Patents

Literature

249 results about "Polar material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

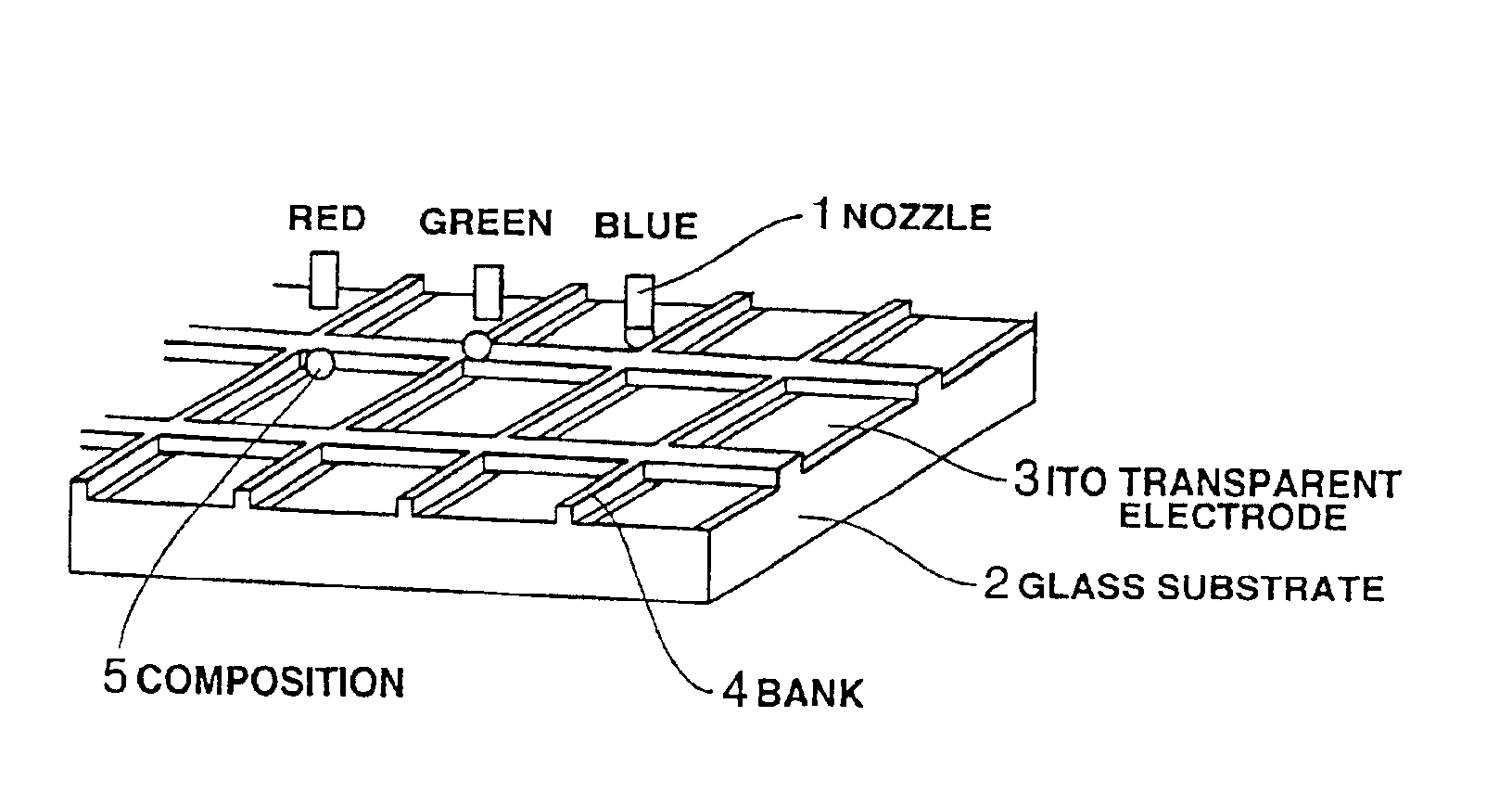

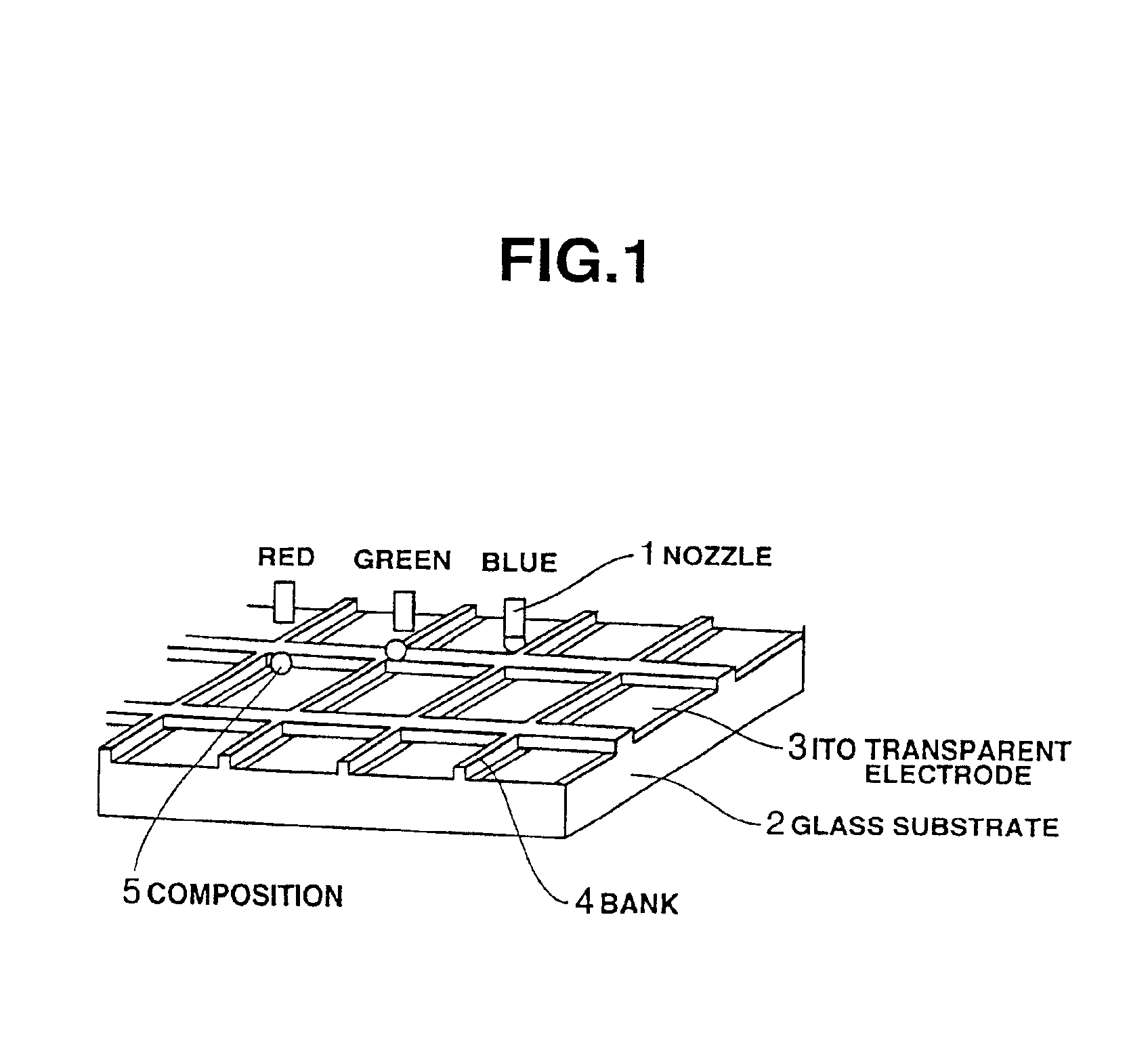

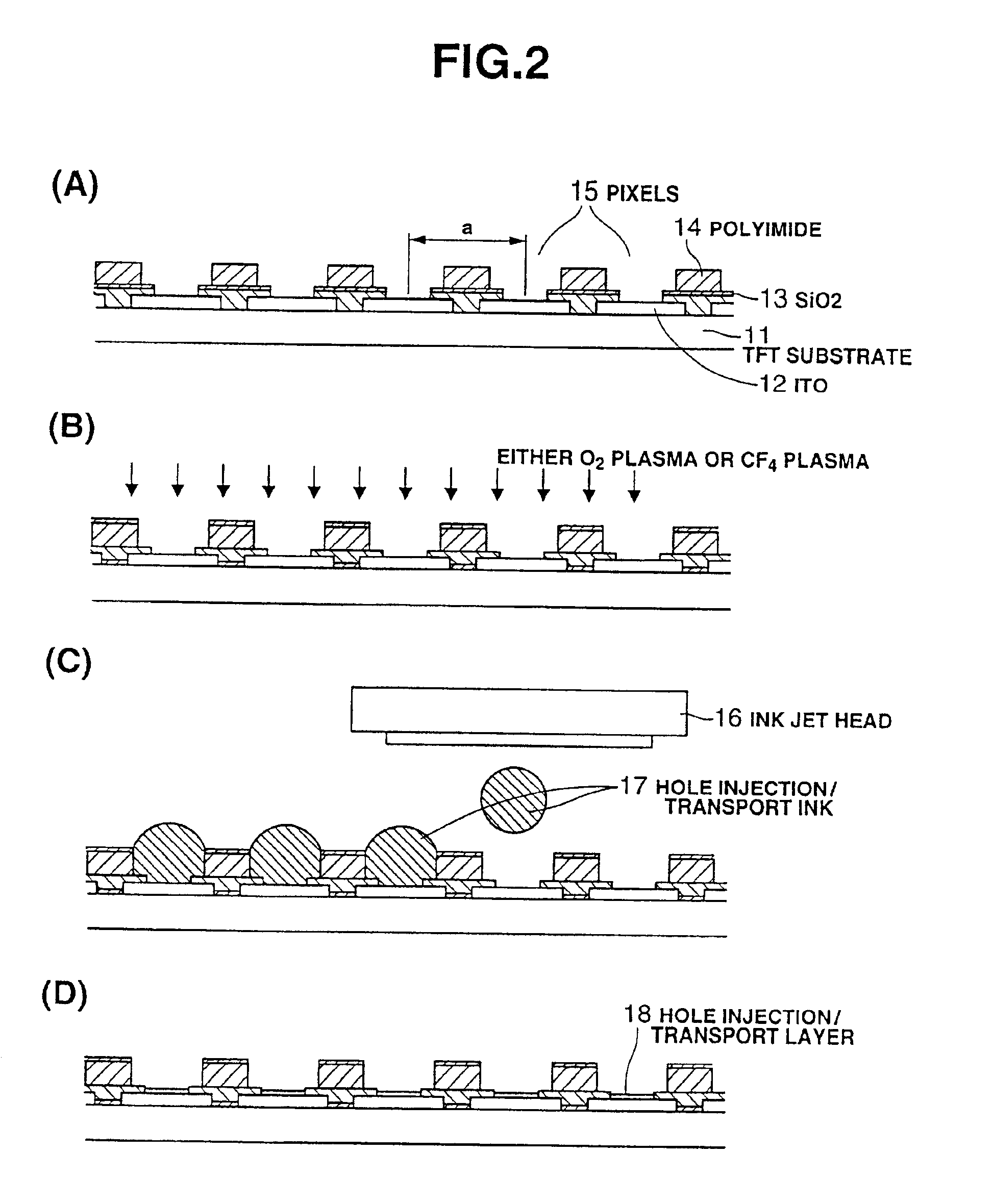

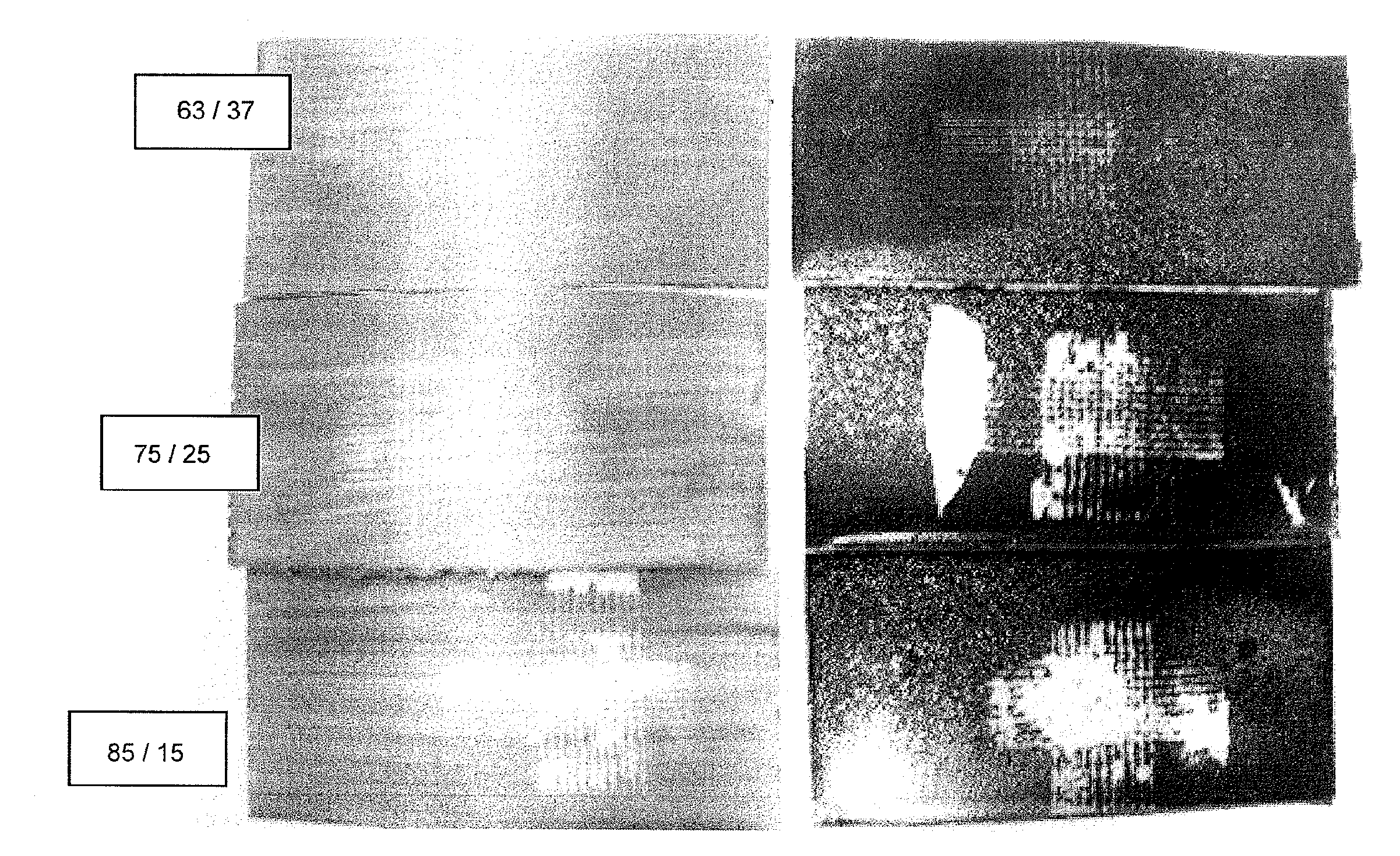

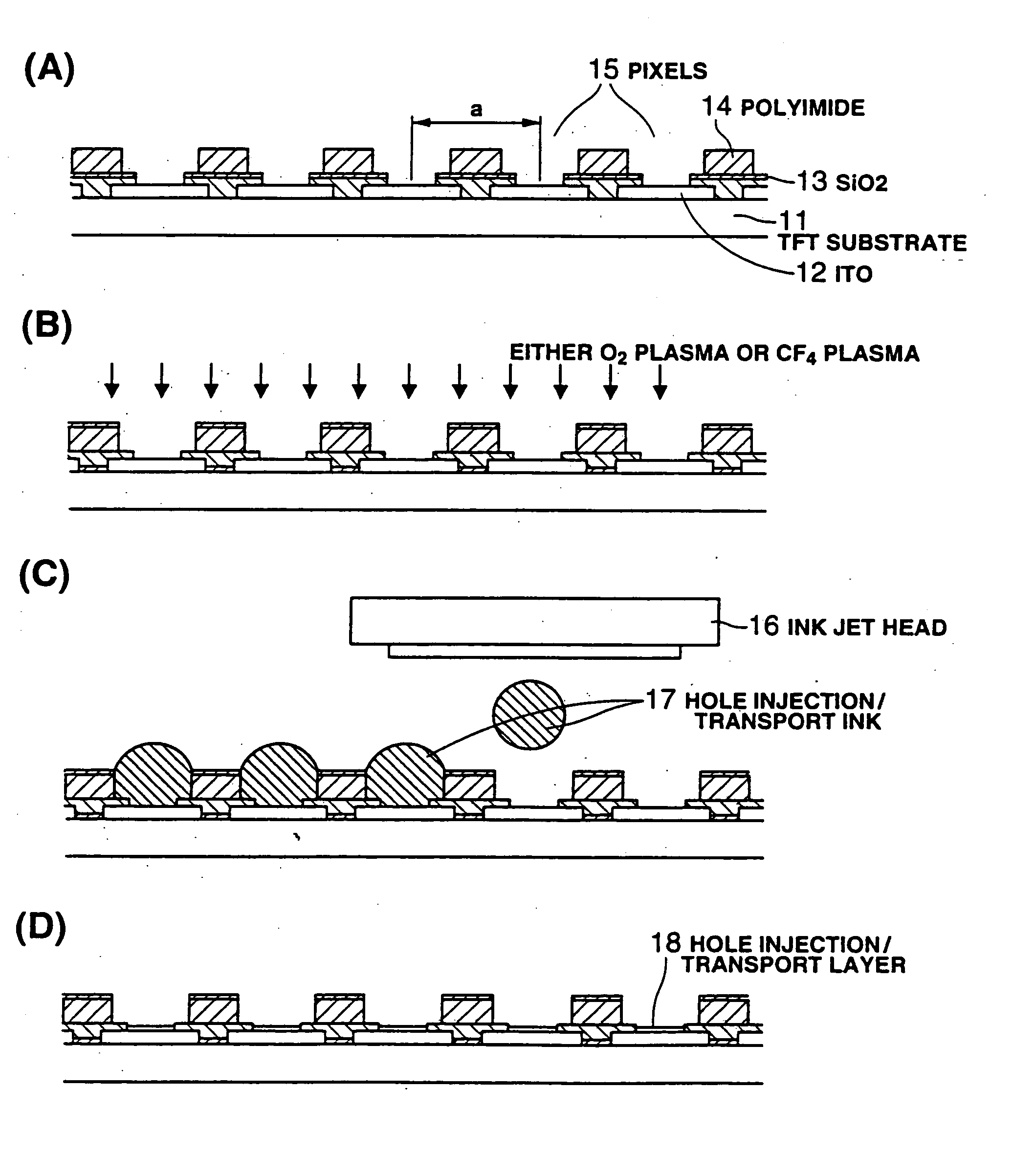

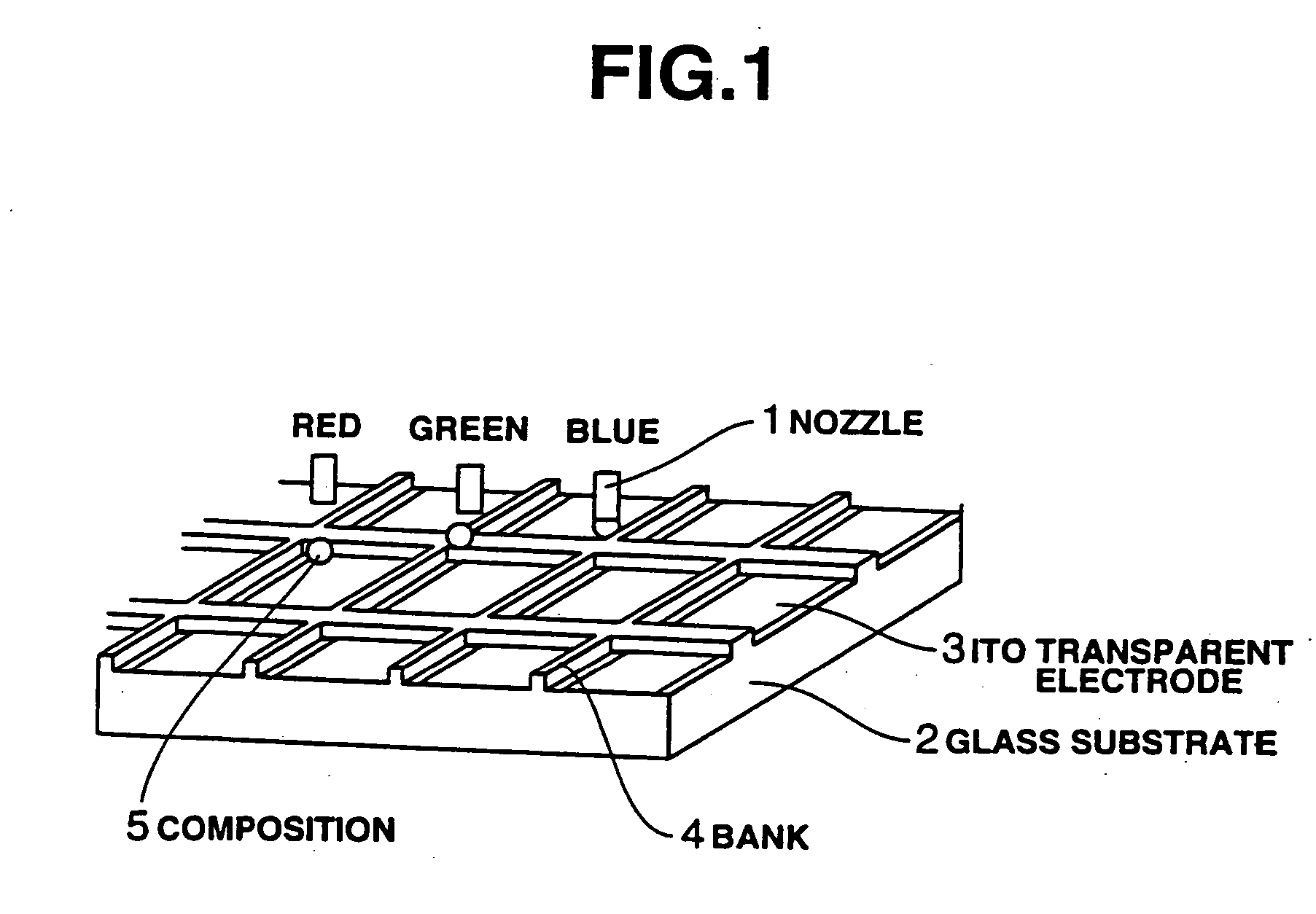

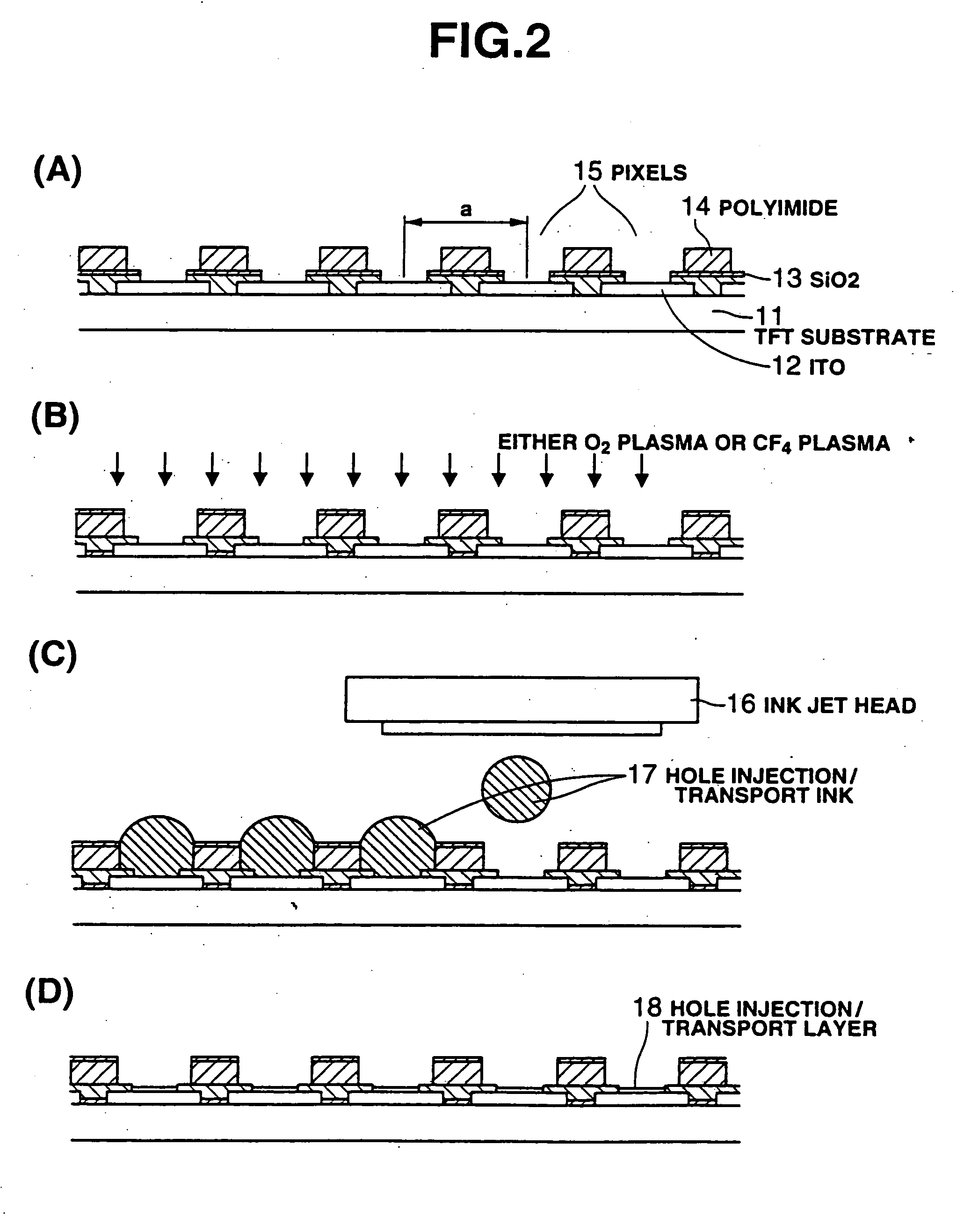

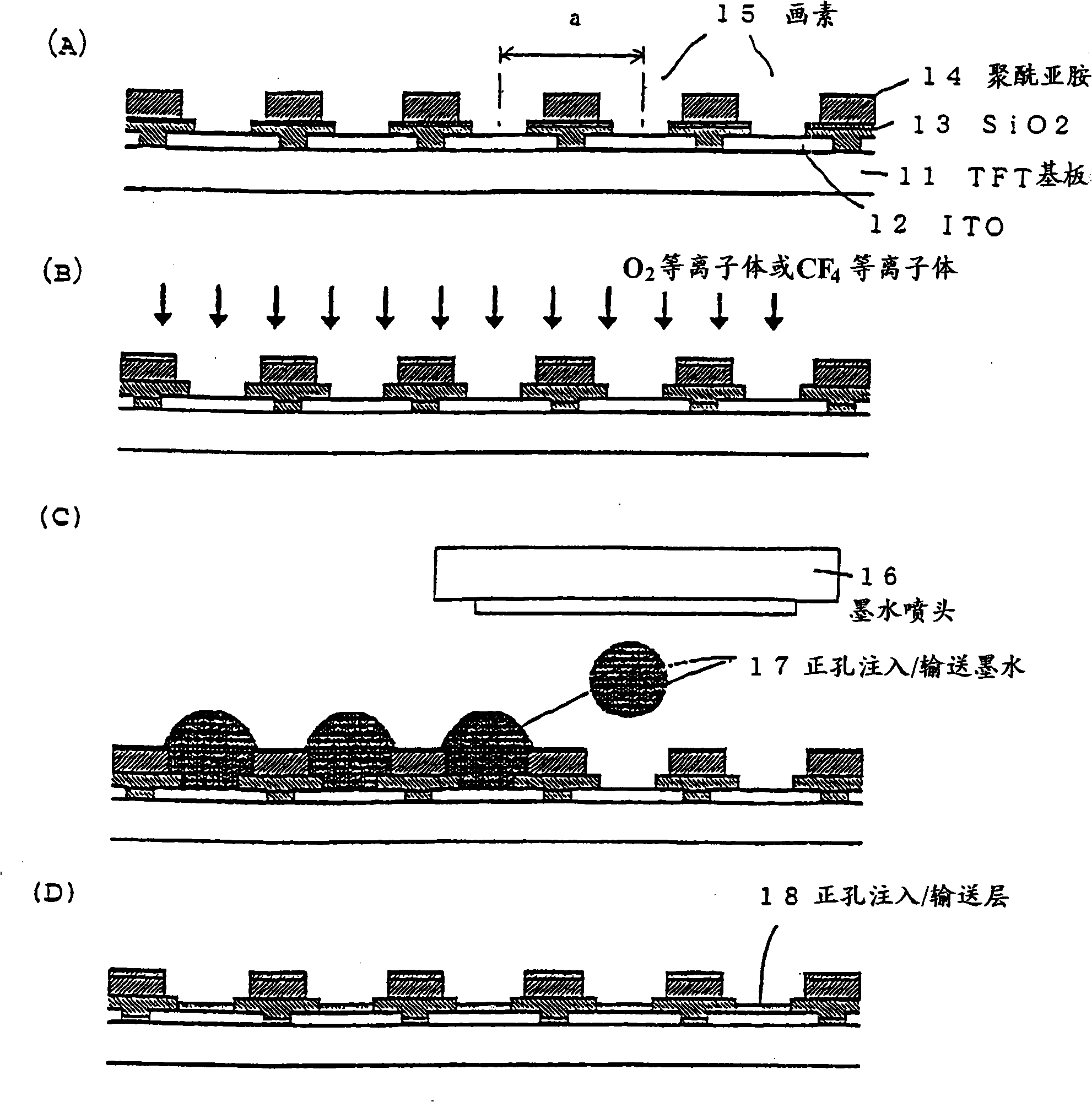

Composition, film manufacturing method, as well as functional device and manufacturing method therefore

InactiveUS6878312B1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A composition, which can be used in an ink jet printing method, can use either a non-polar or a weakly polar material as a functional material, prevents clogging at dispensing time, achieves stable dispensing, and prevents precipitation of content matter during dispensing and phase separation during film formation, a uniform, homogenous functional film formed using this composition and a manufacturing method therefor, as well as an organic EL device or other such display device and a manufacturing method therefor. A composition of the present invention consists of a functional material, and a solvent comprising at least one benzene derivative, which has one or more substituents, and these substituents have 3 or more carbon atoms in total. A functional film of the present invention is formed using the above-mentioned composition. A display device of the present invention comprises luminescent material layers formed using the above-mentioned composition between two electrodes. The above-mentioned display device is an organic EL device or the like.

Owner:CAMBRIDGE DISPLAY TECH LTD

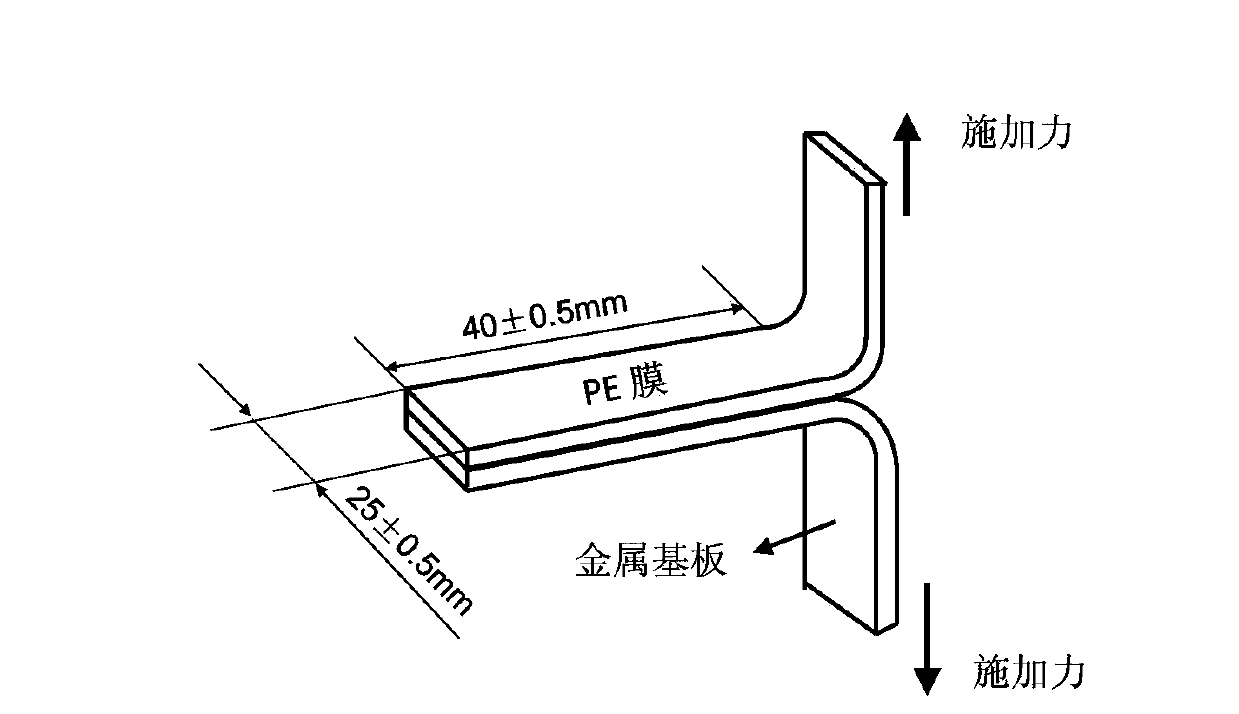

Articles Comprising Nonpolar Polyolefin and Polyurethane, and Methods for Their Preparation and Use

ActiveUS20090275690A1Improve adhesionSynthetic resin layered productsCoatingsPolyesterPolymer science

The adhesion between a low surface energy (i.e., nonpolar) material, e.g., a polyolefin such as polyethylene, and a high surface energy (i.e., polar) material, e.g., a polyester, polyurethane, polycarbonate or polylactic acid, is promoted by blending with the nonpolar material typically from 15 to less than 50 wt % of a diol-based thermoplastic polyurethane (d-TPU), e.g., a polydiene diol-based TPU, based on the combined weight of the nonpolar material and the d-TPU. The promoted adhesion allows for the effective painting, printing, over-molding or HF-welding of a nonpolar substrate, e.g., a polyolefin film, with a polar coating, e.g., a paint, ink, etc. Aqueous dispersions can also be made from the blend of nonpolar material and d-TPU.

Owner:DOW GLOBAL TECH LLC

Environmental protection chloroprene rubber adhesive agent and production method thereof

InactiveCN101418197AHigh viscosityGood storage stabilityHalogen rubber derivative adheisvesChloroprene adhesivesGas phaseEnvironmental labeling

The invention discloses an environment-friendly chloroprene rubber adhesive agent which comprises the following compositions: neoprene, alloprene, thixotropic agent, 2402 phenolic resin, extra light calcined magnesia, catalyst, cyclohexane, acetic ether, environment-friendly solvent oil and antioxidant BHT. The invention simultaneously discloses a method for producing the environment-friendly chloroprene rubber adhesive agent. The environment-friendly chloroprene rubber adhesive agent has the following advantages: 1. the agent is environment-friendly, does not contain