Patents

Literature

222results about How to "Increase intermolecular forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

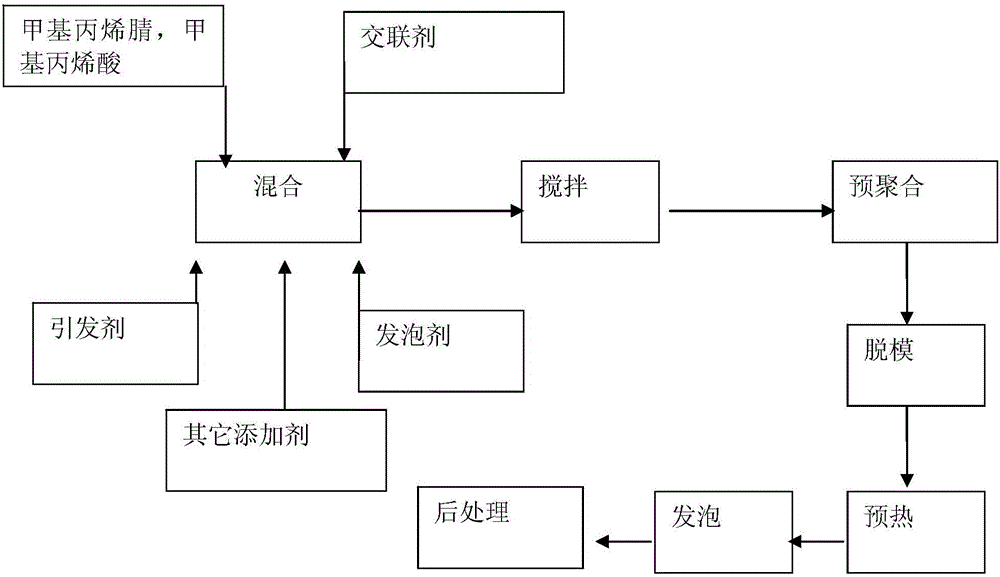

Maleimide modified polymethacrylimide foam and preparation method thereof

ActiveCN101550215AImprove heat resistanceImprove mechanical propertiesHeat deflection temperatureFoaming agent

The invention relates to high-performance copolymer foam, in particular to maleimide modified polymethacrylimide foam and a preparation method thereof. The maleimide modified polymethacrylimide foam is obtained by the mixed reaction of the components according to the weight proportions: 35-60 of methyl acrylic acid (MAA), 65-40 of methacrylonitrile (MAN), 0.1-50 of maleimide modifier, 0.10-2.0 of initiator, 1.0-20 of foaming agent, 0.1-8 of nucleating agent and 0.1-5 of crosslinking agent. The maleimide modified polymethacrylimide foam has high heat resistance, is not changed in color by heating under the temperature of 220 DEG C for long time, has the heat distortion temperature higher than 200 DEG C, and has the highest mechanical performance in all foams under the same intensity.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

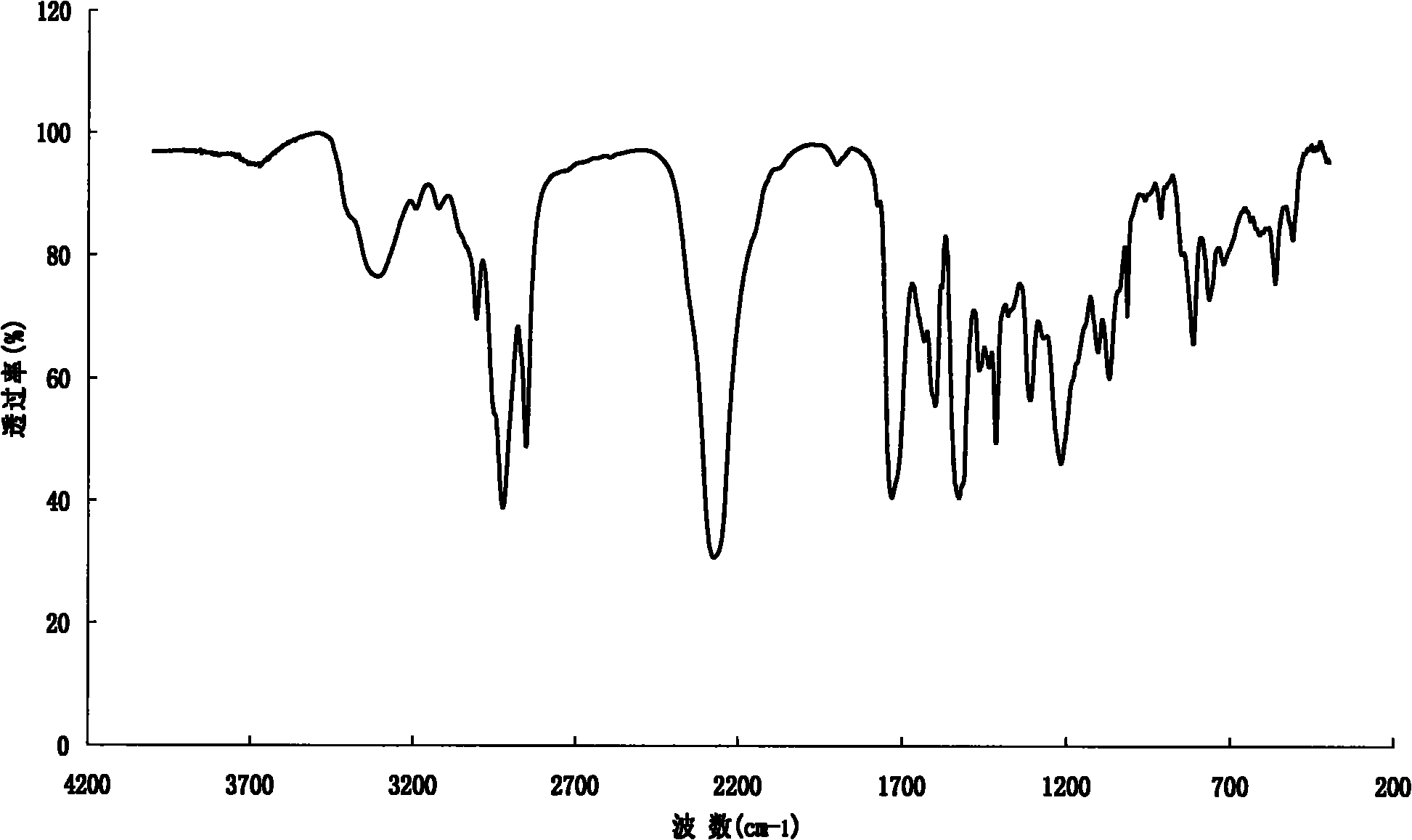

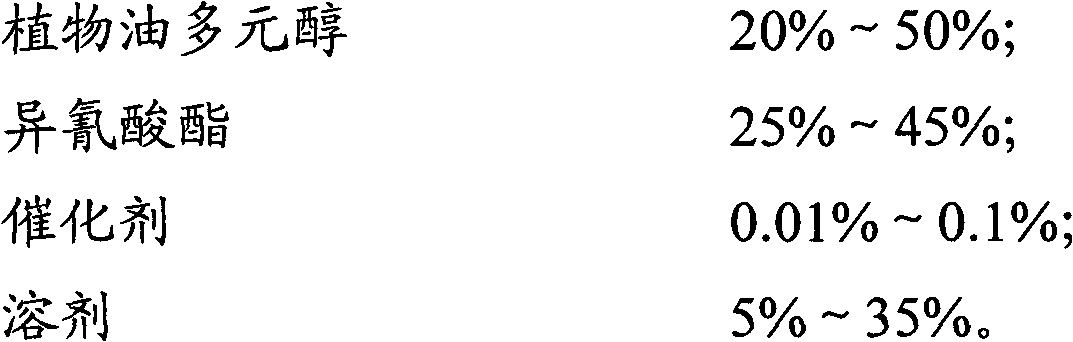

Storable plant oil-based polyurethane wood adhesive and preparation method and application thereof

ActiveCN102140327AIncrease intermolecular forcesImprove cohesive strengthPolyureas/polyurethane adhesivesIsocyanateSolvent

The invention discloses a storable plant oil-based polyurethane wood adhesive. The adhesive is prepared from 20-50 percent by mass of plant oil polylol, 25-45 percent by mass of isocyanate, 0.01-0.1 percent by mass of catalyst and 5-35 percent by mass of solvent, is accordant with the developing trend of novel environmentally-friendly and low-carbon materials, has high storage performance, high cementing property, high water resistance and long storage life, can be cured at room temperature and can be applied to a wood adhesive. The invention also discloses a preparation method of the storable plant oil-based polyurethane wood adhesive. The preparation method has simple steps, low requirements of technological conditions and very high economic benefit, and contributes to industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

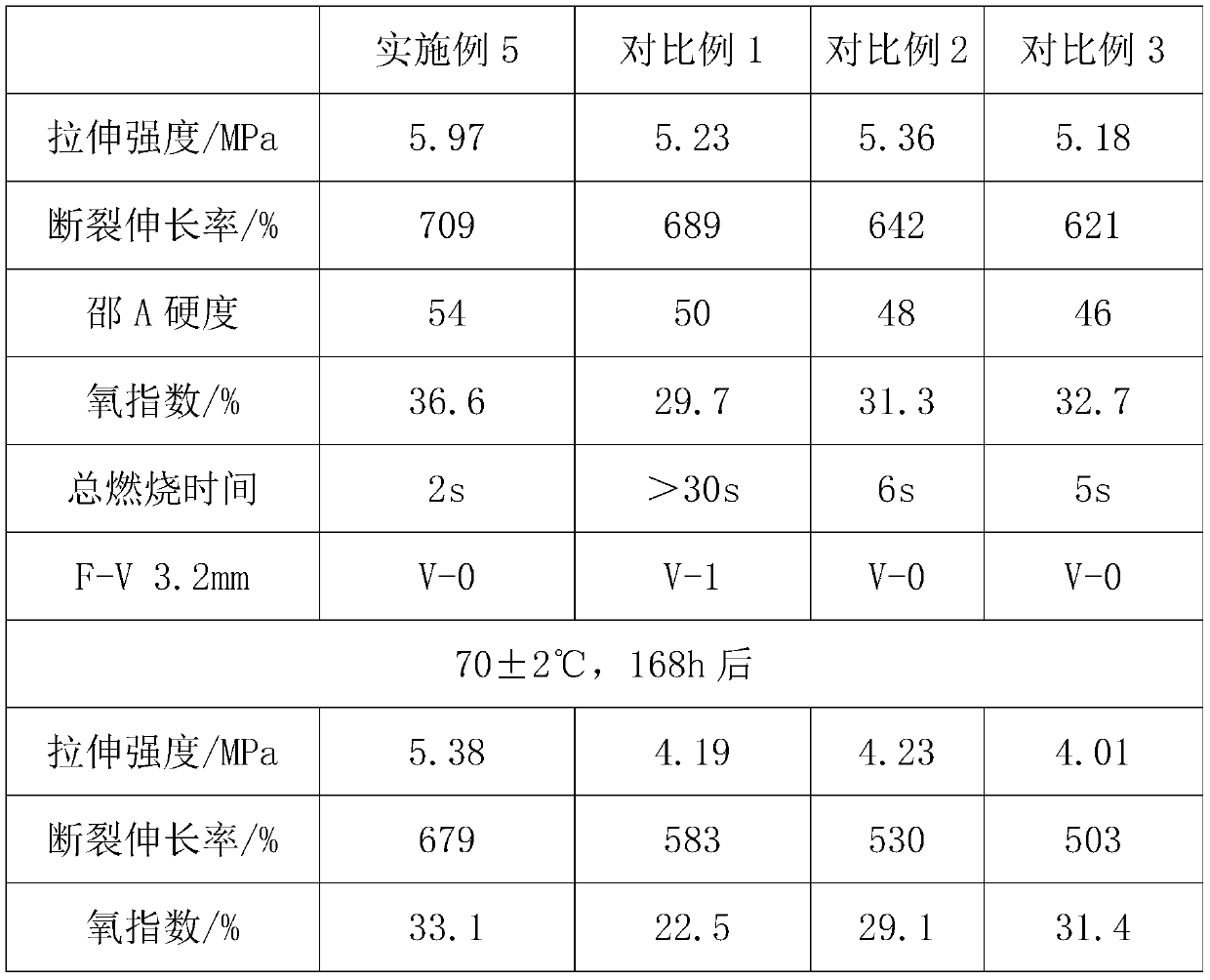

Ceramic fire-resistant and flame-retardant silicone rubber and preparation method thereof

InactiveCN106398231AImprove fire and flame retardant performanceImprove performancePolymer scienceSilanes

The invention relates to the technical field of silicone rubber, and particularly relates to a ceramic fire-resistant and flame-retardant silicone rubber and a preparation method thereof. The ceramic fire-resistant and flame-retardant silicone rubber is composed of a component A and a component B in a weight ratio of 0.8-1.2: 1. The component A comprises the following raw materials in weight part: 60-140 parts of silicone rubber A, 35-45 parts of reinforcing agent, 60-100 parts of filler A, 11.4-17.2 parts of silane auxiliary agent A, 0.15-0.25 part of lubricant A, 0.1-0.3 part of flame retardant, and 0.5-1.5 parts of vulcanizing agent. The component B comprises the following raw materials in weight part: 60-140 parts of silicone rubber B, 230-290 parts of filler B, 3-6 parts of silane auxiliary agent B, and 0.2-0.4 part of lubricant B. According to the technical scheme of the invention, the ceramic fire-resistant and flame-retardant silicone rubber is good in fire-resistant and flame-retardant property, and excellent in comprehensive performance.

Owner:东莞市朗晟材料科技有限公司

High-hardness high-rebound polyurethane elastomer material and application thereof

InactiveCN101633717AImprove mechanical propertiesImprove wear resistancePolyurethane elastomerAlcohol

The invention discloses a high-hardness high-rebound polyurethane elastomer material and introduces an application thereof. The material is obtained by mixing an isocyanate component and a polyhydric alcohol component at the temperature of 25-40 DEG C according to the weight ratio of 100:(50-100), pouring into a mould of 40-60 DEG C and vulcanizing for 30-60min. The hardness is 86-93A, the rebound rate is greater than 70%, the abrasion is smaller than 20mg, the tensile strength is greater than 25MPa, and the tearing strength is greater than 100kN / m. The isocyanate component is a performed polymer with the content of 6-18% of isocyanic acid radicals, and the performed polymer is generated in such a way that 20-60% of PTMG with the molecular weight smaller than or equal to 1,000 and 40-80% of doped PTMG with the molecular weight greater than 1,000 react with isocyanate or a derivative thereof; the polyhydric alcohol component comprises 69.2-89.4% of PTMG with the average molecular weight greater than 1000, 10-30% of fatty group dihydric alcohol, 0.2-0.3% of catalyst and 0.4-0.5% of antiaging agent. The polyurethane elastomer material can be used for preparing butterfly boards, active boards, pulleys used for rapid slide, pulleys of ice skates, pulleys of sliding boards and various castors.

Owner:LIMING RES INST OF CHEM IND

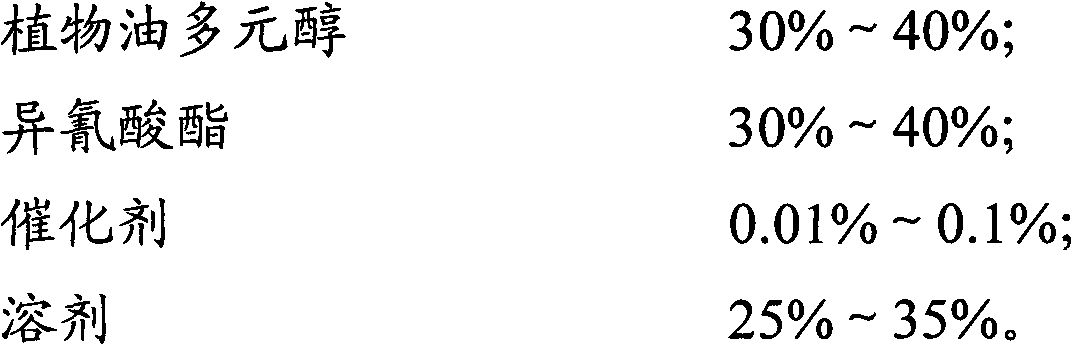

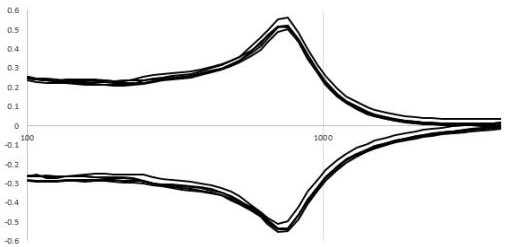

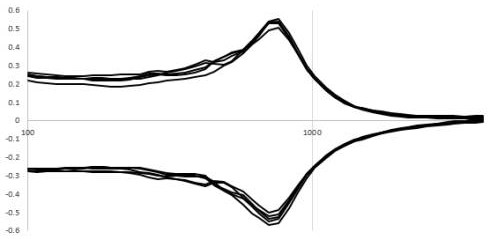

Vibrating diaphragm of sound production device and preparation method thereof and sound production device

ActiveCN111935602AIncrease dampingIncrease intermolecular forcesPolymeric diaphragmsSynthetic resin layered productsPolymer sciencePolysulfide rubber

The invention discloses a vibrating diaphragm of a sound production device and a preparation method thereof and the sound production device. The vibrating diaphragm comprises at least one modified diaphragm layer, the modified diaphragm layer is made of a blend polymer formed by blending and modifying silicone rubber and a modifier, and the modifier is at least one of a butadiene-acrylonitrile copolymer, a butadiene-styrene copolymer, polysulfide rubber, polyurethane rubber and polybutadiene. The vibrating diaphragm provided by the invention is made of a blend polymer formed by blending and modifying silicon rubber and a modifier; the modifier is at least one of a butadiene-acrylonitrile copolymer, a butadiene-styrene copolymer, polysulfide rubber, polyurethane rubber and polybutadiene; the intermolecular force and / or steric hindrance of the silicone rubber can be increased, so that the vibrating diaphragm has excellent damping performance, and the sound production device has excellentconsistency, excellent anti-polarization capability, reduced distortion performance and higher tone quality in the vibration process.

