Patents

Literature

98results about How to "Poor heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

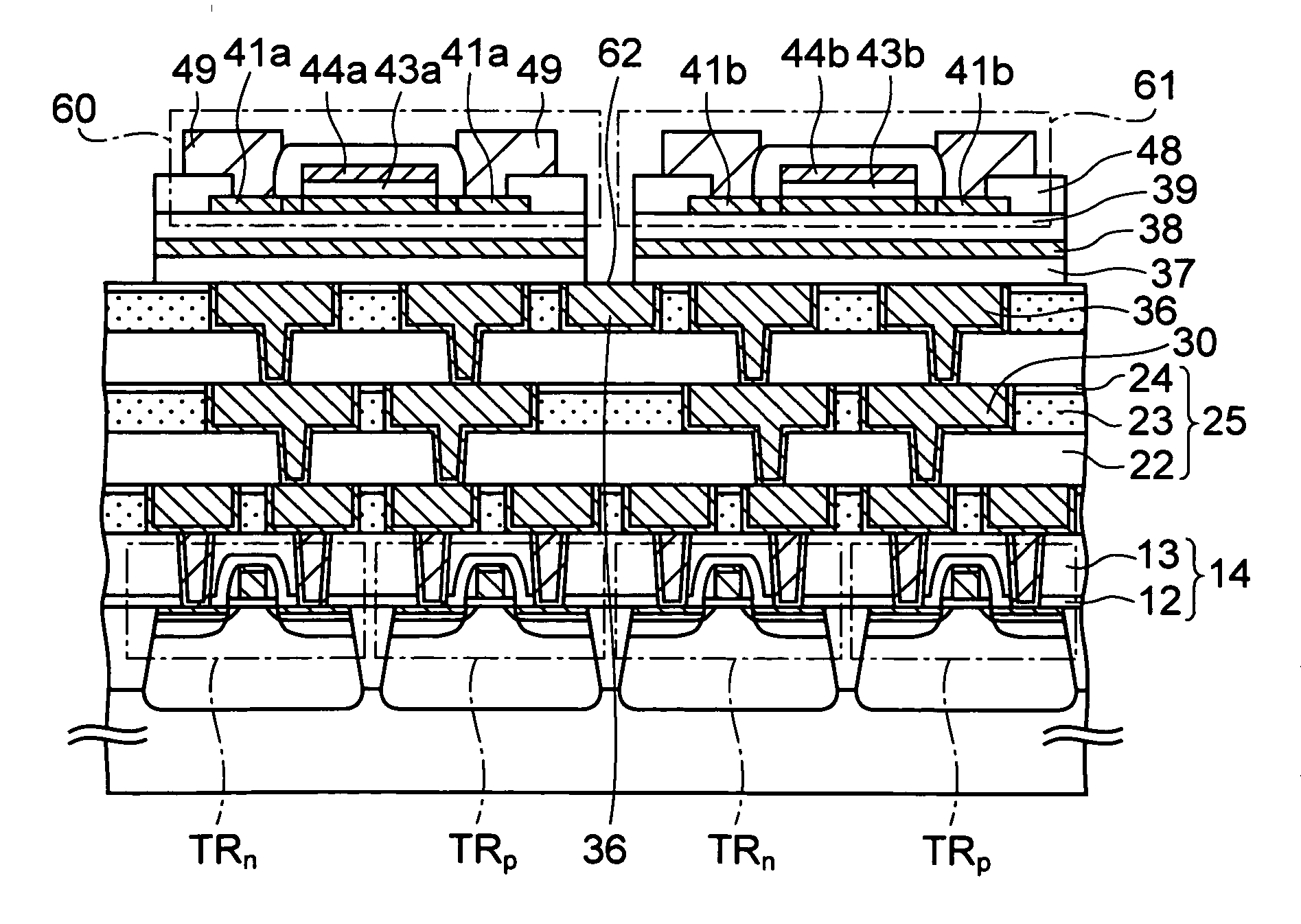

Semiconductor device and manufacturing method thereof

InactiveUS20060170046A1Inhibit deteriorationPoor heat resistanceSemiconductor/solid-state device detailsSolid-state devicesAmorphous semiconductorsEngineering

A method for manufacturing a semiconductor device, including the steps of: forming a shielding film 38 on a first insulating film 37; sequentially forming a second insulating film 39 and an amorphous semiconductor film 40 on the shielding film 38; melting the amorphous semiconductor film 40 at least in portions to be channels of thin-film transistors by irradiating an energy beam onto the amorphous semiconductor film 40, and converting the amorphous semiconductor film 40 into a polycrystalline semiconductor film 41; sequentially forming a gate insulating film 43a and a gate electrode 44a on the polycrystalline semiconductor film 41 on the channels; and forming source and drain regions 41a in the polycrystalline semiconductor film 41 on sides of the gate electrode 44a, and forming a TFT 60 by use of the source and drain regions 41a, the gate insulating film 43a, and the gate electrode 44a.

Owner:FUJITSU SEMICON LTD

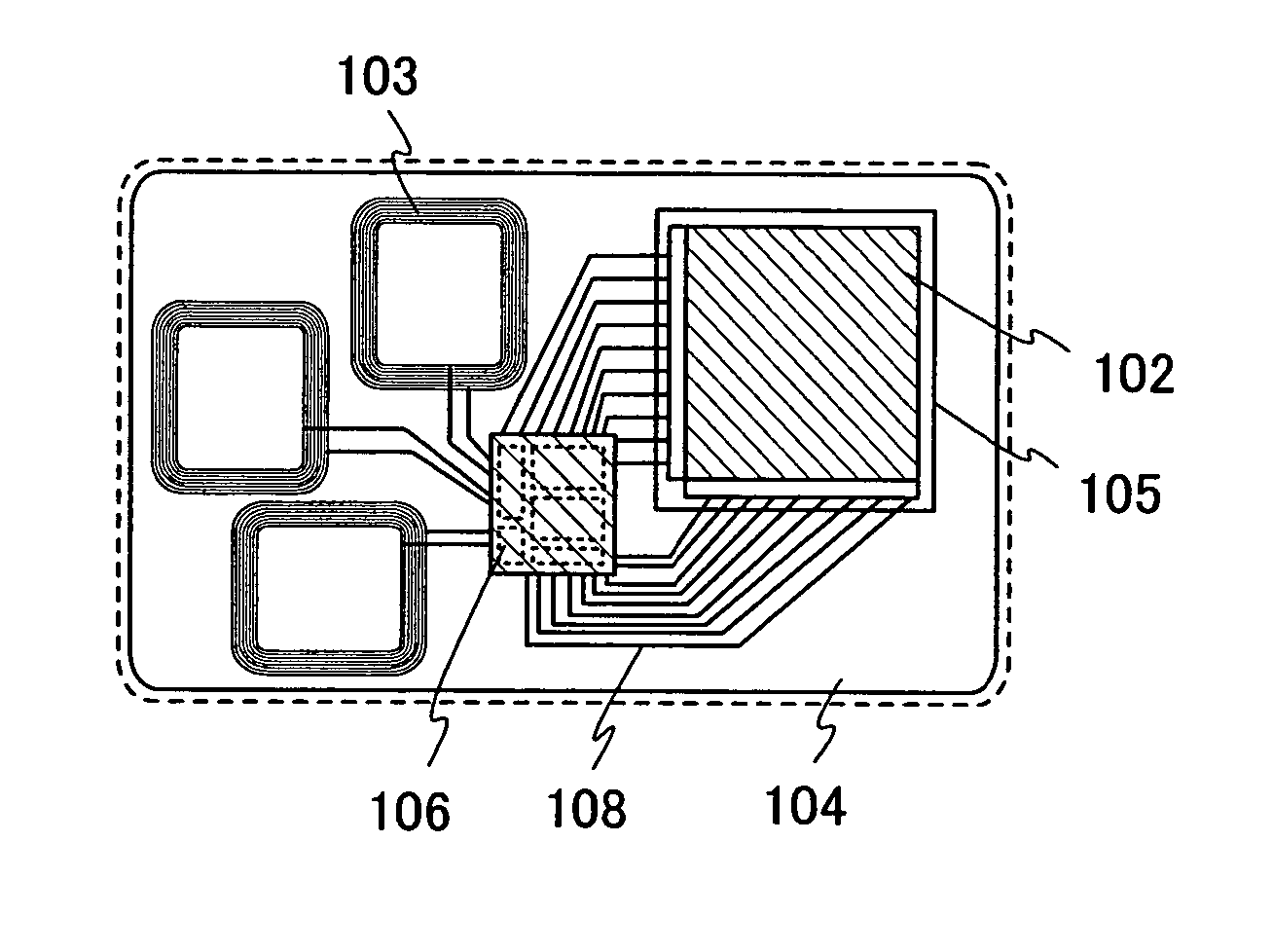

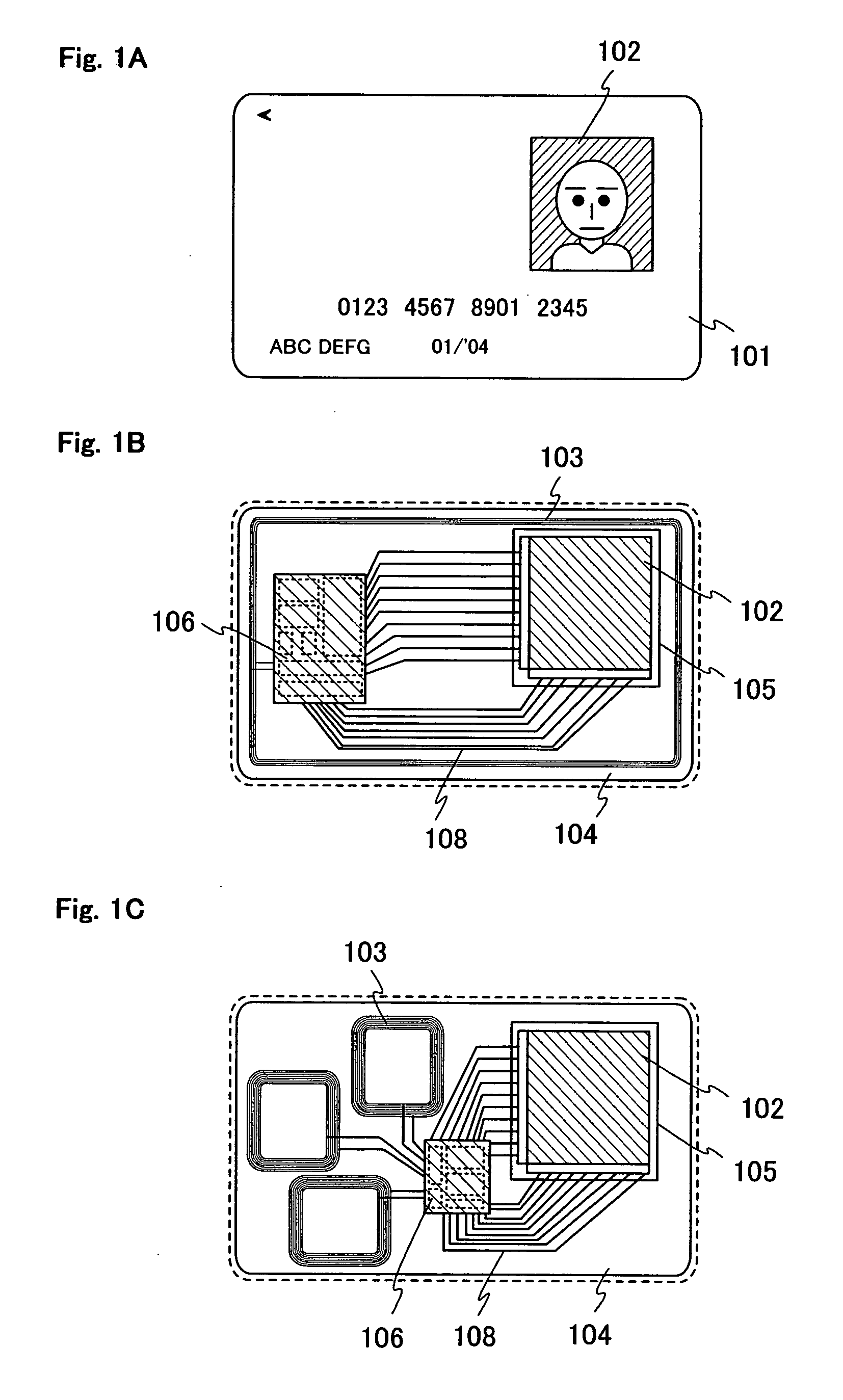

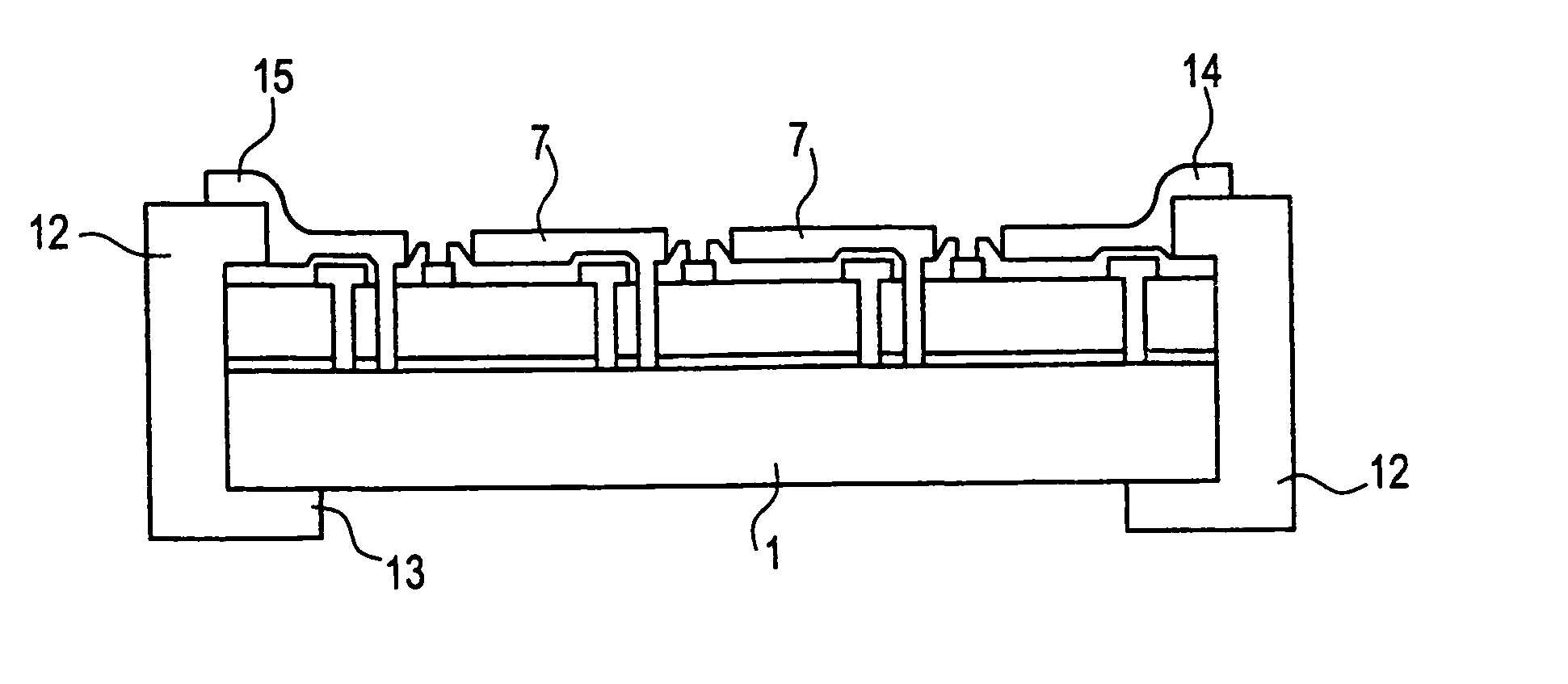

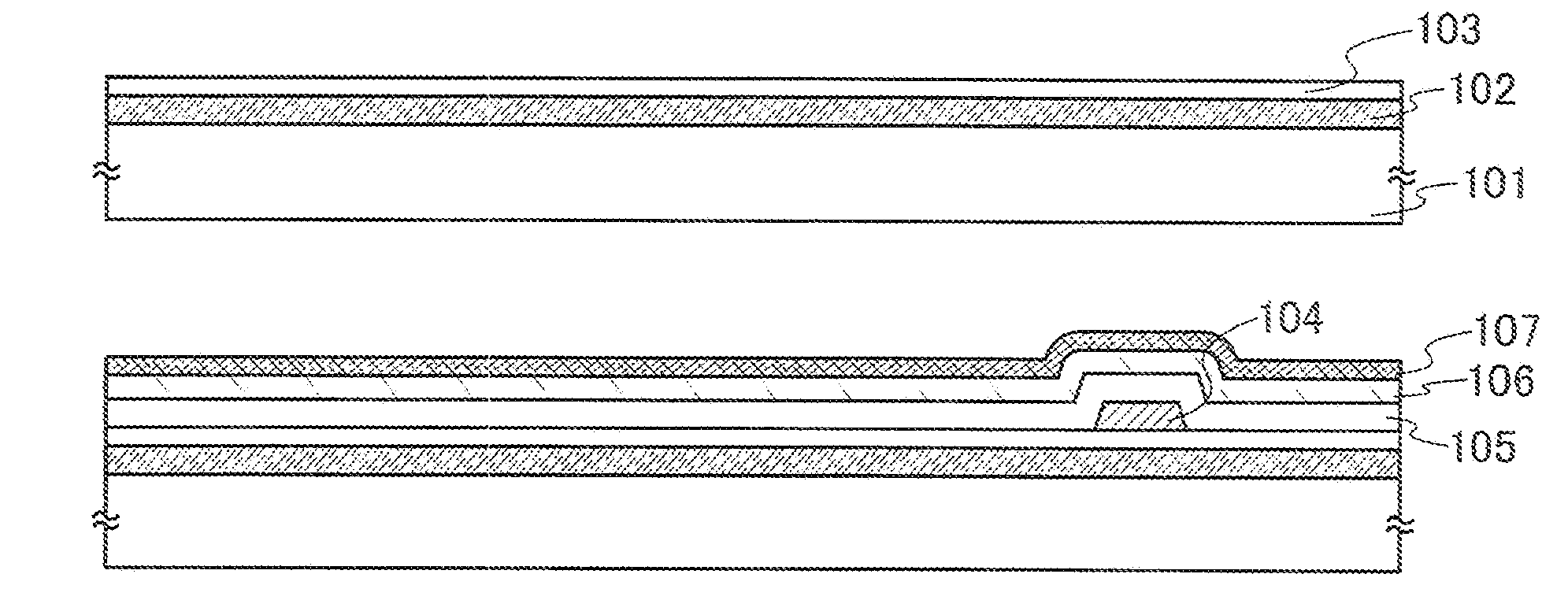

IC card and booking account system using the IC card

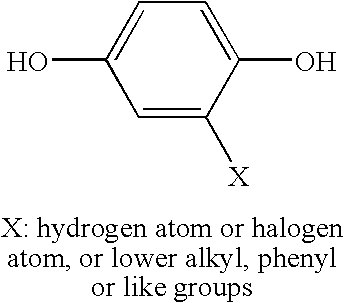

InactiveUS20040129450A1Poor heat resistanceImprove brittlenessSolid-state devicesPayment architectureDisplay deviceIntegrated circuit

It is an object of the present invention to provide a highly sophisticated functional card that can ensure security by preventing forgery such as changing a picture of a face, and display other images as well as the picture of a face. A card comprising a display device and a thin film integrated circuit; wherein driving of the display device is controlled by the thin film integrated circuit; a semiconductor element used for the thin film integrated circuit and the display device is formed by using a polycrystalline semiconductor film; the thin film integrated circuit and the display device are sealed with a resin between a first substrate and a second substrate of the card; and the first substrate and the second substrate are plastic substrates.