toxic solvents of triphen and halogenated hydrocarbon, and meets the standard requirement of Technical Requirement for Environmental Labeling Products-Adhesives HJ / T 220-2005 2. the anhydrous catalyst is adopted for the preparation of a pre-reaction solution which has high viscosity and good storage stability; 3. gas phase method silica aerogel is added as the thixotropic agent; and the thixotropic index can reach 1.5 and is convenient for construction; and 4. the neoprene and the alloprene are combined for use to greatly improve the adhesive force and peeling strength to metal and other polar materials.

Owner:GUANGDONG SANVO CHEM IND TECH

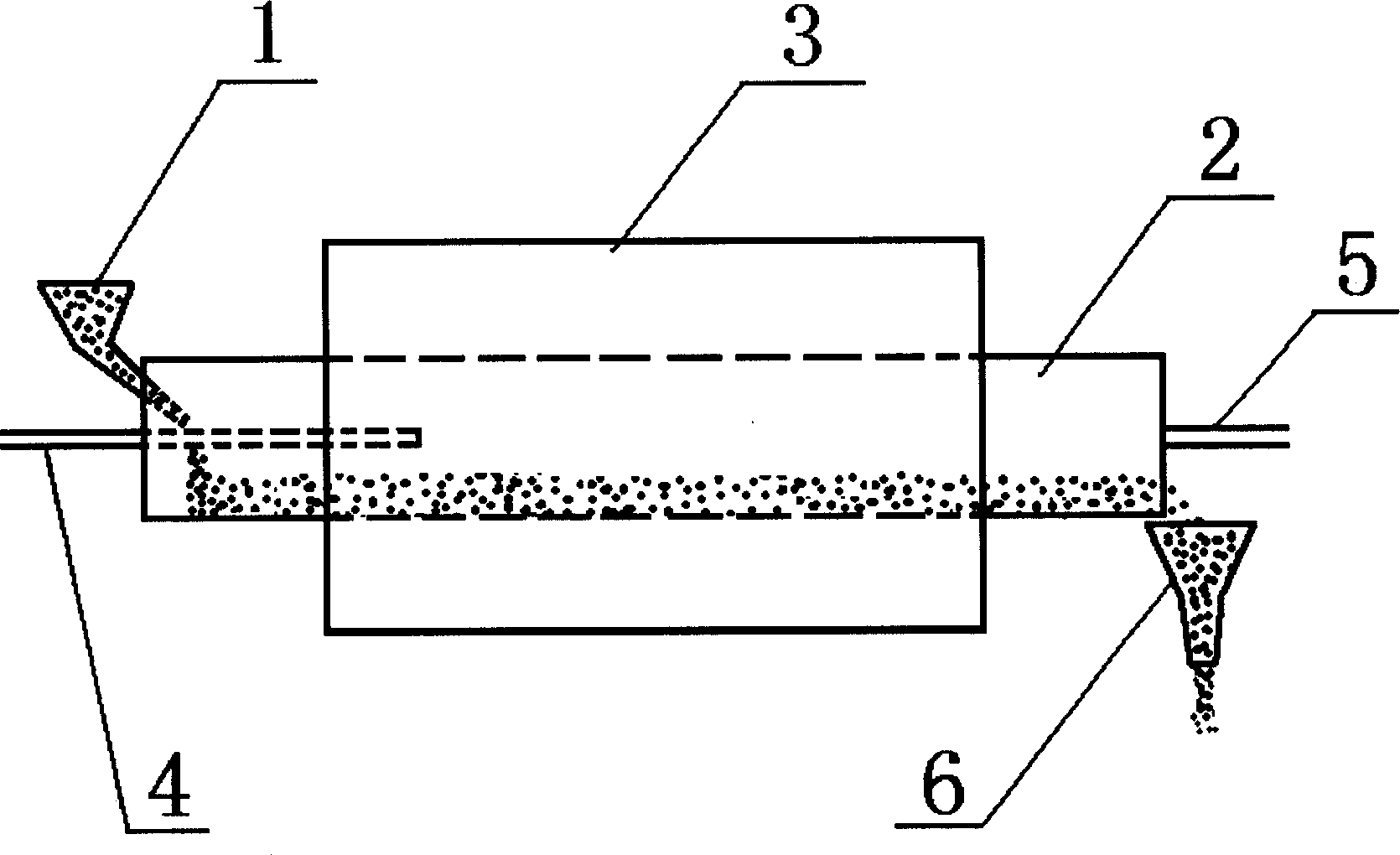

Method for synthesizing lithium ion cell positive cell polar material rotary furnace

InactiveCN1710735AImprove consistencyEvenly heatedElectrode manufacturing processesTemperature controlRotary furnace

The method includes steps: (1) loading hydrate, oxide of lithium or mixed salt with hydrate, oxide or salt of transition metal into revolving furnace; (2) controlling temperature inside revolving furnace at 600 - 950 deg.C and rotation speed at 2 - 5 turns / minute, calcining admixture in revolving furnace for 20 - 40 hours, and then cooling it; (3) anode material of lithium battery is obtained through steps of crushing and sieving cooled materiel. Since calcined materiel is heated evenly inside revolving furnace, thus, physical and chemical characters of obtained materiel are even features are: shortened time for processing in high temperature, and lowered energy consumption.

Owner:广州鸿森材料有限公司

Hydro-insensitive alternating current responsive composites

ActiveUS7651638B2Powder deliveryNon-macromolecular adhesive additivesElectrical polarityAlternating current

Owner:FLEXCON

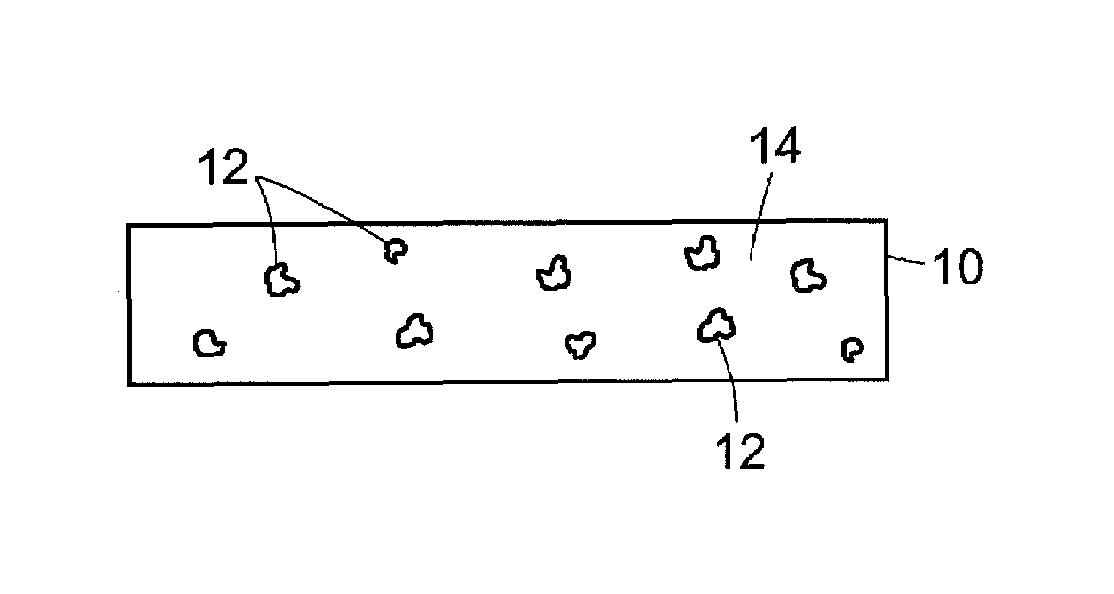

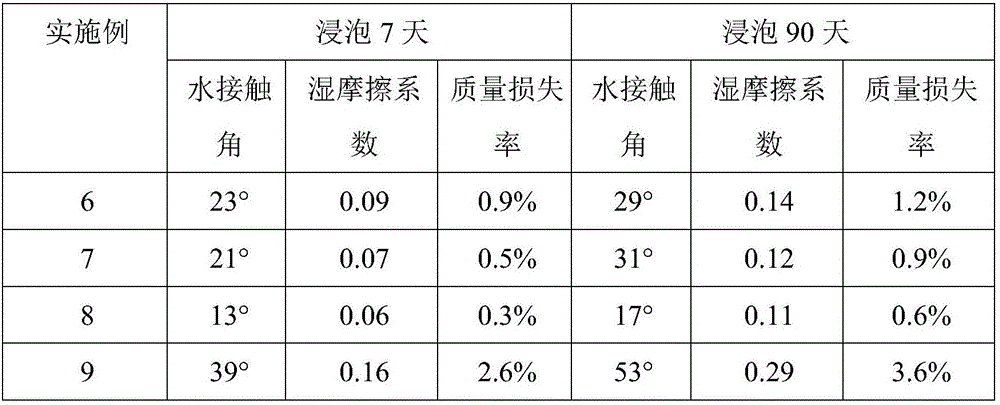

Double-effect composite membrane used for lithium sulphur battery and preparation method thereof

ActiveCN108461694AImprove the utilization rate of active substancesImprove stabilityCell component detailsHigh energyLithium–sulfur battery

The invention provides a double-effect composite membrane used for a lithium sulphur battery and a preparation method thereof. The membrane is composed of a functional composite layer and porous insulating film. The functional composite layer is a composite of conductive carbon base materials, polar materials and a binder, wherein the mass fraction of the conductive carbon base materials and polarmaterials is 5%-90% and 5%-90% respectively. The preparation method comprises the steps that the conductive carbon base materials and the polar materials are used for preparing the functional composite layer, the functional composite layer is loaded on the porous insulating film, and surface loading capacity of the functional composite layer is 0.1-3.0 mg cm-2. The composite membrane in the lithium sulphur battery regulates and controls reaction and deposition behaviors of active substances in different charge-discharge stages and significantly improves the utilization and stability of the active substances of the lithium sulphur battery. Compared with ordinary commercial polymer battery membranes, the composite membrane prolongs the cycle life of the lithium sulphur battery and improvesspecific energy, positive discharge capacity and coulombic efficiency. The method is simple in operation, is beneficial to large-scale preparation, and facilities wide commercial application of the high-energy density lithium sulphur battery.

