Preparation method of high adsorptive activated carbon

A technology of high adsorption and activated carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as unseen processes, environmental pollution, waste of resources, etc., and achieve significant environmental benefits, high adsorption value, and low emissions The effect of less pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

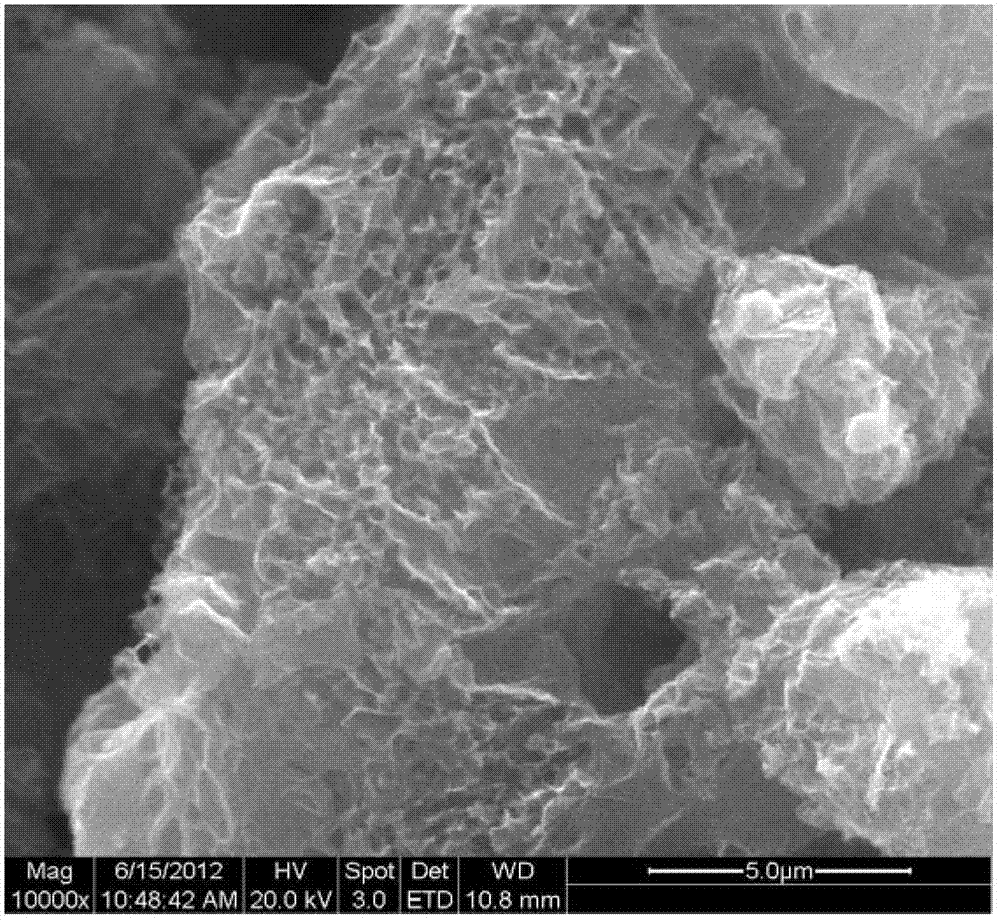

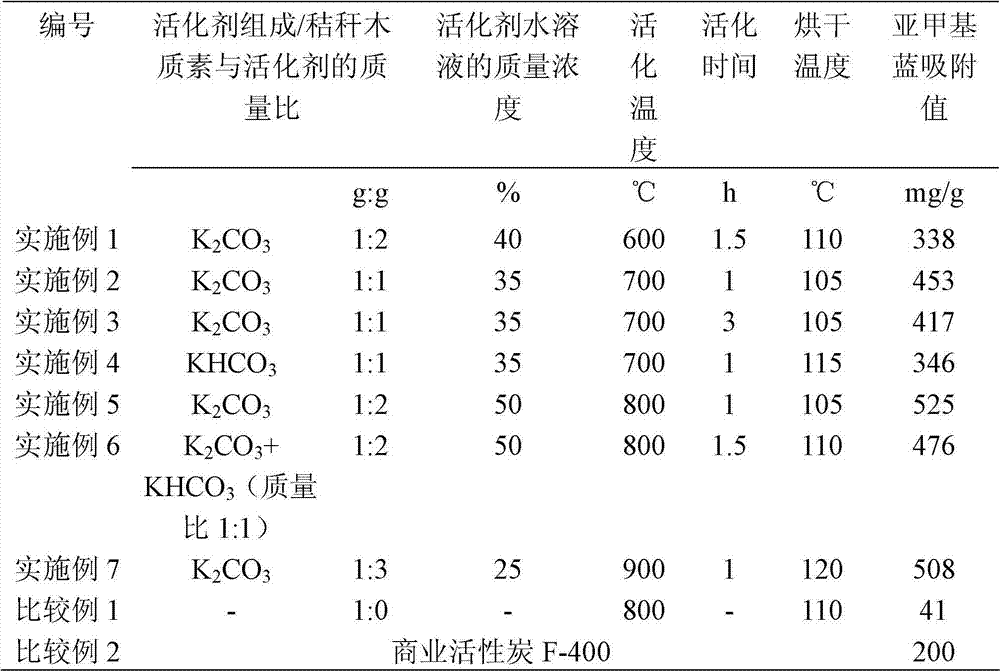

[0015] In order to understand the present invention better, below in conjunction with embodiment the present invention is described in further detail, figure 1 is based on K 2 CO 3 As an activator, adopt the scanning electron microscope image of the gac prepared by the method of Example 3, and the electron microscope model used is Quanta 200SEM (FEI Com, Holland). It can be clearly seen from the figure that the prepared activated carbon has formed a well-developed pore structure. However, the protection scope of the present invention is not limited to the scope indicated by the examples.

[0016] Examples 1-7 The general process of preparing activated carbon with straw lignin is as follows:

[0017] The straw lignin and the activator are weighed according to a mass ratio of 1:1-1:3, and the activator is dissolved in water to form a solution with a mass concentration of 25-50%. The straw lignin and the aqueous solution of the activator are uniformly mixed, and dried at 105-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com