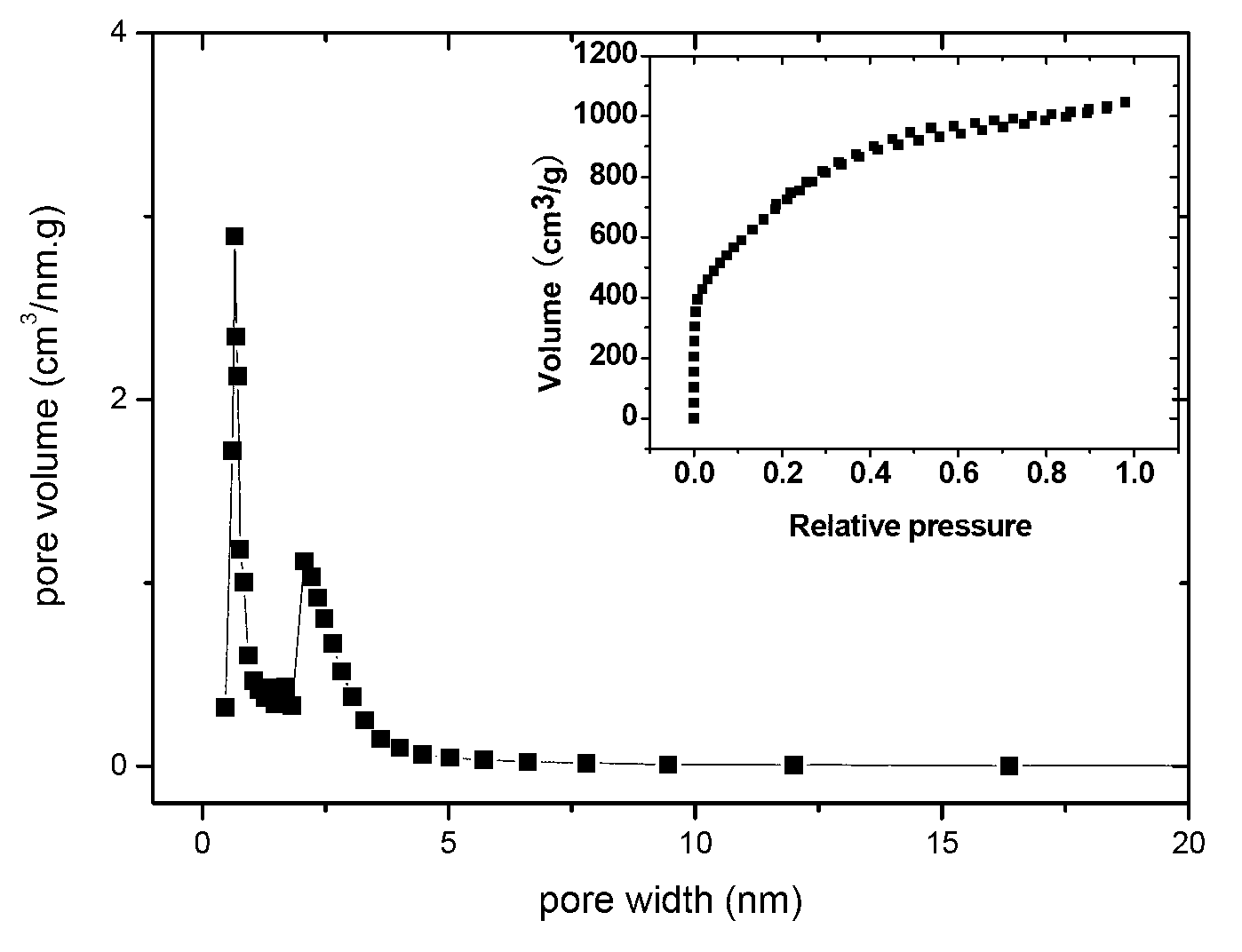

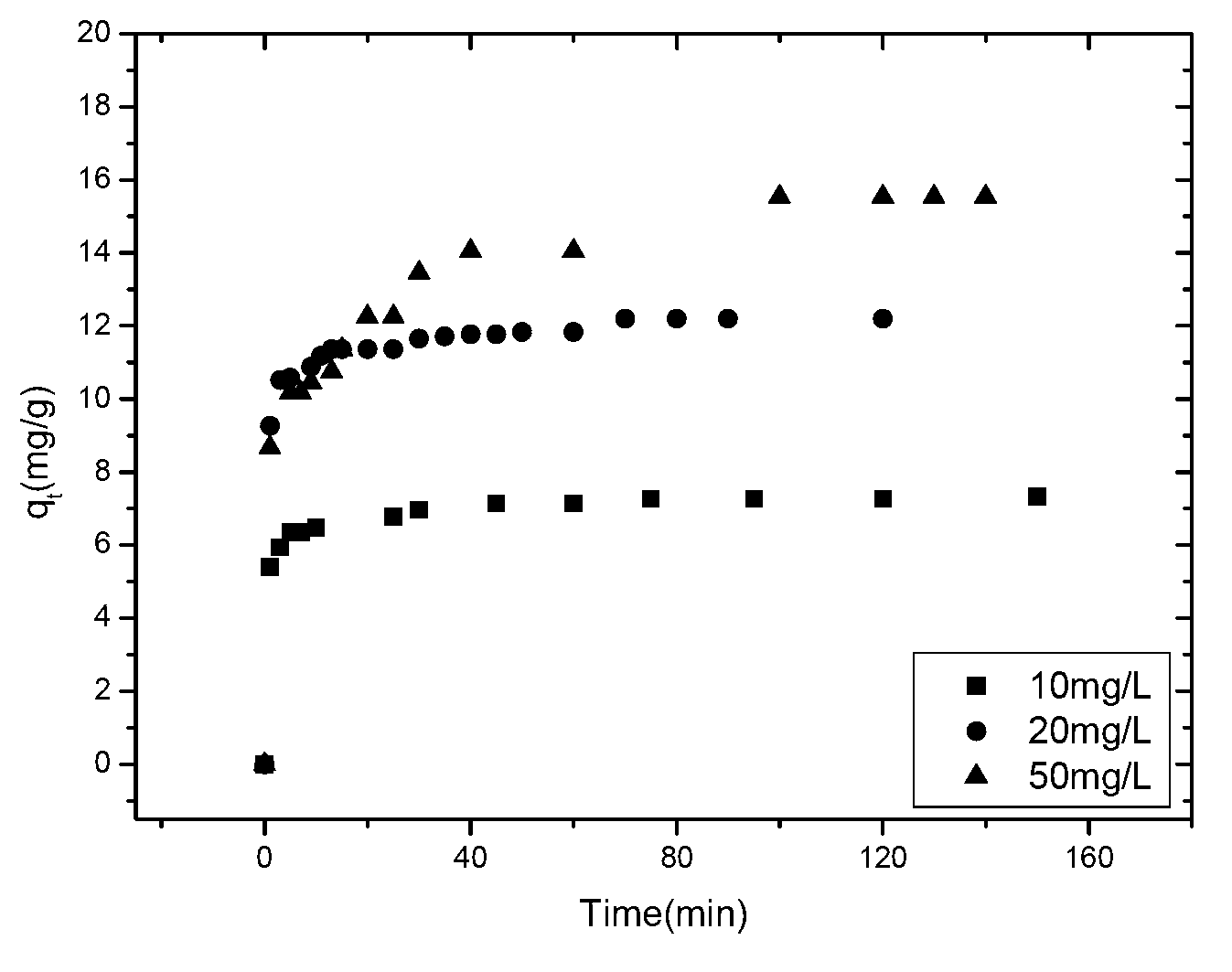

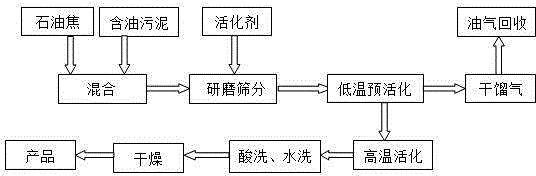

The invention belongs to the petrochemical field, and relates to a method for preparing porous carbon through the co-pyrolysis of petroleum coke and oily sludge. The method comprises the following steps: (1) predrying oily sludge; (2) evenly mixing the obtained oily sludge and petroleum coke; (3) smashing, grinding and screening the evenly obtained oily sludge and petroleum coke mixture; (4) steeping the mixture into a composite activator solution, and drying; (5) putting the obtained mixture into a low-temperature reaction furnace for pre-activating; (6) putting the obtained product into a high-temperature reaction furnace for continuing activation, performing furnace cooling to normal temperature; (7) adding the obtained activated product in a hydrochloric acid or sulfuric acid solution for soaking, washing with distilled water to obtain a solid product, and drying the solid product to obtain the porous carbon material. According to the method, not only can the petroleum coke and oily sludge be recycled, but also the porous carbon material with high adsorptivity can be prepared.

