Patents

Literature

3151results about How to "Reaction is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthetizing biological diesel oil by oil and fat materials

ActiveCN1472280AMild reaction conditionsThe reaction process is simple and easy to controlLiquid hydrocarbon mixture productionBio-feedstockEnzymeEthyl ester

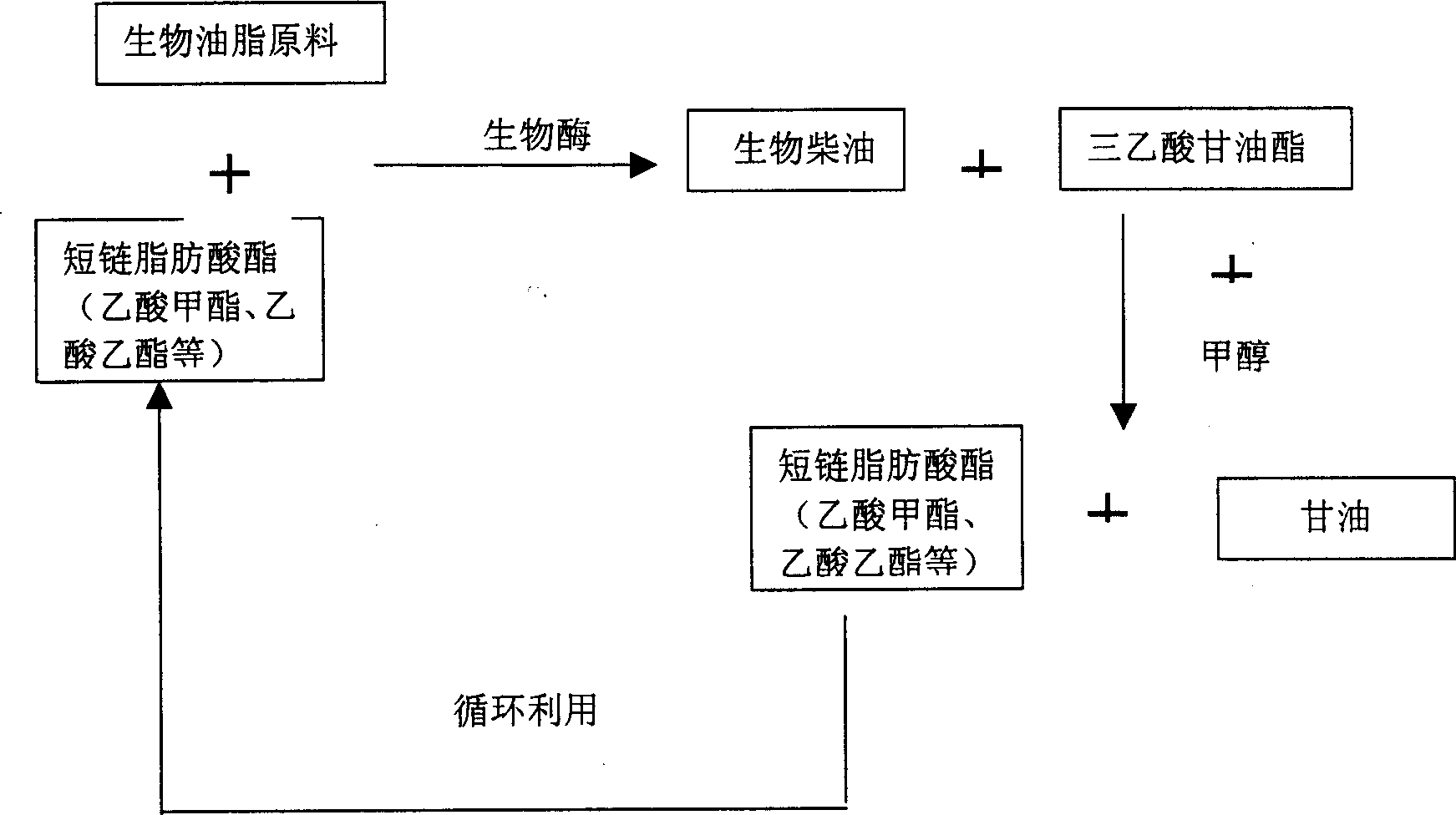

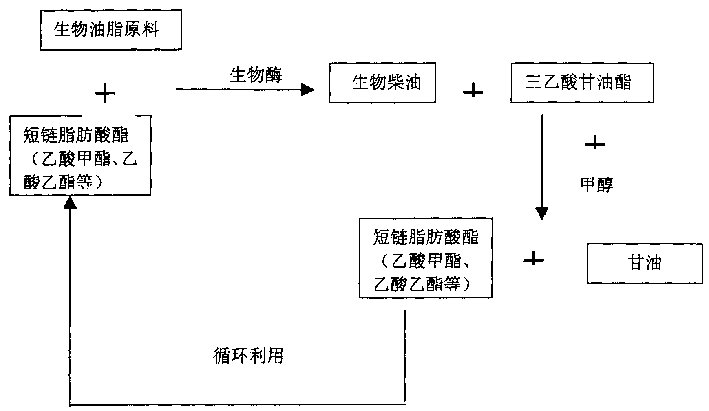

A process for synthesizing biologic diesel oil from raw oil material features that the short-chain ester of fatty acid (methyl acetate or ethyl acetate) is used as acyl receptor and the biologic enzyme is used to catalyze the transesterifying reaction of oil, and includes such steps as transesterifying reaction between said ester of fatty acid and oil to obtain biologic diesel oil and glyceride triacetate, and reaction between said glyceride triacetate and methanol to obtain short-chain ester for fatty acid for cyclic use.

Owner:TSINGHUA UNIV

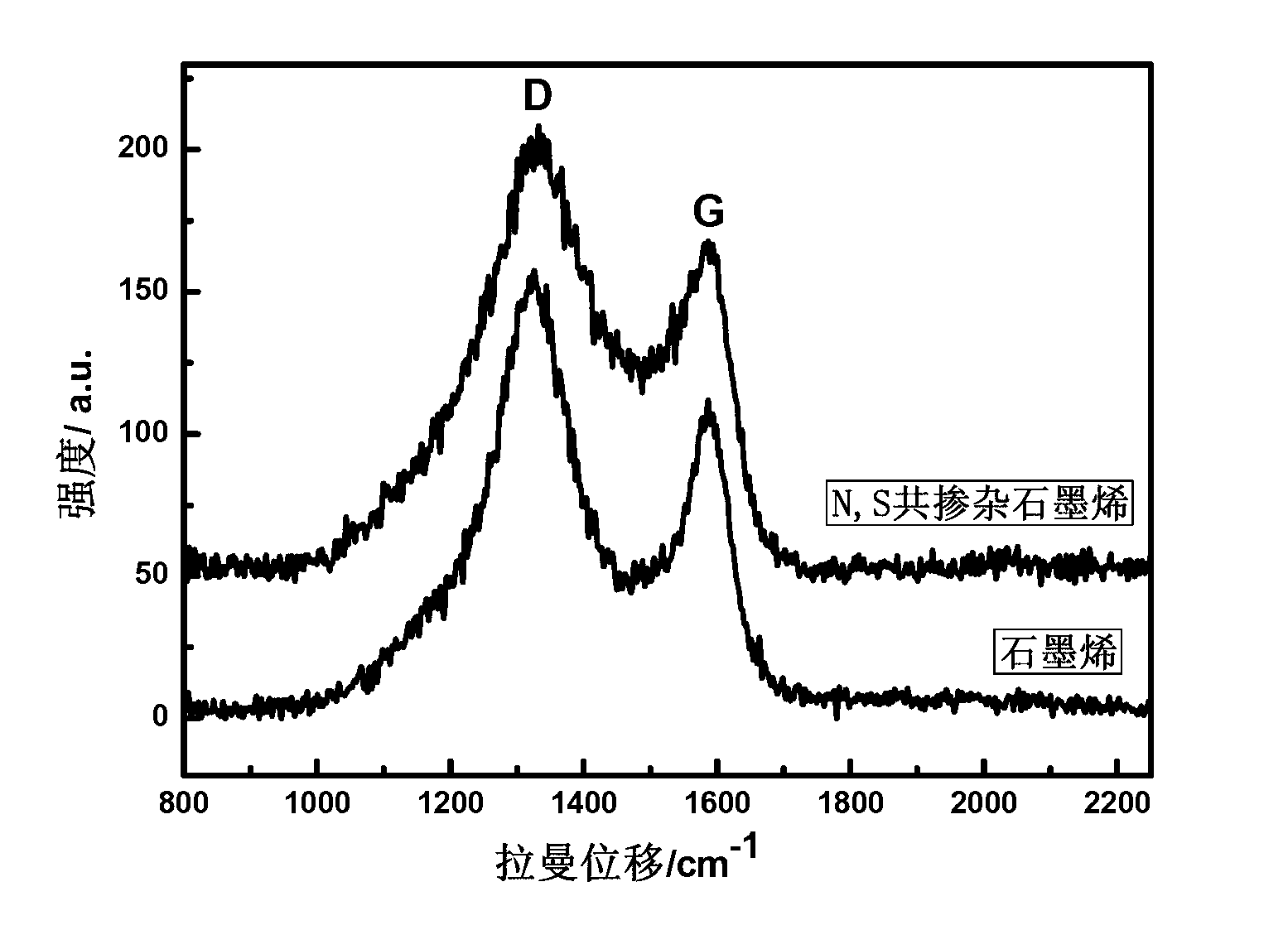

Preparation method of nitrogen and sulfur co-doped graphene

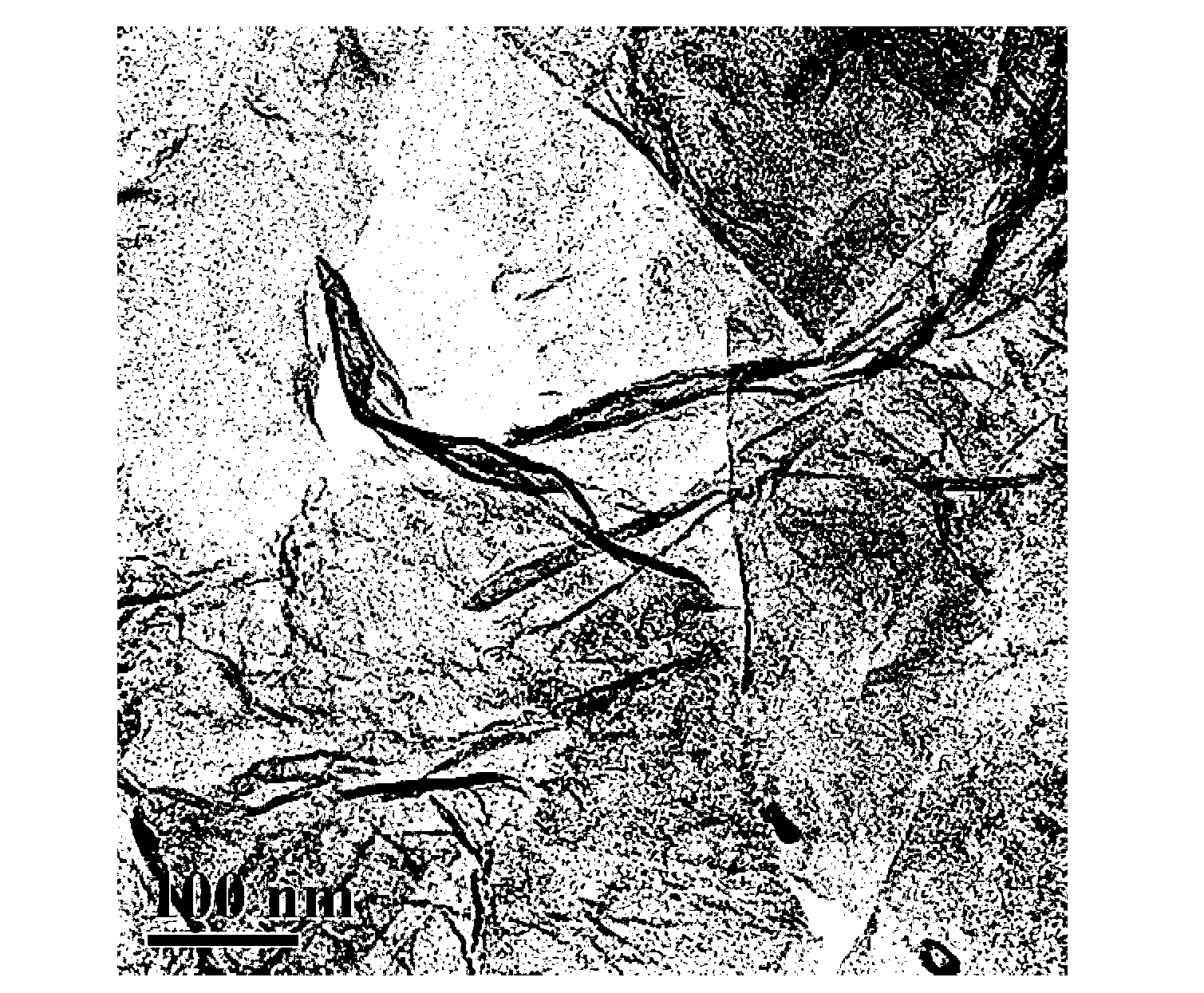

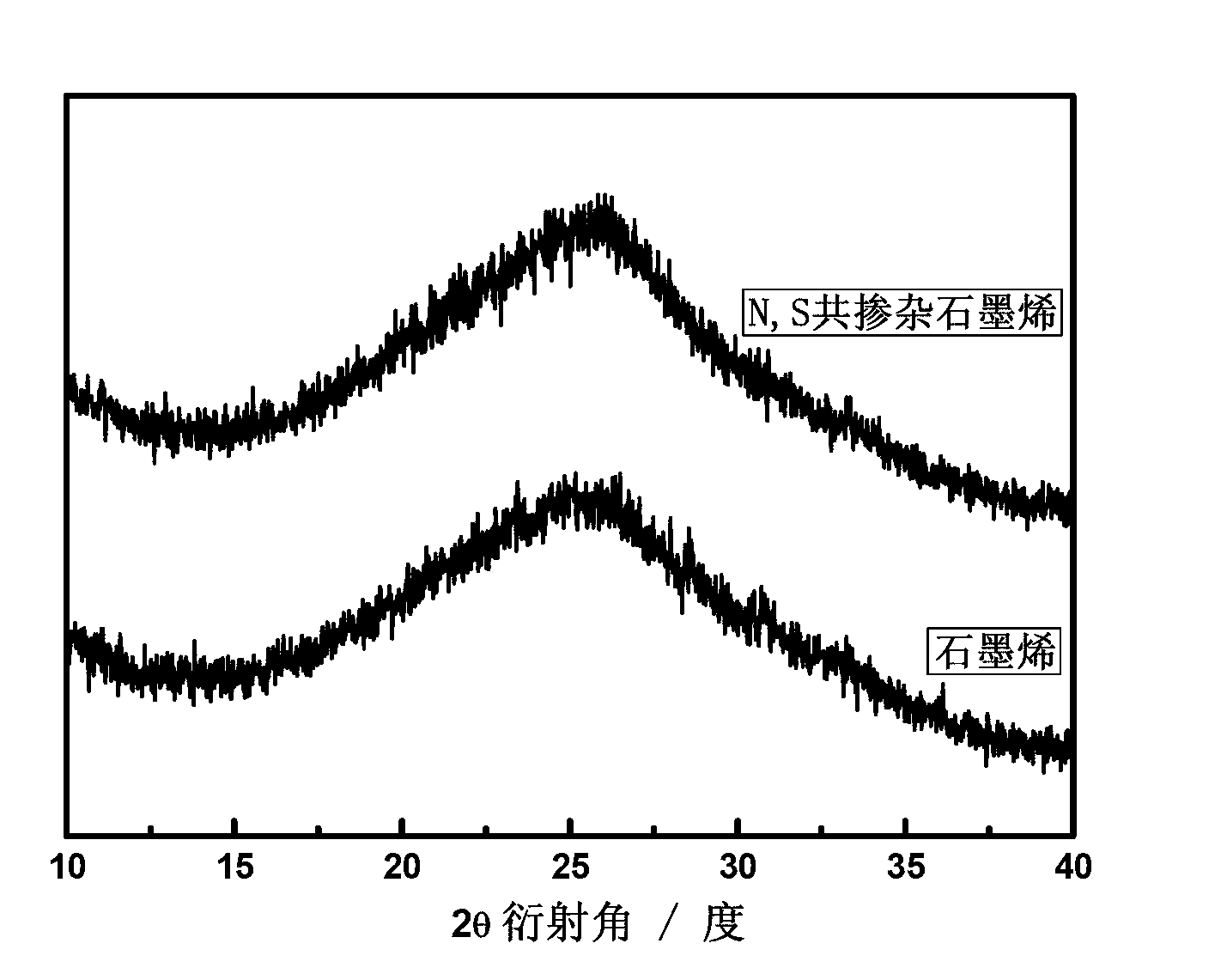

The invention discloses a nitrogen and sulfur co-doped graphene. The method comprises the following steps: grinding and uniformly mixing graphene or a graphene derivative, a nitrogen-containing compound and a sulfur-containing compound, carrying out thermal annealing under the protection of an inert gas at a temperature of 500-1000DEG C, maintaining the temperature for 1-5h, and cooling to room temperature to obtain the nitrogen and sulfur co-doped graphene, wherein content of the nitrogen element in the nitrogen and sulfur co-doped graphene is 1-10at.%, and the content of the sulfur element in the nitrogen and sulfur co-doped graphene is 0.5-2at.%. The method has the advantages of simple technology, low cost, easy control of the reaction process and the like, is suitable for the industrial large-scale production, and can be used in the super capacitor field, the sensor field, the catalytic field, the fuel battery field, the lithium air battery field and the like.