Owner:TSINGHUA UNIV

Adherent, modified thermoplastic elastomeric blends, articles, and methods

A thermoplastic elastomer that is adherent to polar materials may be made from a dynamically vulcanized blend of propylene resin, ethylene / alpha-olefin / non-conjugated diene elastomers, and a bonding agent via a curing system containing a free radical initiator, at least one co-agent including multifunctional acrylates containing at least two acrylate groups, multifunctional maleimides containing at least two imide groups, or mixtures of both, where the elastomer gel content in the modified blend is at least about 97 percent. Reaction mixtures, articles made therefrom, and methods of dynamically vulcanizing are also disclosed.

Owner:SOLVAY ENGINEERED POLYMERS

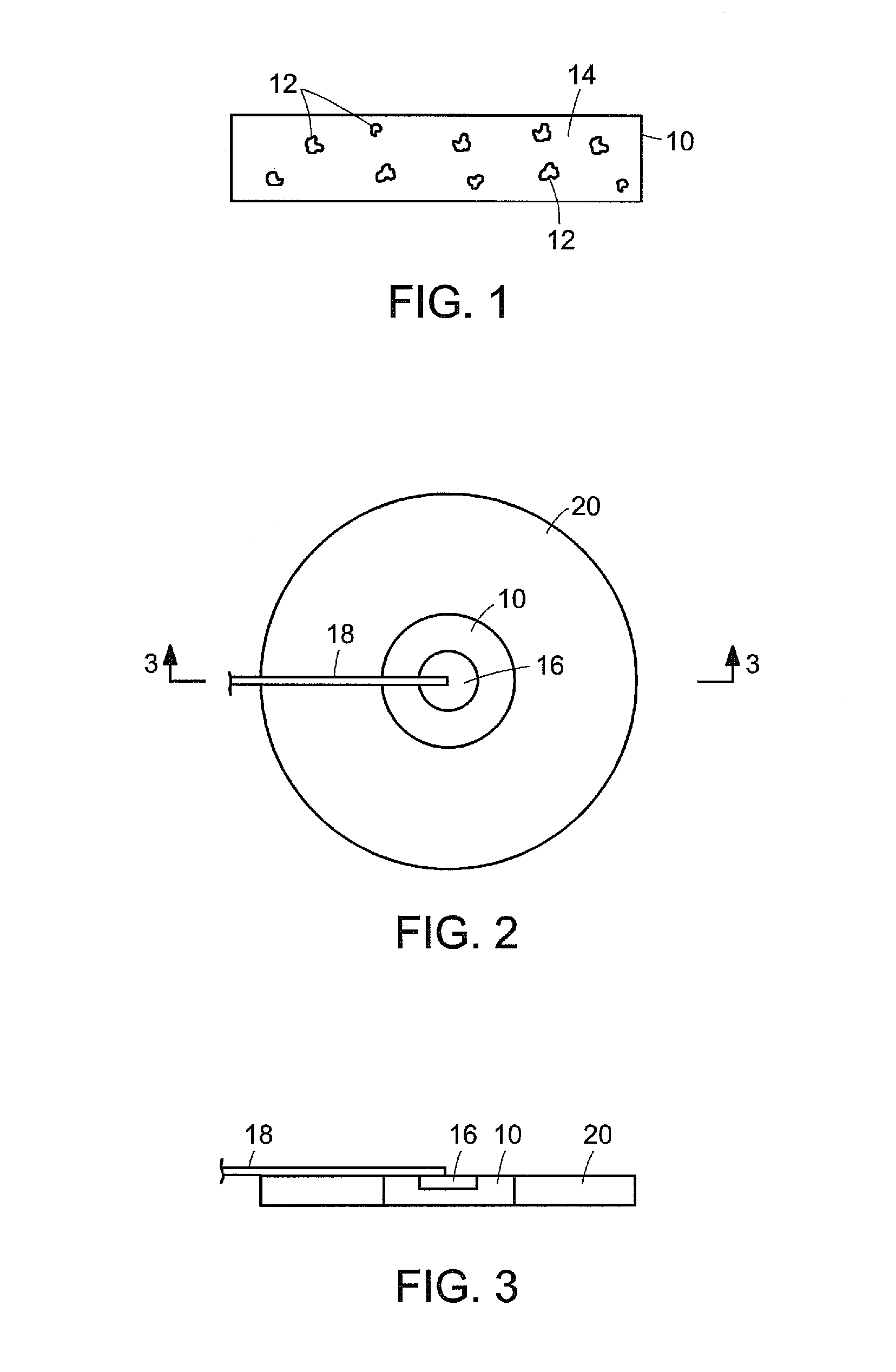

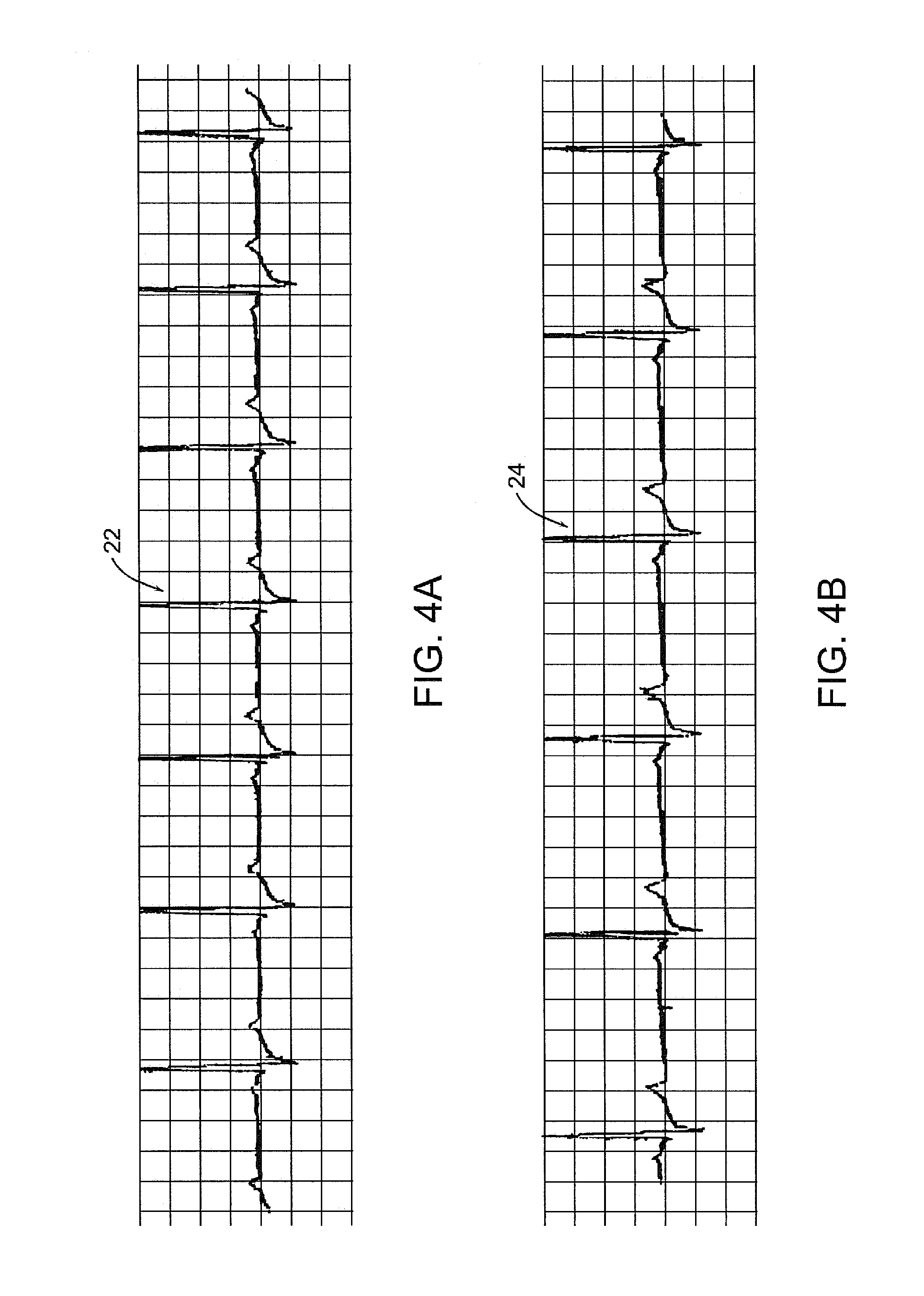

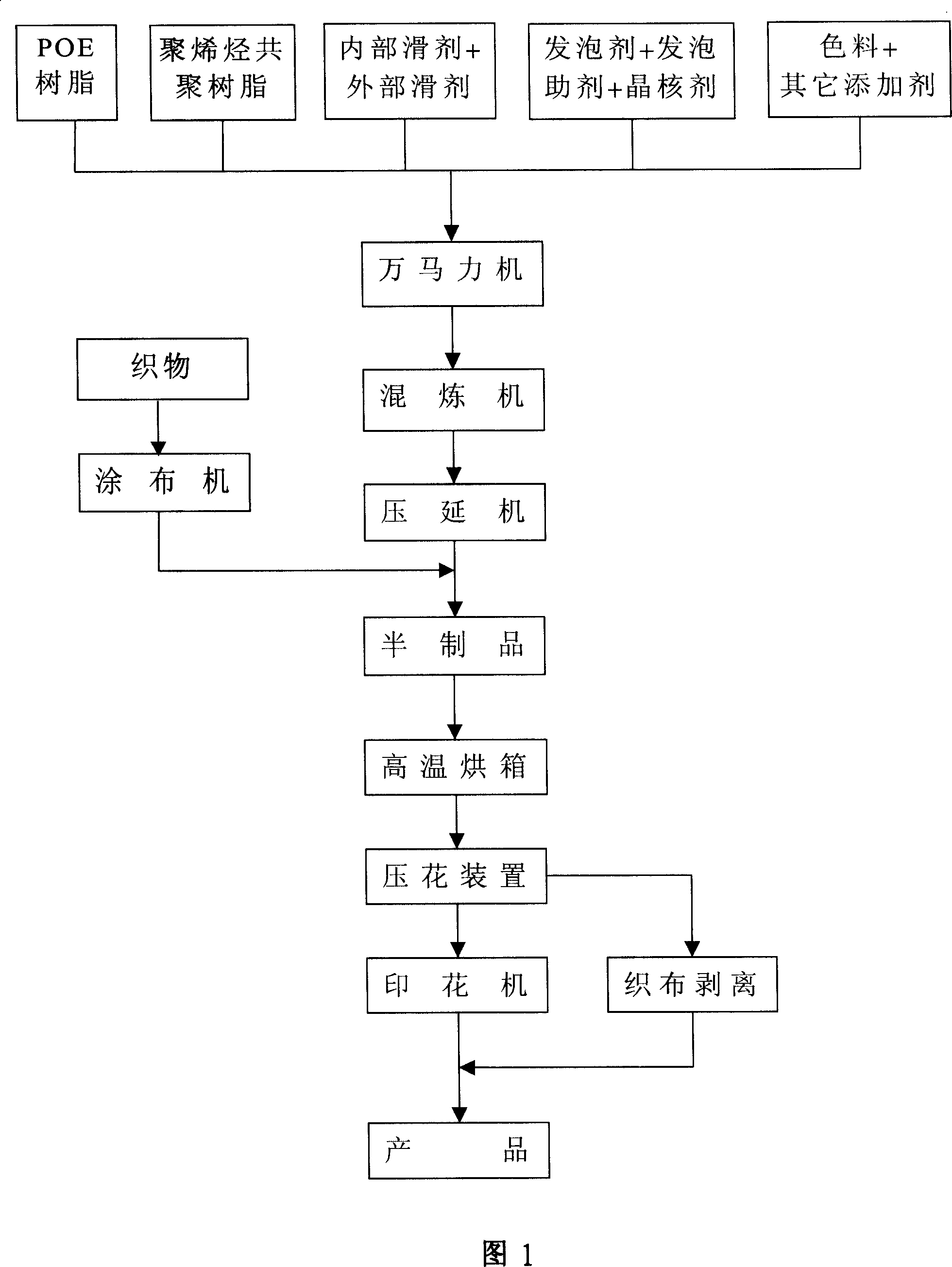

Method for producing polyolefin elastomer false skin and product thereof

InactiveCN101096421AAvoid direct stickingReduce interaction shearingSynthetic resin layered productsElastomerPolyolefin

The invention discloses a rolling method to make polyolefin elastomer leatheret, which is characterized by the following: adding fitful functional modified material to improve its radiofrequency welding property and adhesion of polar material; adopting polyolefin elastomer as main raw material; adding lubrication prescription composition and foamer composition into fusing course; using roller to extract rubber cloth after high temperature gelatination; applying base cloth disposed by adhesion agent; processing the elastic product under high temperature; adding functional copolymerization resin in the formulation to increase radiofrequency fusing property of the product.

Owner:CHINA GENERAL PLASTICS

Moisture cured multi-constituties grafting solvent-based adhesive

The invention discloses a moisture cured multi-constituties grafting solvent-based adhesive, which is prepared by processing the following components in part by weight: 5 to 15 parts of main body, 0 to 0.2 part of initiator, 0.2 to 10 parts of grafting monomer, 1 to 15 parts of thickening agent, 0 to 1 part of antioxidant, 0.5 to 2.5 parts of silane coupling agent and 31 to 95 parts of solvent through processes of grafting, coupling and the like. The adhesive does not contain toxic substances such as benzene and the like which are harmful to human bodies, and has the advantages of good stability of components of products, safety and environmental protection; and simultaneously, the adhesive has the excellent cohesive force for polar materials and nonpolar materials, can bond various materials such as rubber, leather, fabrics, foam plastics, PVC leather, PU leather, plastics, surface veneer of color prints and the like, and are widely suitable for vehicle material markets and shoe manufacturing industry.

Owner:日邦树脂(无锡)有限公司

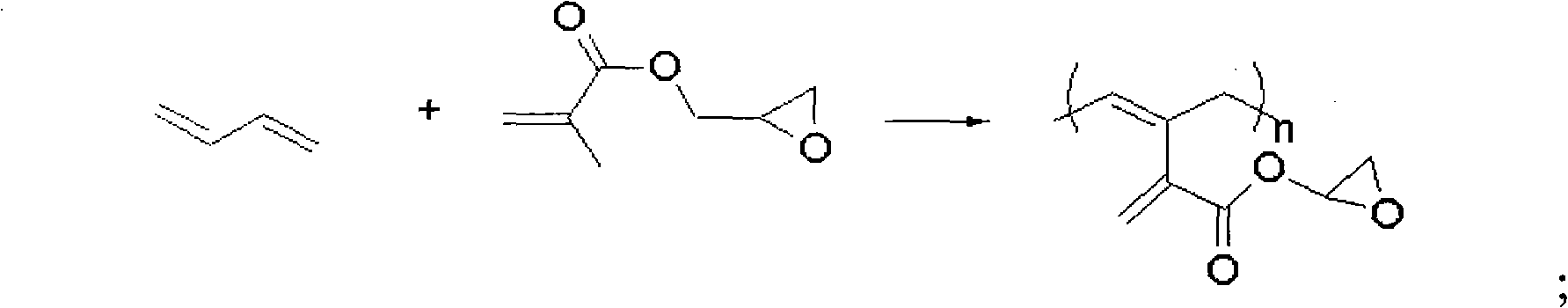

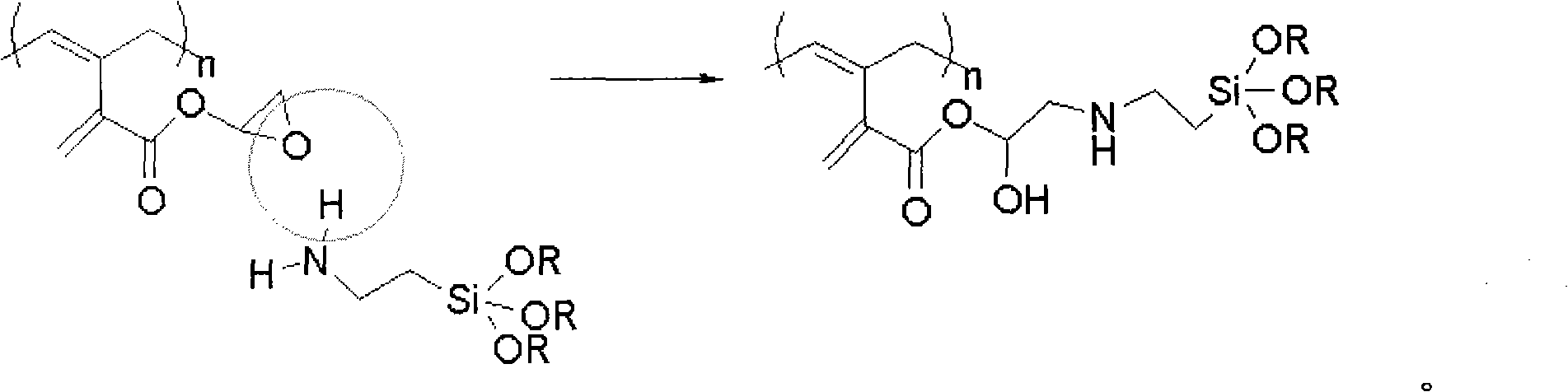

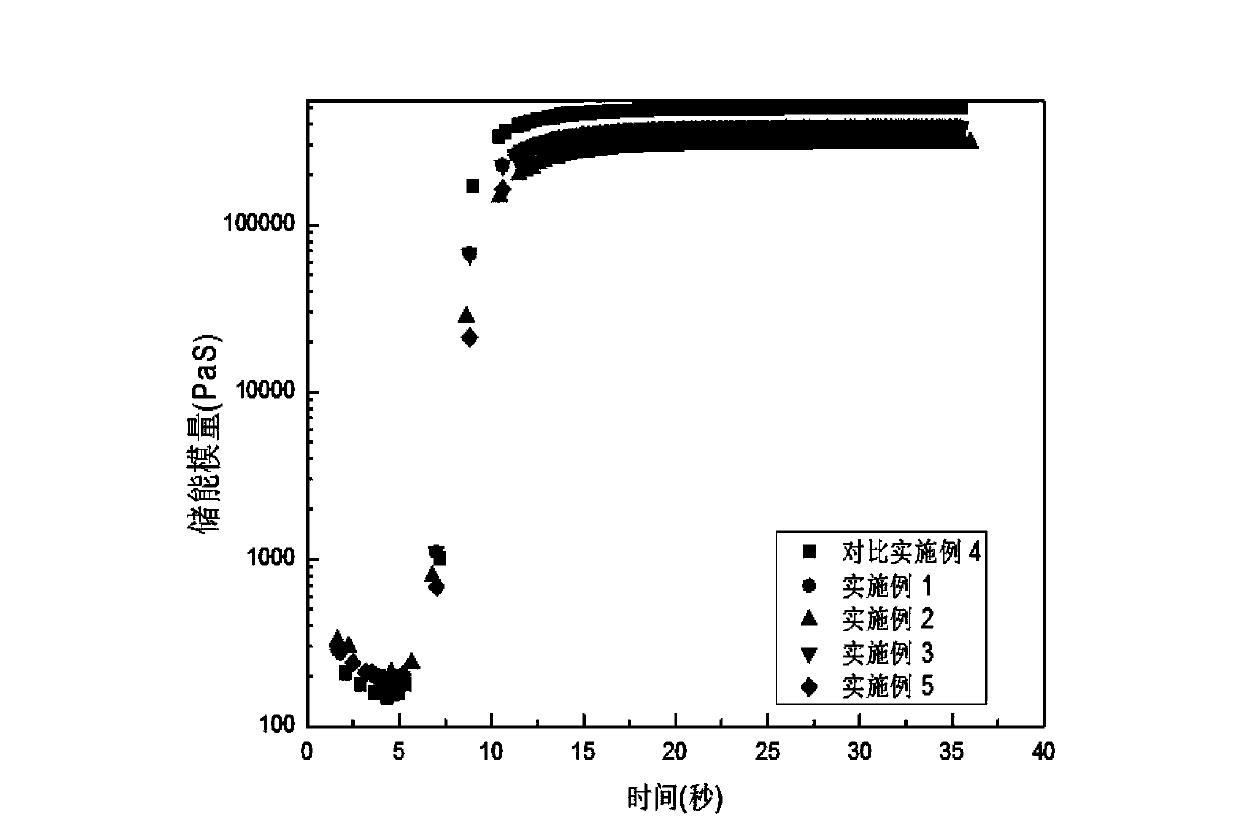

Method for preparing moisture-cured multi-grafted solvent type adhesive

ActiveCN101781539AImprove solubilityHigh bonding strengthNon-macromolecular adhesive additivesGraft polymer adhesivesCross-linkPolymer science

The invention discloses a method for preparing a moisture-cured multi-grafted solvent type adhesive. Rubber and a styrene type thermoplastic elastomer form a skeleton, and under the initiation of BPO, monomers methyl methacrylate (MMA), methacrylamide (AM) and glycidyl methacrylate (GMA) are grafted to a carbon doublebond of the skeleton, thereby changing the polarity of the adhesive with the modification of the monomers; and a silane coupling agent and epoxy groups undergo a cross linking reaction through silane to form three-dimensional net working so as to fulfill the aim of moisture curing, and enhance the bond strength and heat resistance of the adhesive. The moisture-cured multi-grafted solvent type adhesive prepared by using the method of the invention does not contain any toxic substance, such as benzene and the like, threatening human health, has high component stability, is secure and environmentally-friendly, simultaneously has high bonding power for polar materials and nonpolar materials, can bond a plurality of materials, such as rubber, leather, fabrics, foam, PVC leather, PU leather, plastics, colored printed product surface mount plastics and the like, and is widely applied to the vehicle material market and footwear industry.

