Patents

Literature

255results about How to "Smooth peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

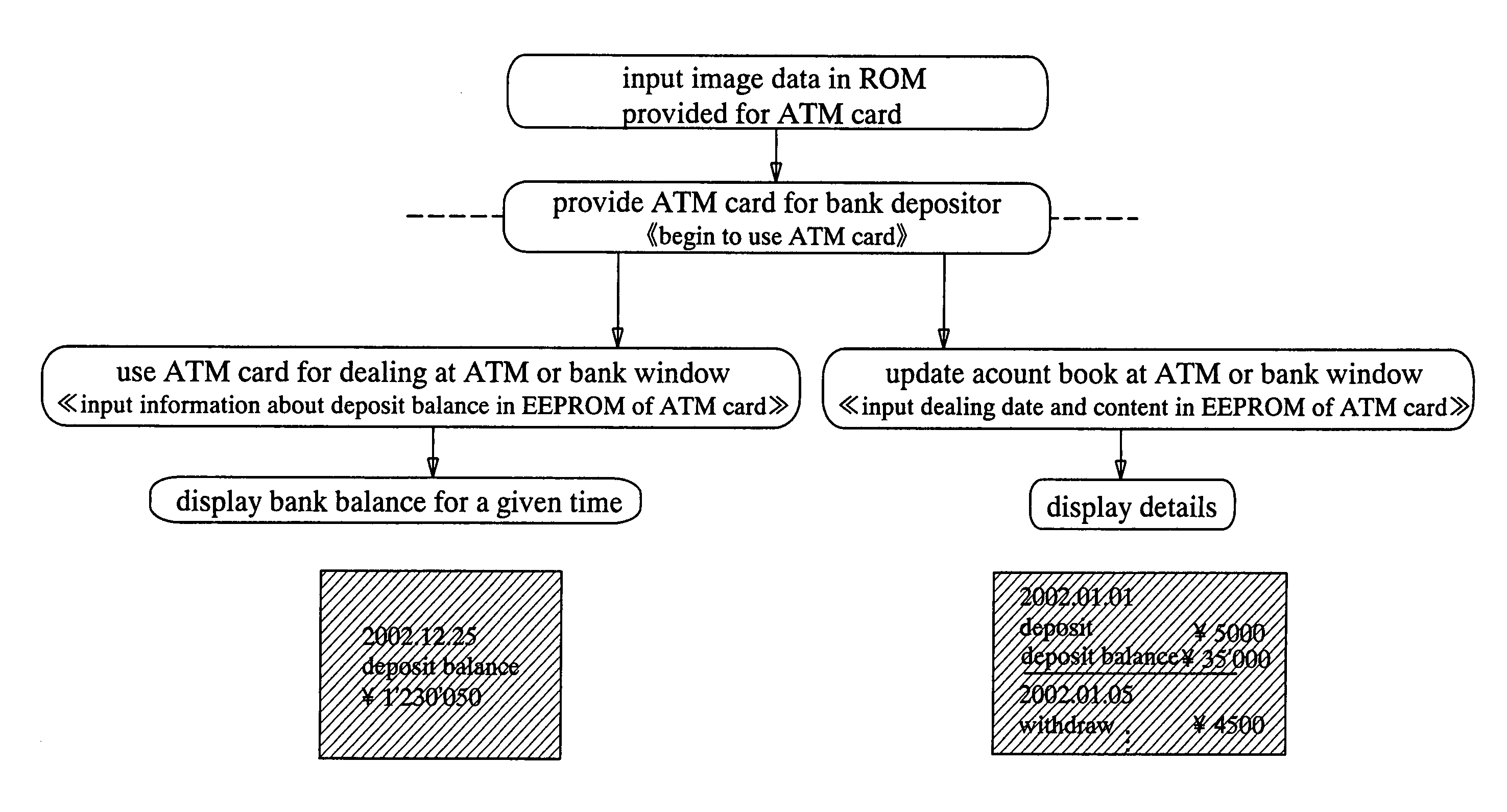

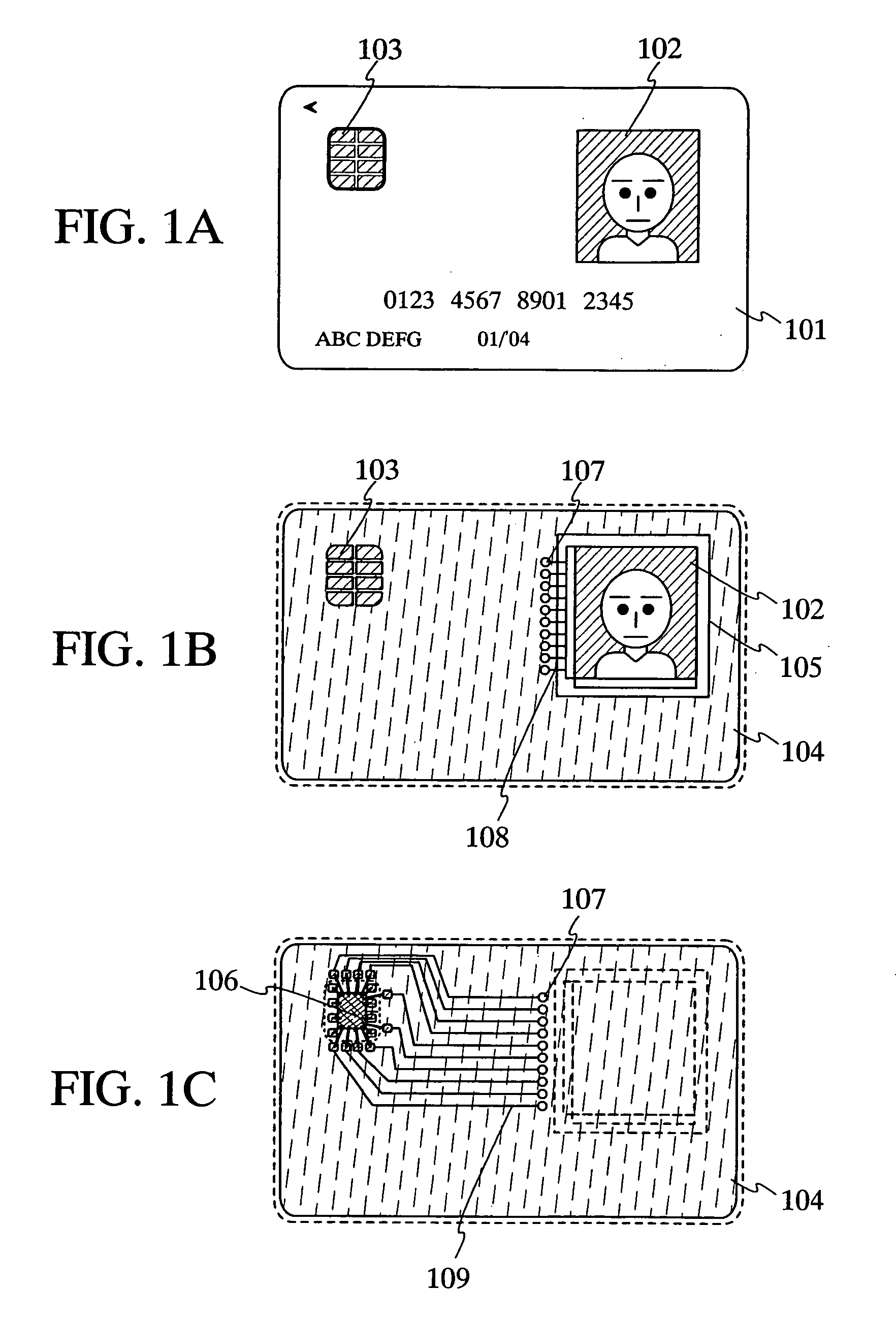

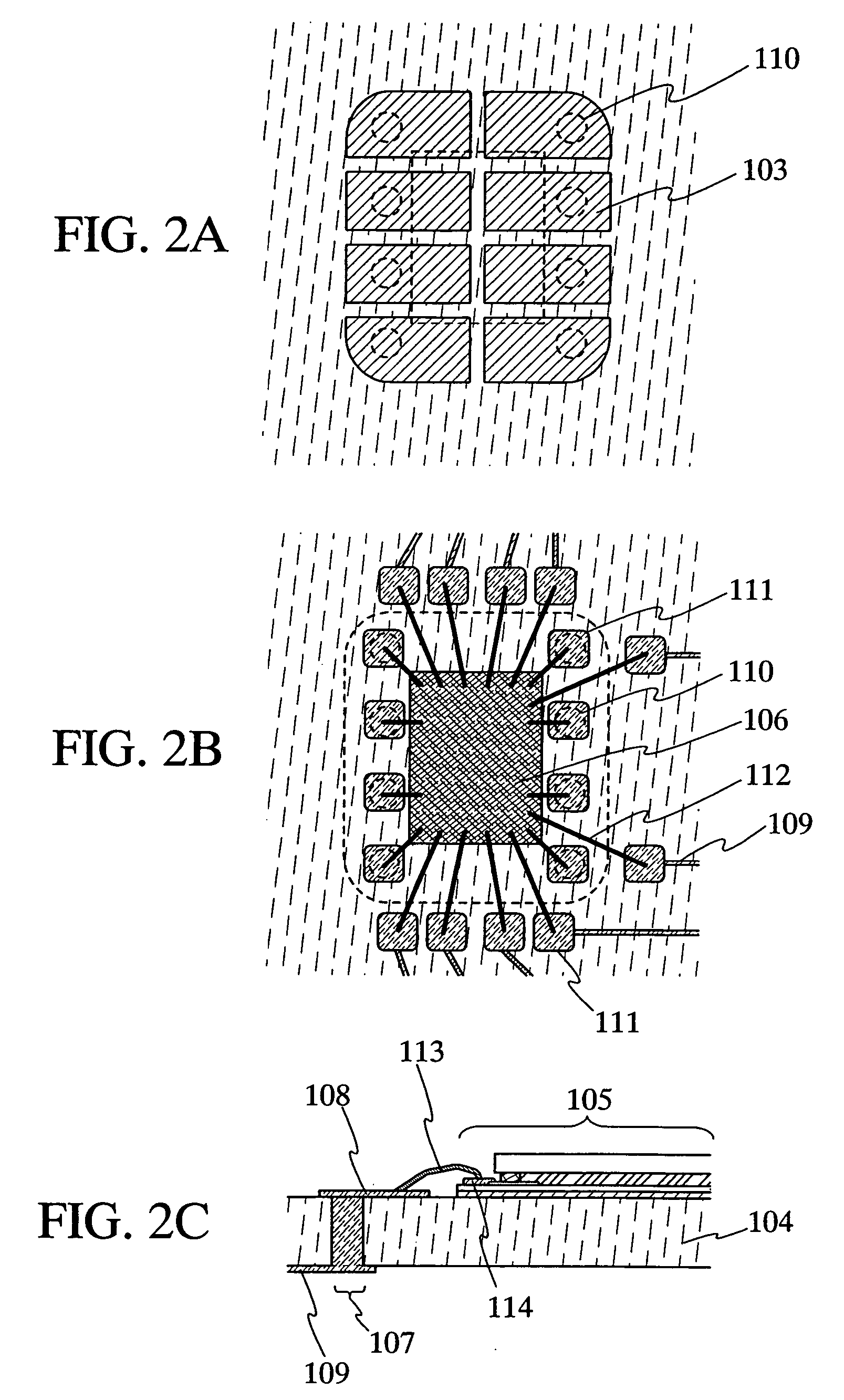

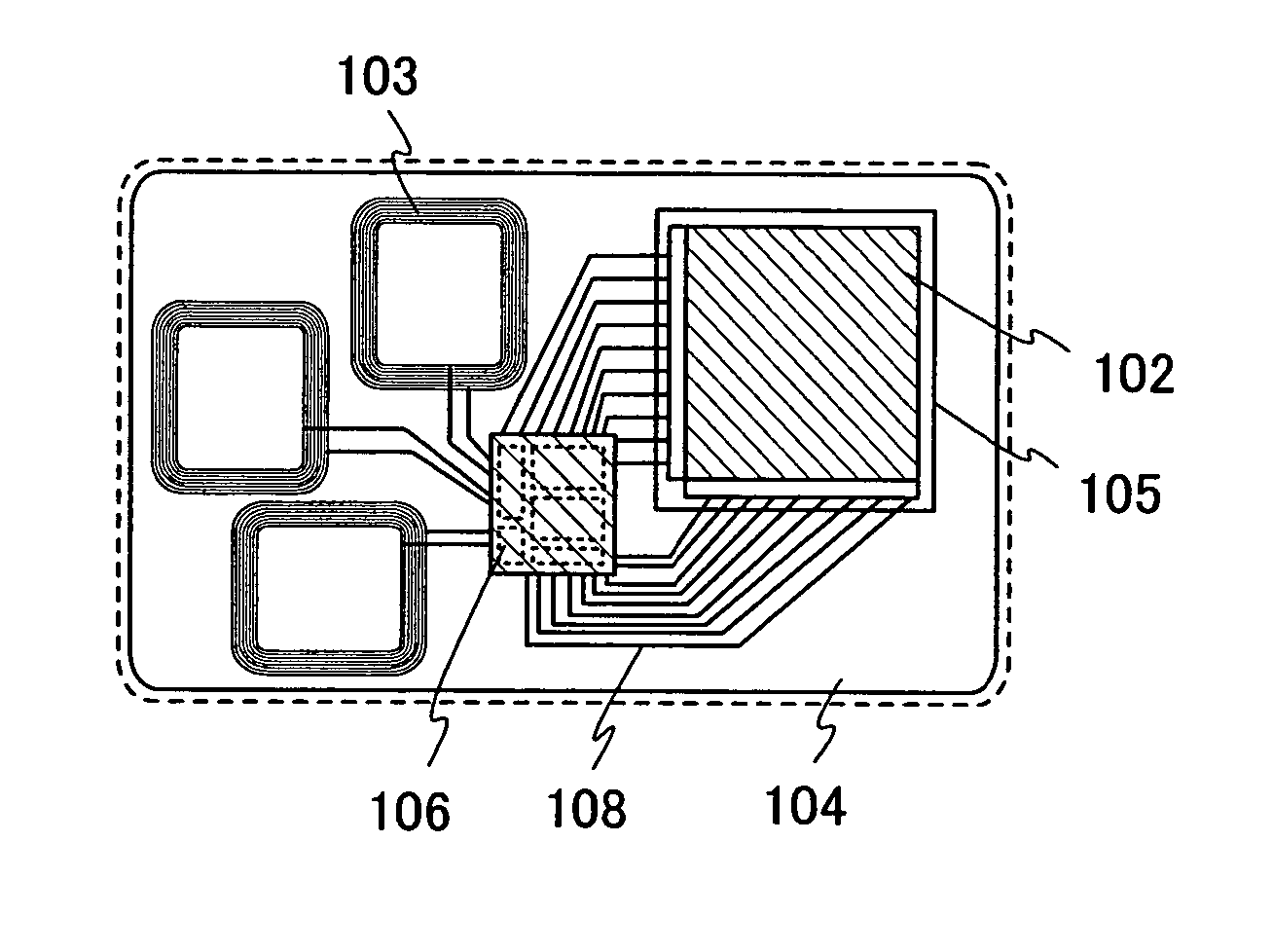

IC card and booking-account system using the IC card

InactiveUS20040128246A1Improve rigidityAvoid damageFinanceStatic indicating devicesDisplay deviceEngineering

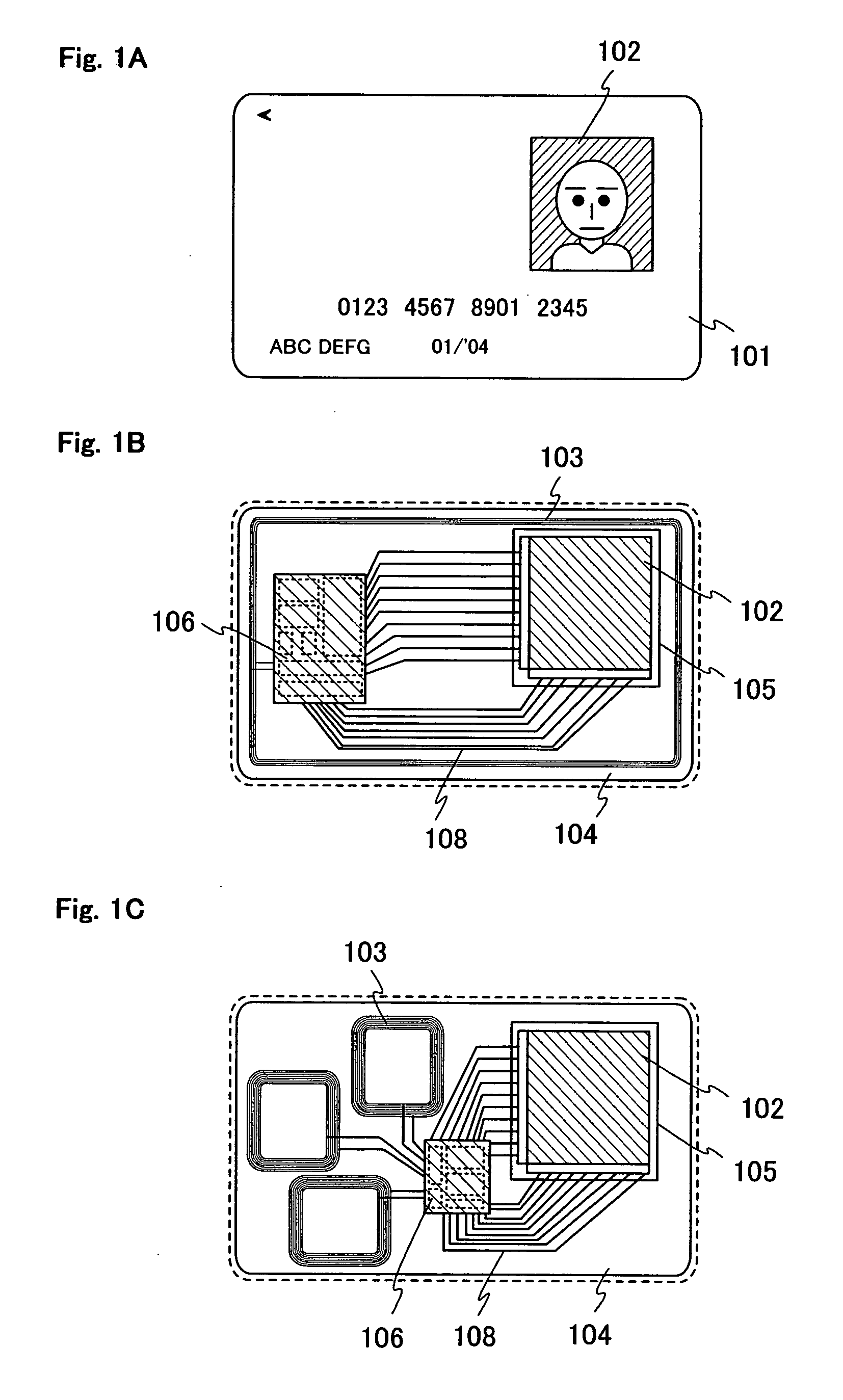

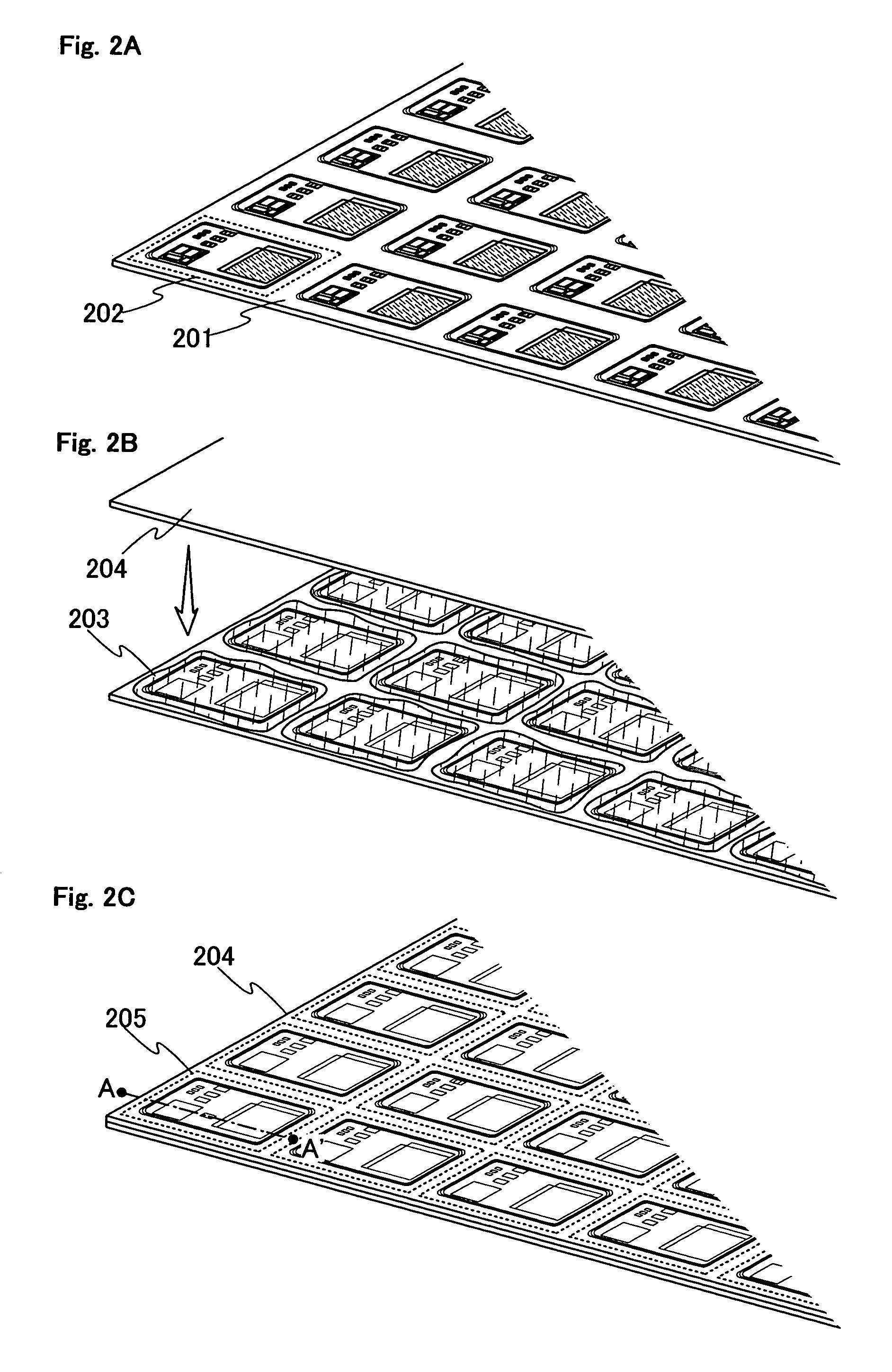

It is an object of the present invention to provide a highly sophisticated functional IC card that can ensure security by preventing forgery such as changing a picture of a face, and display other images as well as the picture of a face. An IC card comprising a display device and a plurality of thin film integrated circuits; wherein driving of the display device is controlled by the plurality of thin film integrated circuits; a semiconductor element used for the plurality of thin film integrated circuits and the display device is formed by using a polycrystalline semiconductor film; the plurality of thin film integrated circuits are laminated; the display device and the plurality of thin film integrated circuits are equipped for the same printed wiring board; and the IC card has a thickness of from 0.05 mm to 1 mm.

Owner:SEMICON ENERGY LAB CO LTD

IC card and booking account system using the IC card

InactiveUS20040129450A1Poor heat resistanceImprove brittlenessSolid-state devicesPayment architectureDisplay deviceIntegrated circuit

It is an object of the present invention to provide a highly sophisticated functional card that can ensure security by preventing forgery such as changing a picture of a face, and display other images as well as the picture of a face. A card comprising a display device and a thin film integrated circuit; wherein driving of the display device is controlled by the thin film integrated circuit; a semiconductor element used for the thin film integrated circuit and the display device is formed by using a polycrystalline semiconductor film; the thin film integrated circuit and the display device are sealed with a resin between a first substrate and a second substrate of the card; and the first substrate and the second substrate are plastic substrates.