Owner:GOERTEK INC

Manufacturing method for resin grinding wheel cutting piece with function of cutting soft and hard materials

InactiveCN101691028AIncrease intermolecular forcesHigh strengthAbrasion apparatusGrinding devicesAluminium oxidePTFE - Polytetrafluoroethylene

The invention relates to a manufacturing method for a resin grinding wheel cutting piece with function of cutting soft and hard materials. In the method, a silicon carbide grinding material with different particle sizes, a brown aluminium oxide grinding material with mixed particle sizes, a phenolic resin binder, a polytetrafluoroethylene dry grinding lubricant and a cryolite packing material are prepared into a resin grinding wheel cutting piece bonding mixed grinding material; the resin grinding wheel cutting piece bonding mixed grinding material is coated on a grinding wheel net according to piece weight specification of the cutting piece; and the resin grinding wheel cutting piece is prepared by spreading and scraping the grinding material with a scraper blade, and pressurizing, molding and hardening the grinding material with a pressing plate. The silicon carbide grinding material and the brown aluminium oxide grinding material in an optimum proportion make the resin grinding wheel cutting piece play a decisive concordant role in cutting the soft and hard materials; and the polytetrafluoroethylene dry grinding lubricant is adopted to make the resin grinding wheel cutting piece have good balance in the aspects of cutting speed and cutting durability. Therefore, the manufacturing method comprehensively improves and expands functions and application of the resin grinding wheel cutting piece.

Owner:武汉法山磨料磨具有限公司

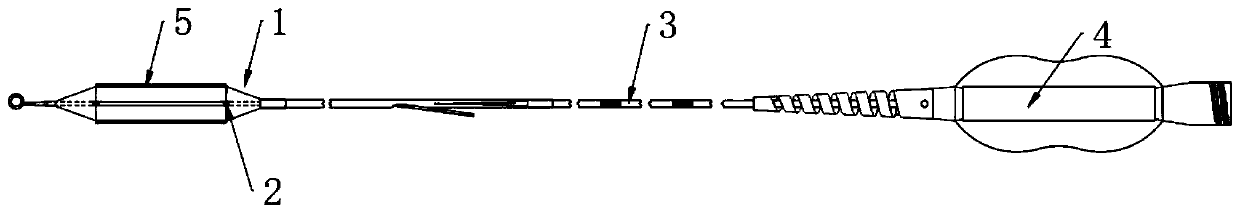

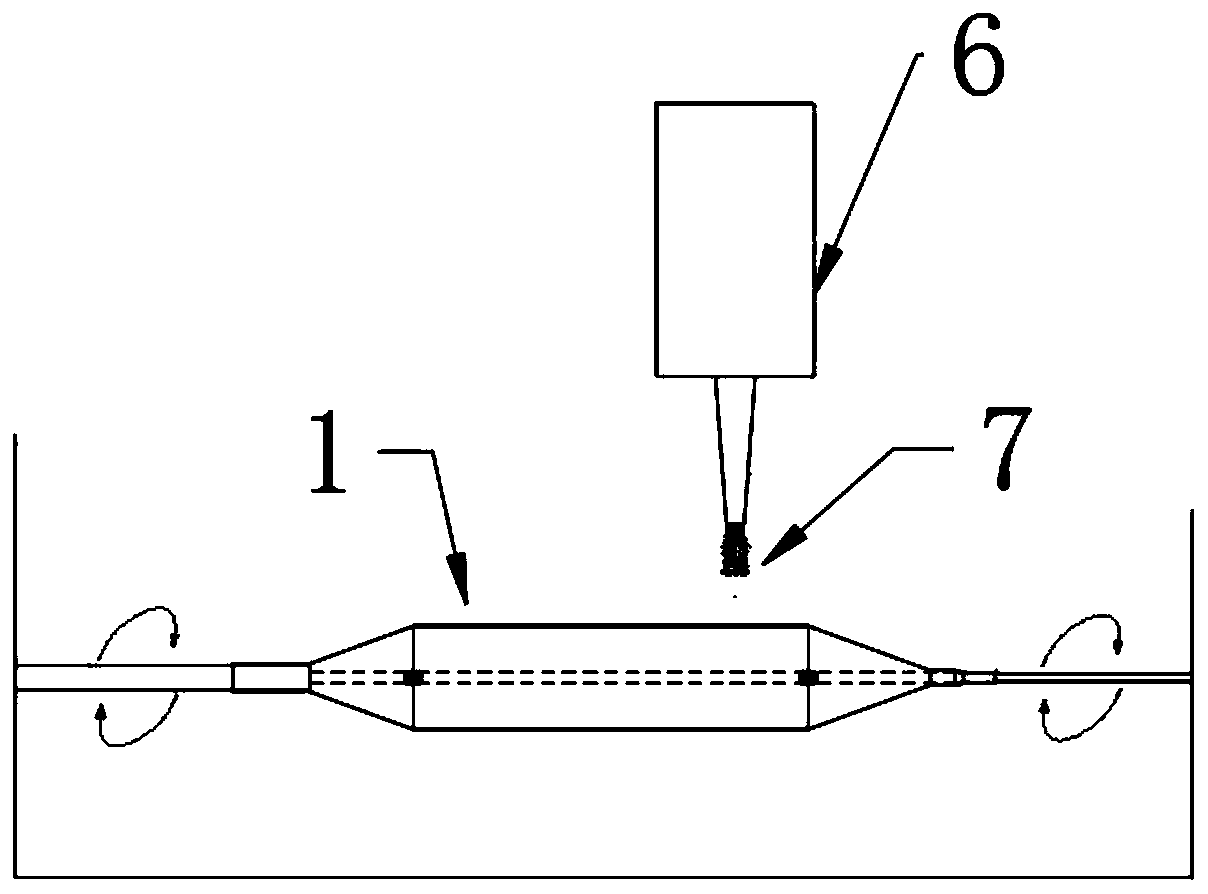

Medicine coating balloon, preparation method and medicine coating balloon dilatation catheter

InactiveCN111298272AAvoid the risk of microembolismStrong penetrating powerBalloon catheterMedical devicesBalloon dilatation catheterPharmacy medicine

The invention discloses a medicine coating balloon. The medicine coating balloon comprises a balloon body and a medicine coating covering the surface of the balloon body, wherein the medicine coatingis formed by spraying a medicine spraying solution to the surface of the balloon body; and the medicine spraying solution is obtained by dissolving medicine, a fat-soluble excipient and a hydrophilicexcipient in a solvent. The invention further discloses a preparation method of the medicine coating balloon and a medicine coating balloon dilatation catheter. According to the medicine coating balloon, the firmness of the medicine coating is higher, the granularity of the medicine is small, the medicine loss can be greatly reduced in the medicine balloon crossing and dilatation process, the tissue absorption rate is high, and the medicine utilization rate is increased.

Owner:KOSSEL MEDTECH SUZHOU

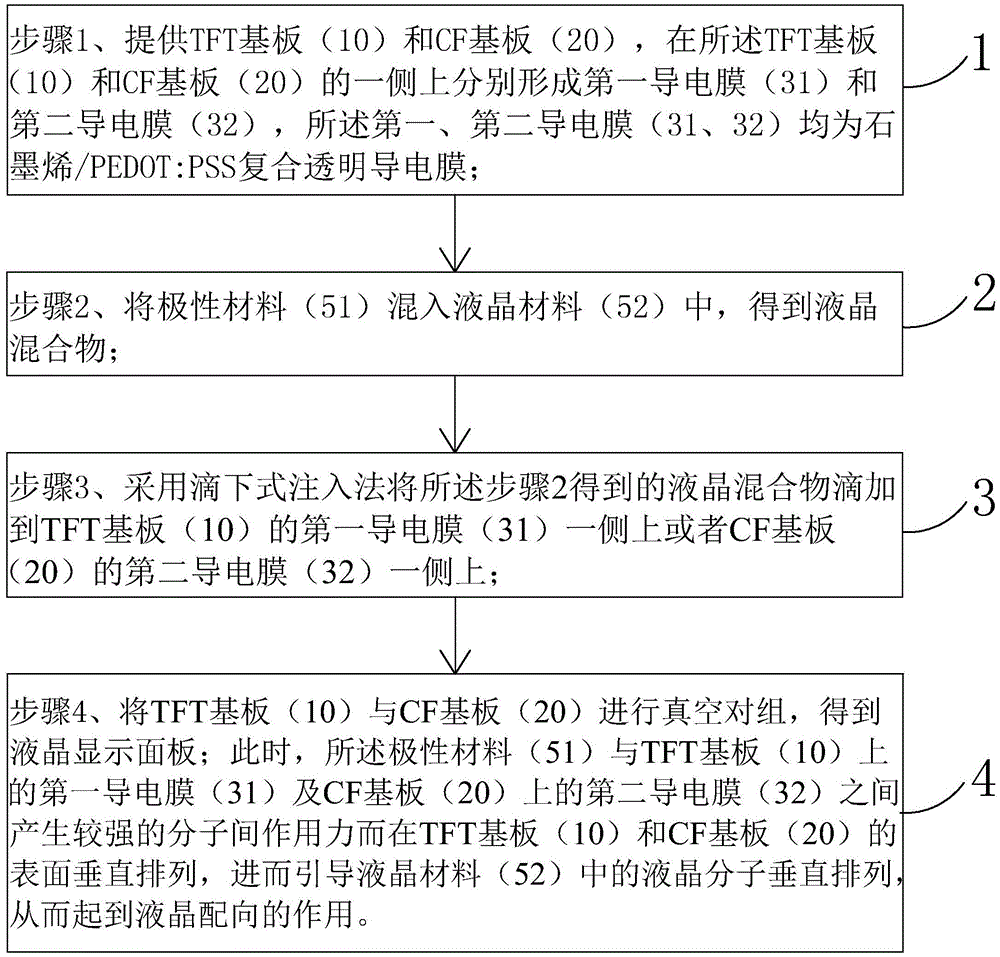

Production method for liquid crystal display panel

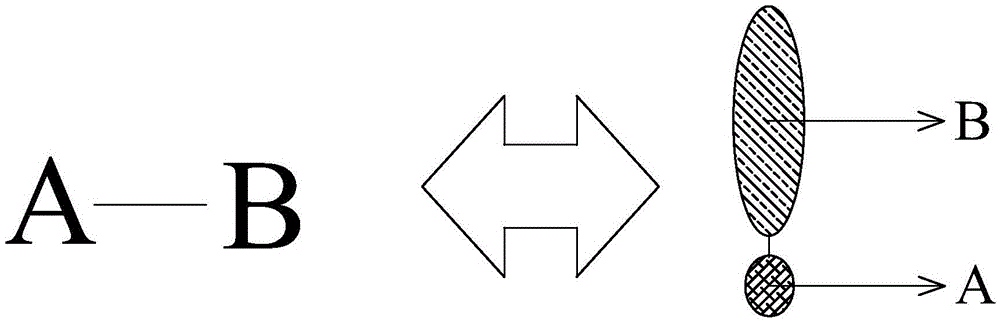

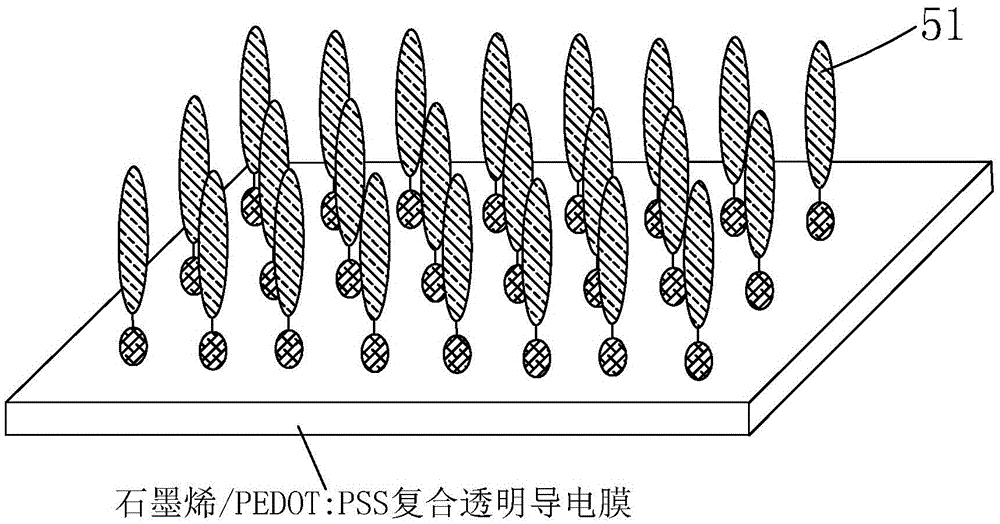

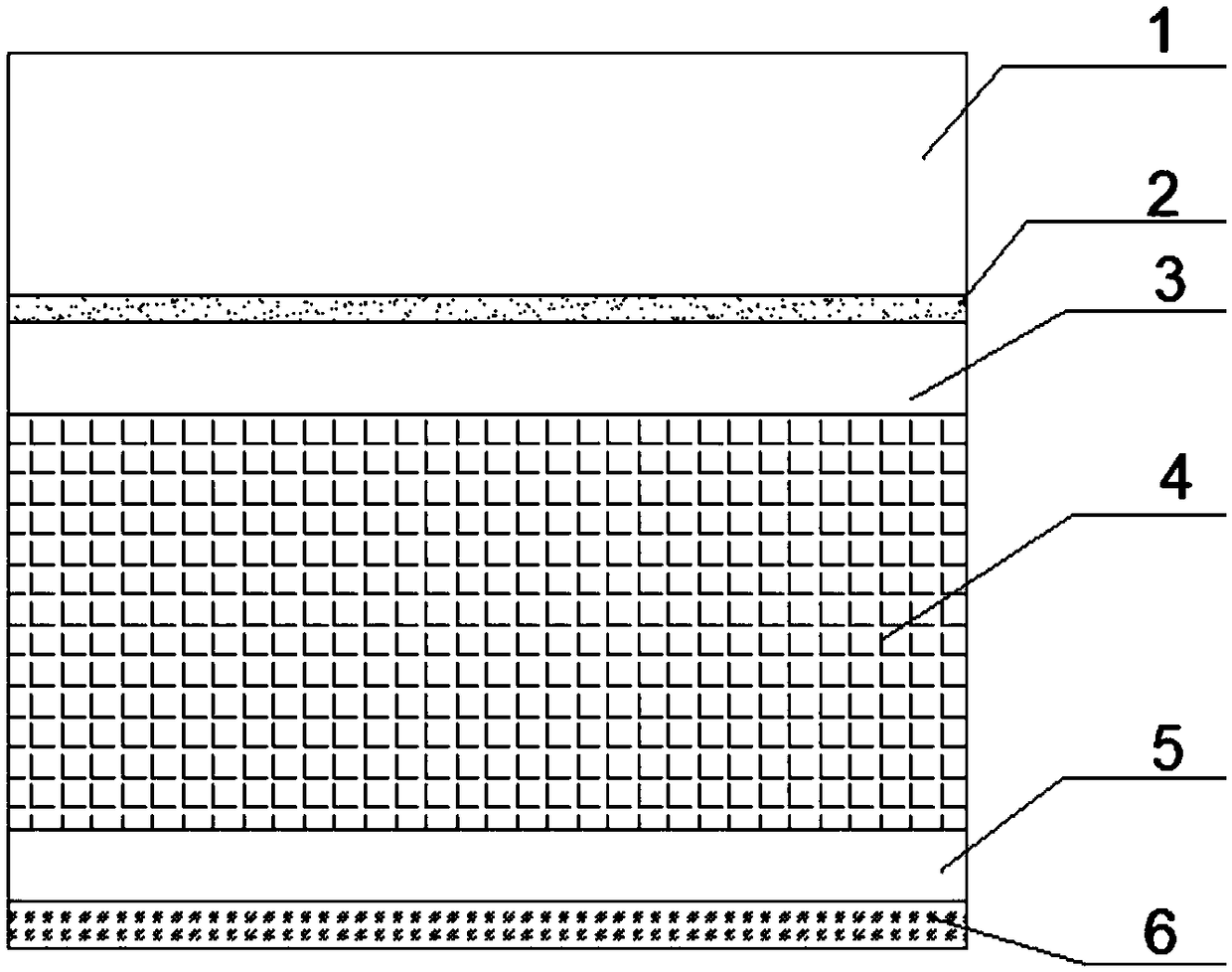

ActiveCN105527757AIncrease intermolecular forcesReduce processLiquid crystal compositionsSolid-state devicesVertical alignmentElectrical polarity