Owner:SEMICON ENERGY LAB CO LTD

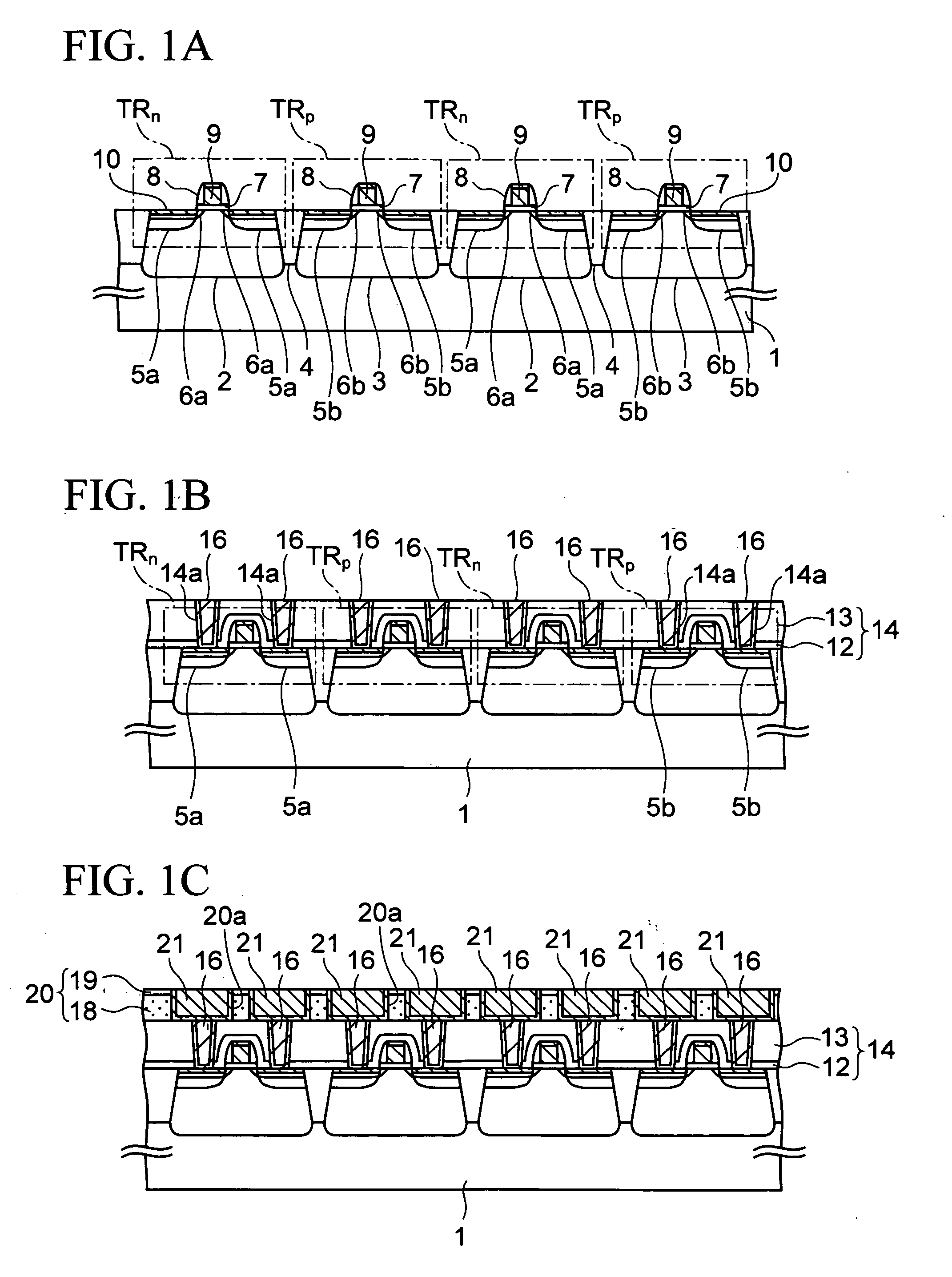

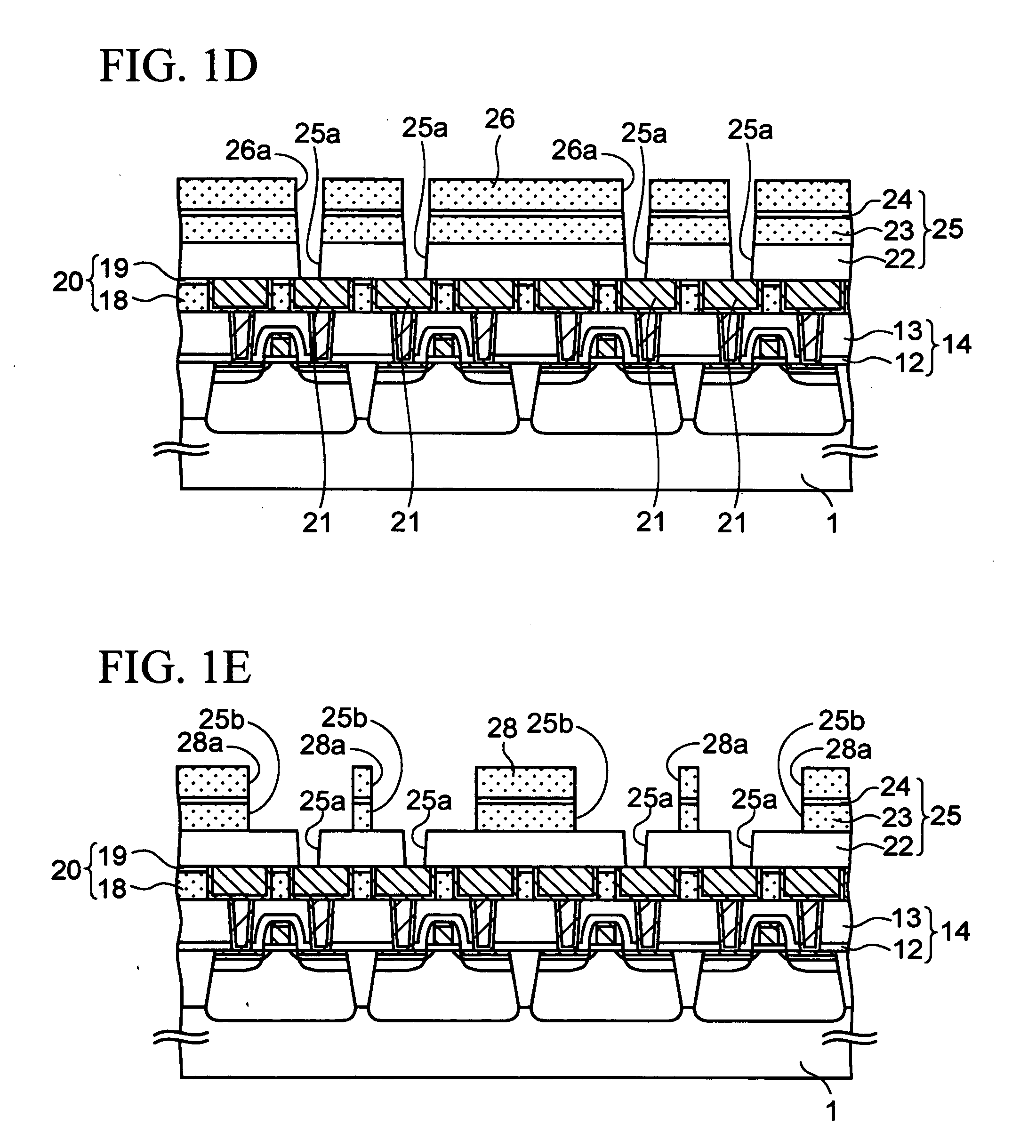

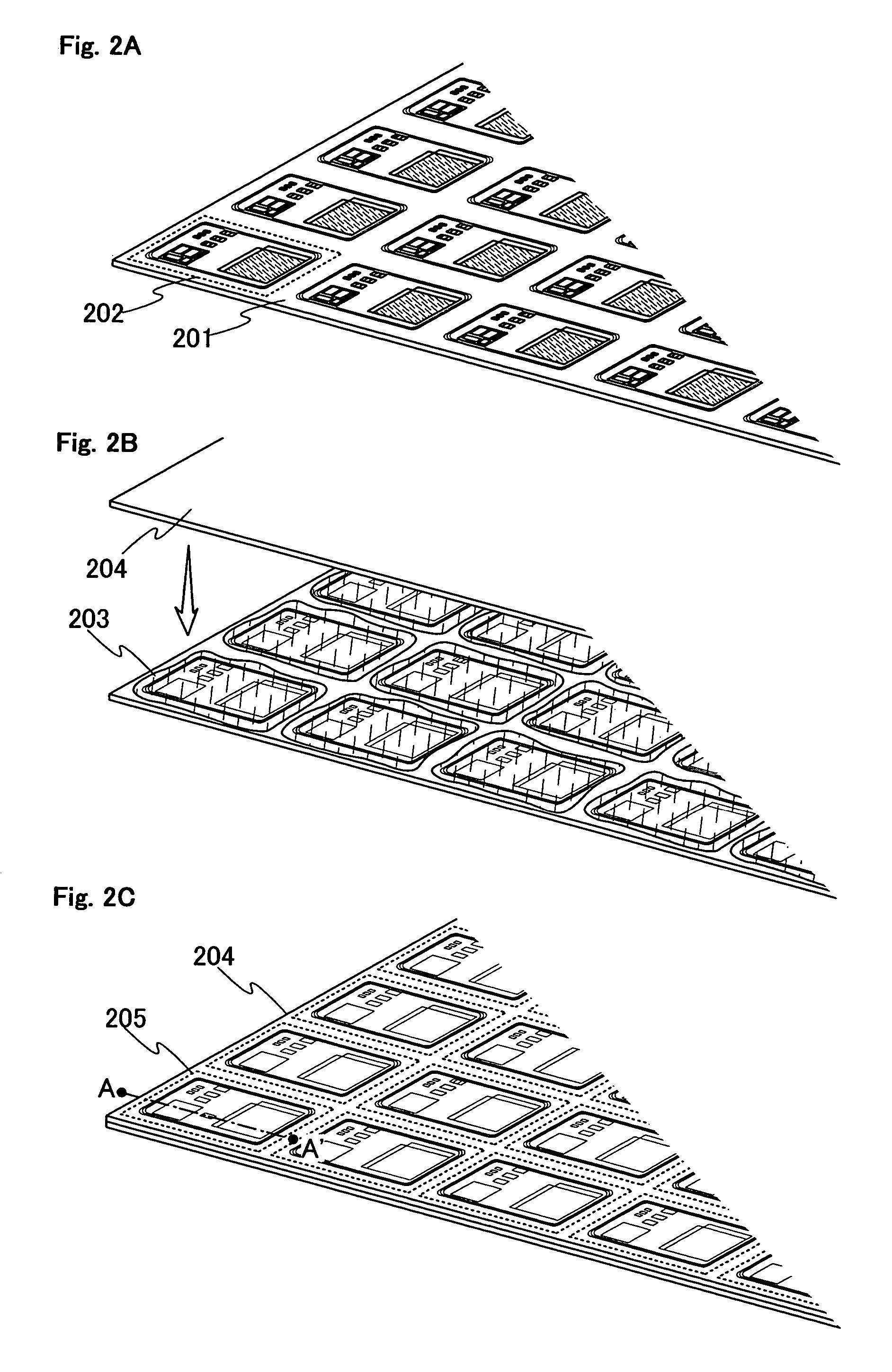

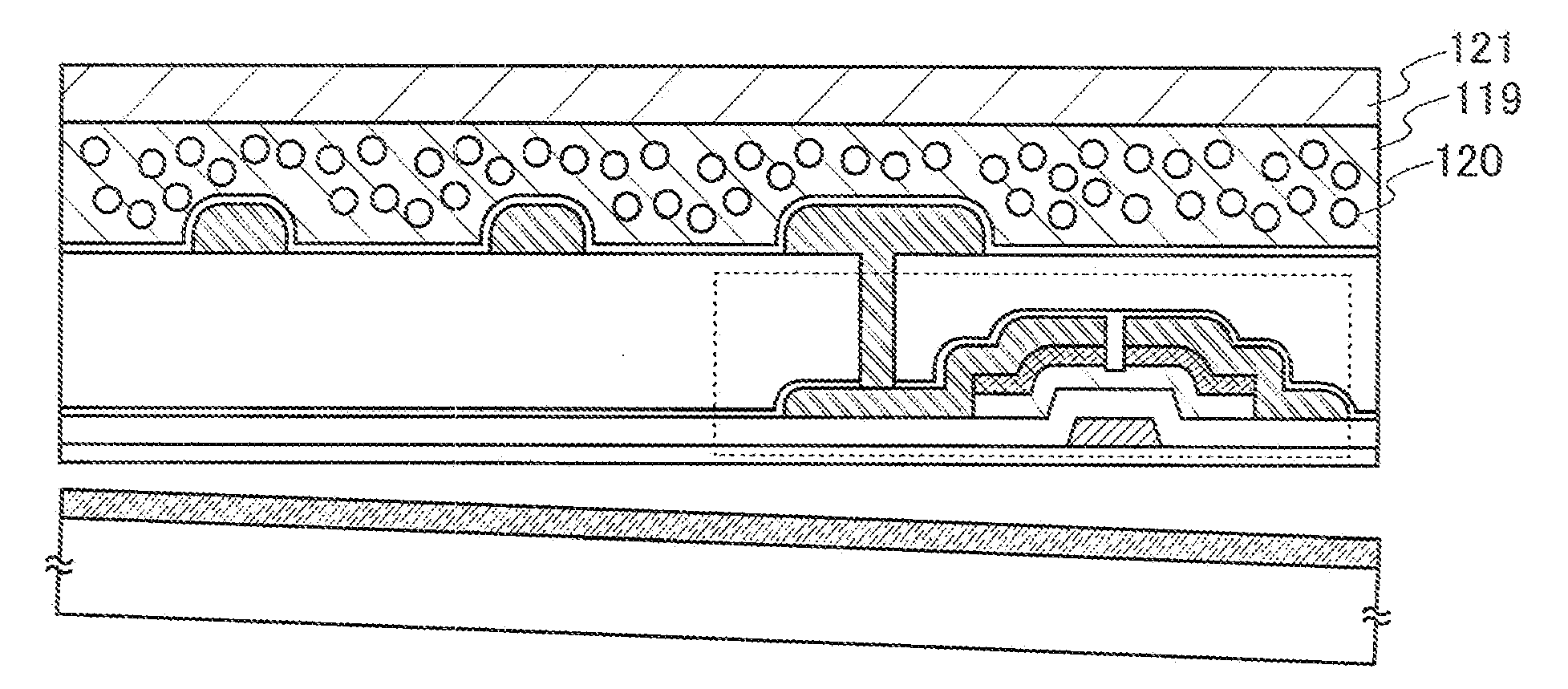

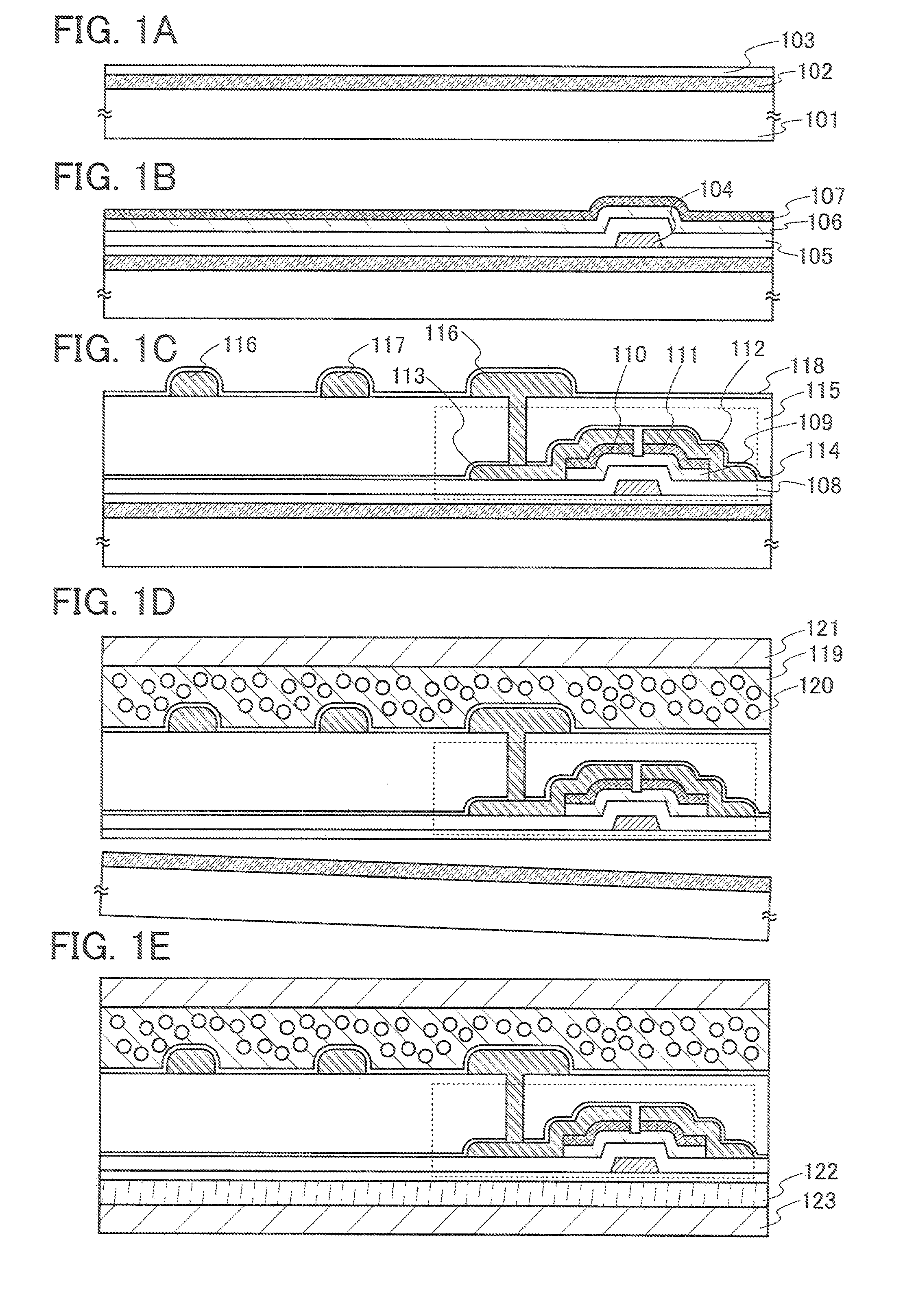

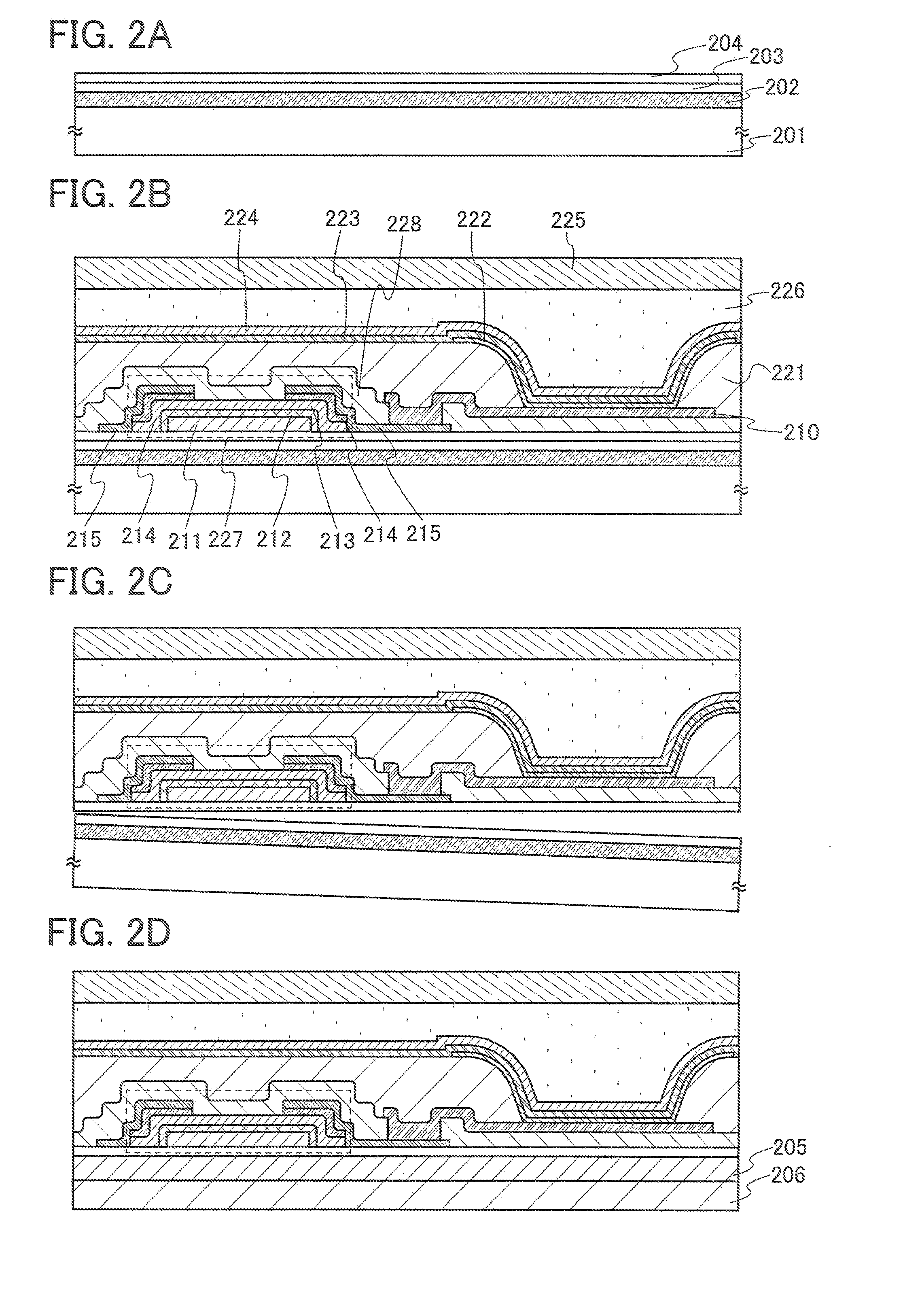

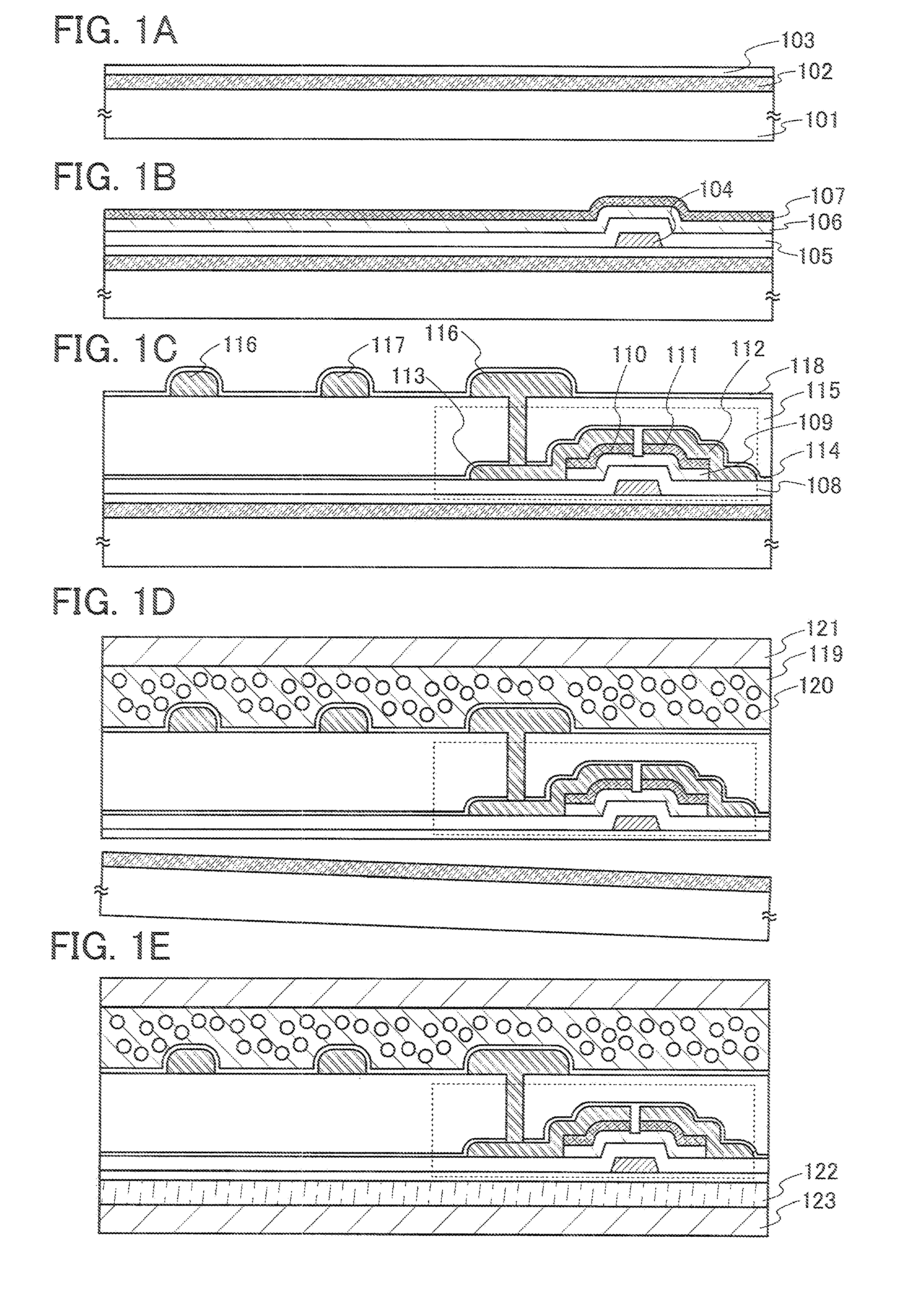

Method for manufacturing semiconductor device

ActiveUS20070254456A1Process stabilityPoor heat resistanceFinal product manufactureSemiconductor/solid-state device detailsEngineeringPlastic film

A technique for peeling an element manufactured through a process at relatively low temperature (lower than 500° C.) from a substrate and transferring the element to a flexible substrate (typically, a plastic film). With the use of an existing manufacturing device for a large glass substrate, a molybdenum film (Mo film) is formed over a glass substrate, an oxide film is formed over the molybdenum film, and an element is formed over the oxide film through a process at relatively low temperature (lower than 500° C.). Then, the element is peeled from the glass substrate and transferred to a flexible substrate.

