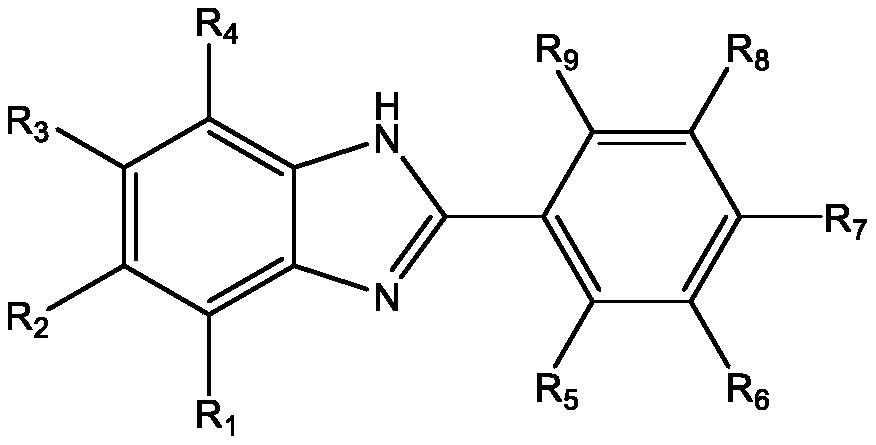

Preparation method of heat-resistant polyimide molding powder containing benzimidazole structure

A technology of benzimidazole and polyimide, which is applied in the field of polymer molding powder preparation, can solve the problems of polyimide heat resistance reduction, achieve stable performance, control the reaction process, and strengthen the intermolecular force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

