Preparation method of nitrogen and sulfur co-doped graphene

A nitrogen-sulfur co-doping, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as relatively high requirements for equipment corrosion resistance and environmental pollution, and achieve easy control of the reaction process. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh graphene, melamine and dibenzyl disulfide according to the mass ratio of 1:6:6, put them into a mortar, mix and grind for 2 hours; After entering high-purity argon to remove air, the temperature was raised to 1000°C at a rate of 3°C / min, kept for 1h, and cooled to room temperature naturally to obtain nitrogen-sulfur co-doped graphene.

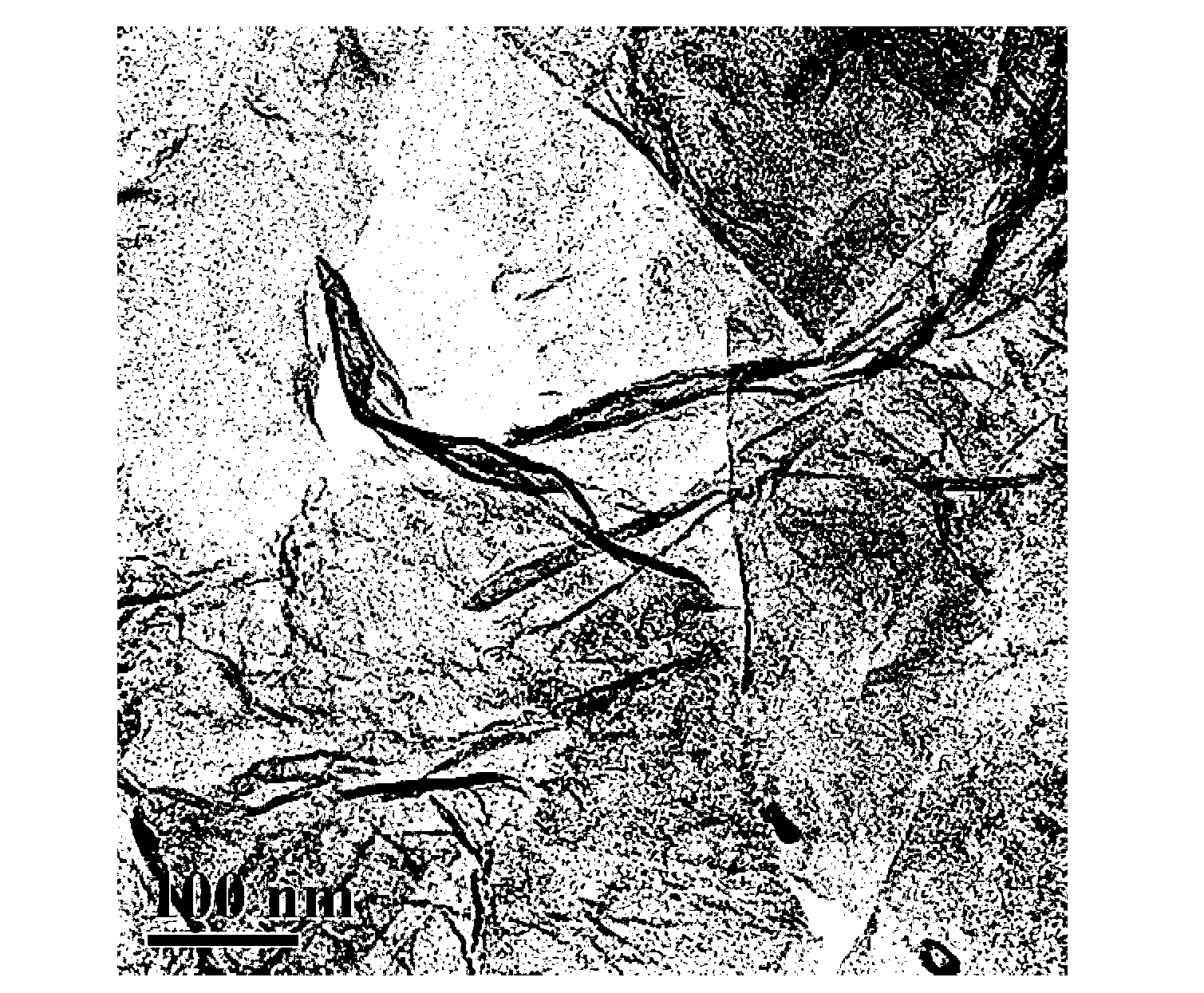

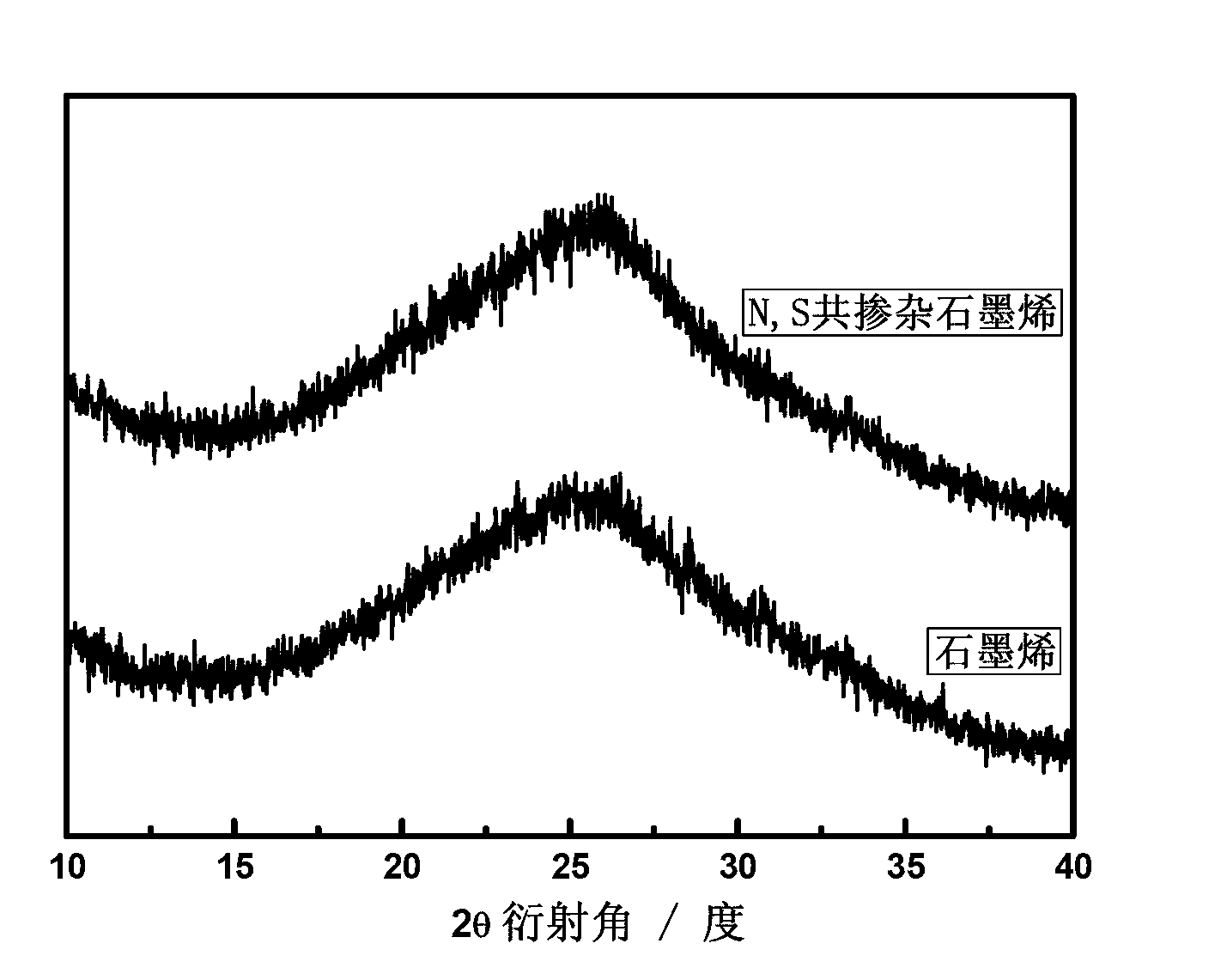

[0025] The transmission electron microscope and X-ray diffraction patterns of gained nitrogen-sulfur co-doped graphene are respectively as follows figure 1 with figure 2 As shown, it can be seen that the resulting nitrogen-sulfur co-doped graphene still has very thin wrinkled shape and few layers.

