Patents

Literature

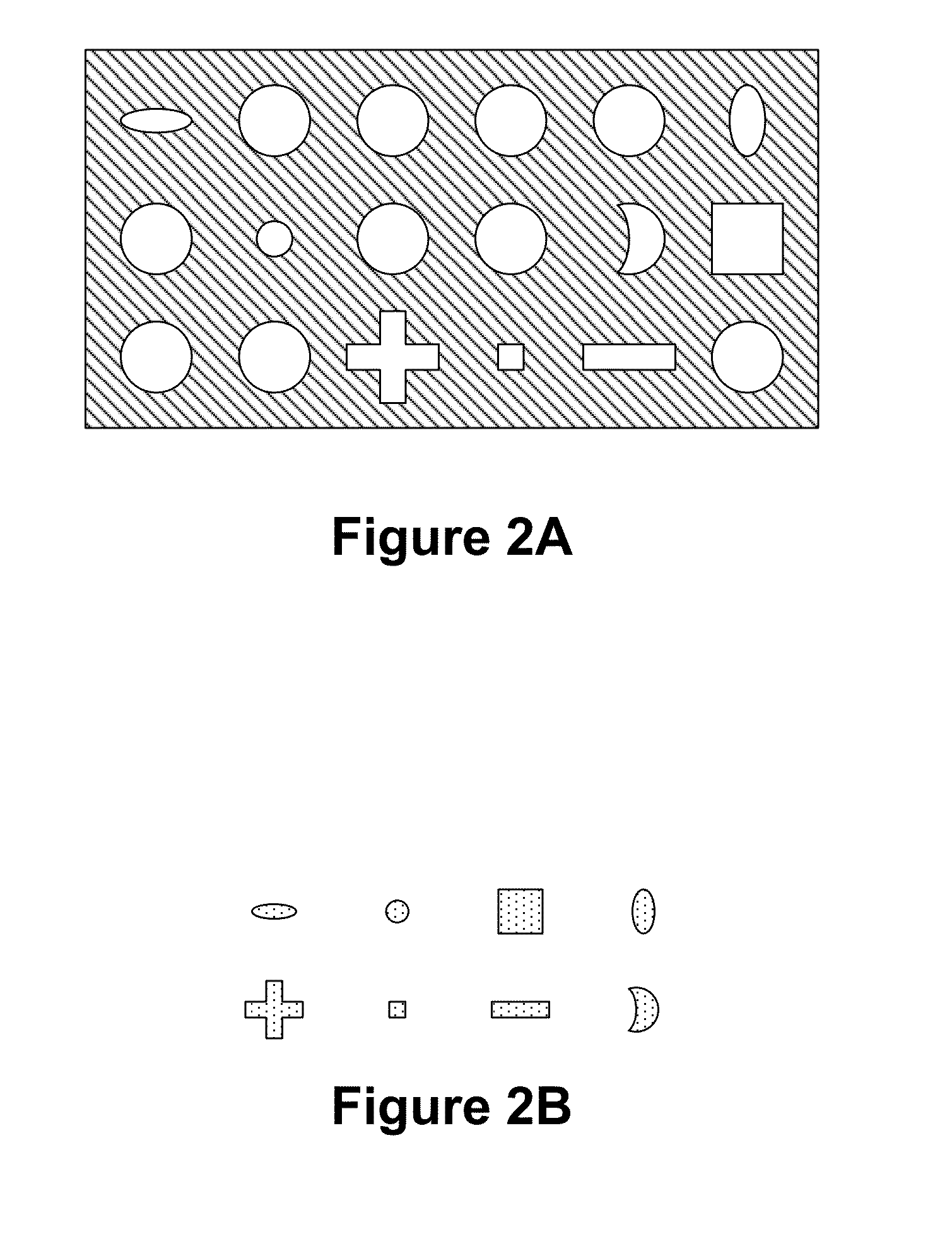

937 results about "Lithium–air battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

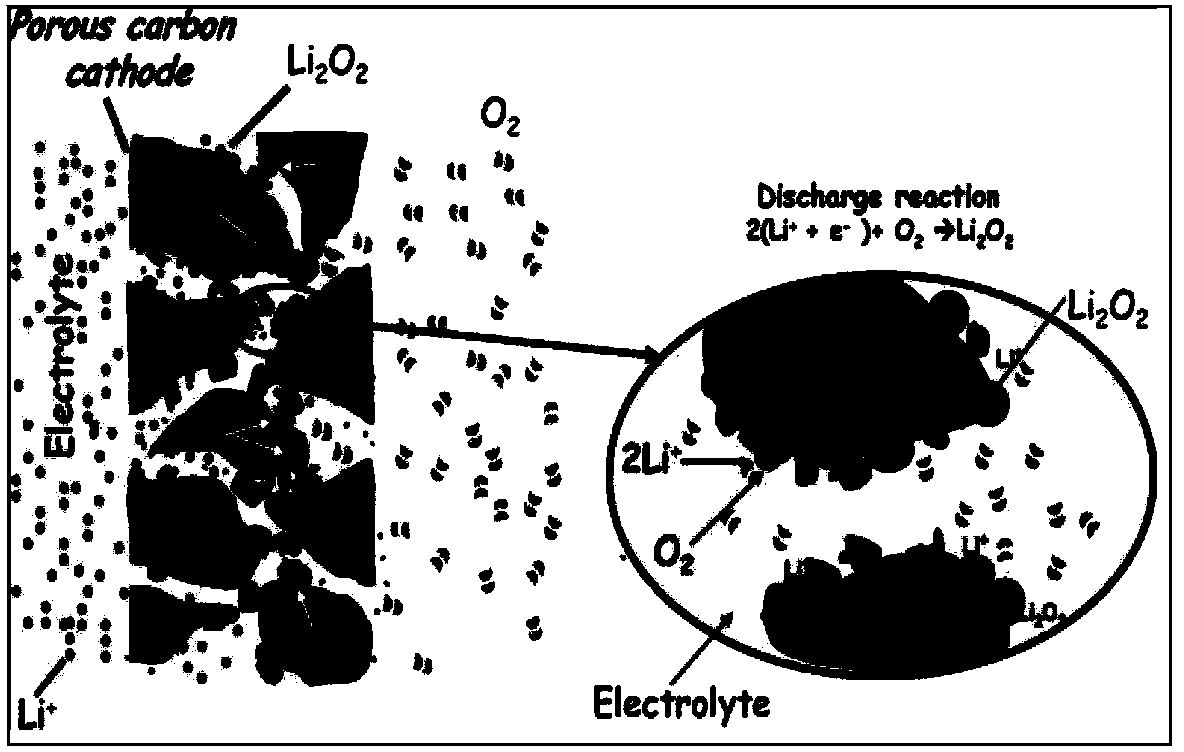

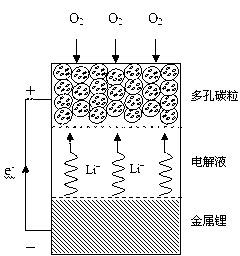

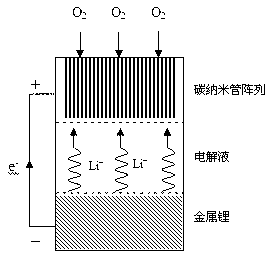

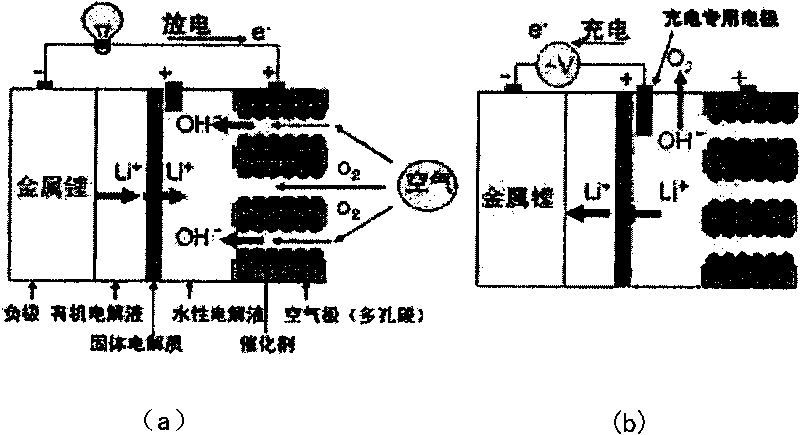

The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow. Pairing lithium and ambient oxygen can theoretically lead to electrochemical cells with the highest possible specific energy. Indeed, the theoretical specific energy of a non-aqueous Li–air battery, in the charged state with Li₂O₂ product and excluding the oxygen mass, is ~40.1 MJ/kg. This is comparable to the theoretical specific energy of gasoline, ~46.8 MJ/kg. In practice, Li–air batteries with a specific energy of ~6.12 MJ/kg at the cell level have been demonstrated. This is about 5 times greater than that of a commercial lithium-ion battery, and is sufficient to run a 2,000 kg EV for ~500 km (310 miles) on one charge using 60 kg of batteries. However, the practical power and life-cycle of Li–air batteries need significant improvements before they can find a market niche.