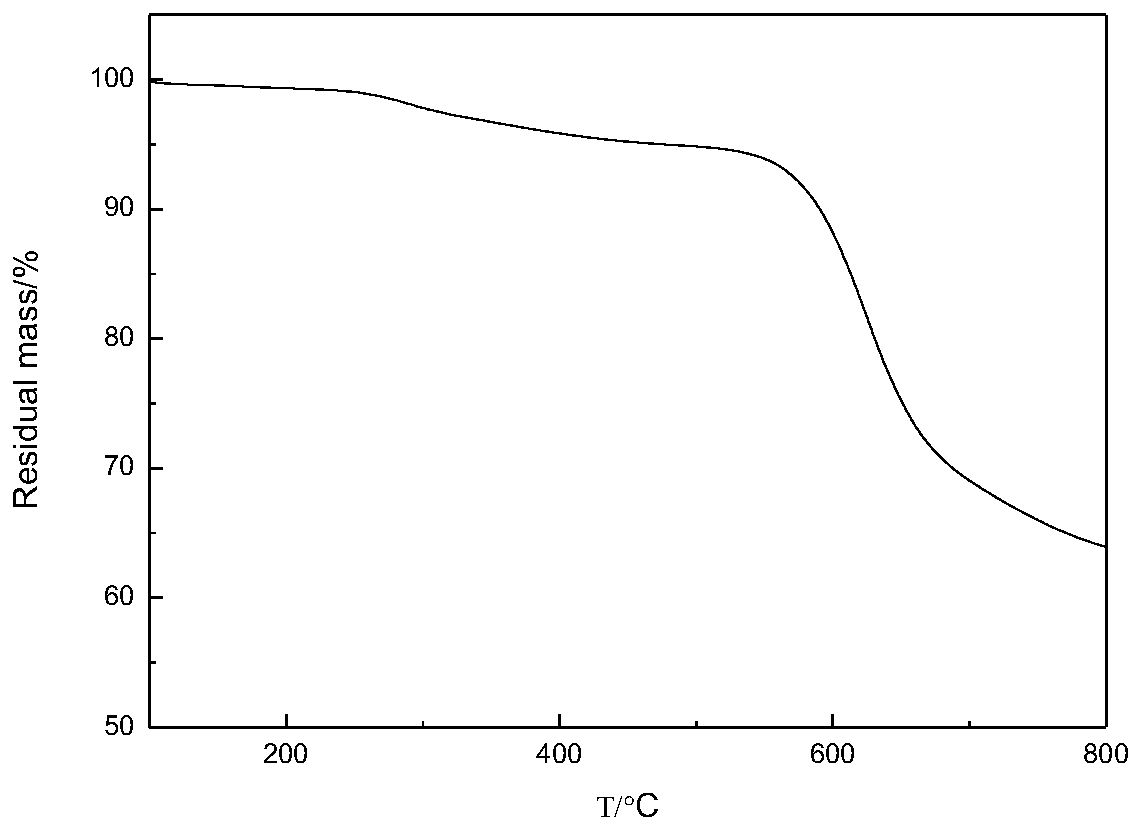

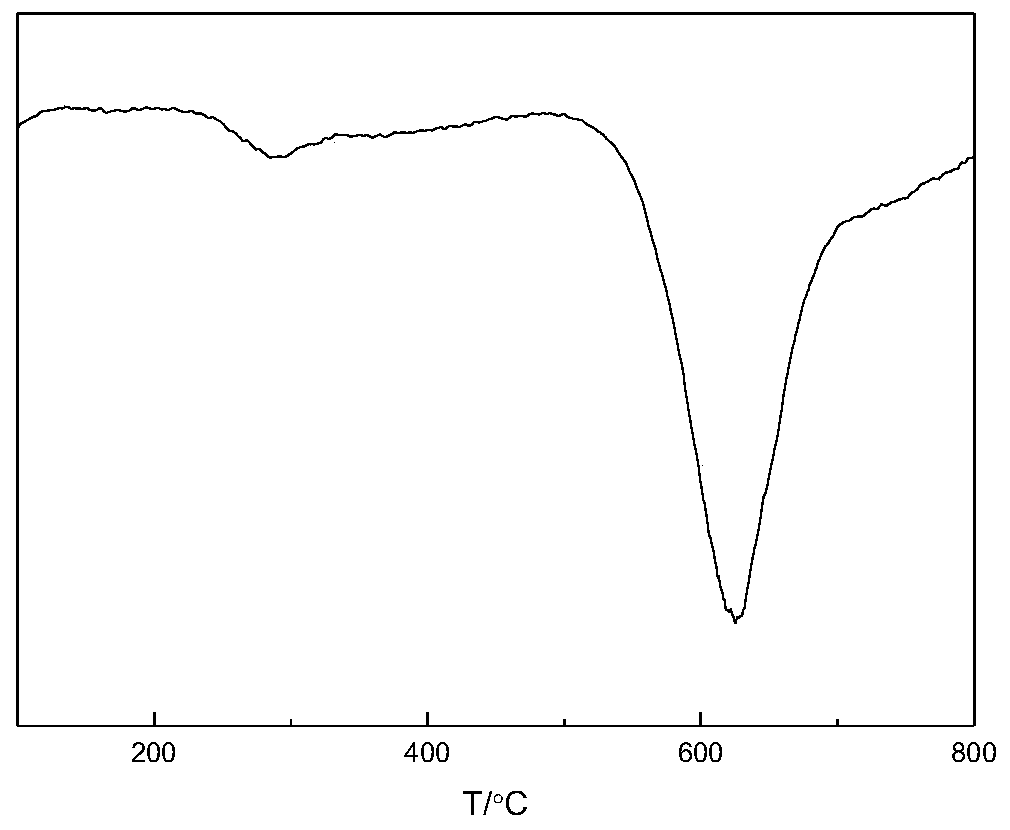

Embodiment 1

[0031] 1. Synthesis of polyamic acid: APABI:BPDA=1:1.03 molar ratio. First add 2-(4-aminophenyl)-5-aminobenzimidazole into the measured solvent N,N-dimethylacetamide, stir under nitrogen to completely dissolve APABI in the solvent, then slowly add Phthalic anhydride, divided into BPDA three times, mechanically stirred, added once every 15 minutes, and ensured that the dianhydride added in the previous time was completely dissolved. When the dianhydride was added for the last time, the viscosity of the solution rose sharply. After the reaction is finished, a polyamic acid solution with larger molecular chains is obtained.

[0032] 2. Preparation of polyimide molding powder: Slowly add catalyst triethylamine and dehydrating agent acetic anhydride to polyamic acid solution, react at 30°C for one hour, then rise to 80°C for one hour, then cool to room temperature , slowly added xylene under stirring at room temperature, the temperature of the oil bath was raised to 150° C. and th...

Embodiment 2

[0035] 1. Synthesis of polyamic acid: APABI:BPDA=1:1.05 molar ratio. First add 2-(4-aminophenyl)-5-aminobenzimidazole into the measured solvent N,N-dimethylacetamide, stir under nitrogen to completely dissolve APABI in the solvent, then slowly add Phthalic anhydride, divided into BPDA three times, mechanically stirred, added once every 15 minutes, and ensured that the dianhydride added in the previous time was completely dissolved. When the dianhydride was added for the last time, the viscosity of the solution rose sharply. After the reaction is finished, a polyamic acid solution with larger molecular chains is obtained.

[0036]2. Preparation of polyimide molding powder: Slowly add catalyst triethylamine and dehydrating agent acetic anhydride to polyamic acid solution, react at 30°C for one hour, then rise to 80°C for one hour, then cool to room temperature , slowly added xylene under stirring at room temperature, the temperature of the oil bath was raised to 150° C. and the...

Embodiment 3

[0038] 1. Synthesis of polyamic acid: APABI:BPDA=1:1.07 molar ratio. First add 2-(4-aminophenyl)-5-aminobenzimidazole into the measured solvent N,N-dimethylacetamide, stir under nitrogen to completely dissolve APABI in the solvent, then slowly add Phthalic anhydride, divided into BPDA three times, mechanically stirred, added once every 15 minutes, and ensured that the dianhydride added in the previous time was completely dissolved. When the dianhydride was added for the last time, the viscosity of the solution rose sharply. The reaction is over. A polyamic acid solution with a larger molecular chain is obtained.

[0039] 2. Preparation of polyimide molding powder: Slowly add catalyst triethylamine and dehydrating agent acetic anhydride to polyamic acid solution, react at 30°C for one hour, then rise to 80°C for one hour, then cool to room temperature , slowly added xylene under stirring at room temperature, the temperature of the oil bath was raised to 150° C. and the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com