Owner:SEMICON ENERGY LAB CO LTD

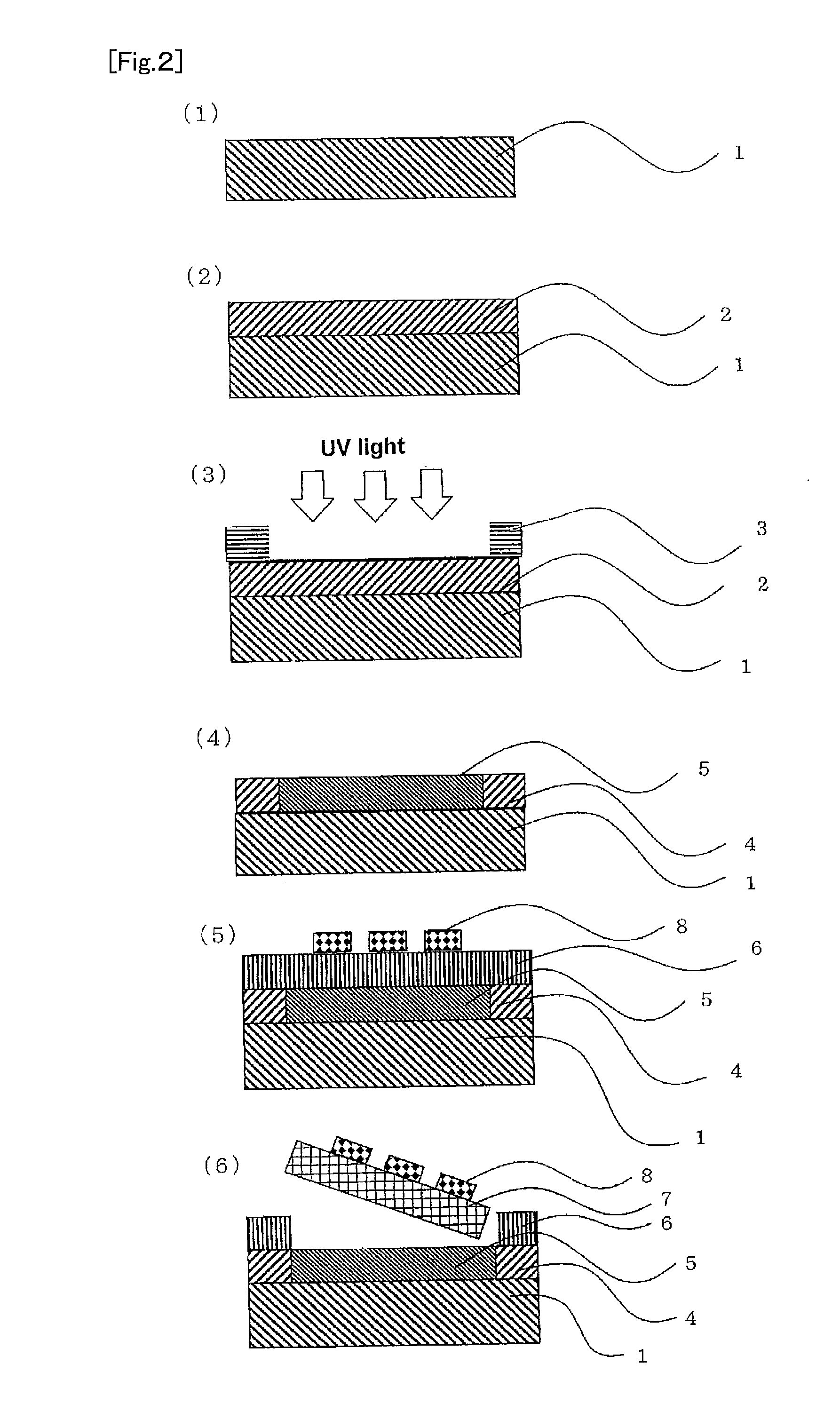

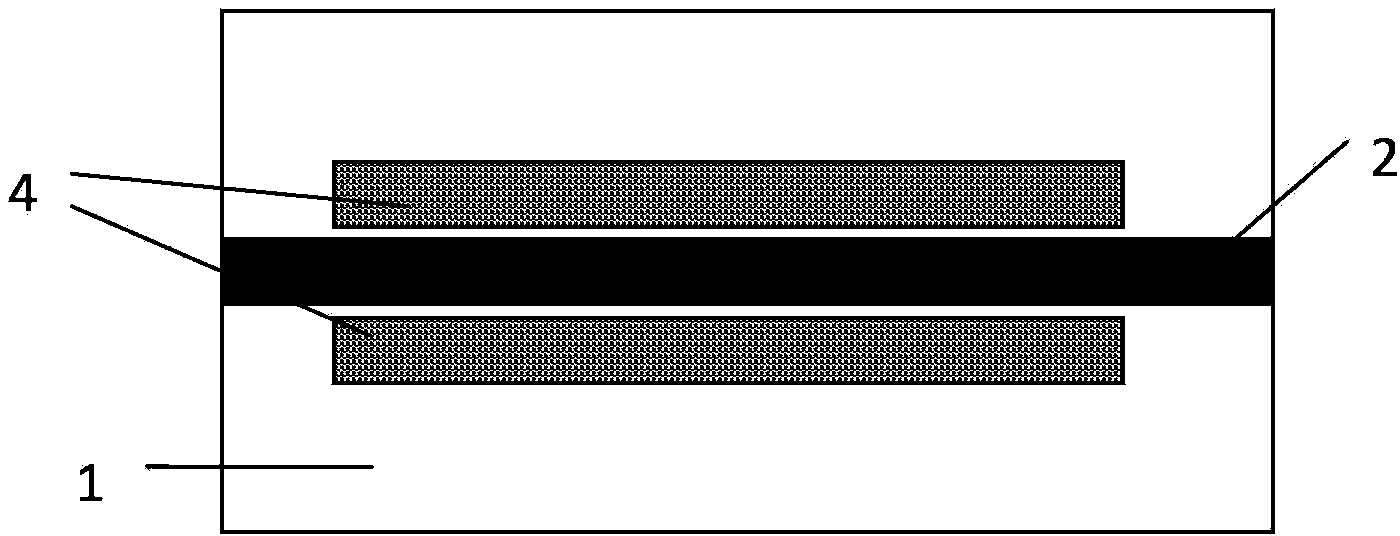

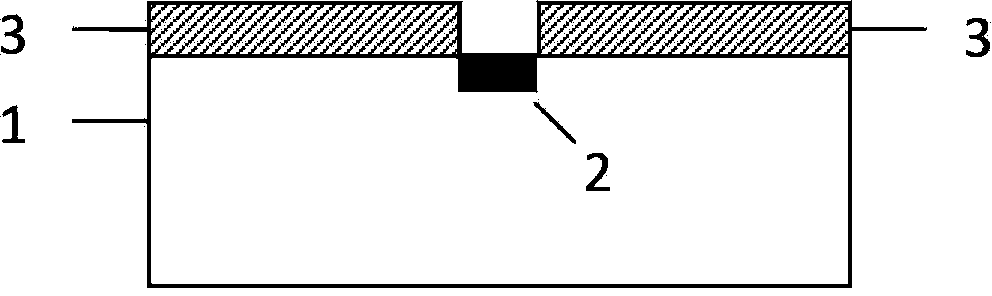

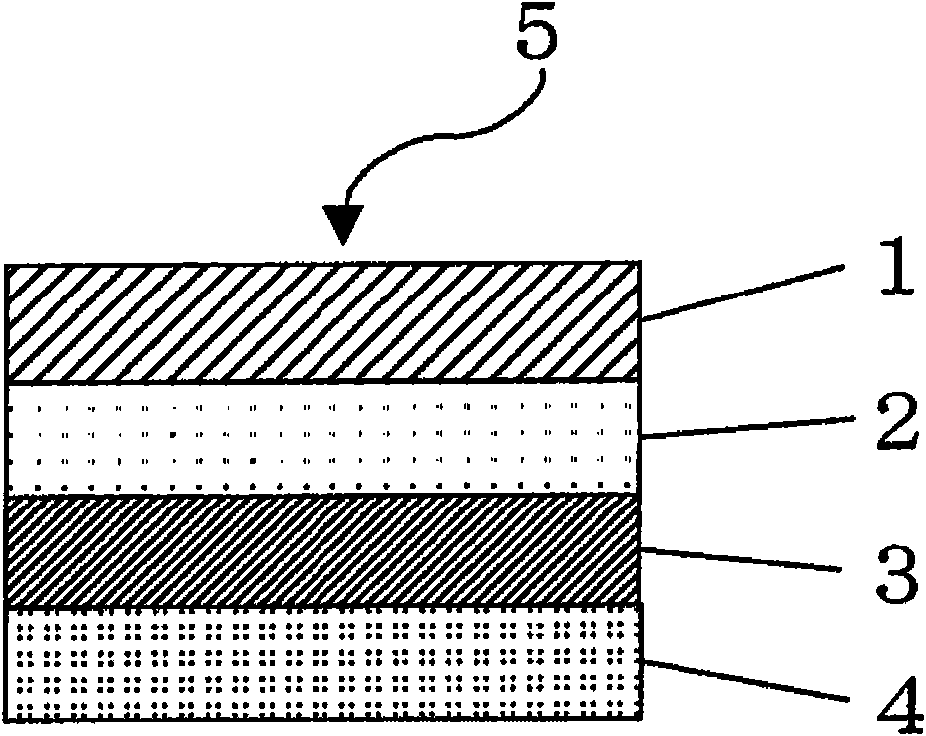

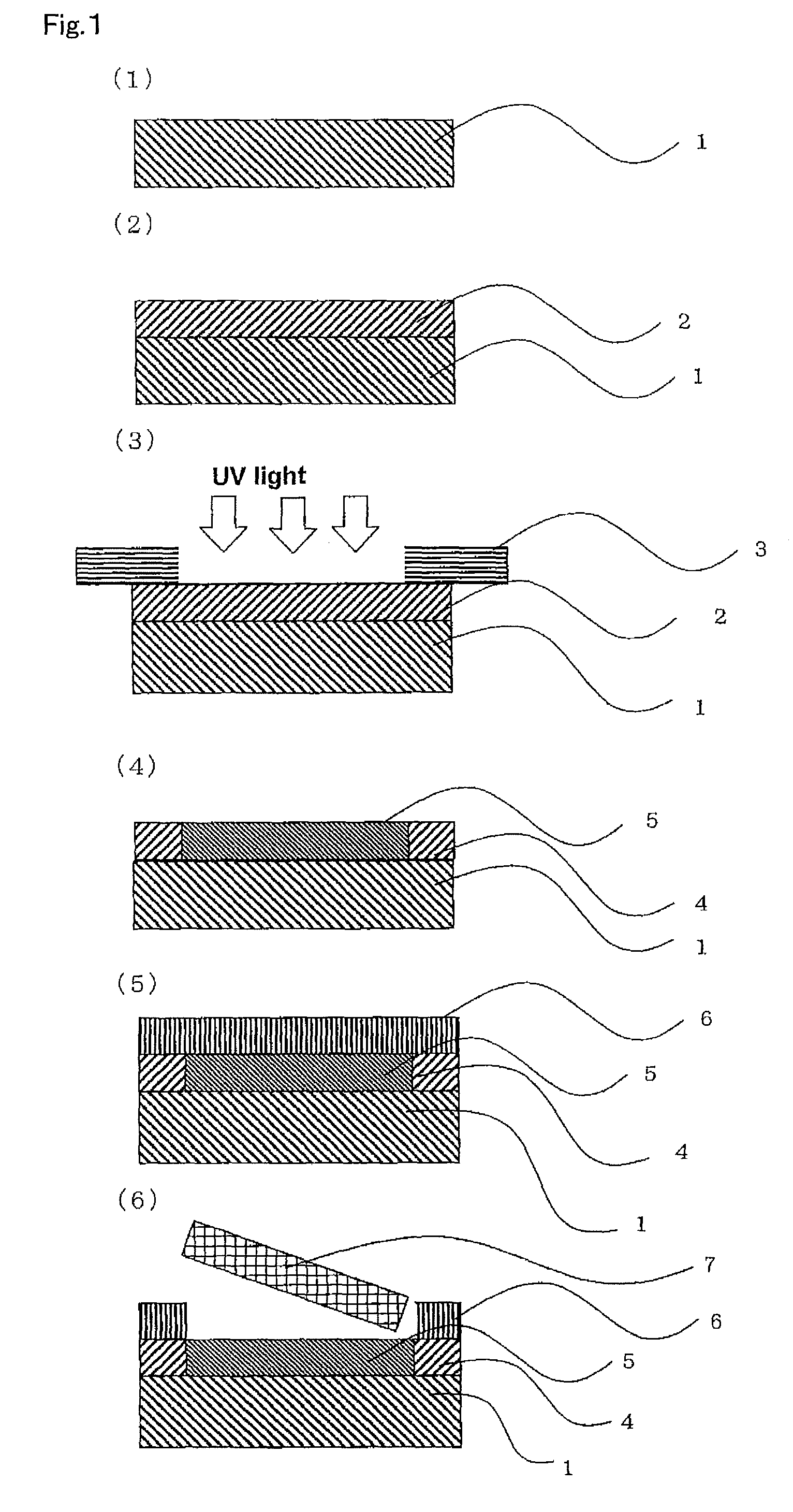

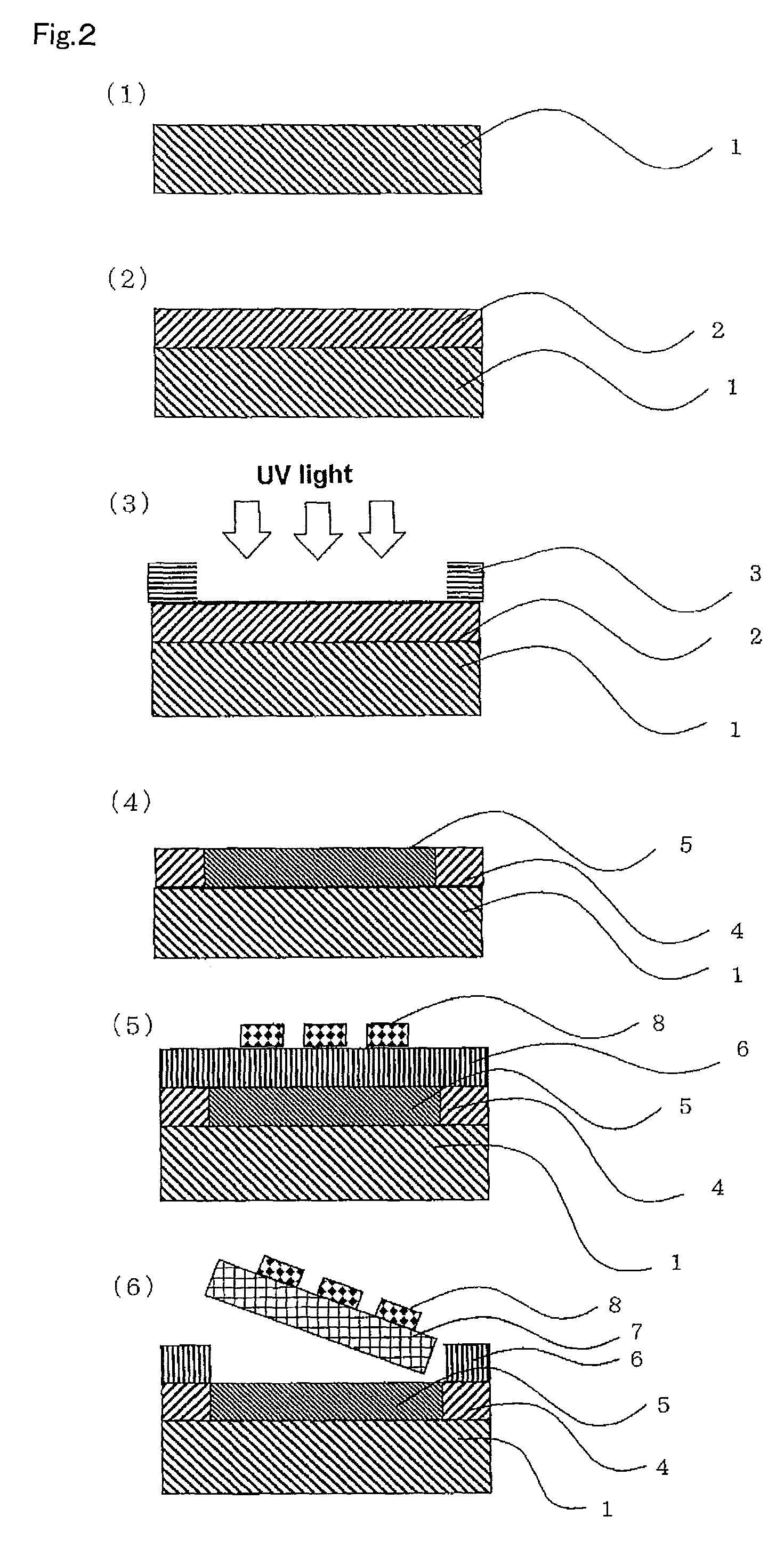

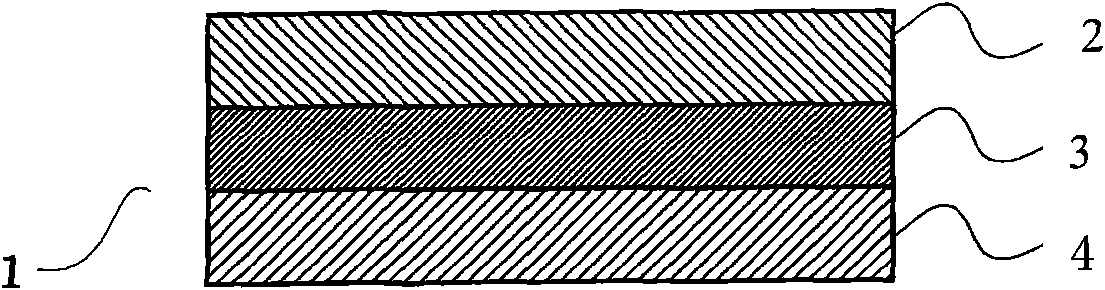

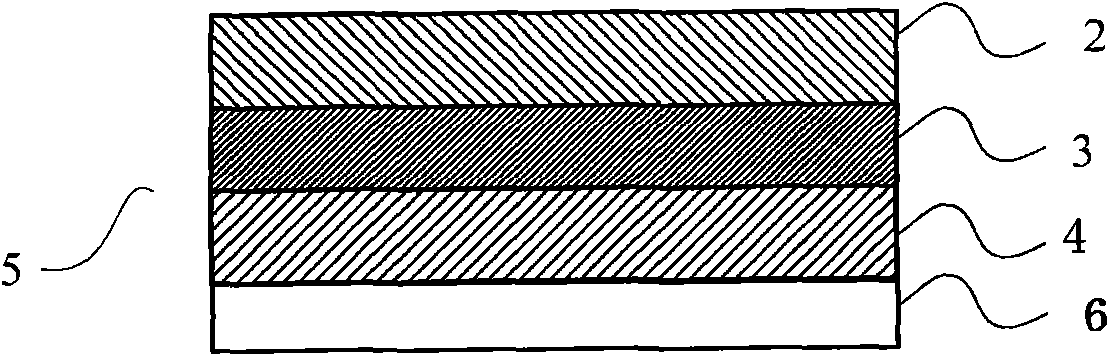

Laminate, method for producing same, and method for producing device structure using same

ActiveUS20140041800A1Easy to getGood partitionLamination ancillary operationsDecorative surface effectsCouplingEngineering

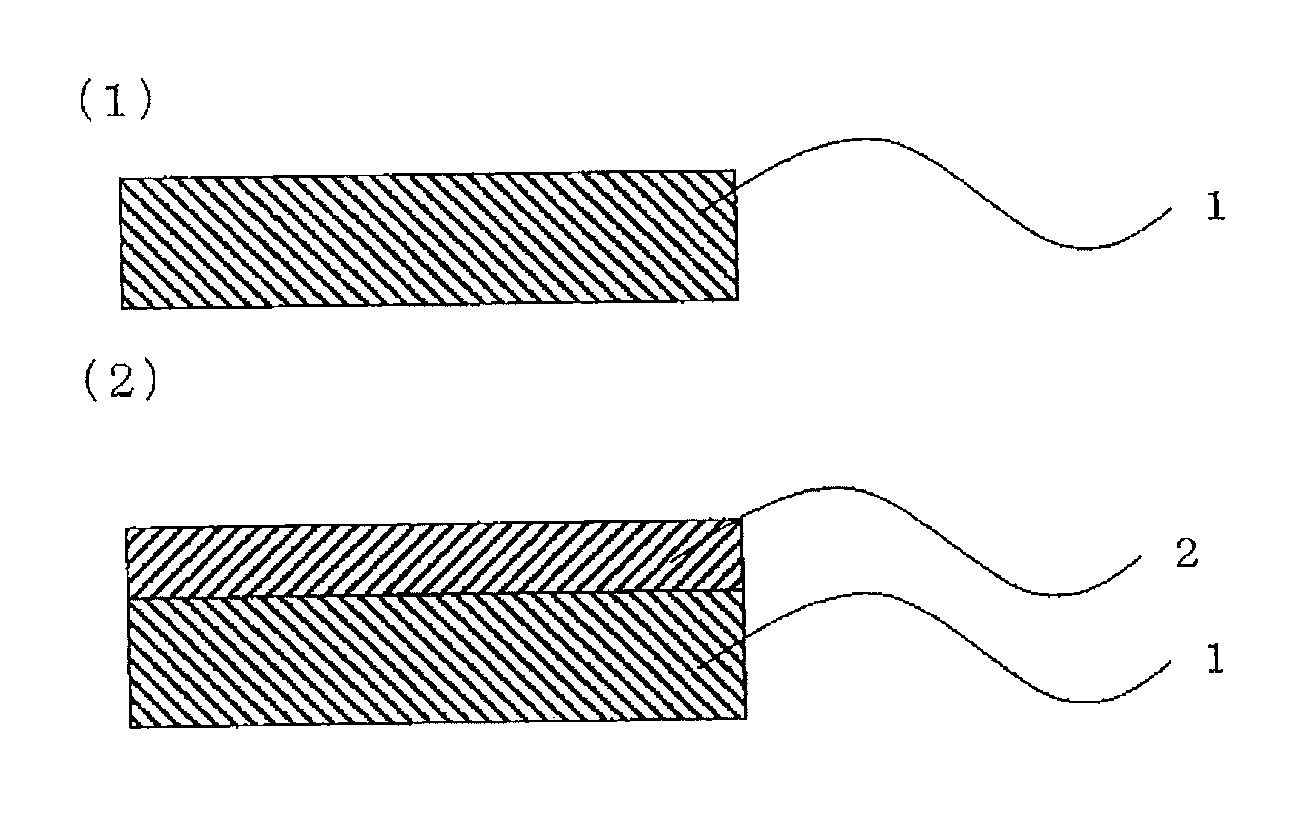

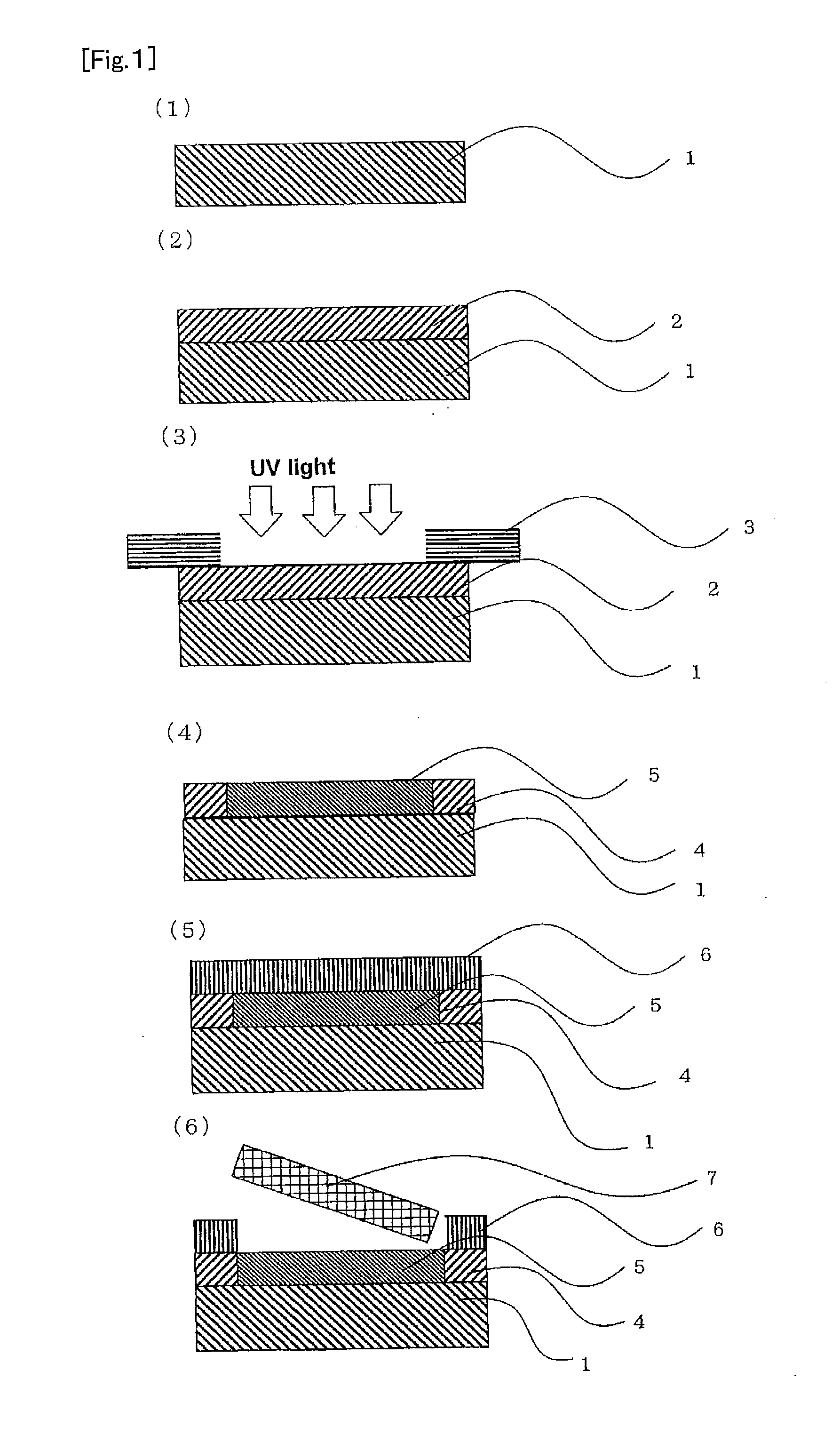

The invention provides a laminate of a substrate, a polyimide film, and a coupling treatment layer interposed therebetween, which provides different delamination strengths between the substrate and the polyimide film to form a prescribed pattern. The invention also provides a method for producing such a laminate formed from at least a substrate and a polyimide film, whereby, using a film obtained by plasma treatment of at least the surface facing the substrate as the polyimide film, coupling agent treatment is performed on at least one of the surfaces facing the substrate and the polyimide film to form a coupling treatment layer, deactivation treatment is performed on a portion of the coupling treatment layer to form a pre-determined pattern, and then pressing and heating are performed with the substrate and polyimide film overlapping.