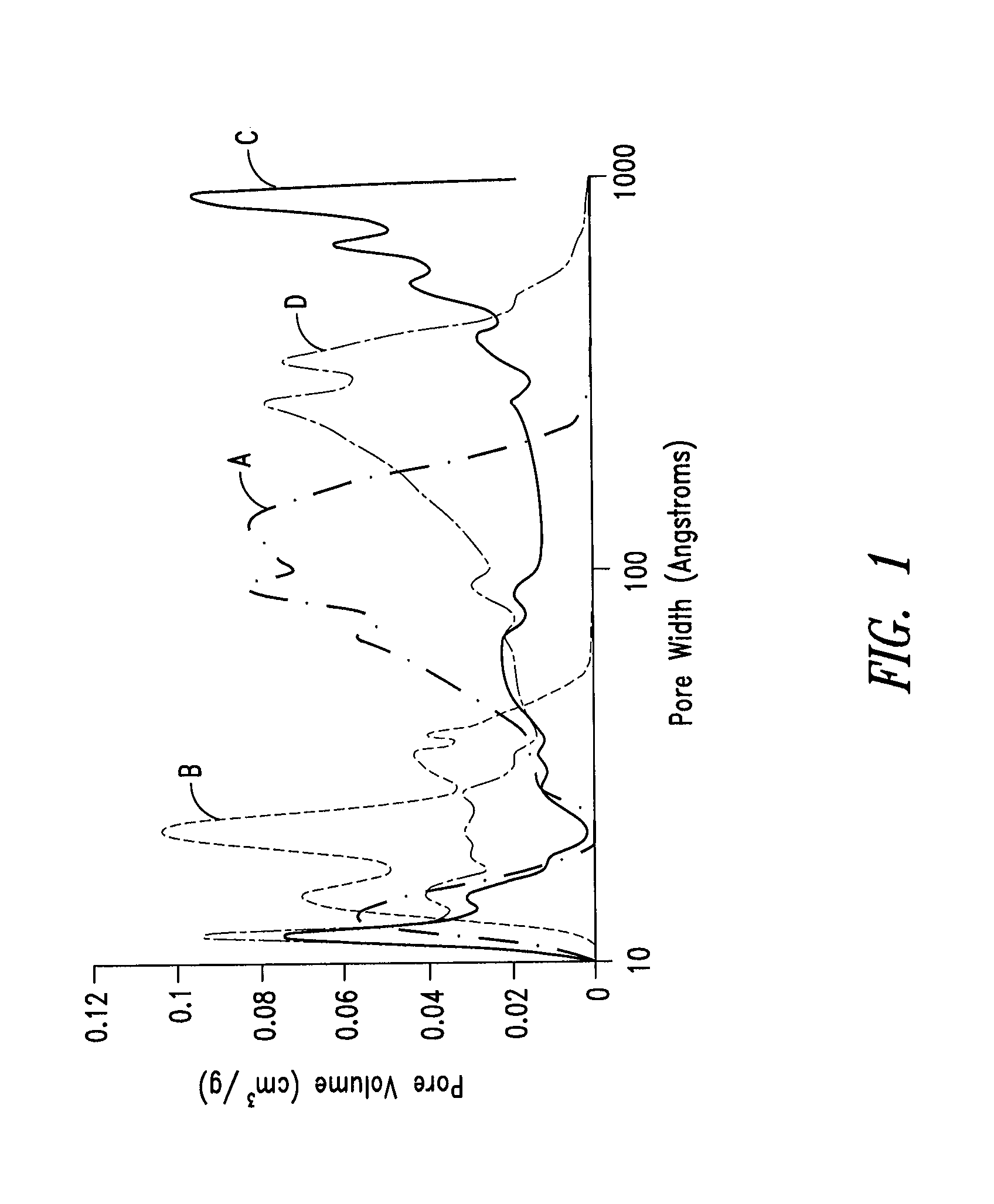

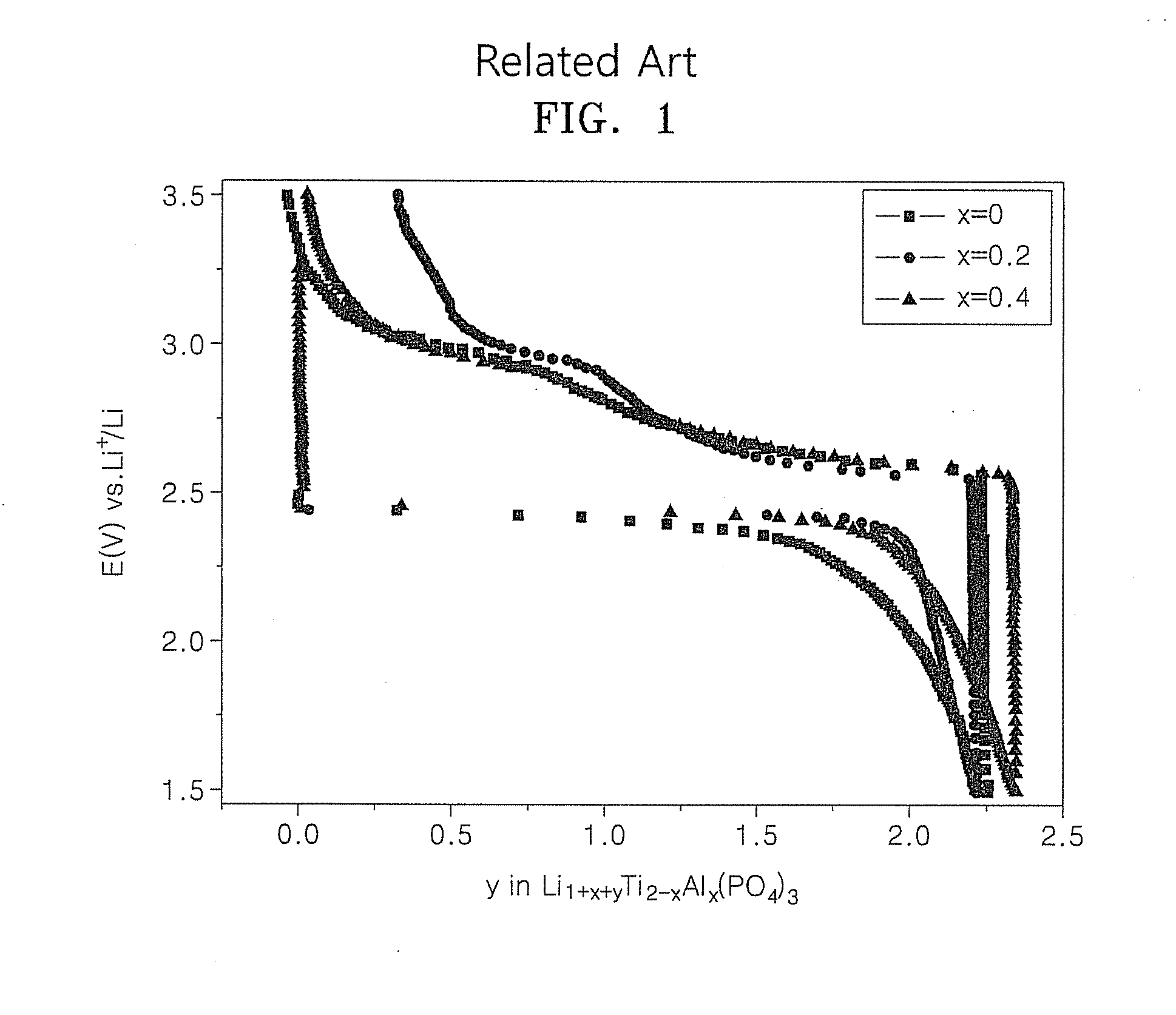

Rechargeable lithium/water, lithium/air batteries

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

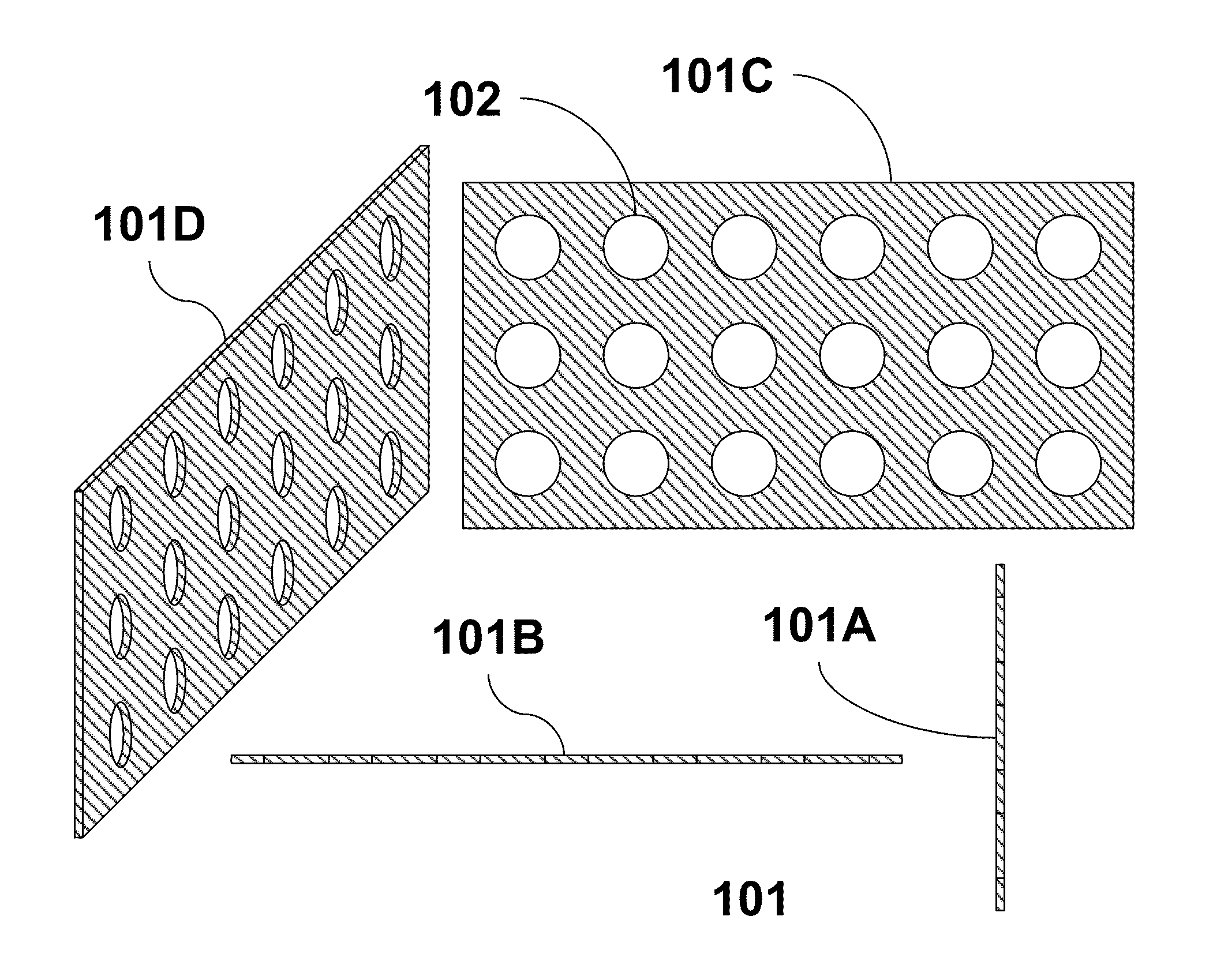

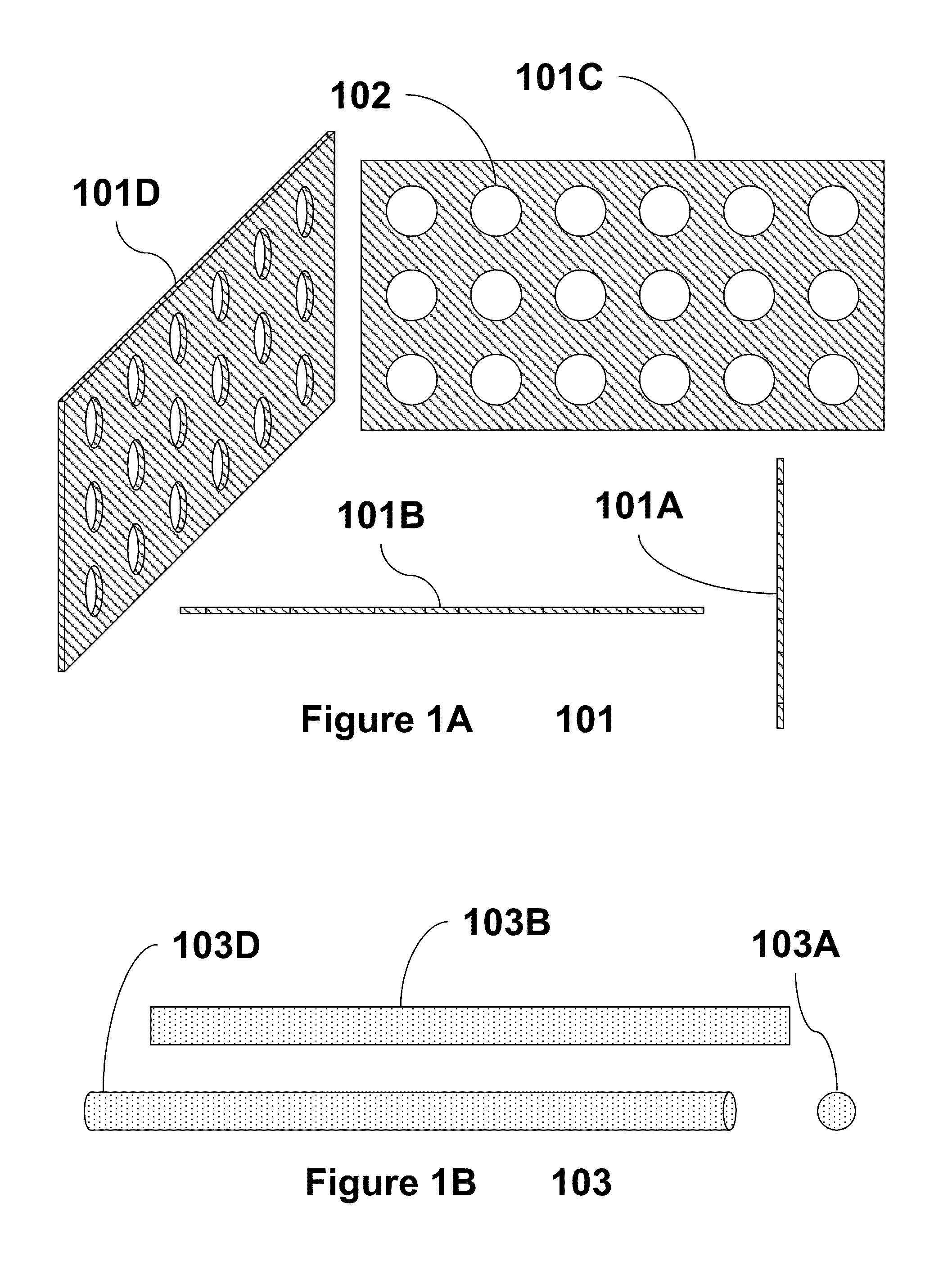

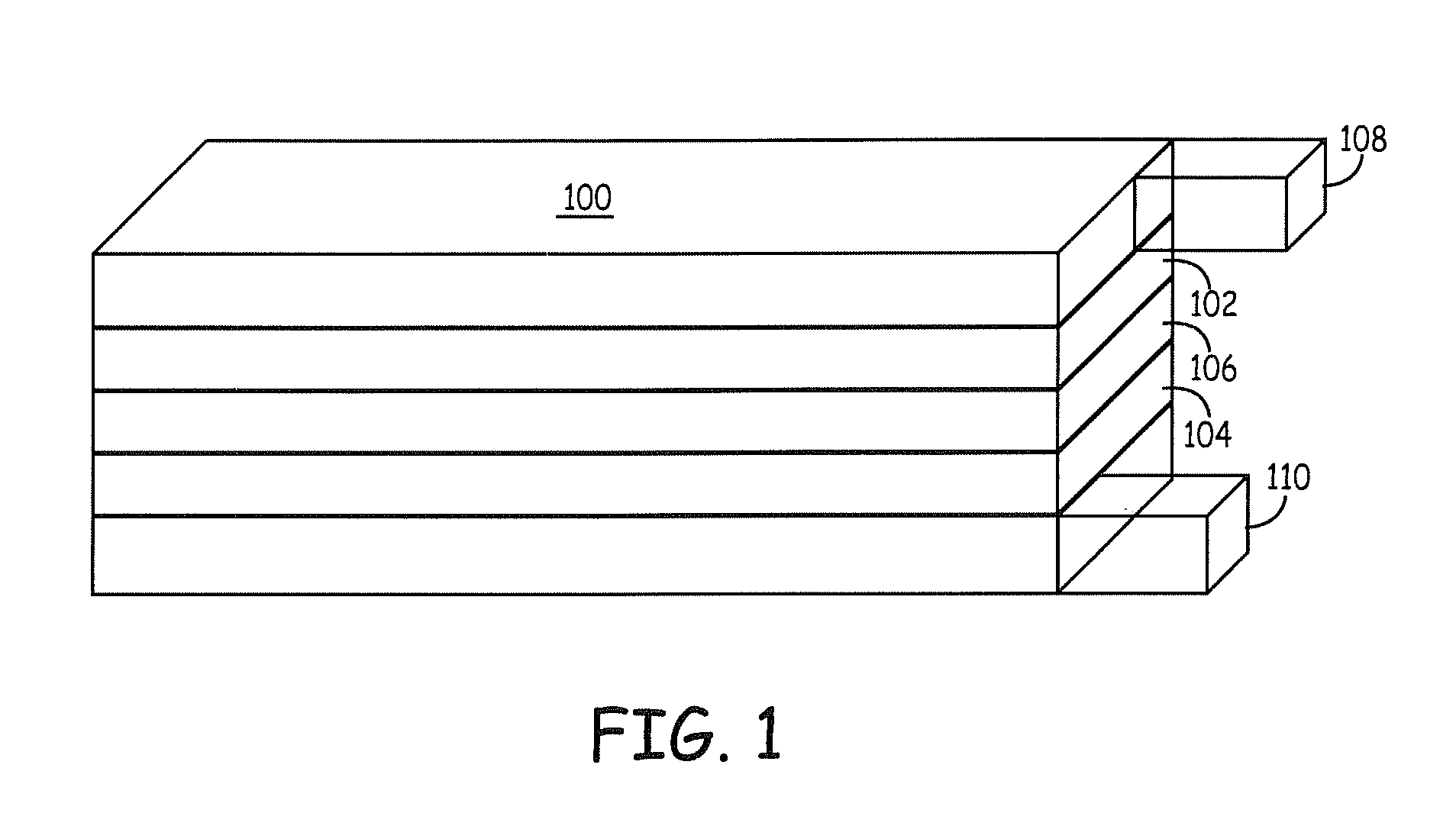

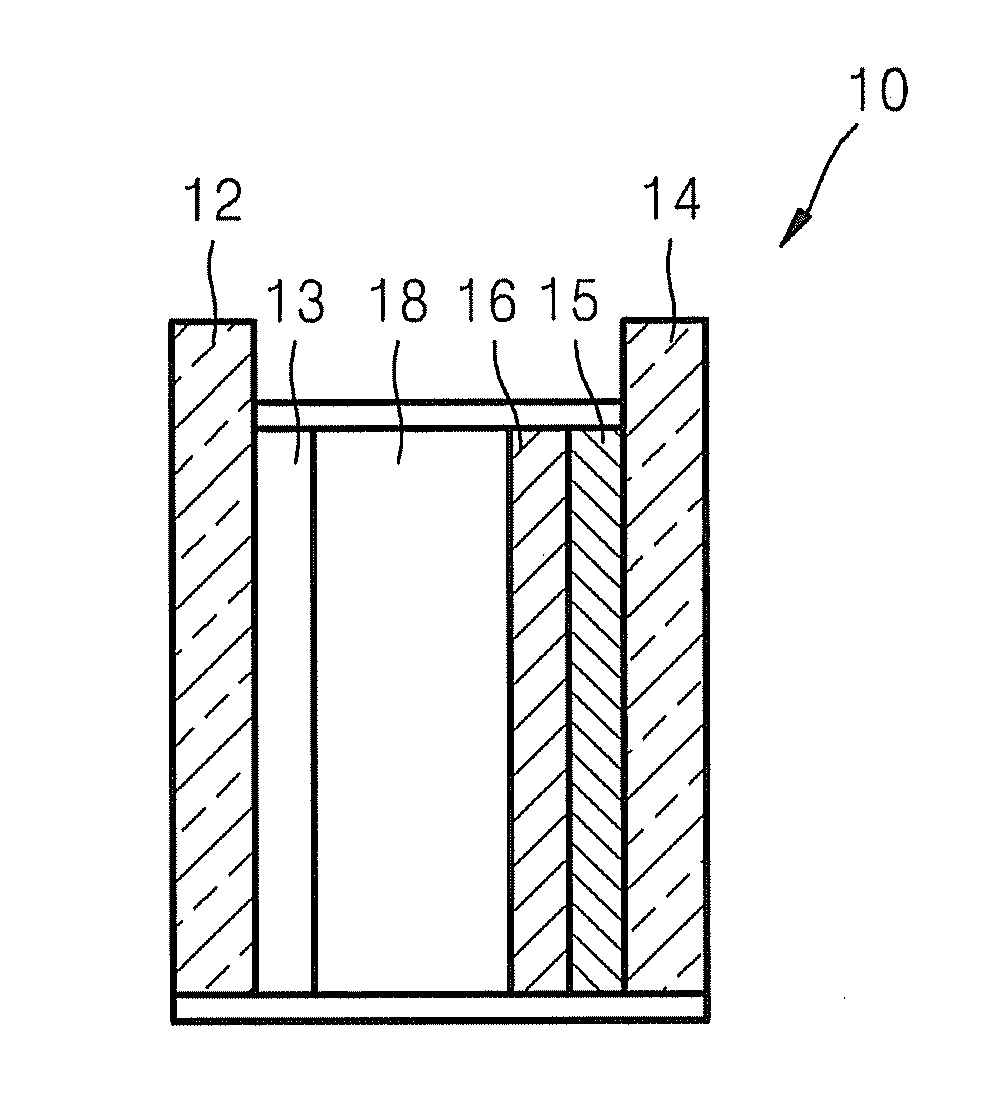

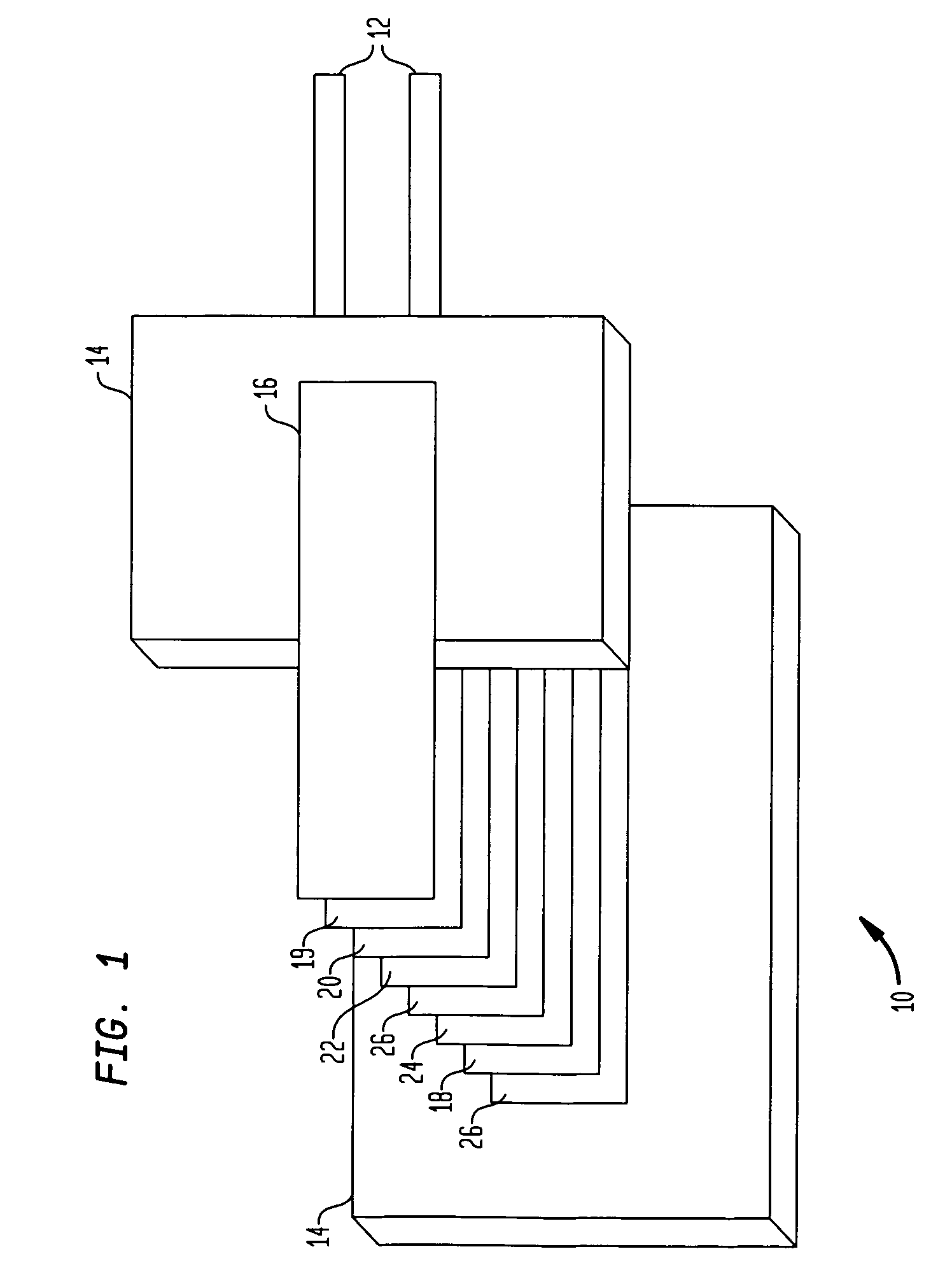

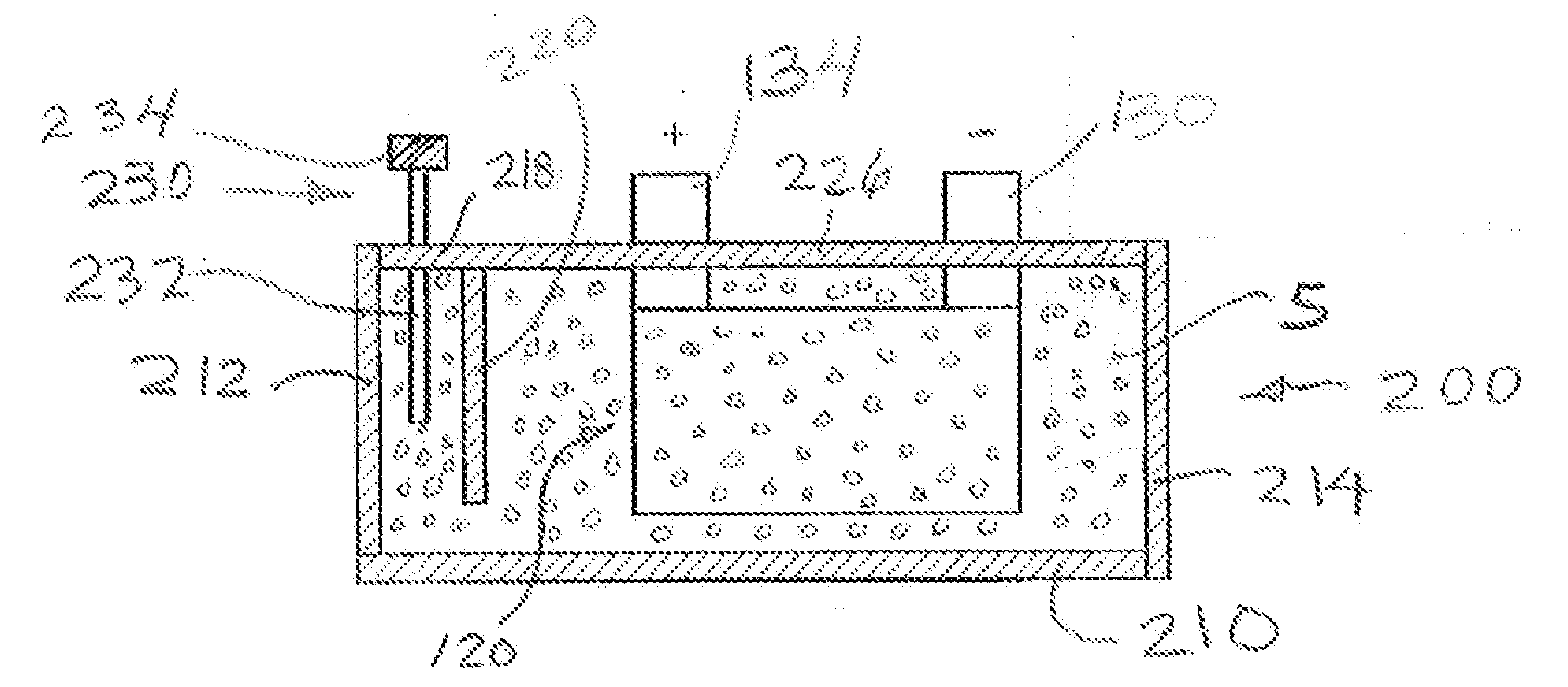

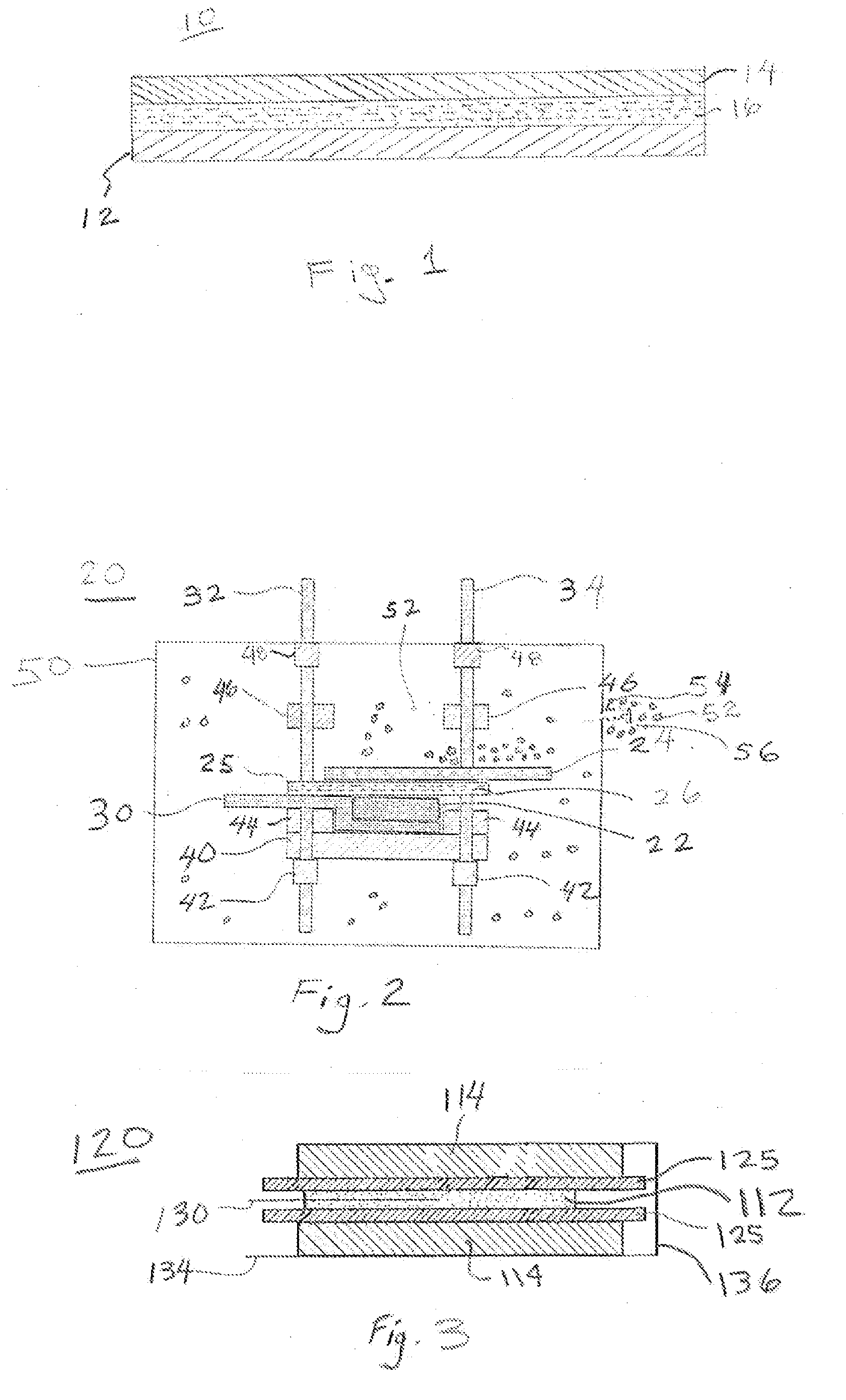

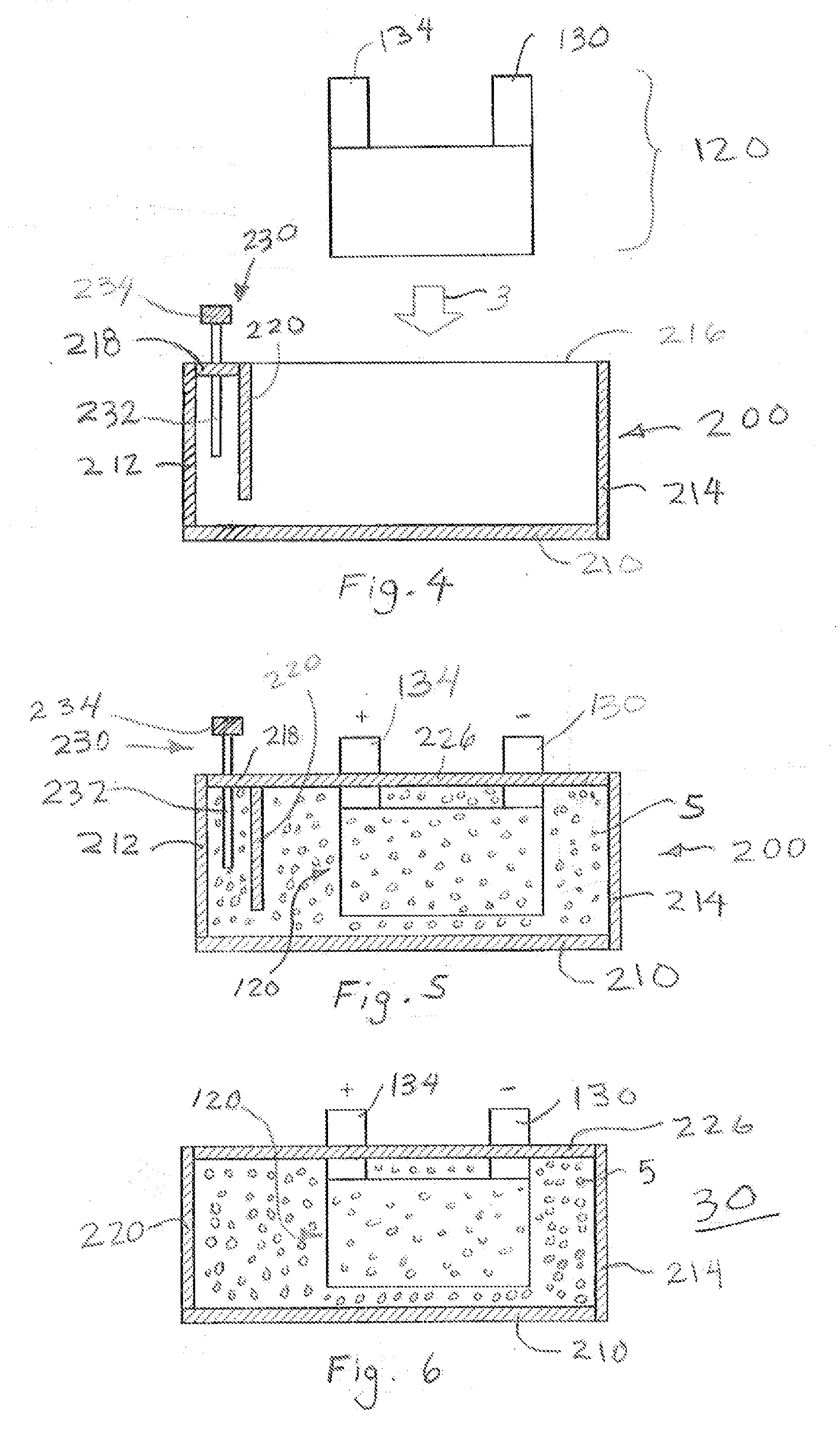

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

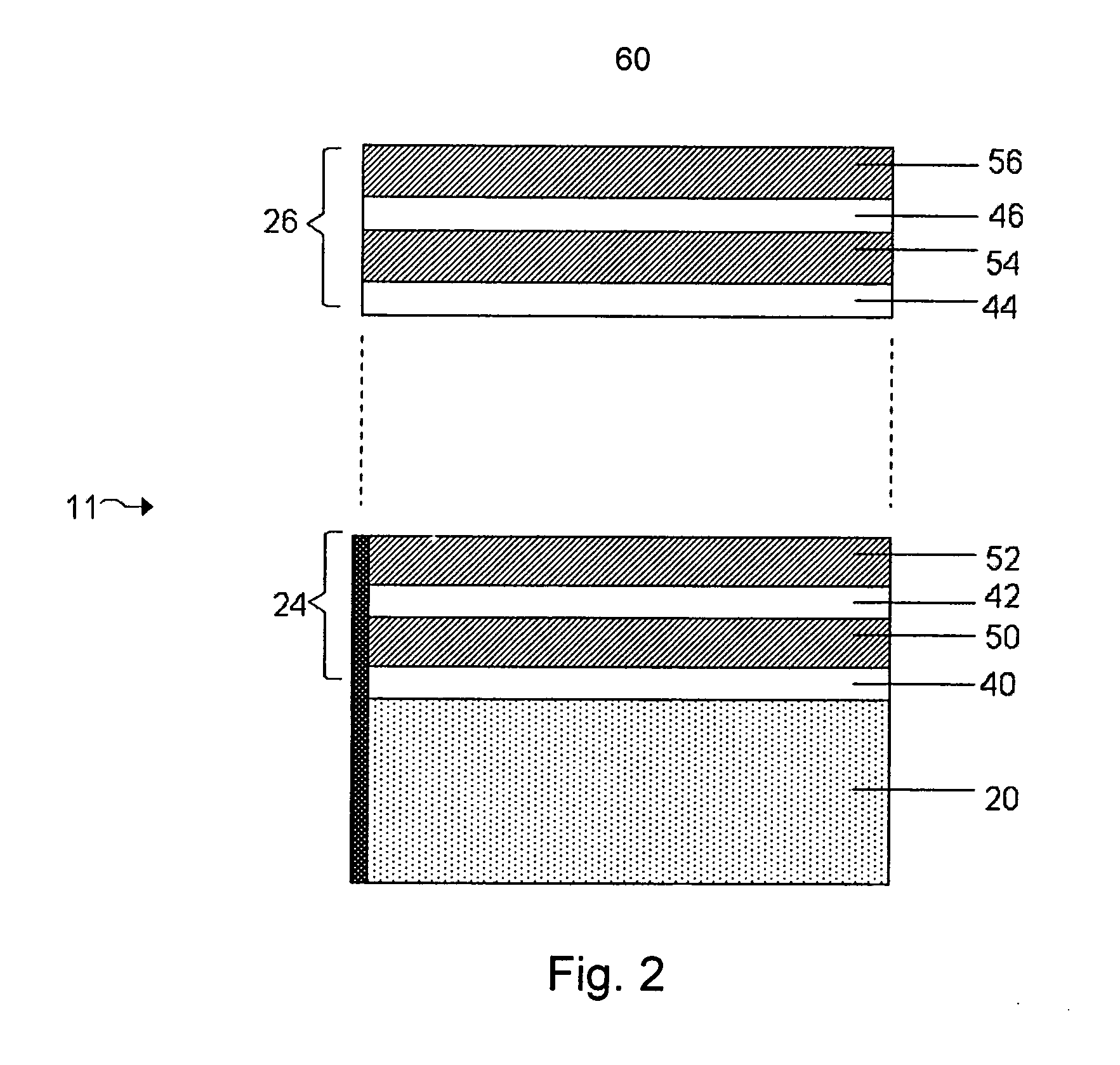

Mesoporous carbon materials comprising bifunctional catalysts

InactiveUS20110223494A1Facilitate metal-air reactionHigh specific energyFuel and primary cellsFuel and secondary cellsLithium–air batteryElectrical devices