The invention provides a production method for a liquid crystal display panel. According to the method, traditional ITO transparent conductive films on a TFT (thin film transistor) substrate and a CF (color filter) substrate are replaced with graphene / PEDOT:PSS composite transparent conductive films, polar materials are added to a liquid crystal mixture of the liquid crystal display panel, and a general structural formula of the polar materials is A-B; the head group A is mainly used for enabling larger intermolecular force to be generated between the polar materials and the graphene / PEDOT:PSS composite transparent conductive films; similar to a function of a PI branch chain, the tail group B is mainly used for enabling liquid crystal molecules to be arranged vertically in a steric hindrance manner and has a vertical alignment effect; that is, the polar materials can generate larger intermolecular force with the graphene / PEDOT:PSS composite transparent conductive films so as to be vertically arranged on the surface of the TFT substrate and the CF substrate, the liquid crystal molecules are guided to be arranged vertically, the polar materials are substituted for a PI alignment film to have a liquid crystal alignment effect, a PI alignment film preparation process is omitted, the production cost of the alignment film is reduced, and the capacity is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

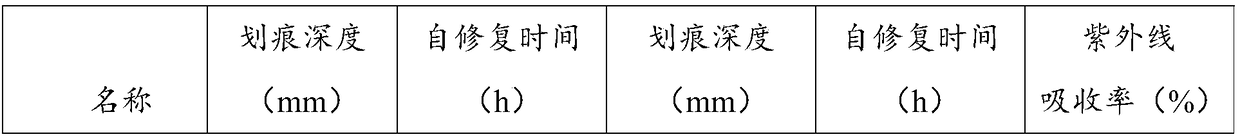

Ultraviolet-proof invisible car cover film with self-repairing function and preparation method of ultraviolet-proof invisible car cover film

InactiveCN108728007AExtend your lifeAchieve absorptionAntifouling/underwater paintsPaints with biocidesUltravioletEngineering

The invention discloses an ultraviolet-proof invisible car cover film with a self-repairing function and a preparation method of the invisible car cover film. The ultraviolet-proof invisible car coverfilm comprises a TPU base material layer, a self-repairing layer, a protecting silica layer, a PET layer, a pressure sensitive adhesive layer and a release layer, wherein the self-repairing layer, the protecting silica layer and the PET layer are sequentially arranged on the upper surface of the TPU base material layer from bottom to top; the pressure sensitive adhesive layer and the release layer are sequentially arranged from top to bottom. By coating the upper surface of the TPU base material layer with a special self-repairing layer, the TPU layer has excellent functions of preventing doodling and fouling and self preparing; an ultraviolet absorbent is added in the self-repairing layer and the pressure sensitive adhesive layer and realizes mass absorption of ultraviolet rays, so thatthe damage of the ultraviolet rays to car paint.

Owner:LONGCHANG YUXI NEW MATERIAL TECH

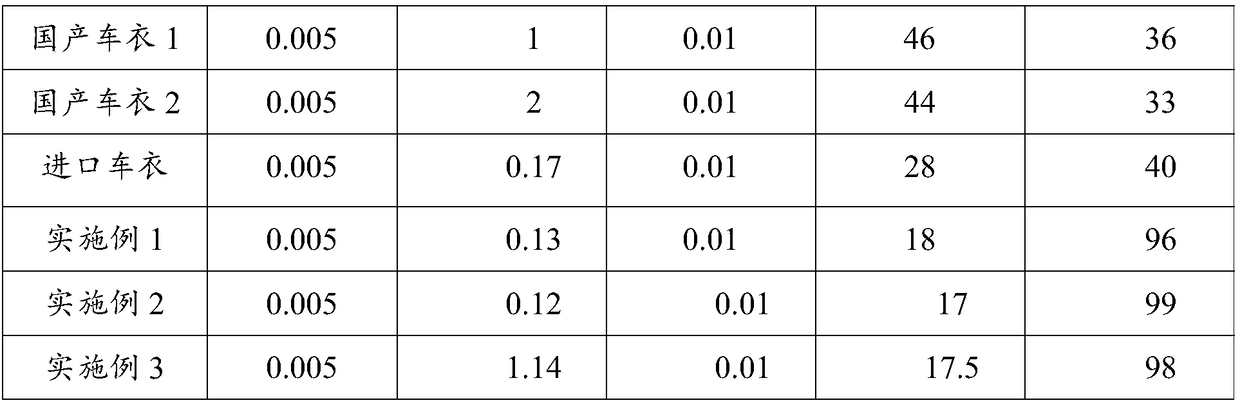

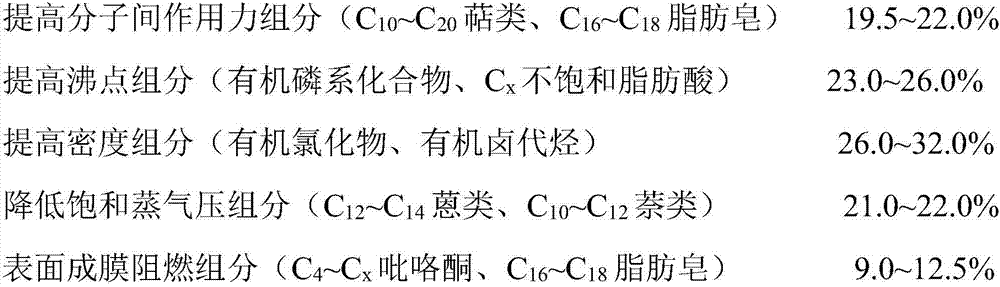

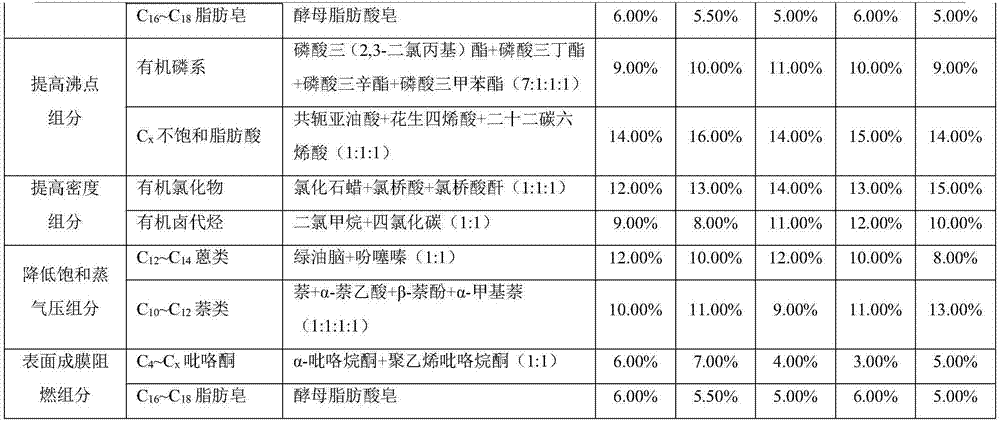

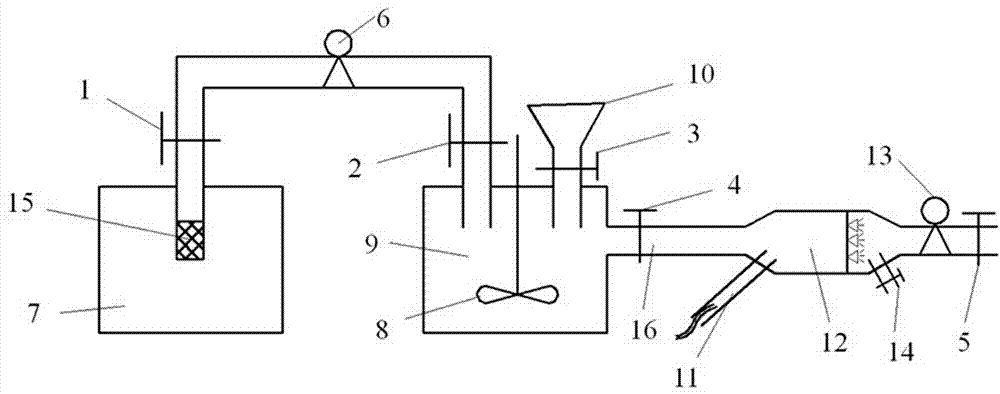

Biological alcohol-based light fuel flash point improver

ActiveCN106906014ATurn waste into treasureTurn waste into energyLiquid carbonaceous fuelsSpontaneous combustionAlcohol

The invention discloses a biological alcohol-based light fuel flash point improver, which is composed of 19.5 to 22.0% of a component capable of increasing intermolecular force, 23.0 to 26.0% of a component capable of increasing the boiling point, 21.0 to 22.0% of a component capable of increasing density, 21.0 to 22.0% of a component capable of reducing saturated vapor pressure, and 9.0 to 12.5% of a component having surface with film forming and flame retardantion. The five functional components can be stirred evenly under normal temperature, and the biological alcohol-based light fuel flash point improver product can be obtained. The improver can increase the intermolecular force, and improves the boiling point of an oil-alcohol system, increases density of the oil-alcohol system, reduces saturated vapor pressure of the oil-alcohol system, forms a flame retardant film on the surface of oil-alcohol system, blocks the spontaneous combustion of methanol, improves the non corrosive performance of the flash point of the oil-alcohol system, has the characteristics of biodegradability, no harmful components and no secondary pollution to the environment, and effectively solves the technical problems of low flash point, large transportation and storage safety hazard of light fuel.

Owner:LANZHOU YINENG BIOTECHNOLOGY CO LTD

Multifunctional liquid foam used for underground coal mine and using method thereof

InactiveCN103883347AHigh strengthInjection distanceDust removalFire preventionSurface-active agentsNonionic surfactant

The invention belongs to the technical field of coal mine safety, and patricianly relates to multifunctional liquid foam used for an underground coal mine and a using method of the multifunctional liquid foam. The multifunctional liquid foam used for the underground coal mine comprises, by mass, 0.5-10% of crystal whisker stopping agents, 0.5-30% of quaternary ammonium salt cationic surface active agents, 0.5-30% of non-ionic surface active agents and 0-10% of additives, the balance of water. The multifunctional liquid foam preparation method and using method are simple, bring convenience for use and manual operation, and are strong in applicability because of being suitable for mines rich in acid gases like sulfuretted hydrogen and sulfur dioxide, tunnels with large coal spontaneous combustion tendency, mine working faces and the like and particularly suitable for mine goaves.

Owner:LIAONING TECHNICAL UNIVERSITY

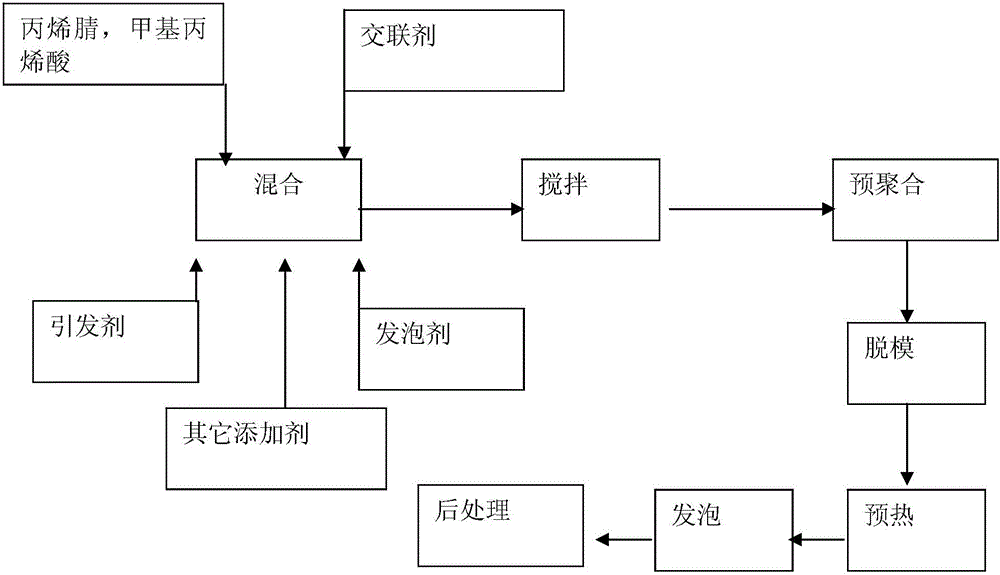

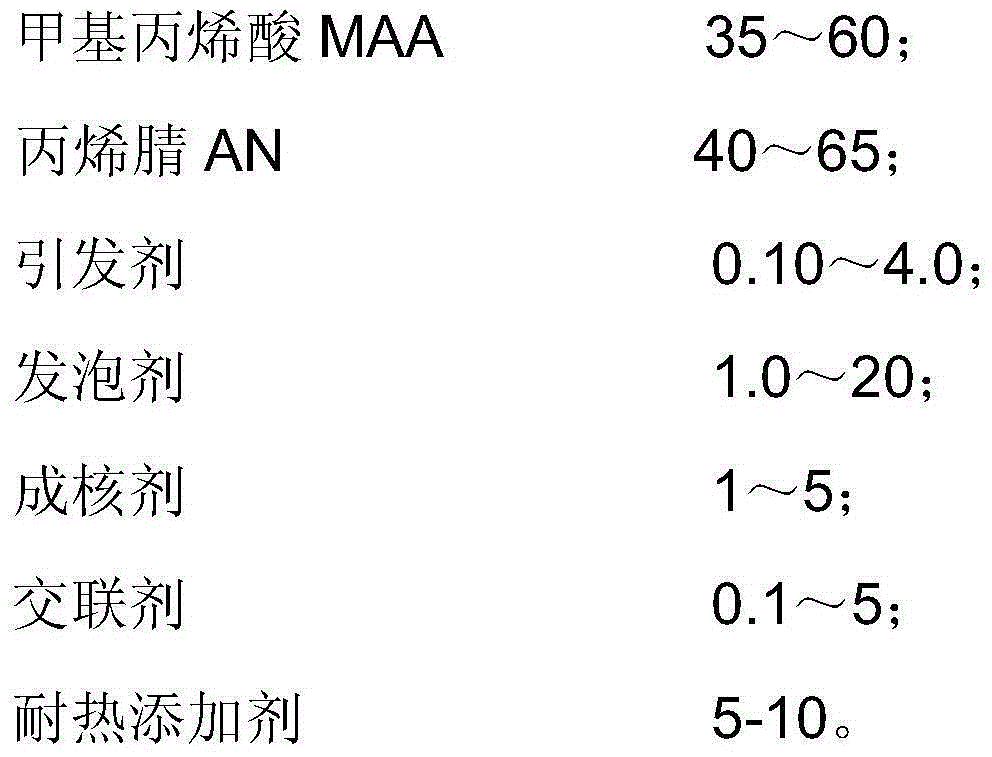

Acrylonitrile-based polymethacrylimide foam and preparation method therefor

ActiveCN105111354AImprove heat resistanceHigh heat distortion temperatureAcrylonitrileDibenzoyl Peroxide

The invention relates to acrylonitrile-based polymethacrylimide foam which comprises the following components in parts by mass: 35-60 parts of methacrylic acid MAA, 40-65 parts of acrylonitrile AN, 0.10-4.0 parts of an initiator, 1.0-20 parts of a foaming agent, 1-5 parts of a nucleating agent, 0.1-5 parts of a crosslinking agent and 5-10 parts of a heat resisting additive, wherein the initiator is an azo compound or a mixture of the azo compound and a peroxide and the initiator at least comprises three different compounds at the same time; the azo compound is azobisisobutyronitrile AIBN, azobisisoamylonitrile or 2,2'-azobisisoheptonitrile; the peroxide is dibenzoyl peroxide, lauroyl peroxide, tert-butyl peroxyoctoate or tert-butyl peroxybenzoate. The acrylonitrile-based polymethacrylimide foam provided by the invention is good in heat resistance, high in heat deformation temperature which is greater than 220 DEG C and excellent in mechanical property.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