Owner:SEMICON ENERGY LAB CO LTD

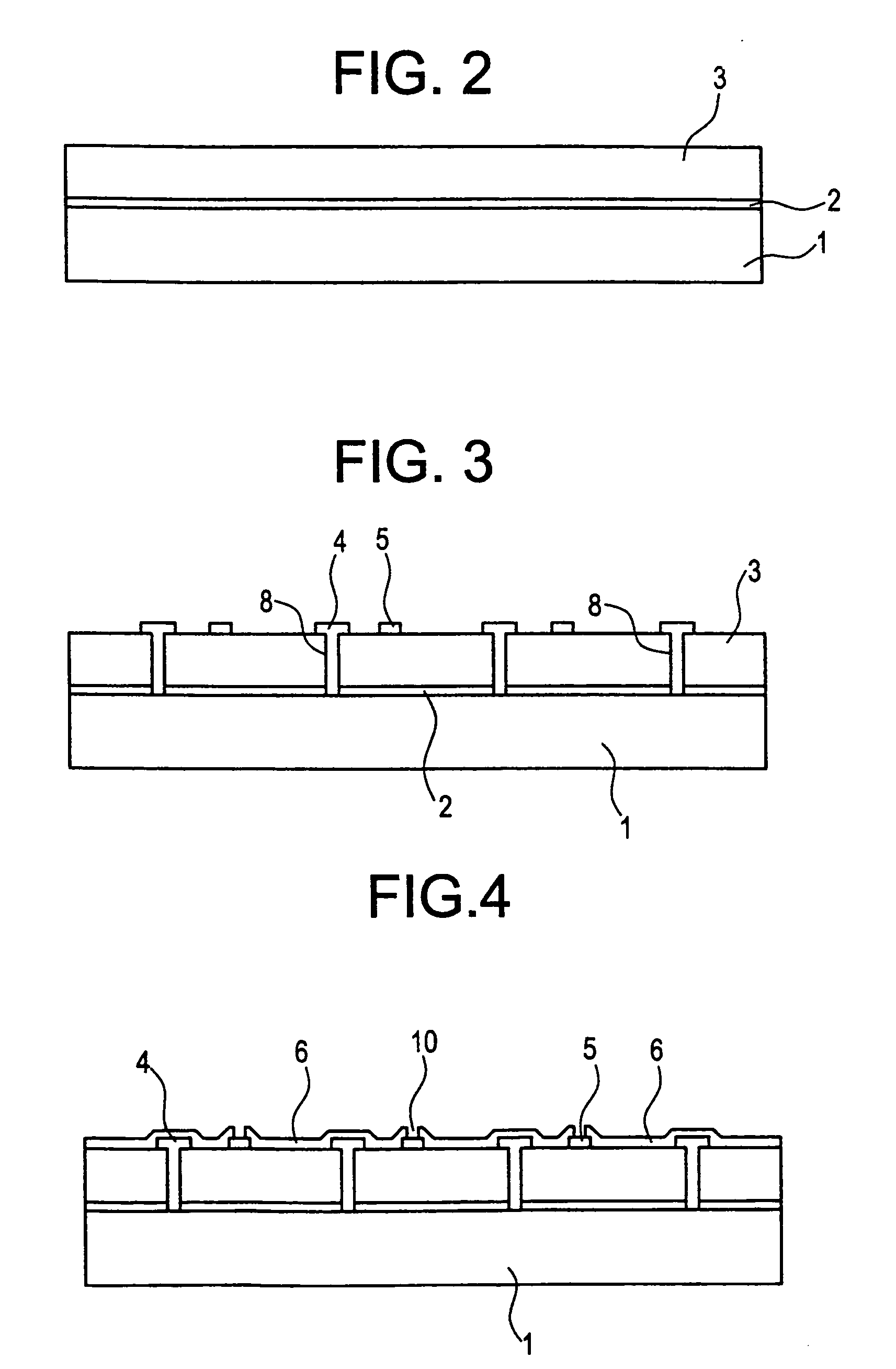

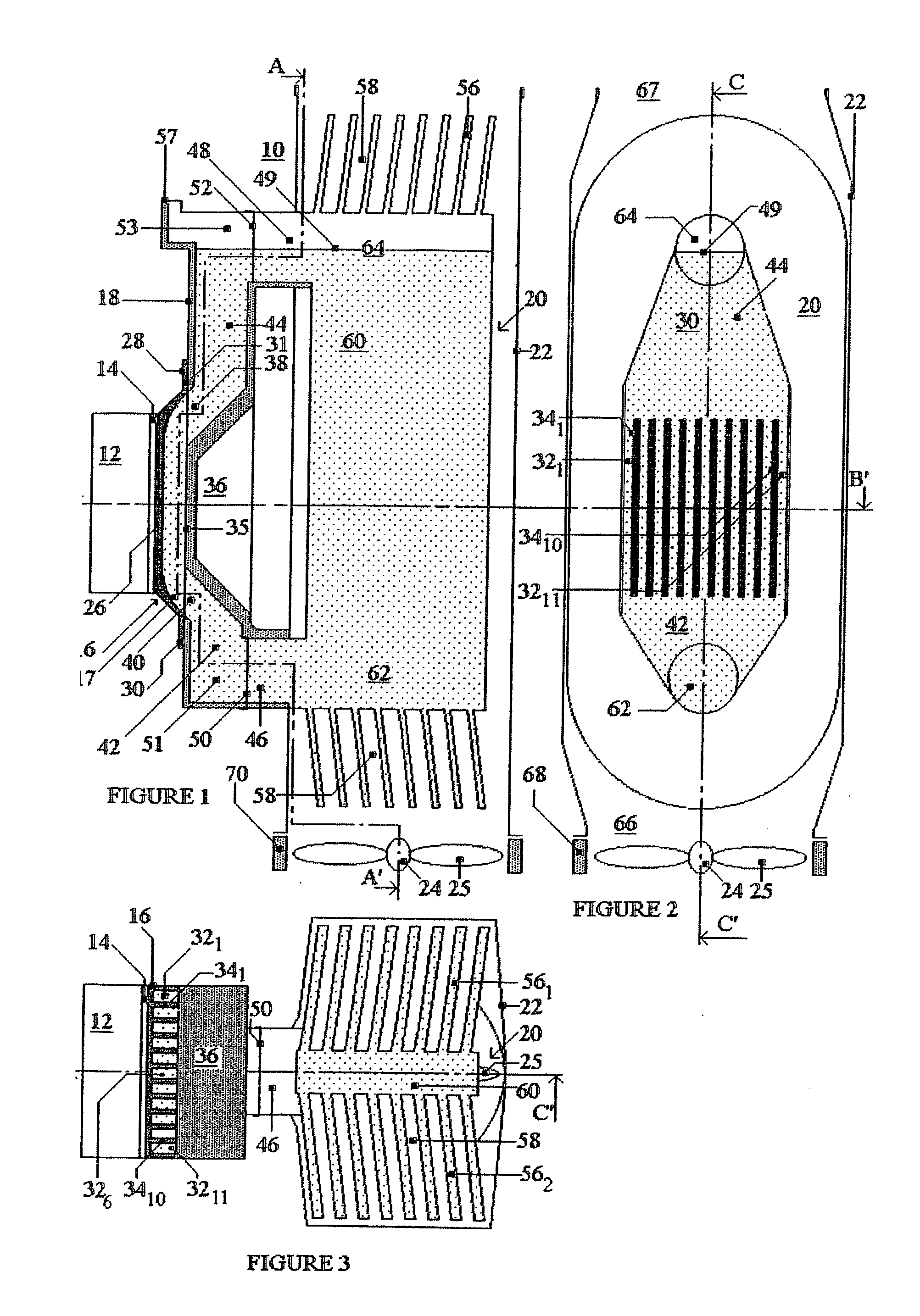

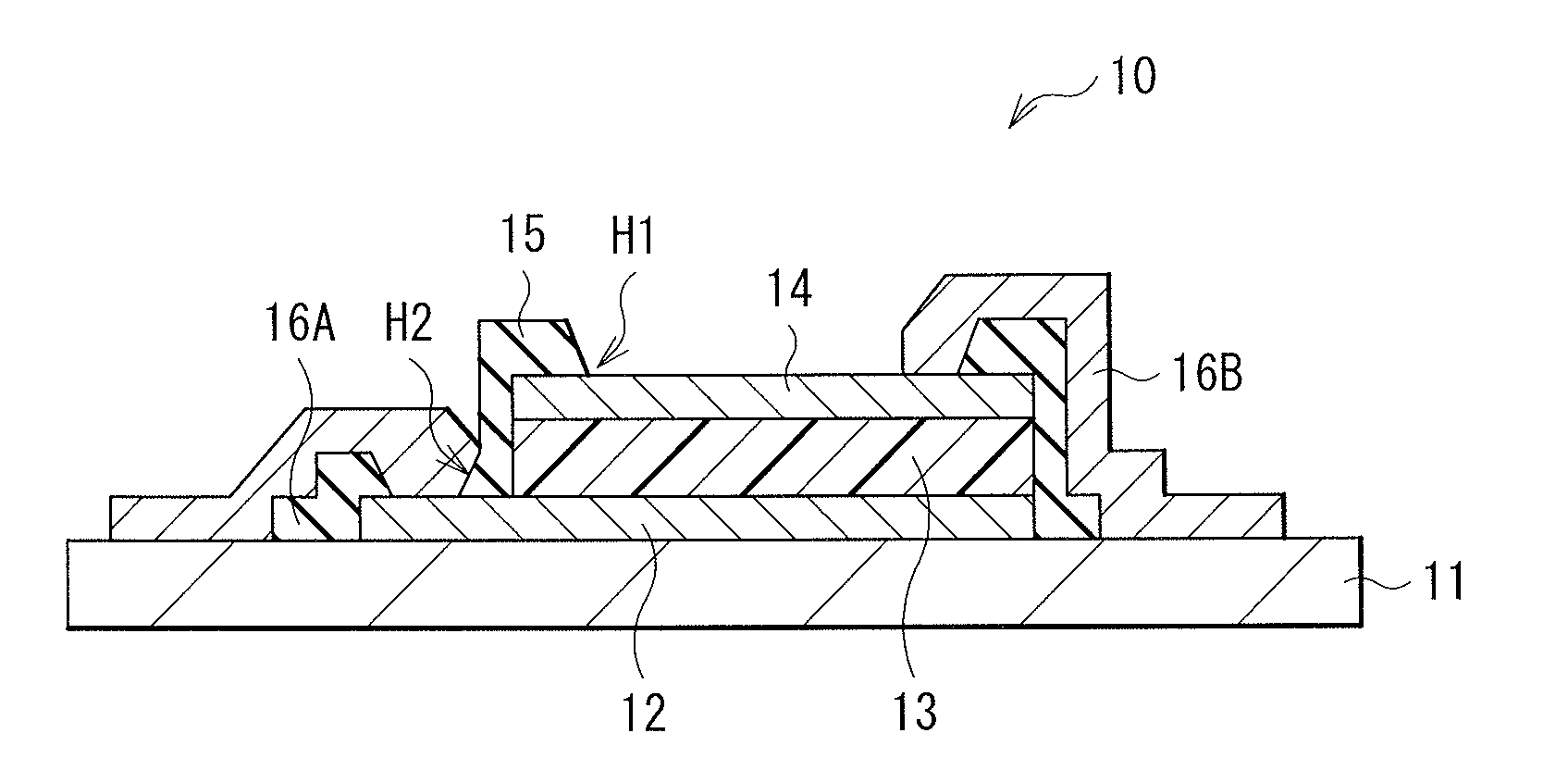

Photoelectric conversion device

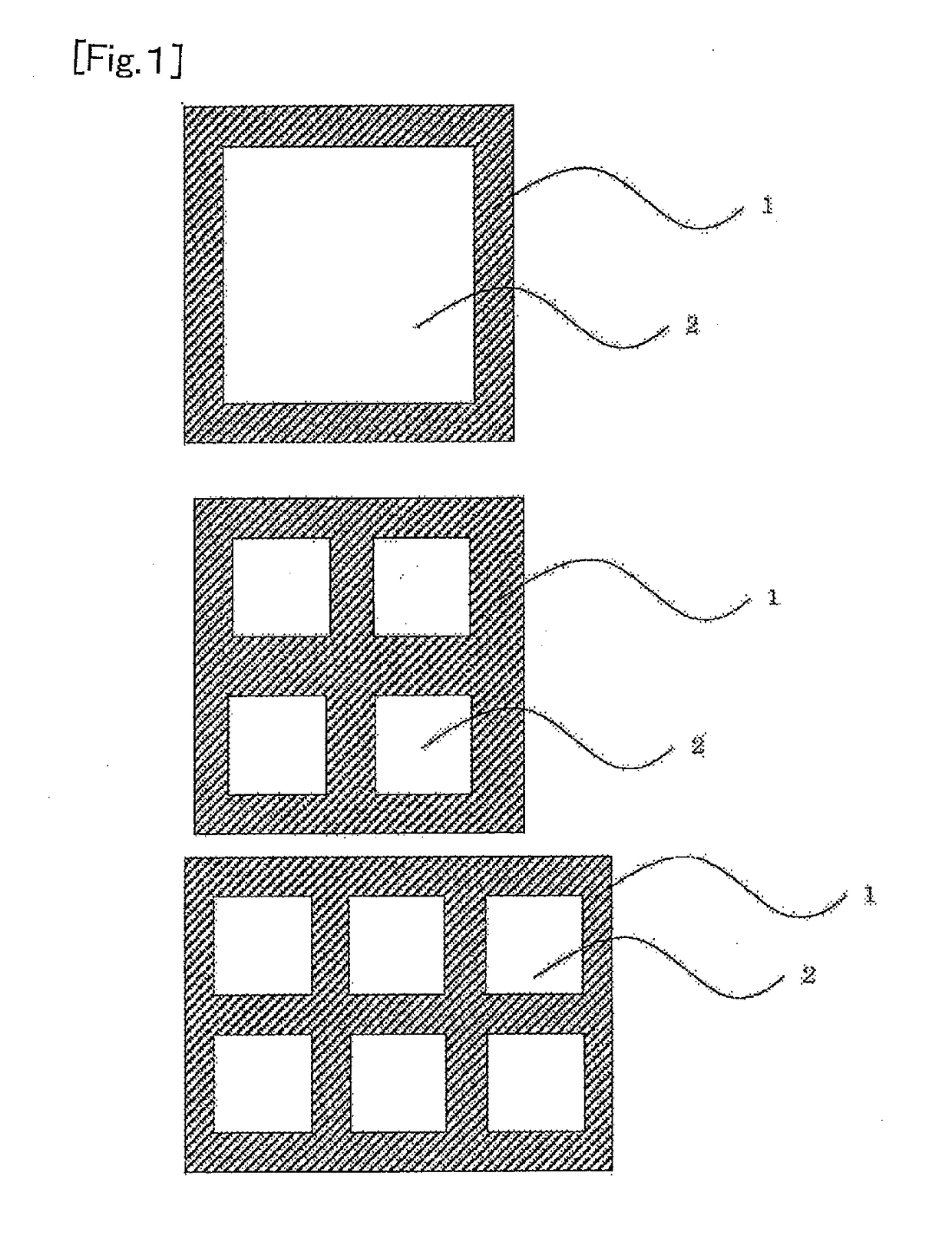

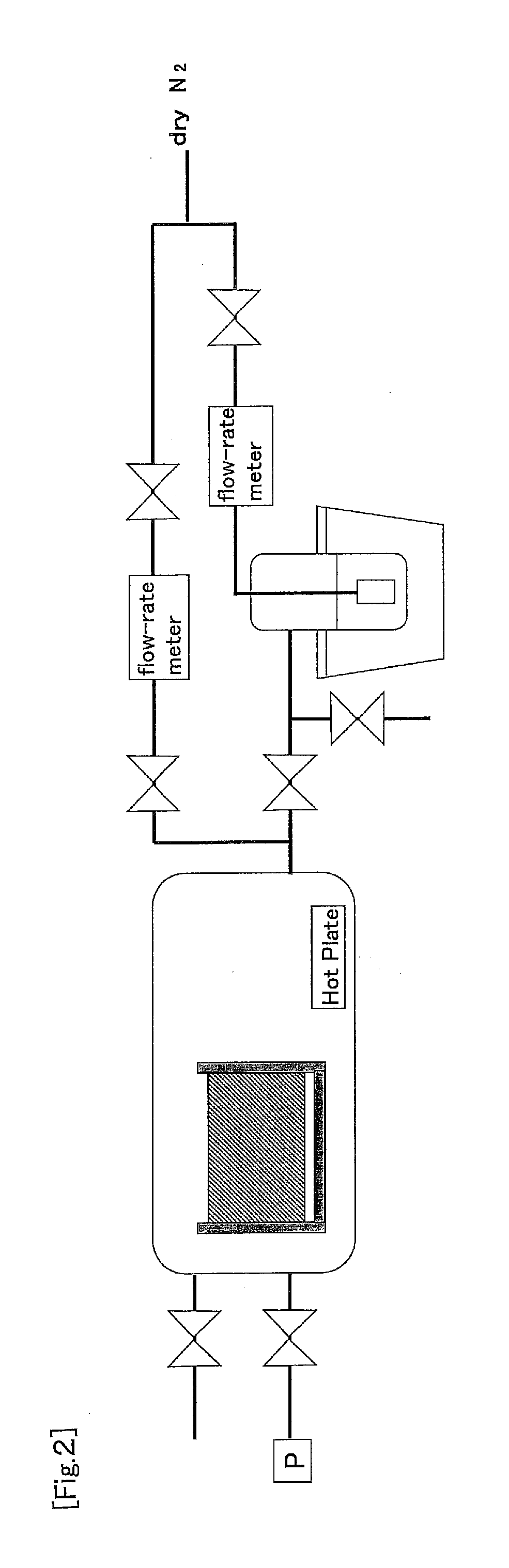

InactiveUS7095090B2Improve productivityHigh productivityFinal product manufactureDiodeElectricityThermal deformation

A photoelectric conversion device taking the form of a thin film and having a substrate exhibiting poor thermal resistance. The device prevents thermal deformation which would normally be caused by local application of excessive heat to the substrate. The device has output terminals permitting the output from the device to be taken out. The output terminals are formed on the surface of the substrate opposite to the photoelectric conversion device. The device further includes electrical connector portions for electrically connecting the electrodes of the device with the output terminals. The present invention also provides a method of treating a substrate having poor thermal resistance with a plasma with a high throughput. The substrate is continuously supplied into a reaction chamber and treated with a plasma. This supply operation is carried out in such a way that the total length of the substrate existing in a plasma processing region formed by electrodes is longer than the length of the electrodes.

Owner:SEMICON ENERGY LAB CO LTD +1

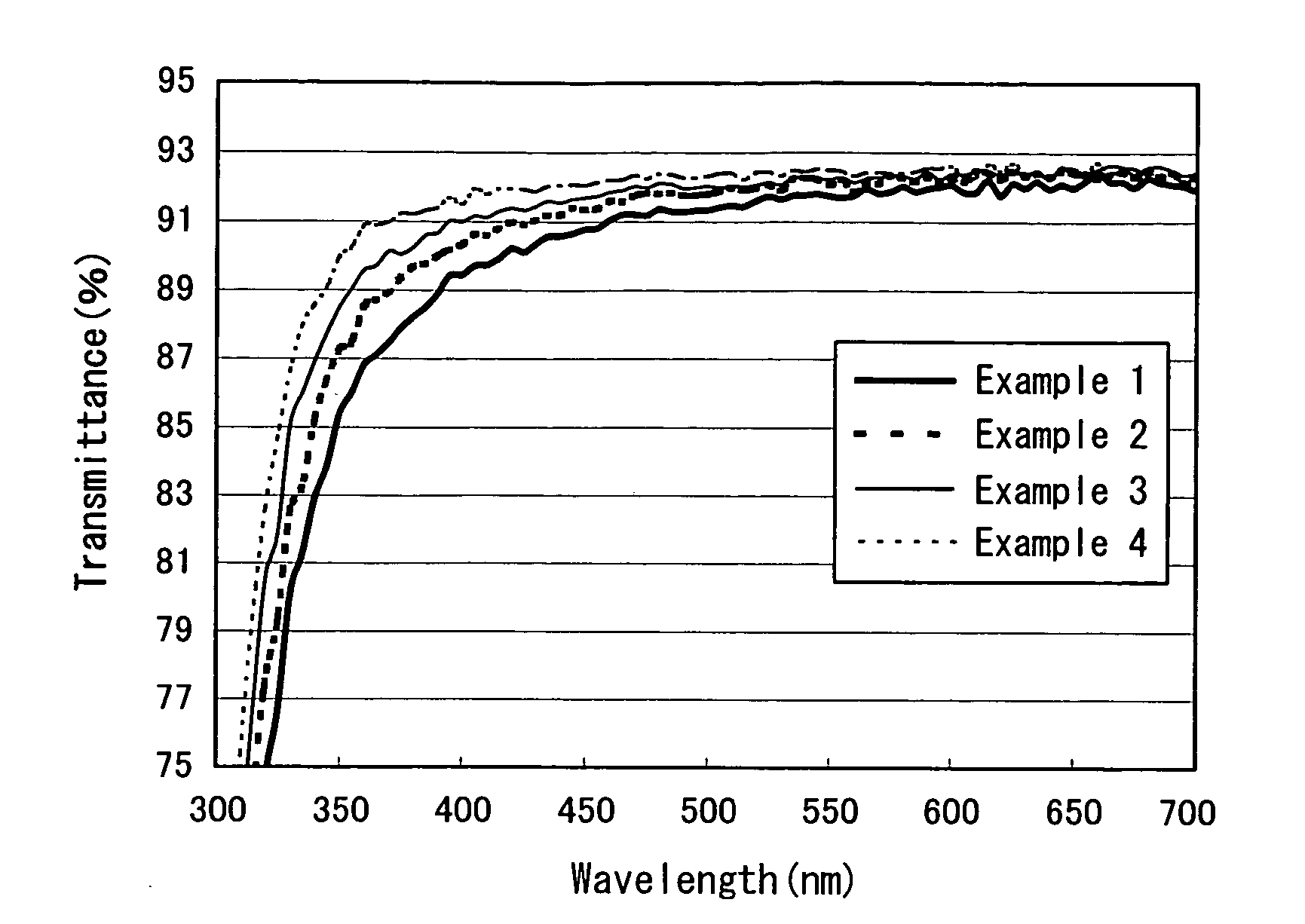

Light diffusive polycarbonate resin composition and light diffusive plate using said resin composition

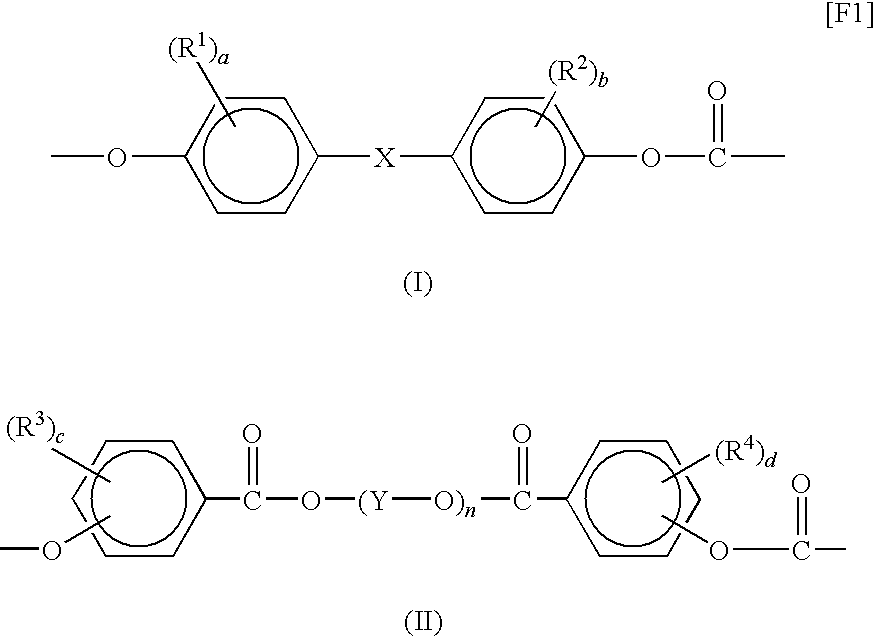

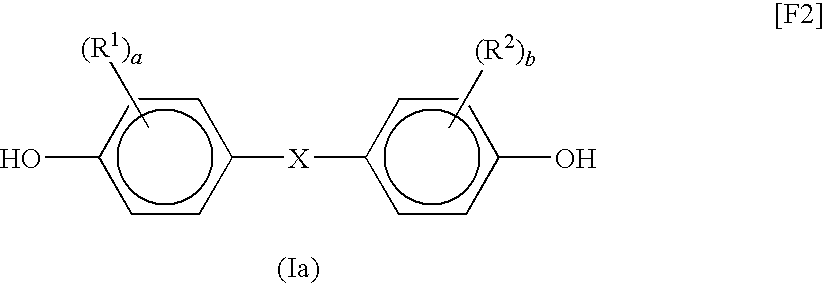

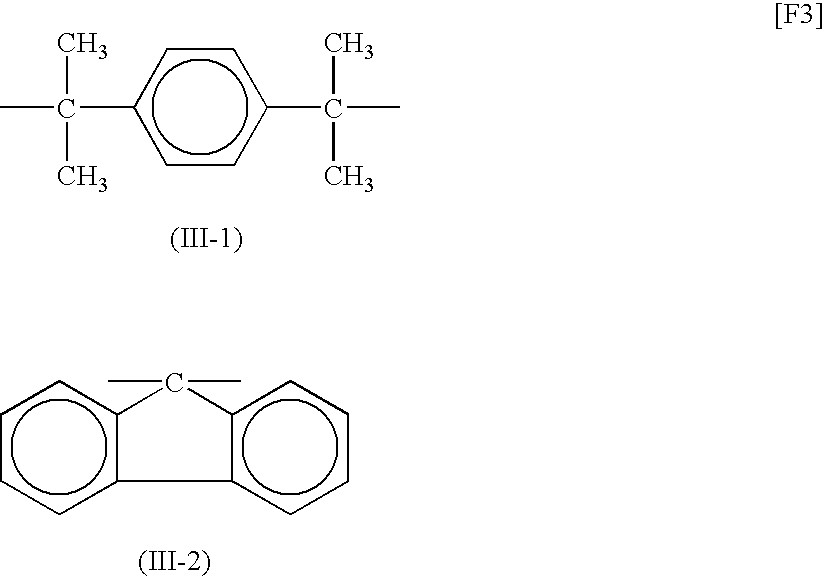

InactiveUS20090080079A1Improve liquidityEnhanced residence stabilityDiffusing elementsGroup 5/15 element organic compoundsMeth-Liquid-crystal display

The present invention provides a light-diffusive polycarbonate-based resin composition which includes (A) 100 parts by mass of an aromatic polycarbonate resin, (B) 0.01 to parts by mass of a light-diffusing agent, and (C) 0.1 to parts by mass of a styrene-(meth)acrylic ester copolymer, and a light-diffusing plate formed from the composition. The light-diffusive polycarbonate-based resin composition can be injection-molded to form a light-diffusing plate having satisfactory precision in thickness for use in comparatively large liquid crystal displays having a size larger than 20 inches.