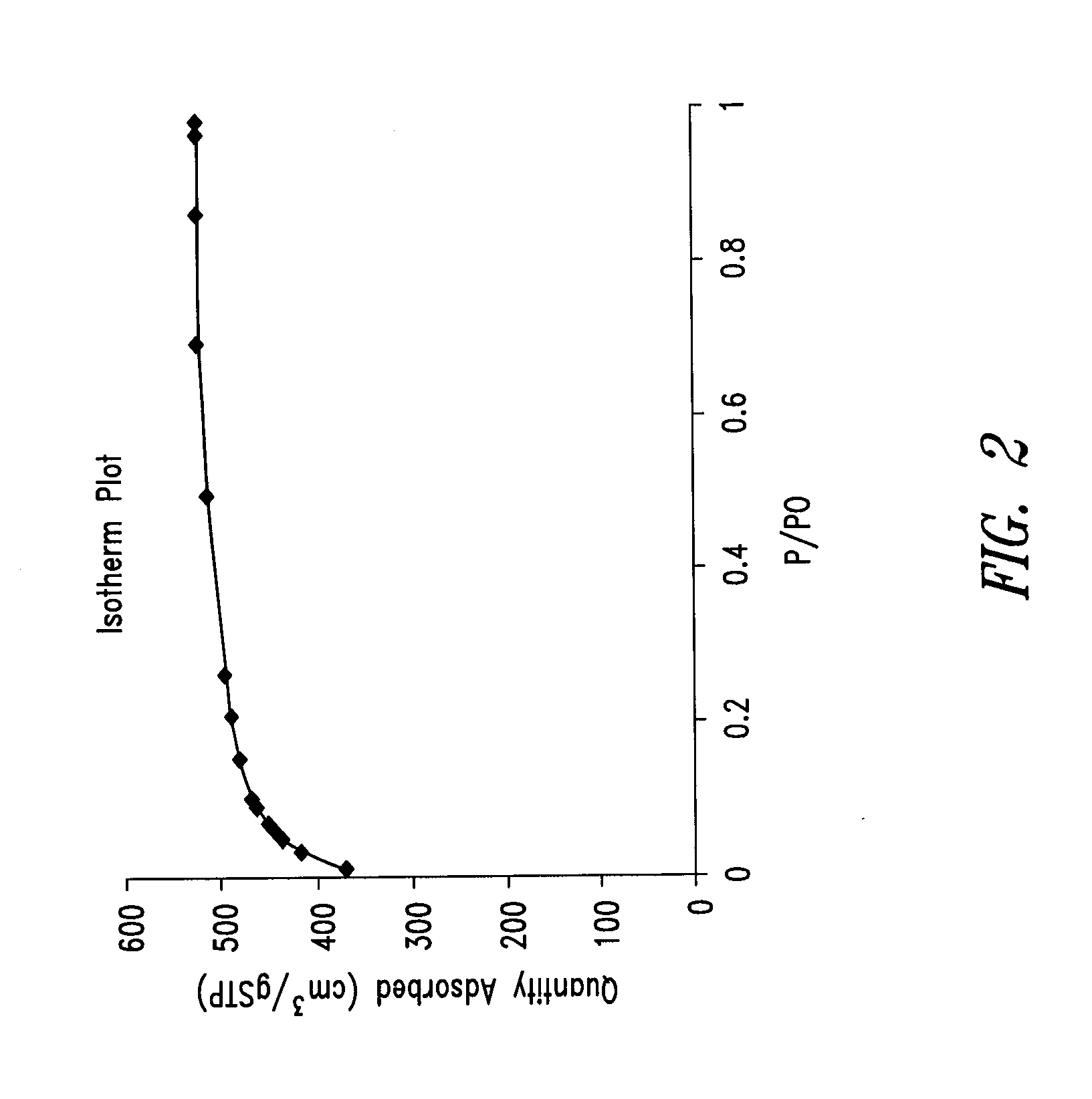

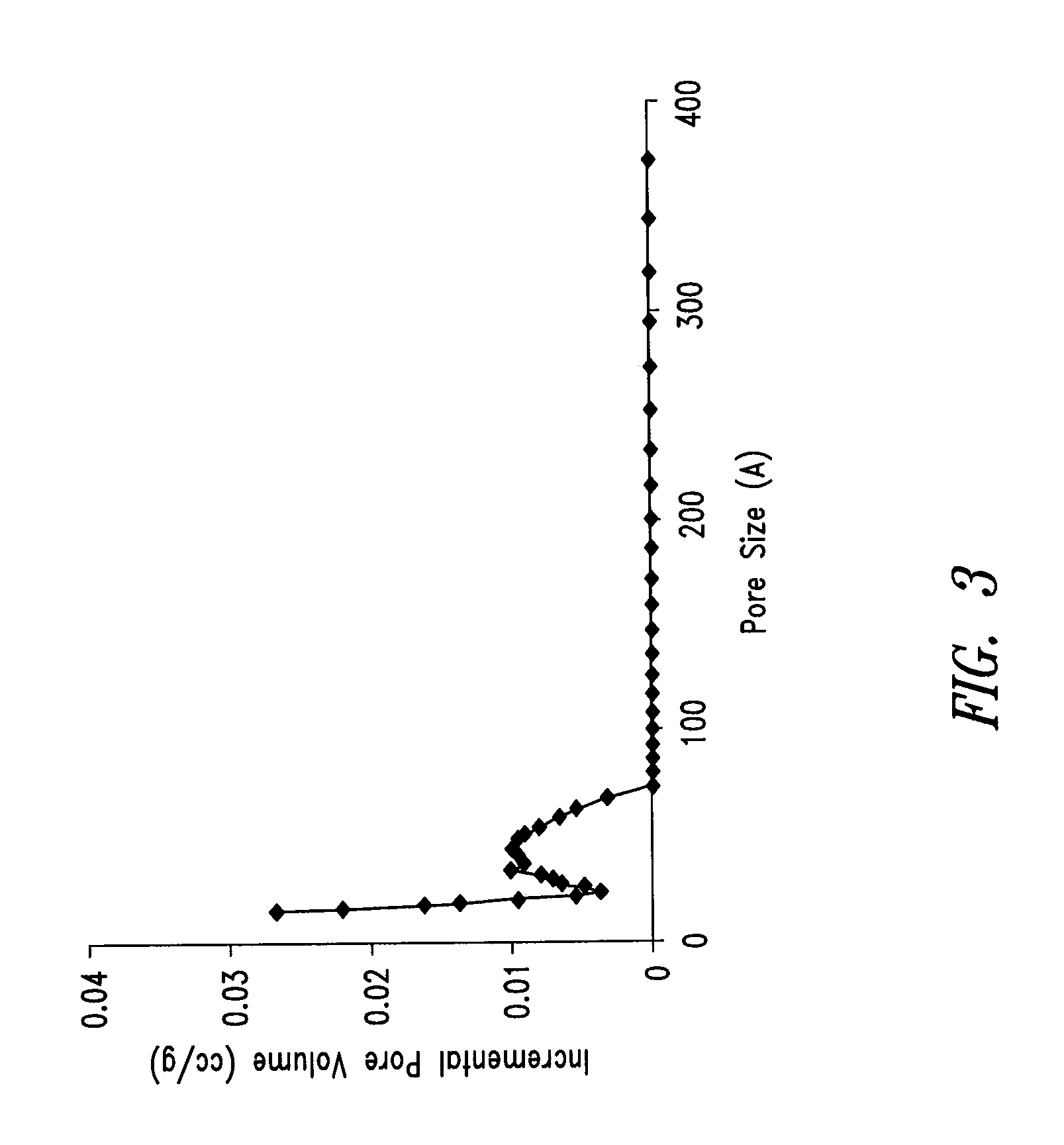

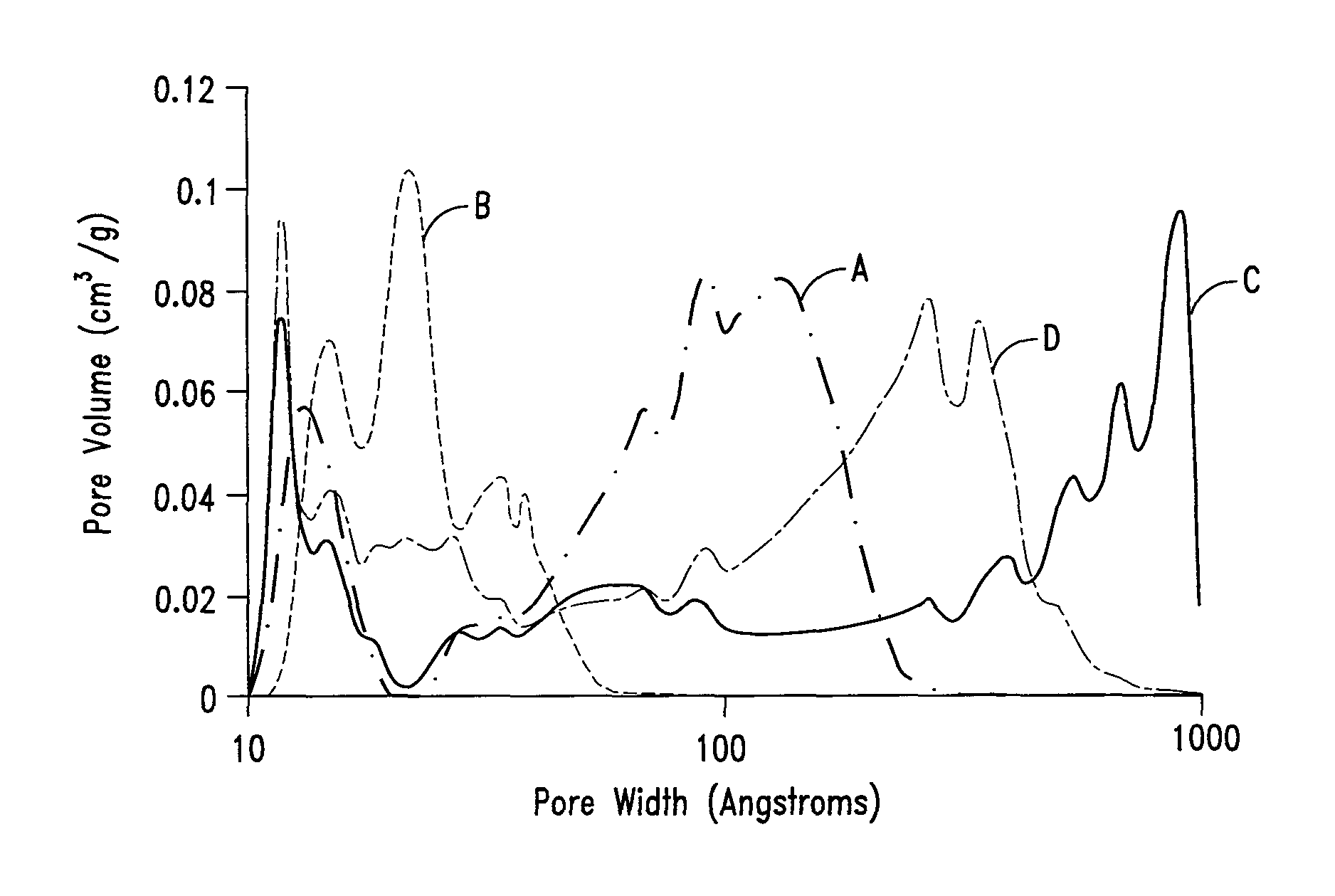

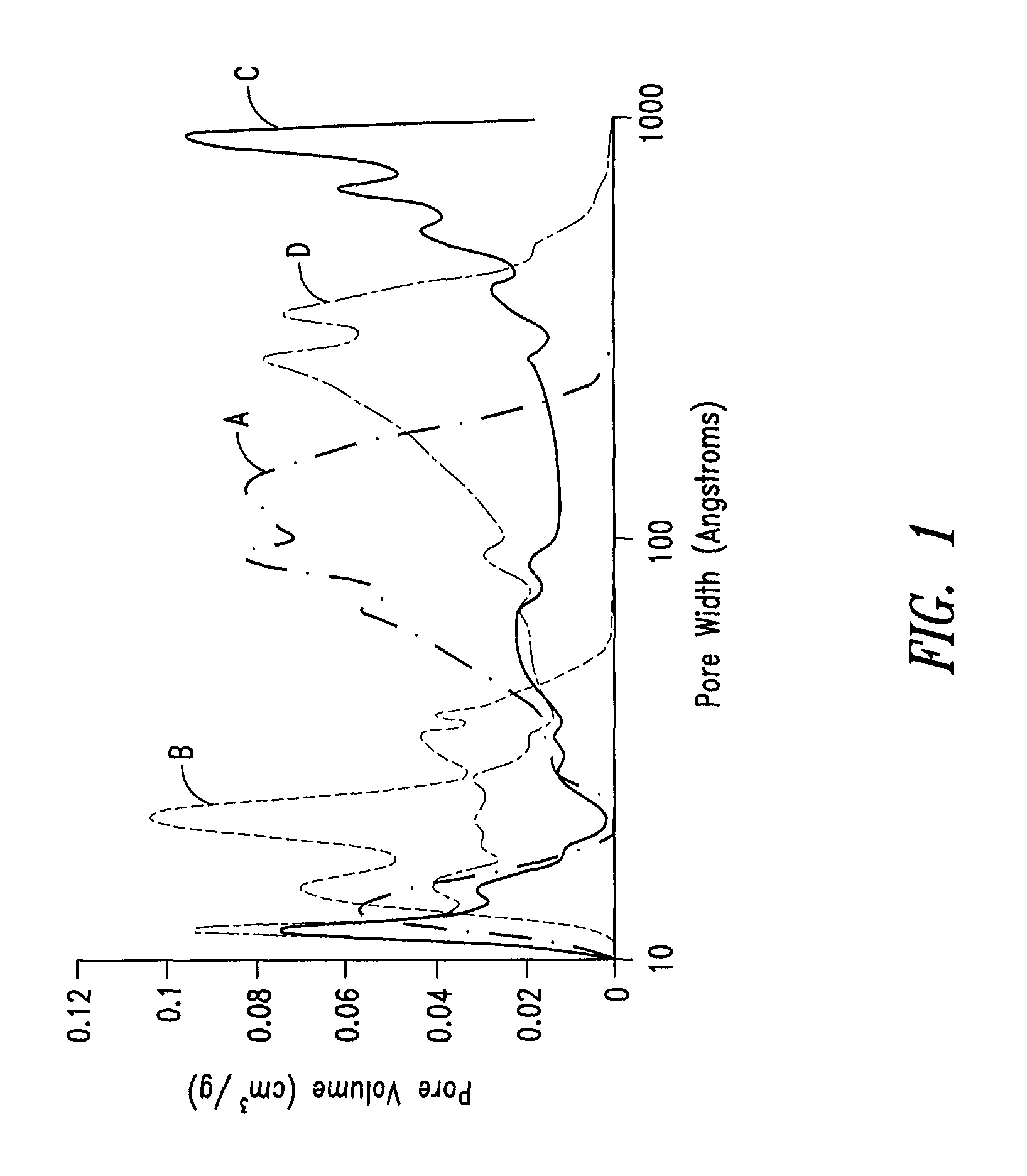

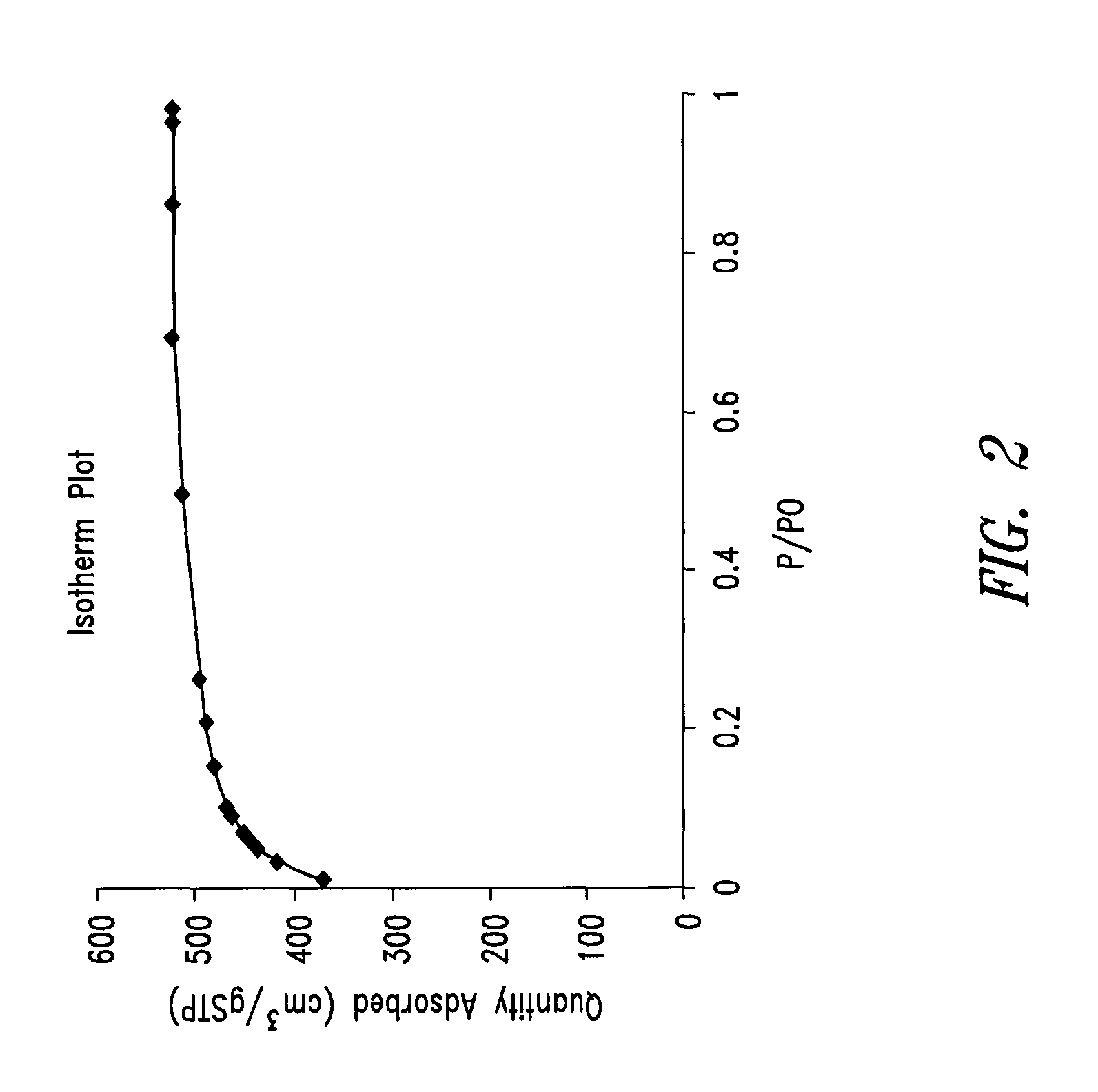

The present application is directed to mesoporous carbon materials comprising bi-functional catalysts. The mesoporous carbon materials find utility in any number of electrical devices, for example, in lithium-air batteries. Methods for making the disclosed carbon materials, and devices comprising the same, are also disclosed.

Owner:BASF AG

Part solid, part fluid and flow electrochemical cells including metal-air and li-air battery systems

PendingUS20130189592A1Provide integrityAvoid shortingPrimary cell to battery groupingFuel and primary cellsLithium–air batteryEngineering

Owner:CALIFORNIA INST OF TECH

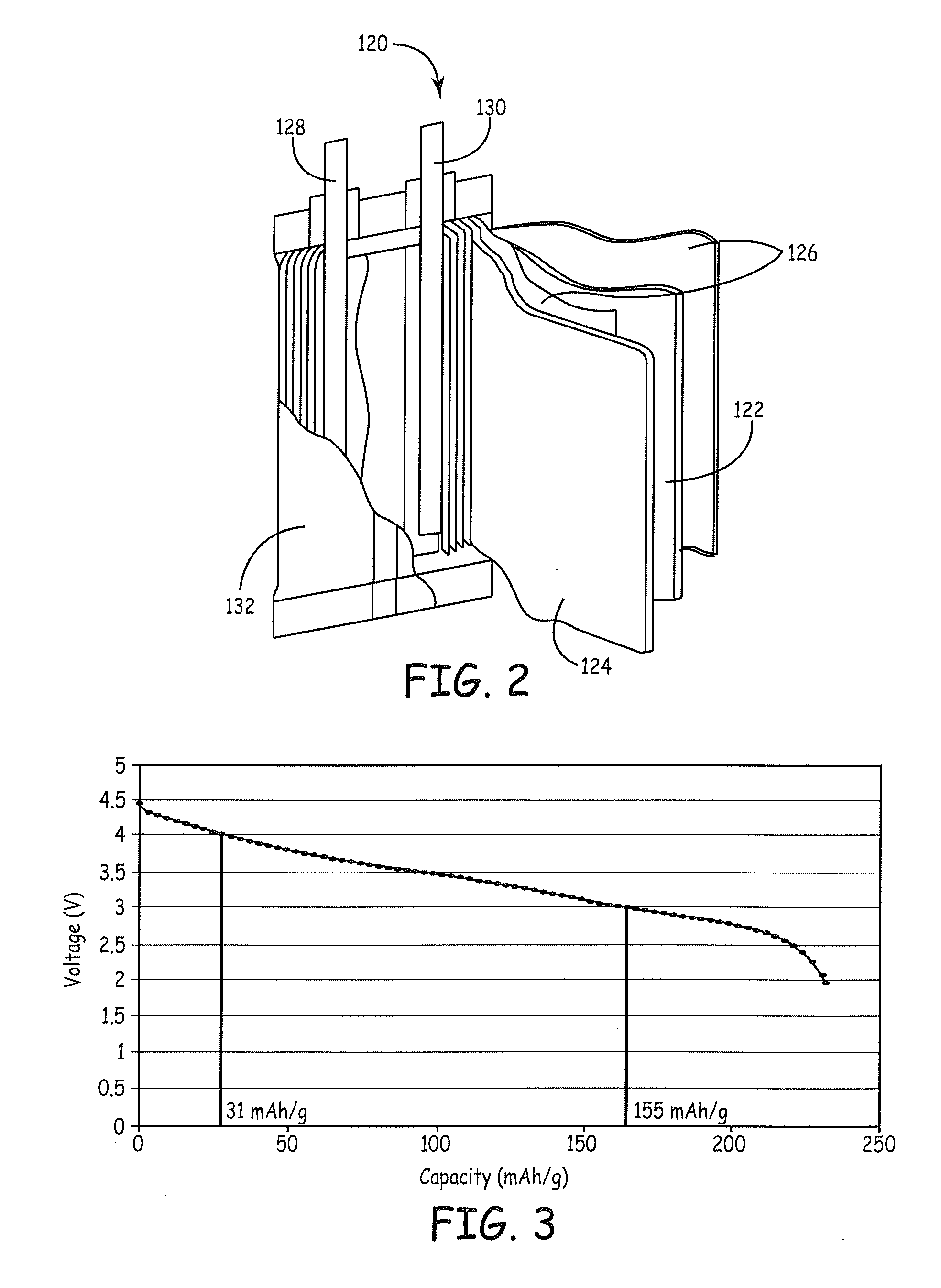

Very Long Cycling of Lithium Ion Batteries with Lithium Rich Cathode Materials

Lithium ion batteries can be activated and then cycled to exploit a moderate fraction of the discharge cycling capacity such that the discharge capacity and average discharge voltage stay within initial values for thousands of cycles. The superior cycling performance has been achieved at relatively high discharge rates and for practical battery formats. Lithium ion battery performance can also be achieved with superior cycling performance with partially activated batteries such that good discharge capacities can be exploited for many thousands of cycles before the discharge capacity and average discharge voltage drops more than 20% from initial values. The positive electrode active material can be a lithium rich metal oxide. The activation of the battery can comprise phase changes of the active materials. As described herein, the phase changes can be manipulated to exploit a reasonable fraction of the available high capacity of the material while providing outstanding cycling stability.