Owner:TOYO TOYOBO CO LTD

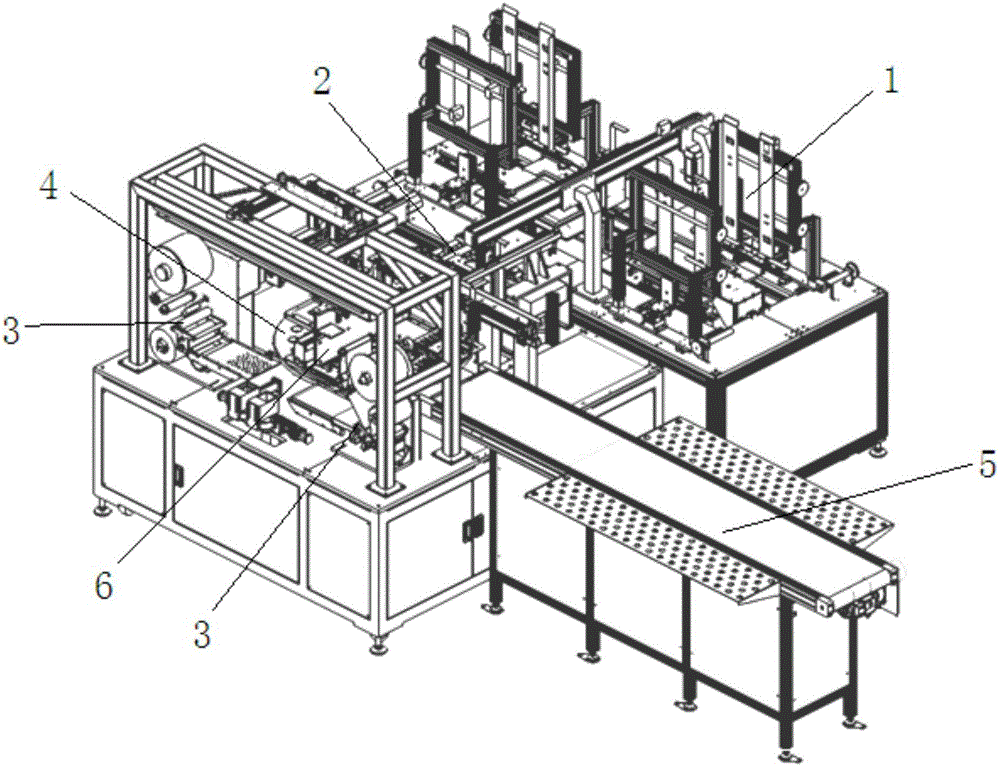

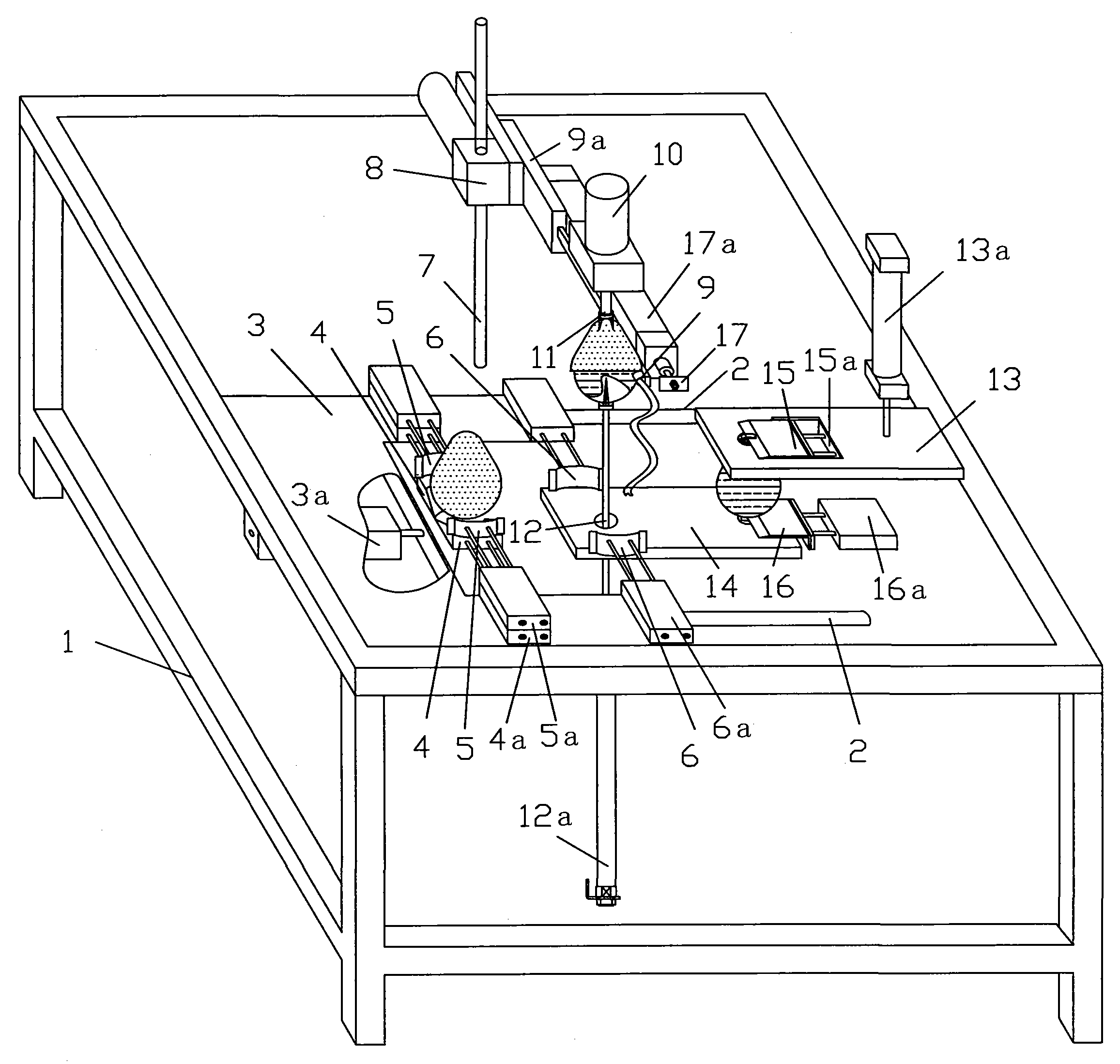

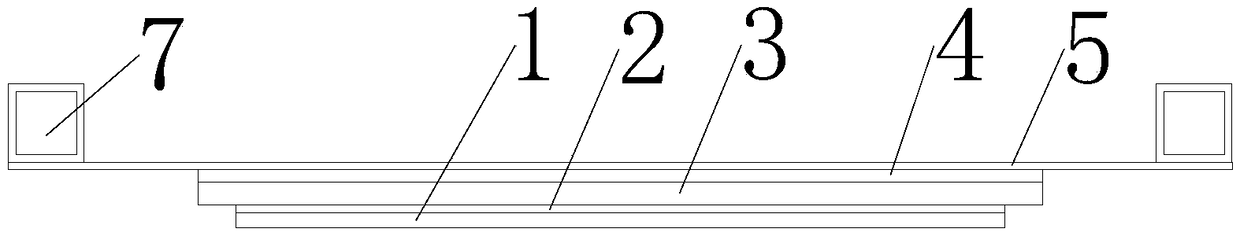

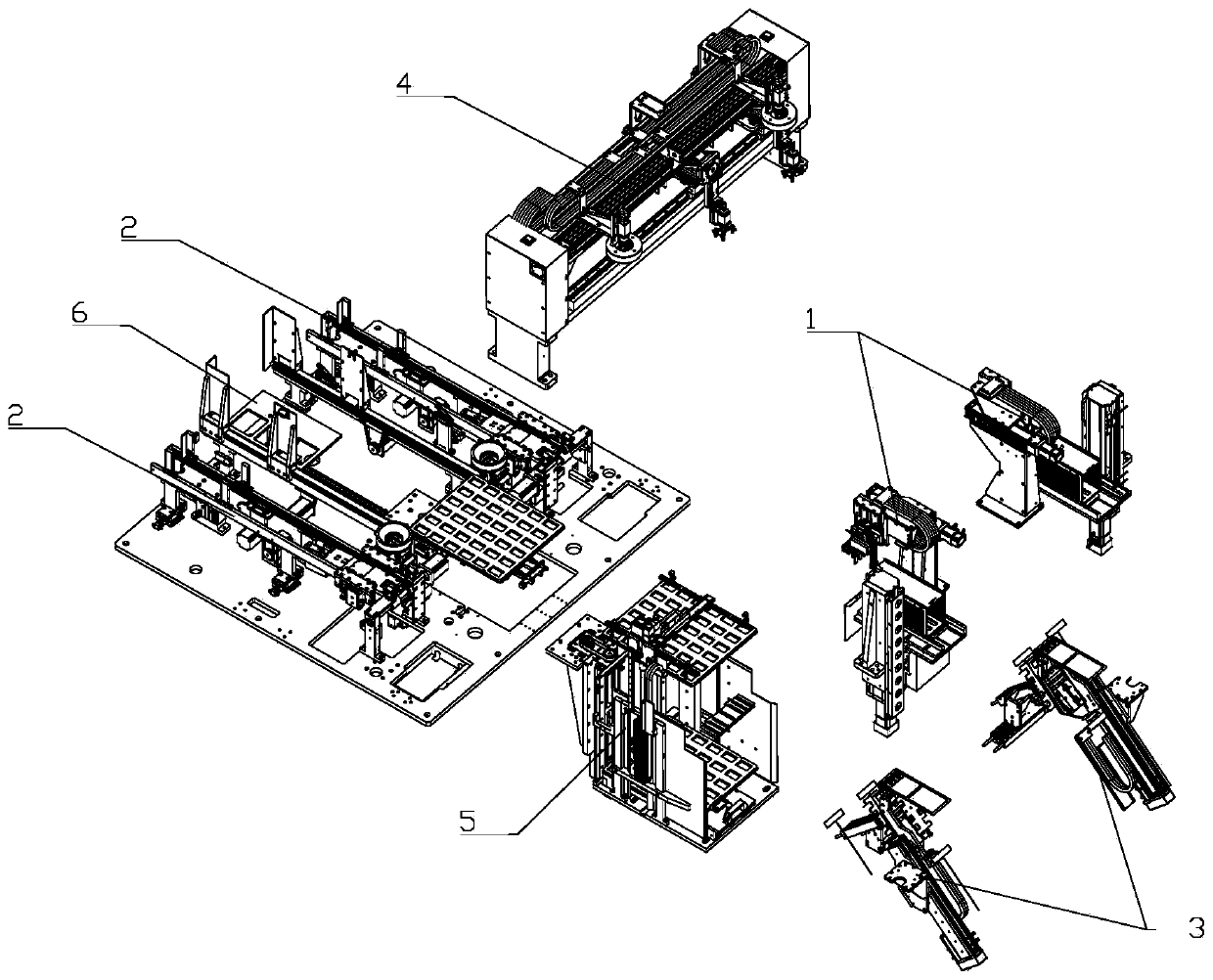

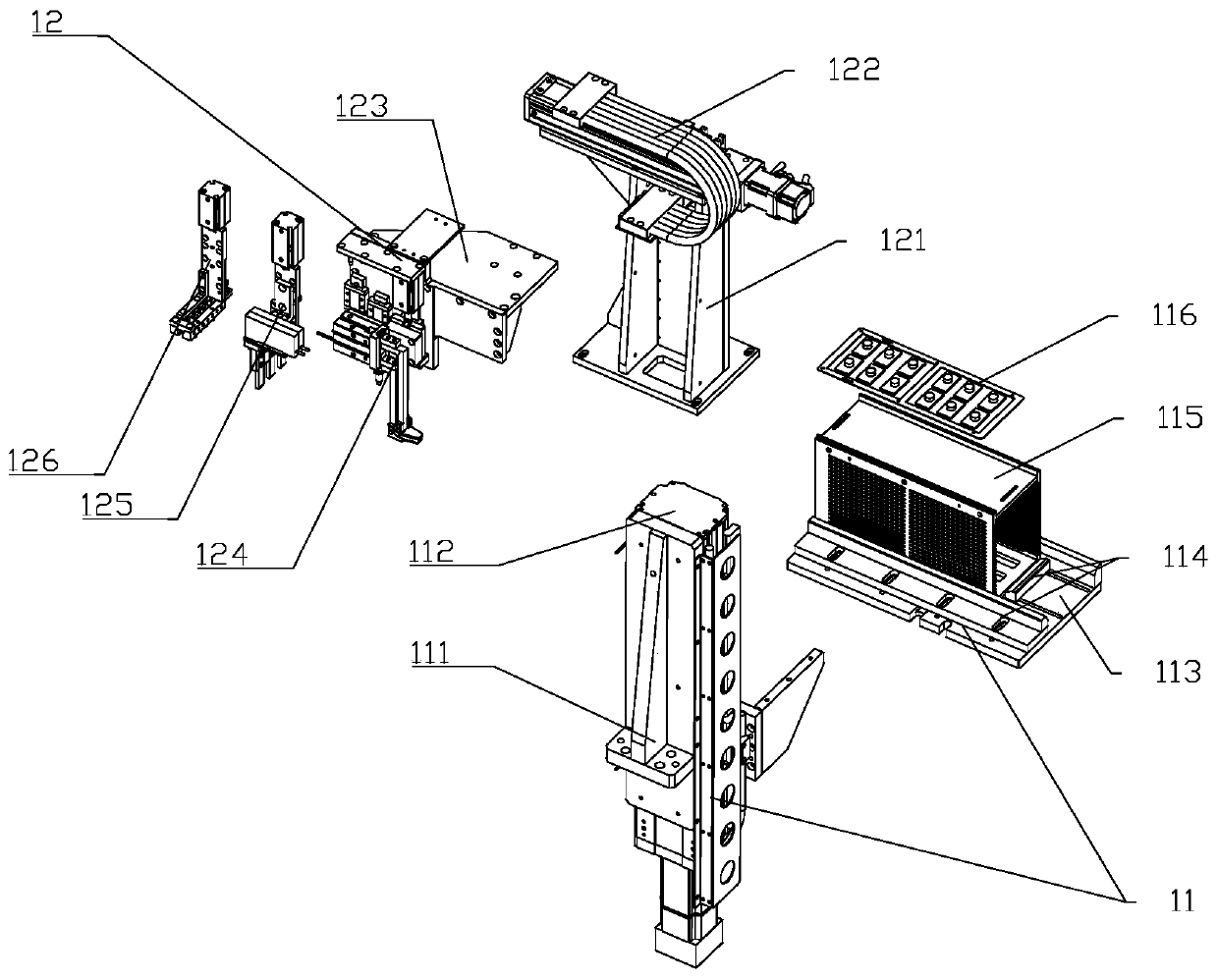

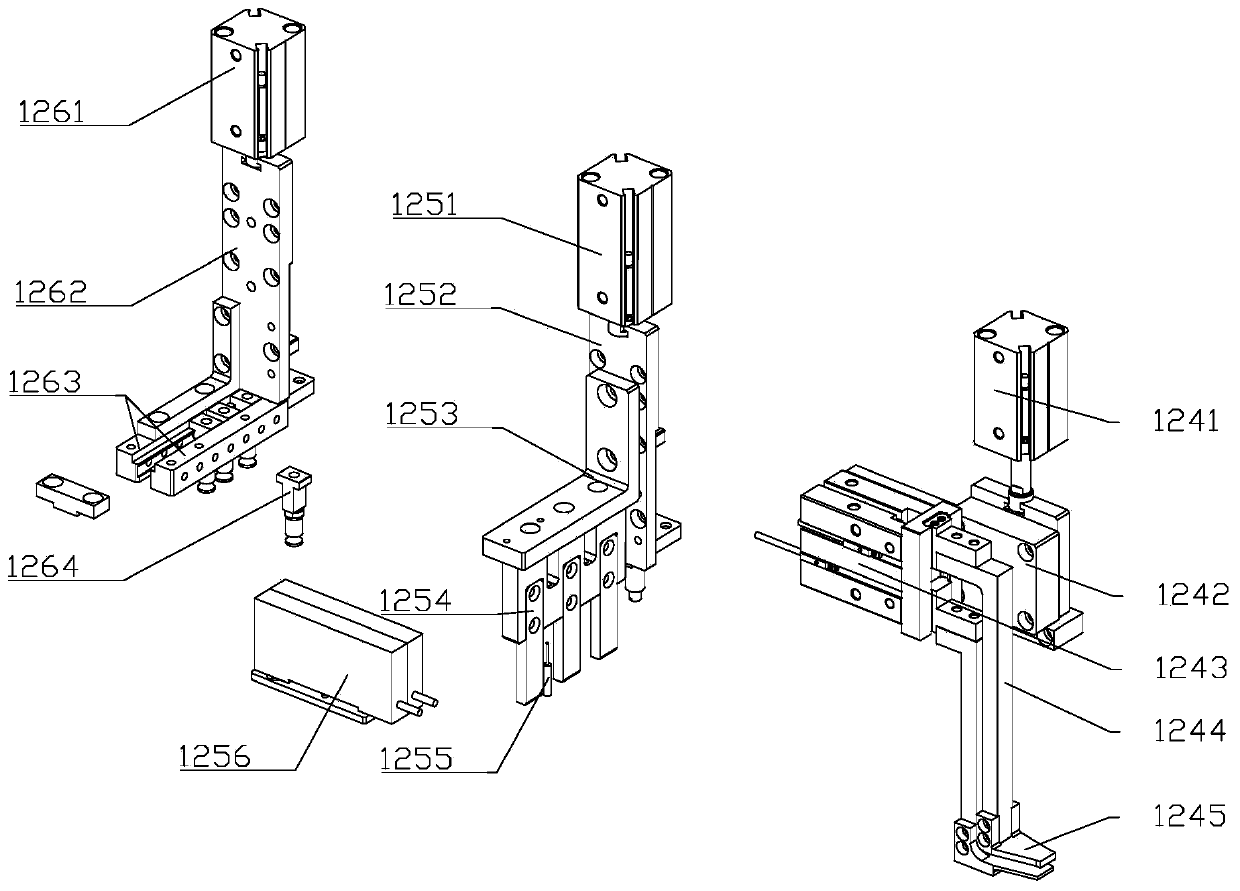

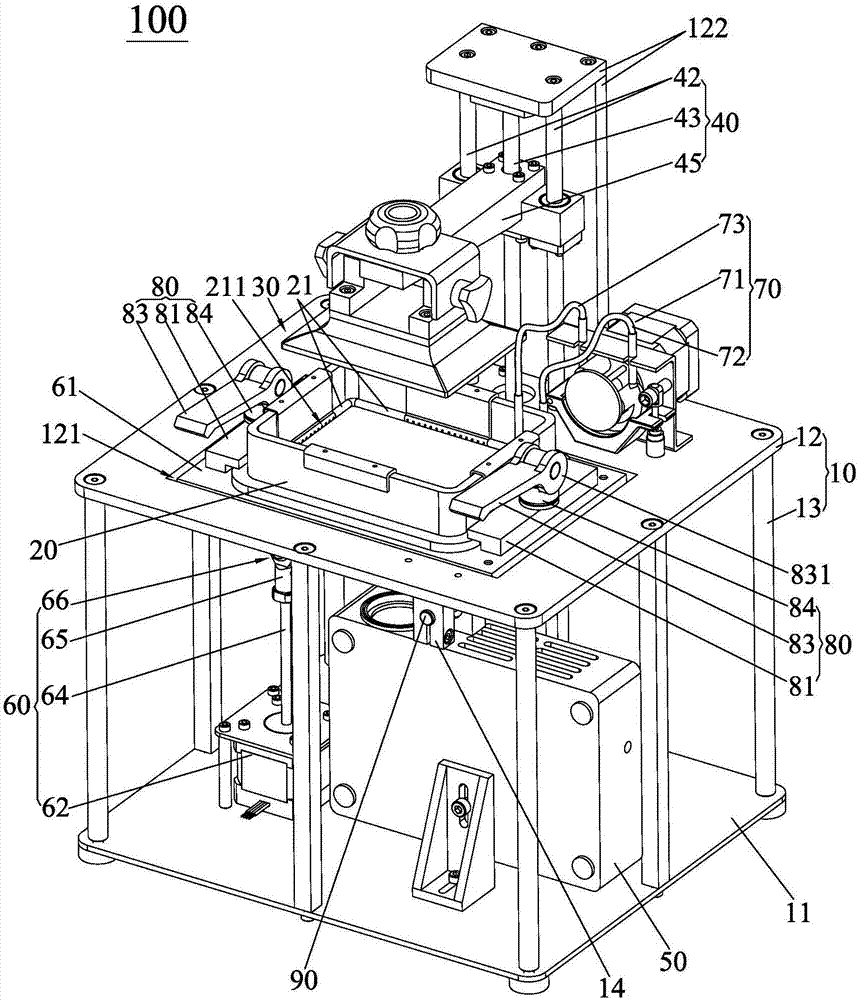

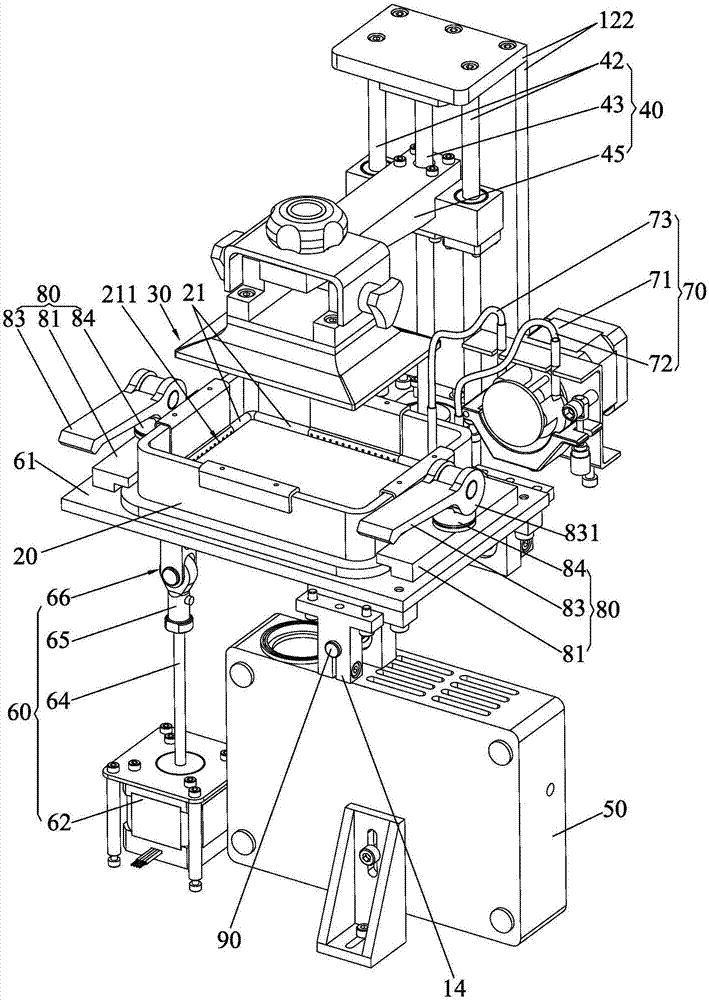

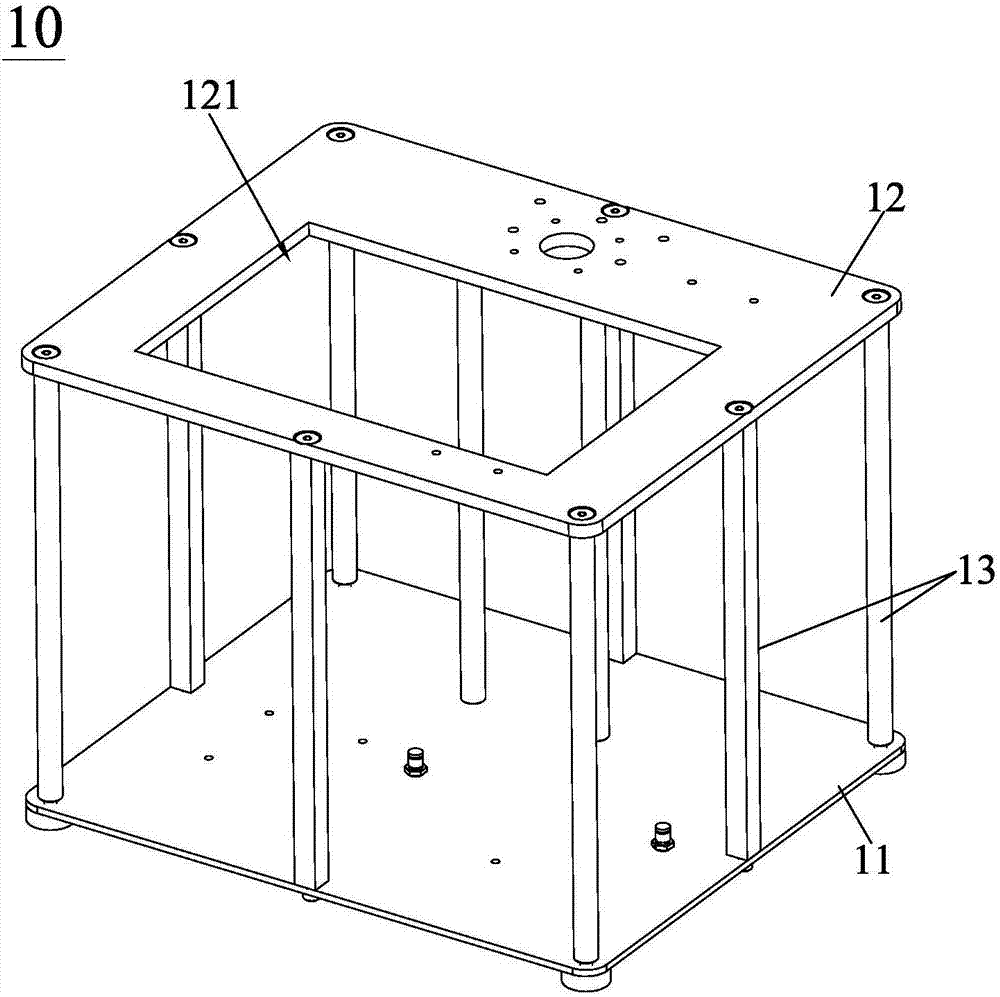

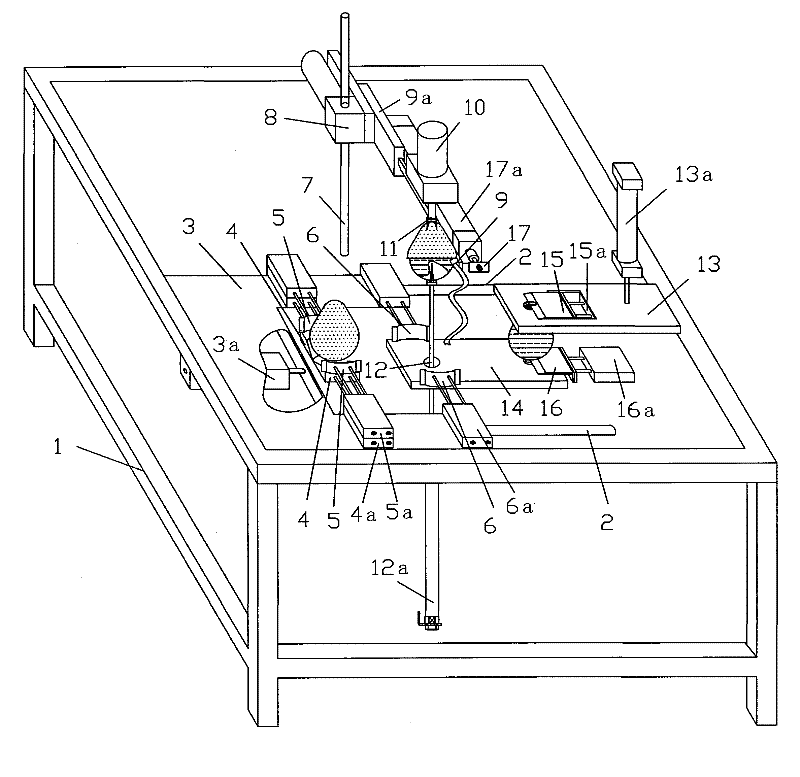

Automatic film sticking machine

ActiveCN106428746AFast and effective film applicationImprove the efficiency of automatic film applicationPackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic film sticking machine. The machine comprises an automatic feeding mechanism, a pre-positioning mechanism, a film sticking automatic stripping mechanism, a film sticking station conversion mechanism, an automatic film sticking mechanism and a finished product output mechanism; according to the automatic feeding mechanism, an element to be subject to film sticking is taken out and conveyed to the pre-positioning mechanism, the pre-positioning mechanism carries out position pre-adjustment on the element to be subject to film sticking, the element to be subject to film sticking and position pre-adjustment is placed on the film sticking station conversion mechanism, the automatic film sticking mechanism enables a sticking film stripped from the film sticking automatic stripping mechanism to be pasted and covered on the element to be subject to film sticking on the film sticking station conversion mechanism, and the element subject to film sticking is output through the finished product output mechanism for quality inspection. The automatic film sticking machine can be suitable for single-layer or multi-layer rapid effective film sticking, full-automatic feeding, cleaning, sticking film stripping, sticking film absorbing and film sticking are achieved, time and labor are saved, the automatic film sticking efficiency is improved, the film sticking yield is high, and the good application prospect is achieved.

Owner:JIANGSU BVM INTELLIGENT TECH

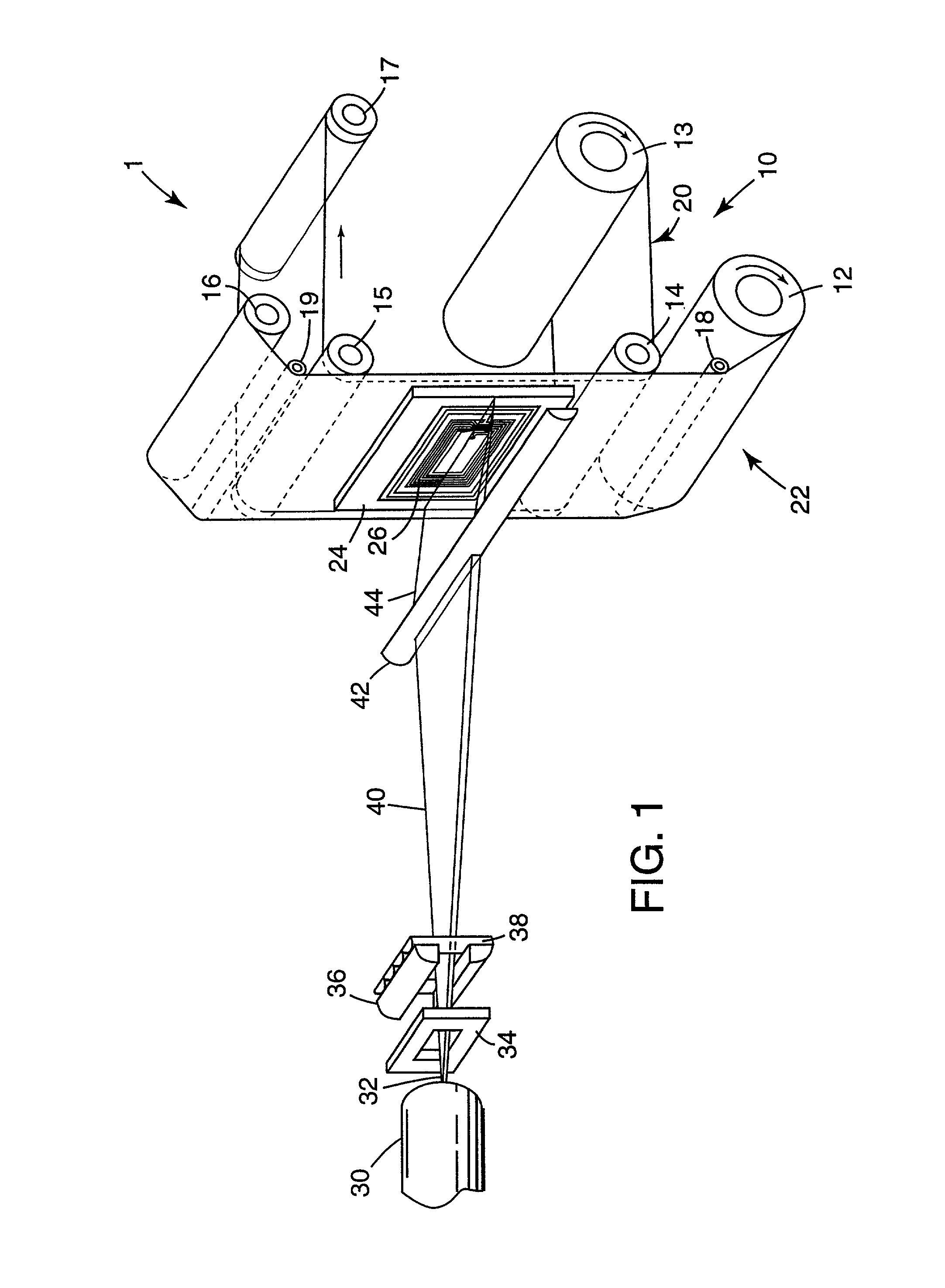

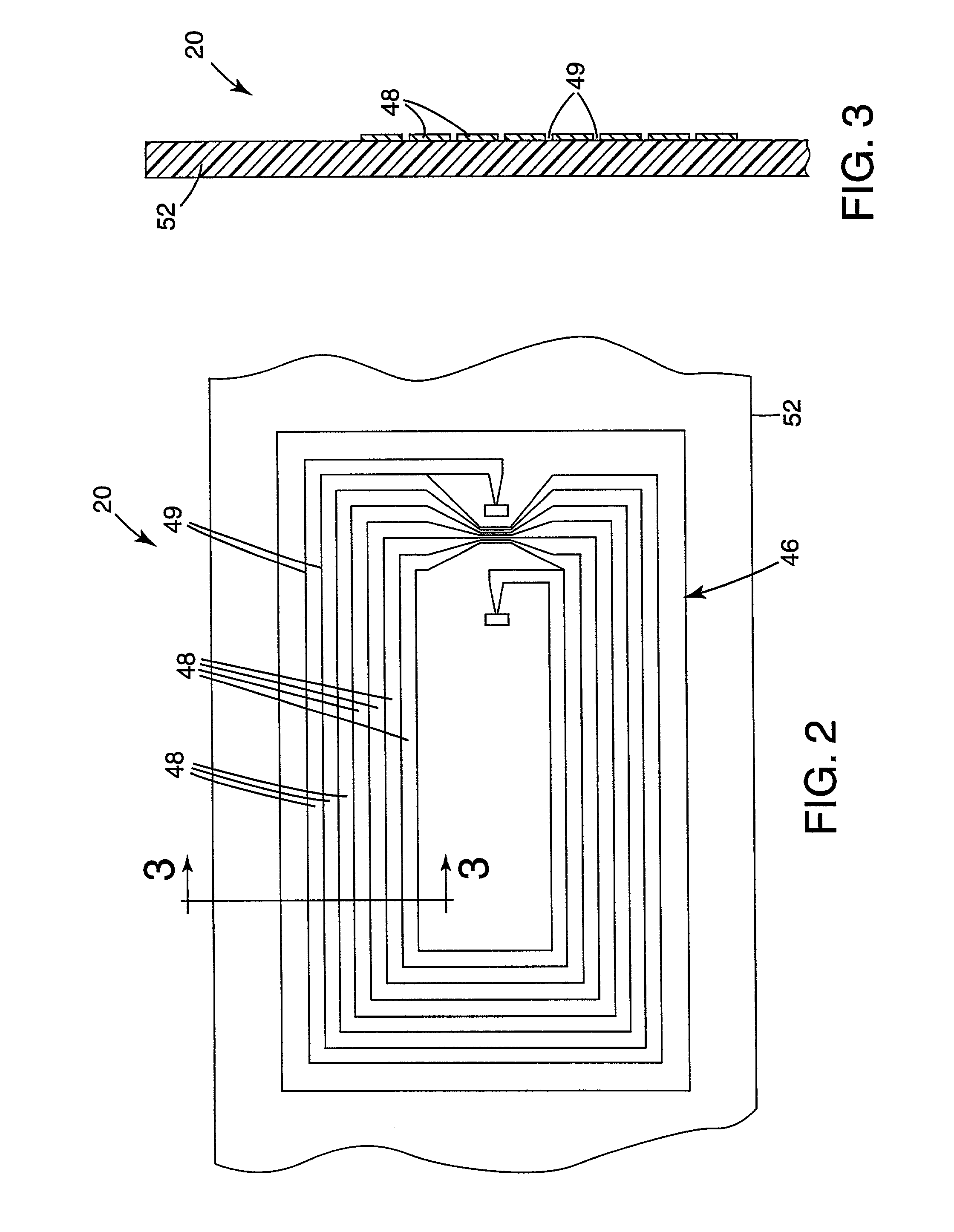

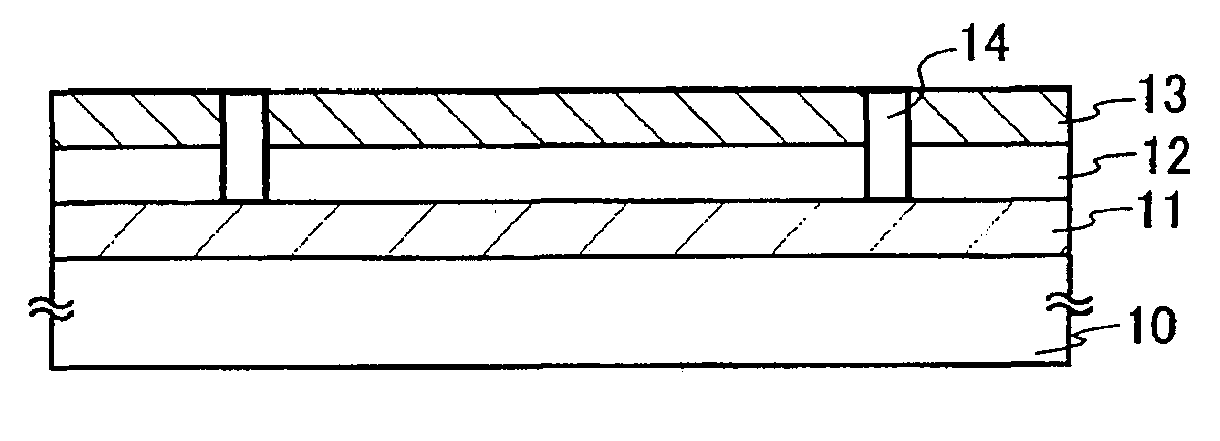

Method for patterning thin films

InactiveUS20010006766A1Great throughput and outputReduce impactPhotography auxillary processesAntenna supports/mountingsResistMicroscopic scale

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of: A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other; B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, Such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating, and C. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation. The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

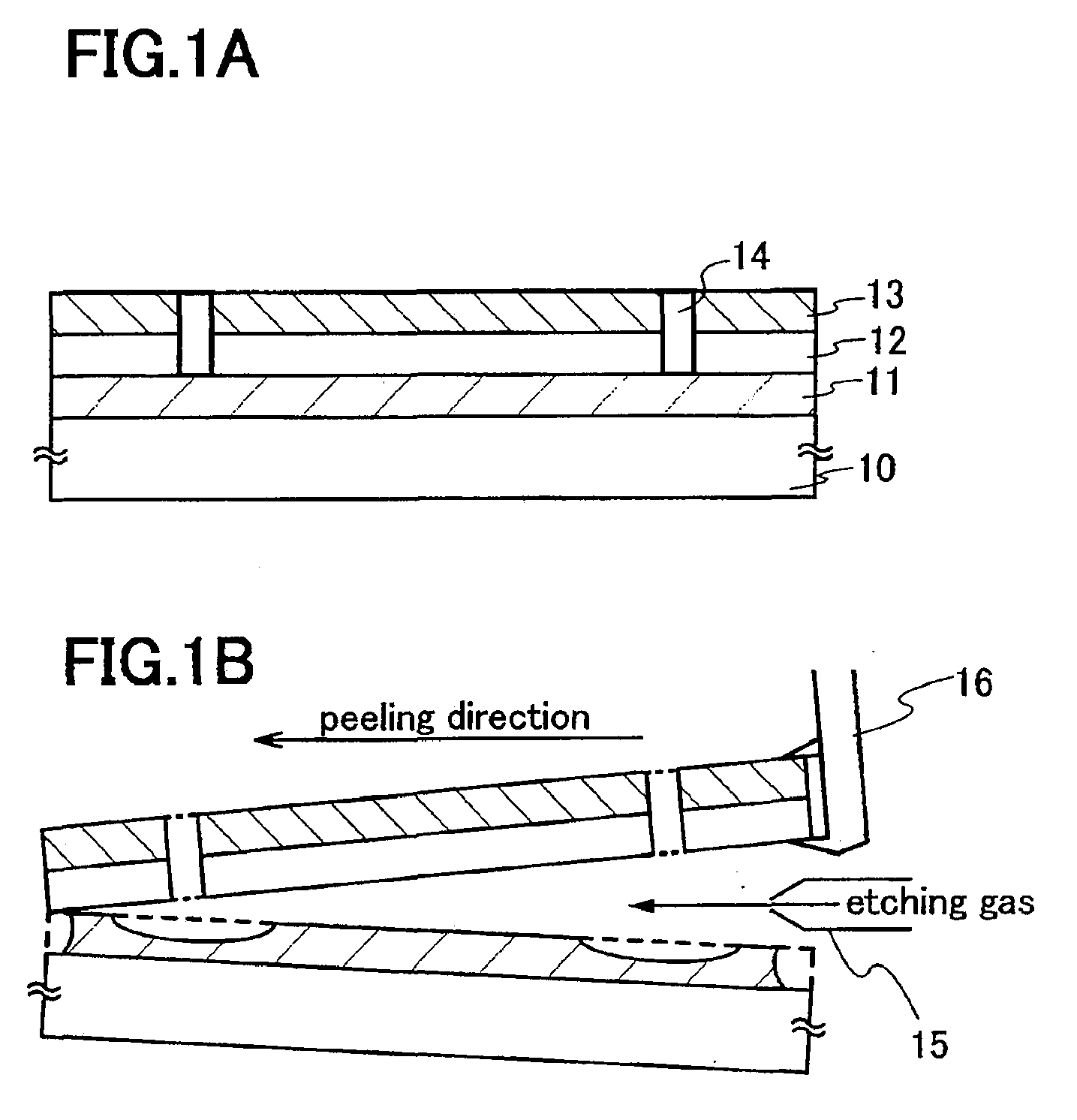

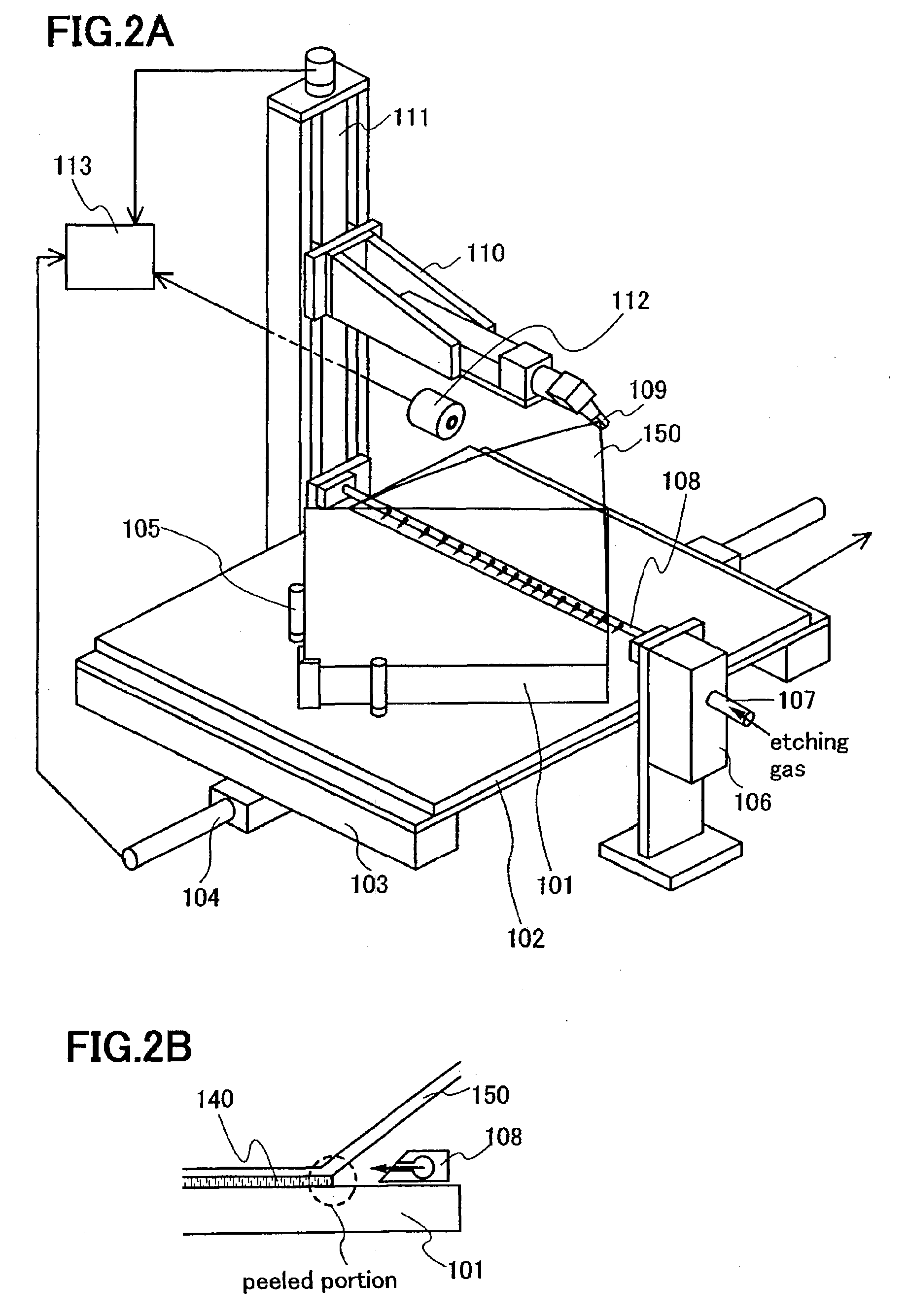

Manufacturing Method of Semiconductor Device

InactiveUS20060199382A1Reduce weightAchieve mass productionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialSemiconductor

The present invention has an object to perform a peeling treatment in a short time. Peeling is performed while a peeling layer is exposed to an atmosphere of an etching gas. Alternatively, peeling is performed while an etching gas for a peeling layer is blown to the peeling layer in an atmosphere of an etching gas. Specifically, an etching gas is blown to a part to be peeled while a layer to be peeled is torn off from a substrate. Alternatively, peeling is performed in an etchant for a peeling layer while supplying an etchant to the peeling layer.