Owner:IDEMITSU KOSAN CO LTD

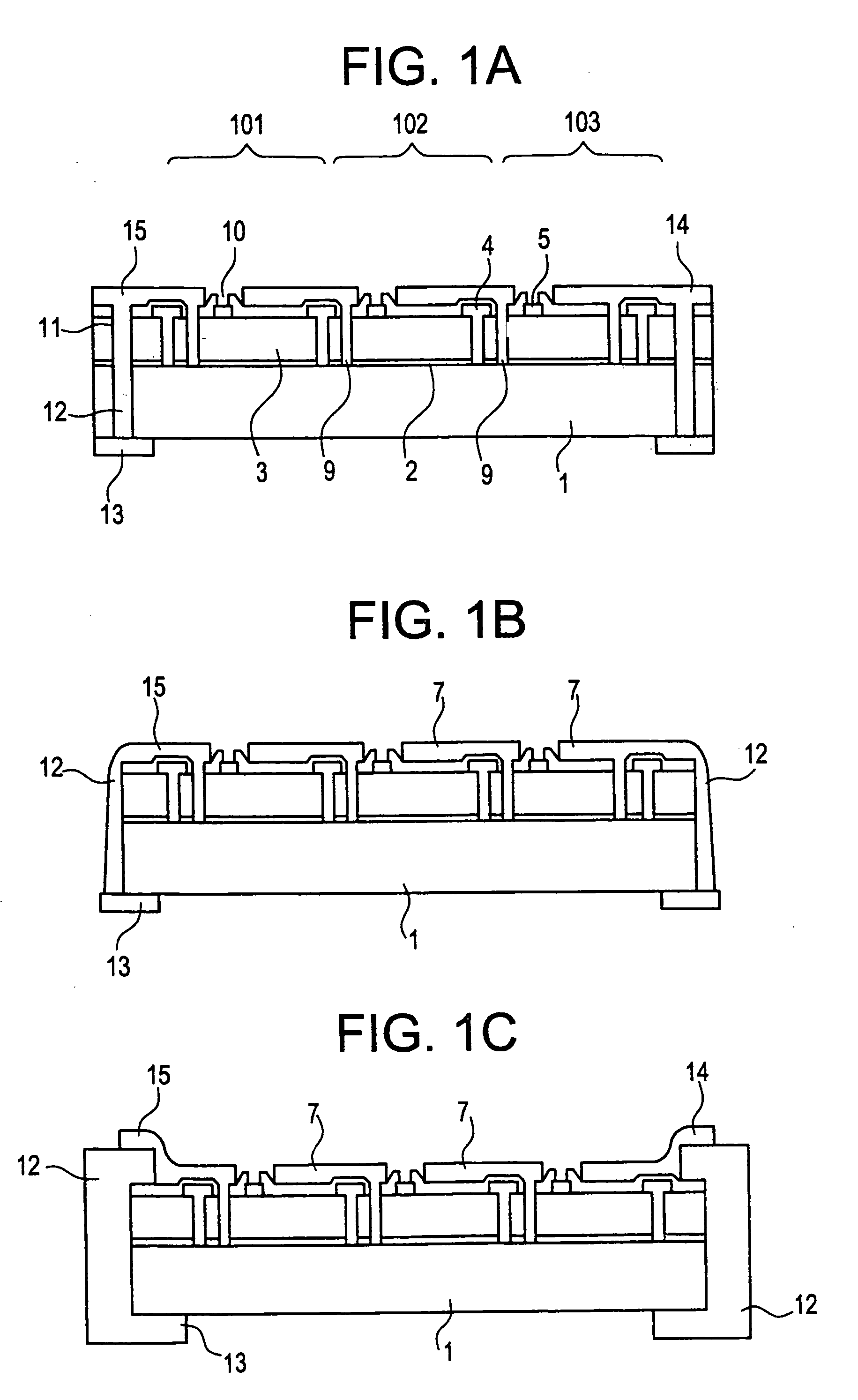

Semiconductor device and manufacturing method therefor

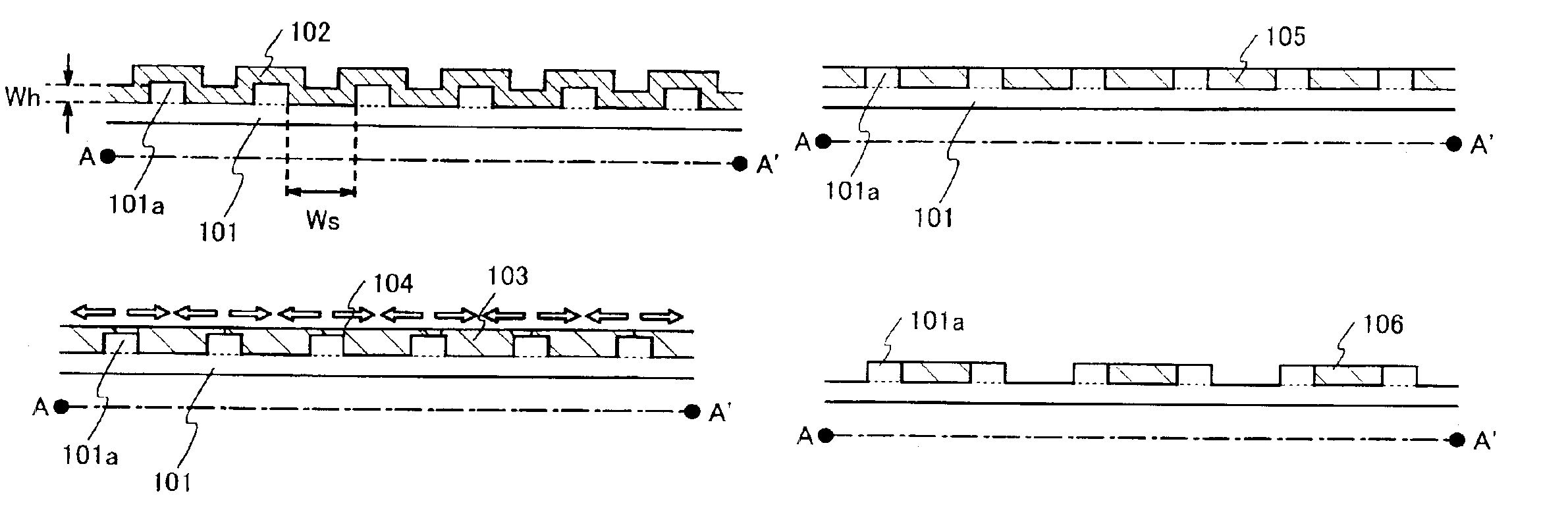

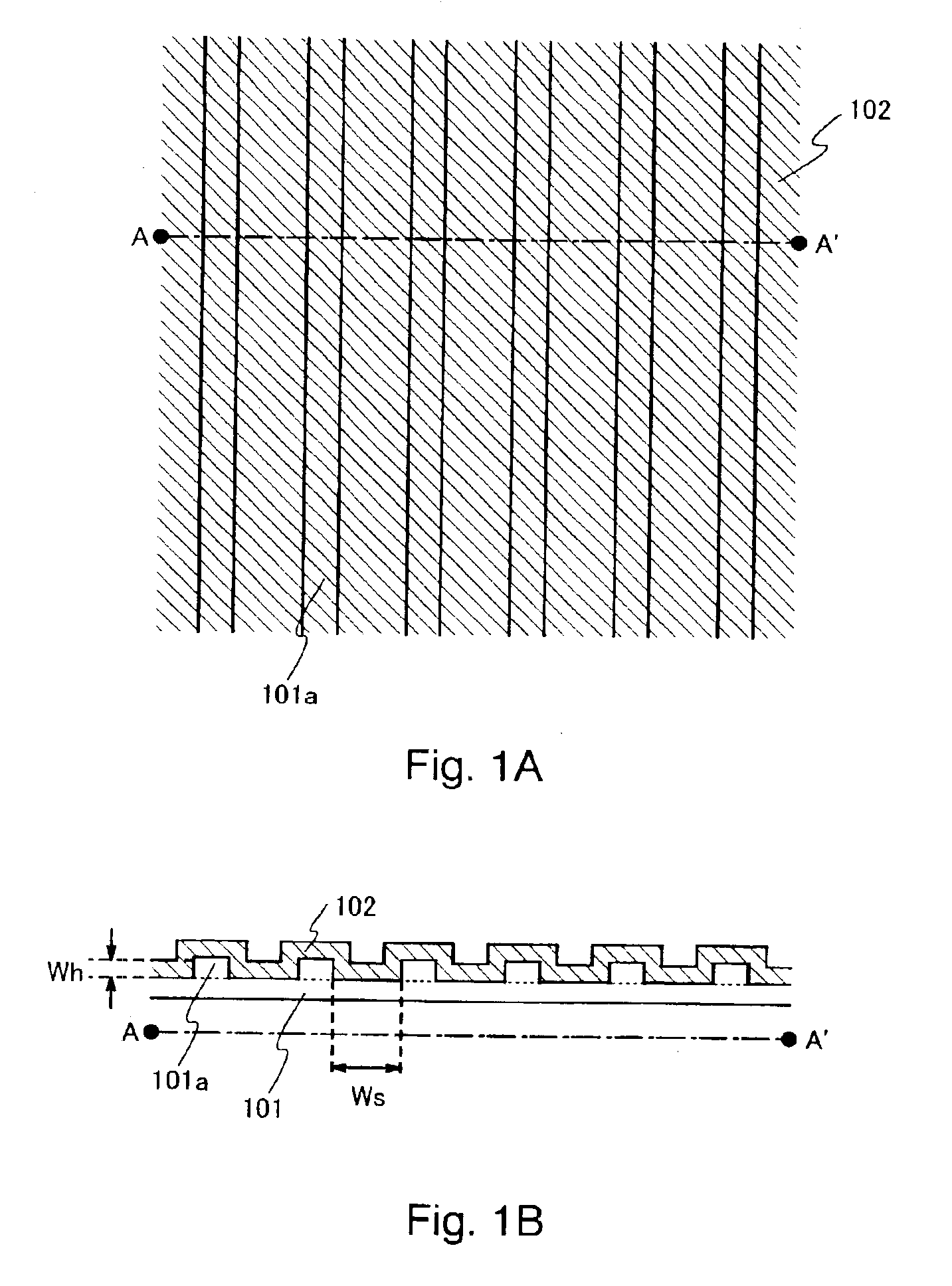

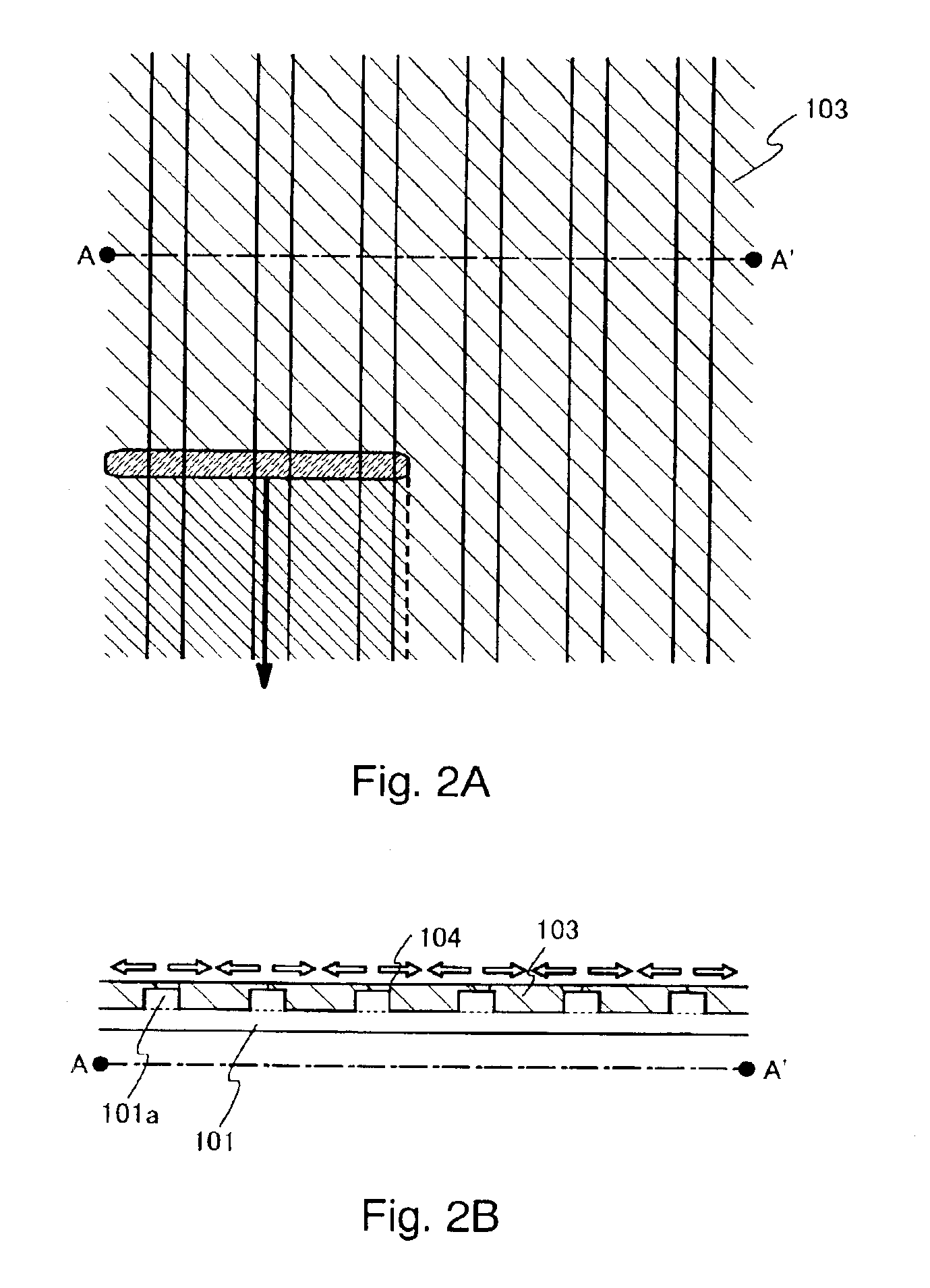

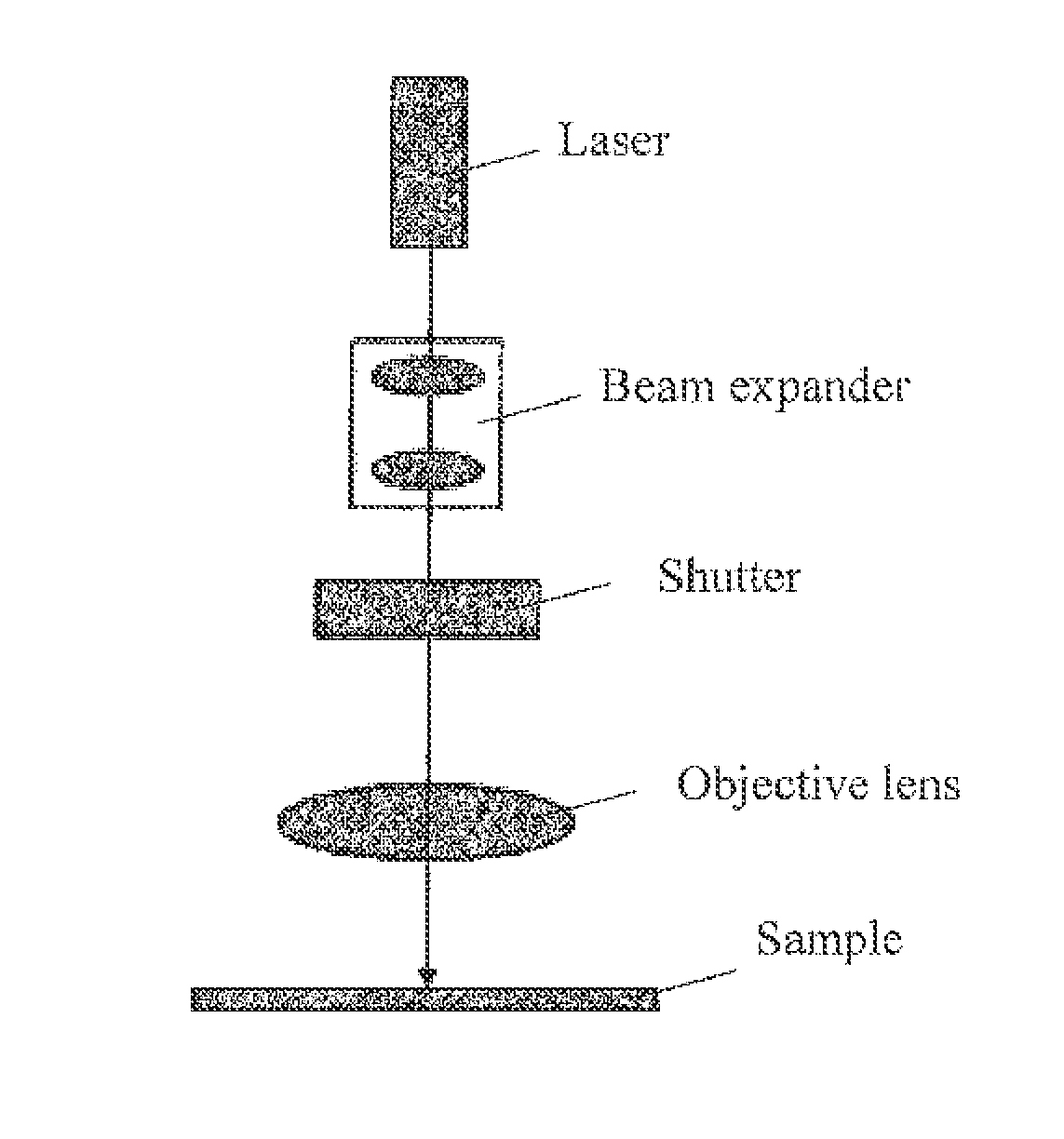

InactiveUS6884668B2Low costPoor heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLaser crystallizationLaser light

To provide devices relating to a manufacturing method for a semiconductor device using a laser crystallization method, which is capable of reducing a cost involved in a design change, preventing a grain boundary from developing in a channel formation region of a TFT, and preventing a remarkable reduction in mobility of the TFT, a decrease in an ON current, and an increase in an OFF current due to the grain boundary and to a semiconductor device formed by using the manufacturing method. In a semiconductor device according to the present invention, among a plurality of TFTs formed on a base film, some TFTs are electrically connected to form logic elements. The plurality of logic elements are used to form a circuit. The base film has a plurality of projective portions having a rectangular or stripe shape. Island-like semiconductor films included in each of the plurality of TFTs are formed between the plurality of projective portions and also, are crystallized by a laser light scanned in a longitudinal direction of the projective portions.

Owner:SEMICON ENERGY LAB CO LTD

Insulated thermal interface material

InactiveUS20130299140A1Increase costPoor heat resistanceSemiconductor/solid-state device detailsSolid-state devicesGrapheneElectronic component

The present invention discloses an insulated thermal interface material for applying between an electronic element and a thermal dissipating element. The insulated thermal interface material at least comprises a base, a first filler and a second filler. The base is a polymer and the first filler is graphene. The first filler and the second filler are dispersed in the base.