Owner:IONBLOX INC

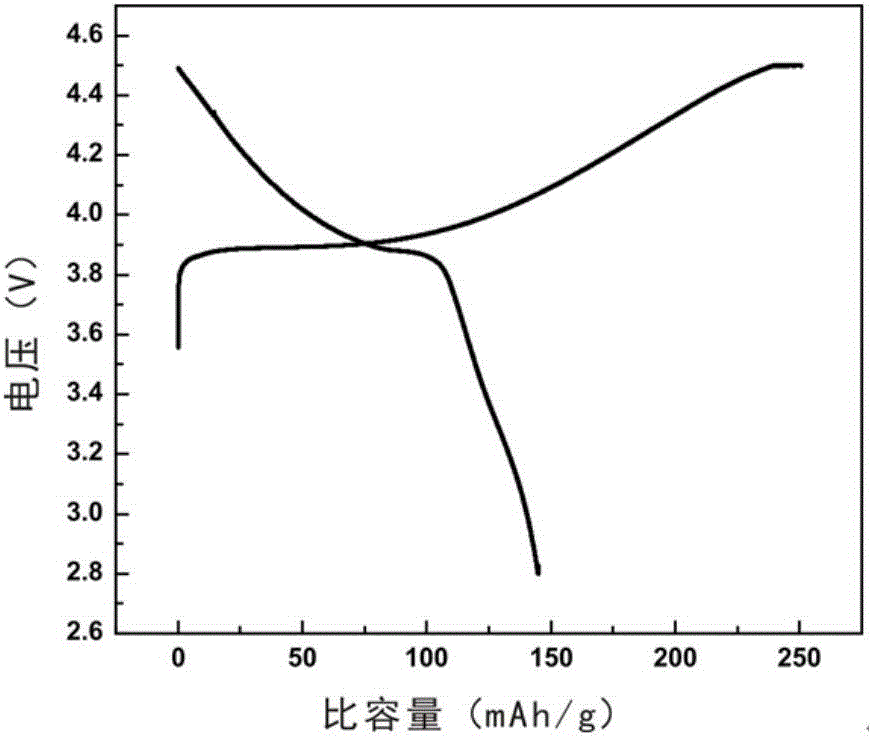

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

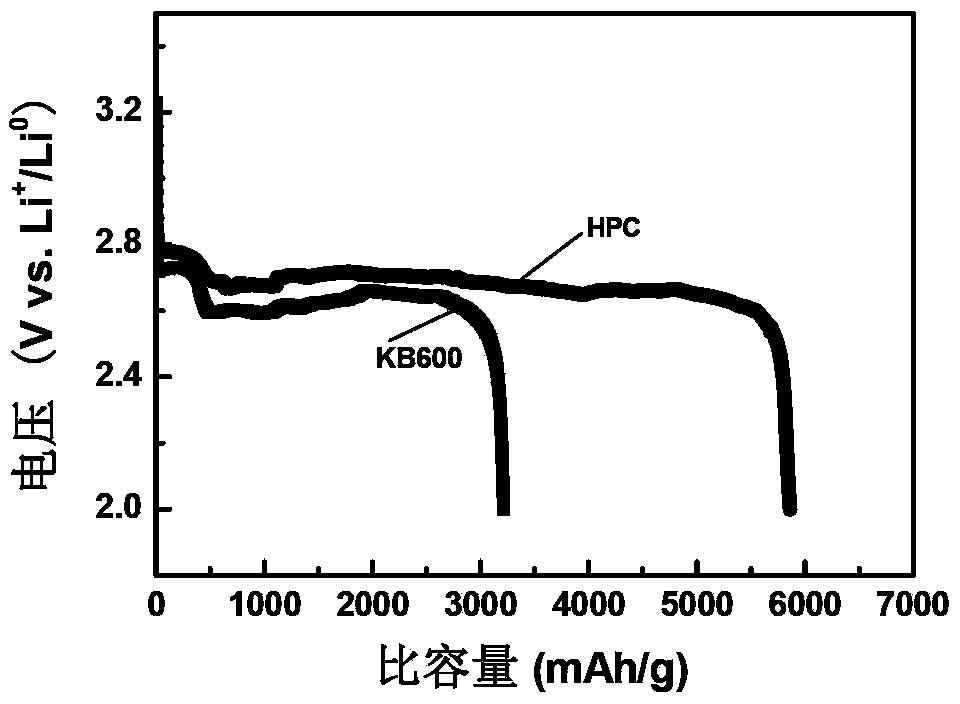

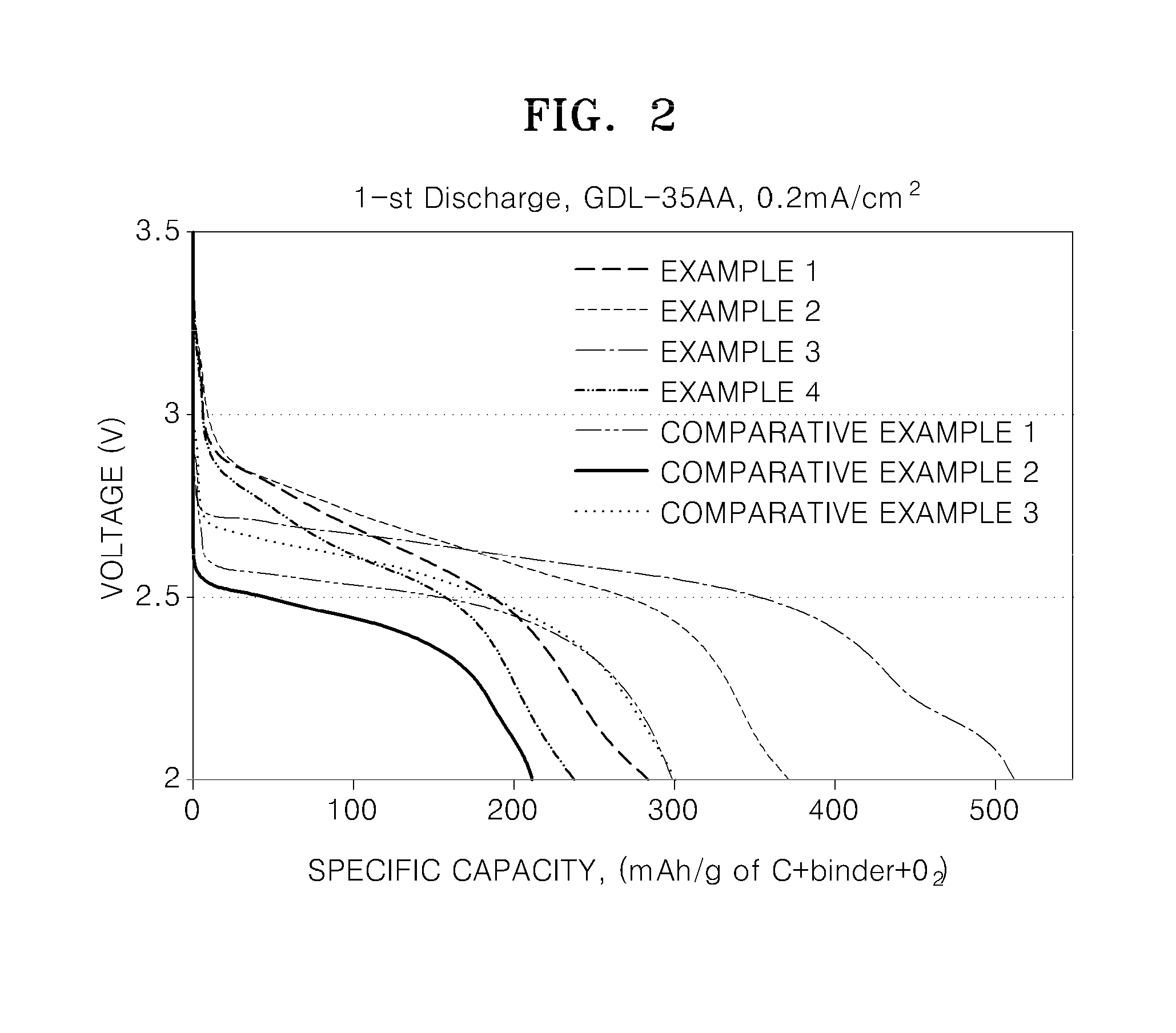

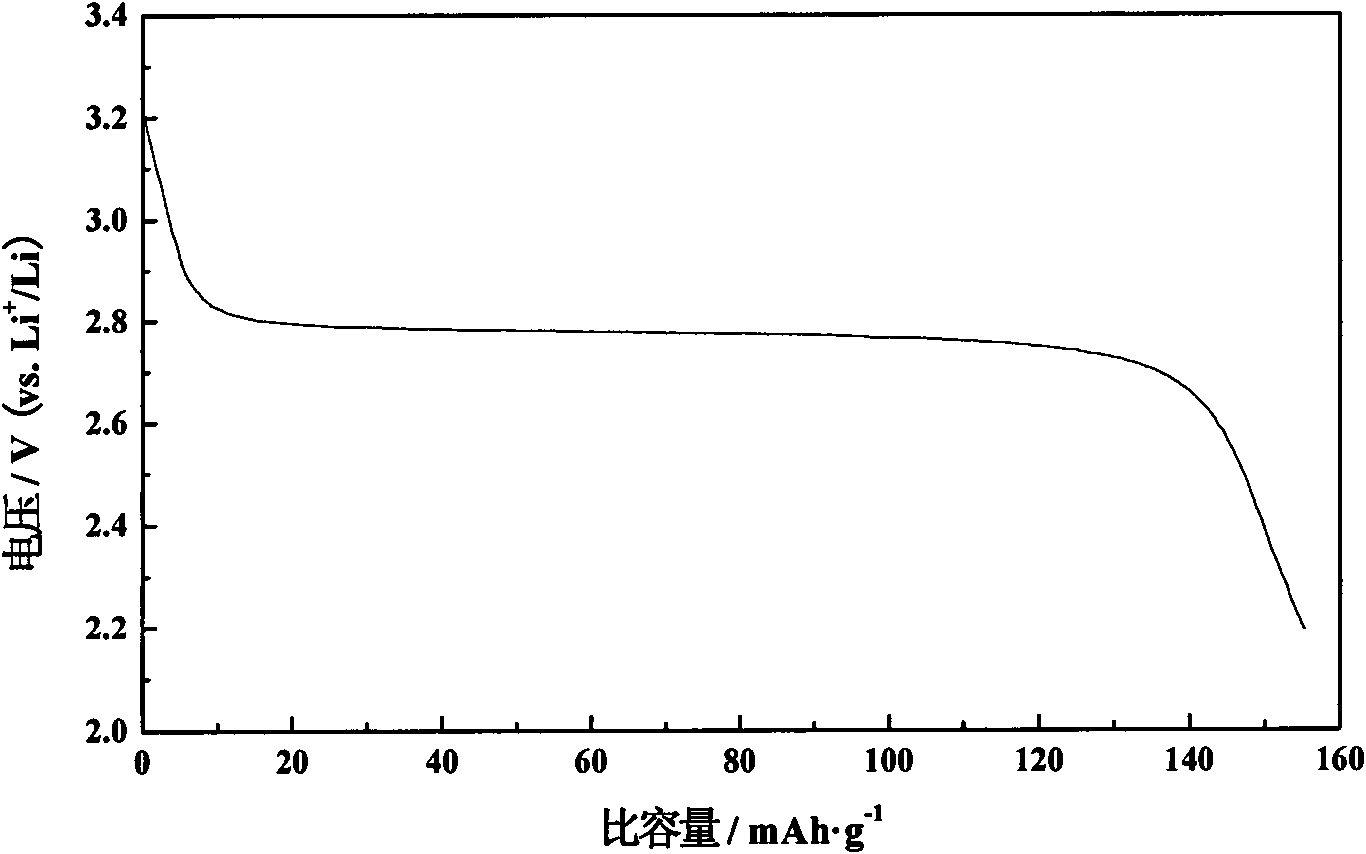

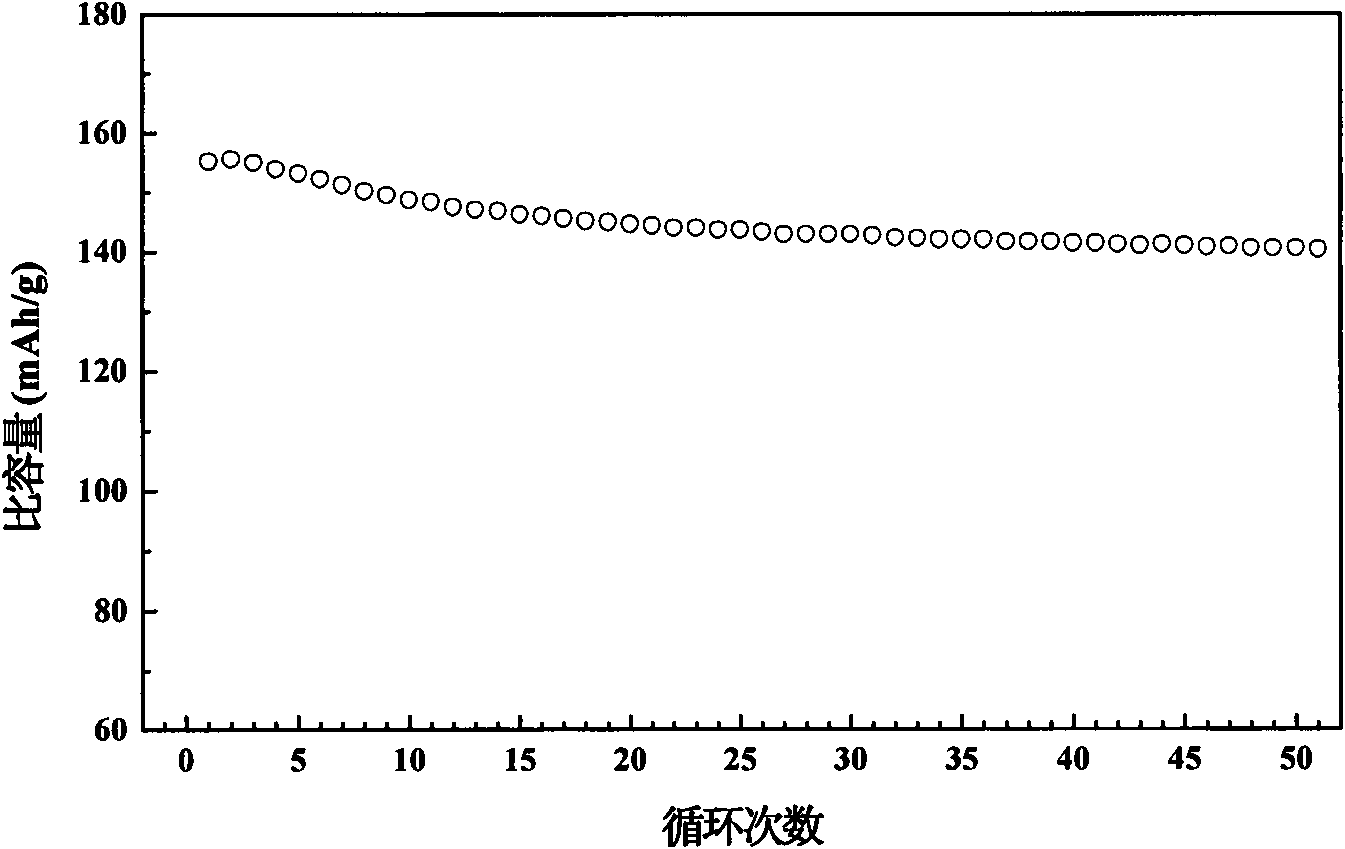

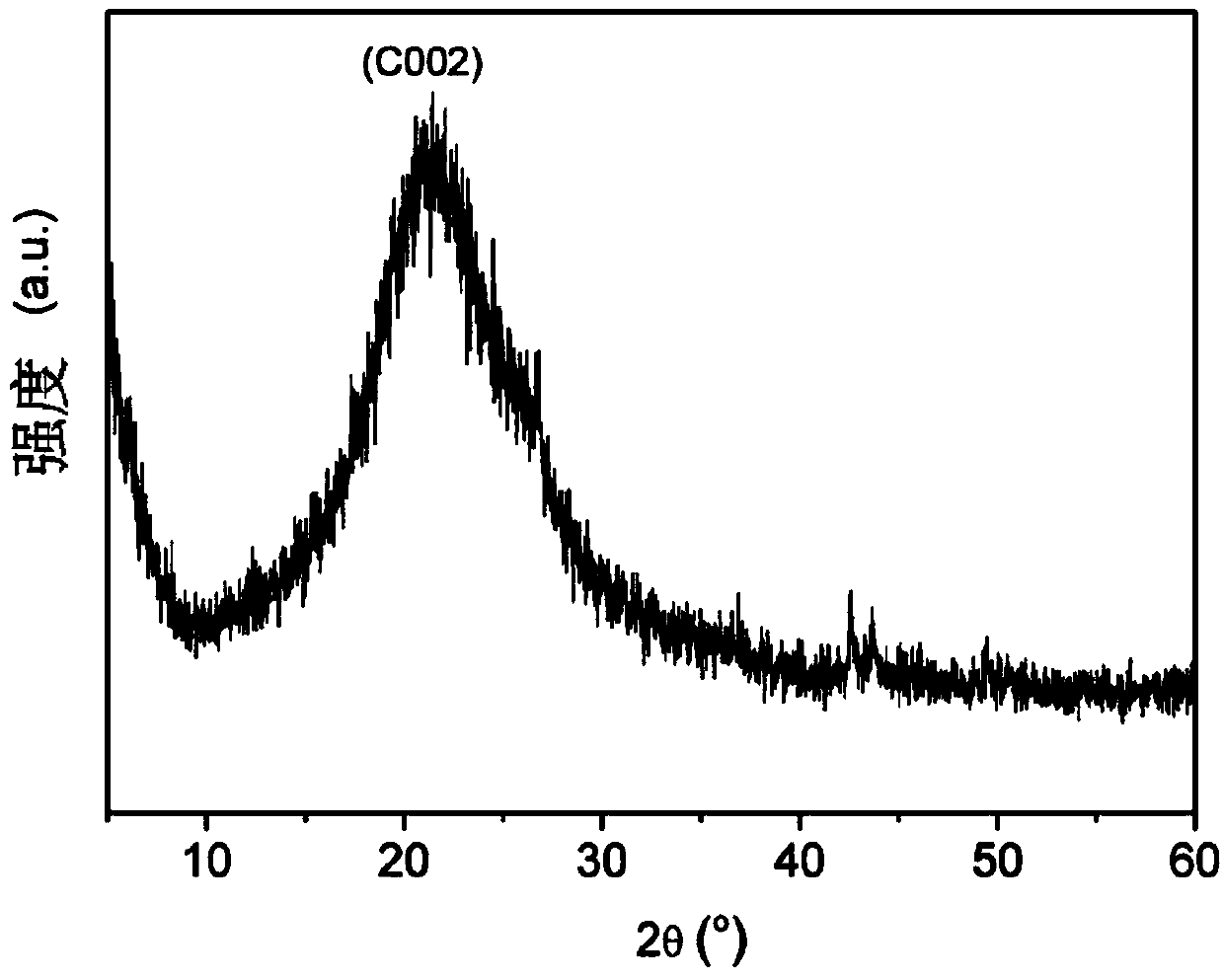

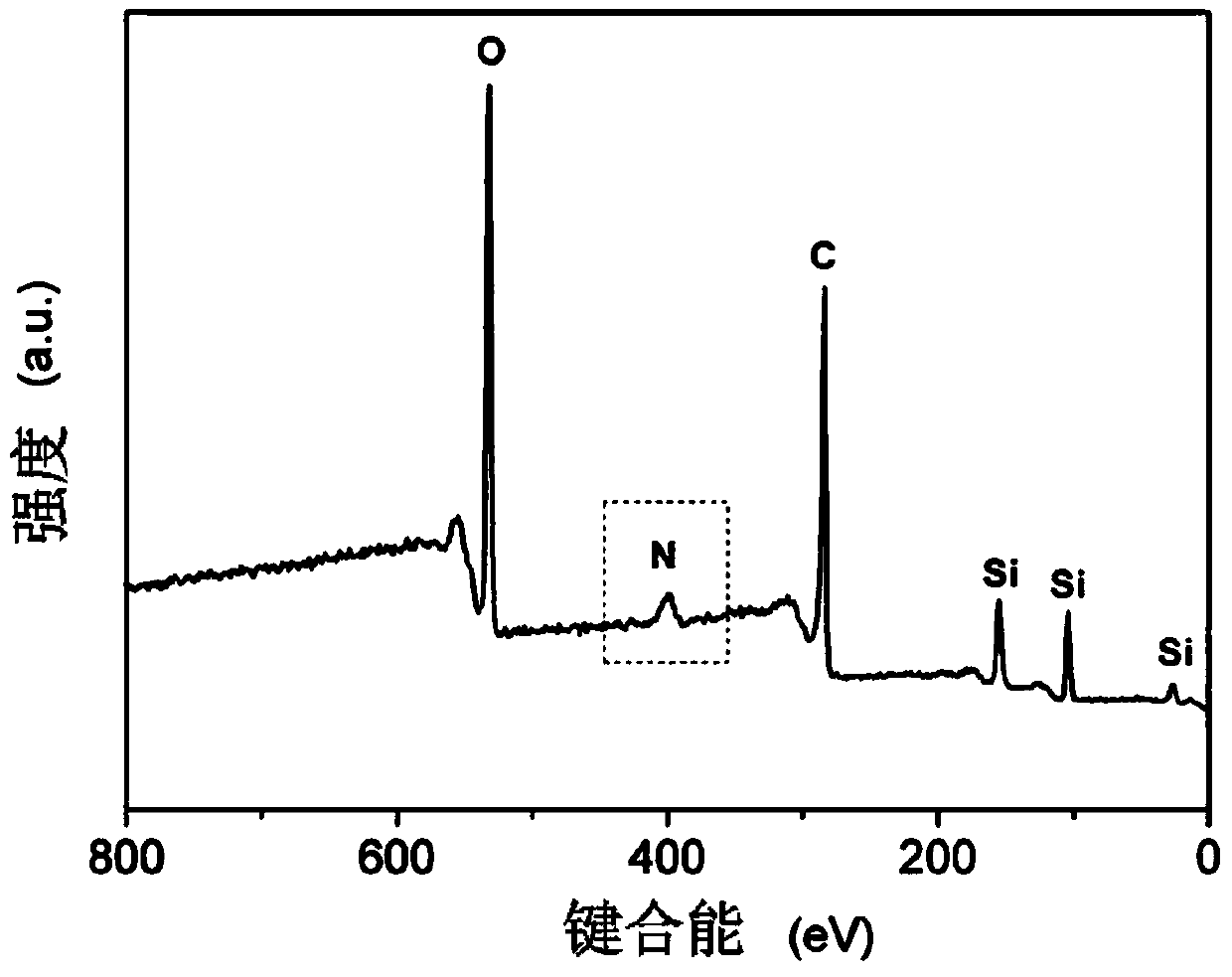

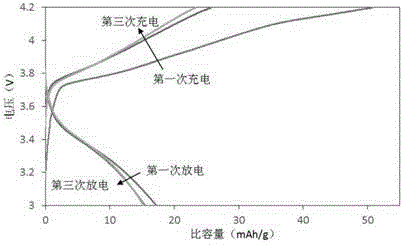

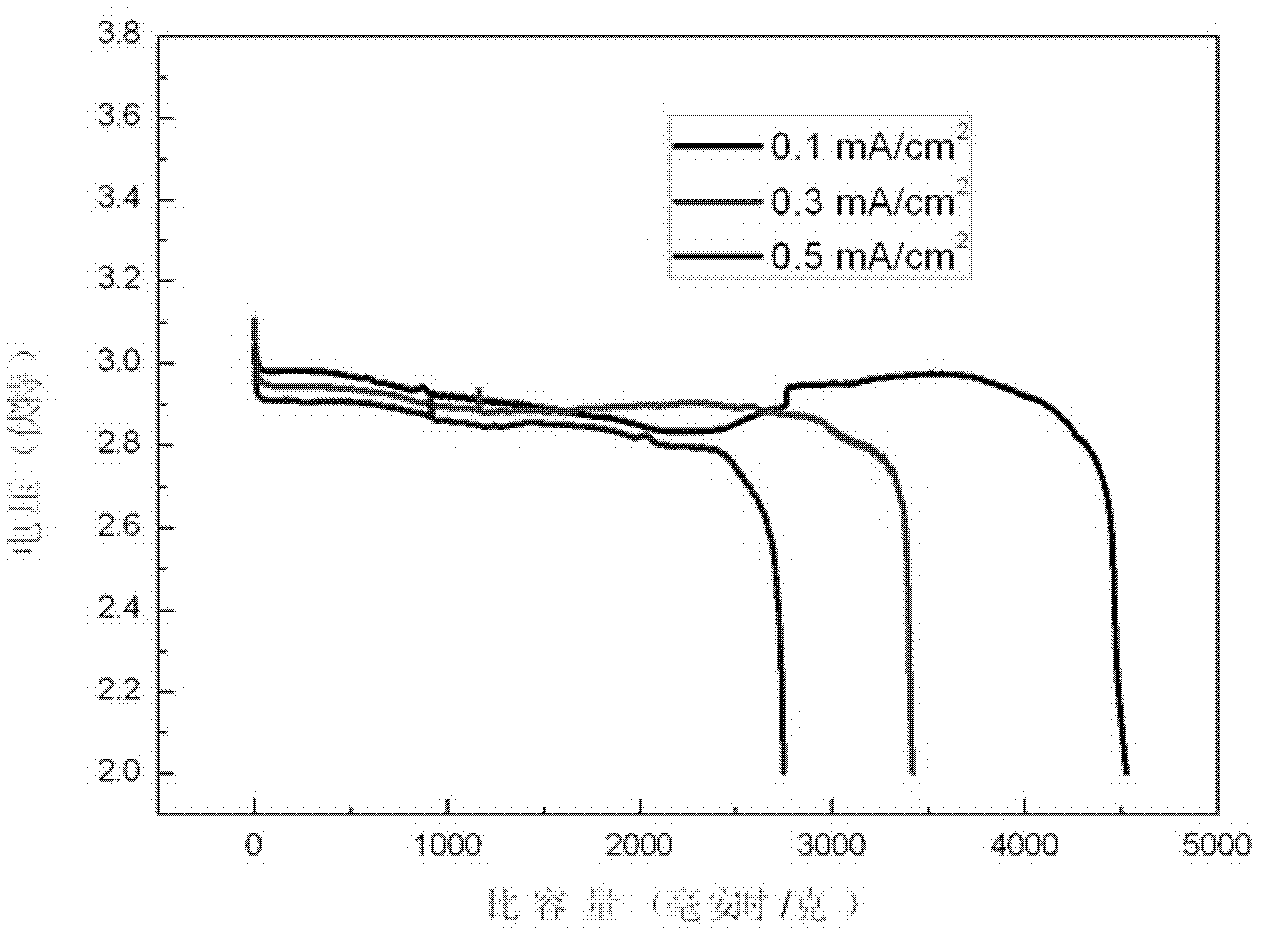

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

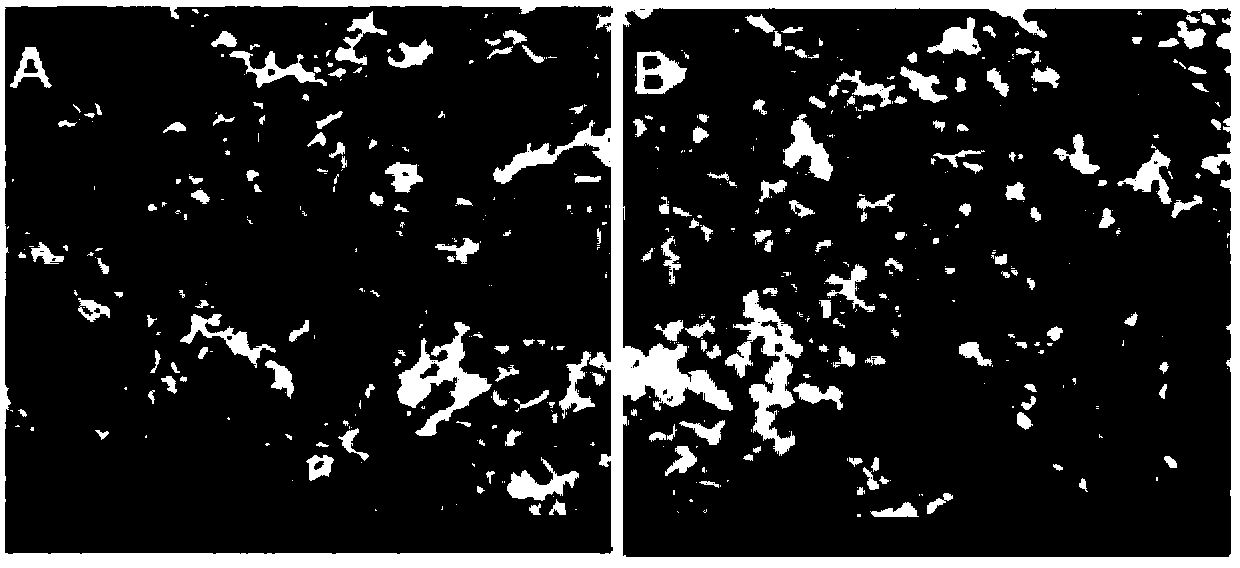

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Mesoporous carbon materials comprising bifunctional catalysts

InactiveUS8916296B2Improve responseHigh specific energyFuel and primary cellsFuel and secondary cellsLithium–air batteryMesoporous carbon

Owner:BASF SE

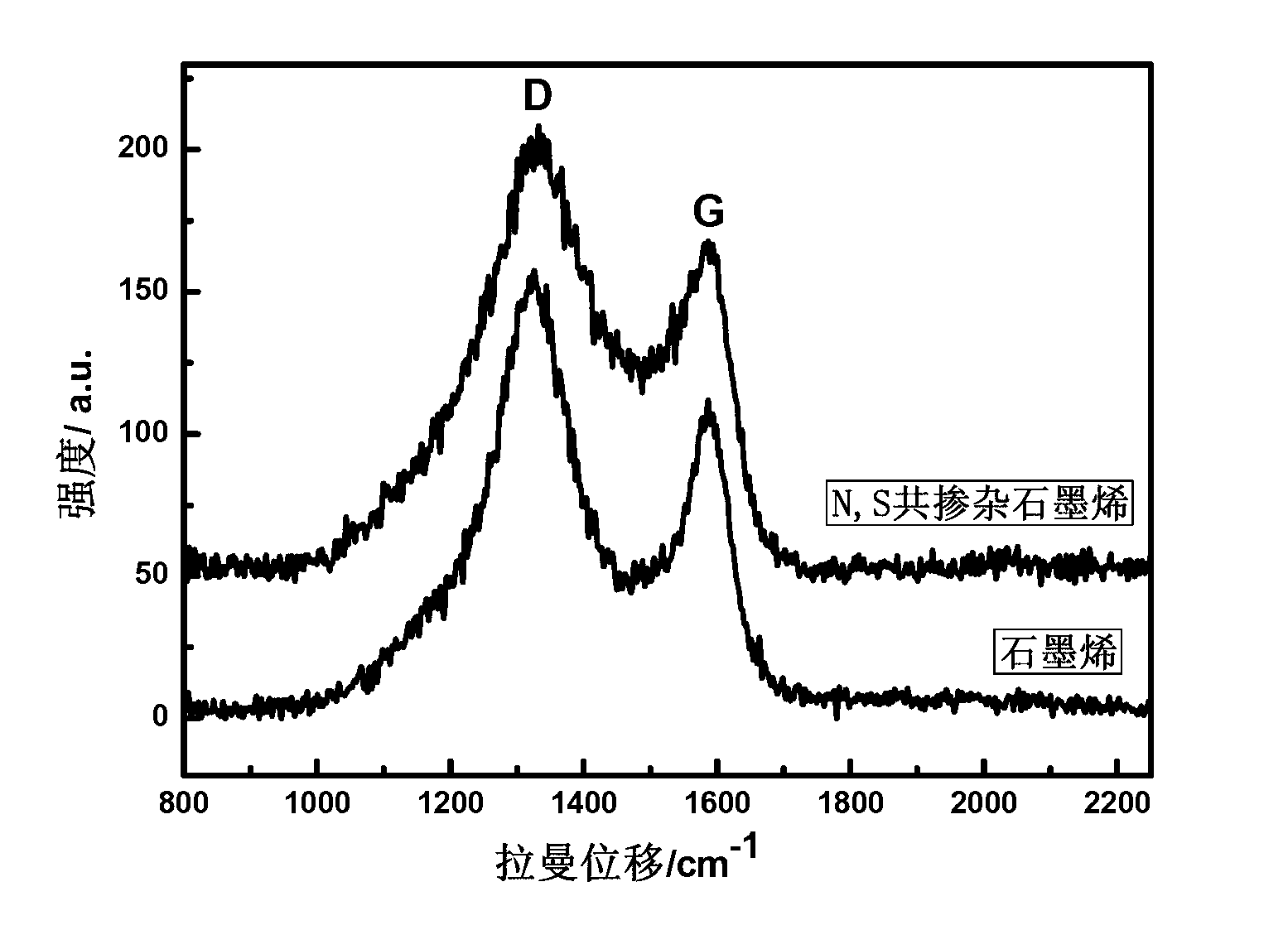

Preparation method of nitrogen and sulfur co-doped graphene

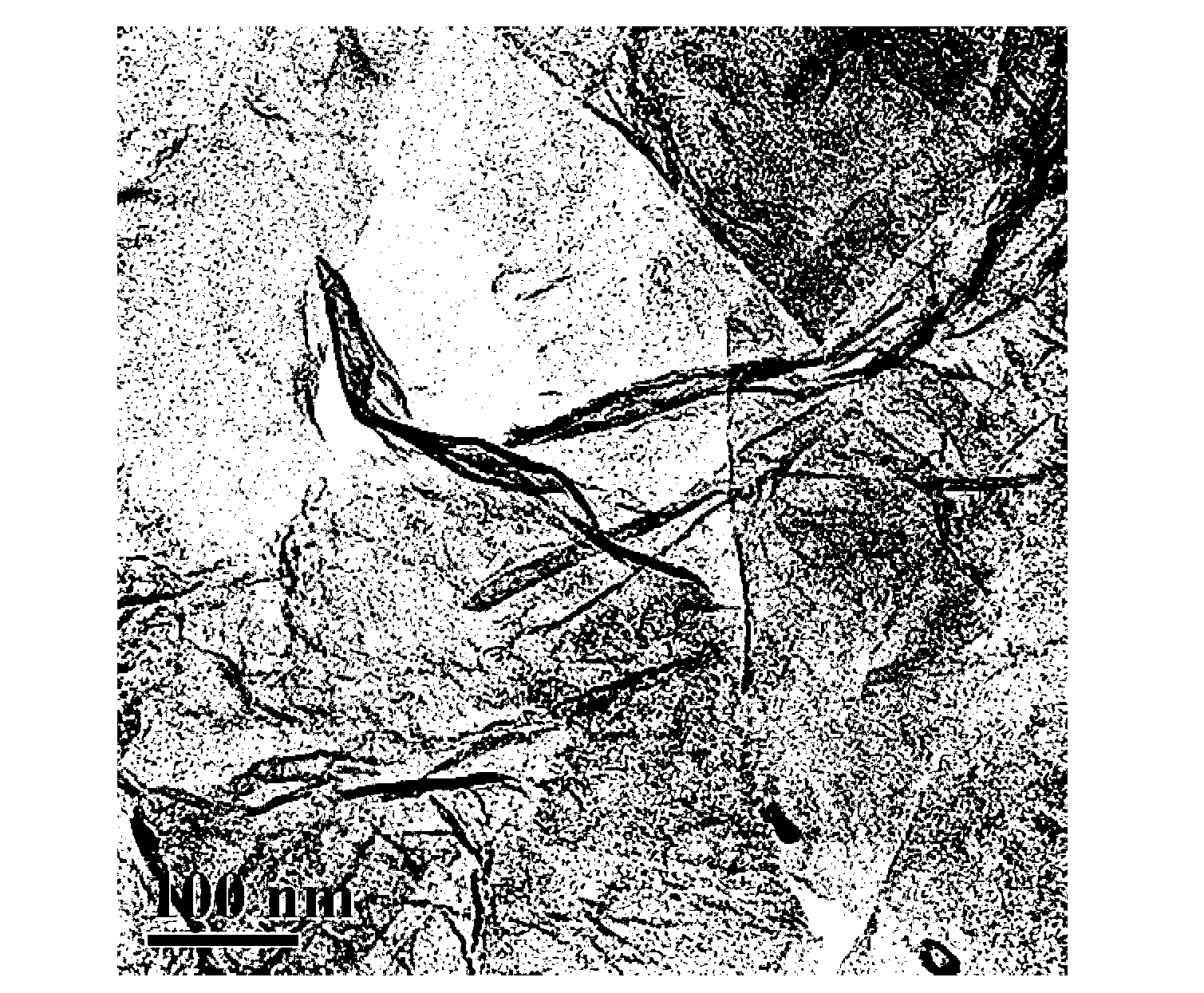

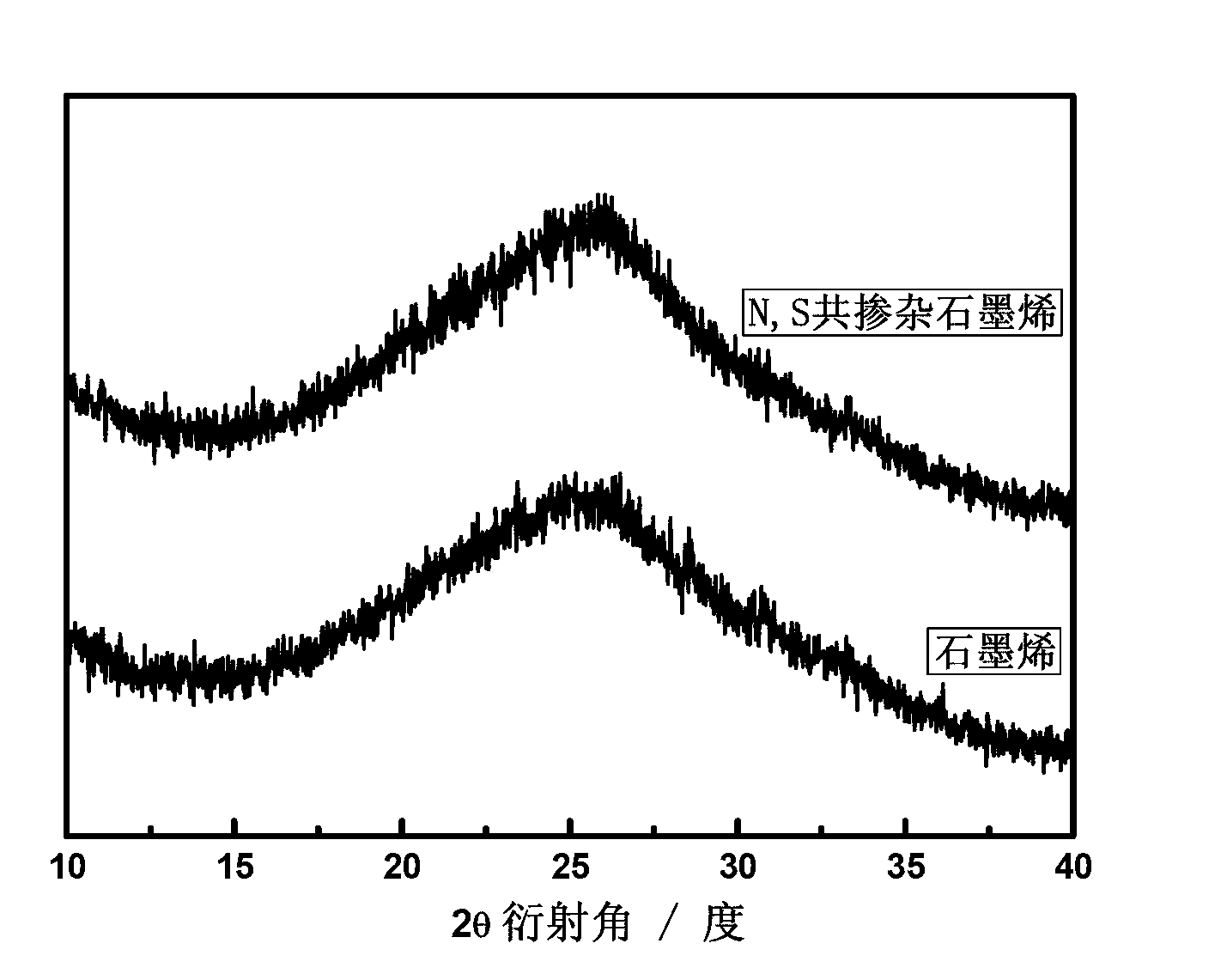

The invention discloses a nitrogen and sulfur co-doped graphene. The method comprises the following steps: grinding and uniformly mixing graphene or a graphene derivative, a nitrogen-containing compound and a sulfur-containing compound, carrying out thermal annealing under the protection of an inert gas at a temperature of 500-1000DEG C, maintaining the temperature for 1-5h, and cooling to room temperature to obtain the nitrogen and sulfur co-doped graphene, wherein content of the nitrogen element in the nitrogen and sulfur co-doped graphene is 1-10at.%, and the content of the sulfur element in the nitrogen and sulfur co-doped graphene is 0.5-2at.%. The method has the advantages of simple technology, low cost, easy control of the reaction process and the like, is suitable for the industrial large-scale production, and can be used in the super capacitor field, the sensor field, the catalytic field, the fuel battery field, the lithium air battery field and the like.

Owner:SOUTH CHINA UNIV OF TECH

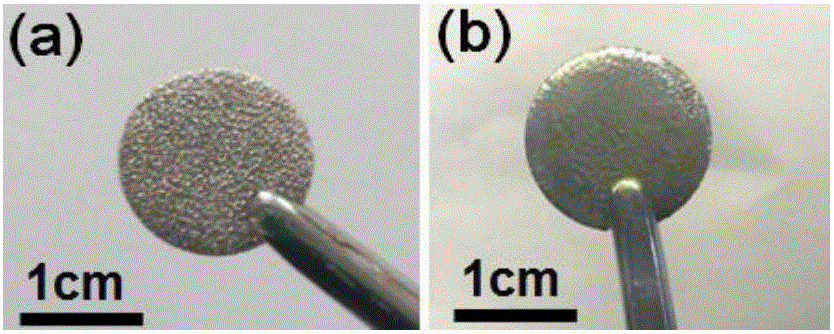

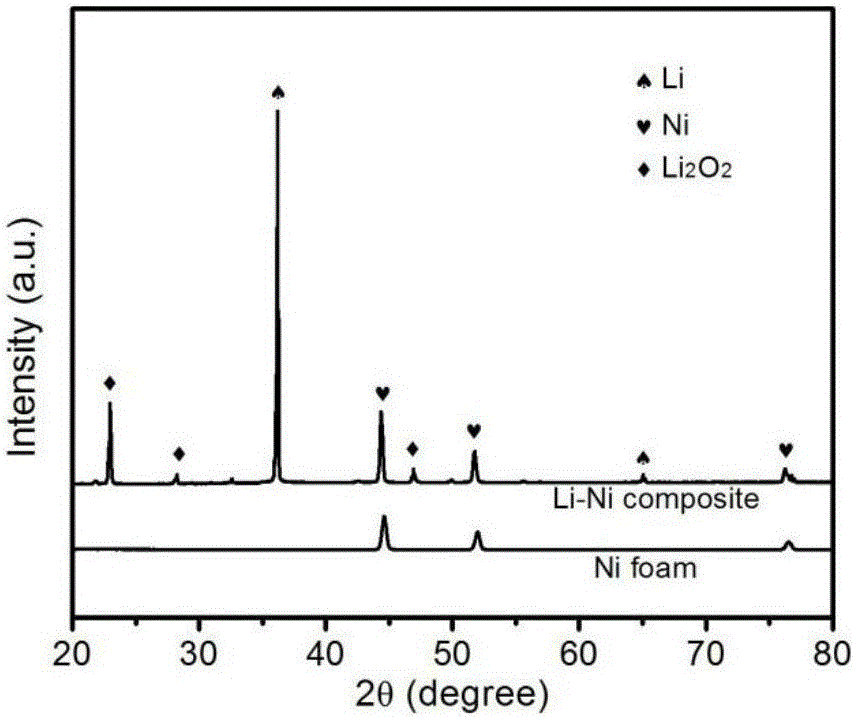

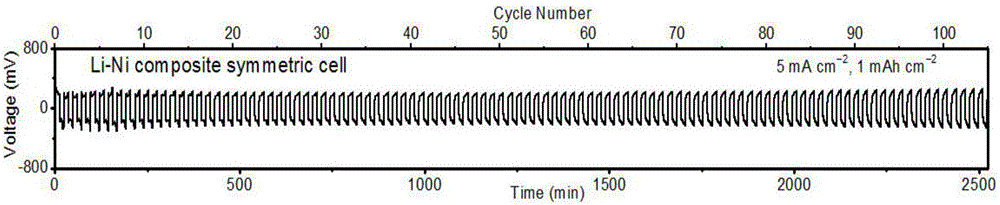

Preparation method of complex lithium negative pole of solid state battery

The present invention discloses a preparation method of a complex lithium negative pole of a solid state battery, and belongs to the technical field of electrochemistry and new energy resources. The preparation method mainly comprises the steps: depositing lithium metal on three-dimensional carbon material or foam porous material gaps by using a heat infusing melting method or an electrodeposition method to obtain the complex lithium negative pole, wherein the application of a three-dimensional framework plays two roles, namely, providing adequate space for pre-storing lithium in the preparation process; providing a carrier for receiving metal lithium in a battery circulation process. The complex lithium negative pole can be widely applied in lithium metal batteries such as lithium ion batteries, lithium-air batteries, lithium-sulfur batteries, and solid state batteries. In the assembled symmetric solid state battery, under large electric current density of 5mA cm-2, a stable voltage decay (200mV) can still be kept after circulation for 100 times, in the battery circulation, the growth of lithium dendrites can be inhibited and the pole volume change can be stabilized, and the advantages of being good in circulation stability, and long service life can be realized; in the present invention, a carrier material is rich, and low in price; the process is controlled, the cost is low, and the batch production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Lithium air battery

ActiveUS20120141889A1Improve energy efficiencyReduced charge-discharge overvoltagesFuel and primary cellsPositive electrodesLithium–air batteryOxygen

A lithium air battery including: a negative electrode including lithium; a positive electrode using oxygen as a positive active material; and an organic electrolyte, wherein the organic electrolyte includes a metal-ligand complex.

Owner:SAMSUNG ELECTRONICS CO LTD +1

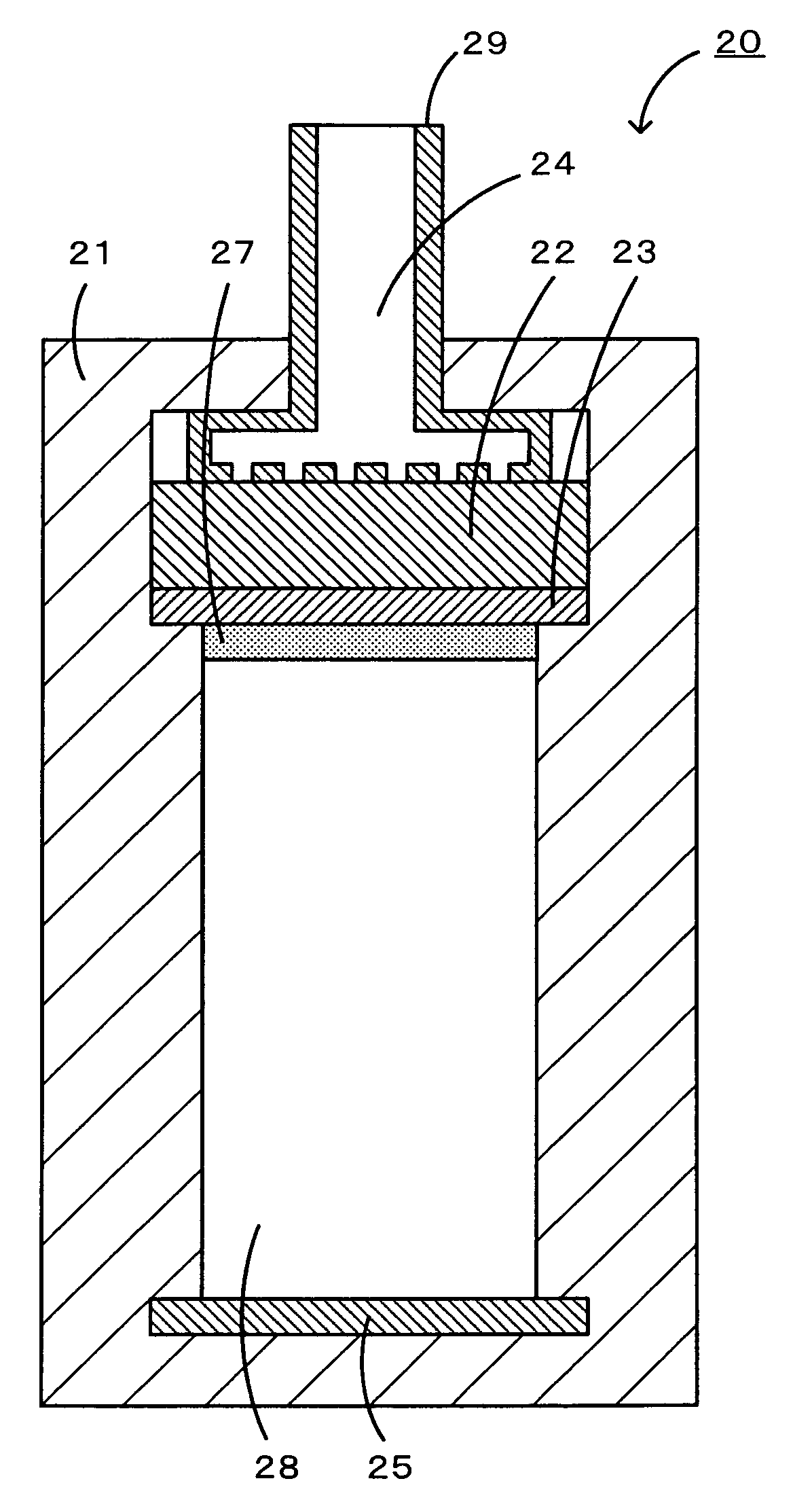

Alkali-hydroxide modified poly-vinylidene fluoride/polyethylene oxide lithium-air battery

InactiveUS7670724B1Reduce passageFuel and secondary cellsCell component detailsPolyethylene oxideMetal foil

A metal-air battery includes a housing having an aperture for the passage of air and a pair of electrodes that extend from the housing. An air cathode may be interconnected with one of the electrodes and an anode may include a metal foil that is interconnected with another of the electrodes. A separator may be interposed between the air cathode and the metal foil and a barrier layer may surround the metal foil. The barrier layer may function to substantially reduce the passage of moisture to the metal foil. A method of making a metal-air battery is also presented.

