Porous silica gel air purifying particles and preparation method thereof

An air purification and porous silica gel technology, which is applied in the field of porous silica gel air purification particles and their preparation, can solve problems such as air pollution control in seldom residential environments, and achieve the effects of developed pores, mature technology and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

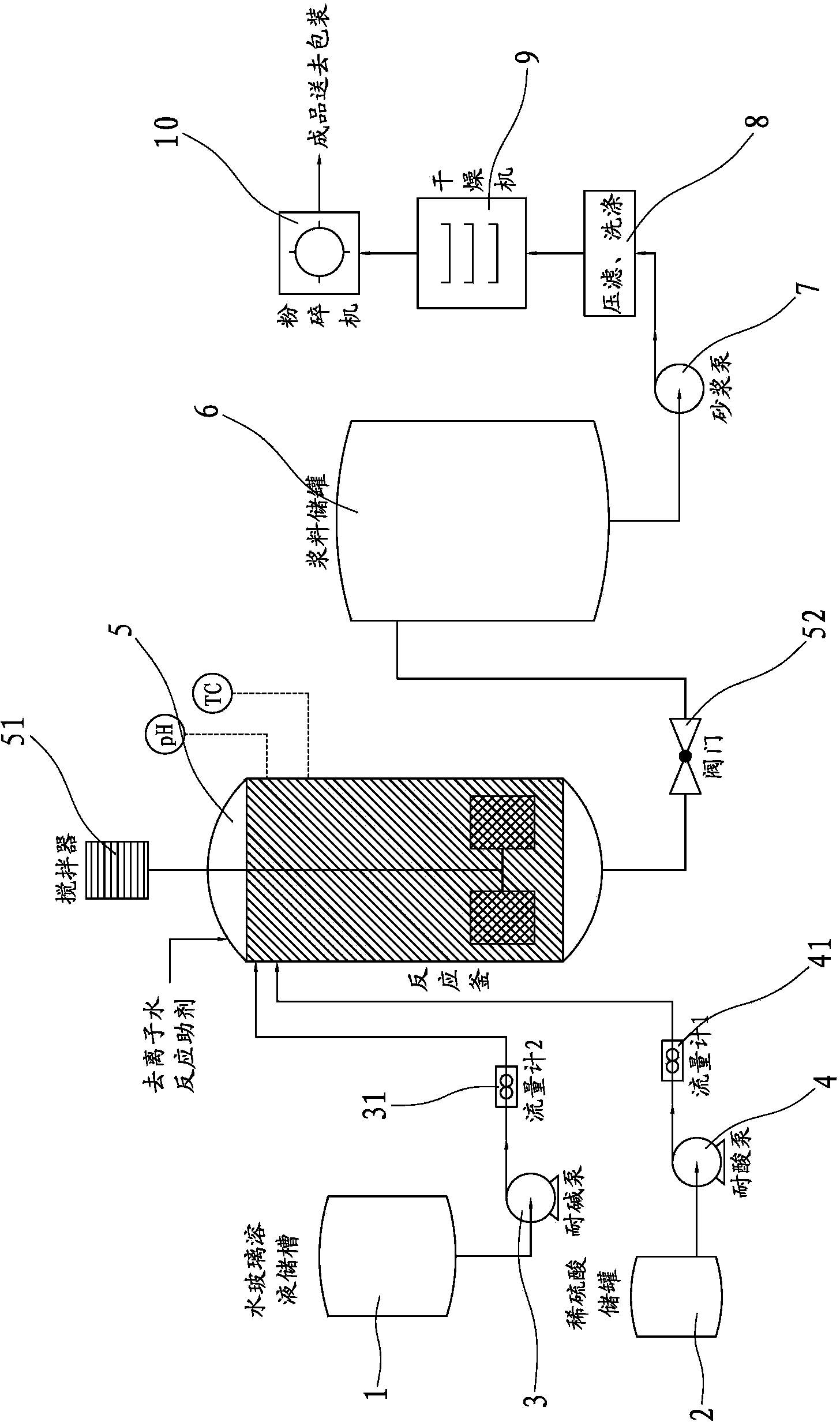

[0029] The present invention is a kind of preparation method of porous silica gel air purification particle, comprises the following steps:

[0030] 1. Add the bottom liquid and surfactant in the reactor 5 in advance, keep stirring and control the temperature at 25-80 o C: inject water glass solution and sulfuric acid solution into the reactor 5 after heating, and control the pH value in the reactor 5 to be 4-10. The surfactant is selected from one or more of polyethylene glycol, ammonium bicarbonate, polyethylene glycol stearate, alkylsulfonic acid amine, castor oil polyoxyethylene ether; by mass percentage The surfactant is 0.01-5% of the water glass solution. The mass concentration of the water glass solution is 5-25%, and the modulus is 3.0-3.4; the mass concentration of the sulfuric acid solution is 15-50%.

[0031] 2. After the silica gel is formed, continue to react for 20-40 minutes, and then raise the temperature to 90-100 o C, adjust the pH value to 2-9, and age f...

Embodiment 1

[0037] Add 1000kg deionized water into the reaction kettle 5 with a stirrer, add 1kgPEG6000 and 4kgNaHCO at the same time 3, The control temperature is 50 o C, under the condition of constant stirring, use a peristaltic pump to inject 700kg of water glass solution with a concentration of 15% into the reactor 5, and simultaneously inject a concentration of 30% sulfuric acid to control the pH of the reaction solution to be about 8, and the feeding time is about 40min . After forming a gel, continue to react for 20 minutes, then adjust the pH value of the reaction slurry to 4, and heat up to 90 o C aging for 2 hours, after aging, continue to add 10% water glass solution until the pH value of the reaction slurry is 7. Finally, filter for solid-liquid separation, and wash the filter cake with deionized water until the conductivity of the filtrate is less than 0.4 μs / cm, dry and pulverize to obtain the finished product.

Embodiment 2

[0039] Add 900kg of deionized water into the reaction kettle 5 with a stirrer, add 1kgPEG6000 and 4kgNaHCO at the same time 3, The control temperature is 50 o C, under the condition of constant stirring, use a peristaltic pump to inject 800kg of water glass solution with a concentration of 12% into the reactor 5, and simultaneously inject a concentration of 25% sulfuric acid to control the pH of the reaction solution to be about 9, and the feeding time is about 40min . After forming a gel, continue to react for 20 minutes, then adjust the pH value of the reaction slurry to 5, and heat up to 90 o C aging for 3 hours, after aging, continue to add 12% water glass solution until the pH value of the reaction slurry is 6.5. Finally, filter for solid-liquid separation, and wash the filter cake with deionized water until the conductivity of the filtrate is less than 0.4 μs / cm, dry and pulverize to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com