Owner:NATIONAL TSING HUA UNIVERSITY

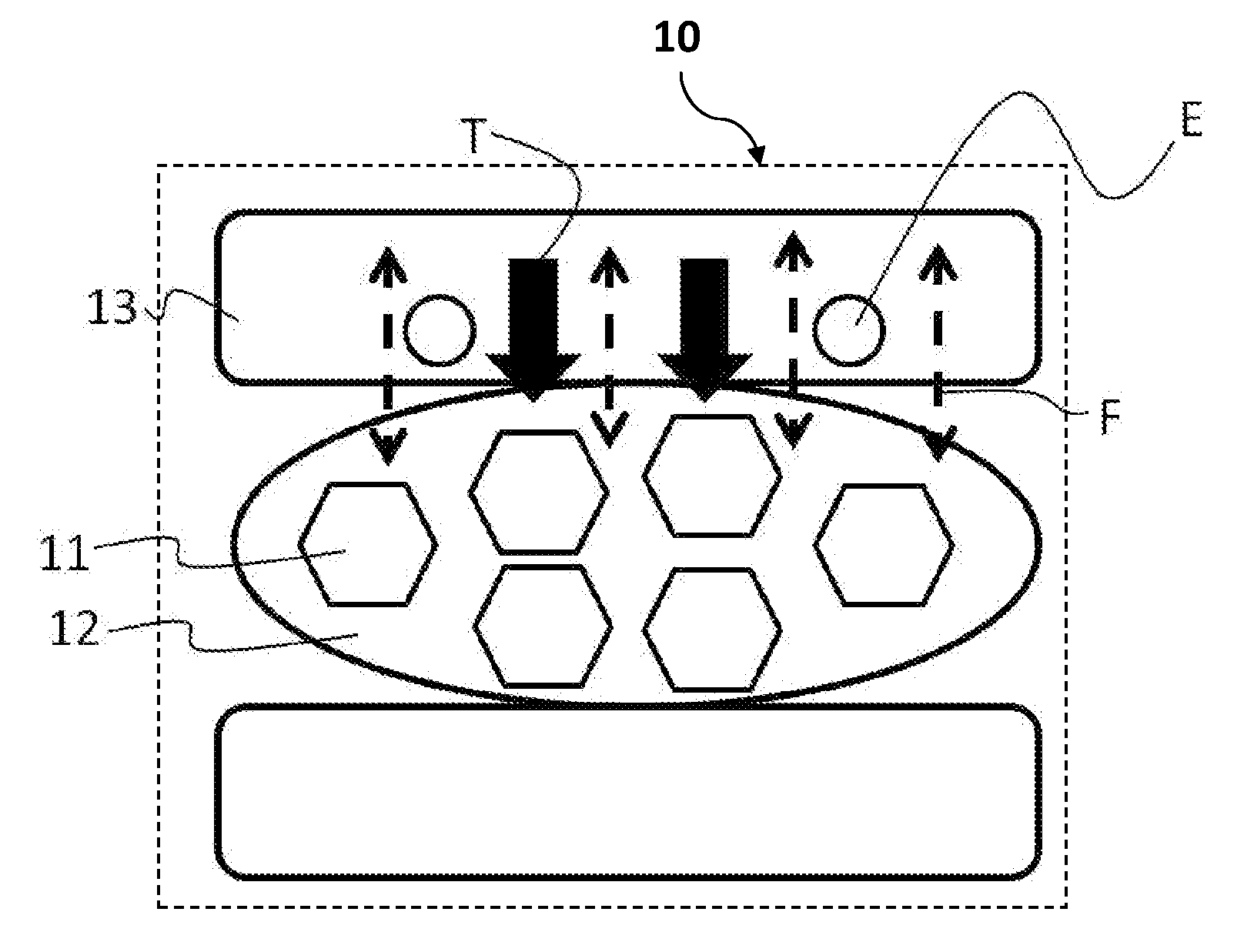

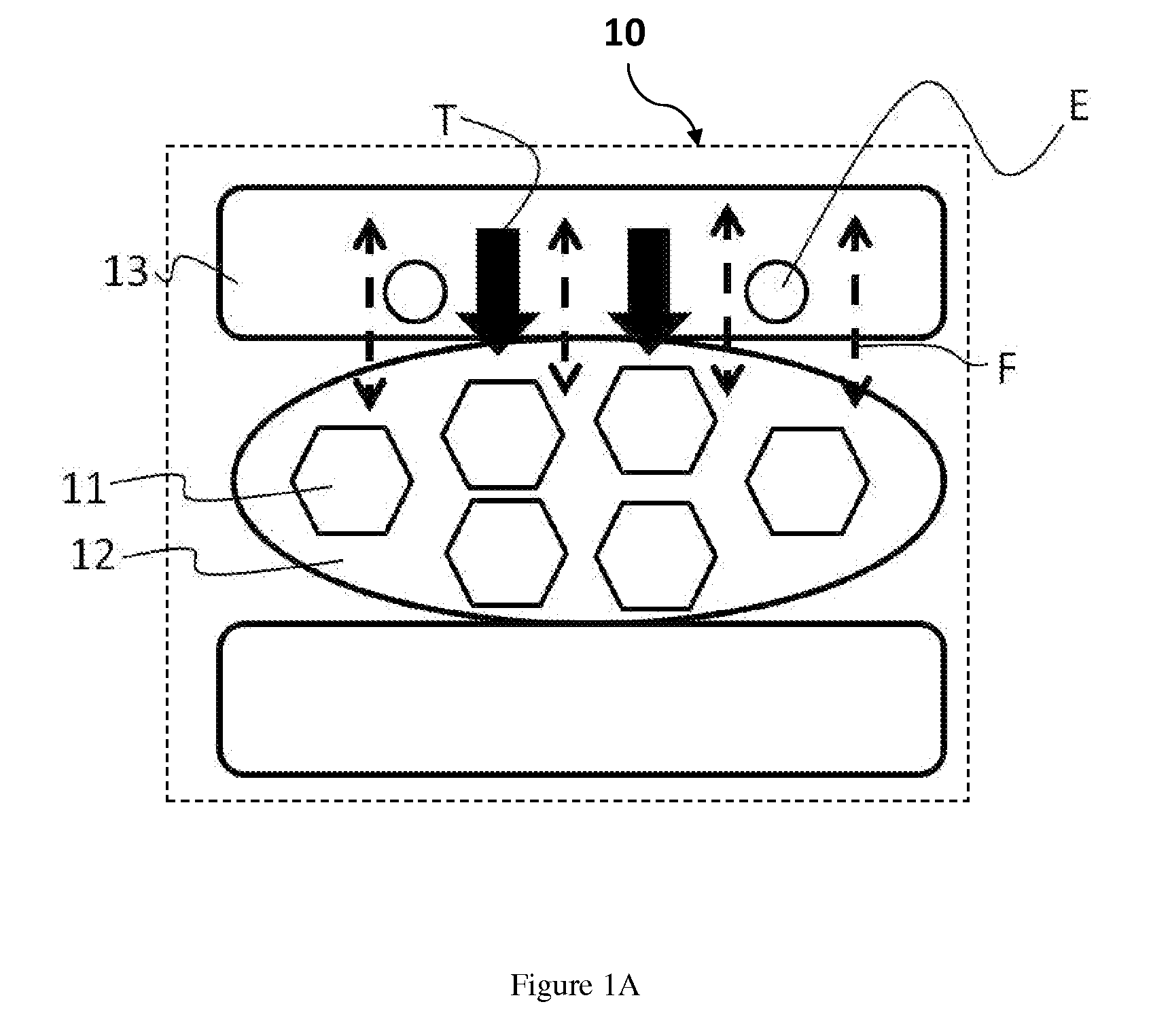

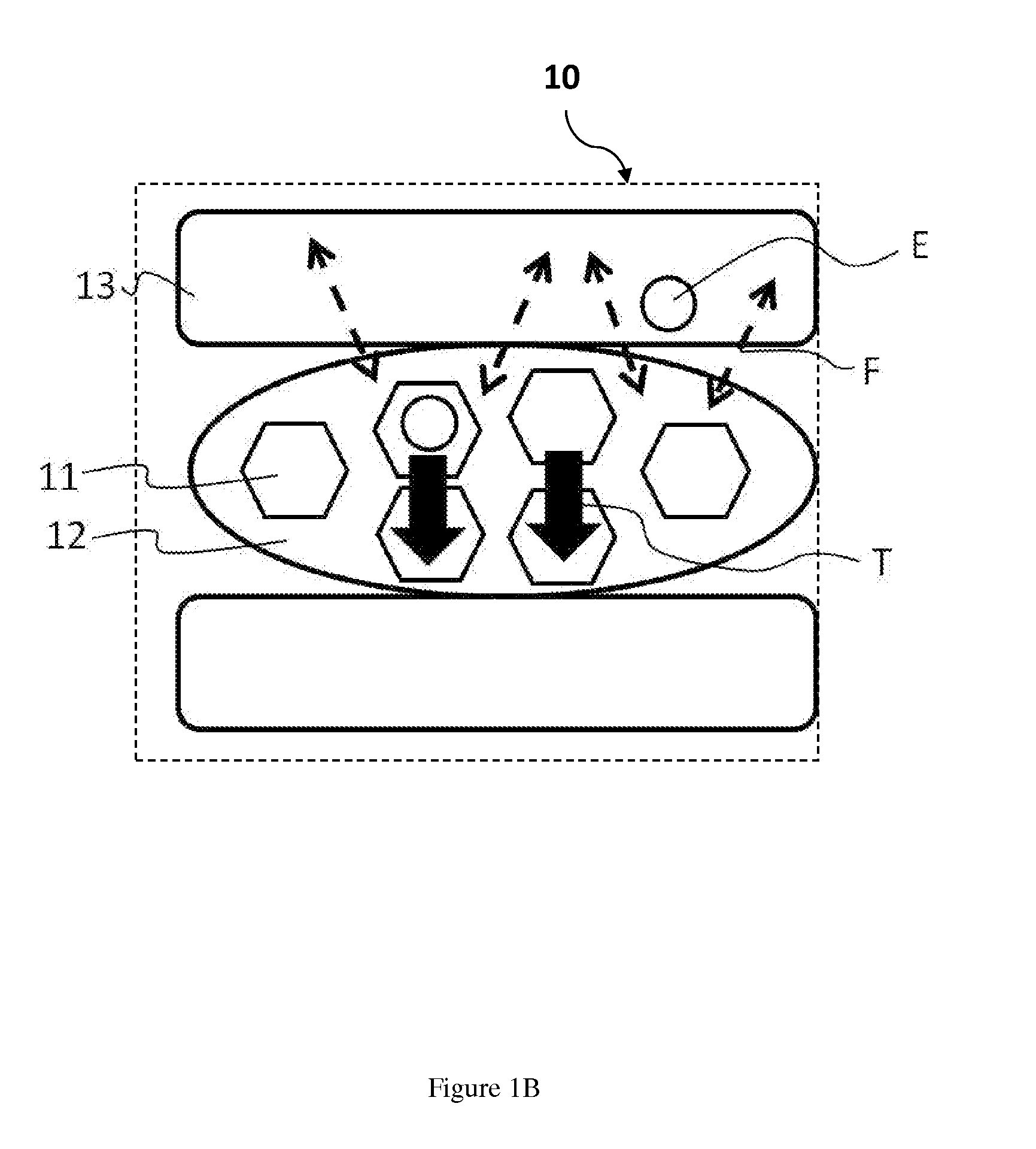

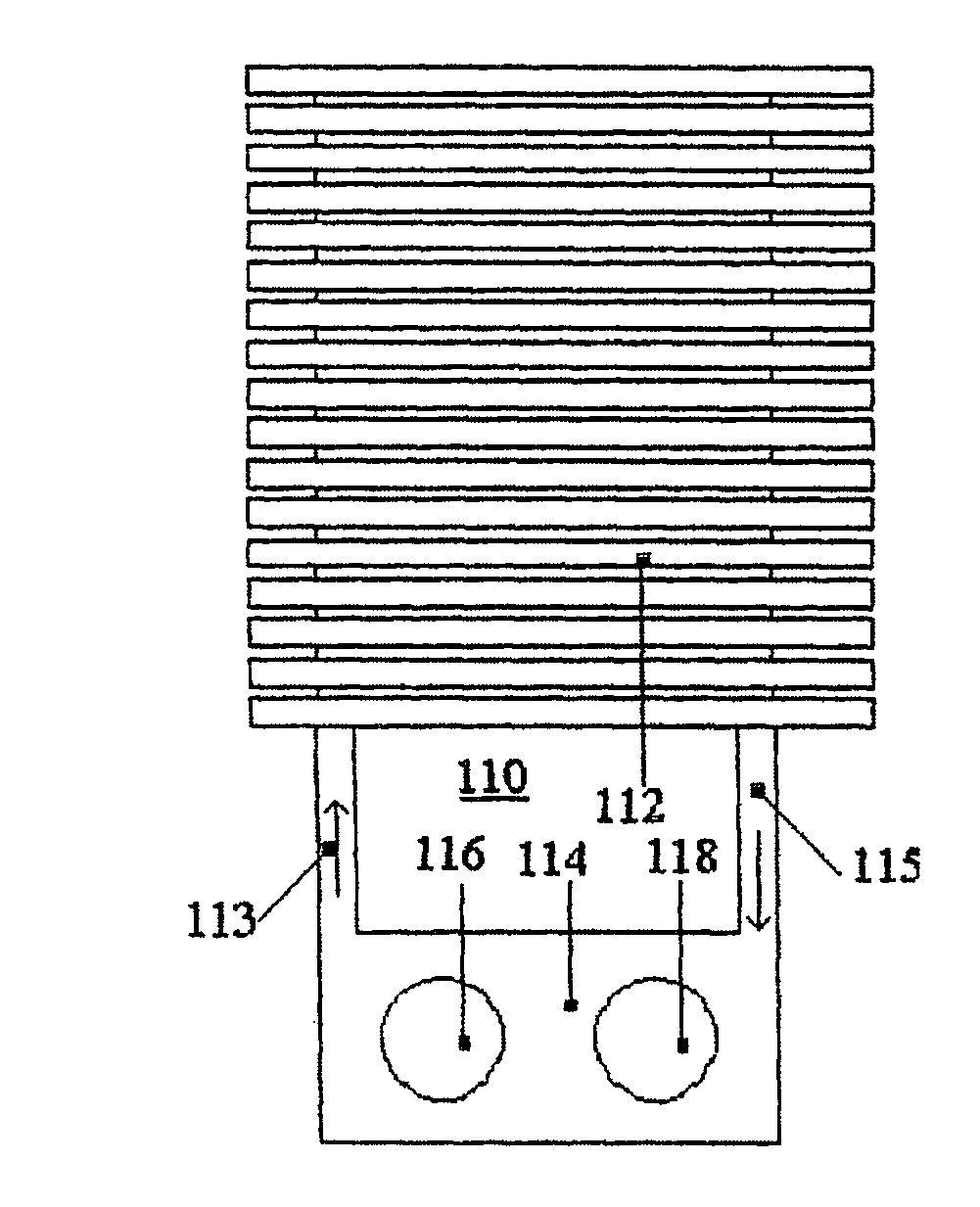

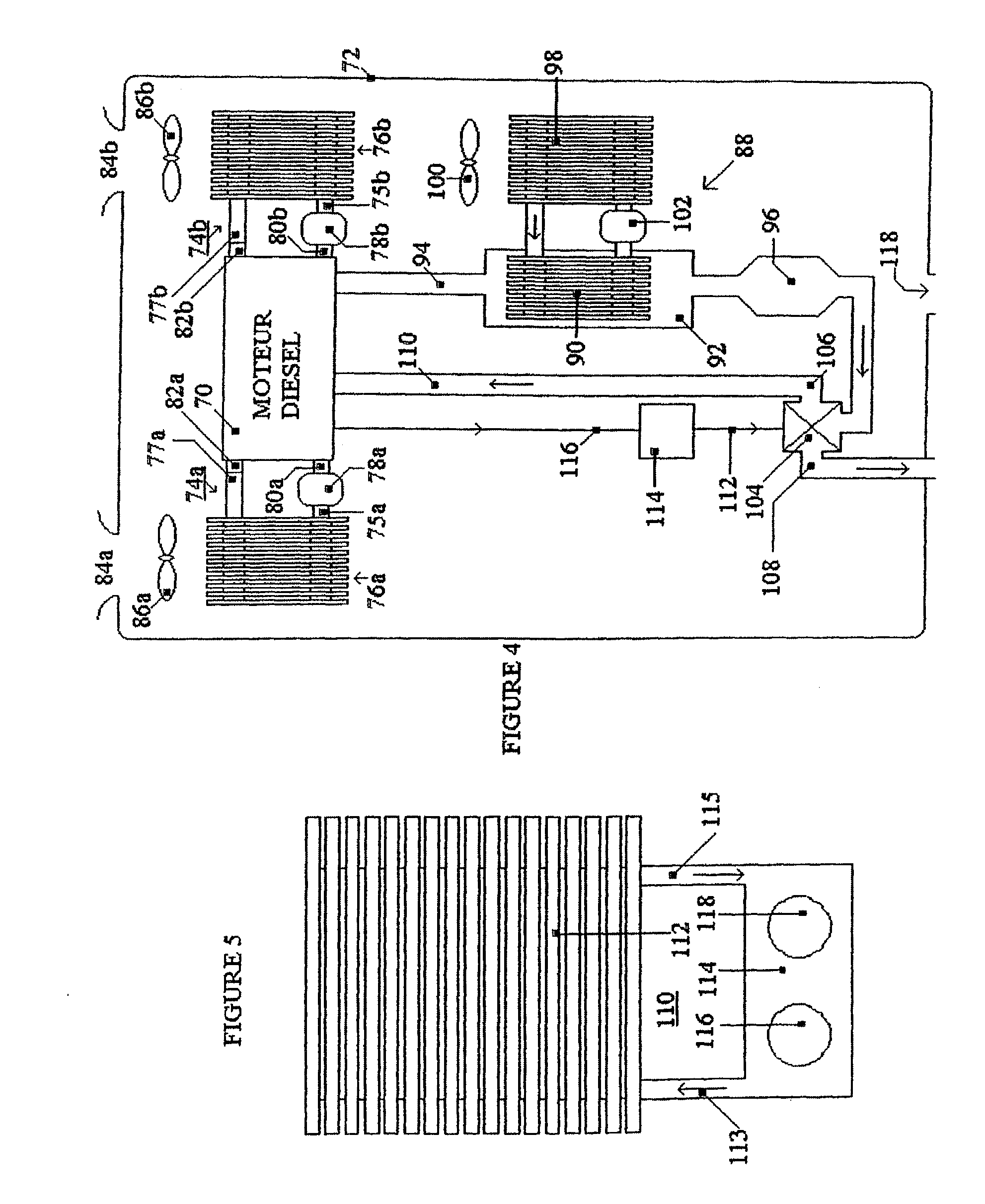

Cooling devices for various applications

InactiveUS20070184320A1Effective, not bulky, and inexpensivePoor heat resistanceInternal combustion piston enginesFuel cells groupingHeat fluxMicroheater

The figure displays the diagram of a laminar flow water cooler (110) for a microprocessor comprising an integral radiator (112) provided with thin-walled and hollow fins which are produced by controlled compression of double convex bellows of a polymer or glass hot-blown blank. In order to form a closed circuit filled with water at the atmospheric pressure, the manifolds (113, 114, 115) of the radiator (112) are connected to the manifolds of an original component (114) formed by a mini heater (116) provided with a copper heating plate with internal grooved face and a mini pump (118) provided with a brushless electric motor devoid of a centrifugal turbine, wherein said mini heater and mini pump are disposed in a rigid small-sized moulded polymer hose. The total thermal resistance of said cooler can be equal to 0.15° / W that is of interest, in particular for high performance microprocessors for dissipating more than 200 W through the very hot central area of 1.5 cm2 of the heat dissipating surface thereof. The concept of the production of the inventive cooler makes it possible to design efficient and low-cost cooling devices which are usable for microprocessors, high-power electronic devices, thermal engines or fuel cells, in particular mounted in a motor vehicle. Said invention can be used for cooling any component dissipating a given thermal flux within the determined power and temperature limits.

Owner:TECH DE LECHANGE THERMIQUE TET

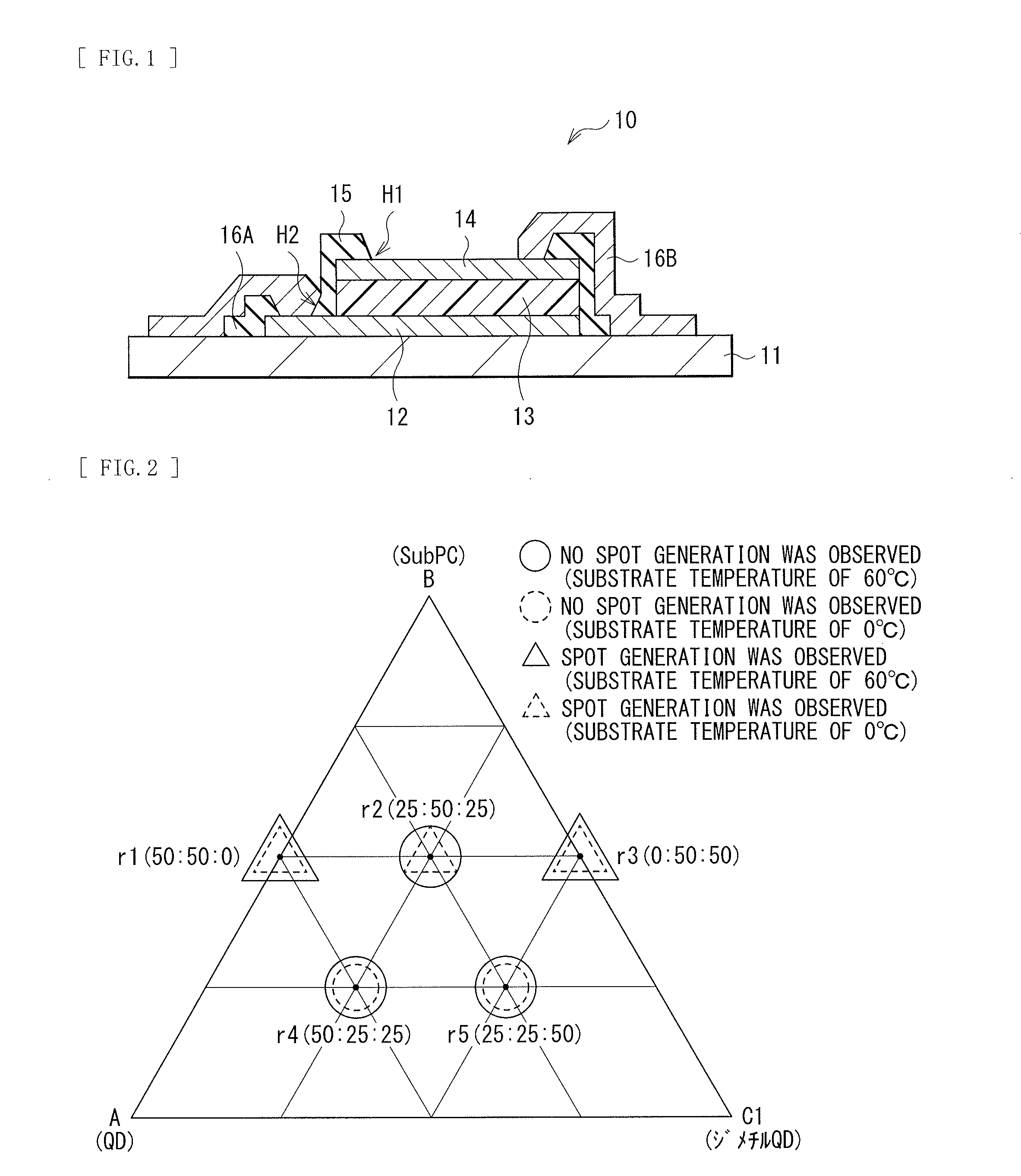

Photoelectric conversion device, solid-state image pickup unit, and electronic apparatus

ActiveUS20150311445A1Reduce variationInhibit aggregationSolid-state devicesSemiconductor/solid-state device manufacturingPhotoelectric conversionOrganic semiconductor

A solid-state image pickup unit of the invention includes a plurality of pixels, each of which includes a photoelectric conversion element. The photoelectric conversion element includes a photoelectric conversion layer; and first and second electrodes provided with the photoelectric conversion layer in between, the photoelectric conversion layer including a first organic semiconductor of a first conductive type and a second organic semiconductor of a second conductive type, and being configured by addition of a third organic semiconductor made of a derivative or an isomer of one of the first and second organic semiconductors.

Owner:SONY CORP

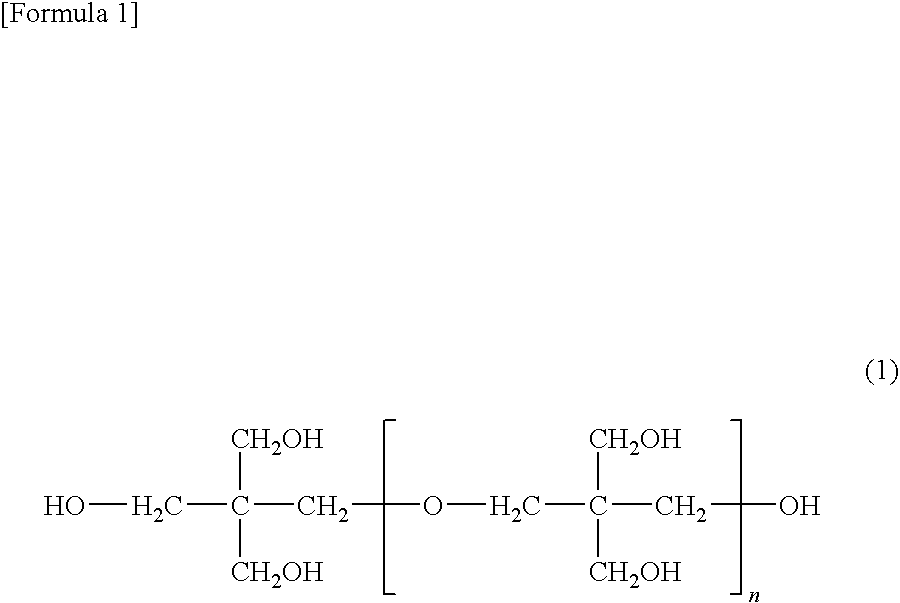

Stabilizer for chlorine-containing resins and chlorine-containing resin composition

ActiveUS20100256278A1Excellent dispersibilitySufficient effectFireproof paintsChemical inhibitorsPentaerythritolPolymer chemistry

A stabilizer for chlorine-containing resins of the invention consists of a polyol mixture composed of pentaerythritol and condensates thereof, wherein, with respect to the total amount of the polyol mixture, the content of pentaerythritol having a degree of condensation (n) of 1 is 0 to 10% by mass and the total content of pentaerythritol and condensates thereof having a degree of condensation (n) of 1 to 3 is 5 to 30% by mass. A chlorine-containing resin composition of the invention contains, with respect to 100 parts by mass of a chlorine-containing resin, 0.01 to 10 parts by mass of the above-mentioned stabilizer for chlorine-containing resins.

Owner:ADEKA CORP

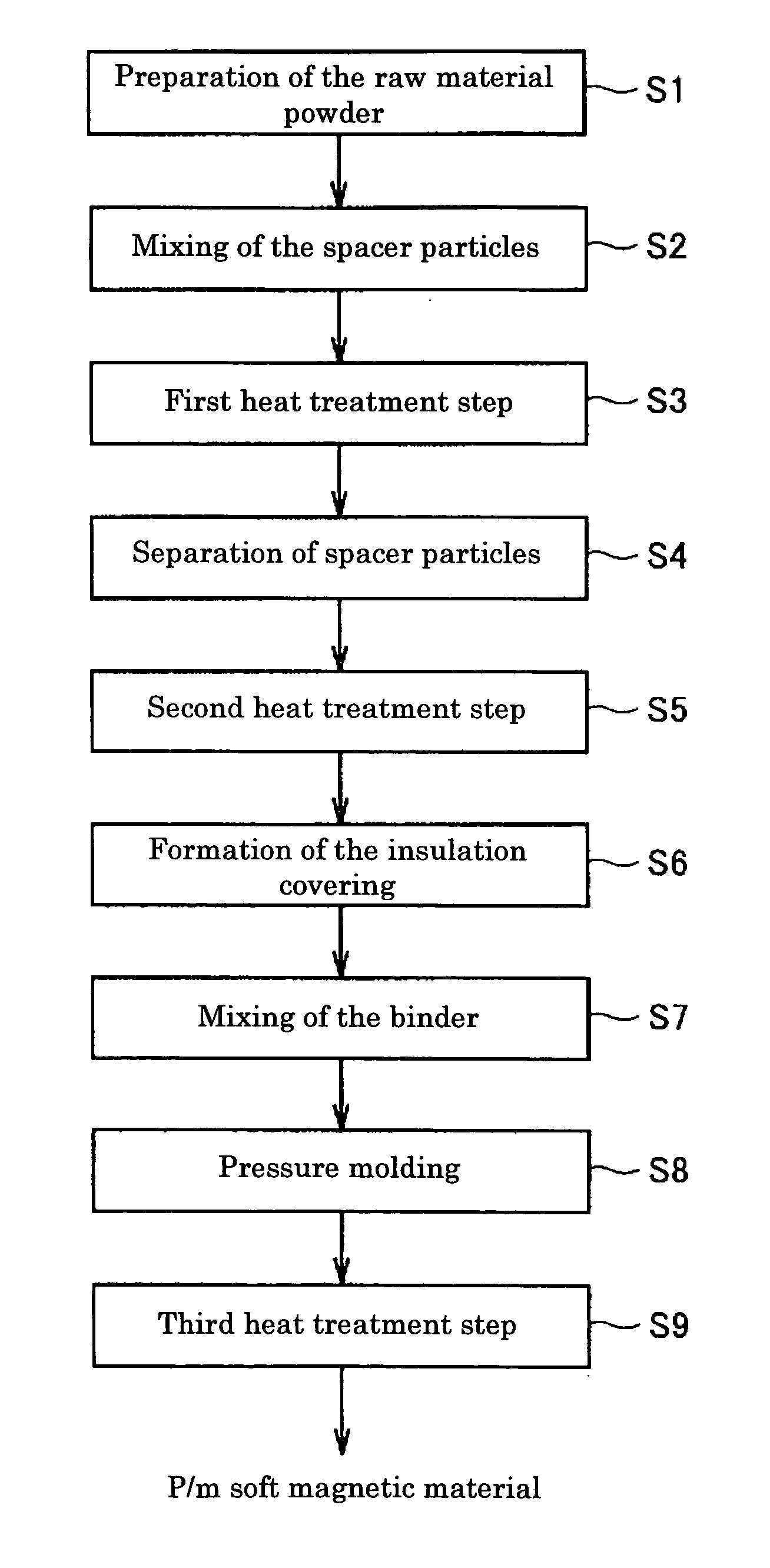

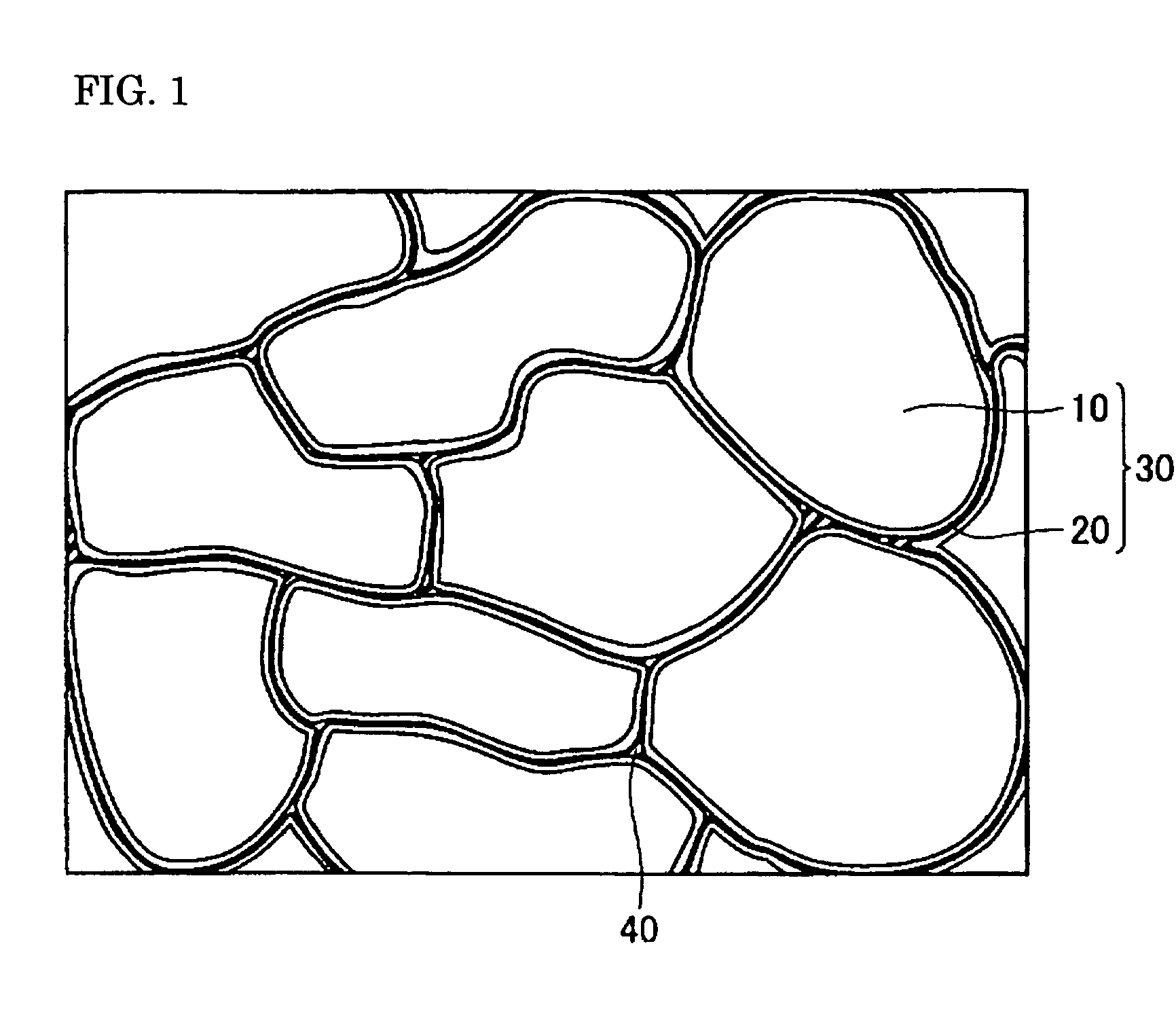

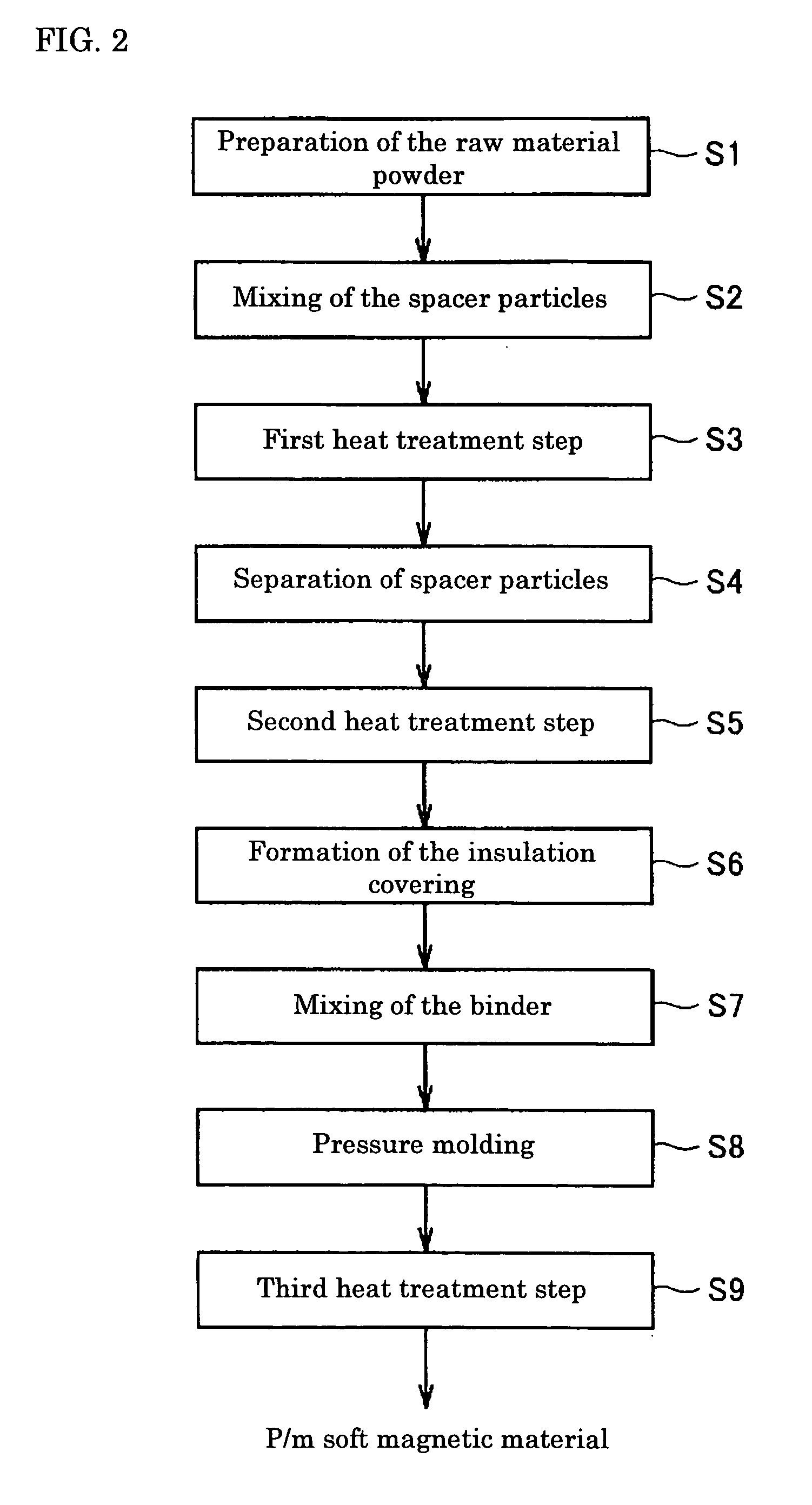

Manufacturing method for a soft magnetic material, a soft magnetic material, a manufacturing method for a powder metallurgy soft magnetic material, and a powder metallurgy soft magnetic material

InactiveUS20050257854A1Reduce distortionPoor heat resistanceInorganic material magnetismInductances/transformers/magnets manufacturePowder metallurgyMelting point

The object of the present invention is to provide a method for manufacturing a soft magnetic material, a soft magnetic material, a method for manufacturing a P / M soft magnetic material, and a P / M soft magnetic material which achieve the desired magnetic properties. In the method for manufacturing the soft magnetic material of the present invention, there is a first heat treatment step (step S3) in which a metal magnetic particle 10, which has iron as its main component, is heat treated to a temperature of 900 degrees C. or greater and less than the melting point of metal magnetic particle 10. After the first heat treatment step (step S3), there is a step for forming a plurality of composite magnetic particles 30 which are metal magnetic particles 10 surrounded by an insulation covering 20 (step S6).