Owner:宁德中同新能源科技有限公司

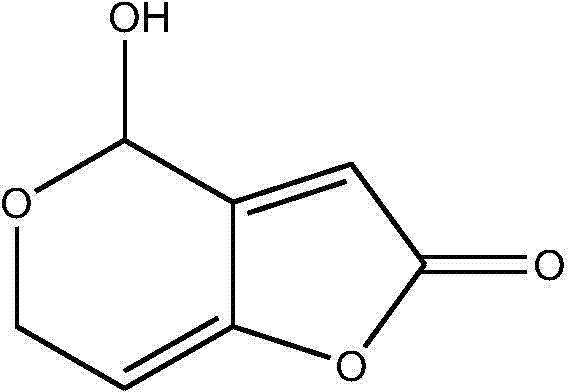

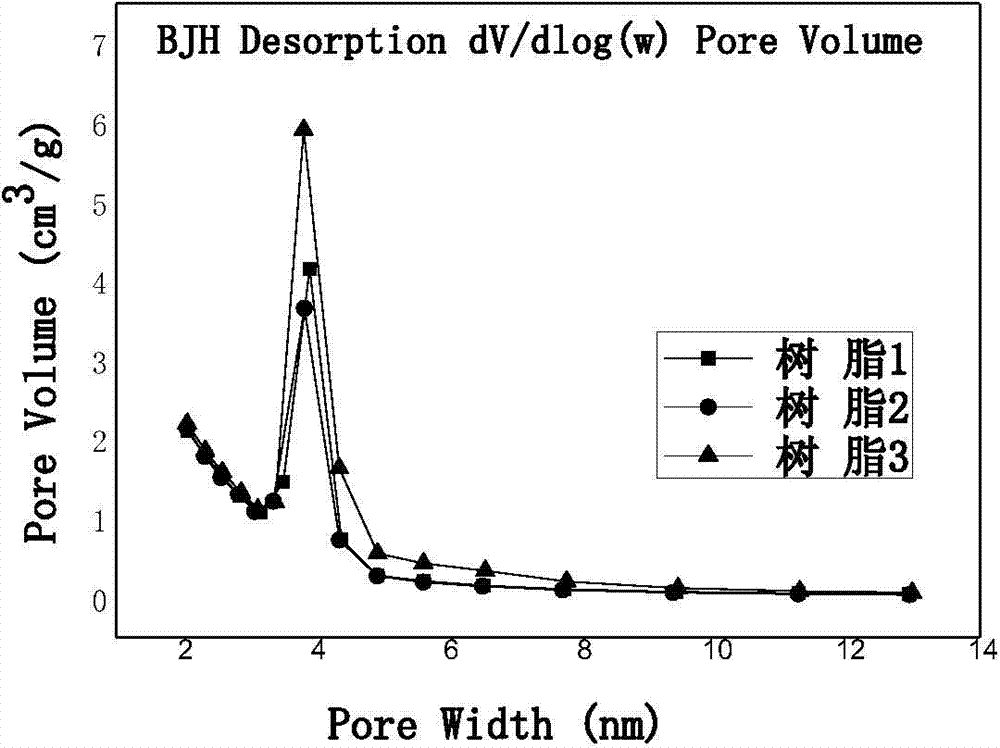

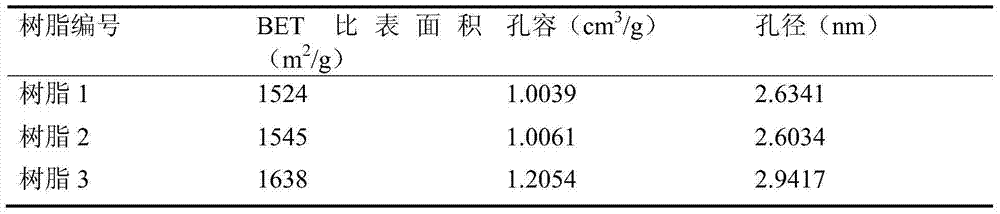

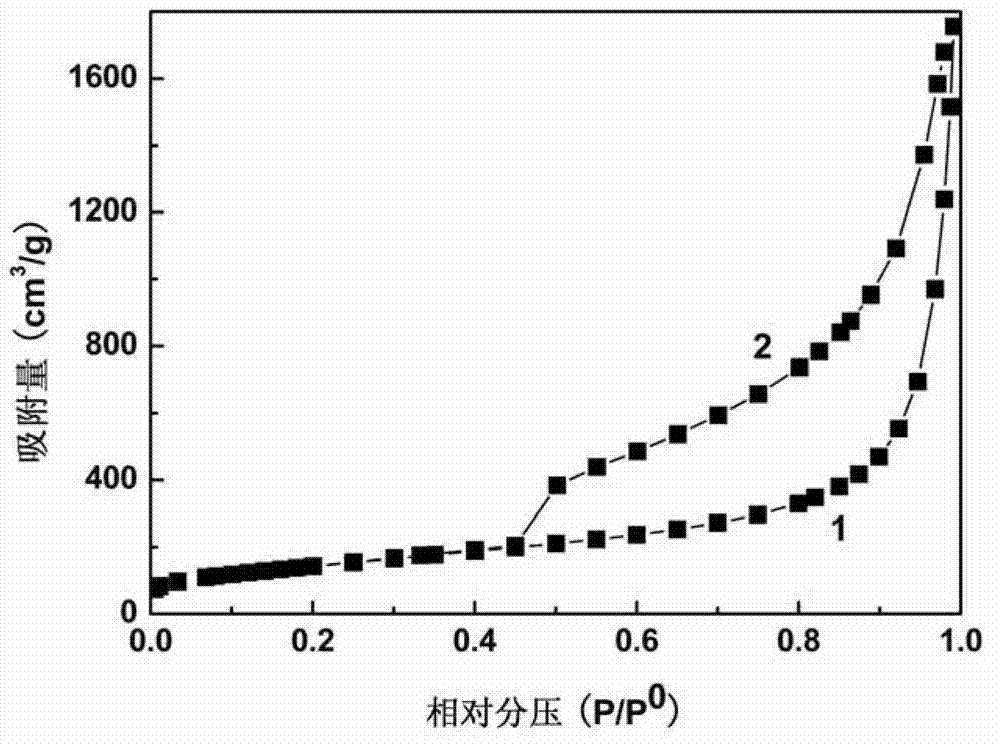

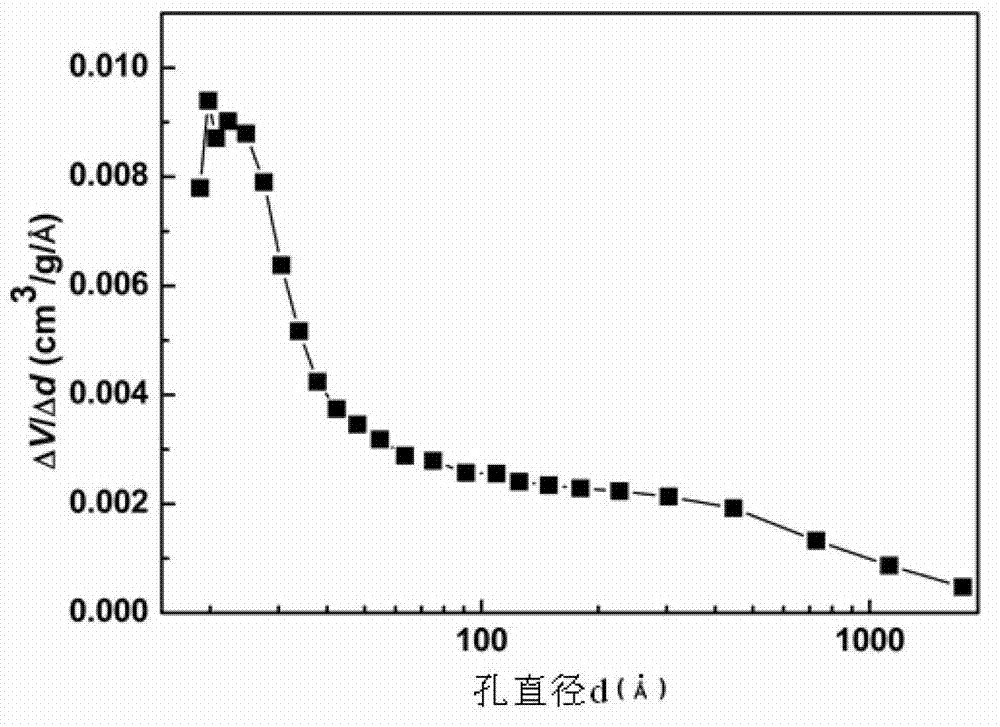

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

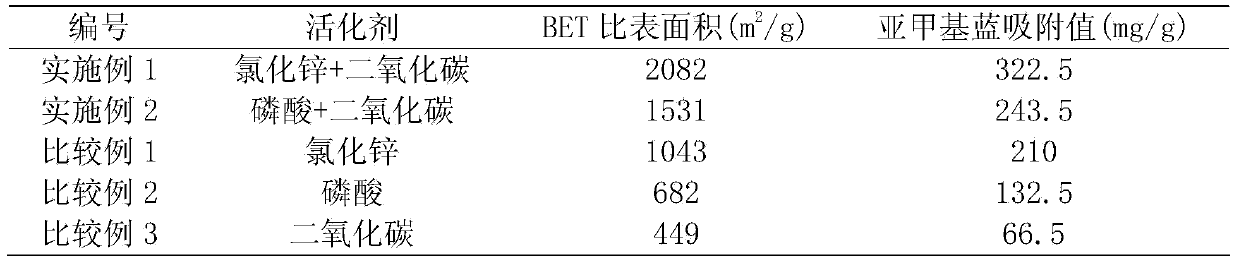

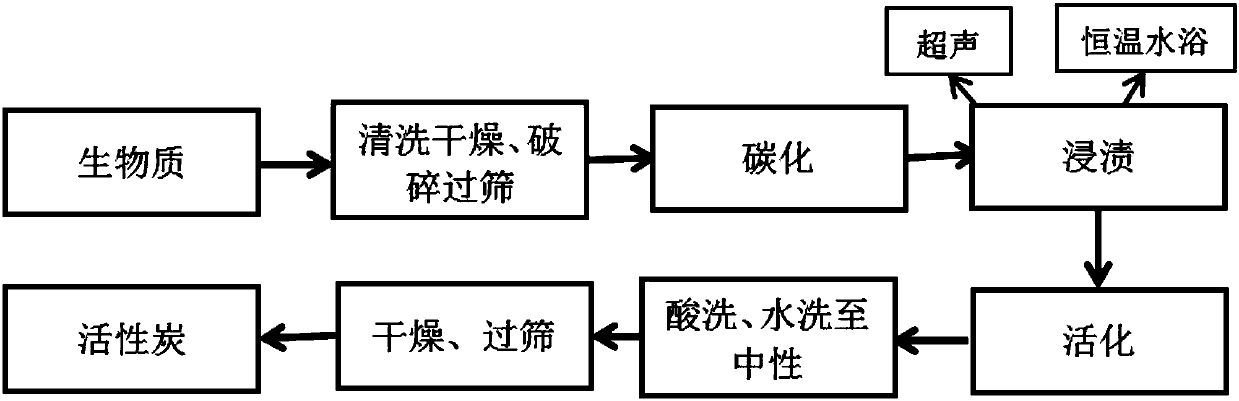

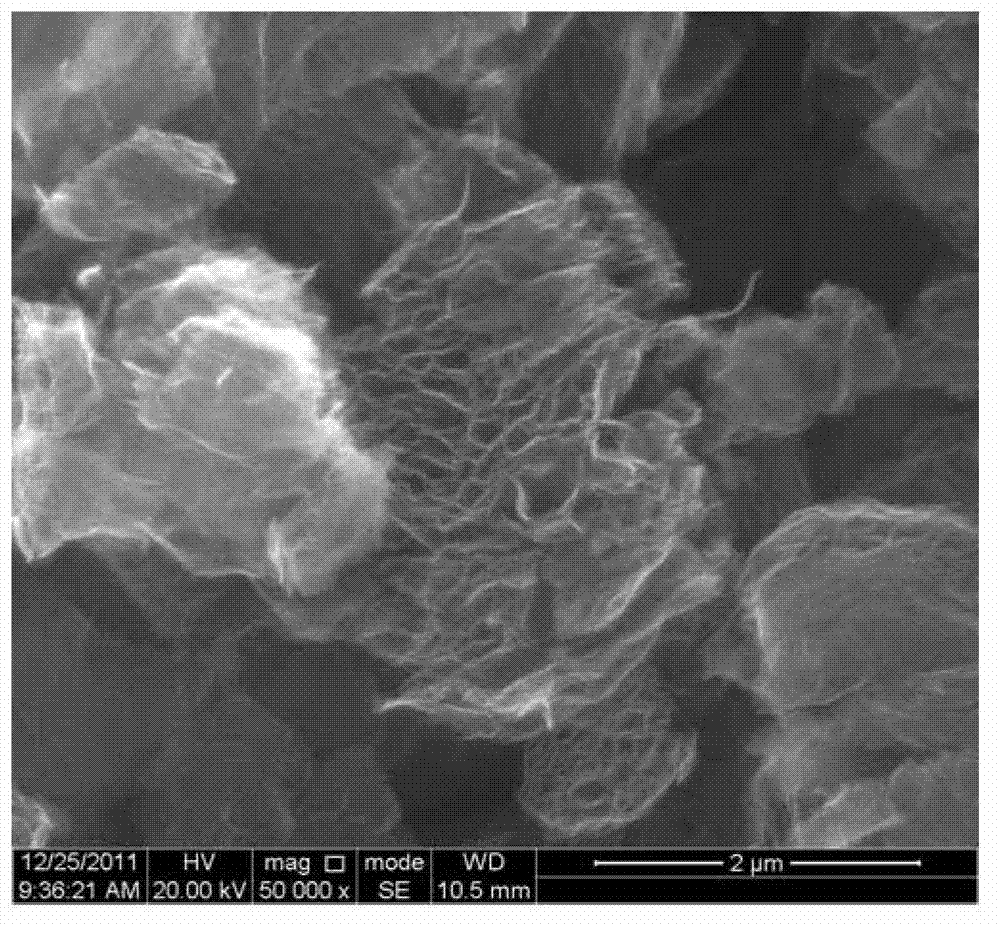

Method for preparing active carbon by taking biomass pyrolytic carbon as raw material

InactiveCN104003387AIncrease added valueImprove performanceCarbon compoundsActivation methodFiltration

The invention relates to a method for preparing active carbon by taking biomass pyrolytic carbon as a raw material, and relates to post processing of the biomass pyrolytic carbon. The method comprises the following steps: cleaning the pyrolytic carbon, stirring, then standing and depositing, drying the pyrolytic carbon floating on an upper layer, and then crushing; preparing a chemical activating agent solution, then mixing, stirring and soaking with the pyrolytic carbon, then drying a soaked mixed solution to obtain a mixed material; and heating the mixed material to 300-800 DEG C at an inert gas atmosphere, introducing a physical activating agent to obtain an active carbon semi-finished product, then adding hydrochloric acid, mixing, then carrying out suction filtration, then cleaning residual hydrochloric acid, and drying to obtain an active carbon finished product. The method disclosed by the invention carries out activating treatment on the biomass pyrolysis of agricultural and forestry wastes and the like, can be used for furthest recycling the agricultural and forestry wastes and can obviously increase the added value of the pyrolytic carbon and obtain the active carbon with excellent property; compared with a product prepared by independently using a chemical activation method or a physical activation method, the prepared active carbon is much larger in specific area, more developed in pore and higher in methylene blue adsorption value.

Owner:XIAMEN UNIV

Method for preparing honeycomb active carbon from coal and coal tar

InactiveCN101503191ASimple ingredientsLow costCarbon compoundsWorking-up peatActivated carbonCarbonization

The invention provides a method for preparing honeycomb-like activated carbon by using coal and coal tar, which takes coal dust and the coal tar as raw materials to prepare the honeycomb-like activated carbon by grinding the coal dust, charge mixture, vacuum pugging, seal aging, vacuum extruding and moilding, drying, carbonization and activation. The method for preparing the honeycomb-like activated carbon only takes the coal tar as cementing agent, so as to overcome the defect that multiple cementing agents are needed to be applied in the technique, thus having the characteristics of simple raw materials, low production cost and easy industrialization. The produced honeycomb-like activated carbon has the characteristics of large geometric area and specific surface area, high mechanical strength and the like, and can be applied for the treatment of waste gas and waste water and catalyst carrier.

Owner:BEIJING UNIV OF CHEM TECH

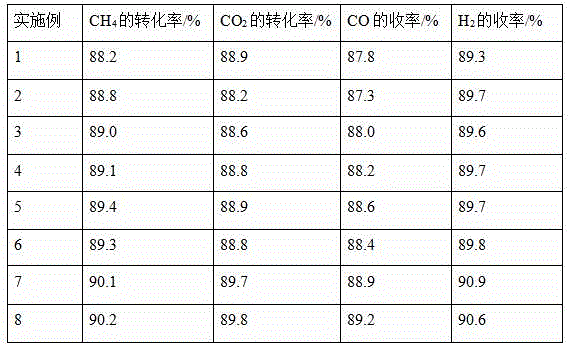

Catalyst for reforming methane and carbon dioxide to prepare synthetic gas as well as preparation method and application thereof

InactiveCN105854885AWell-developed poresLarge specific surface areaHydrogenHydrogen/synthetic gas productionPotassiumCerium

The invention discloses a catalyst for reforming methane and carbon dioxide to prepare synthetic gas as well as a preparation method and application thereof and belongs to the technical field of preparation of catalysts. The catalyst takes compound active carbon as a carrier, takes nickel and cobalt as active components, and takes iron, potassium, cerium, copper or zinc as a cocatalyst component. The preparation method comprises the following steps: firstly, carbonizing, activating and modifying raw materials including brown coal and mao bamboos to prepare a compound carbon material; then, modifying and roasting the prepared compound active compound under the condition of 0.2MPa-10MPa by adopting an HNO3 solution to obtain a catalyst carrier; loading nickel, cobalt, iron, potassium, cerium, copper and zinc on the carrier with the help of ultrasonic waves through an excessive immersion method; and filtering, drying, roasting and reducing to obtain the catalyst. After modification, loaded active components of the catalyst are uniformly distributed and the activity is relatively high; and the carrier takes the brown coal and the mao bamboos as the raw materials so that the carrier is high in content of active oxygen functional groups, large in specific surface area and low in cost.