Owner:SEMICON ENERGY LAB CO LTD

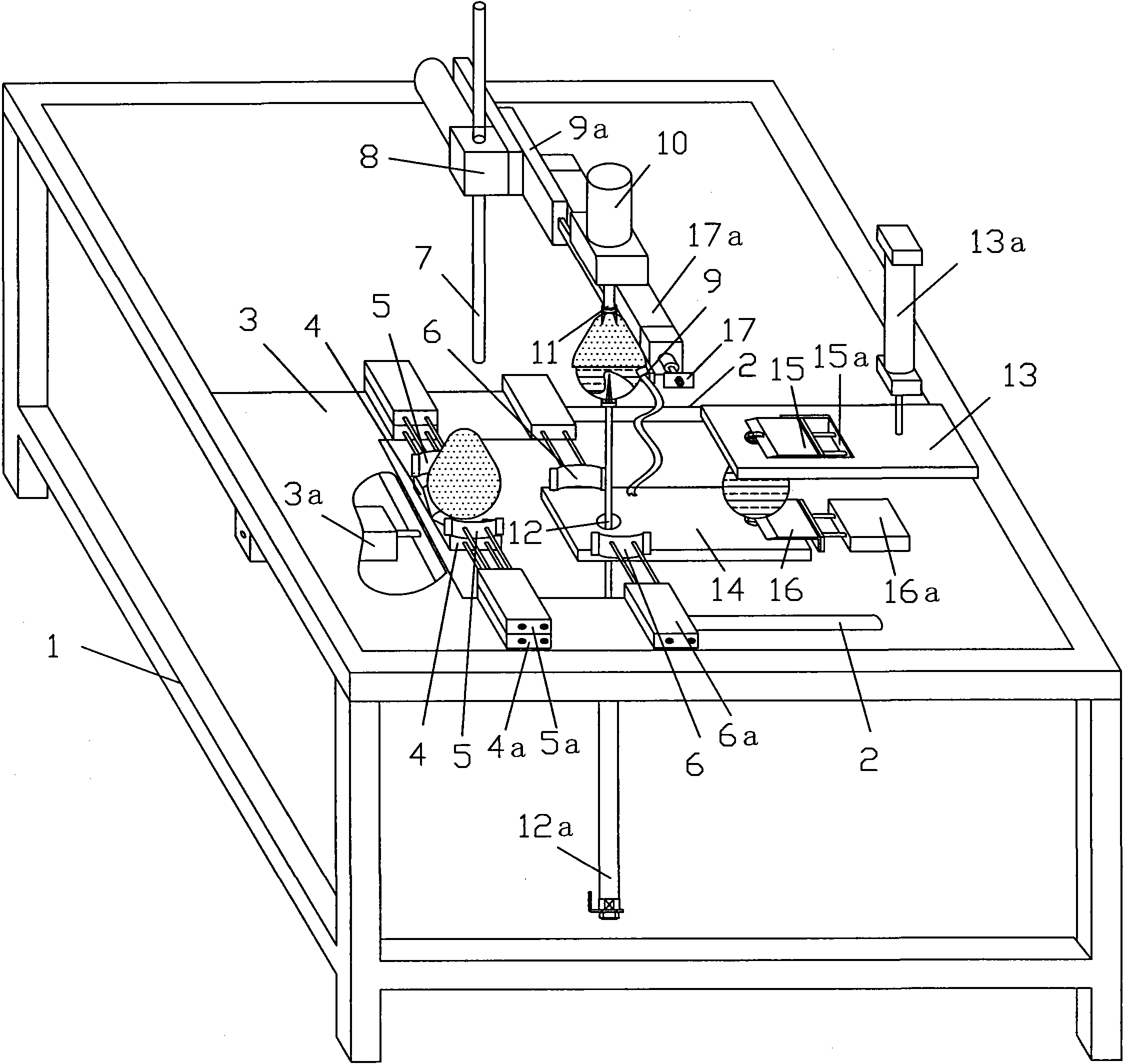

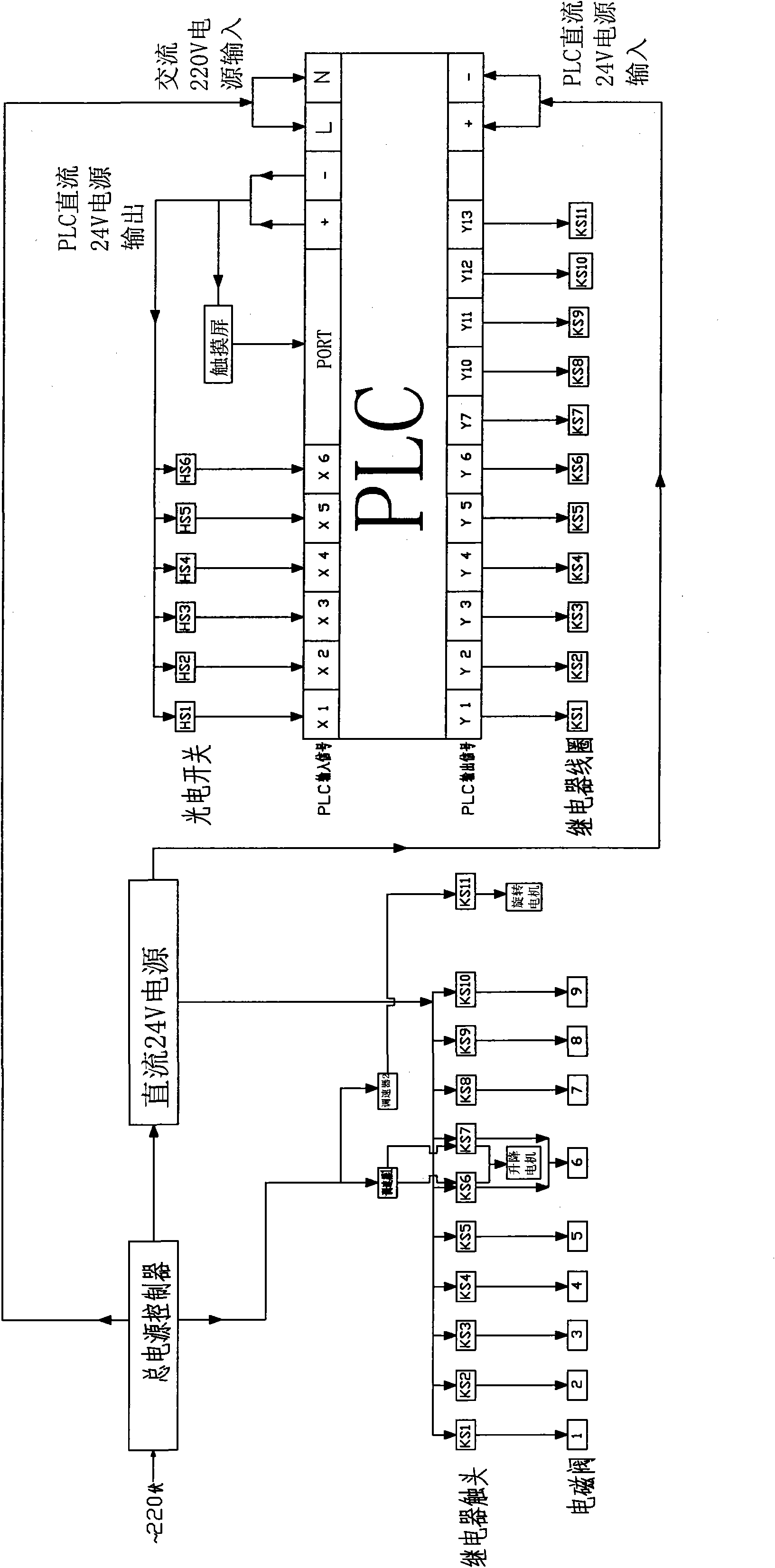

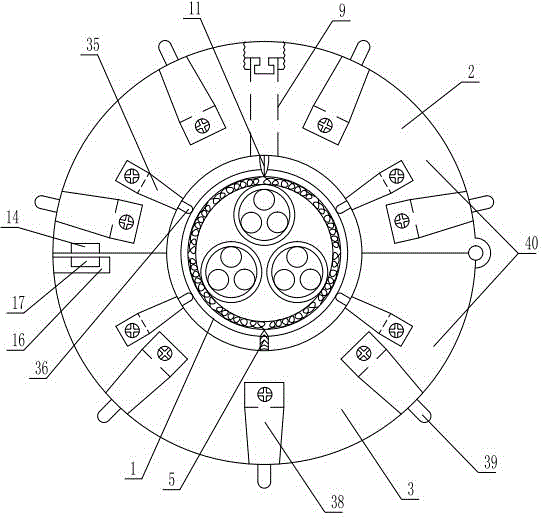

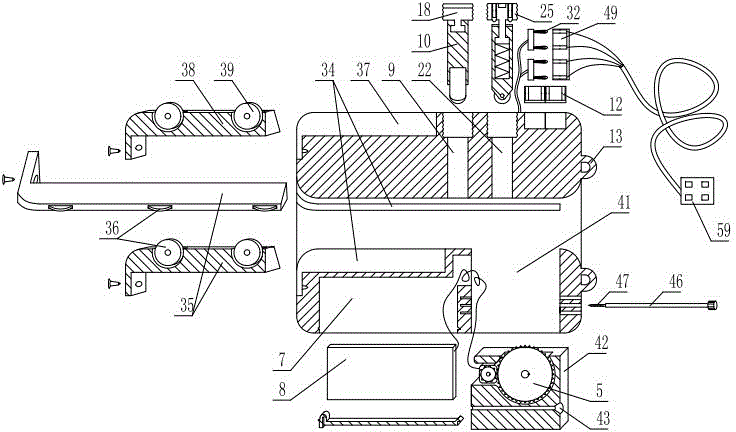

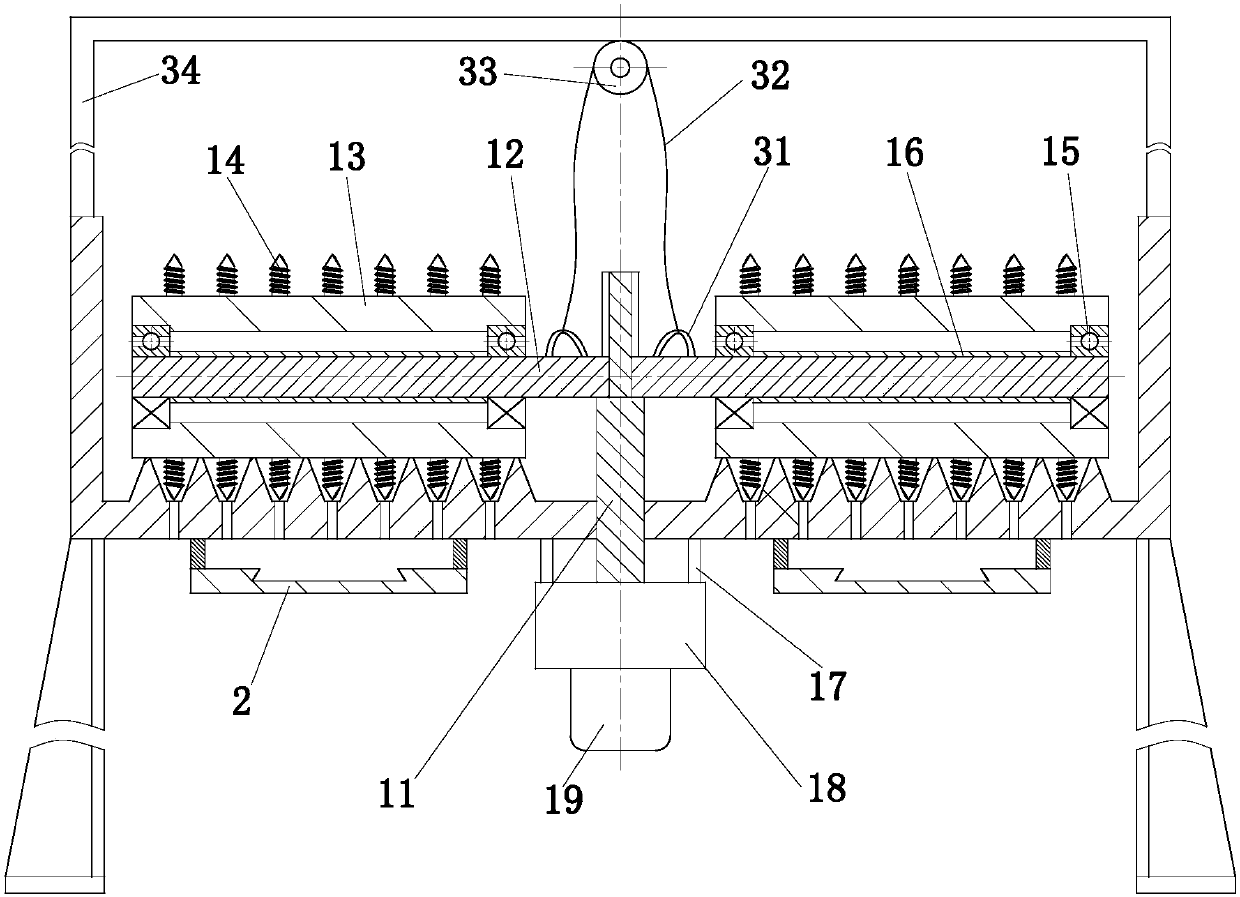

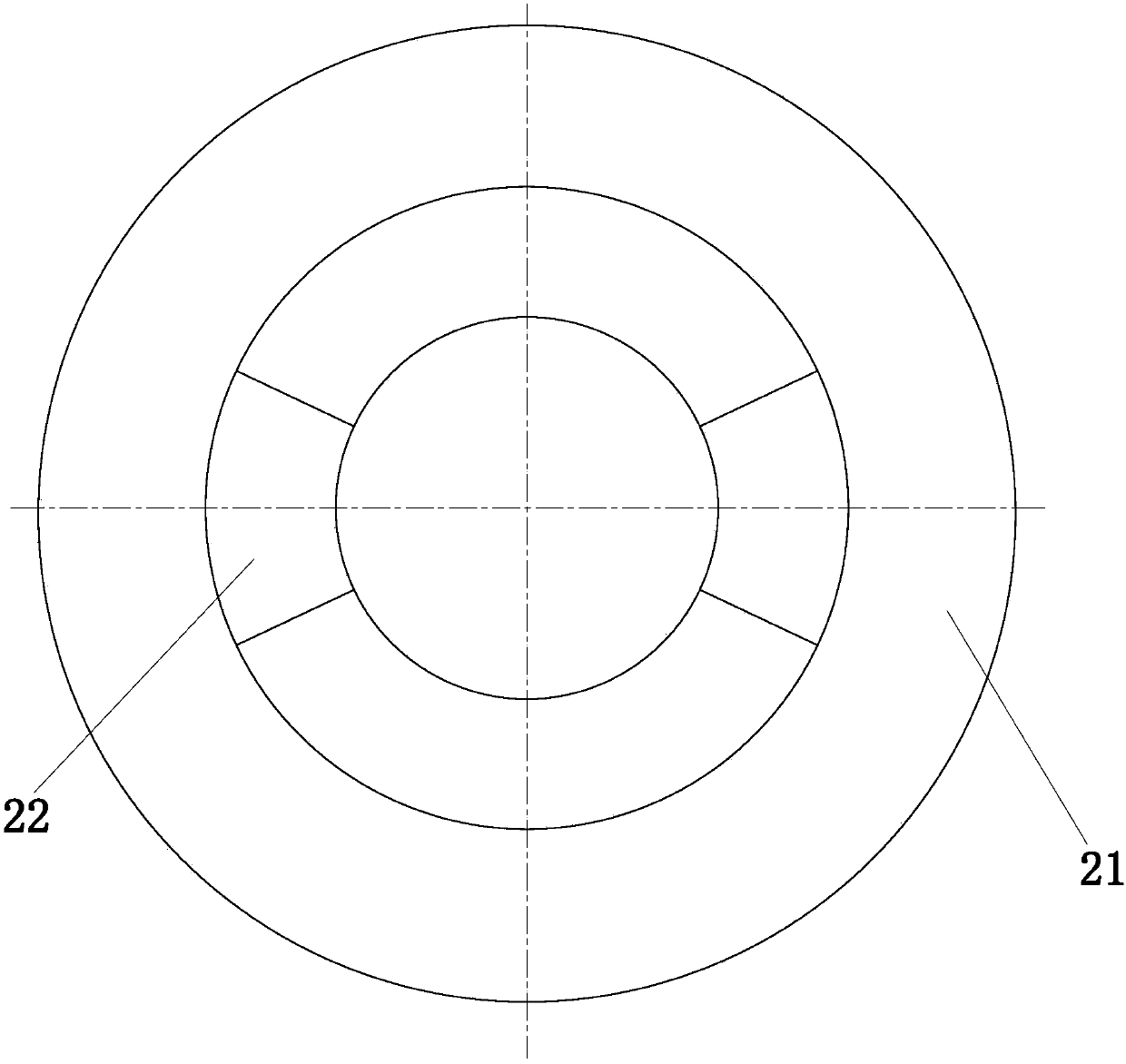

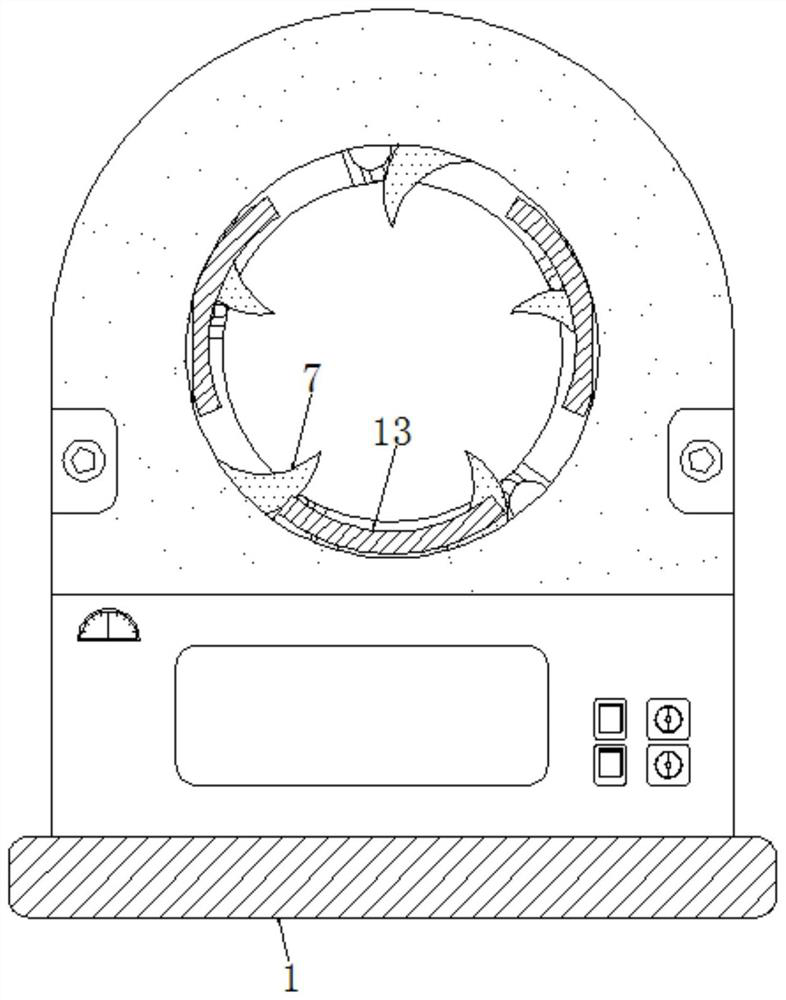

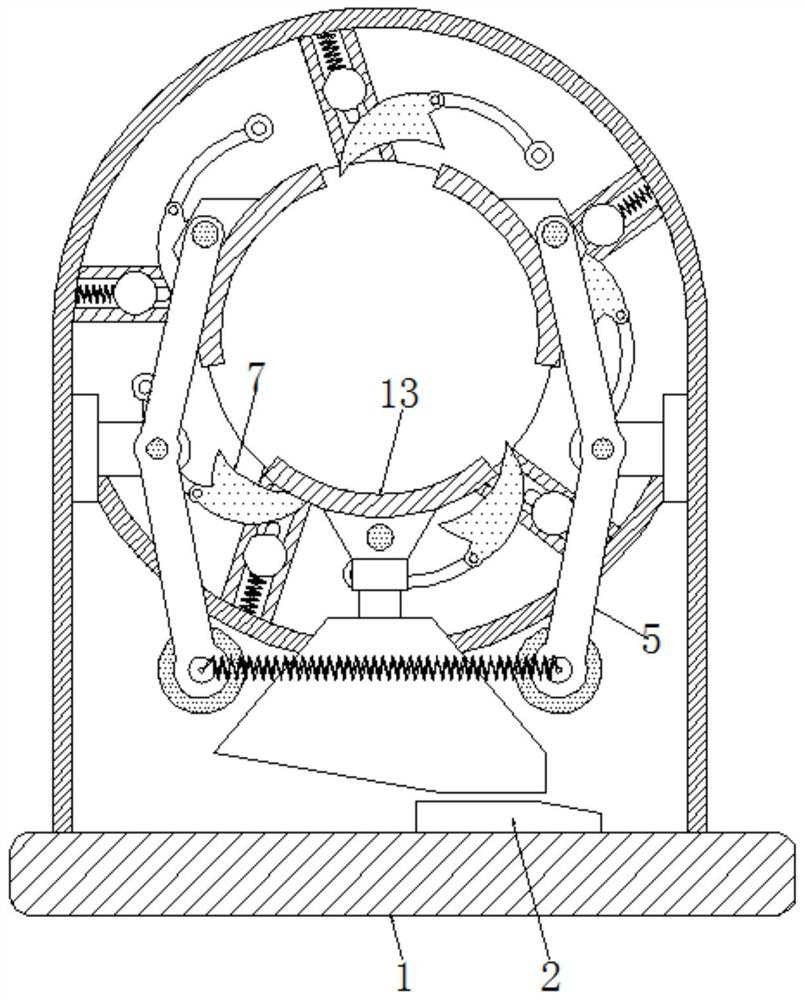

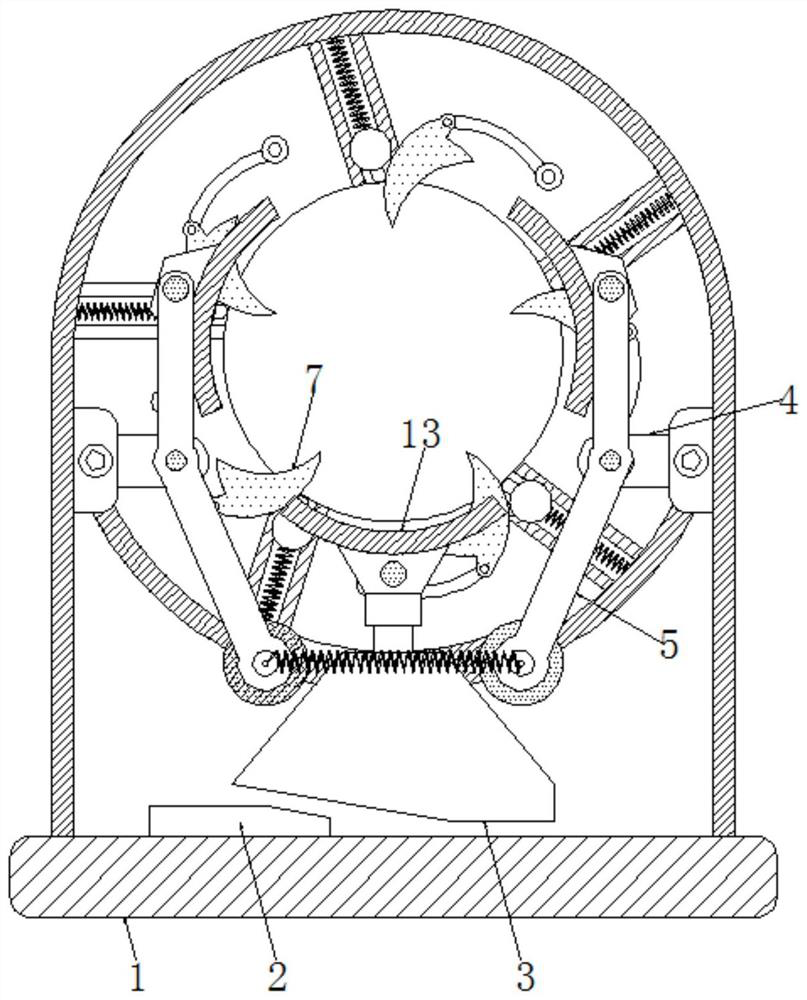

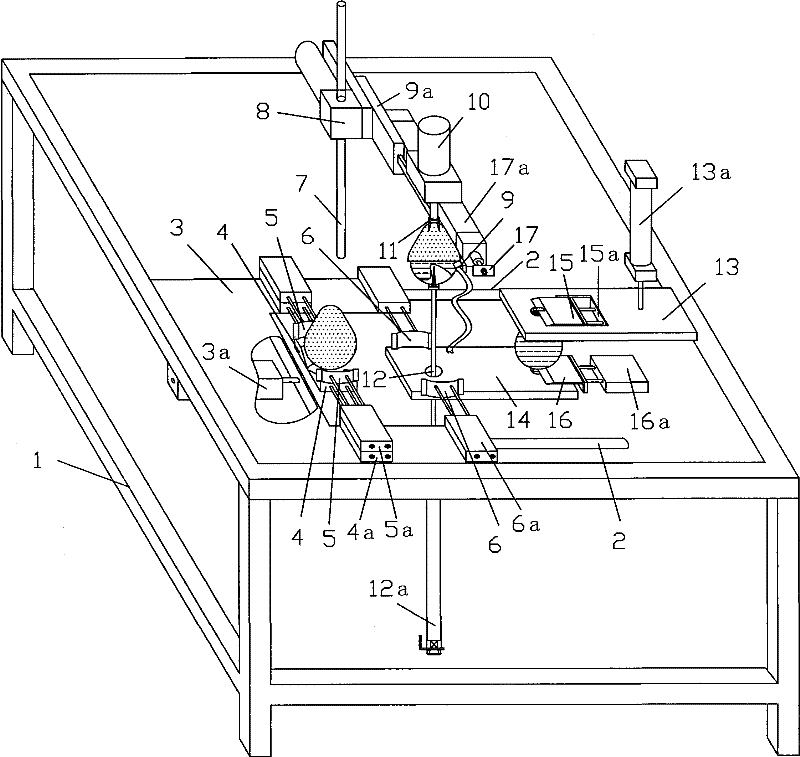

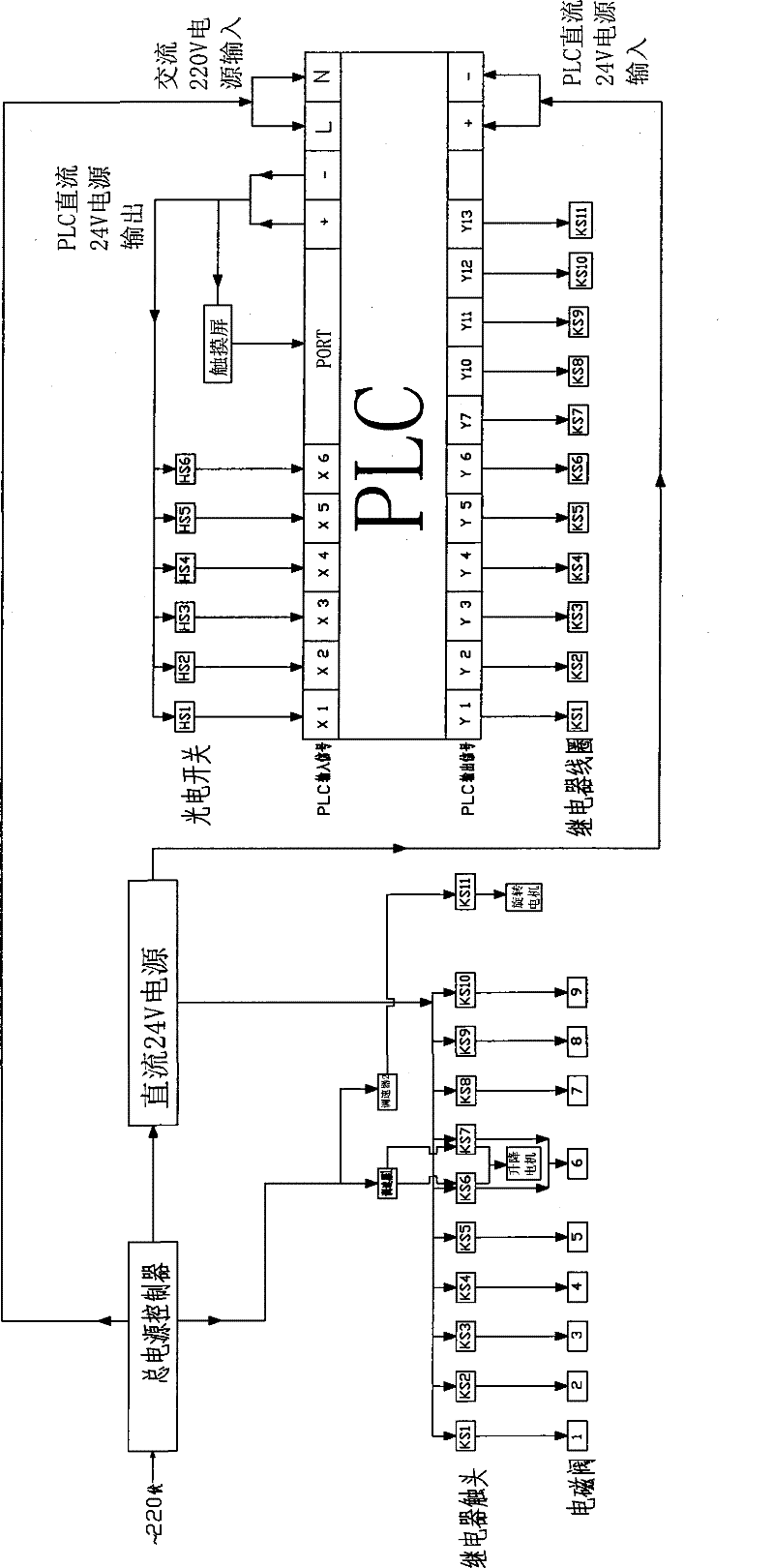

Electromechanical full-automatic peeling machine and peeling method thereof

ActiveCN101856139AReduce labor costsMeet the needs of deep processingVegetable peelingProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses an electromechanical full-automatic peeling machine and a peeling method thereof. The electromechanical full-automatic peeling machine comprises a rack, a fruit feeding mechanism, a peeling mechanism, a cutting mechanism and a control system, wherein the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in the rack; the fruit feeding mechanism is arranged on two lead rails of the rack; the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in sequence according to processing procedures; and the control system connects and controls the fruit feeding mechanism, the peeling mechanism and the cutting mechanism. The invention also discloses a peeling method of the electromechanical full-automatic peeling machine. The electromechanical full-automatic peeling machine has the advantages of high processing efficiency, safety and health.