Owner:SUMITOMO ELECTRIC IND LTD

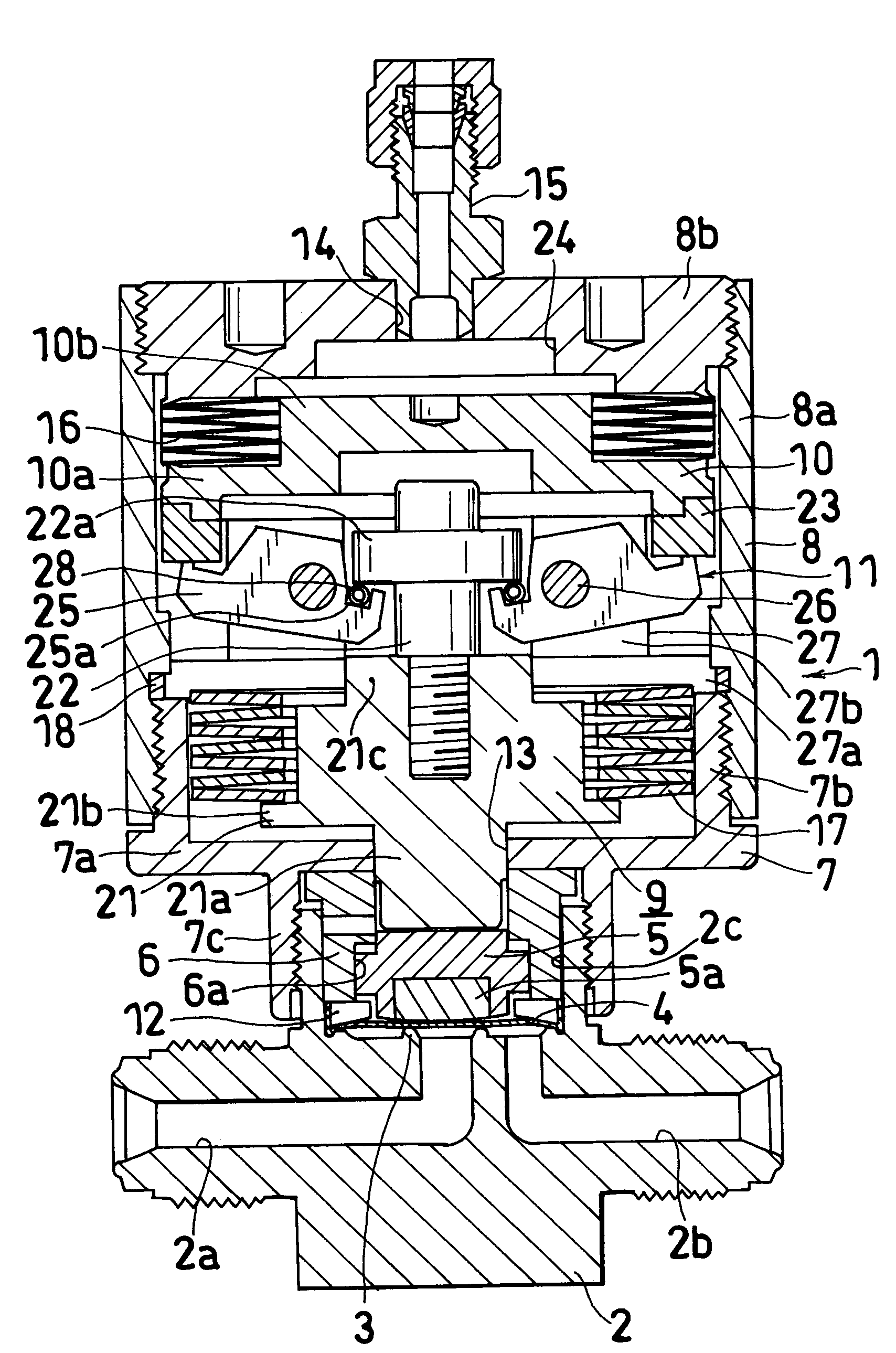

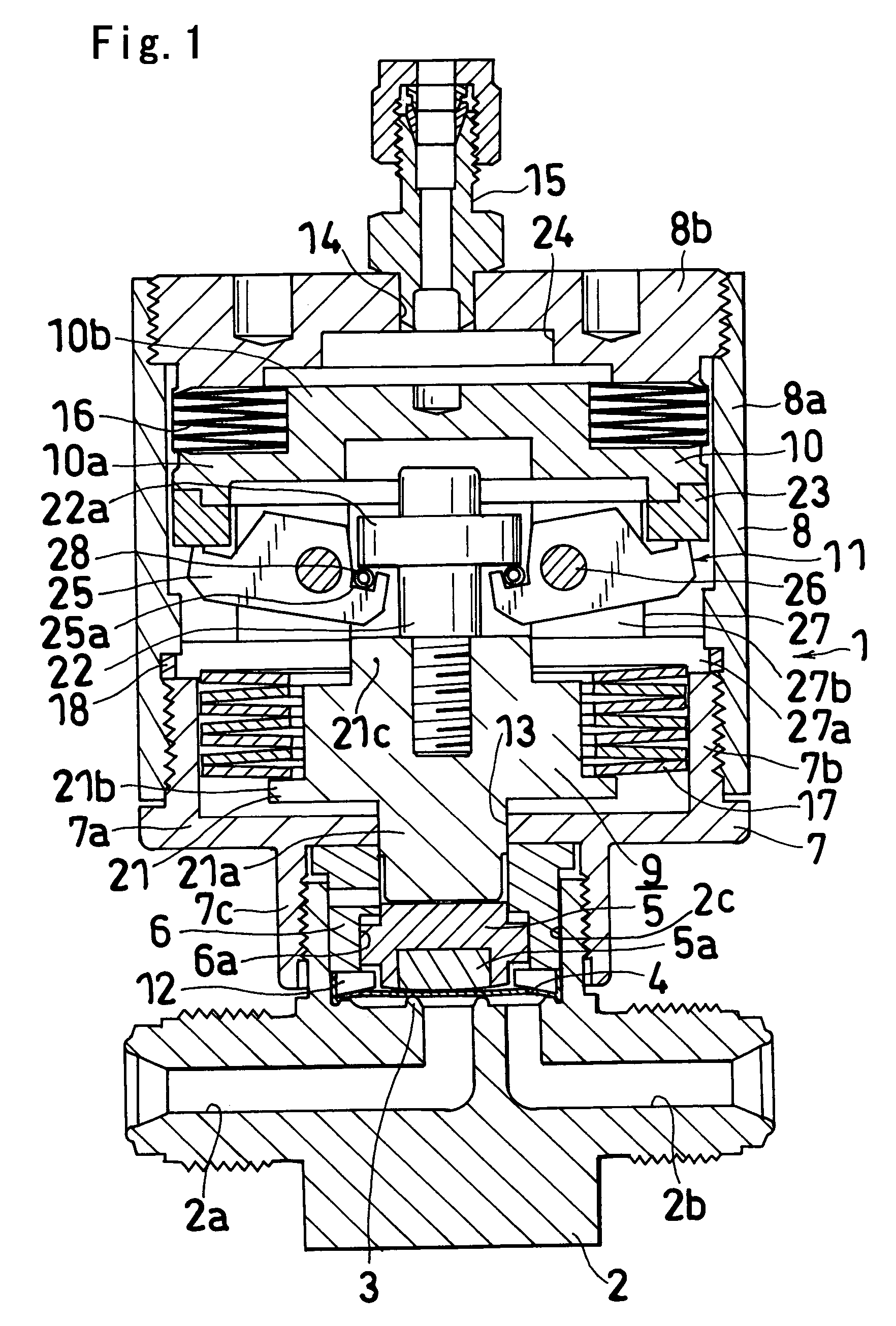

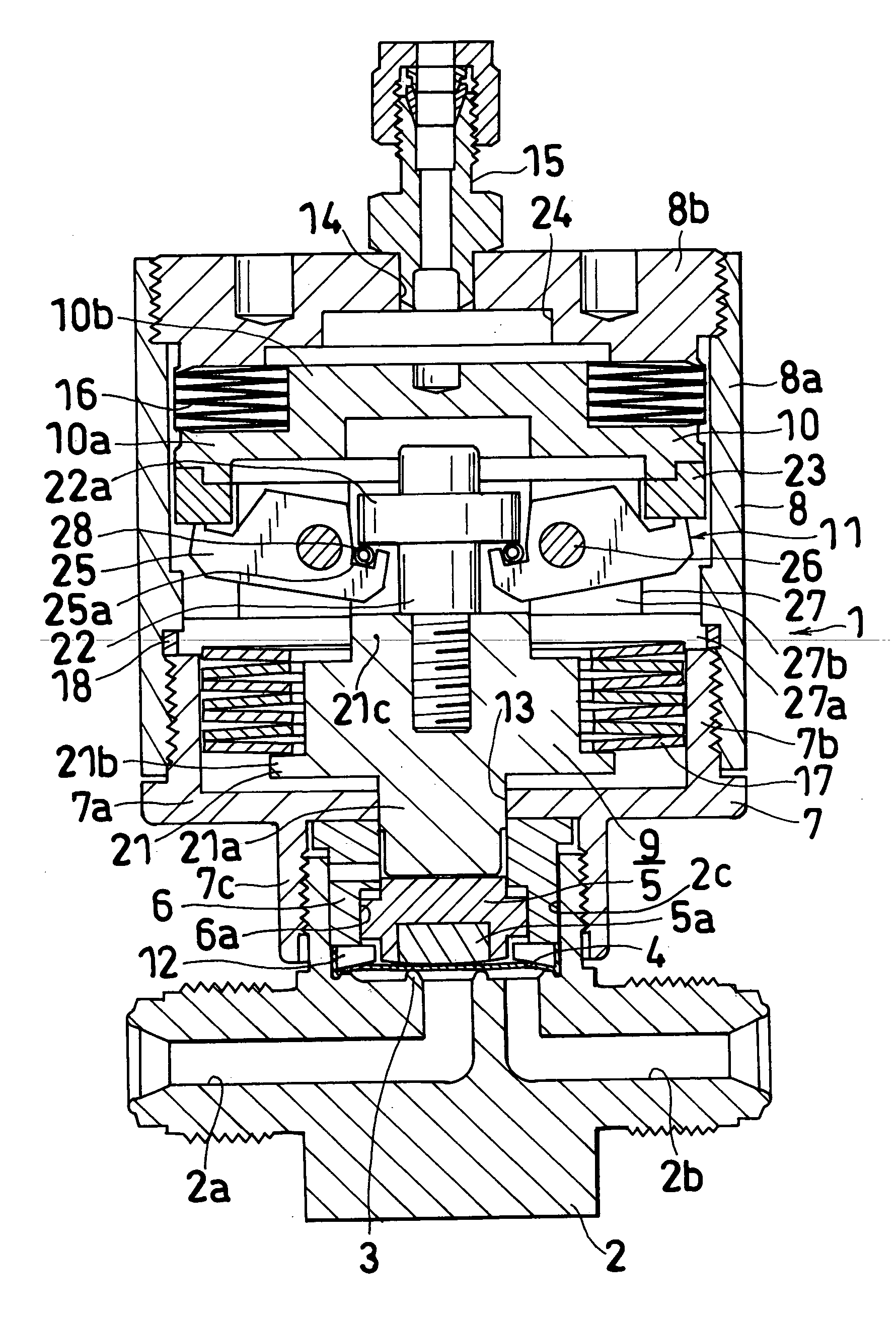

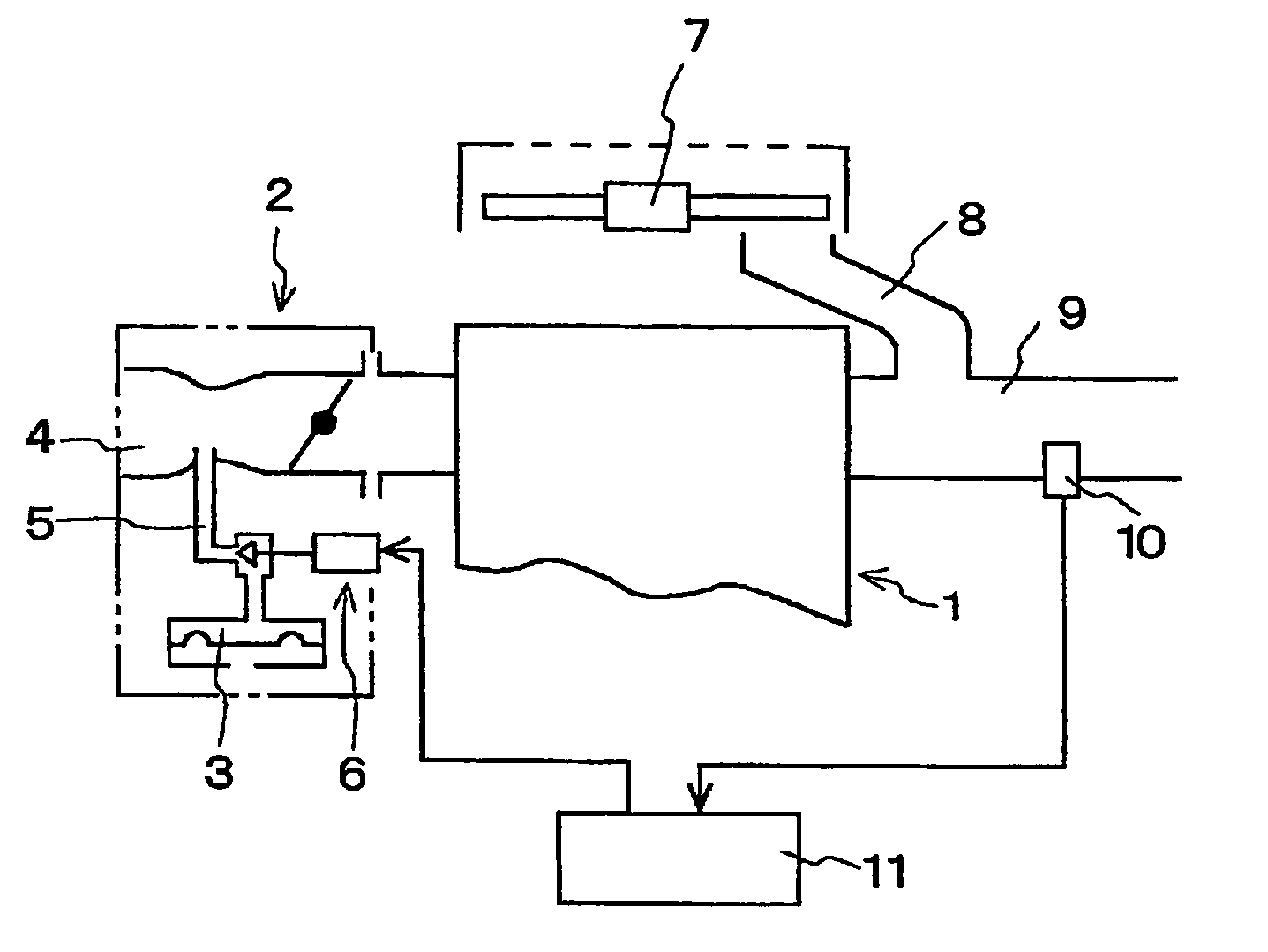

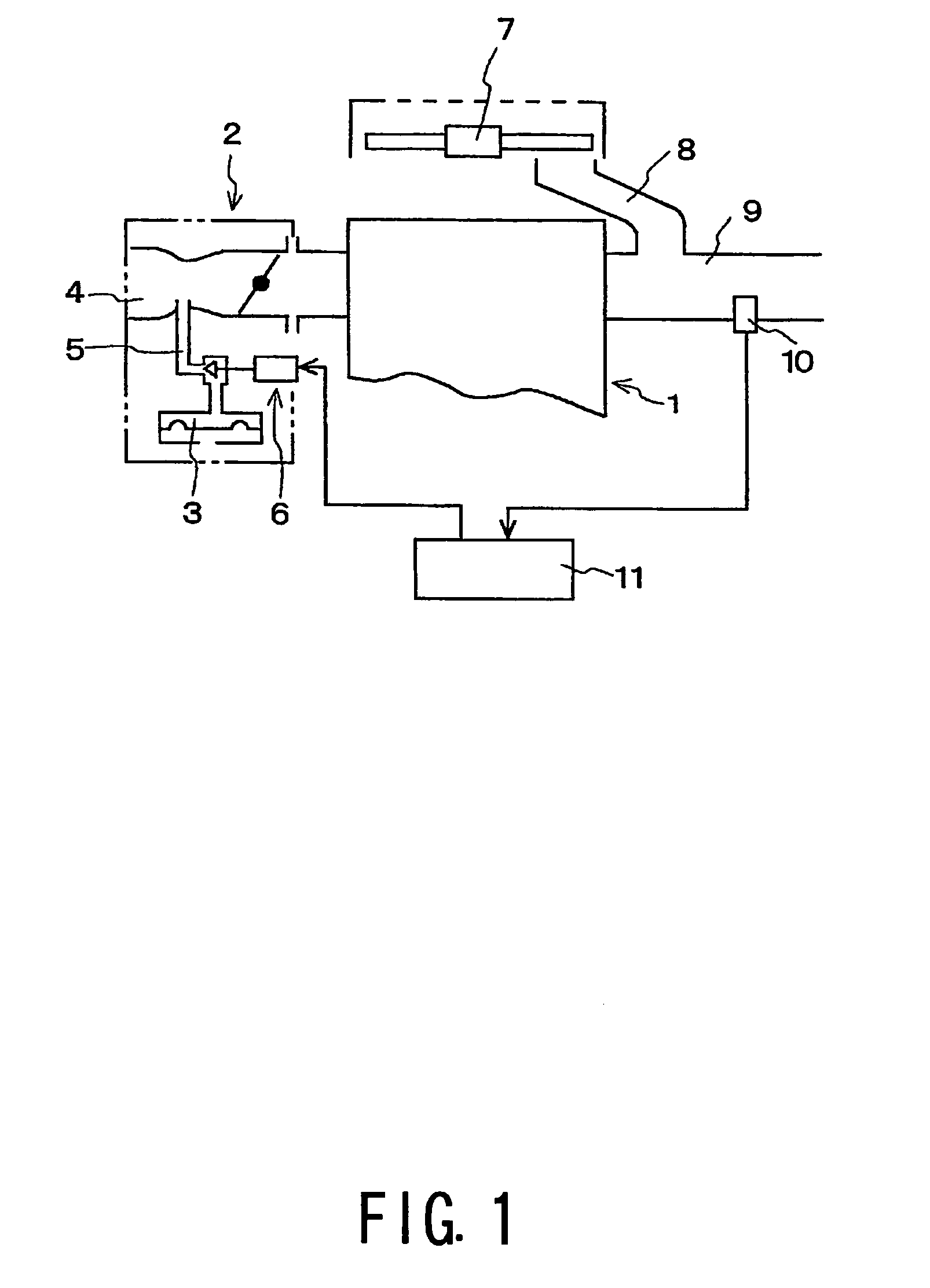

Control device

InactiveUS7159839B2Increase pressureIncrease resistanceDiaphragm valvesEngine sealsEngineeringValve stem

Booster means 11 for transmitting a force acting on a piston 10 to a valve stem 9 on amplification comprises pivotal members 25 each supported by casings 7, 8 so as to hold an outer end and an inner end thereof in contact with an outer peripheral portion of the piston 10 and a flange portion 22a formed on the valve stem 9 respectively from below and to be pivotally movable about a horizontal rod 26 positioned closer to the inner end. Metal bellows 16 are provided between an outer peripheral portion of the casing top wall 8a and the outer peripheral portion of the piston 10 for sealing off a compressed air admitting space.

Owner:FUJIKIN INC

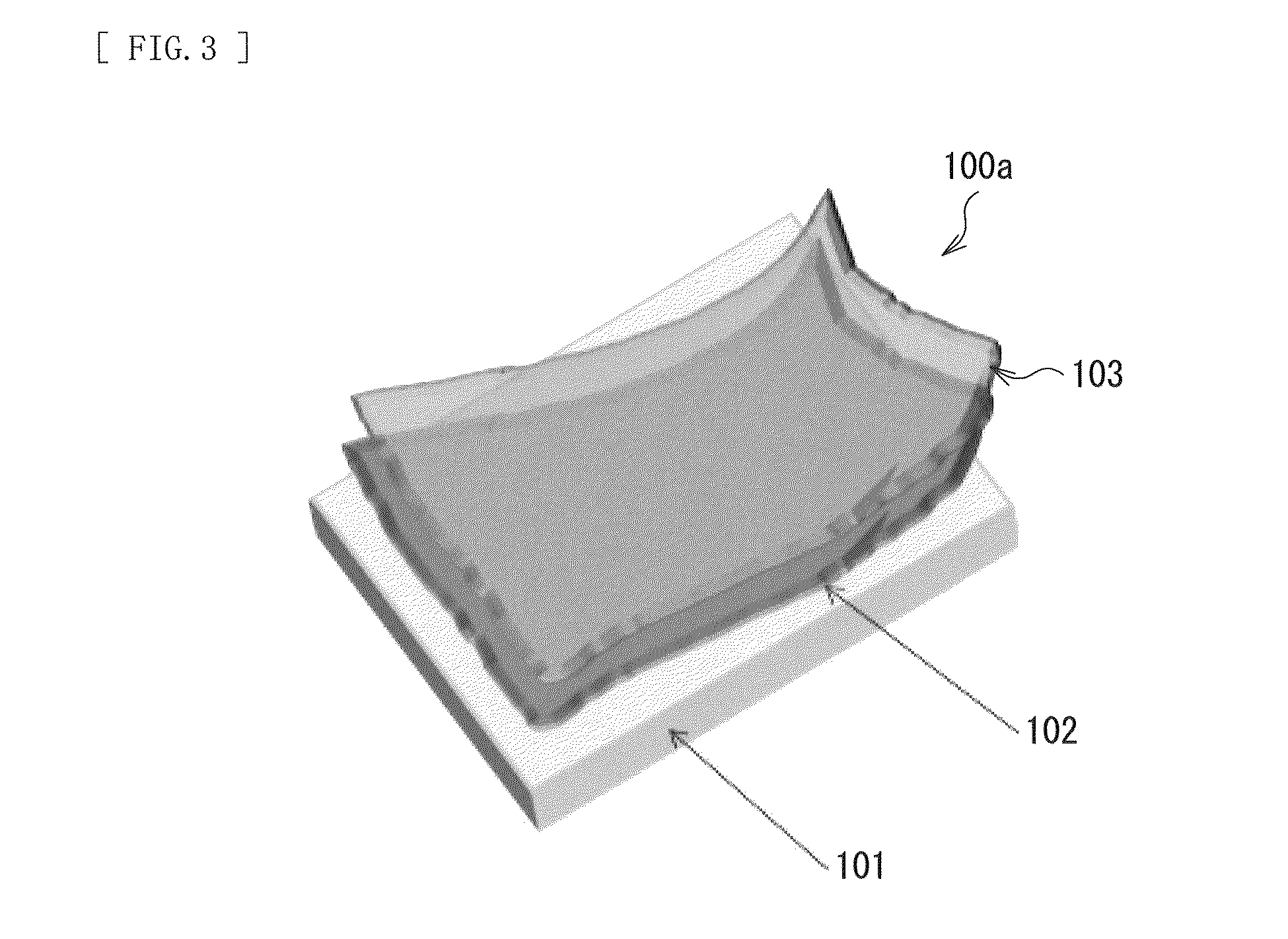

Method for manufacturing a semiconductor device using a flexible substrate

ActiveUS8900970B2Poor heat resistanceHigh yieldFinal product manufactureSemiconductor/solid-state device detailsPower semiconductor deviceEngineering

A technique for peeling an element manufactured through a process at relatively low temperature (lower than 500° C.) from a substrate and transferring the element to a flexible substrate (typically, a plastic film). With the use of an existing manufacturing device for a large glass substrate, a molybdenum film (Mo film) is formed over a glass substrate, an oxide film is formed over the molybdenum film, and an element is formed over the oxide film through a process at relatively low temperature (lower than 500° C.). Then, the element is peeled from the glass substrate and transferred to a flexible substrate.

Owner:SEMICON ENERGY LAB CO LTD

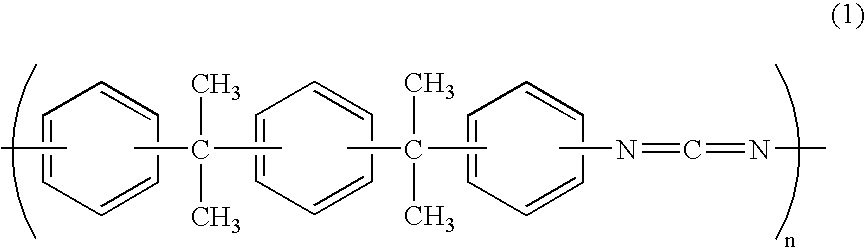

Fiber article comprising a biodegradable plastic

ActiveUS20050233142A1Decrease in hydrolysis resistanceReduced strengthFibre treatmentWoven fabricsBiodegradable plasticFiber structure

A fiber article having excellent hydrolysis resistance, characterized in that the article is fiber structure composed of 10 to 90% by weight of a fiber (A) comprised of a biodegradable plastic formulated with a carbodiimide compound as a stabilizer against hydrolysis and 90 to 10% by weight of at least one fiber (B) selected from a natural fiber, a regenerated fiber, a semi-synthetic fiber and a synthetic fiber, which fiber structure has been subjected to at least one treatment processing selected from scouring processing, bleaching processing, liquid ammonium processing, mercerization processing, biological processing, dyeing processing, or resin treatment, and concentration of total terminal carboxyl groups derived from the fiber (A) in said fiber article is not higher than 30 equivalents / ton based on the fiber (A), etc. It is an object of the present invention to solve conventional problems of a fiber or a fiber article comprising a biodegradable plastic, such as poor hydrolysis resistance, poor heat resistance, strength reduction and coloring by yellowing, and in particular to provide a fiber article superior in hydrolysis resistance, alkali resistance and dyeing resistance.