Owner:SOUTH CHINA UNIV OF TECH

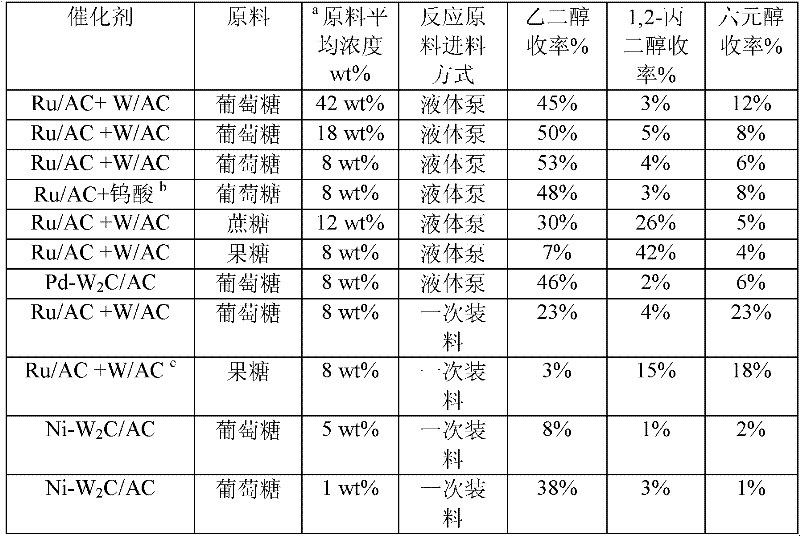

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

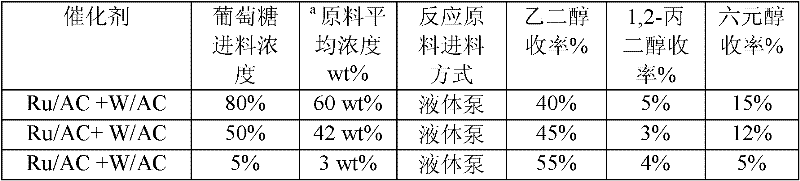

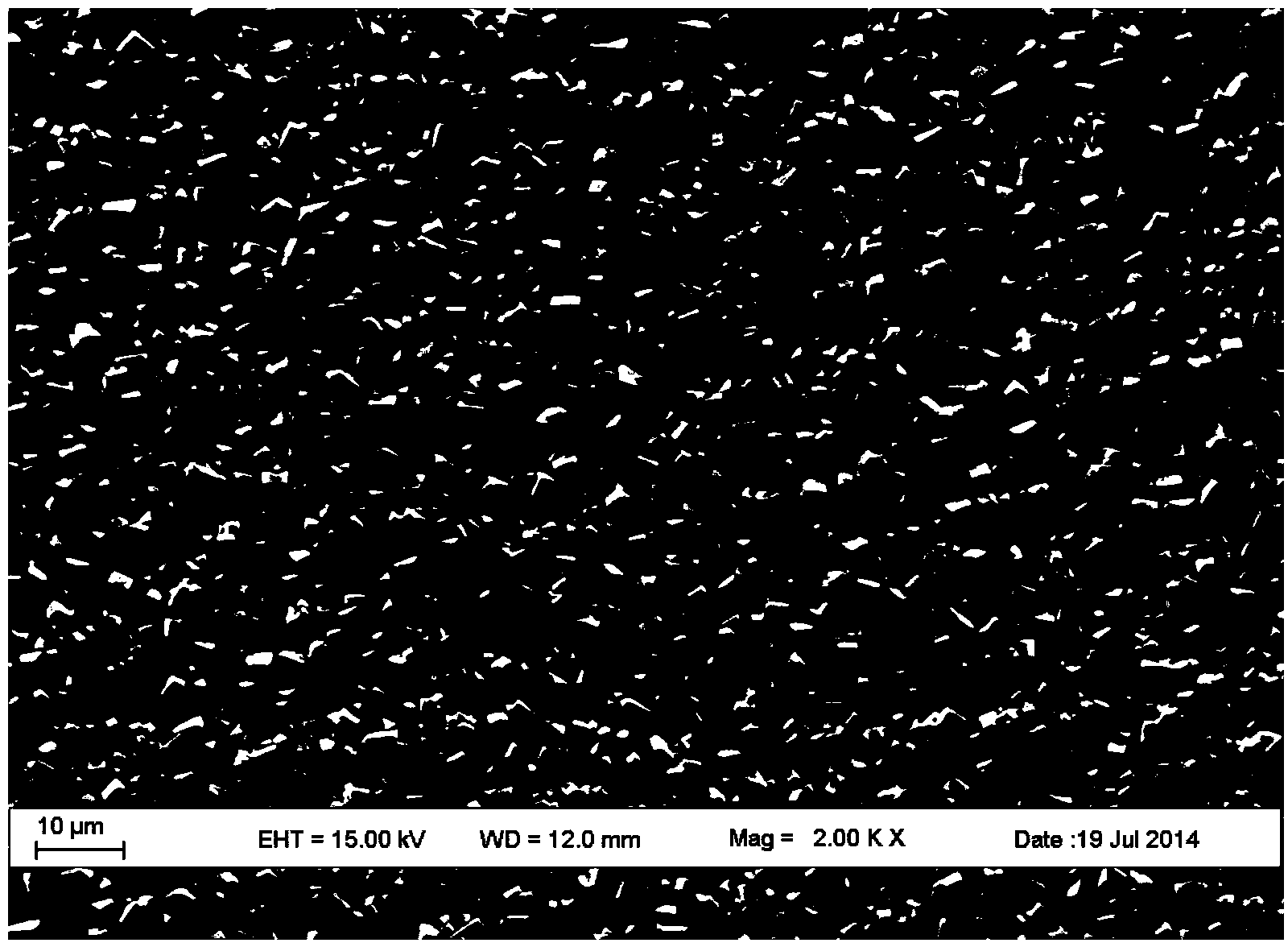

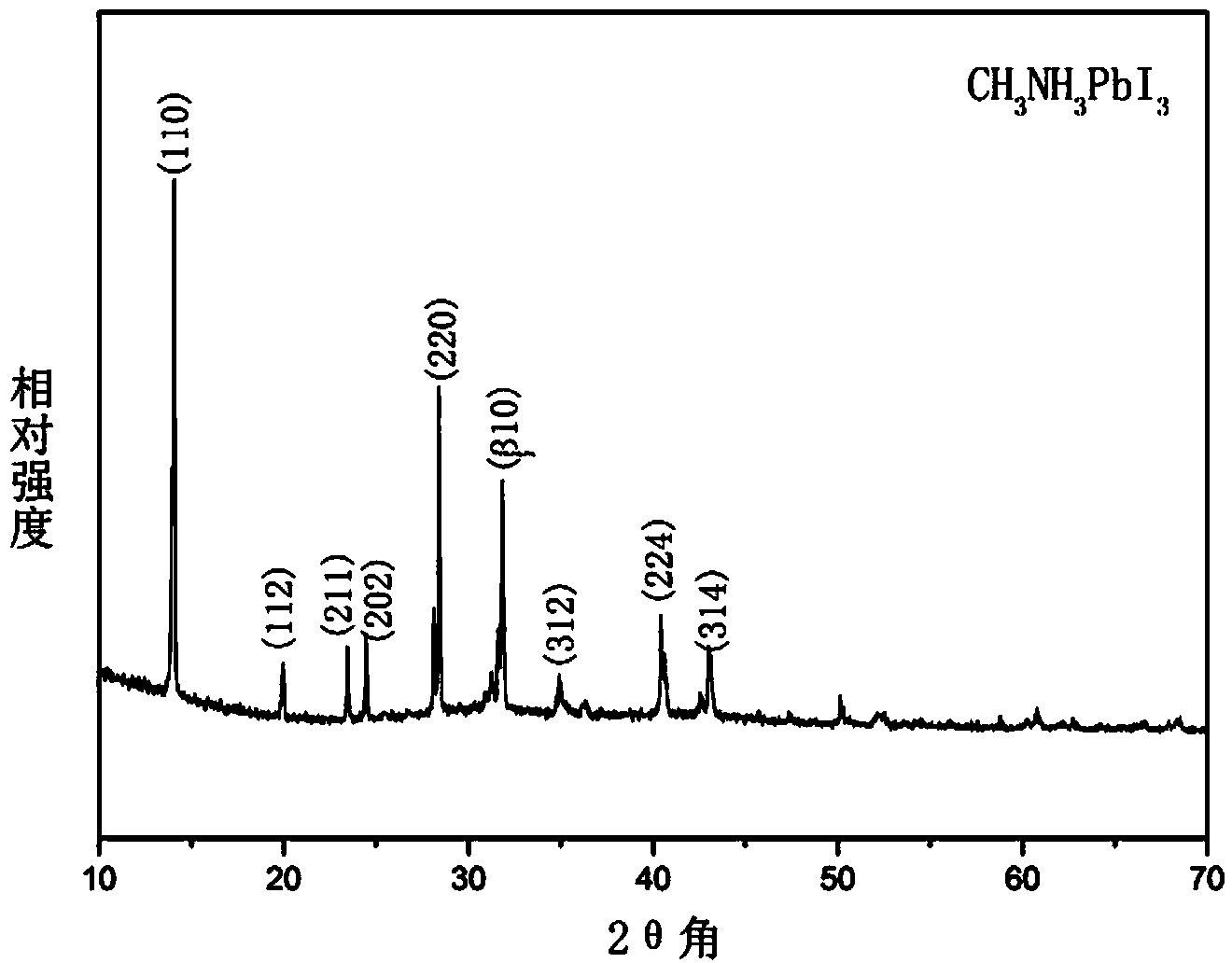

Chemical method for in-situ large-area controlled synthesis of perovskite type CH3NH3PBI3 membrane material based on lead simple-substance membrane

ActiveCN104250723AHigh purityUniform purityVacuum evaporation coatingSputtering coatingPhysical chemistryMethylamines

The invention relates to a chemical method for in-situ large-area controlled synthesis of a perovskite type CH3NH3PBI3 membrane material based on a lead simple-substance membrane. The method comprises: sputtering the lead simple-substance membrane on the surface of a substrate, then horizontally immersing the substrate material possessing the lead simple-substance membrane in an organic solution containing a simple substance iodine and iodinated methylamine, and performing a constant-temperature reaction to prepare a CH3NH3PBI3 membrane material in situ; or putting the substrate possessing the lead simple-substance membrane in a steam atmosphere of a simple substance iodine to perform iodination to generate a lead iodide membrane, then immersing in an organic solution containing iodinated methylamine, and performing a constant-temperature reaction to prepare the CH3NH3PBI3 membrane material in situ. The method is simple in operation, low in energy consumption and low in cost, and has wide industrial application prospect. The obtained CH3NH3PBI3 membrane is high in purity, uniform in membrane-surface crystal and excellent in crystallinity.

Owner:XUCHANG UNIV +1

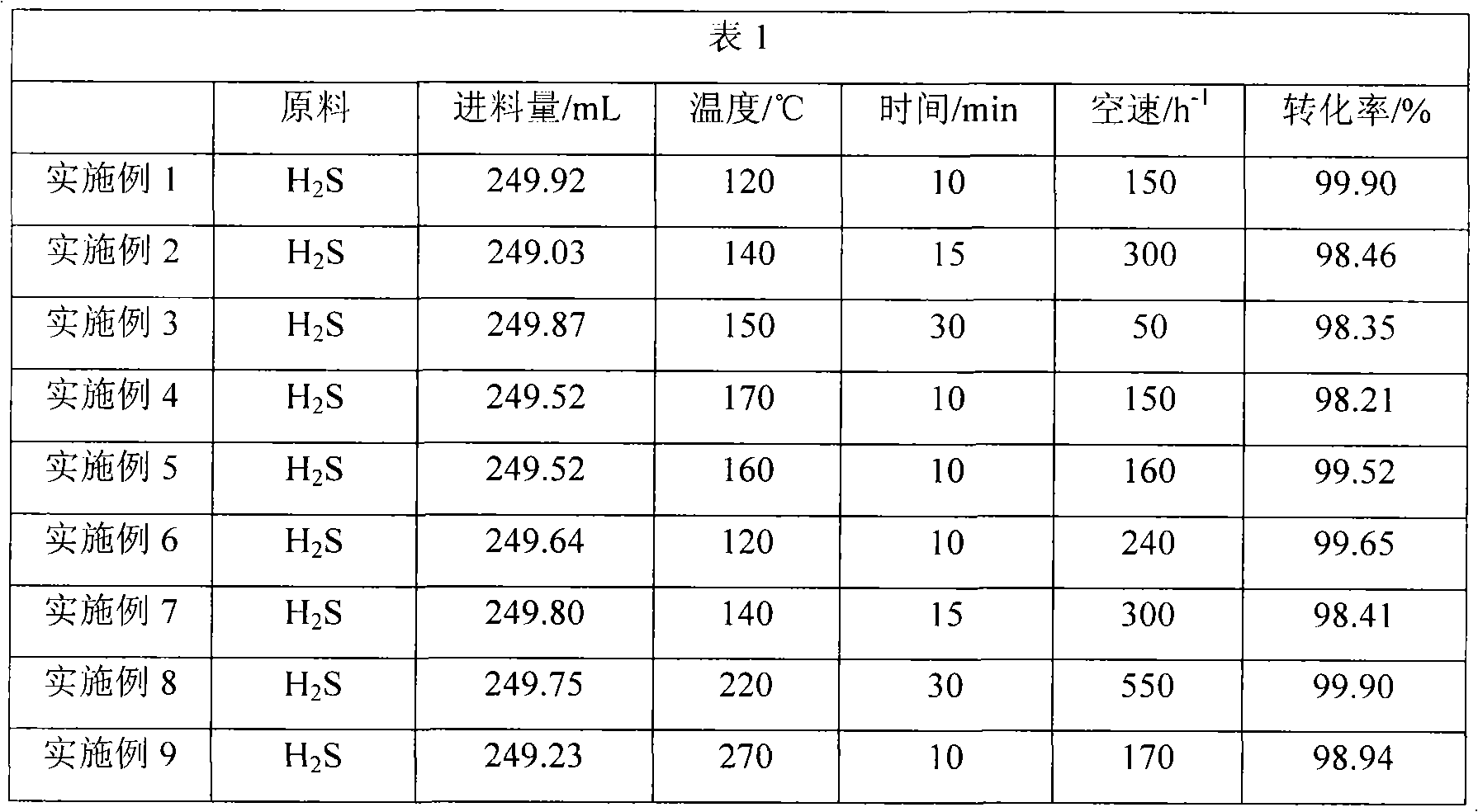

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410ARealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

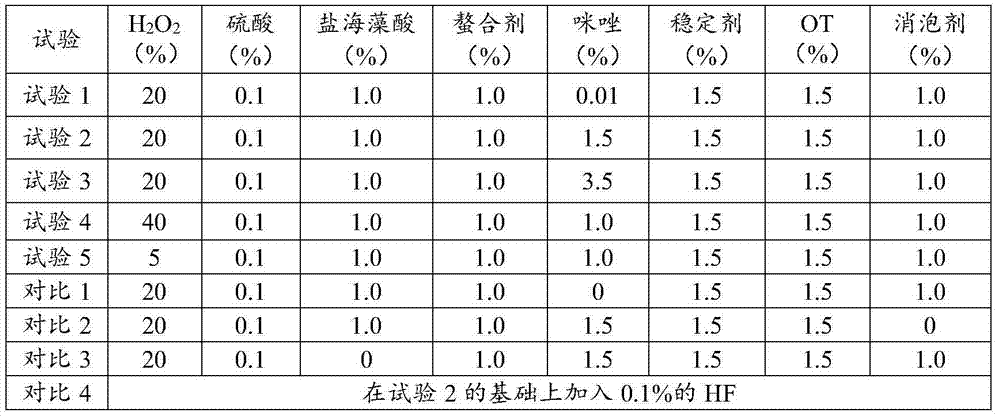

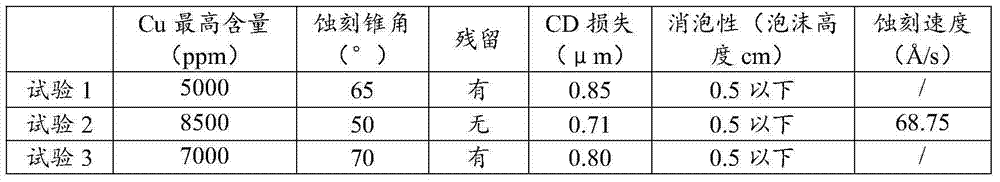

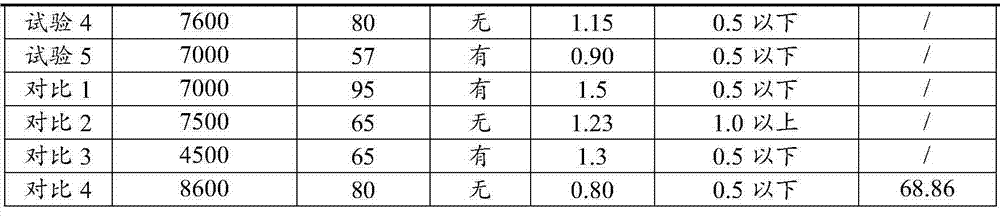

Oxydol etching solution for copper-molybdenum alloy films

The invention discloses an oxydol etching solution for copper-molybdenum alloy films. The etching solution is free of fluorides, and comprises the following main components in percentage by weight: 1-35% of hydrogen peroxide, 0.05-5% of inorganic acid, 0.1-5% of hydrogen peroxide stabilizer, 0.1-5% of metal chelator, 0.1-5% of etching additive, 0.1-5% of surfactant, 0.1-5% of defoaming agent and the balance of deionized water. The etching solution has the advantages of no environment pollution, mild and controllable reaction, proper cone angle after etching, small CD loss, favorable defoaming property and higher overall performance, and lays foundation for high-precision processing.