Owner:广州达桥食品设备有限公司

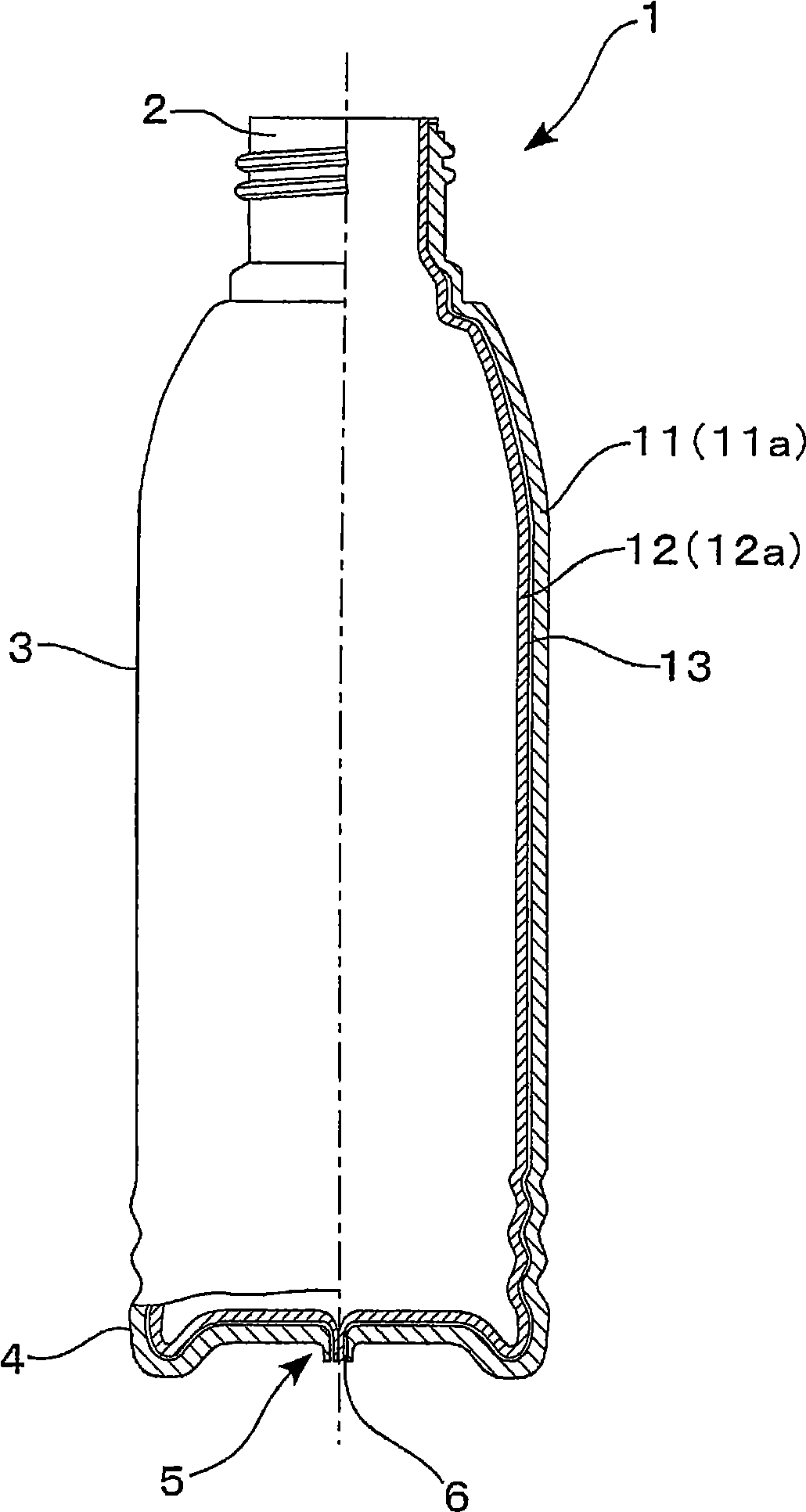

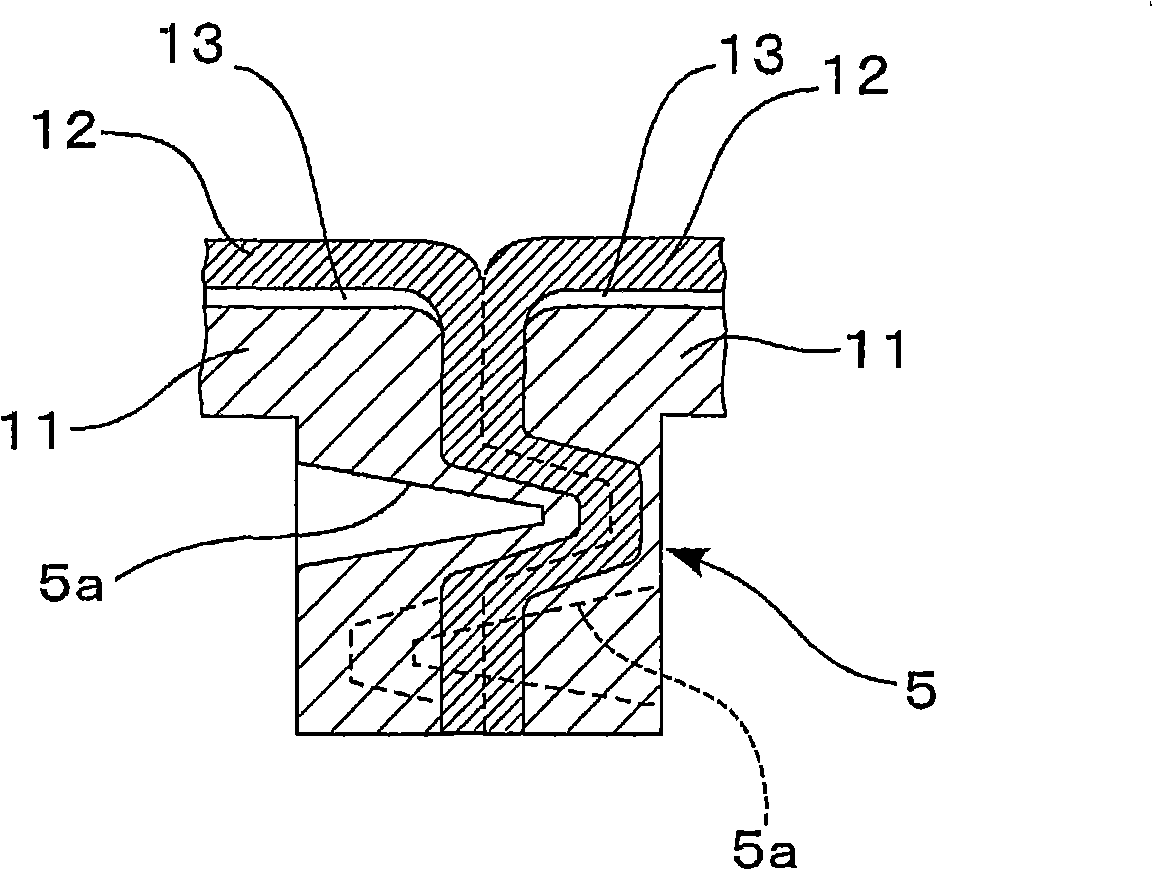

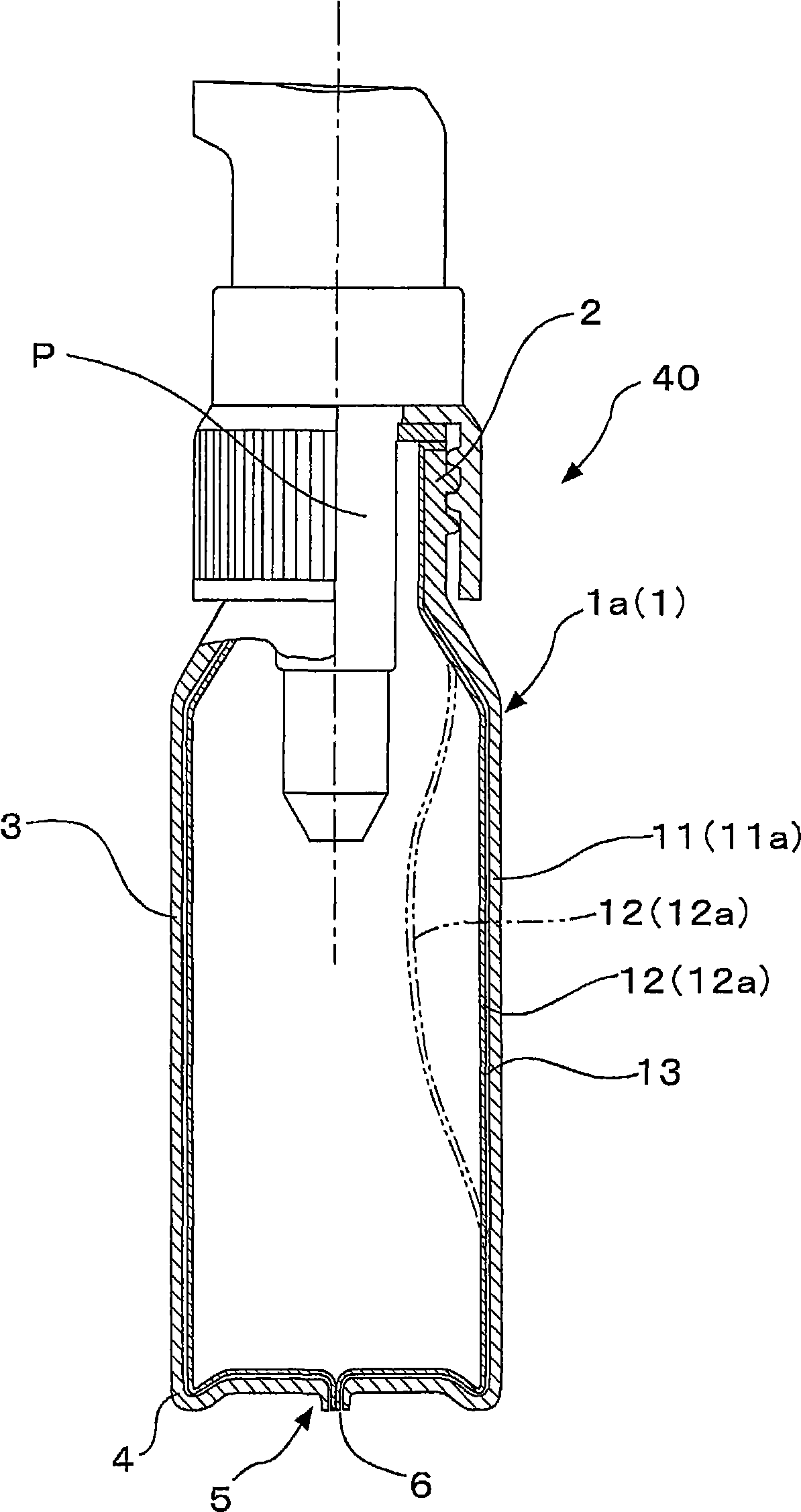

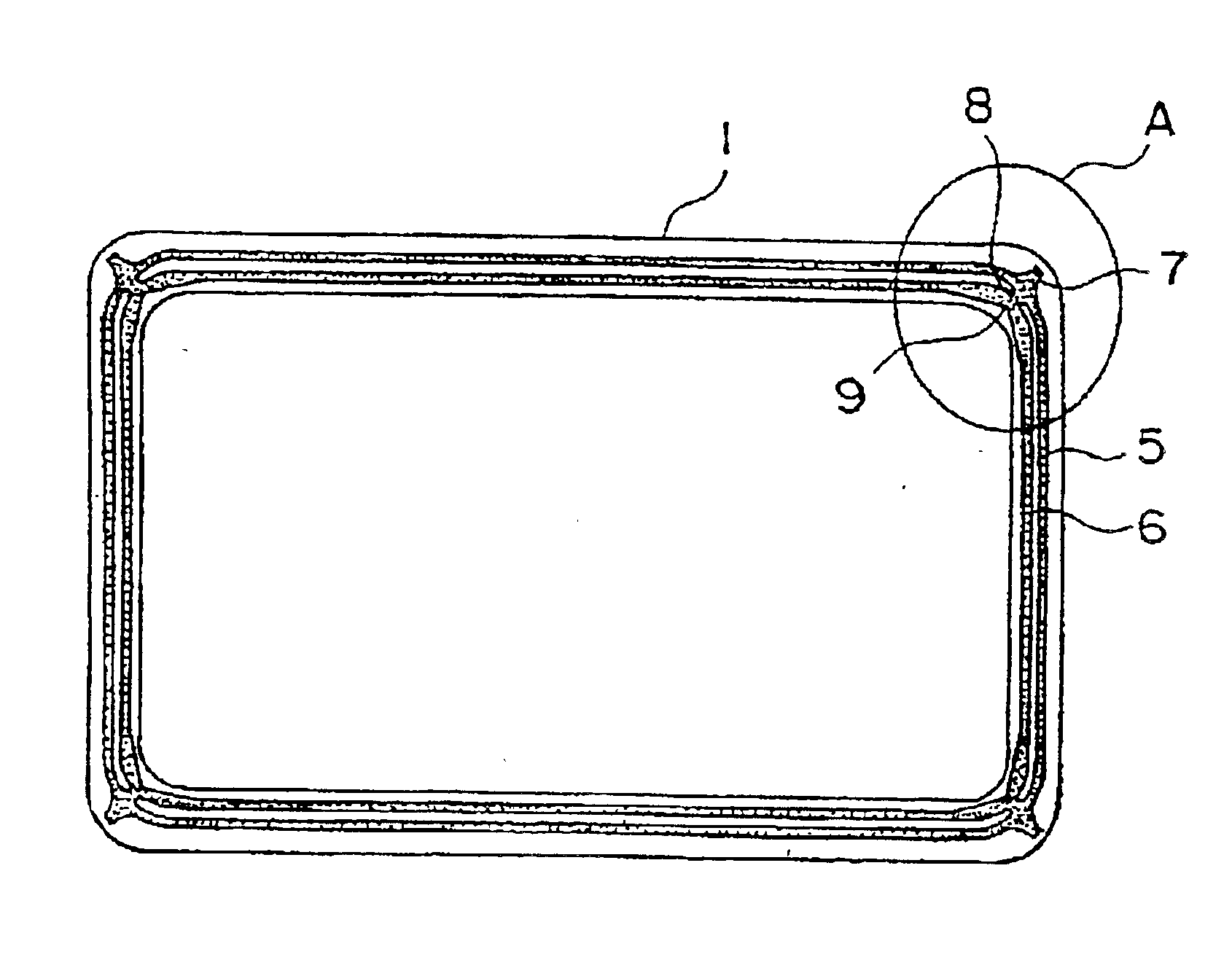

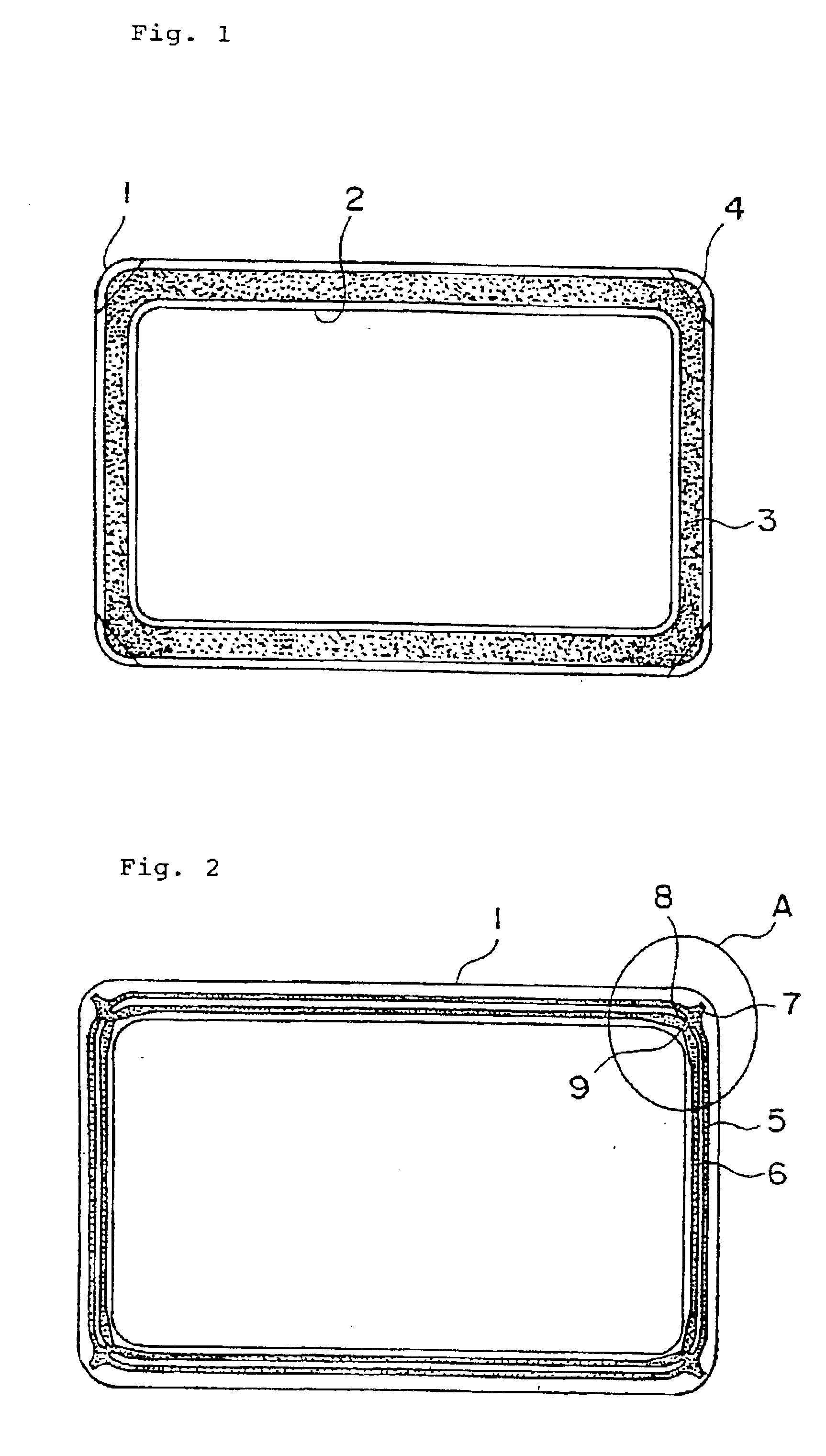

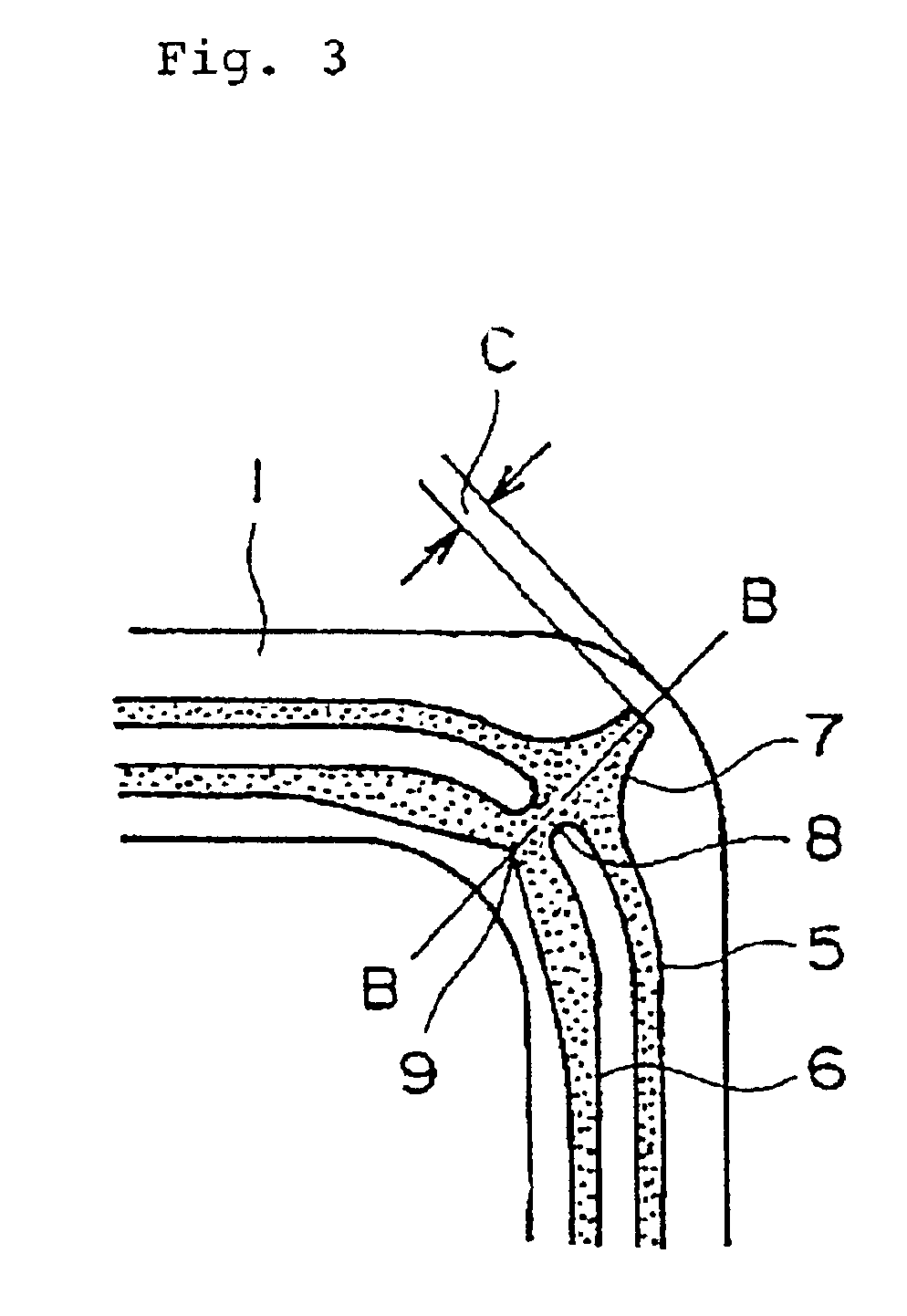

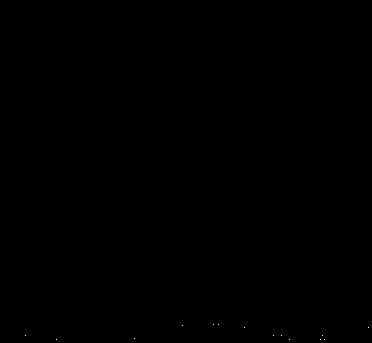

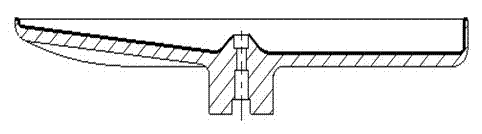

Double container of synthetic resin by direct blow molding method

ActiveCN101547836AEasy to shapeSmooth peelingSynthetic resin layered productsLinings/internal coatingsBlow moldingEngineering

With respect to a double container of synthetic resin composed of an inner container and an outer container, the conventional problems, such as restraints on configuration and need to have an assembly step, are solved. As main means for solving the problems, there is provided a double container by direct blow molding method, comprising an outer layer and inner layer of synthetic resins nonadherent to each other and, interposed therebetween, an air space formed by separation due to a molding shrinkage difference between the outer layer and the inner layer at direct blow molding.

Owner:YOSHINO KOGYOSHO CO LTD

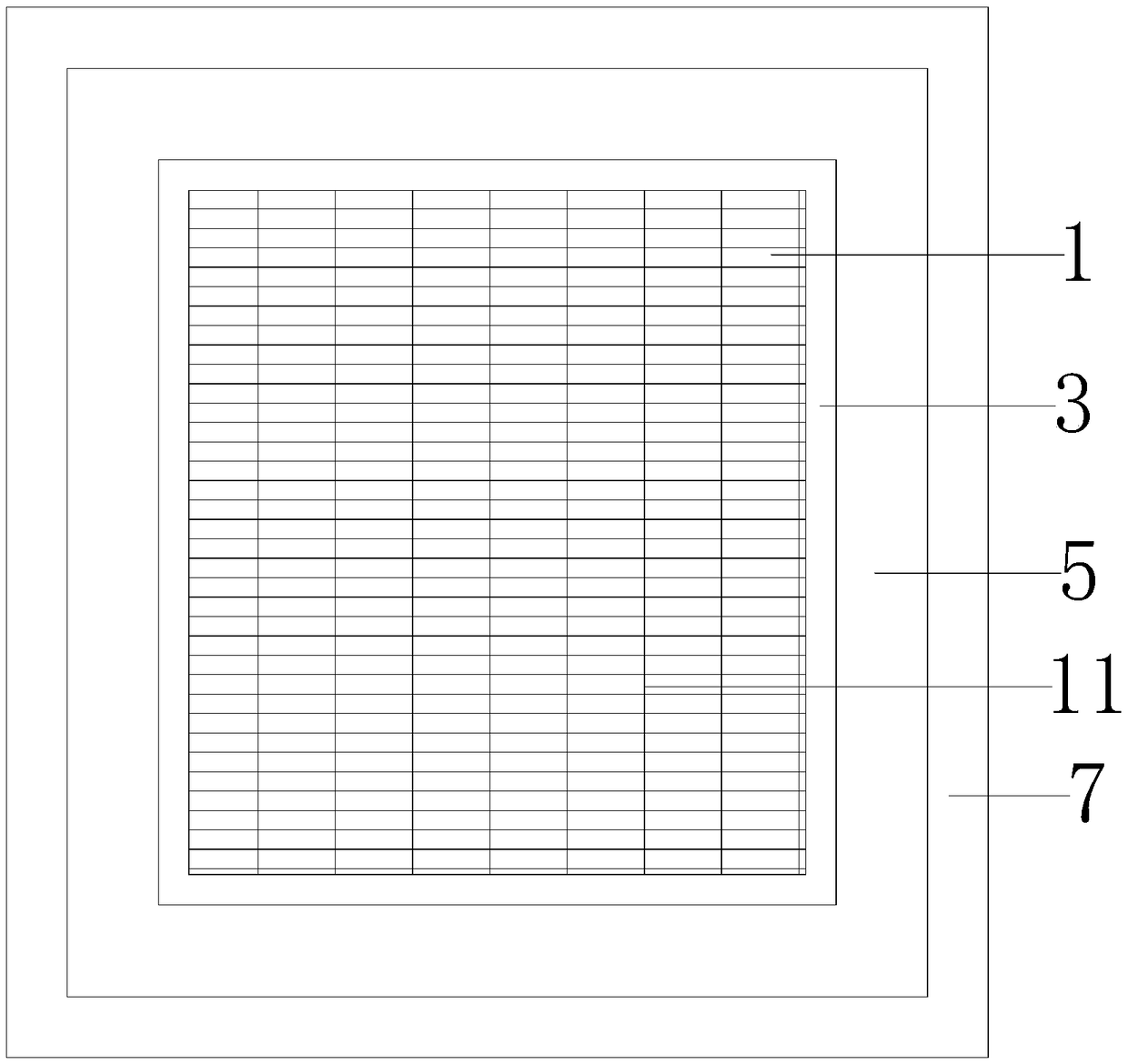

Polyimide solar net plate and manufacturing method

PendingCN108749276ADowngradeReduce manufacturing costScreen printersSynthetic resin layered productsWire gauzeScreen printing

The invention relates to a solar net plate, in particular to a polyimide solar net plate. The polyimide solar net plate comprises a net frame and a polyester wire net. The polyester wire net is tied to the bottom of the net frame. A silk screen printing hole is formed in the center of the polyester wire net, and the polyester wire net is in a concentric square shape. A stainless steel wire net anda polyimide film are further included. The polyimide film is fixed to the bottom face of the stainless steel wire net. A high-temperature glue layer is arranged between the polyimide film and the stainless steel wire net. The polyimide film is provided with a plurality of wire grooves, and a printing pattern is composed of the wire grooves. The top face of the stainless steel wire net is fixed tothe polyester wire net. The stainless steel wire net is larger than the silk screen printing hole and covers the silk screen printing hole, and a hot melt glue layer is arranged between the stainlesssteel wire net and the polyester wire net. The net plate manufacturing technology is simple, the manufacturing cost is low, the yield is high, the service life of the net plate is long, and frictionresistance and cross section sharpness are obviously improved; and the service life reaches 100,000 times or more, and the purchasing cost of printing net plates is reduced for battery piece manufacturers.

Owner:昆山良品丝印器材有限公司

Container packaging method

Owner:DAISEY MASCH CO LTD

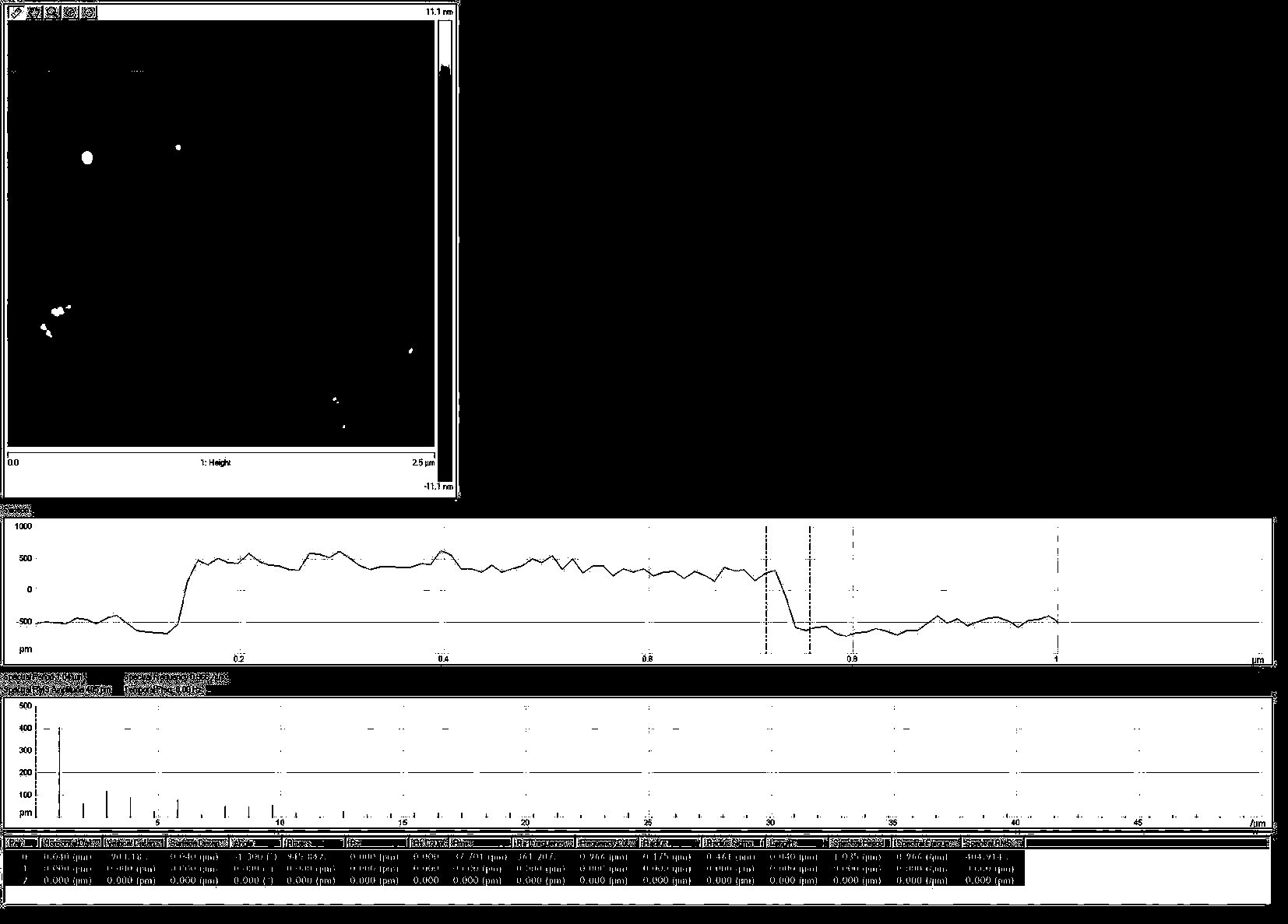

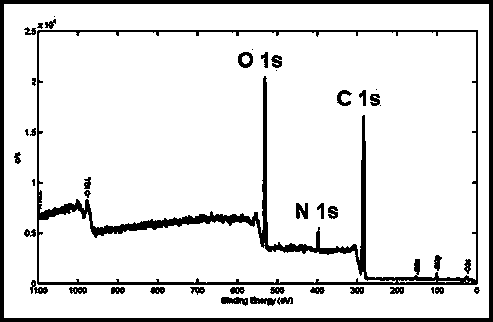

Low-temperature environmentally-friendly preparation method of nitrogen edge doped graphene

The invention relates to a low-temperature environmentally-friendly preparation method of nitrogen edge doped graphene, and belongs to the field of novel carbon nano-materials. The preparation method is characterized in that graphite powder and a nitrogen-containing polymer solid are mixed and subjected to continuous ball milling at a certain ball milling speed under the normal temperature and normal pressure so as to obtain a nitrogen edge doped graphene nanosheet, wherein no liquid agents are added during preparation. By analyzing through a scanning electron microscope and an atomic force microscope, the product is a lamellar structure which is uniform in dispersion and less than 1 nanometer in thickness. The analysis result of an X-ray photoelectron spectroscopy shows that the prepared product contains nitrogen, carbon, oxygen and other elements, and therefore, that the nitrogen edge doped graphene nanosheet is successfully prepared can be verified.

Owner:WENZHOU MEDICAL UNIV

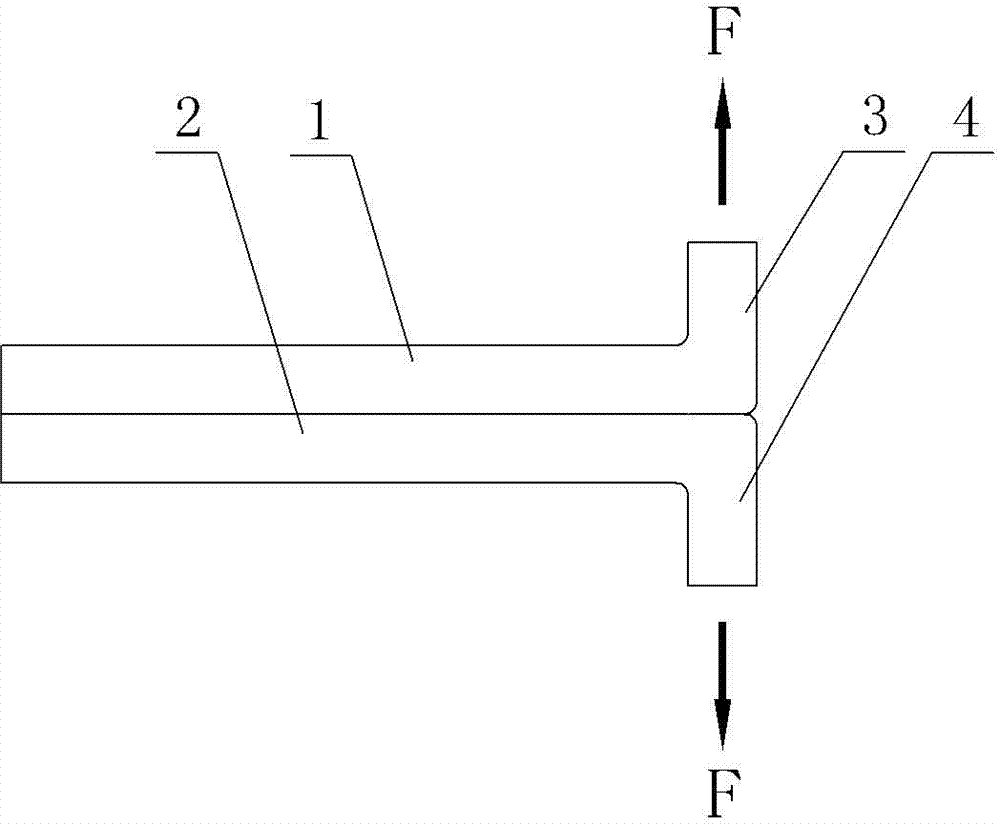

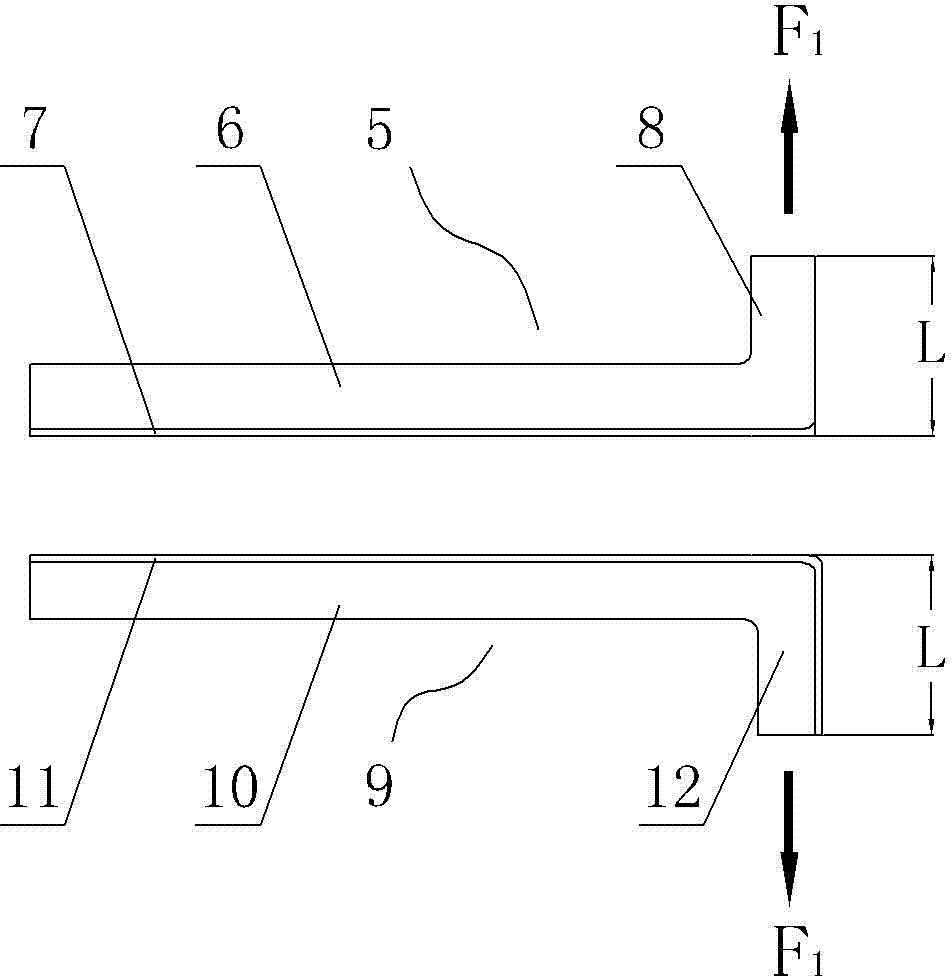

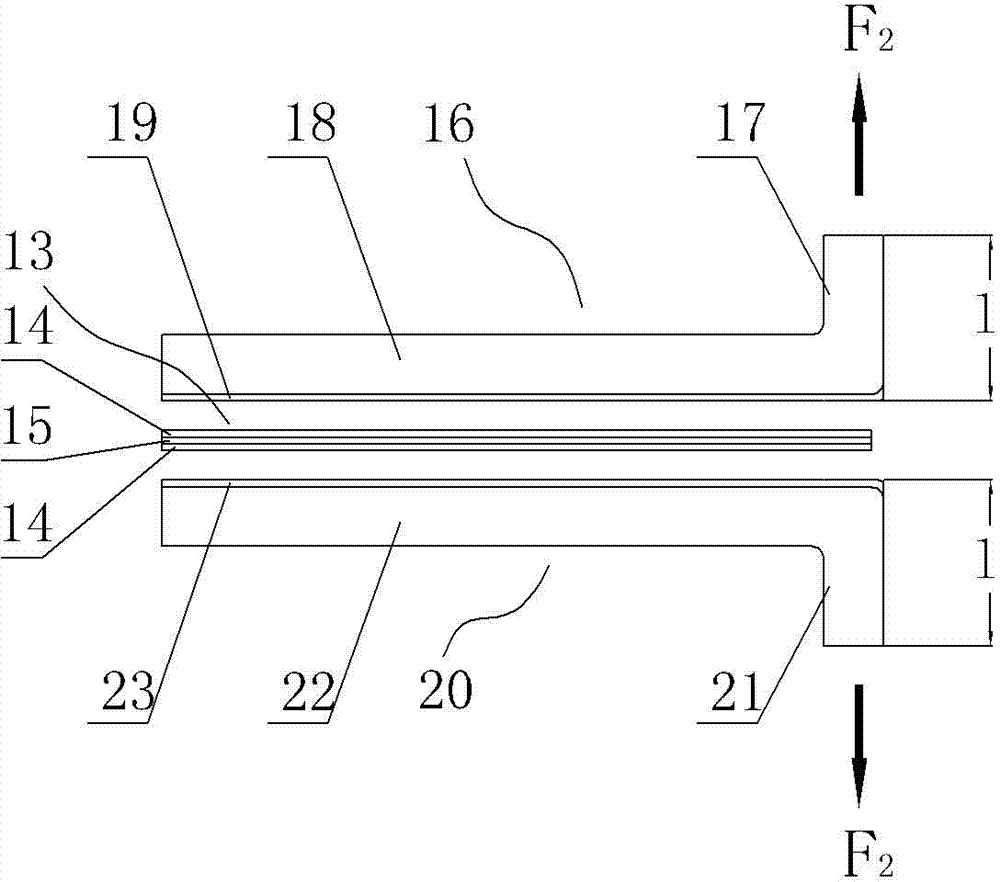

Method for detecting interface binding strength of aluminum-steel composite material for soldering

ActiveCN103776762AMake sure to peel off properlySmooth peelingUsing mechanical meansMaterial analysisTest sampleSoldering

The invention provides a method for detecting the interface binding strength of an aluminum-steel composite material for soldering. The method can be used for accurately detecting the aluminum-steel interface binding strength and quantifying the interface binding effect of the aluminum-steel composite material for the soldering. The method comprises the following steps: firstly, preparing a test sample of the aluminum-steel composite material and carrying out a stripping test on the test sample; and calculating according to a test result to obtain a binding strength value of an aluminum-steel interface. The method is characterized in that the preparation of the test sample comprises the following steps: soldering and connecting a metal reinforced layer on the surface of an aluminum layer of the sample and forming a compound layer by the metal reinforced layer and the aluminum layer of the sample. The binding strength of the metal reinforced layer in the compound layer and the aluminum layer of the sample is greater than the binding strength of the aluminum-steel interface; in the stripping test, the compound layer and a steel layer in the sample are stripped by a tension tester.