Owner:TAIYUAN UNIV OF TECH

Preparation method of special activated-carbon electrode block for capacitive deionizing equipment

ActiveCN106395814AReduce manufacturing costEase of mass productionCarbon compoundsDispersed particle separationActivated charcoal powderFiber

The invention provides a preparation method of a special activated-carbon electrode block for capacitive deionizing equipment. Activated carbon powder, a binding agent, a carbon fiber, expanded graphite powder and conducting carbon black are loaded in a material box to be mixed; an obtained first mixture is agitated and mixed uniformly; the agitated and mixed first mixture is kneaded to be paste with plasticity; the well mixed paste is molded into a green compact in a fixed shape in molding equipment. The green compact is loaded in a heating furnace to be subjected to high-temperature calcination under the protection of a filling material; a primary product of the electric block is obtained. The primary product is made into an electrode according to the size, the shape and the precision needed by the electrode by adopting cutting machining. Finally, the activation treatment is carried out on the electrode; the electrode is made into a final product of the electrode. The method is low in preparation cost, and is easy for large-scale production. No binding agent resides in the electrode; the conductivity is good; the electrode is good in integrality and high in mechanical strength; the electrode can be cut to be in various needed shapes. The electrode can be used for preparing a capacitive deionizing device, and is used for the desalting treatment of water or the removal of harmful ions such as heavy metal ions, hardness, fluorine ions and the like in the water.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

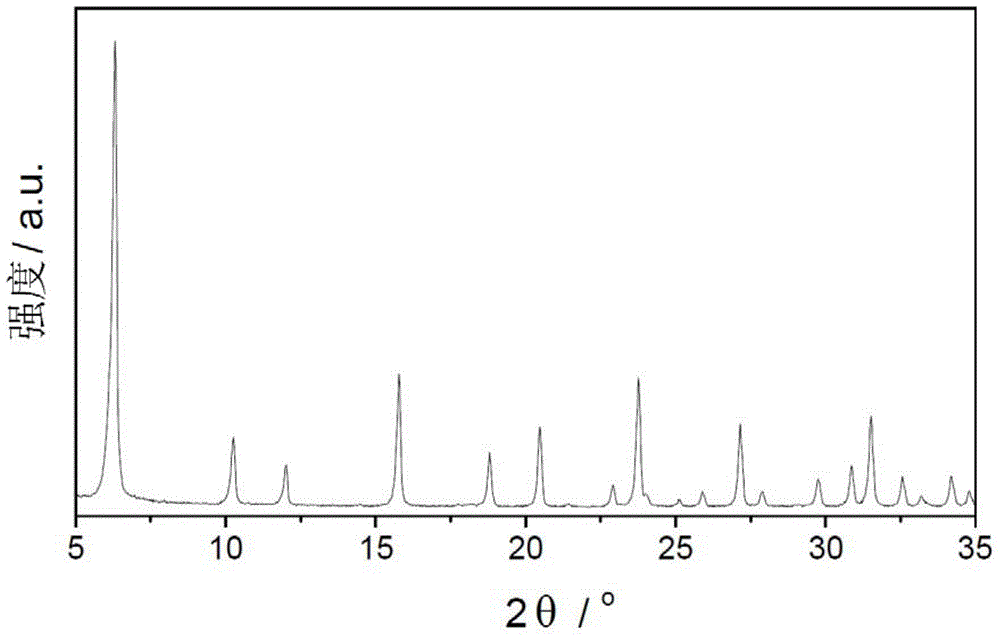

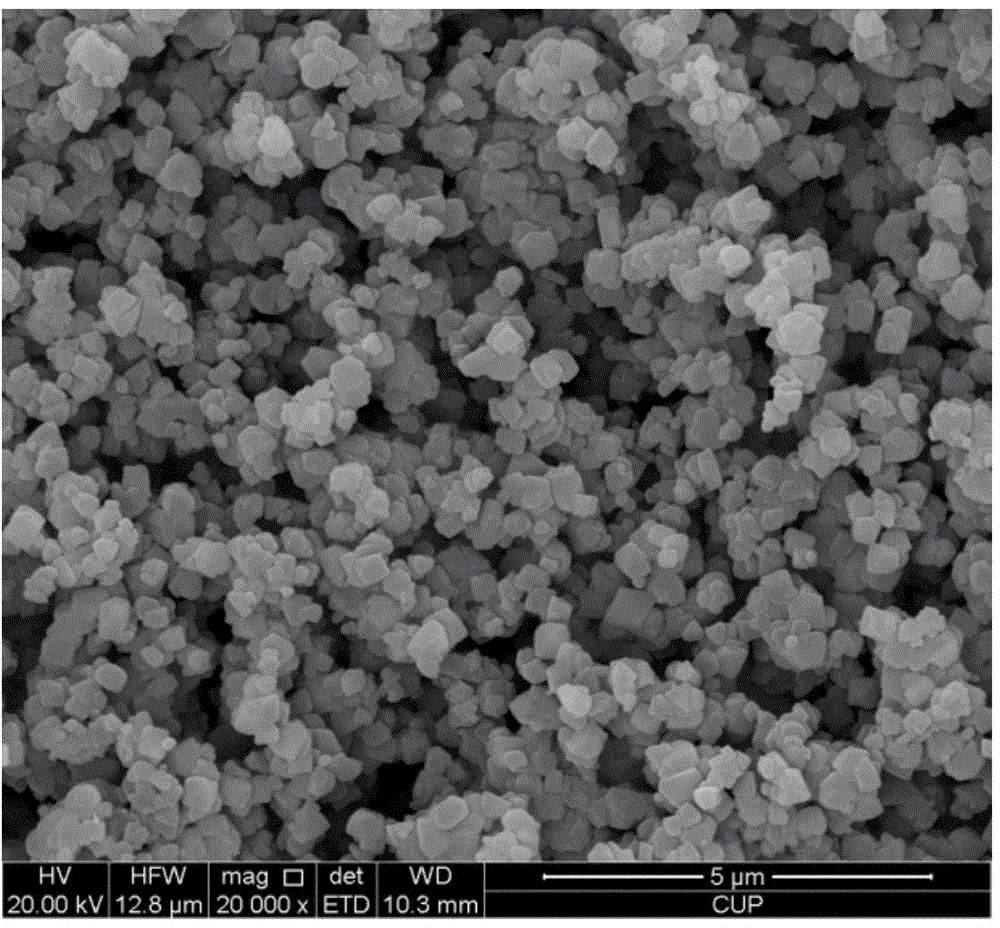

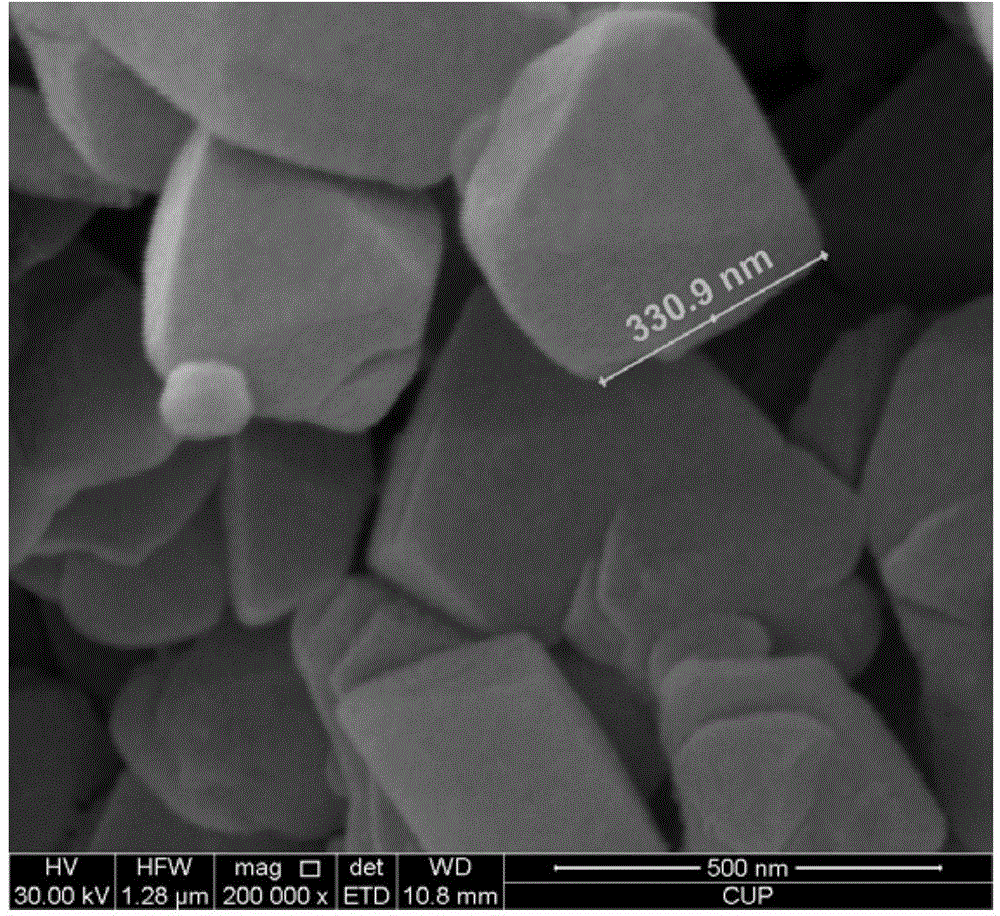

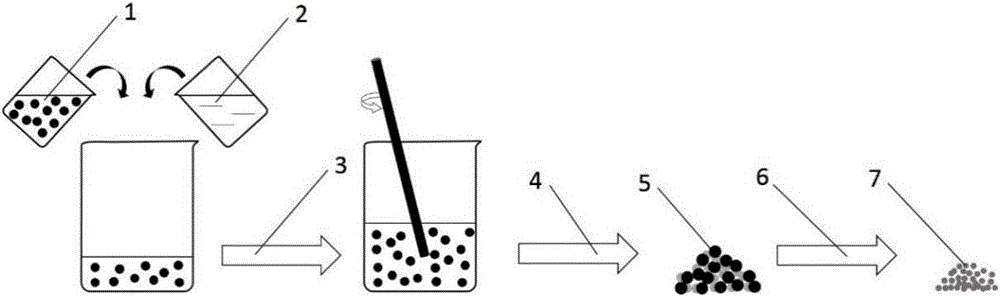

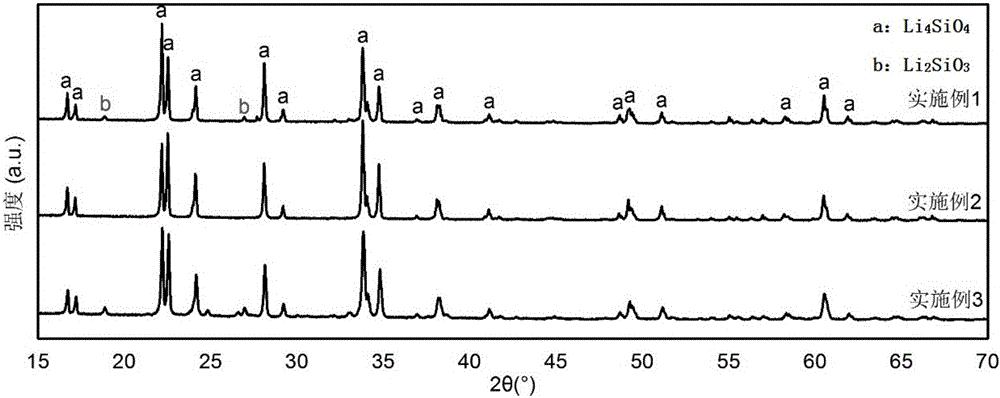

A method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve

InactiveCN104692412AEvenly dispersedHigh solid contentFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention relates to a method of synthesizing a NaY molecular sieve and the synthesized NaY molecular sieve. The method includes following steps: a step of synthesizing a directing agent, namely a step of subjecting a silicon source and NaOH to mixing pretreatment, adding water and an aluminum source, mixing uniformly and ageing to obtain the directing agent, with the mole ratio of Na2O, Al2O3, SiO2 and H2O being 15-25:1:10-30:250-450; a step of preparing reactive gel, namely a step of adding a solid silicon source into a NaOH solution, pretreating to prepare hydrous silica gel, adding an aluminum source, mixing uniformly, adding the directing agent, stirring and mixing uniformly to obtain flow type solid-like reactive gel, with the total adding mole ratio of the Na2O, the Al2O3, the SiO2 and the H2O being 2-6:1:5.5-10.5:50-150; and a step of crystallizing, performing suction filtration and drying, namely a step of crystallizing the prepared solid-like reactive gel, filtering after crystallization is finished, washing and drying to obtain a product.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for making active carbon fibers of cotton stalk skins by using microwave method

InactiveCN102191588AWell-developed poresImprove adsorption capacityFibre chemical featuresVegetable materialChemical treatmentFiber

The invention discloses a method for making active carbon fibers of cotton stalk skins by using the microwave method, comprising the following steps of: (1) a biological treatment: washing cotton stalk skins and removing impurities, cutting the cotton stalk skins into segments, inoculating with white rot fungi to ferment, washing and drying; (2) a chemical treatment: dipping cotton stalk skin fibers processed from the Step (1) into a KOH, NaOH or H3PO4 solution; (3) placing the cotton stalk skin fibers dipped in Step (2) into a microwave oven for carbonization and activation, taking the carbonized and activated cotton stalk skin fibers out of the microwave oven after cooling to room temperature, washing the cotton stalk skin fibers to pH 6-7, kiln drying or air drying to produce the active carbon fibers of cotton stalk skins. The method for making active carbon fibers by using cotton stalk skins as the raw material in the invention has advantages of simple preparation technology, fast preparation speed, low energy consumption, sufficient raw material and low price. The active carbon fibers prepared by using the method have a high carbon content rate, well-developed pores, strong sorption and excellent performance, can effectively remove harmful pollutants, and is good for environmental protection.

Owner:SHANDONG UNIV

Catalyst for preparing synthetic gas by reforming of methane and carbon dioxide as well as preparation method and application of catalyst

ActiveCN103816913AWell-developed poresLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a catalyst for preparing synthetic gas by reforming of methane and carbon dioxide as well as a preparation method and application of the catalyst, and belongs to the technical field of preparing catalysts. The catalyst is characterized in that activated charcoal is adopted as a carrier, multi-metal matters of cobalt, zirconium and molybdenum are adopted as active matters, wherein the content of the activated charcoal is 80-89%; the content of the multi-metal matters of cobalt, zirconium and molybdenum is 11-20%. Raw materials preparing the activated charcoal are broad in source, low in price and easy to obtain; the prepared activated charcoal has good pore structures and large specific surface area and strong sticking function to active matters; the prepared multi-metal catalyst of cobalt, zirconium and molybdenum is favorable in catalytic performance; under normal pressure and at a temperature of 750 DEG C, conversion rate of methane reaches to above 90%; conversion rate of carbon dioxide reaches to above 87%; after a service life test of 300 hours, the catalyst performs excellent catalytic activity and stability.