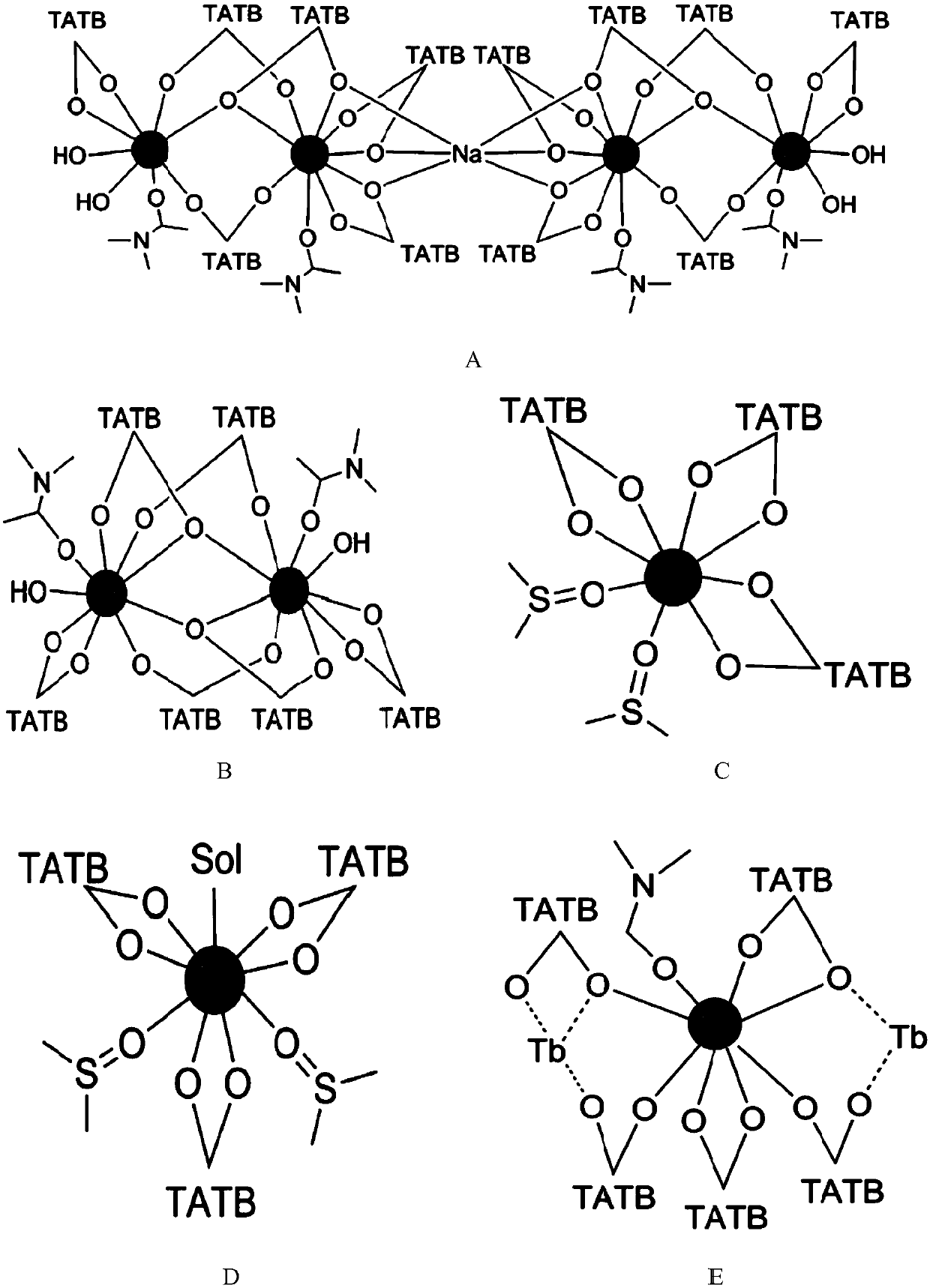

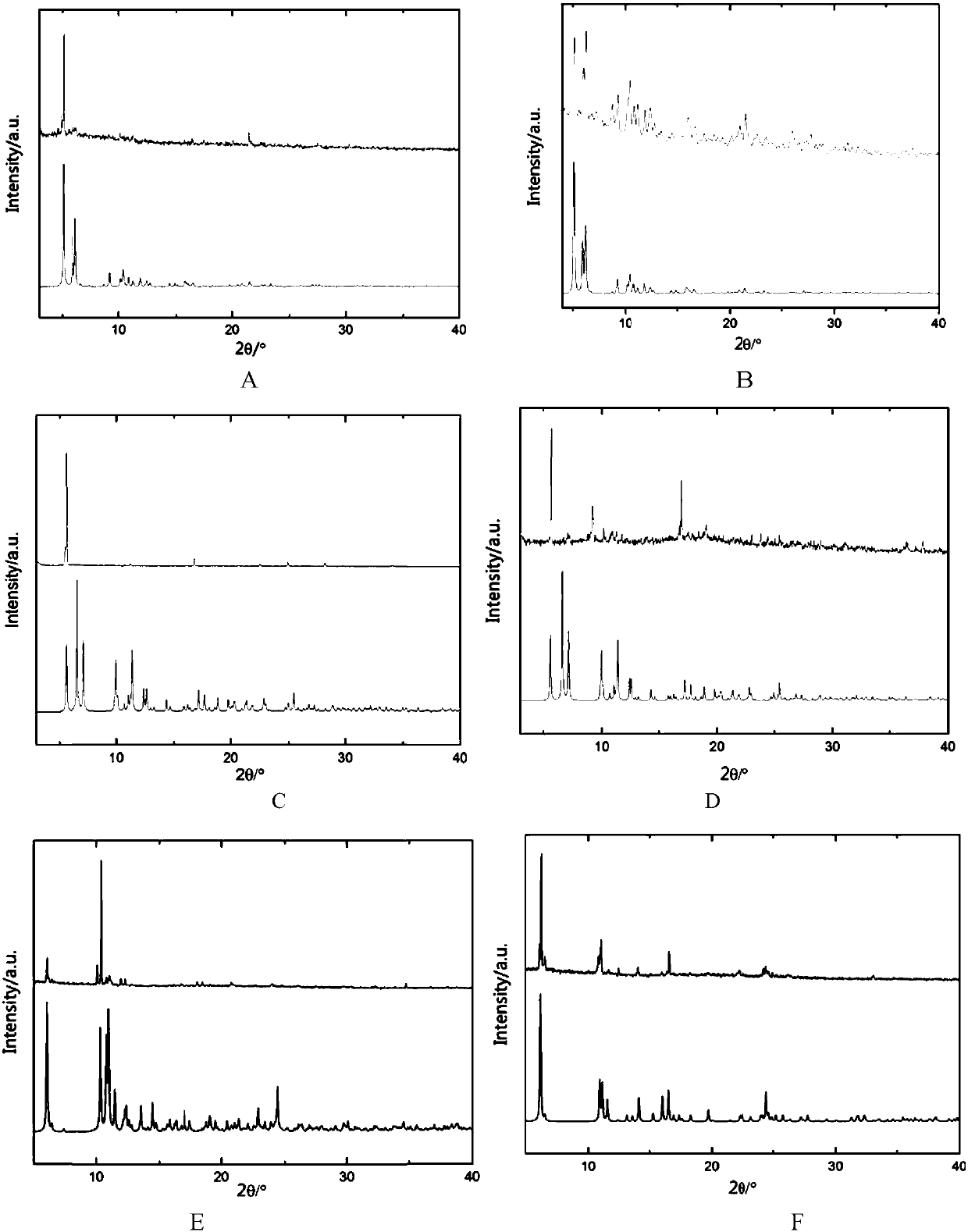

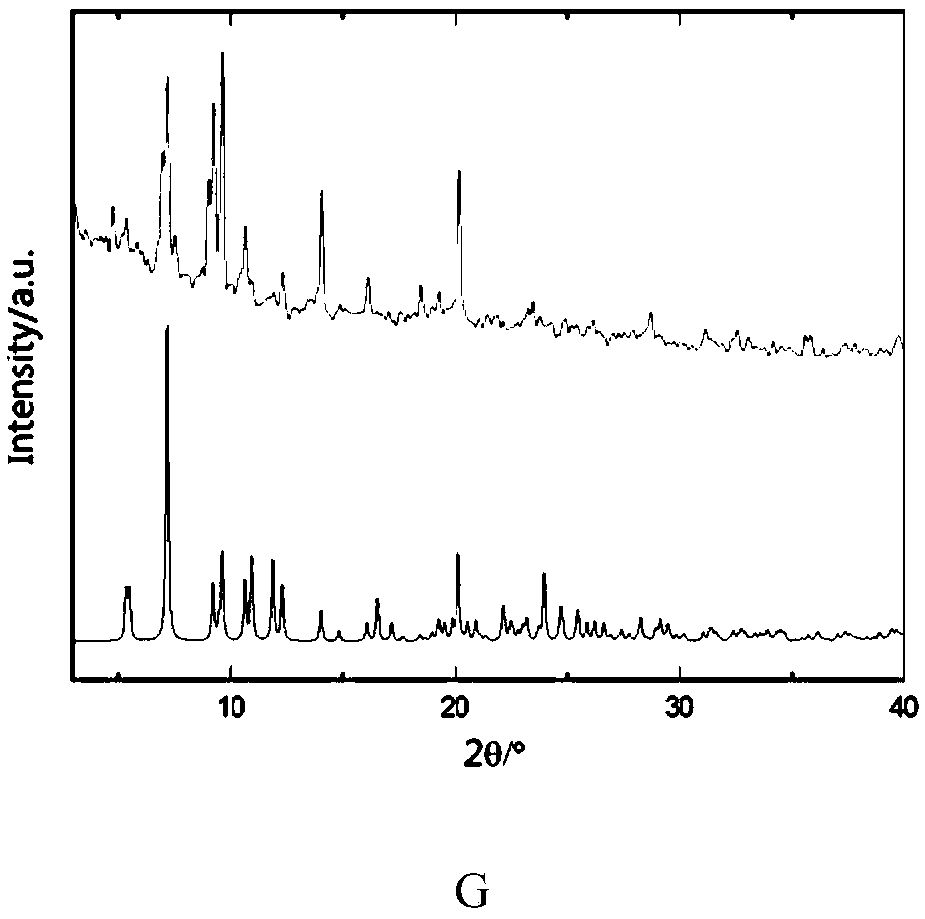

Rare earth metal organic framework material with high quantum yield and preparation method thereof

ActiveCN108912337AReduce distanceReduce strong effectsLuminescent compositionsQuantum yieldRare-earth element

The invention belongs to the field of luminescent materials, and relates to a rare earth metal organic framework material and a synthesis method thereof. The rare earth metal organic framework material is constructed with deprotoned 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine as ligands, with rare earth metal ions as luminescent centers by pi-pi interaction of the ligands or C-H-pi interaction of the ligands and a solvent. The distance between the centers of aromatic rings corresponding to the pi-pi interaction of the ligands is 5 Angstroms, the interaction of the ligand molecules is enhanced,the rigidity of a material skeleton is increased, the loss of energy on the skeleton is reduced, the energy transfer from the ligands to the rare earth metals is also enhanced, the energy utilizationefficiency is greatly enhanced, and thus high quantum yield is obtained. The luminescent metal organic frame material has high energy utilization rate, and the quantum yield of the luminescent metal organic frame material is increased from less than 60% to 99.9% compared with that of a conventional rare earth metal organic frame material.