Owner:力森诺科材料(无锡)有限公司

Sealant for high temperature pressurized leakage stop-up

InactiveCN101880413AEasy to switchReliably eliminates under pressureSpindle sealingsOther chemical processesRubber materialChemical industry

The invention relates to a sealant for high temperature pressurized leakage stop-up, which belongs to the technical filed of polymer chemical industry, and is characterized by taking nitrile rubber and liquid nitrile rubber as main body rubber materials, and adding phenolic resin and a reinforcing filler, an antioxidant, a curing agent, an accelerator, a softener and other additives to prepare the high-temperature leakage stop-up sealant for carrying out pressurized leakage stop-up under different medium states such as high-temperature steam, high temperature hydrocarbon, flue gas and the like after roll mixing. The sealant has wide range of suitable sealants and erosion medium resistance, and keeps stable for long time. The sealant has excellent oil resistance, heat resistance, storage stability and good adhesion of polar materials.

Owner:DALIAN UNIV OF TECH

Solvent assisted oil recovery

InactiveUS20110152136A1Reduce the amount requiredReduce precipitationFlushingDrilling compositionEtherDiluent

The recovery of oil from a reservoir is assisted by injecting a diluent into the reservoir formation to reduce the viscosity of the crude oil. This diluent is a mixture of a material which is an asphaltene precipitant, especially supercritical carbon dioxide, and a more polar material which comprises at least one aliphatic compound which includes at least one of a cycloaliphatic ring, an olefinic unsaturation, an ester or ether group. The inclusion of such an aliphatic compound which is more polar than the asphaltene precipitant reduces asphaltene precipitation and can enhance the efficiency of oil recovery when the precipitant is by supercritical carbon dioxide.

Owner:SCHLUMBERGER TECH CORP

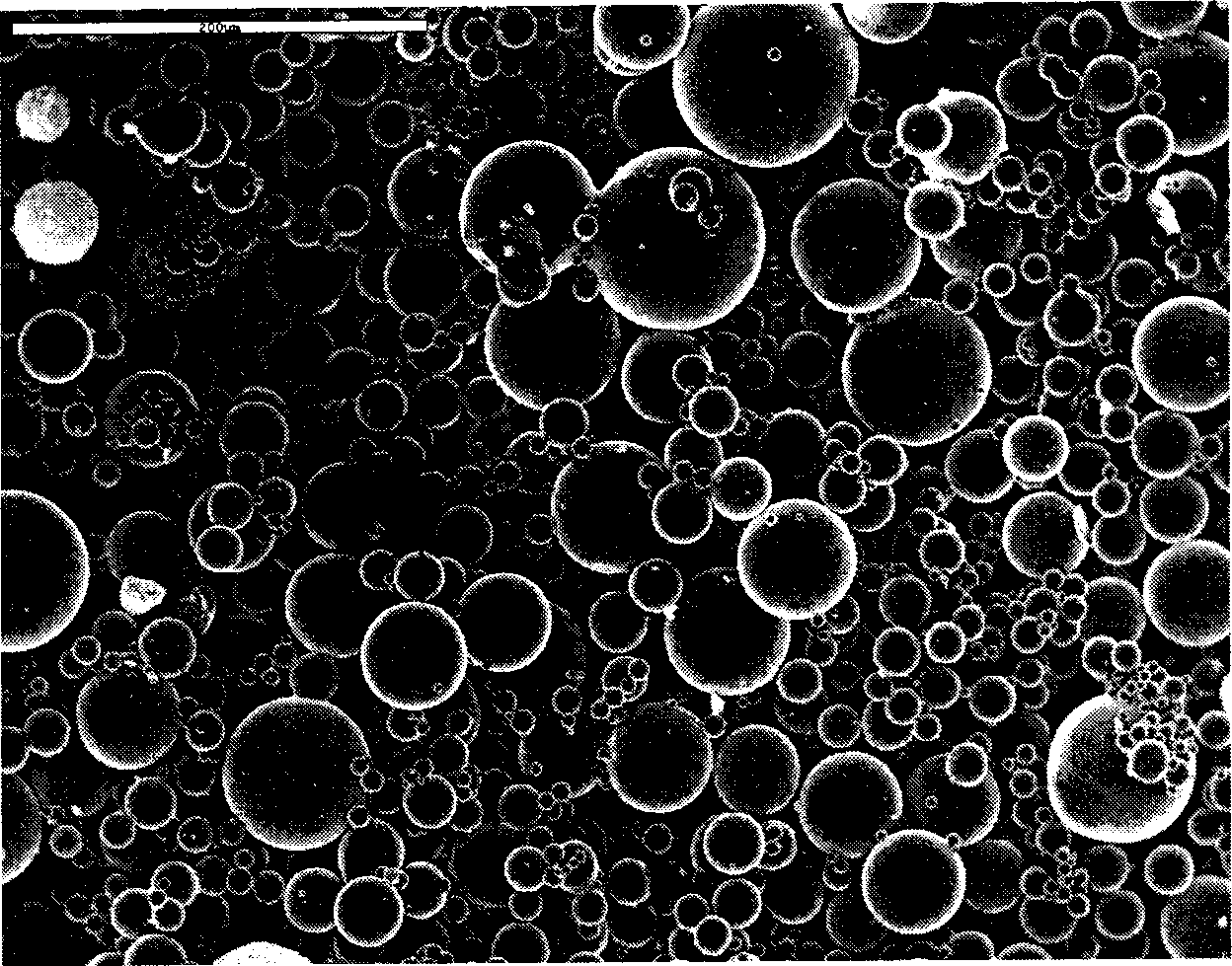

Active-carbon-microball coated metal composition negative polar material and preparing method

This invention relates to a compound negative material with micro-balls of active carbon covering metals and its preparation method characterizing in putting metal particles in hollow carbon micro-balls to make up of the structure of the material, in which, said metal is a Li-stored active metal, the mass percentage is 30-80% taking resorcin, methanal, a metal or its metal oxide as the raw material to be prepared by a method of reverse micelle latex polymerization and high temperature carbonization recovery.

Owner:TSINGHUA UNIV

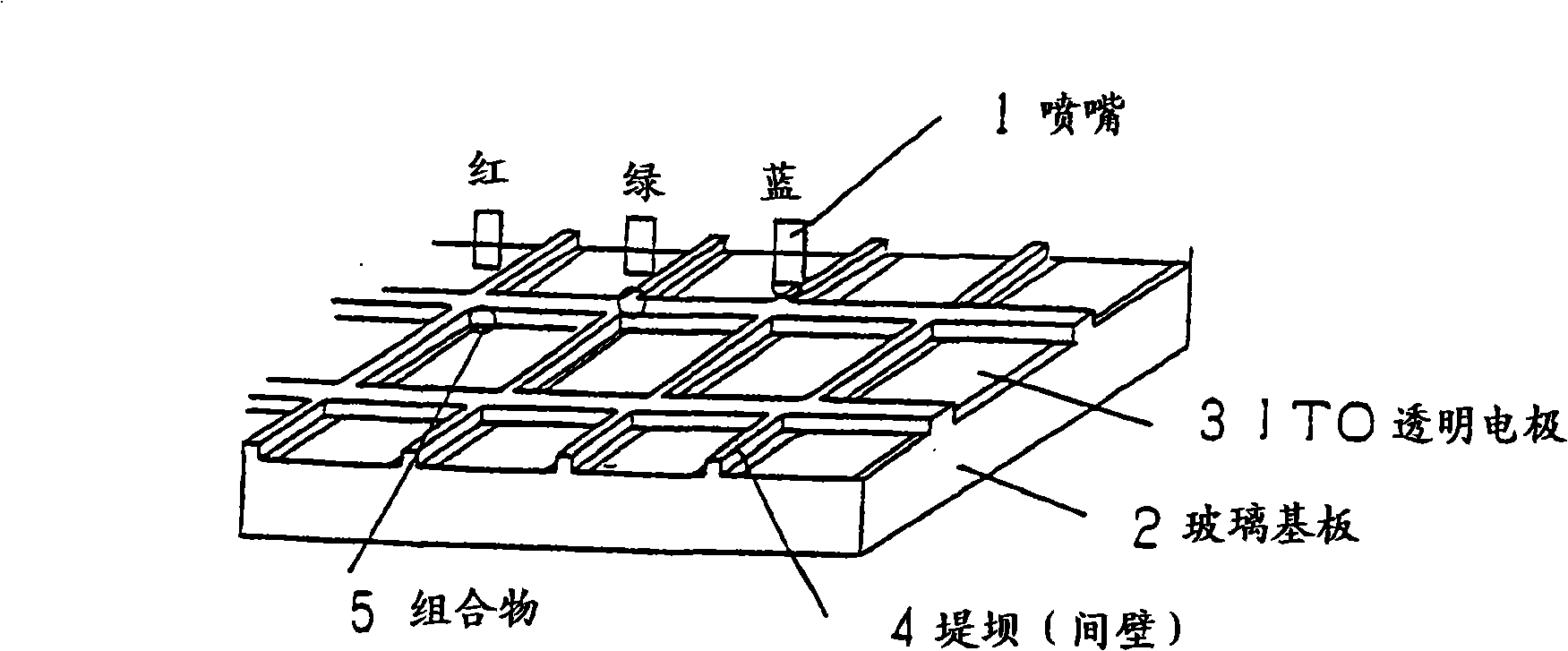

Composition, film manufacturing method, as well as functional device and manufacturing method therefor

InactiveUS20050156148A1Solid-state devicesSemiconductor/solid-state device manufacturingBenzeneDisplay device

A composition, which can be used in an ink jet printing method, can use either a non-polar or a weakly polar material as a functional material, prevents clogging at dispensing time, achieves stable dispensing, and prevents precipitation of content matter during dispensing and phase separation during film formation, a uniform, homogenous functional film formed using this composition and a manufacturing method therefor, as well as an organic EL device or other such display device and a manufacturing method therefor. A composition of the present invention consists of a functional material, and a solvent comprising at least one benzene derivative, which has one or more substituents, and these substituents have 3 or more carbon atoms in total. A functional film of the present invention is formed using the above-mentioned composition. A display device of the present invention comprises luminescent material layers formed using the above-mentioned composition between two electrodes. The above-mentioned display device is an organic EL device or the like.