Owner:ARMY THE UNITED STATES OF AMERICA AS REPRESENTED BY

Positive electrode for lithium air battery, method of preparing the positive electrode, and lithium air battery including the positive electrode

InactiveUS20120115048A1Reduced responseMaterial nanotechnologyCatalyst protectionEngineeringLithium–air battery

Owner:SAMSUNG ELECTRONICS CO LTD

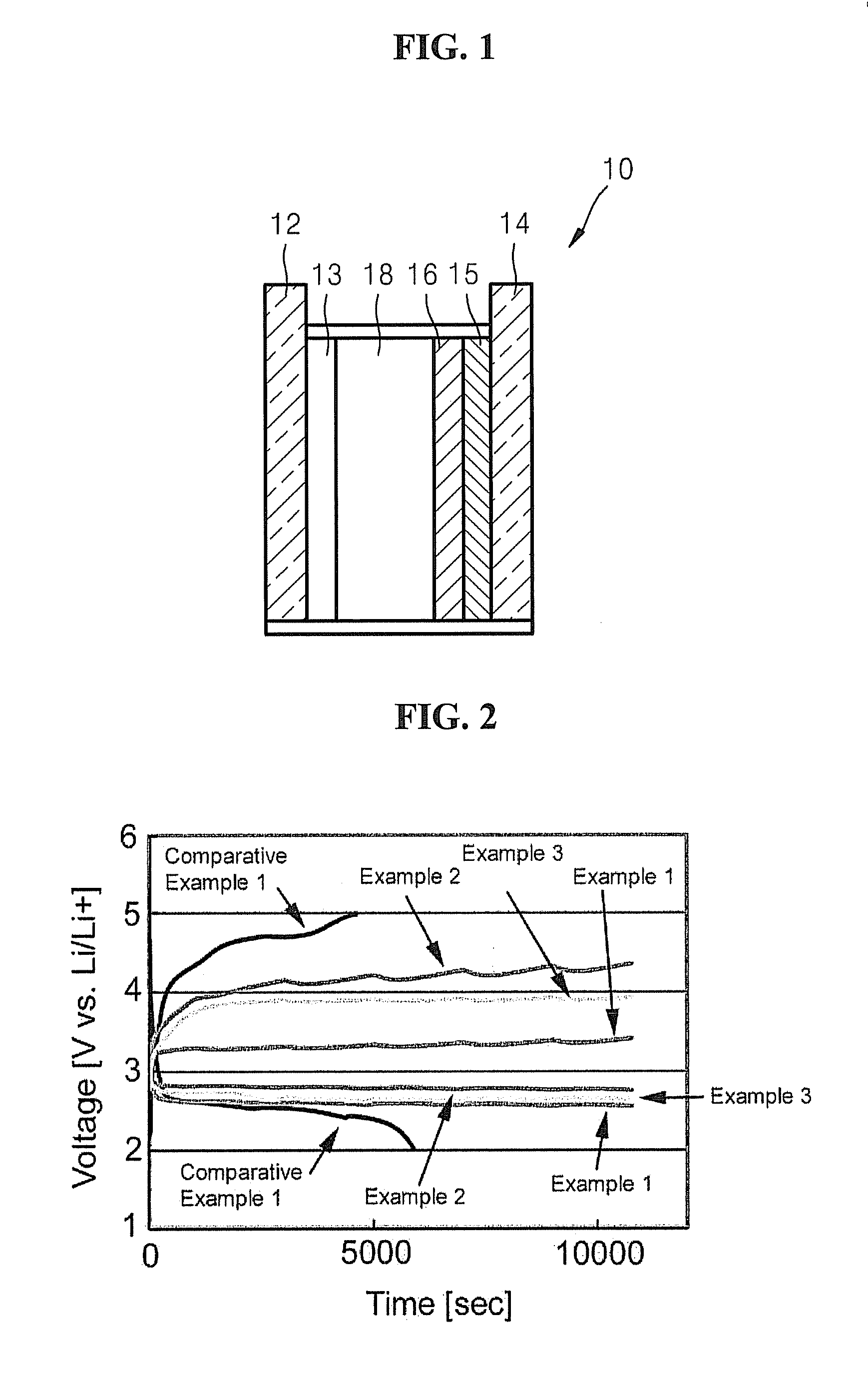

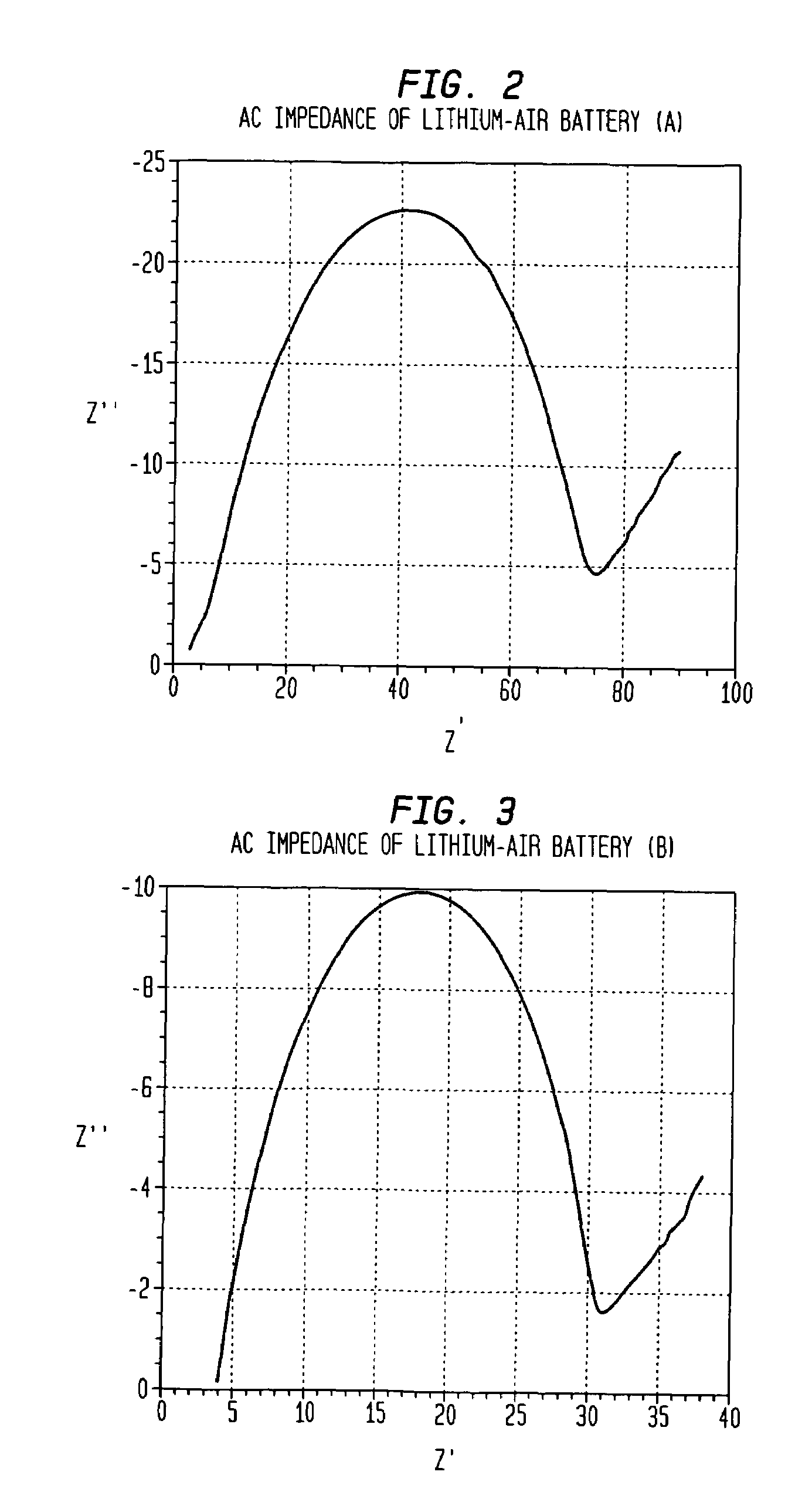

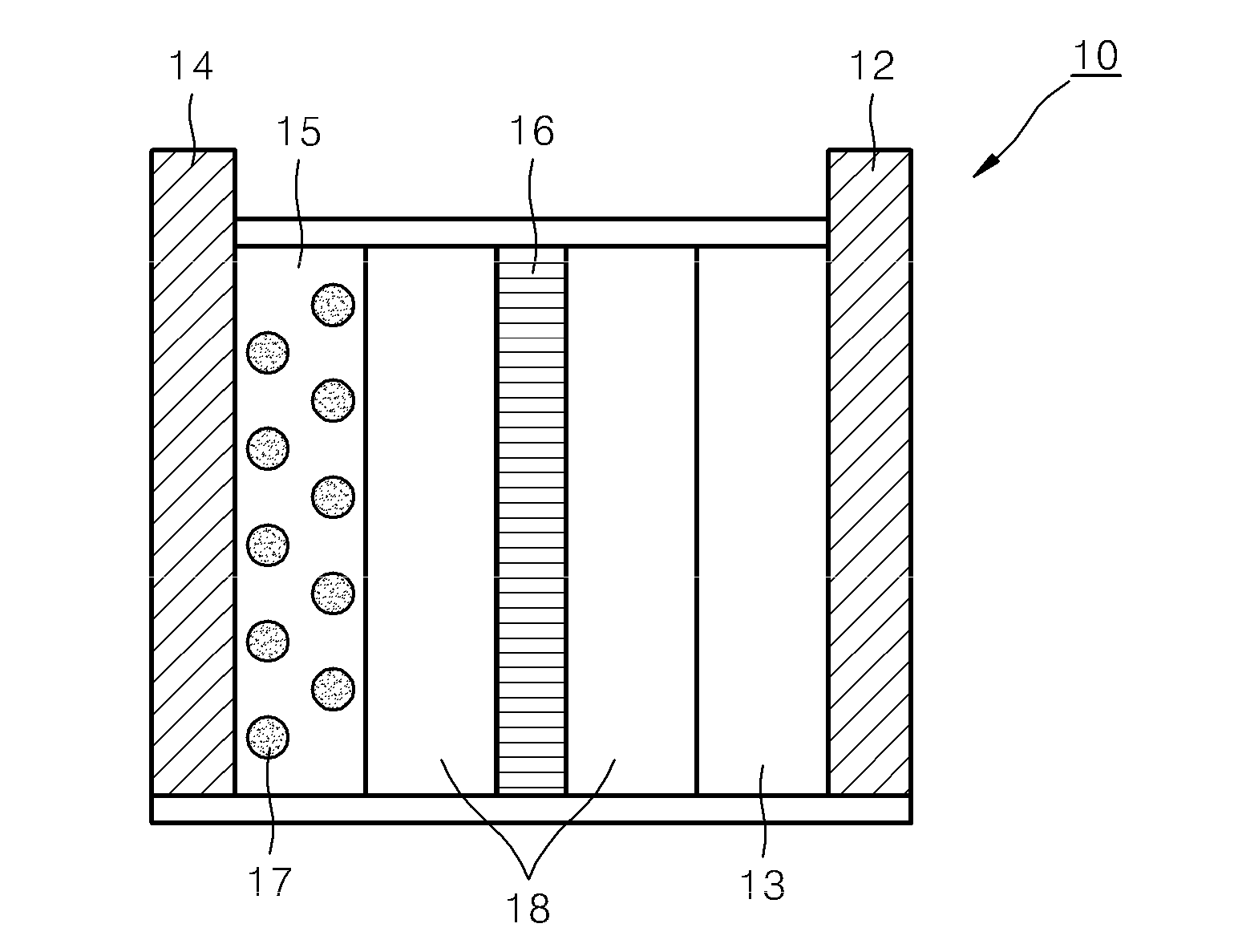

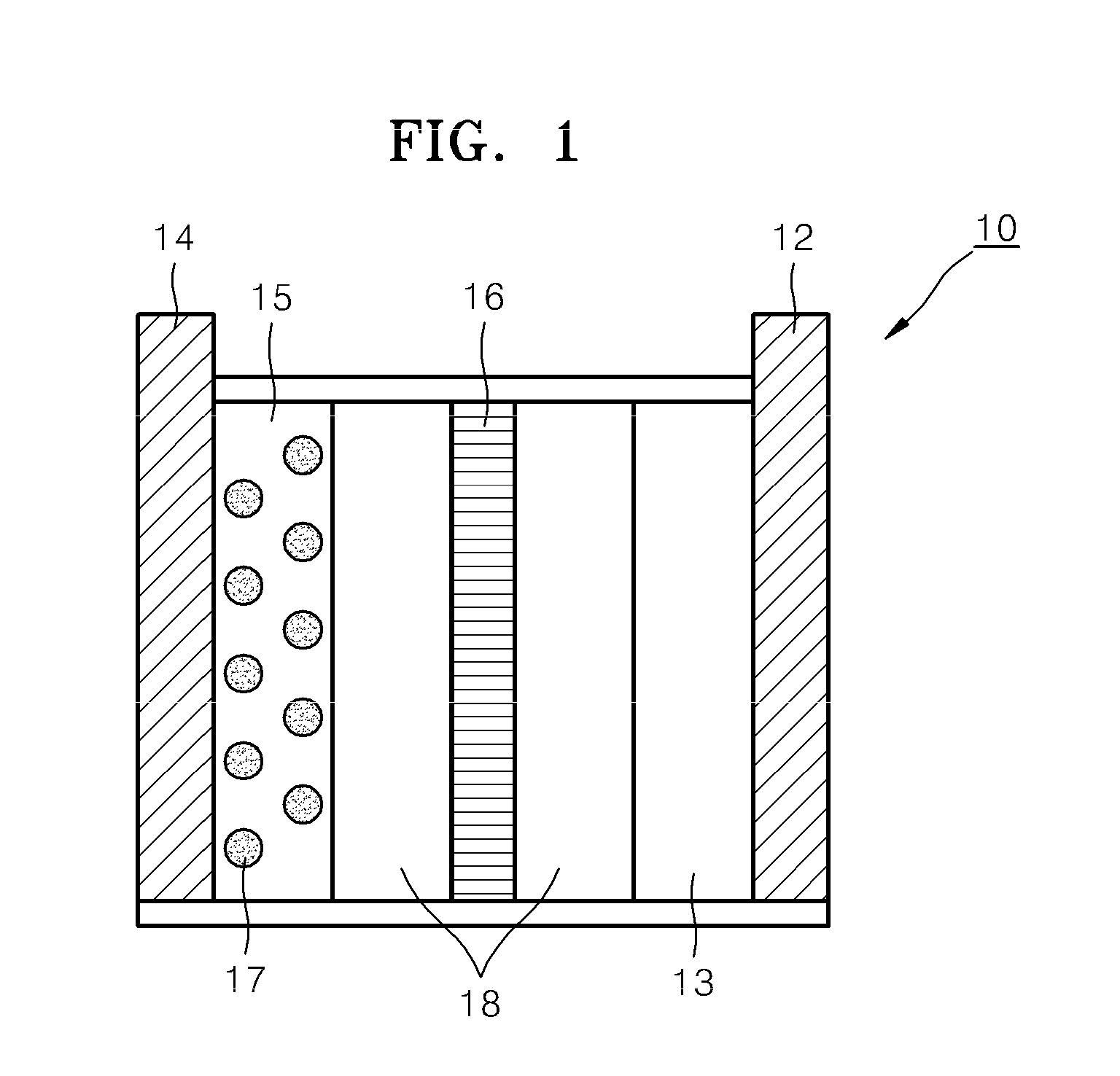

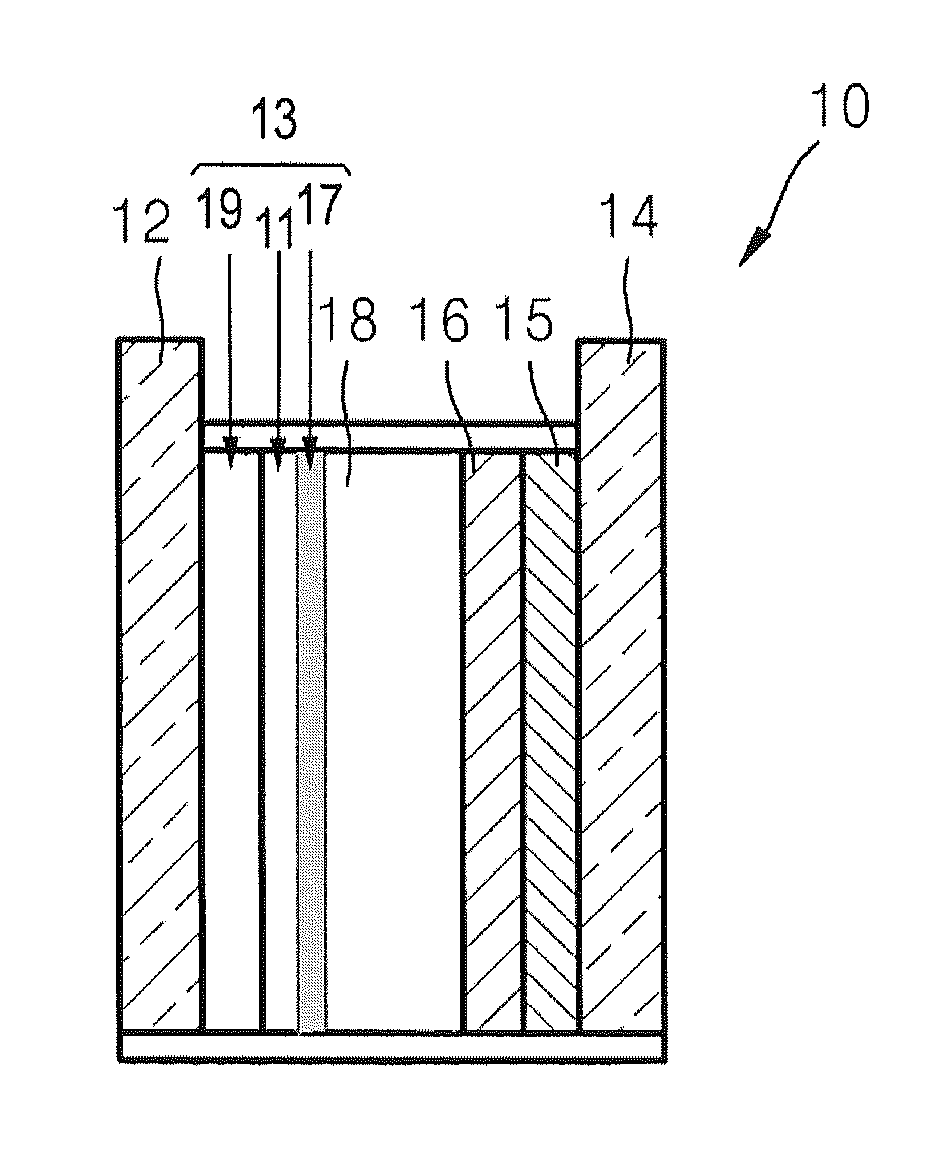

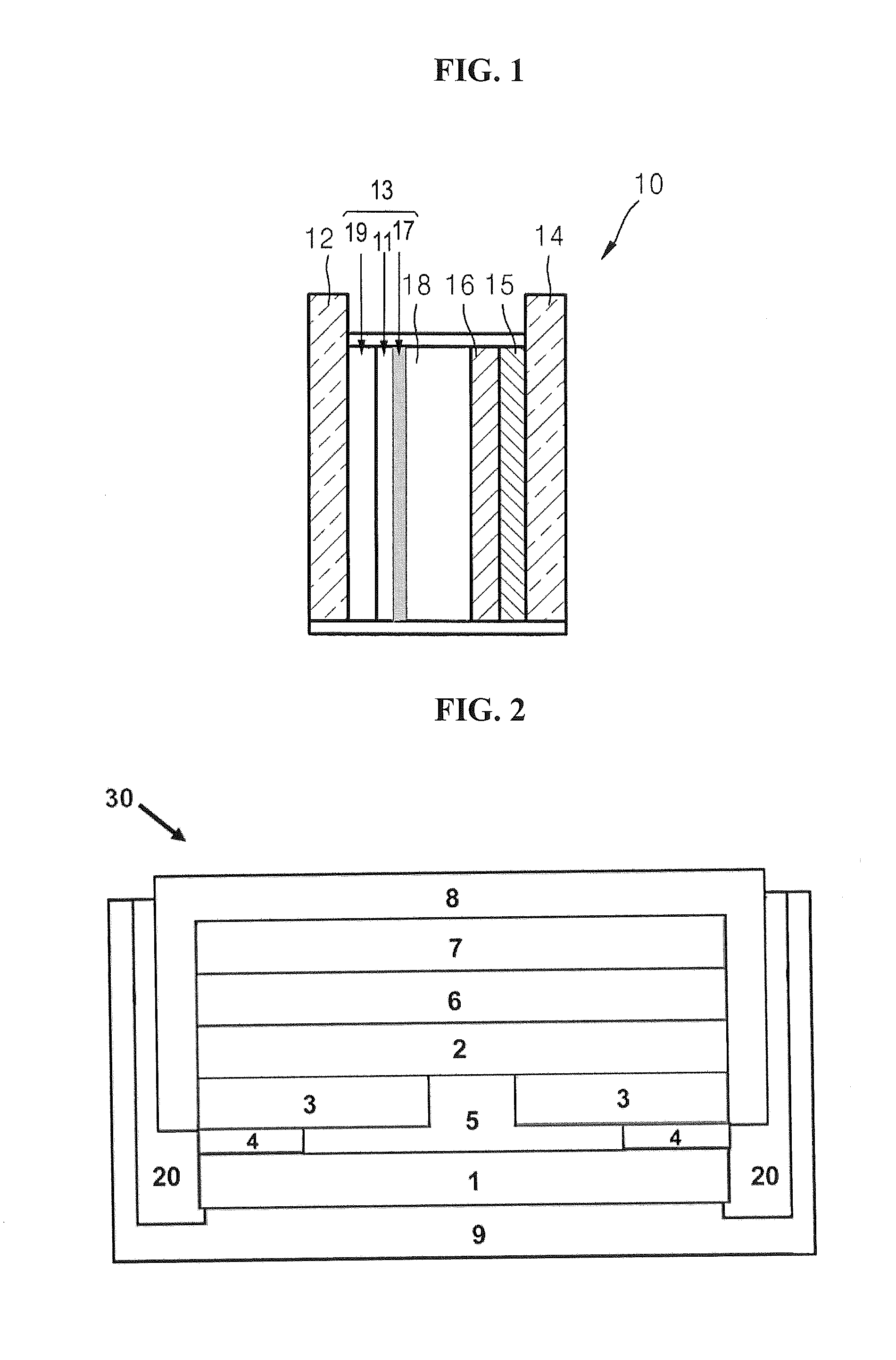

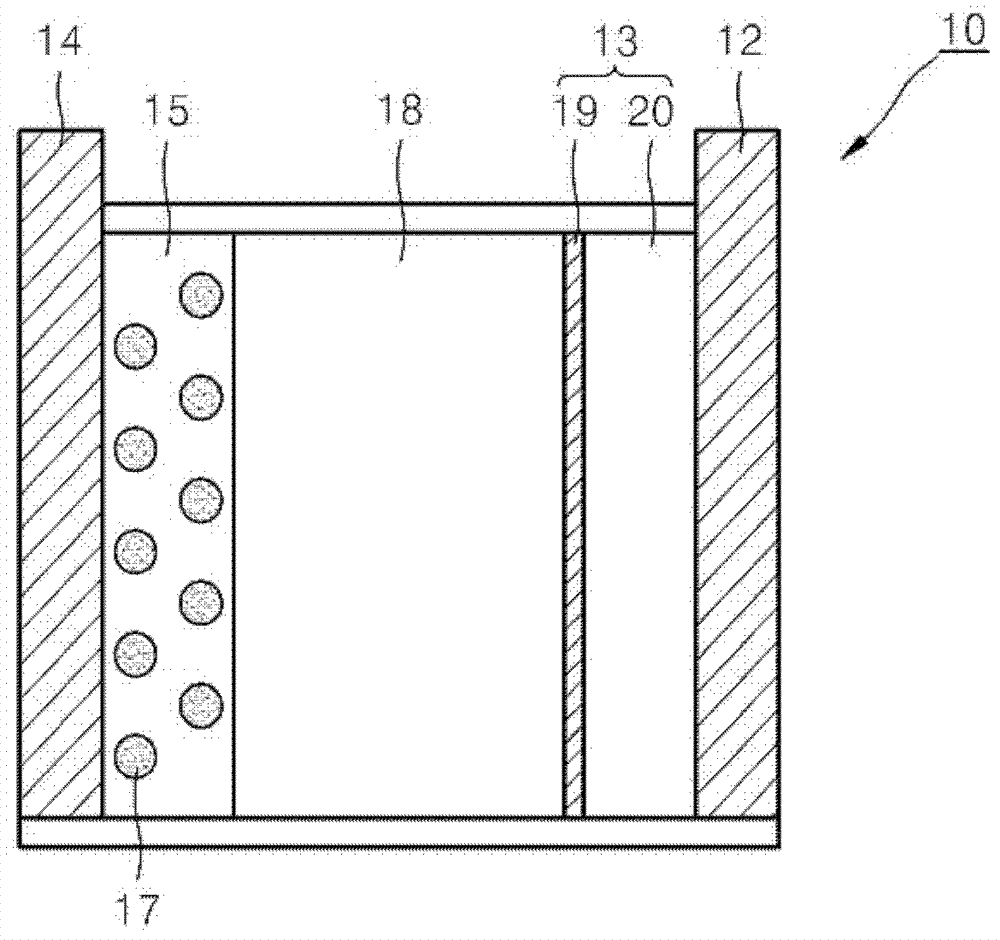

Rechargeable Lithium Air Battery Cell Having Electrolyte with Alkylene Additive

A rechargeable lithium-air battery (10) comprises a non-aqueous, organic-solvent-based electrolyte (16) including a lithium salt and an additive containing an alkylene group, disposed between a spaced-apart pair of a lithium anode (12) and an air cathode (14). The alkylene additive may be alkylene carbonate, alkylene siloxane, or a combination of alkylene carbonate and alkylene siloxane. The alkylene carbonate may be vinylene carbonate, butylene carbonate, or a combination of vinylene carbonate and butylene carbonate. The alkylene siloxane may be a polymerizable silane. The polymerizable silane is triacetoxyvinylsilane.