Owner:银邦(安徽)新能源材料科技有限公司

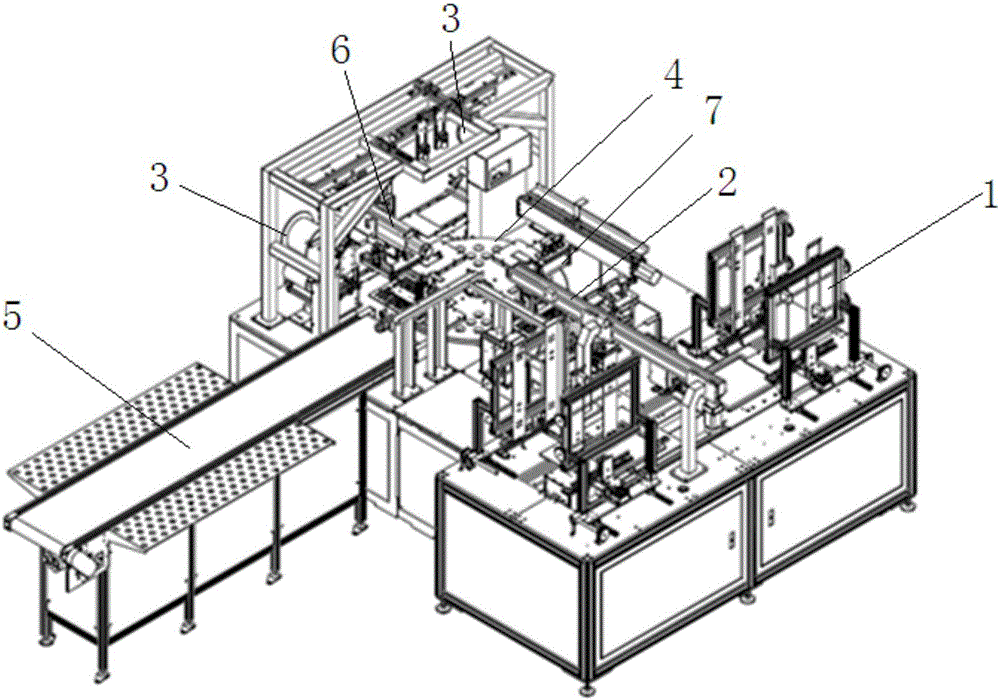

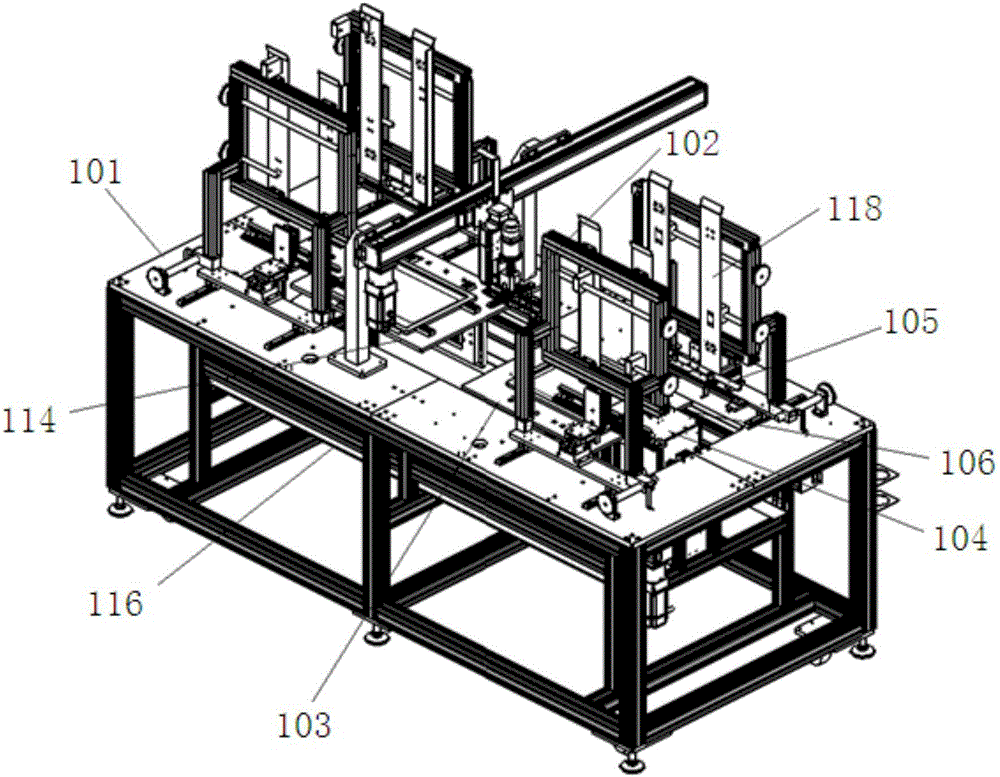

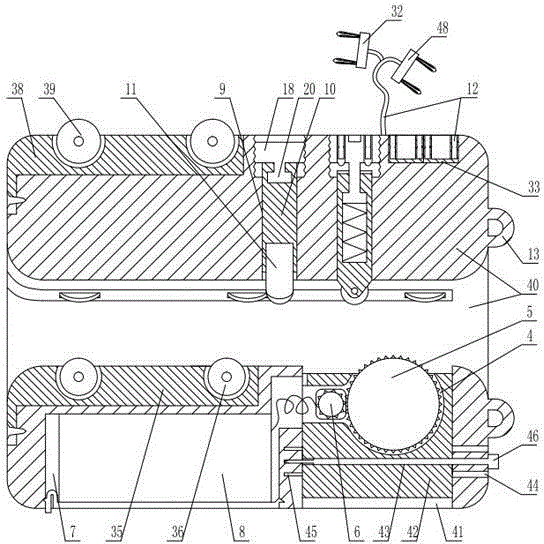

Integrated circuit, film removing method of integrated circuit and film removal arranging device of integrated circuit

InactiveCN110422416ASmooth peelingAvoid clutterSemiconductor/solid-state device manufacturingArticle unpackingIntegrated circuit manufacturingEngineering

The invention relates to the technical field of integrated circuit manufacturing, and discloses a film removal arranging device of an integrated circuit. The film removal arranging device comprises aframe, two symmetrically arranged carrier plate feeding devices, two symmetrically arranged carrier plate conveying line devices, two symmetrically arranged film removing devices, a carrying manipulator, a visual detection device, a tray feeding device and a tray conveying line device, wherein the carrier plate feeding devices, the carrier plate conveying line devices, the film removing devices, the carrying manipulator, the visual detection device, the tray feeding device and the tray conveying line device are arranged on the frame; the film removing devices are positioned below the carrier plate feeding devices; the carrier plate conveying line devices are connected with the carrier plate feeding devices; the tray feeding device is positioned between the two carrier plate feeding devices; the tray conveying line device is positioned between the two carrier plate conveying line devices and is connected with the tray feeding device; and the carrying manipulator and the visual detectiondevice are arranged on the frame and are positioned above the carrier plate conveying line devices and the tray conveying line device. The film removal arranging device has the advantages of being efficient and accurate in glue removing, automatic in feeding and discharging, high in processing efficiency and capable of collecting and arranging the integrated circuit.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

Cable stripper

InactiveCN105281258ASmooth peelingQuick peelApparatus for removing/armouring cablesEngineeringBlade handle

The invention discloses a cable stripper. The cable stripper includes a main half tube and an auxiliary half tube which are locked together through a locking device so as to form a sleeve; a power gear which is in press fit with the outer sheath of a cable and a motor for driving the power gear to rotate are arranged in a power cavity of the sleeve; the outer wall of the sleeve is provided with a switch for controlling the on-off of the power source of the motor; the cross section of a blade cavity of the sleeve is a regular polygon; the edges of the polygon are an positive integer times of four; a blade handle is slidingly inserted in the blade cavity; a blade which can longitudinally cut the cable is fixedly arranged in the inner end of the blade handle; the outer section of the blade cavity is in threaded connection with a positioning device for axially positioning the blade handle; and an end portion of the sleeve is fixedly provided with a connecting ring. With the cable stripper adopted, axial longitudinally-cutting stripping and transverse annularly-cutting stripping can be both realized, and stripping can be initially performed on any portion of the cable, and cable stripping can be performed in a pipeline, and stripping depth can be adjusted. The cable stripper has the advantages of automatic stripping and time-saving and labor-saving operation.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

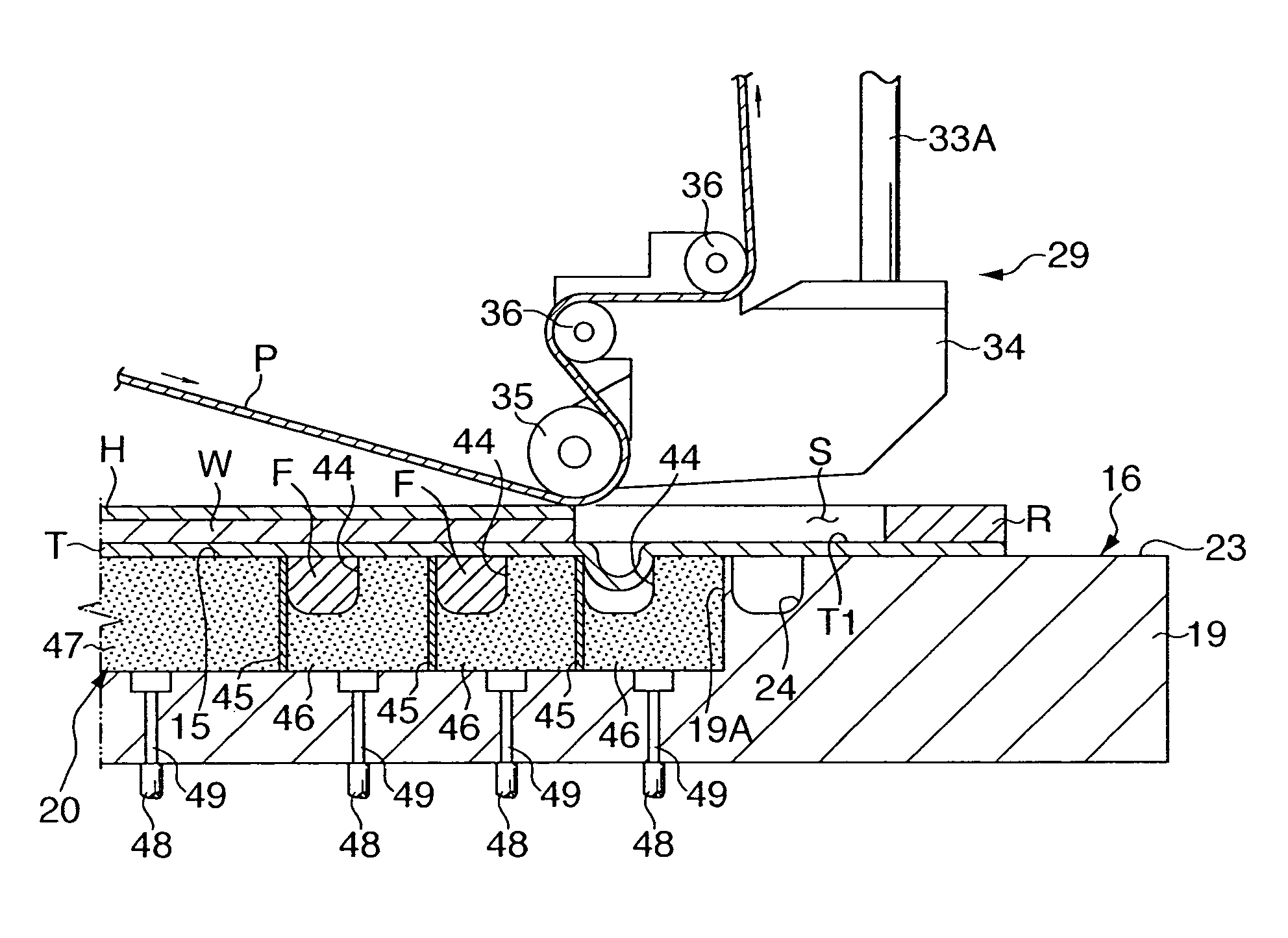

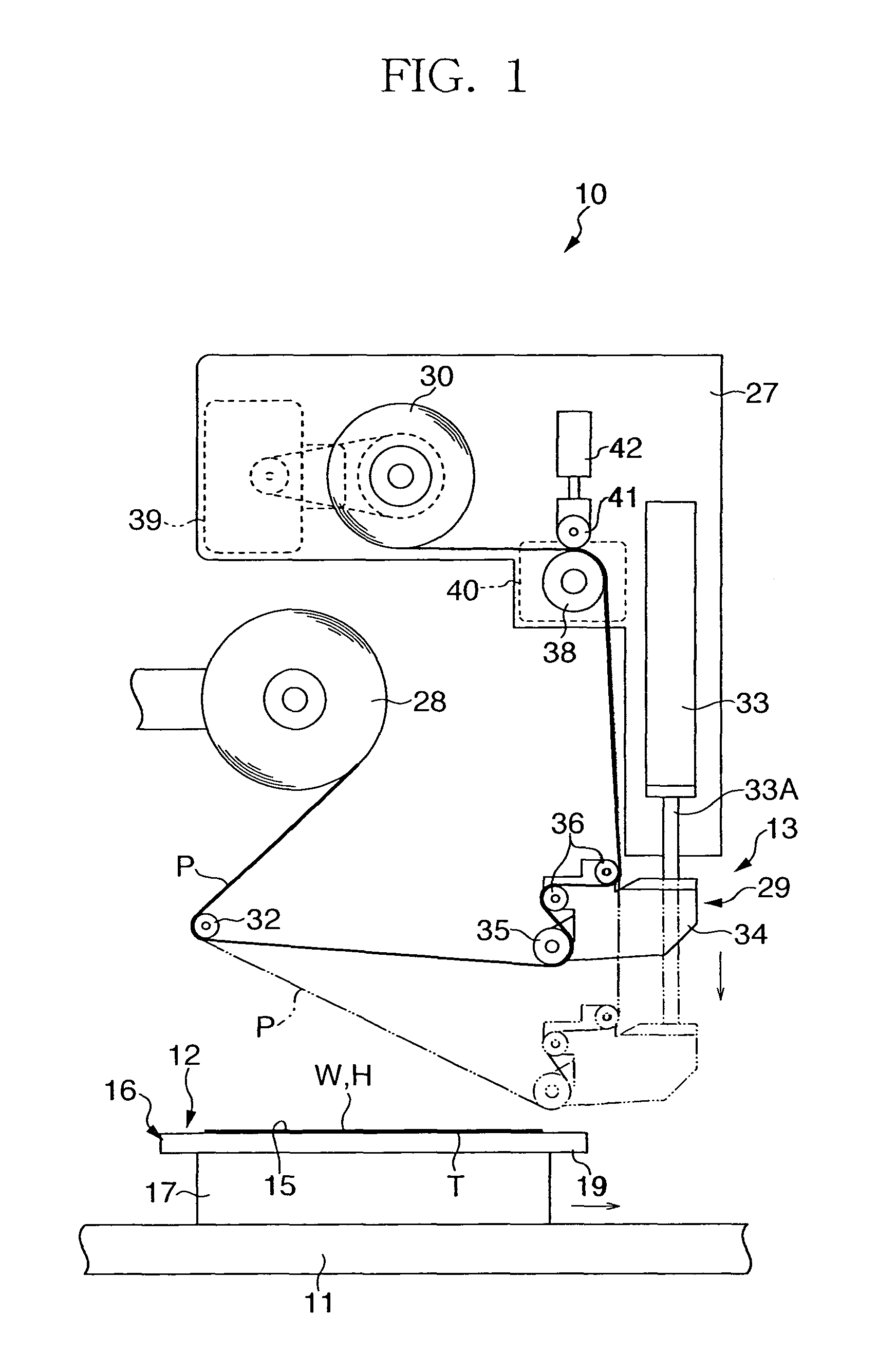

Suction unit

ActiveUS7798195B2Reduce pressureReduce component countSolid-state devicesLight protection screensDicing tapeMechanical engineering

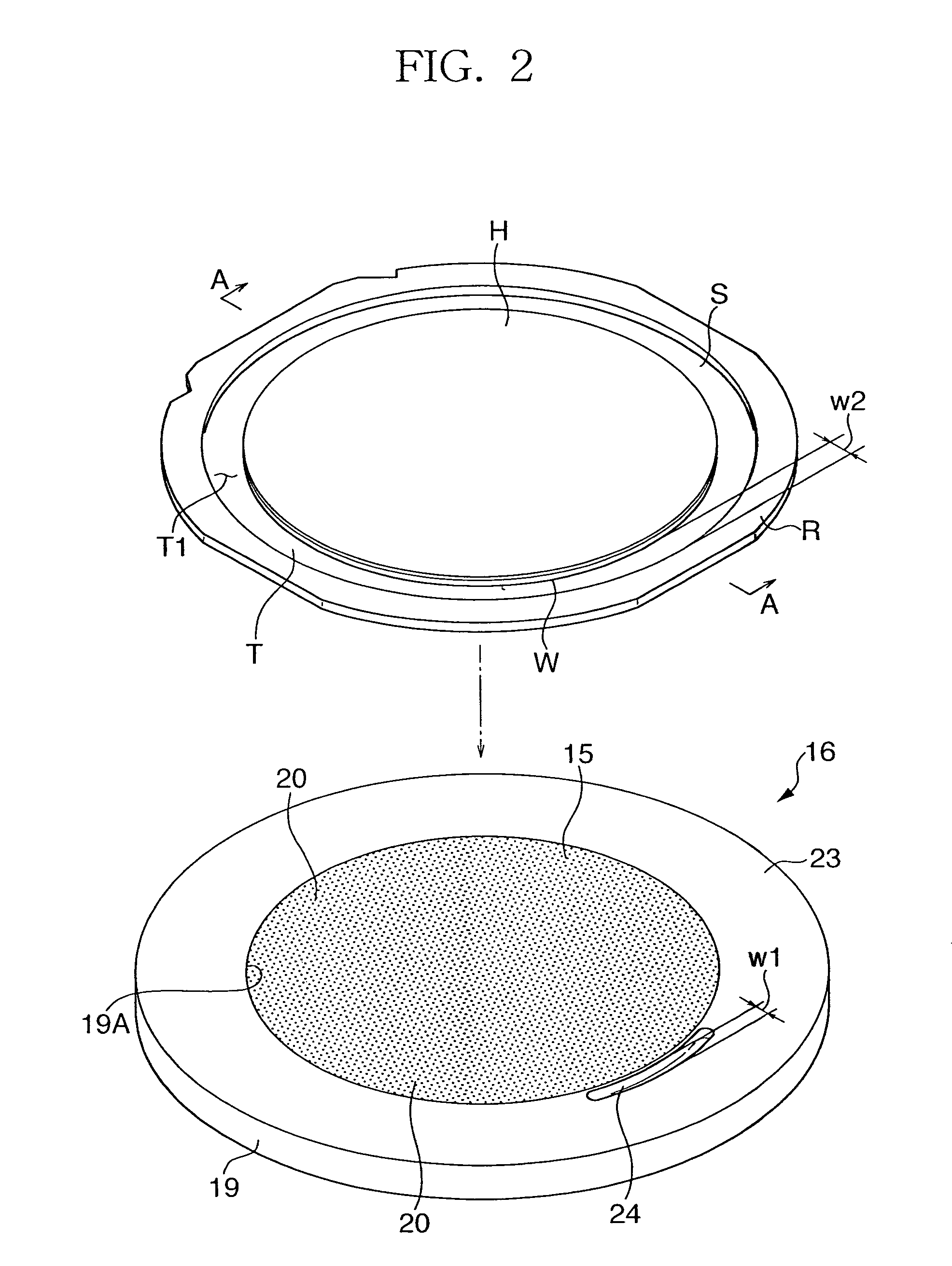

A wafer W is supported on the rear surface side thereof by a ring frame R by means of a dicing tape T, and a protection tape H is stuck on the front surface side the wafer W. A suction unit 12 includes a table 16 having a suction face 15 in the upper face. The suction face 15 sucks the dicing tape T to hold the wafer W through performing a predetermined suction. At least in a partial area along the periphery of the suction face 15, a groove 24 is formed. By sucking through the suction face 15, the inside of the groove 24 becomes negative pressure and the dicing tape T is sunk therein.

Owner:LINTEC CORP

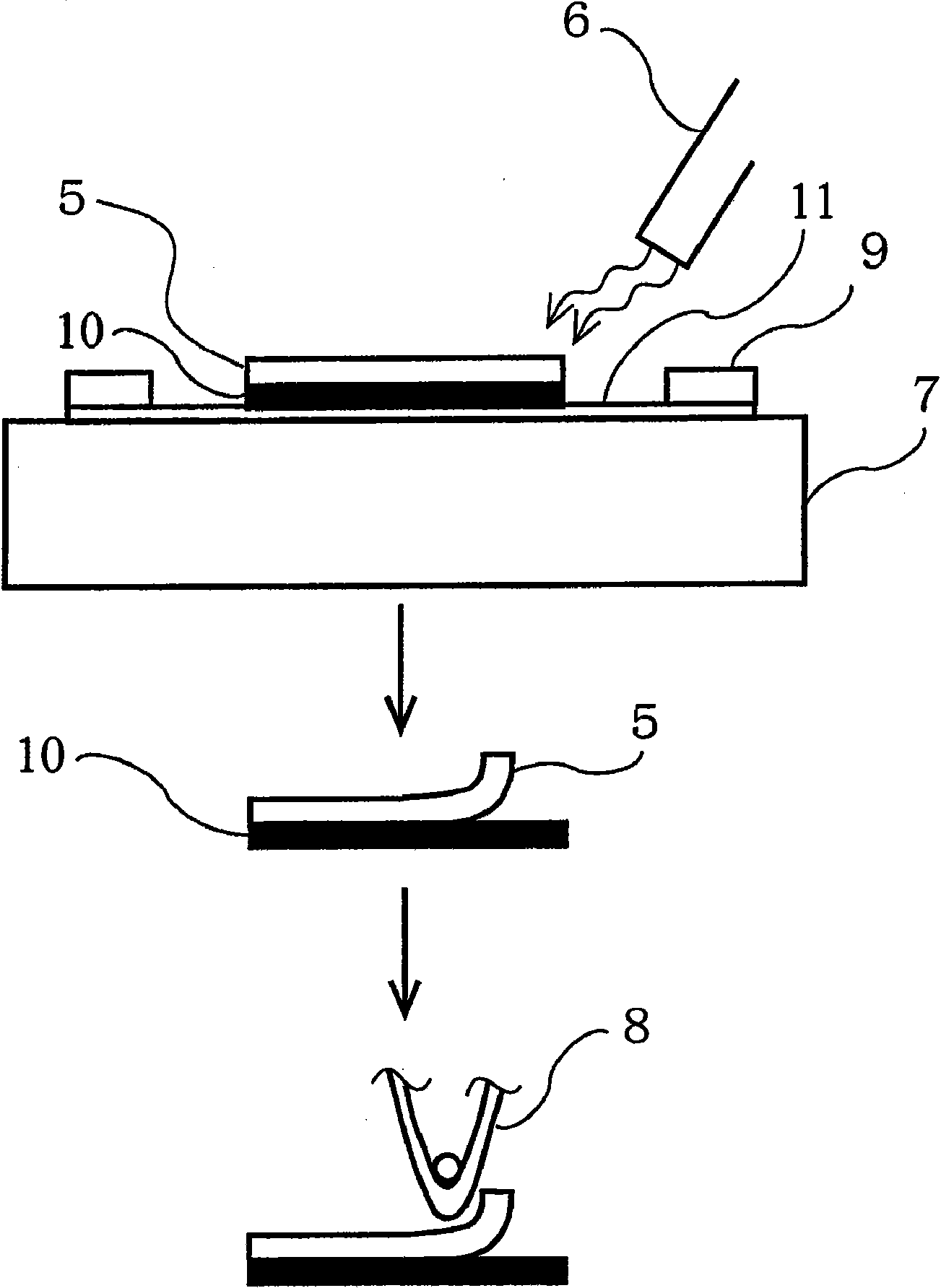

Lift-off method

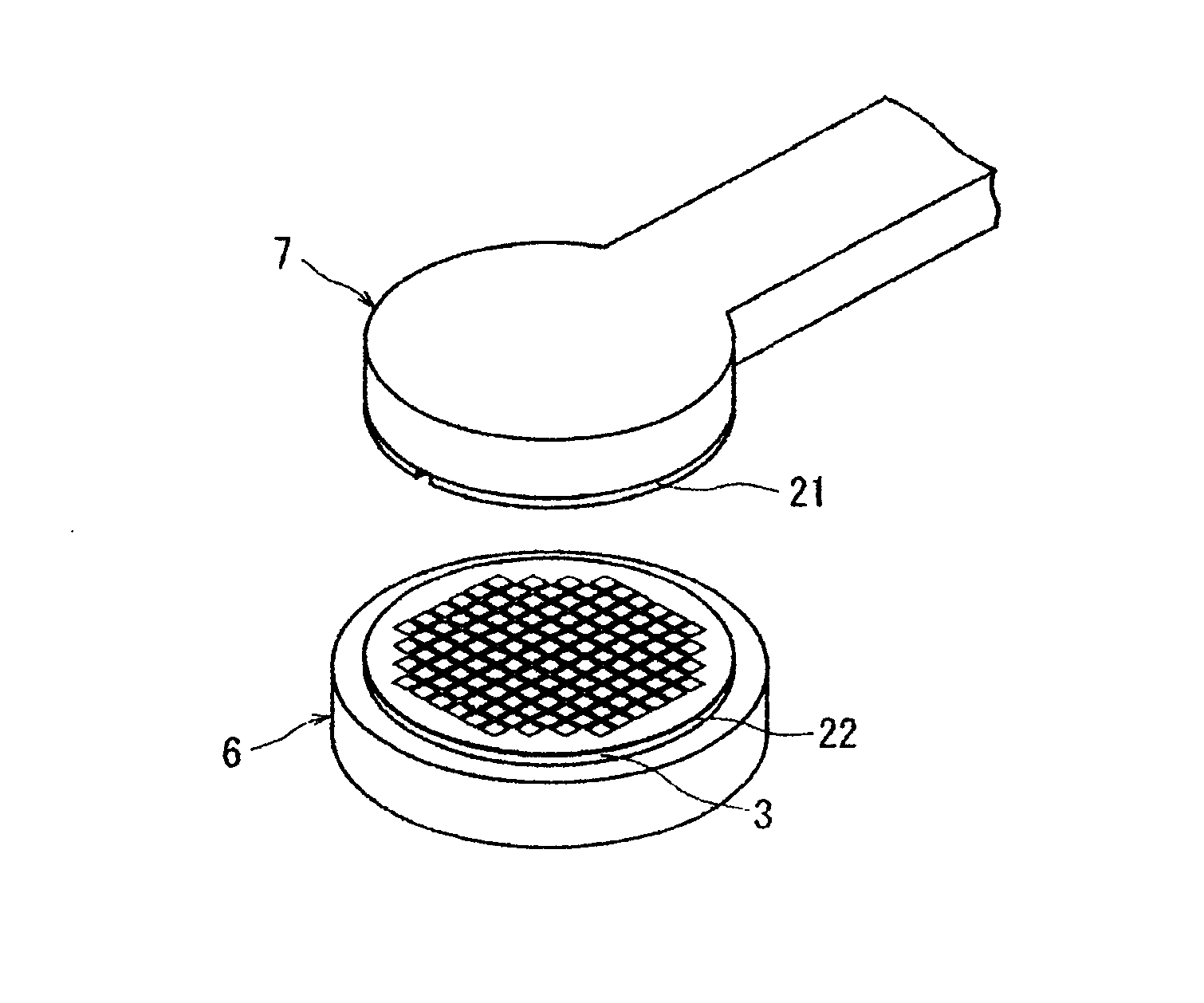

ActiveUS20150328872A1Easily peelImprove qualityLayered product treatmentSolid-state devicesComposite substrateUltrasonic vibration

A lift-off method for transferring an optical device layer in an optical device wafer to a transfer substrate, the optical device layer being formed on the front side of an epitaxy substrate through a buffer layer. A transfer substrate is bonded through a bonding layer to the front side of the optical device layer of the optical device wafer, thereby forming a composite substrate. A pulsed laser beam having a wavelength transmissive to the epitaxy substrate and absorptive to the buffer layer is applied from the back side of the epitaxy substrate to the buffer layer, thereby breaking the buffer layer, and the epitaxy substrate is peeled from the optical device layer, thereby transferring the optical device layer to the transfer substrate. Ultrasonic vibration is applied to the composite substrate in transferring the optical device layer.

Owner:DISCO CORP

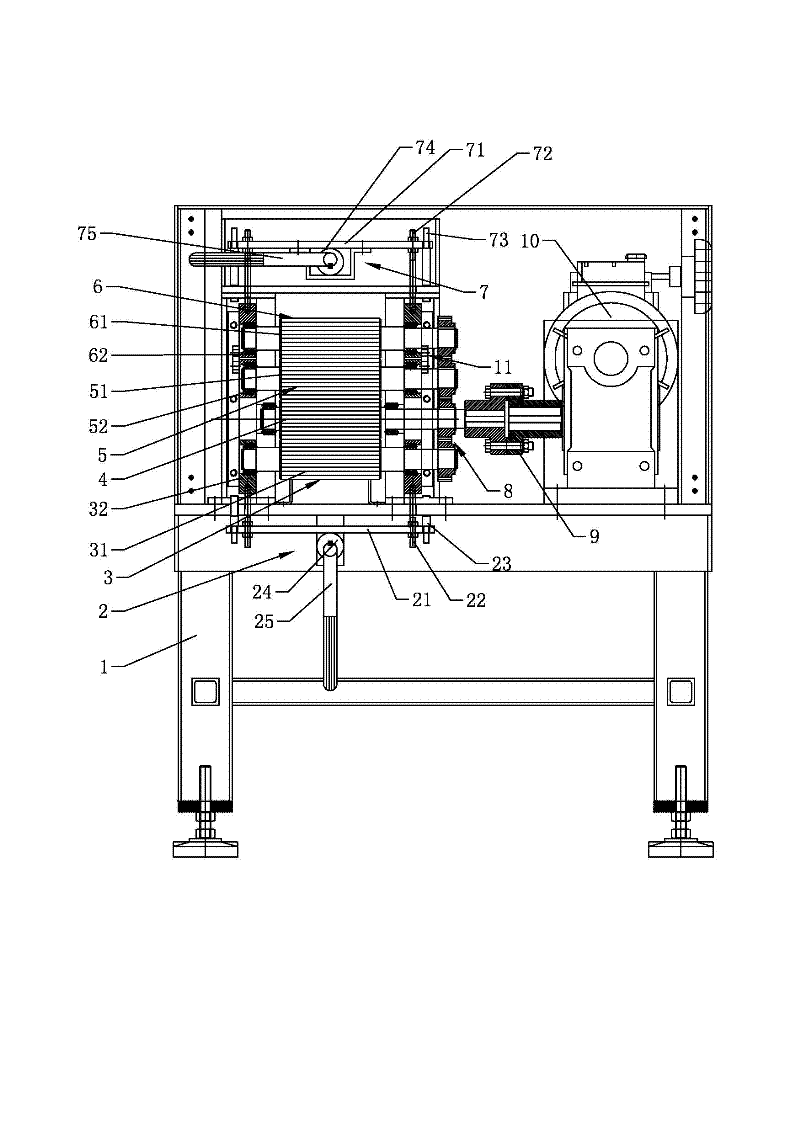

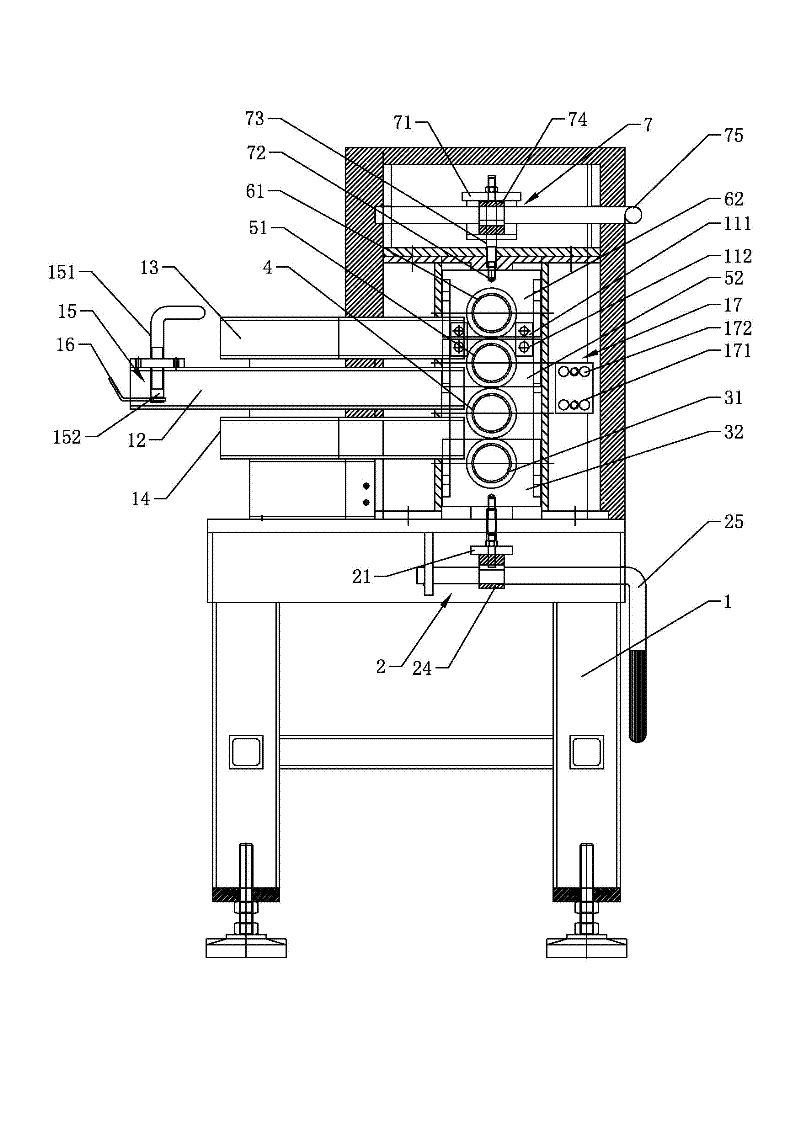

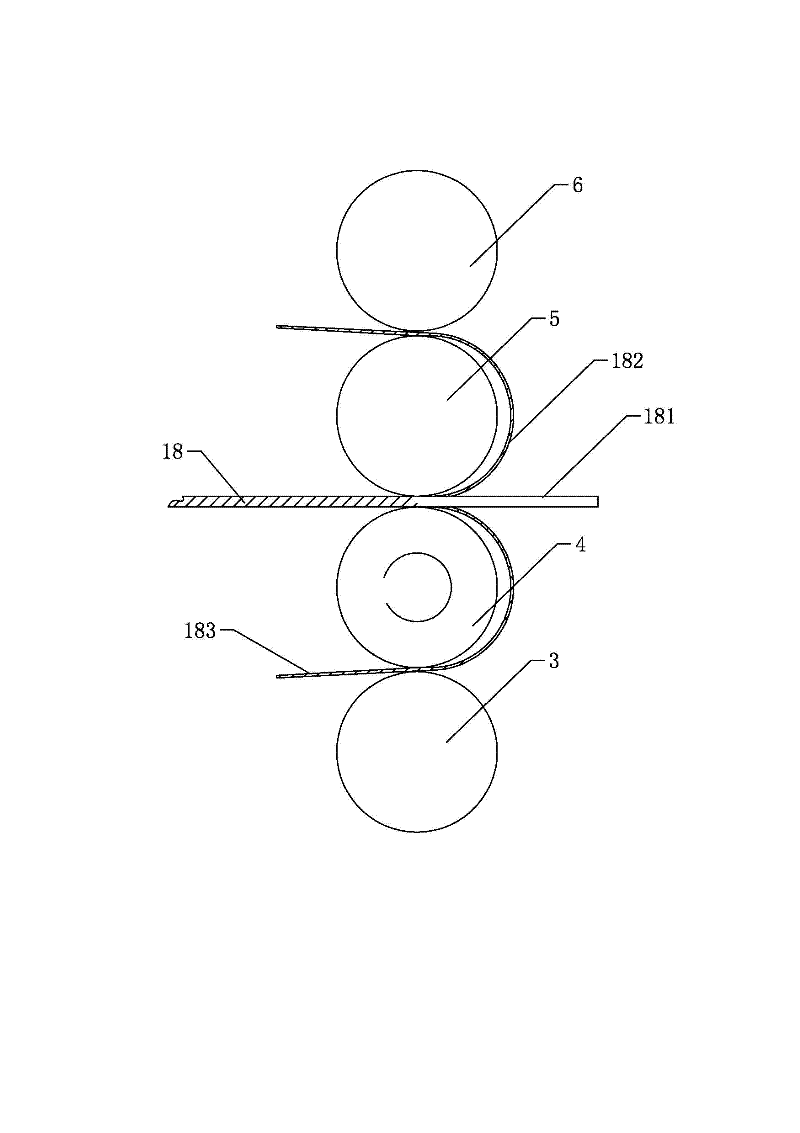

Stripping machine for metal and plastic composite plate

The invention discloses a stripping machine for a metal and plastic composite plate. The stripping machine comprises a stand, a stripping device, a tight supporting operation and control mechanism and a tight pressing operation and control mechanism, wherein the stripping device comprises four stripping rollers which are sequentially overlaid on the stand from bottom to top, the axial lines of the four stripping rollers are parallel and positioned on a same vertical plane, the four stripping rollers are sequentially connected in a transmission way, the first stripping roller and the fourth stripping roller are both vertically and slidably arranged on the stand, and the second stripping roller or the third stripping roller is connected with a power plant; the tight supporting operation and control mechanism is arranged between the first stripping roller and the stand; and the tight pressing operation and control mechanism is arranged between the fourth stripping roller and the stand. According to the stripping machine disclosed by the invention, the four stripping rollers are pairwise mutually matched to press and clamp an upper metal layer, a lower metal layer and a sandwich-layer plastic plate, and can be used for stripping metal and plastic fast and efficiently.