Owner:SHENZHEN CAPCHEM TECH

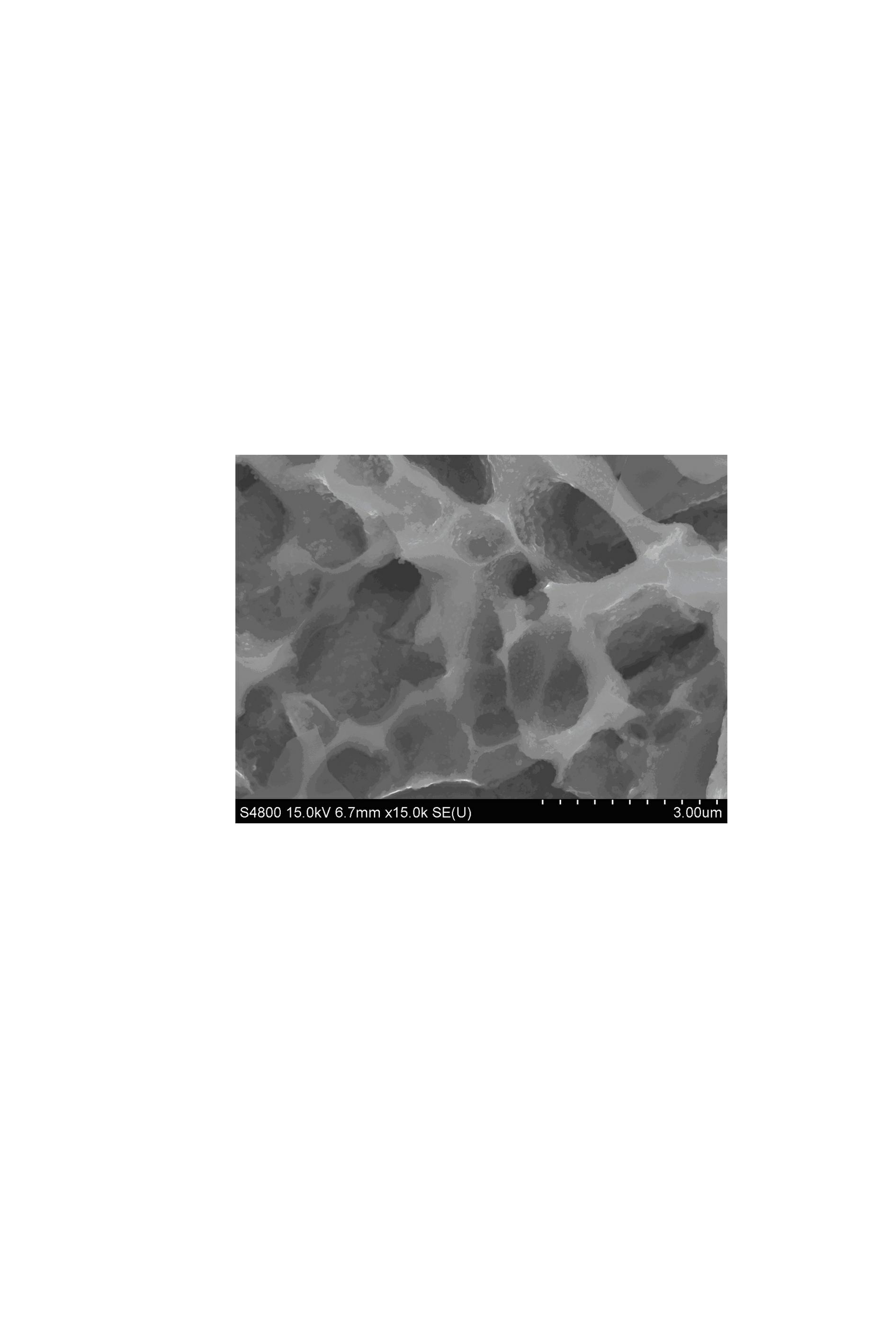

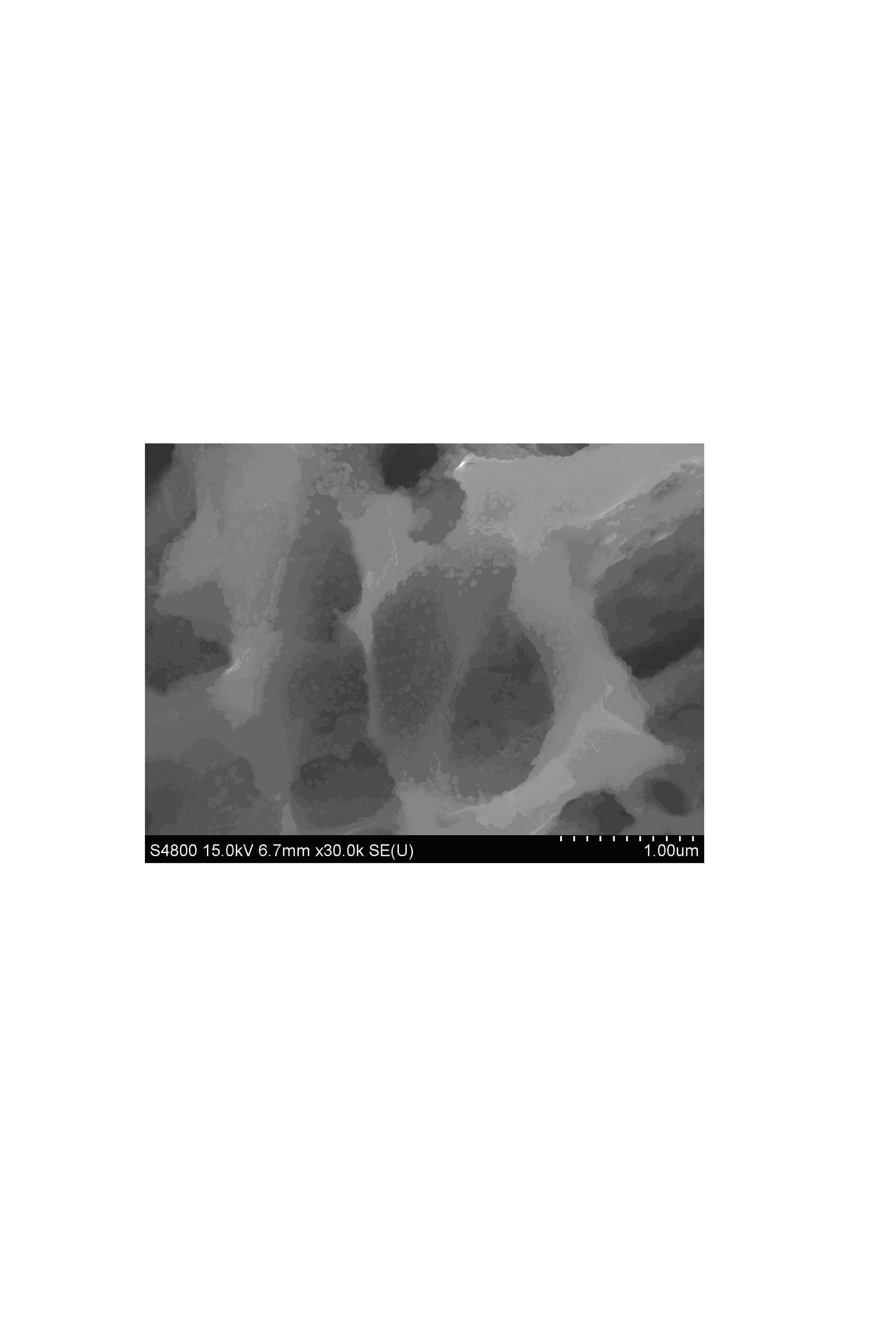

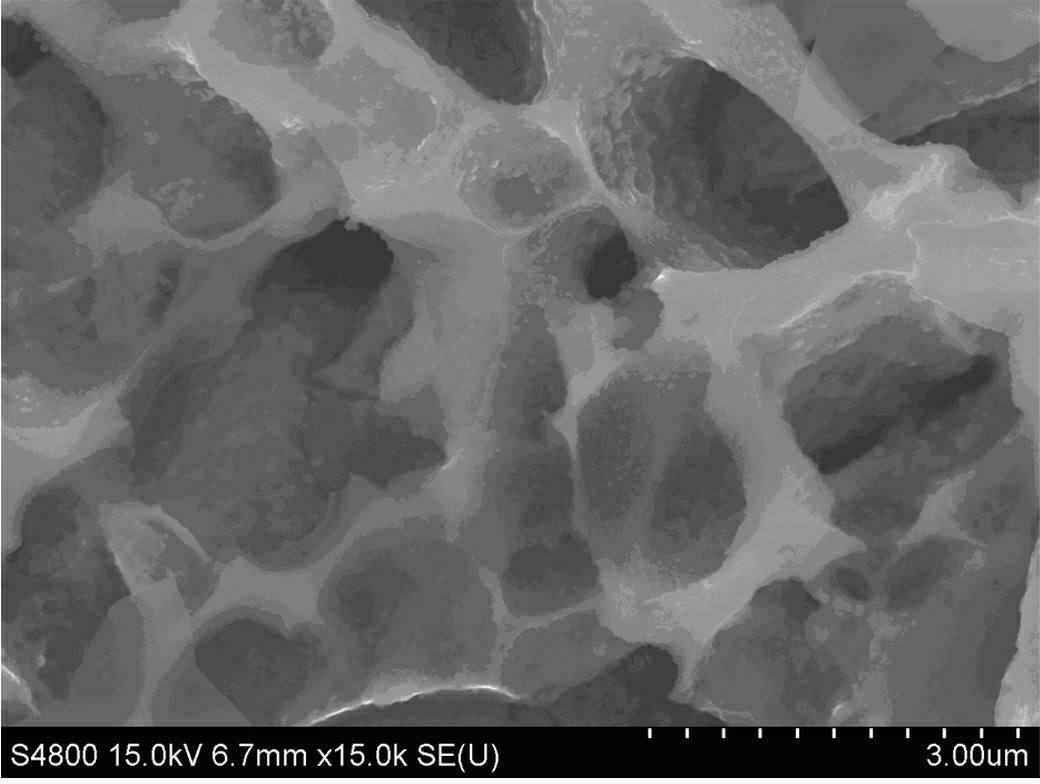

Nanometer perovskite/graphene composite material and preparation method thereof

The invention relates to a nanometer perovskite / graphene composite material. The nanometer perovskite / graphene composite material is of a porous structure, the aperture of the nanometer perovskite / graphene composite material is about 0.5-1.5 microns, nanometer perovskite particles are distributed uniformly on a graphene film, and the average crystallite dimension of the composite material is about 10-20nm. A preparation method of the nanometer perovskite / graphene composite material comprises the following steps of: with graphite paper as an anode, a carbon rod as a cathode and concentrated sulfuric acid as an electrolyte, carrying out oxidation peeling to prepare a thin-layer graphene material, and then preparing graphene suspension from the thin-layer graphene material; adding nitrate and citric acid to the graphene suspension to enable the metal nitrate to be hydrolyzed to form sol, polymerizing the sol to form gel, finally drying and baking the gel to obtain the nanometer perovskite / graphene composite material. The preparation method disclosed by the invention has the advantages of simple process and low cost; and the nanometer perovskite / graphene composite material disclosed by the invention has good chemical uniformity; in addition, a reaction process is easy to control, and nanometer perovskite particles are more uniformly distributed on the graphene film and have smaller particle sizes, thus the nanometer perovskite / graphene composite material prepared by the method disclosed by the invention has excellent electro-catalysis performances and is suitable for being taken as an electro-catalysis material of a fuel cell.

Owner:YANSHAN UNIV

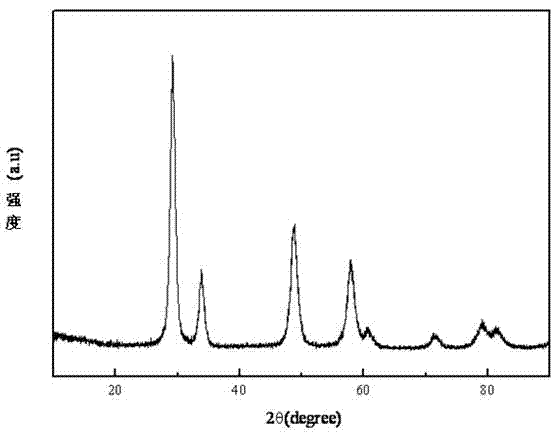

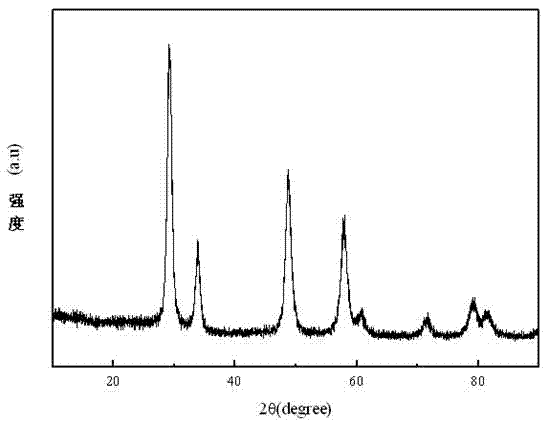

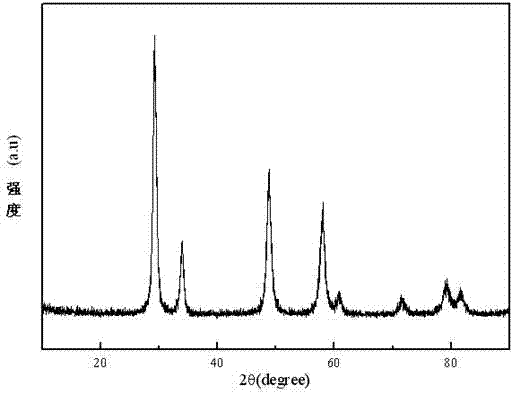

Cubic phase cerium and zirconium based composite oxide with high specific surface area and preparation method thereof

ActiveCN102247826AThe reaction process is easy to controlSave raw materialsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPhysical chemistry

The invention discloses a cubic phase cerium and zirconium based composite oxide with high specific surface area. Rare earth elements are doped in the cerium-zirconium composite oxide and are selected from two or three of Pr, Nd and La, wherein the molar ratio of Zr to Ce is (1.8-2.5):1; the molar ratio of Pr to Ce is (0-0.32):1; the molar ratio of Nd to Ce is (0-0.32):1; the molar ratio of La toCe is (0-0.16):1; and the cerium and zirconium based composite oxide exists in a form of cerium-zirconium solid solution. The invention also discloses a preparation method of the cerium and zirconiumbased composite oxide. The composite oxide is prepared through different precursor precipitating and drying methods; the method has the advantages of simple reaction process and low requirements on drying equipment; the obtained cerium and zirconium based composite oxide has high specific surface area, high thermal stability and high oxygen storage and discharge capacity; and after sintering is performed at the temperature of 1,000 DEG C for 12 hours, the specific surface area is more than 35m<2> / g, particularly more than 60m<2> / g.