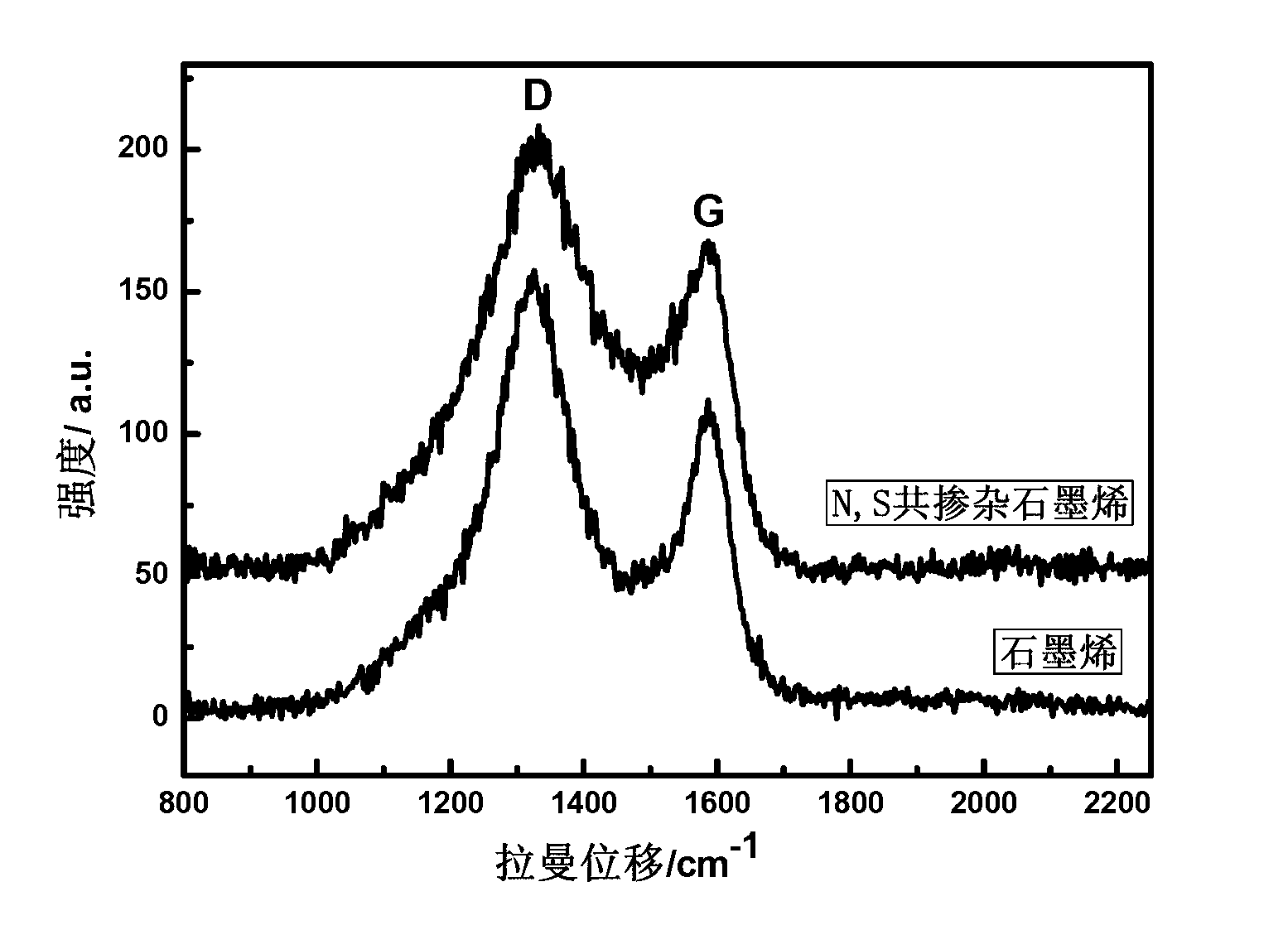

[0026] The Raman spectrum of gained nitrogen-sulfur co-doped graphene is as follows image 3 It can be seen from the figure that the I of graphene D / I G =1.41, the I of nitrogen-sulfur co-doped graphene D / I G =1.21, due to I D / I G Indicates the degree of disorder of graphene, and it can be seen that graphene is more ordered ...

Embodiment 2

[0029] Weigh graphite oxide, urea and p-toluenesulfonic acid according to the mass ratio of 1:20:5, put them into a mortar, mix and grind for 4 hours; After entering high-purity argon to remove air, the temperature was raised to 900°C at a rate of 3°C / min, kept for 5h, and cooled to room temperature naturally to obtain nitrogen-sulfur co-doped graphene.

[0030] It can be obtained by elemental analysis that in the nitrogen-sulfur co-doped graphene, the nitrogen content is 3.2 at.%, and the sulfur content is 2.0 at.%.

Embodiment 3

[0032] Weigh graphene oxide and L-cysteine-S-2-thiophene formaldehyde according to the mass ratio of 1:20, put them into a mortar, mix and grind for 5 hours; then put the mixture into a porcelain boat and place it in a tube furnace After passing high-purity nitrogen into the heating zone to remove the air, the temperature was raised to 700°C at a rate of 3°C / min, kept for 3h, and cooled down to room temperature naturally to obtain nitrogen-sulfur co-doped graphene.

[0033] It can be obtained by elemental analysis that in the nitrogen-sulfur co-doped graphene, the nitrogen content is 5 at.%, and the sulfur content is 1.1 at.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com