Novel method for improving city sludge active carbon performance

A technology for urban sewage and sludge, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as unstable properties, waste of resources, environmental pollution, etc., and achieve good adsorption performance, improved adsorption performance, and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

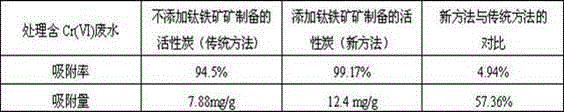

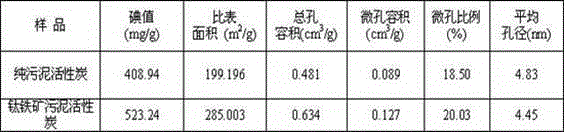

[0022] 1. In the production process of activated carbon, ilmenite, a pore-forming agent, is added, which improves the pore structure of activated carbon products and greatly increases the specific surface area and iodine adsorption value of activated carbon products. See the following table for specific examples:

[0023]

[0024] It can be seen from the above table that after adding ilmenite, the iodine adsorption value of activated carbon reaches 523.24 mg / g, and the specific surface area reaches 285.003 m 2 / g, total pore volume up to 0.634 cm 3 / g, micropore volume up to 0.127 cm 3 / g, the micropore ratio reached 20.03%, and compared with pure sludge activated carbon, it increased by 27.95%, 43.08%, 31.81%, 42.7%, and 8.27%, respectively. The above data show that the addition of ilmenite promotes the generation of more micropores.

[0025] 2. Carbonization and activation are carried out at the same time, the process flow is simplified, and the required reaction temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com