Owner:岳阳振兴中顺新材料科技股份有限公司

Special fertilizer for tomatoes and preparing method thereof

InactiveCN105254410AImprove fertilityImprove disease resistanceFertilizer mixturesBacillus licheniformisPhytase

The invention discloses special fertilizer for tomatoes. The special fertilizer is prepared from, by weight, 20-50 parts of urea, 20-40 parts of monoammonium phosphate, 15-35 parts of potash magnesium sulphate fertilizer, 5-15 parts of monopotassium phosphate, 1-3 parts of manganese sulfate, 1-2 parts of ferrous sulfate, 5-15 parts of calcarea carbonica, 1-5 parts of dolomite powder, 5-15 parts of attapulgite clay, 5-10 parts of kaolin, 40-60 parts of pig manure, 15-30 parts of humic acid, 20-40 parts of maize straw, 8-17 parts of cedarwood charcoal, 5-10 parts of ricinus communis residues, 5-15 parts of bone dregs, 5-10 parts of rape seed cakes, 0.1-0.4 part of bacillus licheniformis, 0.01-0.08 part of bacillus subtilis, 0.02-0.07 part of streptomyces griseus, 0.01-0.05 part of streptomyces jingyangensis, 0.02-0.09 part of metalloprotease, 0.01-0.015 part of phytase and 30-40 parts of water. The invention further discloses a preparing method for the special fertilizer for the tomatoes. The fertilizer is good in slow release effect and yield-increasing effect, and the disease resistance of the tomatoes is high.

Owner:天长市翔净蔬菜种植发展有限公司

Method for preparing porous adsorption material by using microwave low-temperature pore-forming activated granular red mud

InactiveCN102908983AGood water resistanceWon't breakOther chemical processesAlkali metal oxides/hydroxidesPorosityMicrowave

The invention provides a method for preparing a porous adsorption material by using microwave low-temperature pore-forming activated granular red mud. The method comprises the following steps: taking a bonding agent which is 2-10 percent of mass of the red mud, uniformly mixing red mud wastes and the bonding agent, kneading into grains by using a granulator or by a hand and activating the red mud grains for 5-30 minutes at an activation temperature of 80-500 DEG C by utilizing microwaves to obtain the porous adsorption material. The red mud is activated by utilizing the selective heating and resonant sintering effects of the microwaves on iron and other matters in the red mud. The porous adsorption material prepared by the method has a pore volume of more than 0.0826 ml / g and a specific surface area of 18.62-24.25 m2 / g, and the grain size can be different as required. The produced porous adsorption material has the characteristics of fine grain, high porosity, large surface area, strong hydroscopicity, good temperature-resistant stability and low cost and has the great advantage in aspect of wastewater adsorption and treatment.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for lithium silicate CO2 adsorbent

InactiveCN104998608AAdequate responseEasy to prepareOther chemical processesAlkali metal silicatesSolventStoichiometry

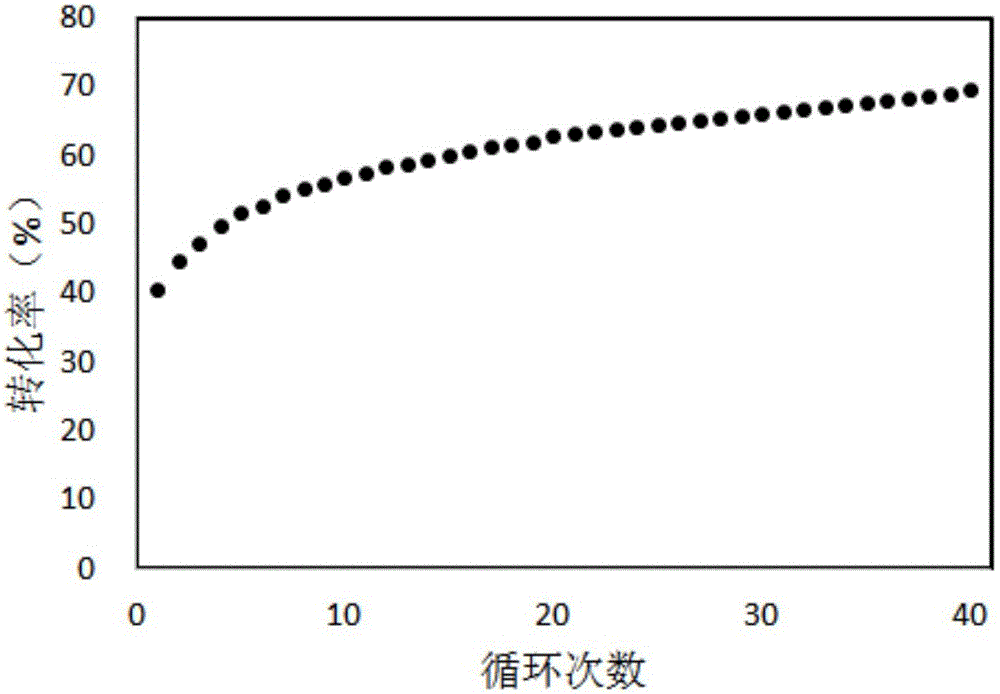

The invention discloses a preparation method for a lithium silicate CO2 adsorbent. The CO2 adsorbent with the component being lithium silicate is obtained by selecting organic lithium salt and a silica sol as precusors of lithium and silicon dioxide, respectively; fully and uniformly mixing the organic lithium salt and the silica sol in a solvent; and calcining the mixture at a high temperature. In the preparation process, by adjusting the stoichiometric number proportioning of lithium and silicon dioxide in the lithium and silicon precusors, the optimization of the reaction is realized. The lithium silicate CO2 adsorbent which is excellent in performance is prepared by virtue of the method disclosed by the invention. The adsorptive property of the adsorbent reaches over 30-50% of the theoretical maximum adsorption. Moreover, in 40 cycles, the adsorbent pores are more developed as the cycle index is increased and the adsorption capacity is further enhanced as the cycle index is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Treatment method for reverse osmosis concentrated water

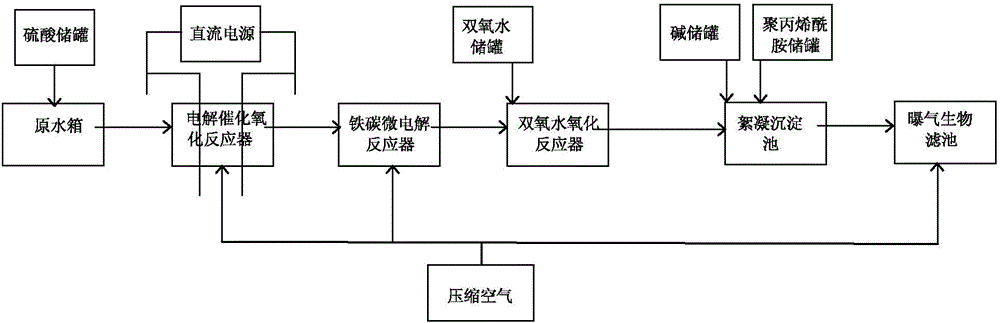

ActiveCN104556533AImprove oxidation efficiencyLarge specific surface areaTreatment using aerobic processesMultistage water/sewage treatmentElectrolysisReverse osmosis

The invention relates to a treatment method for reverse osmosis concentrated water, in particular to a standard treatment method for the reverse osmosis concentrated water which is produced during sewage reusing. The treatment method comprises the following steps: the pH value of the reverse osmosis concentrated water is regulated to be 2.0-4.0, and electrolytic catalysis oxidation is carried out; water produced from the electrolytic catalysis oxidation is subjected to redox reaction in an electrolytic reactor, which is filled with iron-carbon fillers obtained through sintering of iron and carbon; hydrogen peroxide is then added, so that oxygenolysis is further achieved; the pH value is regulated to be 6.0-8.0, and a flocculant is added for flocculent settling; a supernate obtained from the flocculent settling enters an aeration biological tank, and a co-substrate is added for biological degradation. The COD of the reverse osmosis concentrated water with lower biodegradability, which is obtained through reverse osmosis reusing treatment after standard biochemical treatment, is reduced from 70-200 milligrams per liter to below 50 milligrams per liter, so that the strictest local emission standards can be met.

Owner:CHINA PETROLEUM & CHEM CORP

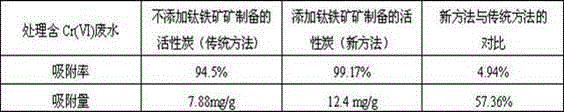

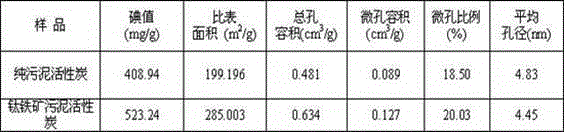

Novel method for improving city sludge active carbon performance

InactiveCN102745687AEasy to handleImprove pore structureCarbon compoundsActivated carbonTube furnace

The invention discloses a method for adopting city sewage processing factory residual sludge and natural ilmenite as raw materials, and for producing active carbon by using zinc chloride as an activating agent. The method comprises specific steps that: the raw material sludge is dried until the water content of the sludge is below 10%; the sludge is mechanically crushed, and is sieved by using a sieve of 120 meshes; ilmenite is crushed, and is sieved by using a sieve of 200 meshes; the ilmenite is added into the raw material sludge with a proportion of 1.5-2%, and the mixture is well mixed; the pretreated raw material sludge is impregnated in a zinc chloride solution with a concentration of 3mol / L under normal temperature for 24h; and the impregnated sludge is dried by baking under a temperature of 80 DEG C for 24h, wherein a solid-liquid ratio (a ratio of the mass of the sludge to the volume of the zinc chloride solution) is 1:2; the bake-dried sludge is placed in a tube furnace (a heating speed is 10 DEG C / min, N2 is adopted as a protective gas, and a flow rate is 30L / h), the temperature is increased to 525-550 DEG C, and further carbonization is carried out for 40-60min (carbonization and activation are carried out simultaneously); the activated carbonized product is cooled to room temperature, and is washed by using a hydrochloric acid solution with a concentration of 3mol / l; the product is rinsed by using water with a temperature of 70-80 DEG C, until the product is neutral; the rinsed product is dried by baking, and is grinded, such that the active carbon finished product can be obtained.

Owner:CHENGDU UNIV OF INFORMATION TECH

Dogwood kernel modified active carbon water purifier and preparation method thereof

InactiveCN103566872AWell-developed poresReduce pollutionOther chemical processesWater/sewage treatment by sorptionCelluloseAcrylonitrile

The invention relates to a dogwood kernel modified active carbon water purifier, which is prepared from the following raw materials in parts by weight: 50 to 60 parts of dogwood kernel, 9 to 12 parts of calcined gypsum, 5 to 6 parts of dried alum, 10 to 15 parts of lignocellulose, 6 to 9 parts of calcium-based montmorillonite, 3 to 5 parts of milk protein, 8 to 10 parts of acrylonitrile, 1 to 2 parts of ammonium persulfate, 100 to 110 parts of active carbon, 7 to 9 parts of gelatin, 10 to 13 parts of chitosan, 4 to 5 parts of modified diatomite and an appropriate amount of water. After the dogwood kernel is carbonized at a high temperature, a structure with multiple pores and strong adsorption capacity is formed, so that the cost is saved and the environmental pollution is reduced; due to use of the macromolecular compounds such as acrylonitrile, gelatin, lignocellulose and chitosan and the like, the adhesive force can be increased, the disintegration is unlikely to happen, an effect of chelating metal ions can be realized, and safe and non-toxic effects are achieved; due to use of calclium-based montmorillonite, an antibacterial function, a deodorizing function and an ion exchanging function can be achieved; due to use of the calcined gypsum and the dried alum, a sterilizing function can be achieved; the dogwood kernel modified active carbon water purifier is safe, healthy, low in cost and particularly suitable for water purification.

