Solid electrolyte film, and preparation method and application of solid electrolyte film

A technology of solid-state electrolyte membrane and solid-state electrolyte, which is applied in electrolytes, fuel cell half-cells, primary battery-type half-cells, circuits, etc., can solve problems such as poor performance and high internal resistance of lithium-air batteries, and achieve internal resistance low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The solid electrolyte membrane provided by the invention, its preparation method, comprises the following steps:

[0029] (1) Preparation of solid electrolyte precursor: according to the element ratio of the target solid electrolyte, the raw materials of the corresponding elements are evenly dispersed in the organic solvent, and the powder obtained by drying the raw materials is uniformly mixed, and the powder is heated at 500°C to 700°C The solid electrolyte precursor powder is obtained by sintering; the raw materials are oxides, carbonate compounds and / or phosphate compounds of corresponding elements; the organic solvent is preferably absolute ethanol.

[0030](2) Preparation of solid electrolyte target material: the solid electrolyte precursor powder prepared in step (1) is added with 1% to 10% of its mass binder, the binder is preferably 1% to 5% by mass fraction The ethanol solution of polyvinyl alcohol or polyvinyl butyral is pressed into a sheet under a press of ...

Embodiment 1

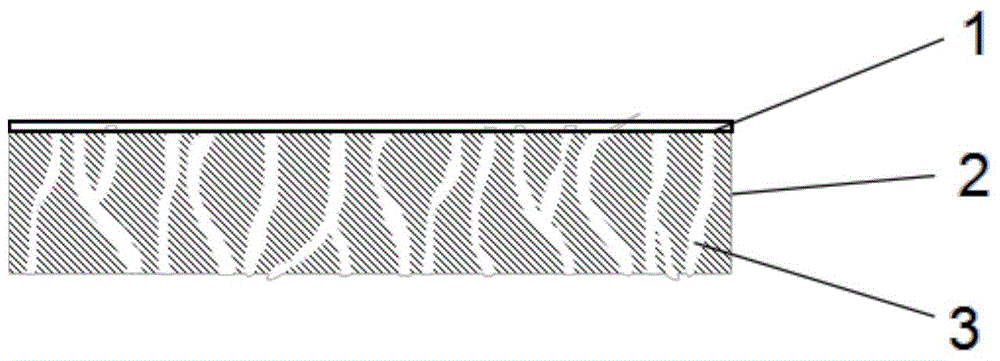

[0038] A solid electrolyte membrane, comprising a solid electrolyte layer and a porous ceramic layer, the thickness of the solid electrolyte layer is 1.8 microns, and the bending strength of the porous ceramic layer is 100N / mm 2 , and its Li-ion conductivity is 6.0×10 -5 Siemens / cm, the thickness of the porous ceramic layer is 170 microns, and the solid electrolyte layer evenly covers the porous ceramic layer.

[0039] The material of the solid electrolyte layer is a perovskite lithium ion conductor Li 3x La (2 / 3)-x TiO 3 (x=0.1, i.e. Li 0.3 La 0.57 TiO 3 , hereinafter referred to as LLTO).

[0040] The porous ceramic layer is double-pass anodized aluminum.

[0041] The solid electrolyte membrane, its preparation method, comprises the following steps:

[0042] (1) Preparation of solid electrolyte precursor: according to the chemical formula Li 3x La (2 / 3)-x TiO 3 (x=0.1) (ie Li 0.3 La 0.57 TiO 3 ) in the stoichiometric ratio of Li, La, Ti 0.3:0.57:1, choose Li 2...

Embodiment 2

[0050] A solid electrolyte membrane, comprising a solid electrolyte layer and a porous ceramic layer, the thickness of the solid electrolyte layer is 1 micron, and the bending strength of the porous ceramic layer is 100N / mm 2 , and its Li-ion conductivity is 1.2×10 -6 Siemens / cm, the thickness of the porous ceramic layer is 170 microns, and the solid electrolyte layer evenly covers the porous ceramic layer.

[0051] The material of the solid electrolyte layer is NASICON type lithium ion conductor Li 1+y Ge 2-x-y Ti x Al y (PO 4 ) 3 (wherein x=0.3, y=0.21, promptly Li 1.21 Ge 1.49 Al 0.21 Ti 0.3 (PO 4 ) 3 , hereinafter referred to as LGATP).

[0052] The porous ceramic layer is double-pass anodized aluminum.

[0053] The solid electrolyte membrane, its preparation method, comprises the following steps:

[0054] (1) Preparation of solid electrolyte precursor: according to the chemical formula Li 1.21 Ge 1.49 Al 0.21 Ti 0.3 (PO 4 ) 3 Medium Li, Ge, Al, Ti, PO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com