Owner:UNIV OF JINAN

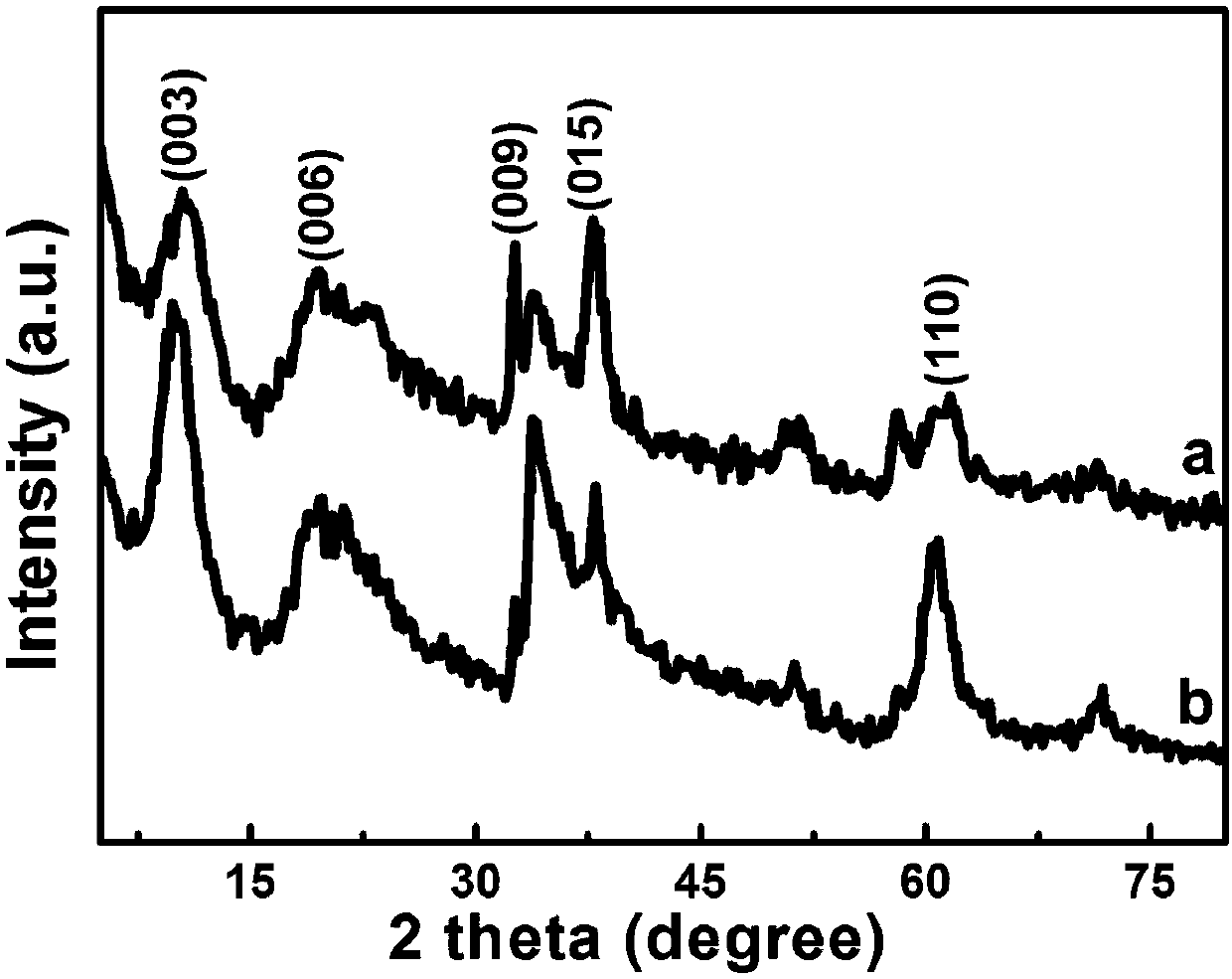

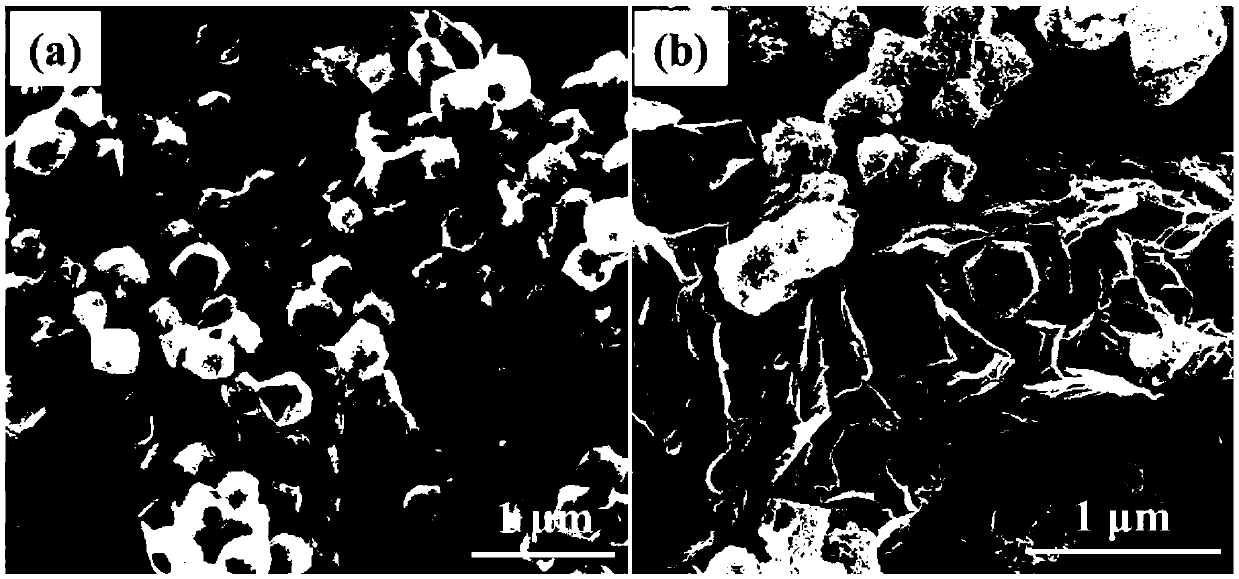

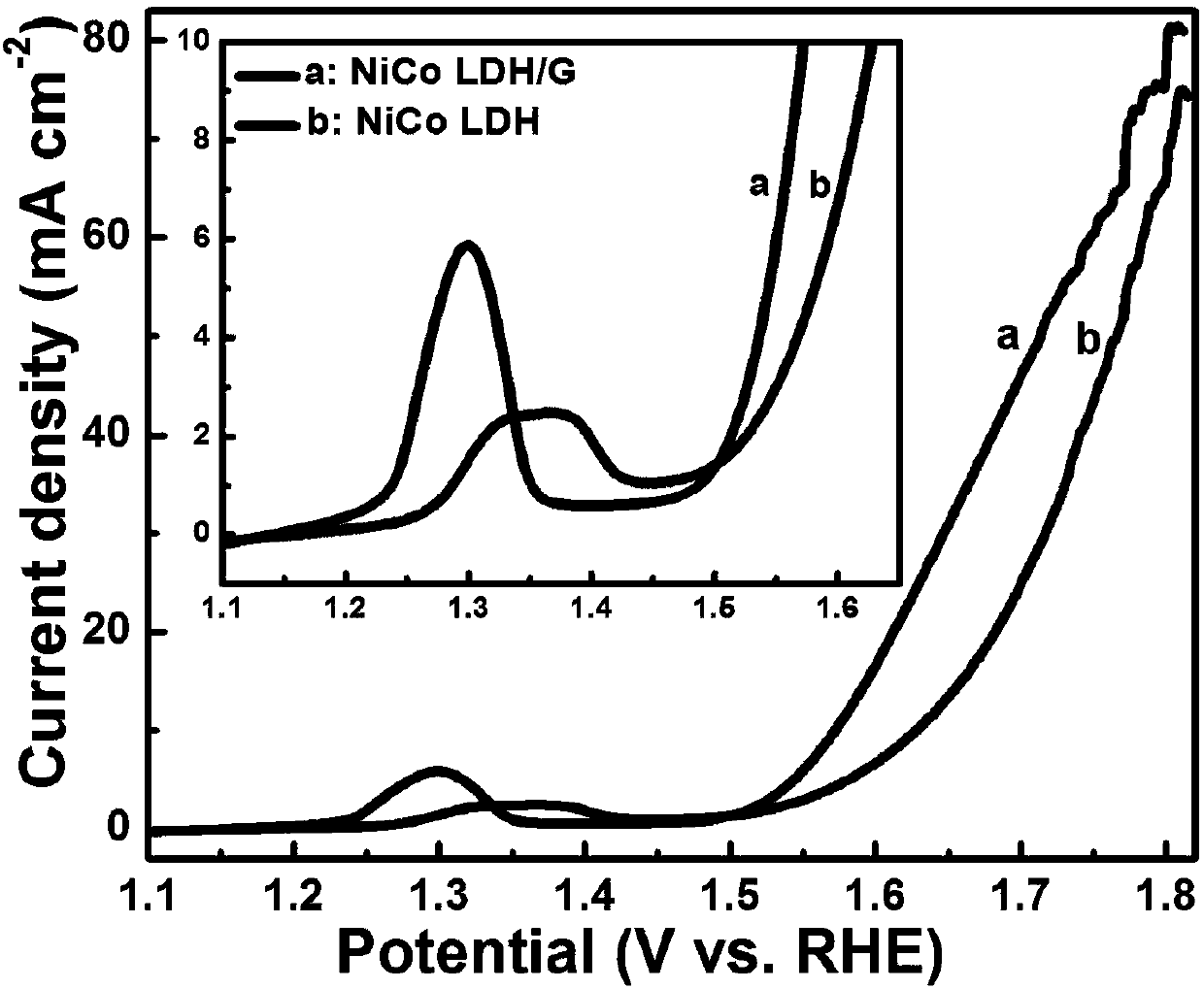

Preparation method of nickel-cobalt layered bimetallic hydroxide/graphene electrocatalyst

ActiveCN107824188ASimple processOvercoming demandsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSynthesis methods

The invention provides a preparation method of a nickel-cobalt layered bimetallic hydroxide / graphene electrocatalyst, which belongs to the technical field of electrocatalysts. The method disclosed bythe invention comprises the following steps: graphene and cobalt nitrate are uniformly dispersed in a methanol solvent by ultrasonic waves, so that an ultrasonic solution is obtained; the ultrasonic solution is added into a methanol solution of dimethylimidazole, is uniformly mixed and then is enabled to stand, and centrifuging, washing and drying are then carried out, so that a ZIF-67 / graphene composite material is obtained; the ZIF-67 / graphene composite material and nickel salt are mixed and dissolved in a solvent, refluxing is carried out for reaction, centrifugal separation is then carriedout, obtained precipitate is washed with absolute ethyl alcohol, and drying is carried out to obtain a NiCo LDH / G composite material with a nanoscale morphology. The method disclosed by the inventionovercomes the defects of high requirement on equipment, need for high temperature and high pressure and need for an expensive surfactant existing in conventional synthesis methods, and compared withthe prior art, the preparation method has the advantages of simple process, low cost, easy reaction process control and the like, and is suitable for industrial mass production.

Owner:GUANGXI NORMAL UNIV

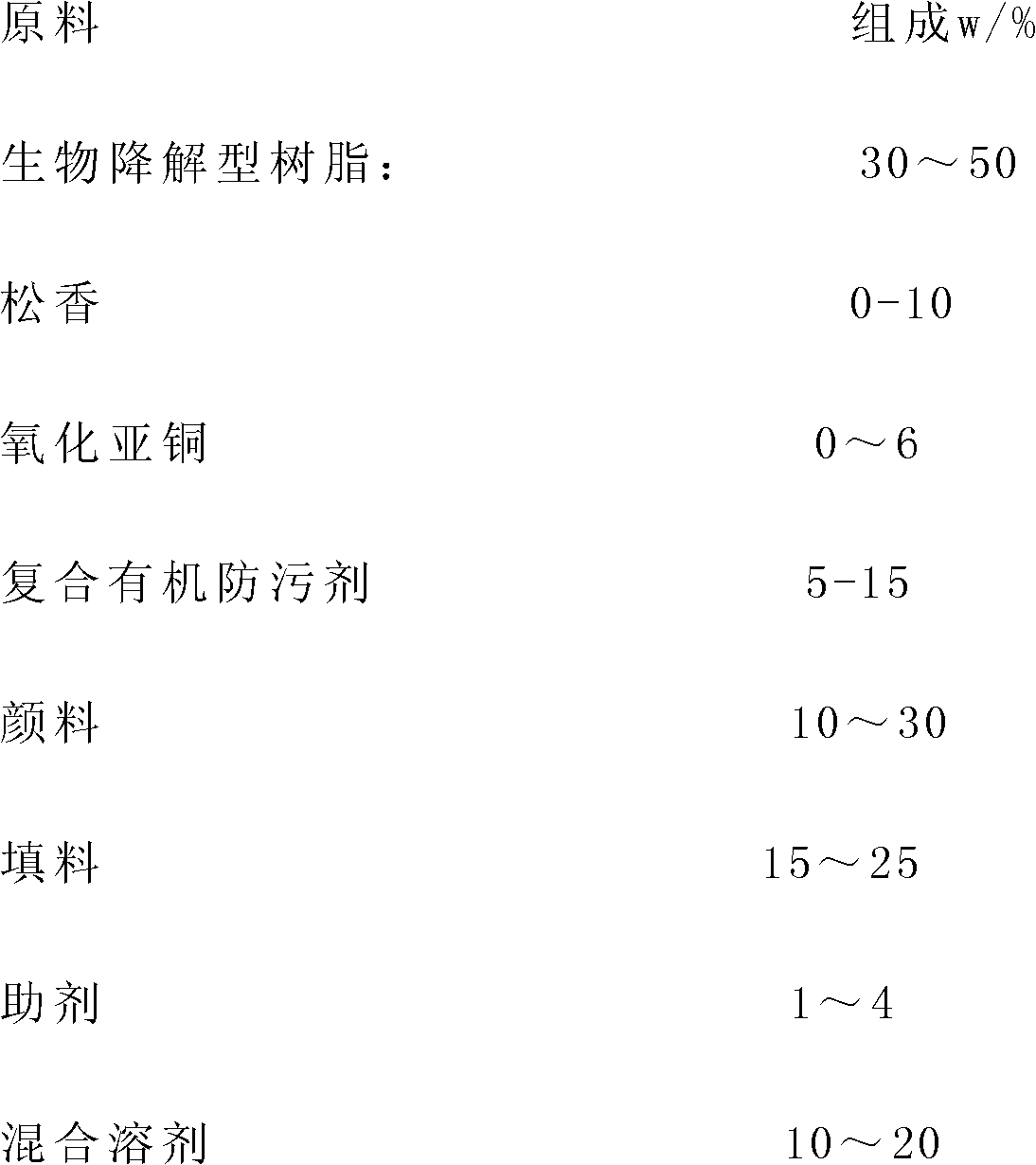

Resin for biodegradable anti-fouling paint, synthetic method of the same, and anti-fouling paint composition containing the same

ActiveCN102432802AReduce dosageHigh requirements for reaction conditionsAntifouling/underwater paintsPaints with biocidesCompound organicEnvironmental resistance

The invention provides a resin for a biodegradable anti-fouling paint. The resin for the biodegradable anti-fouling paint is a polymer containing a multi-block structure, characterized in that: the resin is prepared by polymerizing by polylactic acid oligomer, flexible segments, polyisocyanates under the effect of catalysts, wherein, the polylactic acid oligomer is prepared by carrying out reflux reaction on lactic acid having a monomer content of 80-85 % and aromatic solvents under negative pressure or normal pressure until no water generates; the flexible segments comprises polyols or / and polyester polyols; and the amount of the flexible segments accounts for 5-30 % of the weight percentage of the lactic acid raw material; and the amount of polyisocyanates accounts for 10-30 % of the weight percentage of the lactic acid raw material. The invention further provides a biodegradable anti-fouling paint composition containing the resin as a matrix resin. The anti-fouling paint contains composite organic antifouling agent and contains no or little cuprous oxide, and has the advantages of low toxicity, environmental protection, and good anti-fouling effect.

Owner:MARINE CHEM RES INST CO LTD

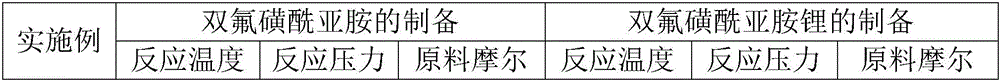

Preparation method of difluoro-sulfimide and lithium difluoro-sulfimide

InactiveCN106365132AFew reaction stepsSimple processNitrosyl chlorideAmidosulfonic acidChemical synthesisDistillation

The invention relates to a preparation method of difluoro-sulfimide and lithium difluoro-sulfimide, and belongs to the field of fluorine chemical synthesis. The preparation method comprises the steps that difluoro-sulfimide is obtained by adding fluoro-sulfoxide into a mixture of sulfamic acid or amino sulfonyl fluoride and fluorosulfuric acid for reacting and then subjected to recrystallization and filtration which are conducted at the temperature of minus 100 DEG C to 16 DEG C and / or reduced / normal-pressure distillation and purification which are conducted at the temperature of 60 DEG C to 169 DEG C; difluoro-sulfimide and a lithium-containing substance react in a solvent to obtain lithium difluoro-sulfimide, and then recrystallization, filtration and purification are conducted. According to the preparation method, difluoro-sulfimide can be prepared through one step, lithium difluoro-sulfimide is obtained through lithiation, and the prepared products can be purified; few steps are needed, the technology is simple, the process is easy to control, the requirement on production devices is low, the production efficiency, the product yield and the purity are high, and large-scale production and application can be achieved.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of aqueous polyurethane emulsion with high solid content

The invention relates to a preparation method of an aqueous polyurethane emulsion with a high solid content. The method comprises the following steps: first, adding polymer polyol, polyisocyanates, catalyst and chain extender into a reactor according to certain steps, and controlling hydrophilic groups to distribute on molecular chain ends; then adding polyisocyanates to form a performed polymer terminated with an NCO group; then reducing system temperature, adding a neutralizer for neutralization, adding deionized water, and stirring with high speed to carry out water dispersion; at last, adding a post chain extender to carry out chain extension in water; removing the solvents under a reduced pressure after reaction to obtain the aqueous polyurethane emulsion. According to the invention, hydrophilic efficiency of the hydrophilic groups is raised to lower intake amount of hydrophilic groups, and a small amount of solvents are added in the reaction to lower a system viscosity. The aqueous polyurethane emulsion prepared by the invention has characteristics of high solid content, low viscosity, good water resistance and stabile storage, and can be used in industries of paint, adhesive, leather finishing and fabric arrangement, etc.

Owner:FUZHOU UNIV

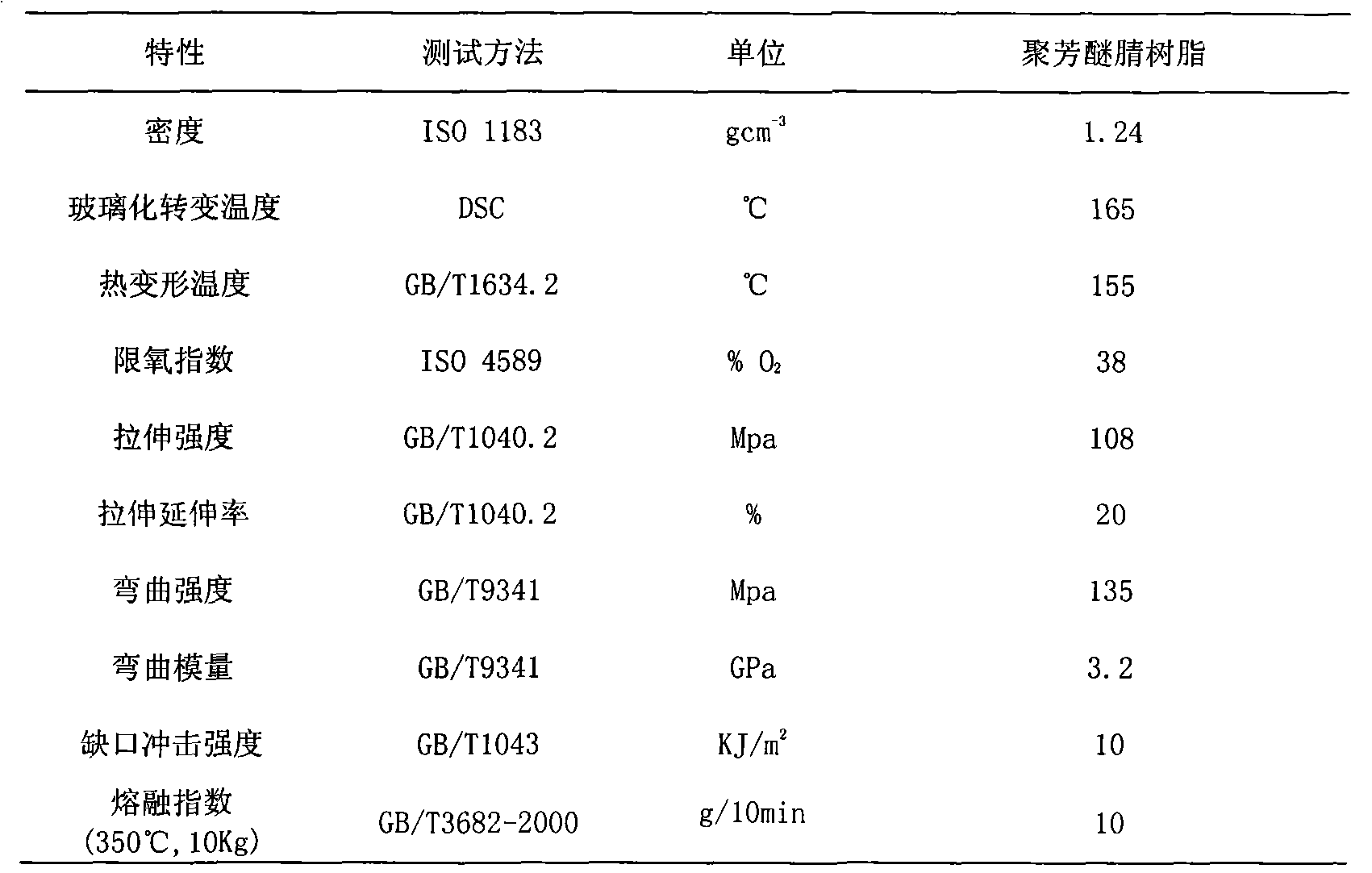

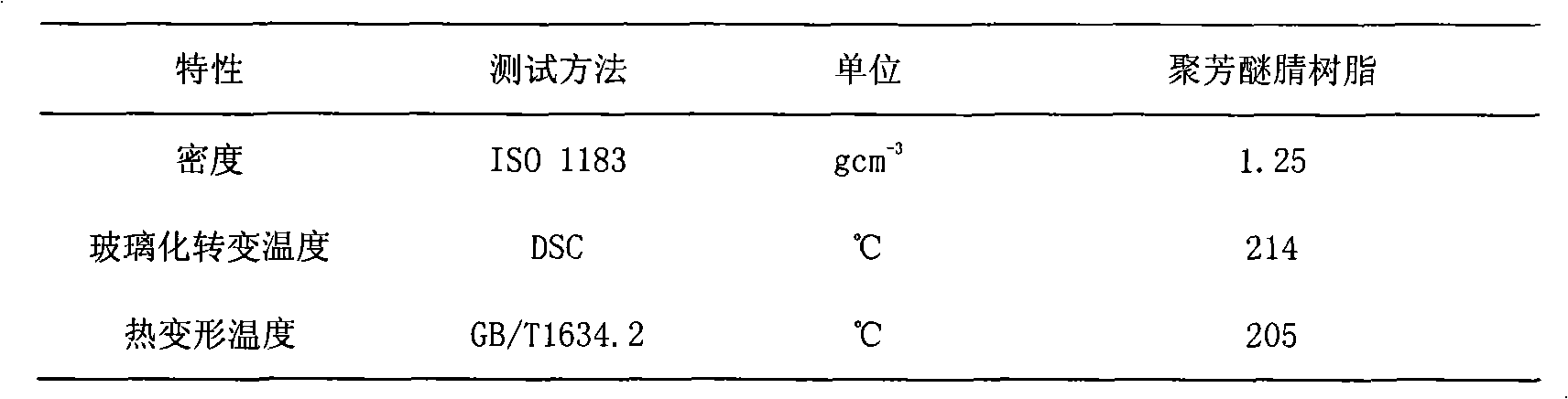

Method for preparing poly(arylene ether nitrile) resin

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials and taking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