Owner:BENGBU HUAFANG FILTER

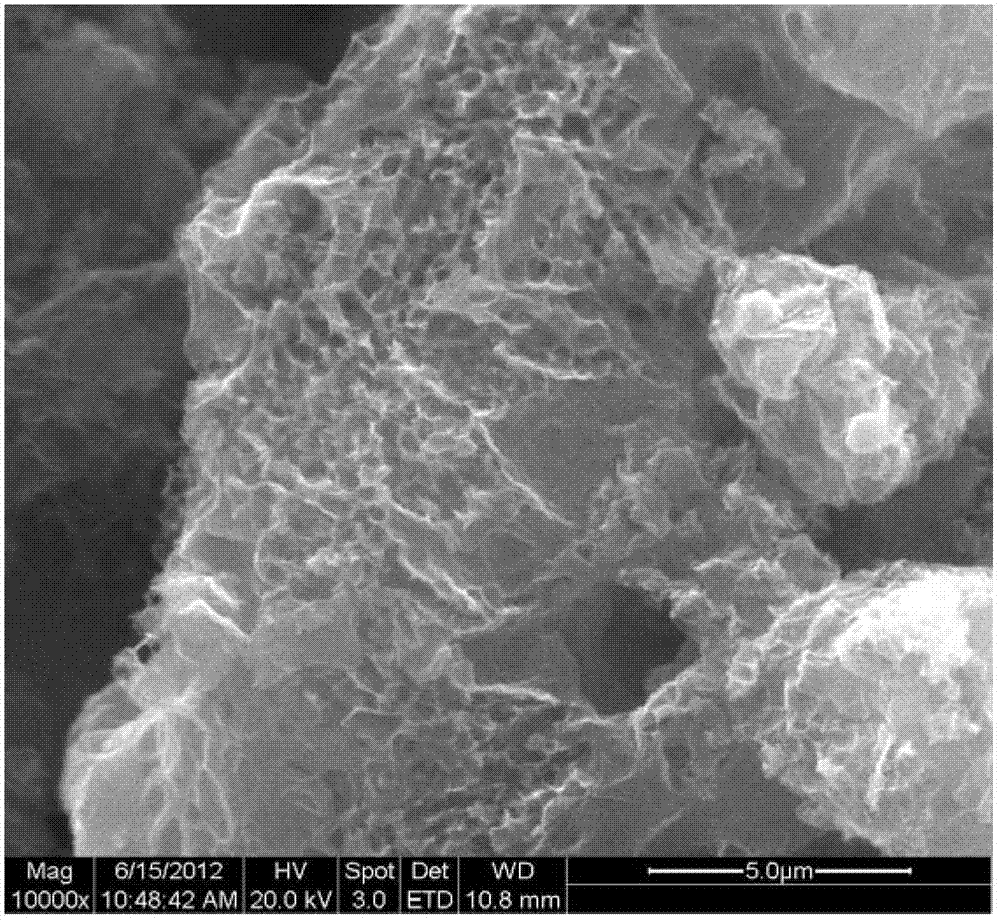

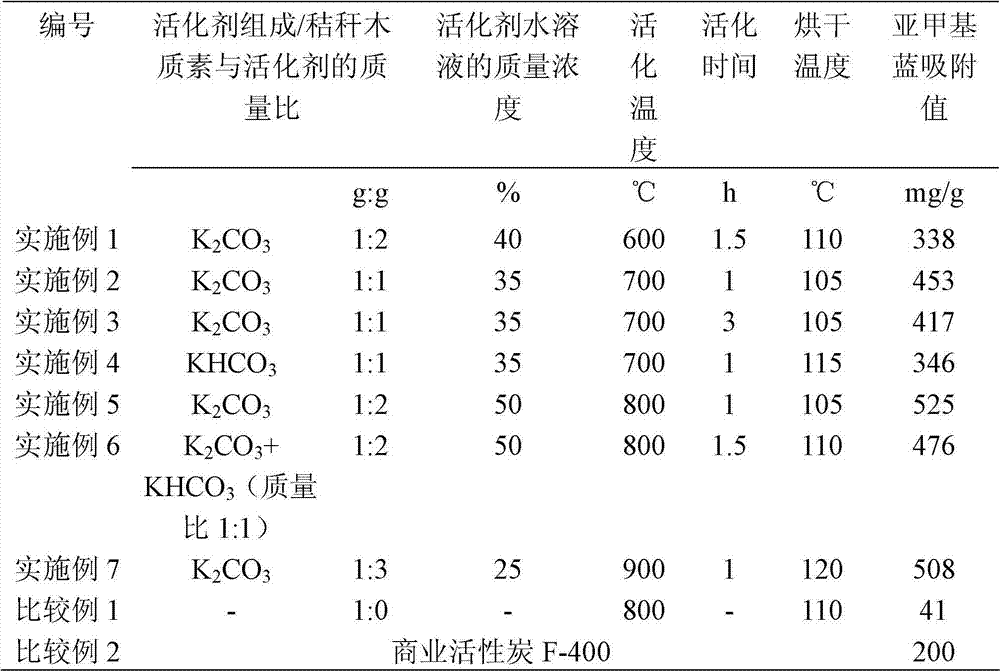

Preparation method of high adsorptive activated carbon

InactiveCN102730681AWell-developed poresImprove adsorption capacityCarbon compoundsChemical industryEnvironmental resistance

The invention discloses a preparation method of high adsorptive activated carbon and belongs to the technical field of activated carbon preparation. The preparation method specifically comprises the following steps of: uniformly mixing an organic solvent lignin with an aqueous solution of an activator (its mass concentration is 25-50%), drying at 105-120 DEG C, carrying out carbonization and activation at 600-900 DEG C with the activation time being 1-3h, cooling to room temperature after carbonization and activation, boiling with water, carrying out thermal filtration, washing until pH value is 6.5-7.5, drying, and grinding to obtain the activated carbon. The lignin is derived from green separative products of crop straw; the carbonization and activation process is simple; there is few emission pollutants; and the prepared activated carbon has large specific surface area, strong adsorbability and substantial benefits, economic significance and social benefits, and is mainly used in the fields of food industry, pharmaceutical industry, chemical industry, energy, environmental protection and the like.

Owner:SOUTHWEST JIAOTONG UNIV

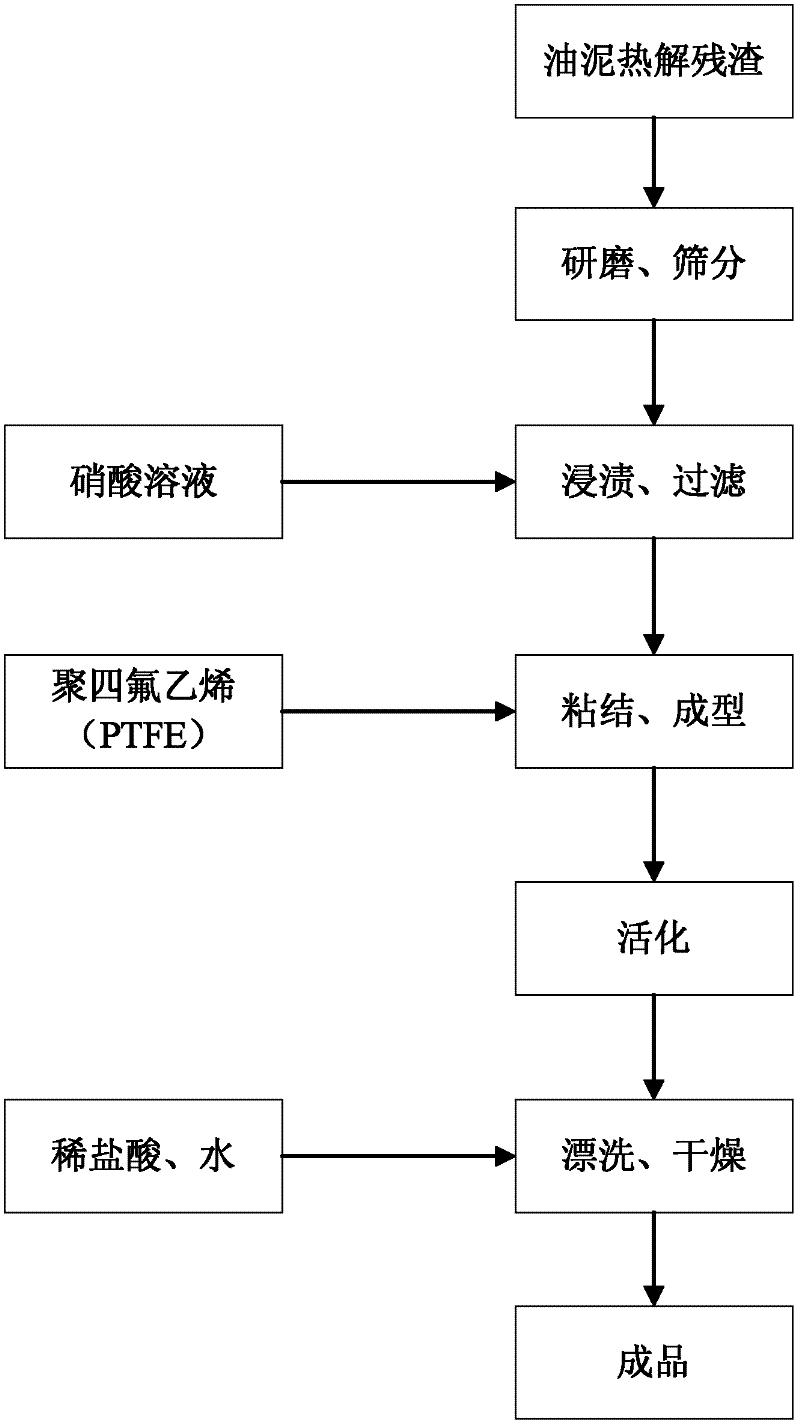

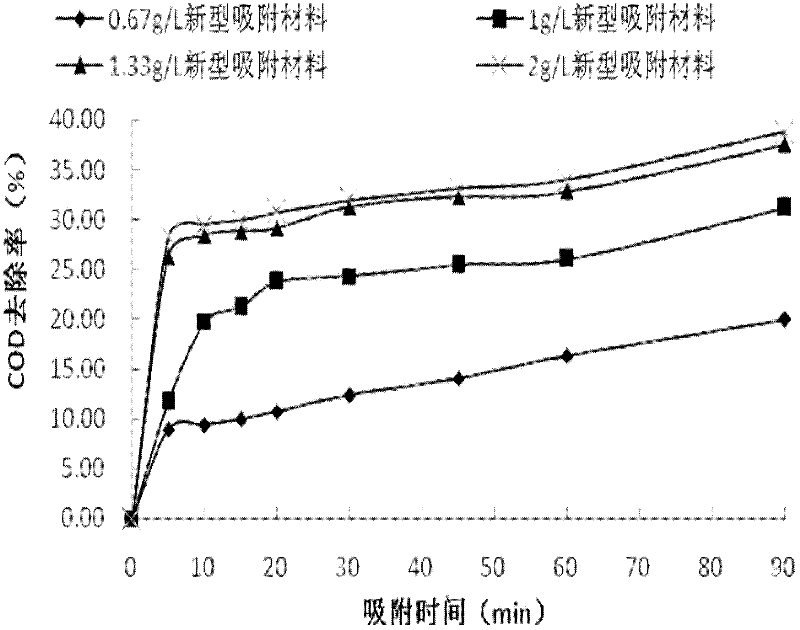

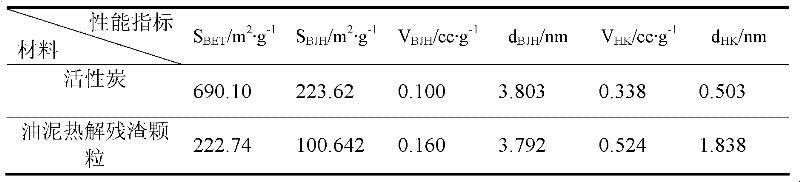

Method for preparing novel oil production wastewater adsorbent by utilizing oil sludge pyrolysis residue

ActiveCN102294217ALarge specific surface areaWell-developed poresOther chemical processesSolid waste disposalSorbentWastewater

The invention discloses a method of preparing an oil-extraction wastewater adsorbent by using pyrolysis residues of oil sludge for applying in sewage treatment of oil field, comprising the following steps: grinding and sieving the pyrolysis residues of oil sludge, carrying out acid dipping process, rinsing to neutral, mixing the pyrolysis residues of oil sludge with Teflon (binder), carrying out cold press for moulding, charring in a carbonization furnace, rinsing and drying. The method improves the adsorptivity of the pyrolysis residues of oil sludge and is applied successfully in the treatment of oil-extraction wastewater.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