Owner:NISSHINBO IND INC

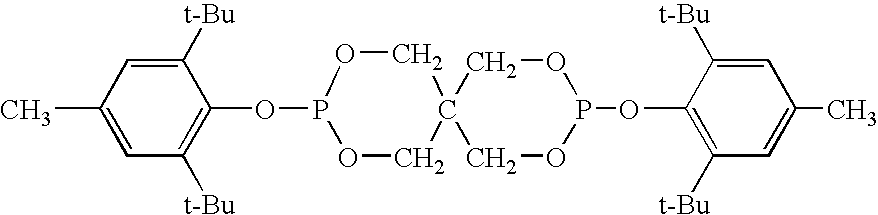

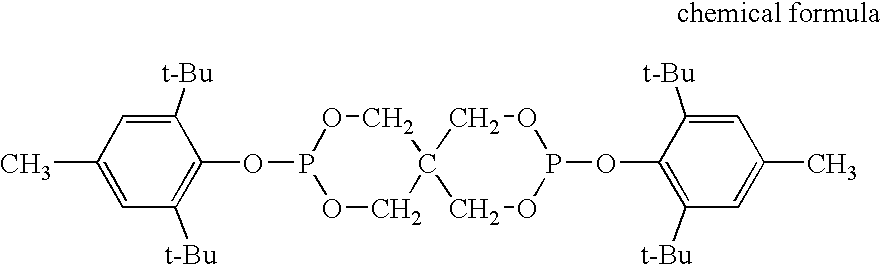

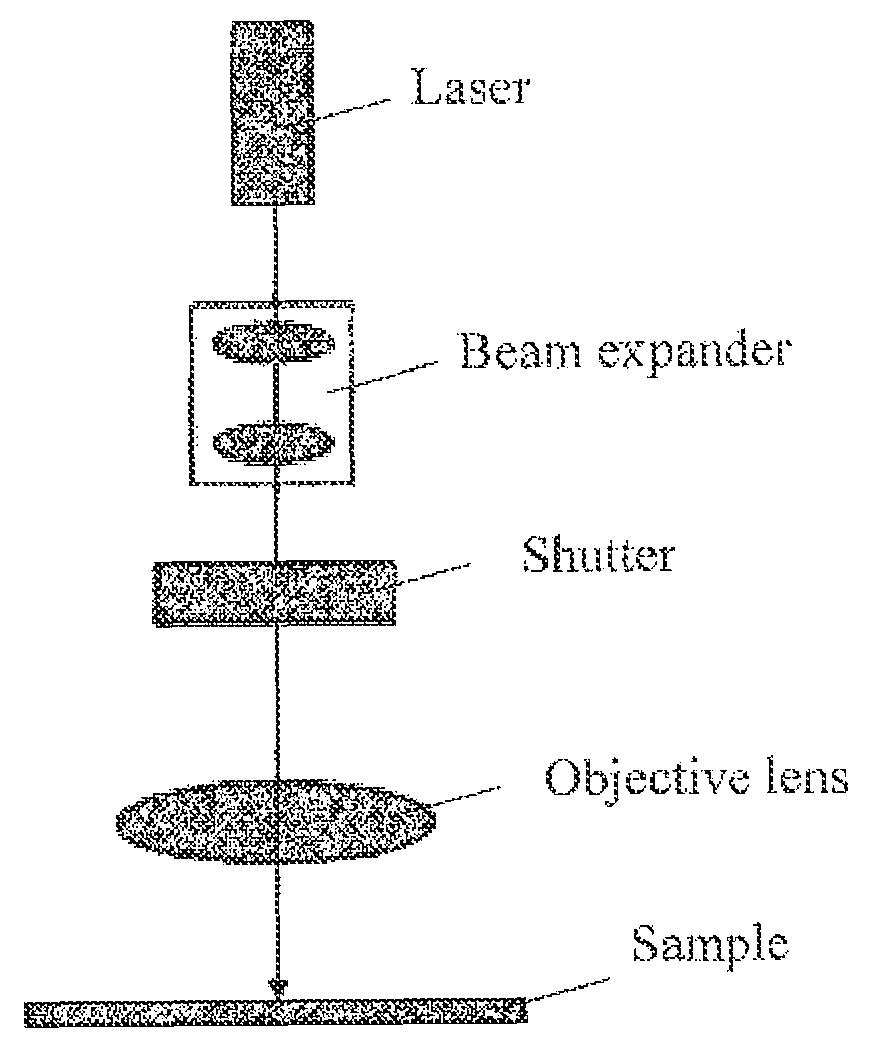

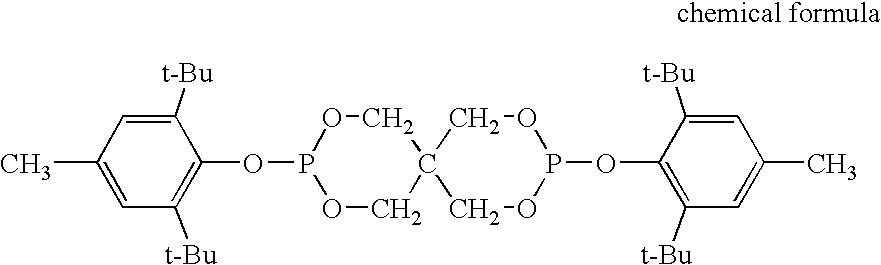

Stabilizer against hydrolysis for an ester-group-containing resin and a thermoplastic resin composition

ActiveUS7273902B2Poor heat resistanceImprove the immunityChemical inhibitorsHeat resistanceAntioxidant

A stabilizer against hydrolysis, which can solve conventional problems of a carbodiimide compound compounded in an ester-group-containing resin or a biodegradable plastic as a stabilizer against hydrolysis, such as poor heat resistance and a coloring problem due to yellowing, and can provide enhanced resistance against hydrolysis, and a thermoplastic resin composition of an ester-group-containing resin or a biodegradable plastic containing the same. Specifically, that the stabilizer against hydrolysis includes a carbodiimide composition comprising an aliphatic carbodiimide compound (A) and a phosphorus antioxidant (B), preferably the stabilizer contains a carbodiimide composition wherein a phosphorus antioxidant (B1) is dispersed and present in the carbodiimide composition by admixing the phosphorus antioxidant (B1) during synthesis of the aliphatic carbodiimide compound (A), and a thermoplastic resin composition having a superior stability against hydrolysis, characterized in that said stabilizer against hydrolysis is compounded in an easily hydrolysable resin (C).

Owner:NISSHINBO IND INC

Cleaning sheets and method of cleaning with the same

InactiveUS20050042958A1Poor heat resistanceEasily removeSynthetic resin layered productsPhotomechanical exposure apparatusPaper sheetMicrofabrication

The invention provides cleaning sheets for use in cleaning, e.g., various substrate-processing apparatus, systems for conveying exposure masks (reticles) in microfabrication, etc., and a method of cleaning these with the cleaning sheets. A cleaning sheet which comprises a sheet material comprising a thermoset resin layer having porosity and, formed on one side of the sheet material, a pressure-sensitive adhesive layer comprising a thermoplastic resin.

Owner:NITTO DENKO CORP

Light transmitting substrate with transparent conductive film

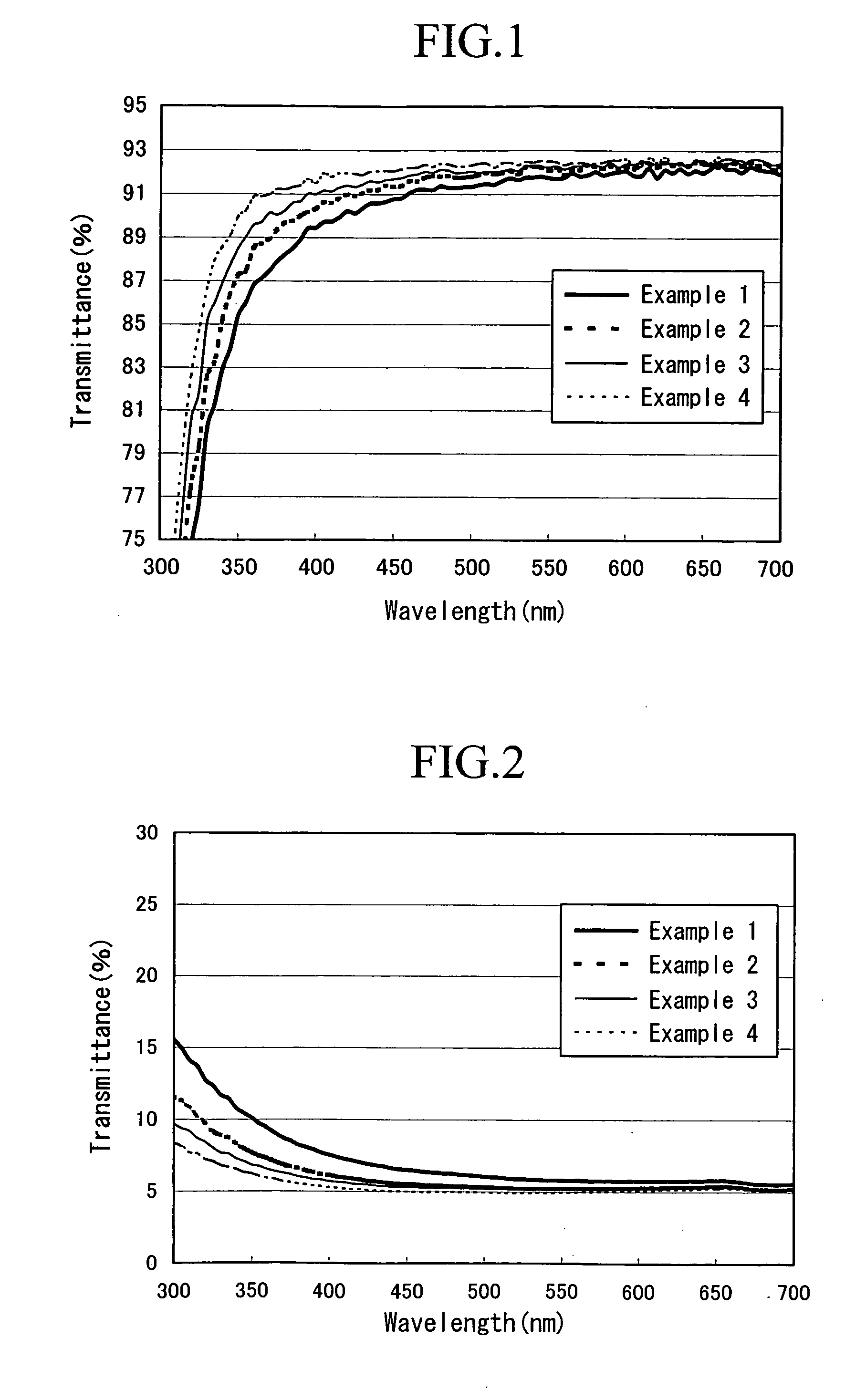

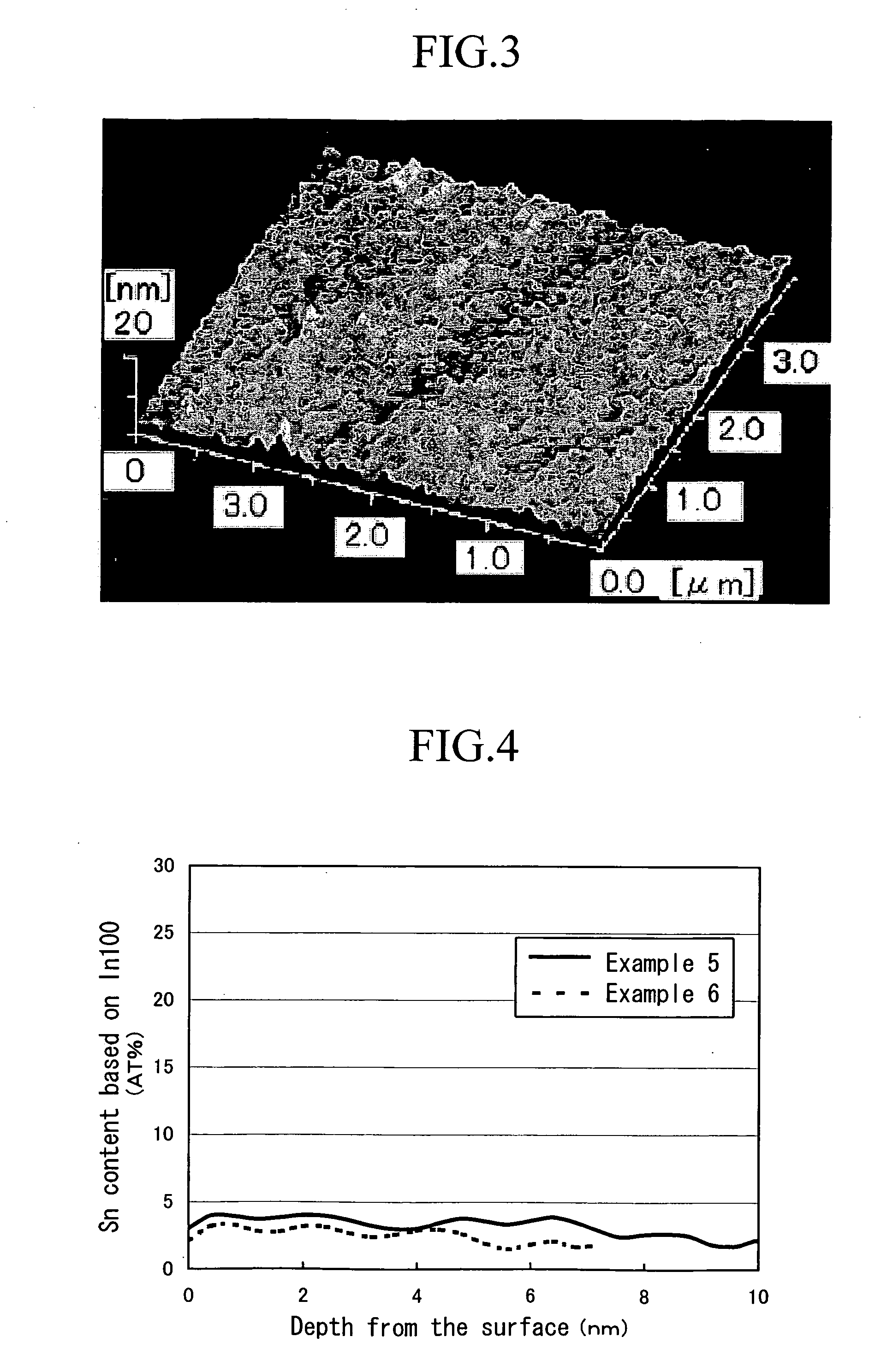

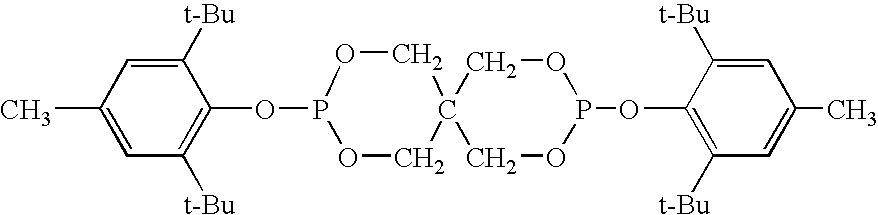

InactiveUS20060285213A1Increase light transmittanceLarge light transmittanceConductive layers on insulating-supportsOxide conductorsElectrically conductiveIndium

A sufficiently high-transparent light transmitting substrate with a transparent conductive film, which is a light transmitting substrate with a transparent conductive film, includes a light transmitting substrate and a continuous transparent conductive film having a thickness of 12 to 2 nm formed on the light transmitting substrate. The transparent conductive film is made of an aggregate of columnar single crystals and has a maximum surface roughness within a range from 1 to 20 nm. It also has an average surface roughness within a range from 0.1 to 10 nm and is a thin film made of a tin-doped indium oxide. Tin atoms are uniformly distributed in the thin film made of the tin-doped indium oxide.

Owner:NIPPON SODA CO LTD

Fiber article comprising a biodegradable plastic

ActiveUS7129190B2Increase resistancePoor in hydrolysis resistanceFibre treatmentWoven fabricsPolymer scienceNatural fiber

A fiber article having excellent hydrolysis resistance, characterized in that the article is fiber structure composed of 10 to 90% by weight of a fiber (A) comprised of a biodegradable plastic formulated with a carbodiimide compound as a stabilizer against hydrolysis and 90 to 10% by weight of at least one fiber (B) selected from a natural fiber, a regenerated fiber, a semi-synthetic fiber and a synthetic fiber, which fiber structure has been subjected to at least one treatment processing selected from scouring processing, bleaching processing, liquid ammonium processing, mercerization processing, biological processing, dyeing processing, or resin treatment, and concentration of total terminal carboxyl groups derived from the fiber (A) in said fiber article is not higher than 30 equivalents / ton based on the fiber (A), etc. It is an object of the present invention to solve conventional problems of a fiber or a fiber article comprising a biodegradable plastic, such as poor hydrolysis resistance, poor heat resistance, strength reduction and coloring by yellowing, and in particular to provide a fiber article superior in hydrolysis resistance, alkali resistance and dyeing resistance.

Owner:NISSHINBO IND INC

Particulate magnetic recording medium and magnetic recording device

ActiveUS8947984B2Poor heat resistanceEasy to writeMagnetic materials for record carriersBase layers for recording layersParticulatesNon magnetic

The magnetic recording medium is a particulate magnetic recording medium for heat-assisted recording, as well as includes a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic organic material support and a heat-diffusing layer of higher thermal conductivity than the magnetic layer between the nonmagnetic organic material support and the magnetic layer.

Owner:FUJIFILM CORP

Artificial leather manufacturing method adopting TPU (thermoplastic urethane) to plasticize PVC (polyvinyl chloride) and reducing use of plasticizer

InactiveCN105088806AInnovativeHave a positive effectTextiles and paperThermoplasticPolyvinyl chloride

The invention discloses an artificial leather manufacturing method adopting TPU (thermoplastic urethane) to plasticize PVC (polyvinyl chloride) and reducing use of a plasticizer. According to the method, 80-90 parts of PVC powder, 3-5 parts of a stabilizer, 50-60 parts of the plasticizer, 10-20 parts of TPU, 2-3 parts of a foaming agent, 5-10 parts of filler and an appropriate quantity of a colorant are mixed uniformly, and an artificial leather product is prepared with a traditional calendering process. PVC and TPU are all polar macromolecules and have good compatibility; the TPU macromolecules contain both soft segments and hard segments, the elasticity modulus of the TPU macromolecules is between that of plastics and that of rubber, the TPU macromolecules can still keep better elasticity in a relatively wide temperature range and further have good performance of low-temperature resistance, solvent resistance, heat resistance and the like; when the TPU is used for plasticizing PVC, the glass-transition temperature of a PVC / TPU blended material is reduced remarkably, the heat resistance is improved, and 30%-40% of the use quantity of a micromolecular plasticizer can be reduced; TPU adopts the macromolecules, is not easy to transfer and has lasting plasticizing effect; besides, polar groups such as epoxy groups, ester bonds and the like in the plasticizer and urethane groups in the TPU macromolecules can form a hydrogen bond or dipole interaction, and accordingly, the transference resistance of the plasticizer is further improved.

Owner:SICHUAN UNIV

Stabilizer against hydrolysis for an ester-group-containing resin and a thermoplastic resin composition

ActiveUS20050054755A1Improve stabilityImproved color stabilityChemical inhibitorsHeat resistanceAntioxidant

A stabilizer against hydrolysis, which can solve conventional problems of a carbodiimide compound compounded in an ester-group-containing resin or a biodegradable plastic as a stabilizer against hydrolysis, such as poor heat resistance and a coloring problem due to yellowing, and can provide enhanced resistance against hydrolysis, and a thermoplastic resin composition of an ester-group-containing resin or a biodegradable plastic containing the same. Specifically, that the stabilizer against hydrolysis includes a carbodiimide composition comprising an aliphatic carbodiimide compound (A) and a phosphorus antioxidant (B), preferably the stabilizer contains a carbodiimide composition wherein a phosphorus antioxidant (B1) is dispersed and present in the carbodiimide composition by admixing the phosphorus antioxidant (B1) during synthesis of the aliphatic carbodiimide compound (A), and a thermoplastic resin composition having a superior stability against hydrolysis, characterized in that said stabilizer against hydrolysis is compounded in an easily hydrolysable resin (C).

Owner:NISSHINBO IND INC

Particulate magnetic recording medium and magnetic recording device

ActiveUS20140219069A1Poor heat resistanceReduce layeringBase layers for recording layersRecord information storageParticulatesMaterials science

The magnetic recording medium is a particulate magnetic recording medium for heat-assisted recording, as well as includes a magnetic layer comprising ferromagnetic powder and binder on a nonmagnetic organic material support and a heat-diffusing layer of higher thermal conductivity than the magnetic layer between the nonmagnetic organic material support and the magnetic layer.

Owner:FUJIFILM CORP

Controller

ActiveUS20050269534A1Inferior heat resistanceIncrease pressureDiaphragm valvesEngine sealsEngineeringFlange

Booster means 11 for transmitting a force acting on a piston 10 to a valve stem 9 on amplification comprises pivotal members 25 each supported by casings 7, 8 so as to hold an outer end and an inner end thereof in contact with an outer peripheral portion of the piston 10 and a flange portion 22a formed on the valve stem 9 respectively from below and to be pivotally movable about a horizontal rod 26 positioned closer to the inner end. Metal bellows 16 are provided between an outer peripheral portion of the casing top wall 8a and the outer peripheral portion of the piston 10 for sealing off a compressed air admitting space.

Owner:FUJIKIN INC

Polymer film coated with a layer of silane coupling agent

ActiveUS20170225433A1Easily peelableEasy to peelLayered product treatmentSynthetic resin layered productsForeign matterPolymer science

It is provided that a polymer film; a preparation method of the polymer film; and a laminated body used the polymer film. The polymer film is suitable for use in producing a laminate body which comprises a support and a polymer film, and is reduced in foreign-matter trapping and which can be used for supplying film devices using conventional apparatuses for glass substrates or silicon substrates. The polymer film coated with the layer of silane coupling agent, which is suitable for producing a laminate that comprises a support and a polymer film, comprises a silane coupling agent layer formed on at least one surface of the polymer film, wherein the silane coupling agent layer has a three-dimensional surface roughness (Sa) of 5.0 nm or less. The method of efficient for producing the polymer film coated with the above layer is the method for producing without using a vacuum.

Owner:TOYOBO CO LTD

Sandstone similar material and preparation method thereof

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

Release film for use in manufacture of printed circuit boards

InactiveUS20090133911A1Poor heat resistancePoint becomes highInsulating substrate metal adhesion improvementSynthetic resin layered productsFlexible electronicsPrinted circuit board

To provide a release film which is used to avoid adherence between a press hot plate and a printed circuit board or a cover lay film at the time of press work effected to printed circuit boards such as printed wiring boards, flexible printed circuit boards and multilayered printed circuit boards and which has a heat resistance, a releasing property, a non-contamination property, a follow up capability relative to the circuit pattern, an excellent workability during processing and a small environmental impact at the time of disposal, the release film has a shear modulus of 5×105˜107 Pa at a hot press lamination temperature and is formed by overlapping at least one thermoplastic resin layer and at least one metallic layer one above the other.