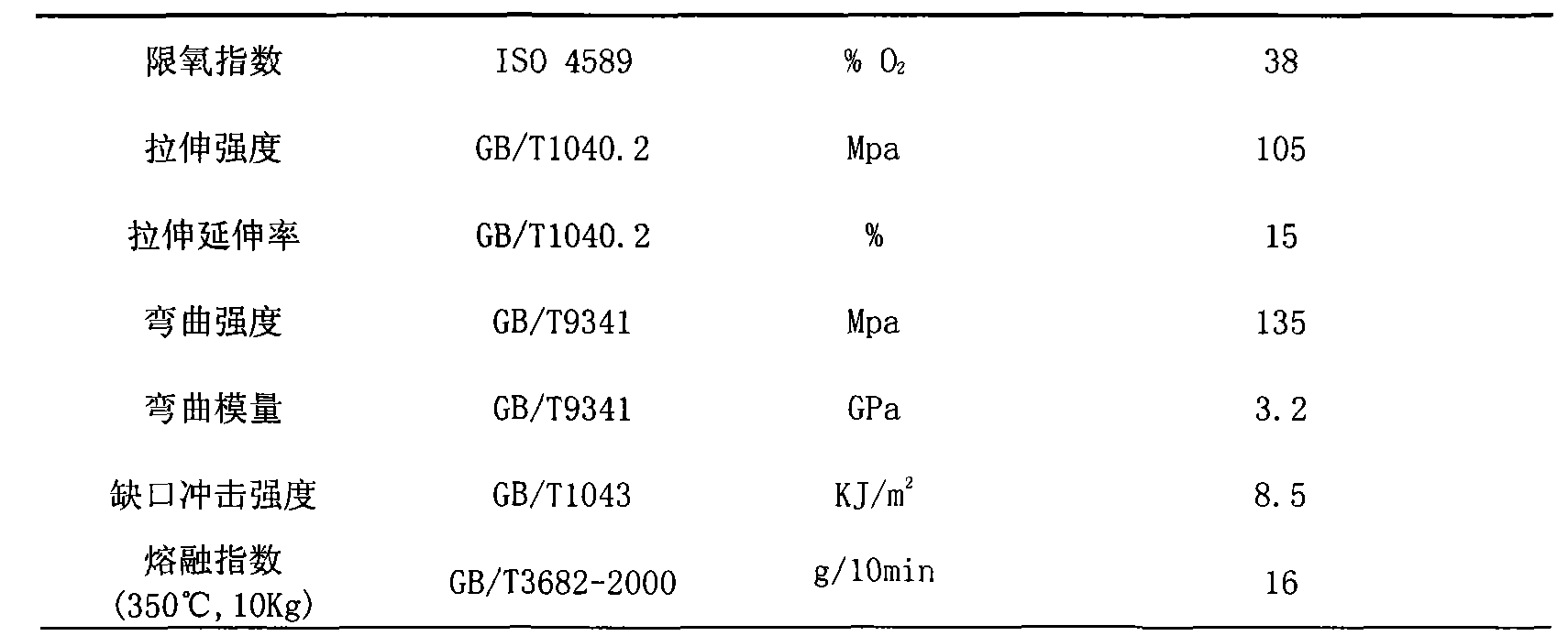

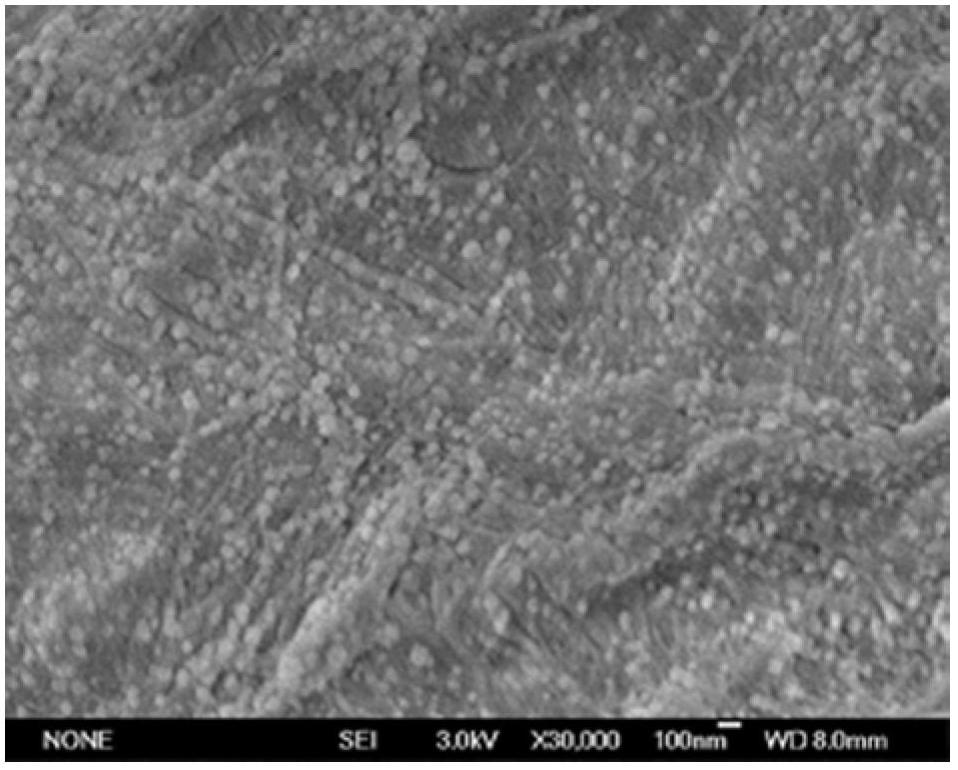

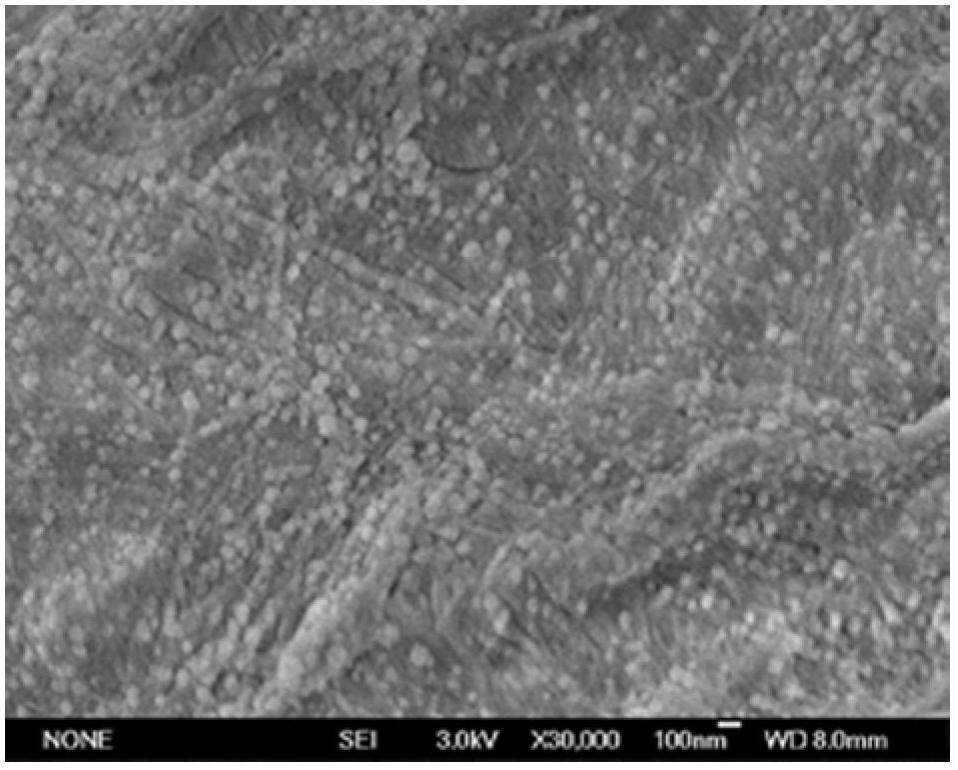

Method for loading silver nano-particles on cellulose-containing material

The invention relates to a method for loading silver nano-particles on a cellulose-containing material, belonging to the field of the preparation of inorganic nano materials. By using the structure that cellulose is rich in hydroxyl and by using the cellulose as a reducing agent, the in-situ growth of nano silver on the cellulose is realized under the condition of heating. The reaction is simple to operate and easy to control, the repeatability is good, no pollution is caused, the cost of raw materials is low and the large-scale production is easy to realize. The obtained cellulose-containing material loaded with the nano silver has the advantages of even nano silver size and distribution and high adhering firmness, and can be widely used for antibacterial packaging paper, medical nursing sterilizing articles, paper for women and the like. The nano silver loaded on the cellulose-containing material has very high and stable enhancing effect and the material can also be used for surface enhanced Raman spectrum substrates.

Owner:SHANDONG UNIV

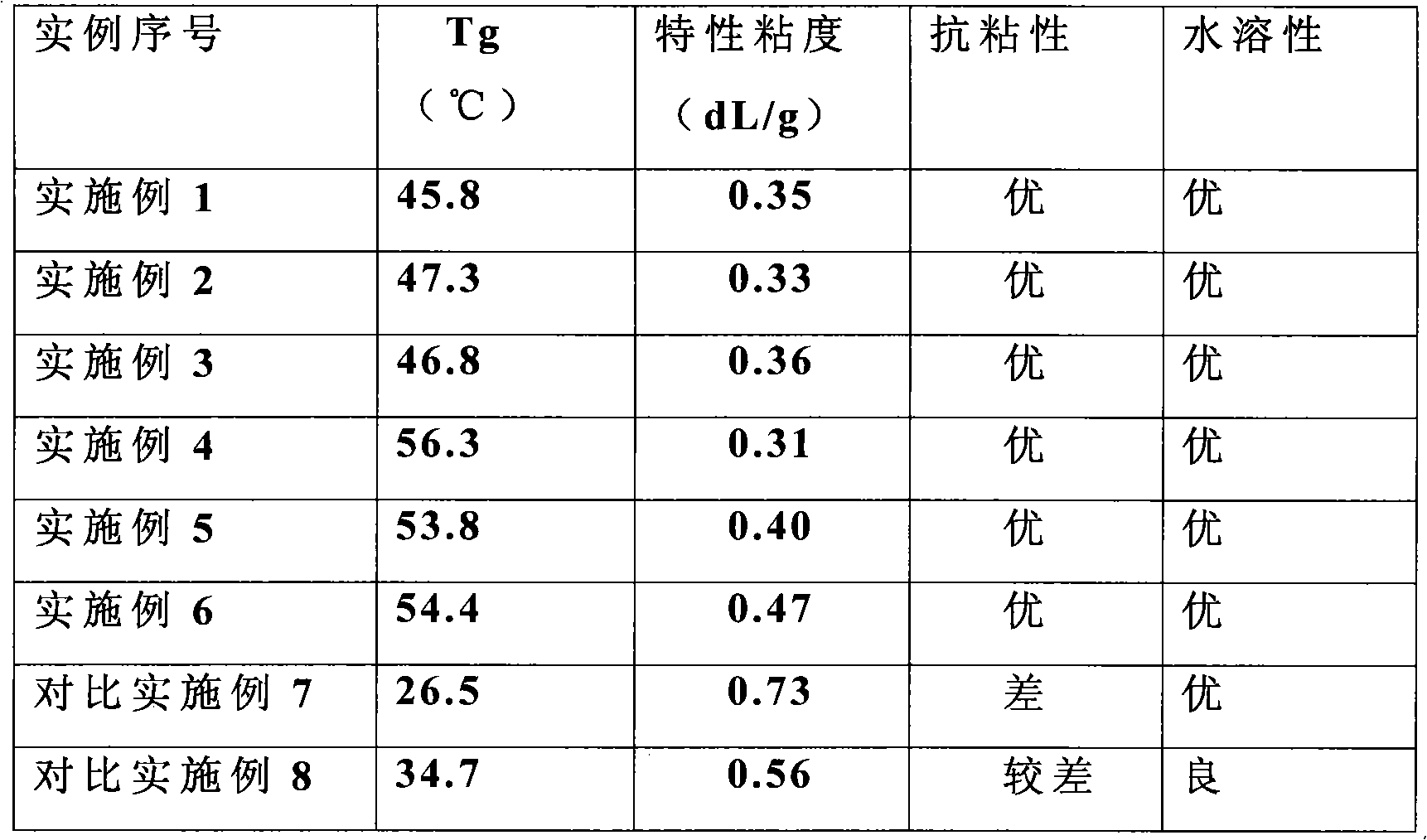

Method for preparing water-soluble sulfo-copolyester

The invention discloses a method for preparing water-soluble sulfo-copolyester used in textile slurry. The method comprises the following steps of: performing esterification reaction or transesterification on dibasic acid / ester at least containing isophthalic acid, sulfo-dibasic acid or ester and terephthalic acid and dibasic alcohol at least containing ethanediol to obtain polycondensation prepolymer; and performing polycondensation under reduced pressure to obtain a product, wherein the molar ratio of the dibasic acid to the dibasic alcohol is 1:1.3-1:1.8; the materials are put at one time; and the polycondensation prepolymer is obtained in one step. The method has the advantages of not using expensive polyethylene glycol materials, adopting a lower molar ratio of the dibasic acid to the dibasic alcohol, putting the materials at one time, reducing cost, along with simple process. The product has high water solubility and higher glass-transition temperature, is suitable for storage, and has good effect in slurry.

Owner:苏州瀚海化学有限公司

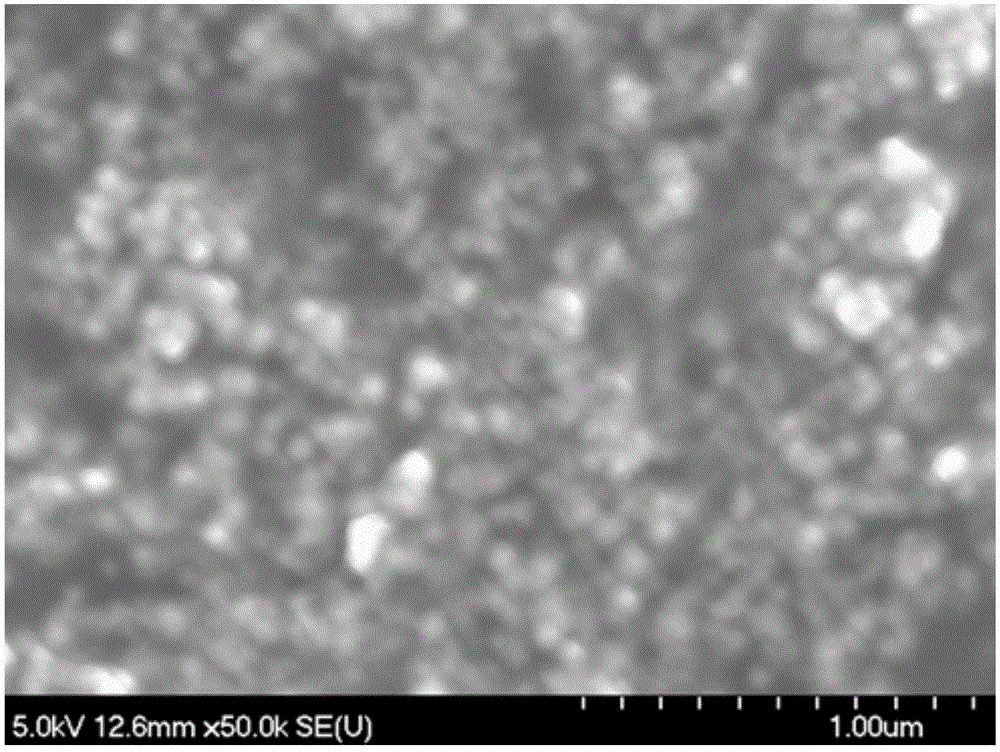

Micro-nano copper powder and preparation method thereof

ActiveCN106513696AModerate reductionEffective size controlMaterial nanotechnologyMicro nanoFiltration

The invention discloses micro-nano copper powder and a preparation method thereof. The preparation method comprises the following steps that compounds containing copper are prepared into a solution, and a system A is obtained; pH conditioning agents, additives and reducing agents are added to the system A, and a system B is obtained and reacts at 50-100 DEG C; and filtration, washing and drying are conducted after reacting, and the micro-nano copper powder is obtained. In the system B, the molarity of the compounds containing copper is 0.001-4 mol / L, the concentration of hydroxyl ion (OH-) is 10<-4>-20 mol / L, the mass concentration of the additives is 0-40%, and the molar ratio of the compounds containing copper to the reducing agents is 1:0.1-100. According to the preparation method, the effective control over the morphology and the size of the micro-nano copper powder is achieved, and the mass content of the impurity phases in the prepared copper powder can be controlled below 0.3%; and in addition, the preparation method further has the advantages that the reaction process is easy to control, and the selected reducing agents are moderate in reducibility, non-toxic, and environmentally friendly.

Owner:GUANGZHOU QIANSHUN IND MATERIAL

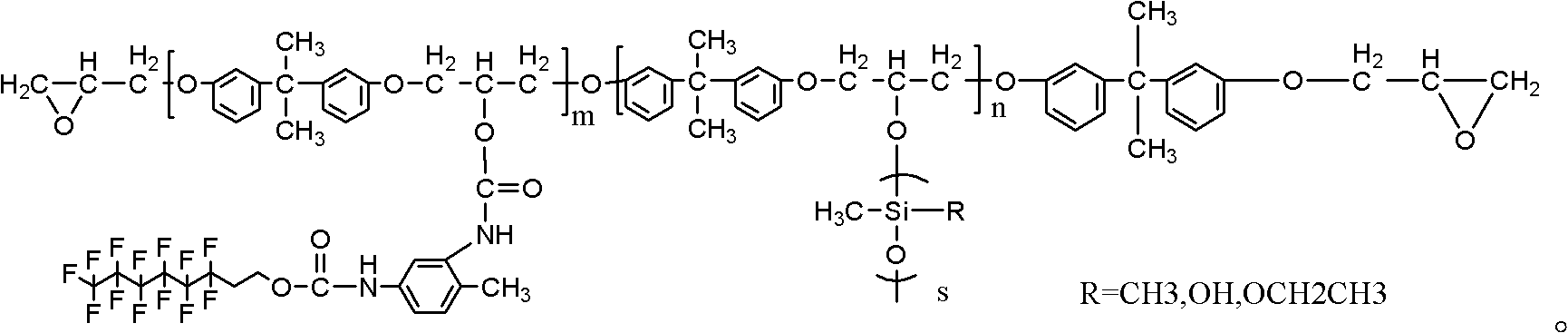

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

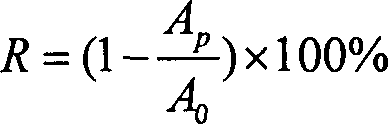

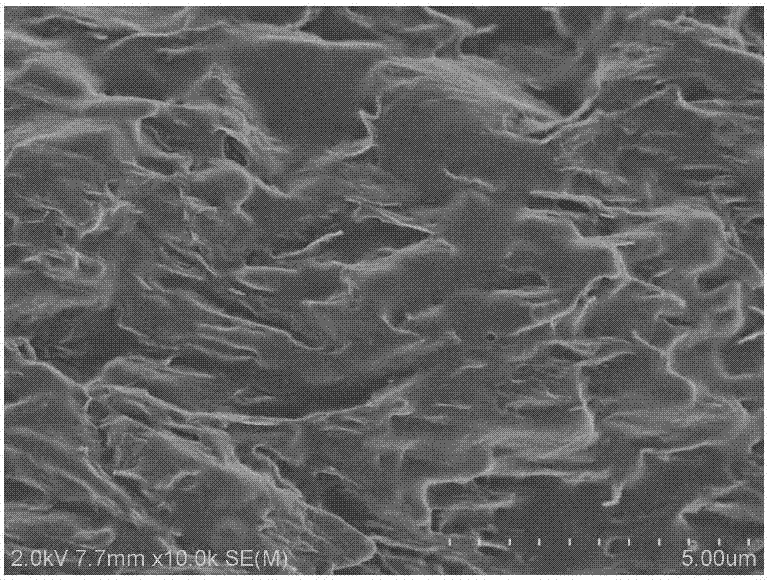

Method for hydrophilic modifying of poly-vinylidene fluoride film

The present invention belongs to the field of polymer film preparing technology, and is especially method of modifying hydrophilicity of polyvinylidene fluoride film. The method combines blending and surface grafting technology, and includes the first blending polyvinylidene fluoride and one other photosensitive polymer and preparing microporous or compact film, and the subsequent surface grafting hydrophilic monomer onto the surface of the blend film. The prepared modified film has excellent chemical stability and mechanical performance similar to that of microporous polyvinylidene fluoride film as well as improved surface hydrophilicity and antifouling performance.