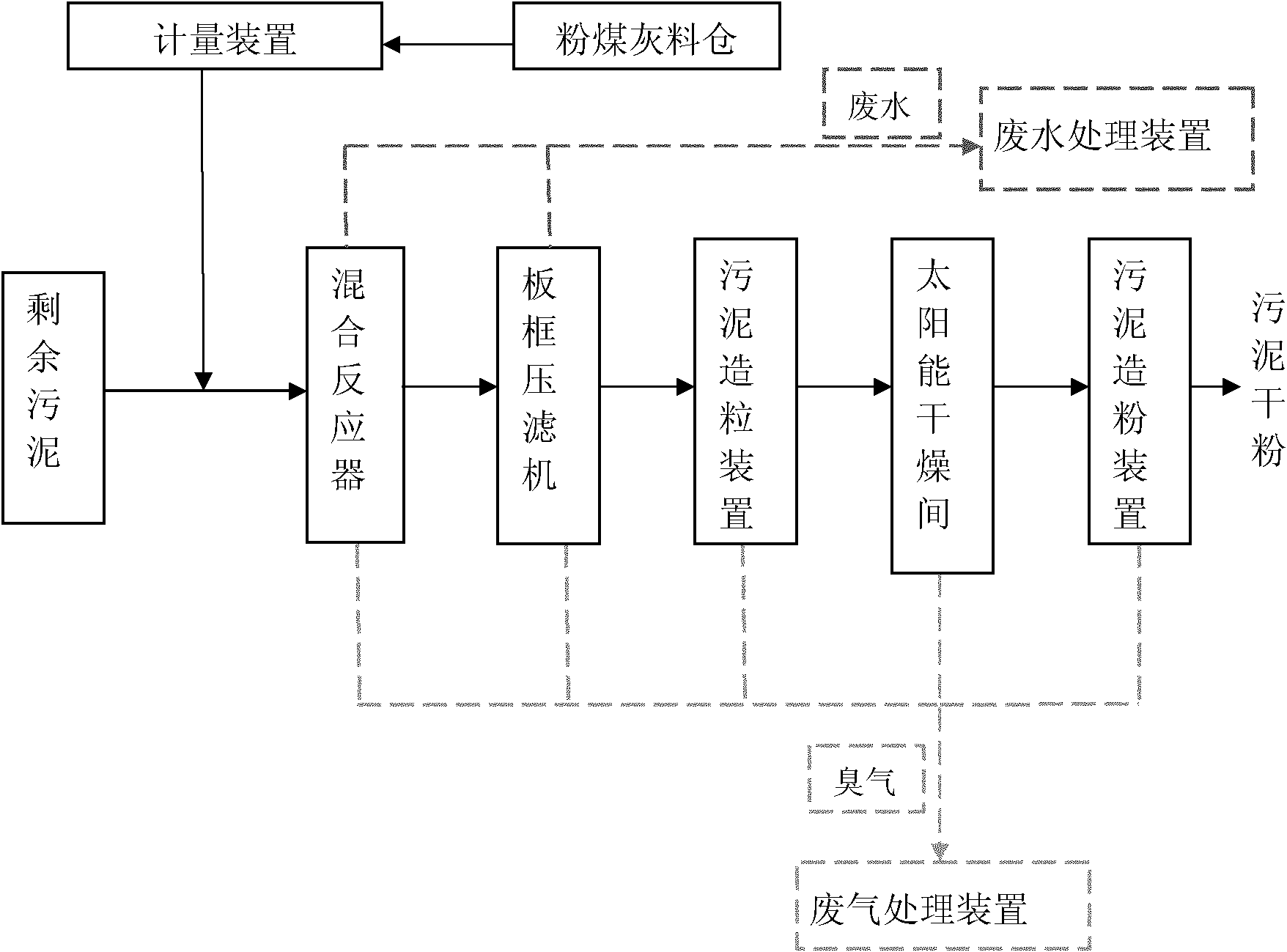

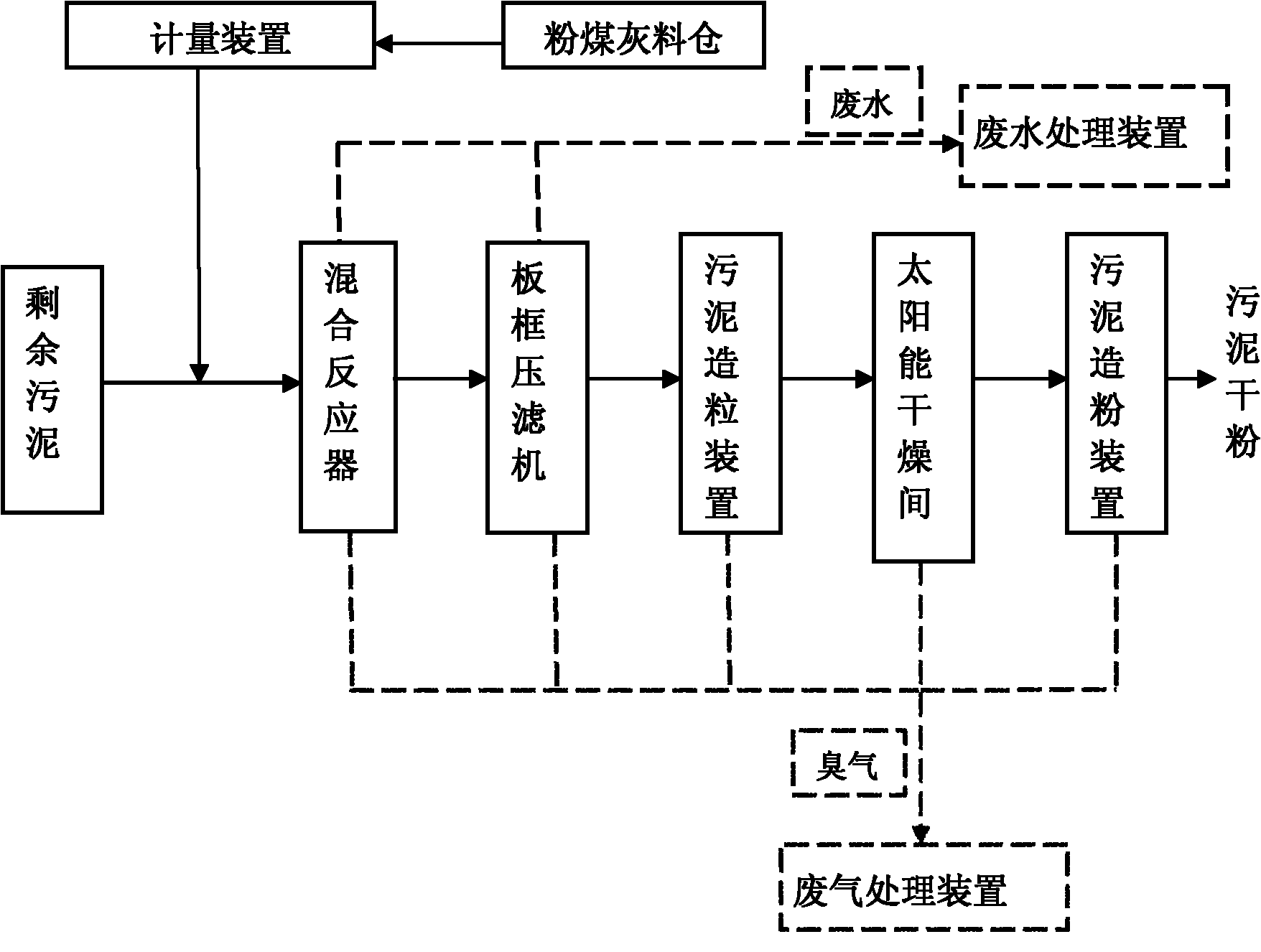

Process for treating excess sludge by utilizing fly ash

ActiveCN102161562ALoose textureWell-developed poresSludge treatment by de-watering/drying/thickeningWaste processingBound waterSolar drying

The invention relates to a process for treating excess sludge by utilizing fly ash. The method specifically comprises the following steps of: 1, feeding excess sludge to be treated which has the water content of between 80 and 90 percent, and fly ash in an amount which is 20 to 50 percent based on the mass of the excess sludge into a mixing agitator; fully mixing and reacting for 5 to 15min; feeding into a plate and frame dehydrator for dehydration to obtain sludge of which the water content is reduced to be between 35 and 45 percent; crushing the sludge into coarse particles with the particle size of between 3 and 5mm by using a sludge granulation device; feeding the sludge particles into a solar drying room, and drying for 24 to 48h at the temperature of above 40 DEG C and under the humidity of below 15 percent to ensure that the water content of the sludge is reduced to between 8 and 15 percent; and treating by sludge pulverization equipment and a high-speed airflow collision technology, wherein the particle size of sludge powder is 150 to 300 meshes and the water content is 5 to 10 percent after the treatment. The method has the advantages that: interstitial water, adsorbed water and capillary bound water in the excess sludge are absorbed into the fly ash; due to the characteristic of high permeability coefficient of the fly ash, the water in the fly ash is easily discharged; and the secondary pollution to the environment is avoided by appropriately treating the excess sludge.

Owner:北京方兴科创环境科技有限公司

Preparation method of high purity porous carbon

InactiveCN108128774AHigh product purityAvoid complex processCarbon compoundsWater solubleHigh polymer

The invention discloses a preparation method of high purity porous carbon. The preparation method comprises the following steps: mixing alkaline metal salt easily dissolved in water with a water soluble high molecular material for a pre-reaction to obtain a mixture, wherein the high molecular material is prepared from one or more of resin, cellulose and a cellulose derivative; then crushing the mixture to particles, the grain sizes of which are 0.01-5mm; heating the particles to 600-1000 DEG C for 0.5-8h at a heating rate of 1-20 DEG C / min in an inert atmosphere, and carbonizing and activatingthe particles to prepare porous carbon; and finally, soaking the cooled porous carbon with a solution to dissolve residual alkaline metal salt, and washing the porous carbon for many times and dryingthe same to obtain the porous carbon. According to the preparation method of high purity porous carbon, the specific surface area of the prepared porous carbon reaches up to 1200-2100m<2> / g; the residual alkaline metal salt can be fully dissolved and removed only with water without processes such as pickling, the ash content is lower than 0.5%, the porous carbon is free of impurities such as ferrum and chlorine, the product quality is high, the service life of the equipment is prolonged favorably, and the environmental pollution is reduced.

Owner:张家港博威新能源材料研究所有限公司

Method for preparing high-performance carbon material from molasses

The invention discloses a method for preparing a high-performance carbon material from molasses. The method comprises the following concrete steps: firstly, subjecting beet molasses with sugar-containing concentration of 8.8% to 52.5% to dehydration and carbonization for 2 to 10 h under the condition of 120 to 180 DEG C, carrying out washing and then carrying out drying for 12 h under the condition of 120 DEG C so as to obtain a colloidal carbon sphere with a size of 1 [mu]m to 10 [mu]m, then pretreating the obtained colloidal carbon sphere for 1 h under the condition of 500 DEG C, then carrying out activating treatment with concentrated phosphoric acid or KOH, subjecting an obtained product to washing until the pH is equal to 6 to 7, then carrying out drying for 12 h under the condition of 120 DEG C, and carrying out heating treatment for 1 h under the condition of 800 DEG C by filling of nitrogen so as to obtain a porous carbon material. The invention has the following beneficial effects: the colloidal carbon prepared from the molasses by hydrothermal treatment, after regulation of the KOH, has more developed porosity, can maintain morphology of the carbon sphere, and has a particle size of 1 [mu]m to 10 [mu]m; whether the colloidal carbon is regulated by the phosphoric acid or etched by potassium hydroxide, the obtained porous carbon material has high yield and small loss; and specifically, the porous carbon prepared from phosphoric acid has a yield up to 79.2%.

Owner:JILIN UNIV

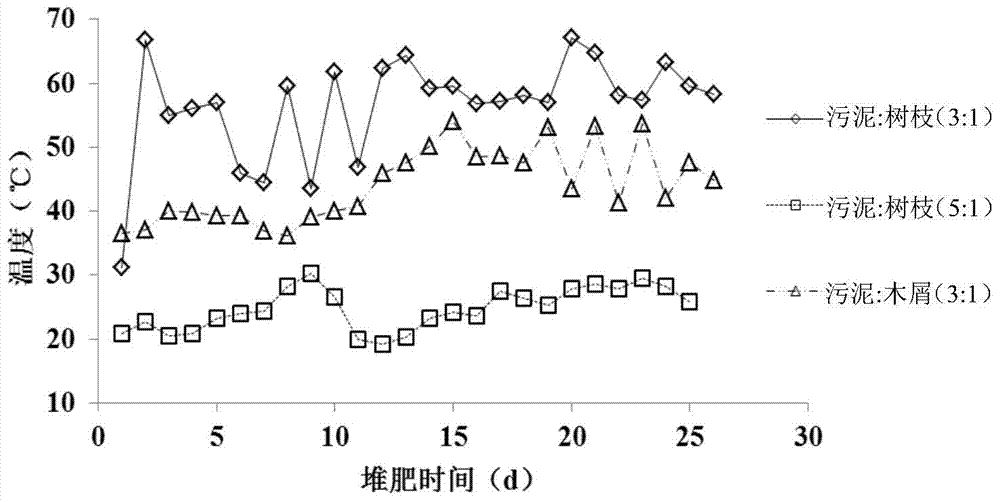

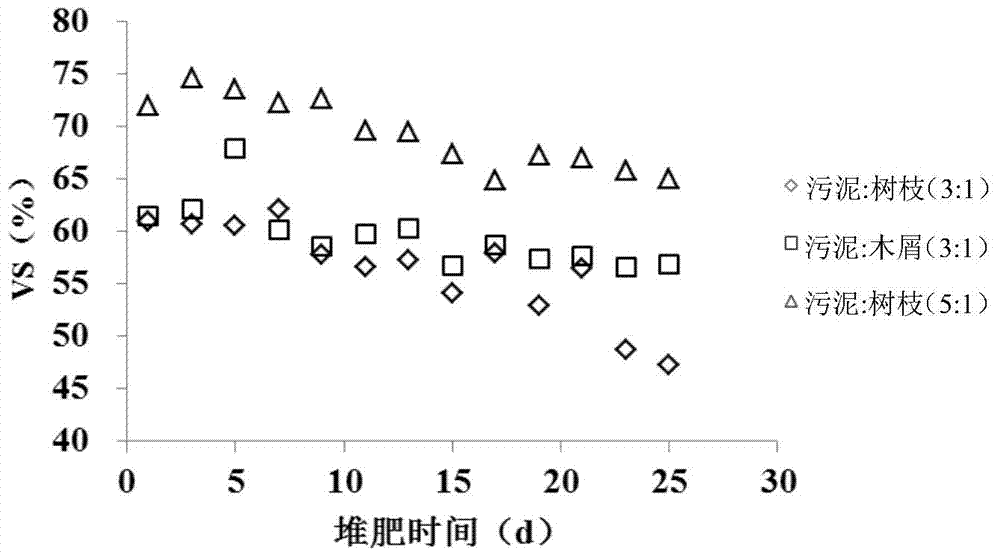

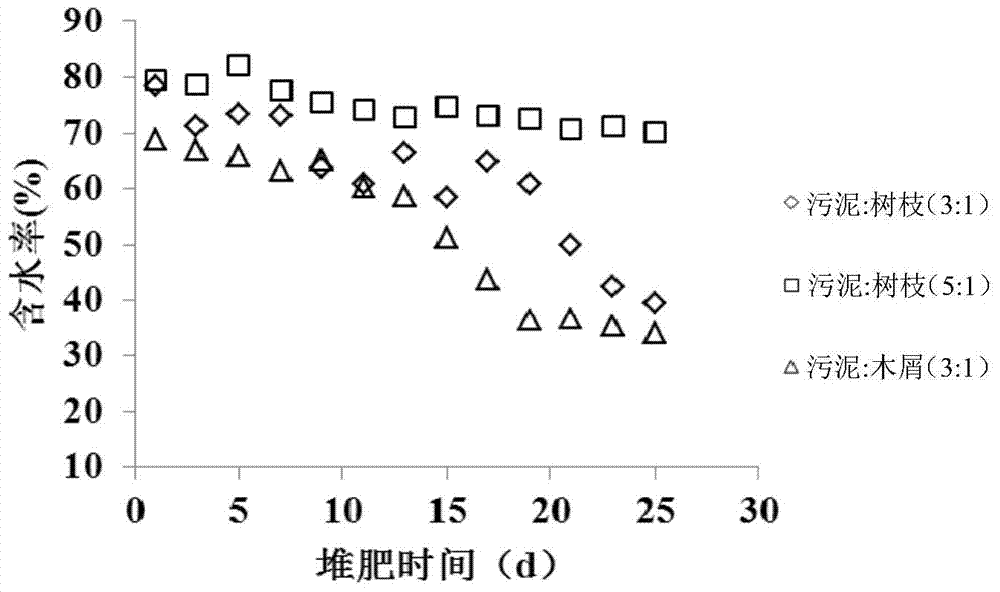

Sludge aerobic composting method

InactiveCN103613418ALower requirementLarge amount of processingBio-organic fraction processingOrganic fertiliser preparationMass ratioSludge

The invention discloses a sludge aerobic composting method. The method disclosed by the invention is a method for carrying out sludge aerobic composting by taking afforest wastes (such as branch sections) as a conditioner, and comprises the following steps: (1) mixing sludge and the afforest wastes according to a mass ratio of (2-4):1, specially 3:1, so as to obtain a mixture; and (2) composting the mixture obtained in the step (1) and monitoring the temperature of a pile body in the composting process; in the composting process, turning for one time when the temperature of the pile body is more than 60 DEG C; finishing the composting after a plurality of times of turning and when the temperature of the pile body is reduced to be lower than 30 DEG C and is not raised. According to the sludge aerobic composting method, the high-temperature aerobic composting of organic wastes is used as the basis and the afforest wastes are used as the conditioner to treat the municipal sludge so as to consume a large amount of the afforest wastes while the harmlessness and the reclamation of the sludge are realized, so that the two aims can be realized by one action. Visibly, the sludge aerobic composting method has a wide application prospect.