Owner:CAMBRIDGE DISPLAY TECH LTD +1

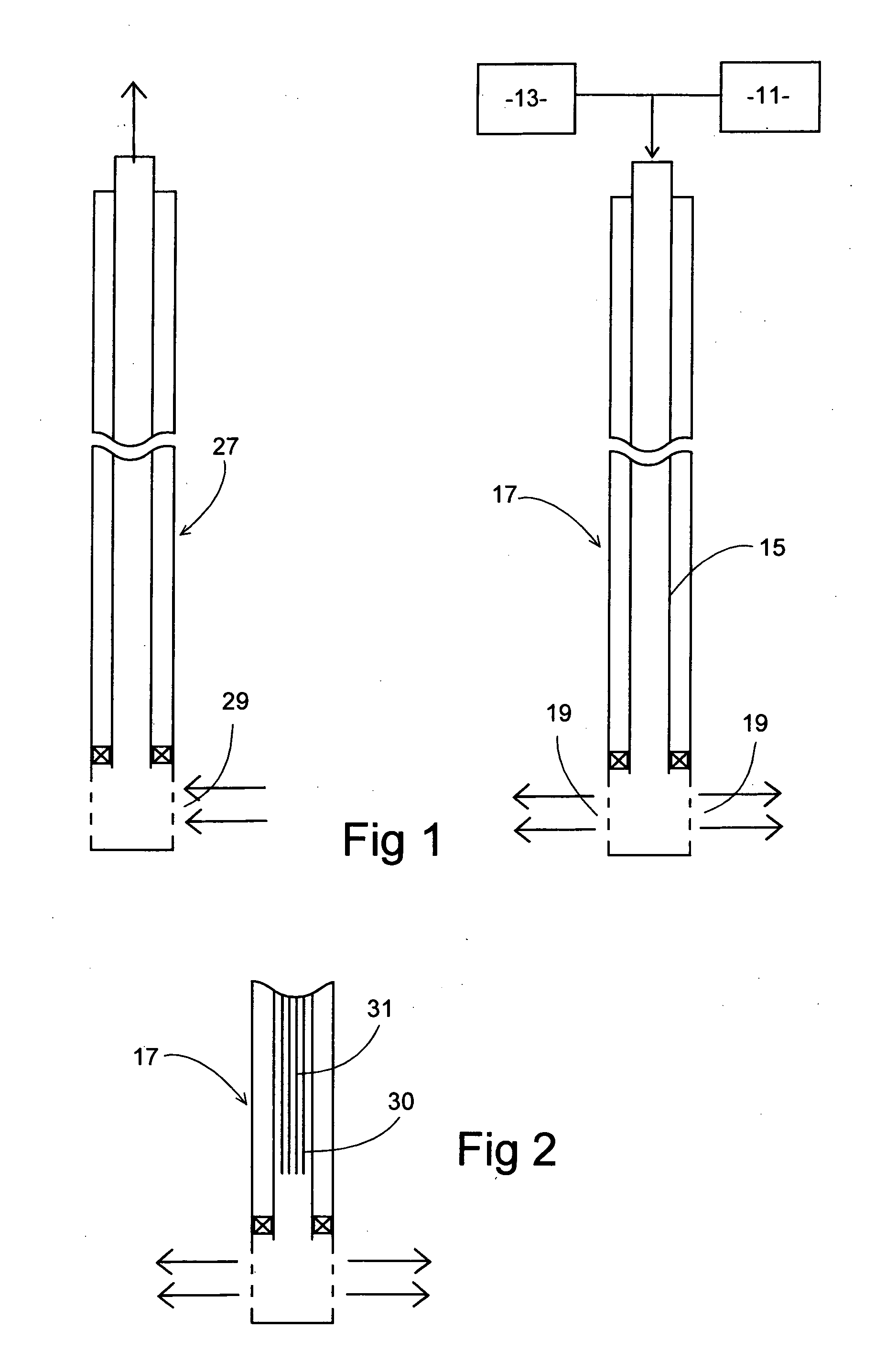

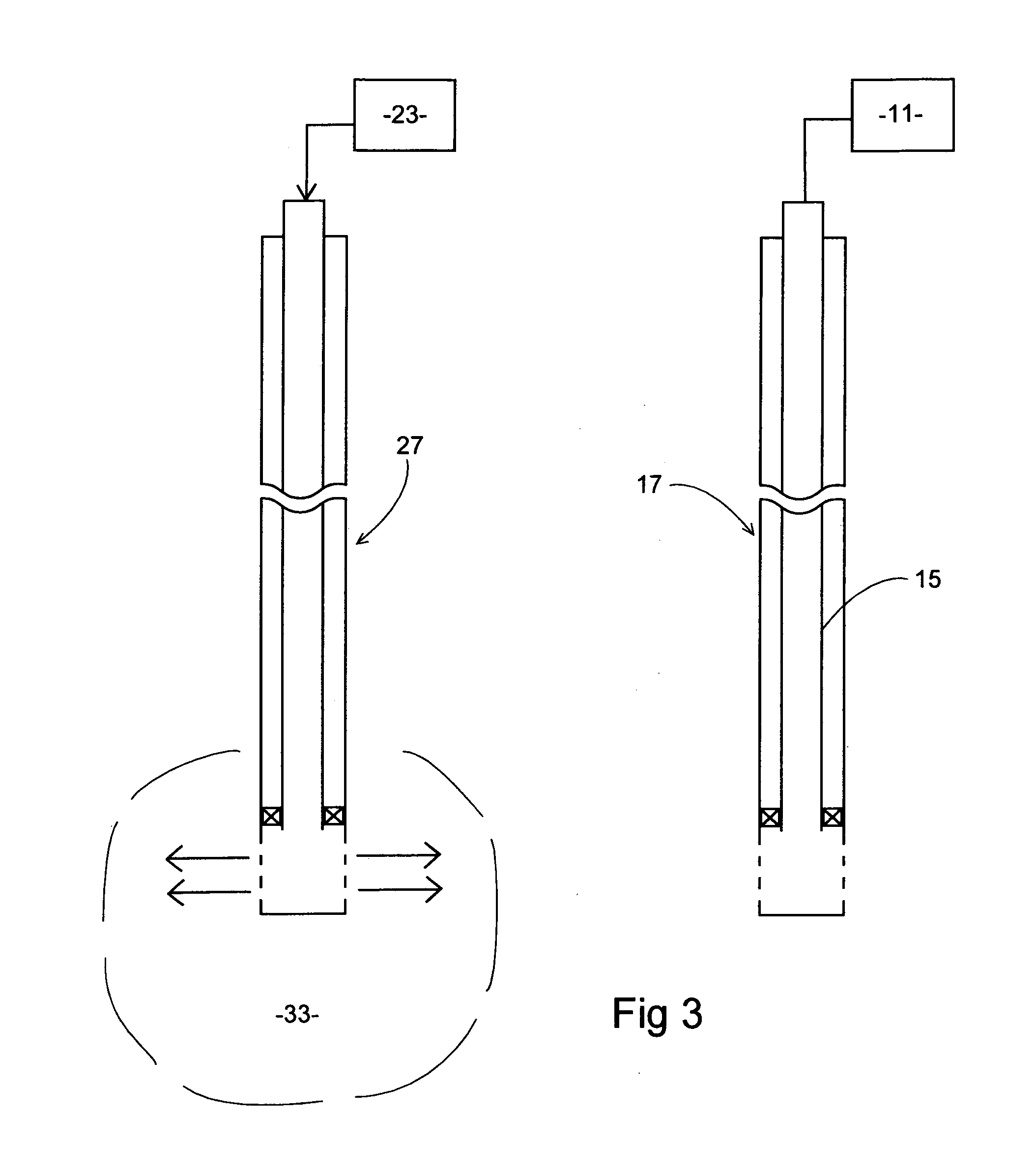

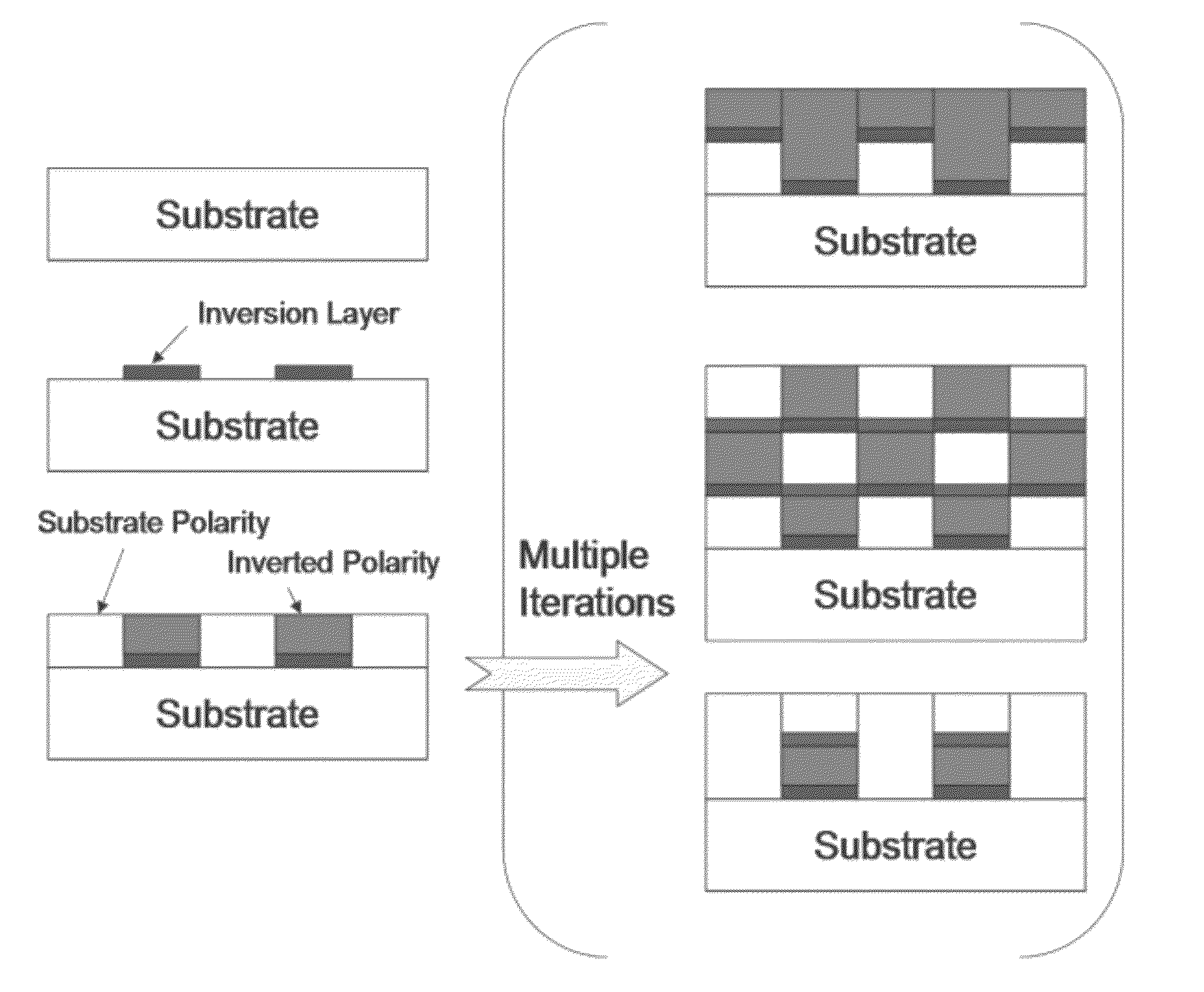

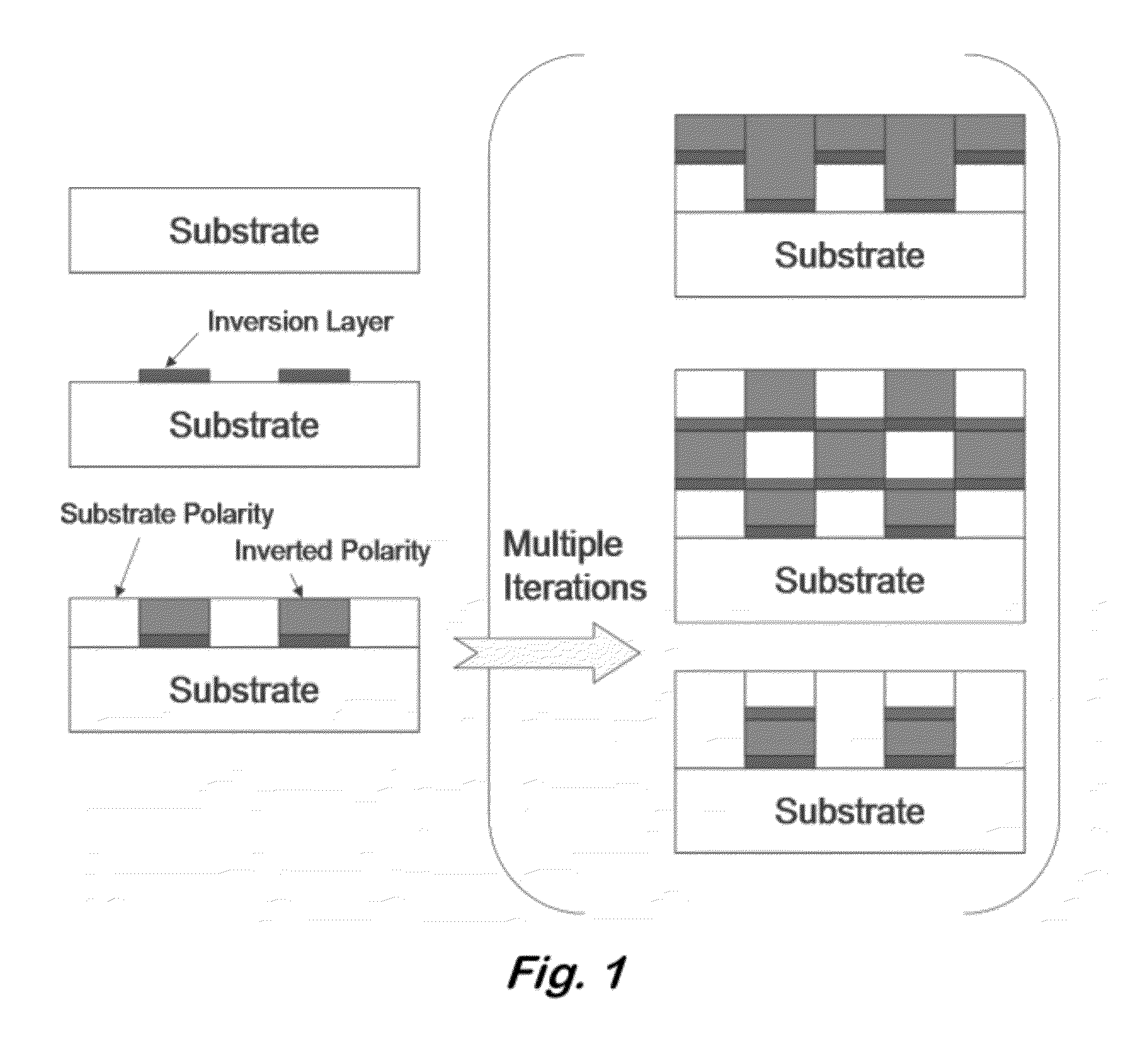

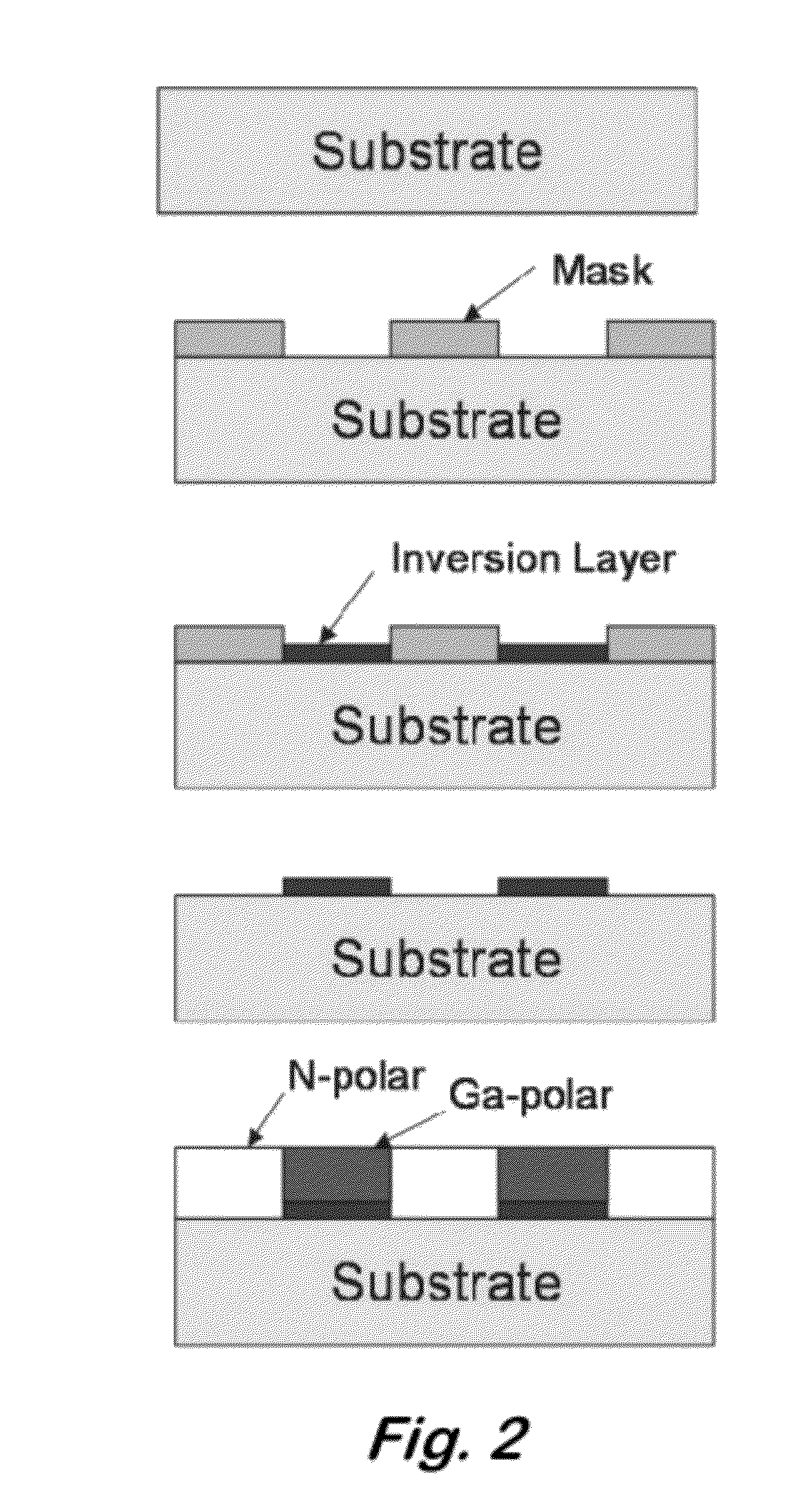

Method for Vertical and Lateral Control of III-N Polarity

ActiveUS20120068189A1Semiconductor/solid-state device manufacturingSemiconductor devicesElectrical polarityPolar material

Disclosed herein is a method of: depositing a patterned mask layer on an N-polar GaN epitaxial layer of a sapphire, silicon, or silicon carbide substrate; depositing an AlN inversion layer on the open areas; removing any remaining mask; and depositing a III-N epitaxial layer to simultaneously produce N-polar material and III-polar material. Also disclosed herein is: depositing an AlN inversion layer on an N-polar bulk III-N substrate and depositing a III-N epitaxial layer to produce III-polar material. Also disclosed herein is: depositing an inversion layer on a III-polar bulk III-N substrate and depositing a III-N epitaxial layer to produce N-polar material. Also disclosed herein is a composition having: a bulk III-N substrate; an inversion layer on portions of the substrate; and a III-N epitaxial layer on the inversion layer. The III-N epitaxial layer is of the opposite polarity of the surface of the substrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

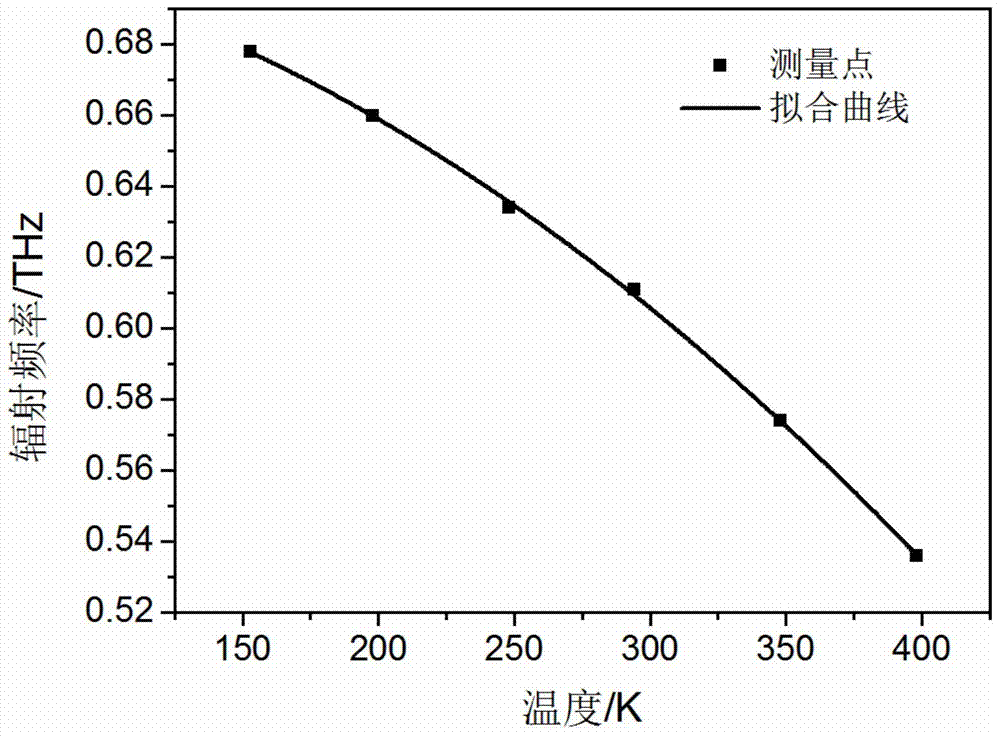

Temperature measurement method based on trivalent rare earth ferrous oxides as temperature sensing materials

InactiveCN103575422ALarge working temperature zoneEasy to measureThermometers using physical/chemical changesWorking temperatureRare earth

The invention discloses a temperature measurement method based on trivalent rare earth ferrous oxides as temperature sensing materials, and belongs to the technical field of thermally responsive materials. The trivalent rare earth ferrous oxides are prepared through a pressureless sintering technology by using trivalent rare earth oxides and ferric oxides as the raw materials. Under the excitation of THz waves, the trivalent rare earth ferrous oxides can radiate out narrow band THz waves, and the center frequency of the narrow band THz waves obviously change along with temperature, so the trivalent rare earth ferrous oxides can be used as the temperature sensing materials and applied to temperature measurement. In the temperature measuring process, a circuit does not need to be led in, and the measurement effect can be good at low temperature. The working temperature range of the temperature sensing materials is wider, theoretically, 0K to antiferromagnetic-paramagnetic transition temperature (650-750K) can be achieved, and the working mode can be in a transmission type or a reflection type. In addition, due to the fact that the THz waves have a good permeance property to most of materials except for metal and strong polar materials, the THz waves can be used for measuring the internal temperature of a closed space.

Owner:TSINGHUA UNIV

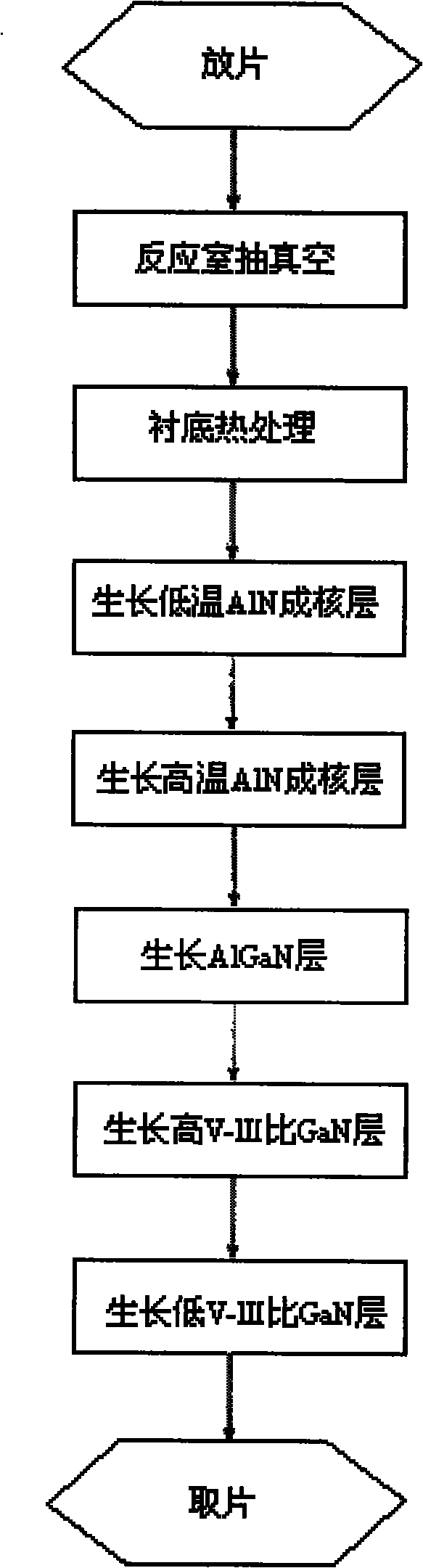

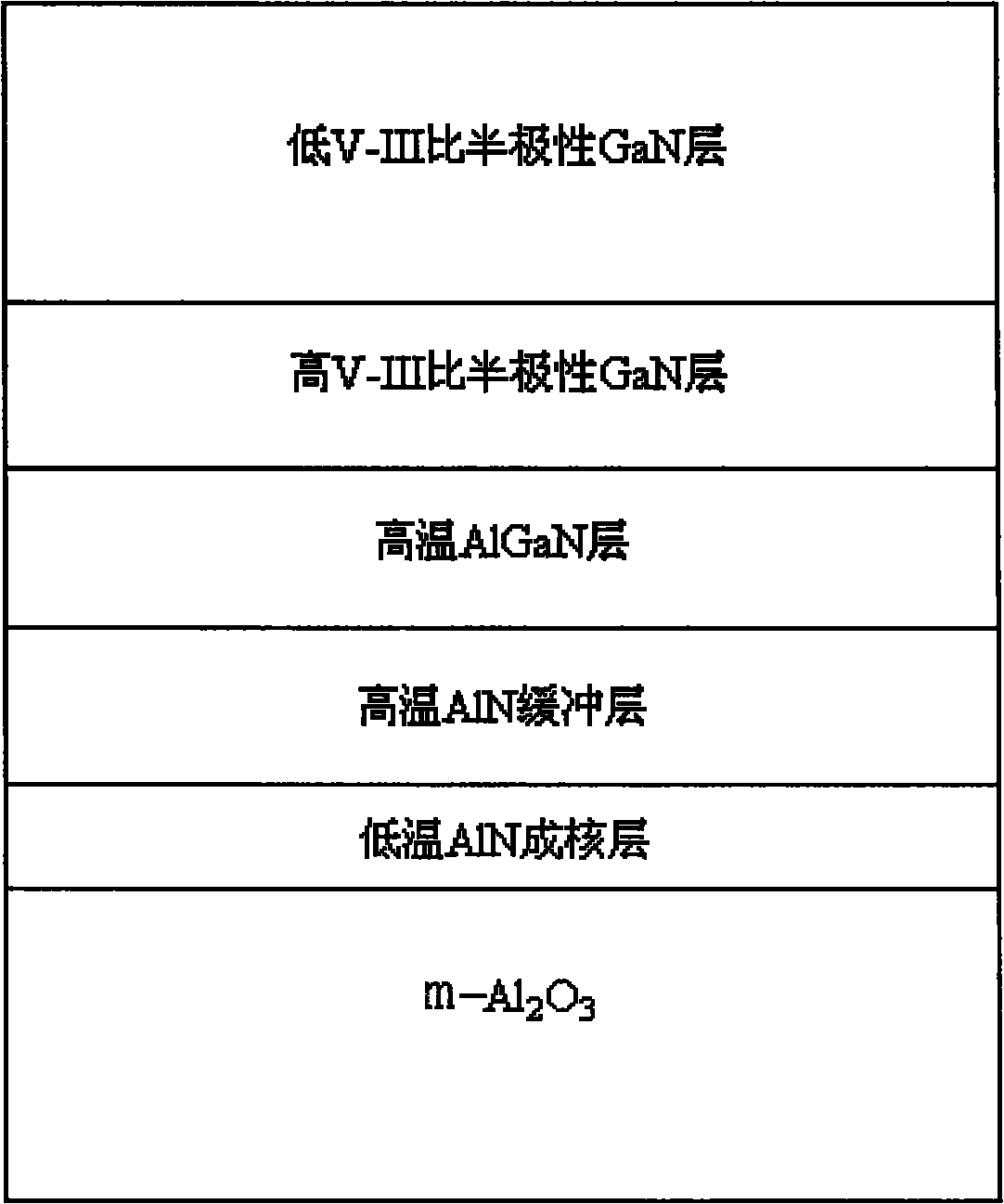

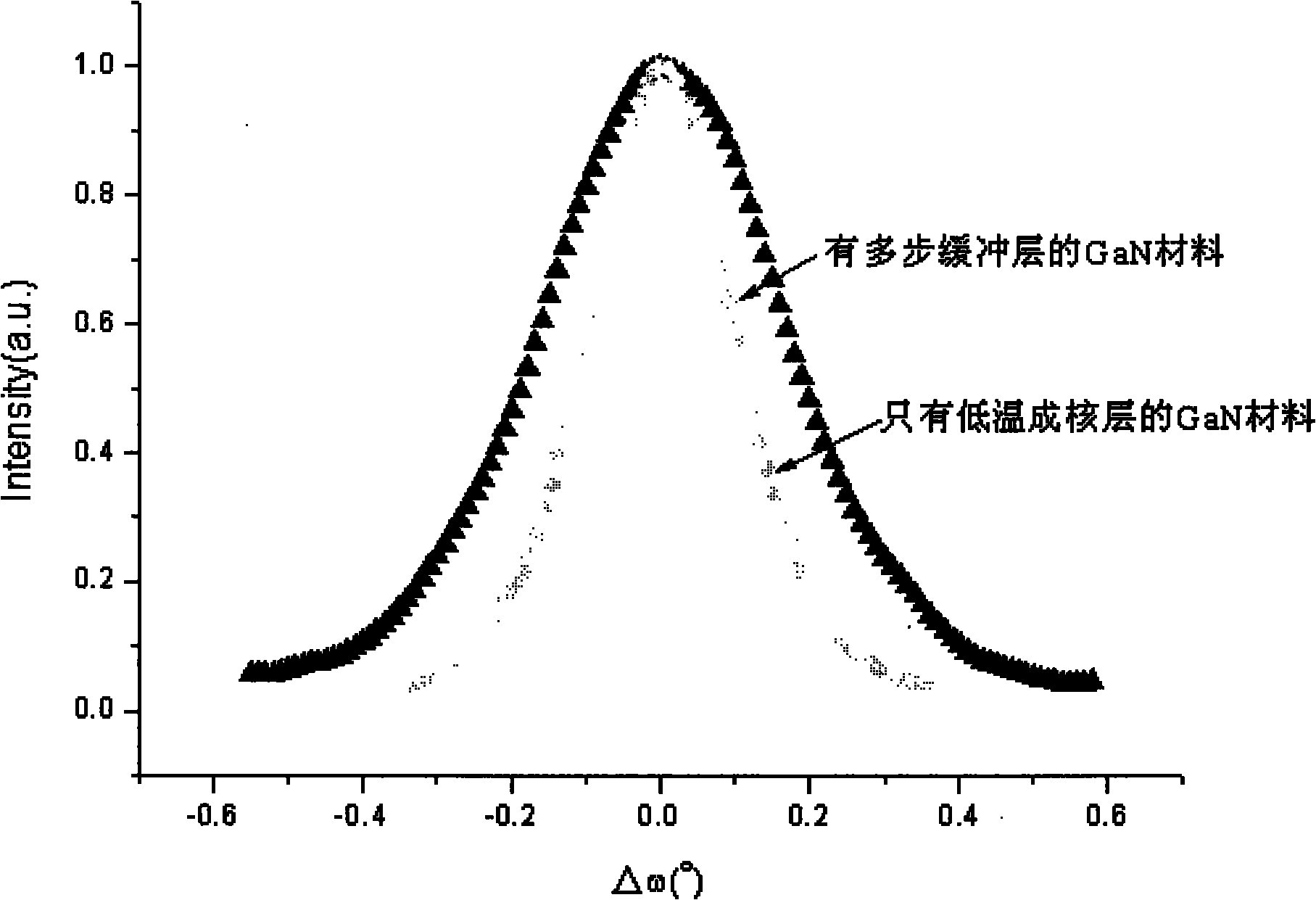

Method for growing semi-polar GaN based on Al2O3 substrate with m sides

ActiveCN101847578AImprove efficiencySimple stepsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingLight-emitting diodeMixed gas

The invention discloses a method for growing a semi-polar GaN membrane based on an Al2O3 substrate with m sides and mainly solves the problems that the conventional semi-polar material has poorer quality and non-attractive surface appearance. The method comprises the following steps of: (1) arranging an Al2O3 substrate with m sides in to an MOCVD (Metal Organic Chemical Vapor Deposition) reaction chamber, introducing the mixed gas of hydrogen and ammonia to the reaction chamber, and thermally processing the substrate; (2) growing a low-temperature AlN (Aluminium Nitride) layer with thickness of 20 to 200 nm and temperature of 500 to 650 DEG C on the Al2O3 substrate with m sides; (3) growing a high-temperature AlN layer with thickness of 50 to 200 nm and temperature of 1000 to 1150 DEG C on the low-temperature AlN layer; (4) growing a high-temperature AlGaN layer with thickness of 50 to 500 nm and temperature of 1000 to 1150 DEG C on the high-temperature AlN layer; (5) growing a semi-polar GaN layer with high V-III ratio, the thickness of 50 to 1000 nm and the temperature of 1000 to 1150 DEG C on the high-temperature GaN layer; and (6) growing a semi-polar GaN layer with low V-III ratio, the thickness of 1000 to 10000 nm and the temperature of 1000 to 1150 DEG C on the semi-polar GaN layer with high V-III ratio. The invention has the advantages of simple process and little fault, and is applied to manufacturing the semi-polar GaN light-emitting diodes and the lasers.