Owner:EXCELLATRON SOLID STATE

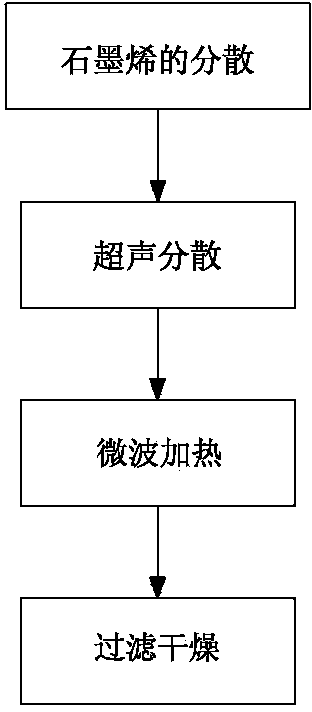

Method for preparing nitrogen-doped graphene with high nitrogen doping amount

The invention discloses a method for preparing nitrogen-doped graphene with high nitrogen doping amount. The method comprises the following steps: (1) dispersing of graphene; (2) ultrasonic dispersion; (3) microwave heating; and (4) filtering and drying. The nitrogen doping amount of the nitrogen-doped graphene prepared by the method disclosed by the invention is 10%-15.0%, the density of free carriers in graphene is greatly increased by the high nitrogen doping amount, the interaction of graphene and metal is enhanced, no oxidation pretreatment is carried out, no toxic solvent is used in the reaction process, reactants are simple in component, reaction conditions are mild, and the prepared nitrogen-doped graphene has excellent electrochemical property and can be used for preparation of new energy materials such as lithium ion battery, lithium-air battery, super capacitor electrode material and fuel cell oxygen reduction catalysts. According to the method disclosed by the invention, a high-pressure kettle is heated by using microwaves without high temperature; the method is low in energy consumption, is carried out in an airtight environment and therefore hardly causes environment pollution; in addition, the method is simple in process and convenient to operate and needs less production equipment, thus, the cost is further reduced.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

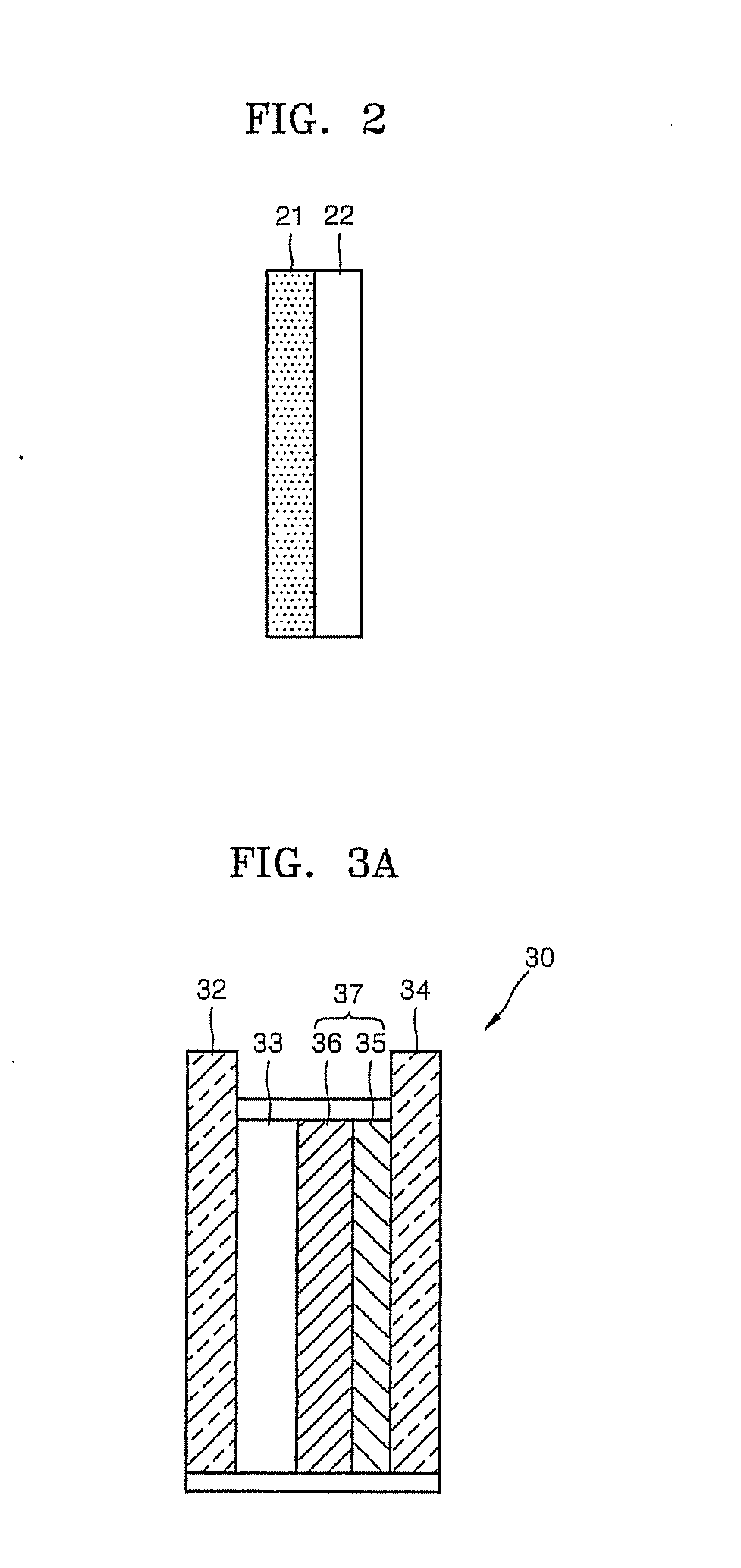

Lithium air battery

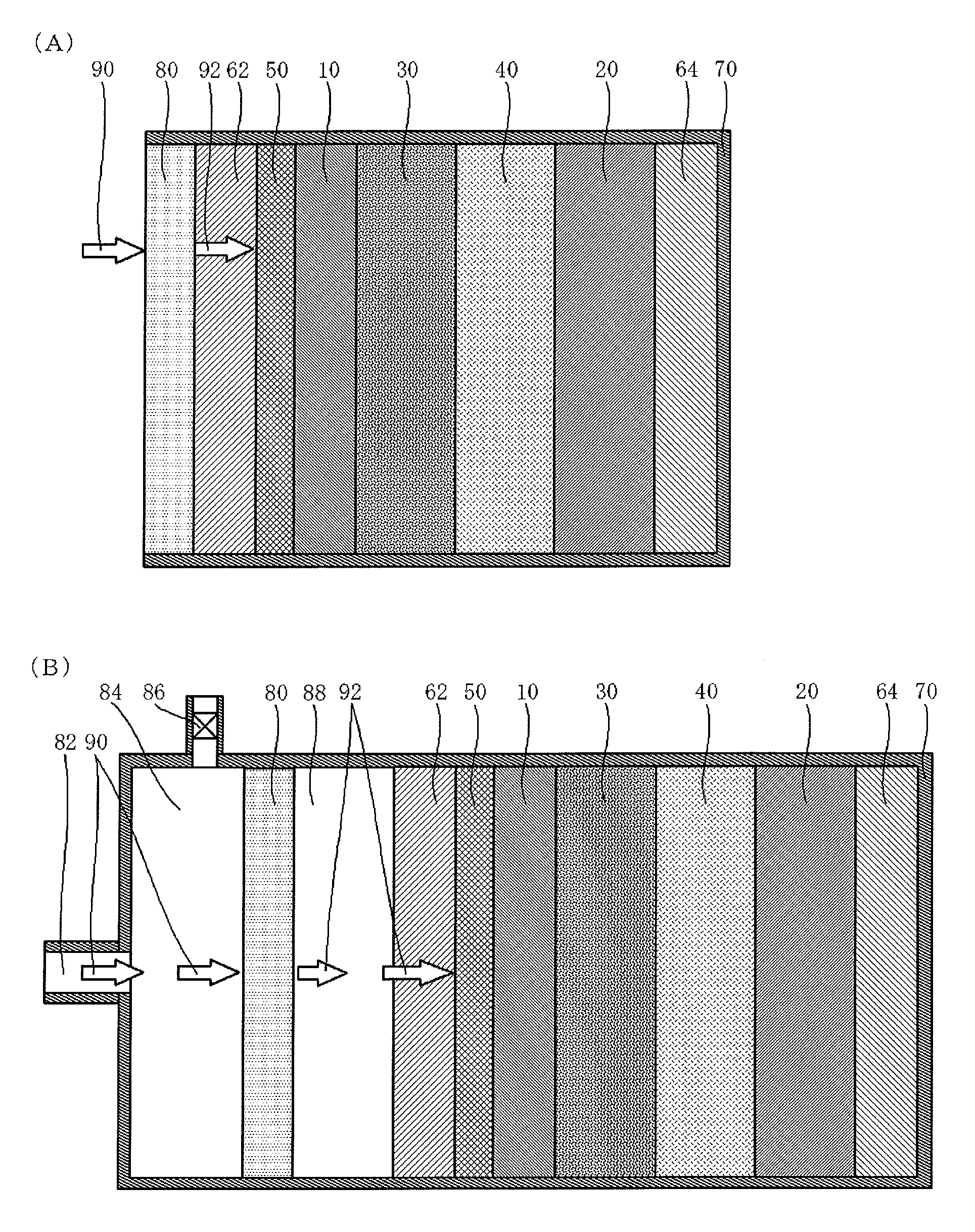

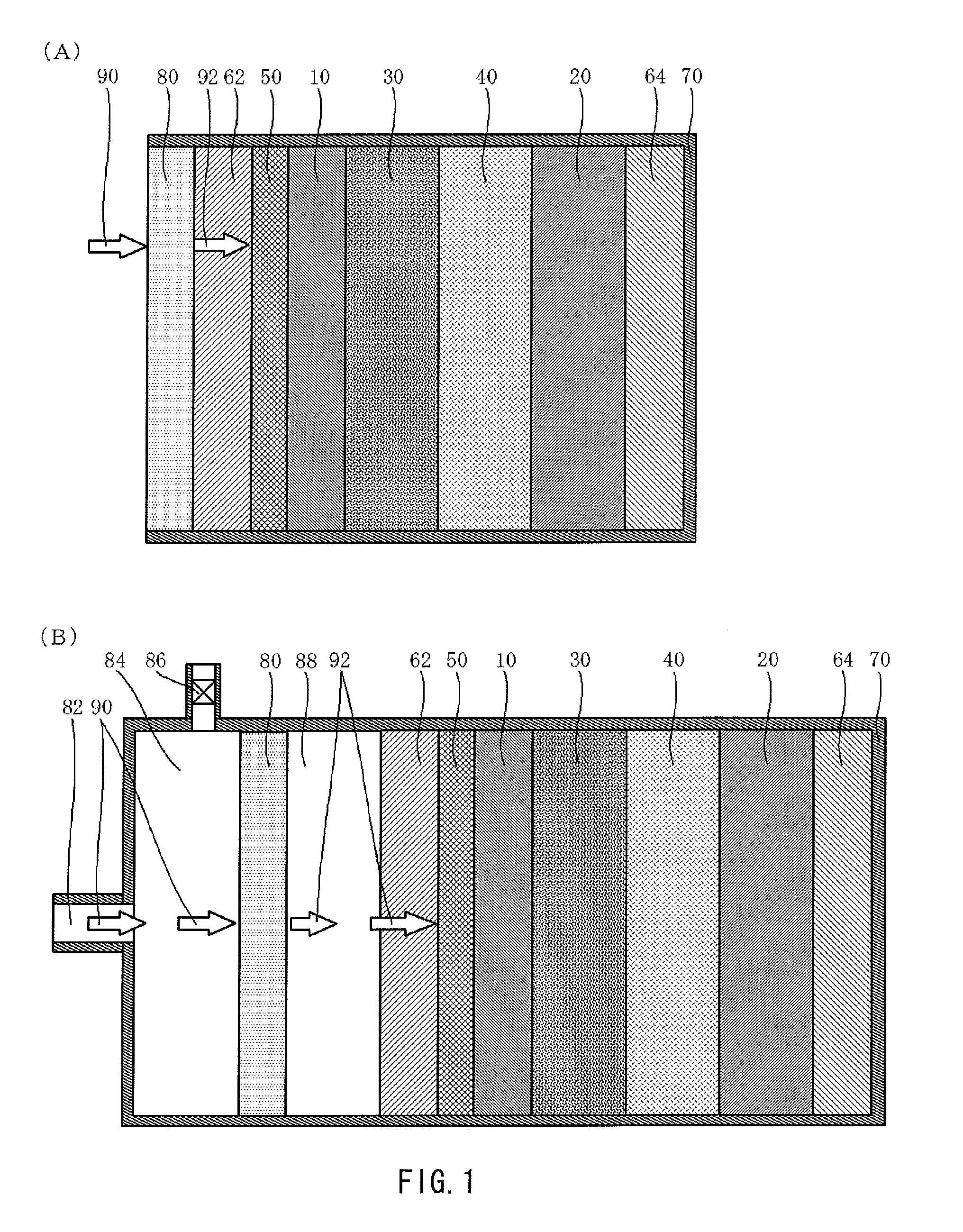

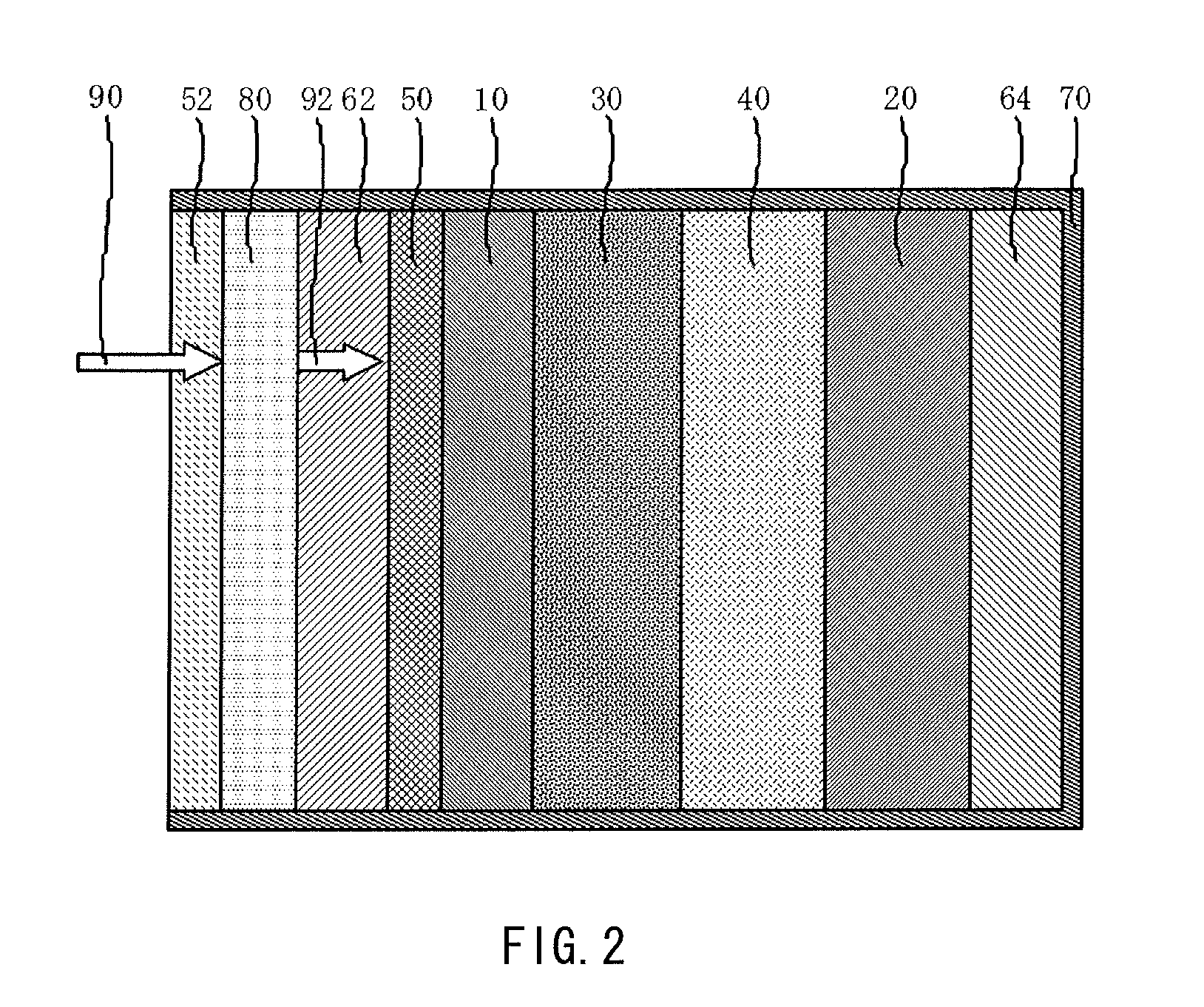

InactiveUS20120237838A1Little deteriorationIncrease battery outputFuel and primary cellsFuel and secondary cellsWater vaporLithium–air battery

A lithium air battery capable of being used for a long time with little deterioration due to influence by moisture in the air in which oxygen supply to a porous cathode is not inhibited by an air electrode current collector is provided. The lithium air battery includes an oxygen permselective film that is less likely to transmit moisture vapor and that selectively transmits oxygen, an oxygen chamber that stores oxygen, an air electrode current collector made of a porous material, a diffusion layer that is arranged between the air electrode current collector and a porous cathode and is made of a conductive material, the porous cathode containing a conductive material and a catalyst material, a separator that is less likely to pass moisture vapor, a nonaqueous electrolyte, an anode that extracts lithium ions, and an anode current collector. The lithium air battery may have a water-repellent layer.

Owner:SONY CORP

Ion conducting polymers and polymer blends for alkali metal ion batteries

ActiveUS20150288028A1Reduced flame retardancyLower glass transition temperatureSolid electrolytesFuel and secondary cellsPolyethylene oxideLithium–air battery

Electrolyte compositions for batteries such as lithium ion and lithium air batteries are described. In some embodiments the compositions are liquid compositions comprising (a) a homogeneous solvent system, said solvent system comprising a perfluropolyether (PFPE) and polyethylene oxide (PEO); and (b) an alkali metal salt dissolved in said solvent system. In other embodiments the compositions are solid electrolyte compositions comprising: (a) a solid polymer, said polymer comprising a crosslinked product of a crosslinkable perfluropolyether (PFPE) and a crosslinkable polyethylene oxide (PEO); and (b) an alkali metal ion salt dissolved in said polymer. Batteries containing such compositions as electrolytes are also described.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

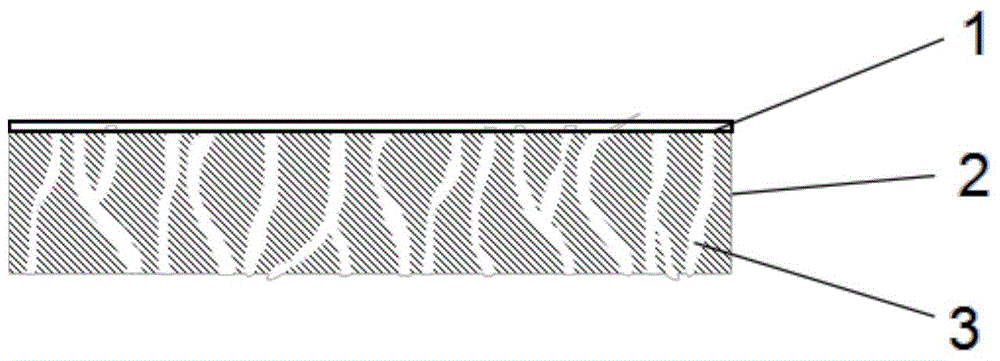

Solid electrolyte film, and preparation method and application of solid electrolyte film

ActiveCN104103873AHigh mechanical strengthLower internal resistanceFuel and primary cellsFuel and secondary cellsSolid state electrolyteLithium–air battery

The invention discloses a solid electrolyte film, and a preparation method and an application of the solid electrolyte film. The solid electrolyte film comprises a solid electrolyte layer and a porous ceramic layer, wherein the thickness of the solid electrolyte layer is 0.5-10 micrometers; the thickness of the porous ceramic layer is 100-300 micrometers; and the solid electrolyte layer uniformly covers the porous ceramic layer. The preparation method of the solid electrolyte film comprises the following steps of (1) preparing a solid electrolyte precursor: sintering raw material powder at 500-700 DEG C, (2) preparing a solid electrolyte target material: adding the powder to a binding agent, pressing the binding agent into sheets and sintering, and (3) applying the solid electrolyte film on a porous ceramic substrate: uniformly applying the solid electrolyte film on porous ceramic by a magnetron sputtering method. The solid electrolyte film has good ionic conduction properties and mechanical properties, is applied to preparation of a lithium air battery, and is low in internal resistance and good in electrical performance. The method is simple in technology and low in cost.

Owner:南京同宁新材料研究院有限公司

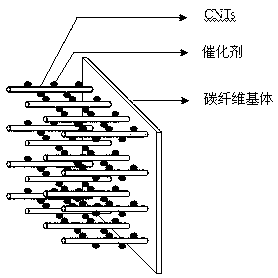

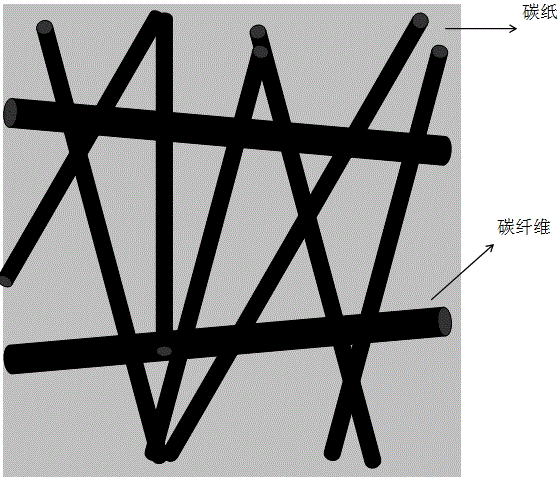

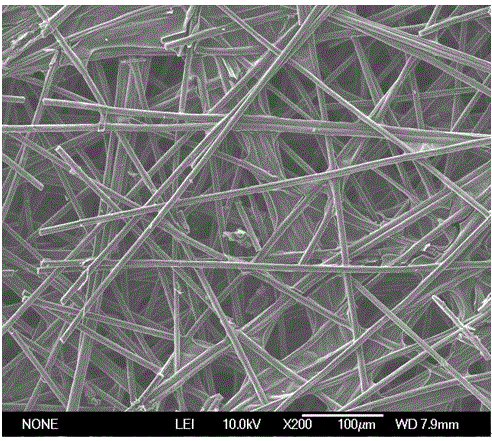

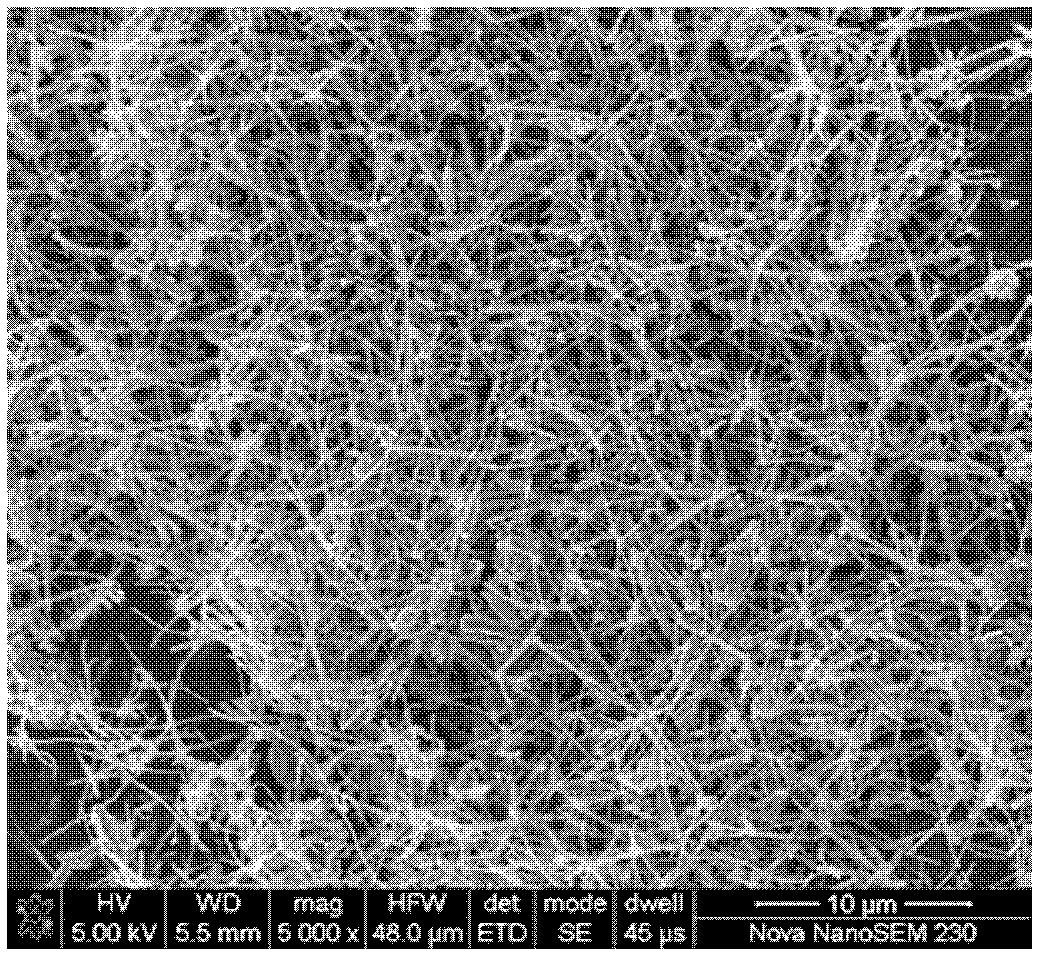

Preparation method of carbon nano tube array/carbon fiber fabric integrated three-dimensional porous air electrode

InactiveCN103337639ALarge specific surface areaHigh mechanical strengthCell electrodesFiberCarbon fibers

The invention discloses a preparation method of a carbon nano tube array / carbon fiber fabric integrated three-dimensional porous air electrode. The preparation method comprises the following steps of: taking carbon fiber fabric as a matrix, depositing a carbon nano tube array on the matrix, taking a carbon tube as a catalyst carrier, carrying nano-level MnO2 particles by an electric depositing method, and finally forming the catalytic air electrode. The air electrode prepared by the preparation method has the advantages of high specific surface area, parallel hole channel structures, high-conductivity electron transporting conductors and excellent mechanical strength and chemical stability, and is an ideal electrode material for preparing a composite air electrode of a large-capacity novel lithium-air battery.

Owner:TAIYUAN UNIV OF TECH

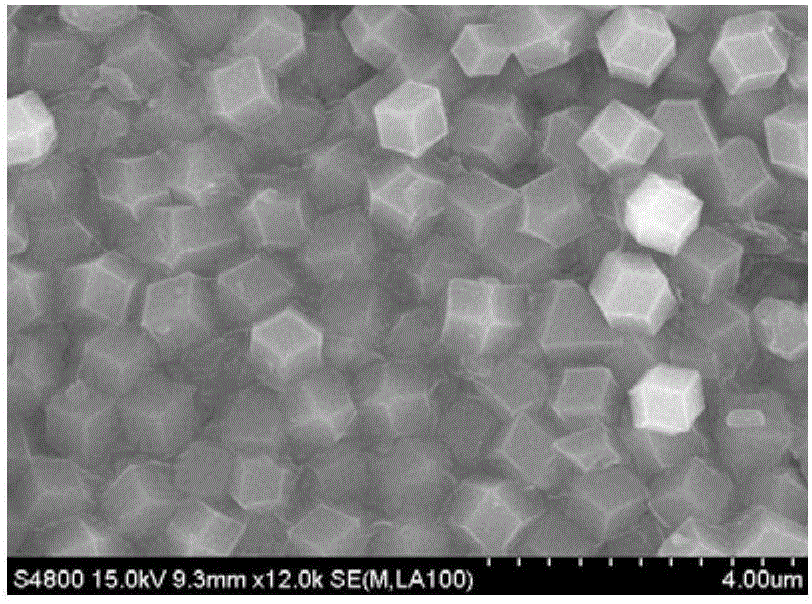

High density lithium ion battery cathode material lithium cobalt oxide and preparation method thereof

InactiveCN102447107AIncrease compaction densityIncrease volumetric energy densityCell electrodesCobalt compoundsManufacturing technologySodium-ion battery

The invention relates to a manufacture technology of a lithium ion battery cathode material and specifically provides a high density lithium ion battery cathode material lithium cobalt oxide and a preparation method thereof. The high density lithium ion battery cathode material lithium cobalt oxide of the invention has a chemical formula of Li1+xCo(1-a-b-c) MgaTibAlcFdO(2-d), wherein a, b, c, d and x satisfy relations of: 0<=a<=0.03, 0.001<=b<=0.02, 0<=c<=0.01, 0<=d<=0.02 and 0<=x<=0.08; and a preferable value of a, a preferable value of b, a preferable value of c and a preferable value of d satisfy relations of: 0.005<=a<=0.01, 0.002<=b<=0.01, 0<=c<=0.005 and 0<=d<=0.005; and a cation M is doped or cladded by one or a composition of several selected from magnesium, titanium and aluminium. The invention can enhance stability of material structure, cycle performance and safety performance of the lithium ion battery as well as effectively increase space utilization rate of the material and compacted density of the cathode material, thereby substantially raising volume energy density of the material.

Owner:JIANGSU KING LITHIUM CELL

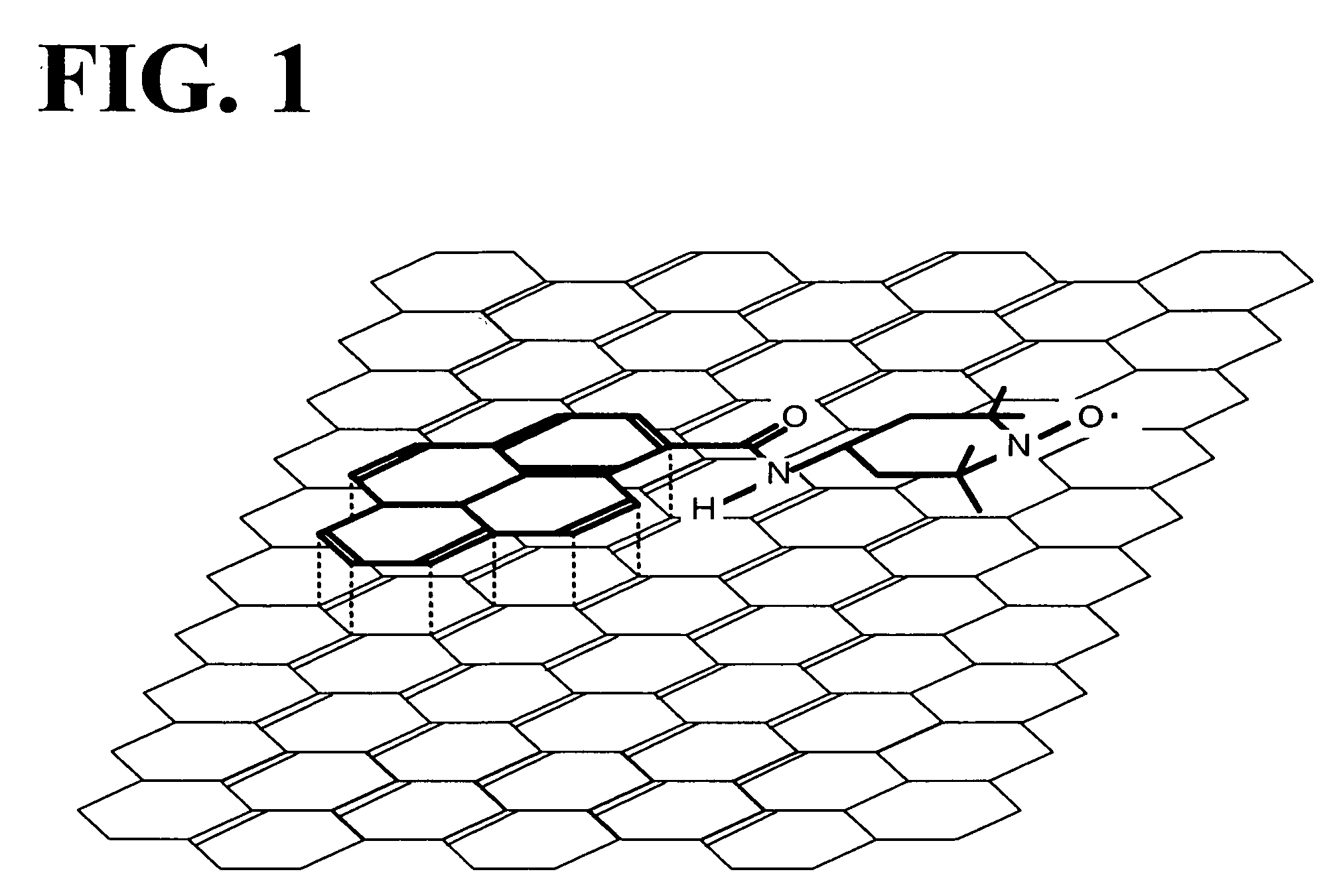

Alkali metal air battery

InactiveUS20090239113A1Raise the discharge potentialCharge capacityFuel and secondary cellsActive material electrodesMetallic lithiumLithium–air battery

A F-type electrochemical cell, which is a lithium air battery, includes a positive electrode facing a negative electrode composed of metallic lithium with a separator provided therebetween in a casing. Air is capable of flow to the positive electrode. A nonaqueous electrolytic solution is charged into a space between the positive electrode and the negative electrode. At least one of the positive electrode and the nonaqueous electrolytic solution of the lithium air battery contains a compound having a stable radical skeleton. The compound also serves as a redox catalyst for oxygen.