Owner:TSINGHUA UNIV

Method for preparing super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation

InactiveCN107644742ARealize high-value utilizationHigh specific capacitanceCarbon compoundsHybrid capacitor electrodesCapacitanceBiological activation

The invention discloses a method for preparing a super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation. The method for preparing the super capacitor based on the biogas residue active carbon after biomass anaerobic dry fermentation performs preprocessing on the biogas residues after biomass anaerobic dry fermentation, then performs high temperaturecarbonization and activation, and immerse an obtained activated product with acid and wash and dry the obtained activated product to obtain an activated carbon as a material of the electrode of the super capacitor. The active carbon prepared through the invention has an aperture structure on which micro holes and middle holes are distributed, has a relatively high specific surface area and has relatively high specific capacitance and cycling stability and is a relatively ideal electrode material of the super capacitor. The method for preparing the super capacitor based on biogas residue active carbon produced after biomass anaerobic dry fermentation uses the biogas to prepare a super capacitor so as to realize high value utilization of the biogas residual and the obtained active carbon isstable in structure and developed in pores, has a relatively high specific capacitance and cycle stability and is a relatively ideal electrode material of the super capacitor.

Owner:HEFEI UNIV OF TECH

Superbattery polar plate containing vacuum puffed grapheme, preparation method thereof and lead acid superbattery assembled thereby

InactiveCN102760868AGood expansion performanceWell-developed poresLead-acid accumulatorsLead-acid accumulator electrodesElectric-vehicle batteryEngineering

The invention relates to an electrode polar plate, a preparation method thereof and a superbattery, in particular to a superbattery polar plate containing vacuum puffed grapheme, a preparation method thereof and a lead acid superbattery assembled thereby, and aims to solve the technical problems that a capacitive electrode material used in a conventional superbattery has small specific capacity and poor rate capacity. The superbattery polar plate containing vacuum puffed grapheme consists of a current collector and an electrode material coated on the current collector, wherein the electrode material contains a capacitive electrode active substance and a battery electrode active substance; the capacitive electrode active substance comprises vacuum puffed graphene; and the mass of the vacuum puffed graphene is 0.01-20 percent of that of the battery electrode active substance. The preparation method comprises the following steps: the electrode material including the vacuum puffed graphene is mixed into an electrode paste to be coated on the current collector, the superbattery polar plate is obtained after the electrode paste is dried, the polar plate serves as the positive and / or negative pole of the superbattery to be assembled into a superbattery, and the battery polar plate can be used for hybrid electric vehicle batteries and energy storage batteries.

Owner:HARBIN INST OF TECH

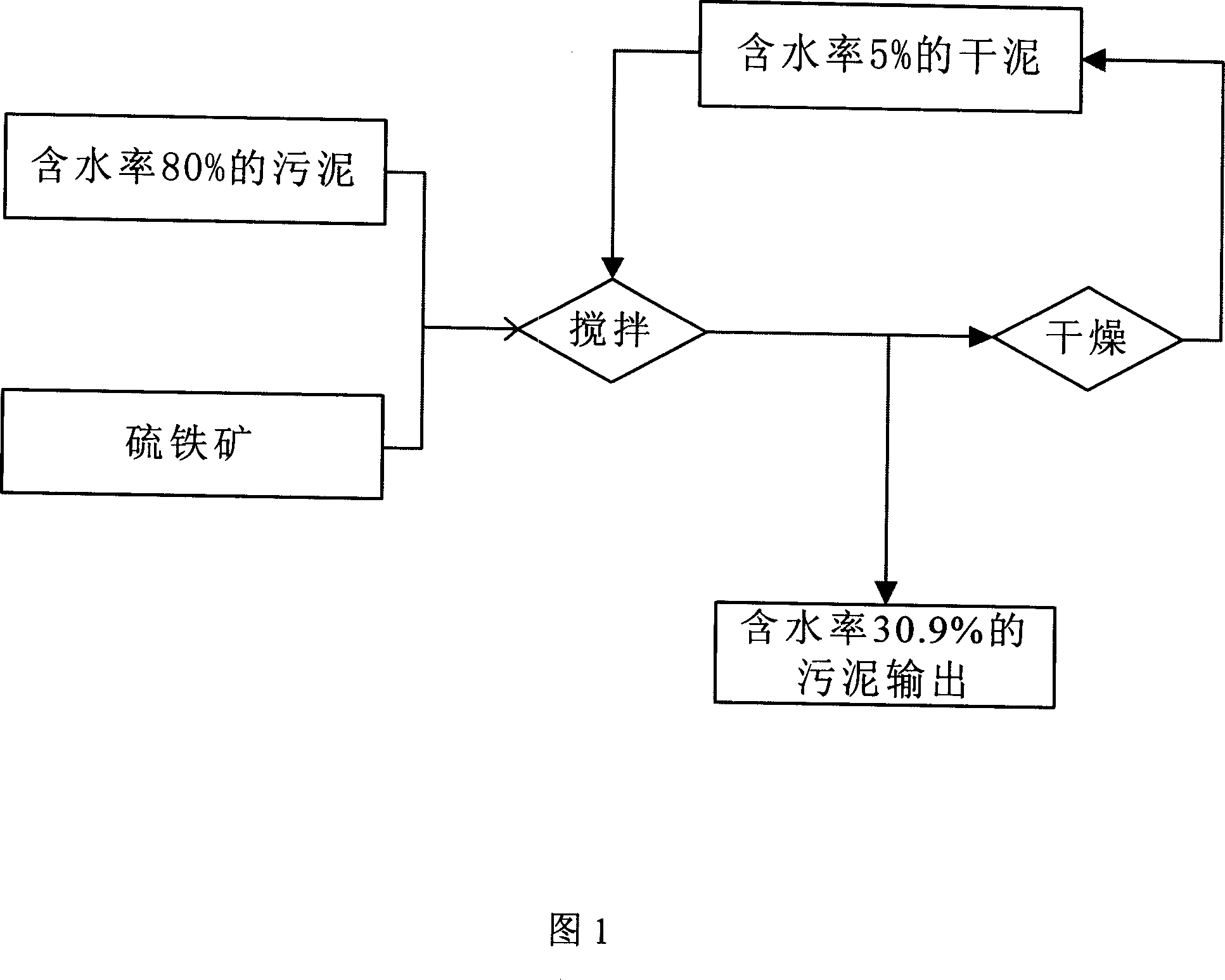

Modified tempering method in sludge treatment process and application thereof

ActiveCN101012097ALoose textureWell-developed poresSludge treatment by de-watering/drying/thickeningSolid waste managementBrickPyrite

The invention discloses a modifying tempering method in the sludge disposing course, which comprises the following steps: doping 1-50% pyrite or coal ash into sludge with water content at 70-80%; transmitting the mixture into stirrer; adding dried sludge with water content at 5-8%; adjusting the water content of sludge at 30-35%; drying the sludge; discharging.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

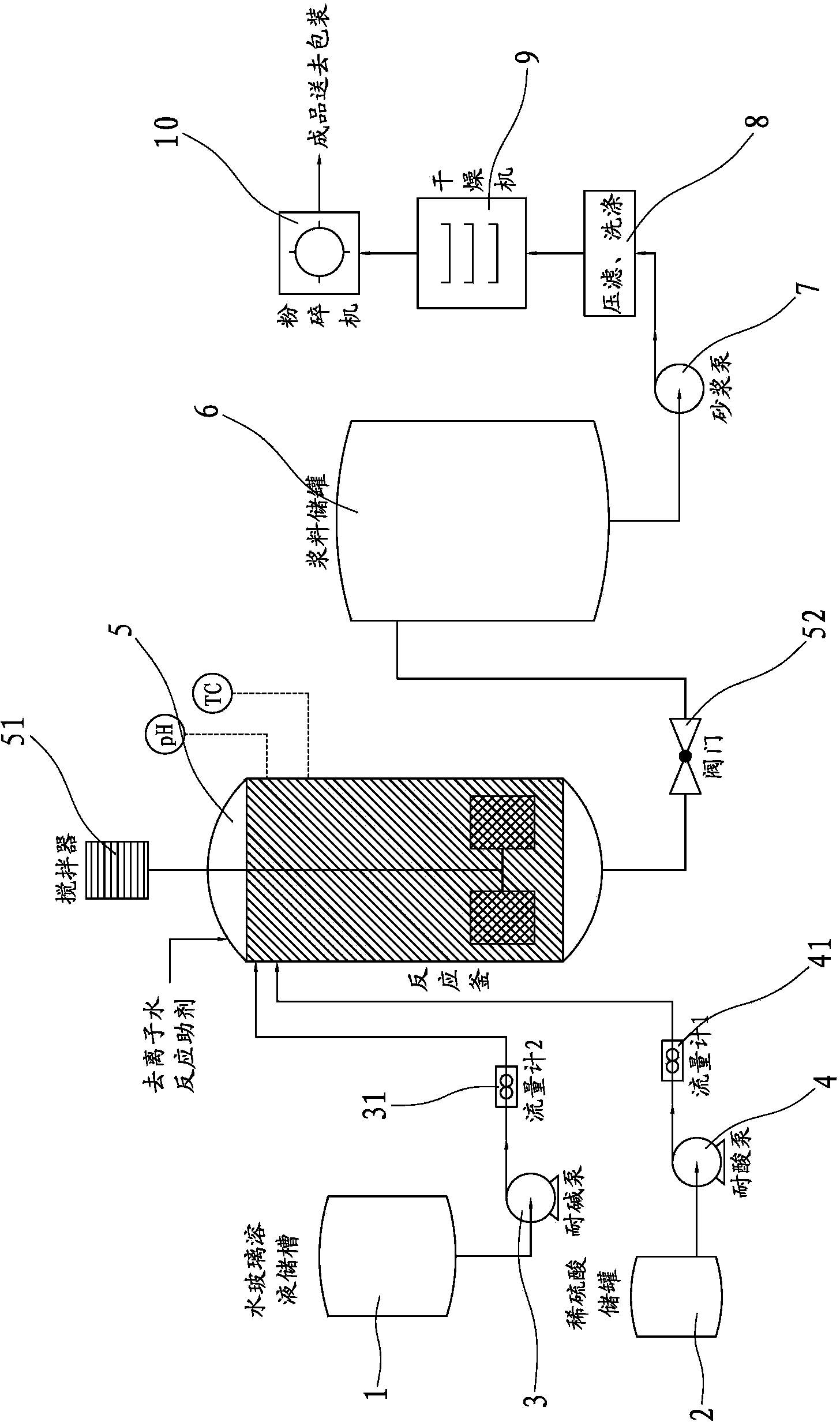

Porous silica gel air purifying particles and preparation method thereof

ActiveCN104258806ALarge specific surface areaWell-developed poresOther chemical processesDispersed particle separationEngineeringOrganic compound

The invention discloses porous silica gel air purifying particles and a preparation method thereof. The porous silica gel air purifying particles have the specific surface areas of 250-500m<2> / g, the pore volumes of 1.2-2.0mL / g, the average pore size of 5-50nm and the average particle size of 10-100mu m, have the characteristics of being large in specific surface areas, developed in pores, high in adsorption capacity and the like, can be used for absorbing gases such as formaldehyde, ammonia, total volatile organic compound (TVOC) and the like, and can be used for purifying the air and removing harmful gas. The surface of silica gel has free hydroxide radical, so that the porous silica gel air purifying particles are very high in adsorption capacity for polar materials such as formaldehyde, and the removal rate of formaldehyde reaches up to more than 85%. Furthermore, the silica gel silicon dioxide is high in purity, non-toxic and harmless, and does not contain any heavy metal, thus being an environment-friendly air purification product. The preparation method is mature in technology and easy in realization of industrial production.