Owner:SUN YAT SEN UNIV

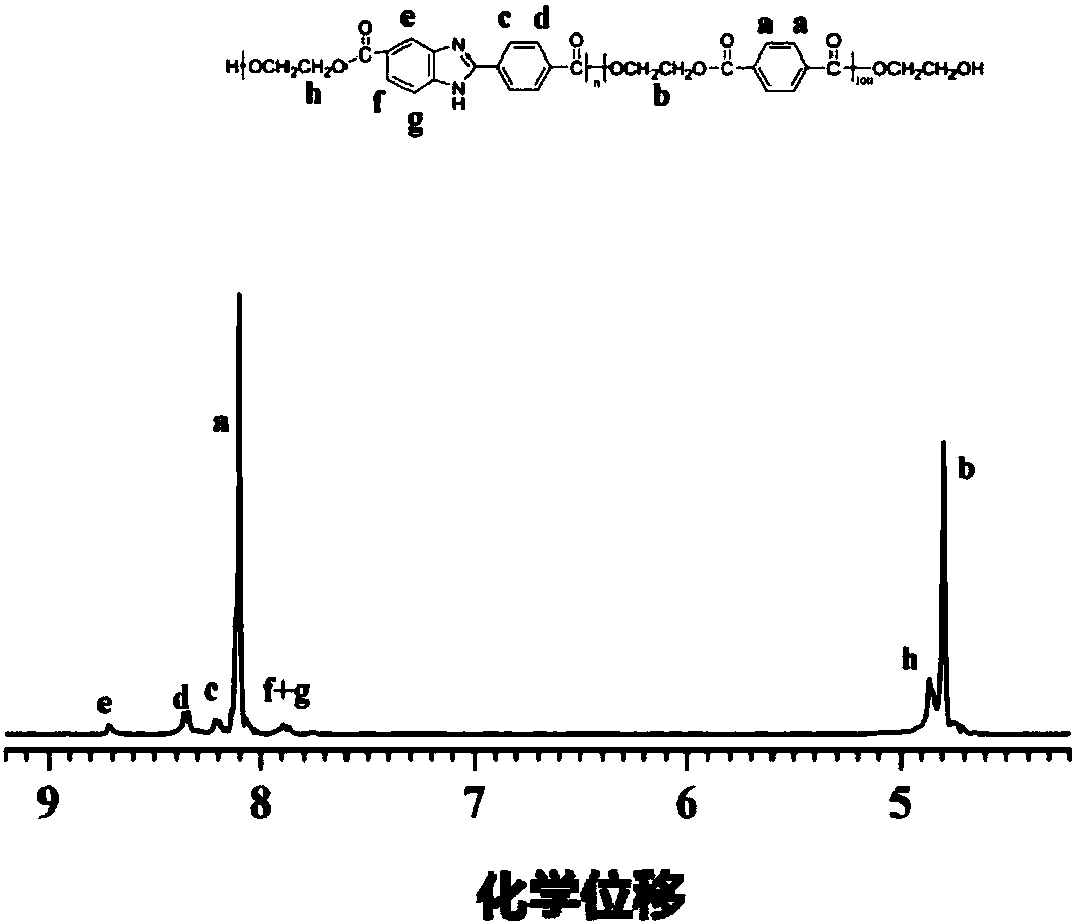

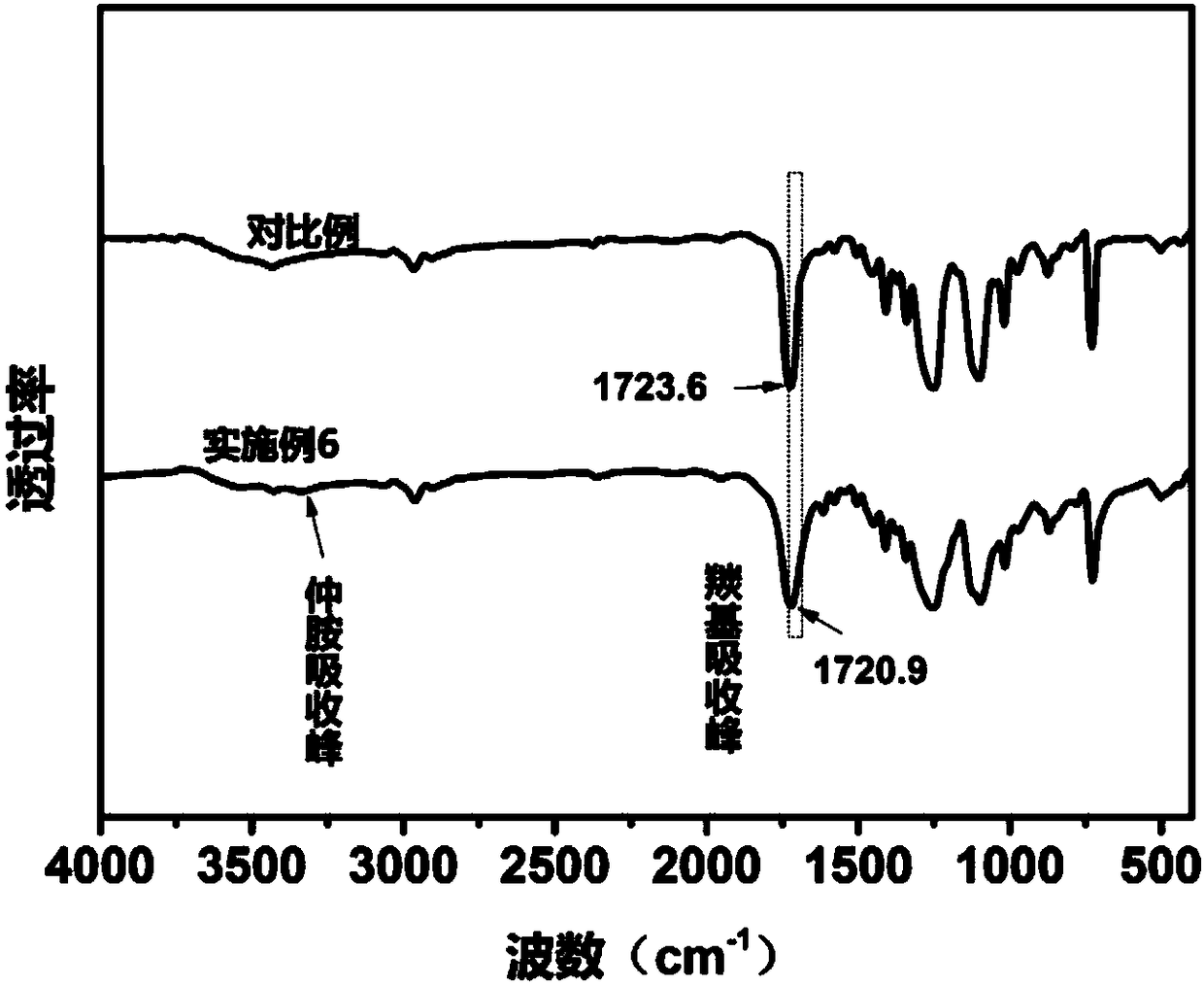

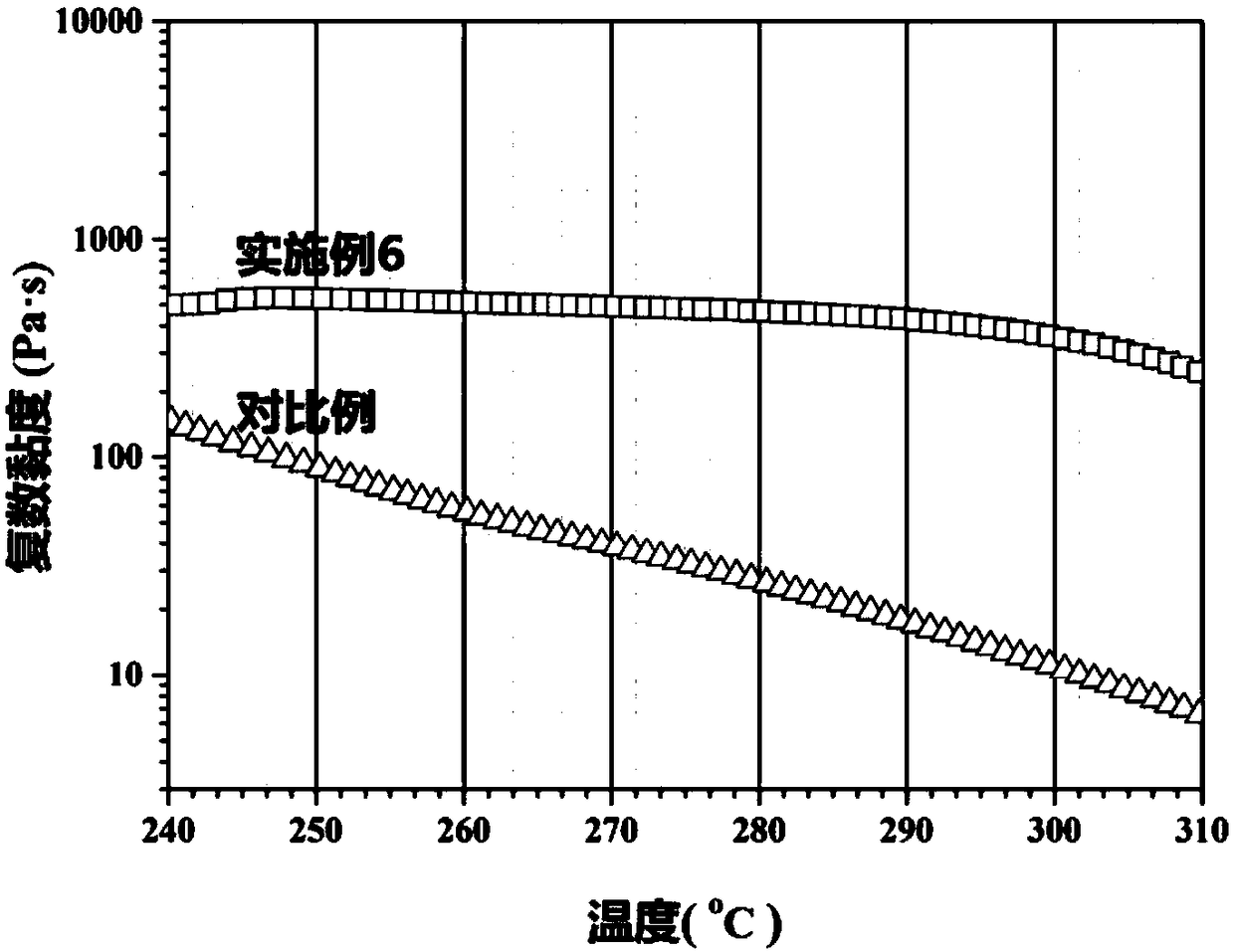

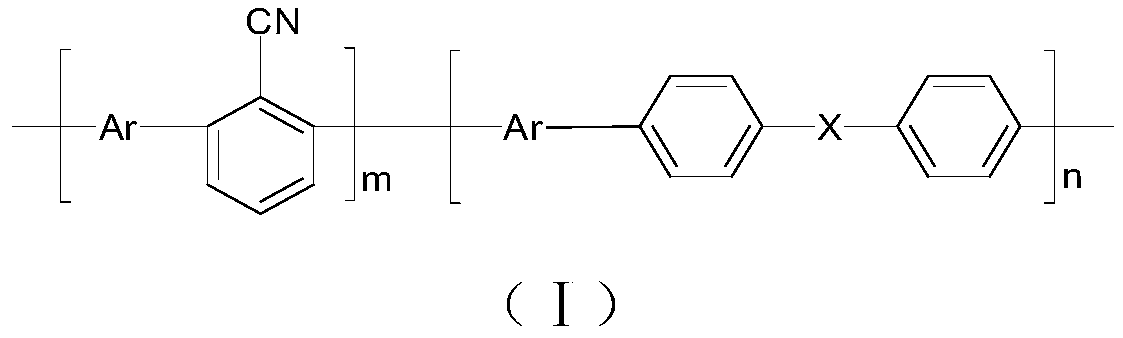

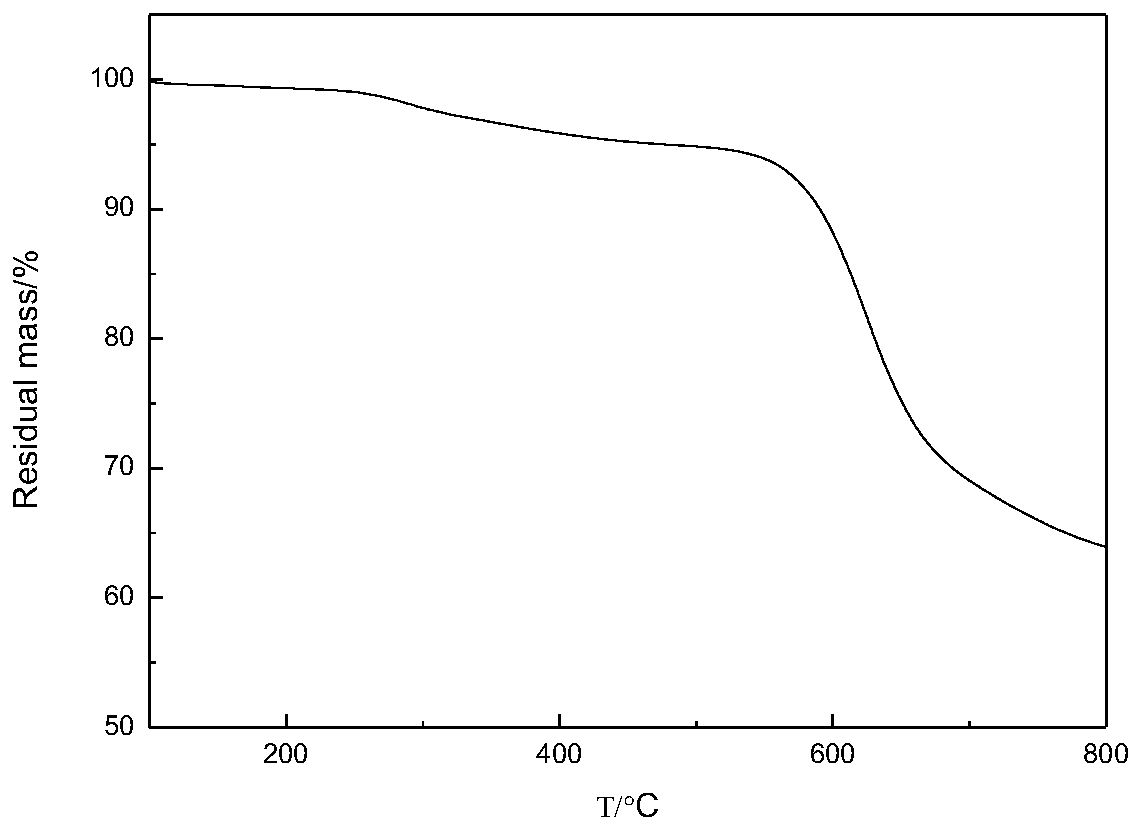

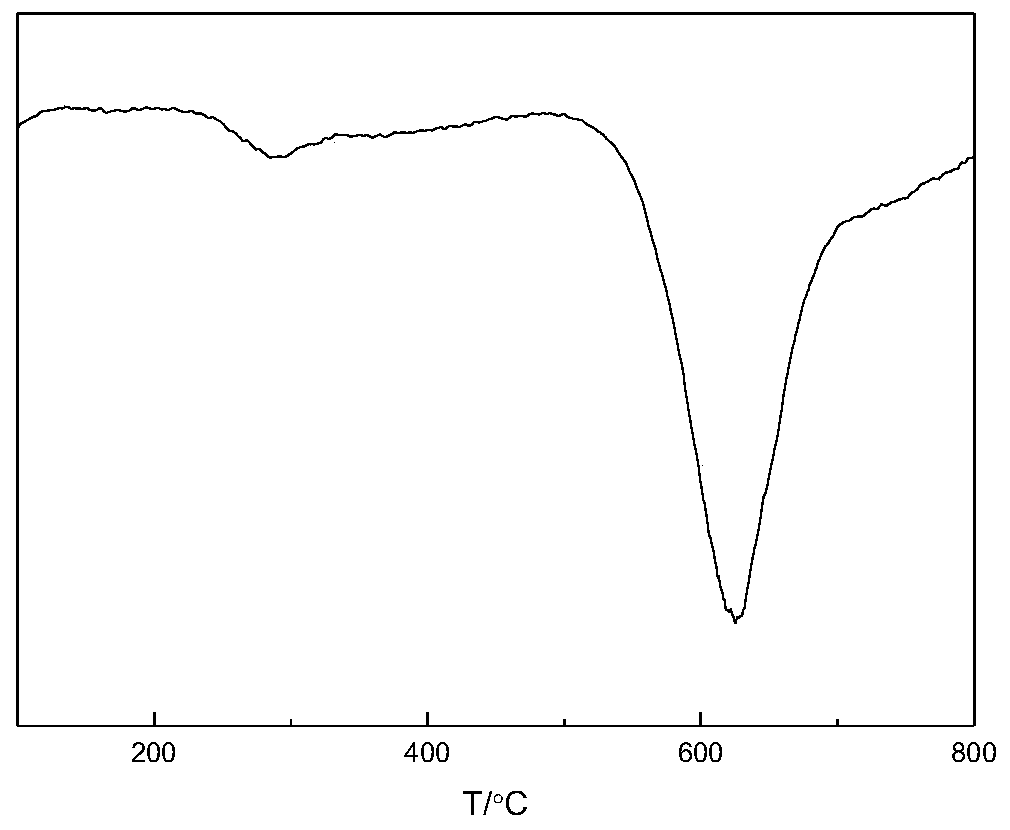

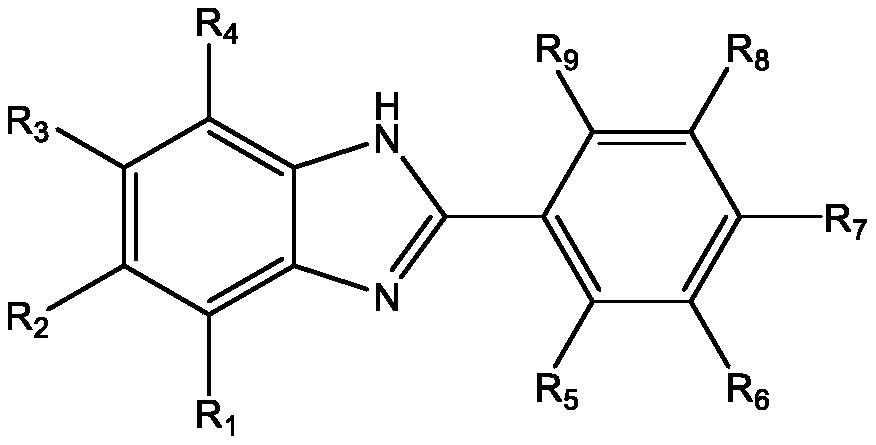

Flame retardant anti-droplet copolyester based on benzimidazole structure, and preparation method thereof

ActiveCN108395526AIncrease intermolecular forcesStabilizing Physical CrosslinkingBenzimidazoleCopolyester

The invention discloses a flame retardant anti-droplet copolyester based on a benzimidazole structure, and a preparation method thereof. The copolyester is composed of structural units represented byformula I, II, III or I, II and IV, the characteristic viscosity [eta] of the copolyester is 0.48-1.36 dL / g, and the limit oxygen index is 25.0-42.0%; the glass transition temperature of the copolyester is 7-62 DEG C higher than that of pure PET; the vertical burning grade is V-2 to V-0 grade; the peak heat release rate p-HRR in cone calorimetry test is 42.8-82.5% lower than that of the pure PET;and the total smoke release amount is 15.8-69.0% lower than that of the pure PET. The benzimidazole structure introduced in the invention can rapidly form a large amount of charcoal during combustionin order to achieve excellent flame retarding, droplet resisting and smoke suppressing effects, can maintain the original processing window of the polyester and realize multi-time repeated processing,and also can greatly improve the glass transition temperature of the copolyester; and the preparation method has the advantages of mature process, simplicity and convenience in operation, and high easiness in industrial production.