Owner:云南凝慧电子科技有限公司

Crosslinkable polyethylene co-mixed composition

The invention discloses a crosslinkable polyethylene co-mixed composition, a preparation method thereof and a product prepared therefrom. Specifically, the invention relates to the crosslinkable polyethylene composition having improved adhesive power to metals, the preparation method thereof and the product prepared therefrom. The crosslinkable polyethylene composition comprises the components: (a) 100 parts by weight of polyethylene resin; (b) 0.5-12 parts by weight of polyolefin grafted with an unsaturated carboxylic acid, anhydride and / or an ester derivative thereof; (c) 0.2-6 parts by weight of a peroxide crosslinking agent; and (d) optionally, 0.01-10 parts by weight of an auxiliary agent. The crosslinkable polyethylene composition after crosslinking has excellent adhesive power to various metals (such as aluminum, copper and steel) and other polar materials.

Owner:NAT INST OF CLEAN AND LOW CARBON ENERGY

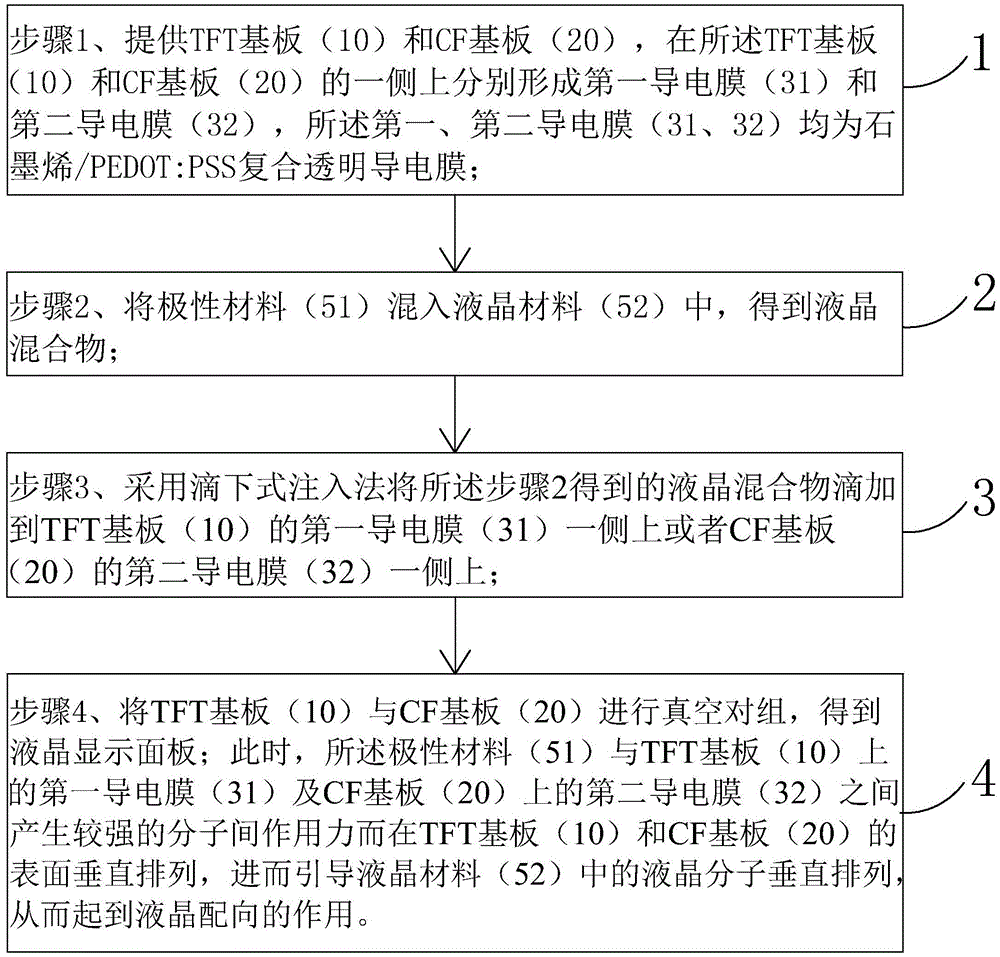

Production method for liquid crystal display panel

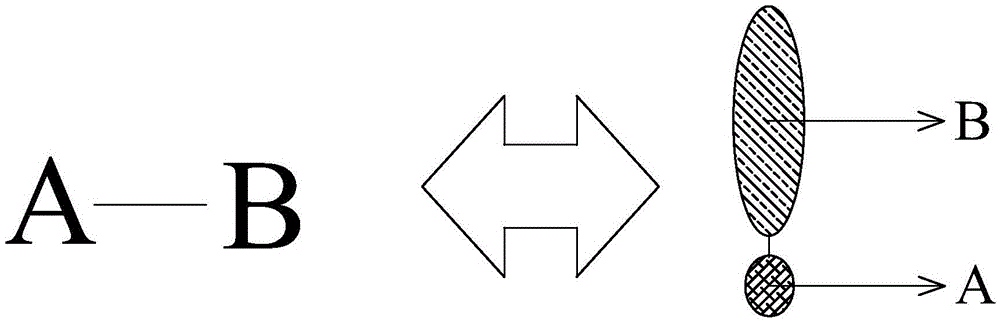

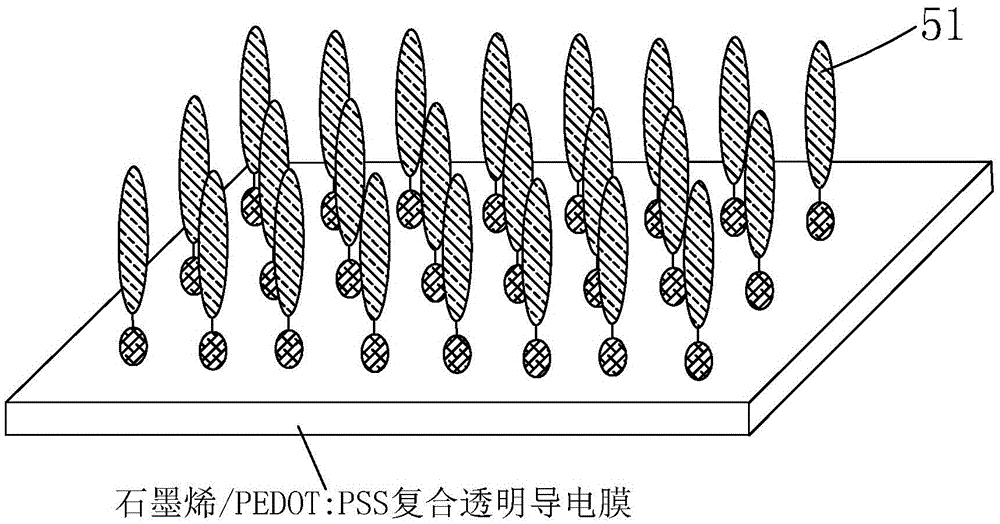

ActiveCN105527757AIncrease intermolecular forcesReduce processLiquid crystal compositionsSolid-state devicesVertical alignmentElectrical polarity

The invention provides a production method for a liquid crystal display panel. According to the method, traditional ITO transparent conductive films on a TFT (thin film transistor) substrate and a CF (color filter) substrate are replaced with graphene / PEDOT:PSS composite transparent conductive films, polar materials are added to a liquid crystal mixture of the liquid crystal display panel, and a general structural formula of the polar materials is A-B; the head group A is mainly used for enabling larger intermolecular force to be generated between the polar materials and the graphene / PEDOT:PSS composite transparent conductive films; similar to a function of a PI branch chain, the tail group B is mainly used for enabling liquid crystal molecules to be arranged vertically in a steric hindrance manner and has a vertical alignment effect; that is, the polar materials can generate larger intermolecular force with the graphene / PEDOT:PSS composite transparent conductive films so as to be vertically arranged on the surface of the TFT substrate and the CF substrate, the liquid crystal molecules are guided to be arranged vertically, the polar materials are substituted for a PI alignment film to have a liquid crystal alignment effect, a PI alignment film preparation process is omitted, the production cost of the alignment film is reduced, and the capacity is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

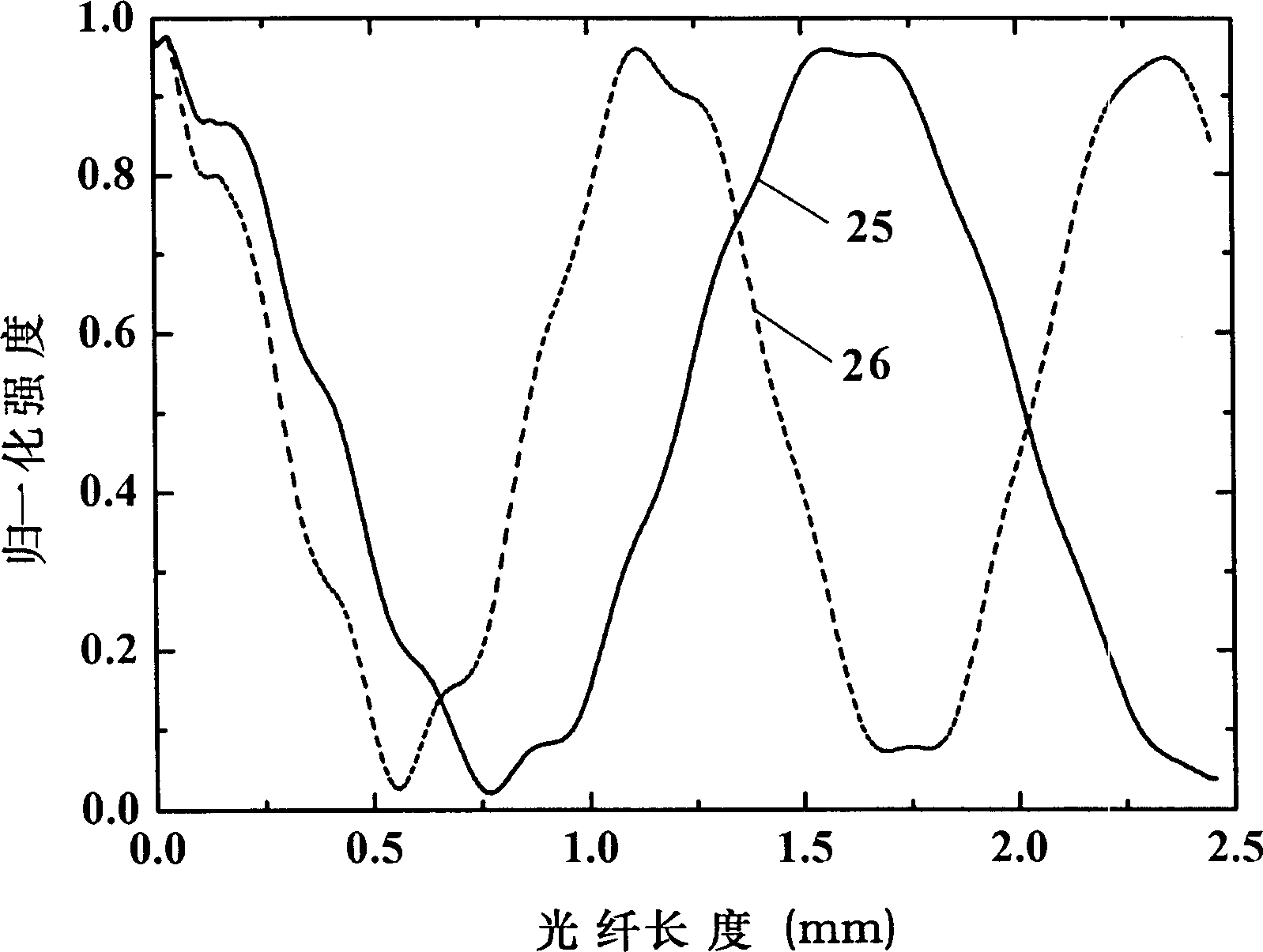

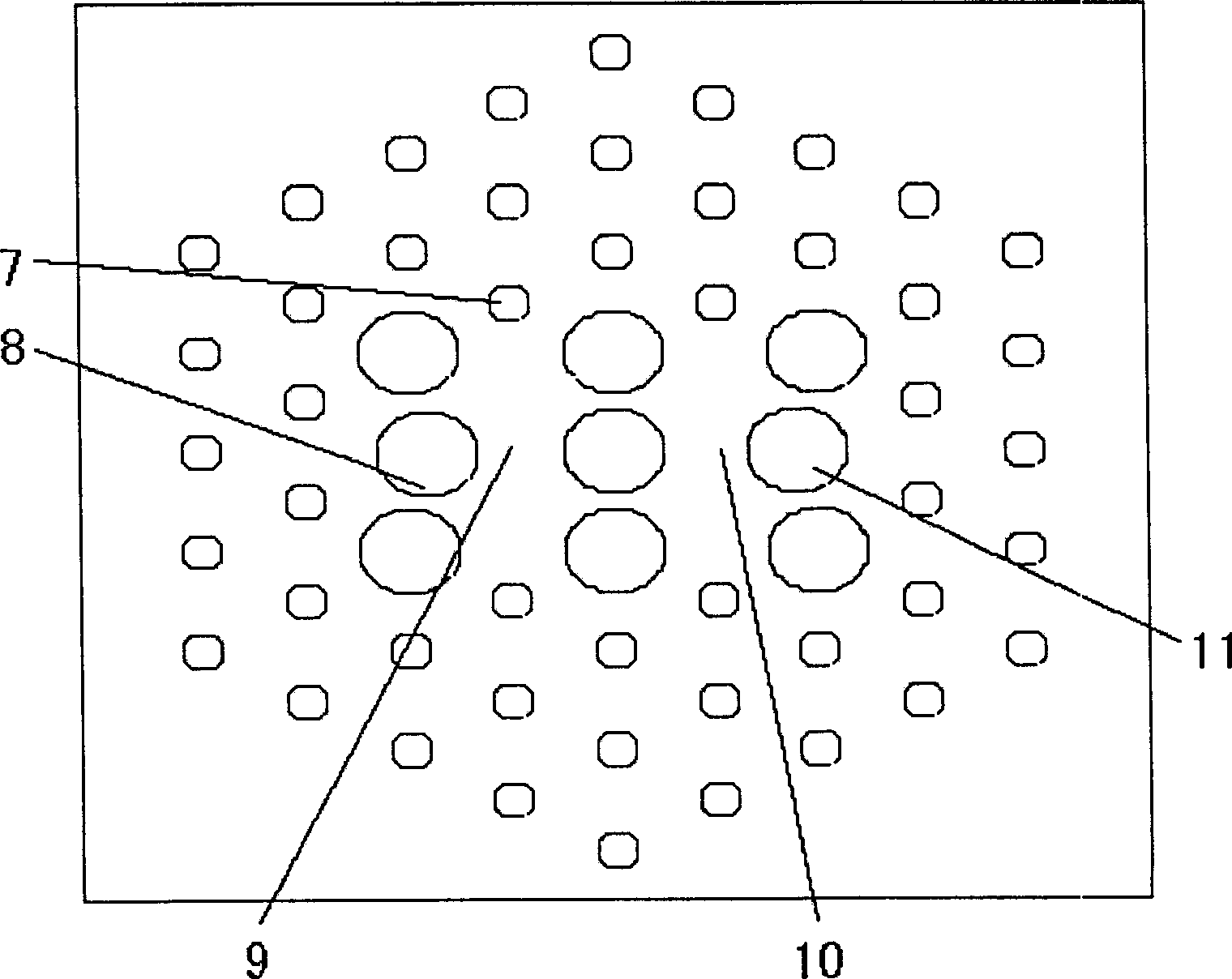

Double core photon crystal optical fibre

InactiveCN1425930ARealize the polarization splitting functionShorten the lengthFibre transmissionOptical light guidesFiberShortest distance

The present invention belongs to the field of fiber communication and optical signal processing, and is especially the design of double core photon crystal optical fiber as one photon device with polarizing split function. The double core photon crystal optical fiber includes one coating layer of low refractive index area formed by pore structure in regular lattice nodes and two high refractive index core areas formed by pore deletion in regular lattice nodes. The present invention features different pore size near the two core areas in two orthogonal polarization directions, unsymmetrical pore deletion, the deflection of the pore center near the core areas to the lattice nodes, or filling of polar material in the pores near the core area. Each of the core areas can produce high double refraction, so that two polarized light beams have great length difference and can be polarizing split in short distance.

Owner:TSINGHUA UNIV

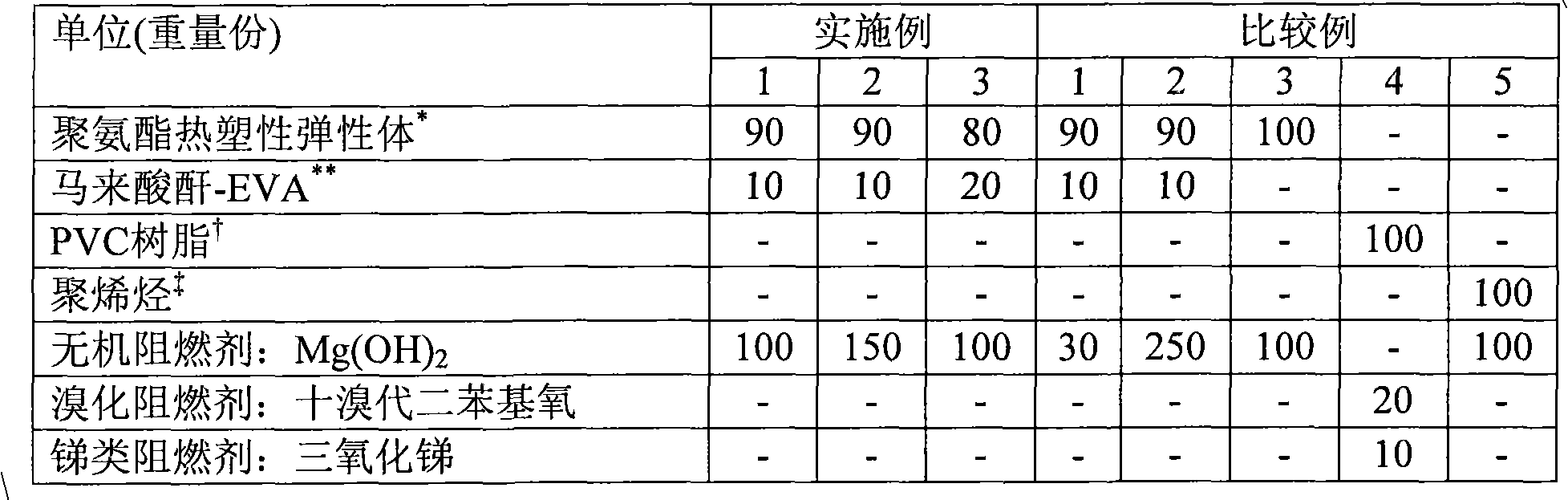

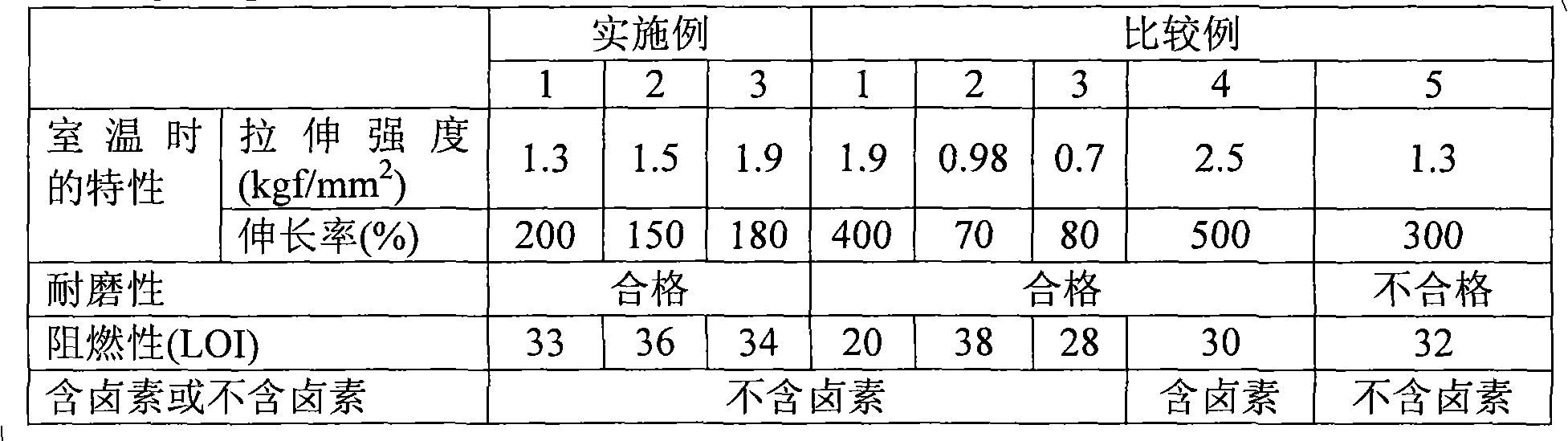

Fire-retardancy polyurethane composition containing no halogen and non-thermal contraction pipe using thereof

The invention discloses a fire-retardancy polyurethane resin containing no halogen and having coordinated room temperature mechanical property and abrasive resistance property. The fire-retardancy resin comprises a basal resin and an inorganic combustion inhibitor, the basal resin comprises a thermoplastic polyurethane elastomer and a polar olefin resin. The polar olefin resin is a polyolefin containing at least one functional group, the functional group is selected from a polar material group composed by maleic anhydride, glycidyl methacrylate, anhydrous maleic acid, silicone hydride and fatty acid. The inorganic combustion inhibitor is a metallic hydroxides or a metallic oxide.