Owner:TOYOTA CENT RES & DEV LAB INC

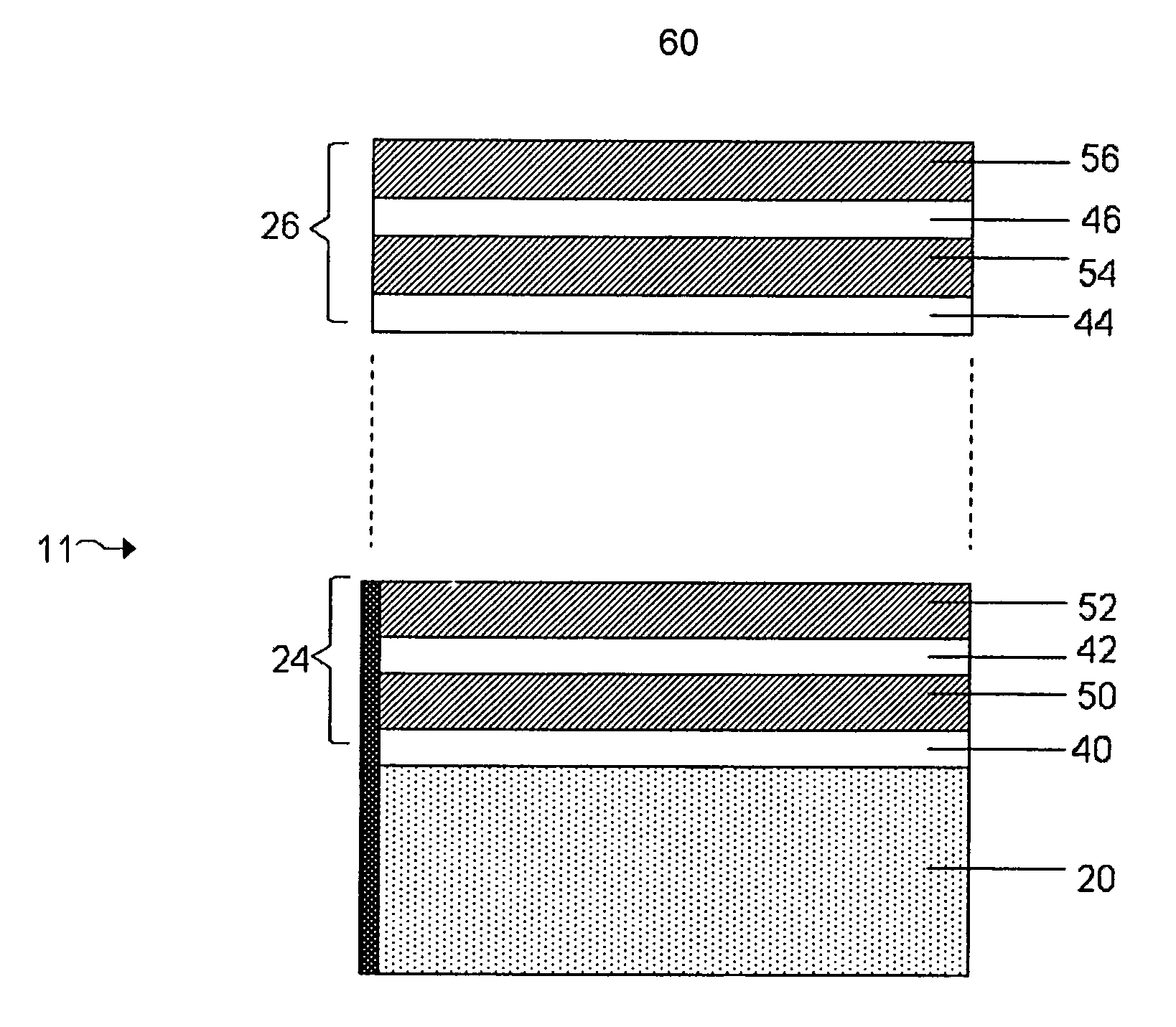

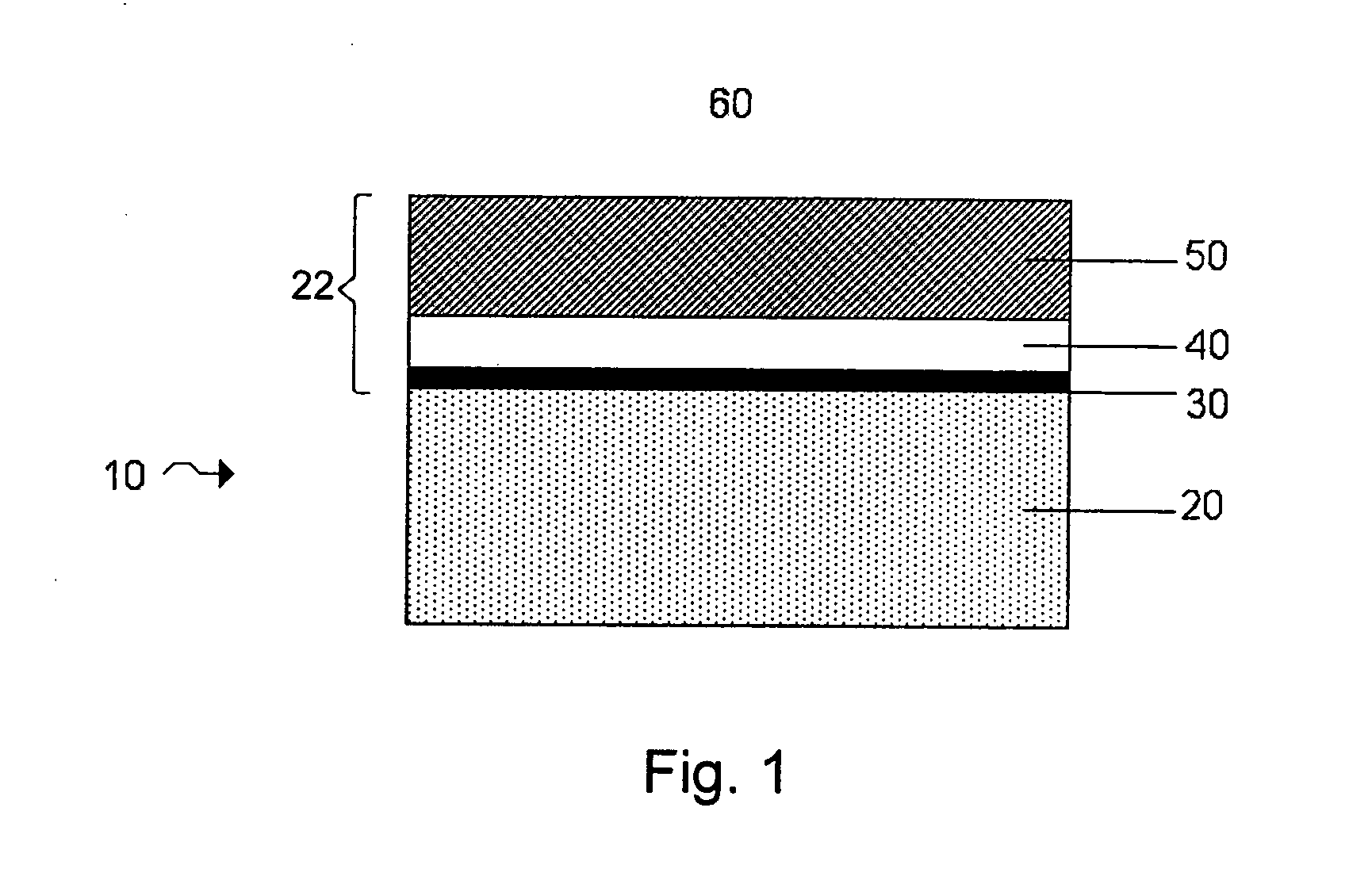

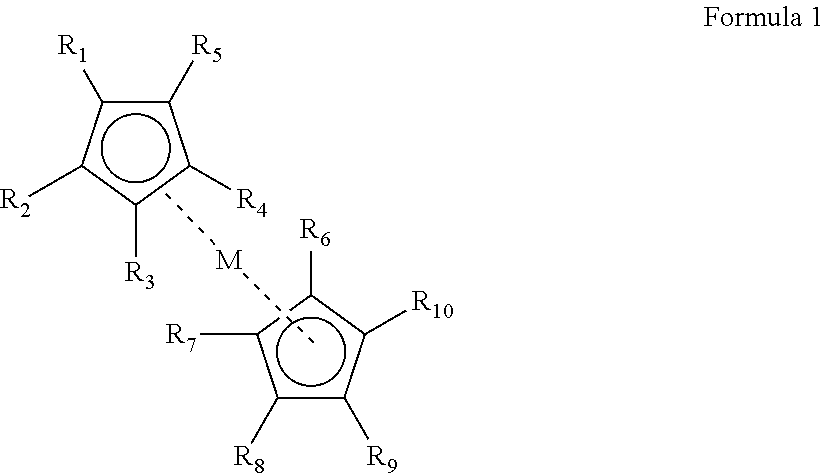

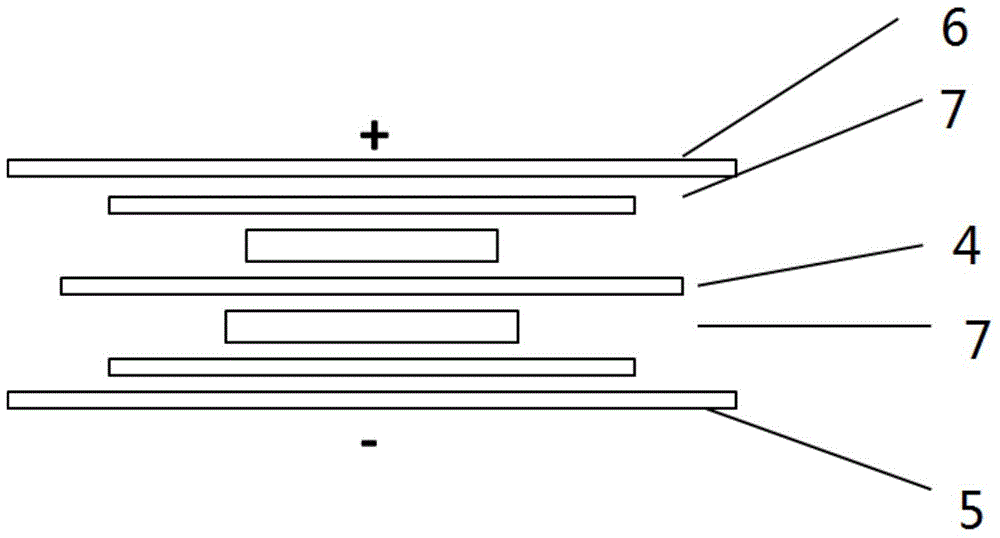

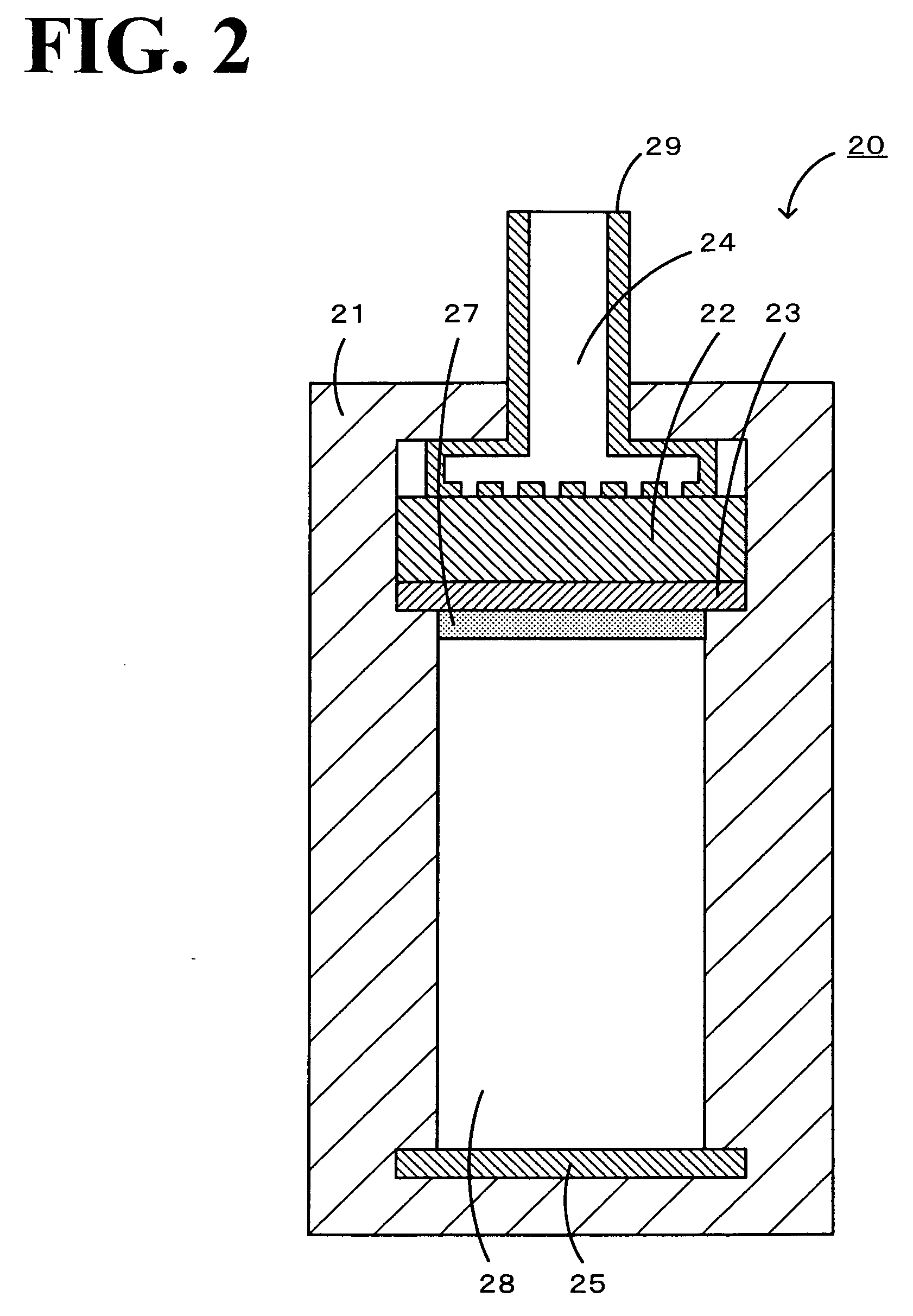

Protected anode and lithium air battery and all-solid battery including protected anode

ActiveUS20130149616A1Improve stabilityFuel and primary cellsAlkaline accumulatorsIndiumLithium–air battery

A protected anode including an anode including a lithium titanium oxide; and a protective layer including a compound represented by Formula 1 below, a lithium air battery including the same, and an all-solid battery including the protected anode:Li1+XMXA2−XSiYP3−YO12 <Formula 1>wherein M may be at least one of aluminum (Al), iron (Fe), indium (In), scandium (Sc), or chromium (Cr),A may be at least one of germanium (Ge), tin (Sn), hafnium (Hf), and zirconium (Zr),0≦X≦1, and0≦Y≦1.

Owner:SAMSUNG ELECTRONICS CO LTD +1

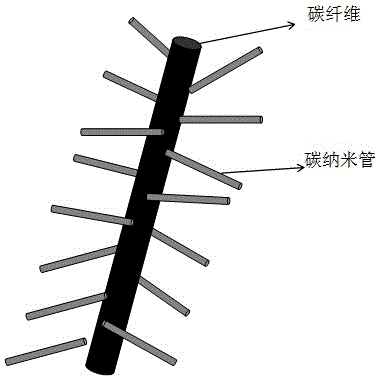

Preparation method for pine-needle-shaped carbon nanotube/carbon fiber conductive network composite carbon material

ActiveCN106082159ASolve the problem of low growth densitySolve the problem of low surface utilizationMaterial nanotechnologyFiberOrganic solar cell

The invention discloses a preparation method for a pine-needle-shaped carbon nanotube / carbon fiber conductive network composite carbon material. The preparation method comprises taking fiber of carbon fiber fabric as a growth substrate, and growing carbon nanotubes arranged in high density on the growth substrate. The carbon nanotubes arranged in high density on the growth substrate and the carbon fiber substrate together form the three-dimensional porous pine-needle-shaped carbon nanotube / carbon fiber conductive network composite carbon material. The material is an ideal material for loading an active substance or reaction substance because of possessed high specific surface area, and is capable of inhibiting structure damage caused during reaction because of excellent mechanical strength. Also, because of intersection or overlapping of carbon nanotube and carbon fiber, the integrity of the conductive framework of the composite material is facilitated to be improved, and the composite material possesses wide application prospect in fields of fuel batteries, supercapacitors, lithium-air batteries, lithium-sulfur batteries, organic solar cells and the like.

Owner:清创人和生态工程技术有限公司

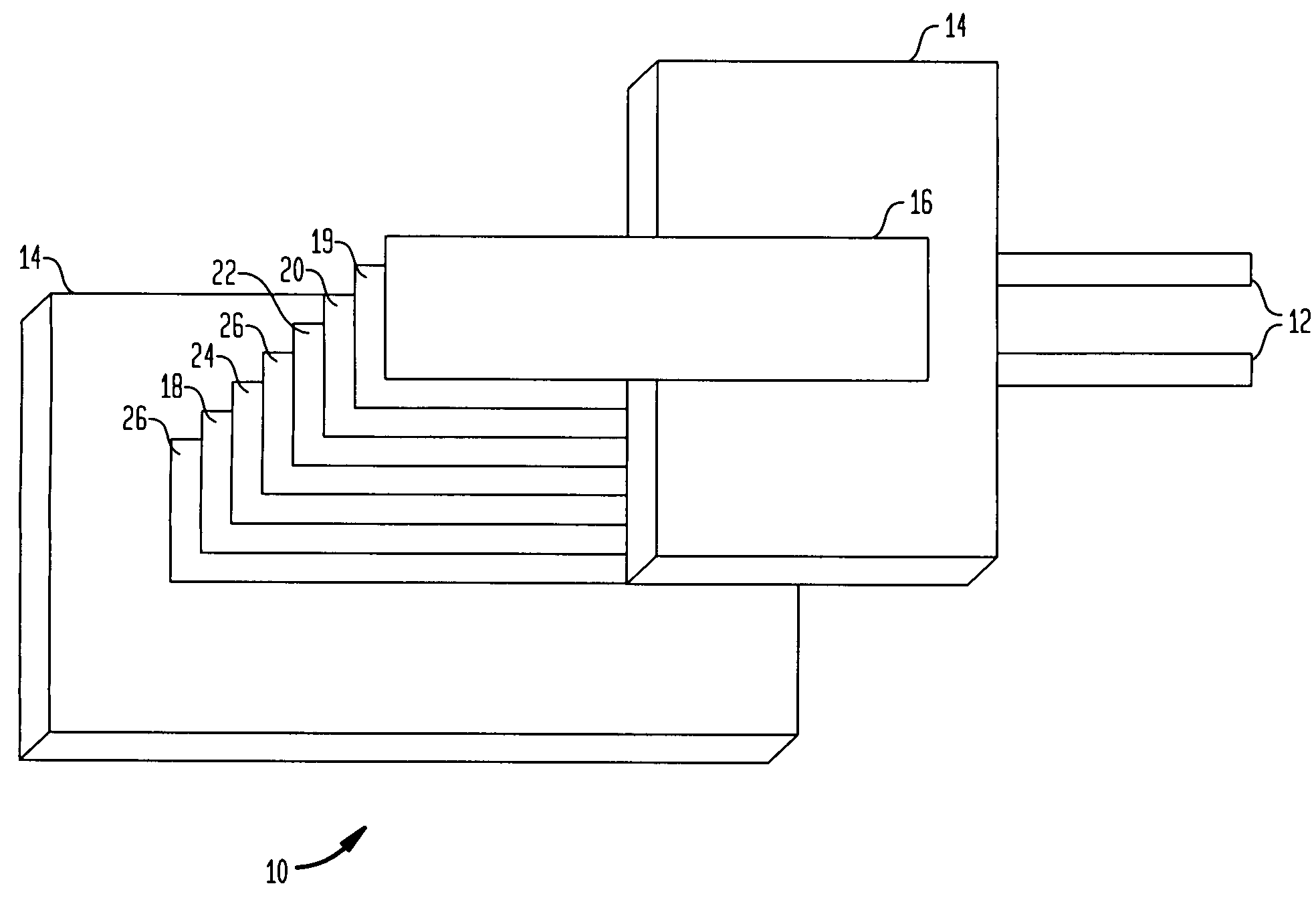

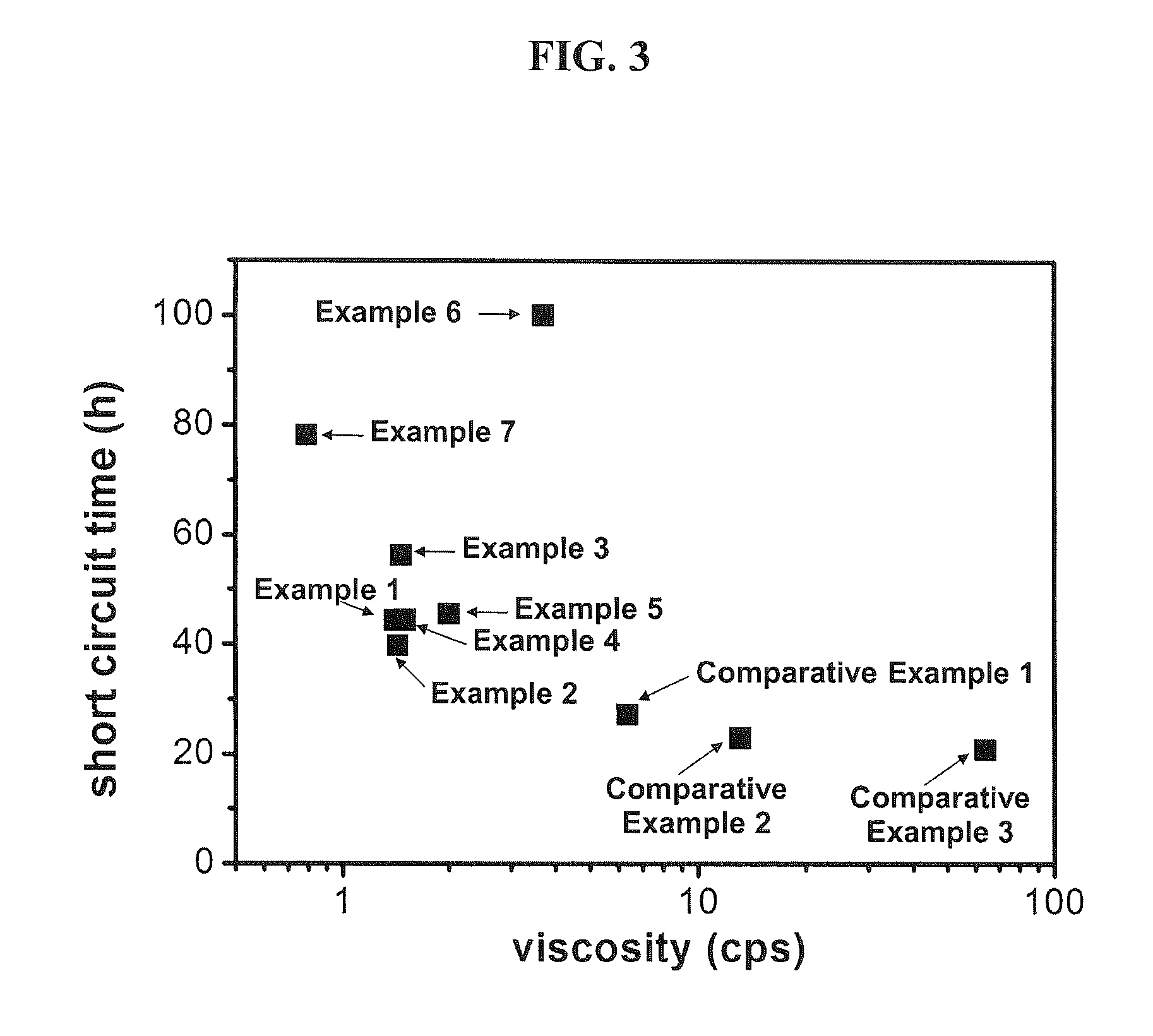

Anode for lithium air battery and lithium air battery including the anode

ActiveUS20140011101A1Extend your lifeLow viscosityFuel and primary cellsSolid electrolytesLithium–air batteryViscosity

An anode for a lithium air battery including an anode active material layer including an anode active material; a first protective layer disposed on the anode active material layer; and a second protective layer disposed on the first protective layer, wherein the first protective layer includes a liquid electrolyte having a viscosity of 5 centipoise or less at a temperature of 20° C., and the second protective layer includes an ion conductive solid electrolyte membrane.

Owner:SAMSUNG ELECTRONICS CO LTD

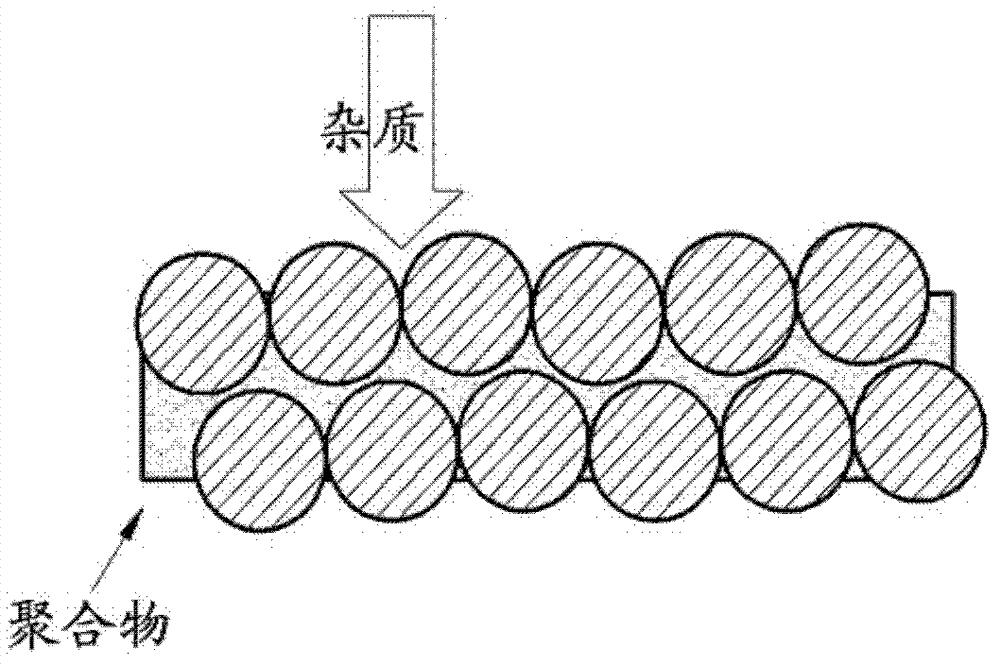

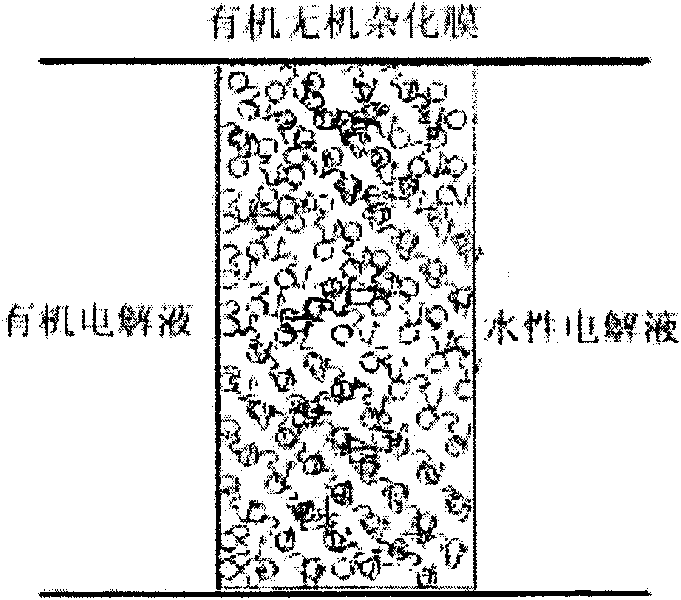

Negative electrode for lithium secondary battery, method of manufacturing the same, and lithium secondary battery employing the same

A negative electrode for a lithium secondary battery that includes an organic-inorganic hybrid protective layer where the lithium ion conductivity of a polymer included in the organic-inorganic hybrid protective layer is about 10 -4 S / cm or less, a method of manufacturing the same, and a lithium secondary battery employing the same.

Owner:SAMSUNG ELECTRONICS CO LTD +1

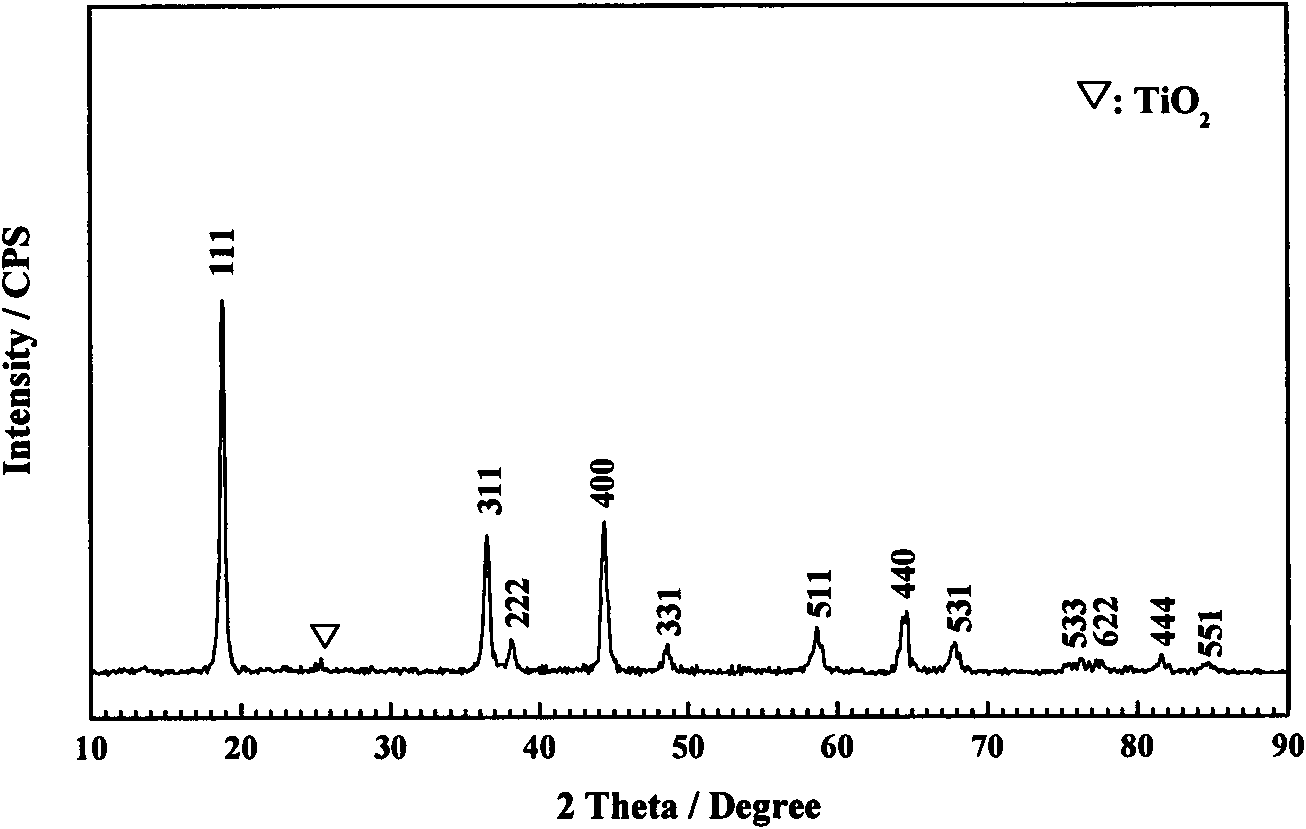

Solid electrolyte material for lithium battery and preparation method and application of solid electrolyte material

InactiveCN106532112ASimple methodSimple post-processingSolid electrolytesFuel and secondary cellsSolid state electrolyteHeat stability

The invention discloses a solid electrolyte material for a lithium battery and a preparation method and application of the solid electrolyte material, and belongs to the field of energy material preparation. The solid electrolyte material comprises a metal organic framework compound, a lithium salt, a film-forming additive and a filling. The solid electrolyte material for the lithium battery does not need polyoxyethylene or a derivative thereof; and compared with other inorganic solid electrolytes, the solid electrolyte material has the advantages of higher lithium ion containing capability, higher ionic conductivity and better heat stability, and the security of the battery can be greatly improved. The lithium-ion all-solid-state battery prepared by the method has the electrochemical properties equivalent to a liquid electrolyte. The solid electrolyte material for the lithium battery can be used for a lithium-ion battery, can be suitable for the systems of a lithium-sulfur battery, a lithium-air battery and the like, and is wide in application.