Owner:福建省宇诚环保科技有限公司

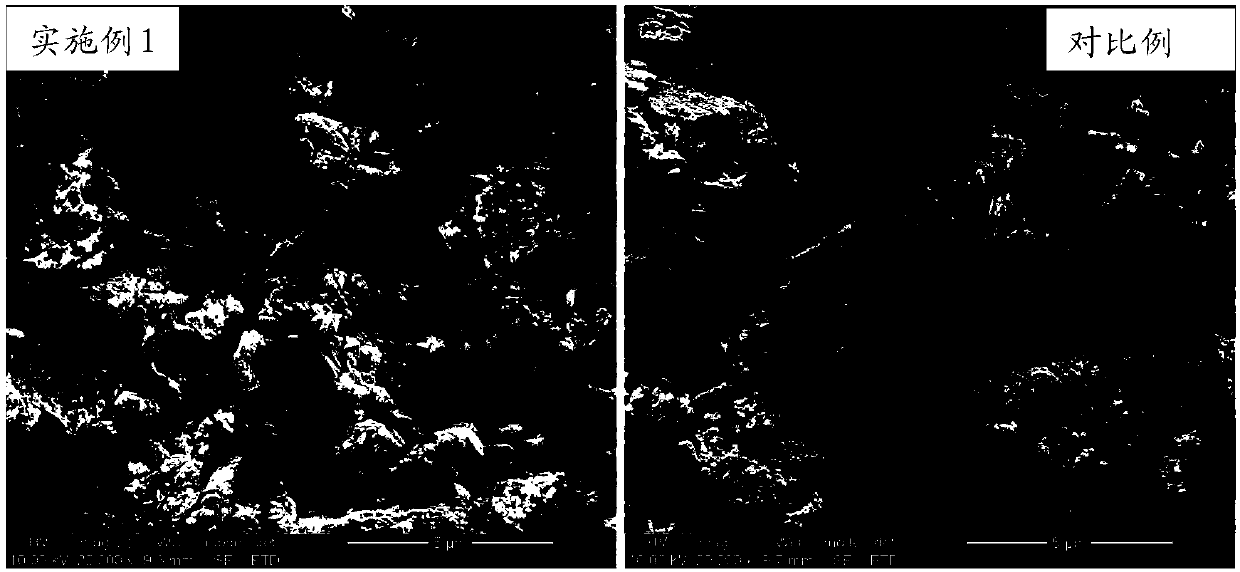

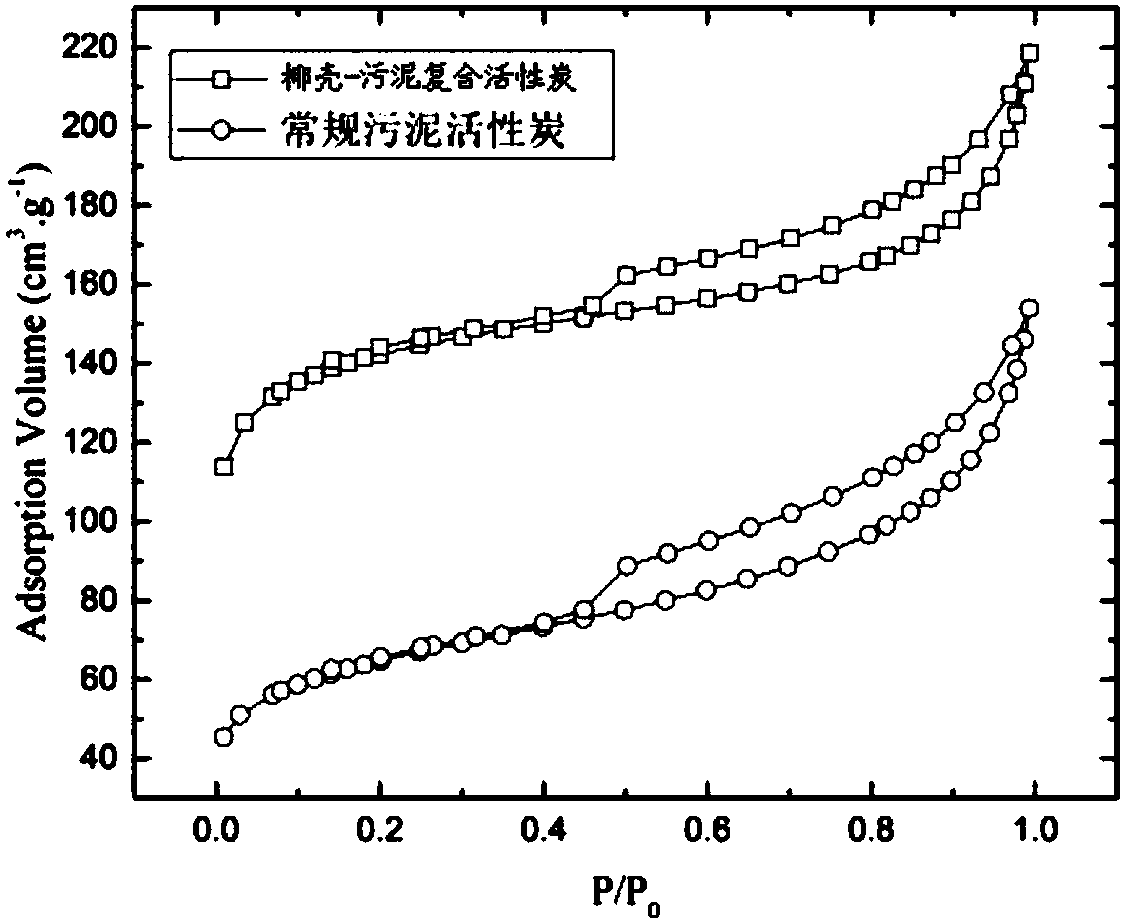

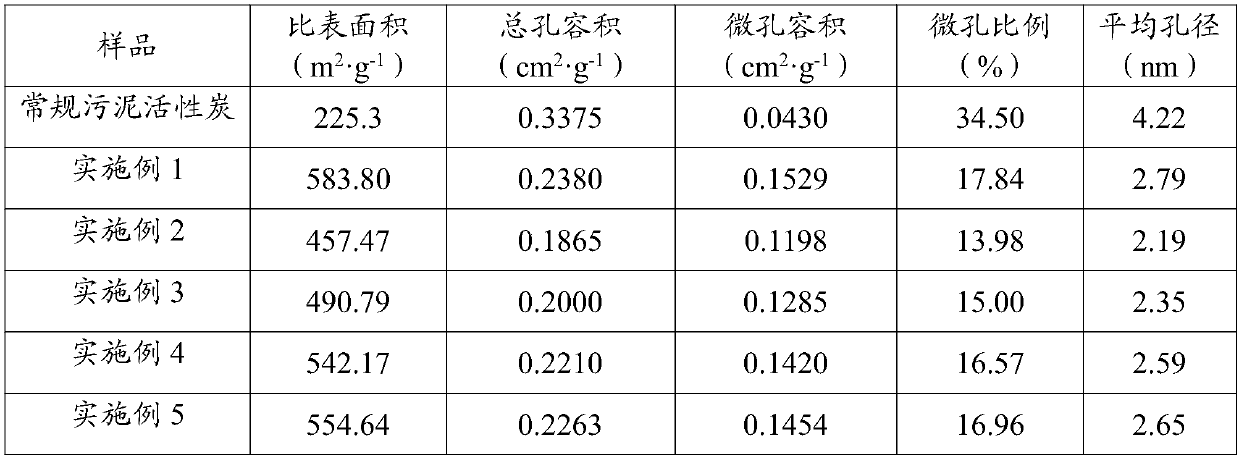

Coconut shell-mud composite active carbon as well as preparation method and application thereof

InactiveCN108033448ALarge specific surface areaHigh adsorption valueCarbon compoundsOther chemical processesActivated carbonMunicipal sewage

The invention provides a preparation method of coconut shell-mud composite active carbon, and belongs to the field of waste water treatment. A two-step chemical activation method is adopted to transform residual sludge coming from urban sewage treatment into the coconut shell-mud composite active carbon having economical value, so that the residual sludge of urban sewage treatment plants is recycled, and stabilization, reduction, hazard-free treatment and recycling of the sludge are realized. The method has the characteristics of simple process and low cost, and the prepared coconut shell-mudcomposite active carbon product has the characteristics of rich pores and high adsorption performance. Coconut shell is doped into the sludge to prepare the coconut shell-mud composite active carbon,so that the carbon content of raw materials is increased, and the defects of lower carbon content of the raw materials mud and higher ash content are overcome. The coconut shell-mud composite active carbon prepared with the method has the advantages of larger specific-surface area, high adsorption value and good adsorption effects on hexavalent chromium and dyes in a water body, and is suitable for being popularized in the field of water treatment.

Owner:SOUTHWEST PETROLEUM UNIV +1

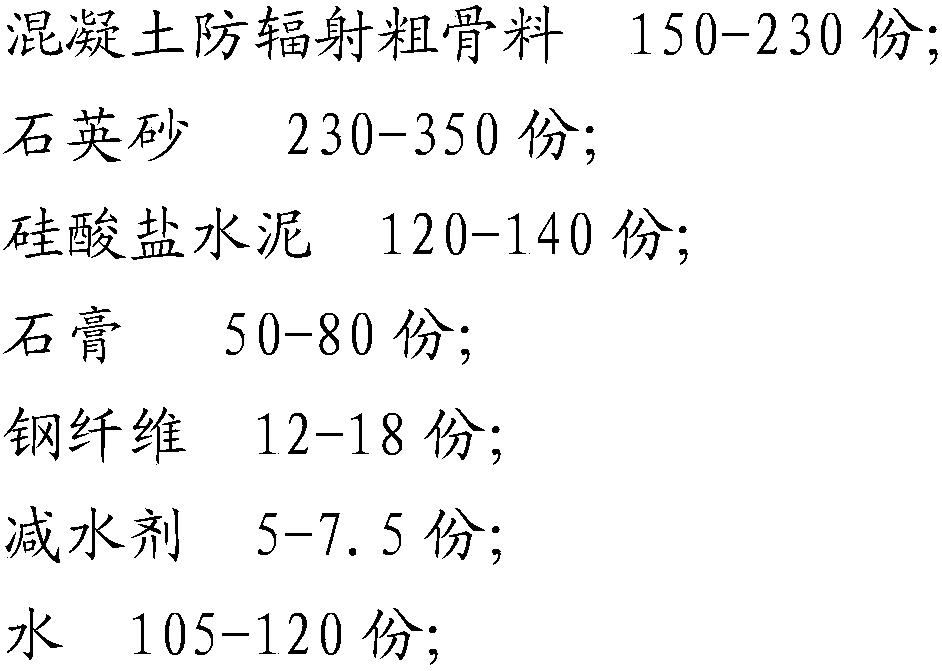

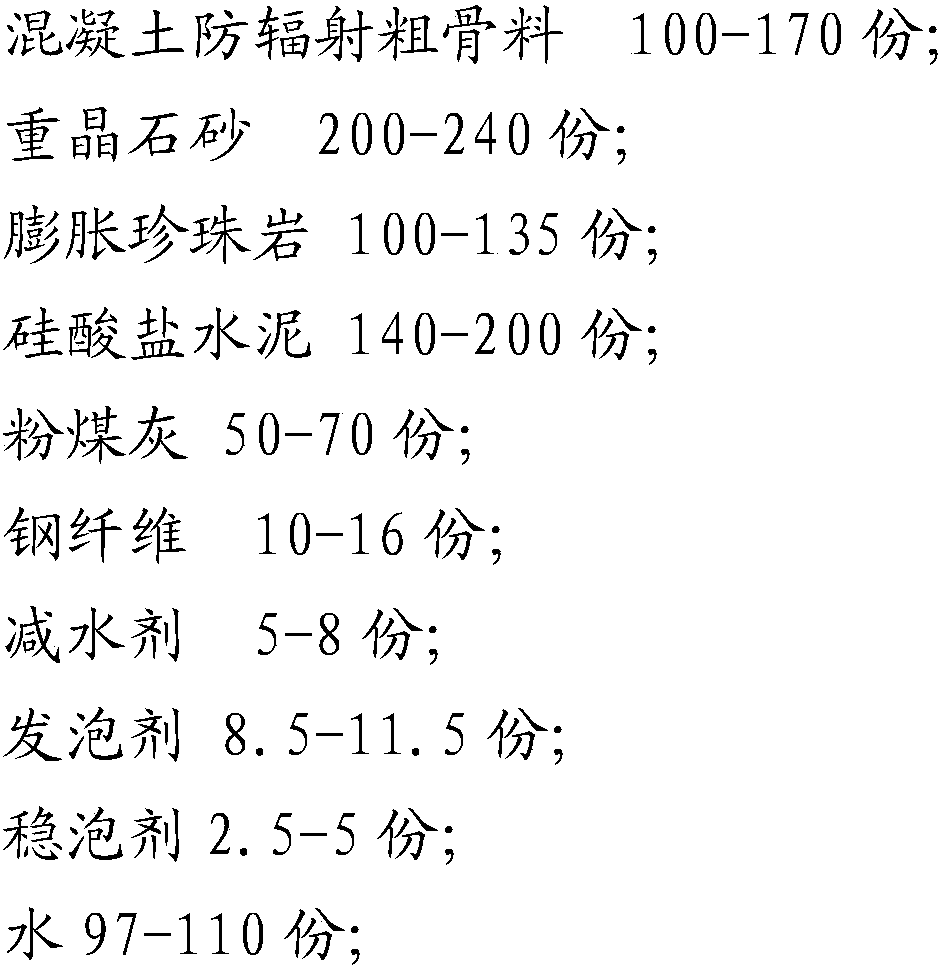

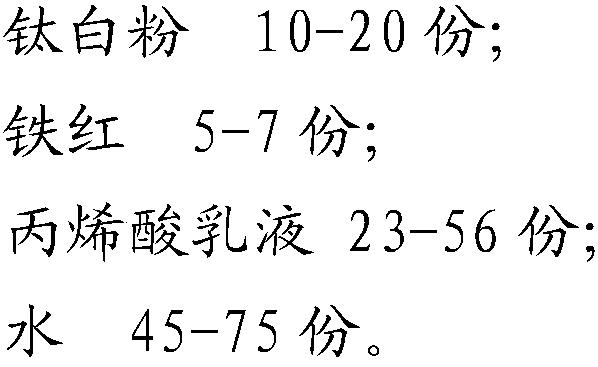

Anti-radiation heat insulation plate and preparation method thereof

ActiveCN108658488AMeet application requirementsHigh strengthCoatingsWater-setting substance layered productRed mudSlag

The invention provides concrete anti-radiation coarse aggregate, an anti-radiation heat insulation plate comprising the aggregate and a preparation method of the anti-radiation heat insulation plate.The method comprises the steps of preparing the concrete anti-radiation coarse aggregate from serpentine acid-leaching slag, red mud and barite powder, and then preparing the anti-radiation heat insulation plate in a four-layer structure. The heat insulation plate has performance such as heat insulation, sound insulation, flame retardance and light weight.

Owner:上海万骊家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com