Owner:佰顿新材料科技江苏有限公司

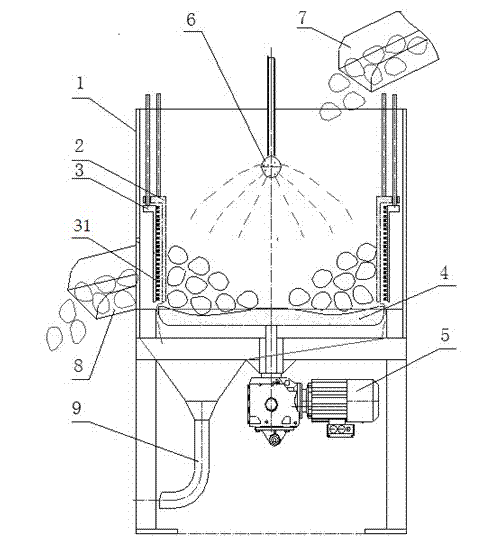

Potato peeling machine

The invention discloses a potato peeling machine which comprises an outer tube body, a liftable first layer working inner tube without a tube bottom, a liftable second layer working inner tube without a tube bottom, and a rotatable circular disk with the outer diameter matched with the inner diameter of the outer tube body. The second layer working inner tube is placed in the outer tube body, and a brush head is arranged on the surface of the inner side of the second layer working inner tube. The first layer working inner tube is placed in the second layer working inner tube, and the surface of the first layer working inner tube is a rough grinding face. The circular disk is arranged in the outer tube body and placed at the bottom of the first layer working inner tube and the second layer working inner tube. A spraying part capable of spraying potatoes is arranged on the top of the outer tube body, and a blow-off pipeline is arranged at the bottom of the outer tube body. A discharging groove is formed in the lower portion of the outer tube body. The potato peeling machine enables the striping damage of the peeled potatoes to be smaller than 3%, peeling is even, and the cleanliness is good.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Method and device for manufacturing battery pack

InactiveCN101878555AStrong pulling forcePulling reallyCell component detailsMaterials scienceBattery pack

The tensile stress applied to a hardening resin should be sufficiently small so that no disconnection is caused in a hardening resin formed in a spool by hardening of a molding material and sufficiently large so that the hardening resin formed in the spool can be separated from the internal surface of the spool by the reduction of the diameter of the cross sectional area. For this, a runner stripper plate holding the hardening resin is separated from a nozzle and a spool bush. This state is maintained for a predetermined time to separate the hardening resin from the internal circumferential surface of the spool.

Owner:PANASONIC CORP

Wire taking device of waste radial steel wire tire circle opening

ActiveCN107694720AIncrease squeezeImprove the effectSolid waste disposalGrain treatmentsEngineeringSeparation problem

The invention belongs to the field of tire recovering, and particularly relates to a wire taking device of a waste radial steel wire tire circle opening. The wire taking device of the waste radial steel wire tire circle opening comprises a grinding module, an attraction module, a lifting module, a machine basin and stabilizer blades; the machine basin is of a barrel-shaped structure, a plurality of circles of upwards-protruding cones are arranged at the bottom of the machine basin, cylindrical material discharging holes are formed in the bottom faces of the adjacent cones, and a through hole for the grinding module to penetrate is formed in the middle portion of the machine basic; the grinding module is installed in the machine basin and grinds and crushes rubber at the tire circle openingin the machine basin; the attraction module is installed below the machine basin and generates downward action force on the grinding module; and the lifting module is installed above the machine basin and is used for lifting the grinding module. The waste radial steel wire tire circle opening wire taking device is mainly used for solving the problem about separation of the rubber in the radial steel wire tire circle opening and a steel wire, grinding and crushing of the tire circle opening are achieved through the grinding module, the attraction module increases extrusion force of the grinding module on the tire circle opening, and separation of the steel wire and the rubber is achieved.

Owner:解波

Intelligent stripping device capable of stripping cables of different sizes

InactiveCN111668765AImprove work efficiencyPeeling stableApparatus for removing/armouring cablesInternet of ThingsStructural engineering

The invention relates to the technical field of Internet of Things, and discloses an intelligent stripping device capable of stripping cables of different sizes. The device comprises a base. a fixed plate, a cutting knife, a moving block and a limiting plate are matched for use, cables with different thicknesses can be stripped, a new peeling device does not need to be replaced, the cable can be peeled more conveniently, work efficiency is improved. A first sliding block, a limiting block, a fixing rod, a special-shaped rod and a clamping plate are matched for use. Therefore, cables with different diameters can be clamped; more stable cable stripping is ensured. Therefore, the cable is ensured to be located at the center of the cutting knife during stripping. Through the cooperation of themovable block, a first connecting rod, a sleeve rod, a limiting plate and a cross rod, when a large-size cable is clamped, the cutting thickness can be automatically adjusted, the linkage performanceof the whole device is improved, and the operation is simpler.

Owner:广州蓝鹏创新科技有限公司

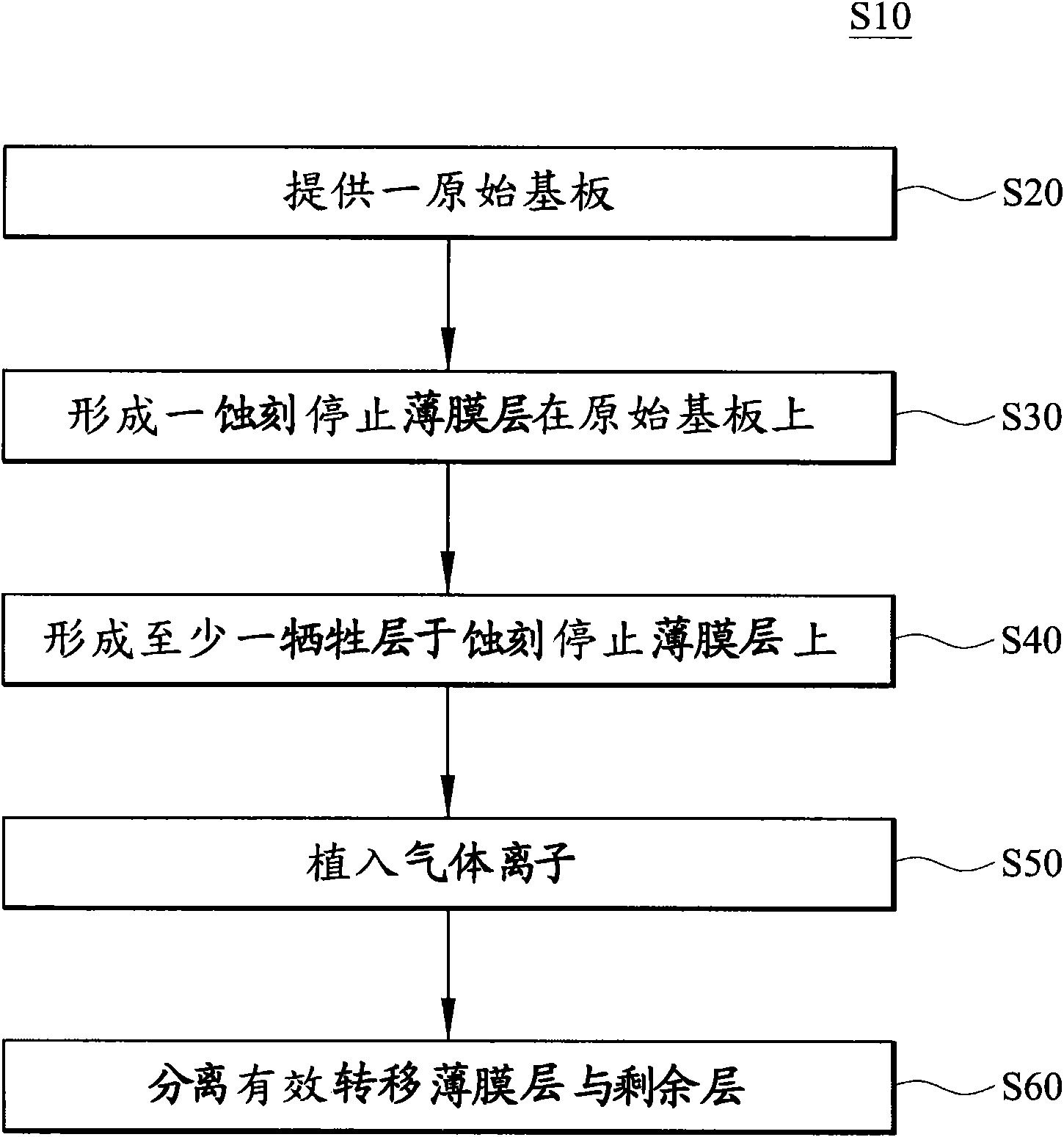

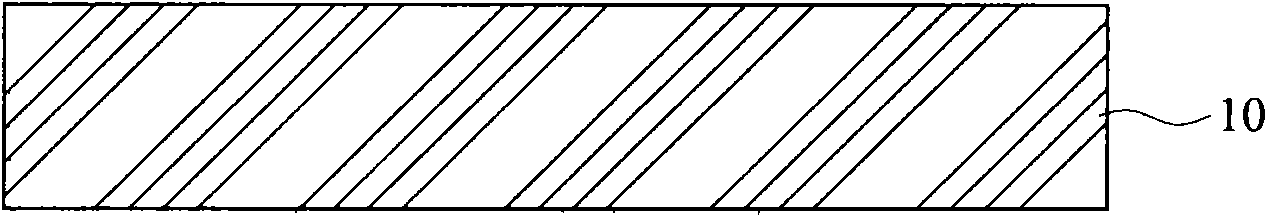

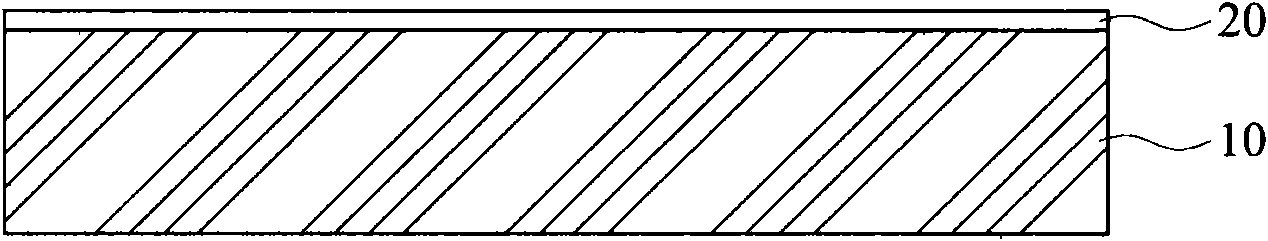

Thin film production method

InactiveCN101620983ASmooth peelingDoes not affect film thickness uniformitySemiconductor/solid-state device manufacturingNanometreOptoelectronics

The invention relates to a thin film production method comprising the following steps: providing an original substrate; forming a etching ceasing thin film on the original substrate; forming a sacrificial layer on the etching ceasing thin film; embedding gas ion to form an ion distribution concentration peak layer and define an effective transferring thin film and a residual layer; and separating the effective transferring thin film and the residual layer. The thickness of the effective transferring thin film can be effectively controlled by controlling the thickness of the sacrificial layer. In addition, the thickness of the effective transferring thin film is even and reaches the nanoscale thickness.

Owner:李 天锡

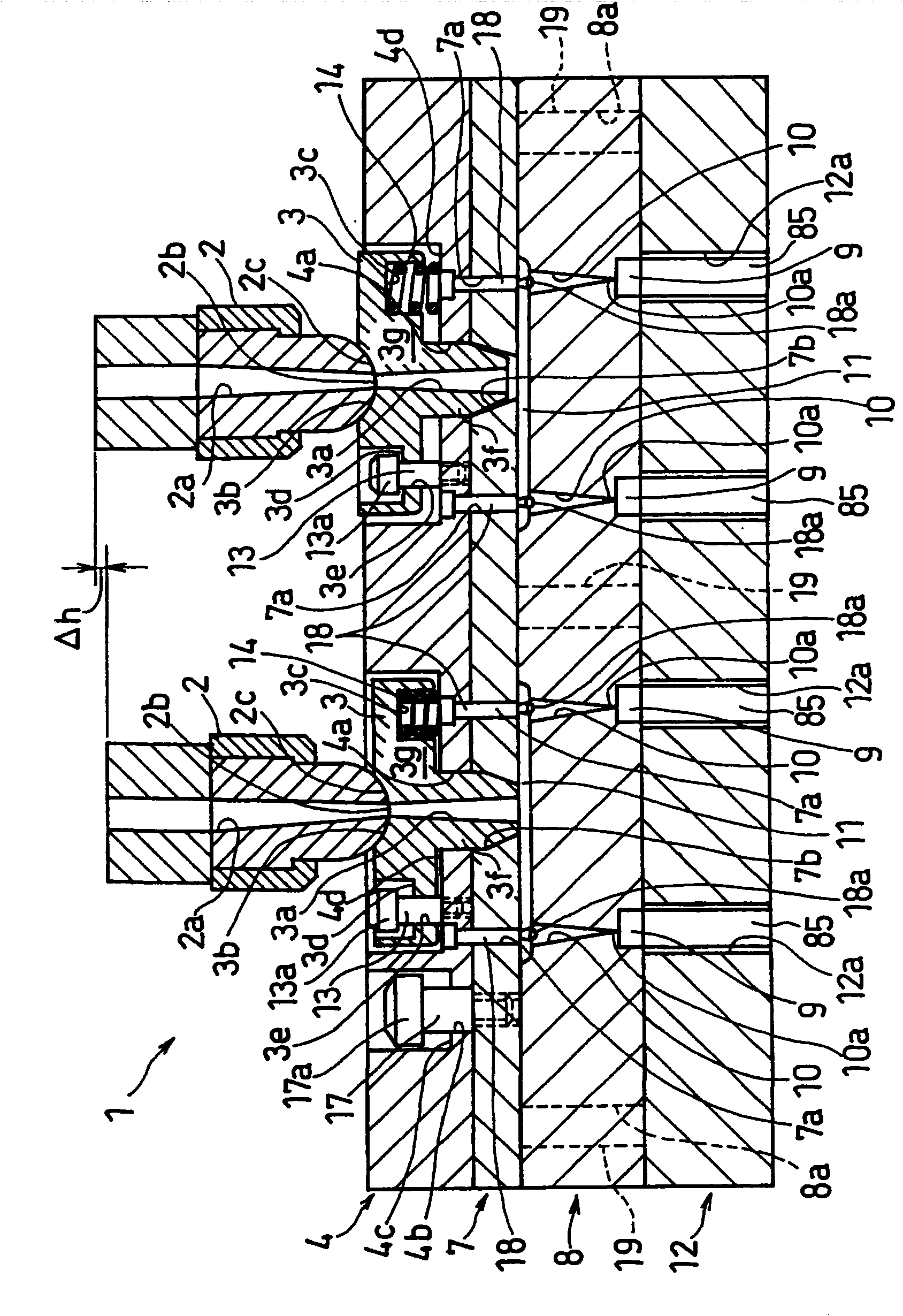

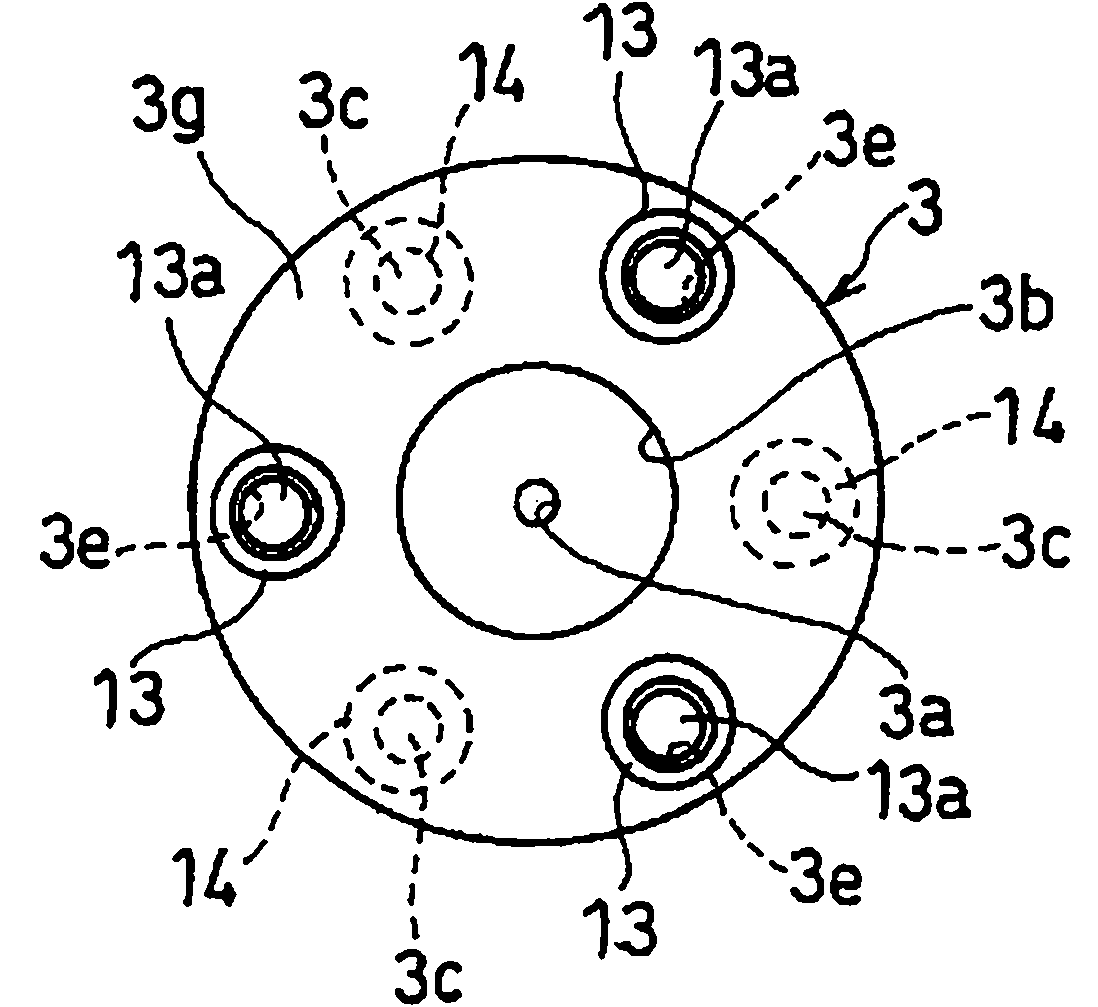

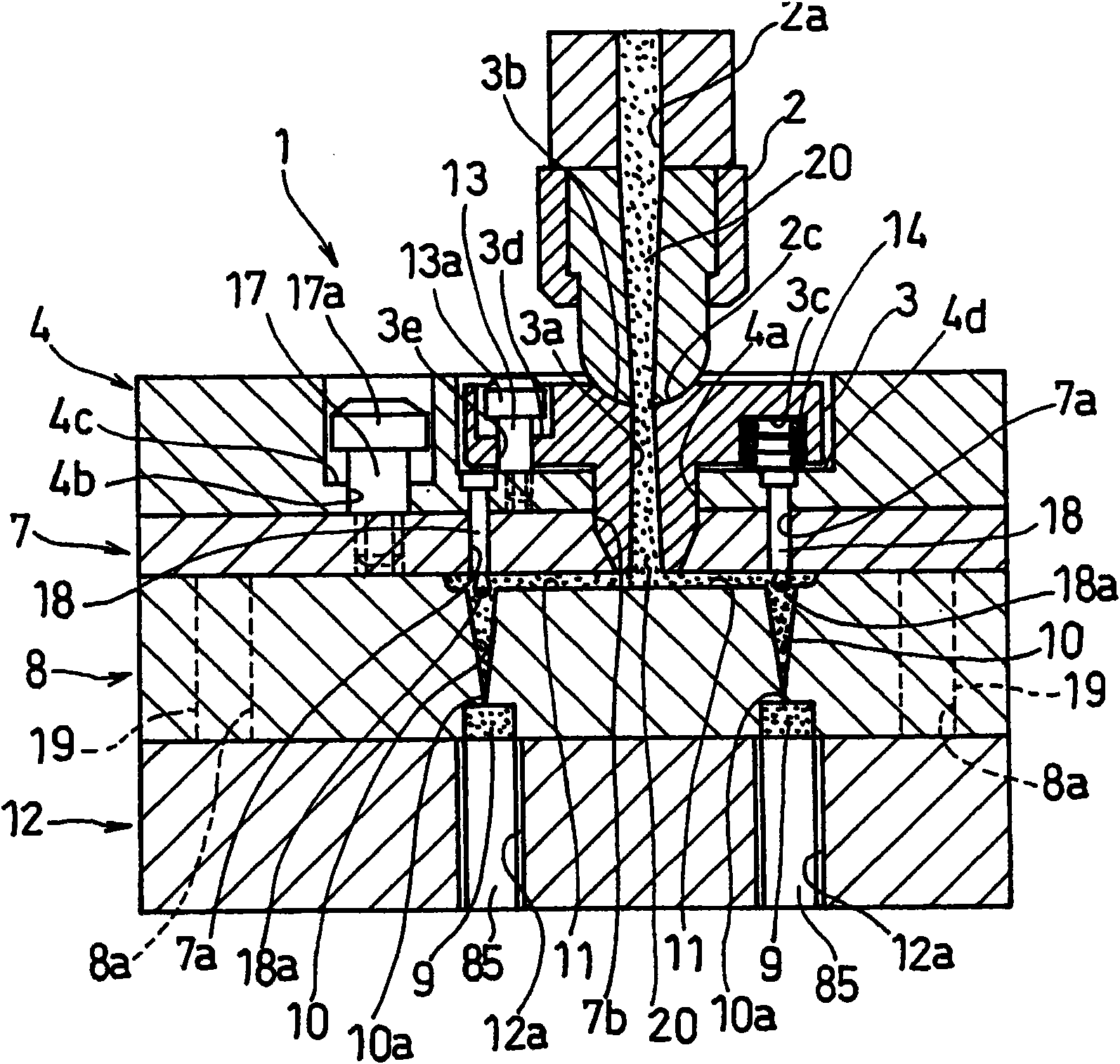

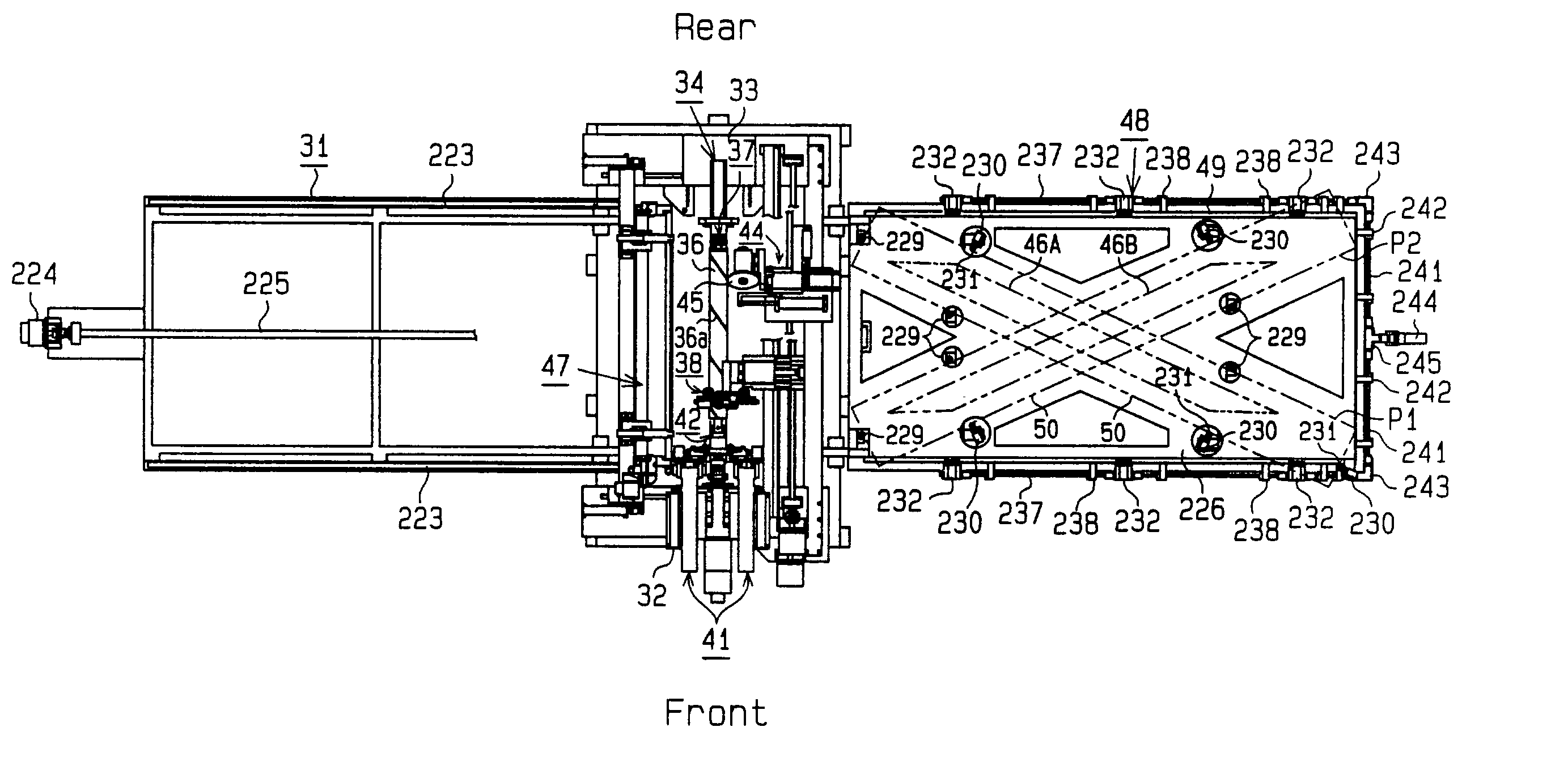

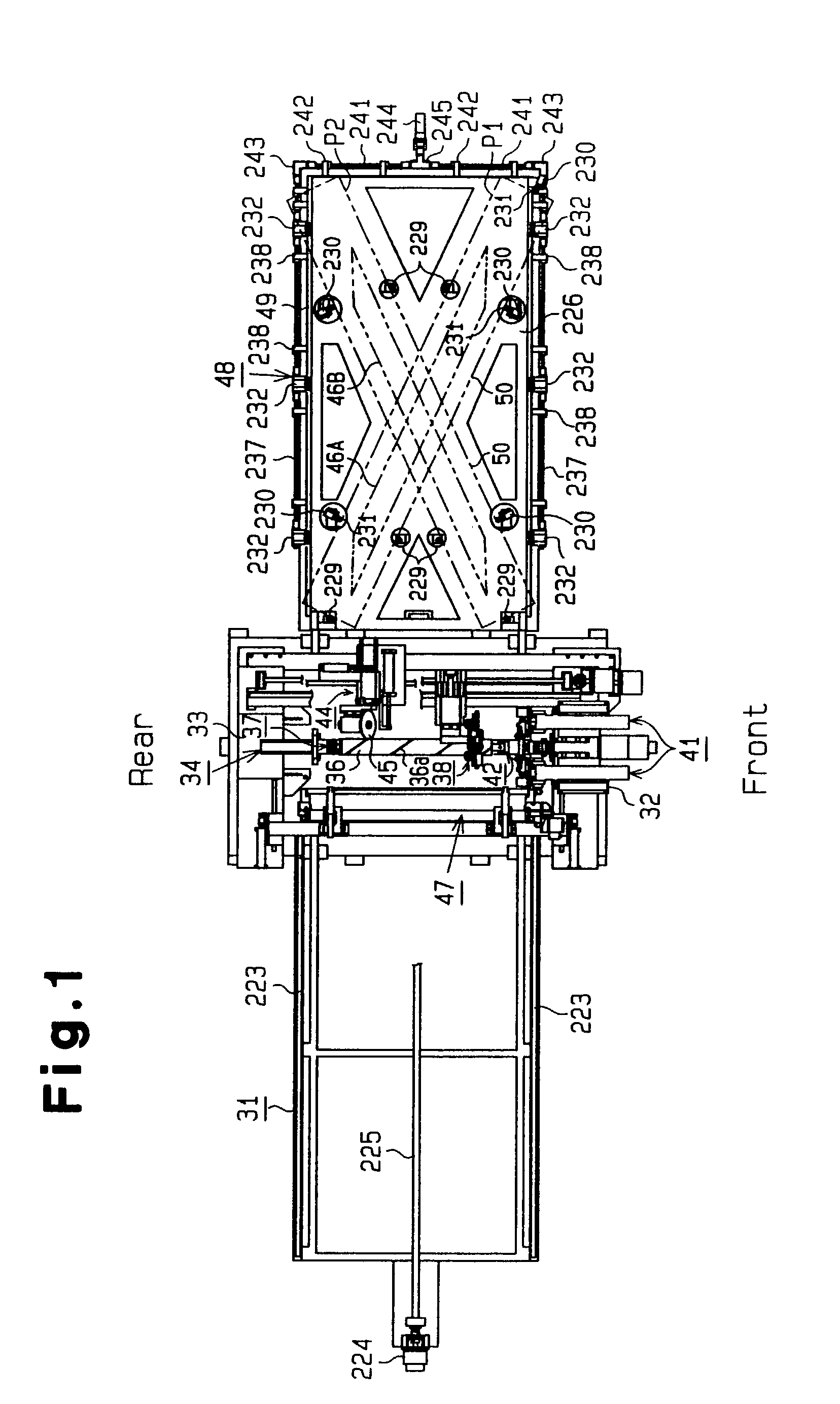

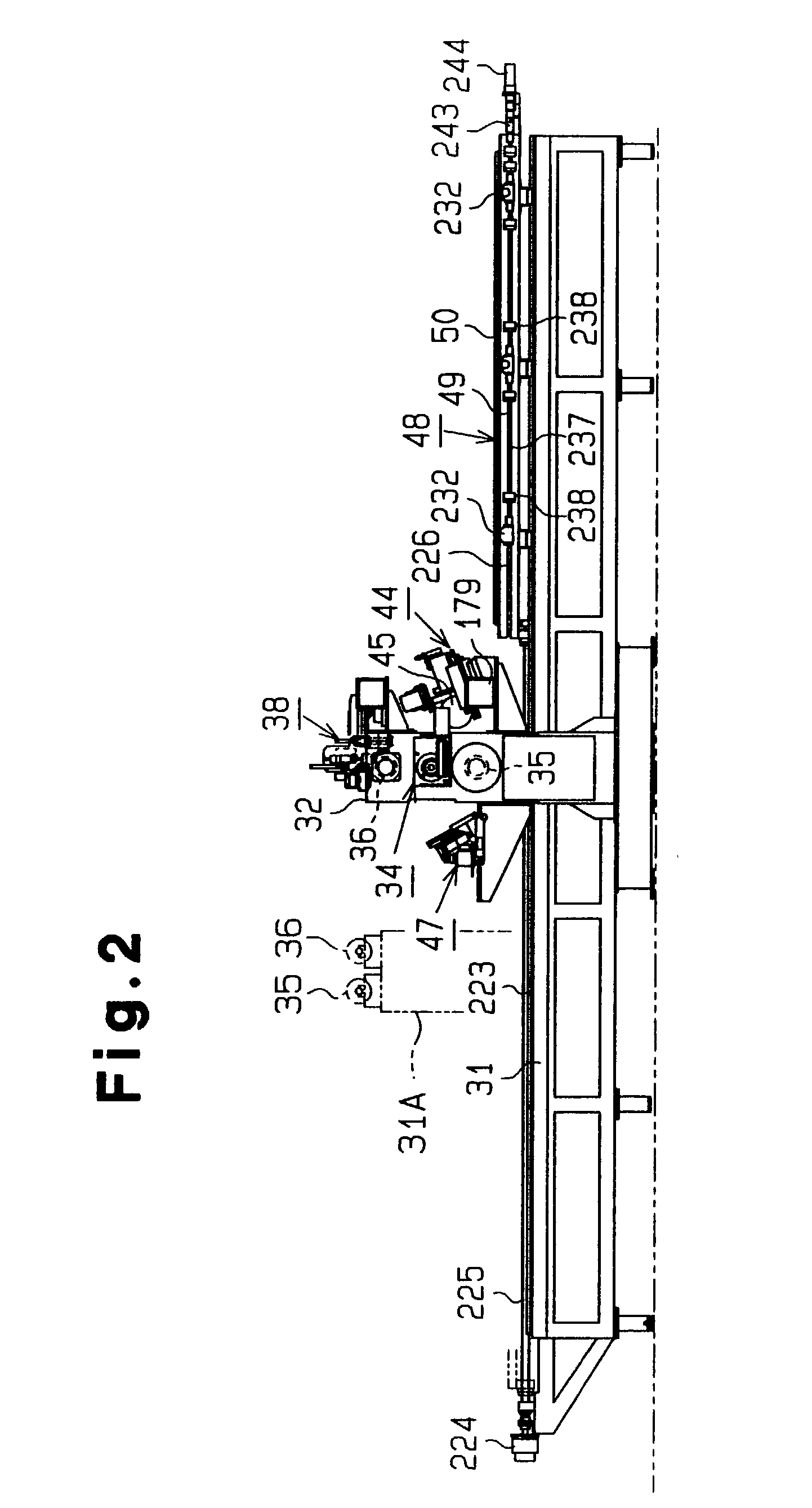

Method and device for manufacturing belt material for tire

InactiveUS6969439B1Reduce spacingReduce manufacturing costTyresMetal working apparatusSpiral bladeEngineering

A method of manufacturing a belt material for tire, comprising the steps of spirally winding a ribbon, having a plurality of linear cords disposed longitudinally and coated with rubber, on the outer peripheral surface of a drum at specified pitches while the drum is rotated, sticking the side edges of the wound ribbon to each other so as to form a cylindrical wound body, and a linearly moving rotating blade in the axial direction of the drum in contact with a spiral blade groove formed in the drum at specified pitches while the drum is rotated so as to cut the wound body spirally so as to form a belt material having a specified width and a cord inclination angle.