Owner:FUDAN UNIV

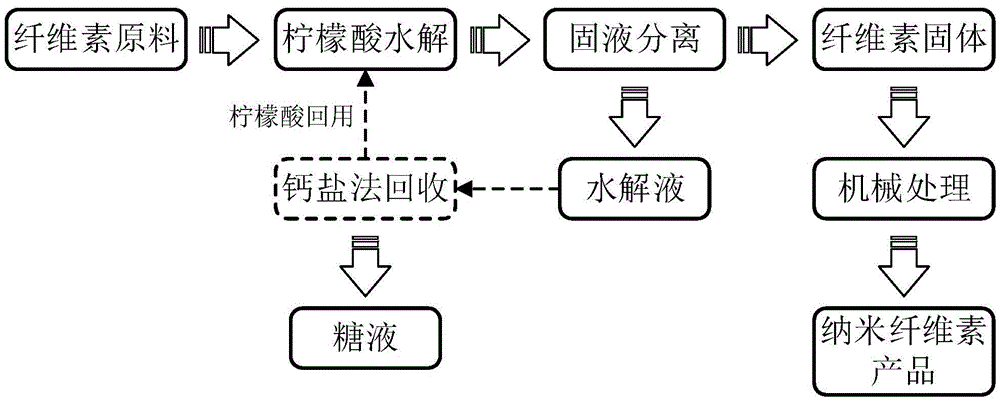

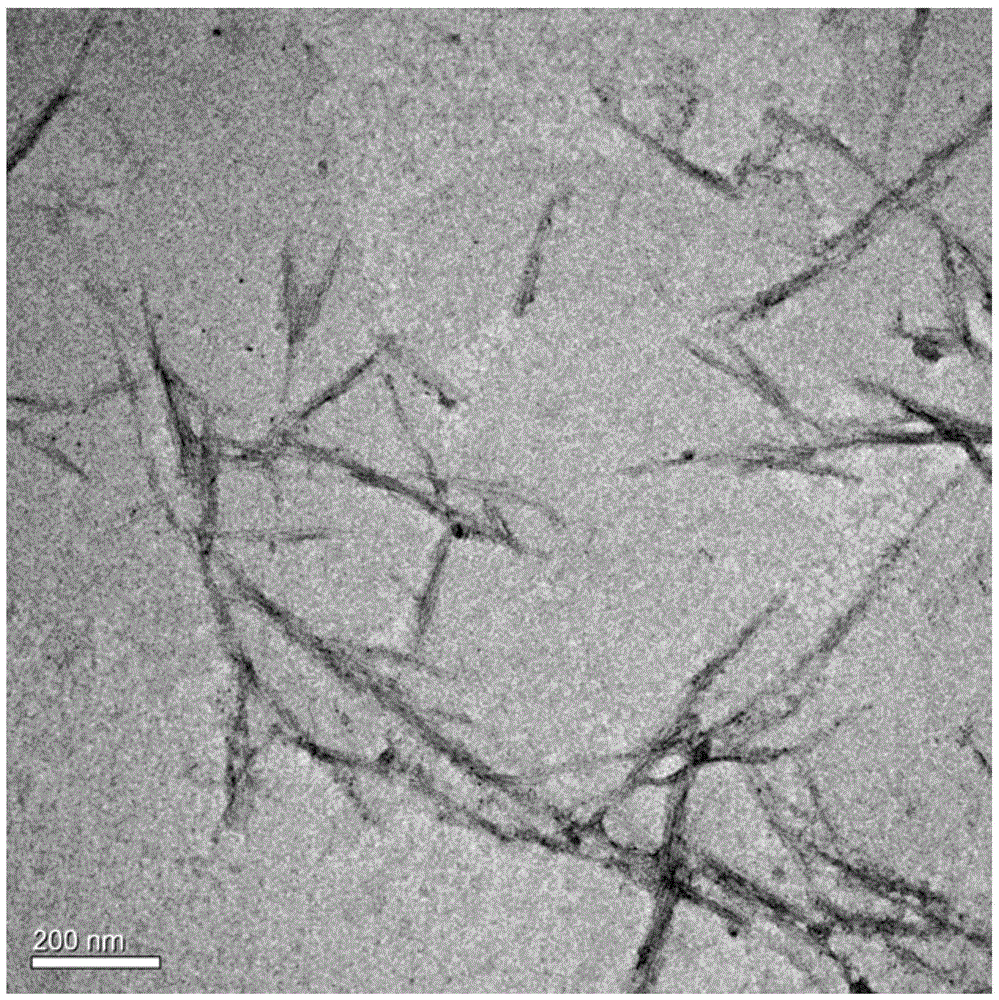

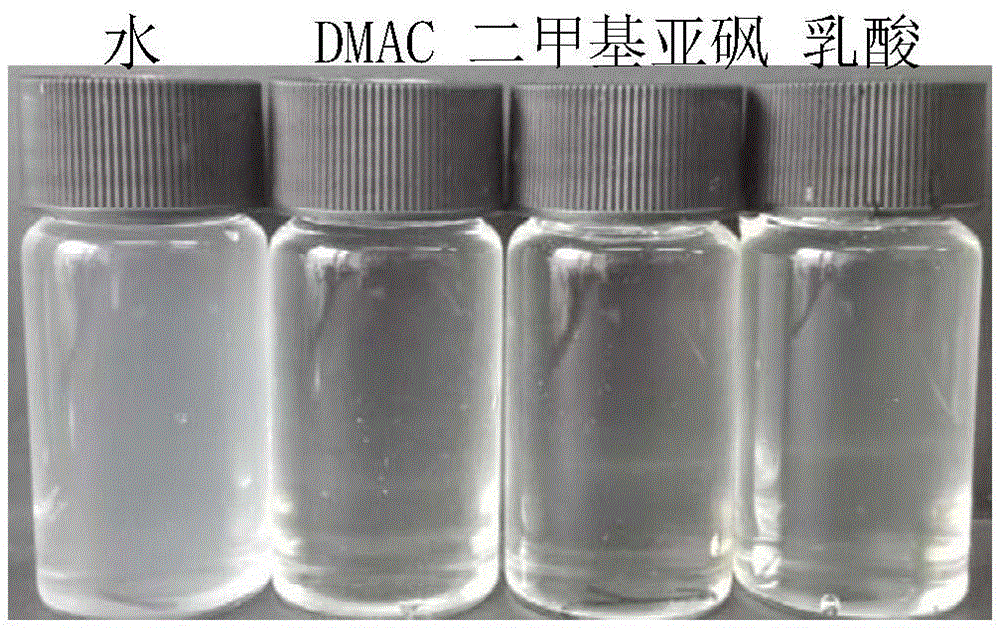

Preparation method of nanocellulose fibrils

The invention relates to a green, economical and sustainable method for preparing nanocellulose fibrils. The preparation method comprises the following steps that 1, a cellulose raw material is added to a citric acid solution to be heated, stirred and hydrolyzed; 2, treated cellulose and hydrolysate are separated through methods of centrifugal sedimentation and the like, and precipitated cellulose is centrifugally washed with water multiple times and diluted into a cellulose suspension; 3, the separated hydrolysate can be directly recycled at least once, citric acid is recovered from the recycled hydrolysate, and the citric acid obtained through recovery can be recycled continuously; 4, the natural structure of the cellulose suspension obtained in the second step is further destroyed through a high pressure homogenizer or ultrasonication or physical mechanical treatment of a disc mill, and the colloidal nanocellulose fibrils are obtained. According to the method for preparing the nanocellulose fibrils, a catalyst is not adopted, the reaction condition is relatively mild, the reaction is easy to control, operation is easy, and the method is friendly to environment.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Novel method for separating gold and silver from gold mud

InactiveCN101451190AReaction is easy to controlReduce process stepsProcess efficiency improvementFilter cakeSodium chlorate

The invention provides a novel method for separating gold and silver from gold slime, which comprises: wet gold slime is subjected to one-step chloridizing leaching and filtered; filtrate is a gold-containing solution, and filter cakes are silver chloride deposit; the gold-containing solution is reduced to obtain gold powder which is then smelted into gold ingots; and the filter cakes, namely the silver chloride deposit, are converted into coarse silver powder which are then smelted into silver ingots. The method adopts one-step chloridizing gold leaching reaction to overcome the defect of large metal loss due to long pretreatment flow of the gold slime and high frequency of filtration reaction in the prior art, only uses a hydrochloric acid and sodium chlorate during chloridizing and gold leaching, is easy to control the reaction, removes the process of pre-leaching the gold slime and removing impurities in the prior art, removes multi-step reduction, reduces the processing step, greatly reduces the discharge amount of wastewater, reduces the heating duration, saves the cost of water and electricity, and improves the recovery rate of the gold and the silver and the quality of the gold ingots and the silver ingots.

Owner:LINGBAO CITY JINYUAN MINING

Synthesis path of Timisatem

InactiveCN1344712AReduce generationHigh yieldOrganic chemistryCardiovascular disorderActive componentEthyl group

The present invention relates to the preparation of Timisatan as one active component for antihypertensive medicine. The carboxylic ester derivative is first obtained through the nucleophilic substitution reaction between some intermediate and 4'-bromomethyl biphenyly-2-carboxylic ester, and then hydrolyzed to eliminnate protection radical and to obtain the destination product. In the technological process of the present invention, methyl radical and ethyl radical are used as protecting radical, and this facilitates and stabilizes the preparation of 4'-bromomethyl biphenylyl-2-methyl carboxylic ester and 4'-bromomethyl biphenylyl-2-ethyl carboxylic ester, and results in easy to control reaction with the intermediate, less impurity, easy elimination of protecting radical and high product yield and quality.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