Owner:LG CABLE LTD (KR)

Extraction head of carbon nano-tube solid phase micro-extraction and preparation thereof

InactiveCN101239302AGood choiceImprove extraction efficiencyOther chemical processesSolid-phase microextractionCarbon nanotube

The present invention provides a carbon nanotube solid phase microextraction extraction head and method for preparing. The carbon nanotube solid phase microextraction extraction head includes a stainless steel fibre and a surface coating layer coating on one end of the stainless steel fibre, characterized in that the surface coating layer has a carbon nanotube. The application of the carbon nanotube can make the solid phase microextraction extraction head fire stand, have high mechanical strength, and longer service life and high enrichment times; the invention also relates three manufacturing method of the carbon nanotube solid phase microextraction extraction head, a carbon nanotube solid phase microextraction extraction head having selectively strong absorption ability to polar material or non-polar material is prepared by the selectively applied field.

Owner:SUN YAT SEN UNIV

Composition, film manufacturing method, as well as functional device and manufacturing method therefor

InactiveCN101353472AElectrical apparatusElectroluminescent light sourcesElectrical polarityDisplay device

A composition, which can be used in an ink jet printing method, can use either a non-polar or a weakly polar material as a functional material, prevents clogging at dispensing time, achieves stable dispensing, and prevents precipitation of content matter during dispensing and phase separation during film formation, a uniform, homogenous functional film formed using this composition and a manufacturing method therefor, as well as an organic EL device or other such display device and a manufacturing method therefor. A composition of the present invention consists of a functional material, and a solvent comprising at least one benzene derivative, which has one or more substituents, and these substituents have 3 or more carbon atoms in total. A functional film of the present invention is formed using the above-mentioned composition. A display device of the present invention comprises luminescent material layers formed using the above-mentioned composition between two electrodes. The above-mentioned display device is an organic EL device or the like.

Owner:SEIKO EPSON CORP +1

Modified asphalt and two-component resin composition

ActiveUS20100056674A1Improve compatibilityHigh cost performanceIn situ pavingsBuilding insulationsFilling materialsEther

Modified asphalts have excellent dispersibility and compatibility with polar materials, are usable in applications including railroad track-filling materials, and are inexpensive.A modified asphalt includes an asphalt (A), a viscosity depressant (B) and a copolymer (C) containing a structural unit from a polyalkylene glycol allyl ether (c1), a structural unit from an unsaturated dicarboxylic acid and / or an acid anhydride thereof (c2), and a structural unit from an aromatic vinyl compound (c3).

Owner:CHUGOKU MARINE PAINTS

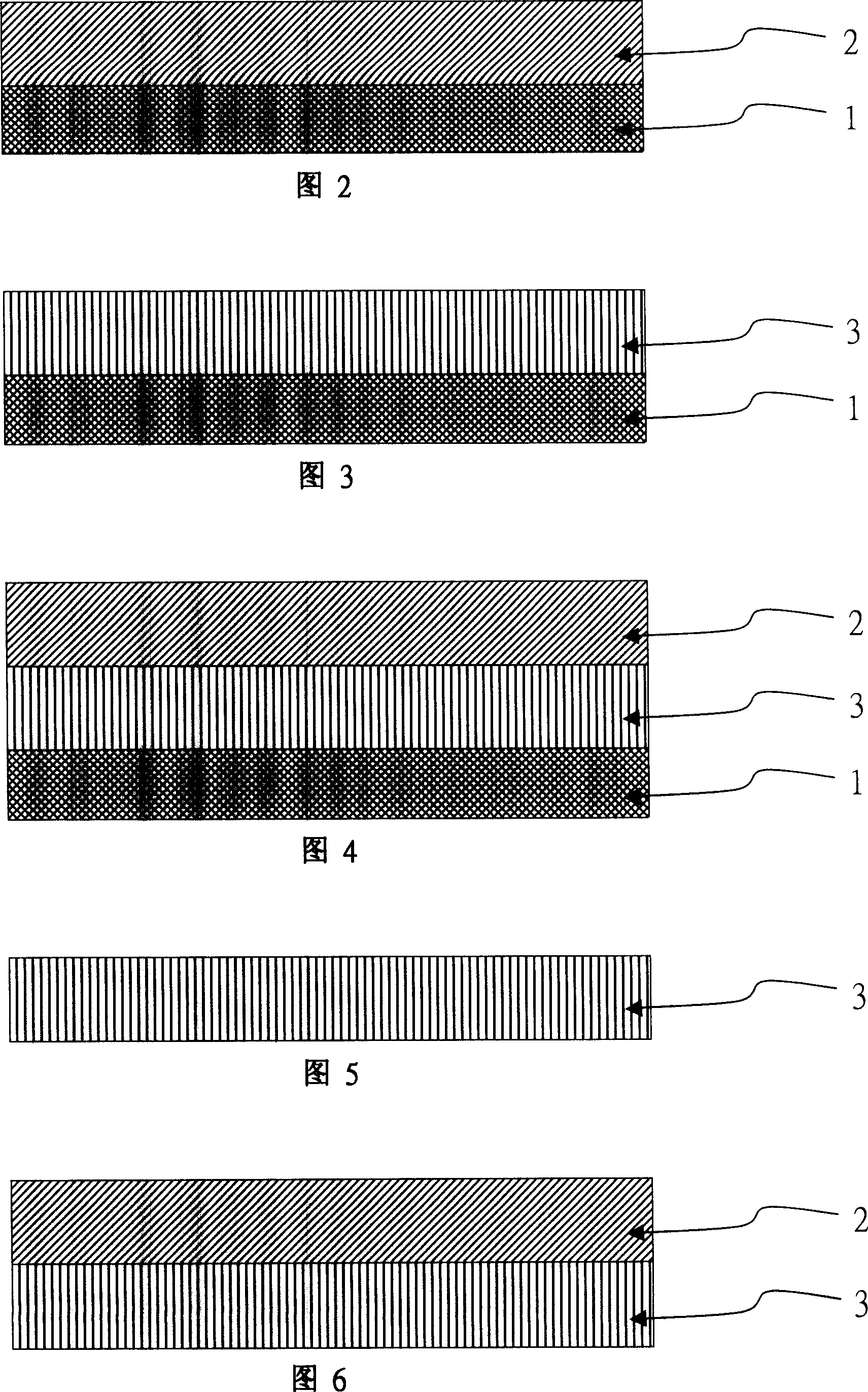

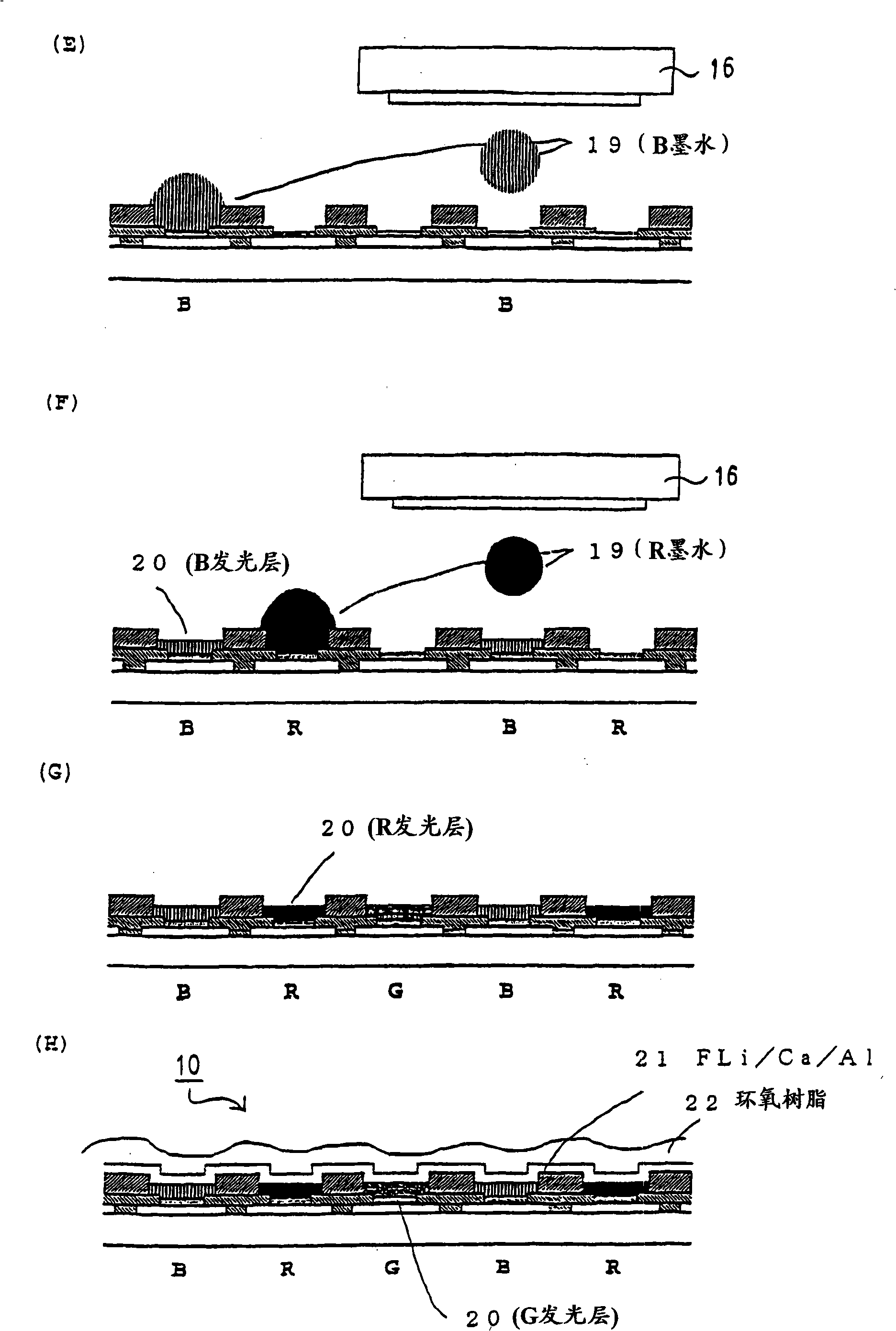

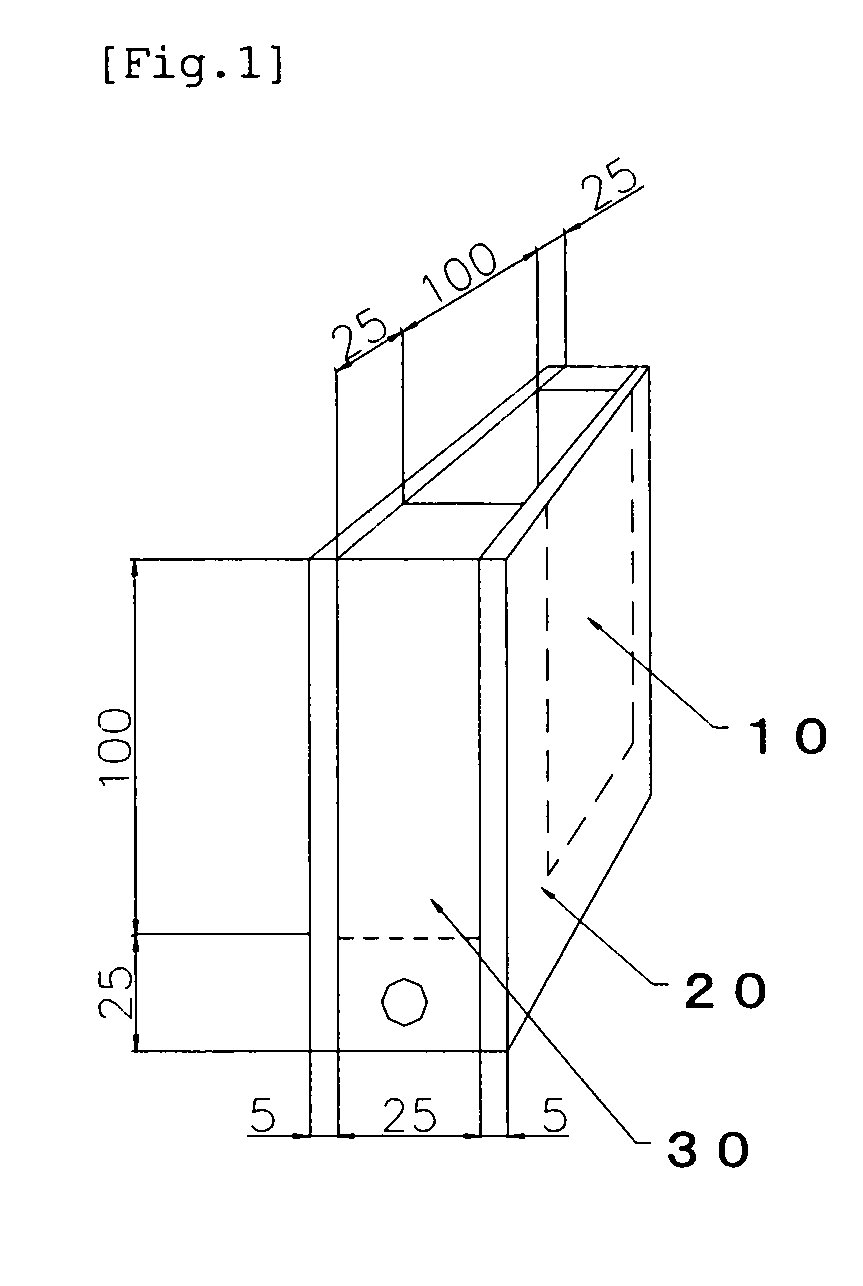

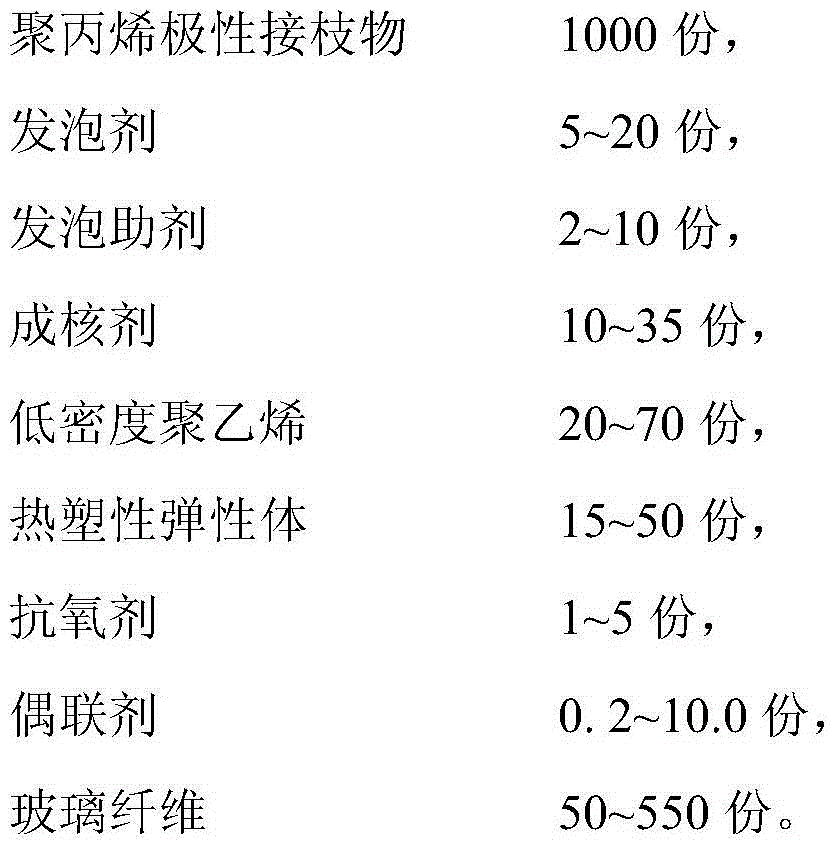

Glass fiber reinforced polypropylene graft microcellular foaming material and preparation method thereof

InactiveCN104419102AMeet polar material requirementsMeets non-polar material requirementsLow-density polyethyleneGlass fiber

The invention belongs to the technical field of polymer materials, and relates to a glass fiber reinforced polypropylene graft microcellular foaming material and a preparation method thereof. The foaming material comprises the following components by weight: 1000 parts of a polypropylene polar graft, 5-20 parts of a foaming agent, 2-10 parts of a foaming assistant agent, 10-35 parts of a nucleating agent, 20-70 parts of low density polyethylene, 15-50 parts of a thermoplastic elastomer, 1-5 parts of an antioxidant, 0.2-10 parts of a coupling agent and 50-550 parts of glass fiber. The glass fiber reinforced polypropylene graft microcellular foaming material using the polypropylene (PP) polar graft or a copolymer for foaming, the PP foaming material can not only meet the requirement of polar materials, but also can satisfy the requirements of non polarity materials, and the scope of application of the PP foaming material is expanded. In addition, glass fiber (GF) is used as a filler, and has the strengthening and toughening effect on the foaming material.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

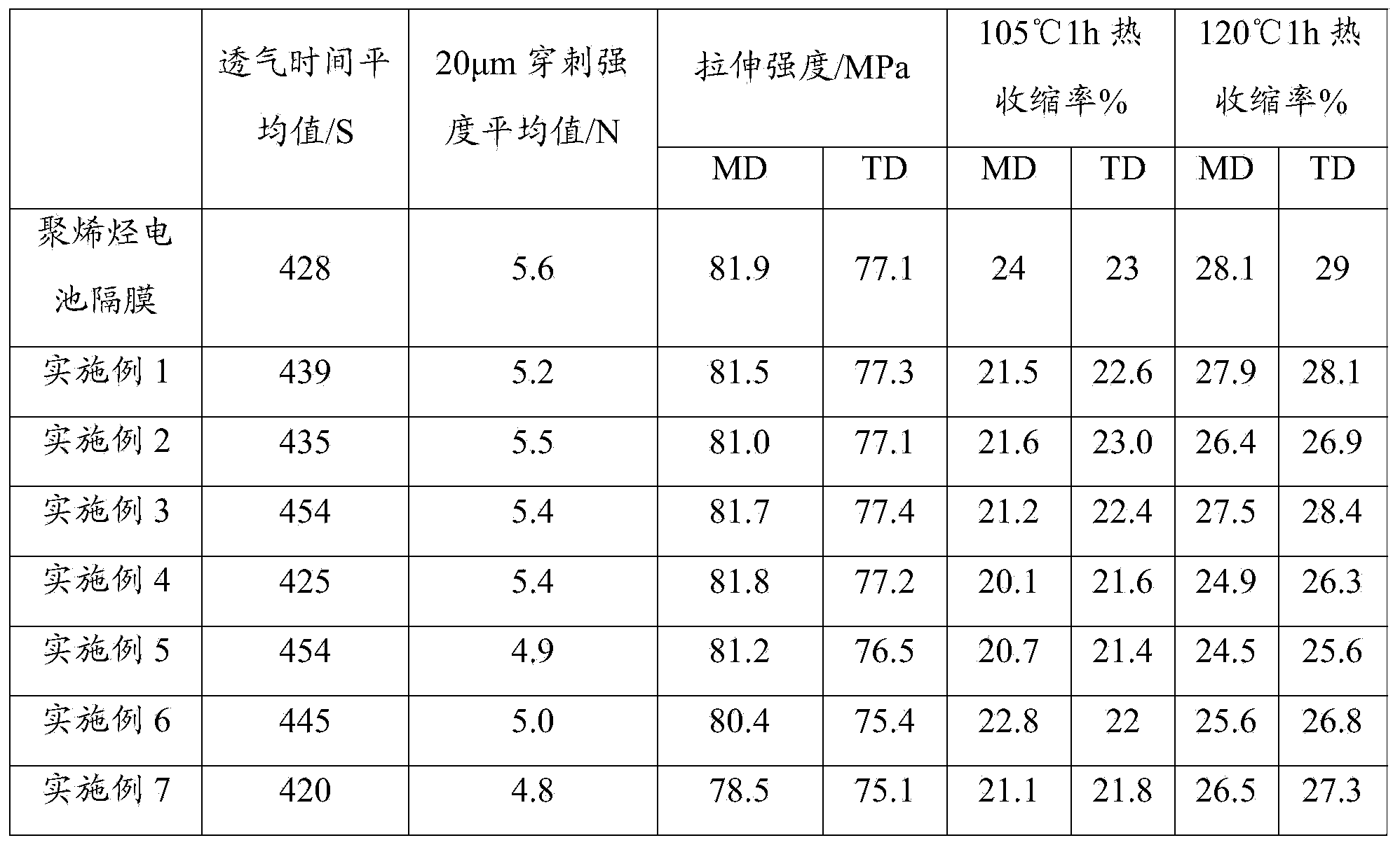

Method for preparing high-performance lithium-ion battery diaphragm through vacuum ultraviolet grating modification

The invention discloses a method for preparing a high-performance lithium-ion battery diaphragm through vacuum ultraviolet grating modification. The method comprises the steps of: irradiating a polyolefin diaphragm by using a vacuum ultraviolet lamp under the protection of nitrogen; after the irradiation, immediately placing in a monomer under pure nitrogen protection and carrying out a grafting reaction; and volatilizing un-grafted monomers to obtain the high-performance lithium-ion battery diaphragm subjected to grafting modification. According to the method for preparing the high-performance lithium-ion battery diaphragm through vacuum ultraviolet grating modification, disclosed by the invention, the defects of low efficiency and complicated preparation process of an existing grating method are overcome, a polar material is rapidly grafted on the surface of the polyolefin diaphragm, and the affinity and the oxidization resistance of an electrolyte of the diaphragm are improved, thus the high-performance lithium-ion battery diaphragm with high magnification, high cycle service life and strong oxidization resistance capacity is obtained.