Owner:SICHUAN UNIV

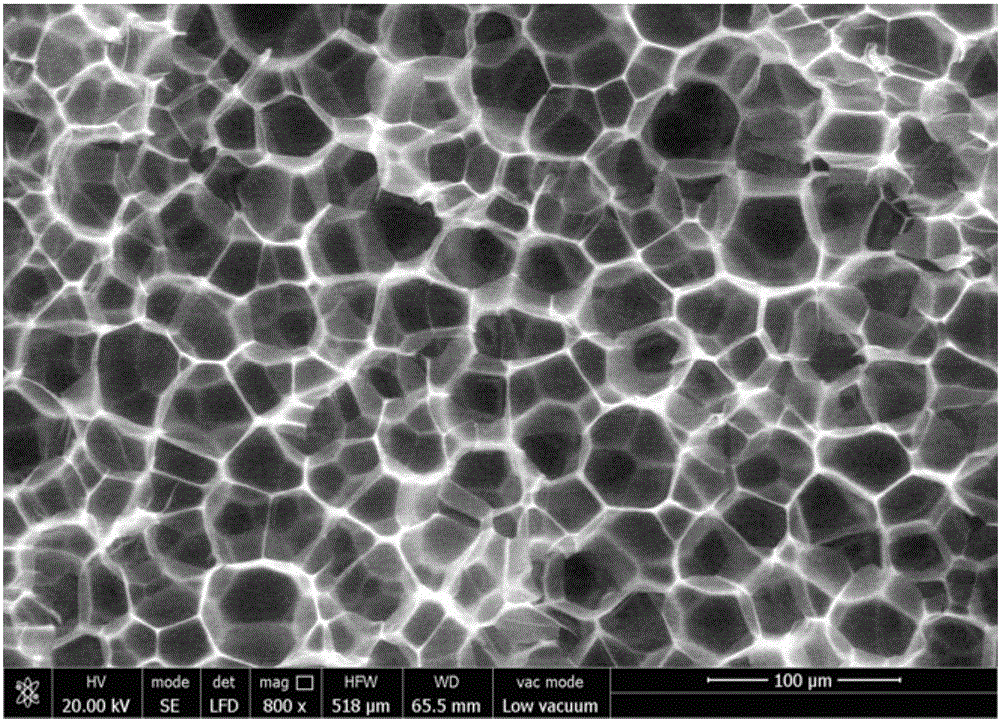

Micropore polymethacrylimide foam with high thermal deformation temperature and preparing method thereof

ActiveCN105037618AImprove heat resistanceHigh heat distortion temperatureCross-linkHeat deflection temperature

The invention relates to micropore polymethacrylimide foam with high thermal deformation temperature. The foam comprises, by mass, 35-60 parts of methacrylic acid (MAA), 65-40 parts of acrylonitrile, 0.10-4.0 parts of initiators, 1.0-20 parts of foaming agents, 1-5 parts of nucleating agents, 0.1-5 parts of cross-linking agents and 5-10 parts of heat-resisting additives; the initiators are azo-bis(4-cyano valeric acid) or mixtures of azo-bis(4-cyano valeric acid) and other azo compounds. The other azo compounds are azodiisobutyronitrile AIBN, azobisisovaleronitrile or azobisisoheptonitrile. According to the micropore polymethacrylimide foam high in thermal deformation temperature, the foam has the small pore diameter phi of 0.1-0.3 mm, thermal resistance is high, the thermal deformation temperature is high and is larger than 200 DEG C, and the mechanical property is excellent.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

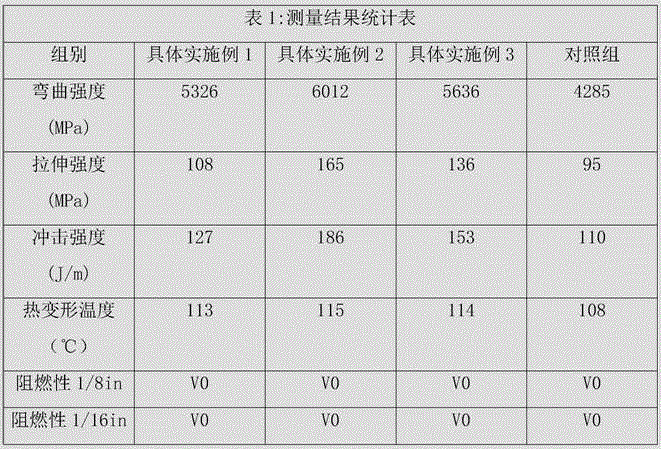

PC/ABS composite based on basalt fiber reinforcement and preparation method thereof

The invention relates to the field of plastic raw materials and particularly relates to a PC / ABS composite based on basalt fiber reinforcement and a preparation method thereof. The PC / ABS composite based on basalt fiber reinforcement comprises the following components in parts by weight: 45-55 parts of PC, 15-25 parts of ABS, 10-20 parts of basalt fiber, 3-8 parts of a toughening agent, 1-2 parts of a lubricant, 1-2 parts of a coupling agent, 2-6 parts of a compatilizer, 5-10 parts of a flame retardant, 1-4 parts of a flame retardant synergist and 0.1-1 part of an antioxidant. The PC / ABS composite provided by the invention has the advantages of high bending strength, high tensile strength, good impact strength, good flame retardance and safety and environmental friendliness.

Owner:DONGGUAN G ONE NUCLEAR MATERIALS CO LTD

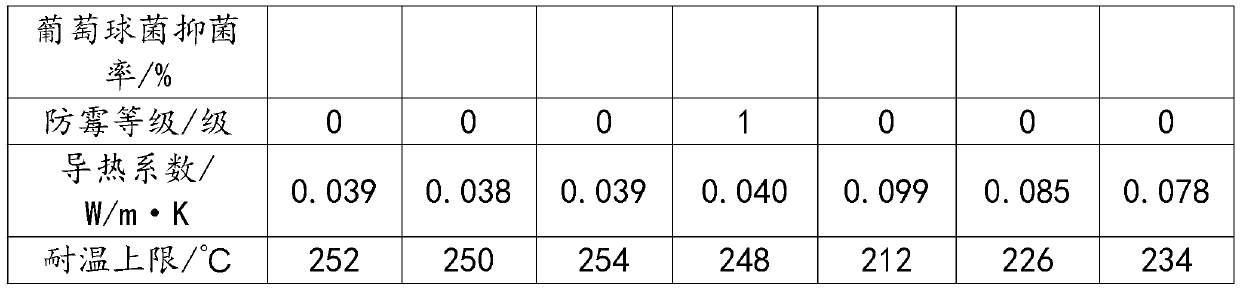

Thermal insulation coating for building exterior walls and preparation method of thermal insulation coating

InactiveCN110484119AHigh porosityExtended heat conduction pathAntifouling/underwater paintsPaints with biocidesThermal insulationRadiant heat

The invention discloses a thermal insulation coating for building external walls. The thermal insulation coating is prepared from the following raw materials in parts by weight: 50-60 parts of modified polyurethane, 30-36 parts of modified composite aerogel, 8-12 parts of floating beads, 1.5-2 parts of rutile titanium dioxide, 1.5-2 parts of silicon carbide, 2-3 parts of mirabilite and 0.6-1 partof an auxiliary agent. The invention also discloses a preparation method of the coating. By adding the composite aerogel, the microporosity in the coating can be greatly improved, and the heat conduction path can be prolonged; besides, the rutile type titanium dioxide and the silicon carbide capable of reflecting radiant heat are introduced to block a propagation path of radiant heat conduction, and a phase change energy storage material mirabilite is introduced, so that the overall performance of the thermal insulation coating can be effectively improved in the coating; by starting from threepaths (conduction, radiation and convection) of heat transfer, the coating has excellent heat preservation and insulation performance; the film-forming substance can endow the paint with favorable antibacterial, mildew-proof and waterproof properties, and the obtained thermal insulation coating is suitable for building exterior walls.

Owner:马鞍山市金韩防水保温工程股份有限公司

Preparation method of flame-retarding nylon 610 and toothbrush hair produced therefrom

InactiveCN105037715AImprove stabilityImprove flame retardant performanceBristleMonocomponent polyamides artificial filamentPolymer sciencePtru catalyst

The invention discloses a preparation method of flame-retarding nylon 610 and toothbrush hairs produced therefrom. The flame-retarding nylon 610 is prepared by mixing and neutralizing sebacic acid with hexamethylendiamine to form amide salt, dissolving the amide salt in water to obtain an amide salt water solution, adding successively a reactive flame retardant, a catalyst and an antioxidant to the reaction system, increasing the temperature and pressure of the reaction system, continuously carrying out the reaction, performing dehydration when the reaction is finished, and reducing the temperature to room temperature and the pressure to normal pressure to obtain the flame-retarding nylon 610. The flame-retarding nylon 610 is subjected to spinning to produce the flame-retarding nylon 610 toothbrush hairs. The preparation method of the flame-retarding nylon 610 is simple in processes and is low in cost. The flame-retarding nylon 610 is prepared under a high pressure, so that the moulding period is effectively reduced and production efficiency is increased. The flame-retarding nylon 610 is good in stability, is free of toxin, is good in flame retarding performance, and can eliminate the inflammable hidden danger during production, storage and use processes of toothbrush hairs.

Owner:淮安市欣佳尼龙有限公司

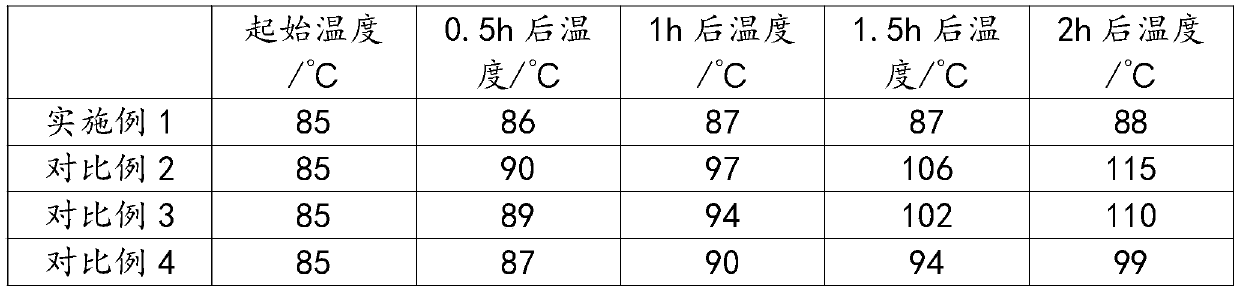

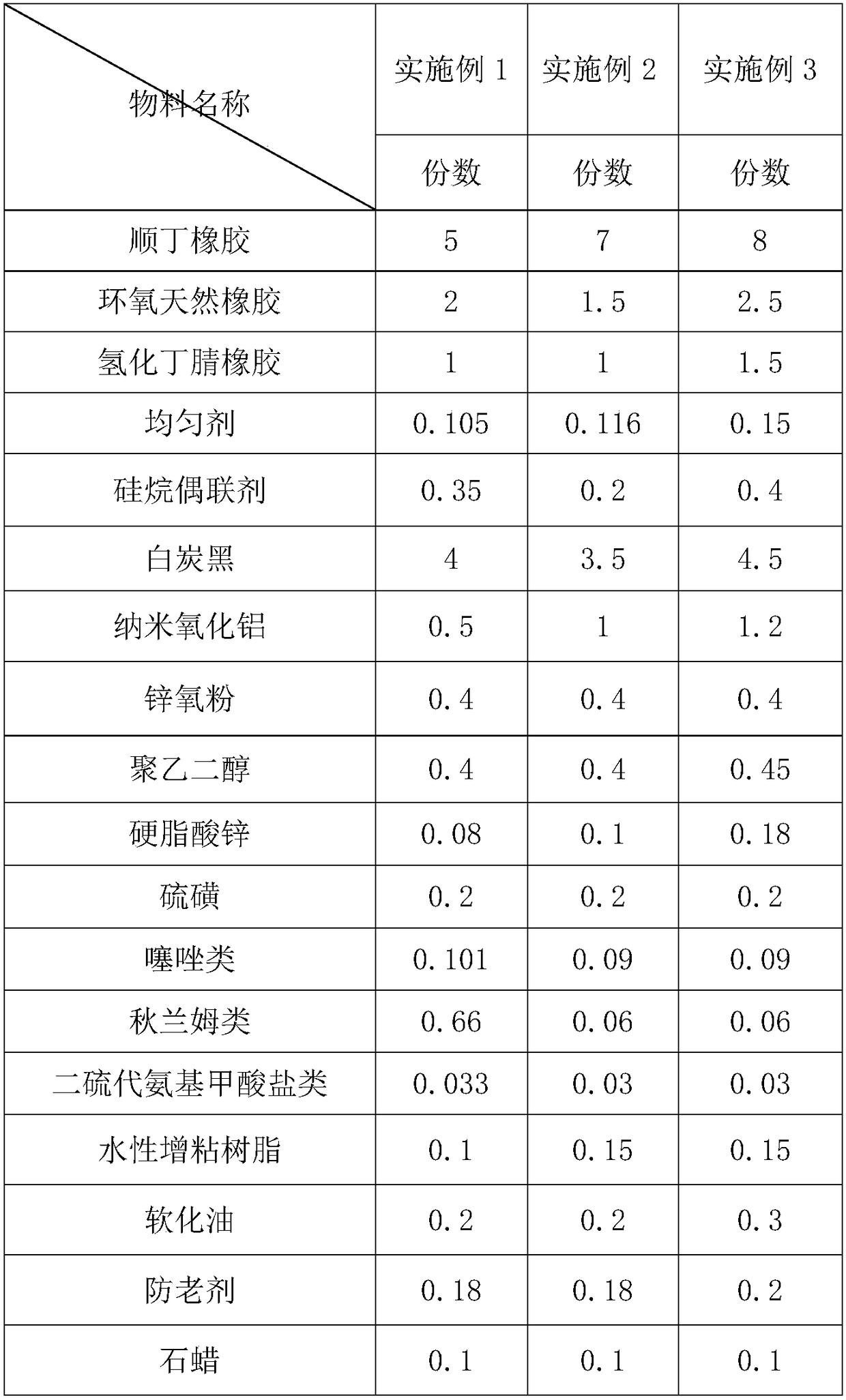

Wear-resistant rubber for sports shoe soles and preparation method thereof

The invention discloses wear-resistant rubber for sports shoe soles. The wear-resistant rubber for the sports shoe soles comprises the following components in parts by mass: 50-80 parts of butadiene rubber, 10-30 parts of epoxy natural rubber, 5-20 parts of hydrogenated butadiene-acrylonitrile rubber, 1-2 parts of a homogenizing agent, 2-5 parts of a silane coupling agent, 25-65 parts of a reinforcing agent, 2-5 parts of zinc oxide powder, 2-5 parts of polyethylene glycol, 0.5-2 parts of zinc stearate, 1.5-2 parts of a vulcanizing agent, 1.6-2.1 parts of an accelerator, 0.5-2 parts of a tackifier, 2-5 parts of a softening oil, 1-3 parts of an anti-aging agent and 0.5-1 part of paraffin. The invention further provides a preparation method of the wear-resistant rubber for the sports shoe soles. Wear-resistant rubber shoe soles for the sports shoe soles, prepared according to the technical scheme adopted by the invention, have super wear resistance which is incomparable with that of ordinary rubber soles, and have many properties such as good weather resistance and folding resistance; the preparation method is simple in production process and is suitable for wide application.