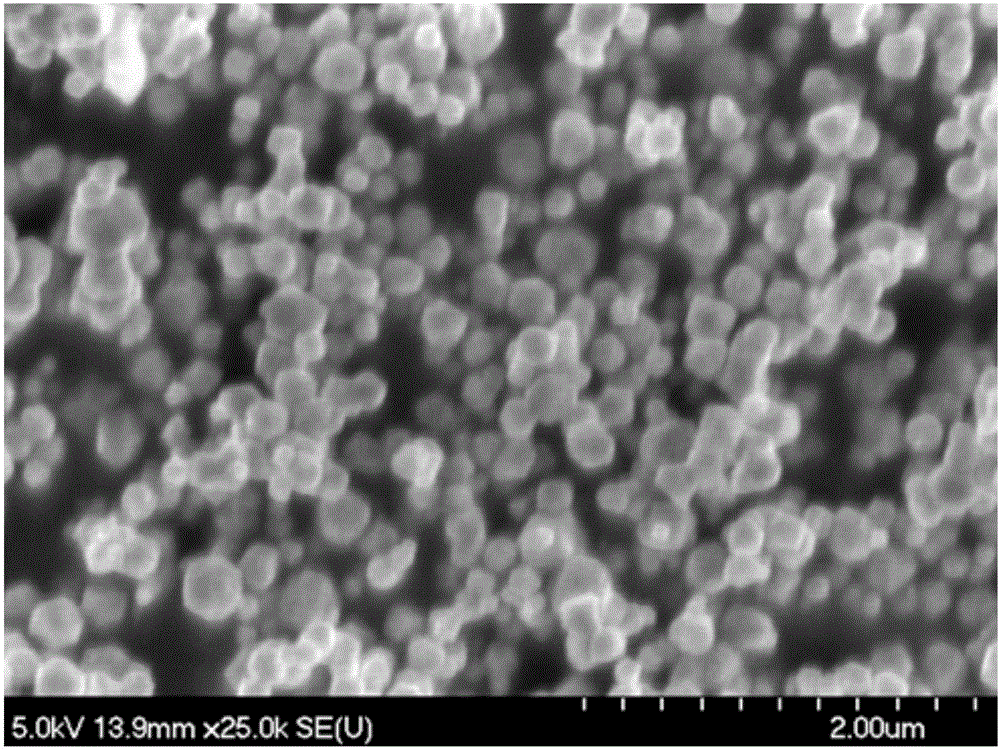

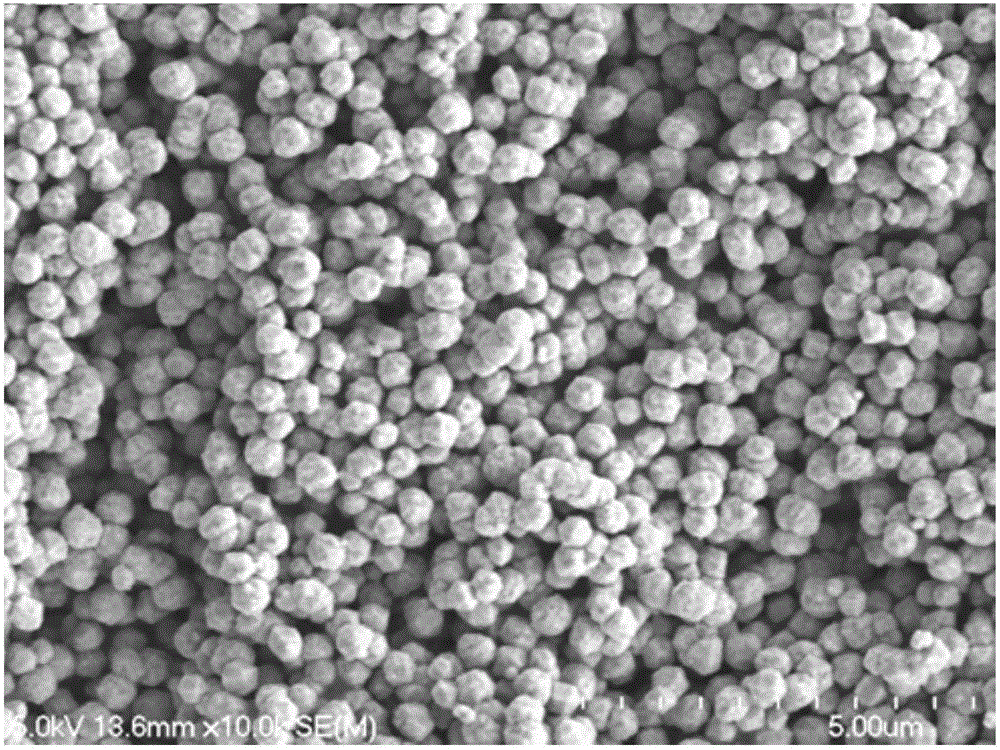

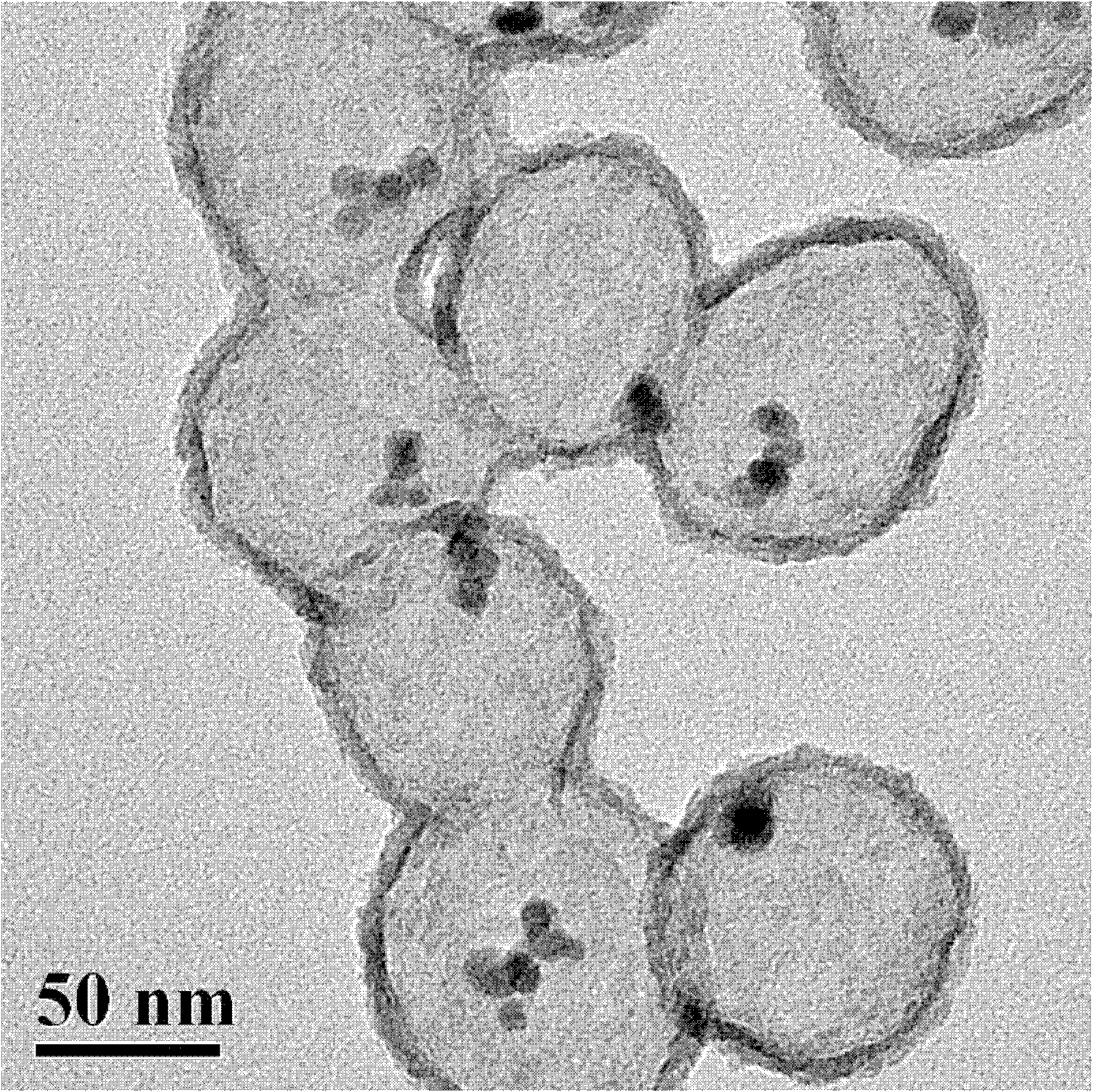

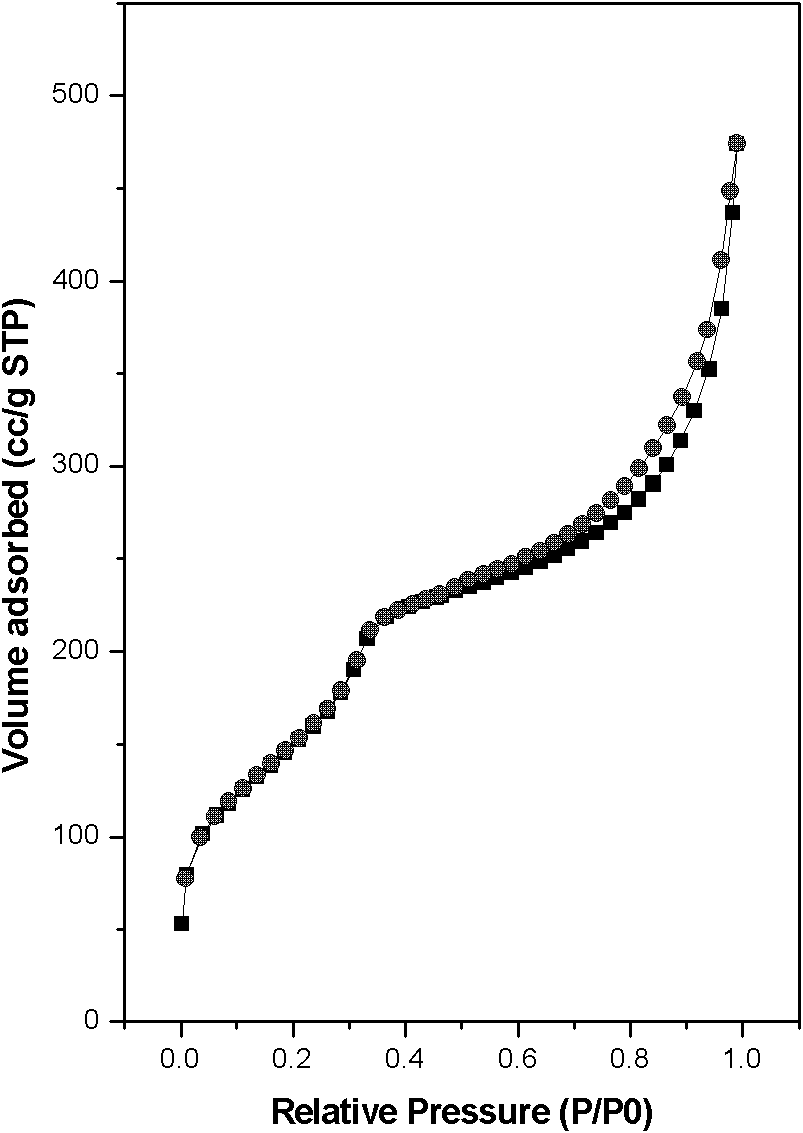

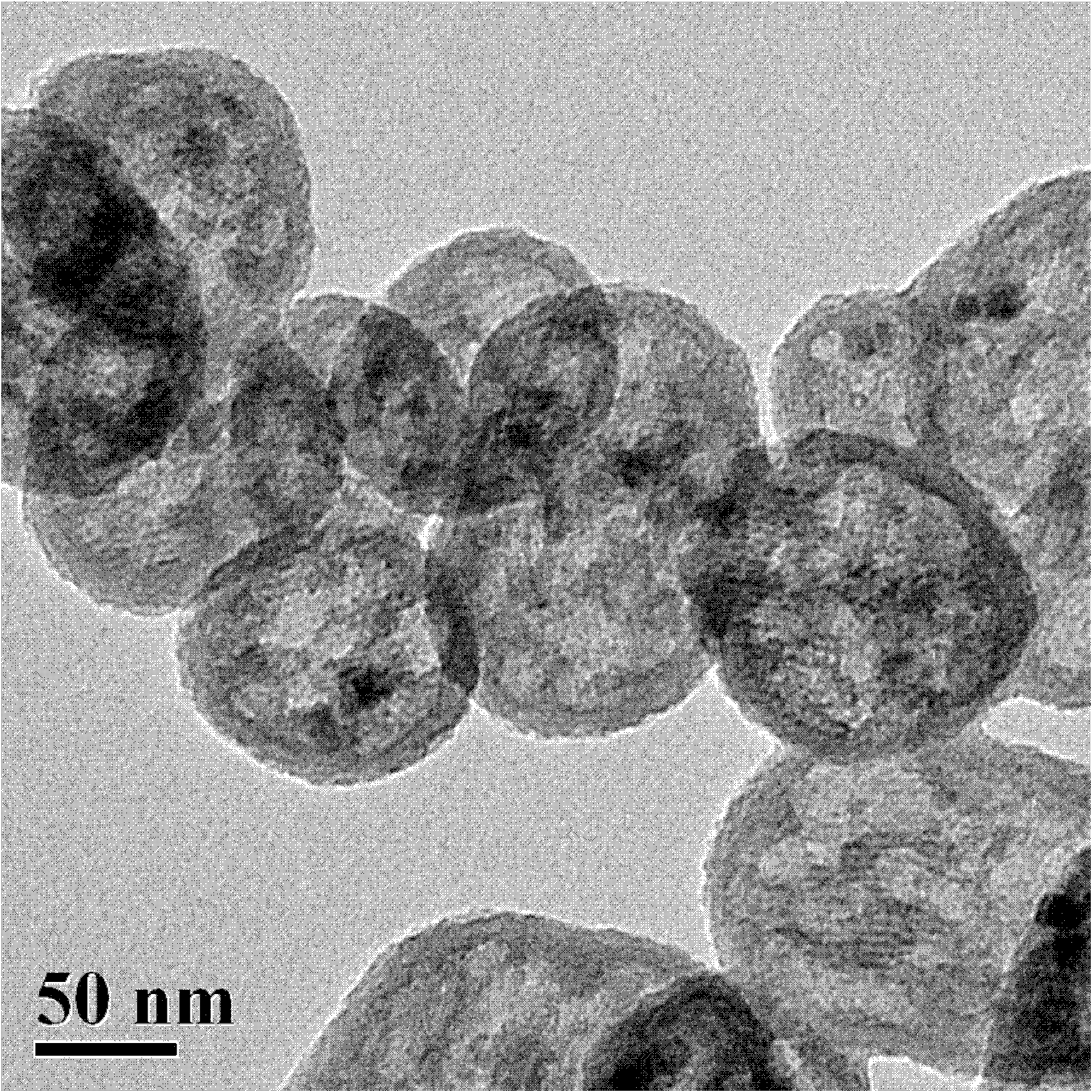

Preparation method for yolk-eggshell-type organic-inorganic hybrid silicon oxide nanosphere

The invention relates to silicon oxide sphere particles, concretely to a preparation method for organic-inorganic hybrid silicon oxide nanospheres with a structure of yolk-eggshell. The invention provides a yolk-eggshell-type organic-inorganic hybrid silicon oxide or a carbon-silicon composite nano-material with adjustable particle size, adjustable core-shell composition and hierarchical pore structure, and the preparation method thereof. In an alkaline system, nanometer silicon oxide spheres with core-shell structures are composed by taking a cationic surfactant as a structure-directing agent. Organosilicon precursor is added to the system. After being stirred, filtered and dried, the organic-inorganic hybrid silicon oxide nanospheres with freely mobile cores and functionalized mesoporous shells are obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of regenerated polyester fibers

ActiveCN104357938AQuality improvementCatalytic recondensation reactionPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsFiberPolyester

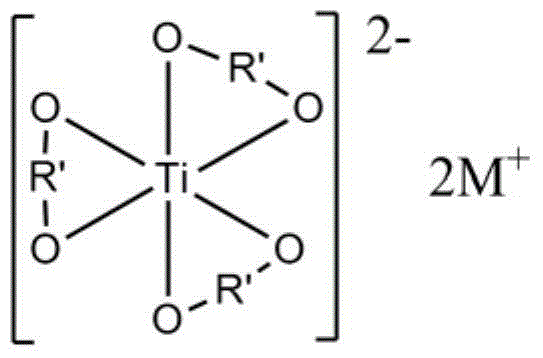

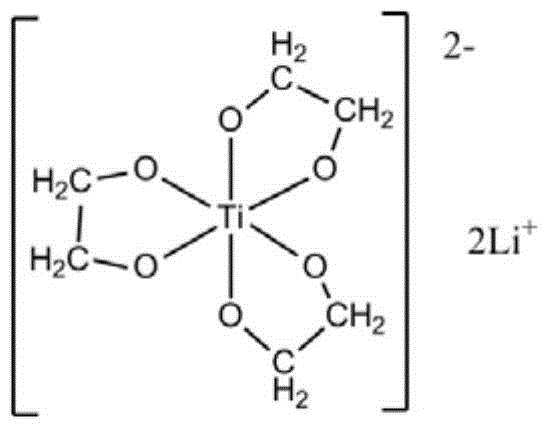

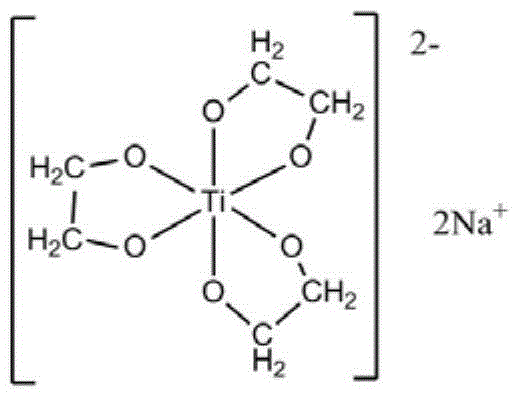

The invention discloses a preparation method of regenerated polyester fibers. The preparation method is used in the field of chemical regeneration of waste polyester. According to the method, a glycol titanium alkali metal coordination compound which can be dissolved in ethylene glycol is used as a catalyst for catalyzing ethylene glycol in a waste polyester product for depolymerization and a repolymerization process of depolymerized products; the catalyst is higher in catalysis activity in ethylene glycol depolymerization of polyester and the repolymerization process of the depolymerized products; therefore, in the preparation method of the regenerated polyester fibers, the catalyst is not required to be removed from the depolymerized products in a regenerated polyester fiber preparation process, and can be used for polycondensation, so that the depolymerized product separation and purification cost is greatly reduced, and the quality of regenerated polyester is guaranteed; the color and the intensity of the regenerated polyester fibers can be obviously improved, and continuous closed-loop recycling of the waste polyester product can be realized.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

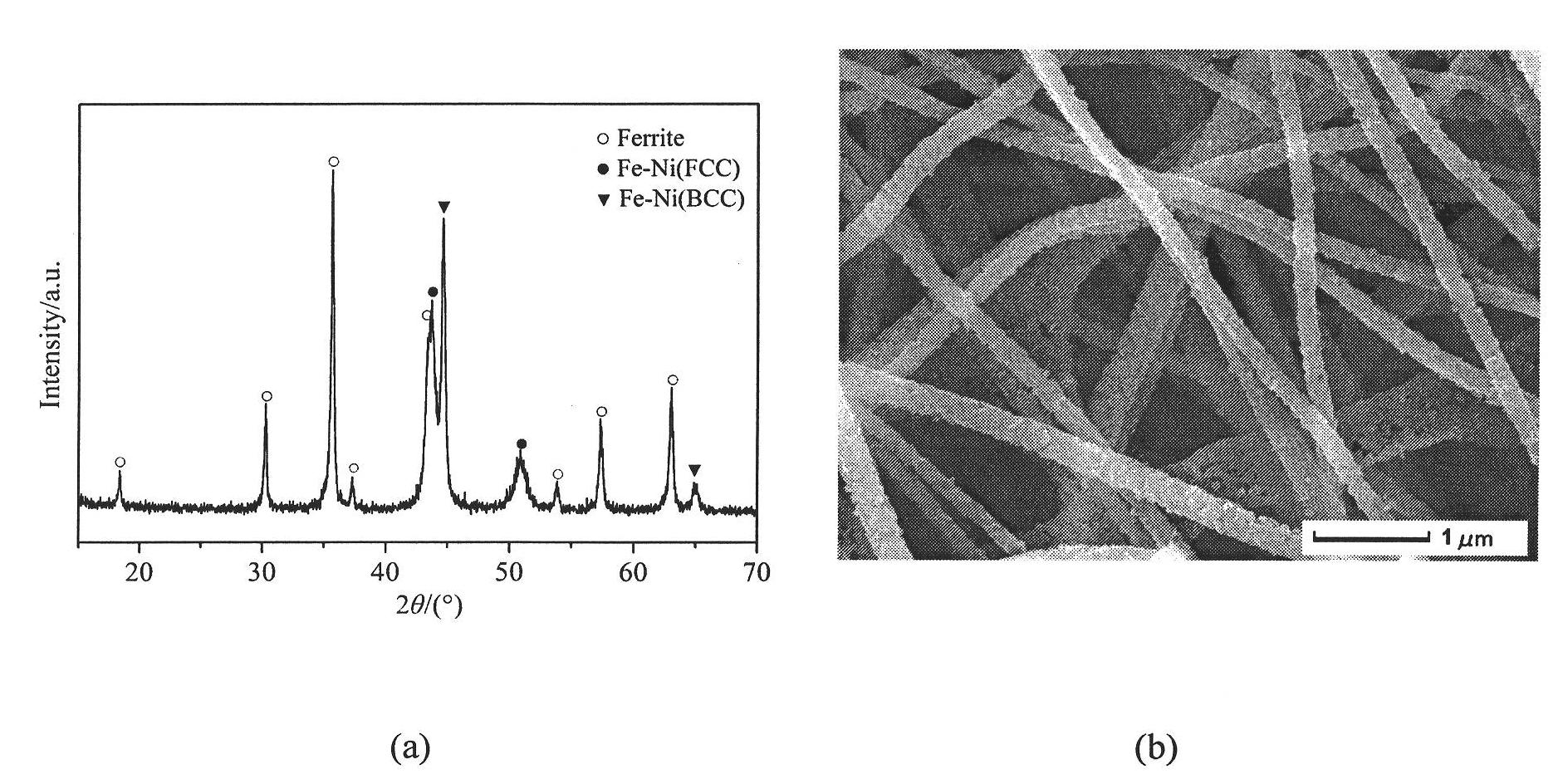

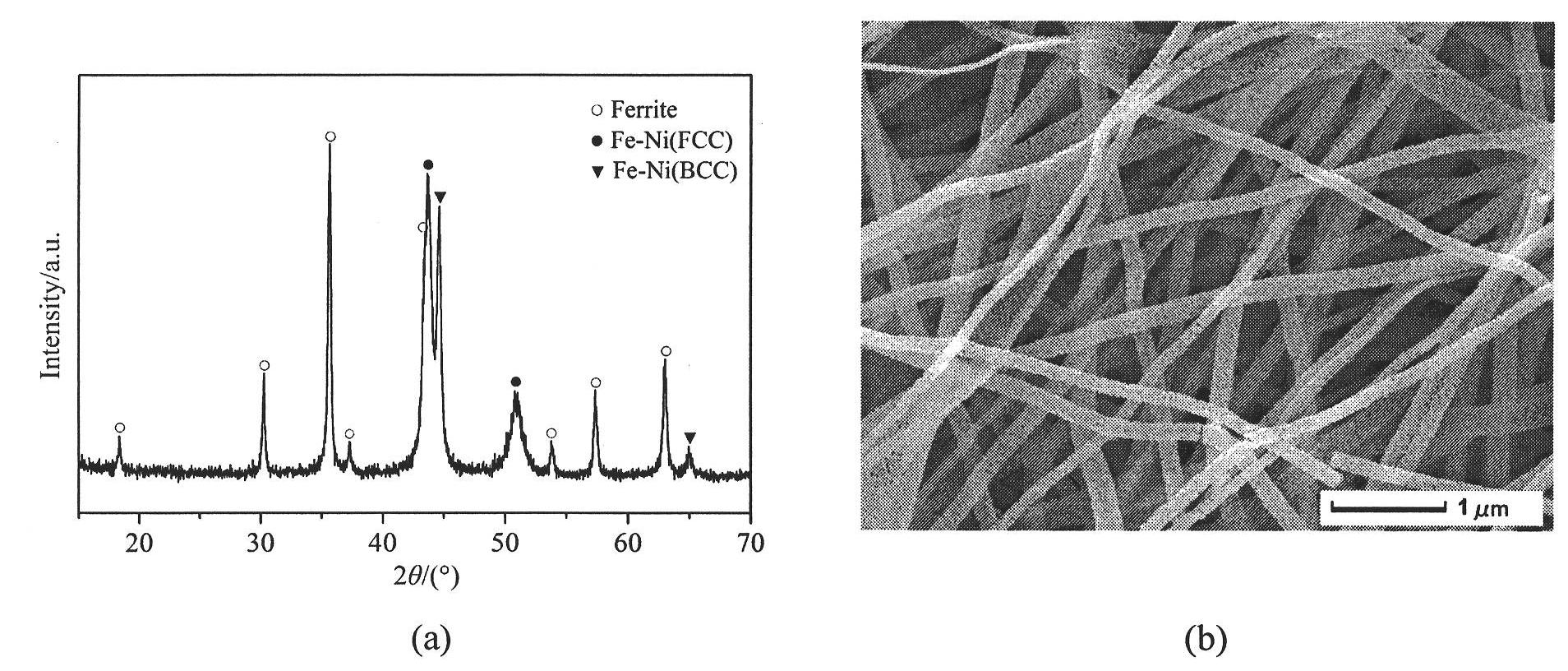

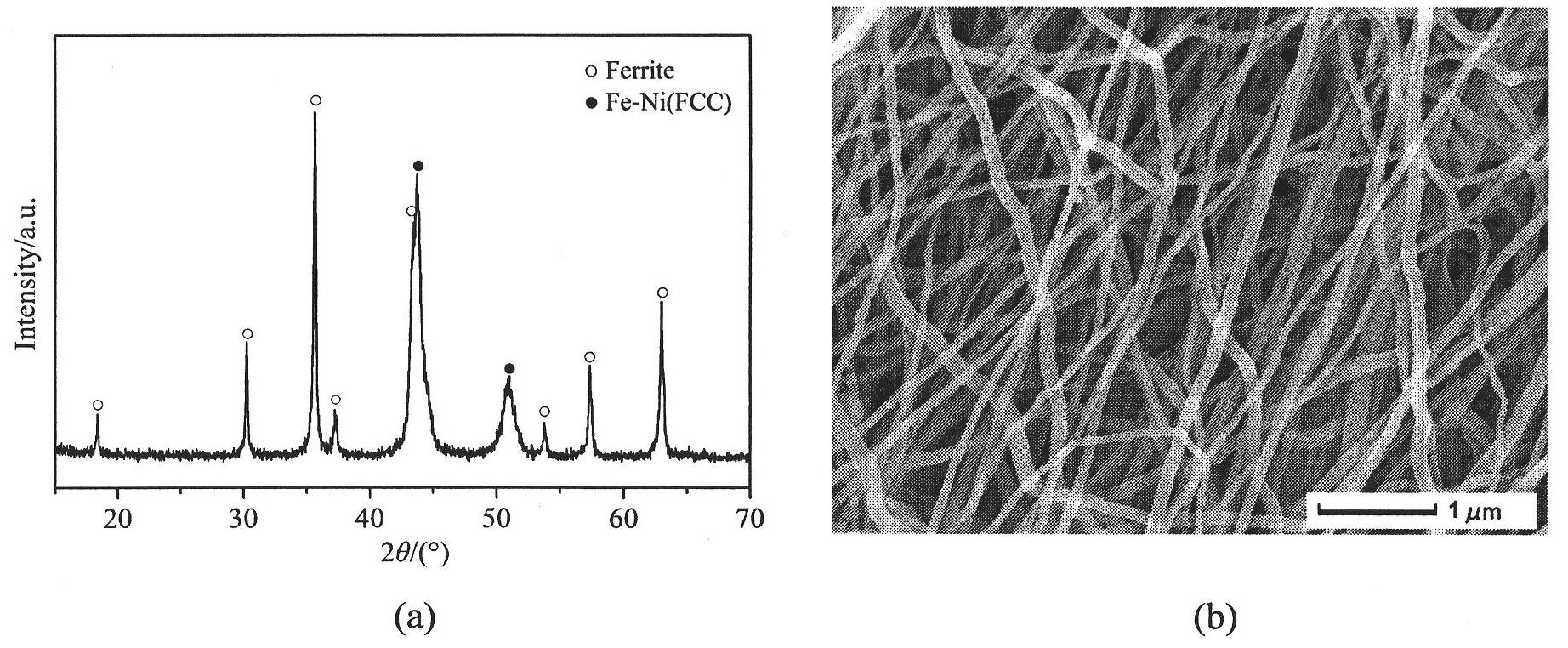

Iron-nickel alloy/nickel ferrite magnetic composite nanofiber and preparation method thereof