Owner:XIAMEN UNIV

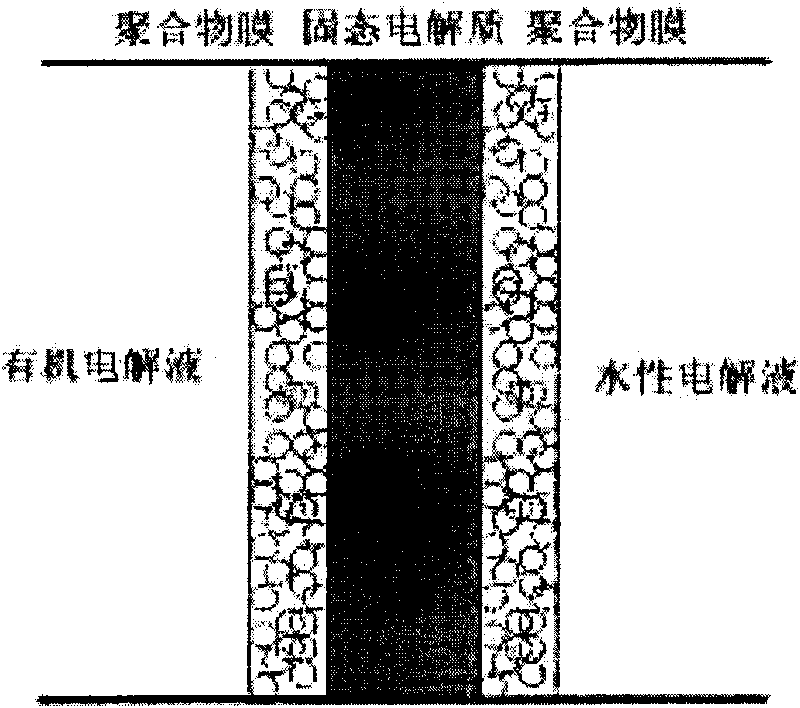

Diaphragm for lithium-air battery and preparation method thereof

InactiveCN101707241AAvoid contactGood chemical stabilityCell component detailsElectrical conductorAqueous electrolyte

The invention discloses a diaphragm for a lithium-air battery, which has a three-layer sandwich structure, wherein an intermediate layer is a solid lithium fast ion conductor which takes LiM2-xNx(PO4)3 or NaM2-xNx(PO4)3 (x is more than or equal to 0 and is less than or equal to 0.8, M is Ti, and N is one of elements such as Ge, Al, Si, Ga and the like) as a matrix; and both sides of the diaphragm are provided with a layer of organic polymer porous film or inorganic-organic composite diaphragm of the LiM2-xNx(PO4)3 or NaM2-xNx(PO4)3 (the x is more than or equal to 0 and is less than or equal to 0.8) lithium fast ion conductor with nanometer particles and an organic polymer respectively. The invention also provides a method for preparing the diaphragm for the lithium-air battery. The diaphragm has quick lithium ion passing performance, isolates an organic electrolyte and an aqueous electrolyte at the same time, prevents the moisture from contacting metal lithium to produce the hazard or generate inert substances to stop the reaction, and has good mechanical property at the same time.

Owner:青岛生物能源与过程研究所

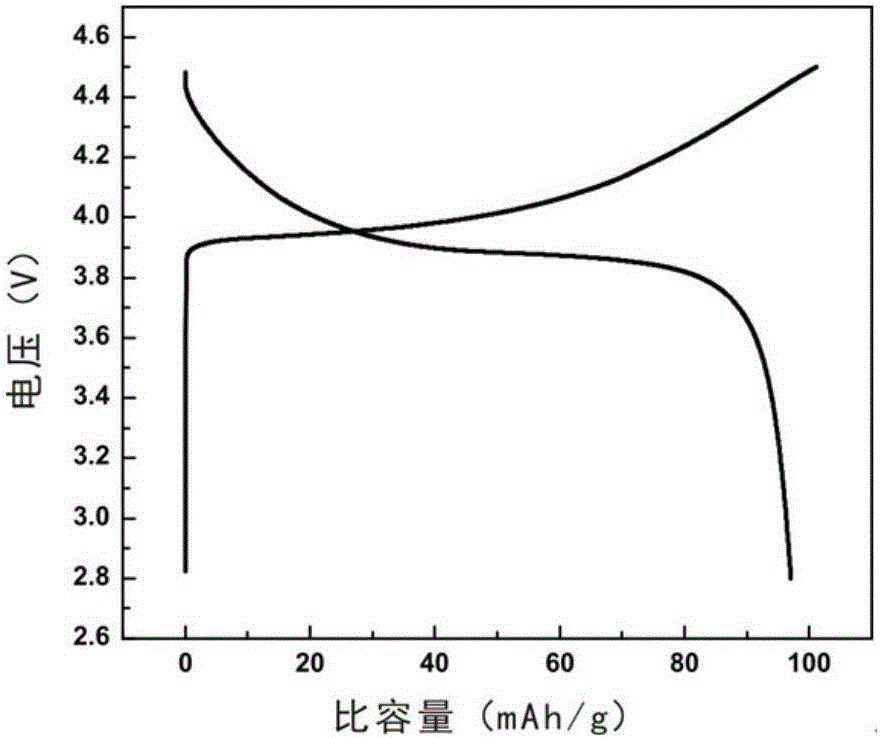

Modified lithium manganese oxide electrode material for lithium ion secondary battery and synthesizing method thereof

InactiveCN102208640AImprove featuresImprove crystallization propertiesCell electrodesAluminium-ion batterySodium-ion battery

The invention provides a modified lithium manganese oxide electrode material for a lithium ion secondary battery, which is characterized in that the general formula is Li(4-x)A(x+y)Mn(5-y)O12.epsilonBOz. The synthesizing method comprises the following steps: weighing and mixing raw materials evenly in accordance with the stoichiometric ratio in the general formula and then adding the mixture of the raw materials to a container; adding an oxidizing solution, evening mixing and reacting for over 10 minutes, and then taking the materials out, washing and drying; and then carrying out high-temperature calcination and reaction for 1-30 hours at a temperature of 400-1200 DEG C under an oxygen-contained atmosphere, and cooling to obtain the modified lithium manganese oxide electrode material. Compared with an existing electrode material and a synthesizing technology, the modified lithium manganese oxide electrode material produced in the production process can improve the crystalline characteristic and the purity of products as well as the specific capacity, the initial coulomb efficiency, the cyclical stability and other characteristics in electrochemical property; and the modified lithium manganese oxide electrode material improves performances of the lithium ion battery, promotes the wider applications of the lithium ion battery and has significant economic meanings and practical value.

Owner:王明月

Hollow graphene ball and preparation method and application thereof

ActiveCN104009205AImprove electrochemical performanceImprove controllabilityFuel and primary cellsCell electrodesReduction treatmentMicrometer

The invention discloses a hollow graphene ball and a preparation method and application of the hollow graphene ball. The preparation method of the hollow graphene ball includes the steps that powder and oxidized graphene are dispersed in liquid at the weight ratio ranging from 1 : 0.01 to 1 : 20, and dispersed suspension liquid is obtained, wherein powder is nanometer powder and / or micrometer powder; spray drying is conducted on the dispersed suspension liquid, and a precursor is obtained; in protective gas, reduction treatment is conducted on the precursor at the temperature ranging from 200 DEG C to 1100 DEG C, the precursor is cooled to the room temperature after being treated, and then reduzate is obtained, wherein reduzate contains powder or reactant of powder; the reduzate is mixed with a solvent to make powder or the reactant of powder dissolved, and then the hollow graphene ball is obtained after solids are separated. The preparation method is simple in operation, environment friendliness is achieved, the yield is high, cost is low, and the preparation method is suitable for industrialized mass production. The hollow graphene ball has excellent electrochemical performance, and can be used as a positive electrode material of a lithium air cell.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

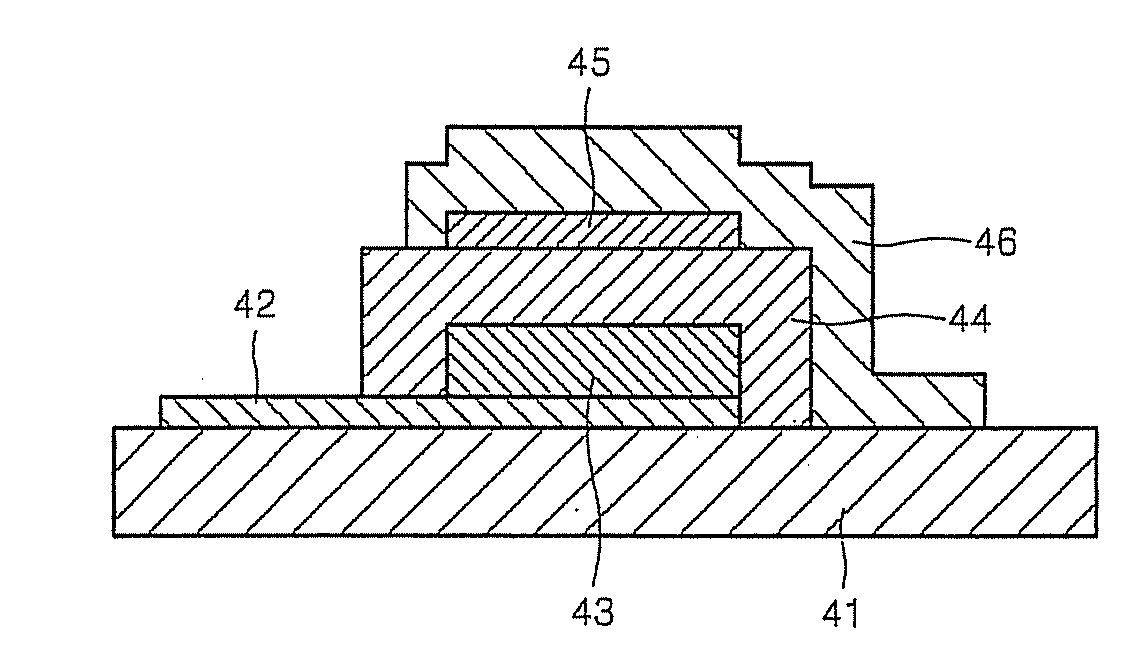

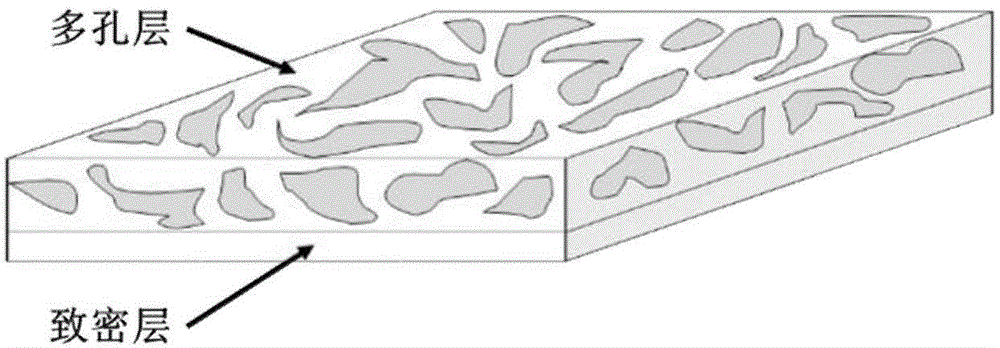

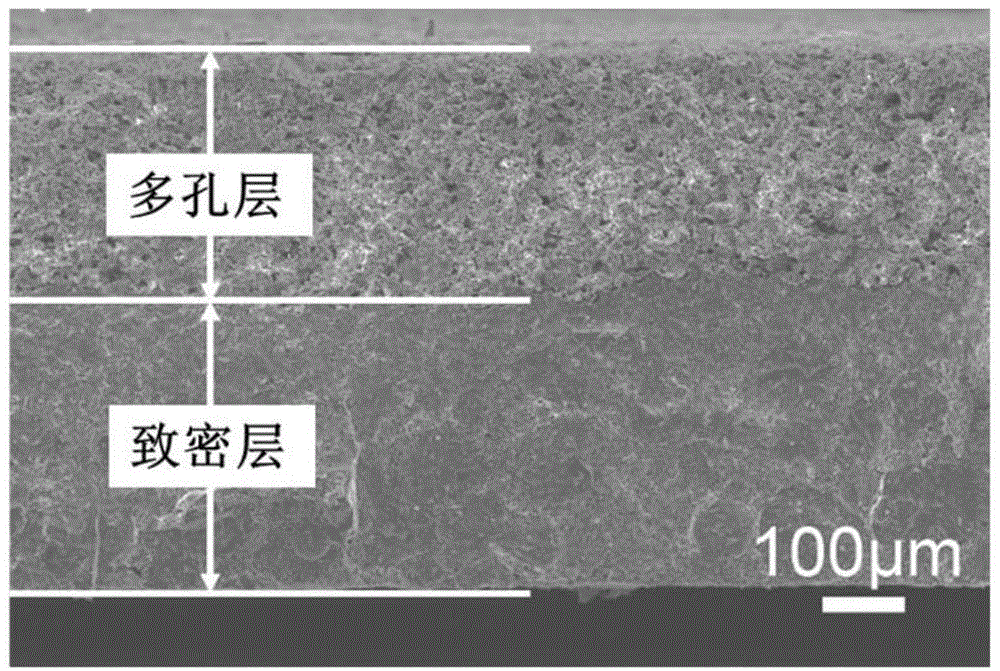

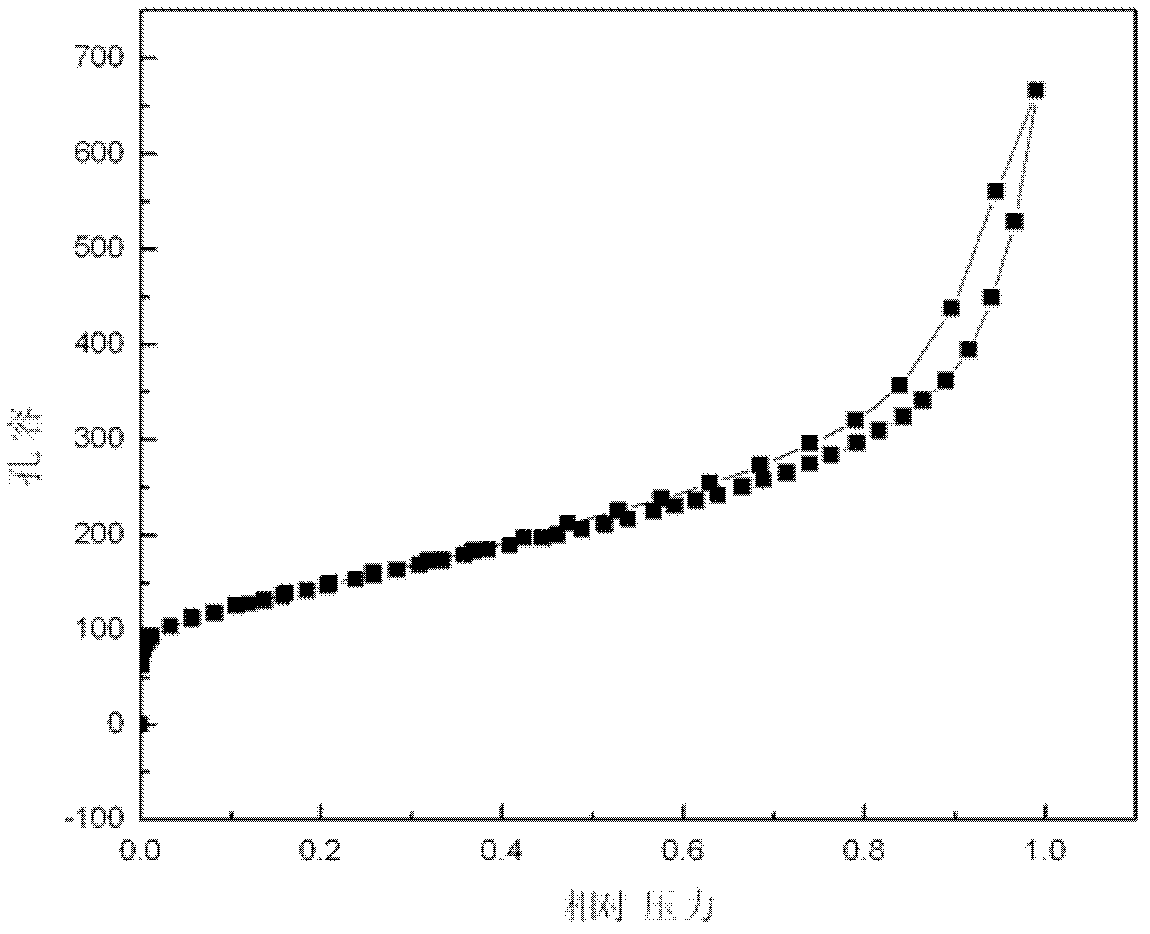

Porous-compact double-layer electrolyte ceramic sintered body, lithium ion battery and lithium-air battery

ActiveCN104916869ASolve the leakFix security issuesFuel and secondary cellsFinal product manufactureCeramic sinteringAll solid state

The invention discloses a porous-compact double-layer electrolyte ceramic sintered body based on inorganic solid state lithium ion electrolyte materials, an all-solid-state secondary lithium ion battery, an all-solid-state secondary lithium-air battery, and preparation methods. The preparation method for the sintered body comprises the following steps: first, powder of inorganic solid state lithium ion electrolyte materials is provided; second, part of the powder and pore forming agents are mixed, and mixed powder is obtained; third, the other part of the powder and the mixed powder form a green body, the green body comprises a first green body layer and a second green body layer which are stacked mutually, the other part of the powder forms the first green body layer and the mixed powder forms the second green body layer; fourth, the green body is subjected to sintering, the pore forming agents are burnt off, the porous-compact double-layer electrolyte ceramic sintered body is obtained, the first green body layer forms a compact layer and the second green body forms a porous layer.

Owner:TSINGHUA UNIV

Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

The invention relates to a micro-nano-structure anode material for a Li-air battery and a preparation method of the micro-nano-structure anode material. The preparation method comprises the following steps of: preparation of hollow composite precursor fibers through electrostatic spinning by blending a metal nitride catalyst precursor with a high-carbon polymer in an organic solvent, preprocessing of the precursor fiber material, nitridation of complex fibers, and pore-forming and pore-expansion through activation. The preparation method is simple in technique and convenient to operate and is easy to realize the uniform distribution of nanoscale catalyst particles in hollow carbon fibers. A prepared anode material tube is hollow internally, a plurality of holes are formed on the wall of the tube, and metal nitride catalysts are uniformly distributed in the three-dimensional holes of the wall of the tube, so that high specific surface area provides a sufficient place for the reaction of the battery, and the hollow pore passage in the tube can ensure an oxygen diffusion channel to be smooth and has good ion transport capacity and electrical conductivity. According to the invention, the charge-discharge capacity of the Li-air battery can be improved effectively, the power multiplying performance and the power density of the Li-air battery can be improved, the internal resistance of the battery can be reduced, and the charge-discharge polarization can be lessened through the uniform distribution of the nanoscale metal nitride, therefore, the micro-nano-structure anode material has good industrialization prospect.

Owner:CENT SOUTH UNIV

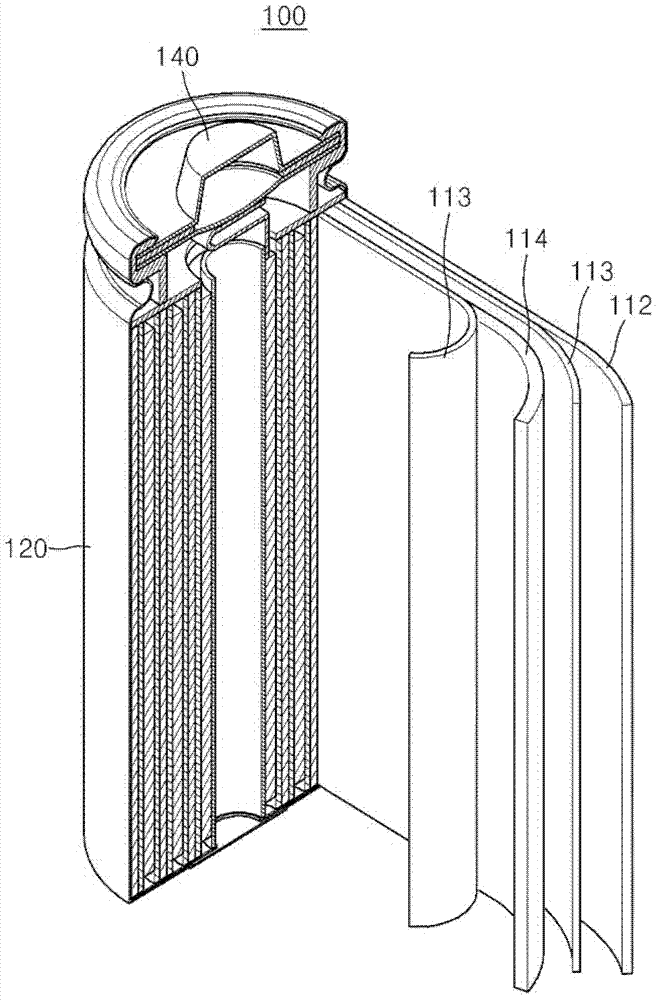

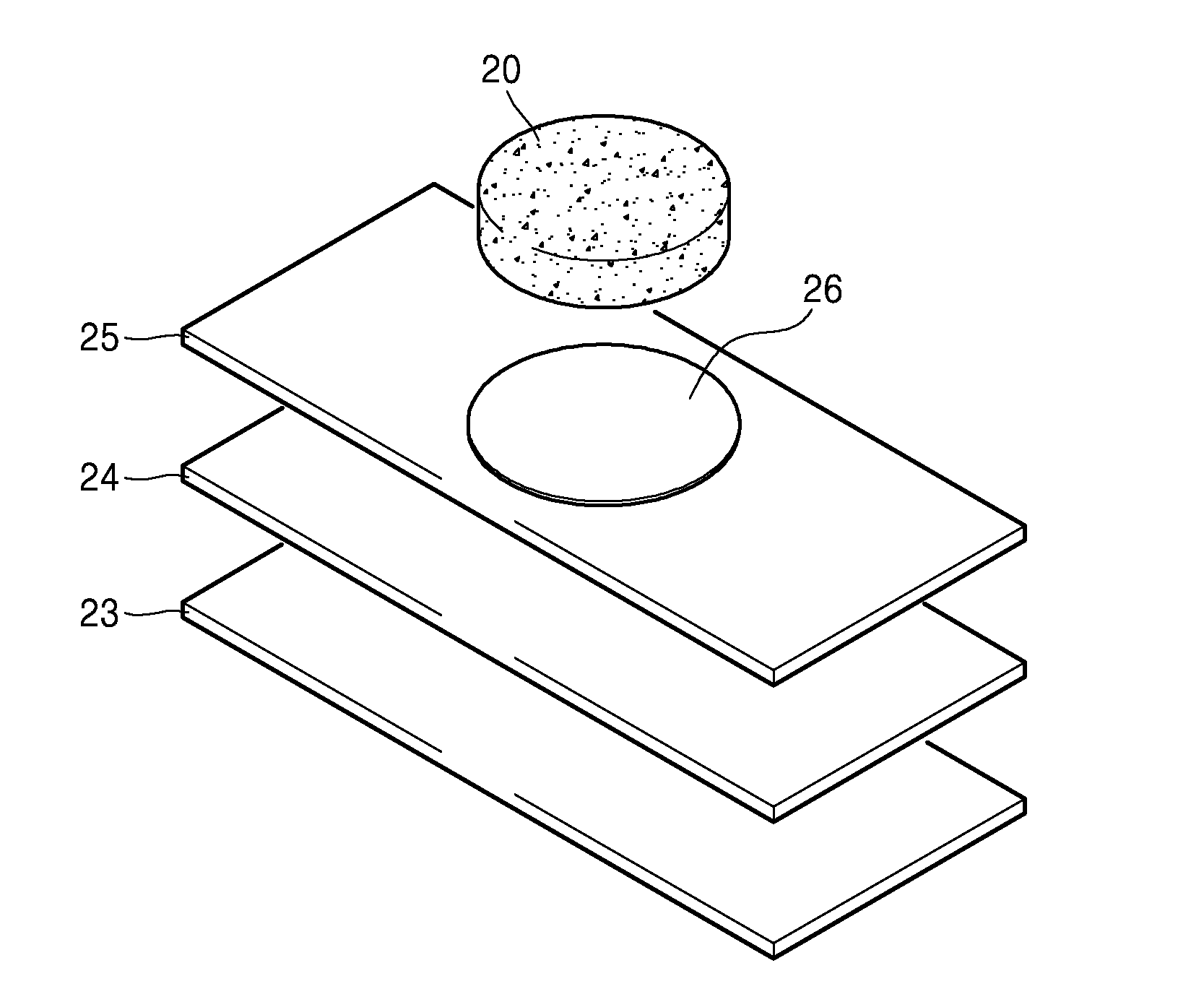

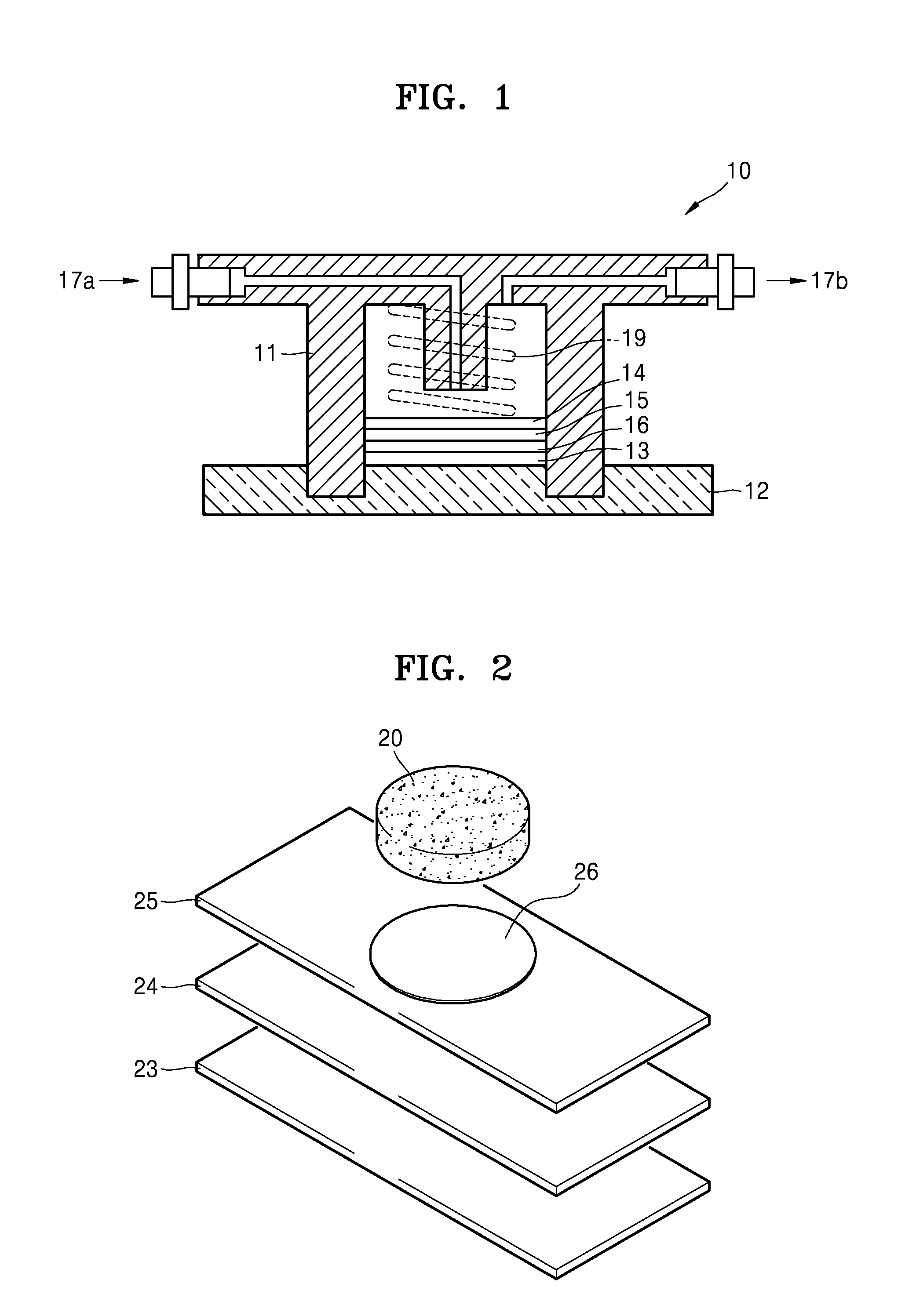

Lithium air battery and method of preparing the same

A lithium air battery including a composite cathode including a porous material and a first solid electrolyte; a lithium metal anode; an oxygen blocking layer adjacent to the anode; and a cathode interlayer disposed between the cathode and the oxygen blocking layer, wherein the cathode interlayer includes a lithium ion conducting second solid electrolyte.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com