Owner:ANTA CHINA

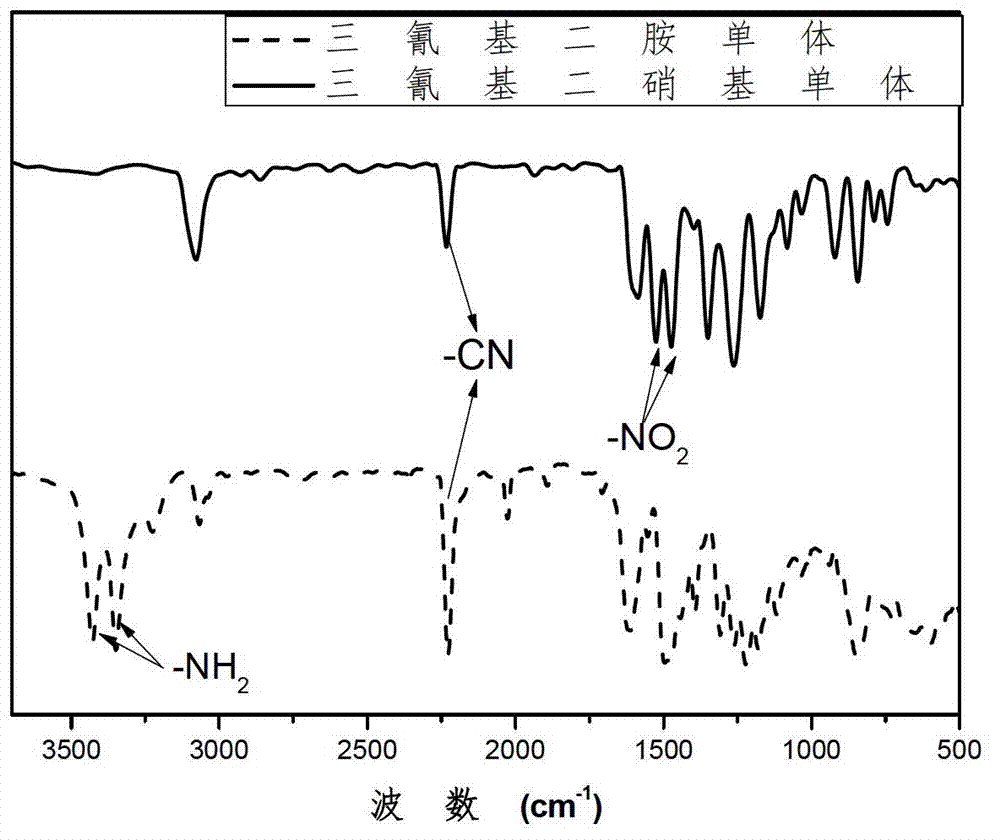

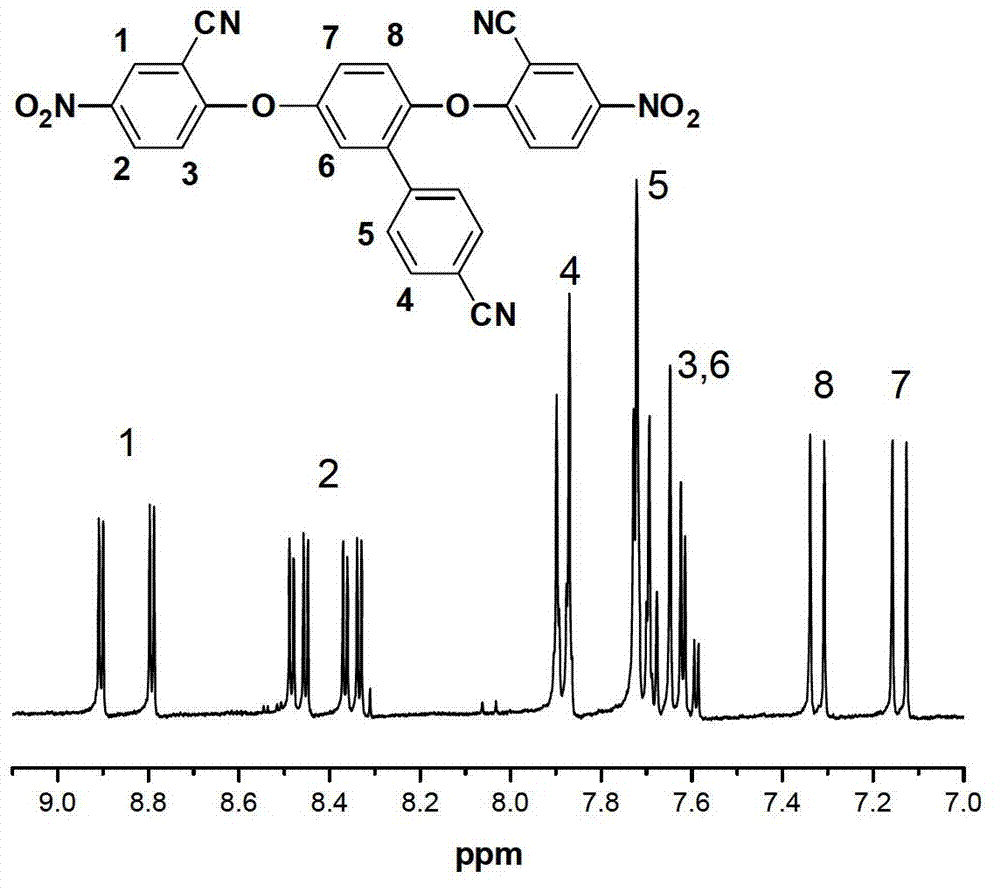

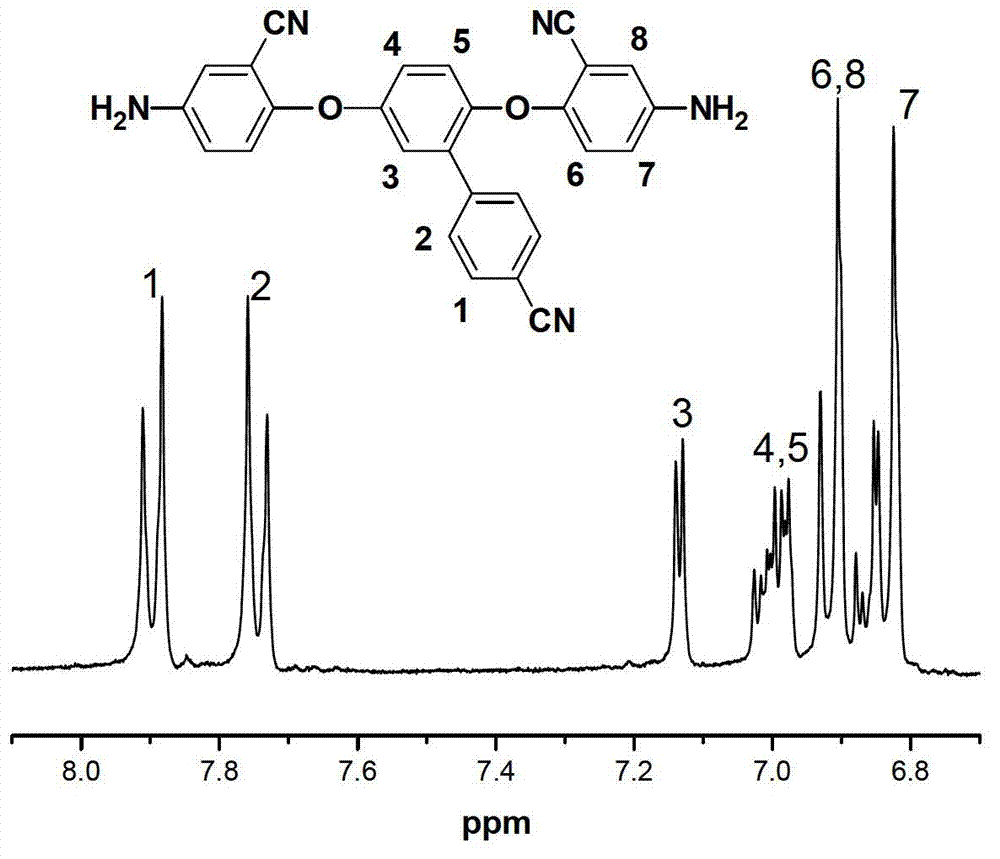

Multi-cyandiamine monomer and preparation and application thereof

InactiveCN103193674AHigh degree of sulfonationSmall swelling coefficientCarboxylic acid nitrile preparationOrganic compound preparationFuel cellsProton

The invention relates to a multi-cyandiamine monomer and preparation and application thereof, and belongs to the technical field of polymer materials and synthesis thereof. The multi-cyandiamine monomer includes tricyandiamine monomers and tetrocyandiamine monomers. The multi-cyandiamine monomer is polymerized with anhydride to obtain polyimide. Various multi-cyanpolyimide polymers are obtained by chemistry ring-closure and heat ring-closure methods. The polyimide polymer is dissolved in a solvent and a plate coating method is used for paving a film to obtain a desired polyimide film material. The multi-cyanpolyimide material of the invention possesses high thermal stability, excellent film-forming property and excellent adsorbability and dimension stability caused by microscopic intermolecular interaction. The cyan can also be introduced to a sulfonate polyimide material to enhance intermolecular forces between main chains, reduce a swelling coefficient of the sulfonate polyimide material, and enhance dimension stability of the film material which can be used as a proton conduction film material for a fuel cell.

Owner:JILIN UNIV

Polymethacrylimide foam with uniform pores and preparation method thereof

The invention relates to the field of new material preparation, and concretely relates to polymethacrylimide foam with uniform pores and a preparation method thereof and a product thereof. The methodis capable of mixing (methyl)acrylic acid, (methyl)acrylonitrile, a third comonomer, an initiator, a foaming agent, a crosslinking agent, a nucleating agent, and a zinc-copper-doped high temperature-resistant surfactant, and performing a reaction to obtain a transparent prepolymer; the transparent prepolymer is heat-treated, and the polymethacrylimide foam having uniform pores is obtained. The surfactant used in the method does not affect the reaction, so the original preparation process does not need to be changed, and the method is simple and convenient; different active agent amounts can beselected according to different foaming temperatures, or complex formulation is carried out, the surface tension during foaming can be regulated and controlled to prepare pore sizes with different sizes, and fine and uniform pores can be obtained; the introduction of atoms such as fluorine and silicon can increase the intermolecular force, and the heat resistance of the material can be increasedat a certain extent.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

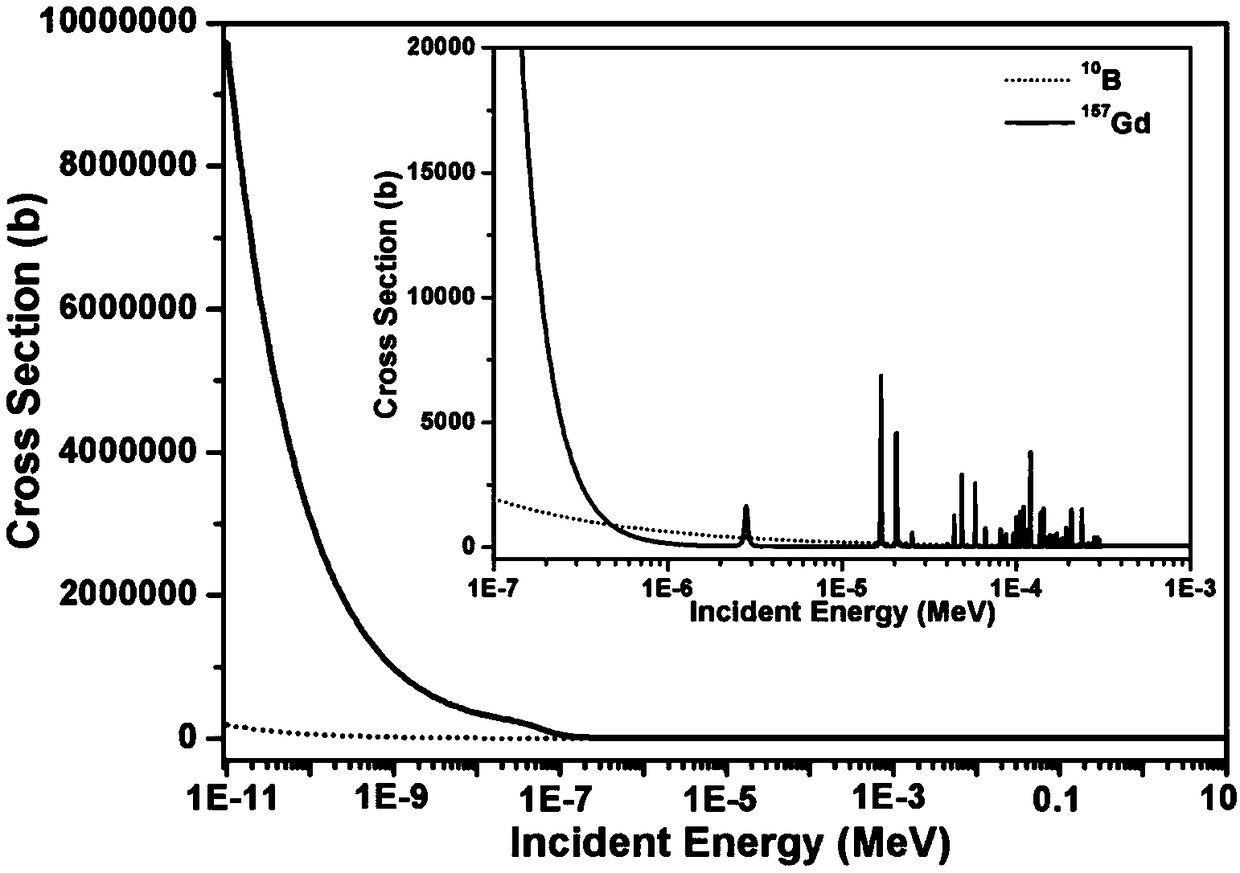

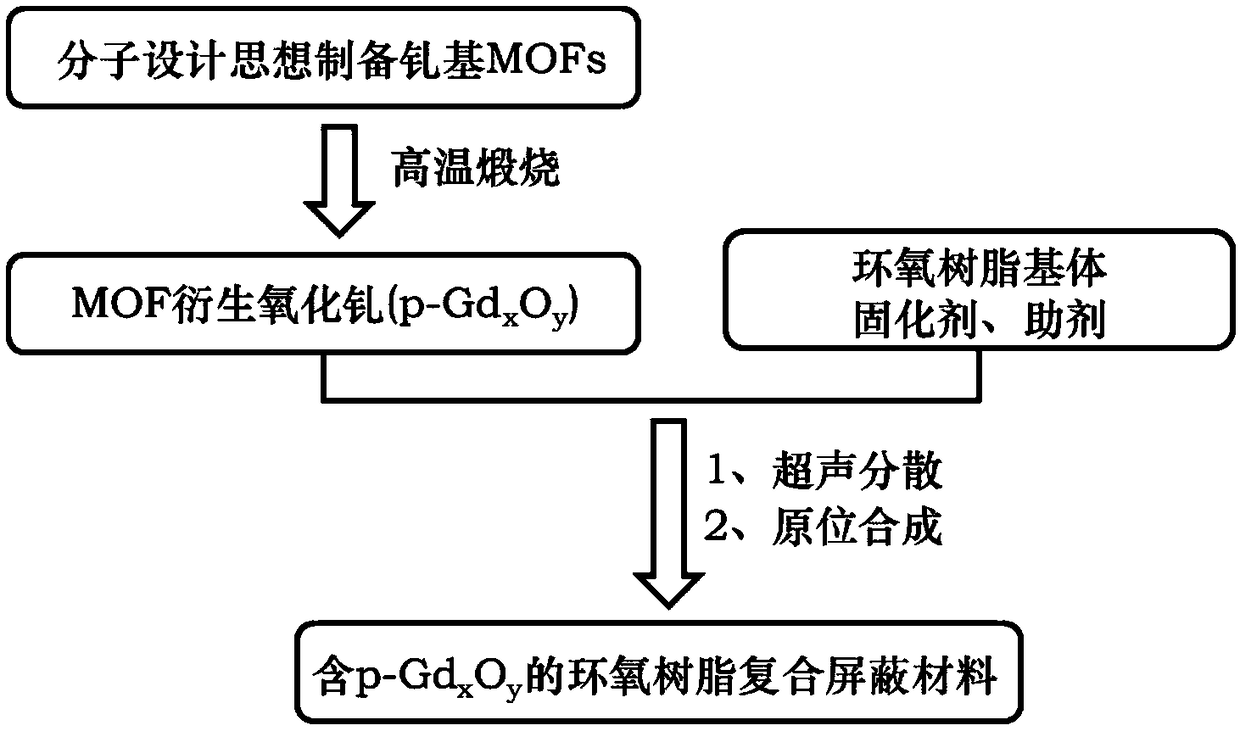

Compound shielding material containing MOF derivative porous gadolinium oxide and preparation method

The invention discloses a compound shielding material containing MOF derivative porous gadolinium oxide and a preparation method and relates to the field of neutron radiation protection. The compoundshielding material is prepared from the following raw materials in parts by weight: 1-100 parts of epoxy resin, 1-10 parts of curing agent, 1-100 parts of auxiliaries and 1-100 parts of MOF derivativegadolinium oxide, wherein the porous gadolinium oxide is acquired from the process of high-temperature calcination and pyrolysis of gadolinium-based metallic organic framework material. Epoxy resin is a neutron slowing material; gadolinium element is a neutron absorbing material; the porous feature of MOF derivative gadolinium oxide is beneficial to strong interaction with an epoxy resin substrate. The compound shielding material containing MOF derivative porous gadolinium oxide provided by the invention has excellent thermal neutron shielding capacity, high thermal stability and high mechanical stability.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

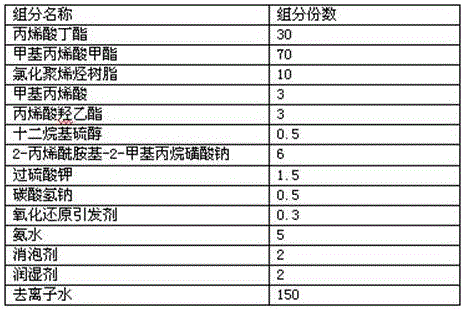

Hydrophobic under-coating paint for polyolefin film and preparation method of hydrophobic under-coating paint

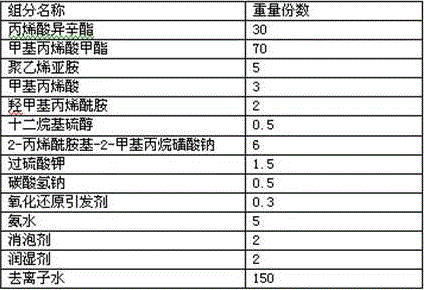

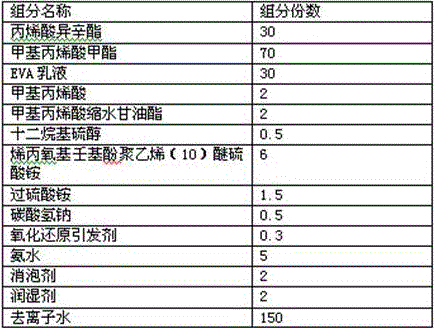

The invention provides hydrophobic under-coating paint applied to a poor-polarity polyolefin film. The under-coating paint is prepared from the following components in parts by weight: 30-50 parts of soft monomers, 50-70 parts of hard monomers, 5-30 parts of vinyl monomers, vinyl monomer synthetic resin, vinyl monomer synthetic emulsion or polyethyleneimine, 1-10 parts of acidic functional monomers, 1-10 parts of cross-linking monomers, 2-6 parts of a reaction type emulsifying agent, 0.5-2 parts of an initiating agent, 0.1-1 part of lauryl mercaptan, 0.5-2 parts of an antifoaming agent, 0.5-2 parts of a wetting agent and 140-160 parts of deionized water by an emulsion polymerization method, wherein the vinyl monomers are vinyl acetate, vinyl ester of tertary carboxylic acids, butadiene, isoprene, vinyl chloride or vinylidene chloride, the vinyl monomer synthetic resin is chlorinated polyolefin resin, and the vinyl monomer polymerization emulsion is an EVA emulsion. The under-coating paint disclosed by the invention is low in cost, has favorable adhesive force to the polyolefin films, and can provide favorable ink-printing adaptability. The invention further provides a preparation method of the under-coating paint.