Owner:KURARAY CO LTD

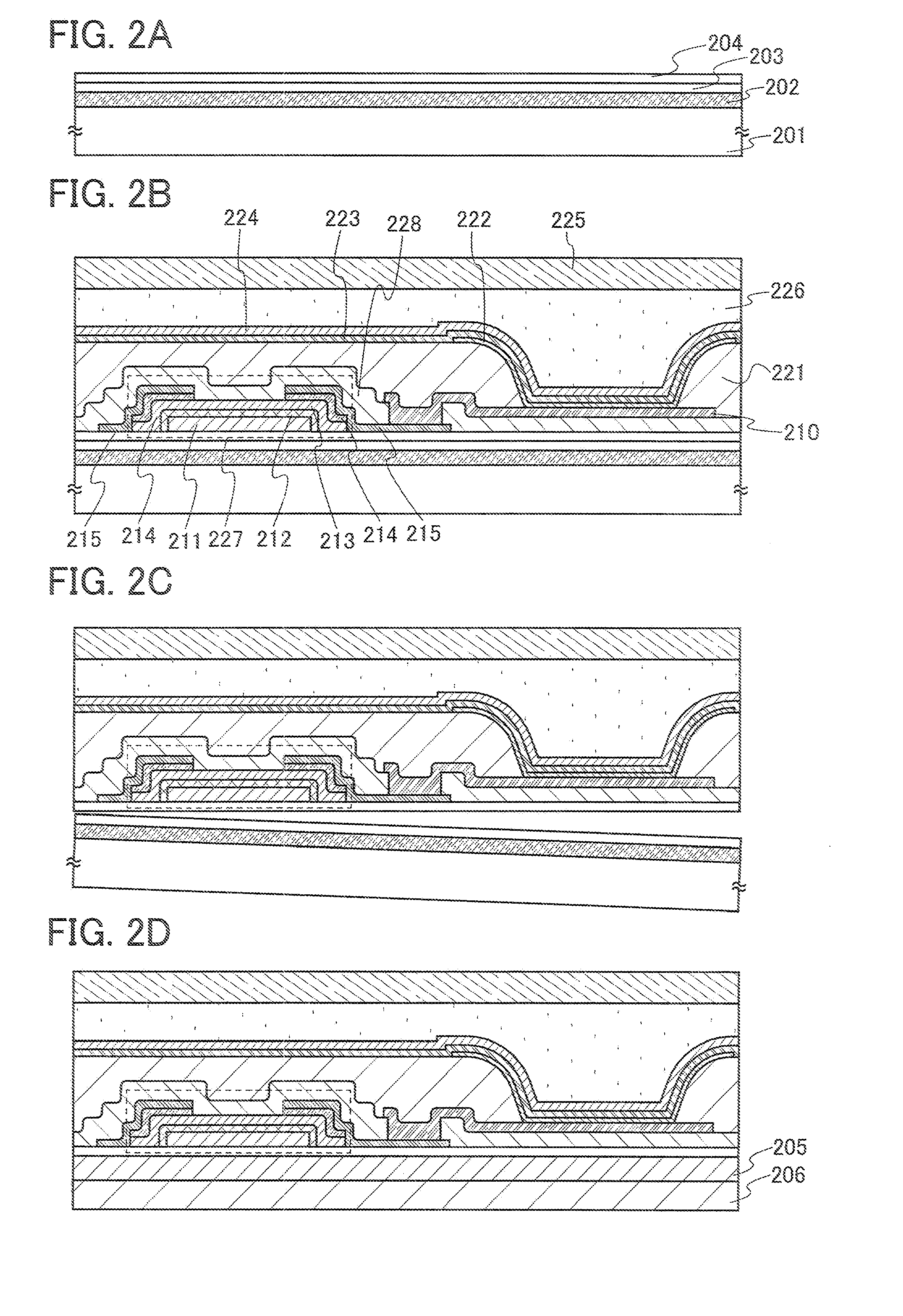

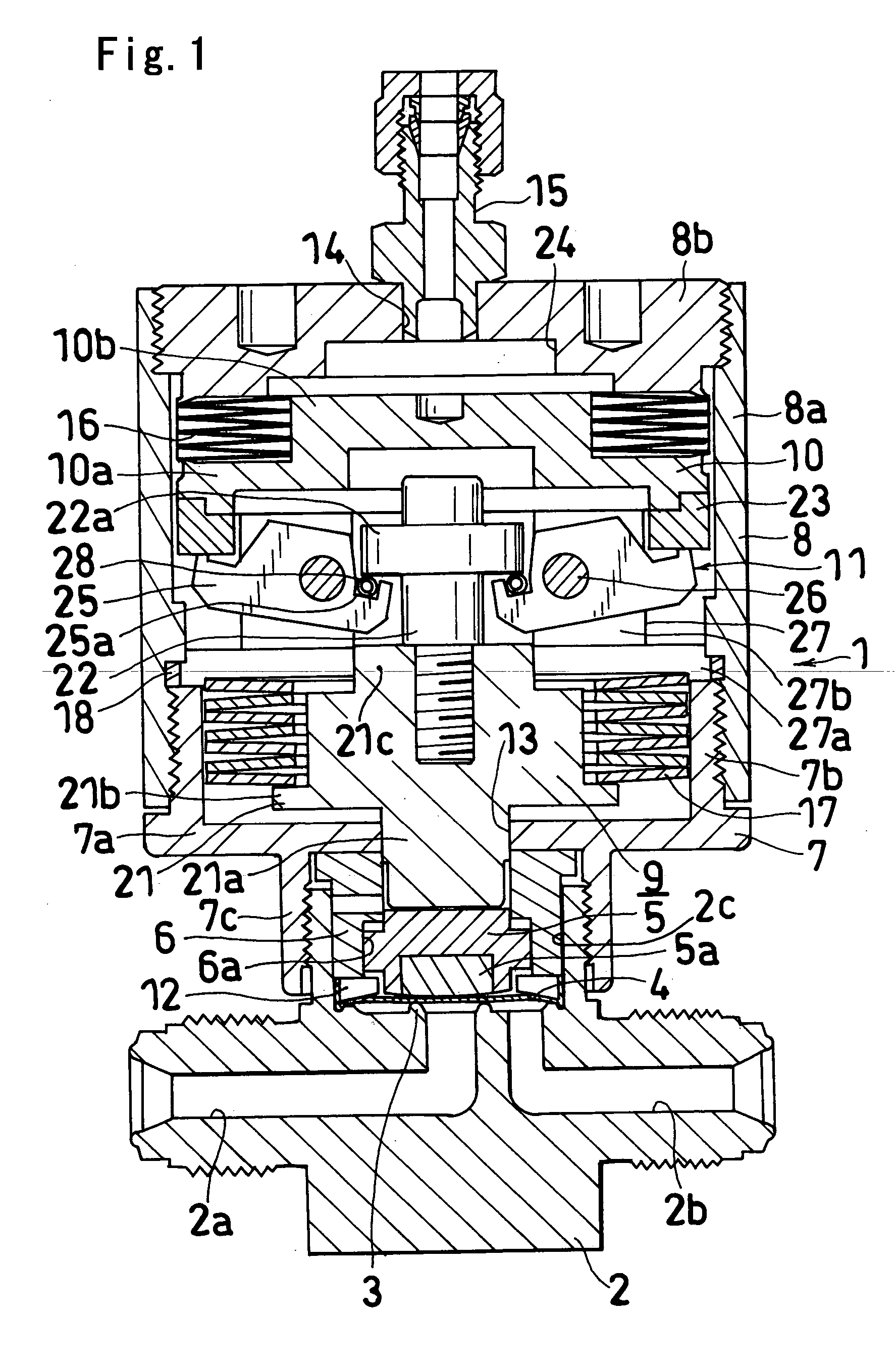

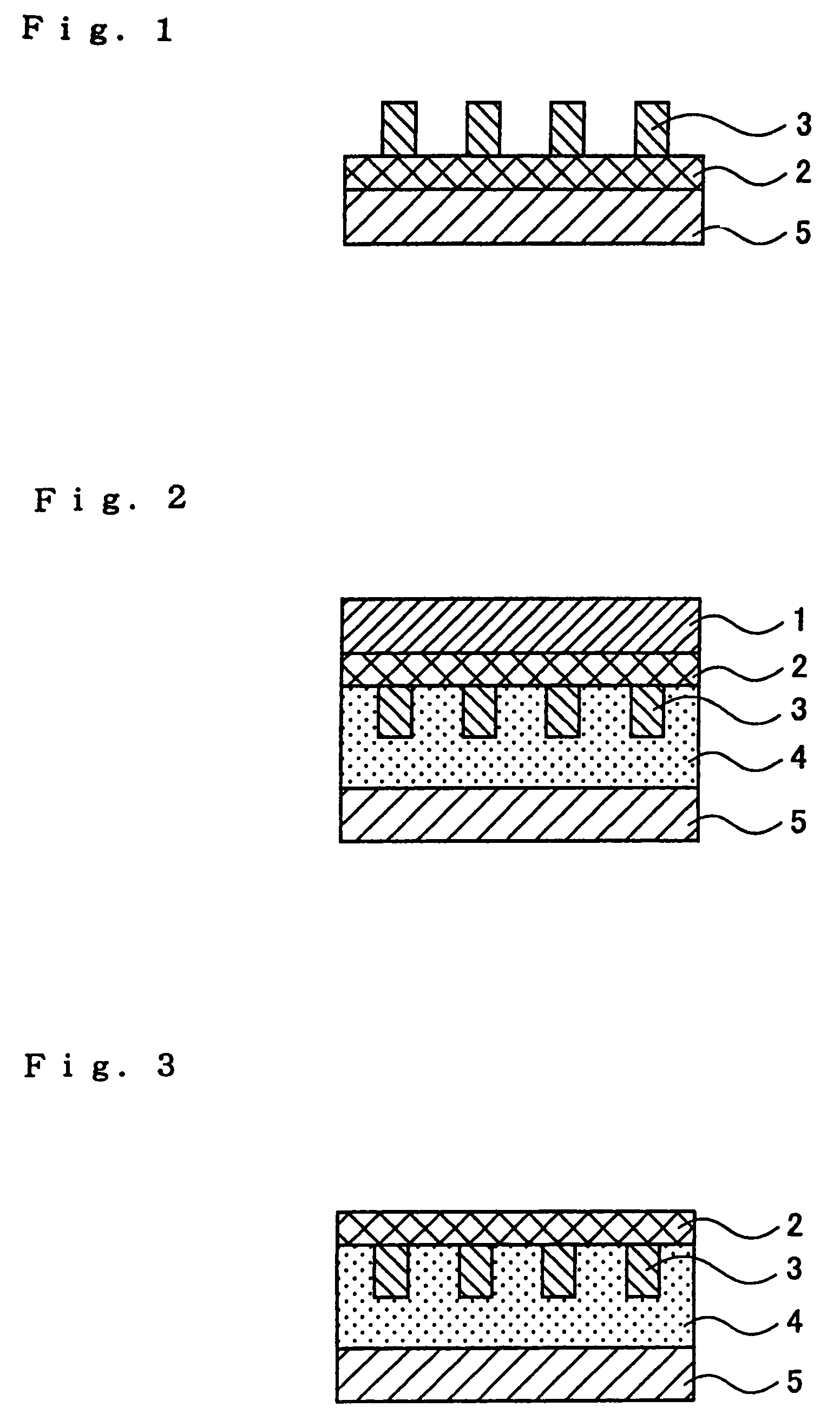

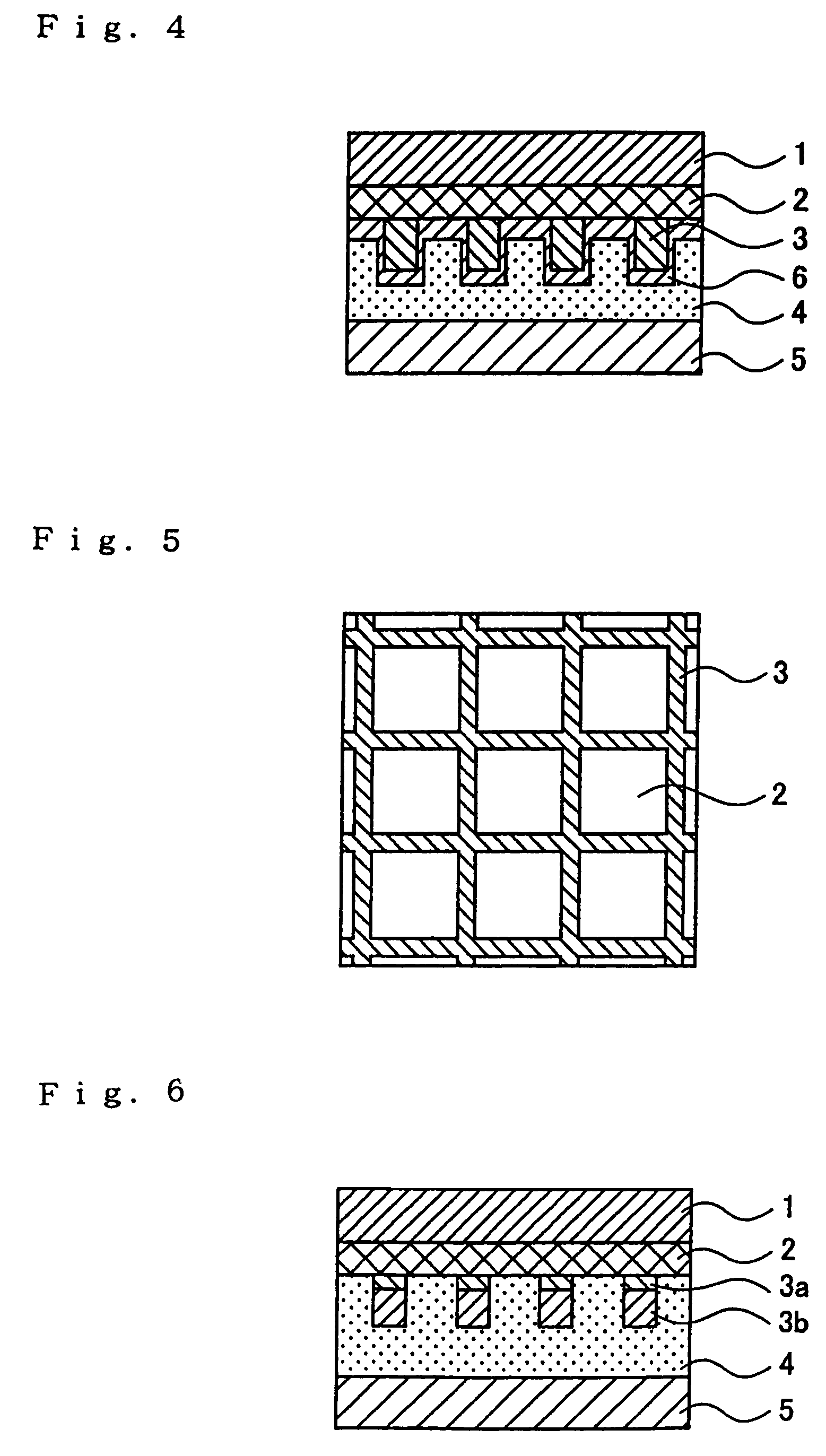

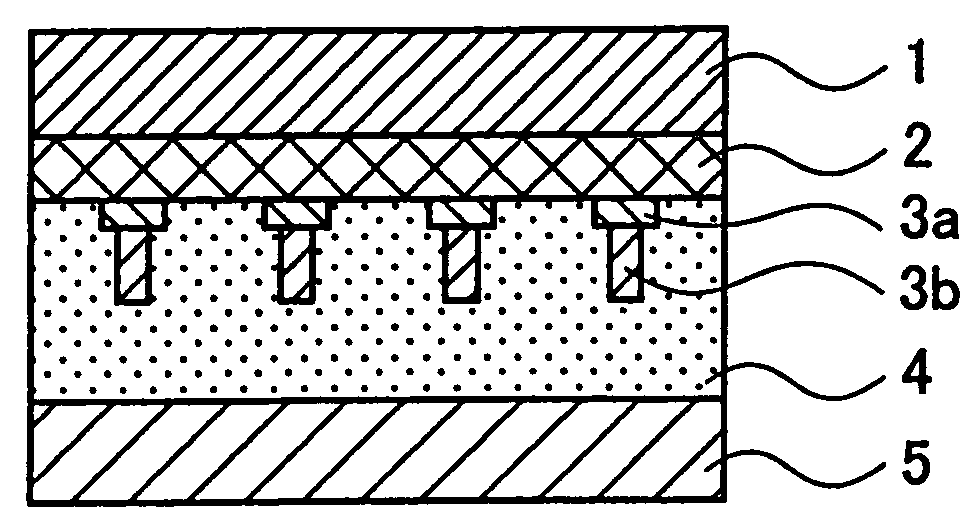

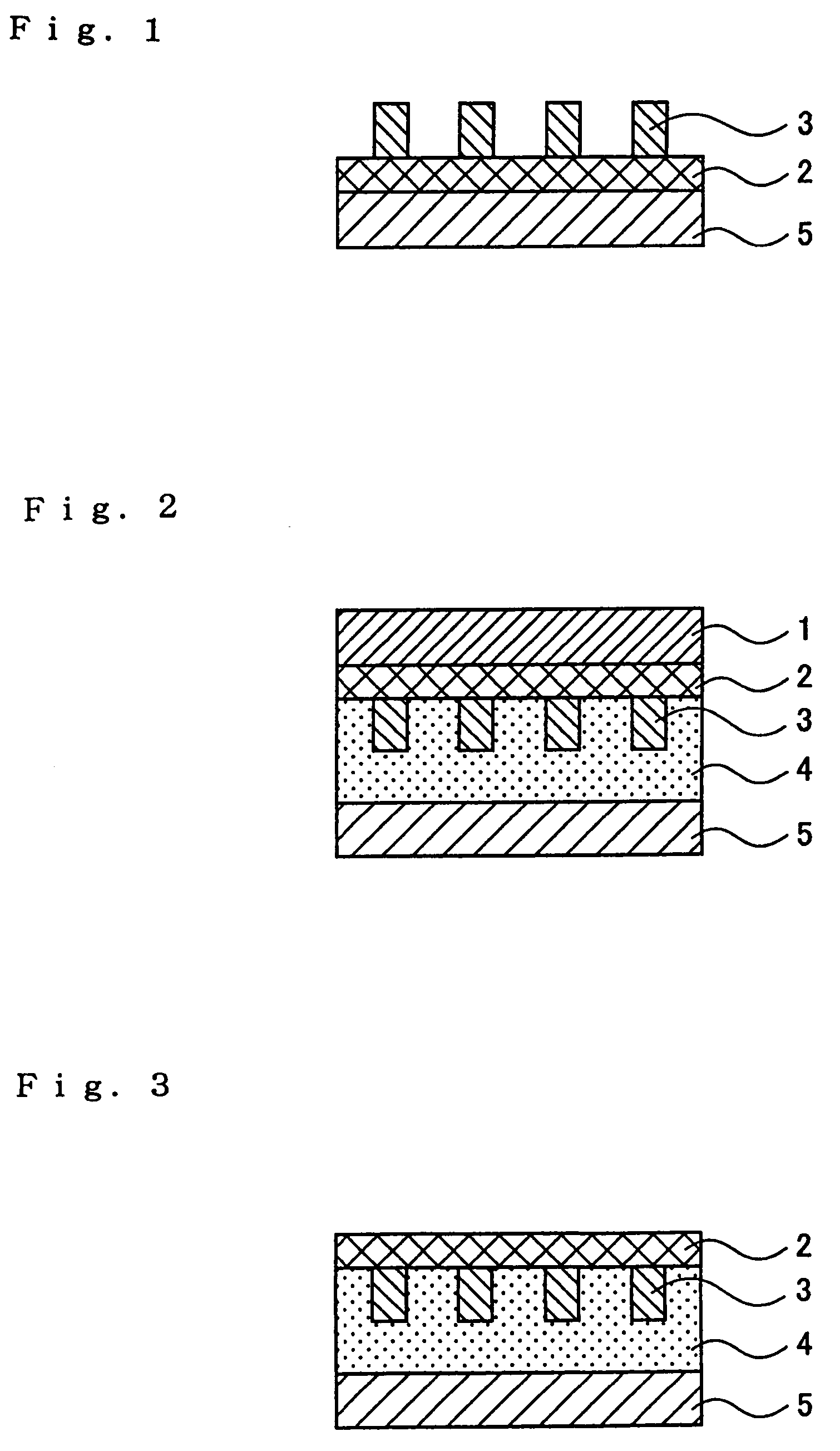

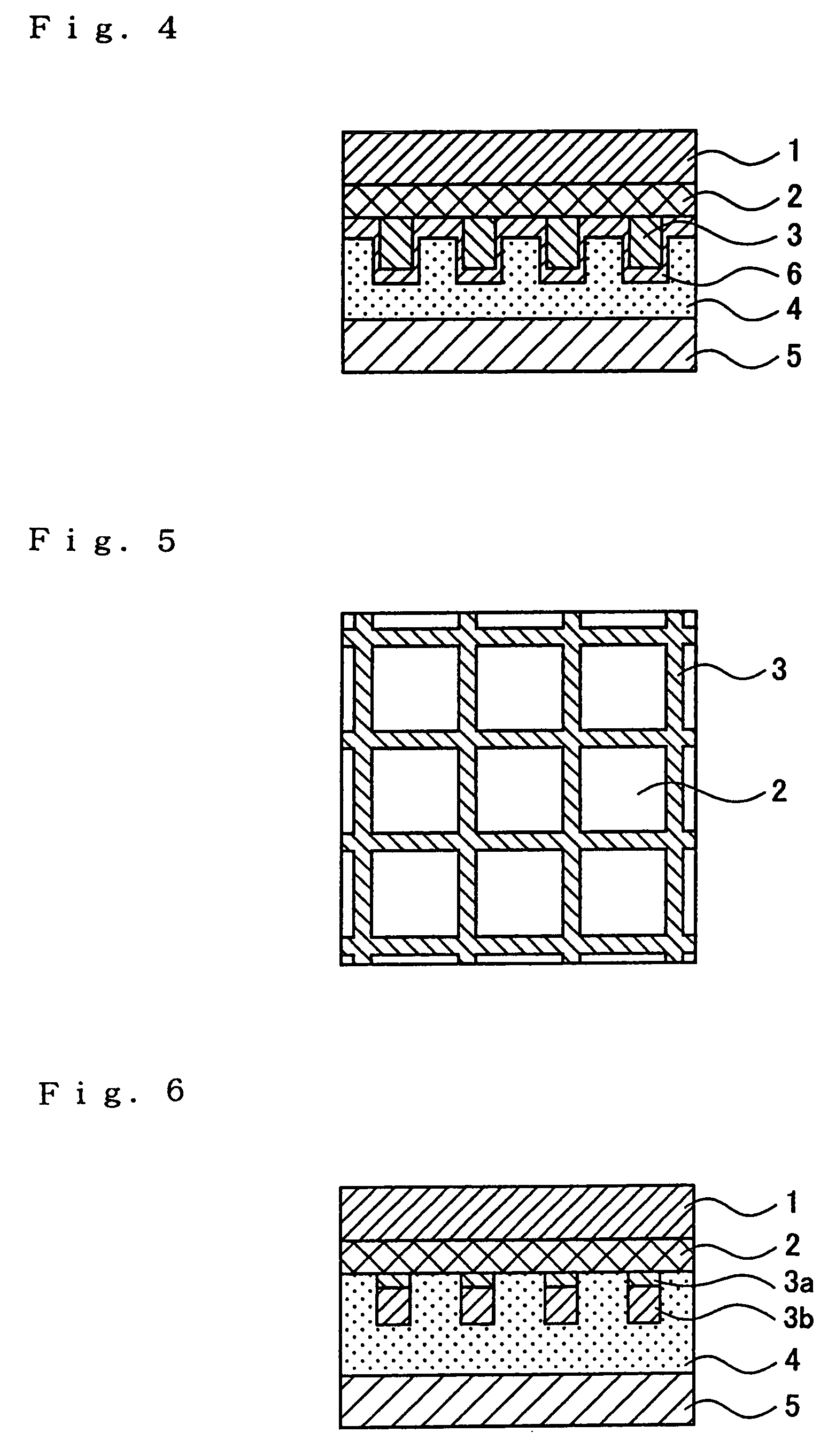

Transparent conductive multi-layer structure, process for its manufacture and device making use of transparent conductive multi-layer structure

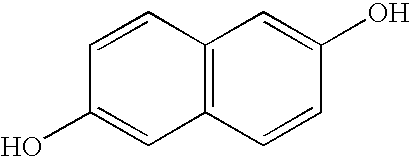

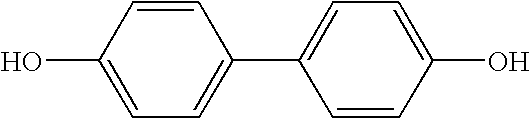

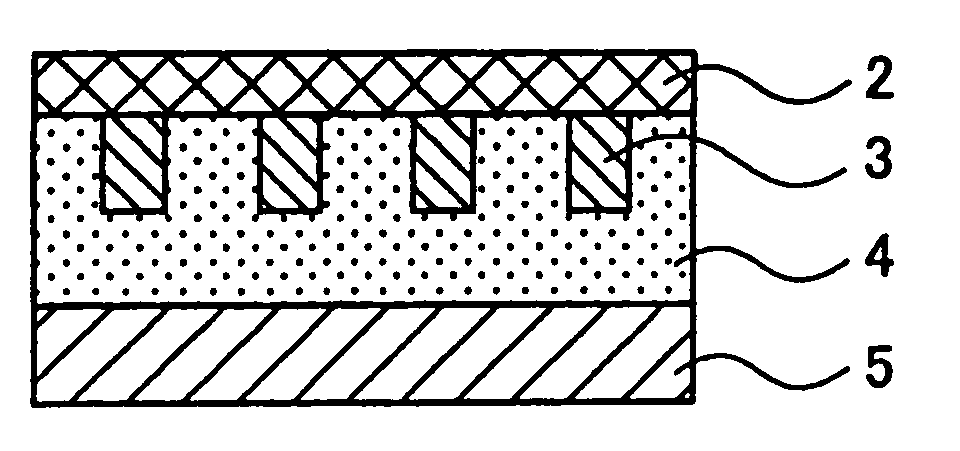

InactiveUS20080271843A1Low resistivityLow costConductive layers on insulating-supportsLight-sensitive devicesAuxiliary electrodeOrganic electroluminescence

A transparent conductive multi-layer structure having a smooth base material 1, a transparent conductive layer 2 formed on the smooth base material 1 by coating, an auxiliary electrode layer 3 formed in a pattern on the transparent conductive layer 2, and a transparent substrate 5 joined to the transparent conductive layer 2 and auxiliary electrode layer 3 through an adhesive layer 4. On a smooth peeled-off surface of the transparent conductive layer 2 from which the smooth base material 1 has been peeled off, various devices are formed to set up devices such as a dye-sensitized solar cell and an organic electroluminescent device.

Owner:SUMITOMO METAL MINING CO LTD

Transparent conductive multi-layer structure, process for its manufacture and device making use of transparent conductive multi-layer structure

InactiveUS7638807B2Low resistivityLow costConductive layers on insulating-supportsLight-sensitive devicesAuxiliary electrodeOrganic electroluminescence

A transparent conductive multi-layer structure having a smooth base material 1, a transparent conductive layer 2 formed on the smooth base material 1 by coating, an auxiliary electrode layer 3 formed in a pattern on the transparent conductive layer 2, and a transparent substrate 5 joined to the transparent conductive layer 2 and auxiliary electrode layer 3 through an adhesive layer 4. On a smooth peeled-off surface of the transparent conductive layer 2 from which the smooth base material 1 has been peeled off, various devices are formed to set up devices such as a dye-sensitized solar cell and an organic electroluminescent device.

Owner:SUMITOMO METAL MINING CO LTD

Air fuel ratio control apparatus for engines

InactiveUS20050235974A1Low concentrations of COLarge capacity of controlElectrical controlMachines/enginesGeneral purposeExhaust fumes

An air fuel ratio control apparatus readily satisfies an emission requirement and is particularly preferable for small-displacement engines. The air fuel ratio control apparatus for an engine includes a fuel control member disposed in a fuel passage delivering fuel from a fuel metering chamber of a carburetor supplying the fuel to a suction passage of a comparatively small engine such as a general purpose engine, a working machine engine and the like, a combustion gas sensor disposed in an exhaust pipe in the engine, and an electronic control unit. The control unit actuates the fuel control member in response to a concentration of a combustion gas component in an exhaust gas detected by the combustion gas sensor so as to control a fuel flow rate.

Owner:ZAMA JAPAN

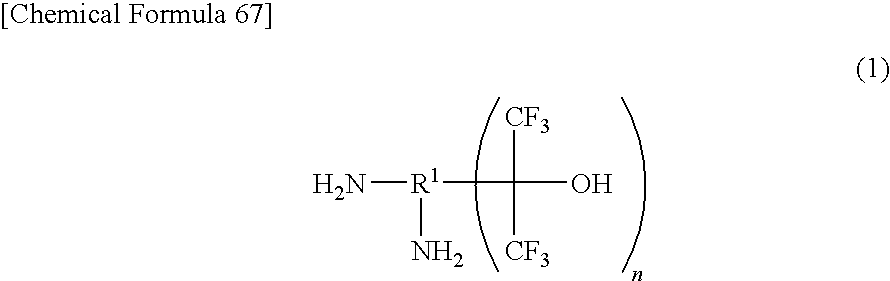

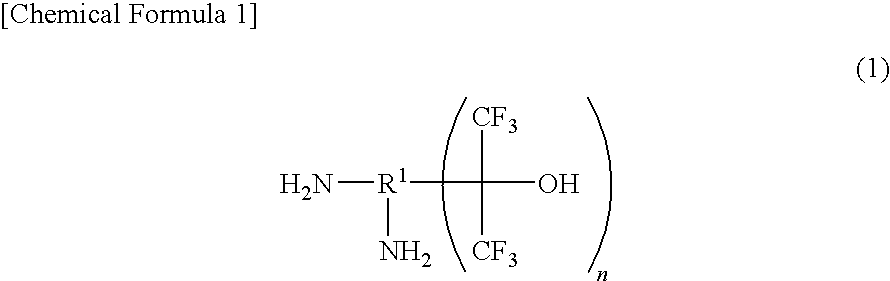

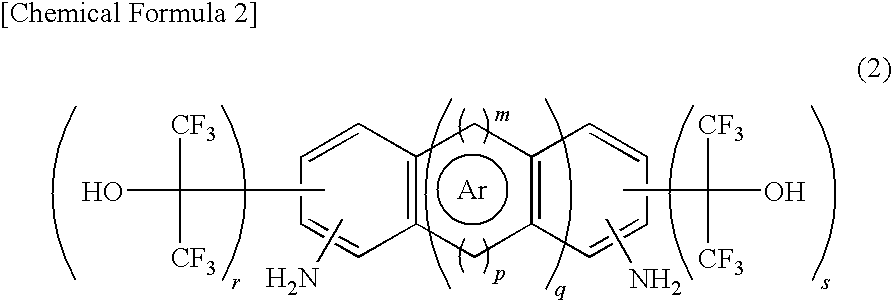

Fluorinated Diamine and Polymer Formed Therefrom

InactiveUS20100029895A1Heat resistance characteristic been improvedImprove rigidityOrganic chemistryOrganic compound preparationThermal expansionAromatic hydrocarbon

There is provided a fluorine-containing diamine represented by formula (1).In this formula, R1 represents a condensed polycyclic type aromatic hydrocarbon group, and at least one —C(CF3)2OH group and at least one —NH2 group are in a relation such that they are attached to adjacent carbons of carbon atoms constituting the condensed polycyclic type aromatic hydrocarbon group. Polymer compounds derived from this fluorine-containing diamine have superior low dielectric property and low water-absorbing property, and, in addition to that, shows low thermal expansion property and high glass transition temperature.

Owner:CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com