Owner:河南惠强新能源材料科技股份有限公司

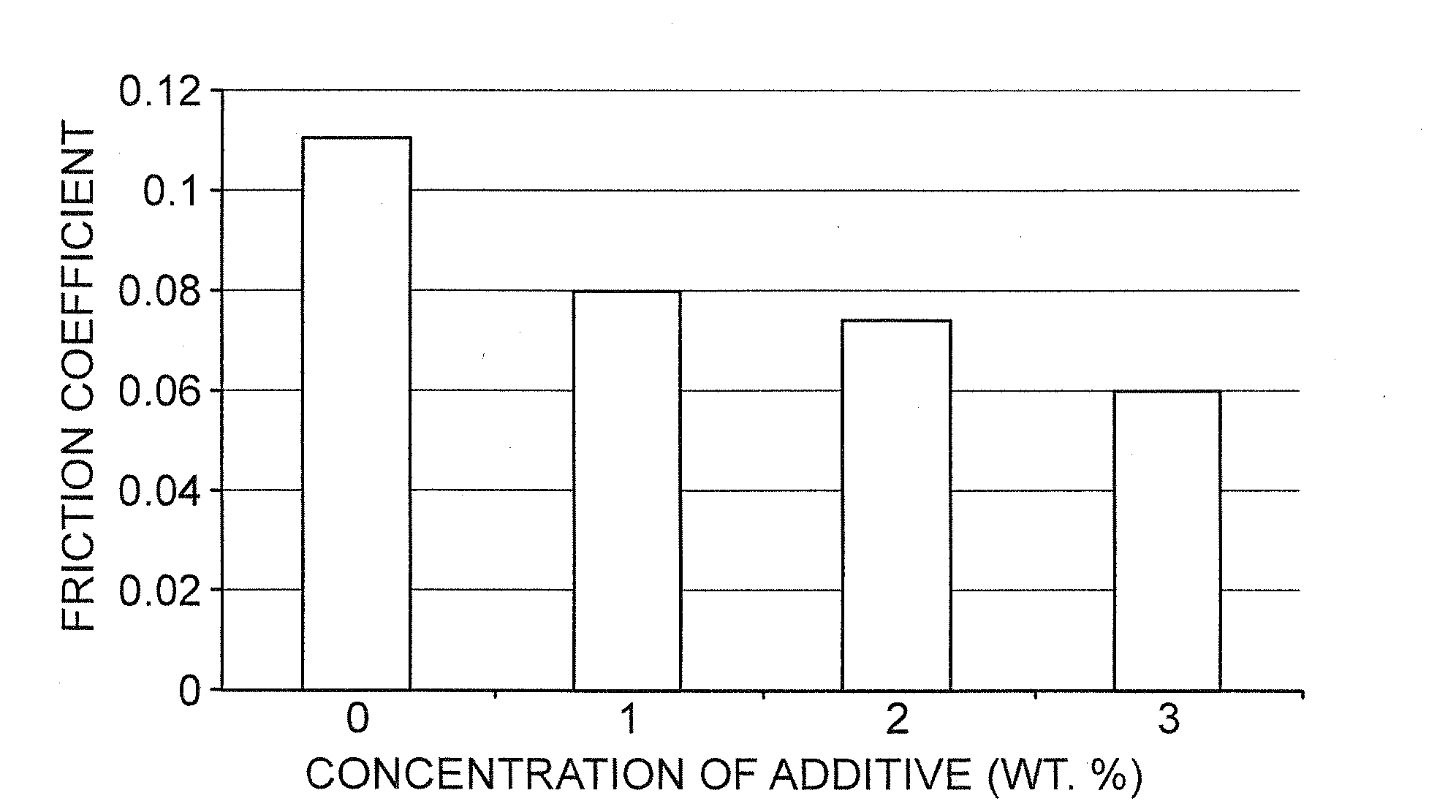

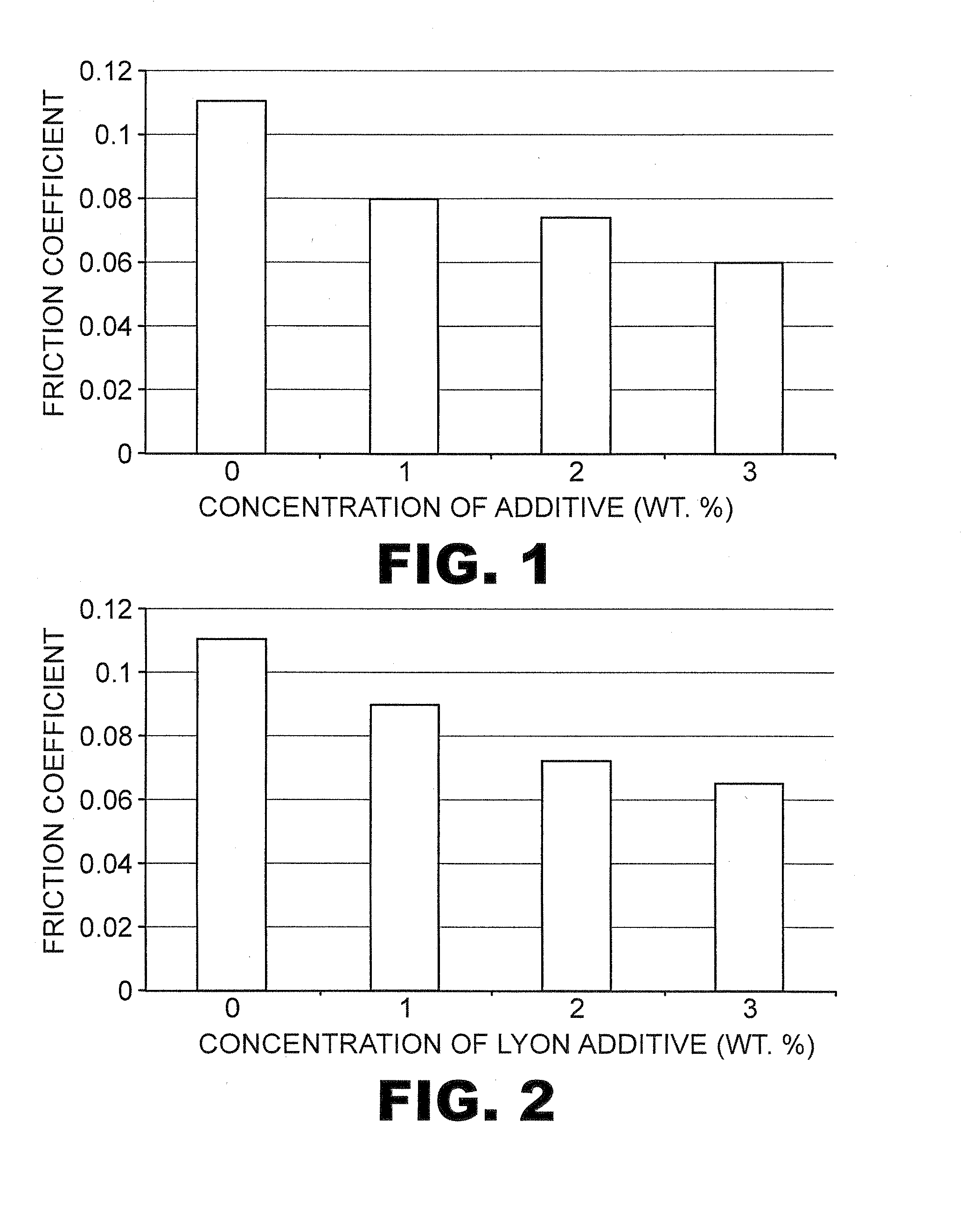

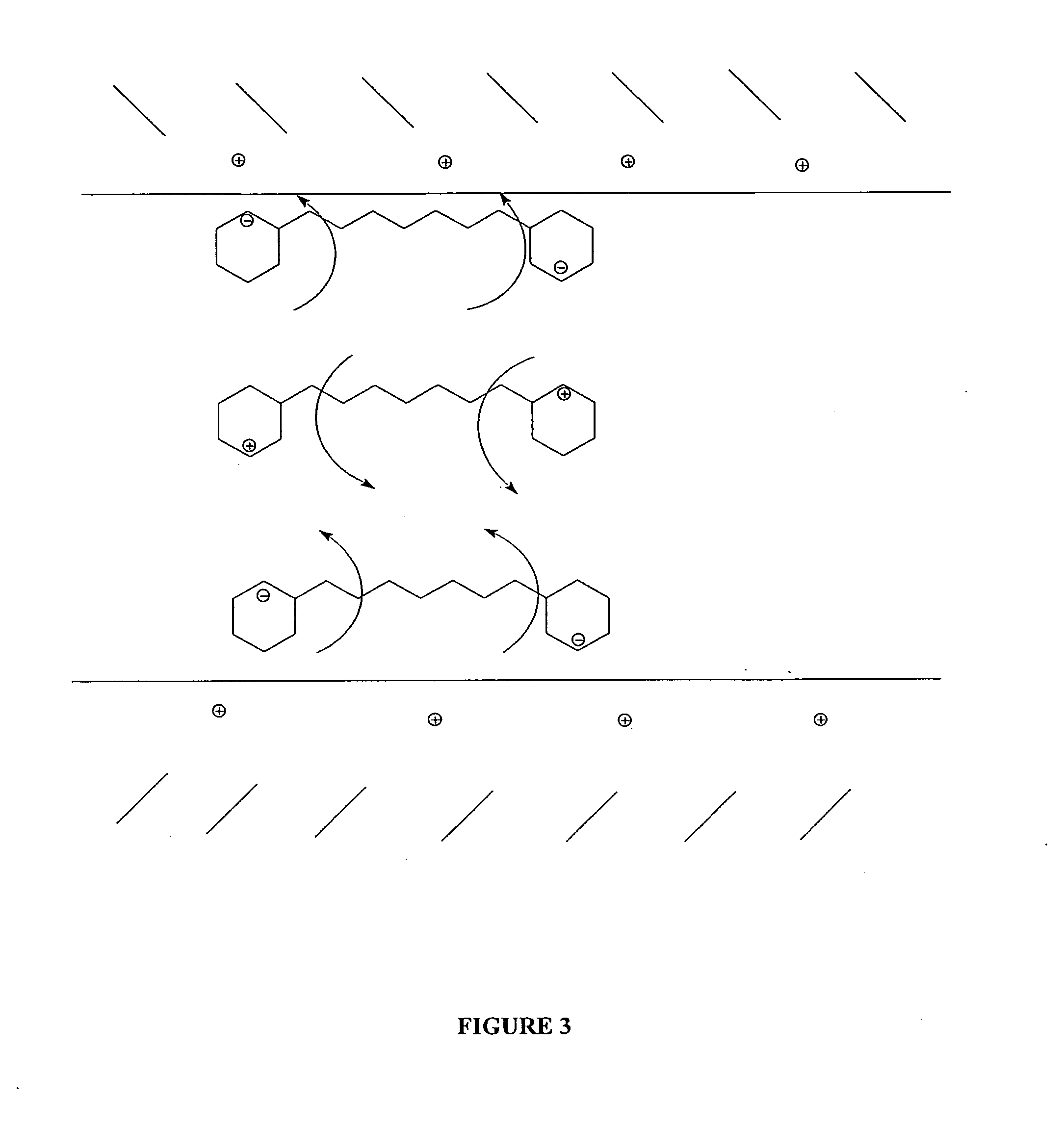

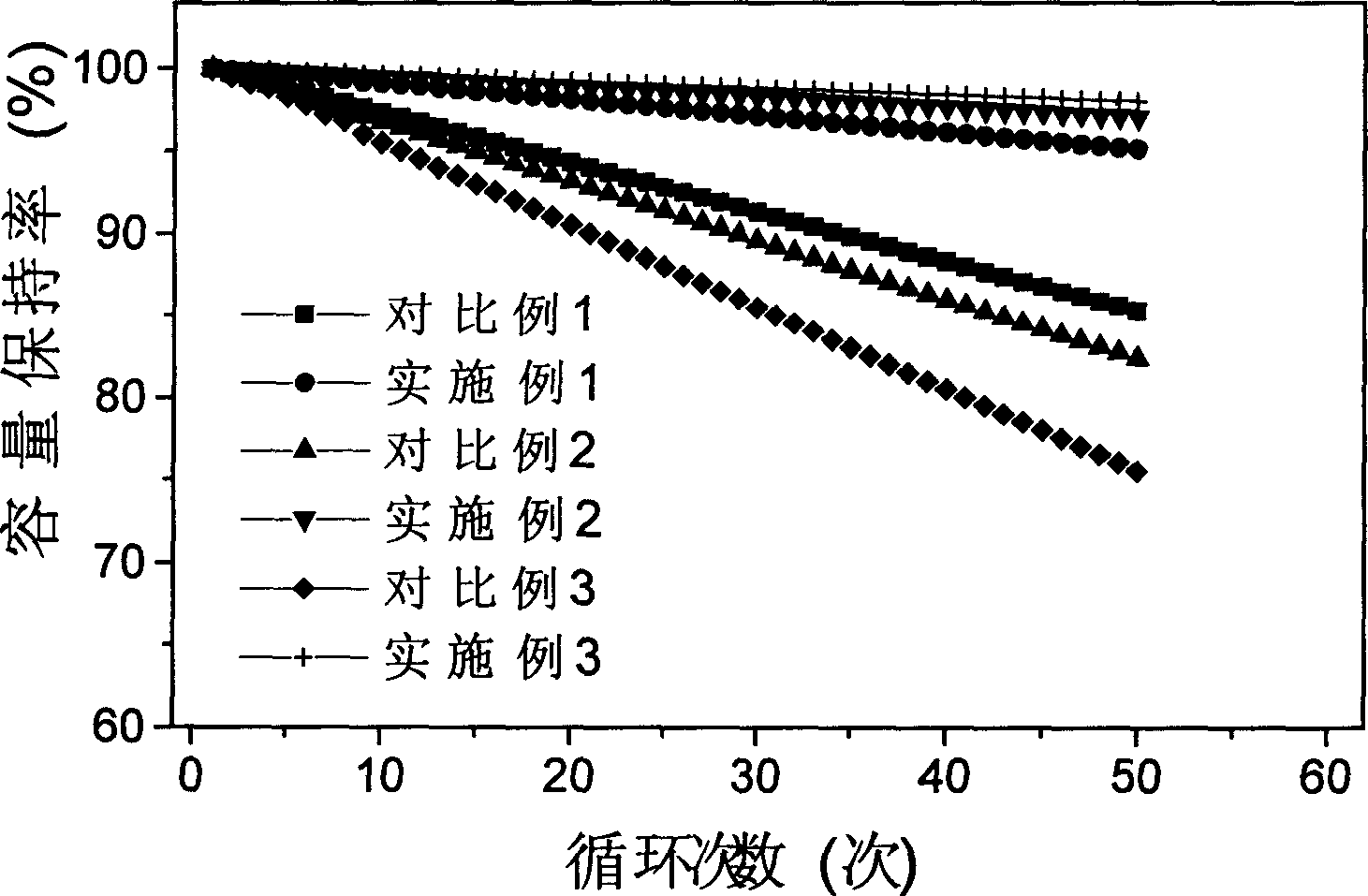

Lubricating formulations for dispersancy and temperature, friction, and wear reduction

InactiveUS20080312112A1Gas consumptionLow gas consumptionLiquid carbonaceous fuelsAdditivesFriction reductionWorking fluid

The present invention provides a working fluid additive for use in conjunction with a working fluid within an operating system having contact surfaces. The working fluid additive may consist solely of a highly polar material, but preferably includes both a highly polar material and a material that is synergistic to the highly polar material. The highly polar materials have a great affinity for the contact surfaces within the operating system and, therefore, produce film layers on the contact surfaces sufficient to significantly eliminate the frictional losses experience in the boundary regime of lubrication. By including a synergistic polar material, the efficacy as well as the thickness of this film layer is increased to further increase friction reduction. Organo-metallics may be utilized to further decrease wear and friction. An enhancing accelerator may be used to increase the compatibility between the host working fluid and the additive. A dispersion agent may also be employed within to disperse the working fluid additive within the working fluid.

Owner:LYON DEV

Method for modifying carbon negative polar material

InactiveCN1710734APromote circulationUniform surface structureElectrode manufacturing processesOperabilityLithium compound

The method modifies surface of material of carbon cathode by using compound of containing lithium so as to obtain material of carbon cathode of lithium ion cell. The material of carbon cathode produced according to the disclosed method possesses full even surface structure. Favorable cohesiveness and cycle performance is possessed between cathodes prepared from the material and afflux body of cathode. Advantages of the invention are: good operability and repeatability, and stable product quality.

Owner:FUDAN UNIV

Preparation method of Hydrophile ultra-slippery coating for medical apparatus

ActiveCN106421934ALong-lasting hydrophilic super smooth effectIncrease productivitySurgeryCatheterUrinary catheterPolyvinyl chloride

The invention discloses a preparation method of Hydrophile ultra-slippery coating for medical apparatus. The apparatus is characterized by being prepared, by mass, from the following material: 5-15 parts of hydroxy vinyl pyrrolidone polymer, 0.5-8 parts of isocyanate, 0.2-8 parts of isocyanate crosslinking agent, 0.05-0.5 parts of leveling agent and 73.5-94.25 parts of solvent A. The preparation method of the ultra-slippery coating comprises the steps of mixing the materials uniformly based on the ratio in normal temperature, and stirring for 3-6 hours to acquire the coating composition, conducting the dip-coating or spraying using the coating composition on the surface of the medical apparatus, drying under the temperature of 5-60 DEG C for 20-40 minutes to acquire the hydrophile ultra-slippery coating which possesses the good effect of the sustainable hydrophile and ultra-slippery properties. The hydrophile ultra-slippery coating prepared by the method is particularly suitable for the medical apparatuses made of polar materials such as polyvinyl chloride, polyurethane, nylon, acrylate and polyether ether ketone. The coating prepared based on the method can be used to produce the medical apparatuses such as urinary catheter, ureteral stent, guide wire, angiographic catheter, endoscopic sheath, balloon catheter, drainage tube and central venous catheter.

Owner:成都德信安创新医疗技术有限公司

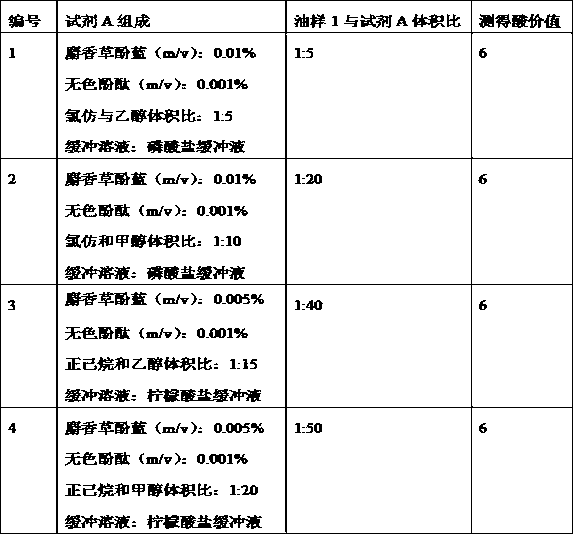

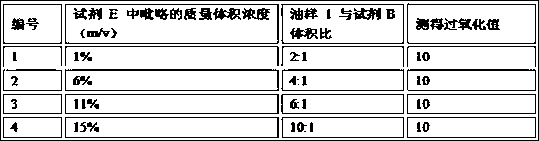

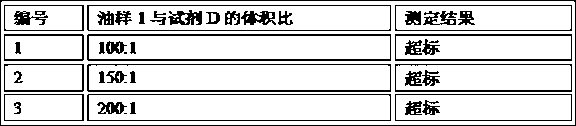

Method and kit for detecting illegal cooking oil

ActiveCN103267760AEasy to operateHigh speedComponent separationMaterial analysis by observing effect on chemical indicatorAcid valueCooking oil

The invention discloses a method for detecting illegal cooking oil. According to the method, the illegal cooking oil is judged by determining four indexes including acid value, peroxide value, polar materials and water content. The invention also discloses a kit special for the method. The method and kit for detecting the illegal cooking oil are simple and easy to operate, high in speed, obvious in detection effect and high in detectable rate.

Owner:WUXI ZODOLABS BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com