Owner:汕头市龙湖昌丰化工有限公司

Preparation method of silica gel with high flame retardant rating

The invention discloses a preparation method of silica gel with high flame retardant rating. The silica gel with high flame retardant rating is prepared by mixing the following raw materials in parts: a raw material A: methyl vinyl silicon rubber; a raw material B: methyl vinyl silicon rubber; a raw material C: precipitated silica; a raw material D: hydroxyl silicon oil; a raw material E: dimethyl diethoxy silane; a raw material F: zinc stearate; a raw material G: stearic acid; a raw material H: methyl silicone oil; a raw material I: aluminum hydroxide; a raw material J: zinc stannate; a raw material K: vinyl trimethoxy silane; a raw material L: platinum water; a raw material M: benzotriazole; a raw material N: ferric oxide; a raw material P: magnesium oxide; and a few of raw material Q: curing agent. The silica gel raw material prepared by mixing the raw materials is excellent in flame retardant performance which can reach 5VB and 5VA of UL94 flame retardant rating.

Owner:东莞市朗晟材料科技有限公司

Efficient non-toxic rare earth calcium-zinc stabilizer and production method thereof

ActiveCN103254524AReduce the speed of the catalytic reactionAvoid generatingPowder mixtureStearic acid

The invention discloses an efficient non-toxic rare earth calcium-zinc stabilizer which comprises the following components in parts by weight: 10-15 parts of lanthanum citrate, 33-36 parts of calcium stearate, 8-13 parts of zinc stearate, 7-11 parts of epoxidized soybean oil, 28-31 parts of layered bihydroxy composite metal oxide (LDH) and 3-7 parts of stearoyl benzoyl methane. The production method comprises the following steps: A, sequentially adding and adequately stirring lanthanum citrate, calcium stearate, zinc stearate, epoxidized soybean oil, layered bihydroxy composite metal oxide (LDH) and stearoyl benzoyl methane; B, weighing the epoxidized soybean oil and uniformly spraying the epoxidized soybean oil into a solid powder mixture being stirred; and C, after spraying the epoxidized soybean oil, further stirring for 5-10 minutes. The stabilizer does not contain heavy metals such as lead, and is non-toxic and harmful, very environment-friendly, lower in cost and good in stability, mobility and compatibility.

Owner:CHONGQING BAOHUA CHEM ADDITIVE PLANT

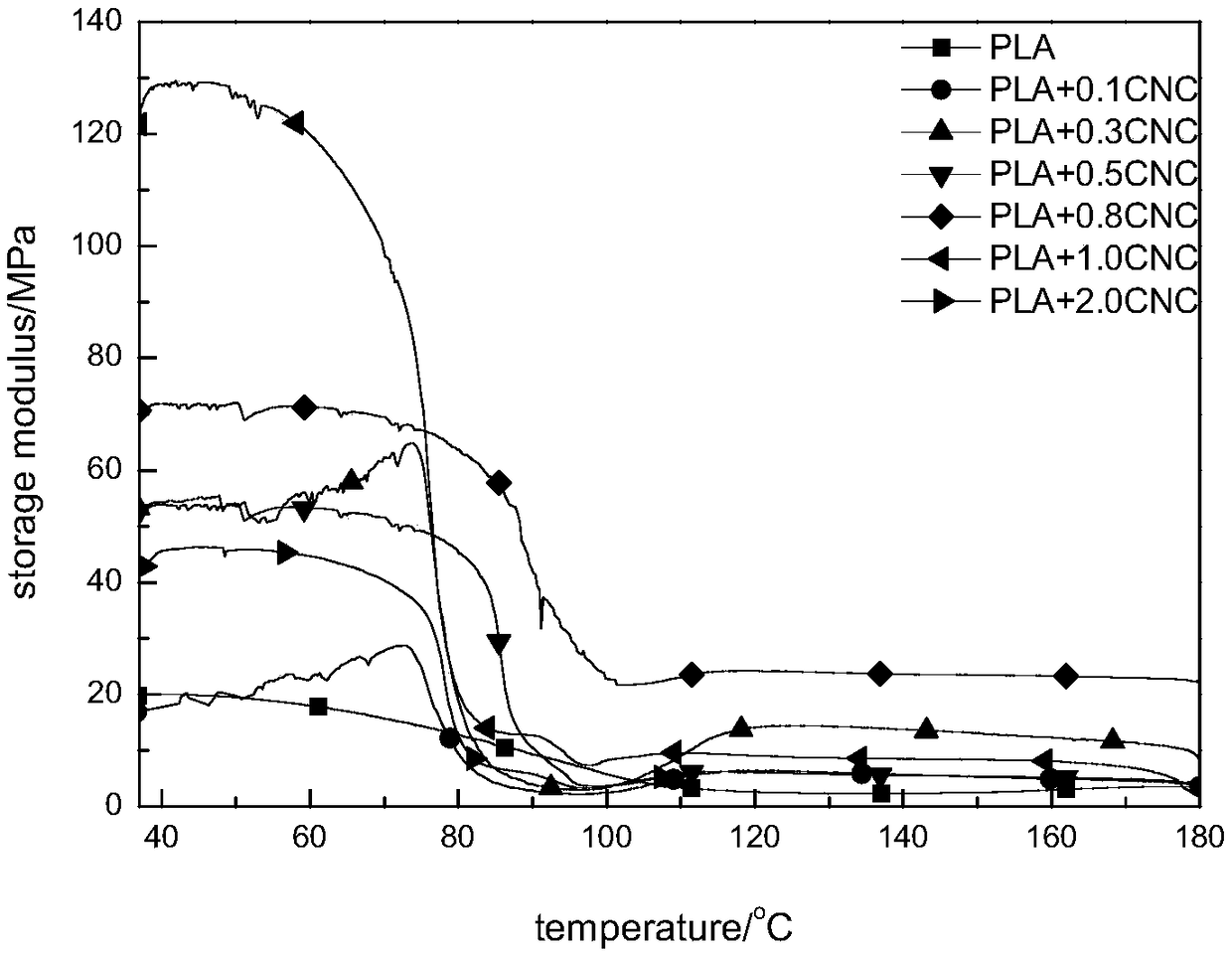

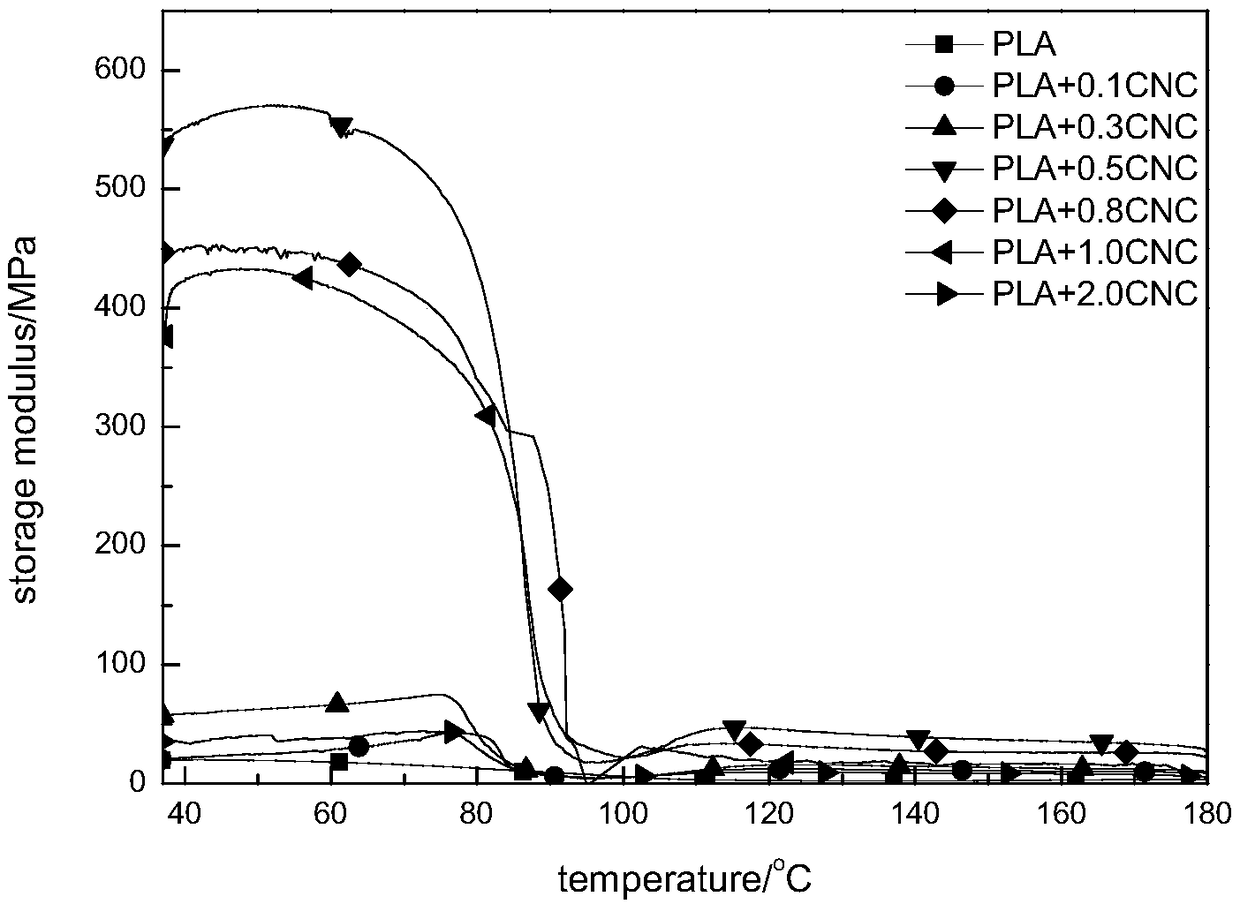

High-performance bio-based composite film and preparation method thereof

InactiveCN108893871AAvoid stickingImprove hydrophilicityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberComposite film

The invention discloses high-performance bio-based composite film and a preparation method thereof, and belongs to the technical field of functional materials. The method mainly adopts polylactic acidas matrix, and uses cellulose nanocrystal as a reinforcing filler, composite fiber film is prepared by an electrospinning method, the addition of the cellulose nanocrystals can increase the storage modulus of the composite film by up to 500%, after water is absorbed, the storage modulus can be increased by up to 900%, the storage modulus of the composite film is obviously improved, pores are larger, cells can be effectively adsorbed and grown on the fiber film, the mechanical strength is also improved, and the addition of the the cellulose nanocrystals further broadens the application of polylactic acid in the field of biomedicine. The method uses an acid hydrolysis method to prepare the cellulose nanocrystals, cellulose raw material sources are wide, the acid hydrolysis method is simpleand easy to operate, and a product price is low. The film functions as a medical stent to promote drug absorption and cell growth.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

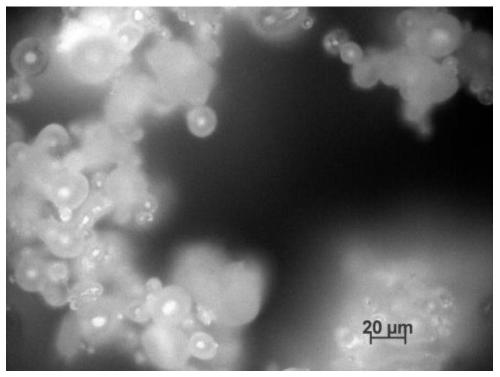

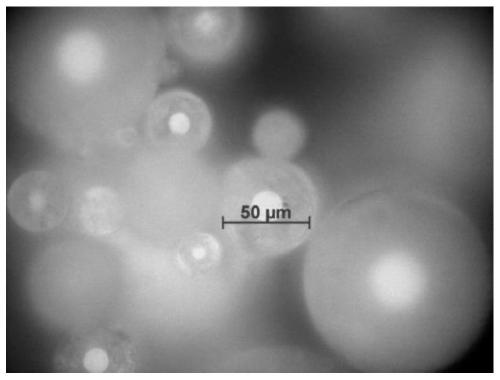

Amorphous polyaryletherketone/sulfone powder for laser sintering 3D printing and preparation method of amorphous polyaryletherketone/sulfone powder

The invention provides amorphous polyaryletherketone / sulfone powder for laser sintering and a preparation method of the amorphous polyaryletherketone / sulfone powder, and belongs to the technical fieldof additive manufacturing. The method comprises the following steps: dissolving amorphous PEKN / sulfone resin coarse powder in a solvent, blending with water, a stabilizer and an emulsifier in a reaction container, and stirring at a high speed at 40-50 DEG C to form an emulsion; heating to 90-95 DEG C in a gradient manner, and evaporating to remove the solvent; and cooling to room temperature, filtering, washing with water and drying to obtain the amorphous polyaryletherketone / sulfone powder for laser sintering. The amorphous polyaryletherketone / sulfone laser sintering powder material which ishigh in sphericity degree, uniform and controllable in particle size and good in fluidity is prepared through a solvent emulsification method.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Photosensitive developed special line transfer glue for sapphire glass base material and preparation method thereof

InactiveCN108517196AImprove performanceGood synergyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhosphate

The invention discloses photosensitive developed special line transfer glue for a sapphire glass base material and a preparation method thereof. The photosensitive developed special line transfer glueis prepared from an acrylic ester active monomer, a photoinitiator, an acrylic acid phosphate assistant, a silane coupling agent, polyester acrylate, and urethane acrylate. The transfer glue does notcontain an organic solvent, and is environmentally friendly. A transfer technology is used as the foundation, and the advantages of a photosensitive developing technology are organically fused, the advantages are adopted and the defects are avoided. Especially, a product of the transfer glue not only can use the organic solvent for developing, but also can use pure water for developing, and is environmentally friendly, non-inflammable and non-explosible, and is a future tendency. The transfer glue has the excellent properties of solvent corrosion resistance, cold and thermal shock resistanceand the like after curing, and an adhesive force of a glue layer and the sapphire glass base material is excellent, especially, the adhesive force of the glue layer and the sapphire glass base material is greater than or equal to 4B after a water boiling test. The transfer glue is capable of solving problems of current UV glue that the adhesive force on the sapphire glass base material is poor, the water boiling is not resistant, and the solvent is not resistant.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

Preparation method of heat-resistant polyimide molding powder containing benzimidazole structure

PendingCN111533907AImprove heat resistanceIncrease intermolecular forcesPolymer sciencePtru catalyst

The invention discloses a preparation method of heat-resistant polyimide molding powder containing a benzimidazole structure. The preparation method comprises the following steps: synthesizing poly(amic acid) with higher molecular weight from a diamine monomer containing a benzimidazole structure and an aromatic dianhydride monomer in an aprotic solvent, adding a catalyst and a dehydrating agent into the poly(amic acid), settling, washing and drying to obtain the heat-resistant polyimide molding powder containing the benzimidazole structure. The polyimide prepared by the preparation method disclosed by the invention not only has excellent thermal stability, but also has good solubility and excellent comprehensive performance.

Owner:HEFEI UNIV OF TECH

Flame-retardant corrosion-resistant polyurethane coating material

InactiveCN109735222AImprove corrosion resistanceImprove hydrophobicityFireproof paintsGroup 5/15 element organic compoundsEpoxyEthyl acetate

The invention discloses a flame-retardant corrosion-resistant polyurethane coating material, which comprises the following raw materials in parts by weight: 75-85 parts of polyurethane prepolymer, 15-25 parts of alkyd resin, 2-5 parts of dimethyl silicone oil, 2-5 parts of epoxy resin, 1-3.8 parts of perfluorooctanol, 0.5-1.5 parts of graphene oxide, 2-3.8 parts of nano boron carbide, 1-5 parts ofbentonite, 0.3-1.5 parts of trimethylolpropane, 0.5-1.3 parts of dipropylene glycol, 2-3 parts of paraxylene, 3-7 parts of ethyl acetate, 0.1-1 part of a silane coupling agent and 2-3.9 parts of plasticizers. The polyurethane prepolymer is prepared from diisocyanate, phosphorus-modified glycol and polyoxypropylene glycol as raw materials. The flame-retardant corrosion-resistant polyurethane coating material has high adhesive force with a basal body, good flame retardancy and excellent corrosion resistance.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com