Owner:FUJISEIKO

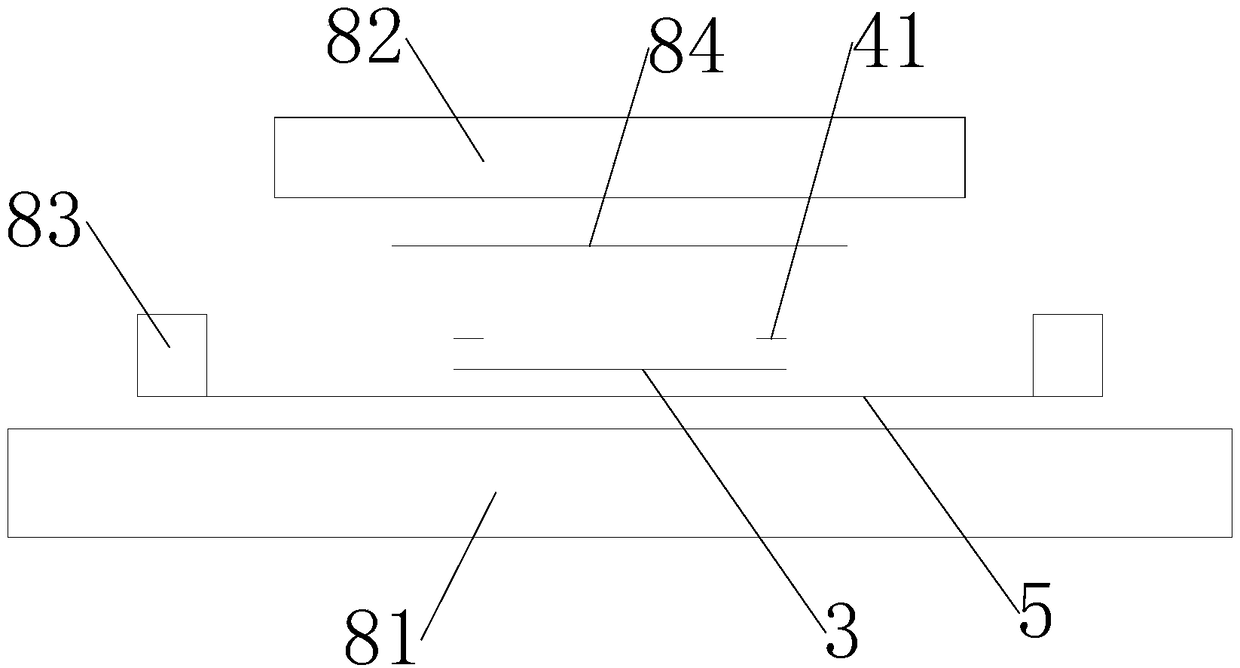

Lower exposure type ceramic photocuring 3D printing equipment and manufacturing method thereof

InactiveCN107030852ASmooth peelingImprove printing accuracyAdditive manufacturing apparatusAuxillary shaping apparatusThree dimensional modelCirculating pump

The invention discloses lower exposure type ceramic photocuring 3D printing equipment and a manufacturing method thereof. The lower exposure type ceramic photocuring 3D printing equipment comprises a machine table, a stripping mechanism, a precipitating preventing mechanism, a trough, a printing platform located over the trough, a lifting mechanism driving the printing platform to ascend and descend relative to the trough, and a projector located on the corresponding lower portion of the trough. The stripping mechanism comprises a pivot swing table and a pivot swing driver, the pivot swing table is pivoted on the machine table around a horizontally arranged pivotal shaft, and the pivot swing driver drives the pivot swing table to vertically pivotally swing around the pivotal shaft. The pivot swing driver is mounted on the machine table, and the trough is mounted on the pivot swing table. The precipitating preventing mechanism comprises a circulating pump, a recycling hose and an output hose. The recycling hose is connected between an inlet of the circulating pump and the trough, and the output hose is connected between an outlet of the circulating pump and the trough. The circulating pump is mounted on the machine table and drives photocuring liquid in the trough to circulate. A three-dimensional model and the trough can be separated more easily, and the situation that the photocuring liquid precipitates, and consequently the forming reliability of the three-dimensional model is influenced is avoided.

Owner:DONGGUAN UNIV OF TECH

Manufacturing method for electrode of lithium niobate optical waveguide device

ActiveCN103353630AGuaranteed not to overlapImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusSputteringMetal strips

Disclosed in the invention is a manufacturing method for an electrode of a lithium niobate optical waveguide device. The manufacturing method comprises the following steps: using SiO2 as a mask and manufacturing an optical waveguide by using annealing proton exchange processing; utilizing the SiO2 mask as a mark to directly carry out self-alignment overlaying on the optical waveguide and an electrode graph; removing the SiO2 mask of the electrode zone by employing a method of combination of dry etching with wet etching; and utilizing sputtering and metal stripping technologies to manufacture the electrode graph and removing the residual SiO2 mask. When the method is used, the electrode graph can be formed at the lithium niobate optical waveguide and accurate overlaying between the optical waveguide and the electrode is ensured; the edge of the electrode is smooth; the defects are less; and the yield is high.

Owner:GUANGXUN SCI & TECH WUHAN

Resin laminate, pressure sensitive adhesive sheet, method for working adherend using the pressure sensitive adhesive sheet, and device for separating the pressure sensitive adhesive sheet

InactiveCN101868349AEasy to peel and goodSmooth peelingAdhesive articlesSolid-state devicesSemiconductorPressure sensitive

Owner:NITTO DENKO CORP

Laminate, method for producing same, and method for producing device structure using same

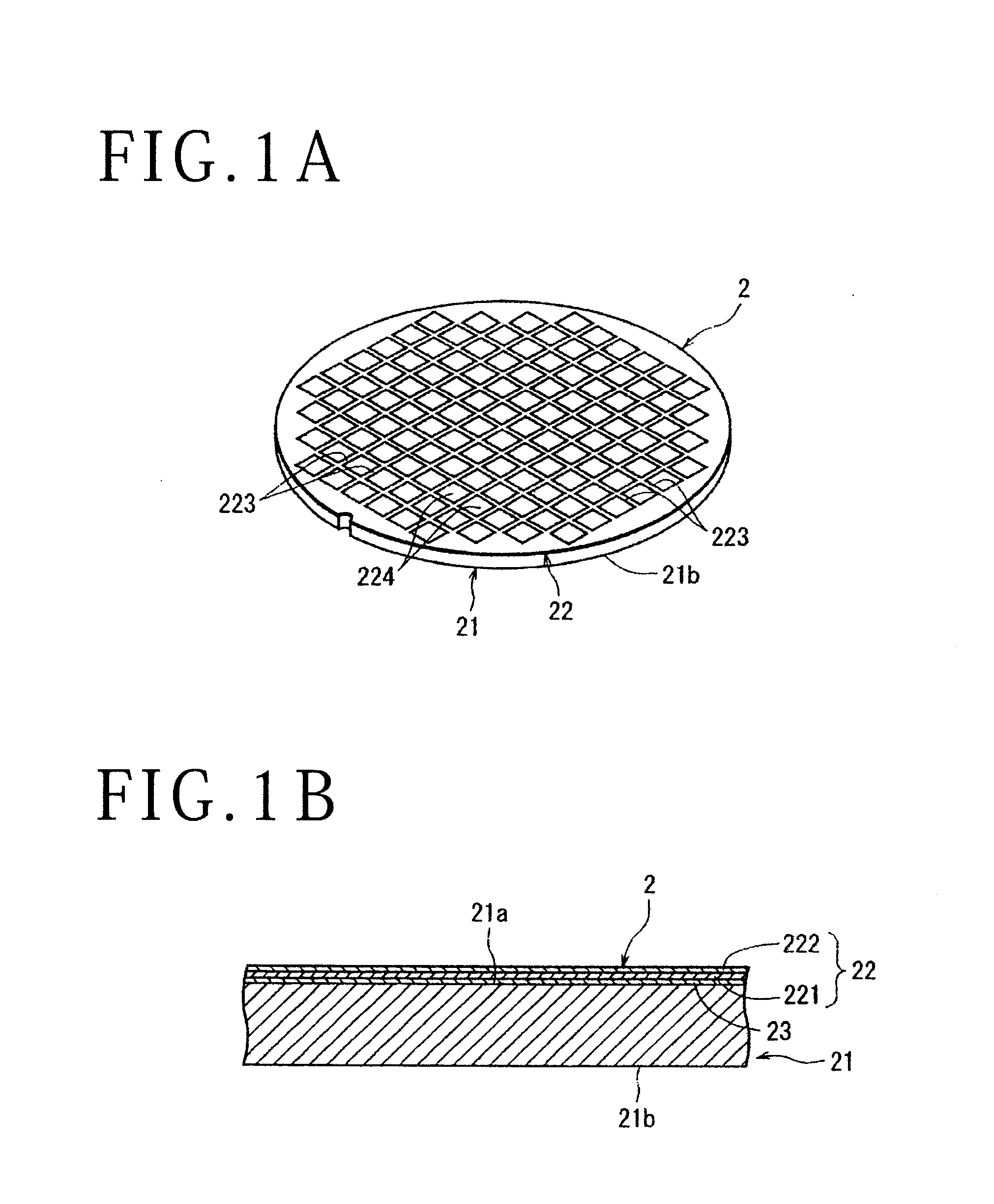

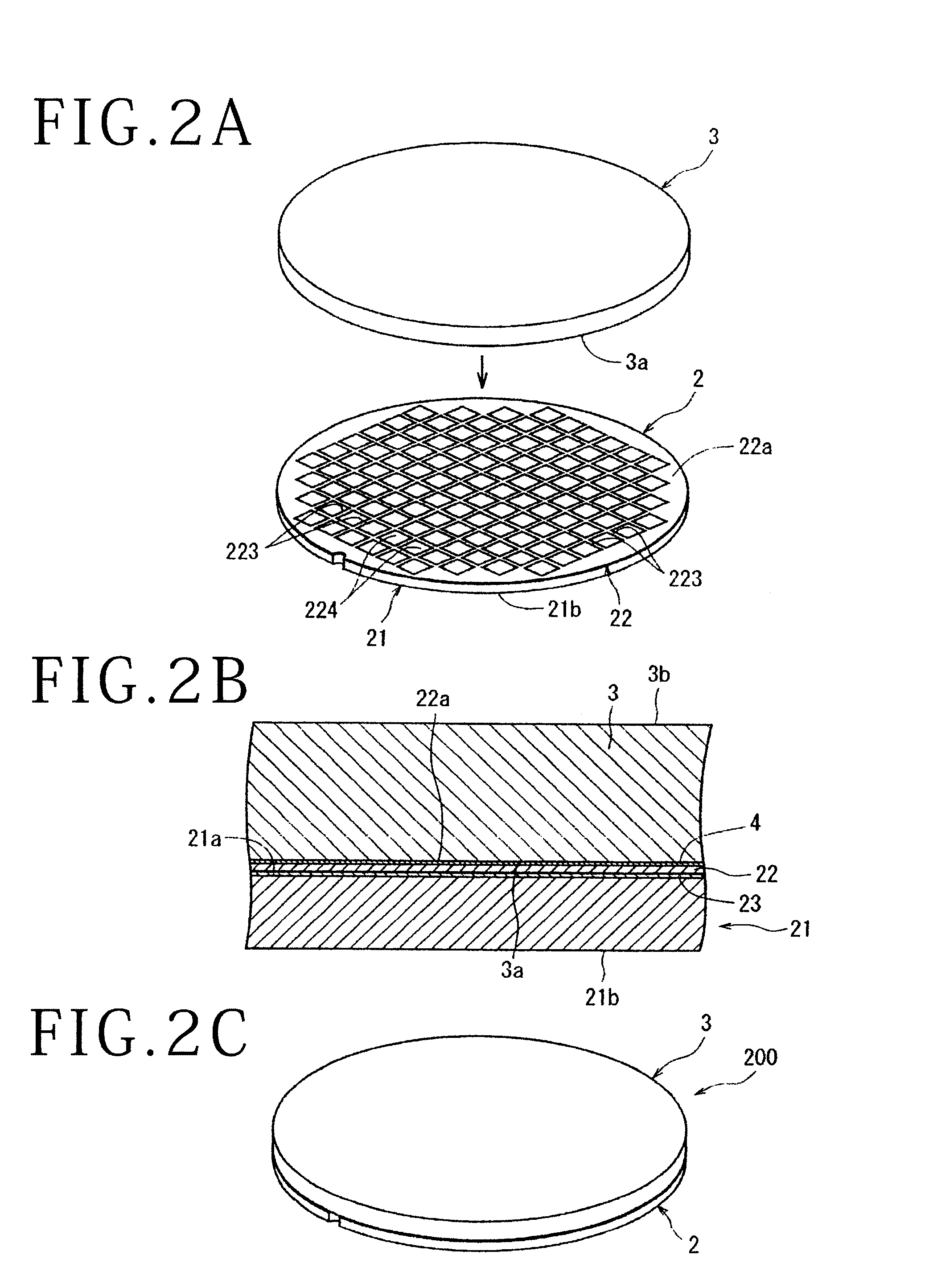

ActiveUS8980409B2Easy to peelGood dimensional stabilityLamination ancillary operationsDecorative surface effectsCouplingEngineering

The invention provides a laminate of a substrate, a polyimide film, and a coupling treatment layer interposed therebetween, which provides different delamination strengths between the substrate and the polyimide film to form a prescribed pattern. The invention also provides a method for producing such a laminate formed from at least a substrate and a polyimide film, whereby, using a film obtained by plasma treatment of at least the surface facing the substrate as the polyimide film, coupling agent treatment is performed on at least one of the surfaces facing the substrate and the polyimide film to form a coupling treatment layer, deactivation treatment is performed on a portion of the coupling treatment layer to form a pre-determined pattern, and then pressing and heating are performed with the substrate and polyimide film overlapping.

Owner:TOYOBO CO LTD

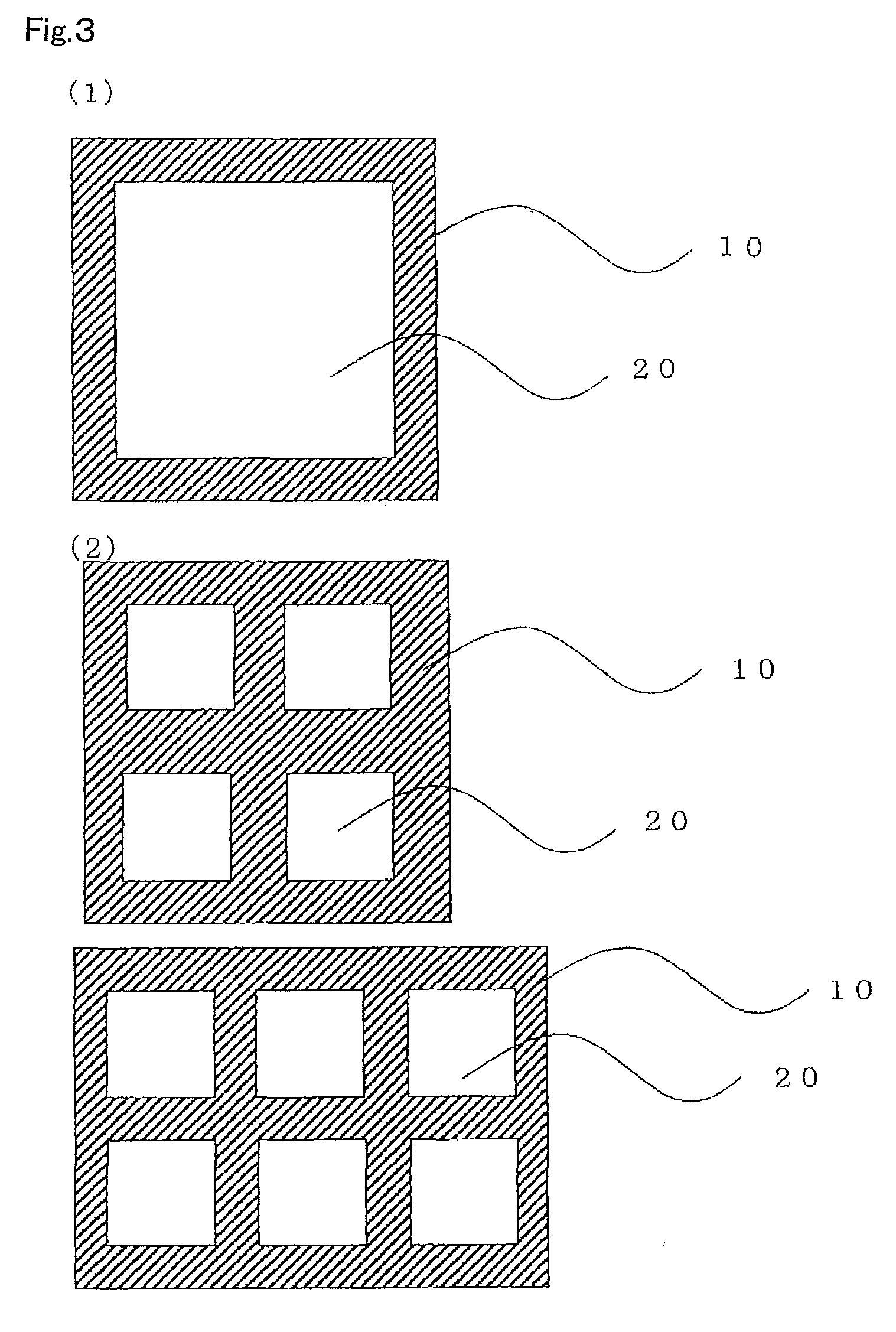

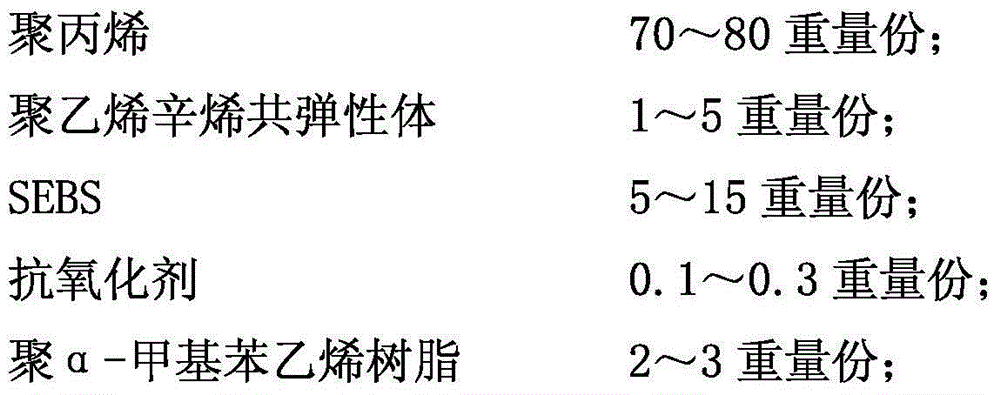

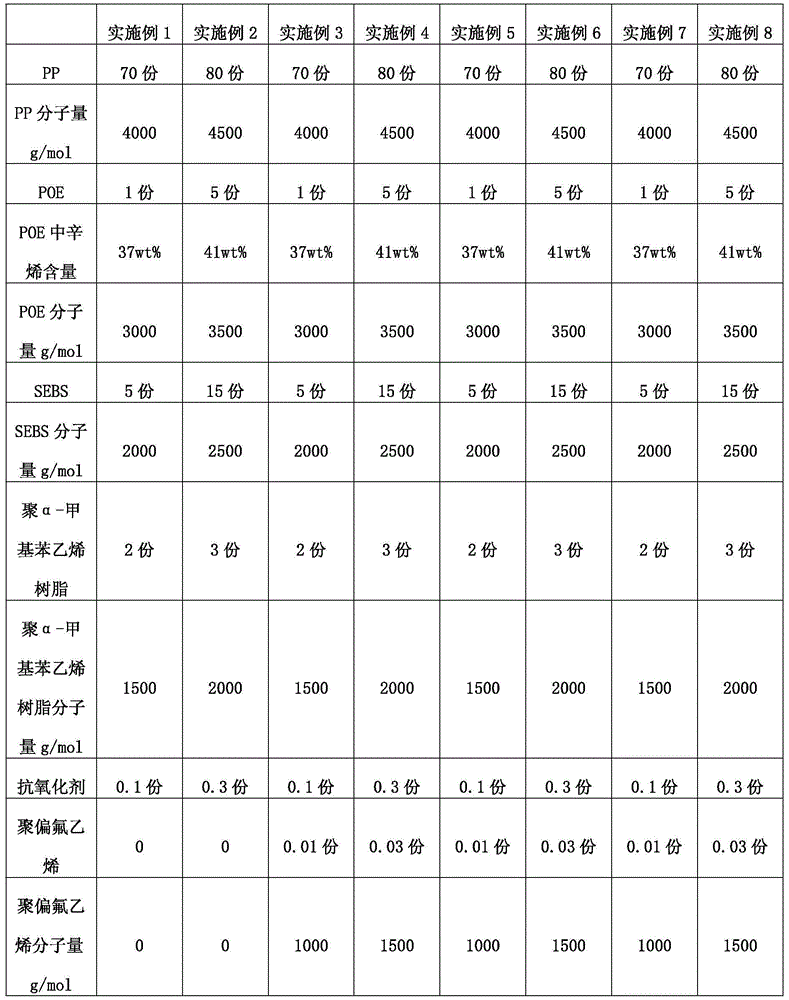

Special PP protecting membrane formula for ITO

The invention discloses a special PP protecting membrane formula for ITO. The special PP protecting membrane formula comprises the following raw materials in parts by weight: 70-80 parts of polypropylene, 1-5 parts of a polyethylene octylene co-elastomer, 5-15 parts of SEBS, 0.1-0.3 part of an antioxidant and 2-3 parts of poly alpha-methyl styrene resin, wherein the content of octylene in the polyethylene octylene co-elastomer is 37-41wt%. As SEBS is adopted as a self-adhering layer, the temperature resistance of polypropylene is improved and the viscosity of SEBS is adjusted by adding POE, and the softening point of SEBS is increased and separation of oil components in SEBS can be controlled by adding the poly alpha-methyl styrene resin, the problems that a coated protecting membrane has residual adhesives, is low in viscosity and poor in temperature resistance, and the like can be solved; as PP is taken as a substrate in the formula, the temperature resistance of the protecting membrane can be effectively improved.

Owner:昆山金华安电子科技有限公司

Electromechanical full-automatic peeling machine and peeling method thereof

ActiveCN101856139BReduce labor costsMeet the needs of deep processingVegetable peelingProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses an electromechanical full-automatic peeling machine and a peeling method thereof. The electromechanical full-automatic peeling machine comprises a rack, a fruit feeding mechanism, a peeling mechanism, a cutting mechanism and a control system, wherein the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in the rack; the fruit feeding mechanism is arranged on two lead rails of the rack; the fruit feeding mechanism, the peeling mechanism and the cutting mechanism are arranged in sequence according to processing procedures; and the control system connects and controls the fruit feeding mechanism, the peeling mechanism and the cutting mechanism. The invention also discloses a peeling method of the electromechanical full-automatic peeling machine. The electromechanical full-automatic peeling machine has the advantages of high processing efficiency, safety and health.

Owner:广州达桥食品设备有限公司

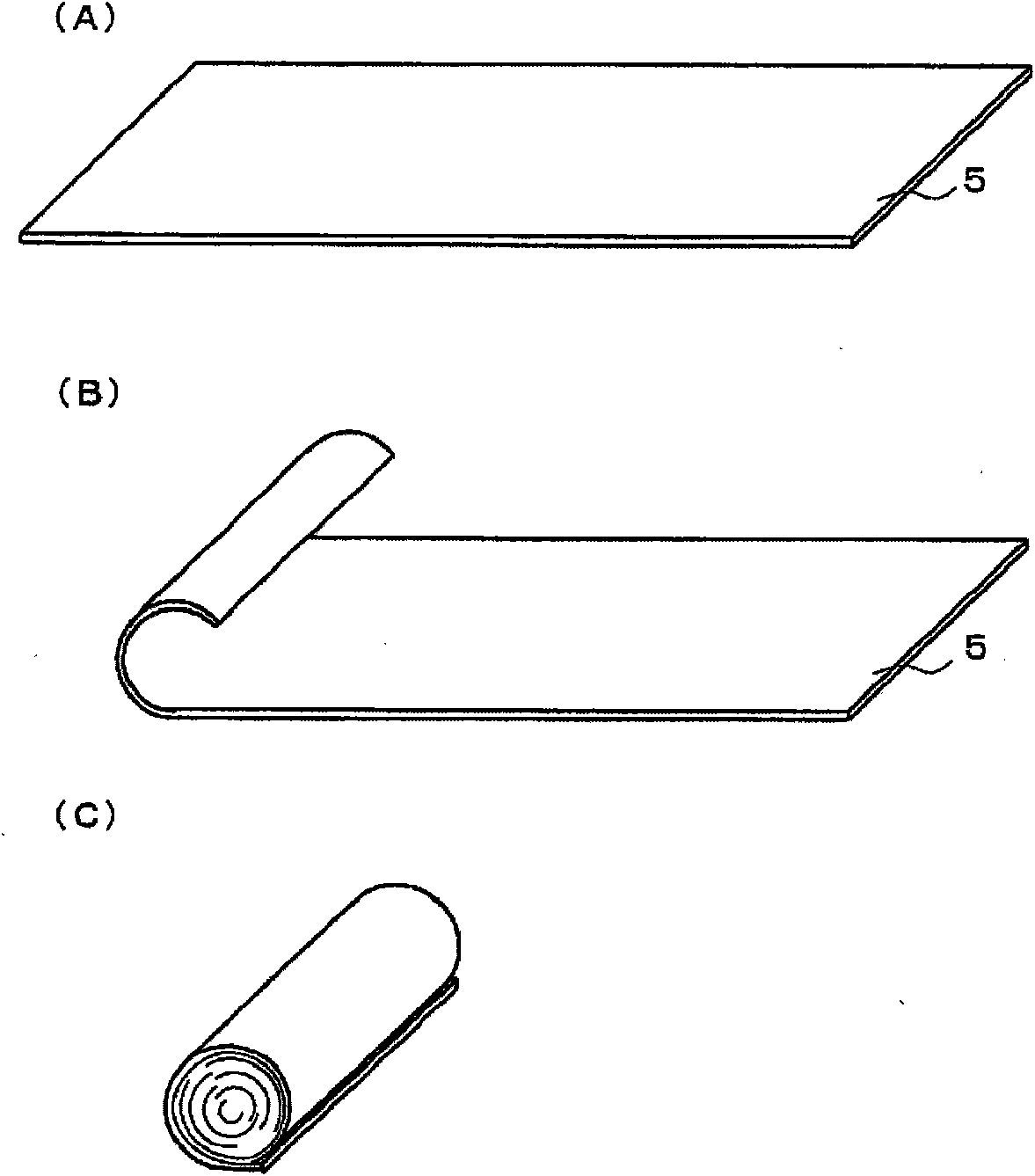

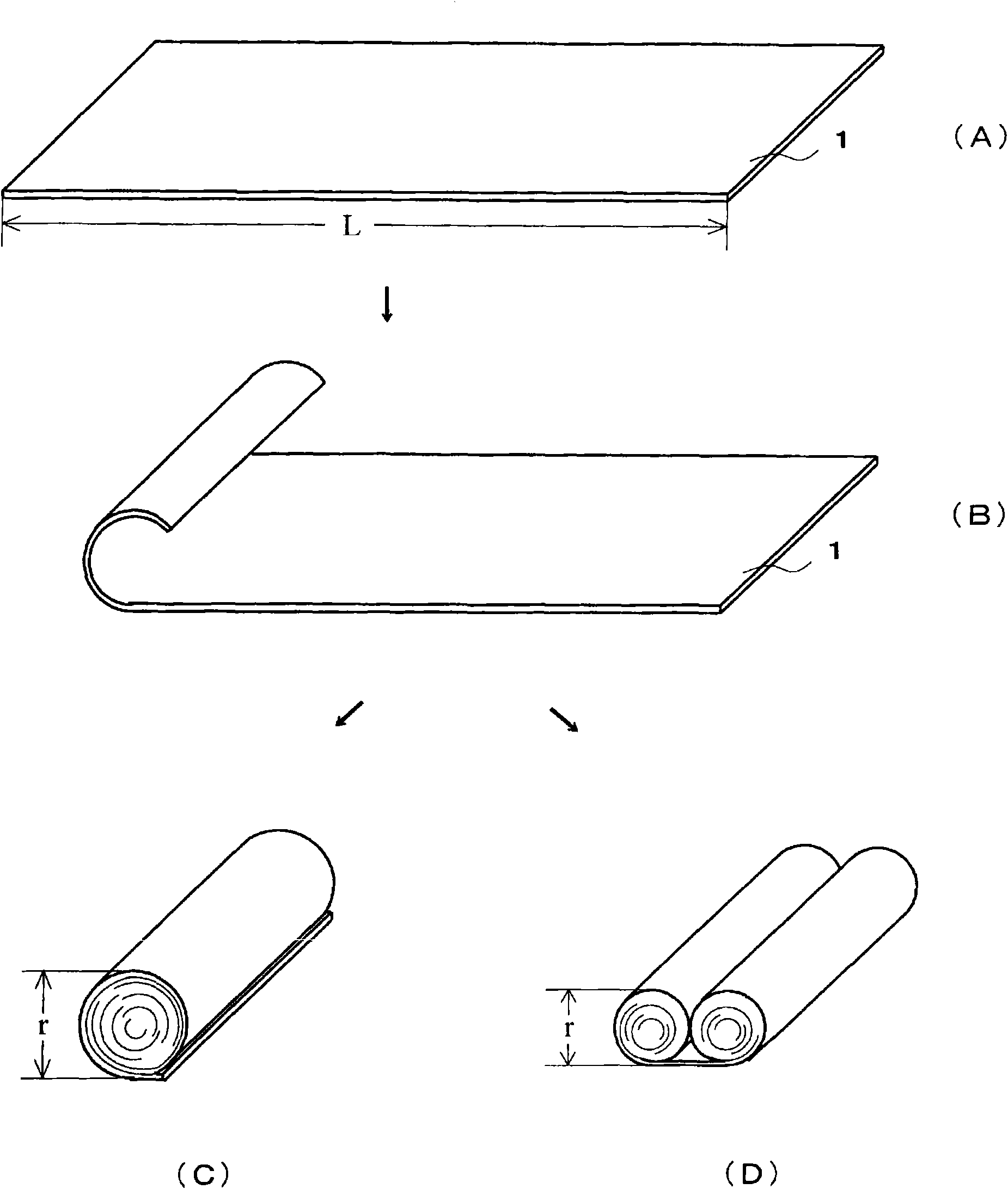

Film and adhesive/bonding sheet

InactiveCN102218865ARigidSmooth peelingSynthetic resin layered productsSolid-state devicesAdhesiveEngineering

The invention provides a film and an adhesive / bonding sheet. When the film that is fixed to a surface of an adherend by means such as adhesion and rolled into a cylinder by heating is grasped by a grasping tool or adhered to a holder in order to remove the film from the surface of the adherend, the grasping tool or holder applies a force to the rolled film to urge the film toward the surface of the adherend. If the rolled film is pressed flat by the force, the area of contact between the film and the adherend increases and so does the strength of adhesion between them. Consequently, the film needs to be re-grasped or reattached to the holder or a larger force is required in order to peel the rolled film off the adherend. To solve the problem, there is provided a film that includes a thermally shrinkable base material, an adhesive resin layer and a non-thermally shrinkable base material stacked in sequence and has the property of rolling up into a cylindrical roll by heating and not automatically returning to the original shape after the change into the cylindrical roll.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com