InactiveCN101851814ASignificant shape anisotropyAbsorb electromagnetic waves to broadenInorganic material artificial filamentsFilament/thread formingSolventAir atmosphere

Owner:JIANGSU UNIV

Synthetic method of waterborne polyurethane emulsion

Provided is a synthetic method of a waterborne polyurethane emulsion. The synthetic method includes the steps that dehydrated polyhydric alcohol, a diol chain extender containing ion radicals and diisocyanate are added into a reactor for a heat preservation reaction, then a solvent-1 and a catalyst are added for continuing the reaction, then castor oil or modified castor oil and a solvent-2 are added, a neutralizing agent is added for neutralization after the reaction, and an intermediate is obtained; an aqueous solution of a diamine chain extender containing sulfonic groups is added into the intermediate and quickly stirred, then deionized water is slowly added with quick stirring, an aqueous solution of a micromolecular diamine chain extender is added after uniform dispersion and evenly stirred, then a heat preservation reaction is performed, vacuum solvent removal is performed, and the milky waterborne polyurethane dispersion liquid is obtained. The waterborne polyurethane emulsion has the advantages of being high in solid content, good in dispersion stability and good in water resistance and heat resistance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Method for preparing n-3PUFA ocean glycerin ester by enzymatical process

A method for preparing n-3PUFA marine glyceride through adopting enzyme method includes following steps: refined fish oil is made into n-3PUFA condensate through saponification, acidification and urea adduct method; lipase catalyzes the synthesis reaction between n-3PUFA and glycerol; n-3PUFA marine glyceride is extracted and separated; moreover, n-3PUFA is effectively concentrated in glyceride to be made into functional products which can prevent and cure cardiovascular diseases and nourish the brain and improve intelligence. The raw material of the invention, n-3PUFA, is extracted from natural fish oil, thereby being safe and effective; during production, nitrogen protection is adopted without adding synthetic antioxidant, thereby effectively preventing oxidation of n-3PUFA; with scientific and reasonable technique, the invention completes synthesis by means of biological enzyme method along with high esterification degree of reaction, higher utilization rate of raw material and easily controlled reaction process; therefore, the invention has wide market prospect.

Owner:GUANGDONG OCEAN UNIVERSITY

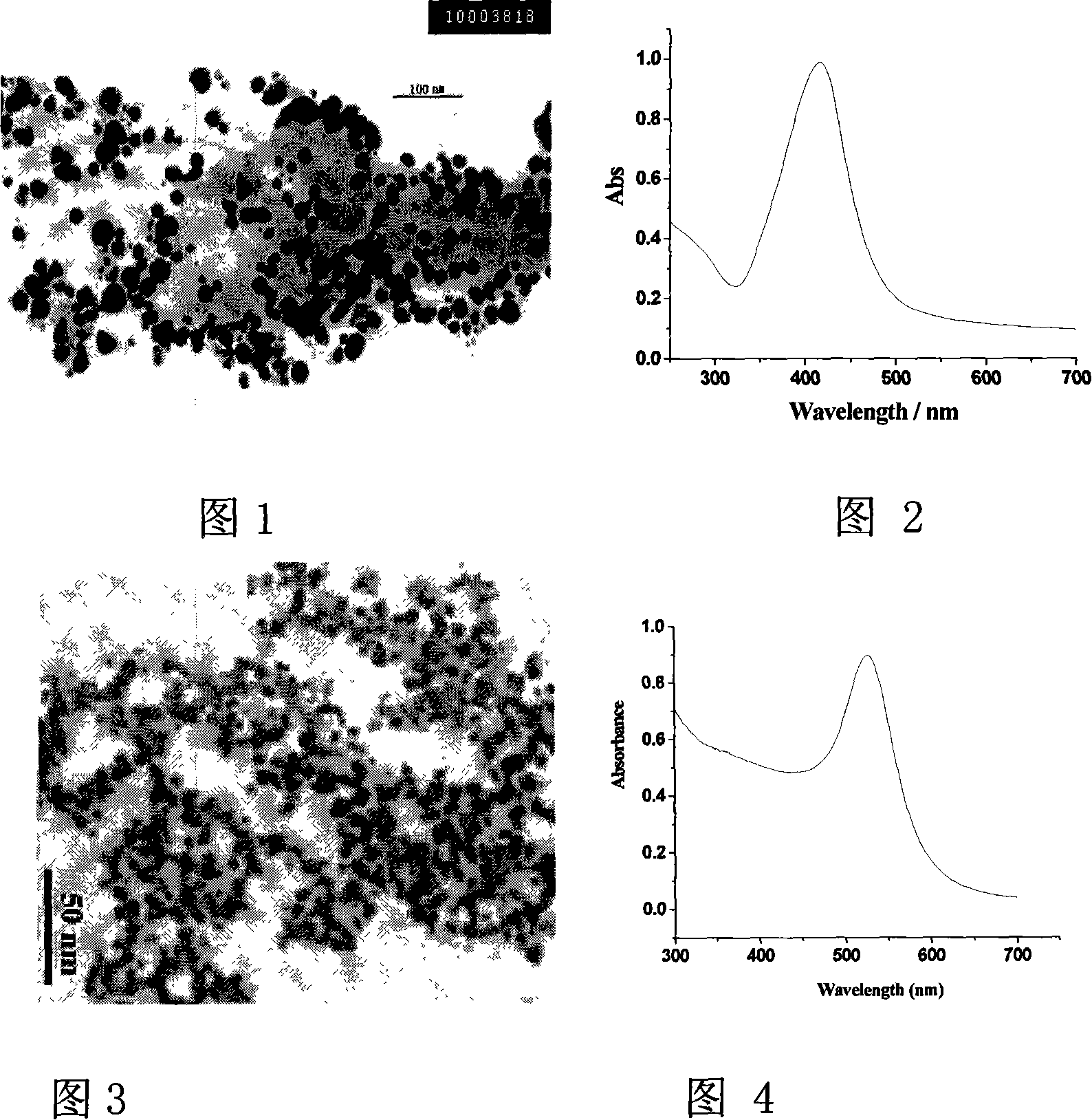

Microwave preparing method for nanometer silver or gold

The present invention discloses a microwave producing method for nano-silver or gold; the reactants are added into the reactor according to the proportion of 1 to 1; the reactants are silver nitrate or auric chloride acid and starch or sodium carboxymethyl cellulose; the reactor is put into a microwave oven; with a mixer of a rotation speed of 100 / min and the microwave power of 0.3 Kw, the reaction time of the reactant starch is one hour while the time of the reactant sodium carboxymethyl cellulose is seven hours; the solution is dried by air or vacuum freeze or spraying after the reaction is over to produce nano-silver or gold powder or concentrated to nano-silver or gold colloid of the needed consistency through vacuum concentration. The present invention discards the ordinary reducing agent in thermochemical synthesis and takes the microwave heating to replace the traditional local heating method and realize homogeneous growing of nano-silver or gold; the grain size distribution of the nano-silver and gold is narrow and the grain shapes are regular; the method is widely used in biochemical and antiseptic material field.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

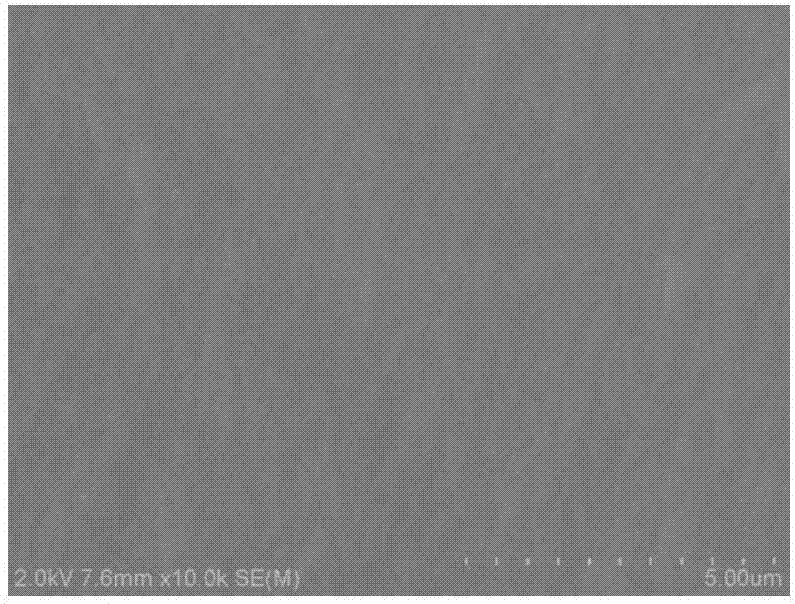

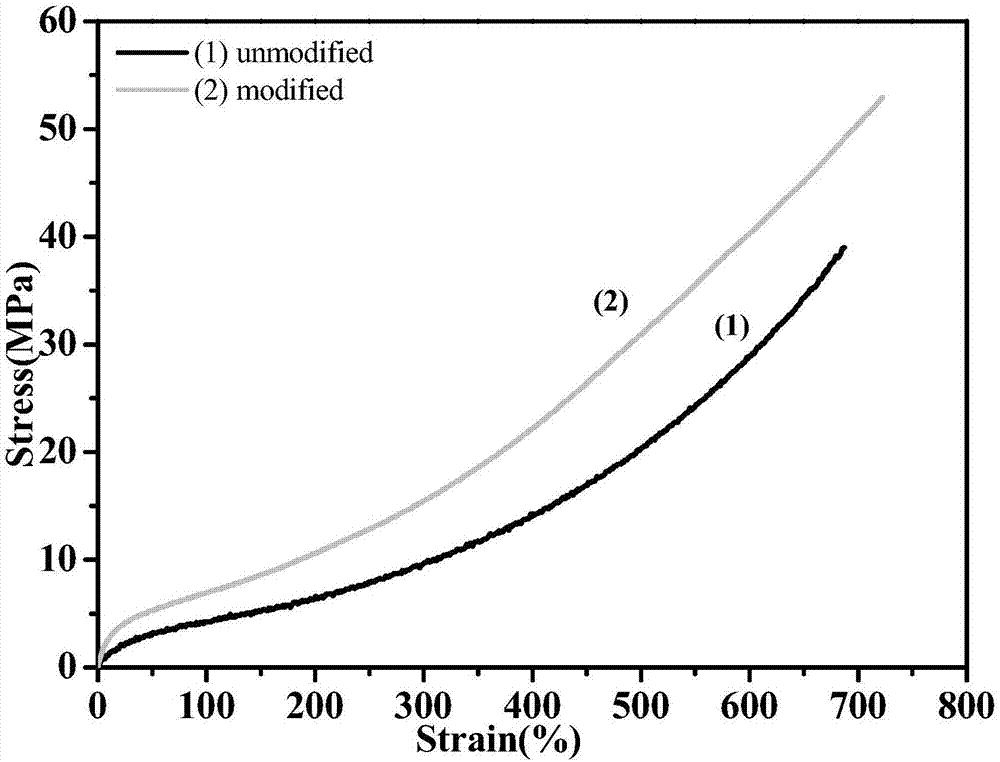

Preparation method of waterborne polyurethane/graphene nano-composite emulsion

The invention relates to a preparation method of waterborne polyurethane / graphene nano-composite emulsion, and belongs to the field of organic-inorganic nano-composite materials. According to the preparation method, graphene oxide dispersion liquid is prepared by adopting an improved Hummers method, and is compounded with waterborne polyurethane to obtain the waterborne polyurethane / graphene nano-composite emulsion. By use of the preparation method disclosed by the invention, the waterborne polyurethane / graphene nano-composite emulsion is prepared by taking oligomer polyol as a soft segment, taking an isocyanate compound as a hard segment and carrying out in-situ introduction of the graphene oxide dispersion liquid in the preparation process of the waterborne polyurethane. The mechanical property, antistatic property, conductive property, electromagnetic shielding property, thermal conductivity, chemical resistance, corrosion resistance and the like of a waterborne polyurethane film and a coating are effectively improved by introducing grapheme. The waterborne polyurethane / graphene nano-composite emulsion has a better application prospect in the fields of coating materials, adhesives, ink, surface treatment agents, elastomers, foaming materials, functional films and the like.

Owner:JIANGNAN UNIV

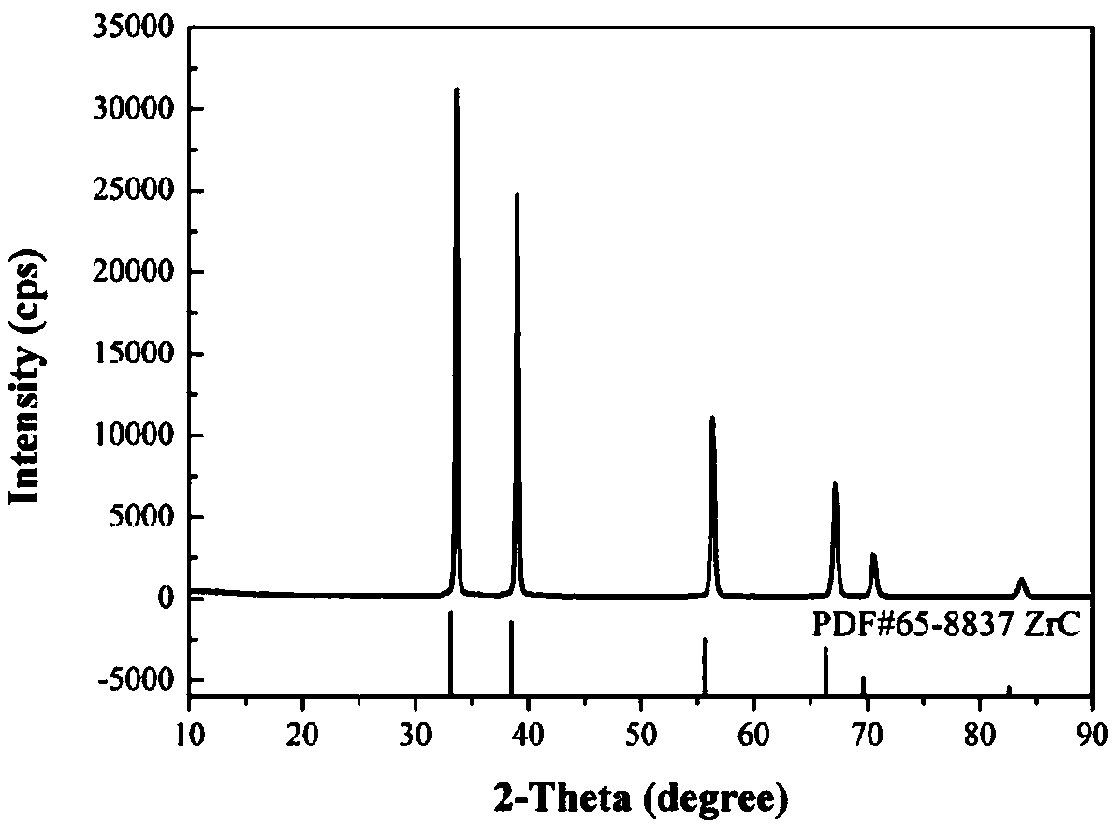

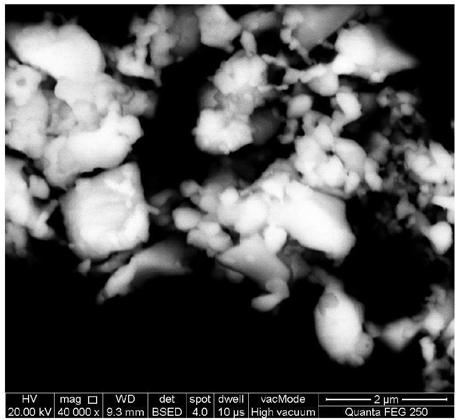

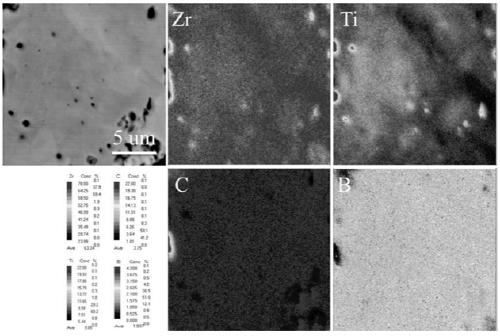

High-entropy boron-containing carbide ultrahigh temperature ceramic powder and preparation method thereof

The invention belongs to the technical field of carbide ceramics, and concretely relates to a high-entropy boron-containing carbide ultrahigh temperature ceramic powder and a preparation method thereof. The molecular formula of the ceramic powder is XCyBz, wherein X is at least two of Zr, Ti, Hf, V, Nb, Ta, Cr, Mo and W, y is equal to or more than 0.6 and less 1.0, z is more than 0 and equal to orless than 0.4, and y + z = 1. The ceramic powder has a single phase face-centered cubic structure. The preparation method comprises the following steps: carrying out ball-milling mixing on at least two metal powders and C powder, carrying out pressureless plasma sintering and crushing to obtain carbide powder, mixing the carbide powder with B2O3 powder and a carbon source, and then performing high temperature sintering and crushing to obtain the ceramic powder. The ceramic powder is a single-phase solid solution, has the face-centered cubic structure, and contains the boron element, so the ceramic powder integrates the high temperature resistance of carbides and the oxidation resistance of borides, and can be used to prepare an ablation and oxidation resistant high-entropy boron-containing carbide ultrahigh temperature ceramic block or composite material.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com